Patents

Literature

1380 results about "Axial symmetry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

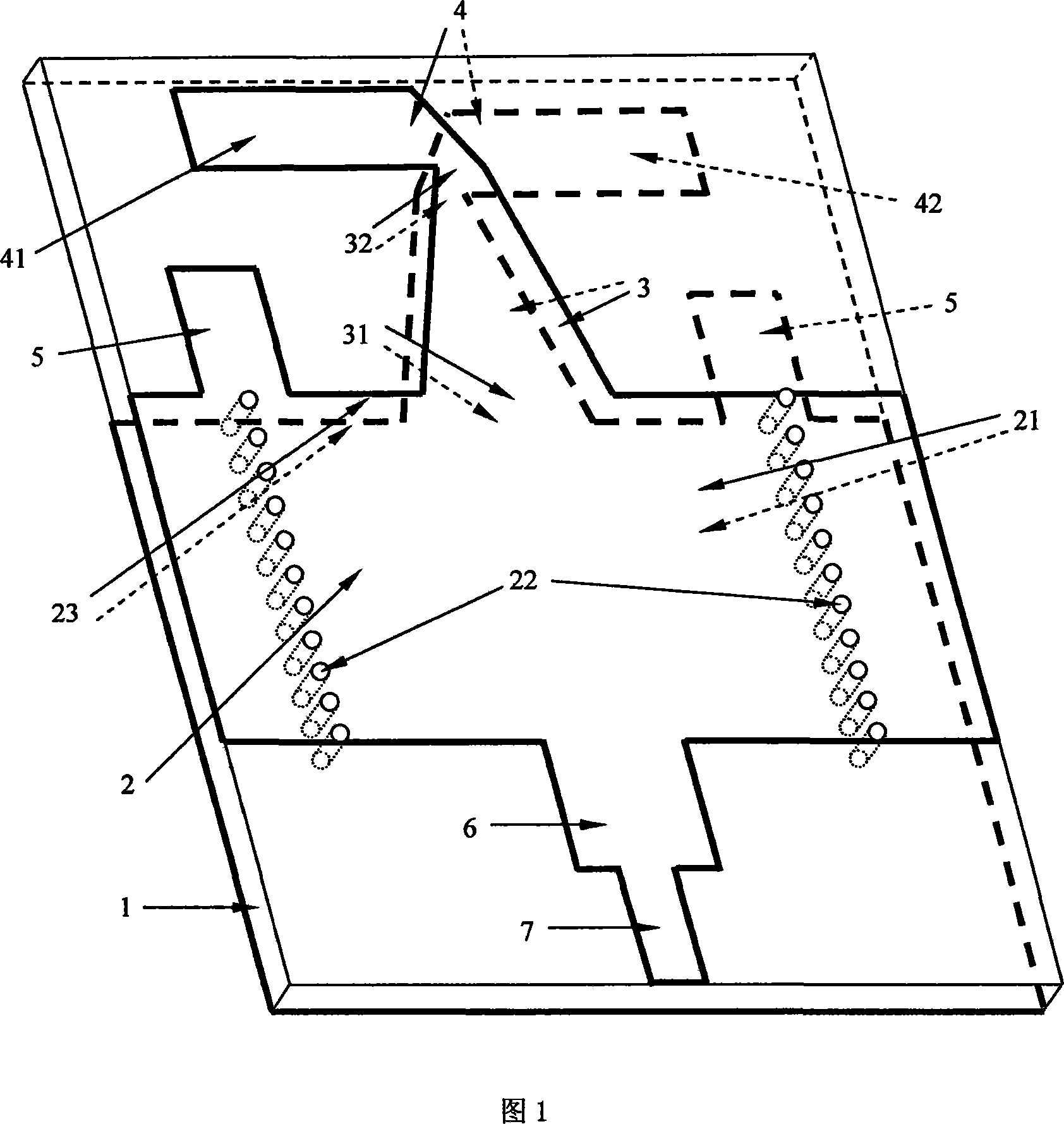

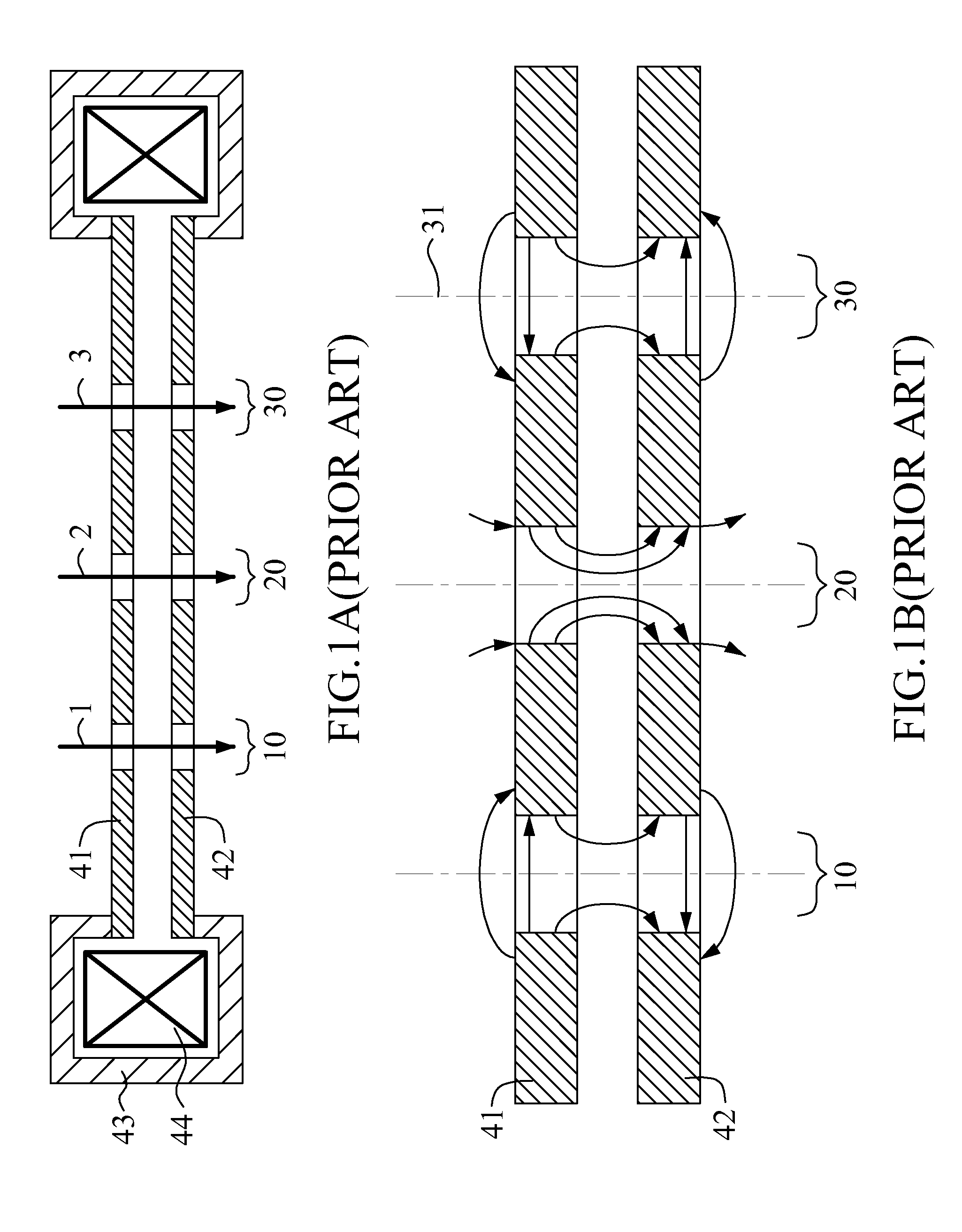

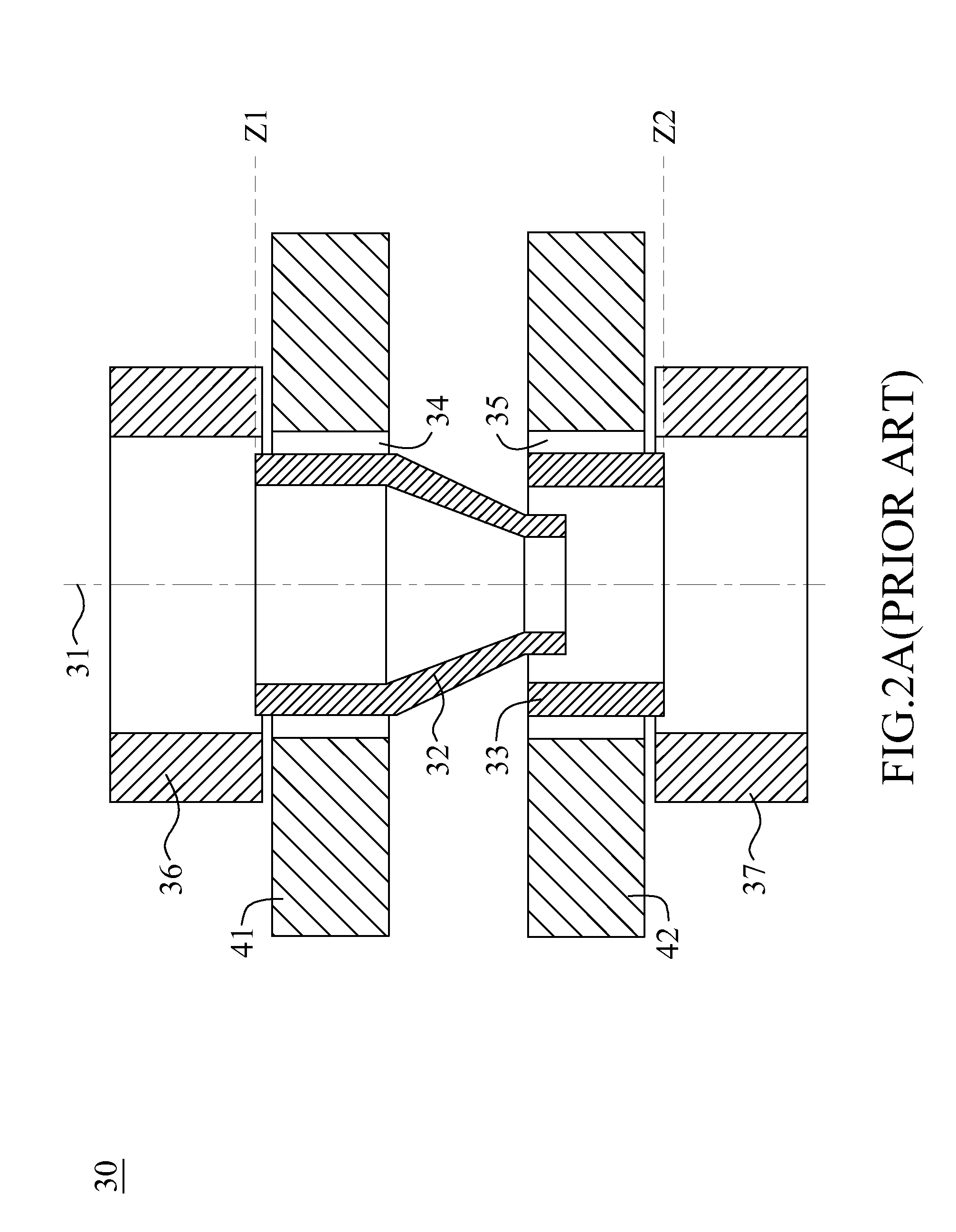

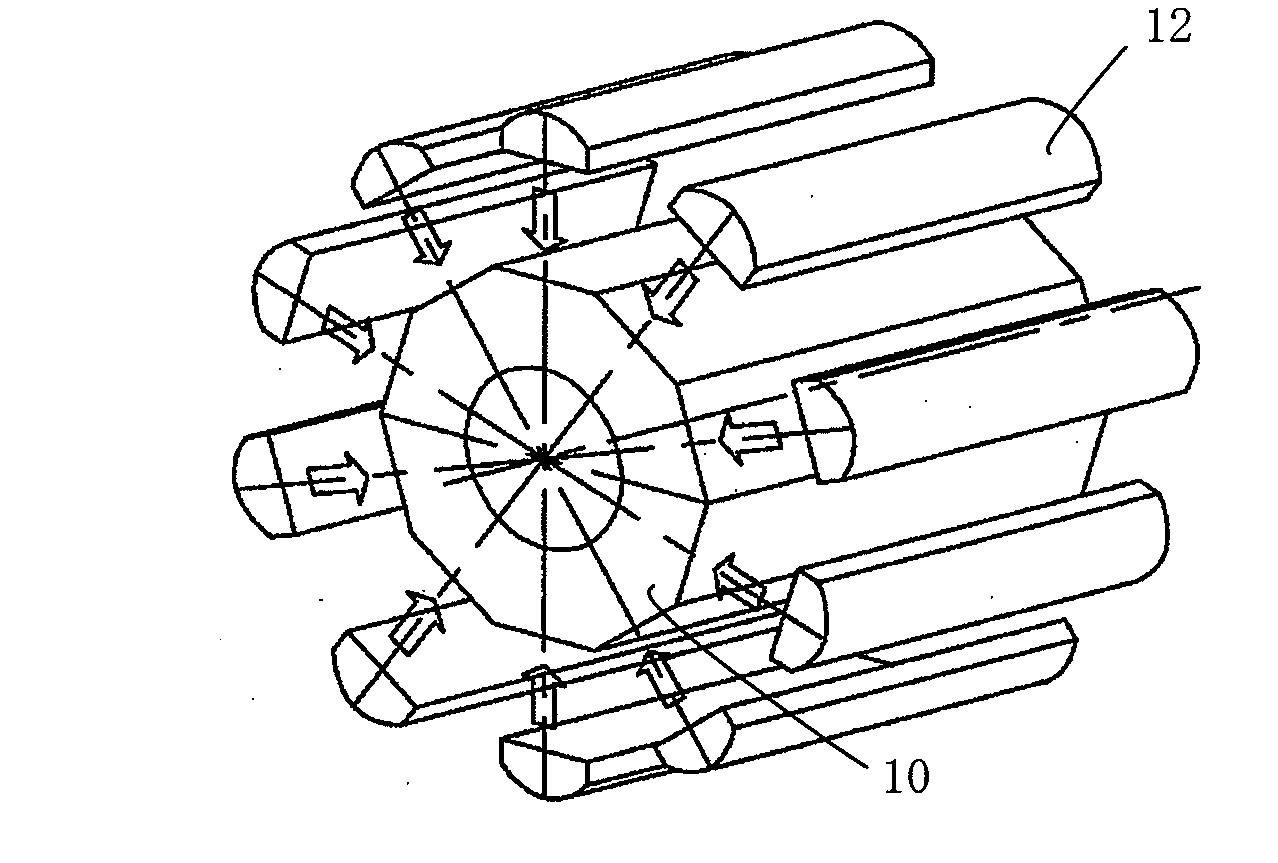

Printing antenna with baseplate integrated waveguide feeder

ActiveCN101075702ASealing is simple, convenient and economicalTo achieve the purpose of sealingRadiating elements structural formsRadarEngineering

A chip integrated waveguide feeding print antenna is composed by a chip with its two metal sides being transfixed with metal through holes in array. The two metal sides are in axial symmetry. There is an intergrading section to one side of the waveguide centerline on two surface of the chip linking with transmission line. To the outer end of the intergrading section links a vibrator antenna. To the opposite side of the intergrading section on the waveguide links a micro-strip intergrading commutator linking with micro-strip transmission line.

Owner:南京易太可通信技术有限公司

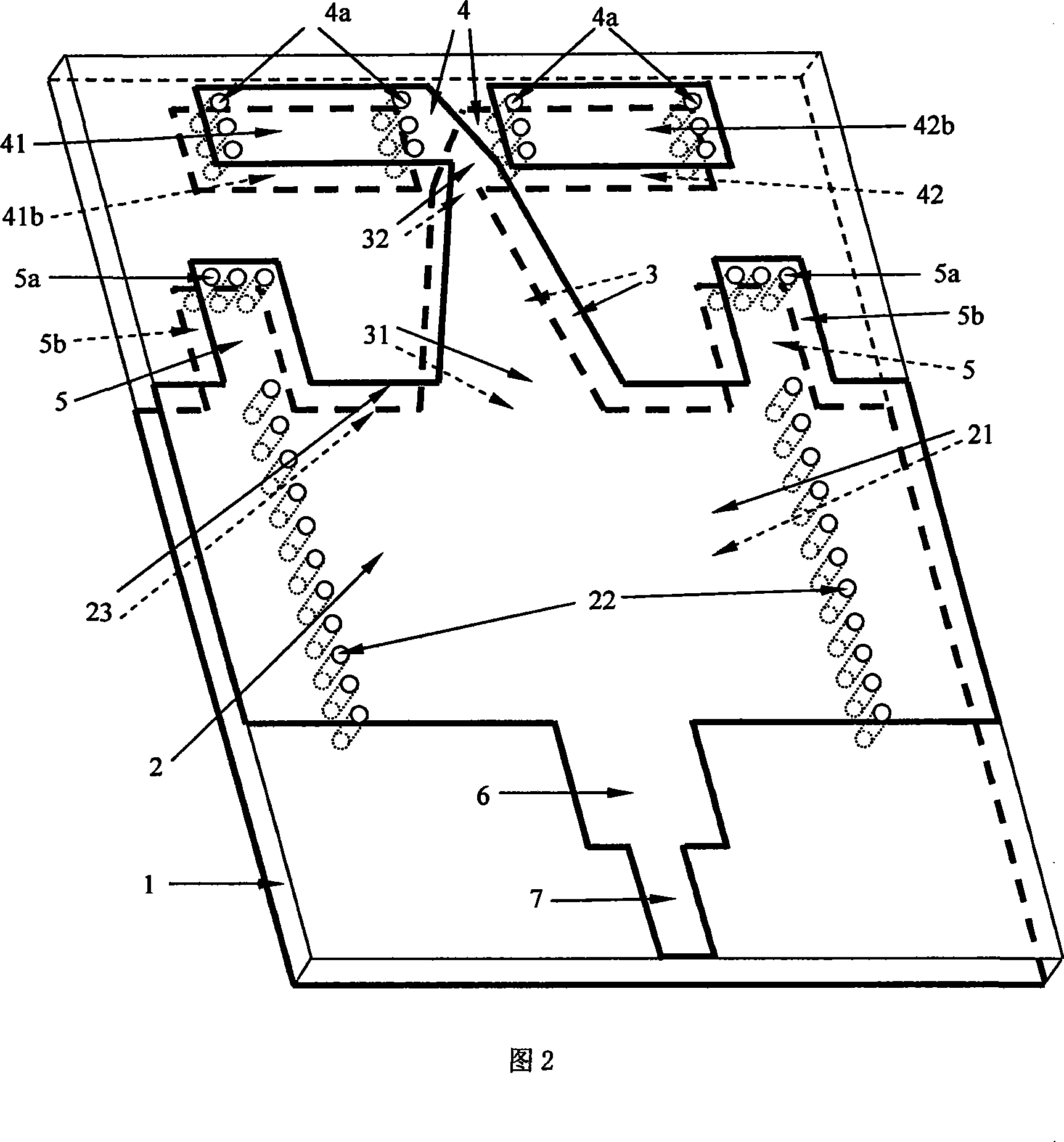

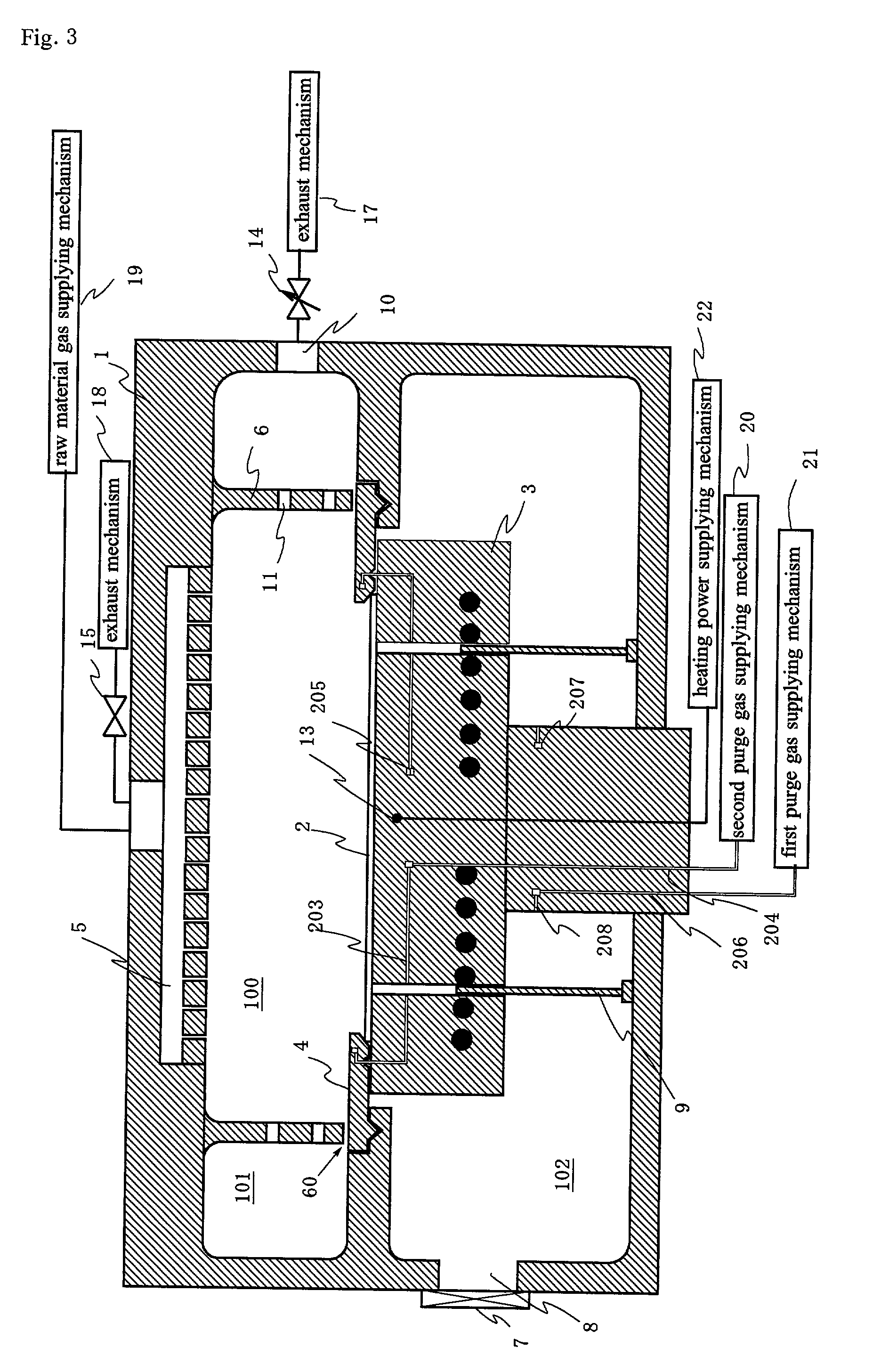

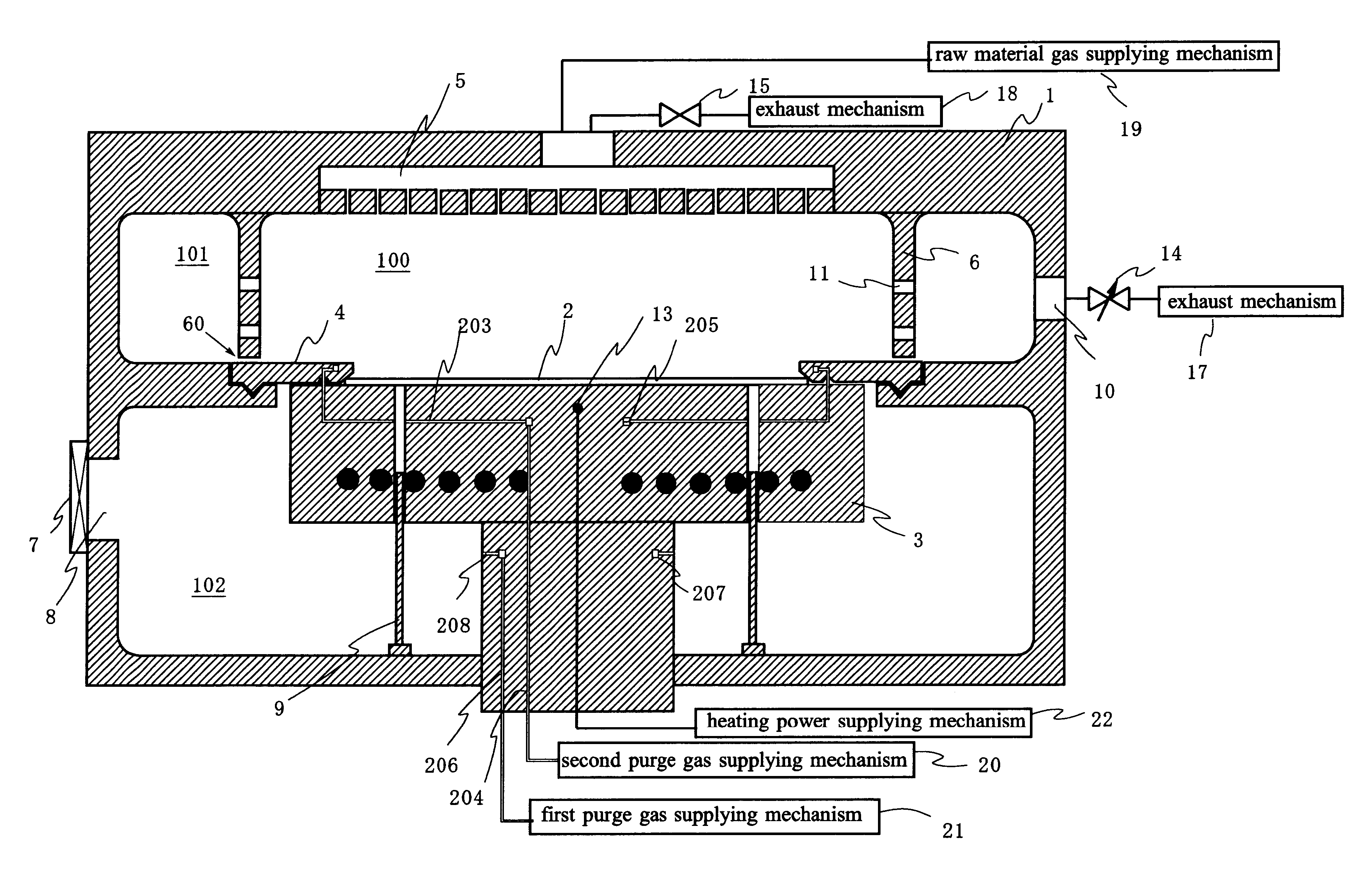

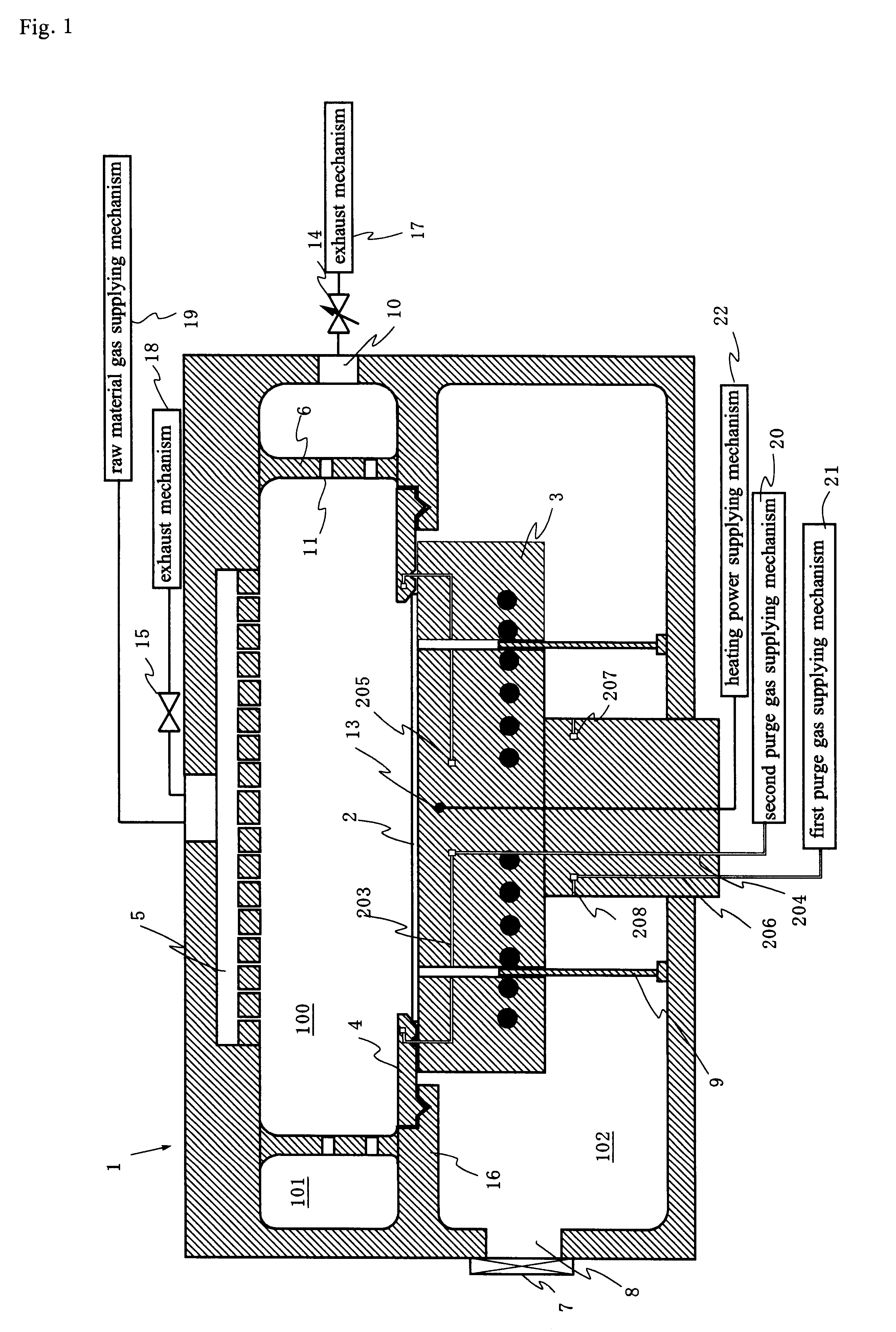

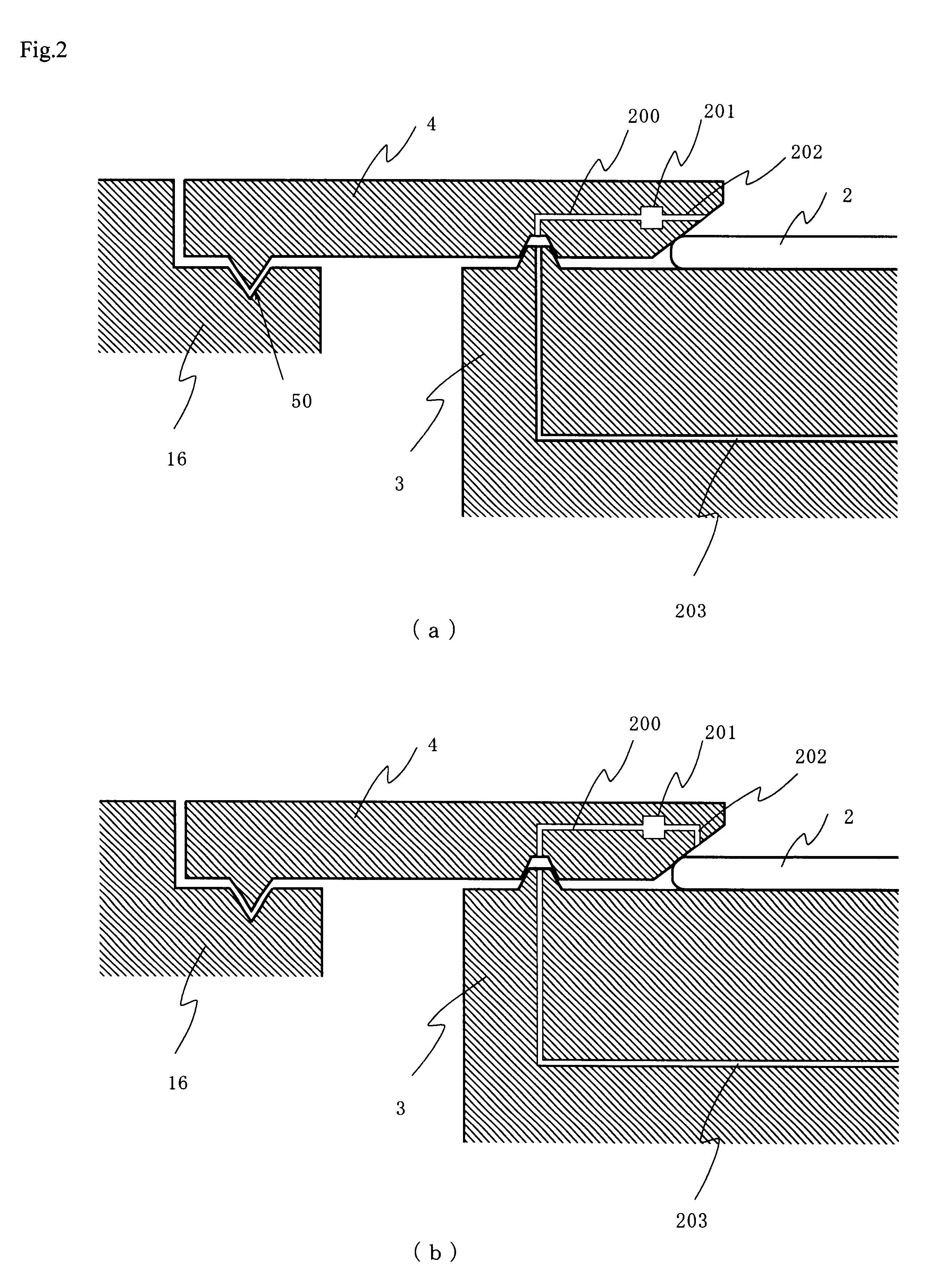

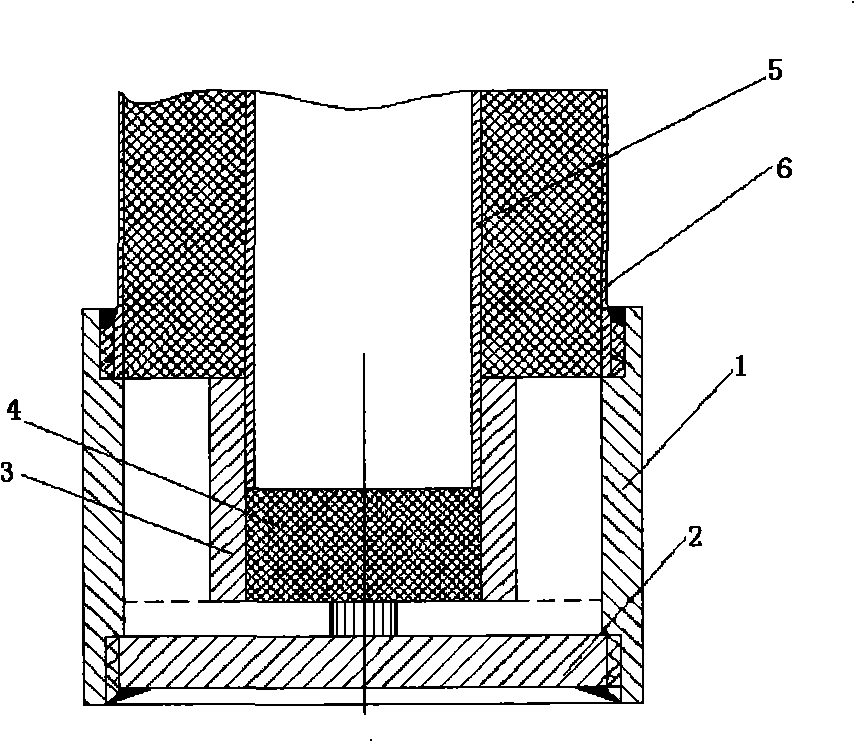

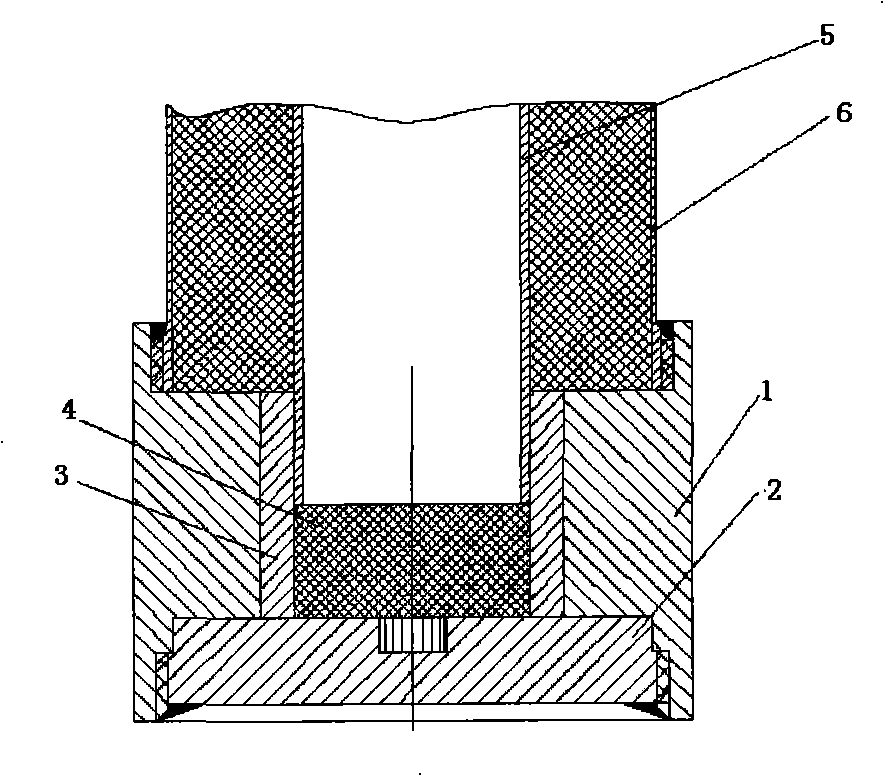

CVD apparatus

InactiveUS20010042514A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingProduction rateEngineering

The present invention is to provide a CVD apparatus having a high productivity, involving less contamination on the back surface of a substrate and having a high yield. A CVD apparatus for forming a thin film is characterized in that the interior of the vessel is divided into a upper portion and a lower portion (transfer chamber) by a support member for holding the ring chuck and the upper portion is further divide by inner wall into a deposition chamber and an exhaust chamber in axial symmetry around the same central axis. The deposition chamber communicated to the exhaust chamber through a gap between the inner wall and the ring chuck and / or holes provided in the inner wall. The transfer chamber is communicated to the deposition chamber or exhaust chamber through a gap formed between the ring chuck and the support member.

Owner:ANELVA CORP

Printing antenna with baseplate integrated waveguide feeder

ActiveCN101075702BSealing is simple, convenient and economicalTo achieve the purpose of sealingRadiating elements structural formsRadarEngineering

A chip integrated waveguide feeding print antenna is composed by a chip with its two metal sides being transfixed with metal through holes in array. The two metal sides are in axial symmetry. There is an intergrading section to one side of the waveguide centerline on two surface of the chip linking with transmission line. To the outer end of the intergrading section links a vibrator antenna. To the opposite side of the intergrading section on the waveguide links a micro-strip intergrading commutator linking with micro-strip transmission line.

Owner:南京易太可通信技术有限公司

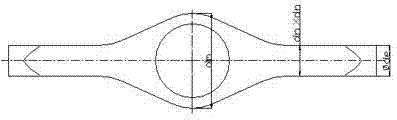

Flow conditioner for a gas transport pipe

InactiveUS6145544AEliminate jet effectEliminate flow swirlFlow mixersFluid dynamicsEngineeringConcentric ring

The flow conditioner for a gas transport pipe comprises at least one perforated plate disposed essentially perpendicularly to the axis XX' of the pipe and comprising a central hole and sets of additional holes that are regularly distributed over at least three concentric rings centered on the axis of the pipe so as to define a perforated plate that is axially symmetrical. Within any one ring all of the circular holes are of the same diameter d1, d2, d3. On going away from the central hole and on passing from any one ring to an adjacent concentric ring, the diameter of the holes changes alternately in a reduction direction and in an increase direction. Each ring has a number of holes that is equal to or greater than six. The perforated plate is advantageously associated with a porous plate situated upstream from the perforated plate and parallel thereto.

Owner:GAZ DE FRANCE

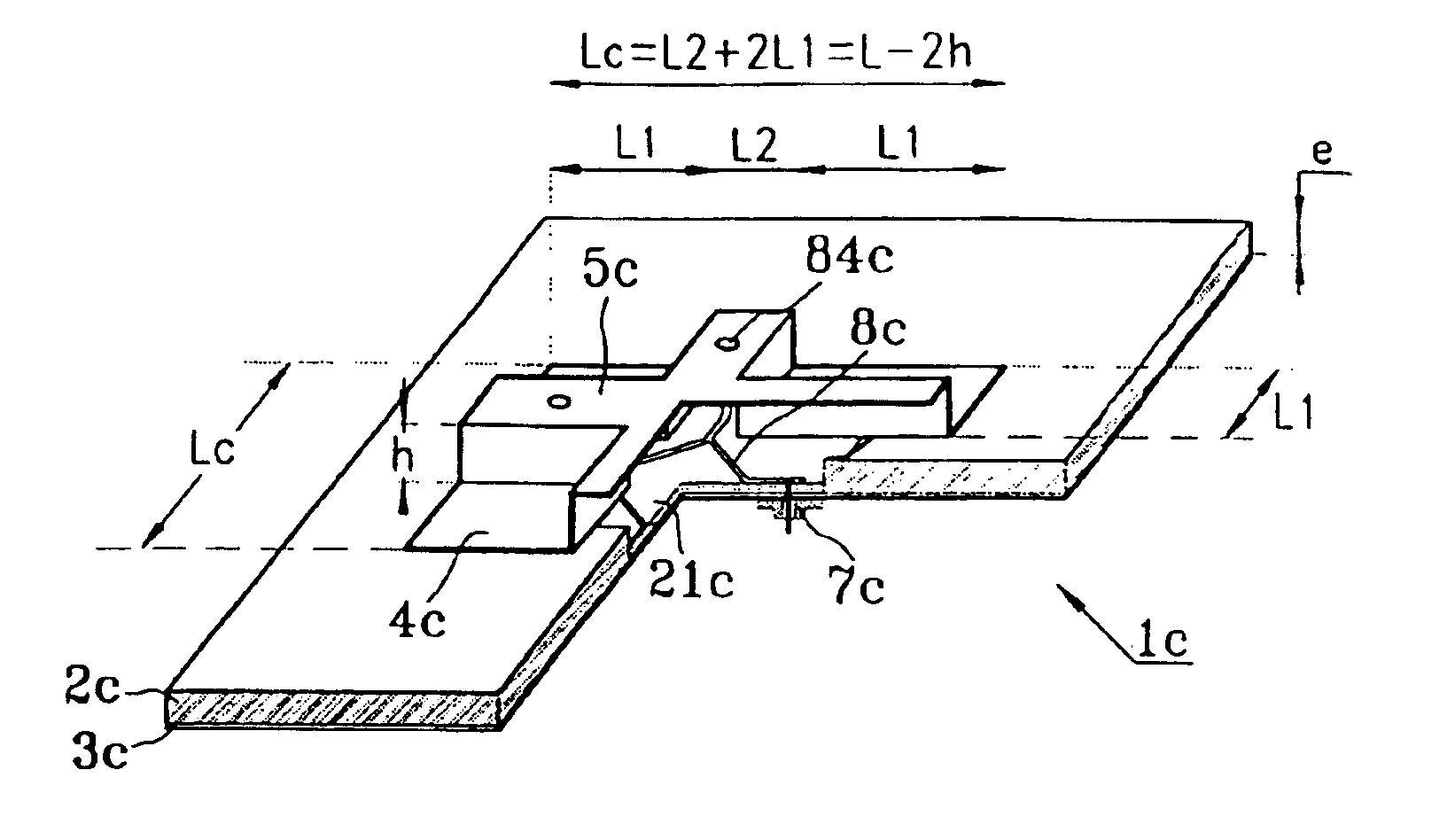

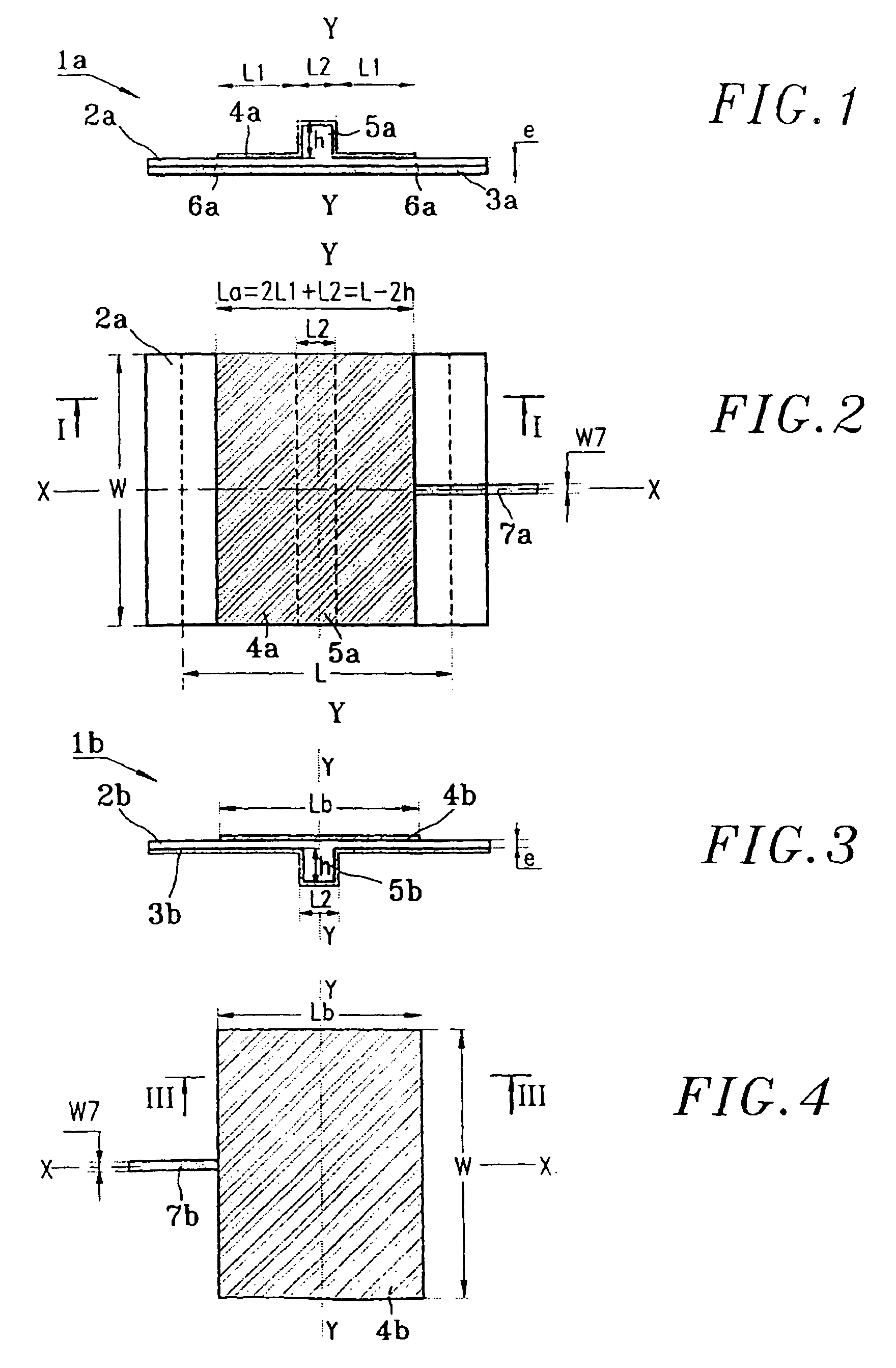

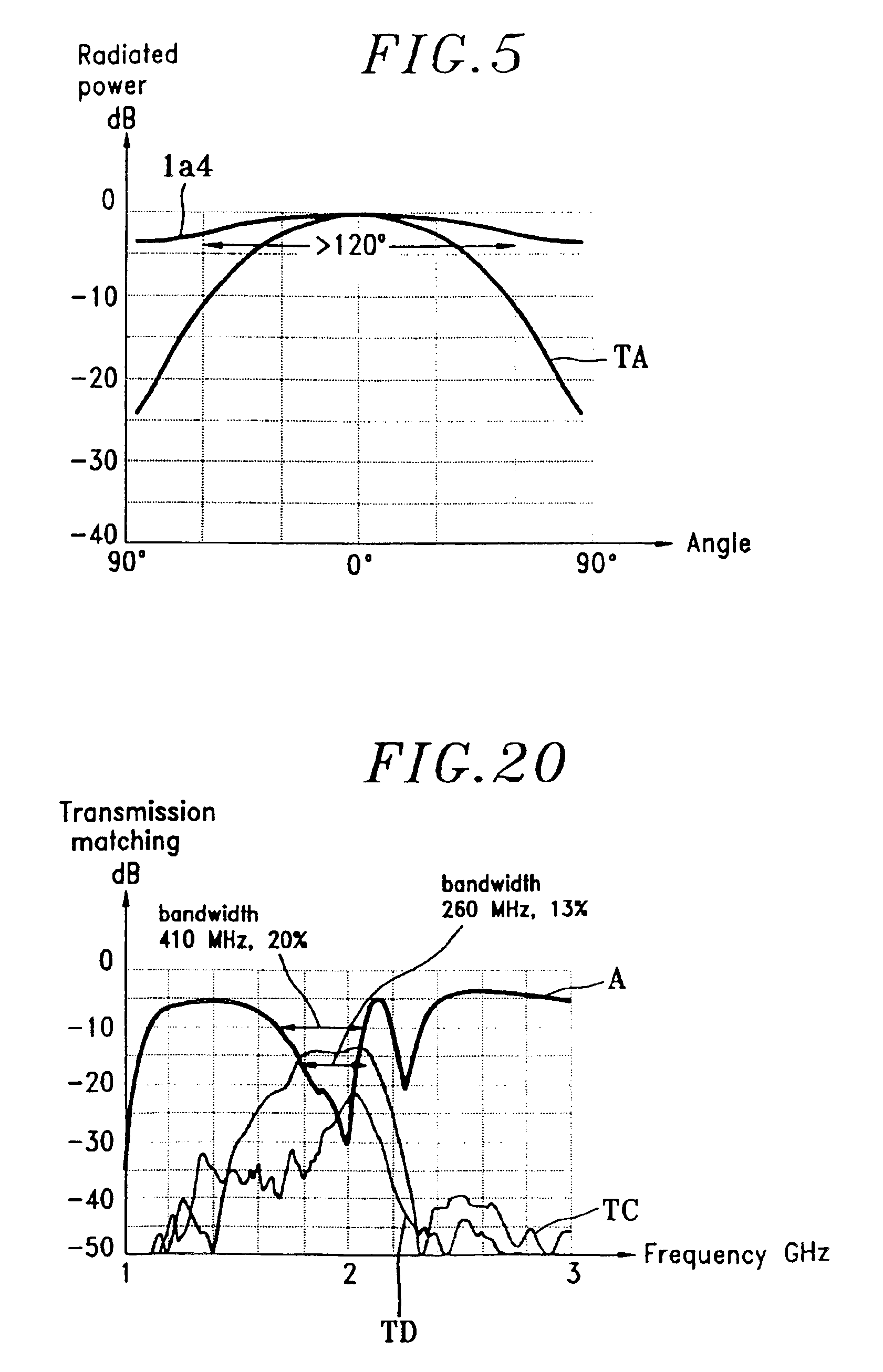

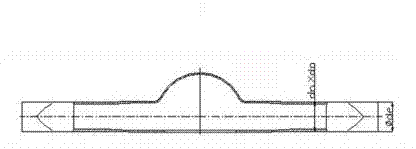

Compact printed "patch" antenna

InactiveUS6879290B1Reduce antenna sizeSmall sizeSimultaneous aerial operationsRadiating elements structural formsDielectric substrateCross polarization

A half-wave printed “patch” antenna includes, symmetrically with respect to a plane of symmetry of the antenna perpendicular to faces of the antenna, a dielectric substrate and two conductive layers on respective faces of the substrate. One face of the substrate includes a raised portion extending lengthwise of the plane of symmetry and one of the conductive layers extends over and along said raised portion. Consequently, the antenna has a small size, combined with a more open radiation diagram. The antenna includes only one raised portion for linear polarization, or two raised portions or a raised portion with axial symmetry for crossed polarizations.

Owner:GULA CONSULTING LLC

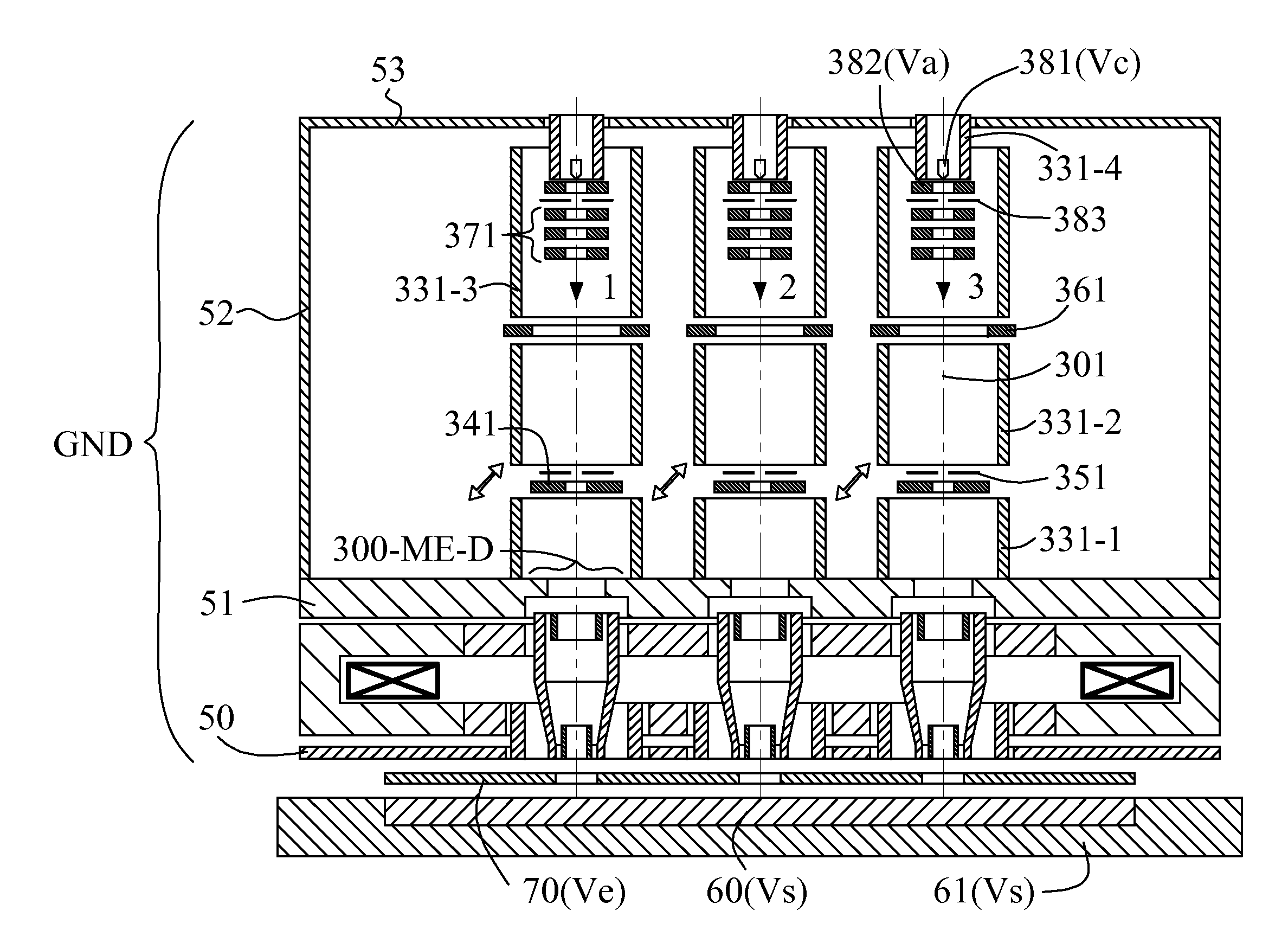

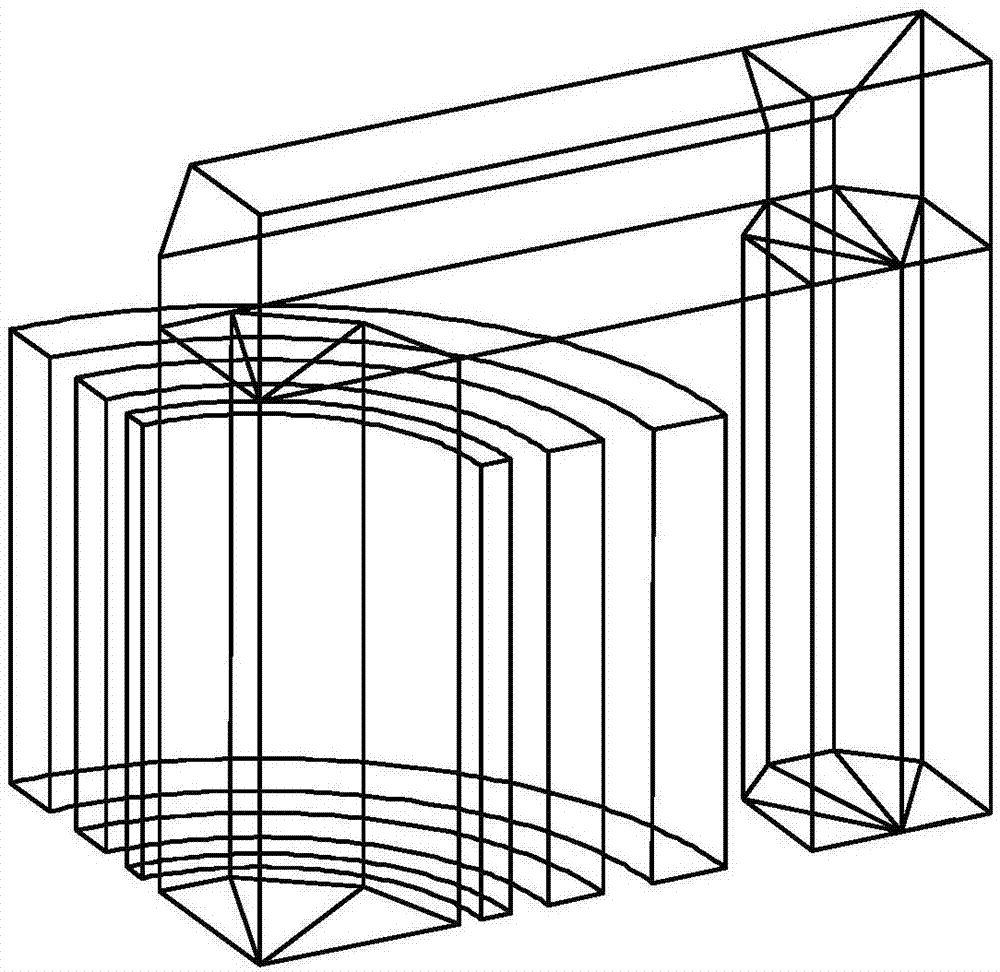

Apparatus of plural charged particle beams with multi-axis magnetic lens

ActiveUS8294095B2Low aberration lowAvoid damageMaterial analysis using wave/particle radiationElectrode and associated part arrangementsCouplingOptical axis

Owner:ASML NETHERLANDS BV

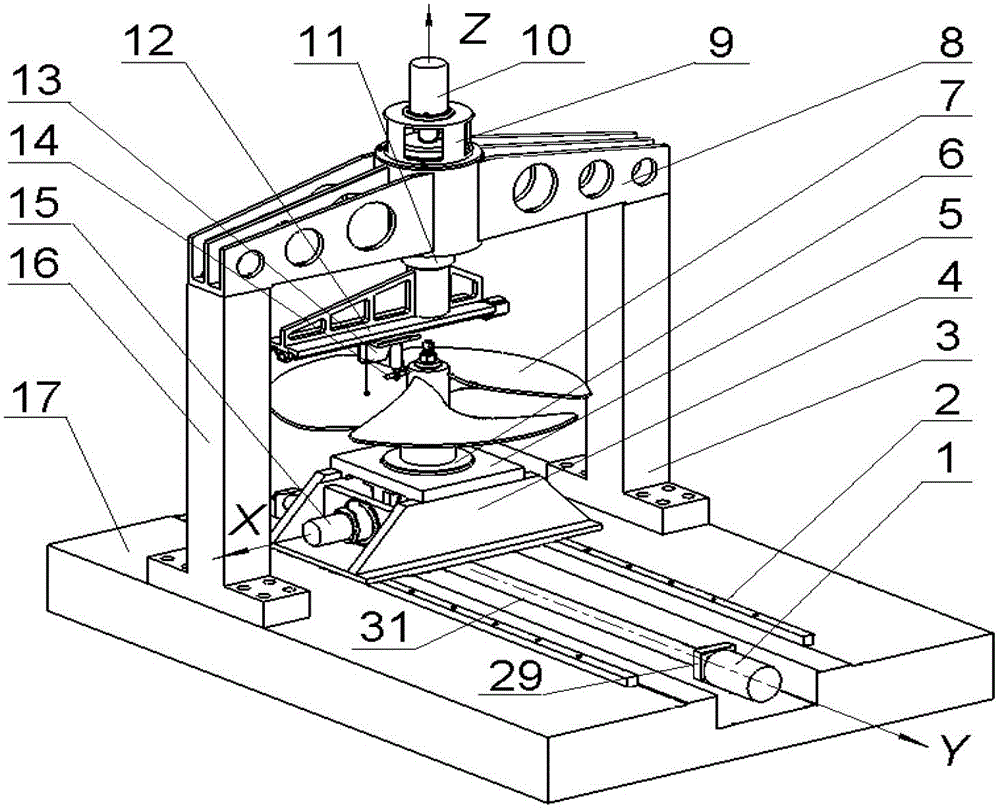

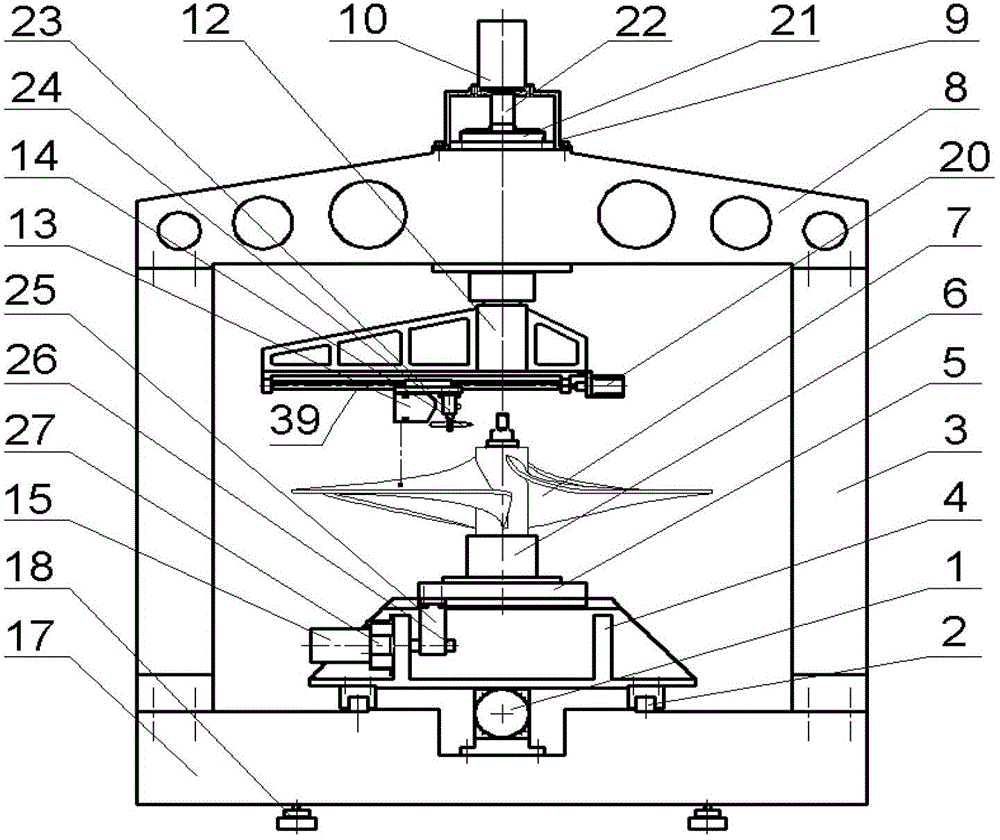

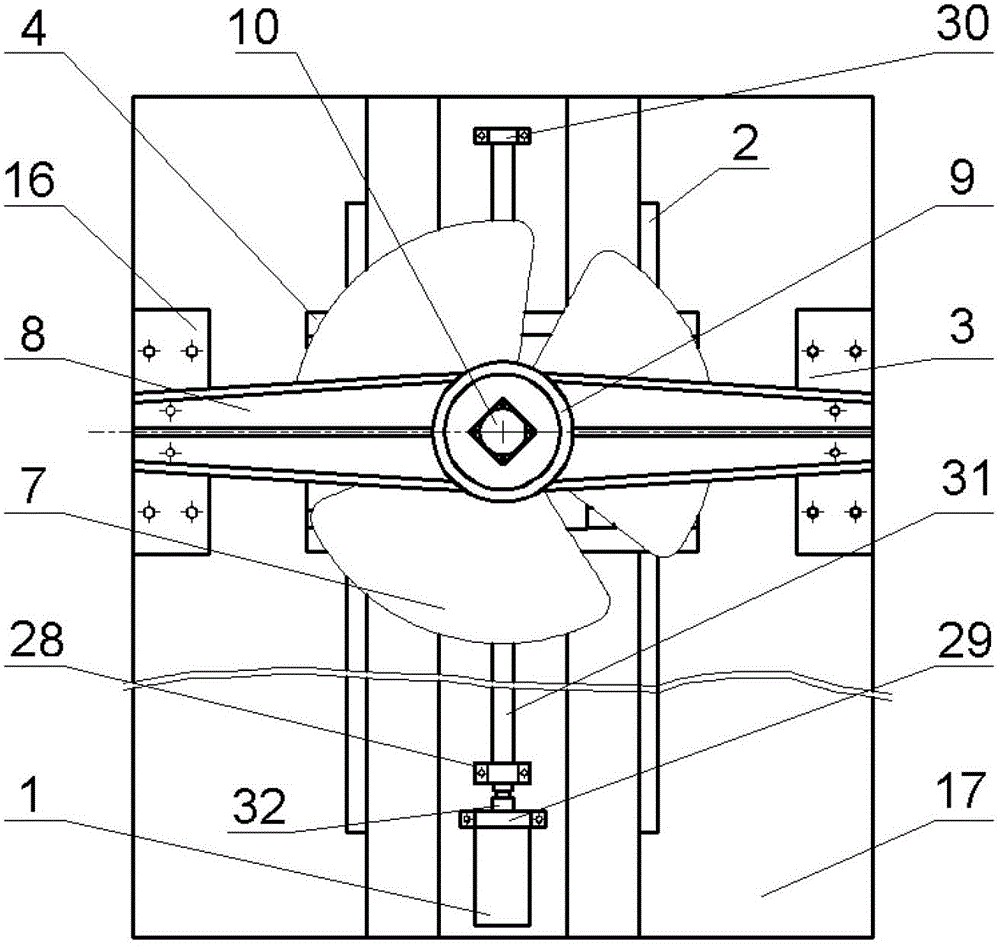

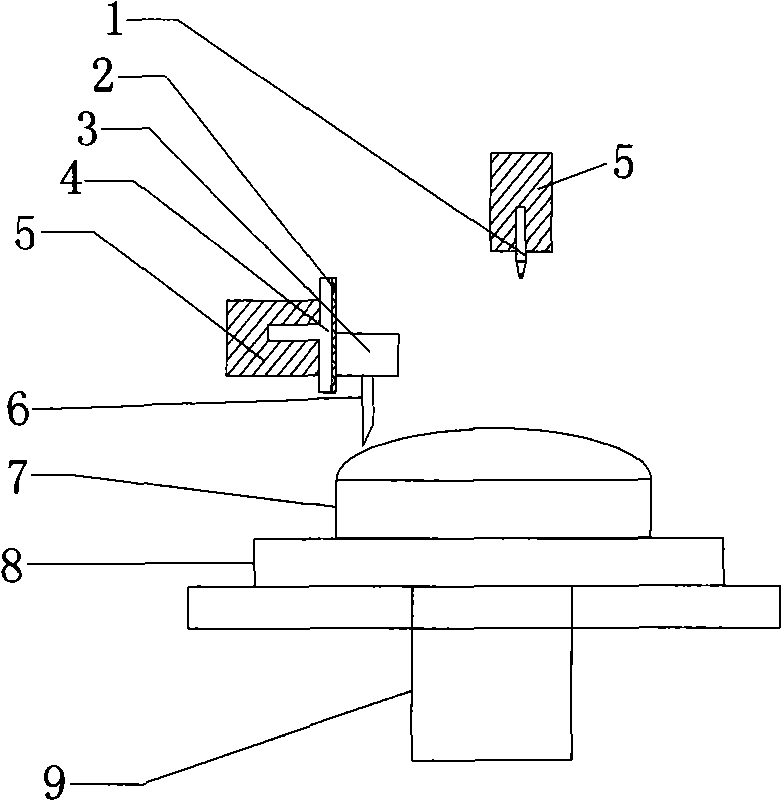

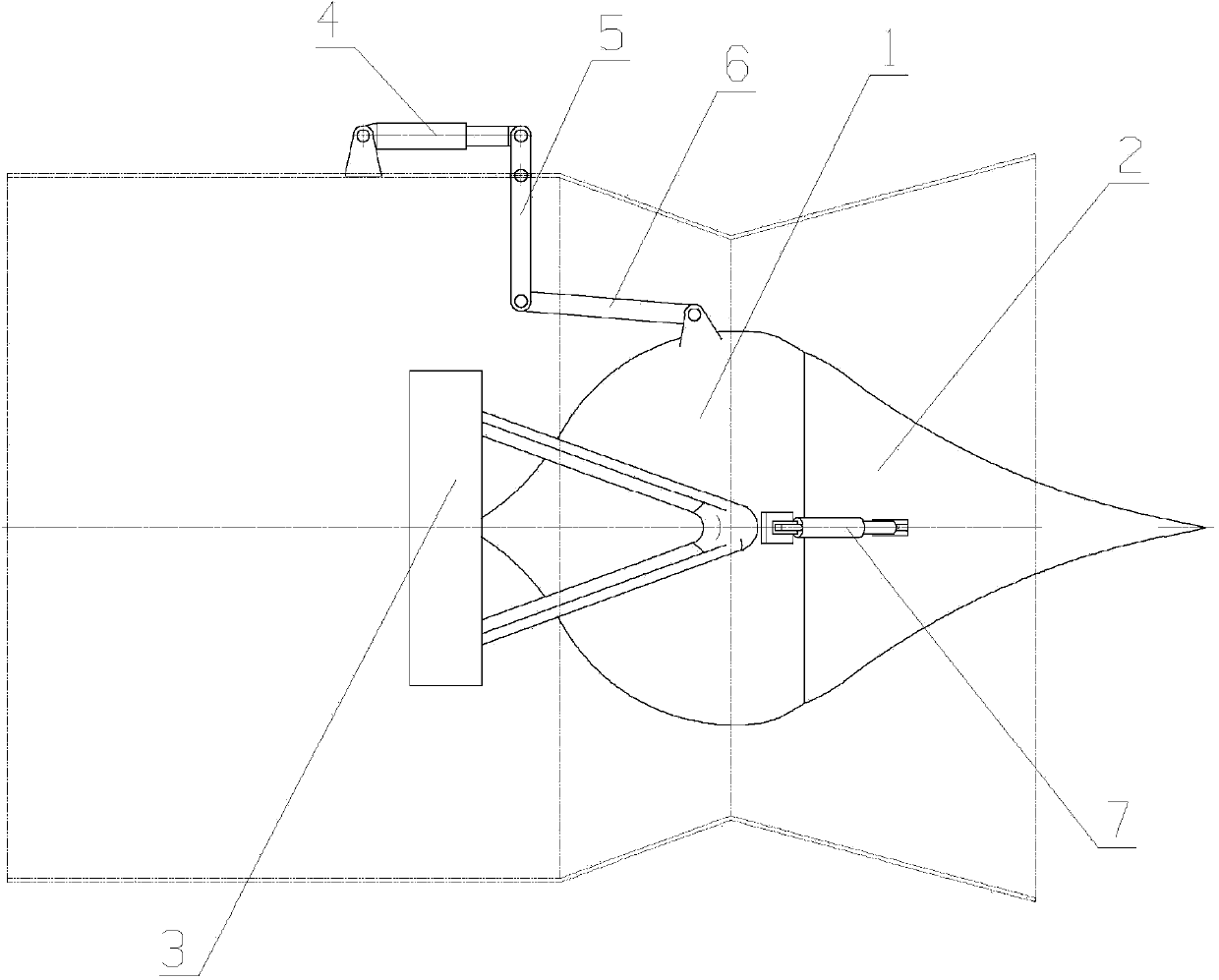

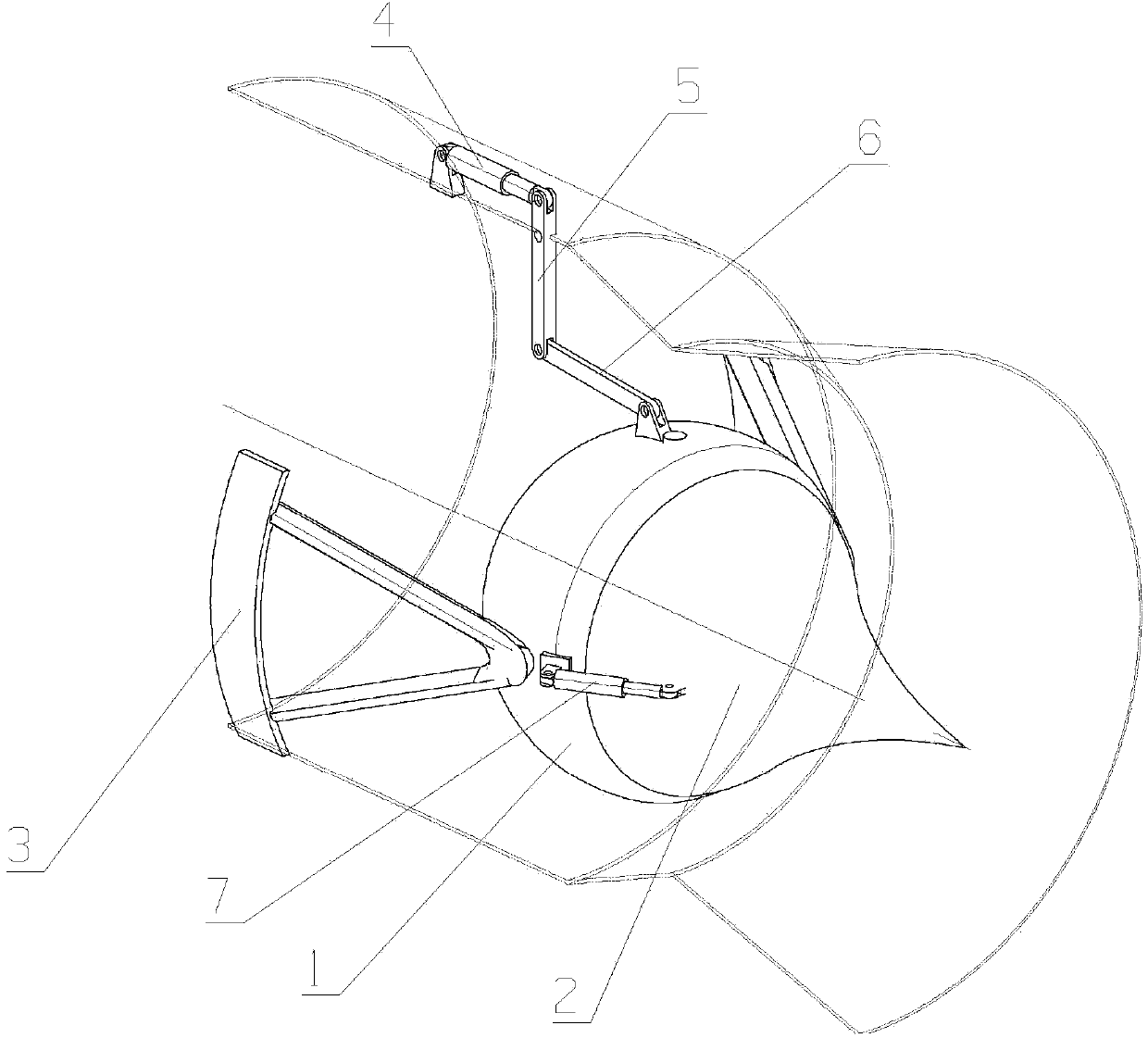

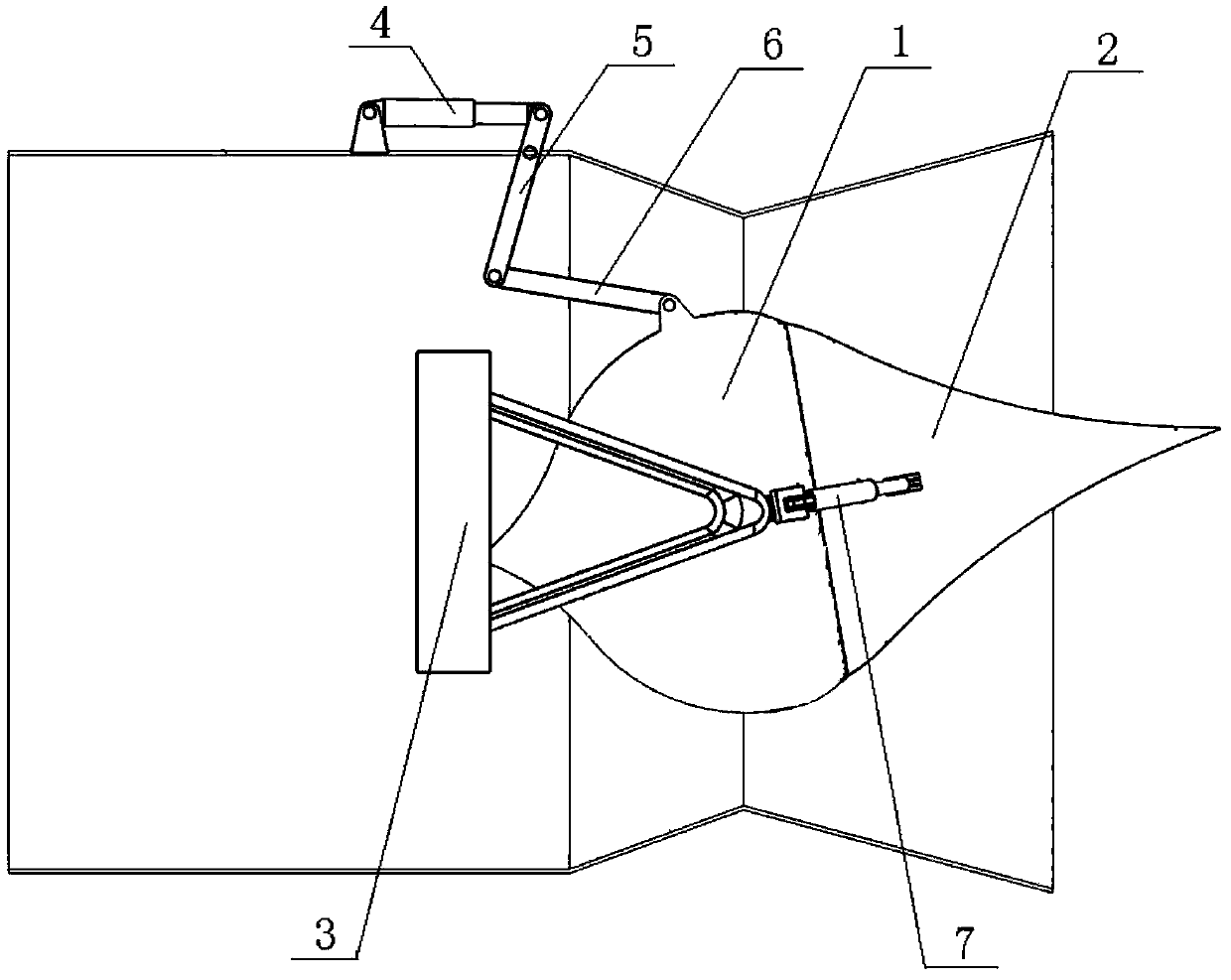

Propeller type surface contour error measurement instrument and method

ActiveCN102749041AEasy to achieve 3D reconstructionAvoiding Probe Radius Compensation ProblemsElectric/magnetic contours/curvatures measurementsUsing optical meansGeometric errorMeasurement device

The invention discloses propeller type surface contour error measurement instrument and method. The propeller type surface contour error measurement instrument is characterized in that a gantry structure is adopted, a left upright, a right upright and a top cross beam are arranged on a base, and a revolving spindle is arranged on a cross beam; the lower end of the revolving spindle is horizontally and fixedly connected with a measuring arm; a linear guiderail is arranged on the bottom surface of the measuring arm along the radial direction of the revolving plane of the measuring arm, a working platform capable of doing linear movement along the linear guiderail is arranged on the linear guiderail, and a displacement sensor is arranged on the working platform; and a Y-direction working platform and an X-direction working platform are arranged on the base in an overlapping, and the blade of a detected propeller is arranged in a positioning groove at the top surface of the X-direction working platform. The measuring device and the measuring method are established by adopting a cylindrical coordinate system according to the axial symmetry structure characteristics of the propeller blade. The measuring device and the measuring method are fast in data acquisition, have no objective errors of an operator, and are simple in follow-up error processing and analysis, and can be used for precision measurement on size parameters and geometric error parameters of large revolving parts.

Owner:HEFEI UNIV OF TECH

CVD apparatus

InactiveUS6663714B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingProduction rateEngineering

The present invention is to provide a CVD apparatus having a high productivity, involving less contamination on the back surface of a substrate and having a high yield.A CVD apparatus for forming a thin film is characterized in that the interior of the vessel is divided into a upper portion and a lower portion (transfer chamber) by a support member for holding the ring chuck and the upper portion is further divide by inner wall into a deposition chamber and an exhaust chamber in axial symmetry around the same central axis.The deposition chamber communicated to the exhaust chamber through a gap between the inner wall and the ring chuck and / or holes provided in the inner wall. The transfer chamber is communicated to the deposition chamber or exhaust chamber through a gap formed between the ring chuck and the support member.

Owner:ANELVA CORP

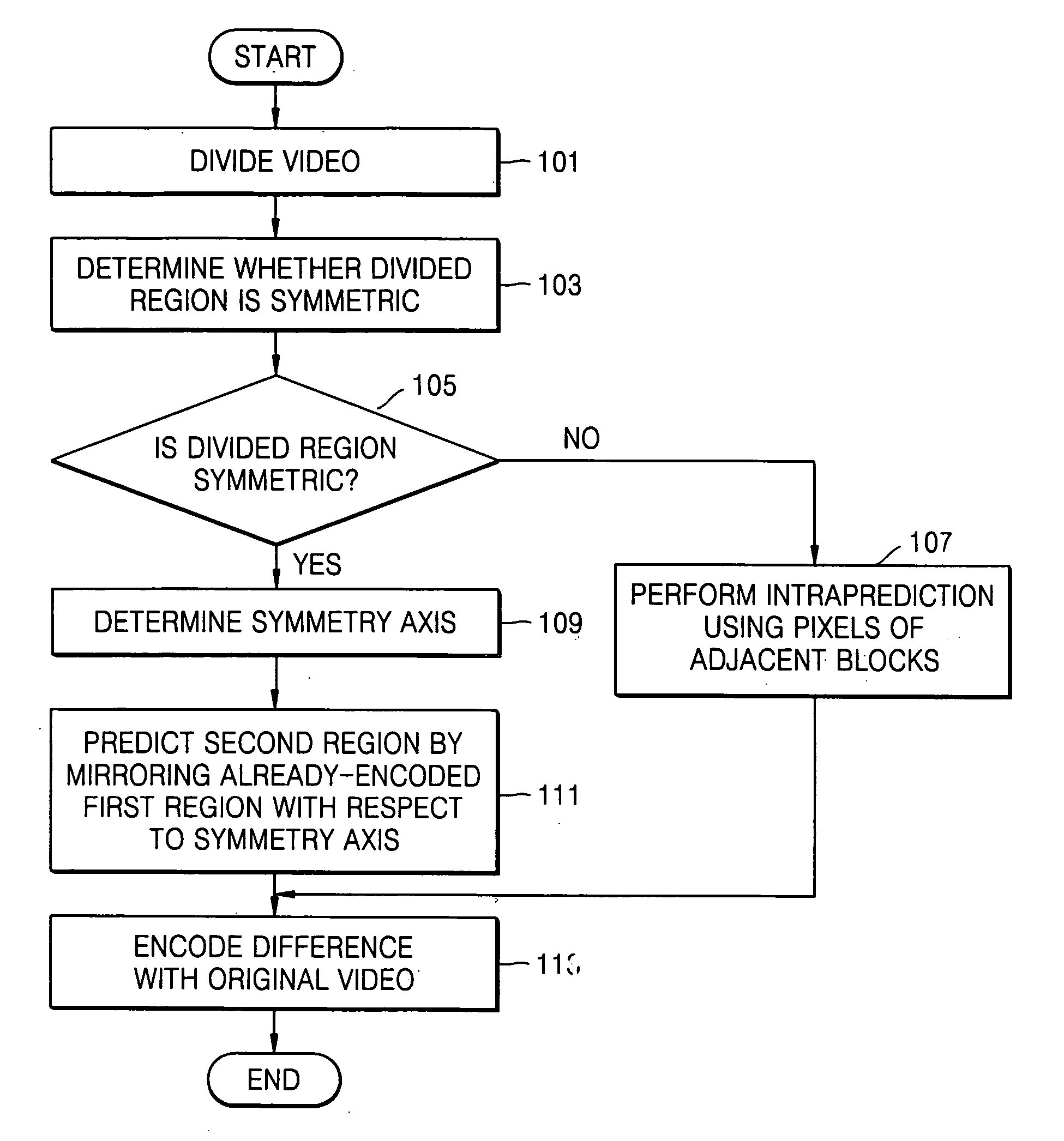

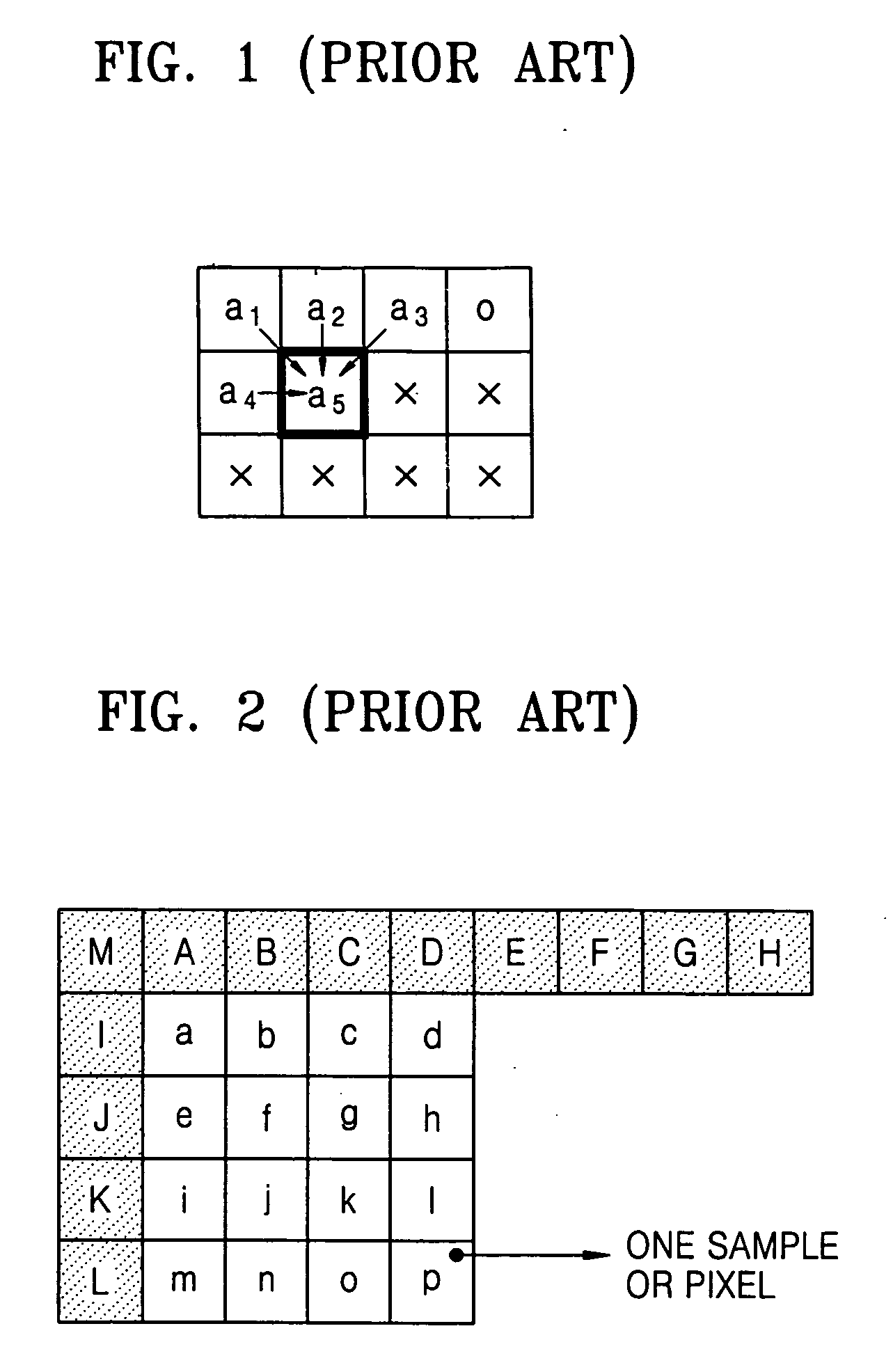

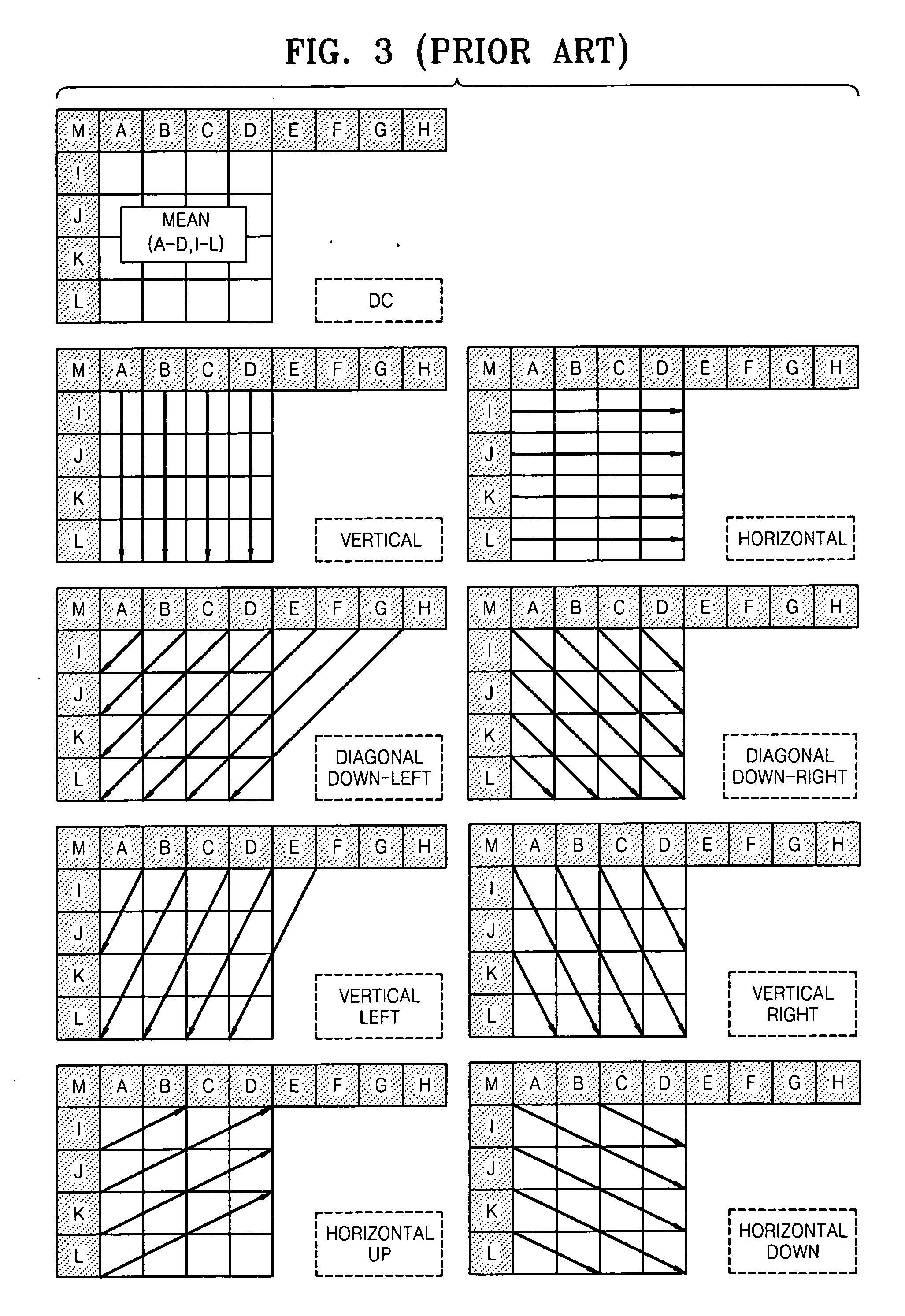

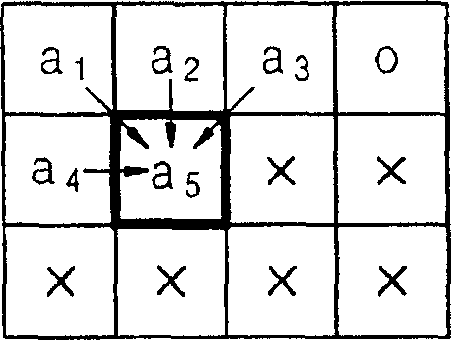

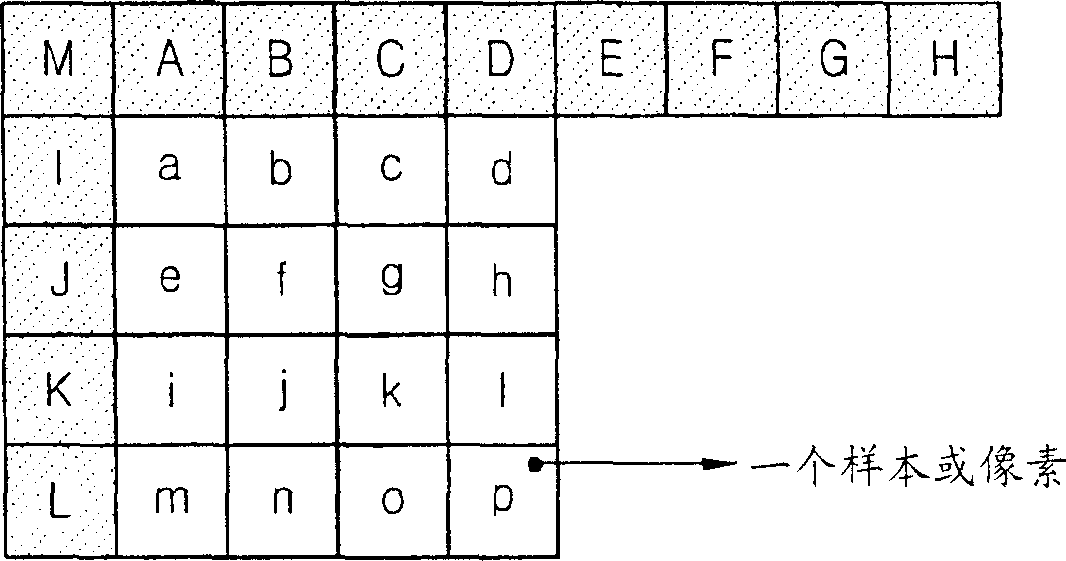

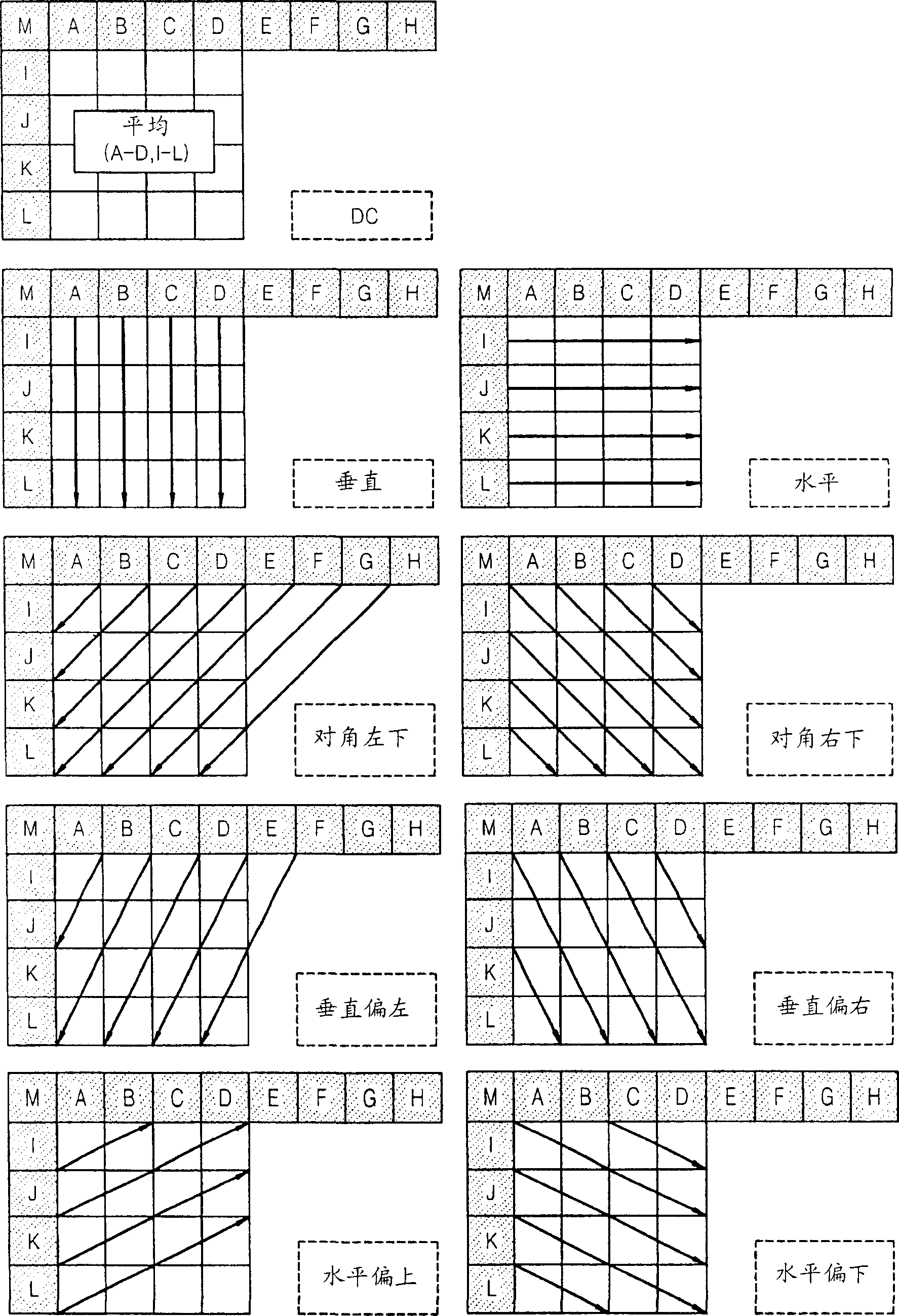

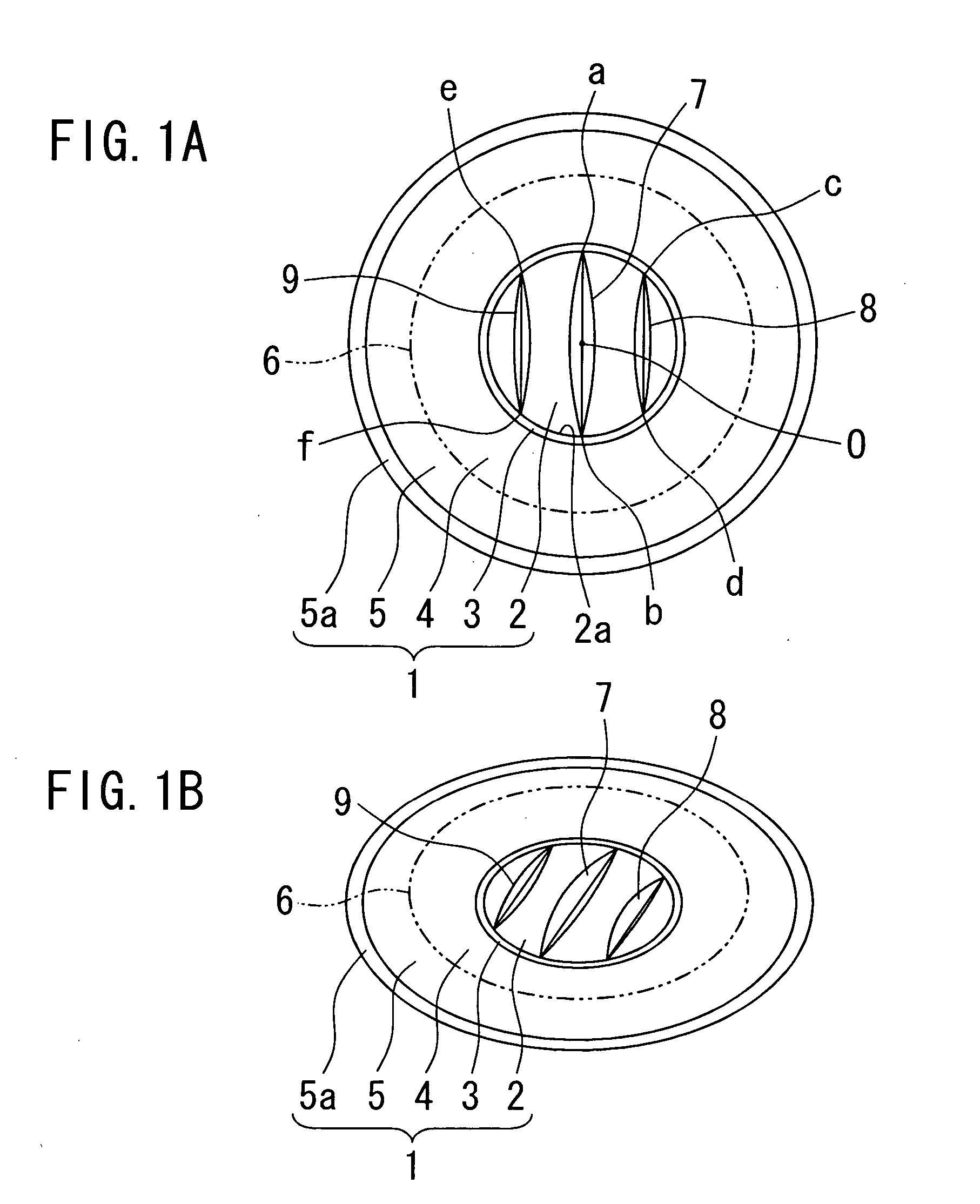

Intraprediction method and apparatus using video symmetry and video encoding and decoding method and apparatus

InactiveUS20060274956A1Improve compression efficiencyColor television with pulse code modulationColor television with bandwidth reductionComputer graphics (images)Video encoding

An intraprediction method which improves compression efficiency using the symmetry of a video in the intraprediction of the video and a video encoding and decoding method and apparatus using the intraprediction method. The intraprediction method includes performing intraprediction by predicting a first region to be encoded in a video based on axial symmetry of a second region of the video with respect to a predetermined axis.

Owner:SAMSUNG ELECTRONICS CO LTD

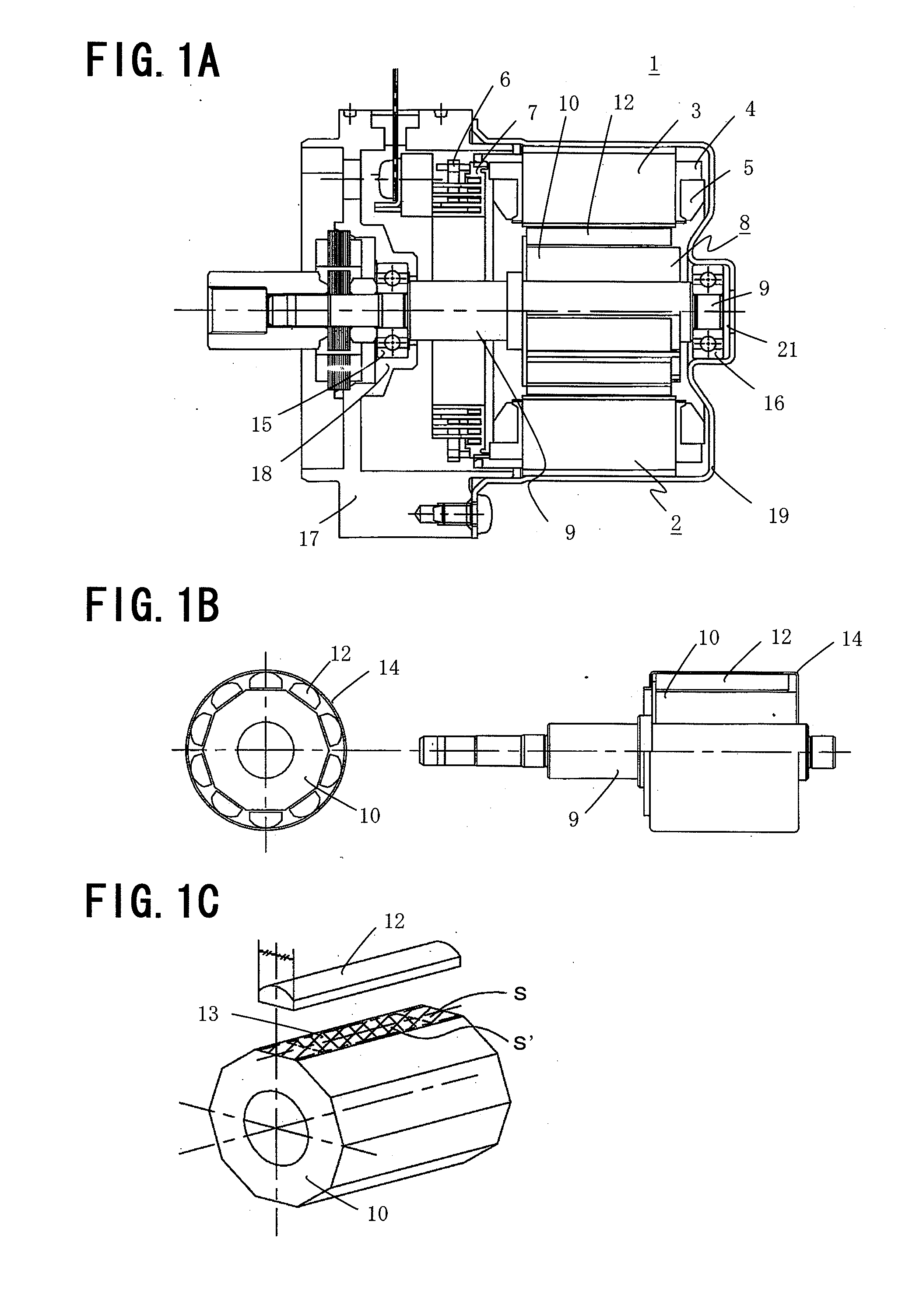

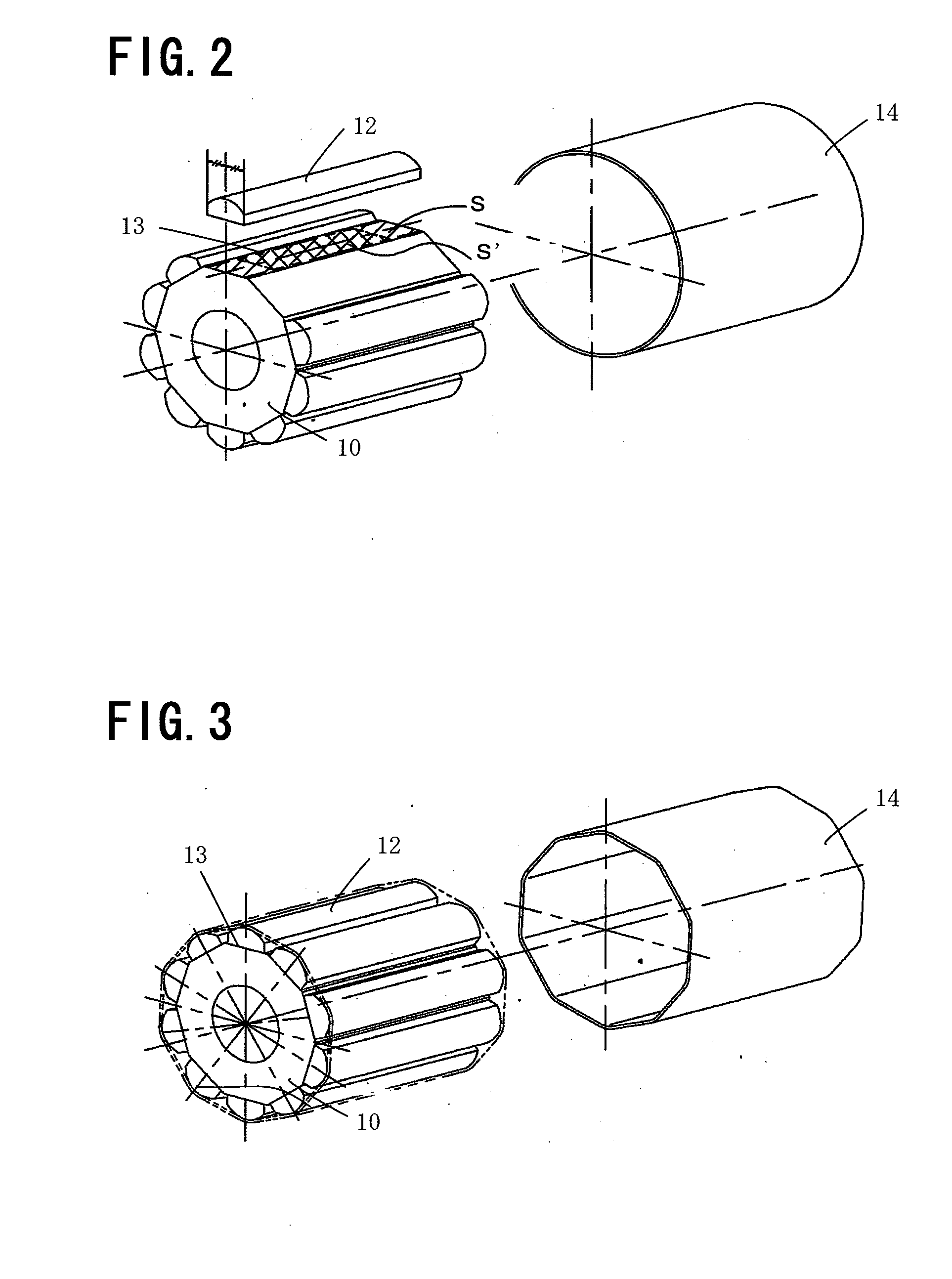

Rotor of rotary electric machine and method of manufacturing the same

InactiveUS20100244607A1Improve reliabilityStable magnet retention strength strengthMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineEngineering

In a rotor of a permanent magnet rotary electric machine, a bonding portion between each of segment shaped magnets and an outer circumference face of a rotor core is provided in axial symmetry with respect to the rotor axial center and has a bonding area equal to or larger than a half of a contact area between each of the segment shaped magnets and the outer circumference face of the rotor core; and a biasing force is applied to an outer circumference face of the segment shaped magnets by a ring.

Owner:MITSUBISHI ELECTRIC CORP

Intraprediction method and apparatus using video symmetry and encoding and decoding method and apparatus

InactiveCN1874519APulse modulation television signal transmissionDigital video signal modificationComputer graphics (images)Video encoding

An intraprediction method which improves compression efficiency using the symmetry of a video image in the intraprediction of the video, and a video encoding and decoding method and apparatus using the intraprediction method. The intraprediction method includes performing intraprediction by predicting a first region to be encoded in a video based on axial symmetry of a second region of the video with respect to a predetermined axis.

Owner:SAMSUNG ELECTRONICS CO LTD

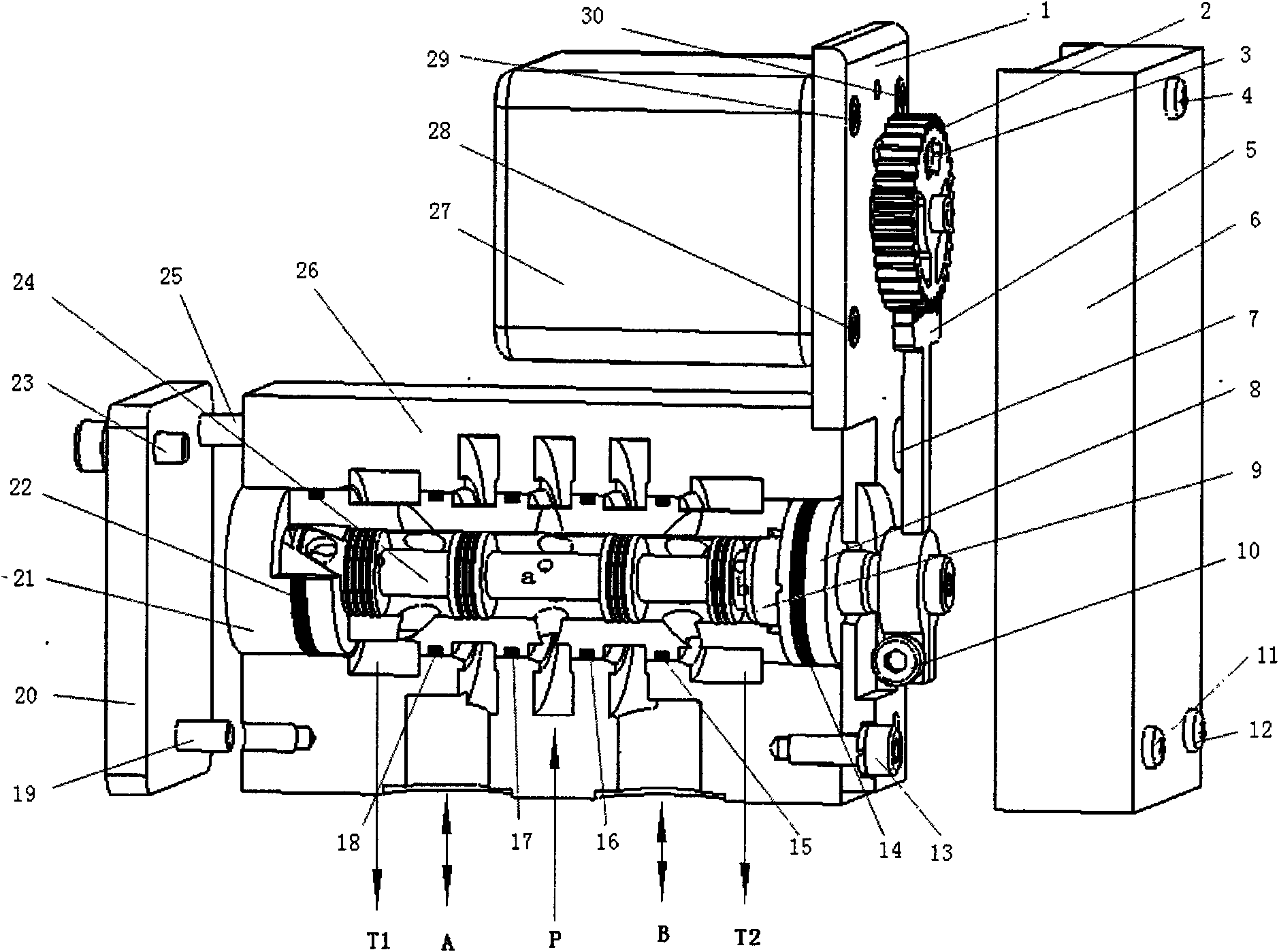

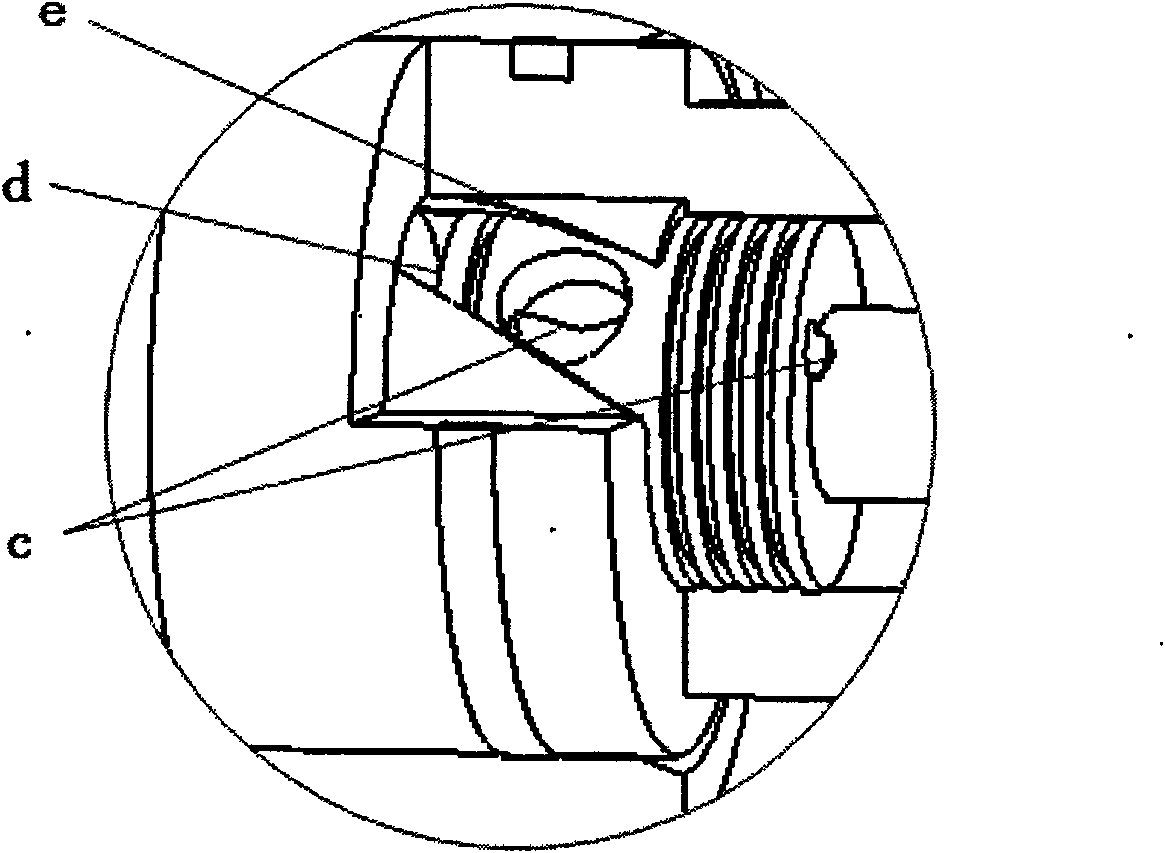

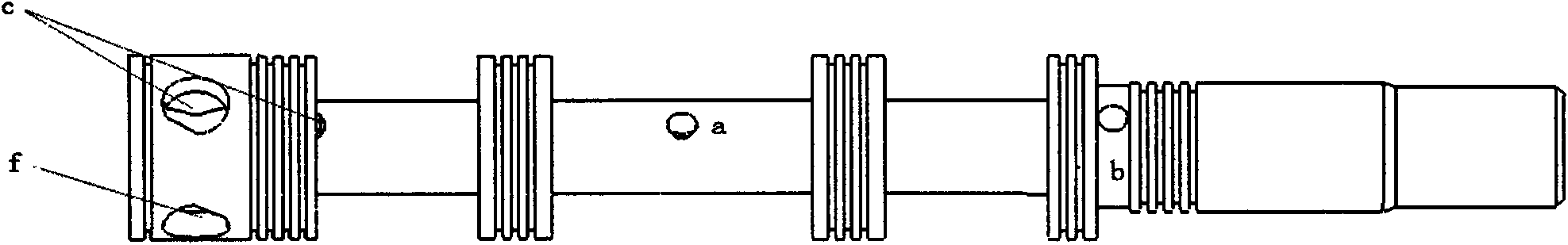

High frequency large flow 2D digital servo valve

ActiveCN101666341AWith self-cleaning functionIncrease the areaServomotor componentsEngineeringHigh pressure

A high frequency large flow 2D digital servo valve comprises a valve body, a mulitpolar AC servo motor, a moment amplifying mechanism, a valve plug and a valve sleeve, the output shaft of the mulitpolar AC servo motor is connected with the input end of the moment amplifying mechanism, the output end of the moment amplifying mechanism is fixedly connected with the front end of the valve plug, the valve sleeve is sealed in the valve body, the valve plug is rotationally installed in the valve sleeve, the left end of the valve plug, the valve sleeve and a back cover plate construct a sensitivity chamber, the surface of ledges of the valve plug in the sensitivity chamber is respectively provided with a high pressure hole and a low pressure hole which are arranged in axial symmetry, both the high pressure hole and the low pressure hole are of bow shape, the bowstring of the high pressure hole and that of the low pressure hole are parallel, the inner surface of the valve sleeve outside the sensitivity chamber is provided with a pair of spiral grooves in axial symmetry, one end of the pair of spiral grooves is communicated with the sensitivity chamber, and the other end thereof covers thearea between adjacent high pressure hole bowstring and low pressure hole bowstring. The invention has excellent dynamic response property, is suitable to work under state of large flow, and has simple structure, high precision and strong anti-pollution capacity.

Owner:河南航天流体控制技术有限公司

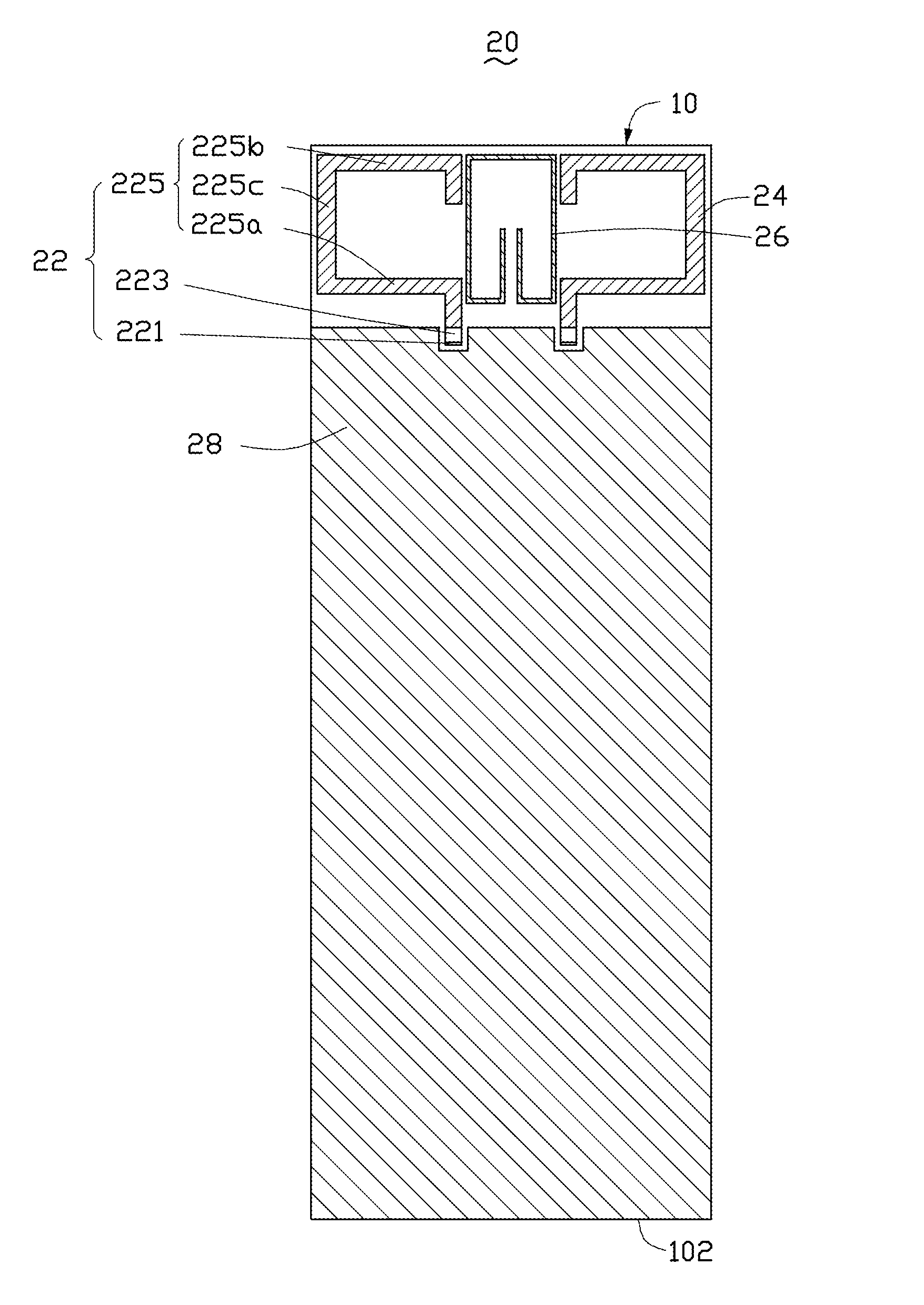

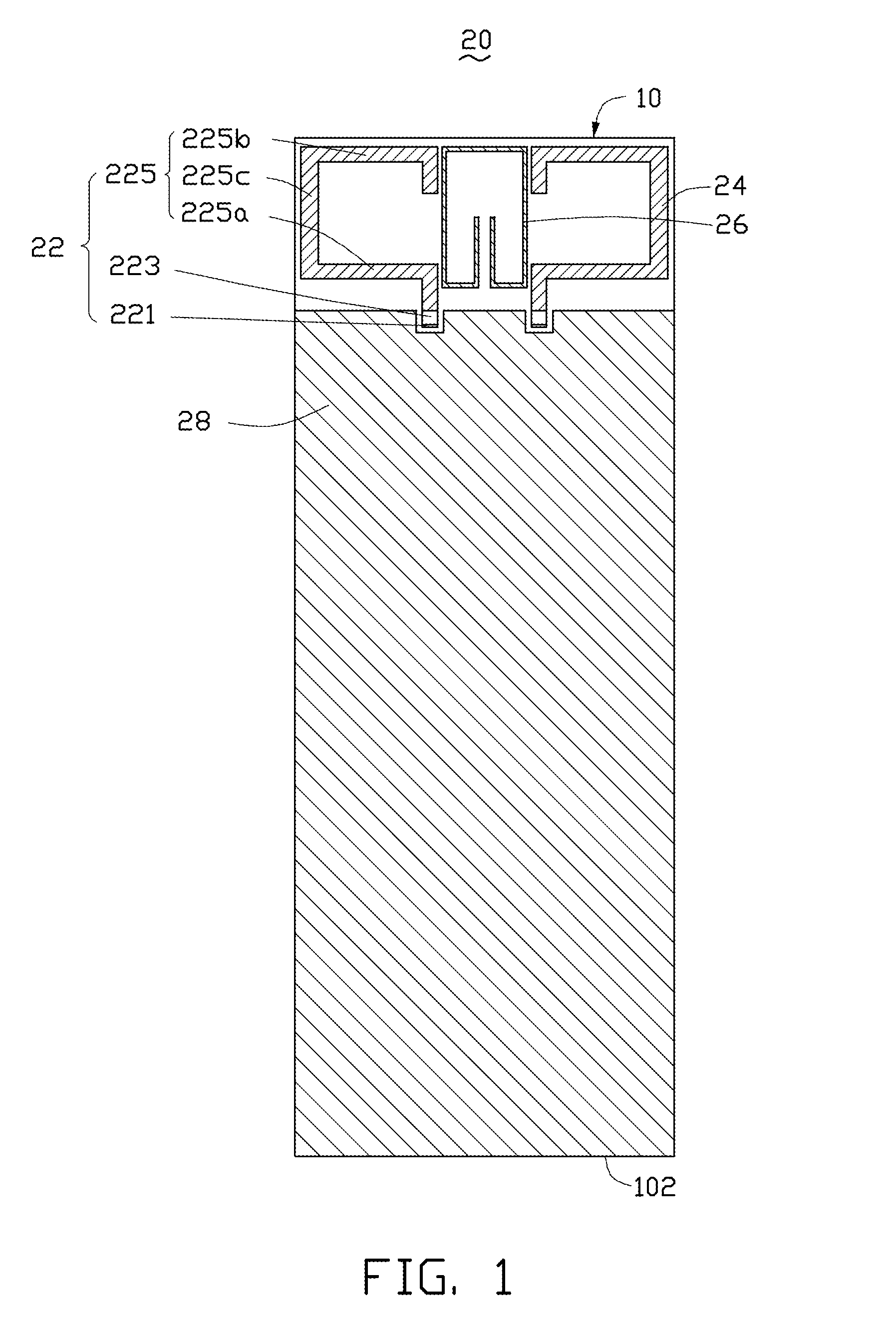

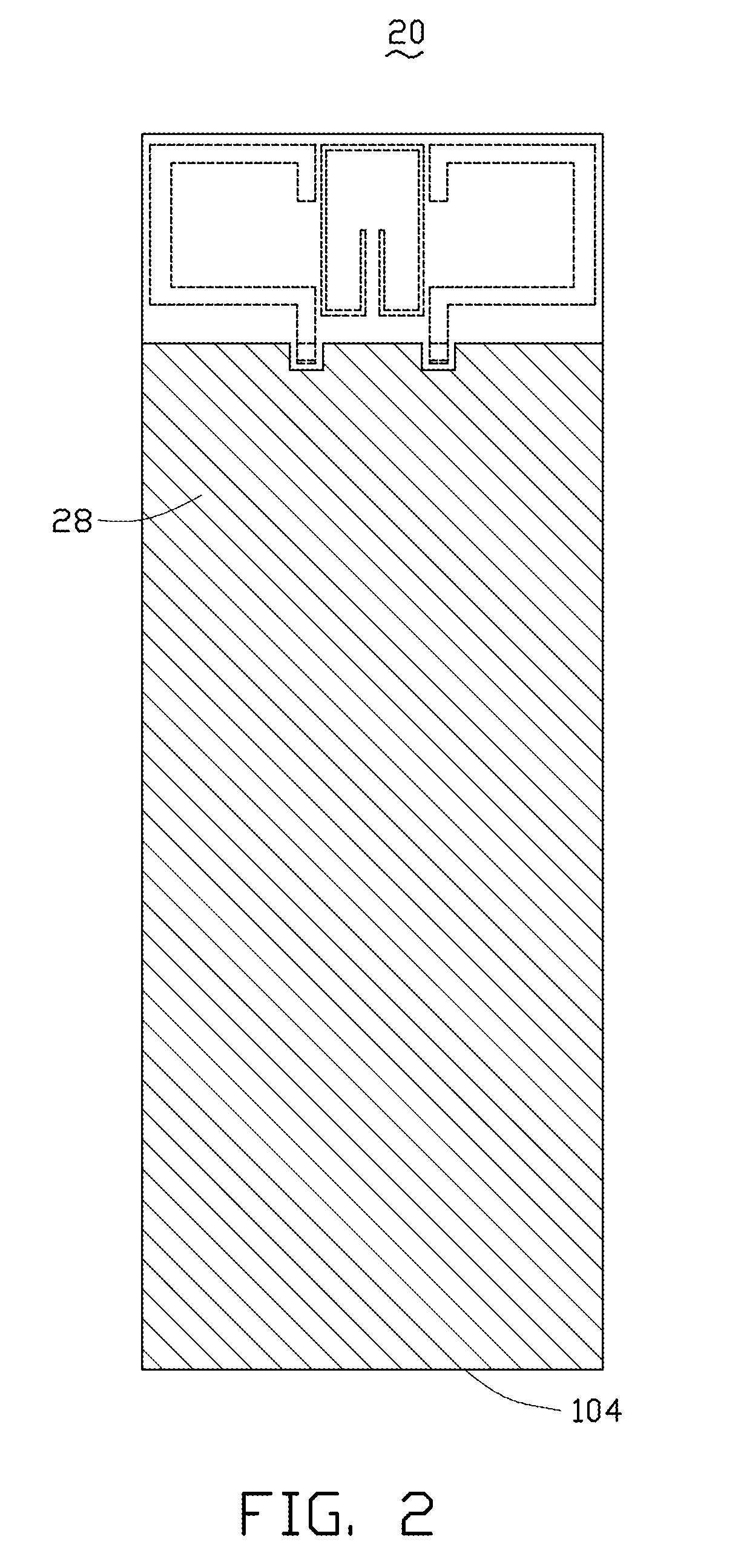

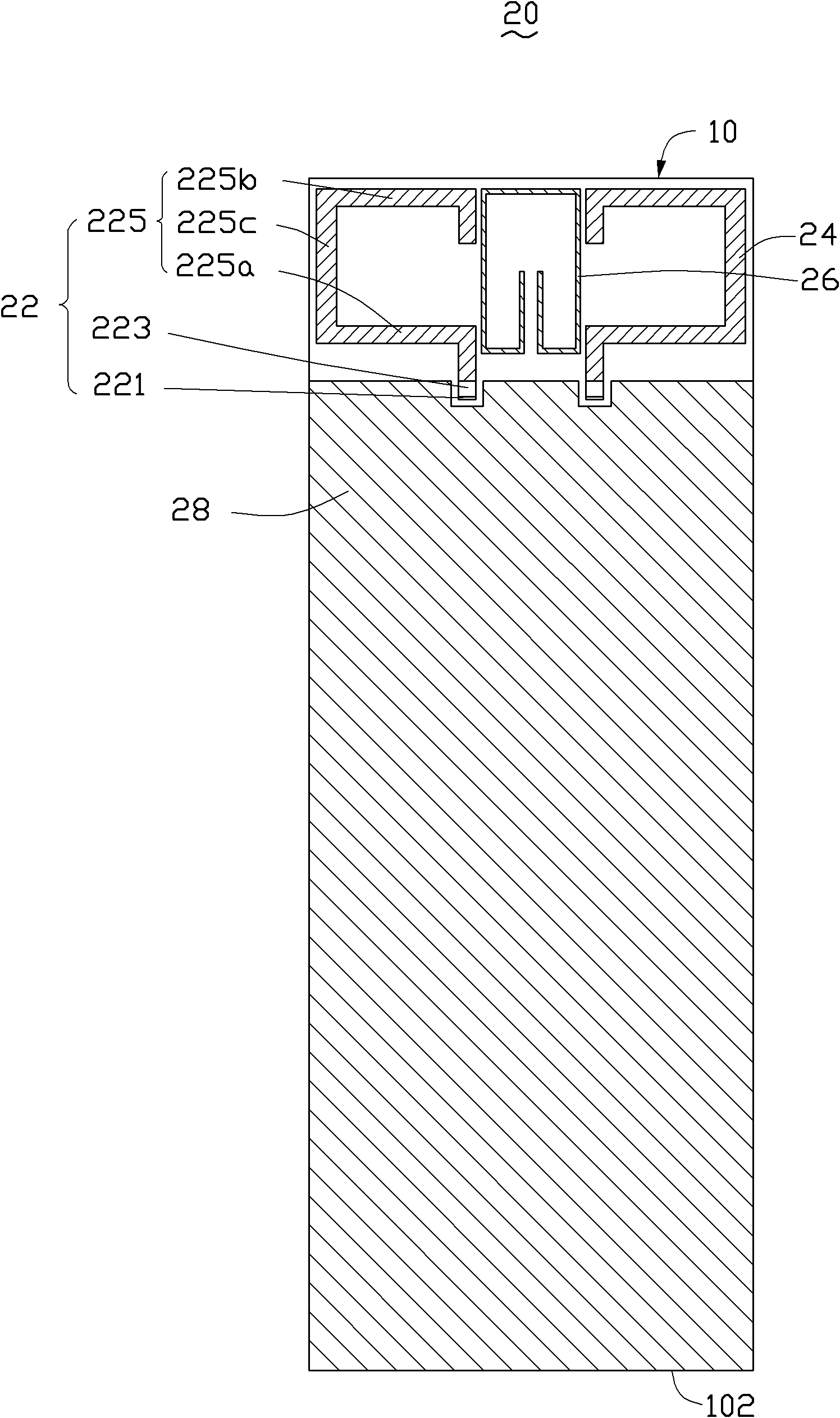

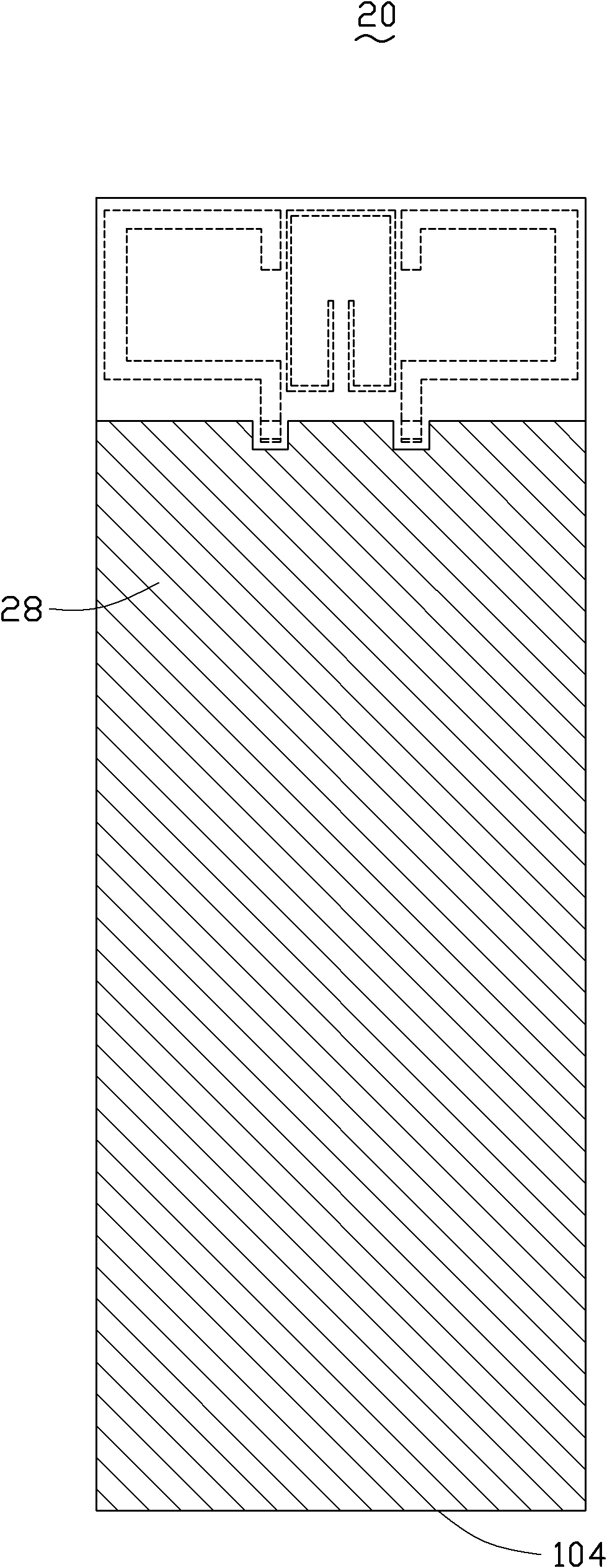

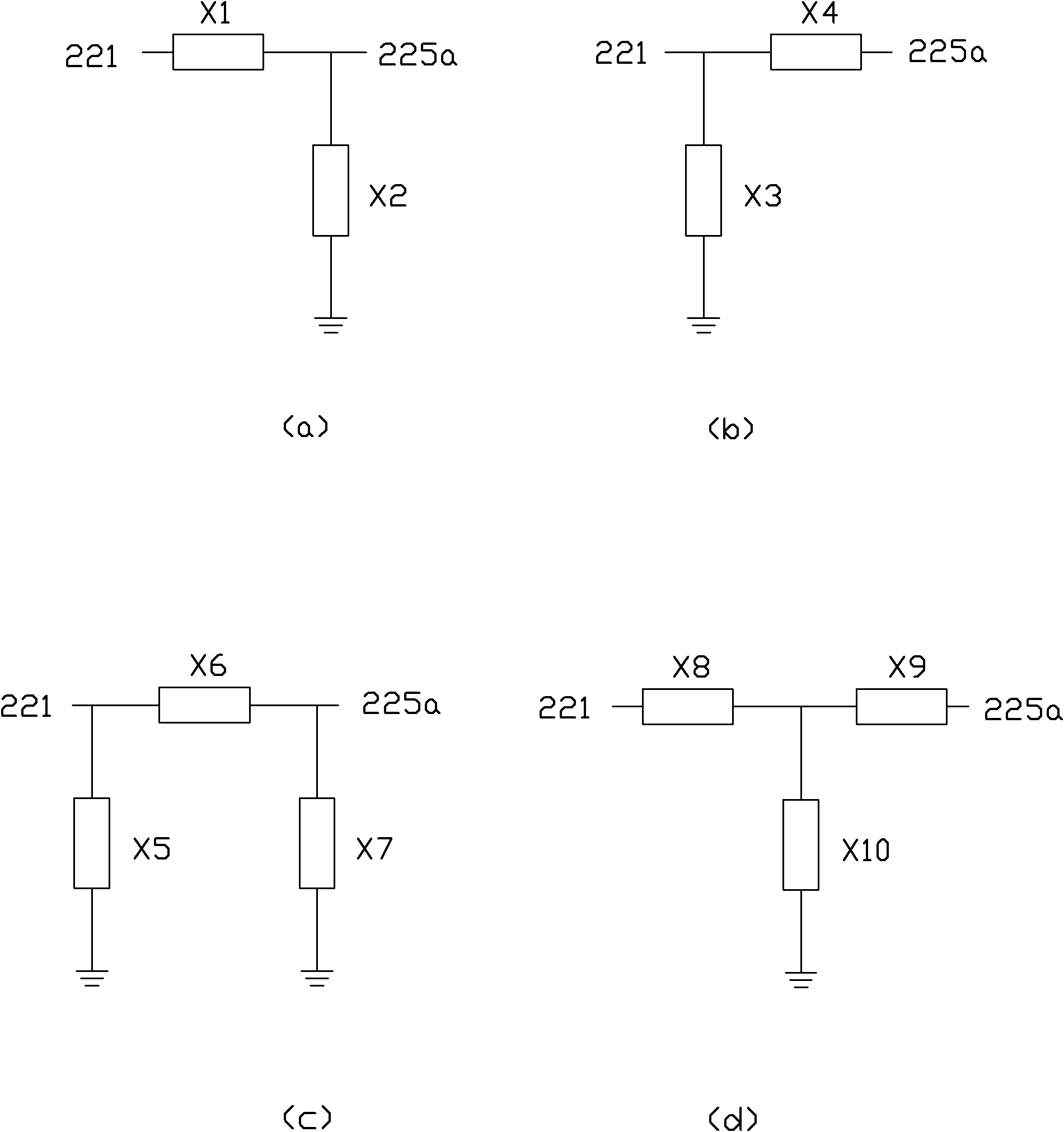

Multiple-input multiple-output antenna

InactiveUS20120274536A1Simultaneous aerial operationsRadiating elements structural formsCouplingEngineering

A Multiple-Input Multiple-Output (MIMO) antenna on a substrate includes first and second antennas defined in axial symmetry, a coupling portion, and a grounding portion. The substrate includes a first surface and an opposite second surface. Each of the antennas includes a feeding portion, a radiating portion, and a matching portion. The feeding portion feeds electromagnetic signals to the antenna. The radiating portion radiates the electromagnetic signals, and is in a meandering “S” pattern. A length of the radiating portion is substantially equal to a quarter wavelength of the electromagnetic signals. The matching portion implements impedance matching between the feeding portion and the radiating portion. The coupling portion is located between the first antenna and the second antenna and is serpentine shape. A length of the coupling portion is substantially equal to a half wavelength of the electromagnetic signals. The grounding portion is located on both the first and second surface.

Owner:HON HAI PRECISION IND CO LTD

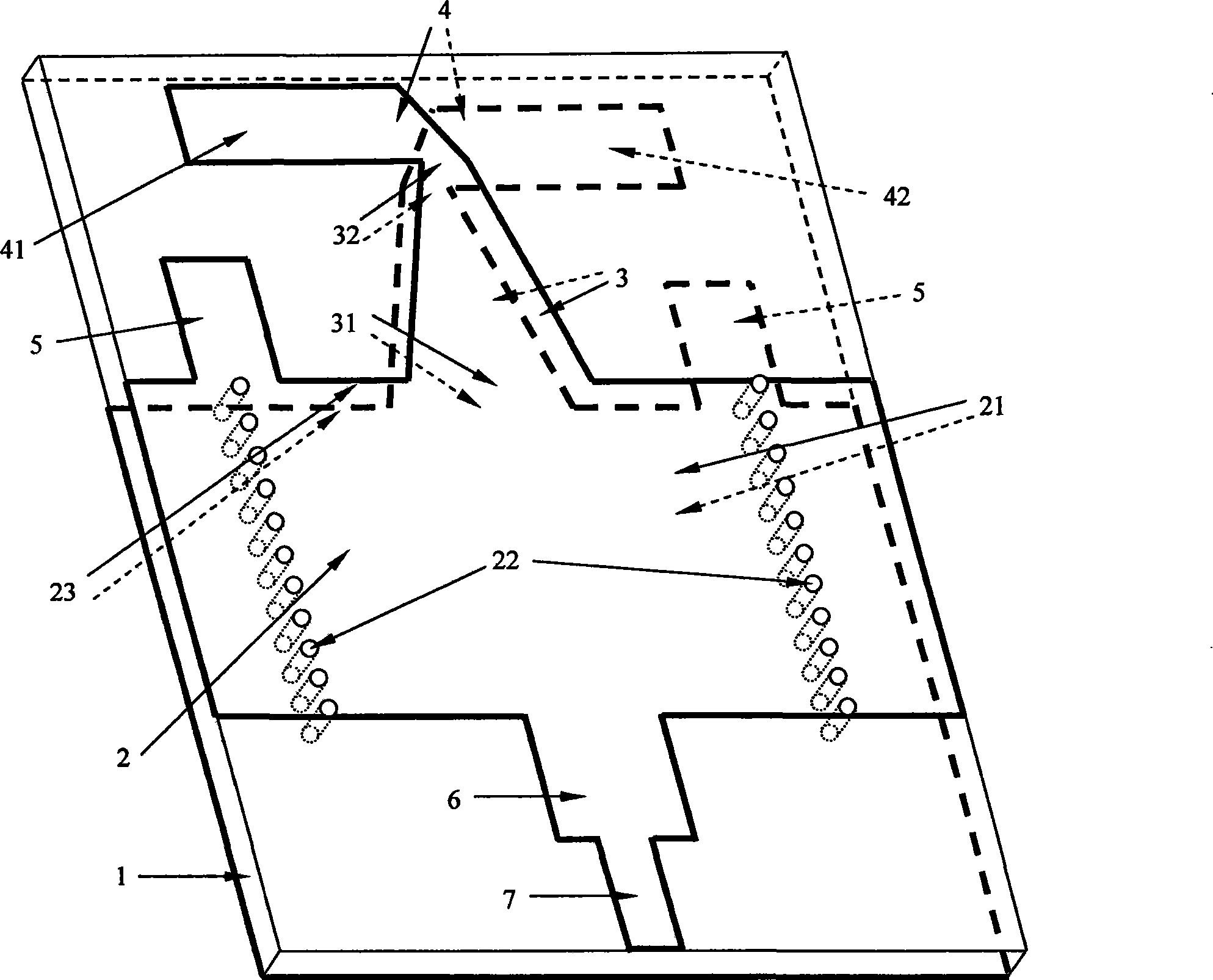

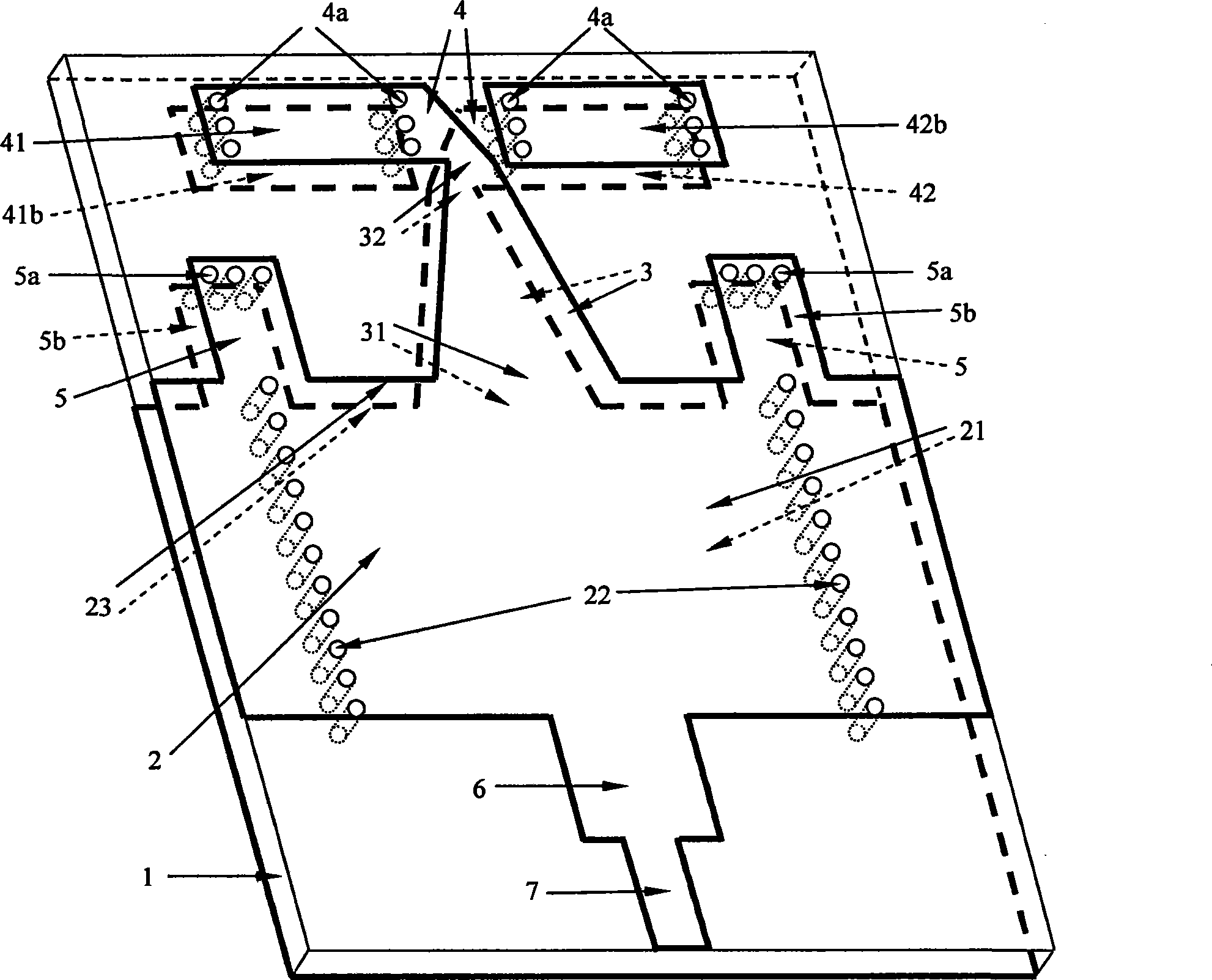

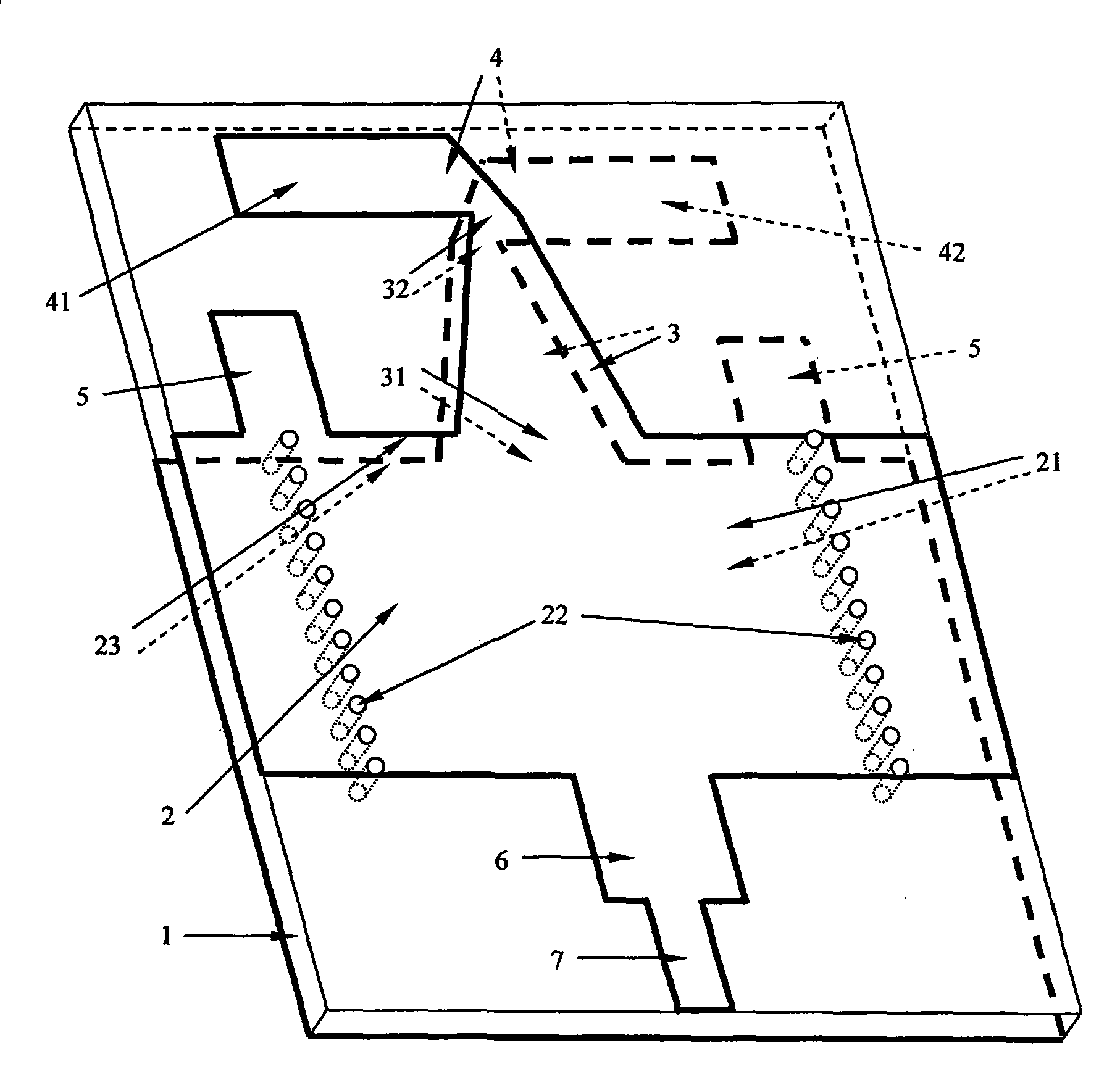

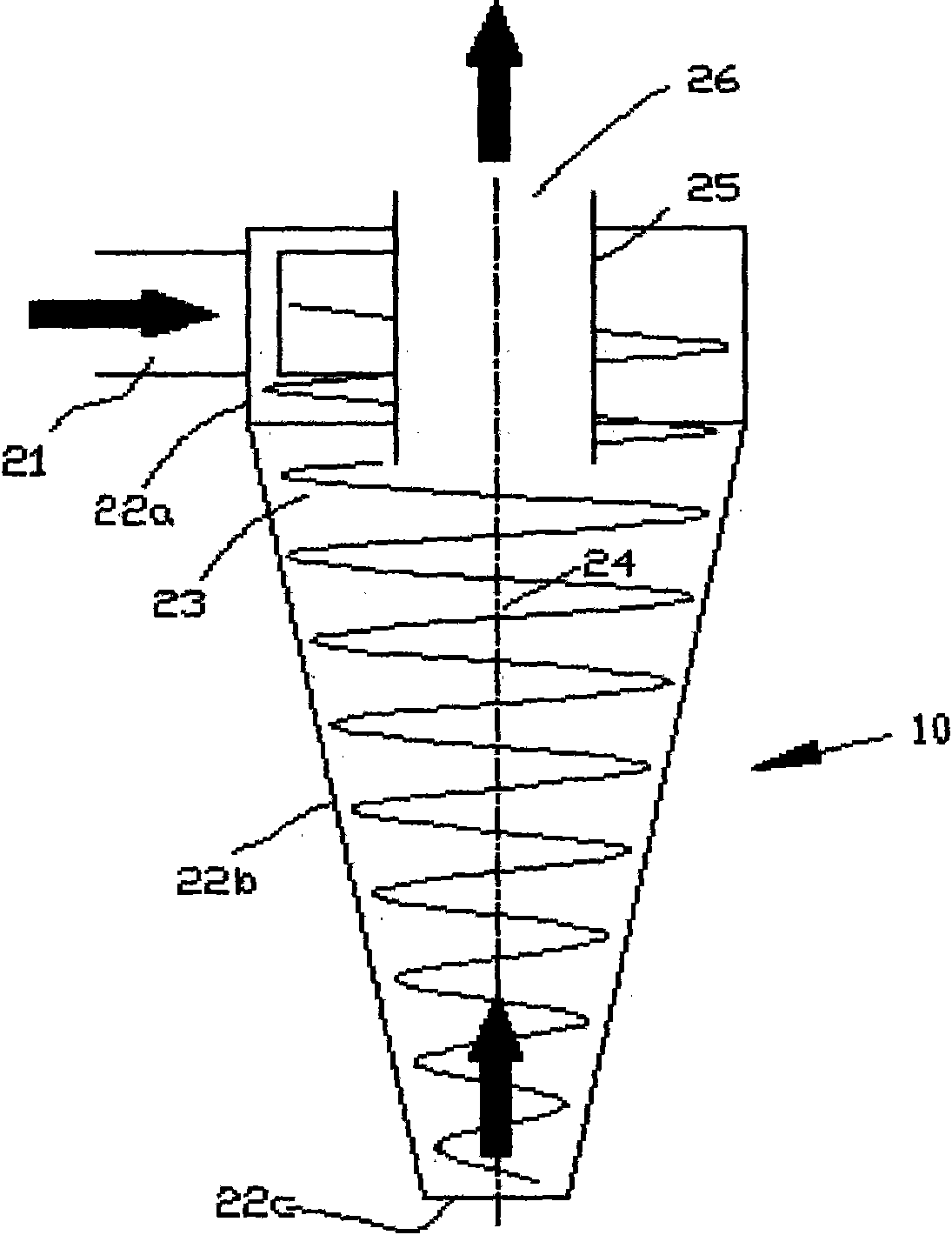

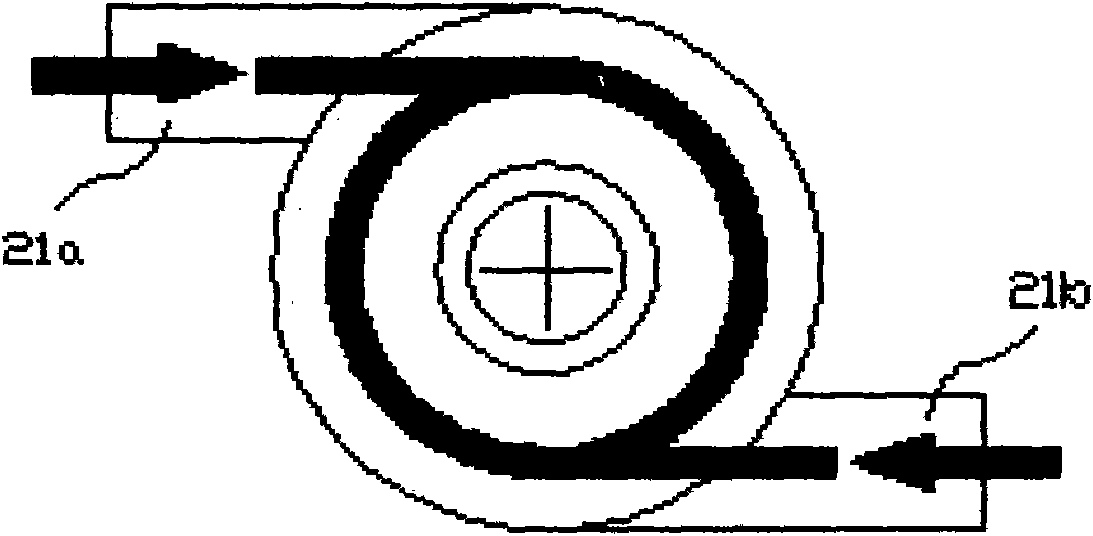

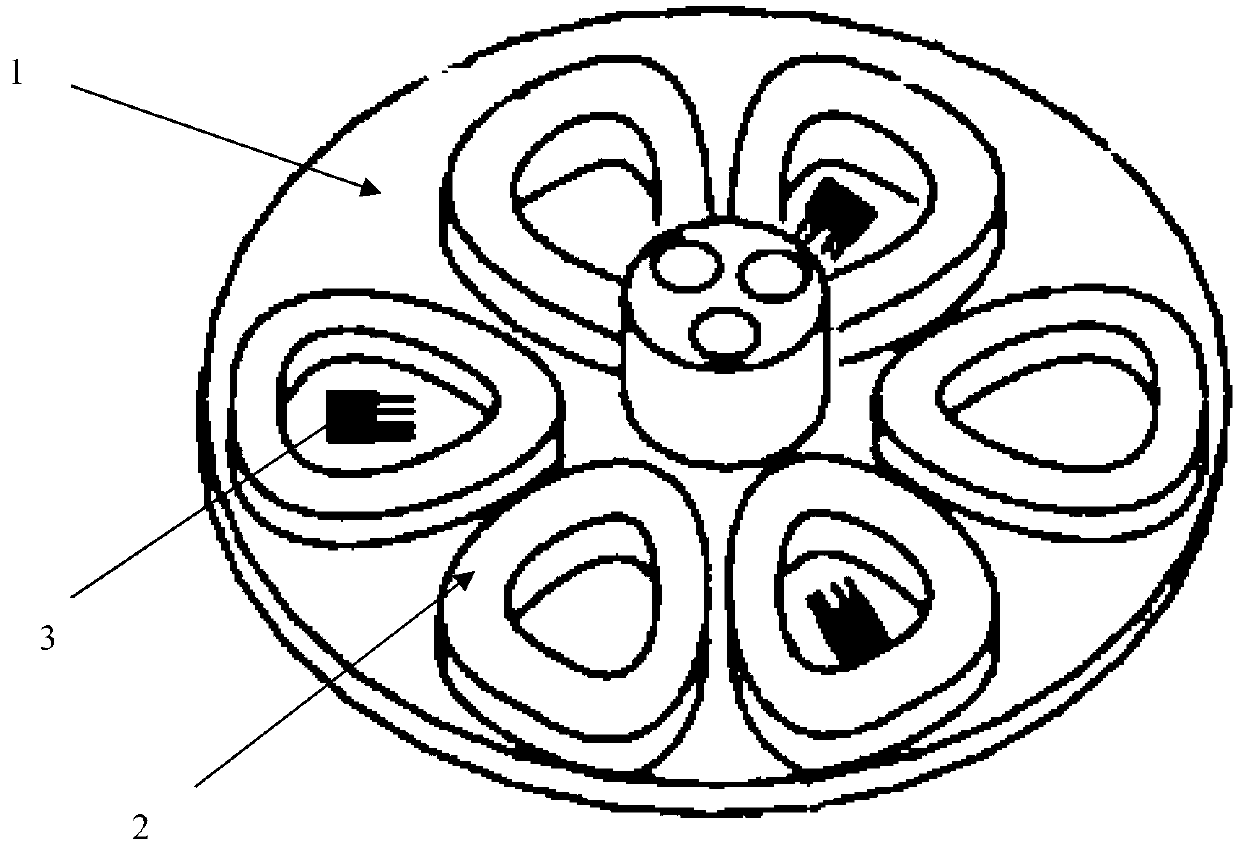

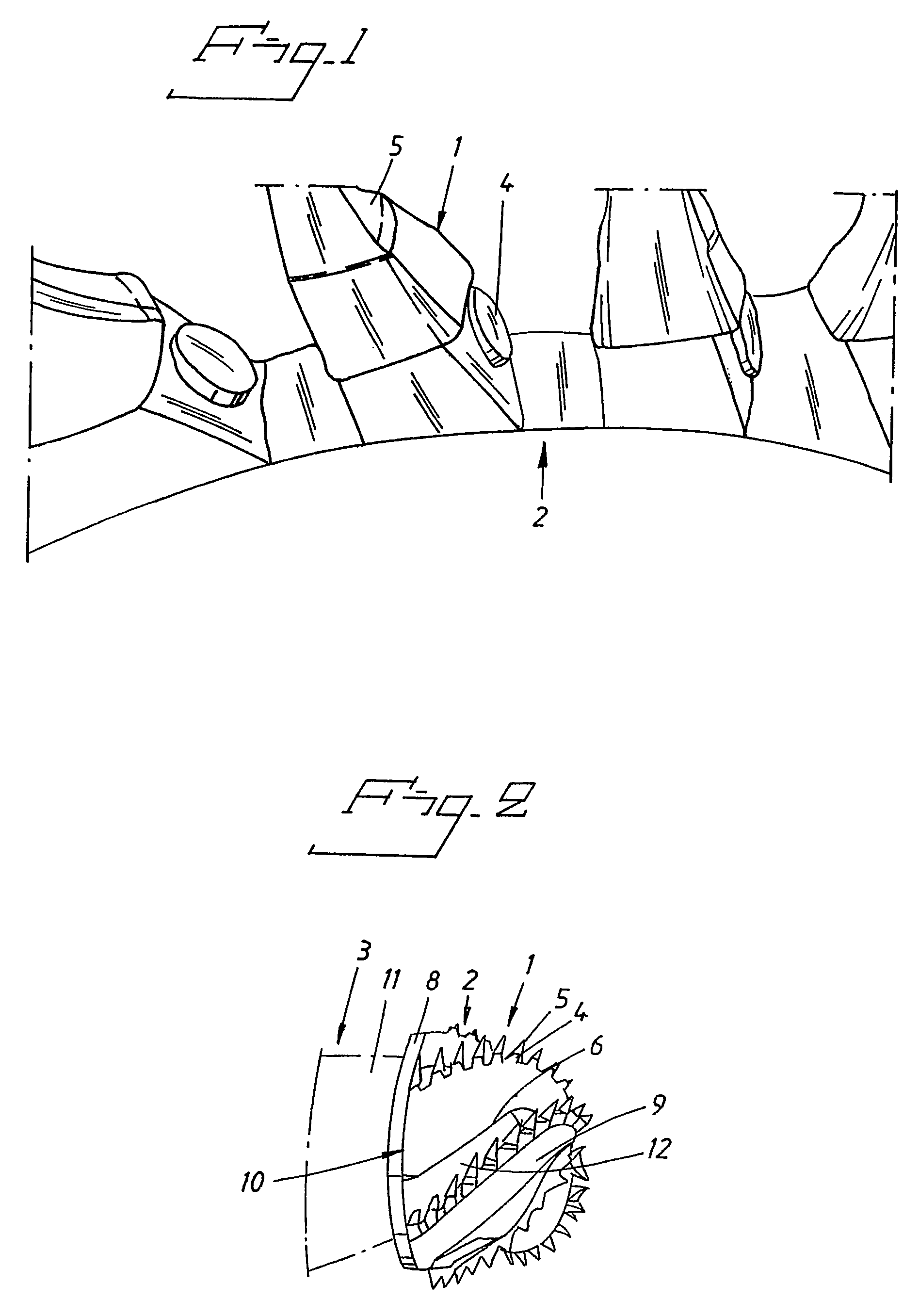

Multistage cyclone separation device of dust collector

InactiveCN101862165AExcellent vortex nuclear deformationReduce resistanceSuction filtersCycloneCyclonic separation

The invention relates to a multistage cyclone separation device of a dust collector, which comprises an upstream first-stage cyclone separation device (1), a downstream second-stage cyclone separation device (2) and a gas flow channel (3), wherein the gas flow channel (3) is used for connecting the upstream first-stage cyclone separation device (1) and the downstream second-stage cyclone separation device (2), the downstream second-stage cyclone separation device (2) comprises a cyclone filter (5), a dust-gas separation cover (6) and a central cylinder (8), at least two tangential air inlets are arranged on the cylindrical later surface of a cyclone cylinder body (20), an exhaust pipe (504) is positioned on the cylindrical top surface of the cyclone cylinder body (20), and the tangential air inlets have equal cross sectional area, are positioned on the same horizontal surface and are arranged relatively to the central shaft of the cyclone cylinder body (20) according to equal phase difference. The invention has the advantages that the short-circuit flow of the exhaust pipe is less than that of a single-gas inlet cyclone separation device, the axial symmetry of a flow field is more excellent, and the proportion that small-granule dust directly enters an exhaust port without cyclone separation after entering a separation chamber is reduced.

Owner:马吉

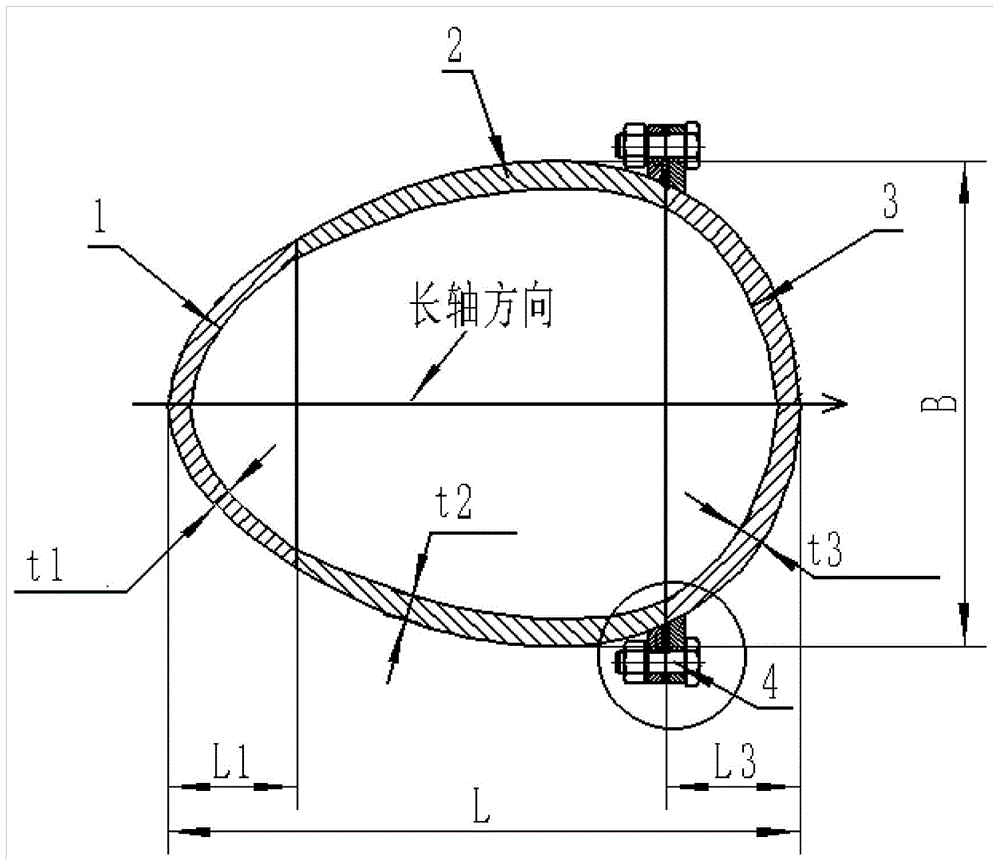

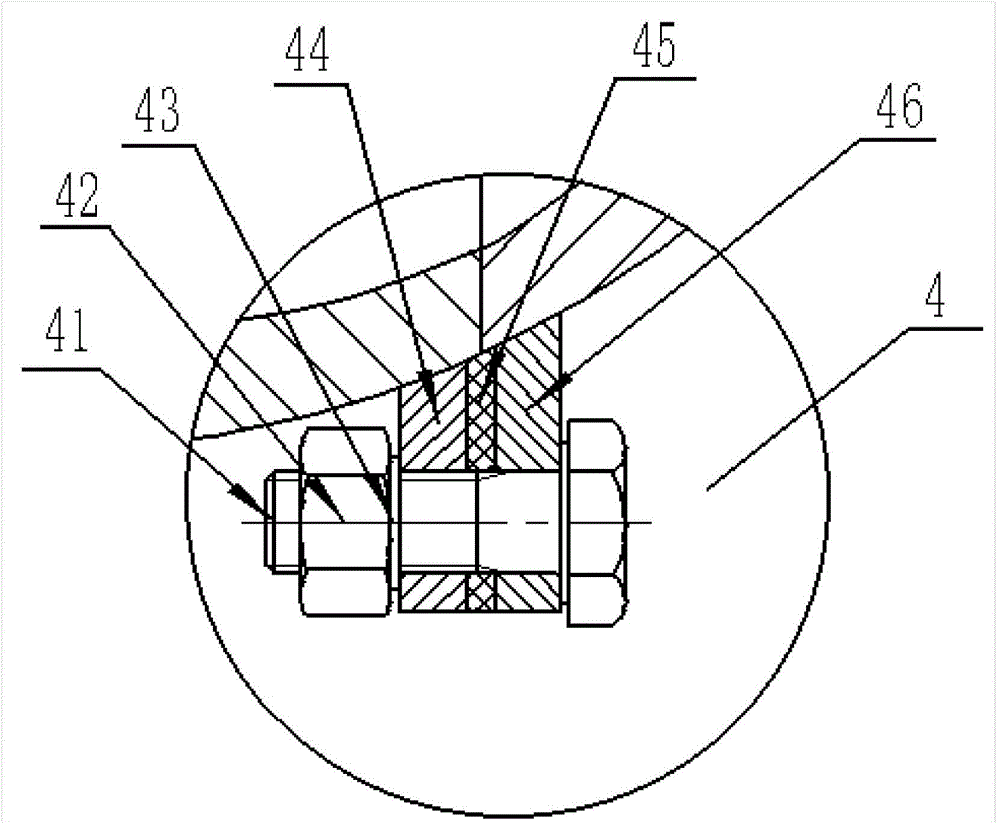

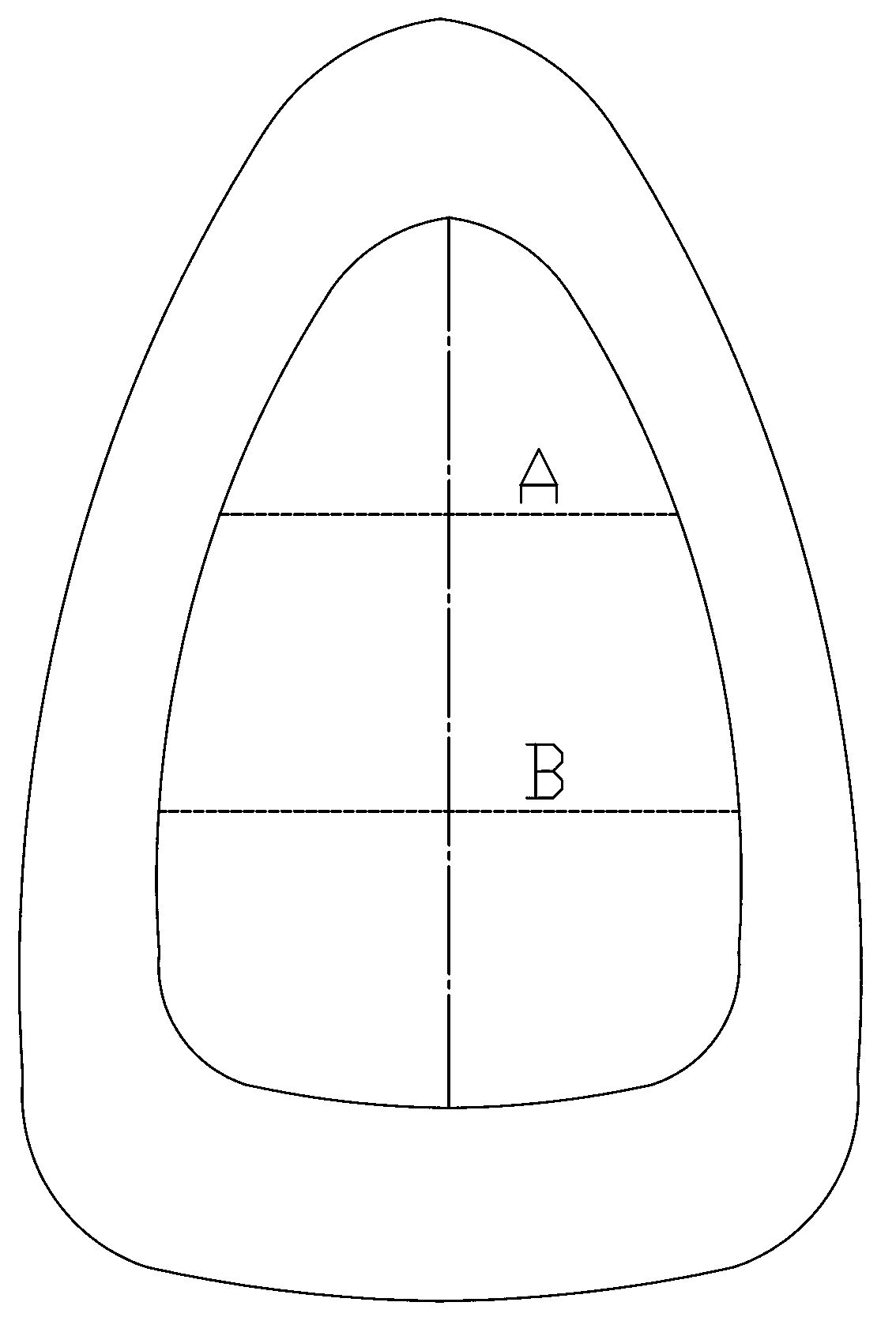

Deep sea bionic pressureproof shell

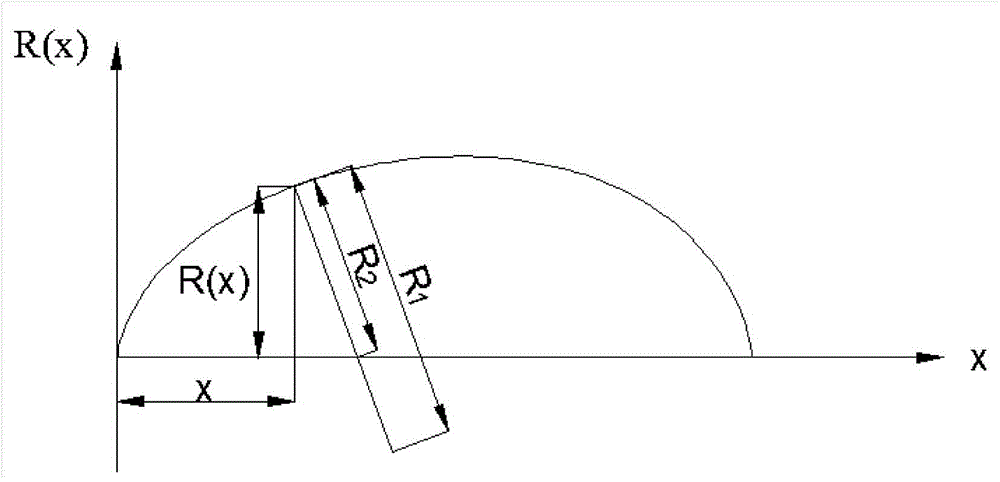

ActiveCN104648638AGood pressure resistanceStreamlinedUnderwater vesselsUnderwater equipmentVariable thicknessCarrying capacity

The invention discloses a deep sea bionic pressureproof shell. An axial-symmetry eggshell-shaped structure with the length of L, the width of B and the turning radius of R(x) is formed by a left end socket, a right end socket and a middle shell, wherein the thickness t2 of the middle shell is of an equal-strength variable-thickness structure, the thickness t1 of the left end socket and the thickness t3 of the right end socket are respectively of an equal-thickness structure, the left end socket and the middle shell are fixedly connected, and the right end socket and the middle shell are connected by a flange bolt or a movable hatch cover with a seal ring. The deep sea bionic pressureproof shell has good mechanical properties, in-shell space utilization rate, hydrodynamic characteristics and passenger comfort, and comprehensive improvement on safety, carrying capacity, mobility and diving time of a diving device is facilitated; meanwhile, the weight of the pressureproof shell is lightened, the reserve buoyancy of the pressureproof shell is increased, and the processing and manufacturing difficulty and cost are reduced.

Owner:JIANGSU UNIV OF SCI & TECH

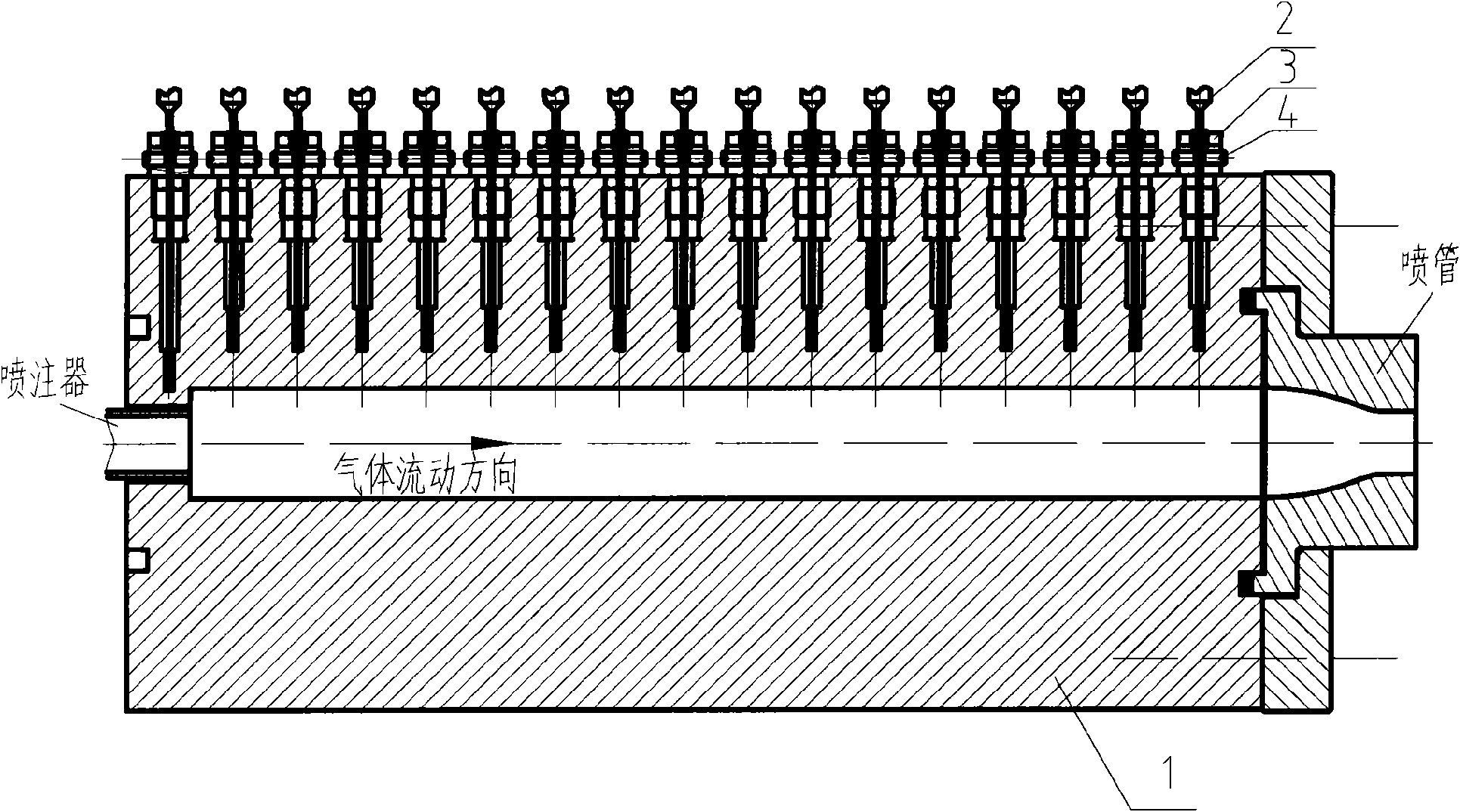

Method and device for measuring temperature and heat flow distribution on internal face of combustion chamber

InactiveCN101608953ALow costEasy to installThermometer detailsThermometers using electric/magnetic elementsHeat flowMeasurement device

The invention relates to a method and a device for measuring temperature and heat flow distribution on the internal face of a combustion chamber, and belongs to the field of temperature and heat flow measurement. The measurement device comprises the combustion chamber, a temperature sensor, a temperature sensor fixing device, a signal transmission line and a computer; the lateral surface of the combustion chamber is provided with a series of equidistant temperature measuring blind holes; the temperature sensor measures the temperatures of the bottoms of the blind holes so as to obtain a temperature output curve of each measure point; and then a certain value computational method is adopted to calculate the temperature and the heat flow distribution on the internal face of the combustion chamber. Due to adopting a proposal of measuring the temperatures of the blind holes, the method and the device solve the problems of high processing and mounting difficulties, inconvenient detachment and the like in the prior art; and the armored thermocouple temperature sensor with mature technology is adopted, so that the cost is low and the use is convenient. The method and the device can be used for measuring the temperature and the heat flow distribution on the internal face of a combustion device with an axial symmetry structure.

Owner:BEIHANG UNIV

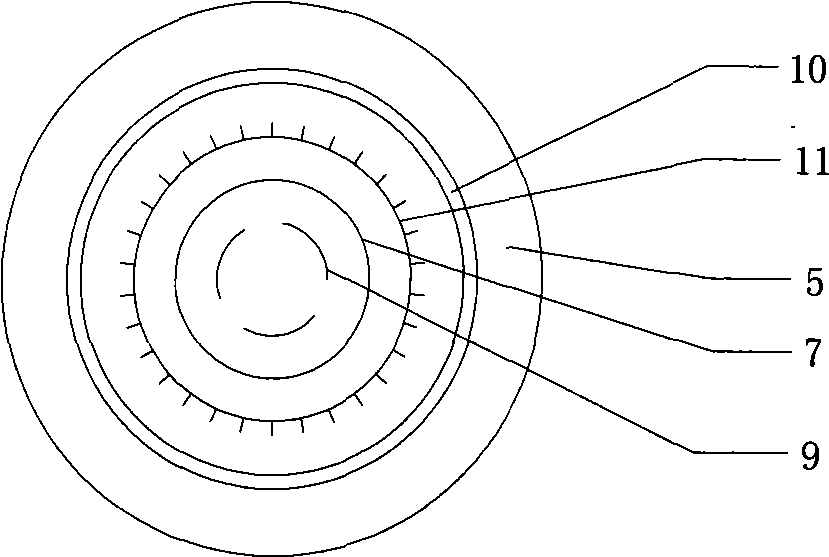

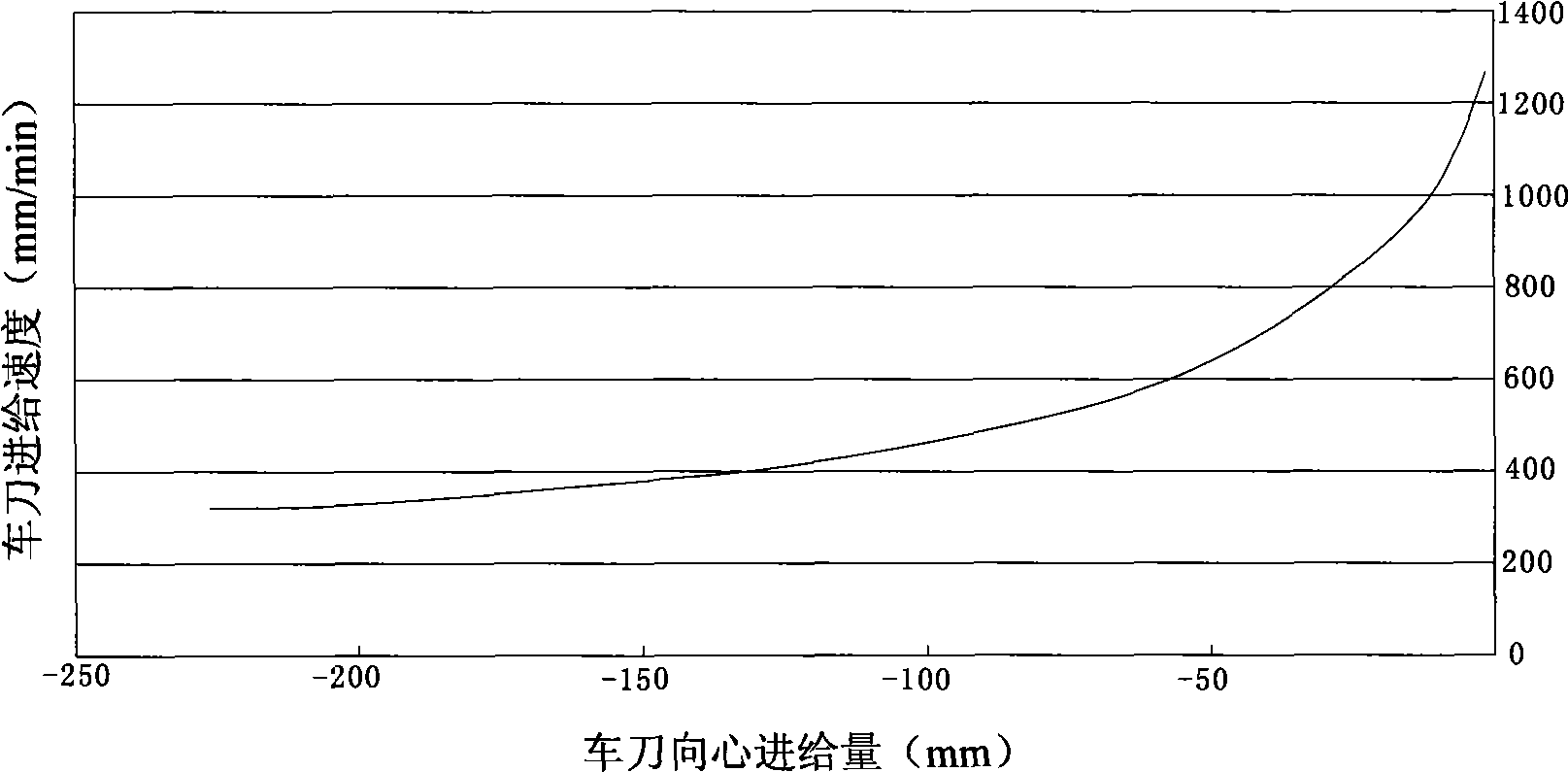

Processing control method of axial symmetry free-form surface of aspheric surface optical elements

The invention belongs to a processing control method for axial symmetrical free curved surfaces of a non-spherical optical element, relates to a non-spherical optical element, and provides a processing control method for axial symmetrical free curved surfaces of a non-spherical optical element and capable of improving the surface precision of the free curved surfaces and a device thereof. The device is provided with a workbench, a laser interferometer, a micro feeding mechanism, a grating scale, a tool post, a rotary encoder, a turning tool, a rotary platform, a main shaft and a controller. The method comprises the following steps: connecting the turning tool and the grating scale, mounting the rotary encoder and the laser interferometer on the workbench, and positioning the turning tool by adjusting and controlling the grating scale and the rotary encoder; calculating control models at a feeding speed; setting processing parameters and carrying out numerical control programming to generate a numerical control processing code and a compensation processing program of each shaft; processing the optical element according to the numerical control processing code; using the interferometer to measure work pieces on line, processing and fitting data for measurement results, and finishing processing if the surface precision requirement is accorded; and returning to the compensation processing program if the surface precision requirement is not accorded.

Owner:XIAMEN UNIV

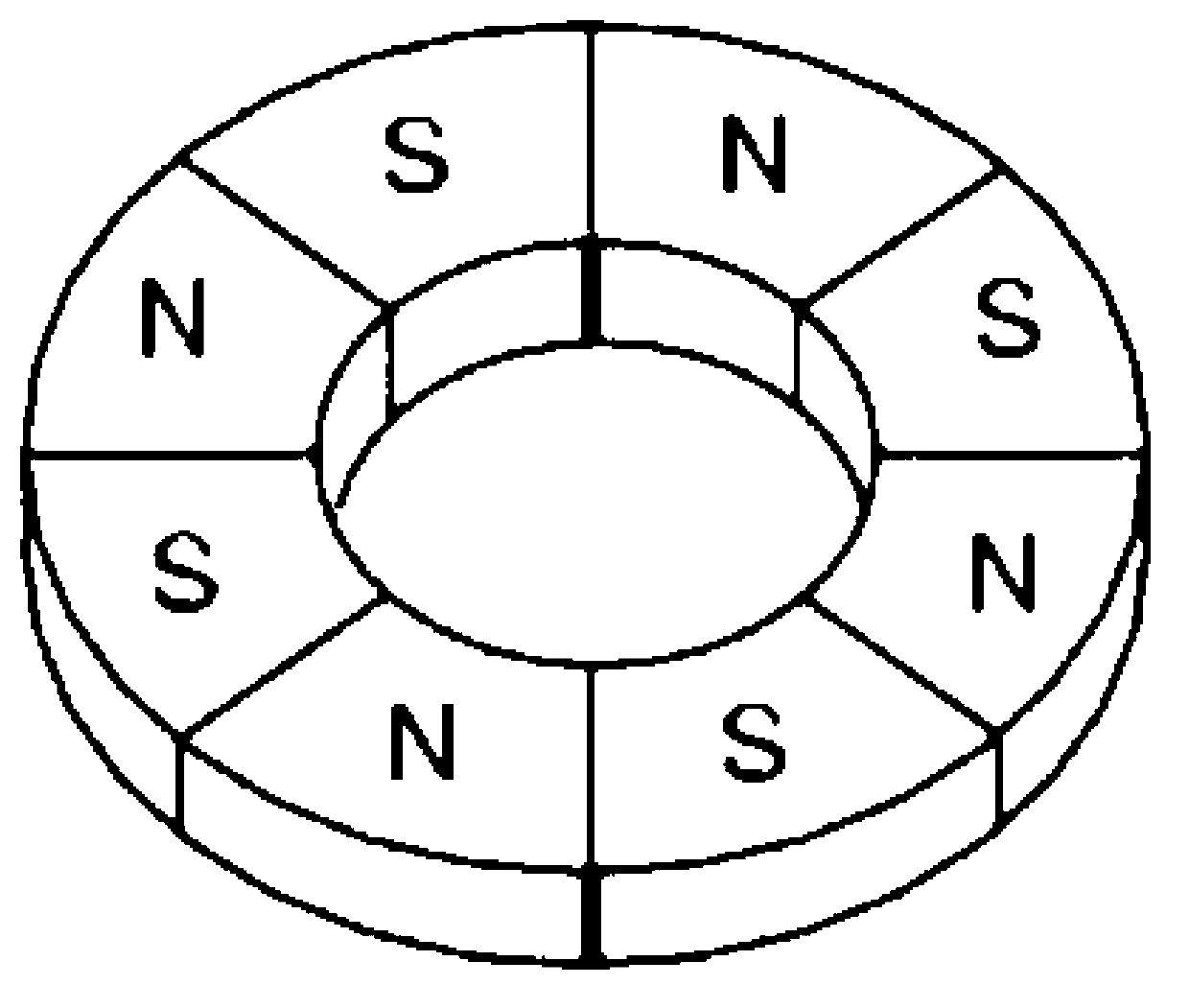

Disc type iron-core-free permanent magnet direct current (PMDC) motor

InactiveCN103124128AAxial dimension shortCompact structureSynchronous machines with stationary armatures and rotating magnetsWindings conductor shape/form/constructionElectricityElectric machine

The invention relates to a disc type iron-core-free PMDC motor. The disc type iron-core-free PMDC motor comprises a middle stator and rotors which are installed on a spindle and in disc shapes, disc surfaces are arranged parallelly and correspondingly, gap flux densities on two sides of the stator are the same, the stator comprises an iron-core-free rolled annular winding which is placed axially, and a magnetic line of force passes gaps and the winding axially; and each rotor is a disc composed of a magnetic conducting disc for accommodating magnetic steel and an aluminum case, a permanent magnet is bonded on the magnetic conducting disc in an N and S alternating mode, and polarities of magnetic steel corresponding to the rotors up and down are opposite. The disc type iron-core-free PMDC motor is characterized in that the annular winding is an axial symmetry conical ring composed of a plurality of sections of arcs, the central axis points to the axis of the stator, and the tip of the conical ring is close to the axis of the stator. The magneto-electricity conversion efficiency of the motor is improved by above 10%.

Owner:浙江义阳光电科技有限公司

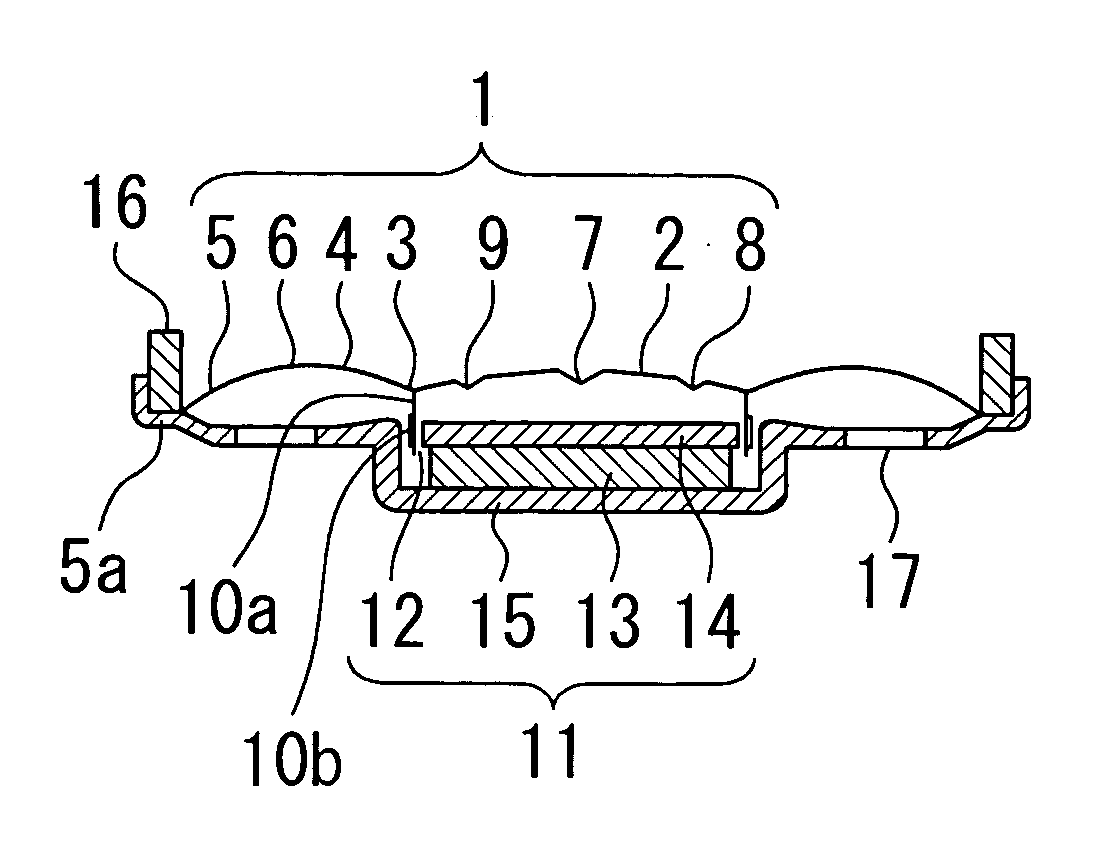

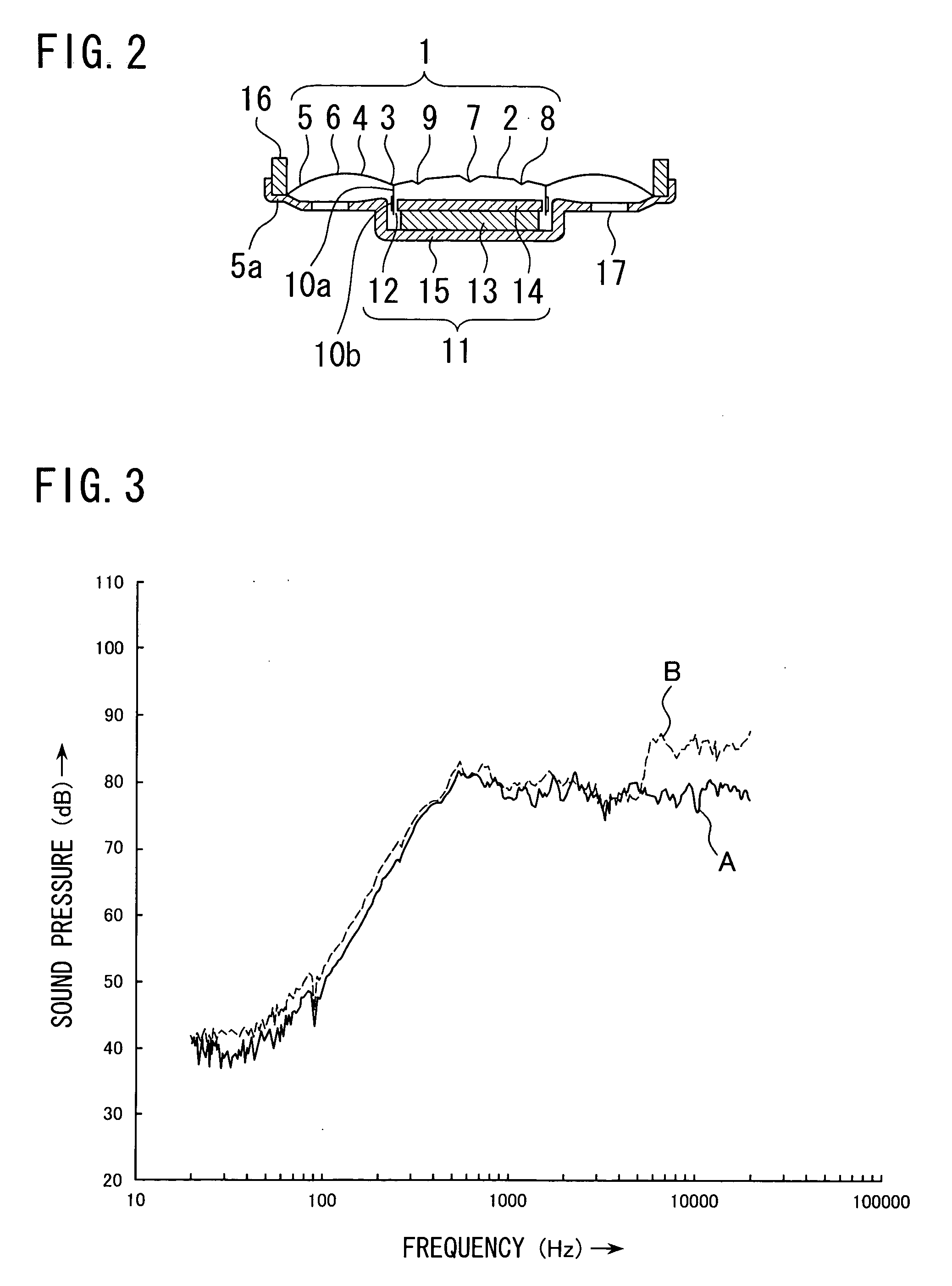

Diaphragm for use in speakers and speaker provided with this diaphragm

A diaphragm for use in speakers in which a center dome is provided with a plurality of ribs in one of axial symmetry and non-axial symmetry patterns, for thereby dispersing the divisional resonance occurring in the center dome during the vibration and lowering the sound pressure specifically in higher sound range frequency characteristics, as well as a speaker comprising the particular diaphragm, are provided.

Owner:FOSTER ELECTRIC CO LTD

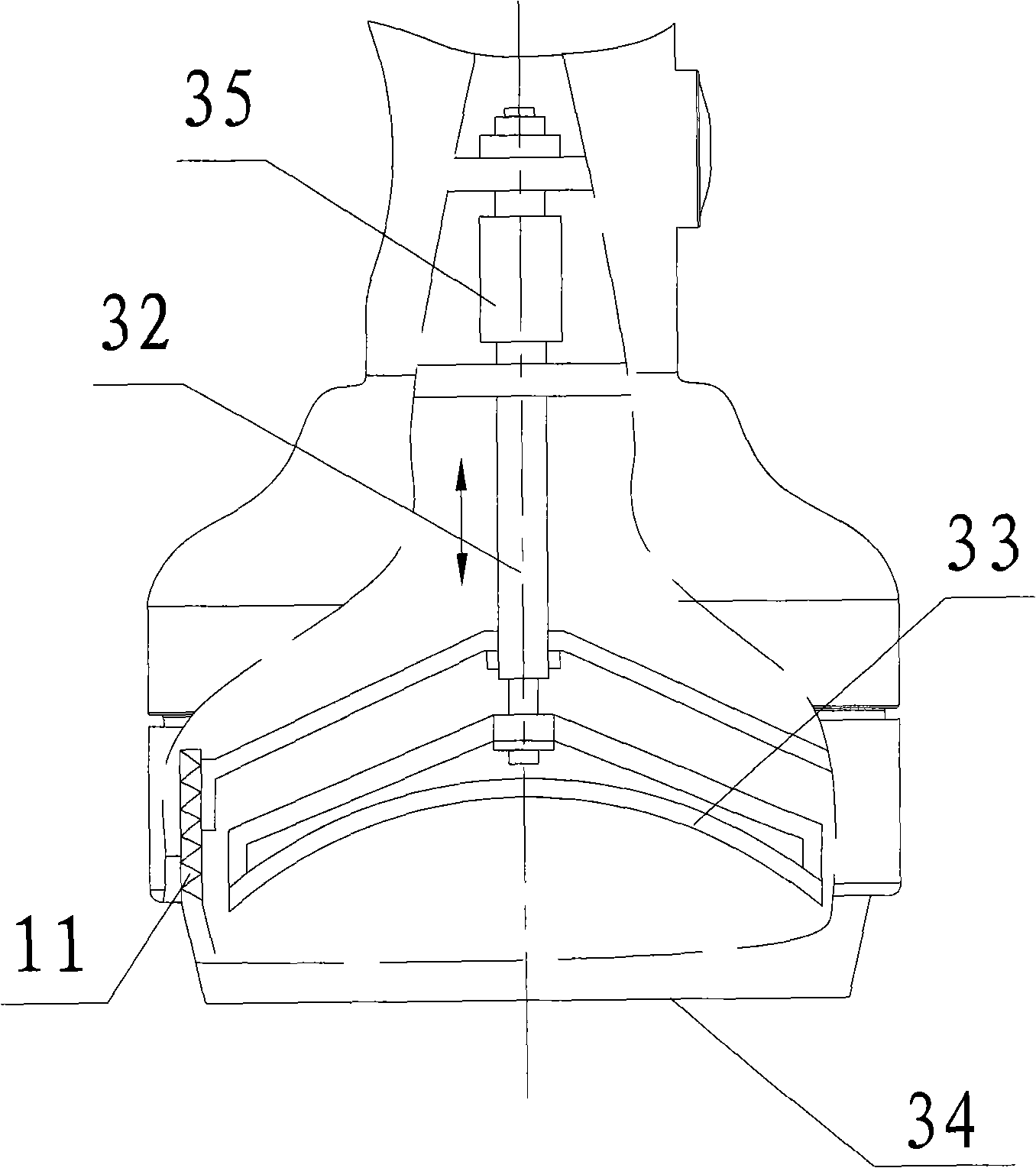

Tapered plug mechanism realizing axial symmetry spray pipe all-direction vector regulation

ActiveCN103423030ARealize omnidirectional vector adjustmentSimple structureJet propulsion plantsEngineeringActuator

The invention discloses a tapered plug mechanism realizing the axial symmetry spray pipe all-direction vector regulation. The tapered plug mechanism comprises a tapered plug front section, a tapered plug back section, a support frame, an actuator cylinder, a rotating rod, a connecting rod and an actuator cylinder, wherein the tapered plug front section and the tapered plug back section form a center taper structure, the sectional surfaces in the contact positions of the tapered plug front section and the tapered plug back section are concentric spherical surfaces, the tapered plug front section and the tapered plug back section are connected through a rotating pair vertical to the axial line of a spray pipe, in addition, the concentric spherical surfaces of the tapered plug front section and the tapered plug back section passed by the rotating pair are connected for realizing the vector regulation of the fuel gas flow of the spray pipe, meanwhile, the shielding effect on front end heat end components can be realized, the support frame is used as a support component of the center taper structure formed by the tapered plug front section and the tapered plug back section for connecting the center taper onto a tube body of the spray pipe, and the center taper realizes the vector rotation in an all-direction 360-degree range. The tapered plug mechanism has the advantages that the structure is simple, the moving components are few, the outline dimension of the traditional axial symmetry plug type spray pipe can be effectively reduced, and the all-direction vector regulation of the axial symmetry spray pipe can be realized.

Owner:AECC SHENYANG ENGINE RES INST

Monolithic molding method of light duty truck weldless axle case

The invention relates to a monolithic molding method of a light duty truck weldless axle case. A weldless steel round pipe is used, first, early hole shrinkage is conducted to two ends of the weldless steel round pipe, two times of hydro-bugling are conducted to the middle of the weldless steel round pipe; and then, later stage hole shrinkage is conducted to the two ends of the weldless steel round pipe to obtain a performing pipe blank which is in an axial symmetry shape or close to an axial symmetry shape. A die left pressure head and a die right pressure head are used on a four-way hydraulic machine for sealing the ends of the performing pipe blank, liquid is injected into the four-way hydraulic machine, an upper die block, a lower die block, a front die block and a rear die block are used for integral pressing and forming on the performing pipe blank from the upper direction, the lower direction, the front direction and the rear direction, an axle case semi-finished product with a hemispherical rear oil cap and an additional front cap is obtained, and an axle case product is obtained by cutting the additional front cap. According to the monolithic molding method, the manufactured axle case is weldless, high in strength and stiffness, and high in material utilization rate. Comparing the used technique with a traditional hydro-bugling technique, the liquid pressure needed in manufacturing process is lowered by more than 60%, and the tonnage of forming devices is lowered by more than 50%.

Owner:QINHUANGDAO TONGQIAO TECH CO LTD

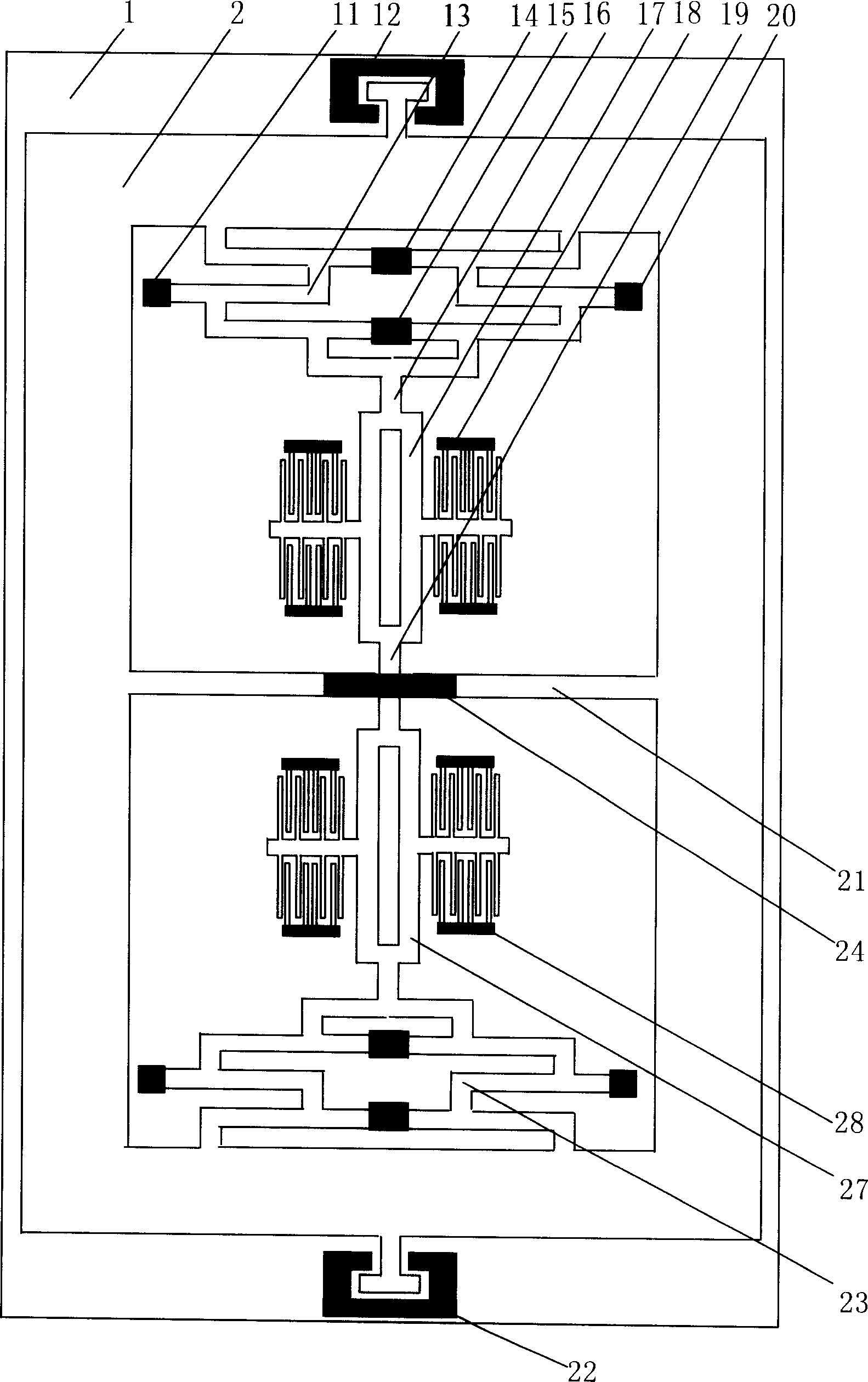

Resonance type micromechanical accelerometer

InactiveCN1844931AAvoid breakingRealize overload protectionAcceleration measurementTuning forkAccelerometer

The invention discloses a resonance micro chemical accelerometer, which comprises a basic plate, a weigh block, a suspend beam, a lever amplifying device, a sound fork, a driving electrode, a detecting electrode, a tooth axle and a backstop. Wherein, said structure is axial symmetry; the weight block is circle whose middle part is mounted with a suspend beam, a lever amplifying device, a sound fork, a driving electrode, a detecting electrode, a tooth axle and a backstop; the backstop is outside the weight block; the circle shape of weight block can make the element own larger weight block in limited volume; the resonance beam has two ends to be fixed with sound forks, while two ends are connected to the outer element with narrow necks, to effectively reduce the energy couple between the resonance beam and outer structure; two symmetry sound forks can realize differential output of resonance frequency. The invention can improve the sensitivity, resolution and detecting accuracy of accelerometer.

Owner:BEIHANG UNIV

Multiple-input-and-output antenna

InactiveCN102760949AImprove Radiation PerformanceImprove isolationSimultaneous aerial operationsRadiating elements structural formsImpedance matchingLength wave

The invention relates to a multiple-input-and-output antenna. The multiple-input-and-output antenna is arranged on a base plate, and the base plate comprises a first surface and a second surface arranged opposite to the first surface. The multiple-input-and-output antenna comprises a first antenna and a second antenna which are arranged in axial symmetry, a coupling part and an earthing part, wherein each antenna respectively comprises a feed-in part, a radiating body and a matching part; the feed-in part feeds in electromagnetic wave signals; the radiating body radiates the electromagnetic wave signals and is in a winding shape, and the length of winding is equal to a quarter of the wavelength of the electromagnetic wave signals radiated by the radiating body; the matching part matches the impedance of the multiple-input-and-output antenna; the coupling part is arranged between the first antenna and the second antenna and is a winding shape, and the length of winding is equal to a half of the wavelength of the electromagnetic wave signals radiated by the radiating body; and the earthing part is arranged on the first surface and the second surface. The multiple-input-and-output antenna provided by the invention can work at the frequency band of 2.5-2.6GHz, and has the advantages of small area, low cost and effectively improved isolation.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

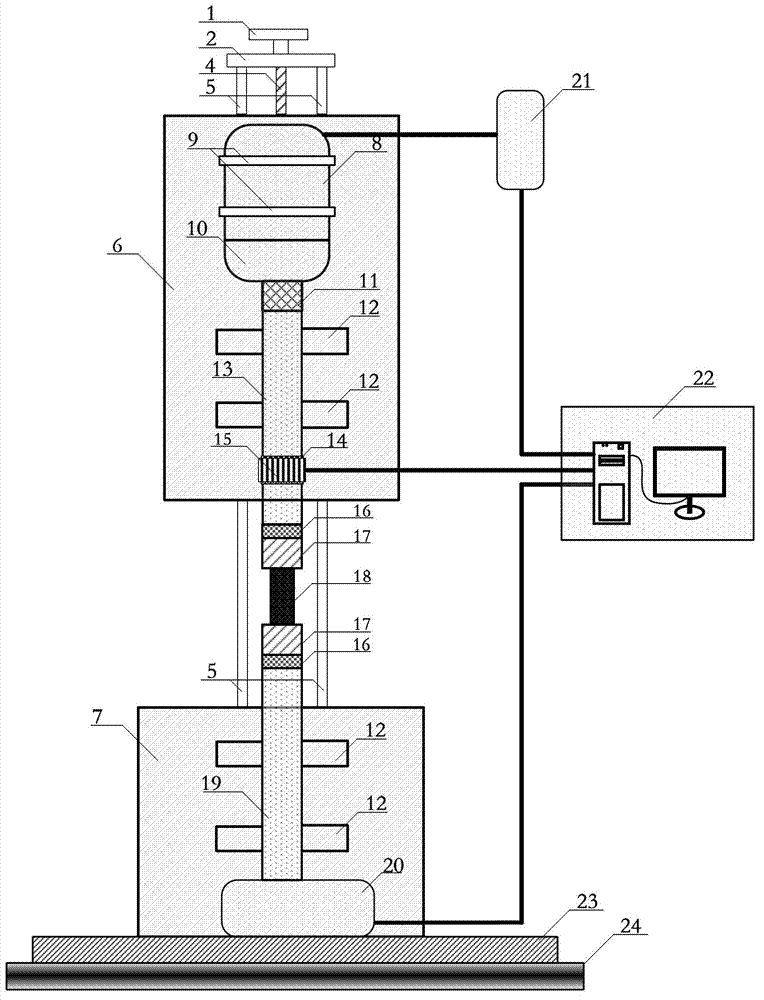

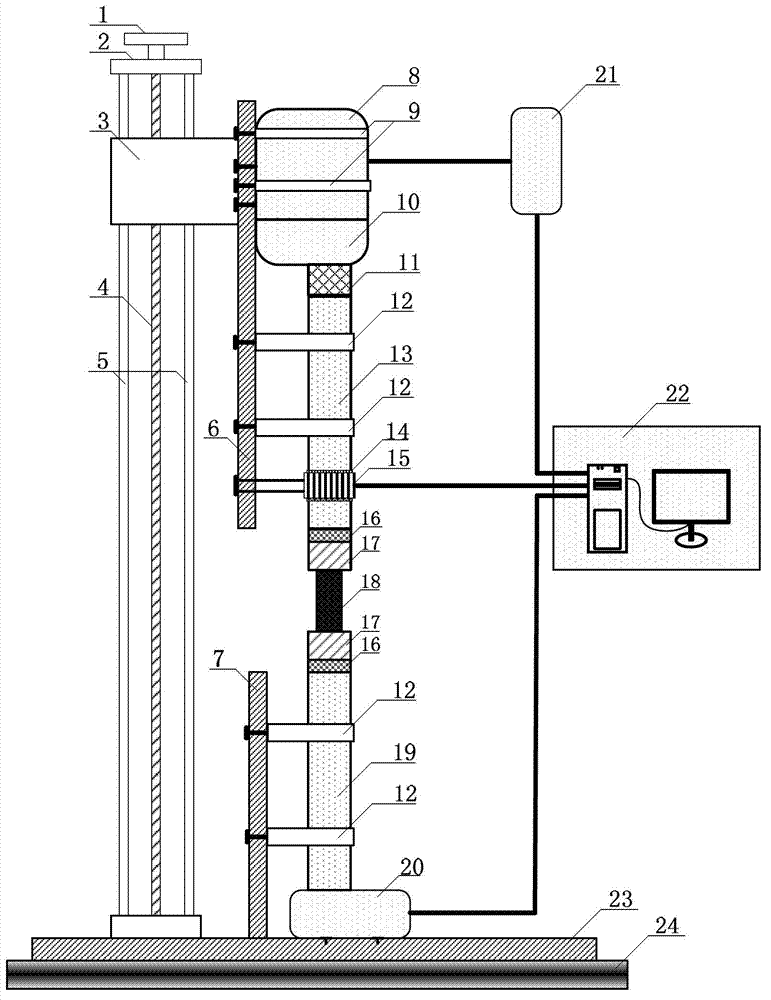

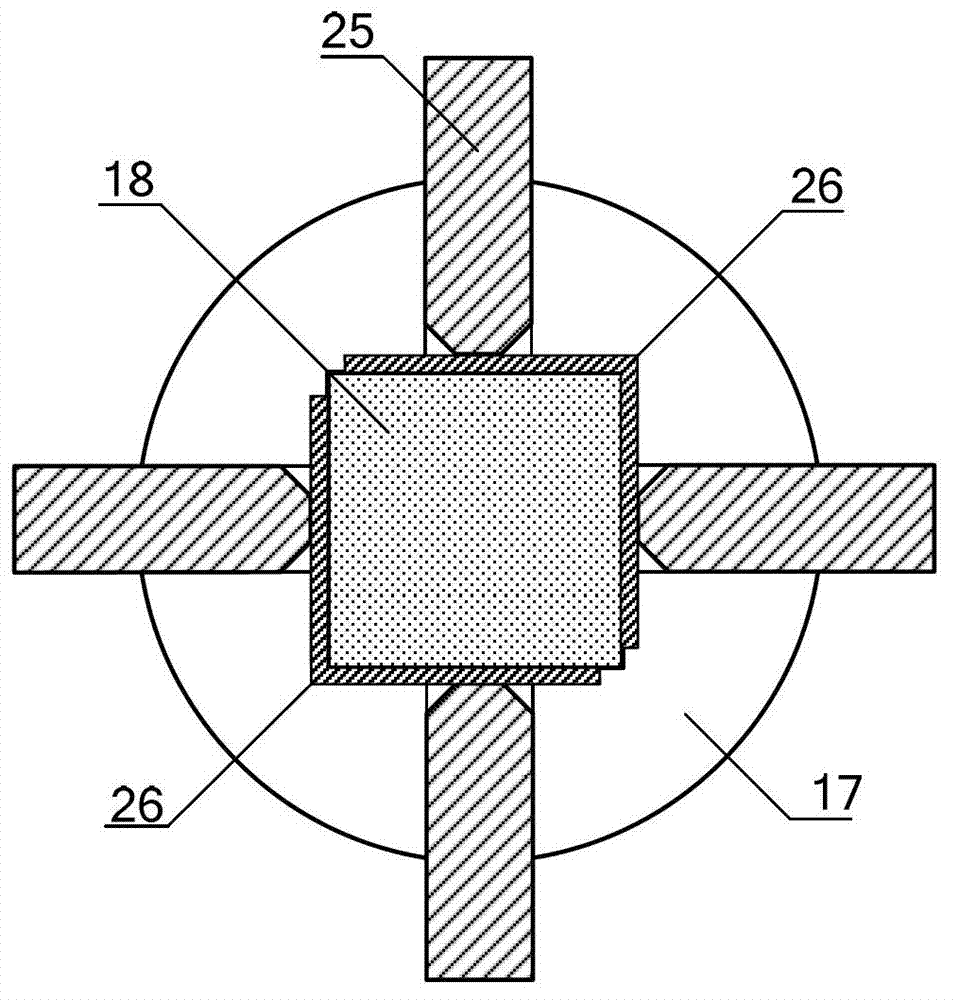

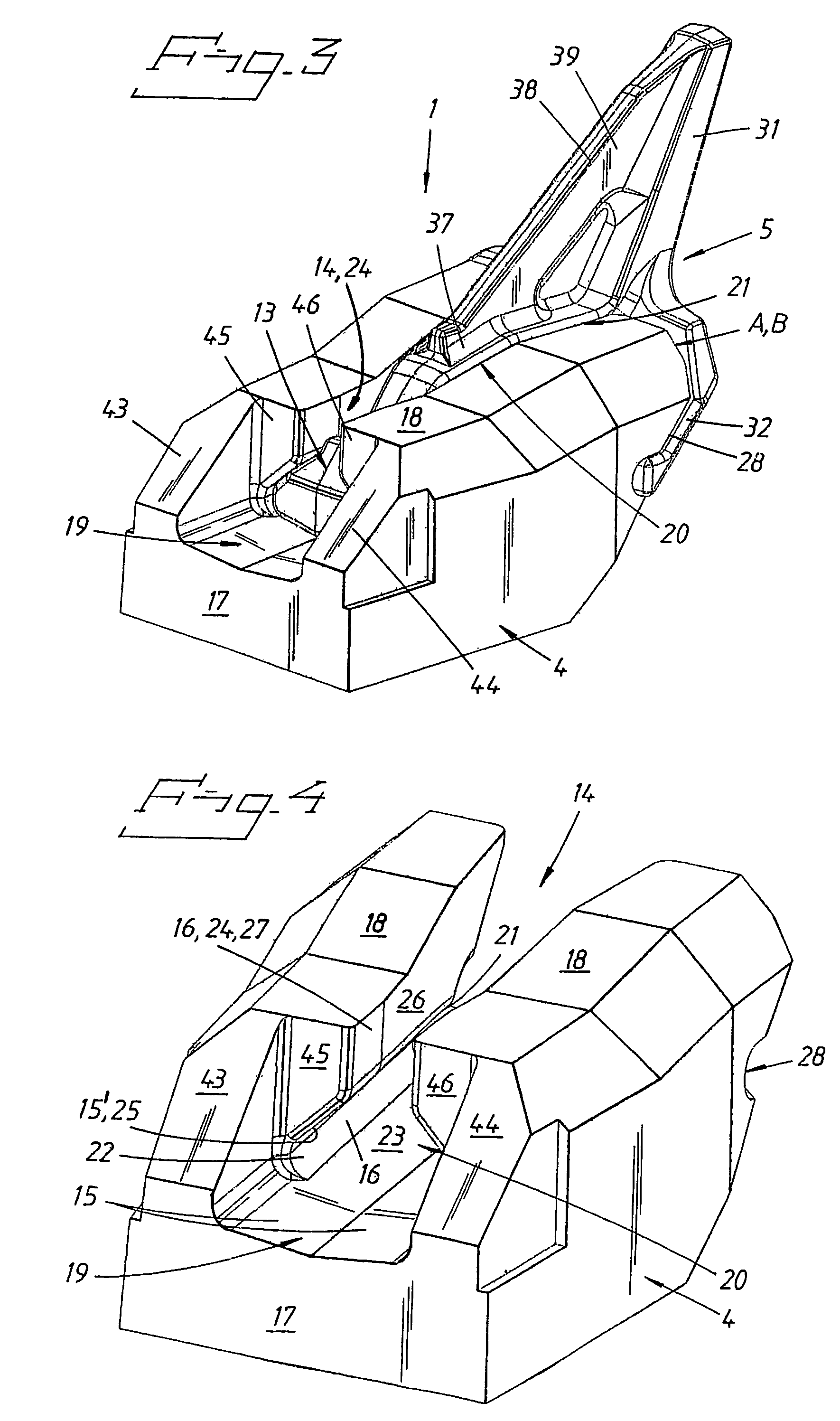

Rotary shear failure performance determination test device of asphalt mixture

InactiveCN103245571AReduce occupancyEasy to testMaterial strength using steady shearing forcesComputer control systemData information

The invention provides a rotary shear failure performance determination test device of an asphalt mixture and belongs to the technical field of mechanical property testing of the asphalt mixture. The rotary shear failure performance determination test device is composed of a testing platform, a loading system and a computer control system, wherein the loading system is used for carrying out rotary shearing loading on an asphalt mixture test piece according to a set shearing speed; the computer control system collects data information in real time; and a rotary shearing method is adopted to test a shear failure performance of the asphalt mixture. The rotary shear failure performance determination test device disclosed by the invention has the advantages that (1) a rotation torque acting on the test piece with an axially-symmetrical section only generates pure shearing deformation and a simple pure shearing stress state can be obtained, so as to be convenient for testing and controlling the maximum shearing stress and strain; (2) due to an axial symmetry property, the testing accuracy can be improved in theory; and (3) testing equipment and a testing process of rotary loading occupy a small testing space; and compared with pulling and pressing deformation, the rotary shearing deformation (angle displacement) can be infinitely great in theory and is basically not limited by the testing space, so that the rotary shear failure performance determination test device is particularly suitable for materials with great plastic failure deformation.

Owner:DALIAN UNIV OF TECH

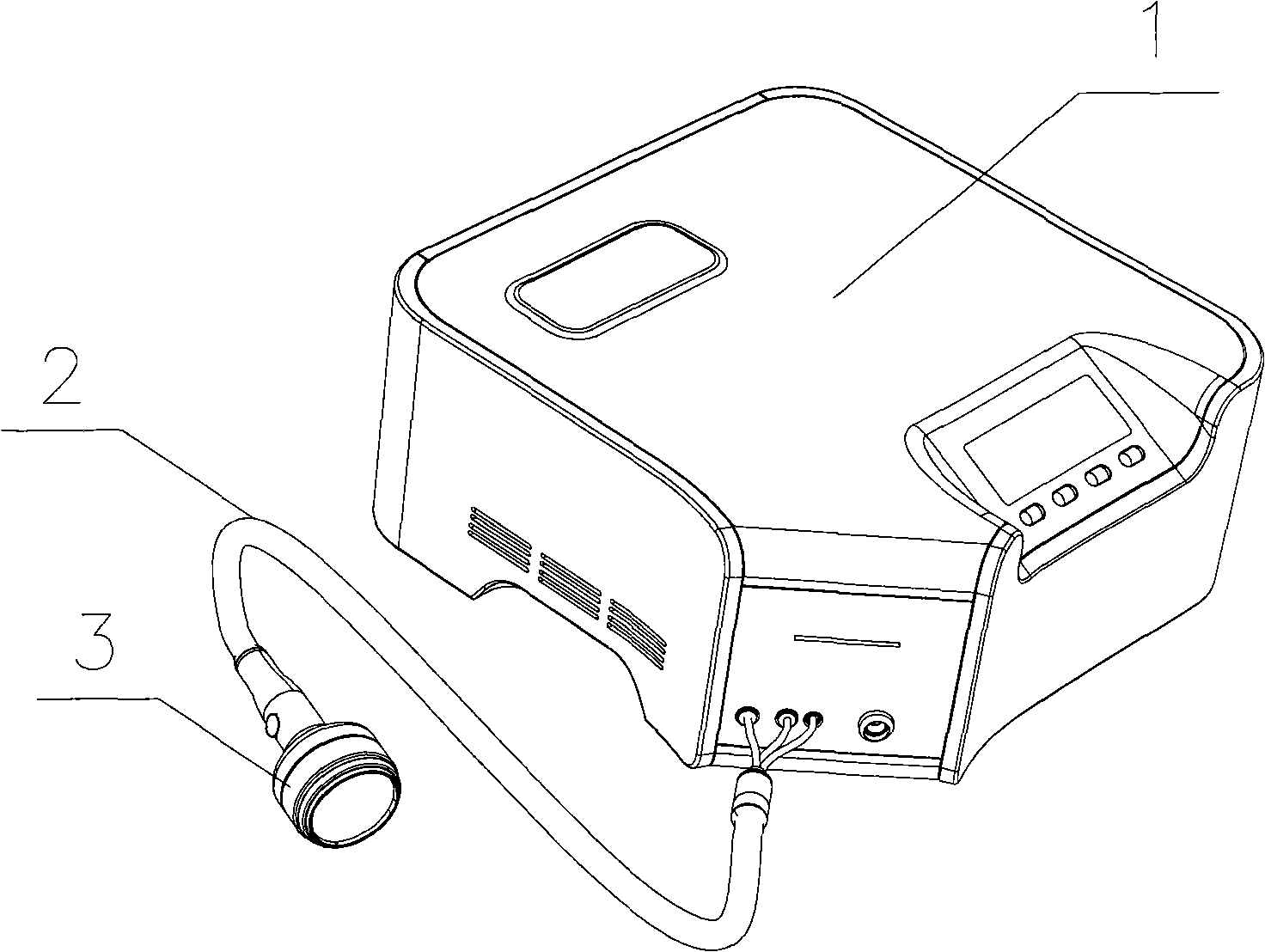

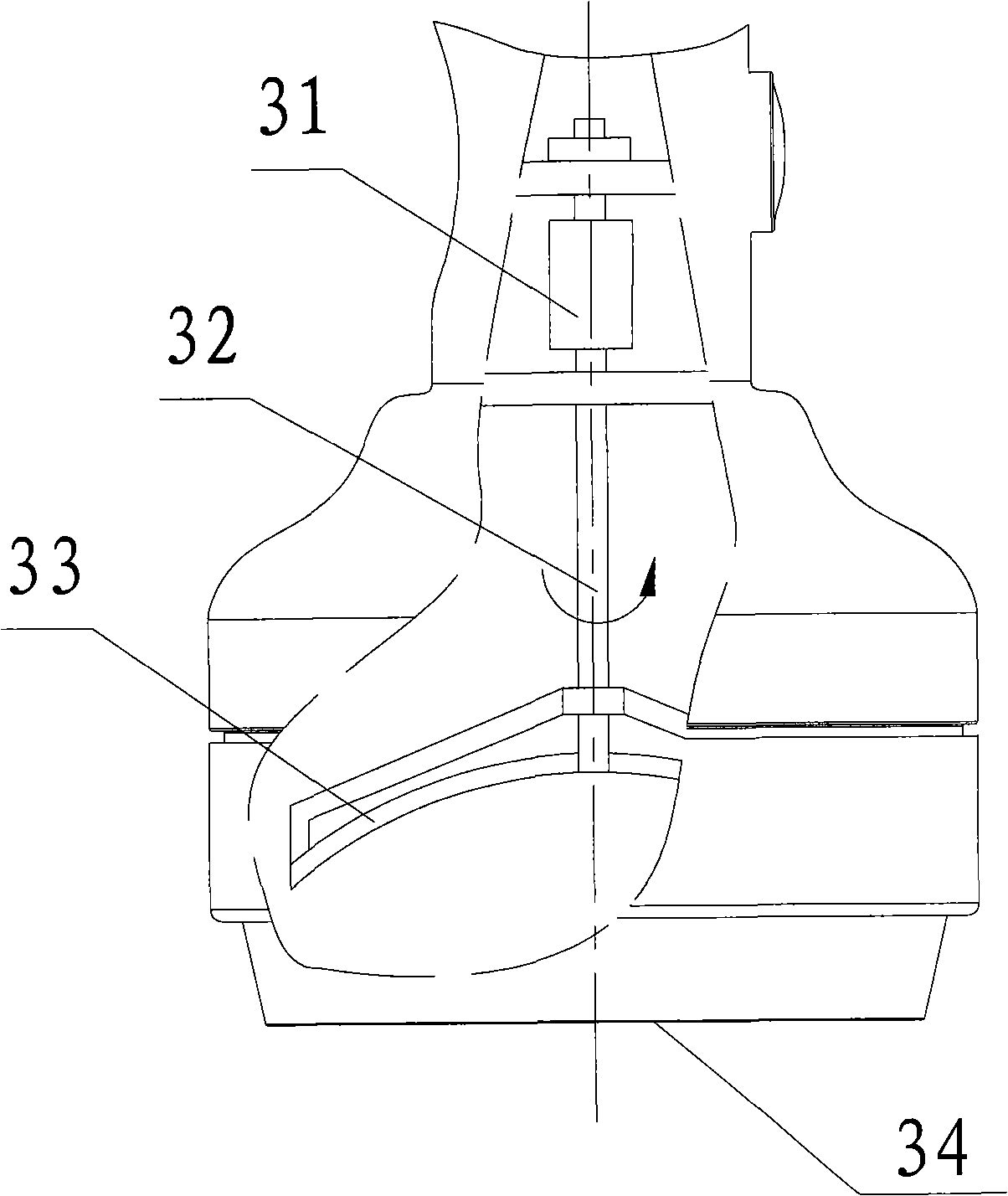

Focused ultrasonic point therapeutic equipment

InactiveCN101284163APenetratingAvoid the risk of infectionUltrasound therapyDevices for heating/cooling reflex pointsUltrasonic sensorCurative effect

The invention discloses a focused ultrasonic-wave point treatment device, comprising a host machine and a treatment gun. The treatment gun is connected with the host machine through a connecting cable; an ultrasonic transducer that can generate focused ultrasonic-waves is arranged inside the treatment gun; an acoustic-field controlling unit that leads the ultrasonic transducer to generate a non-axial symmetry acoustic field is included inside the treatment gun. The focused ultrasonic-wave point treatment device is a noninvasive treatment device, effectively increases the therapeutic safety, and achieves the same curative effect with the traditional acupuncture.

Owner:RONGHAI SUPERSONIC MEDICINE EN

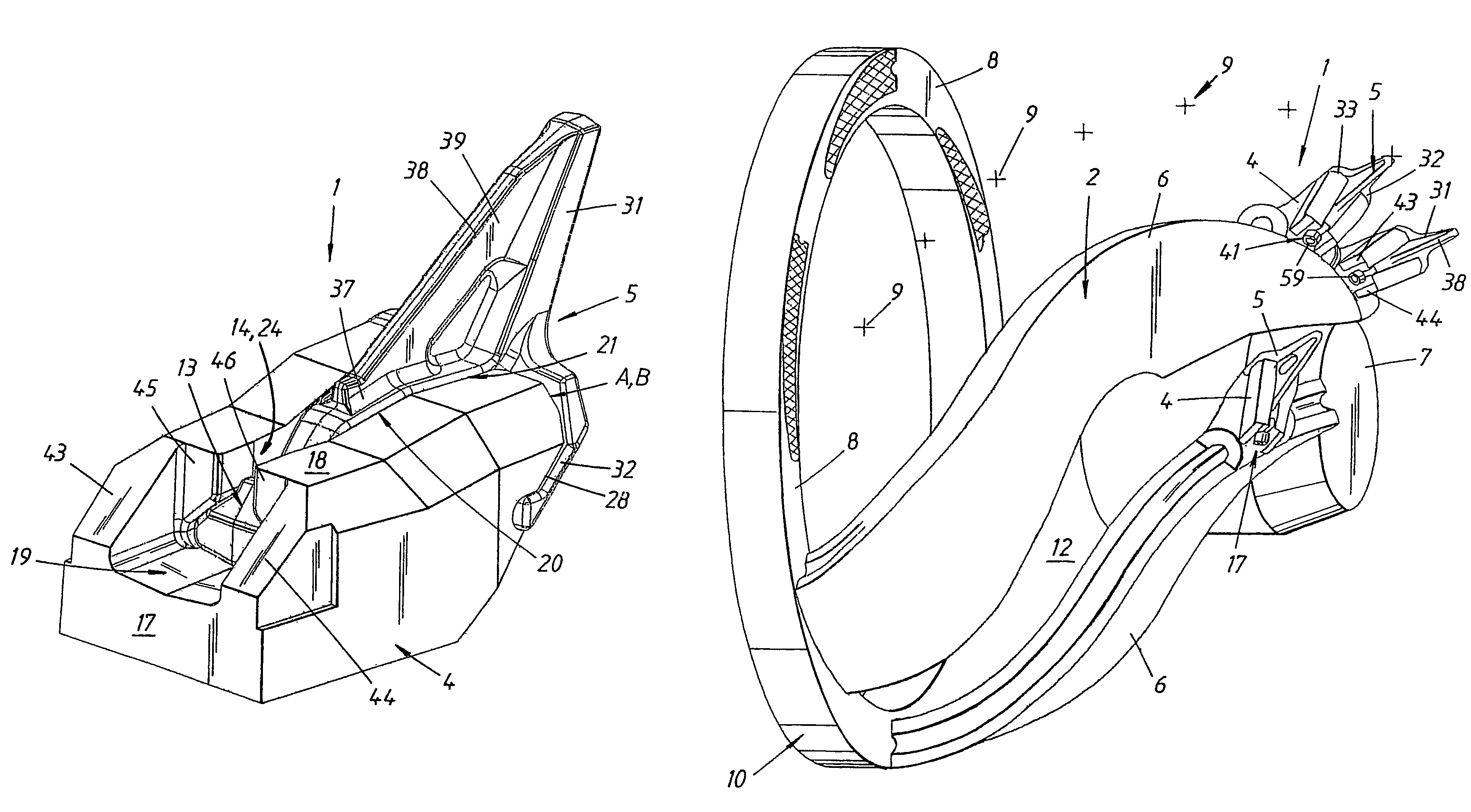

Tooth system

ActiveUS7694443B2Reduce decreaseEliminate wear and tearMechanical machines/dredgersEngineeringAxial symmetry

Owner:COMBI WEAR PARTS AB +1

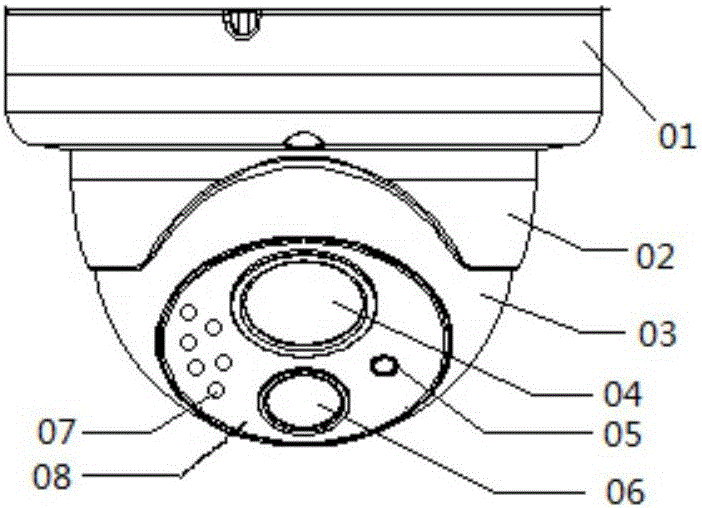

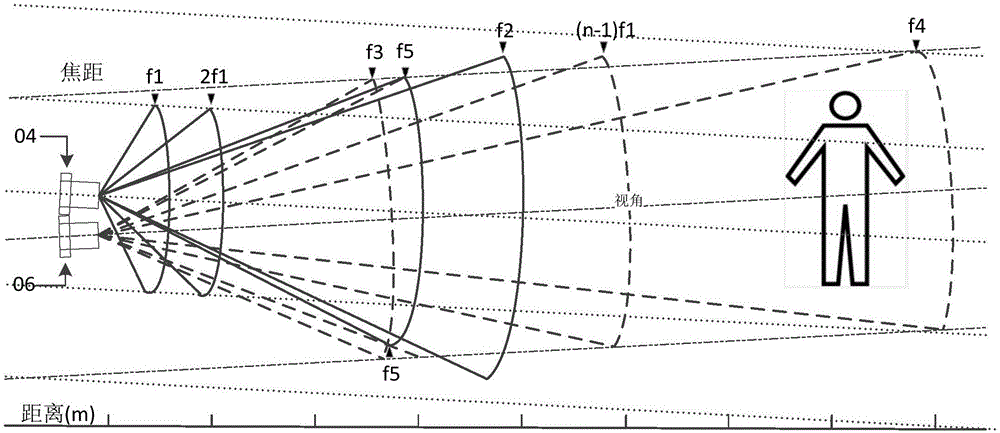

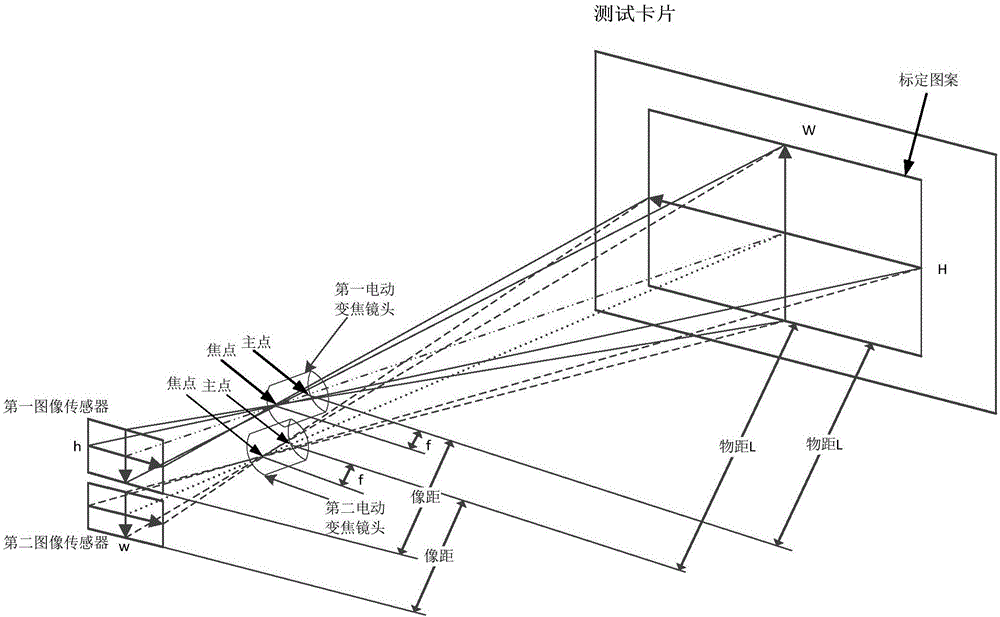

Double-lens and optical-magnification-expansion zoom-lens camera and working method thereof

ActiveCN106791337AExpand the optical zoom magnificationRich shooting applicationsTelevision system detailsColor television detailsCamera lensInfrared lamp

Owner:BEIJING HANBANG GAOKE DIGITAL TECH

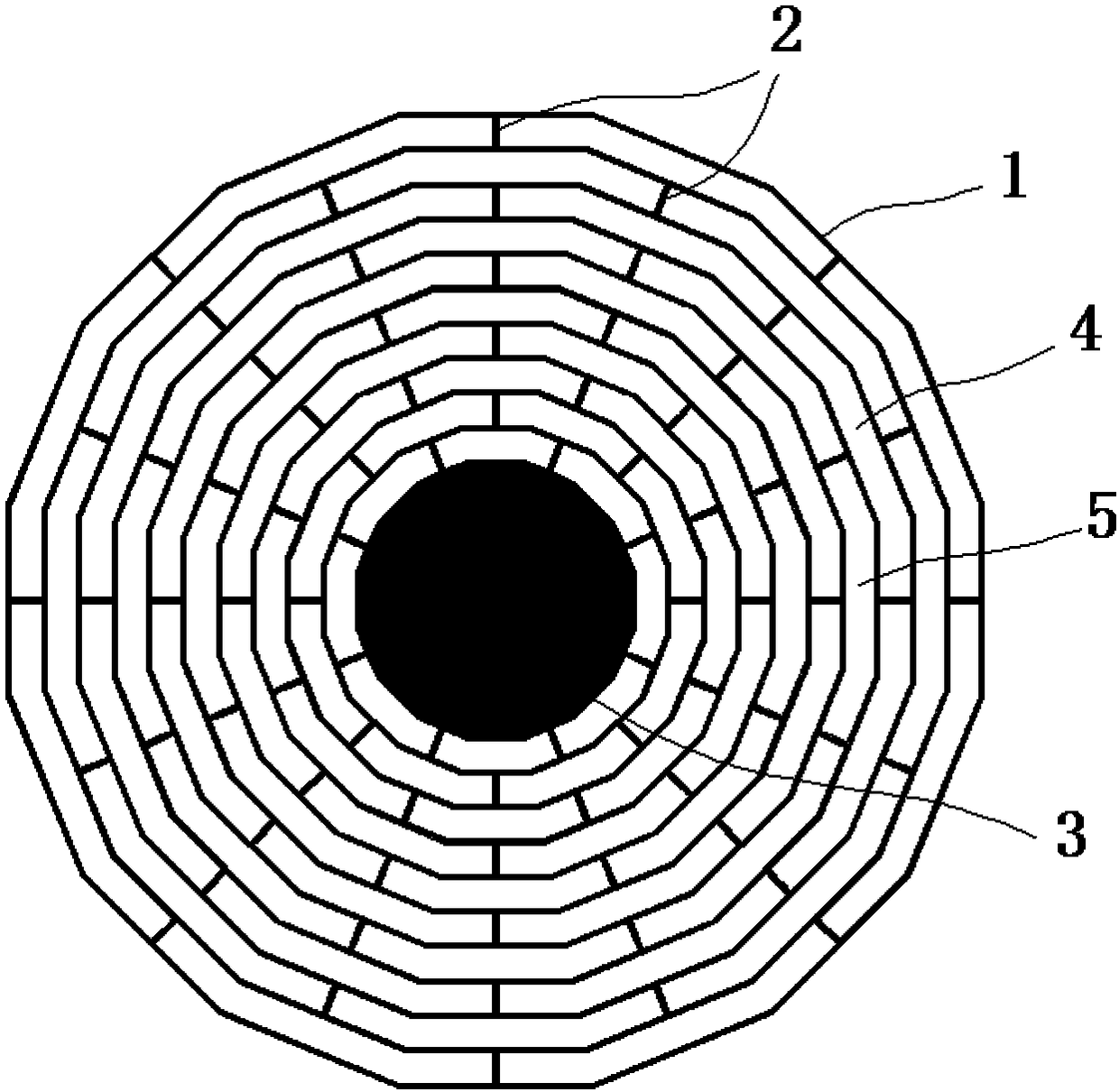

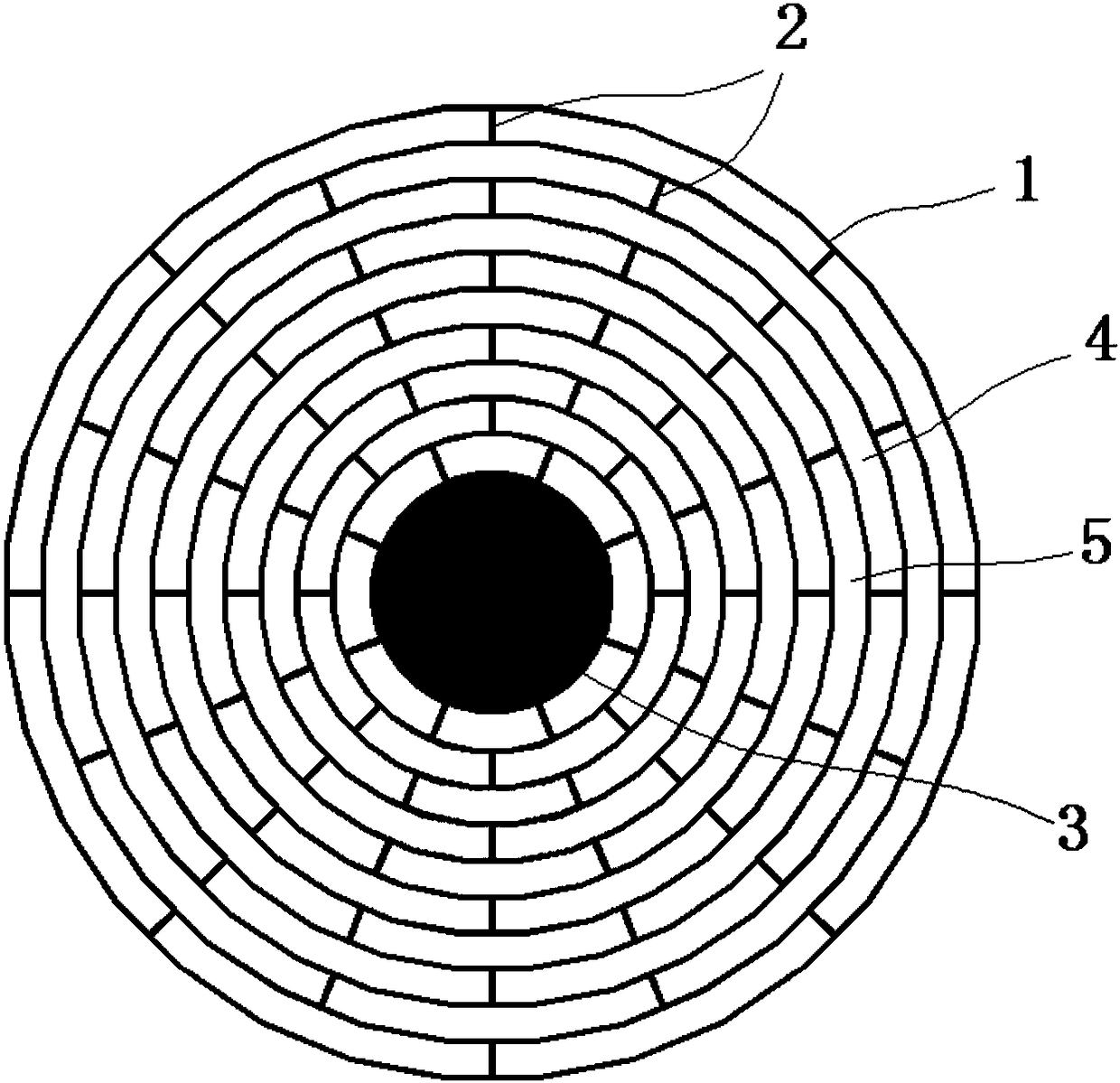

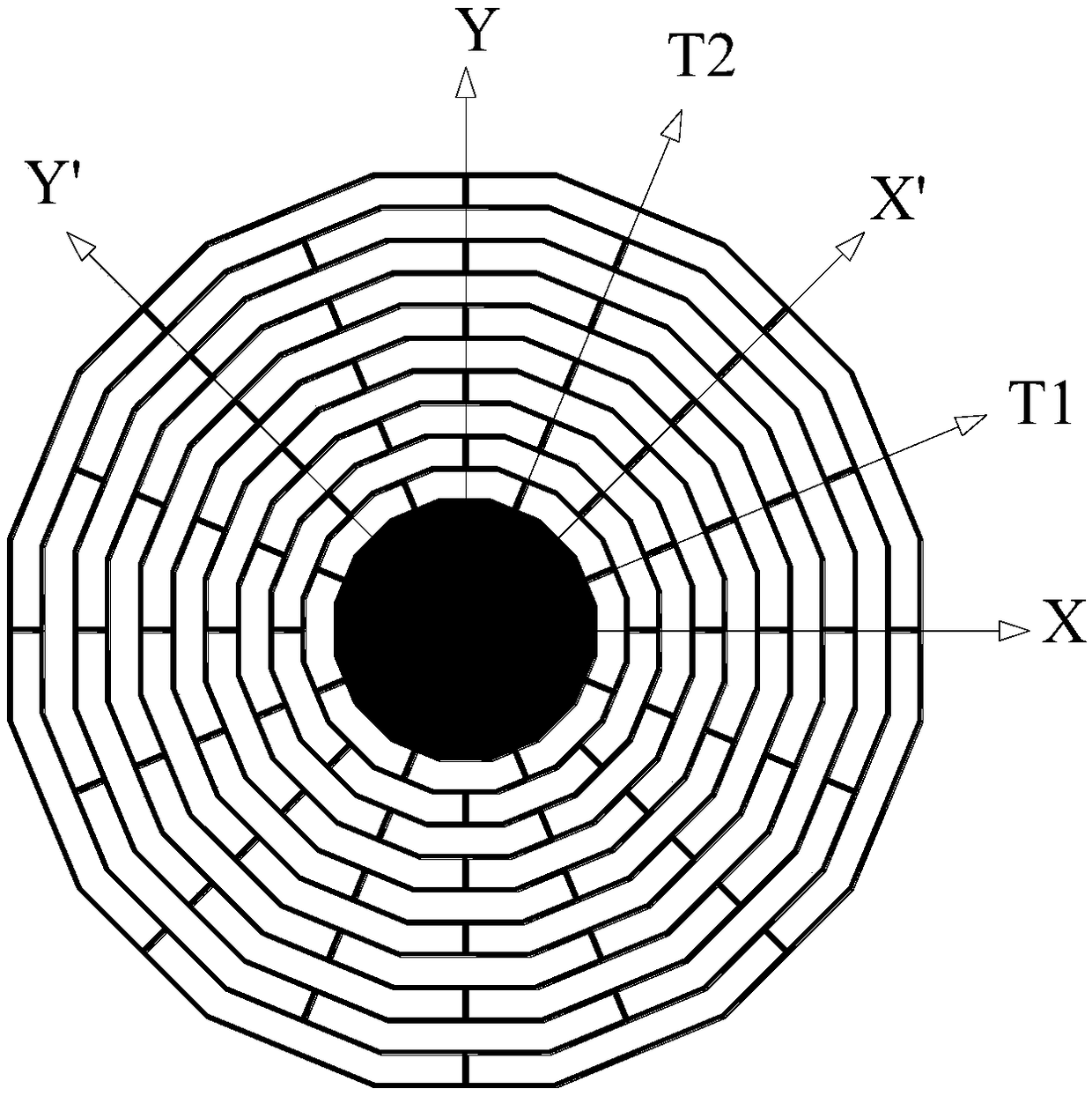

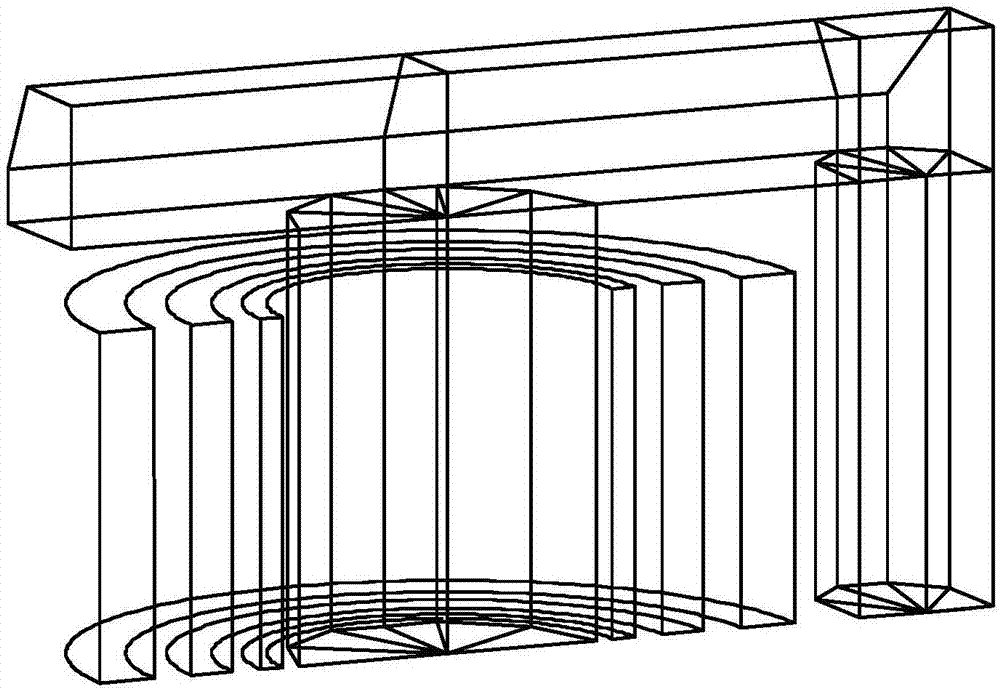

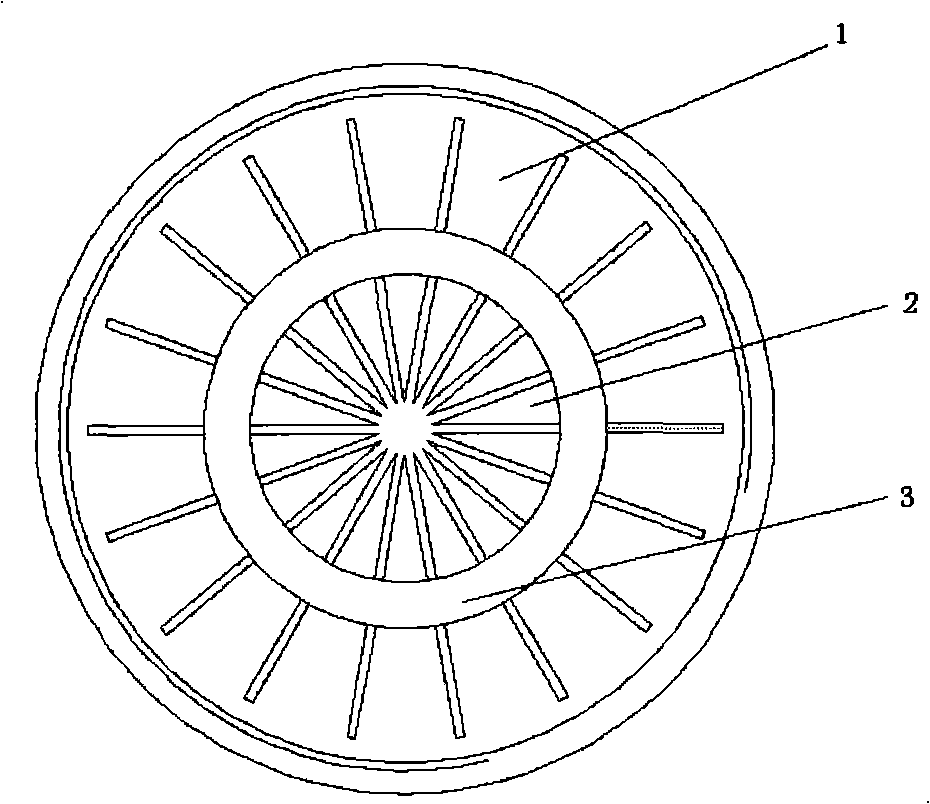

Equilateral polygon discal MEMS resonant gyro

ActiveCN108613669AImprove structural asymmetryHigh precisionSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesAnchor pointEquilateral polygon

The invention discloses an equilateral polygon discal MEMS resonant gyro which comprises a sensitive structure, wherein the sensitive structure includes a harmonic oscillator, fixed anchor points forfixing the entire harmonic oscillator are arranged in the center of the harmonic oscillator, the harmonic oscillator takes the shape of an equilateral polygon disc which is in axial symmetry entirely,the harmonic oscillator includes a plurality of concentric equilateral polygon resonant rings, the concentric equilateral polygon resonant rings are connected through spokes, the fixed anchor pointsare connected with adjacent concentric equilateral polygon resonant rings through the spokes, the plurality of concentric equilateral polygon resonant rings are radially distributed by taking centersof the fixed anchor points as centers, grooves are formed between adjacent equilateral polygon resonant rings and spokes, and electrodes are arranged in the grooves. The equilateral polygon structuresare entirely in line connection without arc line, thereby having a small edge error effect and a relatively smaller symmetry error. Therefore, the resonant frequency of two operating modes are smallin splitting.

Owner:SUZHOU WENZHIXIN MICRO SYST TECH

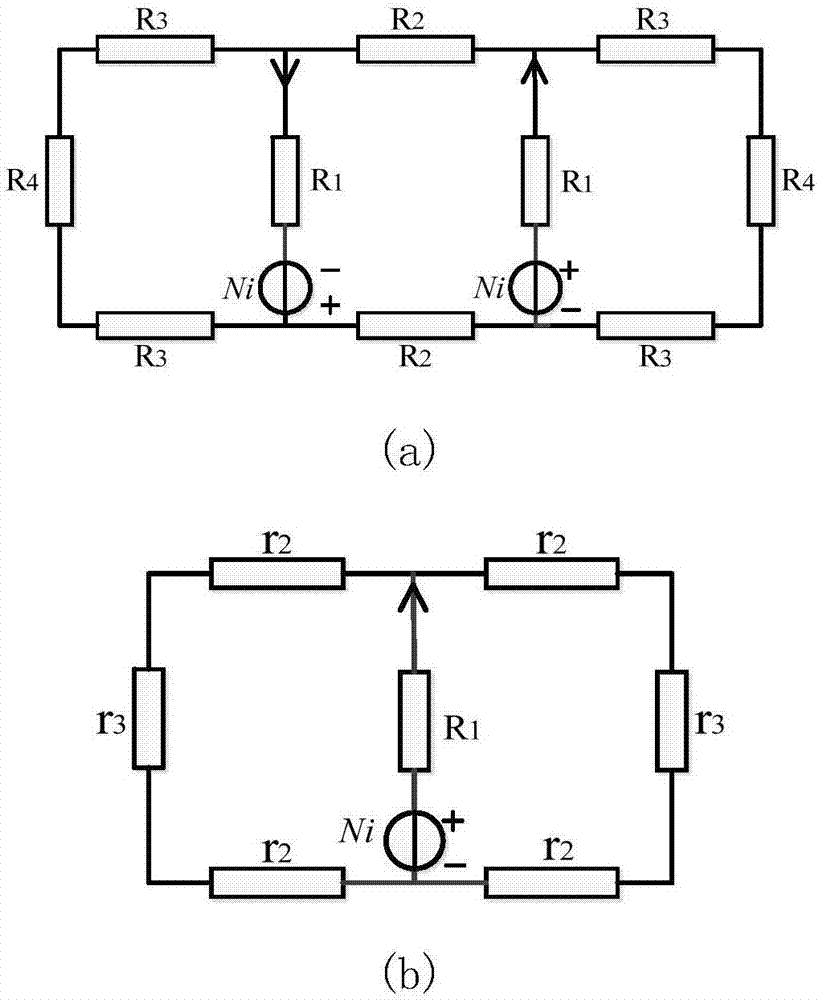

Axial symmetry DC magnetic bias simulation model for extra-high voltage transformer

InactiveCN107317331AReduce problem sizeReduce computational workloadDesign optimisation/simulationSpecial data processing applicationsRunge–Kutta methodEngineering

The invention discloses an axial symmetry DC magnetic bias simulation model for an extra-high voltage transformer, which belongs to the technical field of safe operation of electrical equipment in an extra-high voltage AC network. Through establishment of an equivalent axial symmetry simulation model of an actual three-dimensional model of the extra-high voltage transformer, a complicated magnetic field model is equivalent to a simple two-dimensional magnetic field model and dynamic inductance parameters are obtained; a load DC magnetic bias circuit model of the extra-high voltage transformer is established; current parameters are obtained through a four-order Runge-Kutta method; a time domain field-circuit coupling method is adopted to realize rapid calculation of the load DC magnetic bias of the extra-high voltage transformer; the simulation proves the high precision and high efficiency of analysis of DC magnetic bias through the extra-high voltage transformer to bring convenience to a large amount of researches on a DC magnetic bias problem of the transformer and help to safe and stable operation of the transformer.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

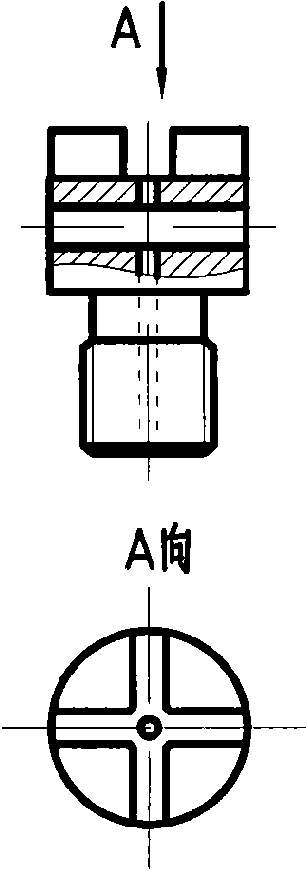

Screw thread welding integral narrow slit type cold junction for coaxial pulse-tube refrigerator

InactiveCN101298948AIncrease the heat exchange areaSmall pressure lossCompression machinesGas cycle refrigeration machinesCopper wirePulse tube refrigerator

The invention discloses a thread weld integral slit type cold head of the coxial vessle refrigerator in the refrigeration technology field, including an upper cold head, a lower cold head, a cold end baffle and a copper wire, wherein the upper cold head and the lower cold head are welded again after the threaded connection, the cold baffle is arranged at the middle of the cold head integer, and the cold baffle is filled with the copper wire, wherein the lower cold head is divided into a base seat and a boss having the uniformly distributed slots in the axial symmetry. The depth of the slot is the same with the height of the boss, and the external thread is arranged at the cirumferential of the base seat; a cylinder is arranged on the upper cold head, a round hole at the center and radial slots in the distributed uniformly arranged at the cirumferential of the round hole. The width of the slot is consistent with the slot of the lower cold head; the internal thread structure of the upper cold head is matched with the external thread of the lower cold head, with the other end in the thread match with the cold accumulator, and is left with the margin for welding after being matched. The invention has large heat exchange area, and the welding structure ensures the leak detection safety of the pressure gas the welding reliability.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com