Deep sea bionic pressureproof shell

A pressure-resistant shell and deep-sea technology, which is applied to ships, special-purpose ships, underwater ships, etc., can solve problems that cannot be simultaneously satisfied or effectively coordinated, poor hydrodynamic properties, poor mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

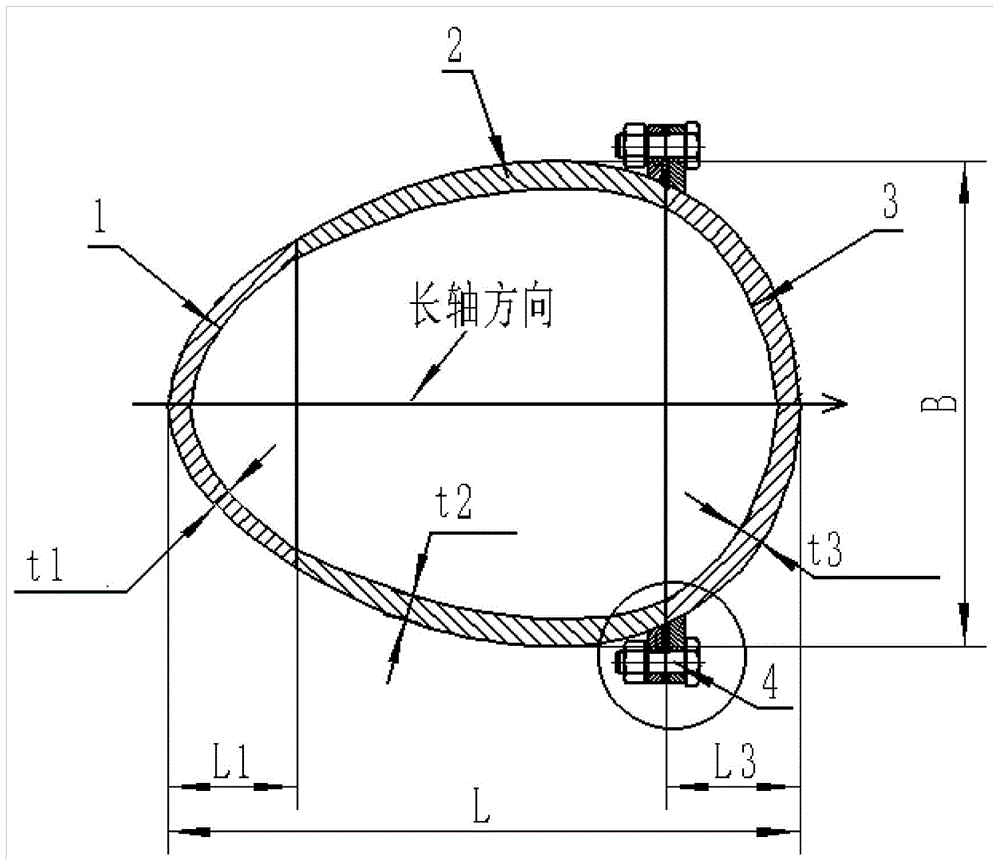

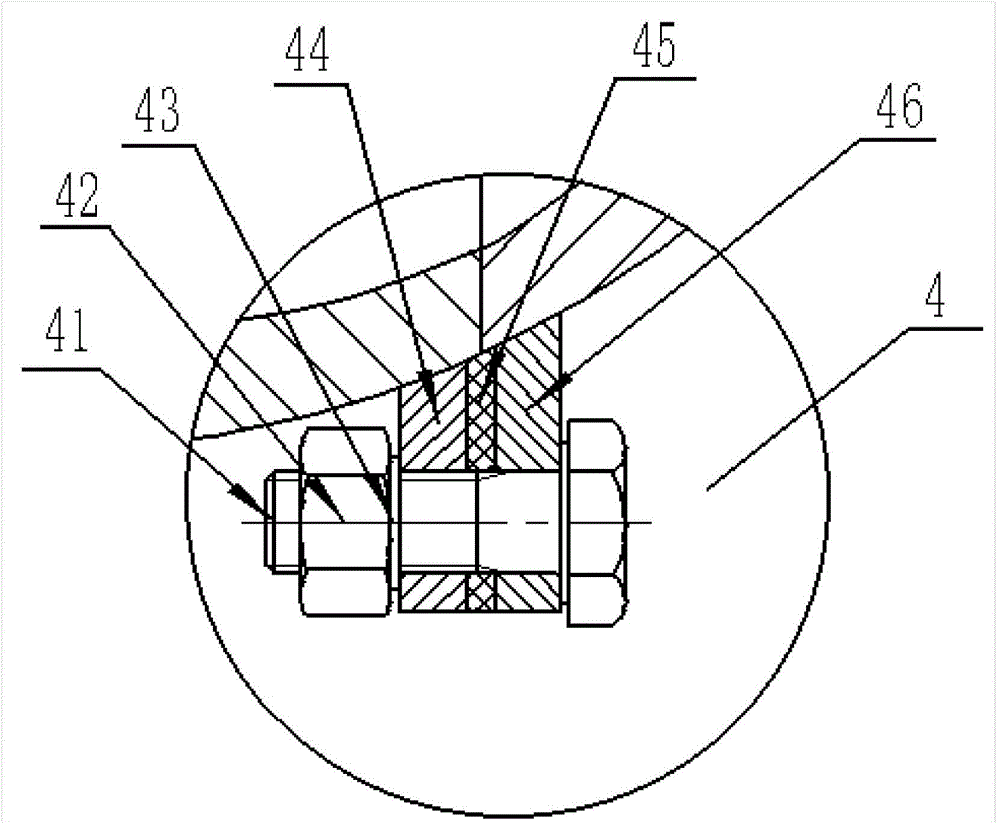

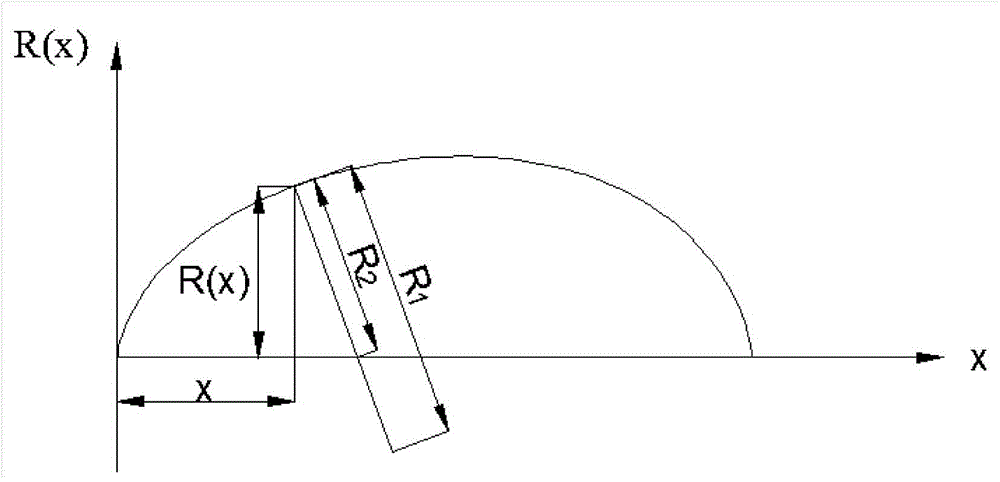

[0048] Assuming that the deep-sea bionic pressure shell is made of titanium alloy Ti-6Al-4V (TC4), the allowable stress [σ] is 830MPa, and the material density ρ is 4.5g / cm 3 , the design water depth is 6km, the calculated pressure P is 98MPa, the total length L is 2.453m, the total width B is 1.835m, then L / B is 1.34; the length L1 of the left end head 1 is 20% of the total length L, and the right end head 3 The length L3 is 25% of the total length L, according to equation (1), the rotation radius equation of the outer surface of the deep sea bionic pressure shell along the long axis direction is:

[0049] R ( x ) = 1.7843 x 1.355 - x 2 - - - ( 4 )

[0050] Find the first and second der...

Embodiment 2

[0067] Assuming that the deep-sea bionic pressure-resistant shell is made of carbon fiber reinforced resin matrix composite material, the allowable stress [σ] is 830MPa, and the material density ρ is 1.6g / cm 3 , the design water depth is 6km, the calculated pressure P is 98MPa, the total length L is 2.453m, the total width B is 1.835m, then L / B is 1.34; the length L1 of the left end head 1 is 20% of the total length L, and the right end head 3 The length L3 is 25% of the total length L, according to equation (1), the rotation radius equation of the outer surface of the deep sea bionic pressure shell along the long axis direction is:

[0068] R ( x ) = 1.7843 x 1.355 - x 2 - - - ( 12 )

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com