Patents

Literature

125 results about "Thin-shell structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin-shell structures (also called plate and shell structures) are lightweight constructions using shell elements. These elements, typically curved, are assembled to make large structures. Typical applications include aircraft fuselages, boat hulls, and the roofs of large buildings.

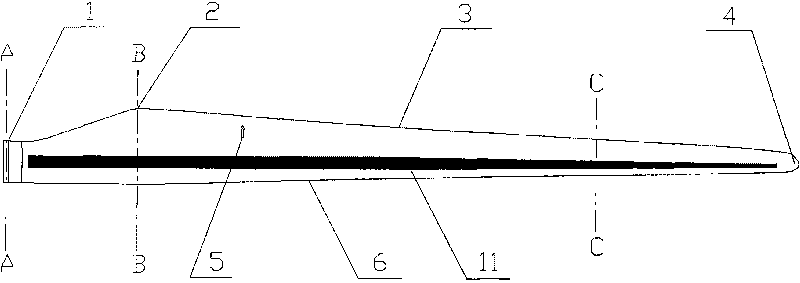

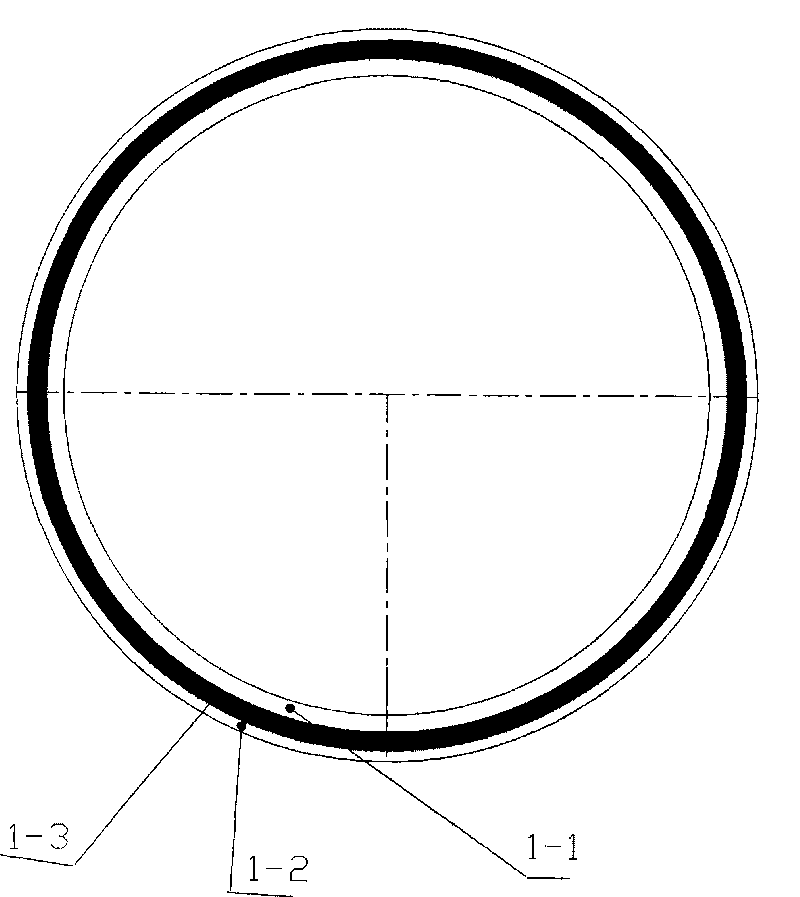

Wind turbine blade for large-scale wind generating set, and molding method thereof

ActiveCN101749194AReduce manufacturing costLess investmentFinal product manufactureMachines/enginesElectricityTurbine blade

The invention discloses a wind turbine blade for a large-scale wind generating set (wind-power blade for short). The wind-power blade has a thin shell structure and is combined by adhering two pieces of semi-shells; crossbeams which are extended from a blade root to a blade tip are respectively arranged in the two shells of the blade; a main shear web is adhered between the two crossbeams so as to form an I-shaped structure; a trailing edge shear web which is parallel to the main shear web is arranged on the side, between the two shells, close to the trailing edge; and the upper end and the lower end of the trailing edge shear web are respectively connected with the two shells. The invention also discloses a molding method for the wind turbine blade, which comprises the step of performing one-time molding on the crossbeams, a blade root enhancement layer and a shell by the technology of vacuum perfusion (RIM). Due to the adoption of the solution of the one-time molding technology, the quality defect caused by post molding of a composite material is avoided, the structural strength of a manufactured wind-power blade is improved and the service life of the manufactured wind-power blade is prolonged, and production efficiency is remarkably improved and production cost is reduced.

Owner:CHONGQING GENERAL IND (GRP) LTD

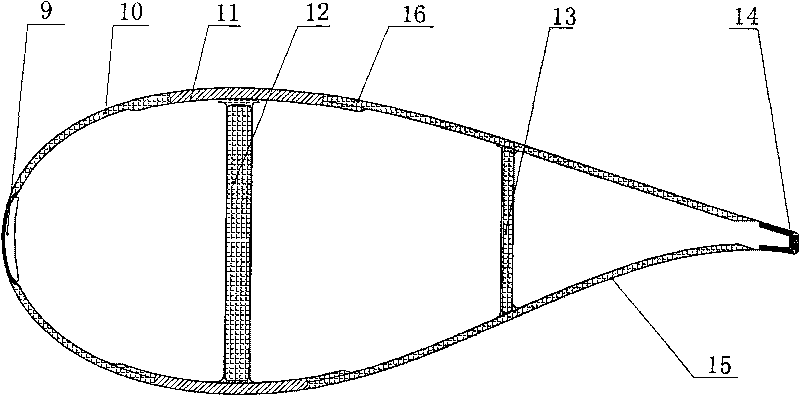

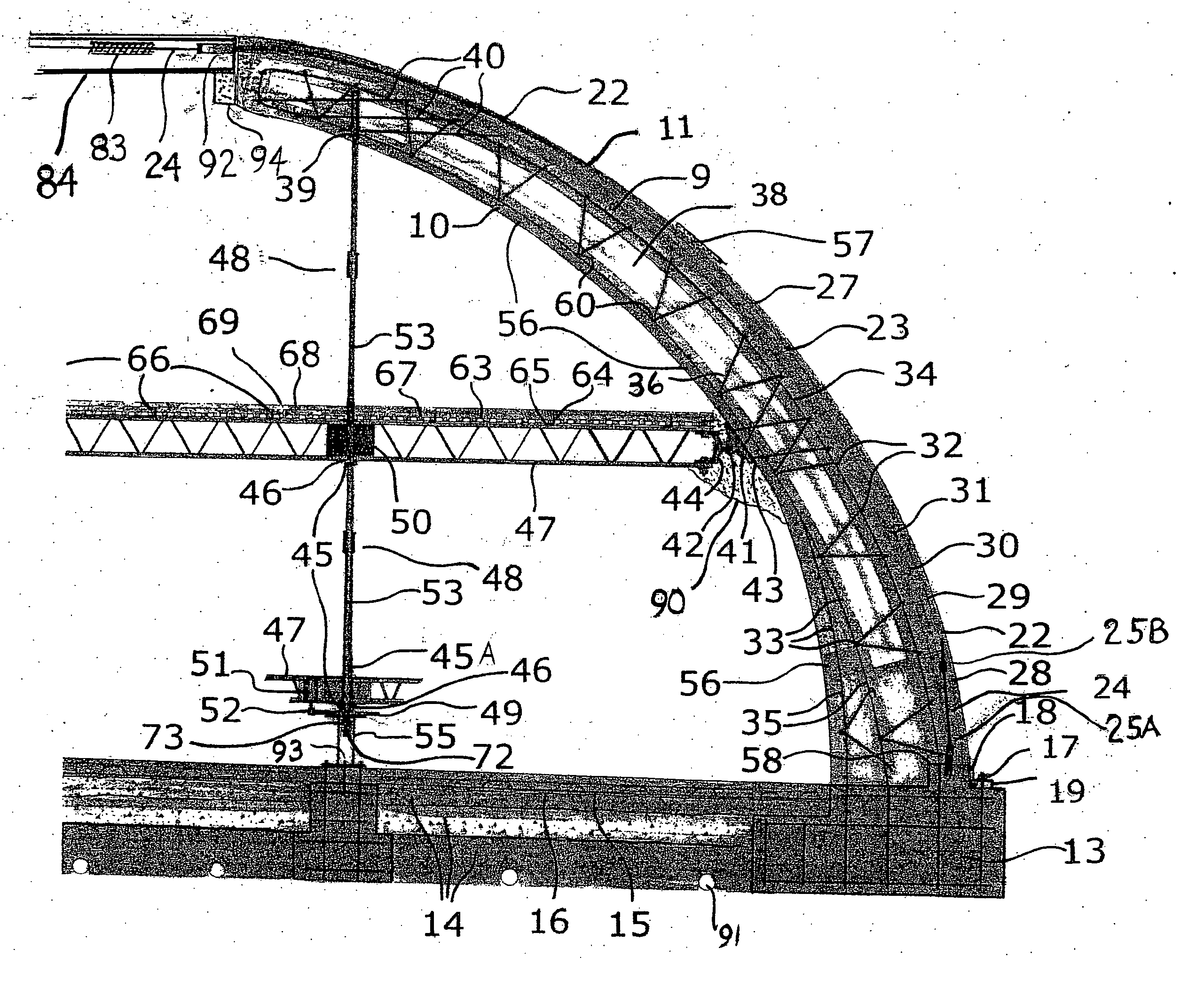

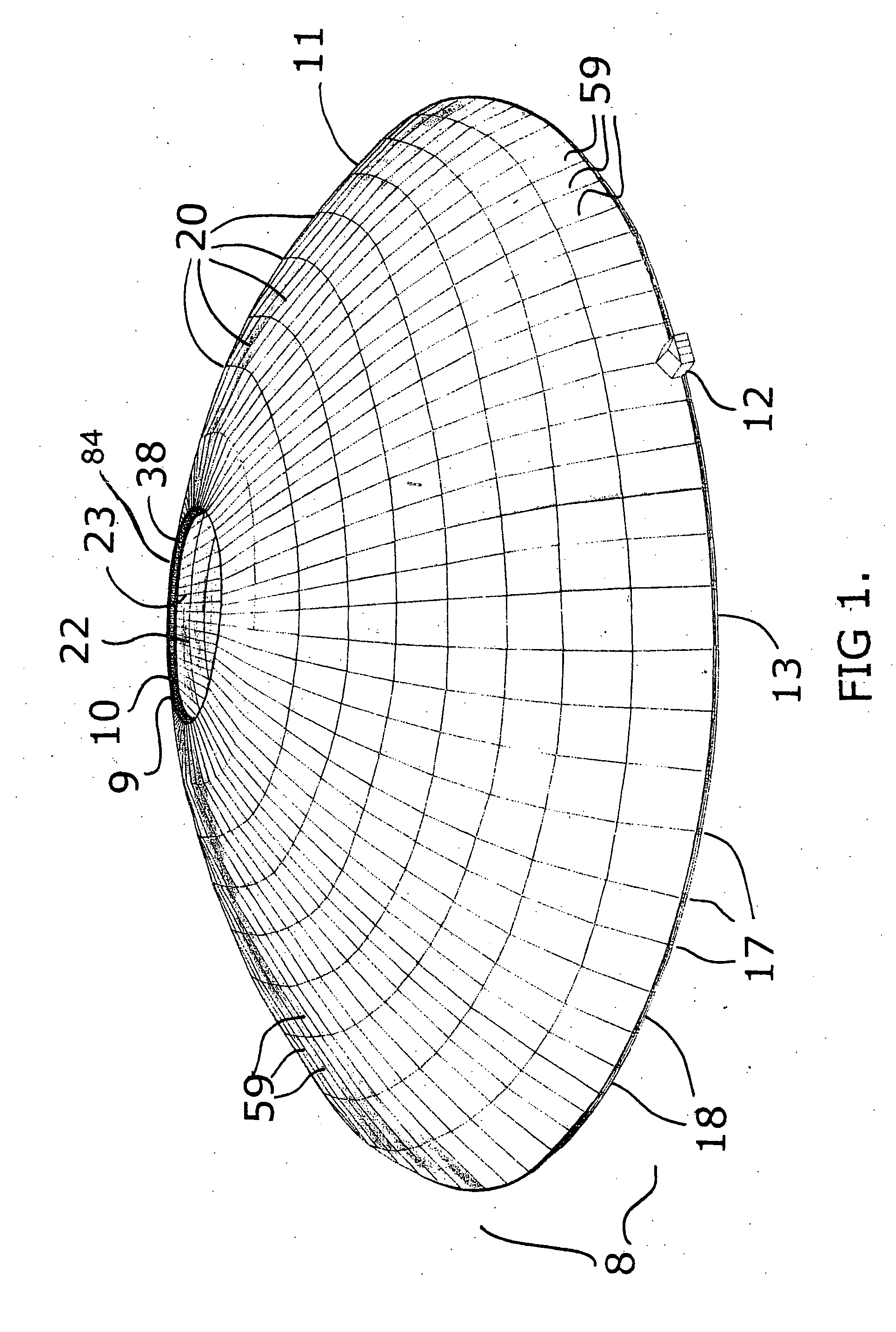

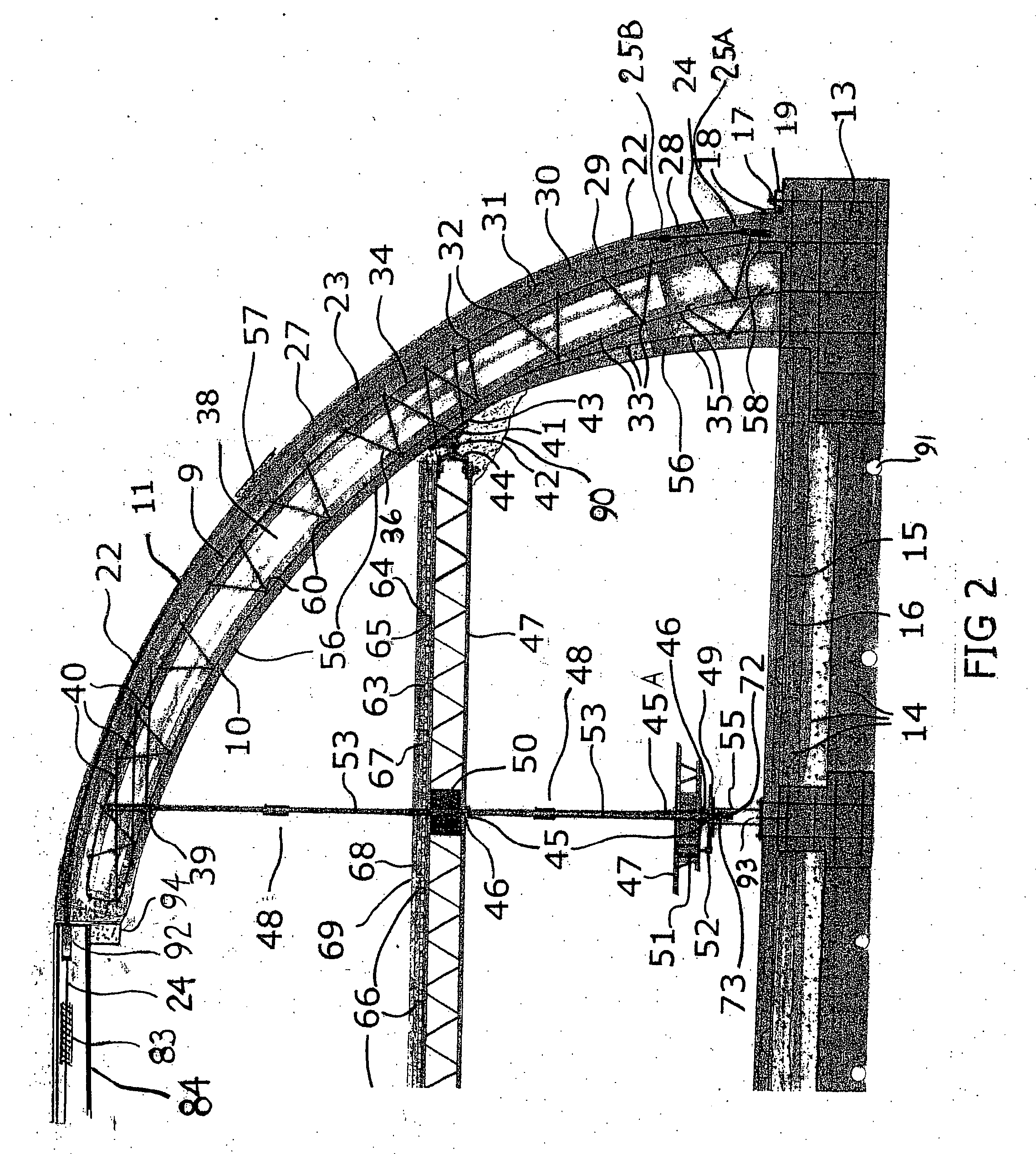

Trilithic and/or twin shell dome type structures and method of making same

InactiveUS20050210767A1Quick connectionImprove load-bearing strengthBuilding roofsArched structuresShotcreteThin shells

Trilithic Shell, Twin Shell, Multiple Shell, Curvilinear Shell as well as Free-formed Structures described herein each employ an inflatable membrane having a peripheral edge secured to an outer foundation base. An ultra-light membrane (air-form) having a network of internal cross connecting restraints is additionally secured to the inner foundation base to permit a novel and unique curvilinear surface. Pressurization then creates the backdrop upon which various urethane layers are applied which when laced with rigidifying tubes become the defining backdrop beneath which numerous cross connecting braces which when snapped into position effectively lock an inner framework to an outer framework thereby producing a self supporting truss like structure both compatible with either current dome construction and / or conventional construction practices. Shotcrete being then sprayed from the interior over said urethane coated backdrop forms highs at framework intersections and natural lows in between followed by the insertion of inflated cell tubes which span the created network of horizontal and vertical cavities are next over sprayed with urethane foam necessary to form the next natural backdrop over which two or more shotcrete / steel reinforced separate yet cross connected planes may be achieved. Such multiple yet independent rigid layers now having thousands of inner-connecting cross braces through which interior voids become natural chase-ways effectively displace 50% or more of what might otherwise be solid concrete as would be the case with all prior art thin shell structures and / or conventional stem wall construction practices. Such Free Formed curve-linear structures effectively reduce material and labor costs by as much as 50%, eliminate snap-through or oil-can buckling tendencies, enhance overall structural capacity, eliminate all height to diameter restraints, permit larger structures, facilitate floor suspension and attachment, and allow mechanical, electrical and HVAC distribution through interior chase-ways which cannot be achieved with prior art concrete thin shell single thickness structures and / or conventional stem wall, construction practices to date.

Owner:DEFEVER MICHAEL D +1

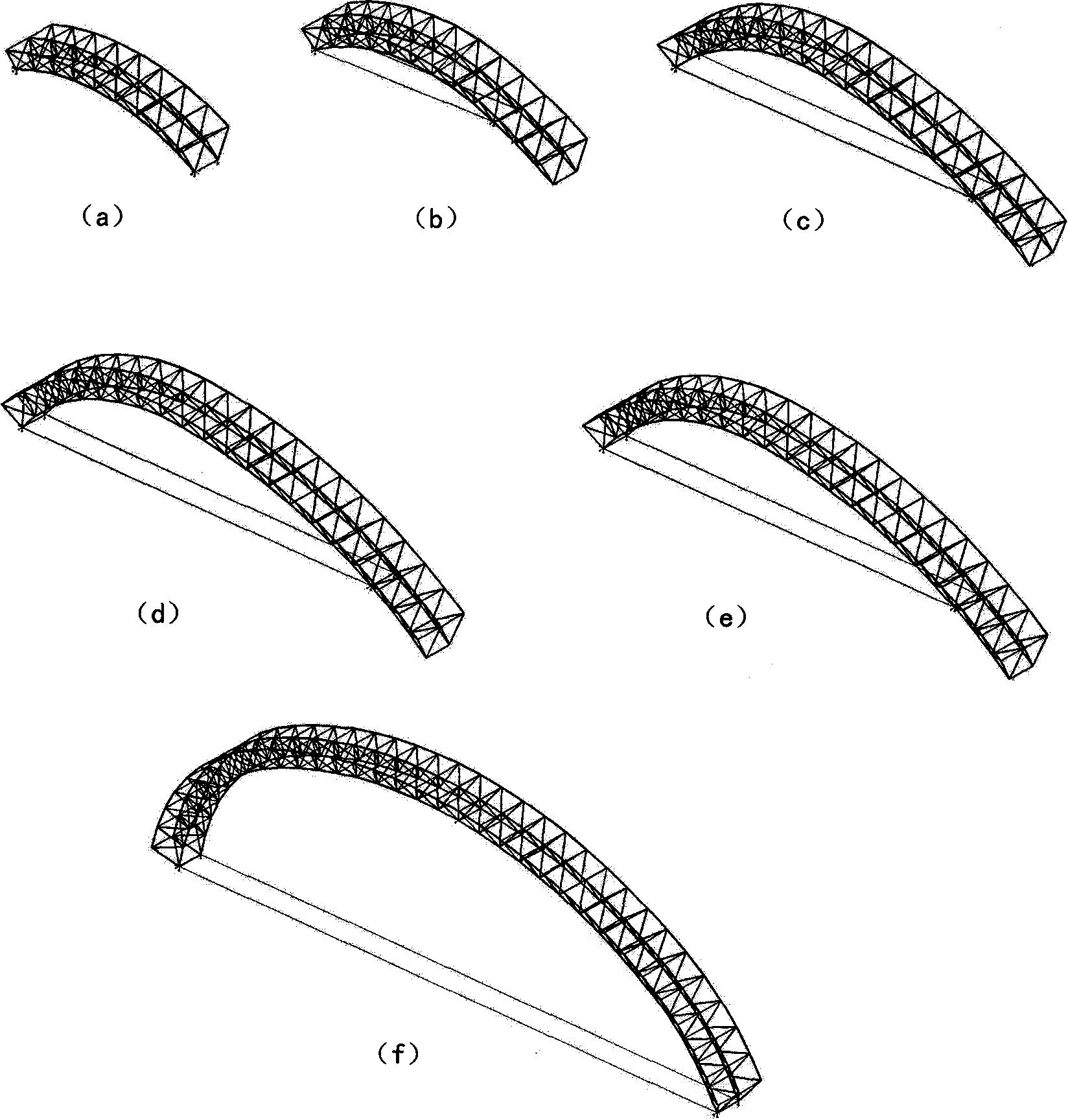

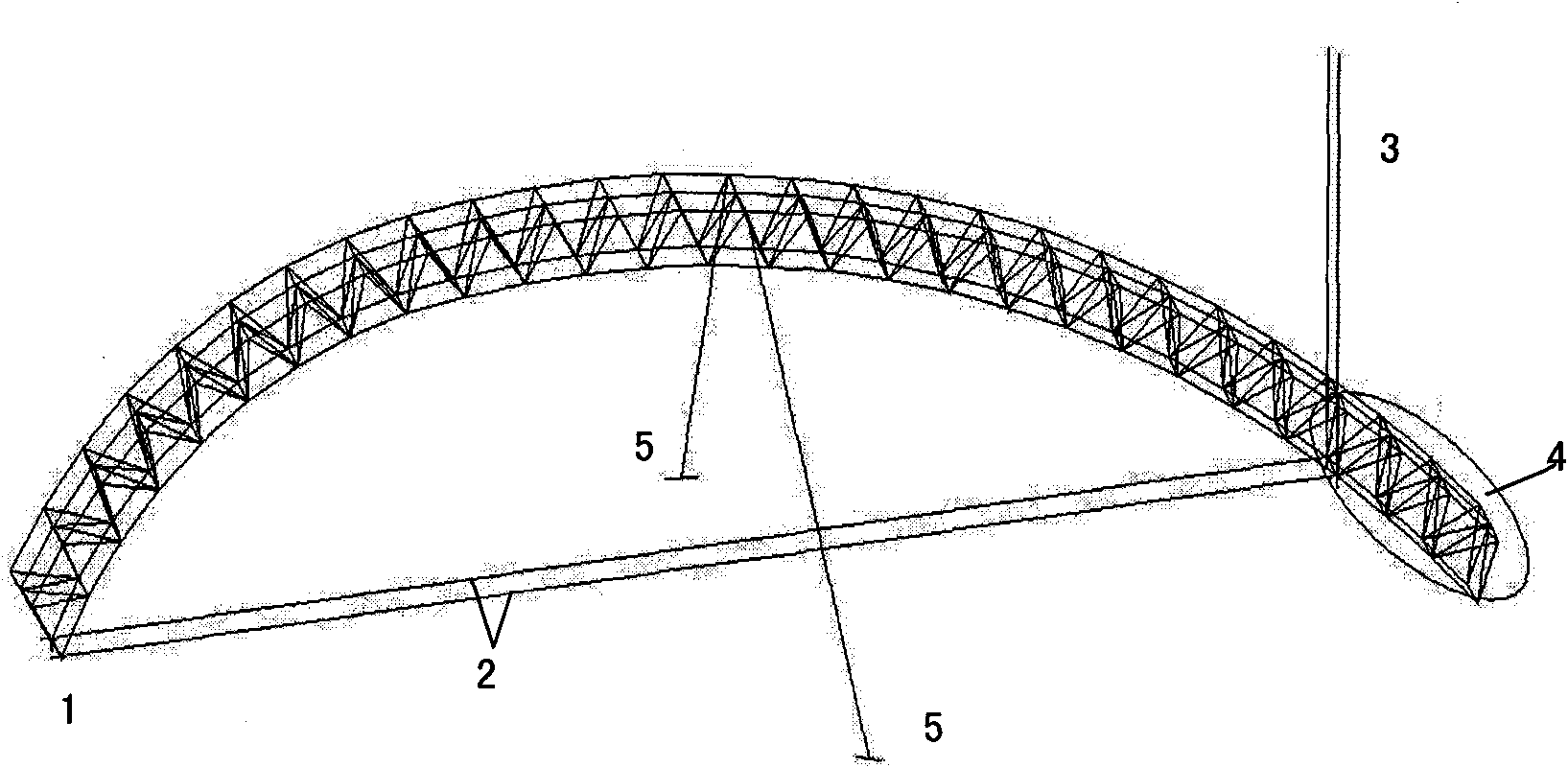

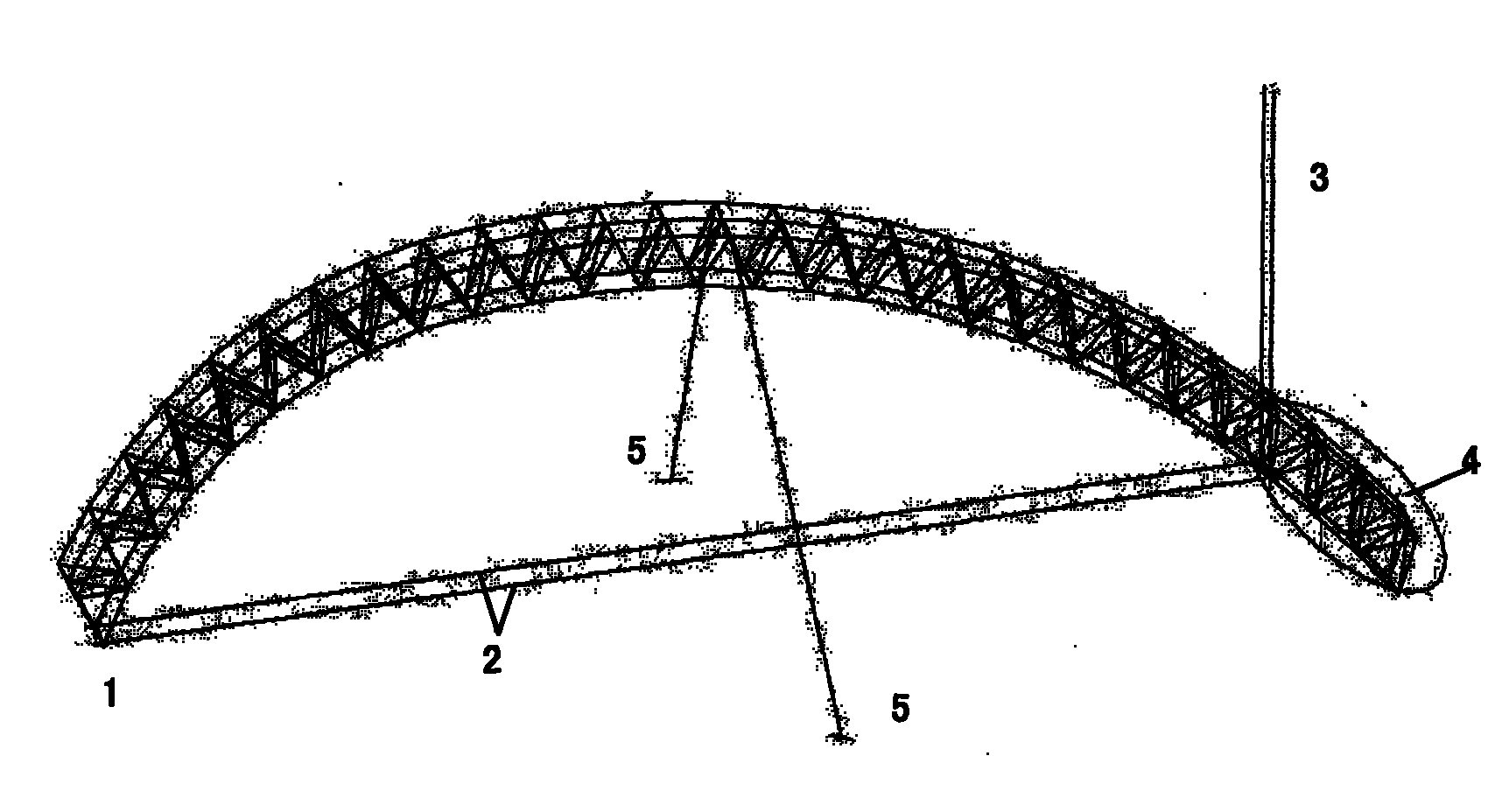

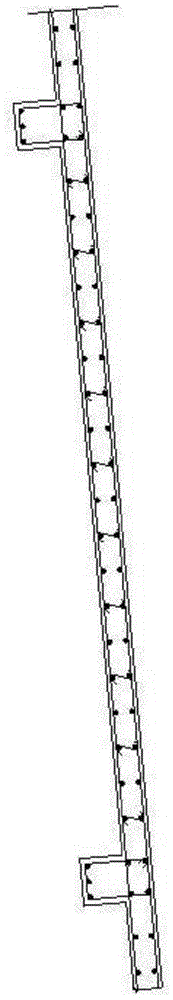

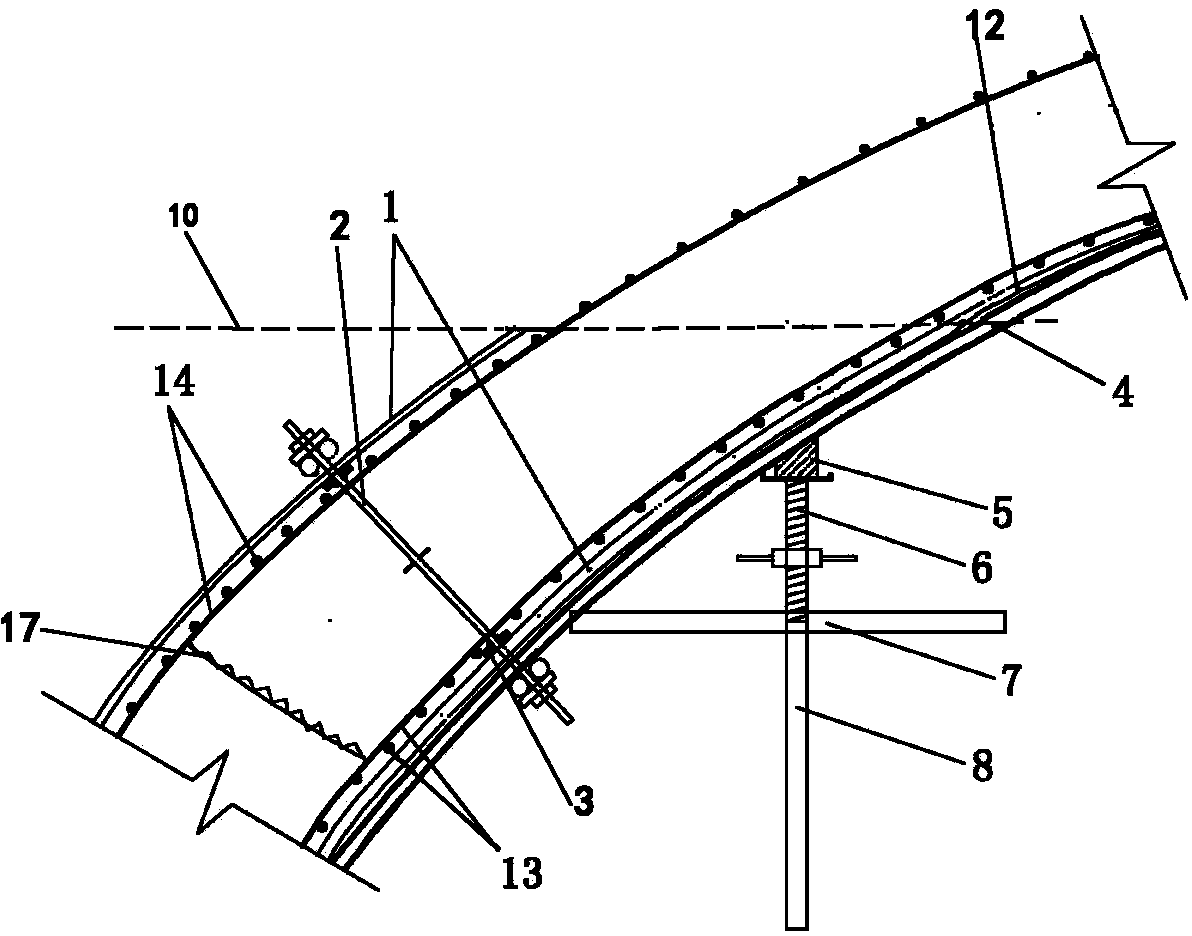

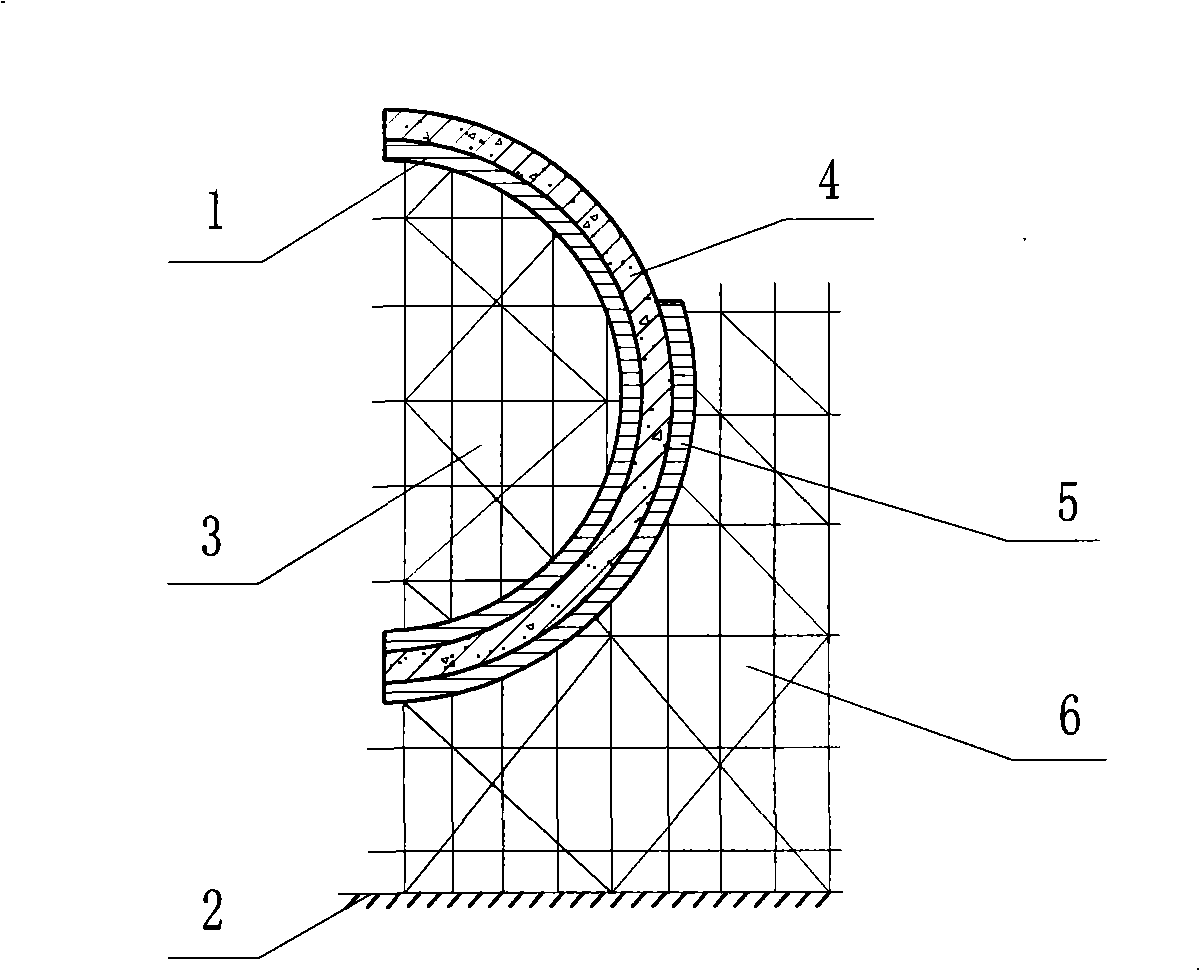

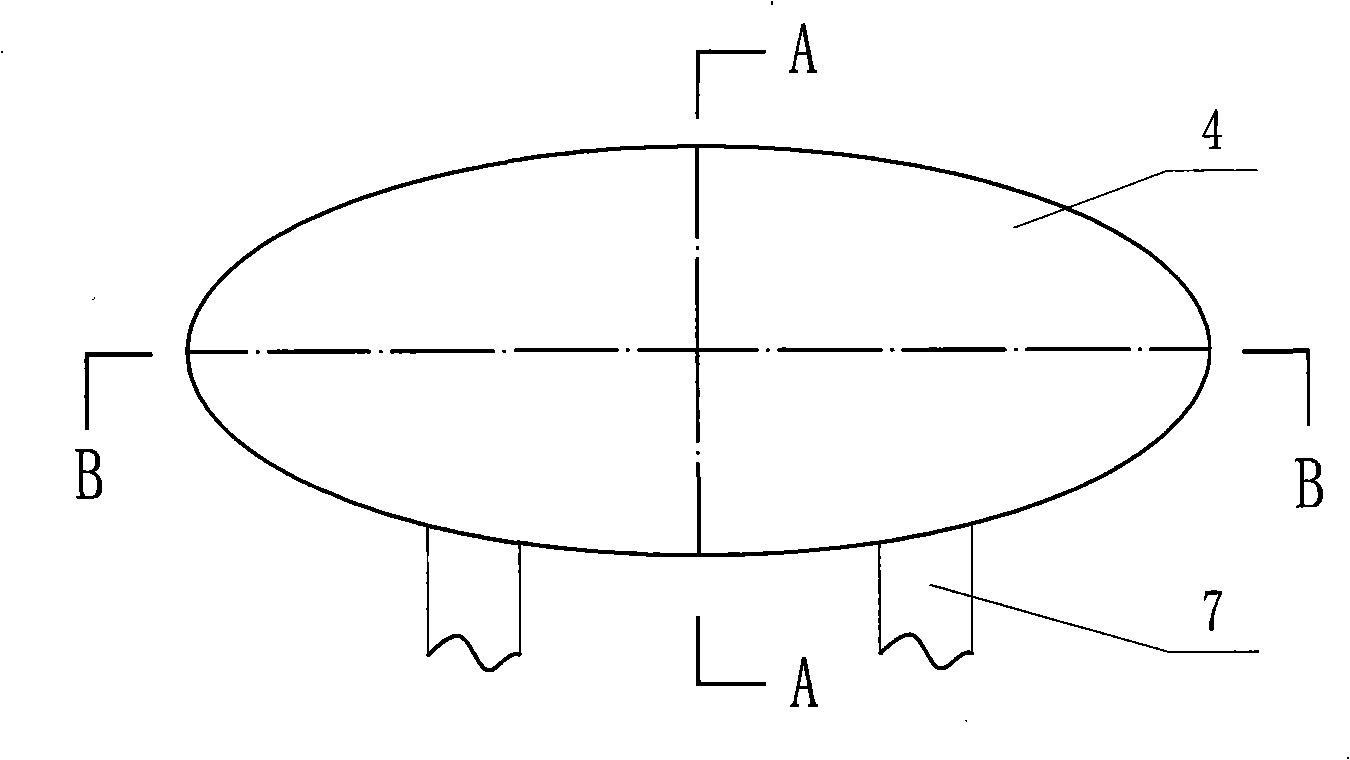

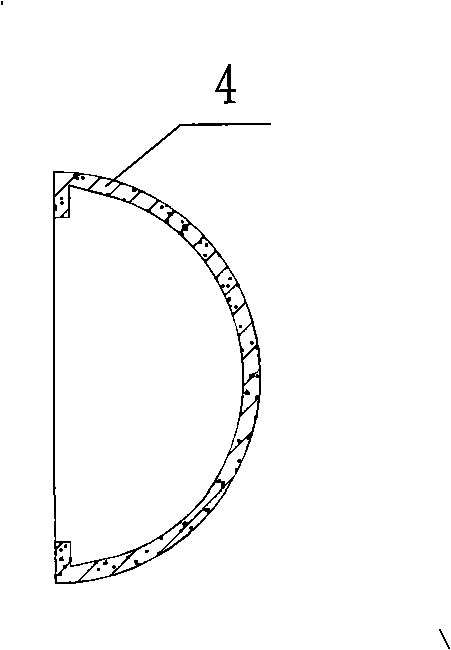

Prestressing method for installing large-span double-layer latticed shell structure

InactiveCN101839068AAvoid settingImprove work efficiencyBuilding material handlingPre stressSpandrel

The invention belongs to the technical field of building installation, in particular to a prestressing method for installing a large-span double-layer latticed shell structure, which comprises the following steps of: firstly, assembling one initial segment of a latticed shell on the ground, fixing one end of the initial segment on a support at one side through hinging, and hanging the other end with a crane; and assembling member bars by steps to extend till the support at the other side of a single latticed shell structure toward the other side of the support. The length of each extension segment equals to the length of 3-4 standard member bars. Whenever the latticed shell is extended by assembly, steel wire ropes are used for connecting the fixed hinge support and installed latticed shell tail nodes, and a prestressing force is applied so that the latticed shell and the steel wire ropes form a structure similar to a beam string structure. The installation method can avoid setting up a high altitude platform so as to increase working efficiency and reduce construction cost, and can also ensure construction safety.

Owner:宝厦建设(集团)股份有限公司

Thin shell cabin cover die for wind-driven generator and manufacturing method thereof

The invention relates to a thin shell cabin cover die for a wind-driven generator and a manufacturing method thereof. The thin shell cabin cover die comprises a bottom die and an upper die, wherein the bottom die is a male hard die; and the upper die is formed by integrating a female hard die which is matched with the bottom die and a silica gel soft die coated on the forming surface of the female hard die. The invention provides a die which is used for manufacturing a large-sized glass fiber reinforced plastic structure and takes the silica gel soft die as the upper die, so that consumable materials and labor force are saved, the edge of the manufactured large-sized glass fiber reinforced plastic thin shell is smooth and regular, secondary processing is not required, a large amount of production cost is saved, and environmental pollution is avoided.

Owner:JIANGSU GLOBAL LONGSHENG ENVIRONMENTAL TECH& DEV

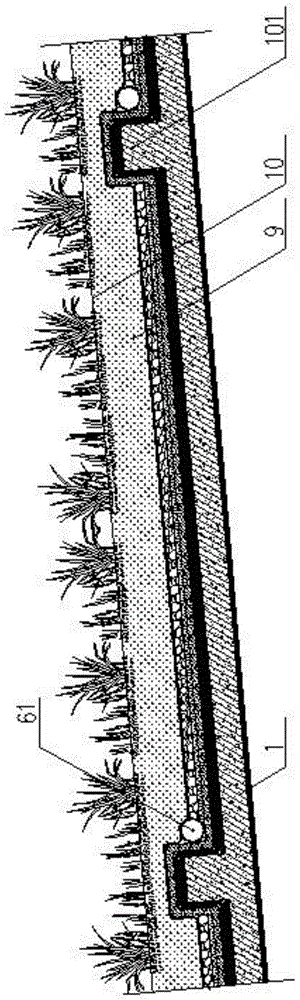

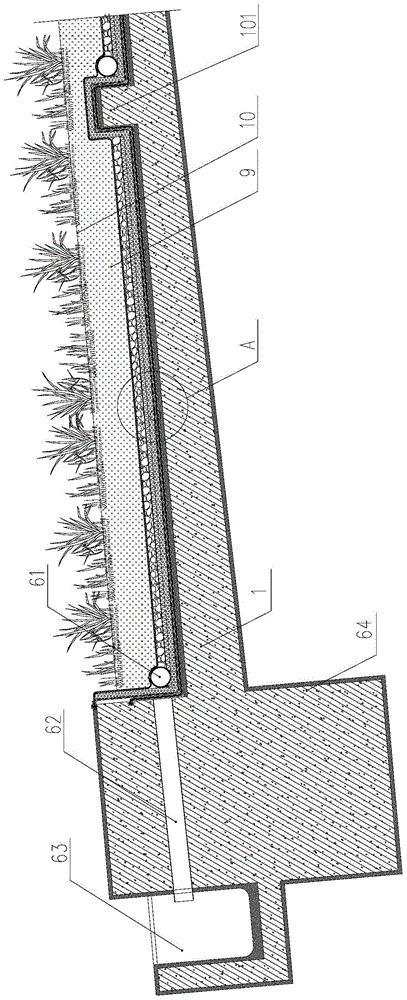

Large-space saddle-shaped overall greening roof system

ActiveCN103953148ASolve the design problems of roof greeningSolving Design ChallengesBuilding roofsRoof coveringEngineeringRebar

The invention discloses a large-space saddle-shaped overall greening roof system. The large-space saddle-shaped overall greening roof system comprises a saddle-shaped reinforced concrete thin-shell structure panel with grid-type reversed beam ribs and a roof greening plantation construction, wherein the saddle-shaped reinforced concrete thin-shell structure panel with the grid-type reversed beam ribs comprises a saddle-shaped shell plate and the grid-type reversed beam ribs which are convexly arranged on the upper surface of the shell plate; the shell plate is a standard single-piece doubly-inclined hyperbolic paraboloid torsional shell; an edge beam is arranged at the edge of the shell plate; the shell plate and the grid-type reversed beam ribs are reinforced in a unified manner and are formed by synchronous overall type pouring; the roof greening plantation construction consists of a waterproof layer, a root puncturing resistance layer, a protection layer, a water drainage layer, a water retention layer, a filter layer, a soil layer and a plant layer which sequentially covers the shell plate and the grid-type reversed beam ribs from bottom to top; a water seepage pipe is arranged on the protection layer along the edge of a plantation groove. According to the large-space saddle-shaped overall greening roof system, the conflict between a large-span space structure and a roof greening load is effectively overcome, and a roof system which is most ecological and energy-saving is created for a large-space building.

Owner:SOUTH CHINA UNIV OF TECH

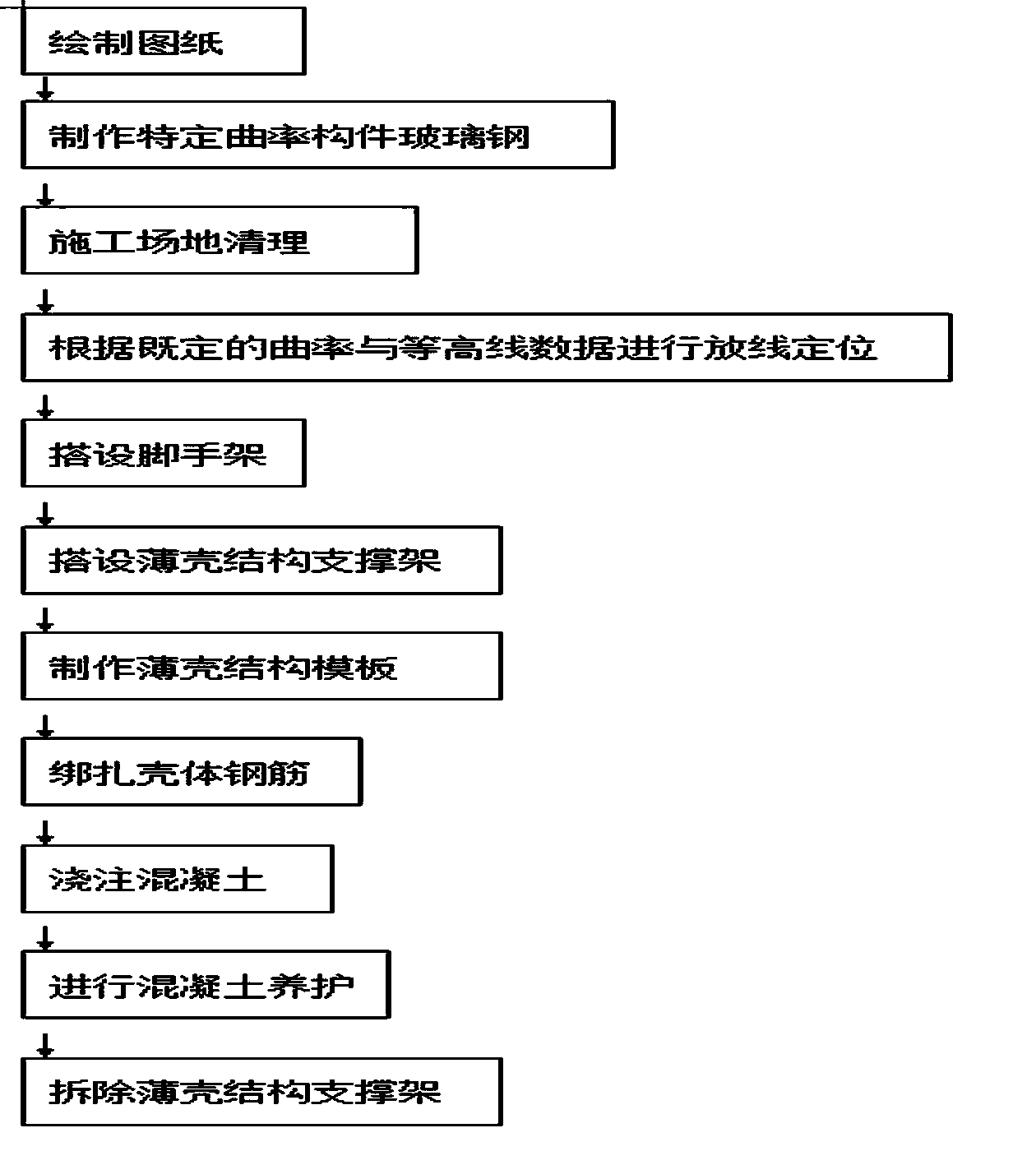

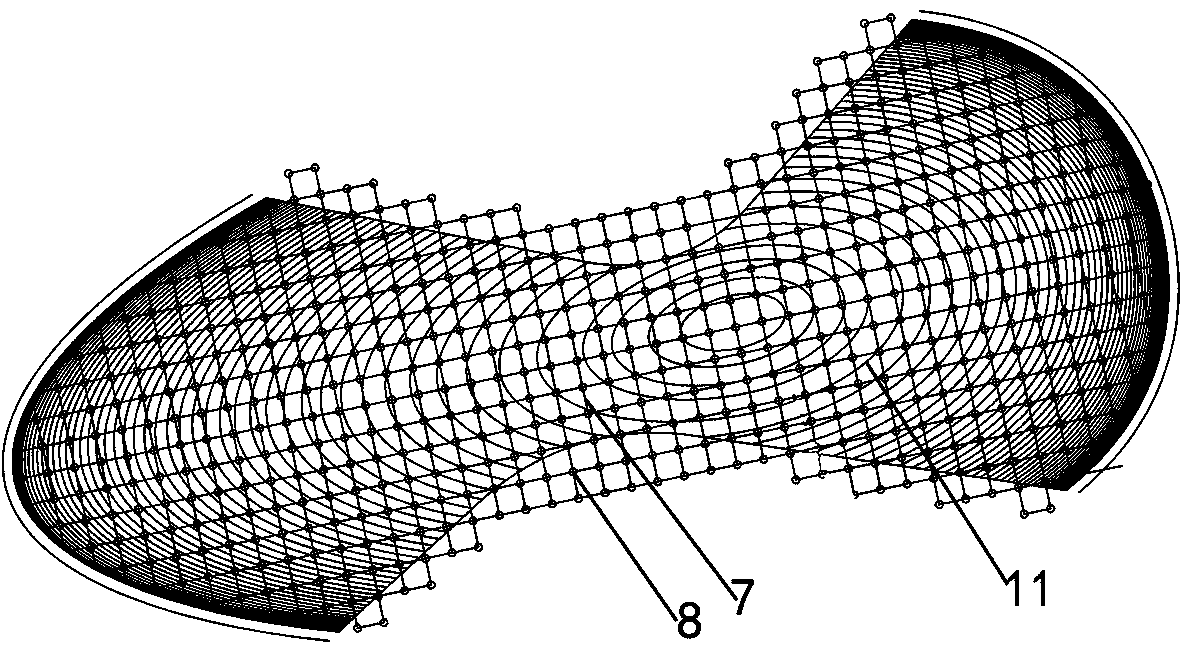

Large-span multi-curvature thin shell reinforced concrete structure construction method

ActiveCN103590603AFast unificationImprove unityForms/shuttering/falseworksBuilding material handlingWire gauzeControl line

A large-span multi-curvature thin shell reinforced concrete structure construction method specifically includes the steps of making drawings, manufacturing and building glass fiber reinforced plastics, cleaning a construction site, carrying out paying-off positioning according to an established curvature and contour line data, setting up supporting frames, setting up thin shell structured supporting frames, manufacturing thin shell structured formworks, binding shell reinforcing steel bars, pouring concrete, dismounting formwork supporting frames and the like. According to the construction method, a contour line mode is adopted to carry out disassembling on the formworks by being coordinated with a control line, so rapid erection is achieved and the construction time is saved. The portion, close to the bottom of a shell is made of dual-side glass fiber reinforced plastic formworks, and formwork sealing is carried out by using steel wire gauze arranged at intervals, so vertical bearing capacity is guaranteed, the problem in large-gradient concrete construction is solved, and the slanting thrust of the structure on frame bodies is removed effectively. In addition, concrete subsection symmetrical pouring is adopted, so the stress of a supporting system can be balanced, and the problem of difficult construction caused by big shell size and steep gradient can be solved.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

Light track

InactiveCN101301908AReduce thickness requirementsHigh strengthEndless track vehiclesGear wheelEngineering

The invention discloses a light apron wheel which is formed by a plurality of apron wheel joints connected end to end, wherein, the space between the adjacent apron wheel joints forms decoupling connection in inhaul cable channels by inhaul cables, the top surface of the apron wheel joint is provided with a transmission element which can be a transmission tooth or a transmission groove hole; thrust power is obtained by toggling by a driving gear wheel continuously, the bottom surface of the apron wheel joint is provided with a grounded tooth, thereby increasing the anti-sliding friction force with the ground, and the intensity of the apron wheel; the apron wheel joint adopts hollow thin shell structure, thereby greatly reducing self weight, saving material, having the floating force suitable for working in water, optimizing the floating function of the chassis of the apron wheel, being easy to implement wideness, being convenient to be exchanged and repaired, prolonging the service life, being the best replacing proposal of the prior apron wheel, and being suitable for situations such as mudflat operation machineries, amphibious tanks, marsh tourist cars, pedrail type engineering machineries and rice combine harvesters, etc.

Owner:杨存俭

Preparation method of intensified tantalum and tantalum alloy material

The invention discloses a making method of high strong tantalum and tantalum alloy as reinforced microscopic tissue structure, which is characterized by the following: increasing oxygen on the surface; forming hard closed thin case structure on the surface with oxygen solid or low-valent tantalum oxide; proceeding heat isostatic pressing solidifying; obtaining dense block material; disposing in the vacuum; adjusting dynamic property of material without growing under 2200 deg. c.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

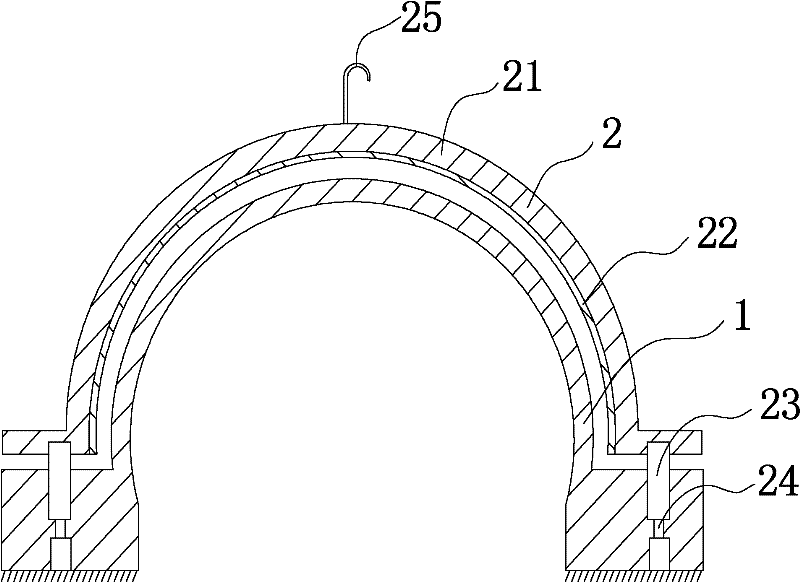

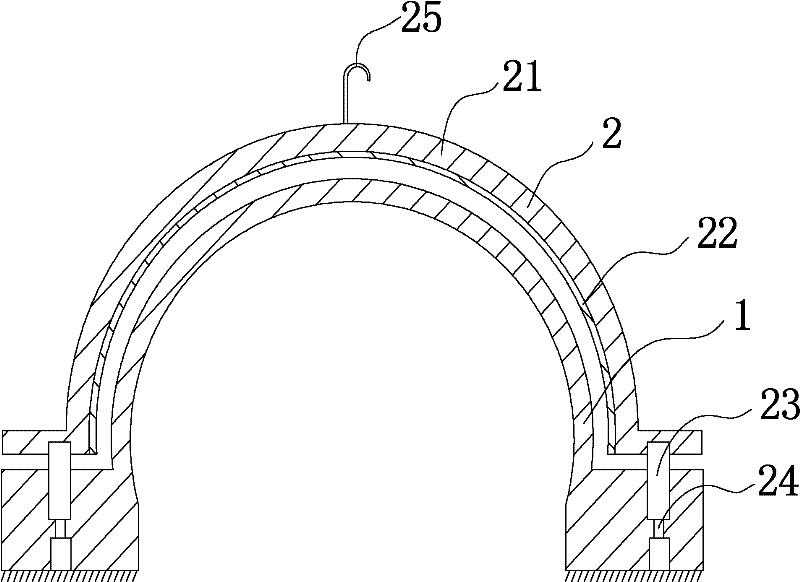

Construction method of thin shell with thin-shell structure

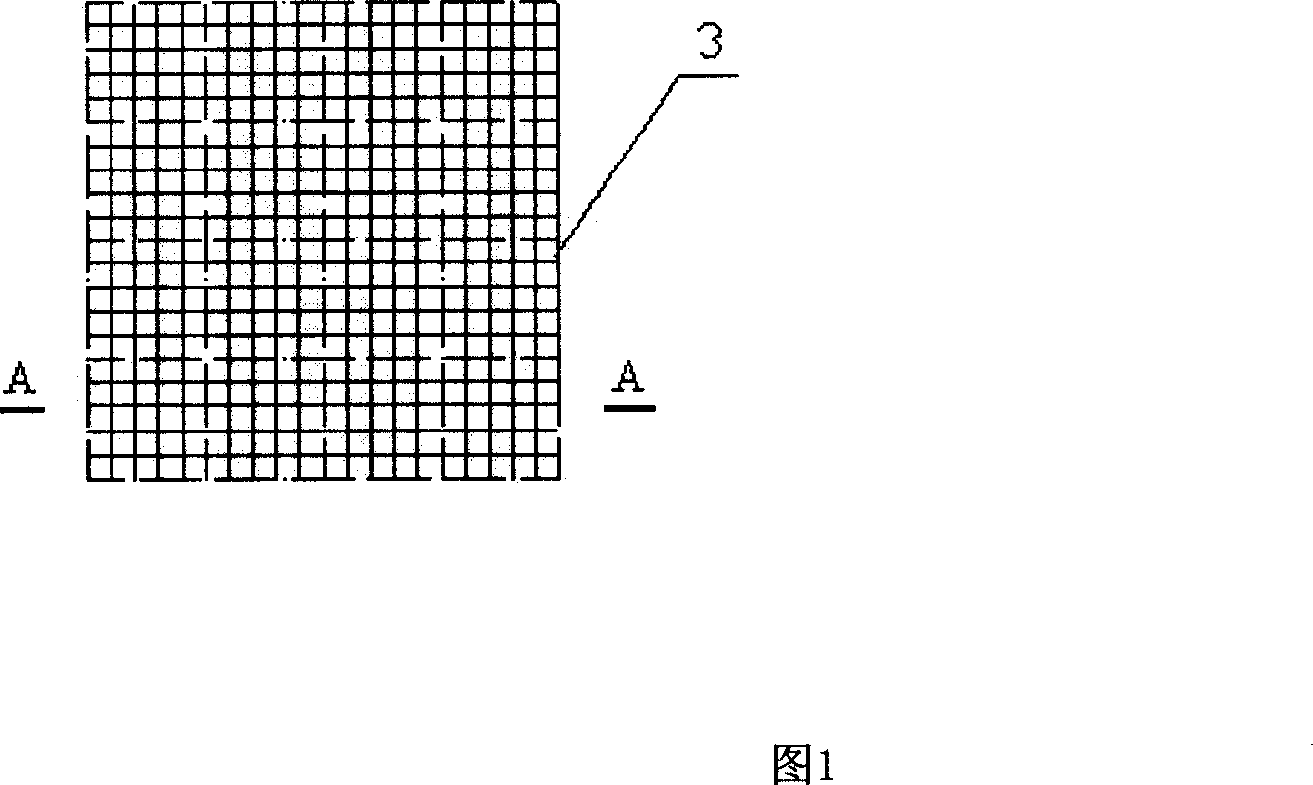

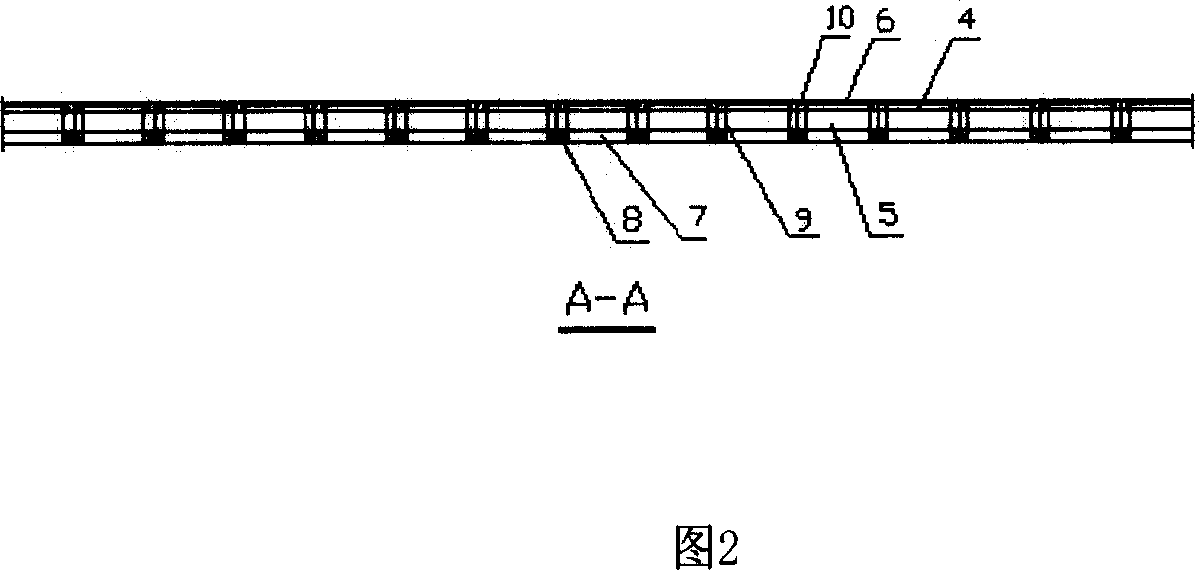

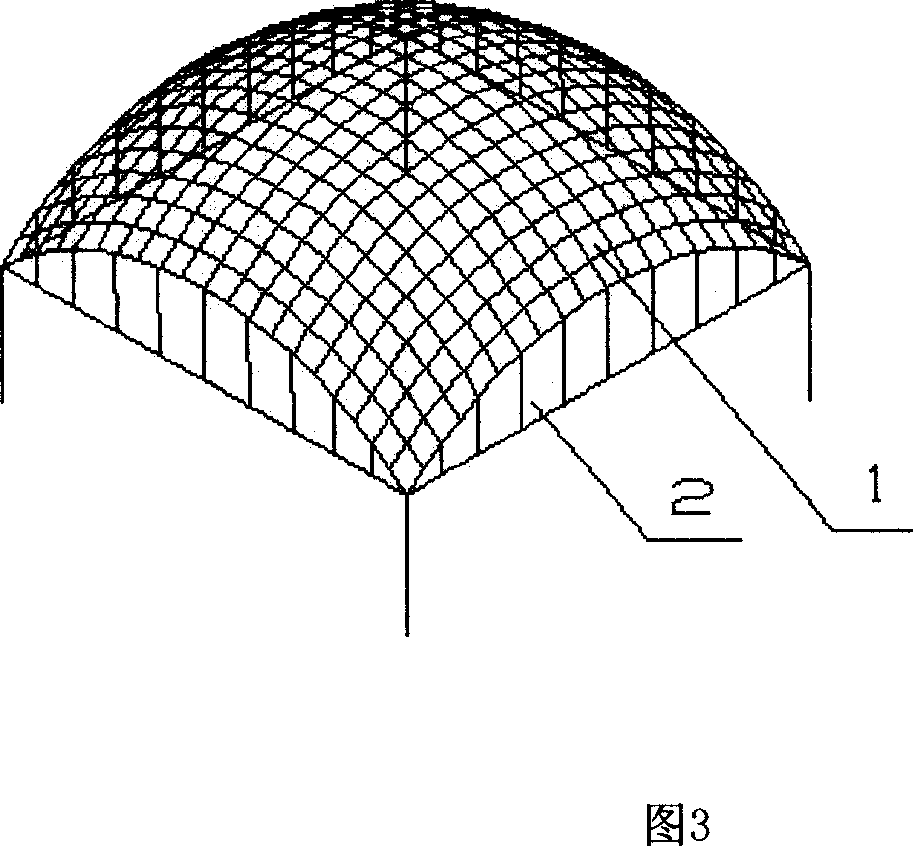

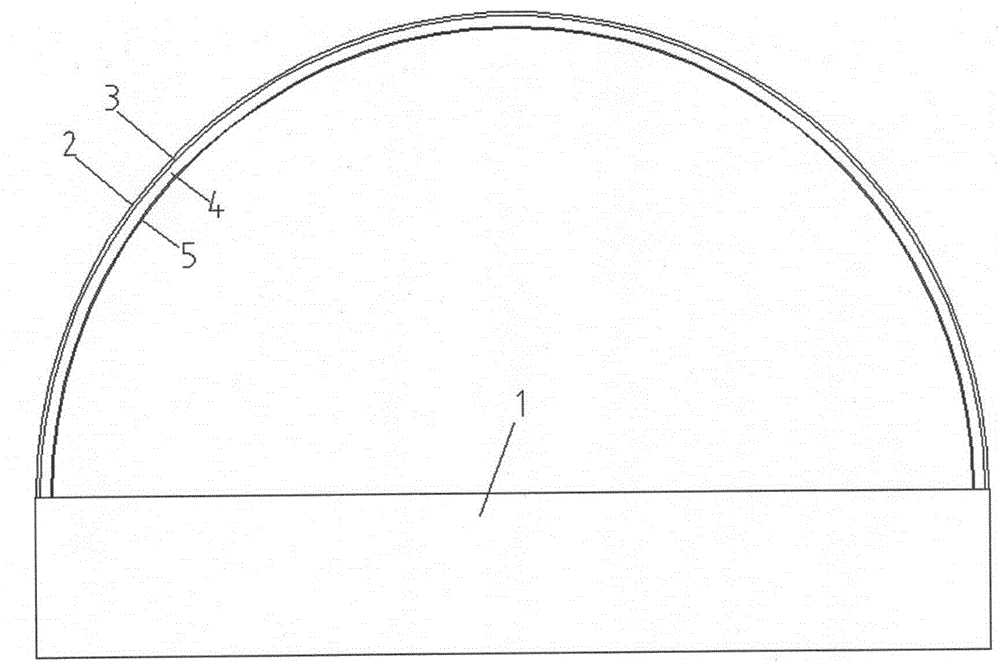

ActiveCN101832028AEasy to controlSimple construction methodBuilding material handlingShotcreteThin shells

The invention discloses a construction method of a thin shell with a thin-shell structure and relates to a reinforced concrete construction method of a thin shell with a thin-shell structure. Aiming to reduce the workload of producing, mounting and stripping a framework, the construction method comprises the following construction steps of: (1) hanging and paving a combined body of a concrete gridded attached carrier for deposing and pouring and reinforcing ribs on a prestress cable net, binding the attached carrier, the reinforcing ribs and the cable net by using the reinforcing ribs with a concrete bearing structure; and carrying out spraying and concreting to generate a form shell of the formwork for pouring concrete; and (2) carrying out spraying concreting on the generated form shell to finish the construction of the thin shell with the thin shell structure. The construction method is simple, can save a large amount of labor force and physical resources and has favorable comprehensive technical and economic performances.

Owner:CHINA CHEM ENG SECOND CONSTR

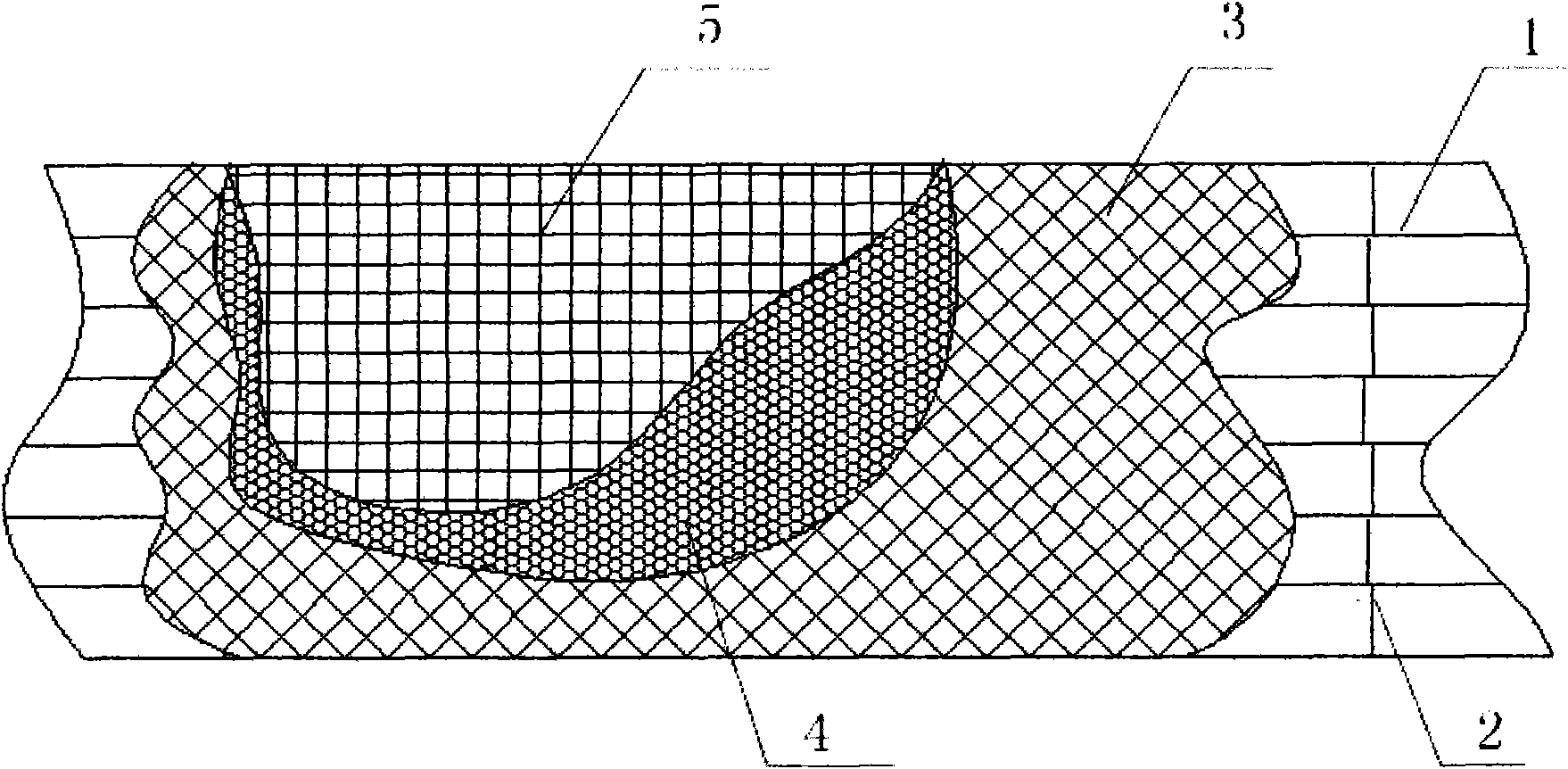

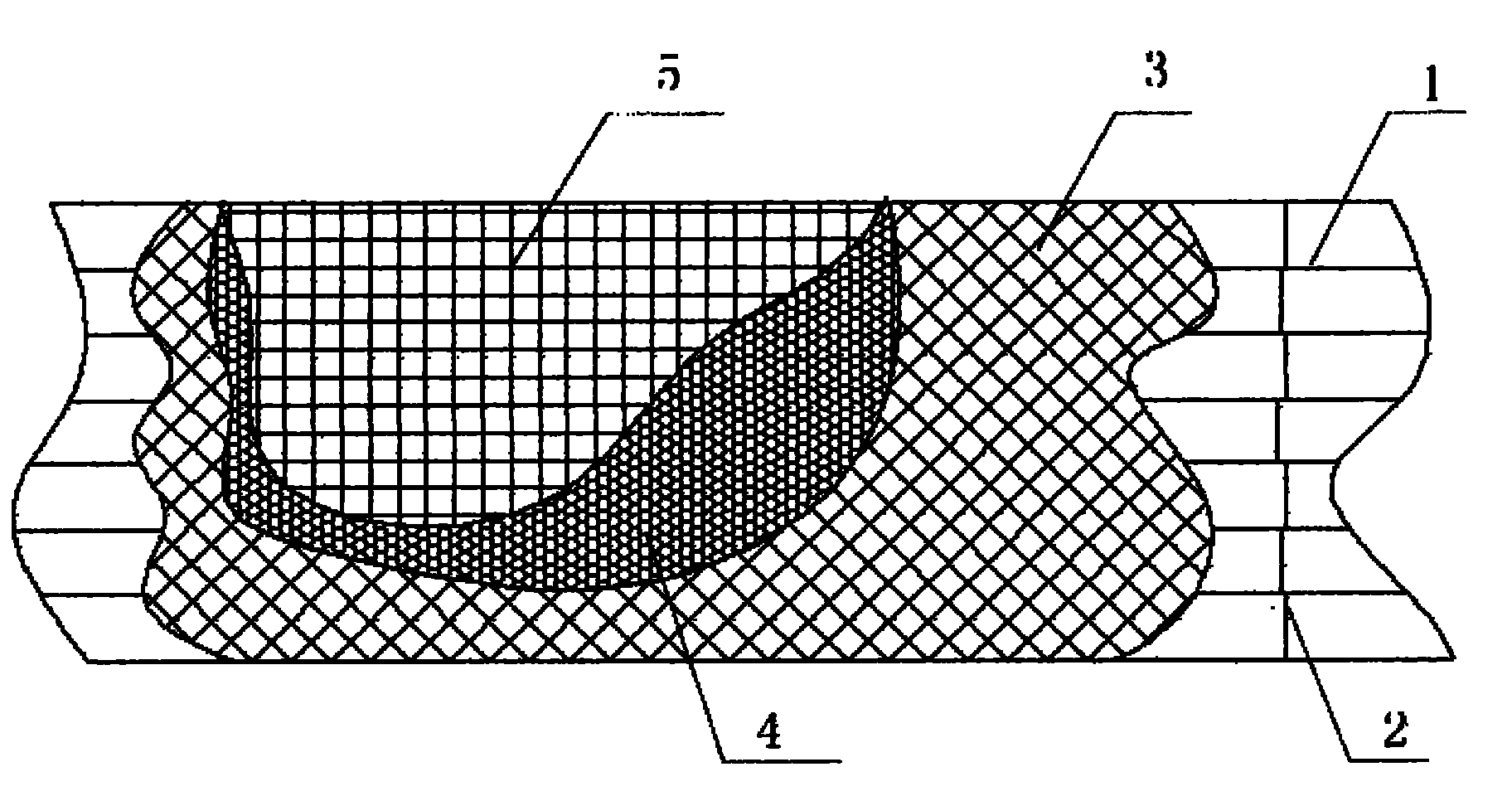

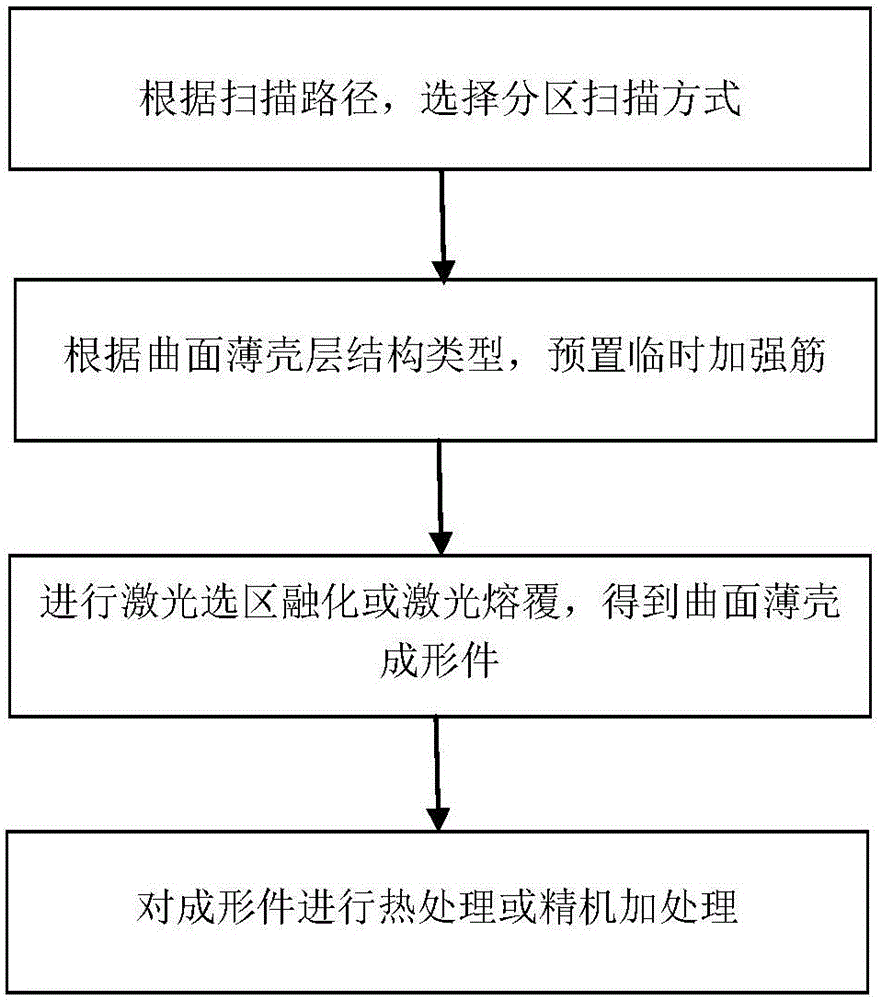

Metal additive preparation method for curved-surface thin shell structure

ActiveCN106001569AReduce continuous heating timeSmall thermal deformationAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingThin shells

The invention relates to a metal additive preparation method for a curved-surface thin shell structure. The metal additive preparation method comprises the following steps: 1) carrying out curved-surface set characteristic analysis according to a curved-surface parameter equation of the curved-surface thin shell structure to obtain a laser scanning path, and determining a partition movable scanning manner; 2) determining to pre-arrange temporary reinforcing ribs on a curved-surface thin shell according to a type of the curved-surface thin shell structure; 3) carrying out selective laser melting or laser cladding to obtain a curved-surface thin shell formed part; and 4) carrying out heat treatment or fine machining treatment on the curved-surface thin shell formed part. The preparation method has the following characteristics: the working procedures of the method are relatively simple, the working efficiency is effectively increased, the deformation amount of the formed part can meet the needs of use and design, the corrosion resistance and fatigue resistance are greatly improved, the service life can be prolonged, the manufacturing cost is reduced, and the like.

Owner:四川天塬增材制造材料有限公司

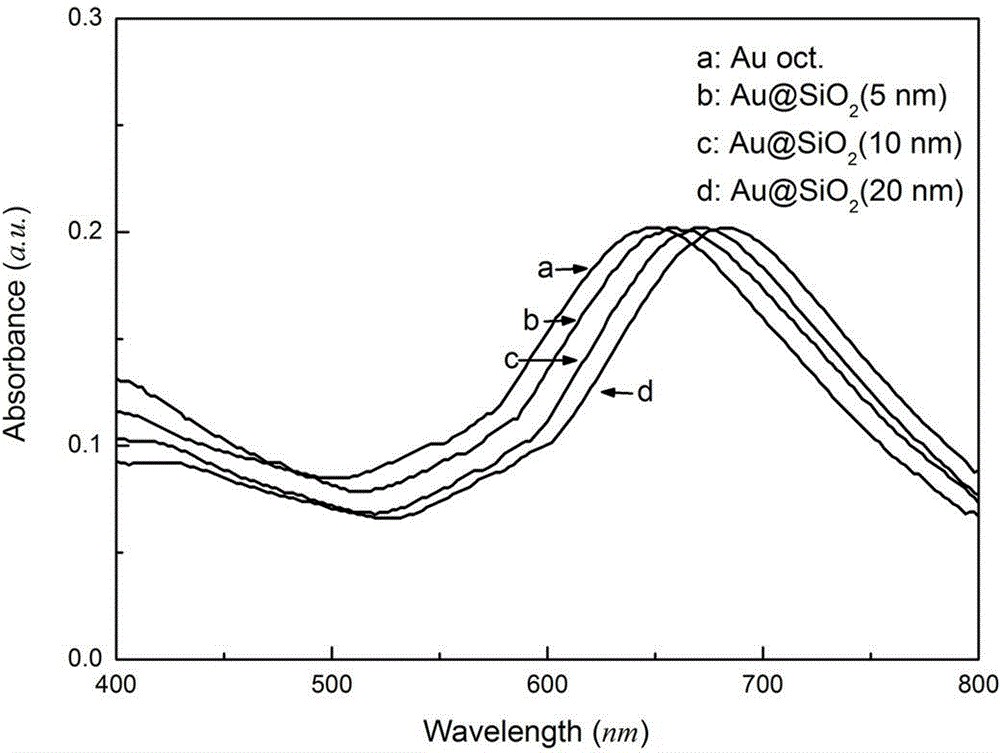

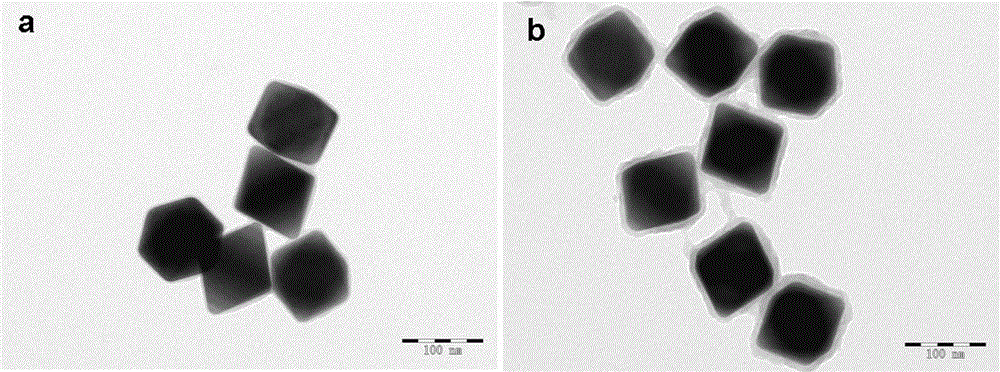

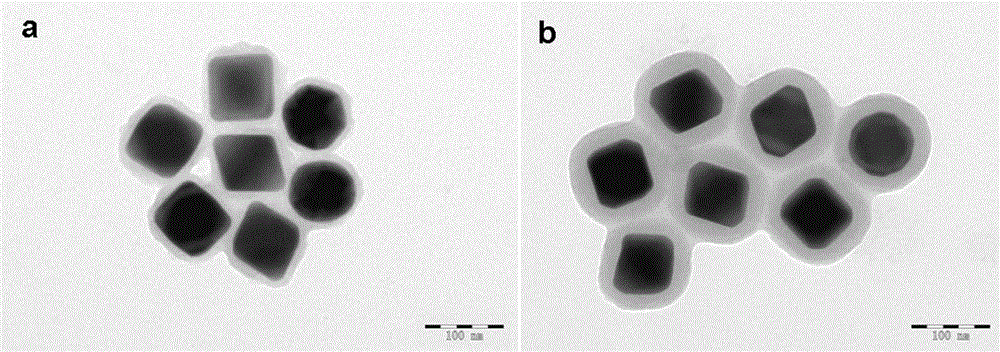

Controllable preparation method for Au@SiO2 nano-composite material with ultra-thin shell

The invention relates to a controllable preparation method for Au@SiO2 core shell nano-material with an ultra-thin shell structure. The controllable preparation method for the Au@SiO2 core shell nano-material with the ultra-thin shell structure mainly solves the problem that SiO2 is difficult to coat gold nano-particles modified by PDDA. The shell thickness of the coated Au@SiO2 core shell nano-material can be controlled through the MPTS amount, reaction time and the like parameters. The prepared Au@SiO2 core shell nano-particles are regular in shape and uniform in shell thickness, and the thickness can be controlled at 5 to 20 nanometers. The Au@SiO2 core shell nano-material with the ultra-thin shell structure has potential application value for the catalyzing, bio-sensing and the like, and more choices are provided for the template material for preparing multi-structure and multi-functional special nano-material.

Owner:UNIV OF JINAN

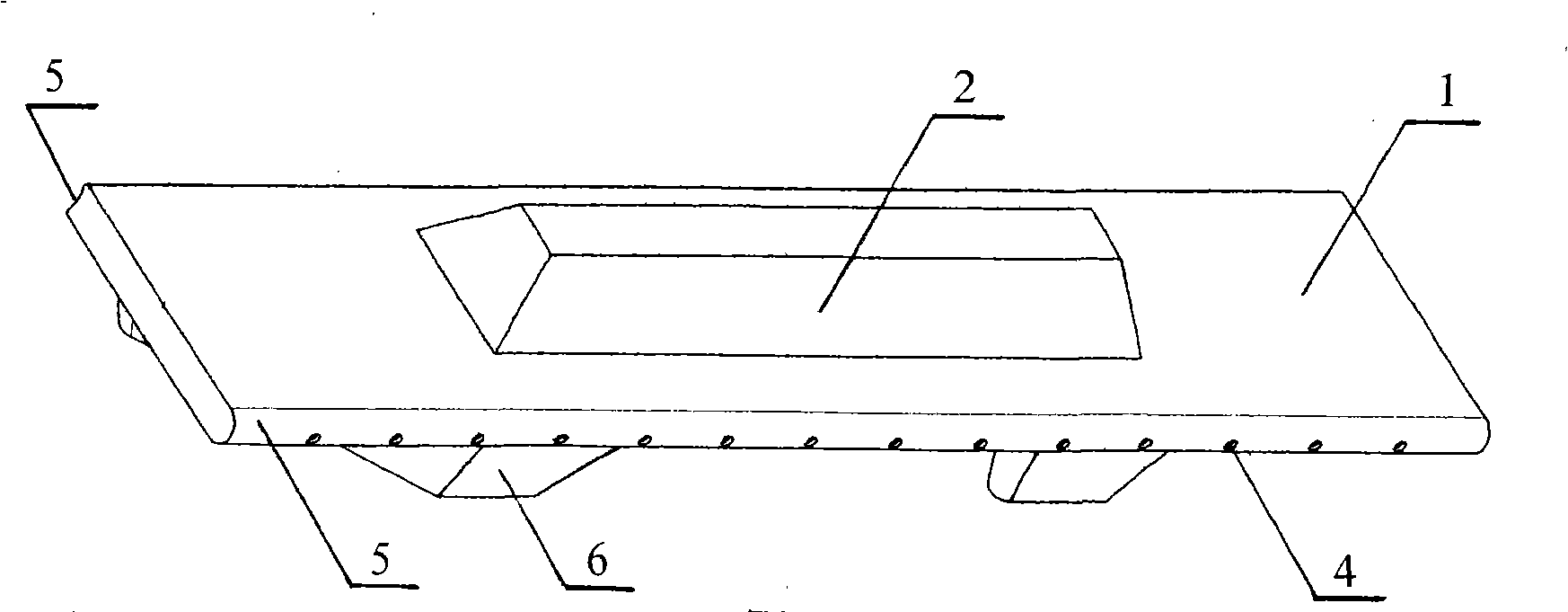

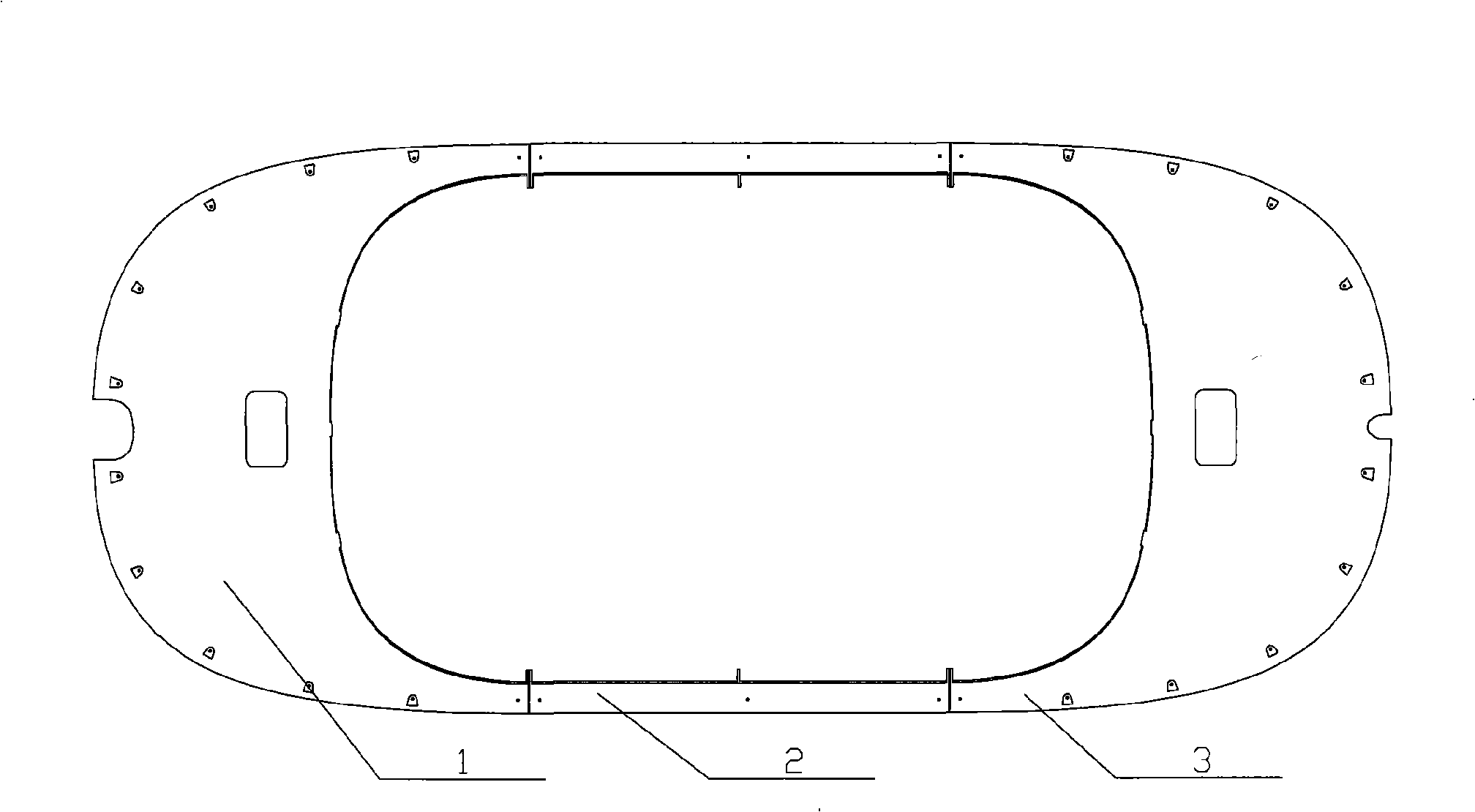

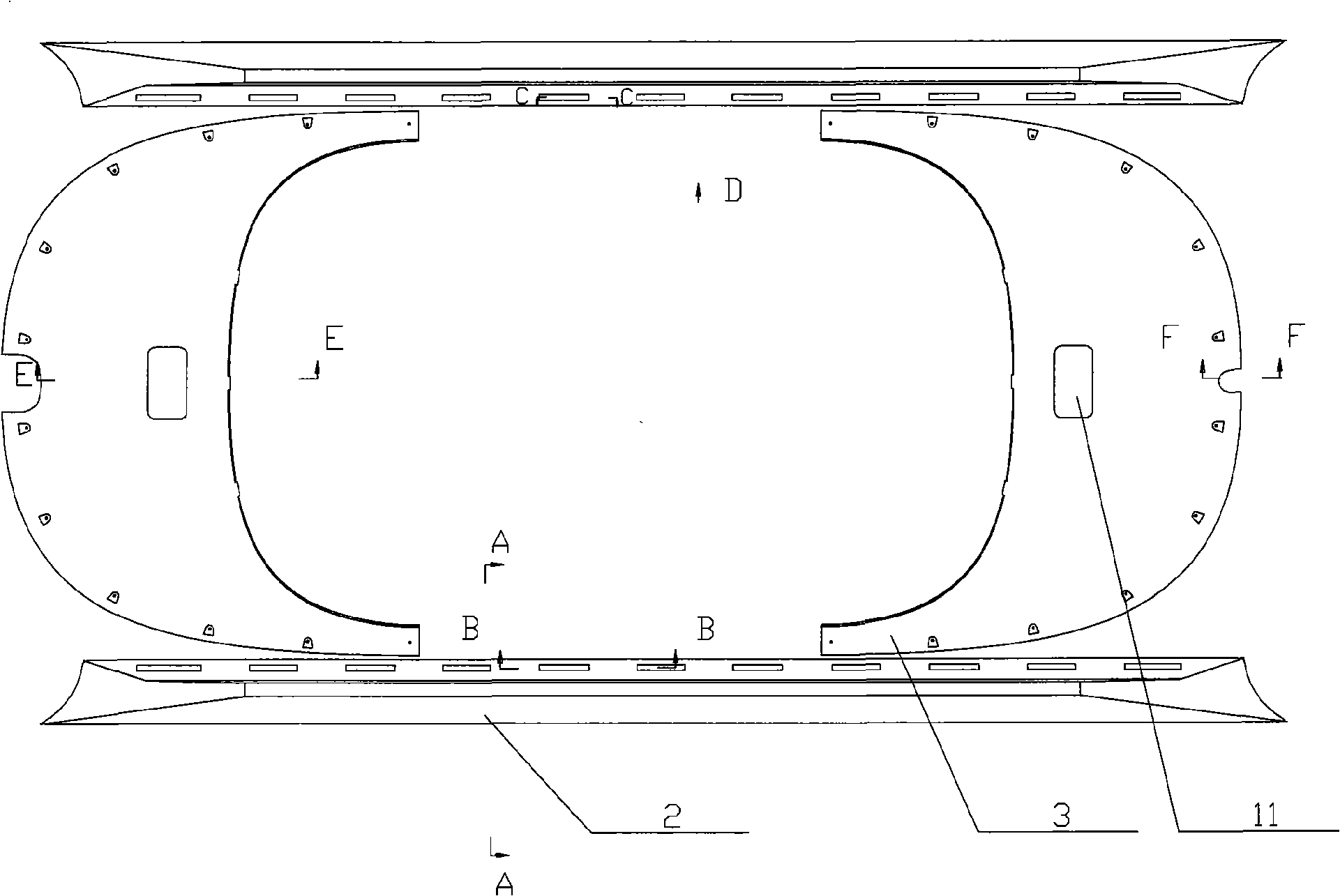

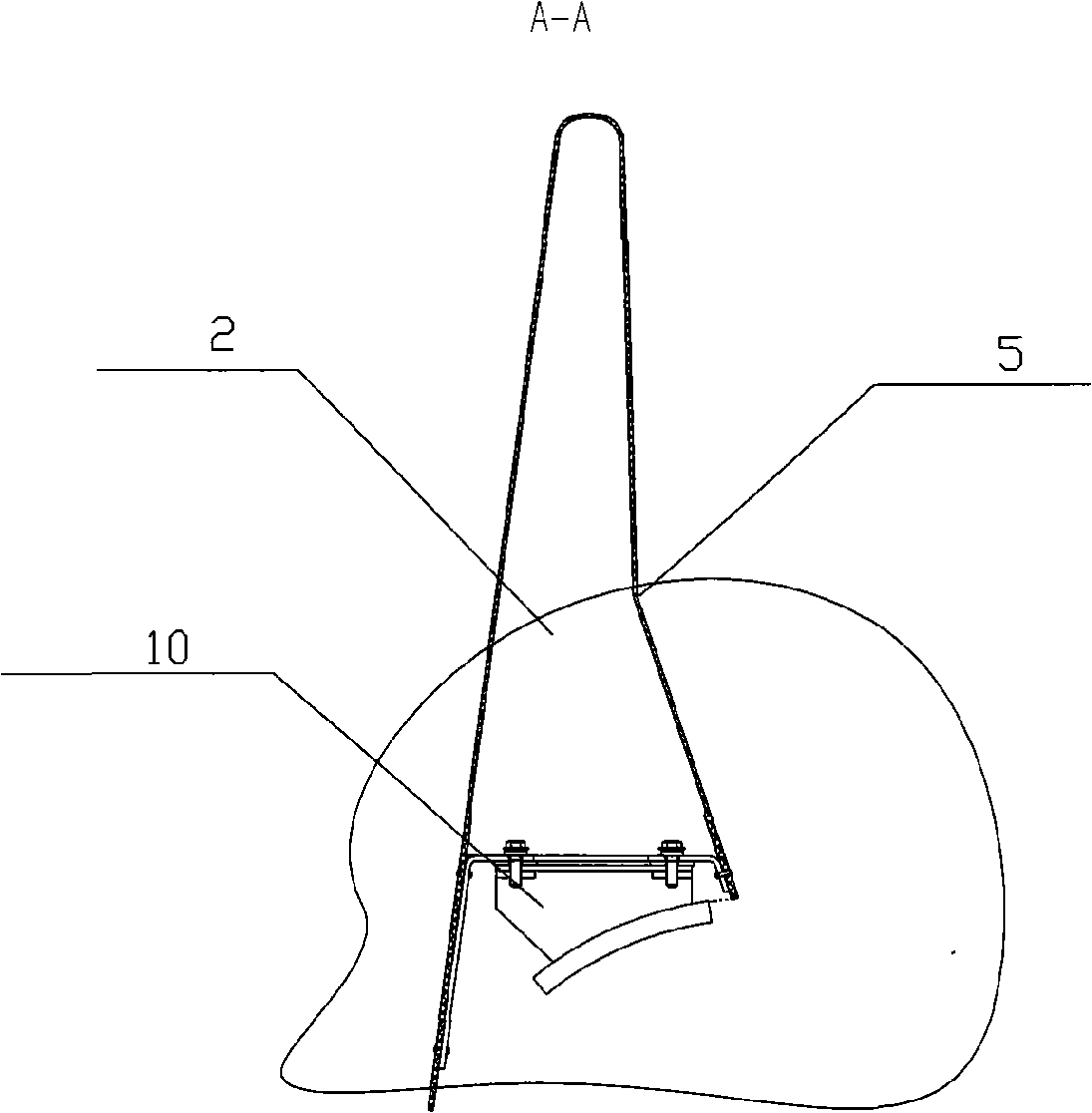

Pantograph flow guiding device of rail vehicle

ActiveCN101348079AAvoid influenceReduce noise sourcesPower current collectorsEngineeringThin-shell structure

The invention relates to a pantograph guide device of a railway vehicle, which comprises an air guide sleeve fixed on the vehicle roof. The air guide sleeve consists of a lateral air guide sleeve, a front air guide sleeve and a rear air guide sleeve; the surroundings of the pantograph are annularly arranged. The lengthwise section of the lateral air guide sleeve is roughly a trapezoid with a narrow top and a wide bottom; the middle lower part of the side of the lateral air guide sleeve which is corresponding to the pantograph is provided with a chamfer angle used for widening the width of the bottom of the air guide sleeve; the lengthwise sections of the front air guide sleeve and the rear air guide sleeve are roughly triangular; the lateral air guide sleeve is a box structure, which is internally and transversely provided with a plurality of first stiffener plates and second stiffener plates; the front air guide sleeve and the rear air guide sleeve are thin-shell structure, which are internally provided with a plurality of stiffener plates. When the railway vehicle runs at high speed, the air guide sleeve can prevent the influence of air stream to the pantograph, thus reducing the noise source of the pantograph and effectively reducing noise of the pantograph. The air guide sleeve can be fixed on the vehicle roof alone, thus being free from the influence of the structural form of the pantograph, and suitable for the pantograph of any structural form.

Owner:CHINA RAILWAYS CORPORATION +1

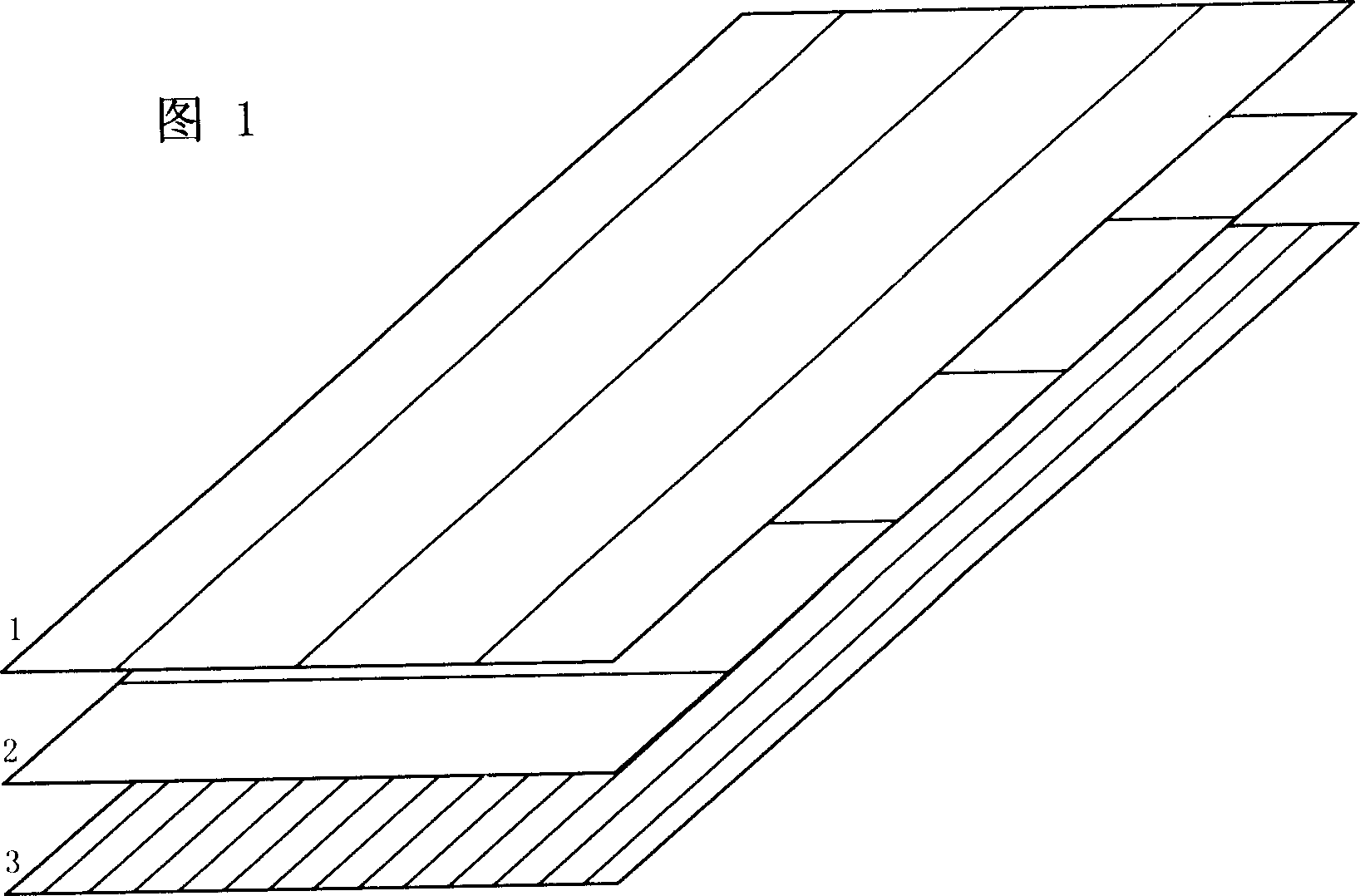

Thin shell structure reinforced type artificial board

InactiveCN1657243AEfficient use ofIncrease profitThicknessing machinesCane mechanical workingThin shellsSurface layer

A thin-shell structure reinforced artificial board is composed of two composite surface layers and a sandwich layer. Its preparing process includes such steps as applying isocyanate adhesive to bamboo curtain, immersing a single wood board in phenolic resin, combining them together, hot pressing to obtain said composite surface layer, preparing sandwich layer from the quickly growing wood (poplar wood), applying adhesive, combining it with two surface layers, and hot pressing.

Owner:NANJING FORESTRY UNIV

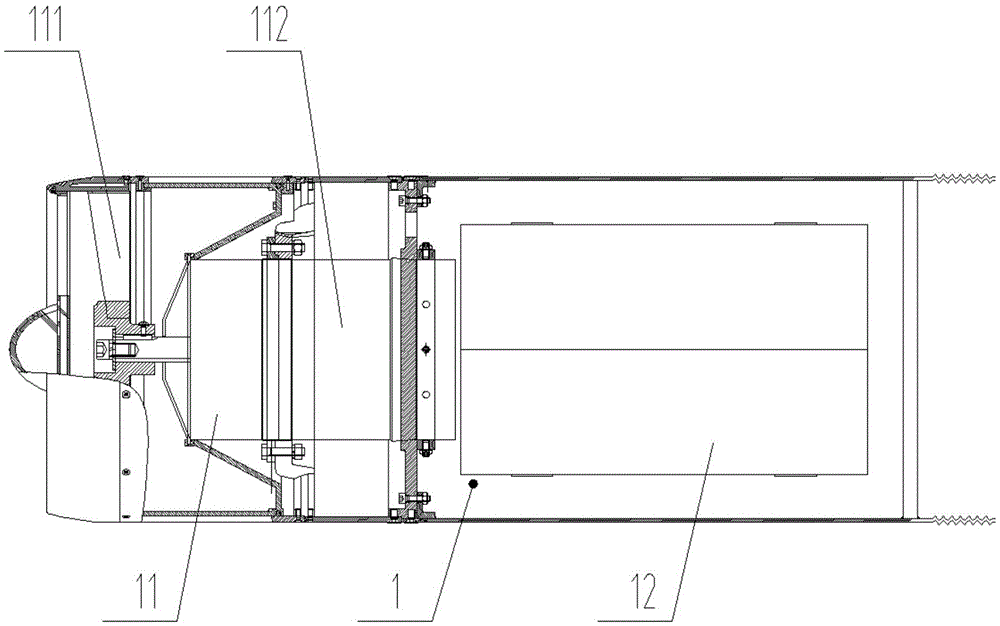

External mounting type aviation electric pod and using method thereof

ActiveCN105539849AHigh degree of automationReduce mechanical wearAircraft componentsLaunching weaponsAir compressionAviation

The invention discloses an external mounting type aviation electric pod. The external mounting type aviation electric pod comprises a pod core and a shell. The pod core is arranged in the shell. High-automation-degree operating design is adopted for the external mounting type aviation electric pod. All operation actions can be completed just through one pilot in a part-time job manner, and therefore the pod can be used for all aircraft with a single seat and multiple seats. Because no hydraulic and air compression systems are arranged, mechanical transmission parts are reduced by 80%, mechanical abrasion is greatly reduced, and the system is single and simplified; rolling of a winch and cable distributing and dragging winding and unwinding speed control precision can be improved, and therefore the fault rate is greatly decreased; and because a cable dragging automatic locking device is arranged, part of cable dragging force is transmitted to a pod body structure, loads on the winch are relieved, and using reliability is greatly improved. A more advanced thin-shell structure is adopted for a pod body, the ratio of strength to weight and the material utilizing rate are greatly increased.

Owner:河北环航科技股份有限公司

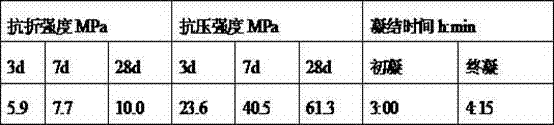

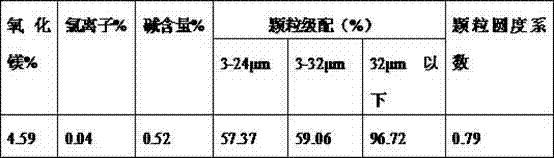

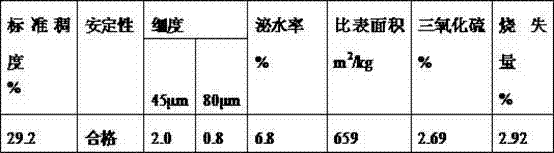

Special composite cementitious material for high-grade concrete of bridge expansion joints and thin-shell structures

The invention provides a special composite cementitious material for the high-grade concrete of bridge expansion joints and thin-shell structures. The invention aims to solve the problems that as the mixing amount of the admixture material of the common Portland cement is little and the corrosion resistance is poor, and the concrete of highways and railway bridge expansion joints is damaged. The key points of the material are as follows: the cementitious material mainly comprises ground general Portland cement clinker, fly ash, slag powder, volcanic ash, silicon ash and gypsum, which are homogenized and mixed to obtain the cementitious material, wherein the total weight of fly ash, slag powder, volcanic ash and silicon ash accounts for 50-60% of the total weight of the cementitious material. The invention has the following positive effects that: the mixing amount of the admixture material is increased, and the components of the cementitious material are changed while the performances are obviously increased.

Owner:DANDONG HAIGONG CEMENT

Improvement method of air-conditioner purifier

InactiveCN102434924AEasy to disassemble and replaceIncrease the areaLighting and heating apparatusAir conditioning systemsAdhesiveFiltration

Owner:SHENYANG JIANZHU UNIVERSITY

Construction method for concrete macrotype xenotype shell construction body

InactiveCN101255714AEasy to pourEasy to shapeBuilding roofsArched structuresEconomic benefitsSteel bar

The present invention discloses a method for constructing a concrete large-scale special-shaped shell structure. The method comprises the steps of building a frame body of a mould frame, placing an external mould to a right position and fixing, tying the structural reinforcing steel bars, arranging an internal mold, pouring the concrete, removing the mould and maintaining the surface. The molding of casing is realized by the steps of respectively fixing different modules through the frame body of the mould frame, assembling to a whole, tying structural reinforcing steel bar on the fiberglass external mould, and then pouring the concrete. Additionally, the poured concrete is added with 1-2kg / m<3> polypropylene fiber, and the occurring of early crack of concrete can be effectively prevented. The cement-based water-proofing material is doped to self-cure the later crack of the concrete to obtain the effect of seepage prevention. The invention has the advantages of reasonable design, simple technique, lower cost, high precision and easy realization. The surface of the concrete large-scale special-shaped shell structure is leaded to be smooth and level. A fair-faced concrete effect is obtained. The invention is especially suitable for the preparation of various semi-sphere concrete casings and has excellent social and economic benefit.

Owner:HENAN NO 1 CONSTR ENG GRP +1

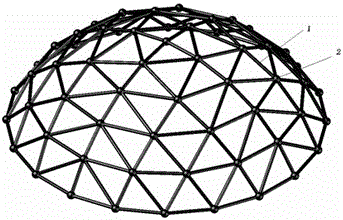

Reverse cumulative lifting construction method for single-layer spherical reticulated shell structure

InactiveCN106836507ALower requirementReduce usageBuilding constructionsMechanical equipmentSpherical form

The invention belongs to the field of steel structure construction, and specifically relates to a single-layer spherical reticulated shell structure cumulative jacking construction method. The specific construction steps are as follows: Step 1: Determine the plane position for assembly, level the site, and position and set out the line; Step 2: According to the calculation Analyze the results, select several jacking points on the reticulated shell structure for the first jacking; Step 3: Set up the operating frame, and assemble the reticulated shell structure for the first jacking on the ground; Step 4: The first jacking operation, Lift the assembled reticulated shell structure to the height of one internode; Step 5: Install the rods of an internode under the assembled reticulated shell structure; Step 6: Cycle the fourth to fifth steps; Step 7: Install Structural support, remove the jacking bracket and jacking equipment. In the construction process of the invention, the force transmission is clear, the force conversion process is uniform and safe, the overall stability of the structure is good, the structure deformation is small, the construction precision is high, and the cost of temporary construction measures and the use of large mechanical equipment are reduced at the same time.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

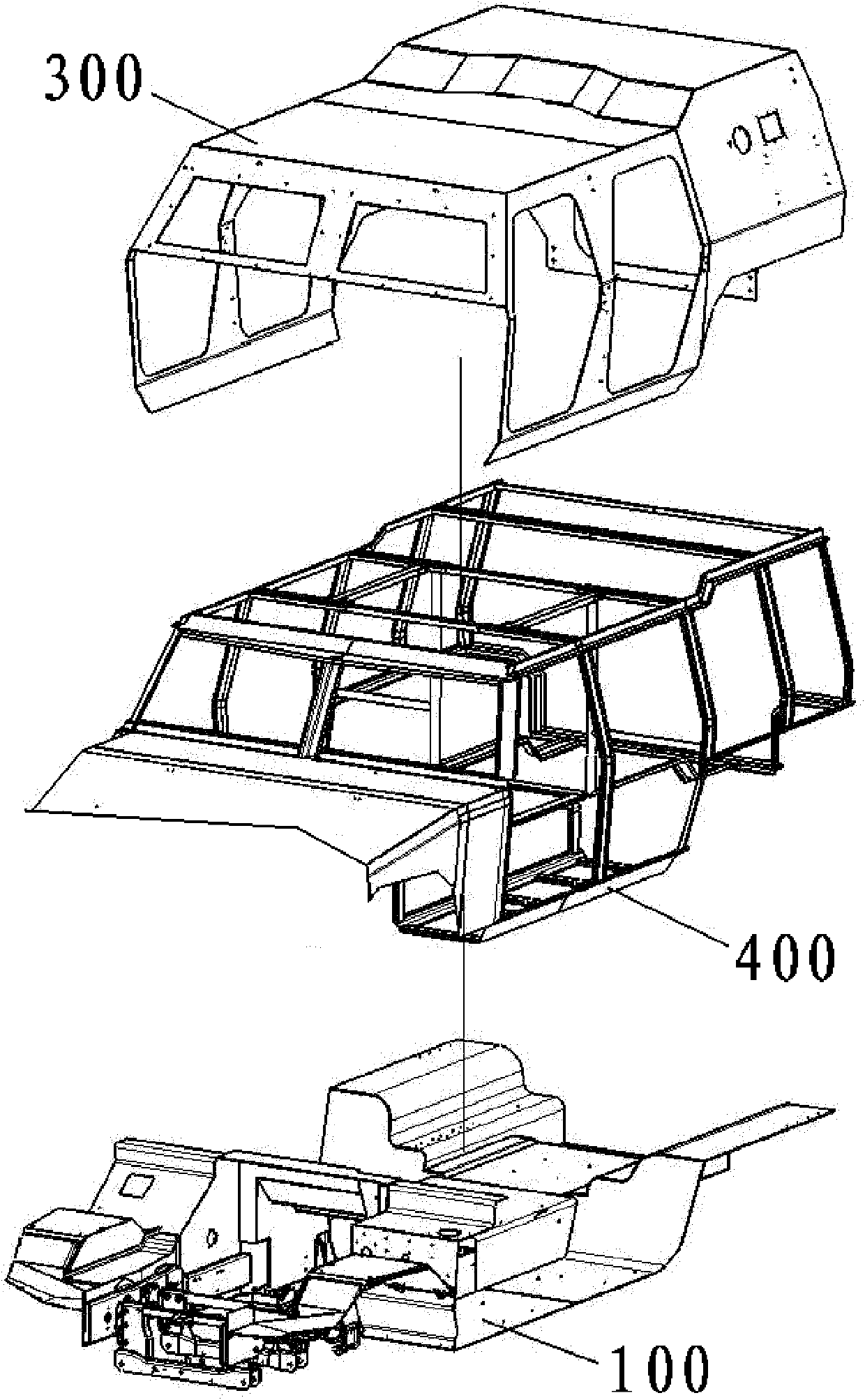

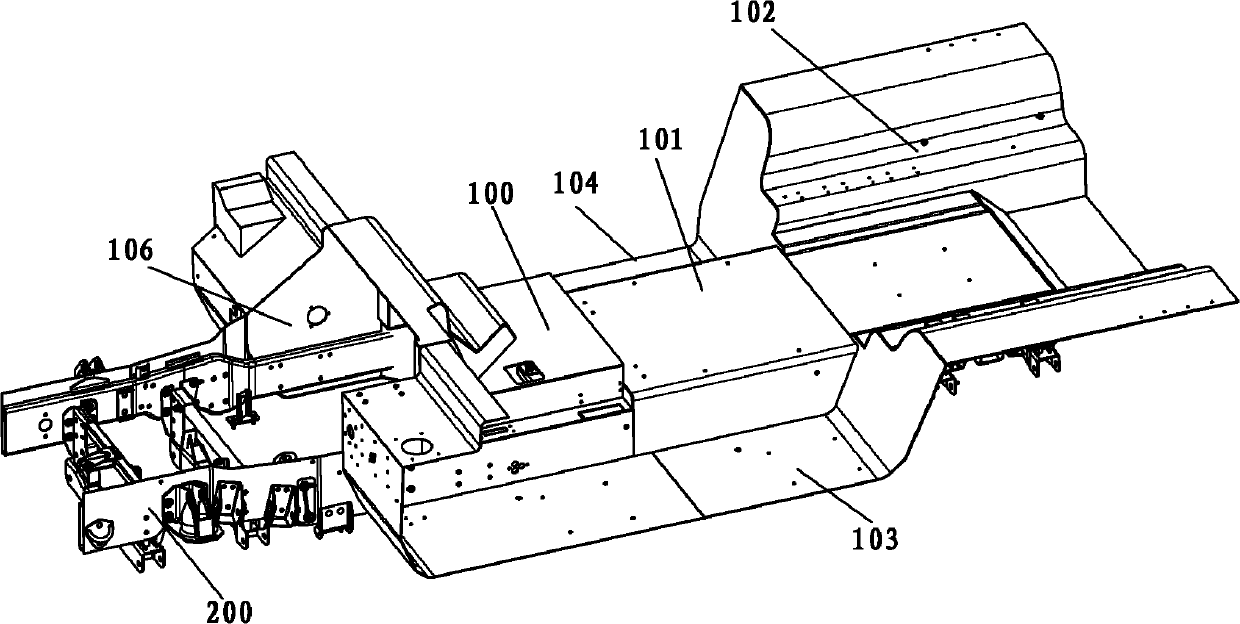

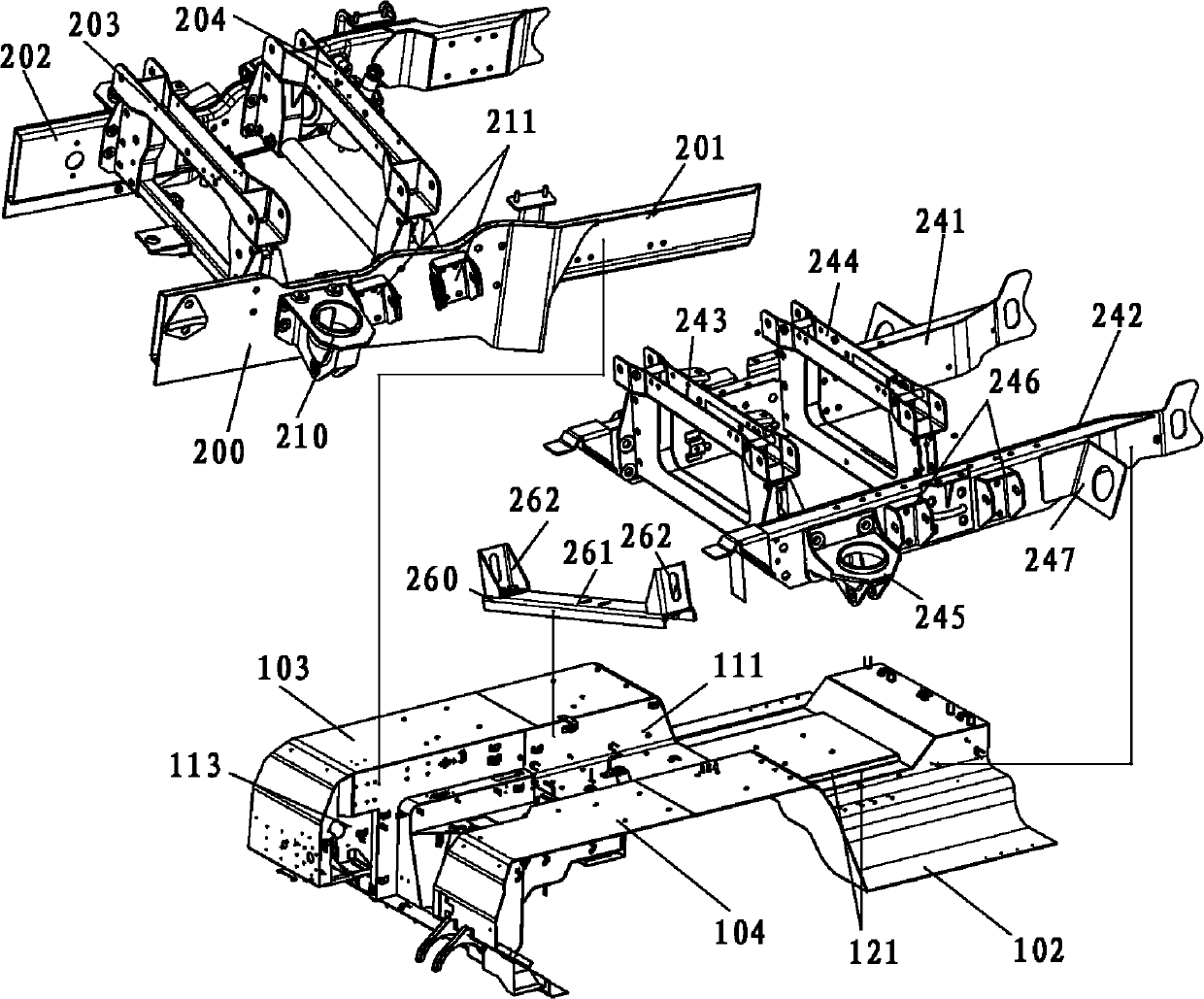

Vehicle body based on truss skeleton thin shell structure of composite load bearing type base board

ActiveCN102167086ALight in massLower center of gravityMonocoque constructionsVehicle frameThin-shell structure

The invention discloses a vehicle body based on the truss skeleton thin shell structure of a composite load bearing type base board. The vehicle body comprises a load bearing type base board, wherein the load bearing type base board is connected with a skeleton formed by a truss structure, a vehicle body shell is connected with the skeleton, the load bearing type base board comprises a non-load bearing type floor board and a split type vehicle frame connected with the floor board, the floor board comprises a front floor board and a back floor board connected with the front floor board, and the front floor board is connected with a left-right floor board; a vehicle frame installing groove is arranged between the front floor board and the left-right floor board, the vehicle frame installing groove is internally connected with the split type vehicle frame, and the split type vehicle frame comprises a front vehicle frame and a back vehicle frame which are not connected with each other; and a board piece splicing place of the vehicle body shell is arranged at a skeleton girder which forms the truss structure. The vehicle body is low in barycenter, light in weight, and good in protection property.

Owner:DONGFENG MOTOR CORP HUBEI

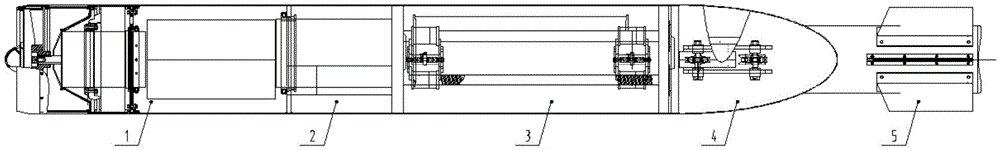

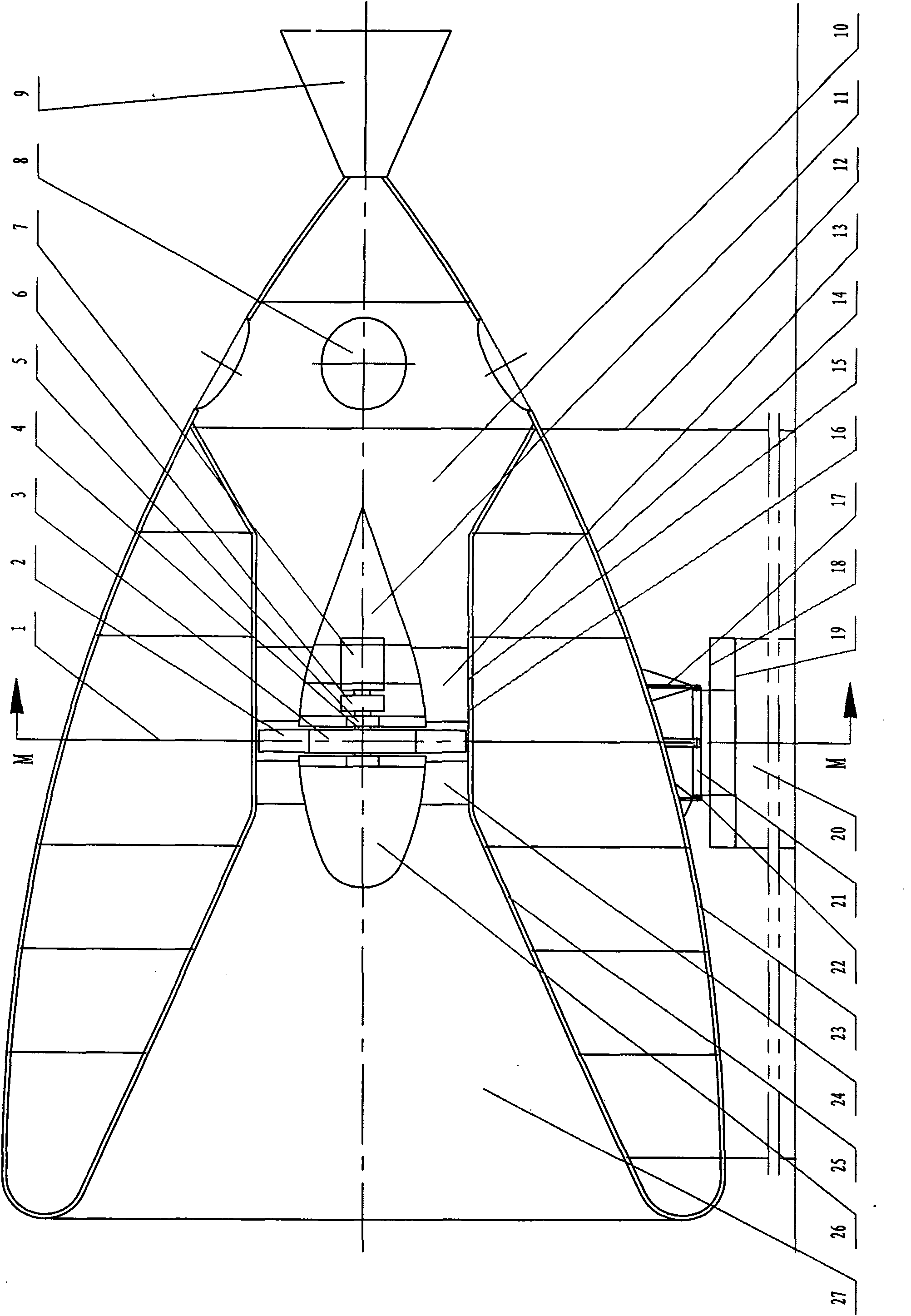

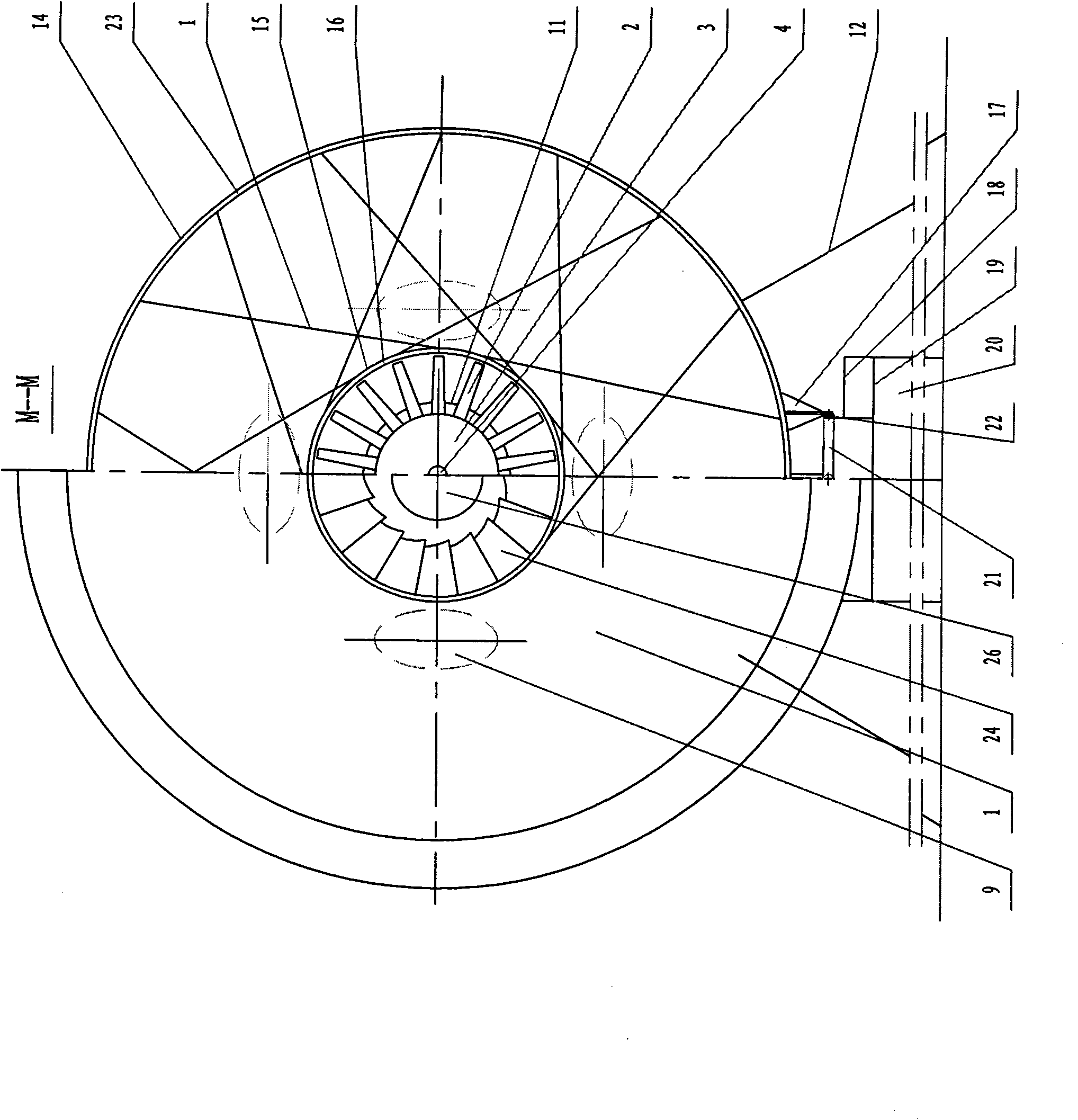

Baffle wind power turbine generating equipment

InactiveCN101660495ABest use of wind energyReduce wind resistanceWind motor controlFinal product manufactureFluid couplingTurbine blade

The invention relates to baffle wind power turbine generating equipment. A streamlined outer baffle accommodates main wind power generating equipment. A spoke suspending structure connects the outer baffle and an inner guiding pipe thin-shell structure into a light structure. A retractable guiding inlet pipe and an inner baffle are used to obtain high-speed wind power. The periphery of a turbine disk body of an air-operated machine is provided with a plurality of turbine blades. A guide plate guides airflow from the axial direction to the circumferential tangential direction to blow the bladesto push a turbine. The turbine rotated at a high speed directly drives a generator through a hydraulic coupler. The baffles are provided with a tail and a raceway gyration device respectively. The generating equipment is arranged on a pylon embedded with electric transmission and transformation and control equipment. Hurricanes are handled through measures of anchoring towlines. The baffle wind power turbine generating equipment has the advantages of reducing the wind resistance by the streamlined outer baffle, having the spoke suspending light structure, reducing the size of the equipment, improving the processability of manufacturing, mounting and maintaining, simplifying the equipment, reducing manufacturing cost, improving wind power generating efficiency, handling the hurricanes, increasing the generating capacity of a single machine, and realizing large-scale wind power stations.

Owner:李泉洞 +1

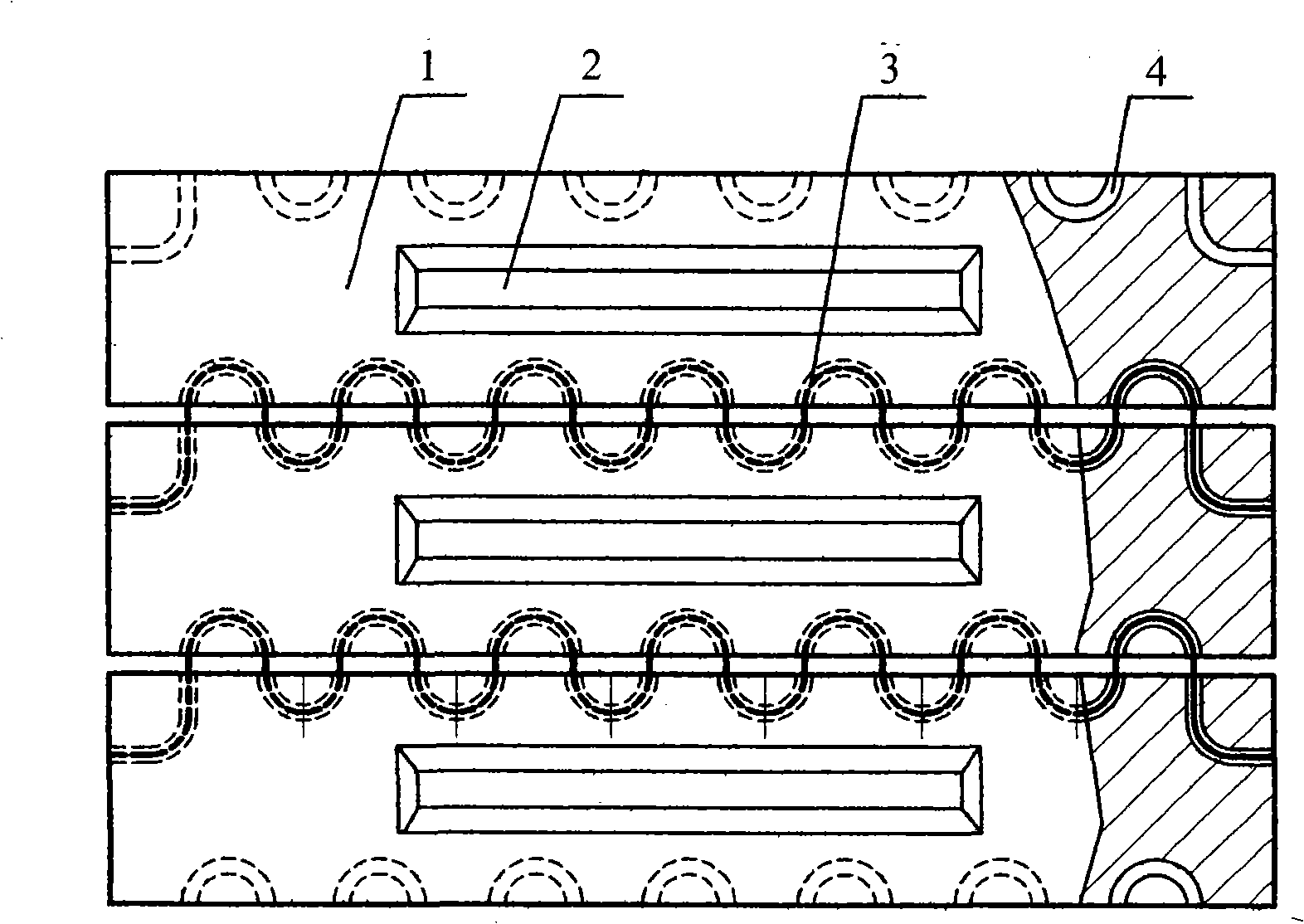

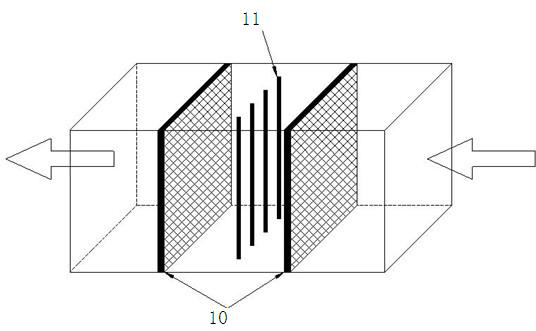

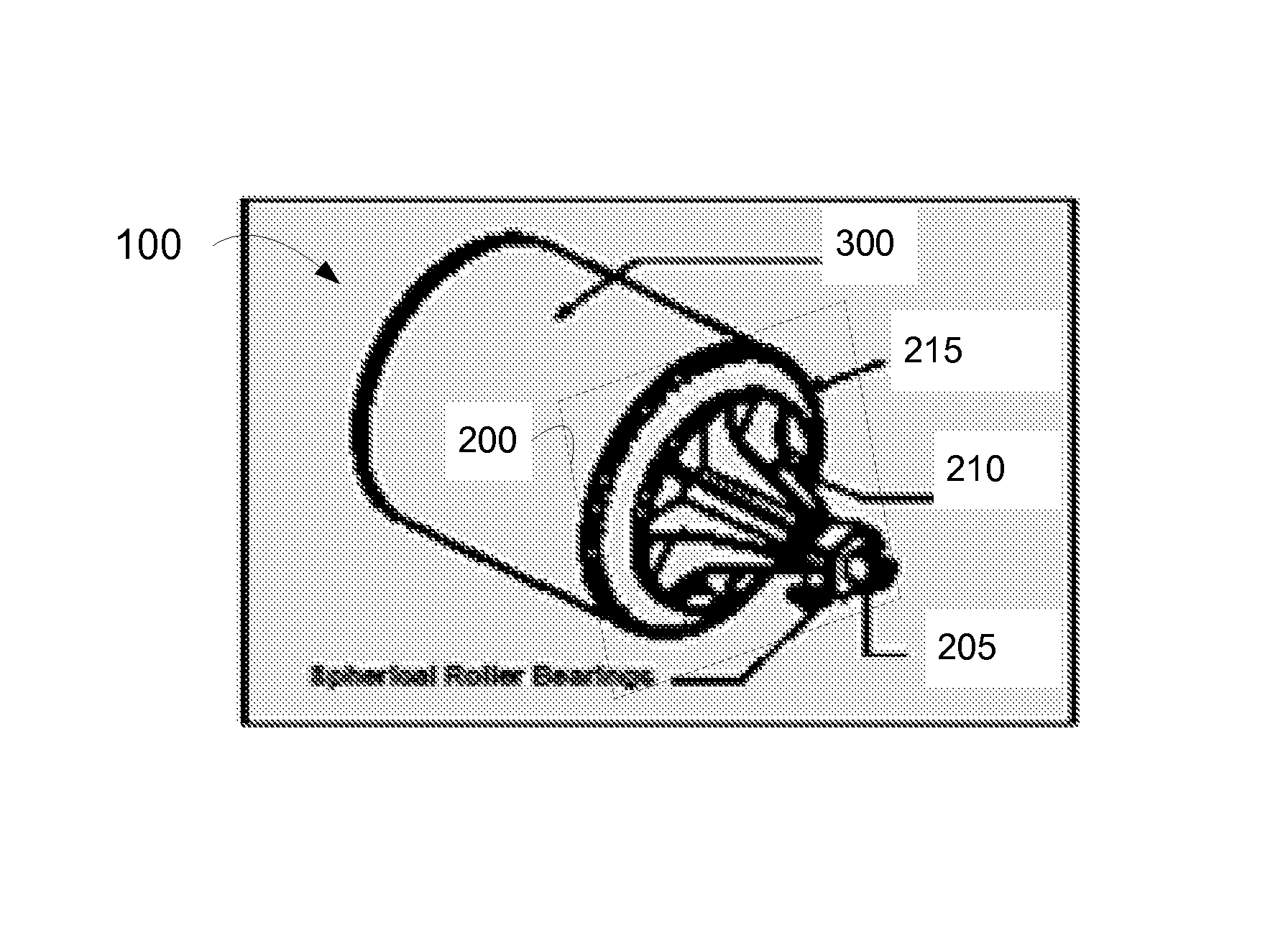

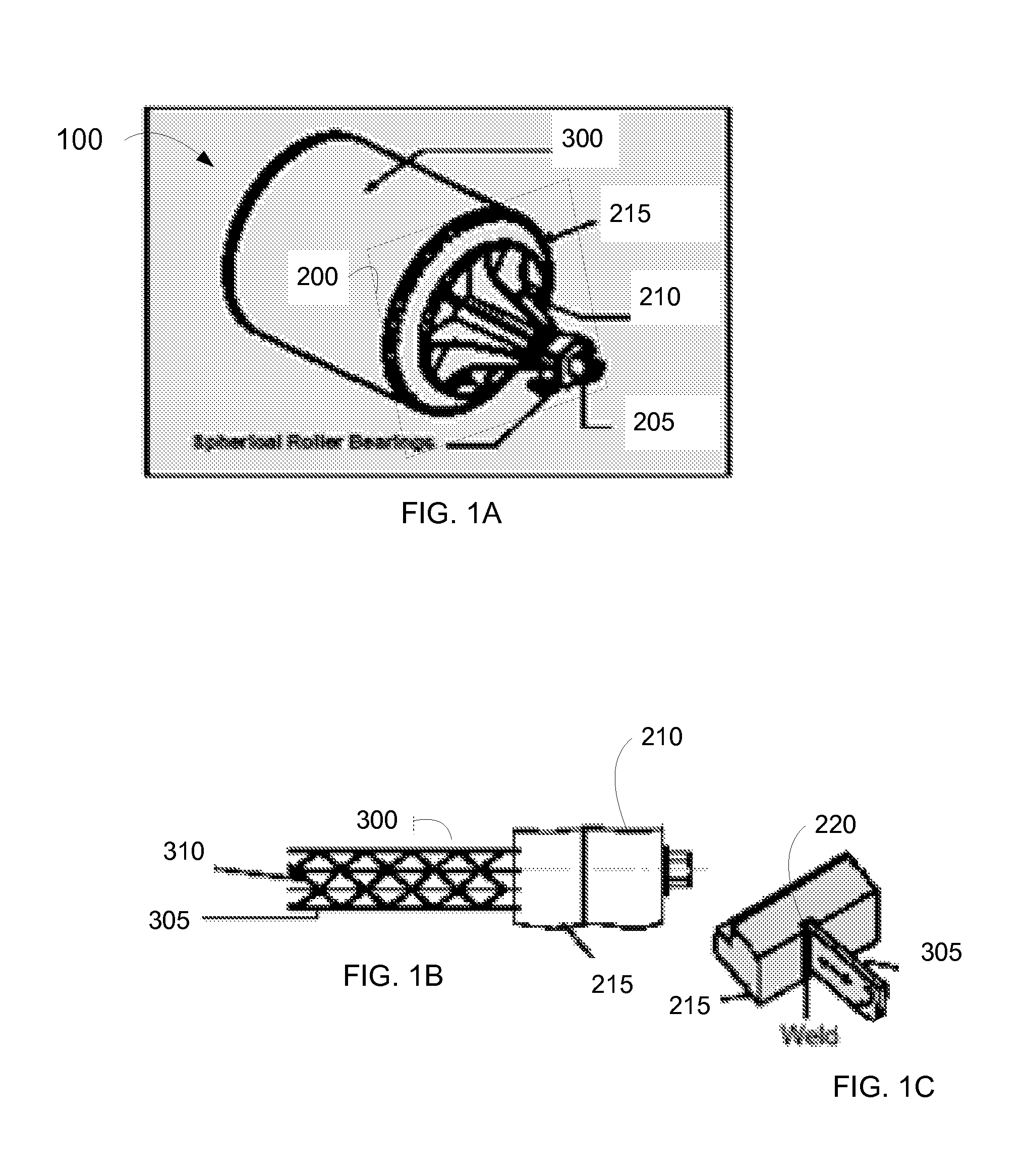

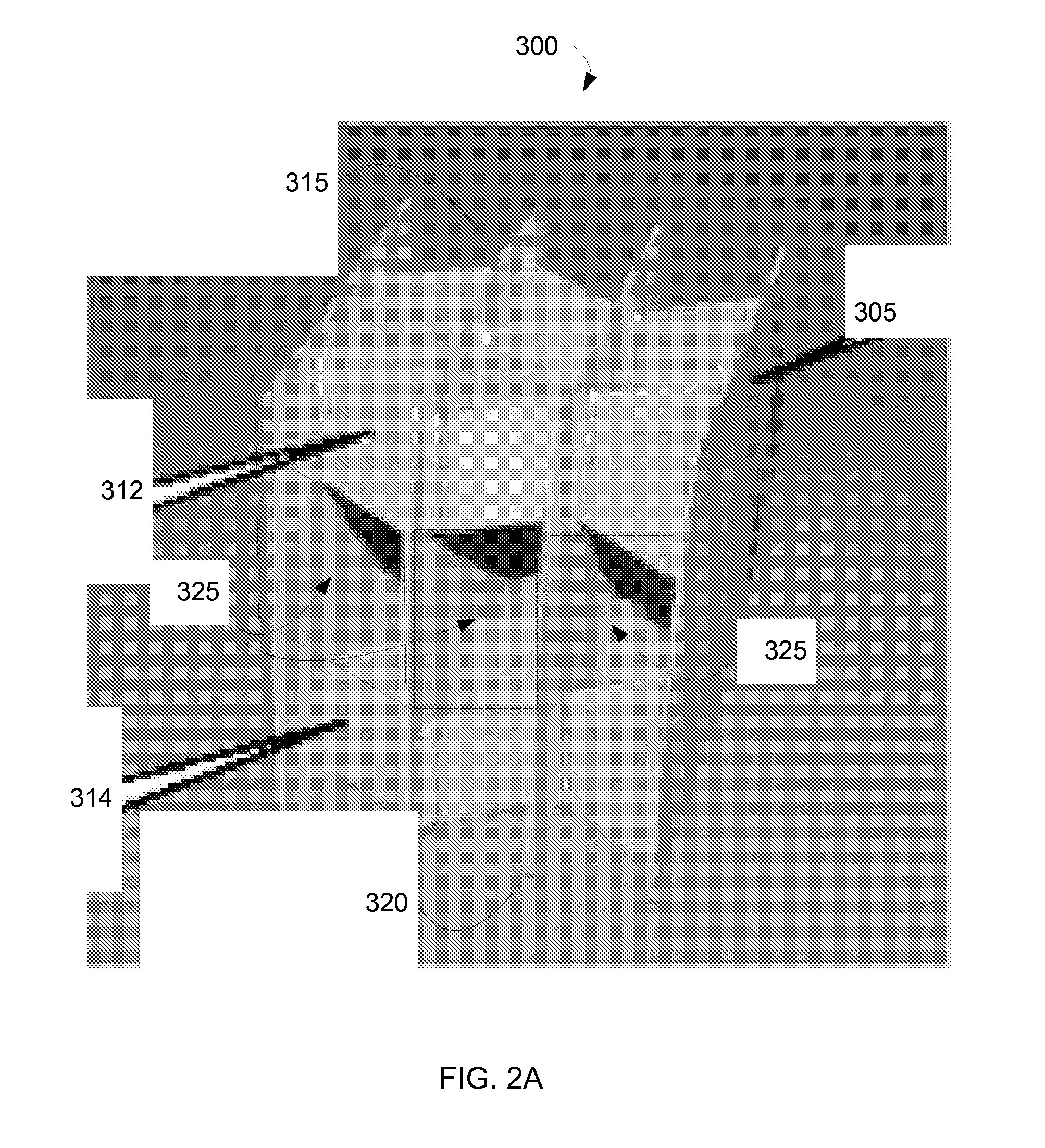

System and method for thermal gradient control in thin shell structures

ActiveUS8656605B2Reduce widthObstruct passageDryer sectionAgricultural rollersThin shellsEngineering

Described herein are devices and methods for reducing thermal stresses in a rotating, foraminous thin-shelled roll for drying permeable and semi-permeable webs by blocking axial flow of heated air through an axial channel formed between two corrugated layers in the shell. The axial channels extend between spaced-apart, parallel end members each having an inner face, and a plurality of alternating straight thin divider strips and bent thin strips extending axially between and evenly-spaced around the circumference of the inner faces of the end members to form an annular cylinder with radial channels therethrough. Affixing at least one impermeable insert into a radial channel so that it extends through the radial channel and across at least a portion of the faces of the two tiers of bent strips blocks the axial channel therebetween and prevents the passage of air therethrough to the end member.

Owner:VALMET OY

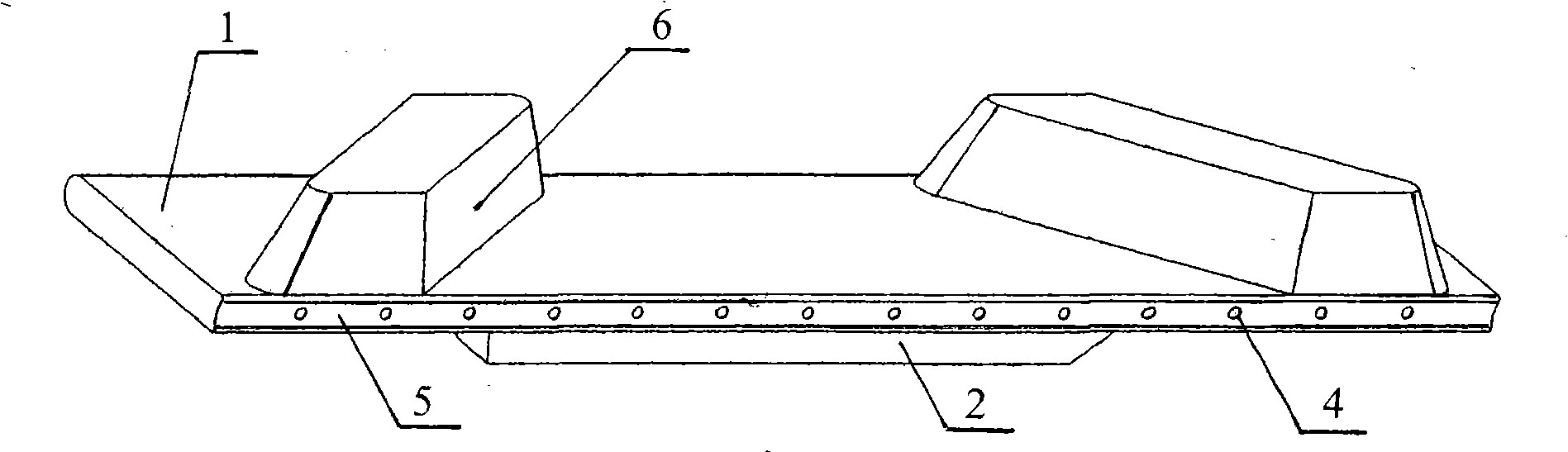

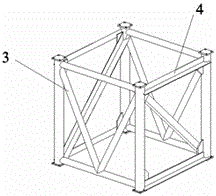

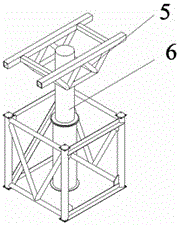

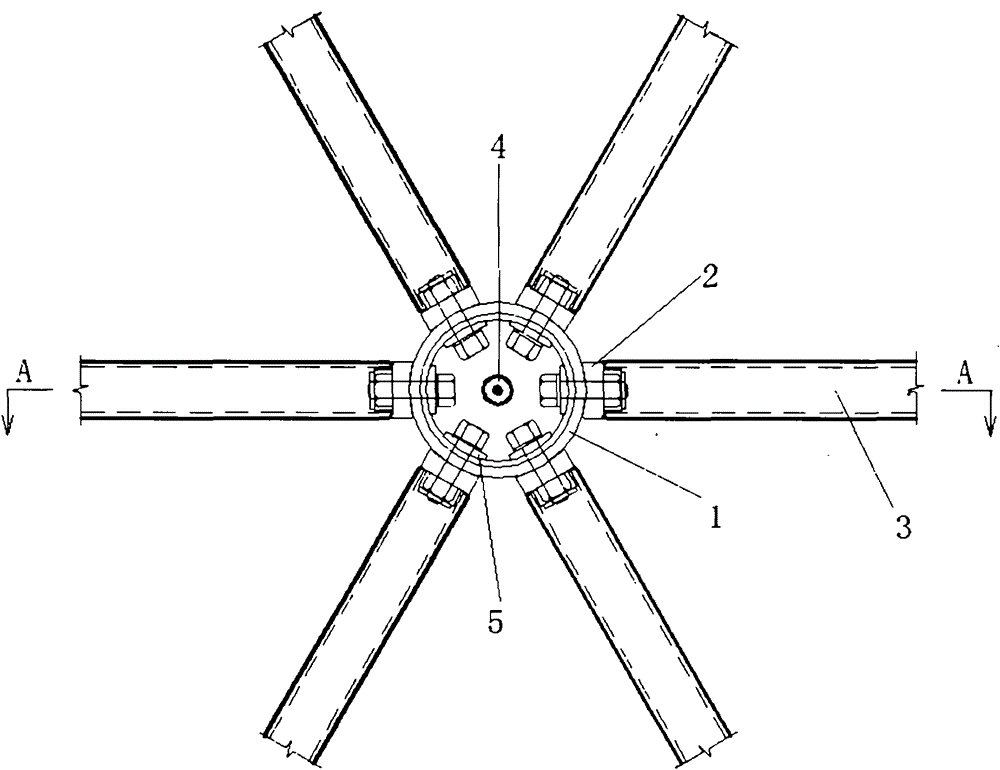

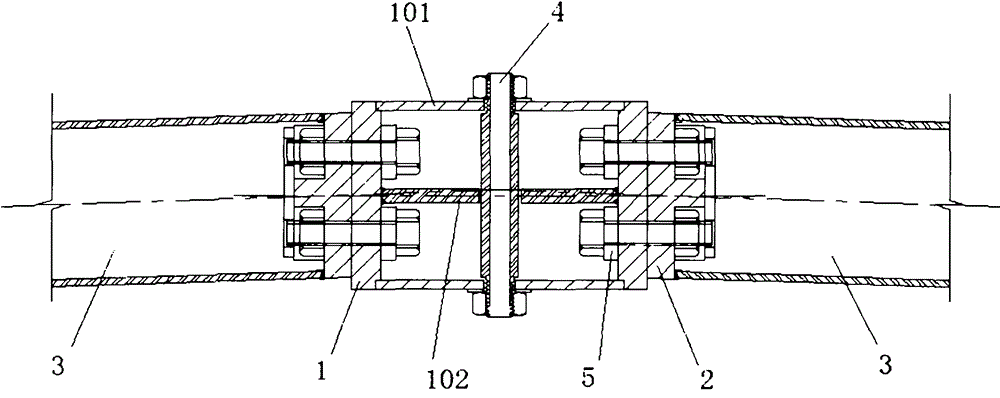

Joint drum structure for connecting steel structural part

InactiveCN104420543AThe structure is complex and beautifulSophisticated node structureBuilding constructionsBolt connectionThin-shell structure

The invention relates to a joint structure, in particular to a joint structure of a single-layer reticulated shell structure, more particularly, is a joint drum structure for connecting a steel structural part, and belongs to the technical field of roof building. A bolt drum joint structure of a rigid single-layer reticulated shell structure is characterized by comprising a bolt drum (1) and six hollow rod pieces (3), wherein the bolt drum (1) is of a hollow cylinder structure; detachable cover plates (101) are arranged on the two end surfaces of the bolt drum; six groups of bolt holes are uniformly distributed in the circumferential direction of the bolt drum (1); the angle of the tangent plane of each hollow rod piece (3) can be adjusted; each hollow rod piece (3) is welded and fixed with a sealing plate (2); a group of bolt holes are formed in each sealing plate (2); the six hollow rod pieces (3) are in bolted connection with the bolt drum (1) through the bolt holes after being welded and fixed with the sealing plates (2).

Owner:上海岑晨钢结构网架有限公司

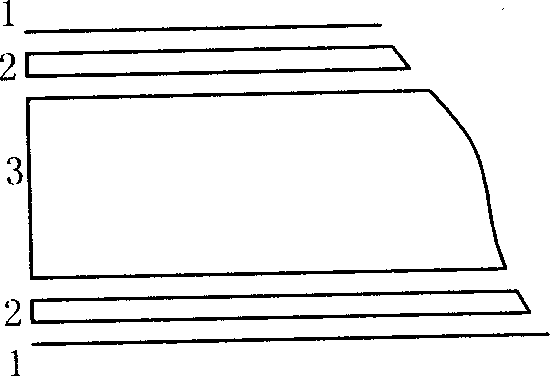

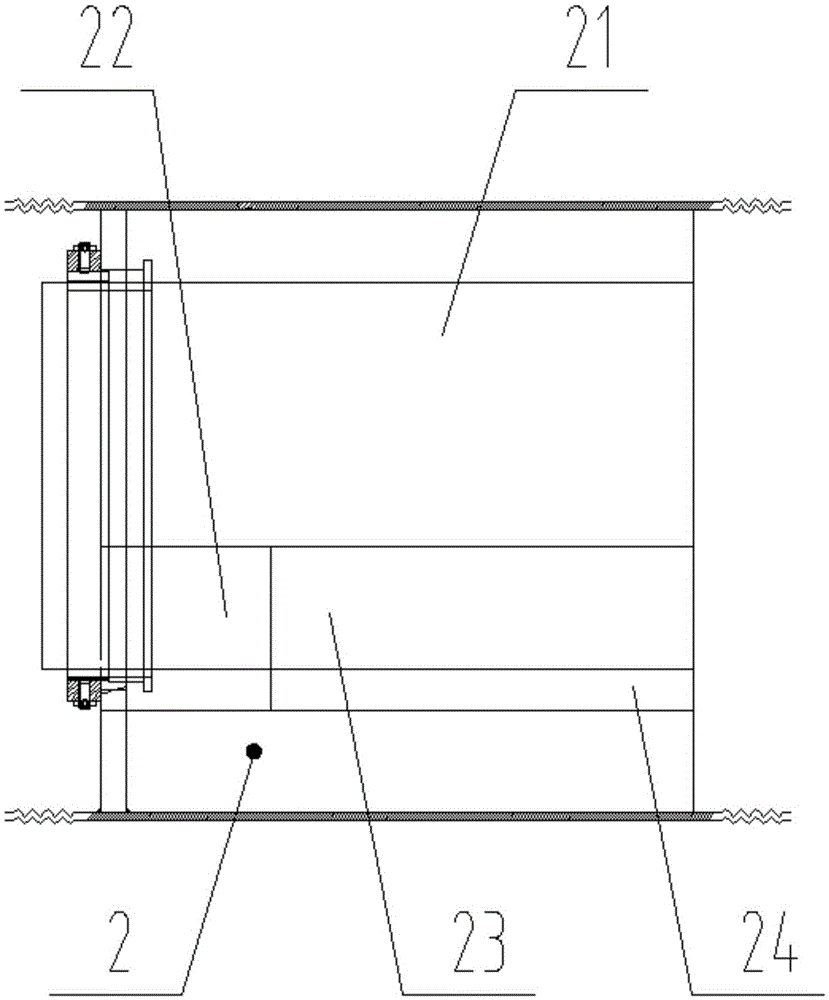

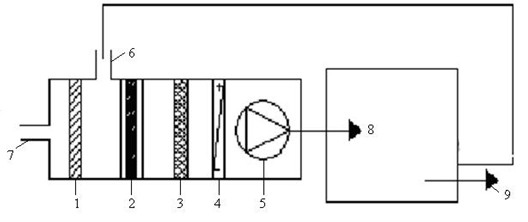

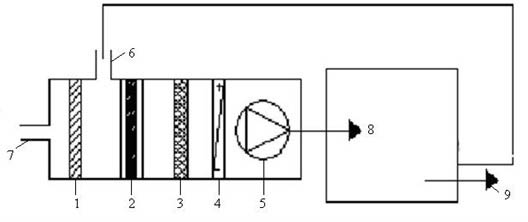

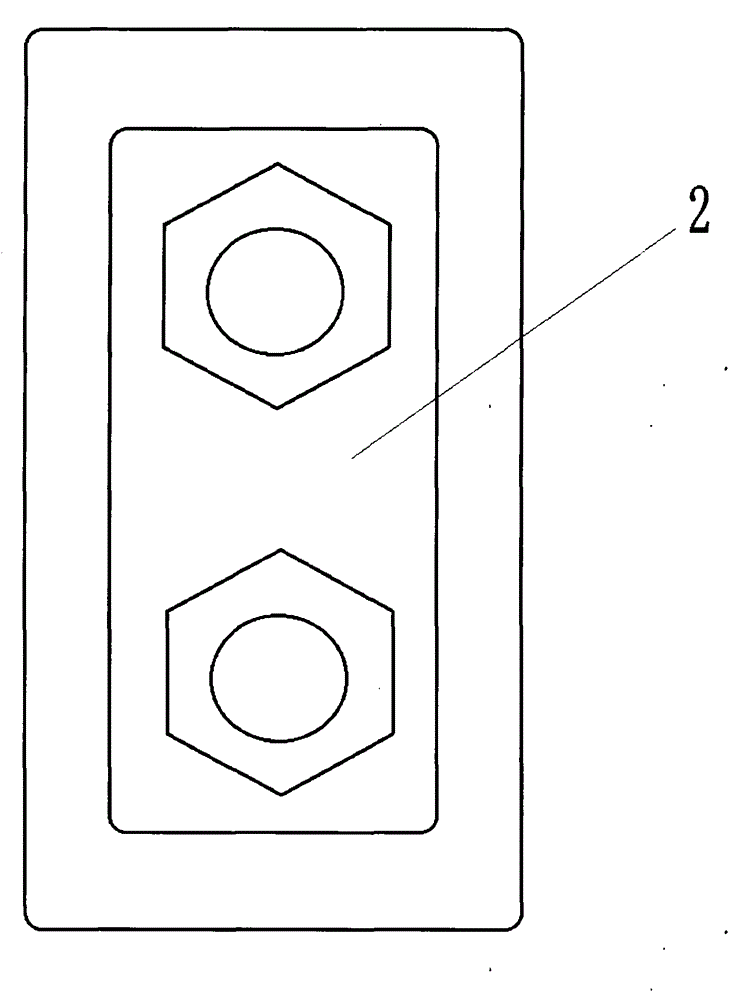

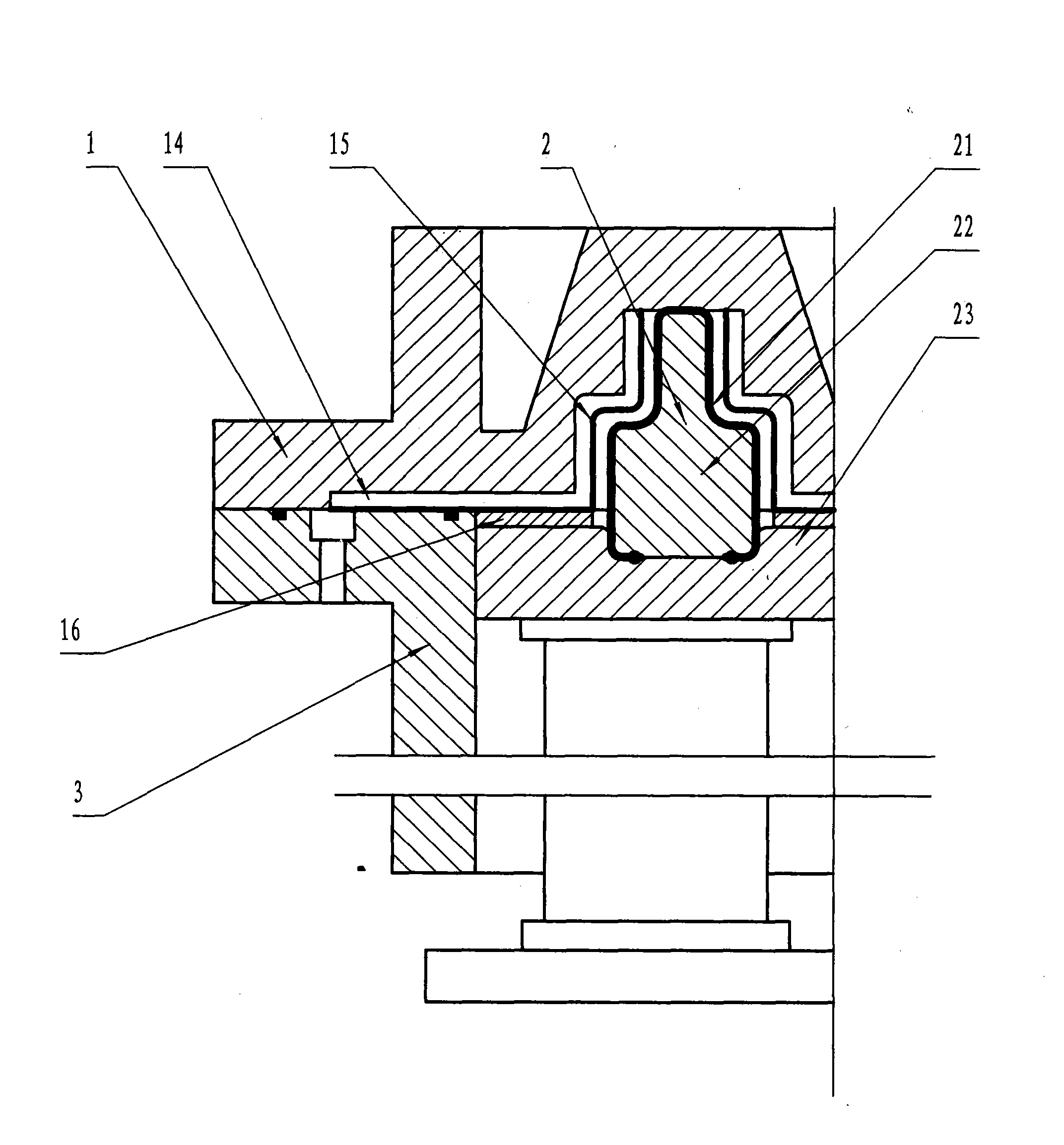

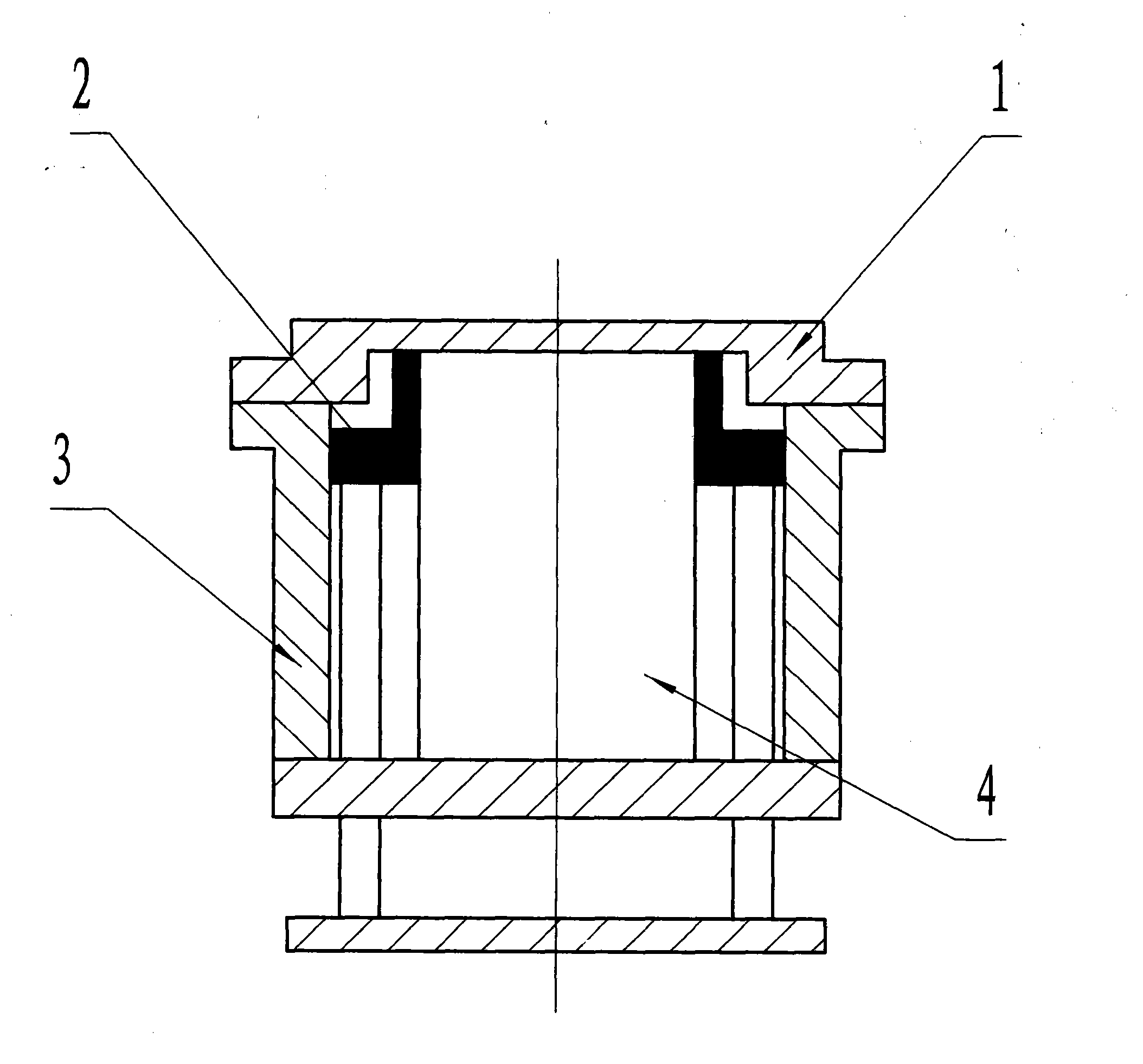

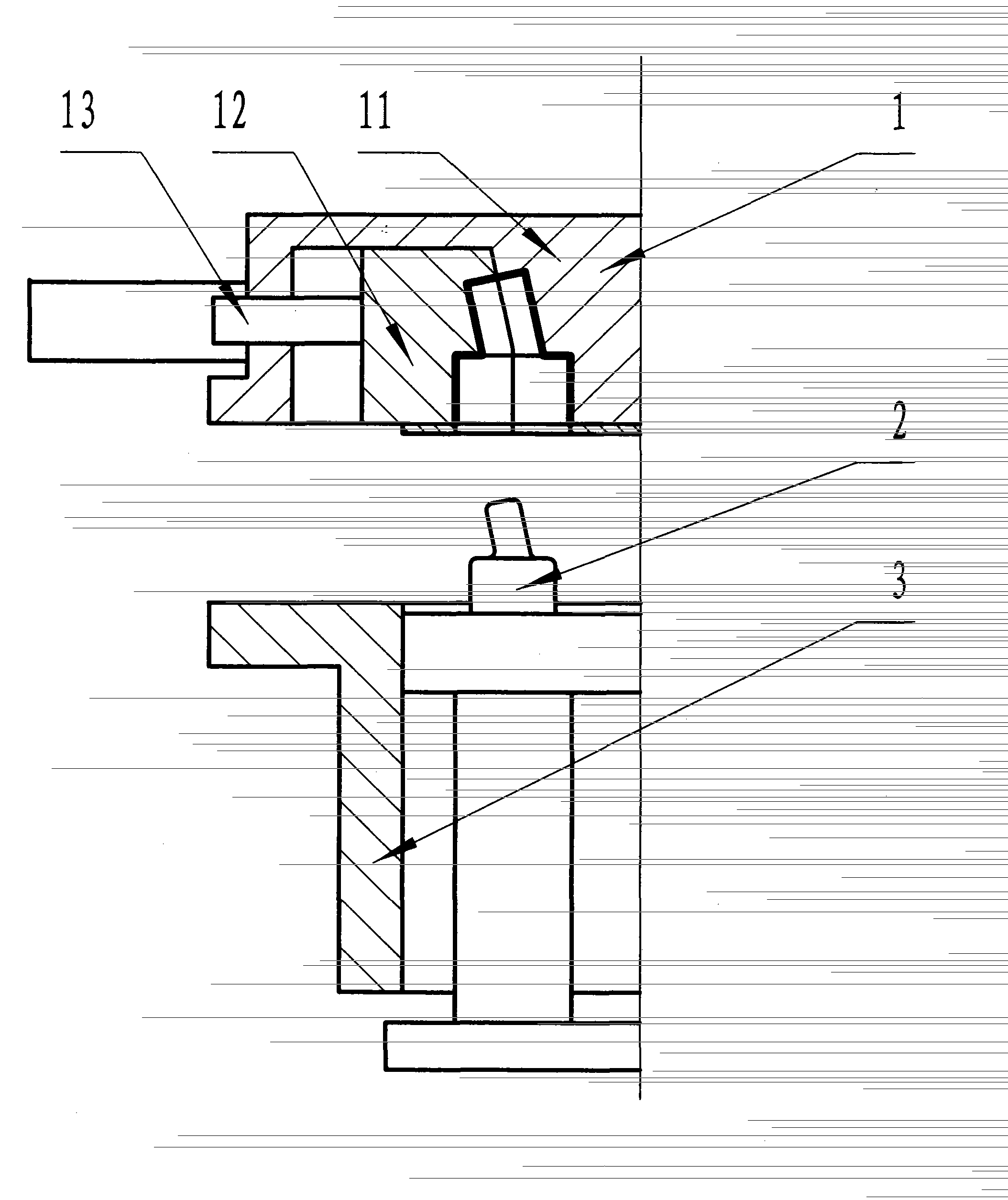

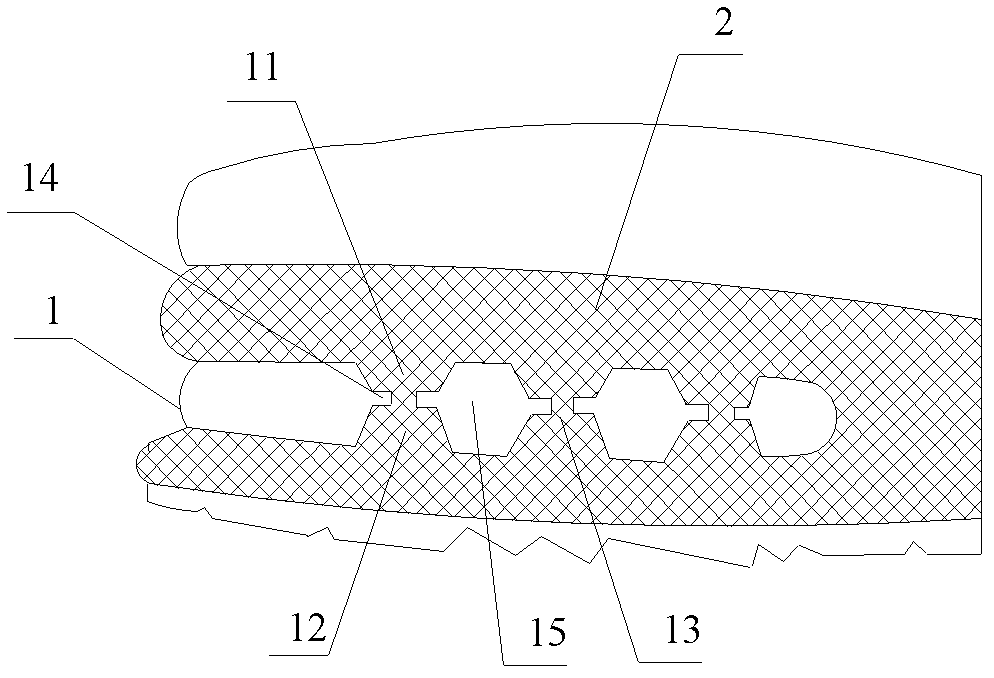

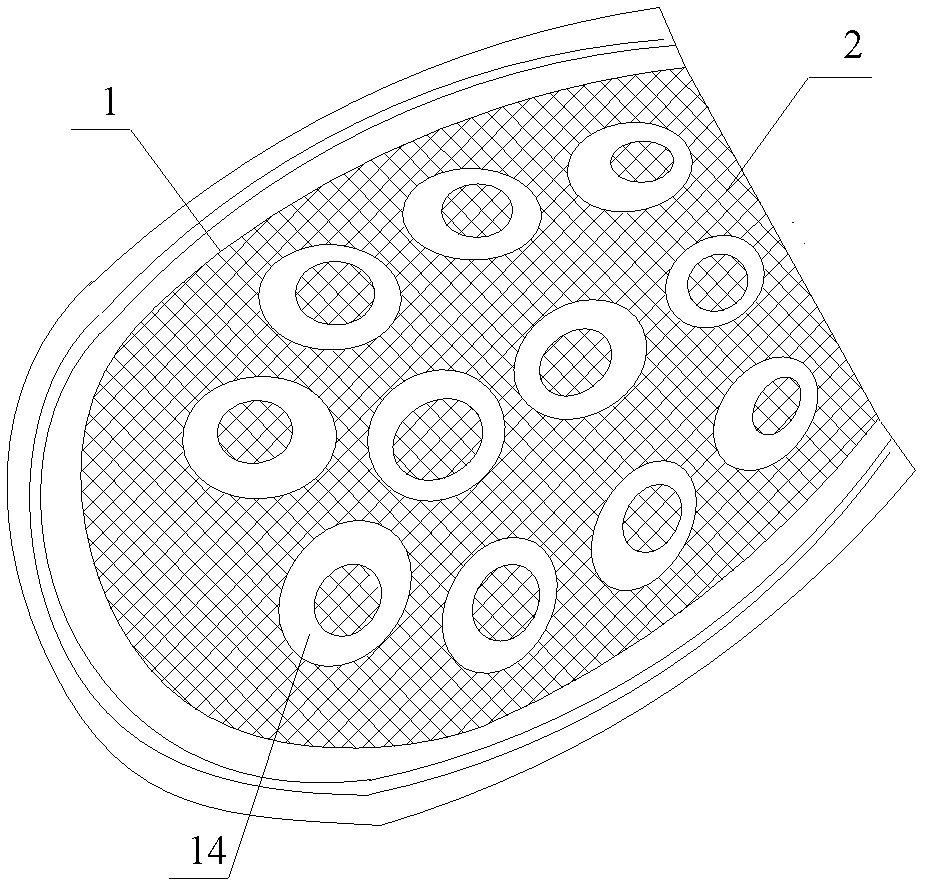

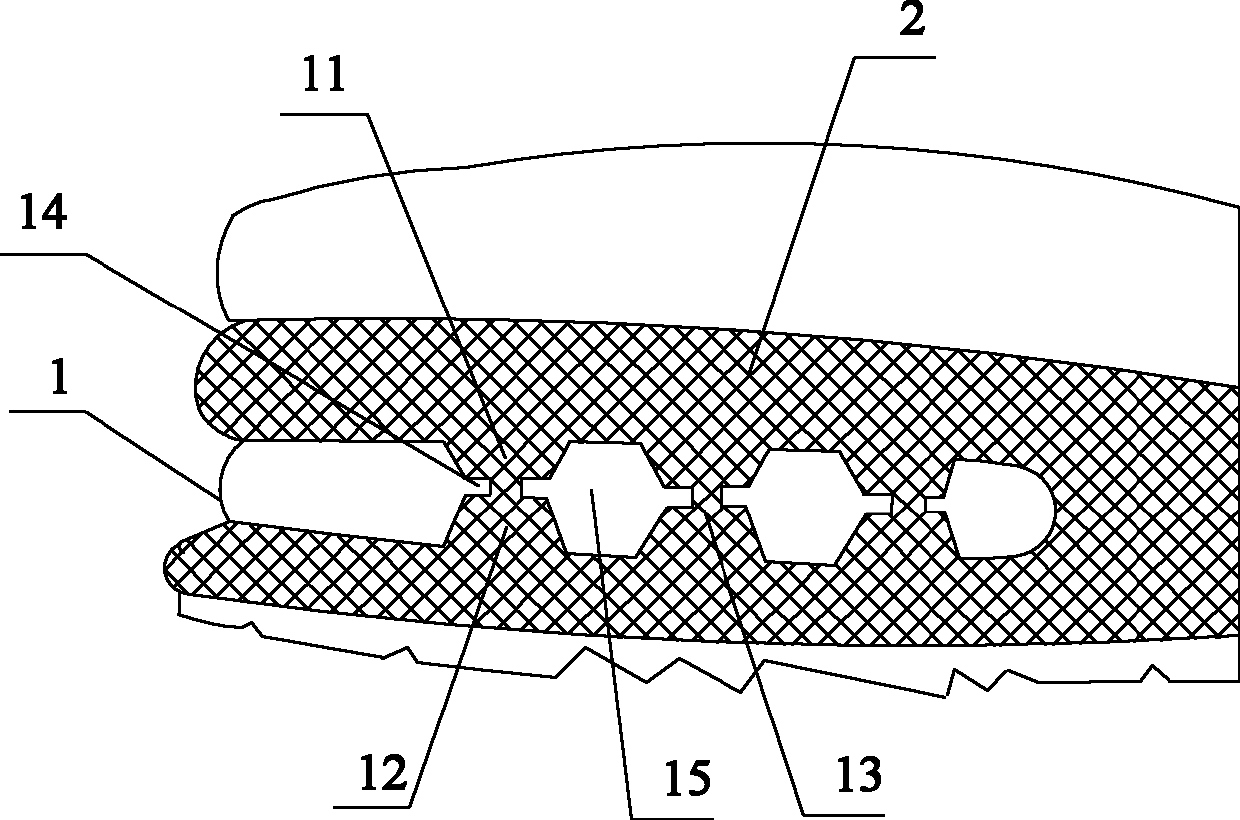

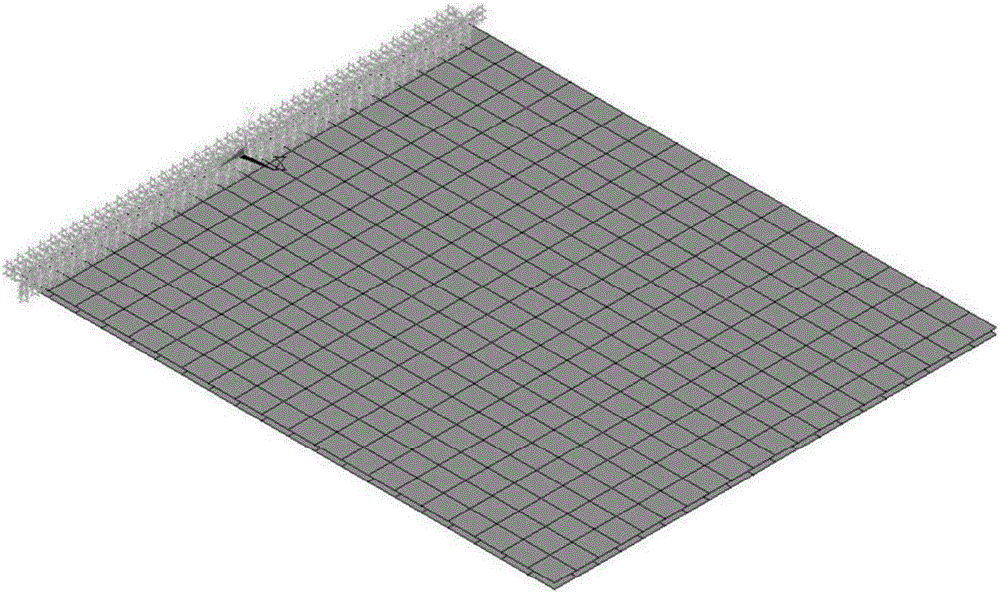

Manufacturing method and device of transformer molding insulating components

InactiveCN103541280ASolve production inefficienciesSolving Quantitative ProblemsTextiles and paperFiberGram

The invention provides a manufacturing method and device of transformer molding insulating components. According to the manufacturing method and device, a paper-pulp high-pressure molding method is applied, and paper pulp with the concentration being 0.3-3% is compressed into a thin-shell structure product with the thickness ranging from 1 millimeter to 6 millimeters and the density ranging from 0.6 gram / cubic centimeter to 1.3 grams / cubic centimeter in a mould. The mould comprises a rigid mould body 1, a flexible mould body 2 and an enclosing frame 3, wherein the rigid mould body 1 is composed of a drainage groove 14, a screen mesh 15, a mesh pressing plate 16 and the like, and the flexible mould body 2 is composed of a flexible bag 21, a mould core 22 and a flexible mould base 23; after relative movement of the rigid mould body 1 and the flexible mould body 2 is finished, the flexible bag 21 is filled with pressure fluid, and the flexible bag 21 expands and applies pressure to a surrounding paper fiber laminated layer with the high moisture content until the surrounding paper fiber laminated layer reaches the required water content and the required thickness. Cost of the transformer molding insulating components manufactured in the manufacturing method and through the manufacturing device is reduced greatly, and the transformer molding insulating components are high in density and accurate in size. The manufacturing method and device can also be used for manufacturing pallets and other thin-shell structure products formed by the paper pulp under high pressure.

Owner:郎旗

Sport shoe and sole thereof

InactiveCN102429401AEffective dispersionEvenly distributed pressureSolesThin shellsReinforced concrete

The invention discloses a sport shoe and a sole thereof. A heel of an insole of the sole of the sport shoe is provided with an opening; a buffer is embedded in the opening, and has a shell with a thin-shell structure; the shell is provided with a plurality of upper and lower through holes opposite to each other vertically; the shell and the insole are integrally formed through injection molding; and support posts are formed in the upper and lower through holes. By referring to a reinforced concrete forming principle in the field of buildings, the support posts are equivalent to concrete, the shell is equivalent to a template, when a foot of a person touches the ground, a cavity formed between a support post and an adjacent support post is stressed and deformed to disperse impact force, the shock strength is high, shock waves can be effectively dispersed, the pressure of the bottom of the foot on the shoe, and reacting force of the ground to the sole are effectively dispersed uniformly, and a wearer exercises more safely, comfortably and enduringly.

Owner:吴荣照

Method and system for identifying mechanical characteristic parameters of hard coating material

ActiveCN106442727AThe preparation process has obvious influenceStrain dependentAnalysing solids using sonic/ultrasonic/infrasonic wavesThin shellsElement model

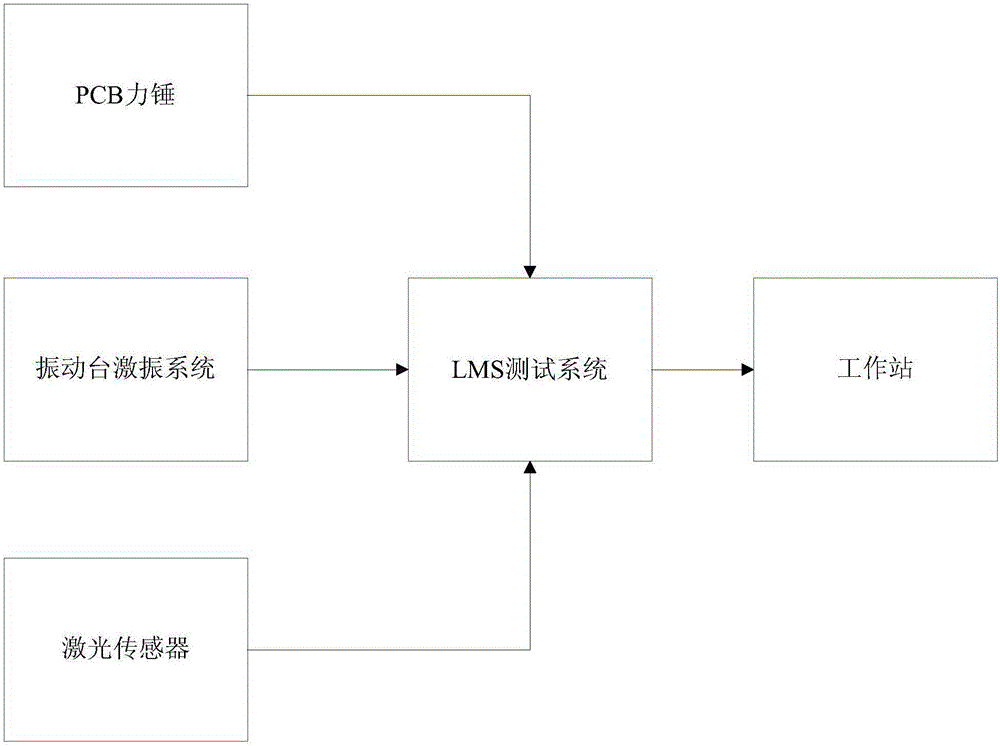

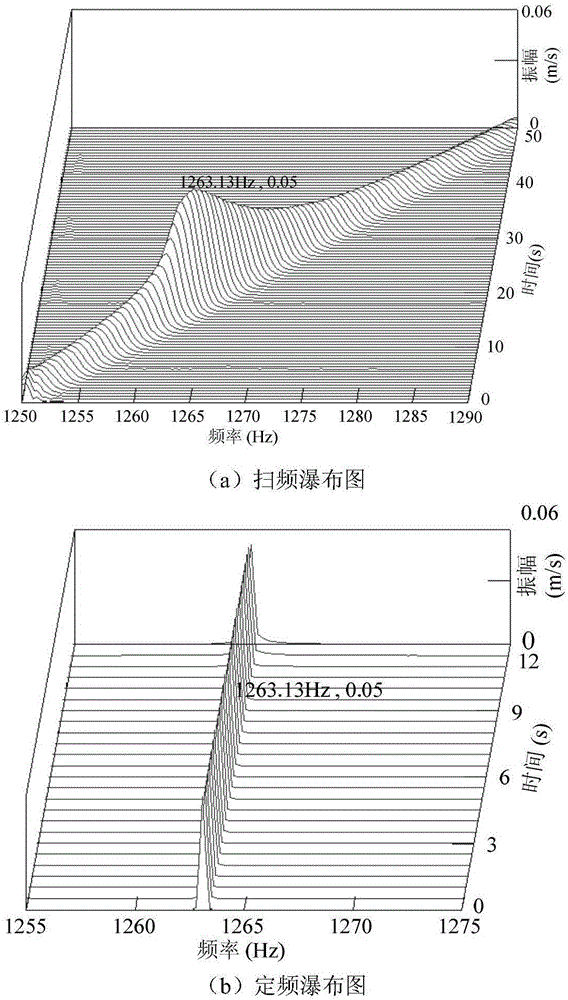

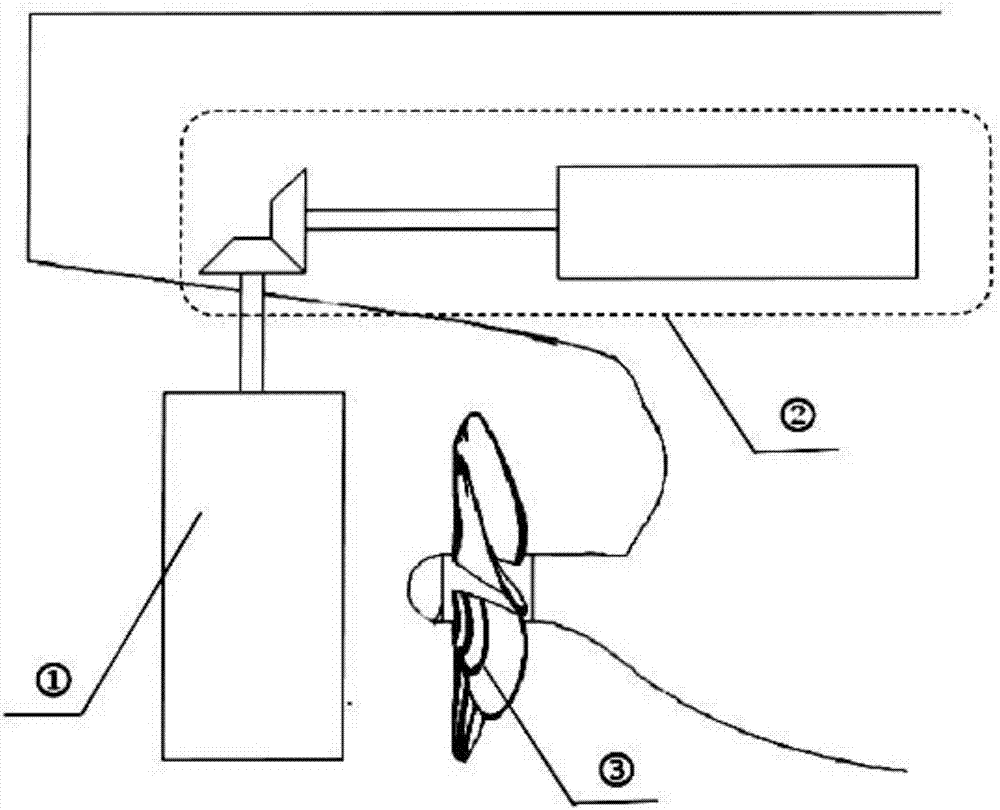

The invention provides a method and a system for identifying mechanical characteristic parameters of a hard coating material. The method comprises steps as follows: a finite element model of a hard coating composite thin-shell structure is established; experimental data required for identification of the parameters of the hard coating material are determined; the initial values of energy storage moduli are determined; the accurate values of the energy storage moduli of the hard coating material at different excitation amplitudes are determined; the initial values of loss factors are determined; the accurate values of the loss factors of the hard coating material under different excitation amplitudes are determined; the maximum equivalent strain value under different excitation amplitudes is calculated; a strain dependence representation curve of the mechanical parameters of the hard coating material is drawn. The system comprises a PCB exciting hammer, a vibrating table exciting system, an LMS testing system, a work station and a laser sensor. An inverse method matching inherent frequency and resonant response obtained through experiment measurement with theoretical calculating values is adopted for effectively identifying the energy storage modulus and the loss factors of the hard coating material, methods for determining the energy storage modulus and the loss factors of the hard coating material are given respectively, and the calculation efficiency is substantially improved.

Owner:NORTHEASTERN UNIV

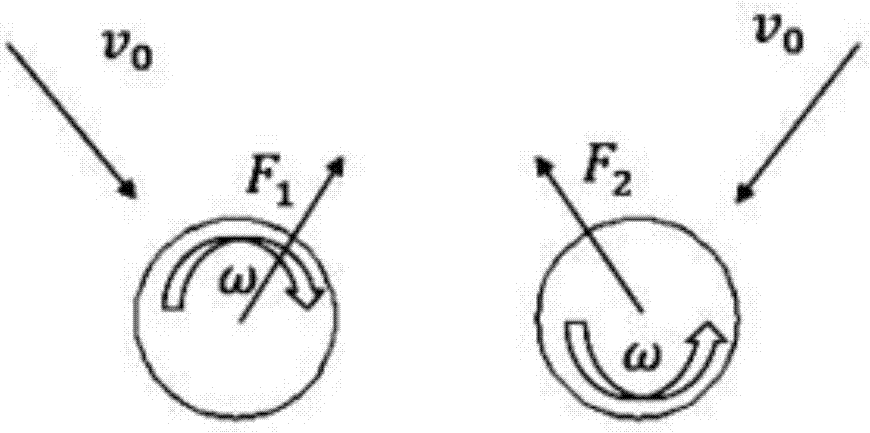

Longitudinal drum-type auxiliary propulsion device of ship

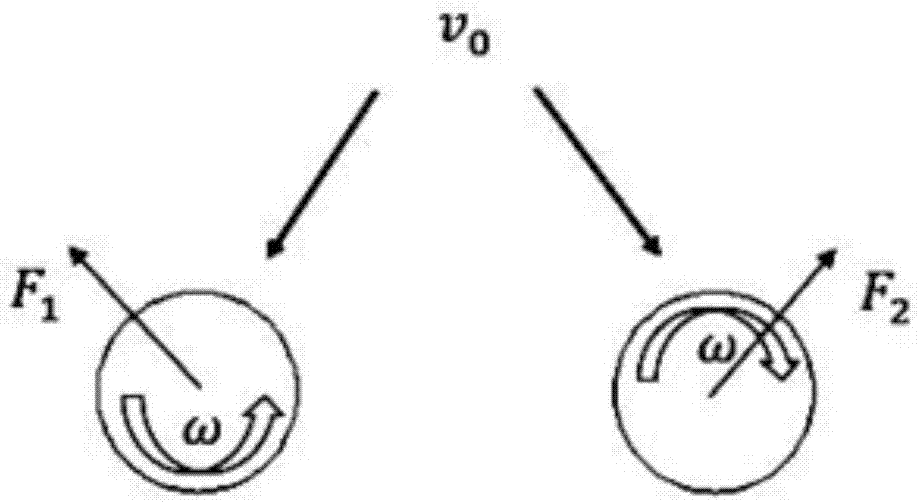

InactiveCN106915425AImprove maneuverabilityGood turnabilityPropulsive elements using Magnus effectSteering ruddersThin shellsPropeller

The present invention provides a longitudinal drum-type auxiliary propulsion device of a ship. Two drum-type structures are arranged at the lower end of the tail of the ship, each drum-type structure is a barrel thin-shell structure having a cylindrical shape, the upper ends of the drum-type structures are connected with a device positioned in the stern of the ship through rotatory shafts, the two drum-type structures are positioned behind ship tail propellers and provided on the same cross section of the ship, wherein the length direction of the ship is the direction of the longitudinal section, and the cross section is the plane perpendicular to the longitudinal section. According to the invention, the energy in the wake flow of the ship can be effectively absorbed, the maneuverability and the course change performance of the ship are better, the structure design is simple, installation is convenient, and certain economic requirements are met.

Owner:HARBIN ENG UNIV

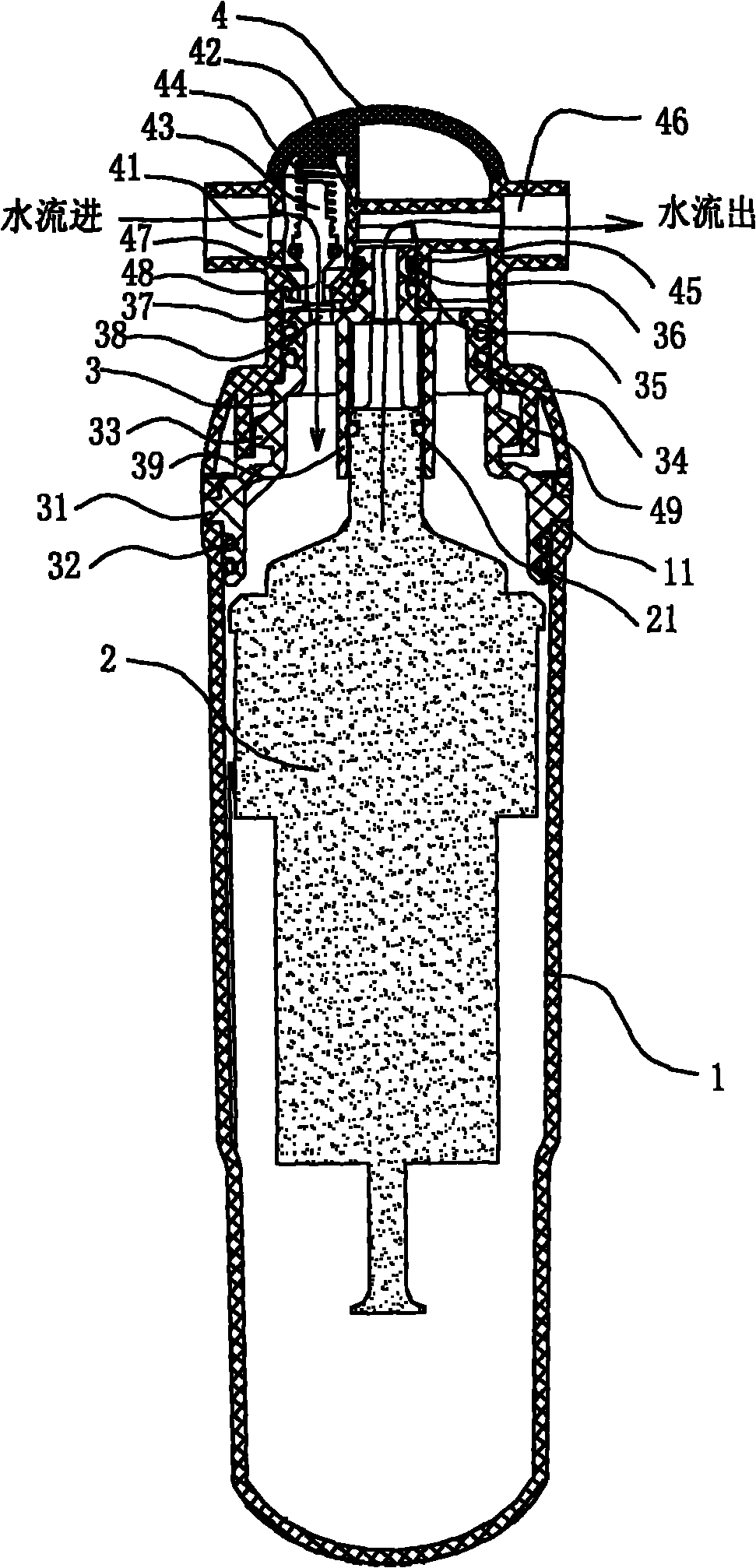

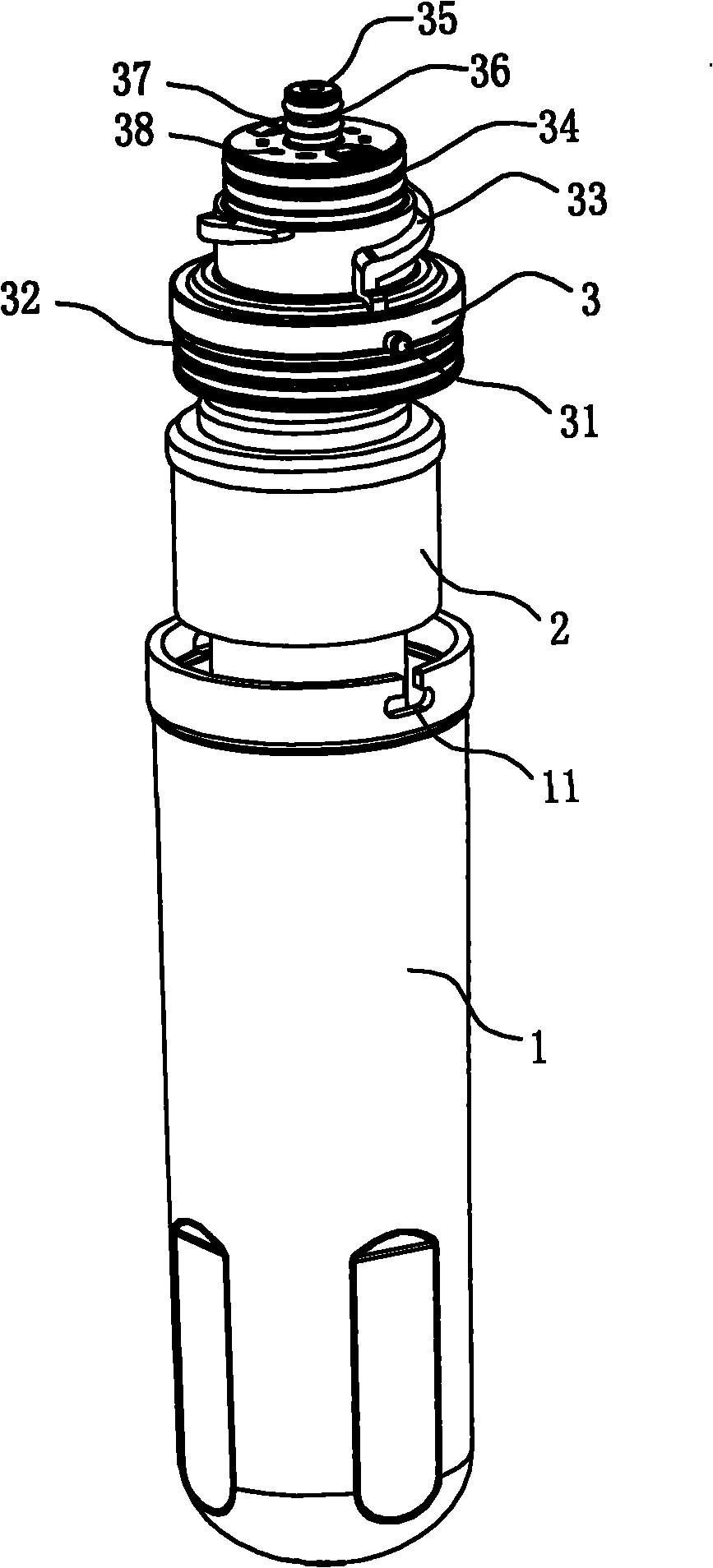

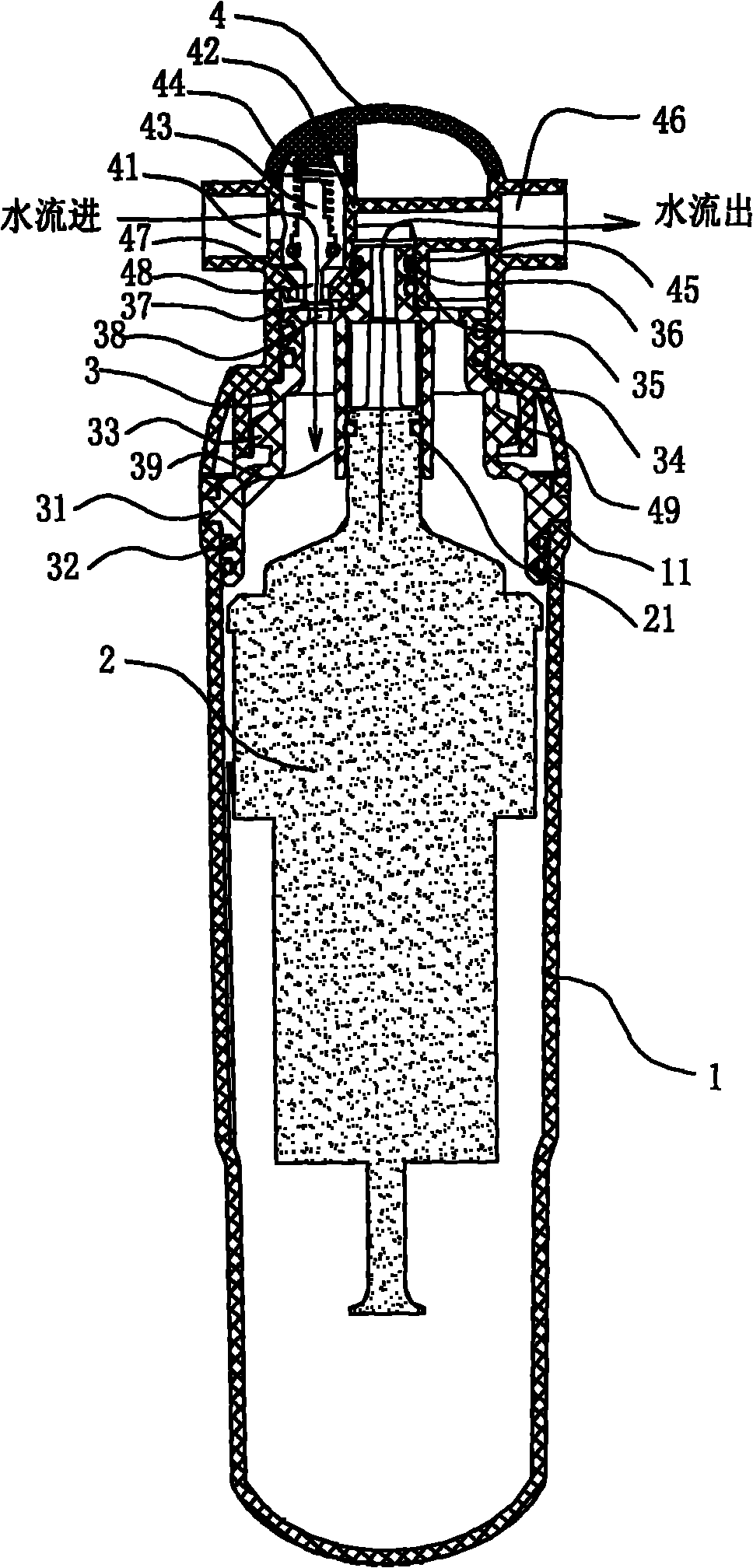

Filtering device with ultrafiltration membrane

InactiveCN102179173ARealize re-cleaning and utilizationSave resourcesUltrafiltrationWater flowEngineering

The invention discloses a filtering device with an ultrafiltration membrane, which comprises a filter cartridge, a filter element and a filter cartridge cover, wherein the filter cartridge has a cylindrical thin-shell structure with one end opened; the shape of the filter element is matched with the internal shape of the filter cartridge and is sleeved in the filter cartridge; a channel for controlling water to flow into the filter cartridge and controlling filtered water to flow out is formed in the filter cartridge cover; and the filter cartridge cover and the filter cartridge are detachably and movably connected. The detachment and replacement of the filter element can be realized through the threaded connection of the outer cover and inner cover of the filter cartridge and the bayonet connection between the inner cover and the filter cartridge. In the invention, through the movable connection between the filter cartridge and the filter cartridge cover, the filter element is re-washed and recycled on the premise of preventing damage to the filter cartridge and the filter cartridge cover, and thus, resources are saved.

Owner:QINYUAN GRP CO LTD

Large span, quadrate structure of house cover prepared from plane reinforcing steel bar concrete in open web interlayer and double arch flat web shell

PendingCN1959023AReduce dosageImprove construction progressBuilding roofsReinforced concreteSteel bar

The present invention discloses a kind of large span square-shaped plane reinforced concrete open-web sandwich doubly-curved flat mesh-shell roof structure. It is composed of shell plate and edge member. Said shell plate is made up by using square-shaped plane reinforced concrete open-web sandwich plate through a bending process according to circular curve bidirectional equal-curvalure. As compared with existent technology the span of the reinforced concrete thin shell structure can be enlarged to 36 m-60 m and its self-weight can be reduced by 30%-50%.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD +1

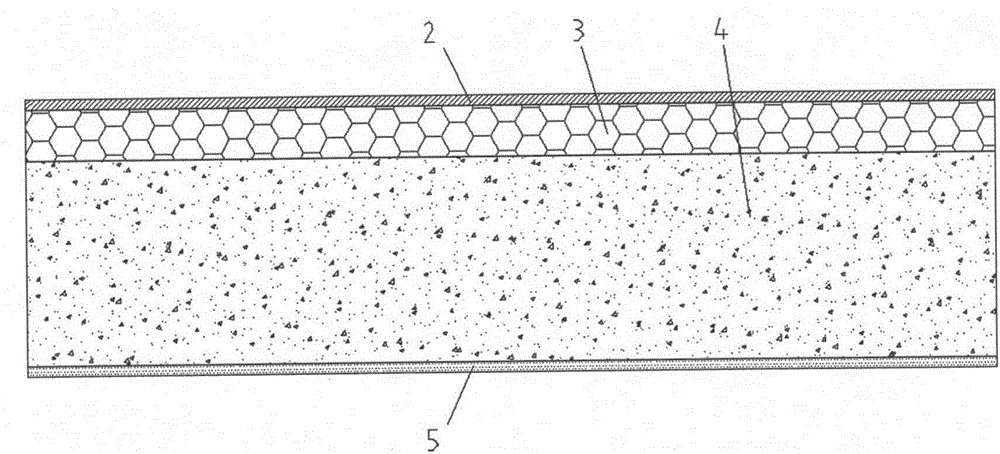

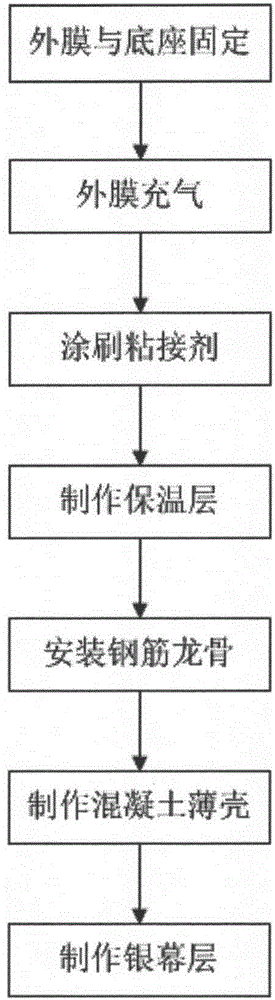

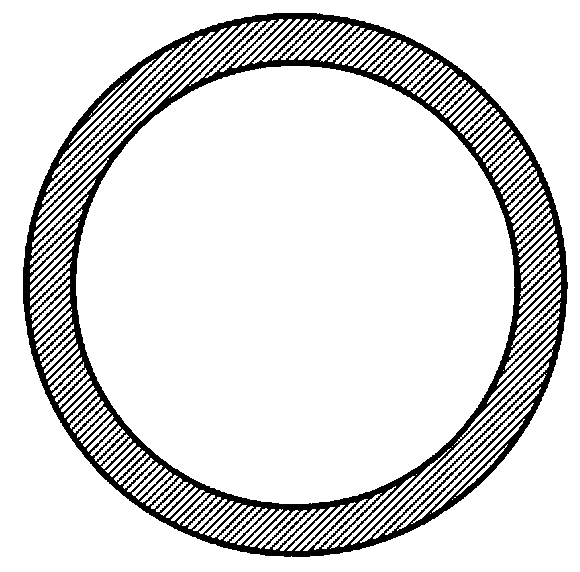

Seamless spherical screen capable of providing large-span interior architectural space and preparation process thereof

InactiveCN106569384ASafe and reliable structureAnti-leakage functionProjectorsShotcreteInsulation layer

Owner:SHANGHAI HIGHBIRD FABRIC STRUCTURES

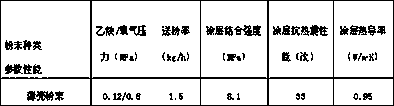

Thin-shell structure zirconium oxide powder for thermal spraying

The invention provides a thin-shell structure zirconia powder for thermal spraying, the powder particles have a thin-shell spherical or nearly spherical hollow structure similar to a table tennis ball, and the wall thickness of the particles is less than 10% of its outer diameter; due to the thin-shell structure oxidation Zirconium powder is easier to melt. When plasma spraying is used, under the same powder feeding rate, the spraying power can be reduced by more than 40%, and the service life of nozzles, electrodes and other components can be extended by more than 50%; under the same spraying power condition The production efficiency (powder feeding amount) can be increased by more than 40%; using the thin-shell structure zirconia powder of the present invention, the flame spraying process can also be used to prepare zirconia coating. The equipment cost of flame spraying is about one-tenth of that of plasma spraying equipment. At the same time, it has the characteristics of low operating cost, small size, and can be easily transported to the product site for coating construction.

Owner:苏州炻原新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com