Joint drum structure for connecting steel structural part

A technology for steel structural parts and joints, which is applied in building structures, buildings, etc., can solve the problems of difficulty in ensuring the connection angle between rods and rods, high skill requirements for welding workers, and incompatibility between rods and rods. Achieve the effect of high assembly precision, exquisite node structure and easy use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

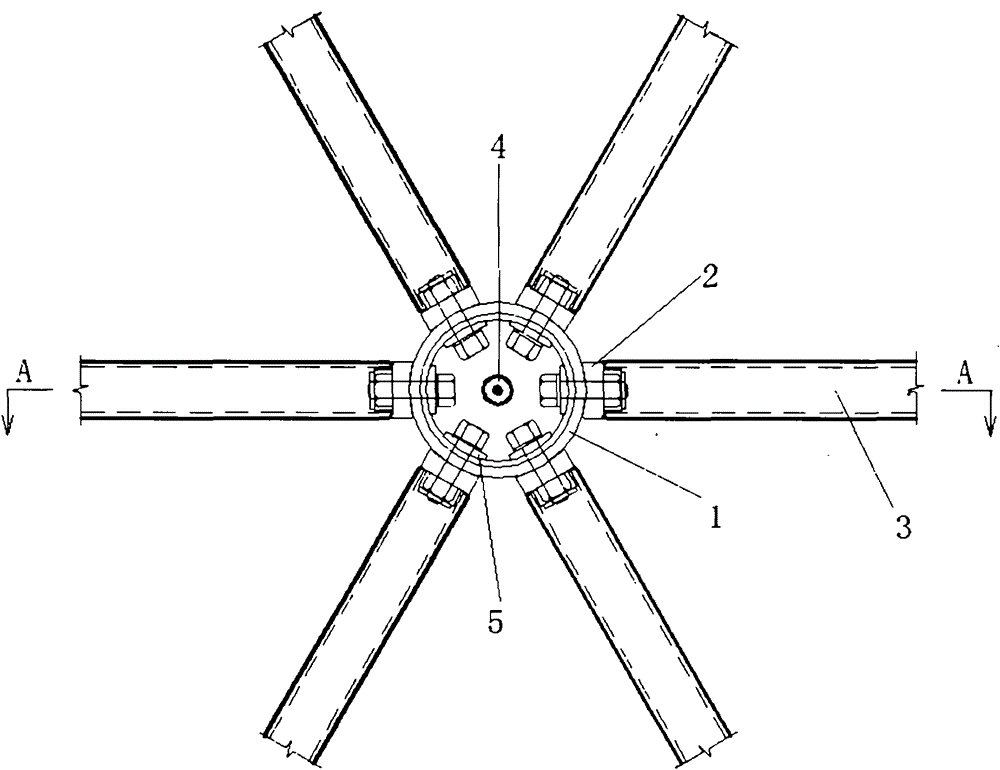

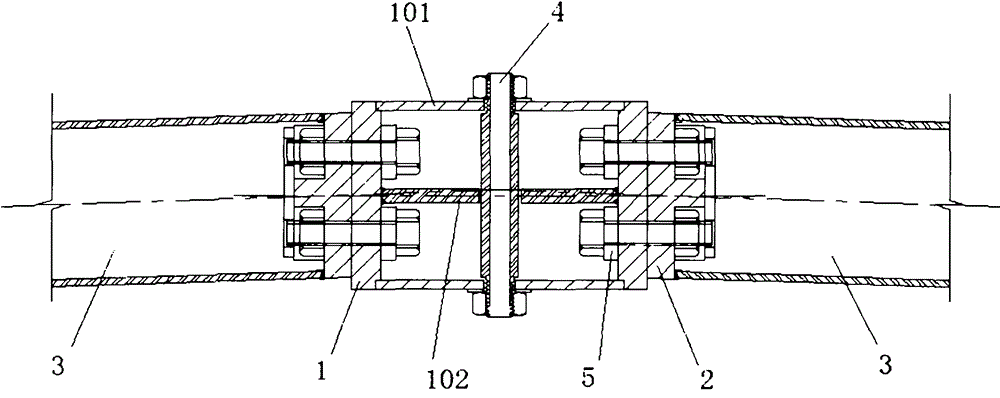

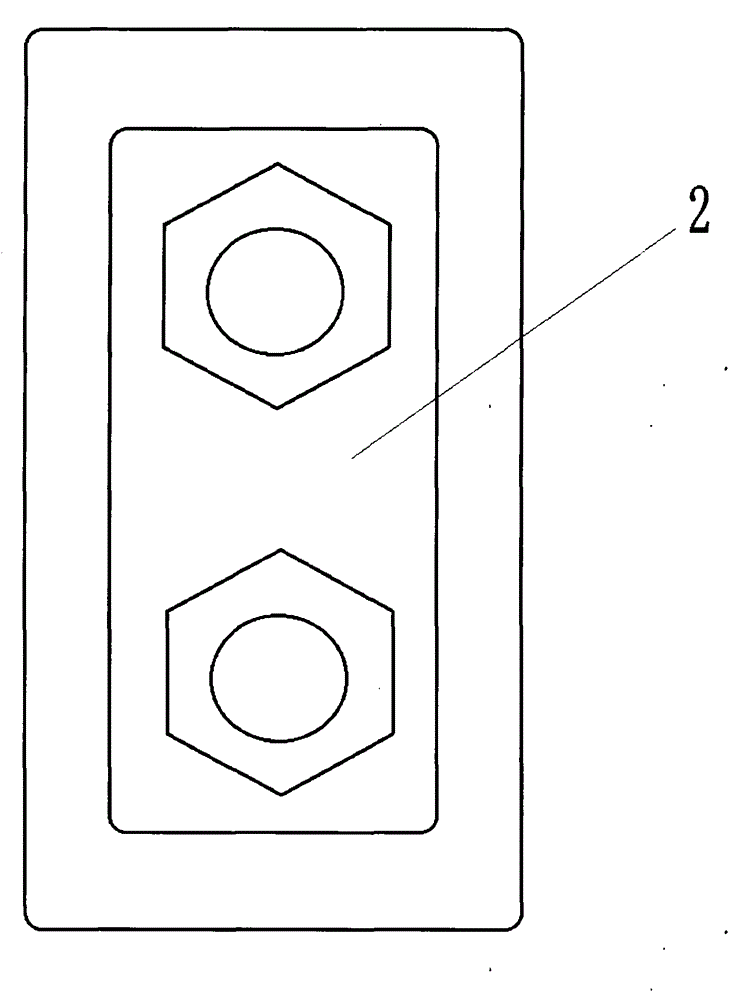

[0031] see Figure 1-2 , a joint drum structure for connecting steel structural parts, including a bolt drum 1, the bolt drum 1 is a hollow cylinder structure, detachable cover plates 101 are provided on both ends, and six groups of bolts are evenly distributed in the circumferential direction of the bolt drum 1 hole; also includes six hollow rods 3, the tangent angle of the hollow rods 3 can be adjusted, the hollow rods 3 and the sealing plate 2 are welded and fixed, the sealing plate 2 is provided with a group of bolt holes; the six hollow rods The rod 3 and the sealing plate 2 are welded and fixed to the bolt drum 1 through the bolt holes; Each group of the six groups of bolt holes includes two bolt holes arranged up and down. A backing plate 5 is also provided between the bolts in the bolt holes and the inner surface of the bolt drum. The hollow rod 3 has a rectangular structure and has a larger force-bearing surface, so it is stronger than the circular tube-shaped hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com