Three-qimension geomechanics model exporiment system

A mechanical model and test system technology, applied in scientific instruments, test material hardness, instruments, etc., can solve the problems of large lateral deflection and deformation of the bench, large lateral deflection of the test device, fixed size of the test device, etc., and achieve flexible assembly Convenience, large device scale, and stable test pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

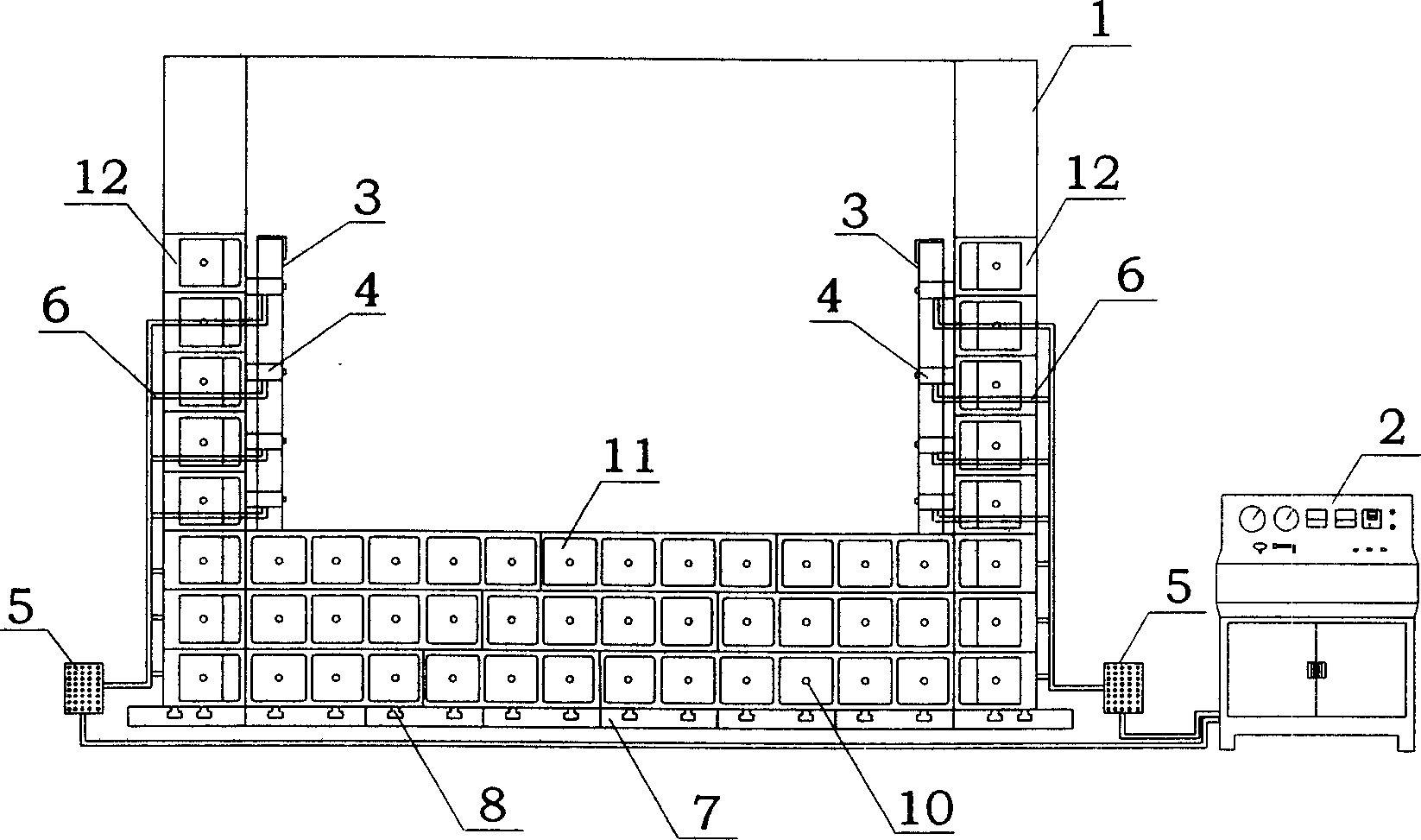

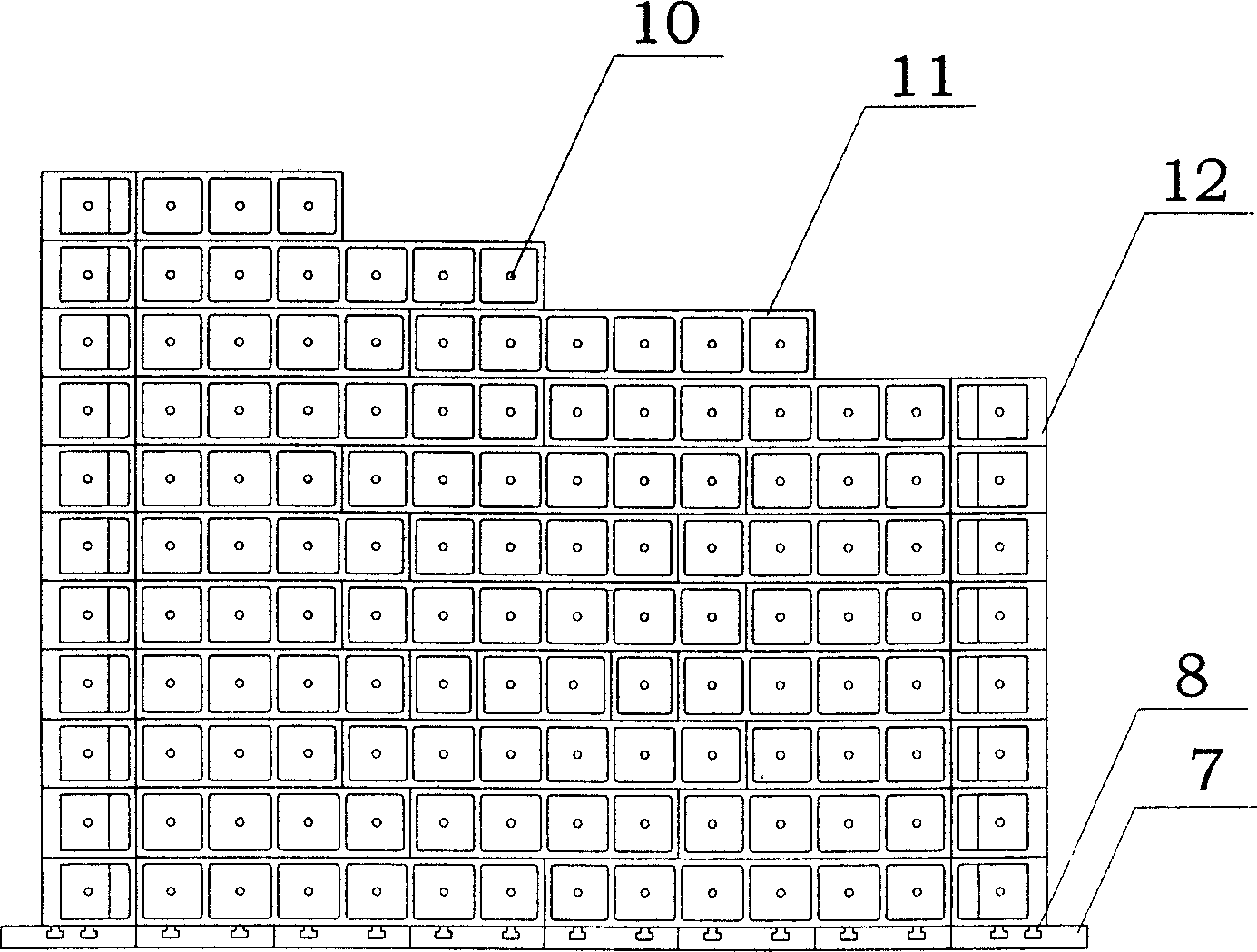

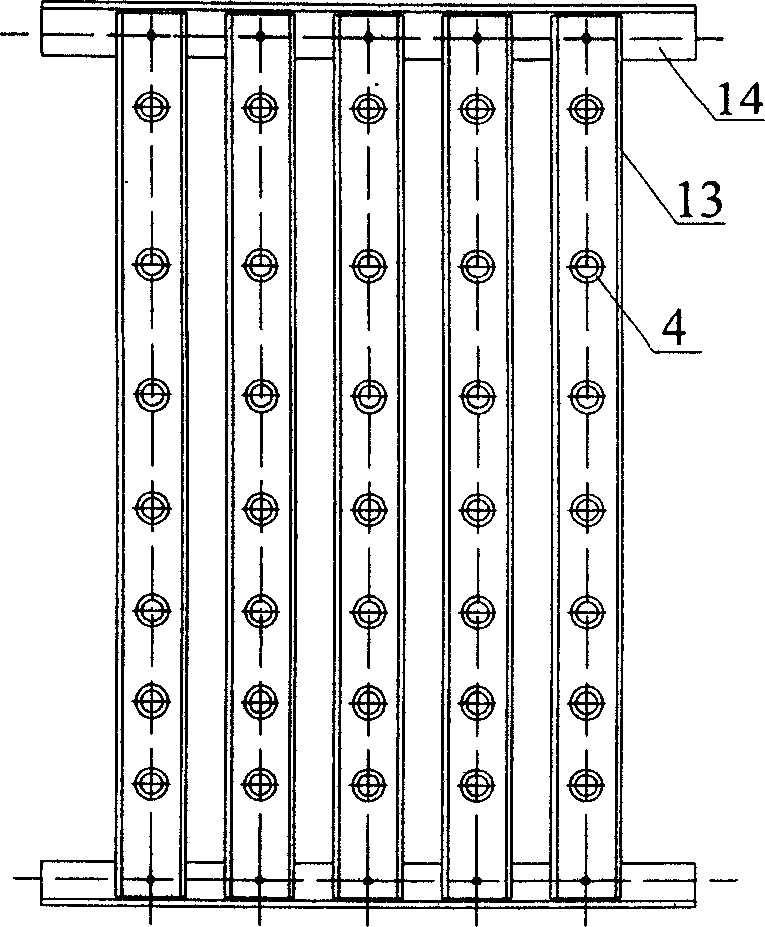

[0043] Example: a structure such as figure 1 and figure 2 As shown, the present invention is composed of a box test device 1 and a hydraulic loading control system. The box-type test device 1 is composed of box-type cast steel components 11, corner fittings 12 and chassis 7 connected by high-strength bolts; the hydraulic loading control system consists of a variable load loading plate 3 with a thin jack 4, a hydraulic loading console 2, and an oil separator 5 and oil pipe 6, wherein the variable load loading plate 3 is connected to the left and right inner walls of the box test device 1 through the thin jack 4, and the hydraulic loading console 2 is connected to the thin jack 4 through the oil separator 5 and the oil pipe 6.

[0044] like figure 2 As shown, the box-type stand body is formed by connecting box-type cast steel components 11 and corner fittings 12 with a wall thickness of 25 mm through high-strength bolts. According to different needs, box-type test devices o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com