Epitaxial slice cleaning device for LED lamp production

A technology of LED lamps and cleaning devices, which is applied in the direction of cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, etc., which can solve the problems of affecting the health of workers, low cleaning efficiency, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

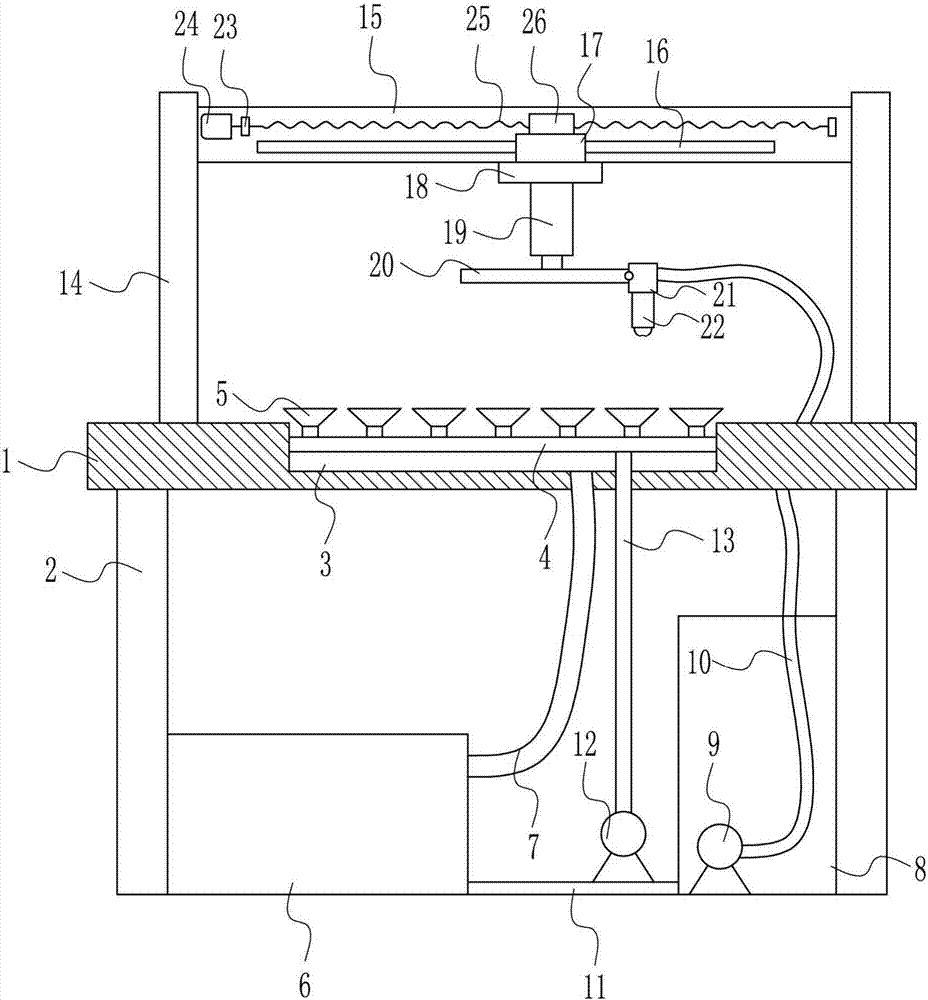

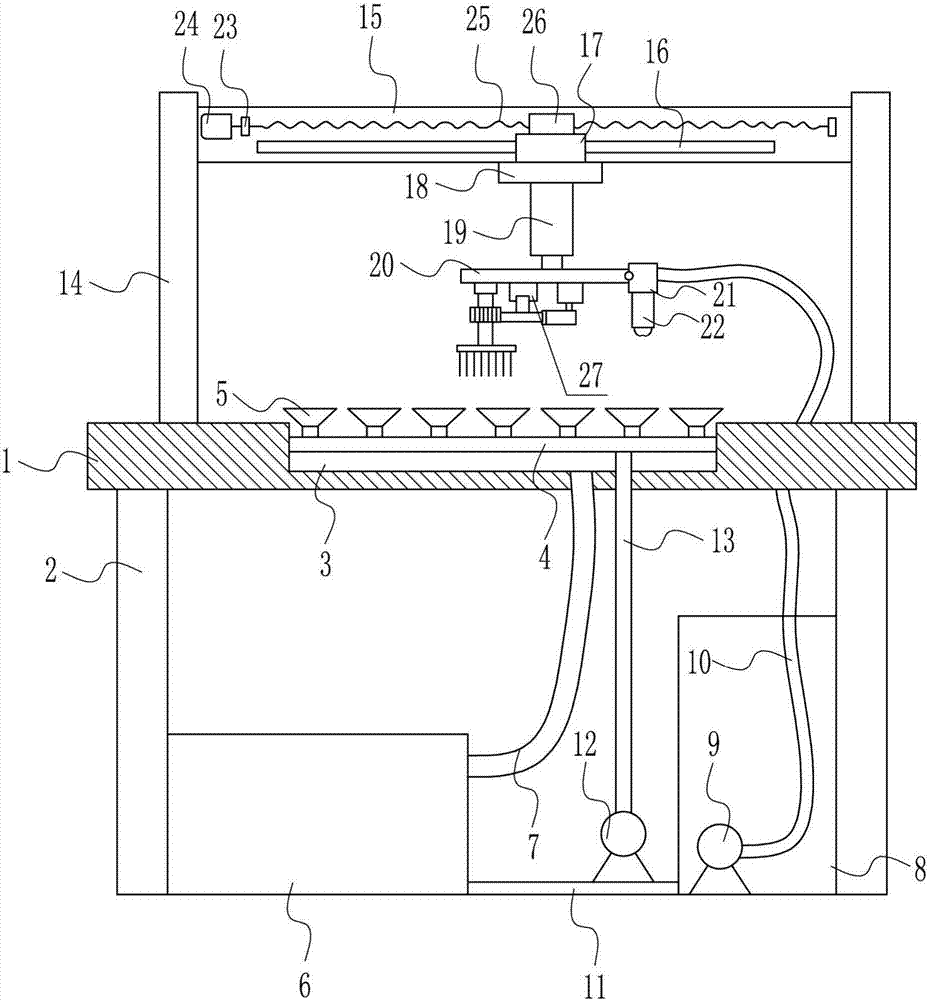

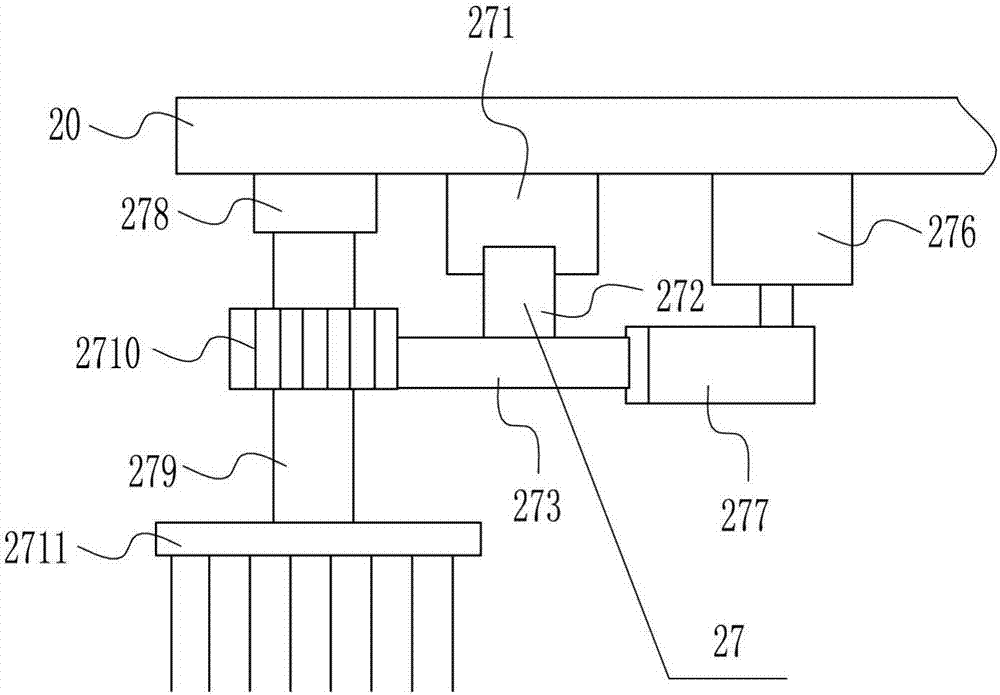

[0034] A kind of epitaxial wafer cleaning device for the production of LED lamps, such as Figure 1-8 As shown, it includes workbench top 1, outrigger 2, first air pipe 4, vacuum suction cup 5, recovery tank 6, return water pipe 7, solution tank 8, water pump 9, water outlet pipe 10, support plate 11, vacuum pump 12, suction Air pipe 13, vertical plate 14, mounting plate 15, sliding rod 16, sliding sleeve 17, horizontal plate 18, first cylinder 19, first connecting plate 20, square pipe 21, nozzle 22, first bearing seat 23, first Motor 24, screw mandrel 25 and nut 26, the bottom of workbench top 1 is connected with outrigger 2 through the mode of bolt connection, there is groove 3 in the middle of the top of workbench top 1, and groove 3 is provided with first air pipe 4 , the first air pipe 4 is connected to the workbench table top 1, a plurality of vacuum suction cups 5 are evenly spaced on the top of the first air pipe 4, and the inner surface of the left leg 2 is connected...

Embodiment 2

[0036] A kind of epitaxial wafer cleaning device for the production of LED lamps, such as Figure 1-8 As shown, it includes workbench top 1, outrigger 2, first air pipe 4, vacuum suction cup 5, recovery tank 6, return water pipe 7, solution tank 8, water pump 9, water outlet pipe 10, support plate 11, vacuum pump 12, suction Air pipe 13, vertical plate 14, mounting plate 15, sliding rod 16, sliding sleeve 17, horizontal plate 18, first cylinder 19, first connecting plate 20, square pipe 21, nozzle 22, first bearing seat 23, first Motor 24, screw mandrel 25 and nut 26, the bottom of workbench top 1 is connected with outrigger 2 through the mode of bolt connection, there is groove 3 in the middle of the top of workbench top 1, and groove 3 is provided with first air pipe 4 , the first air pipe 4 is connected to the workbench table top 1, a plurality of vacuum suction cups 5 are evenly spaced on the top of the first air pipe 4, and the inner surface of the left leg 2 is connected...

Embodiment 3

[0039] A kind of epitaxial wafer cleaning device for the production of LED lamps, such as Figure 1-8As shown, it includes workbench top 1, outrigger 2, first air pipe 4, vacuum suction cup 5, recovery tank 6, return water pipe 7, solution tank 8, water pump 9, water outlet pipe 10, support plate 11, vacuum pump 12, suction Air pipe 13, vertical plate 14, mounting plate 15, sliding rod 16, sliding sleeve 17, horizontal plate 18, first cylinder 19, first connecting plate 20, square pipe 21, nozzle 22, first bearing seat 23, first Motor 24, screw mandrel 25 and nut 26, the bottom of workbench top 1 is connected with outrigger 2 through the mode of bolt connection, there is groove 3 in the middle of the top of workbench top 1, and groove 3 is provided with first air pipe 4 , the first air pipe 4 is connected to the workbench table top 1, a plurality of vacuum suction cups 5 are evenly spaced on the top of the first air pipe 4, and the inner surface of the left leg 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com