Capacitance touch screen and making method thereof

A technology of a capacitive touch screen and a manufacturing method, which are applied in the fields of electrical digital data processing, instruments, and calculations, can solve the problems affecting the display effect of the capacitive touch screen, the transmittance, contrast, and color saturation of the capacitive touch screen. Improve display effect, increase light transmittance, avoid scattering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

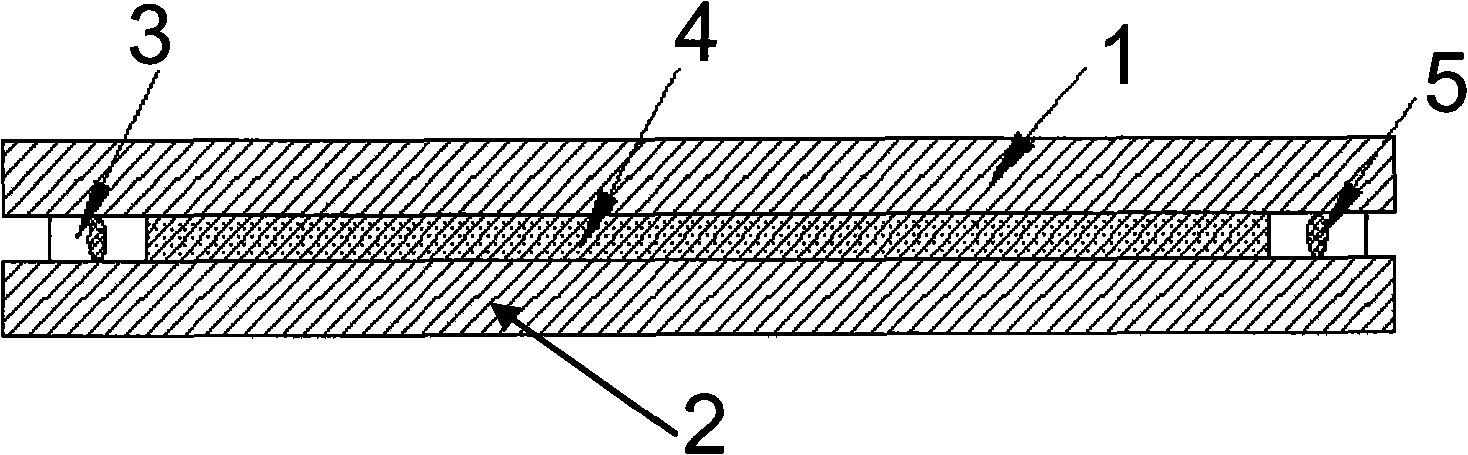

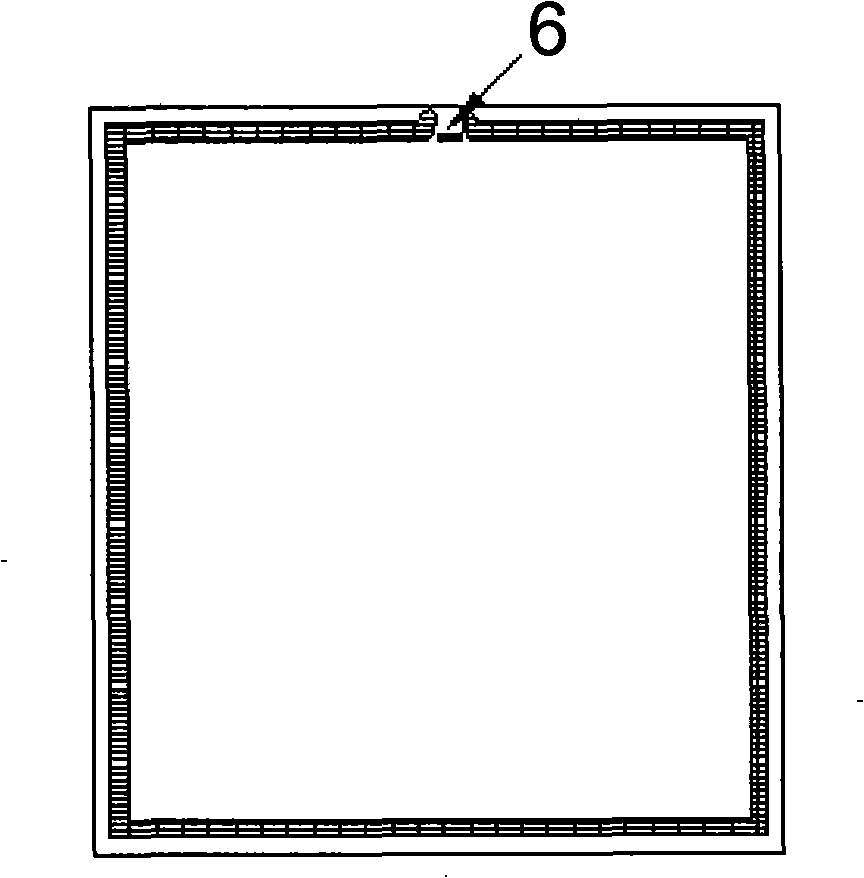

[0024] Such as figure 1 As shown, a capacitive touch screen includes an upper glass substrate 1, a lower glass substrate 2, a frame glue 3 and a colorless transparent glue 4, the upper glass substrate 1 and the lower glass substrate 2 are bonded by the frame glue 3, and the non- The color transparent colloid 4 is filled between the upper glass substrate 1 and the lower glass substrate 2 . Both the upper glass substrate 1 and the lower glass substrate 2 are indium tin oxide (Indium Tin Oxides, ITO for short) glass. The colorless transparent colloid 4 replaces the liner and the air layer in the existing capacitive touch screen, which can effectively avoid the scattering of the air layer, increase the light transmittance, increase the contrast, and increase the color saturation; the present invention Since the capacitive touch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com