Patents

Literature

495results about How to "High color saturation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

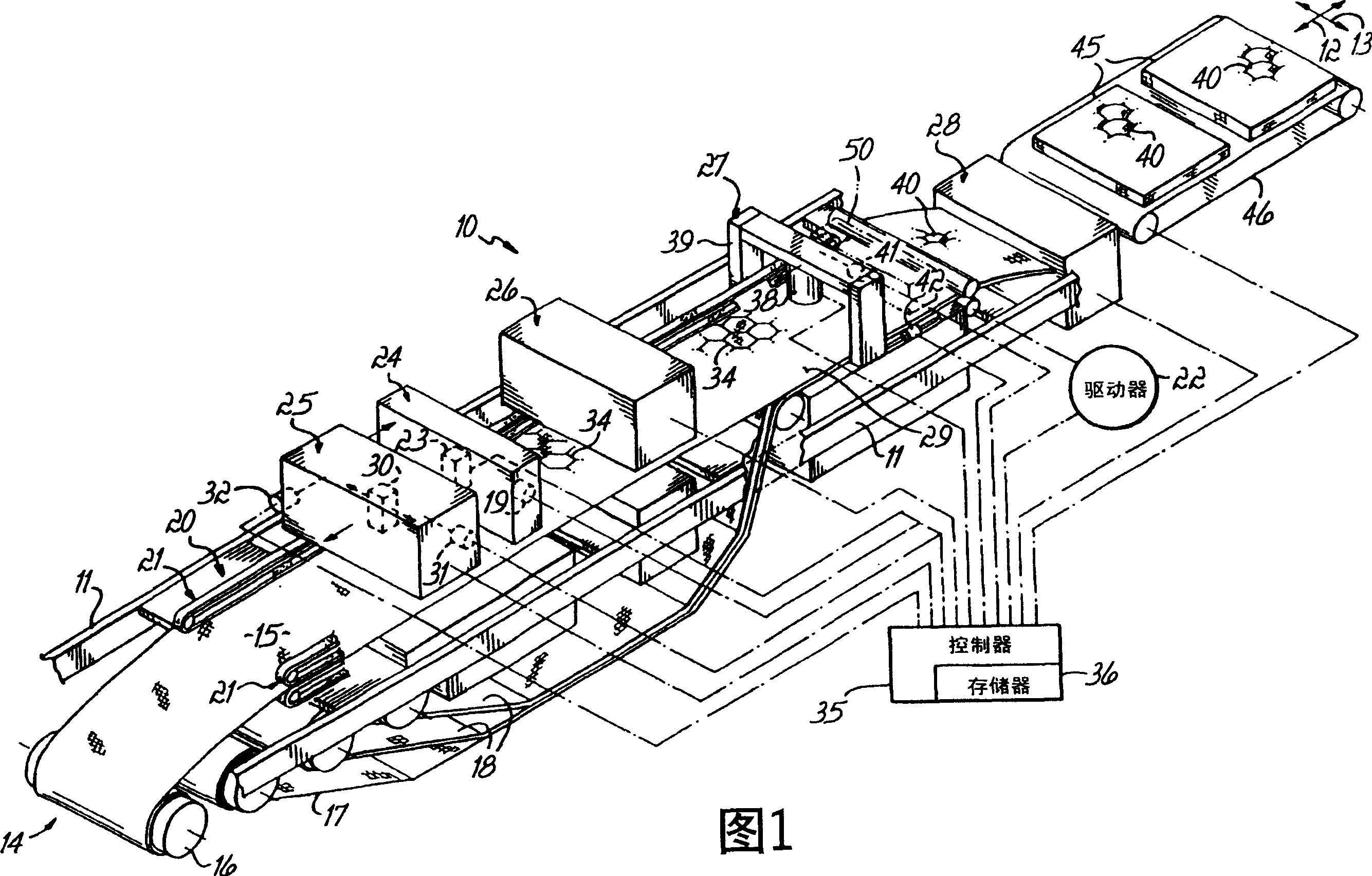

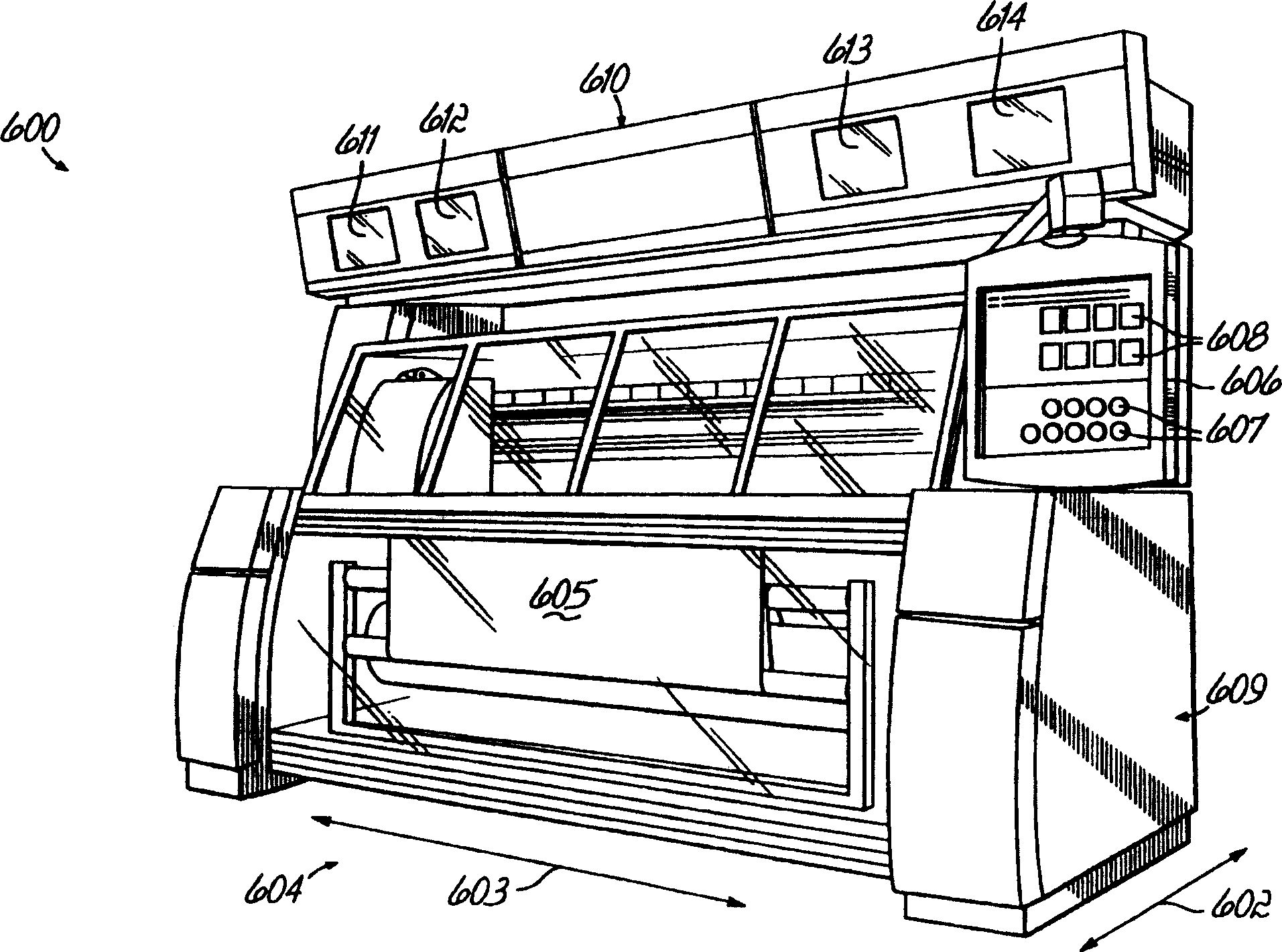

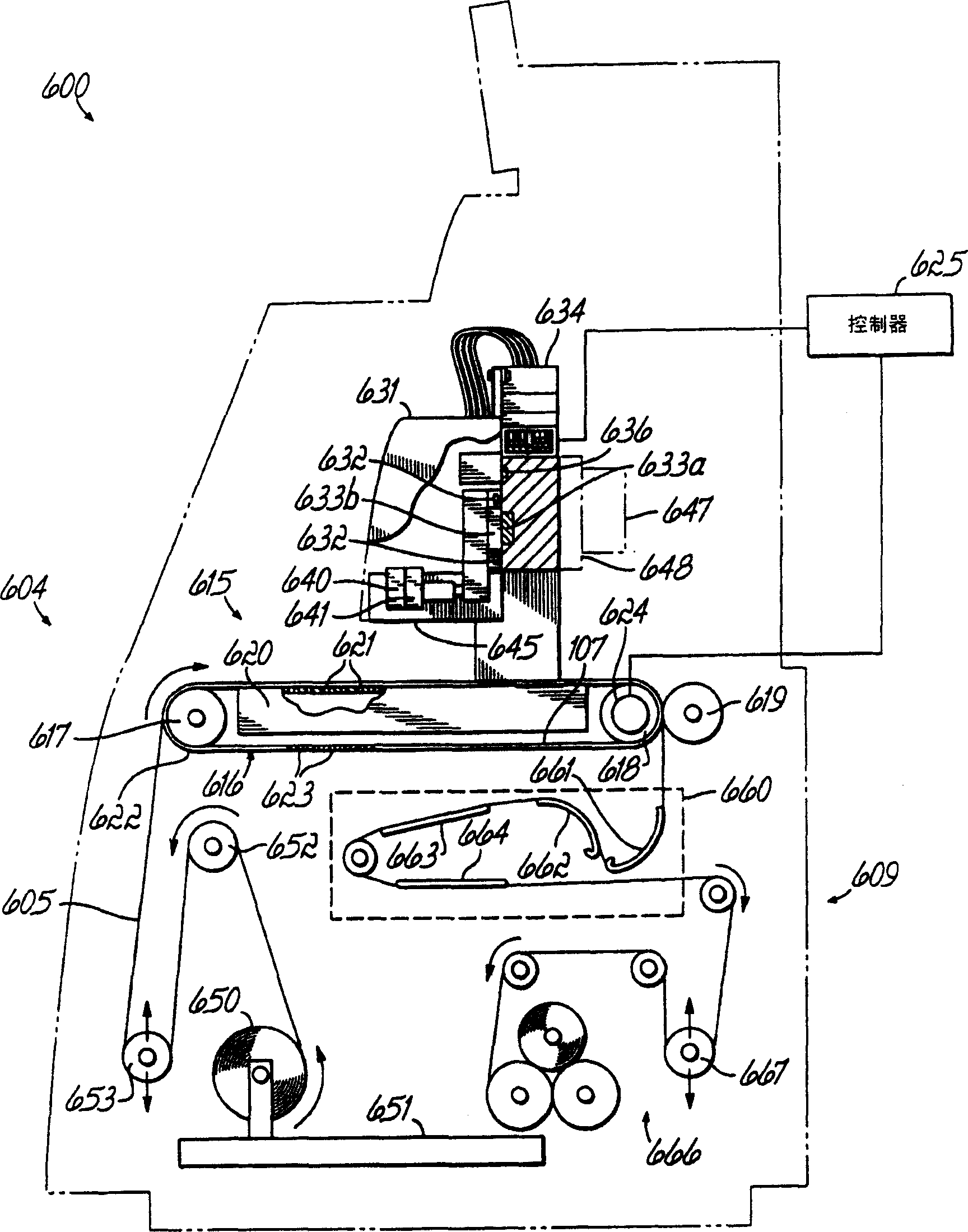

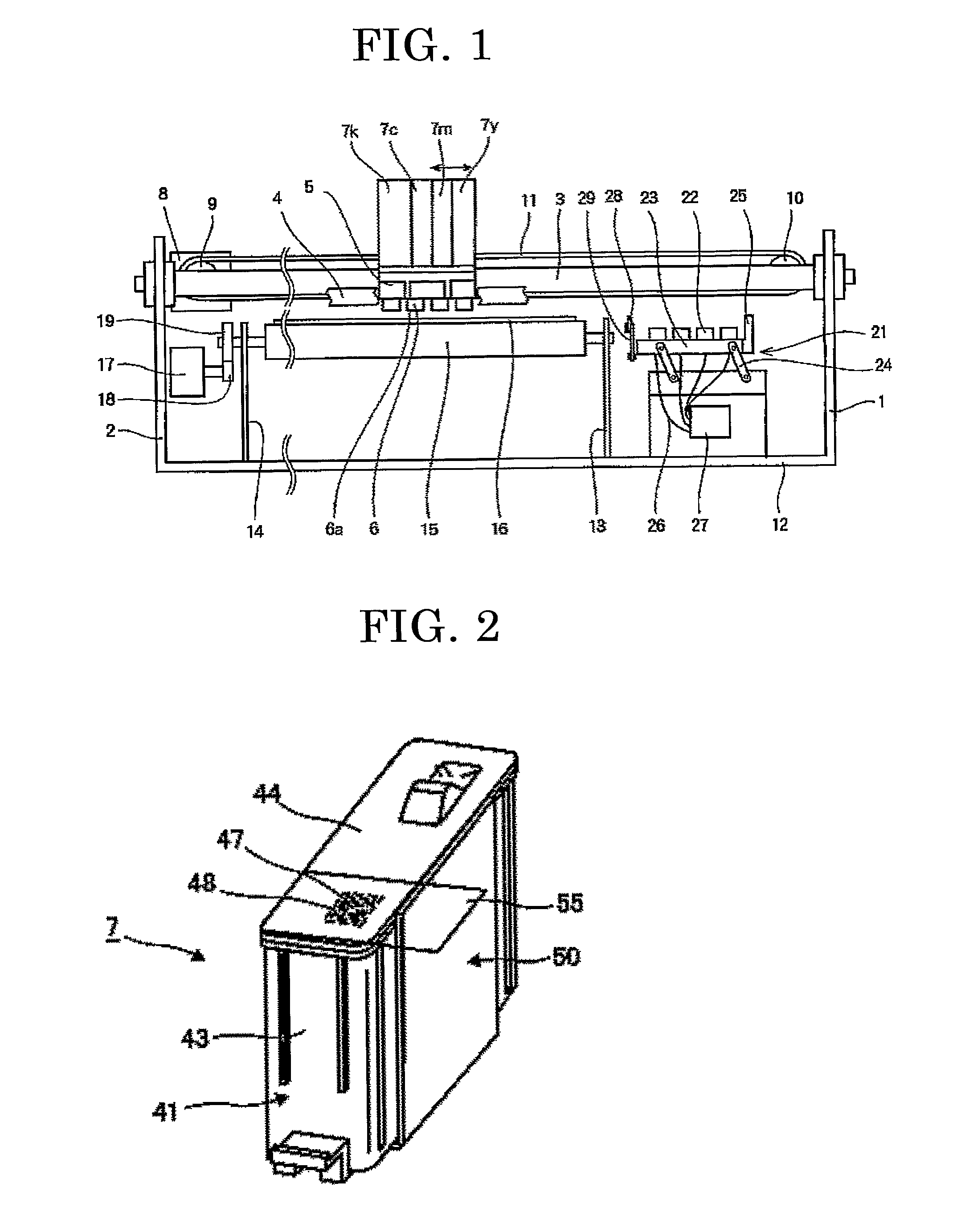

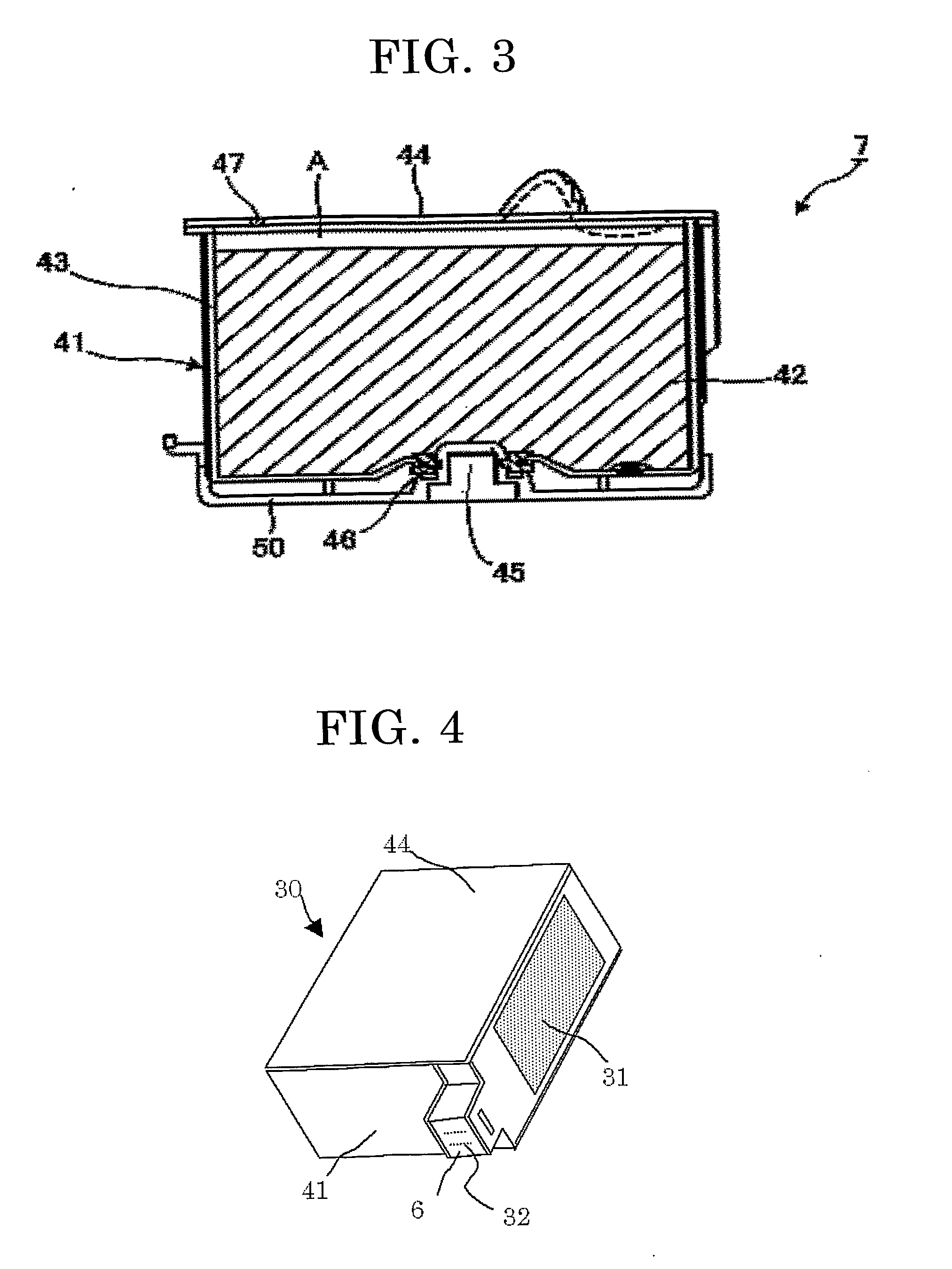

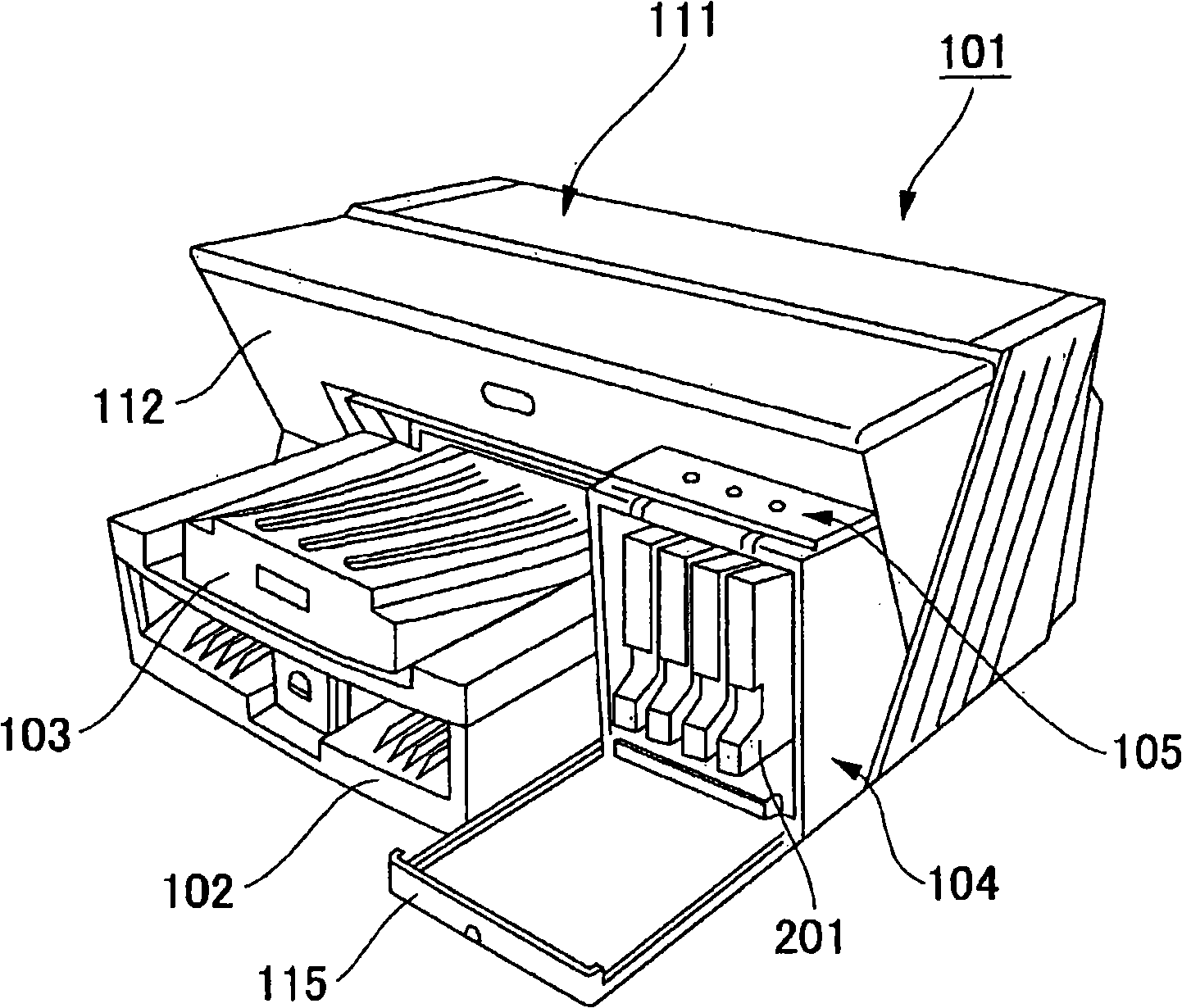

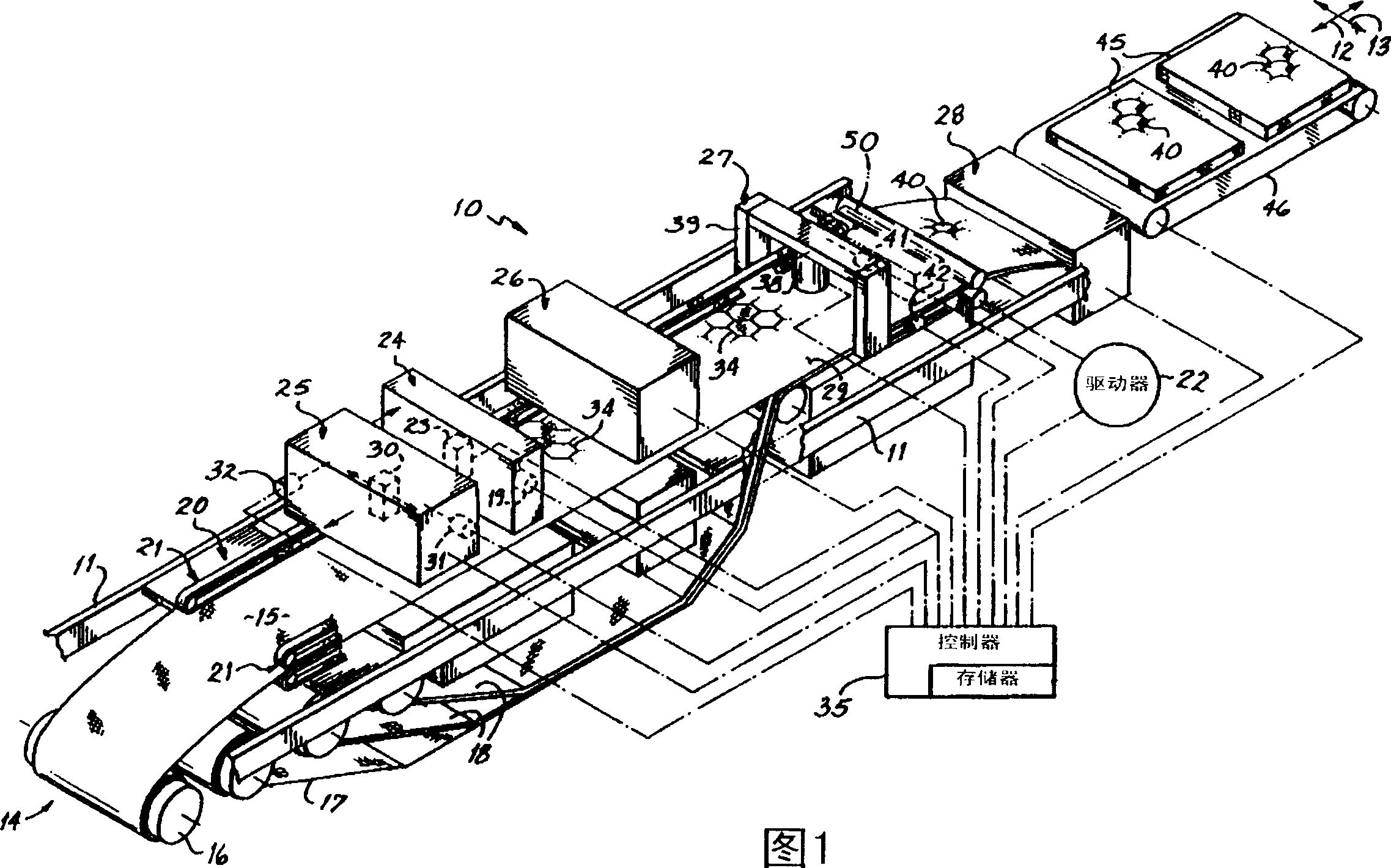

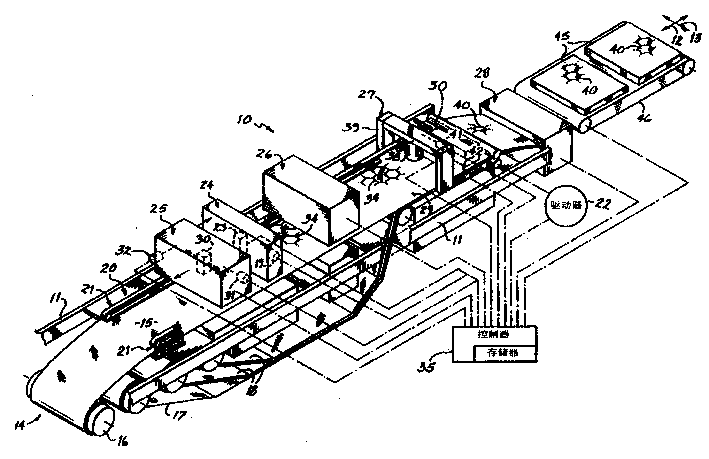

Method and apparatus for ink jet printing

InactiveCN1678458AEliminate cloggingImprove reliabilityDuplicating/marking methodsSpacing mechanismsPorous substratePolyester

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors (633) across a bridge (630) that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads (640, 641), so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light (645, 646) and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate. Preferably, the heat is applied by contacting the substrate with a heated plate (661, 662). Ink jet printing is provided using ultraviolet (UV) light curable or other curable composition or stable or other printable substance. In certain embodiments the UV ink has a dye-component therein. The ink is jetted onto a substrate, the composition is cured, then heated to set the dye. Sublimation dye-based UV ink printing onto polyester is preferred. A release layer of protective material (702, 704) such as a TEFLON film or sheet, covers a substrate support (705, 706). A porous substrate to be printed, such as a textile material (711), is supported on or above the support. Ink is jetted onto the substrate, with some of the ink passing through pores in the substrate and landing on the protective material. UV curable ink is preferably used and is exposed by UV light from a UV light curing head, which solidifies the ink on the substrate. The UV curing light has a long enough focal length to focus on the surface of the substrate and also, where it passes through pores in the substrate, on ink on the protective material, thereby solidifying the ink on the protective material. When the substrate is removed from the support, the solidified ink on the protective material may be wiped from the protective material.

Owner:L & P PROPERTY MANAGEMENT CO

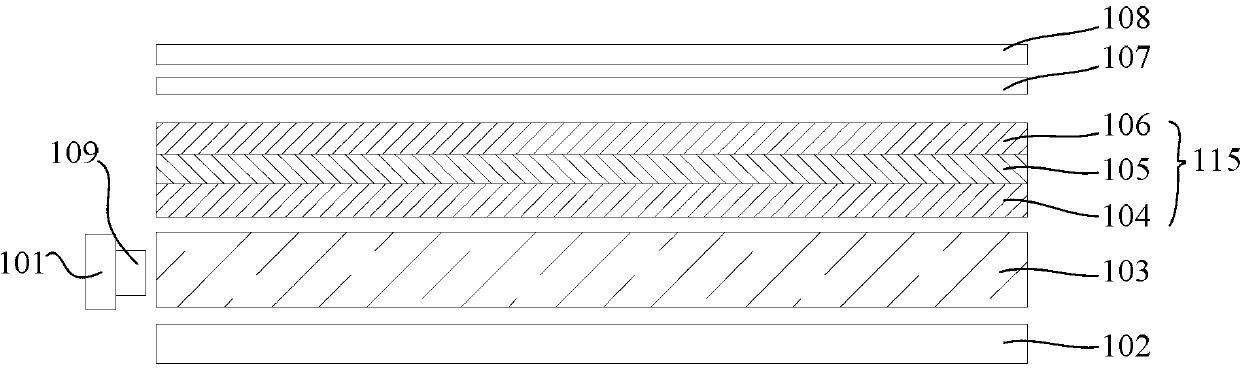

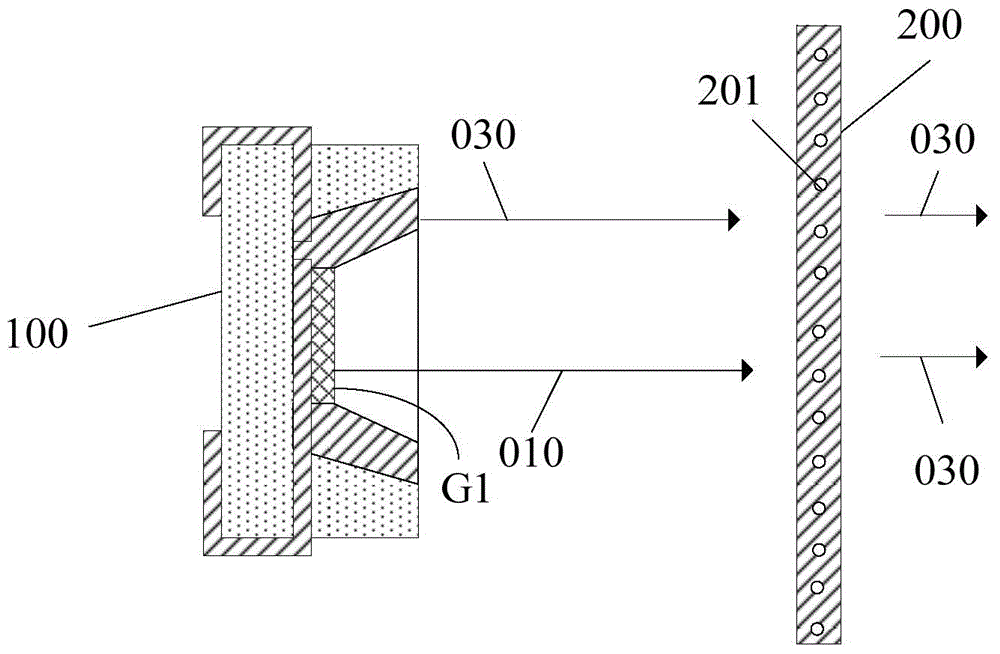

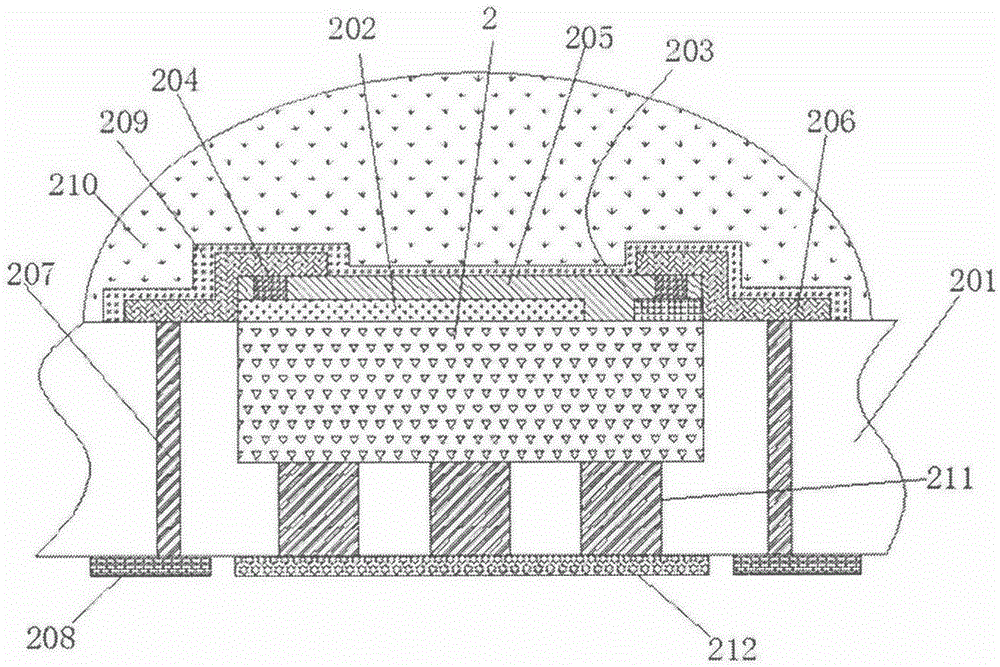

Backlight module of display device and white light LED

InactiveCN103343943AHigh color saturationSolve the problem of reabsorptionPoint-like light sourceSpectral modifiersFluorescenceLight guide

The invention discloses a backlight module of a display device and a white light LED. The backlight module comprises a lamp bar and a light guide plate, wherein the lamp bar is provided with a plurality of ultraviolet light LEDs, and the light-entering face of the light guide plate and the ultraviolet light LEDs are arranged oppositely. A path of the process from light emitted by the ultraviolet light LEDs to the light shot from the light-exiting face of the light guide plate at least comprises an RGB quantum dot fluorescent powder layer. The RGB quantum dot fluorescent powder layer comprises a red light quantum dot fluorescent screen, a green light quantum dot fluorescent screen and a blue light quantum dot fluorescent screen, wherein the red light quantum dot fluorescent screen, the green light quantum dot fluorescent screen and the blue light quantum dot fluorescent screen are sequentially arranged. The RGB quantum dot fluorescent powder layer generates high-purity white light under excitation of ultraviolet light emitted by the ultraviolet light LEDs. As the RGB quantum dot fluorescent powder layer is formed by sequentially arranging the red light quantum dot fluorescent screen, the green light quantum dot fluorescent screen and the blue light quantum dot fluorescent screen, color saturation of the backlight module is improved, and the problem of reabsorption of RGB quantum dot fluorescent powder is solved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

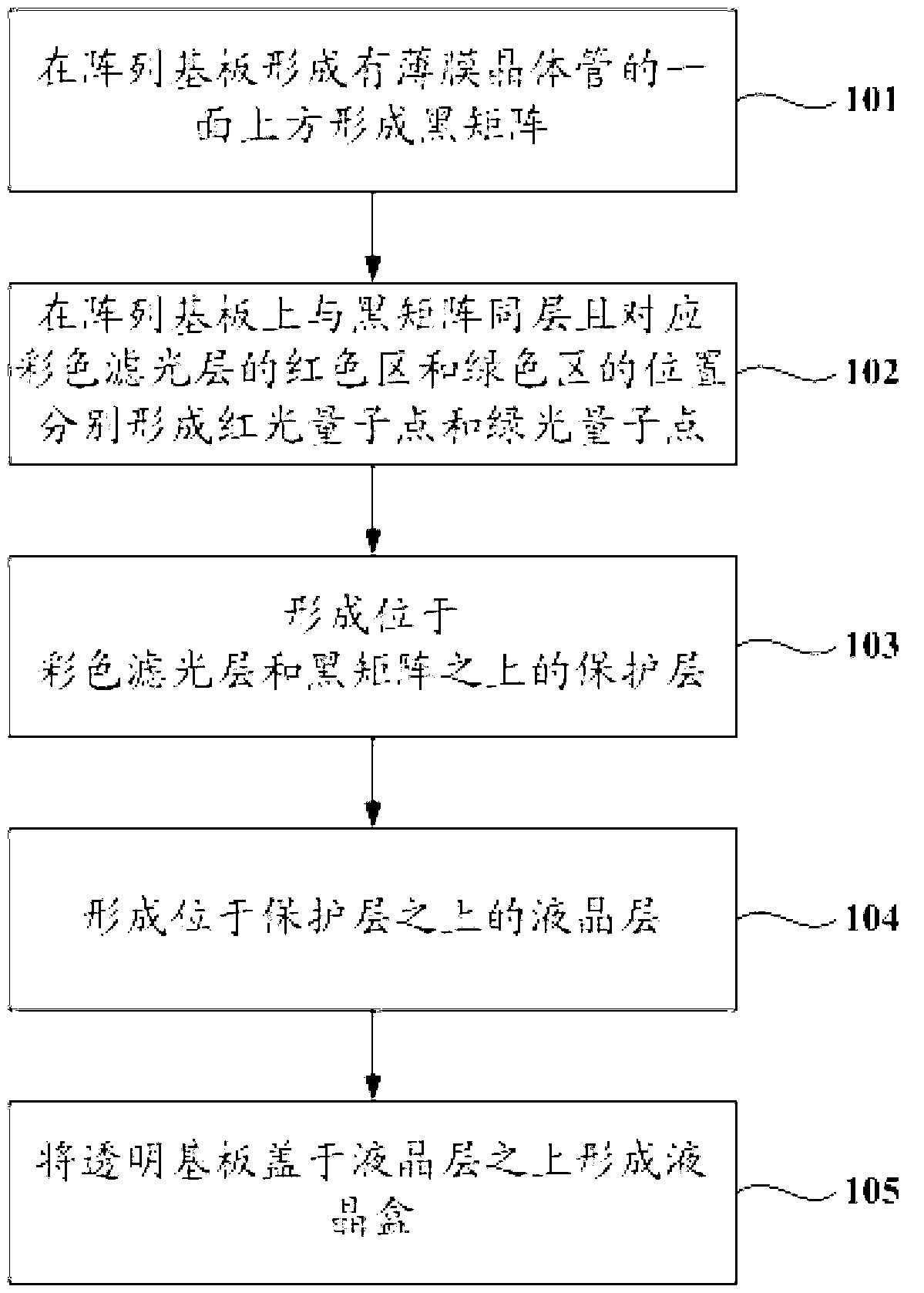

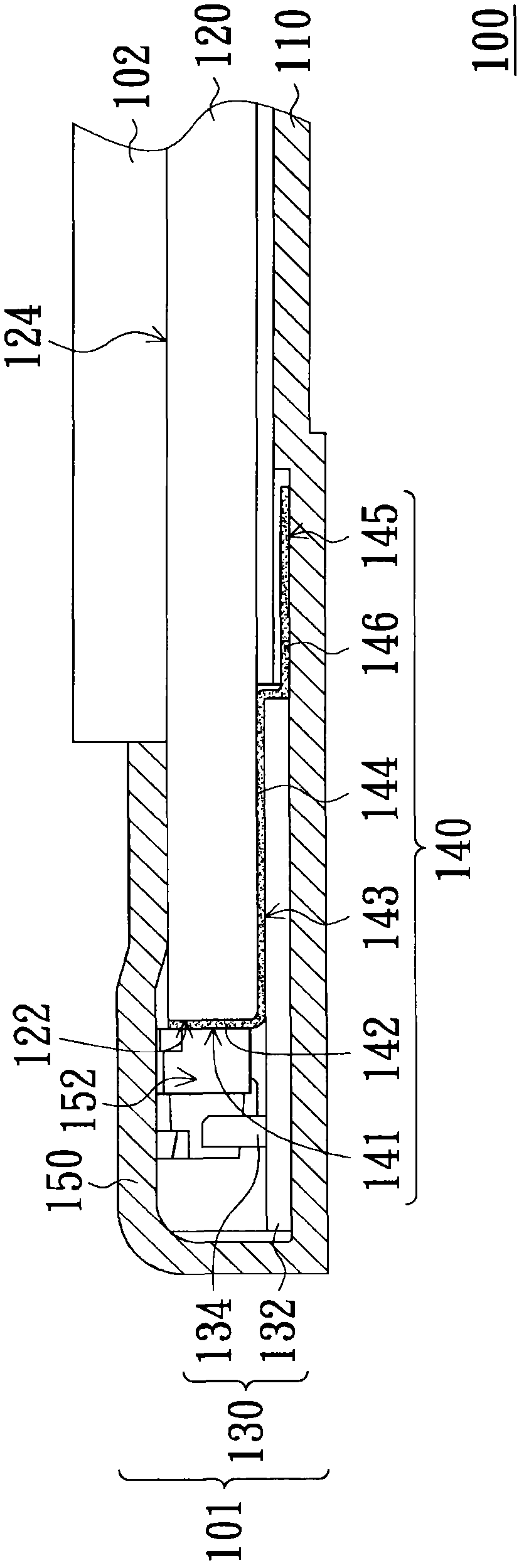

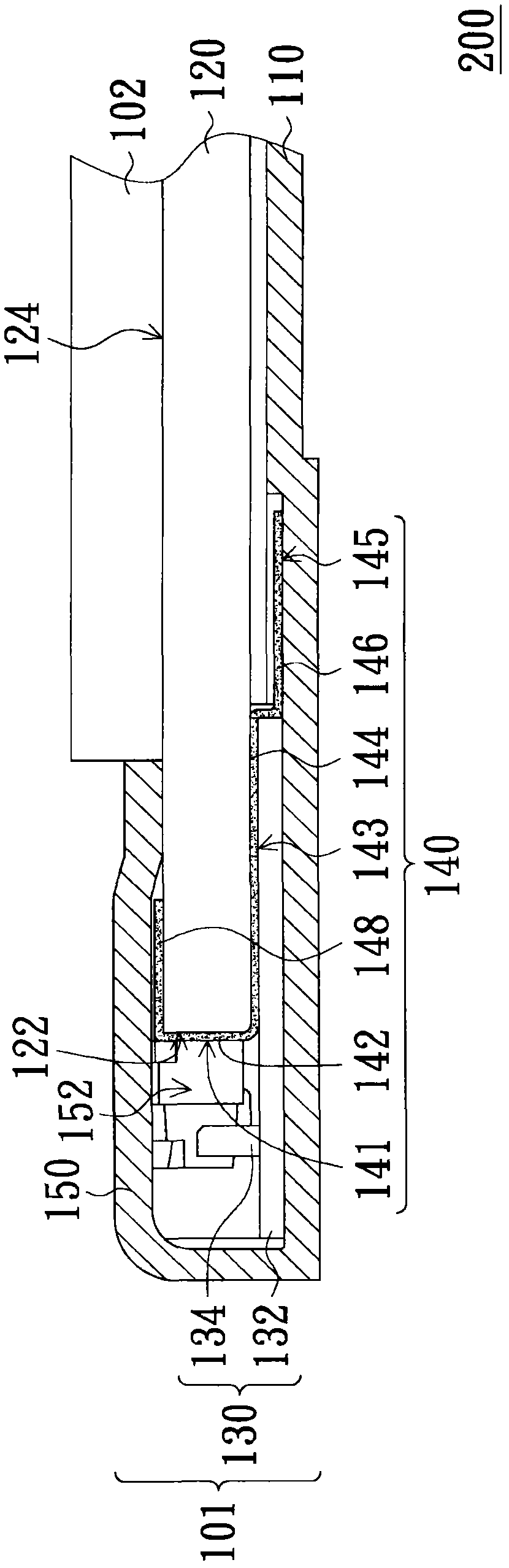

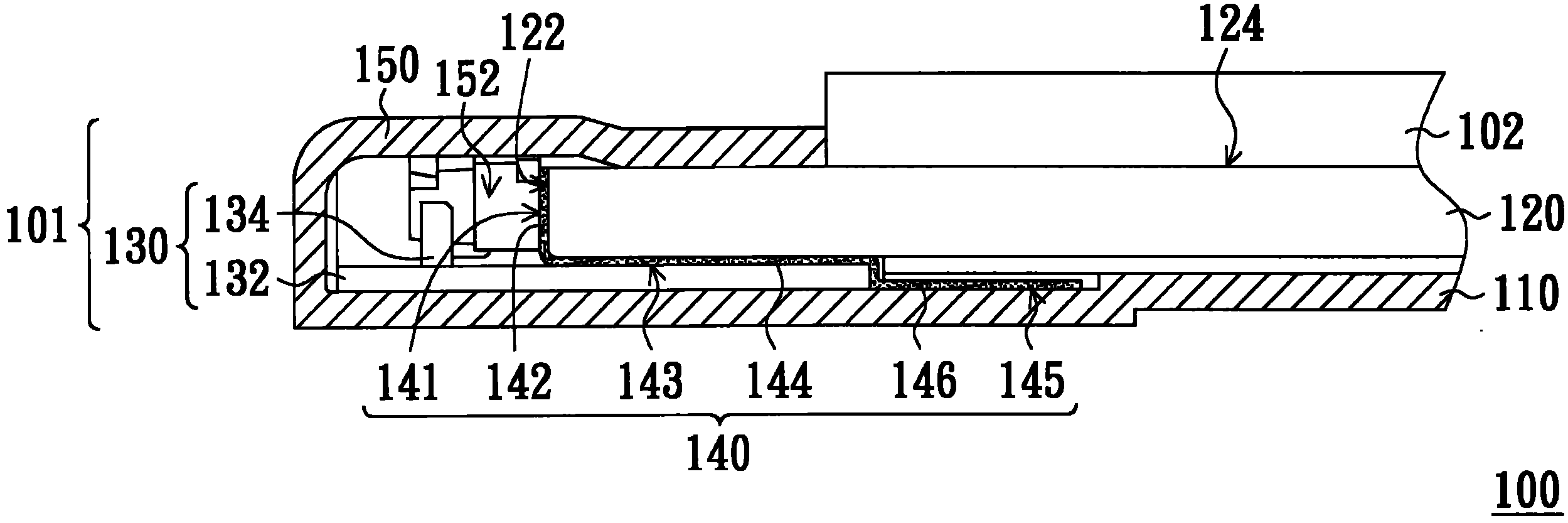

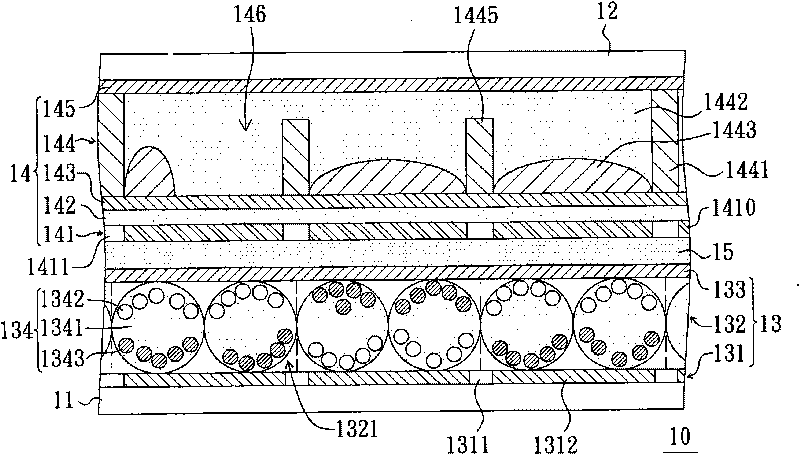

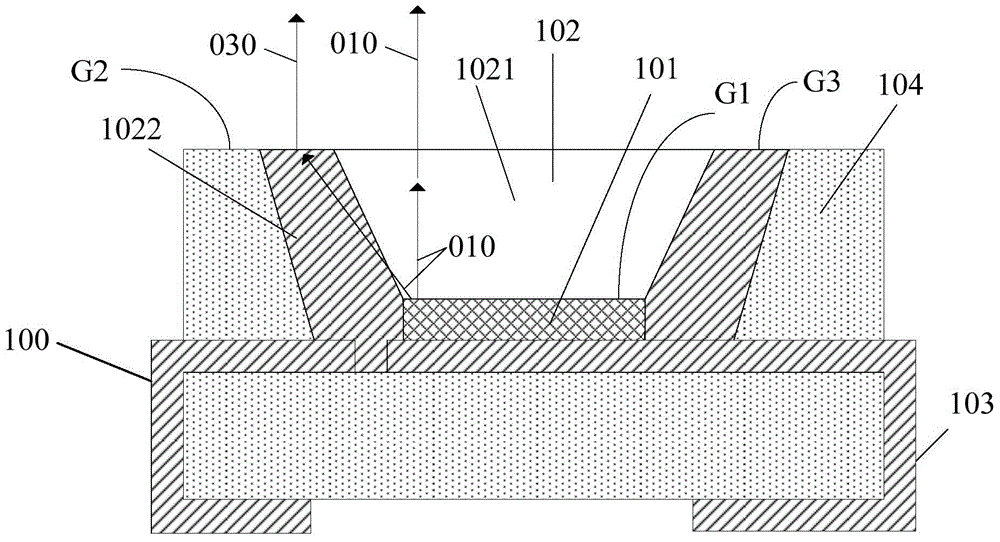

Liquid crystal display panel, display device, and manufacturing method of liquid crystal display panel

The invention relates to the technical field of liquid crystal display and discloses a liquid crystal display panel, a display device, and a manufacturing method of the liquid crystal display panel. The liquid crystal display panel comprises a color filter, a protective layer, a liquid crystal layer and a transparent protective plate, wherein the color filter is positioned on an array substrate and comprises a black matrix and a color filter layer with different color regions; the different color regions respectively have different sizes of quantum dots; the different sizes of quantum dots generate corresponding colors through excitation; the protective layer is positioned on the liquid crystal layer; the liquid crystal layer is positioned on the protective layer; and the transparent protective plate is positioned on the liquid crystal layer. According to the technical scheme of the invention, the emission spectrum of the quantum dots is narrow and the luminous efficiency is high, and light of backlight can be efficiently converted into light closed to monochromatic light, so the color gamut of the liquid crystal display panel is greatly improved and the display quality of the display panel is improved.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

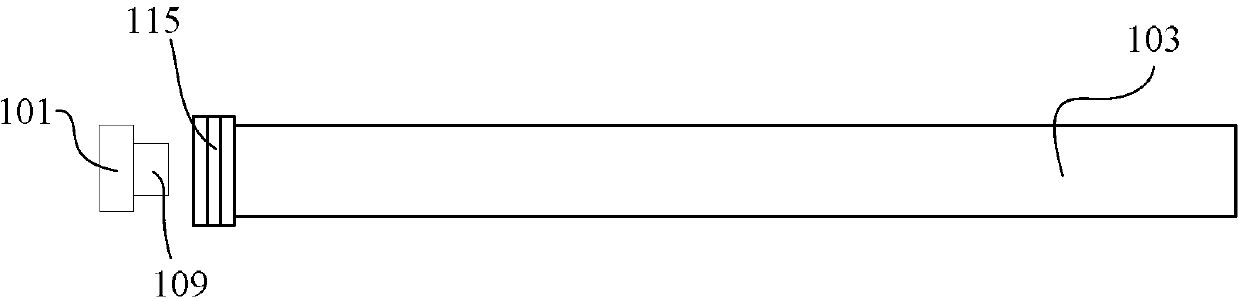

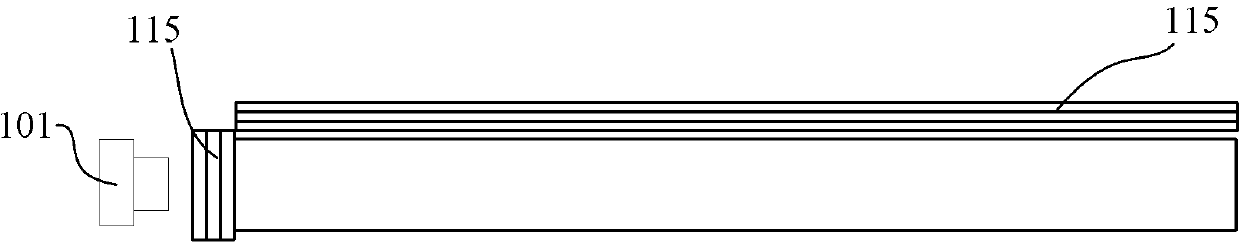

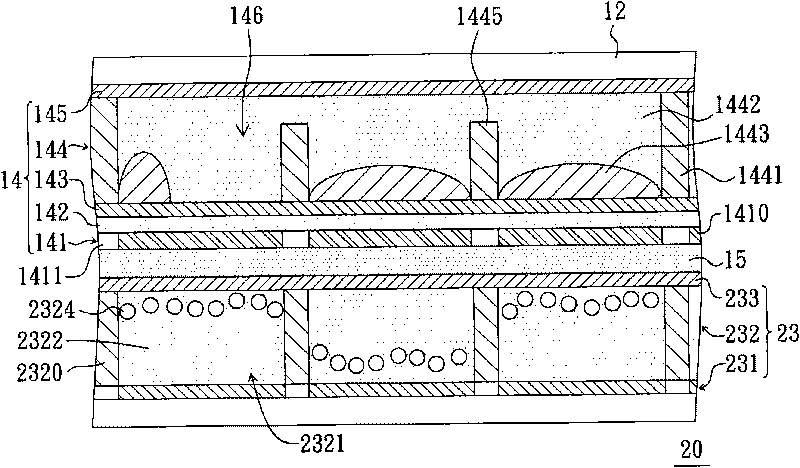

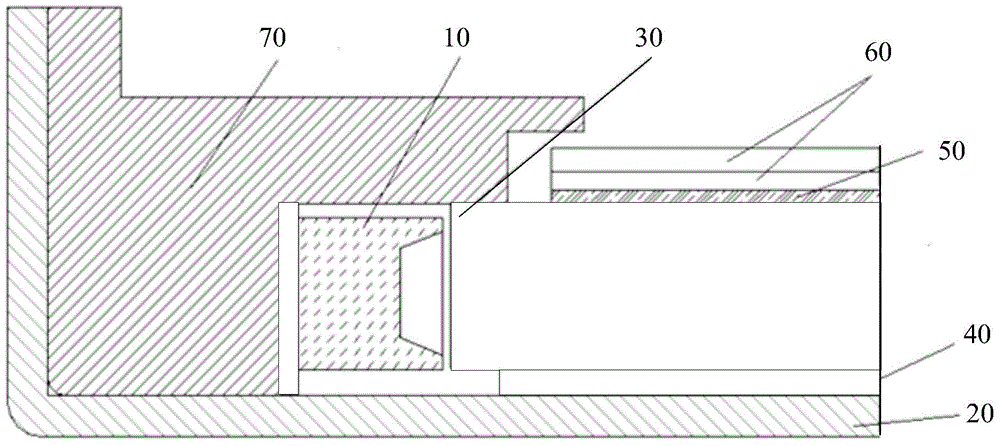

Backlight module and display device using same

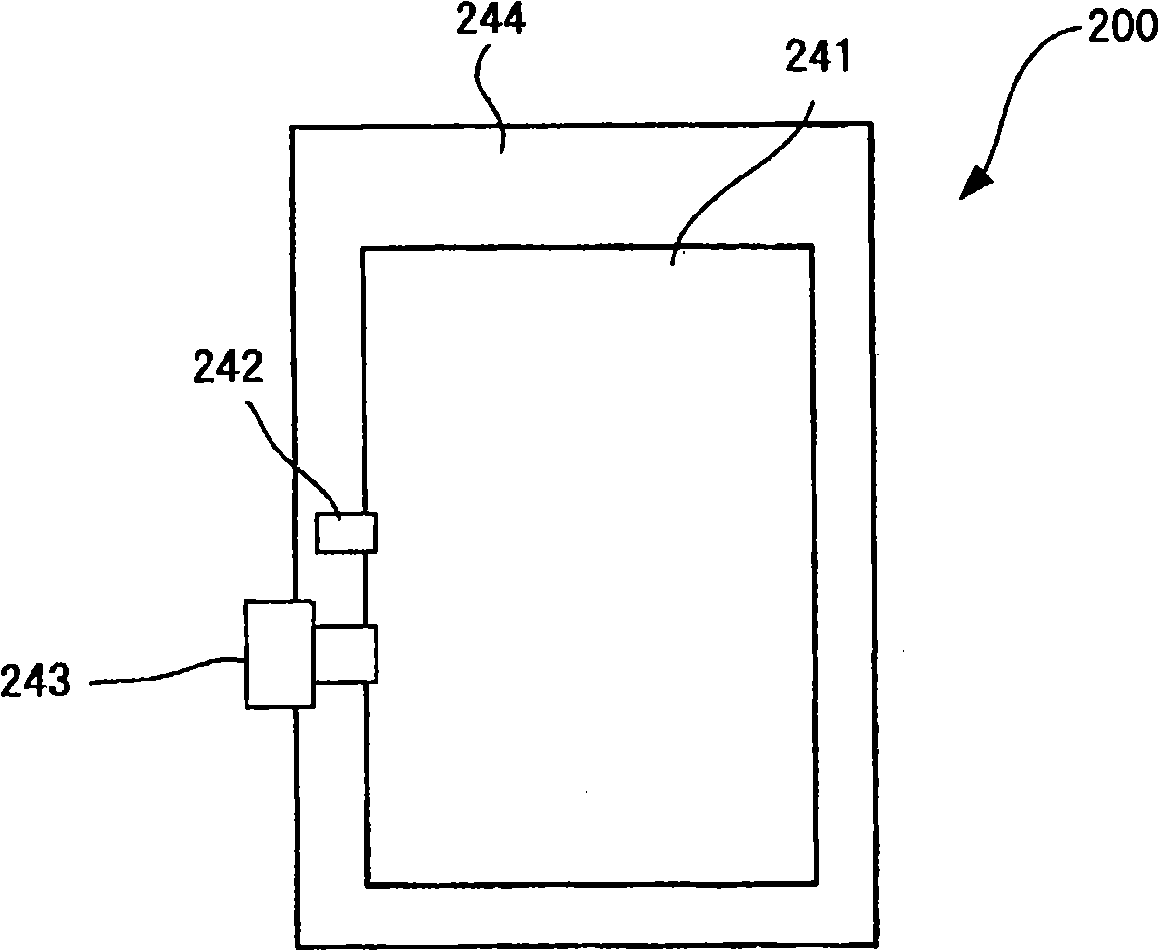

InactiveCN102297369AHigh color saturationLess materialPlanar/plate-like light guidesSpectral modifiersLight guideDisplay device

An exemplary backlight module includes a frame, a light guide plate, a light source module and an optical film. The light guide plate is arranged on the frame and includes a light-incident surface and a light-emitting surface adjacent to the light-incident surface. The light source module includes a circuit board arranged between the frame and the light guide plate board, and a light emitting element arranged on the circuit board and facing the light-incident surface. The optical film includes a wavelength shifting portion arranged between the light emitting element and the light guide plate, a second extending portion arranged between the light guide plate and the frame, and a first extending portion connected between the wavelength shifting portion and the second extending portion and arranged between the light guide plate and the circuit board. A display device equipped with the backlight module is also provided.

Owner:AU OPTRONICS CORP

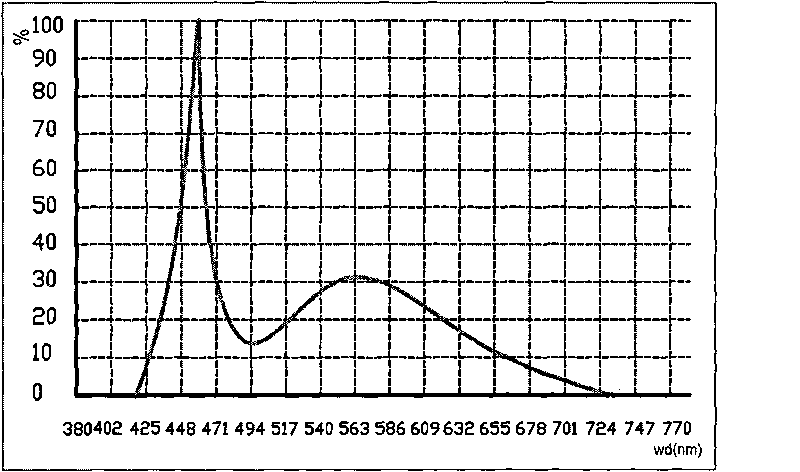

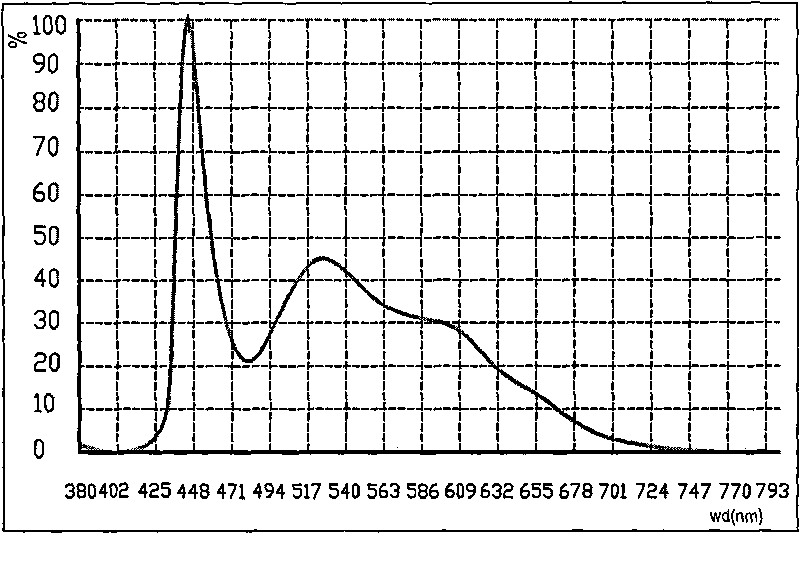

Magenta recording ink composition, inkjet recording method, and ink recorded matter

InactiveUS20100285287A1Excellent ejection stabilityHigh color saturationMeasurement apparatus componentsLayered productsSolid solutionSolvent

The present invention provides a magenta recording ink composition including at least a solid solution pigment (A) containing quinacridone, a lake pigment (B) having a xanthene structure, an aqueous solvent, and water, wherein the solid solution pigment (A) has visible light absorption peaks at wavelength ranges of from 510 nm to 530 nm and from 540 nm to 560 nm, and a mass ratio (B / A) of the lake pigment (B) to the solid solution pigment (A) falls within the range of 0.1 to 5.

Owner:RICOH KK

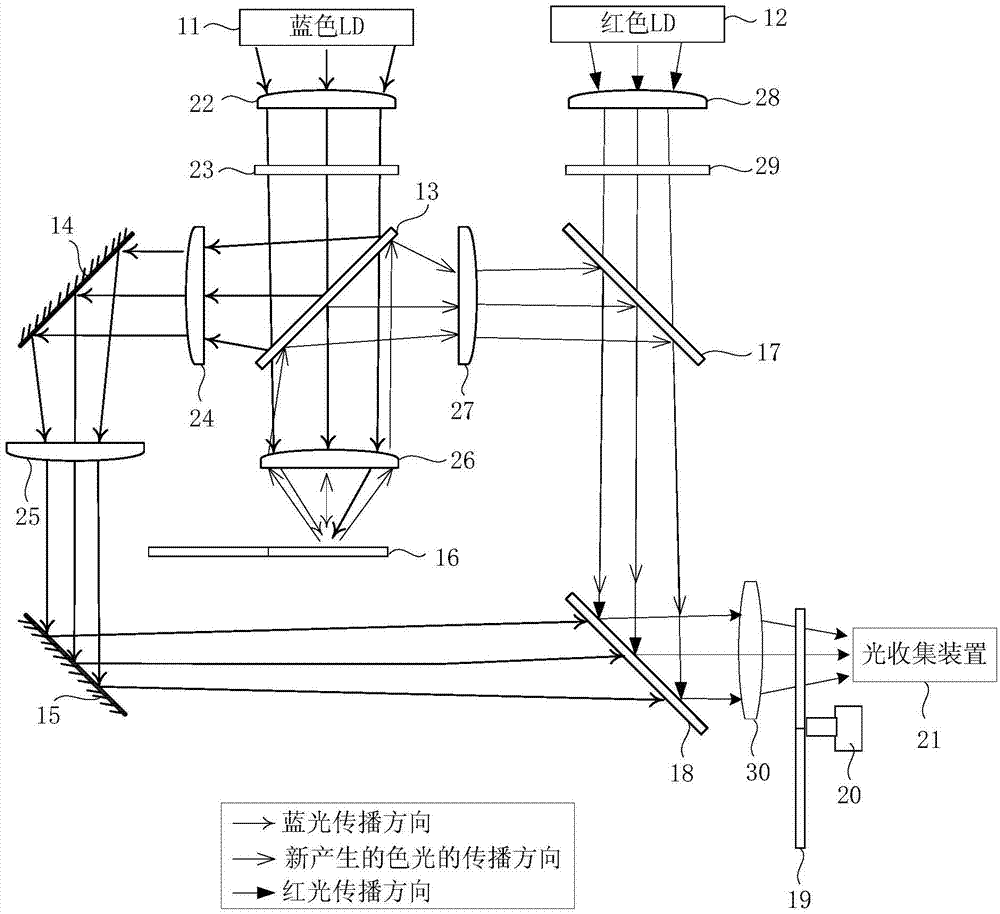

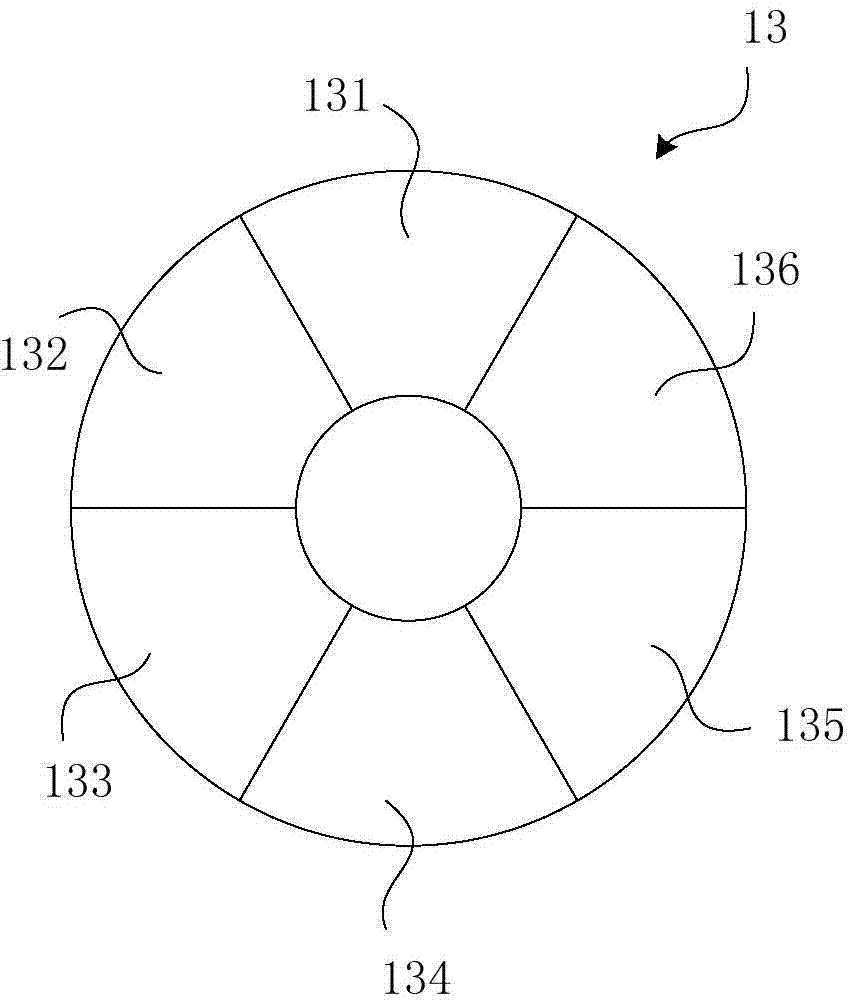

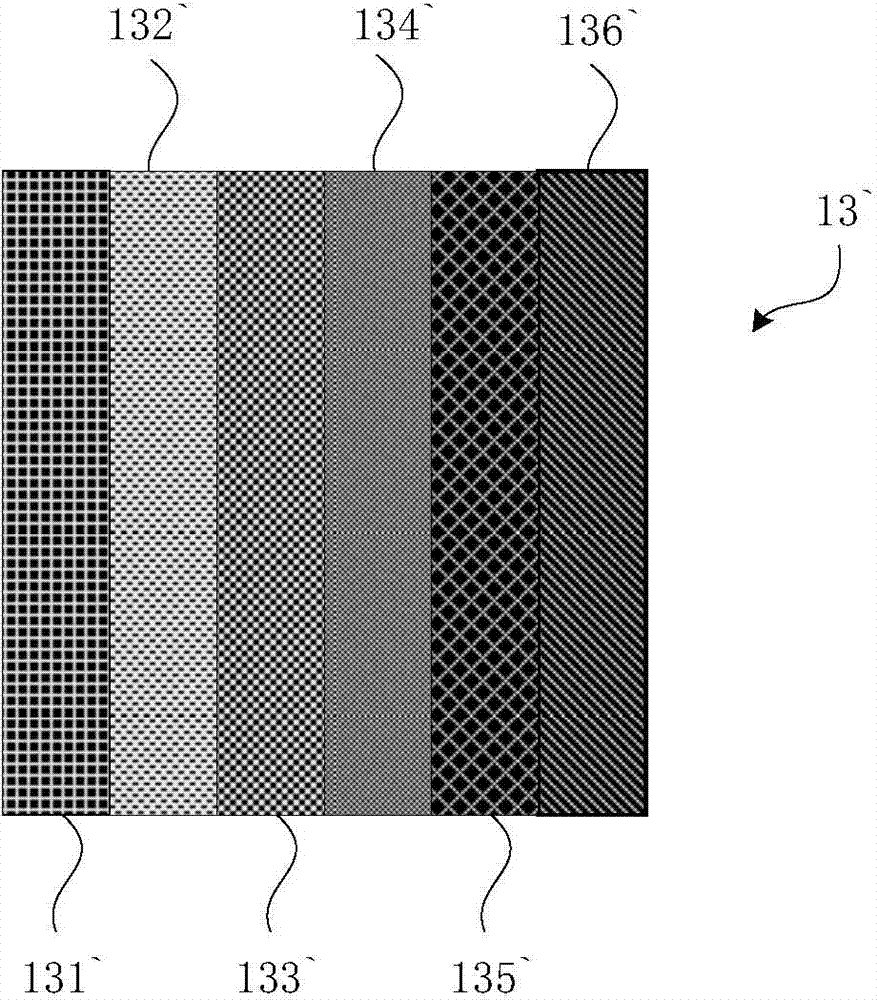

Dual laser light source system

ActiveCN104765240AHigh color saturationHigh color purityProjectorsLight fasteningsColor saturationOptical power

The invention relates to a dual laser light source system. The dual laser light source system comprises a blue LD and a red LD, a beam splitting device, a fluorescent color wheel, a first drive device, a first beam combining device, a second beam combining device, a filter color wheel, a third drive device, a light collection device and a control device. The beam splitting device is used for partially transmitting and partially reflecting blue light and reflecting colored light newly generated by the fluorescent color wheel. The fluorescent color wheel can be used to at least convert the blue light into green light and reflect the green light. The first drive device is used to drive the fluorescent color wheel to rotate. The first beam combining device is used to combine red light and newly-generated colored light. The second beam combining device is used to combine the red light, the newly-generated colored light and the blue light. The third drive device is used to drive the rotation of the filter color wheel. The control device is used to control power switches of the first drive device, the second drive device, the third drive device, the blue LD and the red LD to make the fluorescent color wheel and the filter color wheel keep synchronization so as to generate timing colored light of a target optical power. Through the above method, the dual laser light source system provided in the invention can be used to improve the brightness and color saturation of a picture displayed through projection.

Owner:SHENZHEN ESTAR DISPLAYTECH

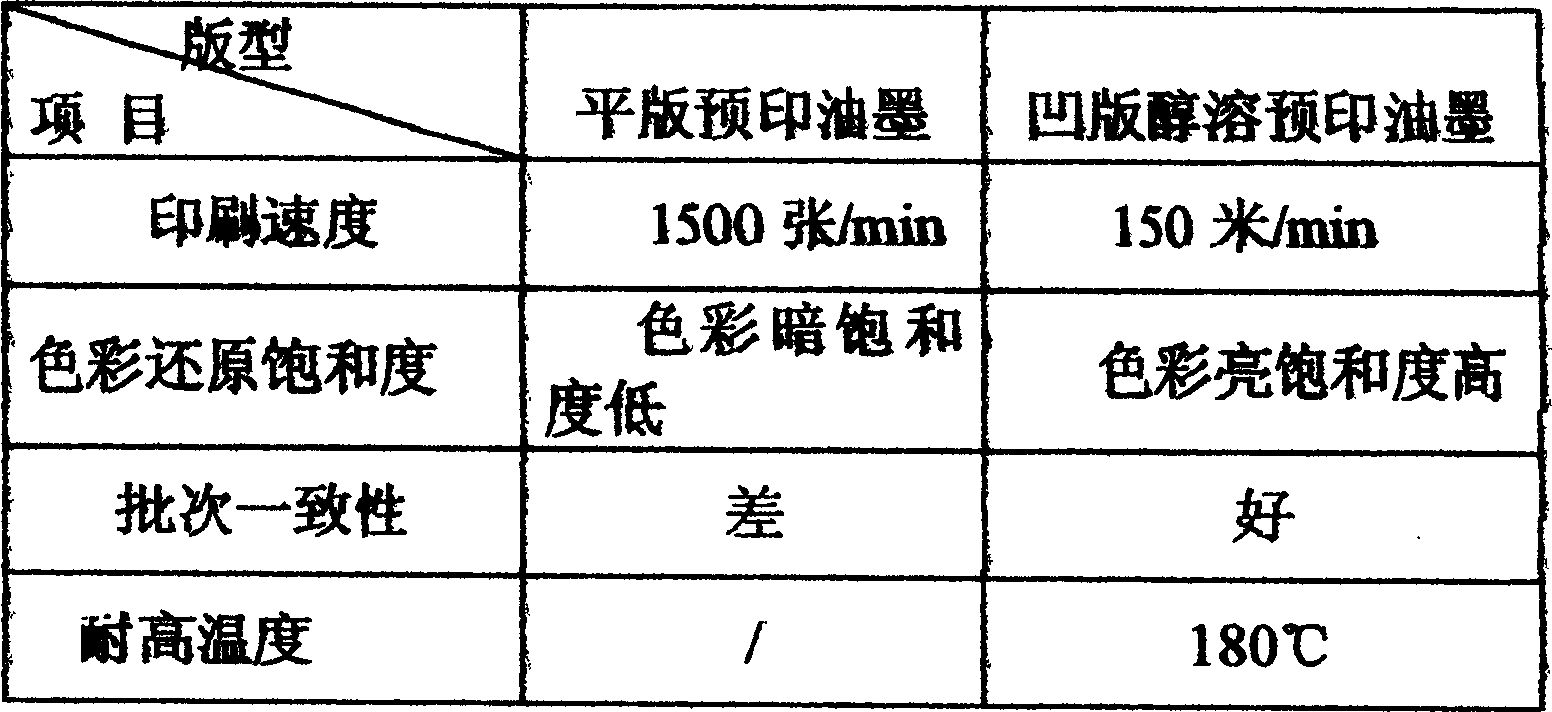

Alcohol soluble notch board paper box preprinting ink

An alcohol-soluble preprinting ink on gravure carton is composed of 6-10% nitrocellulose, methacrylate ester7-13%, propylene glycol methylether acetate 4-12%, dioctyl phthalate 2-6%, the dyestuff 15-25%, acetic ester 12-23%,absolute ethyl alcohol 32-43%. The ink has good glossiness, colour saturation degree and recurrence of halftone dot. It can defend the fake and resist to 180deg.C.

Owner:山西精华科工贸有限公司

OLED display

InactiveCN108922906AHigh color saturationImprove color gamutSolid-state devicesSemiconductor devicesGamutPhotoluminescence

The invention provides an OLED display. The OLED display comprises a TFT substrate, a WOLED layer, a quantum dot photoluminescence film and a color filter film, wherein the OLED display is provided with a plurality of sub-pixels which are sequentially arranged; the sub-pixels comprise red sub-pixels, green sub-pixels and blue sub-pixels; red quantum dots are arranged in a region, corresponding tothe red sub-pixels, in the quantum dot photoluminescence film, and green quantum dots are arranged in the region corresponding to the green sub-pixels; the red quantum dots and the green quantum dotsare excited by white light emitted by the WOLED layer to emit high-color-purity red light and green light respectively, and then are filtered by the color filter film and then are emitted out, so thatthe OLED display has relatively high color saturation, and the color gamut of the OLED display is effectively broadened; and meanwhile, the light of the short wavelength in the white light can be fully utilized, so that the energy utilization rate is improved, and the OLED display has relatively low power consumption.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

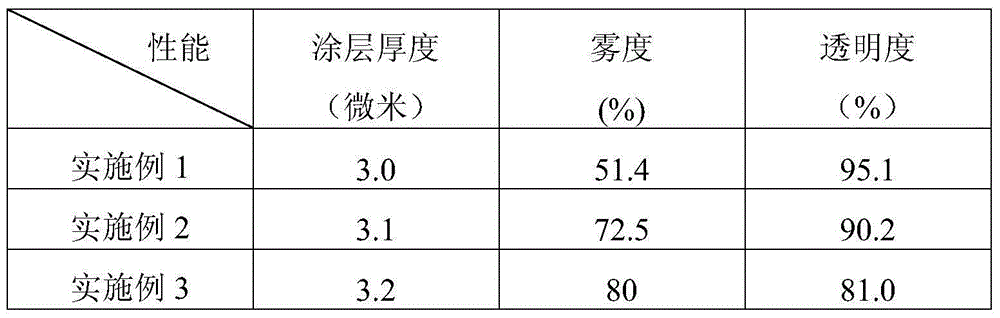

Biaxially oriented polyester matte precoat and preparation method thereof

InactiveCN103911085AHigh color saturationMatte is suitableMonocarboxylic acid ester polymer adhesivesFilm/foil adhesivesLow-density polyethylenePolyester

The invention discloses a biaxially oriented polyester matte precoat and a preparation method thereof. The method includes: coating the first surface of light biaxially oriented polyester film with matte varnish so as to form a matte coating, wherein the light biaxially oriented polyester film and the matte coating form the base material of the biaxially oriented polyester matte precoat; coating the second surface of the light biaxially oriented polyester film with an aqueous polyethyleneimine solution so as to form a middle layer; and compounding at least one of ethylene-vinyl acetate, low-density polyethylene, ethylene-ethyl acrylate and ethylene-methyl acrylate on the middle layer through an extrusion compounding process so as to form a hot melt adhesive layer. The biaxially oriented polyester matte precoat obtained by utilization of the method has characteristics of high color saturation, appropriate matte degree, high tensile strength, high stiffness and high evenness, and improves the exquisite degree of printing products.

Owner:KANGDE XIN COMPOSITE MATERIAL CO LTD

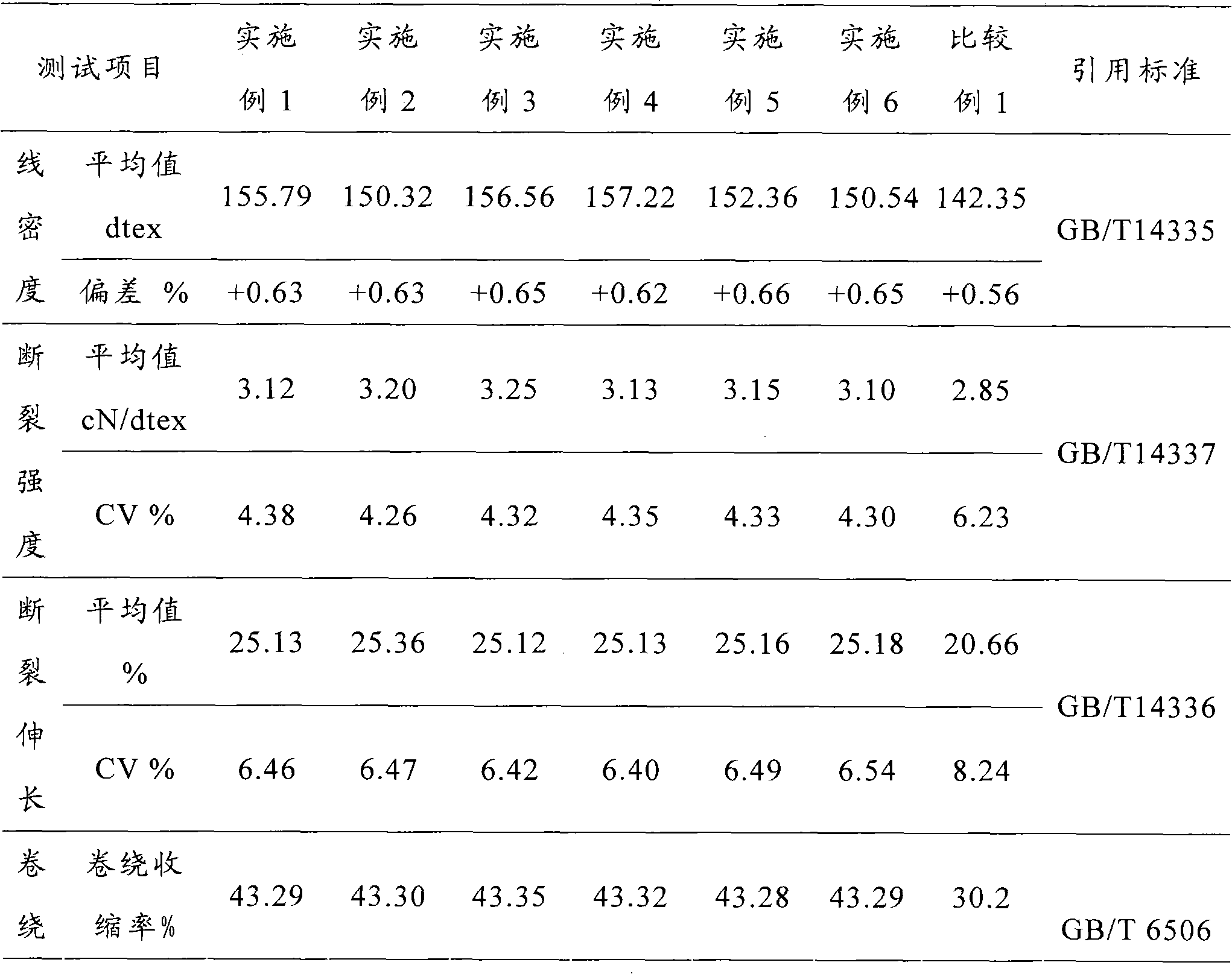

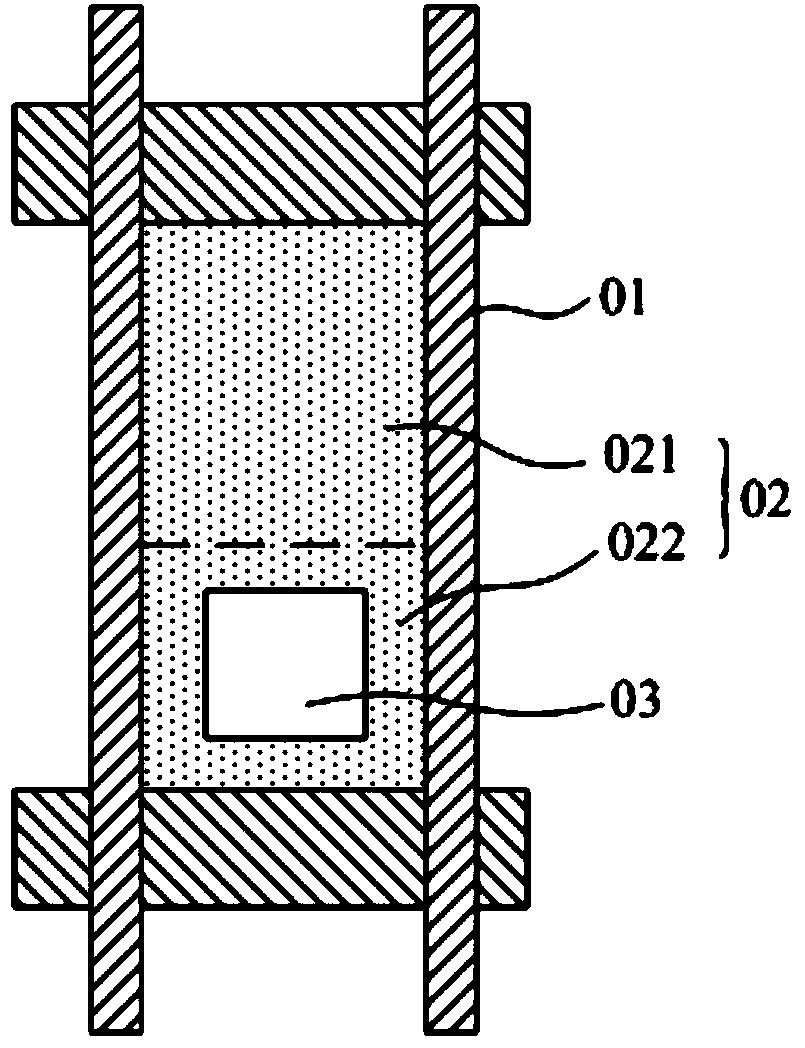

Bi-component sheath-core composite high-stretch fiber and preparation method thereof

ActiveCN101845686AEasy accessImprove dyeing effectConjugated synthetic polymer artificial filamentsStretch-spinning methodsPolytetramethylene terephthalatePolytrimethylene terephthalate

The invention provides a bi-component sheath-core composite high-stretch fiber. The bi-component is a polyester component and a polyamide component respectively, wherein the polyamide component forms an outer sheath part; the polyester component forms an inner core part; the outer sheath part is coated around the inner core part; and the polyester component may be one or more of a cationic normal-pressure dyeable polyester, a polytrimethylene terephthalate and a polybutylene terephthalate. As the bi-component sheath-core composite high-stretch fiber provided by the invention utilizes a polyester of which a molecular chain has flexible branched chains, such as the cationic normal-pressure dyeable polyester, the polytrimethylene terephthalate, the polybutylene terephthalate and the like, the prepared composite fiber is looser, and dyes can enter the fiber more easily to achieve higher dying performance under a conventional dying condition. The invention also provides a preparation method for the bi-component sheath-core composite high-stretch fiber.

Owner:厦门象屿兴泓特种材料有限公司

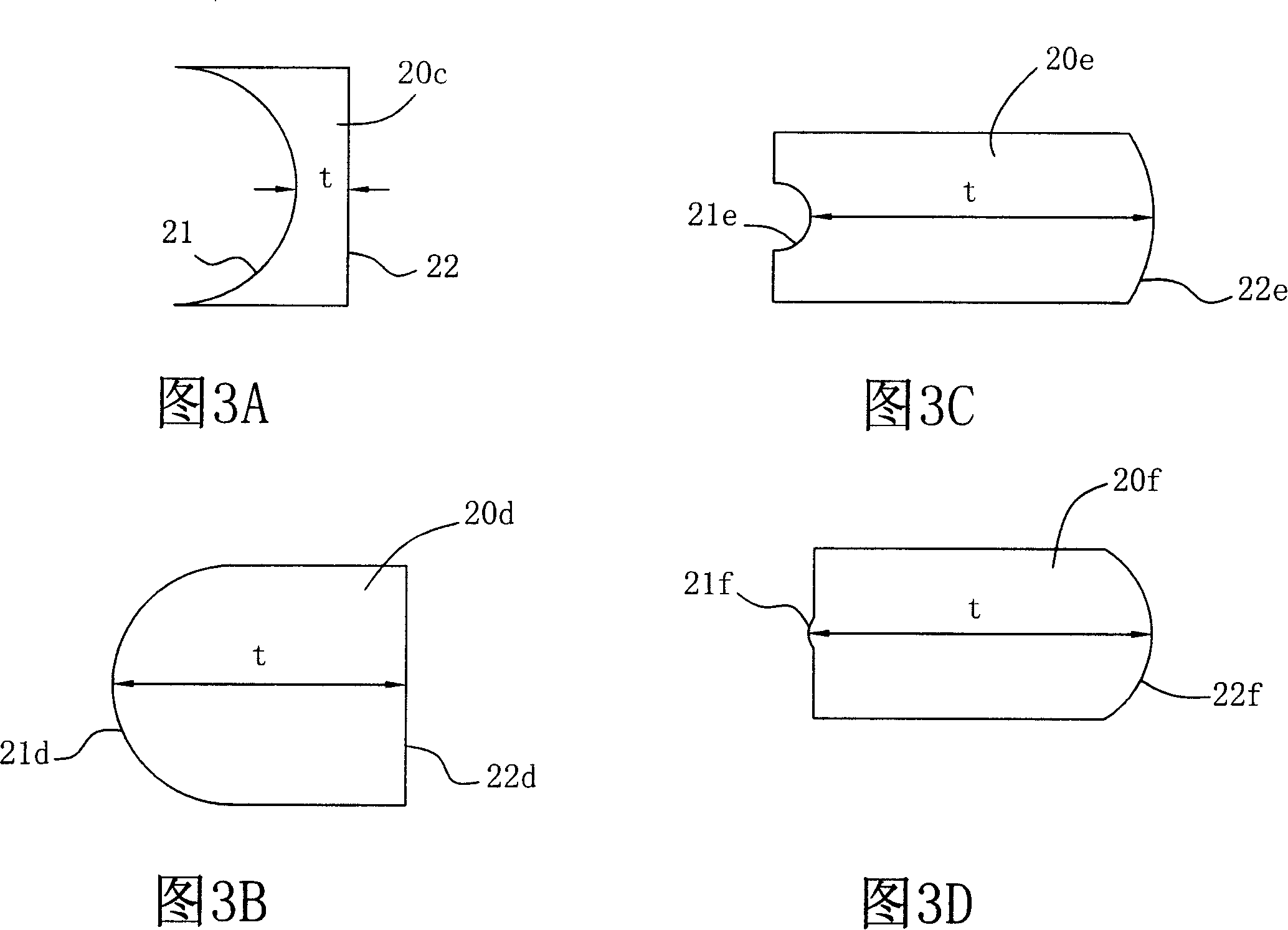

Transflective liquid crystal display panel and liquid crystal display

InactiveCN104199213AHigh color saturationConsistent color saturationNon-linear opticsLiquid-crystal displayButt joint

The invention discloses a transflective liquid crystal display panel and a liquid crystal display. The transflective liquid crystal display panel comprises an upper base plate, a lower base plate and a liquid crystal layer, wherein the upper base plate and the lower base plate are in butt joint, and the liquid crystal layer is arranged between the upper base plate and the lower base plate. The lower base plate comprises a plurality of sub-pixel units distributed in arrays, wherein each sub-pixel unit comprises a reflection area and a transmission area, the reflection area sequentially comprises a substrate base plate, a black matrix, a reflection layer and a first color filter layer in the direction from the lower base plate to the upper base plate, the transmission area sequentially comprises a substrate base plate and a second color filter layer in the direction from the lower base plate to the upper base plate, and the thickness of the first color filter layer is smaller than that of the second color filter layer. By means of the transflective liquid crystal display panel, it is ensured that difficulty in the preparation technology of the transflective liquid crystal display panel can be reduced under the conditions that color saturation of the reflection areas and color saturation of the transmission areas trend to consistence.

Owner:BOE TECH GRP CO LTD +1

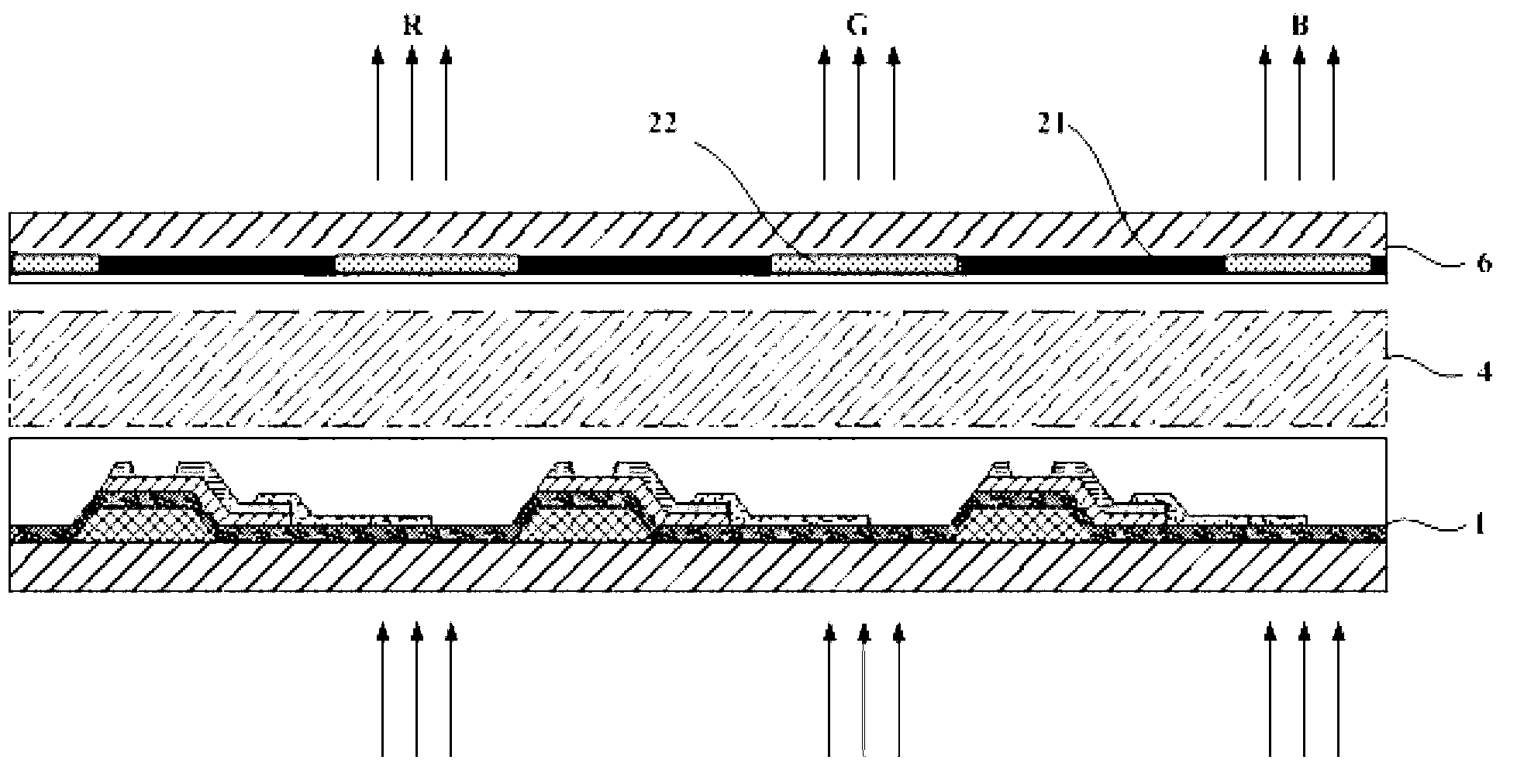

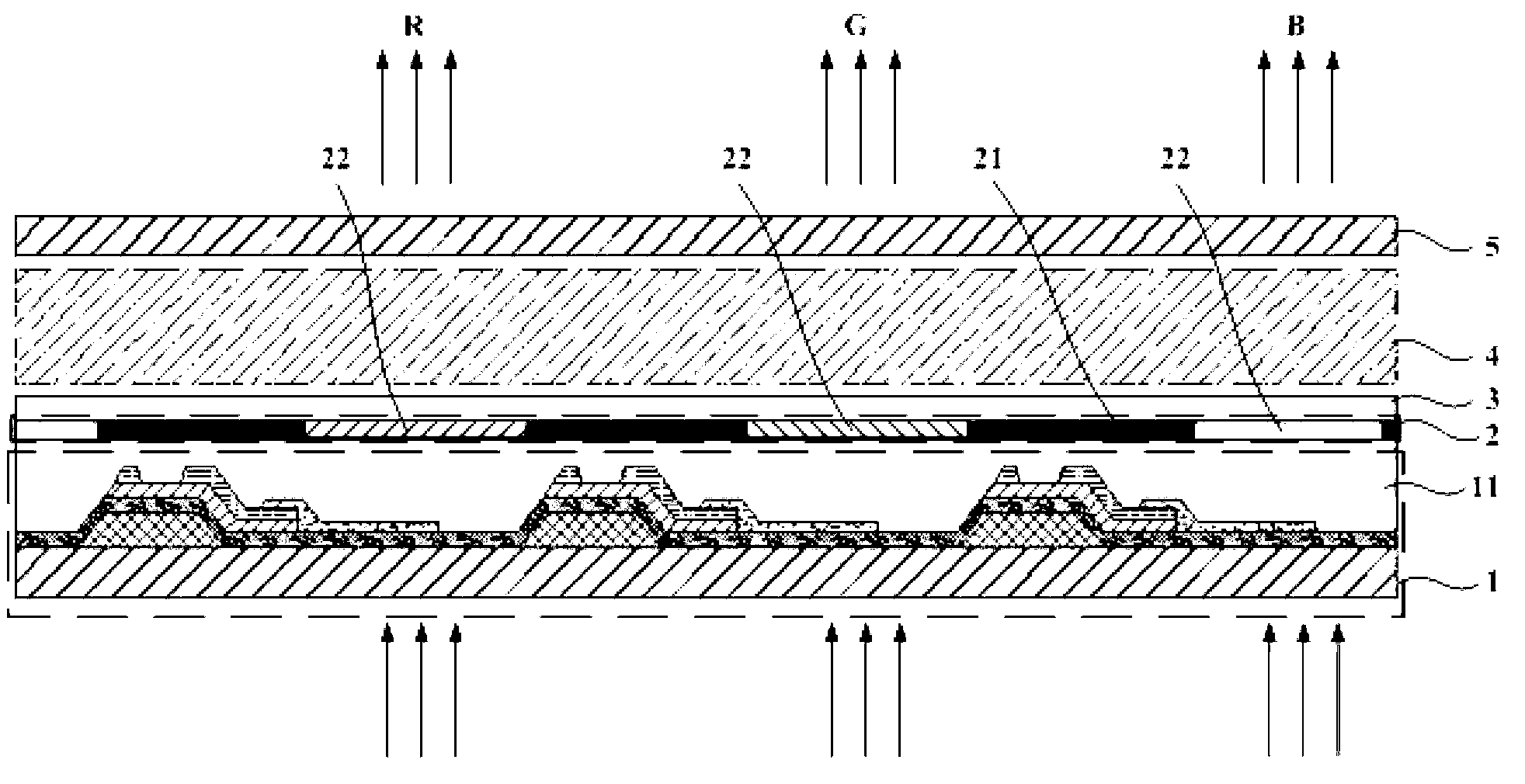

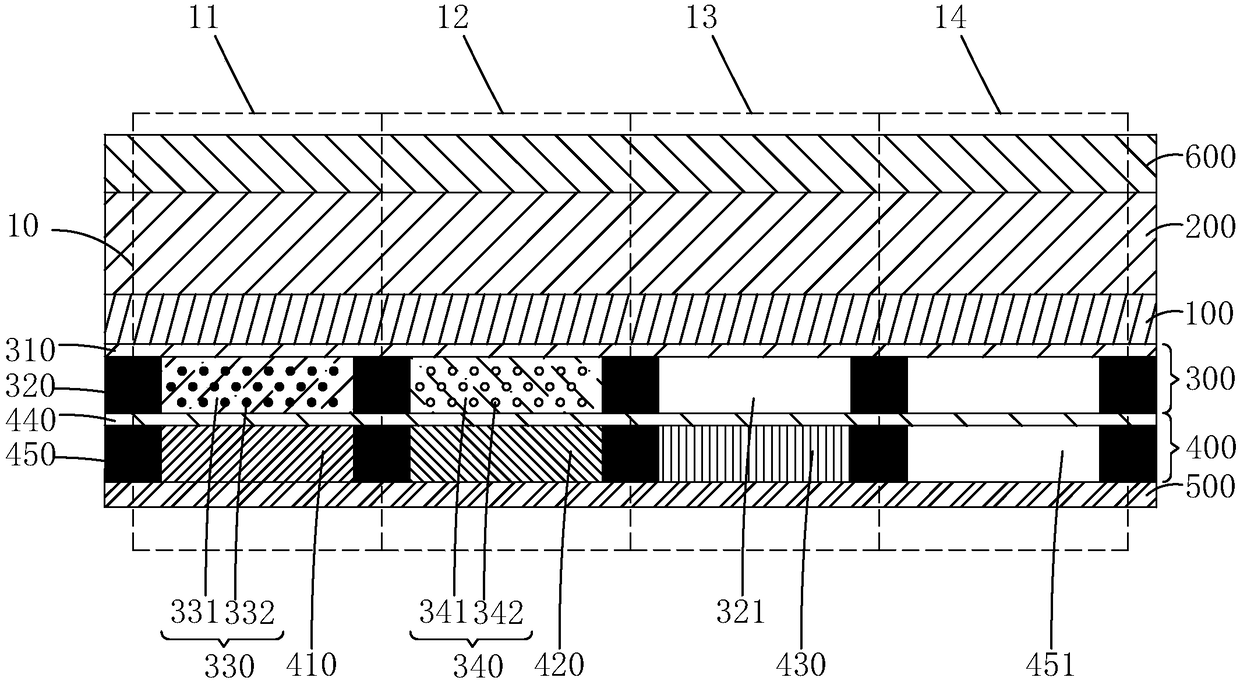

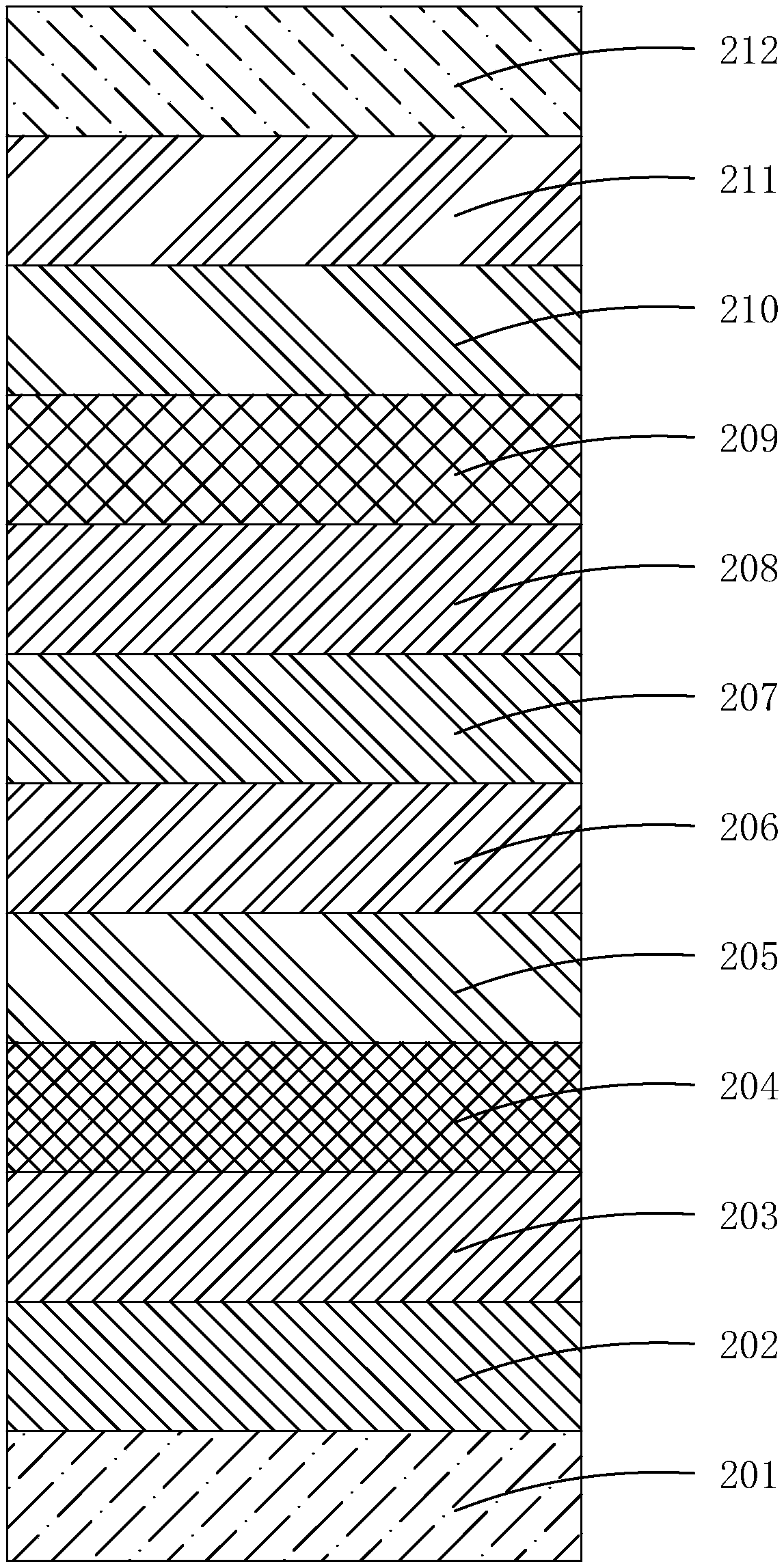

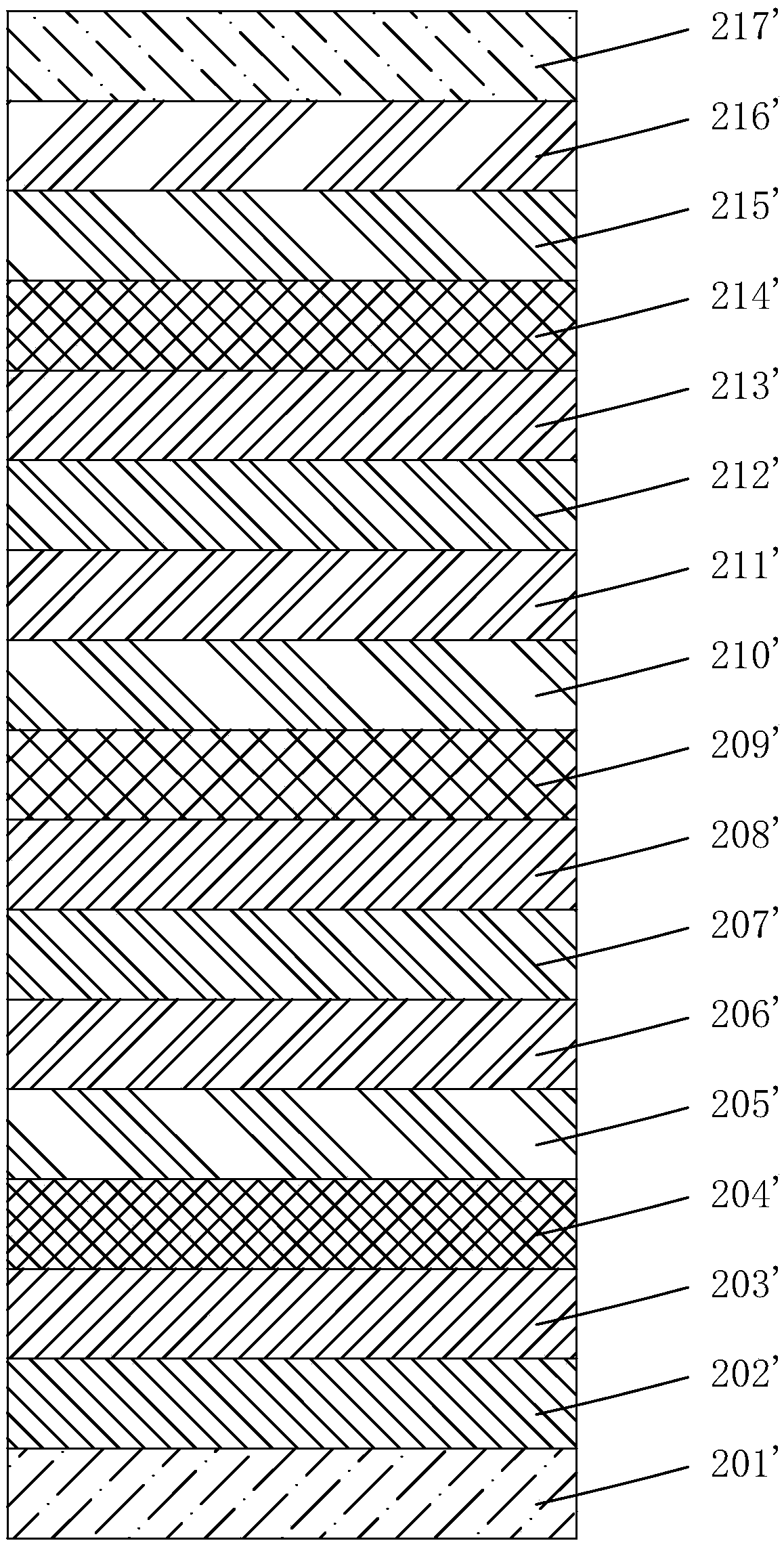

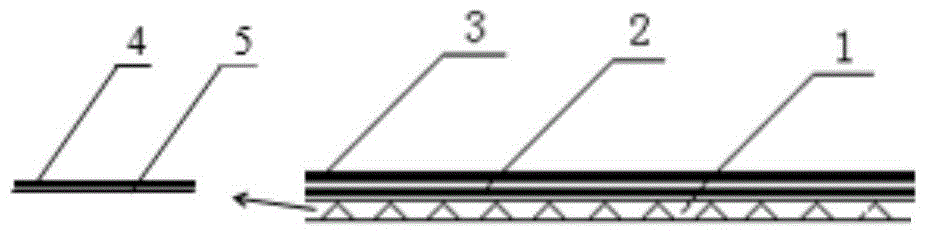

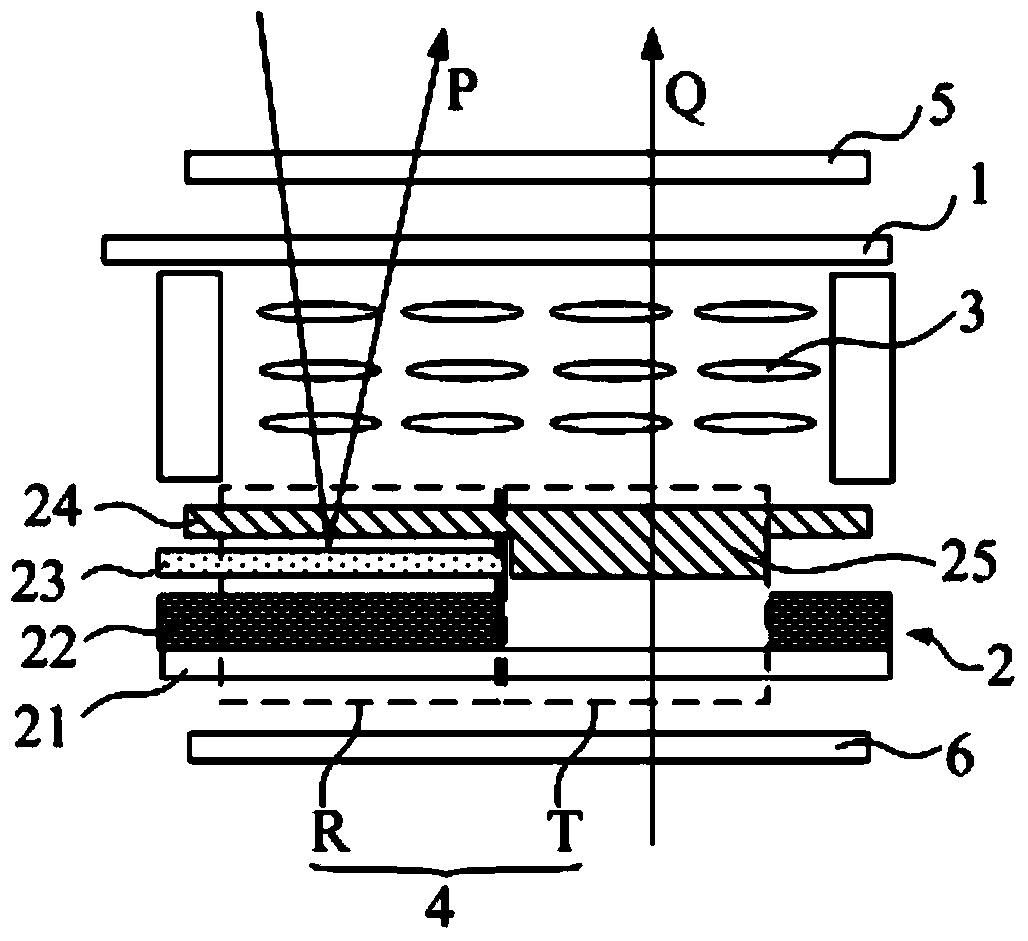

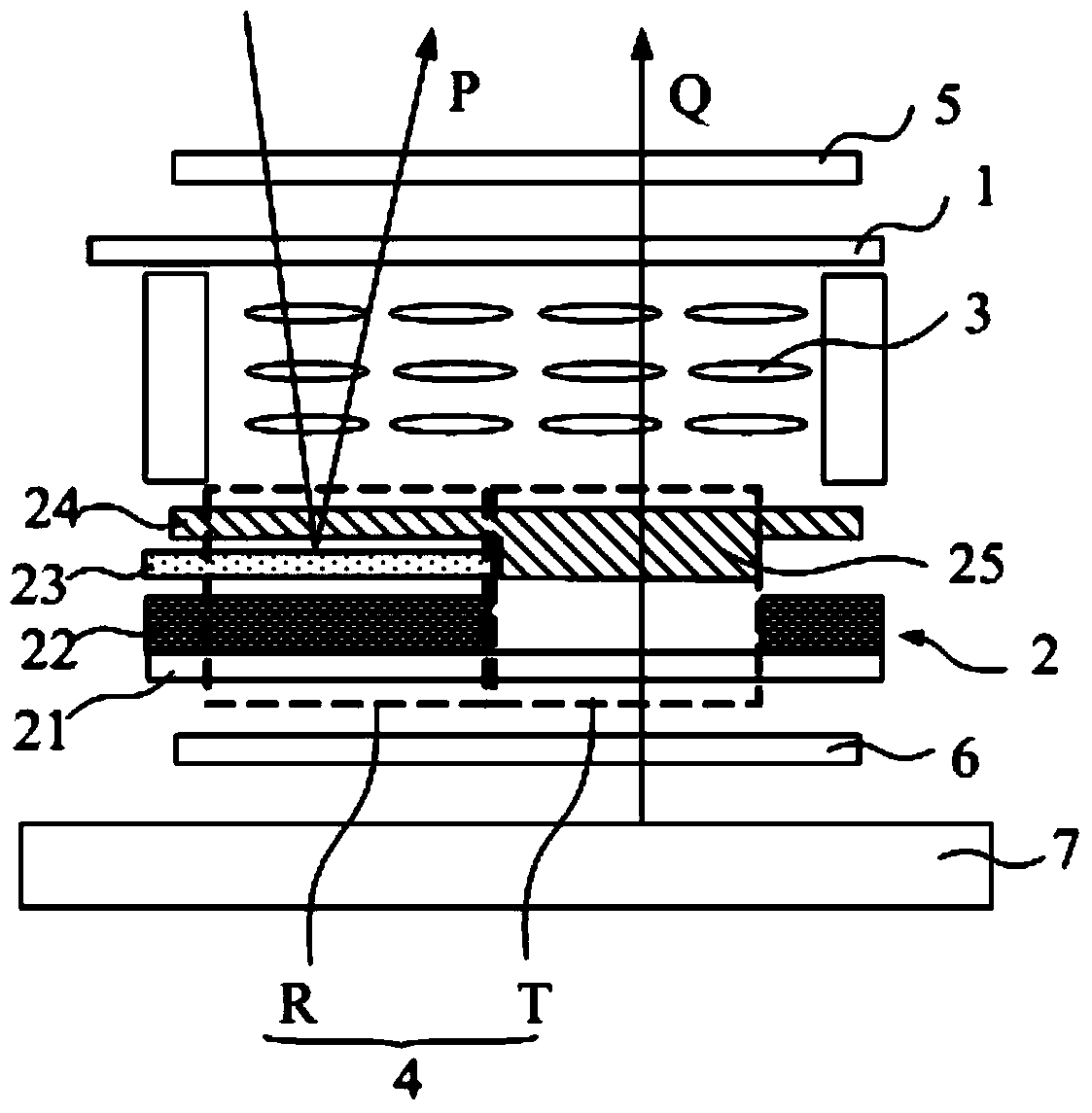

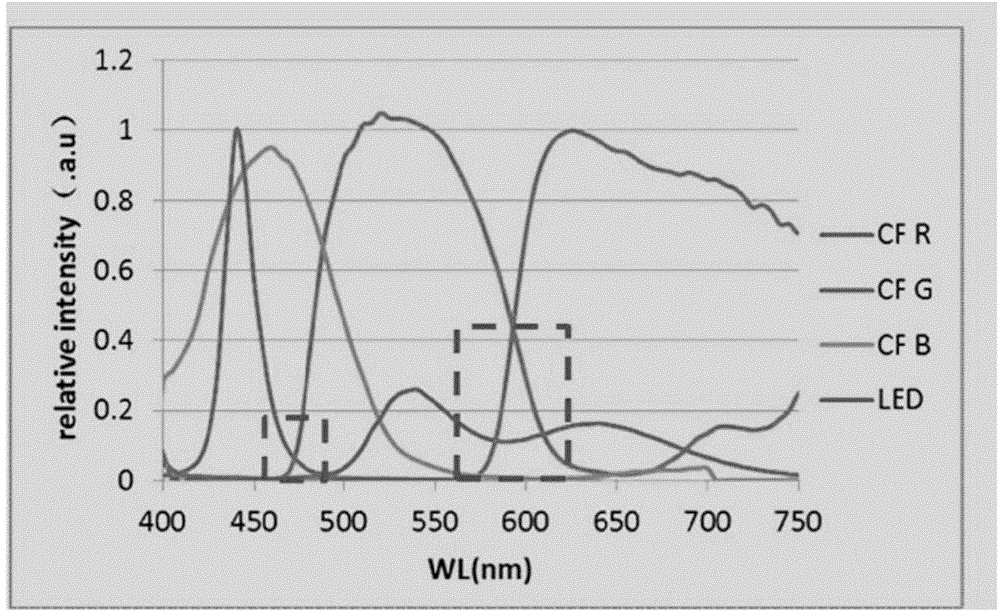

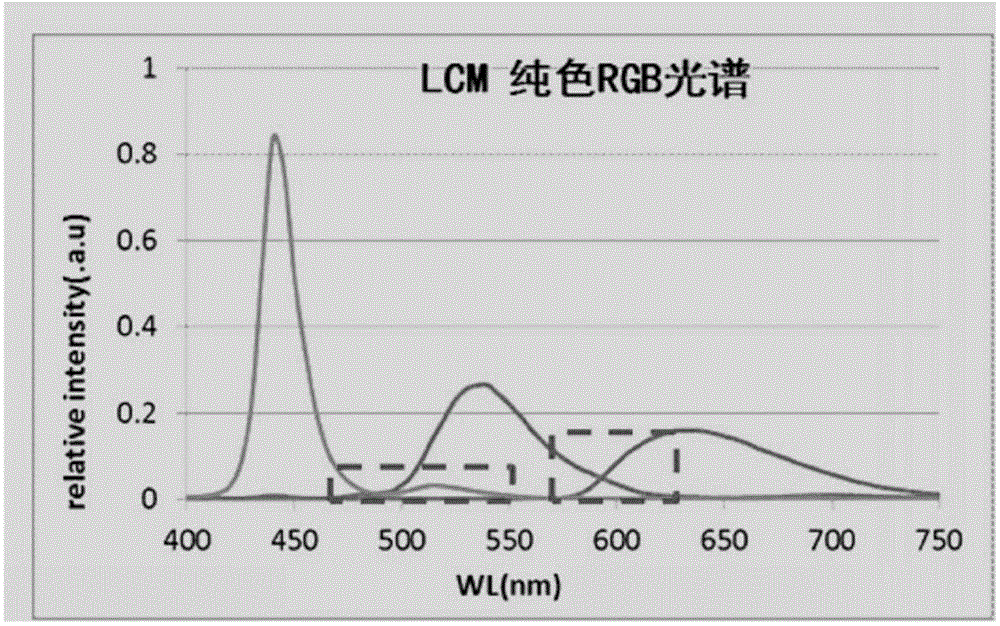

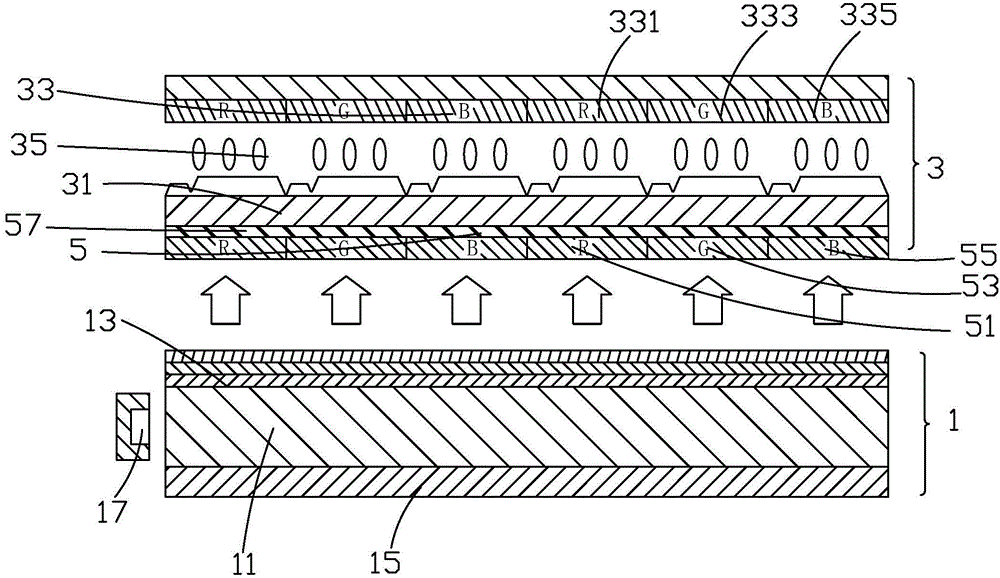

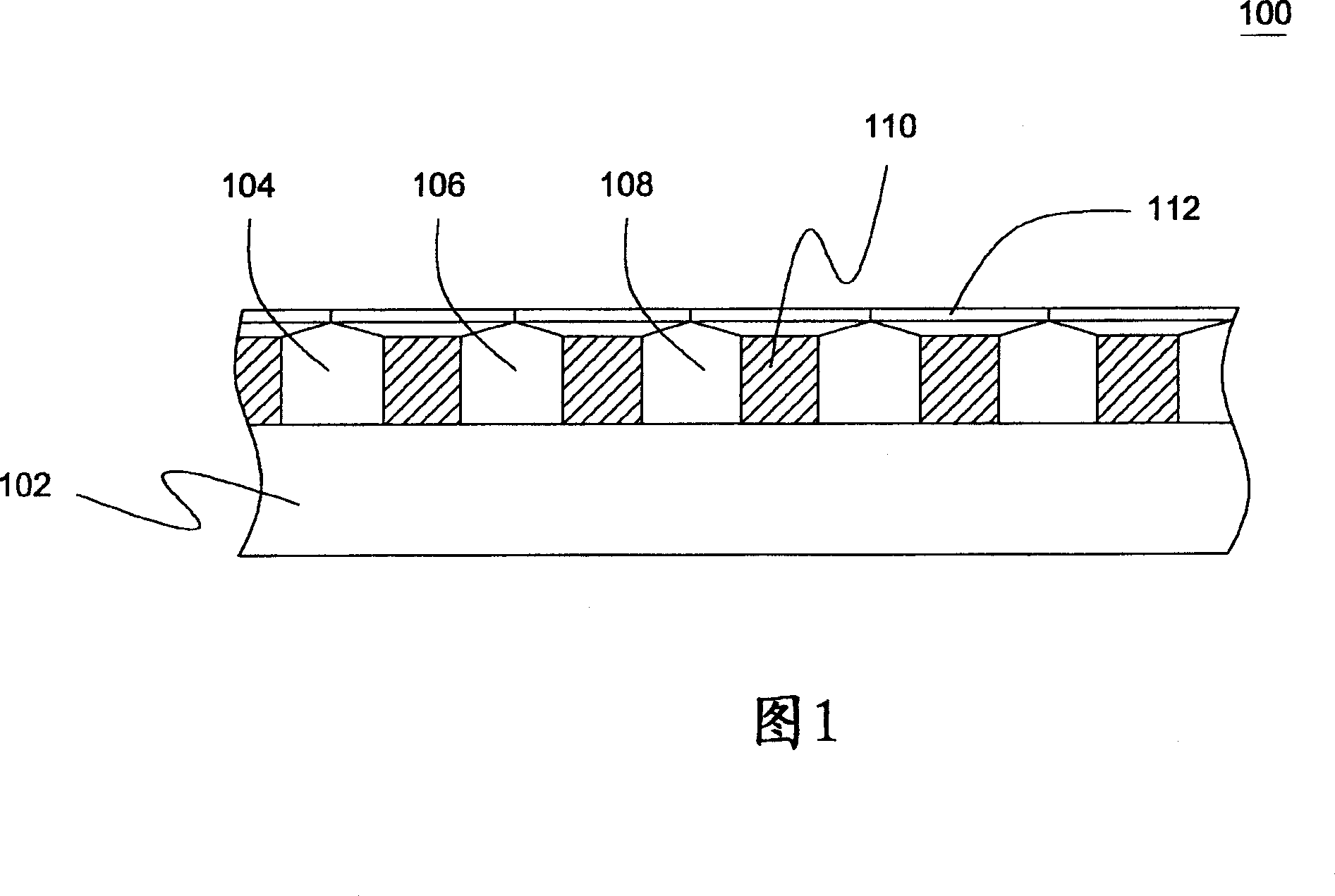

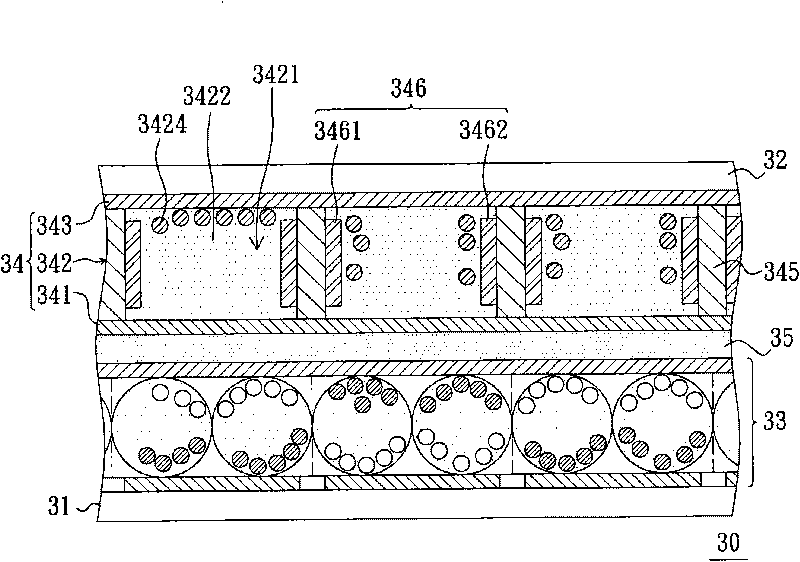

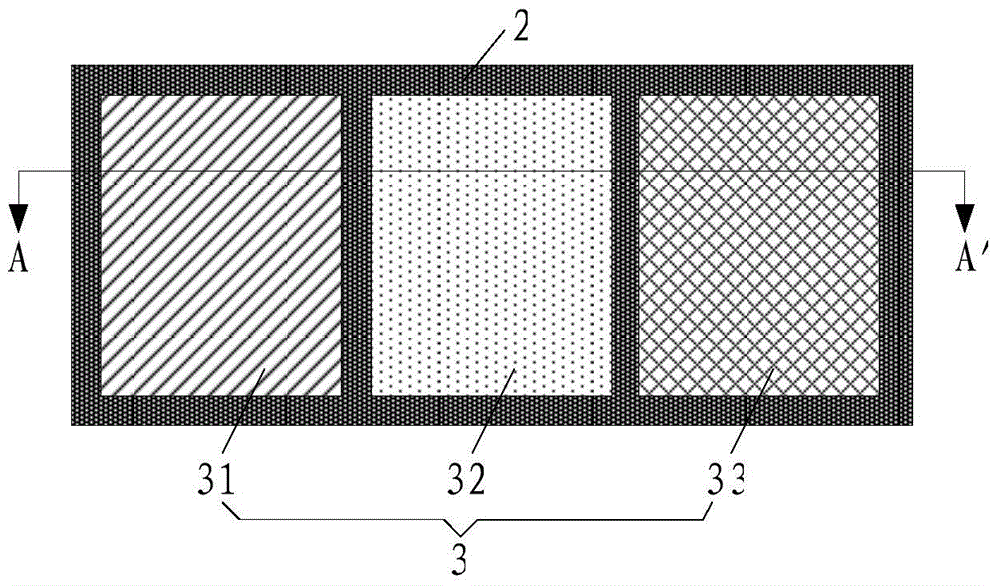

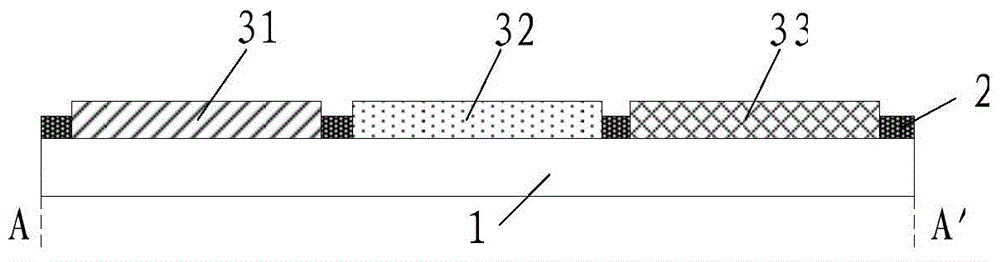

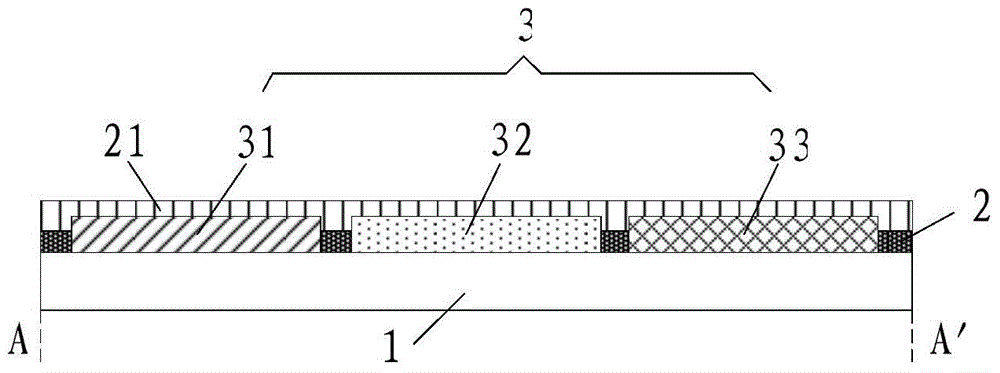

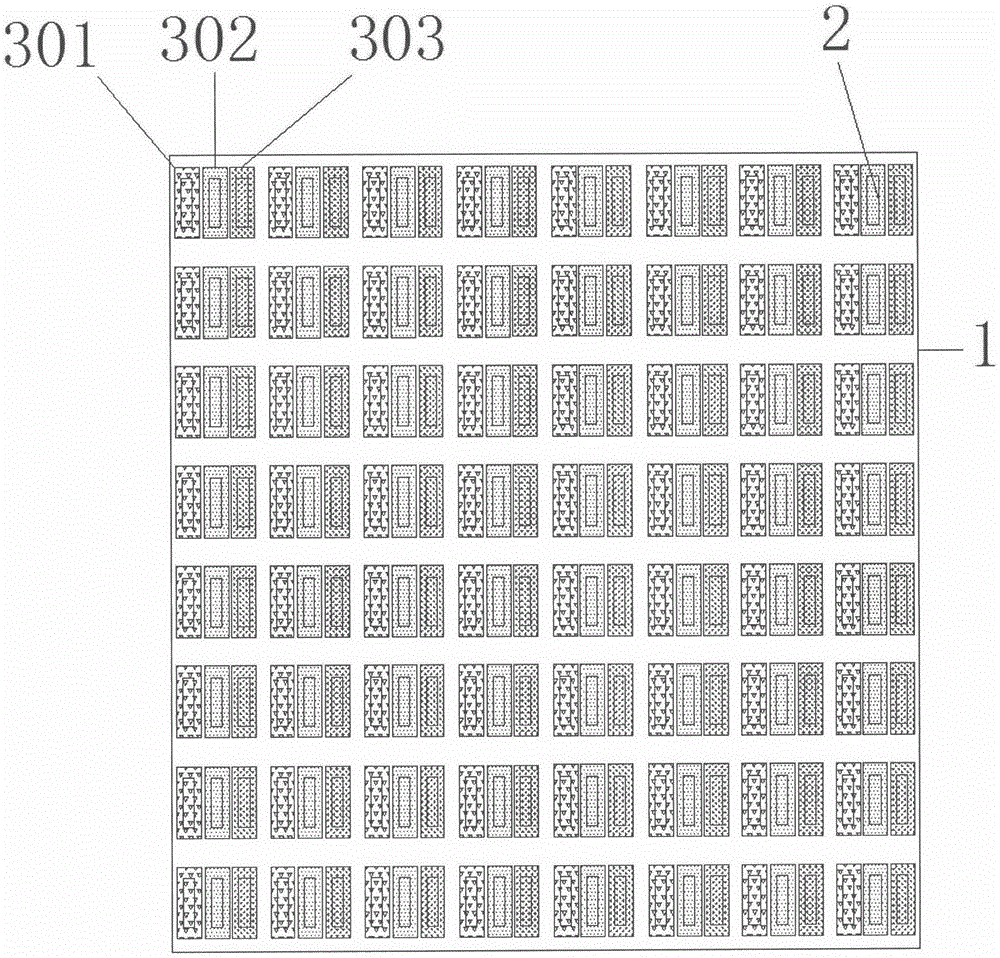

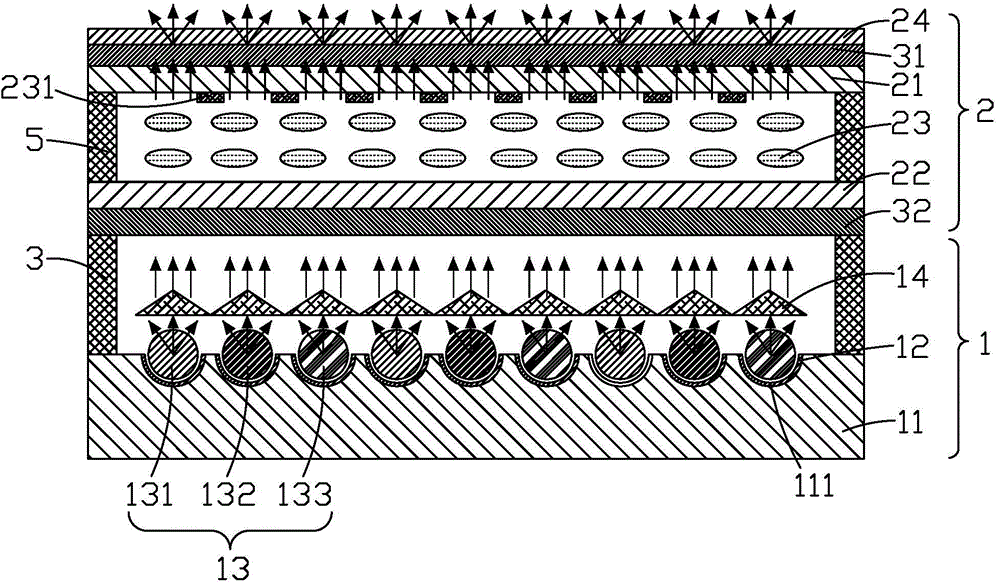

High-color-gamut liquid crystal display module structure

InactiveCN104090408AImprove color gamutHigh color saturationPlanar/plate-like light guidesNon-linear opticsGamutLiquid-crystal display

The invention provides a high-color-gamut liquid crystal display module structure. The high-color-gamut liquid crystal display module structure comprises a backlight module (1) and a liquid crystal display panel (3) arranged above the backlight module (1). The backlight module (1) comprises an LED light source (17) with the wavelength smaller than 460 nm. The liquid crystal display panel (3) comprises a TFT substrate (31), a CF substrate (33) arranged above the TFT substrate (31), a liquid crystal layer (35) arranged between the TFT substrate (31) and the CF substrate (33), and a fluorescent powder layer (5) arranged on the lower surface of the TFT substrate (31), the CF substrate (33) is provided with red, green and blue sub-pixel units arranged in an array mode, the fluorescent powder layer (5) comprises at least two of a red sub-pixel fluorescent powder unit (51), a green fluorescent powder unit (53) and a blue fluorescent powder unit (55) and is arranged corresponding to the red sub-pixel unit or the green sub-pixel unit or the blue sub-pixel unit. According to the structure, the color gamut of a liquid crystal display module can be effectively improved, and the liquid crystal display module has high color saturation.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for preparing mica titanium nacreous material

InactiveCN101235227ANo sintering phenomenonIdeal powder productInorganic pigment treatmentIron saltsSulfate

The invention belongs to the pearlescent pigment preparation process field, particularly relating to a preparation process of mica titanium pearlescent pigment. The process of the invention comprises adopting titanium tetrachloride solution which is partially transformed into titanyl sulfate, ferric trichloride solution and ferrous chloride solution or mixed solution of titanium salt and iron salt as deposition agent, adopting carbamide as neutralizing agent, wherein carbamide adopts the way of filling in batch, and hydrolyzing titanium salt, iron salt or mixed salt of titanium salt and iron salt to prepare mica pearlescent pigment. The process of the invention has the advantages of simple making art and easy operation, and the mica pearlescent pigment product which is prepared has even and compact titanium dioxide, di-iron trioxide film structure on the surface of the product, silver white product has high whiteness and strong pearlescent effect, and neon or color product has saturated color and strong pearlescent effect.

Owner:北京首纳东方科技有限公司

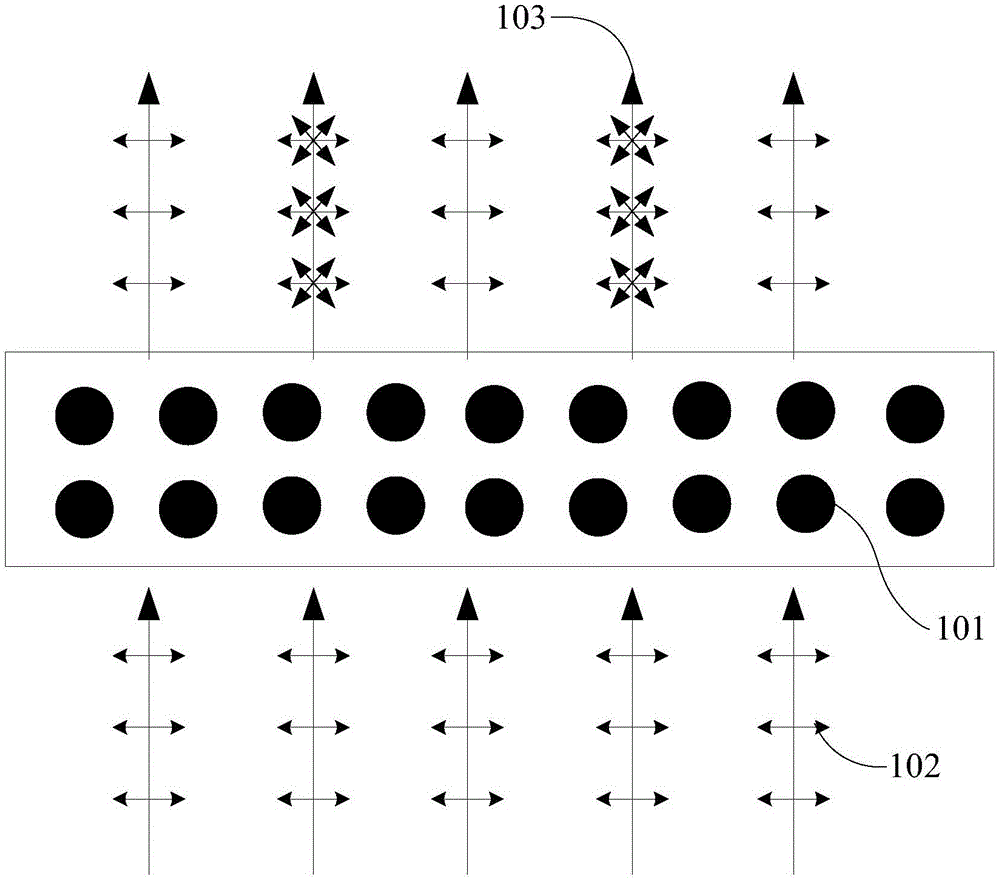

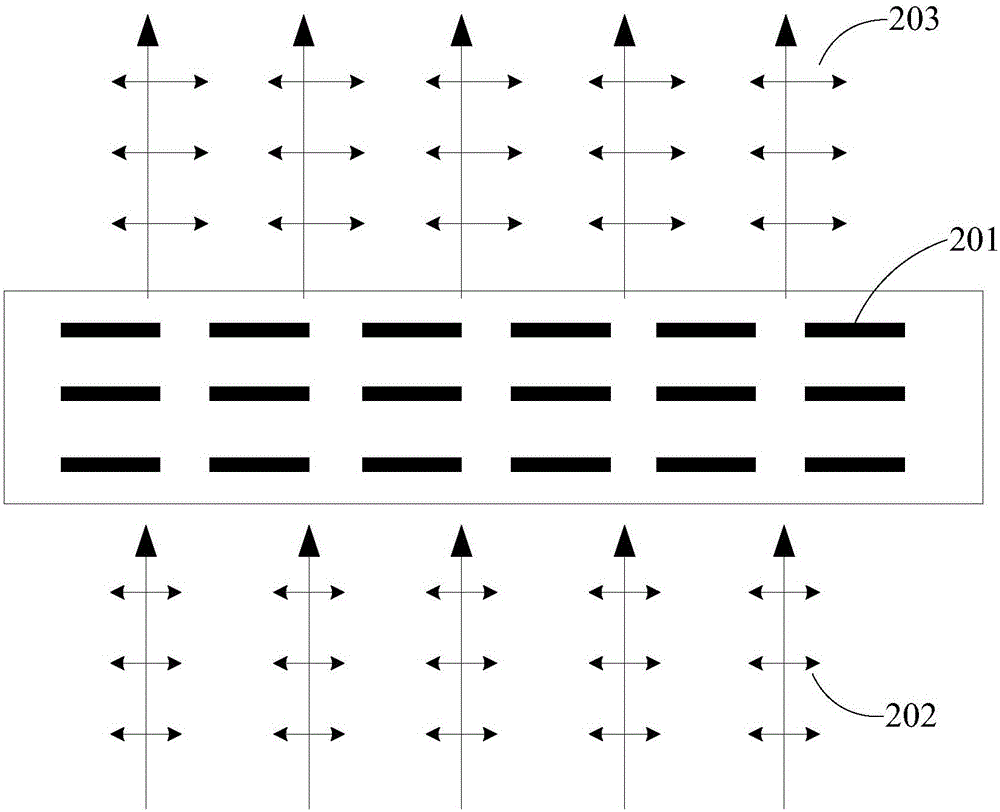

Liquid crystal display and liquid crystal display module thereof

The invention provides a liquid crystal display and a liquid crystal display module thereof. The liquid crystal display module comprises a backlight unit, a liquid crystal display panel and a quantum rod membrane arranged between the backlight unit and the liquid crystal display panel. The liquid crystal display panel comprises an upper substrate, a lower substrate and an upper polaroid. The portion between the upper substrate and the lower substrate is filled with liquid crystals. The upper polaroid is arranged on the outer side of the upper substrate, namely the light-emitting side of the liquid crystal display panel. The quantum rod membrane is specifically arranged between the lower substrate and the backlight unit. Due to the fact that a quantum rod capable of transmitting polarized light is adopted for the liquid crystal display module to replace a traditional color filter or a prism film assembly and a lower polaroid, the purposes of high color contrast, high colour saturation, low power consumption and the low cost of the liquid crystal display are achieved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Colourful optical filter

InactiveCN101063726AImprove resolutionGood transmission spectrumNon-linear opticsOptical elementsColor gelReflective layer

This invention discloses one color filter slice, which comprises one transparent baseboard, one top reflection layer, one bottom reflection layer, one gap adjusting gap layer and one interference layer, wherein the gap layer is set between top reflection layer and bottom reflection layer with three different thickness values on one pixel unit to form color filter slice of red, green and blue one; the interference layer forms top reflection layer relative to red position.

Owner:WINTEK CORP

Pigment dispersion and recording ink, and ink cartridge, ink jet recording method, and ink jet recording device

InactiveCN101360799AHigh image densityHigh color saturationDuplicating/marking methodsInksWater dispersiblePolymer science

A pigment dispersion is provided that comprises a pigment, a pigment dispersant, a polymer dispersion stabilizer and water, wherein the polymer dispersion stabilizer is an alpha-olefin / maleic anhydride copolymer expressed by the formula (1) below. A recording ink is also provided that comprises the pigment dispersion, a surfactant, a water-dispersible resin, a humectant and water. in the structural formula (1), R represents an alkyl group and n is an integer of 30 to 100.

Owner:RICOH KK

Color display device

InactiveCN101727783AHigh color saturationIncrease contrastNon-linear opticsIdentification meansElectrophoresisDisplay device

The invention discloses a color display device, comprising a substrate, a protective layer, an electrophoresis-type display module, an electrowetting-type display module and a first insulating layer. The protective layer is opposite to the substrate, wherein the protective layer and the first insulating layer are made of transparent materials; the electrophoresis-type display module is arranged between the substrate and the protective layer, wherein the electrophoresis-type display module is a white and black display module; the electrowetting-type display module is arranged between the substrate and the protective layer, wherein the electrowetting-type display module is a color display module; and the first insulating layer is arranged between the electrophoresis-type display module and the electrowetting-type display module. The color display device has high color saturation and high contrast.

Owner:E INK HLDG INC

Aqueous flexible plate printing ink and preparation thereof

InactiveCN101328329AReduce pollutionFine inkInksOther printing apparatusSolubilityAtmospheric contamination

A water-basedsoft printing ink comprises the following compositions: 30 to 35 percent of pigment, 25 to 32 percent of acrylic resin, 0.2 to 0.5 percent of antifoaming agent, 2 to 5 percent of ethylene glycol monomethyl ether, 1.0 to 2.5 percent of wax slurry, 0.9 to 1.5 percent of leveling agent, and 23 to 30 percent of water. A preparation method comprises the three working procedures of colored slurry grinding, aquosity treatment and printing ink preparation in turn. The water-basedsoft printing ink has novel compositions, scientific blending, simple preparation, lower cost, fine ink quality, mellow brightness, high color saturation, brilliant color, high drying speed, grid point superimposition and overprinting, good water solubility, easy cleaning, corrosiveness free on printing rollers, low viscosity, high color content, good penetrability and printing adaptability, suitability for multicolor machine high-speed printing, high abrasion resistance, difficult decolorization, wide color range, closeness to a normal color sample, and consistency to the requirements on top-grade printing; and the printing ink also meets EU ROHS standards, and facilitates safe production and environmental protection with low air pollution and without any noxious solvent residual.

Owner:广东佳景科技股份有限公司

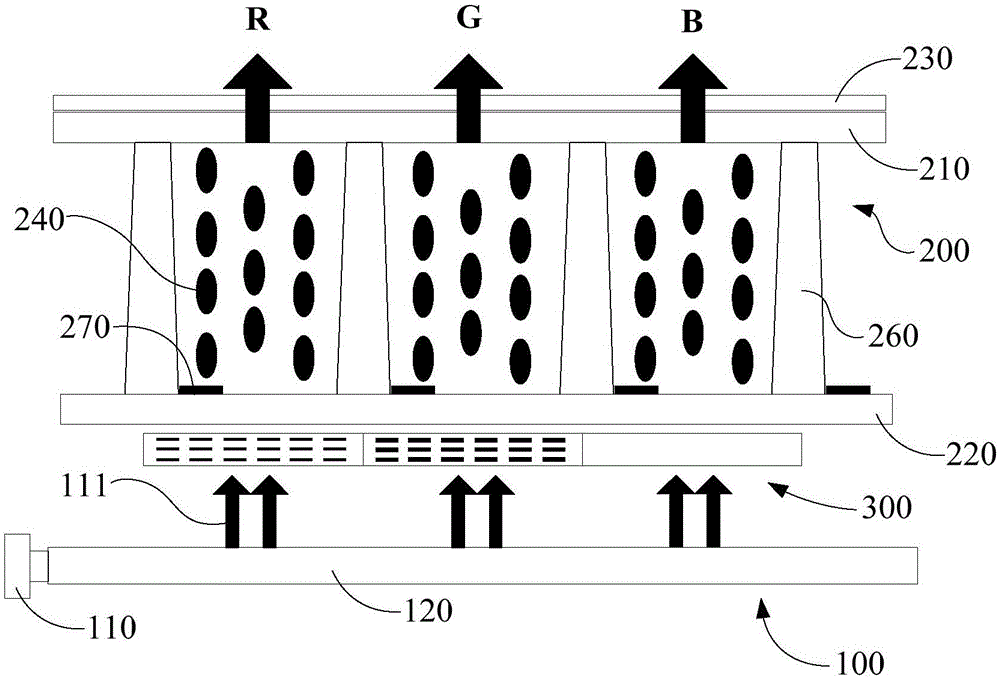

Light emitting device, backlight module and liquid crystal display device

ActiveCN104483778AIncrease brightnessHigh color saturationNon-linear opticsSemiconductor devicesLiquid-crystal displayQuantum dot

The invention discloses a light emitting device, a backlight module and a liquid crystal display device. The light emitting device adopts fluorescent powder excited luminescence and quantum spot luminescence at the same time to emit white light. Compared with a light emitting device only adopting quantum spot luminescence in the prior art, the brightness of the emitted light is higher, and high color saturation can be provided for the display device. The backlight module adopts fluorescent powder excited luminescence and quantum spot luminescence at the same time to emit white light. Compared with a backlight module only adopting quantum spot luminescence in the prior art, the brightness of the emitted light is higher, and high color saturation can be provided for the display device. The liquid crystal display device comprises the backlight module and has better display effect.

Owner:SHANGHAI AVIC OPTOELECTRONICS +1

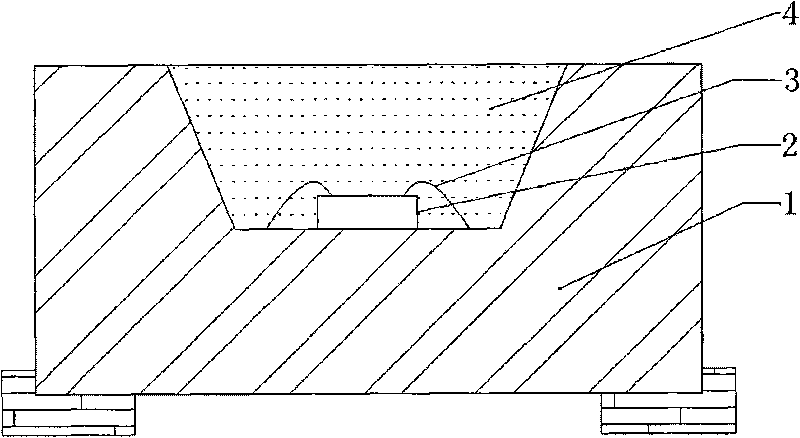

LED white lamp and encapsulation method thereof

InactiveCN101699154AHigh color saturationImprove color gamutPoint-like light sourceElectric circuit arrangementsGamutPhosphor

The invention discloses an LED white lamp and an encapsulation method thereof, and the method comprises the following steps: firstly providing a concave stacker and an LED blue light chip fixed in the concave stacker, wherein the LED blue light chip has a positive electric pole and a negative electric pole which can be energized; secondarily connecting the positive and negative electric poles of the LED blue light chip with the positive and negative electric poles of the concave stacker respectively; mixing glue, green phosphor powder of silicate with red phosphor powder of nitride to prepare phosphor glue; then encapsulating the phosphor glue on the surface of the LED blue light chip of the concave stacker, baking and molding; and finally stripping the molded product from the concave stacker and performing spectrophotometric color. The white light of the LED white lamp prepared according to the above method has three wave peaks of blue, green and red, thus satisfying tri-phosphor conditions, improving color gamut by over 20% compared with the traditional LED white light; and the LED white lamp serving as an LCD backlight has high saturation of image color and strong image layering.

Owner:LEDMAN OPTOELECTRONICS

Method nad apparatus for UV ink jet printing on fabric and combination printing and quilting thereby

InactiveCN1377313AChanging the time of exposure to energyIncrease or decrease the time of energy exposureSewing-machine elementsLayered productsUV curingRadiant heater

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors across a bridge that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads, so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate.

Owner:L & P PROPERTY MANAGEMENT CO

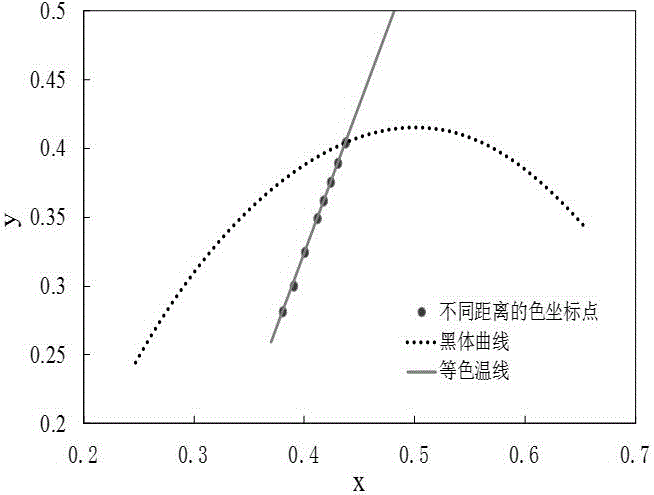

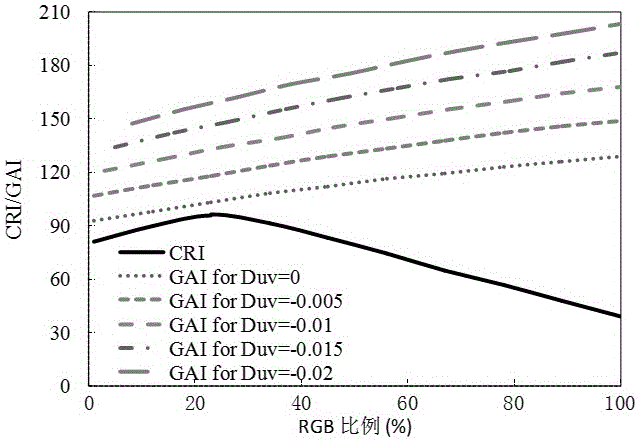

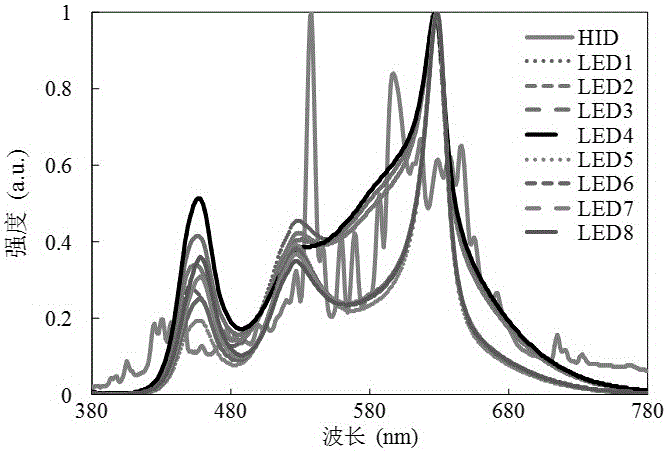

White light LED illuminating system with high light color quality and designing method thereof

InactiveCN105042365AImprove light and color qualityHigh white light preferencePoint-like light sourceElectric lightingGamutLighting system

The invention belongs to the technical field of semiconductor illumination, and particularly discloses a white light LED illuminating system with the high light color quality and a designing method thereof. As the distance Duv from color coordinate points in CIE 1931 color gamut space to a blackbody line is optimized, the LED color mixture illuminating system having the high white light preference degree at the required color temperature is obtained, the color quality of a white light source can be improved, and the lamplight environmental effect can be improved; meanwhile, the required CRI and the high GAI can be guaranteed. The color temperature adjustment range of the white light LED illuminating system is 2,000 K to 10,000K, and the distance Duv from the color coordinate points to the blackbody line is larger than or equal to -0.1 and smaller than or equal to 0. By means of the Duv-optimizing color mixture designing method, the LED illuminating system with the high white light preference degree is obtained, and the white light LED illuminating system and the designing method can be applied to illuminating places with the high light quality requirements.

Owner:FUDAN UNIV

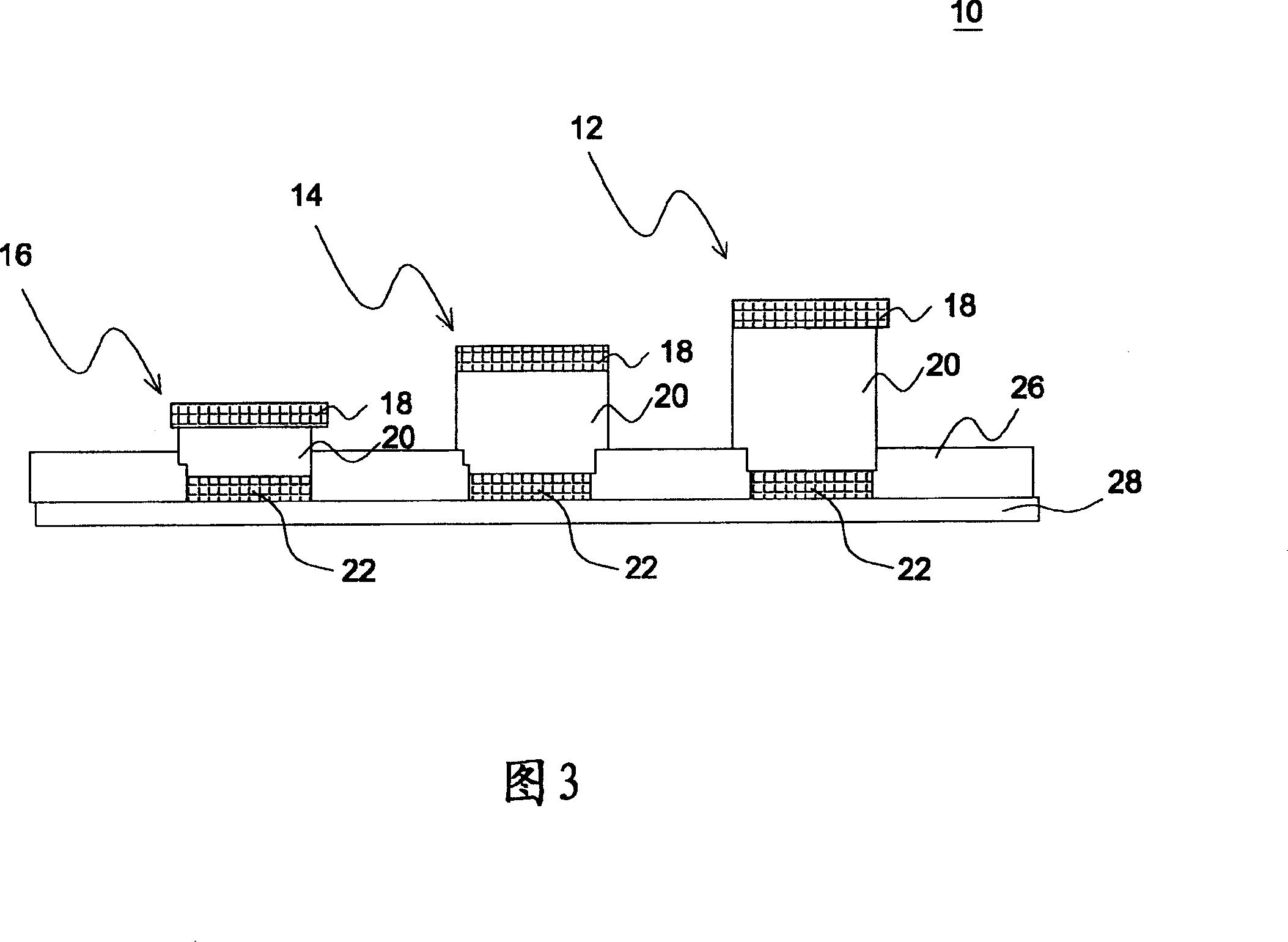

Displaying base plate, manufacture method thereof and display device

InactiveCN104090413AStrong heat resistanceHigh color purityNon-linear opticsOptical elementsHeat resistanceQuantum dot

The invention provides a displaying base plate, a production method thereof, and a display device, relates to the field of display technology, and solves the problems of poor heat resistance and low color saturation in a conventional color film. The displaying base plate comprises a substrate base plate, a color film arranged on the substrate base plate, and a first blocking layer positioned on the color film; the material of the color film comprises quantum dots, and the first blocking layer is used for enabling the color film to be isolated from air.

Owner:BOE TECH GRP CO LTD +1

Super-high-density LED display device and manufacturing method thereof

PendingCN105206642APrevent light diffusionHigh resolutionSolid-state devicesIdentification meansHigh densityLED display

The invention discloses a super-high-density LED display device which comprises a substrate and an LED chip array packaged on the substrate. The chip array comprises a plurality of LED chips distributed evenly at intervals. By means of the Fan-Out Wafer-Level Package (FOWLP) process, the packaging area is narrowed, and the resolution ratio of an LED display screen is increased; all the LED chips are the same in structure, light-emitting wave band and type, the LED chips emit red light, green light and blue light after being coated with red light fluorescent powder, green light fluorescent powder and blue light fluorescent powder in a chip light-emitting curing mode respectively, and therefore it is ensured that the LED chips are consistent in light attenuation in the use process, and the development performance of the display screen is improved; pixel point distances can be smaller than 1 mm and even smaller than 0.1 mm, better performance such as high integrity, high resolution and consistent light color of the LED display device is achieved, and the super-high-density LED display device is importantly applied to indoor high-density display screens, projection devices and wearable display devices.

Owner:NANJING UNIV

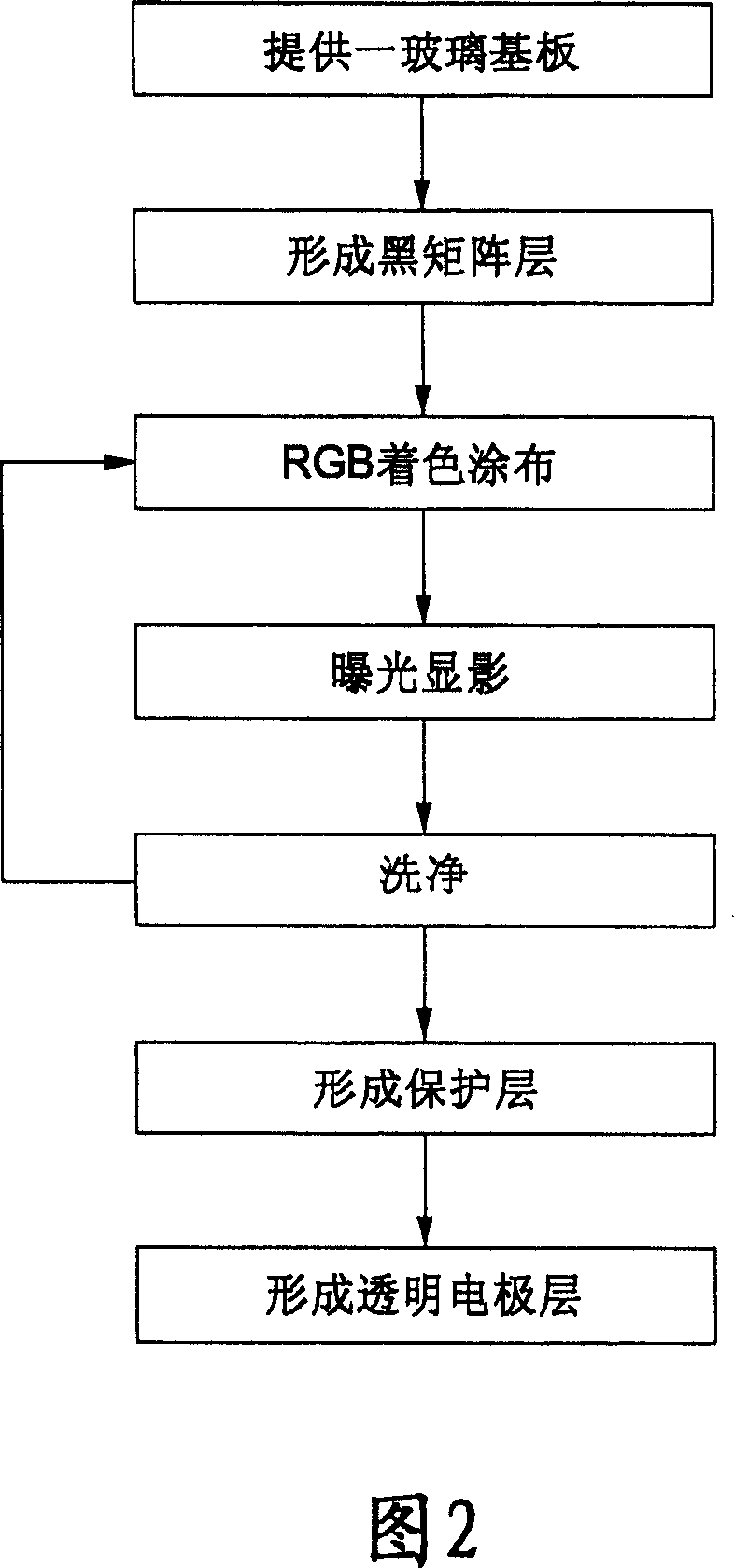

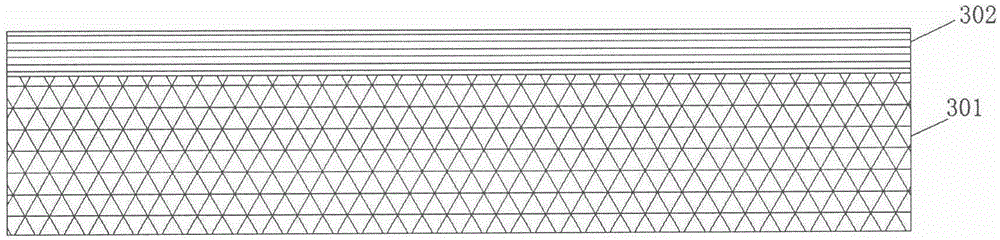

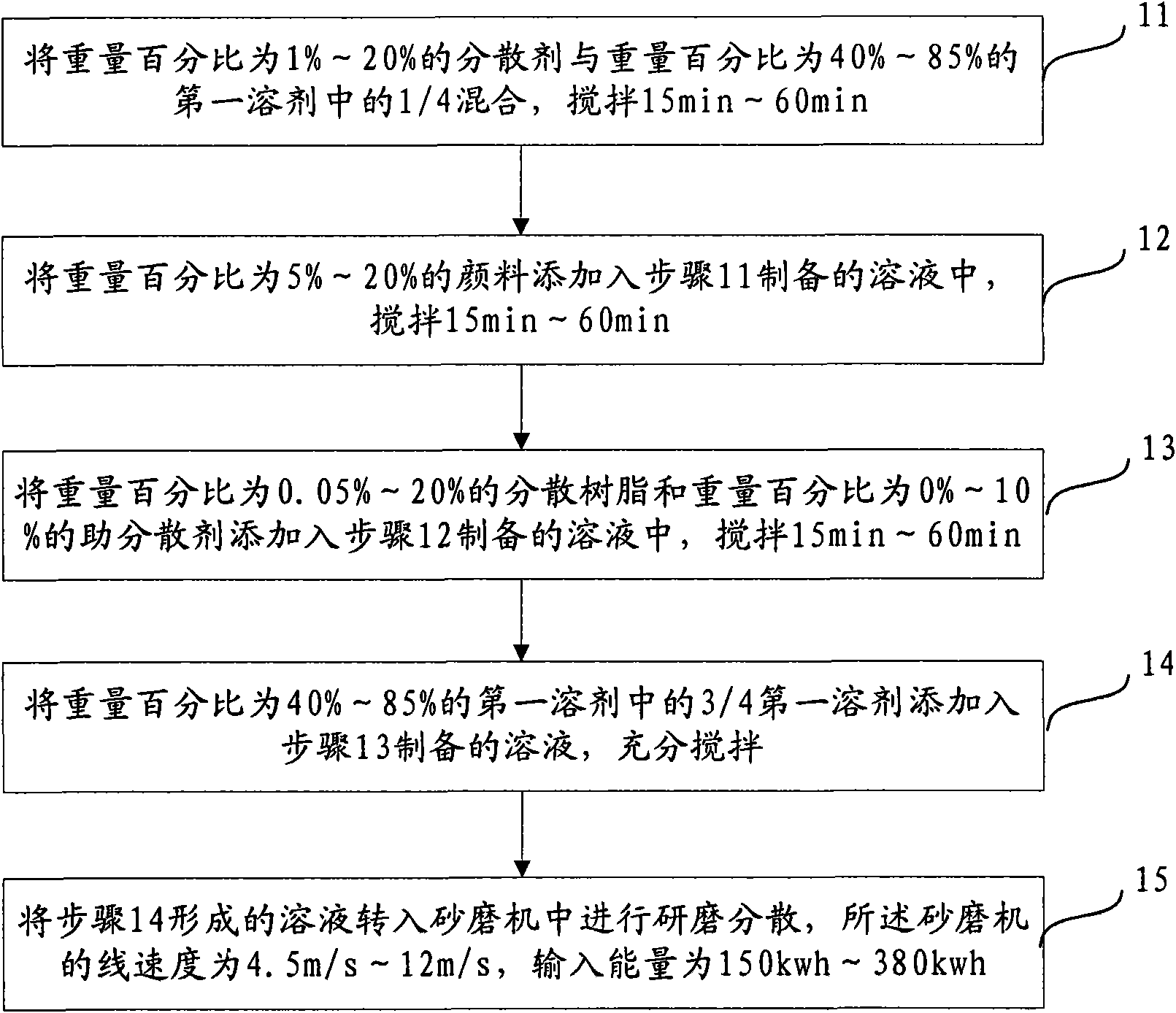

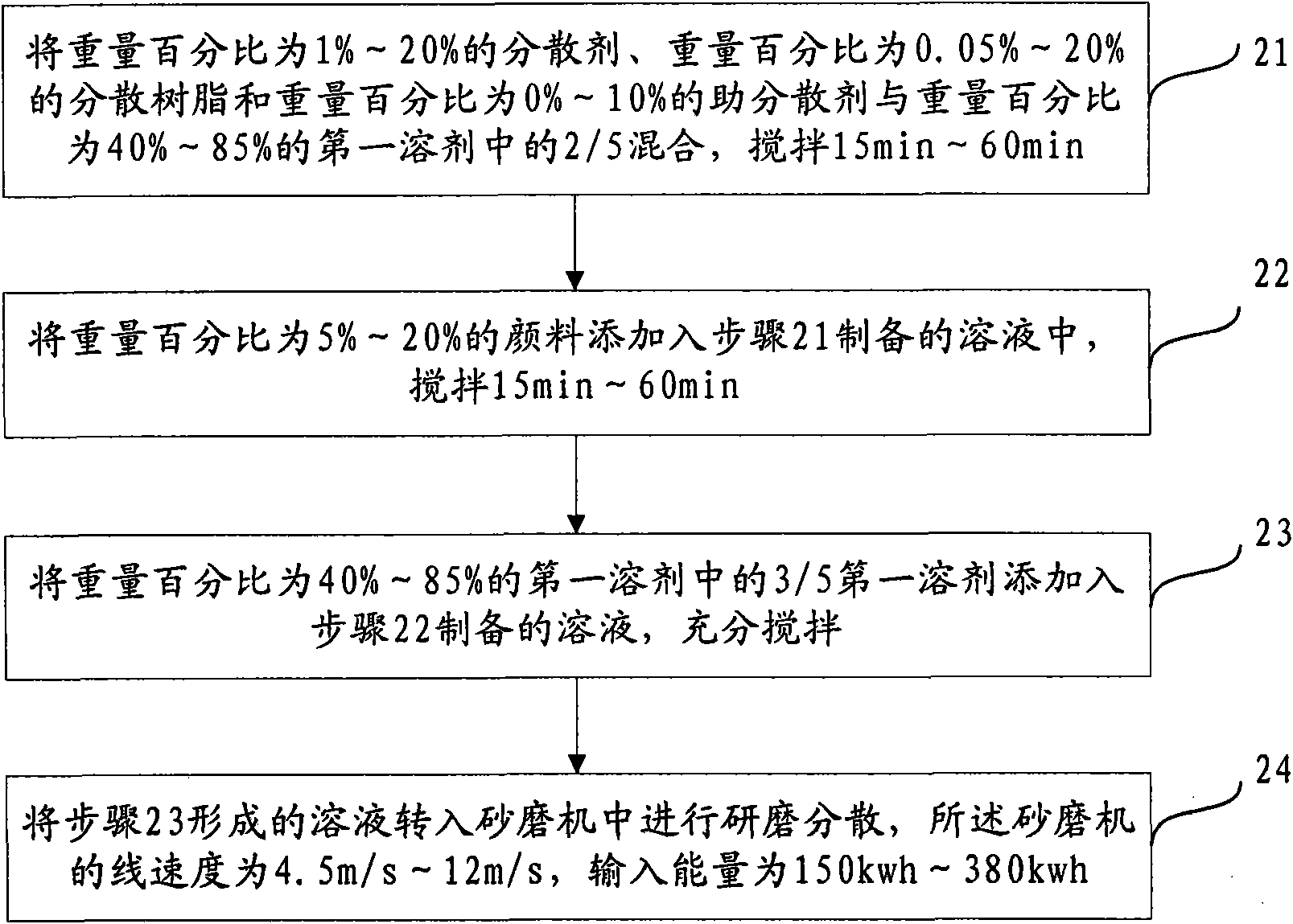

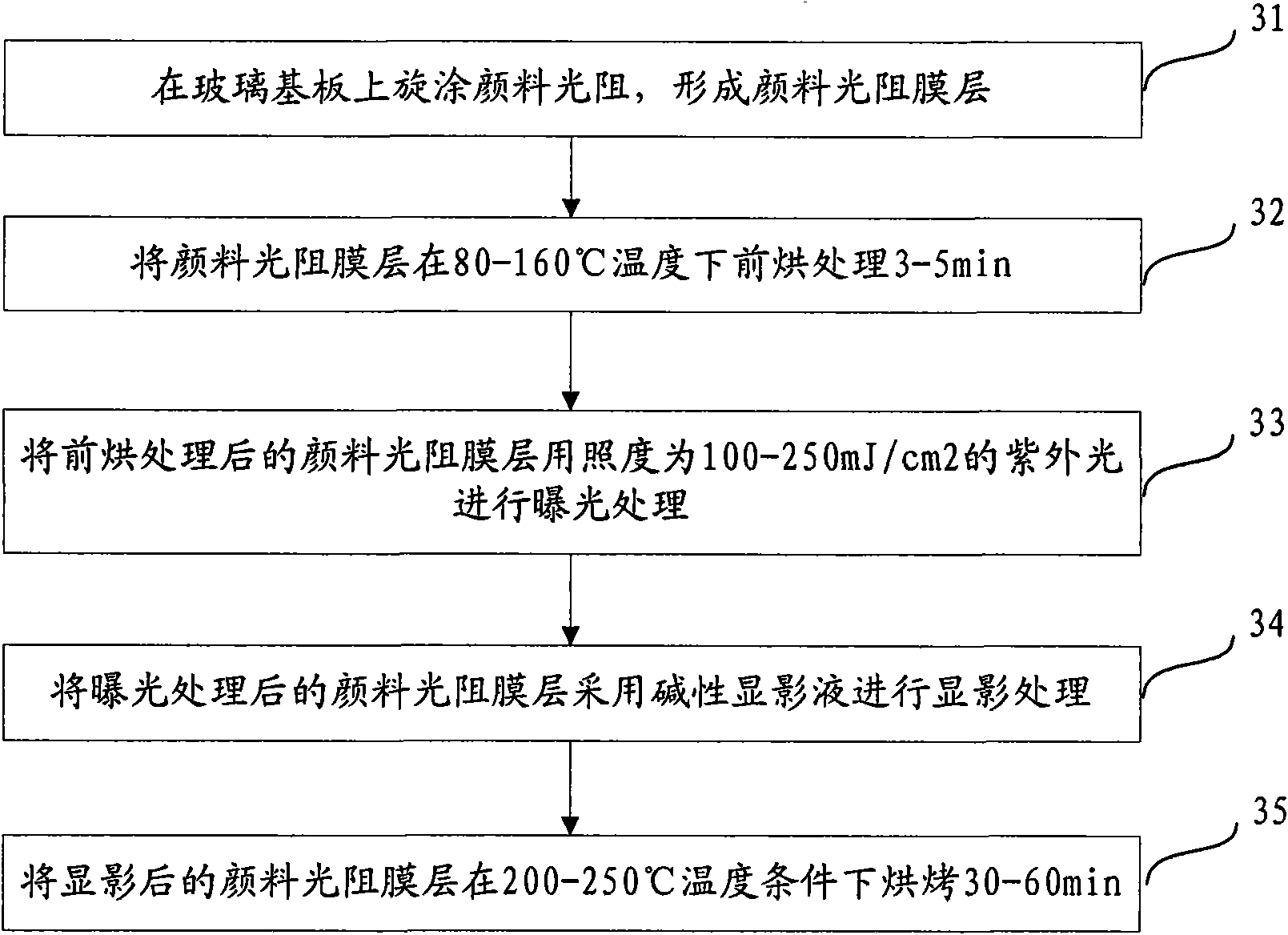

Pigment dispersion, pigment photoresistor and preparation thereof

ActiveCN101659813ASmall granularityNarrow particle size distributionPhotomechanical apparatusOrganic dyesPigment dispersionSolvent

The invention relates to a pigment dispersion, a pigment photoresistor and a preparation method thereof. The pigment dispersion comprises 5 to 20 weight percent of pigment, 1 to 20 weight percent of dispersant, 0 to 10 weight percent of auxiliary dispersant, 0.05 to 20 weight percent of dispersion resin and 40 to 85 percent of first solvent. The pigment dispersion with a small particle size and anarrow particle size distribution range has high storage stability and high colorimetric performance. The pigment photoresistor prepared on the basis of the pigment dispersion meets the material selection requirements of color optical filters and liquid crystal displays; and the color optical filters prepared on the basis of the pigment photoresistor is high in color saturation, so the color display quality of the liquid crystal displays having the color optical filters is improved obviously.

Owner:BOE TECH GRP CO LTD

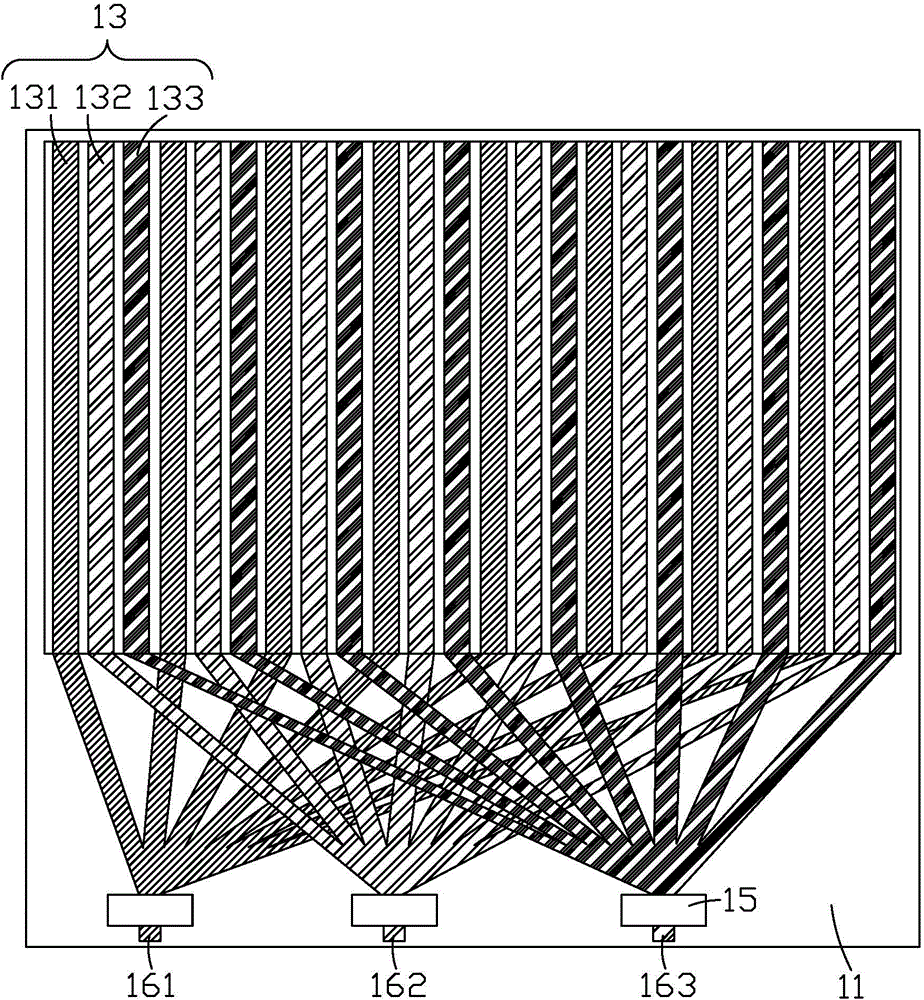

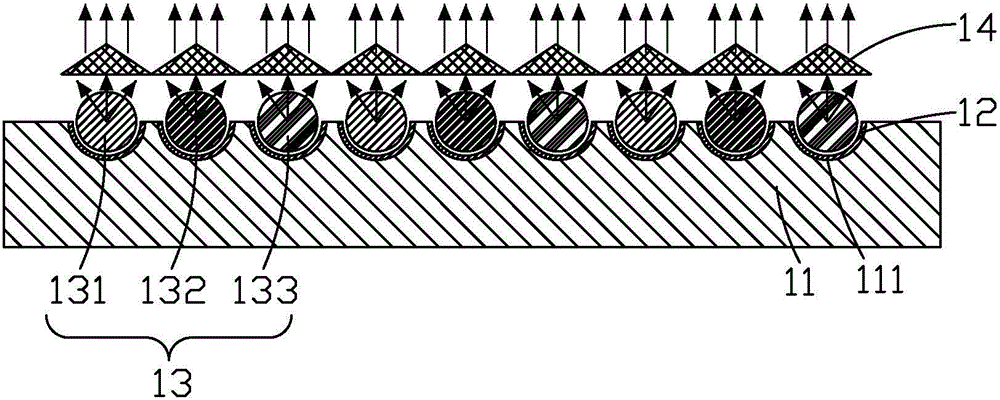

Optical fiber backlight module and liquid crystal display

InactiveCN104676387AStrong penetrating powerHigh color saturationMechanical apparatusPoint-like light sourceArray data structureLiquid-crystal display

The invention provides an optical fiber backlight module and a liquid crystal display. The optical fiber backlight module comprises a back board, a red LED (light emitting diode) light source, a green LED light source, a blue LED light source, multiple groups of optical fibers and prism lenses, wherein the red LED light source, the green LED light source and the blue LED light source are arranged on the side edge of the back board and are successively arranged; the optical fibers are arranged on the back board; the prism lenses are arranged on the optical fibers; the back board is provided with a plurality of grooves which are formed in parallel and are distributed at equal distances; the optical fibers are respectively fixedly arranged in the grooves; each group of optical fibers comprises a red light guide optical fiber, a green light guide optical fiber and a blue light guide optical fiber; the red light guide optical fibers, the green light guide optical fibers and the blue light guide optical fibers are respectively connected with the red LED light source, the green LED light source and the blue LED light source via couplers, and an area light source of three-primary colors (red, green and blue) can be provided for a liquid crystal panel, so that the liquid crystal panel can realize color display without a colorful color filter, a light penetration rate can be improved, and the color saturability of the liquid crystal display is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Magic glazed tile and production method thereof

The invention discloses a magic glazed tile and a production method thereof. The method comprises orderly applying bottom glaze and surface glaze to a ceramic blank subjected to biscuiting through a glaze pouring device, carrying out ink-jet printing on the surface glaze through an ink-jet printer to obtain patterns, carrying out fixed-point printing on the patterns with matt convex glaze and bright convex glaze in turn through first and second silk-screen printing devices continuously arranged, when the ink-jet printing ink does not contain red ink, carrying out fixed-point printing on the patterns with bright red glaze through a third silk-screen printing device and applying candy glaze to the surface of a tile. The method can produce the glazed tiles with matt and bright gloss patterns on the surface. The magic glazed tile has good three-dimensional feeling and soft light and high contrast ratio patterns similar to embossment on the tile surface. The matt convex glaze and bright convex glaze have a high coincidence degree and clear edges, through use of bright red glaze for embellishment, the patterns are lifelike and through use of the candy glaze, the four types of decorative effects makes the tile surface clear and vivid and the whole tile surface shows a magical decorative effect.

Owner:广东协进陶瓷有限公司

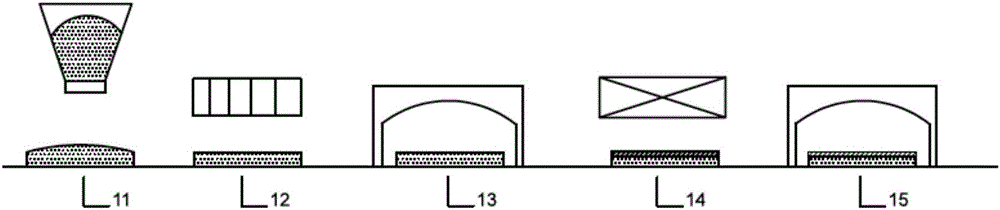

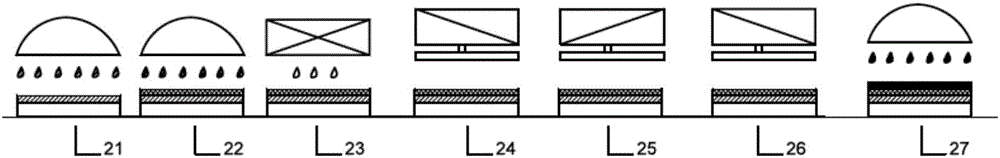

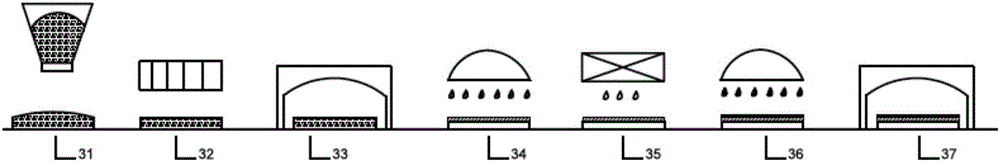

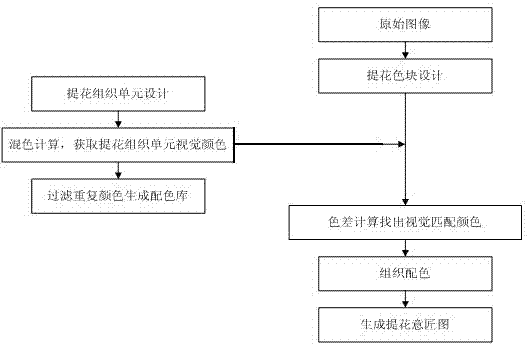

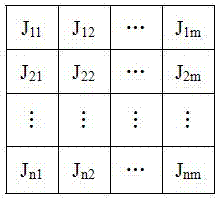

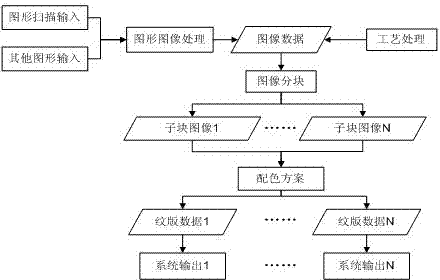

Method suitable for weaving colored jacquard fabric with large texture thread number

InactiveCN103088515ABroaden the application marketVariety of colorsPattern making devicesColor imageYarn

The invention discloses a method suitable for weaving a colored jacquard fabric with a large texture thread number. The method comprises the steps of firstly determining parameters of jacquard texture units, and storing the parameters in a database; then determining the parameters of jacquard color lumps and the size and extension sequence of pattern image blocks, reading colored design patterns to be woven into a computer for division, and carrying out index numbering; and scanning each pixel point for calculation of color difference, arranging the jacquard color lumps based on a weaving scheme with maximal color similarity in a color library to form a weaving program, and splicing all jacquard subblocks after controlling a colored digital jacquard machine to weave respectively. The method can complete the jacquard design and weaving of color images by only utilizing 4-8 colored yarns and achieve the jacquard task with the large texture thread number on the premise of not bringing up new demands on a conventional jacquard machine process; and simultaneously the color level breaks through 256 colors in color selection so as to be more colorful and improve the quality and additional value of products.

Owner:SUZHOU UNIV

Method for preparing reversible discolouring membrane made from polyaniline composite nanofiber

InactiveCN101967279AUniform colorHigh color saturationFilament/thread formingConjugated synthetic polymer artificial filamentsComposite nanofibersPhysical chemistry

The invention relates to a method for preparing a reversible discolouring membrane made from polyaniline composite nanofiber, which is characterized by comprising the following steps: dissolving an eigenstate polyaniline raw material in a stirred tank at room temperature to obtain polyaniline solution with a mass fraction of 0.2-15%; adding blending polymer to polyaniline solution at room temperature, evenly blending the mixture to obtain solution with the mass fraction of the blending polymer being 0.5-30%; inputting the solution to a spinning nozzle of an electrostatic spinning device at a flow velocity of 0.1-4mL / h at room temperature and a relative humidity of 20-60% for carrying out electrostatic spinning to prepare the nanometer composite fibre; and drying the nanofiber membrane obtained from a receiving device for 1-12h at 25-80 DEG C to obtain the reversible discolouring membrane made from polyaniline composite nanofiber. The invention features simple preparation process, low cost and good mechanical property, high flexibility, good corrosion resistance and uniform colour of the polyaniline composite nanofiber.

Owner:DONGHUA UNIV

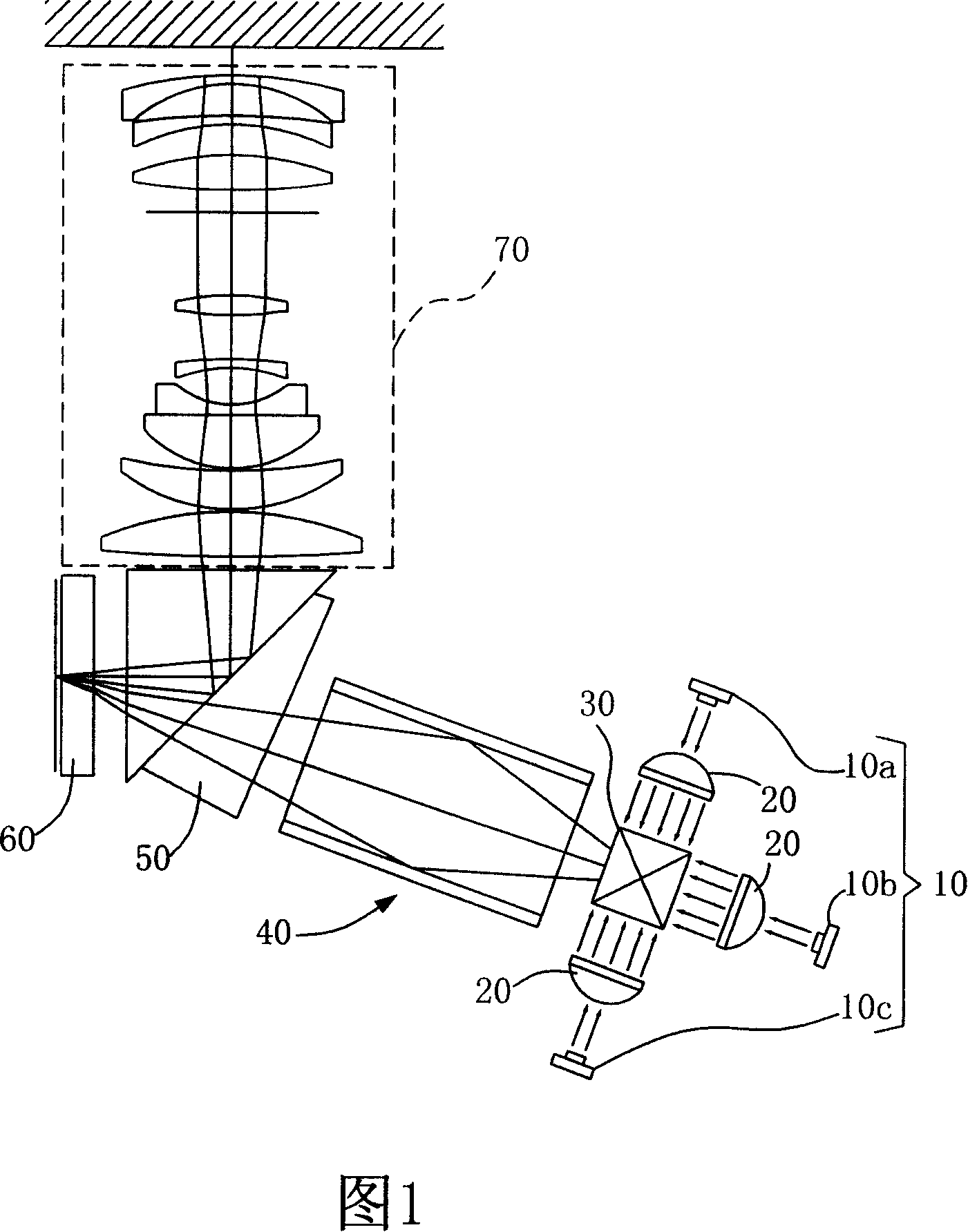

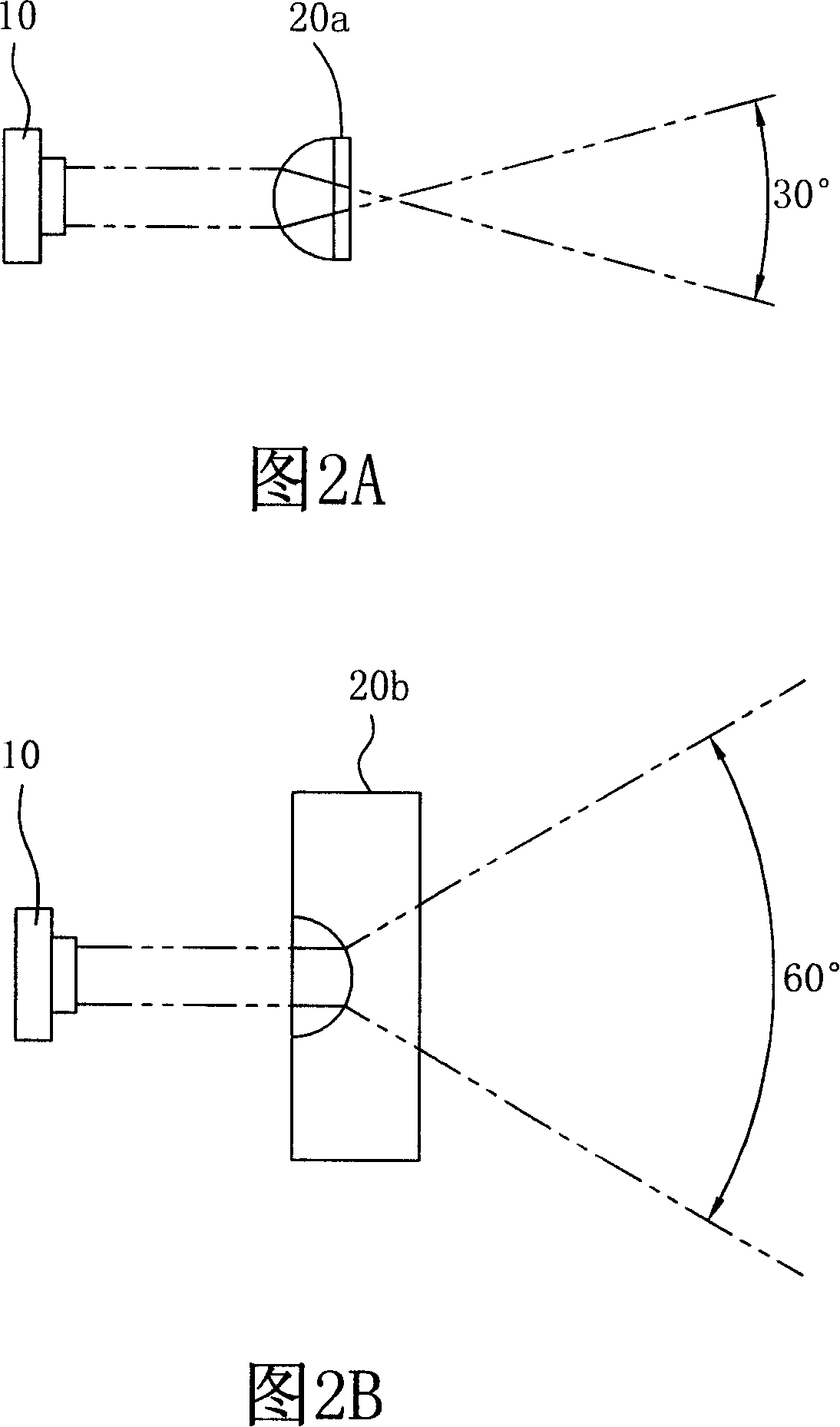

Projector with laser LED as its light source and light source device thereof

InactiveCN101131531AWith beam focusAdjustable Light Polarization PhaseProjectorsOptical elementsCamera lensImaging quality

This invention is a sort of single-disc panel projection which uses the laser LED to be the power, it consists of a laser LED power at least, a extender groupware at least, a composing light set, a leading light groupware, a prism group, a figure micro-lens display unit, and a projection lens group. It uses the small diameter laser bean of primary colors with the red, the green, and the blue which is produced by the laser LED, after the laser bean is to be magnified, combined the light, and transmitted the light by the extender groupware, the combining light set, and the leading set. It makes the bean of light to cast to the display unit of the numeral micro-lens by the prism group, after the image of the display unit of the numeral micro-lens is refracted to the projection lens and fabricated, it is cast to the outside. This invention attains this excellence in that: its image quality is sharper, its image is more vivid, its color is more saturated, its bulk is small, its power consumption is few, its feedback is fast, its life-span is long, and its efficiency is high, and so on by the laser LED.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com