Patents

Literature

143results about "Pattern making devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-fashioned weaving process for production of a woven garment with intelligence capability

A full-fashioned weaving process for the production of a woven garment which can accommodate and include holes, such as armholes. The garment is made of only one single integrated fabric and has no discontinuities or seams. Additionally, the garment can include intelligence capability, such as the ability to monitor one or more body vital signs, or garment penetration, or both, by including a selected sensing component or components in the weave of the garment.

Owner:GEORGIA TECH RES CORP

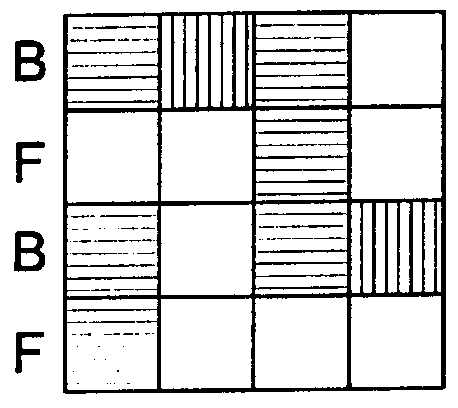

Digitel code manufacturing method jacquard weave double surface beautiful and glorious

InactiveCN1786308AMeet individual needsWide range of materialsPattern making devicesCard-punching apparatusTexture designPersonalization

The invention belongs to silk weaving picture-scenery technique development field, especially relates to a digital pattern two side beautiful brocade manufacturing method. The method includes the following steps: scanning, changing, color separating to set color bank; adding up crossing point according to electron lag; doing knitted texture design and confirming crunode position; inputting electron lag into loom control system. Materials drawing of the invention are very wide. And the product can satisfy consumerí»s individuation demand.

Owner:韩容

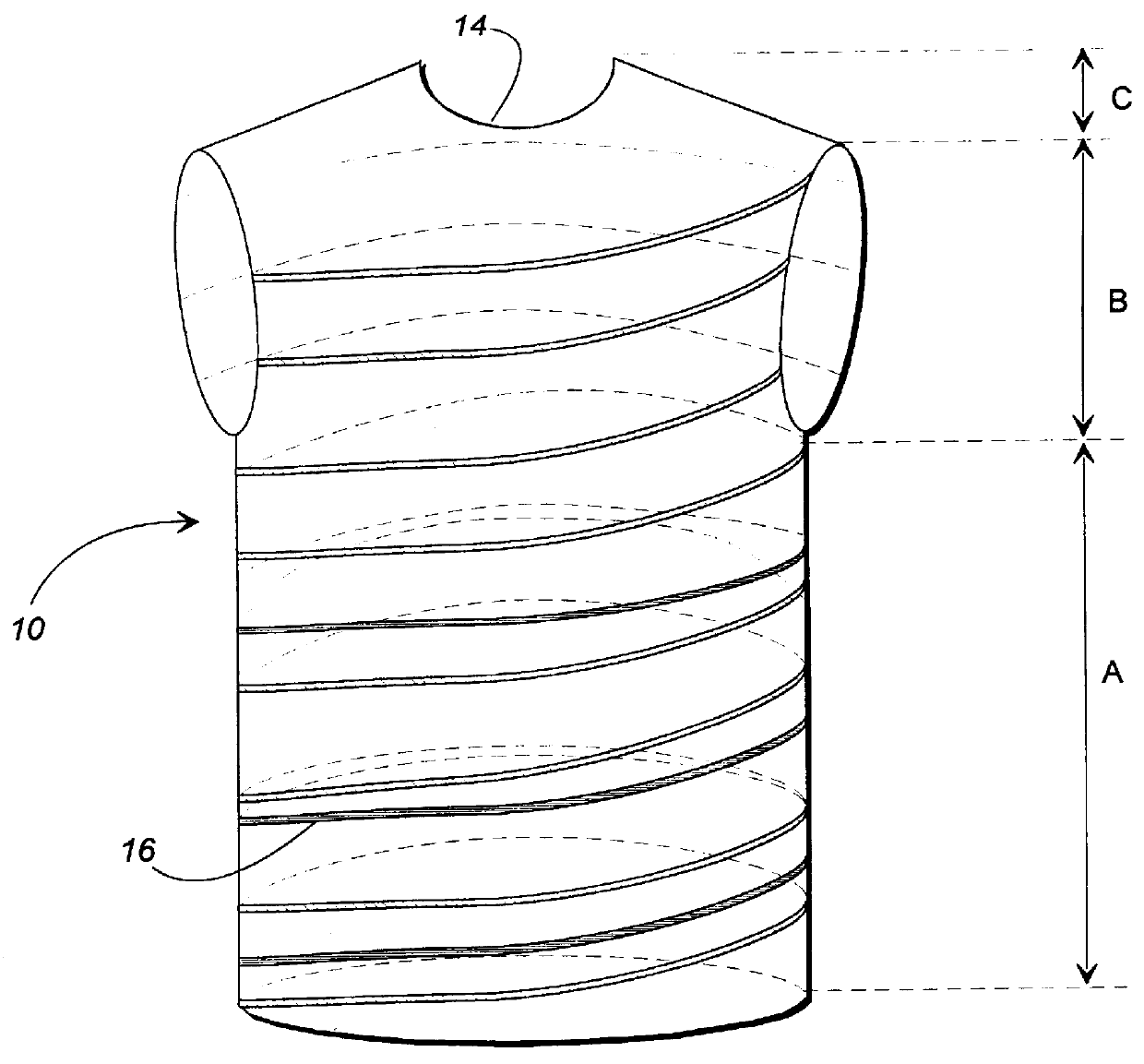

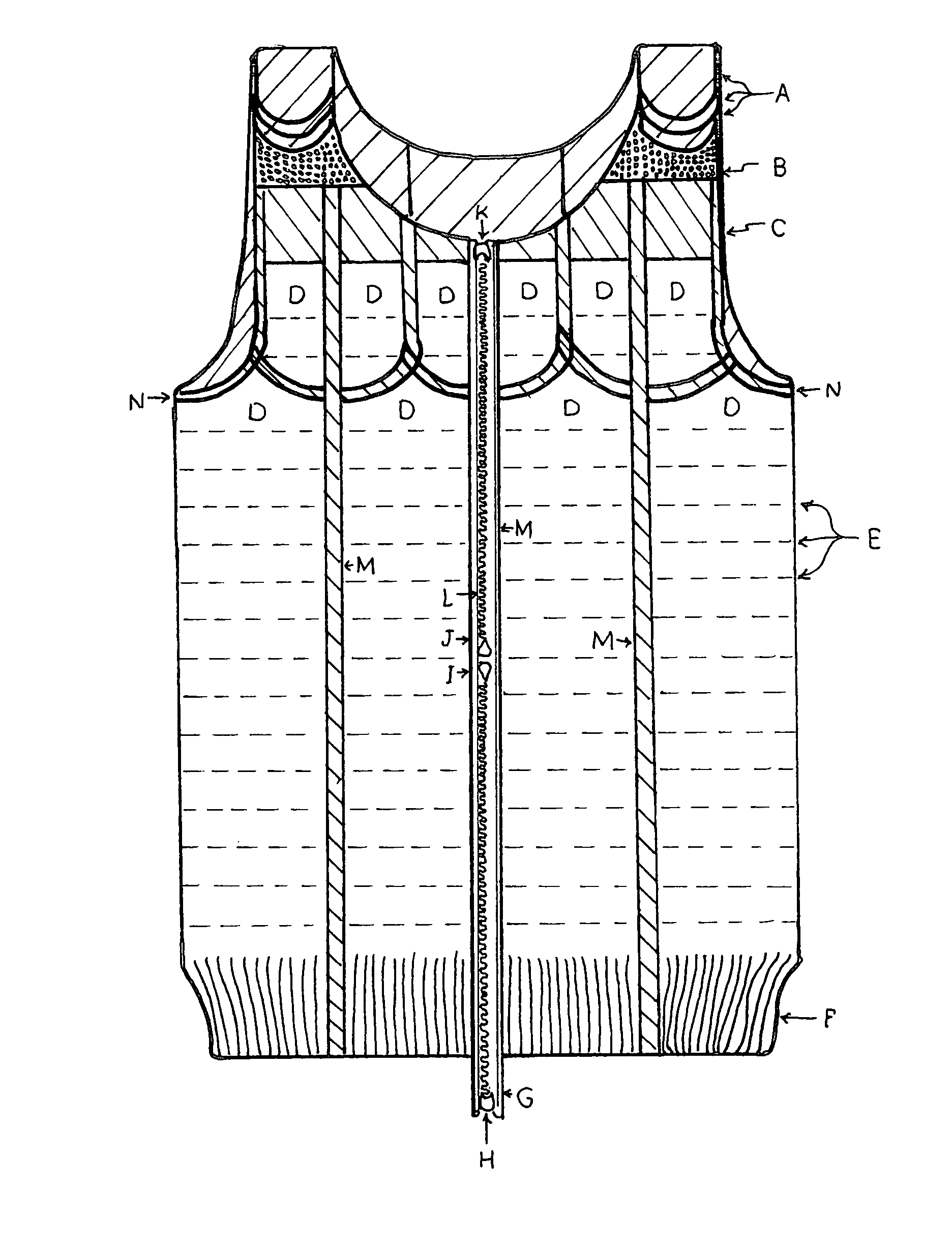

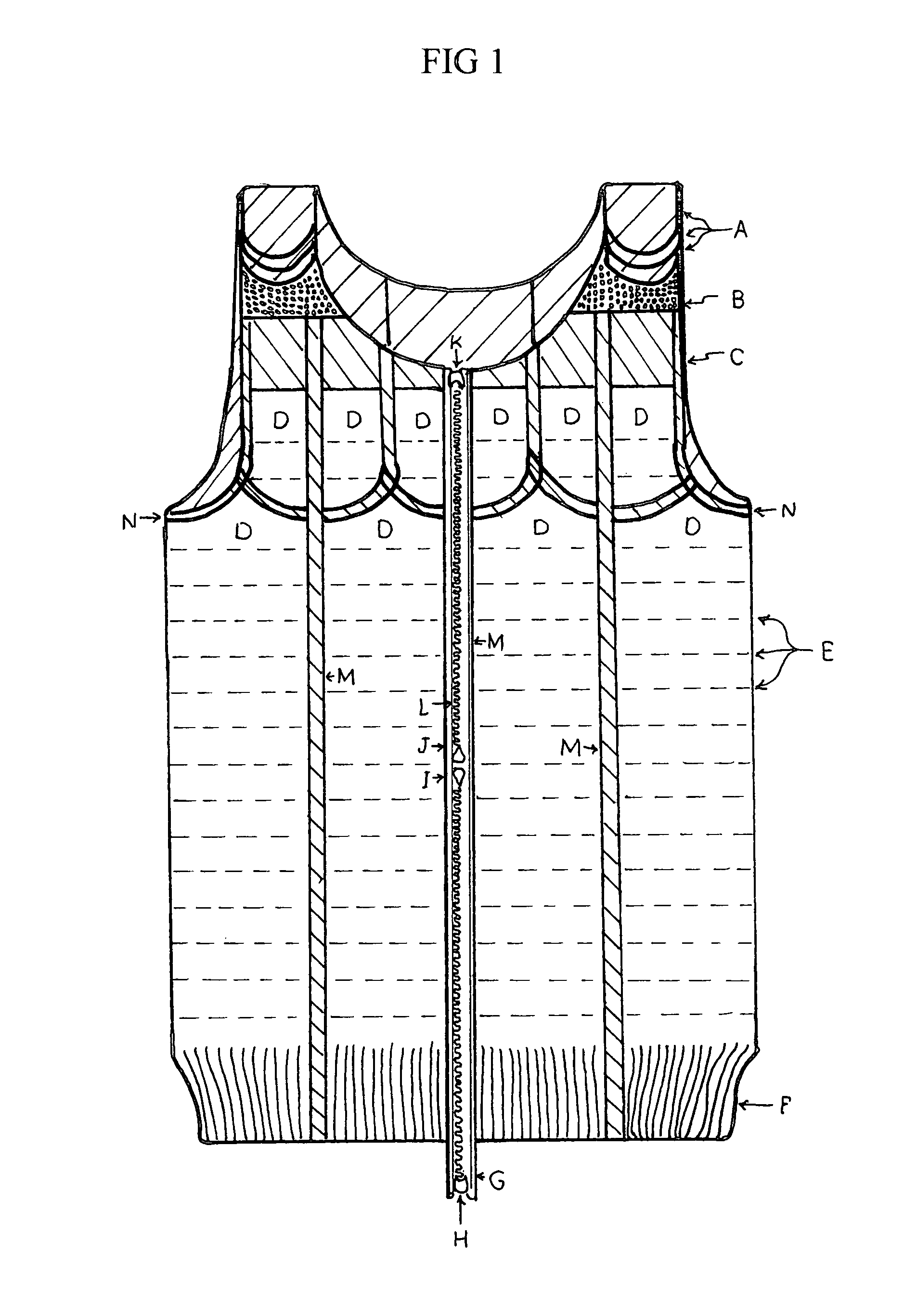

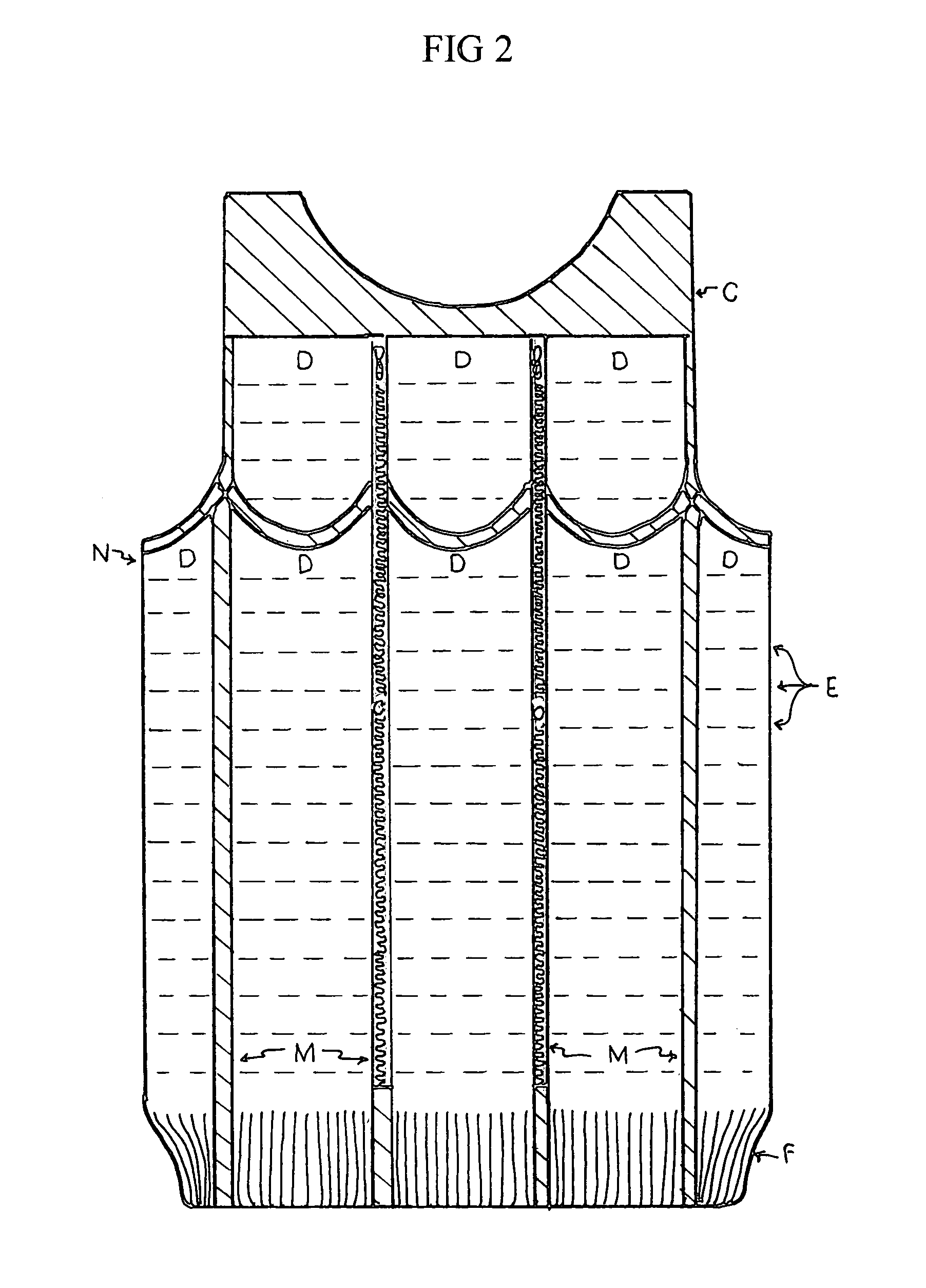

Weaving process for production of a full fashioned woven stretch garment with load carriage capability

InactiveUS7841369B1Easy to useHigher compressive forceJacquardsLoomsPulp and paper industryLoad carriage

A weaving process for constructing weft stretch full fashioned utility garments using a jacquard machine, an electronic loom and highly stretchable elastomeric fill yarns.

Owner:V PARADOX

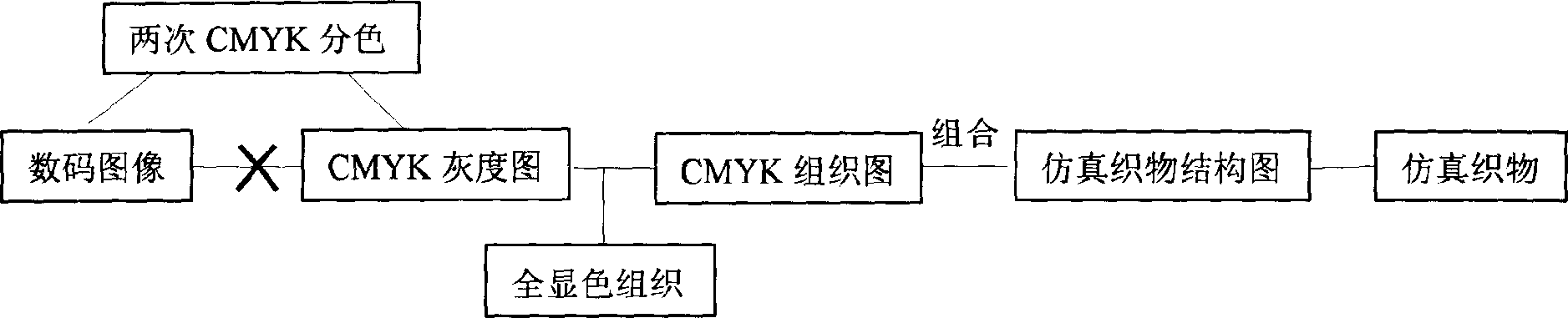

Method for digital image designing emulating fabric

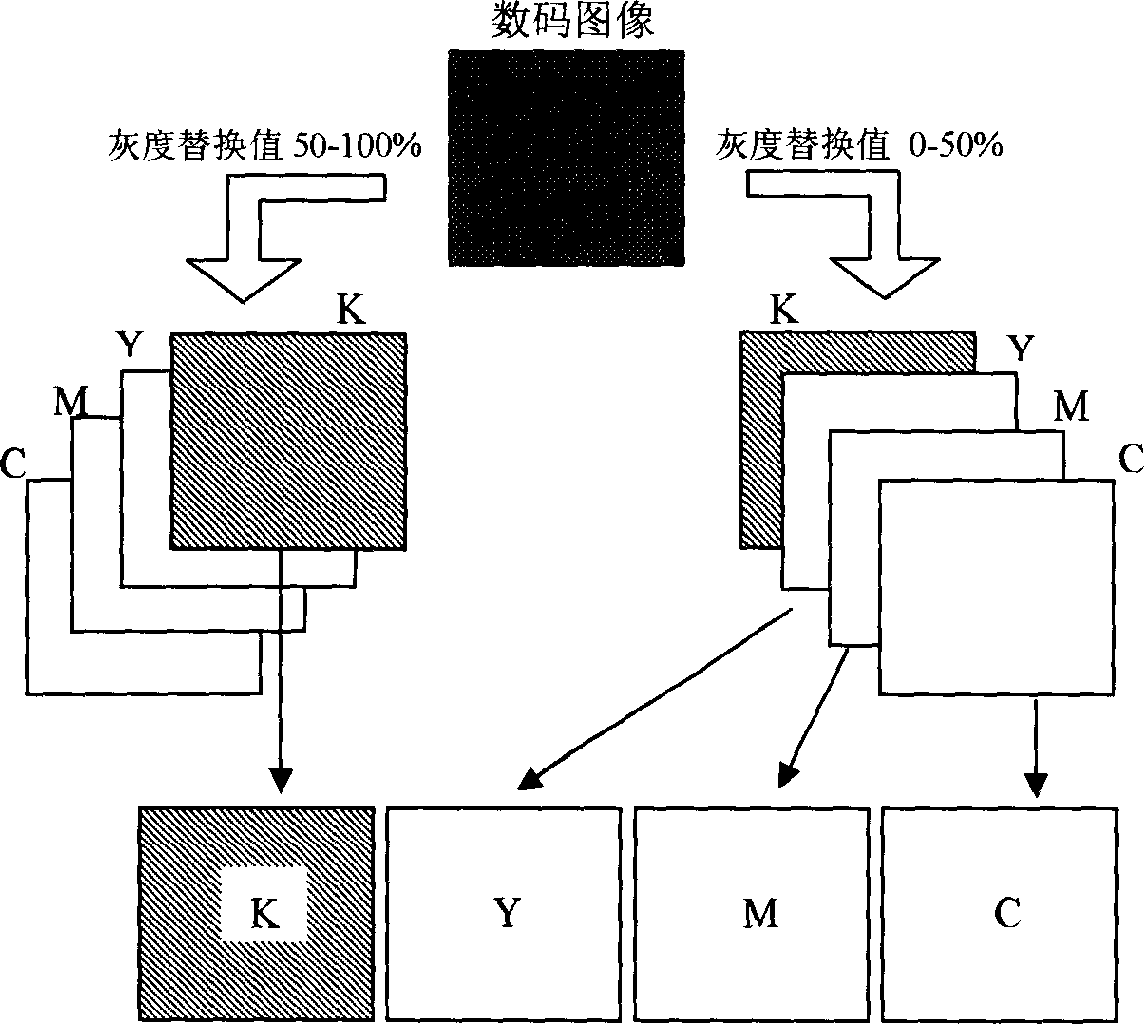

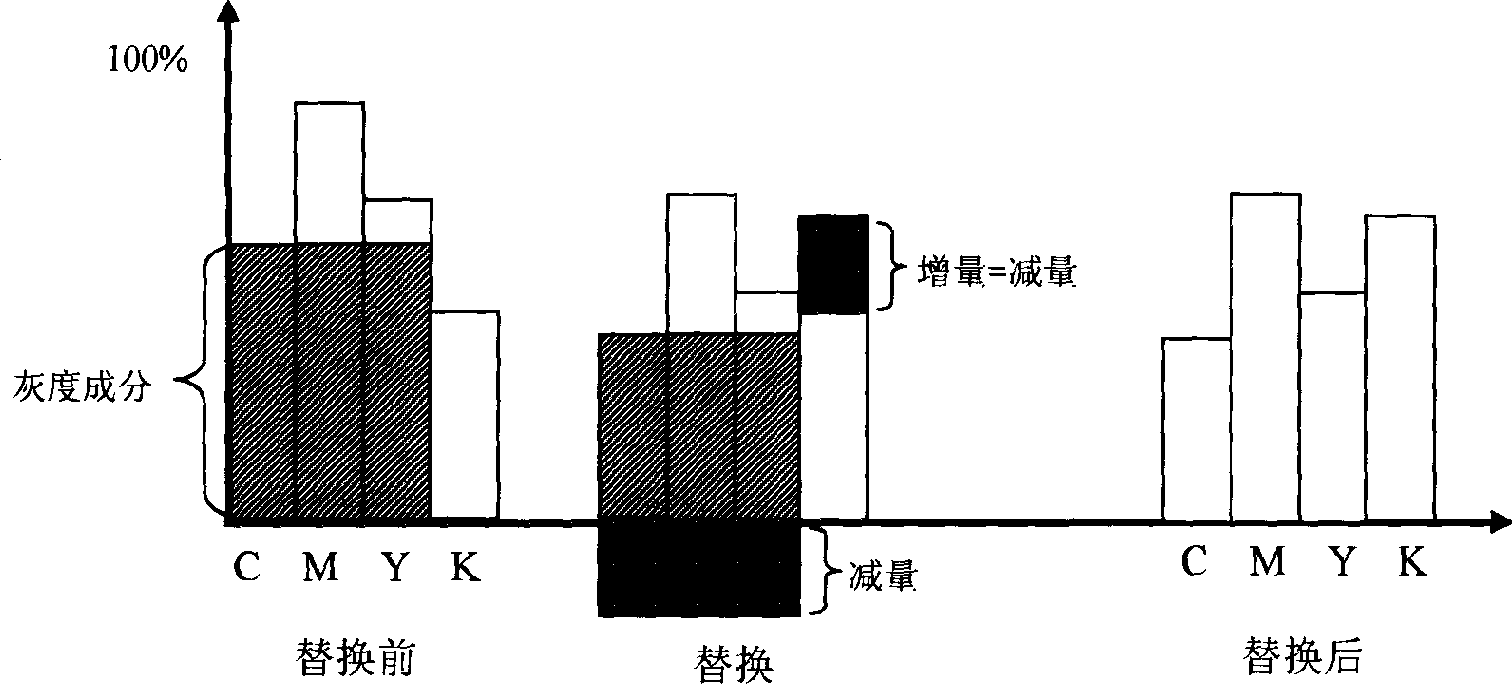

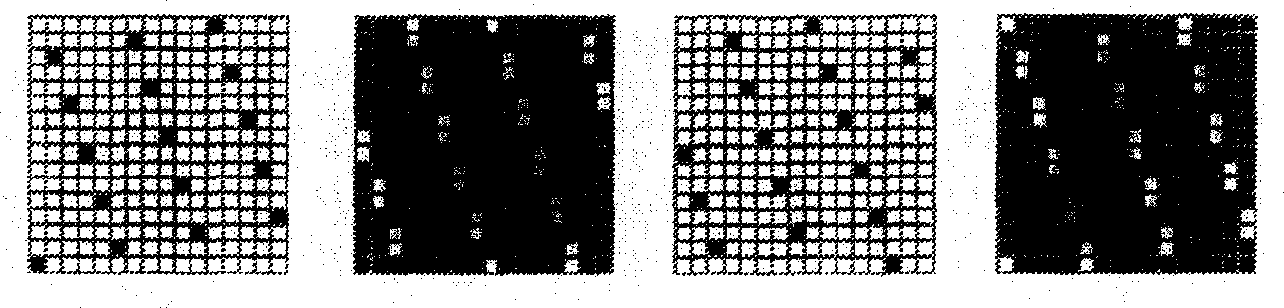

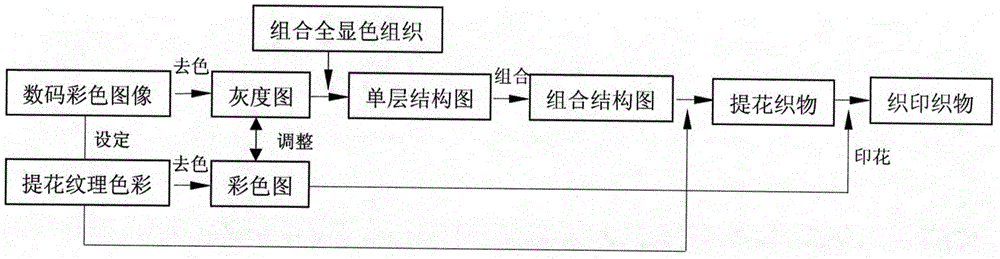

InactiveCN1772989ANo masking effectGuaranteed accuracyPattern making devicesEngineeringDigital image

The present invention provides a design method for designing warp and weft union fabric by using digital image. The designed fabric structure diagram can be used for making union fabric with emulation effect. Its main technical scheme includes the following steps: (1), adopting double color separation method, regulating gray scale replacement value, respectively obtaining green C, magenta M, yellow Y and black K pattern layers of digital image; (2), designing basic weave and matching weave which can meet full development requirements; and (3), making accurate replacement of digital image gray scale and weave, and combining and forming facsimile fabric structure diagram with full development effect.

Owner:ZHEJIANG SCI-TECH UNIV

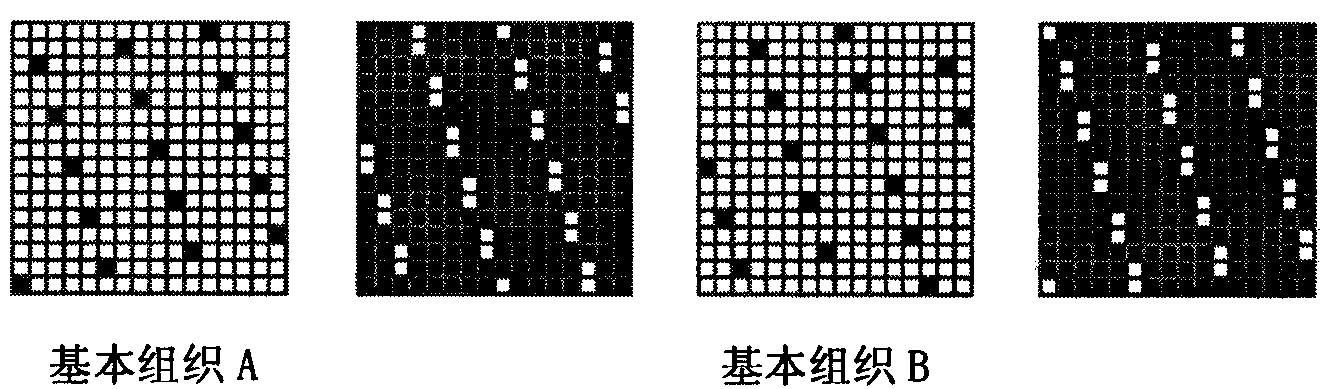

Full colour-rendering jacquard fabric structural design method

InactiveCN1710171AAccurately calculate the maximum combined color rendering numberEnhanced color rendering ability of effective combinationPattern making devicesSystem developmentIntelligent design

The invention discloses a full color jacquard fabric design which reforms the original idea and pattern covering contexture points, provides with a new structure design which acquires the jacquard fabric without covering contexture points. The design is based on phantom pattern alteration design, acquiring graticule full color effect, while satisfying the fabric balance requirement and adapted to computer figures of any subject. Main design programme includes: 1, full color basal texture and adaptive texture design; 2, full color basal texture and associative texture combination; 3, algorithmic method of full color racking pattern maximum efficient combination; 4, verification of full color jacquard texture; 5, production technique of full color jacquard texture. The invention improves the effective coloring combination to a million level, while satisfying the fabric balance requirement, can be applied to new digital racking pattern products, and also is a key technology in jacquard computer aided design system development.

Owner:ZHEJIANG SCI-TECH UNIV

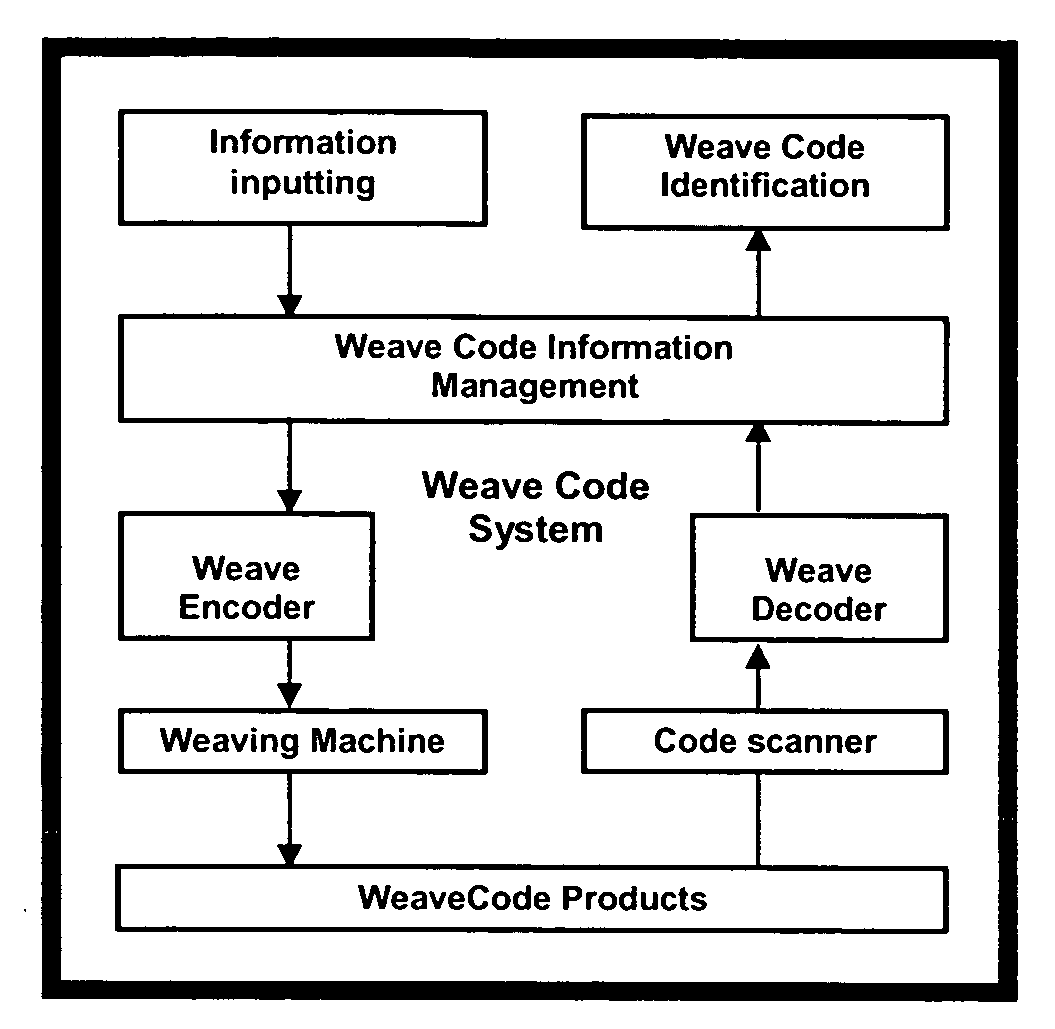

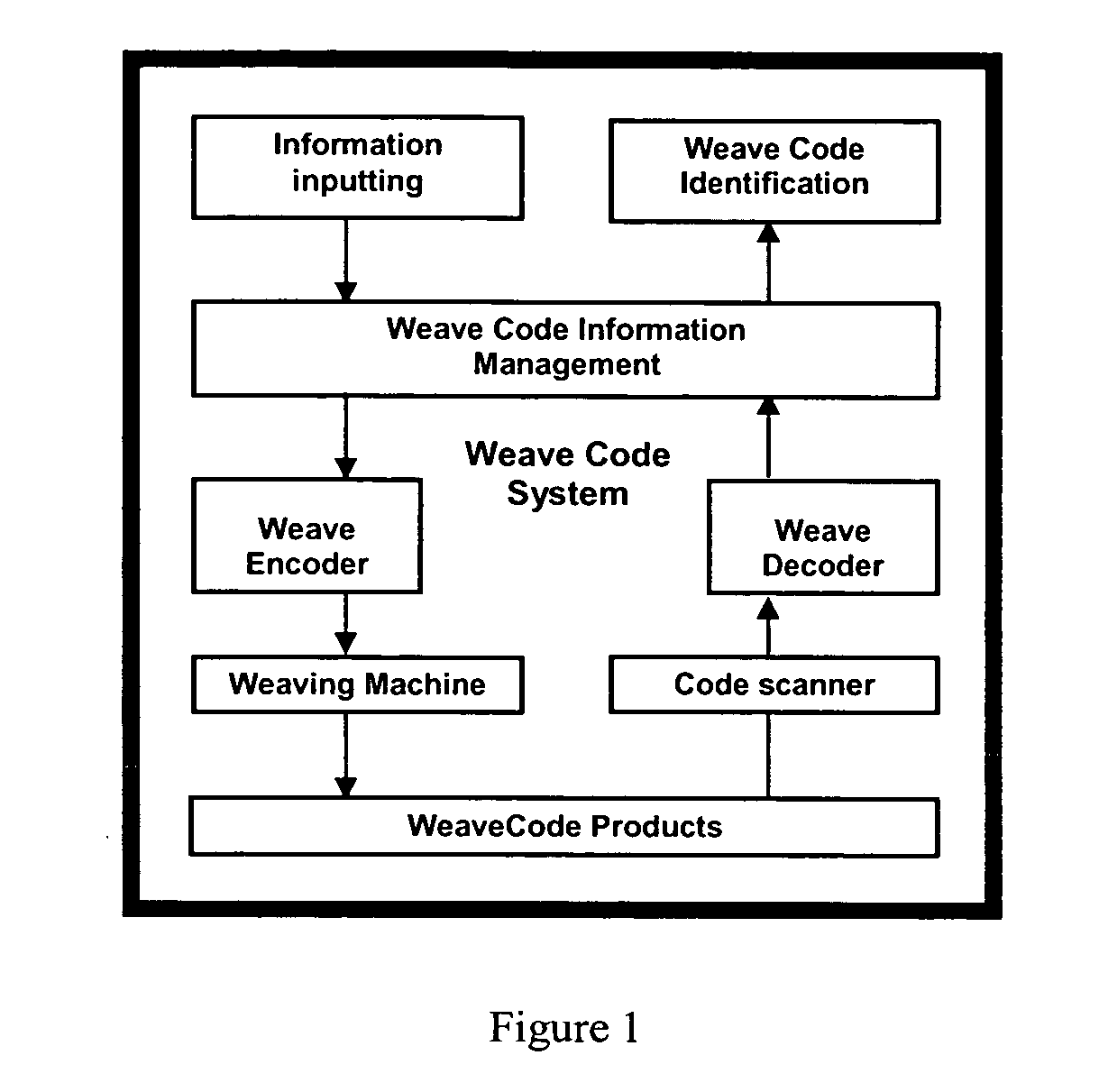

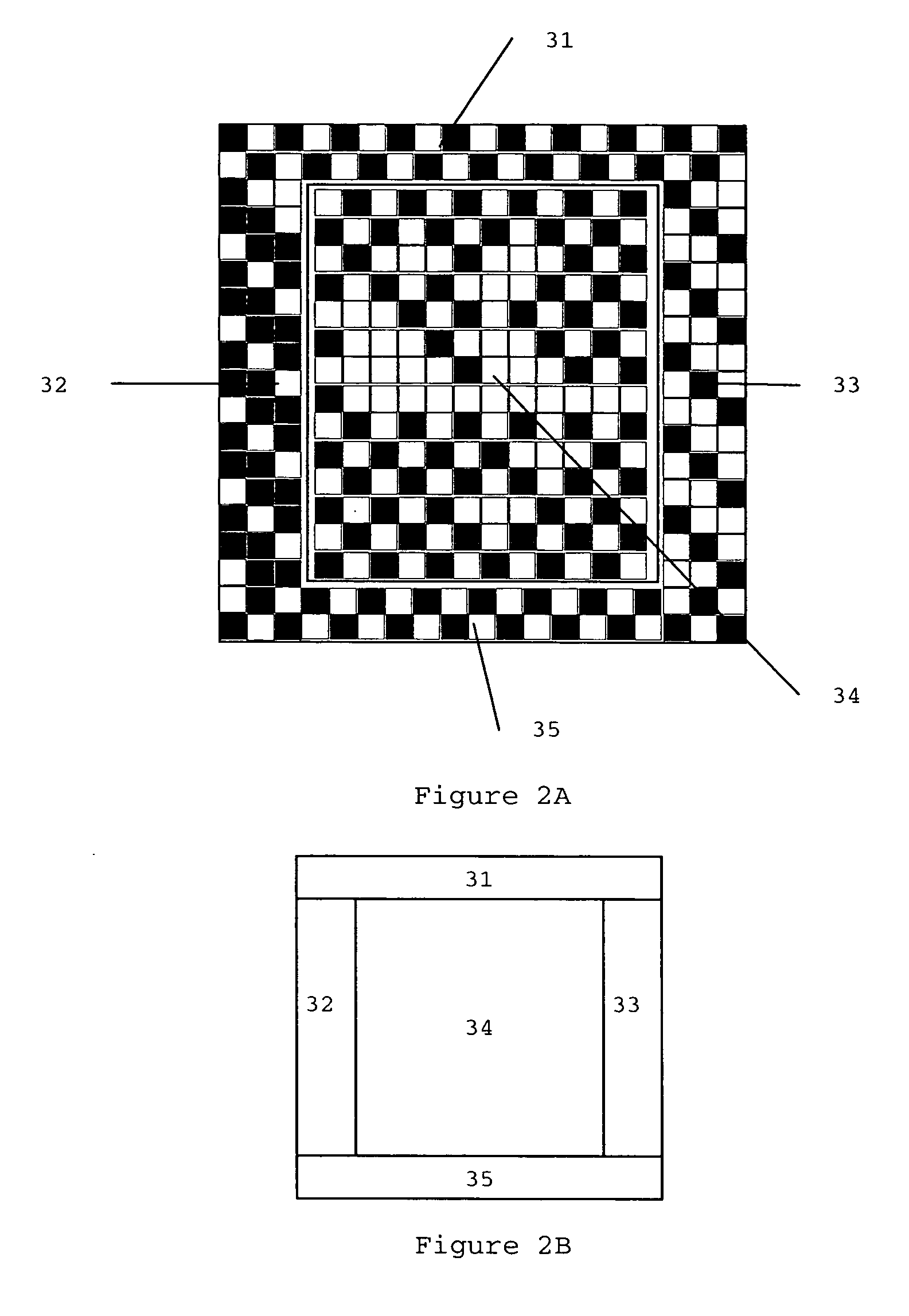

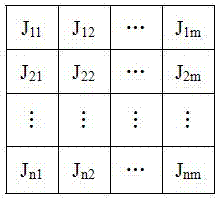

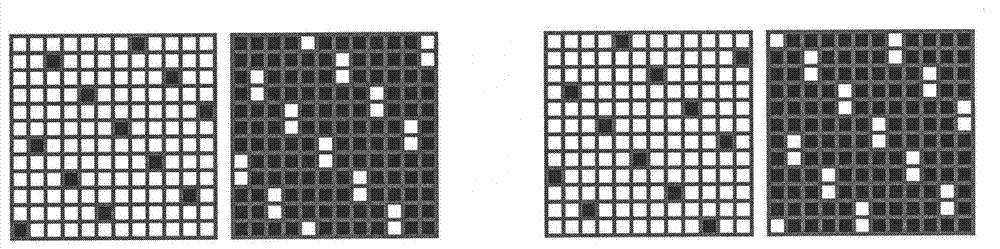

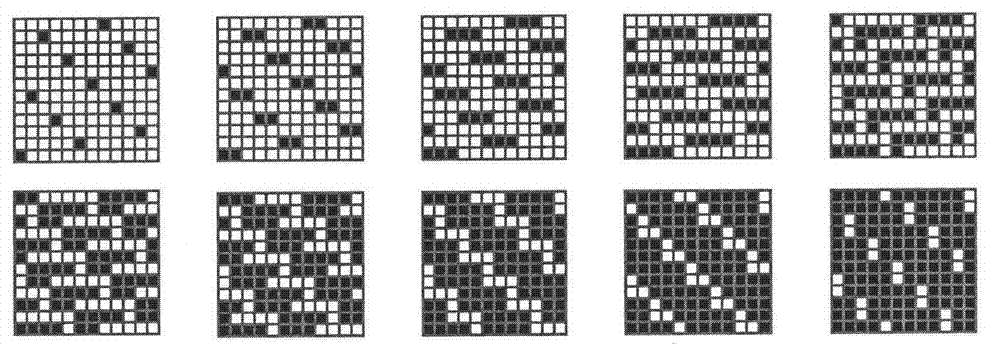

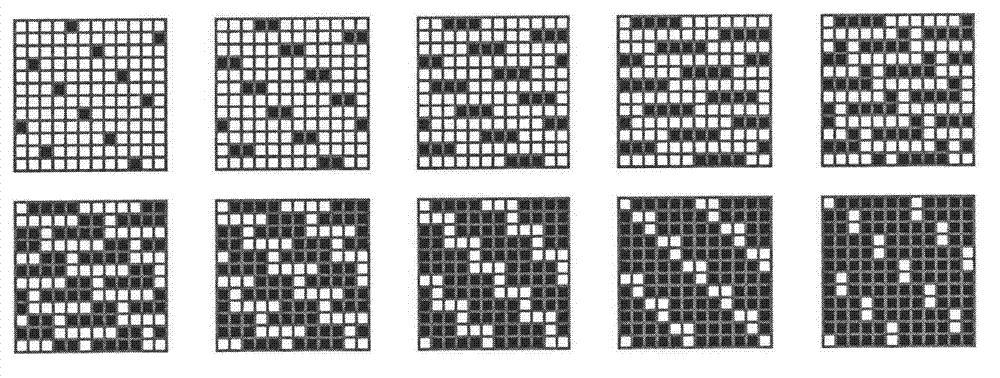

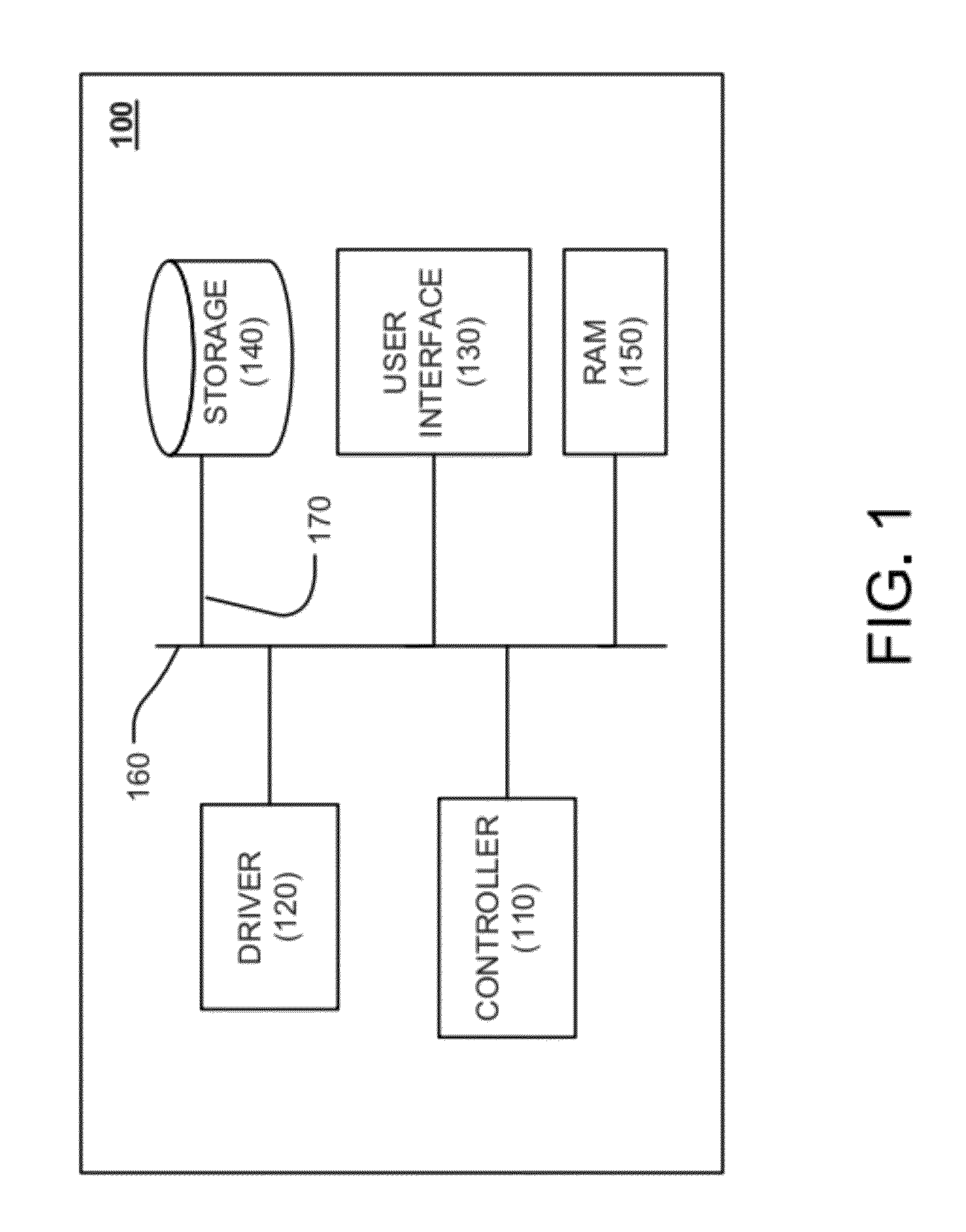

Method and system for utilizing fabric as storage medium

This invention provides a digital technology based on fabric weave for the encoding, identification and decoding of information. A method for storing information in fabric based on weaving, knitting, braiding or other yarn interlacing styles, comprising: inputting information into a computer; converting each unit of the information to a corresponding unit of a binary code; converting each the corresponding code unit into a unit matrix of weave code presenting by 0 and 1; or converting each unit of the information to a unit matrix of weave code presenting by 0 and 1 directly; generating a weave code matrix consisting of all the unit matrixes; manufacturing a piece of fabric according to the weave code matrix, wherein 1 represents warp on a weft and 0 represents weft on a warp.

Owner:THE HONG KONG POLYTECHNIC UNIV

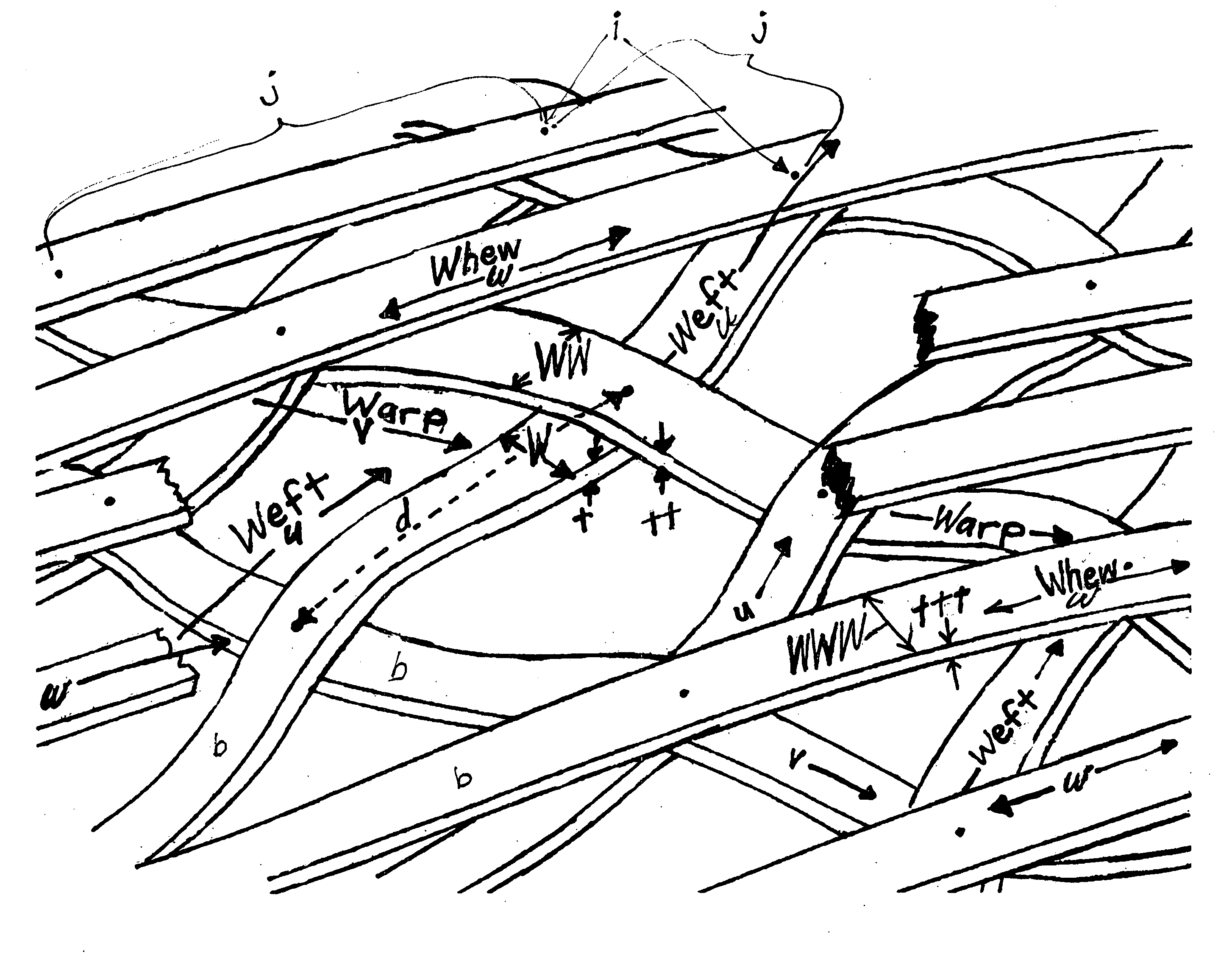

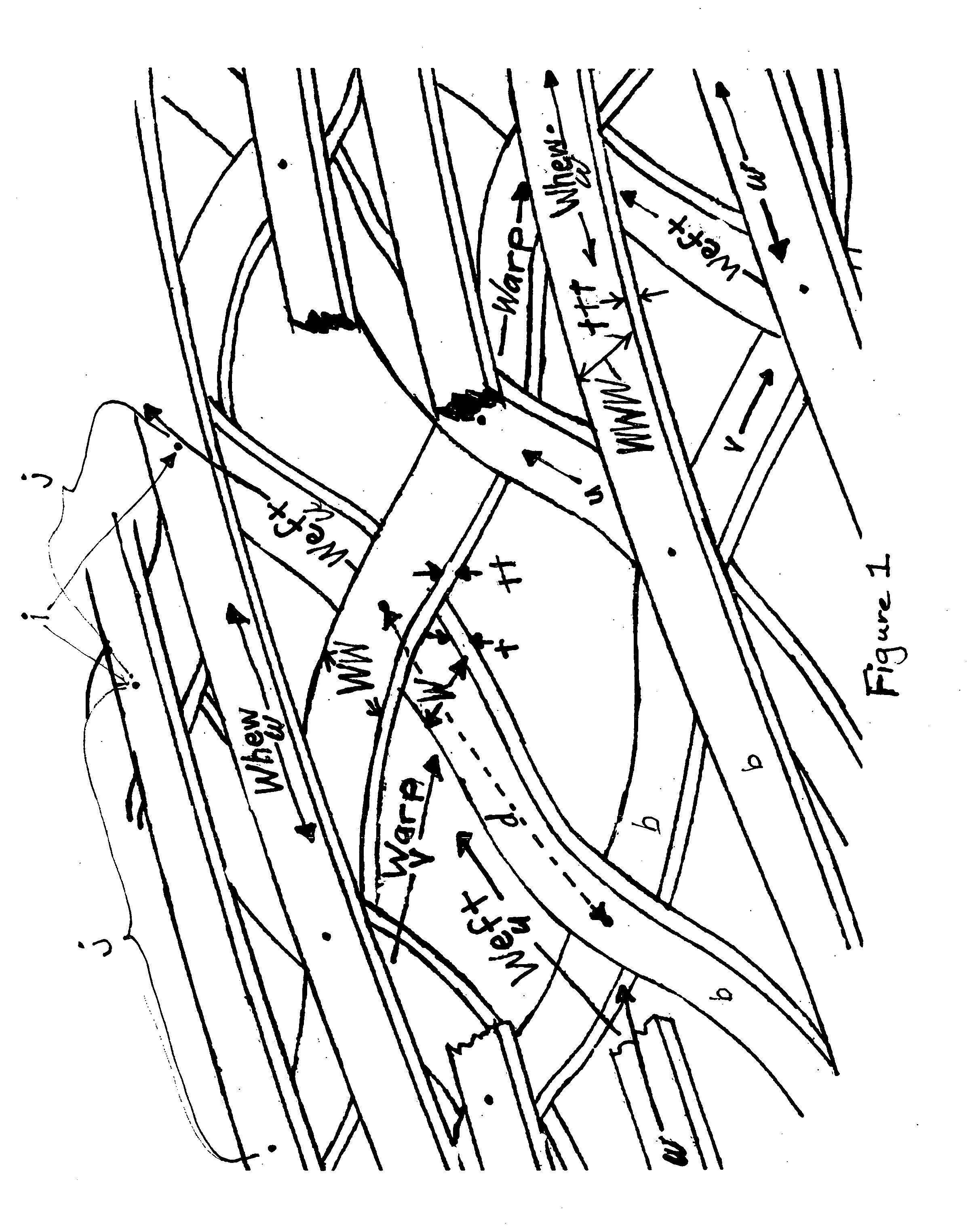

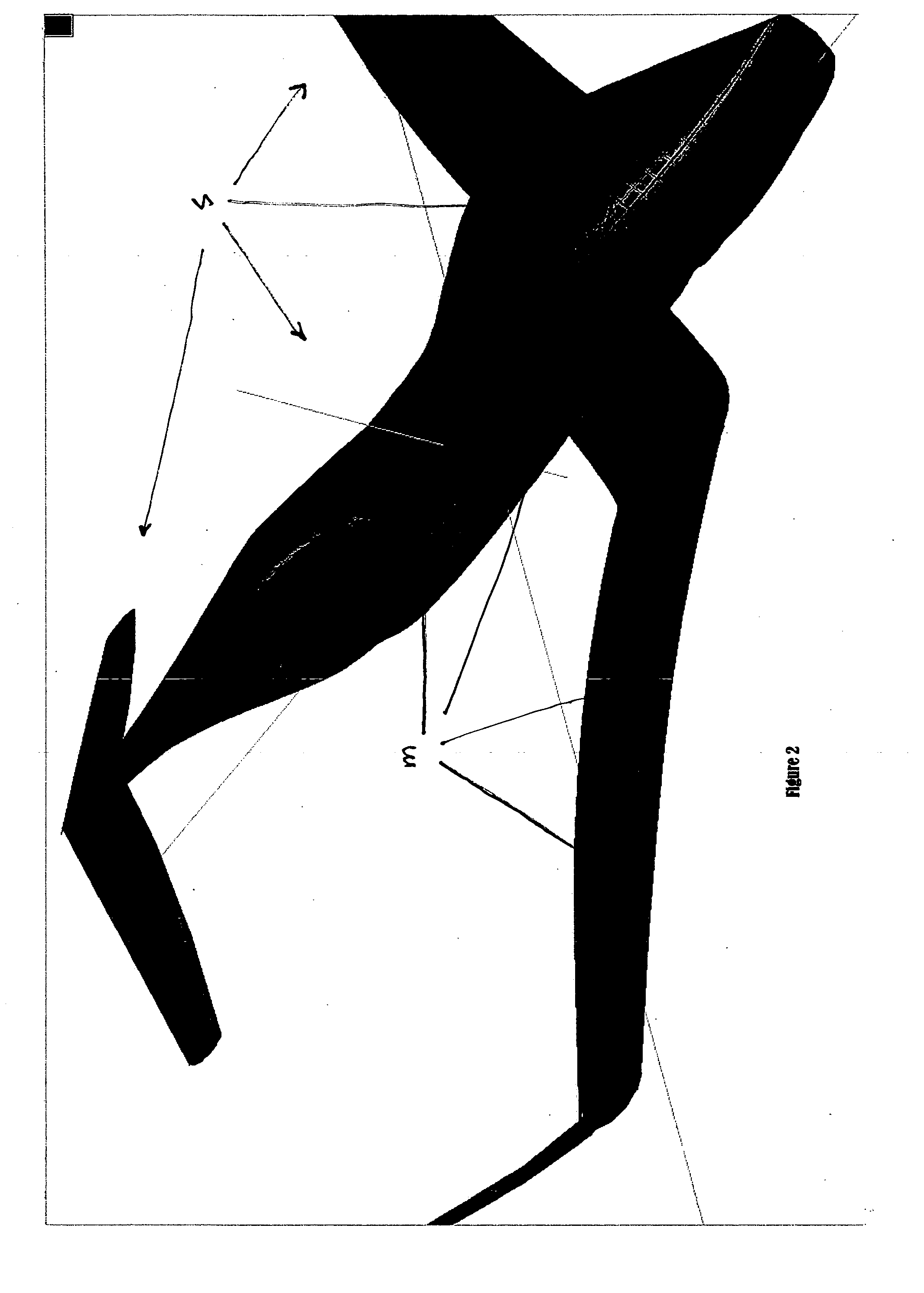

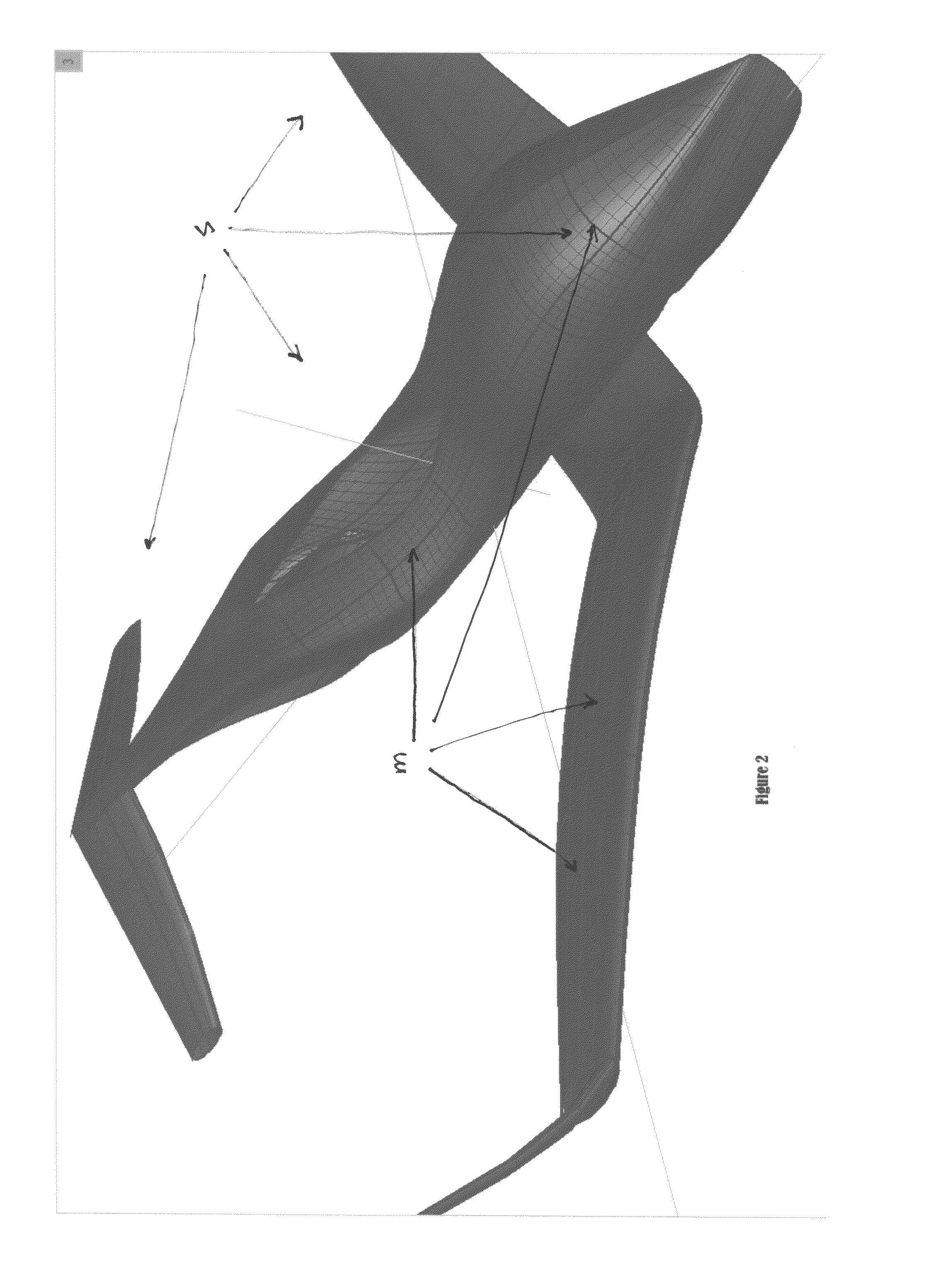

Weave, a utility method for designing and fabricating 3D structural shells, solids and their assemblages, without limitations on shape, scale, strength or material

Weave is a process for fabrication of freeform shells, proceeding from a formal definition of desired final shape(s), to an optimized parametric mesh of said shape(s), to physical battens which, once fastened at calculated crossings, realize the final object of use. This initially iso-parametric mesh is triangulated for self-shaping and rigidity, and optionally spiralized for economy, integrity of raw material, and surface smoothness The mesh's density and topology is controlled by Weave such that the constructed object automatically takes on, as it is fastened, the shape and dimensions of the designed fabrication without explicit registration, alignment or ambiguity. Essential is the precise adjustment of batten length between intersections to accomodate interweaving. Weave's calculations also accomodate all other necessary geometrical and material factors. Weave does not constrain shape type, complexity, scale or material. A single fabrication tool is required, and no special construction skills or building environment are needed.

Owner:SCHWENN PETER THOMAS

Method for fabricating wovens

InactiveUS6918410B1Reduced set per beamReduce rejectionPile-fabric loomsPattern making devicesEngineeringAirbag

A method for weaving single-layered and / or multi-layered woven fabric, especially airbag fabric, includes interweaving warp threads delivered by at least two warp beams.

Owner:GLOBAL SAFETY TEXTILES

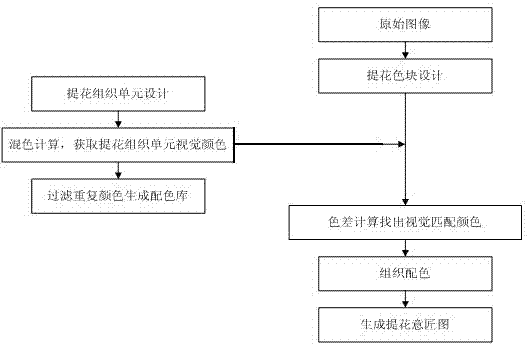

Method suitable for weaving colored jacquard fabric with large texture thread number

InactiveCN103088515ABroaden the application marketVariety of colorsPattern making devicesColor imageYarn

The invention discloses a method suitable for weaving a colored jacquard fabric with a large texture thread number. The method comprises the steps of firstly determining parameters of jacquard texture units, and storing the parameters in a database; then determining the parameters of jacquard color lumps and the size and extension sequence of pattern image blocks, reading colored design patterns to be woven into a computer for division, and carrying out index numbering; and scanning each pixel point for calculation of color difference, arranging the jacquard color lumps based on a weaving scheme with maximal color similarity in a color library to form a weaving program, and splicing all jacquard subblocks after controlling a colored digital jacquard machine to weave respectively. The method can complete the jacquard design and weaving of color images by only utilizing 4-8 colored yarns and achieve the jacquard task with the large texture thread number on the premise of not bringing up new demands on a conventional jacquard machine process; and simultaneously the color level breaks through 256 colors in color selection so as to be more colorful and improve the quality and additional value of products.

Owner:SUZHOU UNIV

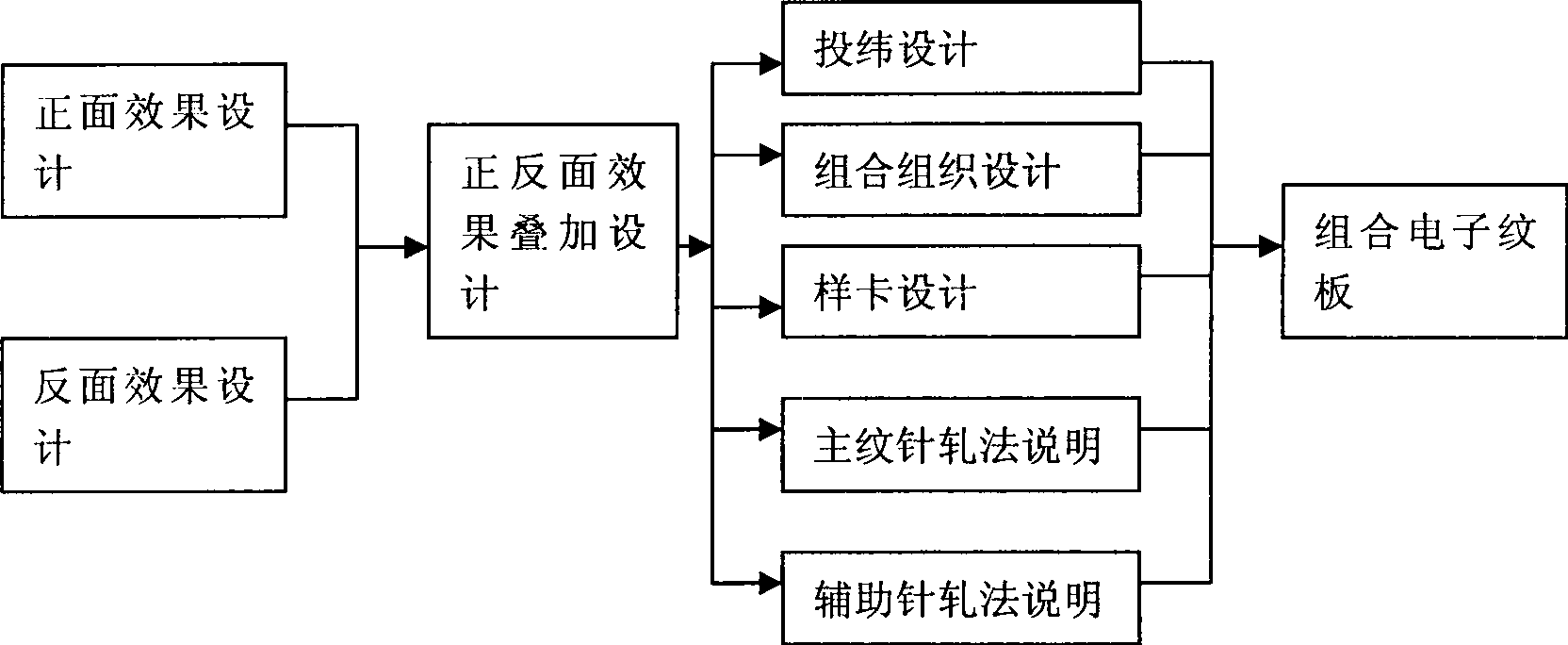

All-coloring-structure-based knitting and printing combined jacquard design method

ActiveCN104532439AMeet the technical requirements of mass productionEnable accurate simulationPattern making devicesColor effectHigh volume manufacturing

The invention provides an all-coloring-structure-based knitting and printing combined jacquard design method which is characterized in that double effects of texture simulation and color simulation on the surface of a fabric are realized by adopting a design method which is characterized in that knitting and printing are combined with each other for a single digital pattern. The method mainly comprises the following technical steps: (1) digital pattern design; (2) all-coloring structure design; (3) design of a combined fabric structure pattern; (4) jacquard fabric production; and (5) printing of the jacquard fabric. The knitted part on the jacquard produced by the design method represents a concave-convex touch effect and a single-color effect of texture simulation of the pattern and the printed part and the jacquard texture color are matched to represent a colorful visual effect of color simulation of the pattern, so that the designed fabric can satisfy the technical requirement of batch production.

Owner:ZHEJIANG SCI-TECH UNIV

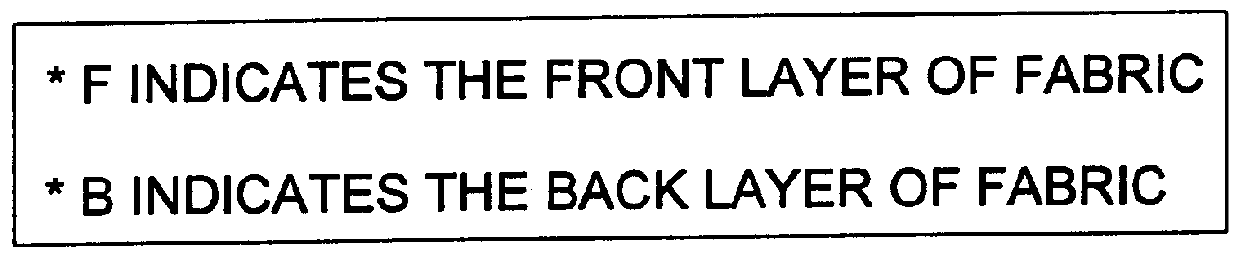

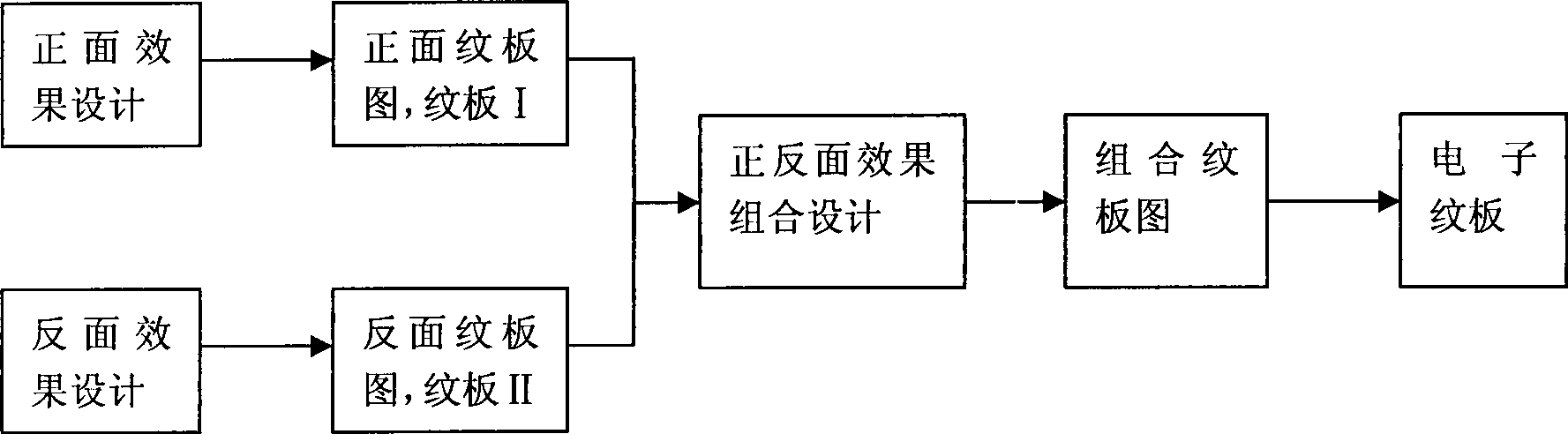

Design method of two-sided different effect digital jacquard dress fabric

InactiveCN101457433ARich varietyProtection precisionPattern making devicesCard-punching apparatusPunchingEngineering

The invention discloses a design method for double-faced different-effect digital jacquard weave garment material. The design method for the double-faced different-effect digital jacquard weave garment material is characterized in that the method comprises the steps as follows: (1) the front face effect design is carried out on the fabric to obtain a front pattern and the back face effect design is carried out on the fabric to obtain a back pattern; (2) the front pattern and the back pattern are superimposed to be displayed in one plan of weave, and then picking design, composite weave design, scale design, major weave needle-punching introduction and accessorial needle-punching introduction are carried out; (3) a composite digital weave plate is generated. The method is applicable to garment material development to weave double-faced different-effect digital jacquard weave garment material with different colors, patterns and stylistic characteristics on the front and back faces.

Owner:JIAXING YUELONG JACQUARD & WEAVING +1

Method for producing variable loop fabric by using fixed jacquard mounting process

Owner:ZHEJIANG SCI-TECH UNIV

Method for producing dobby-jacquard jointly-shedded multilayer jacquard fabric

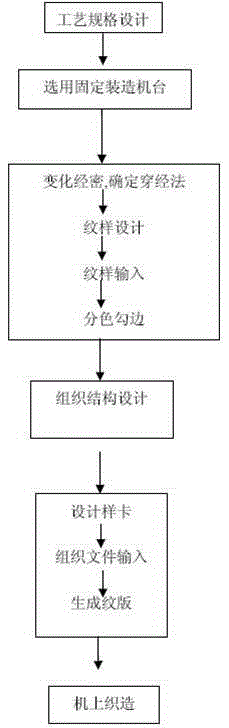

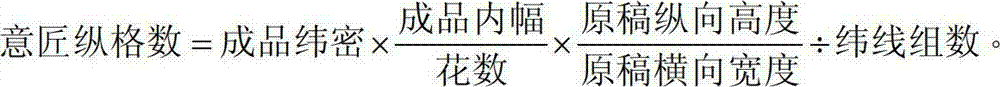

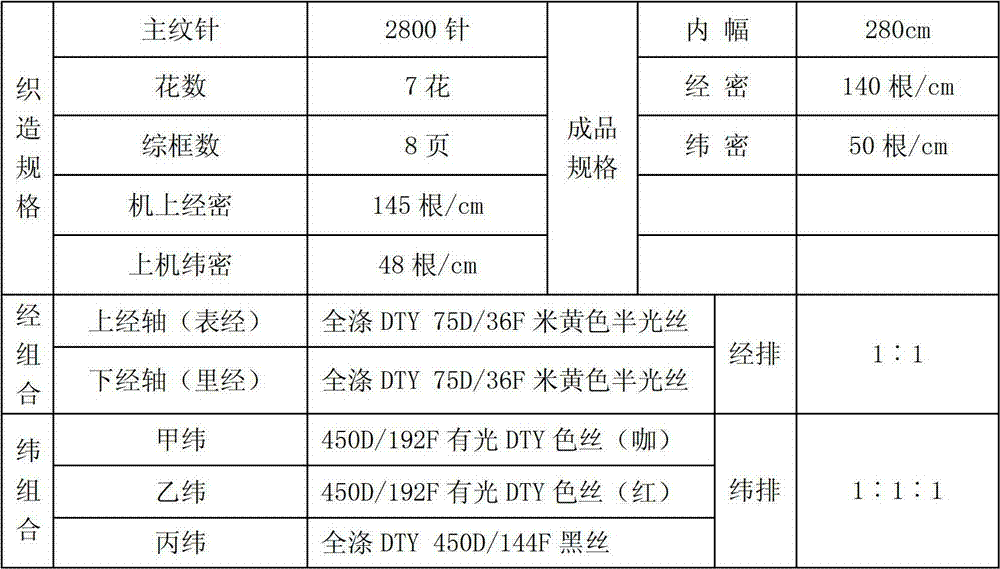

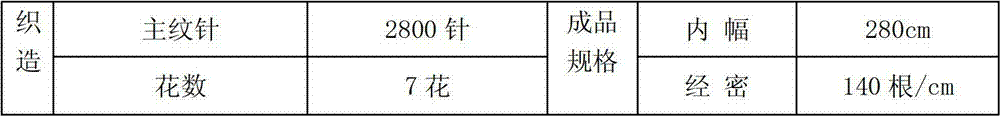

The invention relates to a method for producing a dobby-jacquard jointly-shedded multilayer jacquard fabric, which comprises the following steps in sequence: (a) designing the process specifications; (b) designing the artistic conception; (c) designing the organizational structure; (d) generating a pattern card; and (e) weaving by using a machine. In the step (a), a double-warp-shaft weaving machine which comprises an upper warp shaft and a lower warp shaft is used for weaving two or more groups of warp yarn, and the warp yarn on the upper warp shaft and the warp yarn on the lower warp shaft are arrayed in sequence at the same amount on the double-warp-shaft weaving machine. In the step (c), two shedding controlling mechanisms including a jacquard shedding controlling mechanism and a dobby shedding controlling mechanism are used for designing the organizational structure independently and combining in the weaving process. In the step (e), 8 to 16 heald frames are used for controlling the warp yarn of the lower warp shaft in the process of weaving of the double-warp-shaft weaving machine, and the jacquard weave information is inputted into a jacquard head. Due to the adoption of the method, the multilayer jacquard fabric with high warp and weft density, good shading performance and different usual jacquard effects on two sides can be woven.

Owner:浙江兴澳科技有限公司

Flash coloured cloth design method

ActiveCN1730749AWith flashing effectGood effectPattern making devicesWoven fabricsEngineeringDigital image

The design process of versicolor fabric includes the main technological steps of: 1. design of whole versicolor base texture and the fitting texture; 2. design of computerized digital pattern; and 3. texture substitution to form the combined fabric structure pattern. By means of the designed fabric structure pattern and matched reasonable production process, weft versicolor fabric and warp versicolor fabric may be produced. The present invention can meet the technological requirement of jacquard making, and the designed whole versicolor structure may be combined with digital image in certain technological characteristic to design versicolor fabric with novel pattern.

Owner:ZHEJIANG SCI-TECH UNIV

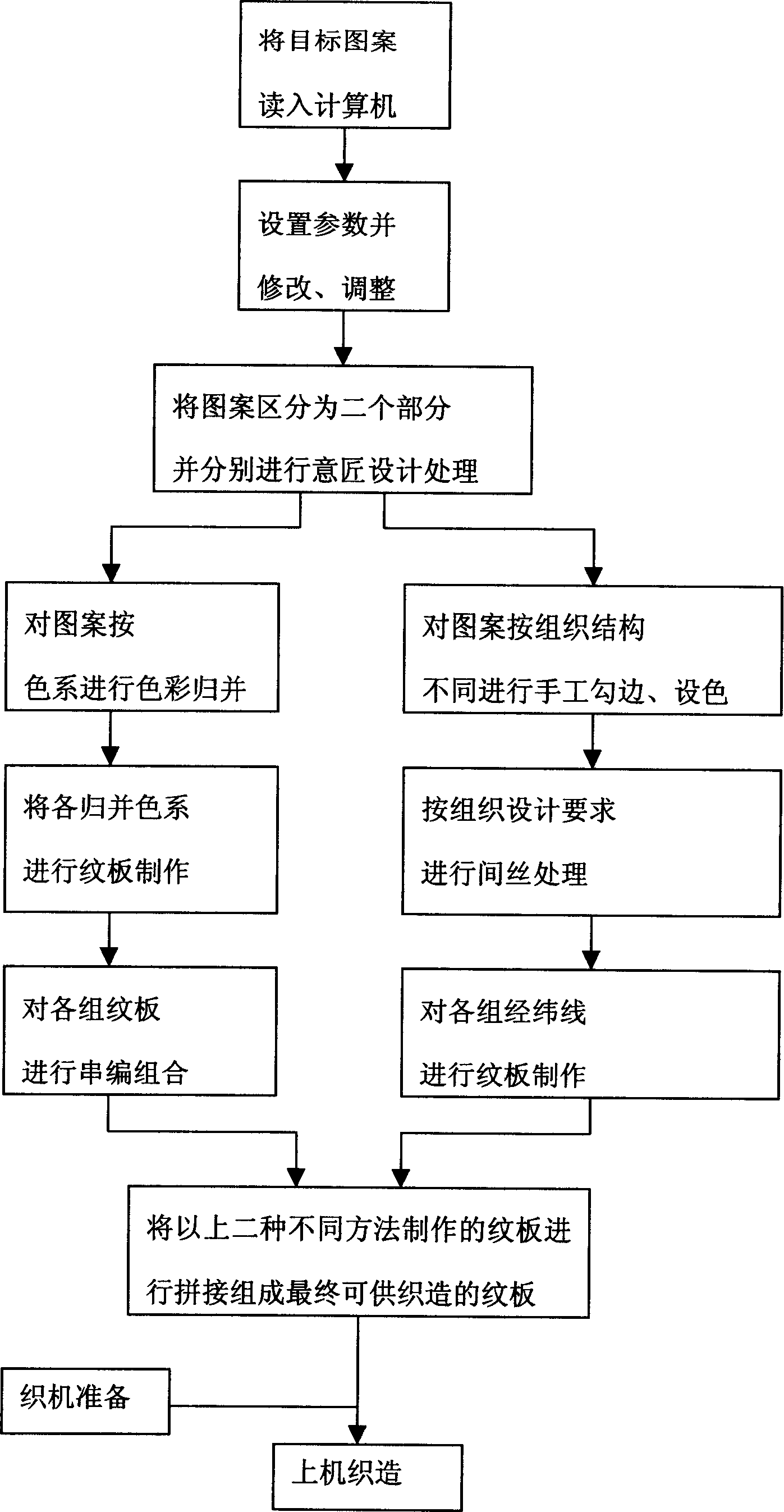

Making process of color jacquard fabric with different speciality

InactiveCN1847489AIngenious combinationRich interweaving color effectJacquardsPattern making devicesSubject matterComputer software

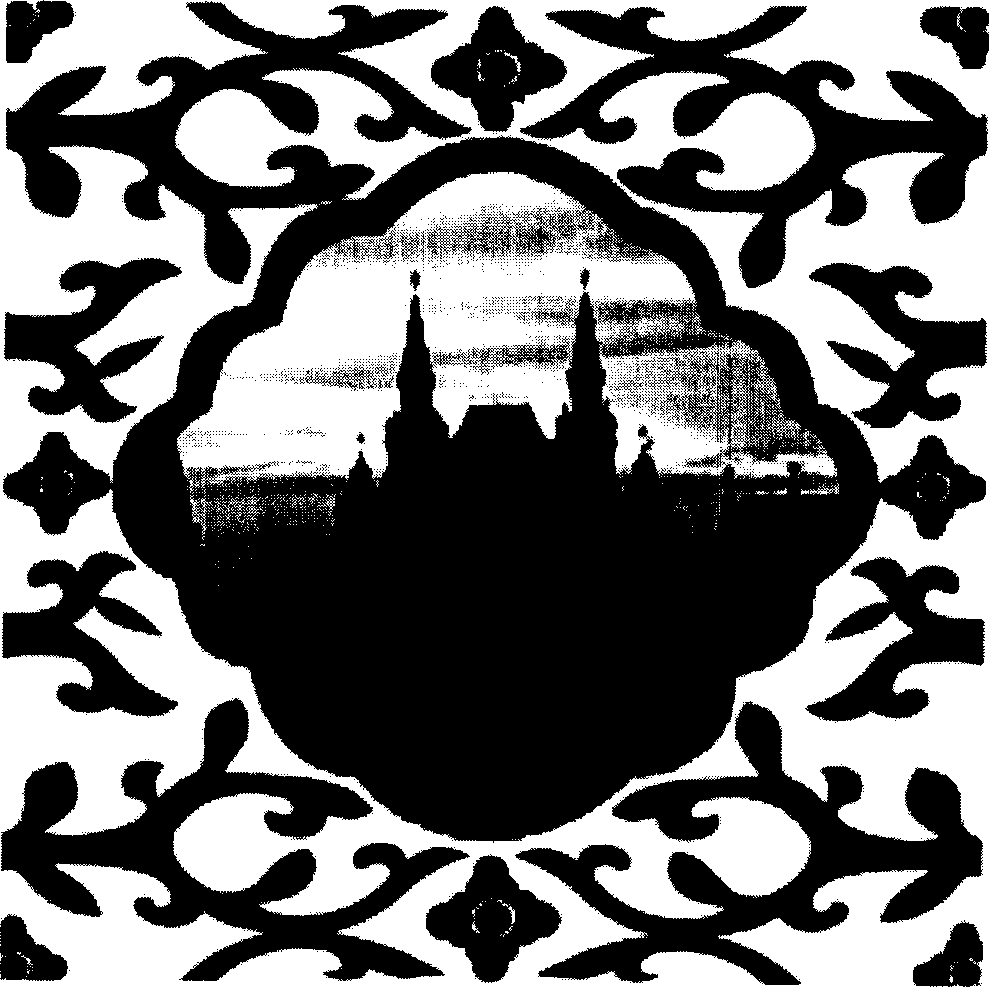

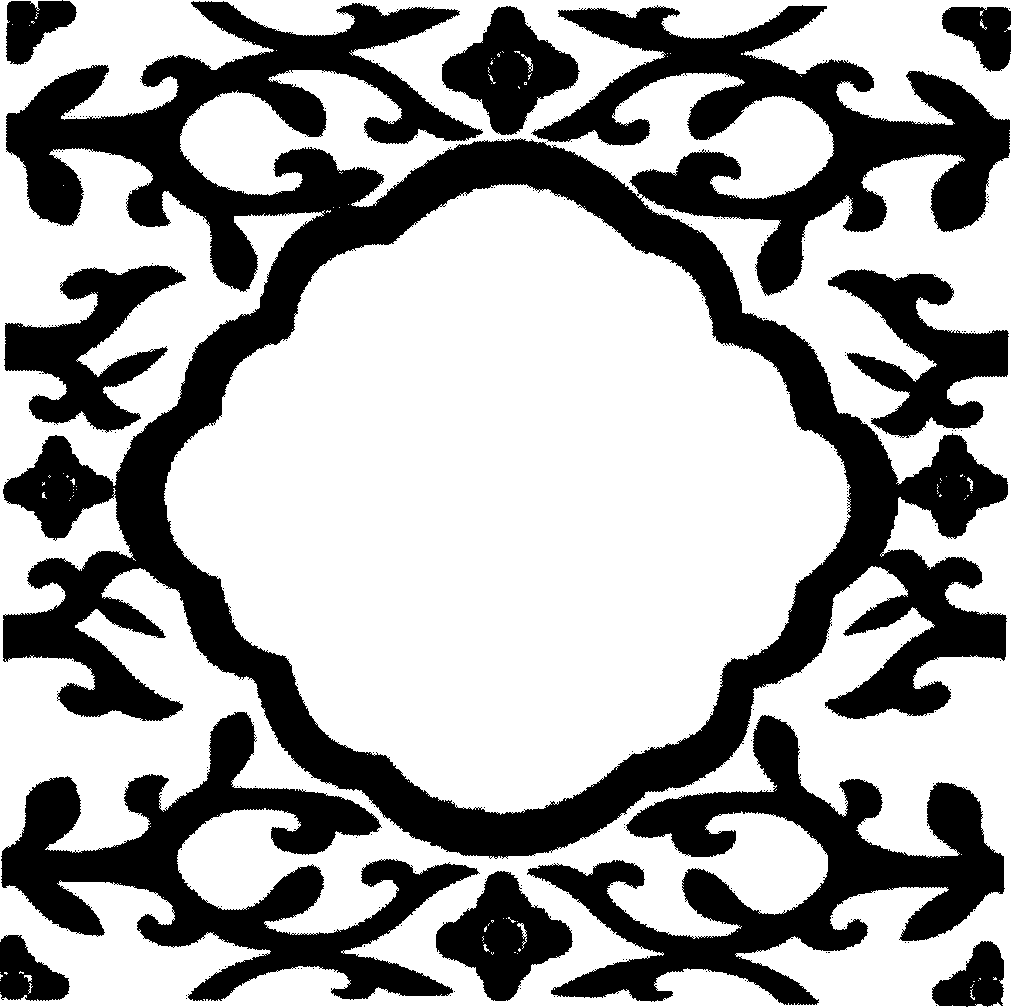

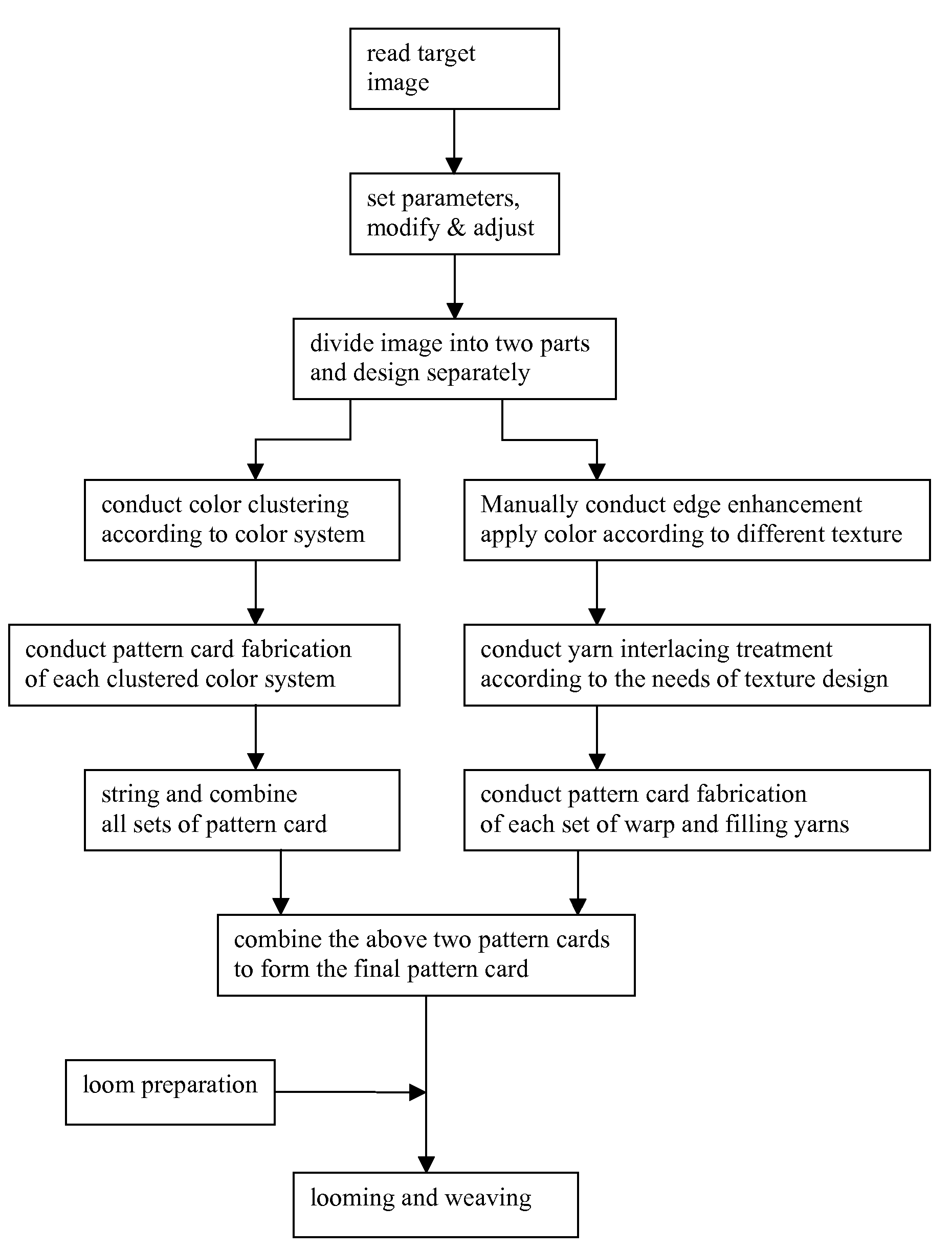

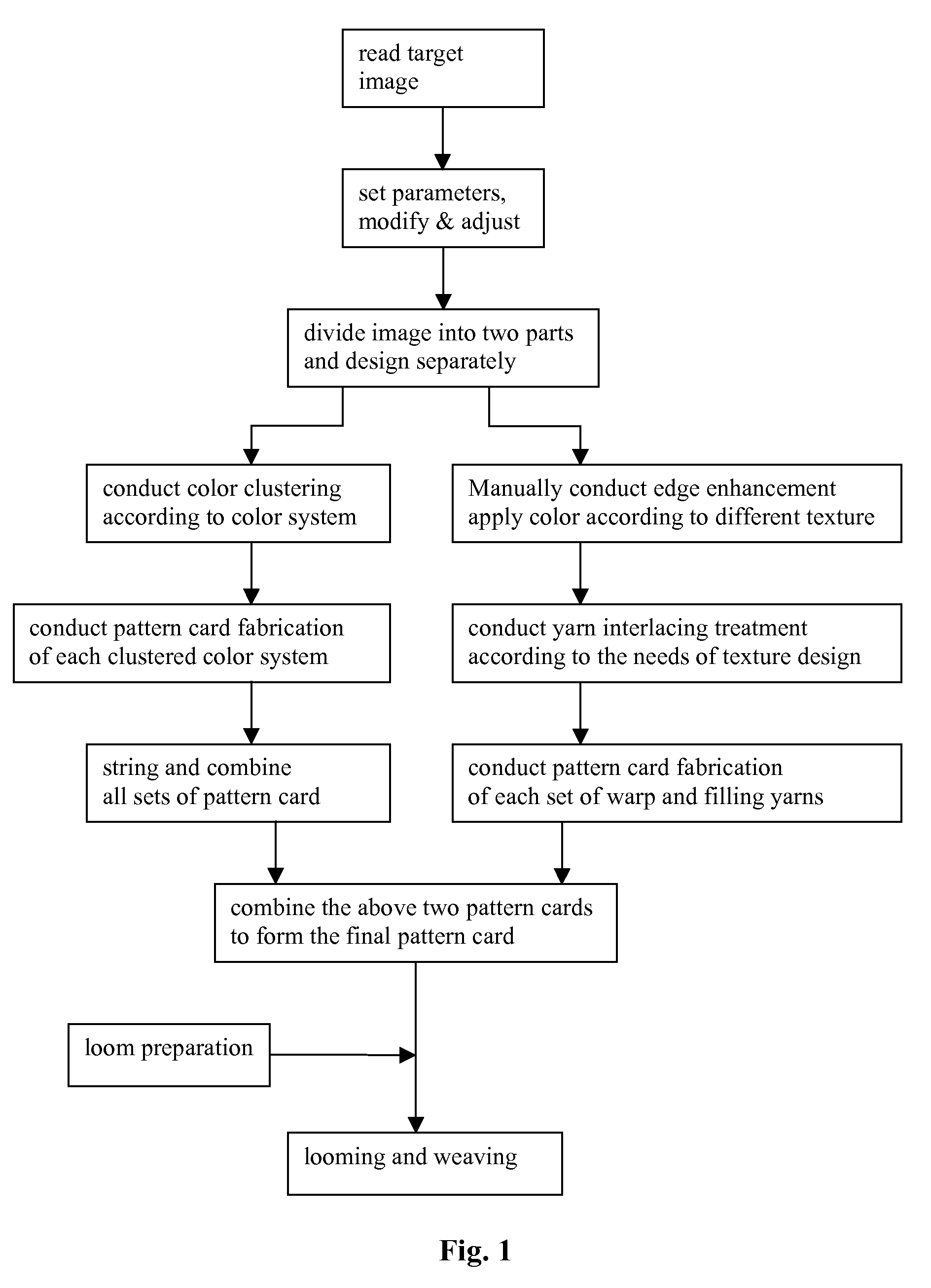

The present invention discloses the making process of color jacquard fabric possessing different speciality. The making process includes the steps of card design and making, loom preparation, and weaving. The step of card design and making includes reading the target image of the jacquard into the computer, regulating the read image and setting parameters, giving image pixel number corresponding to the image sizes, frame modifying design and regulation of the read image, separating the processed target image into subject image part and auxiliary pattern parts and separated image and pattern design and card design with the jacquard computer software, superposing the two designed cards to form one image and pattern card and saving. The said making process can obtain jacquard fabric with vivid picture, rich color representation and patter well combined together.

Owner:李加林

Method of Fabricating Color Jacquard Fabric

InactiveUS20070263008A1Easy to makeEasy to operateCathode-ray tube indicatorsPattern making devicesComputer graphics (images)Algorithm

This invention discloses a method of fabricating color jacquard fabric, comprising the processes of design and fabrication of pattern card, loom preparation, looming and weaving. The steps of design and fabrication of pattern card are: reading target image for jacquard into a computer; adjusting the image and setting parameters; selecting pixel value according to image dimensions; modifying the image; dividing the modified target image into motif image and auxiliary pattern around the motif image, designing and making the pattern card of motif image and auxiliary pattern of different design characteristics by jacquard design software; and finally combining said two pattern cards into a pattern card that represents the image and pattern of different characteristics in one fabric with corresponding warp and filling yarns. The invention can provide vivid lifelike picture of fabric, integrating rich color representation and artful pattern.

Owner:SILK ROAD HLDG GRP CO LTD +1

Method for designing structure of double-side colored jacquard fabric

ActiveCN102828319AFull colorSatisfy the technical requirements of interweave structure balancePattern making devicesSpecial data processing applicationsYarnHigh volume manufacturing

The invention provides a method for designing the structure of double-side colored jacquard fabric, which mainly comprises the following technical steps: (1) designing full-color textures; (2) designing digital patterns on the front side and the back side of the fabric by using a computer; (3) replacing the textures, and combining to form the structural chart of the front side of the fabric; (4) replacing textures, and combining to form the structural chart of the back side of the fabric; (5) designing binding textures; and (6) combining the structures of the front side and the back side of the fabric to form the structural chart of the double-side colored jacquard fabric. The method is technically characterized in that: the front side and the back side of the double-sided fabric are both provided with an even group of yarn in any one interweaving direction and one group of yarn in the other direction, the isodirectional even group yarn for showing the pattern effect of the front side or back side can not cover mutually so that the jacquard fabric is characterized by being colored on double sides and has colorful halo patterns and complicated patterns, and the front side and the back side of the fabric are combined into a whole body by the regular binding textures. The fabric designed by adopting the technology can meet the technical requirements of interwoven structure balance and mass production.

Owner:ZHEJIANG SCI-TECH UNIV

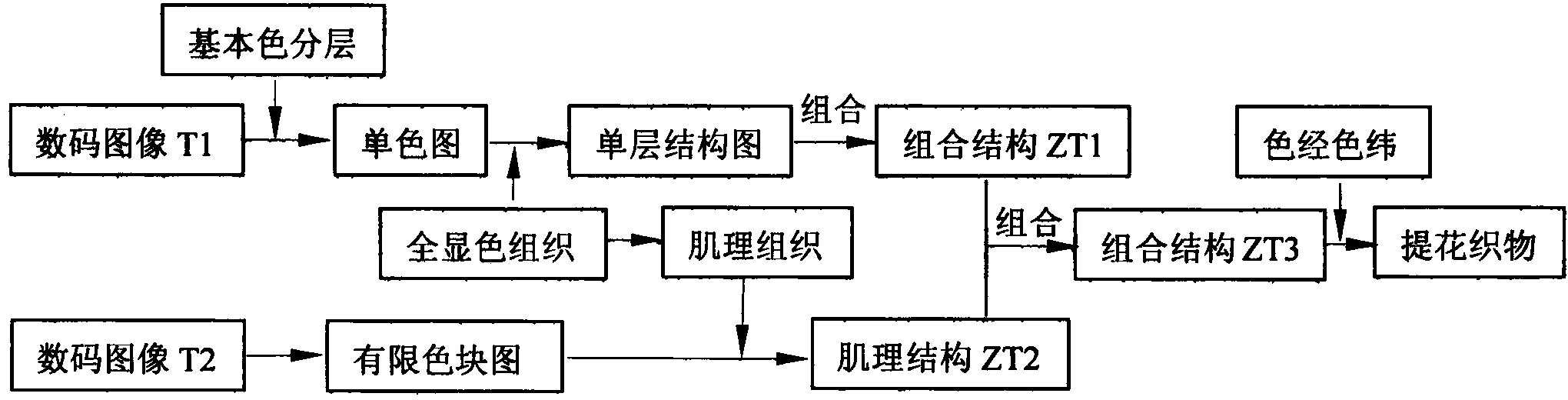

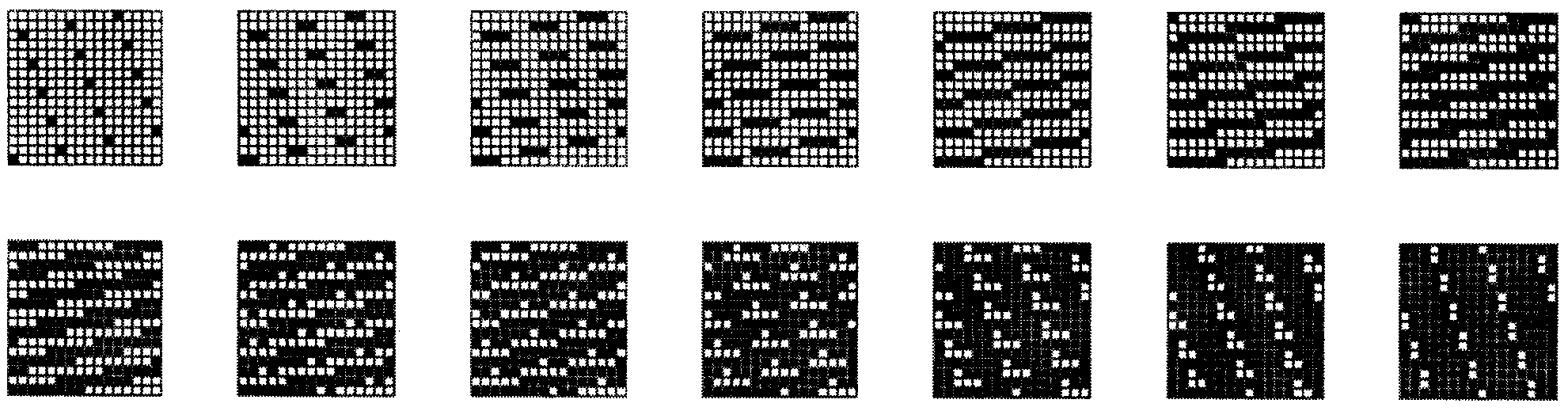

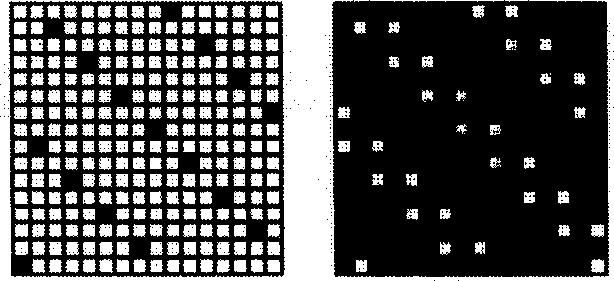

Design method of texture effect jacquard fabric based on combined full-developing structure

ActiveCN104073949AMass productionMeet the design requirementsPattern making devicesHigh volume manufacturingComputer graphics (images)

The invention provides a design method of a texture effect jacquard fabric based on a combined full-developing structure. The technical scheme comprises the following steps: (1) a digital pattern is designed; (2) a full-developing tissue is designed; (3) a texture tissue is designed; (4) the tissues are replaced to form a fabric structure chart with a colorful fringe effect; (5) the tissues are replaced to form a jacquard fabric structure chart with a texture effect; and (6) the fabric structure chart with the colorful fringe effect is combined with the jacquard fabric structure chart with the texture effect to form a combined fabric structure chart with the colorful fringe effect and the texture effect. The jacquard fabric produced by adopting the design method can show the colorful fringe effect and the texture effect on the surface, and the colorful fringe effect and the texture effect can be individually changed without being mutually influenced under the limitation of the technical scheme, so that the designed fabric can satisfy the technical requirements of large-batch production.

Owner:ZHEJIANG SCI-TECH UNIV

Method for disign of organizing structure of full colouring textile

InactiveCN1793459AWon't slipMeet the needs of structural designPattern making devicesPattern recognitionYarn

The invention relates to a full color development union histological structure designing method. Its technique steps as follows: selecting one basic stitch; designing full color development technique point; designing a set of shadow light stitch to gain full color development stitch. The invention can express shadow light effect, and ensure that the interlacing point is not covered and the yare is not slipped. It can be used in signal weft structure fabric design, and multiple sets warp and weft full color development fabric structure design. The design effect has nothing to do with used pattern and yarn material. Thus it can satisfy various patterns and yarn materials using. And its use is very extensive.

Owner:ZHEJIANG SCI-TECH UNIV

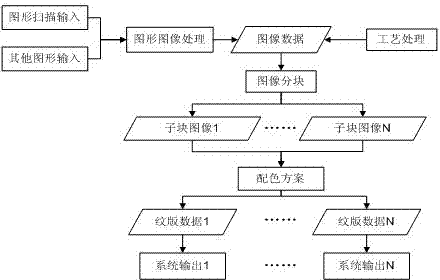

Processing process of ultra-wide digital weaved photograph decorative fabric

InactiveCN103668642AAdd artistryMeet individual needsPattern making devicesPattern cardsComputer graphics (images)Potential market

The invention discloses a processing process of an ultra-wide digital weaved photograph decorative fabric. Design flow of the processing process comprises drawing checking, drawing revising, color separating, process designing and plate-making, wherein the drawing revising process and the color separating process are more critical and directly affect showing effect of a tapestry drawing. The process designing comprises operations such as bordering, surface texture paving, backing texture configuring and shooting-in. The processing process disclosed by the invention has the beneficial effects that an artistic style of the digital waved photograph tapestry drawing is introduced into the decorative fabric by adopting a digital waved photograph designing system and an 8192 needle electronic jacquard faucet, so that a full true-color emulational image ultra-wide ornament is developed, artistry of the decorative fabric is greatly improved, and far-reaching significance is achieved for promoting textile industry development. Meanwhile, breakthrough on technology is realized by digesting and absorbing performances of electronic jacquard equipment, upgrading and modifying the existing cotton-weaving equipment, researching the production process technology, establishing an operating method, and the like, so that the blank of the ultra-wide decorative artware in the field is filled up, personalized needs of the consumer market are satisfied, and potential market efficiency is great.

Owner:TIANJIN TEXTILE ENG RES INST

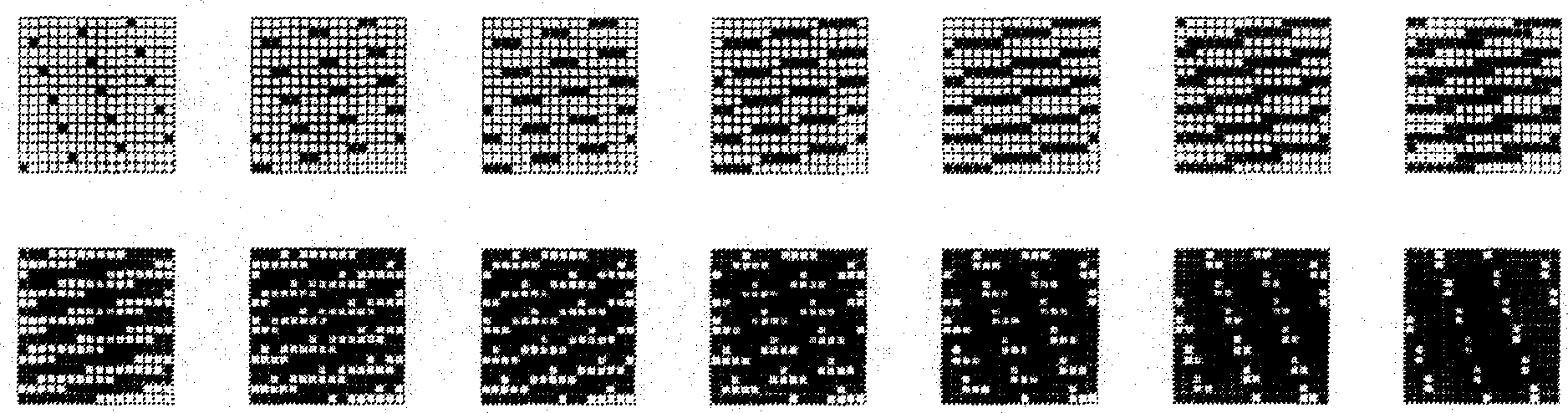

Method for preparing digital line crepe

InactiveCN101445981ANew pattern designNew production processPattern making devicesCard-punching apparatusInformation controlBitmap

The invention relates to a method for preparing a digital line crepe, comprising the following steps: uniform stochastic web graphics are generated and fabric pattern types are generated; line uniform stochastic web graphics are obtained through the regulation of parameters; parts of the selected generated line uniform stochastic web graphics are intercepted; the obtained local graphics of the uniform stochastic web are sheared, stacked, rotated and distorted to design satisfied line decorative pattern effect and are stored as bitmap files; a jacquard weaving CAD method is used for decorative pattern color separation and drafting treatment to generate files; an electronic jacquard information control system or an automatic rolling jacquard card system is used for the plate making; jacquard weaving is adopted for forming fabrics. The method for preparing the digital line crepe has the beneficial effects of new pattern design mode, new production process and new fabric effect. Due to the digital processing on the patterns, a specific line crepe weaving effect is formed.

Owner:ZHEJIANG SCI-TECH UNIV

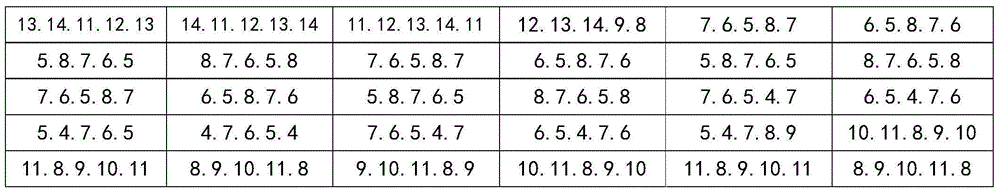

Method for producing jacquard-like pattern with dobby loom

The invention provides a method for producing a jacquard-like pattern with a dobby loom. With an original small pattern as a chief source, the method makes progressive combination in a warp-wise arrangement order of original yarn, i.e. advancing a digit number when every N digits are taken, step by step in an orderly way until the end of a cycle, with the N as an amplification factor in the warp direction; meanwhile, progressive combination is conducted in a broadwise arrangement order of the original yarn, i.e. advancing a digit number when every M digits are taken, step by step in an orderly way until the end of a cycle, with the M as an amplification factor broadwise; the produced jacquard-like pattern is N*M times of the original small pattern in area. With both low cost and high efficiency, the method of the invention solves the problem of producing jacquard fabrics on a dobby loom, and also can produce jacquard patterns of different effects.

Owner:福州华冠针纺织品有限公司

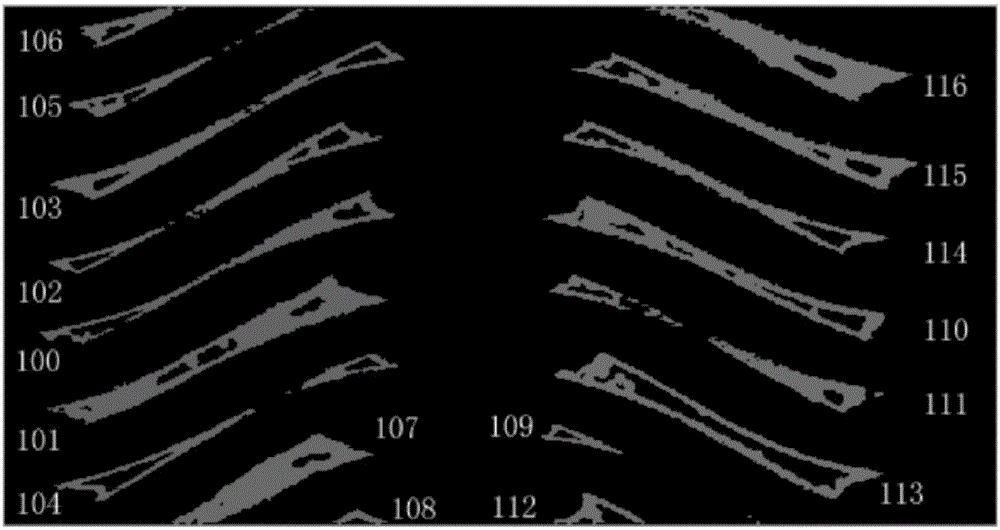

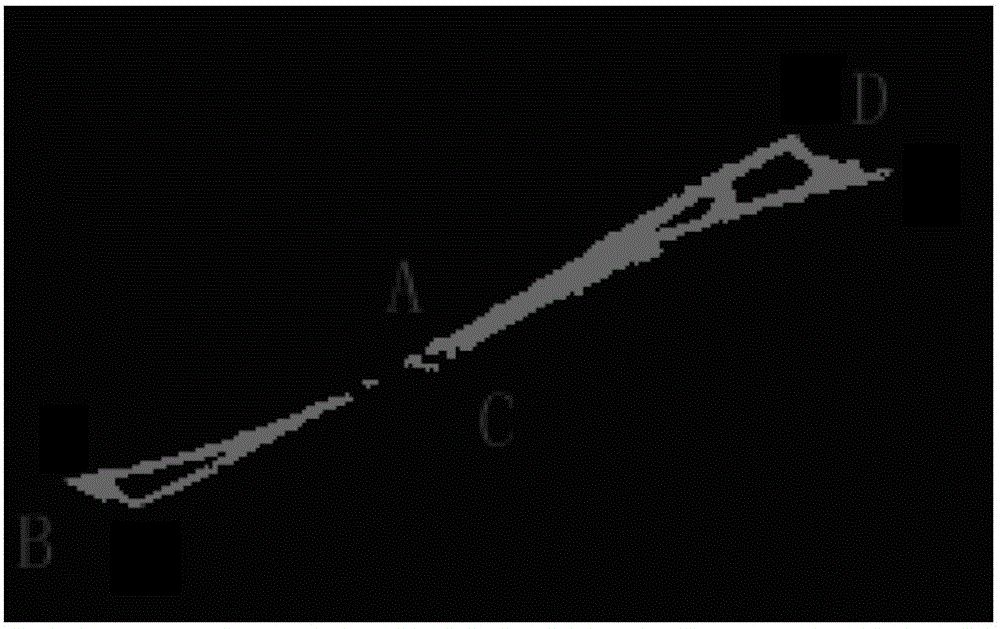

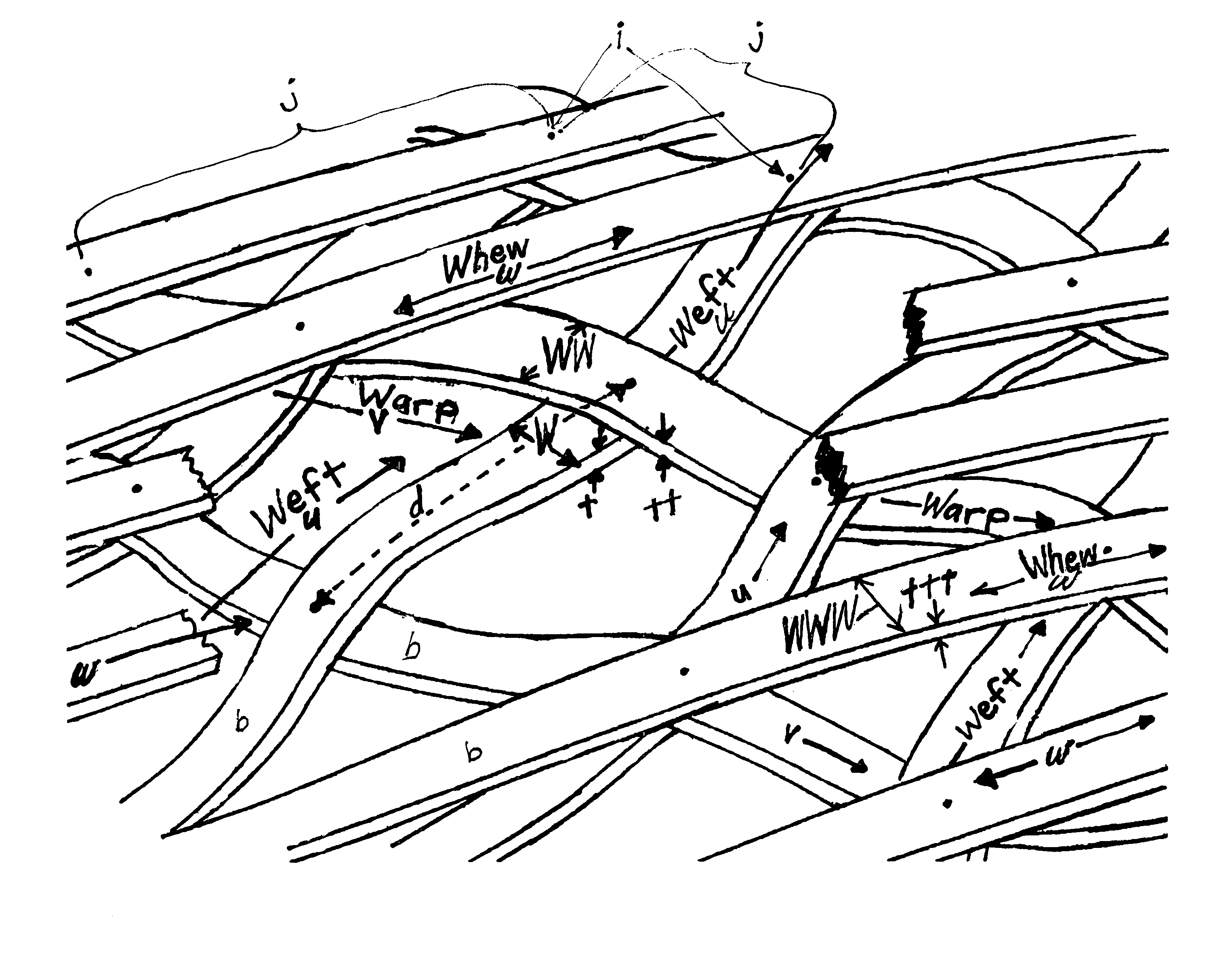

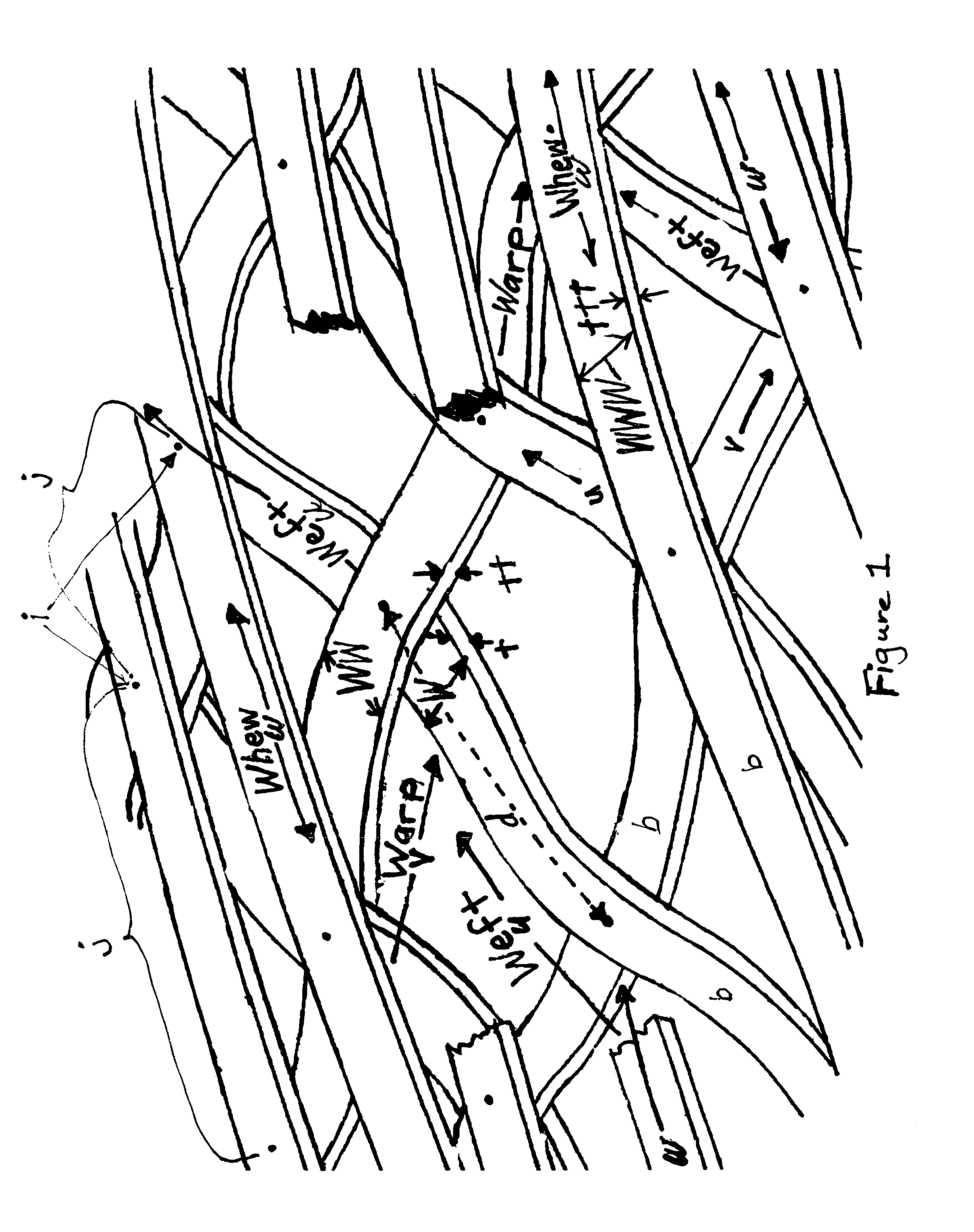

Computer pattern recognition method for composite material microstructure

ActiveCN105803623AOvercome the disadvantage of only being able to build two-dimensional modelsOvercomes the inability to identify components with similar grayscale characteristicsPattern making devicesGraphicsComputer pattern recognition

The invention discloses a computer pattern recognition method for the composite material microstructure. The computer pattern recognition method includes the following steps that pictures of the 2.5-dimensional composite material microstructure are obtained; matrix areas are recognized with the threshold segmentation technology; all the matrix areas serve as twisty quadrilateral structures to be treated, and four boundaries of each matrix area are recognized and marked; the matrix areas matched with the left matrix areas are found; the complete boundaries of warp yarn areas are obtained in a spline fitting mode; in all pairs of symmetrical matrix areas, the areas defined by the boundaries of the left matrix areas, the boundaries of the right matrix areas, upper warp yarn boundary lines and lower warp yarn boundary lines are weft yarn areas, and recognition of components is completed; all the recognized pictures are stacked to build a three-dimensional model of the 2.5-dimensional inside microstructure. According to the computer pattern recognition method, manual intervention is avoided, the three-dimensional model of the composite material microstructure can be built, and warp yarns, weft yarns and matrixes can be automatically recognized by a computer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

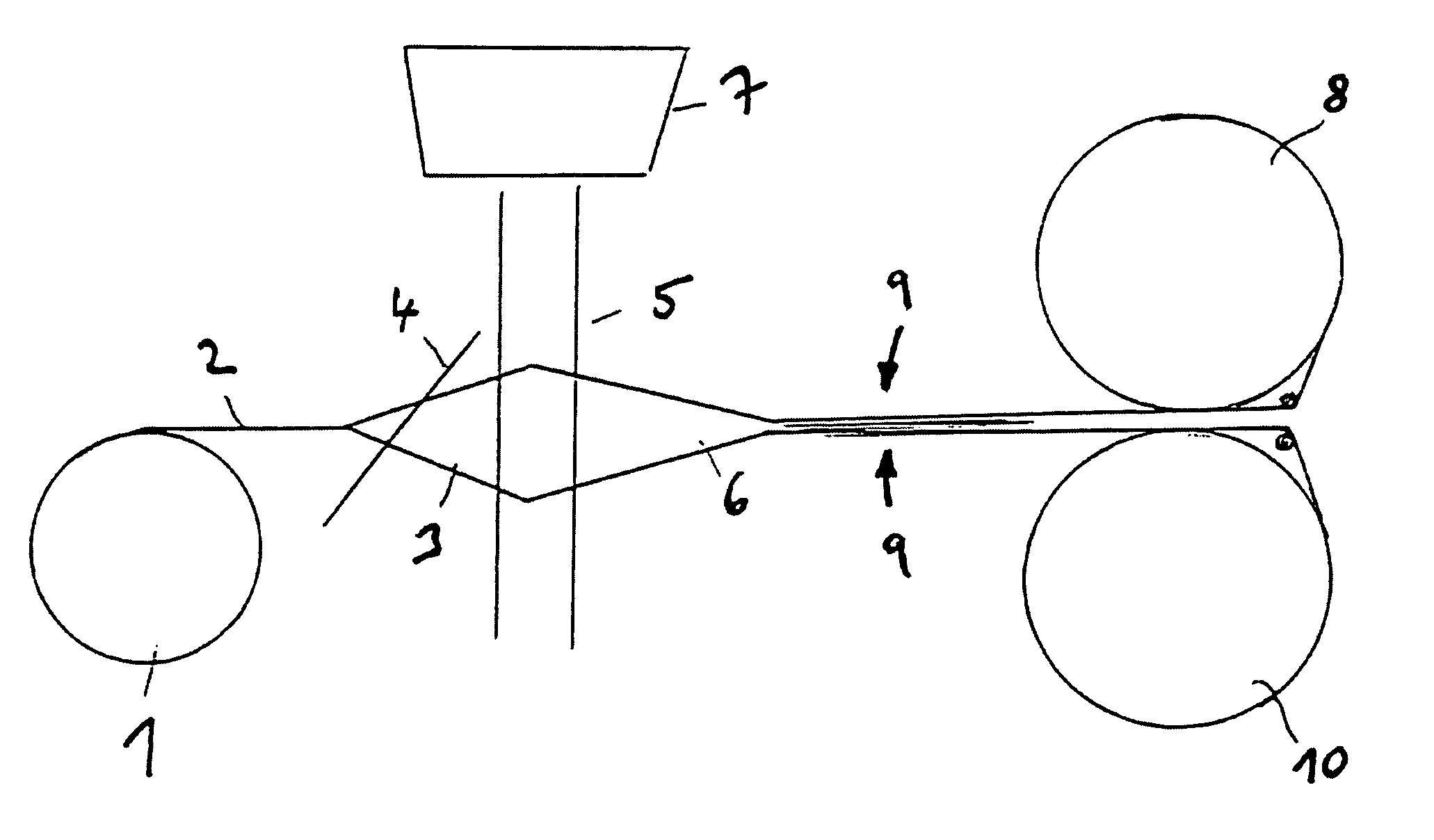

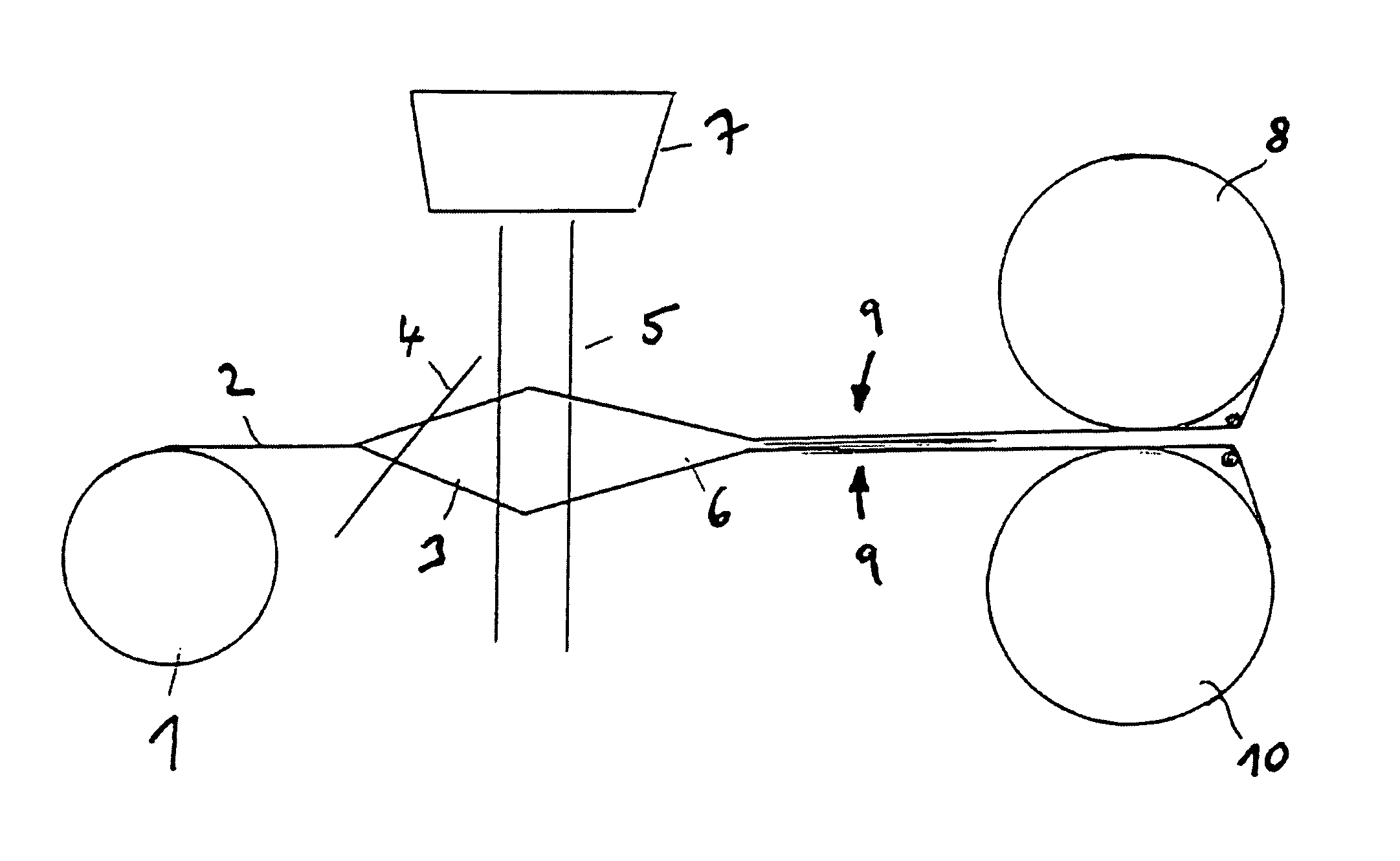

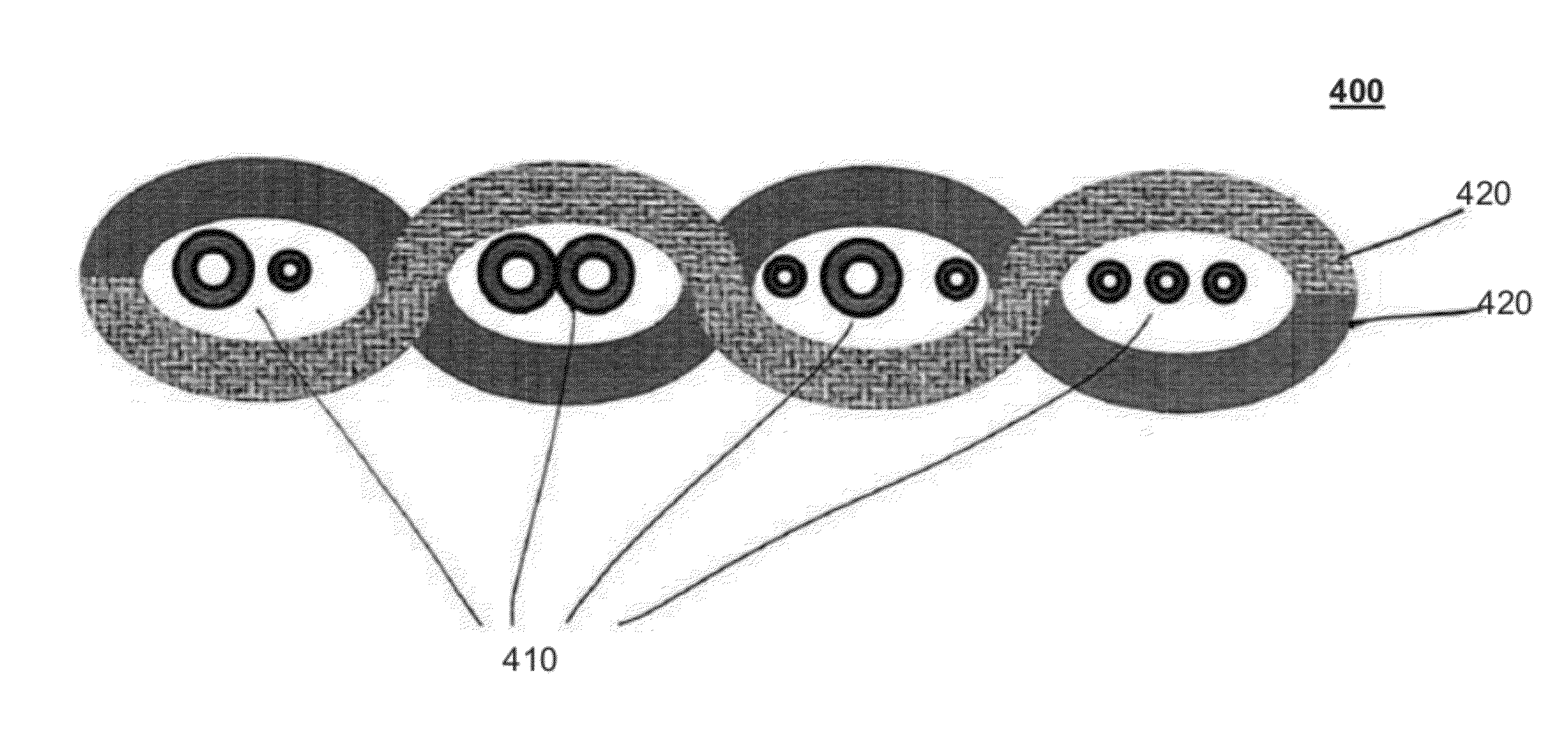

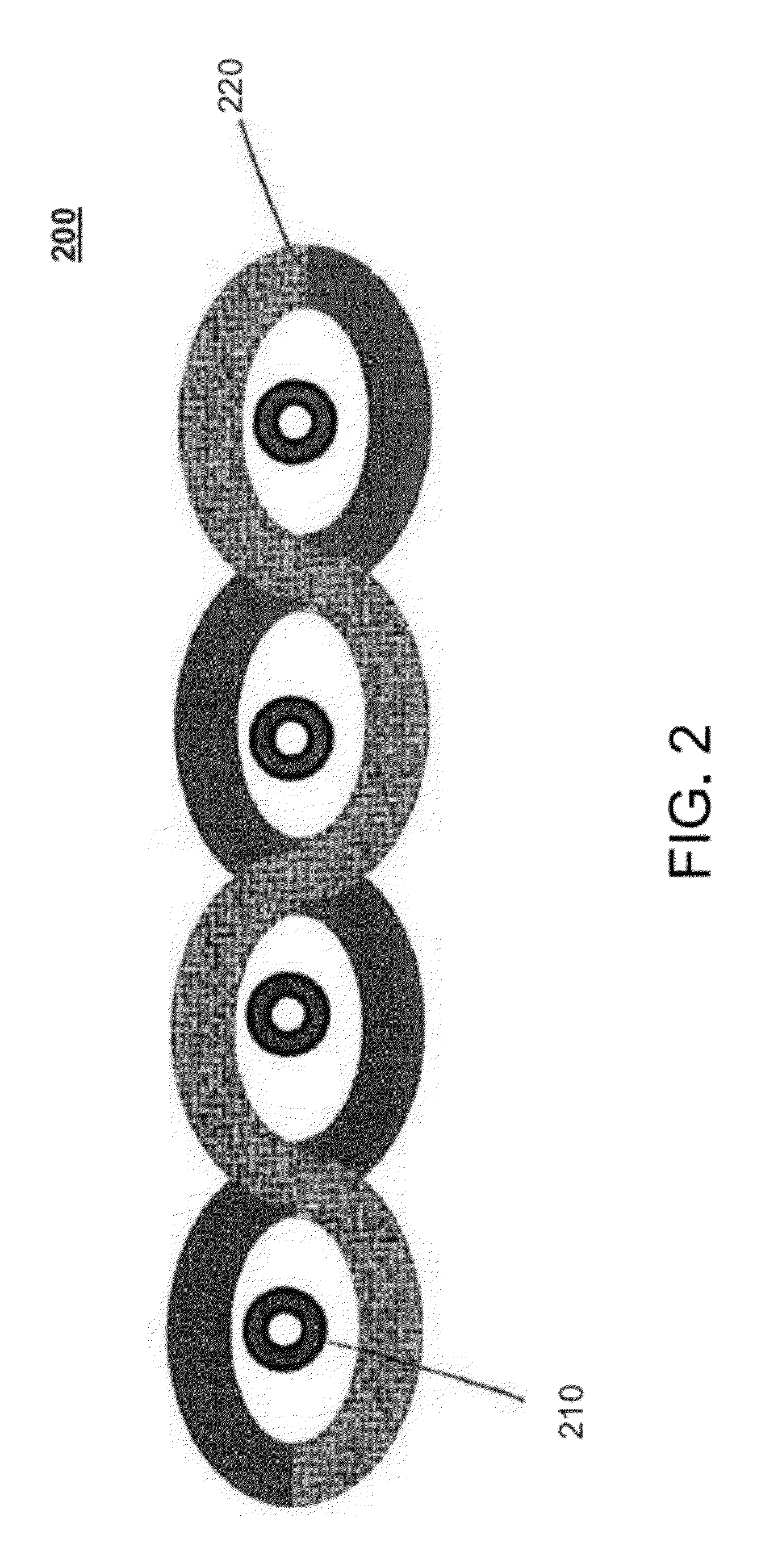

System and a method for manufacturing substrates for coated fabrics

InactiveUS20120253501A1Increase threadcountReducing fabric costLoomsGeotextilesIndustrial engineeringThread count

A system and a method are disclosed for weaving SC fabrics using multiple weft insertion. The system and method may be used to increase the thread count of the SC fabric while reducing fabric costs.

Owner:SPRINGS CREATIVE PRODS GROUP

Weave, a utility method for designing and fabricating 3D structural shells, solids and their assemblages, without limitations on shape, scale, strength or material

Weave is a process for fabricating freeform shells, proceeding from a precise definition of a given desired final three-dimensional shape of such a shell, to an optimized parametric mesh of said shape, to physical battens which, once fastened at calculated crossings, realize the final object of use. The initial iso-parametric mesh may be triangulated for increased rigidity. Such a mesh's battens' geometry is precisedly controlled by Weave such that the shell under construction automatically takes on, as it is fastened, the shape and dimensions of the designed fabrication without explicit registration or alignment. Weave places minimal constraints on shape type, complexity, scale and material. Minimal tools are required for preparing and fastening the battens, and no special construction skills or building environment are needed.

Owner:SCHWENN PETER THOMAS

Clothing fabric having artistic geometric square Rubik's cube-like pattern

ActiveCN105133124ASatisfy avant-garde dressing needsPattern making devicesOther shedding mechanismEngineeringRaw material

The invention discloses a clothing fabric having artistic geometric square Rubik's cube-like patterns. The clothing fabric includes warp yarns and weft yarns having different raw material components, wherein the warp yarns and the weft yarns are arranged in a manner of alternation of a per-five-into-one method and a laminating method. There are at least two drafting methods which are described as follows: the first drafting method is a forward method at least comprising the four steps: (S100) performing the five-into-one method: 1.2.3.4.5; (S110) performing the laminating method: 2,3,4,5*5; (S120) performing the five-into-one method with one number passing forwardly: 2.3.4.5.6; and (S130) performing the laminating method with one number passing forwardly: 3.4.5.6*4; the second drafting method is a backward method at least comprising the four steps: (S200) performing the five-into-one method: 11.10.9.8.7; (S210) performing the laminating method: 10.9.8.7*7; (S220) performing the five-into-one method with one number passing backwardly: 10.9.8.7.6; and (S230) performing the laminating method with one number passing backwardly: 9.8.7.6*3; The clothing fabric can be produced with a fourteen-heald dobby machine and can satisfy a fashion demand of the youths in society.

Owner:FUJIAN LONGFENG TEXTILE TECH IND

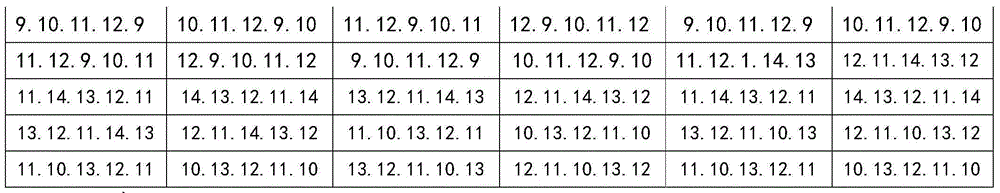

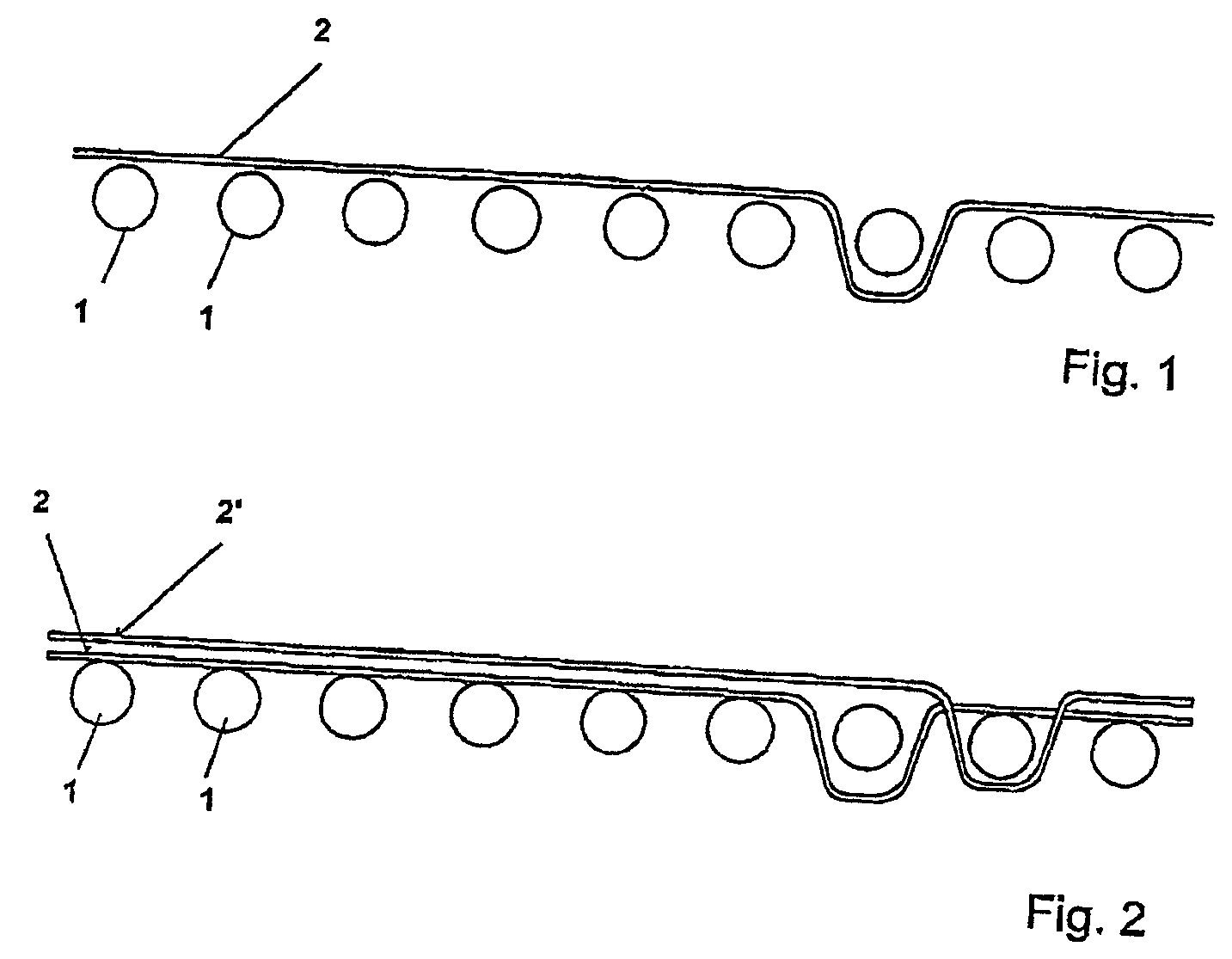

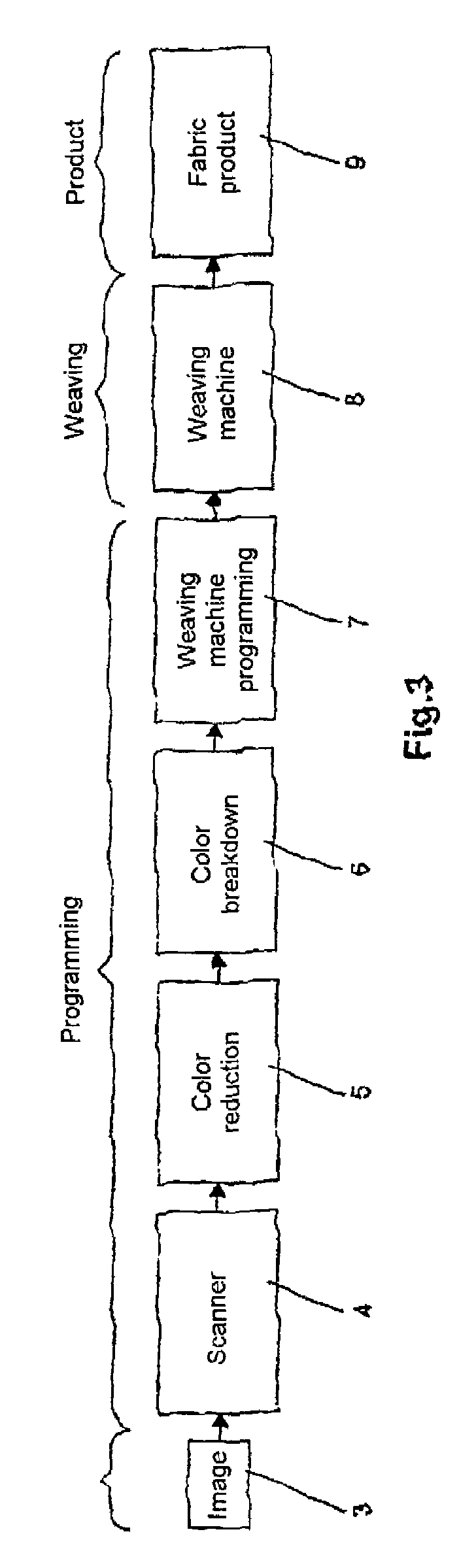

Method and unit for the production of images with high resolution in jacquard fabric

InactiveUS7272244B2High resolutionOptimizationDigitally marking record carriersLoomsHigh resolution imageComputer science

The invention relates to a method for the production of images with high resolution jacquard fabric comprising the following steps: colour scanning of an output image to be reproduced on a fabric, video visualisation of said image with the largest number of colours possible with the means employed for said visualisation. The invention is characterised in that the method comprises further steps: selection of a number of base colours to be used for forming said image on said fabric, said number of base colours is related to the number of warp and weft threads which may be used in the loom and which are to be applied in the weaving of said fabric, reducing the original colours of the output image to a number of reduced colours which it is possible to produce by mixing the base colours of the warp and weft threads.

Owner:BREVITEX ESTAB POUR LEXPLOITATION DE BREVETS TEXTILES

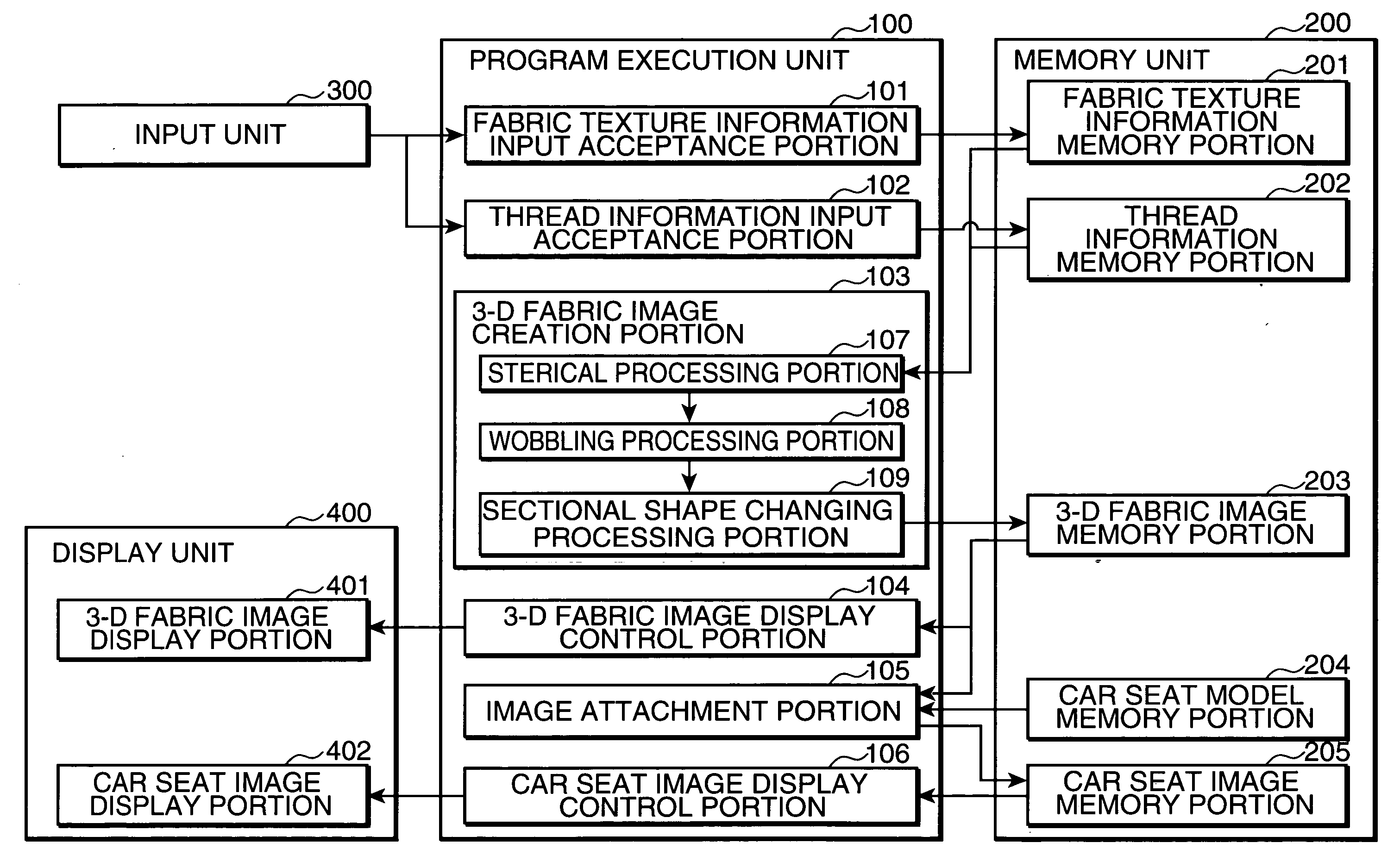

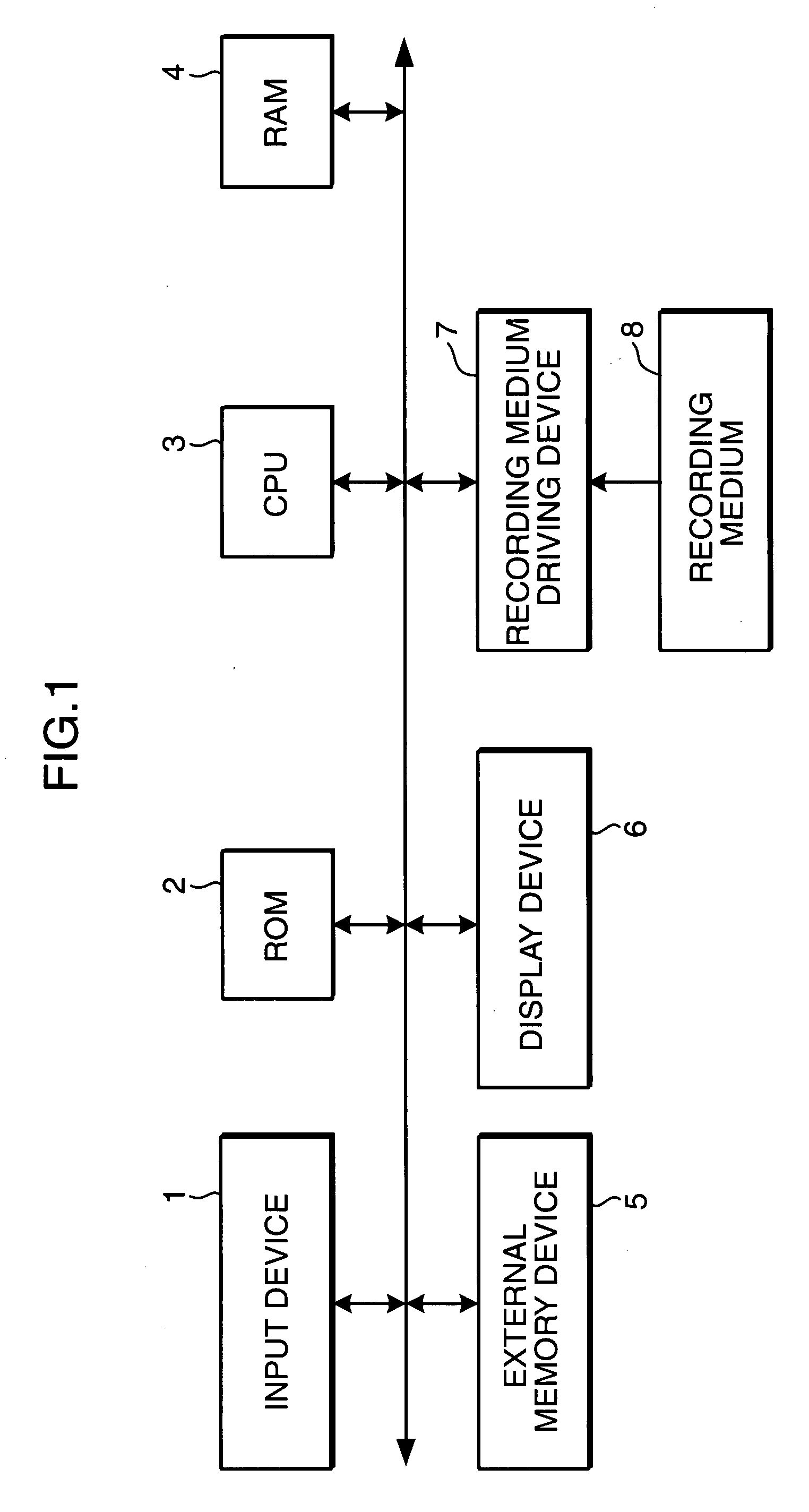

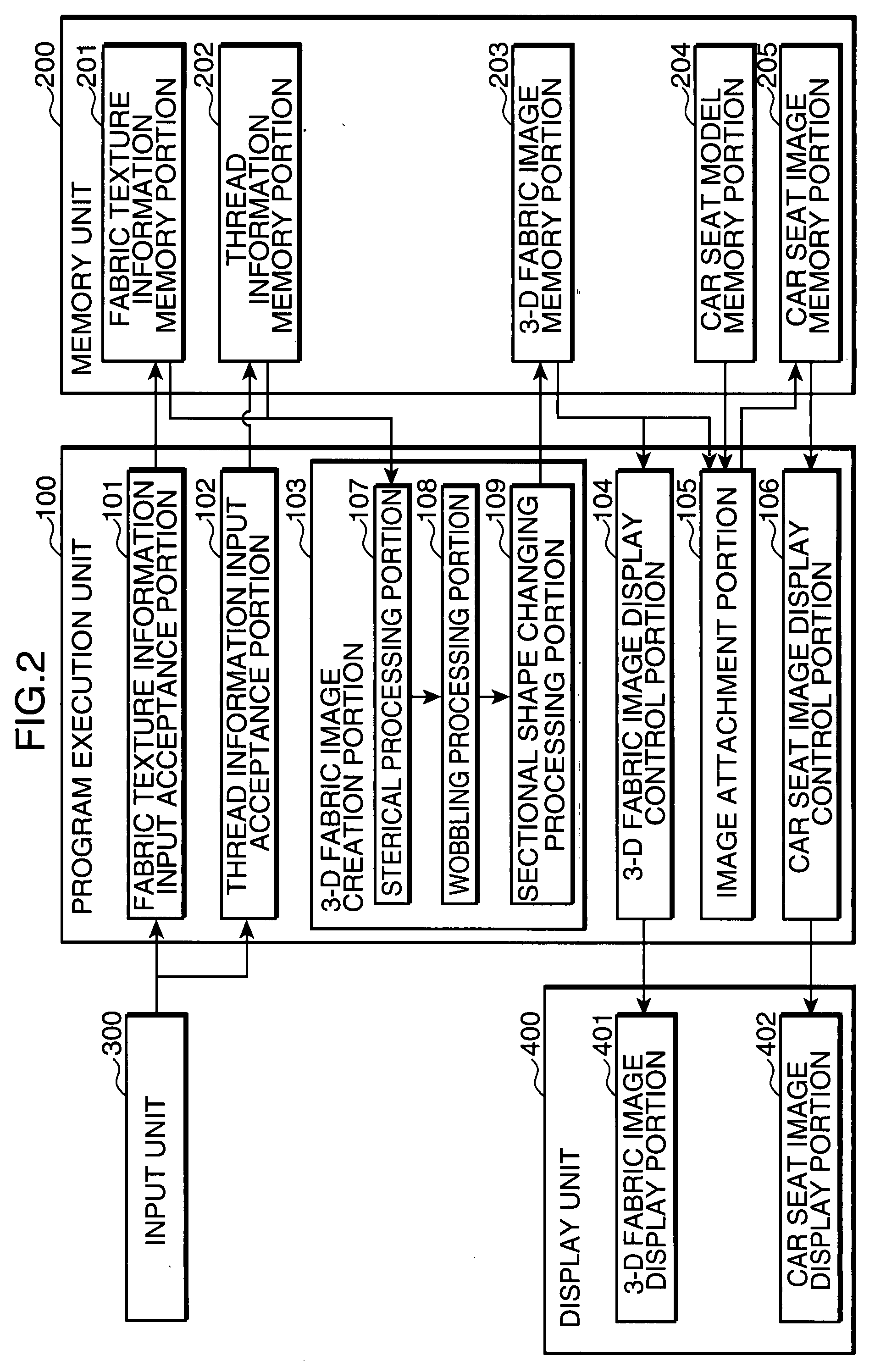

Recording Medium Storing Car Seat Fabric Simulation Program, Car Seat Fabric Simulation Method, Car Seat Fabric Simulation Device, Car Seat Fabric Manufacturing Method, and Car Seat Fabric Trading Method

InactiveUS20090119112A1Low costEliminate needGeometric CADDesign optimisation/simulationCar seatComputer graphics (images)

A car seat fabric is simulated with a feeling of reality. A fabric texture information input acceptance portion (101) accepts texture information about the fabric used for the car seat fabric. A thread information input acceptance portion (102) accepts thread information about threads used for the fabric. A 3-D fabric image creation portion (103) creates a steric structure of the car seat fabric as a 3-D fabric image on the basis of the texture information accepted at the fabric texture information input acceptance portion (101) and the thread information accepted at the thread information input acceptance portion (102). An image attachment portion (105) attaches the 3-D fabric image created by the 3-D fabric image creation portion (103) to a car seat model. A car seat image display (402) displays the car seat model to which the 3-D fabric image is attached by the image attachment portion (105).

Owner:DIGITAL FASHION +1

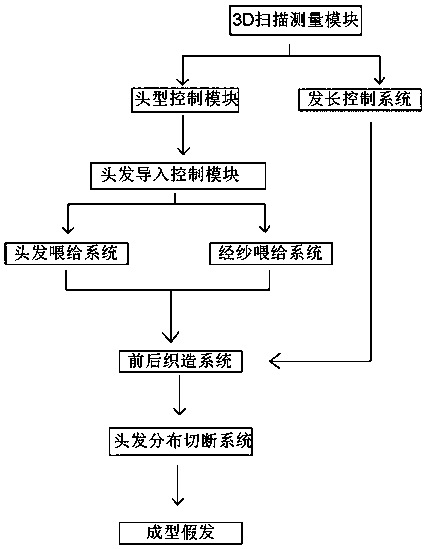

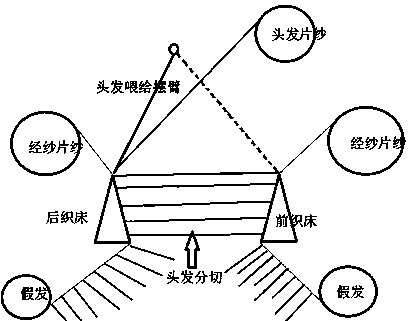

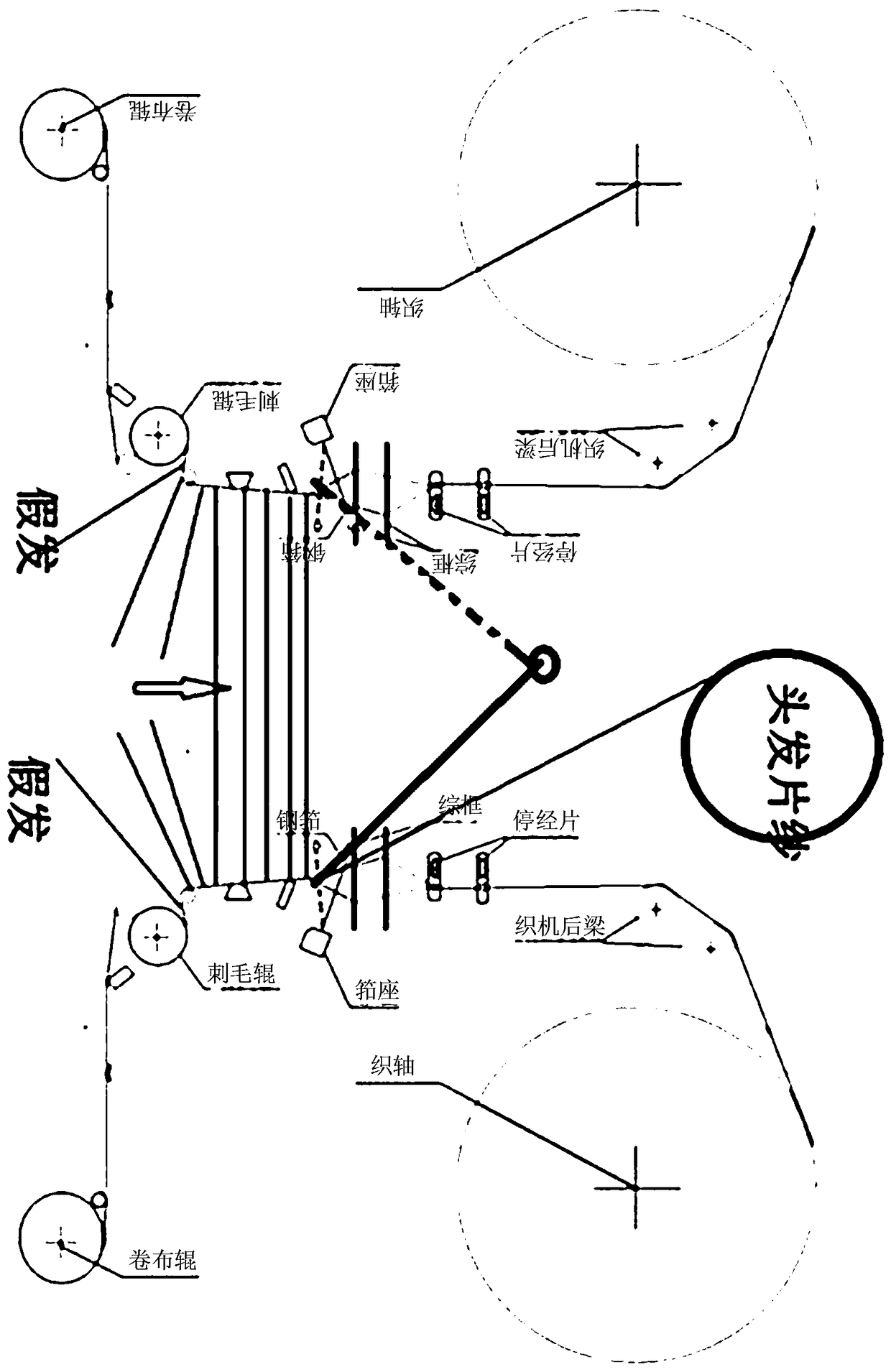

Preparation method of three-dimensional woven hair net

InactiveCN108505181AIncreased freedom of choiceReduce in quantityWigsPattern making devicesAutomatic controlAutomatic train control

The invention relates to the technical field of wig preparation, in particular to a preparation method of a three-dimensional woven hair net. According to the method, a 3D scanning measurement module,a head shape control module, a hair length control module, a hair distribution cutting module, a warp feeding system, a hair feeding system, a hair guide control module and a front-rear weaving system are involved. The preparation method combines 3D scanning measurement and manual parameter input and allows a client to freely select a required wig model, and the free selection right of the clientis enlarged; meanwhile, a self-automatic control system is adopted for the method, the number of required workers is greatly reduced, the requirements for proficiency and quality of the workers are lowered, and the problems of low processing efficiency and high labor cost are solved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

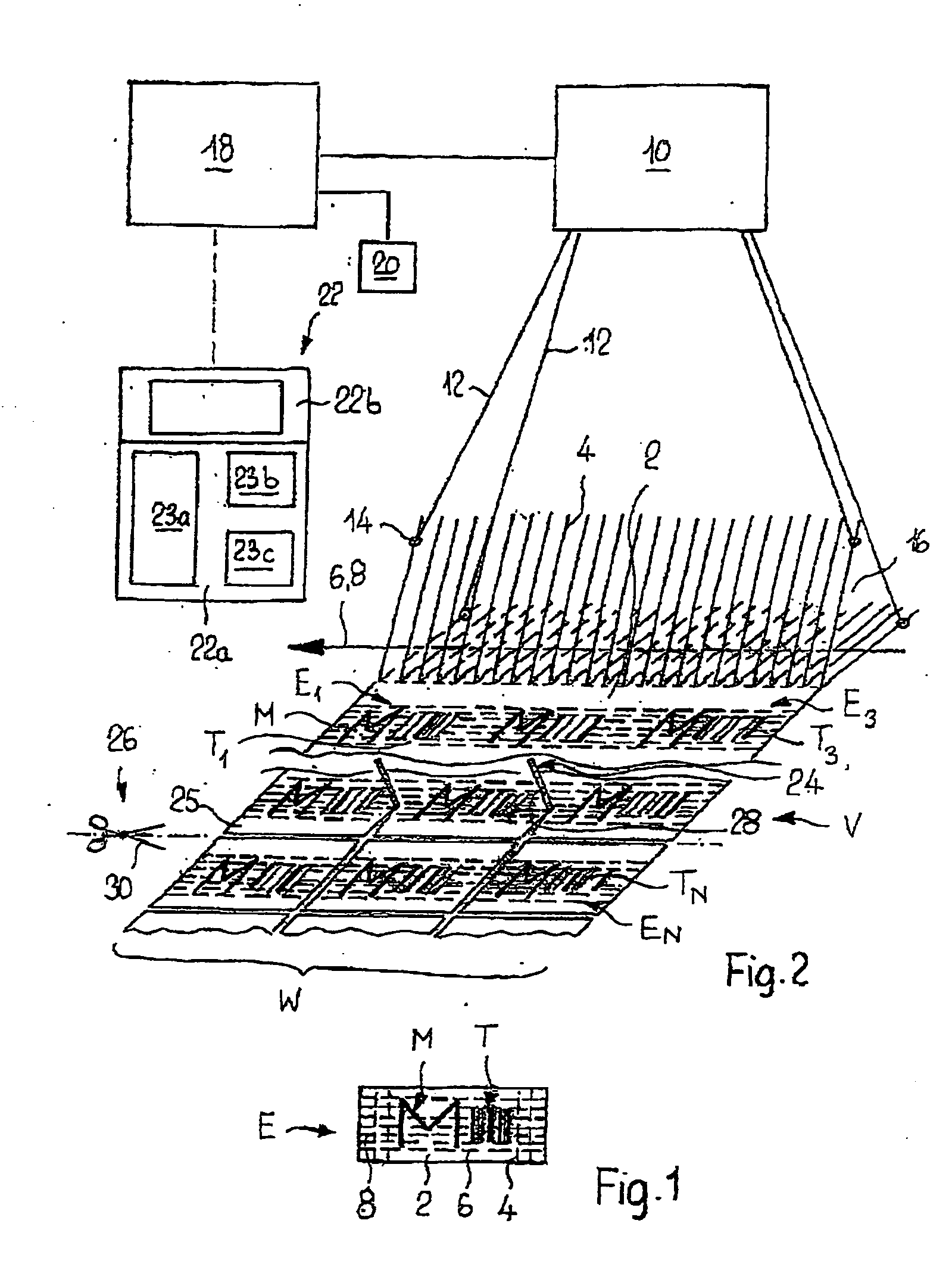

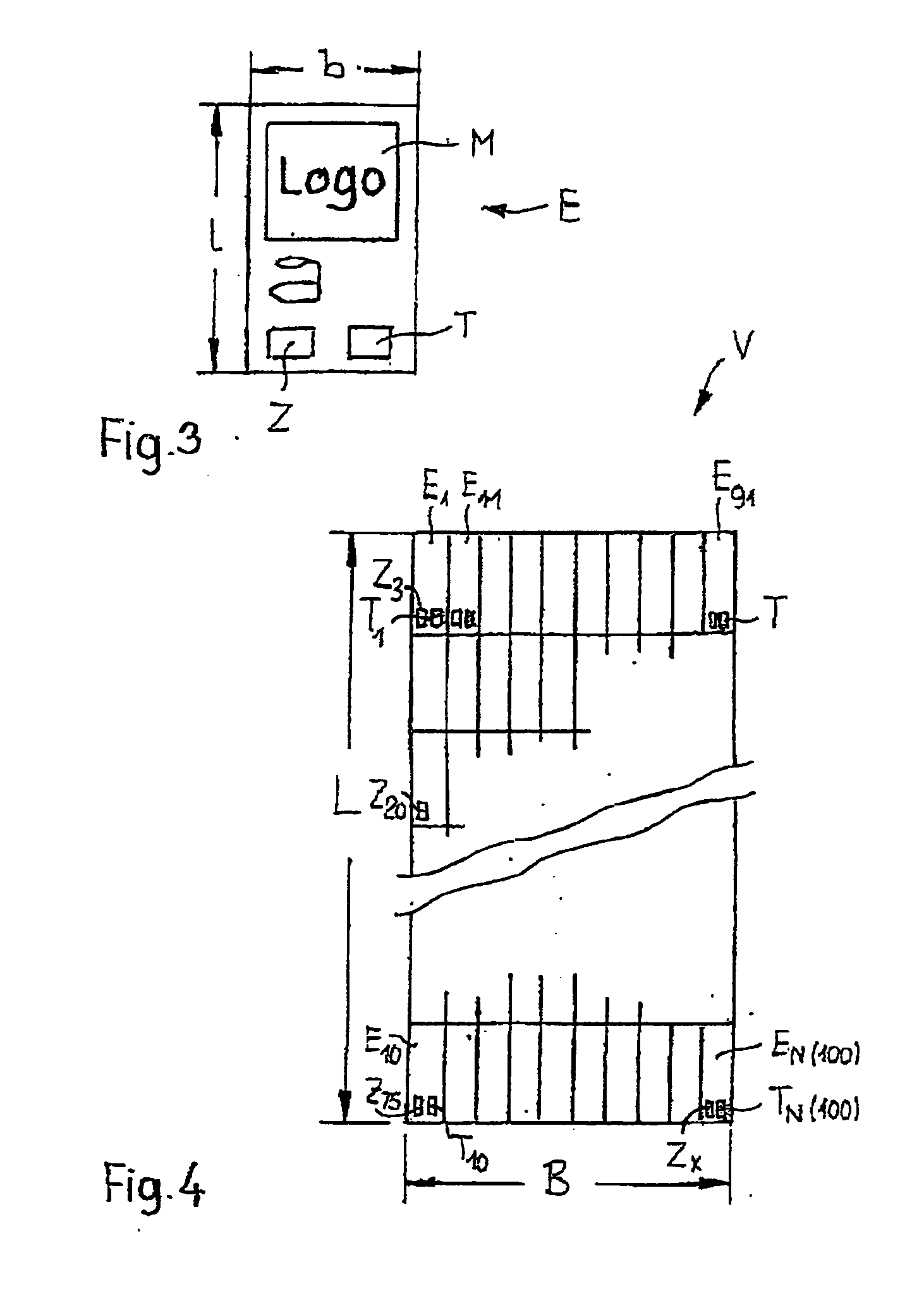

Method and installation for producing patterned textile labels

InactiveUS20060247819A1Simple and reliable processSevering textilesPattern making devicesEngineeringTextile

The invention relates to a method for producing patterned textile labels during which a production machine, which is controlled by a pattern device (22), provides labels (E1 to EN)with a pattern (M), which is the same for all labels, and with pattern sections (T1 to TN) that are different from one another. In order to improve production, a virtual label (V) is created from N individual labels E1 to EN)which are distributed over the width (B) and the length (L) of the virtual label (V) and which have N individual pattern sections (T1 to TN) that are different from one another, and then virtual label (V) is then divided into individual labels (E1 to EN).

Owner:BREVITEX ESTAB POUR LEXPLOITATION DE BREVETS TEXTILES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com