Full-fashioned weaving process for production of a woven garment with intelligence capability

a technology of intelligence capability and weaving process, which is applied in weaving, nuclear engineering, nuclear elements, etc., can solve the problems of not being able to produce a full-fashioned woven garmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Referring now to the above figures, wherein like reference numerals represent like parts throughout the several views, the full-fashioned weaving process and product of the present invention will be described in detail.

A. The Full-Fashioned Weaving Process and Garment of the Present Invention

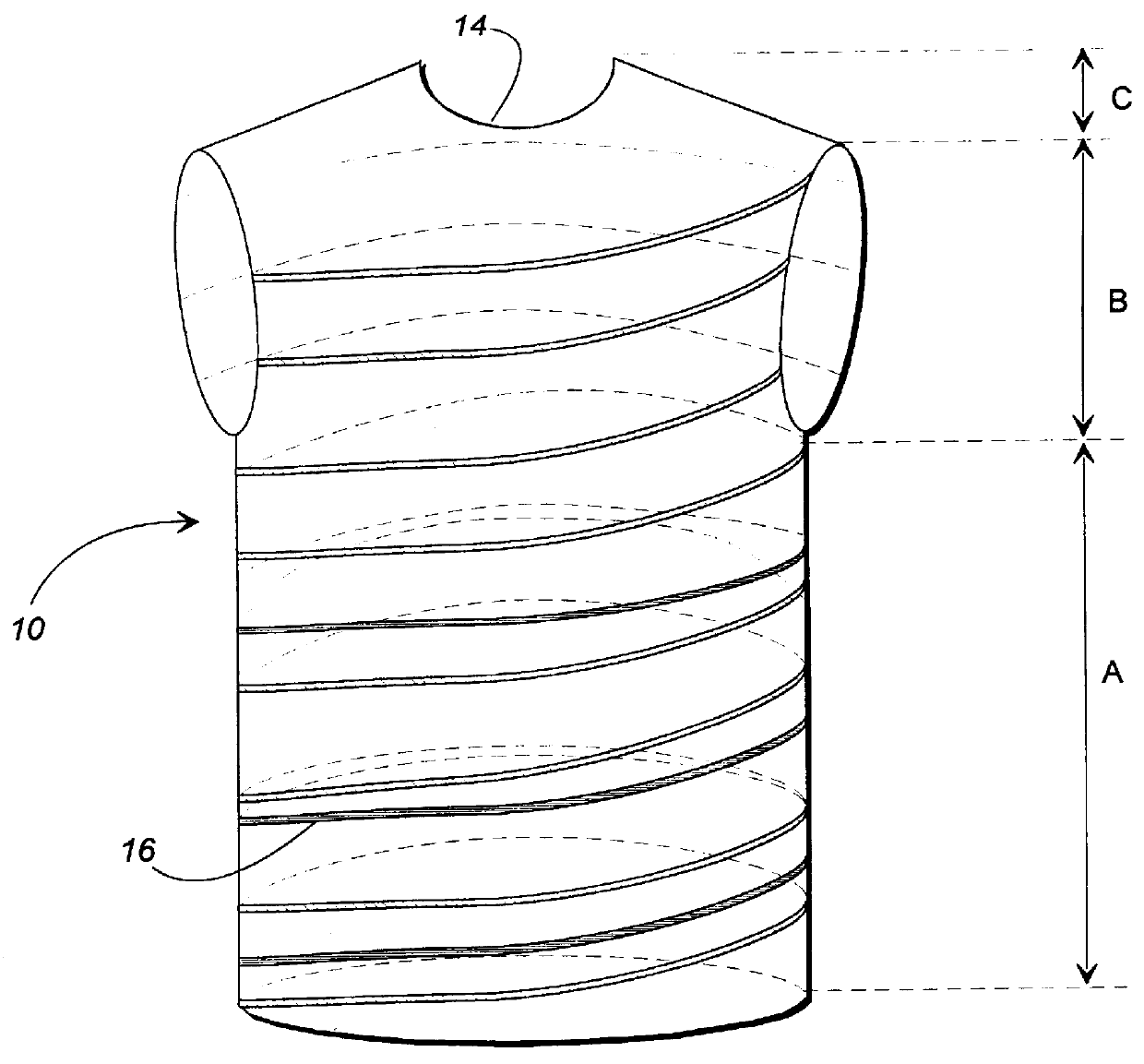

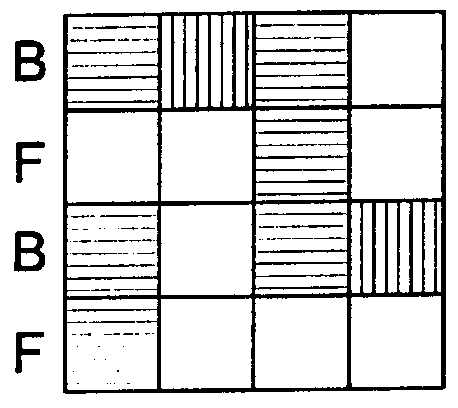

As illustrated in FIG. 1, in a full-fashioned woven garment 10 made in accordance with the present invention, two different weave structures are used: one is the tubular structure for Sections A and C and the other is the double layer structure for Section B. To assist in the description of the present invention, reference will now be made to a garment, such as a sleeveless shirt having a rounded neck 14 similar to a knitted T-shirt, fashioned by the fully-fashioned weaving process of the present invention. However, it should be recognized that the present invention is not limited to only such a garment.

1. Description of Sections A and C of the Garment

Unlike the structure of a regular shirt made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com