Method for producing dobby-jacquard jointly-shedded multilayer jacquard fabric

A production method and jacquard technology, applied in textiles, textiles and papermaking, pattern design devices, etc., can solve the problems of equipment failure rate and cost increase, and achieve the effects of increased warp and weft density, full effect, and thick feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

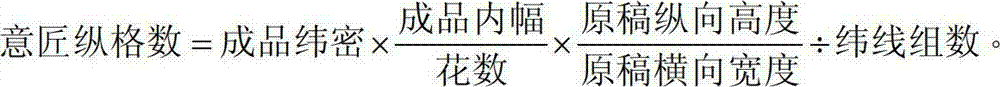

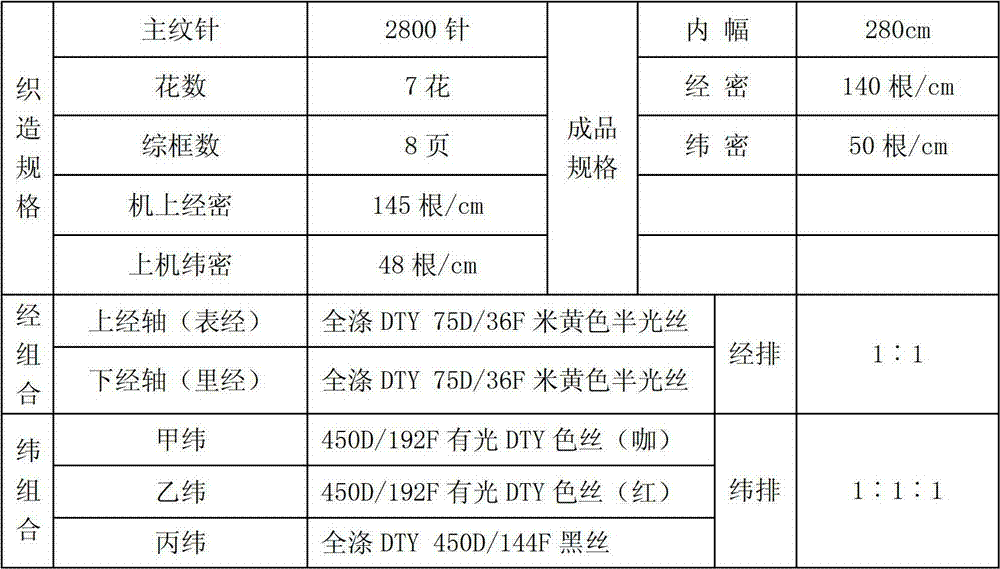

Embodiment 1

[0028] Taking a typical product as an example, in the trial production test, the pattern manuscript adopts a width-to-height ratio of 1:1, and the warp thread material is made of all-polyester 75D / 36F beige DTY semi-glossy yarn, which is arranged on the upper warp beam and the lower warp beam according to 1:1. On the warp axis; the weft thread adopts a combination of 3 sets of wefts: 1 set (C weft) is the back interweaving weft, which is arranged on the lower layer of the fabric, and is interwoven with the lower warp beam warp with 8 pieces of 3 flying weft satin weaves; the other 2 According to the coloring needs of the pattern artist, the weft thread is used to develop the color of the jacquard with a weft double structure. In order to achieve a better shading effect, the weft thread (propylene weft) interwoven with the lower warp beam is made of 450D / 144F black polyester DTY filament, in order to highlight the three-dimensional and fullness of the weft pattern, and the other...

Embodiment 2

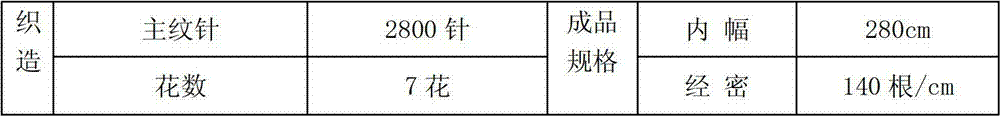

[0037] Taking a typical product as an example, in the trial production test, the width and height ratio of the pattern manuscript is 1:1.5, and the warp thread material is all polyester 75D / 36F beige DTY semi-glossy yarn, which is arranged on the upper warp beam and the lower warp beam according to 1:1. On the warp axis; the weft adopts a combination of 4 groups of wefts: 1 group (button weft) is the back weaving weft, which is arranged on the lower layer of the fabric, and is combined with the warp of the lower warp beam (inner warp) with 8 pieces of satin weave with 3 flying wefts Interweaving; the other three groups of weft threads are used to develop the color of the jacquard with a weft triple structure according to the coloring needs of the pattern artist. In order to achieve a better shading effect, the weft thread (button weft) interwoven with the lower warp beam is made of 450D / 144F black polyester DTY filament, in order to highlight the three-dimensional and fullness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com