Patents

Literature

114results about How to "Evenly bonded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

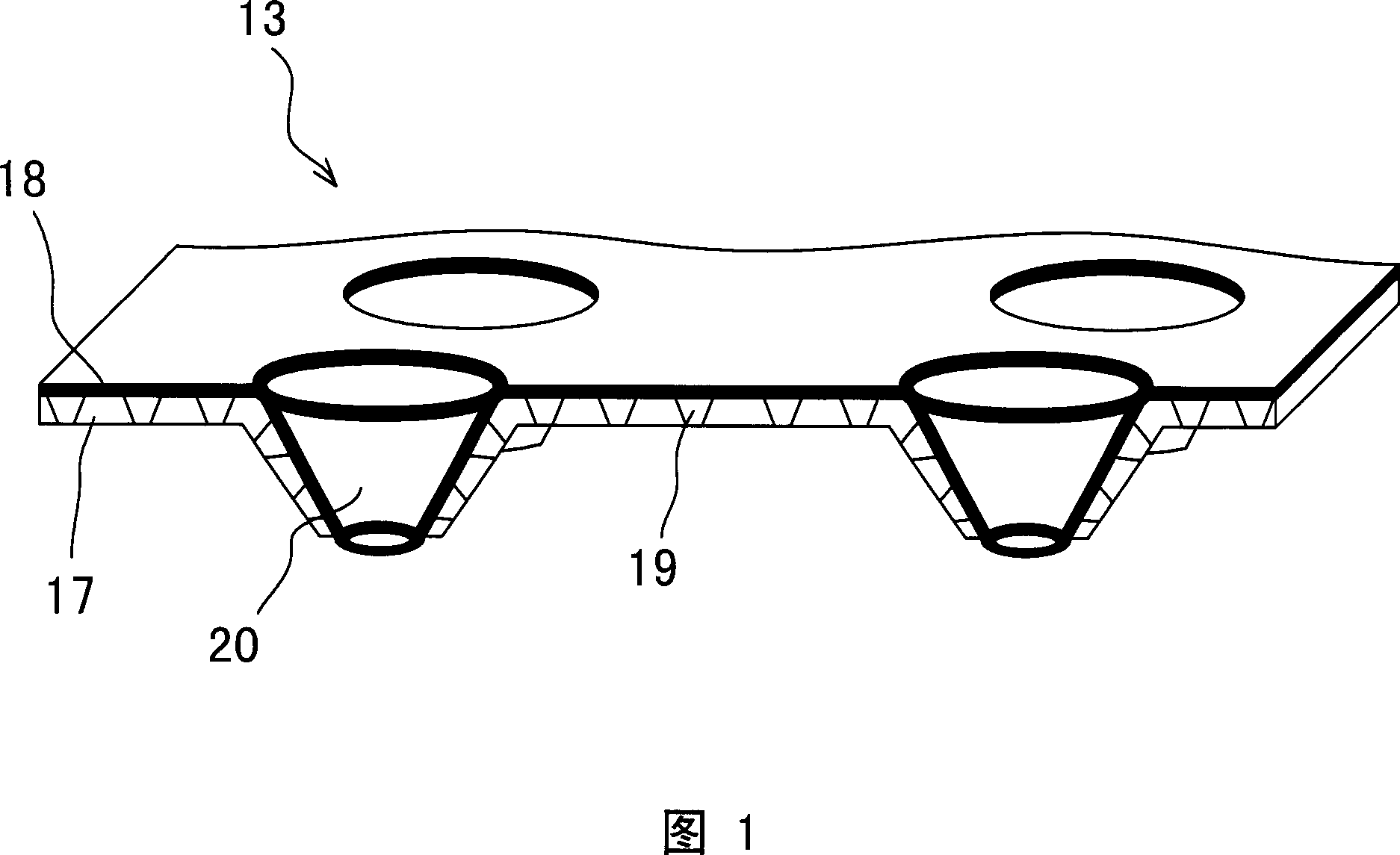

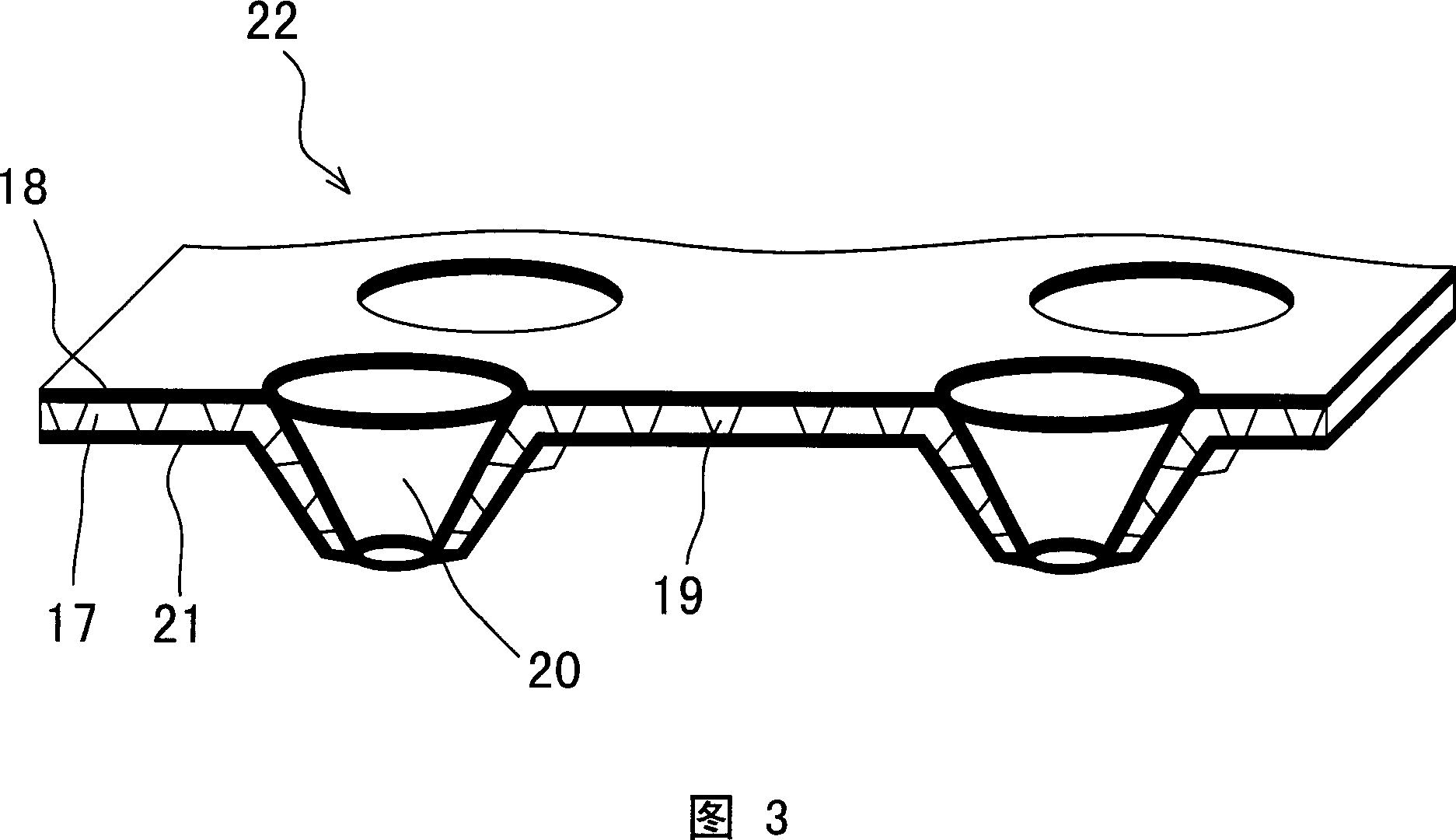

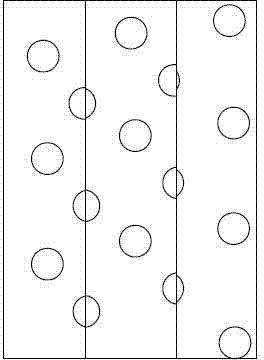

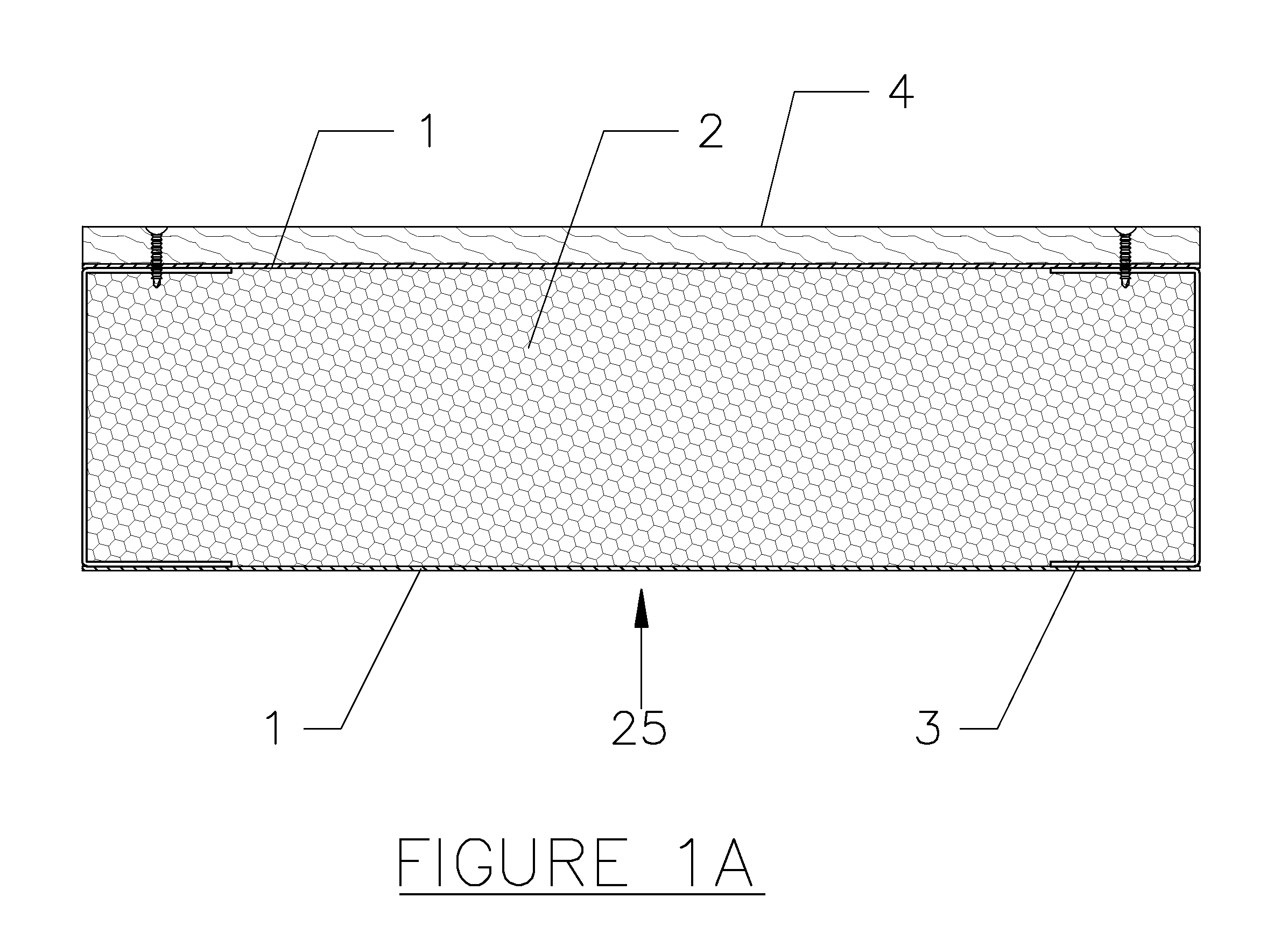

Composite punching film and its producing method

InactiveCN1943530AImprove breathabilityHigh porositySynthetic resin layered productsLaminationPunchingVolumetric Mass Density

A compound punching film and preparation thereof, said punching film consisting of a layer of plastic film and one or two side compound non-woven fabrics. On plastic film is of evenly spread tiny mesh, density thereof is 170-500 mesh / C sqm ,perforating rate is 10-35%. Said whole compound film is perforated of evenly big mesh , aperture thereof greater than that of tiny mesh two times, the shape of big mesh is of funnel, thereof protruding to one side and on the surface of awl is of tiny mesh. Said invention combines PE film technique and punching one, making compound of a layer of non-woven fabric and cast film with the help of high melting temp. of cast film, also making use of mesh cage through vacuum suction nozzle punching tiny mesh, thereafter punching big mesh by pressure roller machine, thus to prepare new compound punching film with good permeability, softness and strong third dimension.

Owner:蔡子辛 +1

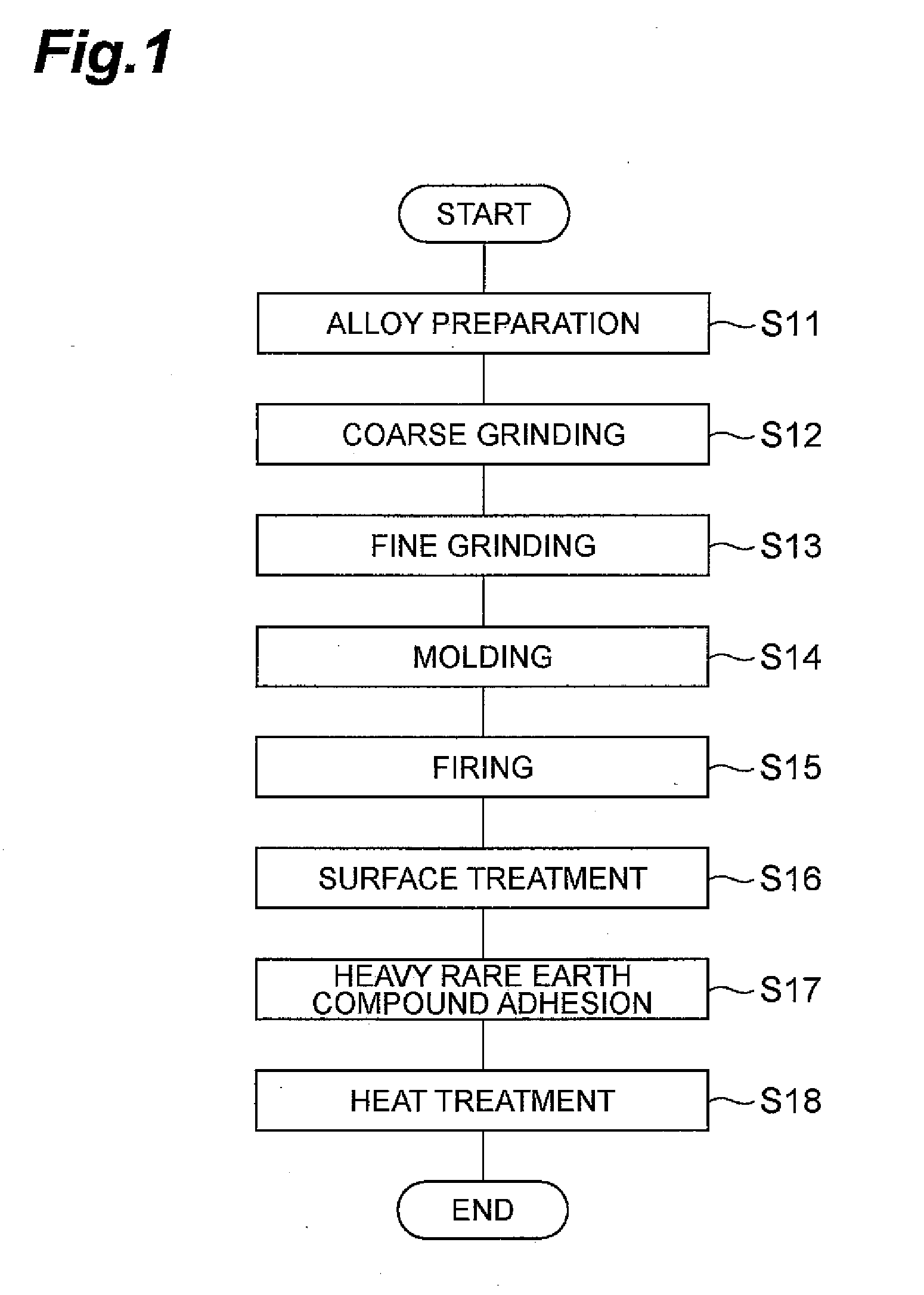

Process for producing magnet

ActiveUS20090297699A1Excellent high magnetic propertyEvenly bondedSpecial surfacesCoatingsRare-earth elementRare-earth magnet

The process for producing a magnet according to the invention is characterized by comprising a first step in which a heavy rare earth compound containing Dy or Th as a heavy rare earth element is adhered onto a sintered compact of a rare earth magnet and a second step in which the heavy rare earth compound-adhered sintered compact is subjected to heat treatment, wherein the heavy rare earth compound is a Dy or Th iron compound.

Owner:TDK CORPARATION

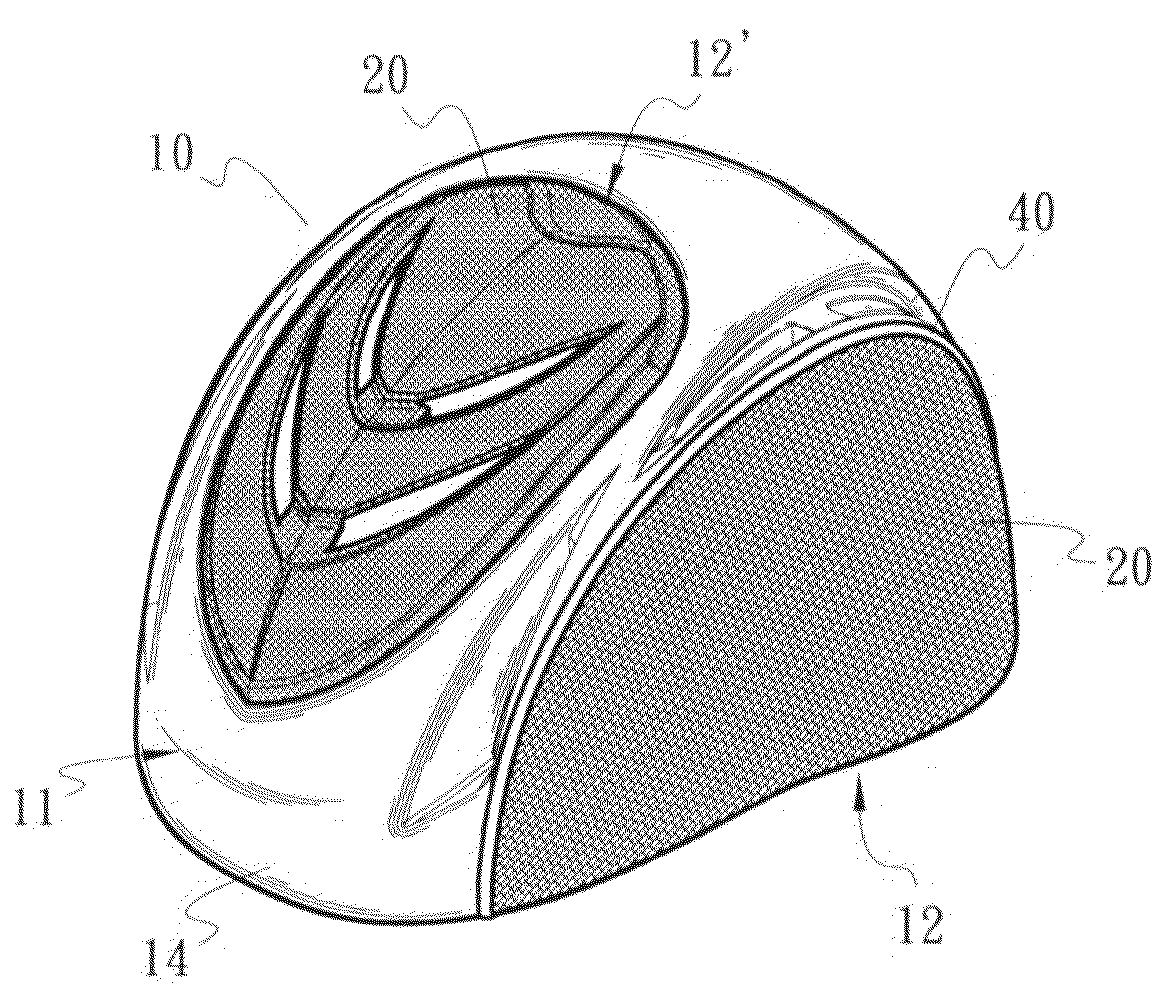

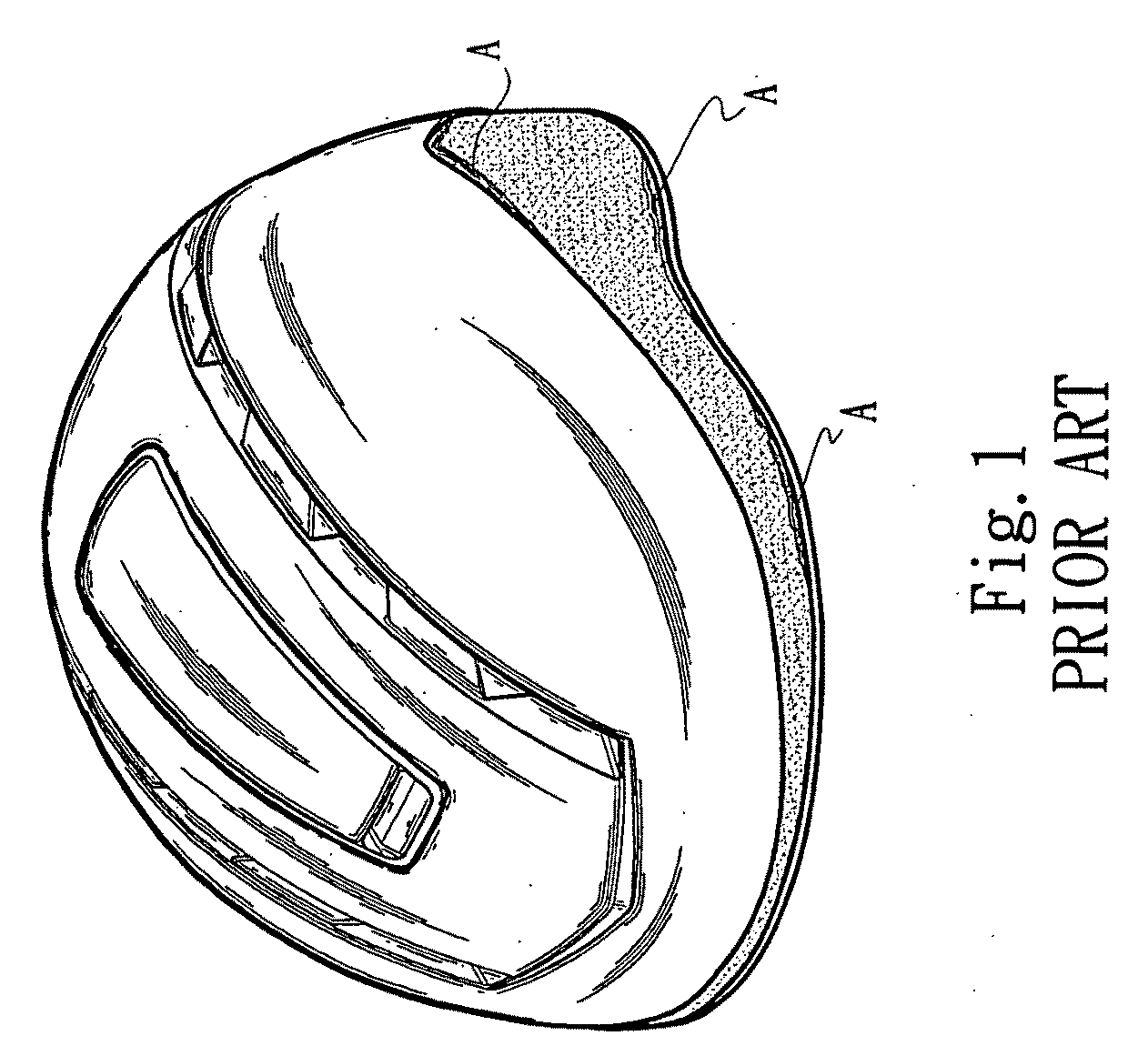

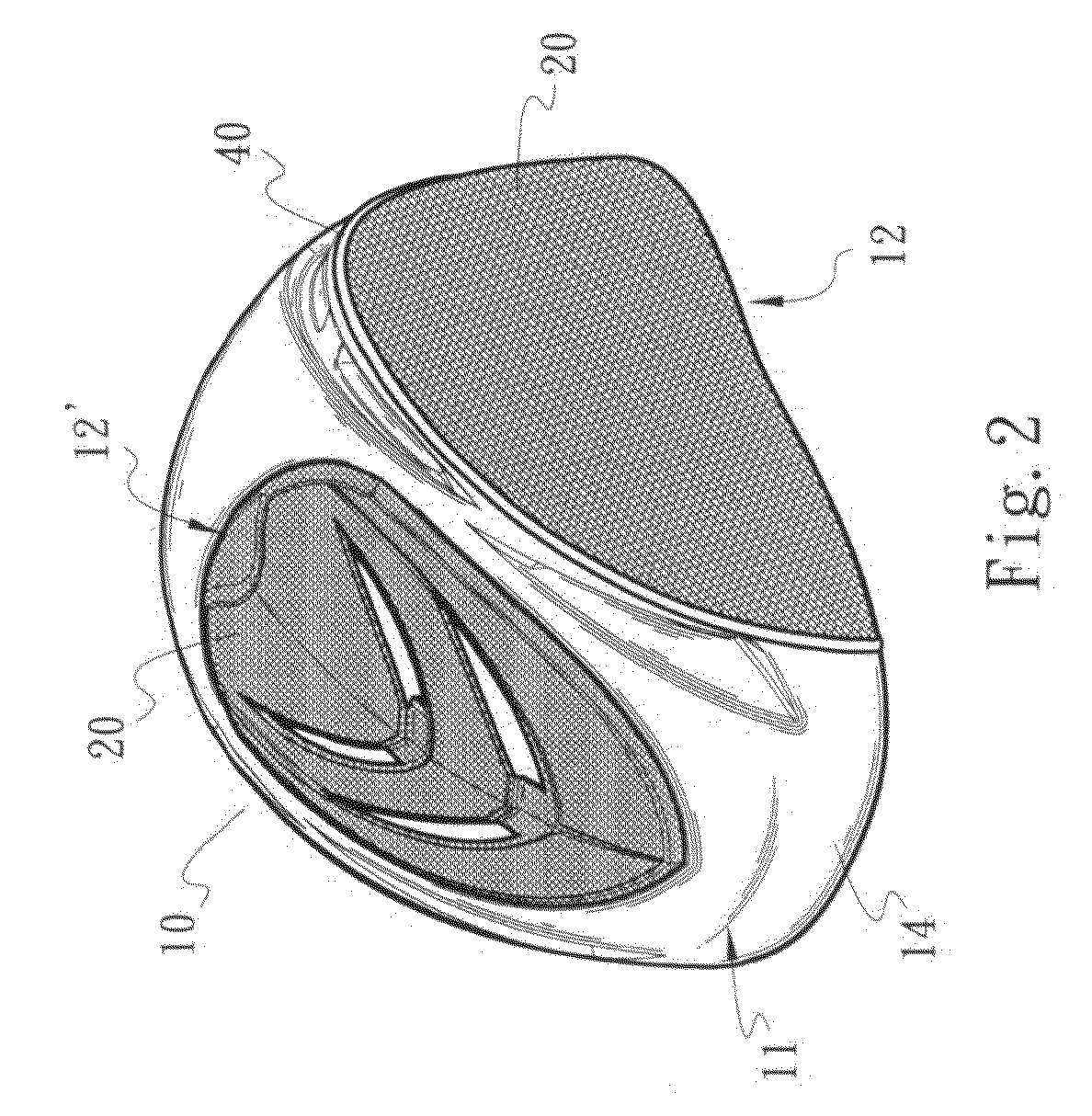

Safety helmet structure and processing method thereof

ActiveUS20100287687A1Long processing timeEvenly bondedHatsHeadwear capsEngineeringMechanical engineering

A safety helmet structure and a processing method thereof. The safety helmet includes a first section, a second section and an extension section defined between the first and second sections. The first section is sprayed with a figure. A decorative section or a figure layers is adhered to the second section. After a periphery of the decorative section or figure layer partially passes over an edge of the second section, the periphery of the decorative section or figure layer enters the extension section. The first and second sections together form a helmet subassembly. The helmet subassembly is placed in a mold and integrally bonded with a buffer material or foam material filler to form a helmet assembly.

Owner:HO CHANG HSIEN

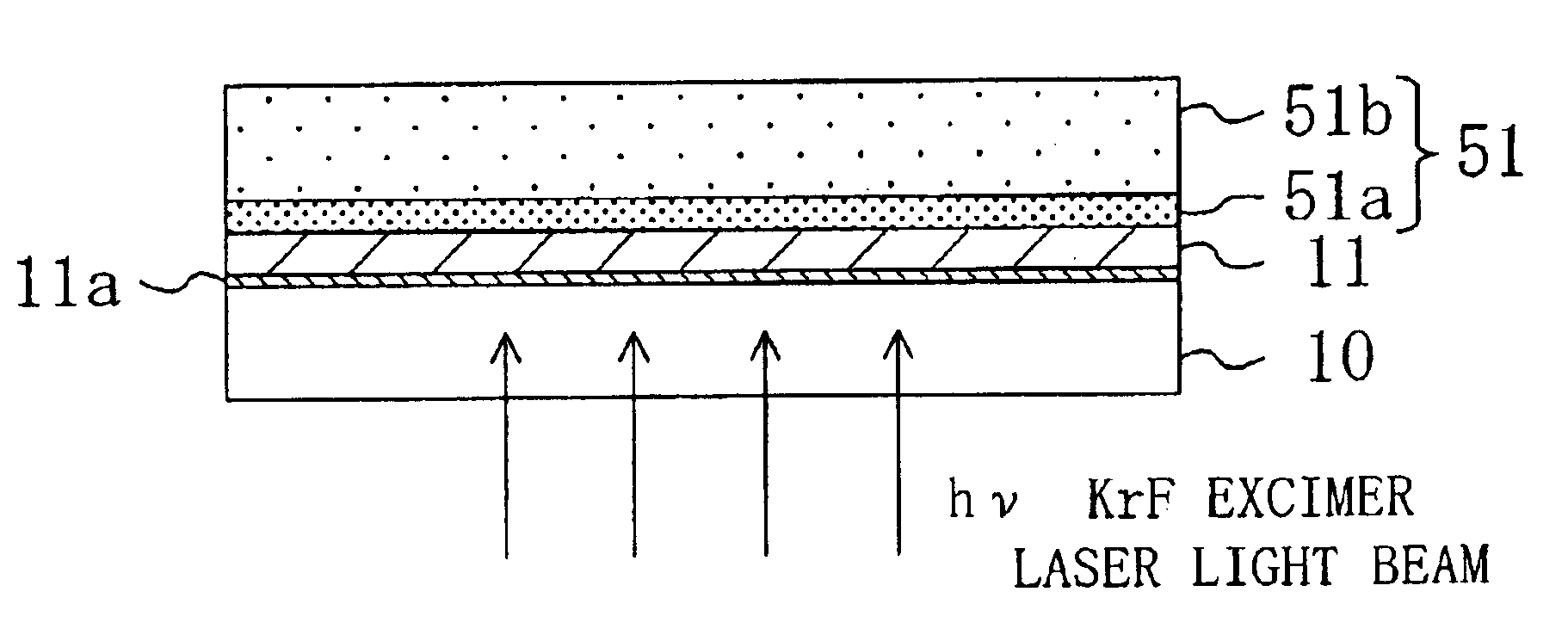

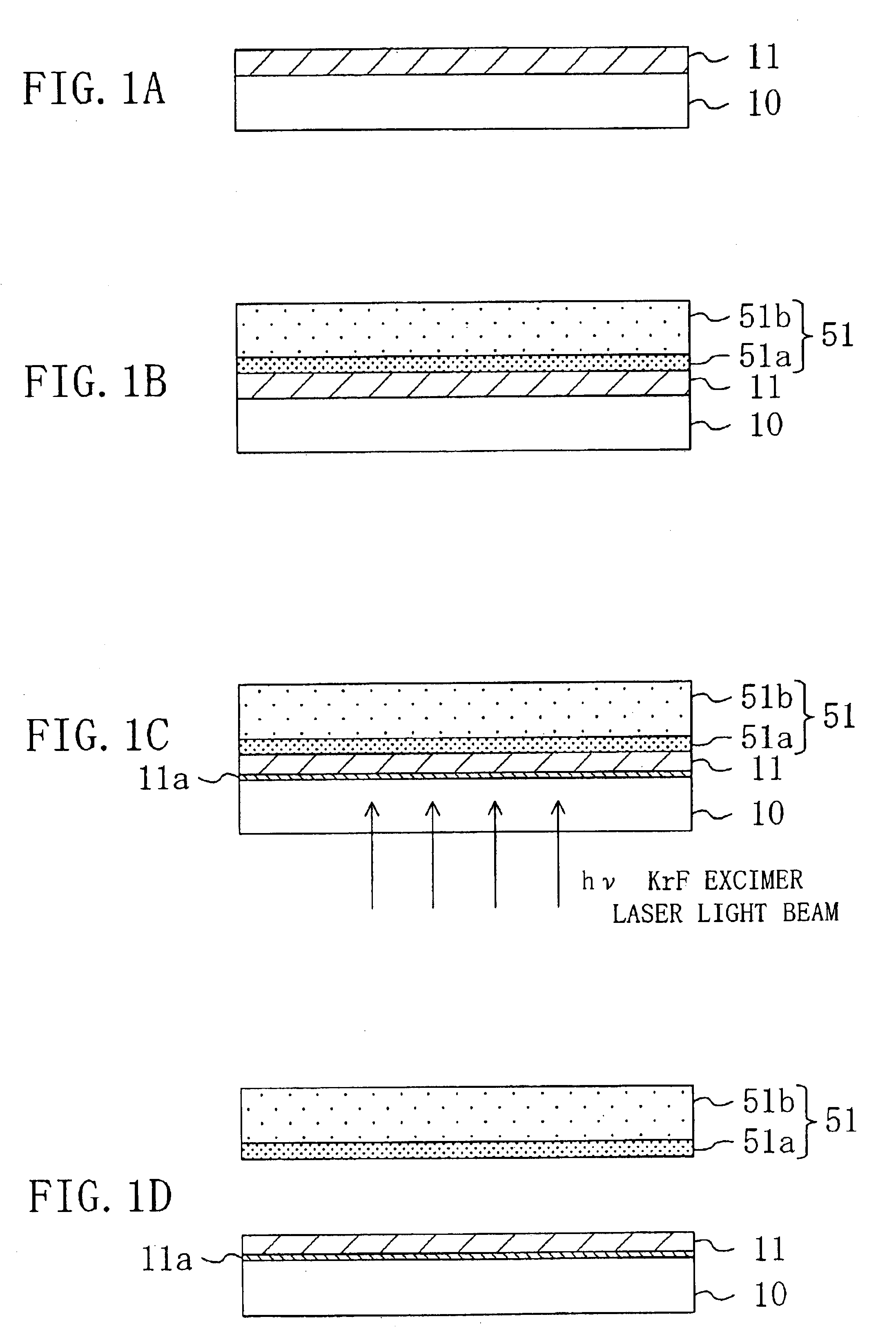

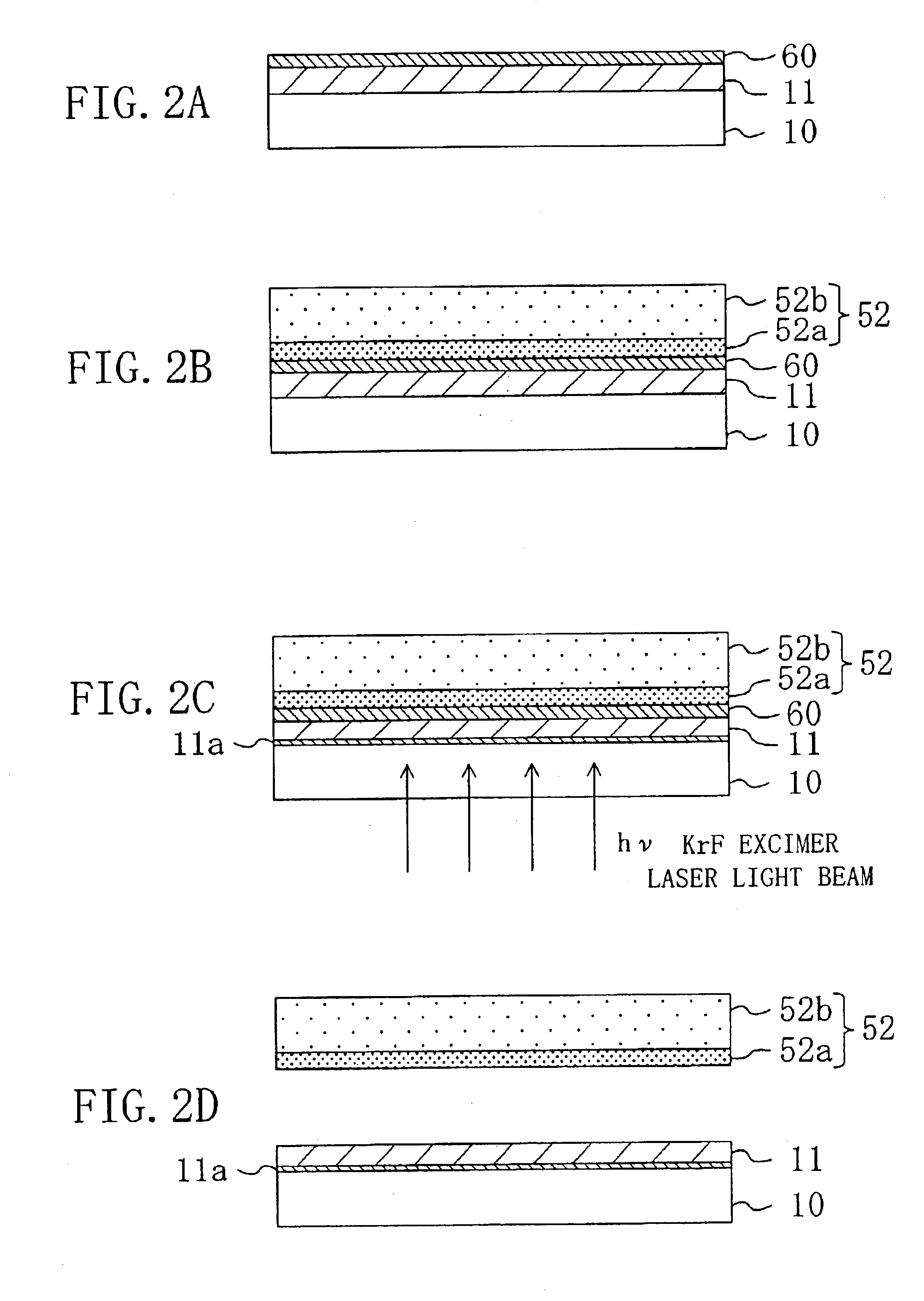

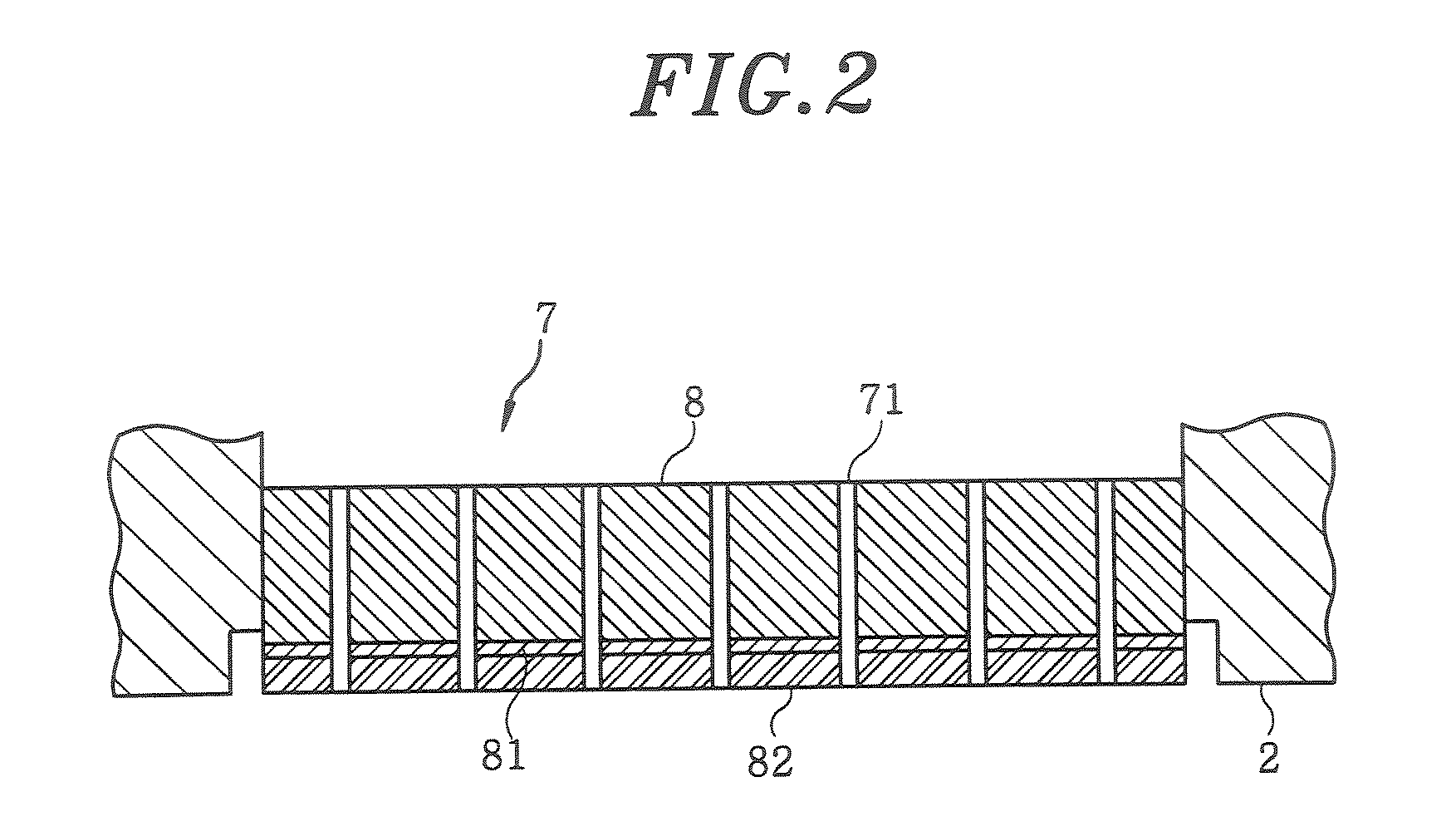

Method for fabricating semiconductor device

InactiveUS6887770B2Increase surface areaEvenly bondedLaser detailsSemiconductor laser structural detailsLight beamSemiconductor

A polymer film including an adhesive layer, which can be peeled off with heat, is bonded to the upper surface of a semiconductor layer. Then, a KrF excimer laser light beam is applied to a surface of a substrate opposite to the semiconductor layer. This causes local heating at the laser spot, so that the bonding of atoms is cut off at the interface between the semiconductor layer and the substrate, thereby forming a thermal decomposition layer between the substrate and the semiconductor layer. Subsequently, the substrate is heated at a given temperature, so that the adhesive layer foams to lose its adhesive power. As a result, the polymer film is easily peeled off from the semiconductor layer.

Owner:PANASONIC CORP

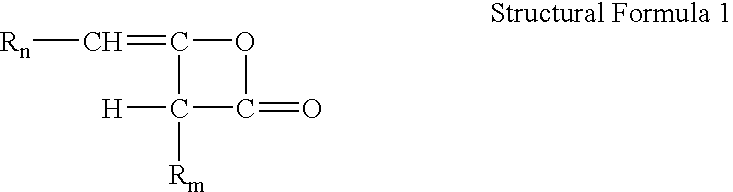

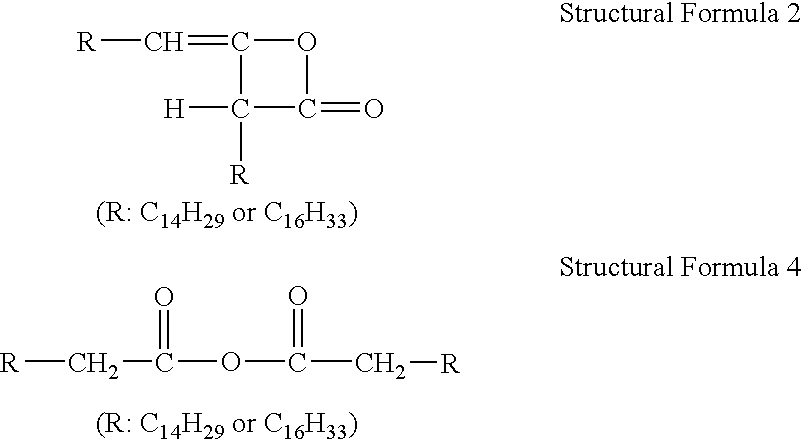

Filter medium for air filter and method for its production

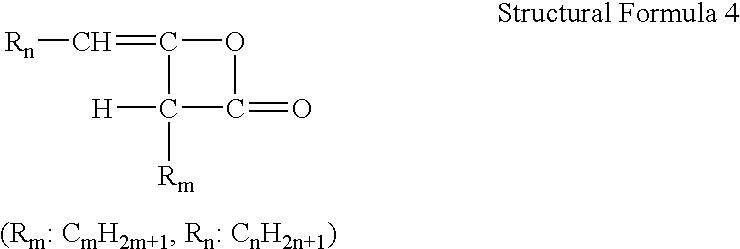

InactiveUS6939386B2High water-repellencyAvoid componentsSynthetic resin layered productsLoose filtering material filtersFiberAir filter

A filter medium for an air filter, characterized in that it comprises a filter material having a glass fiber as its primary component and an alkyl ketene dimer adhered to the surface of the glass fiber; and a method for producing the filter medium which comprises a step of subjecting a dispersed slurry of a raw material fiber to a wet papermaking to form a wet paper, a step of immersing the wet paper in an aqueous dispersion or solution of the dimer or a liquid mixture of the dimer and a binder resin, or applying or spraying any of the above-mentioned liquids to the wet paper, to thereby allow the dimer to adhere onto the surface of the glass fiber, and a step of drying the resultant wet paper having the dimer adhered thereto. The filter medium exhibits a reduced amount of an out gas generated when it is used with ventilation and also exhibits high water-repellency and satisfactory strength in various applications such as air conditioning of a building and semiconductor manufacturing.

Owner:HOKUETSU KK

Seamless embroidery wall fabric and production method thereof

ActiveCN102644363AEvenly bondedNo limitationsCovering/liningsPaper/cardboard layered productsPolymer sciencePaper based

The invention belongs to the technical field of facing decoration materials and particularly relates to a seamless embroidery wall fabric which has a simple sticking method, strong artistry and low possibility of crinkling after being pasted with a wall surface. The seamless embroidery wall fabric comprises embroidery traycloth with embroidery patterns, wherein a wall paper base paper layer is bonded on the back side of the embroidery traycloth by an EVA (Ethylene Vinyl Acetate Copolymer) adhesive film layer. The invention also discloses a production method of the seamless embroidery wall fabric. According to the production method, the produced seamless embroidery wall fabric is full of exquisite embroidery patterns, width wall fabric products can be obtained and the defects that the wall fabric produced by a traditional method is not high in artistry, easy to crinkle and can be only produced into narrow products are overcome.

Owner:ZHEJIANG LIANXIANG EMBROIDERY CO LTD

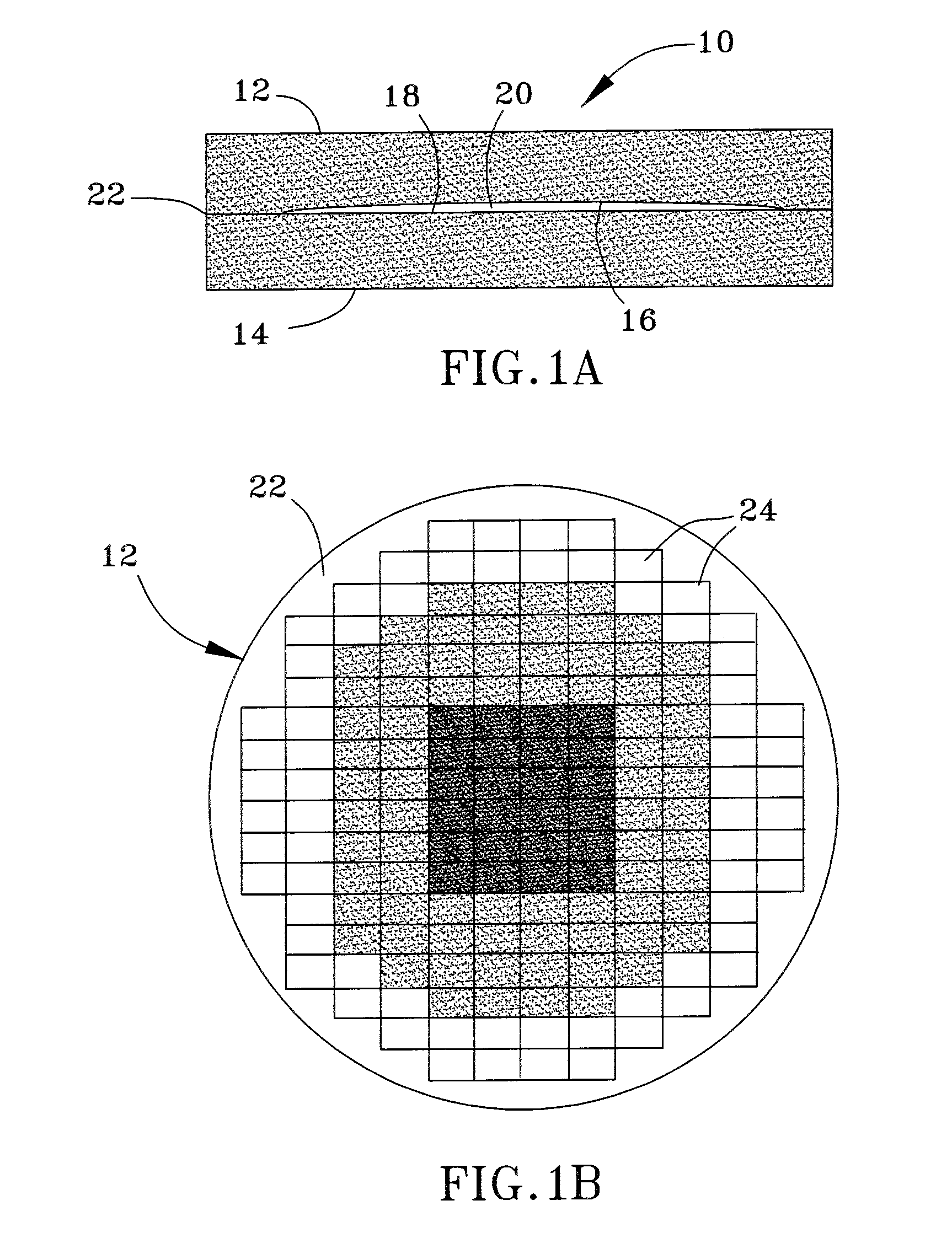

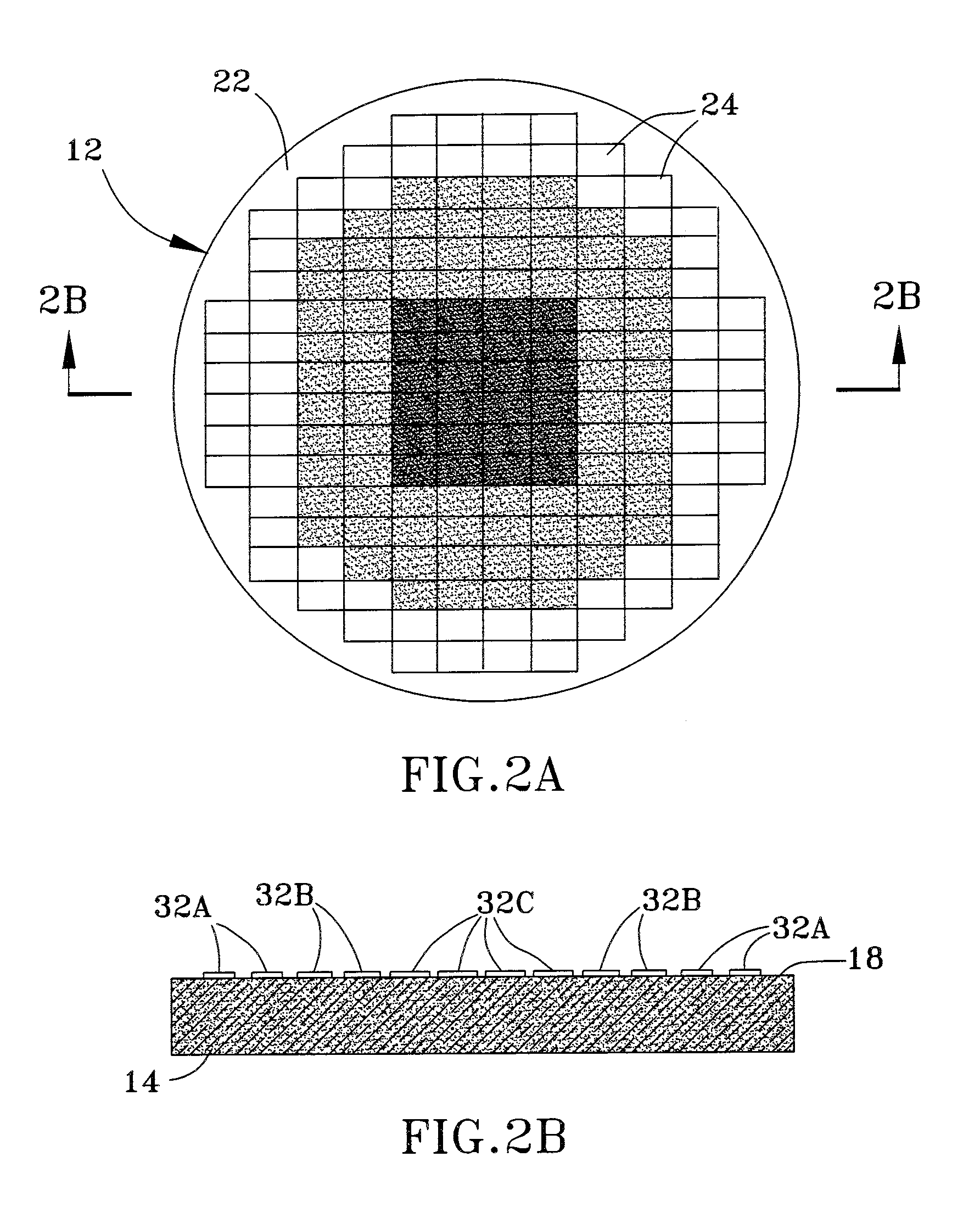

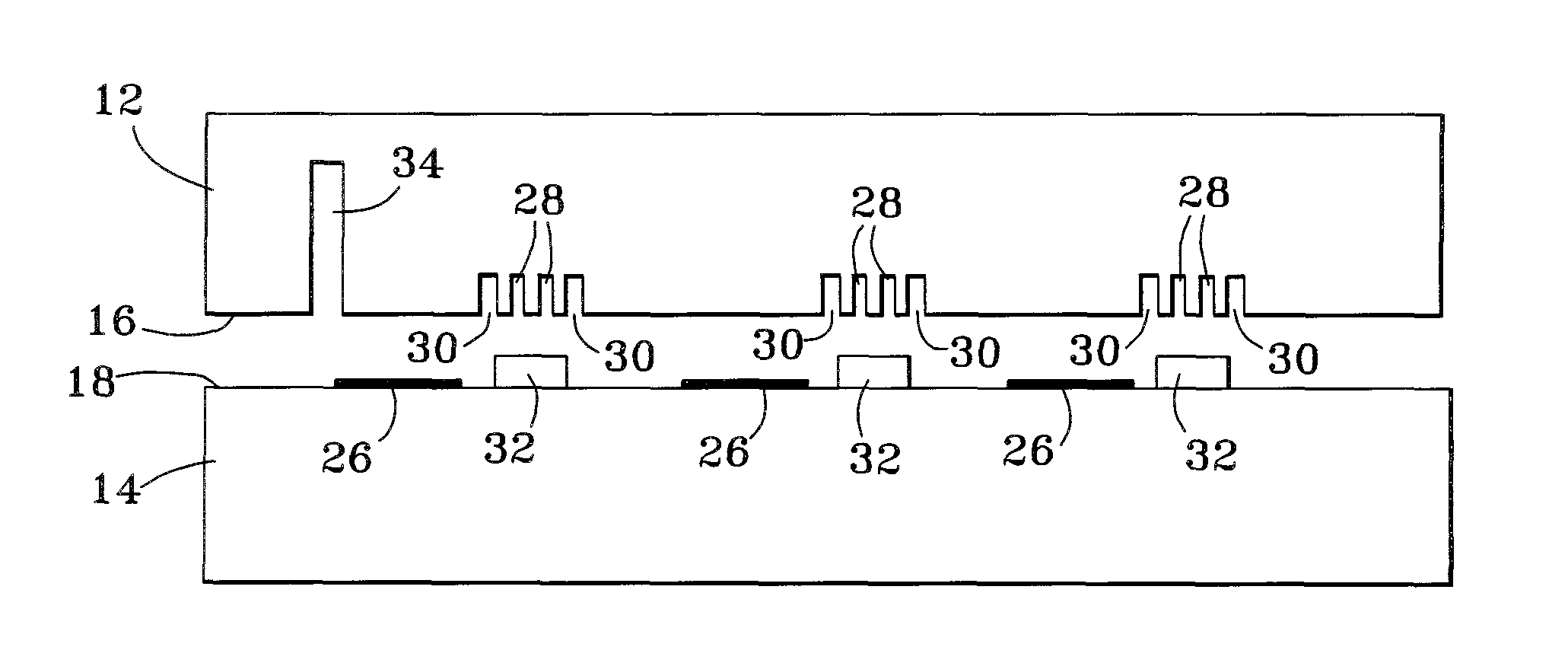

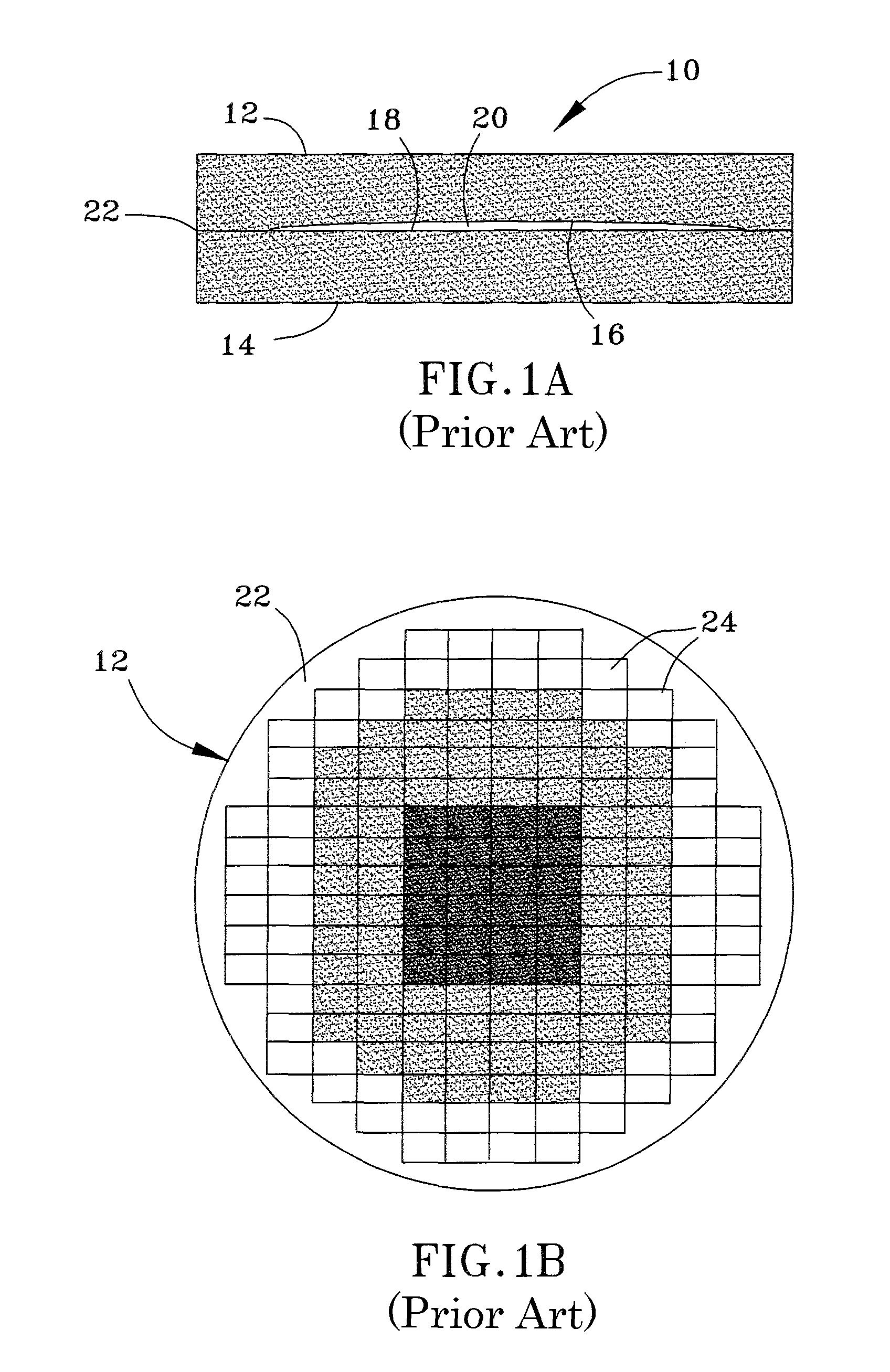

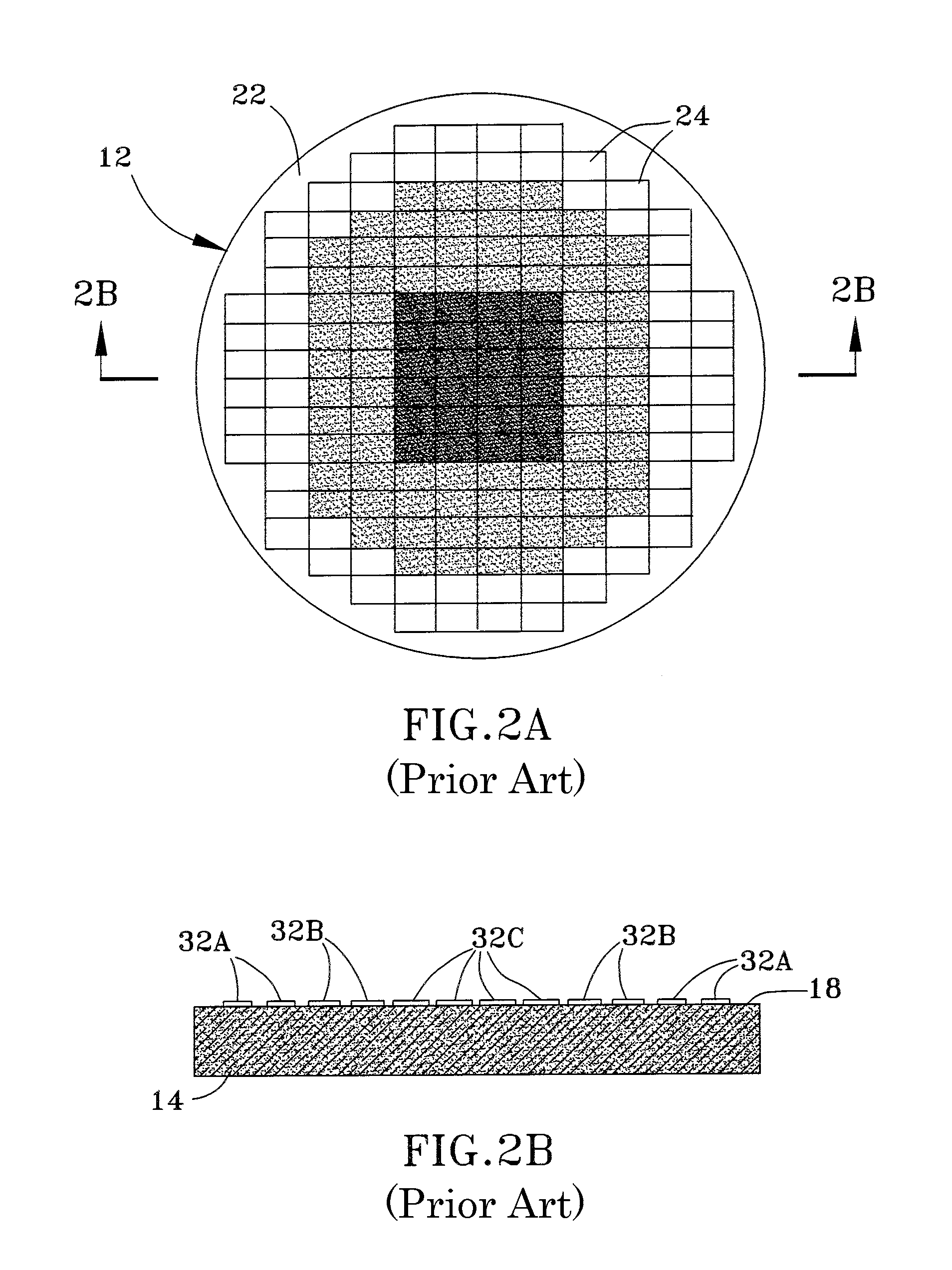

Wafer bonding method and wafer stack formed thereby

ActiveUS20100072555A1Minimize and eliminate detrimental effectLimit electrical shortingSolid-state devicesSemiconductor/solid-state device manufacturingBonding processWafer stacking

A wafer bonding process that compensates for curvatures in wafer surfaces, and a wafer stack produced by the bonding process. The process entails forming a groove in a surface of a first wafer, depositing a bonding stack on a surface of a second wafer, aligning and mating the first and second wafers so that the bonding stack on the second wafer contacts a bonding site on the first wafer, and then heating the first and second wafers to reflow the bonding stack. The groove either surrounds the bonding site or lies entirely within the bonding site, and the heating step forms a molten bonding material, causes at least a portion of the molten bonding material to flow into the groove, and forms a bonding structure that bonds the second wafer to the first wafer. Bonding stacks having different lateral surface areas can be deposited to form bonding structures of different heights to compensate for variations in the wafer gap.

Owner:MICRO INERTIAL LLC

Method for manufacturing interior film-pasting woven bag

ActiveCN105109803AReduce human wasteIncrease productivityEnvelopes/bags making machineryPaper-makingLow-density polyethyleneManufacturing technology

The invention discloses a method for manufacturing an interior film-pasting woven bag, and relates to the technical field of woven bag manufacturing. The interior film-pasting woven bag comprises an outer plastic bag body formed by weaving polypropylene plastics. An ethylene-vinyl acetate film and a high-pressure low-density polyethylene film are sequentially arranged in the outer plastic bag body. The method includes the following operation steps: A, manufacturing plastic ribbon-like filaments; B, manufacturing the two films; C, manufacturing the outer plastic bag body with the double films; D, manufacturing an interior film-pasting woven bag reel by an interior film pasting combining machine through the outer plastic bag body, obtained in the step C, with the double films; and E, carrying out cutting and sewing on the interior film-pasting woven bag reel obtained in the step D, and completing manufacturing of the interior film-pasting woven bag. Compared with the prior art, the method can solve the problem that an inner bag body of an existing interior film-lining woven bag is prone to being damaged.

Owner:GUANGXI LUZHAI GUIZHE PLASTIC PACKAGE CO LTD

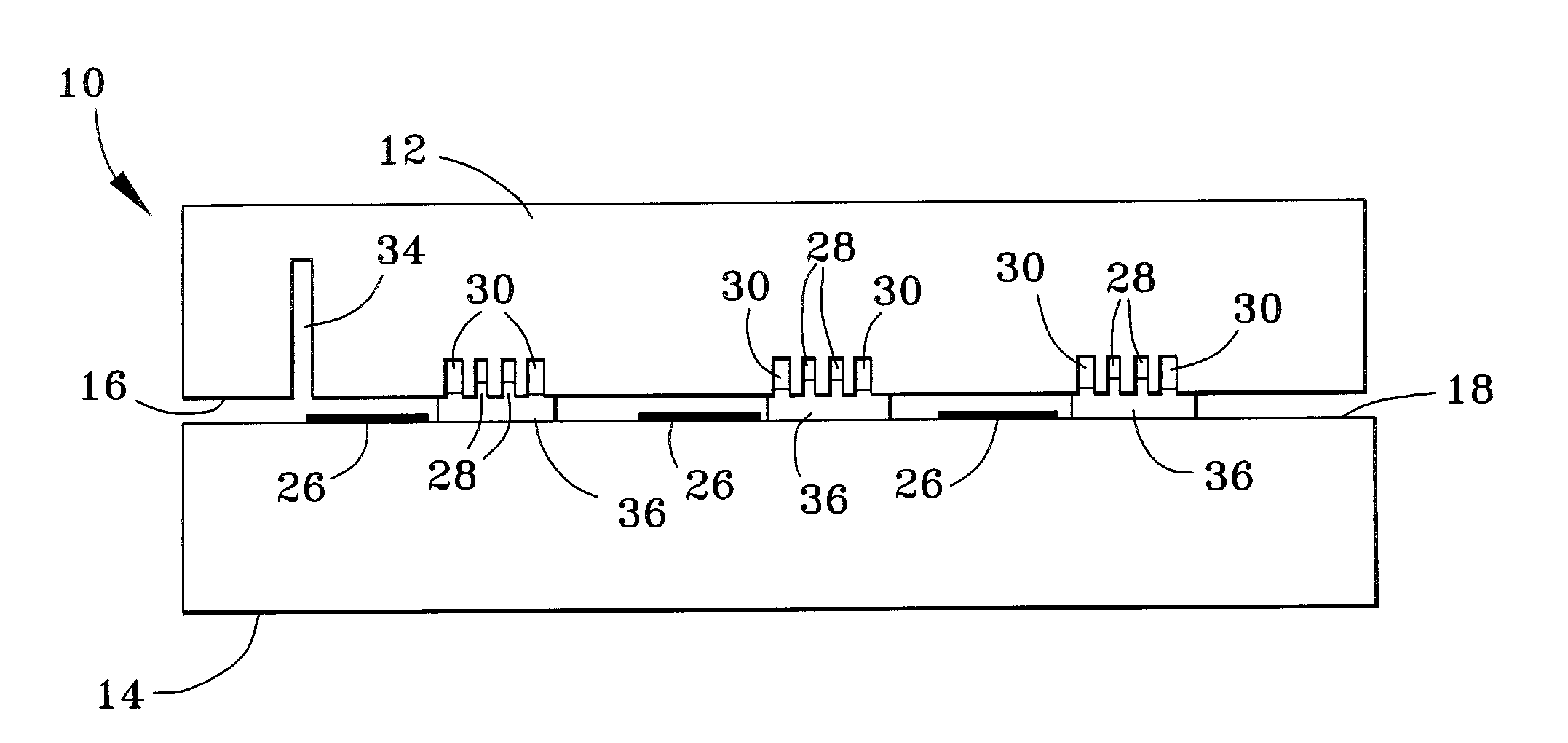

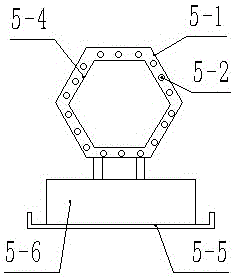

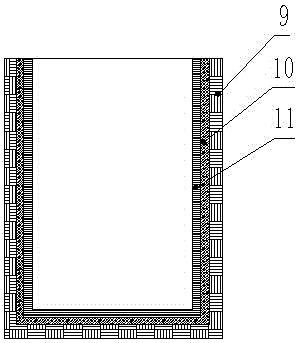

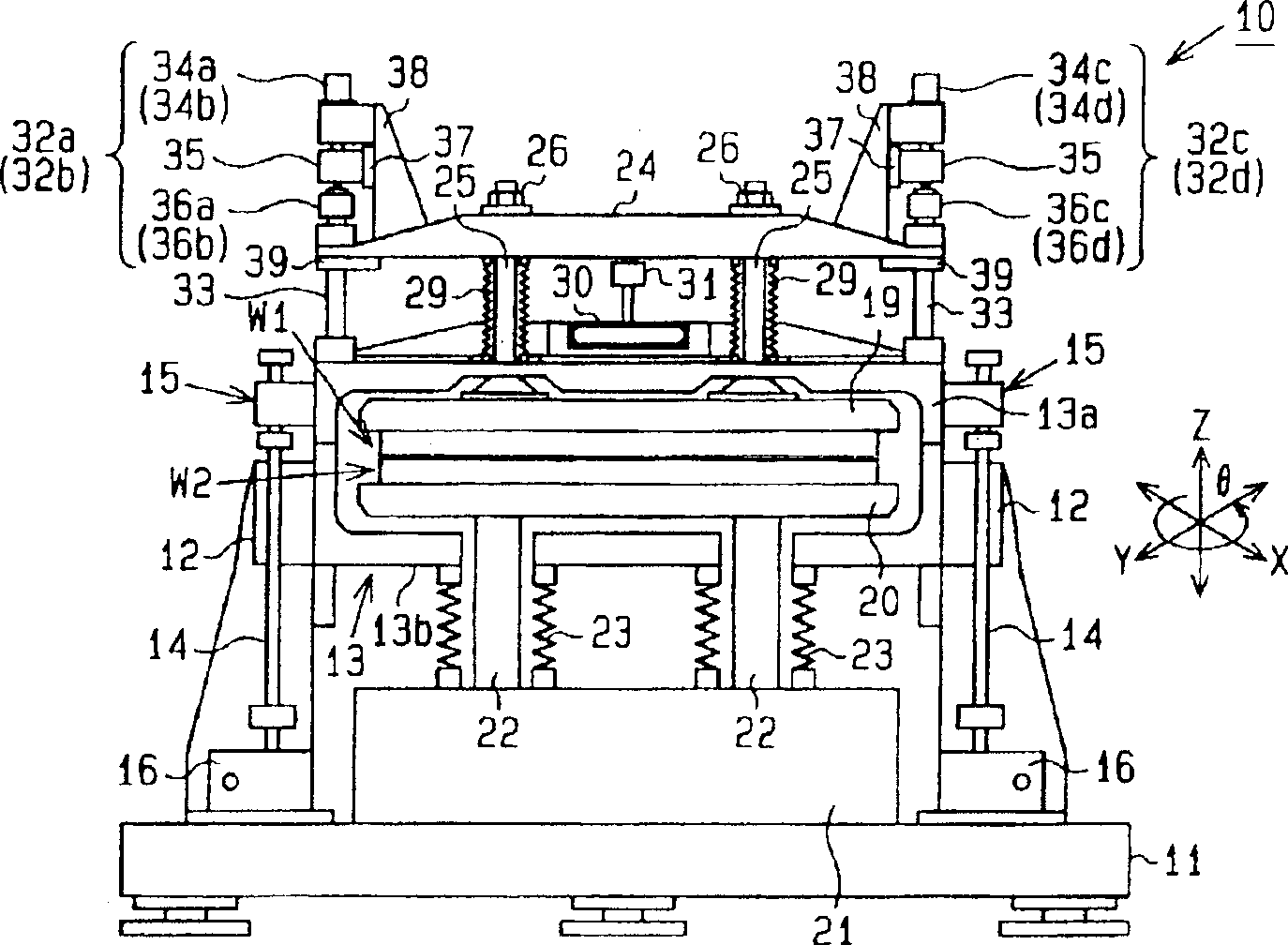

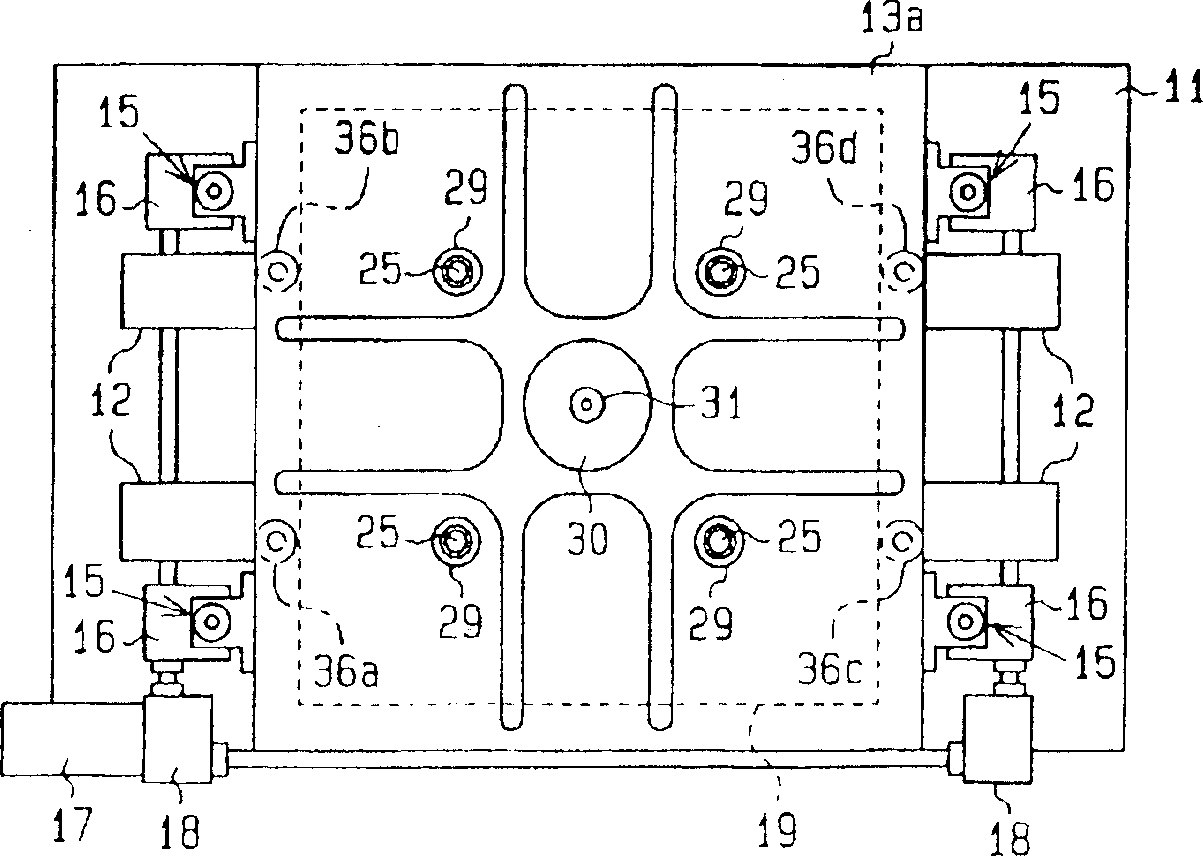

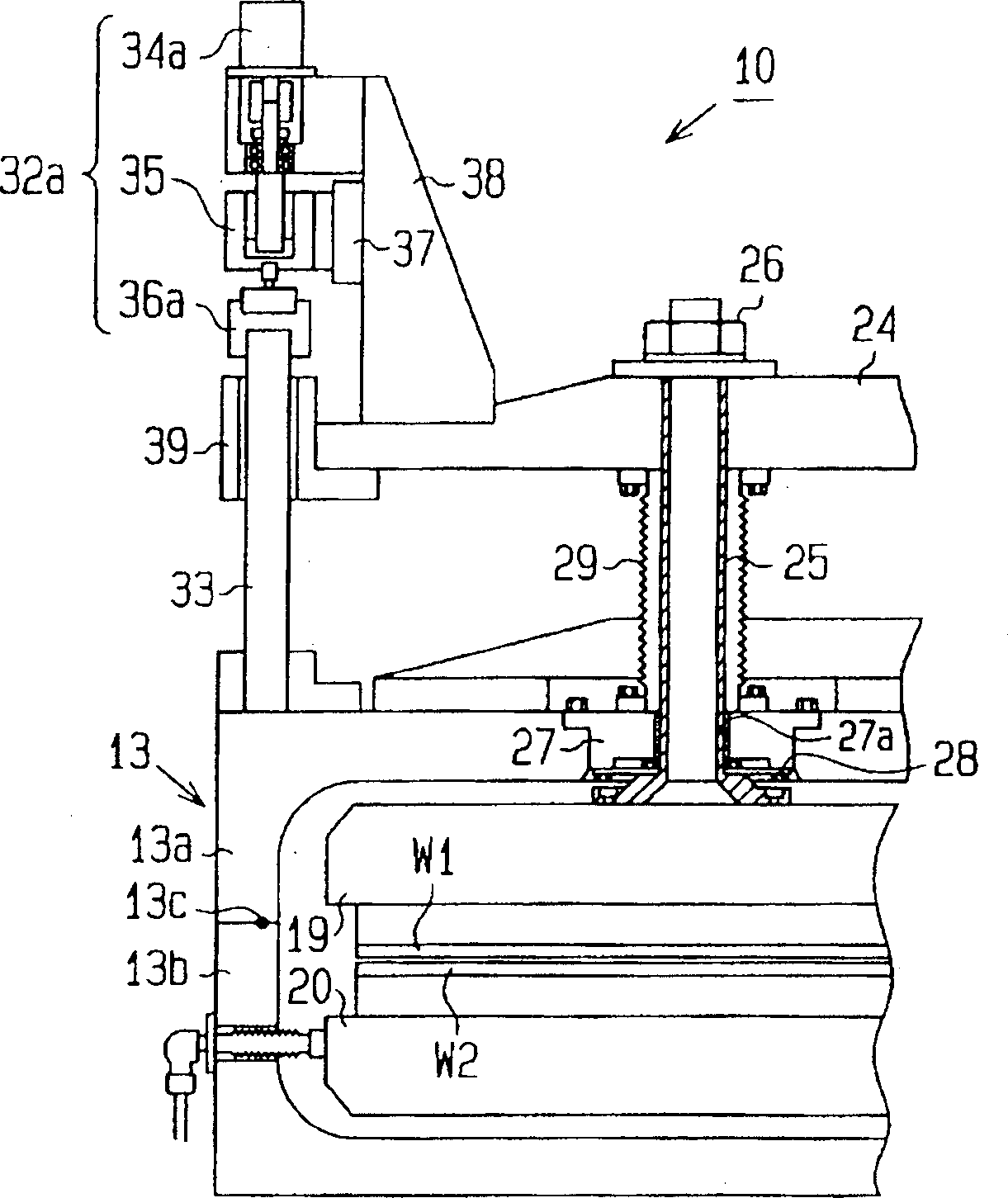

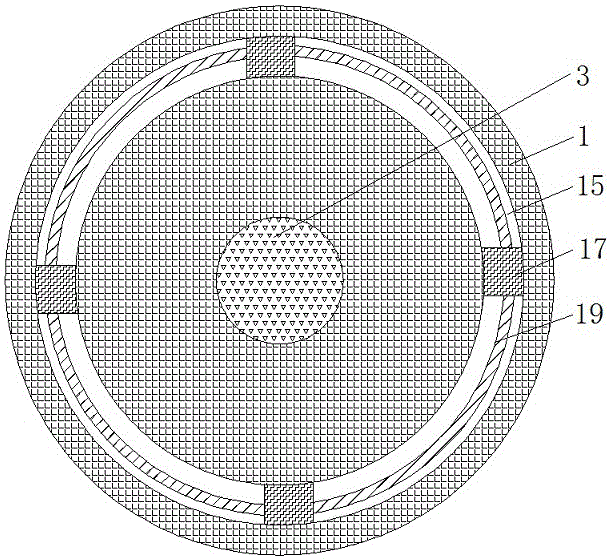

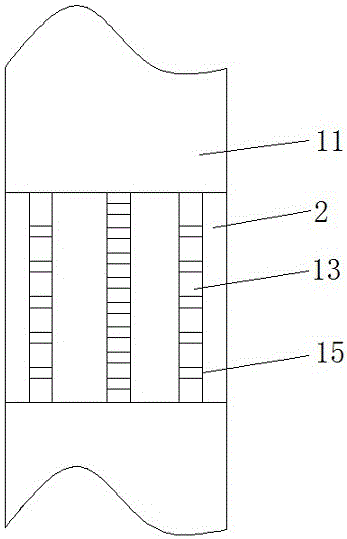

Placode binder and binding method

InactiveCN1530714AEvenly bondedHigh speed bondingSemiconductor/solid-state device manufacturingPress ramWorking pressureEngineering

A laminating device 10 is provided with pressurization correcting mechanisms 32a to 32d which perform pressurization while adjusting working pressure so that the load distribution of a pressurizing plate 19 is equalized in accordance with load displacement by detecting the load displacement of the pressurizing plate 19 when both substrates W1, W2 are laminated.

Owner:FUJITSU LTD

Waterproof storage bag

A waterproof storage bag which comprises a bag body having an open end and a bag opening provided at the open end of the bag body to seal the bag body. The bag opening has inner surfaces which are smooth surfaces made of smooth and soft plastic material and the inner surfaces do not contain any self-adhesive material and are not disposed with any additional adhesive material thereon. A multi-porous resilient member is provided inside the bag body. It is an object of the present invention to provide a waterproof bag which could indicate to a user whether its waterproof function is still functioning properly. It has the advantages of simple structure, easy operation and low manufacturing costs.

Owner:POTTER IND

Anti-Inflammatory Dissolvable Film

ActiveUS20070292487A1Avoid being less adaptablePromote absorptionBiocideOrganic active ingredientsTraditional medicineMoisture

Owner:IZUN PHARMA

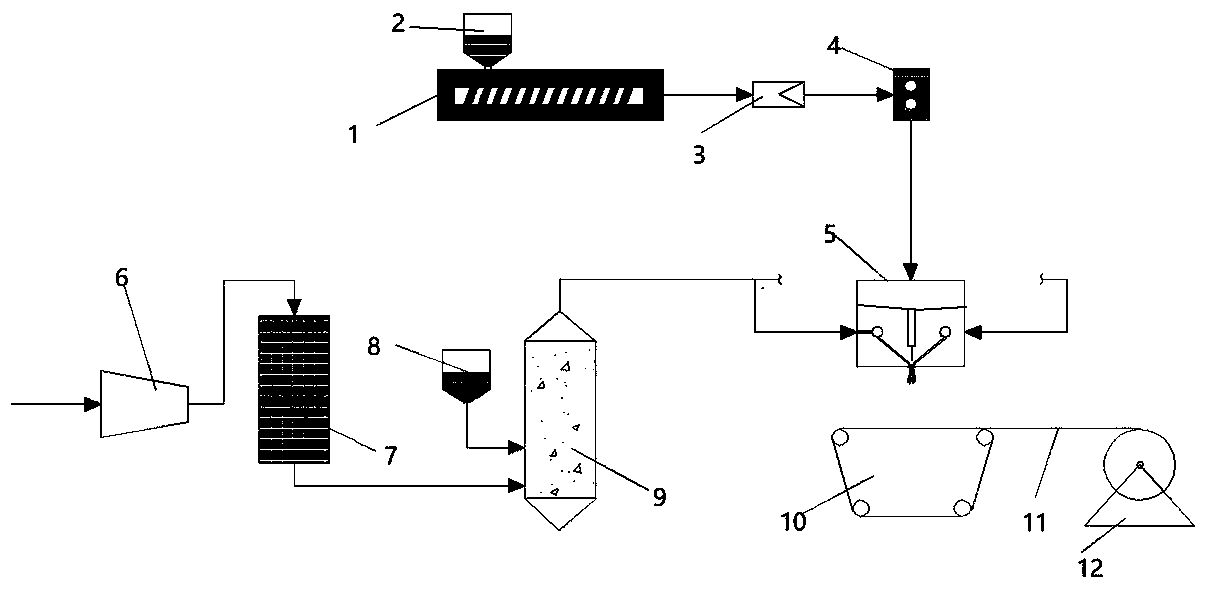

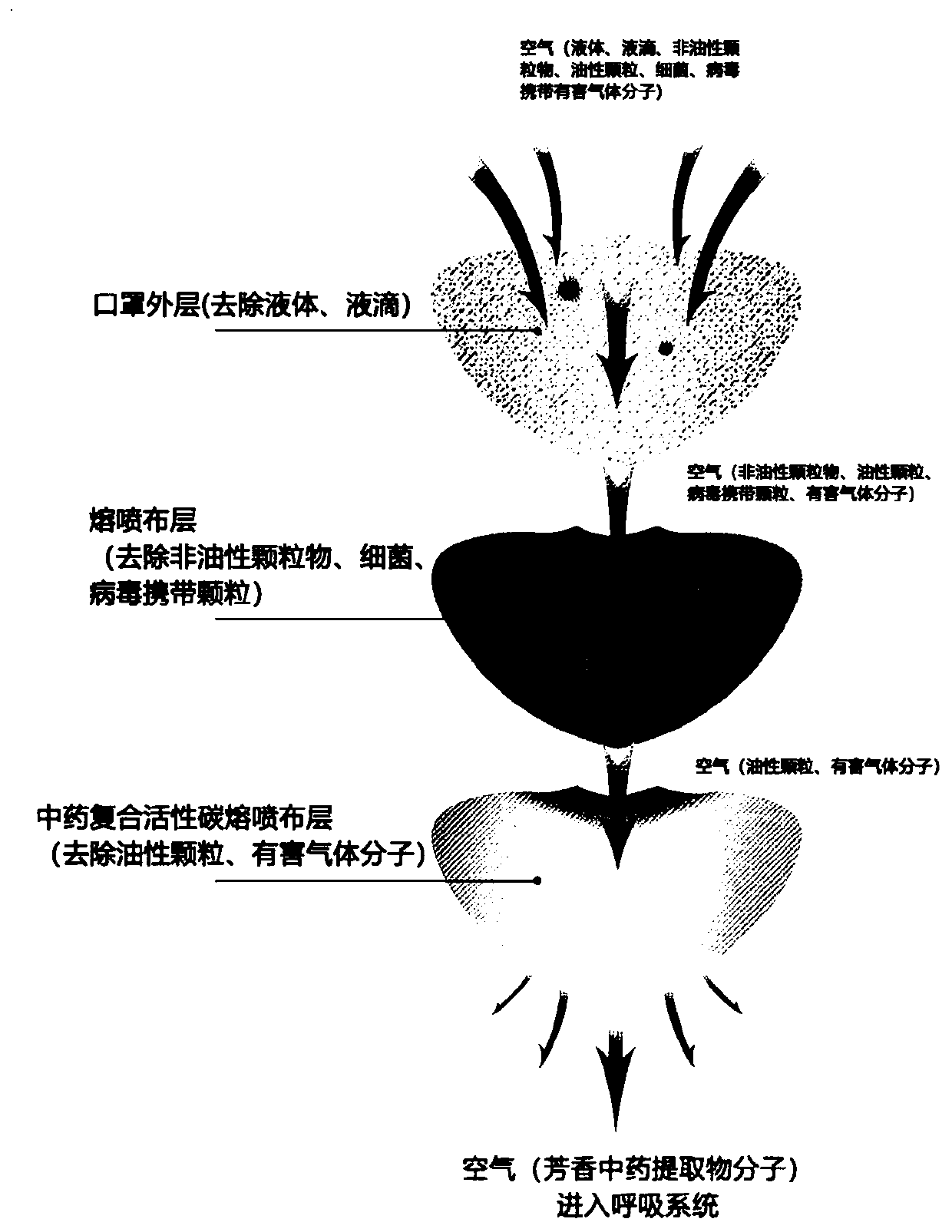

Activated carbon composite melt-blown fabric, preparation method thereof and mask

ActiveCN111424374AReduce sheddingImprove filtering effectDispersed particle filtrationBiochemical fibre treatmentFiberActivated carbon

The invention discloses a preparation method of an activated carbon composite melt-blown fabric. A melt-blown melt is sprayed by using a fluidized state high-temperature high-pressure gas containing activated carbon particles as traction gas, in the process, a gas-liquid-solid three-phase mixed flow field is sprayed forwards, and finally, the melt is cooled and formed and cured in the form of a fiber mesh structure; meanwhile, activated carbon evenly adheres to and is constrained in the fiber mesh structure, and finally the stable activated carbon composite melt-blown fabric is formed. The activated carbon composite melt-blown fabric is soaked in a traditional Chinese medicine extract, so that the melt-blown fabric has the effects of sterilizing, disinfecting, respiratory tract resistanceimprovement, odor freshening and the like. The invention also discloses the activated carbon composite melt-blown fabric obtained through the preparation method and a mask using the activated carbon composite melt-blown fabric. The filtering, sterilizing and protecting effects are good.

Owner:大湾汉唯(广州)医药科技集团有限公司

Manufacturing method of diffused alloy steel powder

A process for preparing diffusion-type alloy steel powder uses water-atomized pure iron powder and powdered alloy elements as raw materials, and includes mixing and diffusion steps. It can be used for high-density and high-strength powder metallurgy with the advantages of low cost and excellent performance.

Owner:山东鲁银新材料科技有限公司

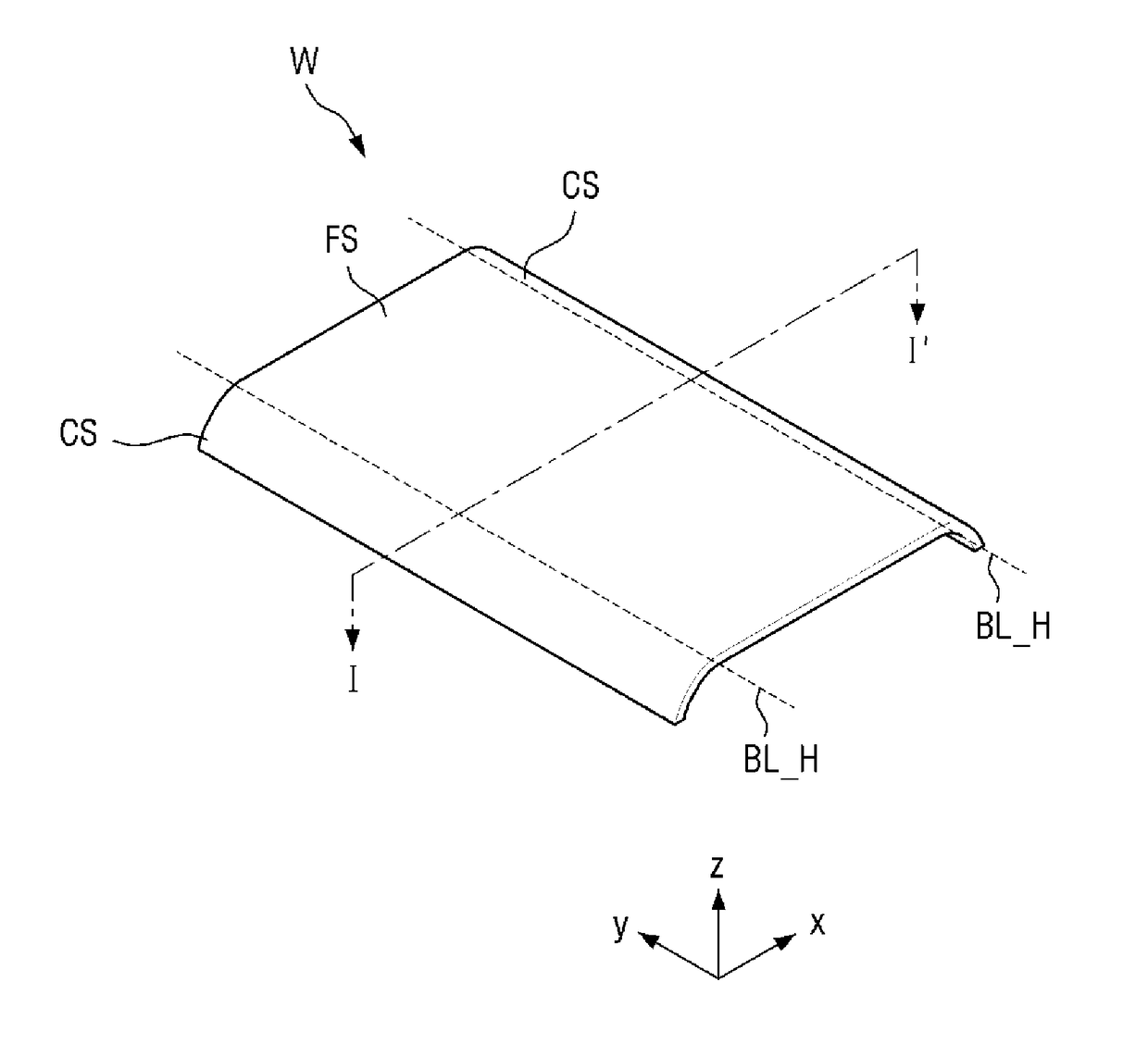

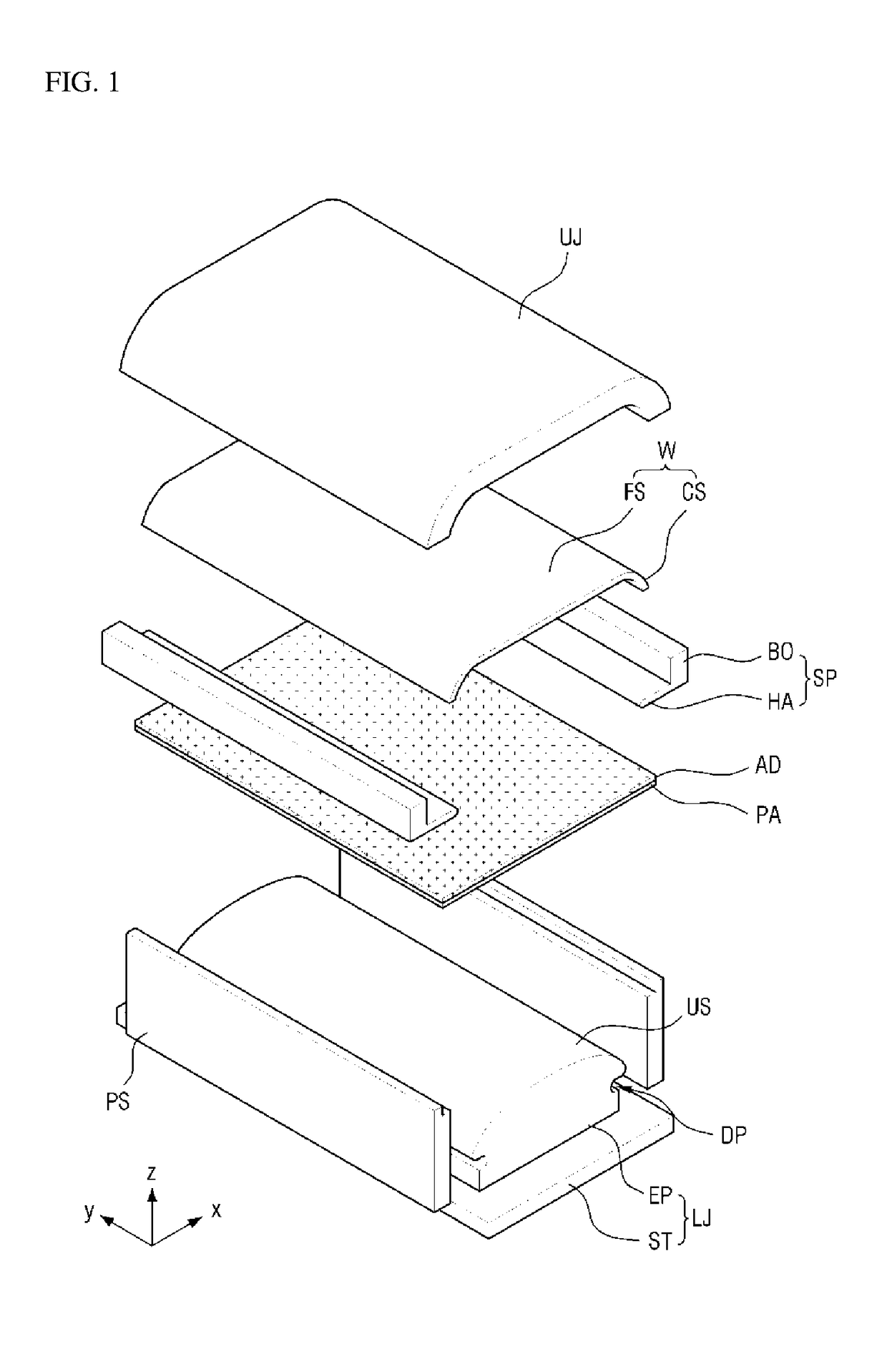

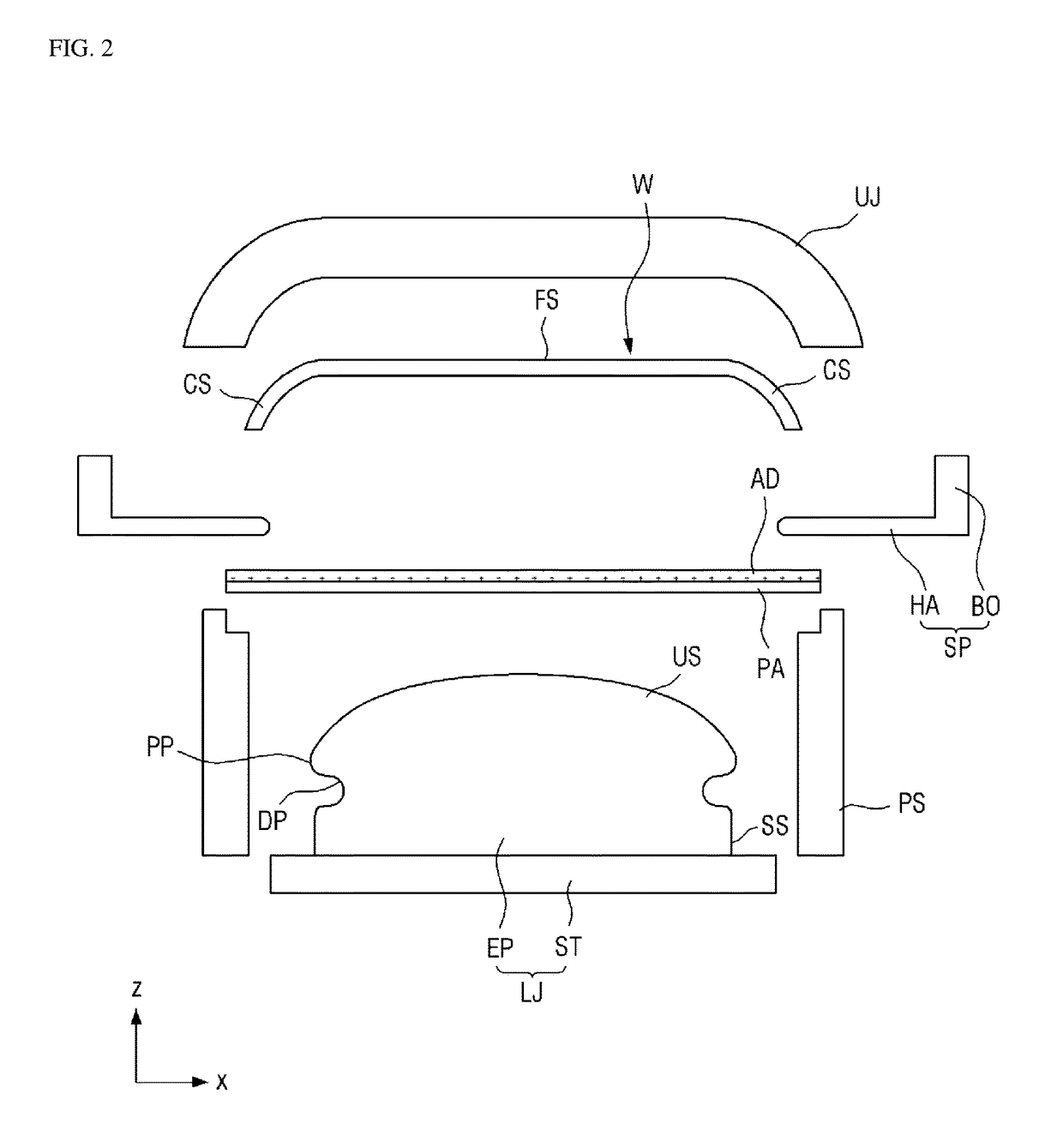

Laminating apparatus and method of fabricating display device using the same

ActiveUS20180056638A1Uniform bondingEvenly bondedLamination ancillary operationsSolid-state devicesBiomedical engineeringDisplay device

A laminating apparatus and method of fabricating a display device are provided. According to an exemplary embodiment of the present disclosure, the laminating apparatus includes a first jig, which is configured to fix a window having curved surfaces, and a second jig, which includes a pressure pad facing the first jig. The pressure pad includes a top surface, which is convex toward the first jig, and depressed portions, which are inwardly depressed from side surfaces, respectively.

Owner:SAMSUNG DISPLAY CO LTD

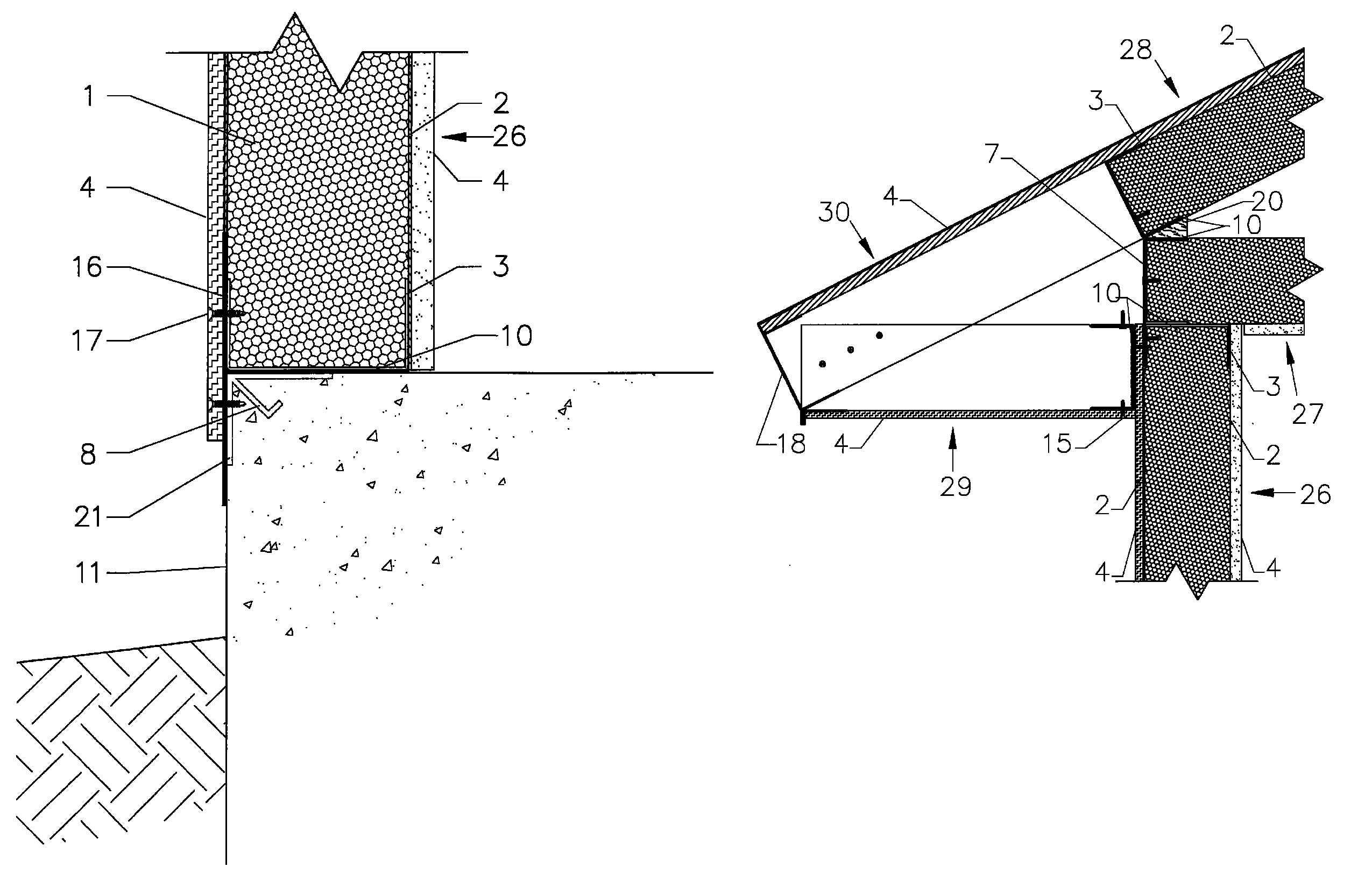

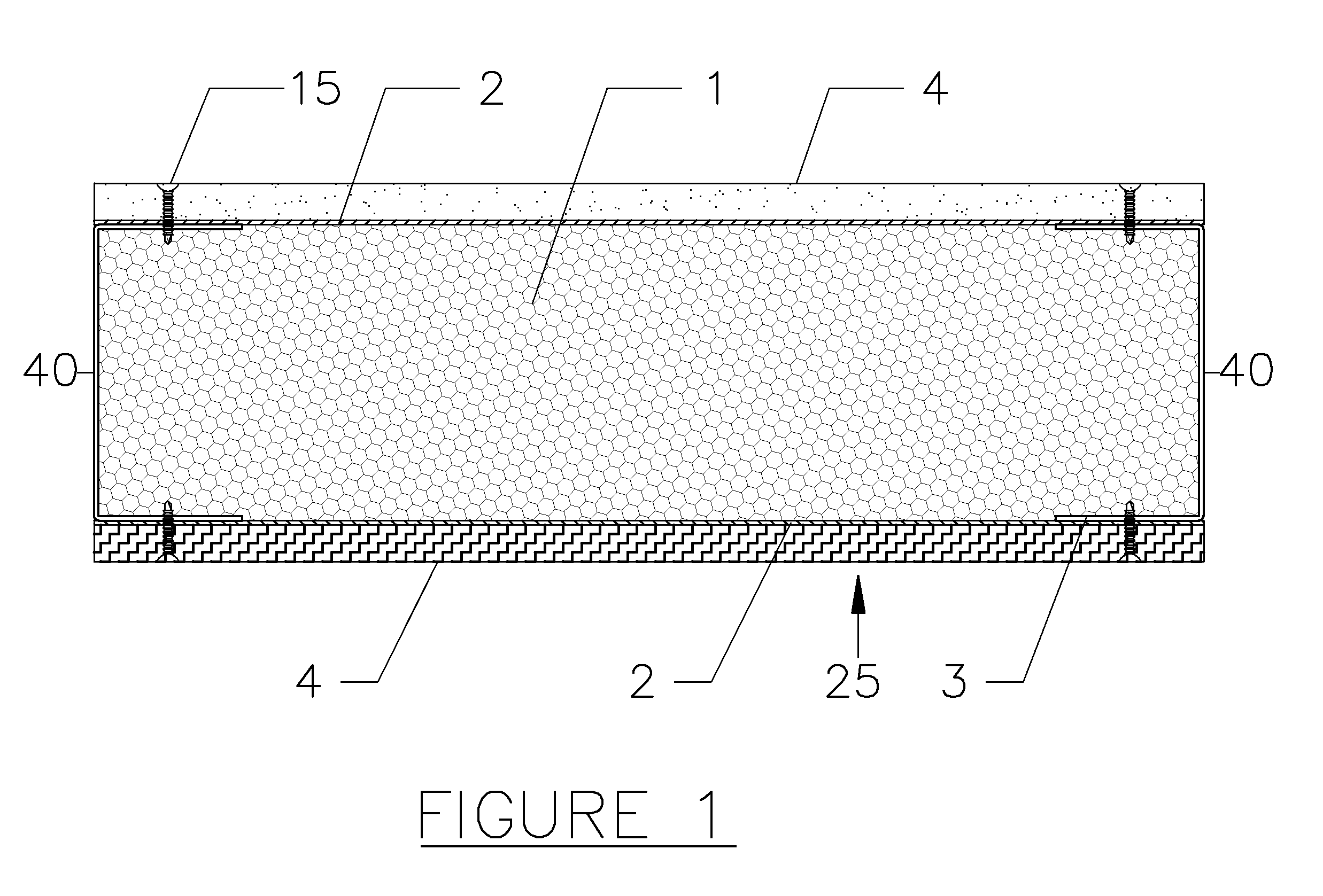

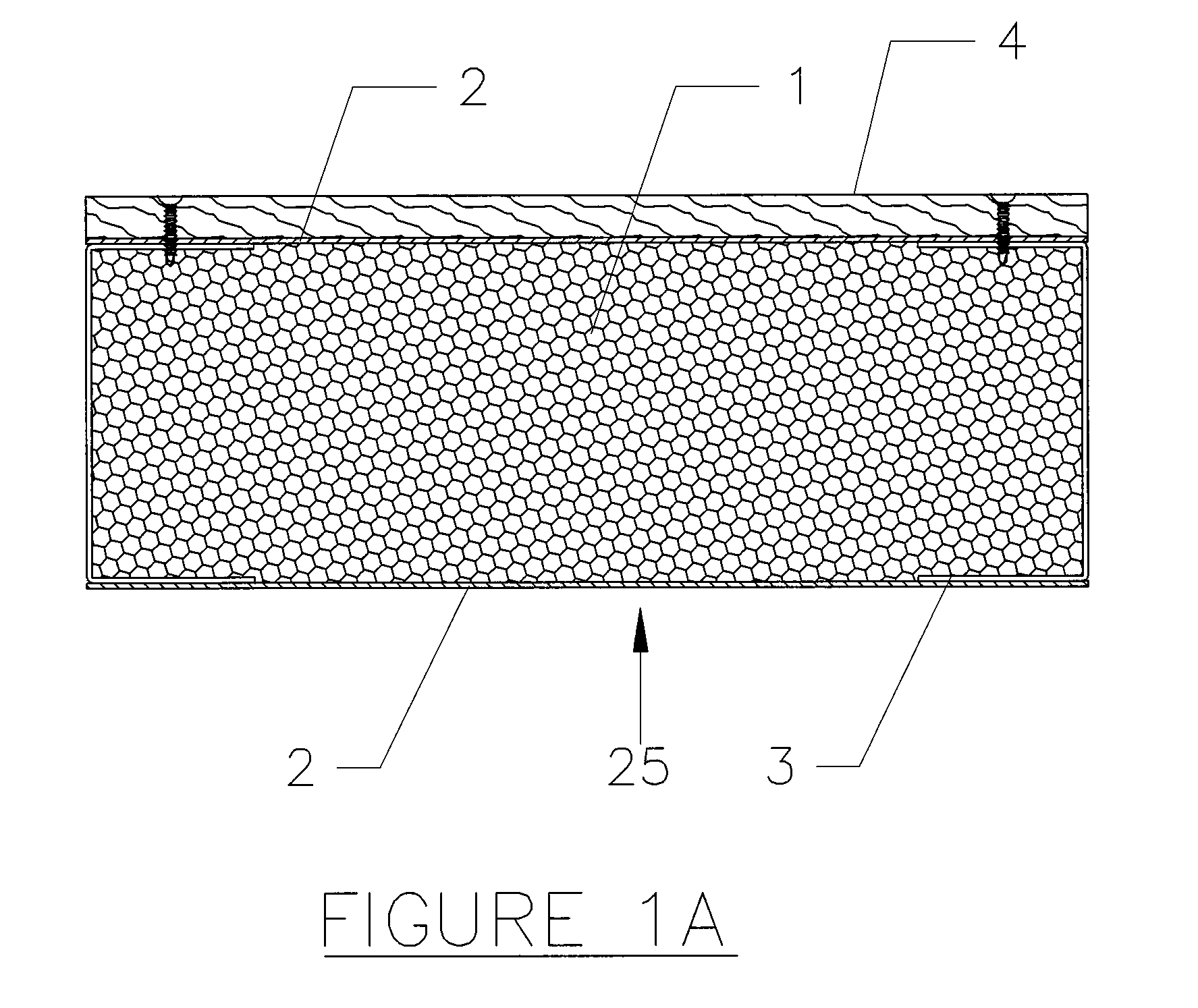

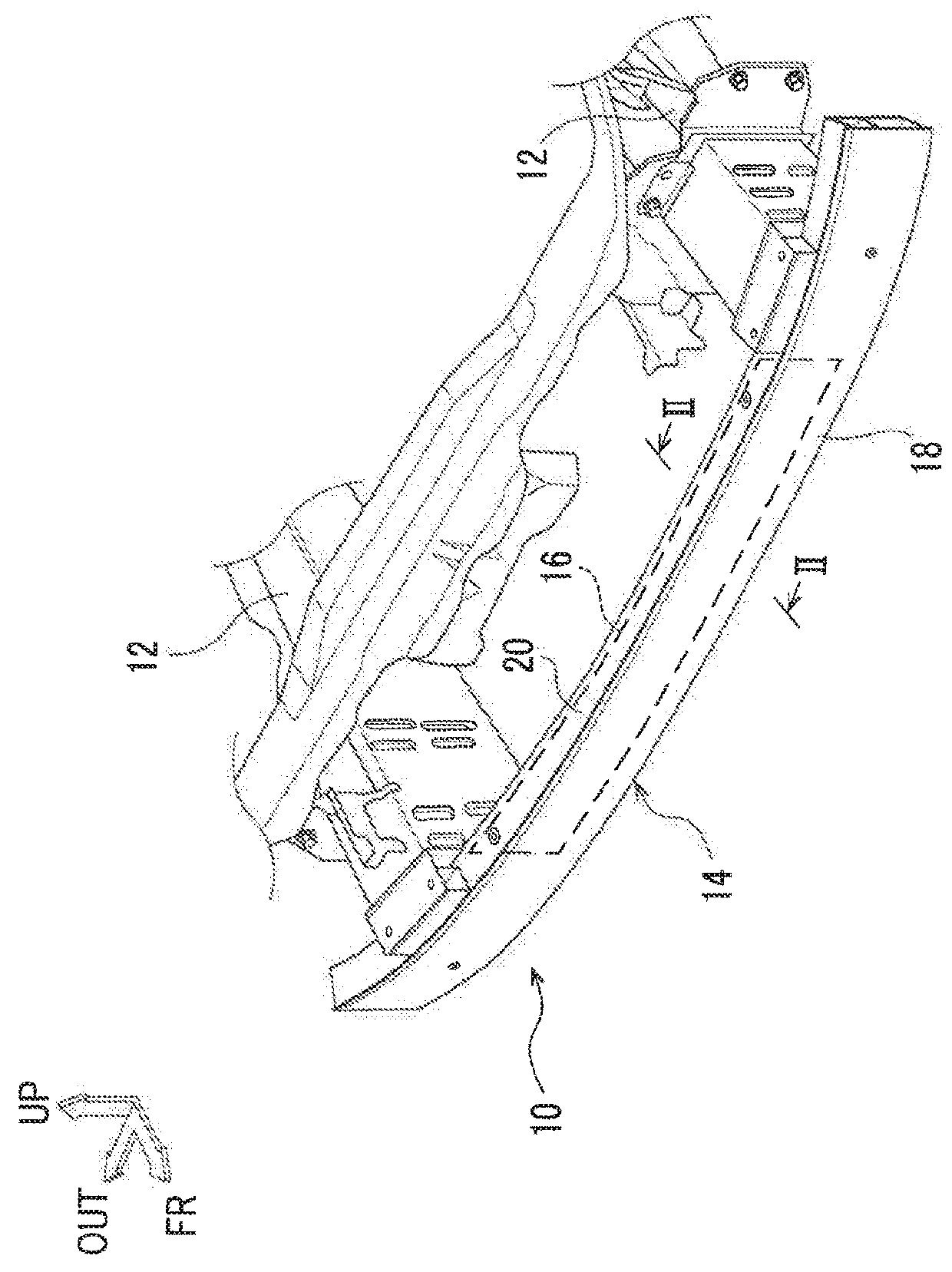

High-strength structure

InactiveUS8176690B2Evenly bondedImprove the immunityRoof covering using slabs/sheetsBuilding roofsEavesHigh intensity

A high strength, lightweight building structure comprising a high-strength connection to a foundation, high-strength eaves, and high-strength structural panels. The fiber reinforced, high-strength structural panels form the walls, ceiling, roof, soffit, and eave of the structure. The panels comprise a rigid foam core having outer membrane layer, panel spacers, and sheeting. The high-strength foundation connection comprises a continuous seam plate with bonding agents, mechanical fasteners, and a metal bearing cap having continuously spaced, angle-shaped anchor studs welded to the metal bearing cap. The high-strength eave structure, comprise of a soffit panel connected to an inclined eave panel, a connection bracket and a rigid wedge continuously bonded between the ceiling panel and roof panel, thus forming a sealed, non-vented attic space.

Owner:STANLEY NEWMAN

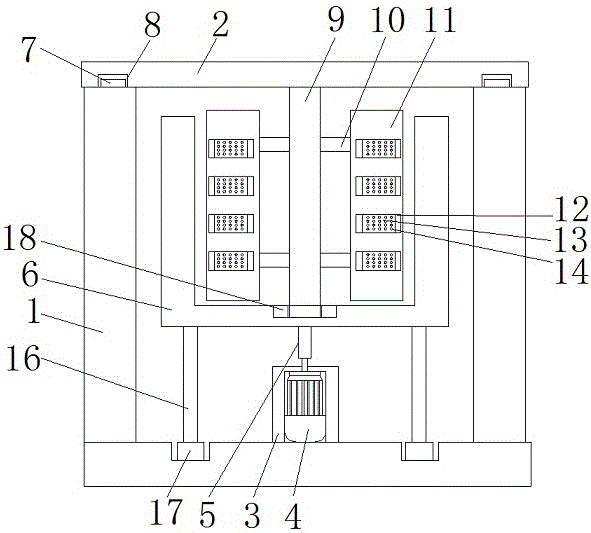

Uniform-stirring adhesive stirring device

InactiveCN106732079AWell mixedStir wellRotating receptacle mixersTransportation and packagingEngineeringAdhesive

The invention discloses a uniform-stirring adhesive stirring device. The uniform-stirring adhesive stirring device comprises a housing and a housing cover, wherein the bottom of the internal cavity of the housing is fixedly connected with the bottom of a motor box, a motor is fixedly mounted in the motor box, one end of an output shaft of the motor penetrates through a top plate of the motor box and is fixedly connected with the bottom end of a connecting rod, the top end of the connecting rod is fixedly connected with the bottom of a stirring barrel, and snapping blocks are fixedly mounted at the top of the housing. According to the uniform-stirring adhesive stirring device, through arranging the motor, the connecting rod and the stirring barrel which are matched with one another, materials for preparing an adhesive are mixed and stirred and are melted so as to form the adhesive; through arranging the snapping blocks and forming snapping grooves in the housing cover, the housing cover is in snap connection with the housing; through a fixing shaft, stirring shafts, stirring plates and stirring screens which are matched with one another, the area of contact of various kinds of liquid can be larger during the stirring of the stirring device, so that the adhesive is mixed more uniformly, and thus, a uniform stirring effect is achieved.

Owner:WUXI HITXINCHENG POLYMER TECH

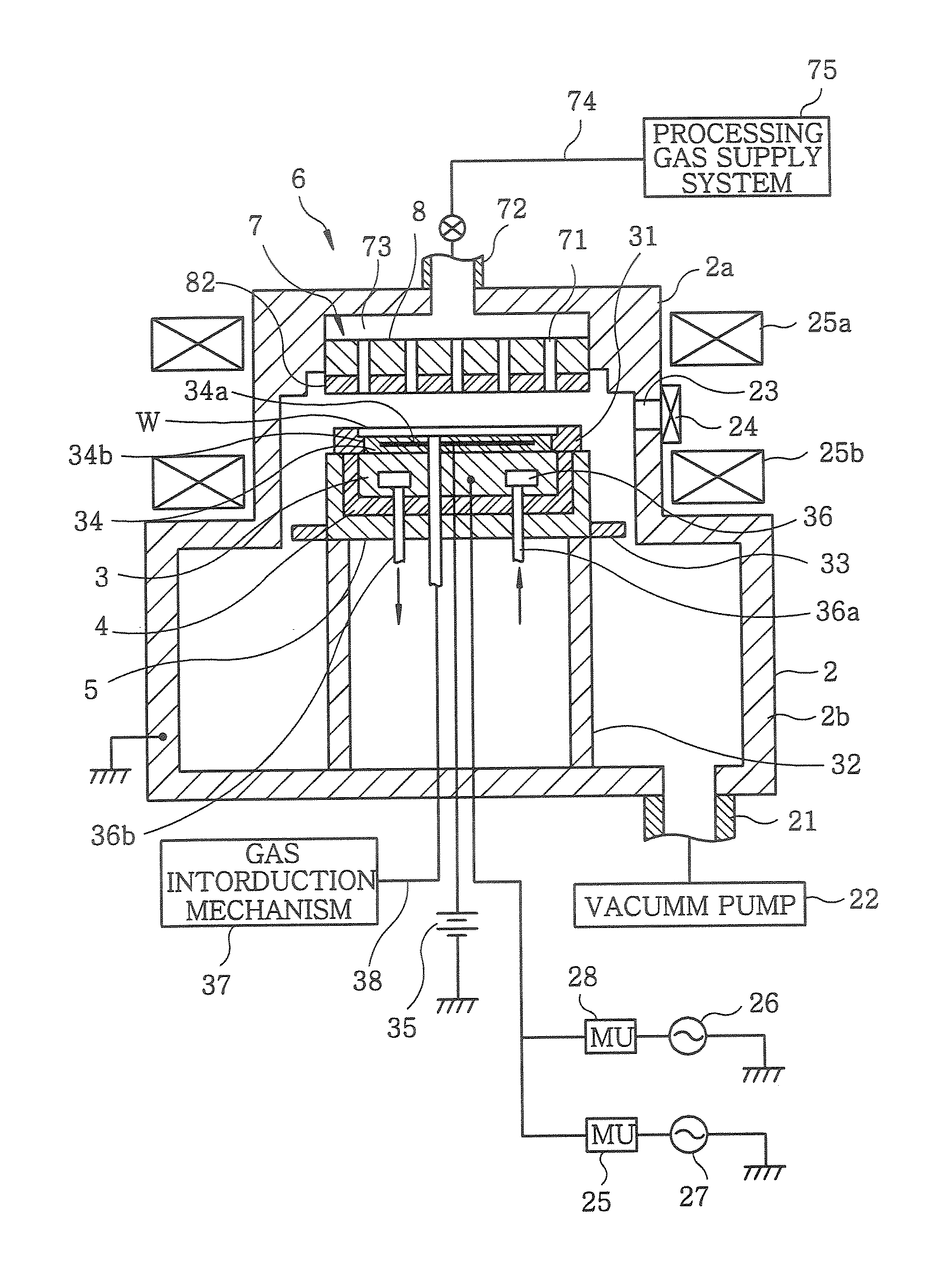

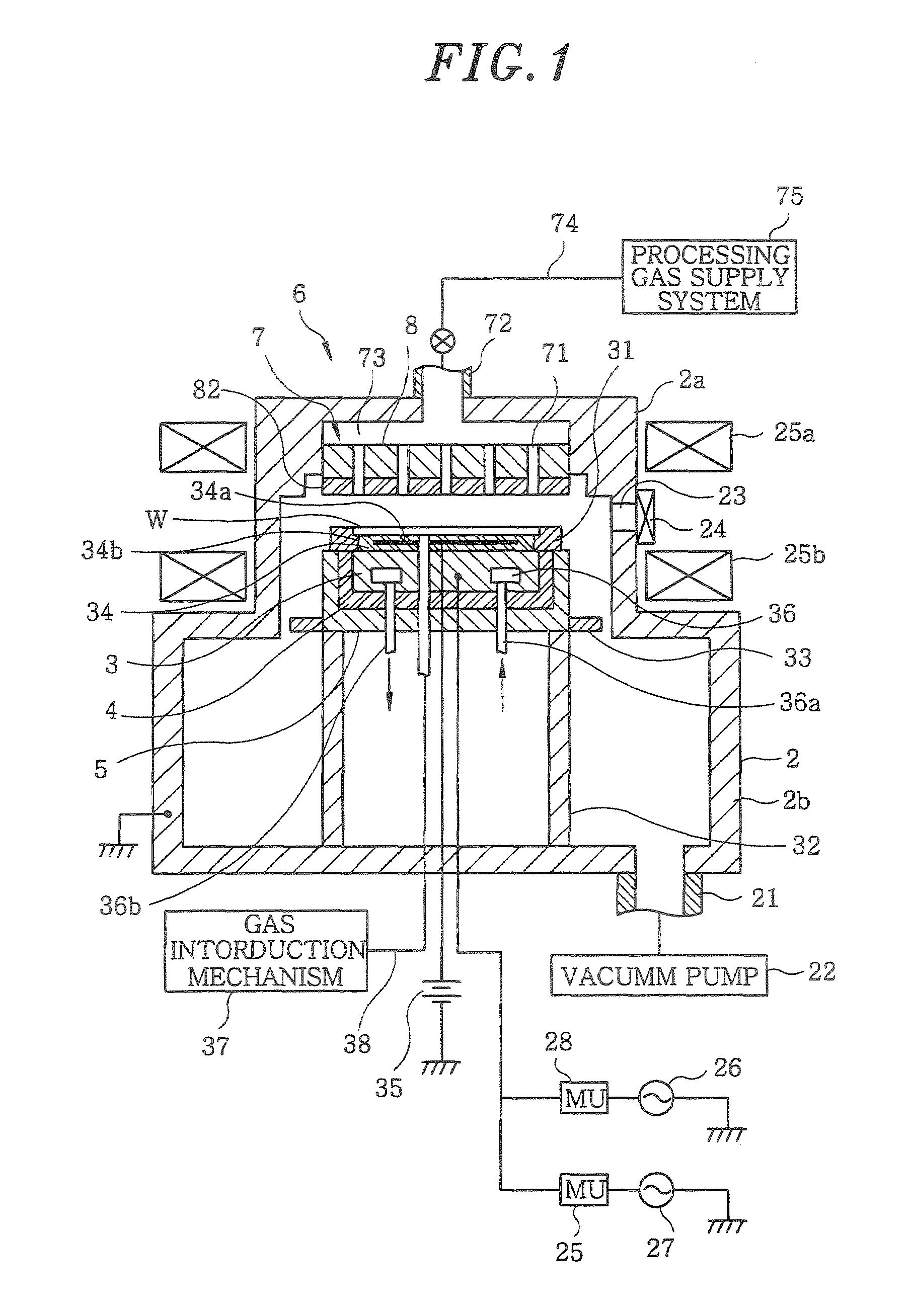

Electrode for generating plasma and plasma processing apparatus using same

ActiveUS7619179B2Avoid damageReduce the possibilityElectric discharge tubesDecorative surface effectsMetal matrix compositeJoint surface

Owner:TOKYO ELECTRON LTD

Wafer bonding method and wafer stack formed thereby

ActiveUS8119498B2Limit electrical shortingReduce and prevent any materialSolid-state devicesSemiconductor/solid-state device manufacturingWafer stackingBonding process

A wafer bonding process that compensates for curvatures in wafer surfaces, and a wafer stack produced by the bonding process. The process entails forming a groove in a surface of a first wafer, depositing a bonding stack on a surface of a second wafer, aligning and mating the first and second wafers so that the bonding stack on the second wafer contacts a bonding site on the first wafer, and then heating the first and second wafers to reflow the bonding stack. The groove either surrounds the bonding site or lies entirely within the bonding site, and the heating step forms a molten bonding material, causes at least a portion of the molten bonding material to flow into the groove, and forms a bonding structure that bonds the second wafer to the first wafer. Bonding stacks having different lateral surface areas can be deposited to form bonding structures of different heights to compensate for variations in the wafer gap.

Owner:MICRO INERTIAL LLC

Method of baking yeast-fermented frozen bread products

InactiveUS6896916B2Shorten defrosting timeNecessary defrost timeBaking mixturesPre-baking dough treatmentYeastAdditive ingredient

A method of making a bread product comprising formulating and mixing a bread dough having flour as a major ingredient, and having the following additional ingredients, where percentages are based on the flour weight:Ingredients%Salt 1.8-2.3Yeast3.0; 2.5-4.5Sweetener 0.3-2.0Gluten 0.5-4.0L-Cysteine 10-100 PPMWater 50-65Oxidant 0.1-0.5Enzymes0.01-0.5Gum0.01-0.5pre-forming the dough into open molds shaped suitably for the bread product;pre-proofing the dough for less than 30 minutes in at least 70% relative humidity at a temperature in the range of 80° F. to 100° F.;freezing the pre-proofed dough to a temperature below 0° C.;partially defrosting the dough for a period of time of 60 minutes or less; andplacing the partially defrosted dough in a pre-heated oven at a temperature of about 170° C. to 180° C. to produce the bread product in less than 3 hours.

Owner:MAPLE LEAF BAKERY

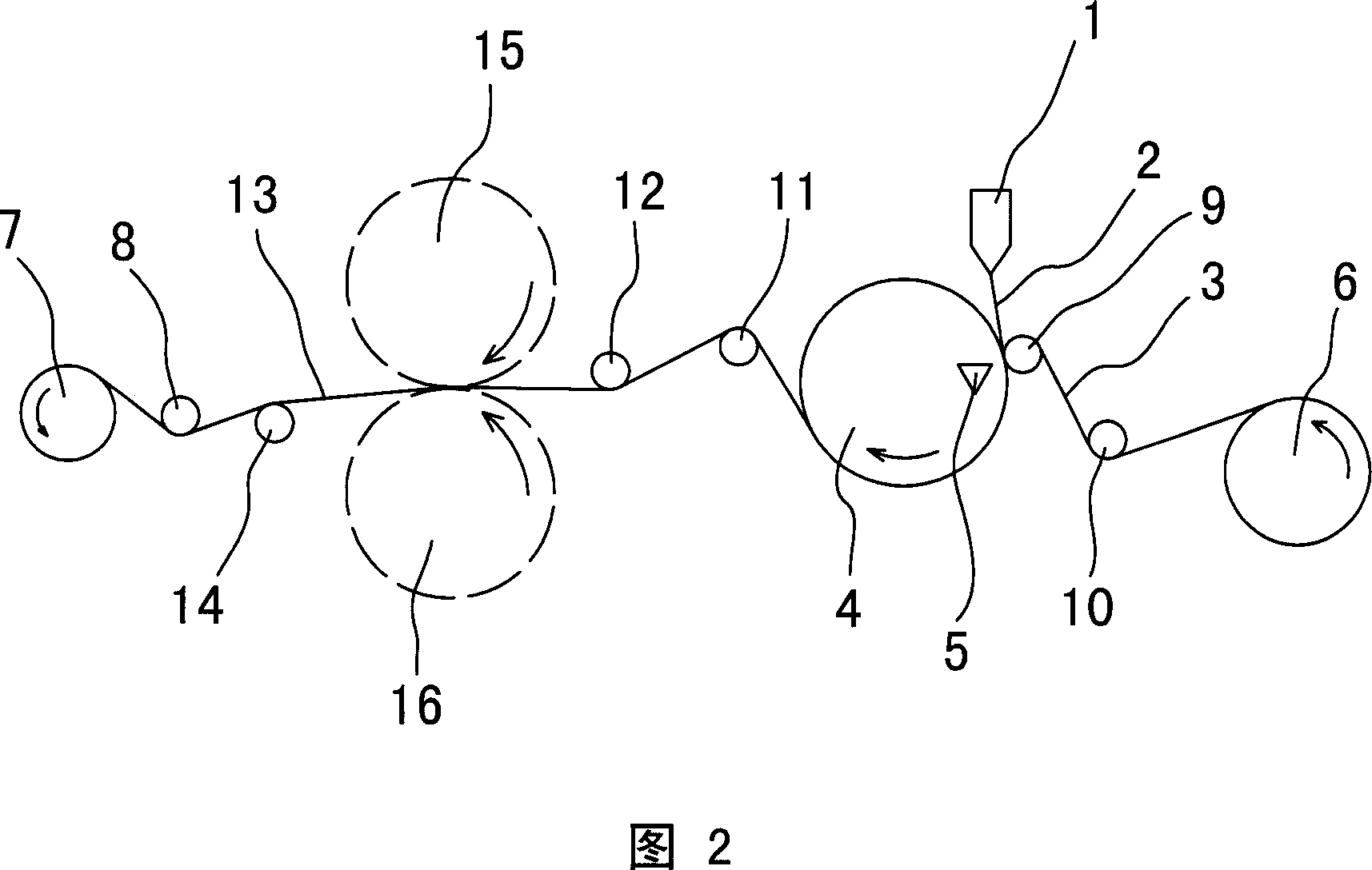

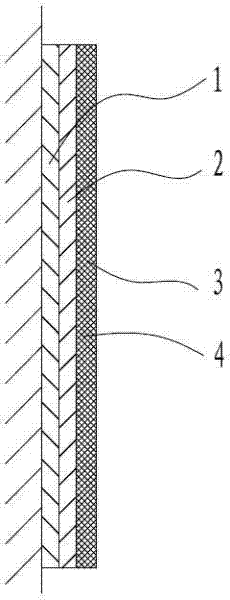

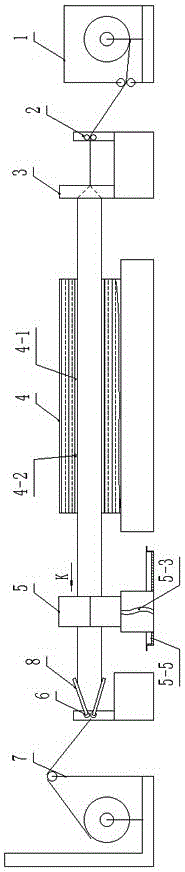

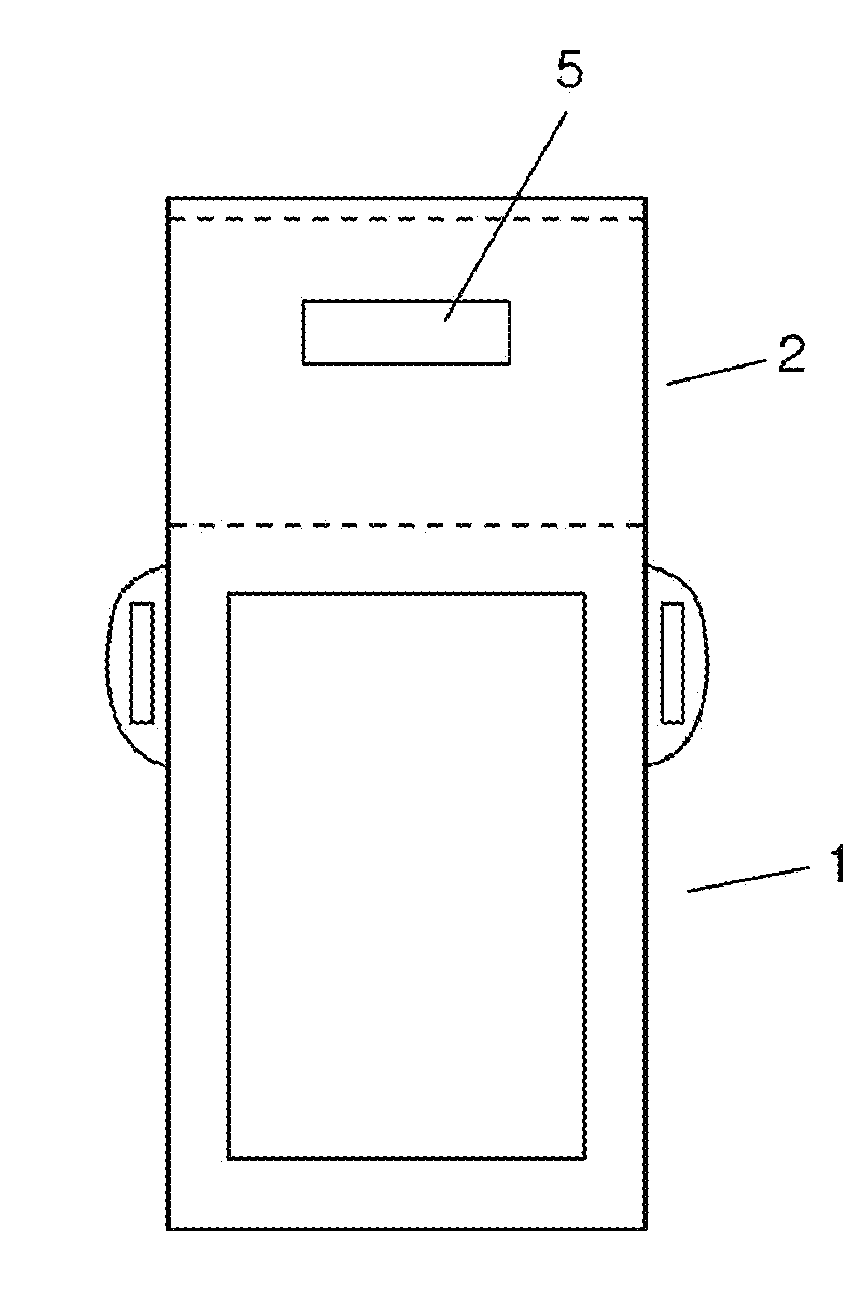

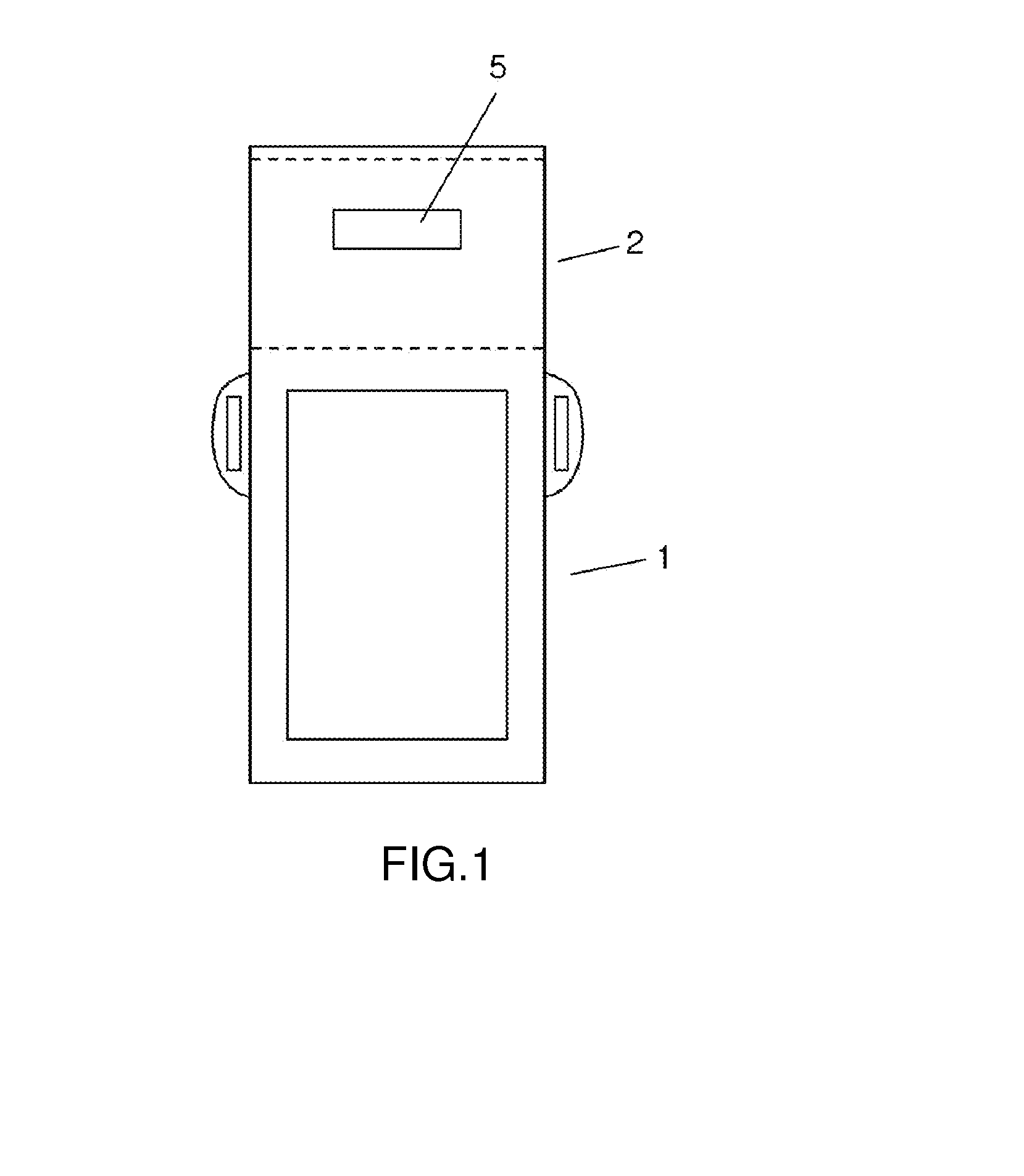

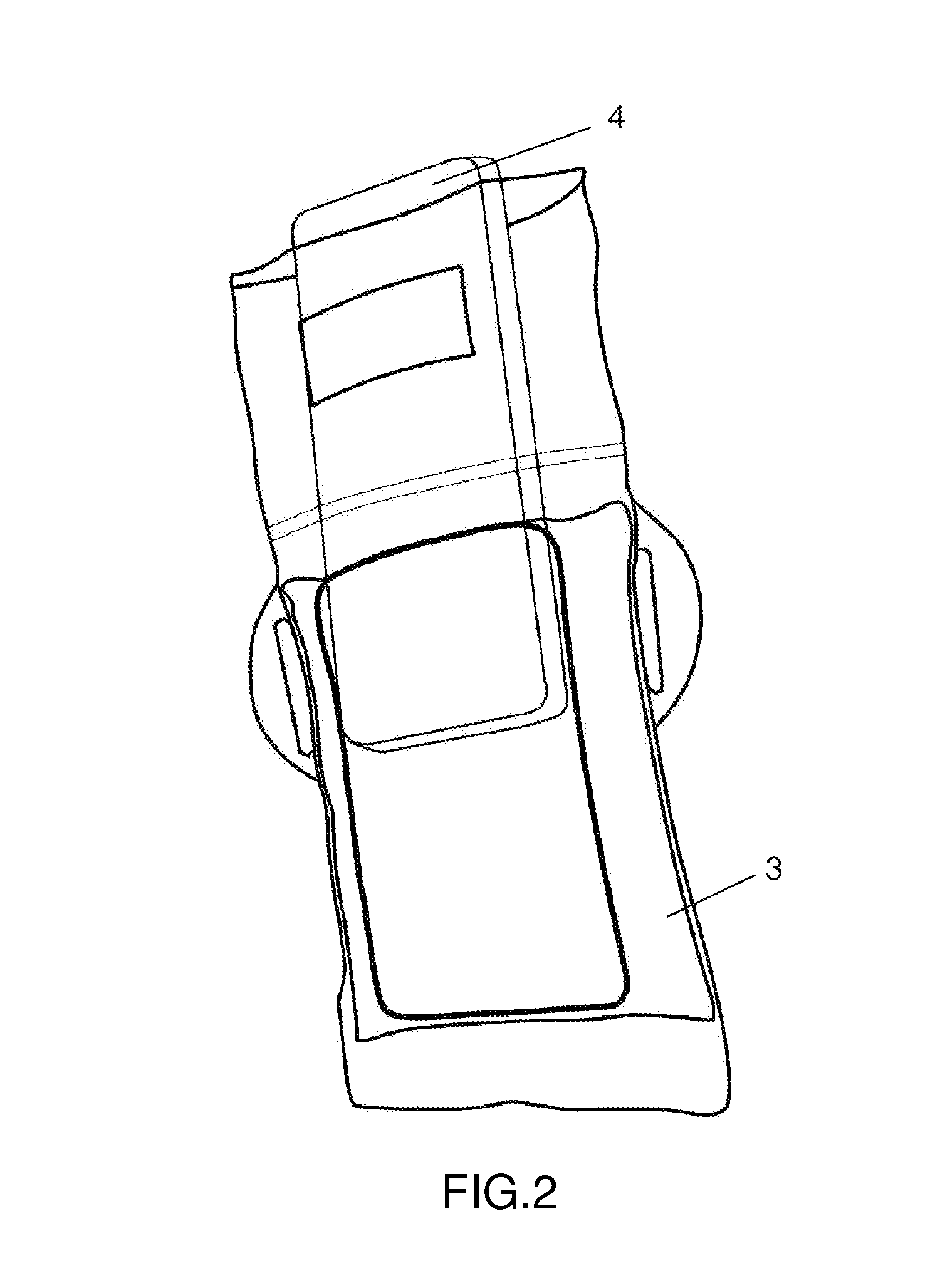

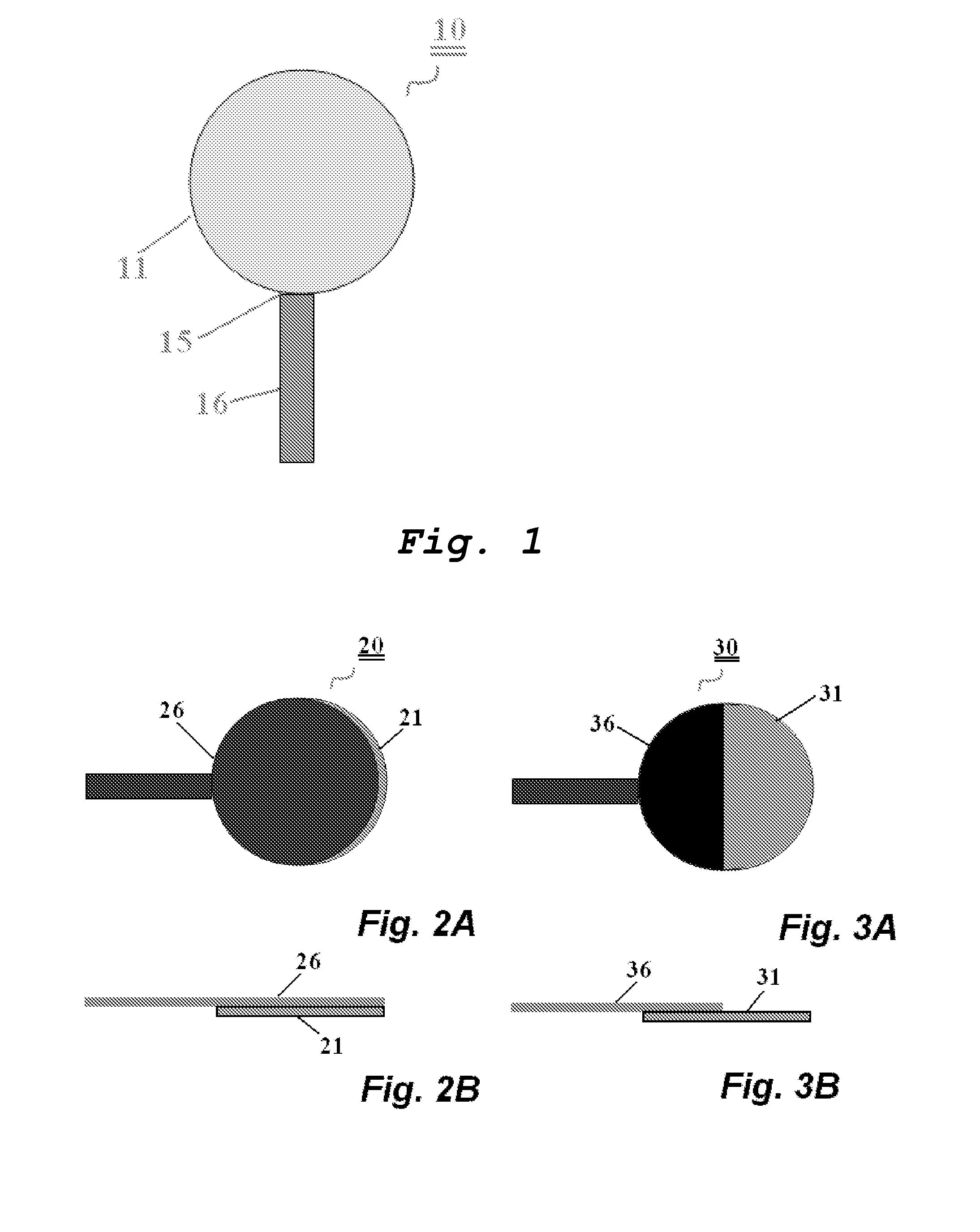

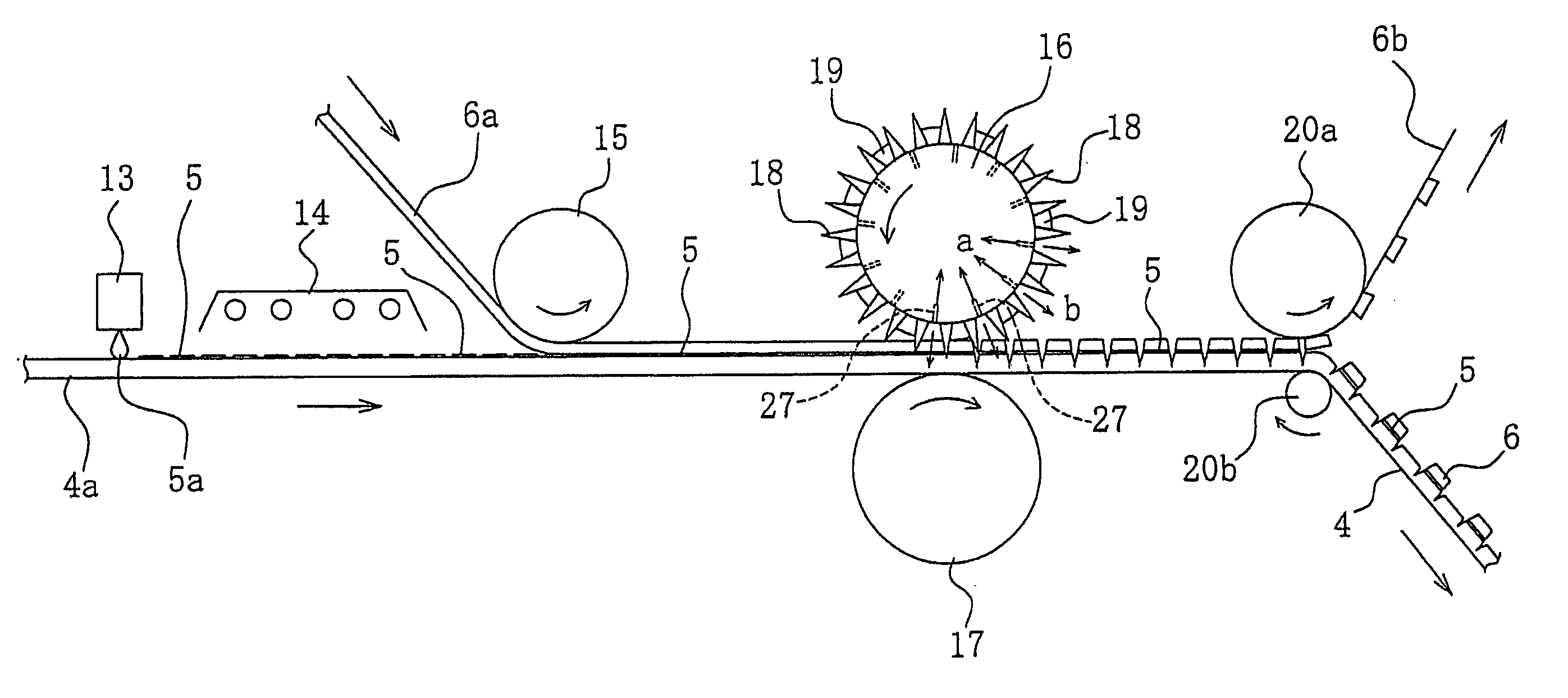

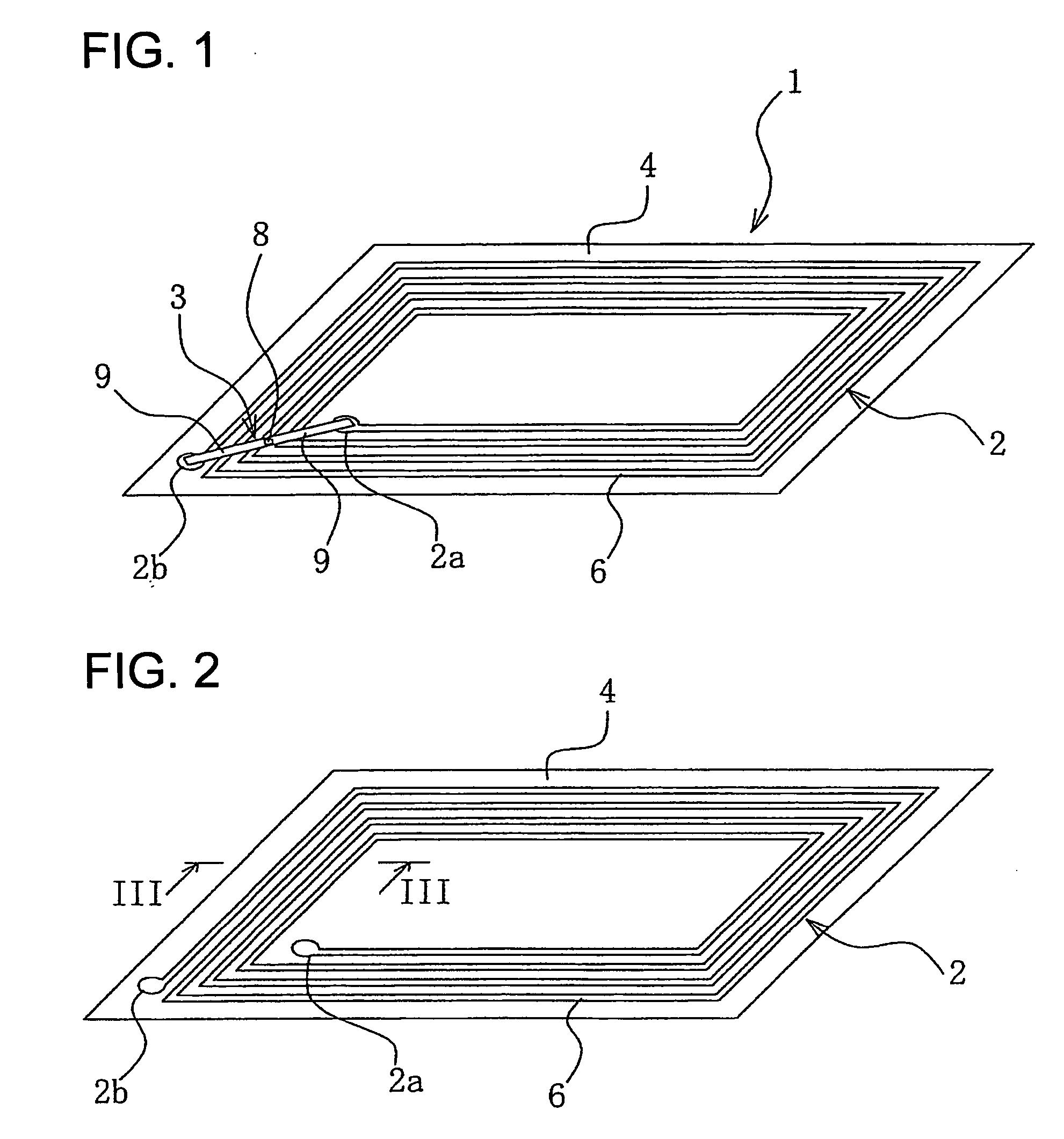

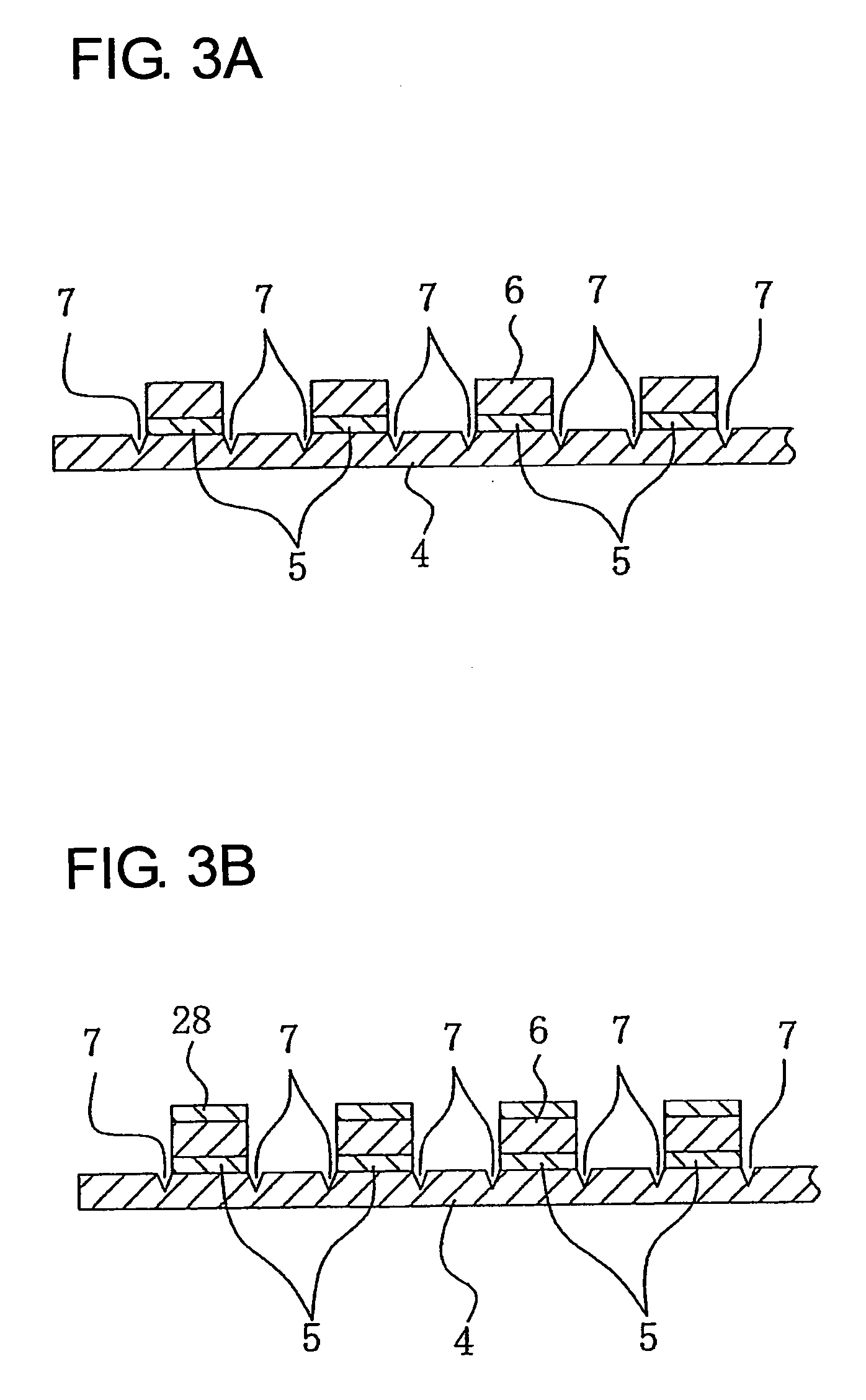

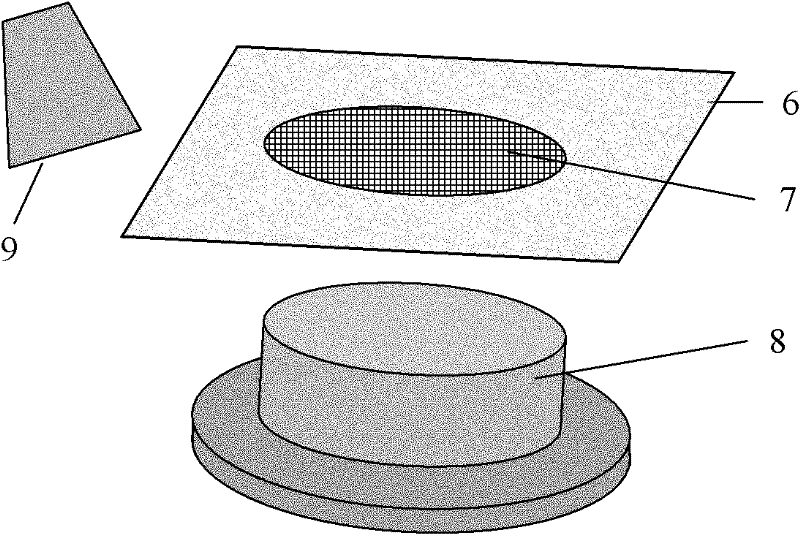

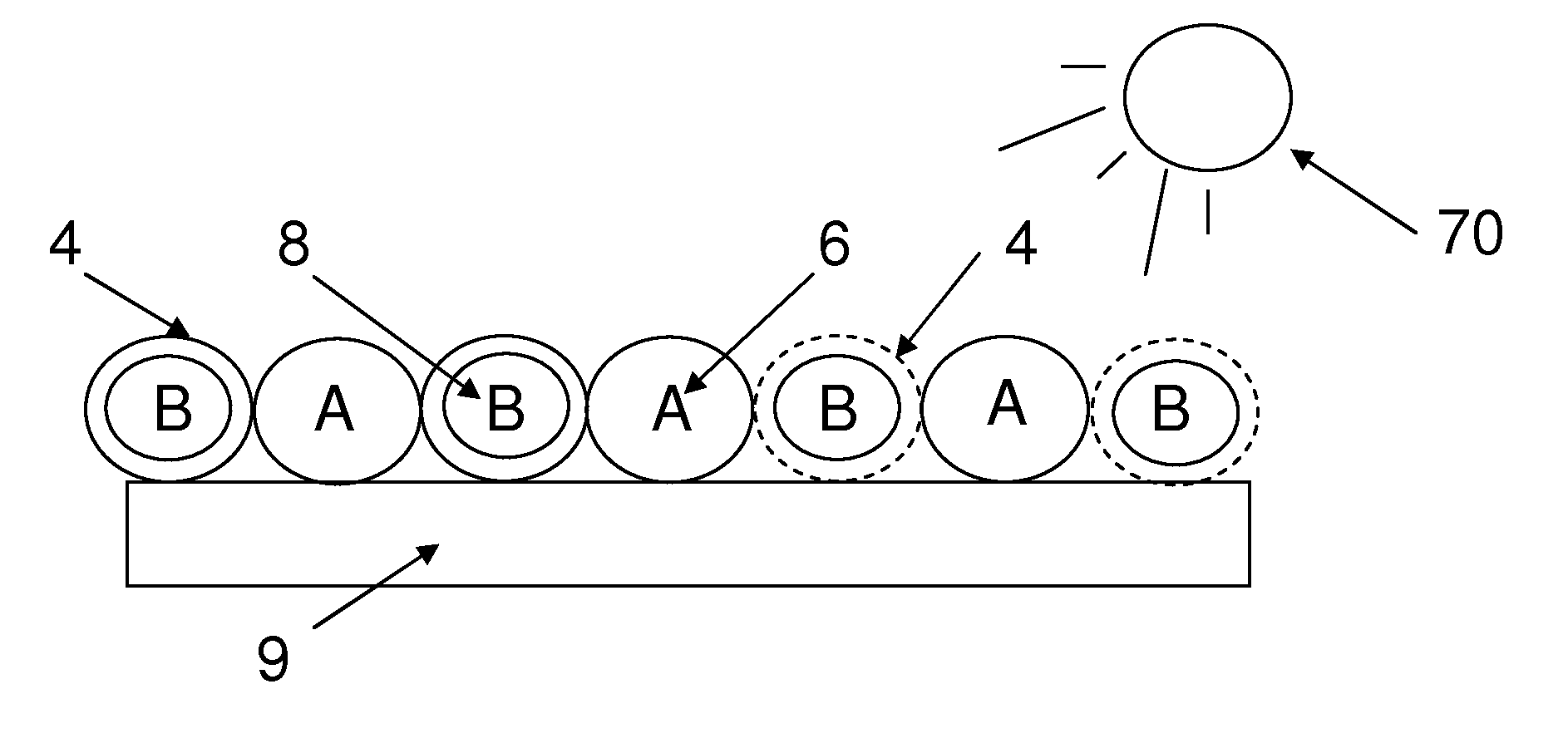

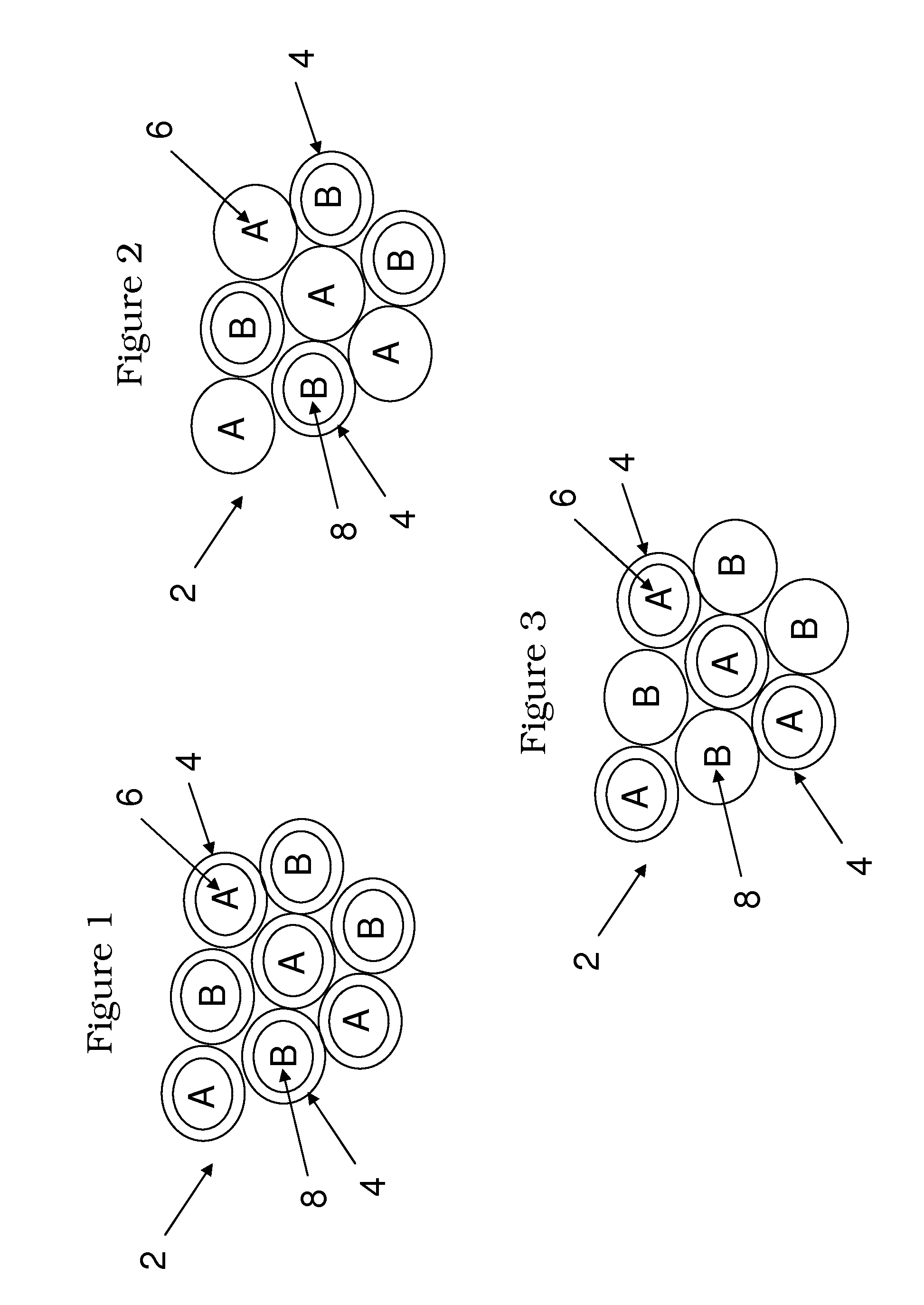

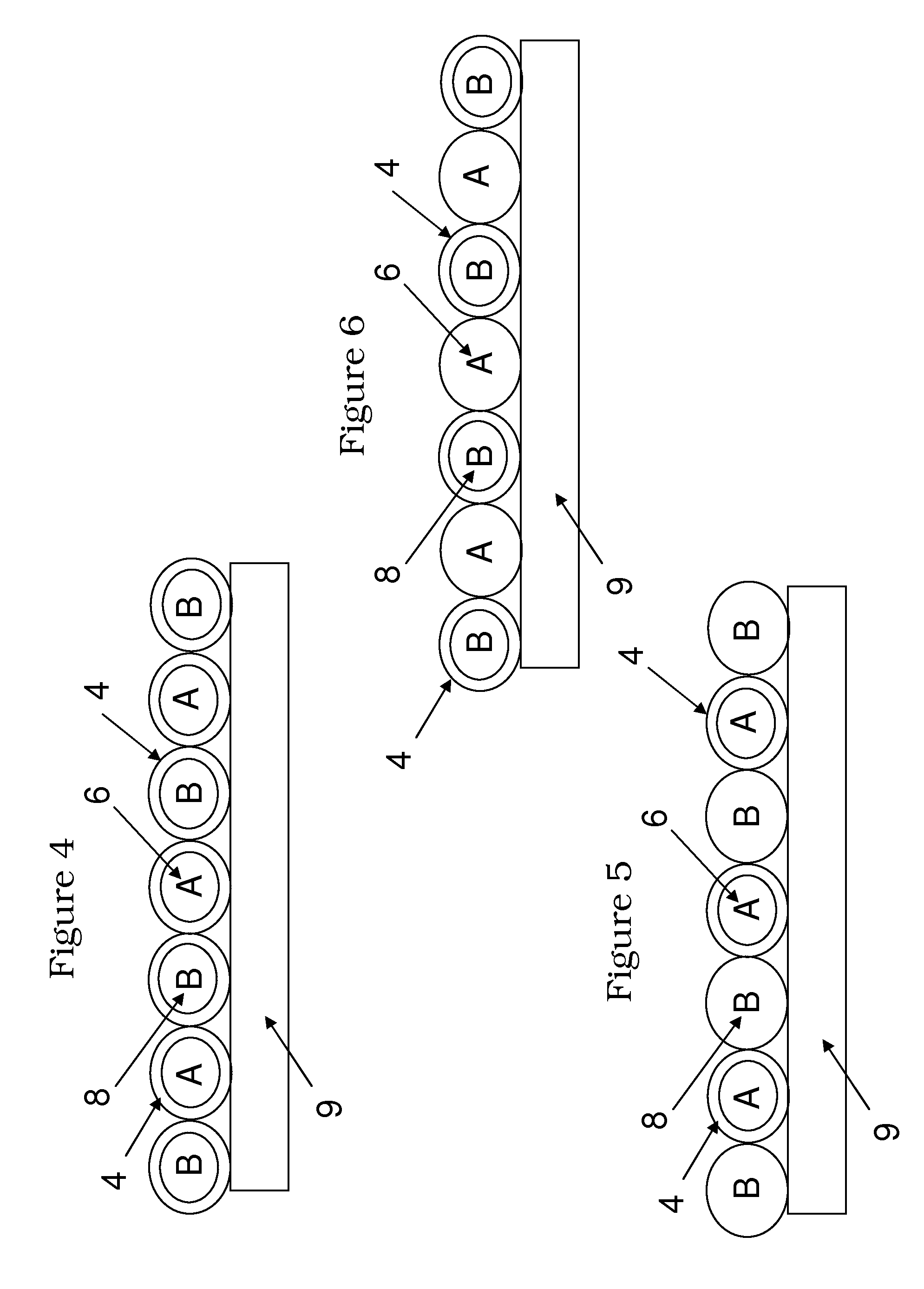

Conductive Member for Non-Contact Type Data Carrier and Method and Device for Manufacturing the Same

ActiveUS20070214637A1Improve featuresEvenly bondedPrinted circuit assemblingLamination ancillary operationsPunchingBonding process

A conductive member for a non-contact type data carrier such as a wireless tag is simply and cheaply manufactured. A method for manufacturing a conductive member for a non-contact type data carrier comprises: a printing process during which, while a base material (4) is run, a bonding agent layer (5) is printed in a predetermined pattern on the surface thereof, and is dried; a bonding process during which a conductive layer (6) is laminated on the surface of the bonding agent layer (5) for heating and bonding; a punching process during which the conductive layer (6) is punched in the above-described pattern on the base material (4); and a separating process during which an unnecessary portion (6b) of the conductive layer (6) is separated from the base material (4). Accordingly, a conventional multilayered laminated sheet is not required to realize reduction in the material.

Owner:DAI NIPPON PRINTING CO LTD

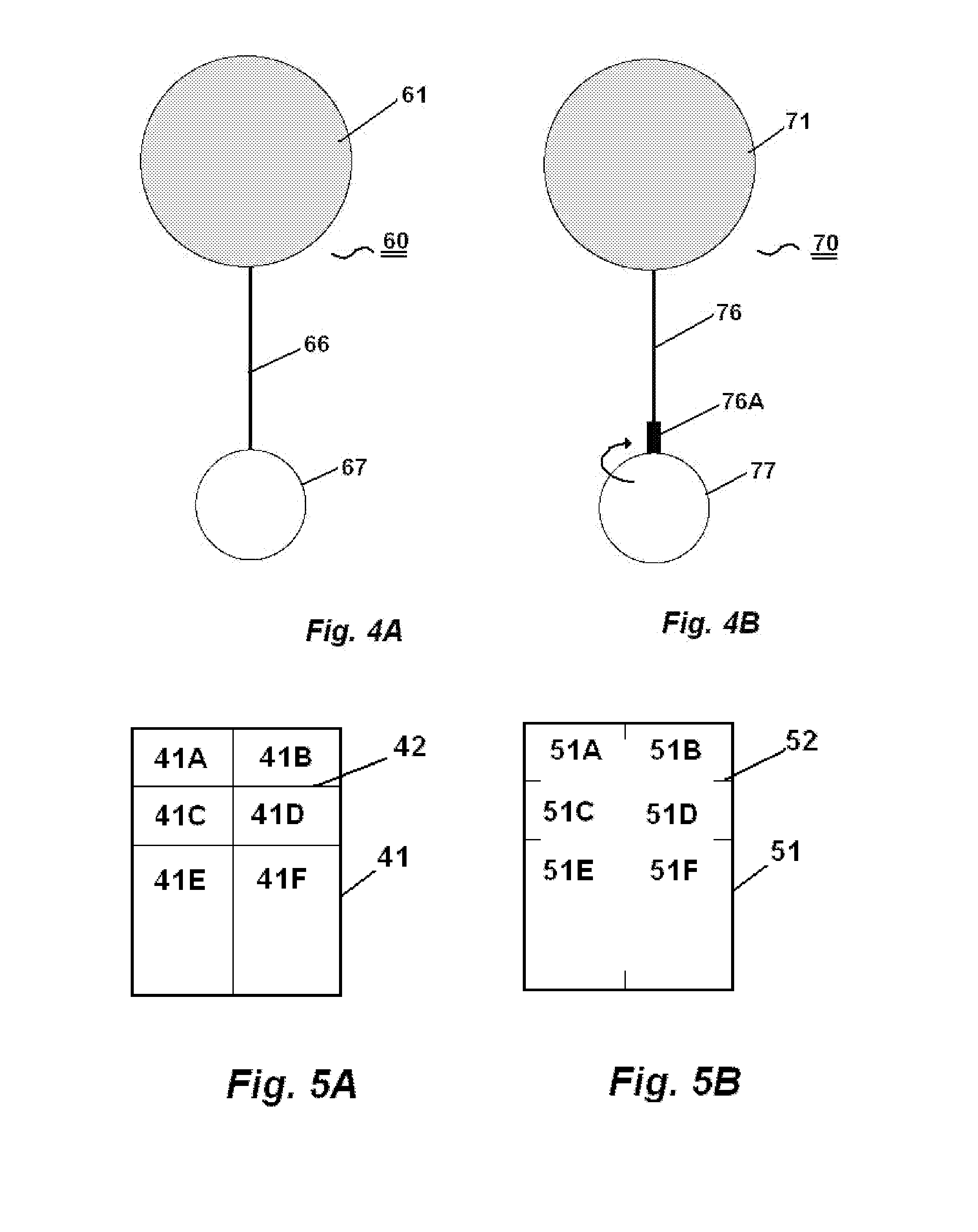

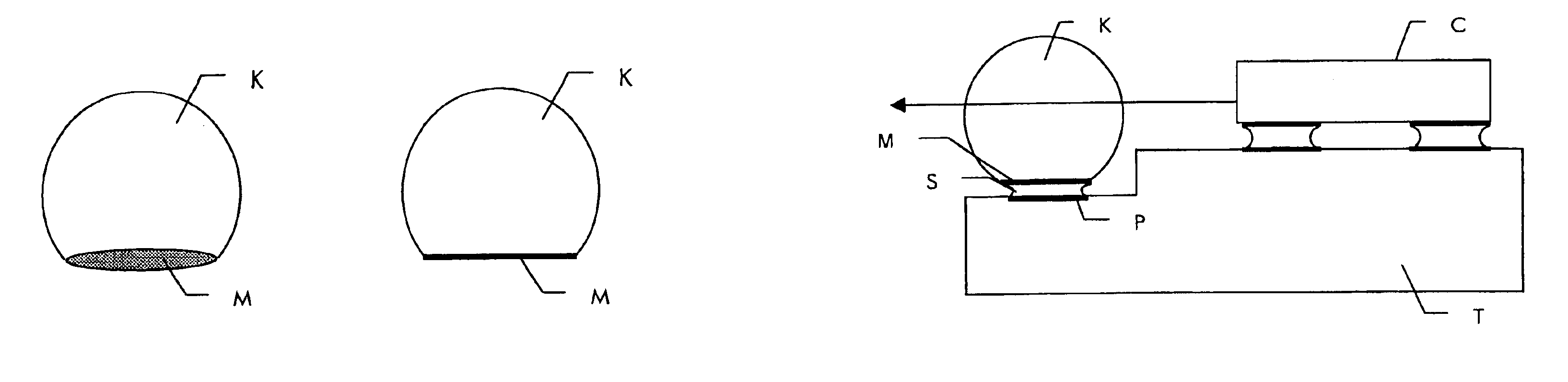

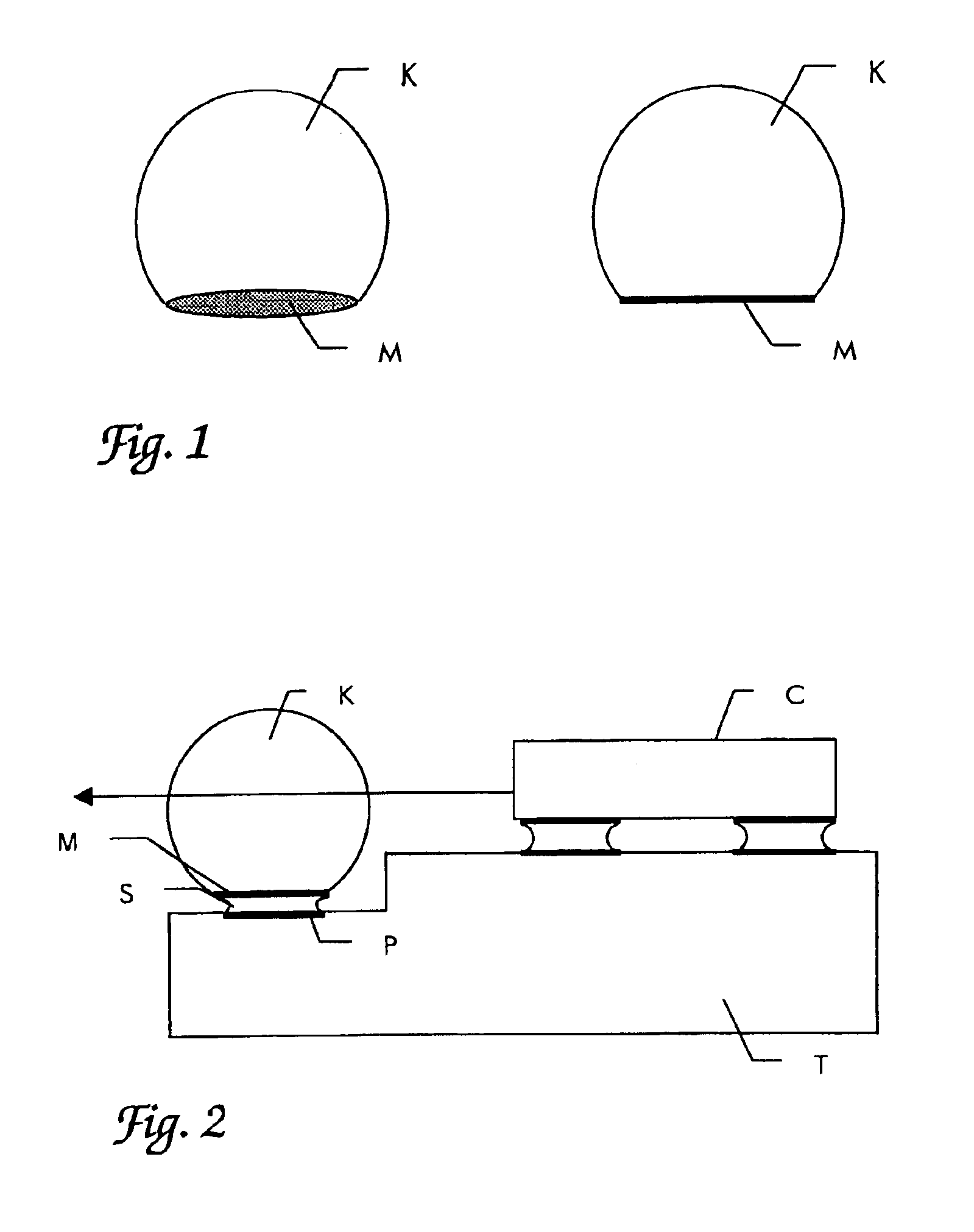

Spherical lens and optoelectronic module comprising the same

InactiveUS6879621B2High precisionEvenly bondedSemiconductor laser optical deviceOptical resonator shape and constructionMetal coatingComputer module

Owner:OCLARO NORTH AMERICA

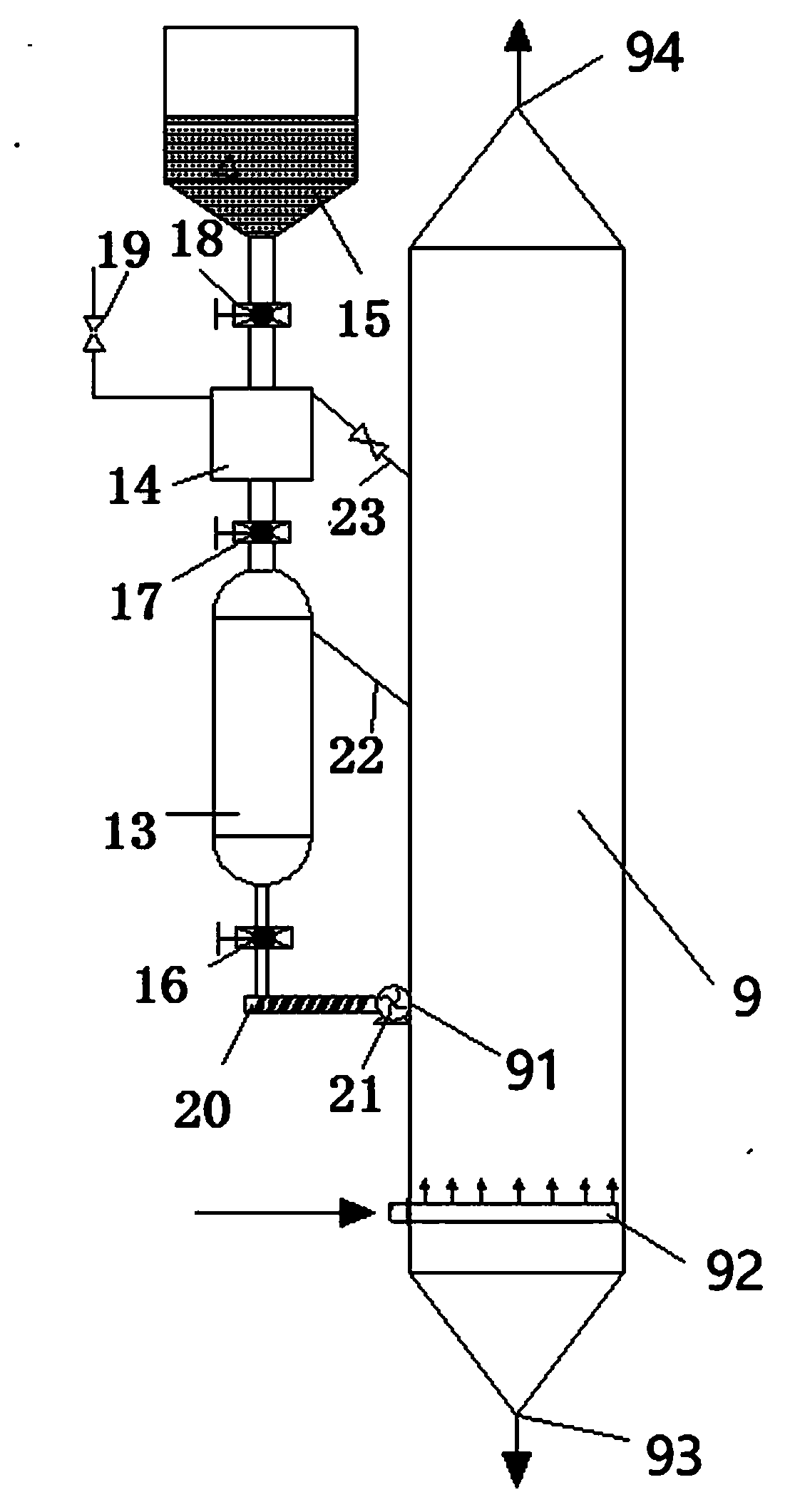

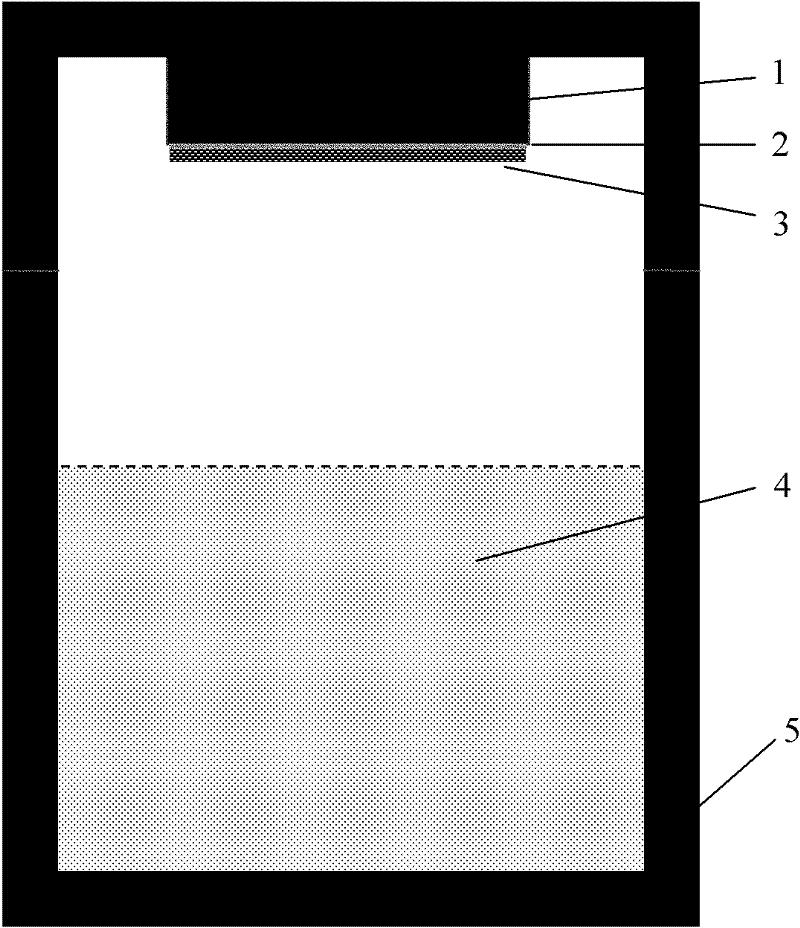

Seed crystal bonding method for growing SiC crystals

InactiveCN102534762AUniform growthQuality improvementPolycrystalline material growthFrom condensed vaporsCrystallographyAdhesive

The invention belongs to the field of crystal growth, and relates to a seed crystal bonding method for growing SiC crystals. The seed crystal bonding method for growing high-quality SiC crystal comprises the following steps of: (1) printing a silk screen; (2) bonding the seed crystals; and (3) curing an adhesive for bonding the seed crystals and a seed crystal support, wherein the thickness of the cured adhesive layer is 7-10 microns. The seed crystal bonding method for growing the high-quality SiC crystals provided by the invention can ensure uniform distribution of the thickness of the adhesive layer between the seed crystals and the seed crystal support and avoid cracking caused by non-uniform mechanical stress and heat stress; and meanwhile, the temperature gradient distribution of the seed crystals is uniform, thereby being beneficial to the uniform growth of the SiC crystals, and further improving the quality of the SiC crystals.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

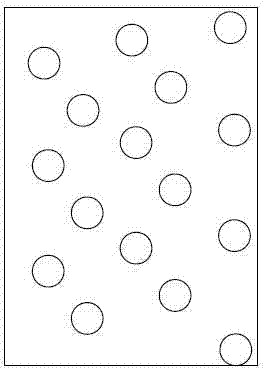

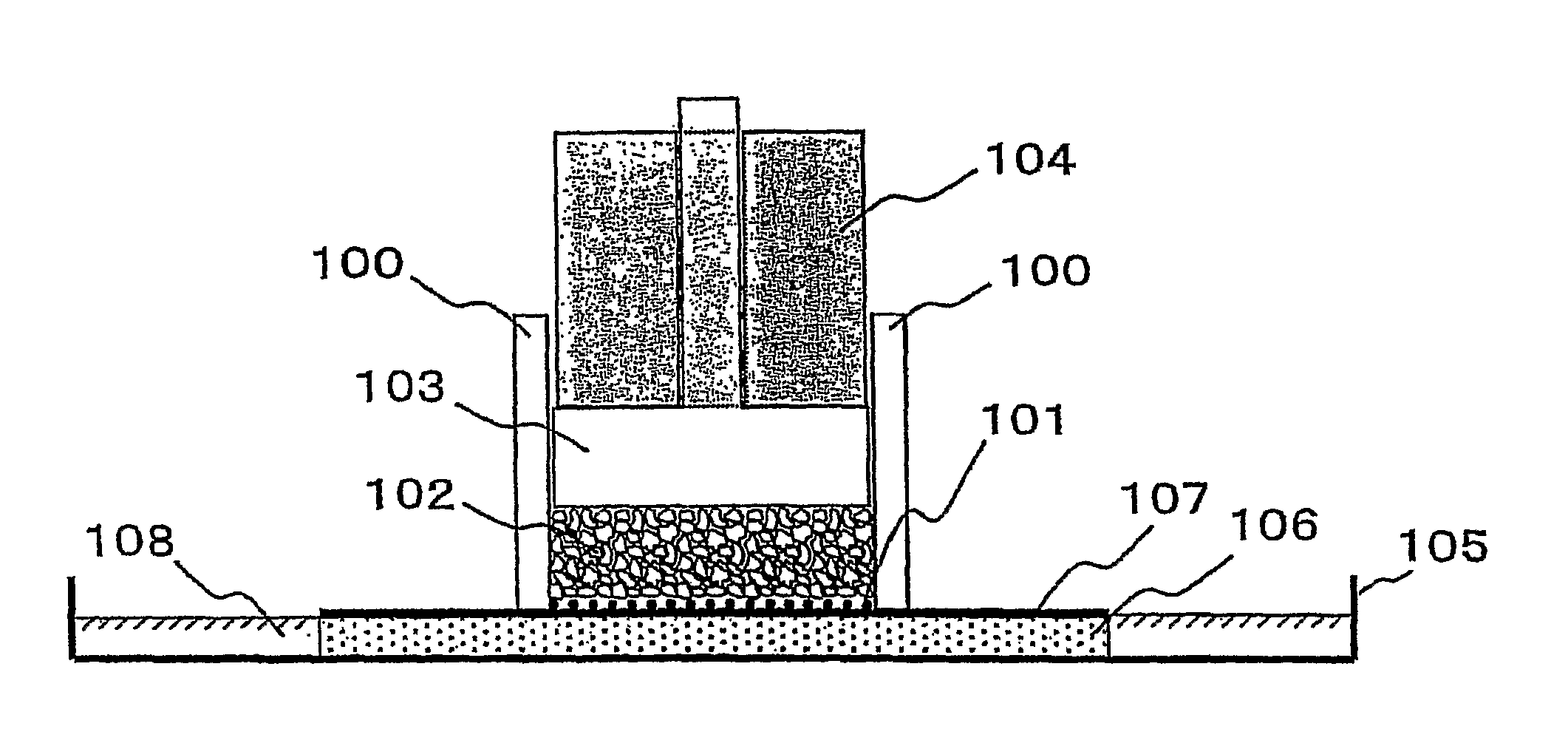

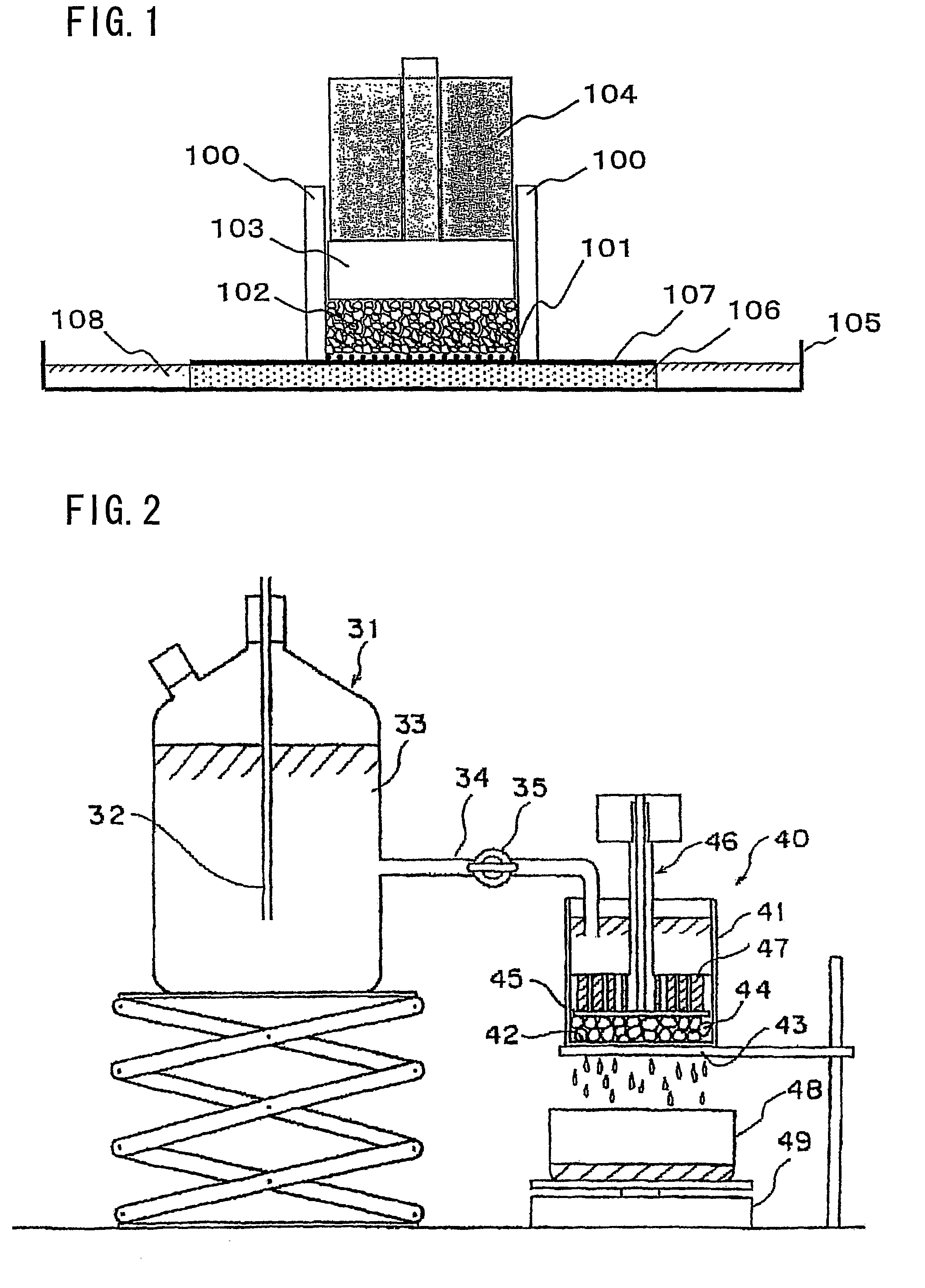

Water absorbing agent and production method thereof

ActiveUS8846823B2Suppressing permeation of metal componentsEvenly bondedOther chemical processesAbsorbent padsCross-linkWater soluble

A water absorbing agent and a method for producing the water absorbing agent are disclosed. Water absorbent resin particles having an internal cross-linked structure obtained by polymerizing a water-soluble unsaturated monomer, organic acid, and water-soluble multivalent metal salt are mixed, so that it is possible to provide a water absorbing agent which suppresses permeation of metal components into the water absorbent resin particles and enables the metal components to evenly adhere to an entire surface of the water absorbent resin in a dot manner.

Owner:NIPPON SHOKUBAI CO LTD

Photoinitiated optical adhesive and method for using same

ActiveUS20100043966A1Minimal image distortionObviates problemLamination ancillary operationsLaminationChemistryFirst glasses

A method for bonding glass components using an encapsulated photo-initiated optical adhesive, and the resulting glass assemblies produced by the same. A mixture containing a catalyst and a resin is provided where at least one of either the catalyst or the resin is encapsulated. The mixture is applied to a glass component. The encapsulated catalyst may then be exposed to ultraviolet light causing the capsules to release the portions contained therein and combine to form an adhesive. A second glass component is then placed on the adhesive so that the adhesive is interposed between the glass components and the adhesive is permitted to cure. Alternatively, the mixture may be exposed to UV light after the second glass component is placed. An exemplary method uses a frame with the first glass component to create a uniform thickness of adhesive and provide a low level of optical defects. Barrier coats and skirting tape may also be used.

Owner:MFG RESOURCES INT INC

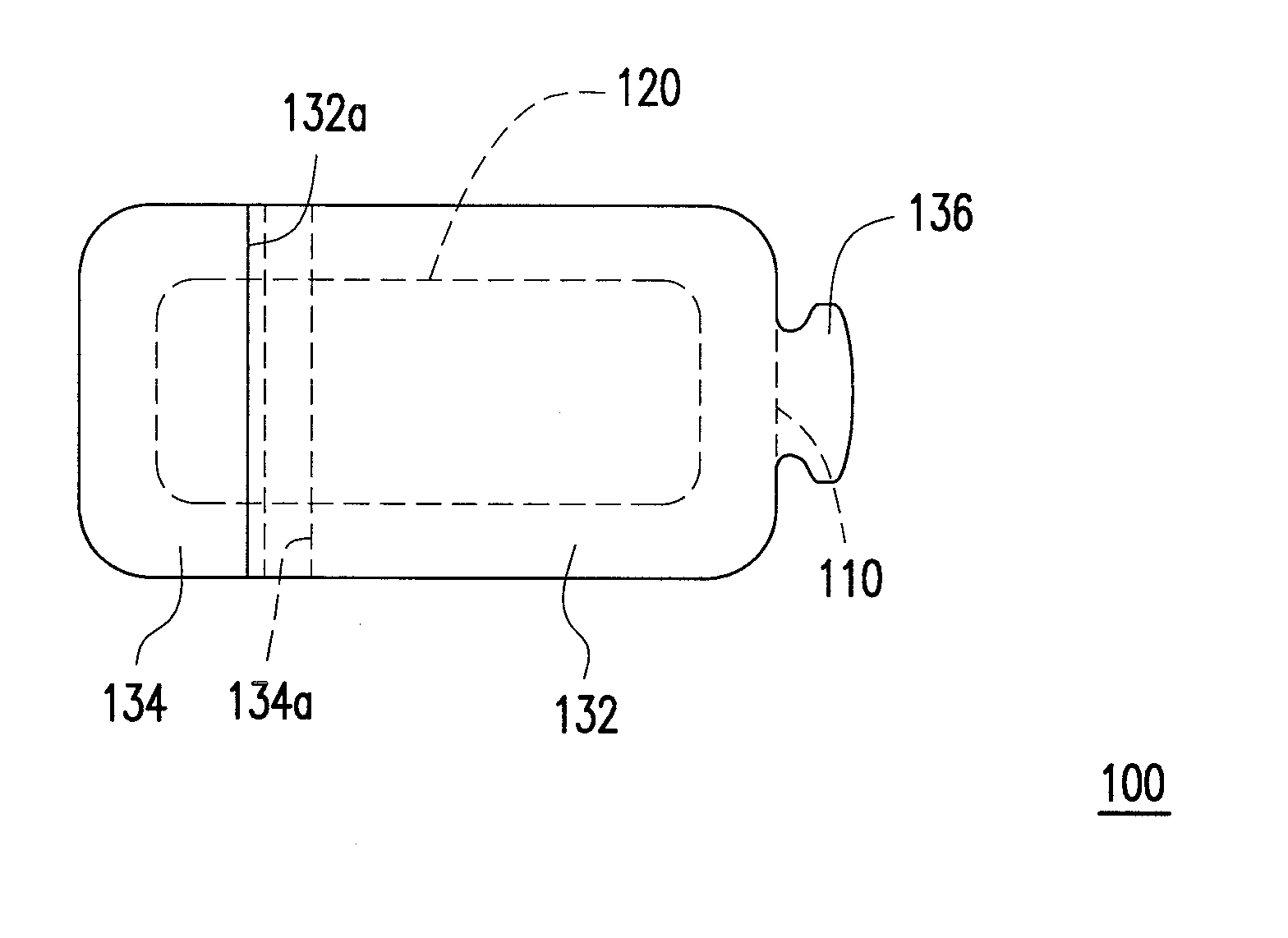

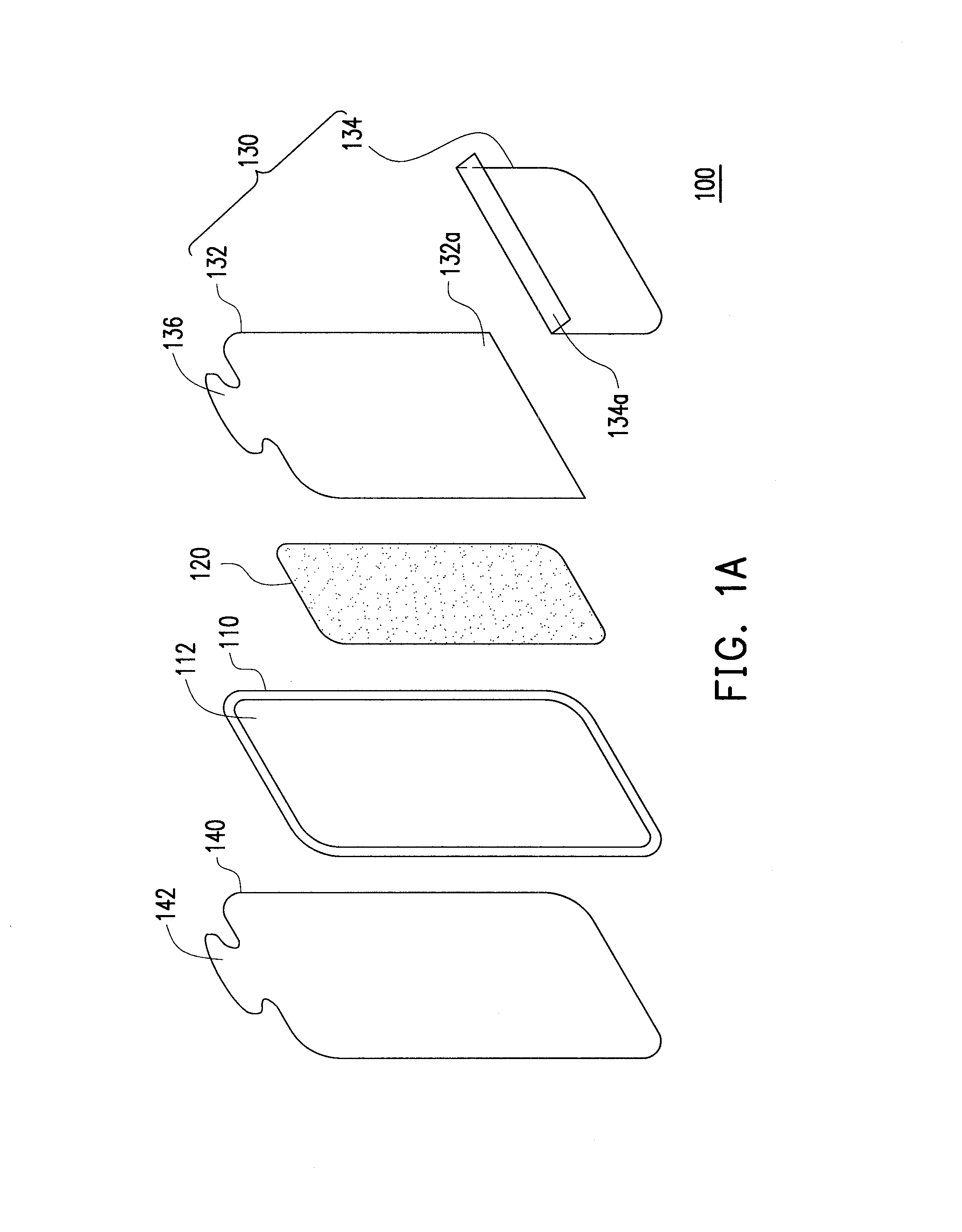

Adhesive wound patch

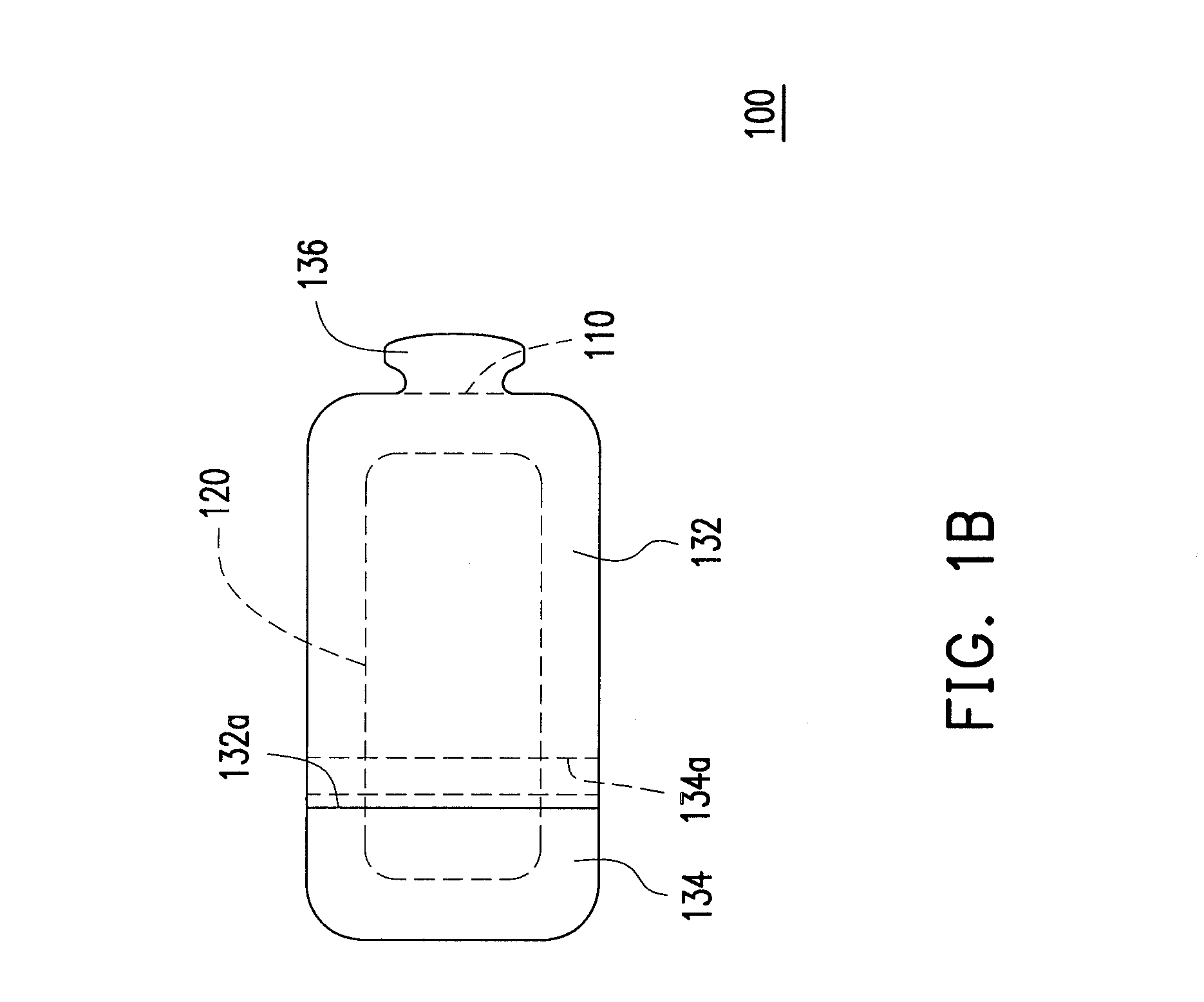

InactiveUS20140121620A1Improve ease of useAvoid layeringAdhesive dressingsBaby linensMedicineAbsorbent material

An adhesive wound patch is provided. The adhesive wound patch includes a covering layer, a dressing layer, a releasing paper and a supporting layer. A pressure sensitive adhesive is coated on an inner surface of the covering layer, and the pressure sensitive adhesive with stickiness may adhere to the surrounding skin tightly. The dressing layer covers the pressure sensitive adhesive, the covering layer includes waterproof-breathable material, and the dressing layer includes hydro-absorbent material. The releasing paper includes separated first and second portions, and covers the entire covering layer. The supporting layer sticks to the covering layer, and has an ear portion, which is in the middle part of one side of the supporting layer and protrudes beyond the edge of the covering layer. After the dressing layer is adhered to the wound, the supporting layer is separated from the covering layer by tearing off the ear portion.

Owner:TATUNG COMPANY

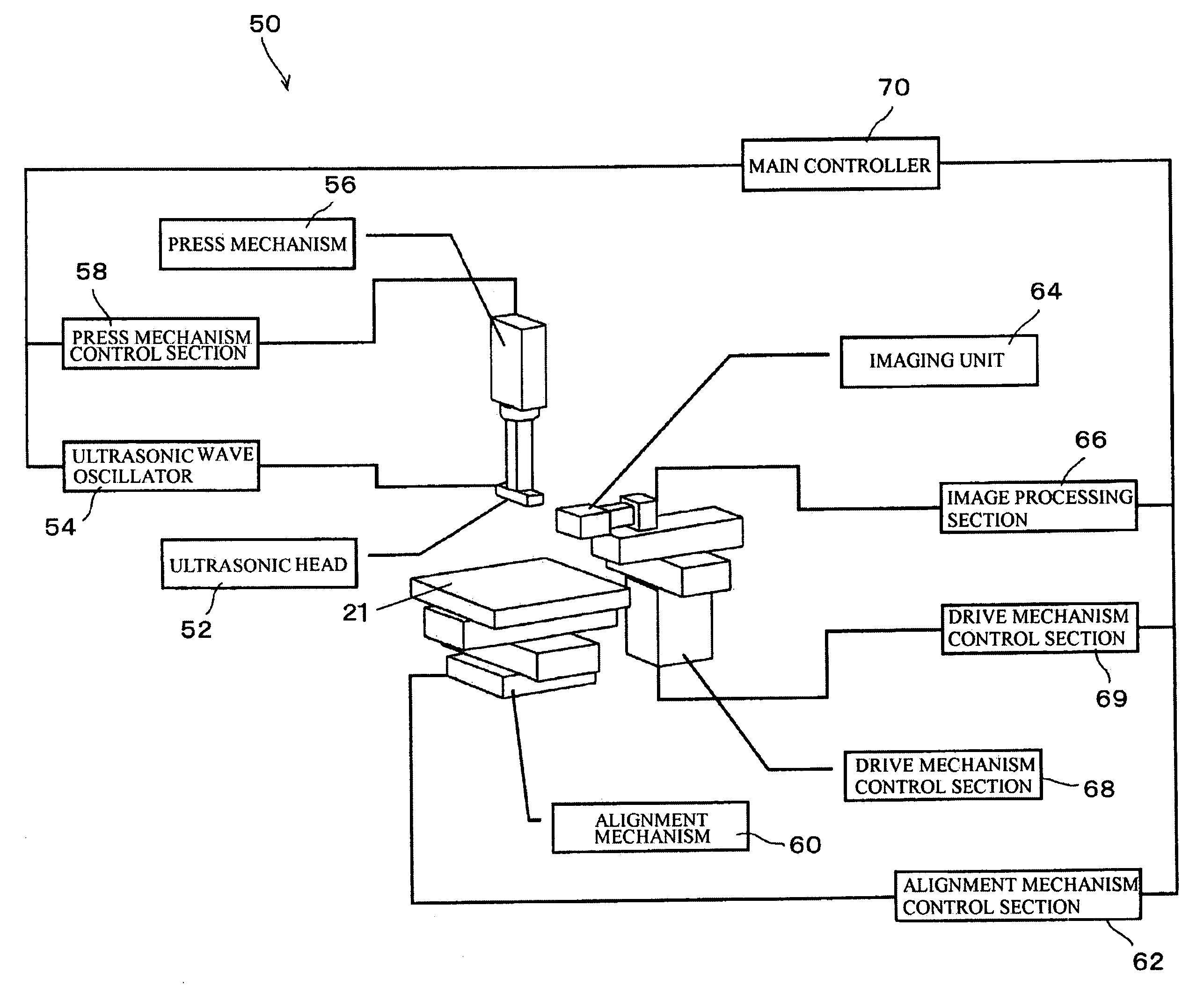

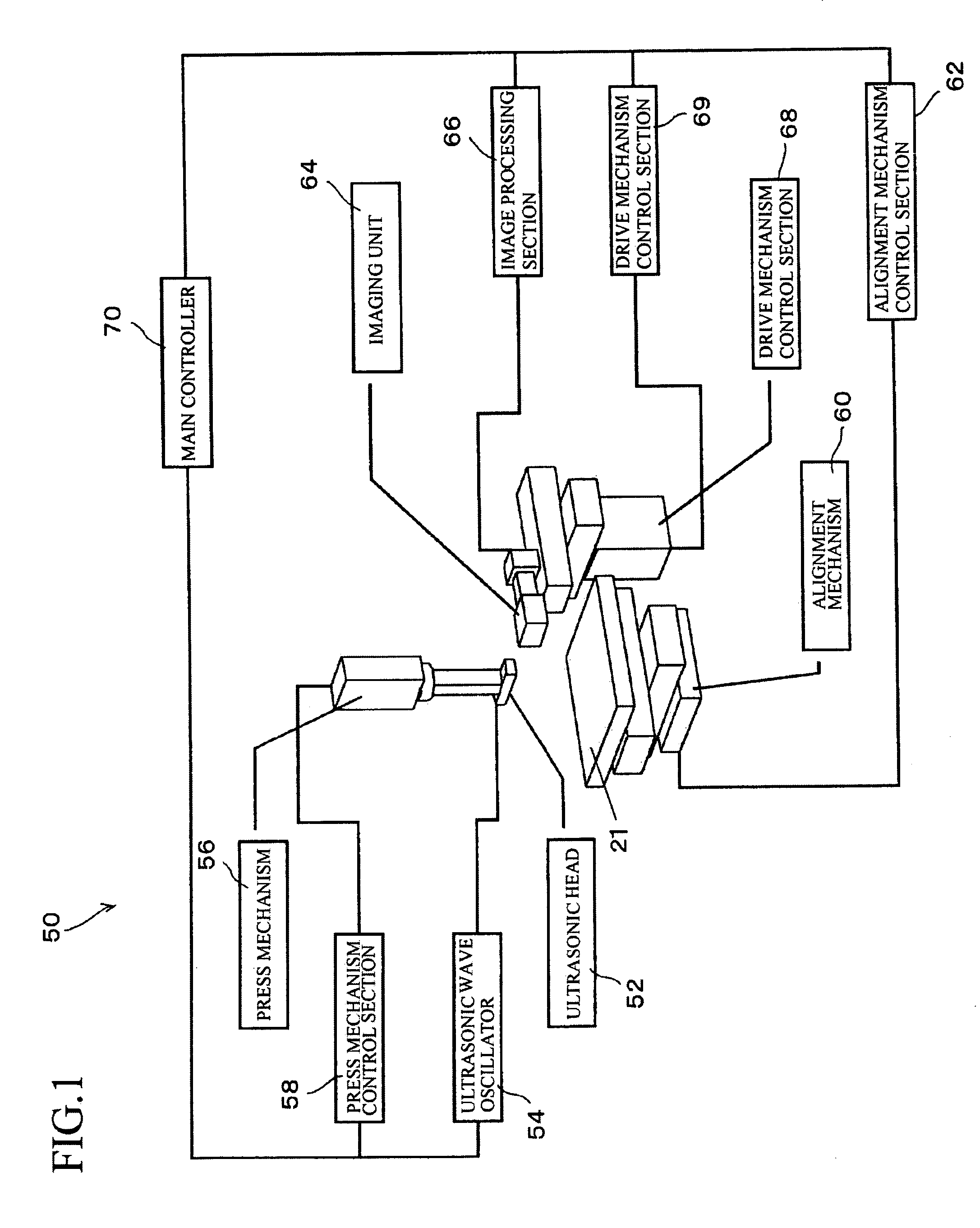

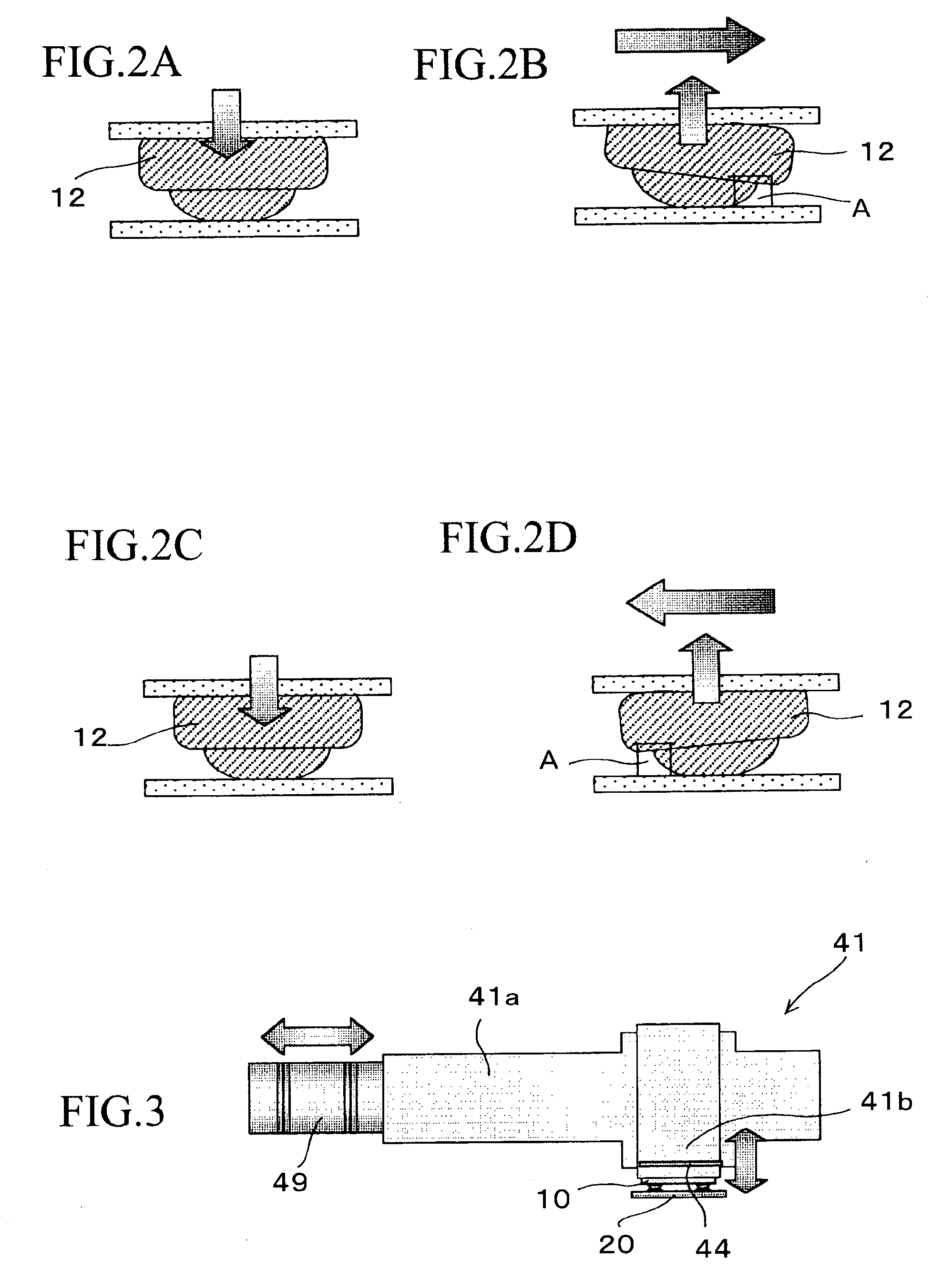

Method of ultrasonic-mounting electronic component and ultrasonic mounting machine

InactiveUS7208059B2Improve reliabilityEvenly bondedLamination ancillary operationsControlling laminationUltrasonic vibrationElectronic component

The ultrasonic mounting method is capable of uniformly bonding bumps of an electronic component to a circuit board and improving reliability of ultrasonic-mounting the electronic component. The method comprises the step of applying ultrasonic vibrations to the electronic component so as to flip-chip-bond the electronic component to the circuit board having electrodes. The ultrasonic vibrations are applied in a direction parallel to a surface of the electronic component, and loads are vertically applied to the surface of the electronic component in conjunction with vibration cycles of the ultrasonic vibrations.

Owner:FUJITSU LTD

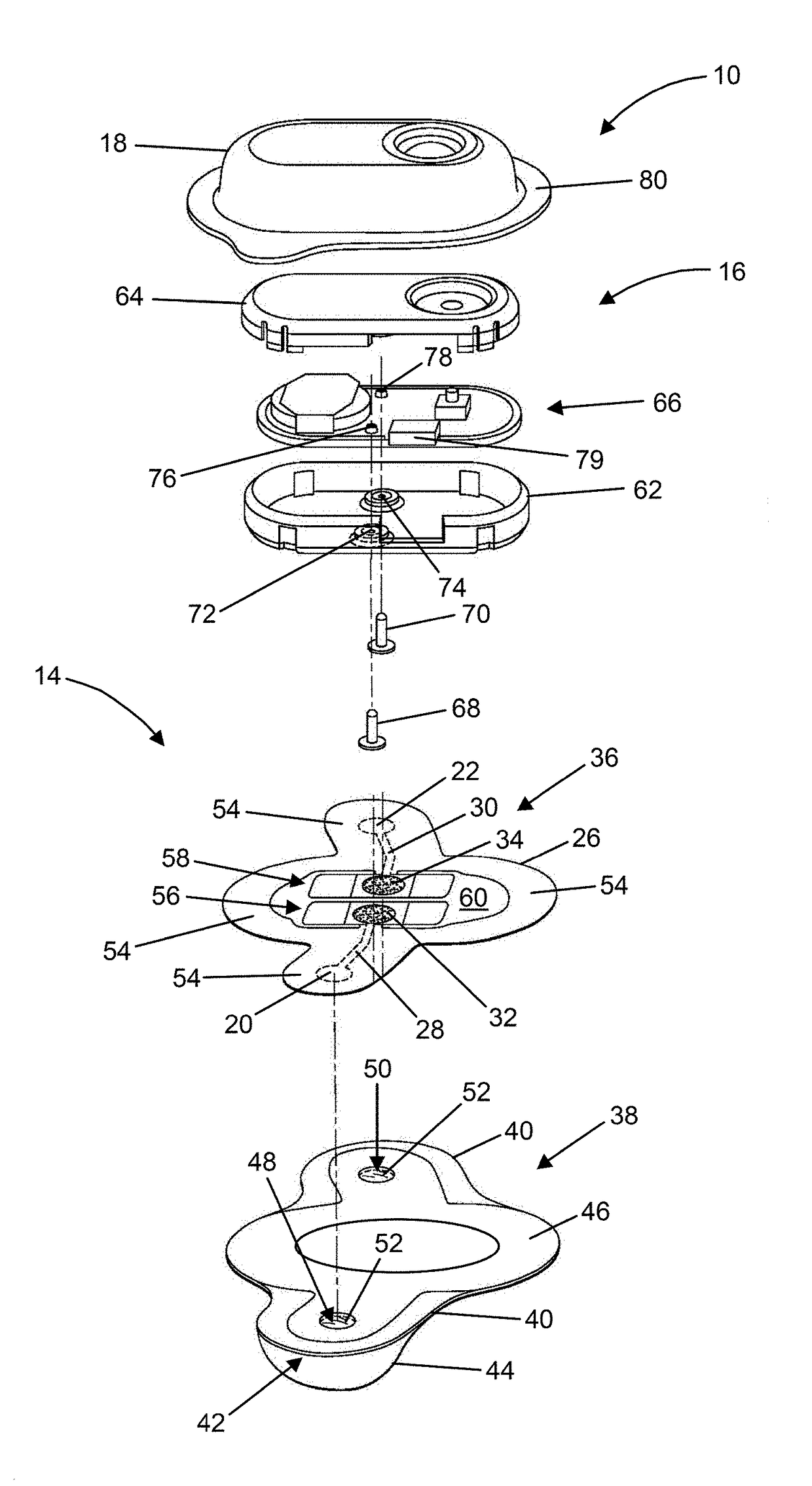

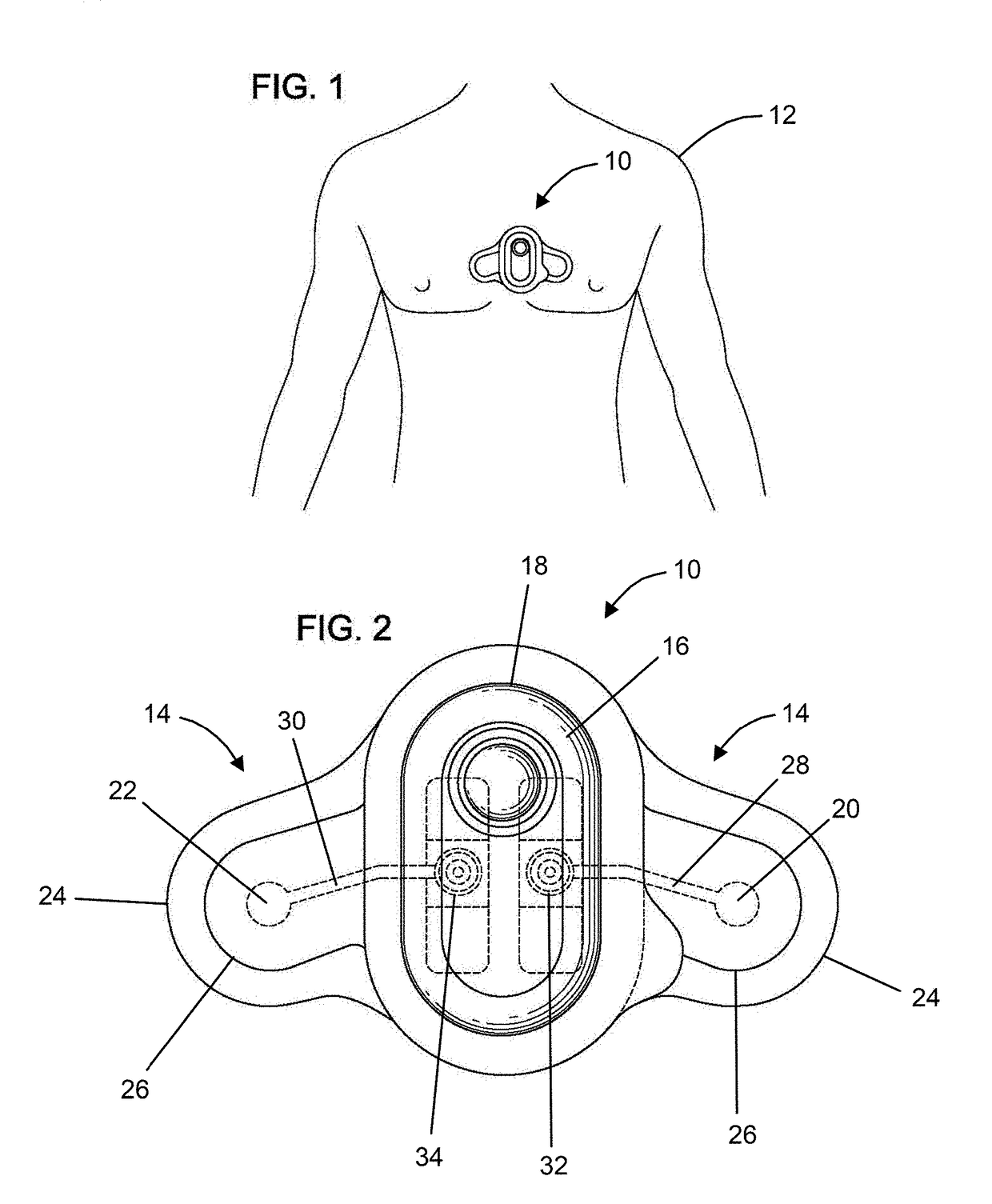

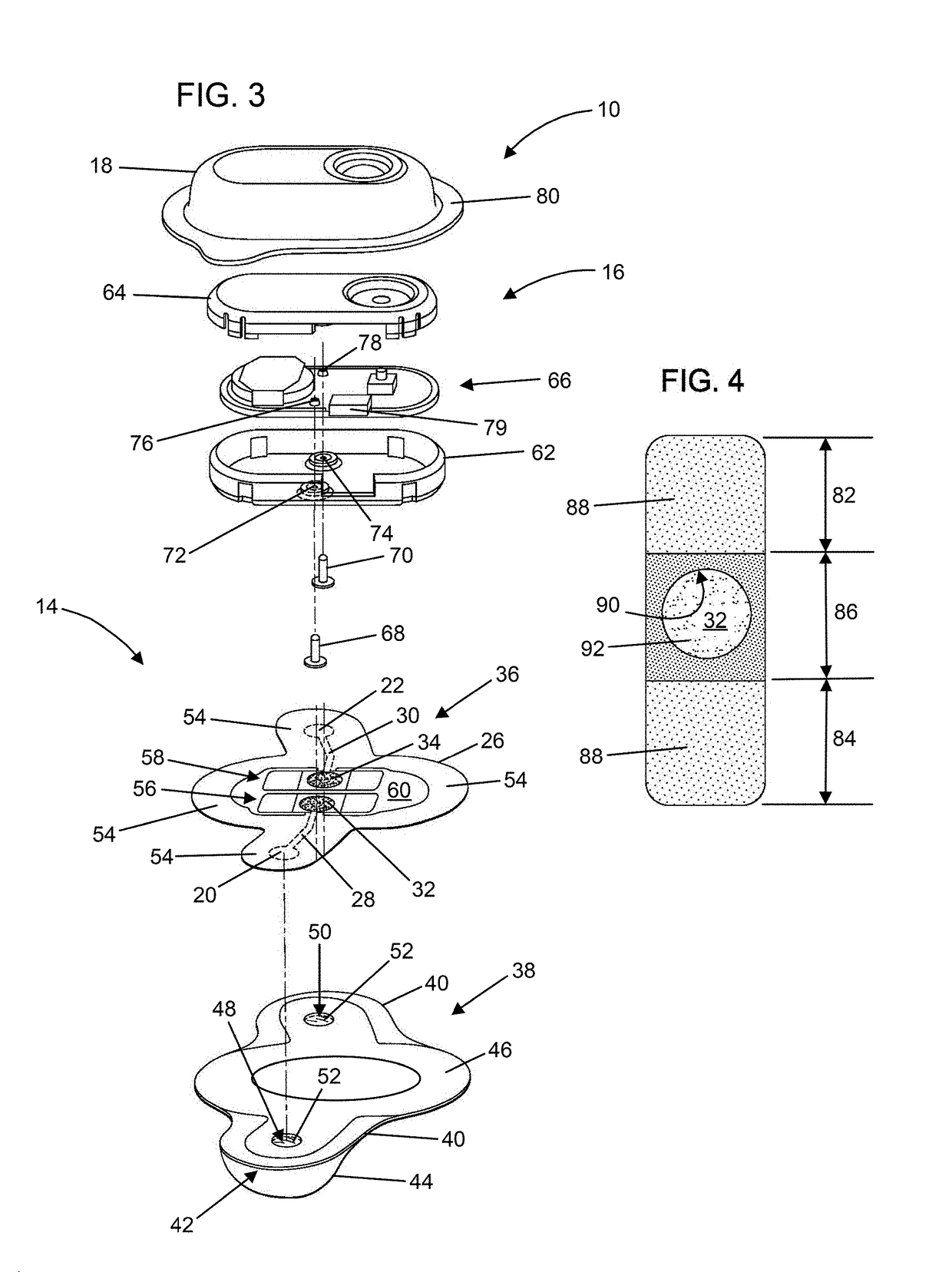

Ambulatory monitor with conductive adhesive and related methods

InactiveUS20180125387A1Inhibit electrical shortingAdhesive layerElectrocardiographySensorsEngineeringData recording

Ambulatory monitors and related methods employ an adhesive layer with conductive and non-conductive regions to improve electrical isolation of electrodes. An ambulatory monitor includes a biocompatible layer, first and second electrodes, an adhesive layer, and a physiological data recording module. The adhesive layer is interfaced with the biocompatible layer and configured to adhere the biocompatible layer to the user's skin. The adhesive layer has a first conductive adhesive region comprising a conductive adhesive electrically coupled with the first electrode, a second conductive adhesive region comprising a conductive adhesive electrically coupled with the second electrode, and a non-conductive adhesive region comprising a non-conductive adhesive. The non-conductive adhesive region serves as an electrical insulator between the first conductive adhesive region and the second conductive adhesive region. The physiological data recording module is configured to store physiological data of the user generated from an electrical signal from the first and second electrodes.

Owner:CARDIAC INSIGHT

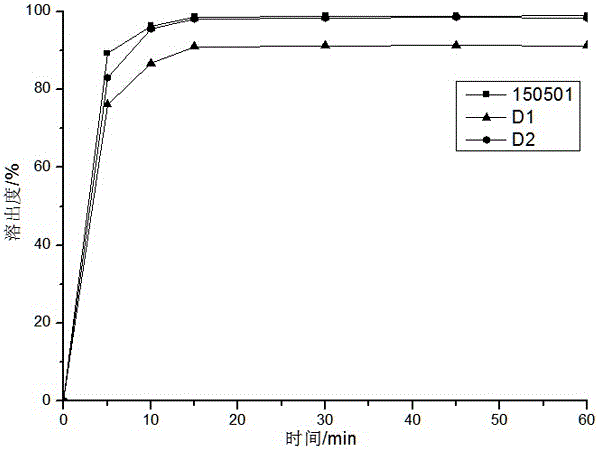

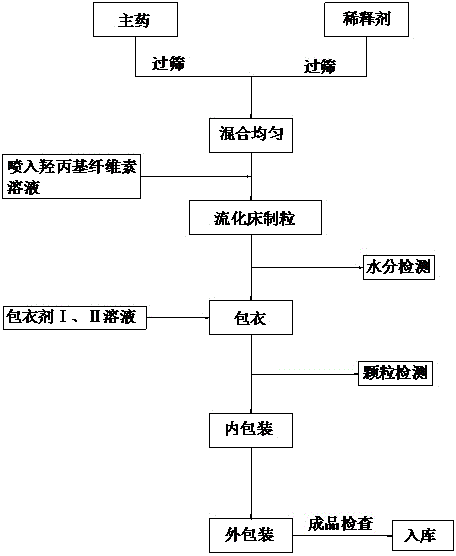

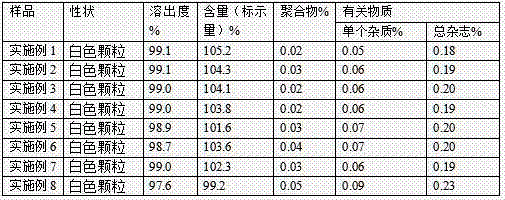

Tebipenem pivoxil granule and preparation method thereof

InactiveCN105963261AImprove stabilityProperly mask the bitternessAntibacterial agentsOrganic active ingredientsHigh humidityDissolution

The invention provides a tipipenem pectin granule and a preparation method thereof, and relates to the technical field of medicine and its preparation. A tipipenem granule, comprising the following raw materials in parts by weight: 600 to 700 parts of tipipenem, 3500 to 4500 parts of diluent, 40 to 50 parts of hydroxypropyl cellulose, and 455 to 470 parts of coating agent I 380-400 parts of coating agent II, the coating agent I is composed of ethyl cellulose suspension and talcum powder at a weight ratio of 10-20:1, the coating agent II is composed of gastric-soluble acrylic resin, Talc powder, hydroxypropyl methylcellulose and aspartame are composed in a weight ratio of 25-40:1-3:1:1.5-2.5. The tipipenem ester granule of the present invention uses tipipenem ester as the main drug, strictly screens and controls the ingredients of the excipients, optimizes the proportion, has stable drug efficacy under high temperature and high humidity environment, safe quality, high dissolution rate and excellent process. Easy to control and suitable for industrial production.

Owner:HENAN QUANYU PHARMA CO LTD

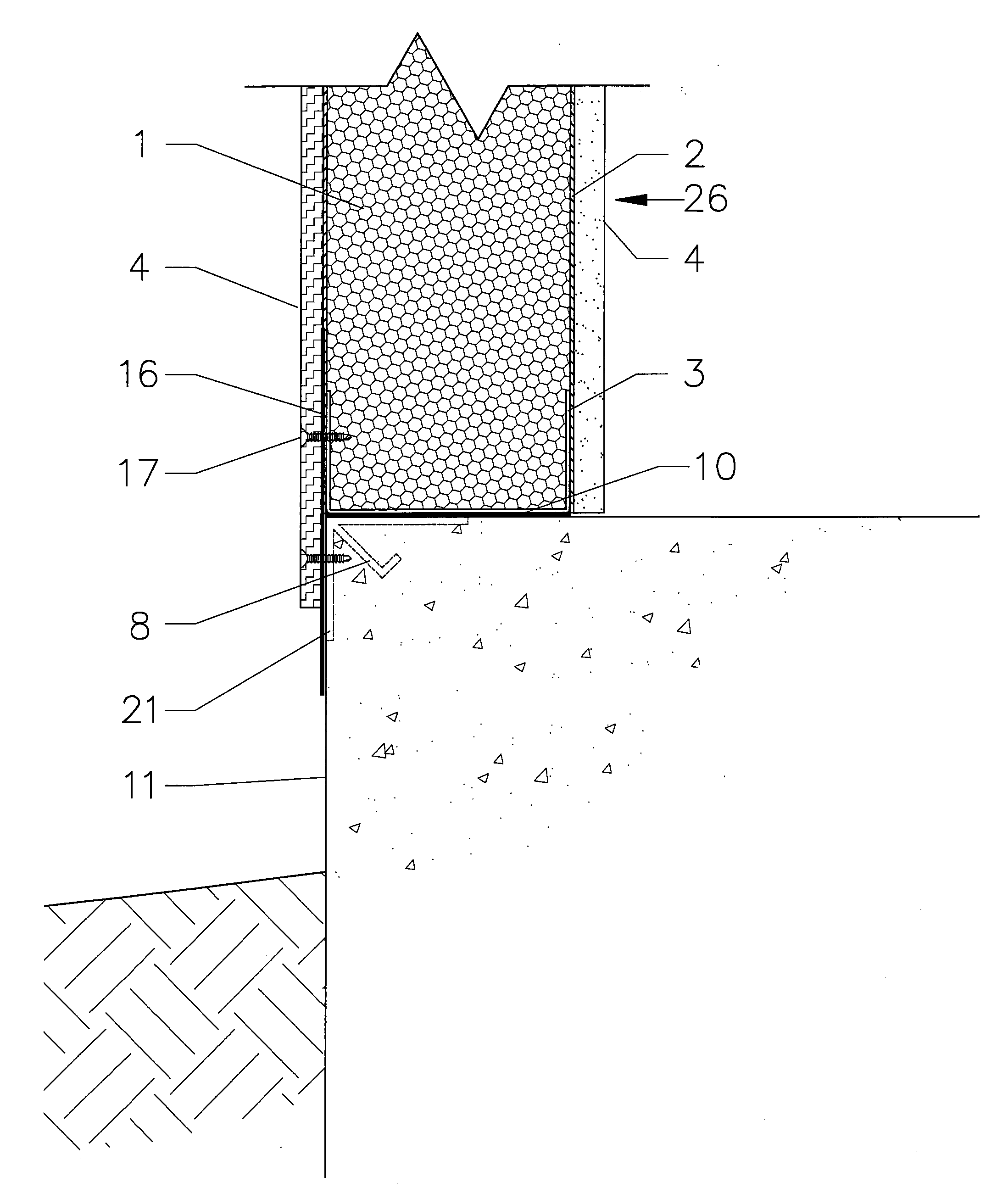

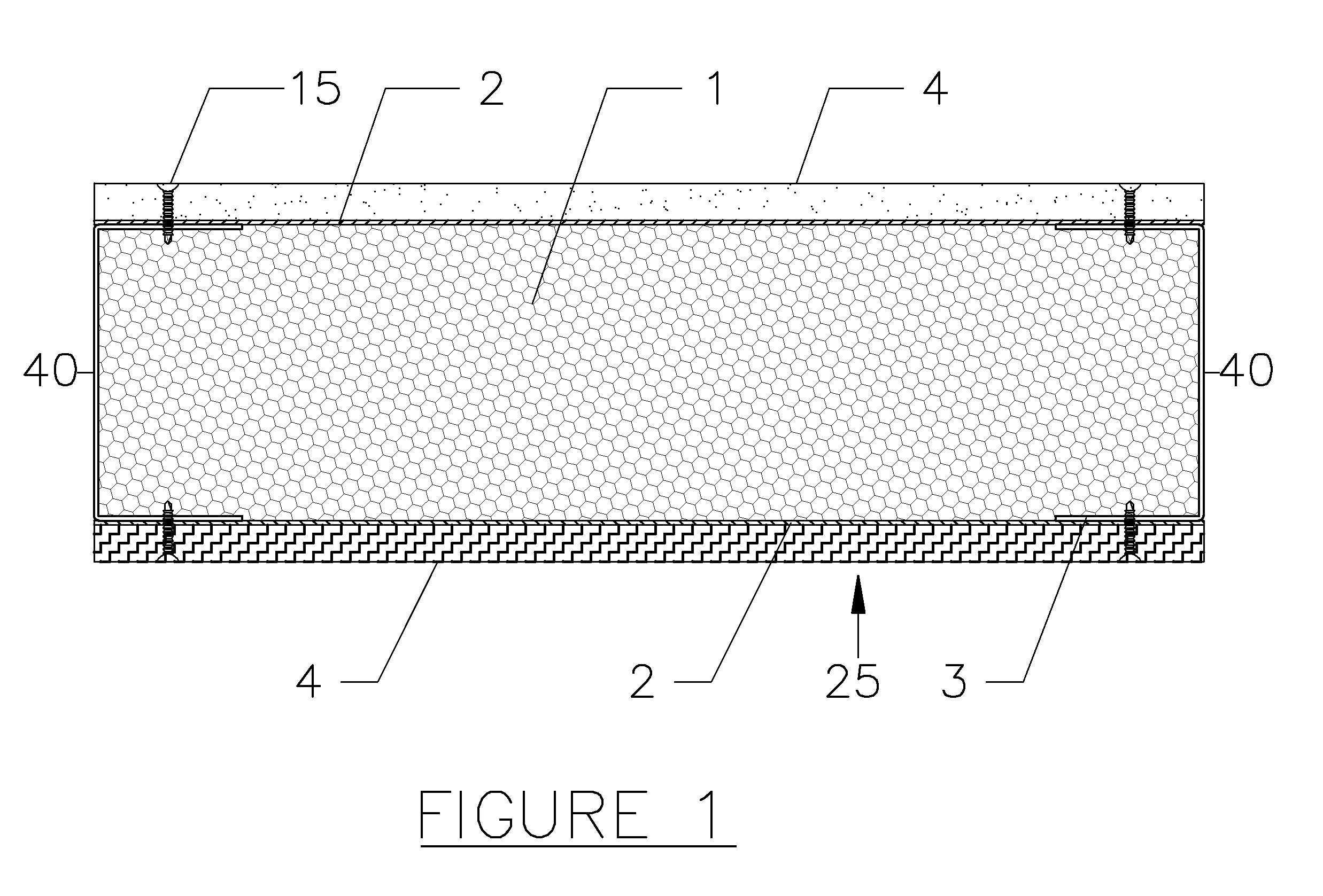

High-Strength Structure

InactiveUS20110162306A1Evenly bondedImprove the immunityBuilding roofsRoof covering using slabs/sheetsEavesHigh intensity

A high strength, lightweight building structure comprising a high-strength connection to a foundation, high-strength eaves, and high-strength structural panels. The fiber reinforced, high-strength structural panels form the walls, ceiling, roof, soffit, and eave of the structure. The panels comprise a rigid foam core having outer membrane layer, panel spacers, and sheeting. The high-strength foundation connection comprises a continuous seam plate with bonding agents, mechanical fasteners, and a metal bearing cap having continuously spaced, angle-shaped anchor studs welded to the metal bearing cap. The high-strength eave structure, comprise of a soffit panel connected to an inclined eave panel, a connection bracket and a rigid wedge continuously bonded between the ceiling panel and roof panel, thus forming a sealed, non-vented attic space.

Owner:STANLEY NEWMAN

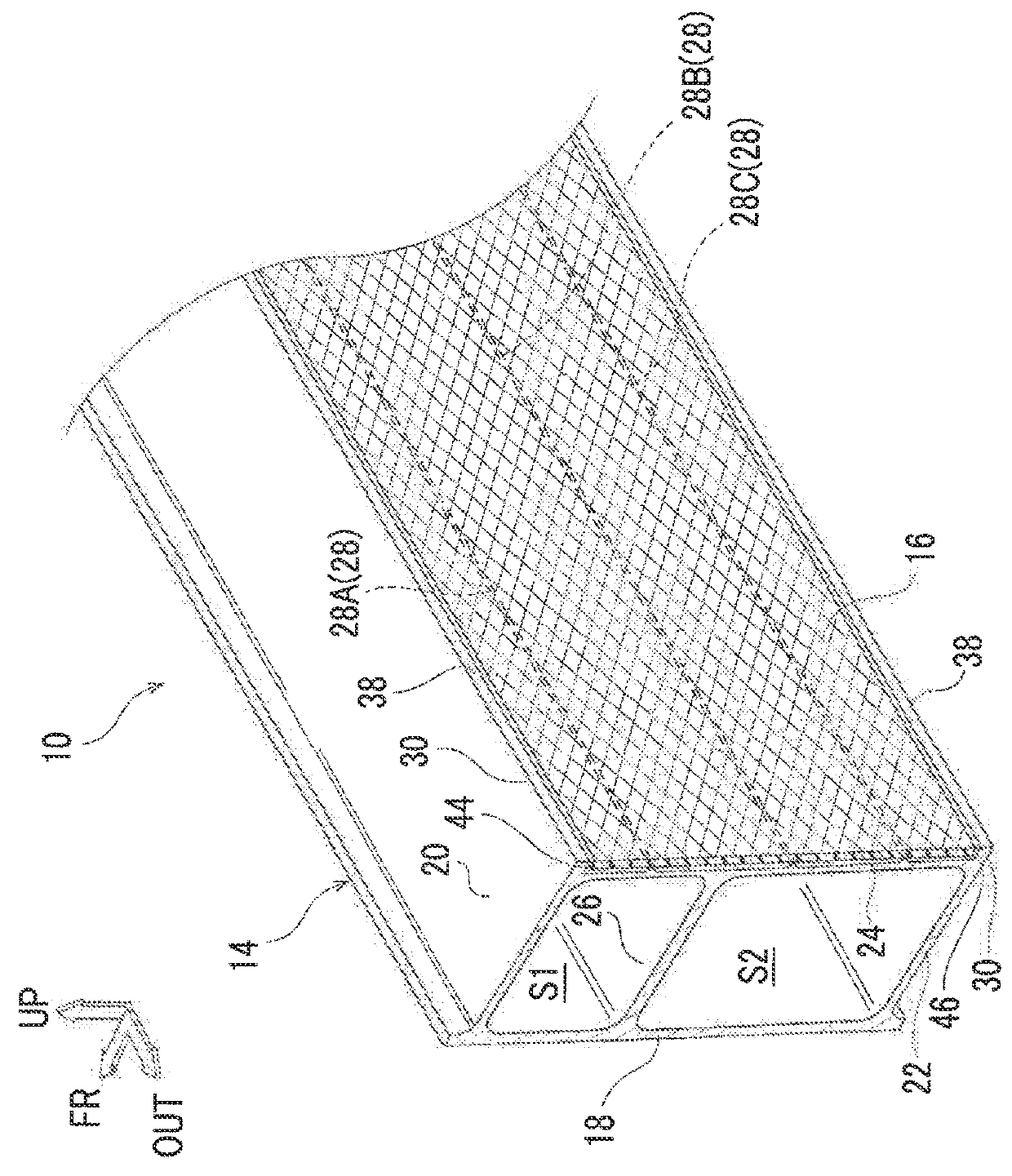

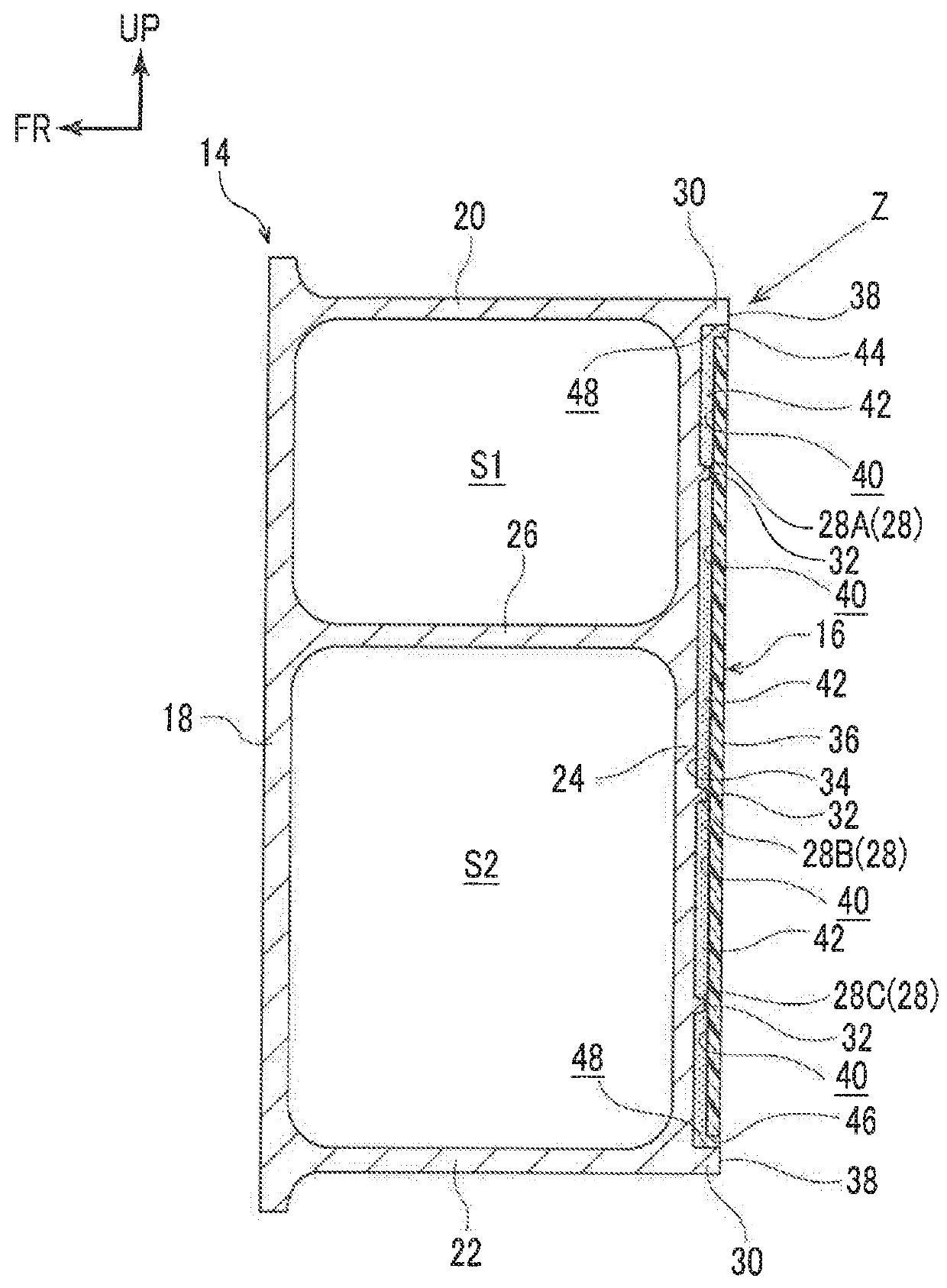

Vehicle body structure

A vehicle body structure includes a reinforcing member formed of a fiber reinforced resin and having a plate shape or a sheet shape and a metallic vehicle framework member. The vehicle framework member includes a rear wall portion and a reinforcing portion, one end face of the reinforcing member in a thickness direction of the reinforcing member being bonded to the rear wall portion and the reinforcing portion being disposed on the rear wall portion and protruding along a vertical direction from the rear wall portion.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com