Seed crystal bonding method for growing SiC crystals

A seed crystal and crystal technology, applied in the field of crystal growth, to achieve the effects of uniform growth, quality improvement, and uniform thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

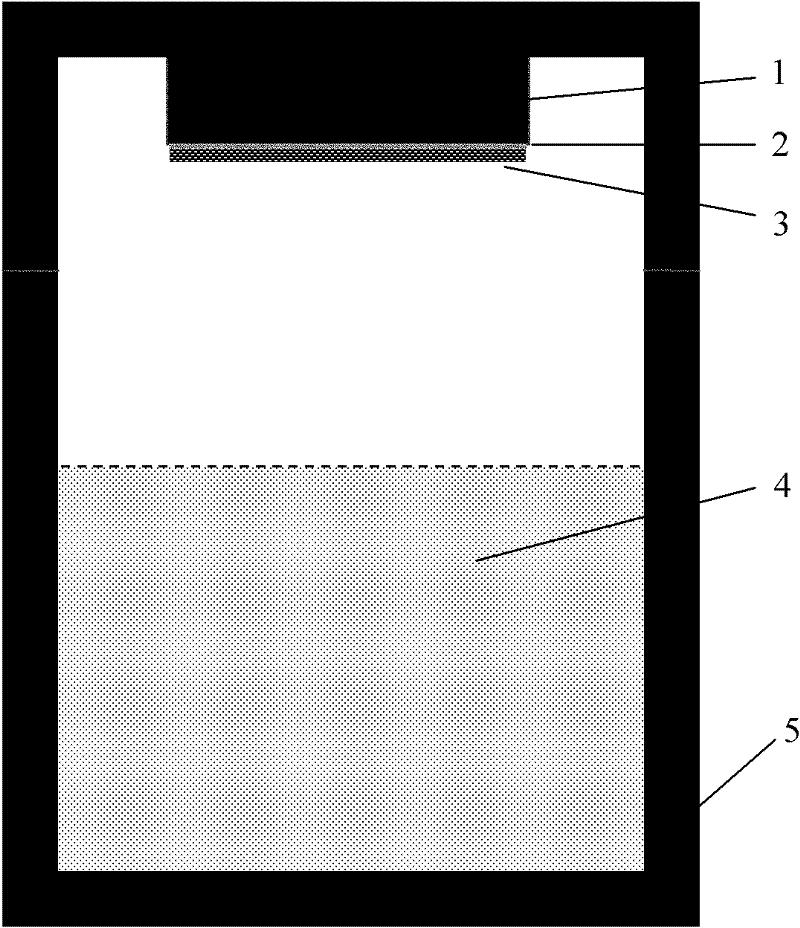

[0035] A seed crystal bonding method for growing high-quality SiC crystals, comprising the steps of:

[0036] 1. Carry out the necessary leveling, processing and cleaning of the seed crystal holder, and use a heating platform to heat the seed crystal holder, seed crystal and edible white sugar to 120°C, so that the white sugar can be melted into fluid liquid white sugar, which is easy to paint evenly.

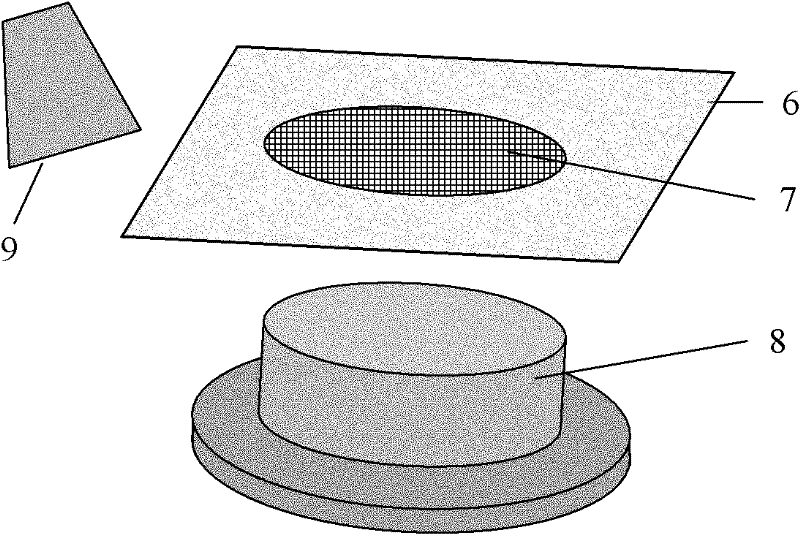

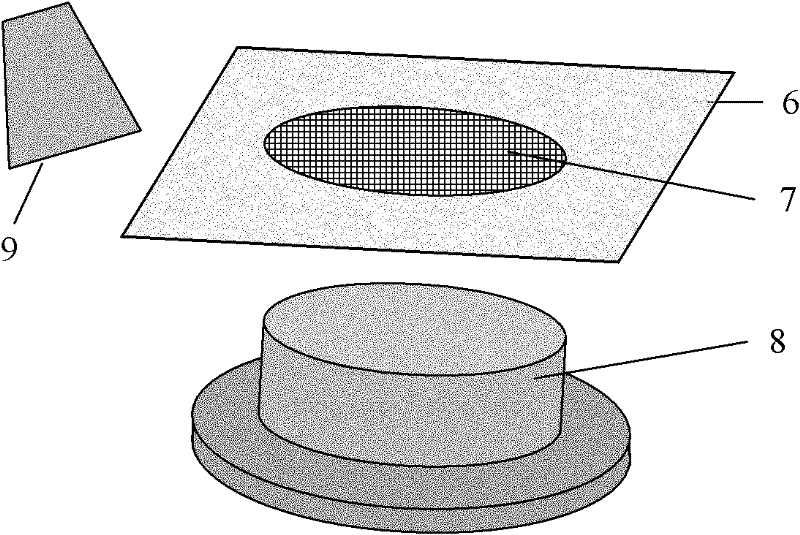

[0037] 2. The silk screen 7 (the wire diameter of the screen is 0.05mm) that adopts 80 mesh polyester material is covered on the seed crystal holder 8 (such as figure 2 As shown), after smearing liquid white sugar on the screen 7, use the brush 9 to brush and scrape the liquid white sugar to ensure that the liquid white sugar is evenly distributed in the brushing area, and finally separate the screen from the seed crystal holder.

[0038] 3. Place the seed crystal on the seed crystal support coated with liquid white sugar, and then use a self-made metal structure pressure devi...

Embodiment 2

[0041] A seed crystal bonding method for growing high-quality SiC crystals, comprising the steps of:

[0042] 1. Carry out the necessary leveling, processing and cleaning of the seed crystal holder, and use a heating platform to heat the seed crystal holder, seed crystal and AB glue to 40°C, so that the AB glue is in a fluid state, which is convenient for even coating.

[0043] 2. The wire mesh 7 (the wire diameter of the wire mesh is 0.02mm) that adopts 120 mesh stainless steel wire materials is covered on the seed crystal holder 8 (such as figure 2 As shown), after smearing the flowable AB glue on the screen 7, use the brush 9 to brush and scrape the flowy AB glue to ensure that the flowy AB glue is evenly distributed in the brushing area, and finally the screen and the seed crystal Support separation.

[0044] 3. Bond the seed crystal on the seed crystal support coated with flowable AB glue, and then use a self-made metal structure pressure device (a metal fixture) to app...

Embodiment 3

[0047] A seed crystal bonding method for growing high-quality SiC crystals, comprising the steps of:

[0048] 1. Use 502 glue as the adhesive at room temperature (about 20-30°C).

[0049] 2. Carry out necessary leveling, processing and cleaning of the seed crystal holder, and then cover the seed crystal holder 8 with a wire mesh 7 (the wire diameter of the wire mesh is 0.07 mm) made of 40 mesh stainless steel wire (such as figure 2 shown), after smearing the flowable 502 glue on the screen 7, use the brush 9 to brush and scrape the flowy 502 glue to ensure that the flowy 502 glue is evenly distributed in the brushing area, and then quickly put the screen and the seed Crystal holder separated.

[0050] 3. Quickly bond the seed crystal to the seed crystal holder coated with flowable 502 glue, and then use a self-made metal structure pressure device (a metal fixture) to apply appropriate pressure evenly on the seed crystal and the seed crystal holder to make the seed crystal T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com