Patents

Literature

213results about How to "Uniform thickness distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

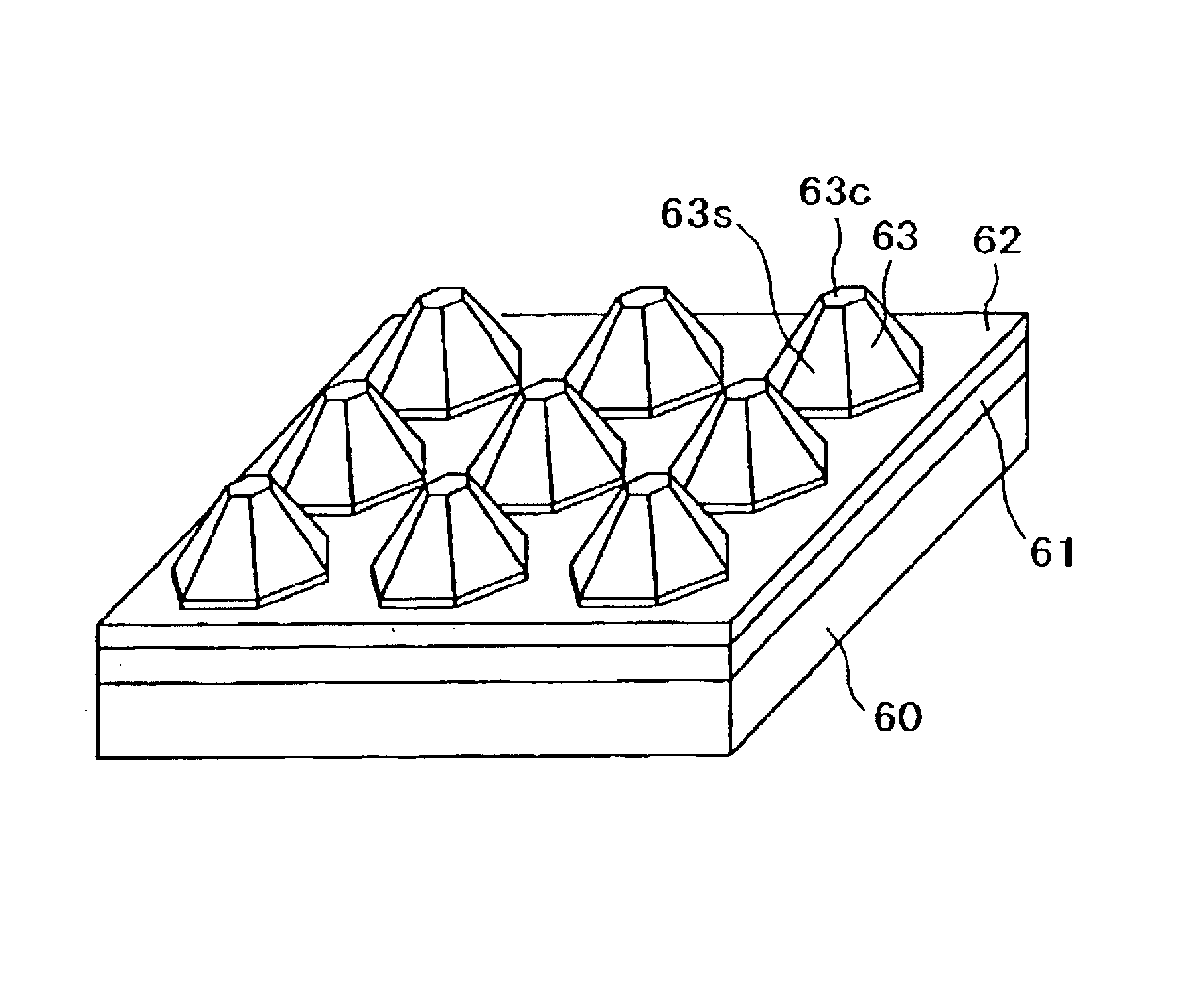

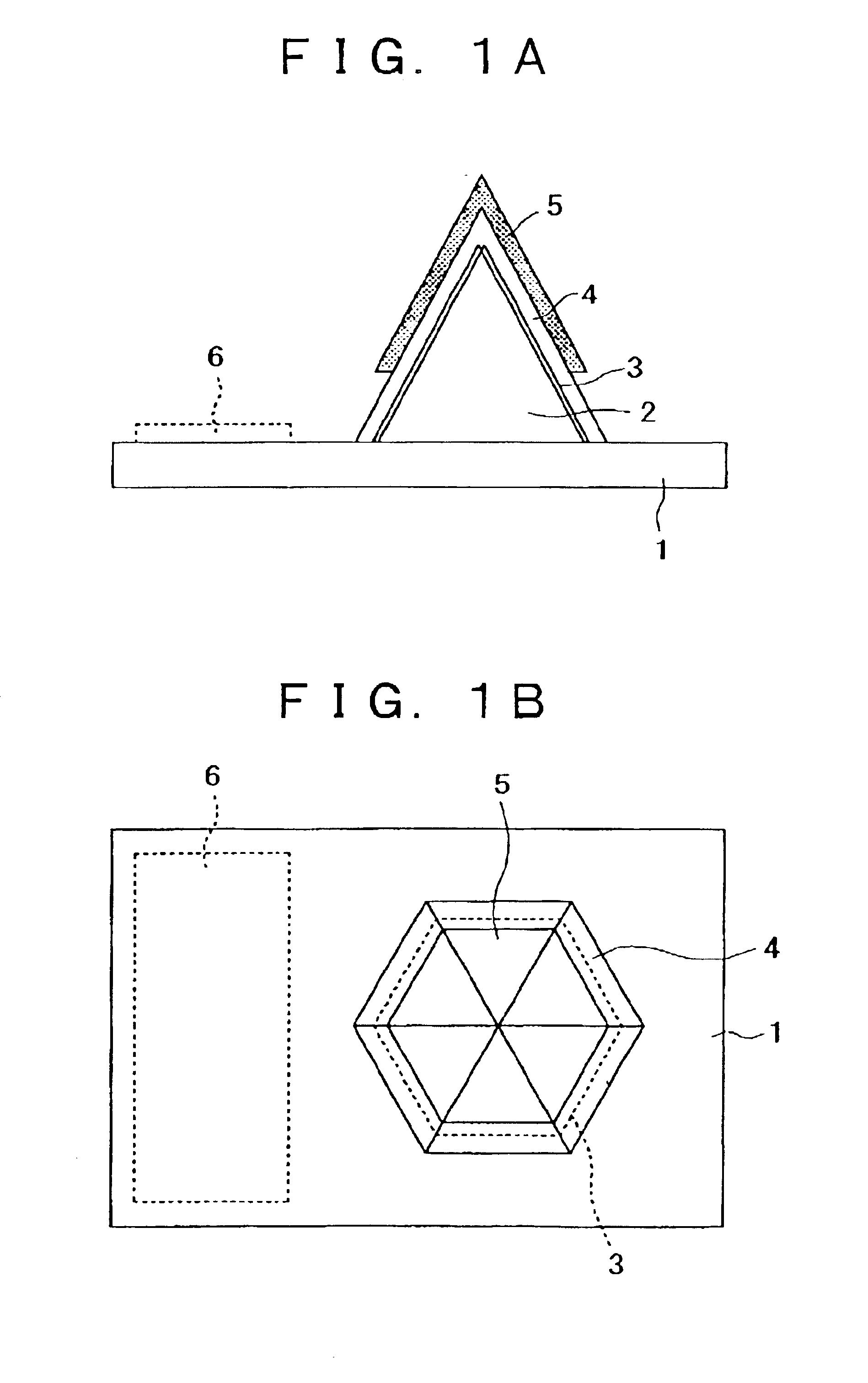

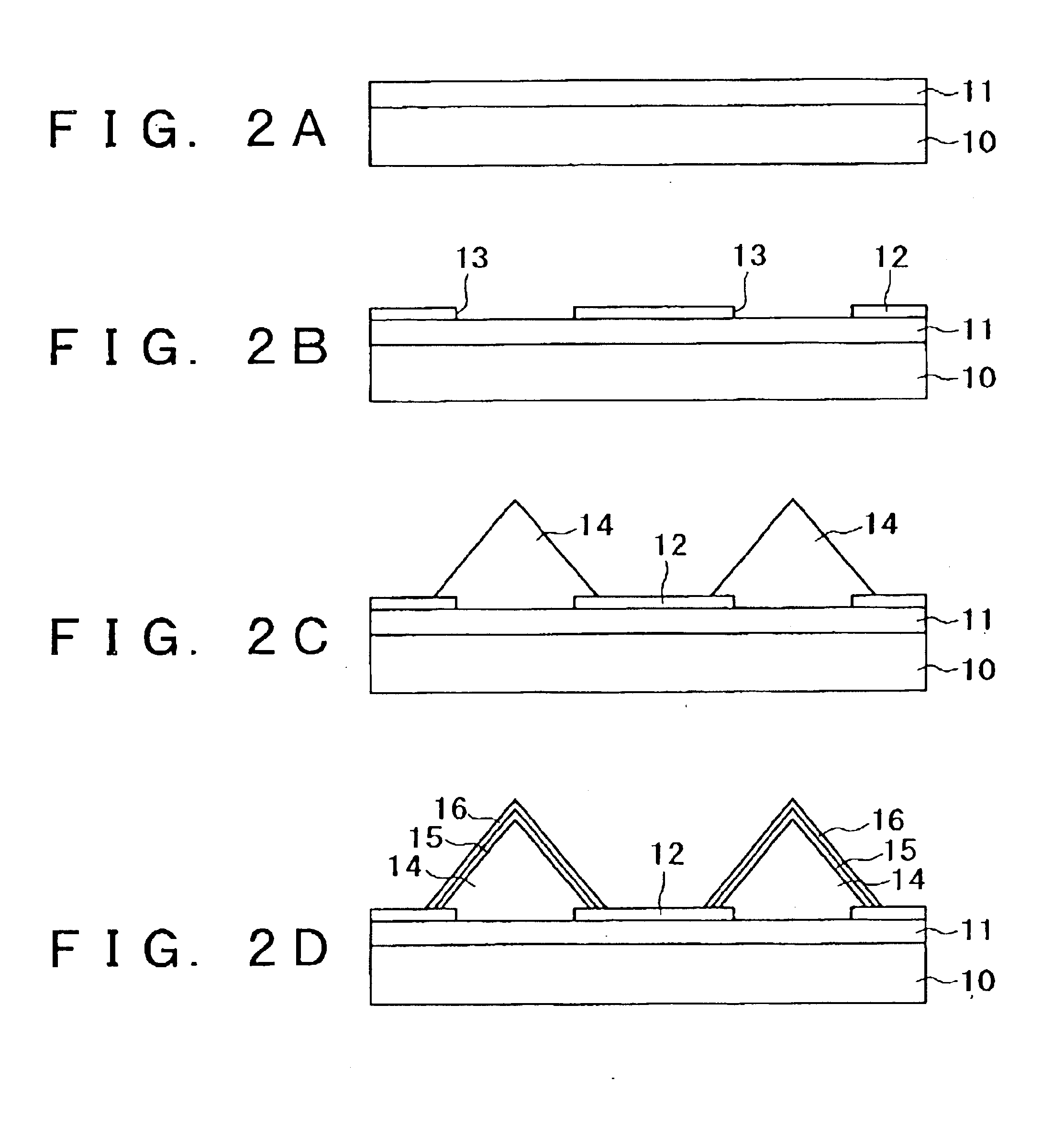

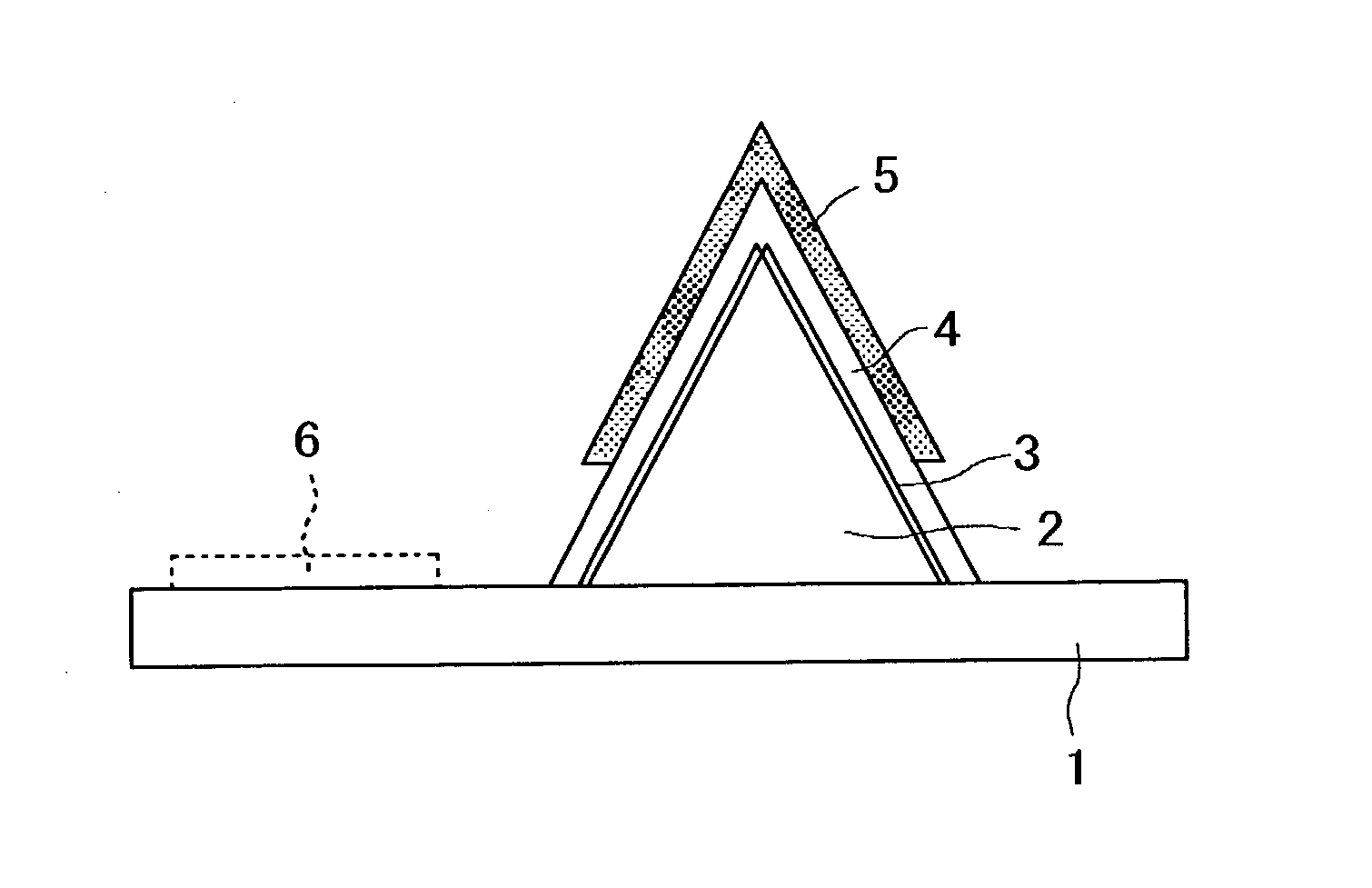

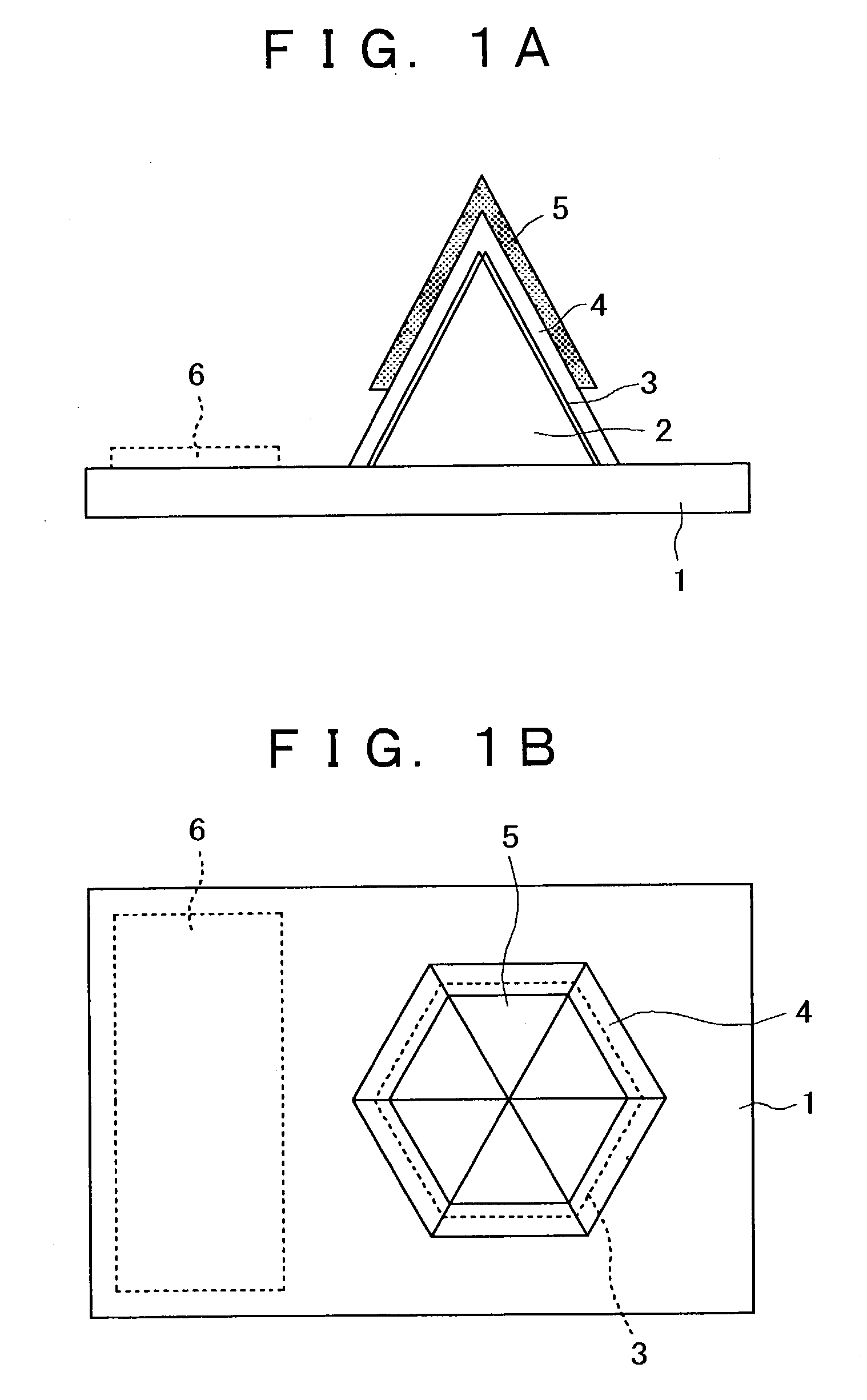

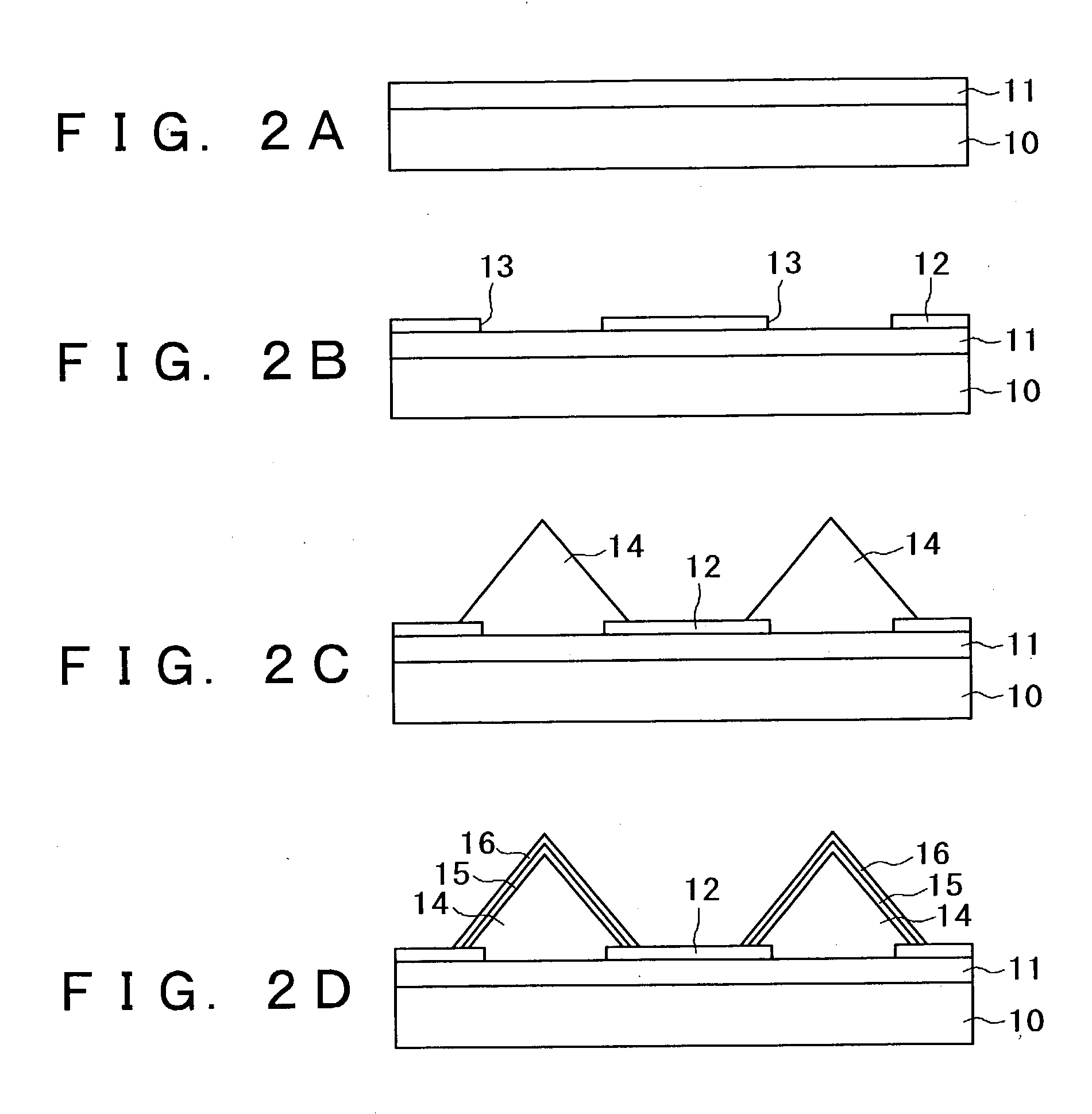

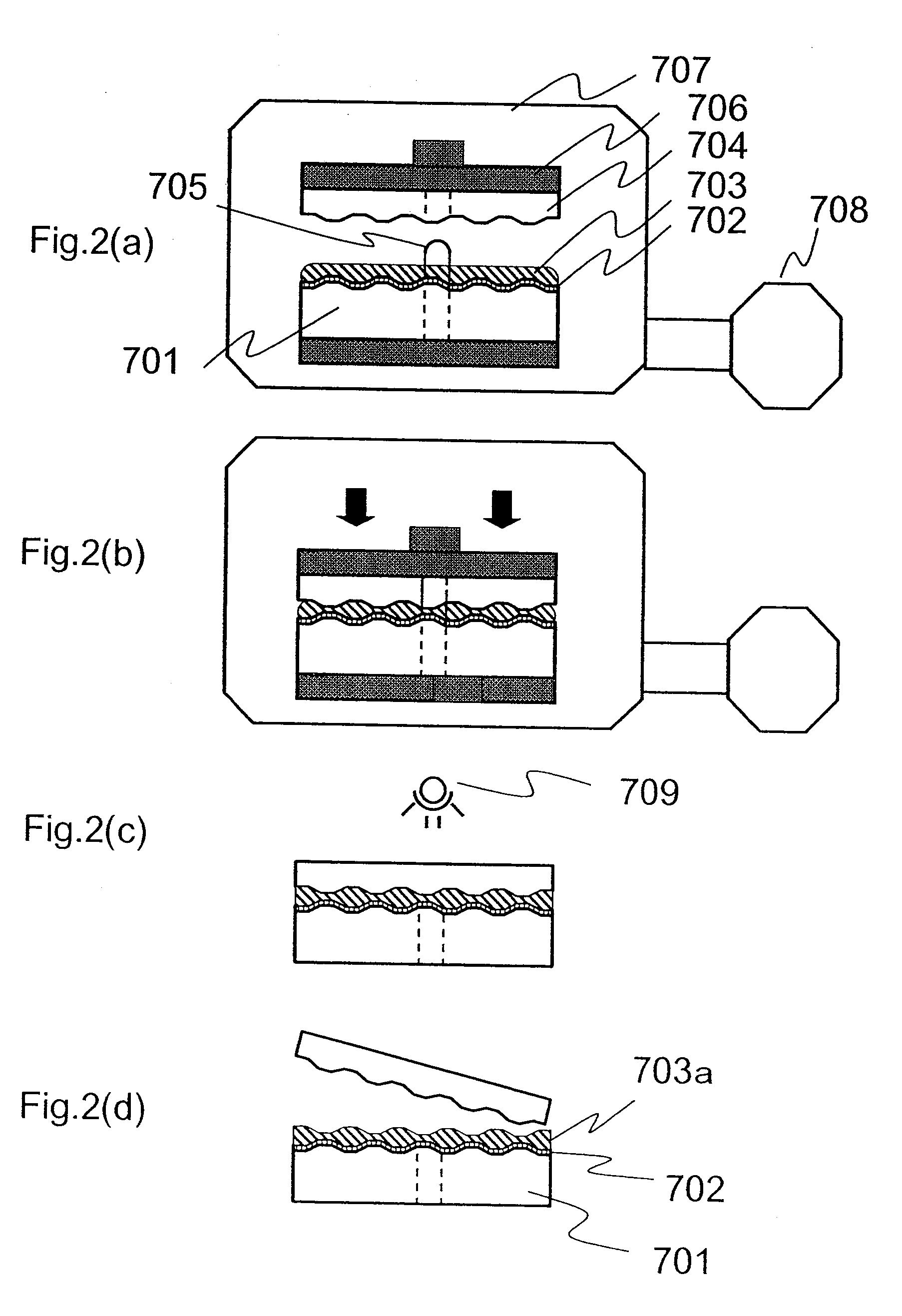

Selective growth method, and semiconductor light emitting device and fabrication method thereof

InactiveUS6858081B2Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

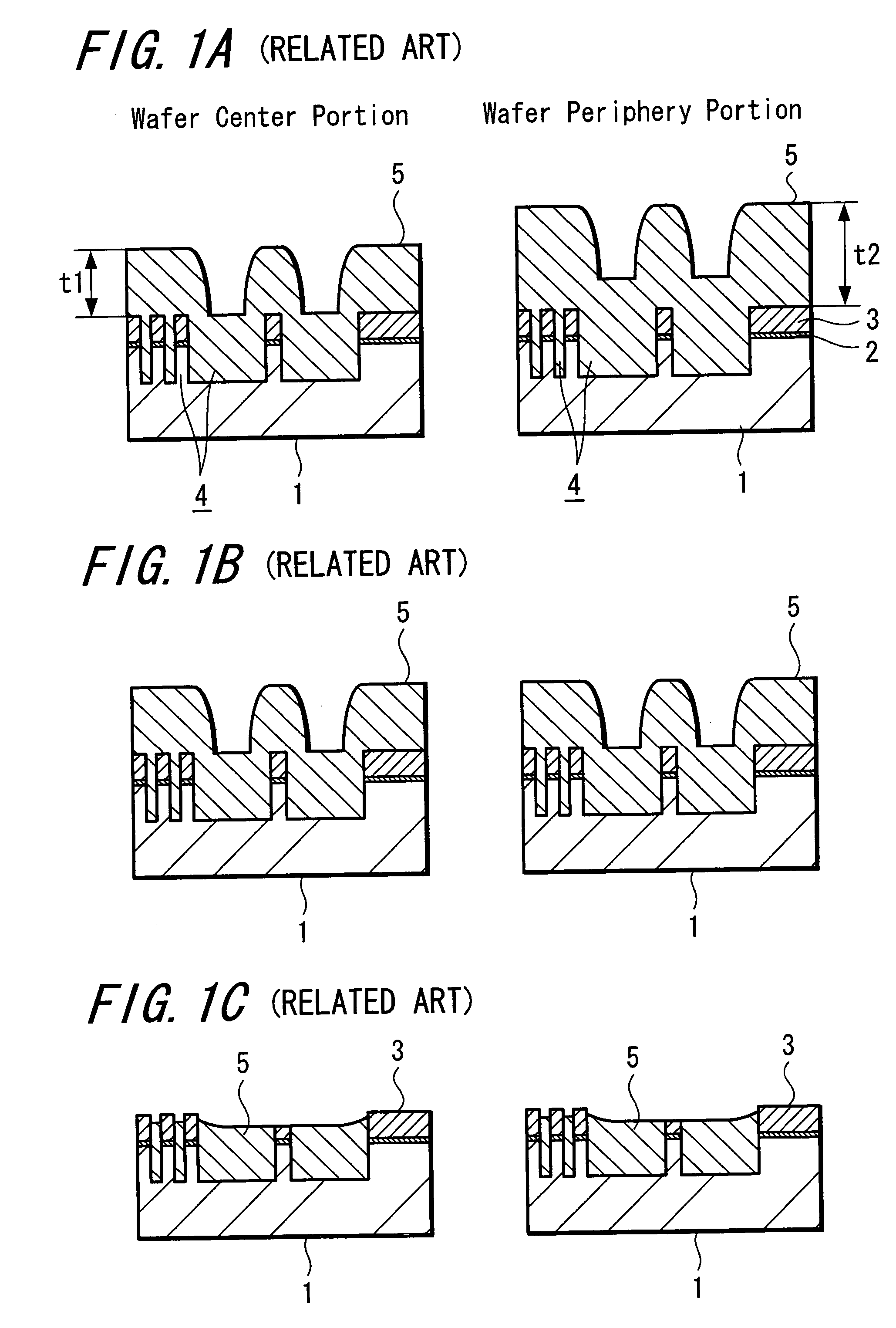

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

Selective growth method, and semiconductor light emitting device and fabrication method thereof

InactiveUS20030140846A1Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

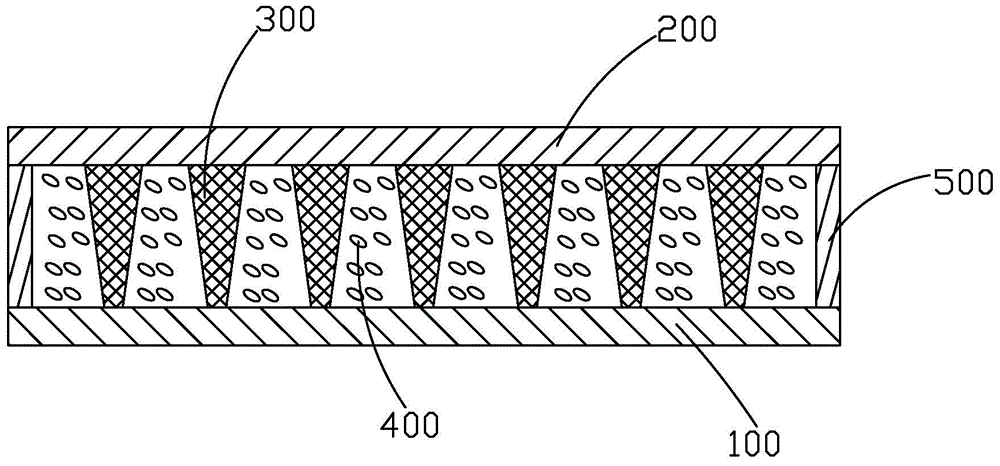

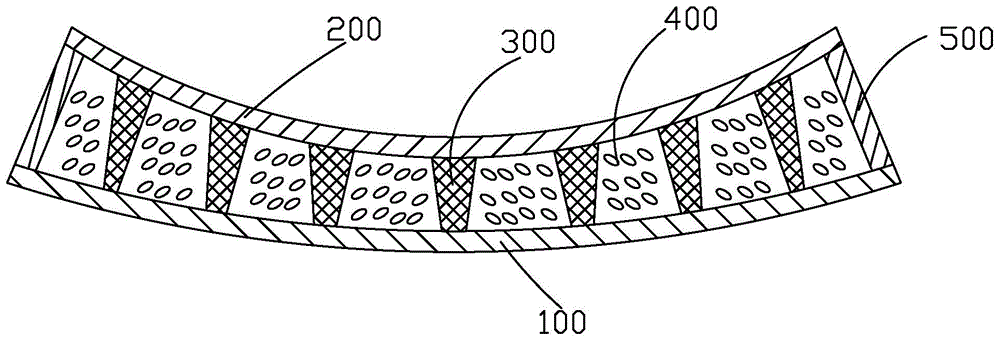

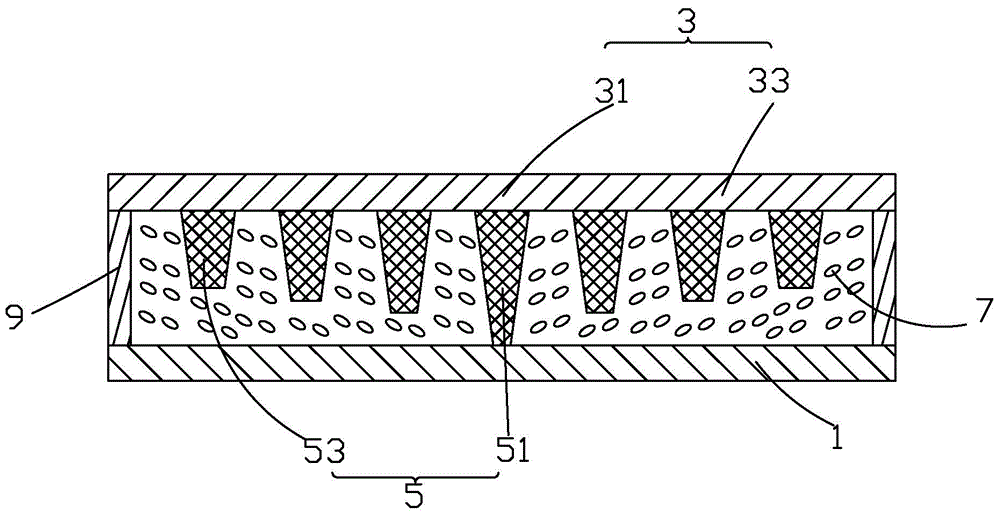

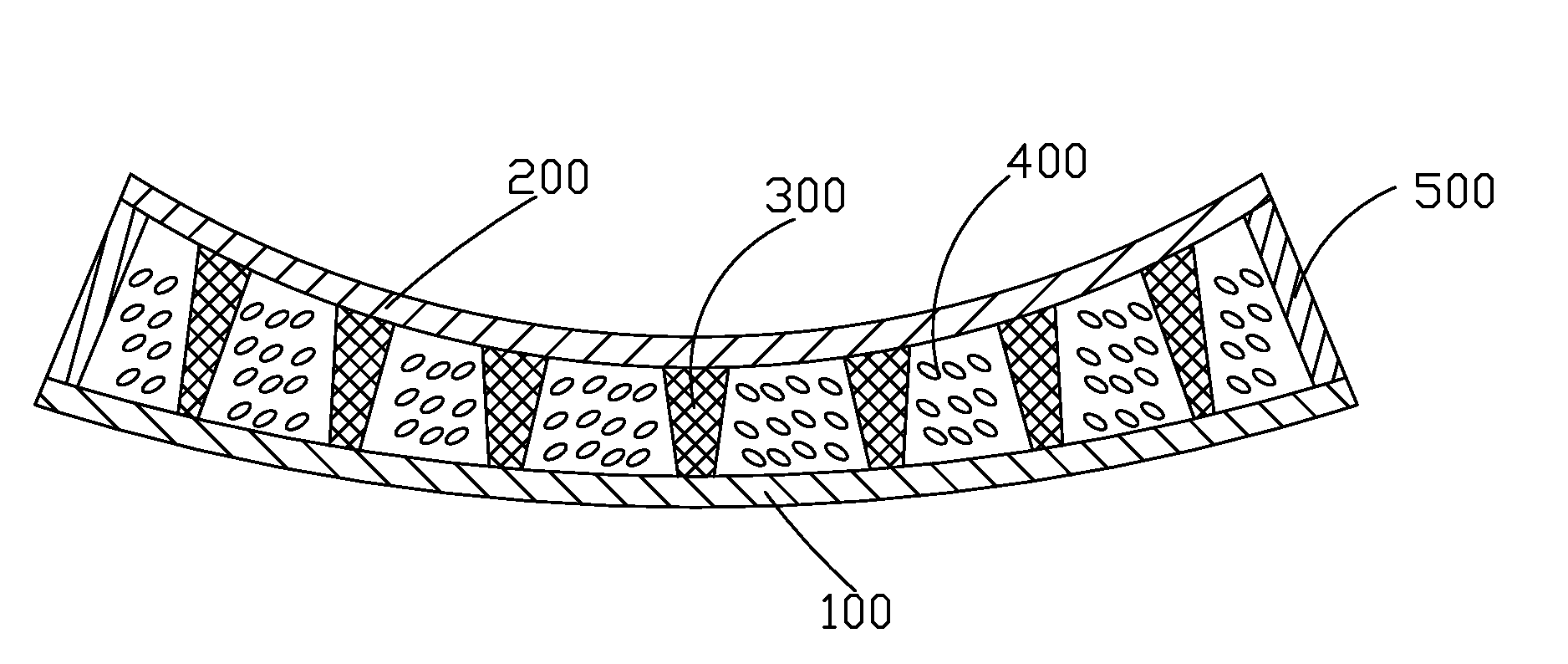

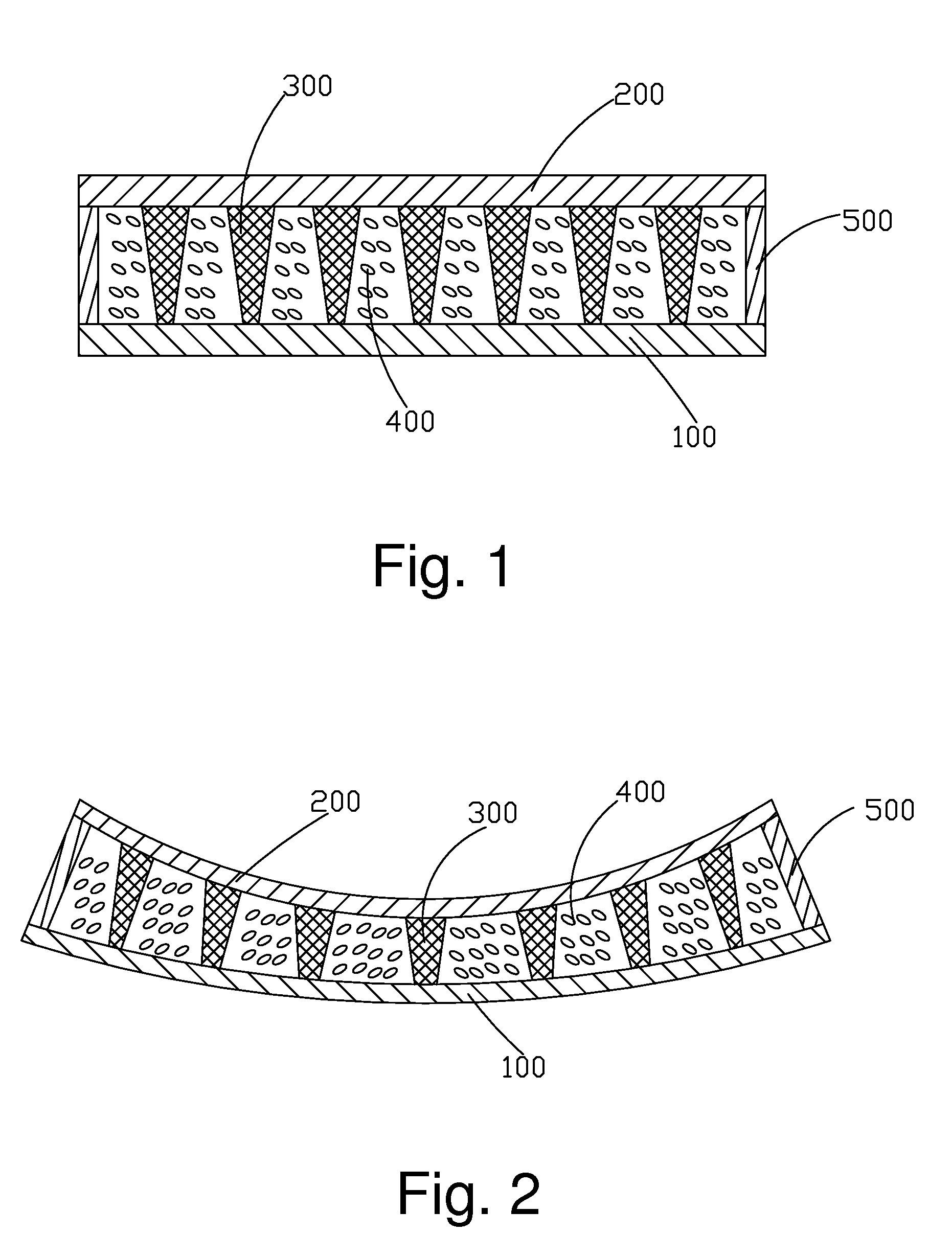

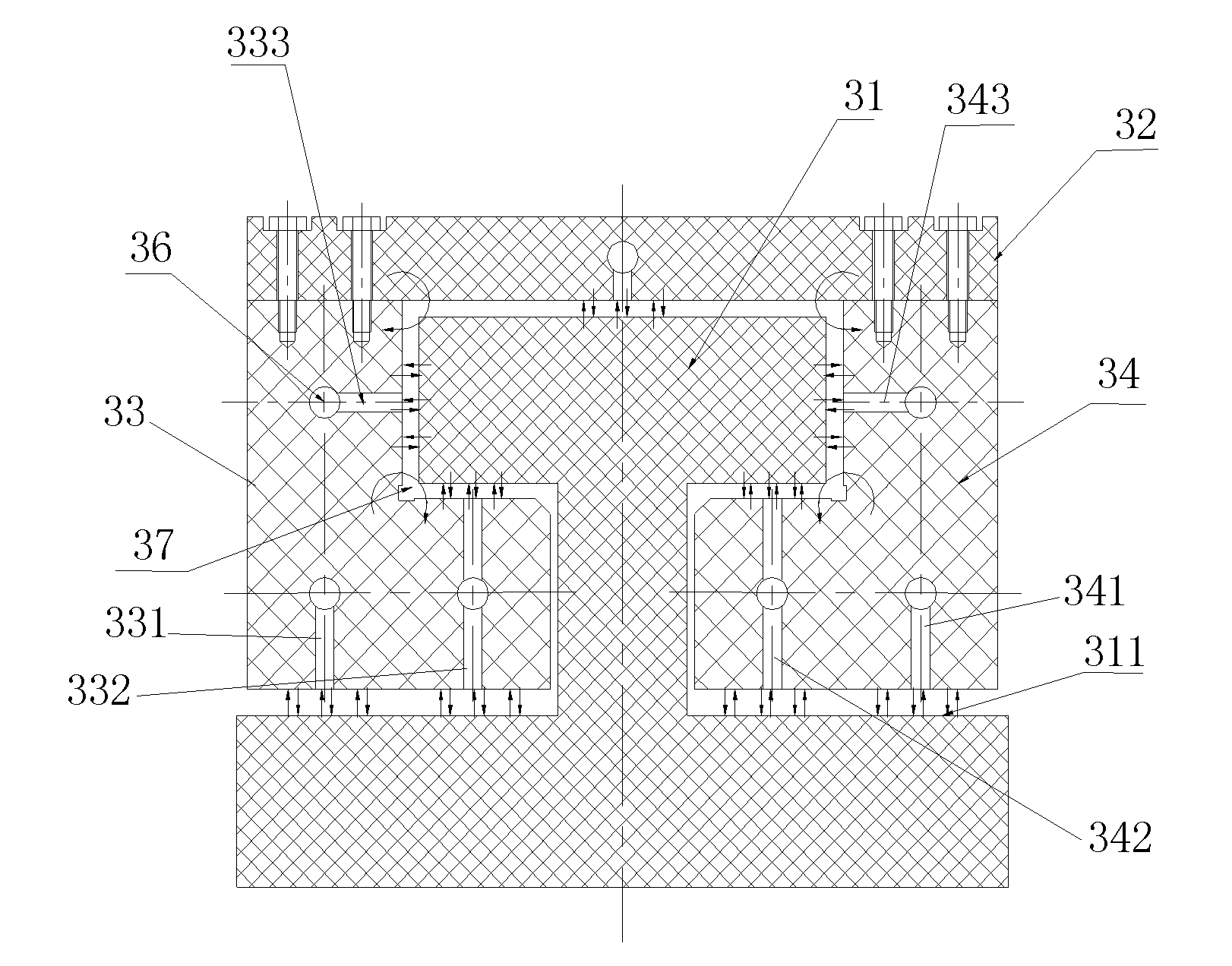

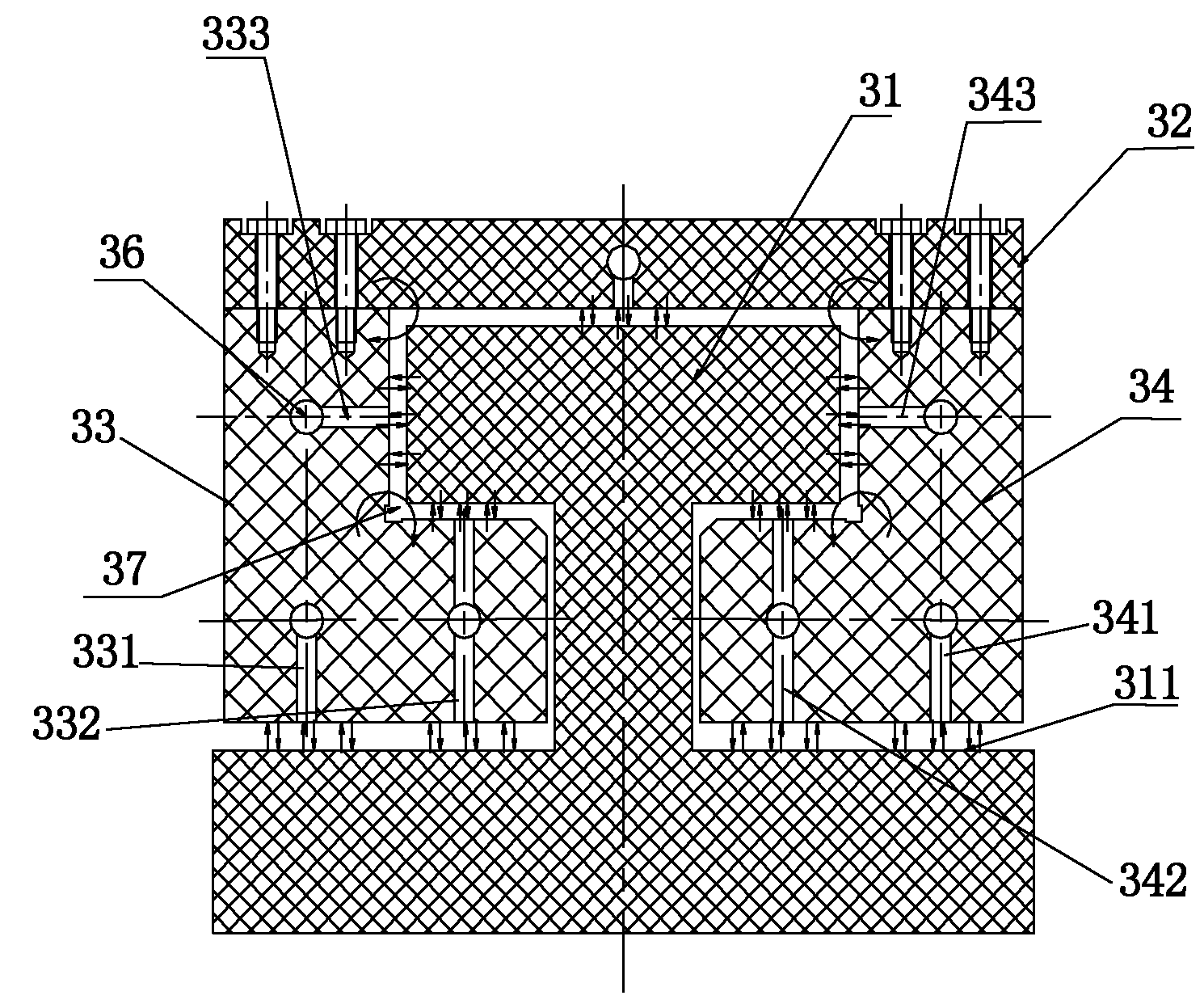

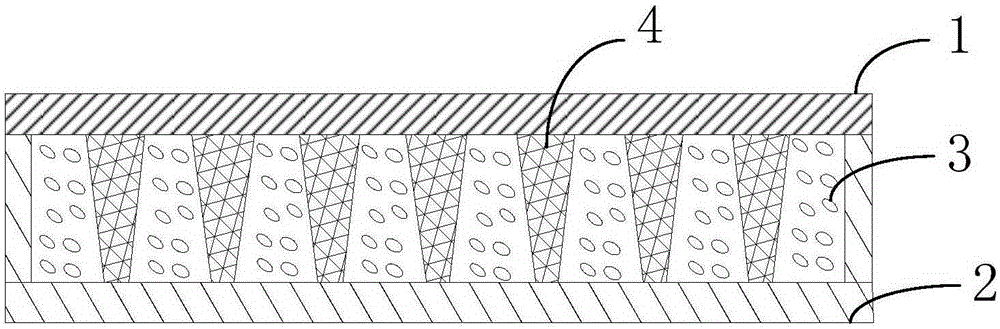

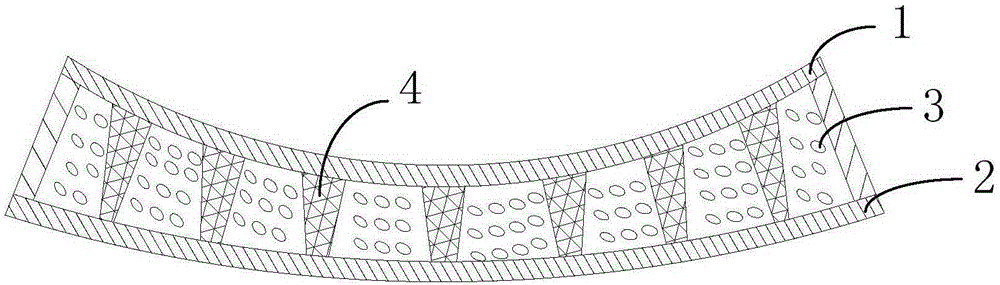

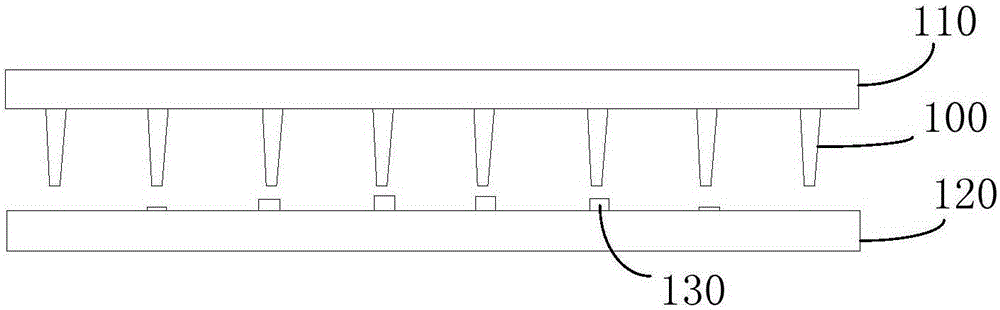

Curved liquid crystal panel structure

ActiveCN103955096AConsistent box thicknessImprove Optical TasteNon-linear opticsLiquid-crystal displaySpace object

The invention provides a curved liquid crystal panel structure, which comprises a TFT base plate (1), a CF base plate (3), spacing objects (5), a liquid crystal layer (7) and a sealing glue layer (9), wherein the CF base plate (3) is in arrangement corresponding to the TFT base plate, the spacing objects (5) are arranged between the TFT base plate (1) and the CF base plate (3), the liquid crystal layer (7) is arranged between the TFT base plate (1) and the CF base plate (3), the sealing glue layer (9) is arranged between the TFT base plate (1) and the CF base plate (3) and is positioned at the edge, in the bending direction of a curved liquid crystal panel, the CF base plate (3) is provided with a middle region (31) and two side regions (33) positioned at two sides of the middle region, the stress born by the middle region (31) is greater than that born by the two side regions (33), and the spacing object (51) positioned in the middle region (51) is set to be capable of bearing higher stress than the spacing object (53) positioned at two side regions (33), so the equal gap is maintained between the CF base plate (3) and the FT base plate (1), and the integral box thickness consistency of the curved liquid crystal panel is ensured.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

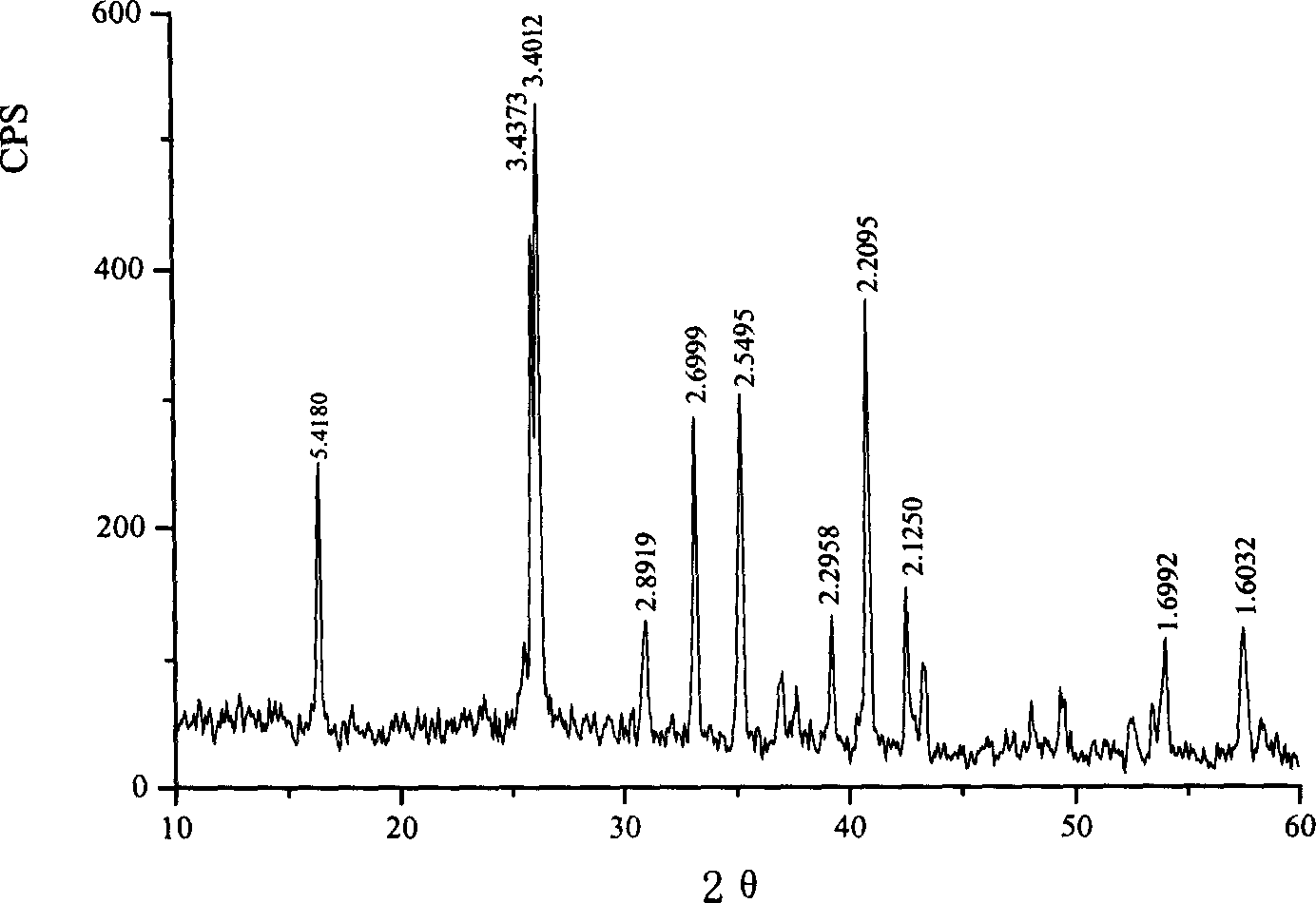

Mullite whisker-mullite composite coating and preparation process thereof

InactiveCN1793017AModerate thicknessOvercome the problem of being thin, dry and easy to crackMulliteOxidation resistant

The invention relates to mullite crystal whisker mullite compounding coating layer that the manufacture method includes the following steps: coating the mixture slime of silica sol, aluminum sol and mullite slime in vacuum of the basal material, or coating orderly, under the catalyzing effect of metal fluoride mineralizer, sintering by high temperature. The invention is simple structure, low cost of raw material, acid proof, alkali proof, etc. it could improve the intension of the material and prolong the use life.

Owner:WUHAN UNIV OF TECH

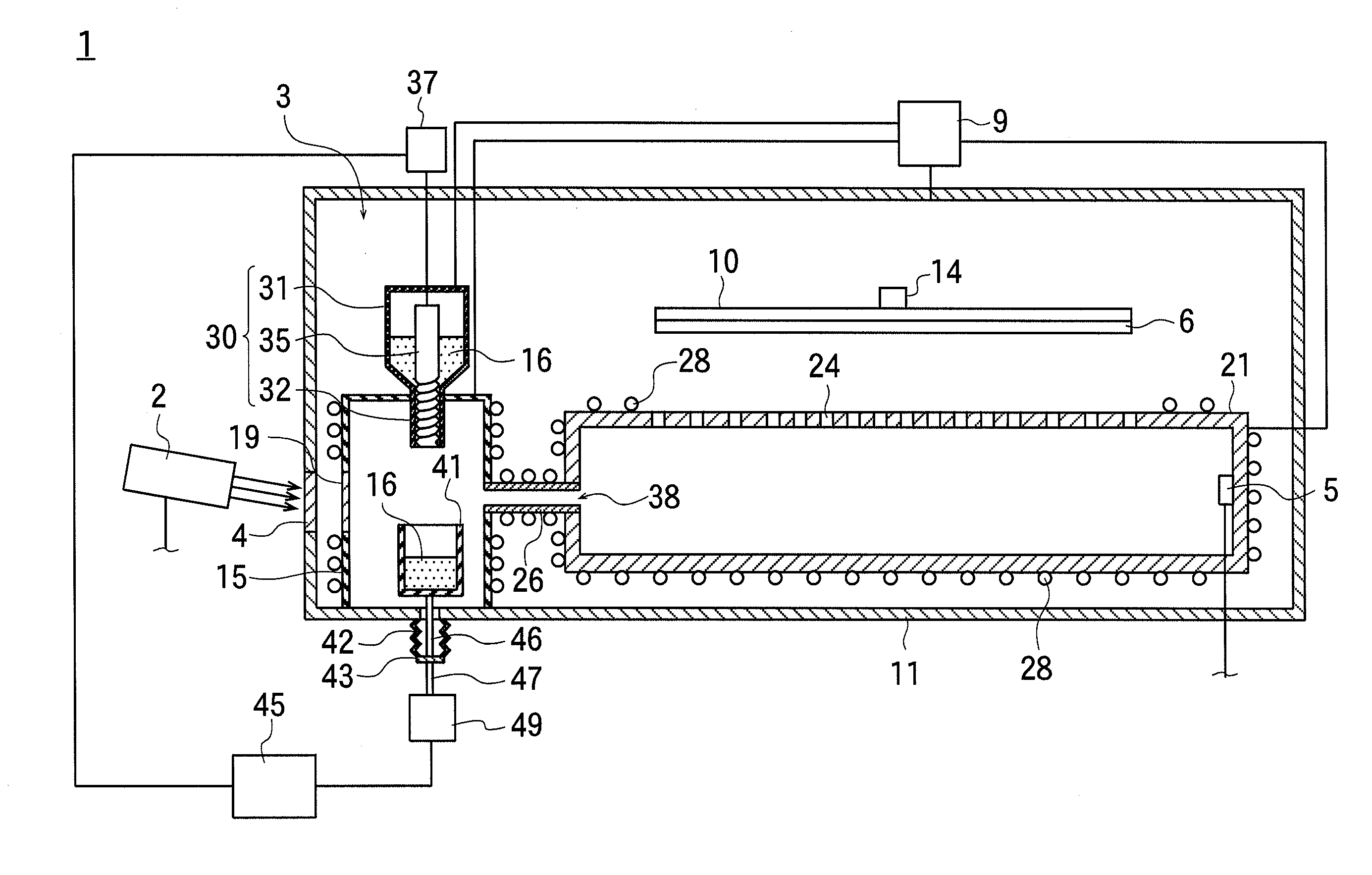

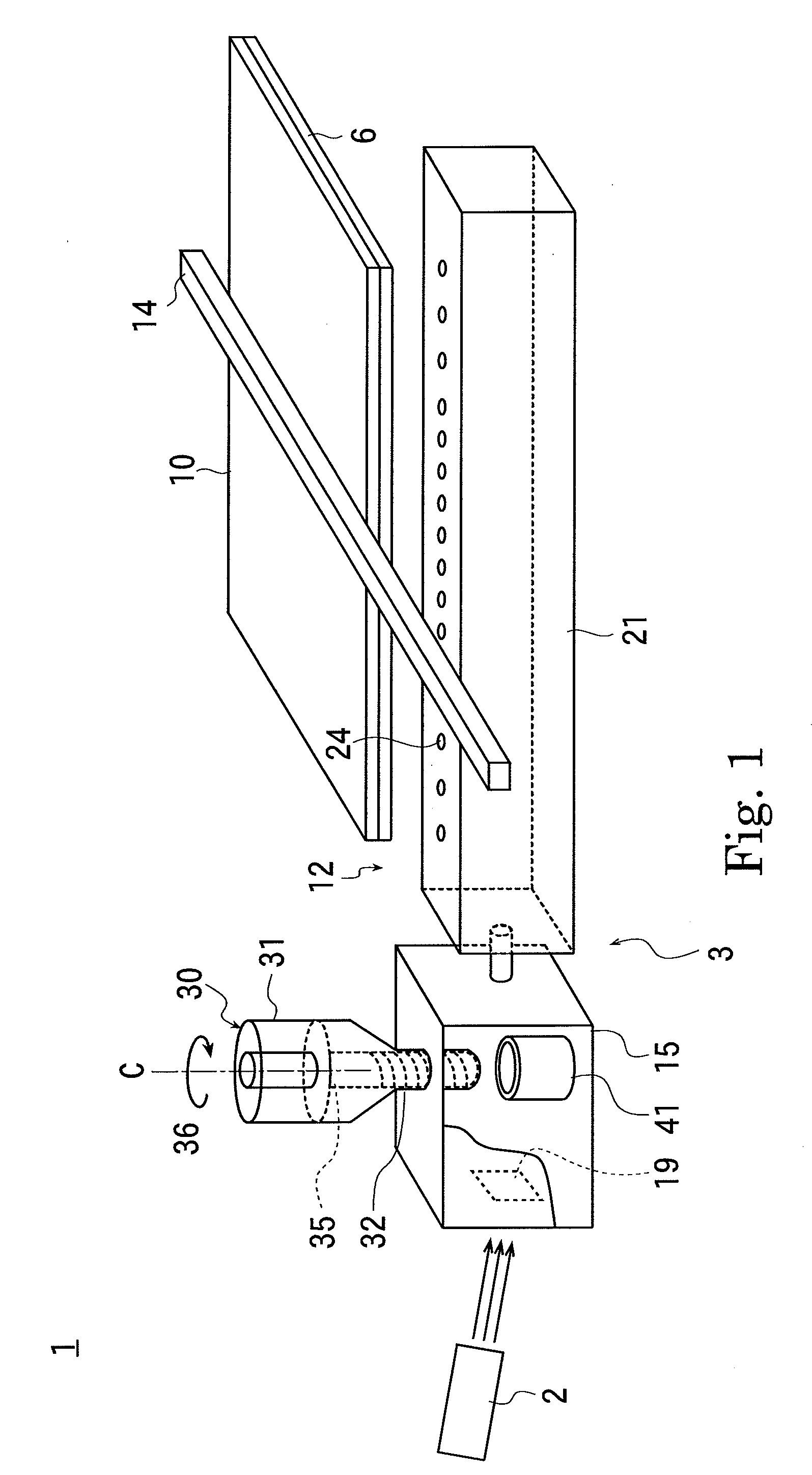

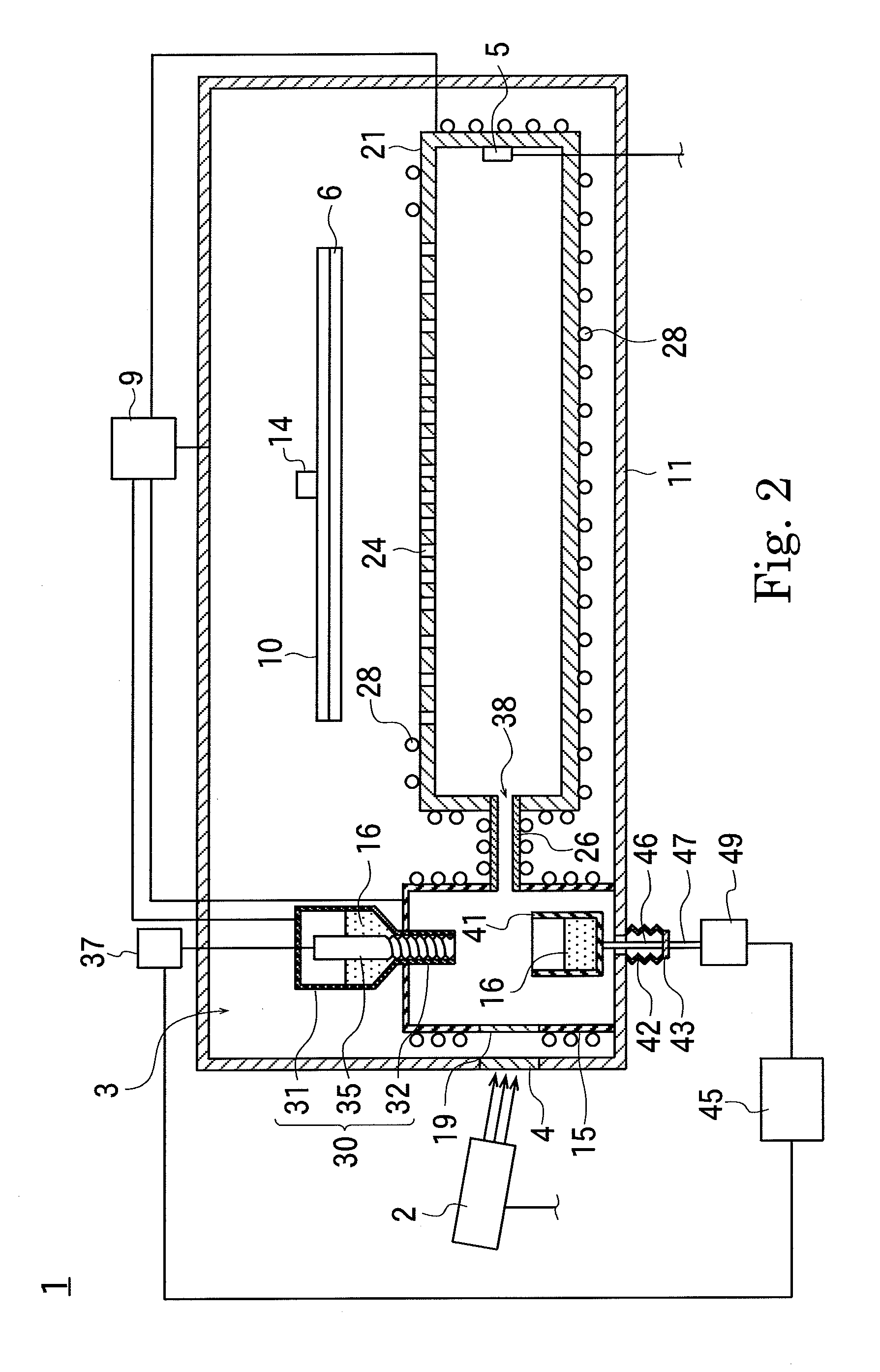

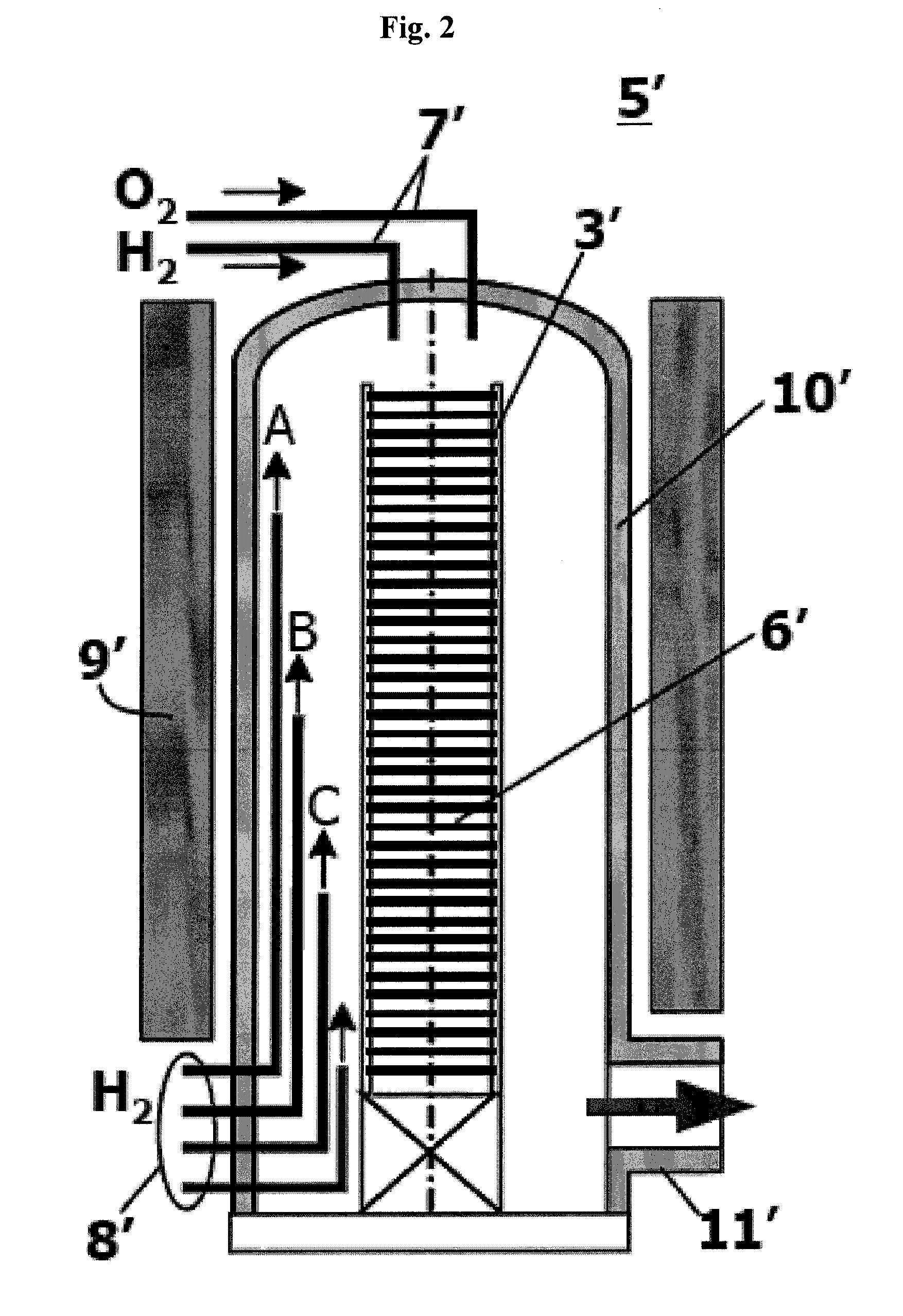

Vapor deposition source, vapor deposition apparatus, and film-forming method

InactiveUS20100015324A1A large amountUniform thickness distributionLiquid surface applicatorsVacuum evaporation coatingEngineeringEvaporation chamber

A vapor deposition apparatus capable of forming an organic thin film having a good film quality is provided. In the vapor deposition apparatus of the present invention, a tray is disposed in an evaporation chamber, and a feed device feeds a vapor deposition material onto the tray. The tray is placed on a mass meter, which measures the mass of the vapor deposition material disposed on the tray, and a controller compares the measured value with a reference value in order to make the feed device feed the vapor deposition material in a necessary amount. Since the vapor deposition material is replenished when needed, the vapor deposition material does not run short during the film formation, or a large amount of the vapor deposition material is not heated for a long time. Thus, the vapor deposition material does not change in quality.

Owner:ULVAC INC

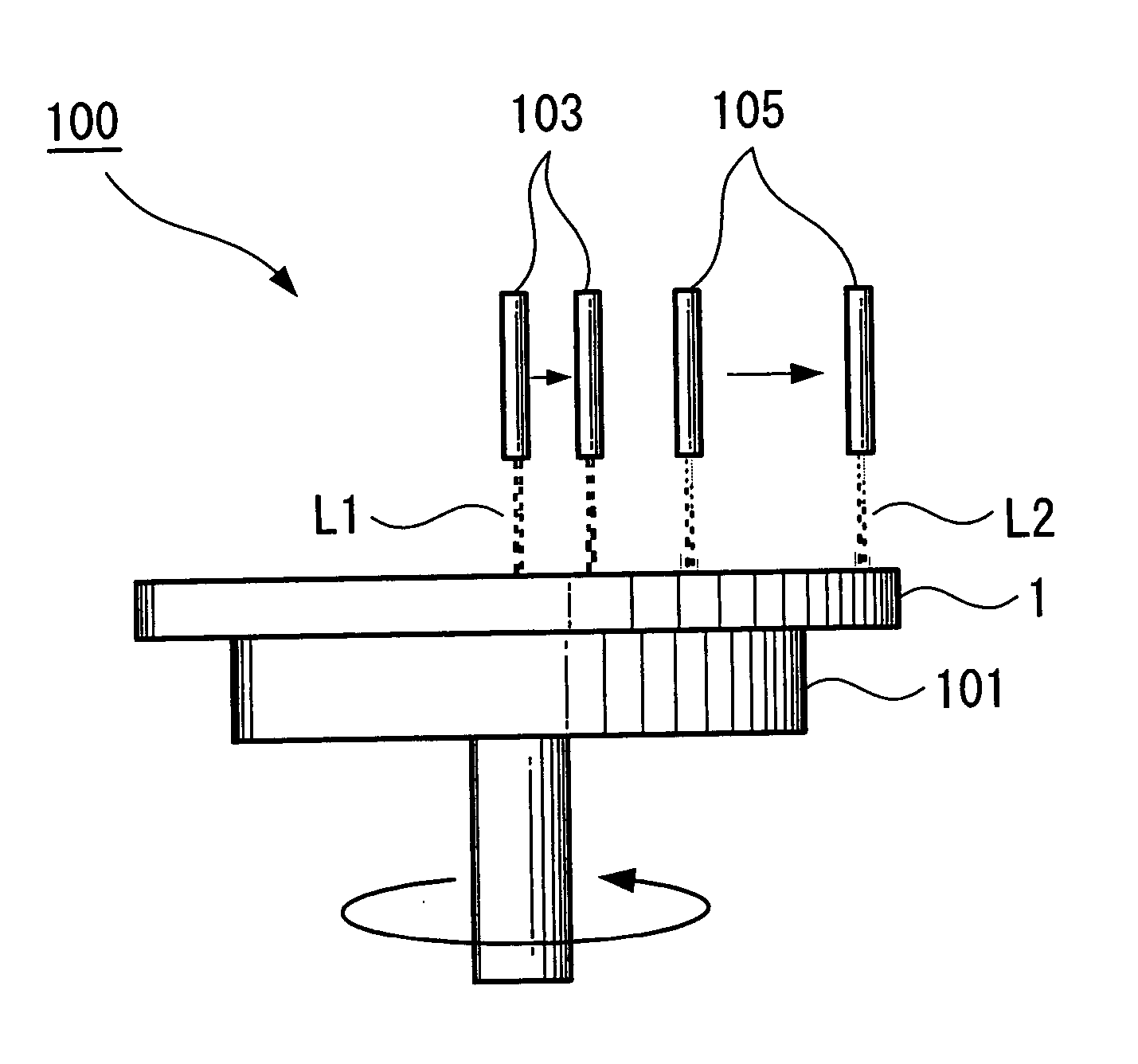

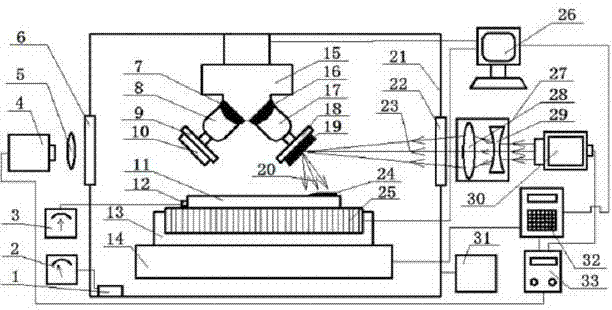

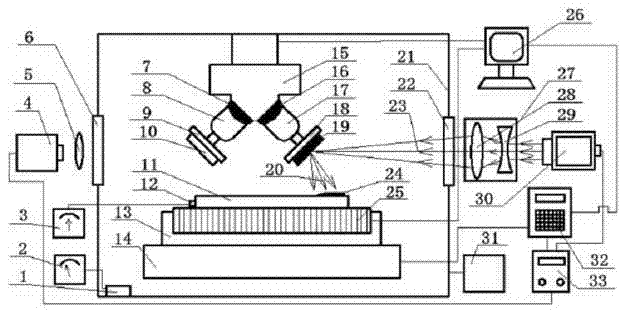

Etching method and etching device

InactiveUS20050000940A1Reduce etch rateReduce probabilityDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingPhysics

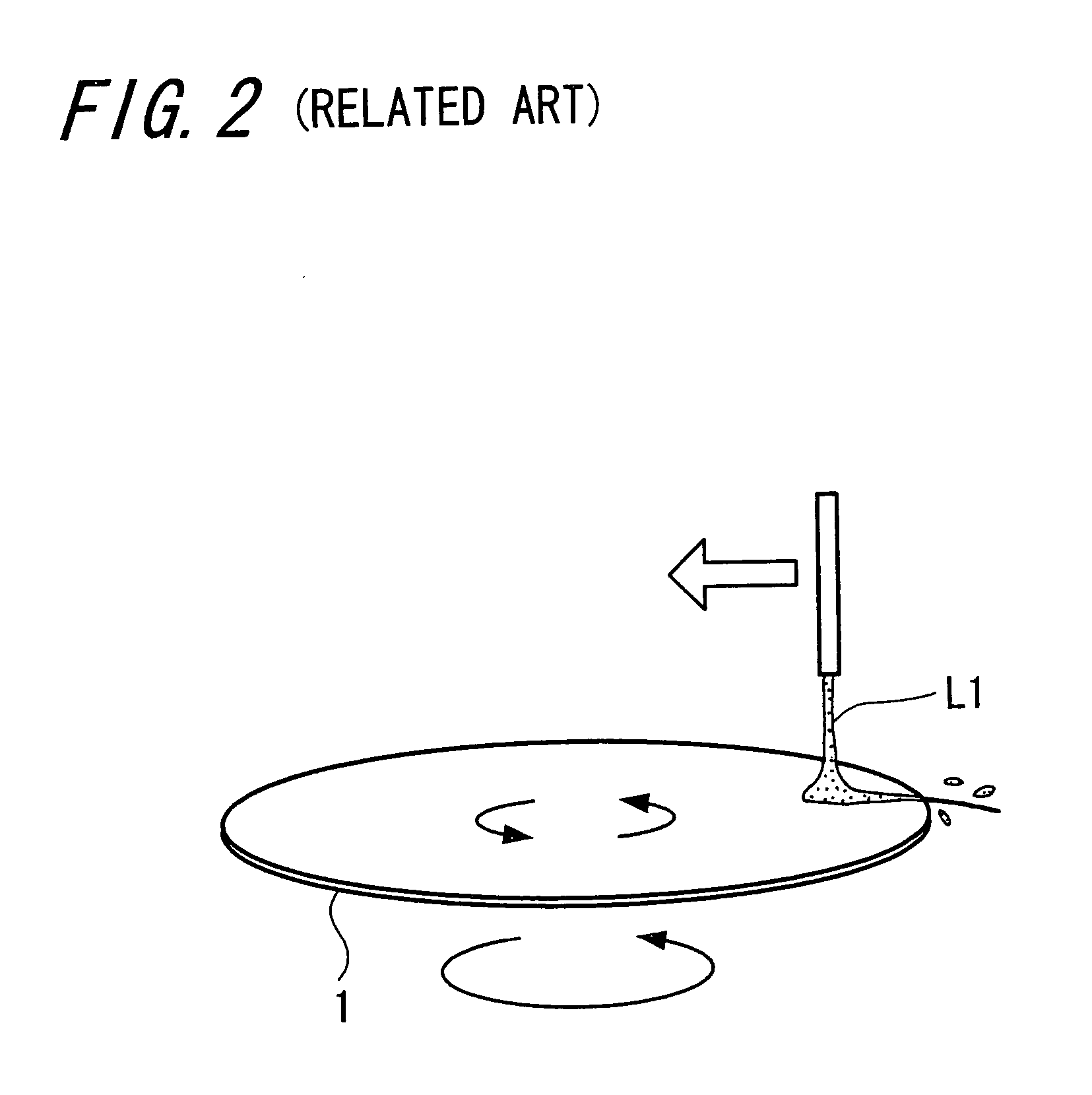

An etching method and etching device are provided, enabling uniform rendering of the thickness of a film for processing on a wafer regardless of the film thickness profile thereof, and thereby enabling global planarizing of the wafer surface. In an etching method, the film thickness profile of the film for processing formed on the wafer is ascertained in advance, and wet etching is performed by discharging an etchant liquid L1 at a thick portion of the film for processing; simultaneously with the discharge of the etchant liquid L1, a diluting liquid L2 for the etchant liquid L1 is discharged at a thin portion of the film for processing.

Owner:SONY CORP +1

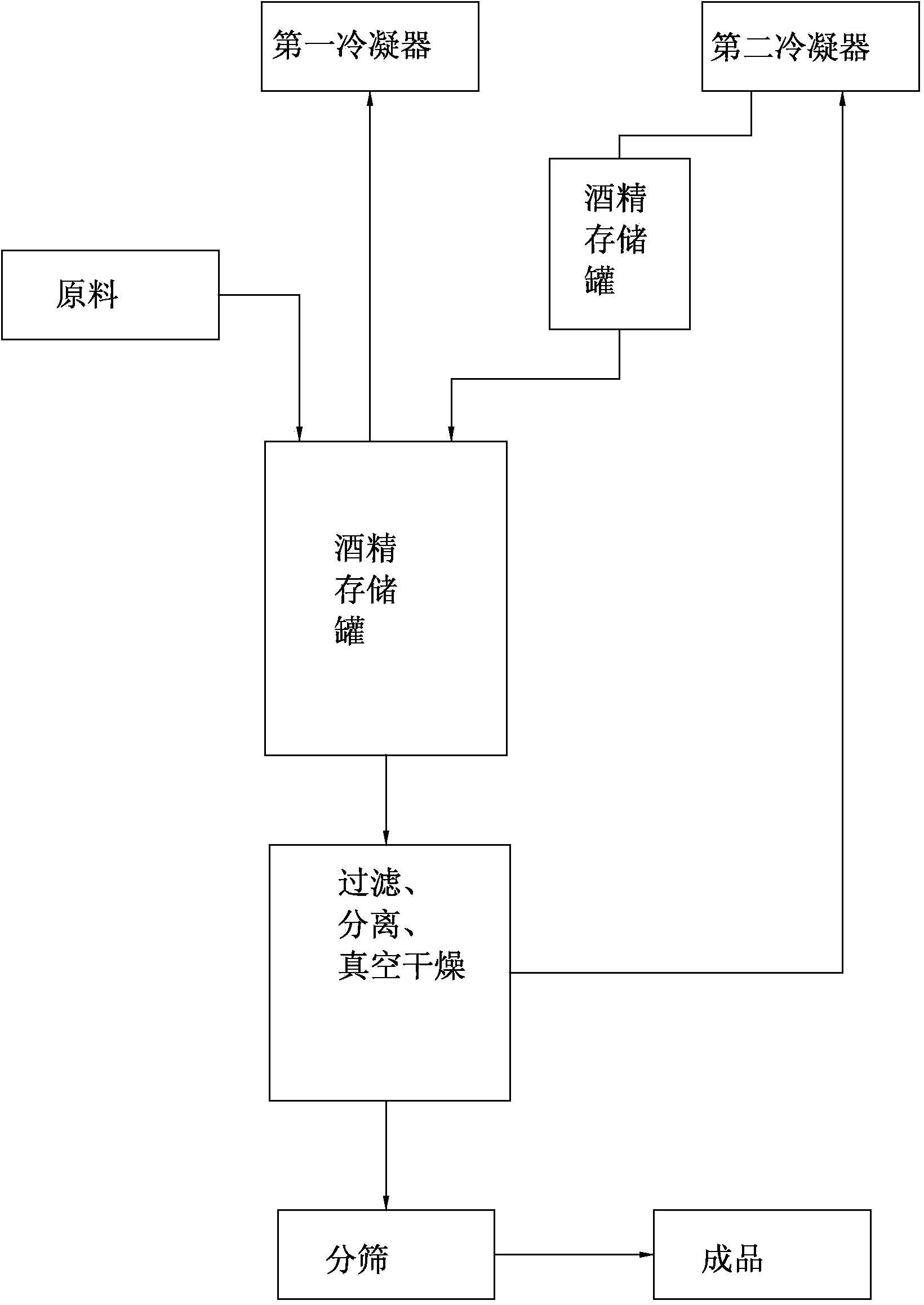

Preparation method of high-molecular nylon powder material used for 3D printing

The invention discloses a preparation method of a high-molecular nylon powder material used for 3D printing. The method comprises the following steps: 1)placing a nylon material, a nucleating agent and alcohol in a high pressure reaction vessel; 2)operating the high pressure reaction vessel for stirring, introducing nitrogen for protection, heating the material in the high pressure reaction vessel to 130-160 DEG C; 3)insulating and dissolving, insulating the reaction vessel for 2-3 hours, fully stirring, dissolving the nylon material; 4)cooling, depositing and precipitating, controlling the stirring speed of the high pressure reaction vessel, slowly cooling, and gradually completing the precipitation and moulding of the nylon powder; 5)filtering, cooling the material in the high pressure reaction vessel to less than 70 DEG C, transferring the mixture to a filter tank, separating the solvent from the solid; 6)centrifuging, transferring the filter residue to a centrifuge for removing the solvent; 7)drying under vacuum; thoroughly removing the solvent in a vacuum drying machine; and 8)sieving the dried nylon powder, and controlling the particle size of nylon powder at 35-50 mum to obtain the required material.

Owner:东莞方易达三维科技有限公司 +1

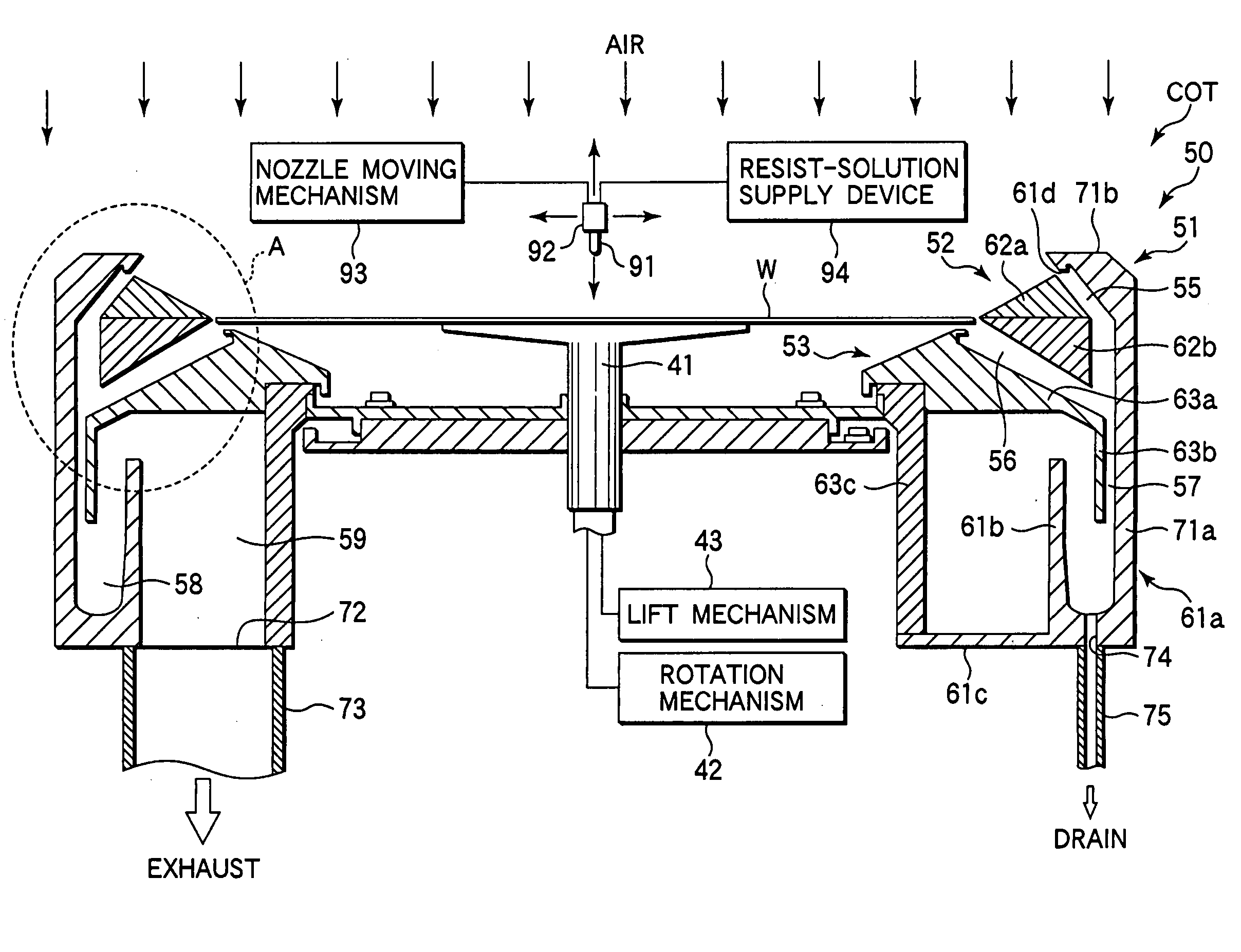

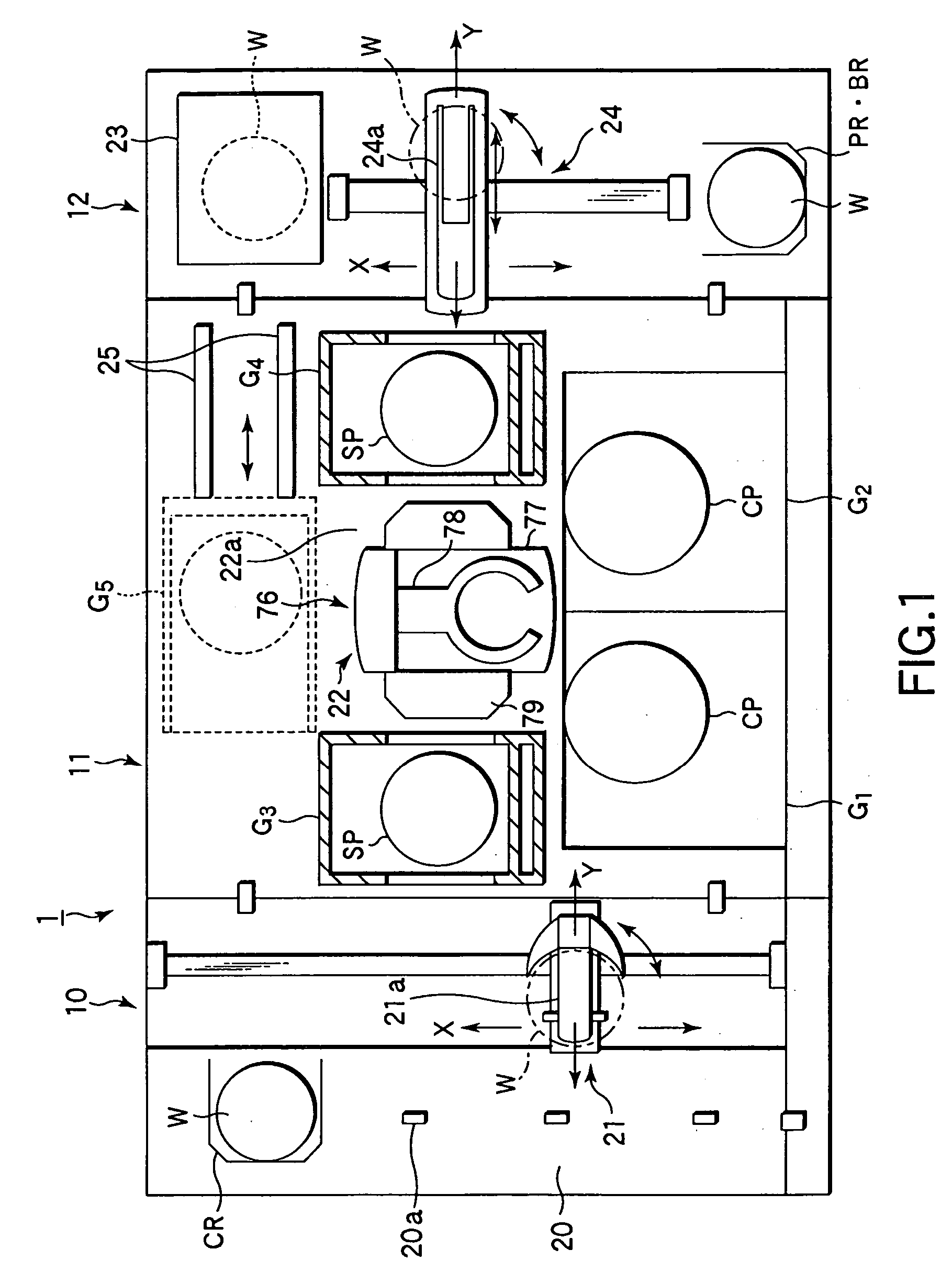

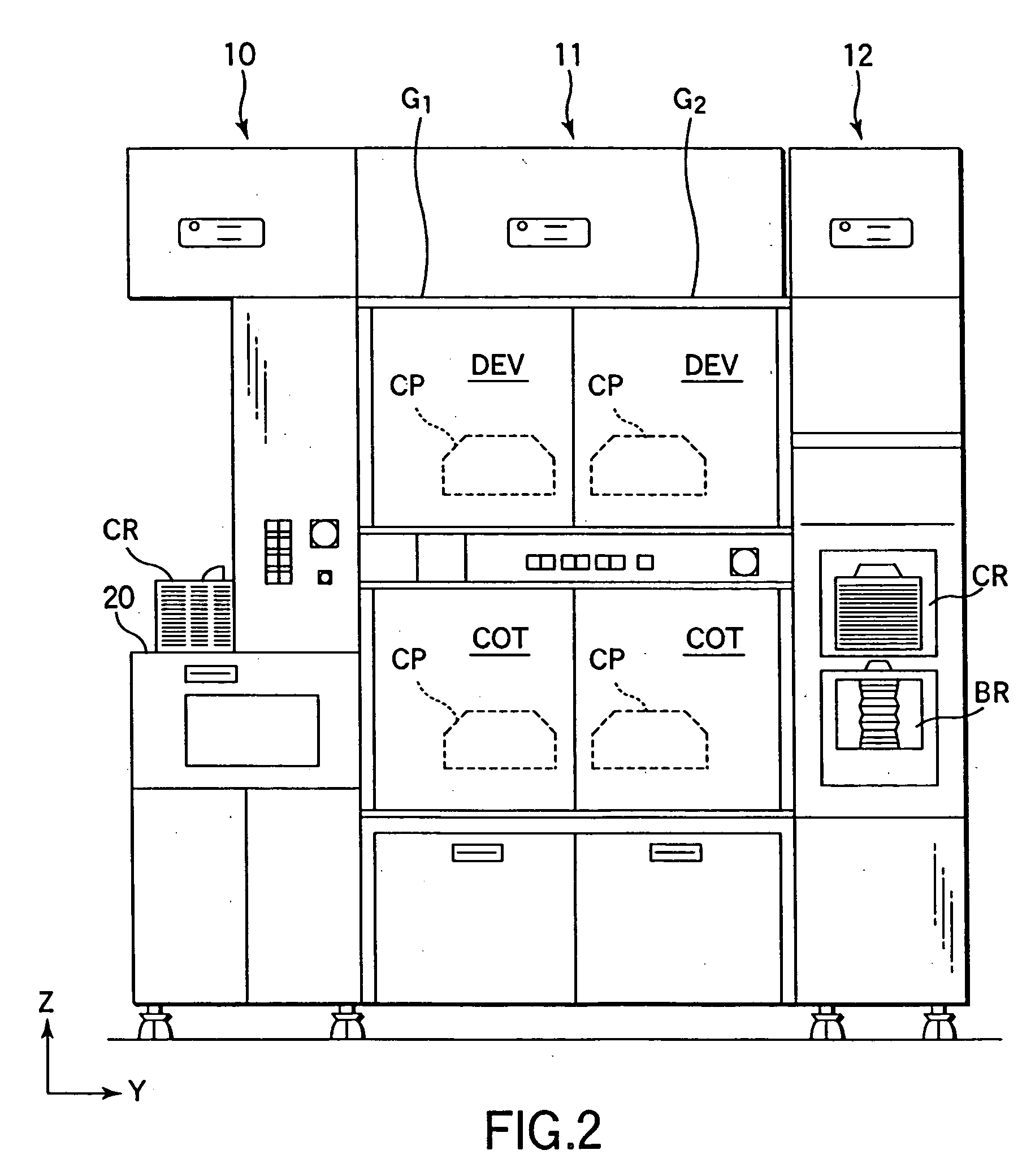

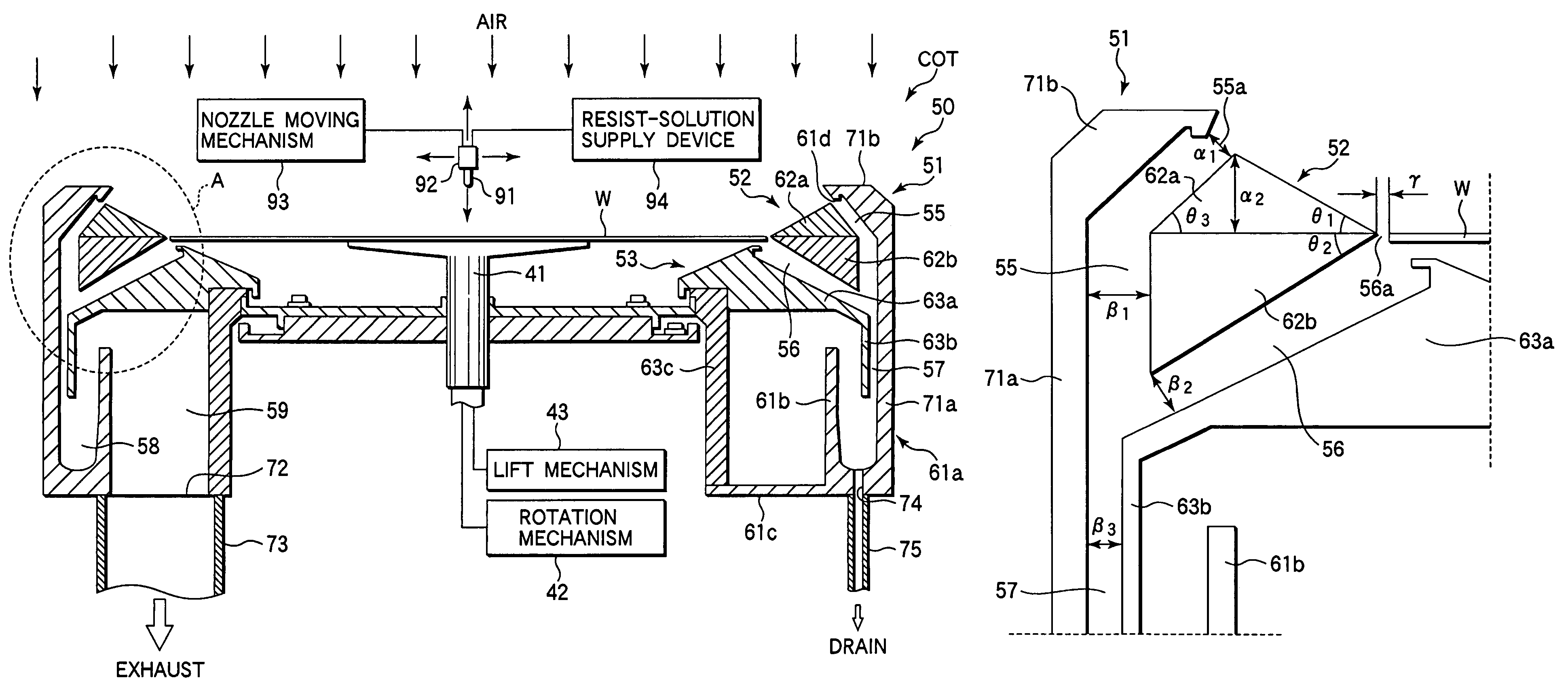

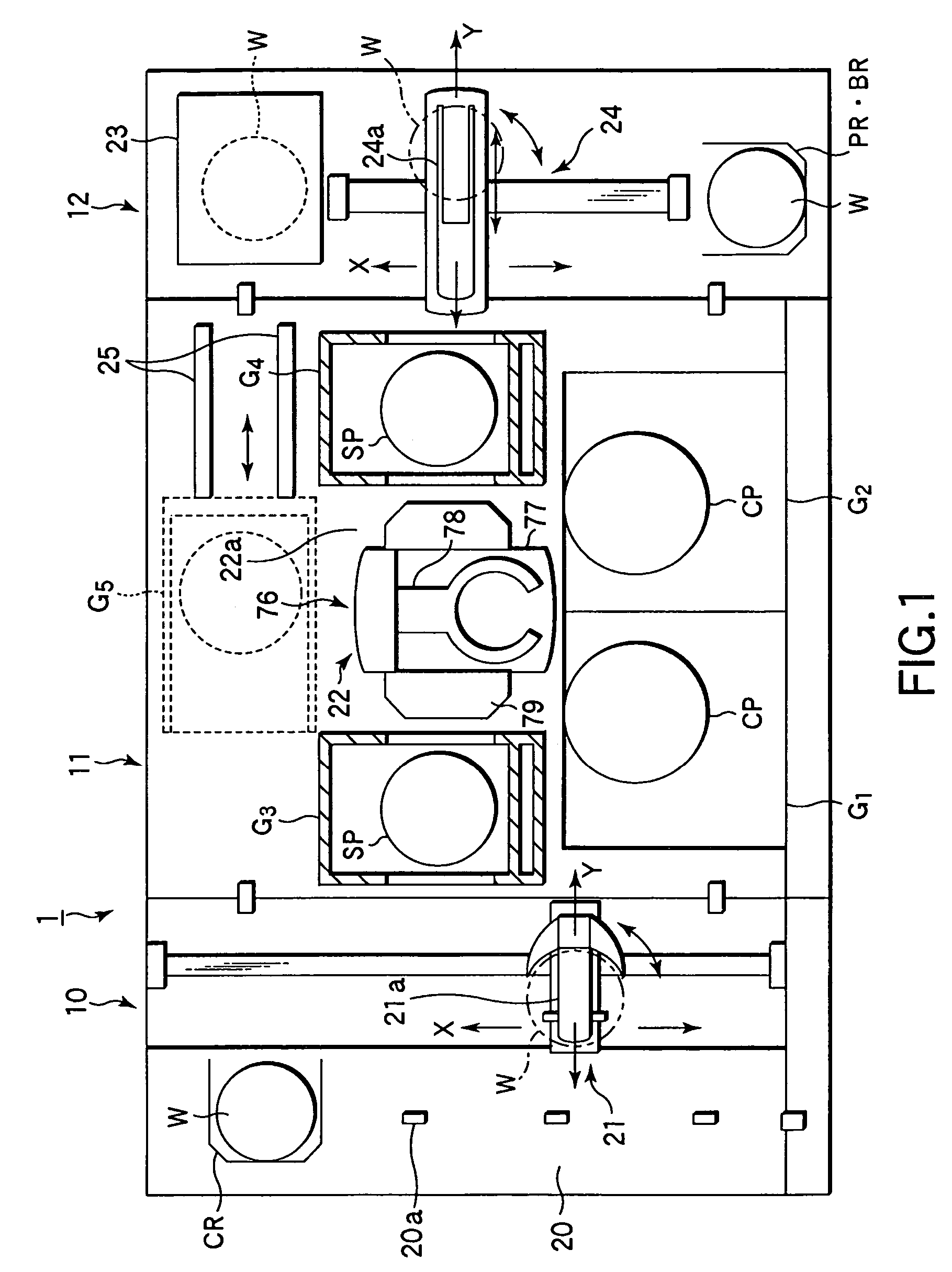

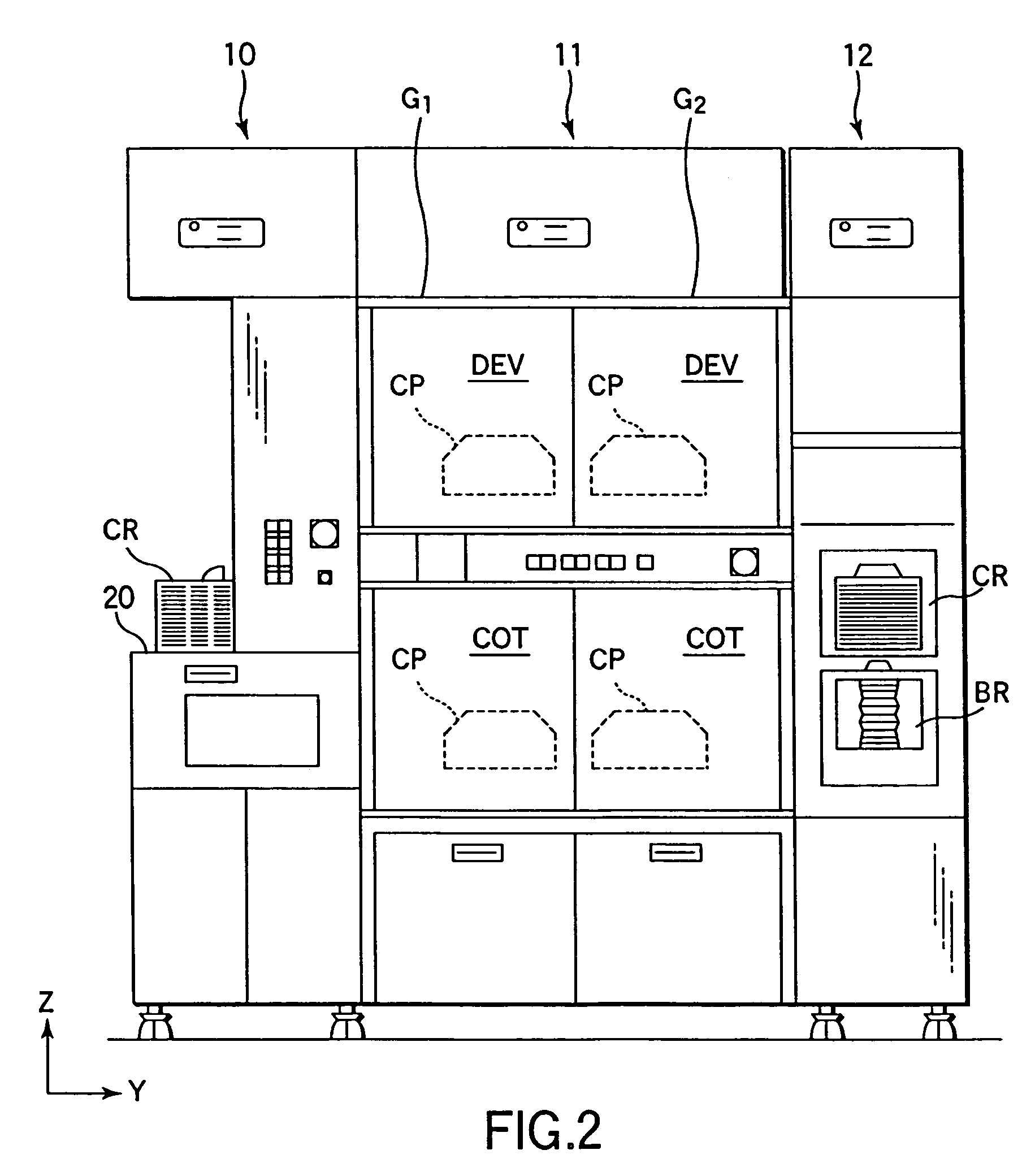

Coating device and coating film forming method

InactiveUS20060068093A1Excellent uniform thicknessUniform thickness distributionSemiconductor/solid-state device manufacturingSpray nozzlesResistEngineering

The resist coating unit (COT) has a spin chuck (41) which holds the wafer to be supplied with a resist liquid, and a process cup (50) which accommodates the spin chuck (41) and exhaustes an atmosphere around the wafer W from a bottom thereof. The process cup (50) comprises a first cup (51) with an outer circumferential wall (61a), and an airflow control member (52) laid out close to the wafer W in the first cup (51) in such a manner as to surround the wafer W. The airflow control member (52) has a vertical cross section of an approximately rectangular shape defined by the upper ring portion (62a) having a cross section of an approximately triangular shape and protruding upward, and a lower ring portion (62b) having a cross section of an approximately triangular shape and protruding downward. An exhaust passage (55) for substantially exhausting the atmosphere around the wafer W is formed between the outer circumferential wall (61a) and the airflow control member (52).

Owner:TOKYO ELECTRON LTD

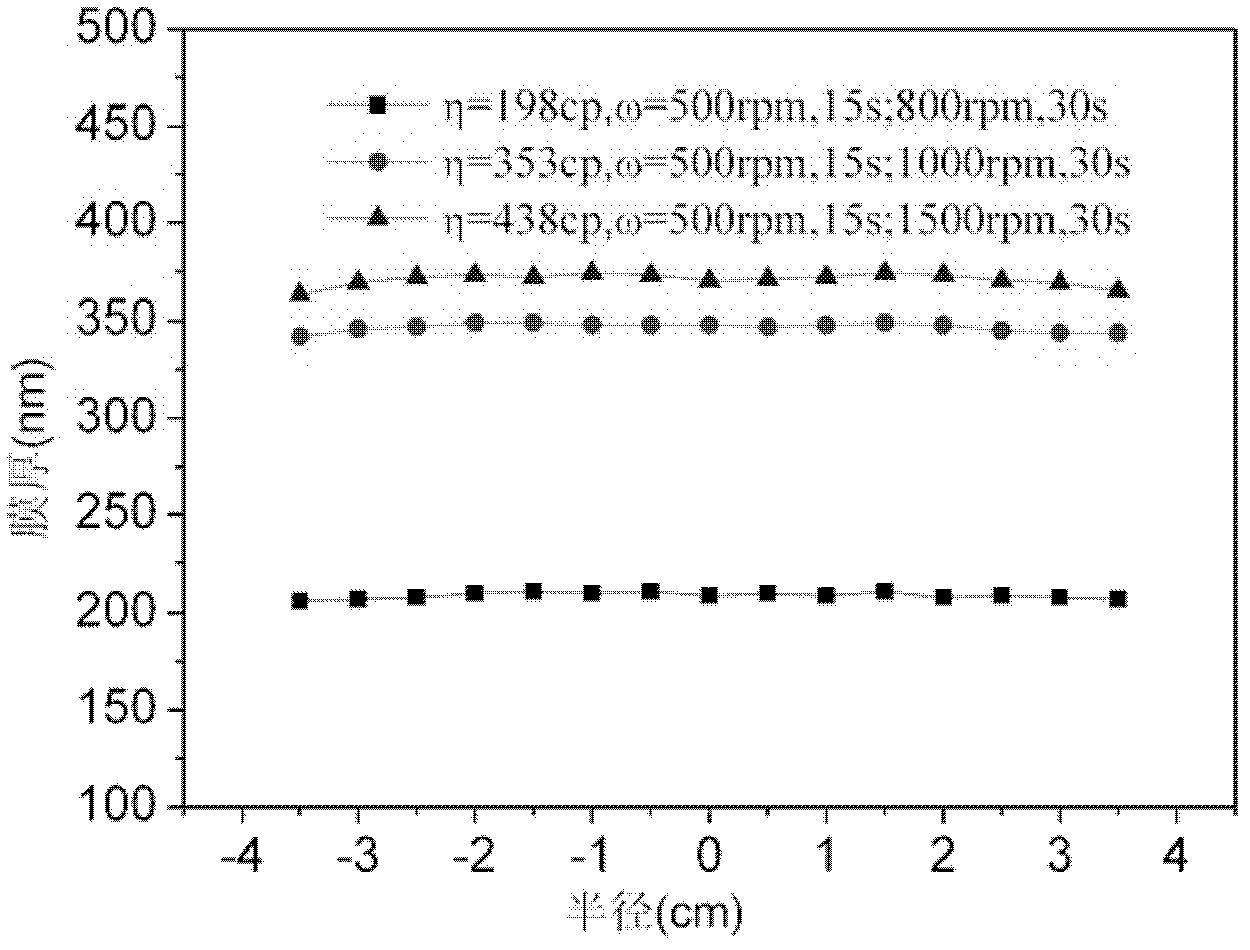

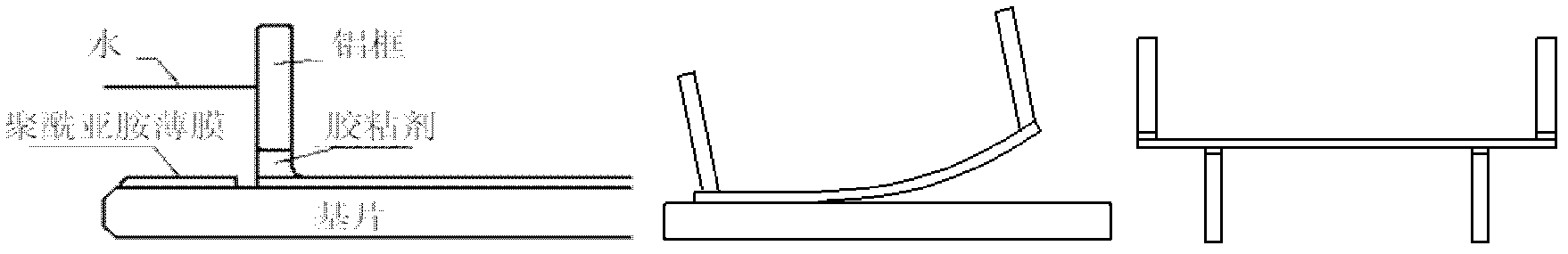

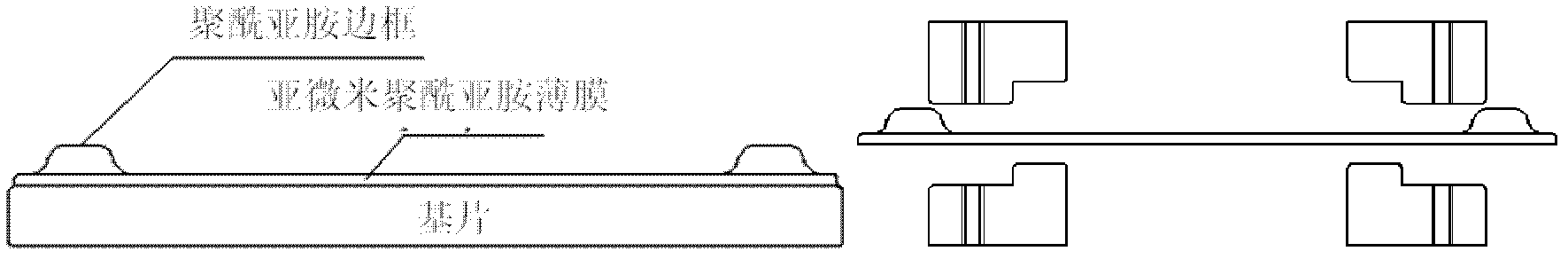

Method for preparing submicron polyimide self-supporting film by adopting spin-coating method

A method for preparing a submicron polyimide self-supporting film by adopting a spin-coating method belongs to the technical field of polyimide self-supporting films. The method comprises the following steps: firstly, preparing a polyamic acid solution, diluting and filtering; preparing a submicron polyamide acid film by adopting the spin-coating method and preliminary drying; secondly, coating the polyamic acid solution with the high solid content on the edge of the submicron polyamide acid film and homogenizing; carrying out thermal treatment and finishing an imidization process; placing a polyimide film with a substrate in a hot mixed solution of deionized water and alcohol; after a period of time, slightly tilting an edge thick film area by using a surgical knife along the edge of the substrate; clamping the thick film area by using tweezers and gradually removing the film from the substrate from the outside to the inside; and drying in air to obtain the polyimide self-supporting film. The film prepared by the method disclosed by the invention has the characteristics of uniformity in thickness distribution, large area, low surface roughness and the like. The method is simple in preparation process and is high in finished product rate.

Owner:BEIJING UNIV OF CHEM TECH +1

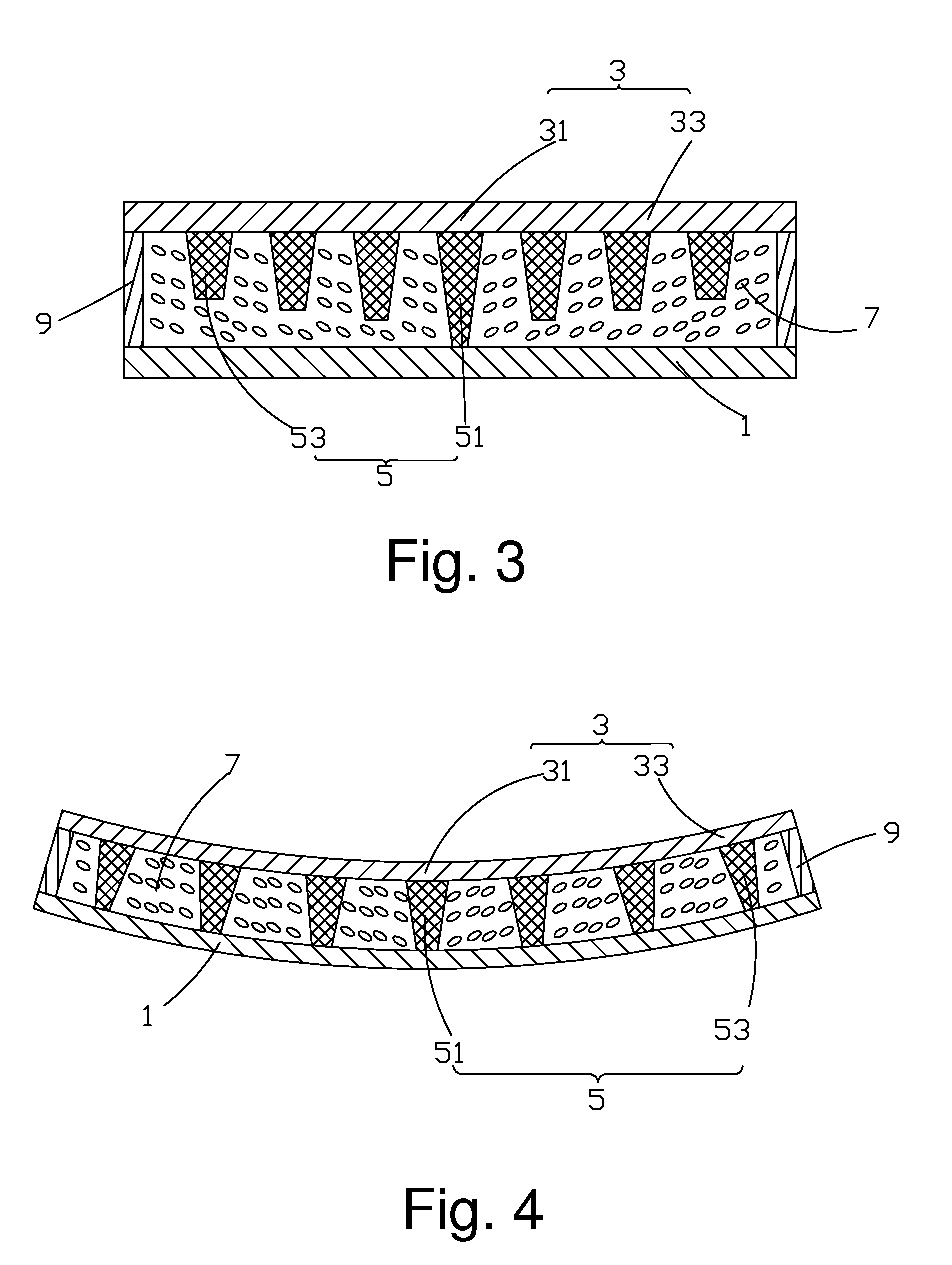

Structure of curved liquid crystal panel

The present invention provides a structure of a liquid crystal panel, which includes a TFT substrate (1), a CF substrate (3) opposite to the TFT substrate (1), spacers (5) arranged between the TFT substrate (1) and the CF substrate (3), a liquid crystal layer (7) disposed between the TFT substrate (1) and the CF substrate (3), and an enclosing sealant layer (9) arranged between and located along a periphery of the TFT substrate (1) and the CF substrate (3). In a curving direction of the curved liquid crystal panel, the CF substrate (3) includes middle zone (31) and two side edge zones (33) at two opposite sides of the middle zone. The middle zone (31) bears a stress greater than stresses born by the two side edge zones (33). The spacers (51) that are located in the middle zone (31) are arranged to bear a stress that is greater than stresses born by the spacers (53) that are located in the two side edge zones (33) so as to maintain a constant distance between the CF substrate (3) and the TFT substrate (1) and achieve the consistency of cell thickness in the entirety of the curved liquid crystal panel.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

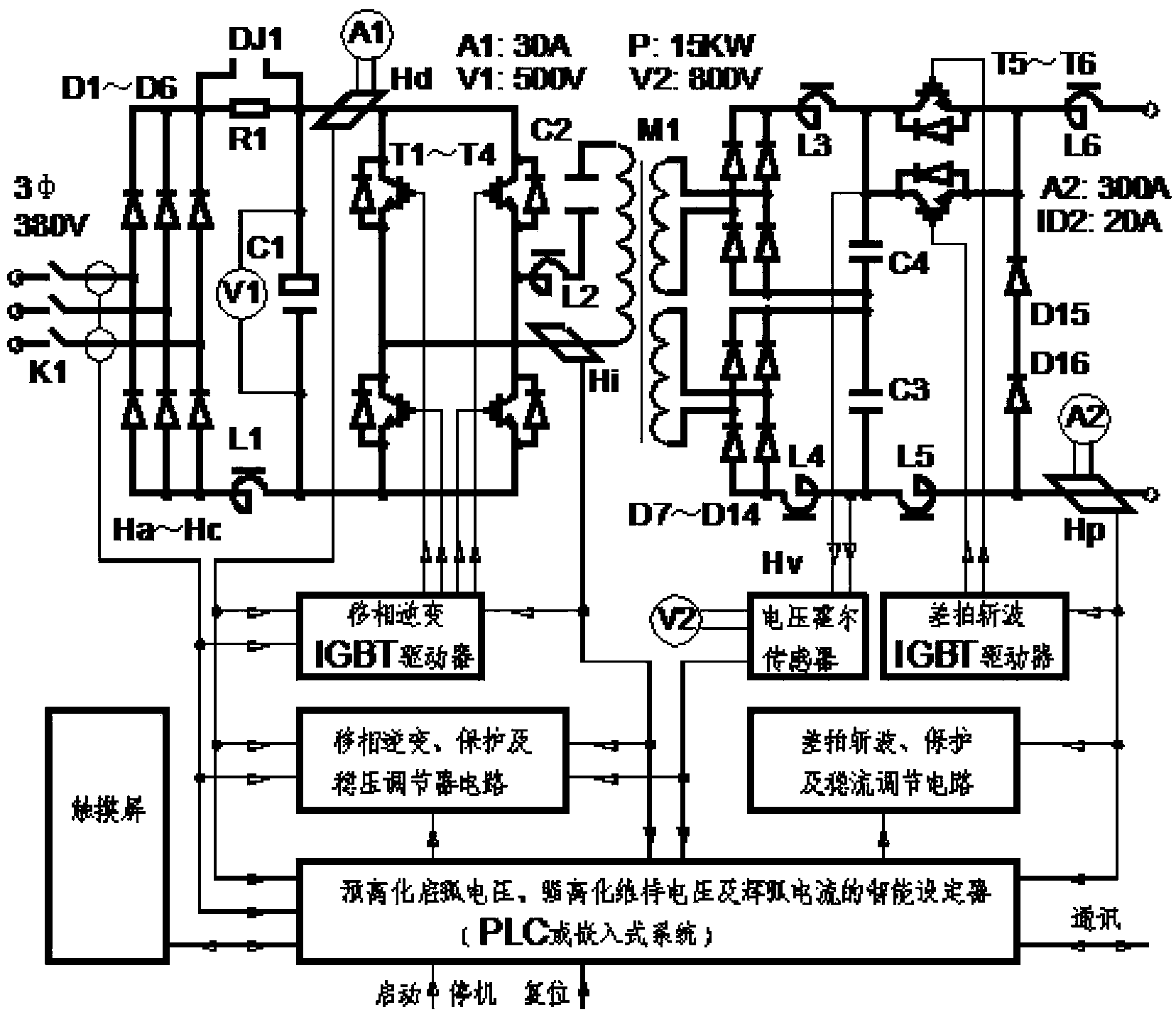

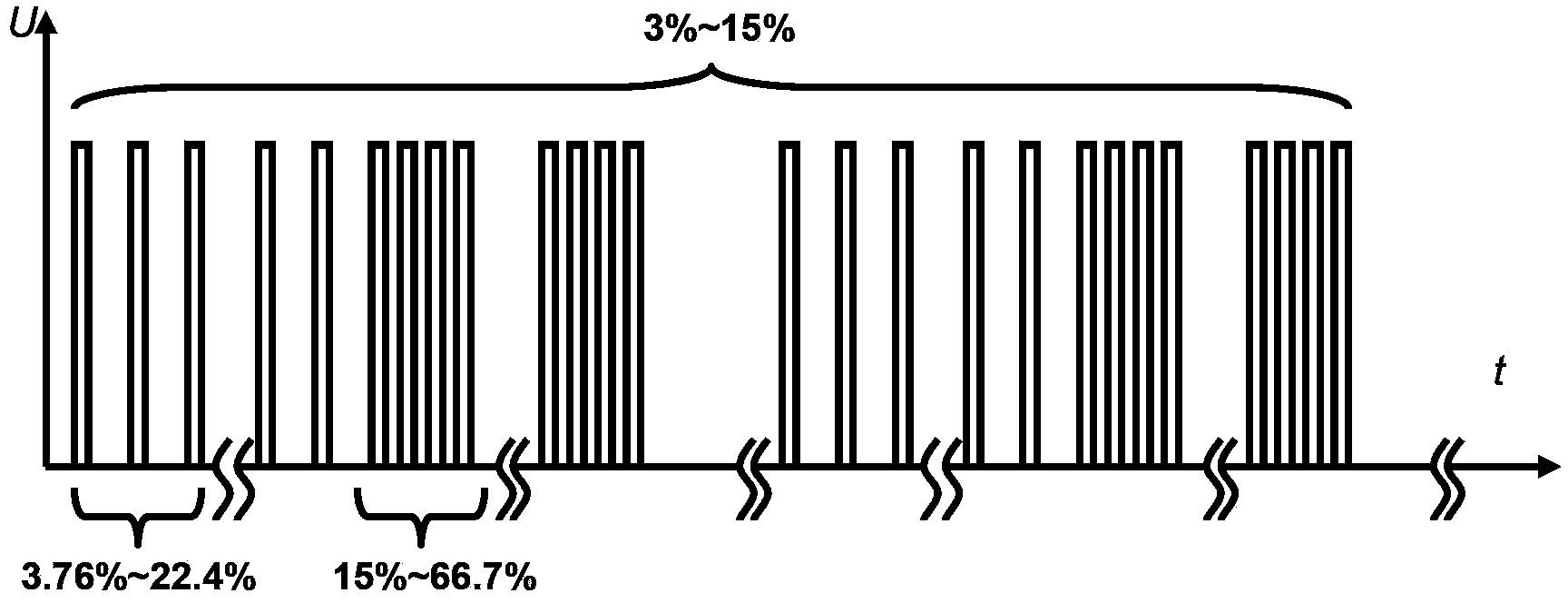

Micro-arc ion plating method

InactiveCN103397304AImprove compactnessGood plating performanceVacuum evaporation coatingSputtering coatingVacuum chamberElectric field

The invention discloses a vacuum plating method integrating advantages of magnetron sputtering and multiple-arc ion plating, in particular to a micro-arc ion plating method. The method comprises the steps as follows: a high-frequency impulse electric field with negative 1,200 V to negative 900 V output voltage, 0.5 KHz-60 KHz frequency and 0.5 mu s-30 mu s pulse width is firstly established, a high-frequency impulse signal output from the high-frequency impulse electric field is modulated by an adjustable inductance attenuation and a digital logic circuit and loaded to a rectangular cathode target with an area of 300 mm*100 mm and two ends of an anode vacuum chamber casing with a volume of Phi 450 mm *H 400 mm, and argon (Ar) gas charged into a vacuum chamber is subjected to an ion plating process when volt-ampere characteristics of negative 900 V to negative 600 V voltage, 100 A-300 A current, 1 ms-5 ms pulse width and 3%-15% duty ratio are generated during discharge. The method is simple and stable; and by means of the method, the yield is high, and industrial production can be realized.

Owner:NANJING HAORANG ENVIRONMENT SCI & TECH

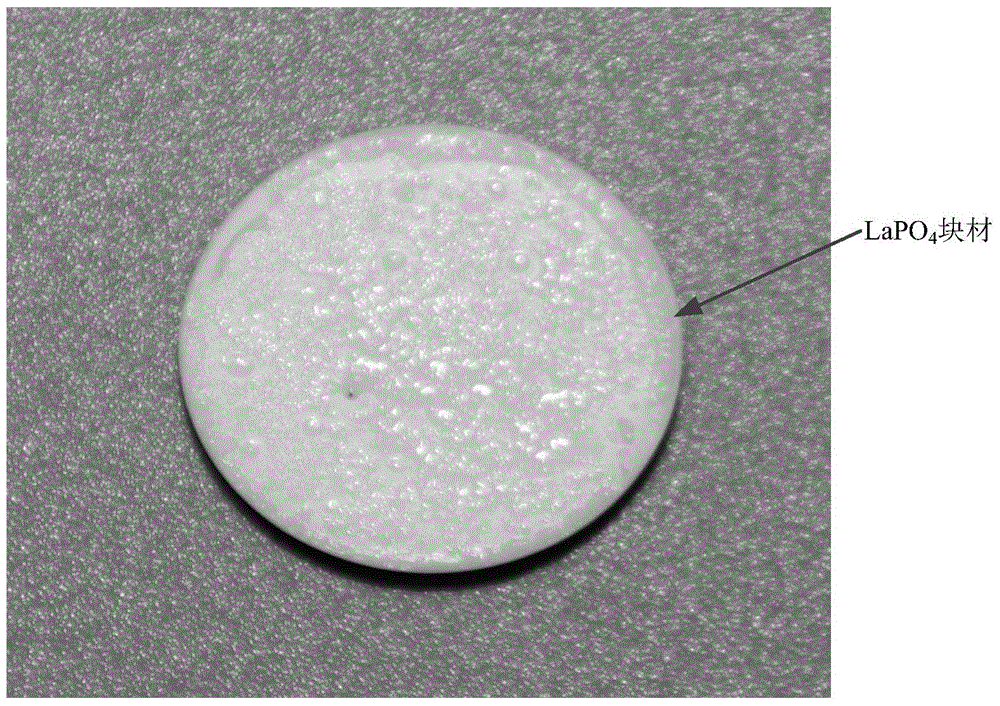

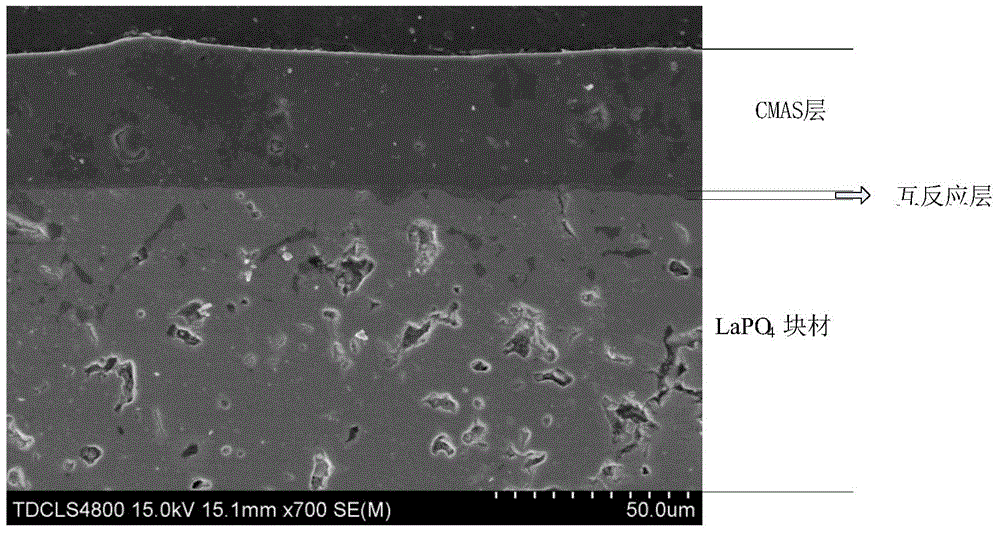

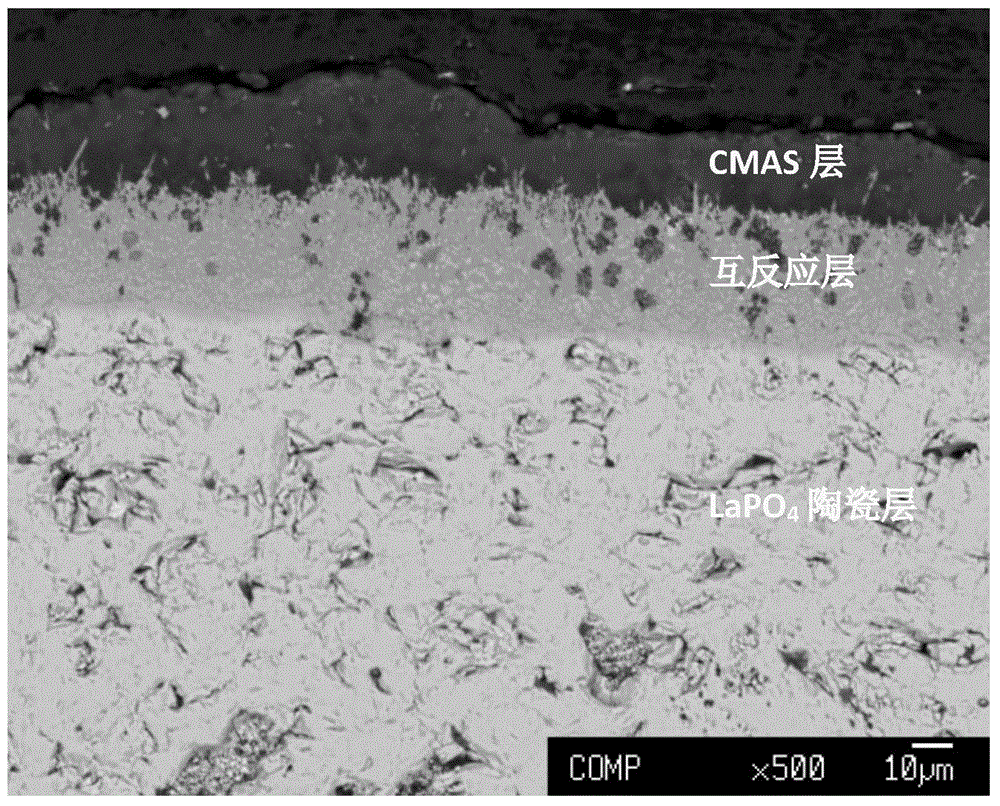

CMAS-resisting ceramic layer and slurry method for preparing CMAS-resisting ceramic layer

ActiveCN105039894APrevent infiltrationMaintain phase stabilityMolten spray coatingReaction layerSlurry

The invention discloses a CMAS-resisting ceramic layer and a slurry method for preparing the CMAS-resisting ceramic layer, and belongs to the field of thermal barrier coating materials and preparation for the same. The CMAS-resisting ceramic layer is a LaPO4 ceramic layer. The slurry method is used for preparing the LaPO4 ceramic layer on a YSZ ceramic layer, and the wettability of the LaPO4 ceramic layer to molten CMAS is poor; after thermal treatment of 1250 DEG C is carried out, a mutual reaction layer is formed on the interface between the LaPO4 ceramic layer and the CMAS, so that further permeation of the molten CMAS is effectively prevented, and the original phase stability of the YSZ ceramic layer is maintained. Accordingly, the prepared LaPO4 ceramic layer can prevent permeation of the molten CMAS, has superior CMAS corrosion resistance and obviously prolongs the service life of a thermal barrier coating under the CMAS coupling effect.

Owner:BEIHANG UNIV

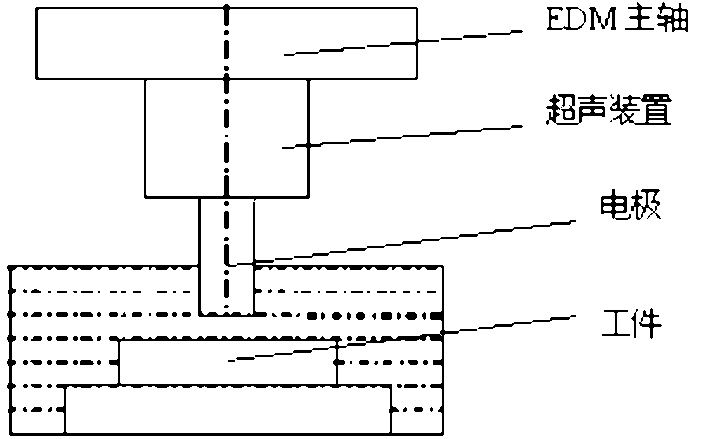

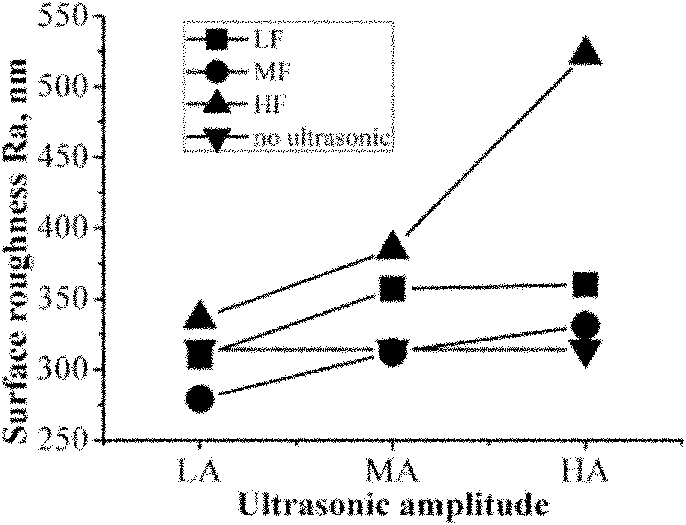

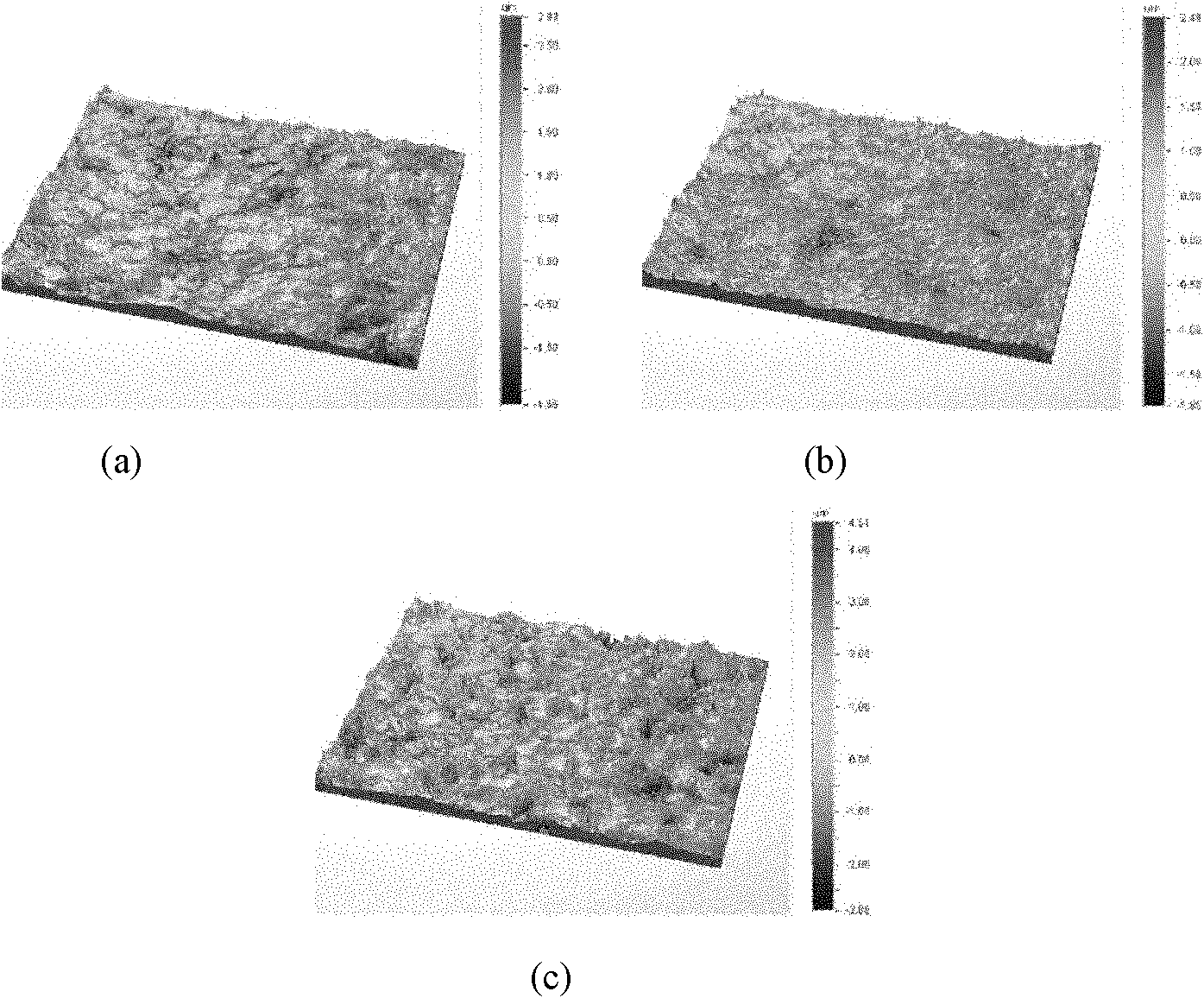

Process for intensifying ultrasonic vibration assisted electric spark pulse discharging surface

The invention discloses a process for intensifying an ultrasonic vibration assisted electric spark pulse discharging surface, comprising the following steps of: selecting 65Mn steel subjected to medium temperature tempering treatment after quenching, as a workpiece electrode and a monocrystal Si as a tool electrode; additionally arranging an ultrasonic vibration device on the tool electrode to assist the electric spark surface intensification; and with coal oil as a working solution, carrying out positive electrode electric spark surface intensification on the 65Mn steel by utilizing an electric spark processing machine tool, wherein the intensifying electricity parameters are that the pulse width is more than or equal to 4.2 mu s and less than 7.5mu s, the pulse width intrapulse ratio is between 0.21 and 0.56, a peak value current is more than or equal to 3.2A and less than 14.2A, the intensifying time is between 15min and 25min, the tool electrode-assisted ultrasonic vibration amplitude range is between 1mu m and 2mu m, and the frequency range is between 15 kHz and 60kHz. The invention improves the surface topography of an intensified layer so that the thickness distribution of the intensified layer is more uniform and more compact, increases the quantity of an intensifying phase and improves microhardness, abrasive resistance and surface Si content of the intensified layer.

Owner:SHANDONG UNIV

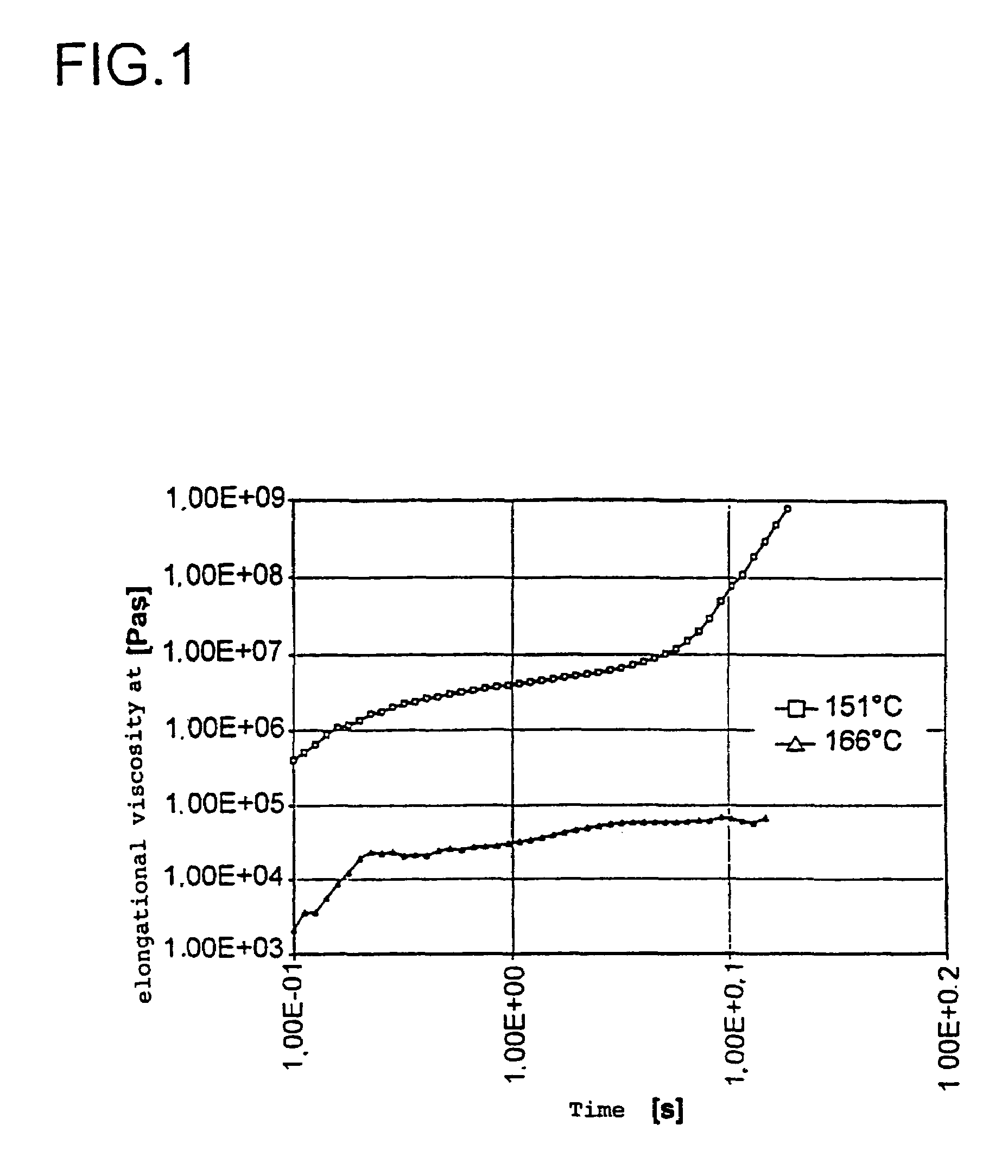

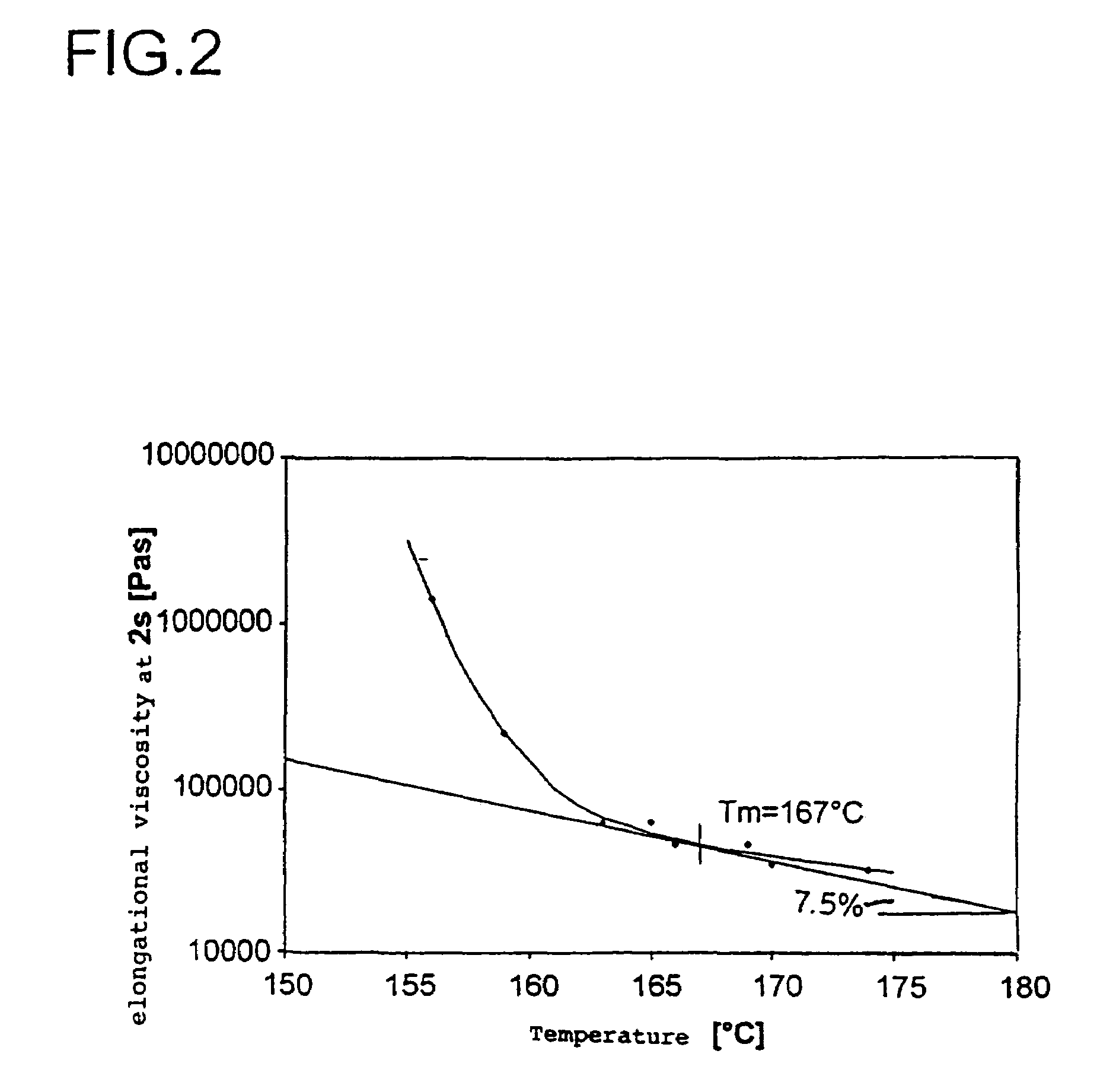

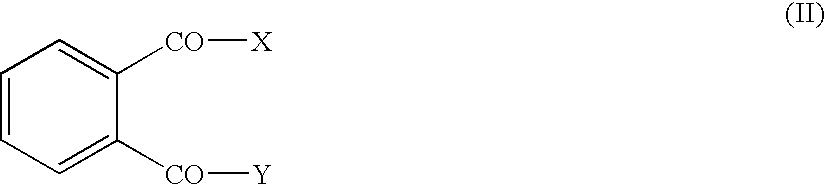

Random propylene copolymers

InactiveUS7001965B2Maintain good propertiesEasy to processSynthetic resin layered productsMonocomponent synthetic polymer artificial filamentFiberAlkene

Random copolymers of propylene with other 1-alkenes having up to carbon atoms,whose content of comonomers is in the range from 0.7 to 1.4% by weight if the only comonomer present in the propylene copolymers is ethylene, orwhose content of comonomers is in the range from 0.7 to 3.0% by weight if at least one C4–C10-1-alkene is present as comonomer, andwhose cold-xylene-soluble fraction is from 1.0 to 2.5% by weight if ethylene is present as a comonomer in the propylene copolymers, orwhose cold-xylene-soluble fraction is from 0.75 to 2.0% by weight if the only comonomers present are C4–C10-1-alkenes,and a process for preparing the random copolymers of propylene is described, as is their use for producing films, fibers or moldings, and also the films, fibers and moldings themselves and biaxially stretched films made from random propylene copolymers of this type and processes for their production.

Owner:LUMMUS NOVOLEN TECH

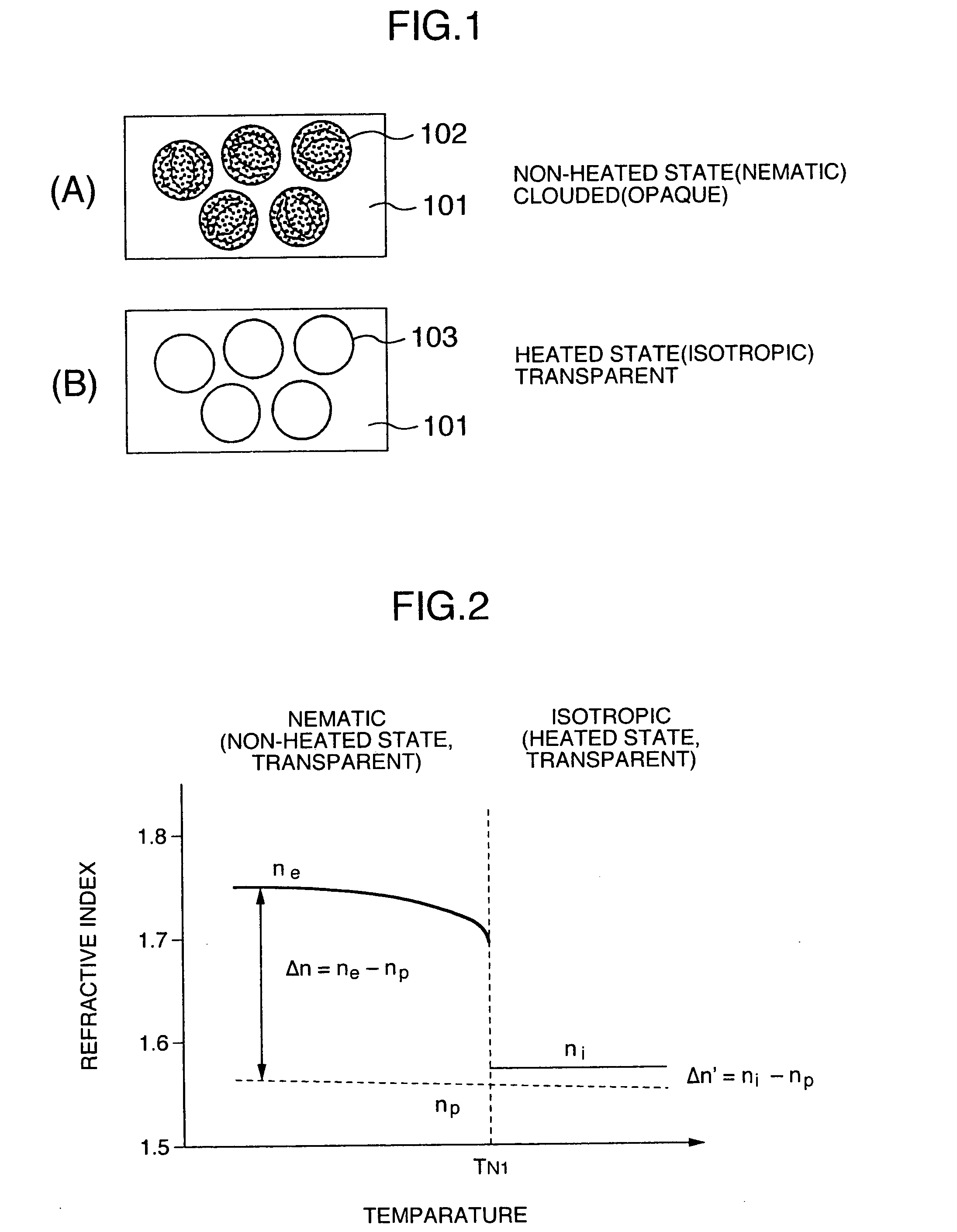

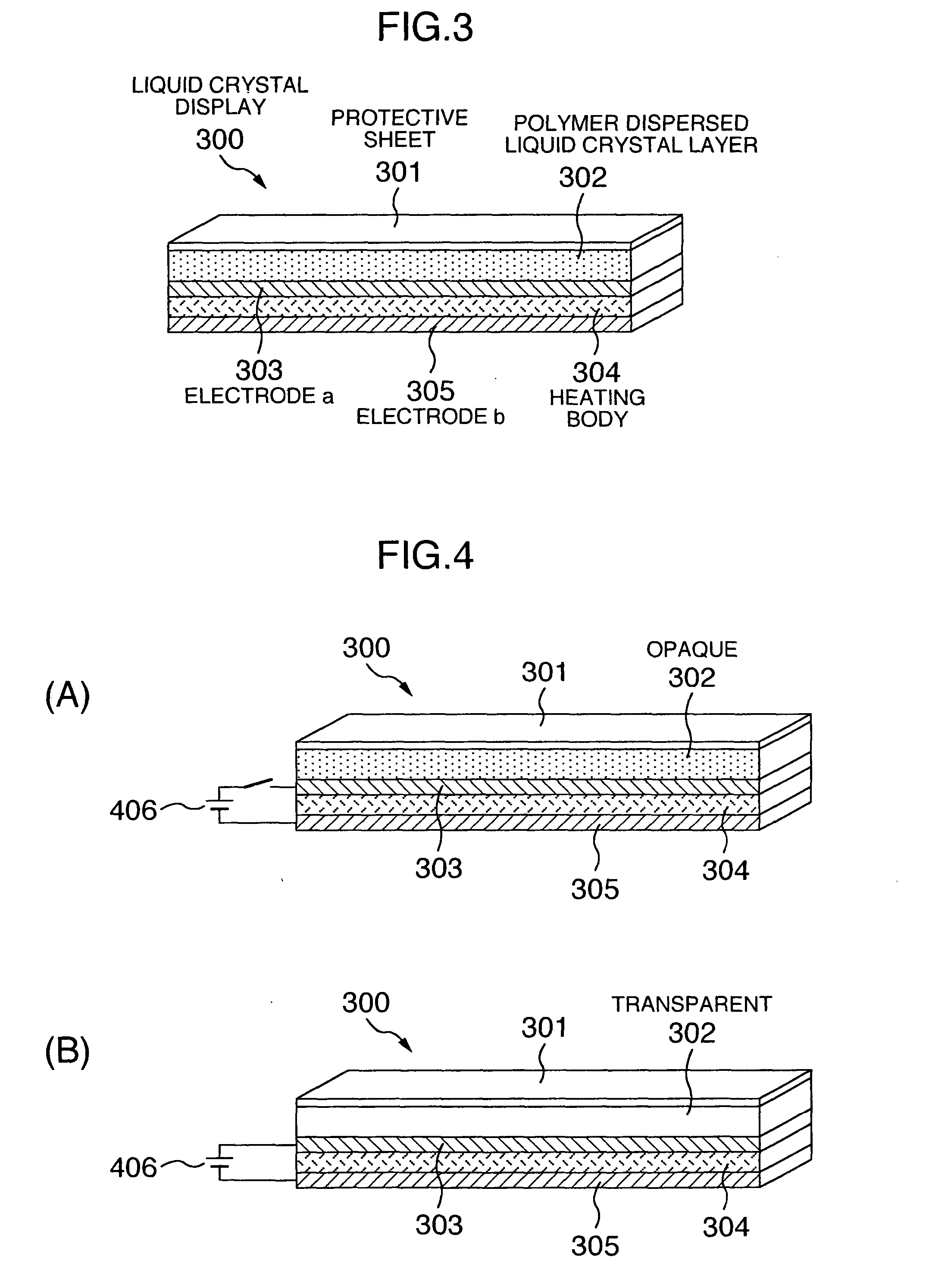

Liquid crystal display device and liquid crystal production method

InactiveUS20040119911A1Improve resistanceHigh mechanical strengthStatic indicating devicesNon-linear opticsHigh contrastLiquid-crystal display

A thermal-responsive liquid crystal display having a polymer dispersed liquid crystal layer formed to have excellent response speed, good display characteristics, uniform thickness distribution, high thickness, high contrast and excellent resistance to thermal cycle. A polymer dispersed liquid crystal layer formed of a composition of a polymer and a liquid crystal is provided on a heating unit. The polymer is a thermoplastic resin, and the glass transition temperature (Tg) of the resin and the phase transition temperature (TNI) of the liquid crystal satisfy the condition of -20<=(Tg-TNI)<=20 (° C.). The polymer dispersed liquid crystal layer is formed by laminating a plurality of polymer dispersed liquid crystal films.

Owner:HITACHT MAXELL LTD

Potassium chloride-type galvanizing plating solution and its preparation method

Belonging to the field of plating solutions, the invention relates to a potassium chloride-type galvanizing plating solution and its preparation method. With water as the solvent, the plating solution of the invention is composed of the following components: zinc chloride at a concentration of 50-80g / L, potassium chloride at a concentration of 180-280g / L, boric acid at a concentration of 30-40g / L, a softening agent at a concentration of 6-10mL / L, a brightener at a concentration of 0.1-0.4mL / L, and a proper amount of a conditioning agent. The plating solution prepared by the method of the invention is characterized by fast lightening speed, good leveling, high temperature resistance, and fewer decomposition products.

Owner:TIANJIN JUXING ELECTROPLATING

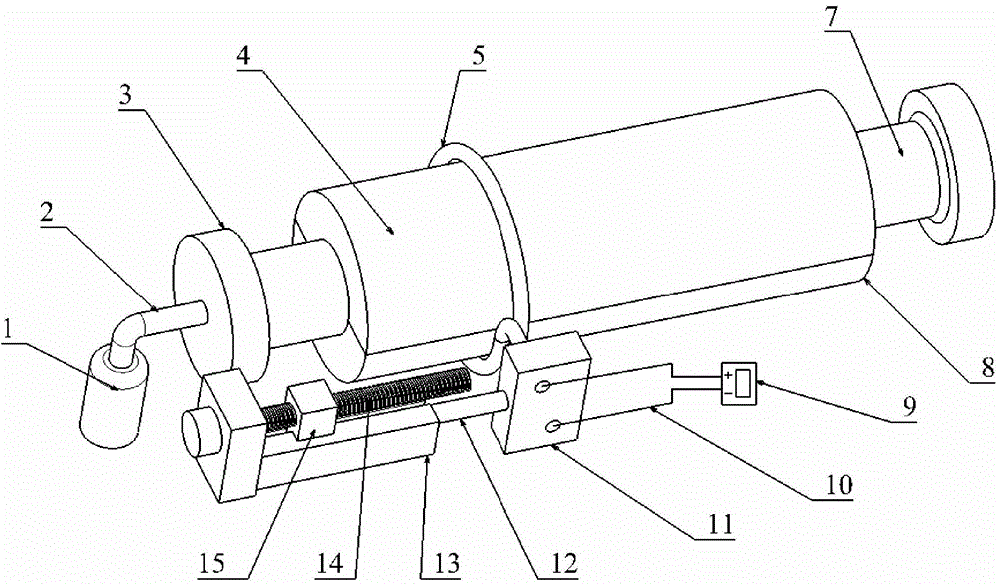

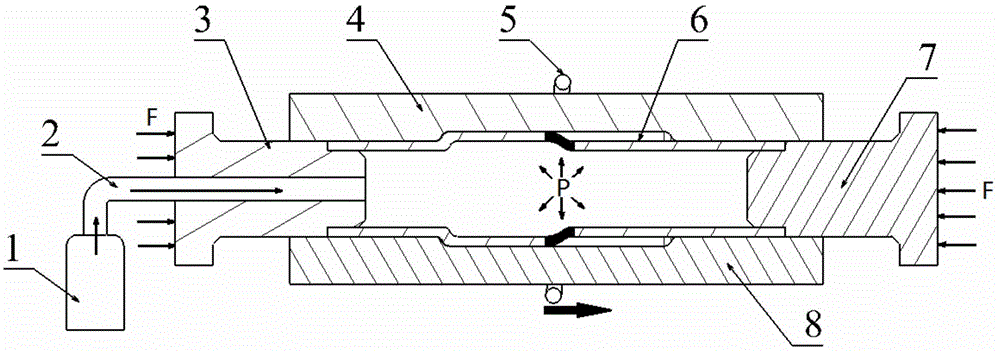

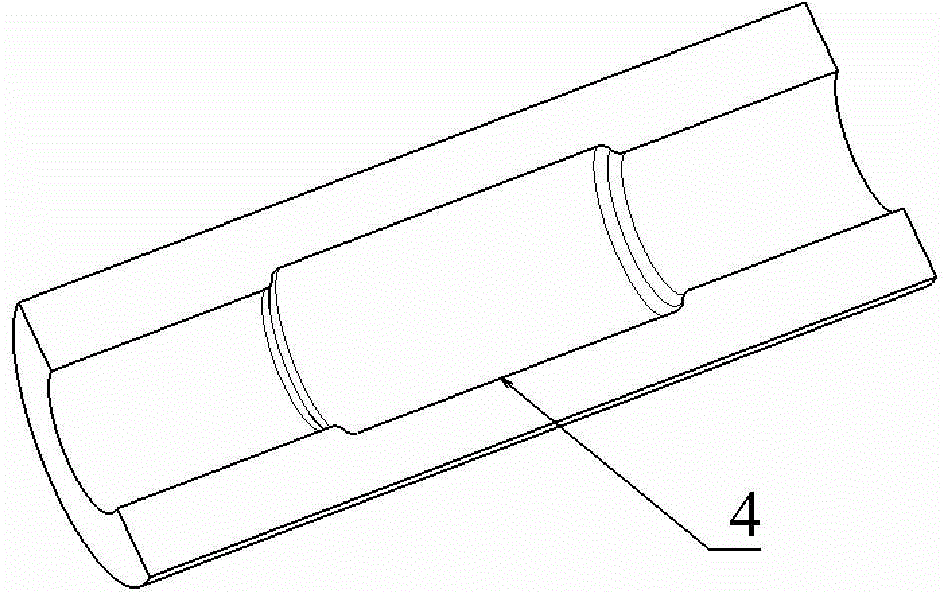

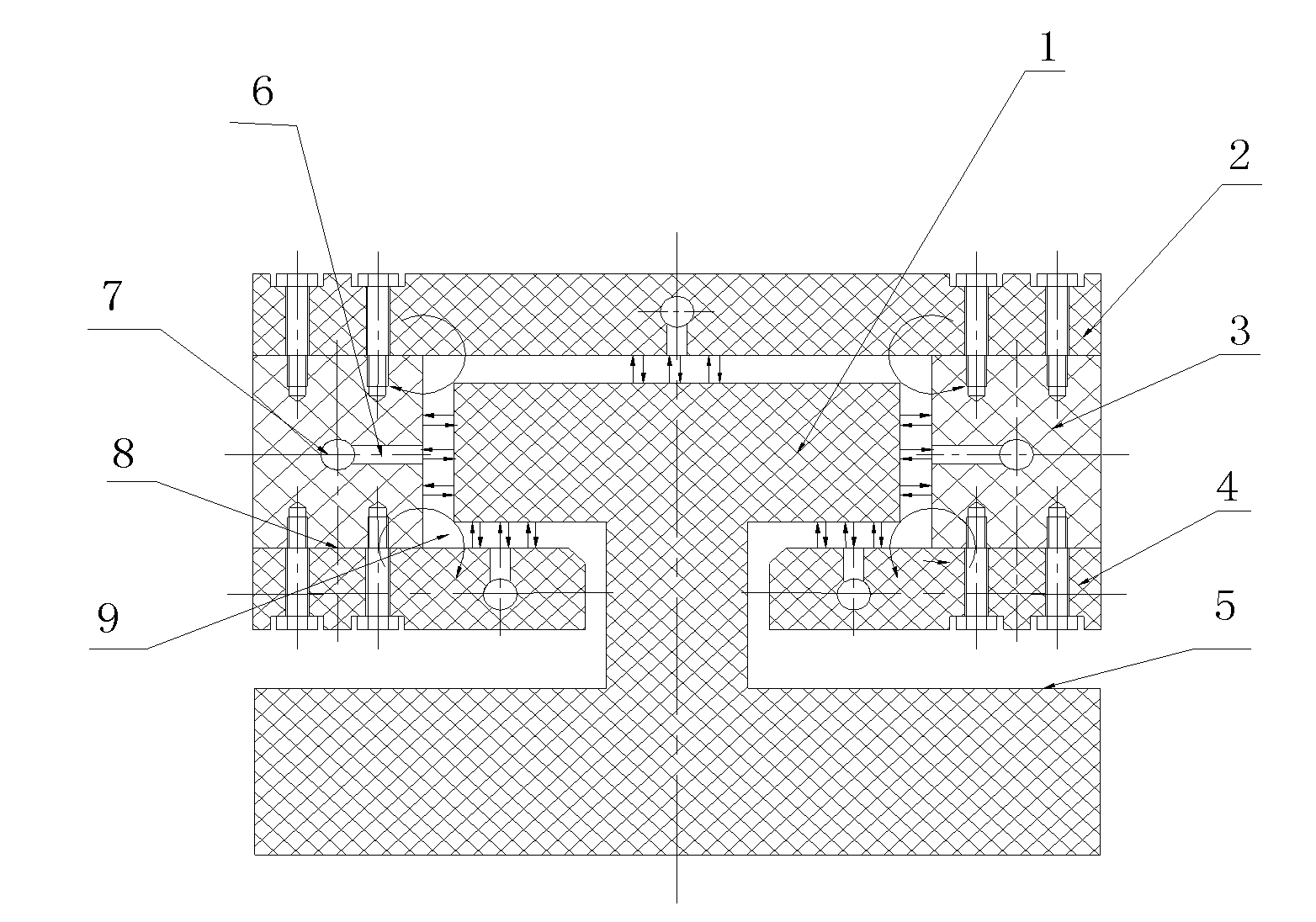

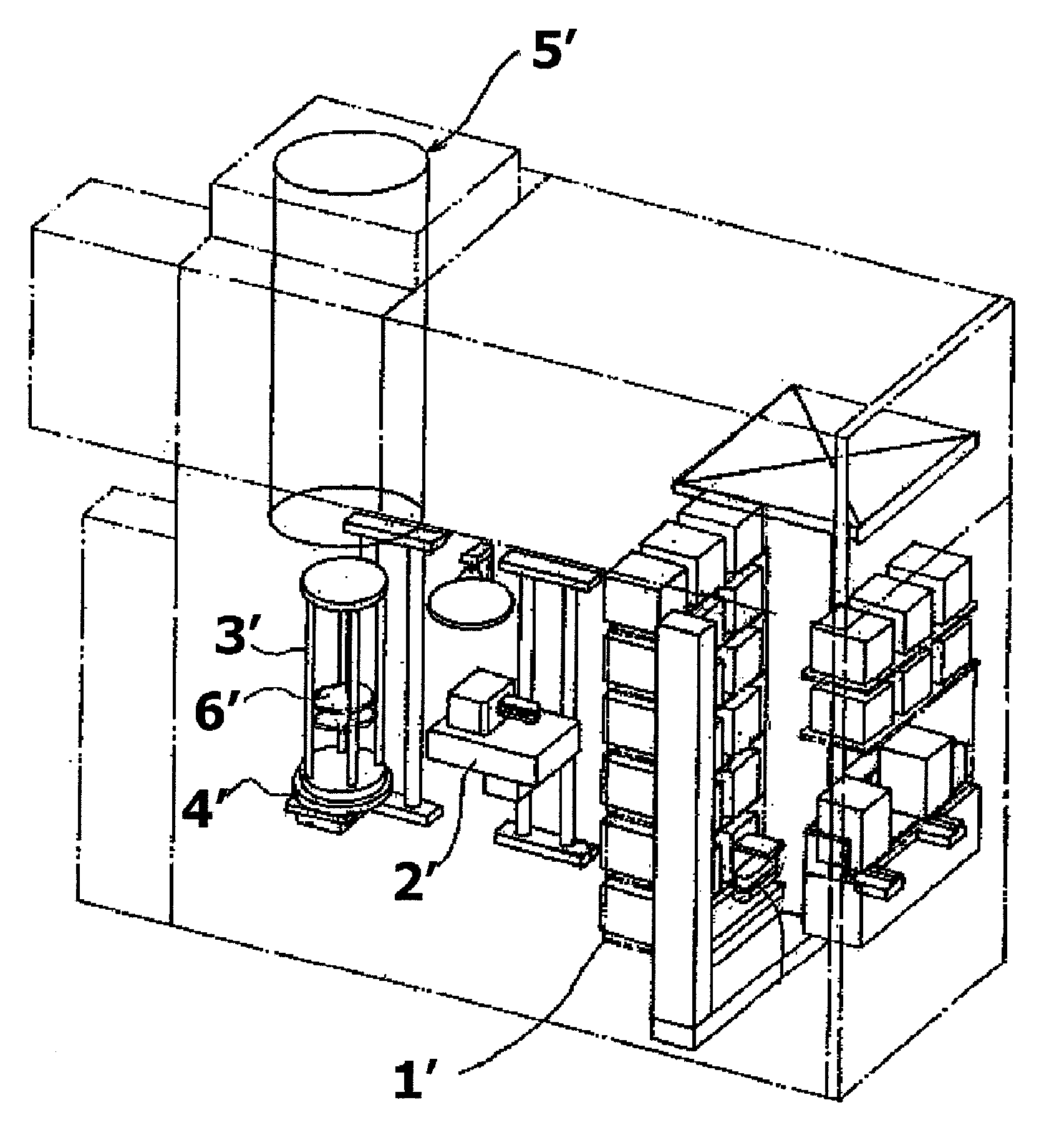

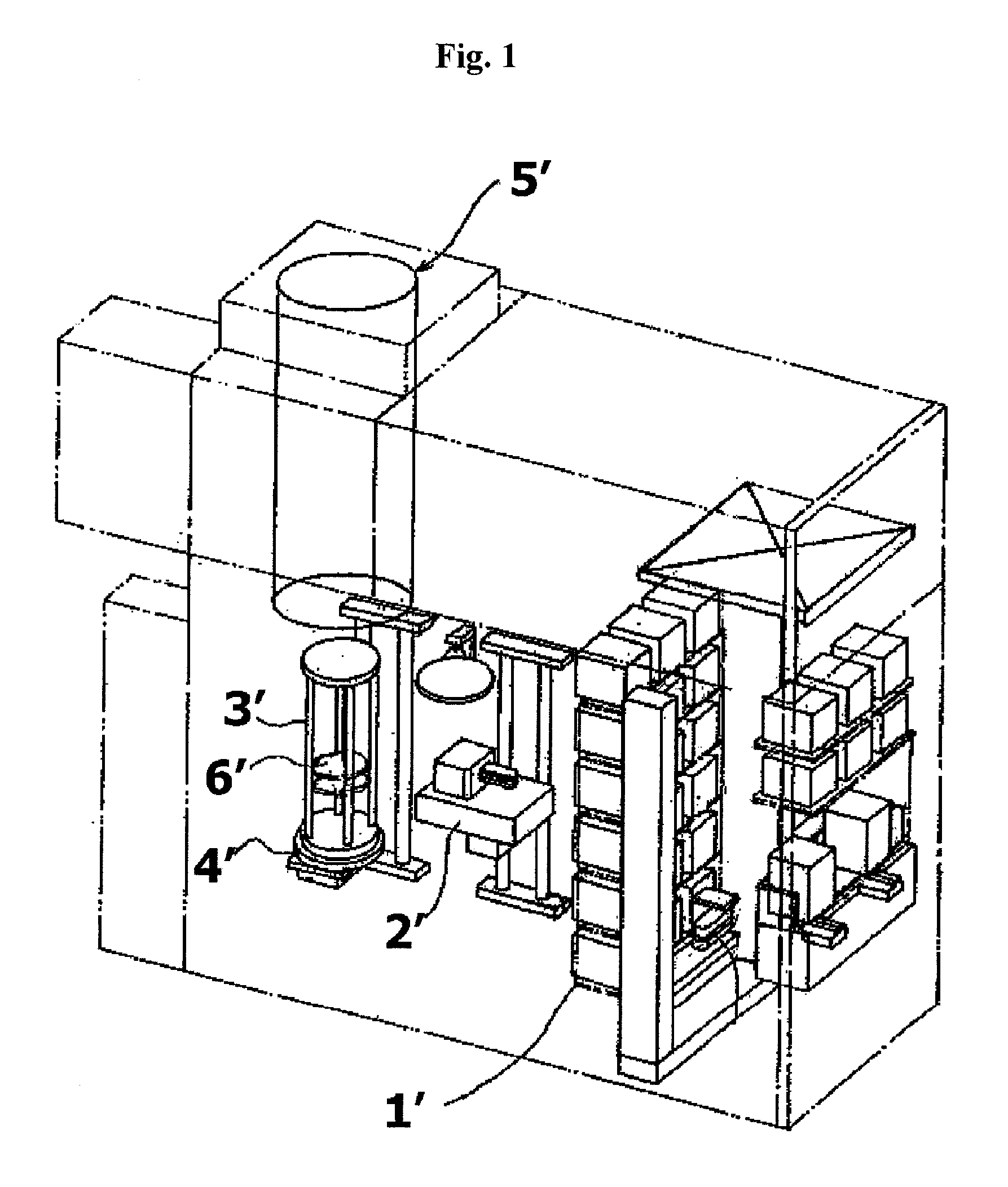

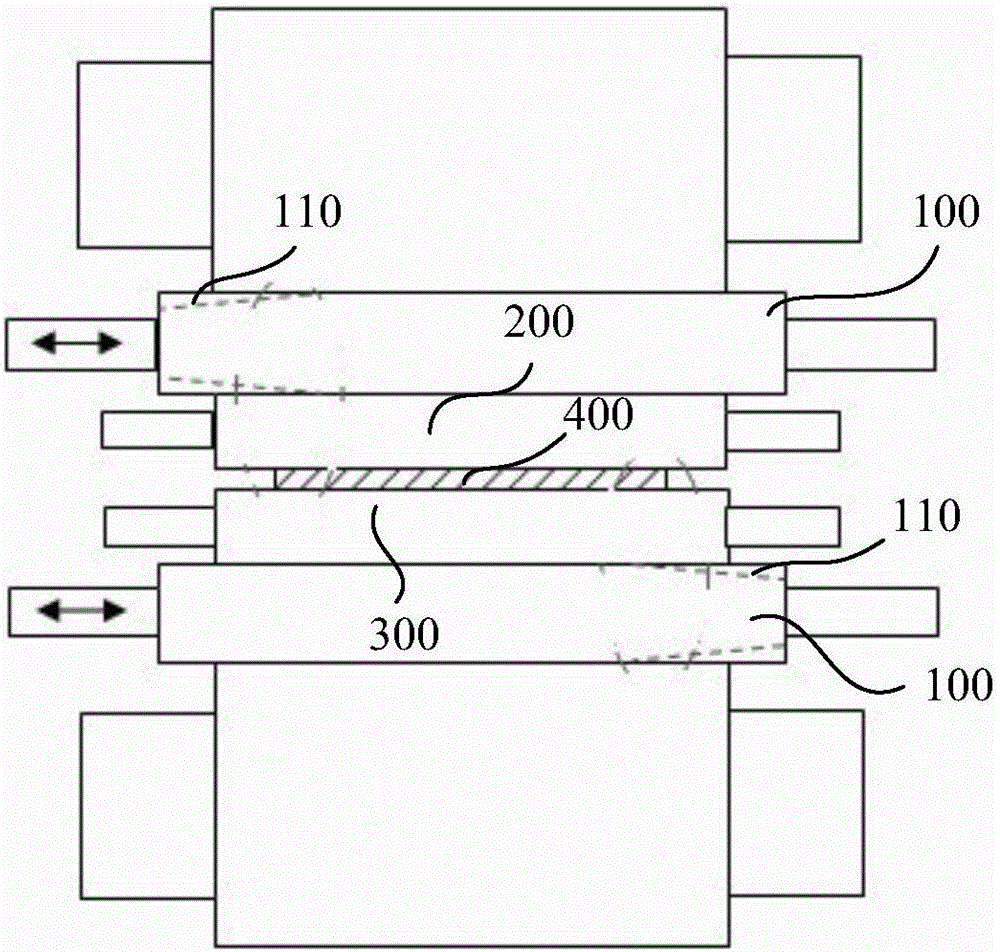

Incremental temperature difference bulging device for metal pipes and bulging method

InactiveCN104874663AGood formabilityReduce reboundShaping toolsTemperature differenceElectromagnetic induction

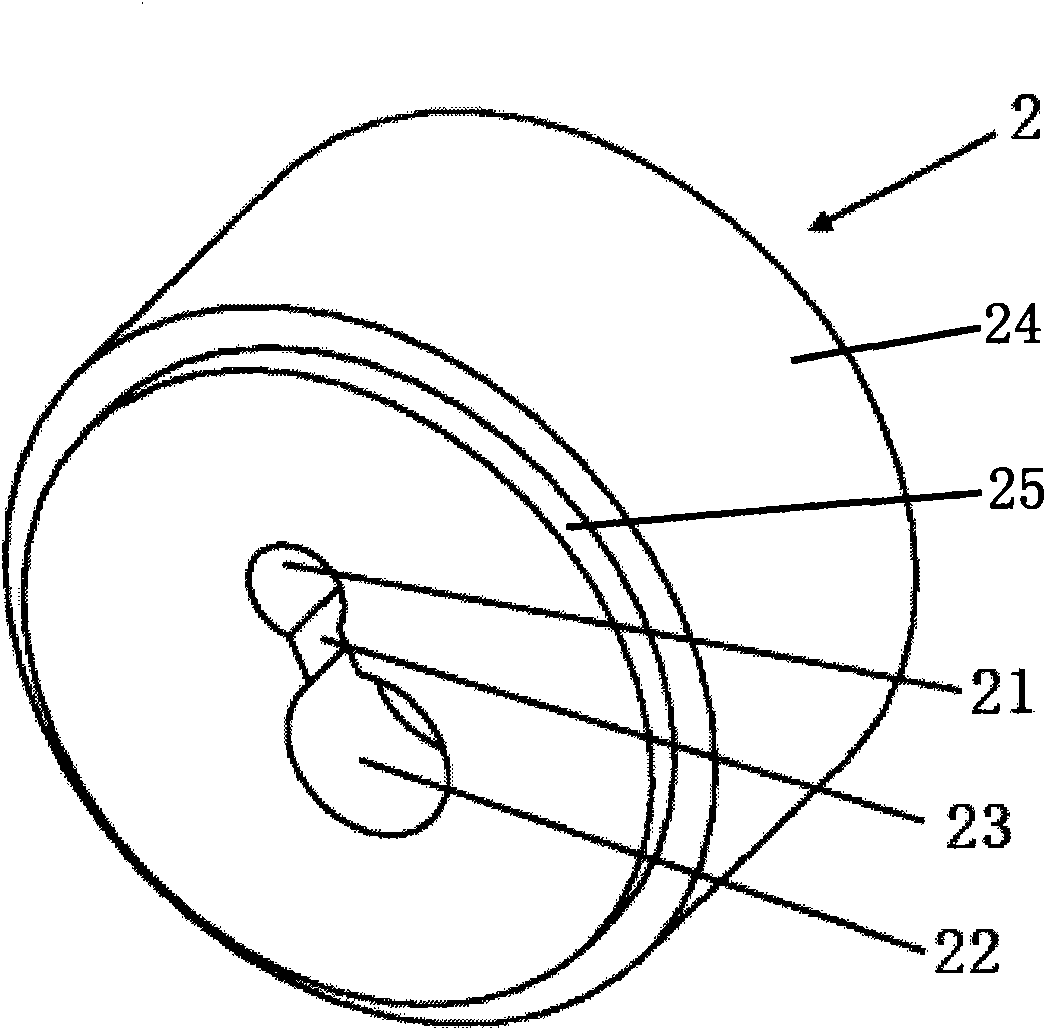

Disclosed are an incremental temperature difference bulging device for metal pipes and a bulging method. The incremental temperature difference bulging device comprises a bulging die, an electromagnetic induction heating mechanism and a coil feeding mechanism. A hole punch and a holeless punch are respectively located at two ends of the bulging die, and center lines of the hole punch, the holeless punch and the bulging die coincide. The coil feeding mechanism is located on the outer side of the bulging die, and an electromagnetic induction coil in the coil feeding mechanism is enabled to sleeve the outer periphery of the bulging die and to be coaxial with the bulging die. A clearance is reserved between the electromagnetic induction coil and the bulging die. In the process of heating and bulging, part of pipe blanks rather than the die are heated sectionally, the heated pipes are bulged, incremental temperature difference bulging of pipe parts is realized, forming property of materials is improved, resilience of the pipes is reduced, the problems of unstability and corrugation of the pipes are solved, and the pipe parts uniform in wall thickness distribution are obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Air-suspending T-shaped rail slider

InactiveCN101935965AAvoid force deformationAvoid Air Gap VariationsRailway tracksEngineeringSurface plate

The invention provides an air-suspending T-shaped rail slider, relating to a rail system and providing an air-suspending T-shaped rail slider capable of effectively overcoming unstable structure problem occurred at the time of air-suspending movement and reducing friction interference in the system. The slider comprises a top panel, a left panel and a right panel, wherein the left panel and the right panel are L-shaped plates; the lower part of the left panel is partially provided with at least one air hole for blowing a guide rail base surface; the lower part of the right panel is partially provided with at least one air hole for blowing the guide rail base surface; and at least one air hole for blowing the guide rail base surface is an one-way air hole or / and an two-way air hole.

Owner:XIAMEN UNIV

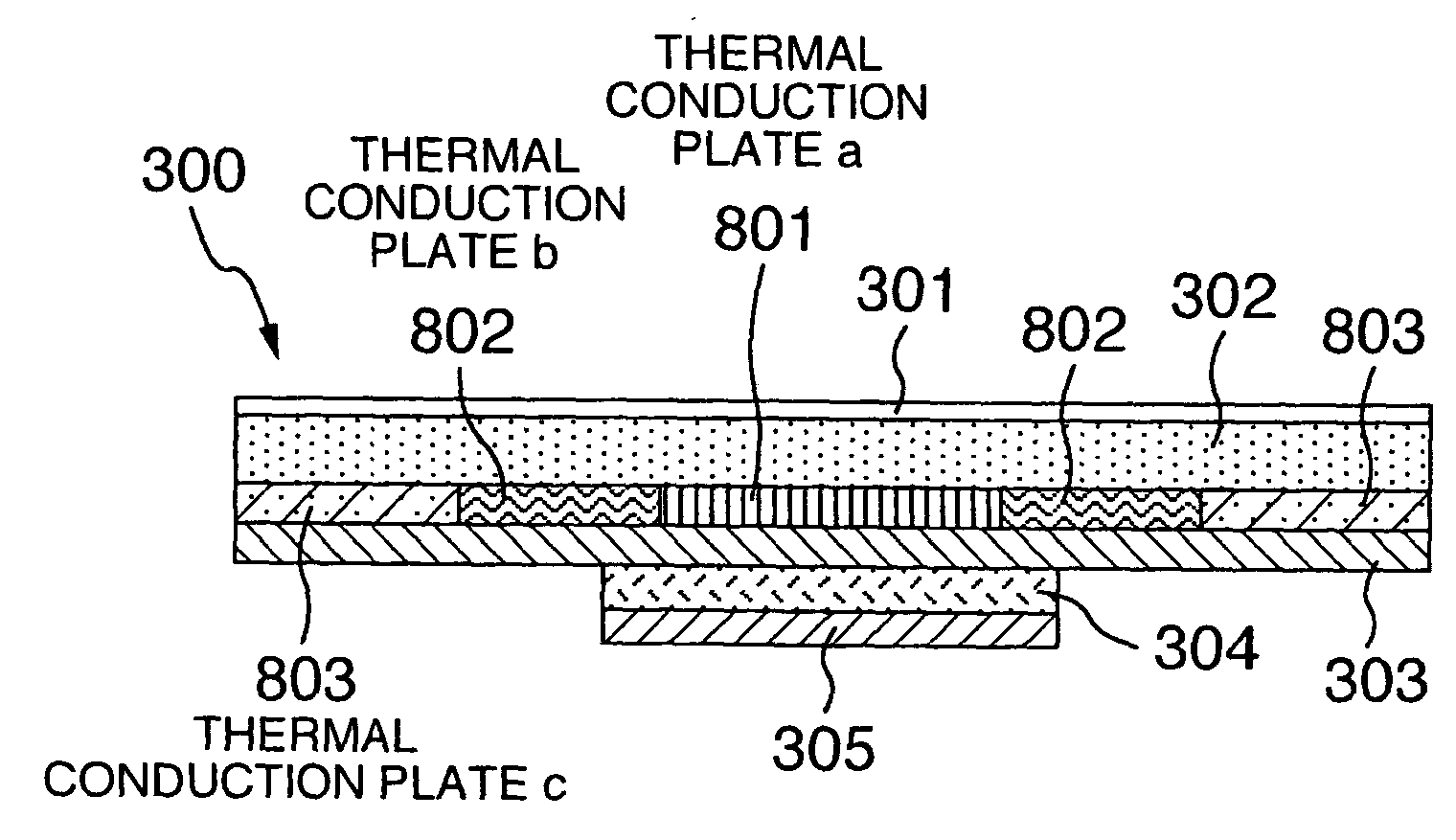

Method of manufacturing semiconductor device and substrate processing apparatus

InactiveUS20110065286A1Uniform thickness distributionLiquid surface applicatorsSemiconductor/solid-state device manufacturingHydrogenWafer stacking

At a low temperature of 500° C. to 700° C., the concentration of atomic oxygen is controlled in a wafer stacked direction, and the thickness distribution of oxide films is kept uniform in the wafer stacked direction. A semiconductor device manufacturing method includes a process of oxidizing substrates by supplying oxygen-containing gas and hydrogen-containing gas through a mixing part from an end side of a substrate arrangement region where the substrates are arranged inside the process chamber so that the gases flow toward the other end side of the substrate arrangement region, and supplying hydrogen-containing gas from mid-flow locations corresponding to the substrate arrangement region. The oxygen-containing gas and the hydrogen-containing gas reacts with each other in the mixing part to produce an oxidation species containing atomic oxygen, and the oxidation species has a maximum concentration at an ejection hole through which the oxidation species is ejected from the mixing part into the process chamber.

Owner:KOKUSA ELECTRIC CO LTD

Preparation method for particle-reinforced iron-based surface composite material

ActiveCN106367661AIncrease volume fractionUniform particle distributionMetal matrix compositeHeat treated

The invention relates to a method suitable for preparing a particle-reinforced iron-based surface composite material and belongs to the field of metal-based composite materials. The method adopts appropriate ceramic particles, a spark plasma sintering technology, a pouring technology and a heat treatment technology, and the particle-reinforced iron-based surface composite material is obtained. A composite layer and a base material as well as the ceramic particles and a base body are all well combined. The abrasion resistance of the particle-reinforced iron-based surface composite material is improved to a great extent by adding the ceramic particles.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

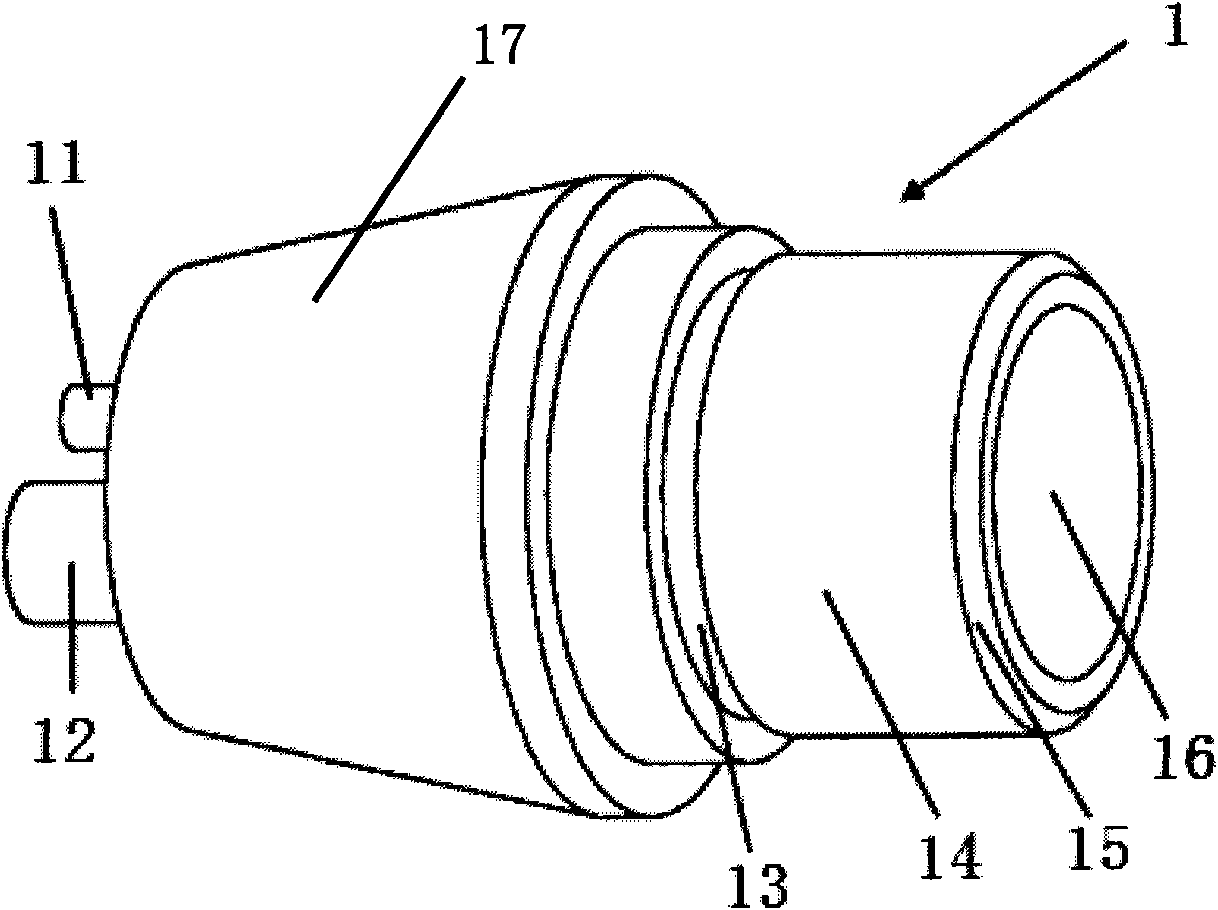

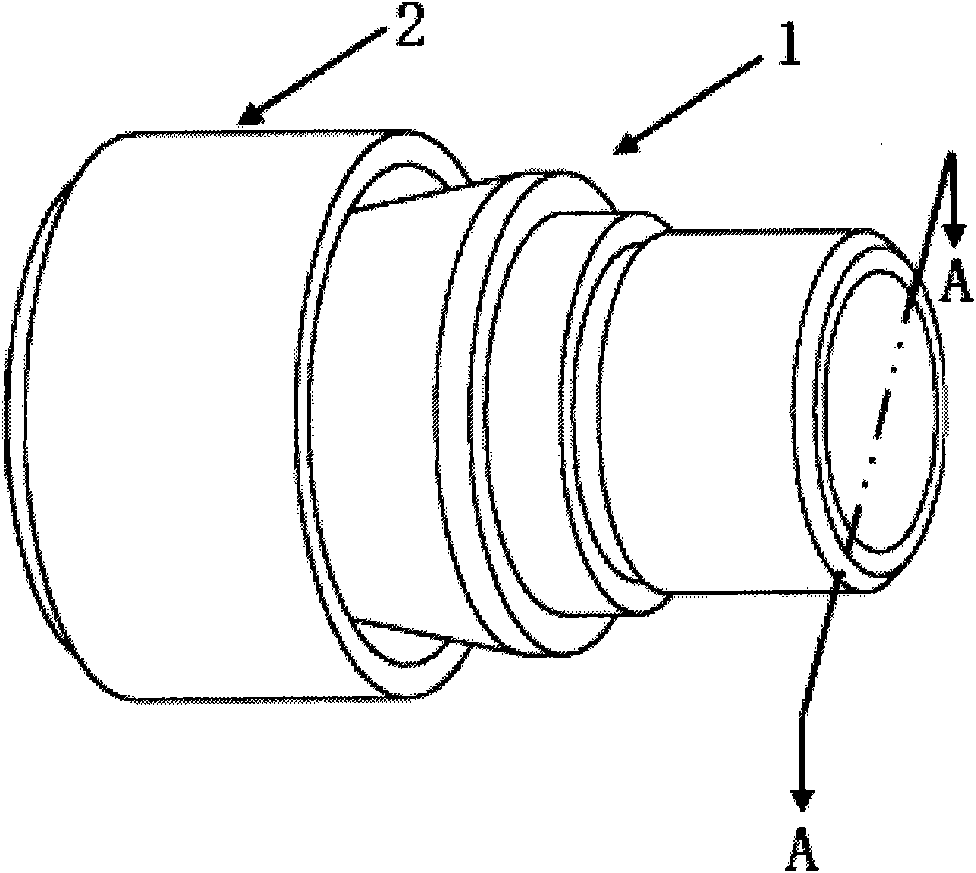

Self-supporting wire cable jacket extrusion mold

InactiveCN101635193AReasonable designCooperate properlyInsulating conductors/cablesEngineeringElectrical and Electronics engineering

The invention relates to a self-supporting optical cable and cable jacket extrusion mold which comprises a mold core unit and a mold cover unit, wherein a line-hanging mold core post, a cable core mold core post, a mold core body, a fixing clamp part and a fixing part are arranged on the mold core unit, and a mold core cavity is arranged in the mold core unit; both the line-hanging mold core post and the cable core mode core post are internally provided with holes communicated with the mold core cavity, and the mold core unit is of a integral structure; the mold cover unit comprises a material discharge end and a mold cover body which is internally provided with a mold sleeve cavity; the material discharge end is provided with a line-hanging protection layer discharge hole, an outer protection layer discharge hole and a strip-hanging hole; and the strip-hanging hole is connected with the line-hanging protection layer discharge hole and the outer protection layer discharge hole and communicated with the mold sleeve cavity. In the invention, because the mold core body and the mold sleeve cavity have reasonable design, the mold core unit is perfectly matched with the mold cover unit, a self-supporting cable produced with the mold has more smooth appearance and evener thick distribution of the jacket; the mold is more wearable, and the product qualification ratio is higher.

Owner:JIANGSU KANGFEITE POWER TECH

Gold-plating process using gold potassium citrate

The invention discloses a gold-plating process using gold potassium citrate, comprising the following steps: step S1 of electrolyzing and degreasing; step S2 of pickling in the solid acid solution; step S3 of pickling in the hydrochloric acid solution; step S4 of pre-plating nickel; step S5 of plating nickel; step S6 of strengthening nickel plating at a high temperature; step S7 of pickling in the citric acid solution step S8 of pre-plating gold; step S9 of plating gold; step S10 of washing by ultrasonic wave; and step S11 of drying with hot air. The process provided by the invention has the advantages as follows: a gold-leaching plating layer with good adhesiveness and uniform distribution thickness can be formed on a surface of a plated piece matrix; and the plating layer has a better crystal structure and high hardness so as to greatly save cost; operable current density range is wide; production efficiency can be increased; radiance can be controlled easily; the process is safe and pollution-free because cyanogens matters are not used; cost is low; and economic benefit and social benefit are good.

Owner:CHENGDU HOMIN TECH

Indium compositions

ActiveCN101307475AUniform thickness distributionLow melting pointSemiconductor/solid-state device detailsSolid-state devicesIndiumCopolymer

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Preparation method of hollow spherical barium-strontium-titanate powder material

ActiveCN108314078AUniform size distributionGood dispersionTitanium compoundsDispersityBarium strontium titanate

The invention discloses a preparation method of a hollow spherical barium-strontium-titanate powder material. The preparation method comprises the following steps of: adopting a hard template method for preparation: using glucose as a raw material, using deionized water as a solvent, and using cetylammonium bromide as a dispersing agent to prepare a carbon-sphere template with negative charges onthe surface; dropping metal precursor solution to the surfaces of the carbon spheres in batches, utilizing in-situ hydrolysis reaction of the surfaces to prepare C@BSTO precursor composite microspheres, removing central carbon cores by high-temperature calcination, and obtaining hollow spherical barium-strontium-titanate powder with cubic perovskite phase. For the obtained powder, the size is uniform, the crystallinity and the dispersity are good, the size can be adjusted to be 0.7-3mu m by controlling the concentration of metal ions, and the shell layer is about 90-300nm in thickness. The preparation method disclosed by the invention has the beneficial effects that the raw materials are easy to obtain, the hazard to the health of a human body is less due to no toxicity and corrosiveness,the requirements for equipment are low; in addition, the preparation method has the characteristics that the process is simple, the process parameters are easily controlled, the product is stable in quality and is easily industrialized.

Owner:淄博宏荣电子科技有限公司

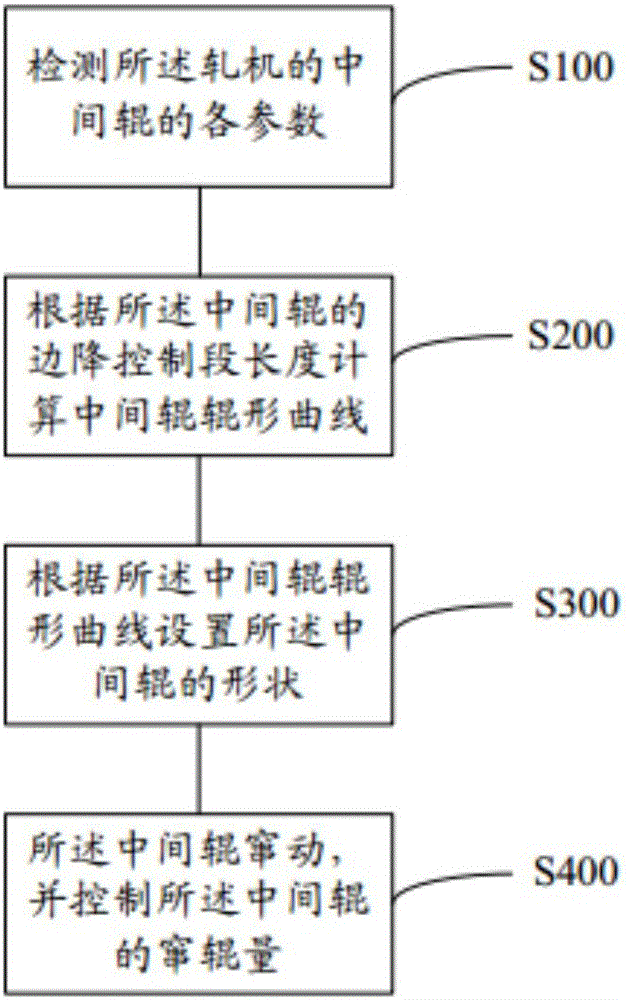

Method for lowering edge drop of tin plate

ActiveCN106111708AImproved edge controlUniform thickness distributionRollsMetal rolling arrangementsTinningEngineering

The invention discloses a method for lowering the edge drop of a tin plate. The method for lowering the edge drop of the tin plate is applied to a rolling mill and comprises the steps that all the parameters of an intermediate roll of the rolling mill are detected, wherein all the parameters of the intermediate roll of the rolling mill comprise the length LIEDC of an edge drop control section of the intermediate roll and the full length LIMR of a roll body of the intermediate roll; according to the length of the edge drop control section of the intermediate roll, a roll shape curve of the intermediate roll is calculated; according to the roll shape curve of the intermediate roll, the shape of the intermediate roll is set; and the roll shifting amount S1 of the intermediate roll is controlled. The method for lowering the edge drop of the tin plate solves the technical problems that in the prior art, the control capacity of the strip steel edge drop of the tin plate is poor and edge waves are difficult to control and achieves the technical effects of improving the control capacity of the edge drip of the tin plate and enabling the thickness distribution of the tin plate to be uniform.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Method and device for preparing diamond film doped with ultrafine nano-structural metal particles

ActiveCN102409291AUniform thickness distributionExtended service lifeVacuum evaporation coatingSputtering coatingHigh energyVolumetric Mass Density

The invention relates to a method and a device for preparing a diamond film doped with ultrafine nano-structural metal particles. The device for preparing the diamond film doped with the metal particles comprises a control system, a target material system, a workpiece control system and an auxiliary system. The method comprises the following steps of: focusing strong laser emitted by a high-power pulse laser device on the surface of a high-purity graphite target material under vacuum; inducing a large quantity of plasmas by using high-energy laser to bombard the surface of a base material which is uniformly heated in advance at a high speed; and performing rapid phase transition on the surface of the base material to form the diamond film. Laser emitted by a quasimolecule laser device is focused on a metal target material, a large quantity of plasmas consisting of a large quantity of metal particles are induced on the surface of the metal target material by using high-energy-density laser to bombard the surface of the prepared diamond film, and gaps on the surfaces of the particles of the diamond film are effectively and tightly filled by a large number of metal particles to form a uniform metal film. By the method and the device, the surface of the diamond film is modified, and the compression strength and the abrasion resistance of the diamond film are improved.

Owner:山西亚德玛斯材料科技有限公司

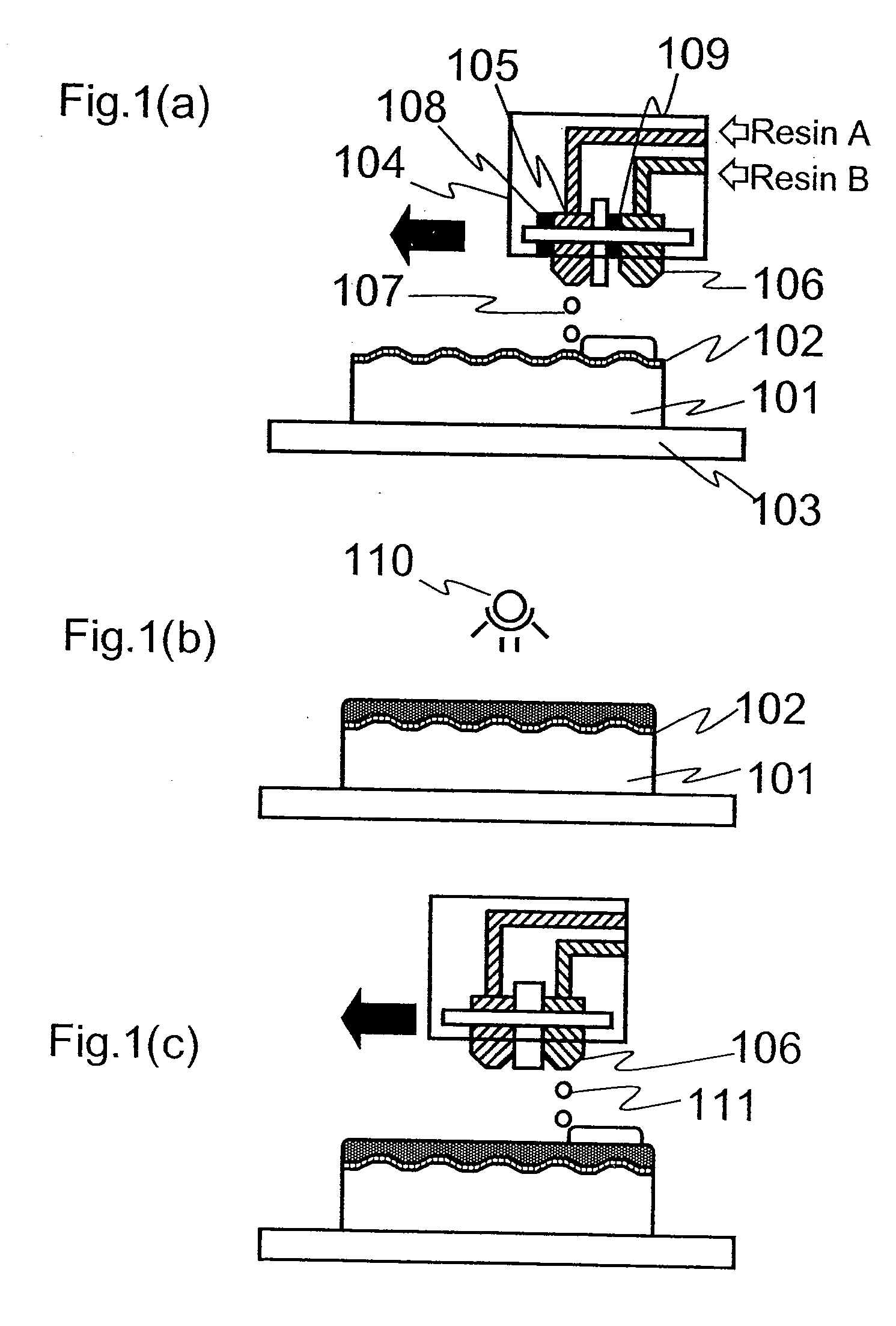

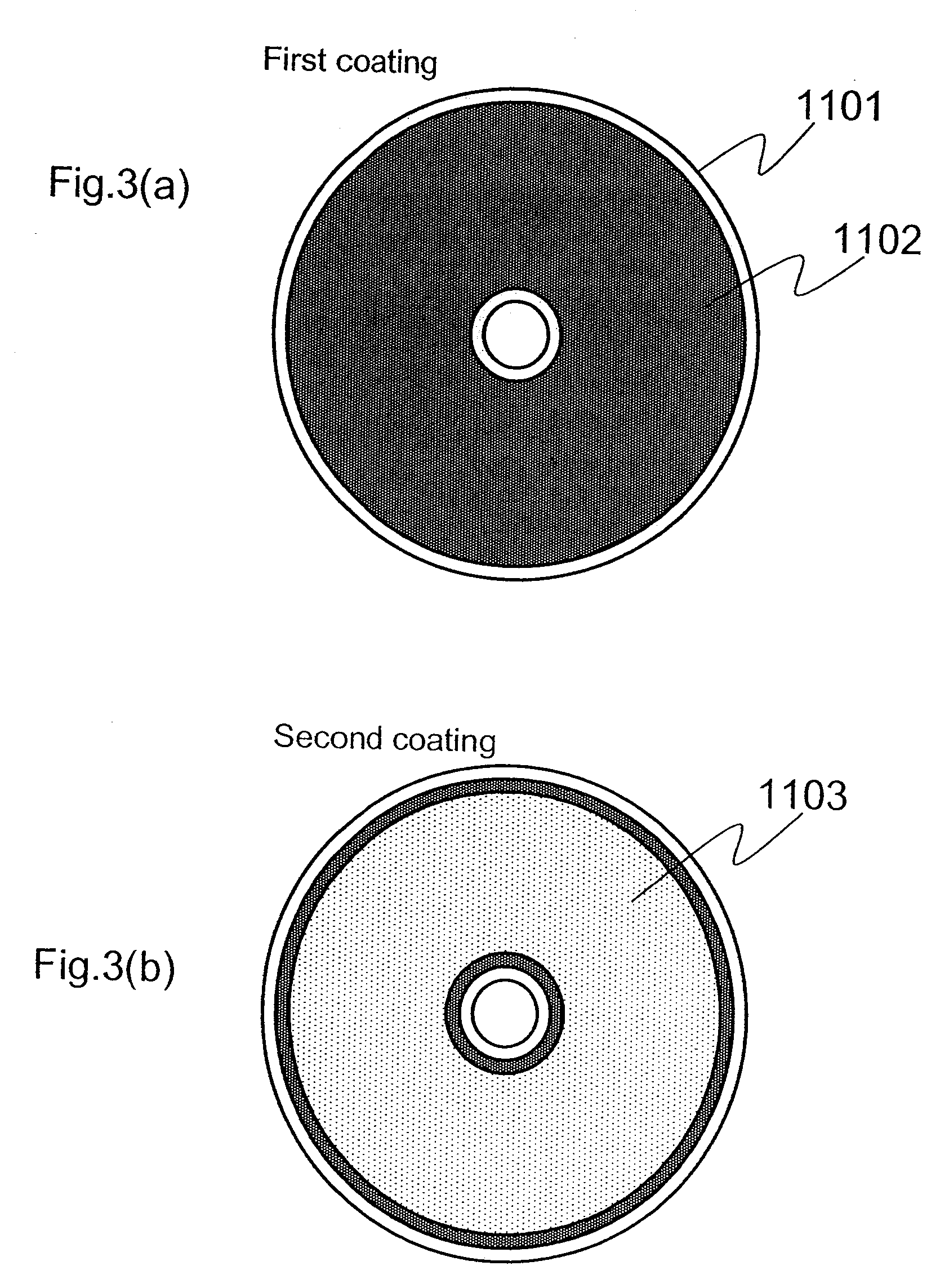

Manufacturing method for multilayer information recording medium, manufacturing apparatus for multilayer information recording medium, and multilayer information recording medium

InactiveUS20100003444A1Surface smoothness is deterioratedHigh viscosityLayered productsRecord information storageEngineeringSurface smoothness

An apparatus for manufacturing a multi-layered information recording medium of the present invention is an apparatus for manufacturing the multi-layered information recording medium for discharging a stiffening resin to a substrate while relatively moving at least one of the substrate and ink jet heads wherein the apparatus has a plurality of ink jet heads disposed on every different kind of the discharged stiffening resin, and constituted so as to stack-coat the stiffening resin to the substrate. With the constitution, a resin intermediate layer of a thick film, for example, greater than 10 μm having uniform thickness distribution and excellent in surface smoothness can be formed.

Owner:PANASONIC CORP

Hook-face liquid crystal display panel and display device

ActiveCN105182622AConsistent thicknessClear imagingNon-linear opticsLiquid-crystal displayDisplay device

The present invention provides a hook-face liquid crystal display panel and a display device. The hook-face liquid crystal display panel comprises a first substrate, a second substrate and separators, wherein the separators are disposed between the first substrate and the second substrate and used for supporting the first substrate and the second substrate, the separators are fixed at an inner side of the first substrate and are equal in height, and compensation structures are disposed at an inner side surface of the second substrate and used for compensating deformation differences occurred in compression of the separators at different positions, thus to enable the thickness of the hook-face liquid crystal display panel to be consistent. The display device comprises the above hook-face liquid crystal display panel. The hook-face liquid crystal display panel can clearly display images, and optical tastes are raised.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Coating device and coating film forming method

InactiveUS7575634B2Uniform thickness distributionSemiconductor/solid-state device manufacturingSpray nozzlesResistEngineering

The resist coating unit (COT) has a spin chuck (41) which holds the wafer to be supplied with a resist liquid, and a process cup (50) which accommodates the spin chuck (41) and exhaustes an atmosphere around the wafer W from a bottom thereof. The process cup (50) comprises a first cup (51) with an outer circumferential wall (61a), and an airflow control member (52) laid out close to the wafer W in the first cup (51) in such a manner as to surround the wafer W. The airflow control member (52) has a vertical cross section of an approximately rectangular shape defined by the upper ring portion (62a) having a cross section of an approximately triangular shape and protruding upward, and a lower ring portion (62b) having a cross section of an approximately triangular shape and protruding downward. An exhaust passage (55) for substantially exhausting the atmosphere around the wafer W is formed between the outer circumferential wall (61a) and the airflow control member (52).

Owner:TOKYO ELECTRON LTD

Non-woven cambric and production thereof

A non-woven bast cloth for the inner surface of car top and the liner of artificial leather used for car, or as polishing material for steel, copper, or aluminium is prepared from bast fibres through airflow netting, immersing and adhering. Its advantages are high tension strength and temp stability, good moisture and air permeability, and high heat insulation.

Owner:张进建

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com