Incremental temperature difference bulging device for metal pipes and bulging method

A metal pipe, incremental technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of pipe instability, pipe heating and forming temperature limitations, liquid medium heating temperature limit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

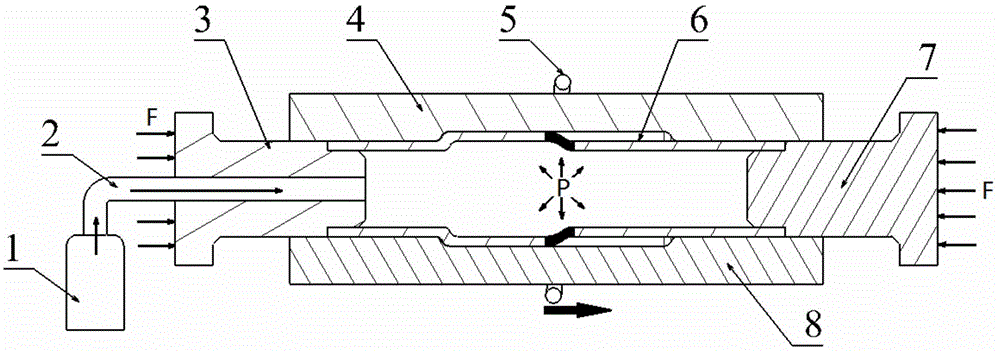

[0059] This embodiment is a metal pipe electromagnetic induction heating incremental temperature difference expansion device. The formed pipe has an outer diameter of Φ20mm, a thickness of 1mm, and a length of 100mm. The formed pipe parts have small diameters at both ends and large middle diameters. , The material is aluminum alloy 6061.

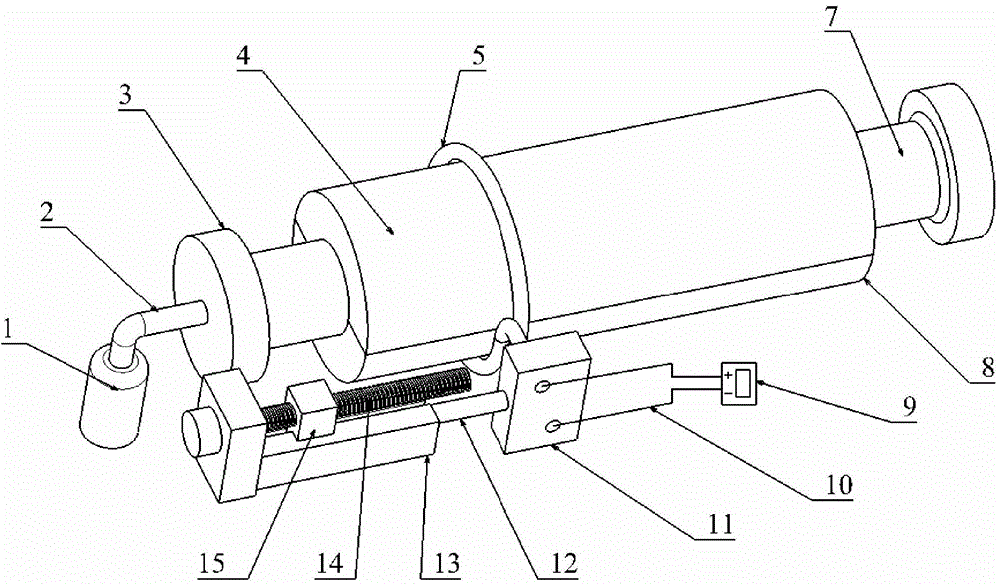

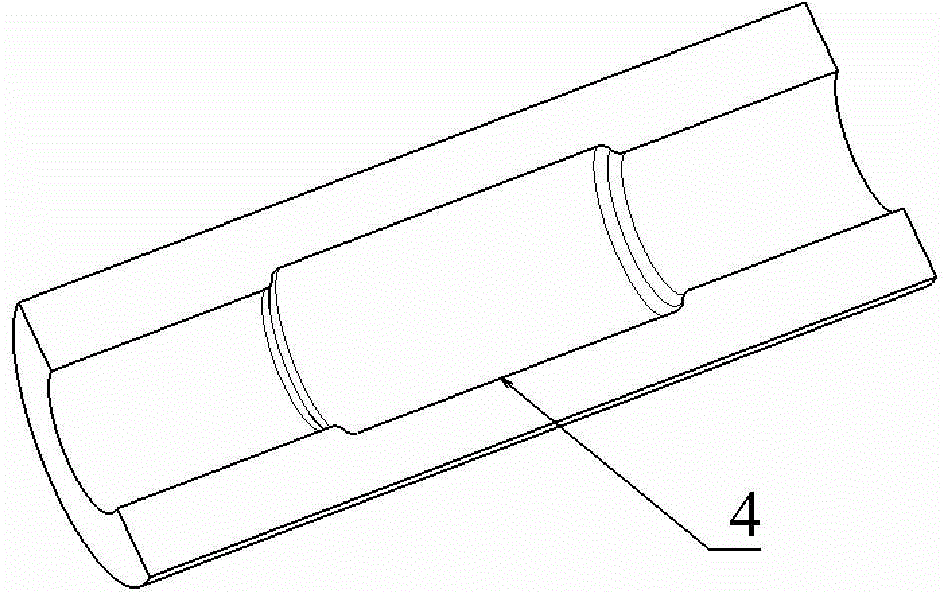

[0060] This embodiment is an electromagnetic induction heating incremental temperature-difference bulging device for aluminum alloy pipes, which mainly includes a bulging mold, an inflation press unit, an electromagnetic induction heating mechanism, and a coil feeding mechanism. The bulging mold includes an upper mold half 4, a lower mold half 8, a punch with a hole 3, and a punch 7 without a hole; the inflation press unit includes an argon cylinder 1 and a pressurizing tube 2; the electromagnetic induction heating The mechanism includes a power source 9, an electromagnetic induction coil 5 and a connecting wire 10; the coil feeding mechanism i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com