Thermal punch forming technique and forming mold for super-strength steel

A technology of hot stamping and ultra-high-strength steel, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problem of affecting the forming accuracy and forming quality of hot stamping parts, affecting the forming performance of sheet metal, surface cracks of formed parts, etc. problems, to achieve good formability, eliminate springback, and avoid cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

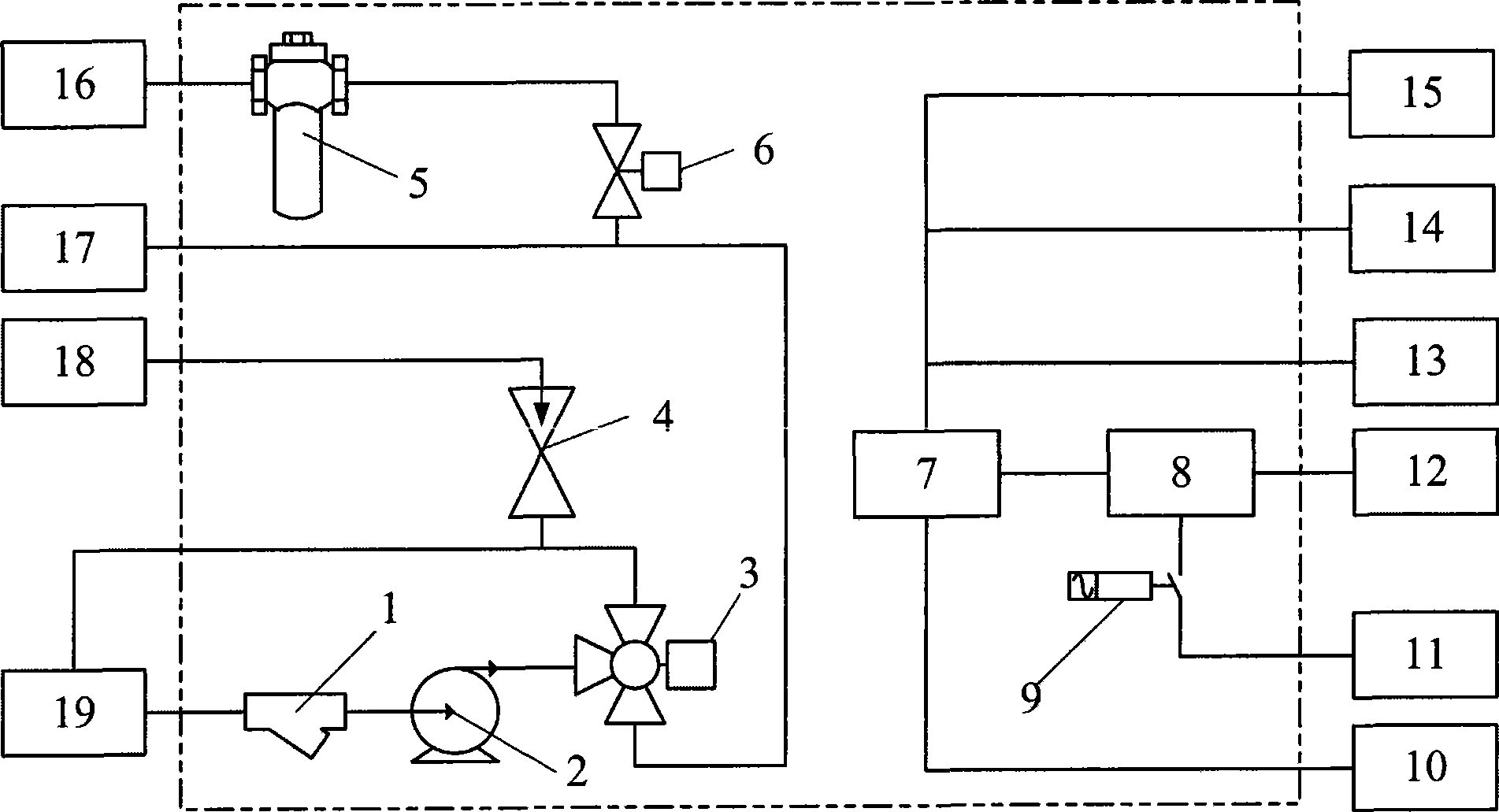

[0029] The ultra-high-strength steel hot stamping forming process of the present invention is exactly before the ultra-high-strength steel stock hot stamping forming, the parts (such as punch, die and binder plate, etc.) that will participate in stamping and contact with ultra-high-strength steel stock ) heating, so that the surface temperature of these parts reaches above the martensitic point temperature of ultra-high-strength steel, and then the ultra-high-strength steel material heated to complete austenitization is placed in the mold for stamping, and the hot stamping mold is closed. , the mold is cooled, and the molded parts are quenched using the mold parts that are in contact with the formed parts.

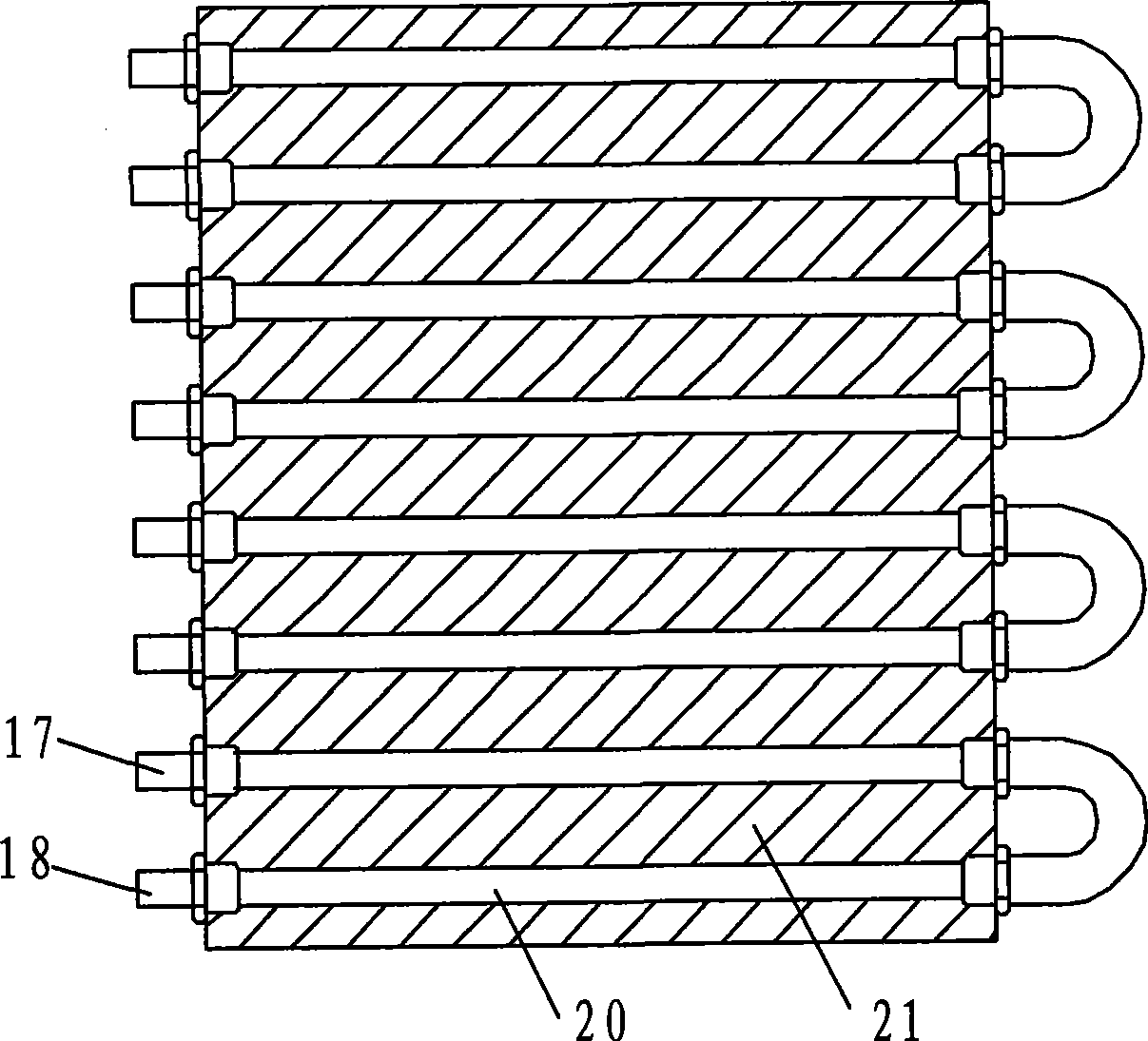

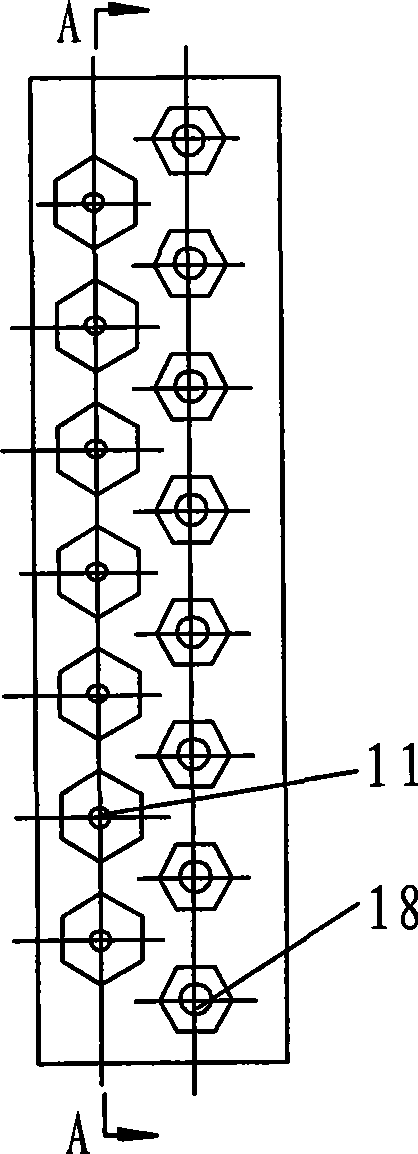

[0030] The ultra-high-strength steel hot stamping die for realizing the above process includes a punch, a die and a control unit. Such as figure 2 , image 3 As shown in FIG. 4 , the inside of the punch or die 21 is provided with an electric heating element 11 and a coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com