Steel for enamel and production method thereof

A manufacturing method and enamel technology, applied in the field of steel grades and their manufacturing, can solve the problems such as peeling off of the adhering porcelain layer, and achieve the effects of good plasticity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

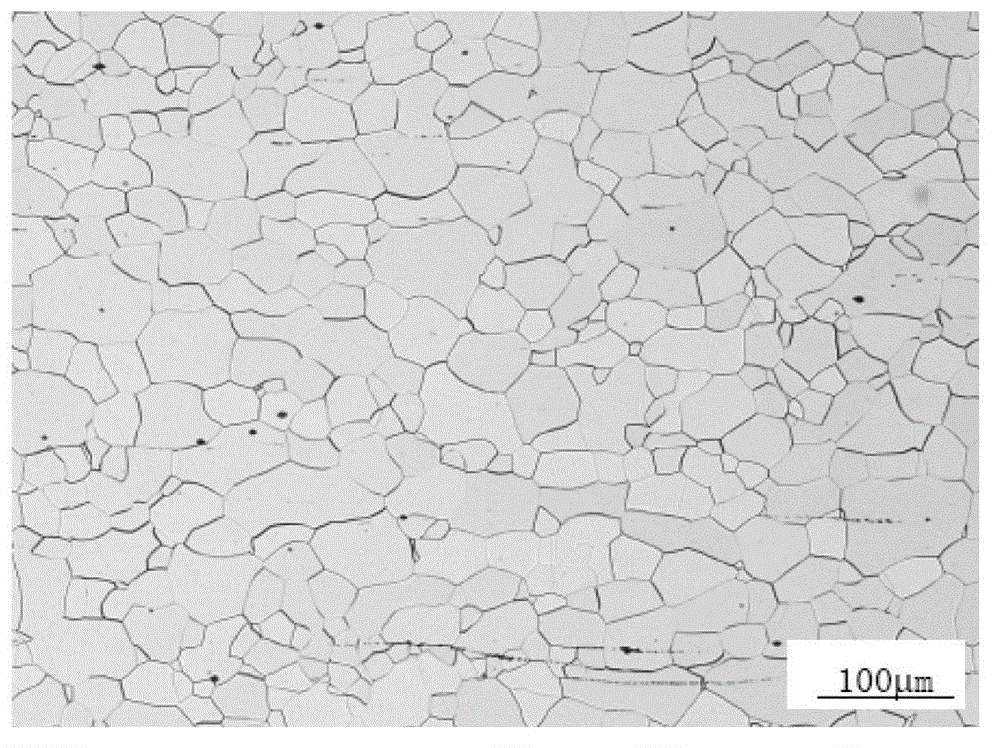

Image

Examples

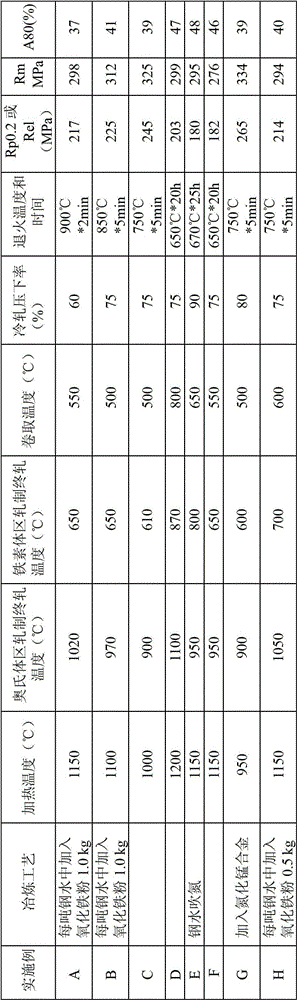

Embodiment A-H

[0054] Manufacture the steel for enamelling of the present invention according to the following steps, control the chemical element ratio of each embodiment as shown in Table 1 (see Table 2 for the specific process parameters of each embodiment):

[0055] (1) Smelting, vacuum degassing: Iron oxide powder is added during the smelting process. The amount of iron oxide powder added is 0.40-2.50 kg per ton of steel. After adding, stir fully. The stirring time does not exceed 30 minutes, so that O≥0.010 in molten steel ~0.050%; blow argon and stir after vacuum degassing, control H<2ppm in the steel, when N≥(0.002~0.015wt%), blow nitrogen after vacuum degassing treatment;

[0056] (2) Continuous casting;

[0057] (3) Hot rolling the cast slab: control the hot rolling heating temperature at 950-1200°C, and roll in two stages. The first stage is rolled in the austenite zone at a temperature of 900-1100°C. Rolling in the body area, the final rolling temperature (FT, °C) satisfies the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com