Manufacturing process of spring steel wire rod

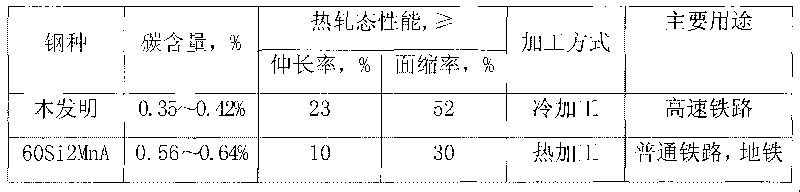

A production process, spring steel technology, applied in the field of metallurgy, can solve the problems of poor plasticity and toughness, complex production process, high production cost, etc., and achieve the effect of good physical quality, high dimensional accuracy and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The production process of 38Si7 spring steel wire rod is characterized in that it includes the following processes: raw material preparation, EAF eccentric bottom tapping electric arc furnace smelting, LF refining outside the furnace, VD vacuum degassing treatment, CCM continuous casting, continuous casting slab shot blasting, flaw detection , Grinding, heating, and high-speed wire rolling mill rolling into wire rod.

[0018] Raw material preparation process: the furnace charge is composed of high-quality steel scrap, molten iron and pig iron, and the composition is as follows (Wt%):

[0019] Table 2

[0020] C

mn

P

S

Si

Cr

Al

Cu

Fe

0.35

0.50

0.025

0.025

1.50

0.35

0.050

0.20

margin

[0021] Control the total amount of harmful residual elements within 0.25%; add 38% of molten iron in each furnace; keep all raw materials in the furnace dry, and add the alloy after baking. ...

Embodiment 2

[0029] The production process of 38Si7 spring steel wire rod is characterized in that it includes the following processes: raw material preparation, EAF eccentric bottom tapping electric arc furnace smelting, LF refining outside the furnace, VD vacuum degassing treatment, CCM continuous casting, continuous casting slab shot blasting, flaw detection , Grinding, heating, and high-speed wire rolling mill rolling into wire rod.

[0030] Raw material preparation process: the furnace charge is composed of high-quality steel scrap, molten iron and pig iron, and the composition is as follows (Wt%):

[0031] table 3

[0032] C

mn

P

S

Si

Cr

Al

Cu

Fe

0.4

0.7

0.020

0.020

1.70

0.3

0.040

0.15

margin

[0033] Control the total amount of harmful residual elements within 0.25%; add 40% of molten iron to each furnace; keep all raw materials in the furnace dry, and add the alloy after baking.

...

Embodiment 3

[0041] The production process of 38Si7 spring steel wire rod is characterized in that it includes the following processes: raw material preparation, EAF eccentric bottom tapping electric arc furnace smelting, LF refining outside the furnace, VD vacuum degassing treatment, CCM continuous casting, continuous casting slab shot blasting, flaw detection , Grinding, heating, and high-speed wire rolling mill rolling into wire rod.

[0042] Raw material preparation process: the furnace charge is composed of high-quality steel scrap, molten iron and pig iron, and the composition is as follows (Wt%):

[0043] Table 4

[0044] C

mn

P

S

Si

Cr

Al

Cu

Fe

0.42

0.80

0.015

0.018

1.80

0.30

0.040

0.1

margin

[0045] Control the total amount of harmful residual elements within 0.25%; add 45% of molten iron to each furnace; keep all raw materials in the furnace dry, and add the alloy after baking. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com