Patents

Literature

434 results about "Bottom ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bottom ash is part of the non-combustible residue of combustion in a power plant, boiler, furnace or incinerator. In an industrial context, it has traditionally referred to coal combustion and comprises traces of combustibles embedded in forming clinkers and sticking to hot side walls of a coal-burning furnace during its operation. The portion of the ash that escapes up the chimney or stack is, however, referred to as fly ash. The clinkers fall by themselves into the bottom hopper of a coal-burning furnace and are cooled. The above portion of the ash is also referred to as bottom ash.

Magnesium cementitious composition

InactiveUS20070017418A1Reduce shrinkReduce crackingSolid waste managementCeramicwareFiberAdditive ingredient

A cementitious product for applications such as stucco, plaster coating, fireproof coatings, casting / molding applications and flooring. The product is a blend of magnesium oxide and magnesium chloride. Suitable fillers such as bottom ash, fly ash, clinker and other pulverized materials may be added. Fibrous materials, foaming agents and surfactants may also be added to achieve product characteristics for specific application. Processes for blending the selected ingredients are also disclosed.

Owner:DENNIS ANDREW C

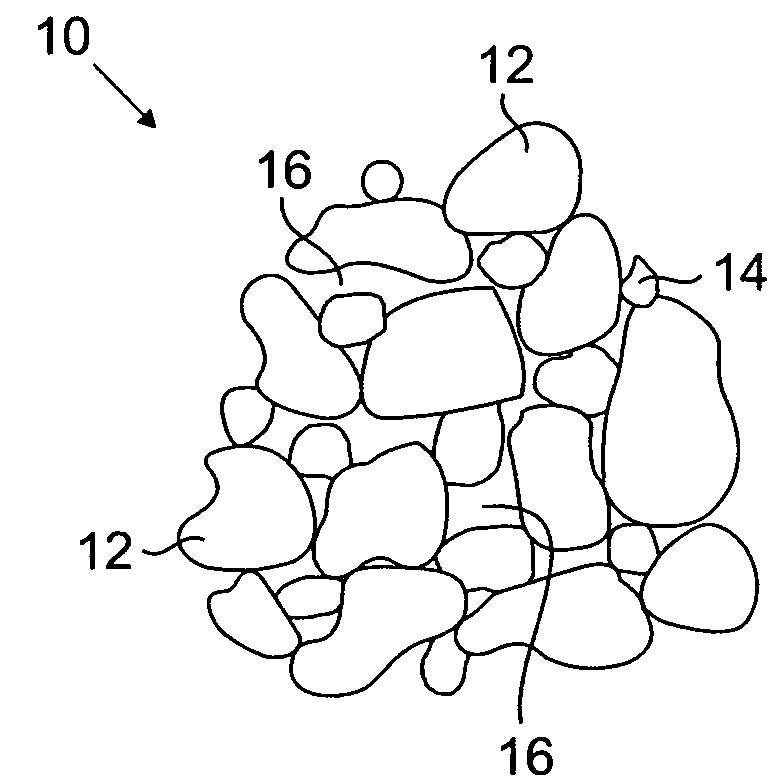

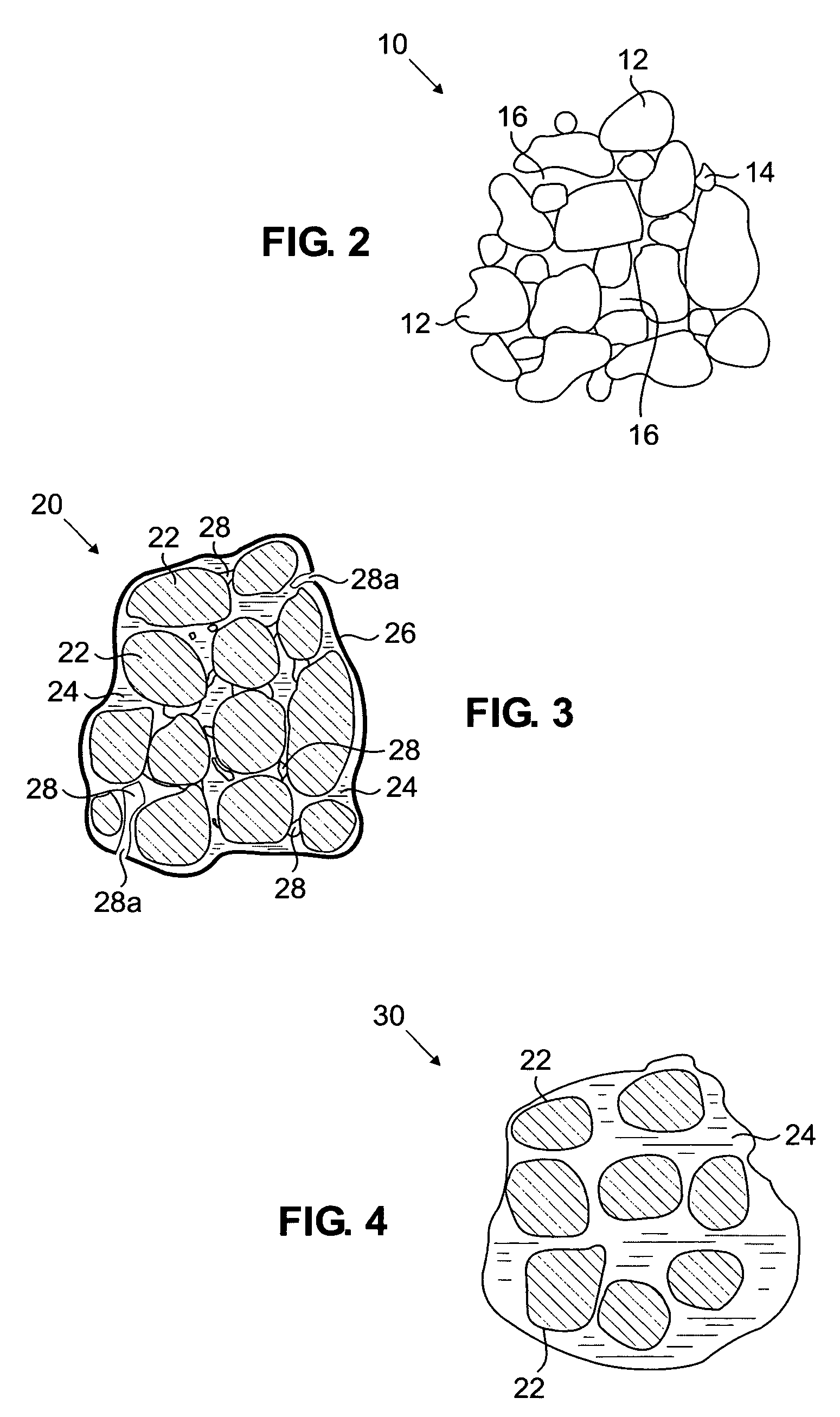

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

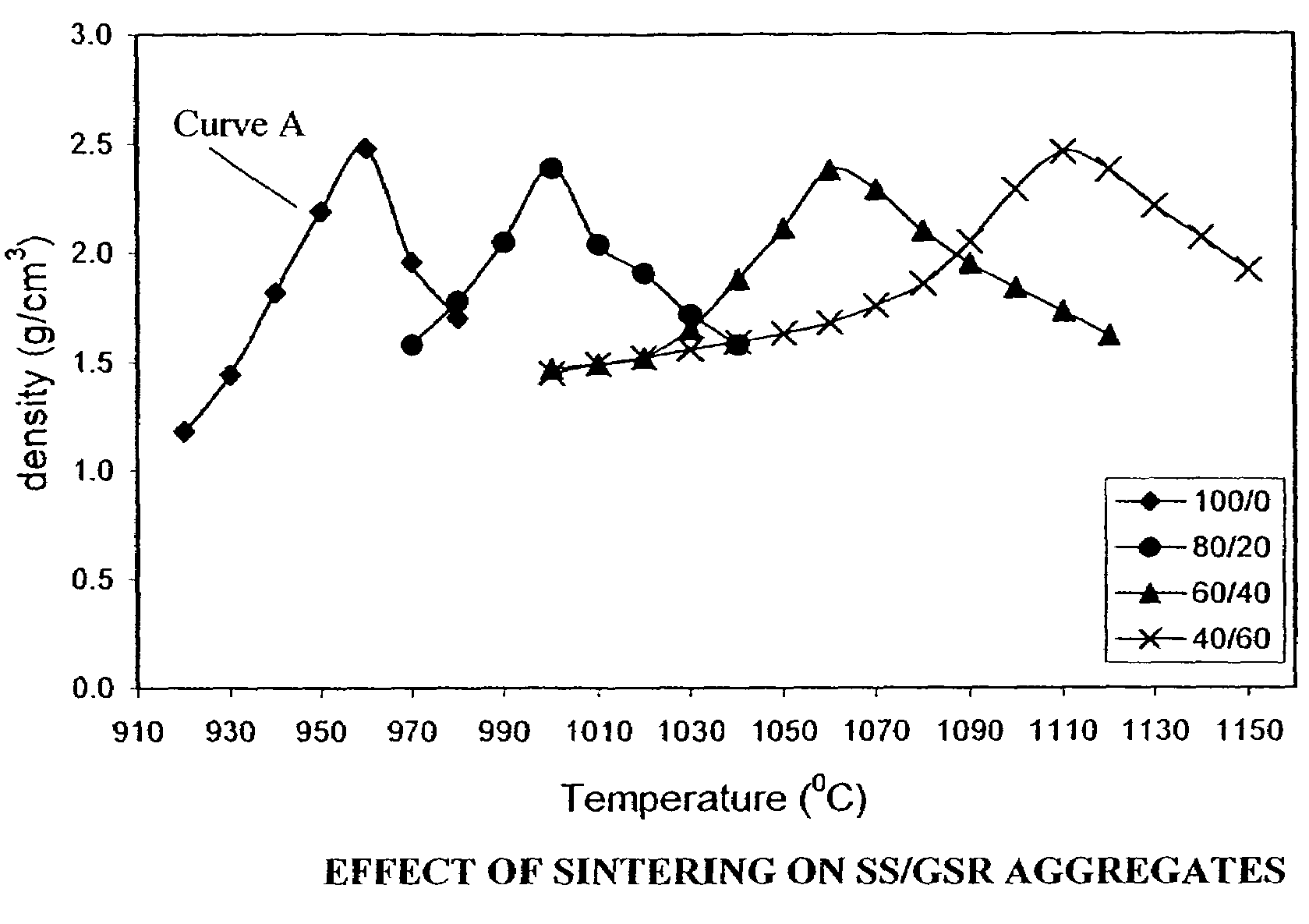

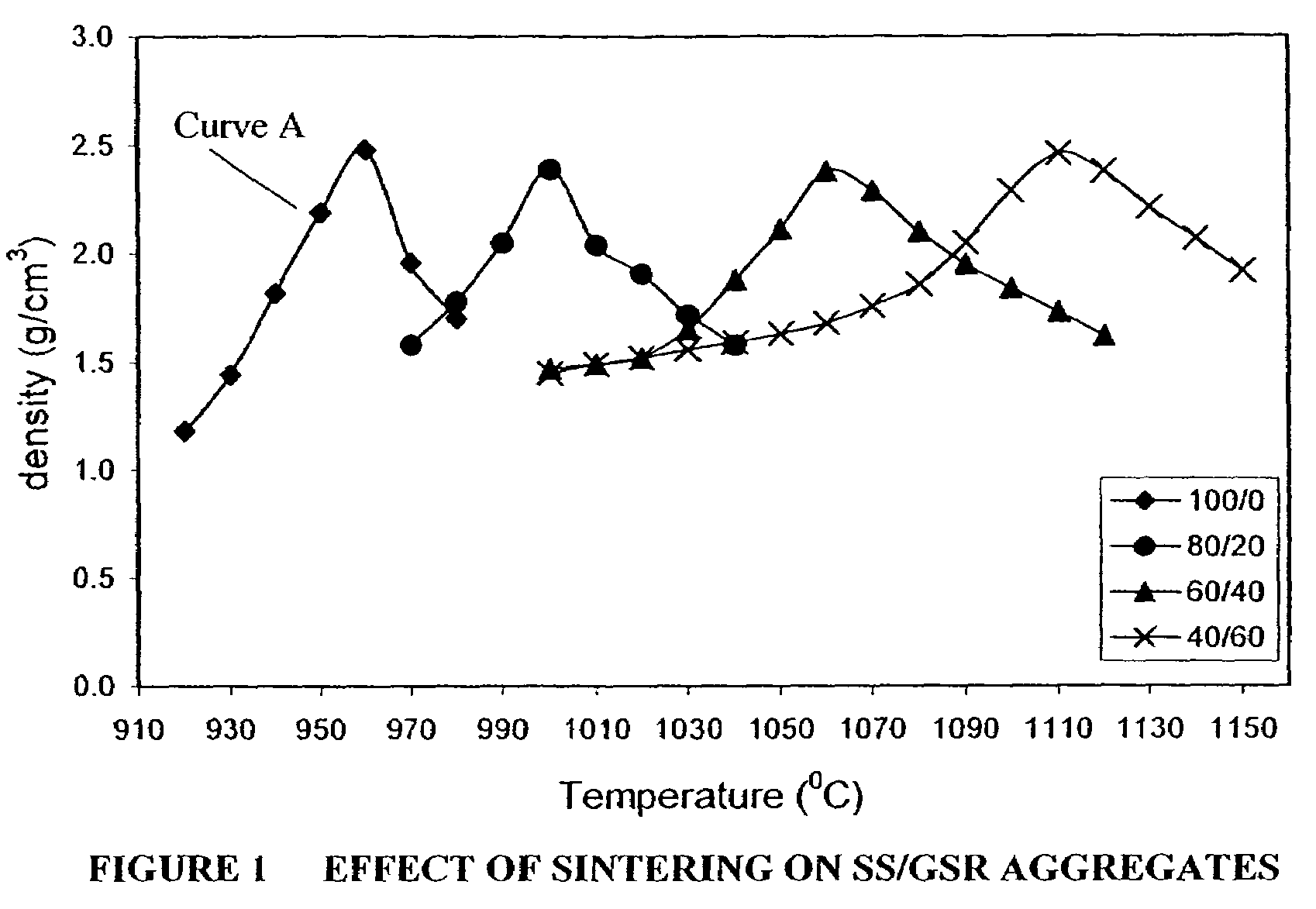

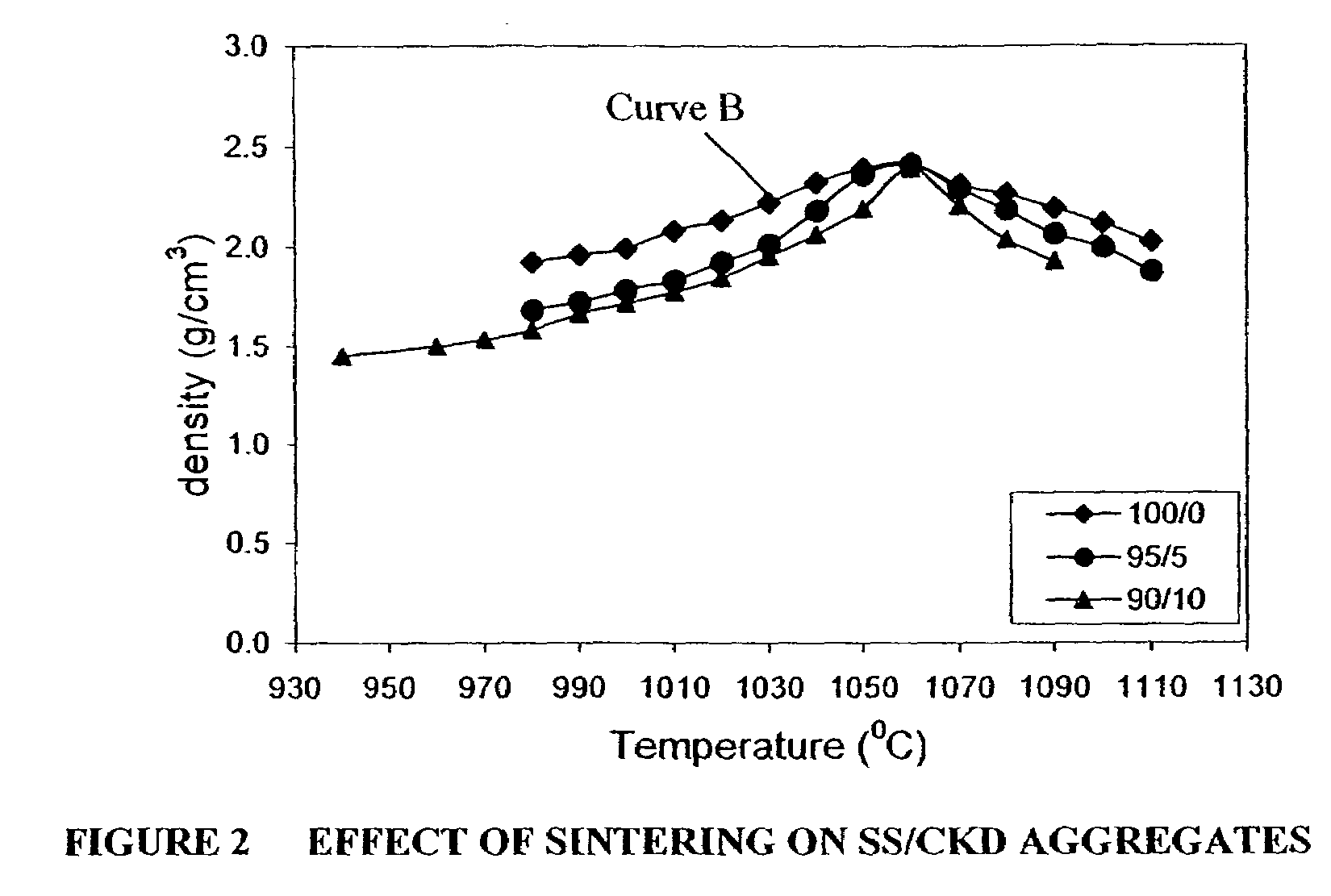

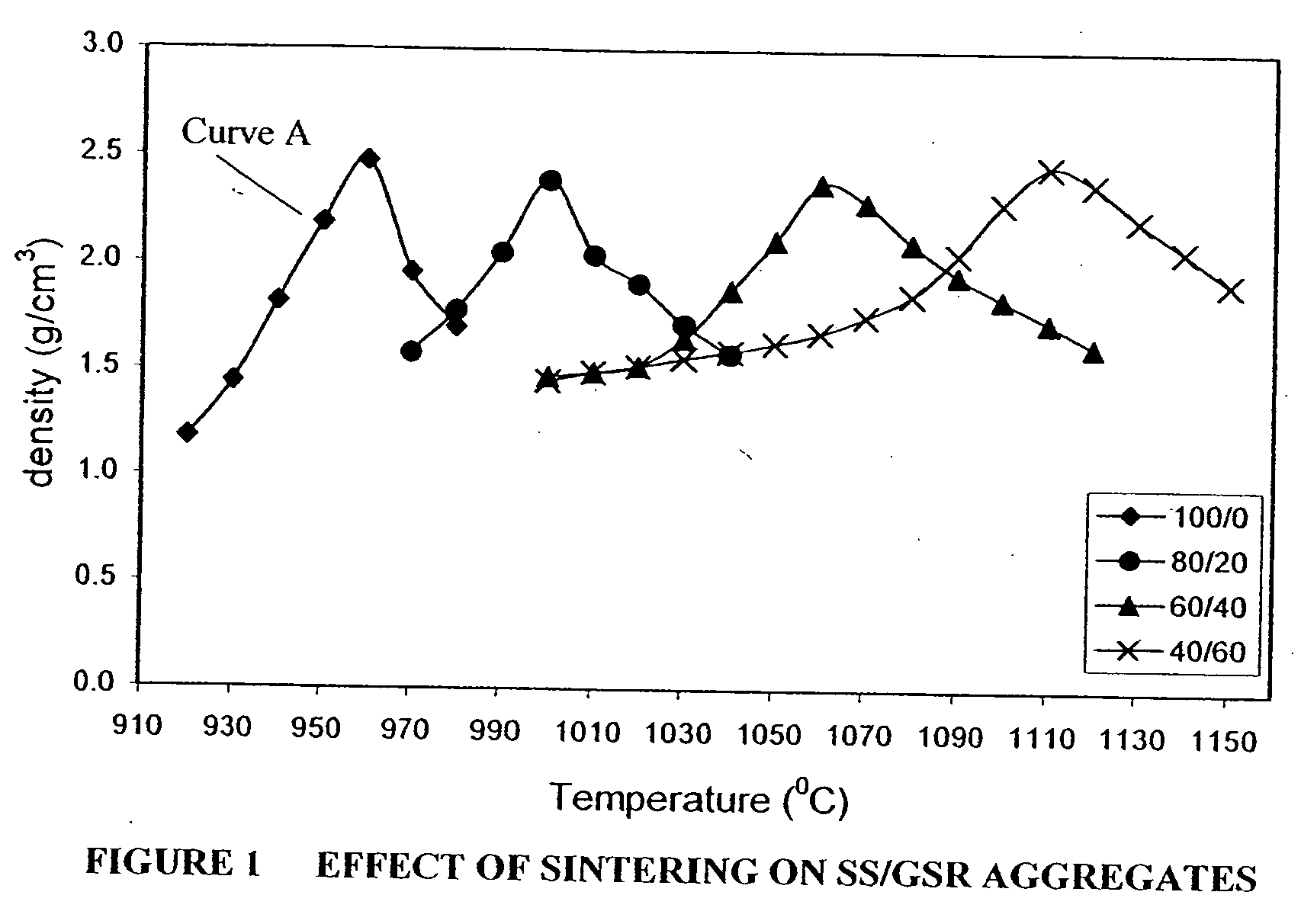

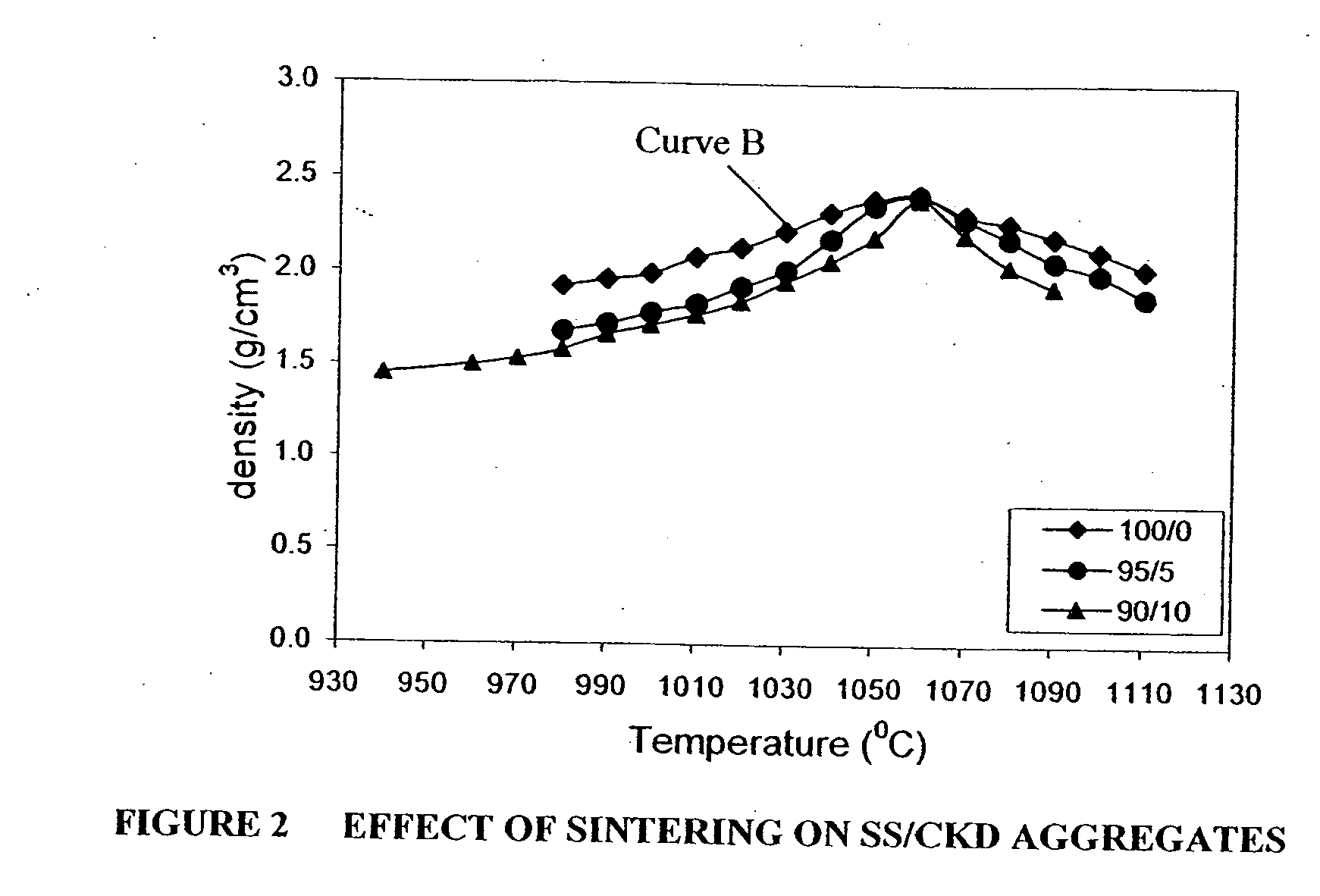

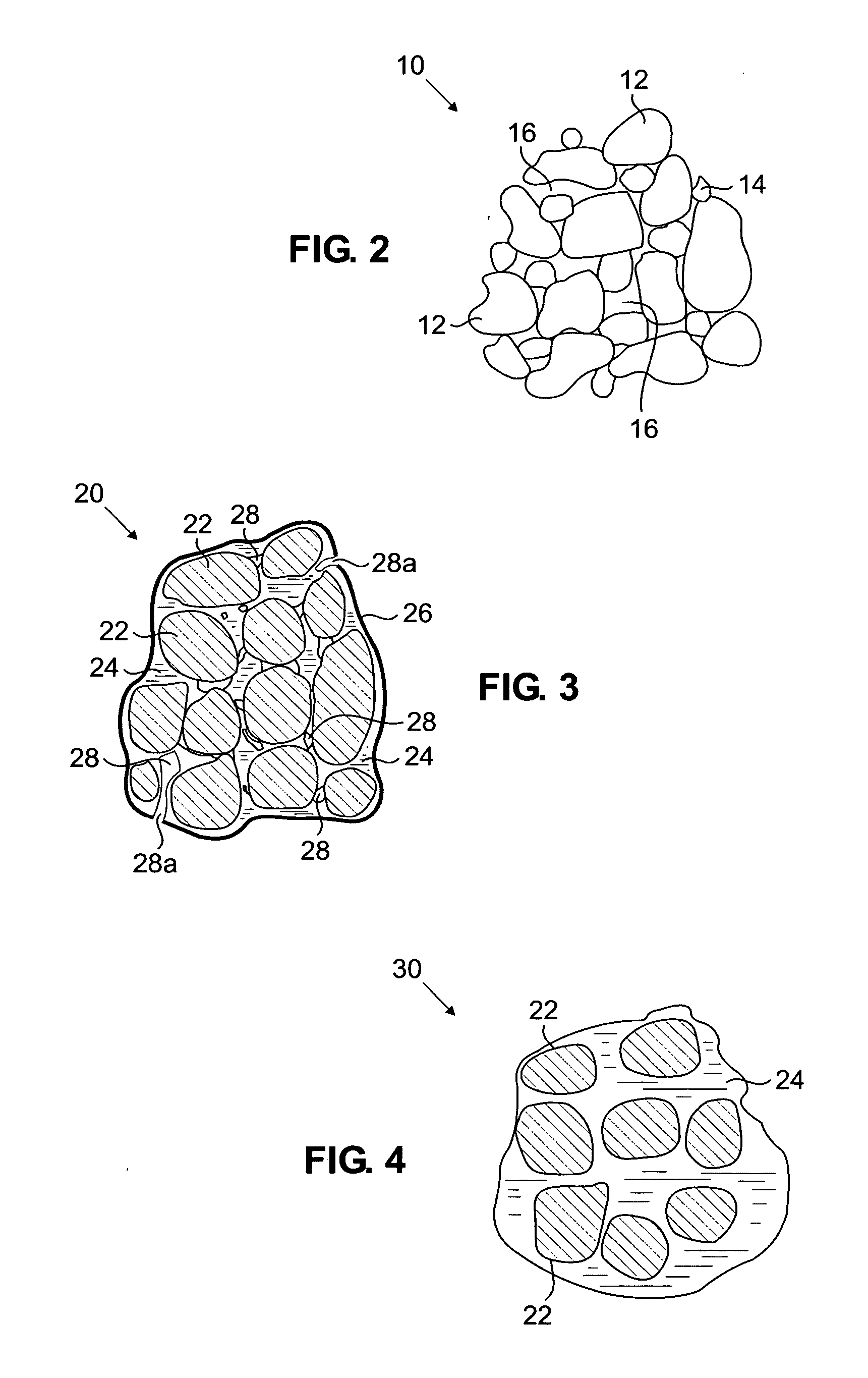

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

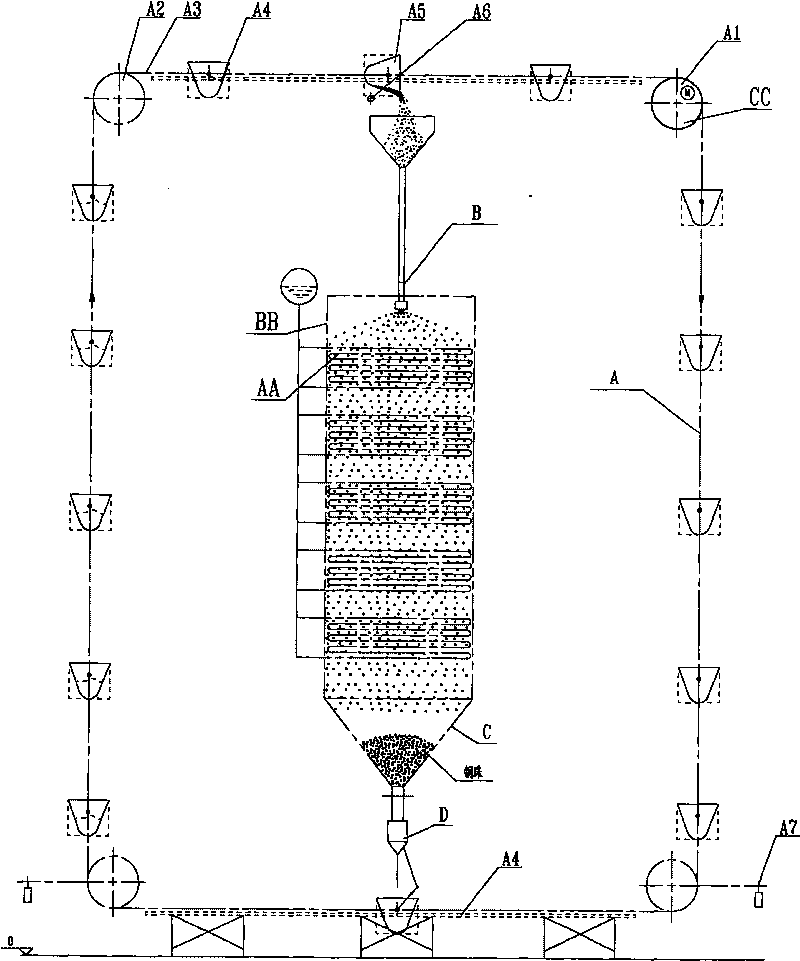

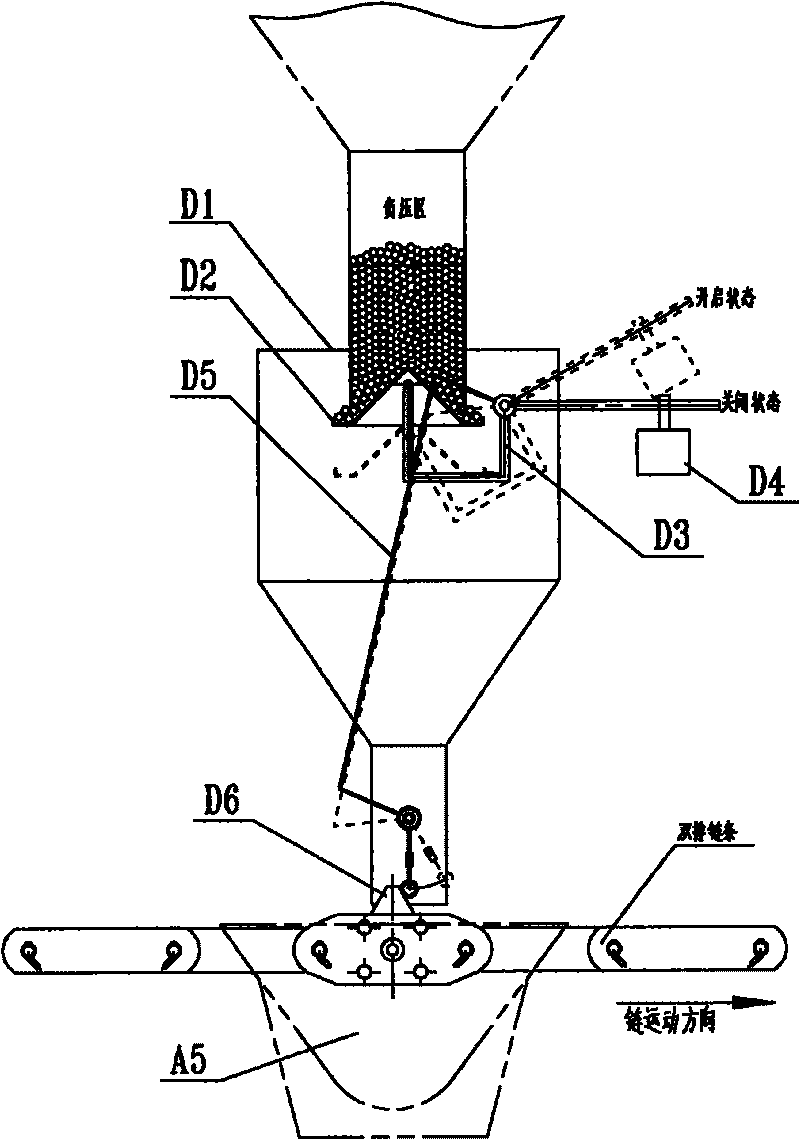

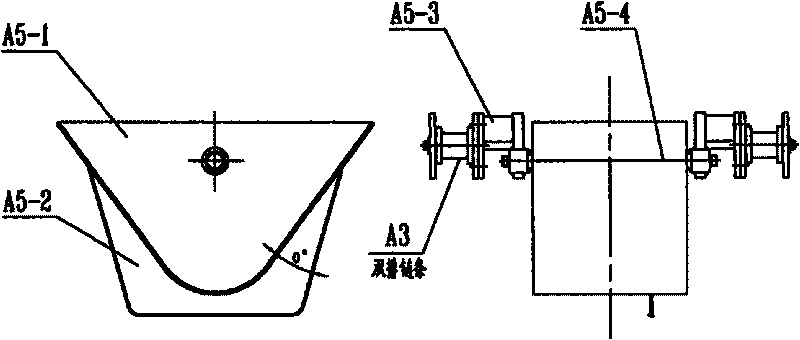

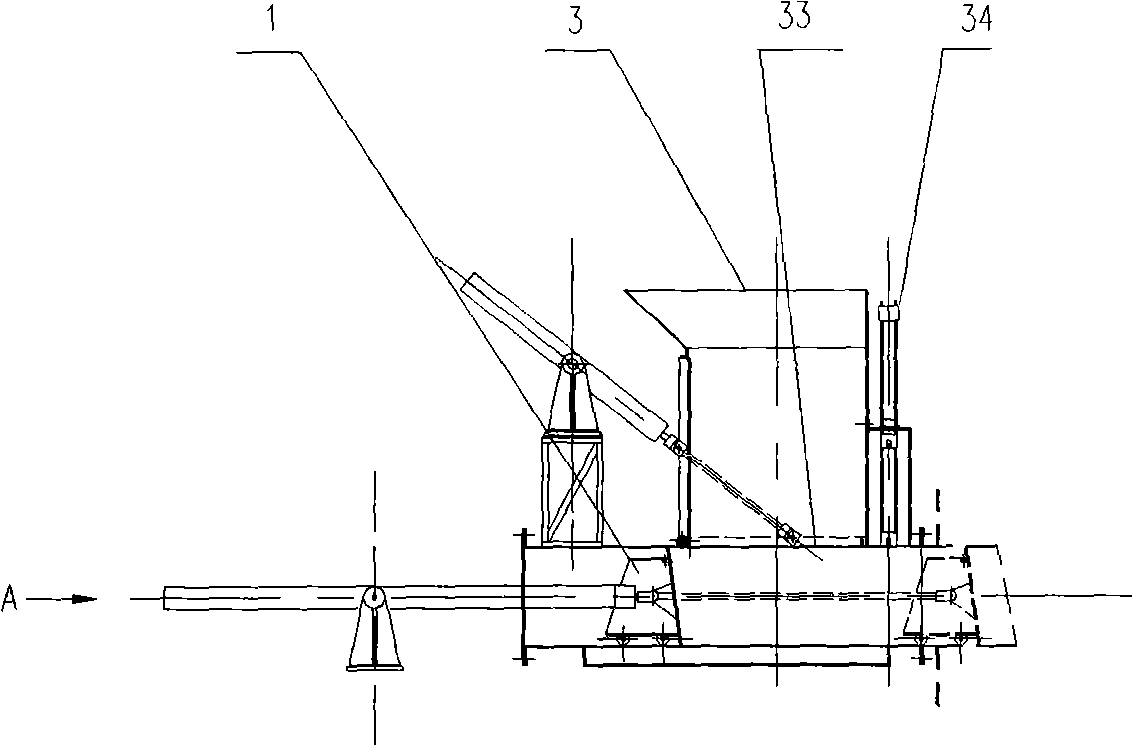

Residual heat boiler of steel ball dedusting type ore heat furnace

ActiveCN101701775AEfficient removalGuaranteed uptimeIncreasing energy efficiencySolid removalBottom ashDrive wheel

The invention relates to a residual heat boiler of a steel ball dedusting type ore heat furnace. The residual heat boiler at least comprises a boiler heated surface, a seal boiler flue gas passage, a furnace top and a furnace bottom ash hopper, wherein the boiler heated surface comprises coil pipe groups; and the seal boiler flue gas passage is formed at the periphery of the boiler heated surface. The residual heat boiler is characterized in that the furnace top is provided with a steel ball spreading device, a steel ball separating and collecting device is arranged under the furnace bottom ash hopper; a circulating type steel ball mechanical transporting device is arranged between the steel ball spreading device and the steel ball separating and collecting device; the circulating type steel ball mechanical transporting device comprises at least one drive wheel, at least three driven wheels, a double-row chain, a horizontal guide rail, a steel ball transporting hopper and a mechanical discharge blocking wheel; the at least one drive wheel and the at least three driven wheels are fixed on a boiler frame, and the steel ball transporting hopper is hung on the double-row chain surrounded between the drive wheels and the driven wheels; and the furnace top is provided with the mechanical discharge blocking wheel capable of turning over the steel ball transporting hopper. The invention has simple mechanism, recycled steel ball, mechanical automation running, low investment and running cost and favorable dedusting effect, and the like, can effectively remove and collect accumulated ash and sticking dust on the residual heat boiler heated surface of the ore heat furnace and greatly develops the energy-conservation and emission-reduction technology of the ore heat furnace smelting industry.

Owner:HANGZHOU HANGGUO INDUSTRIAL BOILER CO LTD

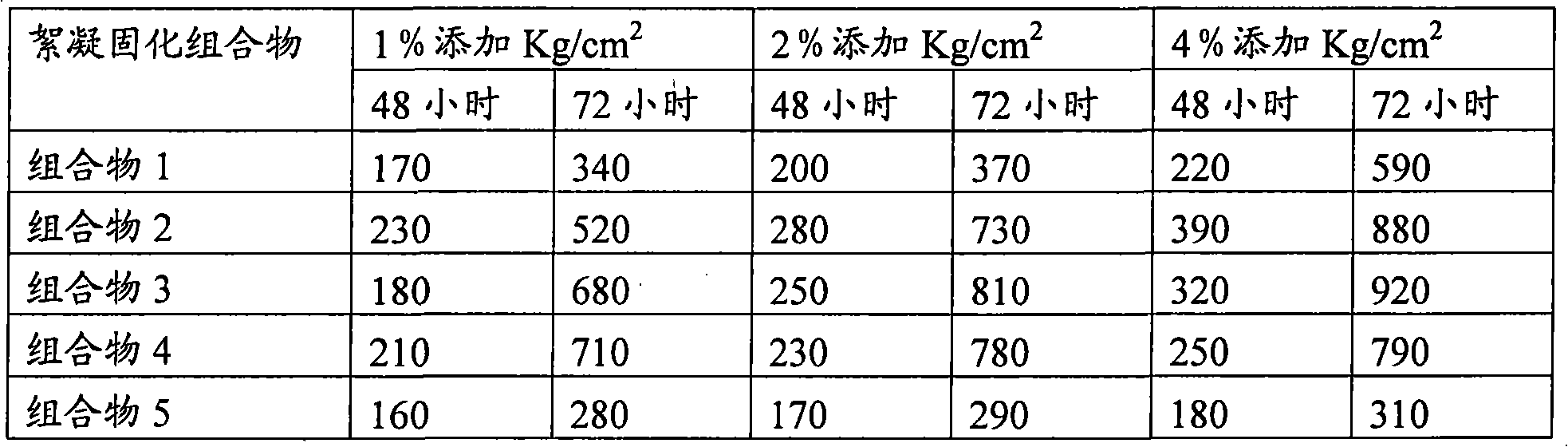

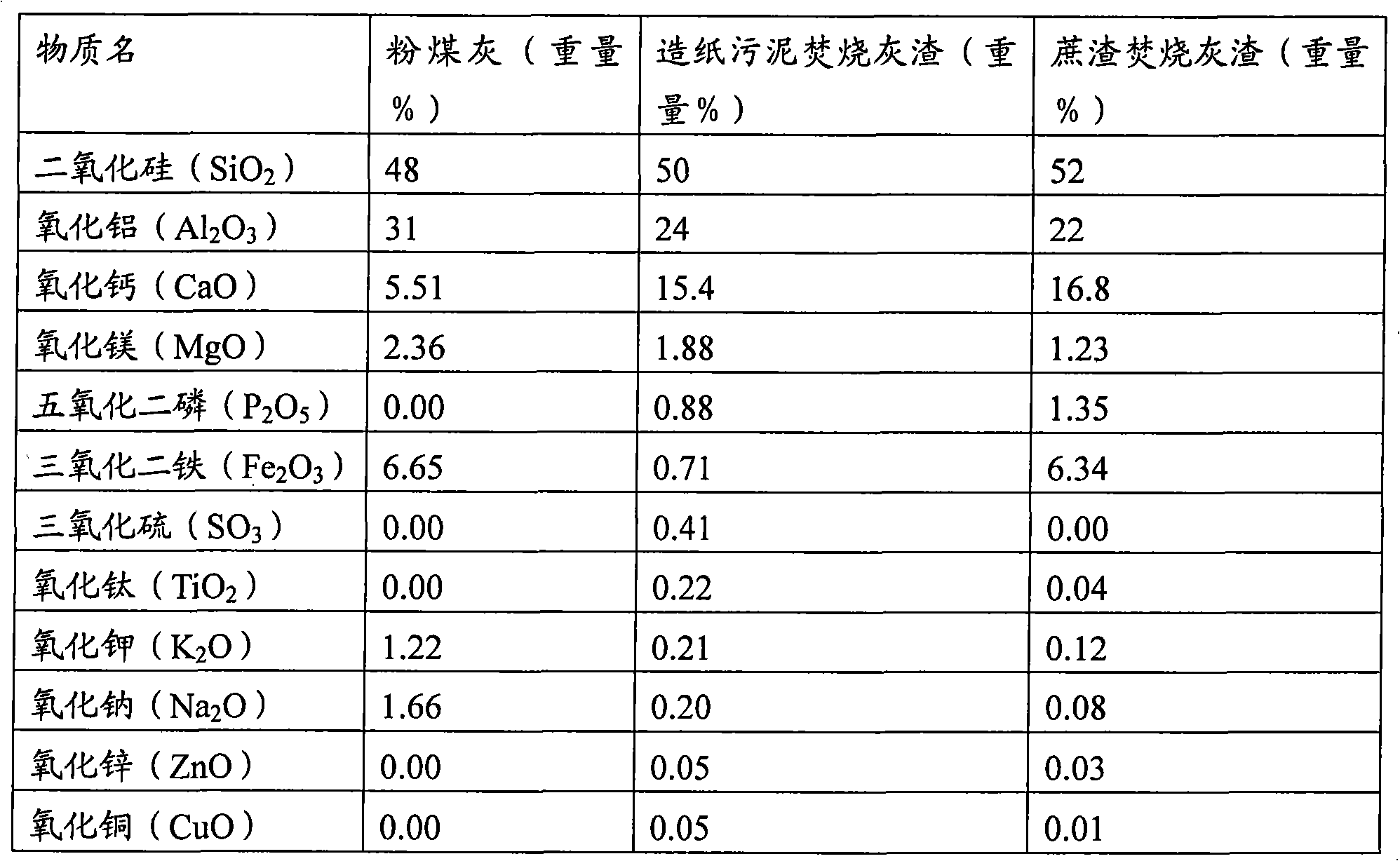

Flocculation curing agent, composition thereof and stabilization improvement method of silt type soil

Owner:株式会社安农津技研 +3

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

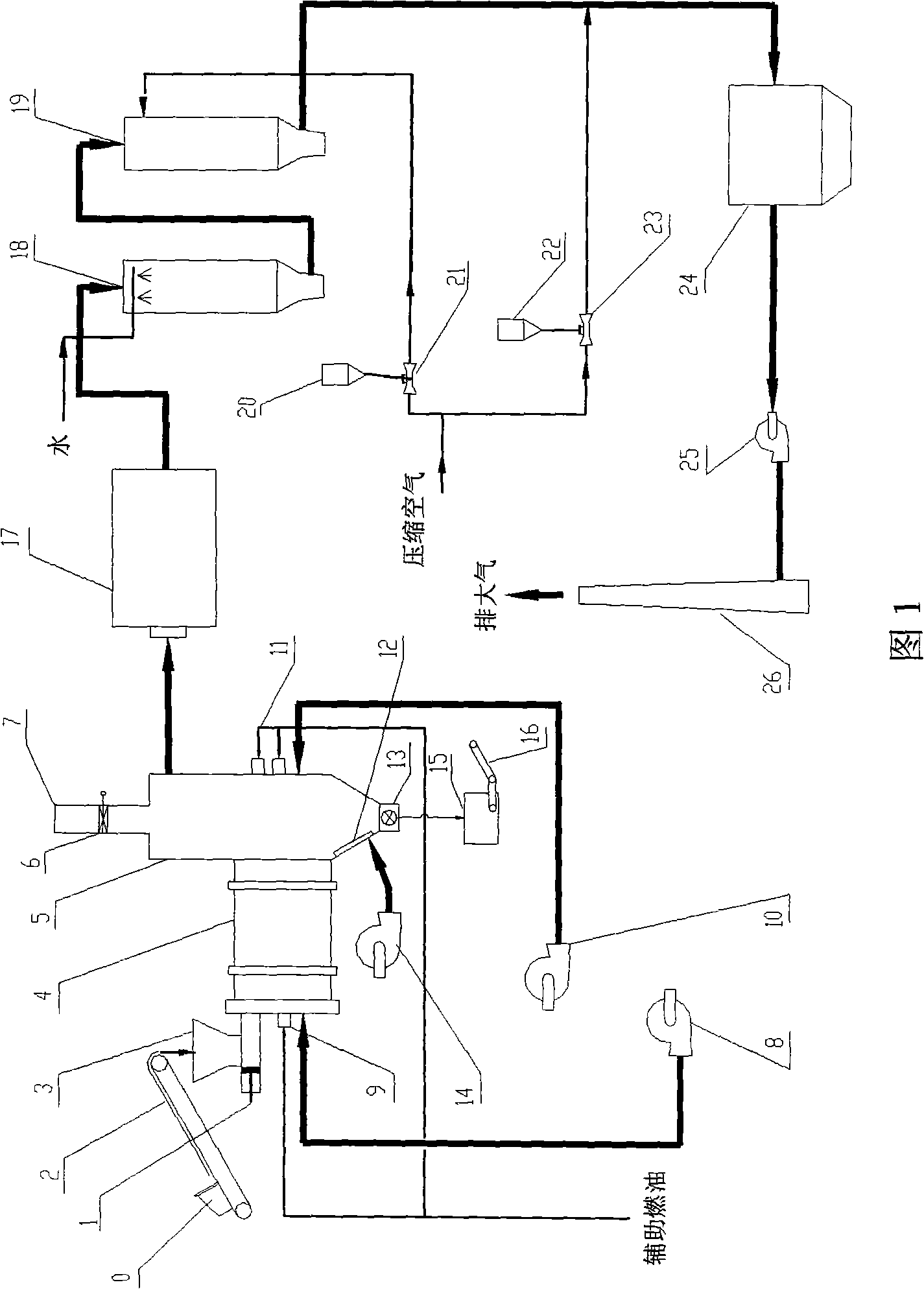

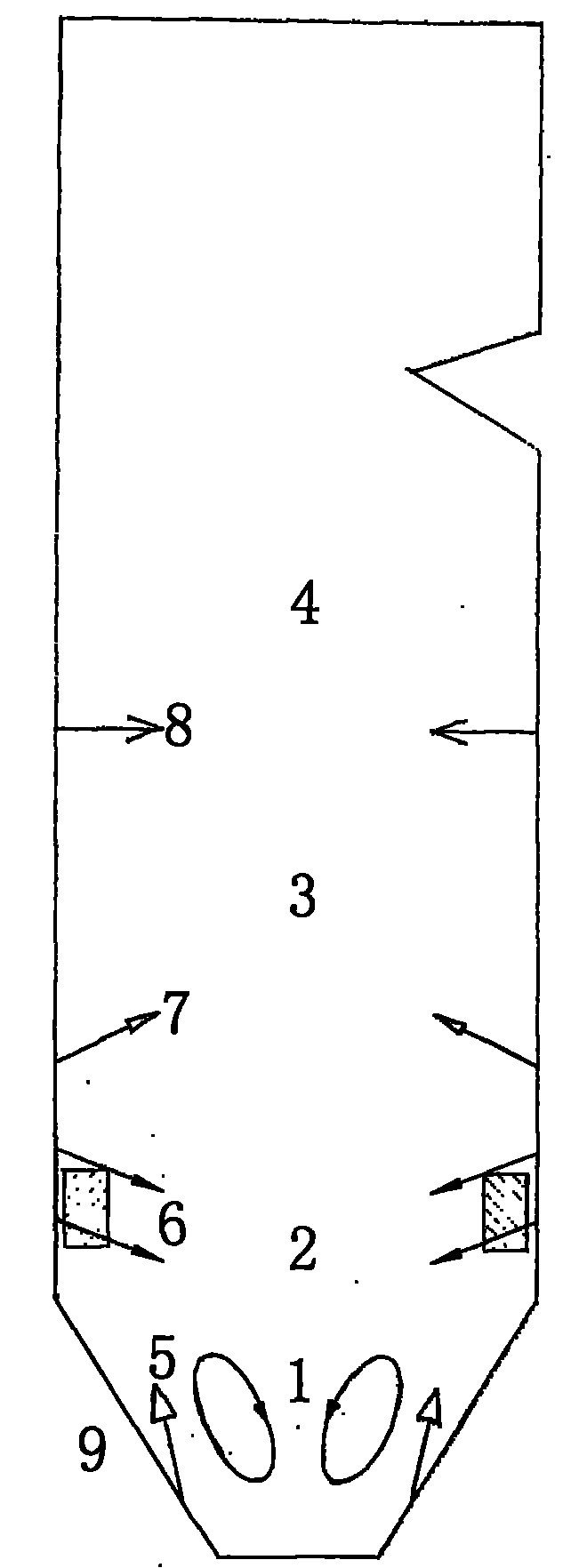

Pneumatic medical waste burning process for rotary kiln and device therefor

InactiveCN101285577AAvoid destructionAchieve turbulent combustionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberAtmospheric air

The invention discloses a process and a device for incinerating rotary kiln gas-controlled medical waste, relating to the environmental protection technical field. The process of the invention comprises the following steps of: collecting the whole packet of medical waste refuse bag and feeding into a feeding hopper, then feeding into a rotary kiln initial combustion chamber by a feeding mechanism which is closed by chain, and completing the processes of drying, pyrolyzing and air controlled anoxycausis of the medical waste. Waste gas generated by the rotary kiln initial combustion chamber enters to a secondary combustion chamber to undergo the process of air controlled oxygen-enriched complete combustion, wherein bottom ash with a little redial carbon is flamed at an inclined fire grate which is arranged in an ash well at the lower part of the secondary combustion chamber. The smoke gas at an outlet of the secondary combustion chamber is exhausted into the atmosphere by a draft fan through a chimney after surplus heat utilization of a surplus heat boiler, smoke gas sharp quenching of a quench tower, a dry-type deacidification and cloth-bag dust removal of a bag-type duster. Compared with the prior art, the process and the device for incinerating rotary kiln gas-controlled medical waste have the advantages of good operating economical efficiency, automatic safety continuous feeding, fluent slag tapping system and low index of pollution emission.

Owner:TSINGHUA UNIV +1

Incombustible composition, incombustible construction product using incombustible composition, and method of producing incombustible construction product

InactiveUS20050066859A1High hardnessHigh strengthSolid waste managementCeramicwareFiberFire retardant

Disclosed is an incombustible composition, an incombustible construction product using the incombustible composition, and a method of producing the incombustible construction product. The incombustible composition includes 1 to 80 wt % of organic or inorganic fiber, 1 to 80 wt % of fly ash or bottom ash, 1 to 80 wt % of fire-proofing agent, and 1 to 60 wt % of fire-retardant curing agent. Additionally, the method includes mixing components, constituting the incombustible composition, with each other, and shaping the incombustible composition using a roller press or an autoclave. Therefore, the incombustible composition is advantageous in that it is environmentally-friendly because it contains waste materials, and that it has excellent hardness, strength, and water resistance. Other advantages are that its production costs are relatively low, and that it has excellent incombustibility, depending on the contents of the components constituting the incombustible composition.

Owner:CHOI JUN HAN

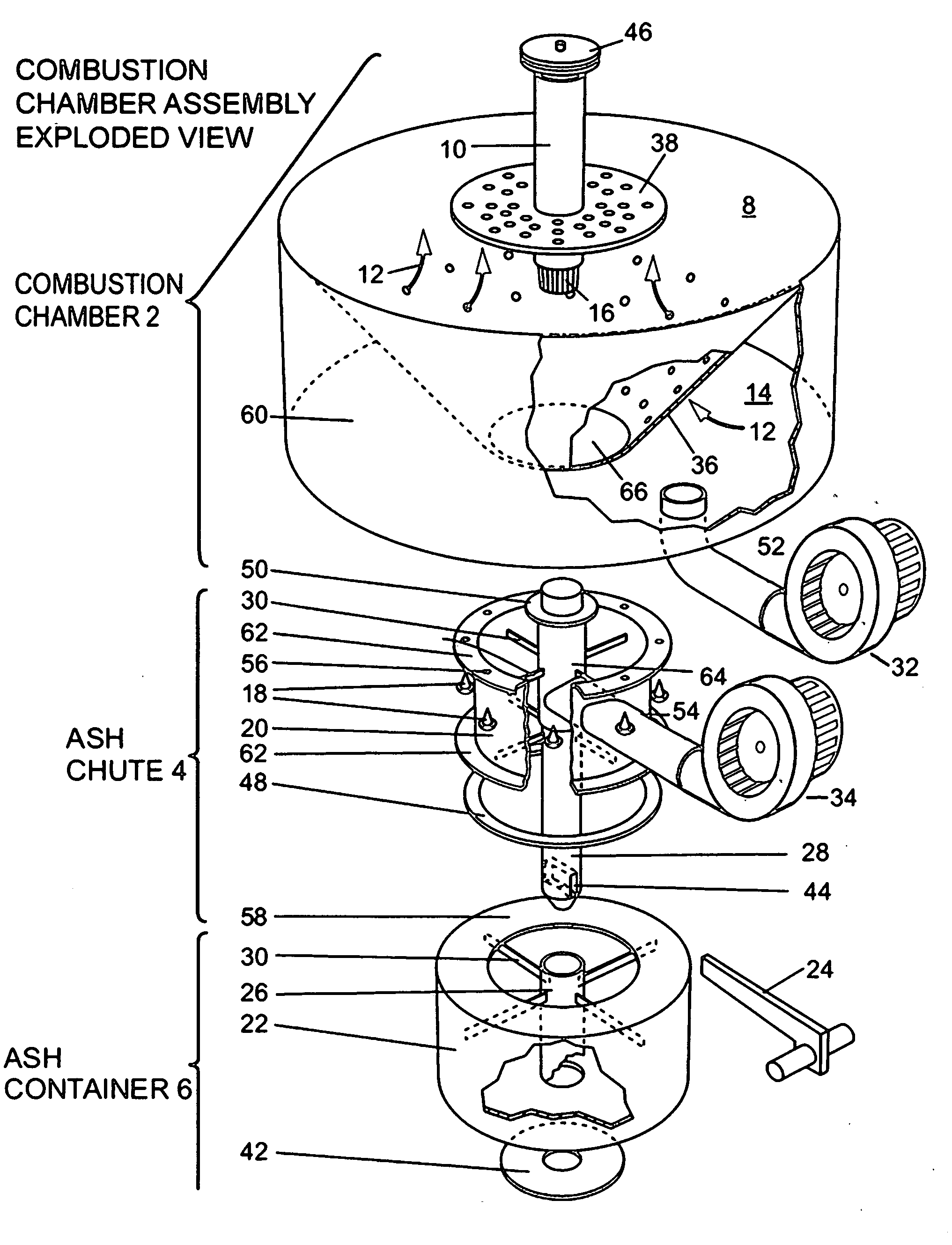

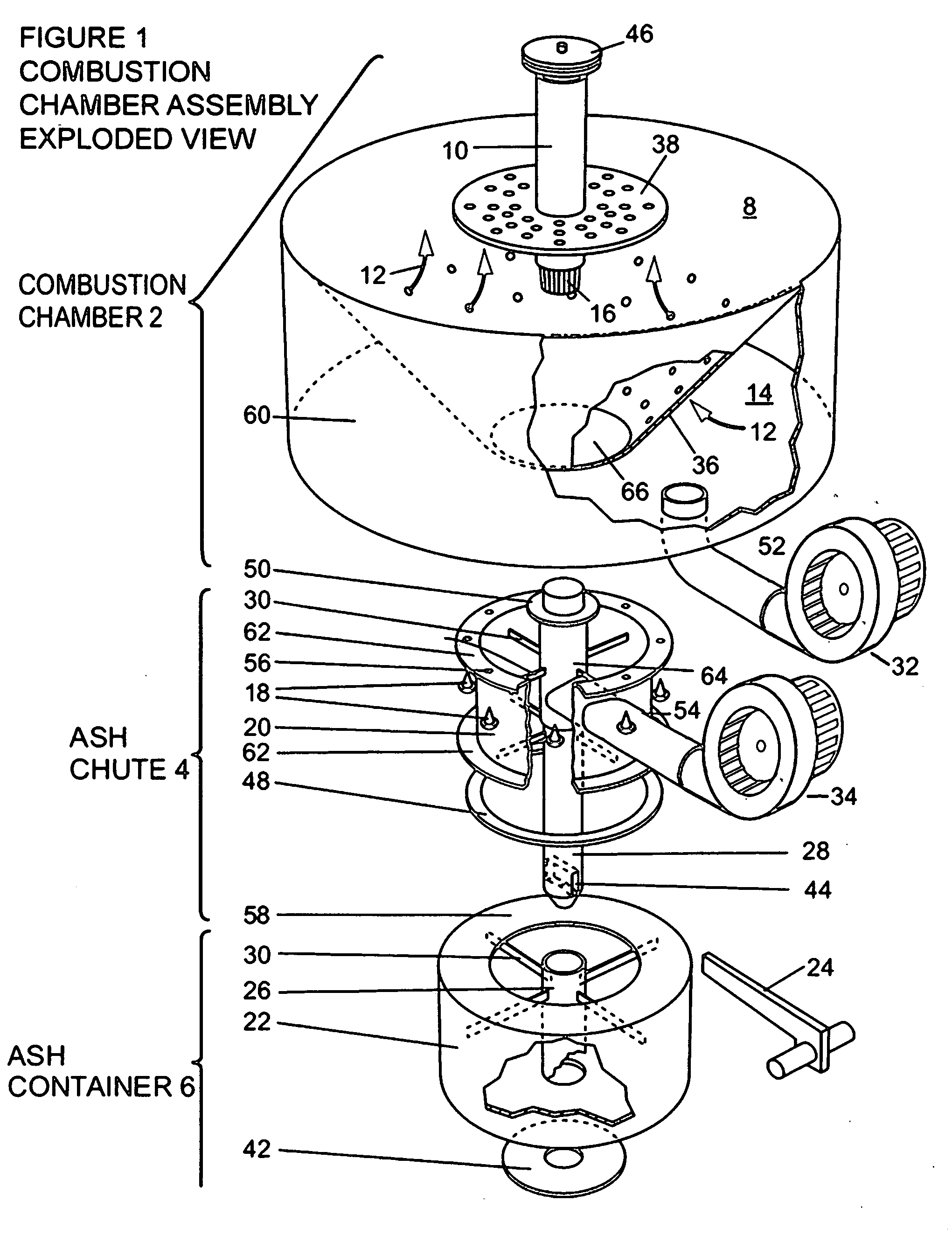

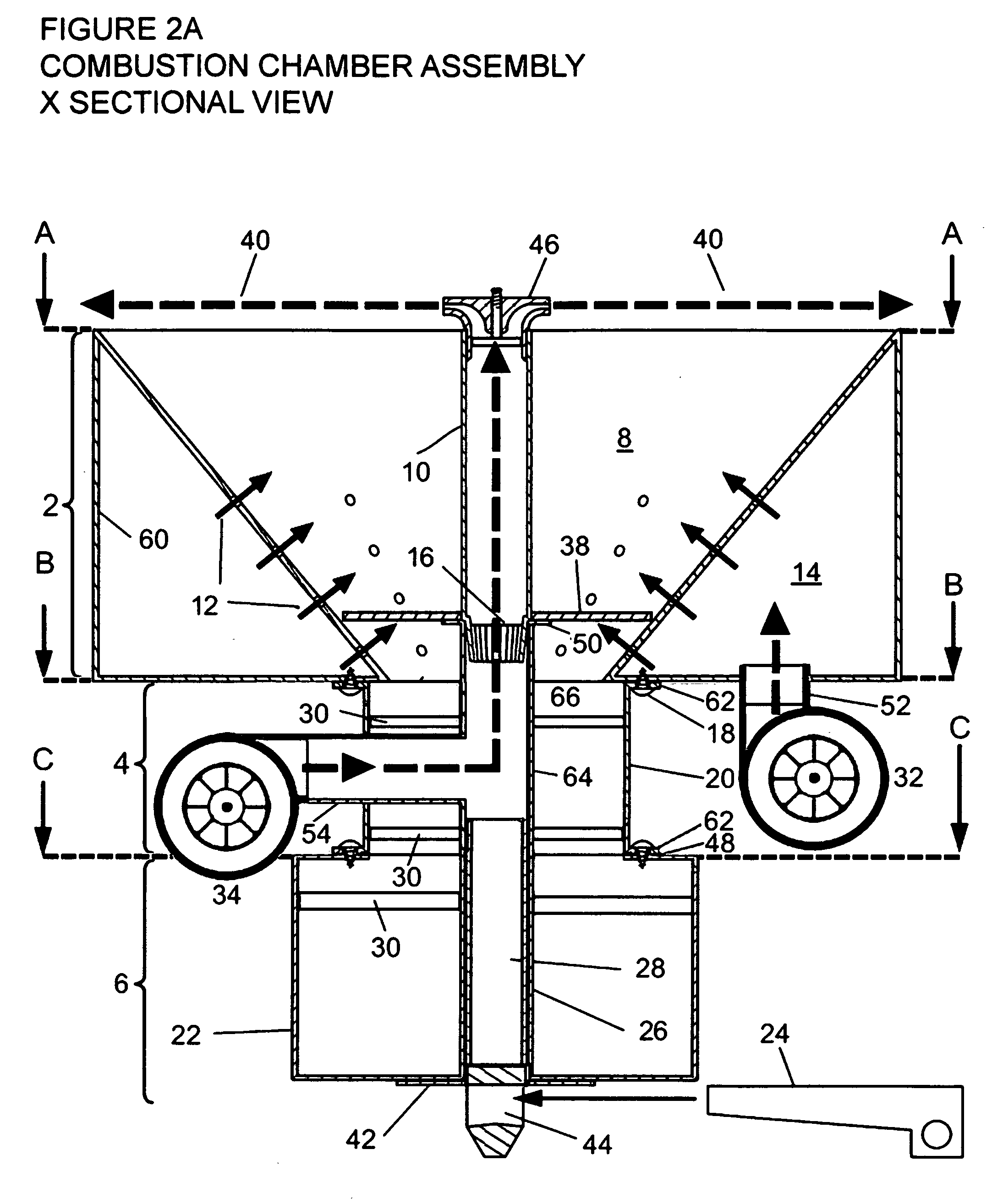

Charcoal / Air BBQ Combustion Chamber Assembly

InactiveUS20090056695A1Master quicklyPrevents excessive and contaminationStoves/ranges with convection heatingCapillary burnersBottom ashCombustor

An open “funnel shaped” Inner Burner inside an open top Outer Casing. The casings closed base has a central hole accommodating the burners small open bottom Ash Exit. The space between the Inner Burner wall and Outer Casing wall forms an Annular Air Plenum that's supplied by an electric variable speed blower. Air enters the Burner Combustion space through perforations in the Burner / Plenum wall. This ensures rapid ignition and controls combustion rate (Temp). This also precipitates ash from burner Ash Exit, through the Ash Chute and into Storage Container fitted to outer casings base. A Radial diffuser centered on the heating surface provides a variable speed Lateral Air Sheet between heating and grill surfaces, instantly blowing “Smoke and Flare-Ups” to the outer burner perimeter. Unit is designed as a “Drop-In” unit to fit a manufacturer BBQ cart suitably equipped to specify basic installation requirements.

Owner:BARRY COSGROVE

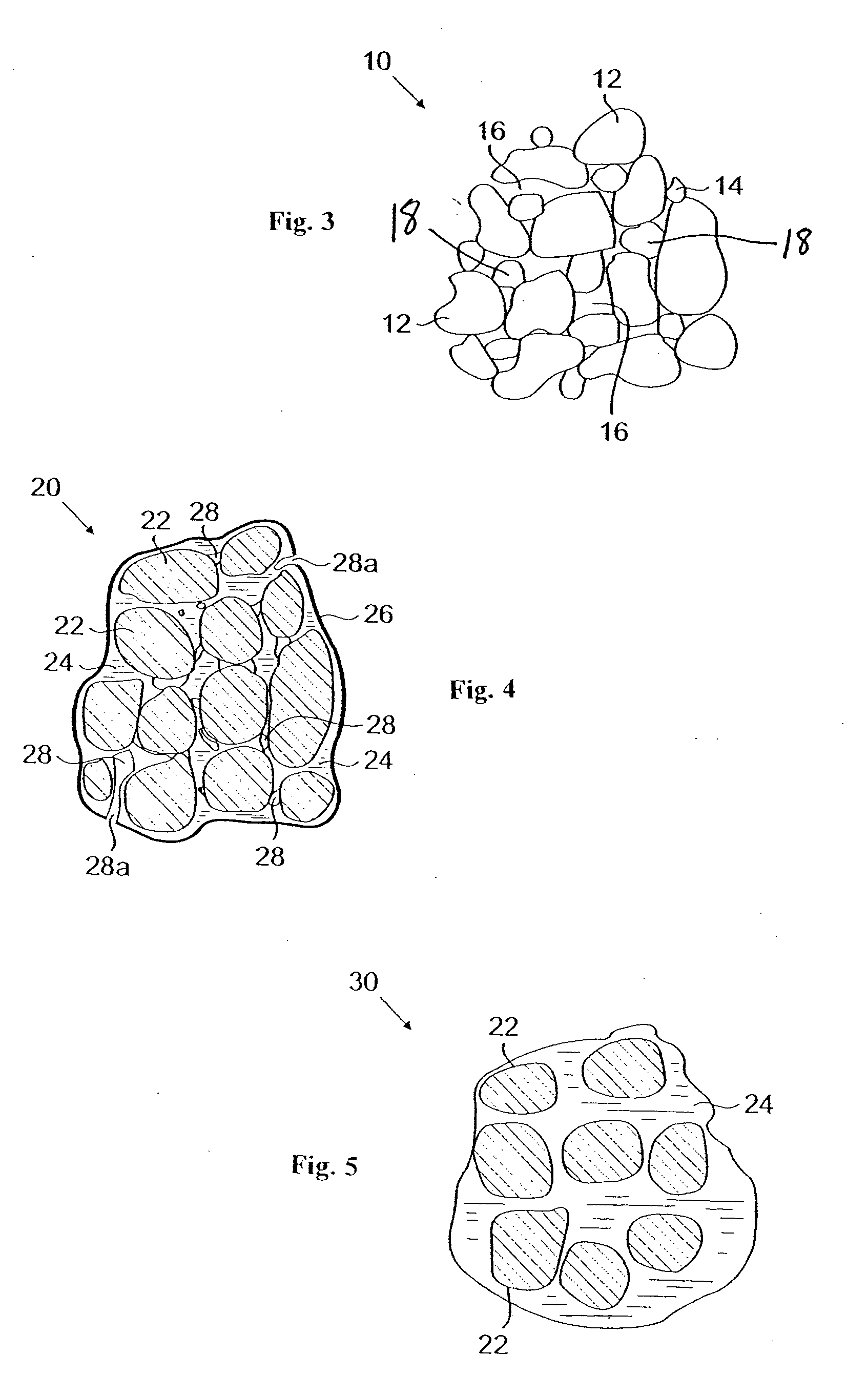

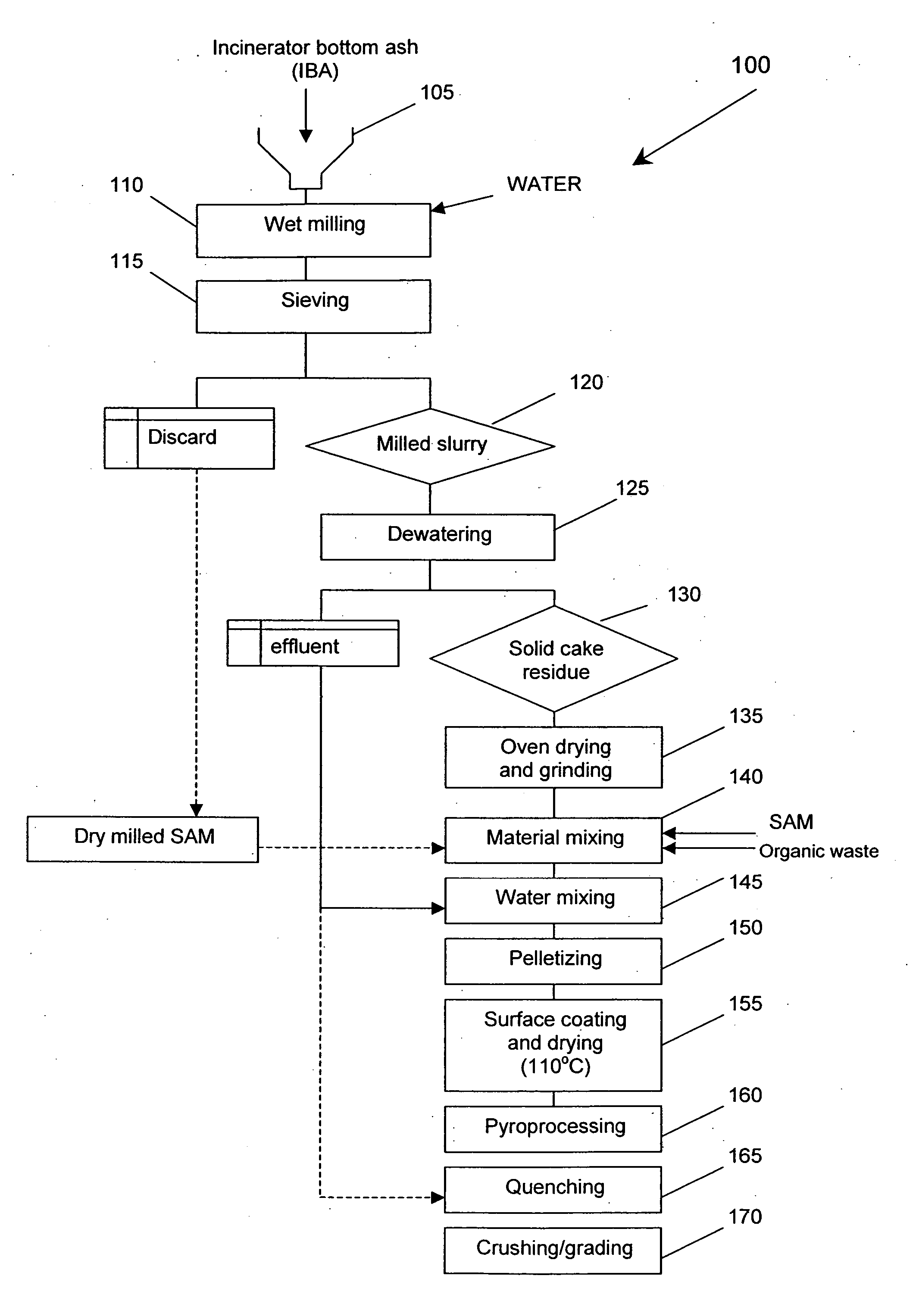

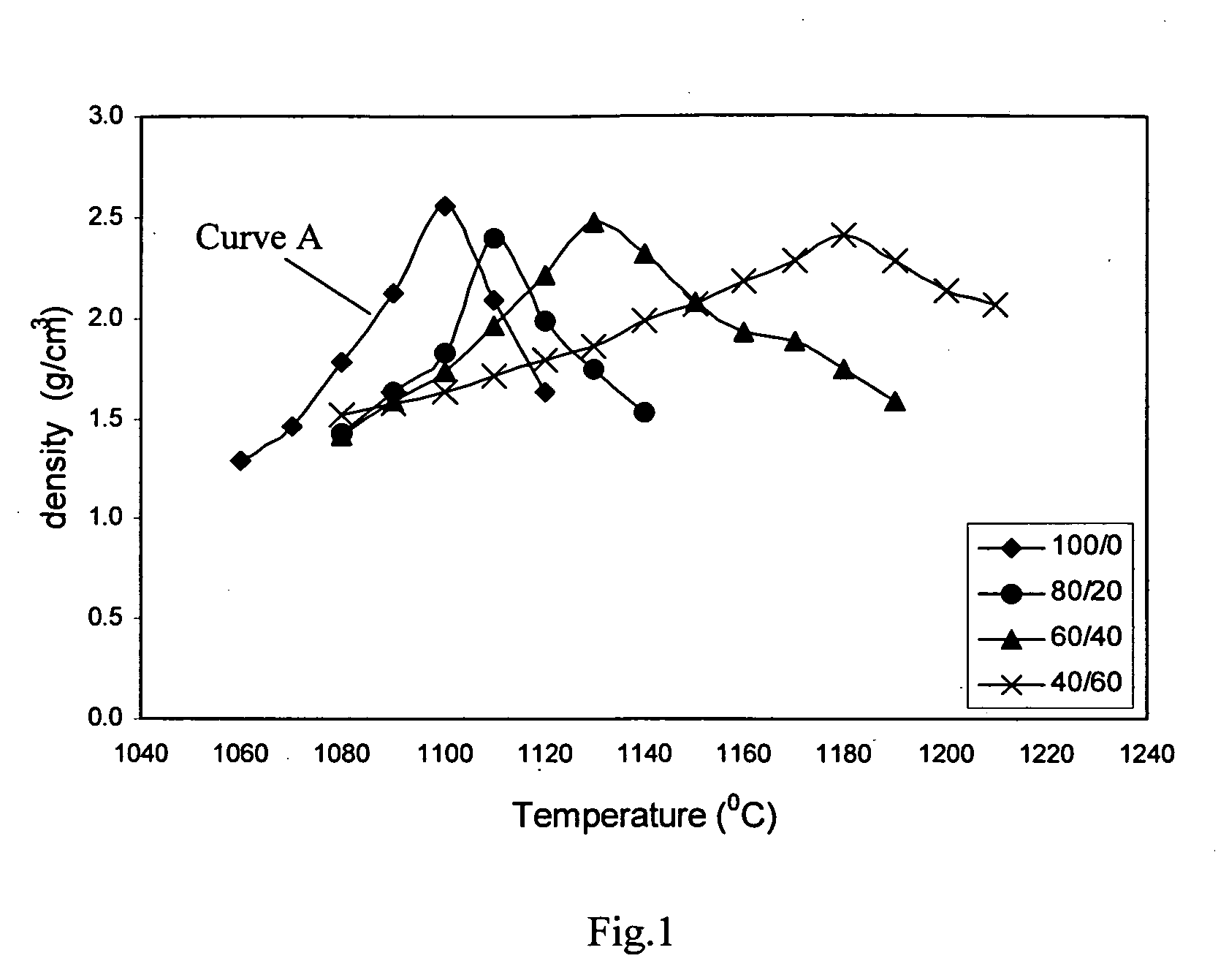

Pyroprocessed aggregates comprising IBA and low calcium silicoaluminous materials and methods for producing such aggregates

InactiveUS20060162619A1Big economySignificant environmental benefitsPigmenting treatmentOther chemical processesBottom ashVitrification

In accordance with an embodiment, a method for producing an aggregate is disclosed comprising mixing IBA and a second, silicoaluminous material having a calcium content less than the IBA. The method further comprises agglomerating the mixture, such as by pelletizing, and pyroprocessing the agglomerates, such as by sintering or vitrification, to form the aggregate. The second material may be a clay, such as bentonite or kaolin, a mining waste, such as granite sawing residues, waste glass, or furnace bottom ash, for example. The addition of the second material has been found to facilitate production of lightweight and normal weight aggregates. Preferably, the IBA or the mixture of IBA and the second material are wet milled prior to agglomeration. A lightweight sintered aggregate comprising IBA and the second material and an aggregate comprising IBA and the second material are also disclosed.

Owner:ALKEMY

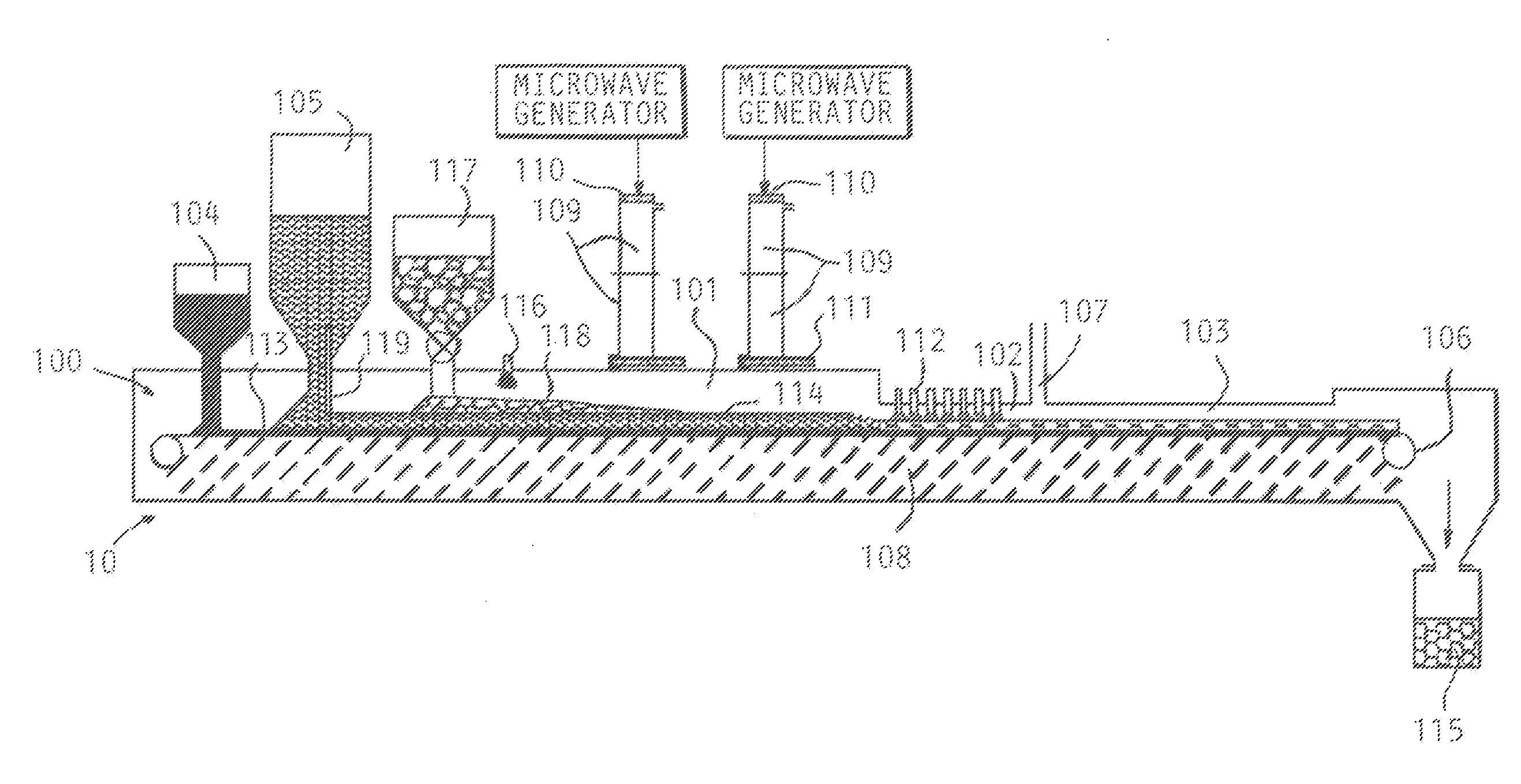

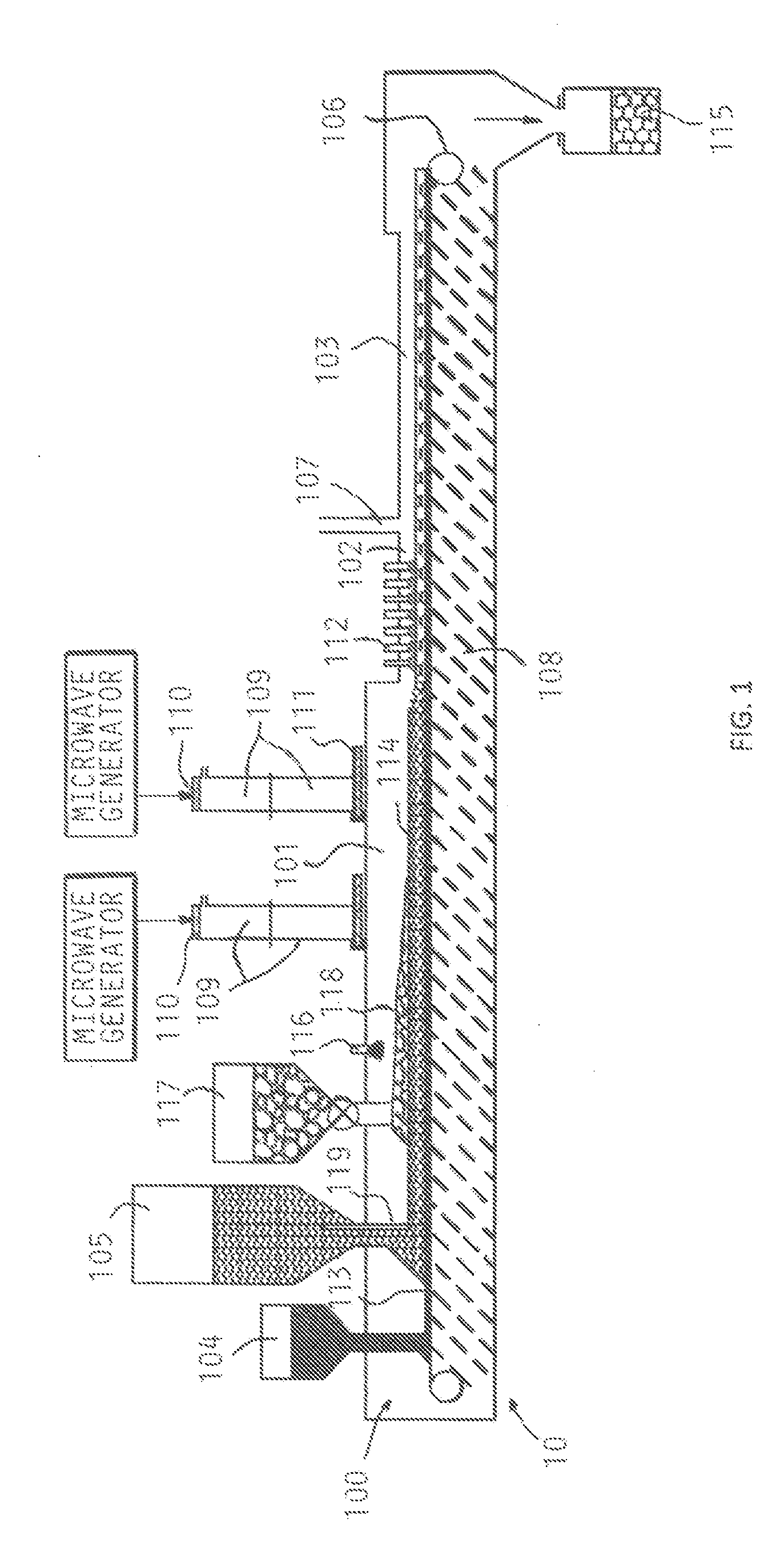

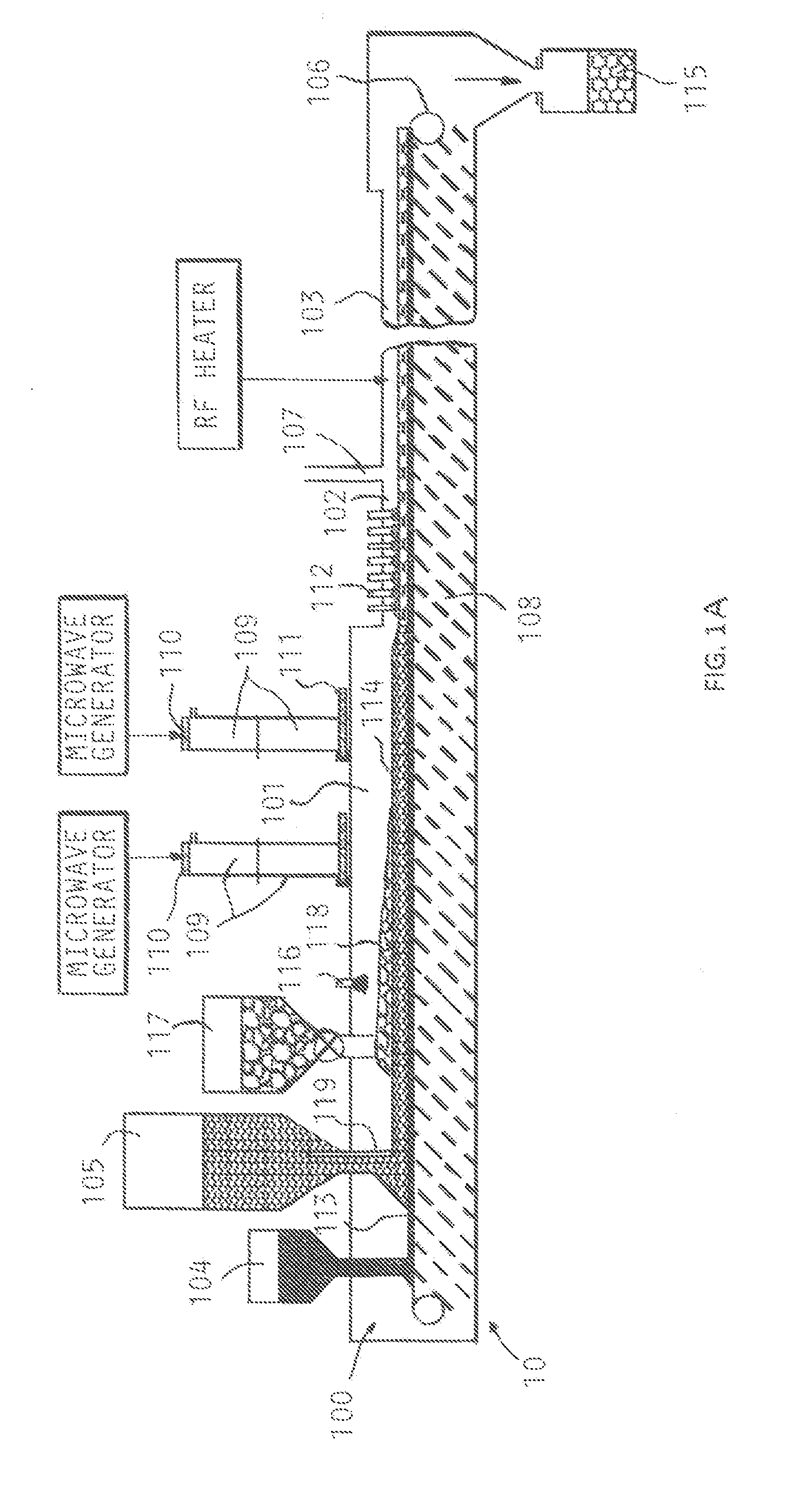

Method and Apparatus For Coproduction of Pig Iron and High Quality Syngas

ActiveUS20120031232A1Improve microwave absorption performanceHeating up fastBlast furnace detailsCharge manipulationSludgeLiquid fuel

Combined microwave heating and plasma / electric arc heating is utilized in several processes and apparatus which involve co-production of pig iron and high quality syngas, biomass to liquid fuel production, coal to liquid fuel production, co-gasification of biomass and coal, municipal solid waste treatment, waste-to-energy (agriculture waste, ASR and PEF), EAF dust and BOF sludge treatment to recover zinc and iron, hazardous bottom ash vitrification, and bromine, chlorine and sulfur removal / recycling.

Owner:HUANG XIAODI +1

Method of making building blocks from coal combustion waste and related products

InactiveUS6068803AIncreased formationHigh strengthOther chemical processesSolid waste managementBottom ashParticulates

A method of making a building block from waste particulate siliceous materials, such as fly ash, bottom ash, and rock mineral fines, includes employing a major amount of such waste particulate materials in combination with a calciferous additive and water to cure and shape the same under the influence of controlled pressure and temperature for a predetermined time to create building block which is characterized by a mineralogical crystalline phase. Preferred ratios of fine waste particulate material and coarser waste particulate materials are disclosed. The product produced by the method is also disclosed.

Owner:PITTSBURGH MINERAL & ENVIRONMENTAL TECH

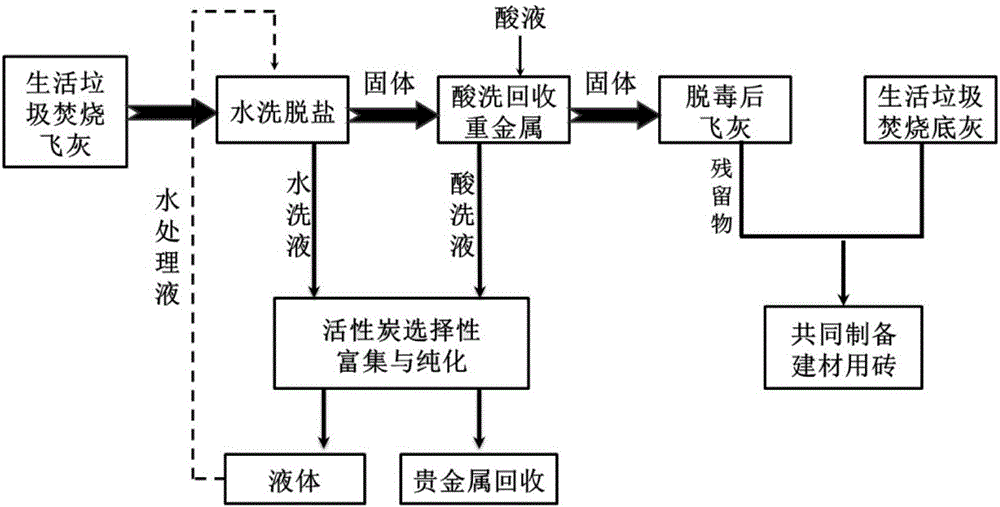

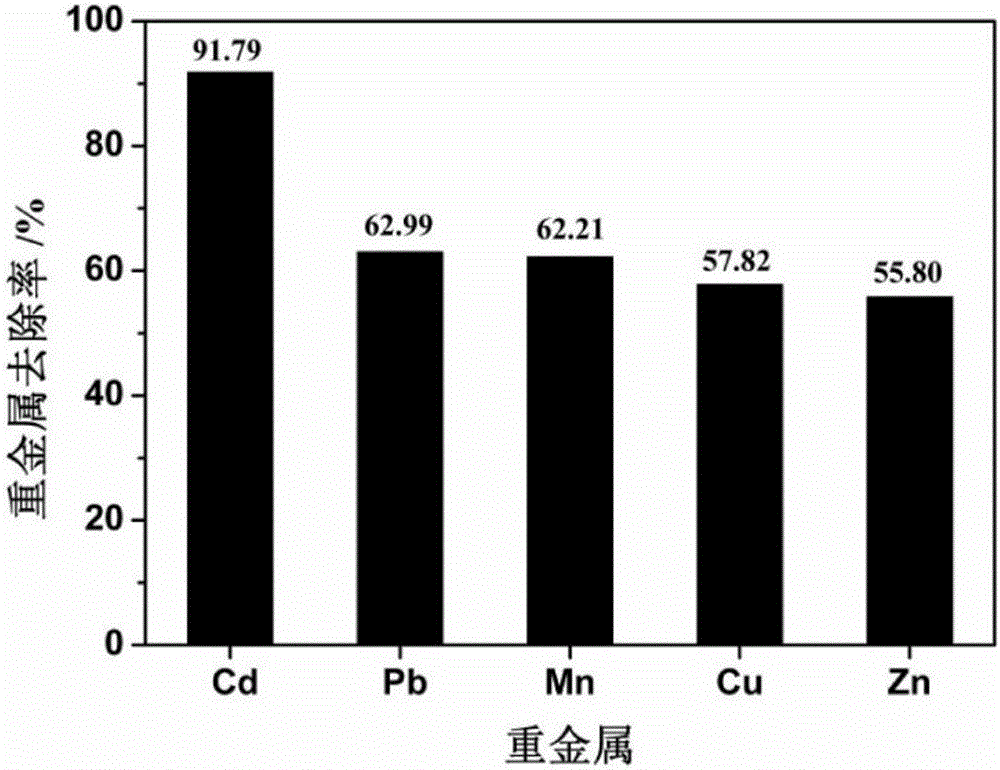

Detoxification graded resource utilization method for household garbage incineration fly ash

ActiveCN106282585AAddress high soluble salt contentSolving Chlorine ProblemsSolid waste disposalProcess efficiency improvementLiquid wasteBrick

The invention relates to a detoxification graded resource utilization method for household garbage incineration fly ash. The method includes the steps that the household garbage incineration fly ash is subjected to desalination and dechlorination through washing, and then subjected to heavy metal removal through acid pickling, and obtained detoxified fly ash and household garbage incineration bottom ash are compounded to prepare water permeable bricks; and a washing solution and an acid pickling solution are mixed, precious metal is enriched and purified selectively through activated carbon, and after soluble salt recovery is conducted on the residual liquid phase, obtained water treating fluid is reused in the washing step. By means of the detoxification graded resource utilization method, soluble salt, the chlorine element and the precious metal in the fly ash can be effectively removed, and the leaching toxicity of residual heavy metal in the fly ash completely meets the national standard; and meanwhile, the precious metal and the soluble salt in the fly ash are effectively recovered, and cyclic utilization of waste liquid and activated carbon is guaranteed. The method has the advantages that energy is saved, the method is ecological and environmentally friendly, resources are recycled, and waste is turned into wealth; and meanwhile, the detoxified fly ash can be safely applied to the industries including construction, environmental protection and the like, and the application and popularization value is quite high.

Owner:中陕核生态环境有限公司

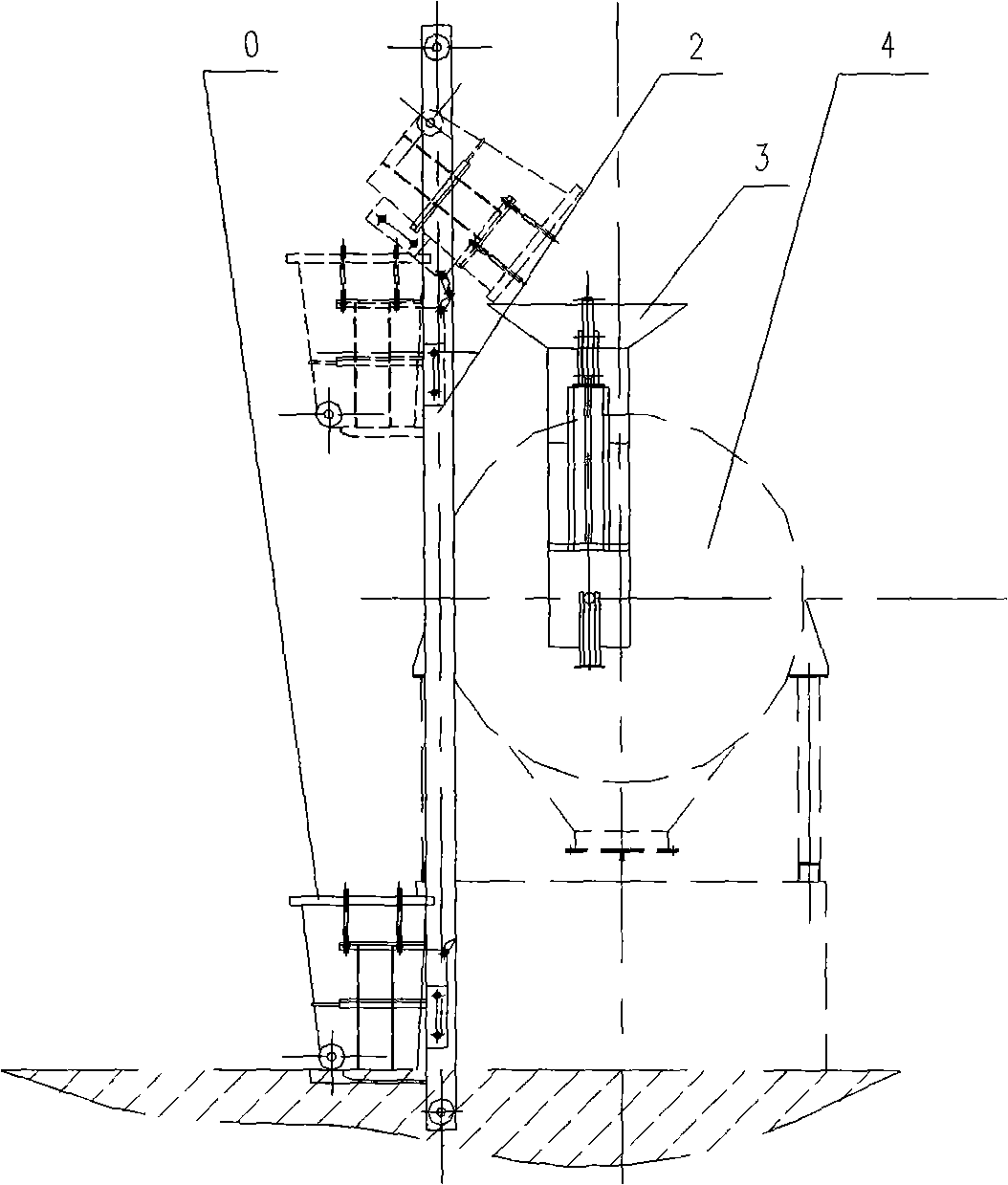

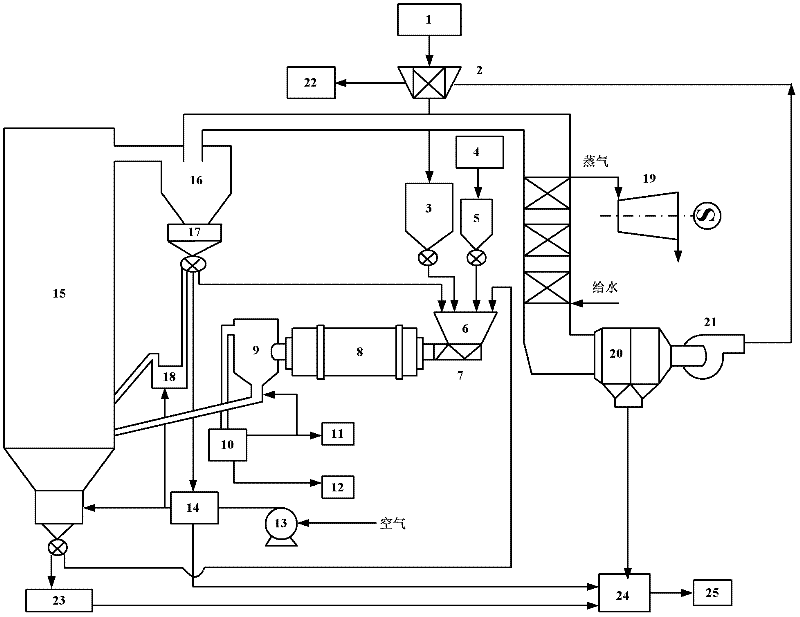

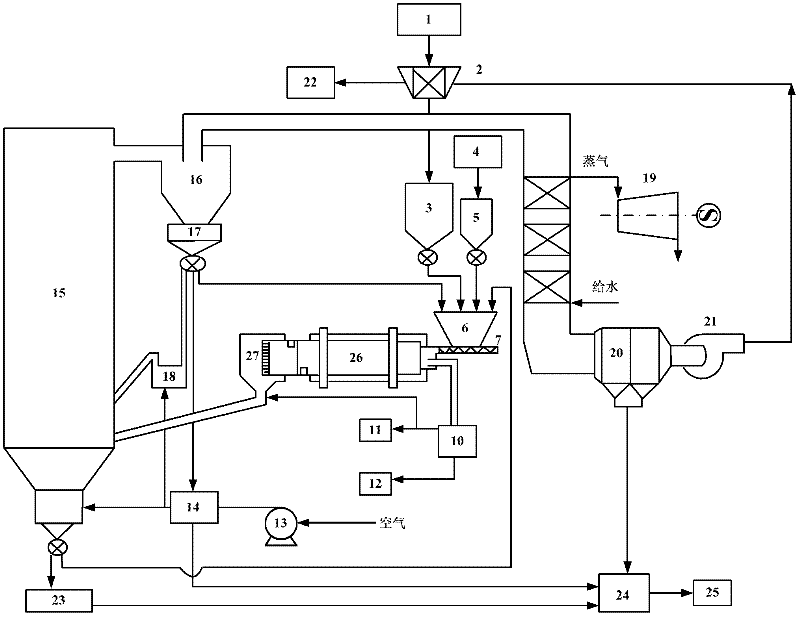

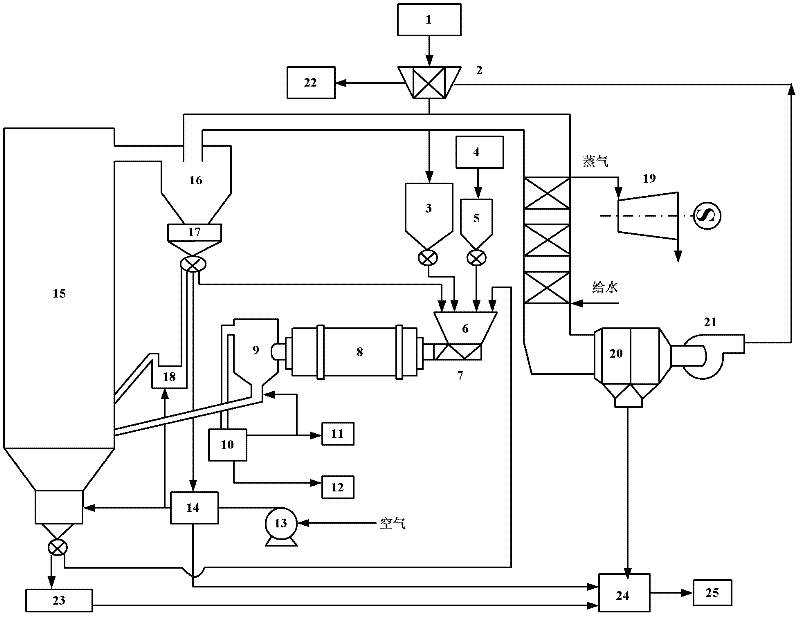

Oil shale rotary kiln dry distillation and circulating fluidized bed combustion process

InactiveCN102533296AImprove combustion efficiencyControl generationDirect heating destructive distillationBiofuelsBottom ashInternal combustion engine

An oil shale rotary kiln dry distillation and circulating fluidized bed combustion process makes organic combination of a rotary kiln dry distillation with a circulating fluidized bed; oil shale particles are mixed with thermal-cycle ash from a circulating fluidized bed boiler and part of circulating fluidized bed boiler bottom ash, and then are sent into a rotary kiln for dry distillation to prepare shale oil and dry distillation coal gas; the dry distillation coal gas has a high calorific value; a part of the coal gas is used as recycle wind of a semicoke material recycle device, and enters the circulating fluidized bed boiler with oil shale semicoke particles for combustion, and the residual part is delivered into an internal combustion engine for combustion generation. The invention can increase shale oil and coal gas quality, reduce energy loss and environment pollution, and improve the comprehensive utilization degree.

Owner:SHANGHAI JIAO TONG UNIV

Lightweight bottom layer plastering gypsum

The invention discloses a lightweight bottom layer plastering gypsum which is characterized by comprising the following components in percentage by weight: 20-70% of building gypsum, 20-70% of furnace bottom ash serving as a lightweight aggregate, 0-20% of ordinary portland cement, 0-20% of granulated blast furnace slag powder, 0-30% of fly ash and 0-30% of an additive, wherein the additive comprises the following components in percentage by weight: 0-0.6% of cellulose ether, 0-0.3% of a retarder, 0-0.3% of a water reducing agent, 0-0.15% of starch ether, 0-2% of re-dispersible latex powder, 0-0.5% of polypropylene fiber and 0-2% of a water repellent. The invention provides an environment-friendly lightweight bottom layer plastering gypsum mortar which is low in density, good in heat retaining property and capable of automatically adjusting temperature and humidity. The lightweight bottom layer plastering gypsum can effectively reduce the mortar density and building dead weight and has good sound insulation and noise reduction effects.

Owner:上海每天生态科技发展有限公司

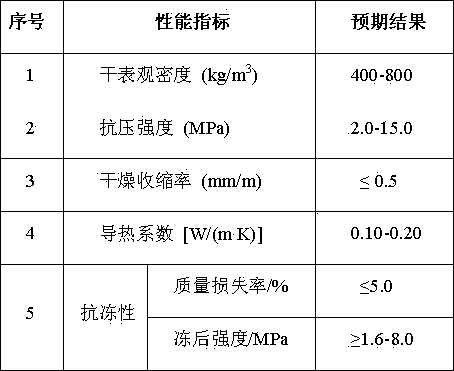

Autoclaved aerated concrete and preparation method thereof

The invention discloses an autoclaved aerated concrete and a preparation method thereof, and the autoclaved aerated concrete comprises mineral raw materials, an alkaline exciting agent, a foaming agent, a foam-stabilizing agent, a slow-release agent and the like. The mineral raw materials comprise 80-100wt.% of fly ash, and other mineral raw materials comprise mineral waste residue, metakaolin, silica fume, steel slag, circulating fluidized bed bottom ash and the like; the alkaline exciting agent mass is 40-55wt.% of the mineral raw material mass, the foaming agent mass is 0.13-5wt.% of the mineral raw material mass, the foam-stabilizing agent mass is 0.03-0.09wt.% the mineral raw material mass, and the slow-release agent mass is 2-3.5wt.% of the mineral raw material mass. The alkaline exciting agent including sodium silicate and NaOH / KOH, the mineral raw materials, the foaming agent and the foam-stabilizing agent are mixed for stirring, then are filled in a mould for prefabrication forming or casting forming, and maintained by autoclaving for 1-24h at 60-160 DEG C under 0.1-1MPa.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Settable Building Material Composition Including Landfill Leachate

InactiveUS20110232532A1High compressive strengthReduce Shrinkage ProblemsSolid waste managementCement productionBottom ashLitter

A composition capable of setting to produce a building material is disclosed. The composition can include from 1% to 30% by weight of an activator, from 1% to 55% by weight of a pozzolan, such as fly ash; from 40% to 90% by weight of an aggregate; and liquid landfill leachate in a sufficient amount such that the composition sets to a building material having a compressive strength of at least 2 MPa, wherein all weight percentages are percent by weight of the total composition. The liquid landfill leachate replaces all or part of the tap water in a conventional composition for forming a building material. The liquid landfill leachate can be recovered after a liquid (typically water) percolates through a landfill and contacts at least one landfilled coal combustion product selected from fly ash, bottom ash, boiler slag, and flue gas desulfurization material. The building material can be a concrete, or a masonry unit.

Owner:WISCONSIN ELECTRIC POWER

Incombustible composition for fire door/wall, fire door/wall using incombustible composition, and method of producing fire door/wall

InactiveUS20050066622A1Poor heat-intercepting propertyHigh hardnessFireproof paintsAntifouling/underwater paintsBottom ashFiber

Disclosed is an incombustible composition for a fire door / wall, the fire door / wall using the incombustible composition, and a method of producing the fire door / wall. The incombustible composition includes 1 to 80 wt % of organic or inorganic fiber, 1 to 80 wt % of fly ash or bottom ash, 1 to 80 wt % of fire-proofing agent, 1 to 30 wt % of curing fire-retardant resin, and 1 to 40 wt % of incombustible hollow filler. Furthermore, the method includes providing the incombustible composition, mixing the fly ash or bottom ash, fire-proofing agent, and curing fire-retardant resin with each other, adding the organic or inorganic fiber into a mixture, shattering the mixture containing the organic or inorganic fiber, mixing an incombustible hollow body with the shattered mixture by use of a mixer using air, pressing the resulting mixture using a high pressure hot press to form a board or a square timber, constructing a frame of the fire door / wall using the board and / or square timber, and embedding an incombustible core material into the fire door / wall. As well, 1 to 70 wt % of the incombustible composition may be made of a waste material. Accordingly, the incombustible composition is advantageous in that the production costs are reduced, and that it is useful as a construction finishing and interior material because no fire and toxic gases occur when the incombustible composition is on fire.

Owner:CHOI JUN HAN

Incombustible composition, incombustible construction product using incombustible composition, and method of producing incombustible construction product

Disclosed is an incombustible composition, an incombustible construction product using the incombustible composition, and a method of producing the incombustible construction product. The incombustible composition includes organic or inorganic fiber, fly ash or bottom ash, fire proofing agent, and curing fire-retardant resin. Additionally, the method includes mixing components, constituting the incombustible composition, with each other, and pressing the incombustible composition using a high pressure hot press, a roller press or an autoclave to give a predetermined shape to the incombustible composition. Therefore, the incombustible composition is advantageous in that it is environmentally- friendly because it contains waste materials, and that it has excellent hardness, strength, and water resistance. Other advantages are that its production costs are relatively low, and that it has excellent incombustibility, depending on the contents of the components constituting the incombustible composition.

Owner:崔俊汉

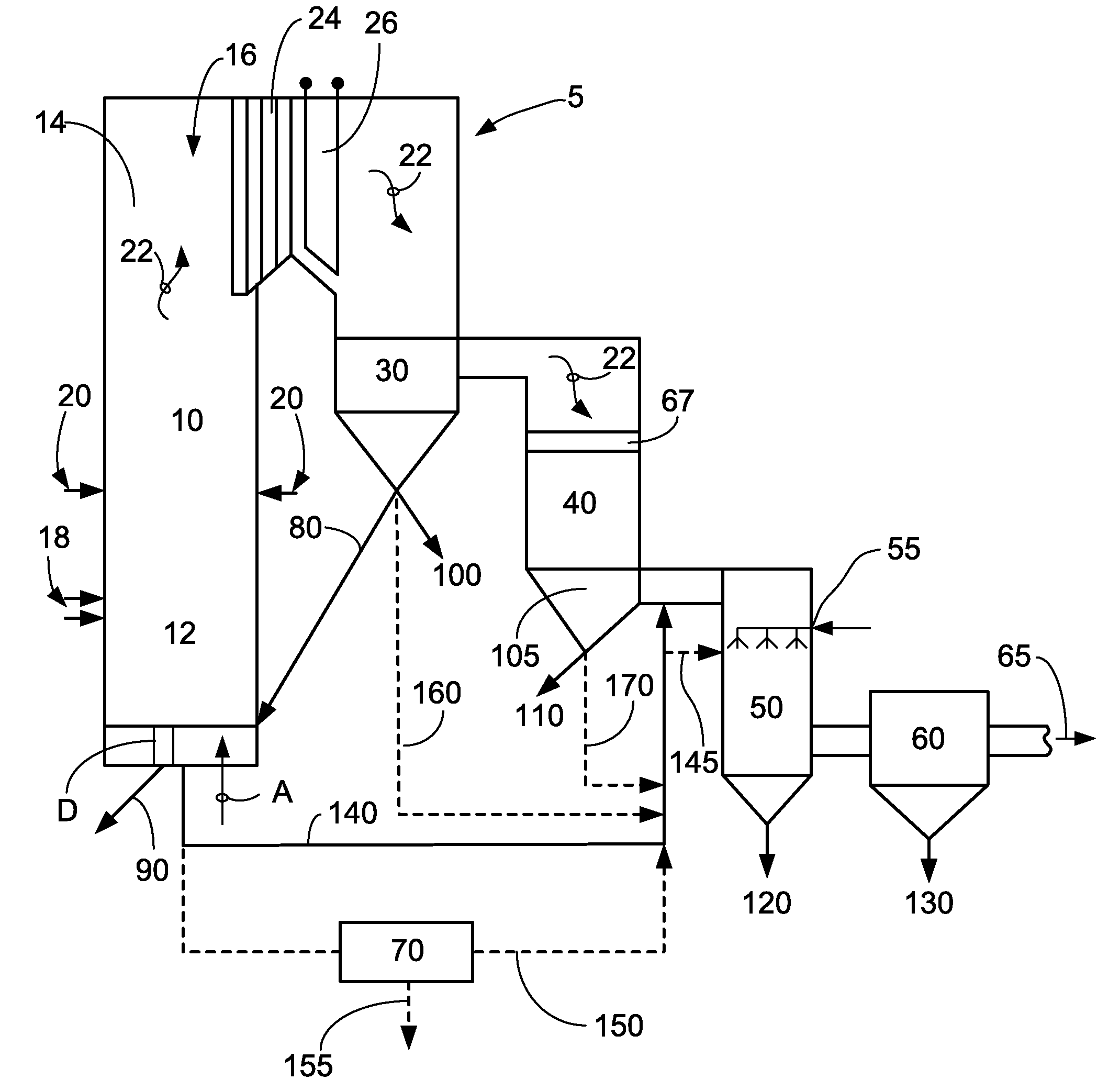

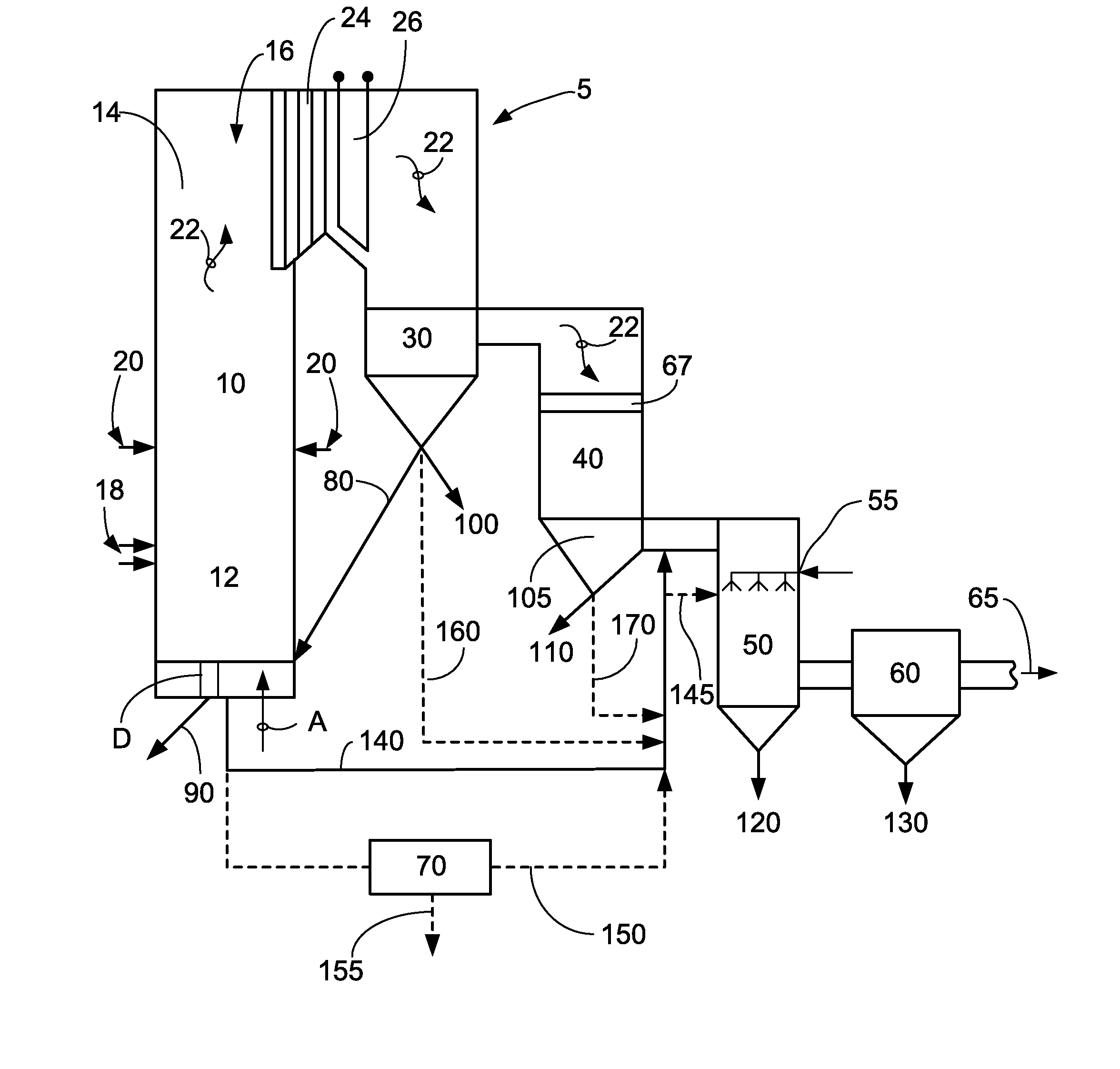

Bottom ash injection for enhancing spray dryer absorber performance

ActiveUS20090074629A1Easy to captureLower potentialCombination devicesFluidized bed combustionBottom ashFluidized bed

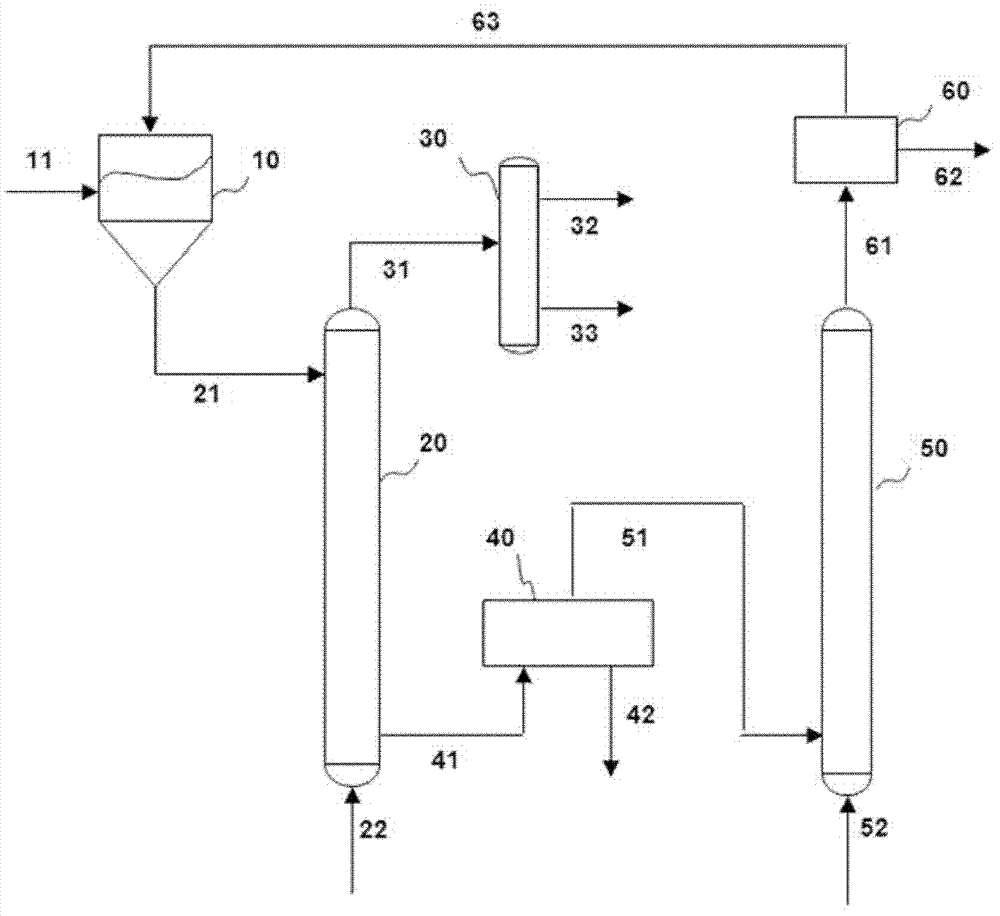

Alkali-containing bottom ash produced by a circulating fluidized bed (CFB) boiler is recycled to downstream spray dryer absorption (SDA) apparatus to more fully utilize the unused reagent present in the ash, and / or to reduce the amount of reagent used while not increasing NOx generation.

Owner:THE BABCOCK & WILCOX CO

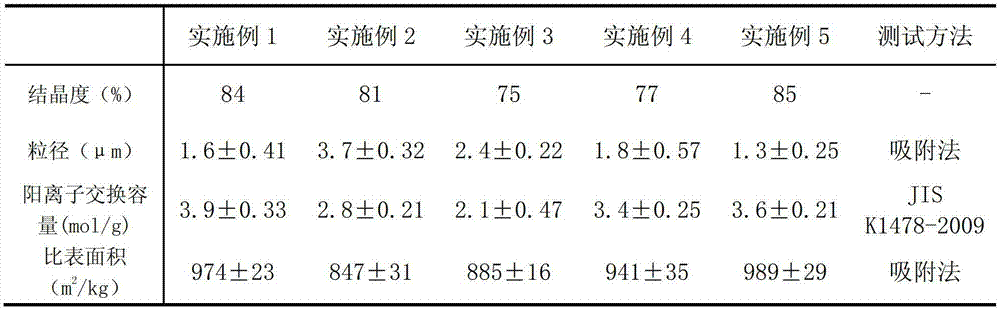

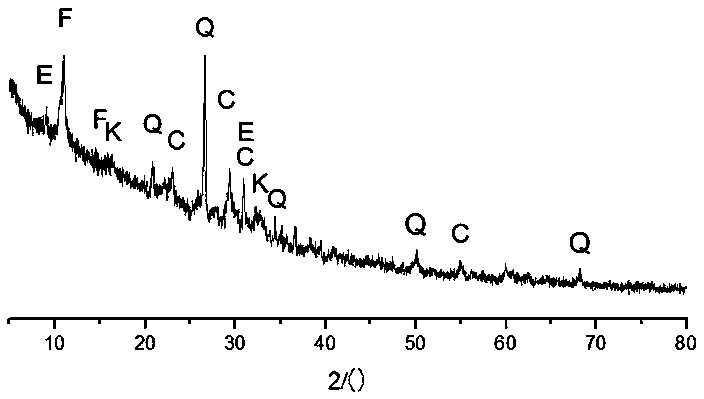

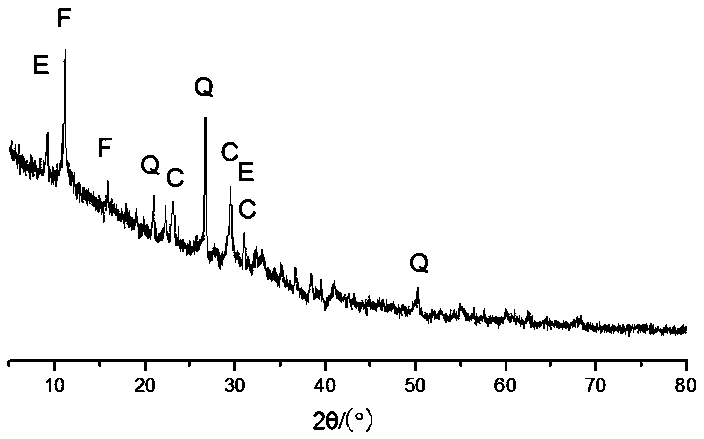

Method for synthesizing zeolite by circulating fluidized-bed coal ash and bottom ash

InactiveCN103204518AImprove water retentionIncrease productionSolid waste disposalFaujasite aluminosilicate zeoliteCation-exchange capacityBottom ash

The invention discloses a method for synthesizing zeolite by circulating fluidized-bed coal ash and bottom ash. The method comprises the following steps of: carrying out decarburization treatment on the coal ash by a screening machine and mixing the treated coal ash with the bottom ash which is milled by a ball mill; adding alkali liquor in a liquid-solid weight ratio of (5:1) to (9:1); reacting for 1-2 hours under the condition of 50r / min-70r / min by stirring, and the reaction temperature being 95 DEG C to 100 DEG C, and crystallizing by stirring for 4-6 hours at the speed of 20 revolutions / minute to 40 revolutions / minute and the crystallizing reaction being 95 DEG C to 100 DEG C; washing and crystallizing until the pH value is 9-10, dehydrating and filtering, and drying for 3-5 hours under the condition of 85 DEG C to 100 DEG C to a dried zeolite product with the content of 76w%-81w%. According to the method for synthesizing zeolite by circulating fluidized-bed coal ash and bottom ash disclosed by the invention, the synthesis material coal ash is free of any roasting pre-treatment and calcining pre-treatment; the synthesis process is a hydro-thermal synthesis process under normal pressure; and the obtained zeolite has the characteristics of being high in cation exchange capacity, high in specific surface area and the like.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

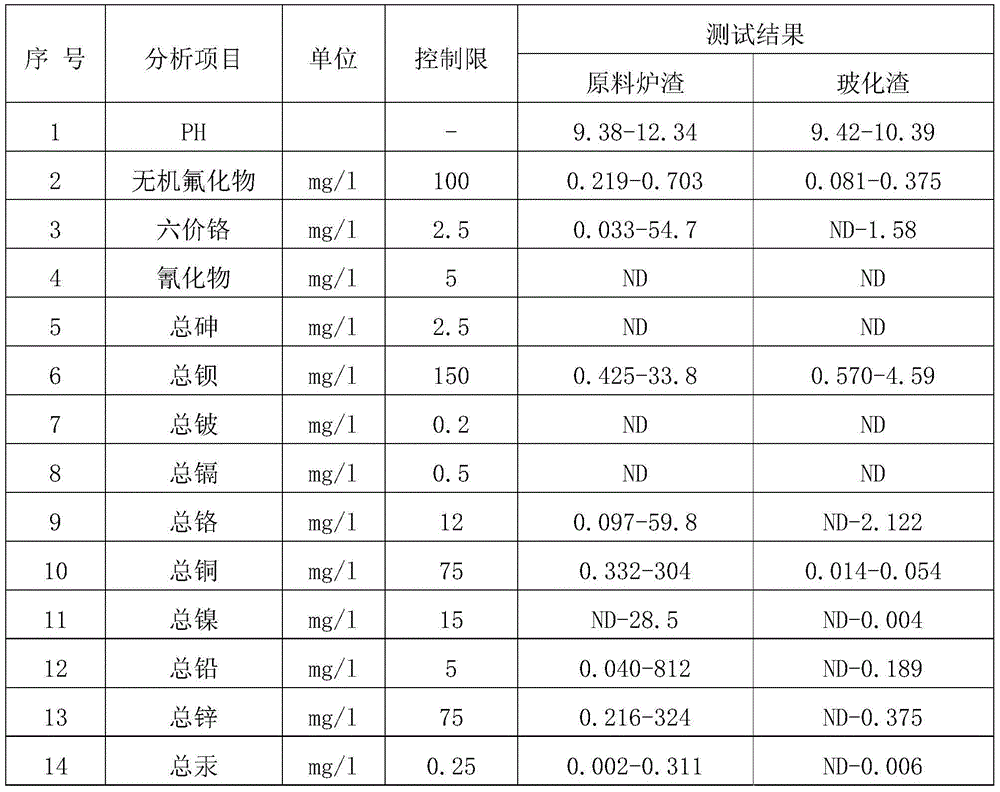

Method for treating hazardous waste incineration bottom ash by using plasma technology

InactiveCN105817459AHigh hardnessAvoid secondary pollutionSolid waste disposalTransportation and packagingPlasma technologySlag

The invention discloses a method for treating hazardous waste incineration bottom ash by using plasma technology. According to the invention, high temperature produced by plasma is utilized to decompose and destroy residual toxic organic matters including dioxin in the incineration bottom ash, and heating and cooling are carried out so as to form high-hardness high-strength vitrification slag of enclosed structure. As heavy metal ions included in the incineration bottom ash are immobilized, secondary pollution can be avoided, and technical requirements for ultralow leaching toxicity can be met, so hazardous wastes can be efficiently converted into non-hazardous wastes and do not need landfilling at great expense; and the vitrification slag formed after treatment can be converted into a road building material, constructional material or the like for comprehensive utilization, so the method has wide promotion space.

Owner:SHANGHAI SOLID WASTE DISPOSAL CENT +1

Coal mine early strength type low-cost filling material and preparation method thereof

The invention belongs to the technical field of a coal mine, and particularly relates to a coal mine early strength type low-cost filling material and a preparation method thereof. The filling material is prepared from water, a bonding material, an excitant, an auxiliary excitant and a mixture of tunneling waste rock and furnace bottom ash, wherein the water accounts for 21 to 23 percent of the filling material; the bonding material is a mixture of portland cement clinker, fly ash and water quenched ore slag, and accounts for 15.2 to 19.5 percent of the filling material; the excitant accounts for 0.5 to 0.9 percent of the bonding material; the auxiliary excitant is a mixture of sulphoaluminate cement clinker and desulfurized gypsum, and accounts for 2.5 percent of the bonding material; the balance is the mixture of the tunneling waste rock and the furnace bottom ash. The coal mine early strength type low-cost filling material has the advantages that the early strength is high; the flowing performance is good; the bleeding rate is low; the requirements of most coal mines on the performance of the filling material can be met; solid waste and mine waste water account for 93 percent or more of the total mass of materials in the filling material, so that the cost of the filling material is reduced; the waste is sufficiently utilized; good economic benefits and environment benefits are realized.

Owner:HENAN INST OF ENG

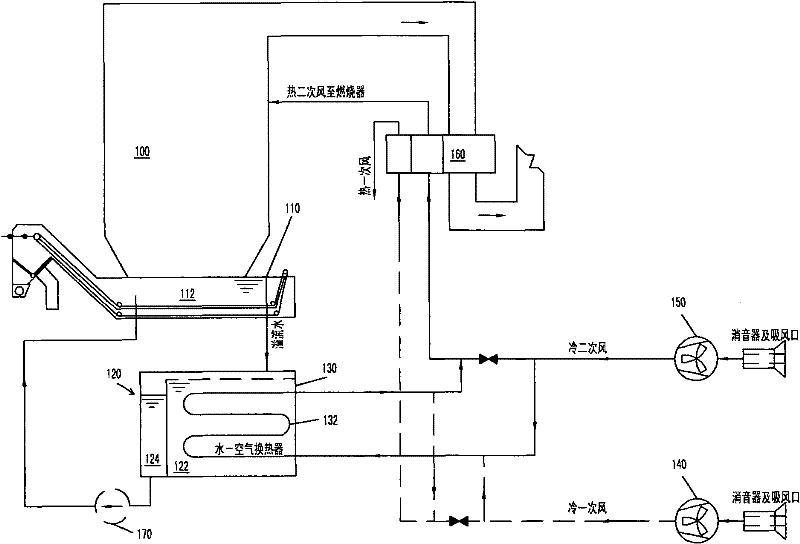

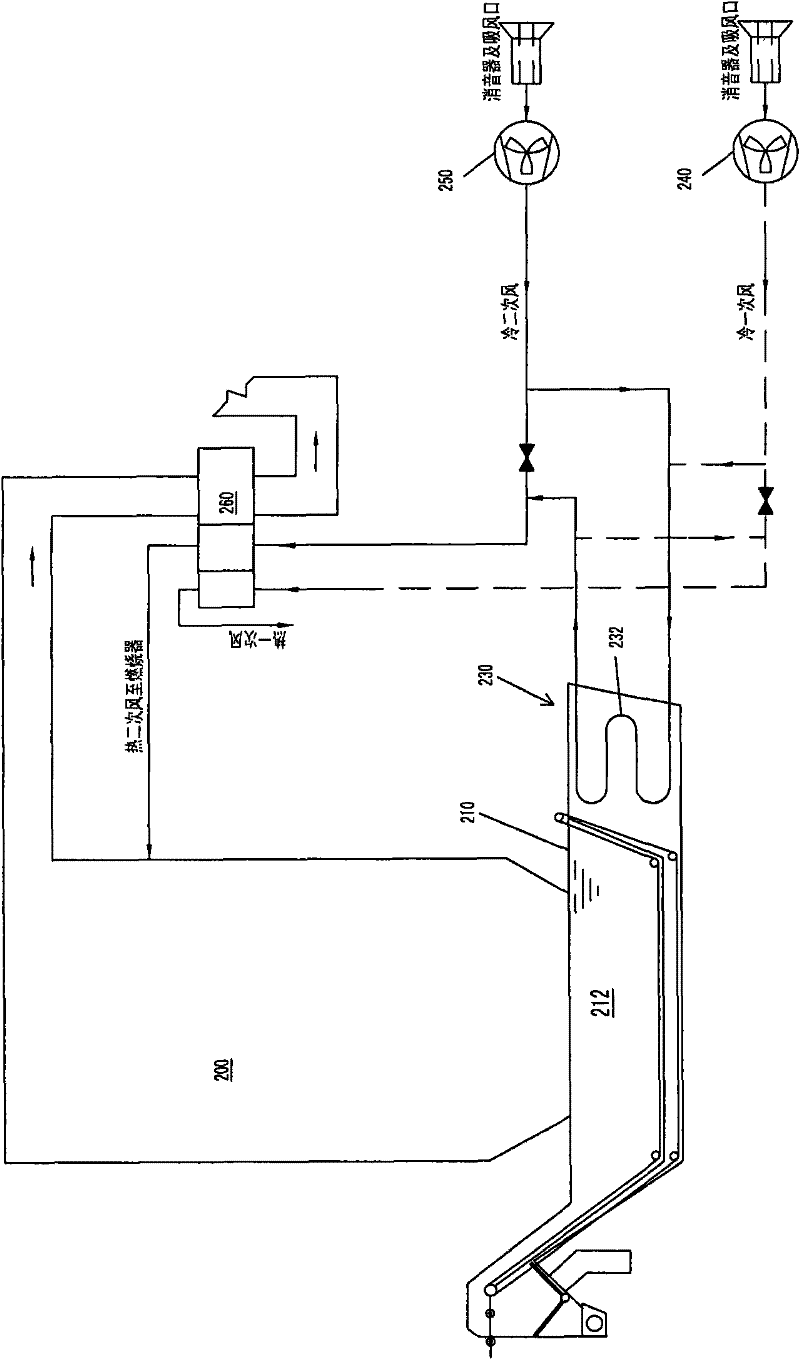

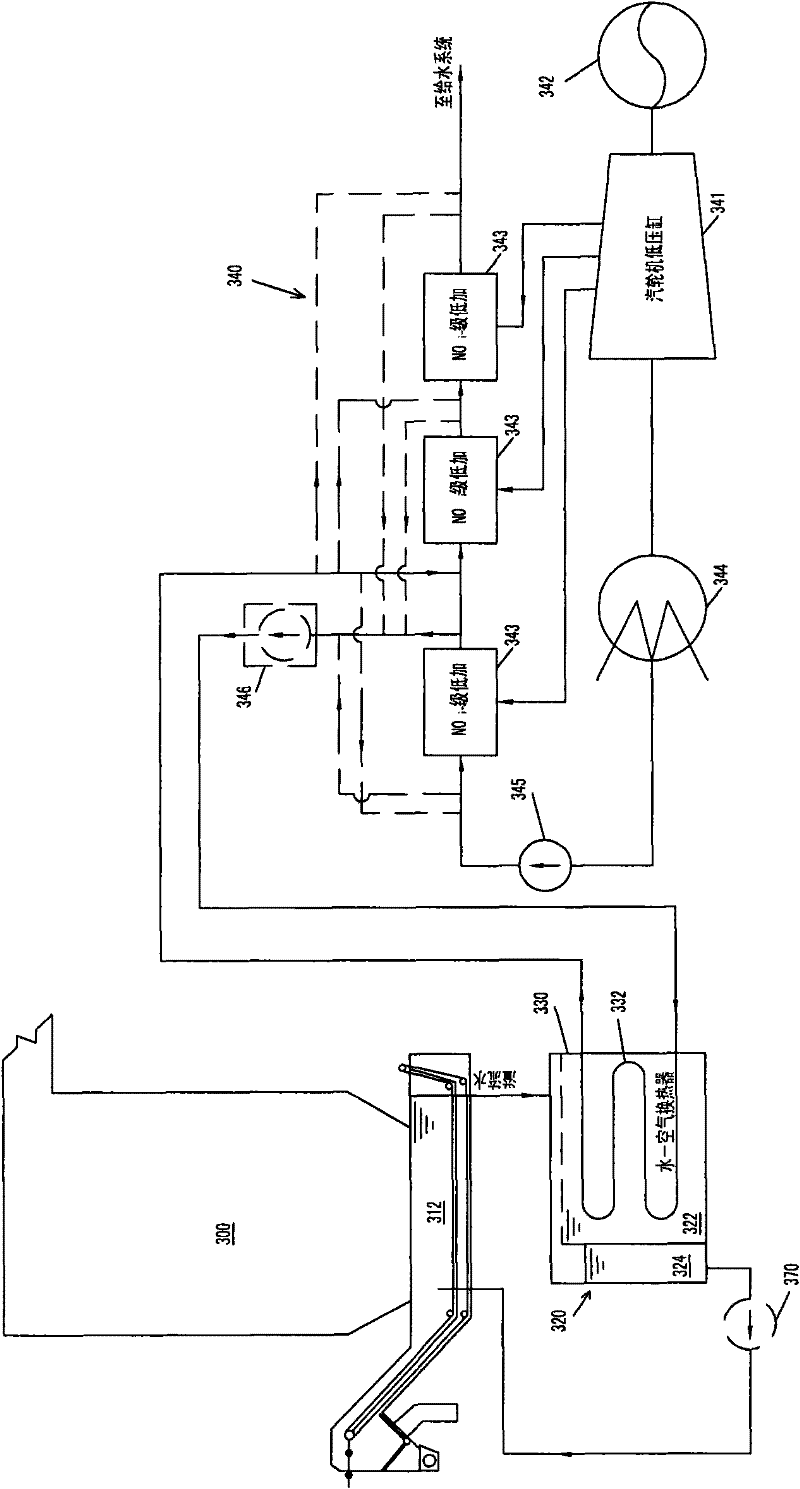

Boiler wet slag removal system

InactiveCN102287835AIncrease power generationReduce fuel consumptionCombustion processMachines/enginesAir preheaterBottom ash

The invention relates to a boiler wet slag removal system, which comprises a slag extractor and a heat exchanger. The slag extractor is located under the boiler and has a water tank for receiving boiler bottom slag. The heat exchanger includes a heat exchange surface, one side of the heat exchange surface introduces the water in the water tank as the first heat exchange medium, and the other side of the heat exchange surface is the flowing second heat exchange medium to absorb the water in the water tank energy. In one solution of the present invention, the second heat exchange medium can be air, which is provided by the blower or the primary blower of the boiler, and is sent to the air preheater for the boiler together with the cold air of the blower or the primary blower after being heated . In another solution of the present invention, the second heat exchange medium can be condensed water, which is provided by one or more low-pressure heaters of the steam turbine condensate system, and is heated and delivered to one or more low-pressure heaters . In this way, the waste heat of the slag can be recovered, which simplifies the structure of the wet slag removal system and reduces the water consumption.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

Architectural pottery prepared by secondary waste flyash or bottom ash and method thereof

The invention relates to an architectural pottery prepared by secondary water flyash or bottom ash and a method thereof. The method comprises the following steps; mixing flyash or bottom ash with kaoline and quartz according to weight percentage and ball milling the mixture; placing the mixture into a green body for tooling; placing the formed green body into a kiln, baking and preserving heat for some time; cooling, glazing or polishing the green body and obtaining the ceramics. In the invention, secondary water is used as the main raw material to prepare low temperature and fast firing pottery, thus saving natural resource and energy, lowering ceramics cost and obtaining fine quality architectural pottery. Compared with the method of heavy metal melting and solidification, due to the lower reaction temperature, the processing method of secondary waste can prevent parts of heavy metal from volatilization and migration in the process of melting at high temperature. Compared with the method of solidification by using phosphate, cement, concrete and the like, the secondary water is subjected to sintering at high temperature so that the solidification effect is good, and the toxic organism is completely decomposed in the process of sintering. The invention processes secondary waste effectively while improving added value of the secondary waste.

Owner:JILIN UNIV

Pyroprocessed aggregates comprising IBA and low calcium silicoaluminous materials and methods for producing such aggregates

InactiveUS7780781B2Low melting pointPyroprocessing behavior unpredictablePigmenting treatmentOther chemical processesBottom ashVitrification

In accordance with an embodiment, a method for producing an aggregate is disclosed comprising mixing IBA and a second, silicoaluminous material having a calcium content less than the IBA. The method further comprises agglomerating the mixture, such as by pelletizing, and pyroprocessing the agglomerates, such as by sintering or vitrification, to form the aggregate. The second material may be a clay, such as bentonite or kaolin, a mining waste, such as granite sawing residues, waste glass, or furnace bottom ash, for example. The addition of the second material has been found to facilitate production of lightweight and normal weight aggregates. Preferably, the IBA or the mixture of IBA and the second material are wet milled prior to agglomeration. A lightweight sintered aggregate comprising IBA and the second material and an aggregate comprising IBA and the second material are also disclosed.

Owner:ALKEMY

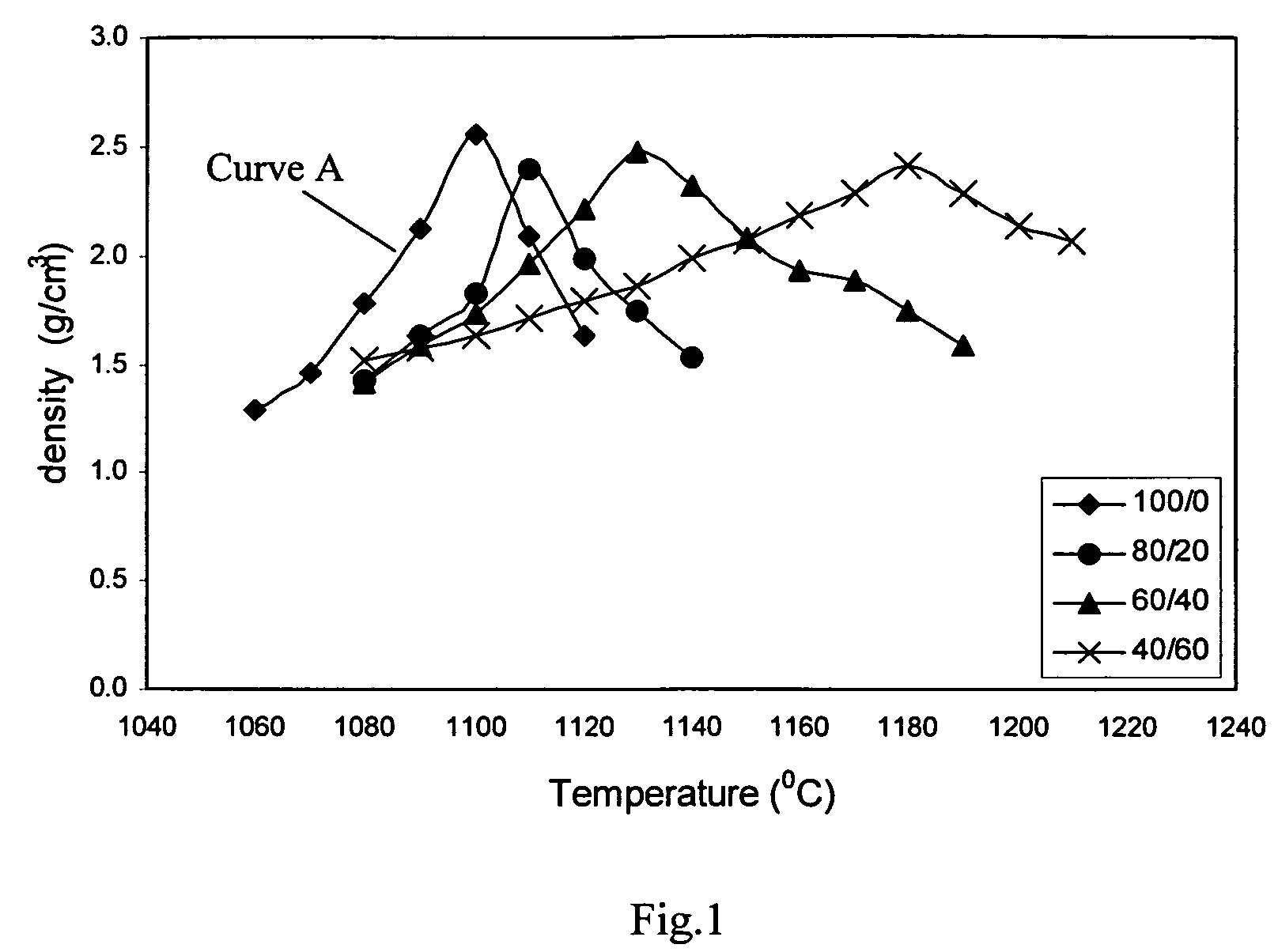

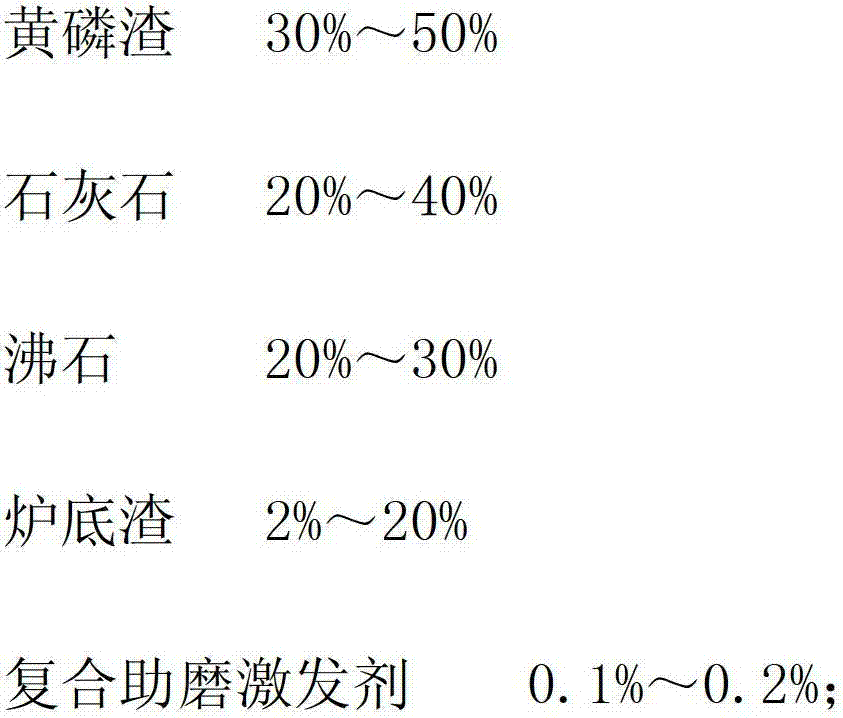

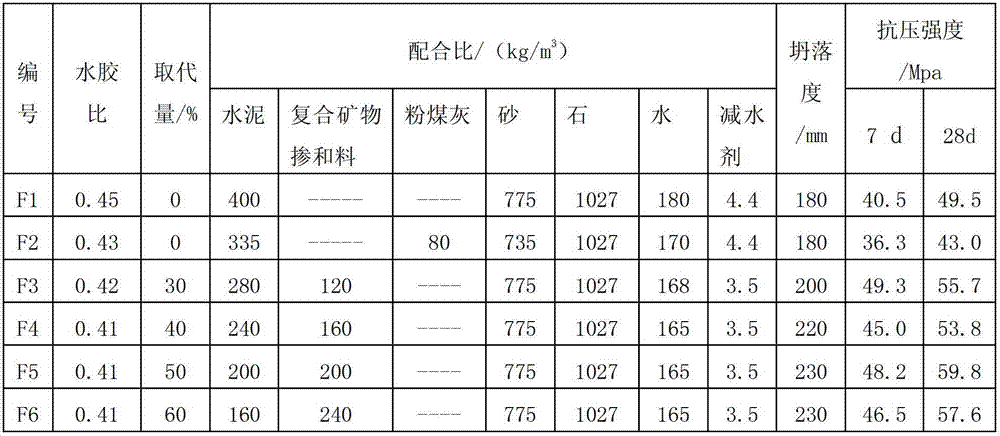

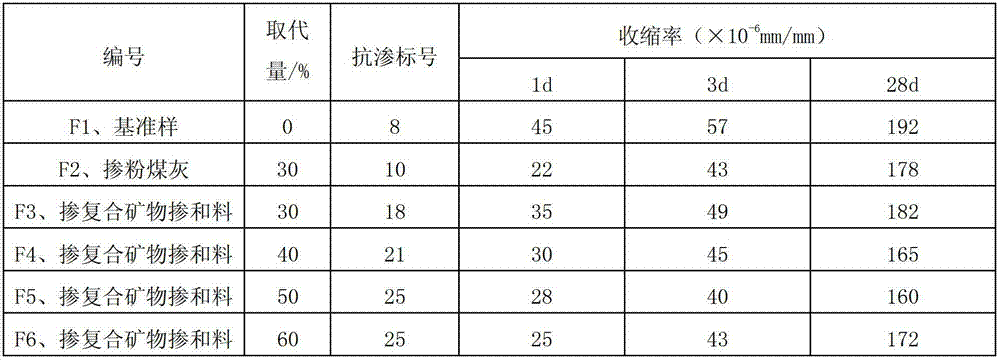

Concrete complex mineral admixture and preparation technology thereof

InactiveCN102826779AImprove early strengthImprove flexural strengthSolid waste managementBottom ashSlag

The invention relates to the technical field of concrete, and specifically discloses a concrete complex mineral admixture which comprises the following components in percentage by weight: 30-50% of yellow phosphorus slag, 20-40% of limestone, 20-30% of zeolite, 2-20% of bottom ash and 0.1-0.2% of complex grinding-aid activator, wherein the complex grinding-aid activator consists of the following components in percentage by weight: 2-4% of triisopropanolamine, 3-6% of triethanolamine, 6-10% of glycerol and the balance of water; and the concrete complex mineral admixture is powder with a specific surface area of greater than or equal to 650m<2> / kg. Furthermore, the concrete complex mineral admixture can contain 0.1-15% of ardealite. By adding the concrete complex mineral admixture disclosed by the invention into concrete, the early strength of concrete can be effectively improved, and various properties of concrete are obviously enhanced.

Owner:SICHUAN JINGUILAN CEMENT

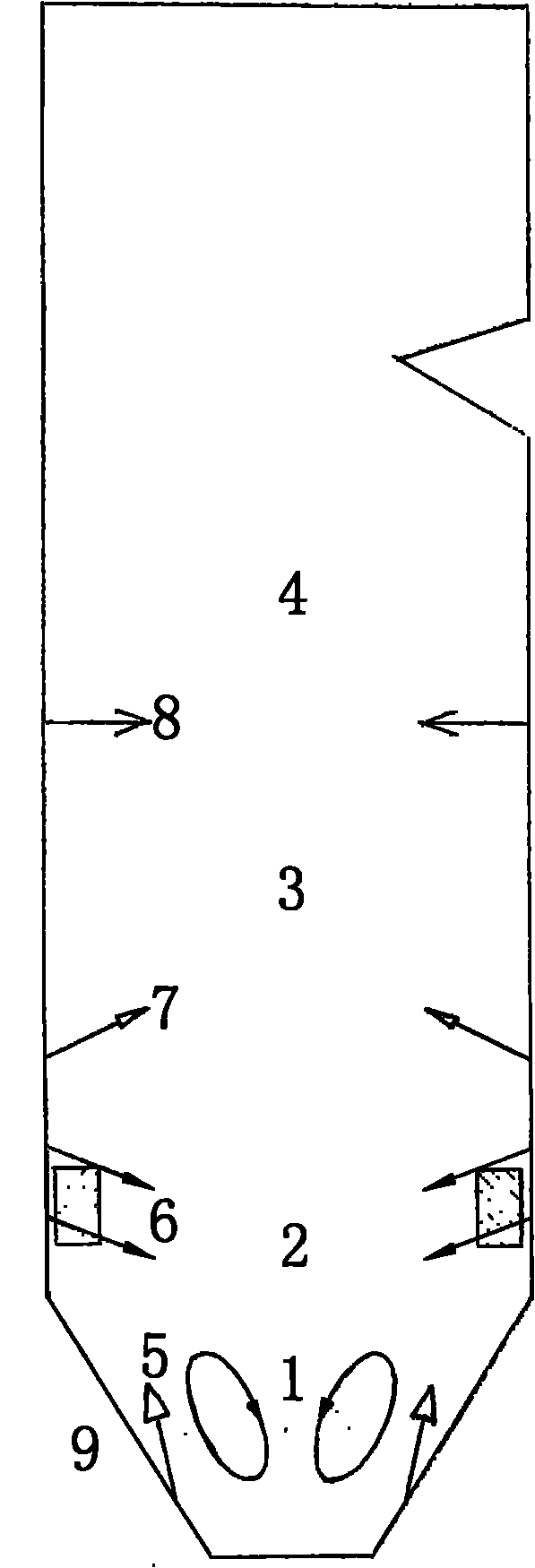

Low NOx coal dust combustion method and device based on underfire air and overfire air

InactiveCN102003701AEmission reductionReduce carbon content in fly ashCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBottom ashEngineering

The invention relates to a combustion improvement technology of an industrial fire coal boiler, aiming to provide a low NOx coal dust combustion method and device based on underfire air and overfire air. The method comprises: injecting parts of two-strand air required for combustion into a hearth from a boiler bottom ash hopper; strongly mixing with aslant downward injected fuel jet flow; fully utilizing the space of the bottom ash hopper to prolong smoke dwell time; burning fuel in a low-temperature oxidation zone; preventing volatile components from converting to nitric oxide; upwards and aslant injecting upper-layer fuel to form a reducing zone, so as to reduce generated nitric oxide into N2; and lowering nitric oxide emission amount. The invention also provides a boiler device for realizing the method. Under the condition that the original combustion condition is not influenced essentially, the invention effectively lowers the emission of nitric oxide and is easy to reform the existing boiler.

Owner:ZHEJIANG UNIV

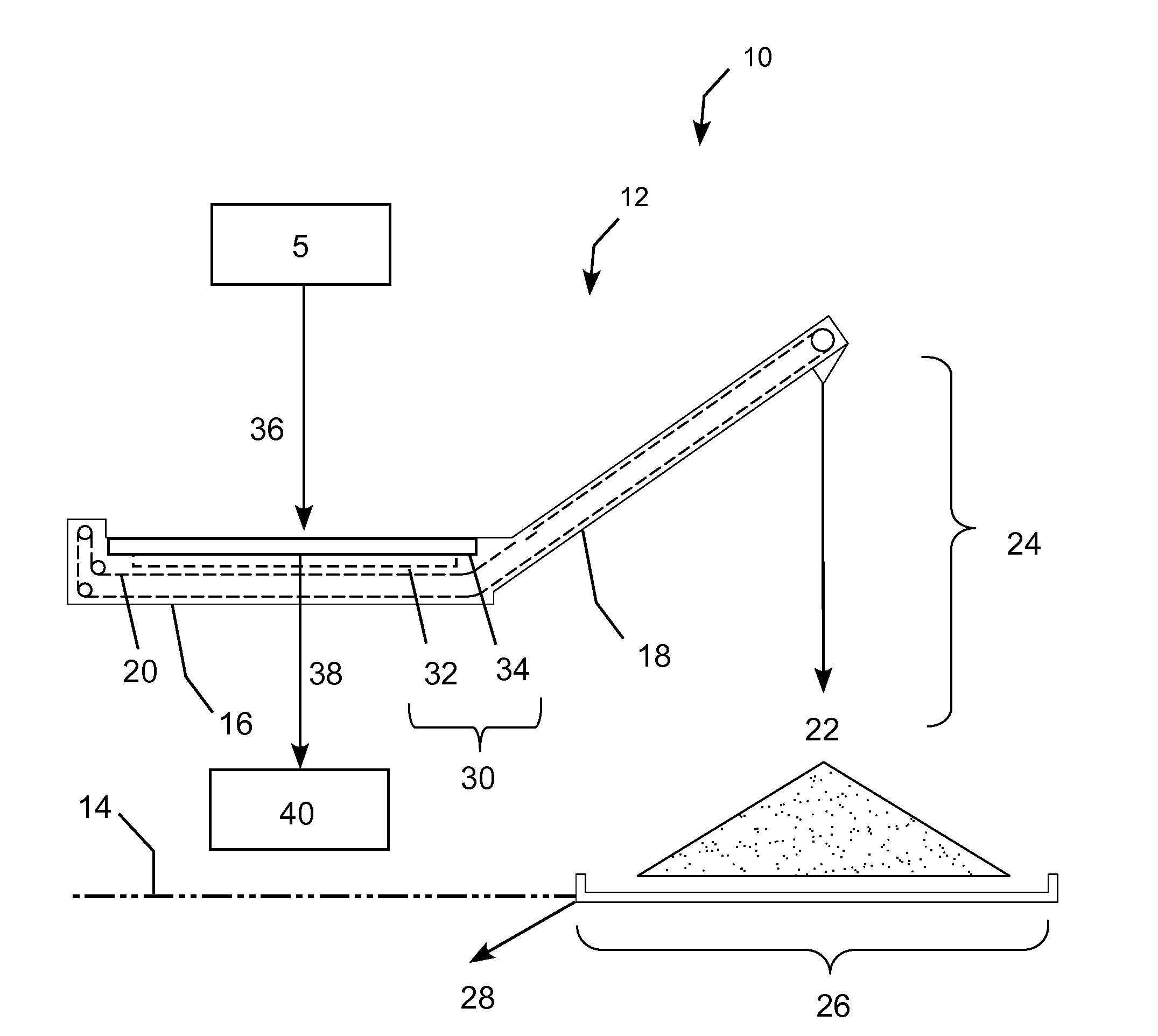

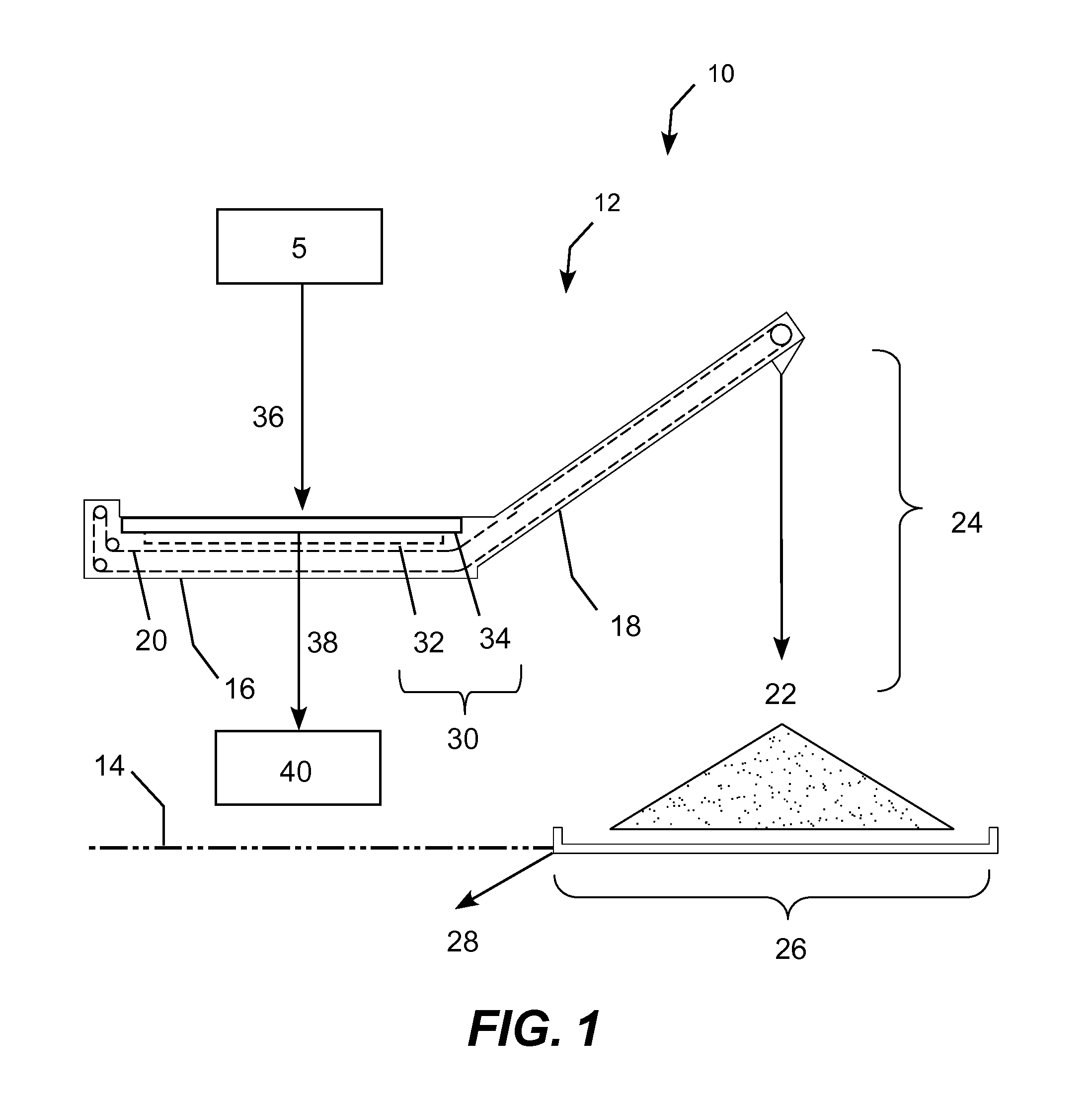

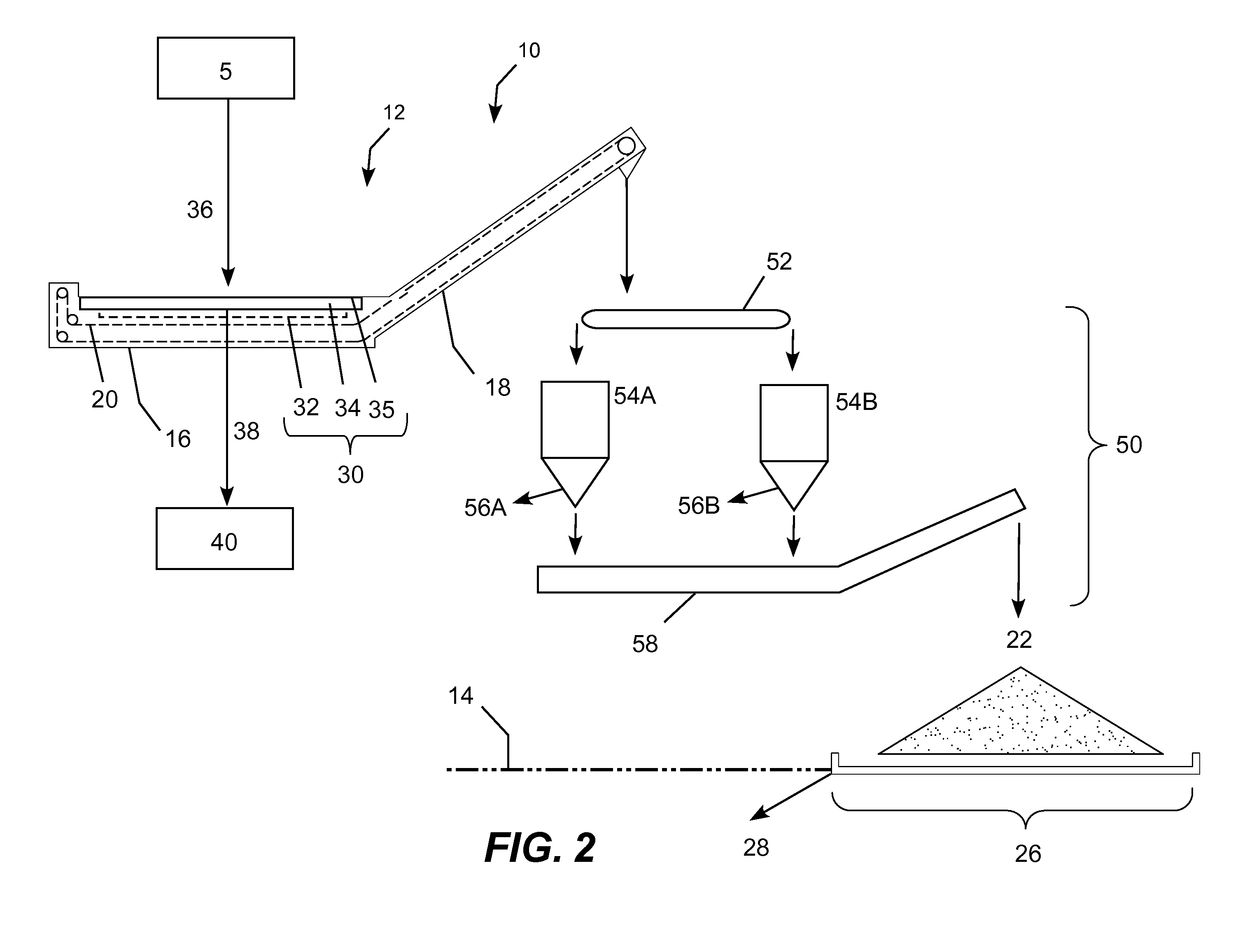

Bottom Ash Dewatering System Using a Remote Submerged Scraper Conveyor

Remote submerged scraper conveyor (SSC) consists of a conventional SSC modified to include a slurry processing system, which allows it to be located remotely from associated boilers at or slightly above grade level rather than directly under a boiler like a conventional SSC. The slurry processing system includes a pair of overflow troughs 34 and associated weirs located exterior to and along the top edge of each side of the horizontal section of the SSC and an underflow baffle, which extends from a position above the water line down into the horizontal section of the SSC below the water line. The slurry processing system allows the Remote SSC to receive a high volume wet ash slurry discharge via a slurry discharge pipe conventionally sent to an ash pond or a tall dewatering bin system.

Owner:CLYDE IND +1

Incombustible composition for fire door/wall, fire door/wall using incombustible composition, and method of producing fire door/wall

InactiveUS7211318B2High hardnessHigh strengthFireproof paintsAntifouling/underwater paintsBottom ashFiber

Disclosed is an incombustible composition for a fire door / wall, the fire door / wall using the incombustible composition, and a method of producing the fire door / wall. The incombustible composition includes 1 to 80 wt % of organic or inorganic fiber, 1 to 80 wt % of fly ash or bottom ash, 1 to 80 wt % of fire-proofing agent, 1 to 30 wt % of curing fire-retardant resin, and 1 to 40 wt % of incombustible hollow filler. Furthermore, the method includes providing the incombustible composition, mixing the fly ash or bottom ash, fire-proofing agent, and curing fire-retardant resin with each other, adding the organic or inorganic fiber into a mixture, shattering the mixture containing the organic or inorganic fiber, mixing an incombustible hollow body with the shattered mixture by use of a mixer using air, pressing the resulting mixture using a high pressure hot press to form a board or a square timber, constructing a frame of the fire door / wall using the board and / or square timber, and embedding an incombustible core material into the fire door / wall. As well, 1 to 70 wt % of the incombustible composition may be made of a waste material. Accordingly, the incombustible composition is advantageous in that the production costs are reduced, and that it is useful as a construction finishing and interior material because no fire and toxic gases occur when the incombustible composition is on fire.

Owner:CHOI JUN HAN

Catalytic heat carrier for pyrolysis of carbonaceous material and preparation method thereof

The invention relates to catalytic heat carrier for pyrolysis of carbonaceous material and a preparation method thereof. The catalytic heat carrier is made from transition metal, oxide and / or sulfide of transition metal, clay mineral used as molecular sieve, ore containing transition metal, waste or tailings and / or mixture of them, preferably residual burning bottom ash by direct liquefaction of coal, waste fluidization catalysis cracking catalyst, catalyst by direct liquefaction of waste coal, red mud and / or mixture of them, or more preferably mixture of residual burning bottom ash by direct liquefaction of coal and / or waste fluidization catalysis cracking catalyst and / or catalyst by direct liquefaction of waste coal. The catalytic heat carrier circulates between a pyrolytic reactor and a reheater of the catalytic heat carrier to provide heat for the pyrolytic reactor, and accordingly quick feeding and effective heating of carbonaceous material are achieved and catalytic activity, and oxygen and / or nitrogen transfer capacity of the catalytic heat carrier for various reactions in pyrolysis are given to play to obtain solid, gas and liquid products. A way of pyrolysis of carbonaceous material is performed by an environment-friendly and low-cost method.

Owner:NAT INST OF CLEAN AND LOW CARBON ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com