Concrete complex mineral admixture and preparation technology thereof

A technology for compounding minerals and concrete, applied in the field of concrete, can solve the problems of unsuitable ratio of yellow phosphorus slag to active ingredients, insufficient early strength of concrete, unsatisfactory other properties, etc., and achieves improved compactness, improved impermeability, and increased flow. Effects of degree and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 This embodiment is the formula and preparation embodiment of concrete composite mineral admixture

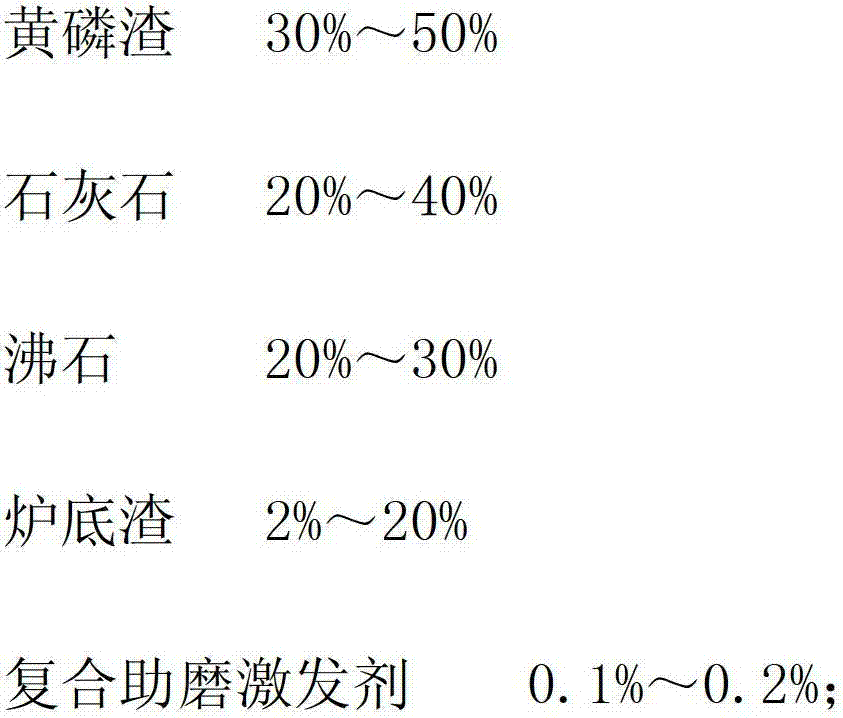

[0035] Concrete composite mineral admixture 1000kg, composed of the following ingredients:

[0036] Yellow phosphorus slag 300kg (accounting for 30% of the total weight of concrete composite mineral admixture)

[0037] Limestone 400kg (accounting for 40% of the total weight of concrete composite mineral admixture)

[0038] Zeolite 200kg (accounting for 20% of the total weight of concrete composite mineral admixture)

[0039] Furnace bottom slag 98kg (accounting for 9.8% of the total weight of concrete composite mineral admixture)

[0040]Composite grinding aid activator 2kg (accounting for 0.2% of the total weight of the concrete composite mineral admixture), of which triisopropanolamine accounts for 0.08kg (accounting for 4% of the total weight of the compound grinding aid activator), and triethanolamine accounts for 0.12kg (accounting for 6% of the total...

Embodiment 2

[0044] Embodiment 2 This embodiment is the formula and preparation embodiment of concrete composite mineral admixture

[0045] Concrete composite mineral admixture 1000kg, composed of the following ingredients:

[0046] Yellow phosphorus slag 500kg (accounting for 50% of the total weight of concrete composite mineral admixture)

[0047] Limestone 200kg (accounting for 20% of the total weight of concrete composite mineral admixture)

[0048] Zeolite 200kg (accounting for 20% of the total weight of concrete composite mineral admixture)

[0049] Bottom slag 99kg (accounting for 9.9% of the total weight of concrete composite mineral admixture)

[0050] Composite grinding aid activator 1㎏ (accounting for 0.1% of the total weight of the concrete composite mineral admixture), of which triisopropanolamine accounts for 0.02 kg (accounting for 2% of the total weight of the compound grinding aid activator), and triethanolamine accounts for 0.03 kg (accounting for 3% of the total weigh...

Embodiment 3

[0052] Embodiment 3 This embodiment is the formula and preparation embodiment of concrete composite mineral admixture

[0053] Concrete composite mineral admixture 1000kg, composed of the following ingredients:

[0054] Yellow phosphorus slag 300kg (accounting for 30% of the total weight of concrete composite mineral admixture)

[0055] Limestone 200kg (accounting for 20% of the total weight of concrete composite mineral admixture)

[0056] Zeolite 298kg (accounting for 29.8% of the total weight of concrete composite mineral admixture)

[0057] Bottom slag 200kg (accounting for 20% of the total weight of concrete composite mineral admixture)

[0058] Composite grinding aid activator 2kg (accounting for 0.2% of the total weight of the concrete composite mineral admixture), of which triisopropanolamine accounts for 0.04kg (accounting for 2% of the total weight of the compound grinding aid activator), and triethanolamine accounts for 0.06kg (accounting for 3% of the total weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com