Patents

Literature

86results about How to "Reduce grinding power consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

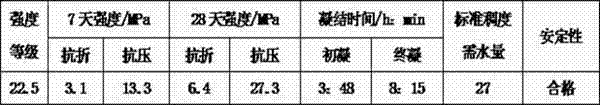

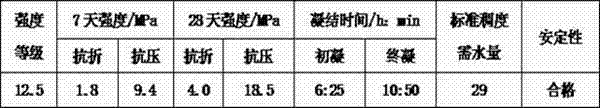

Chlorine-free powdery cement grinding aid and preparation method thereof

InactiveCN101665338AHigh strengthStrong compound synergistic effectCement productionSulfateLignosulfonates

The invention discloses a chlorine-free powdery cement grinding aid suitable for fly ash, which comprises the following components in parts by weight: 0-5 parts of alkanolamine, 2-5 parts of polylol,15-75 parts of sulfate, 5-20 parts of acetate, 0-5 parts of lignosulphonate, 2-6 parts of carbohydrate organic matter, 5-25 parts of miltonite, 0-25 parts of carbamide and 5-50 parts of inorganic carrier material. The invention also discloses a preparation method of the chlorine-free powdery cement grinding aid suitable for the fly ash. A compound grinding aid can lower the cement cost and uses the fly ash for replacing partial clinker to save the clinker dosage by 10-15 percent on the premise of keeping the cement strength unchanged, and uses extra 10-15 parts of fly ash without increasing the required water amount of cement standard consistency; the cost of the cement per ton is lowered by more than 10 Yuan.

Owner:NANJING ZHUJI ENERGY SAVING TECH

Cement grinding aid and preparation method thereof

InactiveCN101125742AImprove grinding efficiencyReduce grinding power consumptionCement grindingTriisopropanolamine

The invention discloses a cement grinding aid and a preparation method thereof. Raw materials of the cement grinding aid consists of 10-30 percent of triethanolamine, 12-30 percent of tirisopropanolamine, 5-20 percent of ethylene glycol, 3-10 percent of propanediol, 15-40 percent of water, 1-5 percent of sodium dodecyl benzene sulfonate, 3-10 percent of lignin and 2-5 percent of anhydrous sodium sulfate; water is poured into a reactor and heated to 40-50 DEG C to be reserved; the sodium dodecyl benzene sulfonate is added to be stirred for 15min; the anhydrous sodium sulfate is added and stirred for 10min, then the lignin is added and stirred for 30min; materials in the reactor are filtered by a 150 mesh screen; the ethylene glycol and the propanediol are added and stirred for 20min; the triethanolamine and the tirisopropanolamine are added and stirred for 30min and the grinding aid products are obtained. The cement grinding aid can improve grinding efficiency and early and later strength of cement and reduce cement cost.

Owner:洛阳万顺建材有限公司

Ecotypic cementing material

ActiveCN102515588AIncreases hydration activityImprove grinding efficiencyCement productionSodium metasilicateBrick

The invention relates to an ecotypic cementing material, which comprises the components of: 40-60 parts of building waste brick powder, 15-30 parts of slag, 10-20 parts of steel plant semi-dry sintering flue gas desulfurization ash, and 10-15 parts of a composite grinding aid activator, which is prepared by raw materials in the following weight ratio: 70-85 parts of calcination modified desulfurization gypsum, 5-10 parts of sodium metasilicate pentahydrate, 5-10 parts of sodium aluminate, 1-5 parts of a naphthalene-based water reducer, 0.1-0.5 part of triethanolamine, 0.05-0.1 part of potassium humate, and 0.05-0.1 part of glycerol. The cementing material of the invention utilizes the synergetic and complementary effects of component materials, realizes resource utilization of building waste brick powder and semi-dry desulphurization ash as well as other solid wastes, thus making waste profitable.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of functionalized adjustable amphiprotic polycarboxylates cement grinding aid

ActiveCN102134300AImprove grinding efficiencyReduce grinding power consumptionNitrogenCarboxylic acid

The invention discloses a preparation method of a functionalized adjustable amphiprotic polycarboxylates cement grinding aid. The method comprises the following steps: according to a certain ratio, adding unsaturated polyether, unsaturated sulfoacid and water in a kettle; preparing unsaturated acid, a catalyst, a ligand and water into an aqueous solution A, and preparing an initiator and water into an aqueous solution B; heating the kettle to 75-95DEG C under the protection of nitrogen, and dropwise adding the aqueous solutions A and B at the same time for 3-5 hours; after the dropwise addition is finished, reacting under heat insulation condition for 1 hour; and after the reaction is finished, adding a certain part of sodium hydroxide for neutralization, and adding water for dilution until the concentration is 40% to obtain a finished product. In the invention, an active / controllable free radical polymerization and macromolecule design theory is adopted to research and develop the functionalized adjustable amphiprotic polycarboxylates cement grinding aid aiming at the effect required by the cement grinding aid, so as to prepare the product of the functionalized adjustable cement grinding aid.

Owner:KZJ NEW MATERIALS GROUP CO LTD +2

Phosphorous slag activation modifier

InactiveCN1457937ALow costImprove grinding effectSolid waste managementSolid waste disposalPhosphorous acidNitrate

The phosphorous slag activating modifier is precipitant comprising one or several kinds of oxide, hydroxide, chloride and nitrate of Ca, Mg and Ba, and prepared through crushing. It is added into phosphorous slag to convert the slowly coagulating components in phosphorous slag into insoluble precipitate as stuffing component. The present invention makes it possible to utilize phosphorous slag to produce high-quality and low-cost cement and other building material.

Owner:尹小林

Industrial waste residue activating grinding aid

InactiveCN1451624APromotes hydration activityAchieve clinker effectOther chemical processesSolid waste disposalBiochemical engineeringElectric consumption

An activating grinding aid for industrial waste residues is prepared from catalyst (1-8 wt.%), activating agent (30-80 wt.%), setting regulator (0-20 wt.%), grinding aid (3-12 wt.%) and carrier (3-30wt.%). Its advantages are effective use of industrial waste residues, low electric consumption of grinder, and improve cement performance.

Owner:尹小林

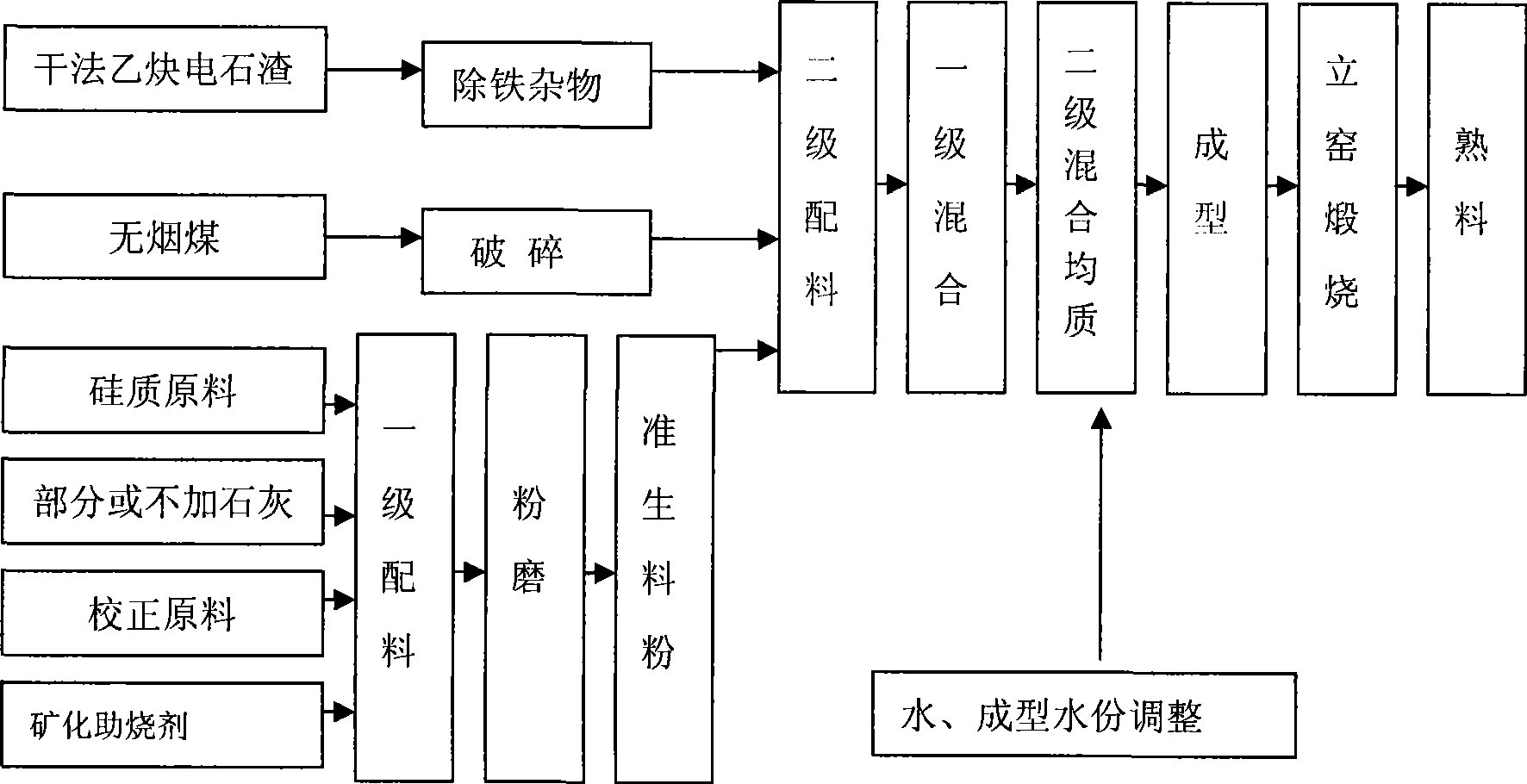

Novel technology of vertical kiln for manufacturing cement clinker by utilizing dry acetylene sludge two-stage batching

The invention discloses a novel technology of a vertical kiln for manufacturing cement clinker by utilizing dry acetylene sludge two-stage batching, which comprises the steps of utilizing dry acetylene sludge to substitute limestone in cement raw meal batching fully or partially, taking the dry acetylene sludge as the main material of the cement raw meal to be subjected to second-stage batching directly with other materials after first-stage batching grinding, mixing evenly, manufacturing a raw meal rod or a raw meal ball, entering the vertical kiln and forming the cement clinker by calcining. The invention has less investment and low energy consumption, takes effect rapidly, is easy for achieving environment protection standard, saves resources of coal, electricity and limestone and reduces CO2 discharge, thus being a novel energy-saving, consumption-reducing and environment-protecting technology.

Owner:尹小林

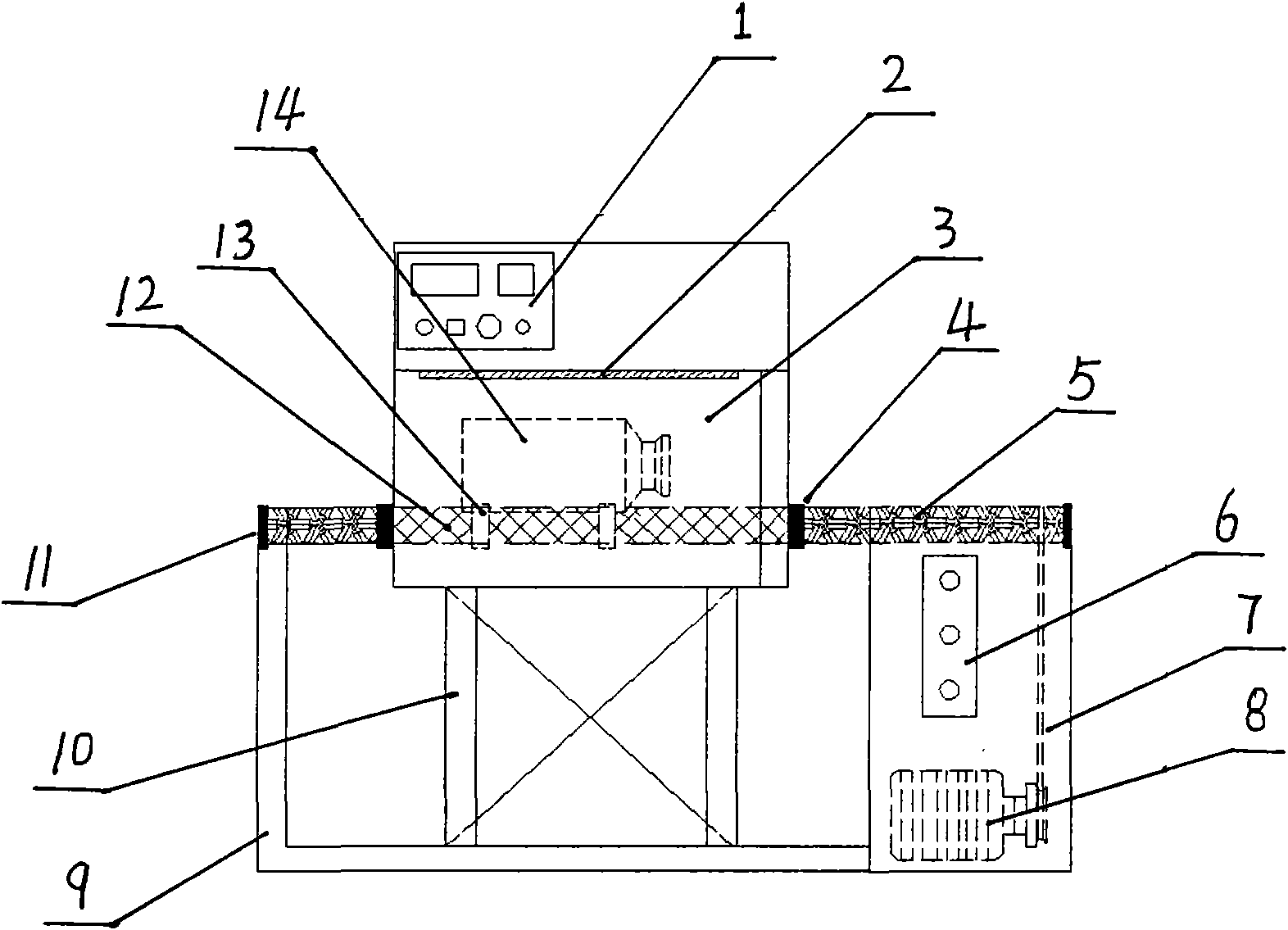

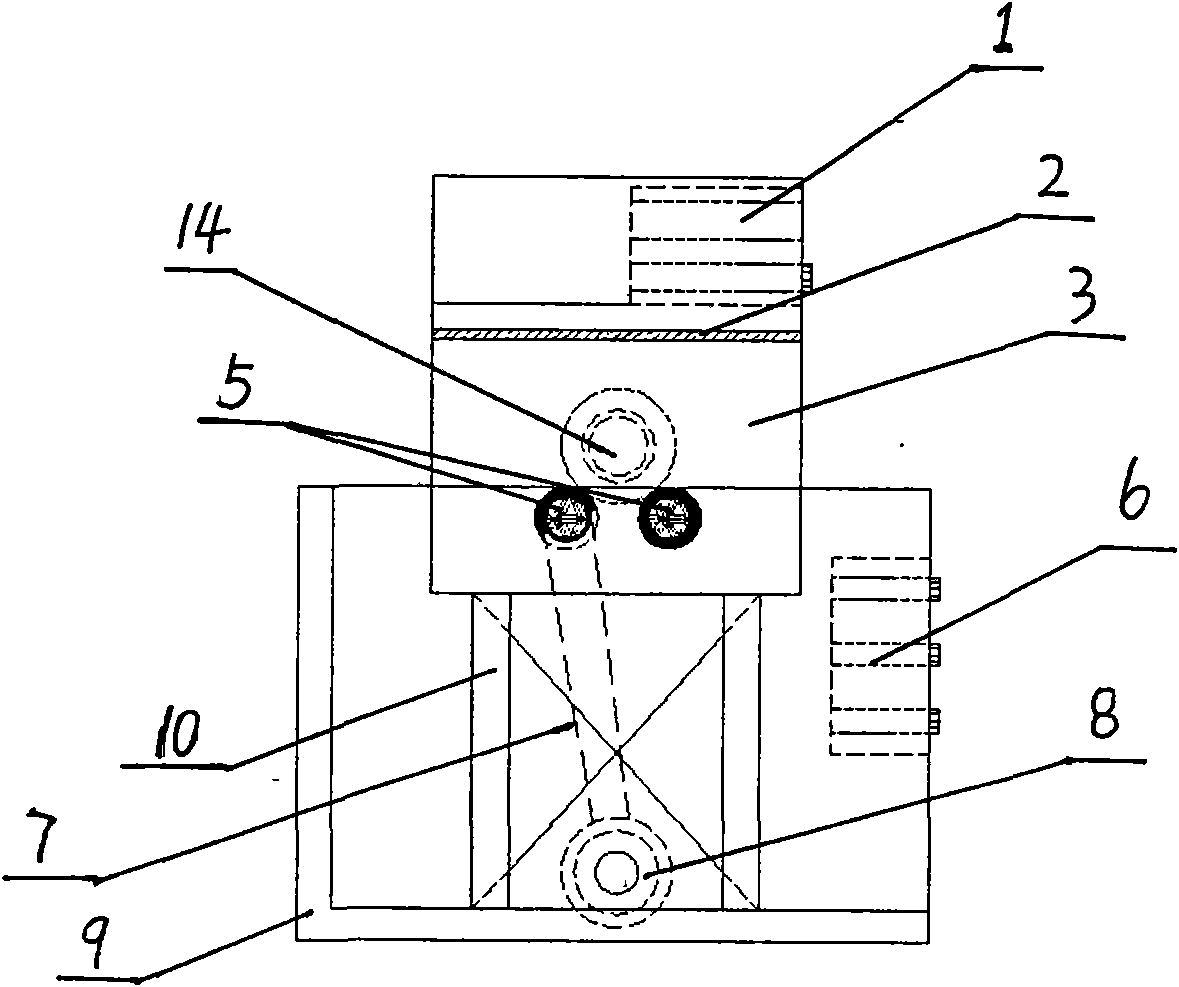

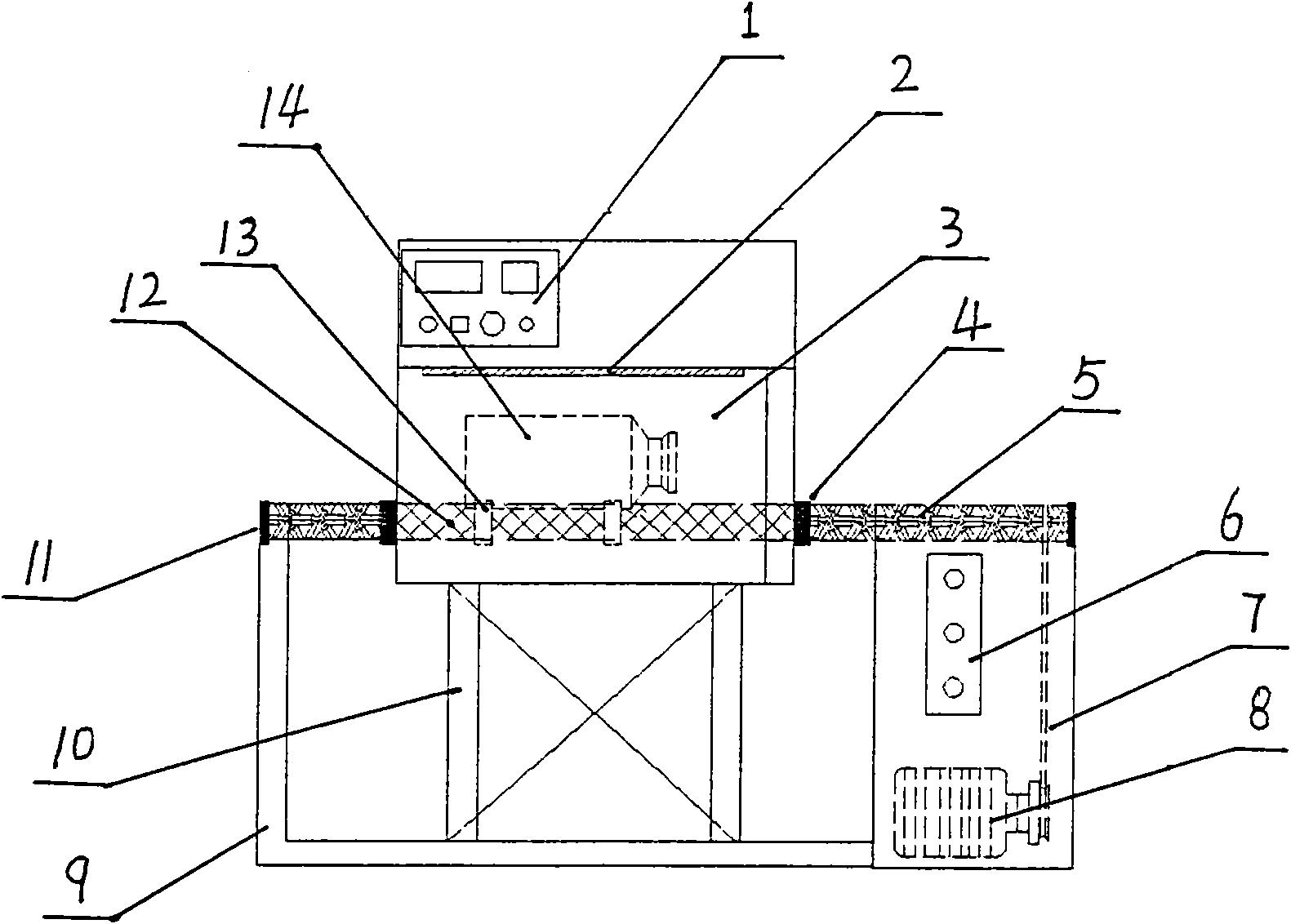

Roller grinder

InactiveCN101890387AEasy to GrindShorten grinding timeMicrowave heatingGrain treatmentsMotor driveEngineering

The invention discloses a roller grinder, which comprises parallel rolling shafts, a grinding controller, a belt, a motor, a base frame, a metal fixing piece and a grinding tank, wherein the parallel shafts are fixed on the base frame by the metal fixing piece; the motor drives the parallel rolling shafts to rotate through the belt; the grinding controller is connected with the motor and is fixedly arranged on the upper part of the motor; a grinding ball is arranged in the grinding tank; the middle parts of the parallel rolling shafts are connected with sections of quartz parallel rolls through metal casings; the quartz grinding tank is arranged on the quartz parallel rolls; the quartz parallel rolls and the quartz grinding tank are arranged in the inside of a microwave emitting cavity; the upper part of the quartz grinding tank is provided with a microwave generator and a microwave controller respectively; the microwave generator is connected to the microwave controller; the synchronous operation of microwave selective heating and grinding improves the heating efficiency during grinding and reduces ore grinding time and ore grinding power consumption; and the equipment is low in temperature and easy and safe to operate.

Owner:HENAN POLYTECHNIC UNIV

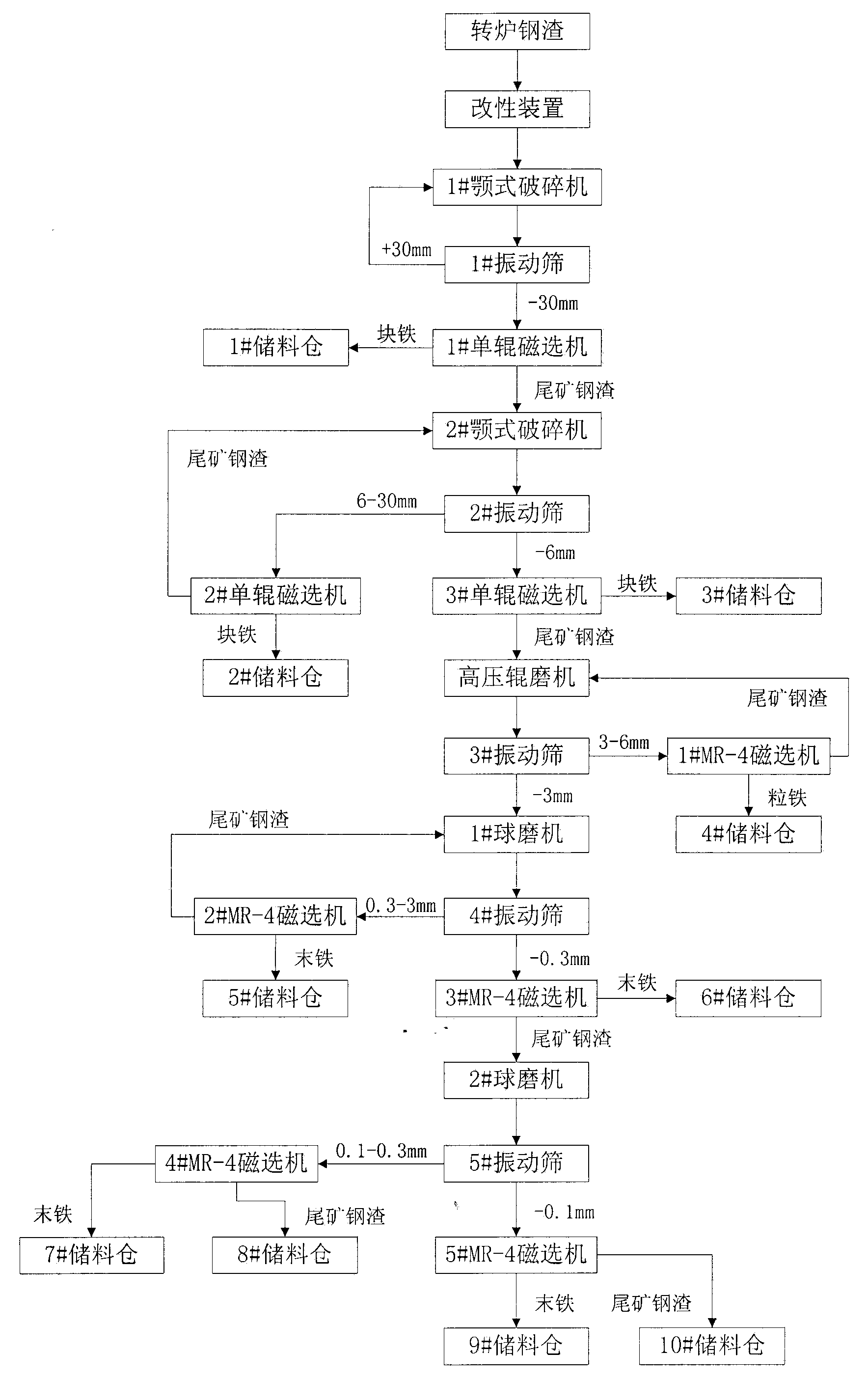

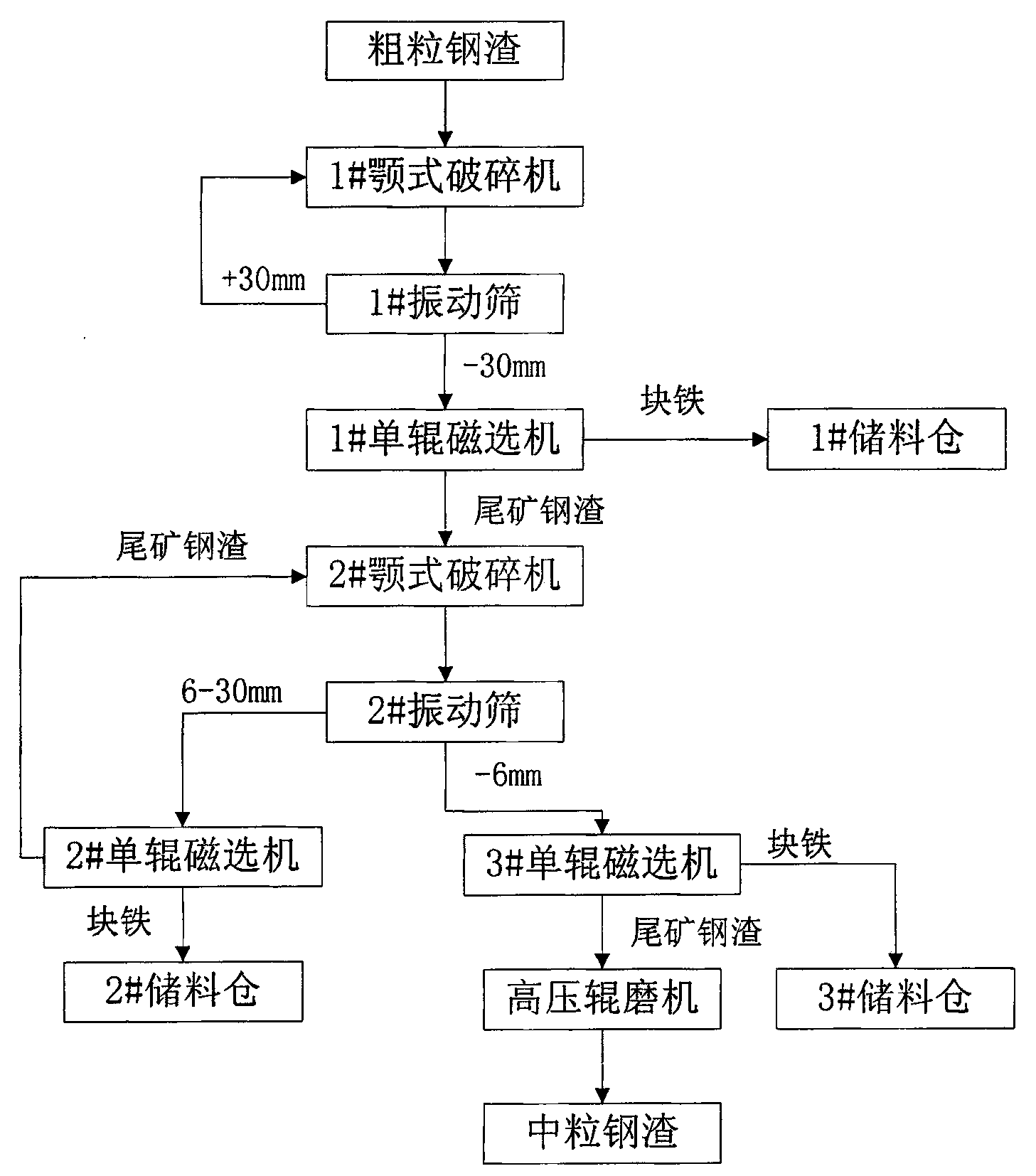

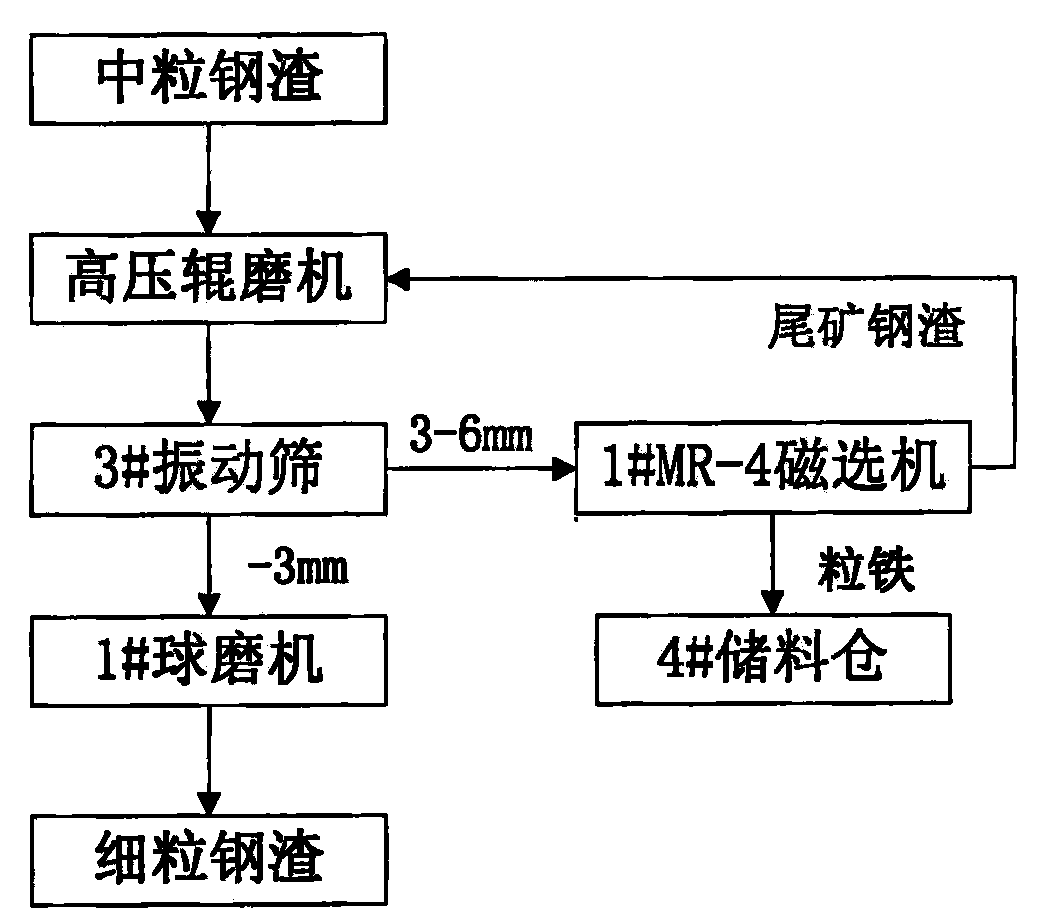

Embedded-type all-grain-size dry magnetic separation technology for closed recycle of iron-containing minerals in steel slag

InactiveCN103586118AIncrease profitReduce accumulationMagnetic separationGrain treatmentsSlagGranularity

The invention discloses an embedded-type all-grain-size dry magnetic separation technology for closed recycle of iron-containing minerals in steel slag. The technology mainly comprises modified treatment of the steel slag, treatment of coarse-grain steel slag, treatment of medium-grain steel slag and treatment of fine-grain steel slag. Specifically, when a steel furnace pours the steel slag, with utilization of the heat of the steel slag, lignite is added to serve as a reduction modifier so as to improve the magnetic property of the iron-containing minerals in the steel slag; and the modified steel slag is subjected to two times of crushing by a jaw crusher and enters a high-pressure roller mill for intermediate crushing after the iron-containing minerals in the steel slag are recycled by magnetic separation of a single-roller magnetic separator, the steel slag after the intermediate crushing enters a ball grinder twice for grinding, and according to the separation effect of the steel slag and a separation requirement of the magnetic separator, the optimal granularity range is 0.1 mm to 0.3 mm. According to the dry magnetic separation technology, efficient separation of different steel slag with coarse, medium and fine grains can be achieved, the magnetic separation technology is optimized, the dry magnetic separation technology for multiple products has higher market competitiveness, and meanwhile, the technology is energy-saving and environment-friendly, thereby according with relevant national policies.

Owner:HENAN POLYTECHNIC UNIV

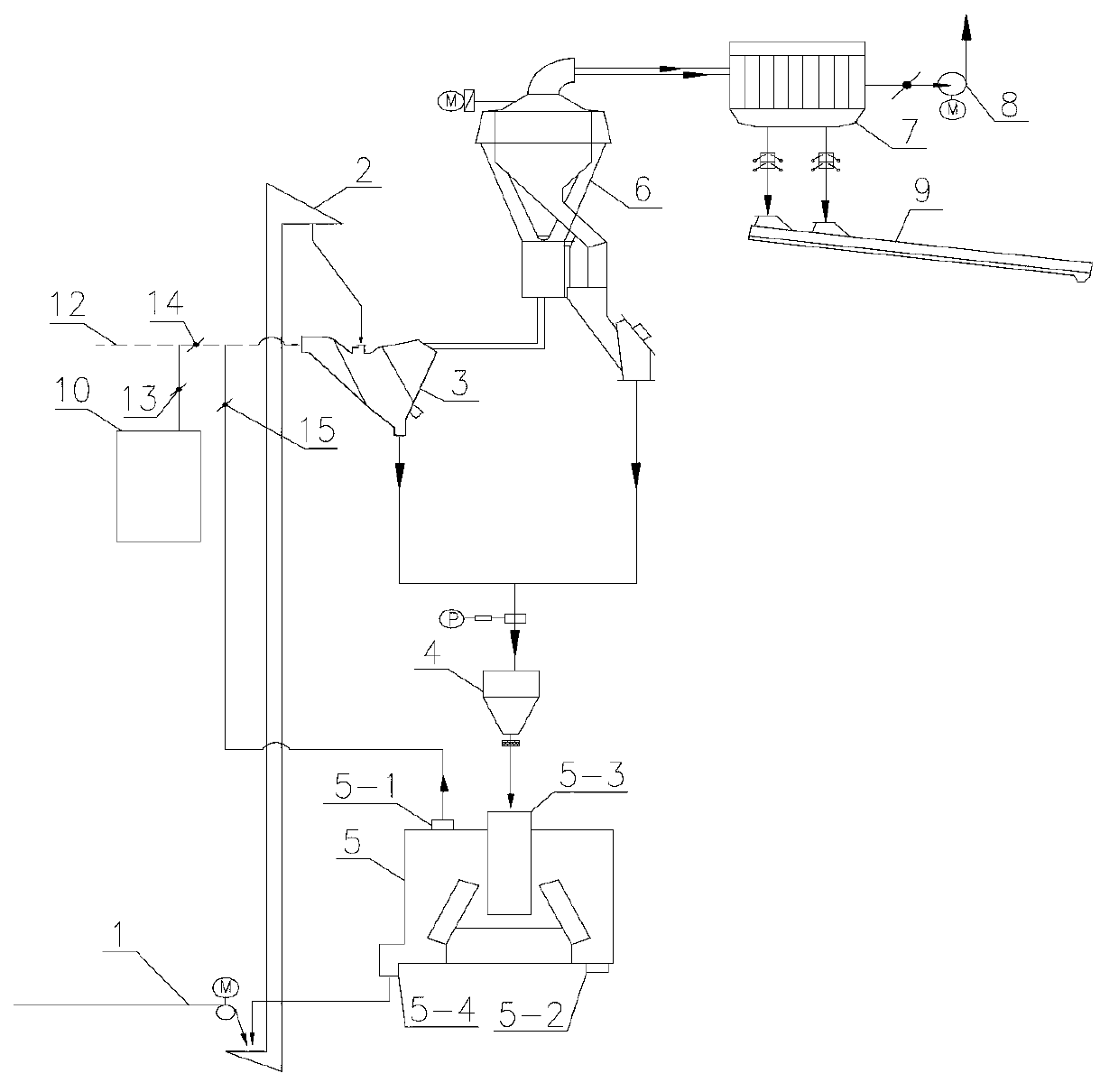

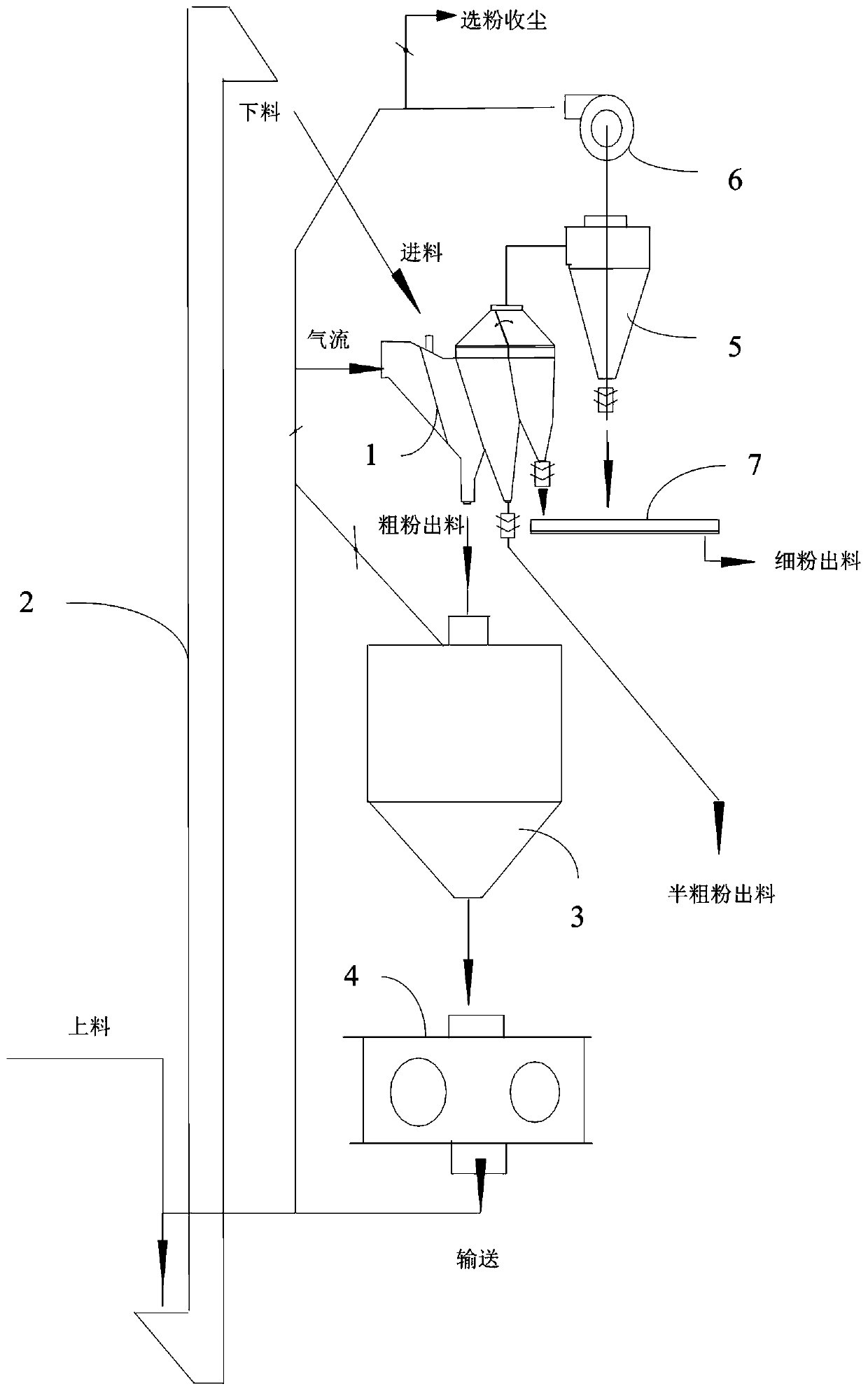

External-circulation cement finish grinding system for vertical mill

The invention discloses an external-circulation cement finish grinding system for a vertical mill. The external-circulation cement finish grinding system comprises a belt conveyor, a bucket elevator, a steady current bin, a vertical mill, a dust collector, a fan and a chute, wherein the belt conveyor is used for conveying materials inside, and the chute is used for conveying fine powder finished products outside. The external-circulation cement finish grinding system is characterized in that the bucket elevator, a coarse powder concentrator, the steady current bin and the vertical mill are sequentially connected to form a circulating system; the bucket elevator, the coarse powder concentrator, a refined powder concentrator, the steady current bin and the vertical mill are sequentially connected to form a circulating system; the bucket elevator, the coarse powder concentrator, the refined powder concentrator, the dust collector and the fan are sequentially connected; a powder concentration device is positioned outside the vertical mill and is formed by serially connecting the coarse powder concentrator and the refined powder concentrator; the coarse powder concentrator comprises three paths of air inlet pipelines which are connected in parallel, one path is connected with a heat source, one path is connected with cold air, and one path is connected with a dust collecting air inlet of the vertical mill.

Owner:NANJING KISEN INT ENG

Composite blending material of slag powder and use method

InactiveCN102173627AReduce alkalinitySpeed up the hydration reactionSolid waste managementSocial benefitsSlag

The invention relates to a composite blending material of slag power and a use method. Slag, quick lime and calcined gypsum are mixed according to a certain proportion, and then, are finely ground into the composite blending material with specific surface area of 400m<2> / kg to 600m<2> / kg. When the composite blending material is used for producing cement concrete products with a steam curing process, the composite blending material can replace 10-40% of cement with the strength grade above 32.5 in an equal quantity manner; and by using the composite blending material, the production cost of the cement concrete products is lowered, resources are saved, and favorable economic benefits and social benefits are achieved.

Owner:蒋元海

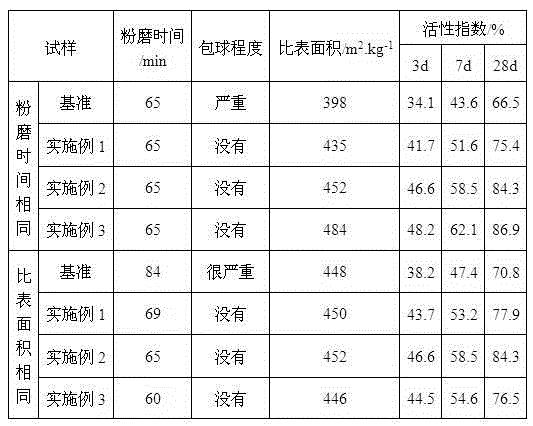

Method for improving nickel slag grinding efficiency and activity

ActiveCN102942322ASolve the ballSolve the phenomenon of reunionSolid waste managementSocial benefitsSlag

The invention discloses a method for improving nickel slag grinding efficiency and activity, and belongs to the technical field of building materials. 2-10wt% of limestone and 90-98wt% of nickel slag are mixed and then added into a mill for mixed grinding for 60-90min, the problems of balling and conglobation in nickel slag grinding process can be effectively solved, grinding efficiency is improved, and grinding power consumption is reduced. Besides, the grain composition and the activity of the nickel slag are obviously improved. The method is simple in process, low in cost and easy to popularize and apply, and has remarkable economic and social benefits.

Owner:福建源鑫环保科技有限公司

Method for producing belite-gypsum material by using sludge and waste gypsum through dry-process rotary kiln

The invention discloses a method for producing a belite-gypsum material by using sludge and waste gypsum through a dry-process rotary kiln. The method comprises the following steps of (1) melting a sludge ridge grain seed crystal with high water content into modified sludge residues; (2) proportioning raw materials of the modified sludge residues, the waste gypsum and a correcting material according to a certain ratio, and grinding the raw materials by using a vertical mill to form raw material powder; (3) delivering the raw material powder obtained in the step (2) into a dry-process rotary kiln system, and calcining the raw material powder to form clinker; and (4) grinding the obtained clinker to obtain powder with the fineness of 0.08mm and the screen residue content of less than 20%. The method disclosed by the invention is simple, low in investment and cost, free of other secondary pollution and capable of absorbing the sludge and the waste gypsum on a large scale and in a recycling way, greatly reducing the energy consumption and relieving the environment pollution.

Owner:长沙紫宸科技开发有限公司

Additive applied to saving energy and increasing effect in cement production and preparation method thereof

ActiveCN102432209ARationalization of particle distributionGood dispersionNickel saltINCREASED EFFECT

The invention discloses an additive applied to saving energy and increasing effect in cement production. The additive is characterized by comprising the following components in percentage by weight: 60-80 percentage of triethanolamine, 8-12 percentage of monoethanolamine, 0.5-3 percentage of sodium polyacrylate, 0.5-3 percentage of sodium dodecyl sulfate, 0.5-1.5 percentage of abietin, 0.5-2.5 percentage of nickel salt, and 10-18 percentage of water. The additive has the main advantages of: 1, respectively improving output of a raw material grinder and a coal grinder for more than 10%, saving power consumption in grinding by more than 10%; 2, saving the coal consumption in the cement production process by more than 8%; 3, improving output of clinker by more than 8%; 4, improving the strength of the clinker at different ages for 2-5 MPa, and being capable of improving the stability of the clinker; 5, improving the comprehensive economic benefit of the clinker by more than 10 Yuan / ton; and 6, respectively reducing emission of CO2 and SO3 in the cement production by more than 8%.

Owner:长沙市保灵建材助剂有限公司

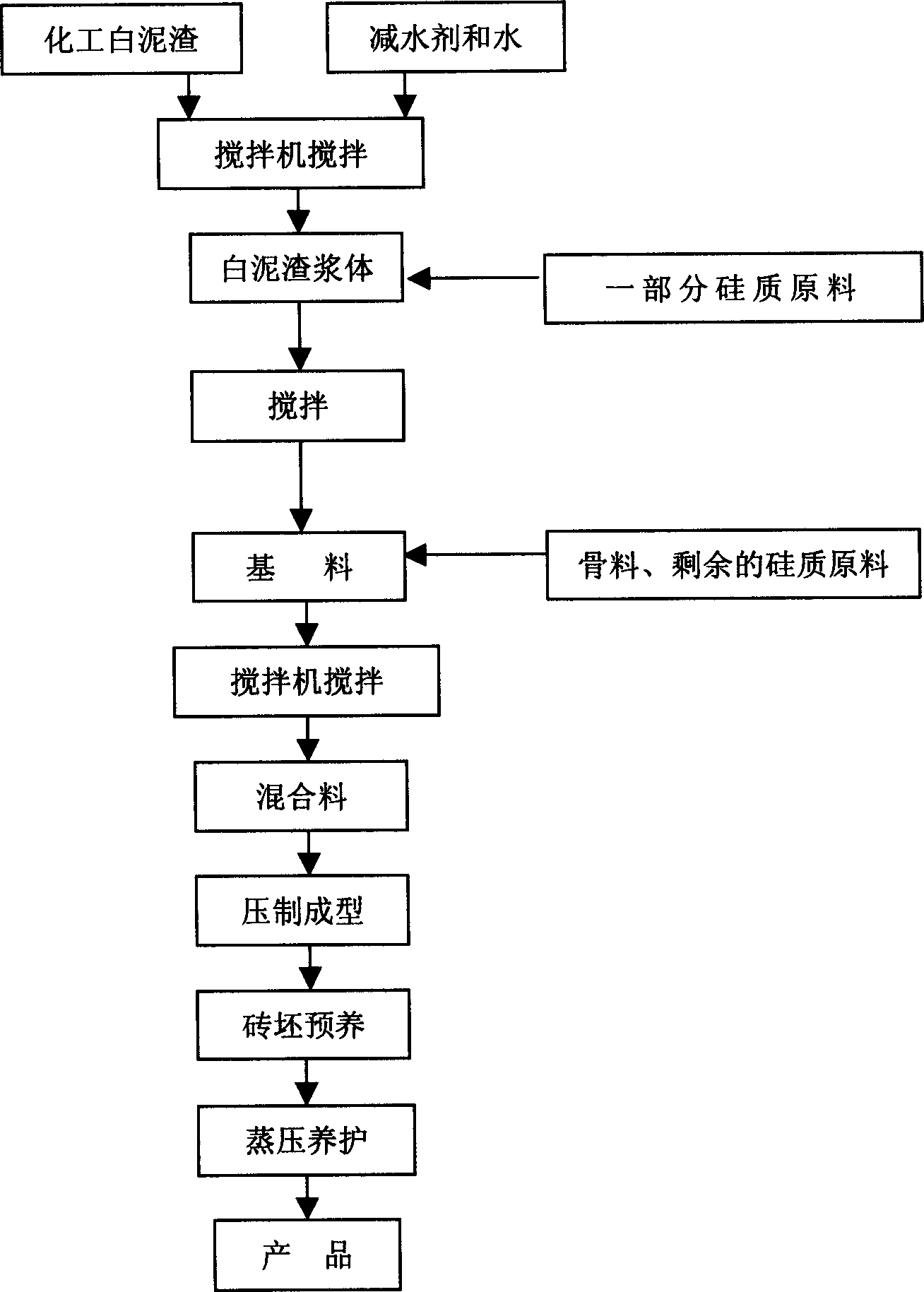

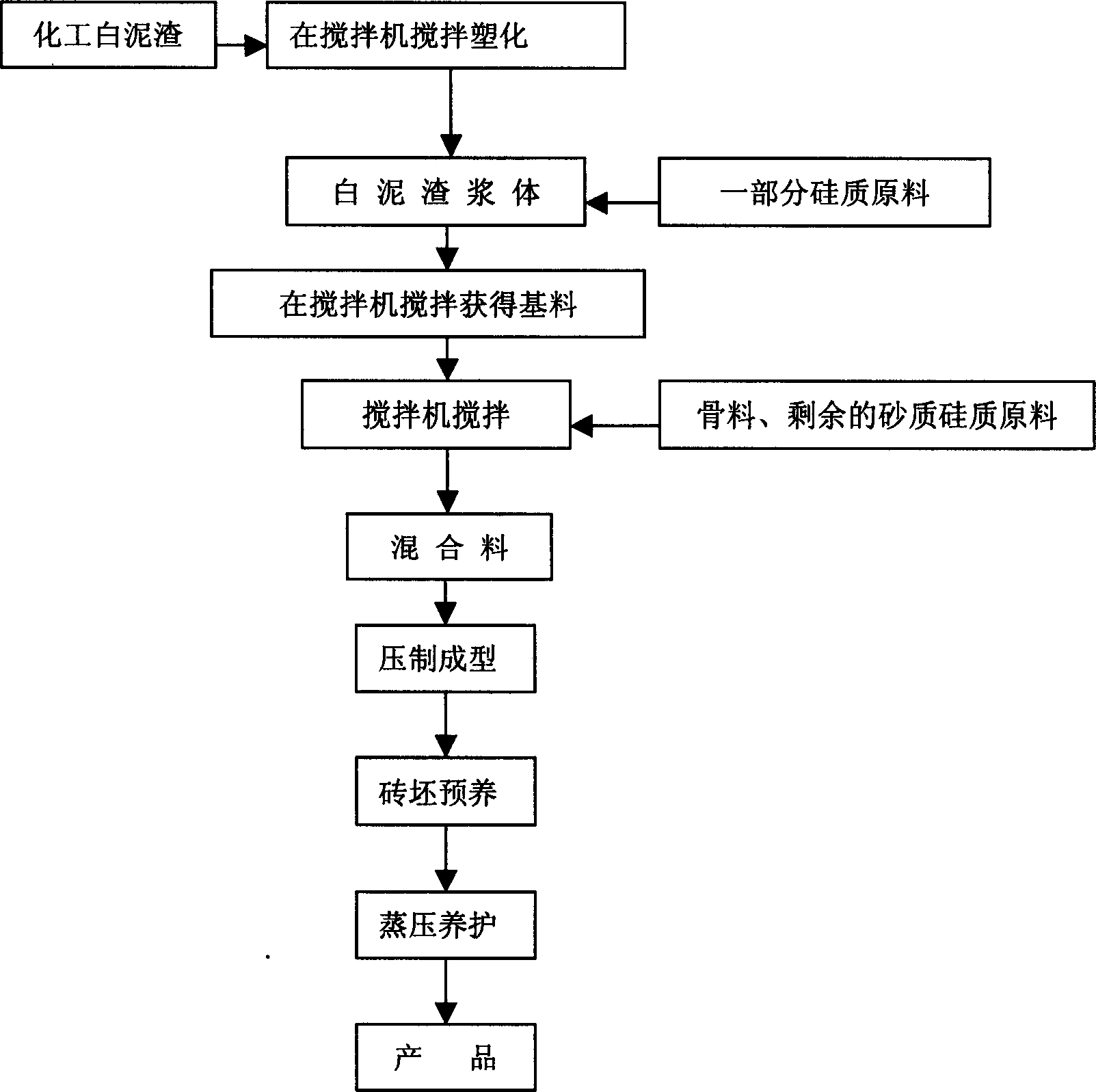

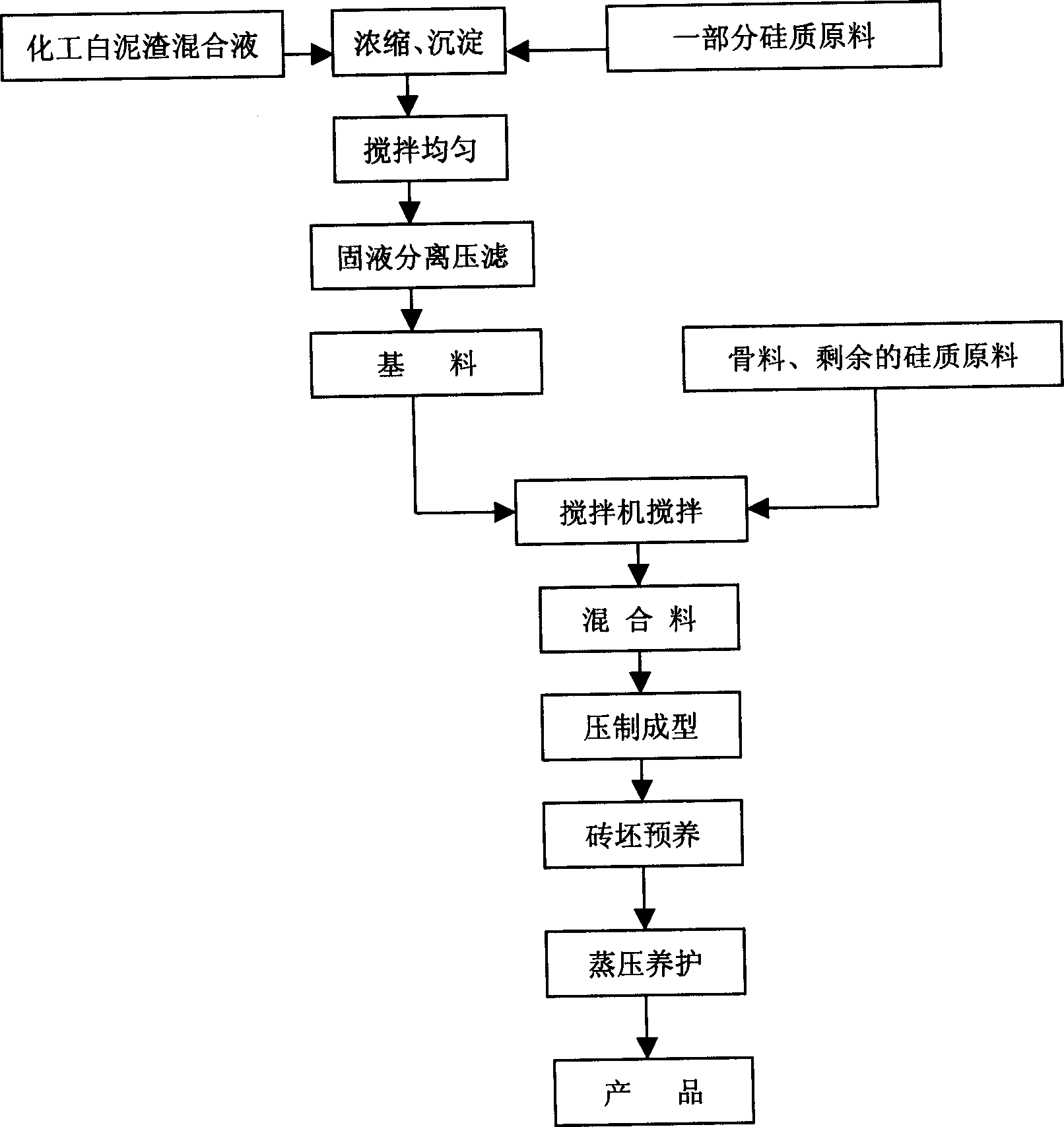

Method of preparing high-strength silicate wall material by utilizing chemical white sludge

The invention discloses a method of preparing high-strength silicate wall material by utilizing chemical white sludge which comprises the steps of, charging siliceous raw material into white sludge grout by the weight ratio of 1:1-0.25, agitating homogeneously, then charging aggregate accounting to 30-50 wt% of total mixture and remaining portion siliceous raw material, stirring to obtain mixture, press forming, curing the unfired brick, and maintaining through pressured stream. The chemical white cement slag being calcium carbide slag and chlorohydrin epoxypropane white cement slag, the siliceous raw material being fine yellow sands, fine konilite or coal ash.

Owner:NANJING UNIV OF SCI & TECH

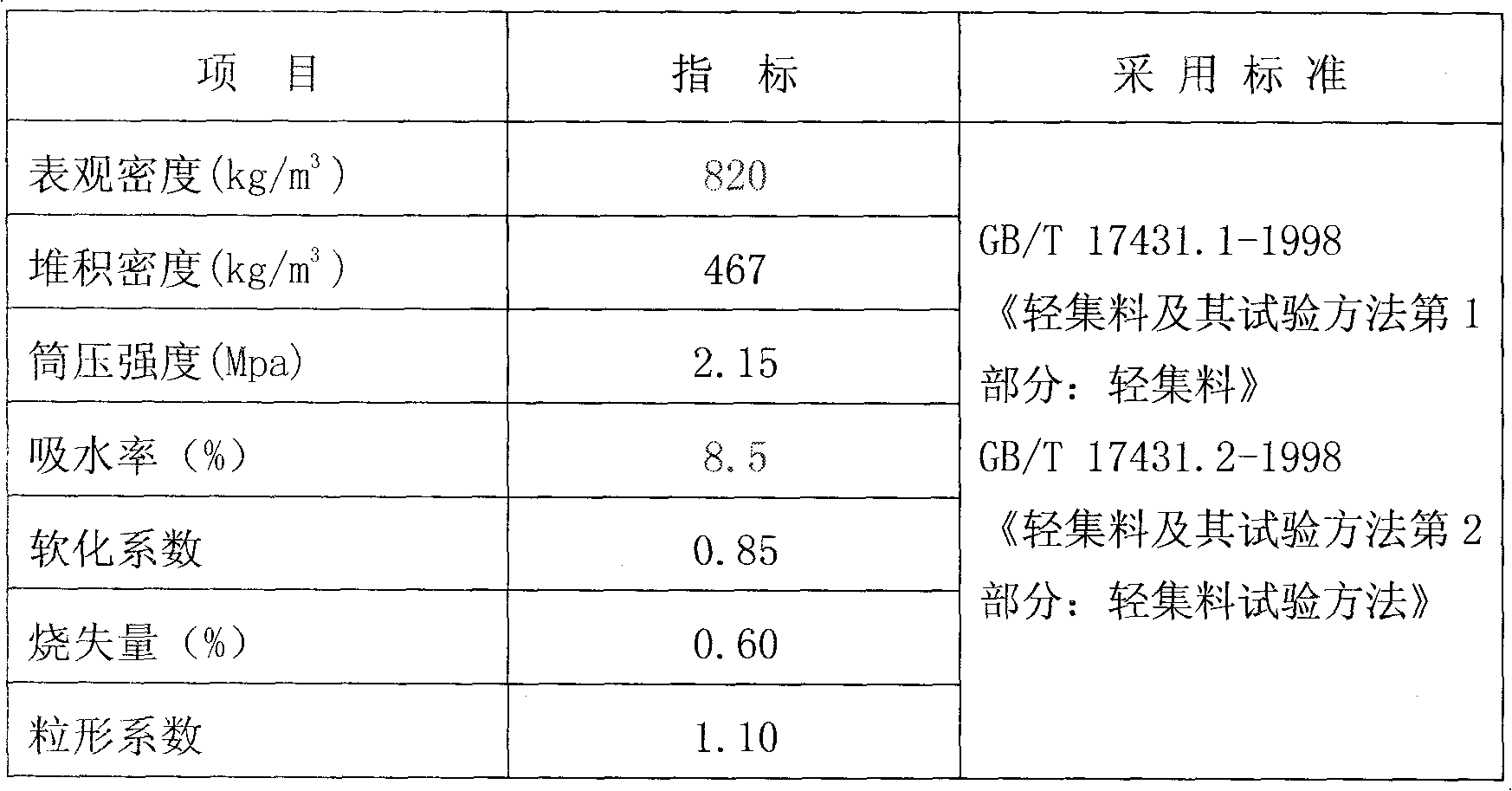

Method for preparing light building material ceramic particle by utilizing slate sawn mud

InactiveCN101851110ASimple production processReduce manufacturing costSolid waste disposalCeramicwareSodium silicateBuilding material

The invention relates to a method for preparing light building material ceramic particle by utilizing slate sawn mud. The product formula includes: 60-100% of slate sawn mud (containing 30% of moisture) and 0-40% of slate dry powder; and 1-2% of sodium silicate binder is additionally doped. The manufacturing processing step includes that the slate sawn mud is filtered until moisture is less than 30%, the slate sawn mud and powder material obtained by sieving crushed slate are pre-stirred into bulk particles in a dual spindle stirring machine, so as to form cue ball, when the moisture contained in the slate sawn mud is less than 15%, the slate sawn mud also can be independently stirred and broken into particles in the stirring machine, then the cue ball is fed into a ball forming mill to be sprayed with mist water, and a small amount of binder is added, so that the particle forms a spherical particle with the diameter Phi of 5-30mm by rolling, then the material ball is fed into a rotary kiln to be calcined, the calcining temperature is 1100-1200 DEG C, and calcining time is 25-40min, and the fiery material ball taken out from the kiln is cooled by adopting a monocular cooling machine. The method has simple production technology and low cost, and the prepared slate sawn mud ceramic particle has high tube pressure strength and wide application.

Owner:NANCHANG UNIV

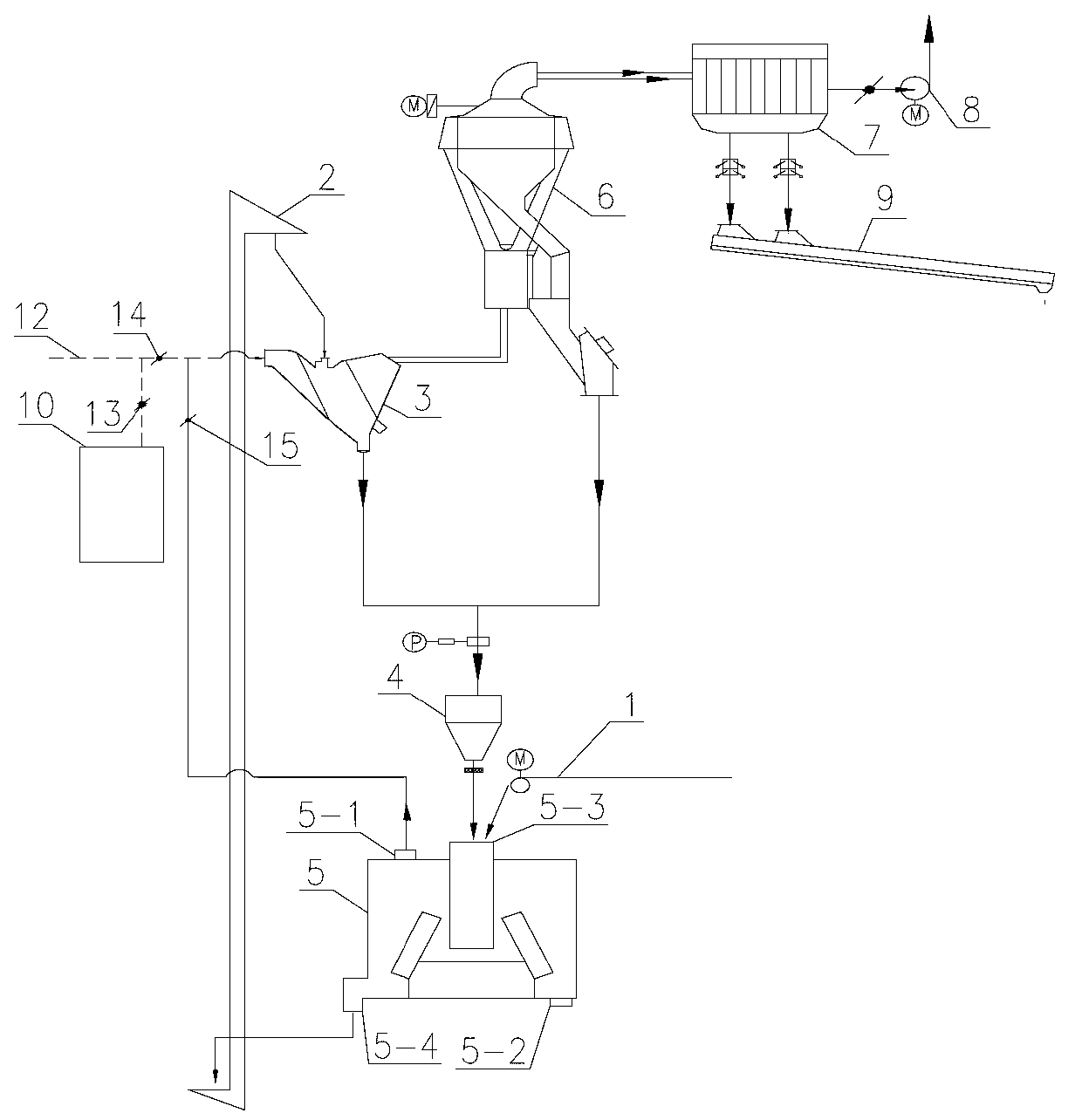

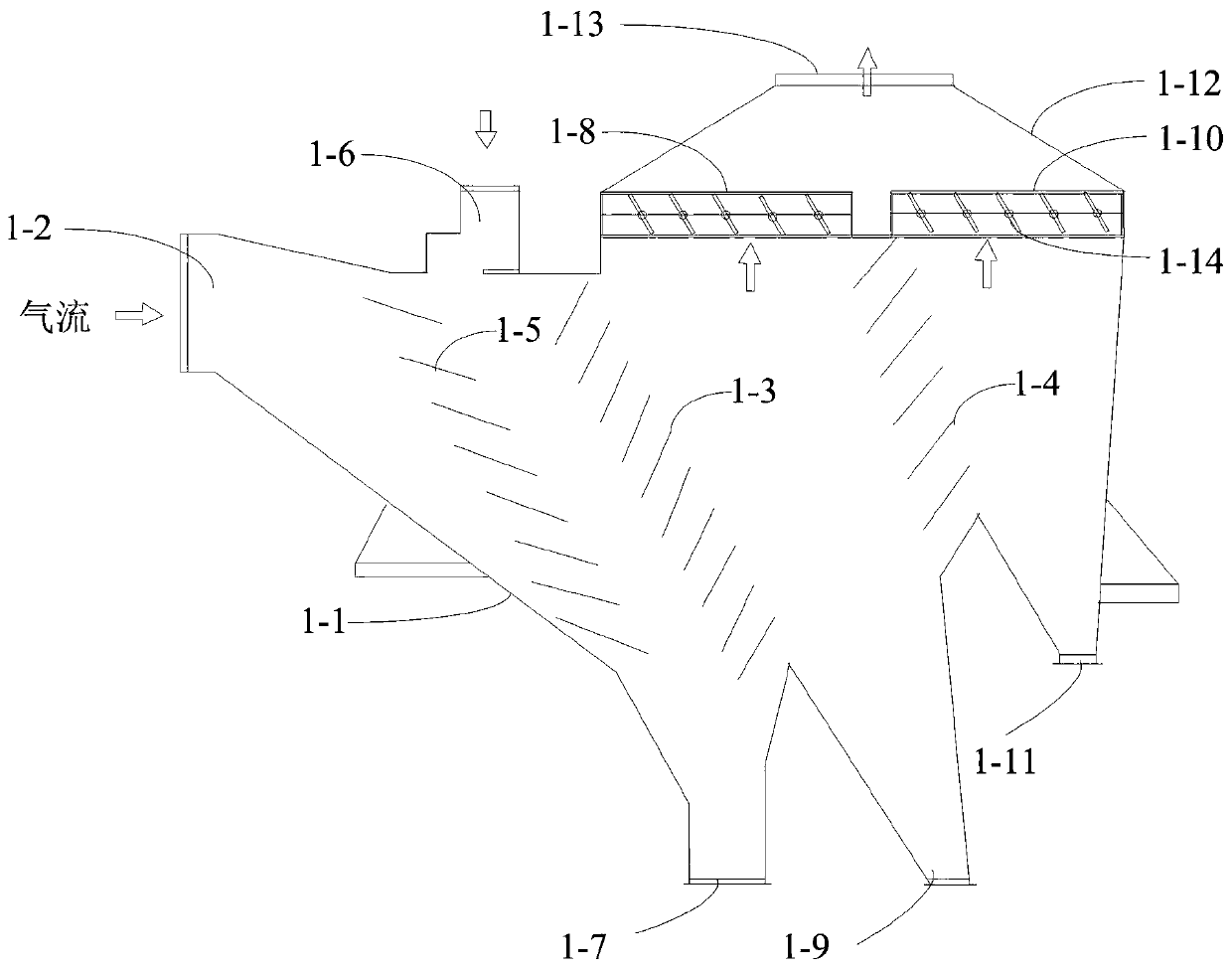

Static-state double-classification powder concentrator and semi-finished pre-grinding system

The invention discloses a static-state double-classification powder concentrator and a semi-finished pre-grinding system. According to the static-state double-classification powder concentrator, an air inlet is arranged at the position, close to the top, of the side face of a shell, and the shell is internally divided by a coarse material guiding baffle set and a fine powder guiding baffle set into a coarse material sieving cavity, a semi-coarse material sieving cavity and a fine powder sieving cavity. The coarse material sieving cavity is internally provided with a material slide carriage setwith the top inclining towards the air inlet. The part, above the material slide carriage set, of the shell is provided with a feed port, and the part, below the material slide carriage set, of the shell is provided with a coarse powder outlet. The part, above the semi-coarse material sieving cavity, of the shell is provided with a first air outlet, and the part, below the semi-coarse material sieving cavity, of the shell is provided with a semi-coarse powder outlet. The part, above the fine powder sieving cavity, of the shell is provided with a second air outlet, and the part, below the finepowder sieving cavity, of the shell is provided with a fine powder outlet. The size of the first air outlet and the size of the second air outlet are controlled through valves. The powder concentrator can be applied to various pre-grinding systems. According to the powder concentrator, an existing v-shaped powder concentrator can be directly improved, and coarse particles, semi-coarse particles and fine powder finished products in materials can be efficiently separated.

Owner:NANJING TECH UNIV

Method for producing belite-gypsum material by calcining sludge and waste gypsum through vertical kiln

The invention discloses a method for producing a belite-gypsum material by calcining sludge and waste gypsum through a vertical kiln. The method comprises the following steps of (1) melting a sludge ridge grain seed crystal with high water content into modified sludge residues; (2) carrying out two-stage proportioning on raw materials of the modified sludge residues, the waste gypsum and a correcting material according to a certain ratio, homogenizing, adding a proper proportion of fire coal in the proportioning and homogenizing processes, and molding grains or charging bars to obtain a black raw material molding material; (3) delivering the obtained black raw material molding material into the vertical kiln, and calcining the black raw material molding material at the temperature of 1250-1400 DEG C to form clinker; and (4) grinding the obtained clinker to obtain powder. The method disclosed by the invention is simple, low in investment and cost, free of other secondary pollution and capable of absorbing the sludge and the waste gypsum on a large scale and in a recycling way, greatly reducing the energy consumption and relieving the environment pollution.

Owner:长沙紫宸科技开发有限公司

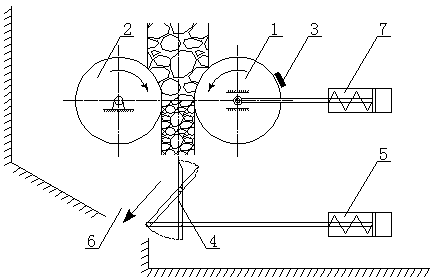

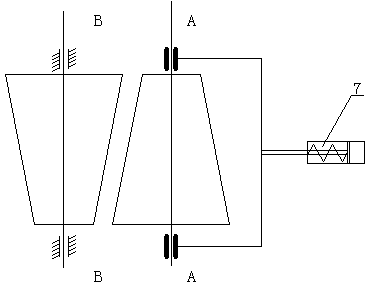

Cement final grinding roller press with material grinding and waste discharging functions

InactiveCN103406169ASimple structureEasy to useCement productionGrain treatmentsHydraulic cylinderPulp and paper industry

The invention discloses a cement final grinding roller press with material grinding and waste discharging functions, and aims to solve the problems that the current cement final grinding roller press is complex in structure and relatively high in manufacturing and operation costs and the quality of a cement product is lowered because wastes are mixed in a product. The cement final grinding roller press disclosed by the invention has the advantages of reasonable structure, convenience in use, lower cost, capability of automatically discharging wastes and improving the quality of the cement product, and the like. The cement final grinding roller press structurally comprises two rollers which are arranged on a rack and shaped like a frustum along the axis direction, wherein one of the rollers is a movable roller, the other roller is a fixed roller, and the two rollers rotate at different speeds. The movable roller is pressurized through a hydraulic cylinder and used for squeezing and grinding materials. A waste discharging device is arranged below the two rollers.

Owner:YANCHENG INST OF TECH

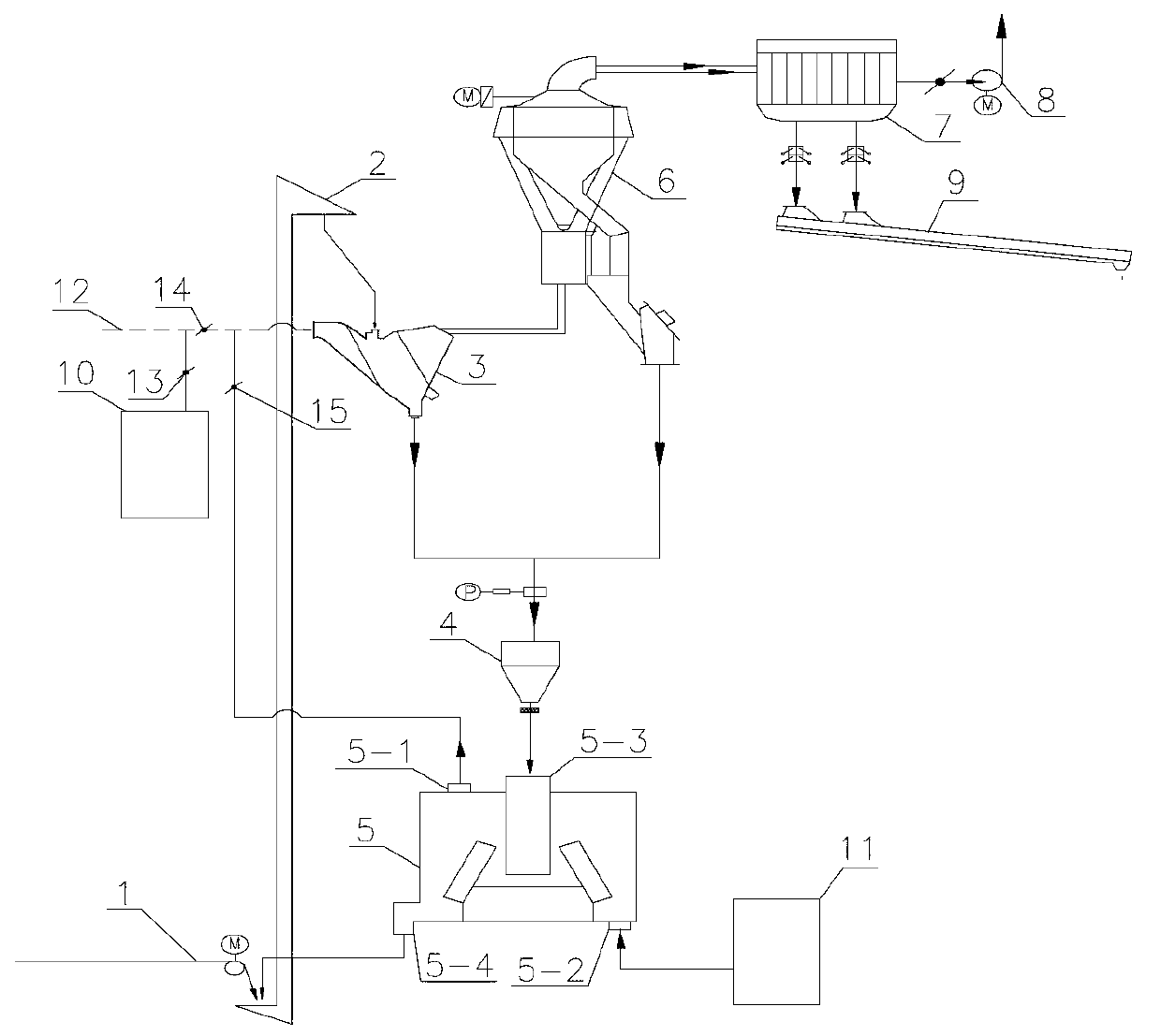

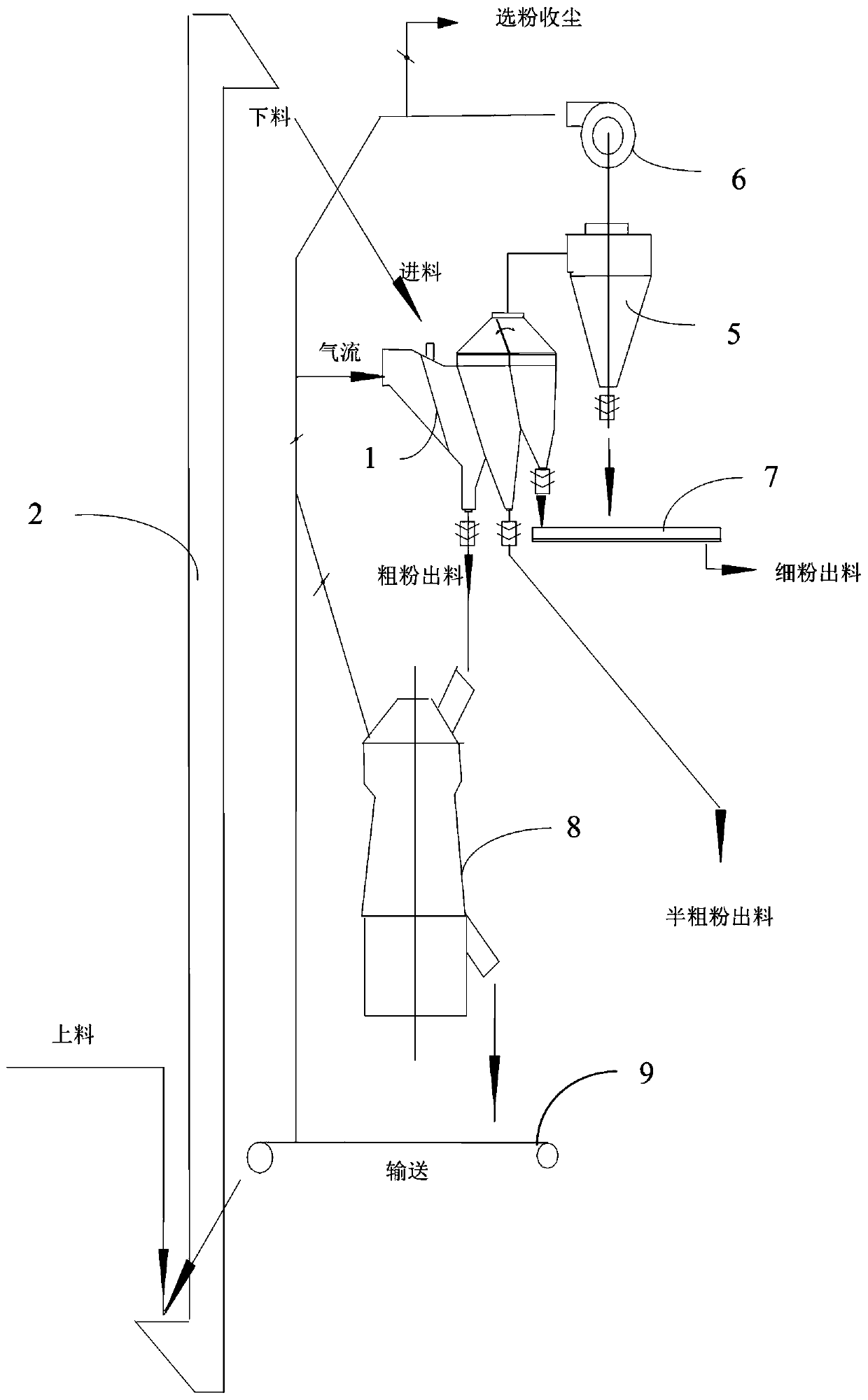

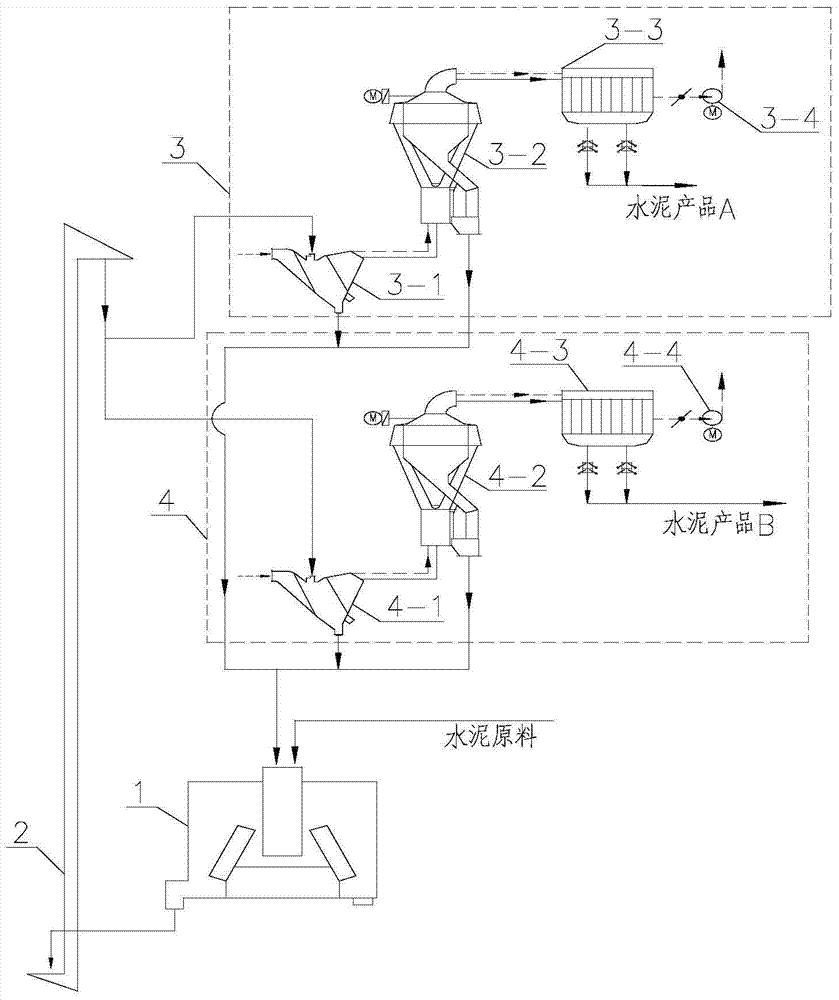

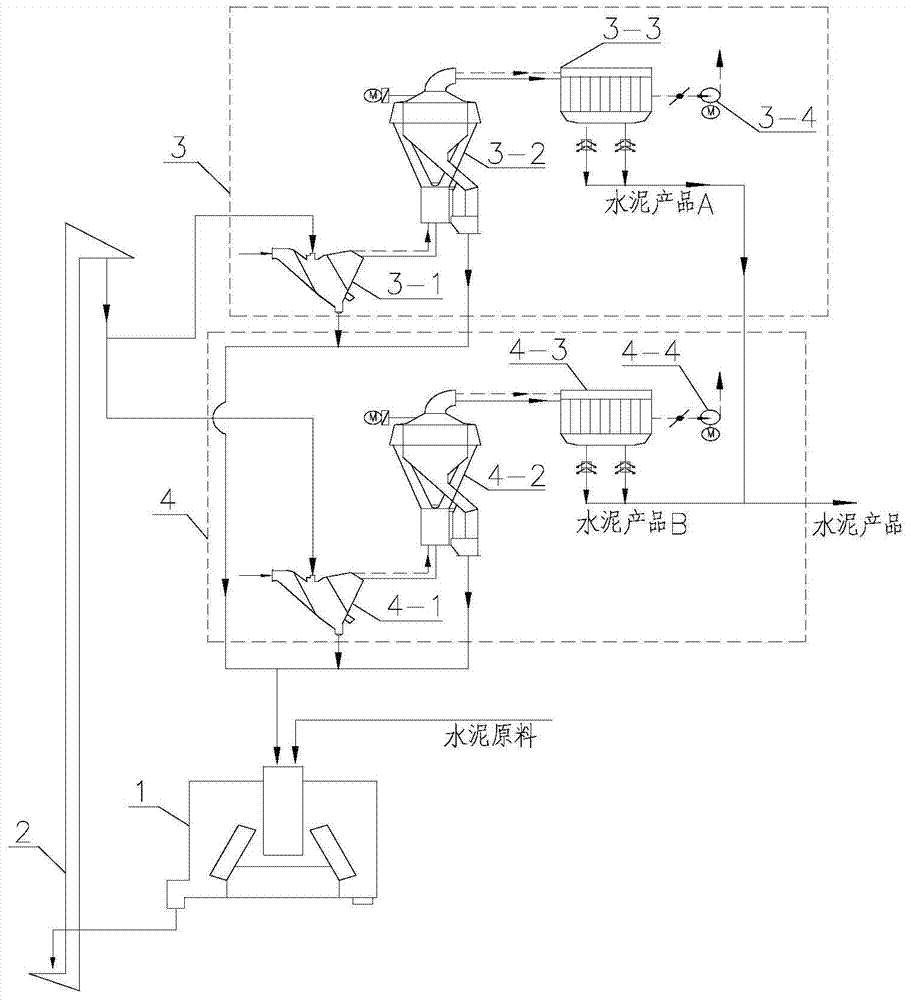

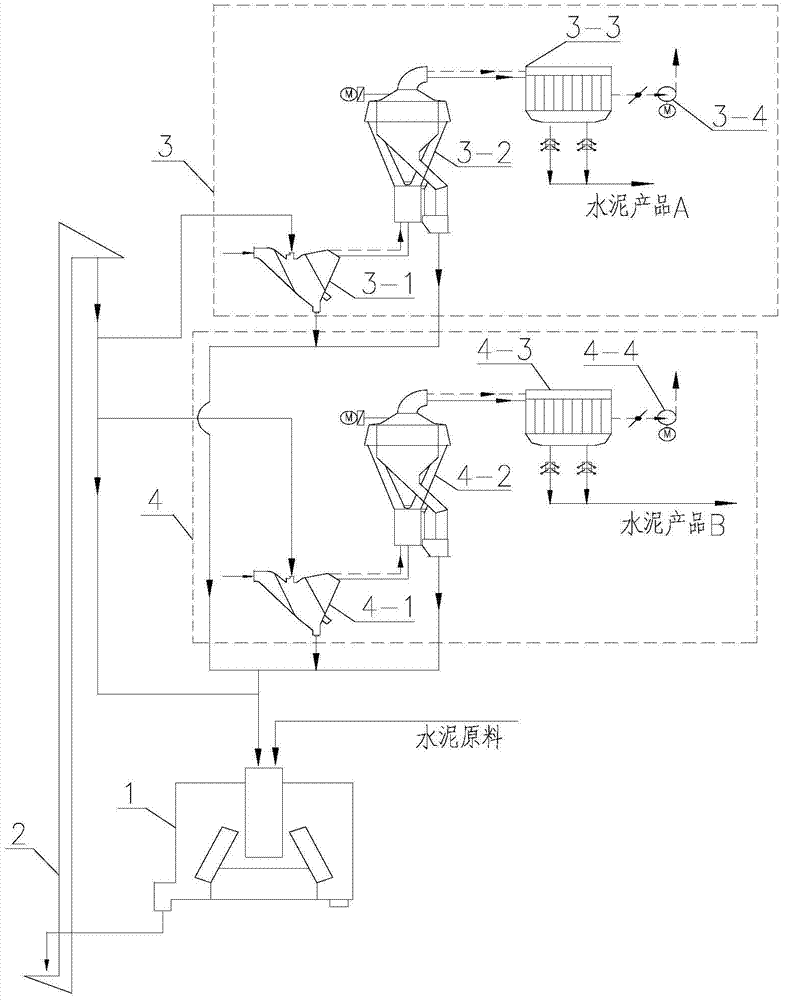

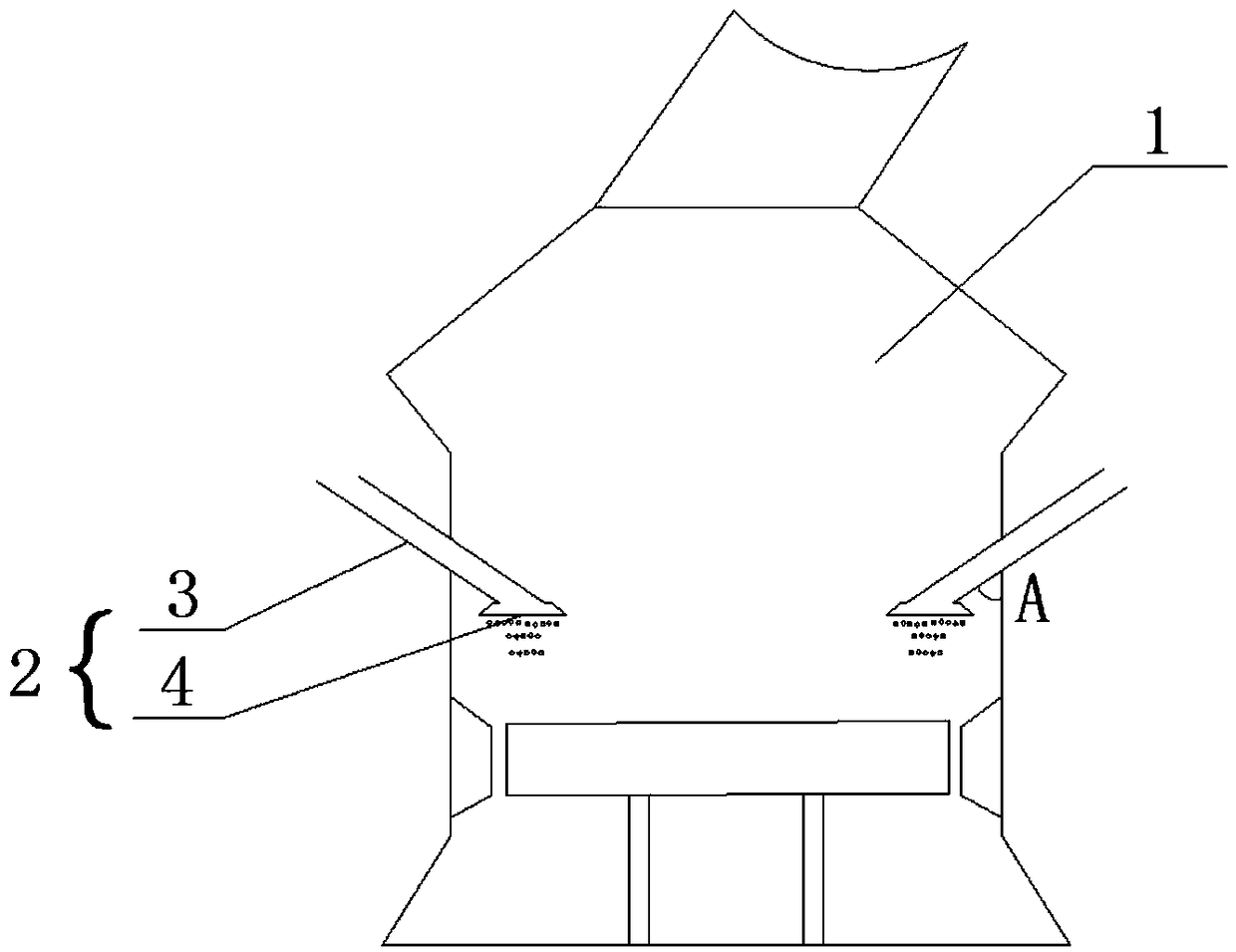

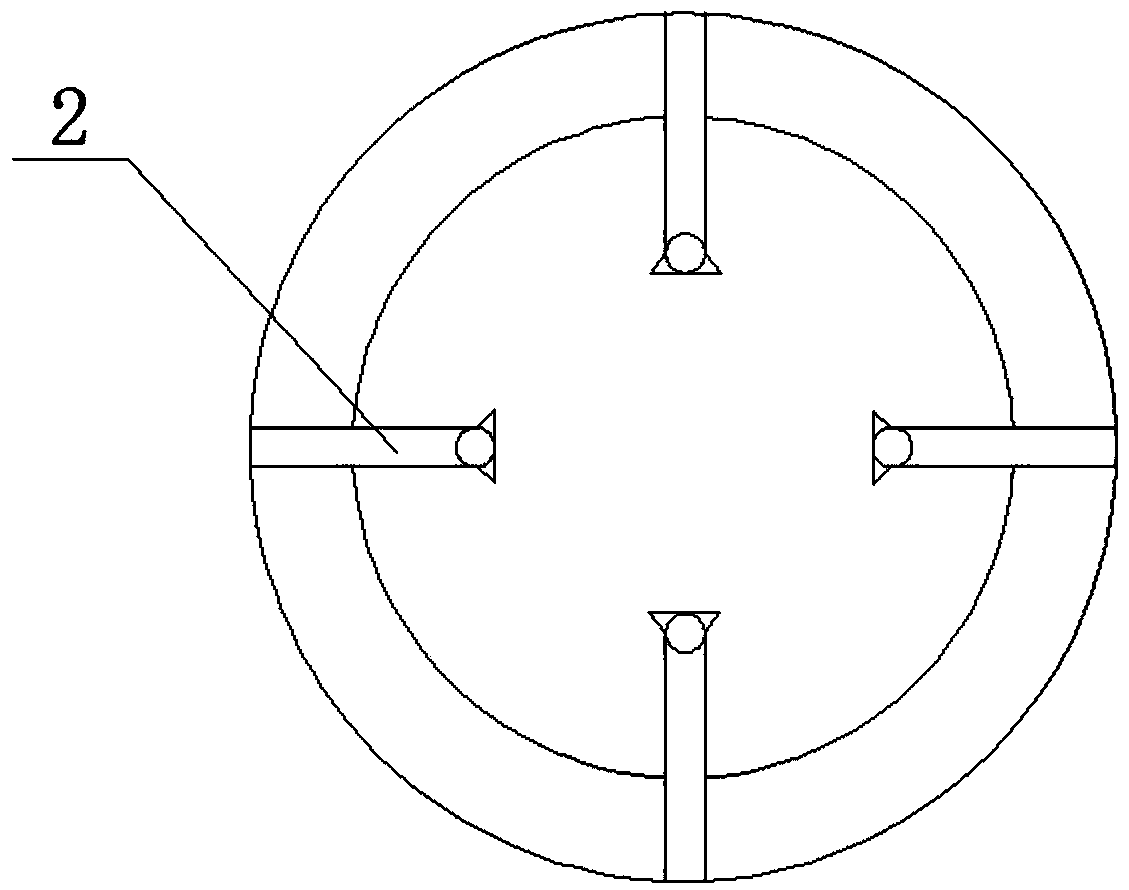

Cement external-circulation vertical milling preparation system capable of adjusting particle size distribution

ActiveCN104261707AReduce grinding power consumptionParticle size distribution range can be narrow or wideCement productionBucket elevatorParticle-size distribution

The invention relates to a cement external-circulation vertical milling preparation system capable of adjusting particle size distribution. The cement external-circulation vertical milling preparation system comprises a vertical mill, a bucket elevator and a cement powder separator, wherein the cement powder separator comprises two sets and more of powder separating subsystems which are connected in parallel and arranged behind the bucket elevator, wherein each powder separating subsystem comprises a V-shaped powder separating machine, a fine powder separating machine, a dust collector and a fan which are sequentially connected in series. Cement raw materials are milled by virtue of the vertical mill and fed into two sets and more of powder separating subsystems by virtue of the bucket elevator, cement with different particle size distributions is separated by virtue of multiple sets of powder separating subsystems connected in parallel and then cement separated in multiple paths is warehoused separately or in a mixed way and thus the cement products with different particle size distributions can be obtained.

Owner:NANJING KISEN INT ENG

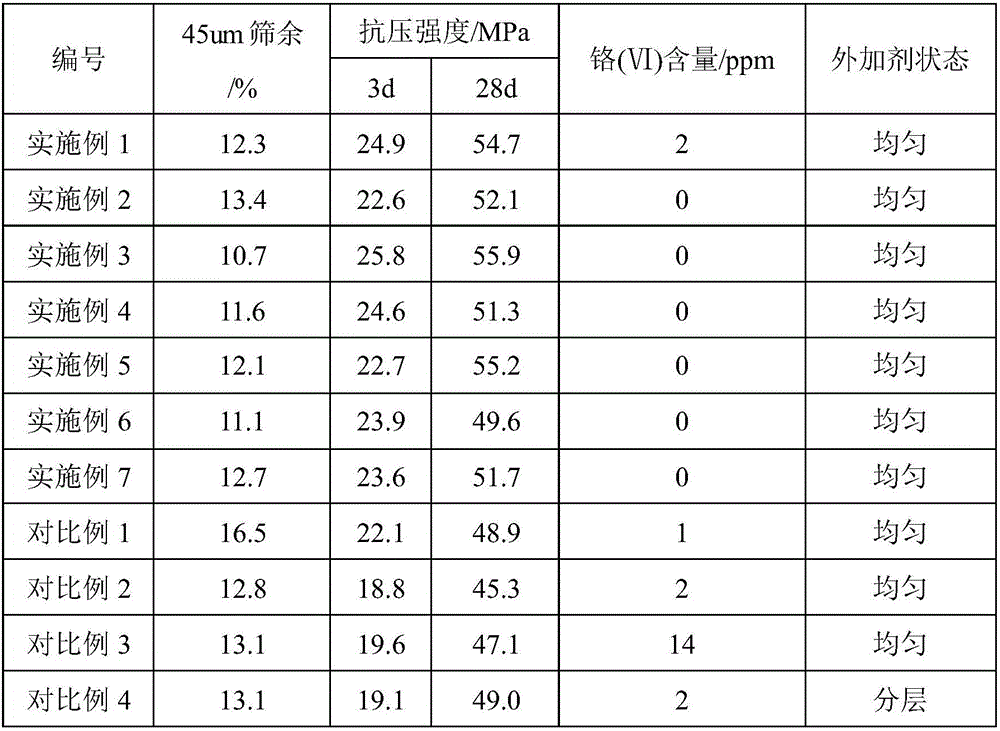

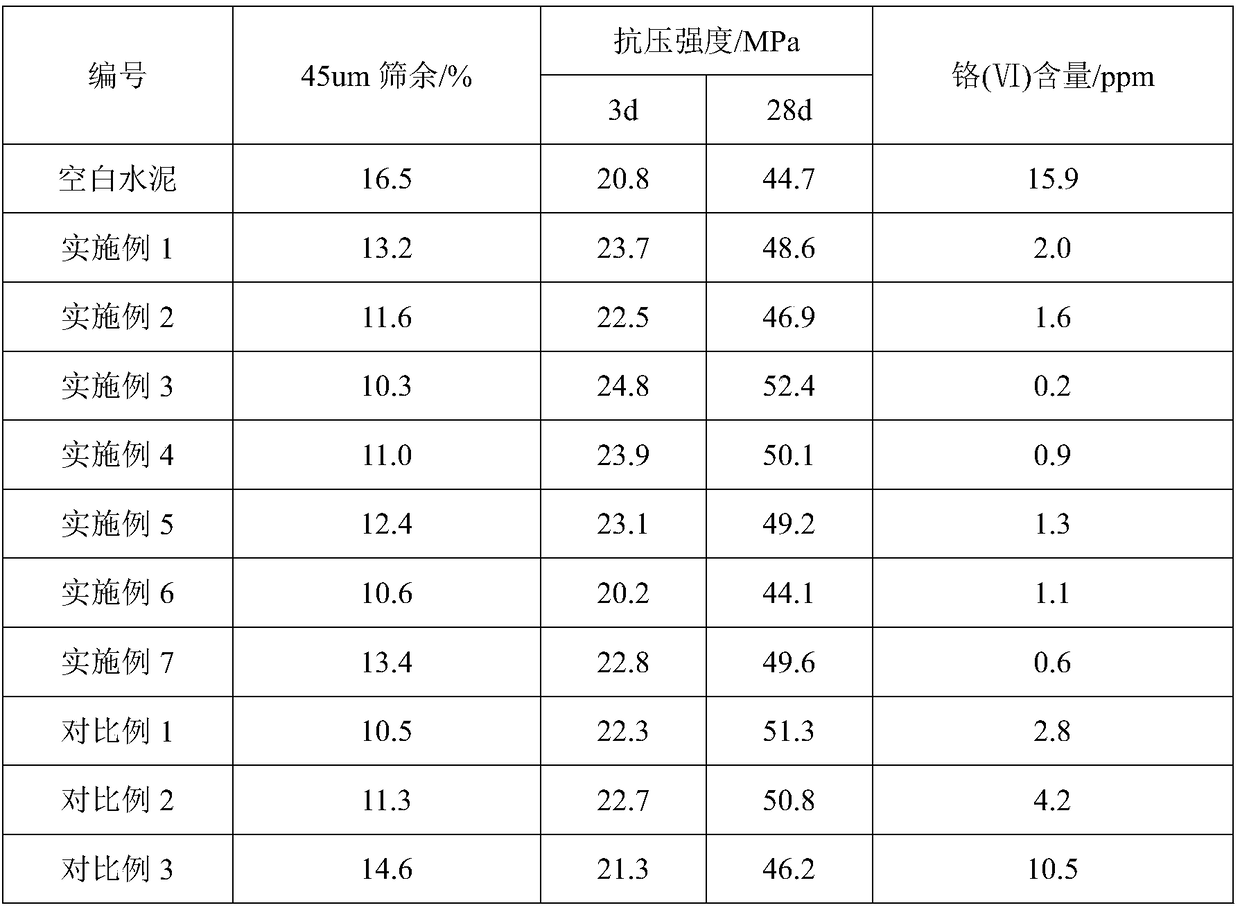

Environment-friendly cement technological additive

The invention belongs to the technical field of environmental protection and specifically relates to an environment-friendly cement technological additive. The additive is prepared from the following raw materials: 10%-20% of grinding aid, 10%-20% of reinforcing component, 10%-20% of hexavalent chromium reducing component, 2%-5% of cosolvent and the balance of water. The environment-friendly cement technological additive has a good grinding-aiding effect; the output of the grinding machine can be increased by above 10%; the power consumption for grinding the cement is saved; the reinforcing effect is good; after the cement technological additive is added, the 3d strength of the cement is increased by above 4MPa and 28d strength is increased by above 6MPa; under the condition of unchanged cement performance, above 12% of the clinker dosage can be reduced; above 12% of the industrial residue is additionally used, so that the resource is saved and the environment is protected; a chromium removing effect is excellent; and more than 90% of water-soluble hexavalent chromium in the cement can be reduced.

Owner:志成信(天津)科技有限公司

Portland cement clinker, and preparation method and production equipment thereof

The invention discloses a Portland cement clinker, and a preparation method and production equipment thereof. The Portland cement clinker comprises 80 to 84% of limestone, 4 to 8% of fly ash, 4 to 8%of graphite mine tailing, and 4 to 6% of silica. The preparation method comprises following steps: the above four raw materials are introduced into a raw mill from a blending tank at a certain ratio for grinding together; after grinding, an obtained raw material is introduced into a homogenizing tank for homogenizing; after homogenizing, the raw material is introduced into a preheater for preheating decomposition; after decomposition, the raw material is introduced into a rotary kiln for calcining so as to obtain the Portland cement clinker. The particle sizes of the fly ash and the graphite mine tailing are extremely low, so that raw material grindability is improved, the particle size is reduced by 8.3% of the particle size of conventional raw material, raw material grinding electricityconsumption is reduced by about 1.5kwh / t; the raw material particle size grade combination is more reasonable, raw material burnability is improved, and the yield is increased by 5%.

Owner:吉林亚泰明城水泥有限公司

Method for preparing porous ceramsite filter material from slate saw mud

InactiveCN102068855AConducive to gas expansionSelf-inflatingFiltration separationDry basisFilter material

The invention discloses a method for preparing a porous ceramsite filter material from slate saw mud. According to a formula, a product prepared by the method comprises the following raw materials in percentage by mass: 60 to 80 percent of slate saw mud (a dry basis), 15 to 30 percent of dry slate powder and 5 to 10 percent of kieselguhr, wherein the raw materials are mixed and stirred into spherical particles, then calcined and cooled to obtain the product. The method has the advantages of simple process and low production cost, and has great significance to resource cycling and environmental protection.

Owner:NANCHANG UNIV

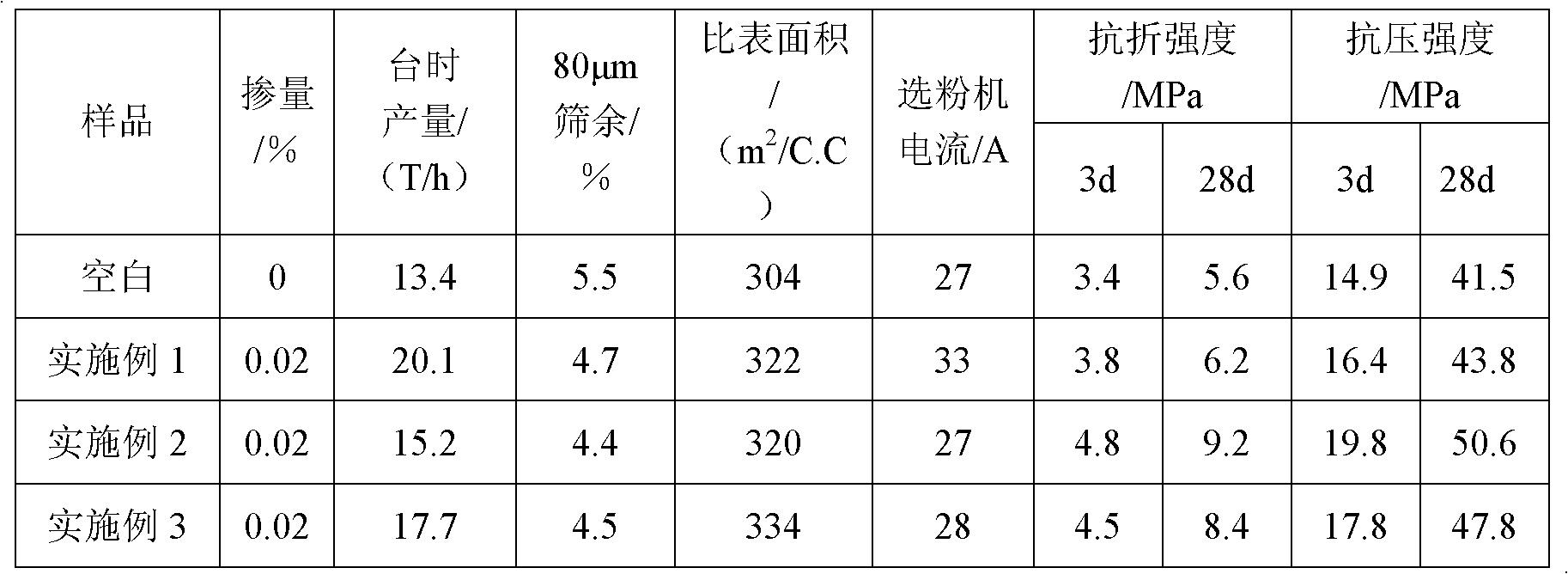

Cement grinding aid suitable for low-activity cement admixtures and preparation method thereof

The invention discloses a cement grinding aid suitable for low-activity cement admixtures and a preparation method thereof. The cement grinding aid comprises the following components by weight percent: 30-40% of triisopropanolamine, 3-7% of sodium lignosulphonate, 5-7% of sodium alkyl benzene polymerase sulfonate, 8-12% of sugar lime, 2-4% of barium chloride and 40-42% of water. When used in cement production, the cement grinding aid has the advantages of increasing the output per machine-hour of cement mills by 15-25%, saving the power consumption for powder grinding by 15-25%, increasing thestrength of the cement at all ages by nearly 25%, additionally adding the amount of the low-activity cement admixture by 10-15%, shortening the initial setting time and the final setting time of thecement by about 60 minutes so as to be beneficial to the construction operation of the cement, and increasing the comprehensive economic benefit of the cement by about 10 yuan / ton.

Owner:王秀贵

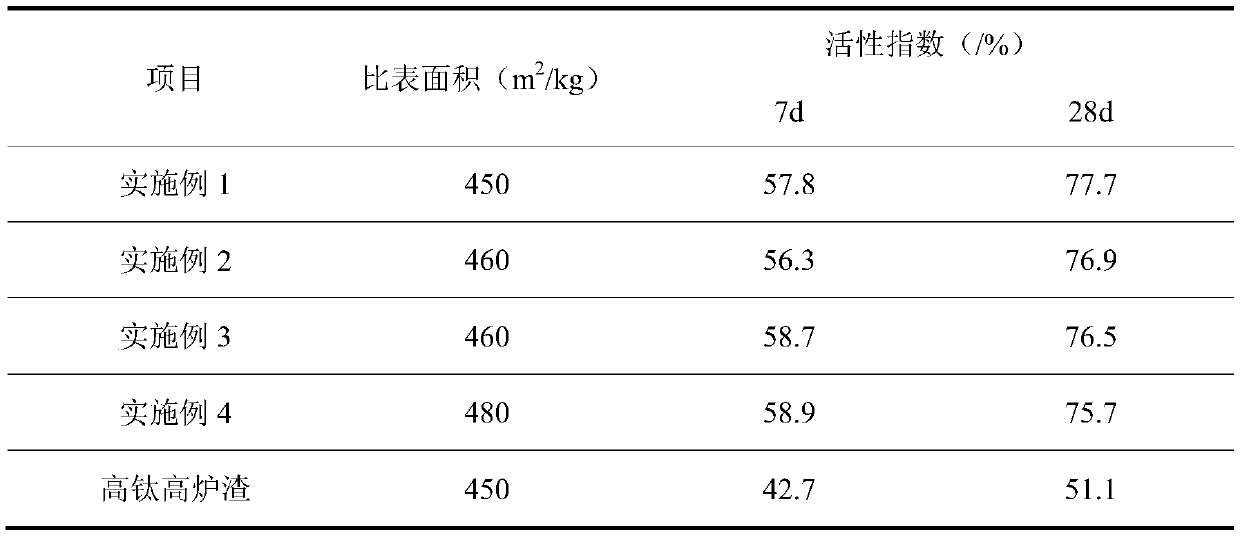

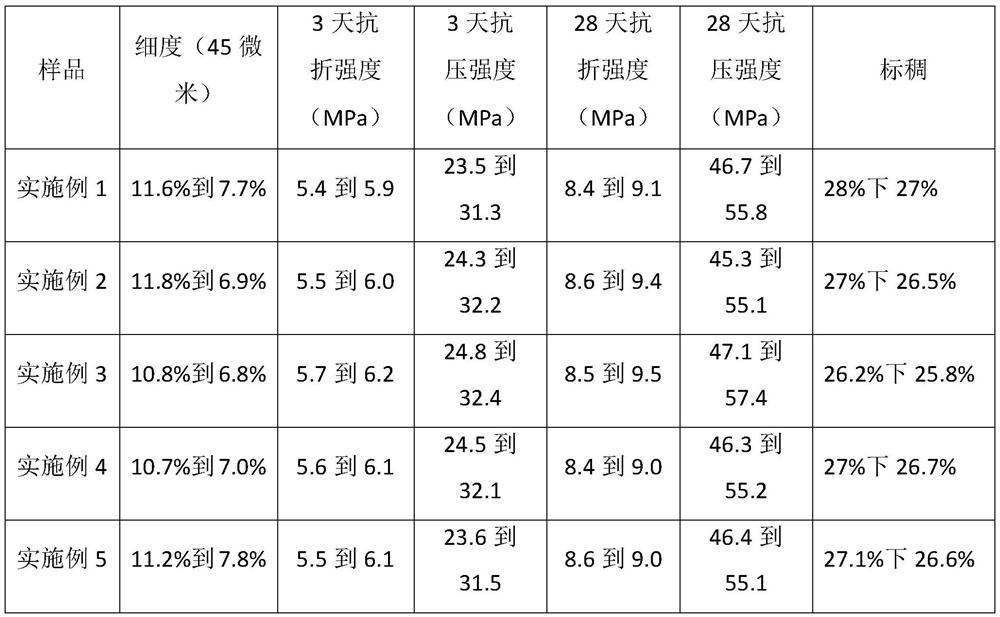

Activating agent for S75-grade high-titanium slag micro-powder

InactiveCN111302690AImproved particle size distributionGive full play to the physical filling effectCement productionEconomic benefitsSilicon

The invention discloses an activating agent for S75-grade high-titanium slag micropowder. The activating agent is characterized by being prepared from the following components in proportion: an exciting agent, a silicon-aluminum material and a grinding aid component, wherein the sum of the mass of the components is 1, and based on the mass of the mixed slag, the proportions of the other materialsare as follows: 3.2%-5% of the silicon-aluminum material, 0.25%-0.5% of the exciting agent and 0.02%-0.04% of the grinding aid component. By implementing the activating agent, the efficient resource utilization path of the high-titanium blast furnace slag is expanded, a new design thought is provided for solving the problems of low activity and high grinding power consumption of the high-titaniumblast furnace slag, the process is simple and easy to implement, outstanding technical advantages and economic benefits are achieved, and the large-scale application and popularization potential is huge.

Owner:四川星明能源环保科技有限公司

Cement grinding aid

The invention belongs to the technical field of cement production, and discloses a cement grinding aid. The cement grinding aid is prepared from the following raw materials in parts by weight: 8%-12%of a phosphite anhydride-ethylene glycol reactant, 1%-3% of a polycarboxy compound, 3%-5% of a grinding aid, 1%-5% of potassium metabisulfite, 0.1%-1% of a defoamer and the balance of water. The cement grinding aid can improve grinding efficiency of cement and also has a good function of reducing water-soluble hexavalent chromium in cement.

Owner:鸡西市恒昌新材料科技有限公司

Preparation method of functionalized adjustable amphiprotic polycarboxylates cement grinding aid

ActiveCN102134300BImprove grinding efficiencyReduce grinding power consumptionCement grindingPolycarboxylate Cement

The invention discloses a preparation method of a functionalized adjustable amphiprotic polycarboxylates cement grinding aid. The method comprises the following steps: according to a certain ratio, adding unsaturated polyether, unsaturated sulfoacid and water in a kettle; preparing unsaturated acid, a catalyst, a ligand and water into an aqueous solution A, and preparing an initiator and water into an aqueous solution B; heating the kettle to 75-95DEG C under the protection of nitrogen, and dropwise adding the aqueous solutions A and B at the same time for 3-5 hours; after the dropwise addition is finished, reacting under heat insulation condition for 1 hour; and after the reaction is finished, adding a certain part of sodium hydroxide for neutralization, and adding water for dilution until the concentration is 40% to obtain a finished product. In the invention, an active / controllable free radical polymerization and macromolecule design theory is adopted to research and develop the functionalized adjustable amphiprotic polycarboxylates cement grinding aid aiming at the effect required by the cement grinding aid, so as to prepare the product of the functionalized adjustable cement grinding aid.

Owner:KZJ NEW MATERIALS GROUP CO LTD +2

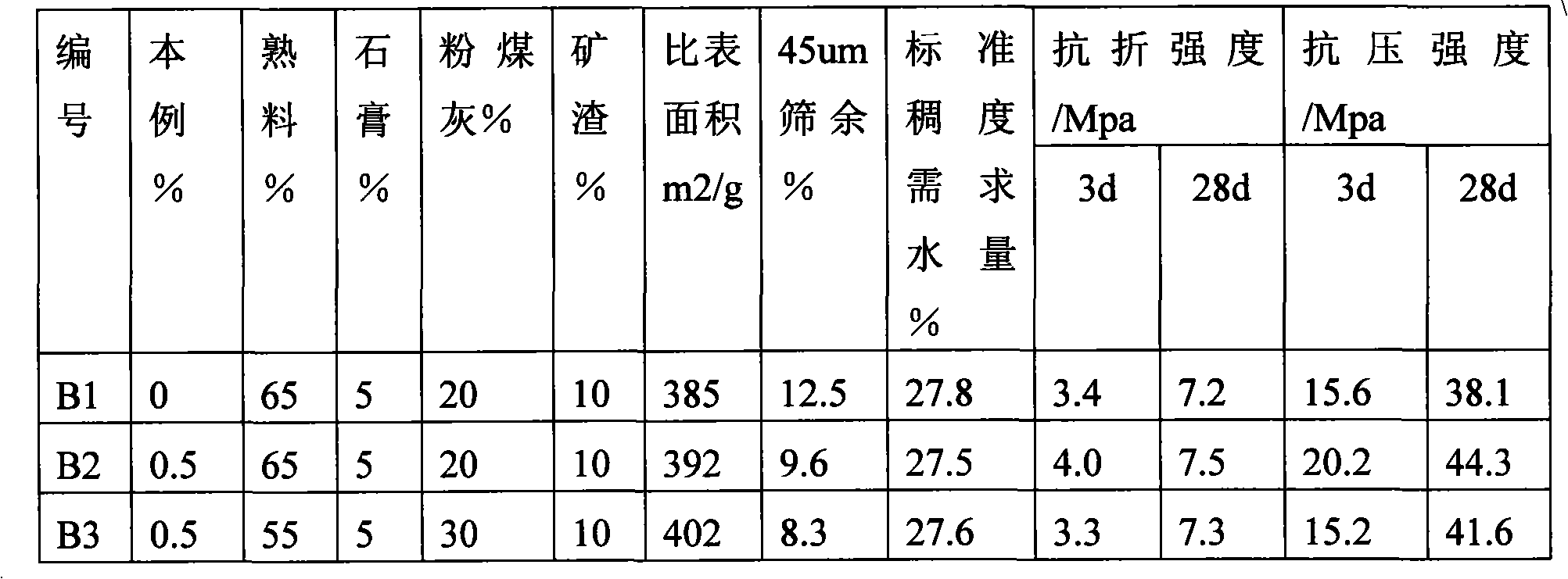

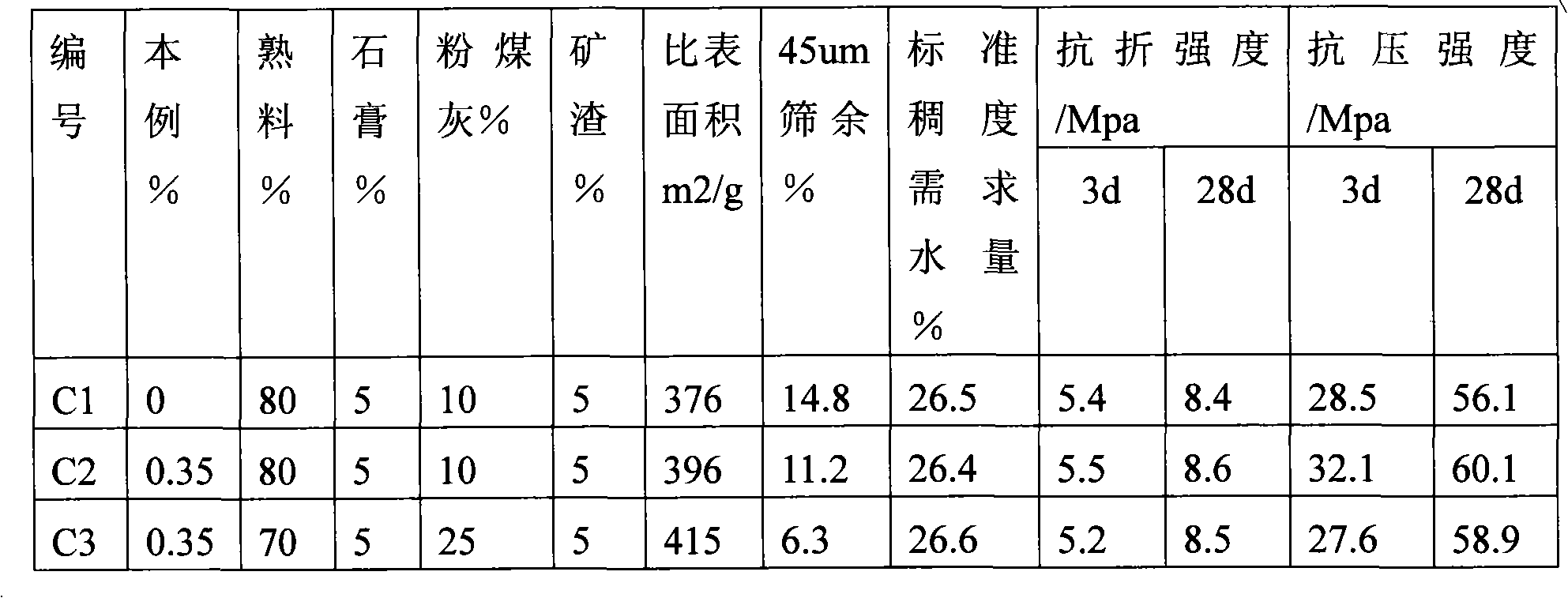

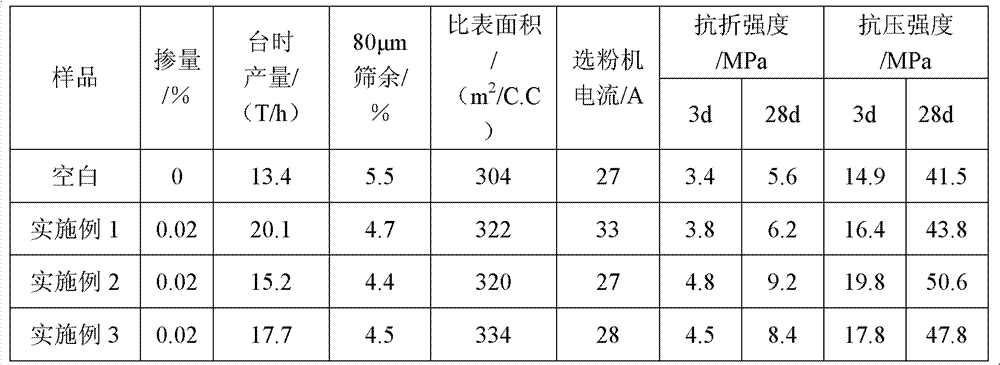

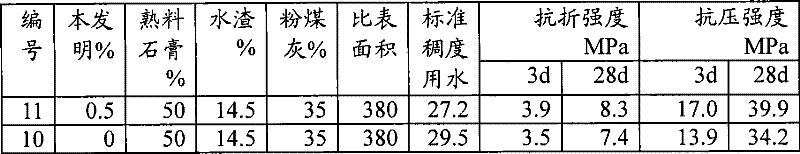

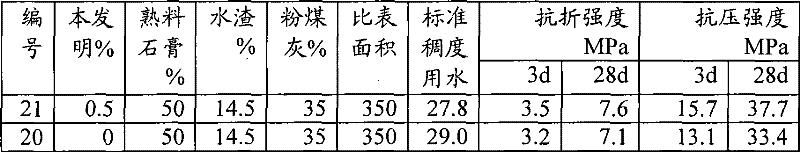

Composite grinding aid, production method and uses thereof

InactiveCN101428985BImprove compound synergyHigh strengthSolid waste managementCement productionSlagElectric consumption

The invention relates to a composite grinding aid for cement production and a preparation method and application thereof. The grinding aid contains 1 to 10 percent weight of organic aid and 90 to 99 percent weight of inorganic matrix material. The organic aid comprises at least one of polycarboxylic acid and lignosulphonate, C2-C5 polyfatty alcohols, C2-C5 polyfatty alcohol amines and gluconate, and the inorganic matrix material comprises at least one of sodium silicate and sodium carbonate, sulfate, calcined gypsum and calcium oxide. The invention also discloses the preparation method and the application for the composite grinding aid. The product can remarkably improve early and later strengths of cement, reduce the electric consumption of the grinding, and reduce the using amount of clinker. The compressive strength of the cement is obviously improved, the grinding efficiency is improved by between 10 and 20 percent, and the water consumption of the standard consistency of the cement is kept unchanged basically when 10 to 15 percent of the using amount of the clinker is reduced. The composite grinding aid is particularly suitable for a cement production technology which uses pulverized fuel ash and furnace bottom slag of coal-fired power plants as a composite material.

Owner:魔水科技(北京)有限公司

Method for producing belite-gypsum material from roasted sludge and waste gypsum of furnace in fluid bed

The invention discloses a method for producing a belite-gypsum material from roasted sludge and waste gypsum of a furnace in fluid bed. The method comprises the following steps: (1) transforming high water-content sludge ridge grain seeds into modified sludge residues; (2) carrying out raw material compounding and homogenizing on the modified sludge residues obtained in the step (1) with waste gypsum, waste rock ballasts and a corrective material; (3) drying the raw material mixture obtained in the step (2) by virtue of hot exhaust air of the furnace in fluid bed, and carrying out flue gas desulfuration and sulfur fixation; (4) mixing the raw material mixture dried in the step (3) with a proper amount of fire coal, adding to the furnace in fluid bed and roasting into a clinker; and (5) grinding the clinker obtained in the step (4) to obtain powder, namely the belite-gypsum material, or taking the clinker obtained in the step (4) as the belite-gypsum material. The method is simple in process, low in control requirements, and low in grinding energy consumption and firing energy consumption; bulk waste residues such as sludge and industrial waste gypsum can be largely and widely dissolved; and the prepared belite-gypsum material is wide in application.

Owner:长沙紫宸科技开发有限公司

Mineralized material used in cement grinding process

The invention is suitable for the technical field of cement grinding aids, and provides a mineralized material used in a cement grinding process, the mineralized material is composed of the following substances by mass: 2-5% of sodium sulfate, 4-7% of sodium thiosulfate, 0-3% of sodium sulfite, 1-3% of maleic anhydride dimer acid triethanolamine ester, 1-3% of ethylene glycol, and 79-92% of fly ash. By determining proper substances and content, promoting early hydration of cement and greatly improving the early hydration rate of cement particles, the early strength is improved, the hydration durability is considered, the later hydration of the cement is promoted through sodium thiosulfate, maleic anhydride dimer acid triethanolamine ester and ethylene glycol, the strength of cement paste is improved, and the cement paste can also wrap the surface of cement particles to form a protective film to eliminate bonding and adsorption agglomeration, the maleic anhydride dimer acid triethanolamine ester can form an oxidation protection film on the metal surface to retard the corrosion of steel bars so that the machine-hour yield of a mill is increased, the comprehensive performance of the product is improved, the power consumption of cement grinding is reduced, and the damage to the cement concrete caused by excessive chloride ions is avoided.

Owner:山西天润恒德新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com