Patents

Literature

31results about How to "Speed up the hydration reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

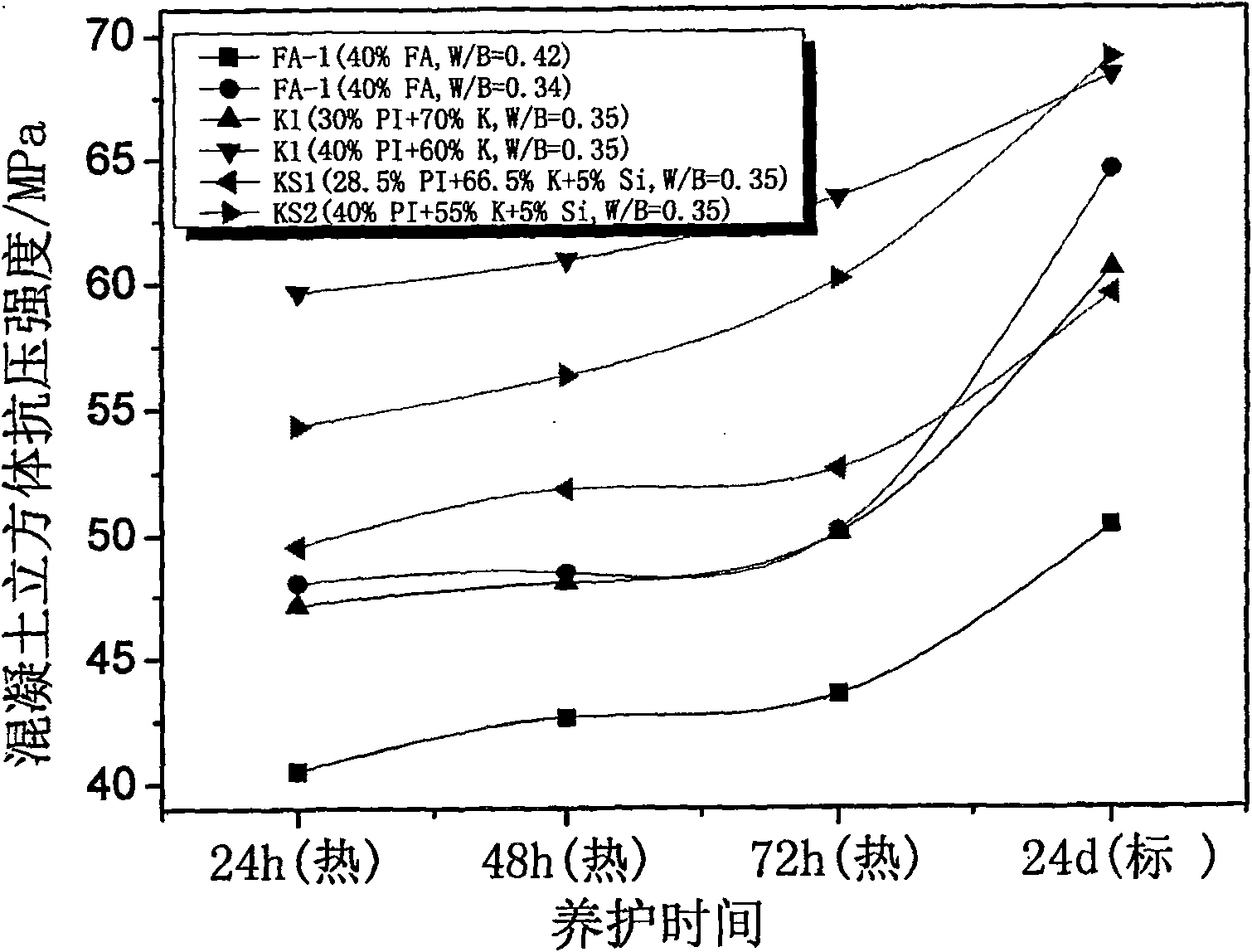

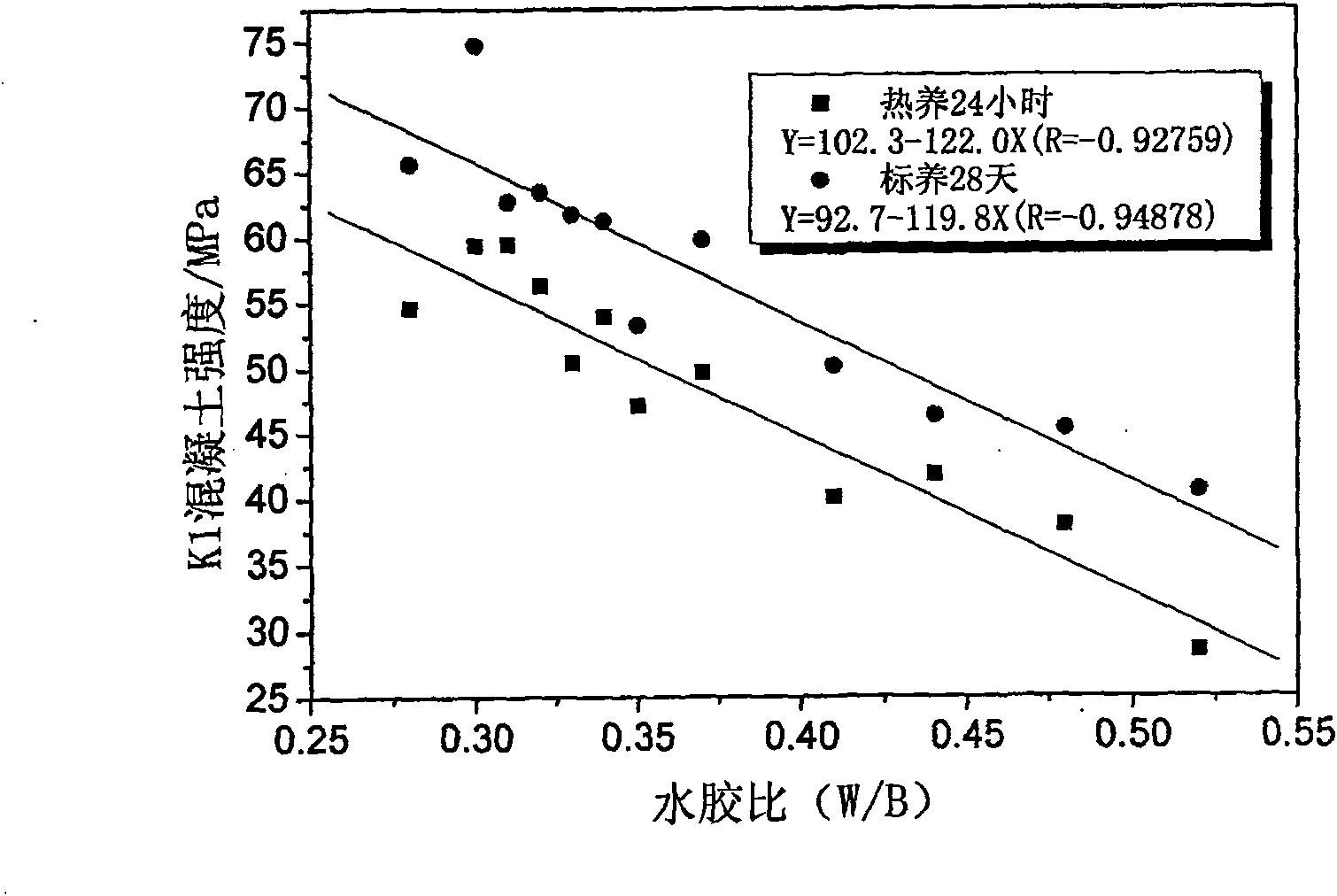

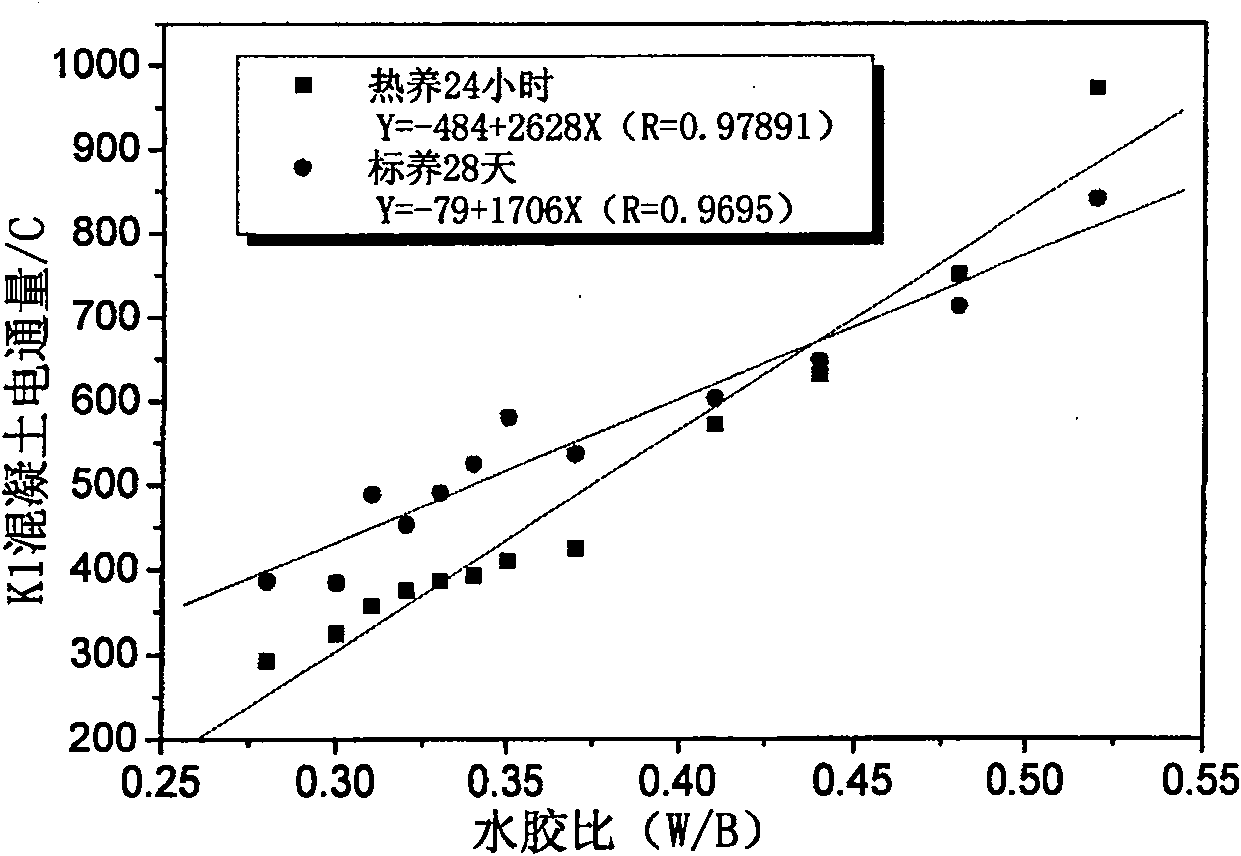

Method for testing capacity of concrete resisting chlorides corroding

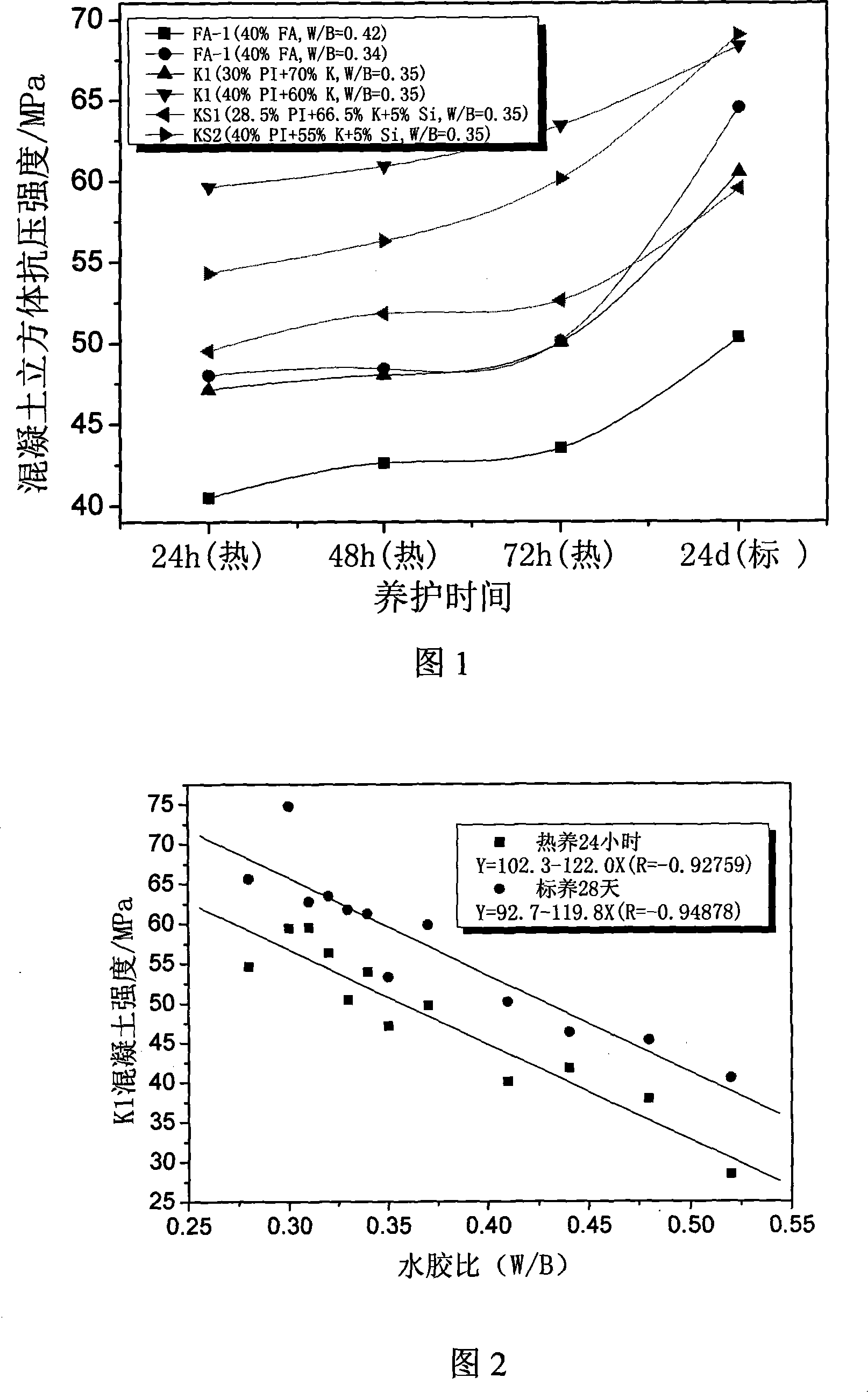

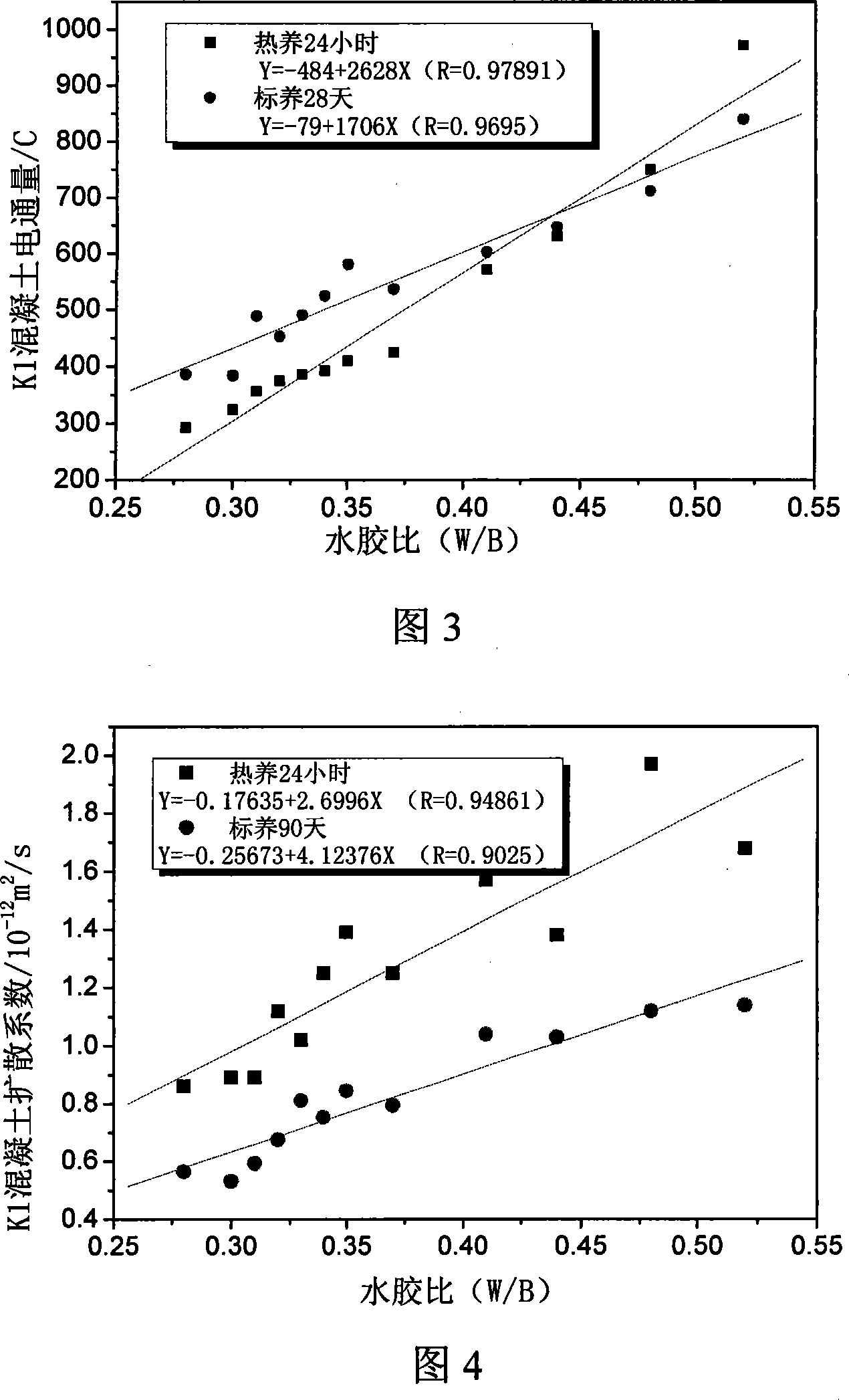

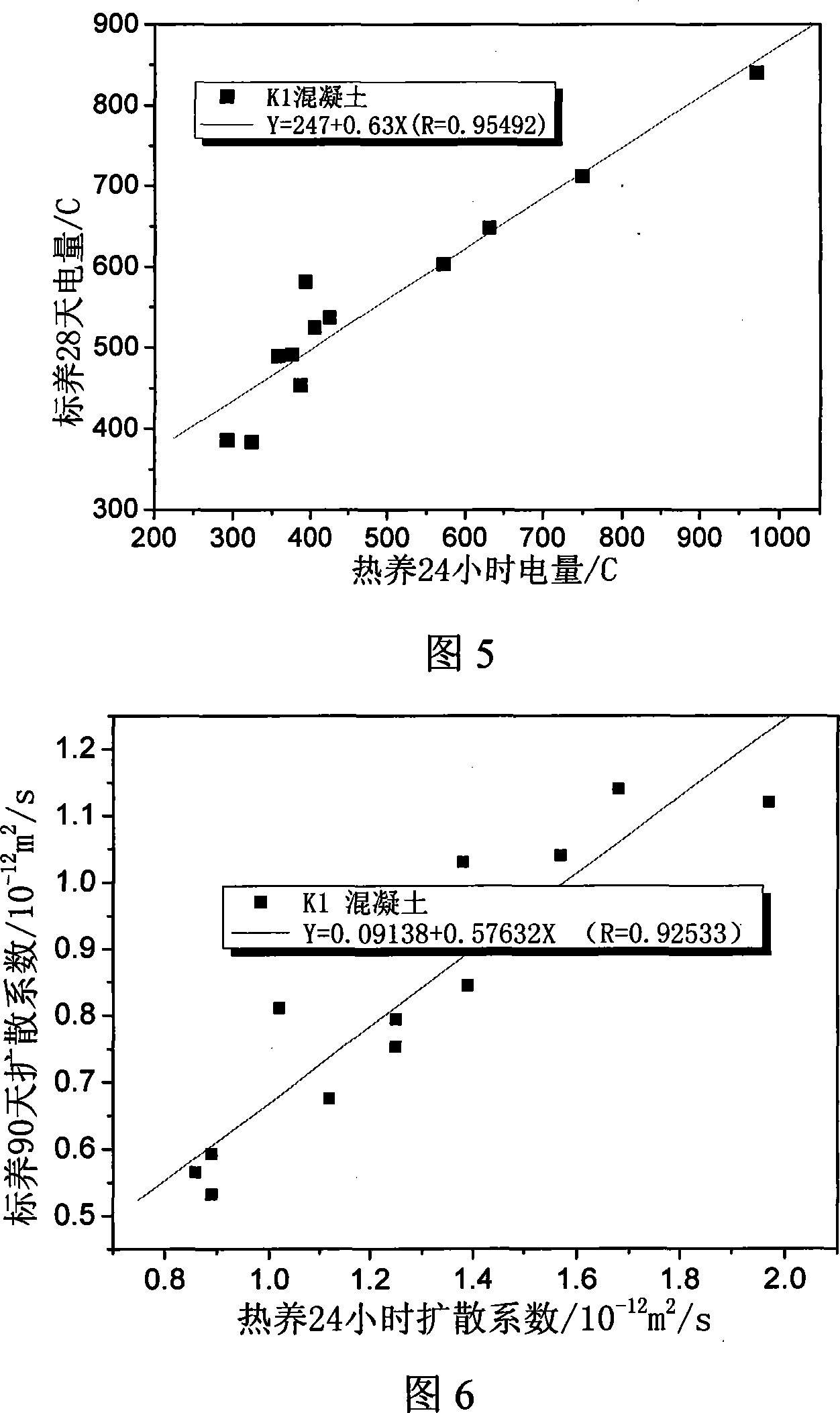

InactiveCN101082563ASpeed up the hydration reactionShorten the regular maintenance periodWeather/light/corrosion resistanceMaterial testing goodsIonDiffusion

The invention discloses a kind of method of testing the concrete erosion-chloride resisting ability. It is characterized in that: concluding the follow steps: A. makes the concrete material after hot curing at 60-90deg.C as the test piece and at time of hot curing the weight ratio of the water and the jelling material is 0.28-0.54; B. after hot curing the concrete assays the value of flux and chloride ion diffusion coefficient individually; C. accords the formula Qstandard=M+NQhot to impute the value of concrete flux with the standard curing and in the formula Qstandard is the value of concrete flux with the standard curing and the Qhot is the flux measured at step B and the M,N are constants; D. accords the formula Destandard=M1+N1Dehot to calculate the chloride ion diffusion coefficient of standard curing concrete and in the formula Destandard is the value of chloride ion diffusion coefficient of standard curing concrete and the Dehot is the chloride ion diffusion coefficient measured at step B and the M1,N1 are constants. The method of the invention can test the concrete erosion-chloride resisting ability quickly.

Owner:CCCC SHANGHAI THIRD HARBOR SCI RES INST CO LTD +3

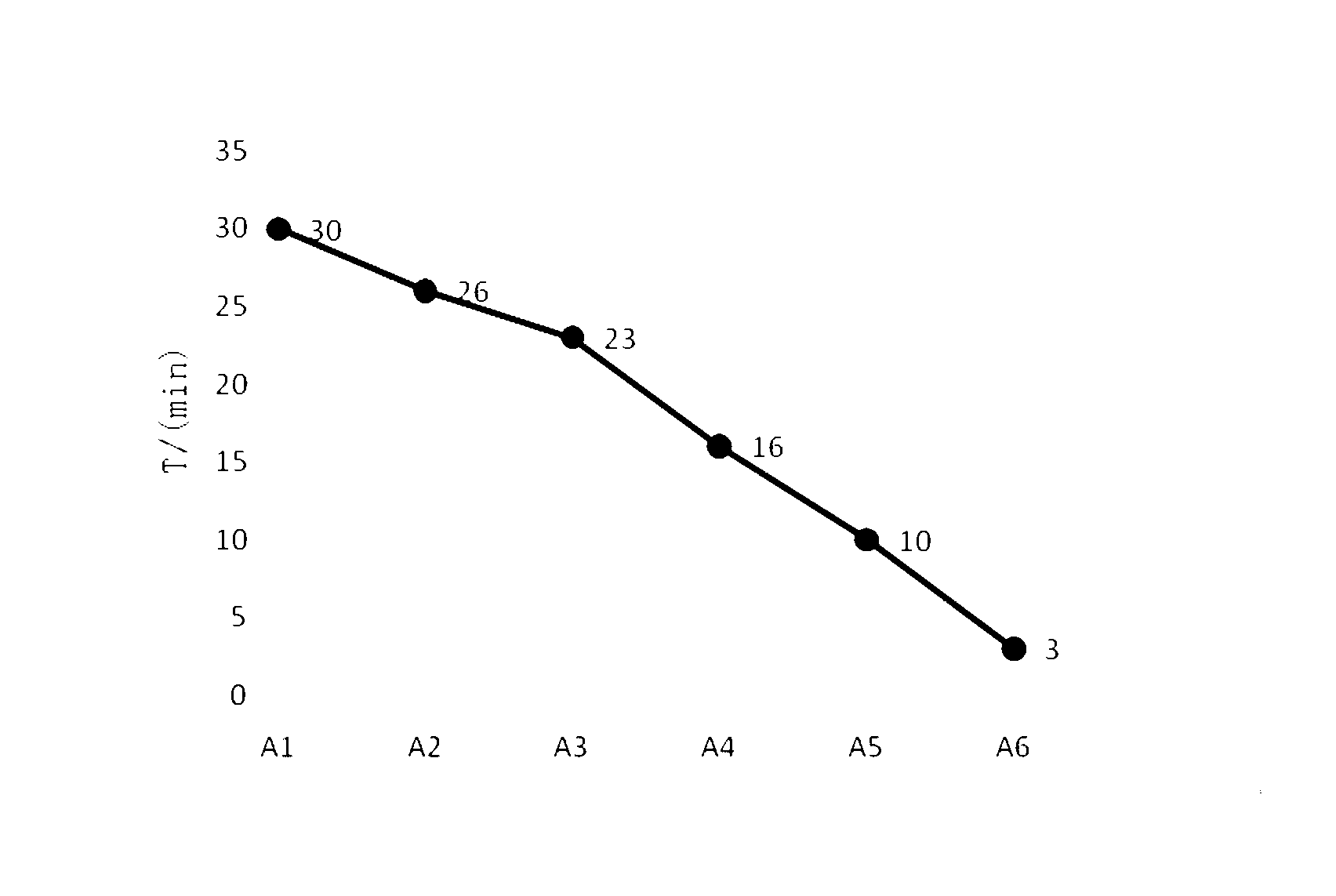

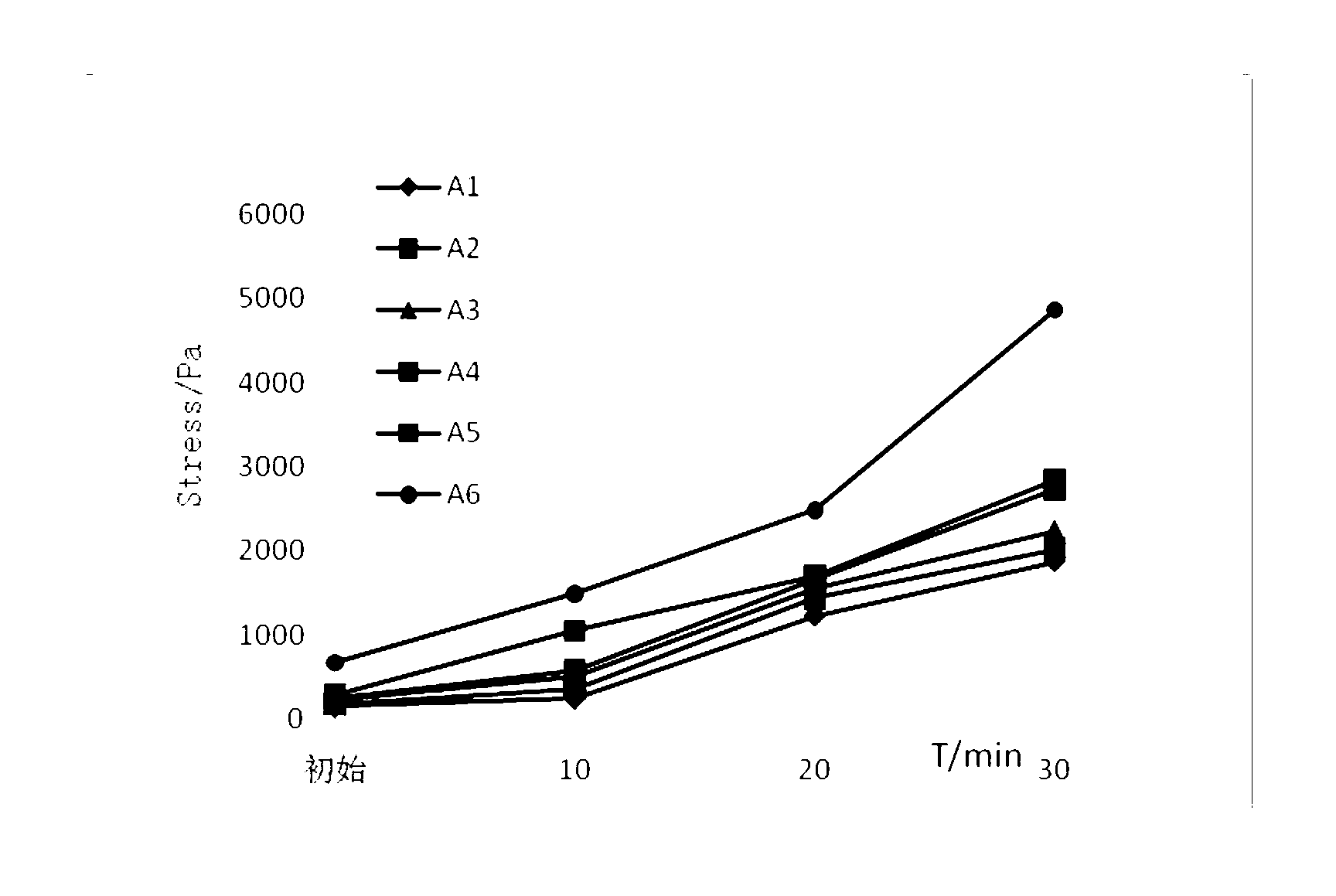

Beach sludge composite curing agent as well as preparation method, use method and application thereof

InactiveCN105924109AEnvironmental protection is goodObvious superioritySludge treatment by de-watering/drying/thickeningPortland cementSludge

The invention discloses a beach sludge composite curing agent as well as a preparation method, a use method and an application thereof. The beach sludge composite curing agent is obtained by mixing and grinding of an ordinary Portland cement clinker, a sulphoaluminate cement clinker, phosphogypsum, desulfurization gypsum, mineral waste residues, a naphthalene-based additive and sulfates, wherein the weight percentages of the raw materials are as follows: 40-60% of the ordinary Portland cement clinker, 5-10% of the sulphoaluminate cement clinker, 2-4% of the phosphogypsum, 3-6% of the desulfurization gypsum, 30-50% of the mineral waste residues, 1-3% of the naphthalene-based additive and 3-5% of the sulfates. The beach sludge composite curing agent disclosed by the invention can greatly shorten the curing time of sludge, and is small in doping amount, high in concretion strength, low in construction cost, and good in curing stability.

Owner:天津市三川恒泰科技有限公司

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Bonding agent of baking-free bricks prepared from drilling well solid waste materials

ActiveCN101805161AIncreased contact surface areaHigh strengthSolid waste managementBrickPhosphogypsum

The invention relates to a bonding agent of baking-free bricks prepared from drilling well solid waste materials, which is applied to the field of treating petroleum drilling well solid waste materials into resources for preparing baking-free bricks. The bonding agent comprises the following ingredients in parts by weight: 3.3 to 8 of polyaluminium chloride, 6 to 25 of phosphogypsum, 10 to 26 of lime, 20 to 60 of fly ash and 4.4 to 12 of ferrous sulfate. A method for using drilling well solid waste materials for preparing the baking-free bricks comprises the following steps that: the baking-free bricks are prepared from the following ingredients in parts by weights: 10 to 22 of bonding agents of baking-free bricks prepared from drilling well solid waste materials, 30 to 55 of drilling well solid waste materials and 35 to 45 of crude aggregate; and the ingredients are uniformly mixed, are extruded and formed through a baking-free brick machine, and are maintained for 14 to 21 days to prepare the baking-free bricks. The invention has the advantages that the baking-free bricks can be prepared, and through the analysis via the sampling and the water soaking experiments on the baking-free bricks, all contaminant indexes reach the primary standard. Through the examination according to the standard JC422-1991, the detected items of the samples reach the requirements of the standard.

Owner:PETROCHINA CO LTD

Modified limestone powder-based mineral admixture and preparation method thereof

InactiveCN102659336AImprove early and late strengthIncreased durabilitySolid waste managementSocial benefitsHigh activity

The invention discloses a modified limestone powder-based mineral admixture and a preparation method thereof. The modified limestone powder-based mineral admixture includes, by weight, from 50 to 70 parts of limestone powder, from 30 to 50 parts of mineral waste residue powder, from 3 to 5 parts of calcined gypsum and from 0.01 to 0.03 part of triethanolamine which are used for preparing the modified limestone powder-based mineral admixture by means of stirring and mixing. The modified limestone powder-based mineral admixture has high activity, the strength and the durability of cement concrete can be obviously increased, the mixing amount of the limestone powder in the cement concrete can be increased, cost is reduced, and the modified limestone powder-based mineral admixture has remarkable economic and social benefits.

Owner:CENT SOUTH UNIV

Composite blending material of slag powder and use method

InactiveCN102173627AReduce alkalinitySpeed up the hydration reactionSolid waste managementSocial benefitsSlag

The invention relates to a composite blending material of slag power and a use method. Slag, quick lime and calcined gypsum are mixed according to a certain proportion, and then, are finely ground into the composite blending material with specific surface area of 400m<2> / kg to 600m<2> / kg. When the composite blending material is used for producing cement concrete products with a steam curing process, the composite blending material can replace 10-40% of cement with the strength grade above 32.5 in an equal quantity manner; and by using the composite blending material, the production cost of the cement concrete products is lowered, resources are saved, and favorable economic benefits and social benefits are achieved.

Owner:蒋元海

Foaming cement

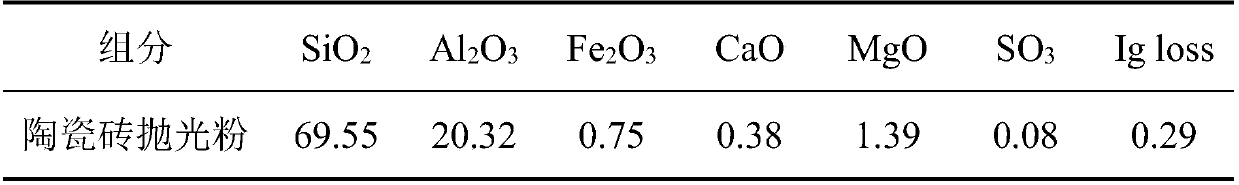

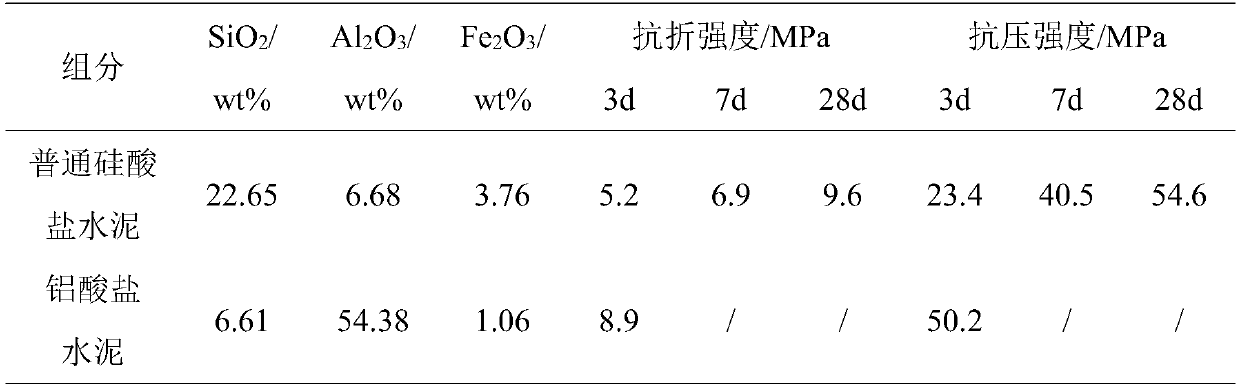

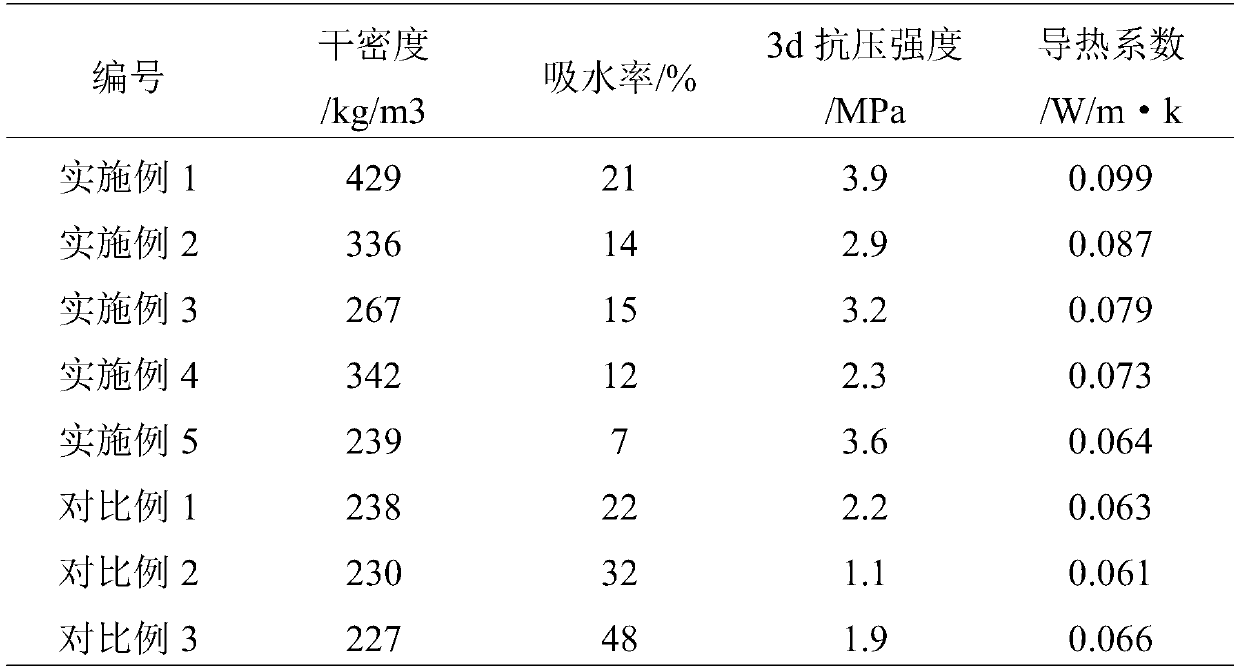

ActiveCN106517972AImprove early strengthSpeed up the hydration reactionCeramicwareSocial benefitsBrick

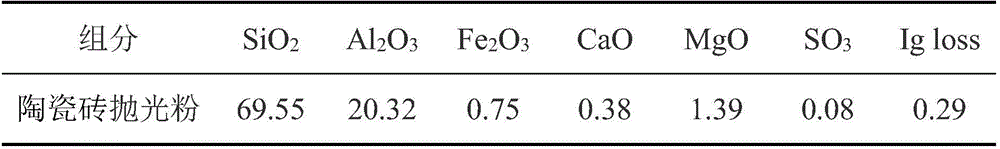

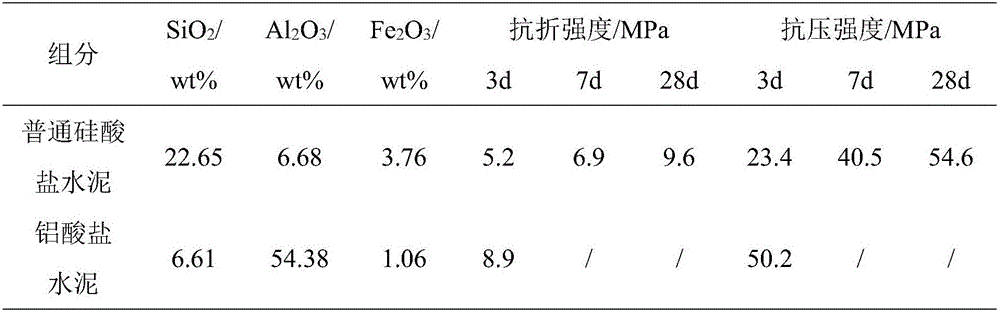

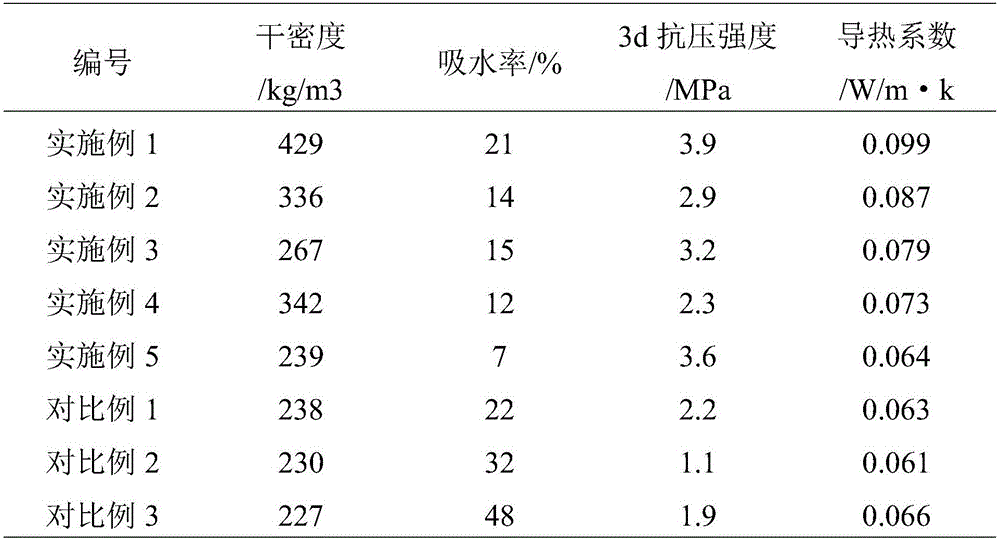

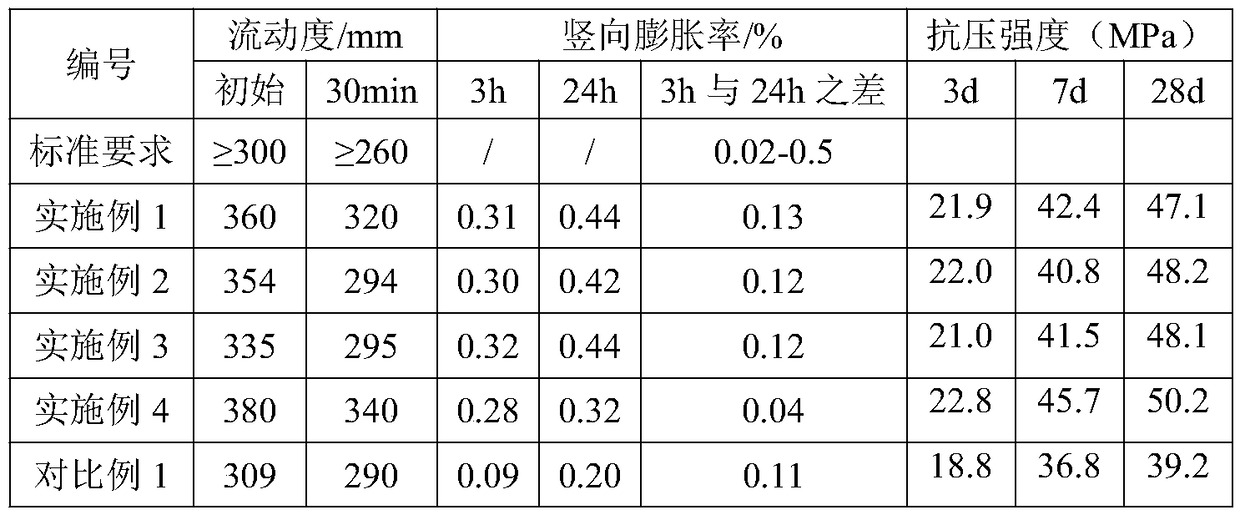

The invention discloses foaming cement which comprises the following components in percentage by mass: 30-45% of cement, 5-10% of ceramic brick polishing powder, 1-4% of a foaming component, 0.1-1% of a foam stabilizing component, 0.5-2% of a waterproof component, 0.5-2% of a reinforcing component and the balance water, wherein cement is composed of silicate cement and aluminate cement in a mass ratio of (5-10) to 1. The foaming cement disclosed by the invention has the characteristics of high strength, good waterproof performance, good thermal insulation effect, good durability and the like; and a great deal of ceramic brick polishing powder further can be comprehensively utilized, so that social resources are saved, using efficiency is improved, and economic benefits and social benefits are remarkable.

Owner:北京宝辰联合科技股份有限公司

Composite foam mortar, and preparation and construction method thereof

ActiveCN101412608AWater retentionFunctionalSolid waste managementCeramicwareCrack resistanceMicrosphere

The invention relates to a composite foam mortar, which is prepared from the components by the following weight percentage through mechanically and evenly stirring: 20 to 30 percent of ordinary Portland cement, 5 to 8 percent of white lime, 8 to 10 percent of fly ash, 15 to 20 percent of light aggregate, 30 to 40 percent of heavy aggregate, 1.6 to 2.0 percent of foam initiator, and 3.0 to 5.0 percent of strength-keeping rubber powder, wherein the light aggregate is an inorganic vitrification hollow microsphere material; the heavy aggregate is a mixture of sand and coarse whiting powder; and the foam initiator is a mixture of an anionic surfactant and a foam stabilizer. The 30 to 50 weight percent of composite foam mortar is diluted by water, is constructed on a wall surface by a mortar mixer with instant mixed spray coating, and is scraped evenly by a running rule or a putty knife. The composite foam mortar can be constructed by adopting a mechanical guniting technology, thus the construction efficiency and the construction quality are improved, the material dosage on a unit area is reduced, and the cost is reduced. The composite foam mortar also has the advantages of water resistance and heat insulation, improved crack resistance, good compatibility with base layer brickworks, and simple and practical process; besides, the composite foam mortar is applicable to waterproof and heat insulation decoration engineering on the inner and outer surfaces of the outer walls of all buildings, in particular to the moist environments with high requirements on water resistance and heat insulation in south China.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

High-activity composite ferronickel slag cementing material and preparation method thereof

The invention discloses a high-activity composite ferronickel slag cementing material which comprises the following components in parts by mass: 3-5 parts of gypsum, 5-10 parts of quartz powder, 20-50parts of blast furnace ferronickel slag, 10-30 parts of submerged arc furnace ferronickel slag, 5-20 parts of steel slag, 0.3-0.8 part of composite excitant and 0.1-0.2 part of drag reducer. The composite excitant comprises at least three of alkali metal hydroxide, an alkali metal calcium source, sulfate and water glass. The utilization rate of ferronickel slag is increased, the gel performance is good and the production cost is reduced.

Owner:福建源鑫环保科技有限公司

Waste concrete recycling method with low processing cost

InactiveCN111848006ASoft natureNot easy to changeSolid waste managementGel preparationEnvironmental engineeringSorptivity

The invention discloses a waste concrete recycling method with a low processing cost. The invention belongs to the technical field of concrete processing. The method comprises: arranging hydrogel powder, drying the prepared hydrogel, preparing the hydrogel into a solidified block, crushing the waste concrete into powder with the same size as the waste concrete granular material, at the moment, adding the waste concrete granular material and the hydrogel powder into stirring equipment, and mixing. When adding waste concrete granular materials and hydrogel powder into stirring equipment, stirring equipment needs to be set, stirring directions are the same, the hydrogel is soft in property, the shape is kept, a large amount of water can be absorbed, the mixed modified concrete has certain water absorption performance, the shape of the modified concrete is not easy to change after the modified concrete absorbs water, the internal adhesiveness of the modified concrete is improved, the interior of the modified concrete is not easy to be too dry due to the fact that the hydrogel has certain water absorption performance, and cracks of the modified concrete due to the fact that the interiorof the modified concrete is too dry are reduced.

Owner:汉江城建集团有限公司

Pin type porcelain insulator and preparation method thereof

InactiveCN111646777AAvoid agglomeration and condensationHigh breaking strengthAntifouling/underwater paintsPaints with biocidesFiberMetallurgy

The invention discloses a pin type porcelain insulator and a preparation method thereof and relates to the technical field of insulators; the pin-type porcelain insulator is prepared from the following raw materials in parts by weight: 16-24 parts of mullite12-20 parts of vermiculite, 12-18 parts of clay, 8-16 parts of zeolite powder, 10-18 parts of mica powder, 20-30 parts of allophane, 10-20 parts of medical stone, 2-6 parts of zircon sand, 4-10 parts of diatomite, 1-3 parts of sodium hexametaphosphate, 1-3 parts of nano silicon nitride, 1-5 parts of nano calcium carbonate, 0.8-1.4 parts ofsepiolite fiber, 0.4-1 part of lignin fiber, 1-5 parts of hexamethyldisilazane, 1-5 parts of dimethylformamide and 3-7 parts of vinyltriethoxysilane. The pin type porcelain insulator has the beneficial effects that the raw materials are reasonably matched, and a proper preparation method is adopted, so that the structural strength and breaking strength of the insulator are improved, and the service life of the insulator is prolonged.

Owner:萍乡欧姆绝缘子有限公司

Dry-hard concrete applied to parking apron

InactiveCN108892453AEvenly dispersedGood dispersionHelicopter landing platformUltimate tensile strengthFly ash

The invention discloses dry-hard concrete applied to a parking apron, and belongs to the technical field of concrete. The dry-hard concrete is prepared from 375-429 parts of cement, 857-985 parts of sand, 1,200-1,478 parts of broken stone, 57-69 parts of activated fly ash, 85-110 parts of mineral powder, 5-10 parts of plasticizing agent, 2-6 parts of expanding agent and 120-163 parts of water. Thedry-hard concrete has the advantages of being good in liquidity, high in compactibility, high in strength and good in durability.

Owner:北京建工新型建材有限责任公司

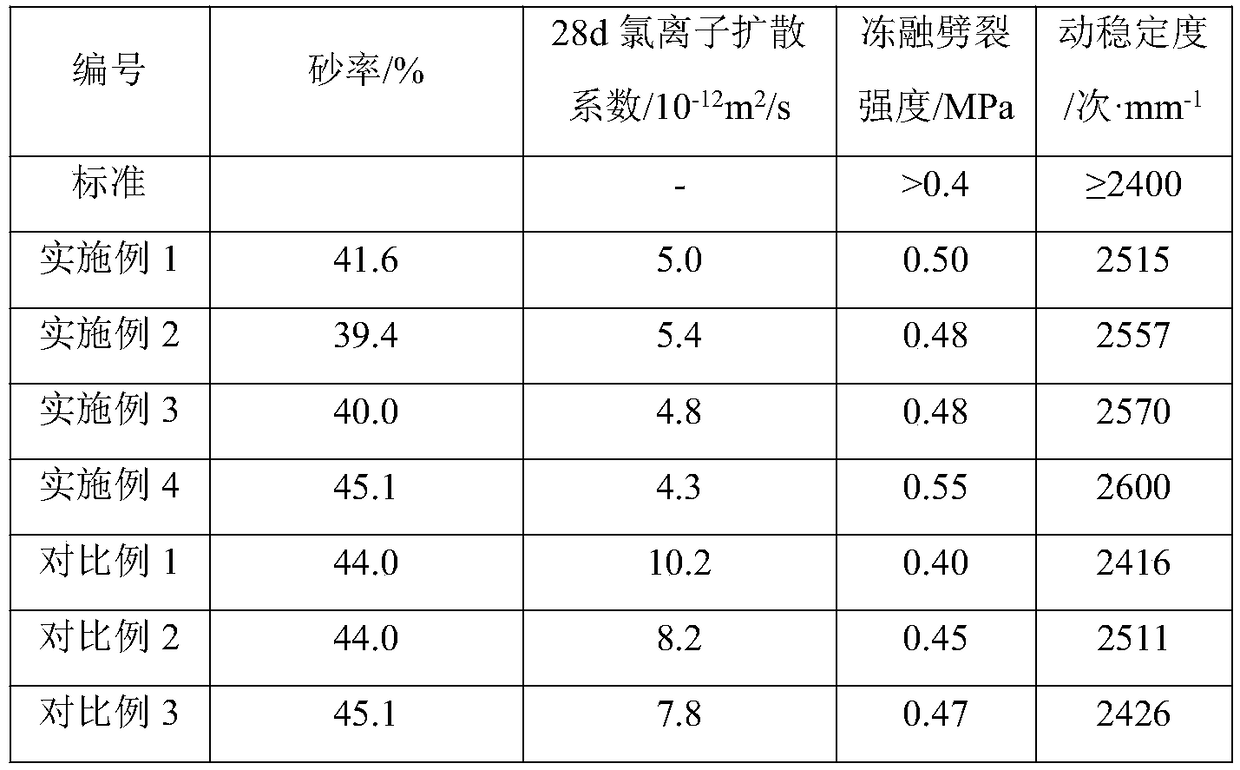

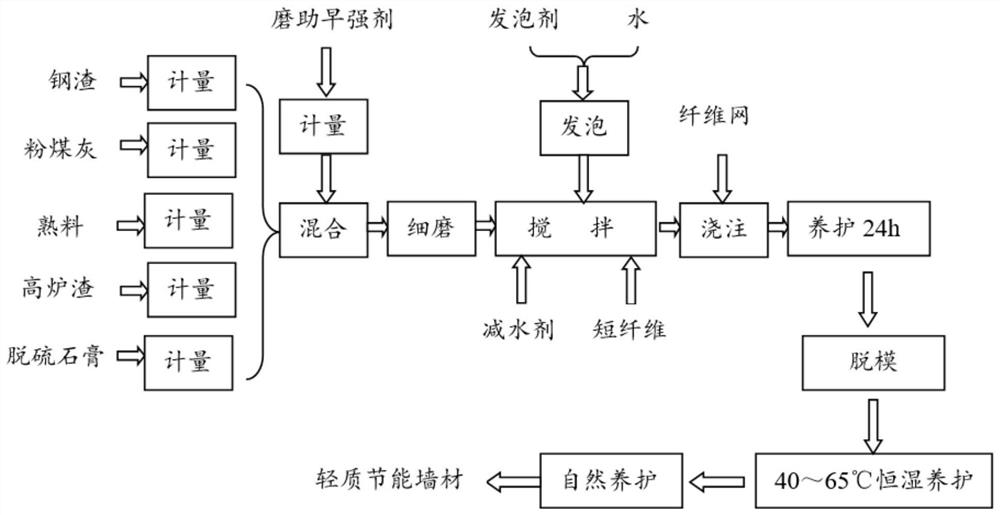

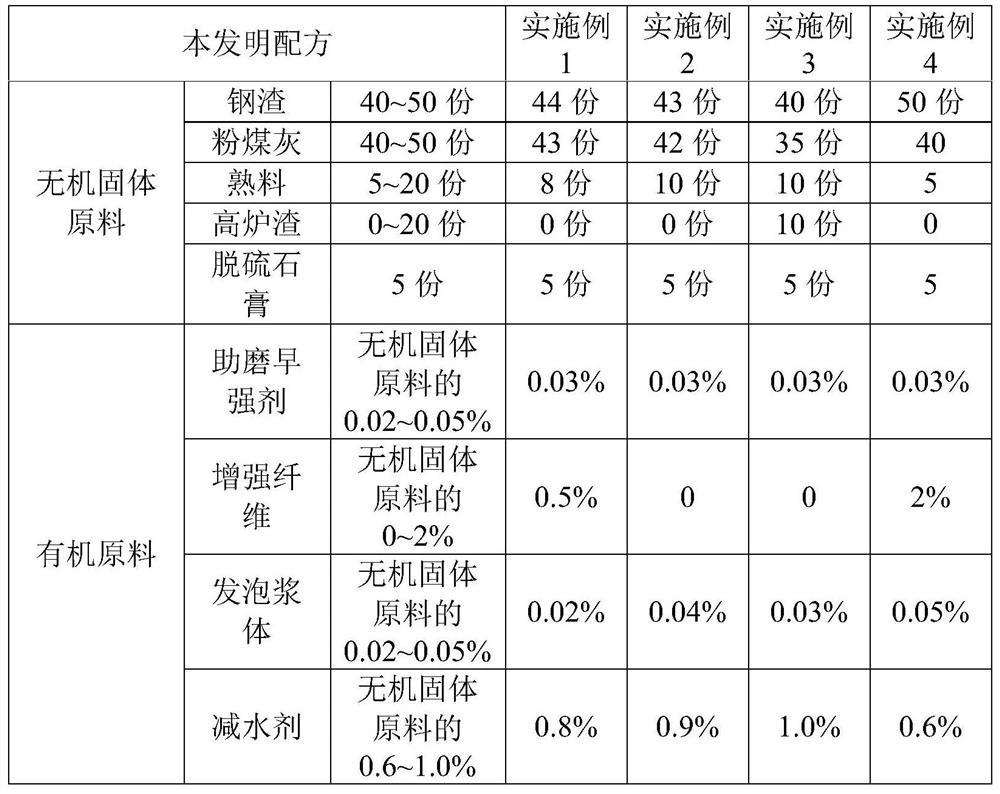

Method for preparing lightweight energy-saving building wall material from high-content steel slag

InactiveCN112919877AEliminate negative effectsImprove mechanical excitation effectSolid waste managementCeramicwareFiberSlag

The invention discloses a method for preparing a lightweight energy-saving building wall material by using high-content steel slag, and solves the problems of low utilization rate, low additional value and low consumption of the existing steel slag. The preparation method comprises the following steps: mixing 40-50 parts of steel slag, 10-20 parts of clinker, 0-20 parts of blast furnace slag, 40-50 parts of fly ash and 5 parts of desulfurized gypsum powder; performing mixing, adding 0.02-0.05% of a grinding-aid early strength agent, and performing fine grinding; adding 0-2% of reinforcing fibers into the mixture after fine grinding; mixing with foaming slurry, and adding a water reducing agent; after uniform stirring, pouring the mixture into a mold; curing the test piece for 1 day under the condition of constant humidity of 30 DEG C, performing demolding, performing curing for 3-6 days under the condition of constant humidity of 35-65 DEG C, and performing natural curing for 28 days to prepare the qualified light energy-saving wall material. The solid waste utilization rate can reach 90%, and the steel slag utilization rate can reach 42.5% or above.

Owner:安徽马钢嘉华新型建材有限公司 +1

Method for testing capacity of concrete resisting chlorides corrosion

InactiveCN100575922CShorten the regular maintenance periodPromote maturityWeather/light/corrosion resistanceMaterial testing goodsDiffusionChloride corrosion

The invention discloses a kind of method of testing the concrete erosion-chloride resisting ability. It is characterized in that: concluding the follow steps: A. makes the concrete material after hot curing at 60-90deg.C as the test piece and at time of hot curing the weight ratio of the water and the jelling material is 0.28-0.54; B. after hot curing the concrete assays the value of flux and chloride ion diffusion coefficient individually; C. accords the formula Qstandard=M+NQhot to impute the value of concrete flux with the standard curing and in the formula Qstandard is the value of concrete flux with the standard curing and the Qhot is the flux measured at step B and the M,N are constants; D. accords the formula Destandard=M1+N1Dehot to calculate the chloride ion diffusion coefficient of standard curing concrete and in the formula Destandard is the value of chloride ion diffusion coefficient of standard curing concrete and the Dehot is the chloride ion diffusion coefficient measured at step B and the M1,N1 are constants. The method of the invention can test the concrete erosion-chloride resisting ability quickly.

Owner:CCCC SHANGHAI THIRD HARBOR SCI RES INST CO LTD +3

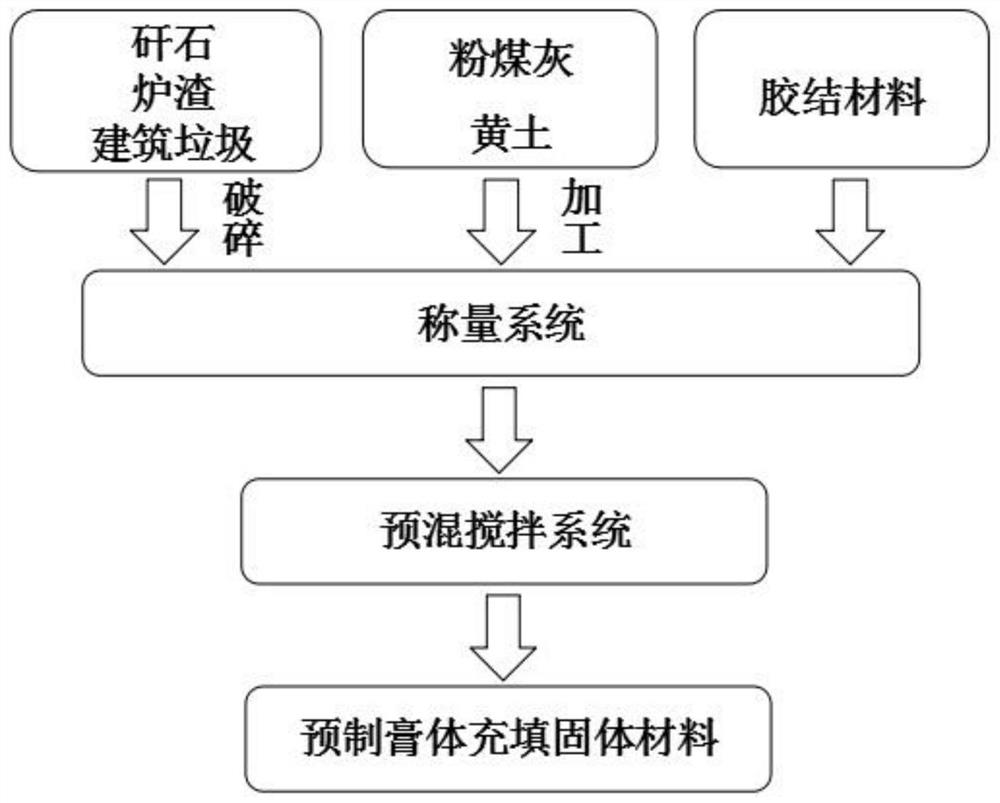

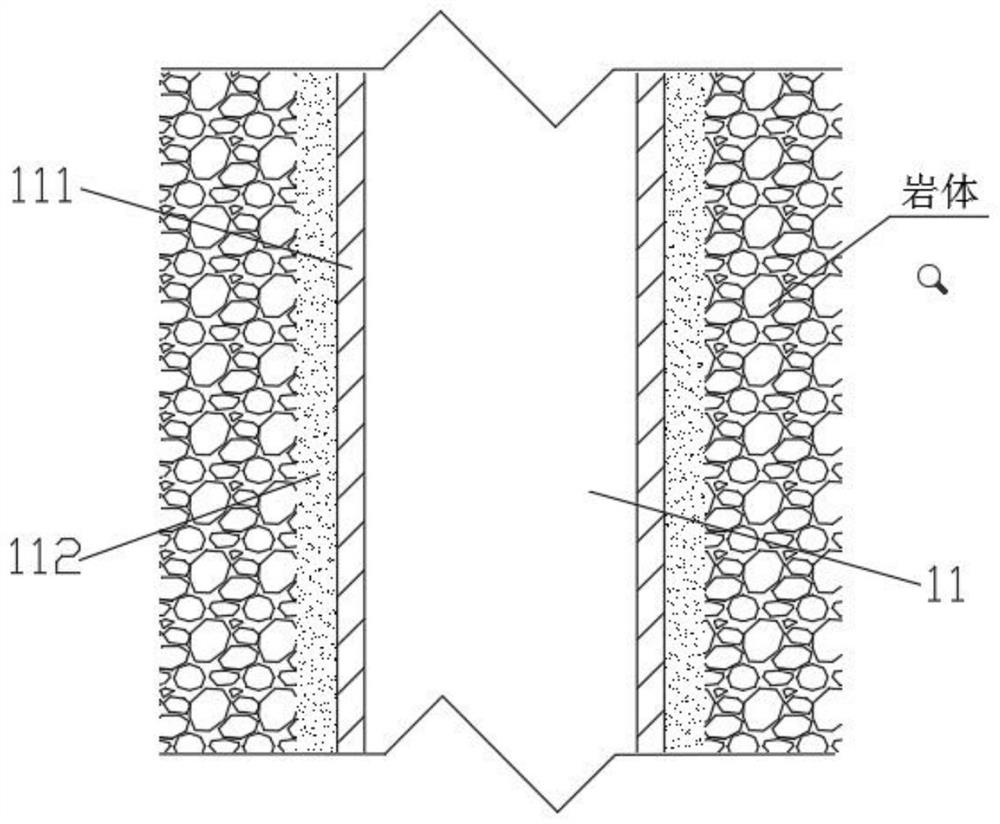

Industrial solid waste-based inorganic paste filling material, preparation method and rapid filling method

PendingCN112897963AGuaranteed StrengthLow costCement productionMaterial fill-upMining engineeringProcess engineering

The invention provides an industrial solid waste-based inorganic paste filling material, a preparation method and a rapid filling method, and belongs to the technical field of mine filling. The industrial solid waste-based inorganic paste filling material provided by the invention is prepared by mixing coarse aggregate, fine aggregate and a solid waste filling cementing material. The rapid filling method comprises the steps that the industrial solid waste-based inorganic paste filling material is taken and conveyed to the underground through a ground feeding hole, then the industrial solid waste-based inorganic paste filling material is evenly mixed with mine water, and the goaf is filled with the obtained paste filling slurry. The industrial solid waste-based inorganic paste filling material does not need underground weighing and can be directly added with water for use, and compared with an existing paste filling process, and the difficulty of underground classified conveying of various solid materials is reduced; meanwhile, the space occupancy rate of underground equipment and a weighing system is also reduced, the underground working intensity is reduced and the safety coefficient and the working efficiency are improved.

Owner:河北充填采矿技术有限公司 +1

Suspension insulator and preparation method thereof

InactiveCN111646779AImprove structural strengthExtended service lifeClaywaresPyrrolidinonesKaolin clay

The invention discloses a suspension insulator and relates to the technical field of insulators. The suspension insulator is prepared from the following raw materials in parts by weight: 22-30 parts of Kaolin, 16-24 parts of vermiculite, 10-18 parts of allophane, 0.5-1.5 part of sepiolite fiber, 0.5-1 parts of lignin fiber, 1-3 part of polypropylene fiber, 10-16 parts of natural zeolite powder, 12-20 parts of mica powder, 5-15 parts of barite powder, 20-30 parts of nacrite, 10-20 parts of bailai stone, 5-10 parts of zircon sand, 1-7 parts of polyvinylpyrrolidone, 1-3 parts of chromium sesquioxide, 1-3 parts of boron oxide, 1-3 parts of polyacrylic acid ethyl ester and 1-4 parts of vinyltriethoxysilane. The invention further discloses a preparation method of the insulator. The invention hasthe beneficial effects that the raw materials are reasonably matched, and a proper preparation method is adopted, so that the structural strength and breaking strength of the insulator are improved,and the service life of the insulator is prolonged.

Owner:萍乡欧姆绝缘子有限公司

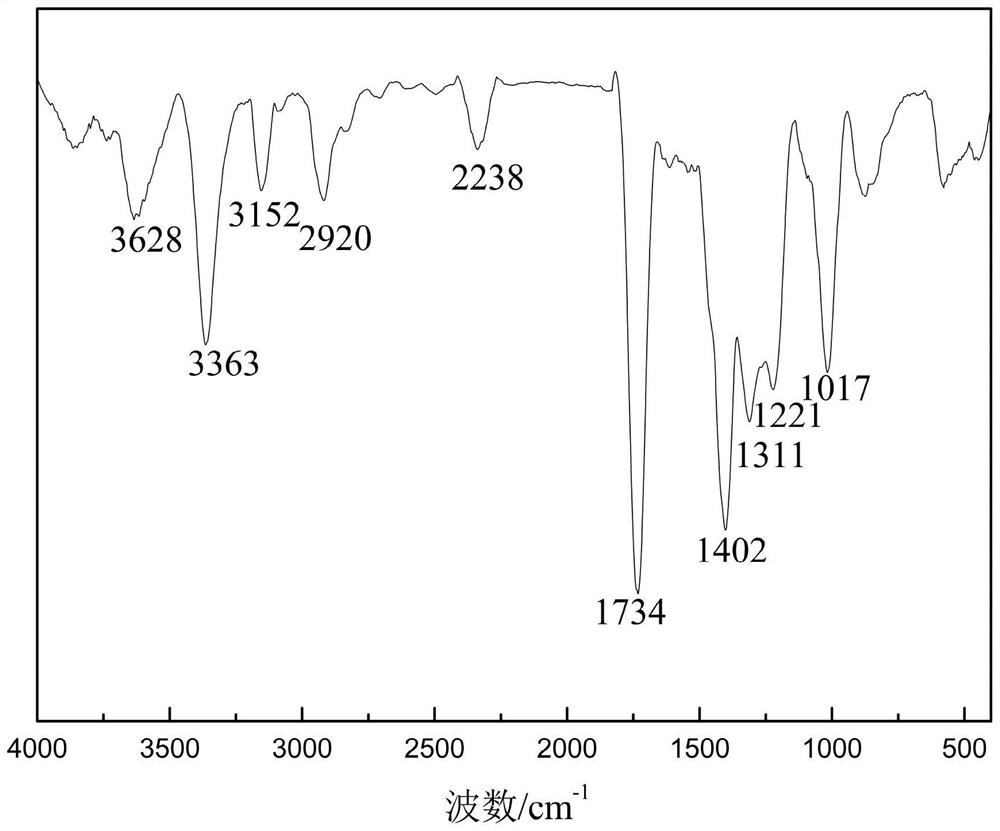

Grinding aid specially used for phosphogypsum cement, and preparation method of grinding aid

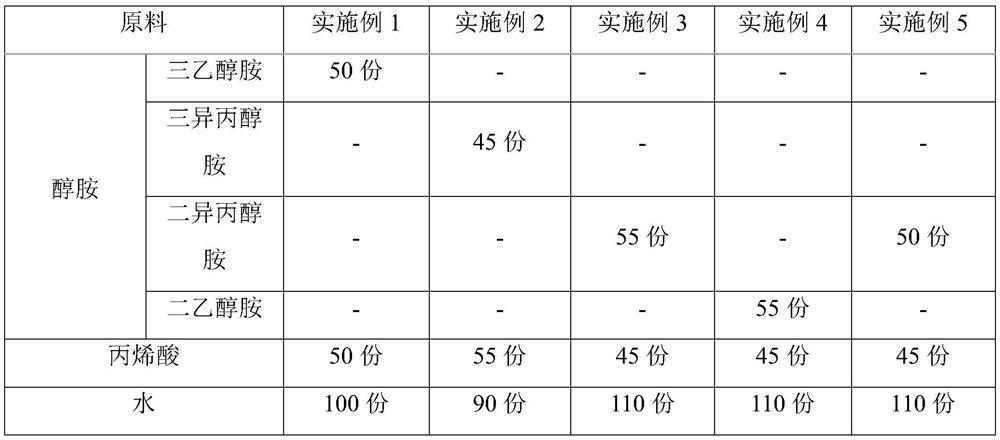

The invention discloses a grinding aid specially used for phosphogypsum cement, and a preparation method of the grinding aid, belonging to the technical field of cement additives. The grinding aid isprepared from the following raw materials in parts by weight: 10-30 parts of an alcohol amine-based grinding aid component, 40-70 parts of hydrated calcium silicate seed crystals, 0.5-2 parts of a thickening dispersing agent, 0.1-0.5 part of a defoaming agent and 20-40 parts of water. The prepared hydrated calcium silicate seed crystals are used as a substance for inducing cement hydration, so that the induction period of a cement hydration process is shortened, and the hydration reaction speed is accelerated; furthermore, the grinding acid also can absorb a water-soluble phosphorus compound in phosphogypsum, thereby accelerating the cement hydration and reducing the impact of phosphorus-containing impurities of the phosphogypsum on the cement hydration. The alcohol amine-based grinding aid component is also introduced, and all the substances have a synergistic effect, so that the problems such as later strength reduction caused by the impurities of the phosphogypsum are reduced to a certain extent. The product provided by the invention is in a liquid form, and has the advantages of being simple to use, convenient to transport, and the like.

Owner:SHANDONG HONGYI TECH

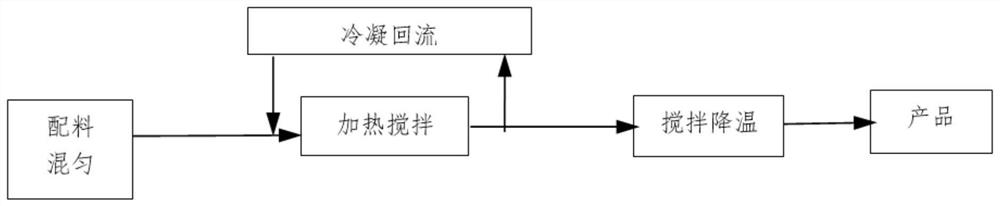

Modified grinding-aiding early strength agent for steel slag as well as preparation method and application method of modified grinding-aiding early strength agent

The invention discloses a modified grinding-aiding early strength agent for steel slag as well as a preparation method and an application method of the modified grinding-aiding early strength agent, and relates to the field of steel slag grinding aiding. The modified grinding-aid early strength agent comprises (a) 60%-75% of ester compounds based on the total weight of the modified grinding-aid early strength agent; (b) 5%-15% of polyacrylic acid based on the total weight of the modified grinding-aid early strength agent; (c) 10%-35% of alcohol amine and acrylic acid monomers based on the total weight of the modified grinding-aid early strength agent, the preparation method comprises the following steps: adding water into alcohol amine and acrylic acid, uniformly mixing, heating while stirring, reacting at 60-80 DEG C for 3-4 hours, and cooling the solution to room temperature to obtain the modified grinding-aiding early strength agent which is applied to grinding of a gel material with high doping amount of steel slag, so the problems of low grinding efficiency of an existing grinding aid, low activity of the steel slag in the early stage, complex synthesis process, high cost and the like are solved. The preparation process is simple, the raw material cost is low, the finished product quality and performance are stable, the use effect is good, and the 7d strength increase is greater than or equal to 30%.

Owner:安徽马钢嘉华新型建材有限公司 +1

a foam cement

ActiveCN106517972BImprove early strengthSpeed up the hydration reactionCeramicwareSocial benefitsBrick

The invention discloses foaming cement which comprises the following components in percentage by mass: 30-45% of cement, 5-10% of ceramic brick polishing powder, 1-4% of a foaming component, 0.1-1% of a foam stabilizing component, 0.5-2% of a waterproof component, 0.5-2% of a reinforcing component and the balance water, wherein cement is composed of silicate cement and aluminate cement in a mass ratio of (5-10) to 1. The foaming cement disclosed by the invention has the characteristics of high strength, good waterproof performance, good thermal insulation effect, good durability and the like; and a great deal of ceramic brick polishing powder further can be comprehensively utilized, so that social resources are saved, using efficiency is improved, and economic benefits and social benefits are remarkable.

Owner:北京宝辰联合科技股份有限公司

Cement-based water permeable brick with cementing strength being improved by aluminum dihydrogen phosphate and lithium ore slag synergistically

InactiveCN106830815ABlocking connected poresHigh strengthSolid waste managementCeramicwarePolyesterBrick

The invention discloses a cement-based water permeable brick with the cementing strength being improved by aluminum dihydrogen phosphate and lithium ore slag synergistically. The brick is prepared from the following raw materials in parts by weight: 40 to 43 parts of granite corner waste, 30 to 32 parts of waste concrete, 20 to 22 parts of 42.5-grade ordinary Portland cement, 2 to 2.5 parts of polyester-cotton fabric leftover materials, 0.1 to 0.12 part of epicholorohydrin-dimethylamine polymer, 0.3 to 0.4 part of an early-strength type polycarboxylate superplasticizer, a proper amount of water, 2 to 3 parts of lignin-based hydramine, 1 to 1.5 parts of aluminum dihydrogen phosphate, 7 to 8 parts of the lithium ore slag and 1.5 to 2.5 parts of gelatin. The brick adopts the energy-saving and environment-friendly raw materials, the production cost is lowered, the compressive strength and the permeation coefficient are good, and the brick is applicable to paving of urban road surfaces, is capable of fast absorbing rainwater, and is not prone to cause urban inland inundation.

Owner:闻承岳

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Bonding agent of baking-free bricks prepared from drilling well solid waste materials

ActiveCN101805161BIncreased contact surface areaHigh strengthSolid waste managementBrickPhosphogypsum

The invention relates to a bonding agent of baking-free bricks prepared from drilling well solid waste materials, which is applied to the field of treating petroleum drilling well solid waste materials into resources for preparing baking-free bricks. The bonding agent comprises the following ingredients in parts by weight: 3.3 to 8 of polyaluminium chloride, 6 to 25 of phosphogypsum, 10 to 26 of lime, 20 to 60 of fly ash and 4.4 to 12 of ferrous sulfate. A method for using drilling well solid waste materials for preparing the baking-free bricks comprises the following steps that: the baking-free bricks are prepared from the following ingredients in parts by weights: 10 to 22 of bonding agents of baking-free bricks prepared from drilling well solid waste materials, 30 to 55 of drilling well solid waste materials and 35 to 45 of crude aggregate; and the ingredients are uniformly mixed, are extruded and formed through a baking-free brick machine, and are maintained for 14 to 21 days to prepare the baking-free bricks. The invention has the advantages that the baking-free bricks can be prepared, and through the analysis via the sampling and the water soaking experiments on the baking-free bricks, all contaminant indexes reach the primary standard. Through the examination according to the standard JC422-1991, the detected items of the samples reach the requirements of the standard.

Owner:PETROCHINA CO LTD

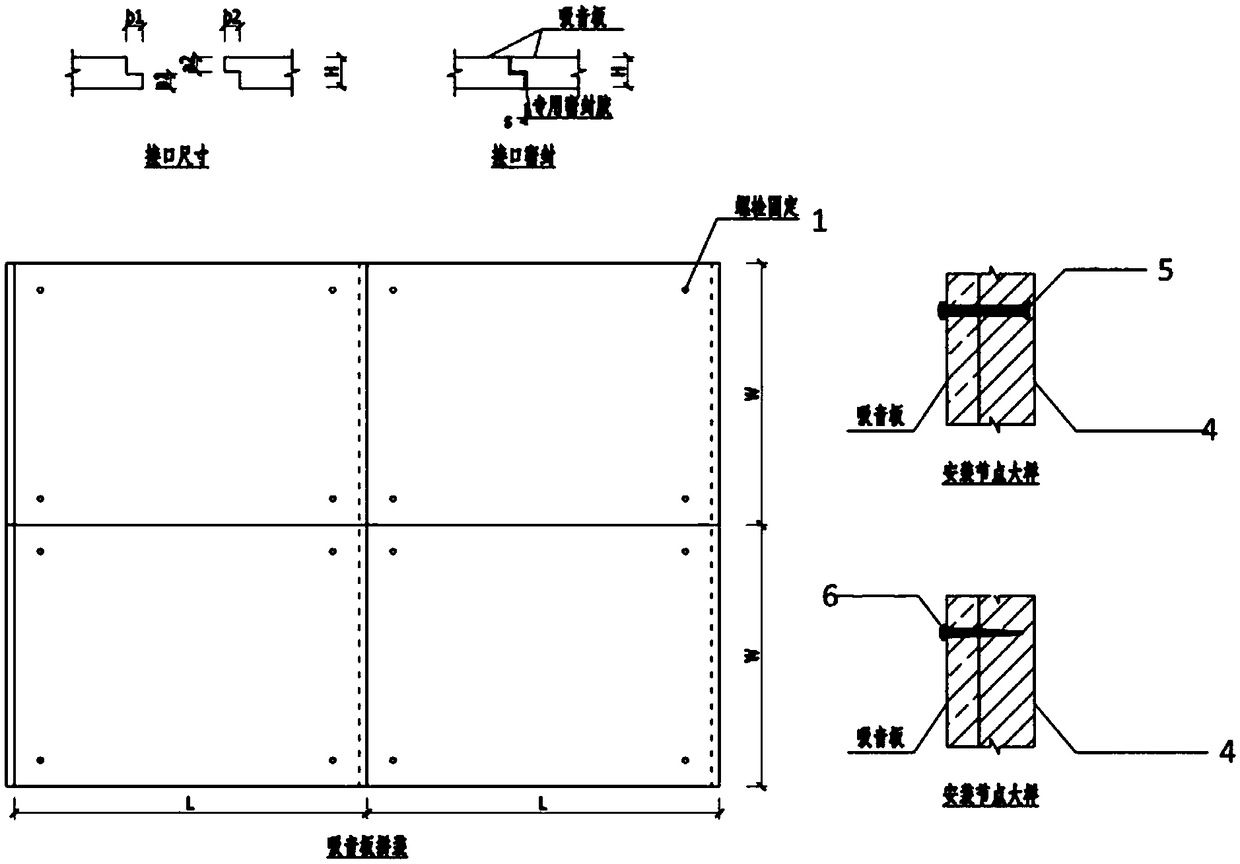

Light renewable resource acoustic board and preparation method thereof

PendingCN109133738AImprove sound absorptionImprove mechanical propertiesSound proofingAcoustic absorptionFire resistance

The invention relates to the technical field of acoustic boards, and discloses a light renewable resource acoustic board which is prefabricated with solid waste acoustic materials in an adding reinforced manner. The aggregate size of the solid waste acoustic materials is not larger than 20mm, the compressive strength of the solid waste acoustic materials is higher than 10MPa, and the acoustic absorption coefficient of the solid waste acoustic materials is larger than 0.65. By an assembled production and construction mode, all prefabricated parts are prefabricated in a factory, transformed to asite and directly assembled, the acoustic board is easy to operate, good in performance and short in construction period, resources are saved, environments are protected, and the requirements of green energy-saving ecological development are met. The problems of low industrial waste use ratio, environmental pollution and the like are solved, the production cost of the acoustic board is reduced, and the mechanical property, the fire resistance and the durability of the acoustic board are improved.

Owner:惠州富盈新材料科技有限公司

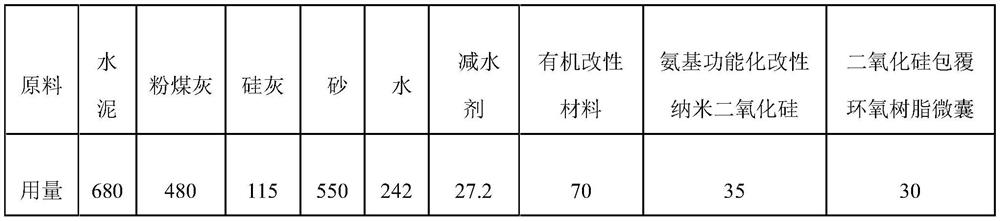

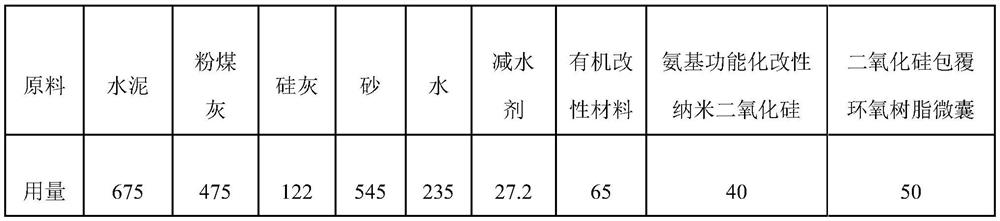

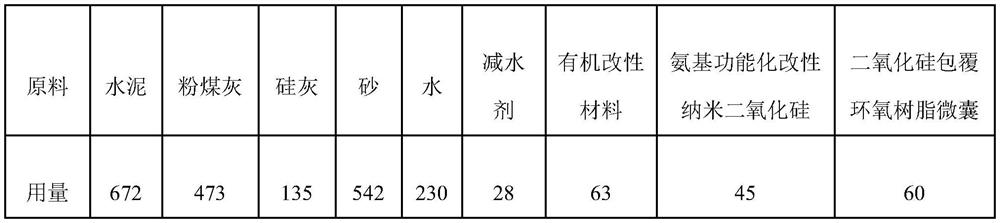

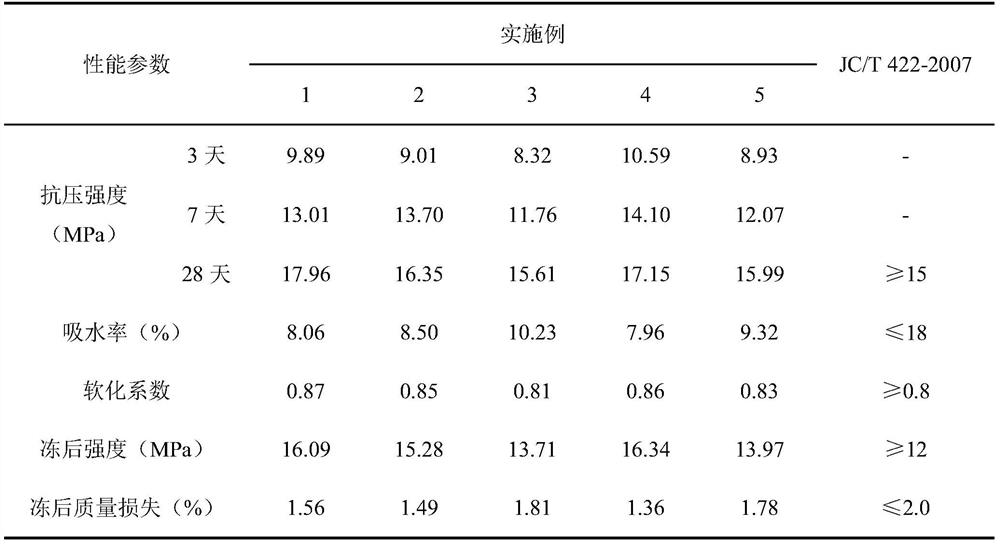

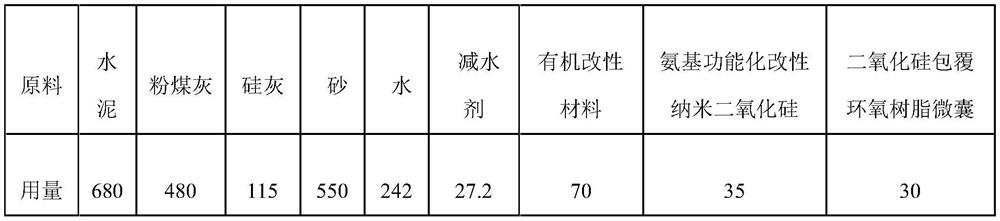

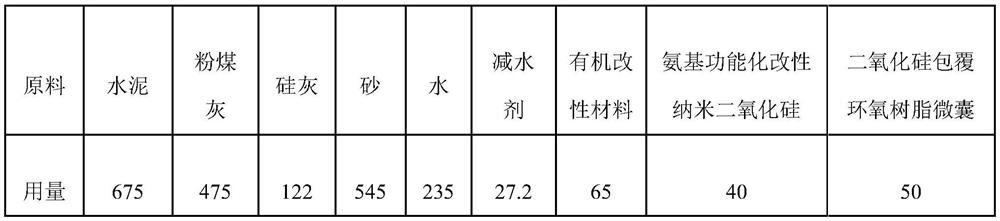

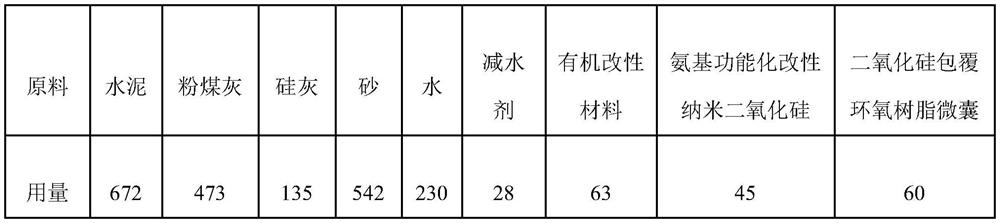

Crack self-healing ultra-high performance cement-based composite material and preparation method in cold regions

The invention belongs to the technical field of building materials and basic engineering construction, and relates to a crack self-healing ultra-high performance cement-based composite material in cold regions and a preparation method thereof, which is made of the following components: cement, fly ash, silica fume, sand , water, water reducing agent, amino-functionalized modified nano-silica, silica-coated epoxy resin microcapsule material, organic modified material; amino-functionalized modified nano-silica composed of water, tetraethoxy silane, 3-aminopropyltriethoxysilane and ammonium hydroxide; silica-coated epoxy resin microcapsules are made of water, tetraethoxysilane, epoxy resin; organically modified materials are made of polymer It is made of material-modified reinforced materials and nano-reinforced materials. The self-healing ultra-high-performance cement-based composite material for cracks in cold regions provided by the present invention exerts the self-healing characteristics of the two-component epoxy amine system and the quantum size effect of nanomaterials, the filling effect and the hydration reaction induced by crystal nuclei. Improve the frost resistance and durability of the material.

Owner:CHANGAN UNIV +1

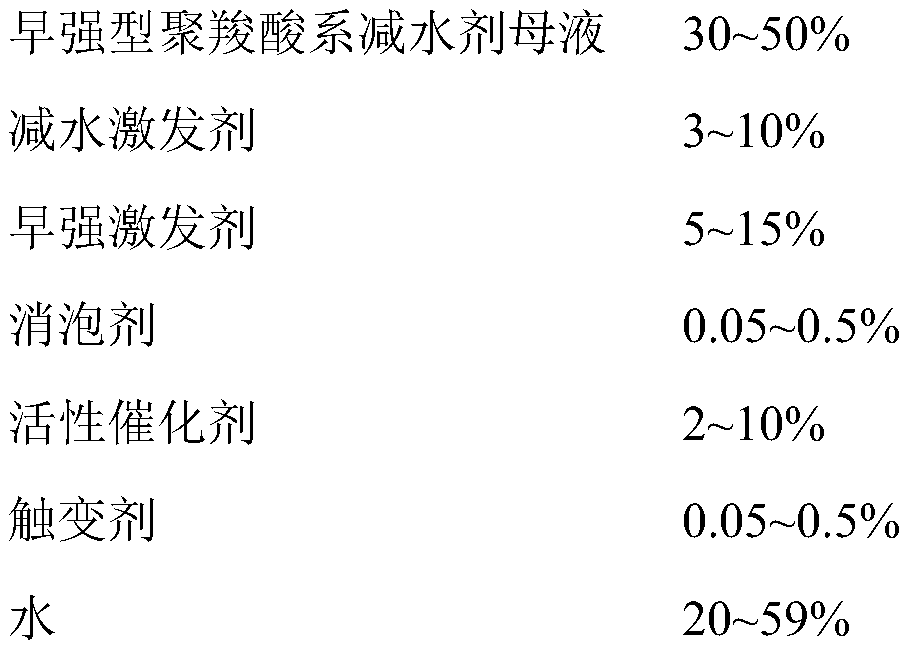

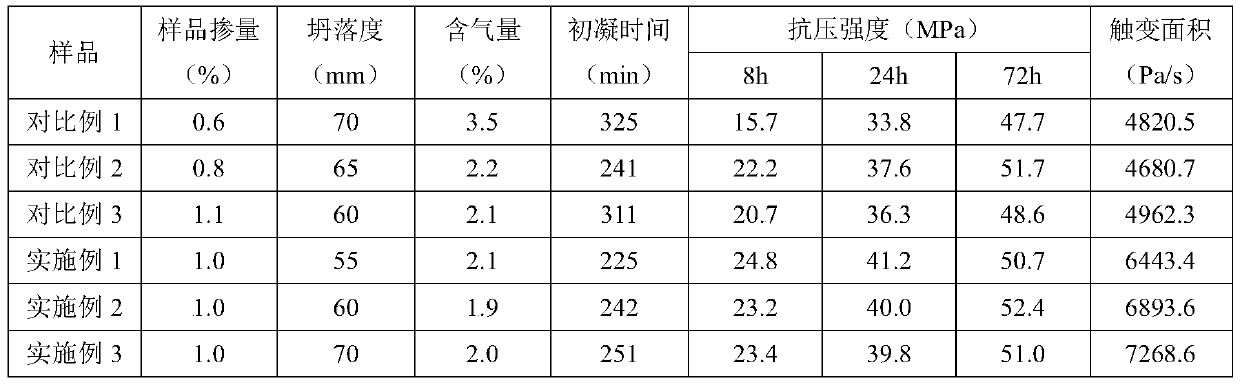

A high-early-strength polycarboxylate water-reducer for subway segment concrete

The invention relates to a high early strength type polycarboxylate water reducer for metro segment concrete. The water reducer is prepared from the following raw materials by weight percent: 30-50% of early strength type polycarboxylate water reducer mother liquor, 3-10% of water reducing excitant, 5-15% of early strength excitant, 0.05-0.5% of de-foaming agent, 2-10% of active catalyst, 0.05-0.5% of thixotropic agent and 20-59% of water. The invention aims to utilize the synergistic effect of the high early strength type polycarboxylate water reducer for metro segment concrete to various regulation techniques, such as, high dispersion, low air bleeding, high reaction speed and high reaction degree of concrete to promote the early strength of the concrete and meanwhile to shorten the setting time of the concrete and properly reduce the gas content of the concrete. The high early strength type polycarboxylate water reducer is especially suitable for the preparation of segment prefabricated concrete. The quick promotion of the early strength and the quick shortening of the settling time are both beneficial to the reducing of the de-molding time of the prefabricated concrete part and the increasing of the template turnover efficiency, so that the production efficiency of the prefabricated part is increased.

Owner:NANJING RUIDI HIGH TECH

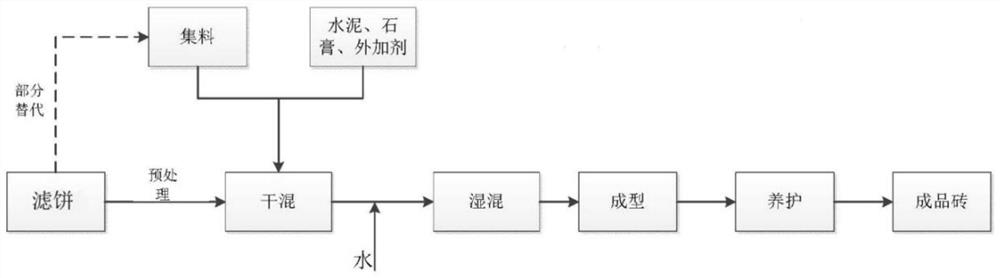

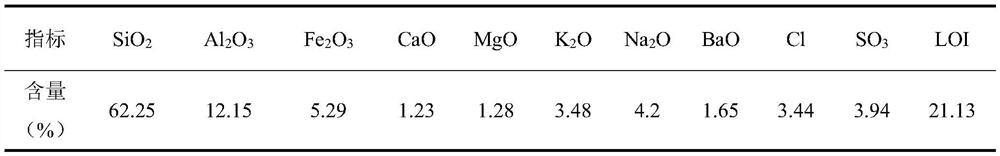

A method for preparing unburned bricks from offshore drilling waste mud

The invention discloses a method for preparing non-burning bricks from offshore drilling waste mud. The steps are as follows: S1. Solid-liquid separation is performed on the offshore drilling waste mud, and the solid phase is dehydrated by pressure filtration to obtain a filter cake; S2. The filter cake is passed through drying, crushing, ball milling, and washing to remove chloride ions to obtain the base material; S3, adding cement, gypsum, polyvinyl alcohol, and aggregates to the base material, mixing evenly to obtain a mixture, adding water to the mixture to obtain a semi-dry aggregates; aggregates include coarse aggregates and fine aggregates; coarse aggregates are crushed pebbles, the particle size distribution is between 5mm and 10mm, and the bulk density is 1663kg / m 3 ; The fine aggregate is river sand with a fineness modulus of 2.4. S4. The semi-dry mixture is made into adobe, and after the adobe is demoulded, it is naturally cured for 28 days to obtain an unfired brick. The preparation method of the invention realizes the problems of safe and environment-friendly disposal and resource comprehensive utilization of the waste mud from offshore drilling.

Owner:SOUTHWEST PETROLEUM UNIV

Cold region crack self-healing ultra-high performance cement-based composite material and preparation method thereof

The invention belongs to the technical field of building materials and infrastructure construction, and relates to a cold region crack self-healing ultra-high performance cement-based composite material and a preparation method thereof. The composite material is prepared from the following components: cement, fly ash, silica fume, sand, water, a water reducing agent, amino functionalized modifiednano silicon dioxide, a silicon dioxide coated epoxy resin microcapsule material and an organic modified material. The amino functional modified nano silicon dioxide is prepared from water, tetraethoxysilane, 3-aminopropyltriethoxysilane and ammonium hydroxide; the silicon dioxide coated epoxy resin microcapsule is prepared from water, tetraethoxysilane and epoxy resin; and the organic modified material is prepared from a polymer modified reinforcing material and a nano reinforcing material. According to the cold region crack self-healing ultra-high performance cement-based composite materialprovided by the invention, the self-healing characteristic of a bi-component epoxy amine system and the quantum size effect, the filling effect and the crystal nucleus induced hydration reaction of anano material are exerted, so that the anti-freezing performance and durability of the material are improved.

Owner:CHANGAN UNIV +1

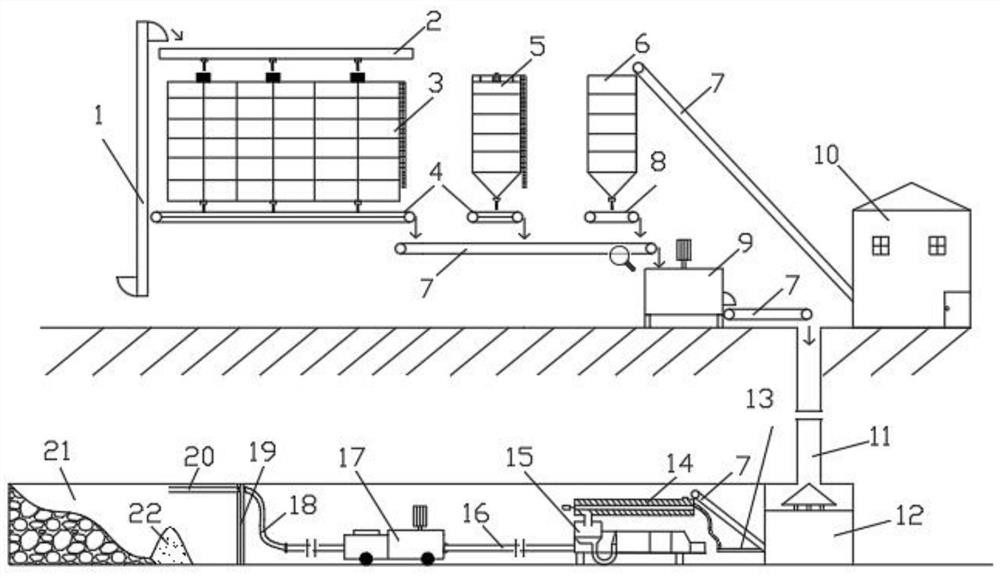

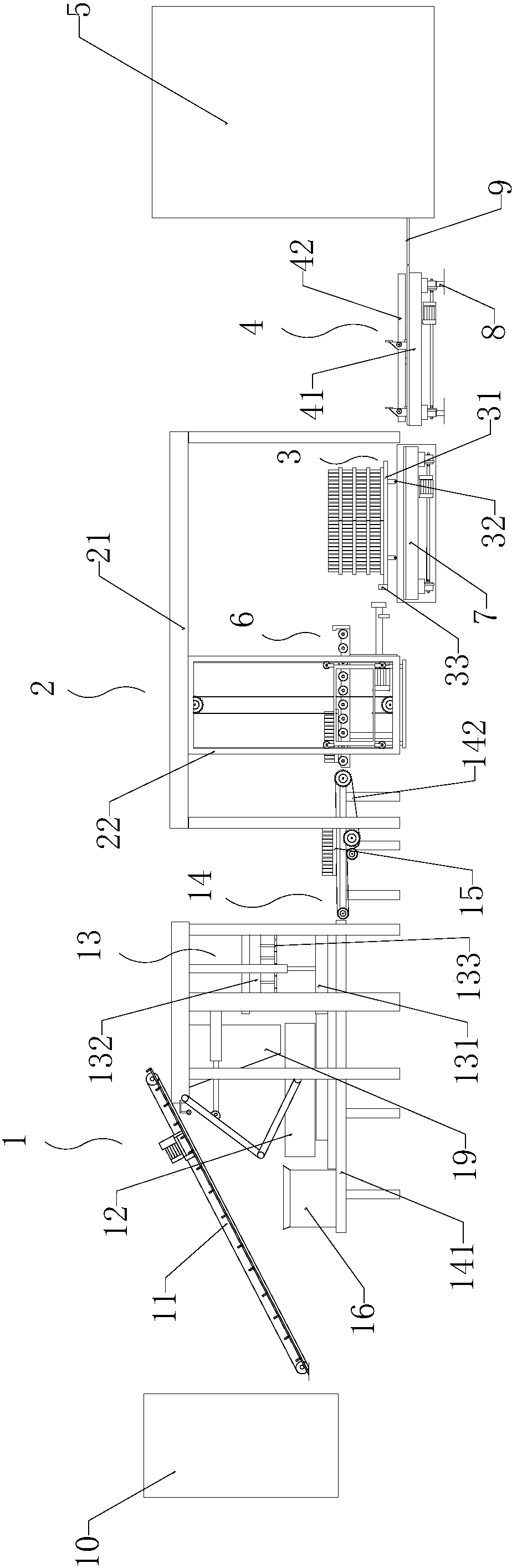

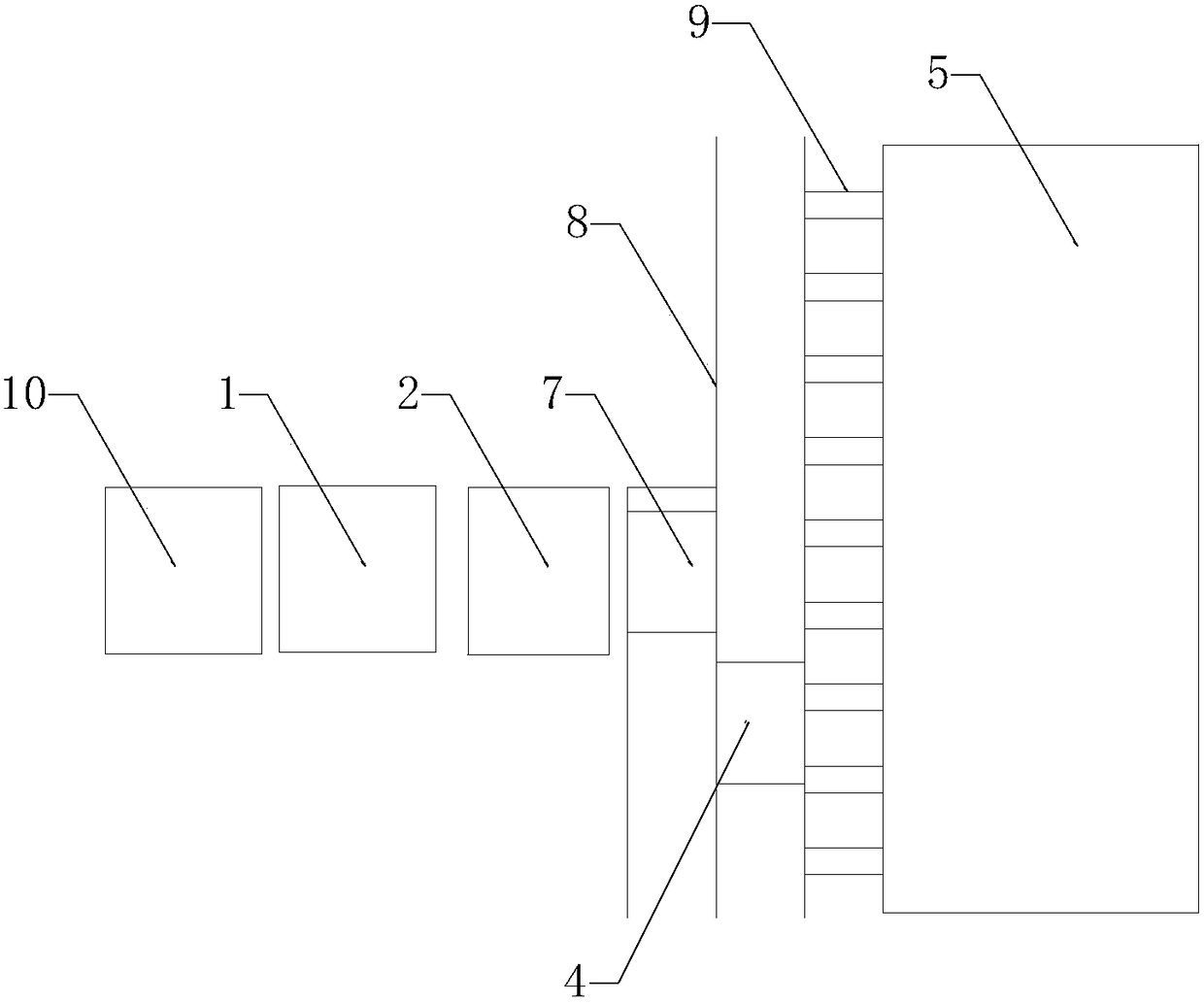

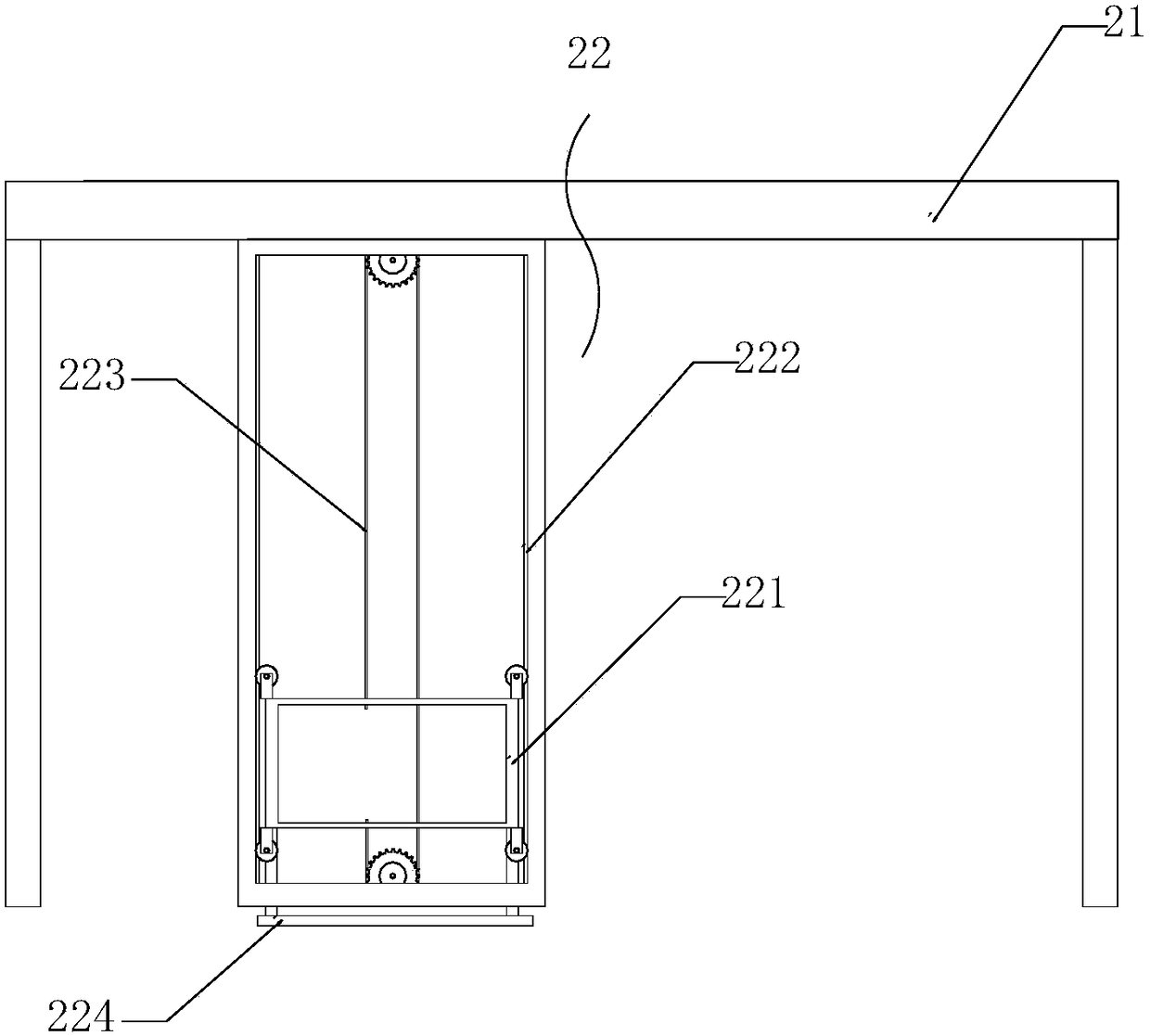

Block natural maintenance production line and production method

ActiveCN105835216BSmall footprintReduce labor intensityCeramic shaping plantsAuxillary shaping apparatusProduction linePush and pull

The invention belongs to the field of machinery manufacturing technology and provides a natural curing production line for building blocks. The natural curing production line for the building blocks comprises a block making machine, a palletizing machine, a conveying car, a ferry car and a solar curing room in order. The ferry car is arranged on longitudinal rails. Transverse rails for a bearing car to move along are arranged on the conveying car, on the ferry car and in the solar curing room. The ferry car comprises a master car and a subsidiary car which is arranged on the master car. A hydraulic propulsion device used for pushing and pulling the subsidiary car to move laterally is arranged on the master car. At least two sets of movable pushing plates are arranged on the subsidiary car. The bearing car can pass through the pushing plates in order and the pushing plates push the bearing car to move forward after the bearing car passes through the pushing plates. The invention further provides a production method for the building blocks using the natural curing production line for the building blocks. The natural curing production line for building blocks is skillful in design, and reasonable in structure, conforms to the production requirements of the building blocks, and solves the technical problems that in the prior art the design of the production line is complicated, the equipment is more, the cost is high, the occupied area is larger, the working efficiency is unsatisfactory and the curing mode is unreasonable.

Owner:QINGYUAN TONGYE MACHINE MFG CO LTD

A special grinding aid for phosphogypsum cement and its preparation method

The invention discloses a special grinding aid for phosphogypsum cement and a preparation method thereof, belonging to the technical field of cement admixtures. The grinding aid of the present invention is prepared from the following raw materials in parts by weight: 10-30 parts of alcohol amine grinding aid components, 40-70 parts of calcium silicate hydrate seed crystals, 0.5-2 parts of thickening dispersant, Foam agent 0.1-0.5 part, water 20-40 part. The present invention uses the prepared hydrated calcium silicate crystal seed as a substance to induce cement hydration, shortens the induction period in the cement hydration process, and improves the hydration reaction speed; at the same time, it can also adsorb water-soluble phosphorus-containing compounds in phosphogypsum, thereby Accelerate cement hydration and reduce the impact of phosphorus-containing impurities in phosphogypsum on cement hydration. The invention also introduces alcohol amine grinding aid components, and the synergistic effect of each substance can alleviate the problems such as the later strength reduction caused by the phosphogypsum impurities to a certain extent. The product provided by the invention is in the form of liquid, and has many advantages such as simple use and convenient transportation.

Owner:SHANDONG HONGYI TECH

Anti-crack concrete and preparation method thereof

The invention provides anti-crack concrete and a preparation method thereof, and belongs to the technical field of concrete. The concrete comprises the following components in parts by weight: 100-150 parts of water, 200-400 parts of cement, 30-50 parts of epoxy resin modified polypropylene fiber, 10-20 parts of reinforced fiber, 9-14 parts of a water reducing agent, 7-10 parts of an expanding agent, 30-70 parts of fly ash, 30-70 parts of coarse aggregate, 20-50 parts of fine aggregate and 0.1-0.3 part of sodium dioctyl sulfosuccinate. In the anti-crack concrete, the modified polypropylene fibers are uniformly distributed in a concrete matrix, and the hydration reaction speed is increased by forming a fiber net structure, so that the crack resistance and impermeability of the concrete are remarkably improved, and the strength of the concrete is improved.

Owner:胡志强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com