Patents

Literature

1590 results about "Acoustic board" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An acoustic board is a special kind of board made of sound absorbing materials. Its job is to provide sound insulation. Between two outer walls sound absorbing material is inserted and the wall is porous. Thus, when sound passes through an acoustic board, the intensity of sound is decreased. The loss of sound energy is balanced by producing heat energy.

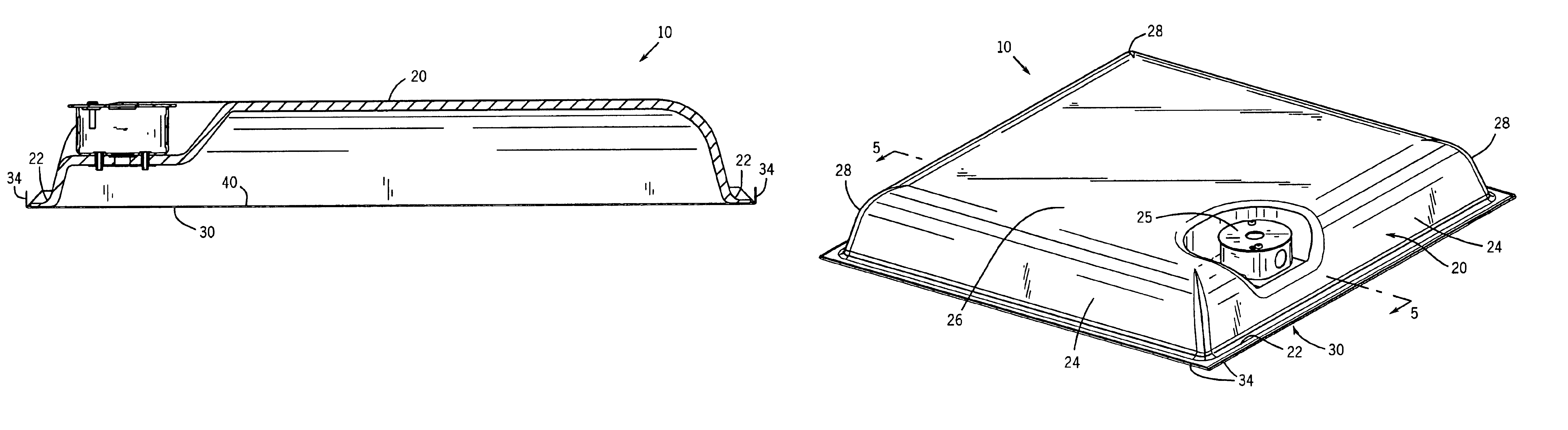

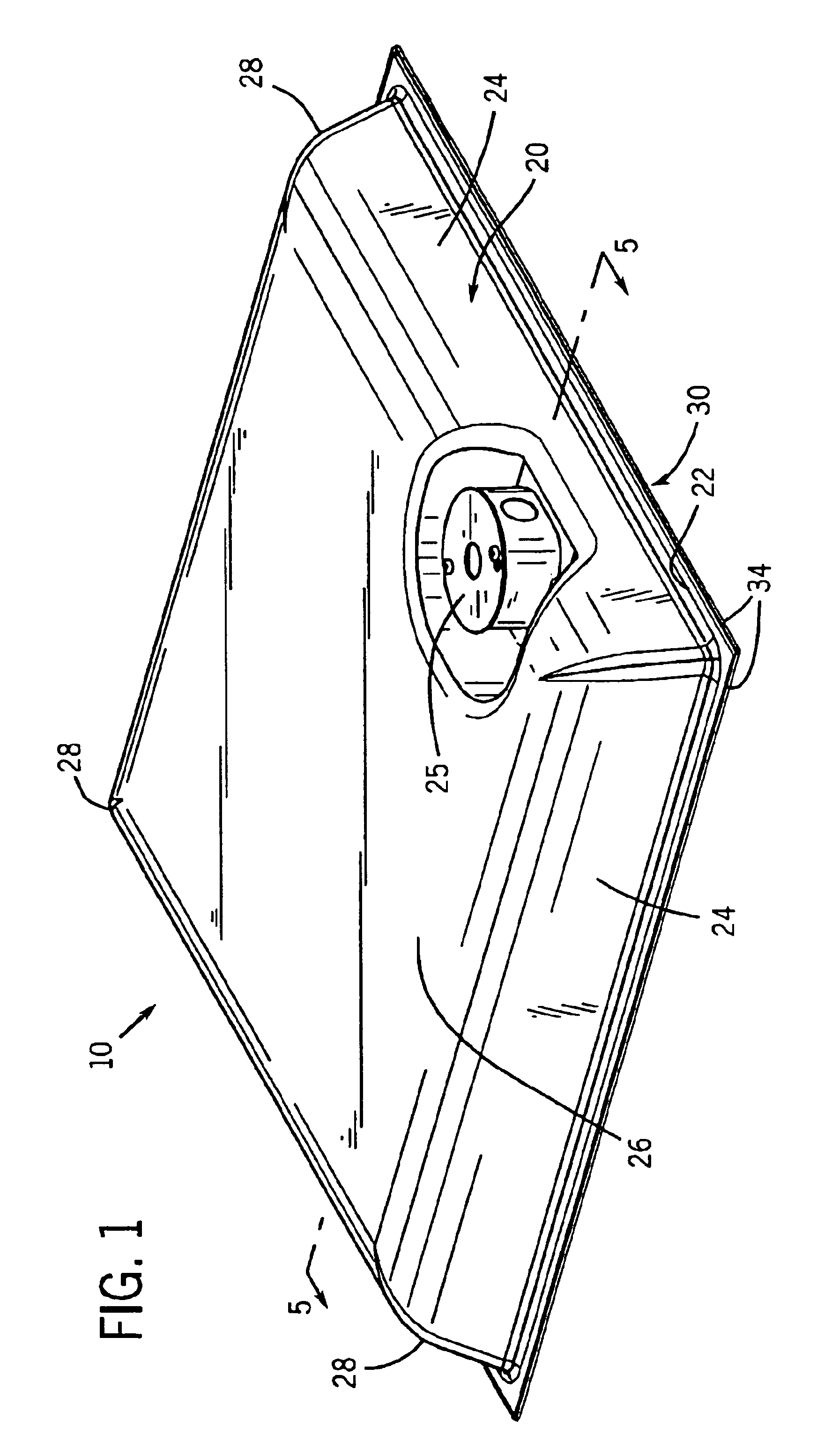

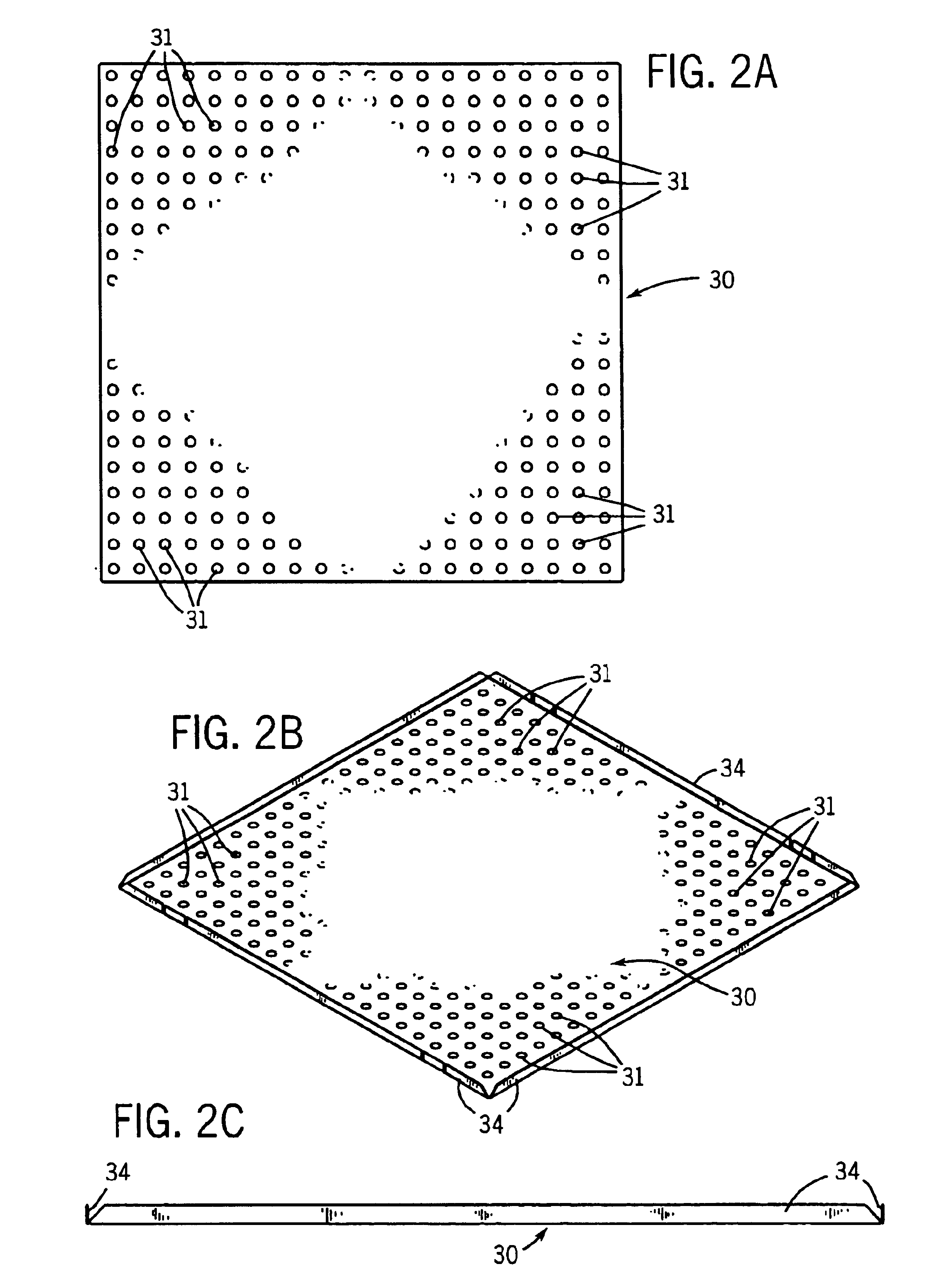

Lay-in ceiling speaker

InactiveUS6944312B2High strengthGood high-temperature insulation propertyMicrophonesLoudspeaker transducer fixingSound baffleAcoustic board

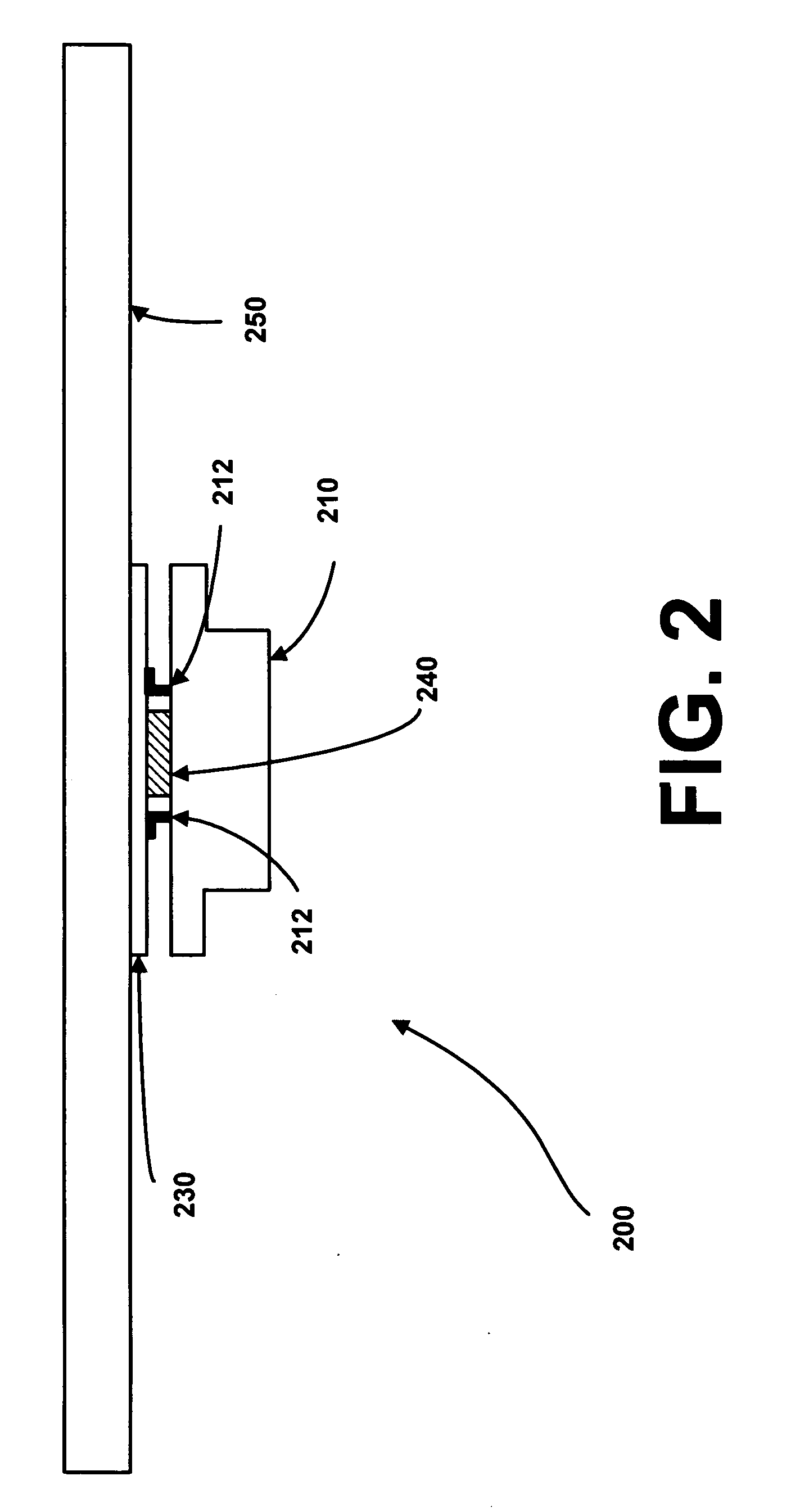

A light weight fully assembled speaker enclosure is provided that includes a backbox having a peripheral edge; a grill that is crimped around the peripheral edge of the backbox, and a sound-baffle sheet disposed between the backbox and the grill, the sound-baffle sheet having an opening for placement of a speaker. Also provided is a speaker system having an audio speaker; a backbox having a peripheral edge; a grill that is crimped around the peripheral edge of the backbox and that is affixed to the speaker; and a sound-baffle sheet disposed between the backbox and the grill, the sound-baffle sheet having an opening for placement of the speaker.

Owner:VALCOM

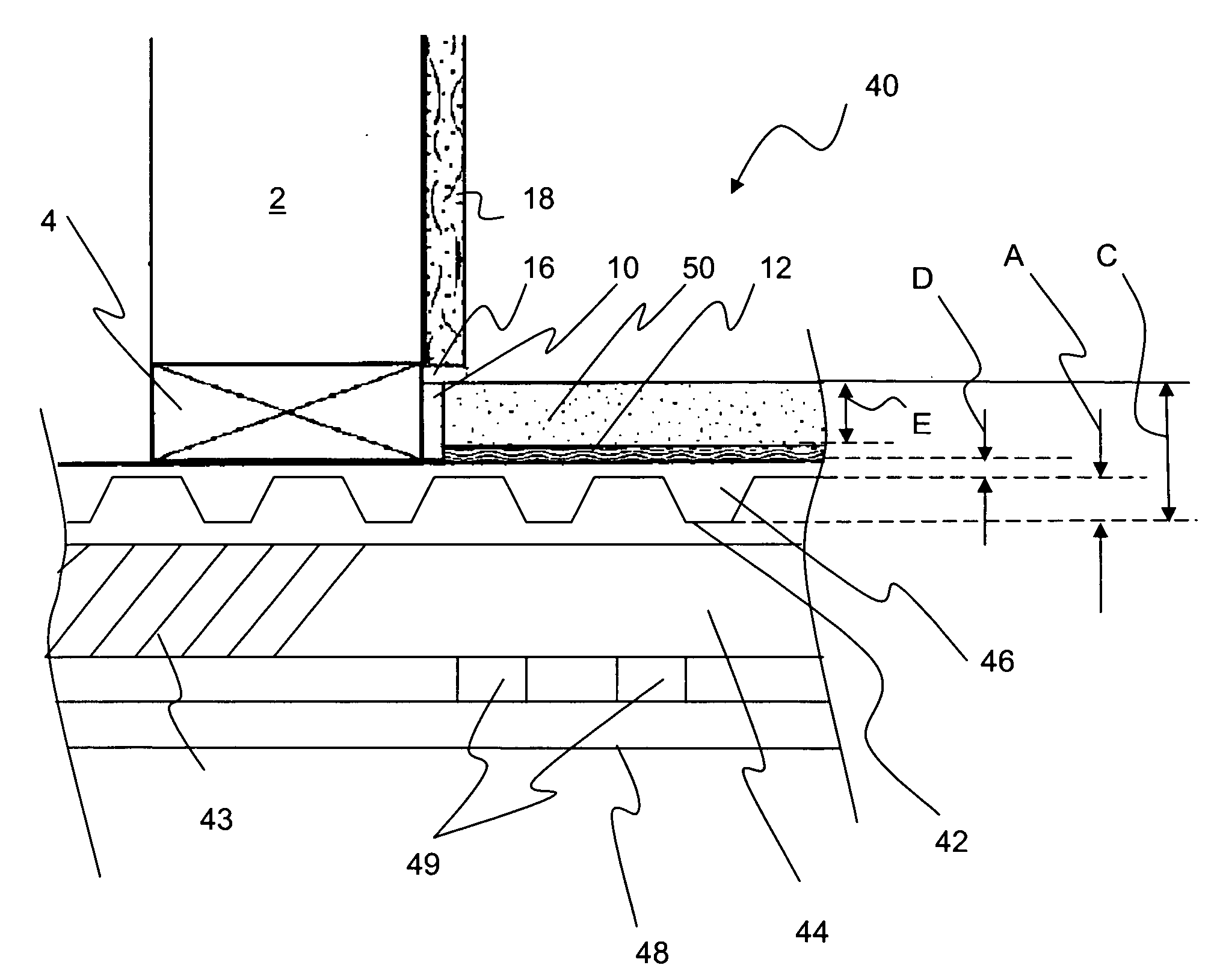

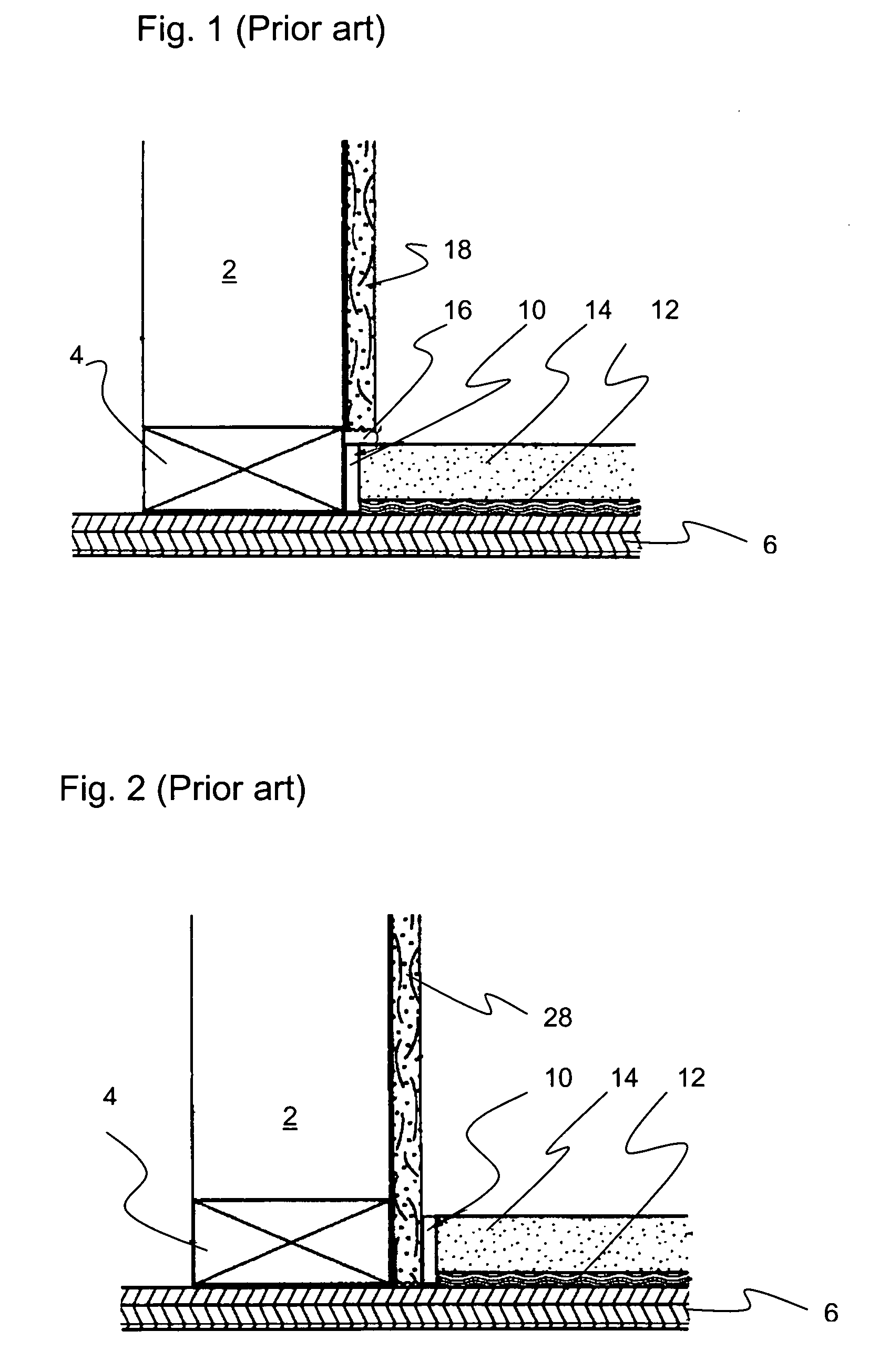

Corrugated steel deck system including acoustic features

ActiveUS20070000198A1Solve the slow construction speedReduce laborCeilingsCovering/liningsCarrying capacityEngineering

The present invention relates to a sound rated floor system for inhibiting sound transmission between floors. The system includes a corrugated steel deck; a first layer of cementitious material or board or sheet applied over the corrugated steel deck; a sound insulation mat or board applied over the first layer; a second layer of cementitious material applied over the sound insulation mat or board. The floor system has an IIC rating of at least 25 and the corrugated steel deck provides at least 50 percent of the ultimate load carrying capacity under static and impact loading of the floor system with a floor deflection of at most 1 / 360 of the floor span.

Owner:UNITED STATES GYPSUM CO

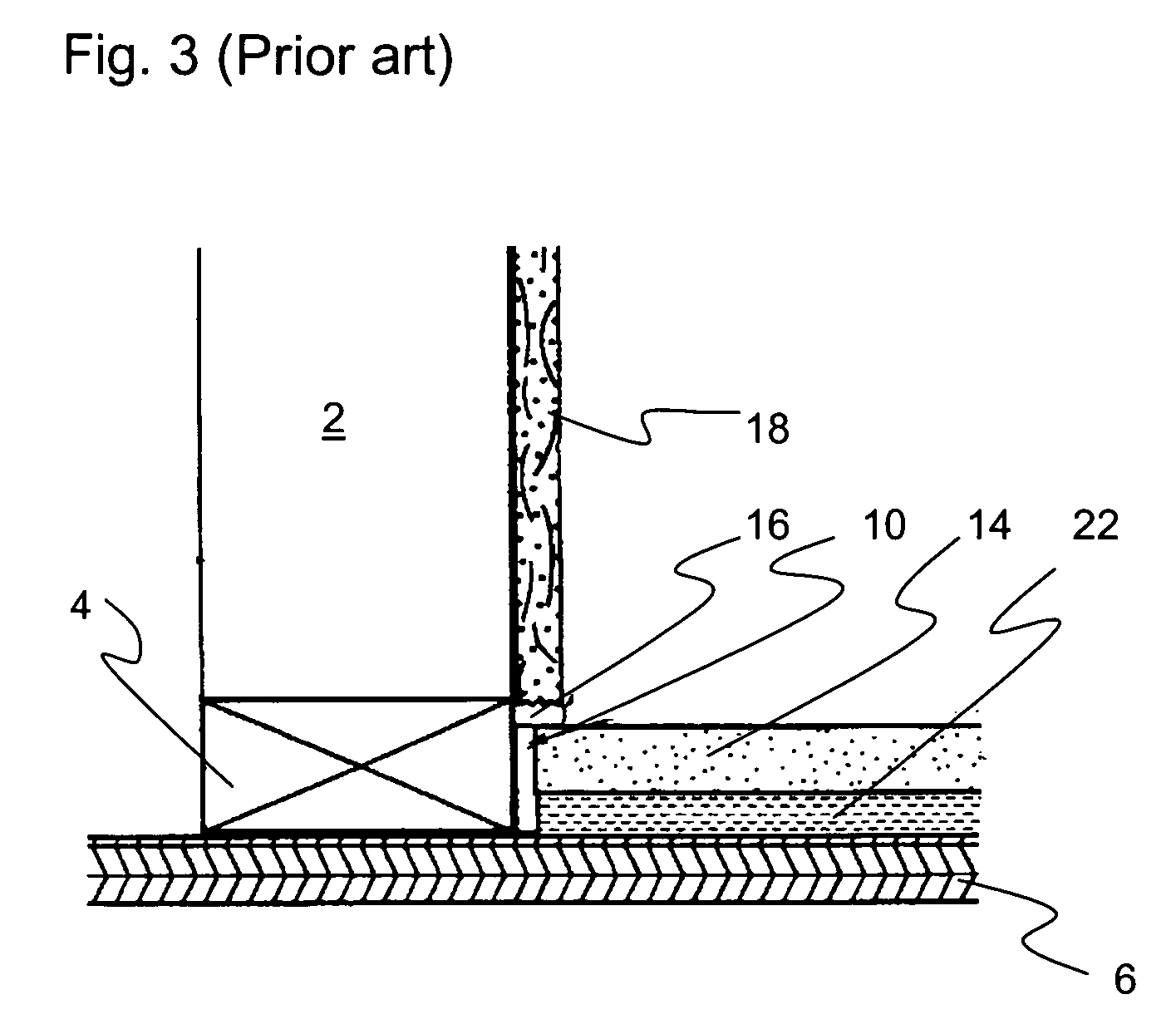

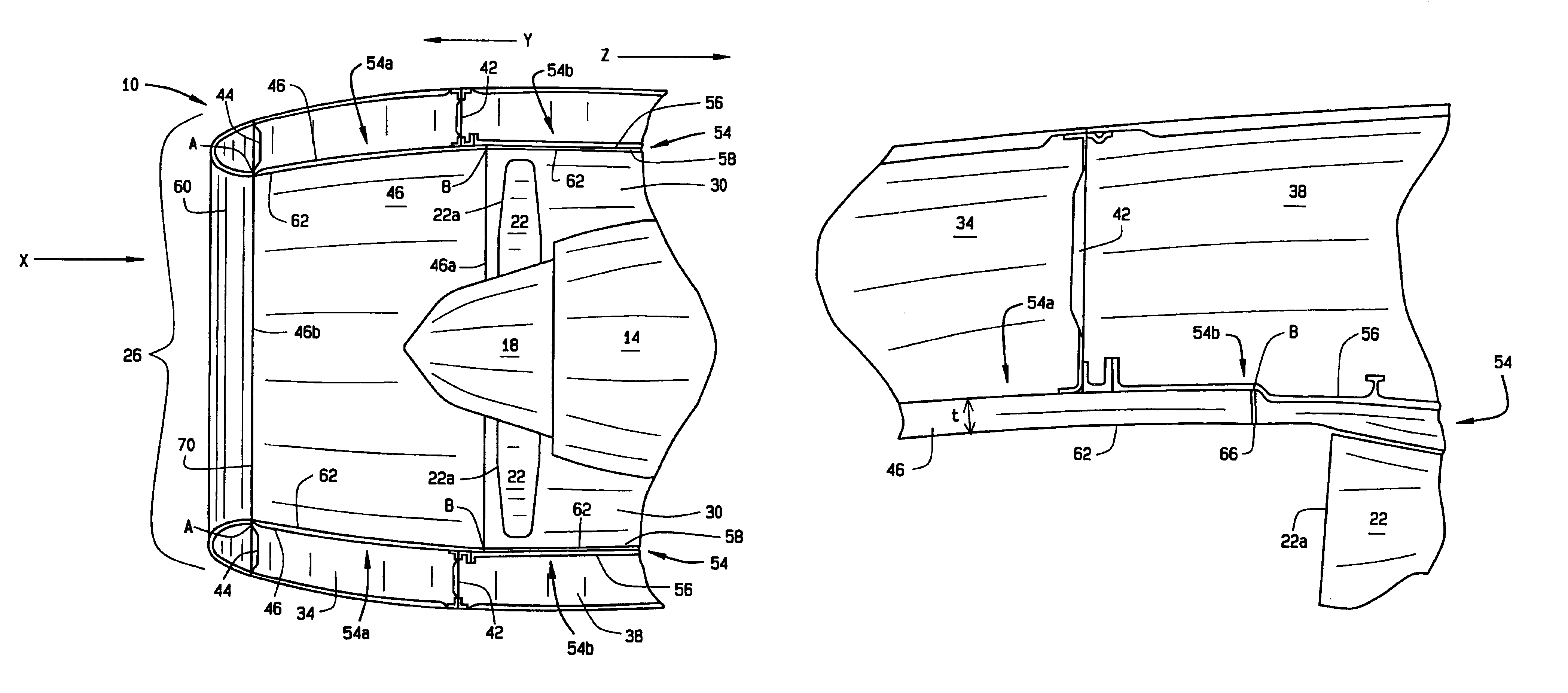

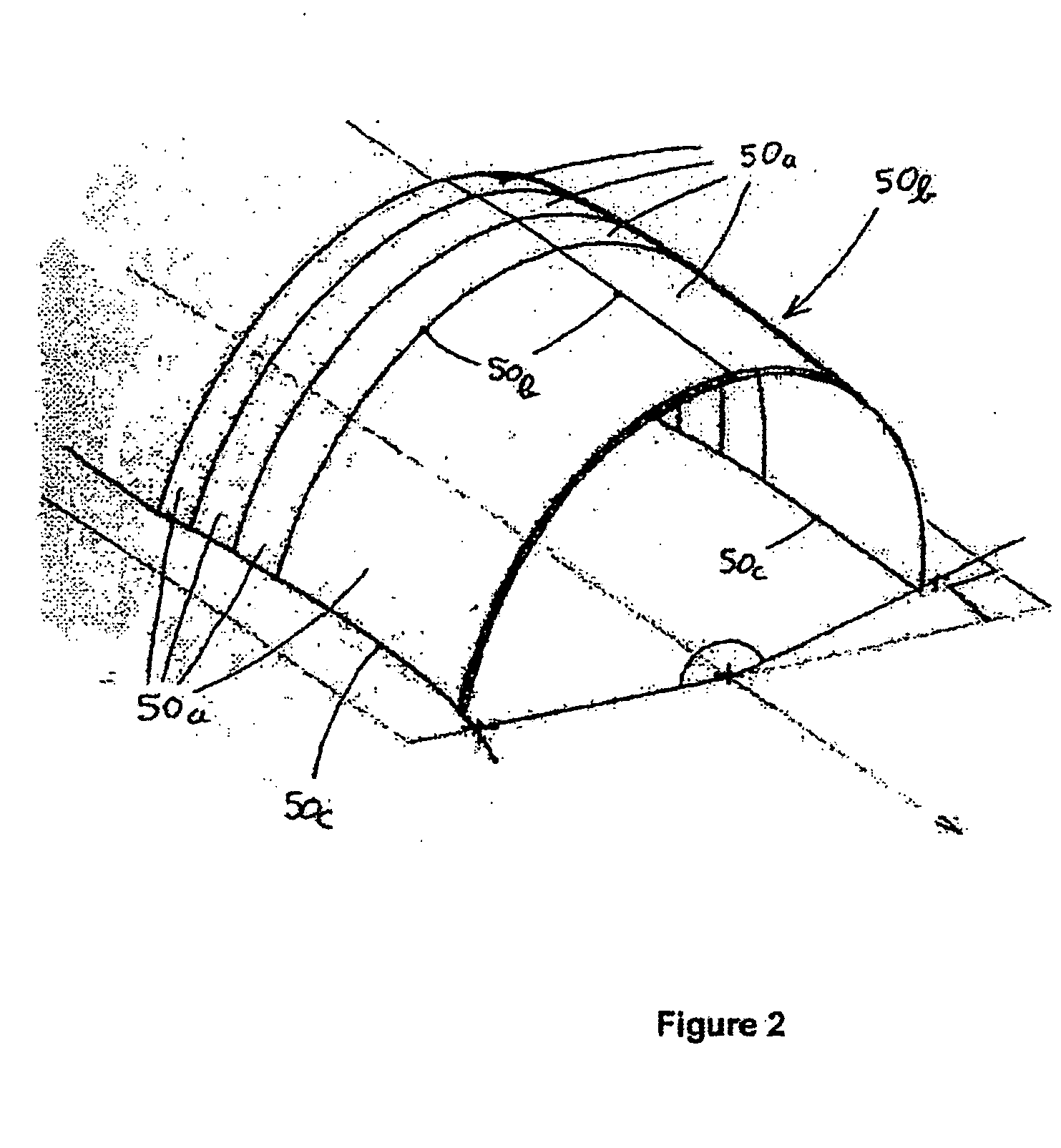

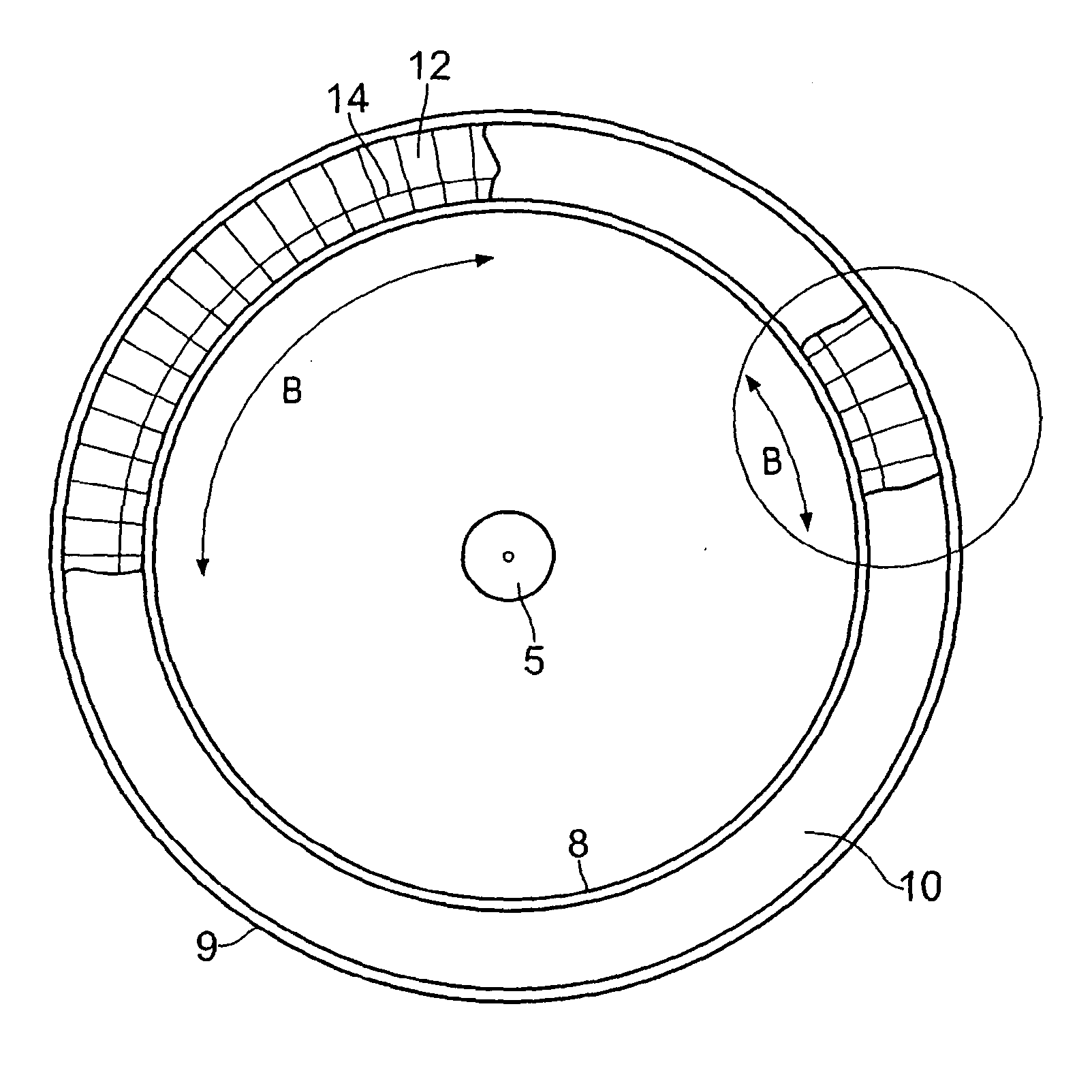

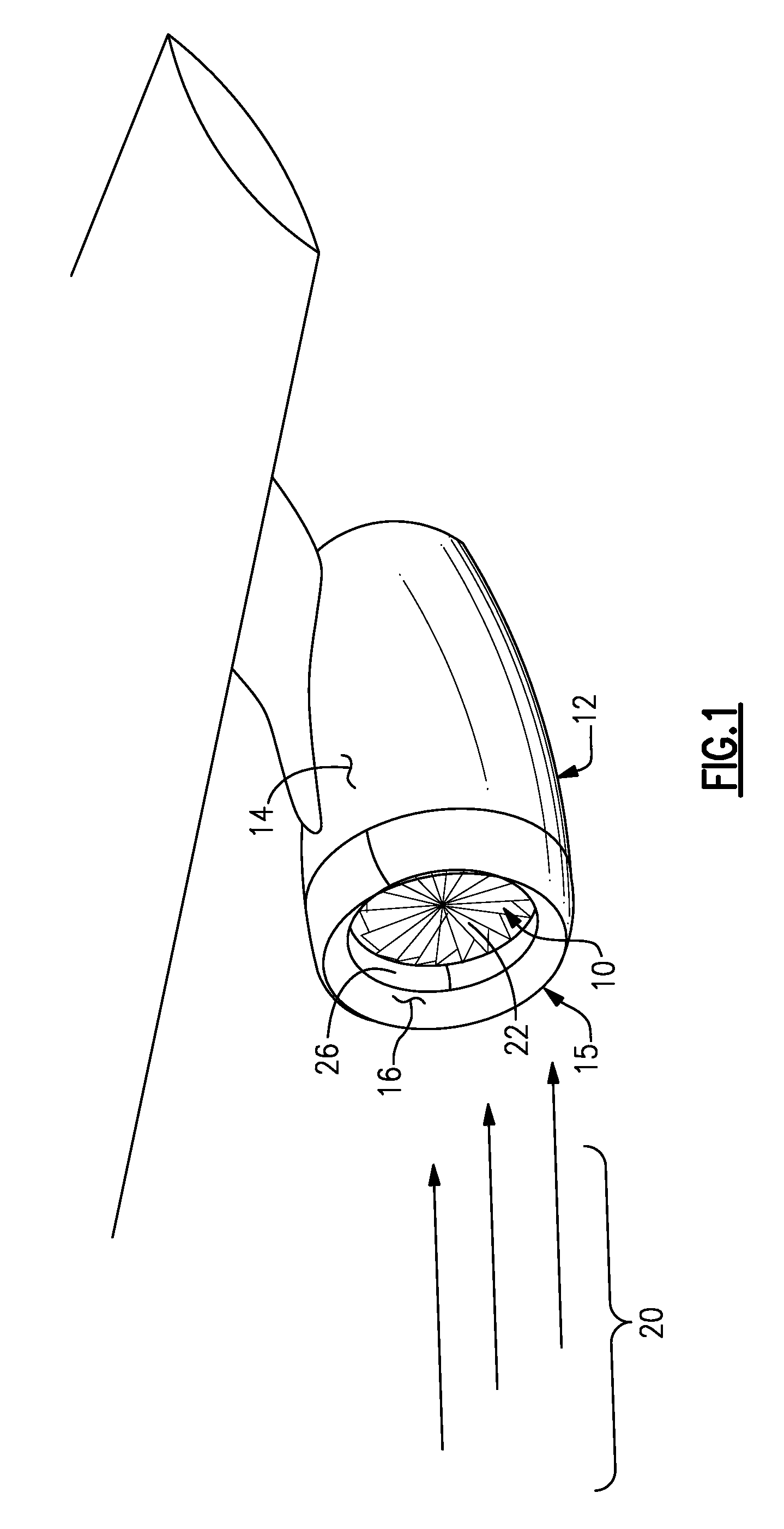

Annular acoustic panel

InactiveUS6920958B2Reduce noiseIncreasing noise absorption qualityNoise reduction installationsEngine fuctionsNacelleEngineering

An aircraft engine assembly is provided that is adapted to reduce noise produced by an engine included in the engine assembly. The engine assembly includes a nacelle having an inlet section and a main section that is houses the engine and fan assembly associated with the engine. The inlet section is coupled to the main section at a main bulkhead junction between the inlet section and the main section. A one piece annular acoustic panel is located within a recess in an internal wall of the nacelle. The annular acoustic panel extends from a forward portion of the inlet section to a forward portion of the main section such that the bulkhead is covered by the annular acoustic panel.

Owner:THE BOEING CO

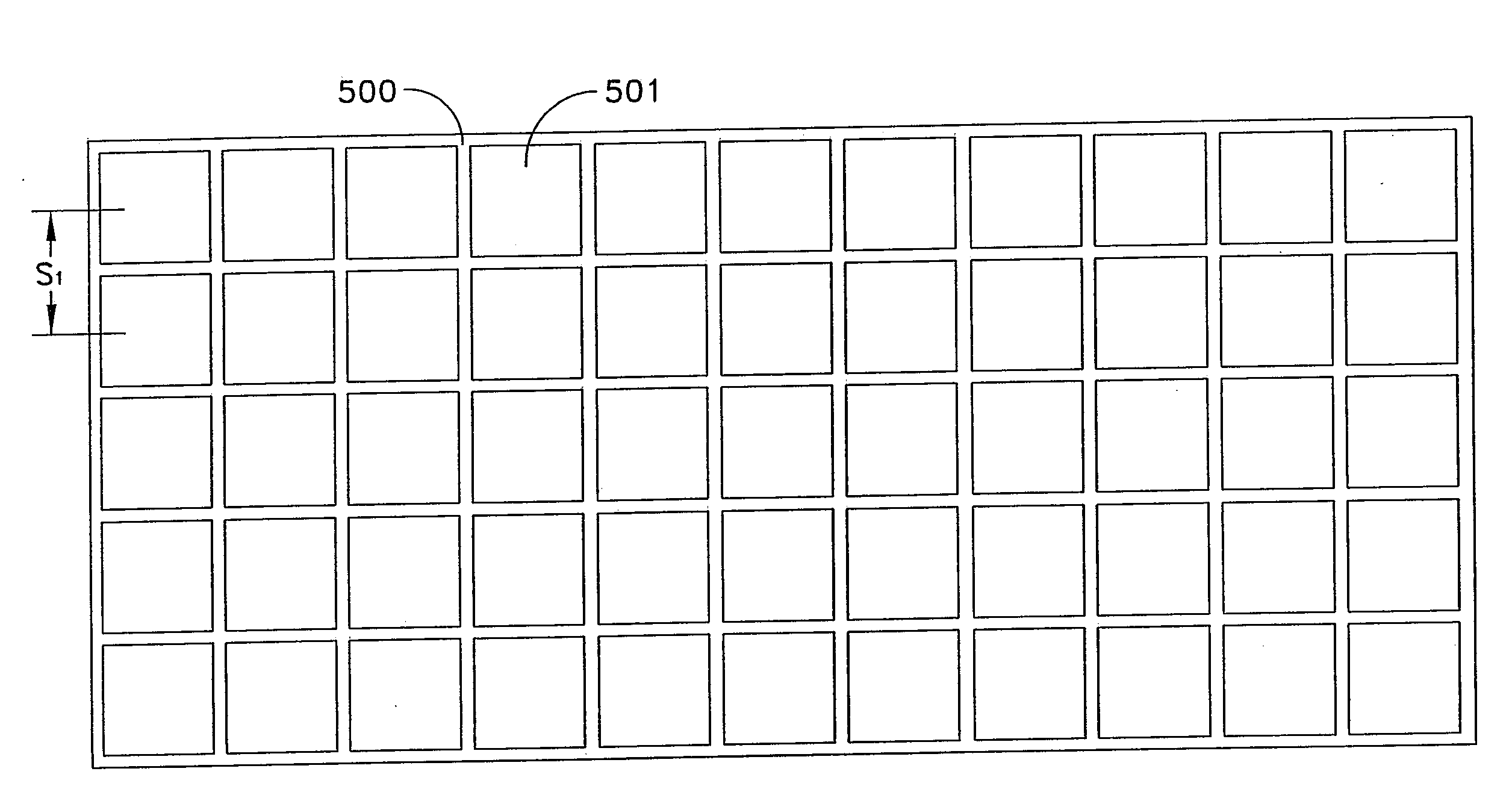

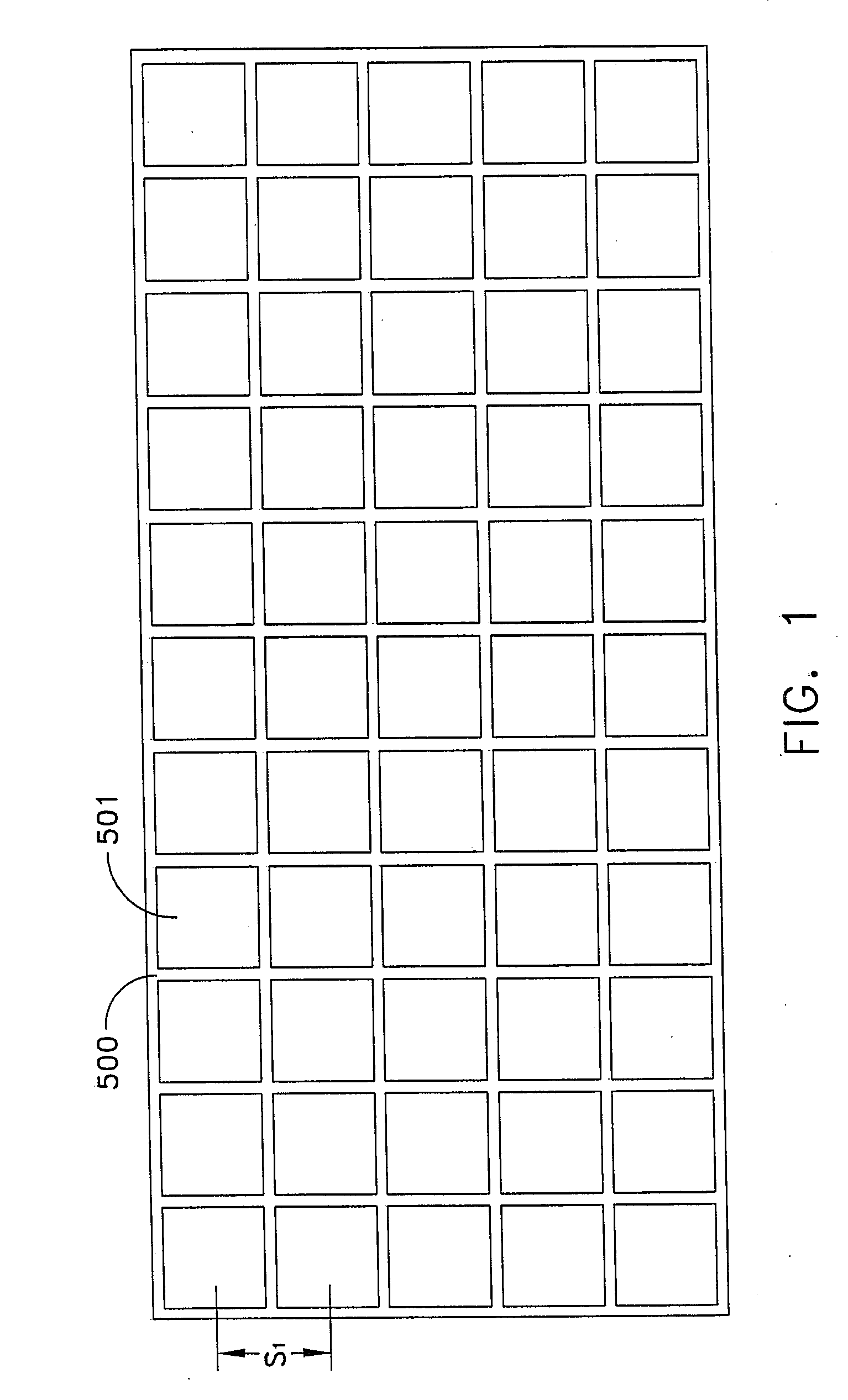

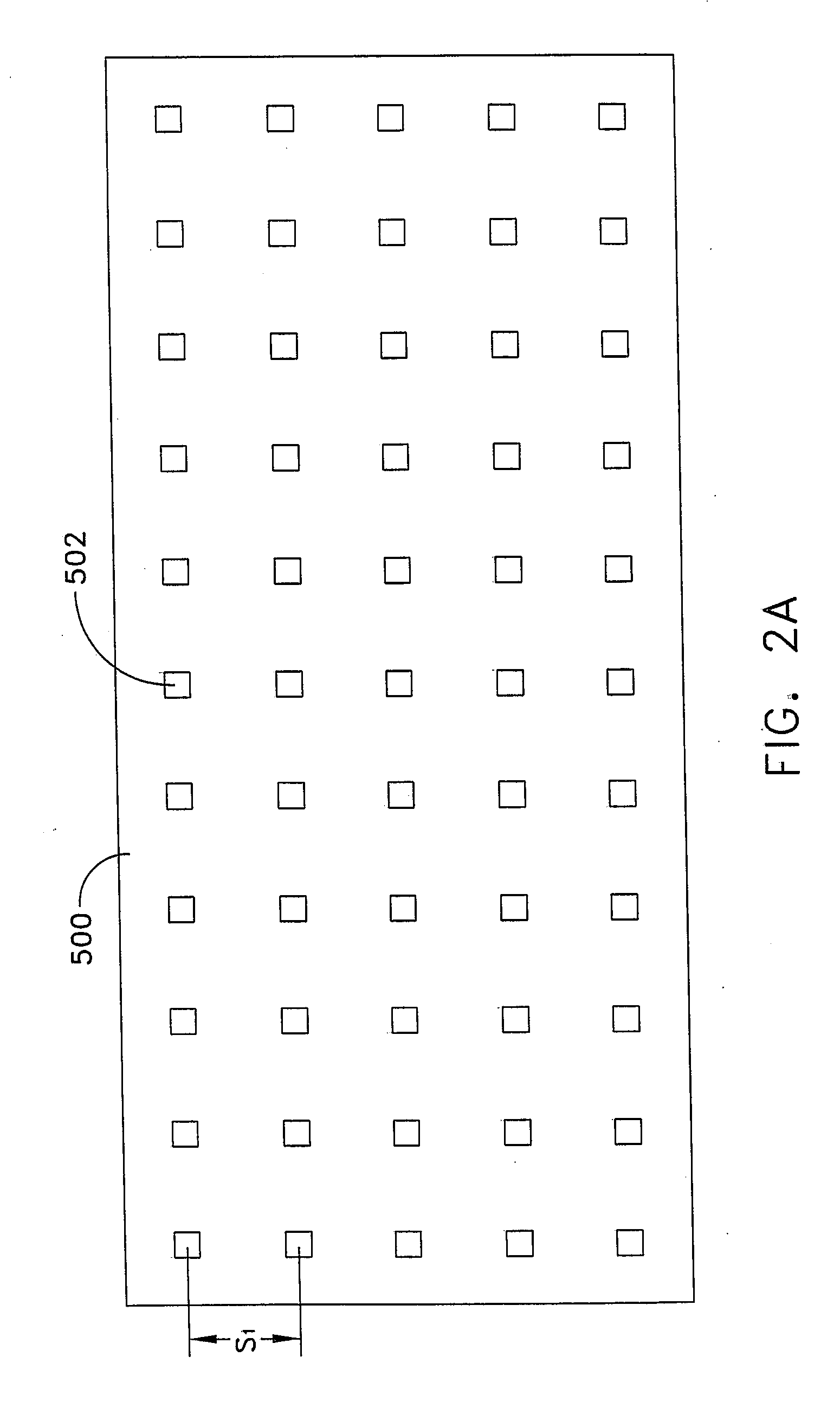

Lightweight acoustic array

ActiveUS20080316866A1CeilingsPiezoelectric/electrostrictive transducersAcoustic arrayAcoustic energy

An acoustic transducer array and method of baffle construction is presented to provide an improved array for use in underwater installations. The array is presented wherein a significant majority of the acoustic energy receiving surface is formed by lightweight acoustic baffling material while still maintaining a fully functional, fully populated array. The acoustic baffle constructed is incompressible and suitable for deep water operation while demonstrating both improved acoustic performance and positive buoyancy when necessary. In addition, the invention eliminates the non-uniform element to element spacing that occurs between sub-panels in similar arrays.

Owner:LOCKHEED MARTIN CORP

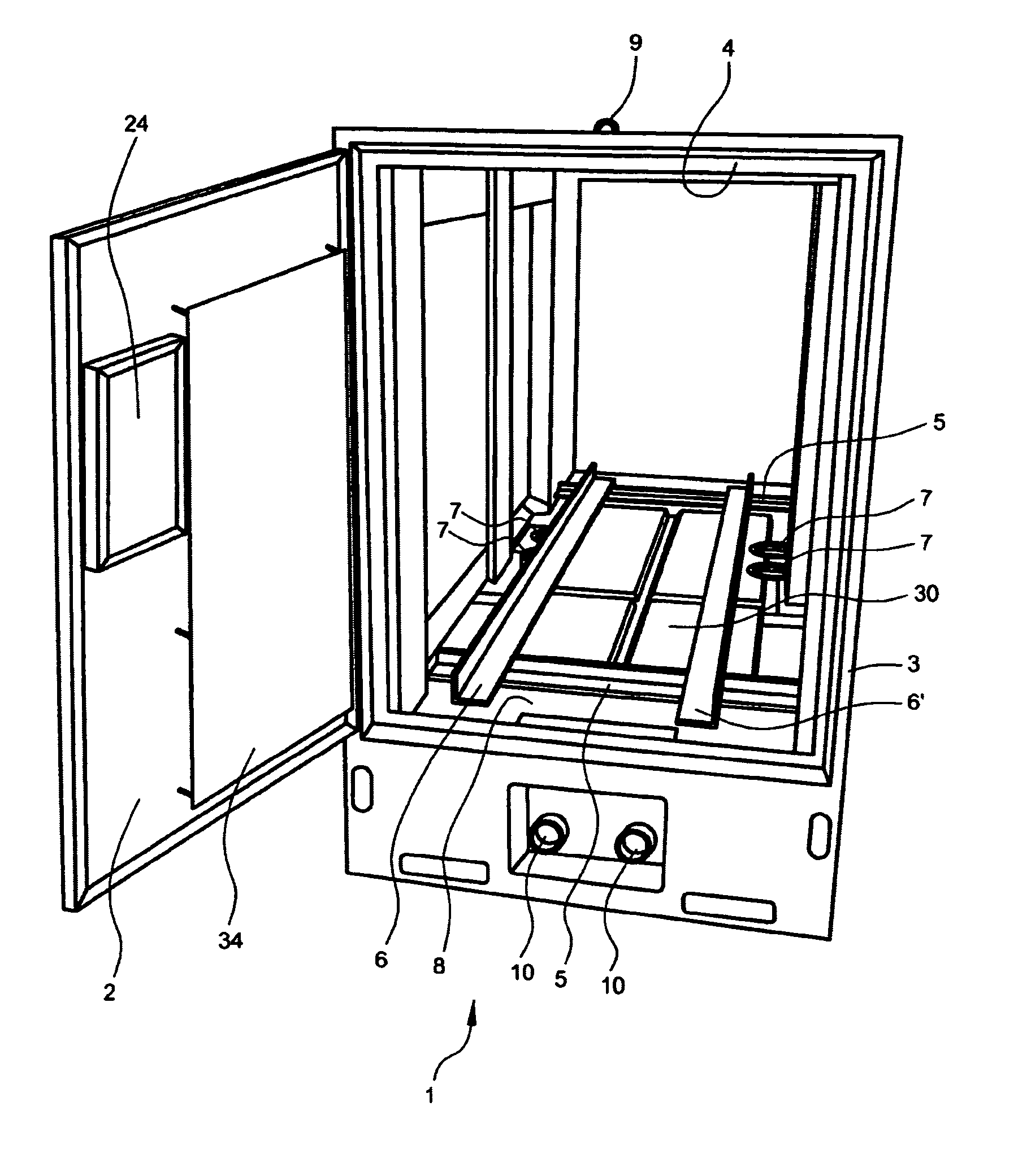

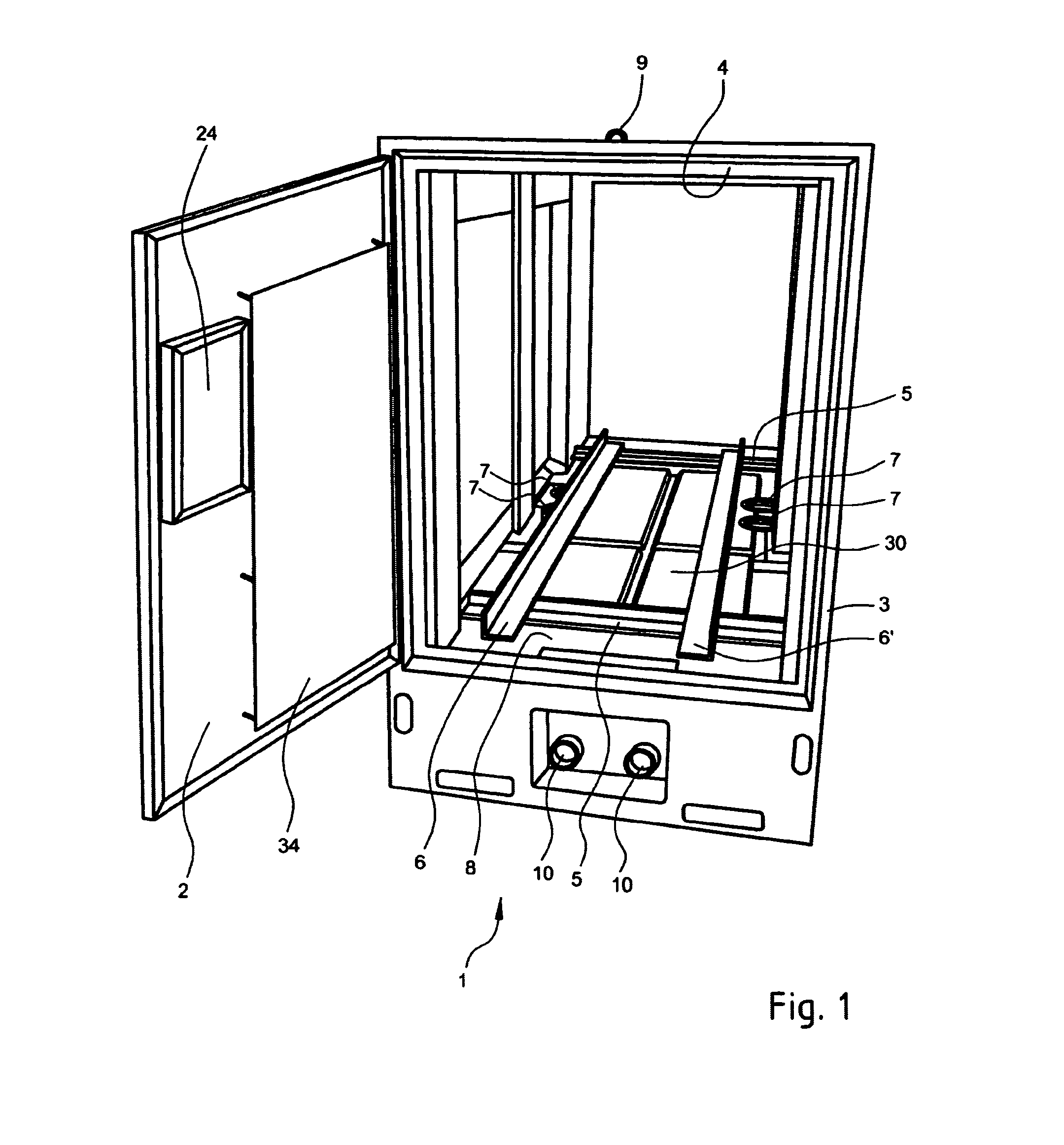

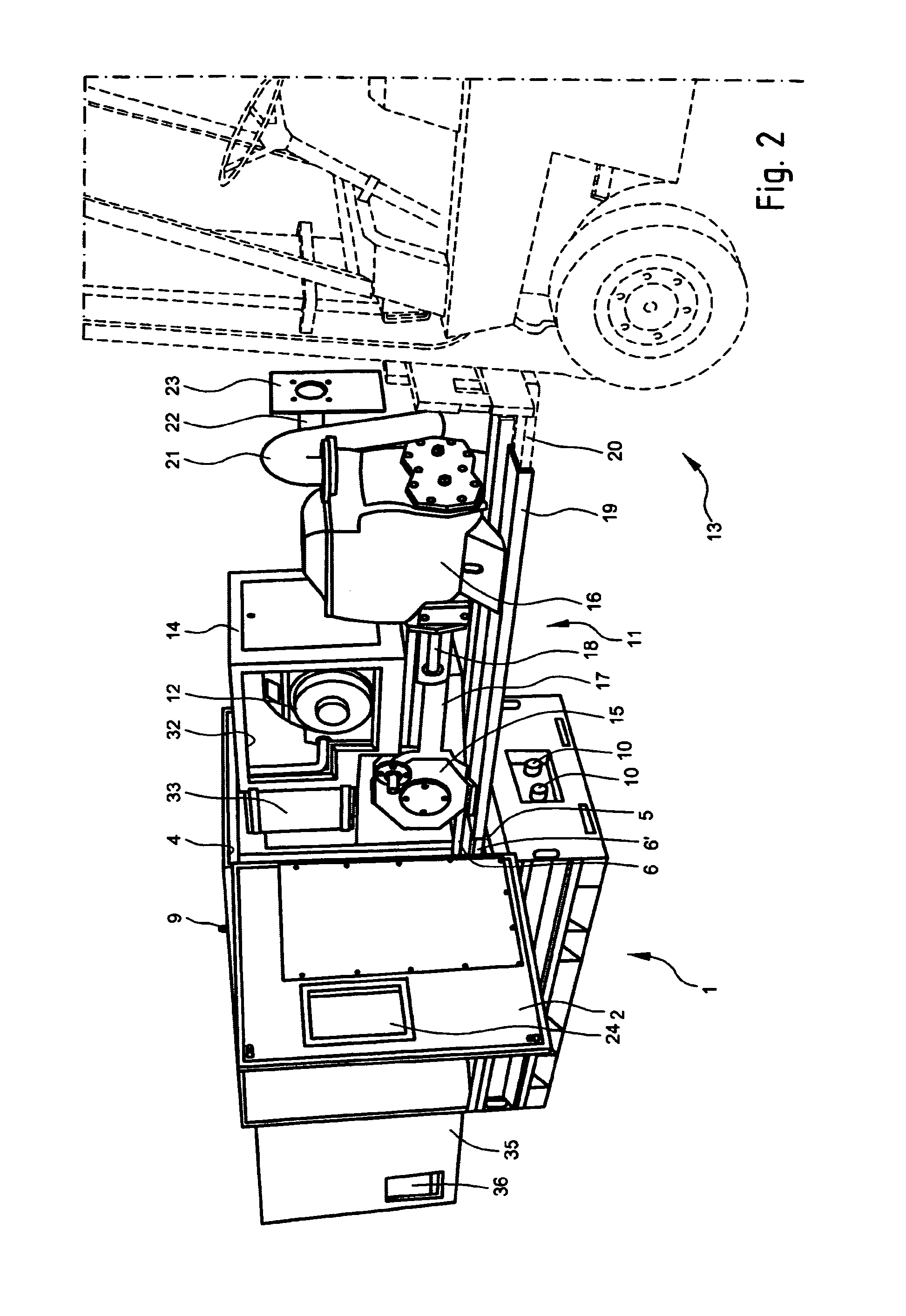

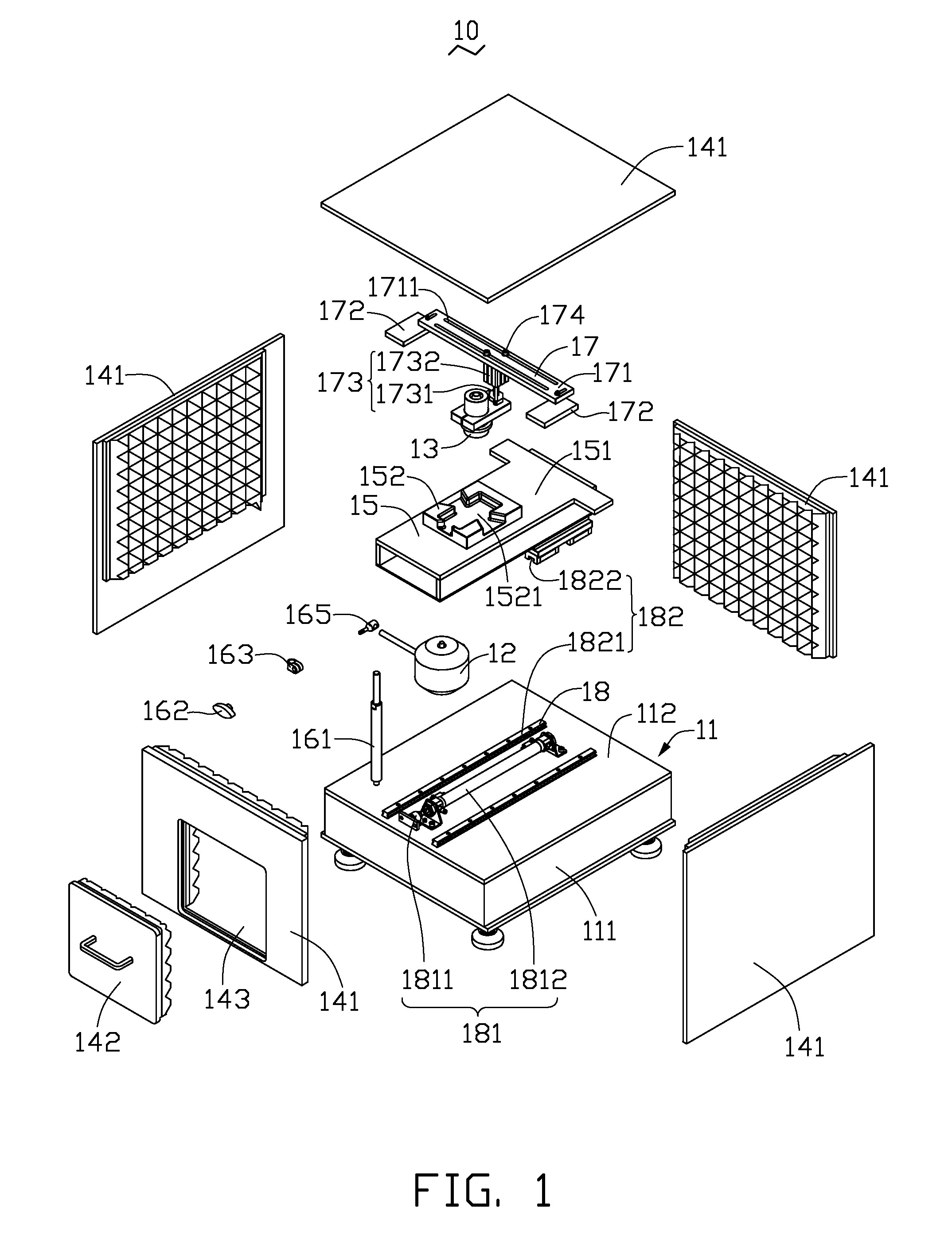

Sound-damping housing for a pump and for a drive motor for said pump

ActiveUS8727068B2The way is simple and fastEasy accessPlural diverse prime-mover propulsion mountingAir cleaners for fuelDamp housingEngineering

Sound-damping housing for a pump and for a drive motor for said pump, comprising a block-like casing assembled from sound-damping panels and provided with a support construction and a first door opening for successively placing into and removing from the casing the pump and its drive motor on the support construction, and with at least one guide extending over the support construction transversely of the door opening for the purpose of guiding a pump and its drive motor to be placed in the casing.

Owner:B B A PARTICIPATIES

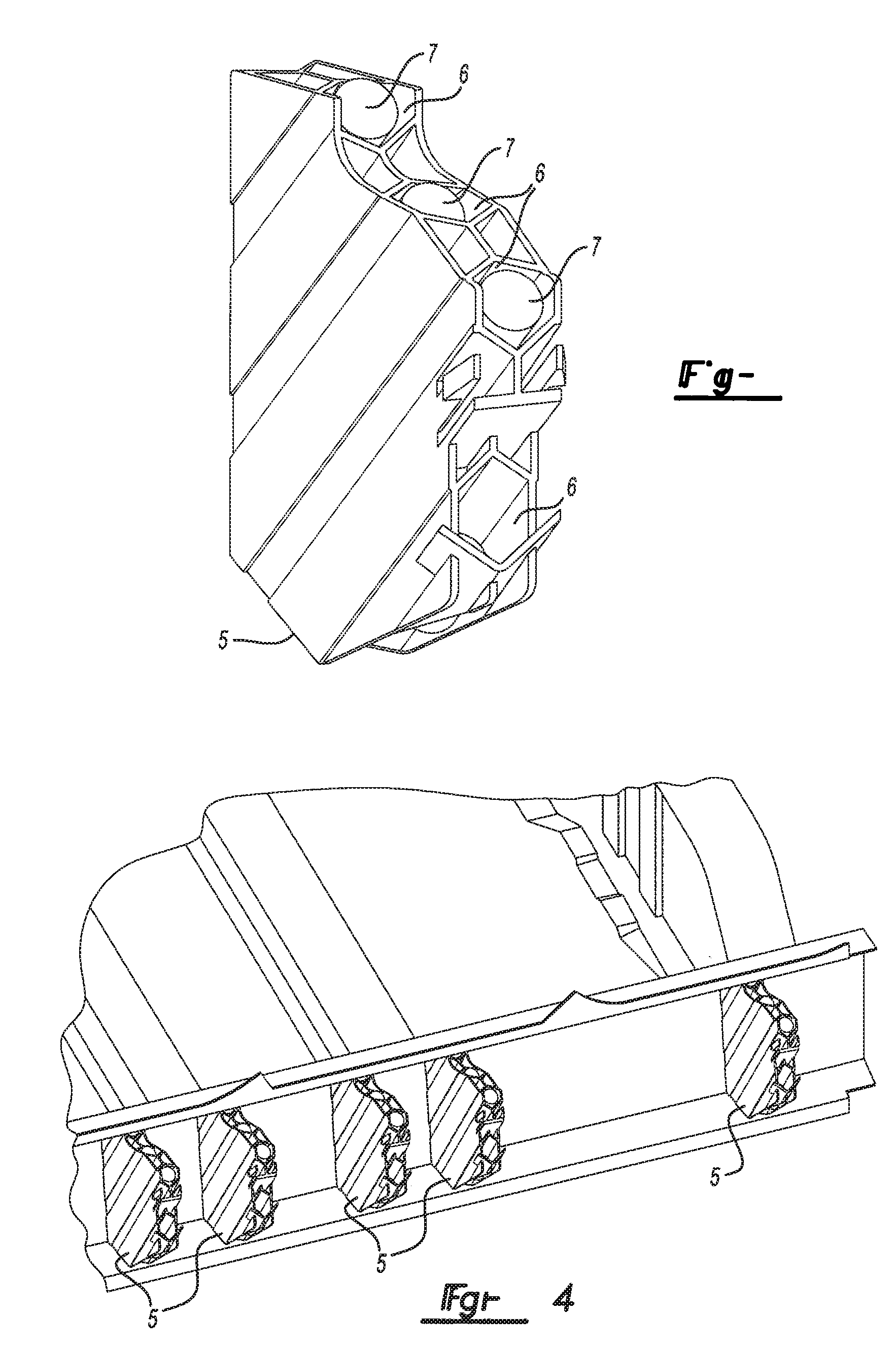

Components

Components useful for the provision of structural reinforcement of hollow profiles and / or sealants and / or acoustic baffles are provided. The components comprise a carrier in which is formed a plurality of cavities for receipt of foamable material, the foam may then be foamed to bridge the gap between the carrier and the internal surface of the hollow profile to form a bond there between. Different types of foam may be employed in different cavities to provide a multifunctional component.

Owner:ZEPHYROS INC

Method for making a soundproofing panel with at least one double resonator

InactiveUS20050147790A1Solution value is not highMore automatedLayered productsEfficient propulsion technologiesHoneycombEngineering

The invention concerns a method for making a soundproofing panel with at least one double resonator used for example on pods enclosing aircraft turbojets. Said method is characterized in that the septum is formed by assembling a plurality of parts against one of the honeycomb cores, said parts being cut out in foil, said parts being defined to enable the shape of the septum to be more or less adapted to extensible surfaces, said parts enabling significant reduction of the cost for perforating the septum.

Owner:AIRCELLE

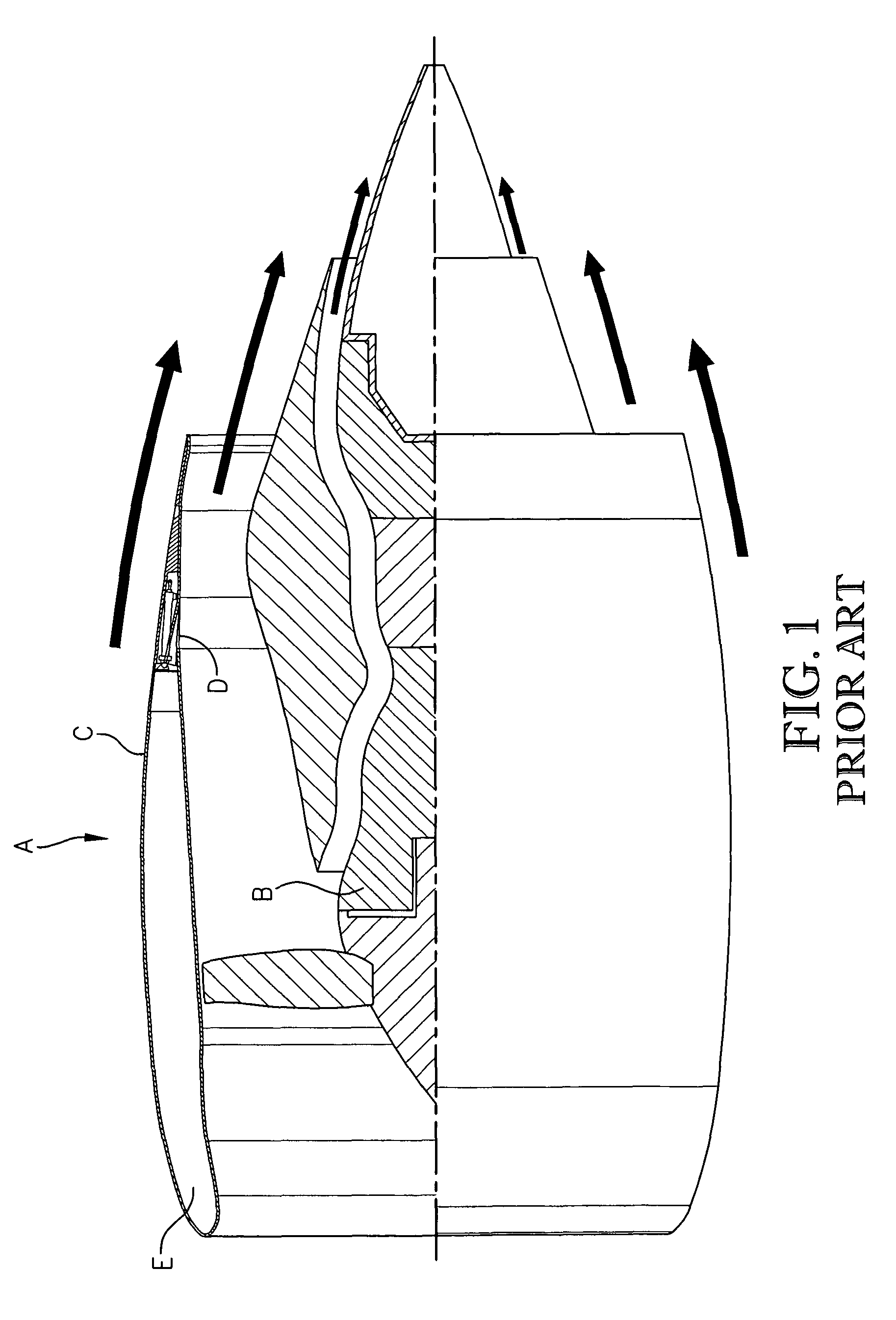

Engine inlet deep acoustic liner section

An inlet of an aircraft nacelle having an acoustic barrel configured to reduce engine fan flutter by attenuating various frequencies. The acoustic barrel may comprise an acoustic panel of a honeycomb configuration sandwiched between a first back sheet and a face sheet and extending from a forward bulkhead to an aft bulkhead of the inlet. The acoustic barrel may further comprise a deep liner section bonded to and sandwiched between the first back sheet and a second back sheet. The deep liner section may have a narrower width than the acoustic panel and may be located proximate the aft bulkhead. The sections of the first back sheet, the face sheet, and a septum of the acoustic panel may be perforated and may contain additional holes formed in portions aligned radially inward of the deep liner section.

Owner:ROLLS ROYCE DEUT LTD & CO KG

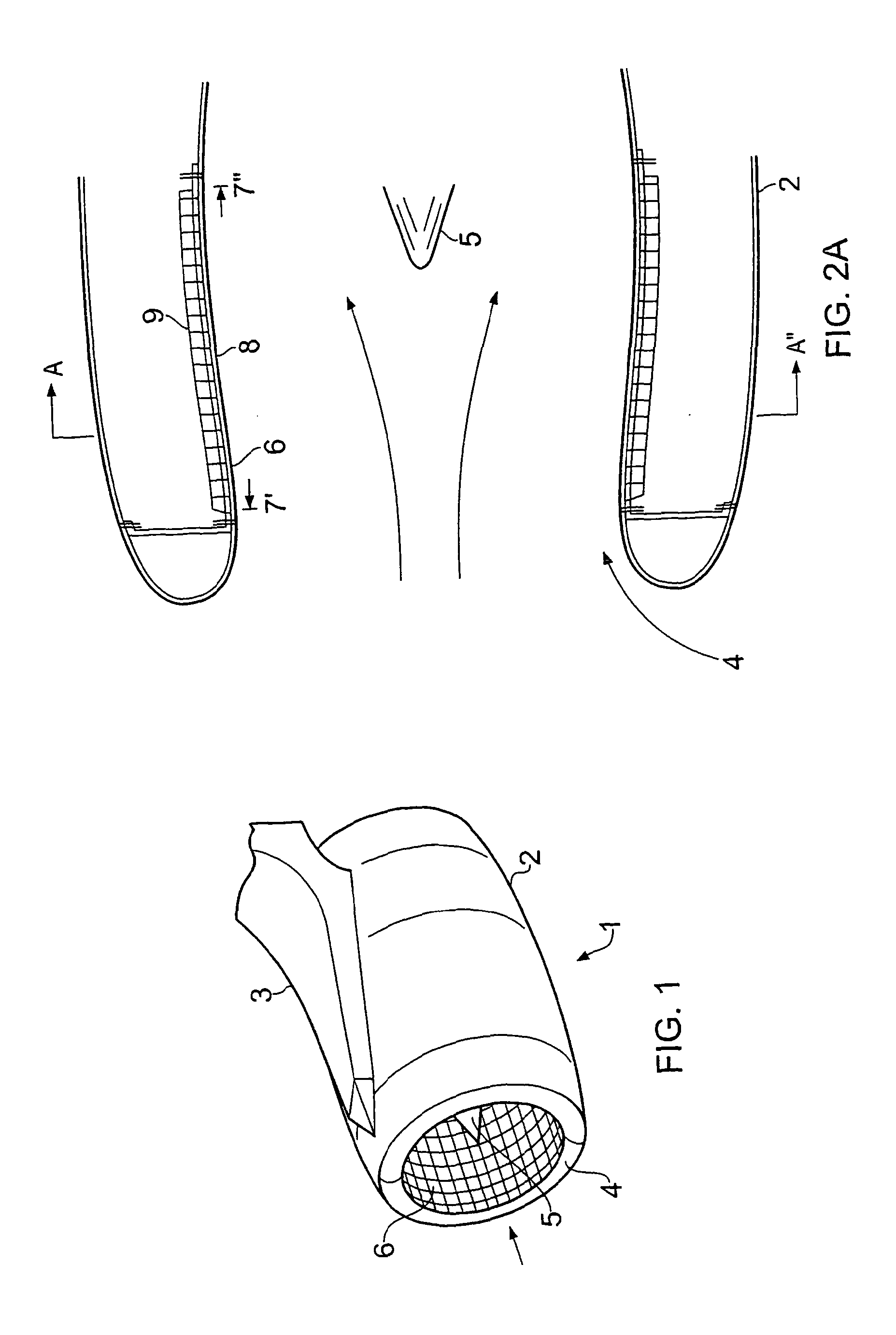

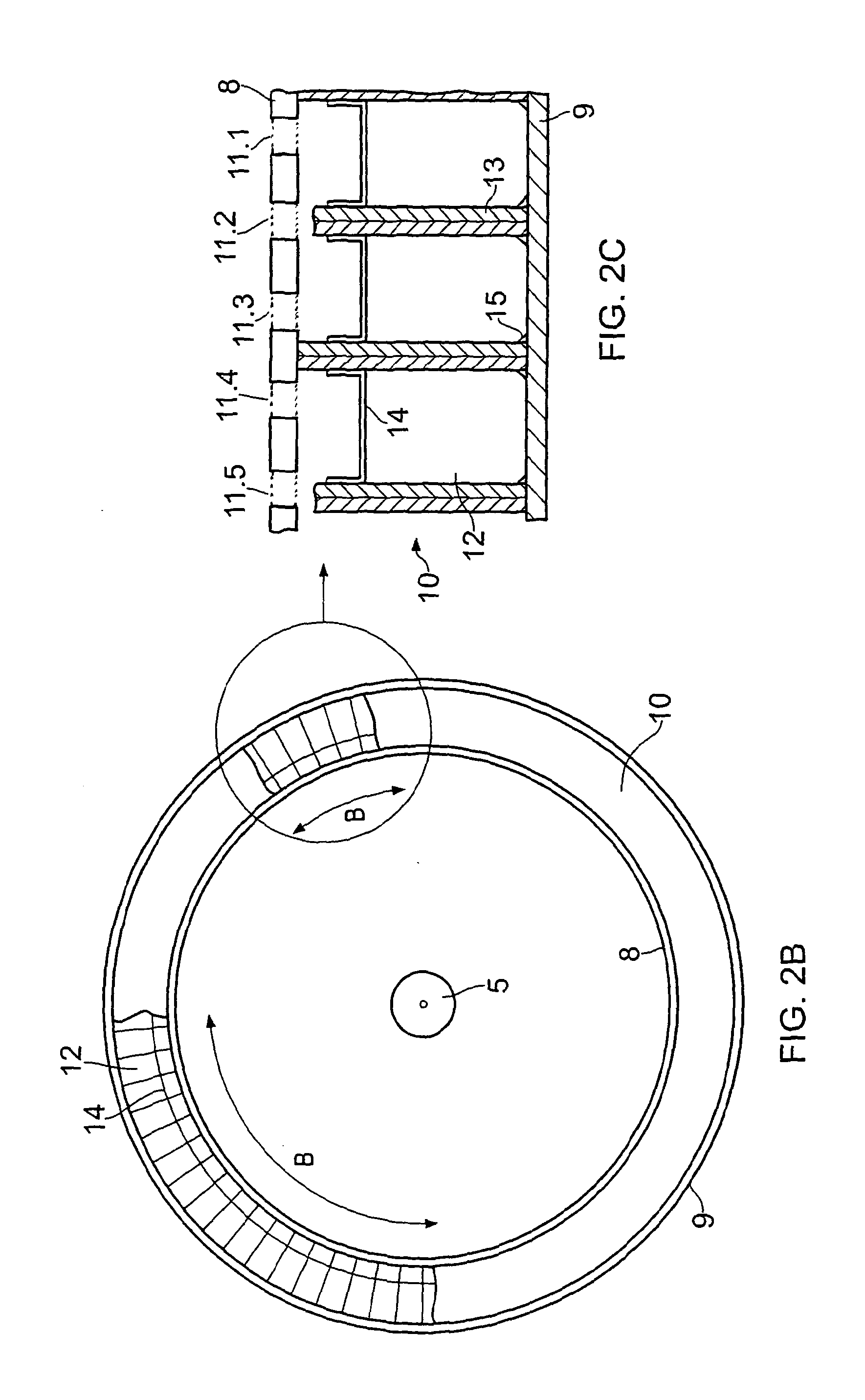

Seamless acoustic liner

ActiveUS20130075193A1Add partsAvoid introducingCeilingsTurning machine accessoriesEngineeringTurbine

The invention relates to a method of manufacturing a composite acoustic panel employed in an inlet passage of a gas turbine engine (1). The acoustic panel comprises a permeable face-layer (8), an impermeable backing sheet (9) and a sound absorbing layer (10) disposed therebetween. The method comprises a double polymerisation process for the face-layer and the remainder of the acoustic panel and finally a perforation step to perforate the face-layer according to a pre-determined perforation distribution (11.1, 11.2, 11.3, 11.4, 11.5).

Owner:GKN AEROSPACE SERVICES LTD

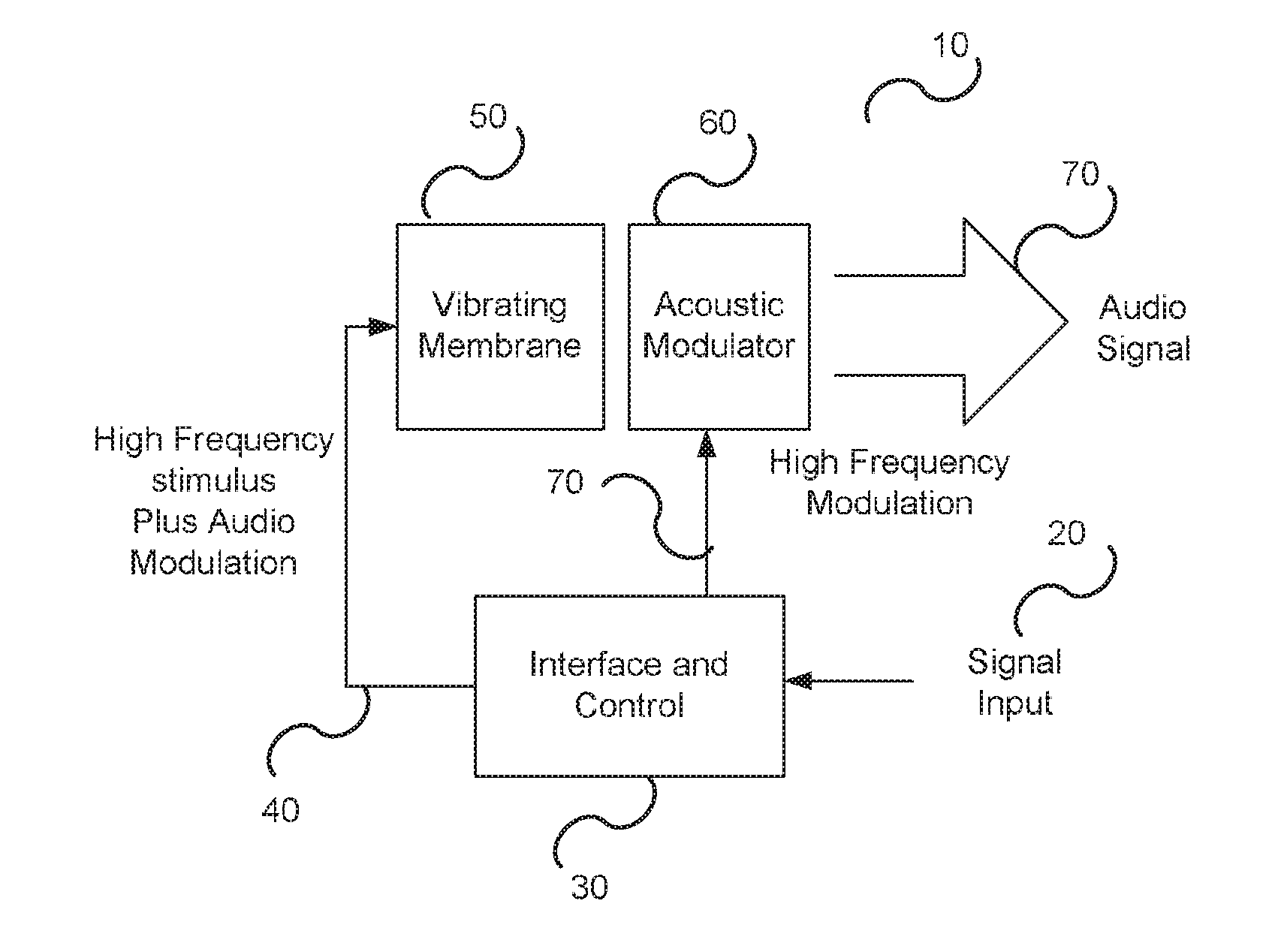

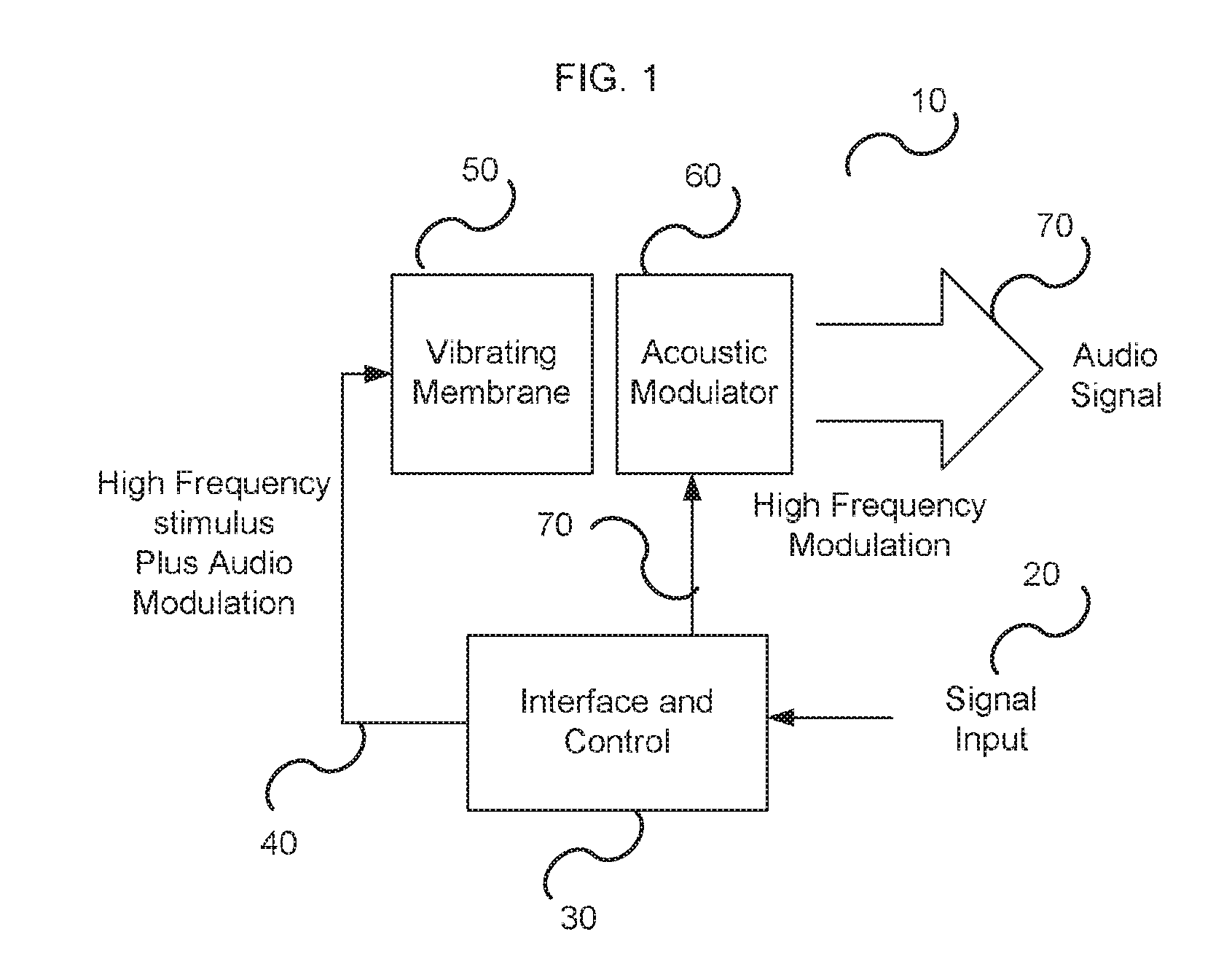

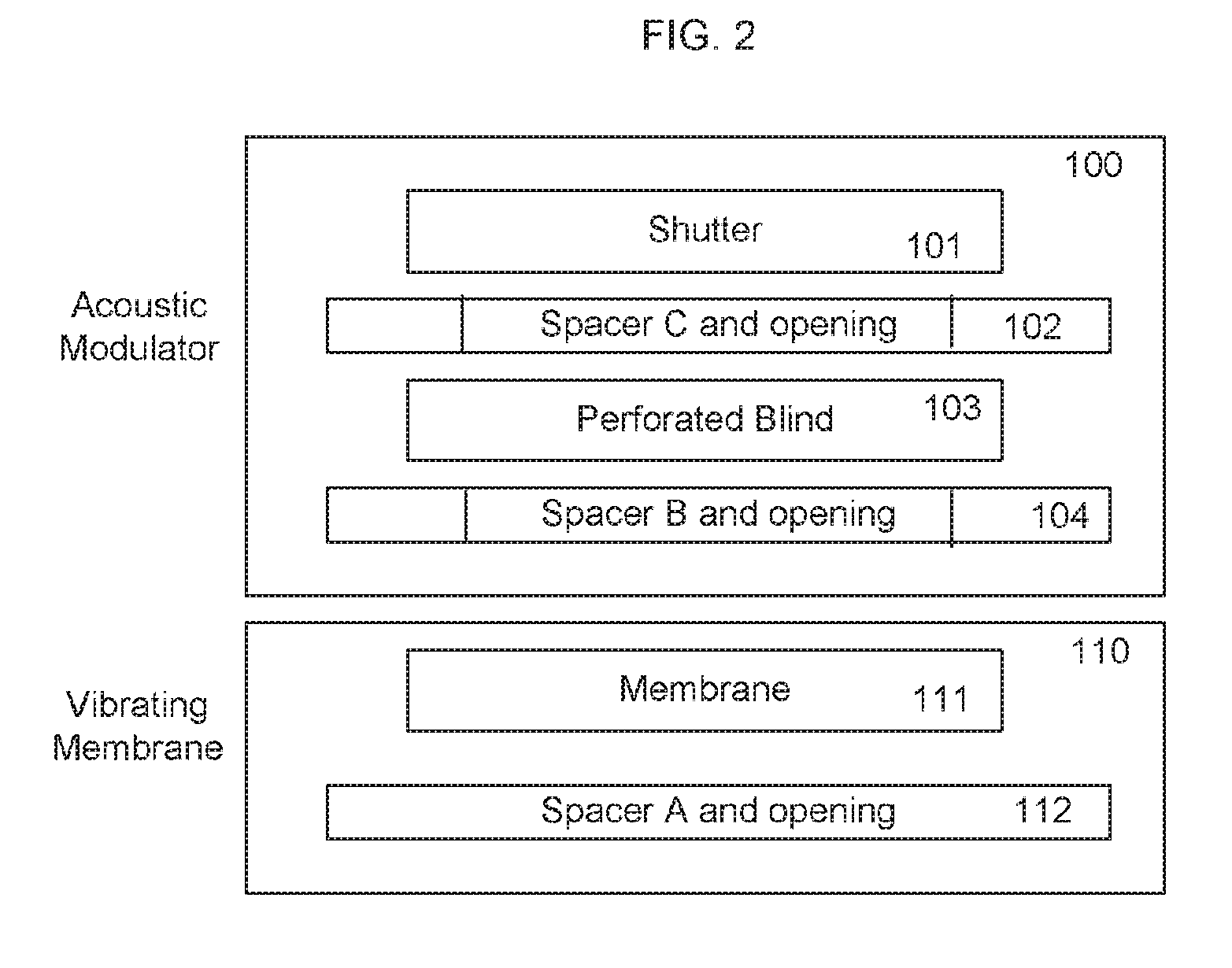

Two port speaker acoustic modulator

InactiveUS20160381464A1Piezoelectric/electrostrictive transducersElectrostatic transducer loudspeakersSonificationLow distortion

A two-port air pump speaker that includes at least two active, phase-modulated, bi-directional shutters and an ultrasonic pumping chamber having at least two ports; a first port facing towards the listener, the forward port, and a second port facing another direction, the backward port which may be behind an acoustic baffle or inside a speaker enclosure. A two-port speaker with two active steering shutters can create continuous bi-directional airflow which leads to low distortion reproduction of low audio frequencies. The same improved design can be used also for other applications where acoustic modulation is required, especially in ultrasonic frequencies.

Owner:DSP GROUP

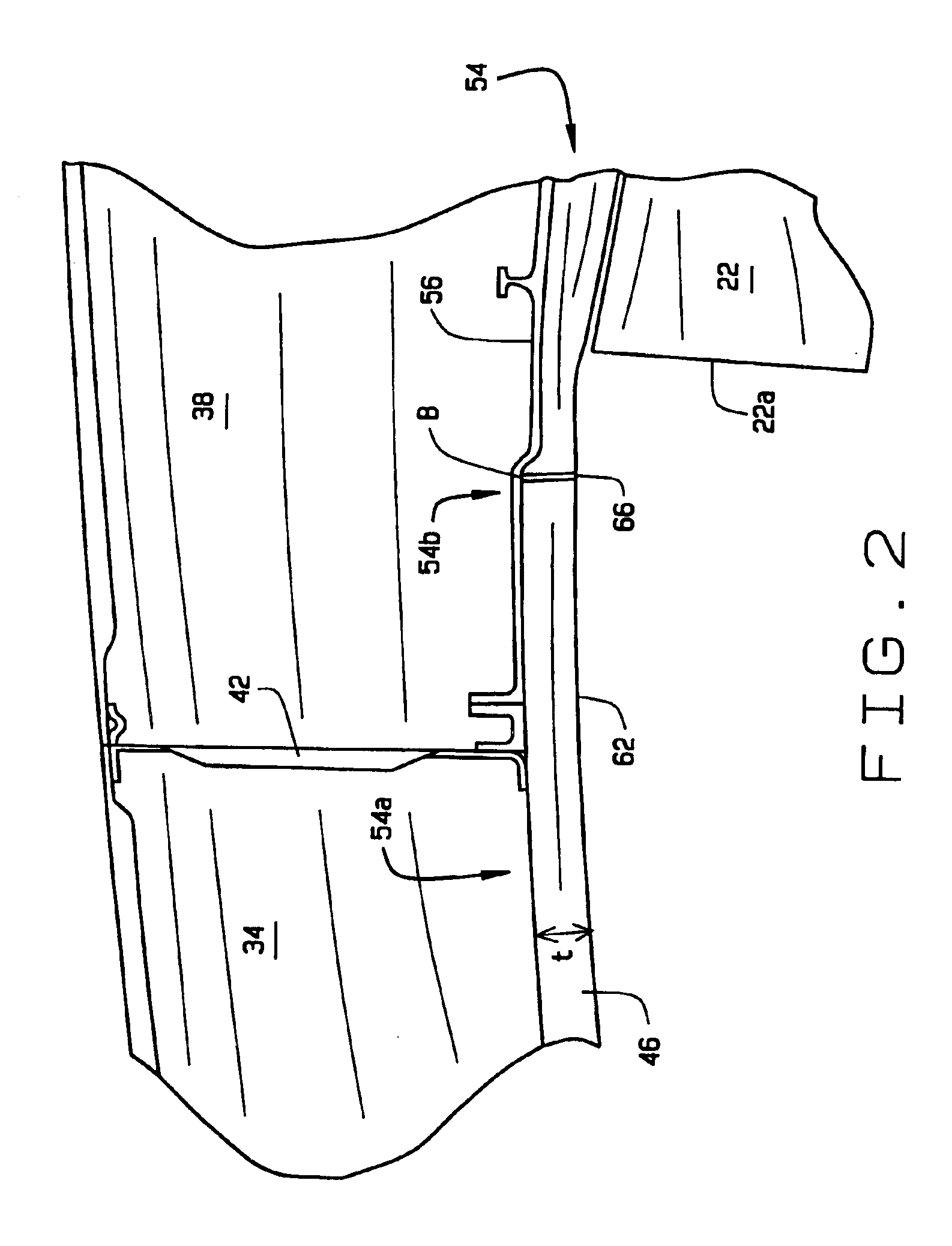

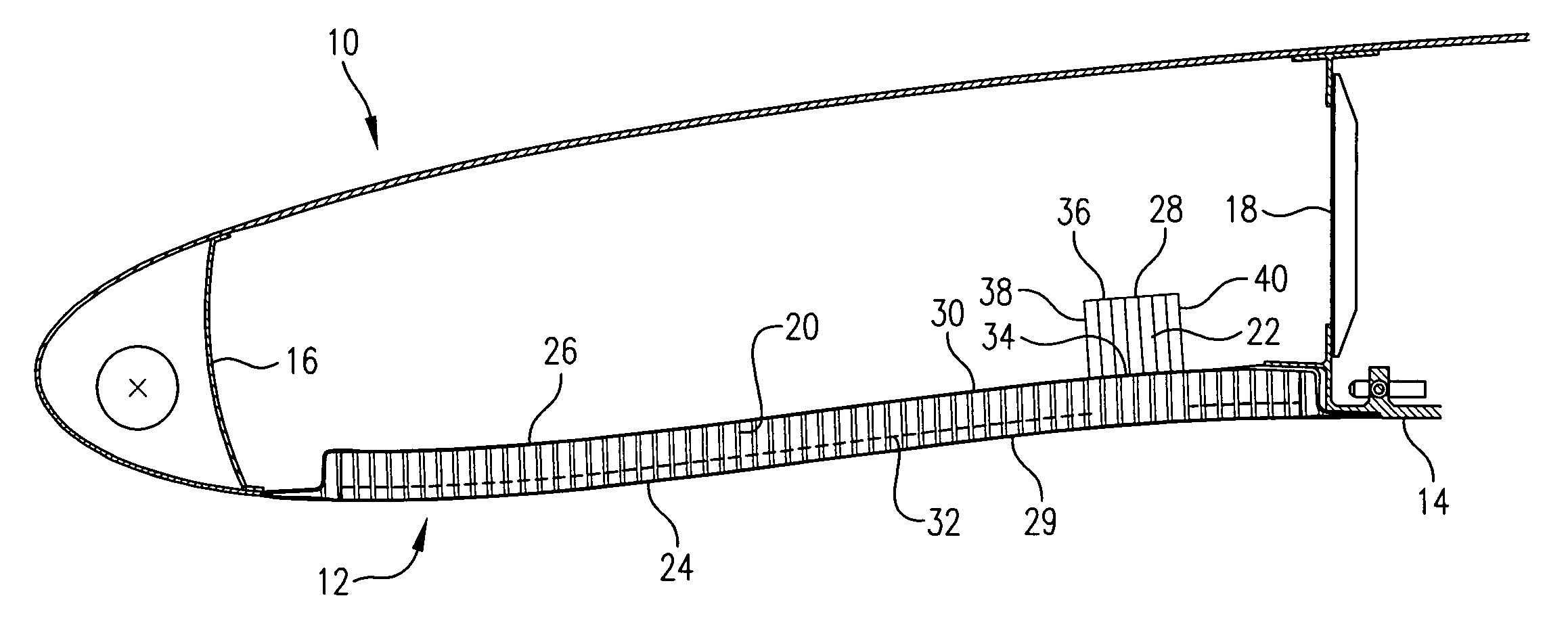

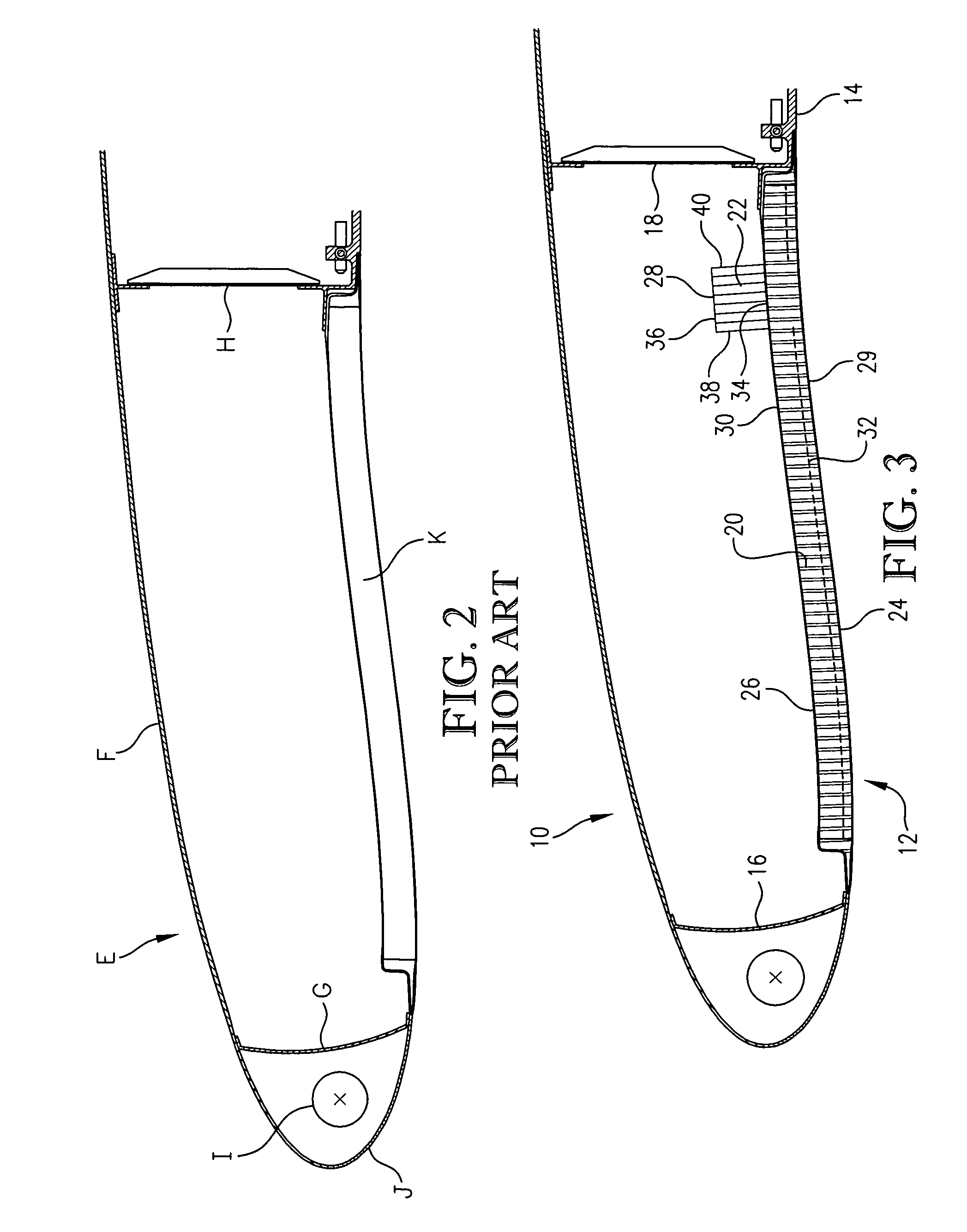

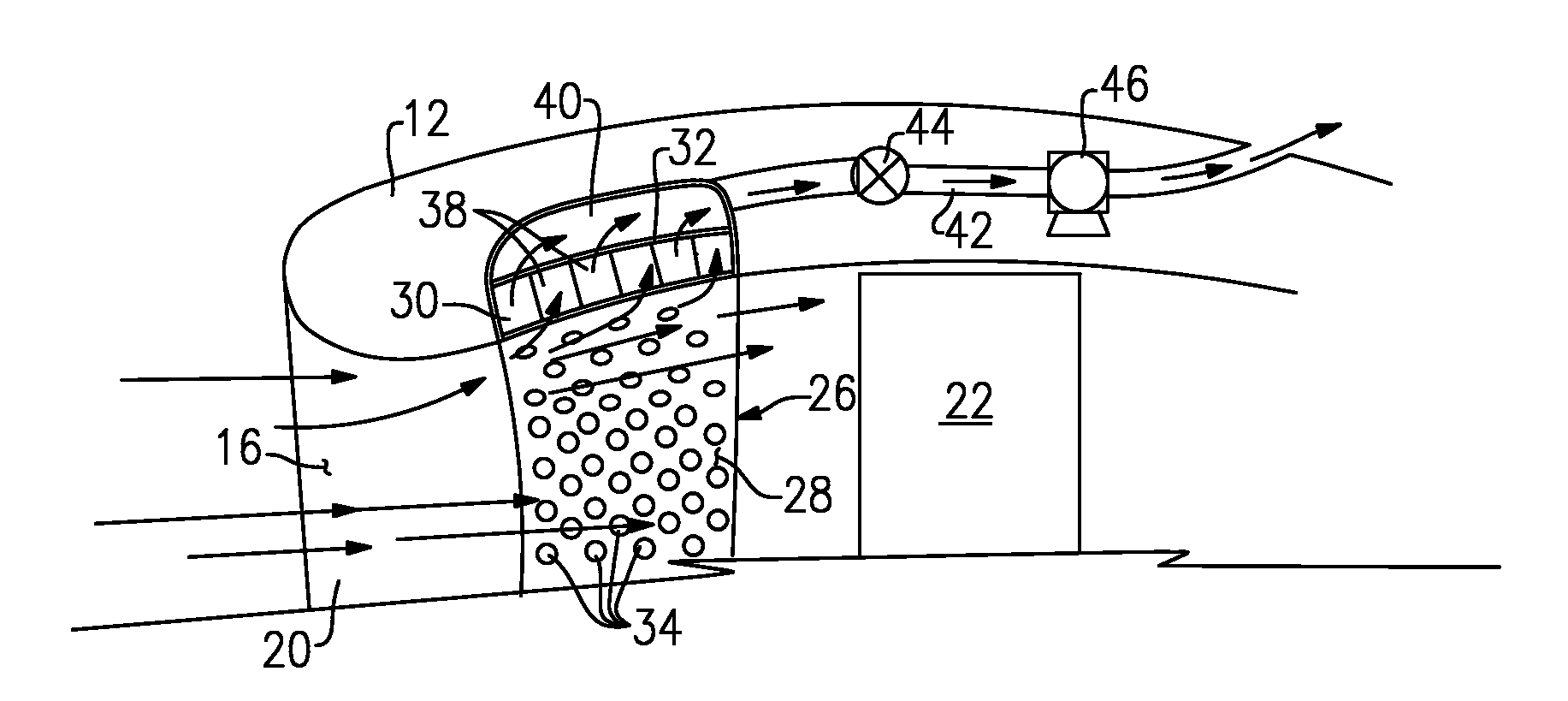

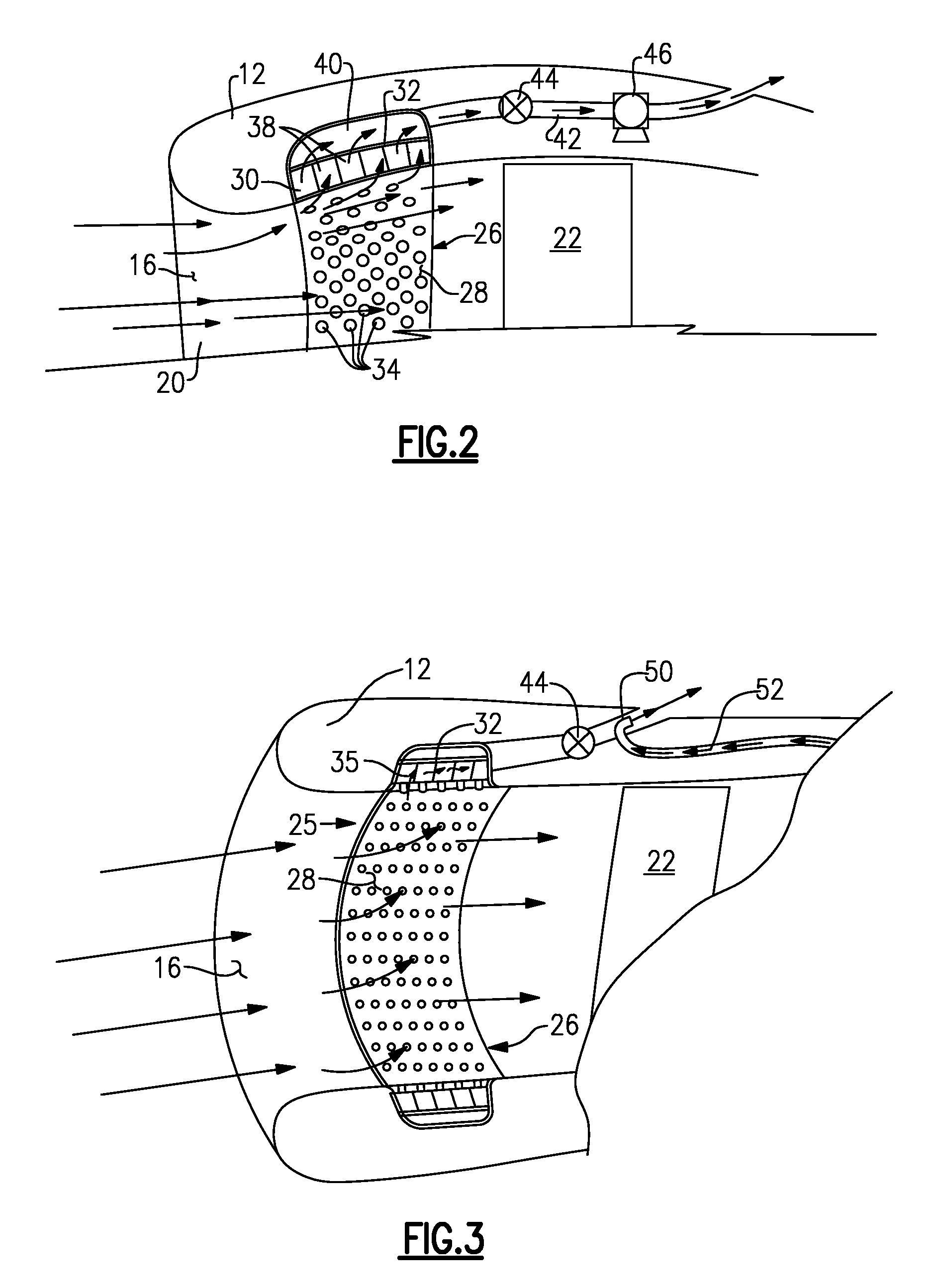

Integral suction device with acoustic panel

InactiveUS20080296439A1Avoid separationLower performance requirementsEngine fuctionsWingsNacelleControl system

An inlet flow control system disposed within a nacelle includes a panel on an inner surface of that nacelle. The panel includes a noise attenuation layer that dissipates noise energy. A vacuum source generates a pressure differential across the noise attenuation layer for drawing airflow through the panel and away from an inner surface of the nacelle.

Owner:RAYTHEON TECH CORP

Decoration acoustic absorption sheet material of tripolite and method for producing the same

InactiveCN101428999AWith sound absorption and sound insulationMoisture-adjusting and anti-cleaning lotionFiberAcoustic absorption

The invention discloses a diatomite decorative acoustic board, which belongs to the field of building material. The invention solves the problems that the prior porous acoustic material has low acoustical absorptivity to middle and low frequencies, a mineral wool acoustic board pollutes the environment and so on. The board consists of 70 to 80 weight percent of diatomite, 18 to 25 weight percent of gypsum, 1 to 3 weight percent of pigment, 0.9 to 1.5 weight percent of adhesive, and 0.1 to 0.5 weight percent of fiber; the content of SiO2 in the diatomite is more than 85 percent, and the white content is more than 82; and the white content of the gypsum is more than 90 degrees. The method for preparing the board comprises the following steps: solid materials, namely the diatomite, the gypsum, the adhesive, the pigment and the fiber are added into a mortar mixer to be stirred for 20 to 30min, water which accounts for 1 to 1.5 times of the amount of the solid materials is added into the mixture after the mixture is stirred evenly to be prepared into uniform slurry, the slurry is cast into board molds with different specifications, and the mold stripping and drying are performed after 24h of maintenance. The board has functions of sound absorption and sound insulation, humidity conditioning and dewing prevention, fire resistance and flame retardation, thermal insulation, environmental protection, beautiful decoration, high strength, light mass, easy installation, convenient maintenance and so on, and is suitable for mass production.

Owner:北京大地远通(集团)有限公司 +1

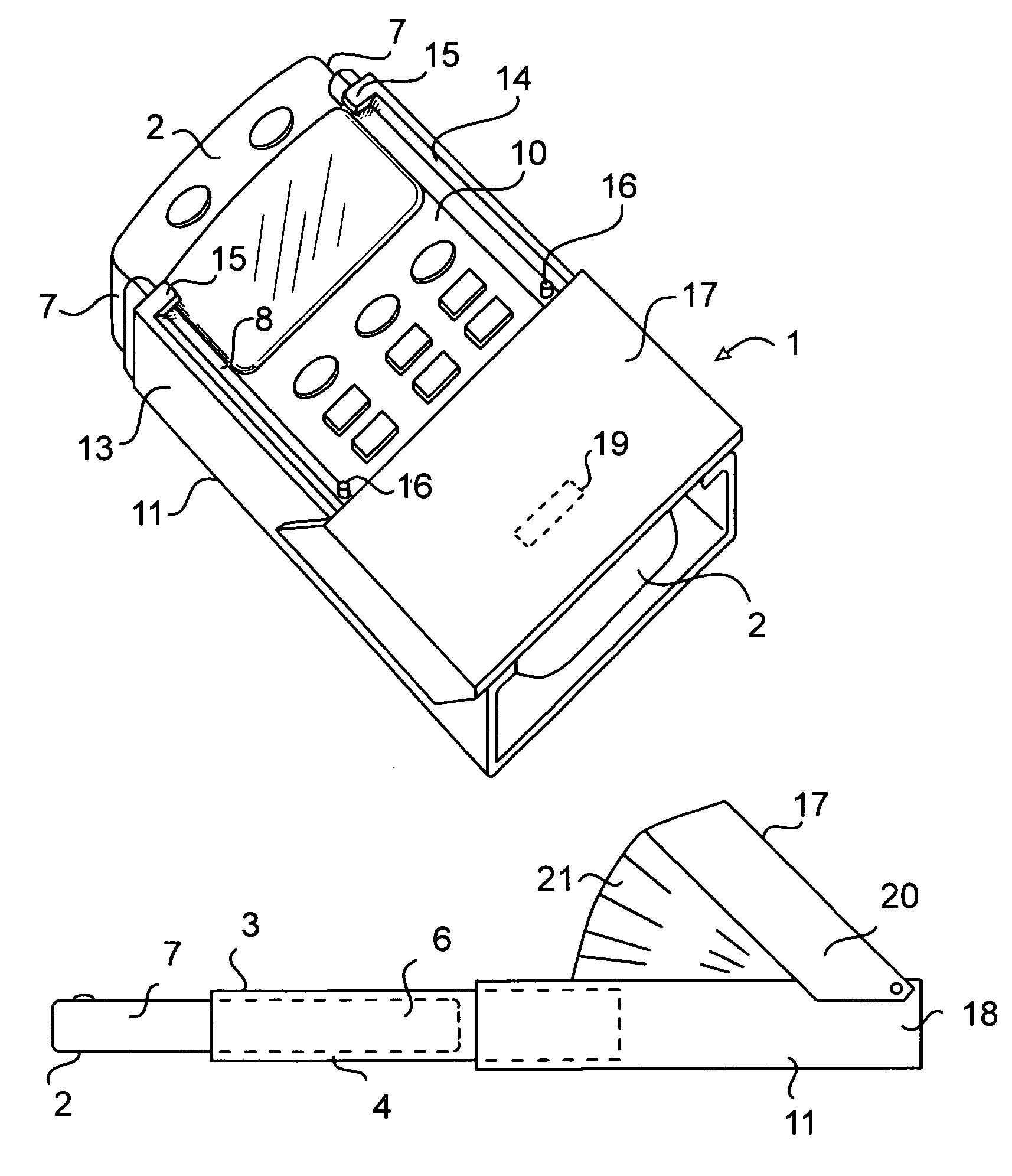

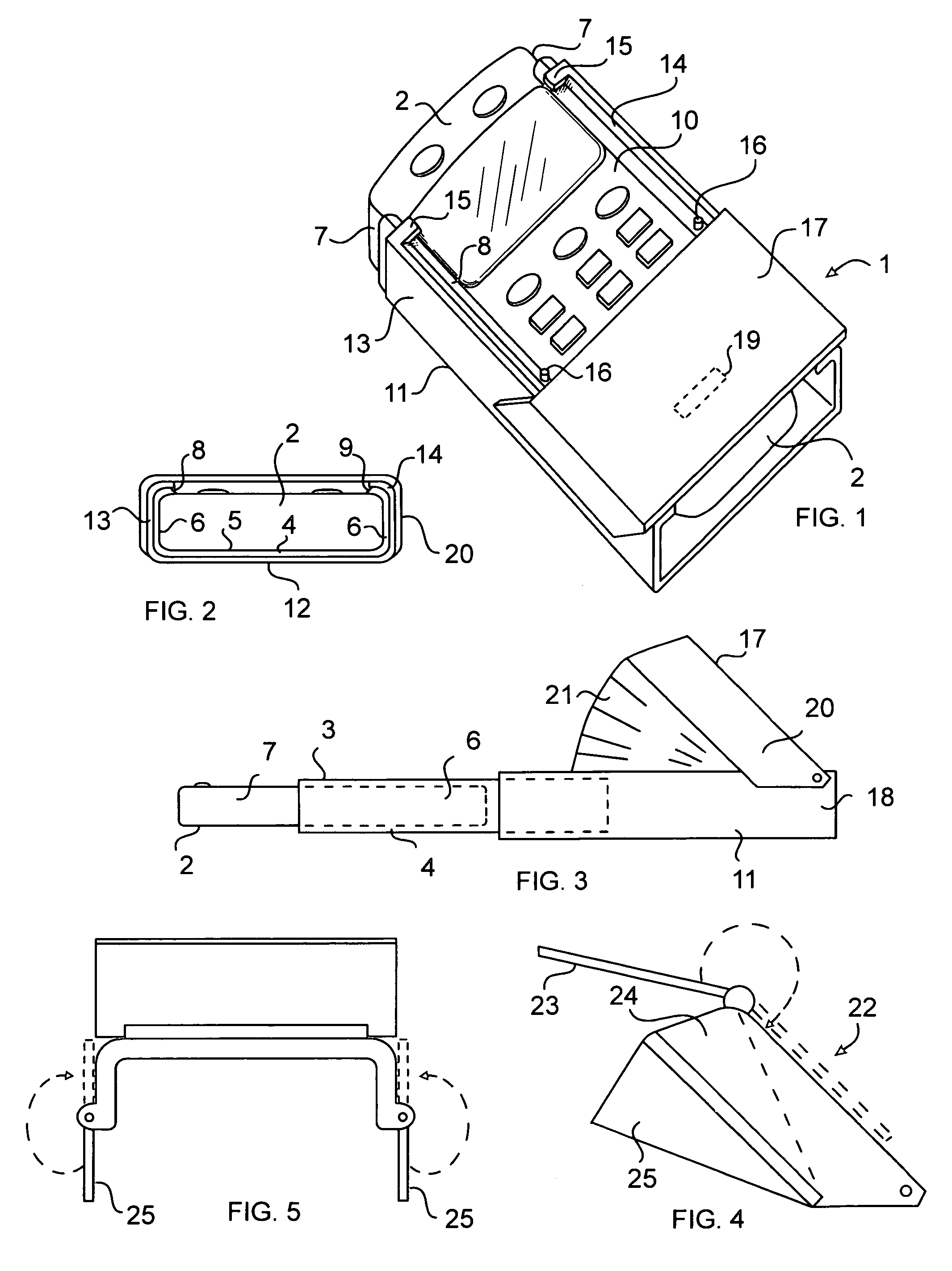

Sound baffle for portable telephone handset

InactiveUS7197140B2Lower the volumePromote densificationInterconnection arrangementsTelephone set constructionsSound baffleEngineering

A sound baffle attached to a telephone handset comprises a pair of telescopically connected members shaped and dimensioned to act as a sound guide in combination with a reflecting cover plate that can be obliquely adjusted to direct the sound waves emitted by the user toward the handset microphone, and to muffle his conversation to the surroundings for improved privacy.

Owner:ASARO V FRANK

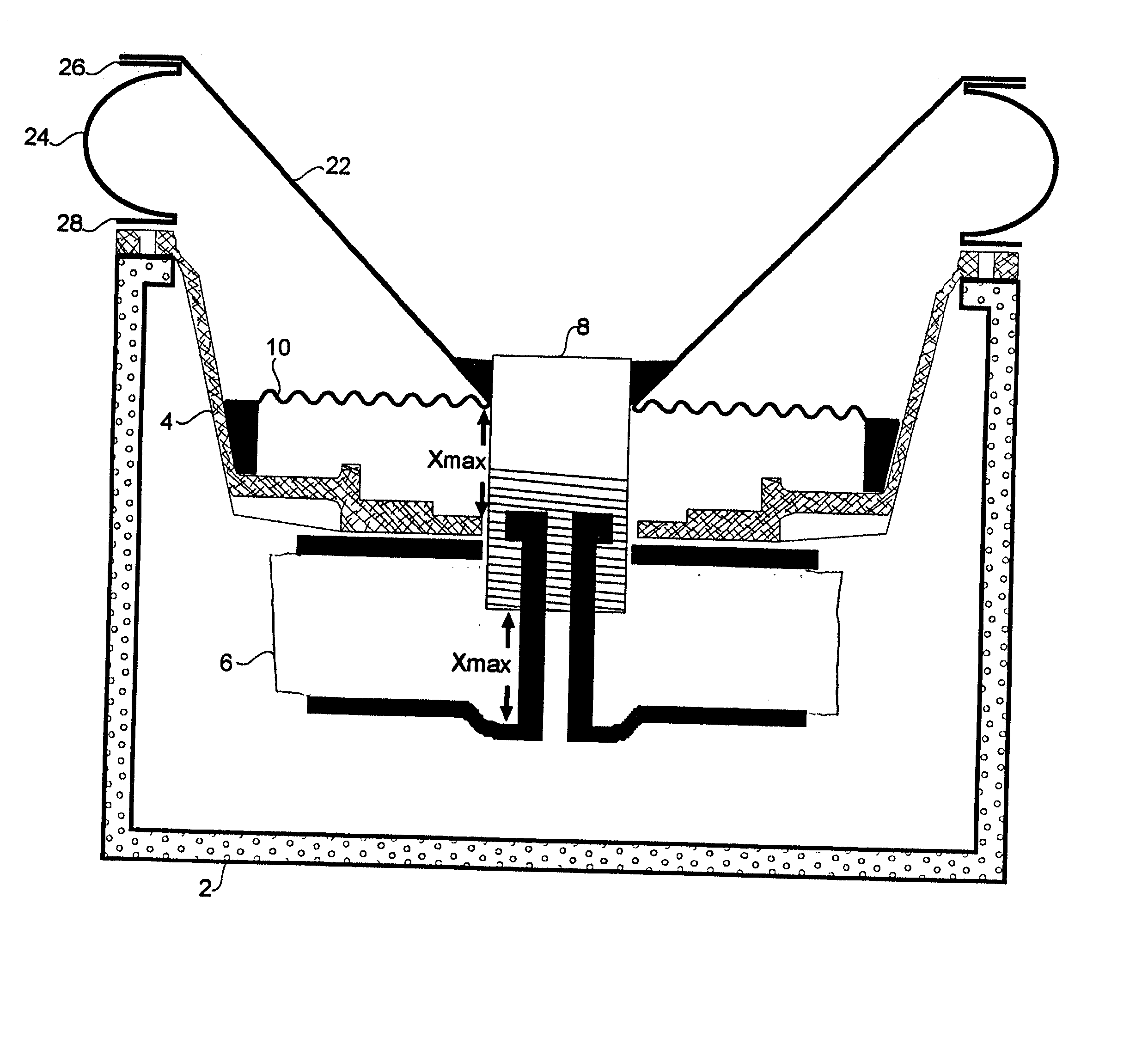

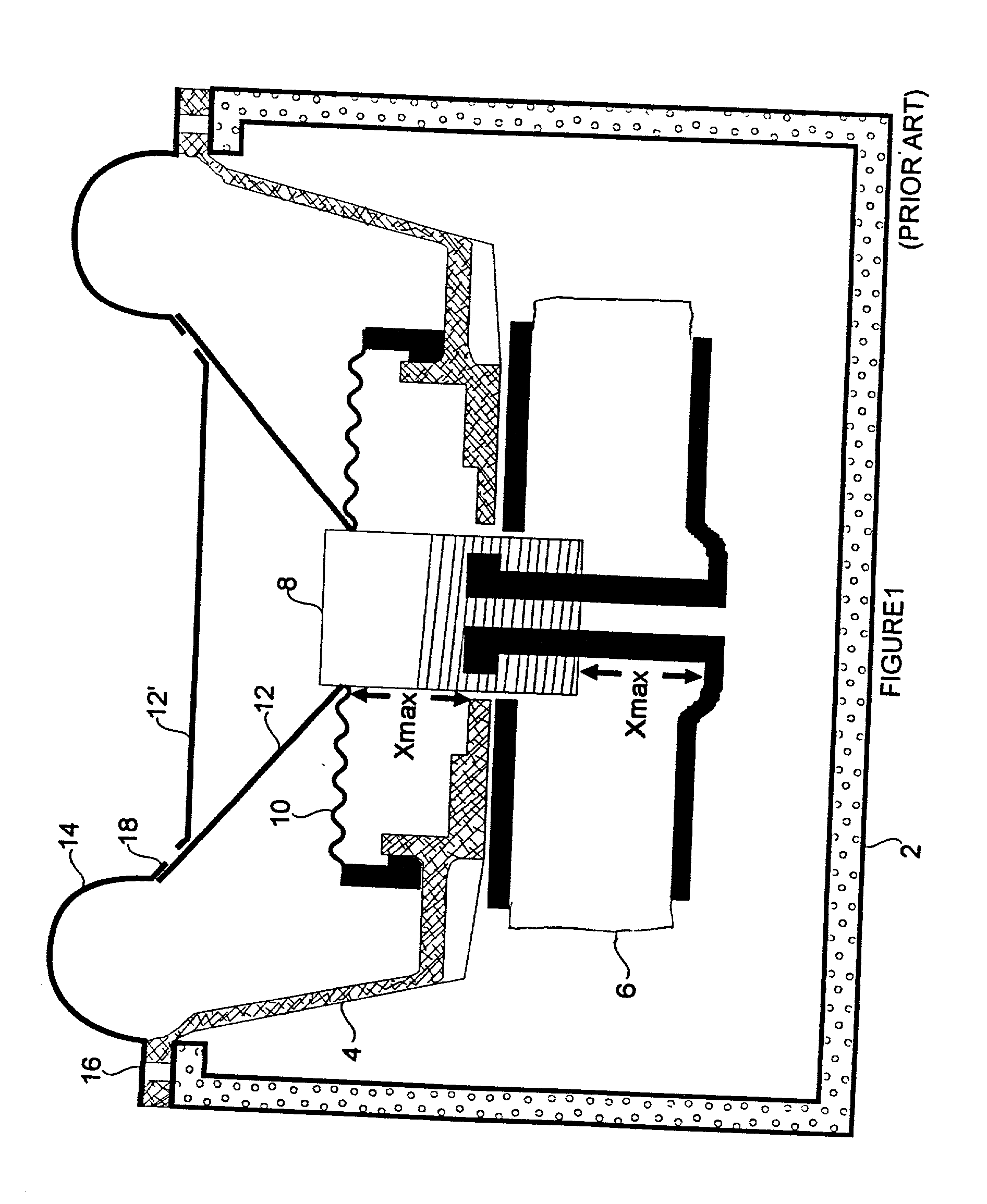

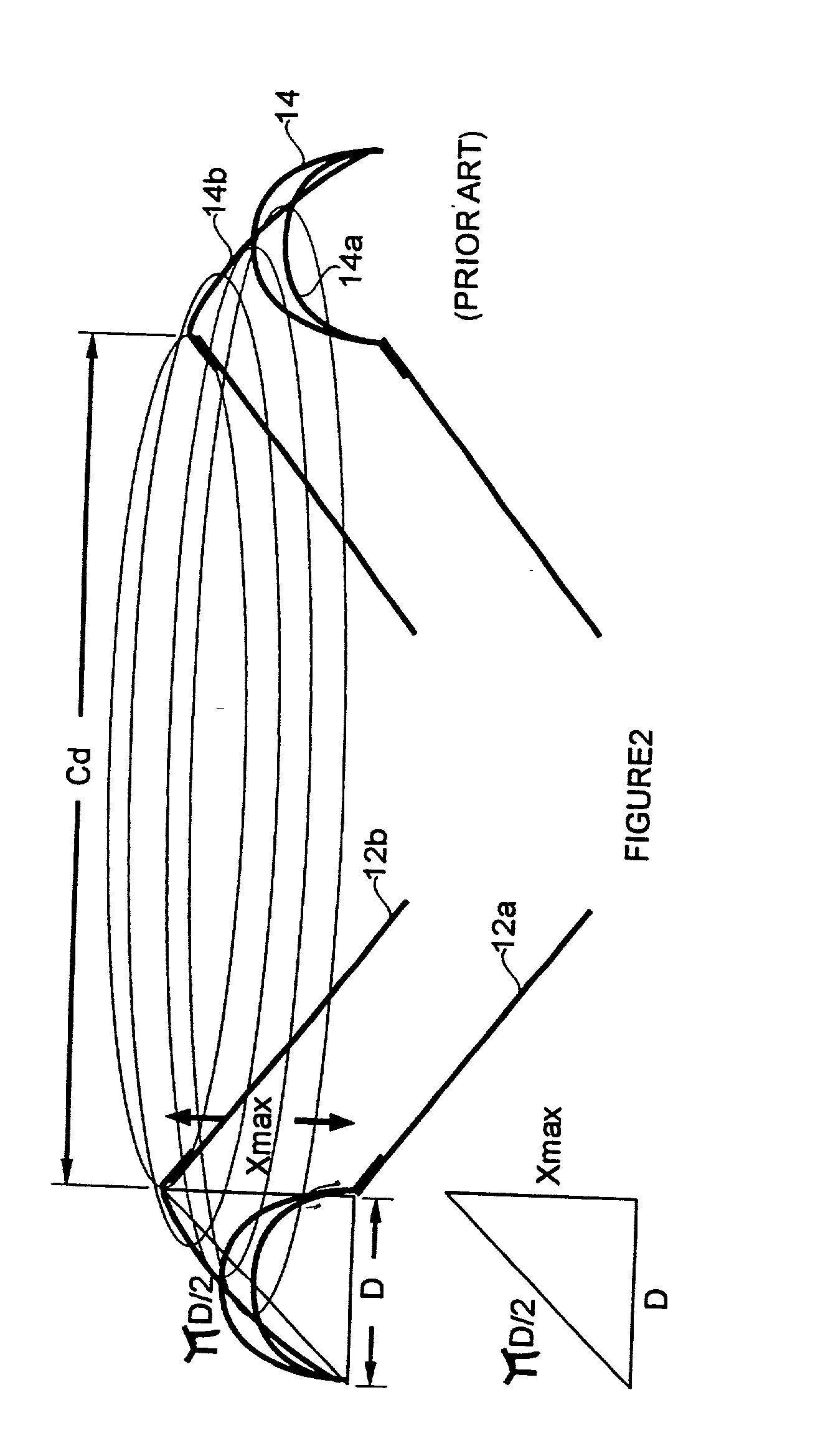

Acoustic radiator with a baffle of a diameter at least as large as the opening of the speaker enclosure to which it is mounted

InactiveUS20020148678A1Loudspeaker diaphragm shapeSound producing devicesPassive radiatorEngineering

Several different acoustic radiator designs improve performance over the prior art while providing a larger baffle (cone), a lesser volume of air displaced than by the smaller prior art speaker design, while maintaining the same enclosure mouth diameter and allowing the use of a shallower enclosure. These advantageous are achieved in a variety of ways with several configurations that include: a substantially vertically oriented resilient mount for the baffle (cone) where that resilient mount is entirely beneath the outer edge of the baffle (cone), between the outer rim of the baffle (cone) and the outer flange of the basket; a resilient mount that resembles prior art surround rotated outward by 45° to 70° extending the outer edge of the baffle (cone) outward allowing the use of a larger diameter speaker baffle (cone); and surround mounted to the outer flange of the basket beneath the dome of the surround moving the surround outward from the center of the enclosure allowing for a larger diameter baffle (cone) in an enclosure with the same mouth size than provided by prior art speakers and passive radiators.

Owner:EARTHQUAKE SOUND

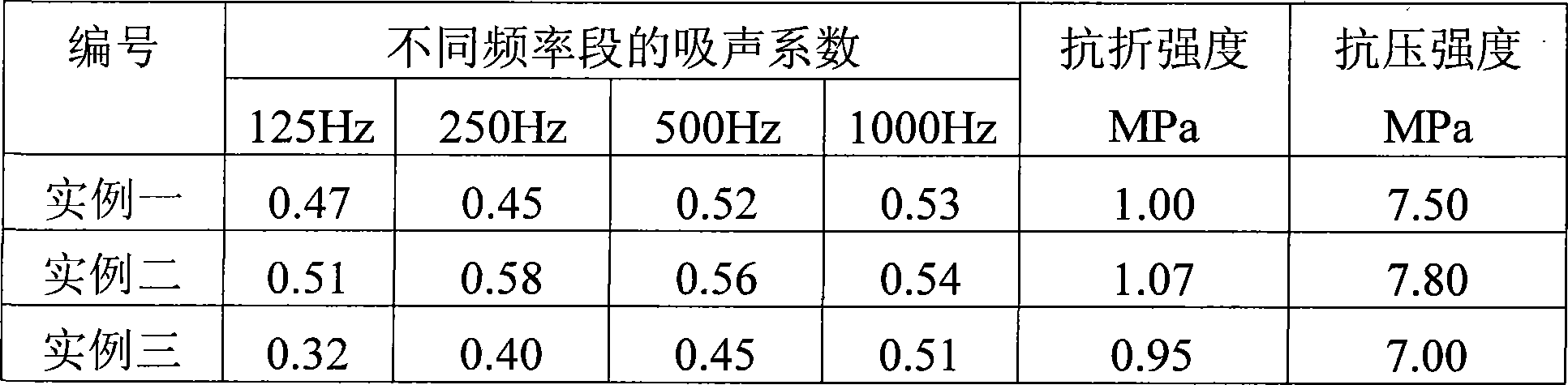

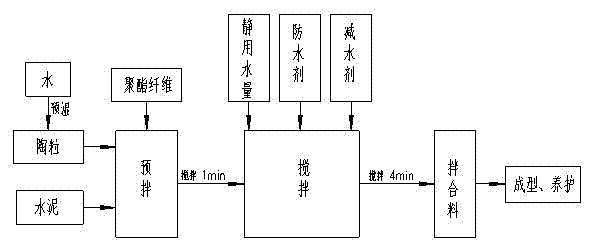

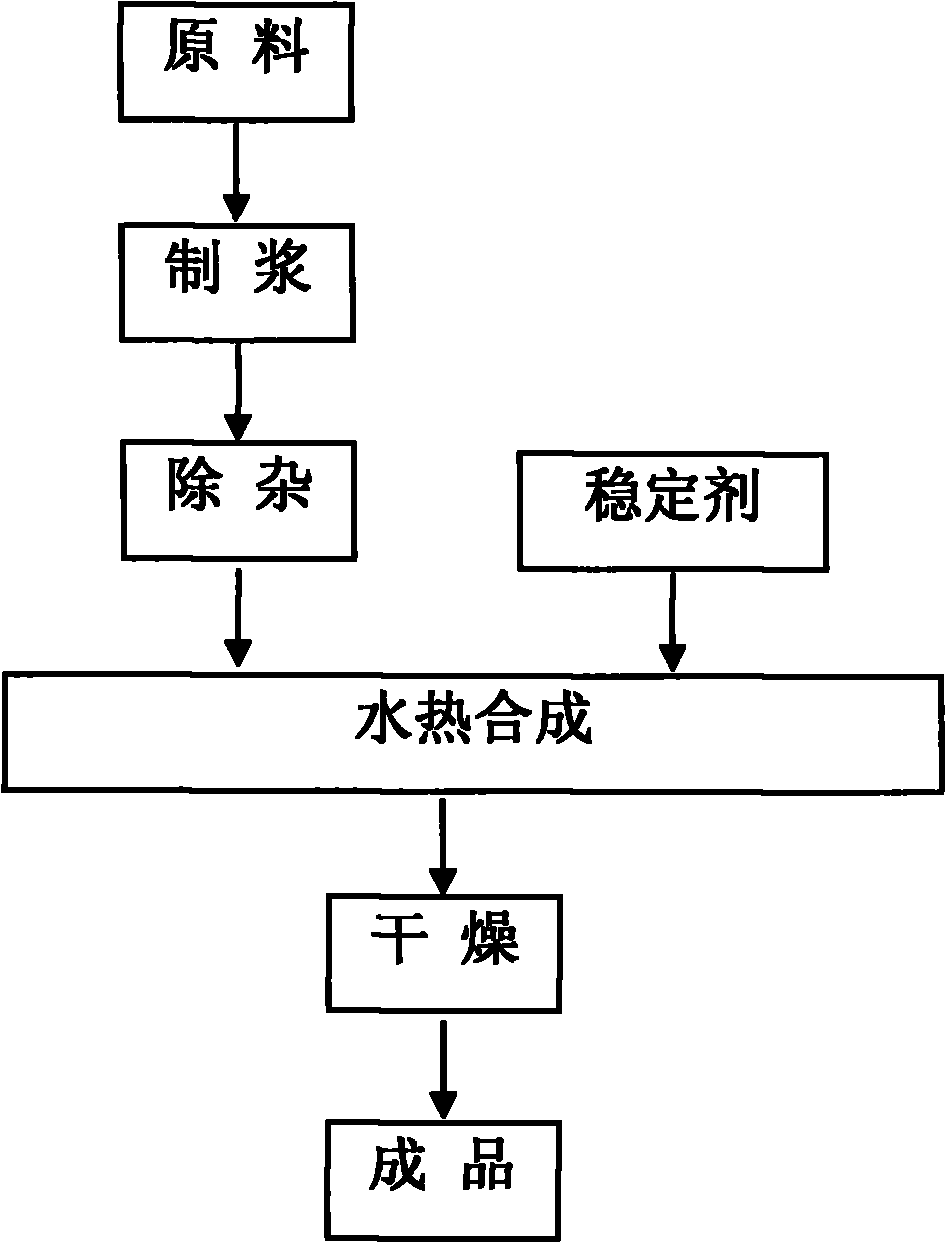

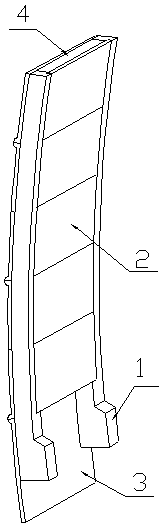

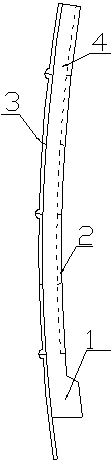

Manufacturing method of cement-based ceramsite porous ballastless track acoustic board

InactiveCN102964101AOvercome the disadvantages that cannot be used normallyImprove sound absorptionPolyesterFiber

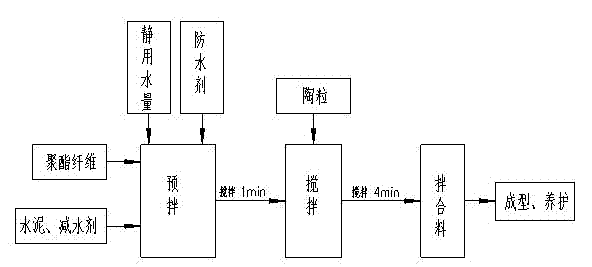

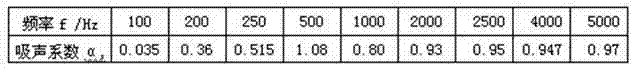

The invention discloses a manufacture method of a cement-based ceramsite porous ballastless track acoustic board which comprises the following components in percentage by weight: 45-55 percent of ceramsites, 28-38 percent of cement, 4.8-15 percent of water, 0.1-0.3 percent of polyester fiber, 0.6-1.2 percent of water reducing agent and 0.25-0.7 percent of waterproof agent, wherein the ceramsites play a role of a framework, the ceramsites with the grain size of 2.5-4mm account for 70 percent, the ceramsites with the grain size of 1.5-2.5 mm account for 20 percent, and the ceramsites with the grain size of 0-1.5mm account for 10 percent. The manufacturing method comprises the following steps of: prewetting the ceramsites, and then adding the cement and the polyester fiber for mixing and stirring for 1 minute, then adding the waterproof agent and the water reducing agent and stirring for 4-5 minutes; or mixing and stirring the cement, the polyester fiber, the waterproof agent and the water reducing agent for 1 minute, then adding the ceramsites and stirring for 4-5 minutes; manufacturing a mixture; and introducing the mixture into a mould for pressing and molding, and then normally curing. The cement-based ceramsite porous ballastless track acoustic board has the advantages of little investment, good sound absorption and high strength, can be applied to sound absorption and noise reduction of a track, and can also be suitable for noise treatment of industrial and civil buildings and highway bridges.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

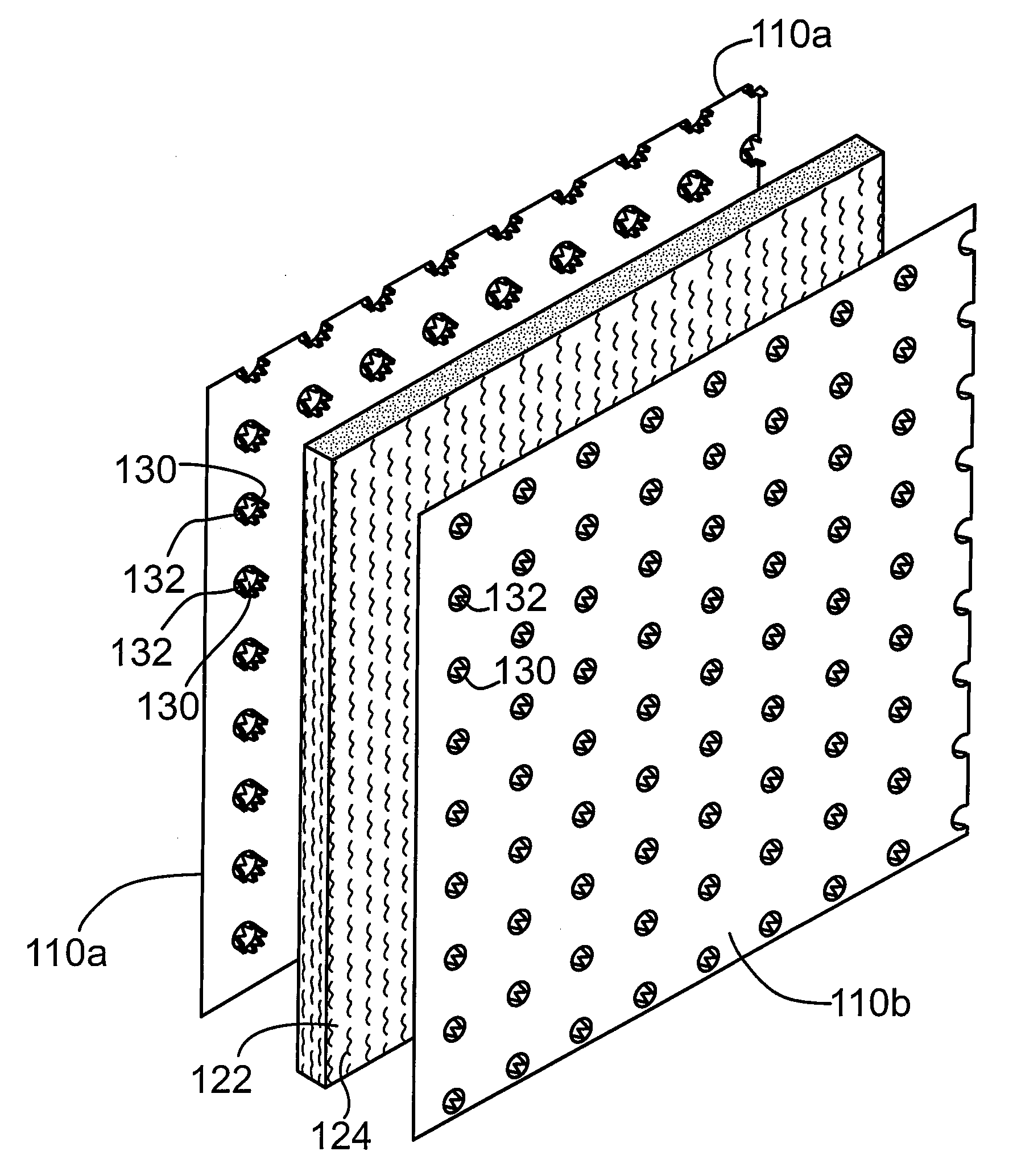

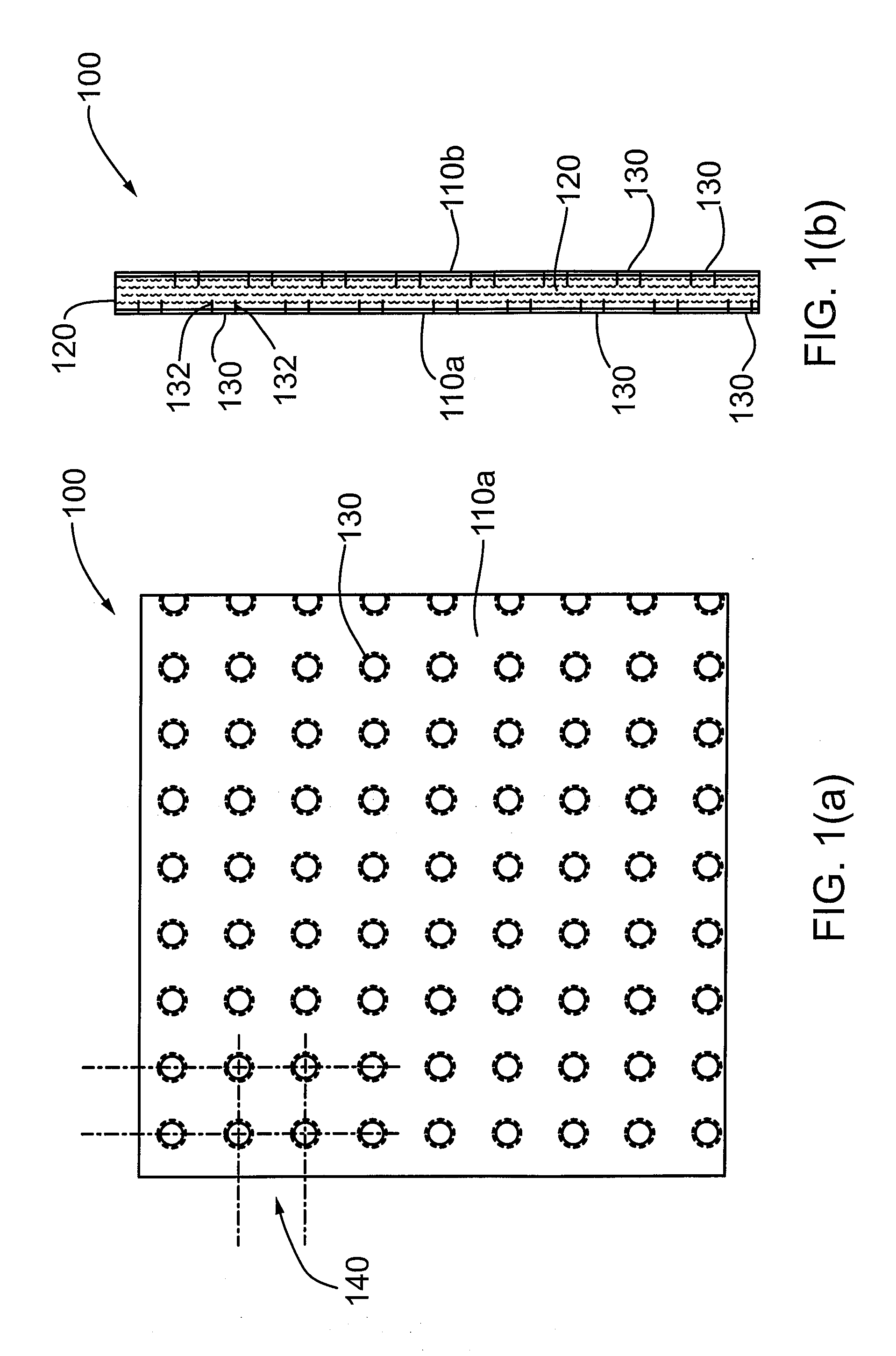

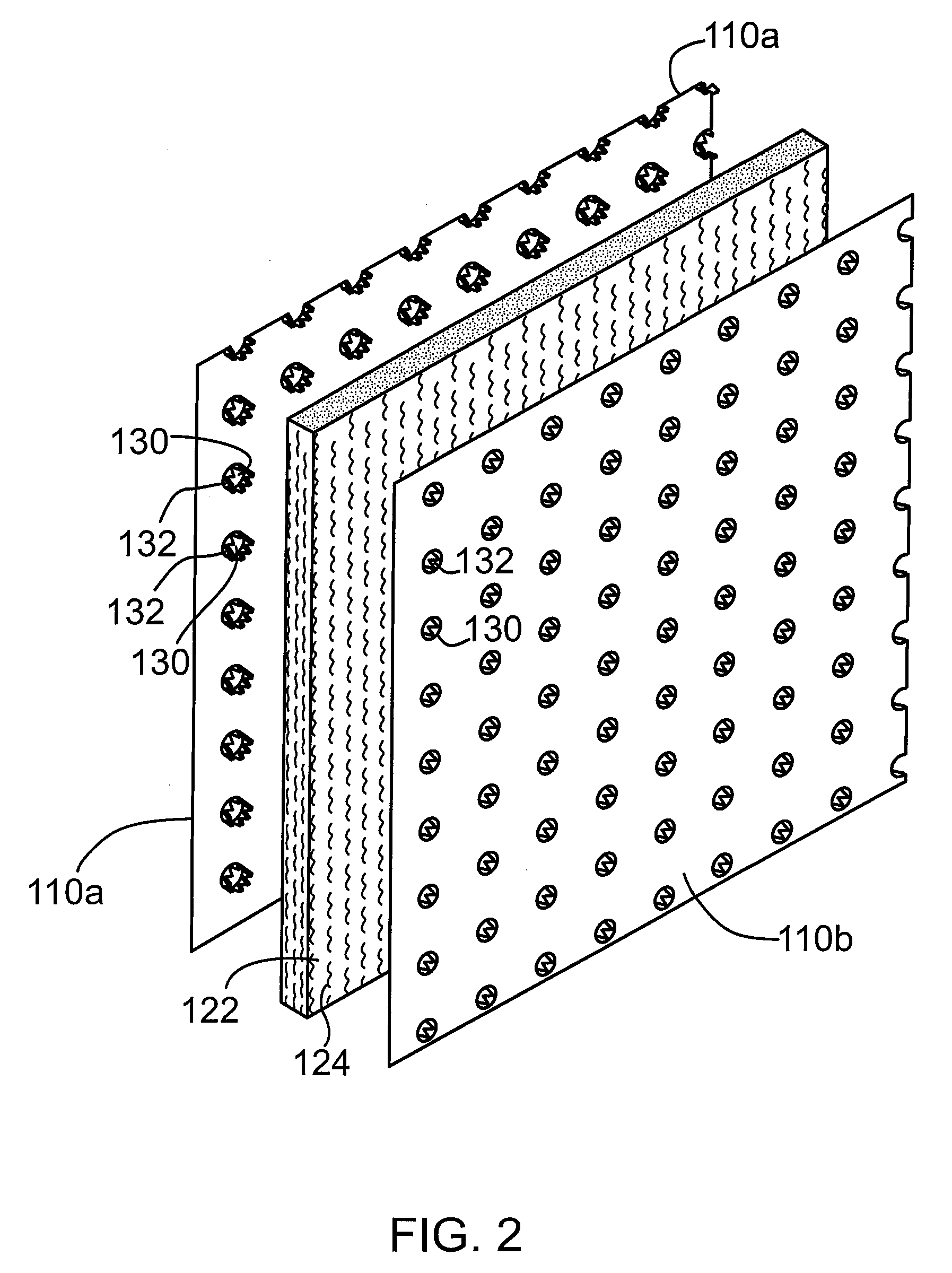

Porous membrane

A new acoustic insulating sheet material comprises in laminar assembly a) a primary sound absorbing sheet, and b) a dense porous membrane that i) has an air-flow resistance of about 5000 rayls or less and ii) has an Acoustic Value Ratio as defined herein of at least 3000. Preferably, the membrane is about 200 micrometers or less in thickness, and more preferably is about 150 micrometers or less in thickness. Also, the Acoustic Value Ratio is preferably at least 7,000. The described membrane can also be used alone to acoustically insulate a space, e.g., by mounting it in planar array over an air gap and in position to attenuate noise from a noise source.

Owner:3M INNOVATIVE PROPERTIES CO

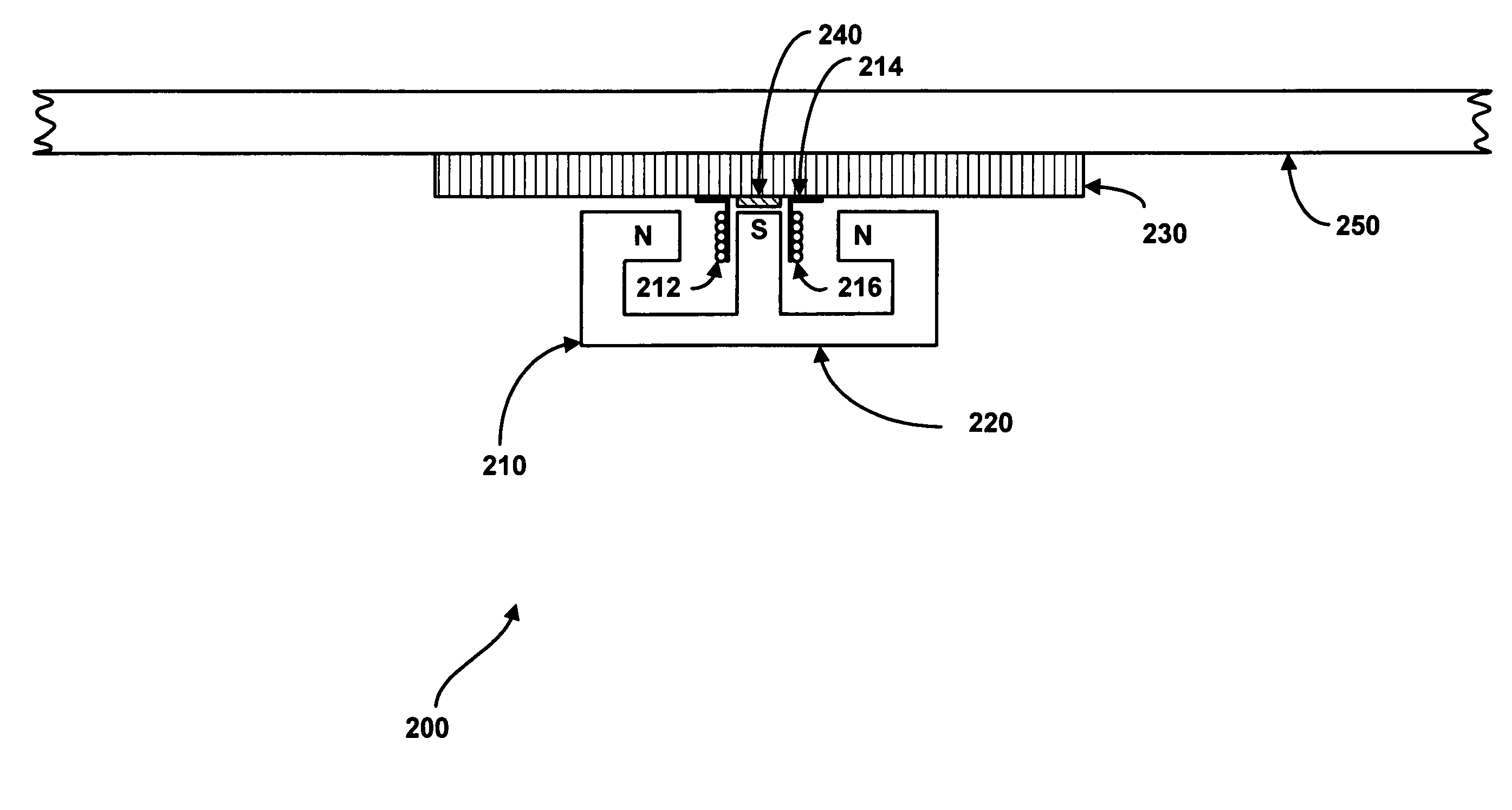

Noise power-generating device and noise power-generating equipment consisting of same

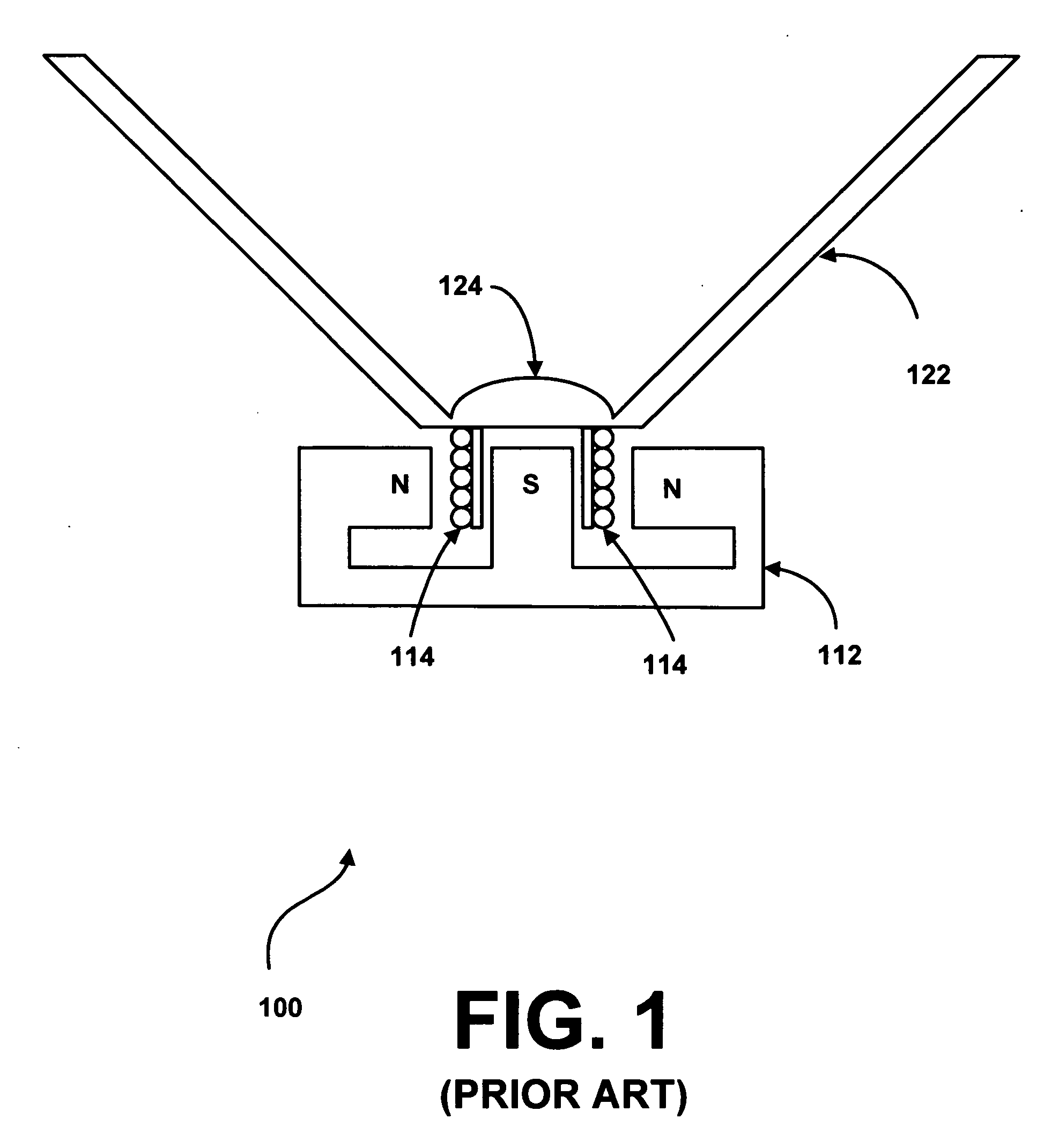

InactiveCN103219862ASave energyImprove efficiencyDynamo-electric machinesHelmholtz resonatorMagnetic poles

The invention provides a noise power-generating device and noise power-generating equipment consisting of the same. The noise power-generating device comprises a sound wave collecting pipe, wherein one end of the sound wave collecting pipe is opened; an air-isolating and sound-transmitting thin film is sealed at the opening of the sound wave collecting pipe; a trumpet-shaped inlet is also formed at the opening of the sound wave collecting pipe; a sound-isolating plate is arranged outside the sound wave collecting pipe 4; one end of the sound-isolating plate is connected with the trumpet-shaped inlet 1; the other end of the sound-isolating plate is connected with the closed end of the sound wave collecting pipe 4; the sound-isolating plate and the outer wall of the side surface of the sound wave collecting pipe form a cavity; a plurality of columns of acoustical-electrical converting units which are uniformly arranged along the axial direction are arranged on the side surface of the sound wave collecting pipe; each of the acoustical-electrical converting unit comprises a helmholtz resonator with a resonating cavity and an acoustical-electrical converter connected with the helmholtz resonator; the acoustical-electrical converter comprises a vibrating film arranged in the cavity in the tail end of the resonating cavity and connected with a coil through a connecting rod; a coil is sleeved on a magnetic pole; and the magnetic pole is arranged on the sound-isolating plate. The coil is connected with an output bus through a current-collecting wire, so that the mechanical energy of noise is converted into electric energy.

Owner:XI AN JIAOTONG UNIV

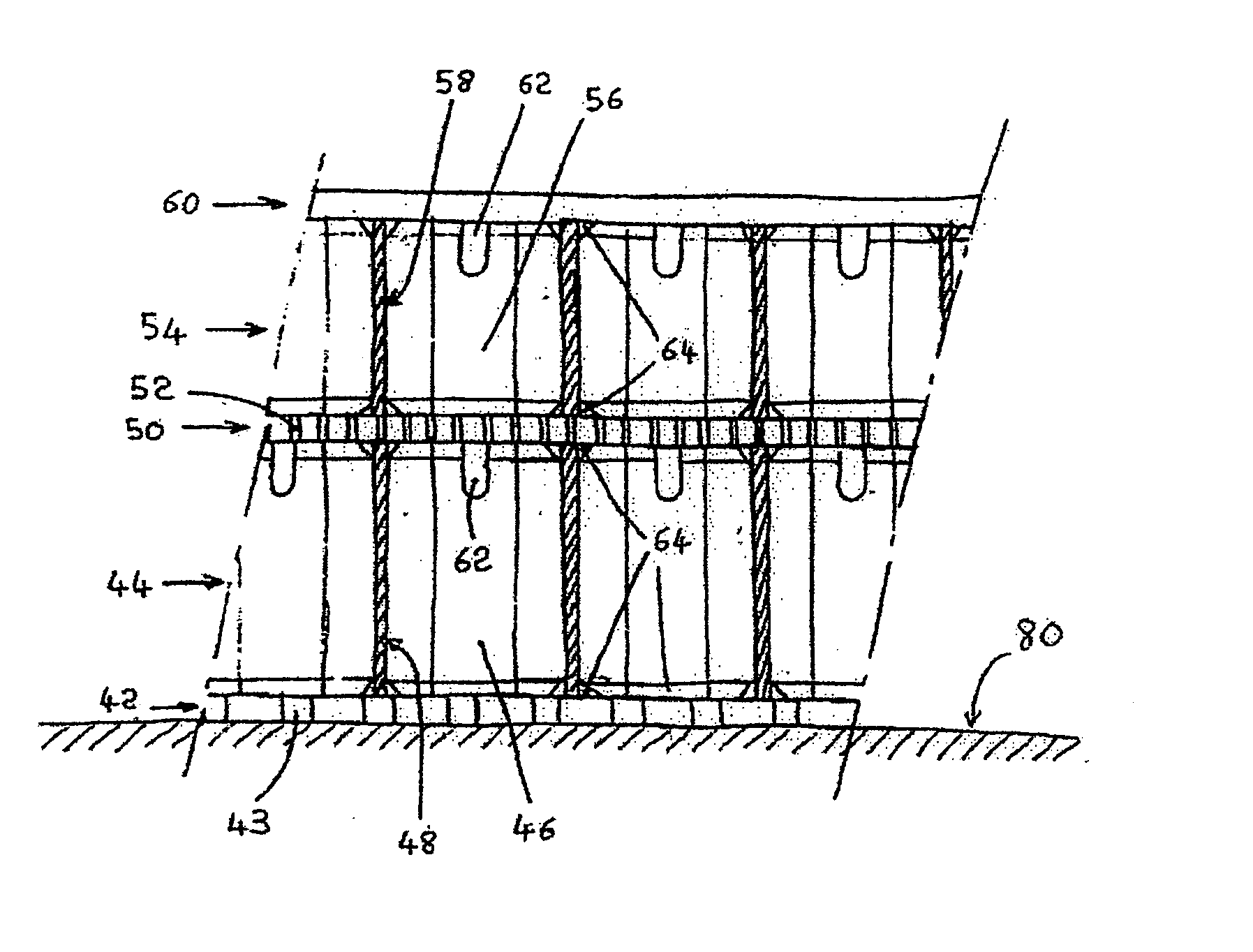

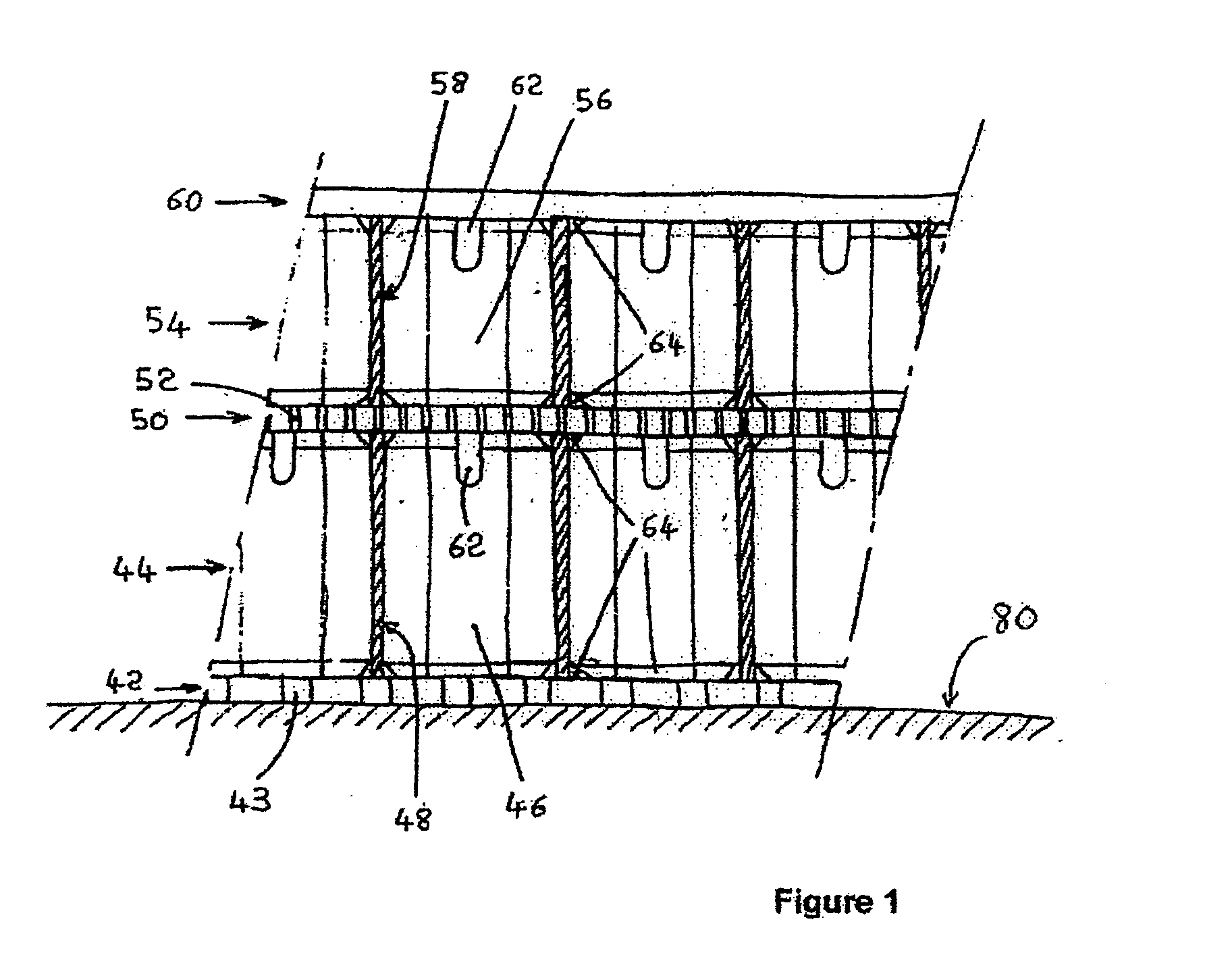

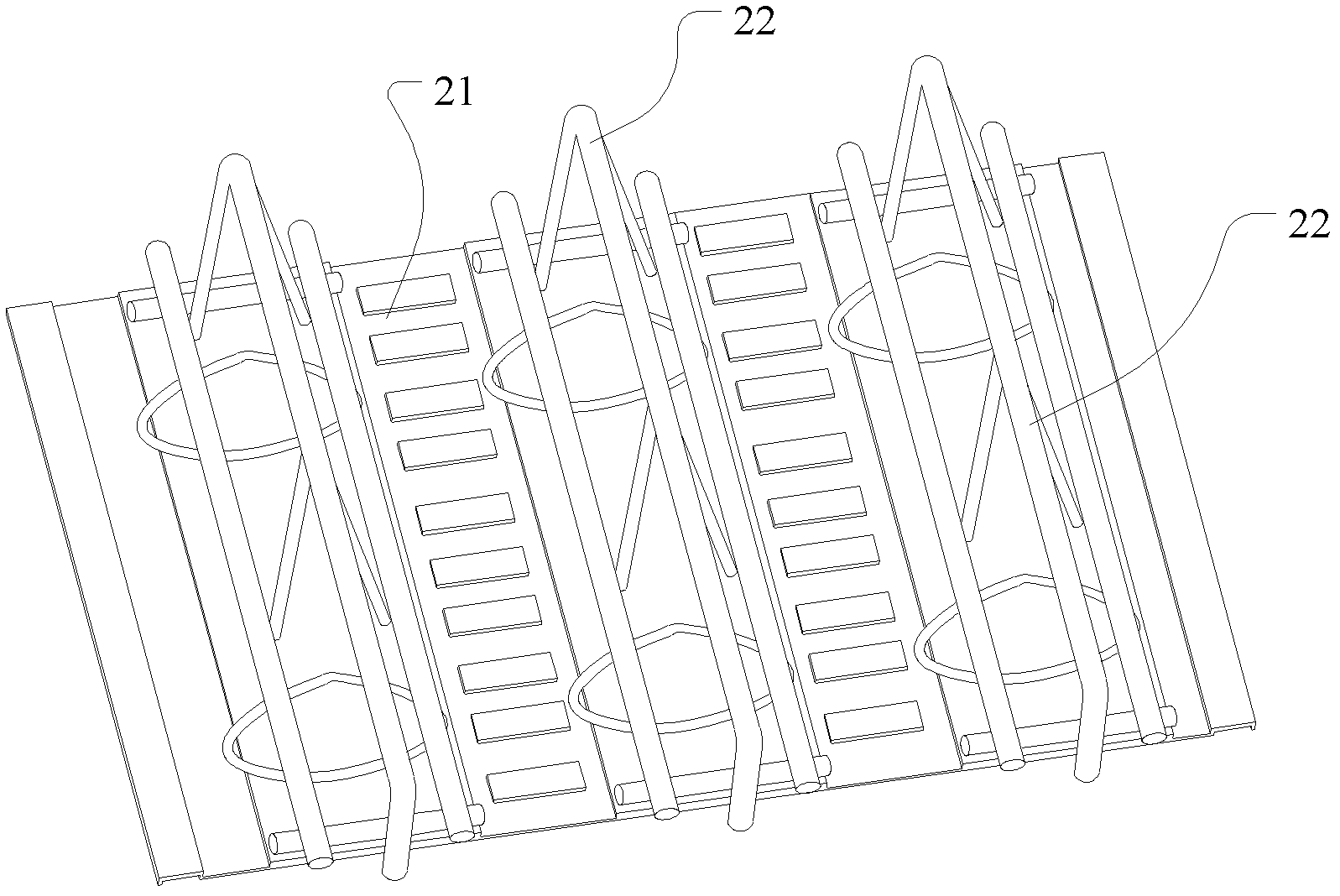

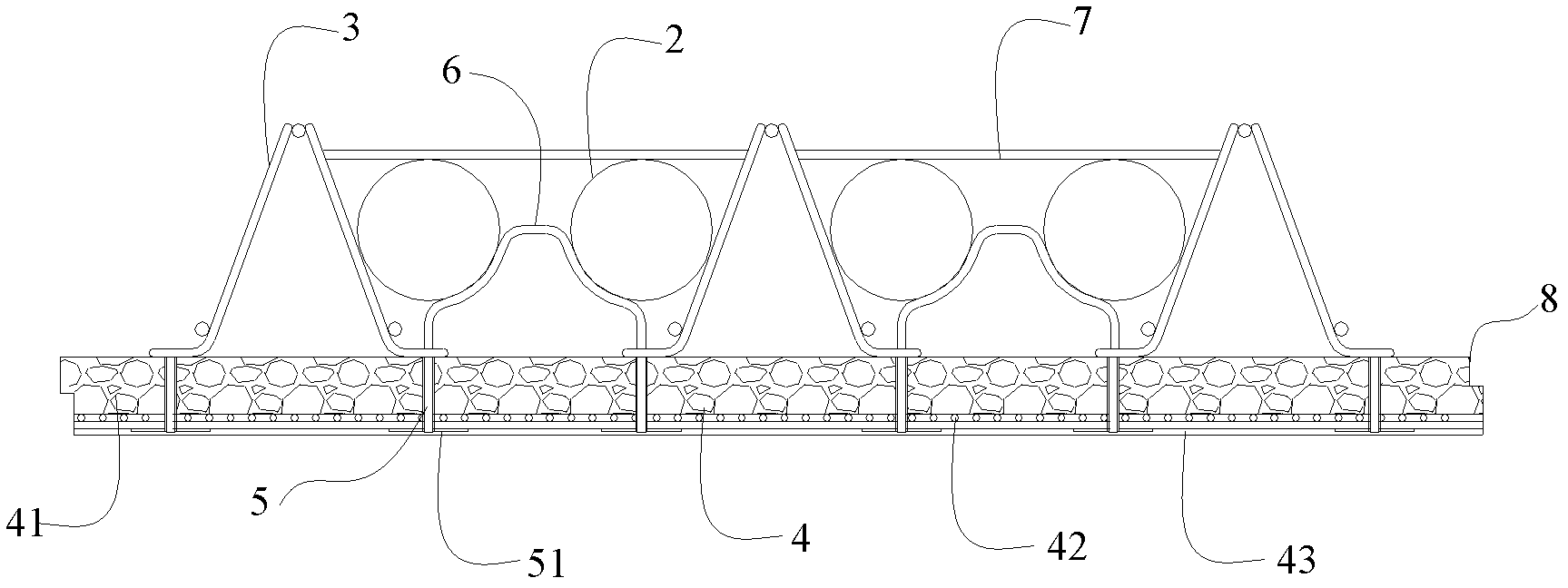

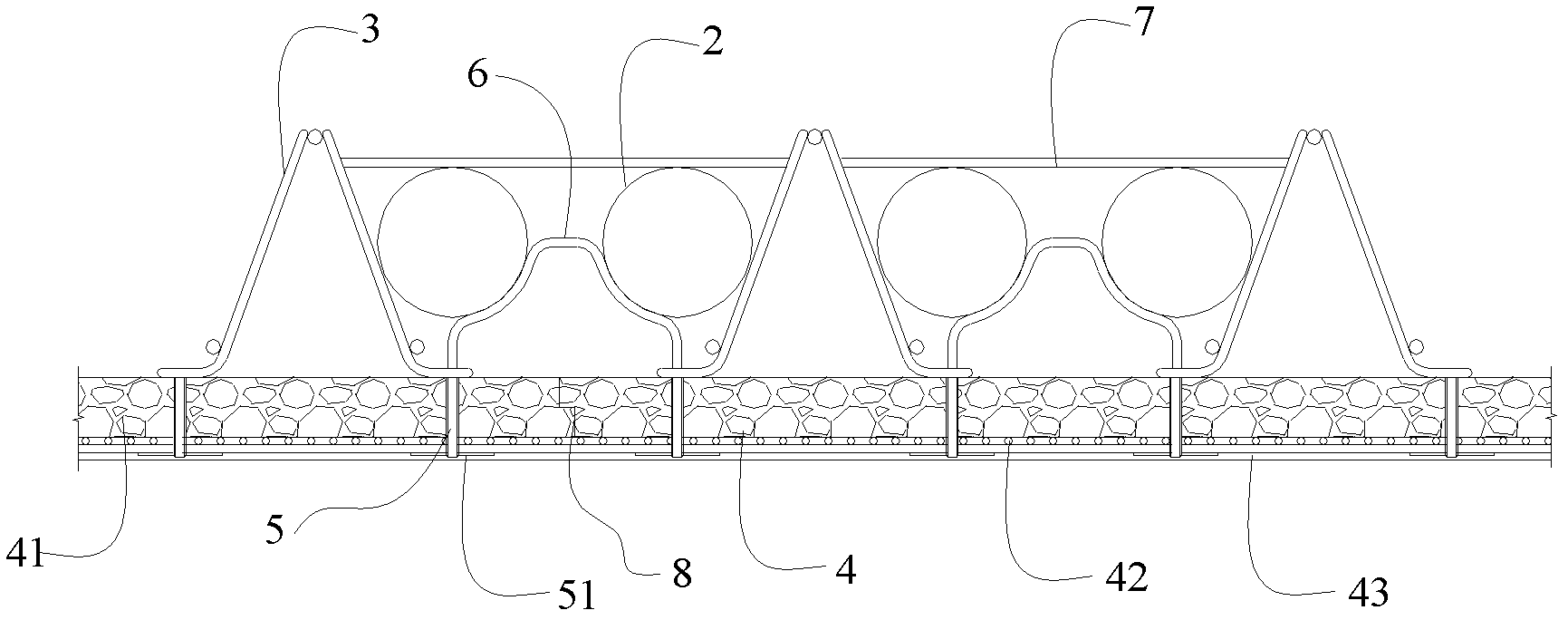

Self-supporting thermal insulation hollow floor slab and construction method thereof

InactiveCN102296736AReduce dosageWith heat preservation functionClimate change adaptationFloorsWire gauzeFloor slab

The invention discloses a self-supporting heat insulation hollow floor and a construction method thereof. The self-supporting heat insulation hollow floor comprises a plurality of frameworks consisting of bottom plates and multiple steel bar trusses erected above the bottom plates and connected with the bottom plates, the opposite ends of the bottom plates of the two adjacent frameworks are connected, and concrete is poured on the steel bar trusses. The self-supporting heat insulation hollow floor is characterized in that: the bottom plate comprises a steel wire gauze and heat insulation plates and / or sound insulation plates positioned on the steel wire gauze, and the bottoms of the steel bar trusses are connected with the bottom plates through a plurality of connectors. The self-supporting heat insulation hollow floor has the function of heat insulation or sound insulation; and meanwhile, the consumption of steel is reduced, so that the production cost is reduced. The invention has the advantages that: the construction method is simple in operation and is easy to learn and use.

Owner:CABR TECH CO LTD +2

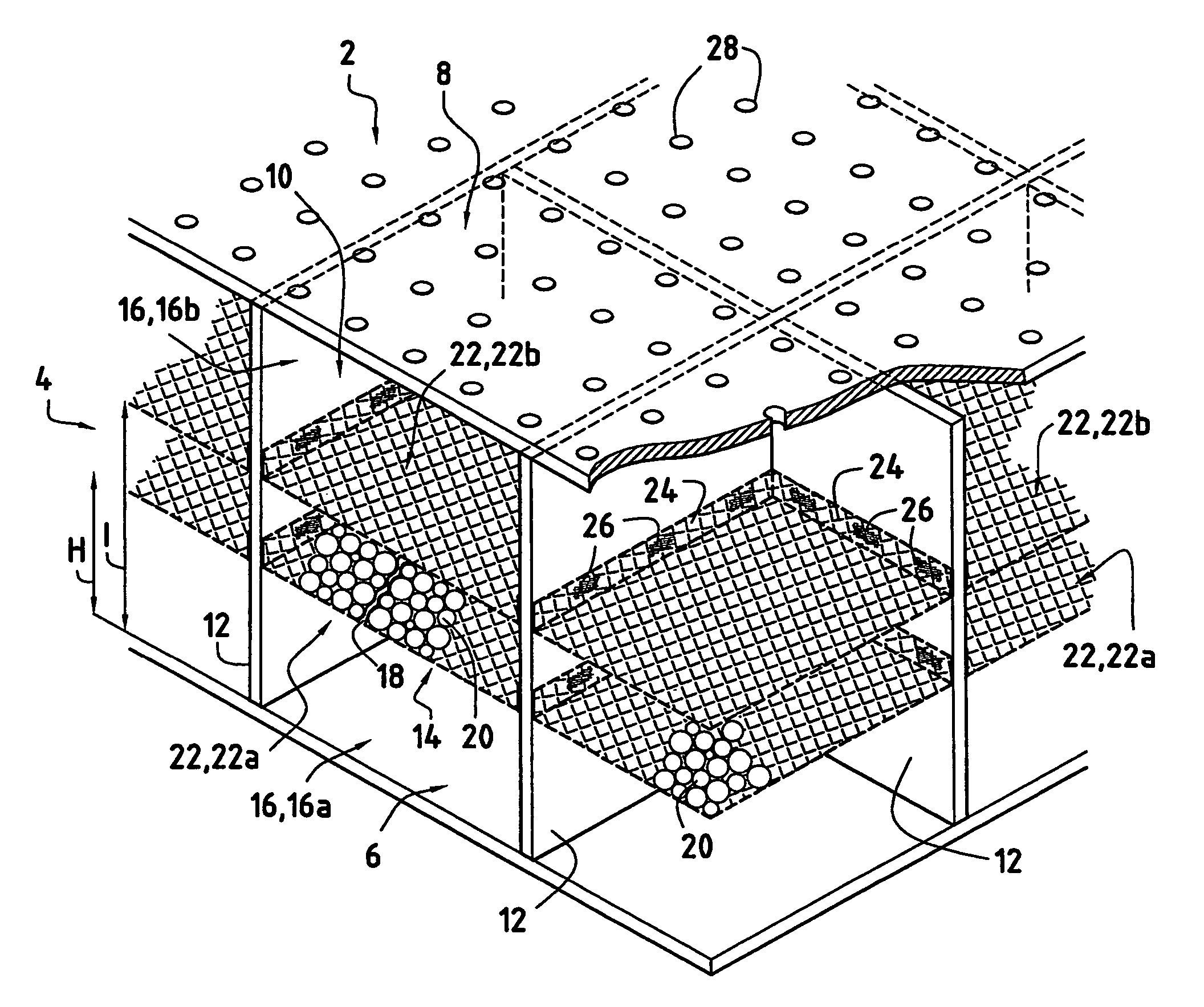

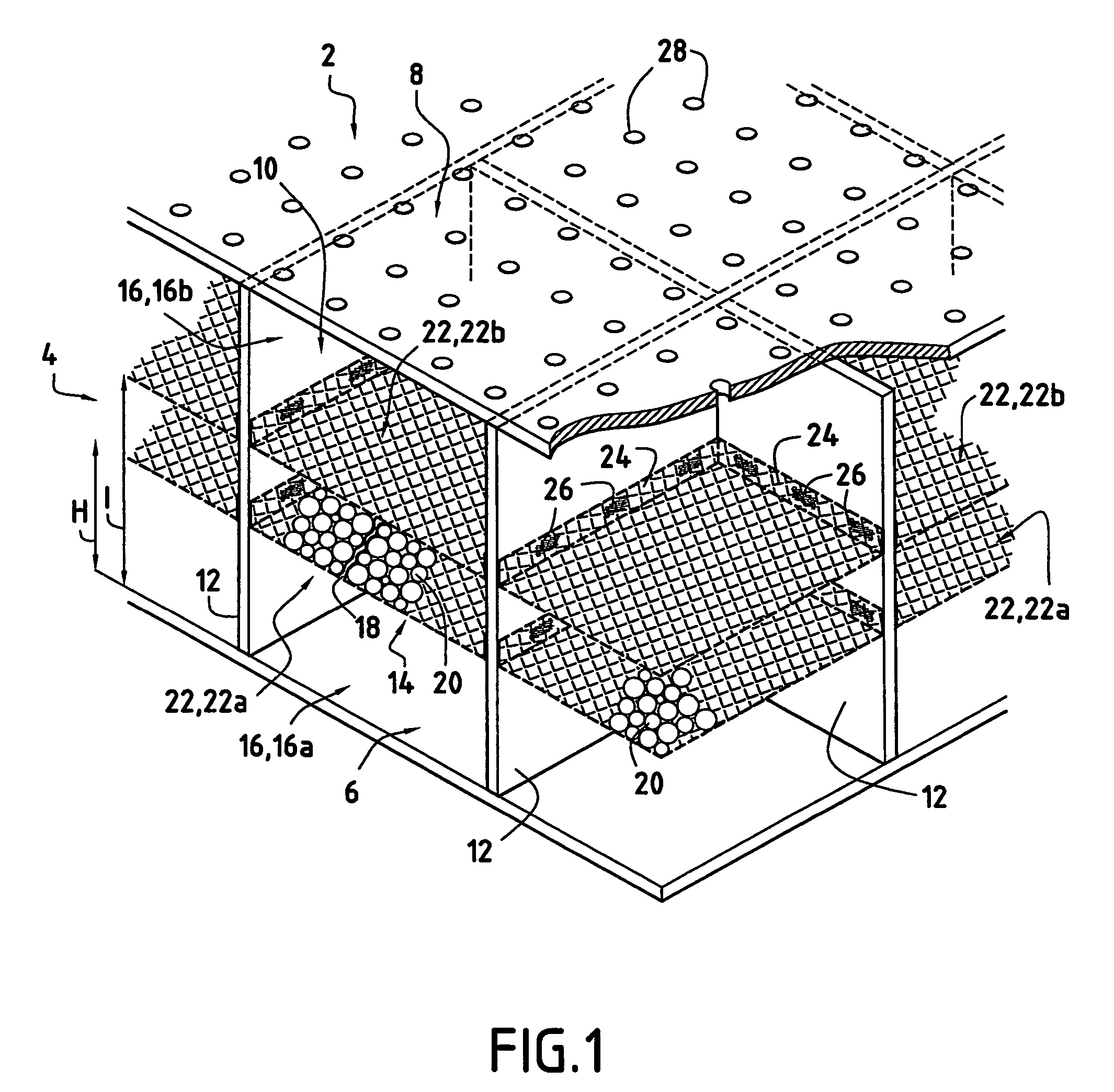

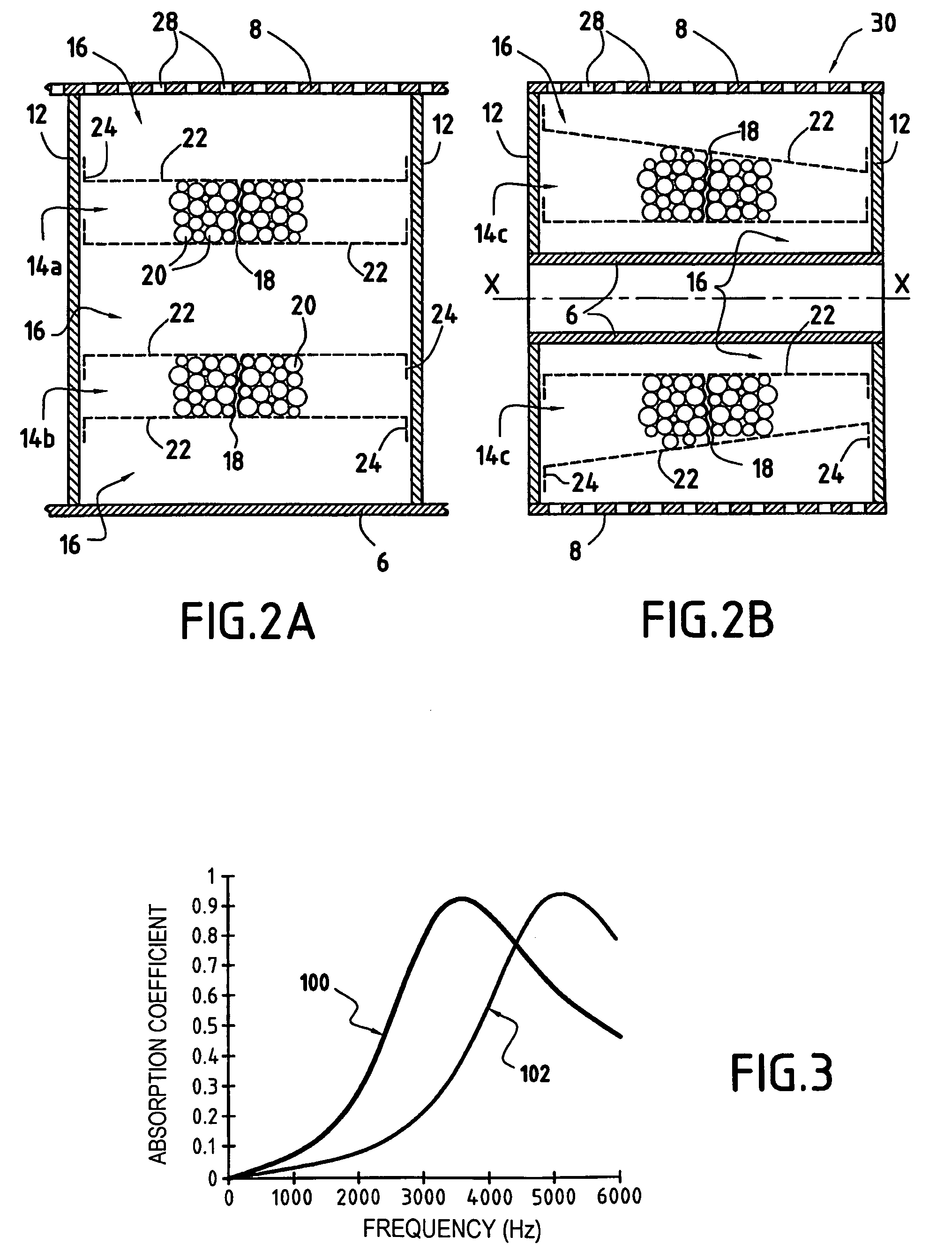

Soundproofing panel with beads, and a method of manufacture

ActiveUS7520369B2Mitigate such drawbackImprove acoustic performanceCeilingsWallsSound energySolid wall

A soundproofing panel having a core sandwiched between a solid wall and a porous wall. The core being connected to the walls and having partitions extending in the thickness direction between the two walls so as to form cells. Each cell containing at least one sound energy dissipating layer constituted by hollow spherical beads having mutually contacting walls that are porous and micro-perforated, and being held in position in the thickness direction between the two walls by nets that are secured to the partitions.

Owner:ATECA +1

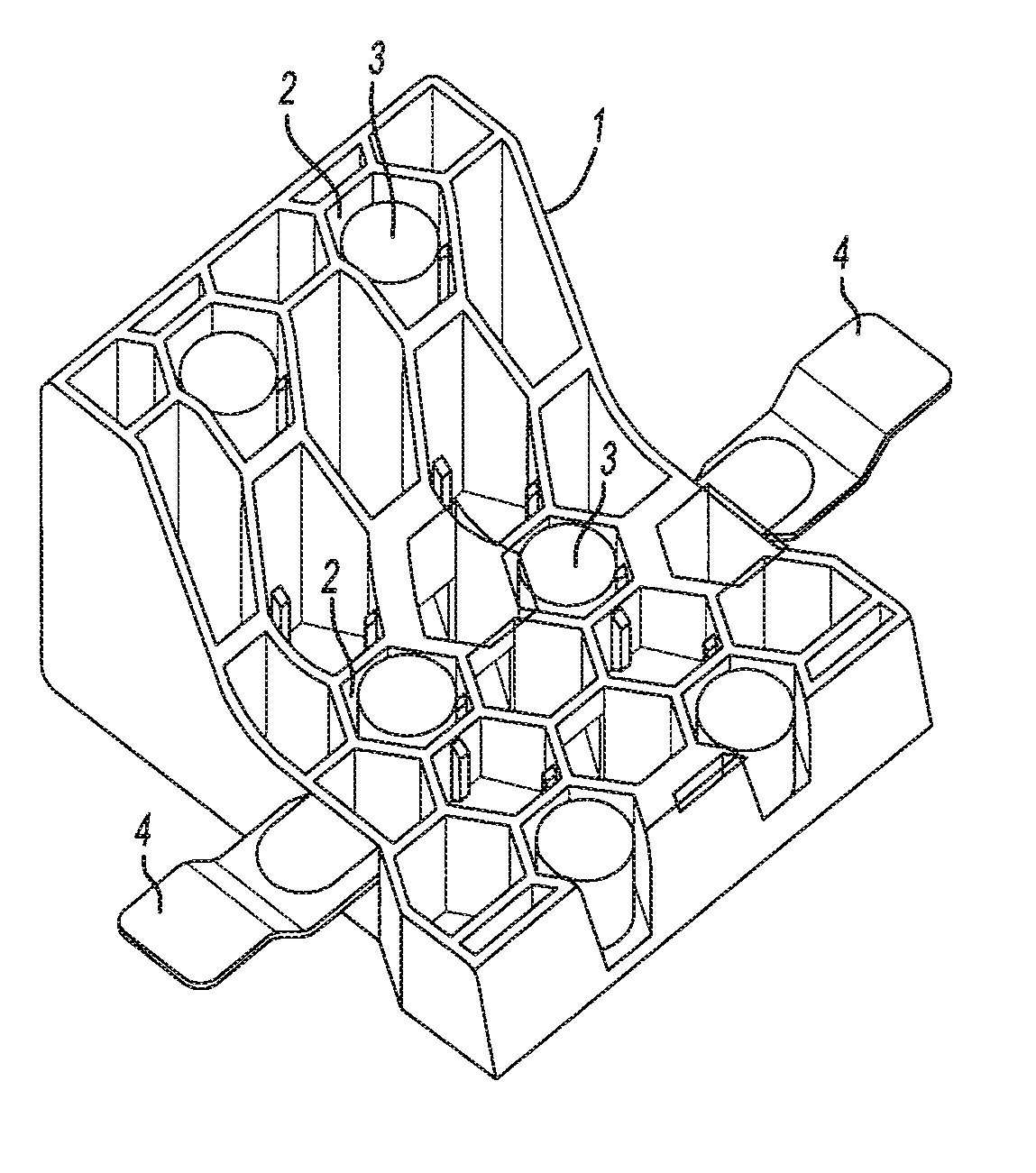

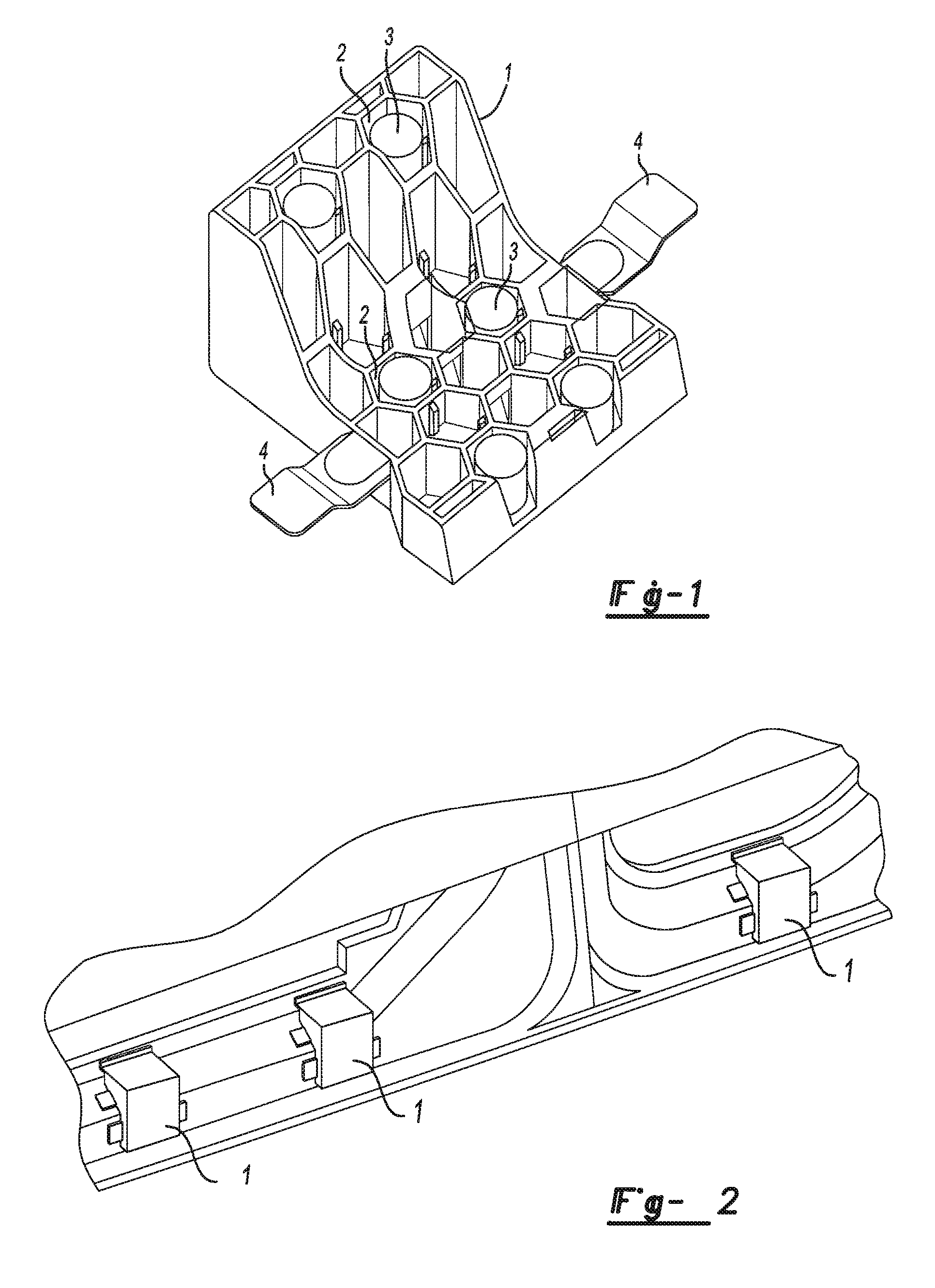

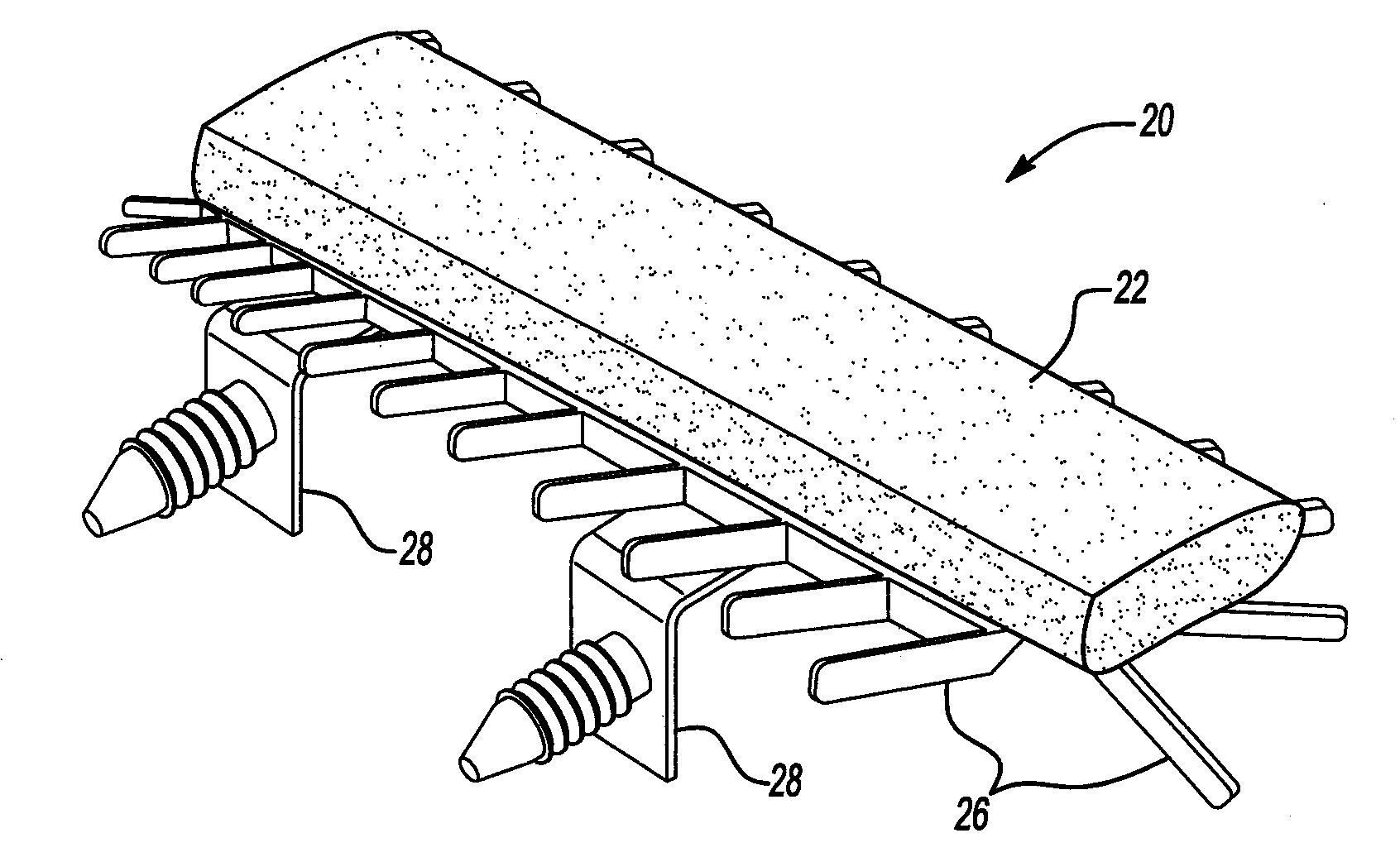

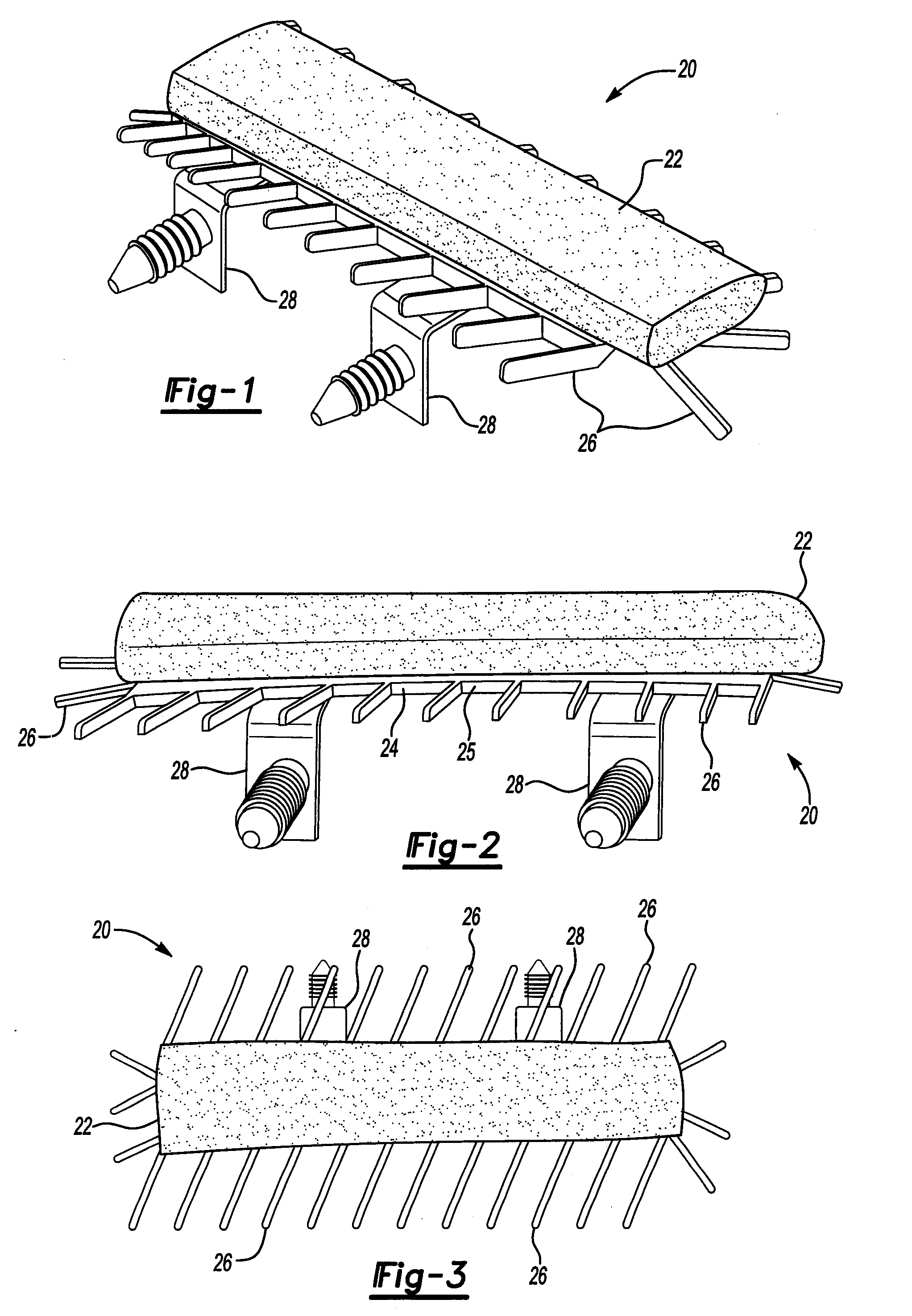

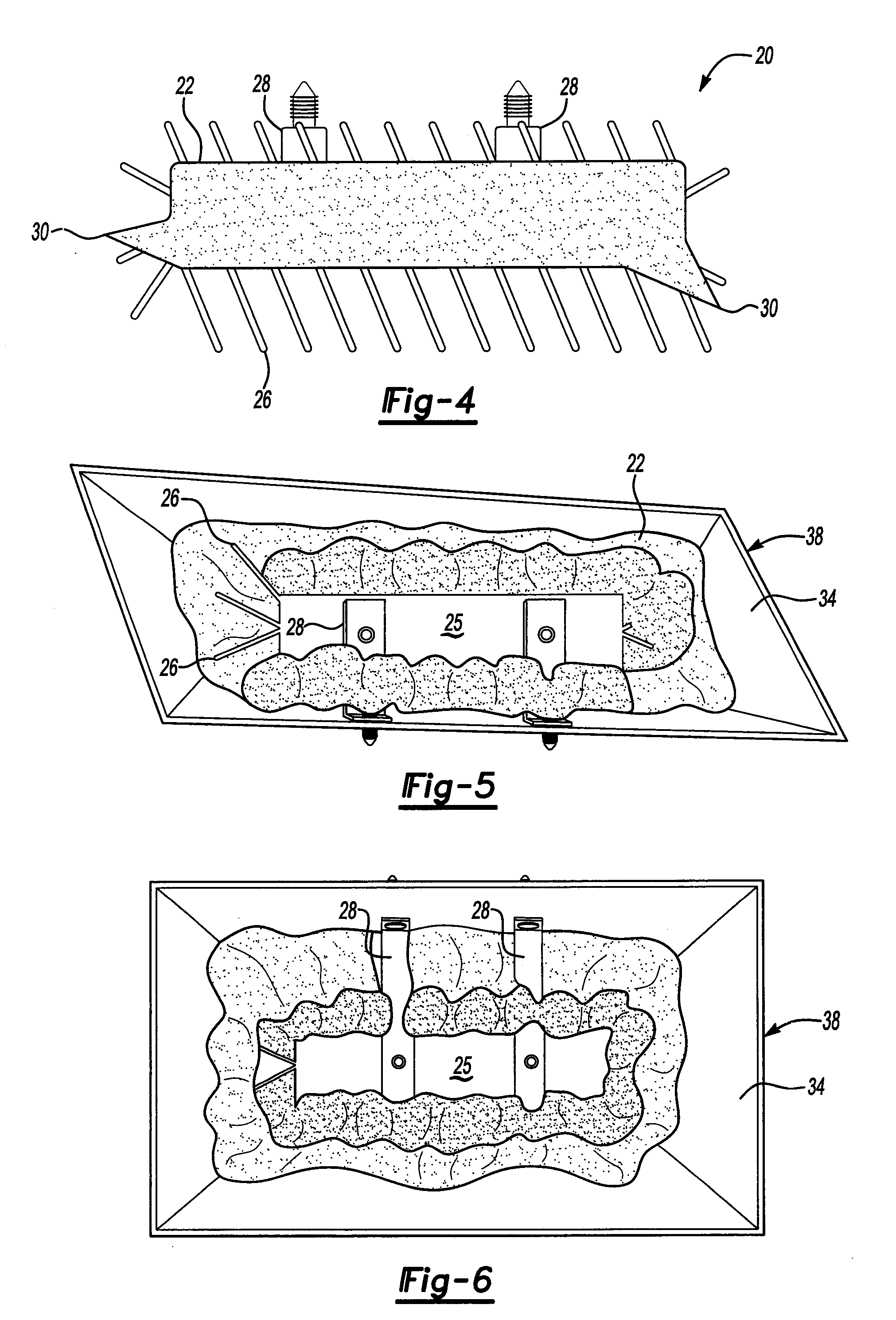

Acoustic baffle assembly

An acoustic baffle assembly for sealing or baffling a hollow body having a mass of heat activated expandable material that is capable of activating at a predetermined temperature. A substrate supports the mass. The substrate has a central portion and spaced apart projections extending outwardly from the central portion. The projections are configured to control expansion of the mass.

Owner:HENKEL CORP

Panel for acoustic damping and fire protection applications

An acoustic panel comprising an inner core sandwiched between outer sheets formed from a different material. According to an embodiment, the inner core comprises a cementicious material that also has fire resistant properties, and the outer sheets comprise metallic sheets. According to an embodiment, the outer sheets include metal tines for forming a bond between the respective metallic sheets and the inner core. The metal tines are formed as projections during the piercing of holes in the metallic sheets. According to an embodiment, the diameter of the holes and / or the thickness and / or composition of the cementicious material can be varied or configured to change the acoustic damping properties of the panel. According to another aspect, the panel comprises a fire resistant acoustic panel suitable for use as a fire protective or blast protection barrier.

Owner:DUFFY WILLIAM CHRISTOPHER

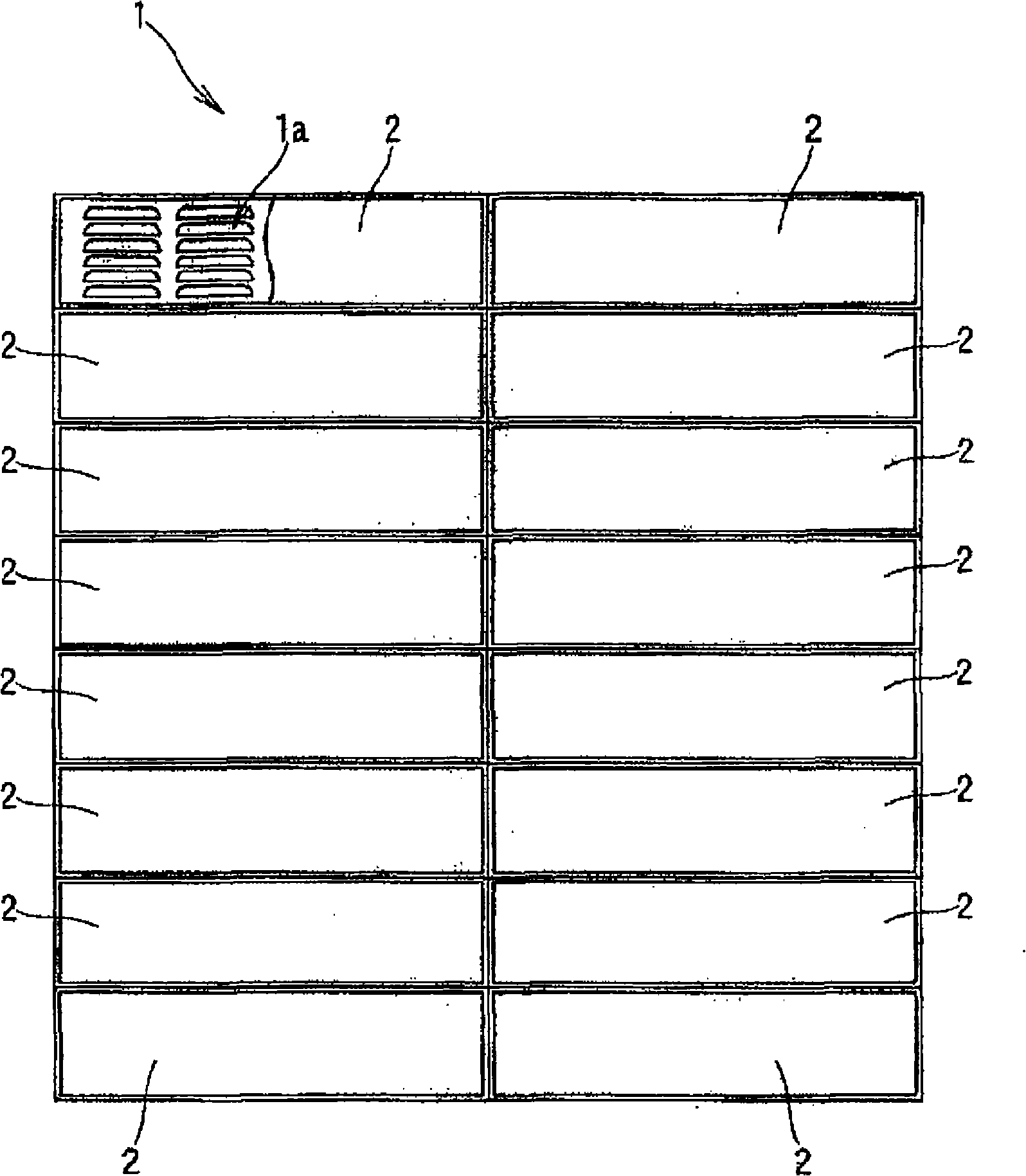

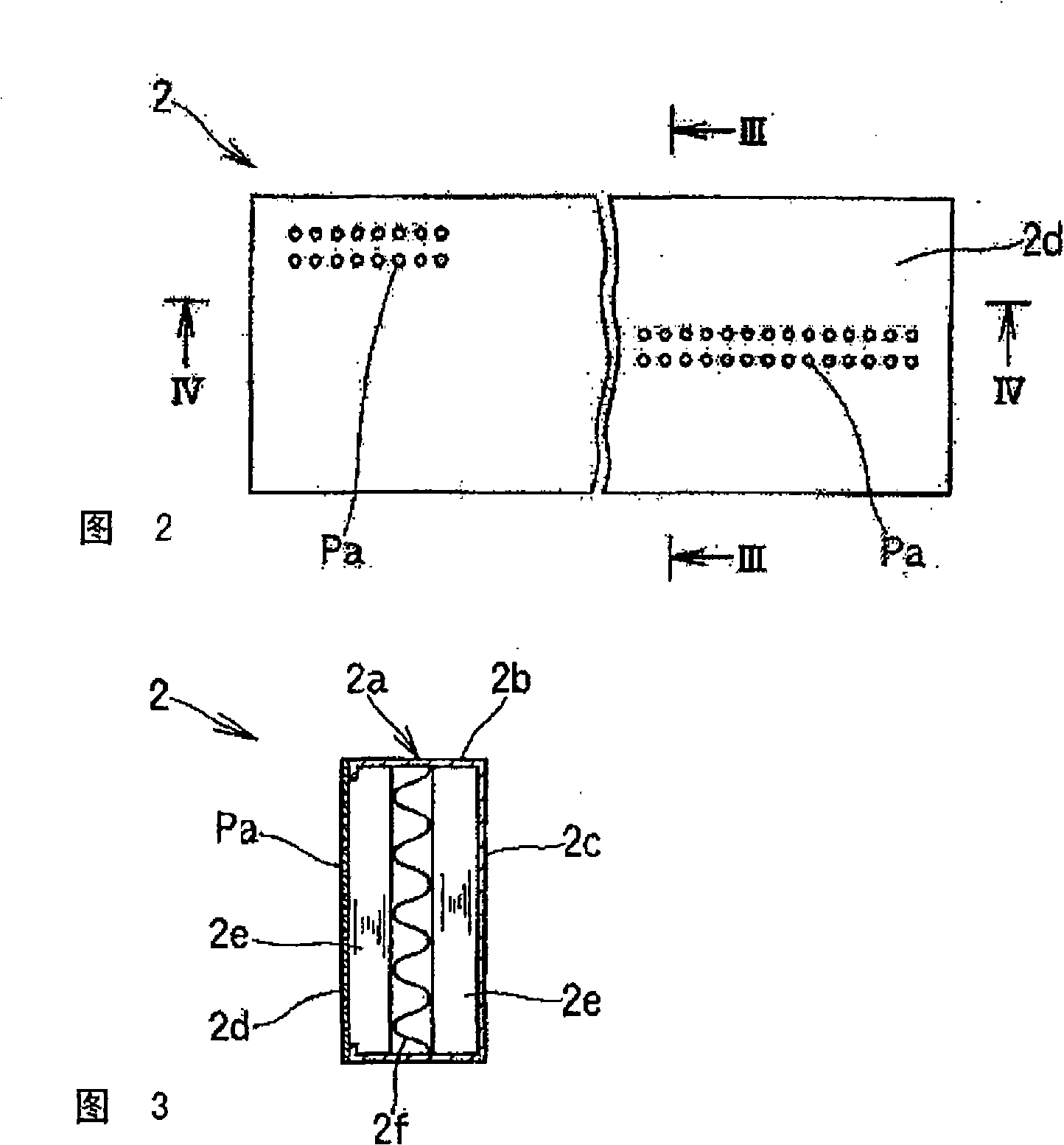

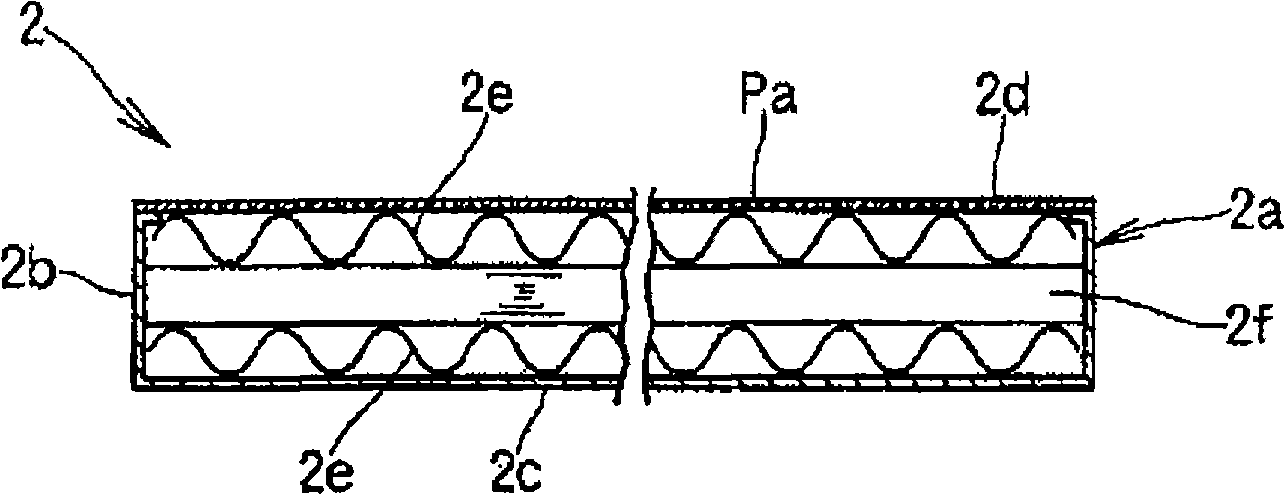

Soundproof panel

InactiveCN101278336AImprove sound absorptionEasy to recycleTransportation and packagingNoise reduction constructionWave shapeEngineering

The purpose of the invention is to provide a sound insulation panel which can exhibit superior sound insulating performance in a wide frequency band and whose sound insulating material is easily recycled. The sound insulation panel 2 constituted by putting the sound absorbing material in a case 2a which has a rectangular frame part and a back plate 2c on one side of the frame part and also has an opening side on the other side covered with a detachable front plate 2d having a plurality of sound wave passages where sound waves pass is characterized in that the sound absorbing material is formed by alternately stacking a longitudinally corrugated aluminum thin plate 2e which has a plurality of corrugations formed in one direction of the case 2a and also has many fine through holes and a laterally corrugated aluminum thin plate 2f which has a plurality corrugations formed in the other direction orthogonal to the corrugation processing direction of the longitudinally corrugated aluminum thin plate 2e and also has many fine through holes.

Owner:KOBE STEEL LTD

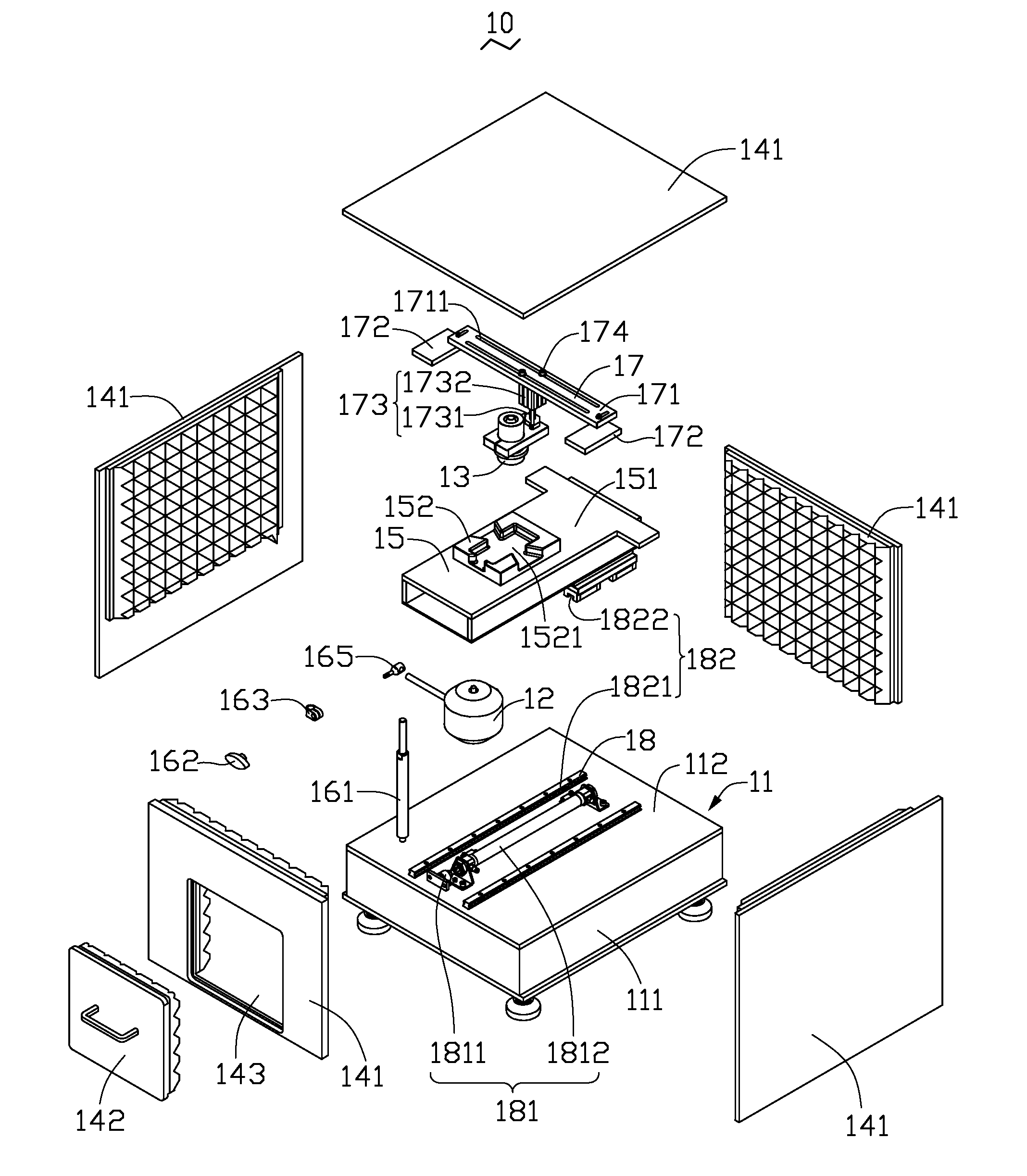

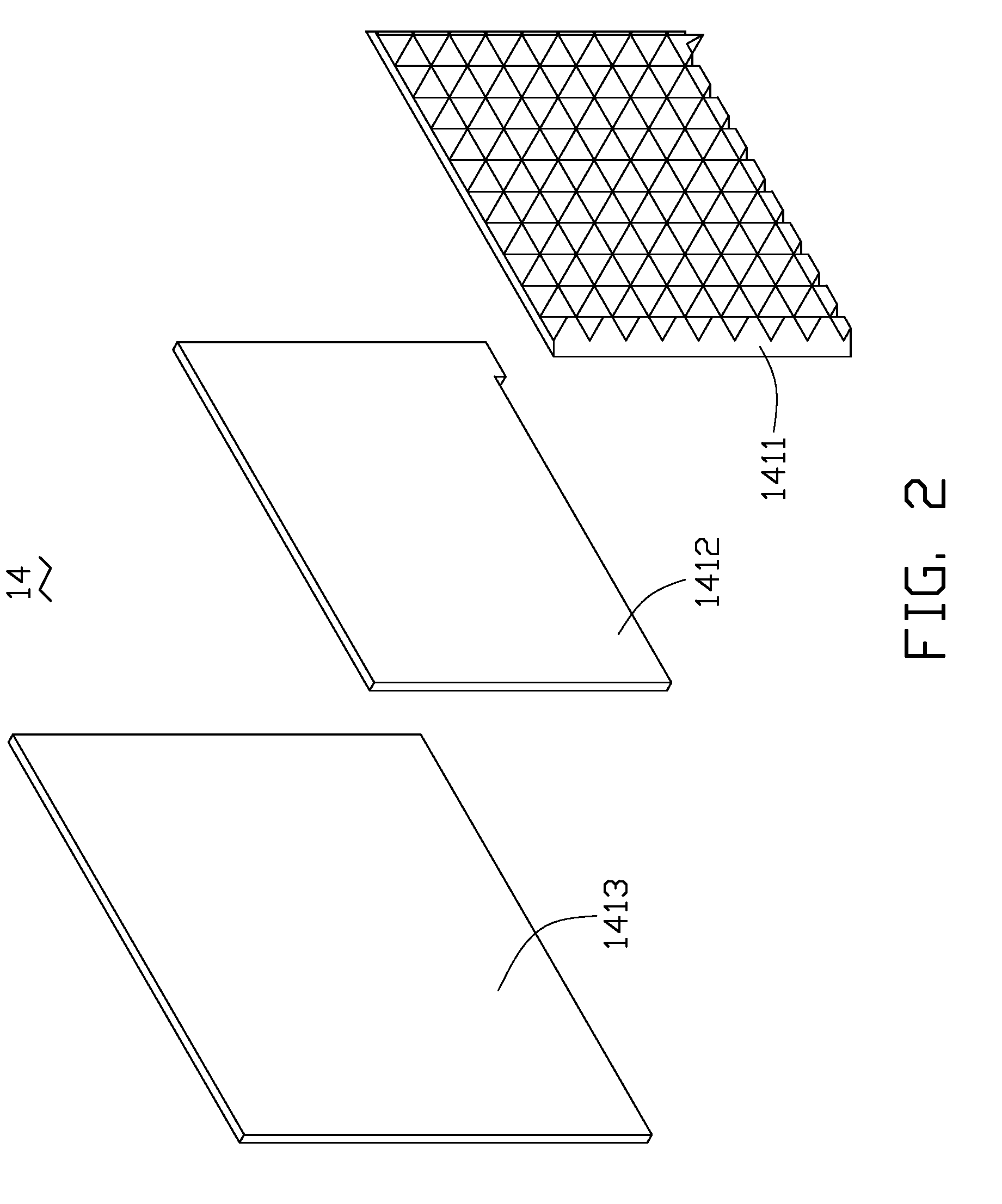

Sound insulating device

InactiveUS20100054487A1Transducer acoustic reaction preventionFrequency/directions obtaining arrangementsEngineeringLoudspeaker

A sound insulating device used to carry out audio testing of a mobile phone is provided. The sound insulating device includes a sound speaker, a sound receiver, a clamping platform clamping the mobile phone thereon and a sound insulating chamber. The sound insulating chamber receives the sound speaker and the sound receiver and the clamping platform therein. The sound insulating chamber is enclosed by several sound insulating boards. Each sound insulating board includes a sound absorbing layer, a cushion layer and an aluminium-alloy layer combined together. The cushion layer is sandwiched between the absorbing layer and the aluminium-alloy layer.

Owner:CHI MEI COMM SYST INC

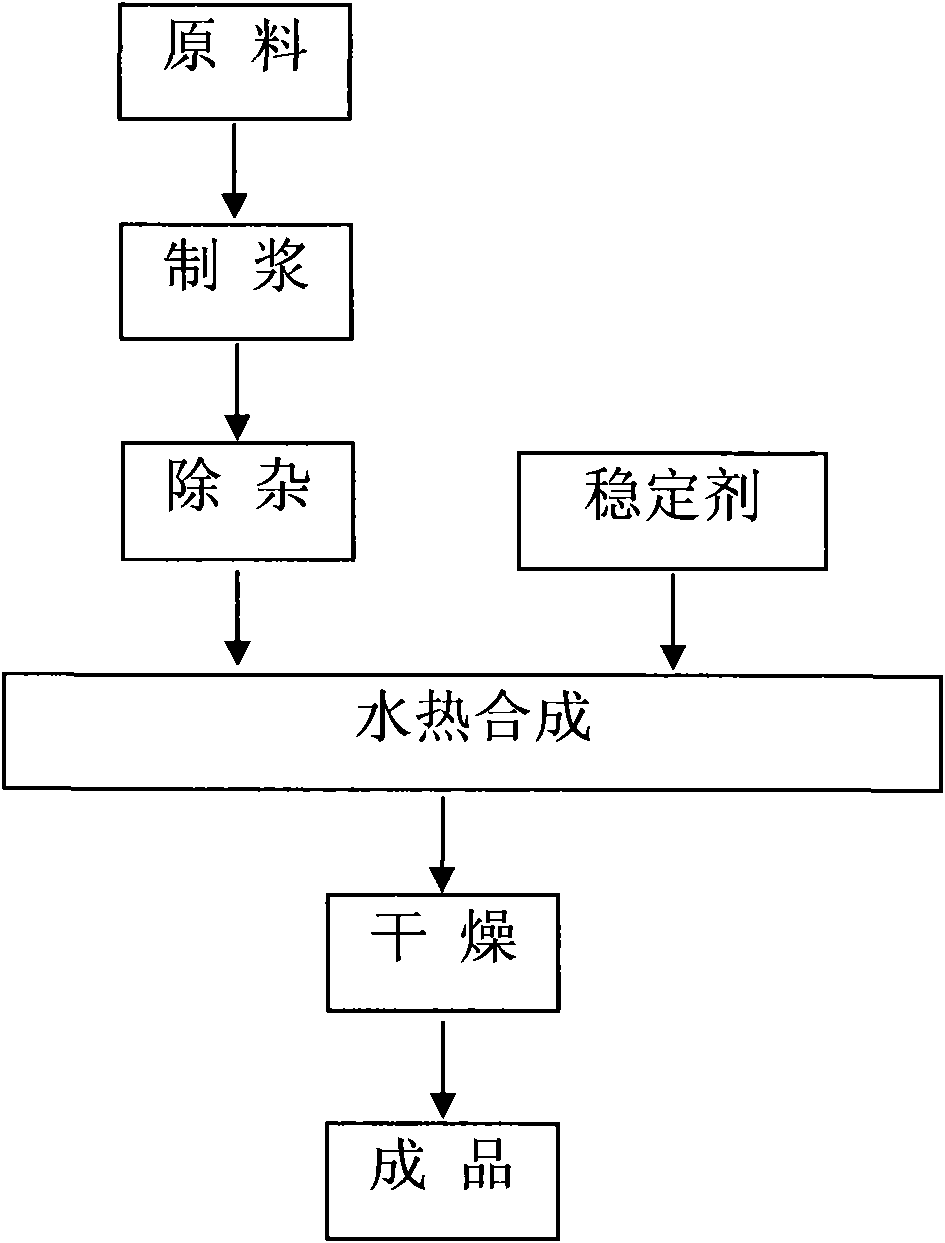

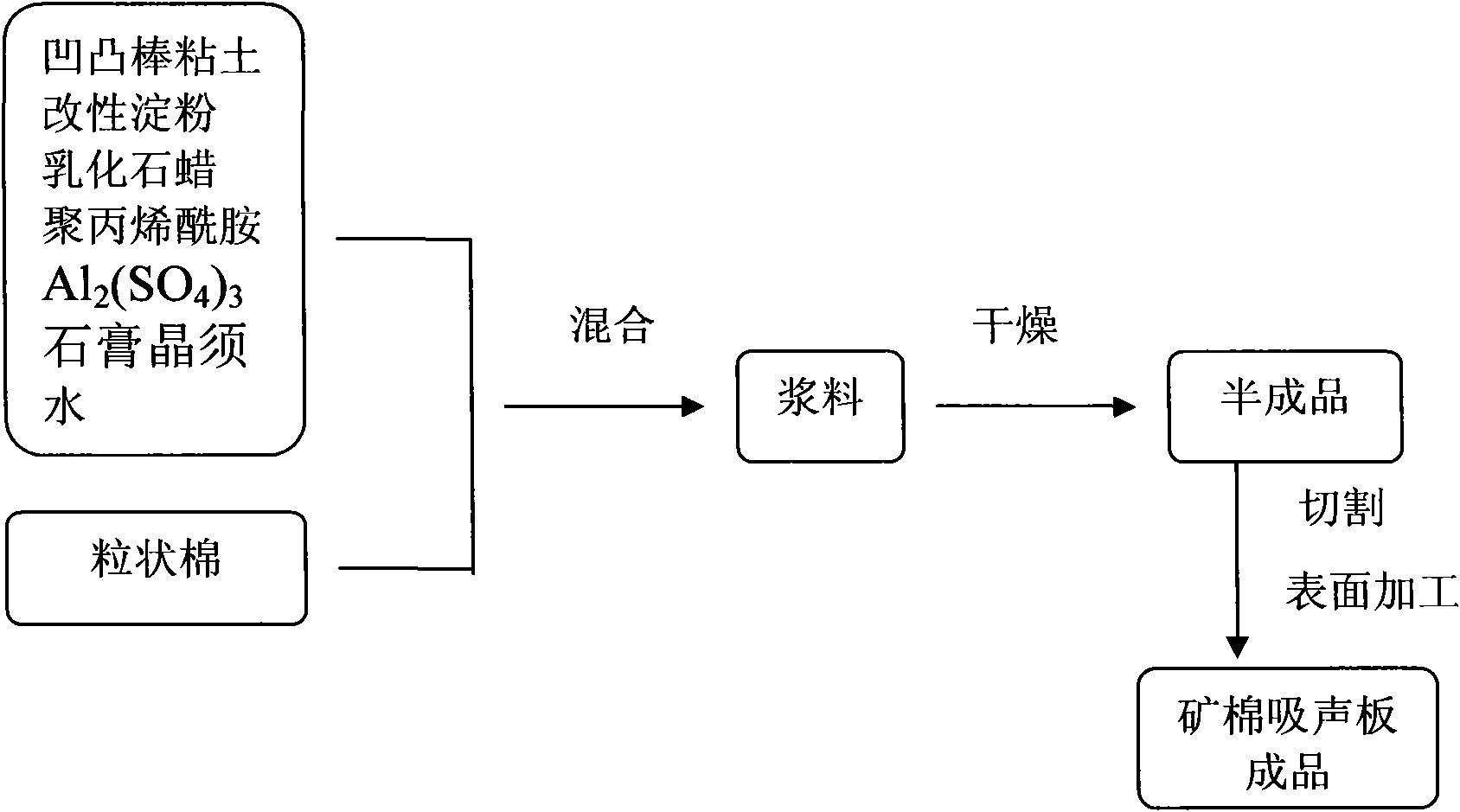

Novel enhanced mineral cotton acoustic board and preparation method thereof

ActiveCN102400498ATake advantage ofHigh strengthSolid waste managementSound proofingTemperature resistanceImpurity

The invention discloses a novel enhanced mineral cotton acoustic board, which comprises 100 weight parts of mineral cotton, 1.6 to 1.0 weight part of polyacrylamide, 5 to 9 weight parts of modified starch, 10 to 16 weight parts of attapulgite clay, 0.4 to 0.7 weight part of aluminum sulfate, 0.5 to 0.7 part of emulsified paraffin and 2 to 30 parts of gypsum crystal whisker. The invention also discloses a preparation method for the novel enhanced mineral cotton board. The method comprises the following steps of: preparing, forming, drying and performing surface finishing. In the method, the gypsum crystal whiskers are prepared from desulfurized gypsum with low purity, and the strength of the mineral cotton acoustic board is enhanced by adding the gypsum crystal whiskers. The gypsum crystal whiskers have the advantages of high strength, high toughness, temperature resistance, chemical corrosion resistance and the like; and the gypsum crystal whiskers which are used as fine monocrystals have complete internal structures, and due to highly-ordered atomic arrangement, the gypsum crystal whiskers do not almost have the defects of cavity, impurities, granular interfaces and the like of any ordinary material, and the strength of the gypsum crystal whiskers is close to a crystal theoretical value, namely the strength of an interatomic valence bond.

Owner:BEIJING NEW BUILDING MATERIALS PLC

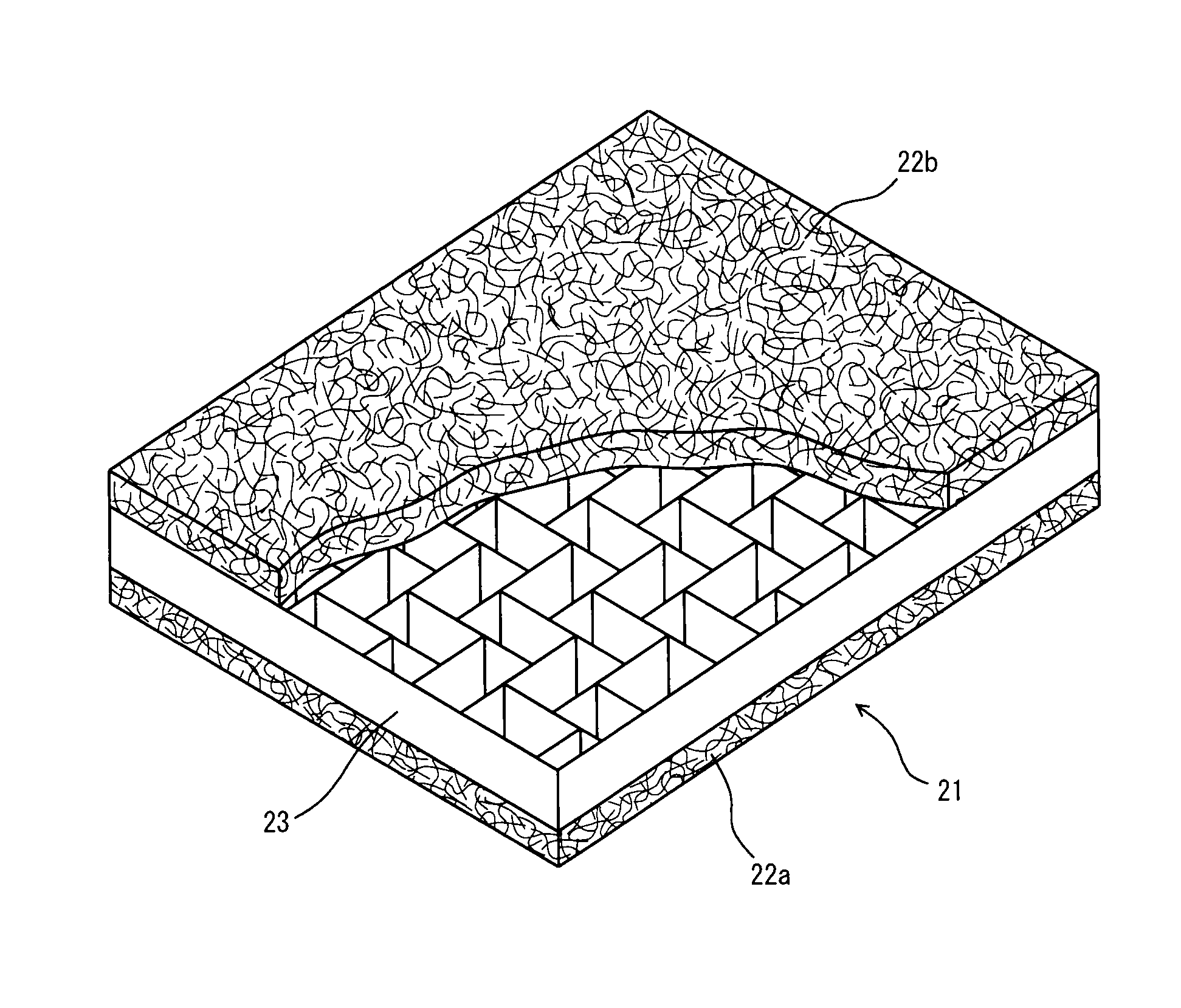

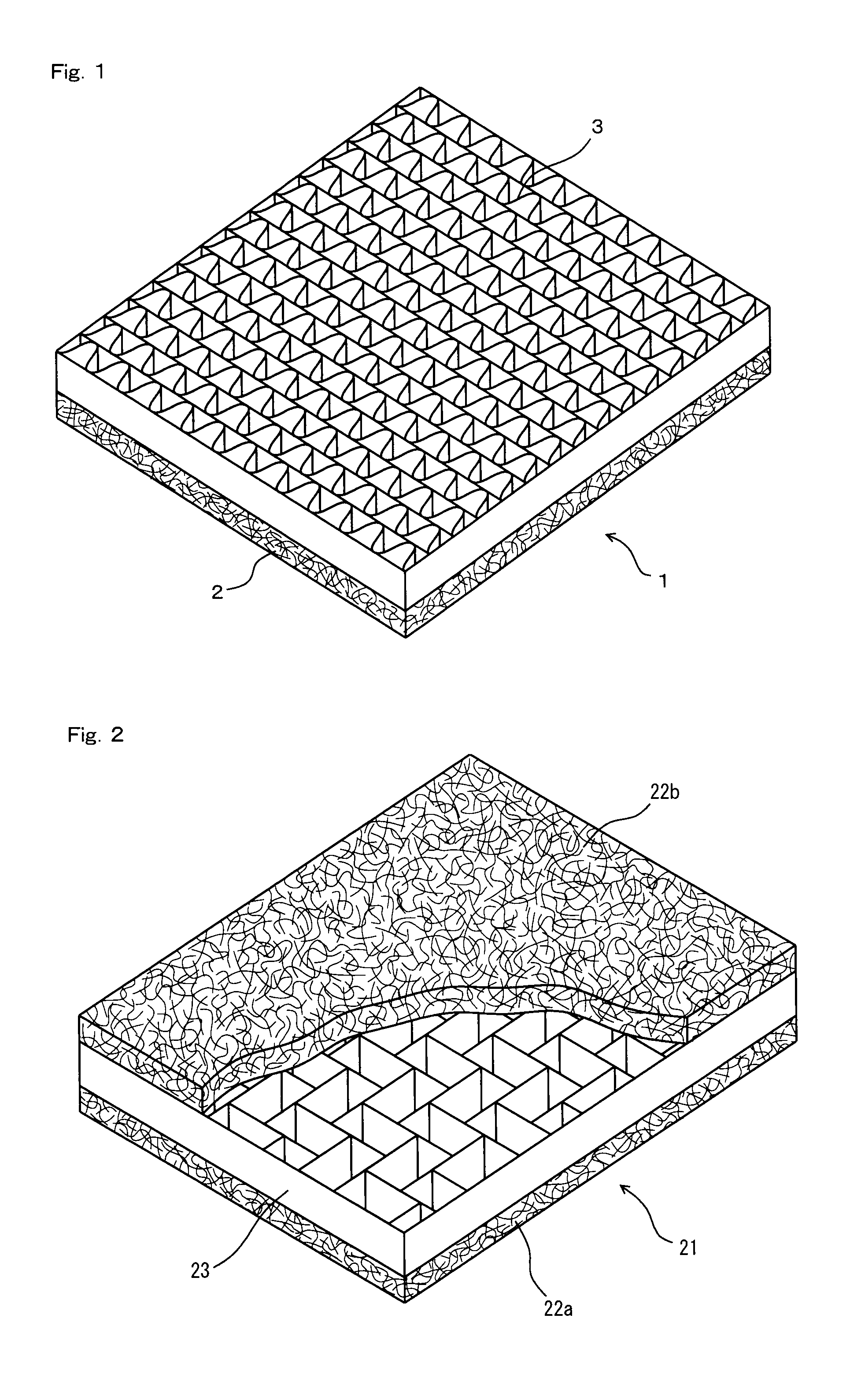

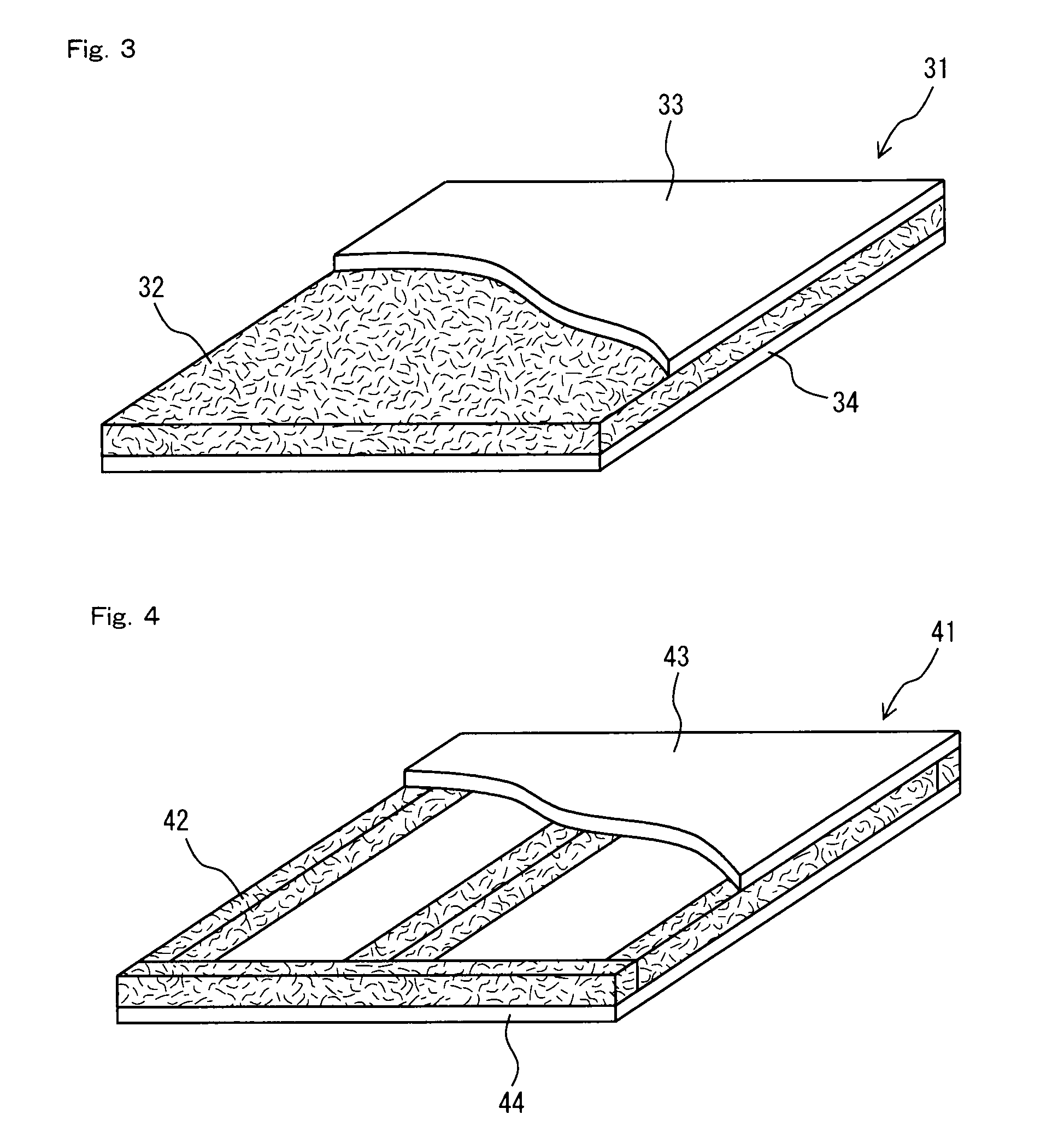

Soundproof panel and soundproof structure

A soundproof panel comprising a nonwoven structural member and a board member is prepared. The nonwoven structural member comprises a thermal adhesive fiber under moisture which is melt-bonded to a fiber of the structural member to fix the fibers. The soundproof panel may be a soundproof panel 1 comprising a nonwoven structural member 2 and a honeycomb member 3 stacked thereto. Moreover, the soundproof panel may be a soundproof panel comprising a board-like nonwoven structural member and first and second surface members stacked to first and second sides of the board-like nonwoven structural member, respectively. Further, the soundproof panel may be a soundproof panel having first and second surface members stacked through a square-pole rail member comprising a nonwoven structural member. The soundproof panel of the present invention has toughness for the lightweight design and has excellent sound absorption and sound insulation properties.

Owner:KURARAY CO LTD

Fly-ash fiber outer wall heat-insulation board and preparation method thereof

The invention discloses a fly-ash fiber outer wall heat-insulation board and a preparation method thereof. Weight percentage of each component is as follows: 70-90 wt% of fly-ash fiber, 8-19 wt% of an inorganic binder, 2-5 wt% of an organic binder and 0-6 wt% of an additive. The fly-ash fiber outer wall heat-insulation acoustic board has wide source of raw materials and low cost, has volume density of 200-350 kg / m<3>, heat conductivity coefficient of 0.032-0.044 W / (m.K) and compression strength of 2.0-3.5 MPa, and has no poisonous and harmful materials to human health and environment. The combustion performance of the fly-ash fiber heat-insulation acoustic board reaches to A-grade non-combustible requirements of the ISO 1182-2002 standard. The fly-ash fiber outer wall heat-insulation acoustic board can effectively prevent fire accidents from happening.

Owner:SHANGHAI HUAMING HI TECH GRP

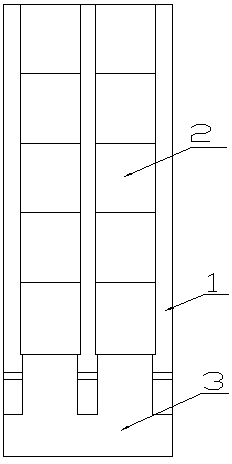

Acoustic barrier

ActiveCN103526700AImprove sound absorptionHigh strengthNoise reduction constructionCeramic compositeAcoustic absorption

The invention discloses an acoustic barrier comprising supporting rib columns, acoustic boards and a back board. A hollow structure is formed between the acoustic boards and the back board, and the supporting rib columns are fixedly bonded on a railway foundation. The acoustic boards are microporous ceramic composite boards with three-dimensional meshy pore structures in disordered communication. The acoustic barrier composed of the supporting rib columns, the acoustic boards and the back board has a camber surface, and the concave direction of the camber surface faces to a railway train operation surface. The lower edge of the back board extends out of the bottom ends of the supporting rib columns. The acoustic barrier is of a three-layer hollow acoustic-absorption acoustic structure, and the microporous ceramic composite boards adopted as the acoustic boards not only have an excellent noise reduction function but also have better processability; the noise-reduction acoustic barrier of the camber-surface structure has better acoustic absorption and reflection properties, and escaped noise can be further reduced. Tests prove that the acoustic barrier has better acoustic absorption performance, and is high in acoustic absorptivity, wide in acoustic absorption frequency band and low in low-frequency acoustic absorption effect. A prefabricated structure of the acoustic barrier is more convenient to process and install, and higher in construction efficiency.

Owner:CHENGDU ZHONGHONG RAIL TRANSIT ENVIRONMENTAL PROTECTION IND +1

Speaker having a transparent panel

InactiveUS20050152564A1Dampening qualityMinimizes bending of the portionSound producing devicesPlane diaphragmsEngineeringLoudspeaker

A speaker having a transparent sound panel and an exciter connected to the transparent sound panel for converting electrical energy received by the exciter, into vibrations that are transmitted to the transparent sound panel, resulting in the transparent sound panel transmitting sound. The speaker also contains a stiff panel located between the exciter and the transparent sound panel, where the stiff panel minimizes dampening qualities associated with material utilized to fabricate the transparent sound panel and minimizes bending of the portion of the transparent sound panel that is in contact with the stiff panel. In addition, a dampening pad is located within the exciter for absorbing a portion of excessive mid-high frequency vibrations emanating from the exciter prior to transmission to the transparent sound panel.

Owner:BROOKSTONE PURCHASING

Holder for hand-held electronic communication device

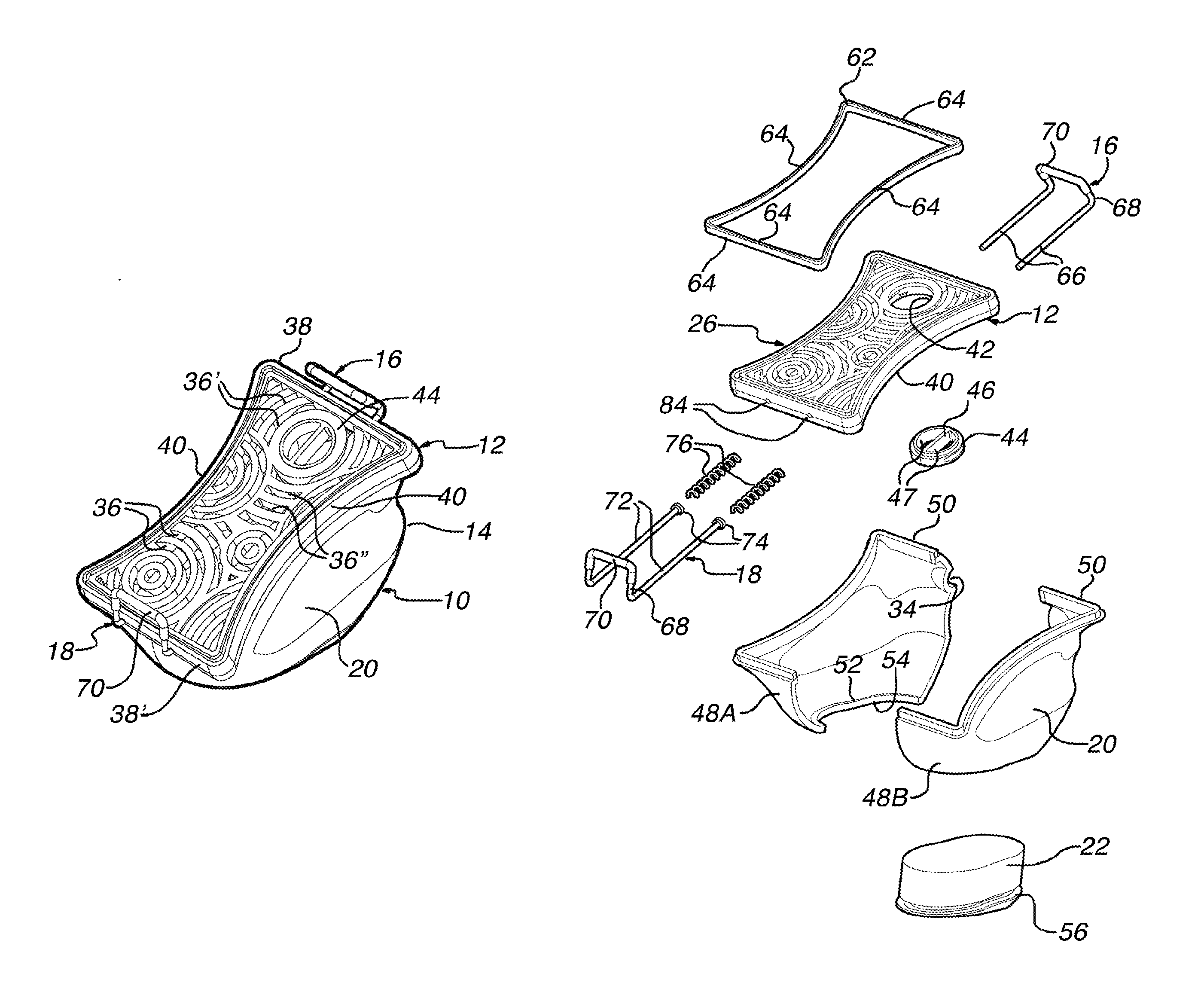

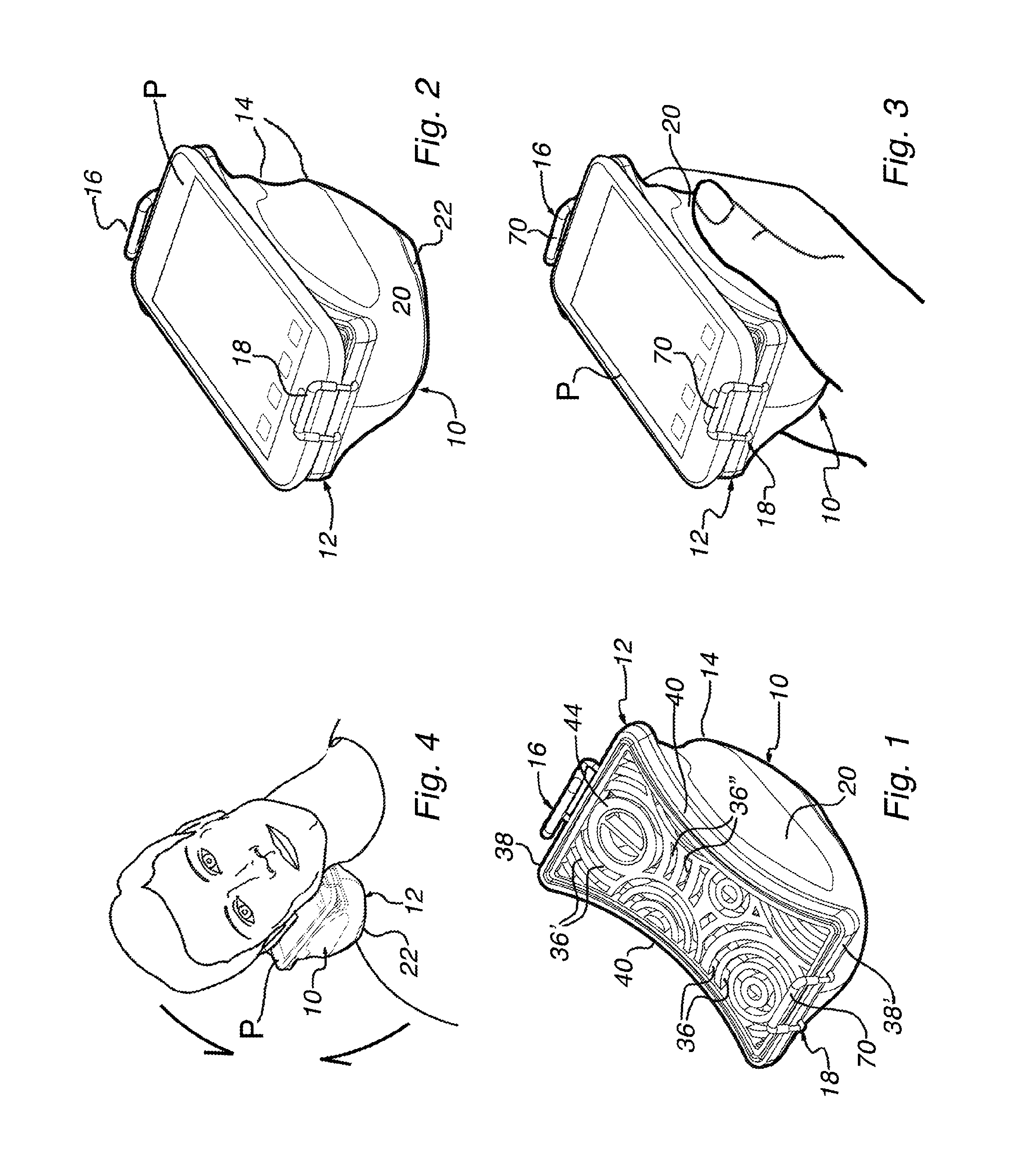

The holder for a hand-held electronic communication device is lightweight and comprises a perforated faceplate and a base of ergonomic form symmetrically constructed for ambidextrous, hand-held use, shoulder support, and surface support in both portrait and landscape orientations. The faceplate incorporates two clamping mechanisms, one being operative for fixing its gripping part in selected positions of extension from the faceplate and the other dynamically adjusting to position its gripping part for cooperatively clamping the communication device therebetween. A peripheral gasket on the front of the faceplate cushions and positionally stabilizes the mounted device, and is formed to promote the projection of sound waves from under the mounted device. The base may have holes and / or an internal acoustic baffle to further promote the projection of sound waves from its cavity, and holes in the faceplate and / or the base may enhance aesthetic attributes.

Owner:SMART & HOW

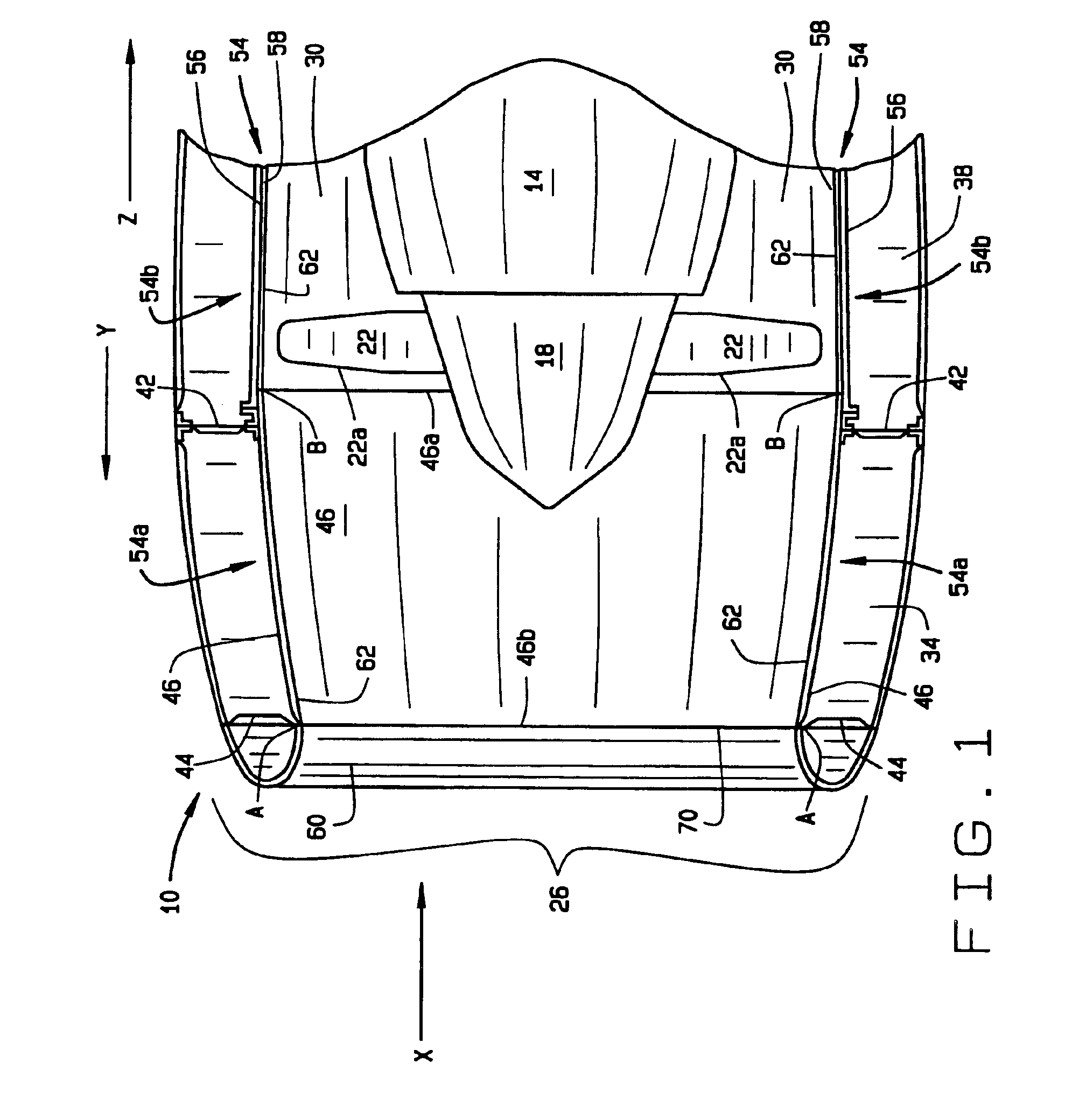

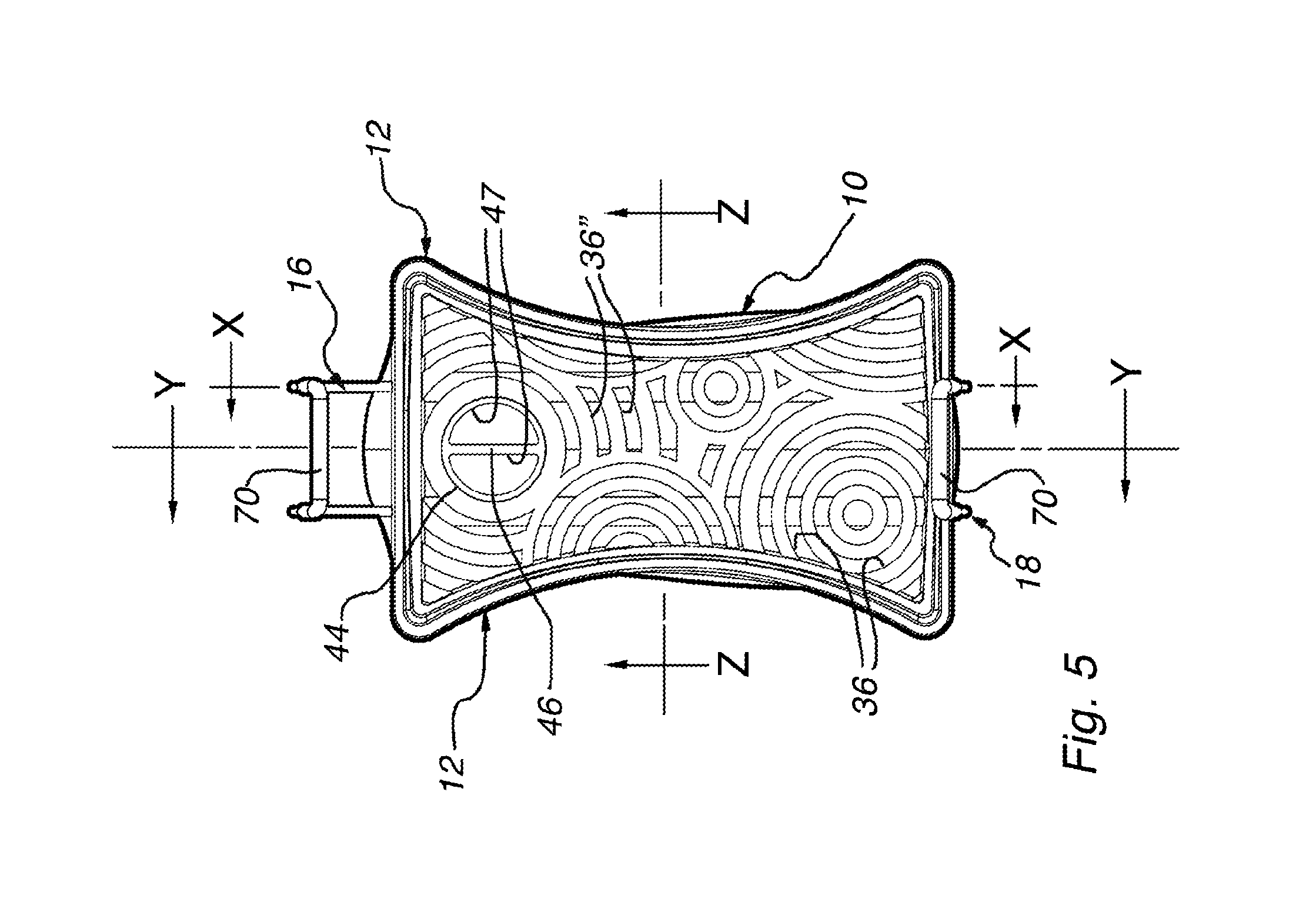

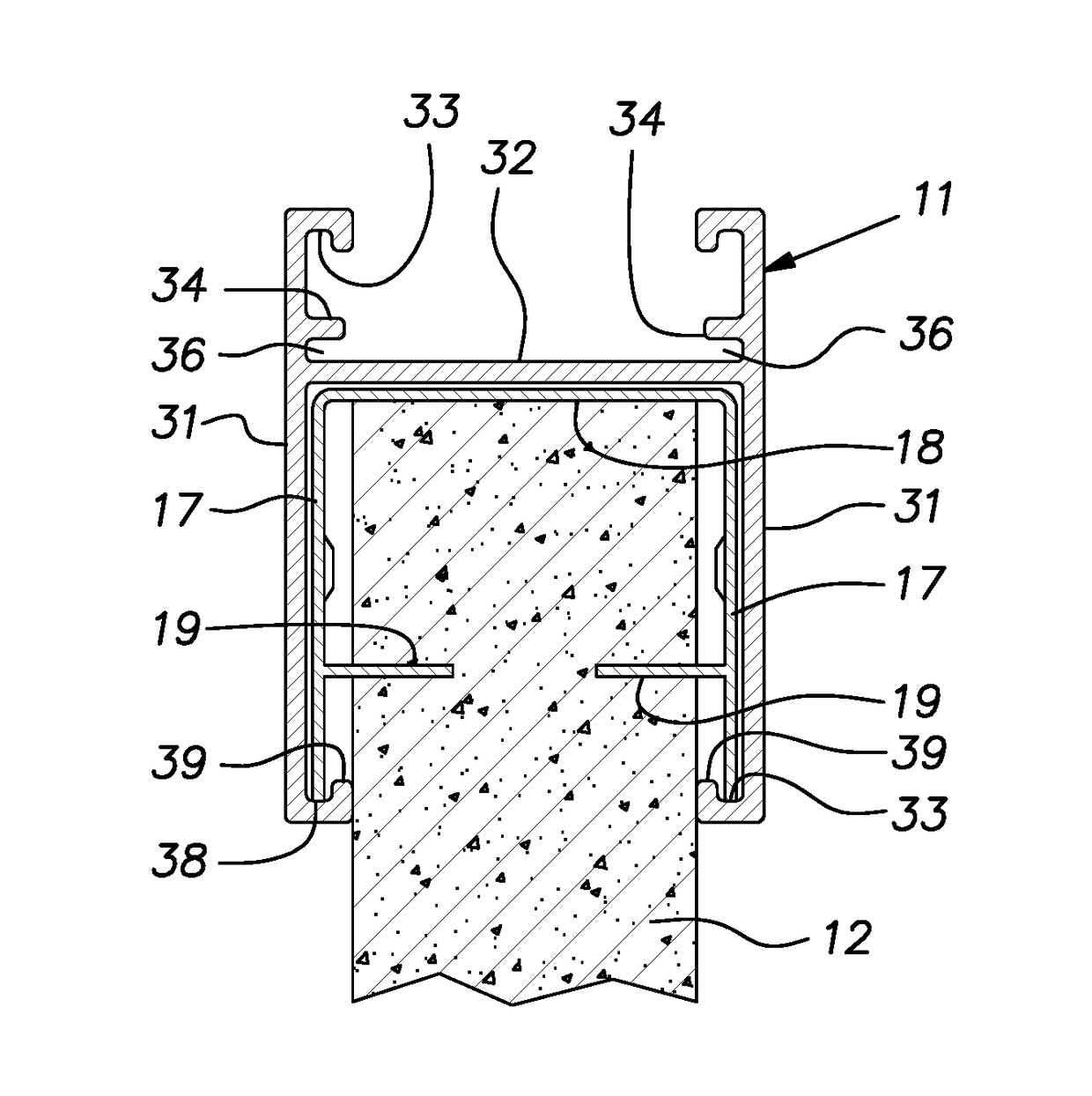

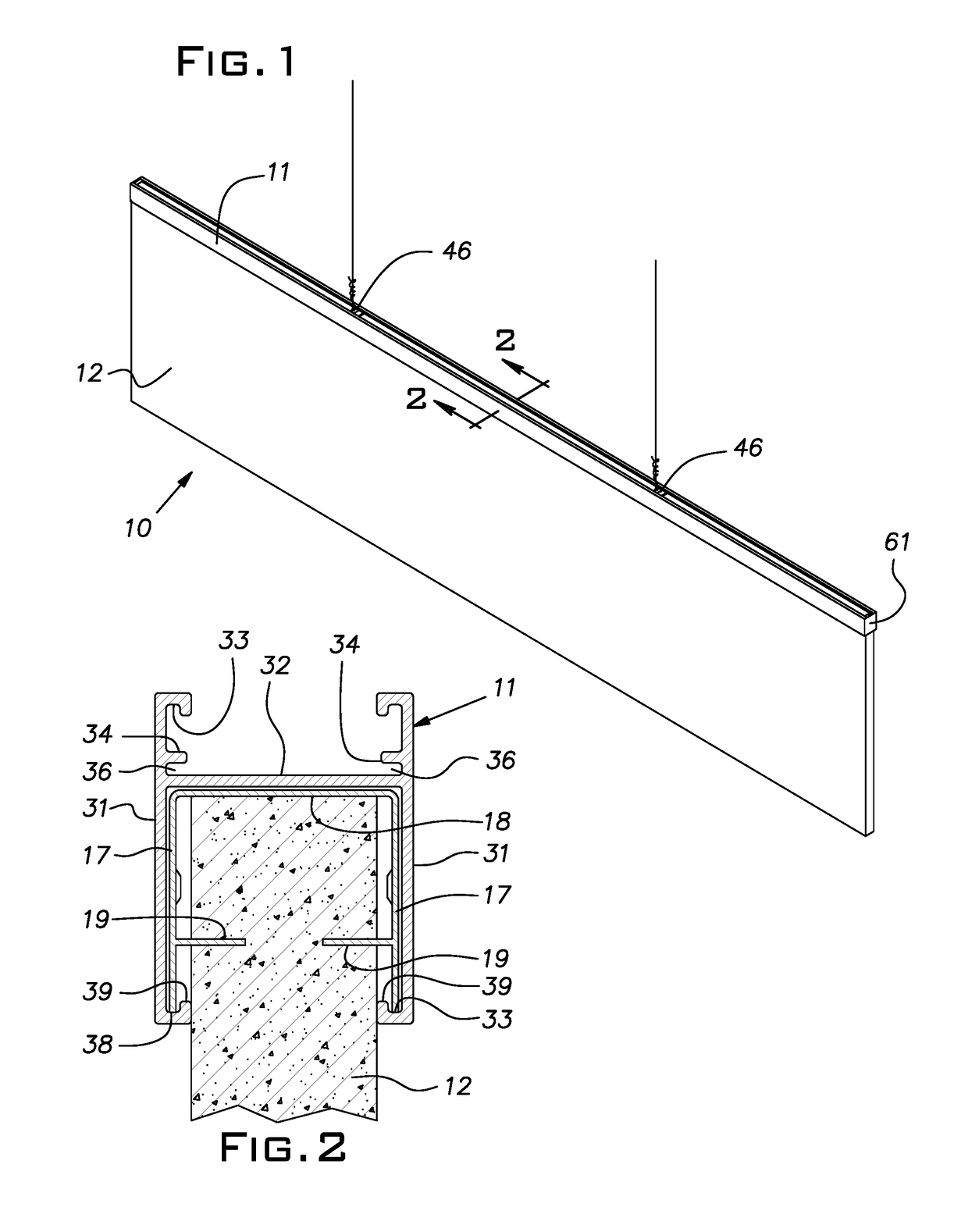

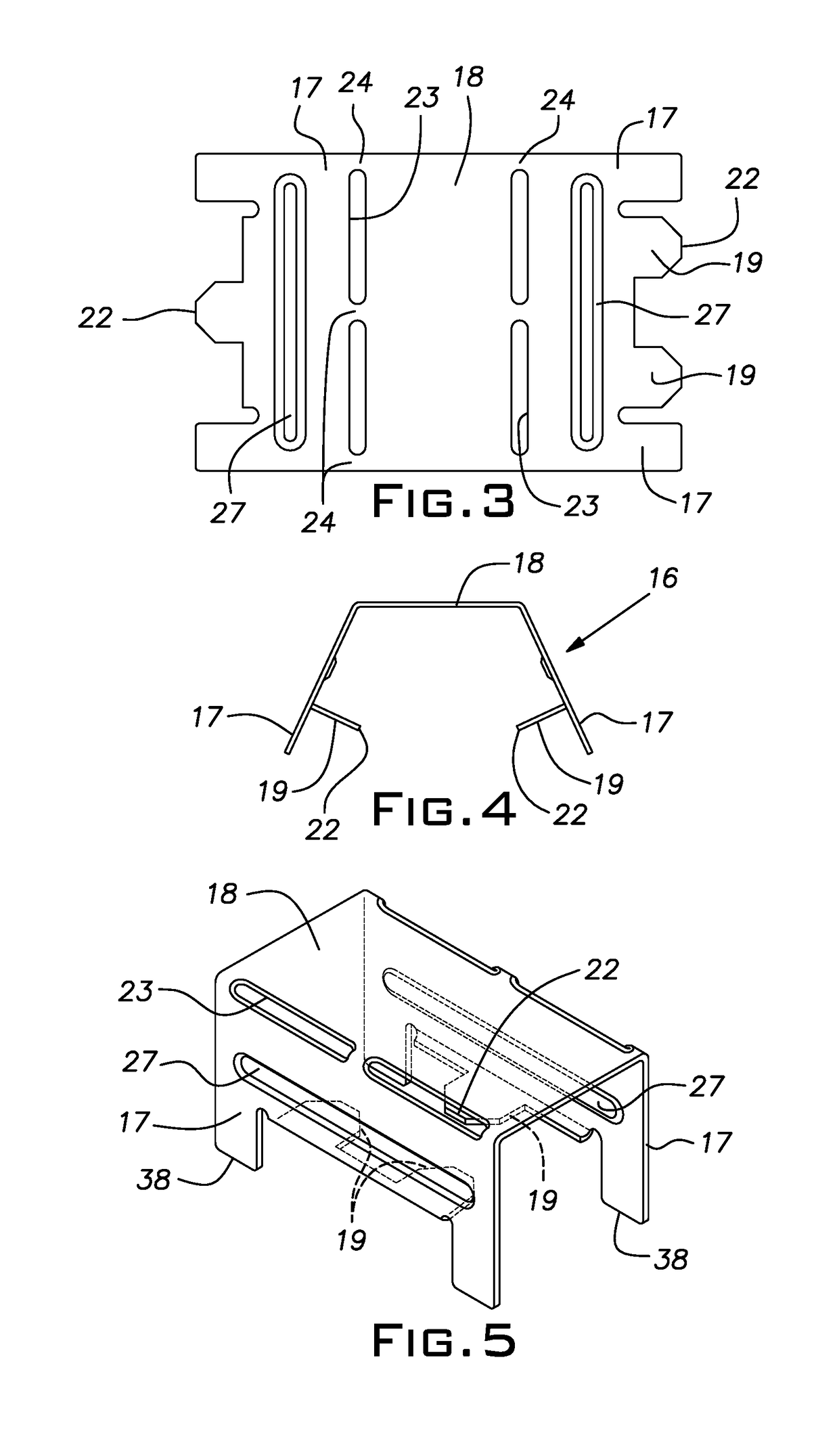

Acoustical baffle panel system

ActiveUS9920525B1Ease of assemblySolve the quick installationCeilingsSound proofingEngineeringAcoustic board

An acoustical baffle assembly comprising an elongated rigid upper carrier, a rigid panel supported on the carrier and a plurality of clips attaching the panel on the carrier at a plurality of locations along the length of the carrier, the clips each being clinched on an upper edge of the panel and being engaged with the carrier.

Owner:USG INTERIORS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com