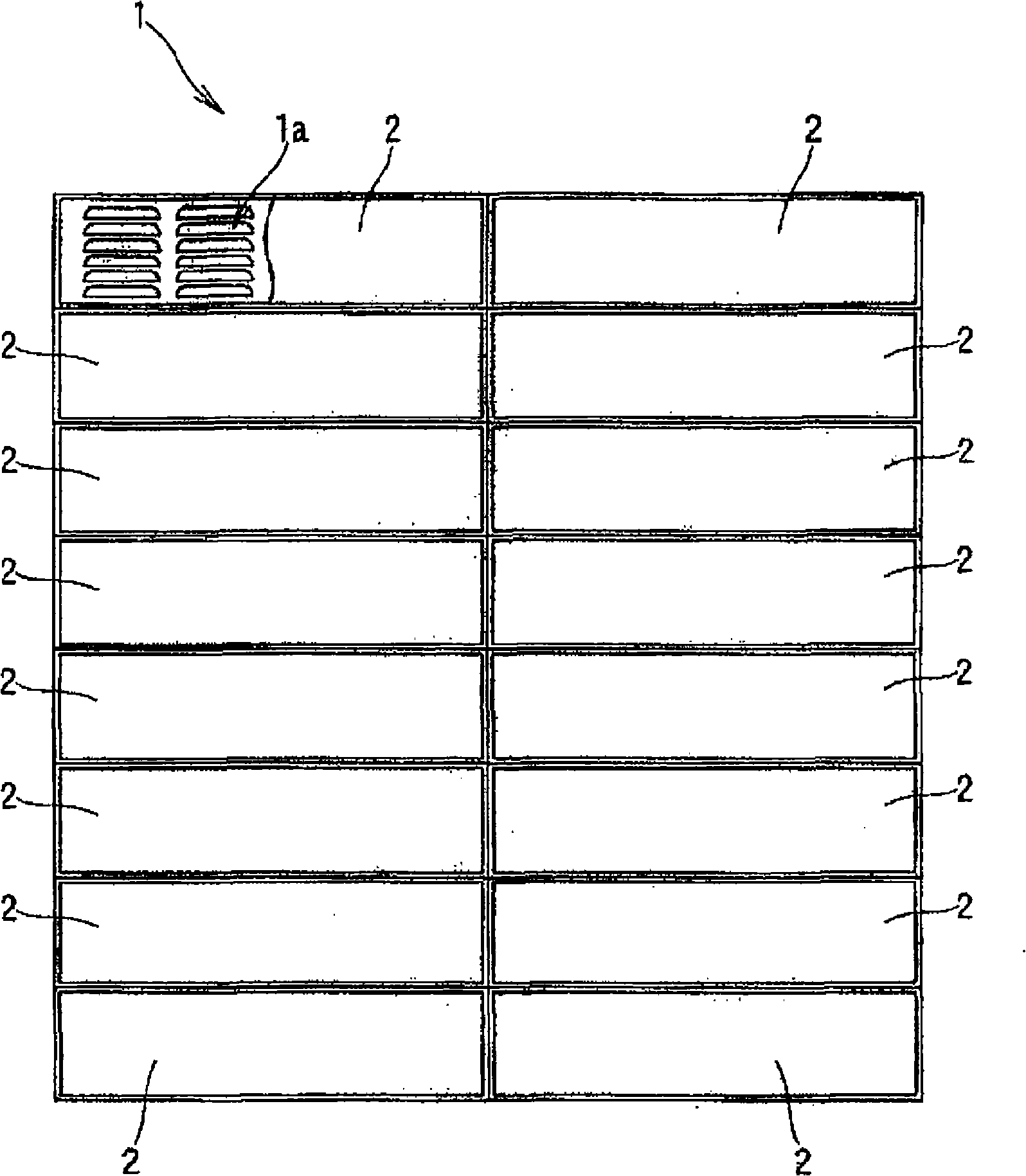

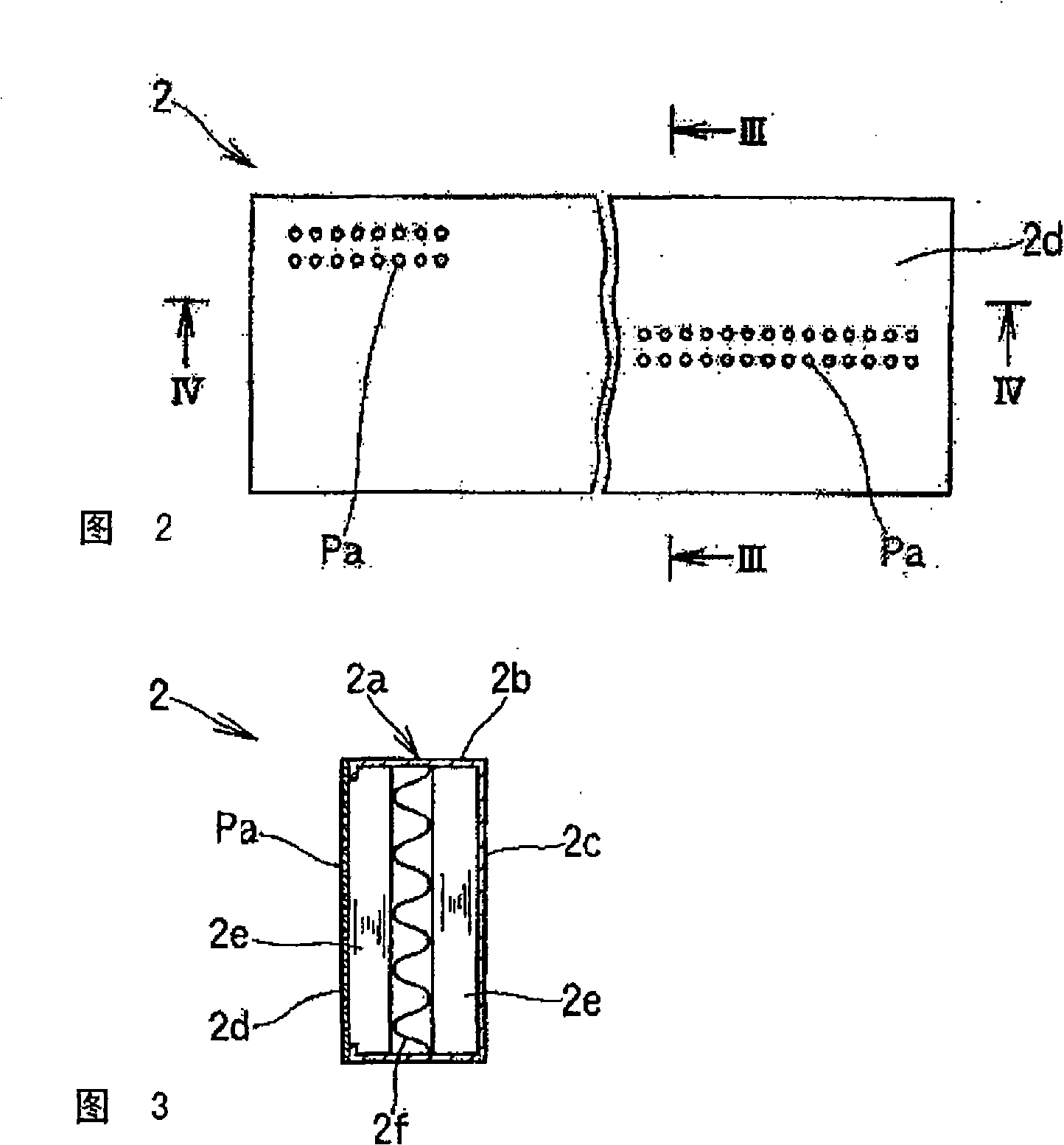

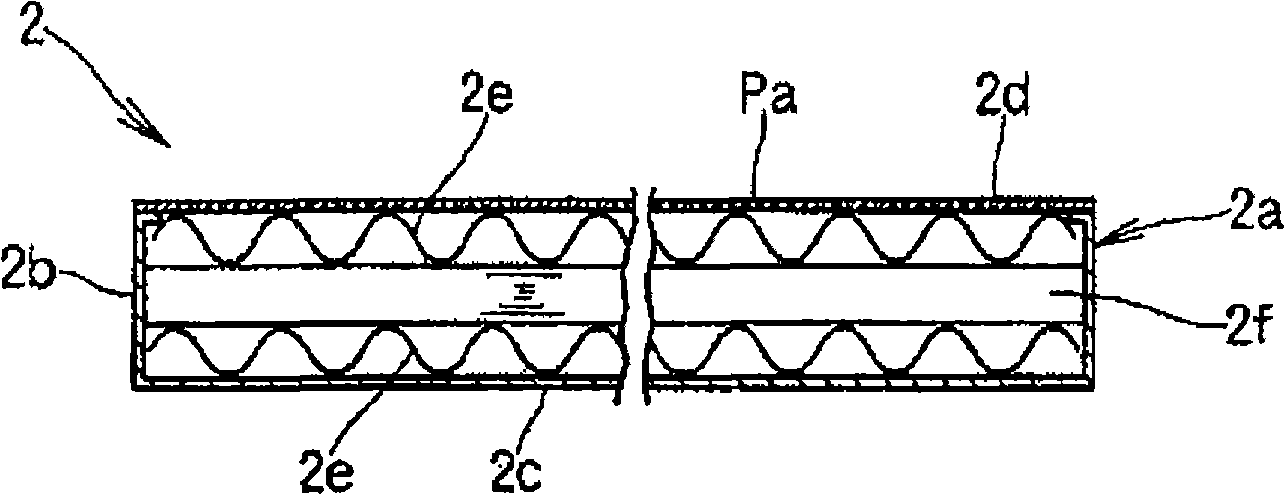

Soundproof panel

A technology of sound insulation panels and back panels, which is applied in the direction of sound insulation, noise absorption devices, and sound-generating devices. It can solve the problems of no public structure, etc., and achieve excellent sound-absorbing performance and easy recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0093] Next, an example in which the oblique incidence sound absorption rates of the sound insulating wall 1 according to Embodiment 1 of the present invention and the sound insulating wall according to Embodiment 6 of the present invention were measured will be described. This oblique incidence sound absorption rate measurement test is shown in the explanatory diagram of the measurement test status Figure 11 The device of the structure shown is carried out. That is, the reflected sound in the regular reflection direction when the pulse sound is incident on the complete reflection surface (concrete floor) at a certain angle and the reflected sound when the sample (sound insulation wall) is installed on the complete reflection surface are respectively measured. As a result, the oblique incidence sound absorption rate α(θ) was obtained from the following equation. However, Es(f) and Er(f) in the following equations are the energy spectrum of the reflected pulse of the perfect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com