Patents

Literature

54results about How to "Reduce road noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

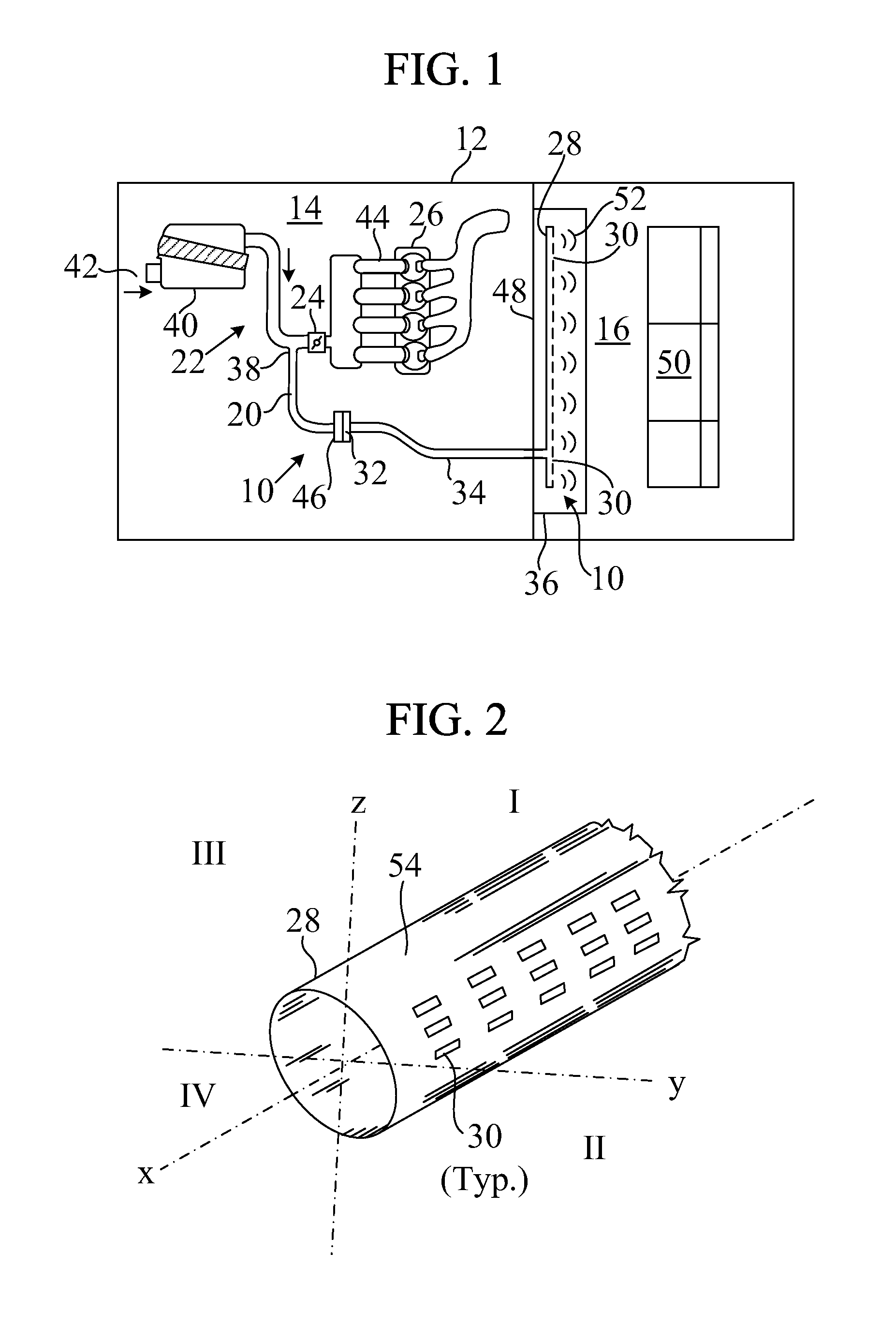

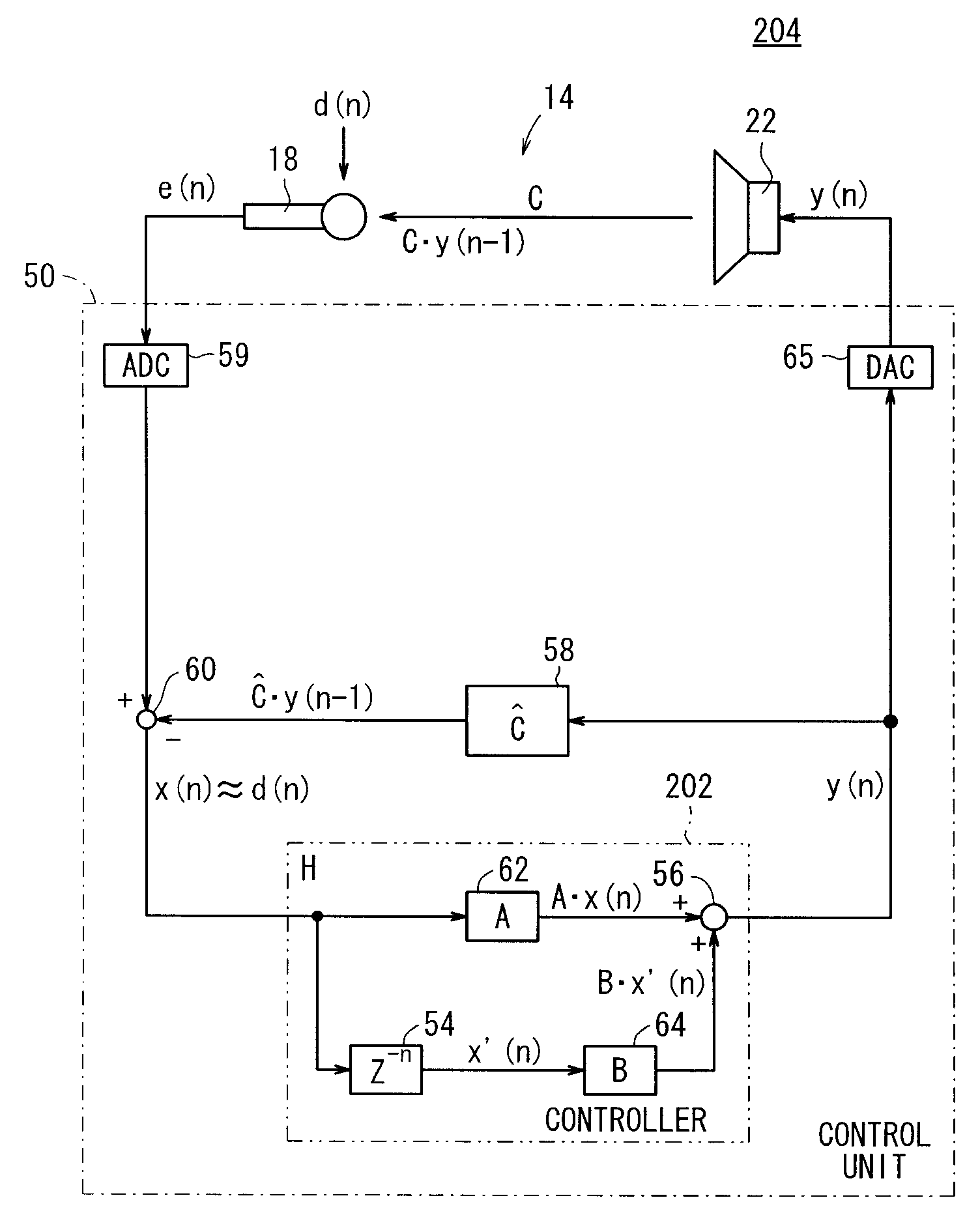

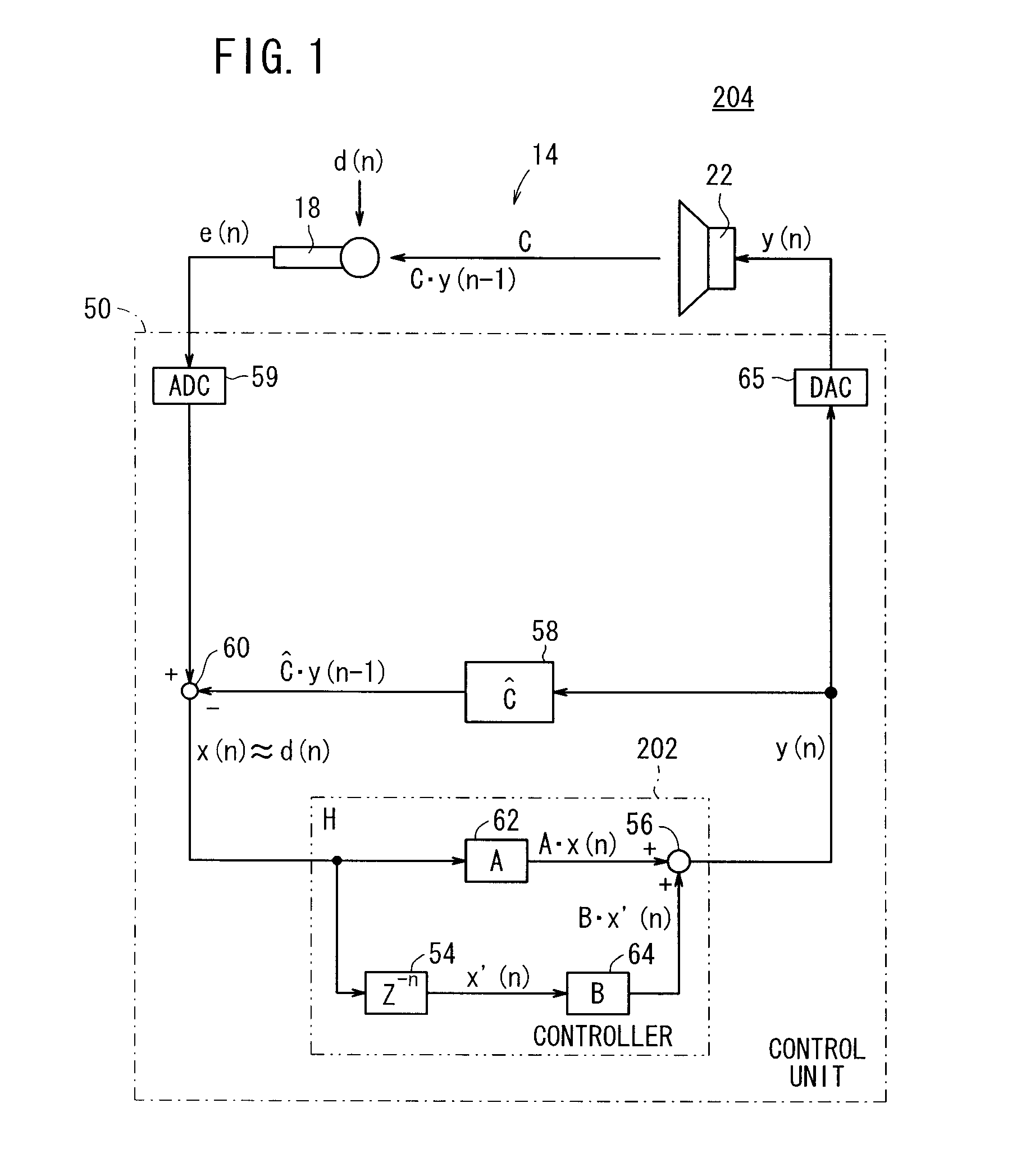

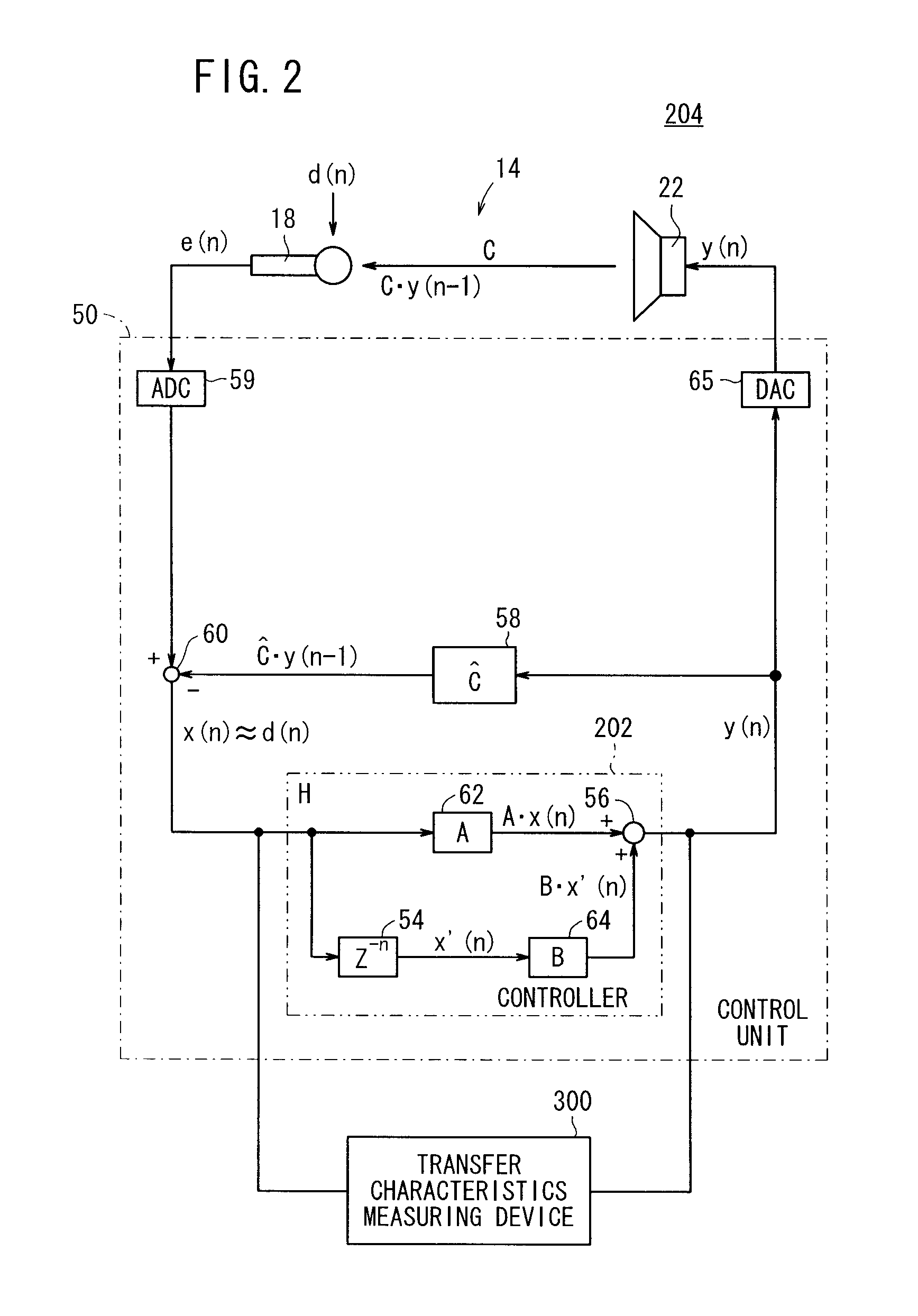

Active noise control apparatus

InactiveUS20080240455A1Reduces computational burdenInexpensive to manufactureEar treatmentNoise generationMicrophoneEngineering

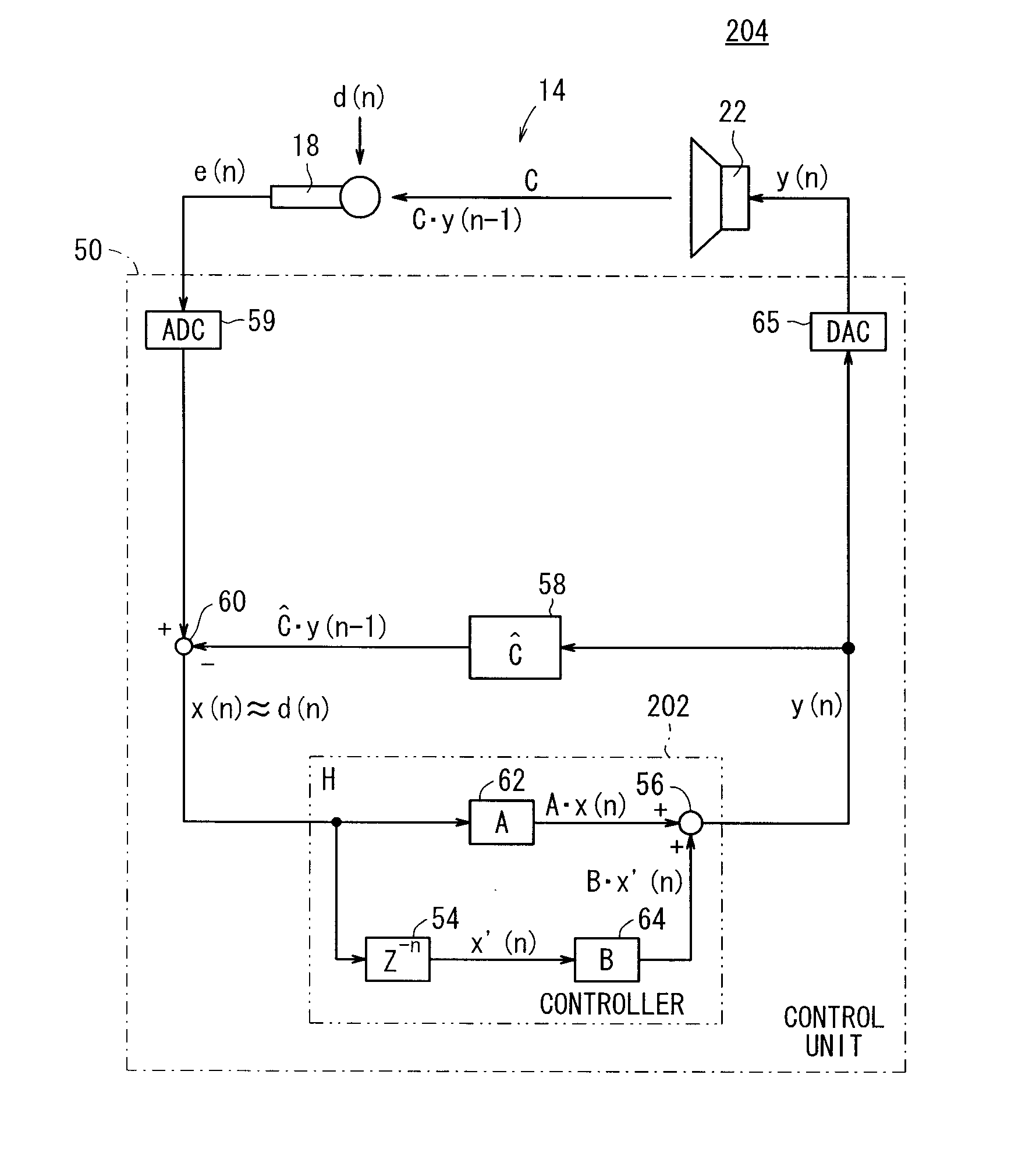

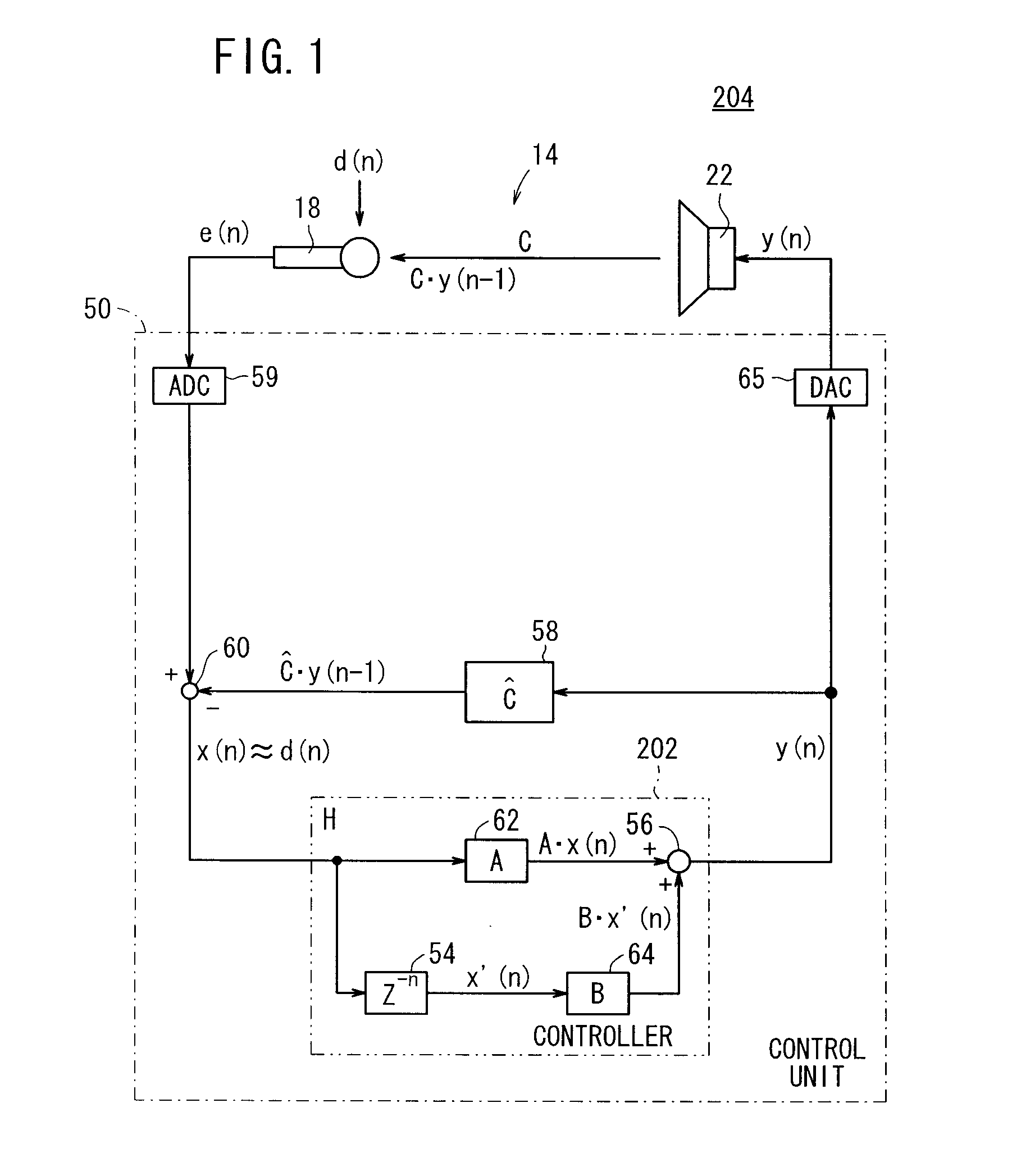

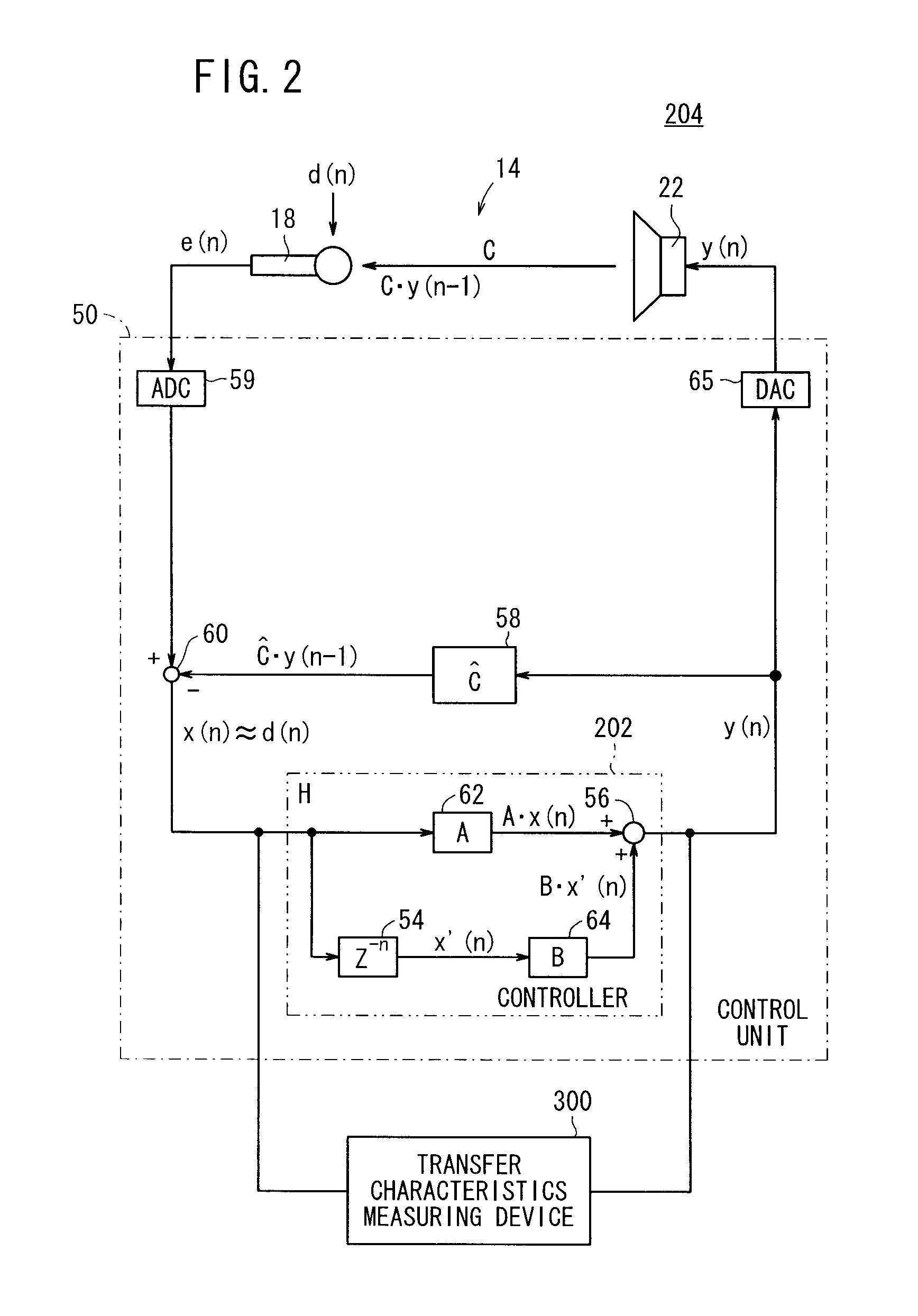

A subtractor subtracts an echo canceling signal (Ĉ·y1(n−1)) from a canceling error signal (e(n)) to estimate the resonant noise (d(n)) to be silenced at a position of a microphone, and outputs a first basic signal (x1(n)) representing the estimated resonant noise d(n) as an input signal supplied to a controller. In the controller, a delay filter generates a second basic signal (x′(n)) by delaying the first basic signal (x1(n)) by a time value (Z−n) The controller generates a control signal (x(n)) based on the first basic signal (x(n)) and the second basic signal (x′(n)).

Owner:HONDA MOTOR CO LTD

Engine sound distribution apparatus for a motor vehicle

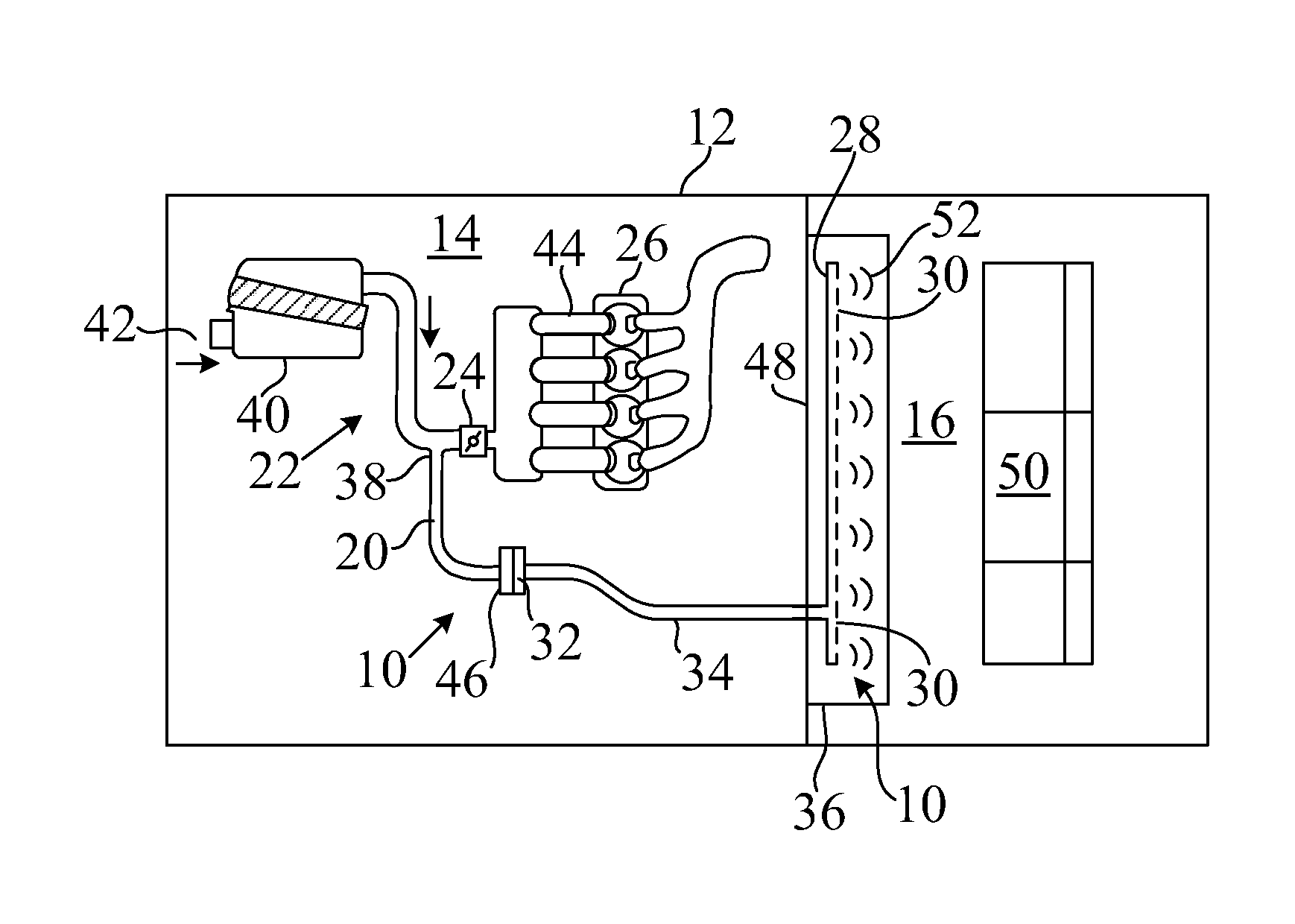

ActiveUS8127888B1Reduce sound levelReduce road noiseSilencing apparatusMachines/enginesSound transmission classDashboard

A sound distribution apparatus provides a driver with an audible impression of the operating speed, load and performance of a vehicle engine. The sound distribution apparatus includes an assembly of one or more sound transmission ducts interconnected to conduct or transmit engine sounds from the air intake tract into the passenger compartment and to distribute the sound in a uniform fashion from behind the dashboard at the front to the passenger compartment. The sound distribution duct includes a plurality of sound diffusion apertures arranged on the outer wall, each configured to diffuse a portion of the transmitted sound into the passenger compartment. A sound permeable airflow blockage device seals the sound transmission duct interior in a gas-tight way preventing airflow.

Owner:MANN HUMMEL GMBH

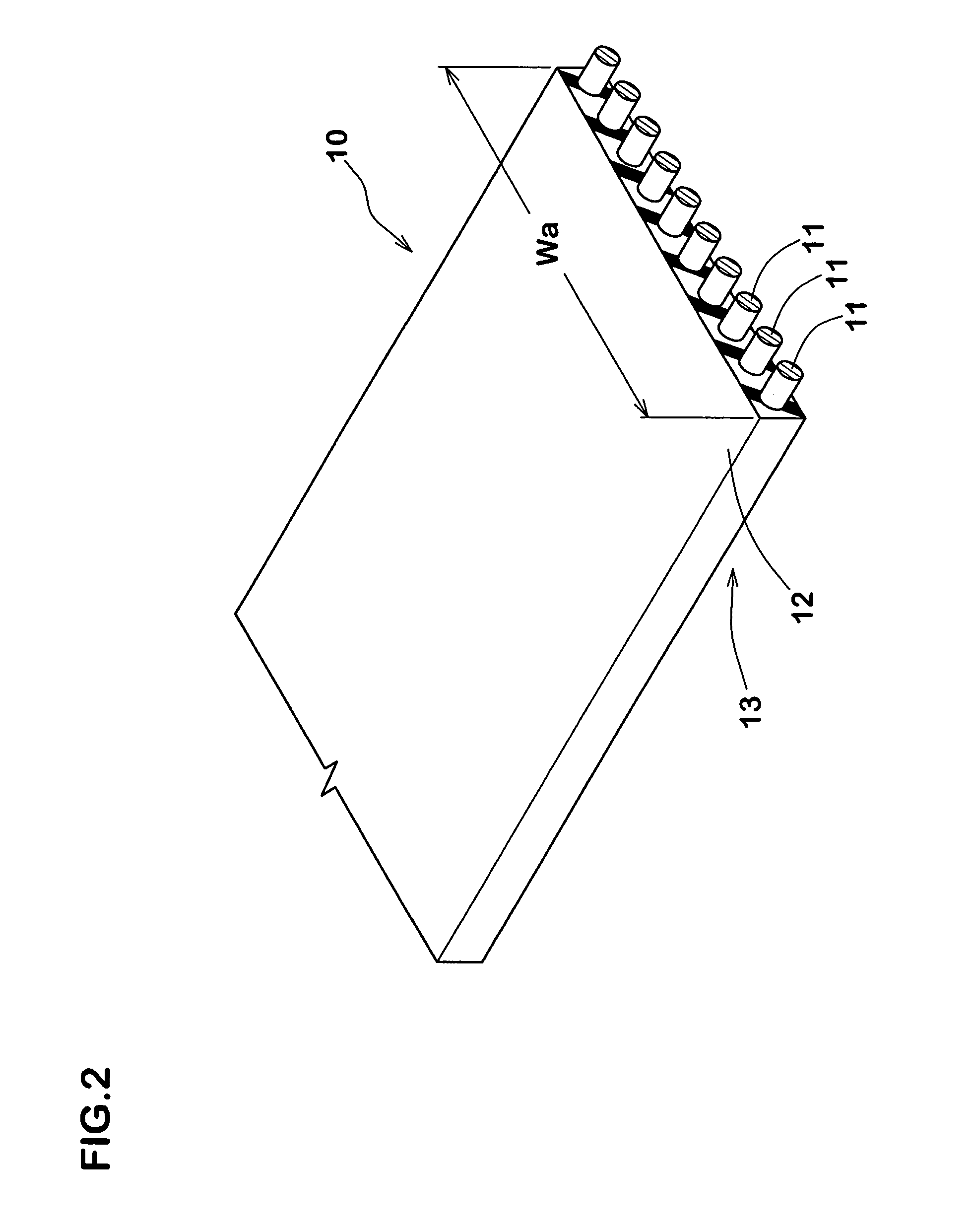

Pneumatic tire and method of manufacturing of the same

InactiveUS20110220264A1Deteriorating productivityReduce road noiseTyresPneumatic tyre reinforcementsEngineeringMechanical engineering

A pneumatic tire has a plurality of projections extending in a tire width direction while protruding out of an inner surface of a tire. The projections are formed in a region coming to an inner side in a tire width direction than an end portion of a belt layer embedded in a tread portion so as to be spaced in a tire circumferential direction.

Owner:TOYO TIRE & RUBBER CO LTD

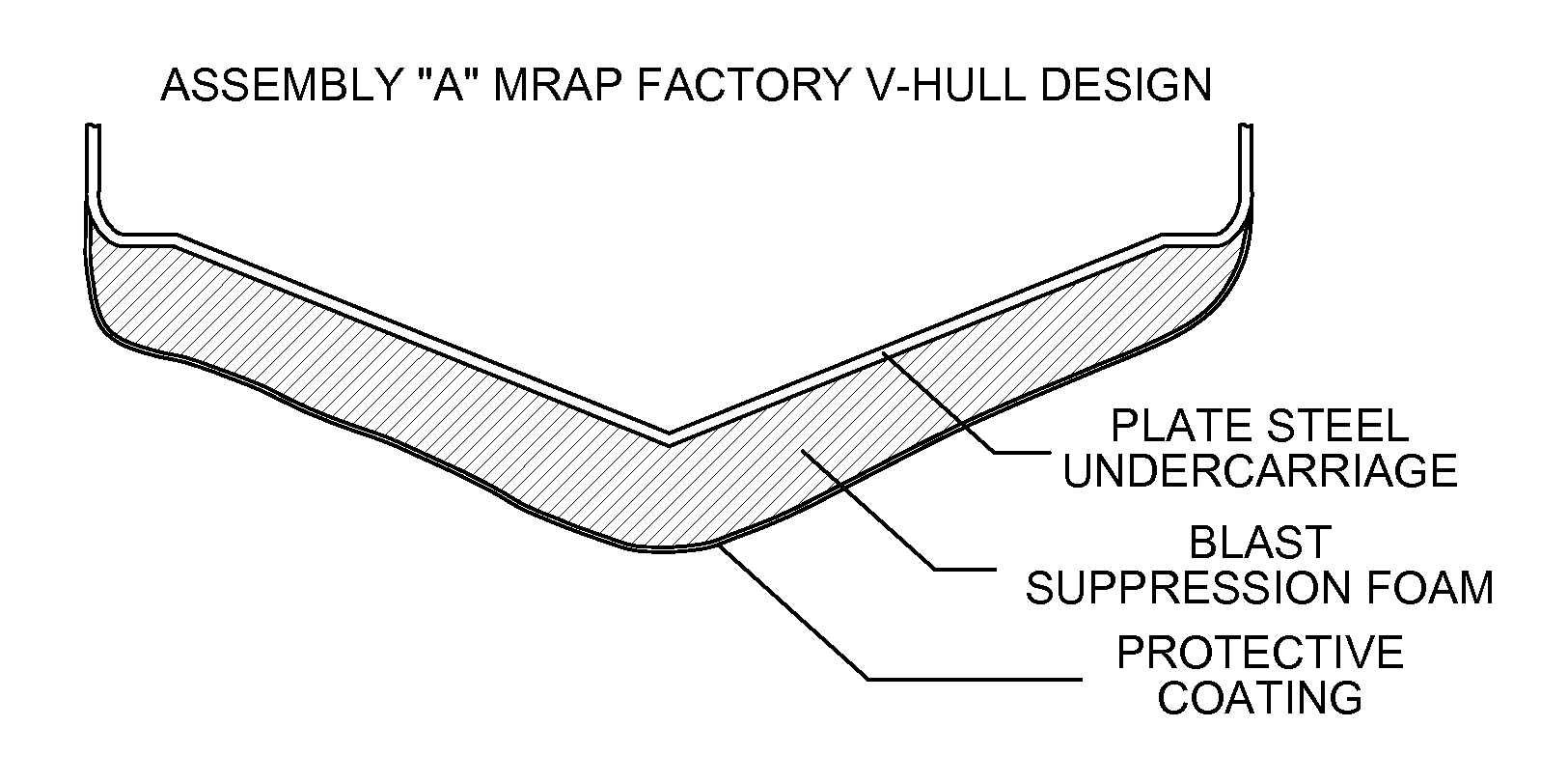

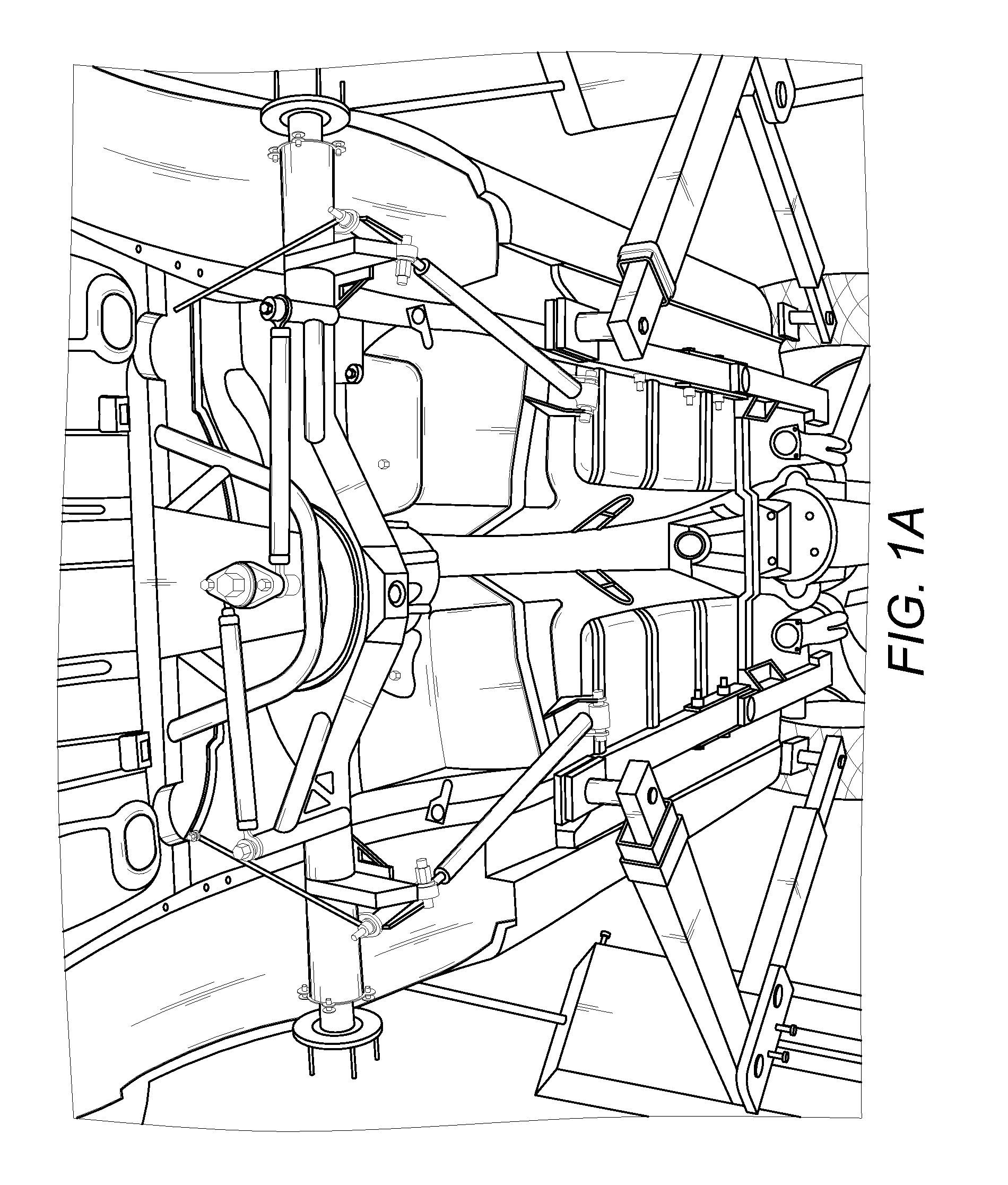

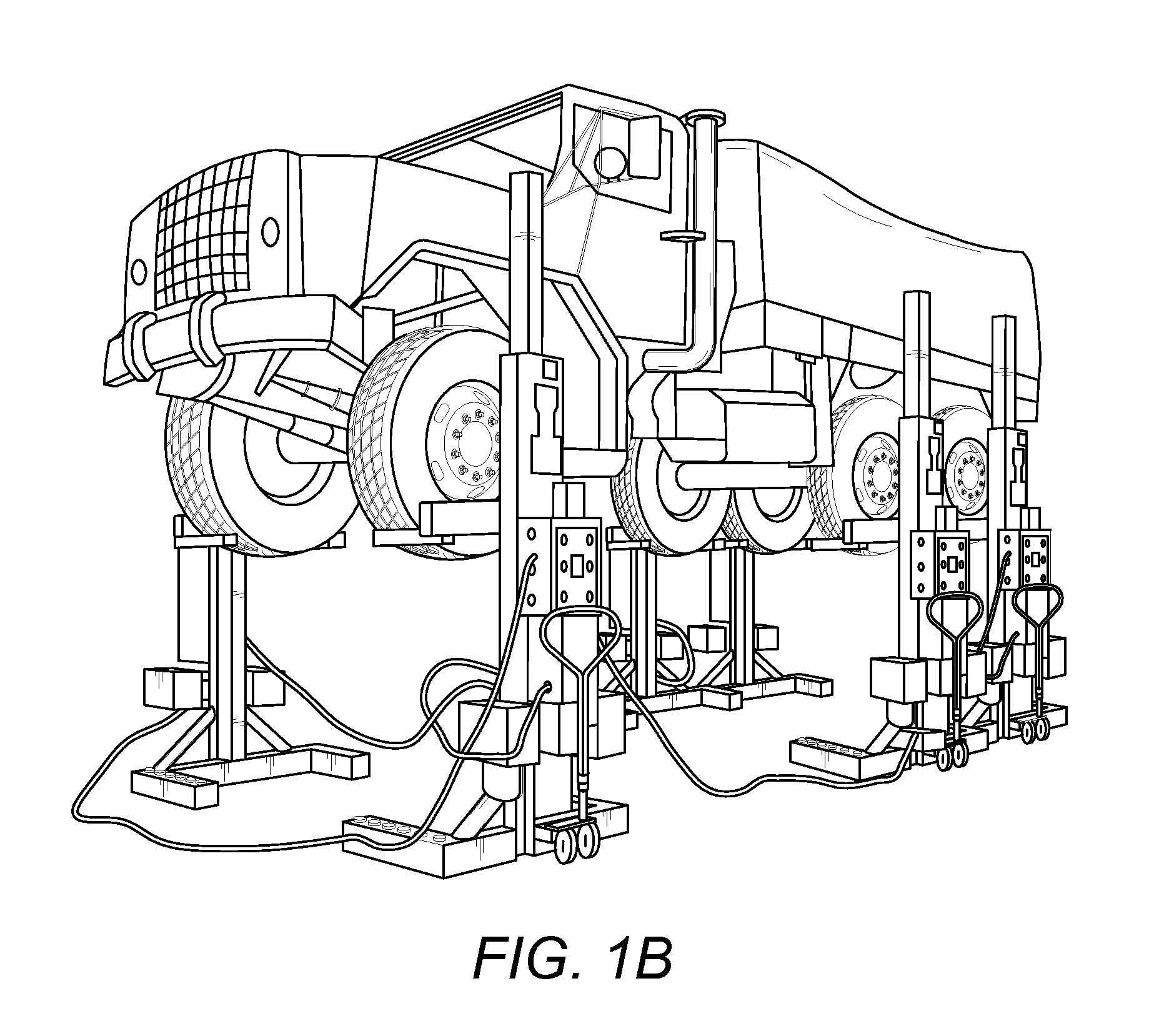

Blast mitigation system for military vehicles

InactiveUS20130036899A1Improved vehicular protectionImprove protectionArmoured vehiclesArmour platesShock waveAbsorbed energy

Disclosed is a system and method to both reduce a degree of explosive shock waves and to absorb a degree of explosive blast energy from the undercarriage of a vehicle which comprises the use of one or more layers of rigid closed-cell spray polyurethane foam, applied to the armored undercarriage of the vehicle. This invention combines two key aspects: 1) blast suppression or mitigation materials that absorb energy and 2) traditional military hardened armor solutions. The effectiveness of spray applied rigid foam has been proven to both dramatically reduce shock waves and absorb energy from explosive blasts (e.g., IEDs).

Owner:HONEYWELL INT INC

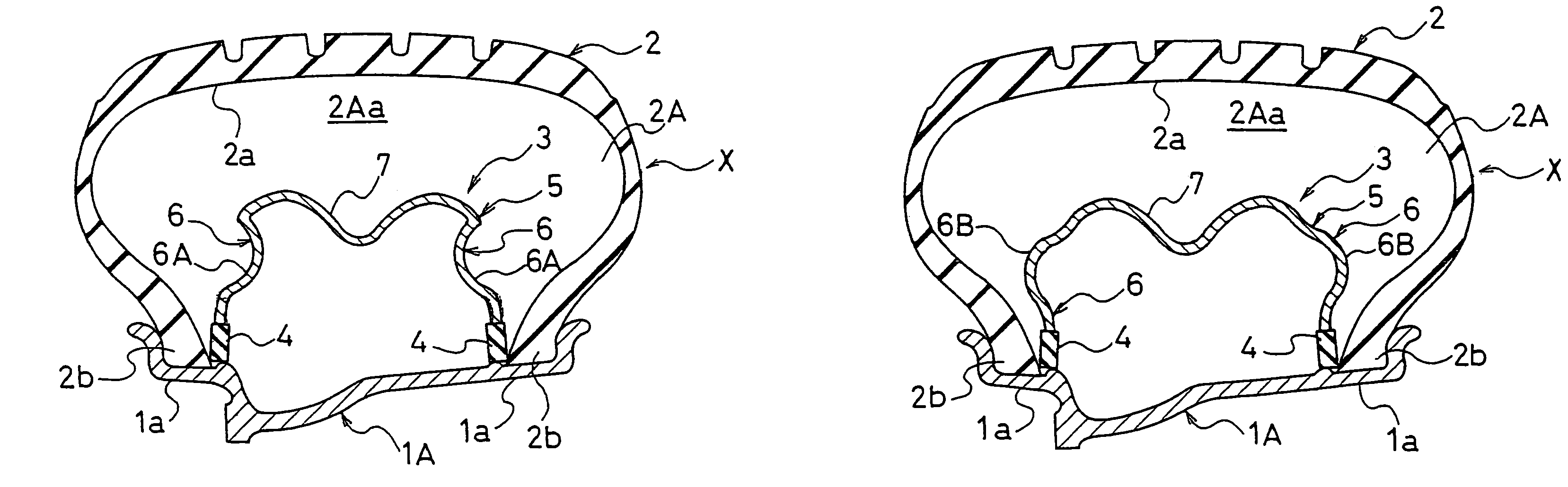

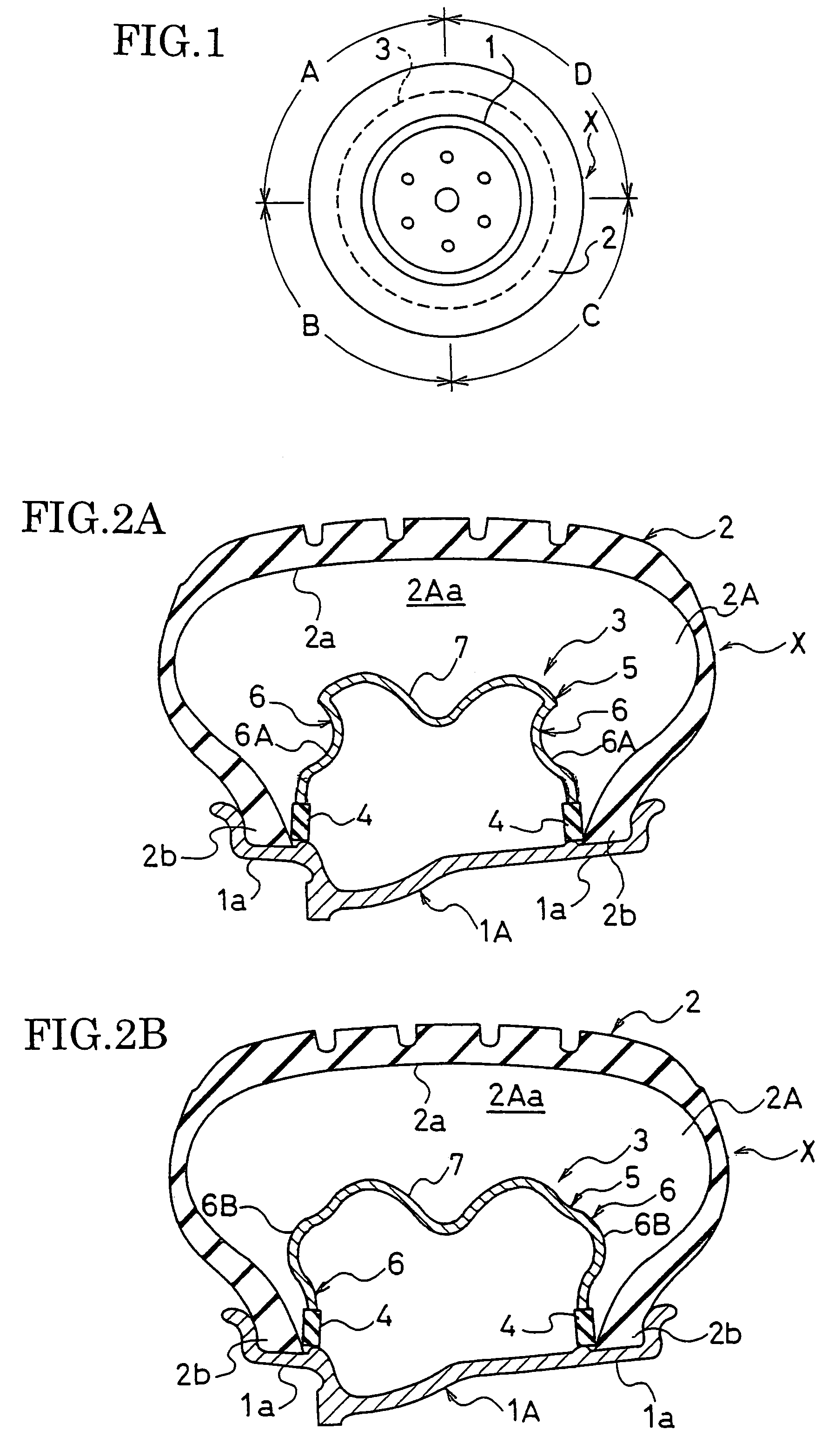

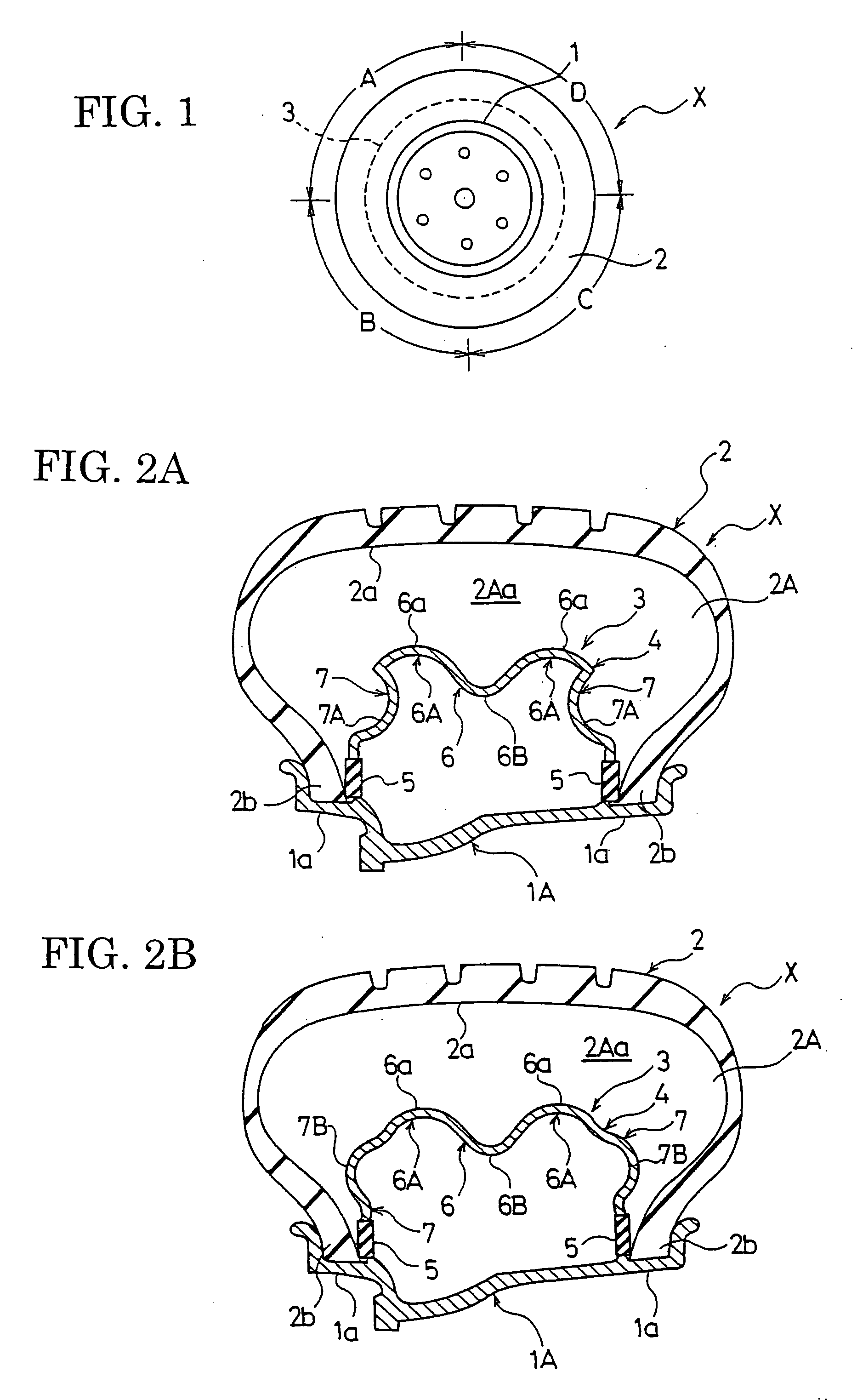

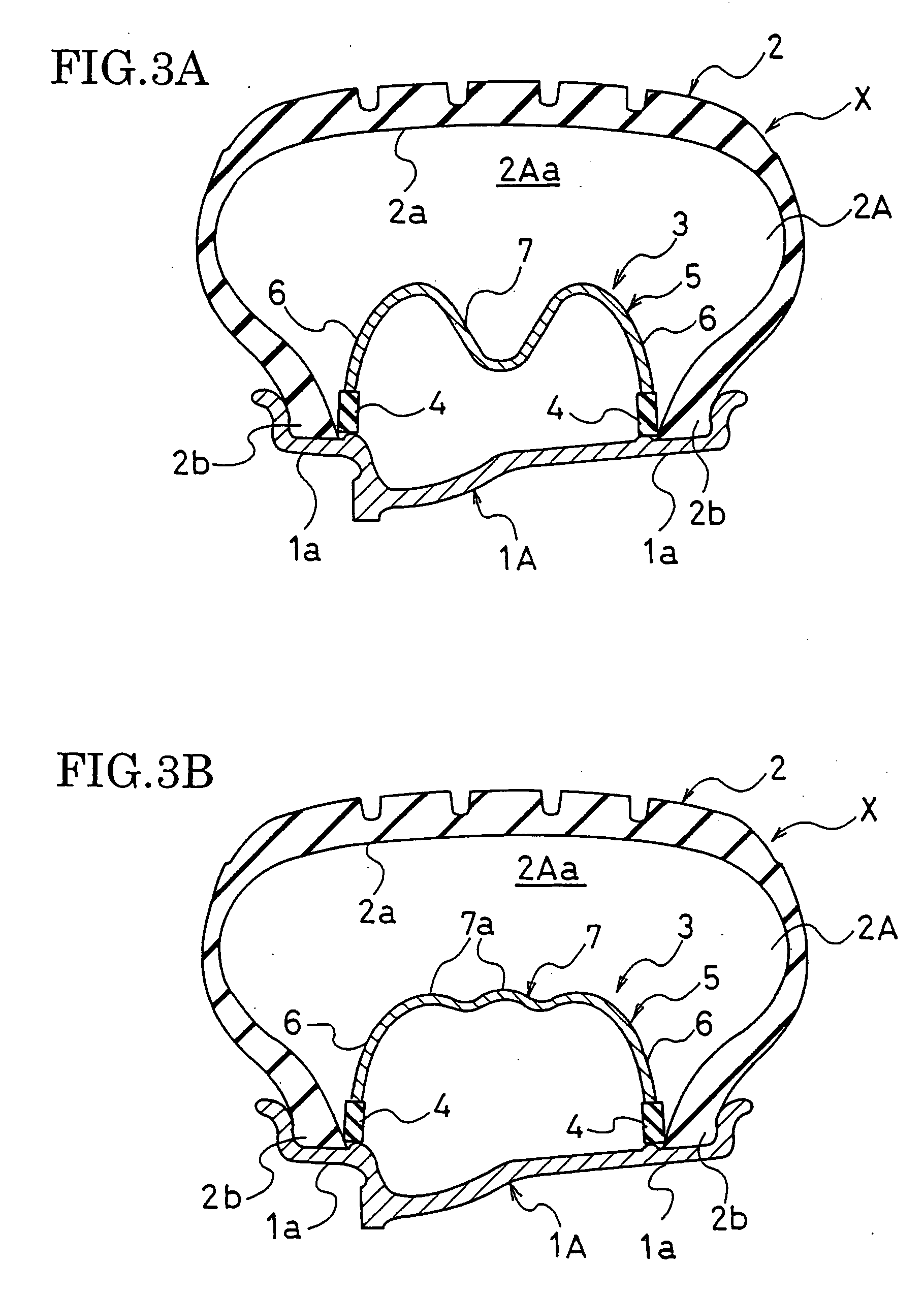

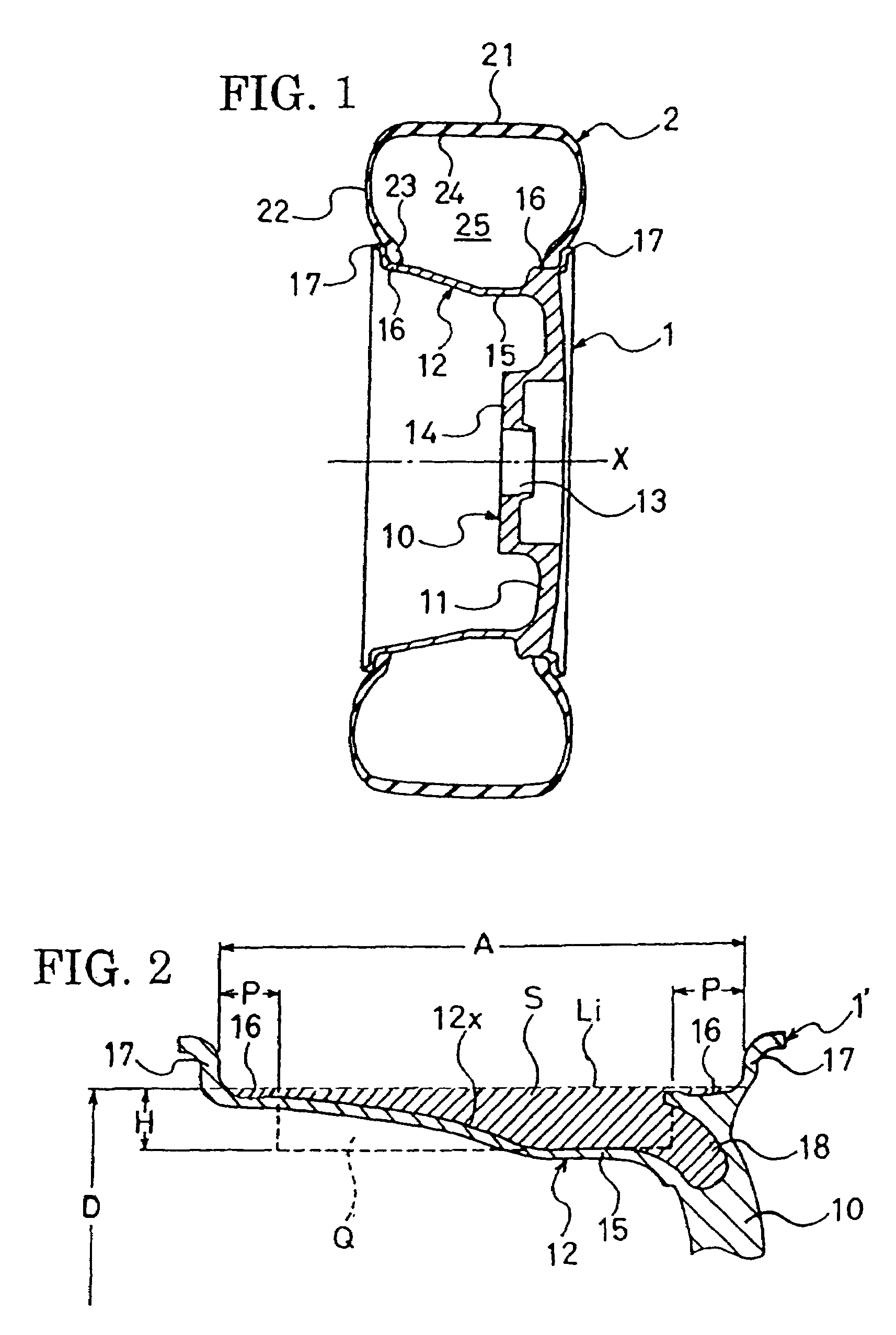

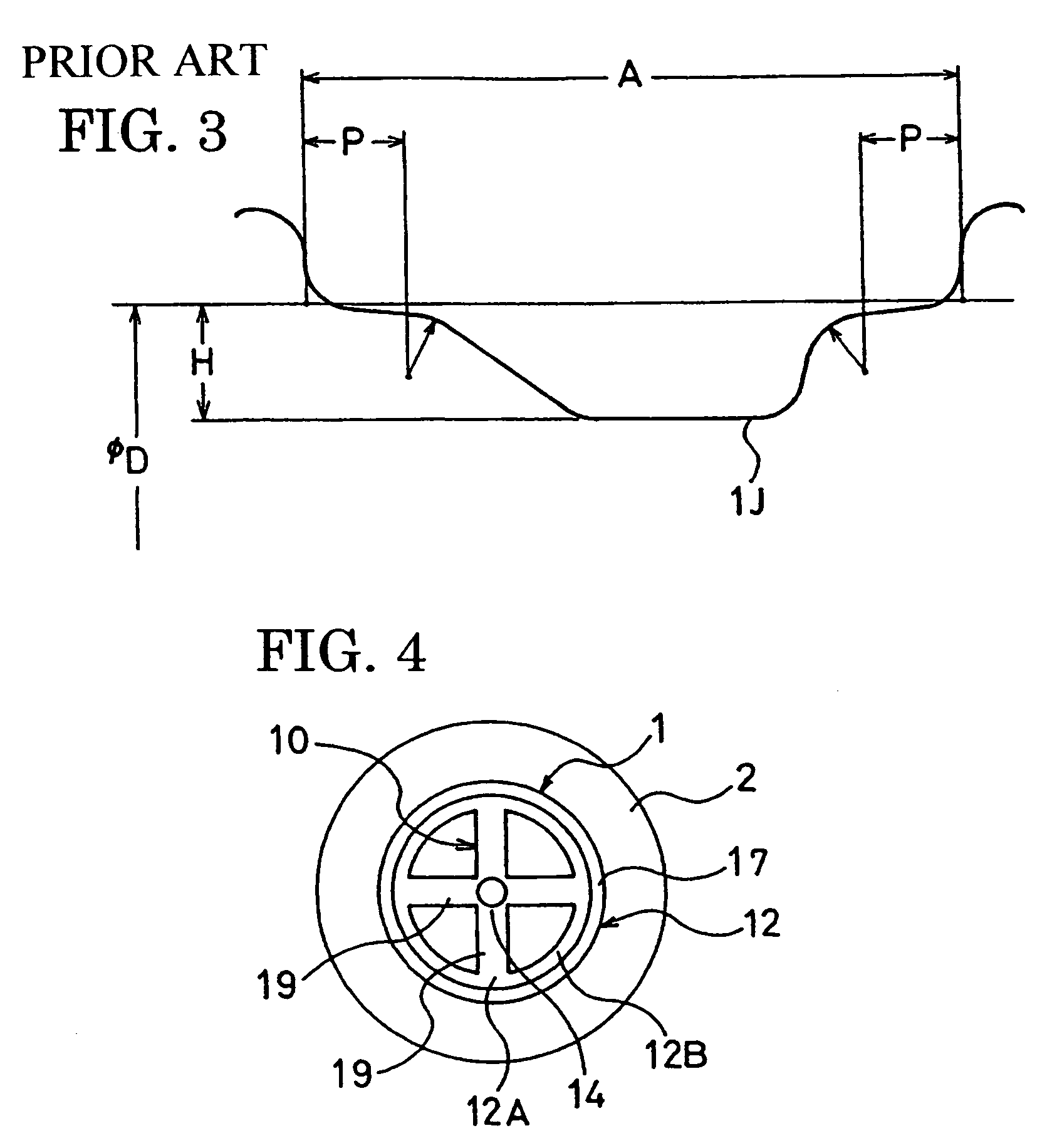

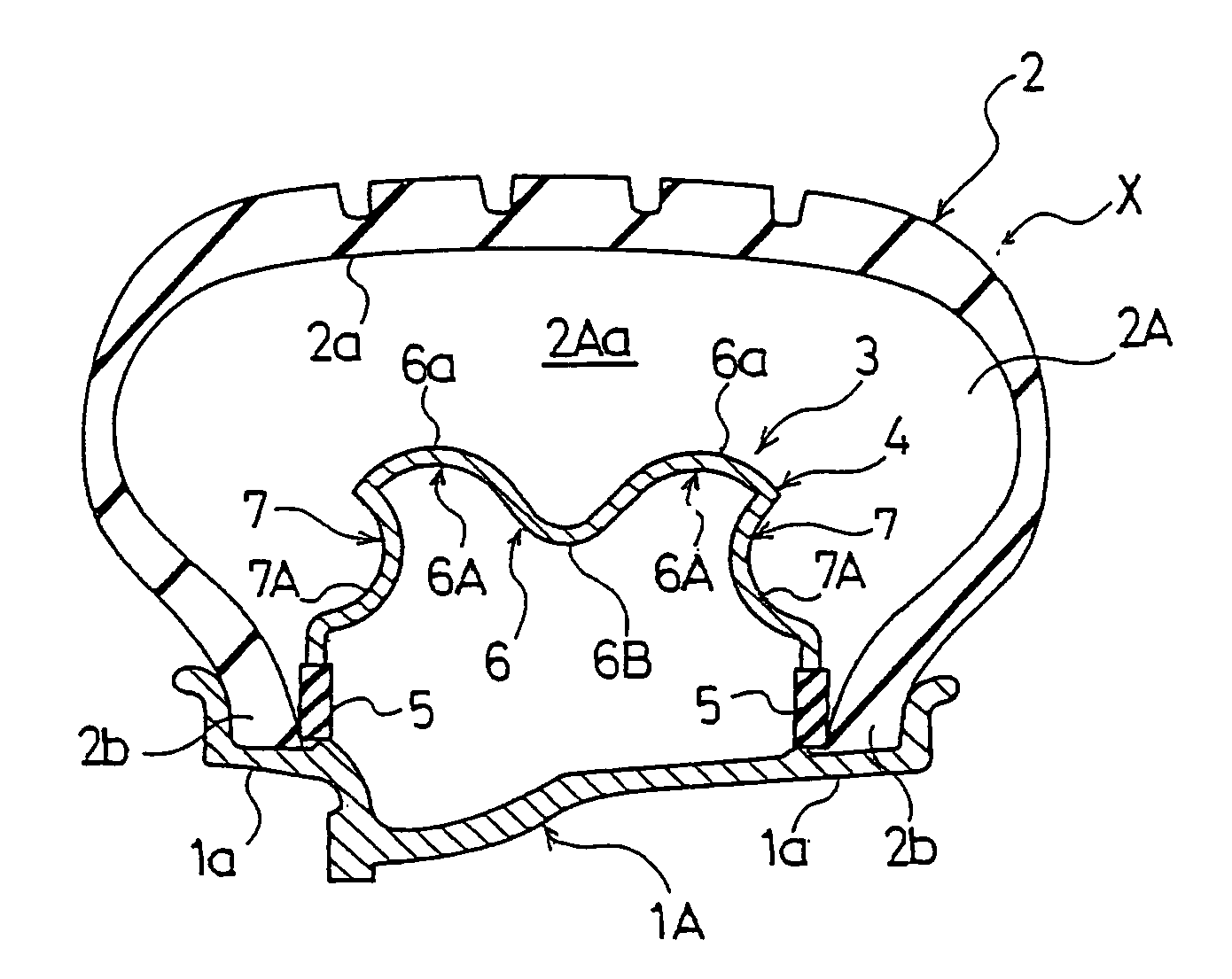

Tire/wheel assembly and noise reduction interior member

InactiveUS7475713B2Reduce noiseReduce road noiseWithout separate inflatable insertsRimsNoise reductionMechanical engineering

A tire / wheel assembly comprising a wheel having a rim, a pneumatic tire mounted on the rim of the wheel and a noise reduction interior member disposed in the cavity of the pneumatic tire. The noise reduction interior member includes left and right elastic rings fitted to the rim and an annular body attached between the elastic rings. The annular body is configured such that an annular cavity portion surrounded by the noise reduction interior member and the pneumatic tire has a cross-sectional area that varies in a circumferential direction of the tire.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic radial tire

InactiveUS20070012394A1Improve rigidityRolling resistance is prevented from deterioratingPneumatic tyre reinforcementsYarnFiberYarn

Disclosed is a pneumatic tire which comprises belt layers in a tread part and belt cover layers formed by winding organic fiber cords spirally and continuously in the tire circumferential direction on outer peripheries of at least both edge portions of the belt layer respectively. The organic fiber cords are twisted cords of at least one polyketone fiber yarns having a heat shrinkage stress at 150° C. of 0.19 to 0.60 cN / dtex.

Owner:YOKOHAMA RUBBER CO LTD

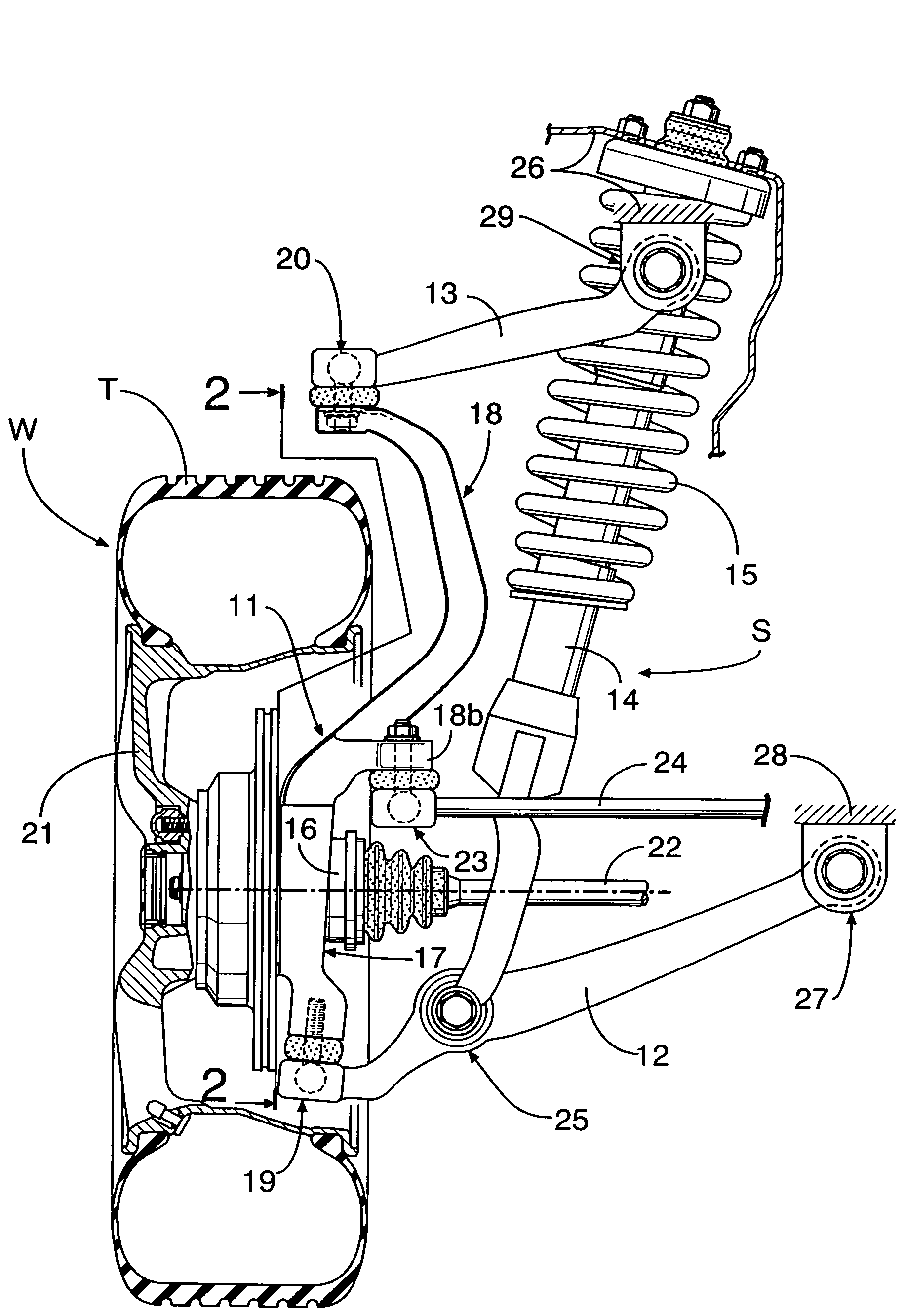

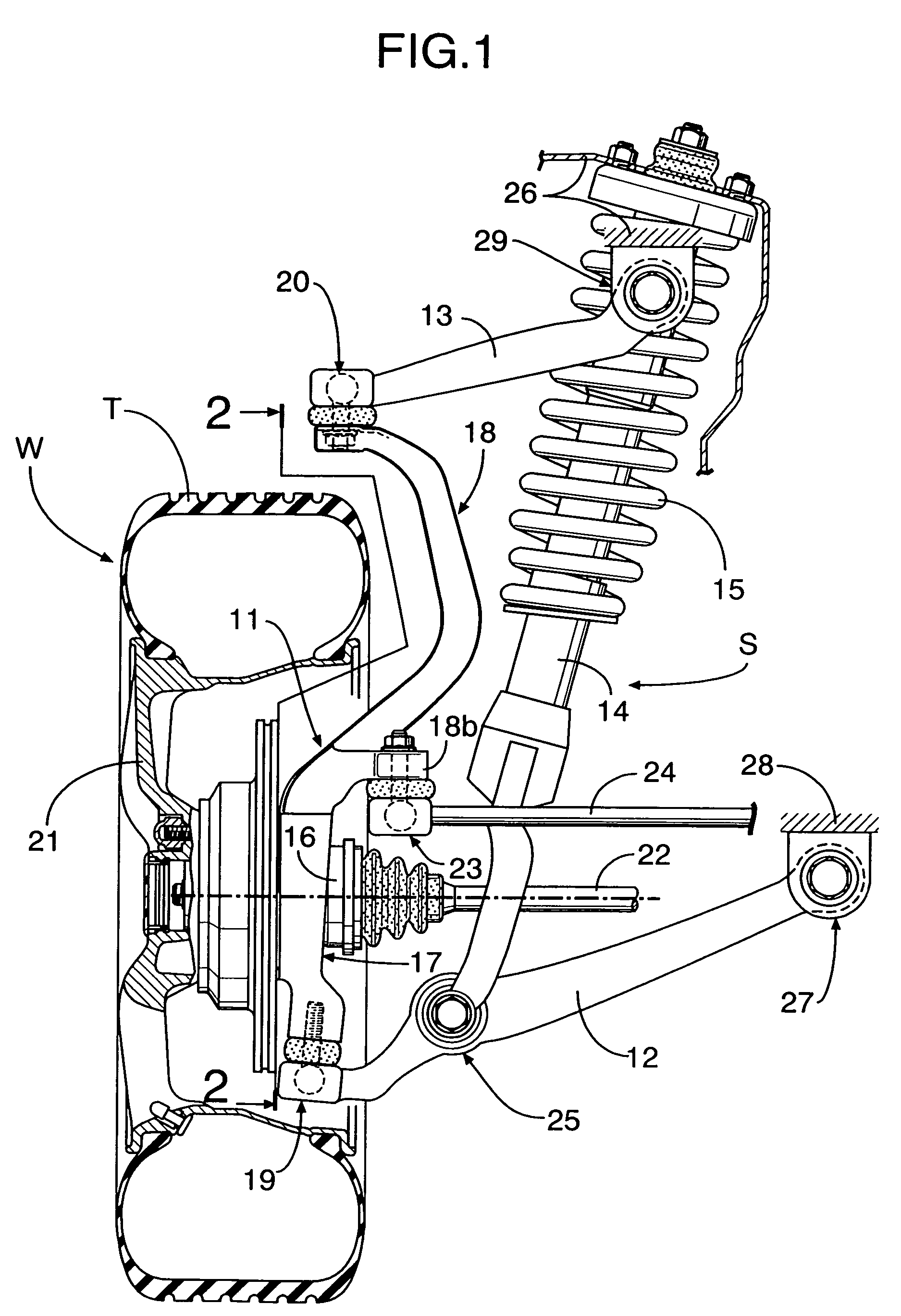

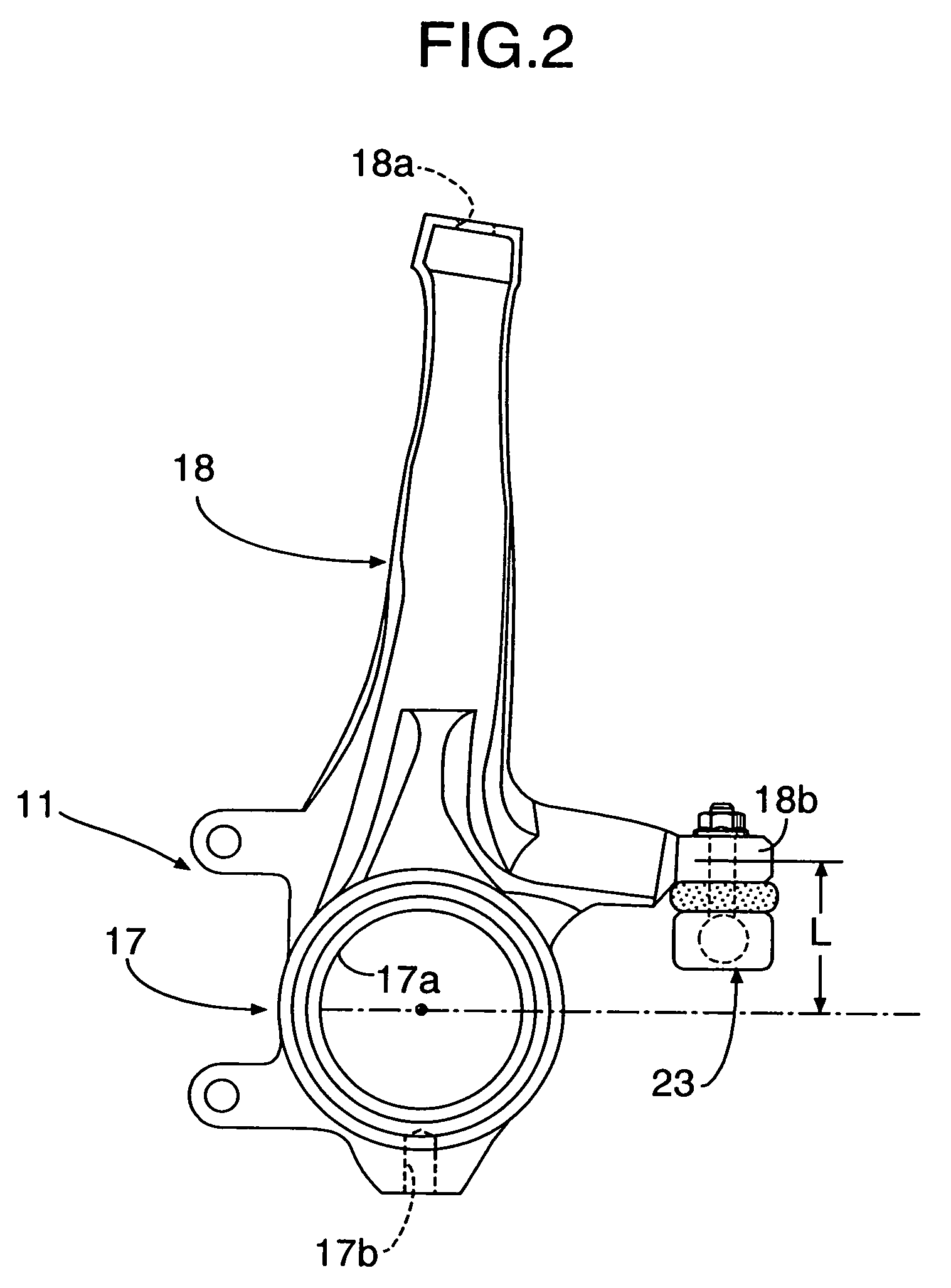

High-mounted double wishbone suspension device

InactiveUS7234712B2Reduce the numberReduce weightSteering linkagesResilient suspensionsDouble wishbone suspensionEngineering

In a high-mounted double wishbone suspension device, an arm portion extending upward from a knuckle main body portion, through which an axle runs, is provided with a tie rod connection portion. A tie rod for turning a wheel is connected to the tie rod connection portion. The distance between the axle and the tie rod connection portion is increased to effectively suppress knuckle lateral vibration centered on the axle by the tie rod. Therefore, it is possible to reduce road noise without increasing the number of components or the weight. In particular, since the tie rod is connected to a joint provided on a lower face of the tie rod connection portion, it is possible to minimize vertical positional change of the tie rod, while suppressing lateral vibration of the knuckle by raising the position of the tie rod connection portion, whereby the arrangement can be easily applied to a conventional vehicle merely by replacing the knuckle alone.

Owner:HONDA MOTOR CO LTD

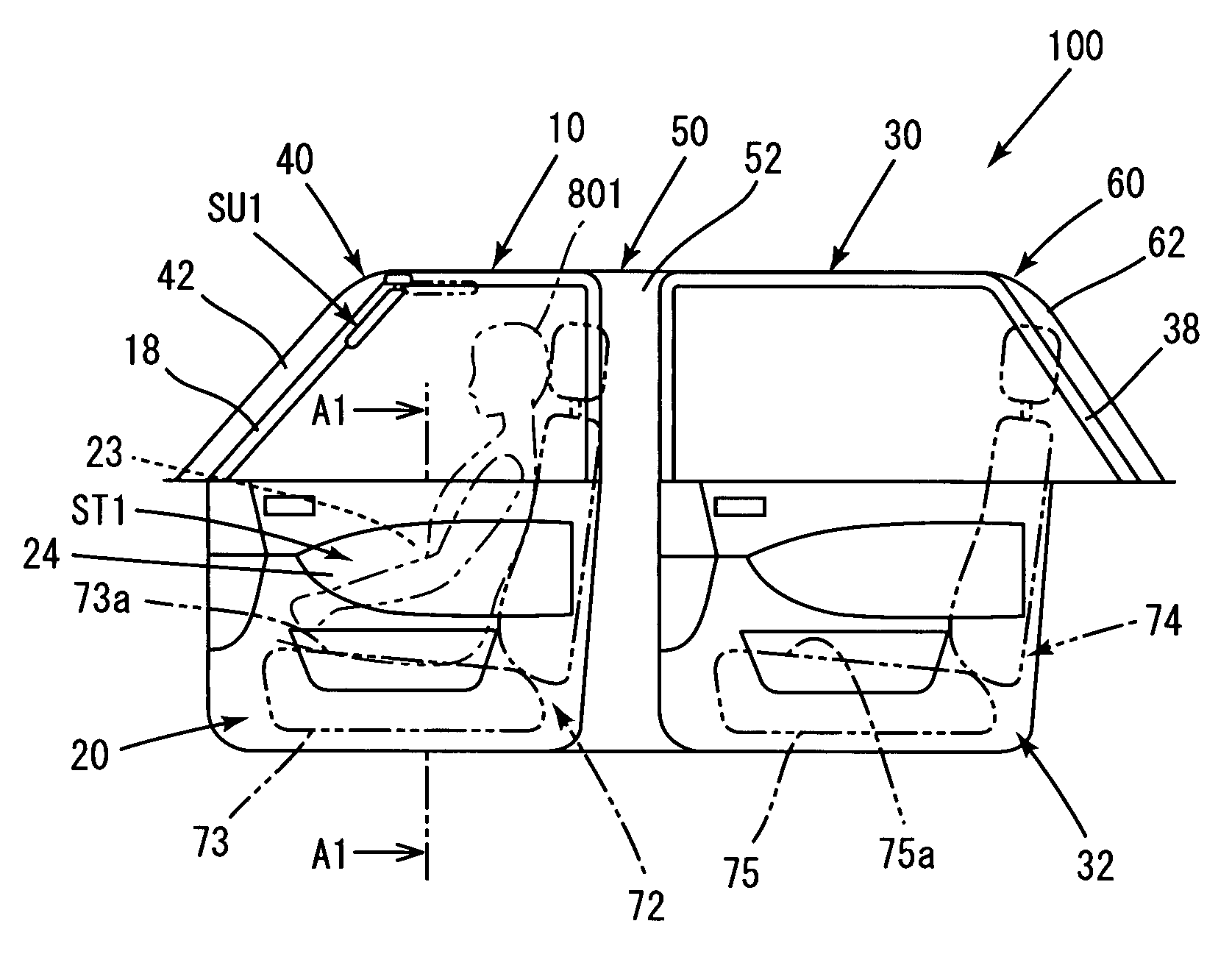

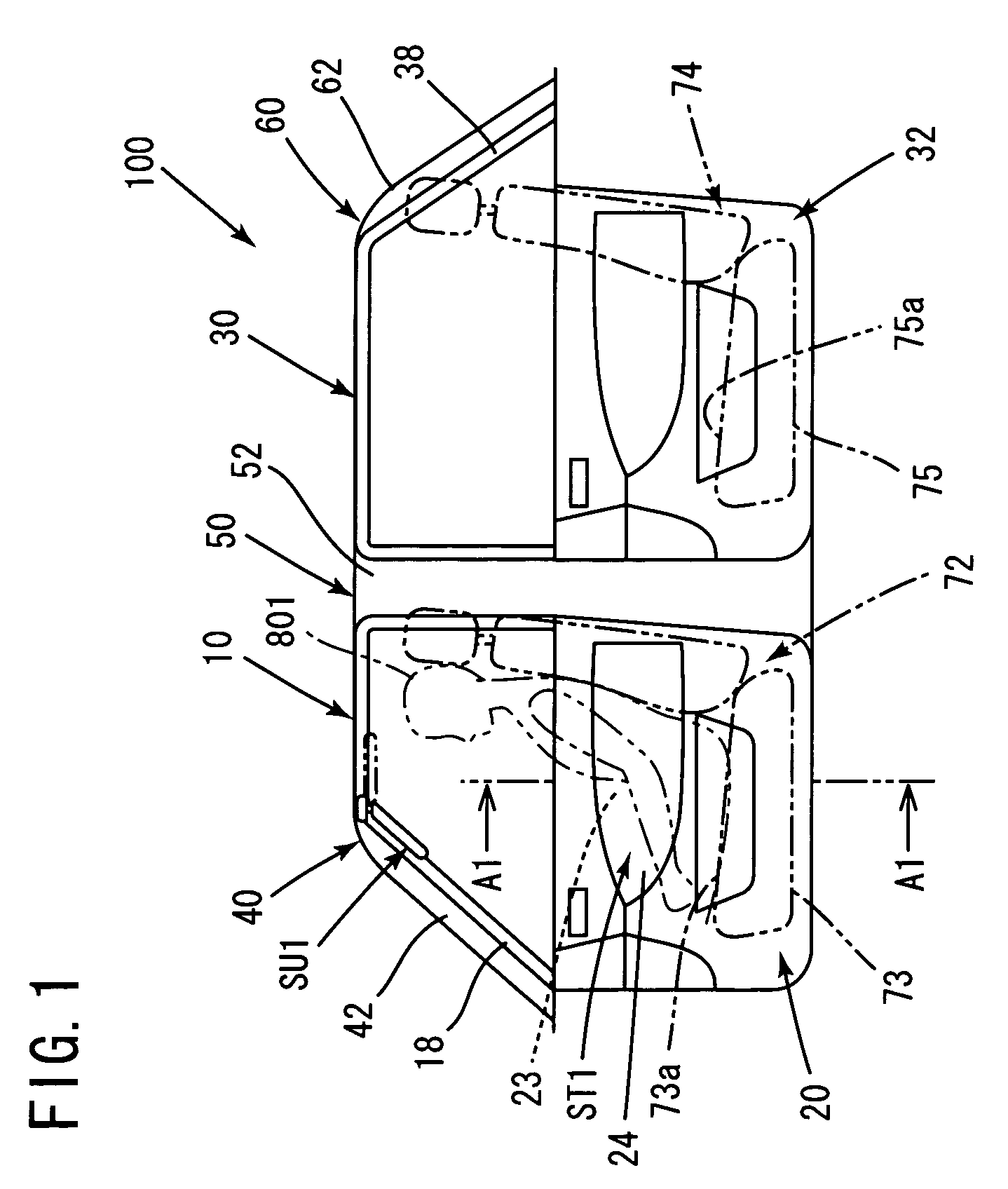

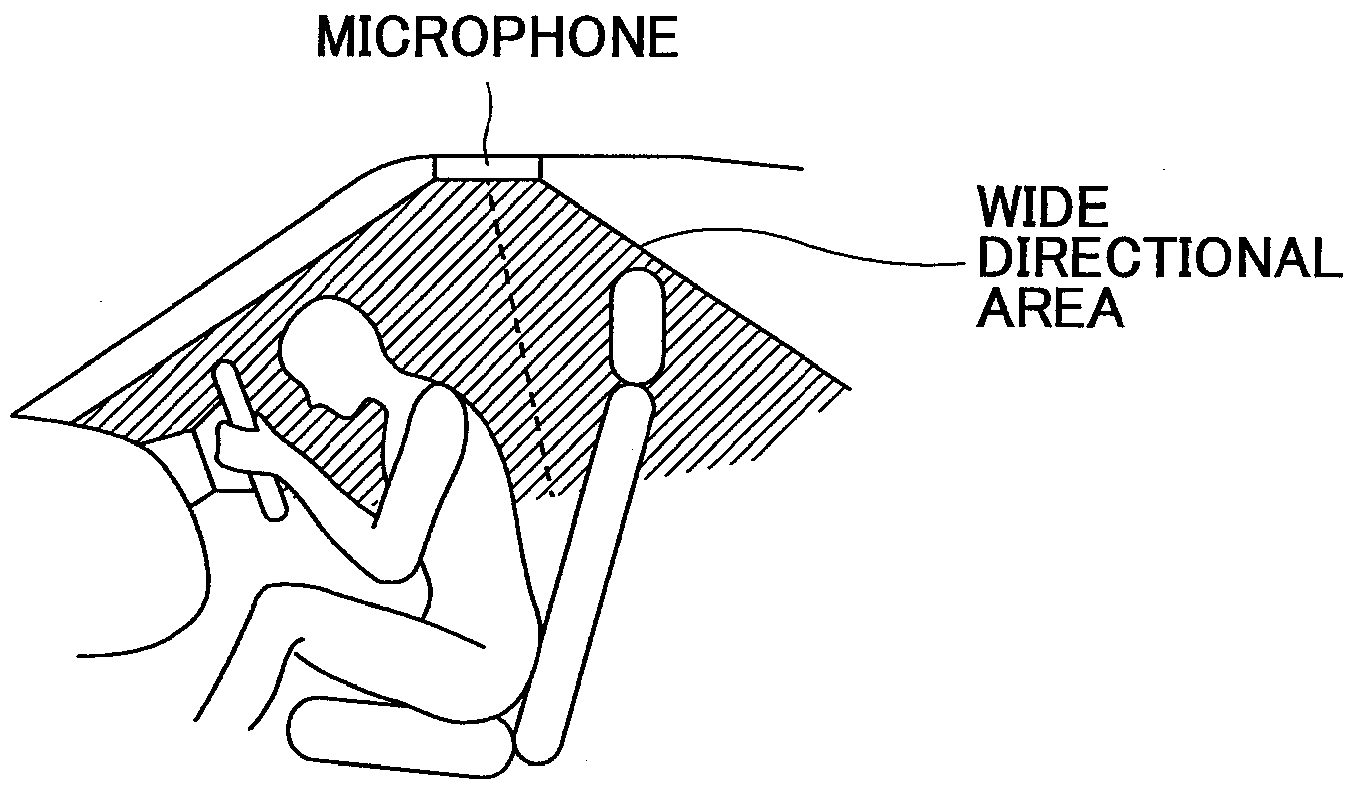

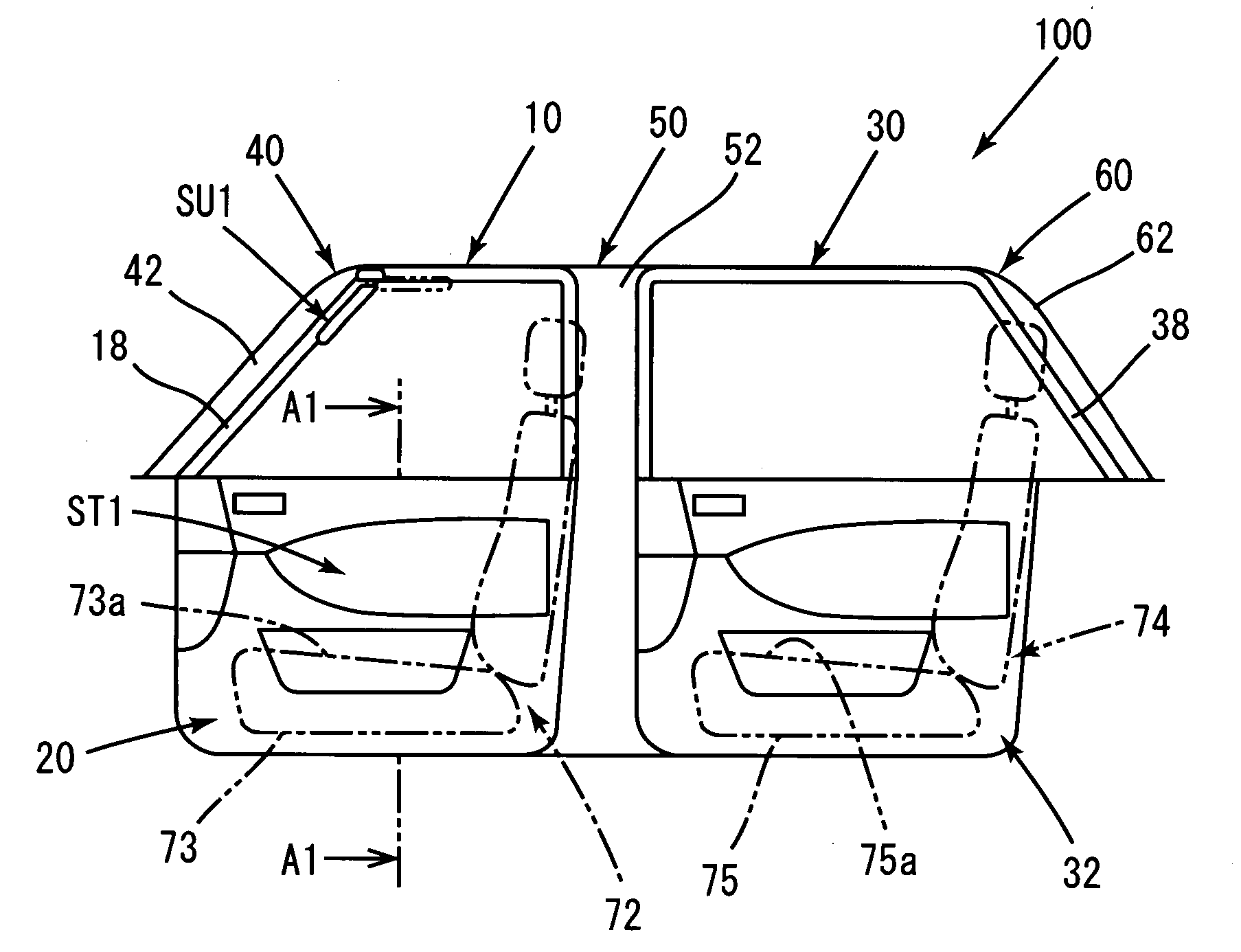

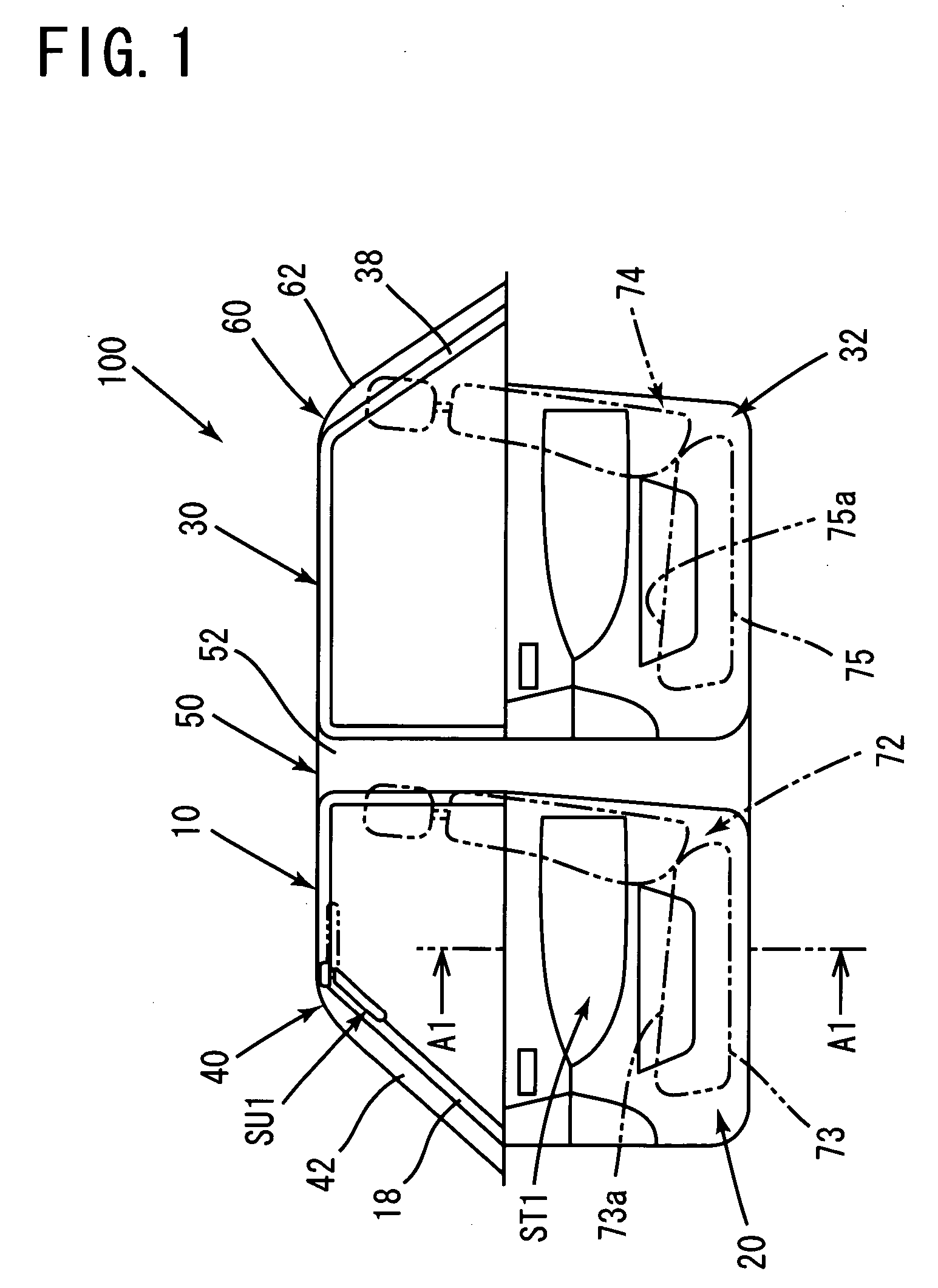

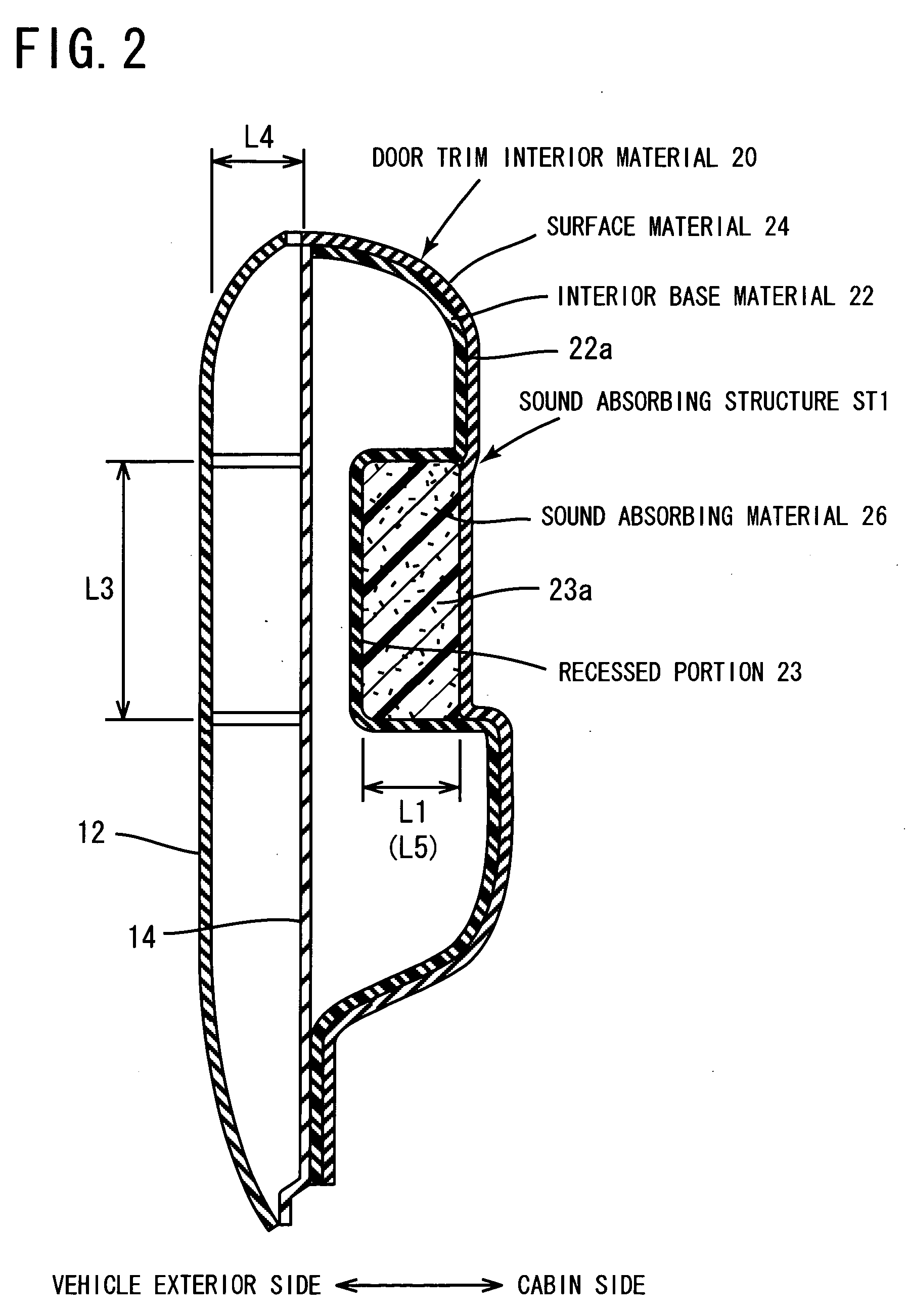

Sun visor for automobile and sound absorbing structure for an automobile

InactiveUS7380858B2Effectively reduces infiltrating sound entering the earsImprove rigidityAntiglare equipmentMonocoque constructionsCushioningEngineering

A sound absorbing structure for an automobile having a seating portion, an upper surface of which serves as a passenger seating surface in the cabin, the structure includes an interior base material provided on a cabin side of a body panel; the interior base material forming a side face when seen from a passenger seated on the seating portion; the interior base material having a recessed portion formed in the cabin side of the interior base material; the recessed portion formed on an upper side of the seating surface; and a sound absorbing material buried in the recessed portion. An automobile sun visor includes a plate-form core material; an air-permeable cushioning material covering a surface of the core material; and the plate-form core material having a large number of air holes penetrating in a thickness direction formed in a dispersed manner.

Owner:HAYASHI GIJUTSU KENKYUSHO KK

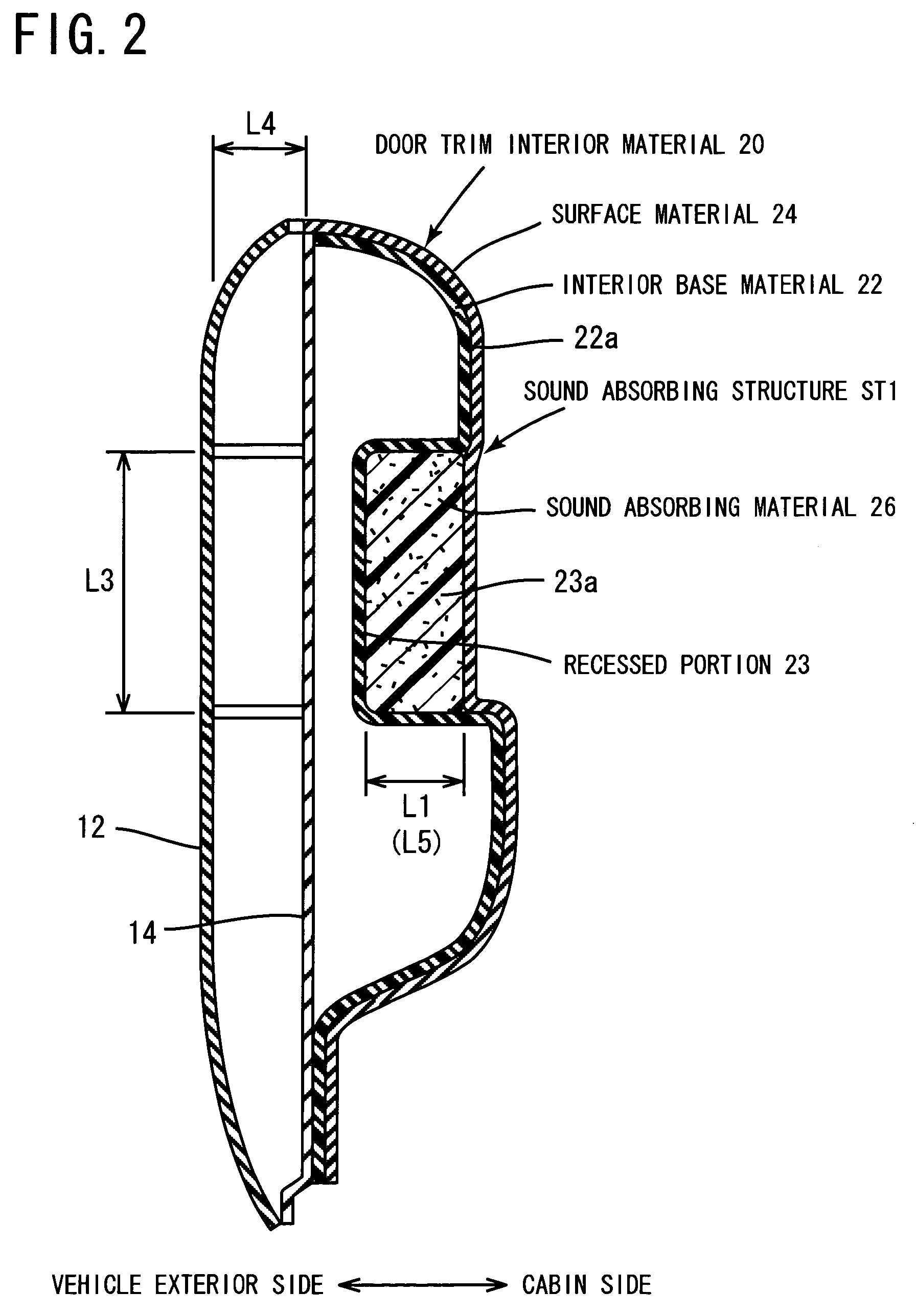

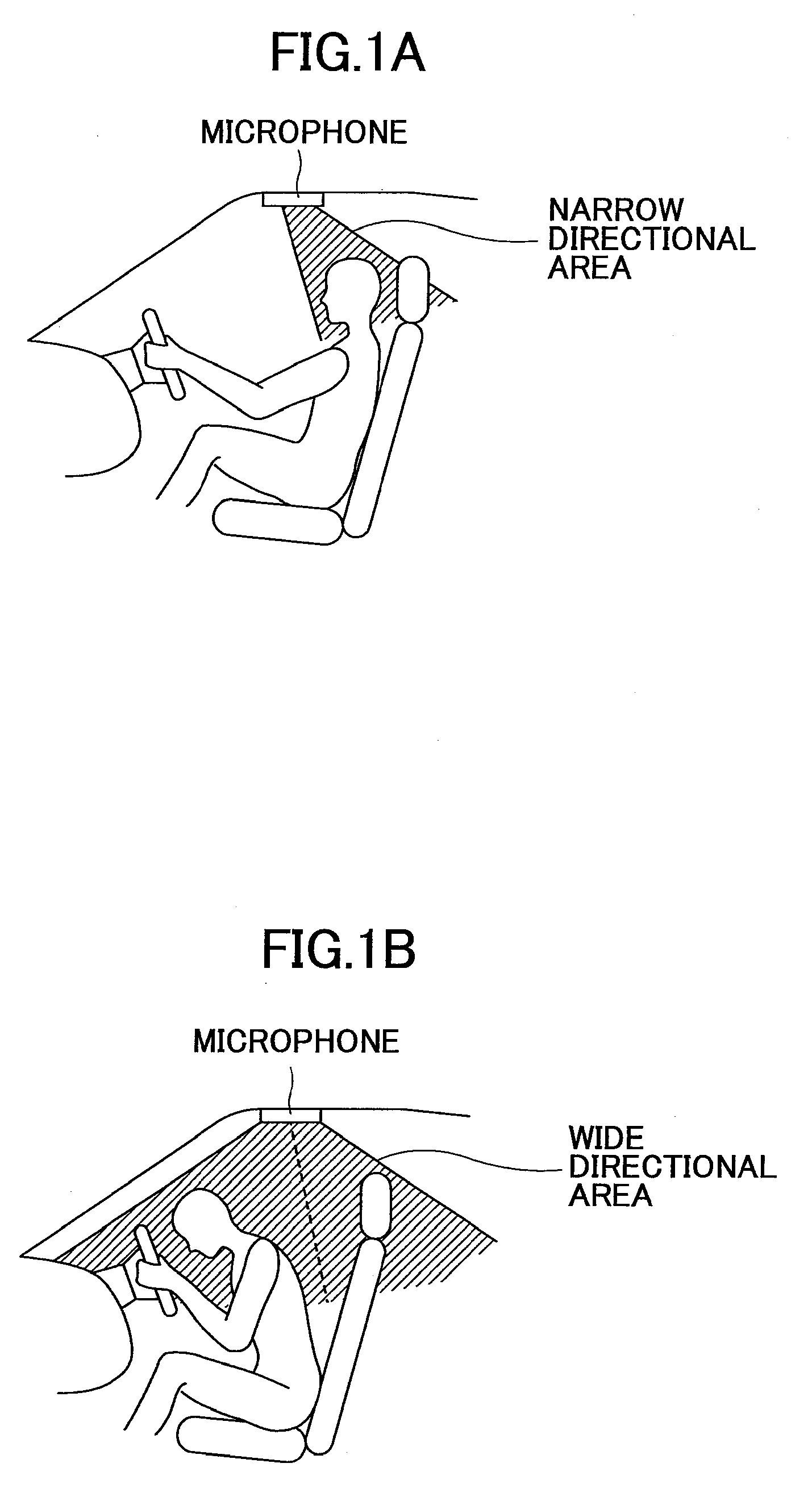

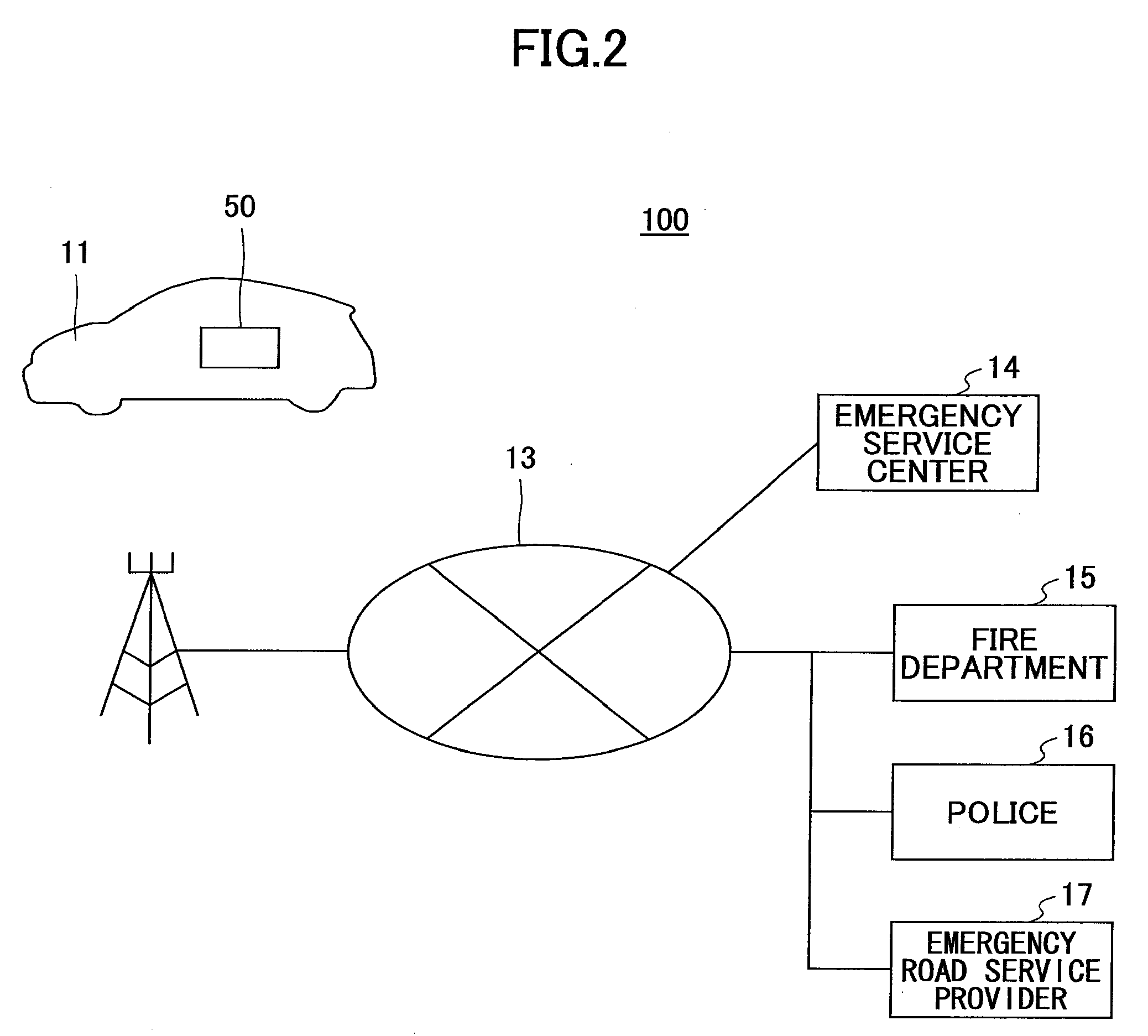

Vehicle call device and calling method

InactiveUS20090129607A1Easy to chooseReduce road noiseMicrophonesSignal processingEngineeringSTI Outpatient

A vehicle call device and a calling method capable of making it easier to pick up a voice of an occupant of a vehicle in an emergency situation are disclosed. The vehicle call device includes a speaker in a vehicle for outputting a received voice of an opposite party; a microphone in the vehicle for picking up a voice of an occupant of the vehicle; a detecting unit detecting an emergency situation of the vehicle; and a controlling unit, when the detecting unit detects the emergency situation, controlling directional characteristics of the microphone so that the voice can be picked up from an area wider than an area provided before the emergency situation is detected.

Owner:TOYOTA JIDOSHA KK

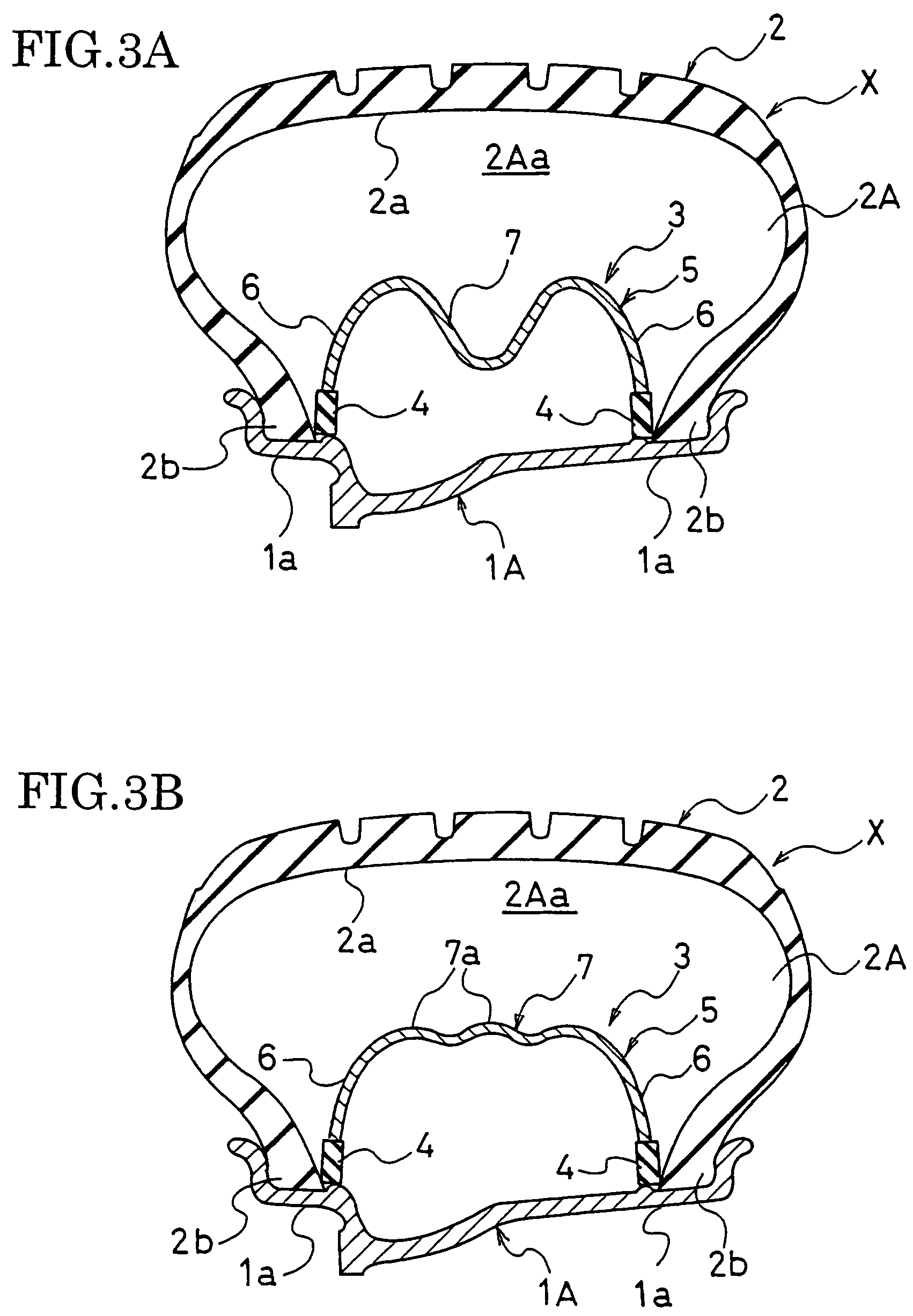

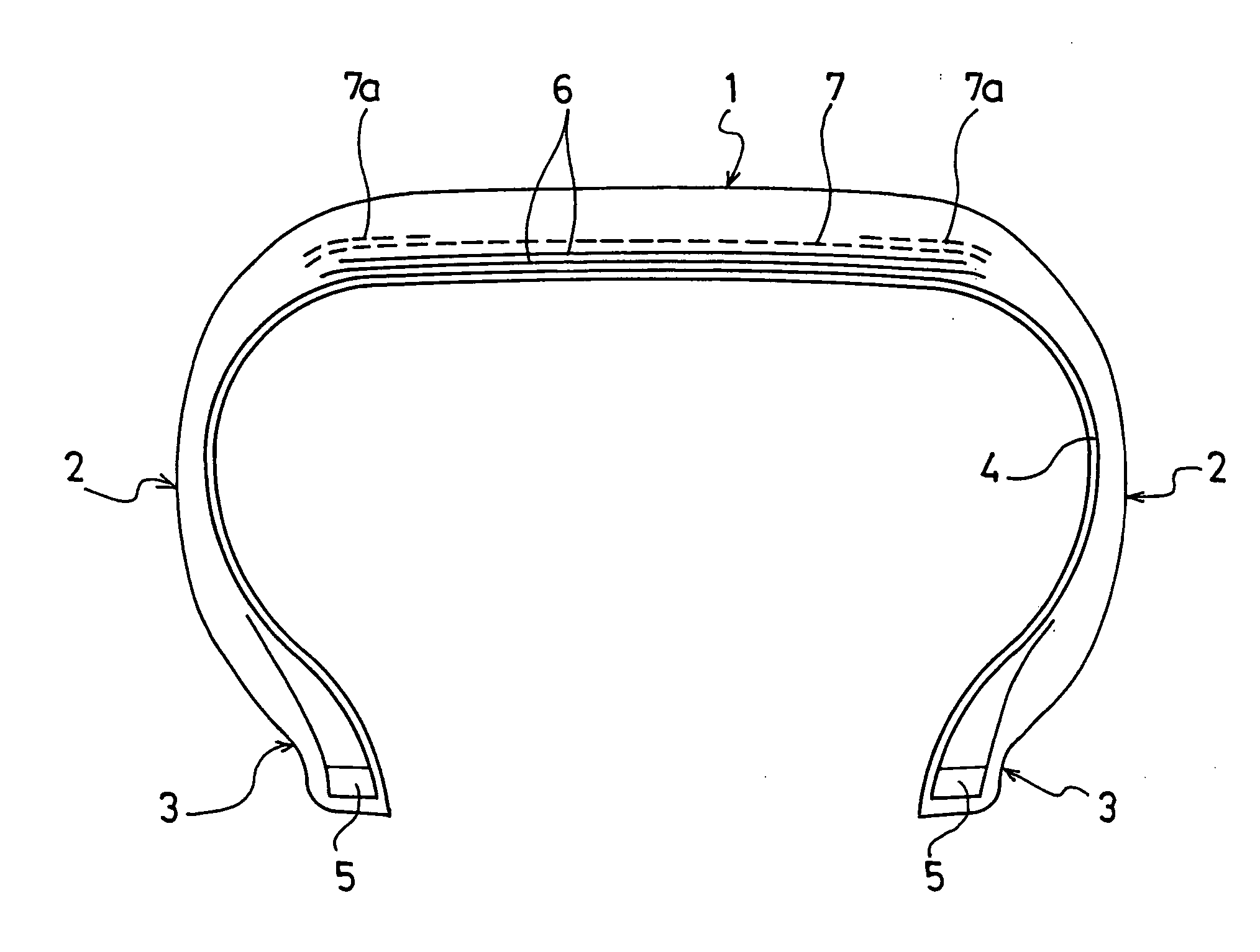

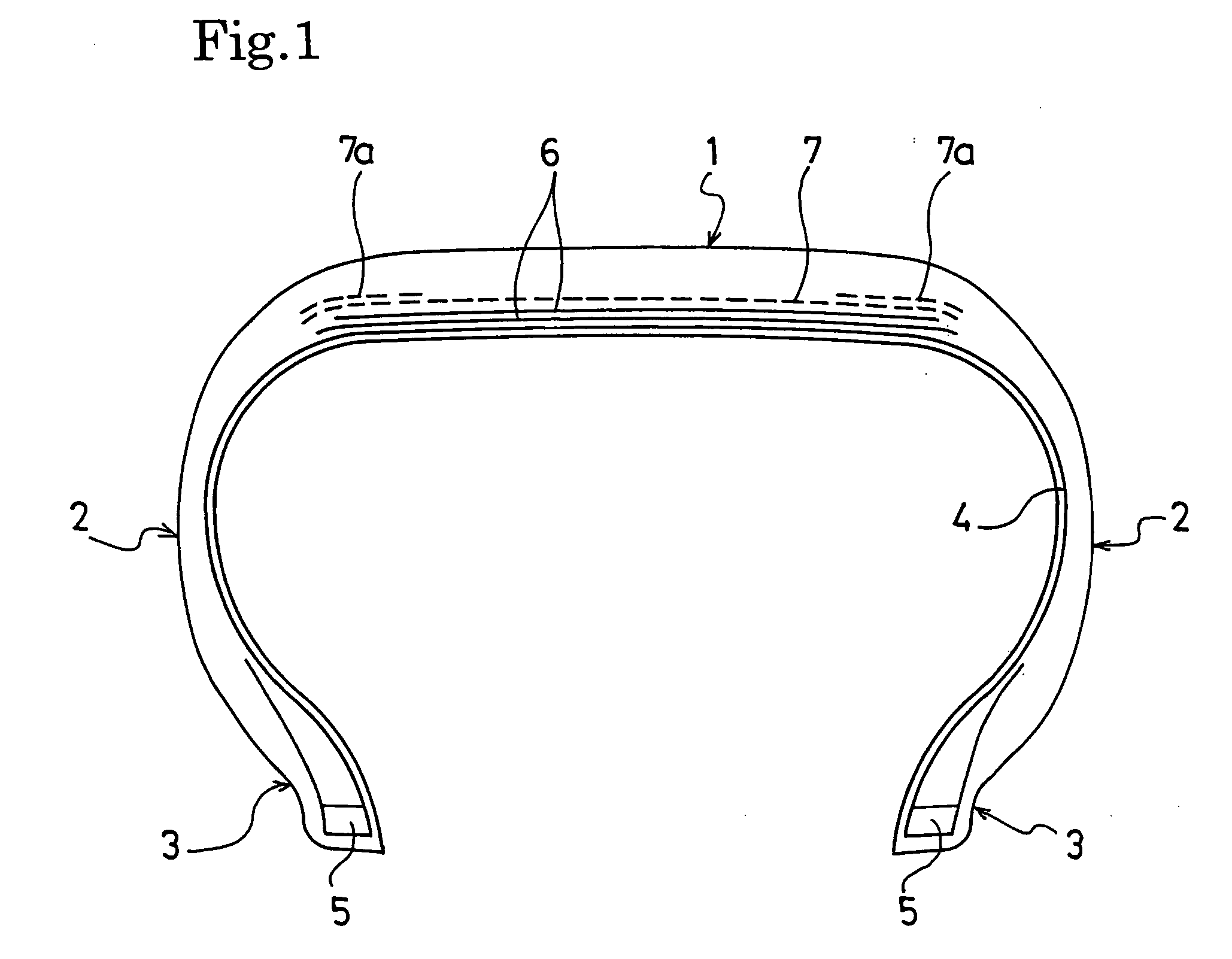

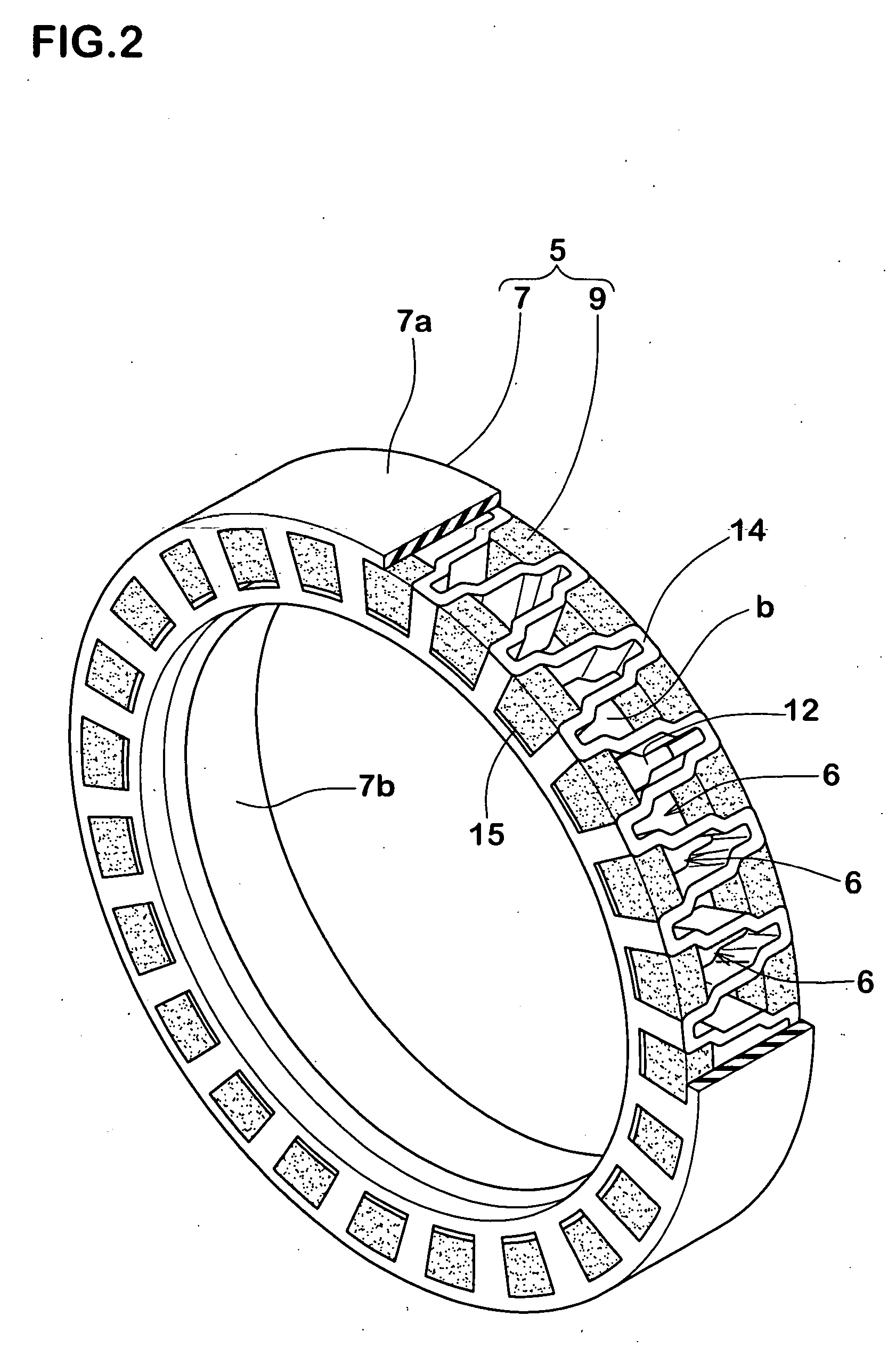

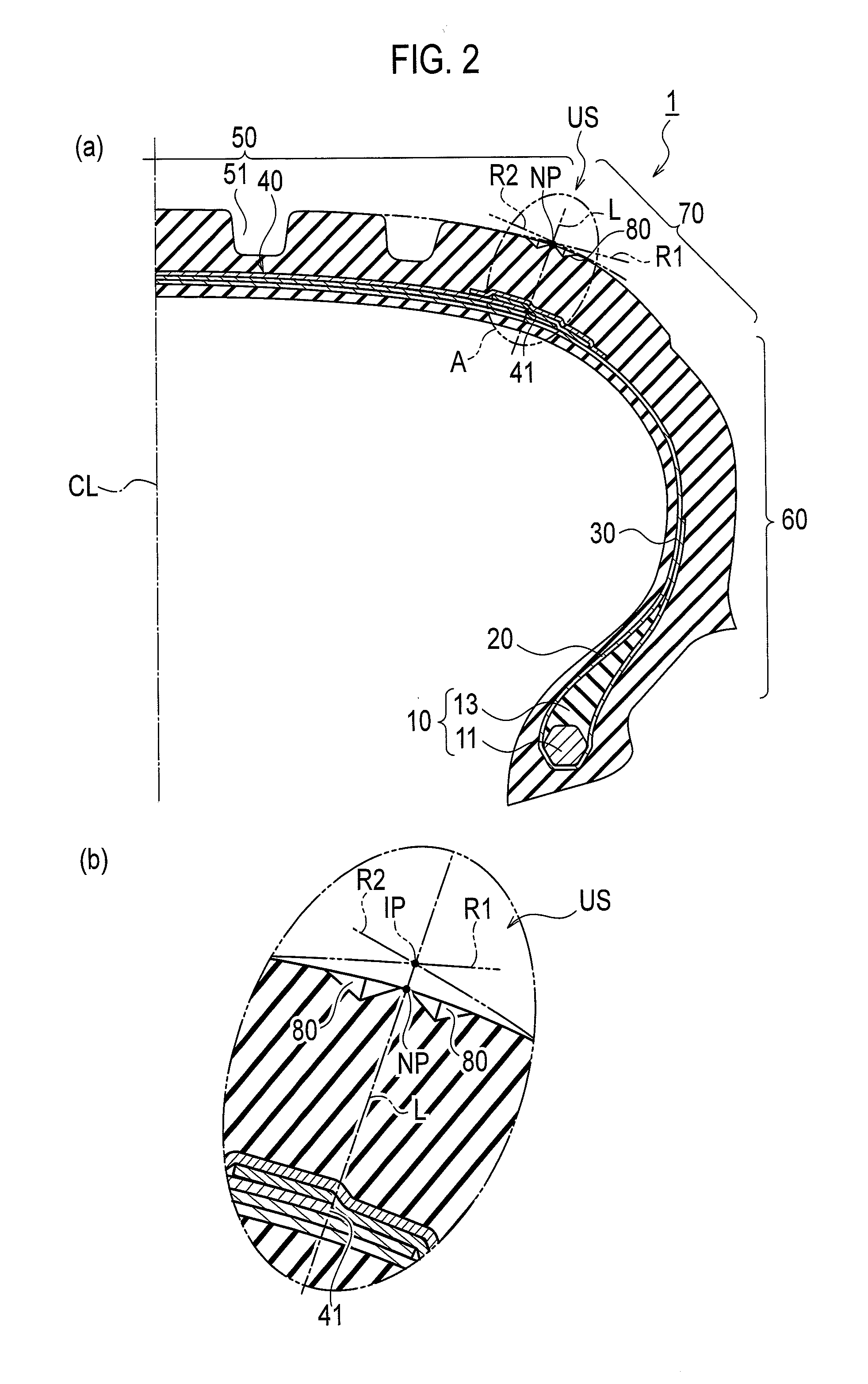

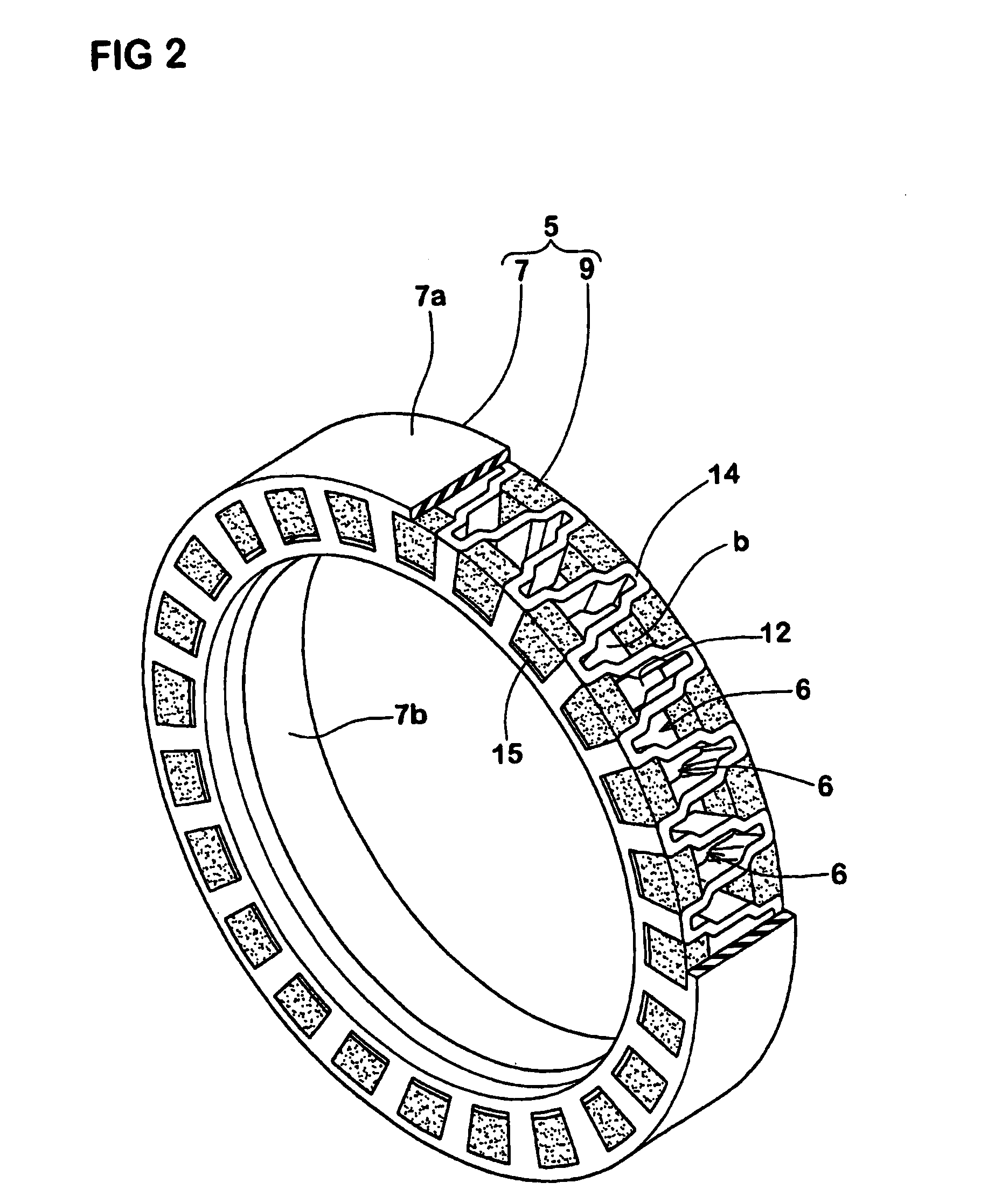

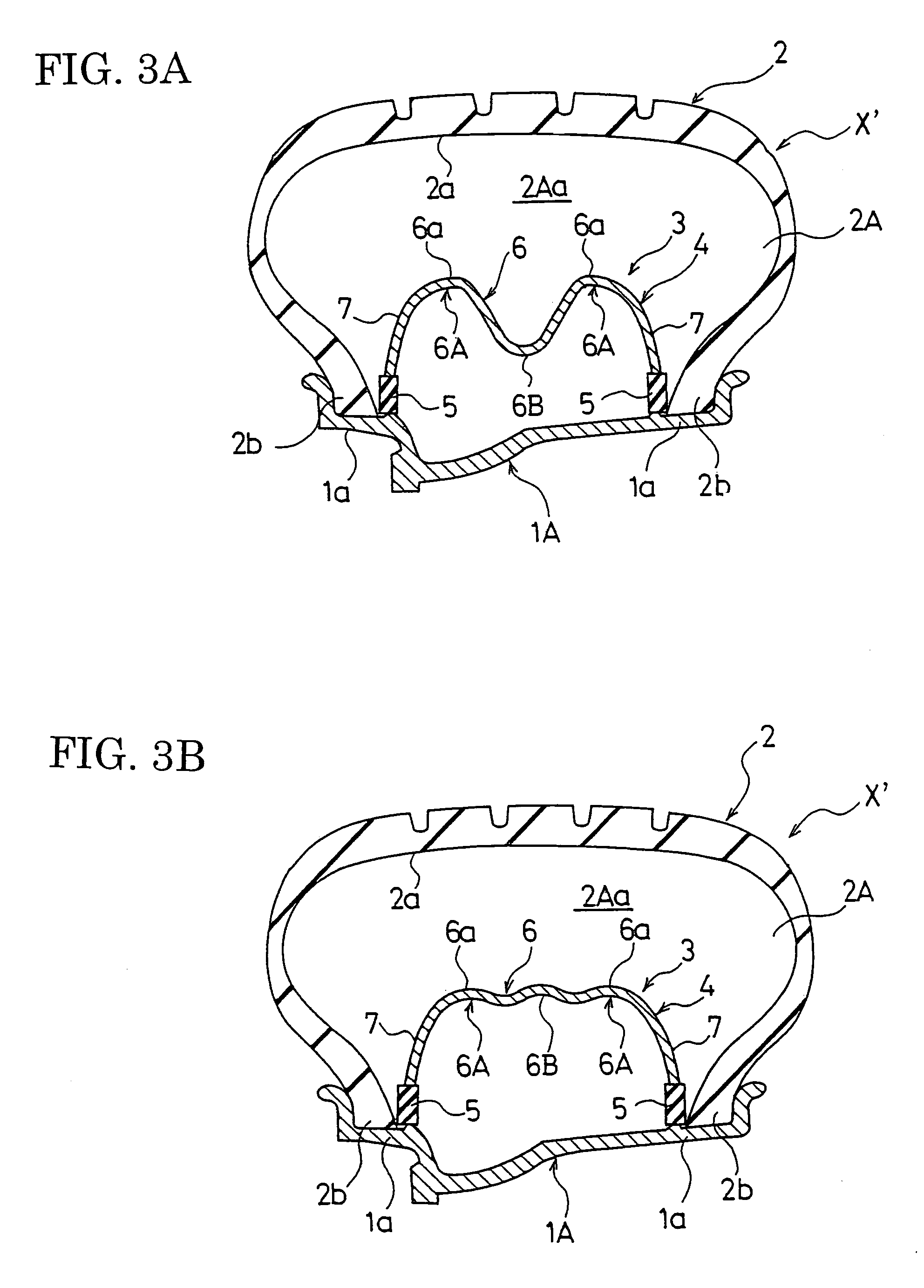

Runflat tire system and support ring therefor

InactiveUS20050211352A1Comfortable habitability in a passenger roomReduce road noiseRimsInflatable tyresApparent densityEngineering

A runflat tire system comprises: a pneumatic tire; a wheel rim on which the pneumatic tire is mounted; and a support ring made of elastic material and disposed in a cavity surrounded by an inner surface of the rim and an inner surface of the tire mounted thereon, wherein the support ring comprises an annular body extending in a circumferential direction of the tire and provided with a plurality of hollows opening at the cavity, and at least one noise dumper made of sponge material having apparent density of 0.1 g / cm3 or less and disposed in the hollow such that the noise dumper does not protrude into the cavity from an inlet surface of the hollow.

Owner:SUMITOMO RUBBER IND LTD

Sun visor for automobile and sound absorbing structure for an automobile

InactiveUS20070007788A1Favorable sound absorption effectFavorable degree of hardnessAntiglare equipmentSuperstructure subunitsCushioningSurface plate

A sound absorbing structure for an automobile having a seating portion, an upper surface of which serves as a passenger seating surface in the cabin, the structure includes an interior base material provided on a cabin side of a body panel; the interior base material forming a side face when seen from a passenger seated on the seating portion; the interior base material having a recessed portion formed in the cabin side of the interior base material; the recessed portion formed on an upper side of the seating surface; and a sound absorbing material buried in the recessed portion. An automobile sun visor includes a plate-form core material; an air-permeable cushioning material covering a surface of the core material; and the plate-form core material having a large number of air holes penetrating in a thickness direction formed in a dispersed manner.

Owner:HAYASHI GIJUTSU KENKYUSHO KK

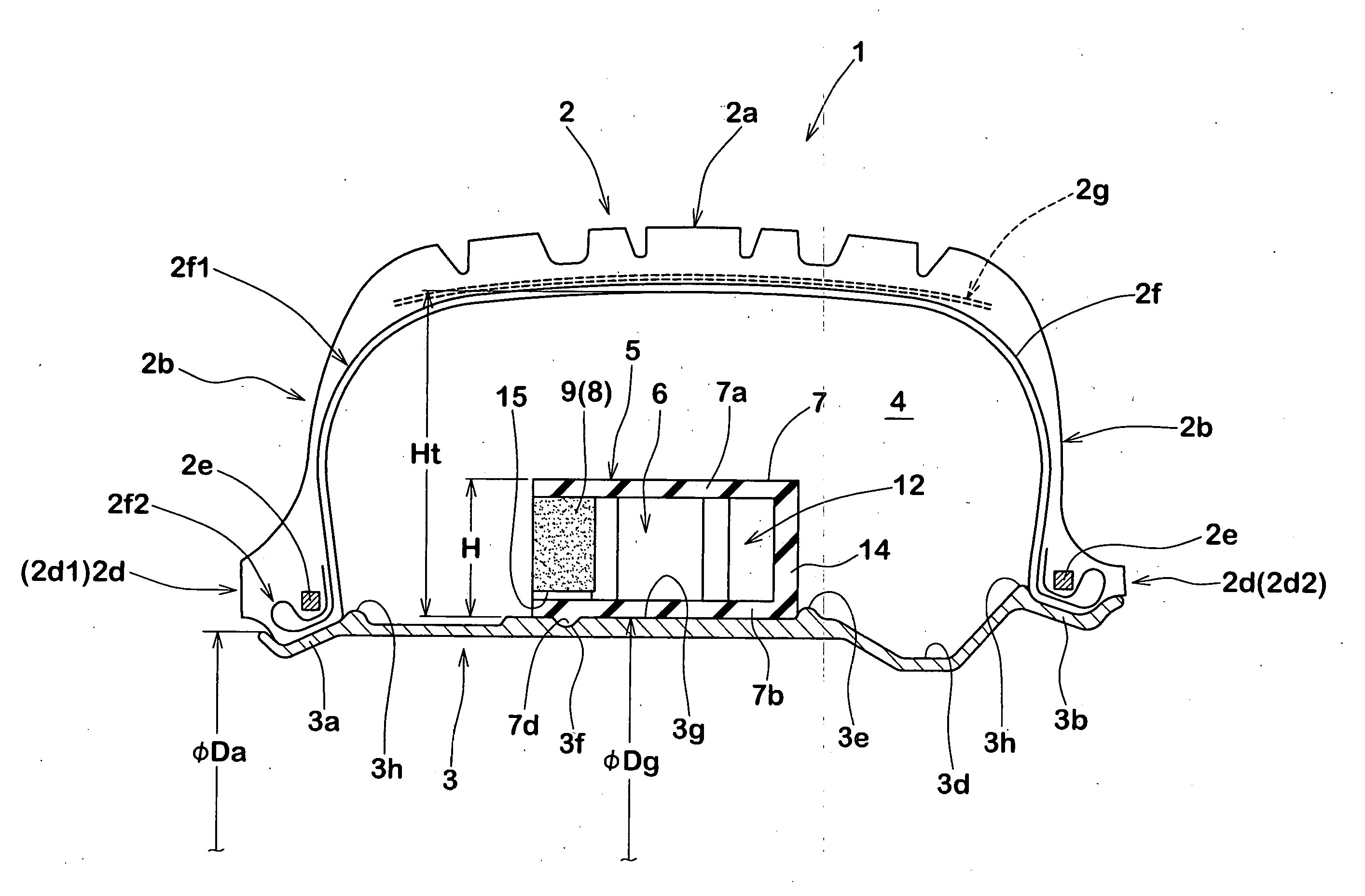

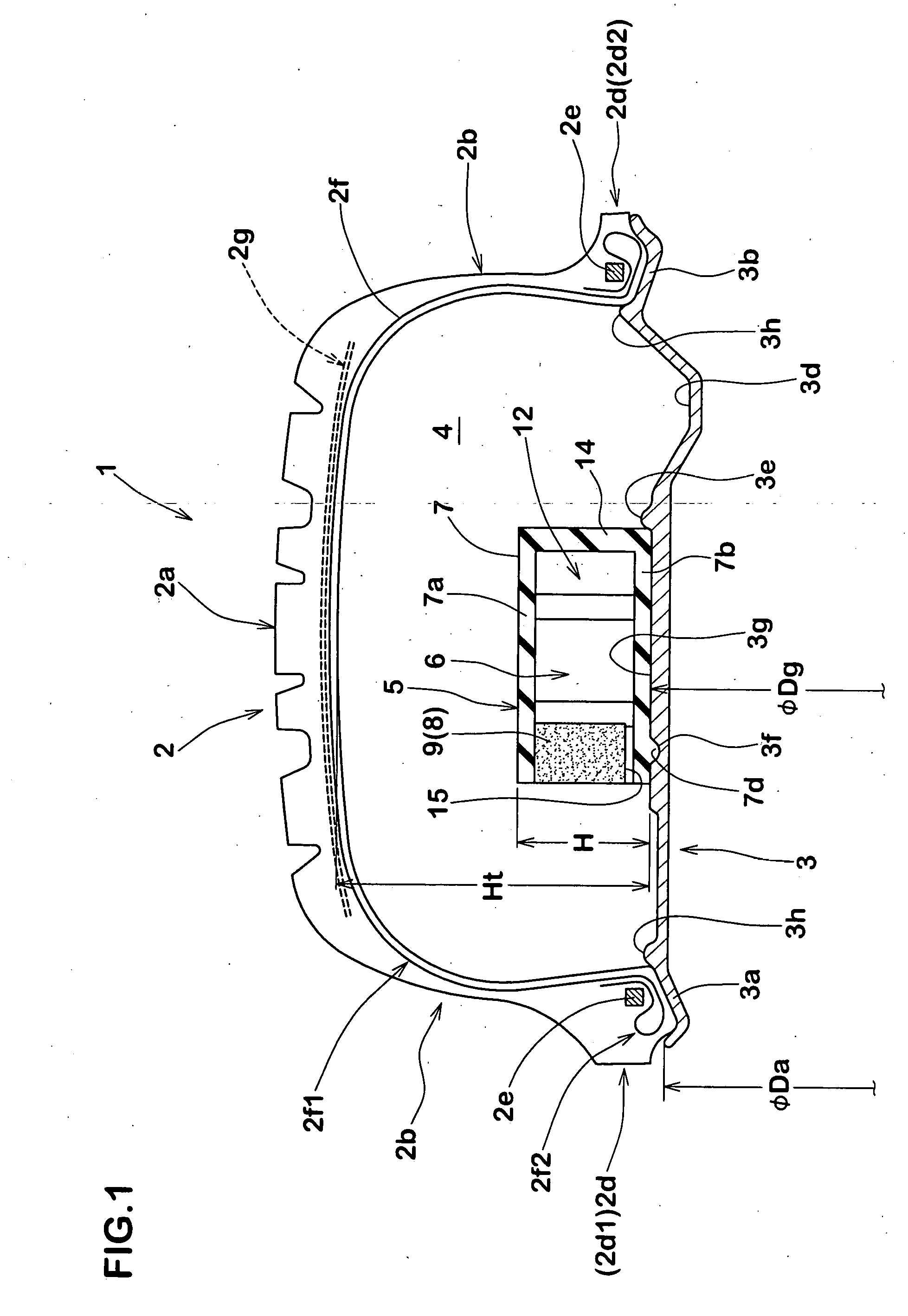

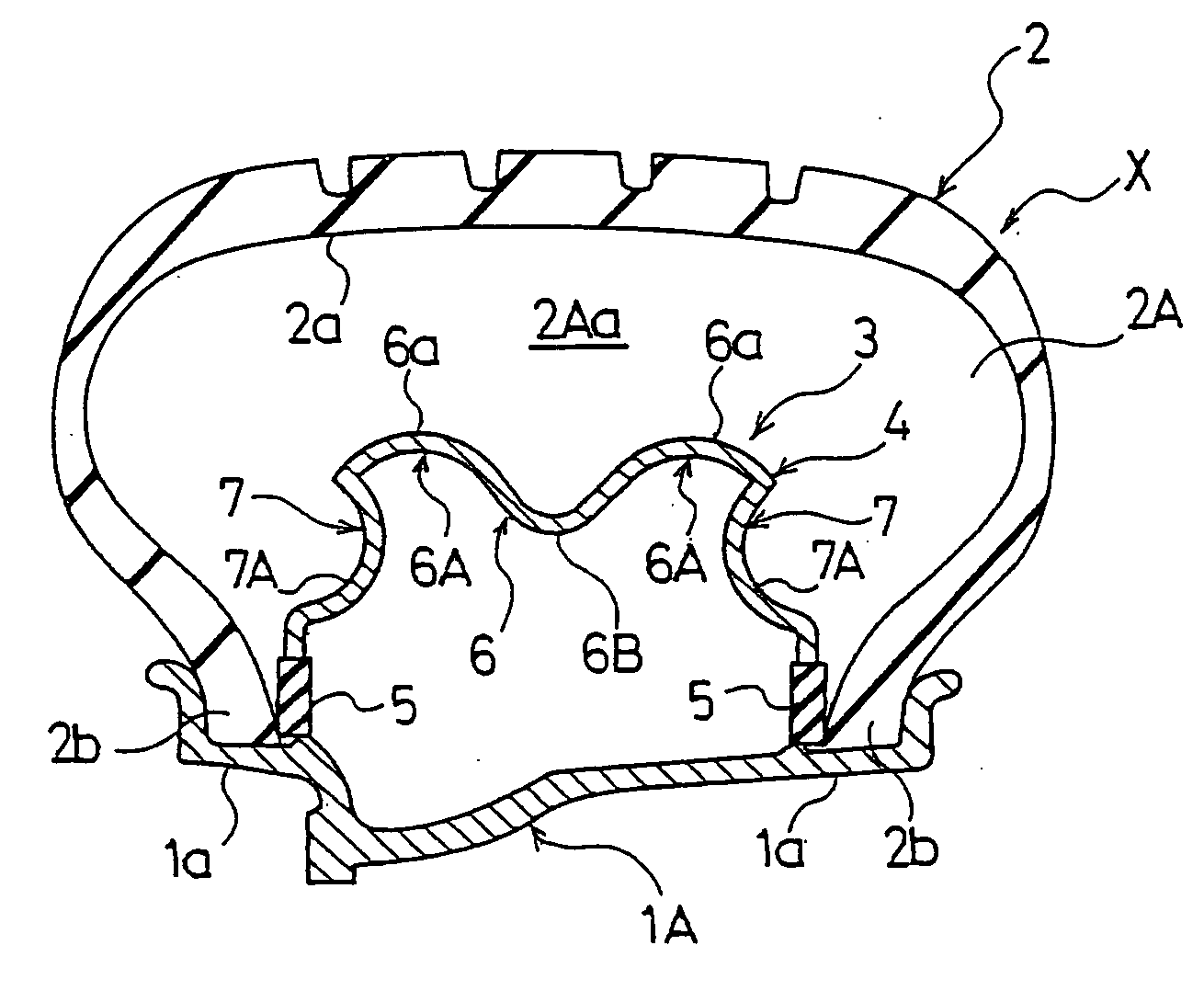

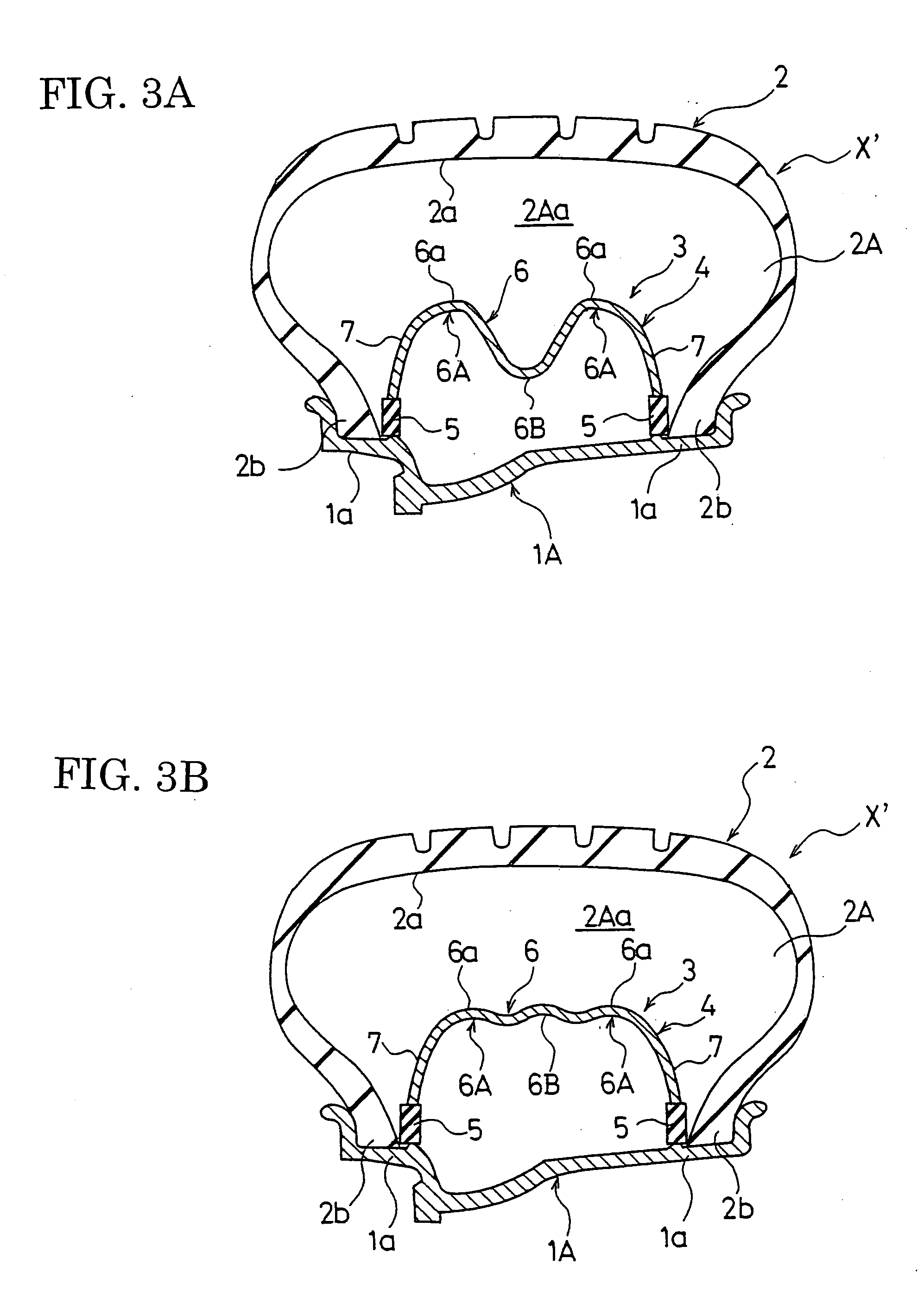

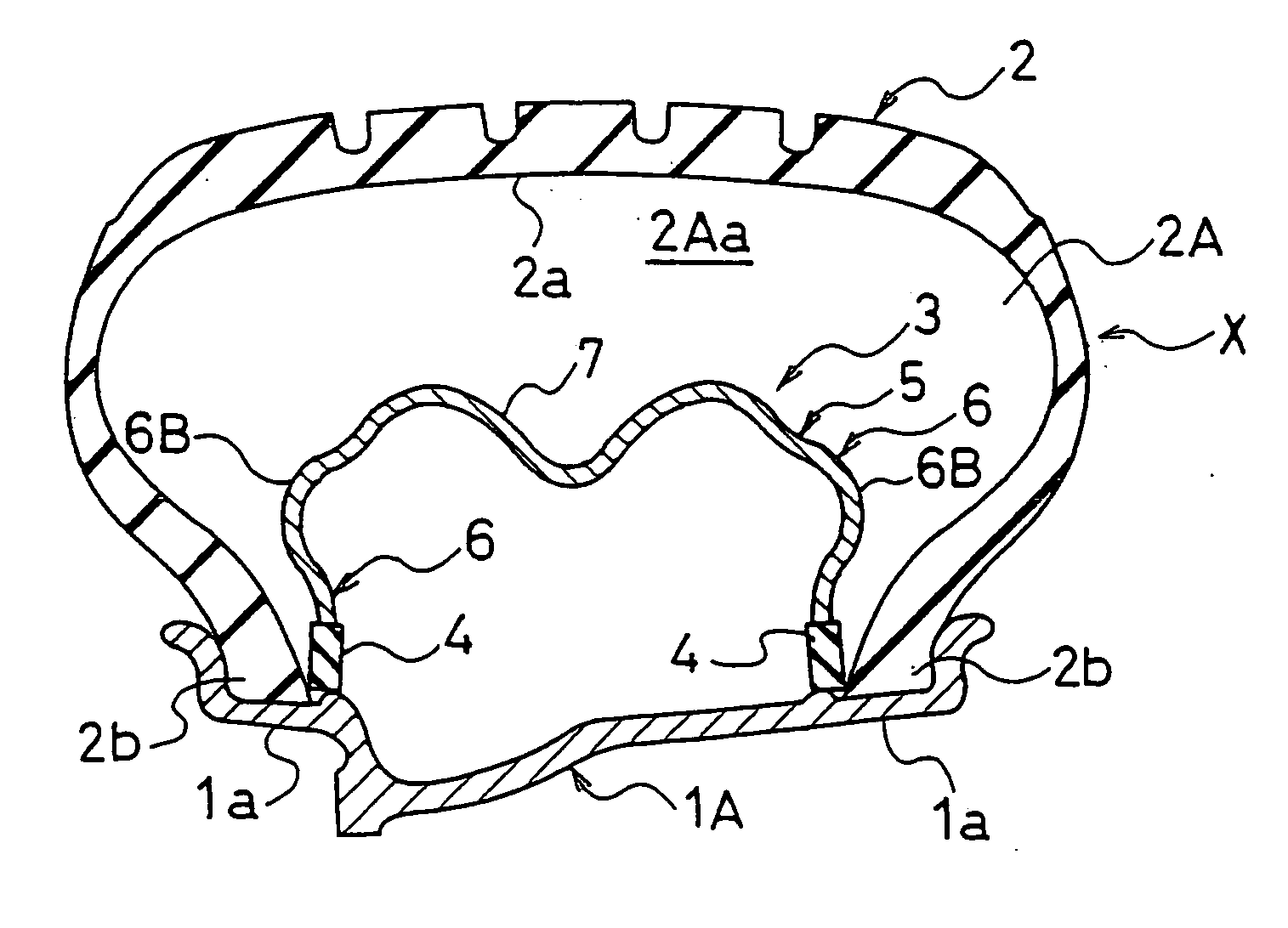

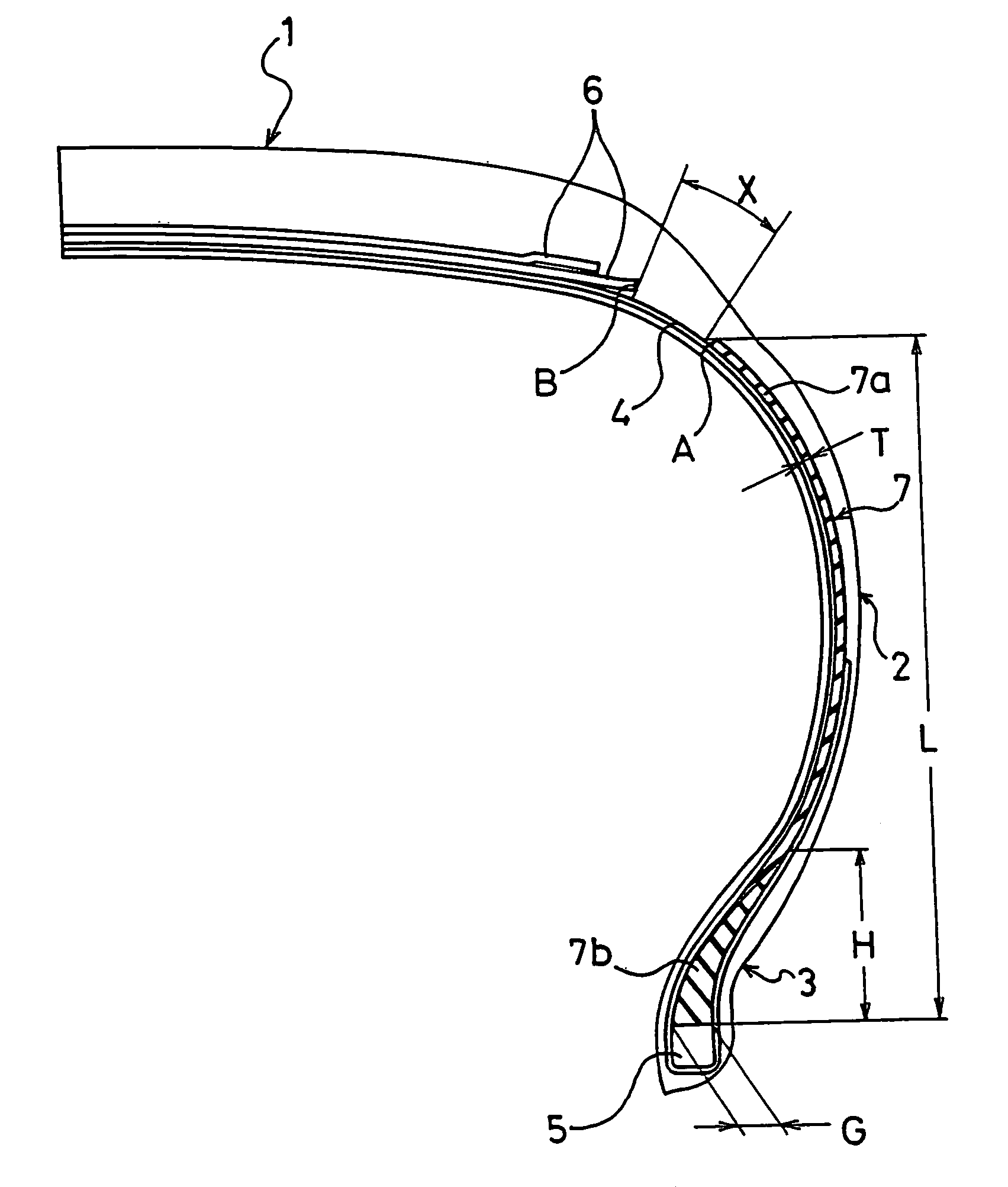

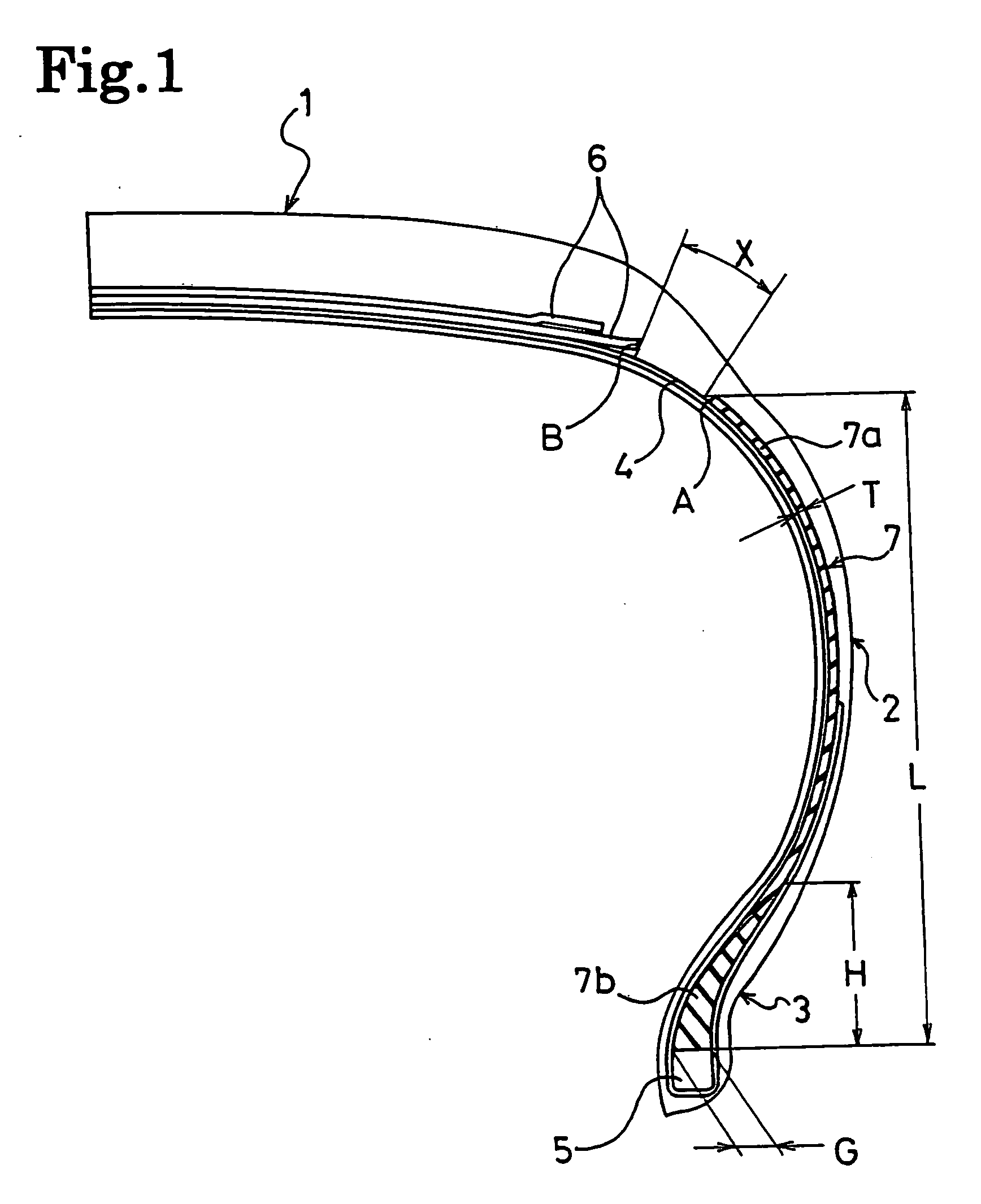

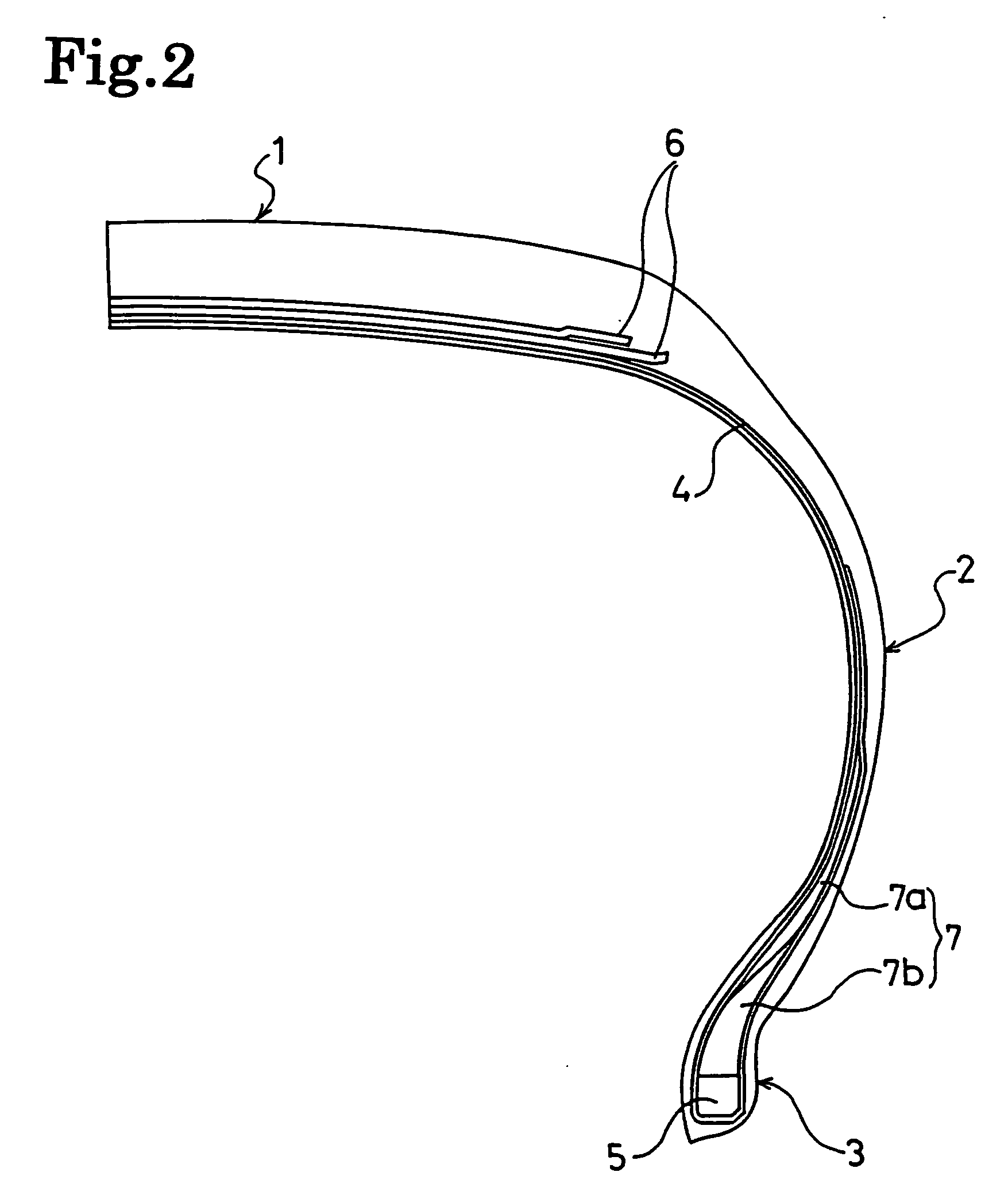

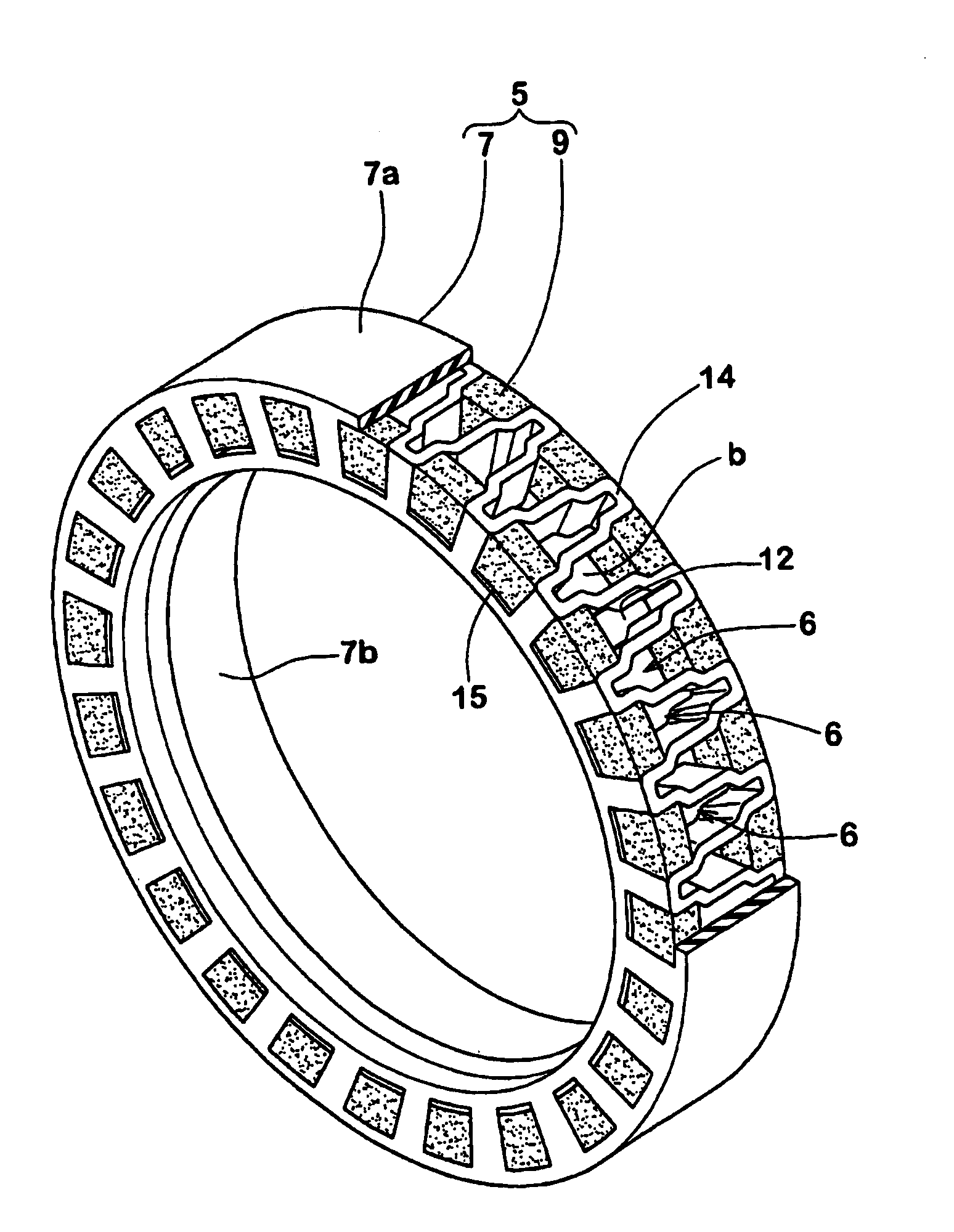

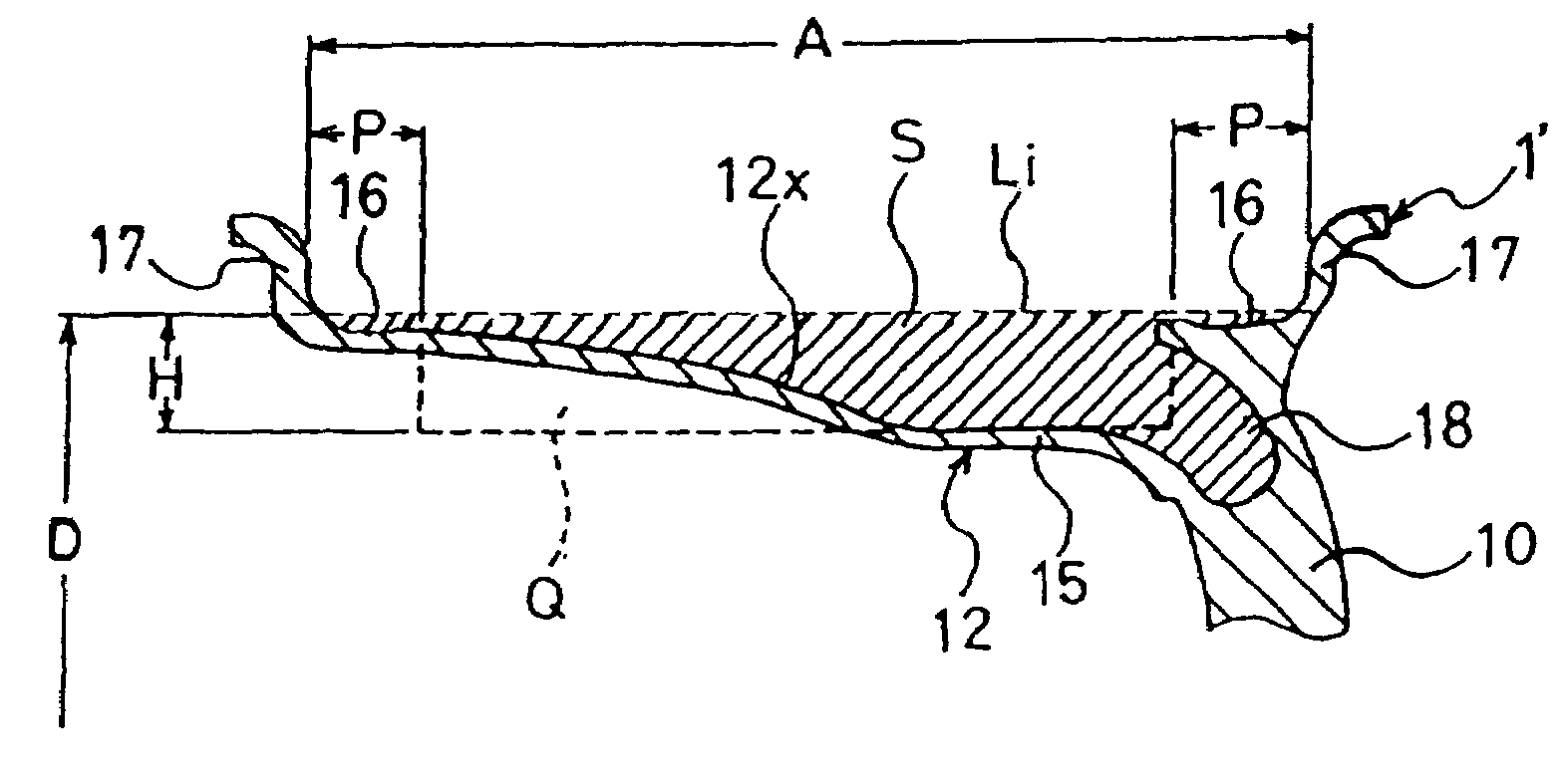

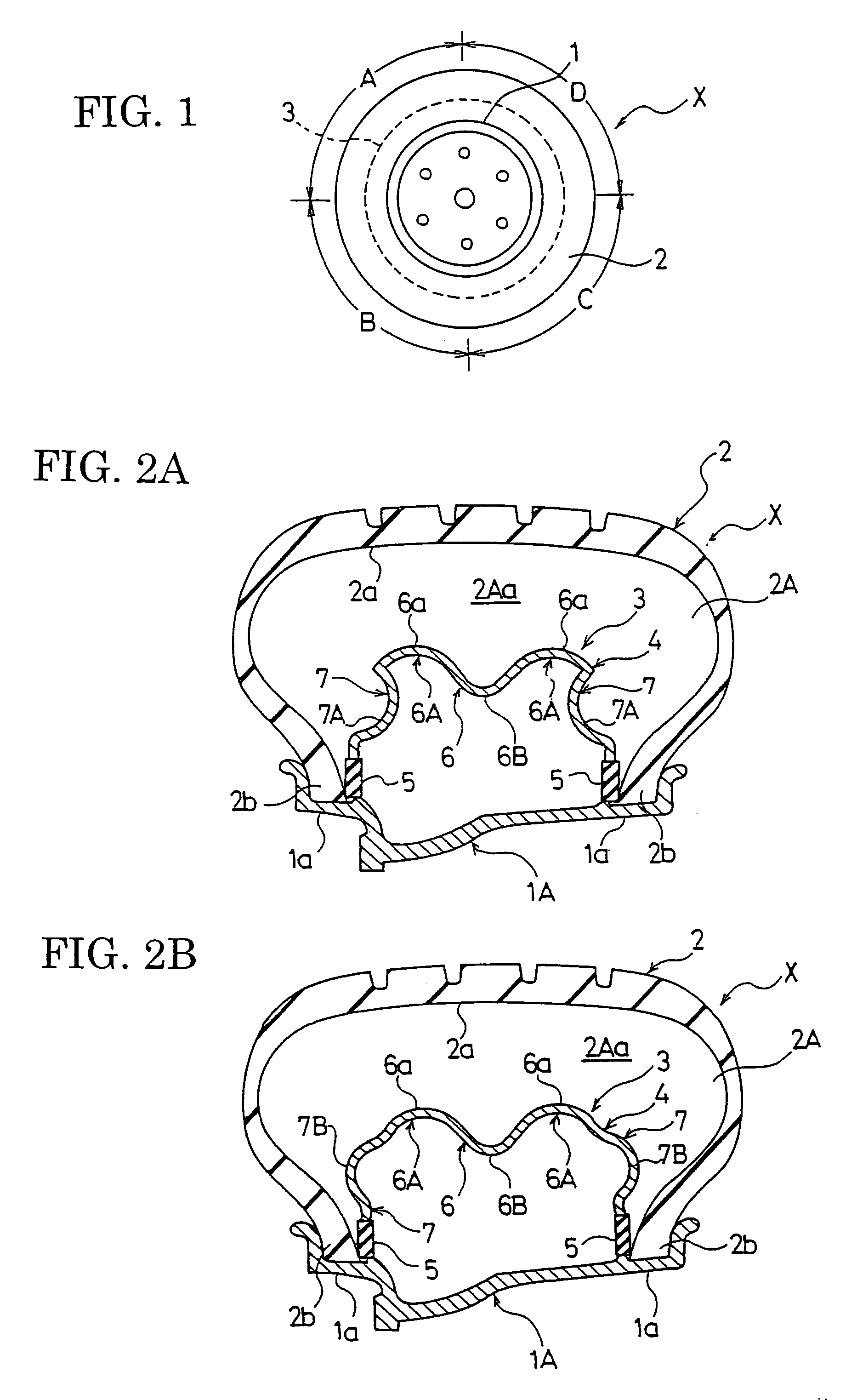

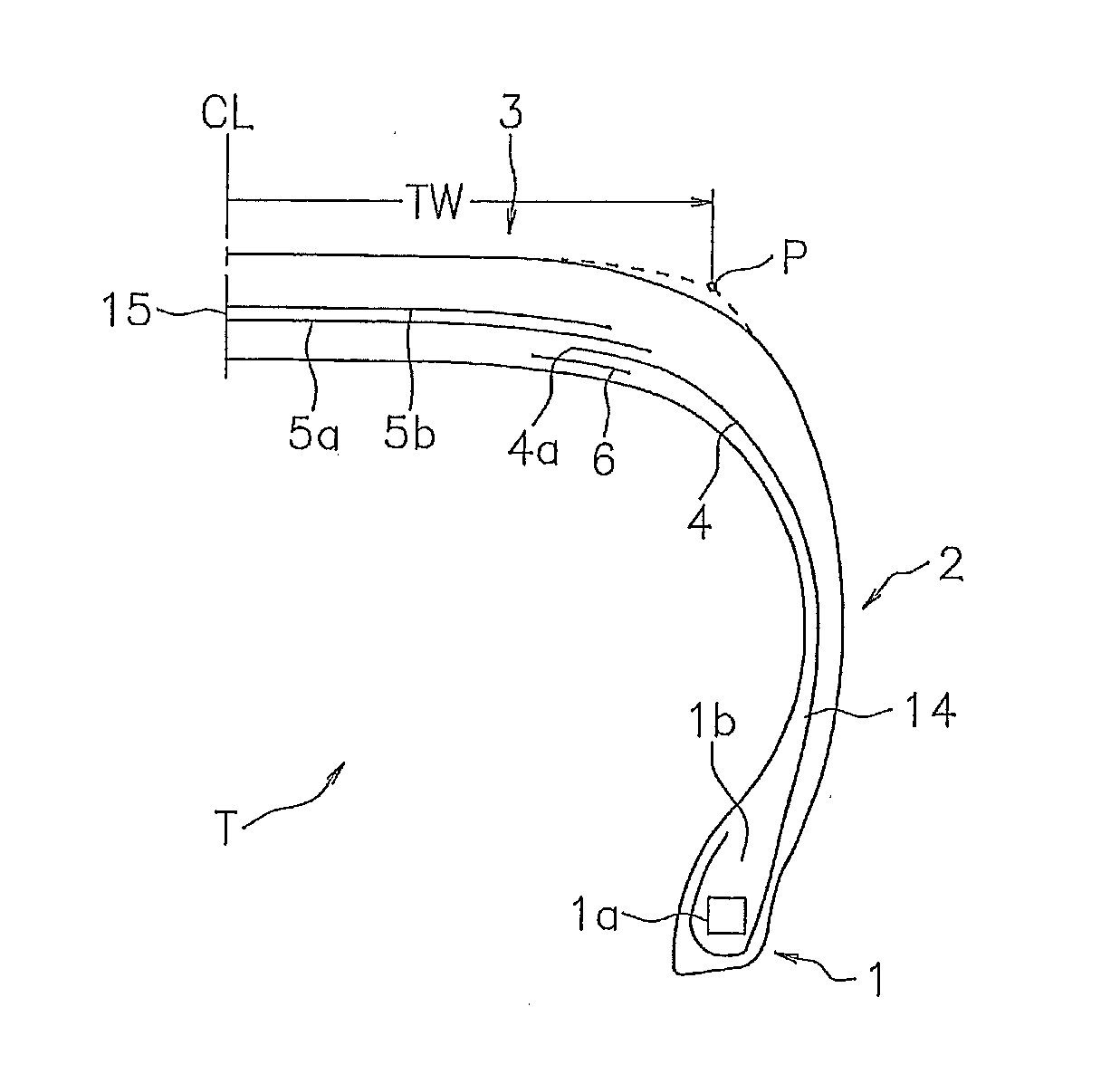

Tire/wheel assembly and run-flat support member

InactiveUS20060113018A1Reduce road noiseEasy to inflateWithout separate inflatable insertsNon-inflatable tyresEngineeringSupport surface

A tire / wheel assembly comprising a wheel having a rim, a pneumatic tire mounted on the rim of the wheel and a run-flat support member disposed in the cavity of the pneumatic tire. The run-flat support member includes an annular shell and elastic rings. The annular shell has a support surface located radially outward and two leg portions formed radially inward in a straddling state. The elastic rings support the leg portions on the rim. The annular shell is configured such that an annular cavity portion surrounded by the run-flat support member and the pneumatic tire has a cross-sectional area that varies in the circumferential direction of the tire.

Owner:THE YOKOHAMA RUBBER CO LTD

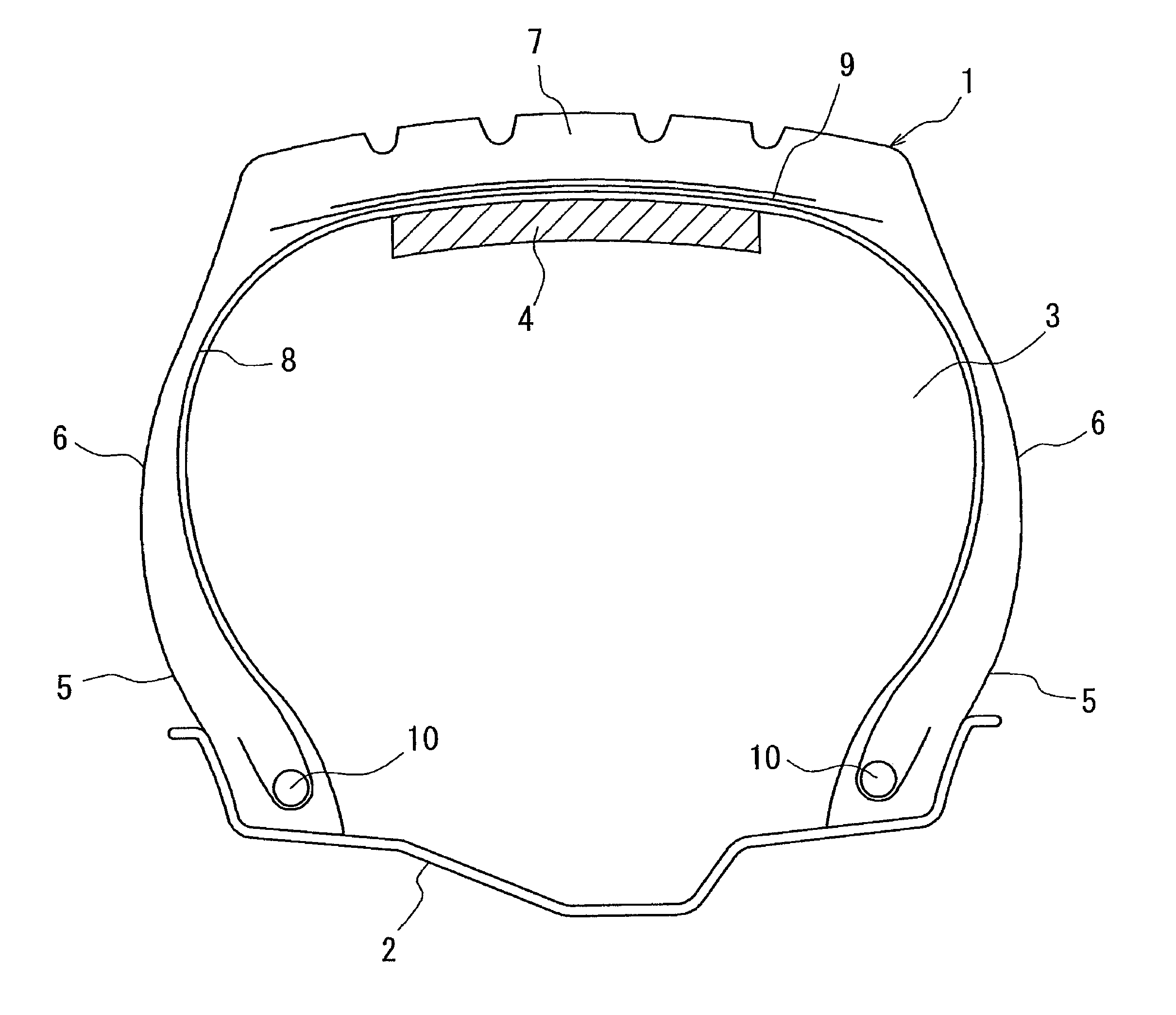

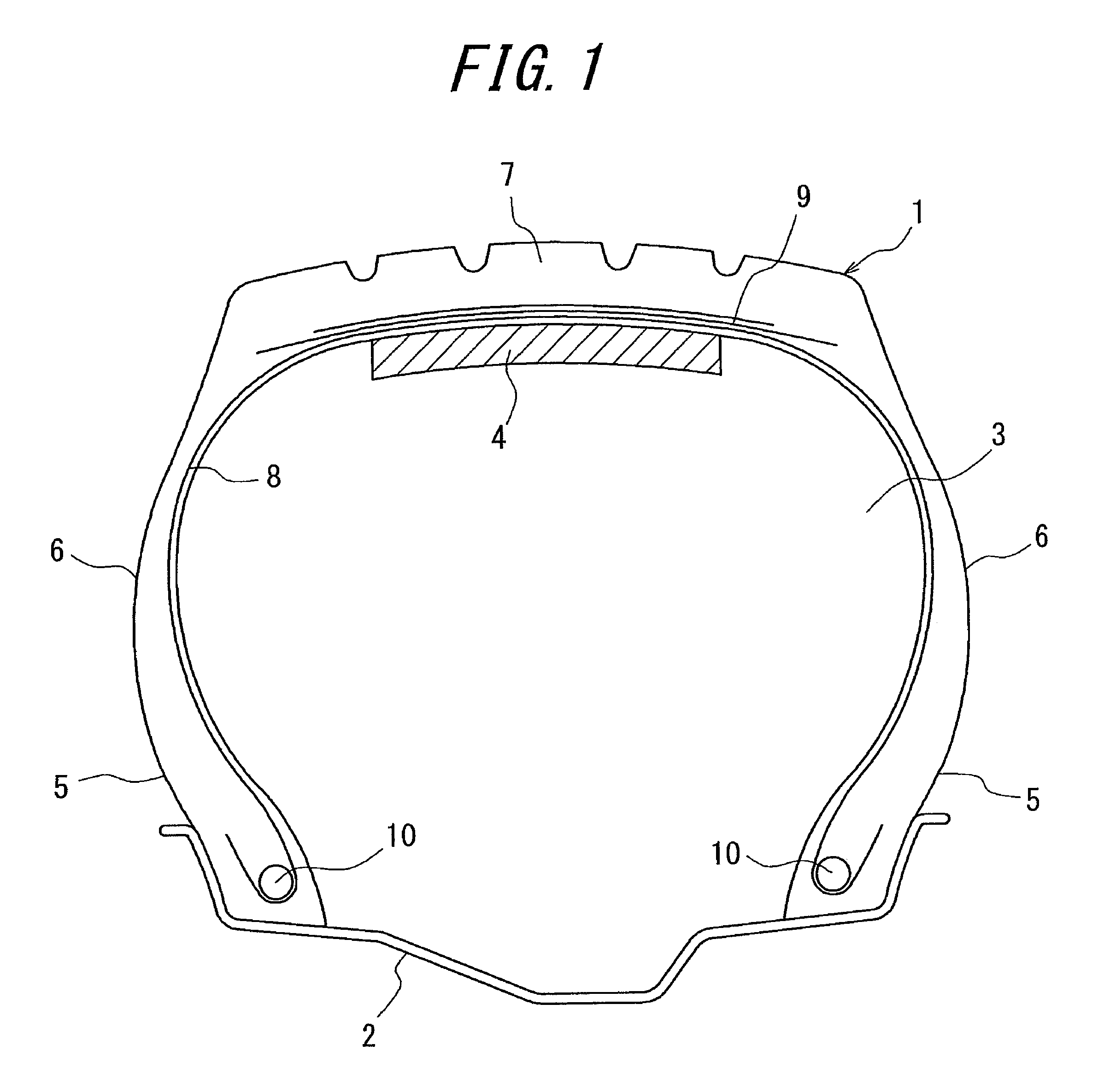

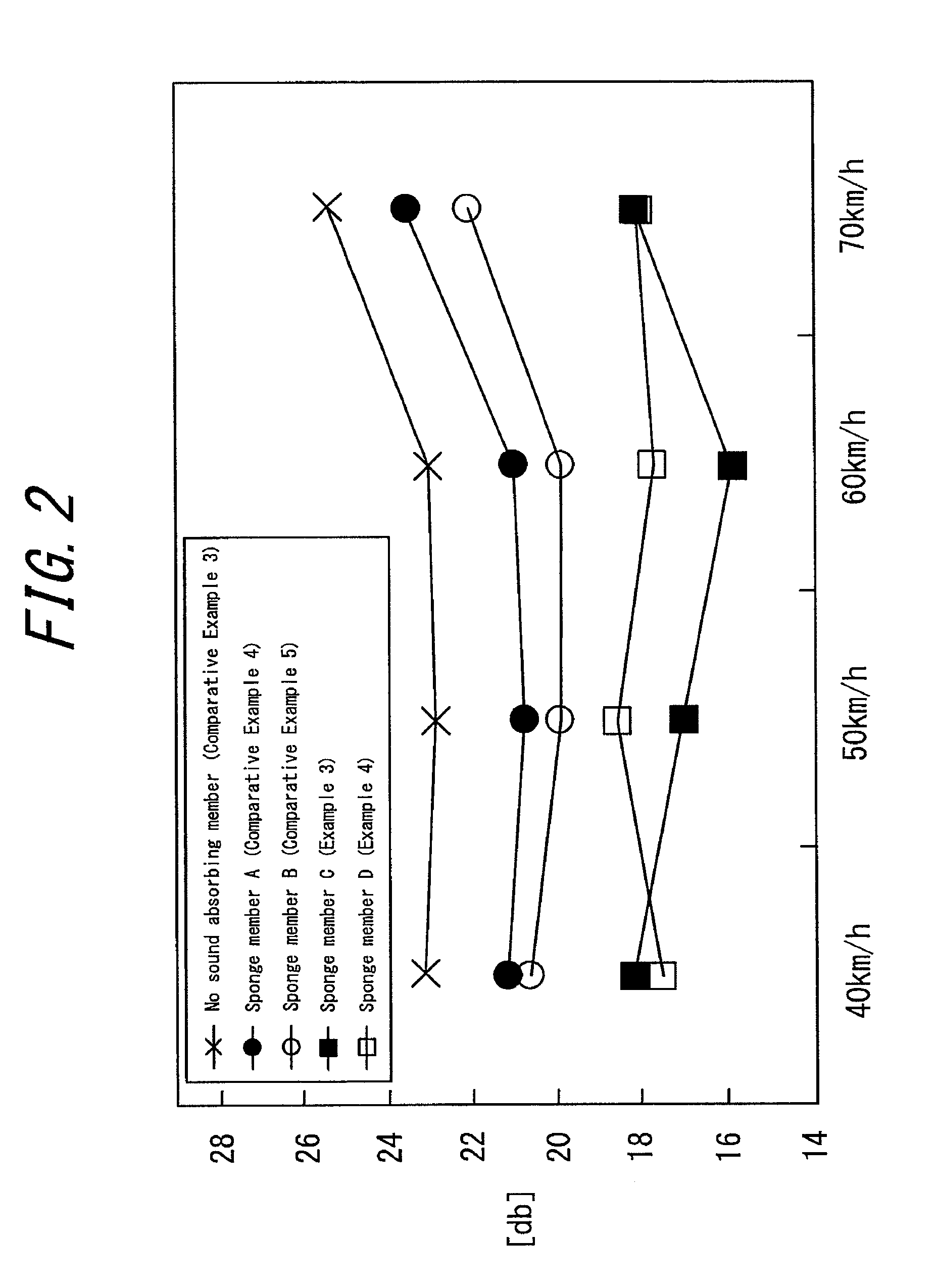

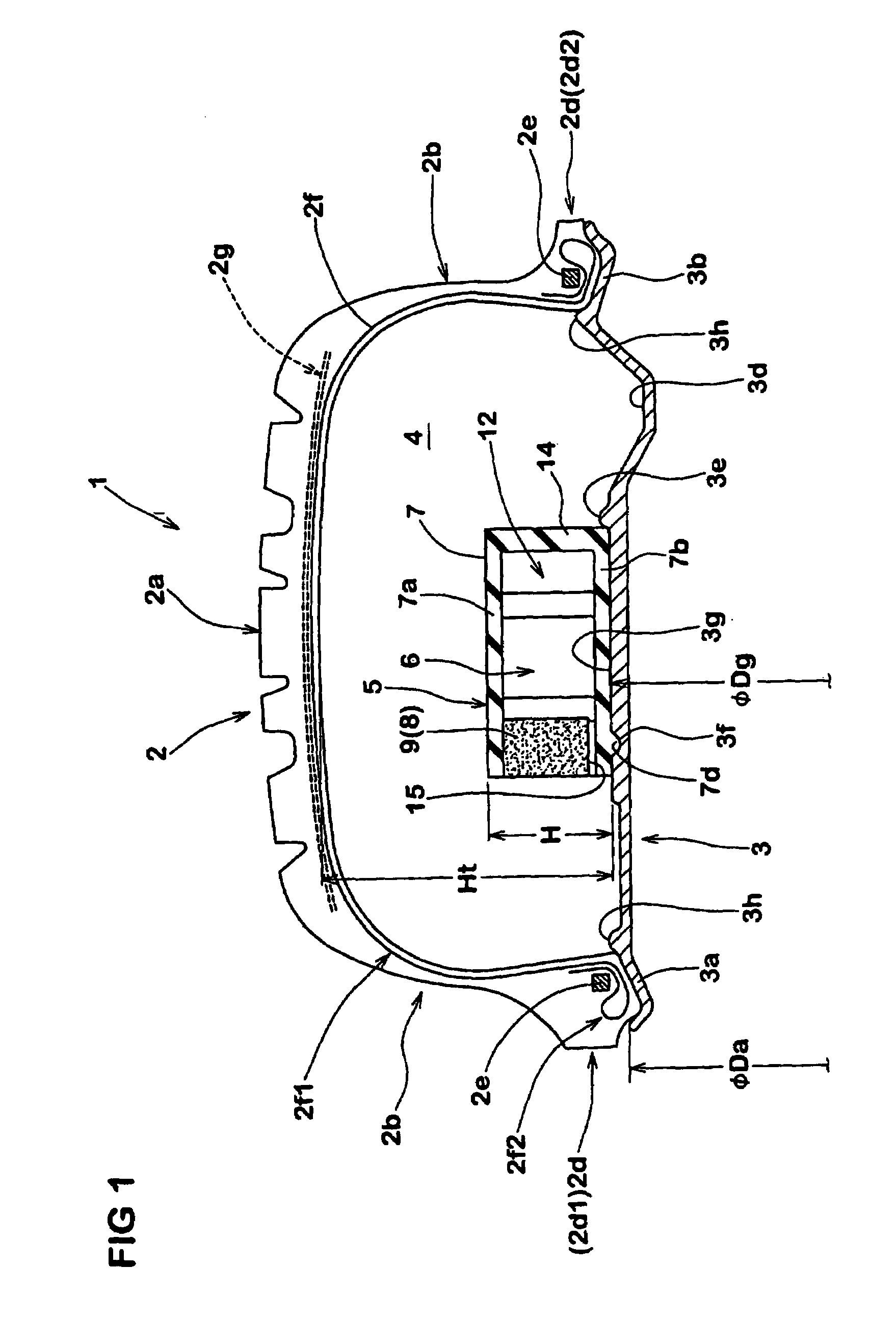

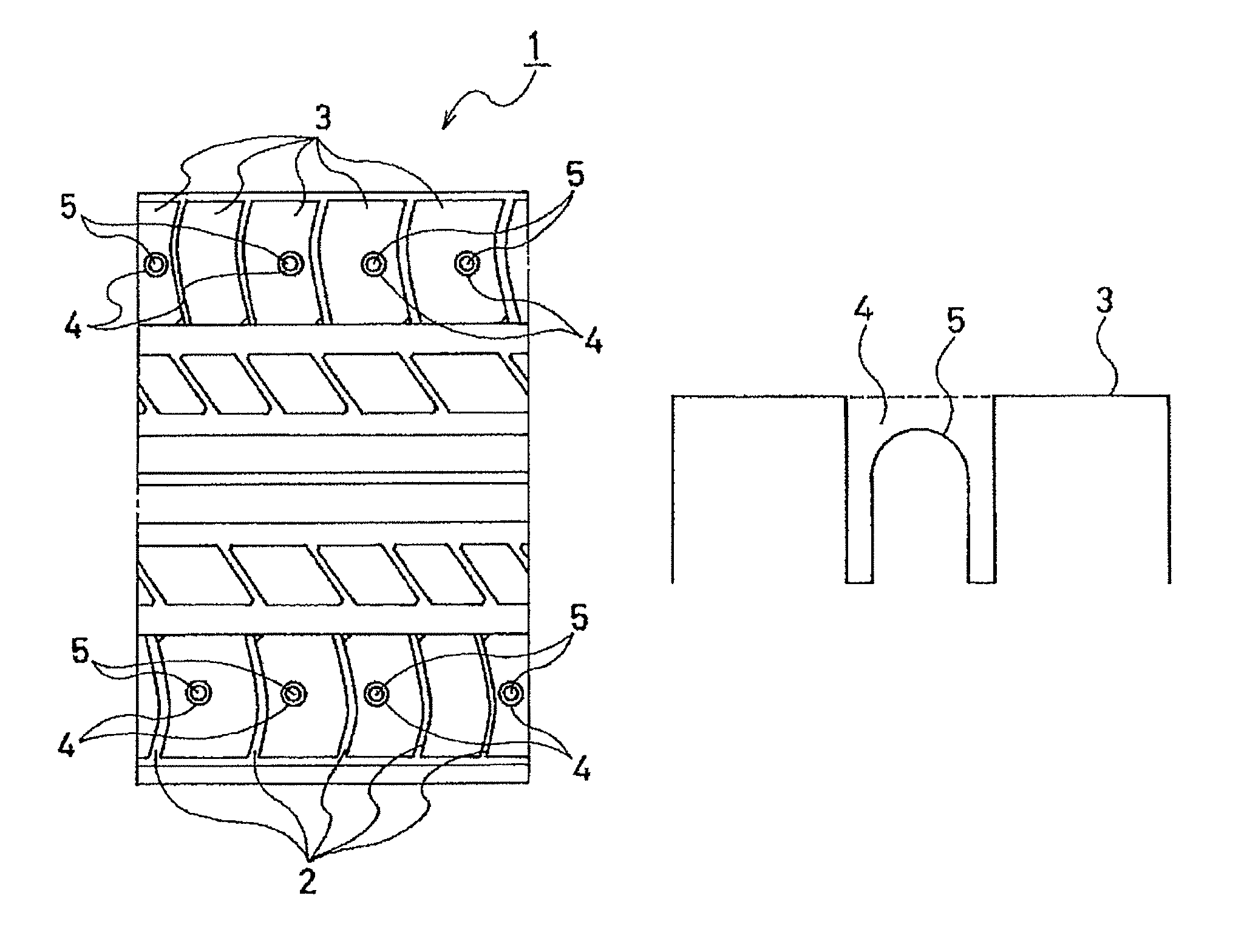

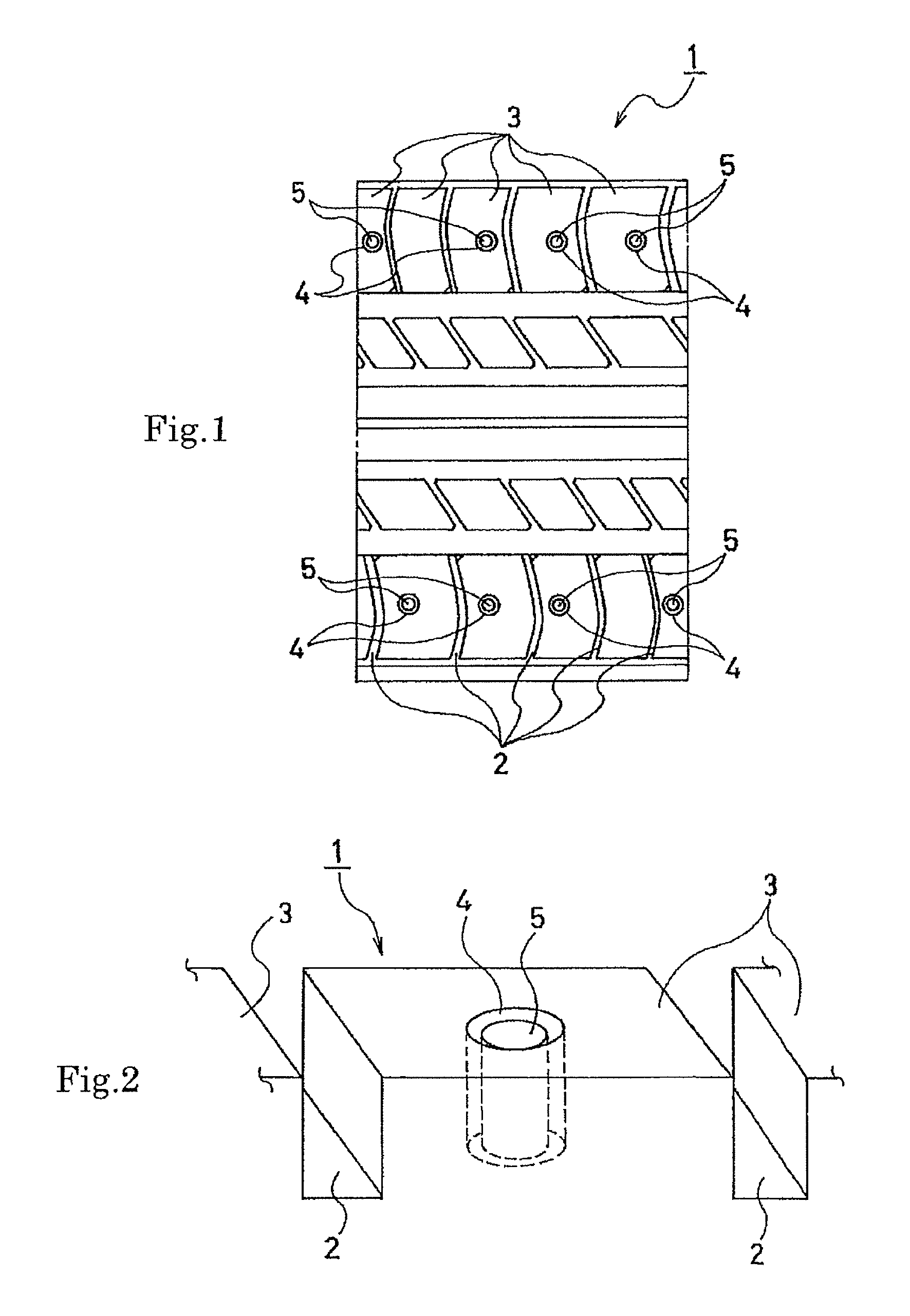

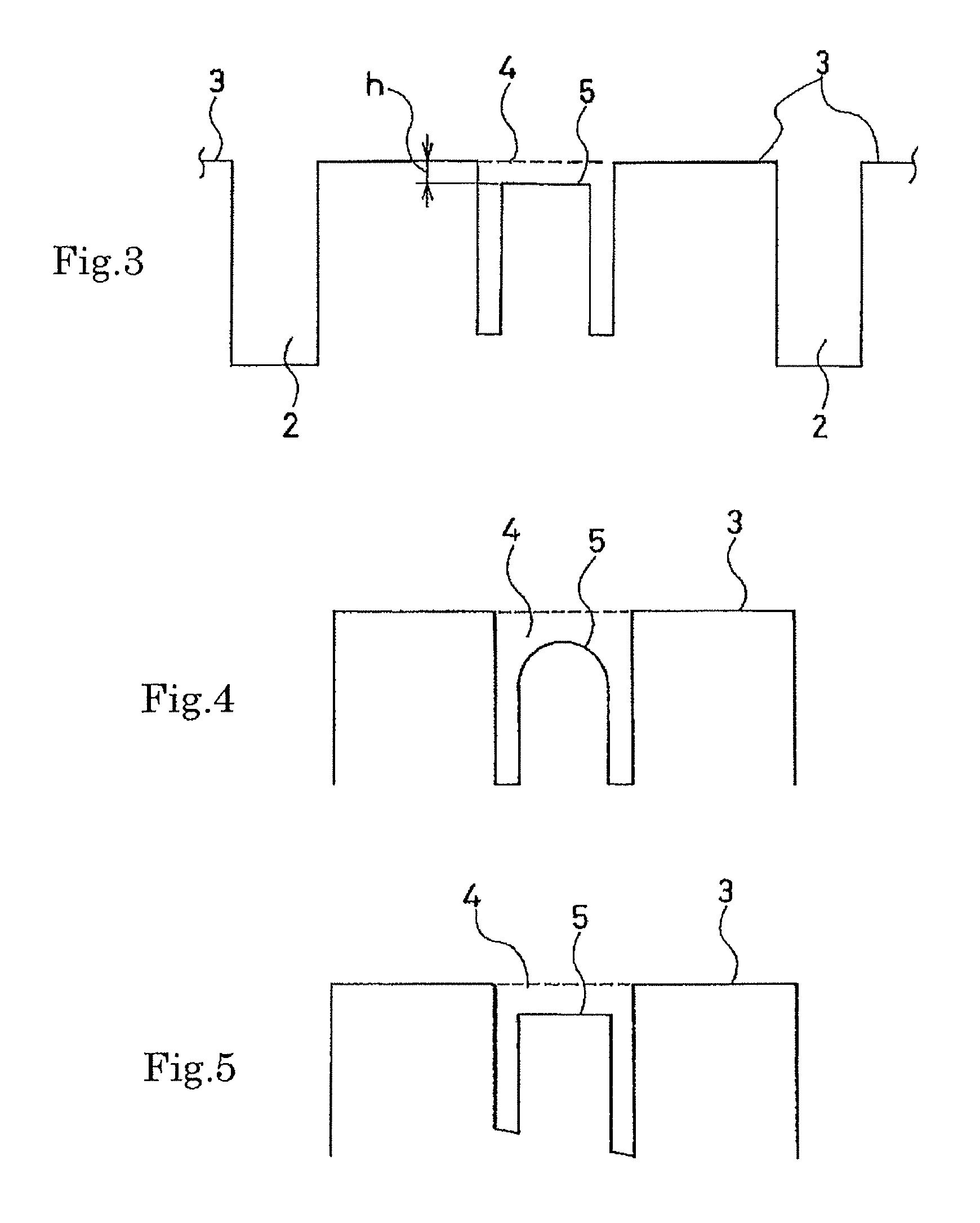

Tire-rim assembly and sponge member used in the same

This invention relates to a tire-rim assembly which is easily produced at low cost, excellent in durability and capable of notably reducing road noise, and more particularly to a tire-rim assembly comprising a pneumatic tire (1), a rim (2) and a sponge member (4) disposed in a tire internal cavity (3) defined by the pneumatic tire (1) and the rim (2), characterized in that the sponge member (4) has a specific gravity of higher than 0.06 but not higher than 0.25 and / or an air permeability of not higher than 5 cc / cm2 / sec.

Owner:BRIDGESTONE CORP

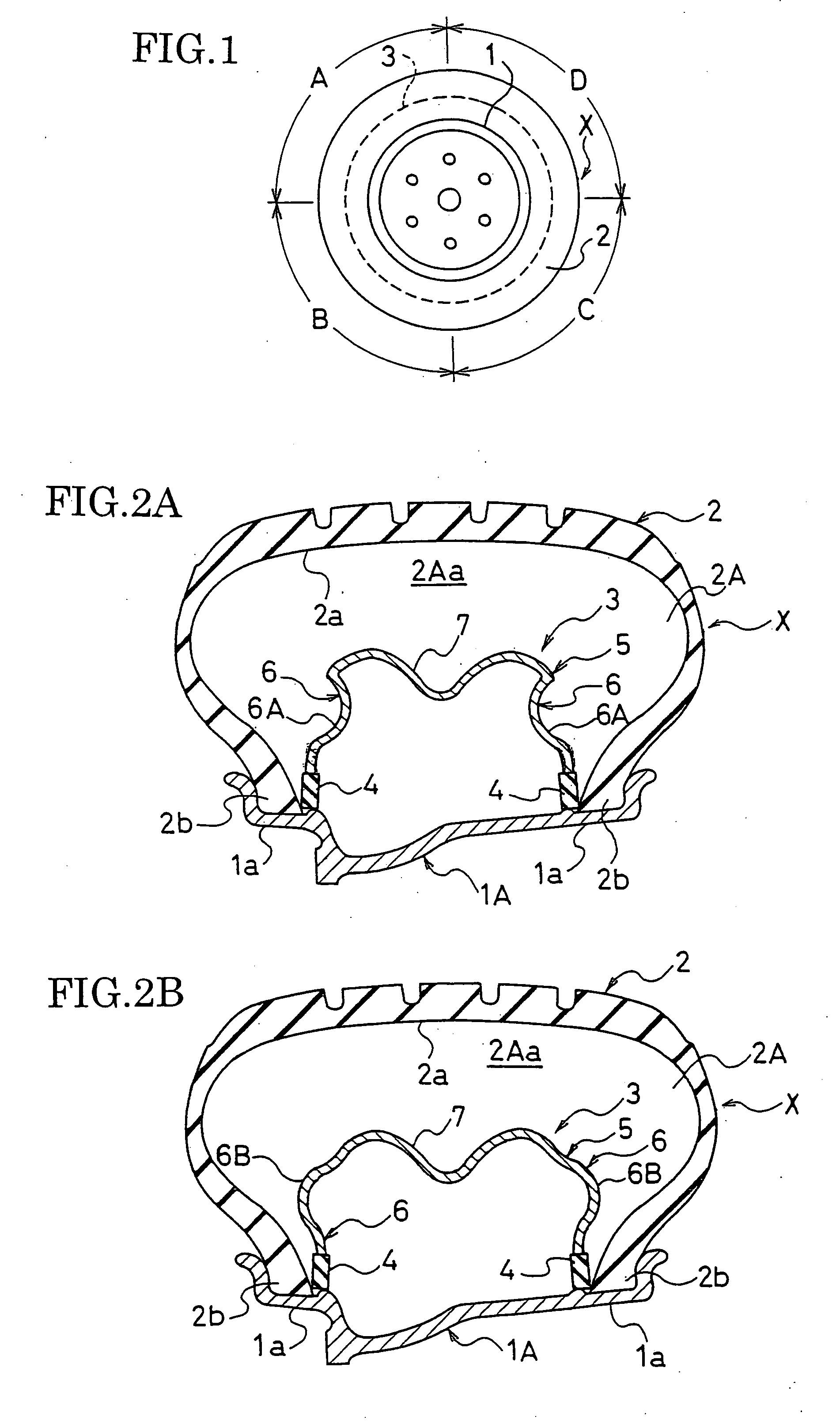

Tire/wheel assembly and noise reduction interior member

InactiveUS20060124216A1Reduce resonanceRoad noise increaseWithout separate inflatable insertsRimsEngineeringNoise reduction

A tire / wheel assembly comprising a wheel having a rim, a pneumatic tire mounted on the rim of the wheel and a noise reduction interior member disposed in the cavity of the pneumatic tire. The noise reduction interior member includes left and right elastic rings fitted to the rim and an annular body attached between the elastic rings. The annular body is configured such that an annular cavity portion surrounded by the noise reduction interior member and the pneumatic tire has a cross-sectional area that varies in a circumferential direction of the tire.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

InactiveUS20060207709A1Improve noiseDeteriorating durabilitySpecial tyresPneumatic tyre reinforcementsTire beadRolling resistance

A pneumatic tire reducing road noise without deteriorating durability and rolling resistance. In this pneumatic tire, the bead filler includes a triangle portion abutting a bead core and having a substantially triangular cross-sectional shape, and a uniform-thickness portion extending from a top of the triangle portion in a radially outward direction of the tire and having a substantially uniform thickness. An upper-end position of the uniform-thickness portion is outward, in a radial direction of the tire, from a position 1.6 times as high as the height of the triangle portion, and is at least 5 mm apart from the belt layers. A thickness of the uniform-thickness portion is thicker than 0.1 mm and thinner than 0.5 times a lower-end width of the triangle portion. The bead filler includes a plurality of rubber layers formed of mutually different rubber compositions. The rubber compositions forming these rubber layers have loss tangents (tan δ) gradually decreasing from the outermost-periphery rubber layer toward the innermost-periphery rubber layer, are harder than other rubber compositions neighboring the bead filler, and have breaking elongations whose mutual differences are 50% points or less.

Owner:YOKOHAMA RUBBER CO LTD

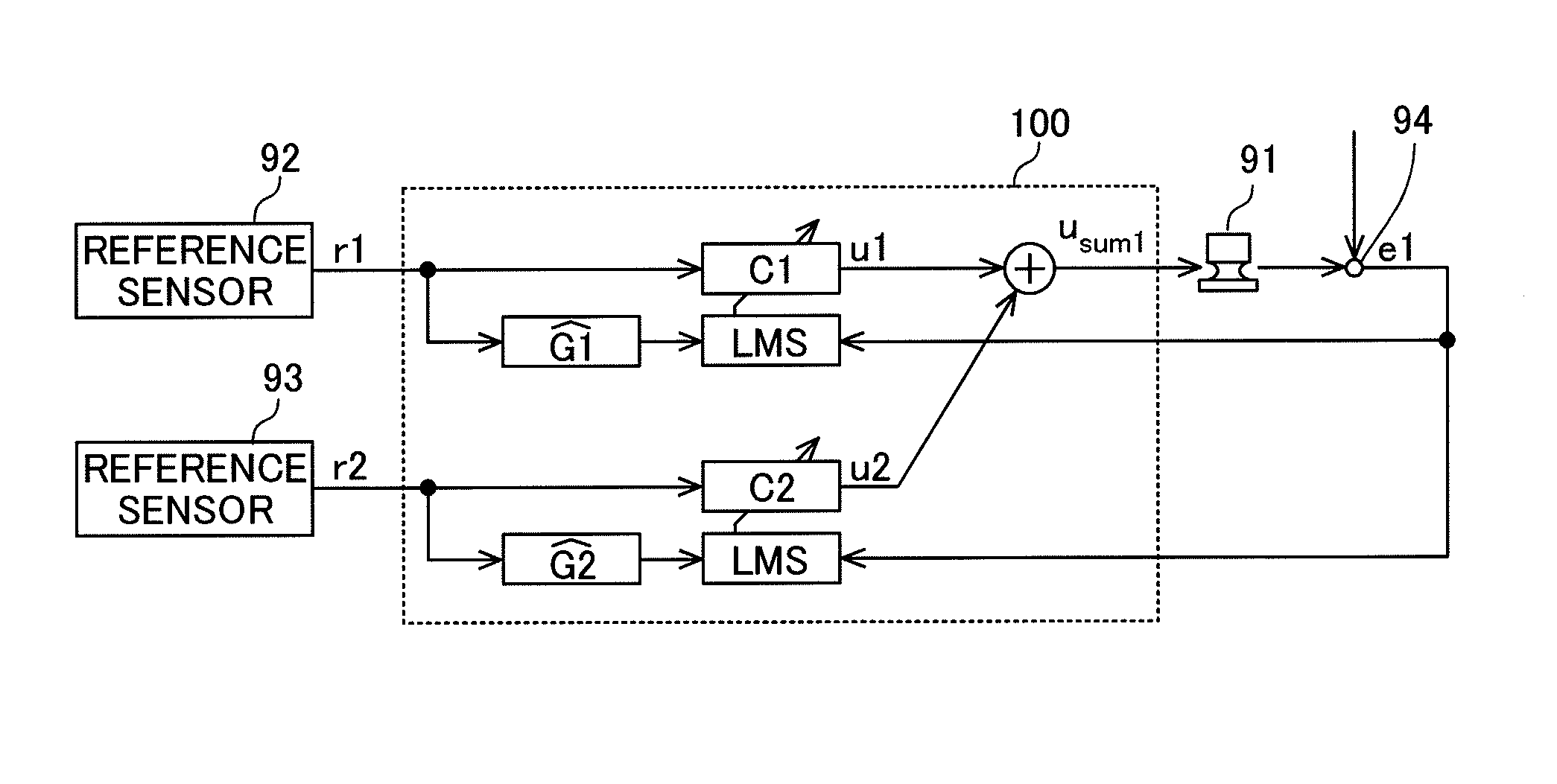

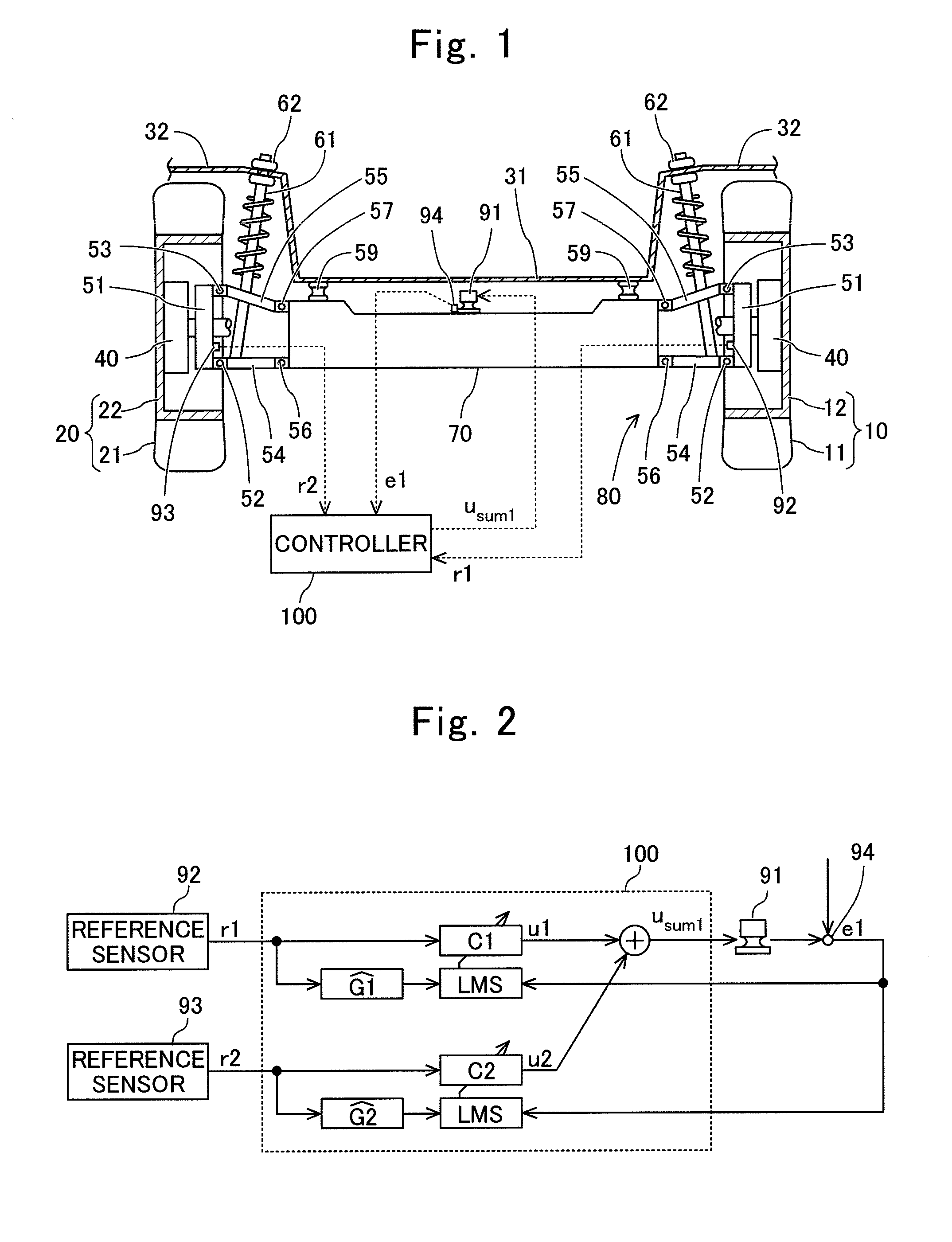

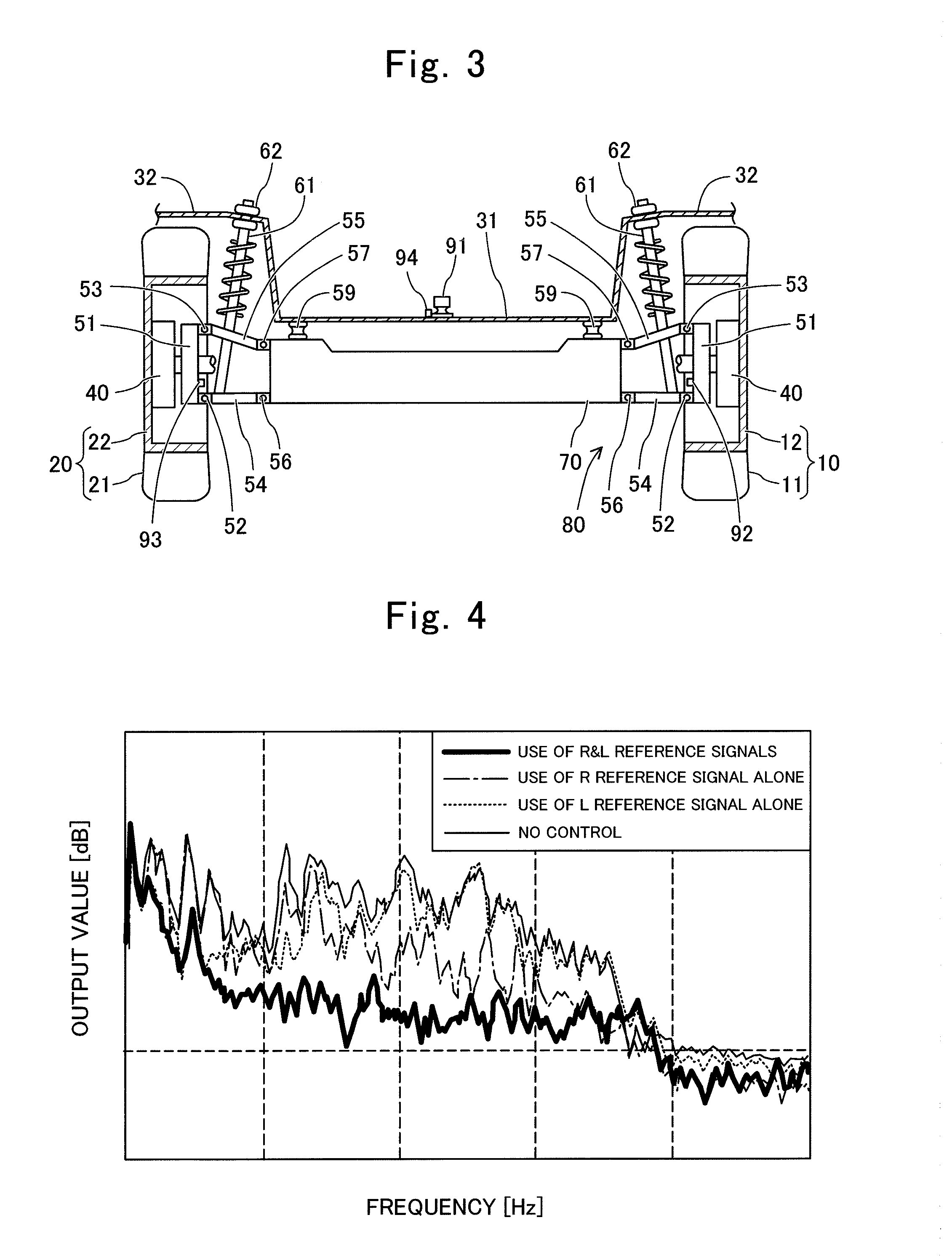

Active noise cancellation

ActiveUS20140348338A1Reduce power consumptionReduce road noiseEar treatmentTransducer circuit dampingEngineeringSignal detector

Provided is an active noise cancellation apparatus capable of reliably reducing road noise by reducing vibration of a vehicle component part which generates road noise by using a vibration generator. A plurality of reference signal detectors are placed respectively on right and left knuckles for respectively supporting right and left wheels. A vibration generator and an error signal detector are placed on a vehicle component part. A controller performs respective adaptive controls based on each of reference signals and an error signal so as to reduce the error signal, and controls the vibration generator based on a sum of respective output values of the adaptive controls.

Owner:SUMITOMO RIKO CO LTD

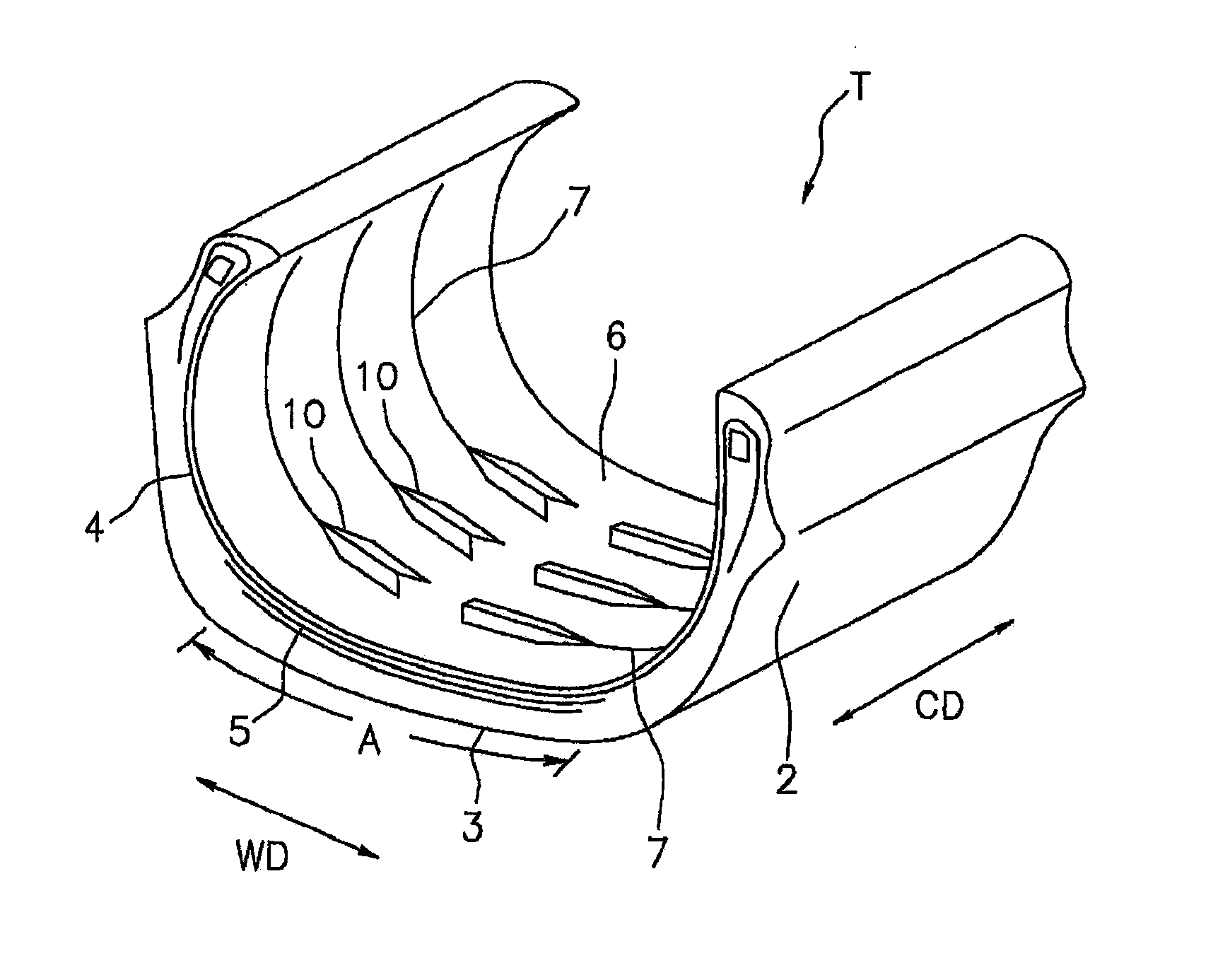

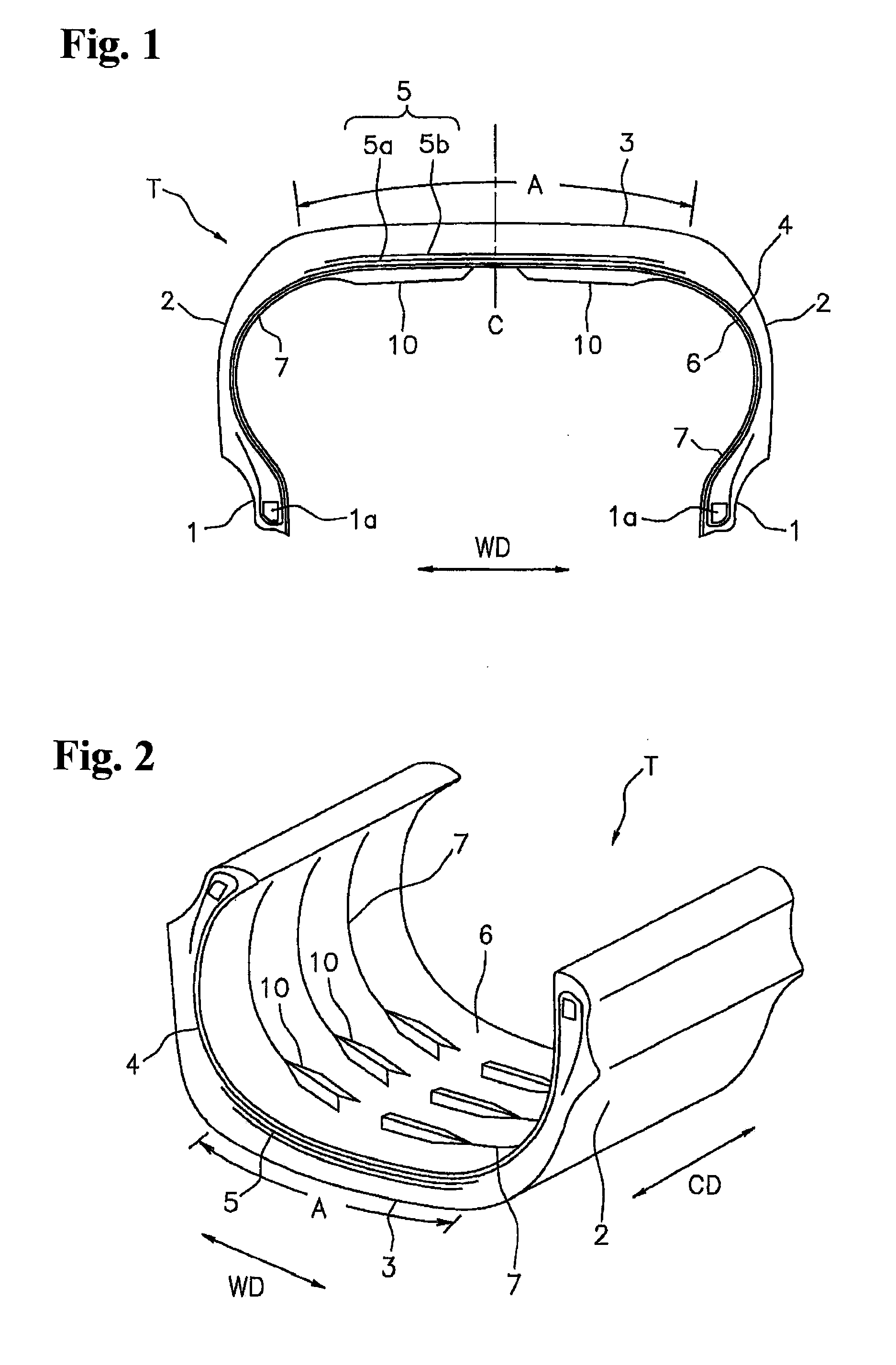

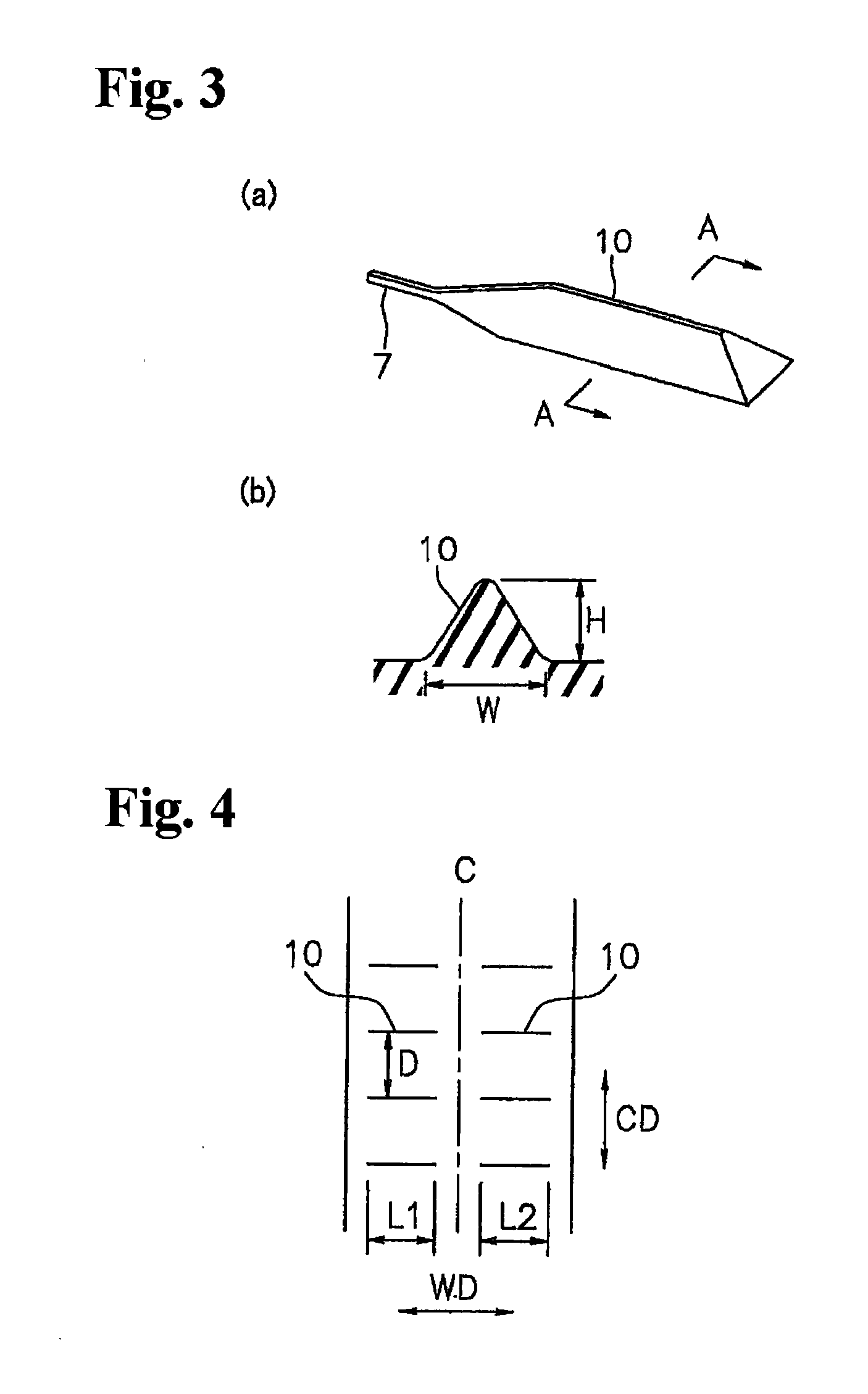

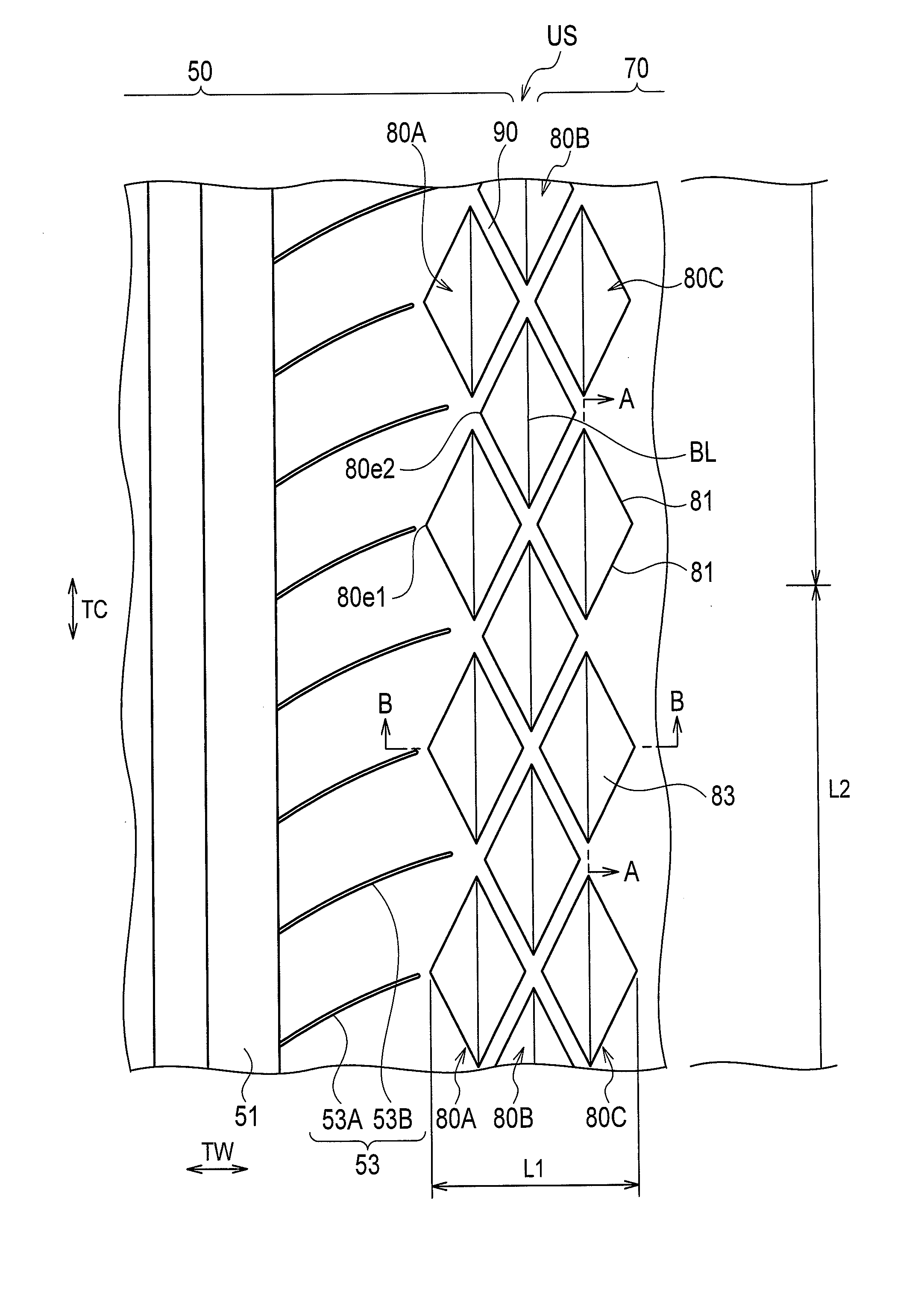

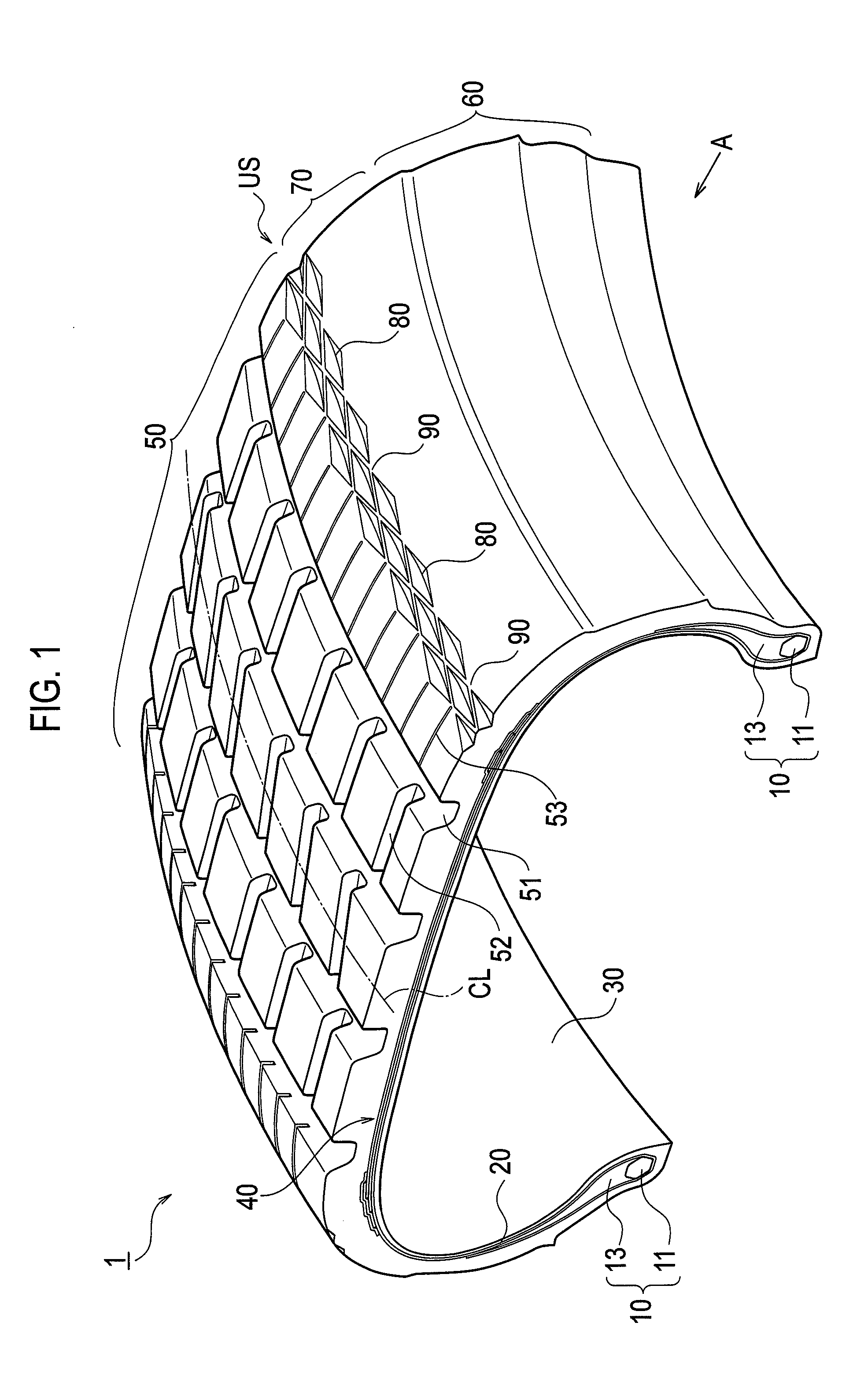

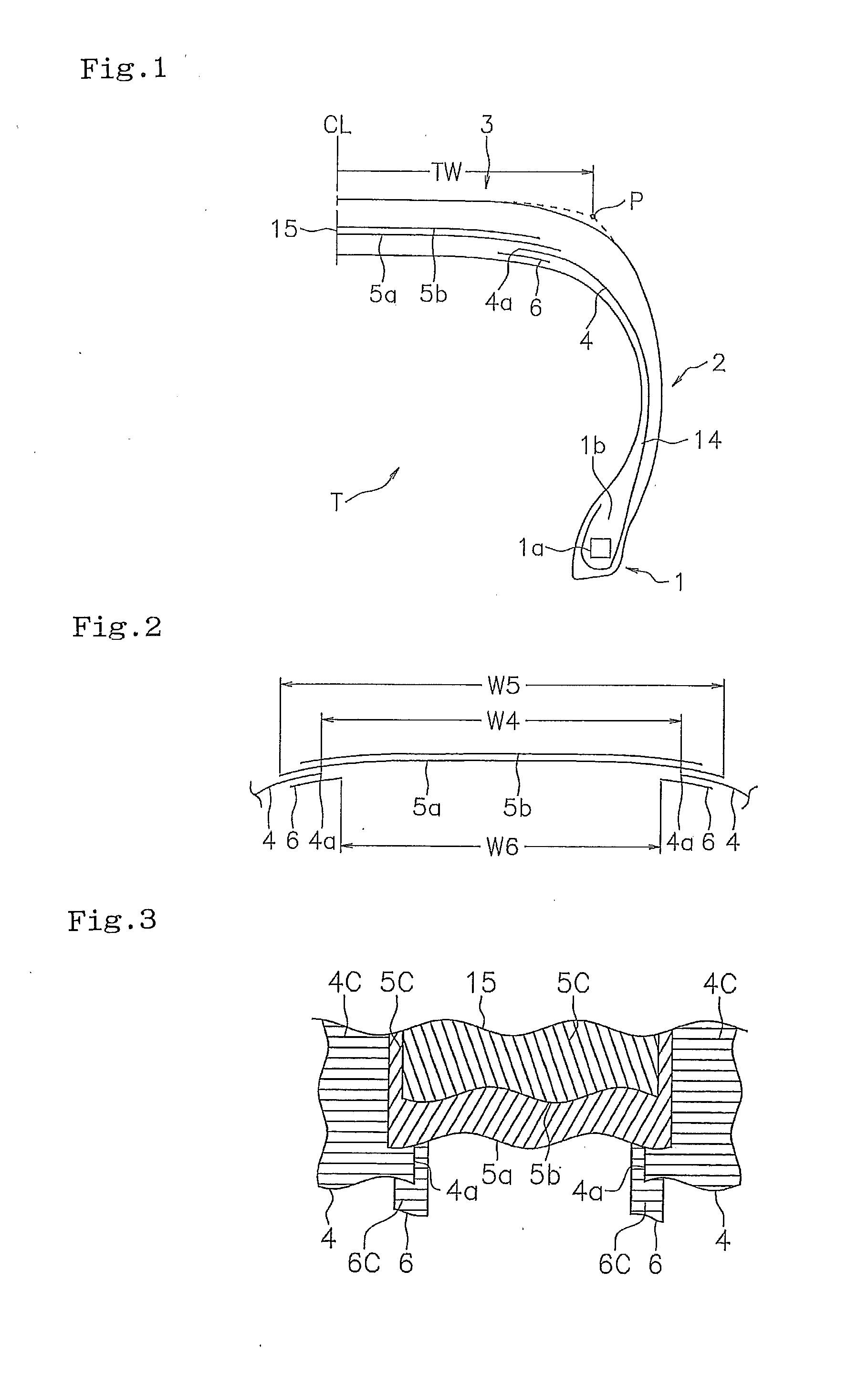

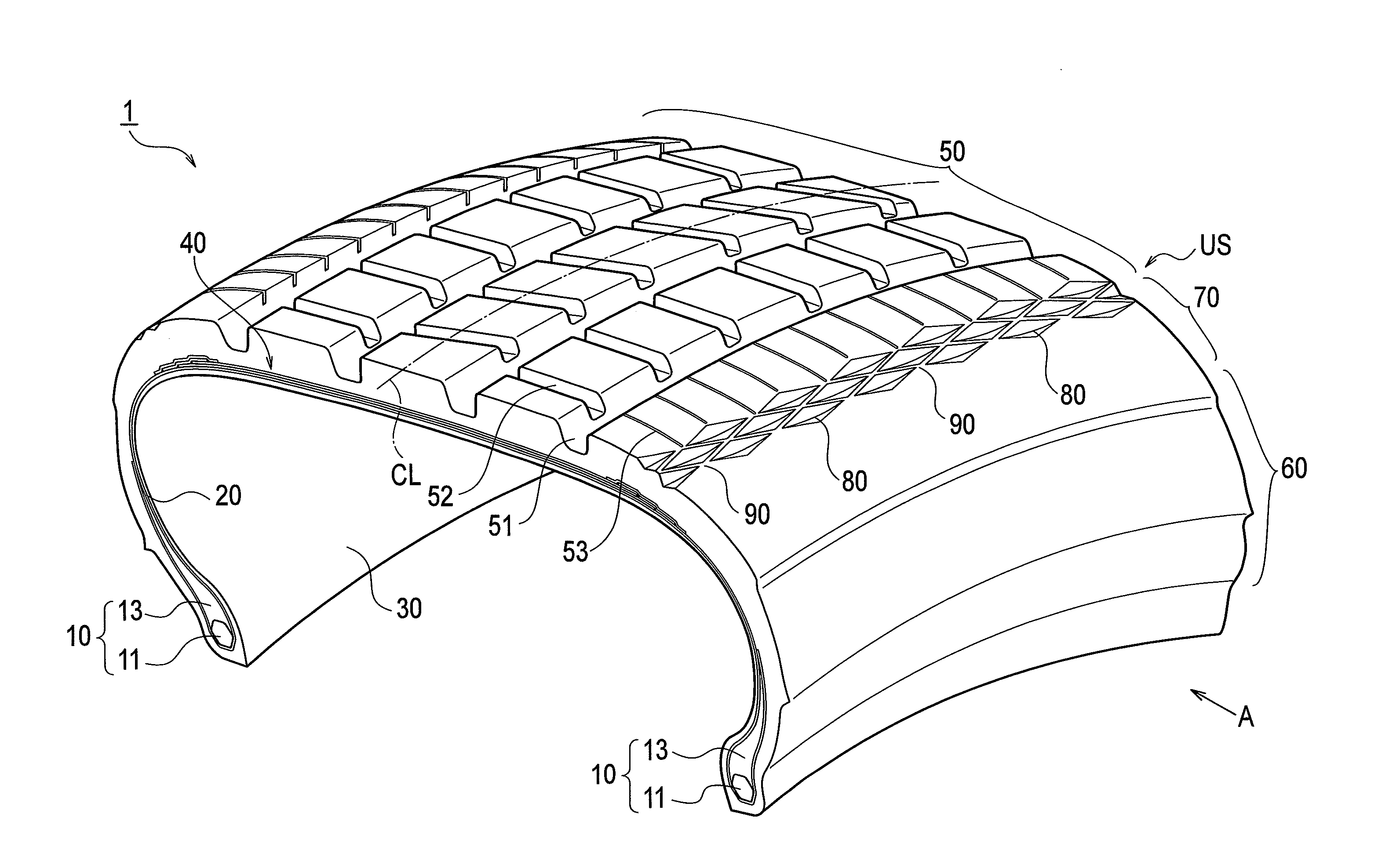

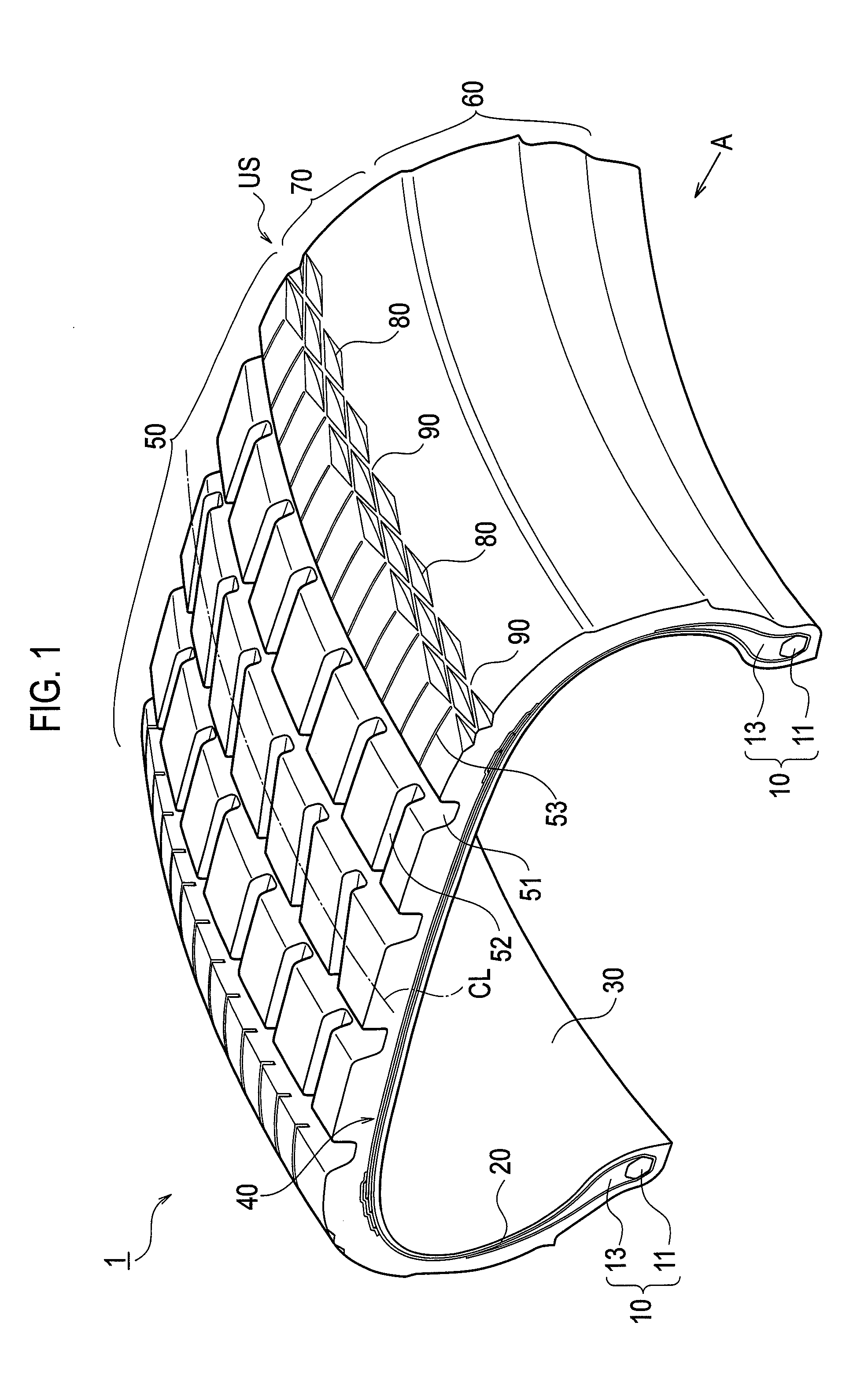

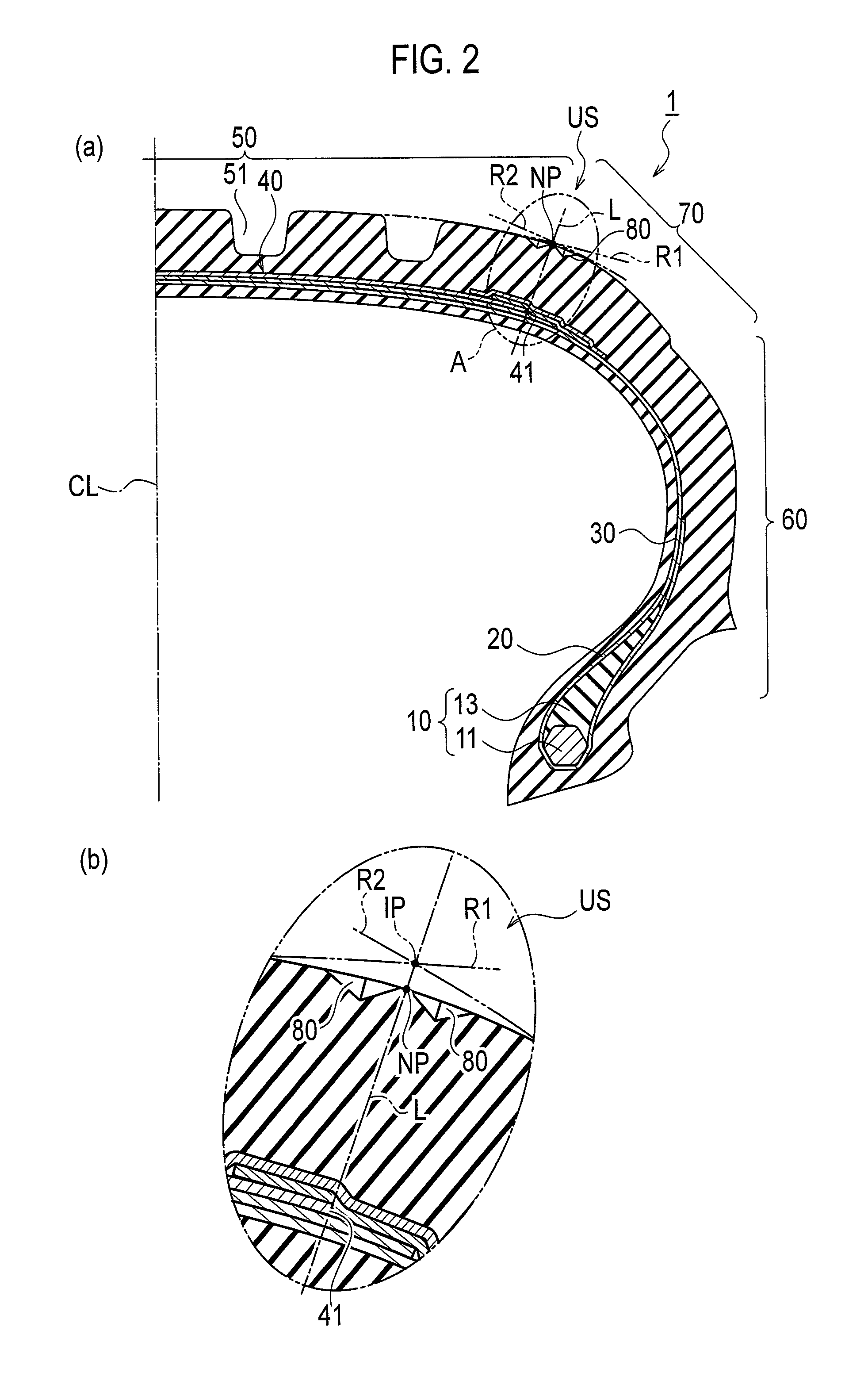

Tire

InactiveUS20120211135A1Reduce road noiseSuppress generationInflatable tyresTyre tread bands/patternsShoulder regionEngineering

A pneumatic tire (1) comprises a tread (50), side walls (60), and buttress portions (70). In a cross-section of the pneumatic tire (1) in the tread width direction (TW), if the point at which a first curved line (R1) which follows the curvature of the surface of the tread (50) and a second curved line (R2) which follows the curvature of the surface of a buttress portion (70) intersect is defined as an imaginary point (IP) and also if the point at which a straight line (L) passing through the imaginary point (IP) and substantially perpendicular to the carcass (20) intersects the surface of the pneumatic tire (1) is defined as an intersection point (NP), the pneumatic tire (1) has a recessed shoulder region (US) including the intersection point (NP) and having a predetermined width. The recessed shoulder region (US) is provided with recesses (80) recessed from the surface of the pneumatic tire (1) and also with a surface portion (90) in which no recess (80) is formed. The recessed shoulder region (US) extends in the tire circumference direction (TC).

Owner:BRIDGESTONE CORP

Runflat tire system and support ring therefor

InactiveUS7188649B2Comfortable habitability in a passenger roomReduce road noiseRimsInflatable tyresApparent densitySurface mounting

A runflat tire system comprises a pneumatic tire, a wheel rim on which the pneumatic tire is mounted, and a support ring made of elastic material and disposed in a cavity surrounded by an inner surface of the rim and an inner surface of the tire mounted thereon, wherein the support ring comprises an annular body extending in a circumferential direction of the tire and provided with a plurality of hollows opening at the cavity, and at least one noise damper made of sponge material having apparent density of 0.1 g / cm3 or less and disposed in the hollow such that the noise damper does not protrude into the cavity from an inlet surface of the hollow.

Owner:SUMITOMO RUBBER IND LTD

Active noise control apparatus

InactiveUS8111835B2Lighten the computational burdenReduce manufacturing costEar treatmentNoise generationNoise controlControl signal

A subtractor subtracts an echo canceling signal from a canceling error signal to estimate the resonant noise to be silenced at a position of a microphone, and outputs a first basic signal representing the estimated resonant noise as an input signal supplied to a controller. In the controller, a delay filter generates a second basic signal by delaying the first basic signal by a time value. The controller generates a control signal based on the first basic signal and the second basic signal.

Owner:HONDA MOTOR CO LTD

Tire-wheel assembly

A tire-wheel assembly having a wheel with a rim and a pneumatic tire mounted on the rim, the pneumatic tire having a cavity inside for charging air. The pneumatic tire has a cavity's resonant frequency Fc arising from the cavity, and the wheel has a plurality of natural frequencies. The difference between the cavity's resonant frequency Fc of the pneumatic tire and the natural frequency Fw of the wheel closest to the cavity's resonant frequency is 10 Hz or more.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveUS8950453B2Prevent stone retentionReduce road noiseTyre tread bands/patternsNon-skid devicesMechanical engineeringTread

Owner:THE YOKOHAMA RUBBER CO LTD

Tire/wheel assembly and run-flat support member

InactiveUS7287566B2Reduce road noiseImprove noiseWithout separate inflatable insertsNon-inflatable tyresSupport surface

A tire / wheel assembly comprising a wheel having a rim, a pneumatic tire mounted on the rim of the wheel and a run-flat support member disposed in the cavity of the pneumatic tire. The run-flat support member includes an annular shell and elastic rings. The annular shell has a support surface located radially outward and two leg portions formed radially inward in a straddling state. The elastic rings support the leg portions on the rim. The annular shell is configured such that an annular cavity portion surrounded by the run-flat support member and the pneumatic tire has a cross-sectional area that varies in the circumferential direction of the tire.

Owner:THE YOKOHAMA RUBBER CO LTD

Modified rubber cement seam repairing material for bridge

The invention provides a modified rubber cement seam repairing material for a bridge. A preparation method of the modified rubber cement seam repairing material comprises the following steps: firstly, preparing modified rubber powder: weighing the following components in parts by weight: 100 parts of natural rubber, 5 to 20 parts of glycidyl methacrylate, 5 to 10 parts of potassium stearate and 3 to 5 parts of calcium lignosulfonate; uniformly mixing and adding a mixture into an internal mixer, wherein the internal mixing time is 5min to 8min and the internal mixing temperature is 110 DEG C to 120 DEG C; adding 3 to 10 parts of 8 to 10 parts of high-styrene resin by weight and mixing for 10min to 15min; putting a mixed mixture on an extruder and extruding. According to the modified rubber cement seam repairing material for the bridge, provided by the invention, the modified rubber powder is added to increase the porosity of concrete and the deformation of rubber powder particles absorbs sound waves so that road surface noises are reduced; inorganic materials including talcum powder and quartz powder are introduced into modified rubber powder-emulsion so that a modified rubber powder-emulsion-inorganic powder three-dimensional net-shaped structure can be formed in a cement system and the material has a very good enhancing effect on a cement matrix system; the material has strong physical and chemical stability.

Owner:厦门百城建材有限公司

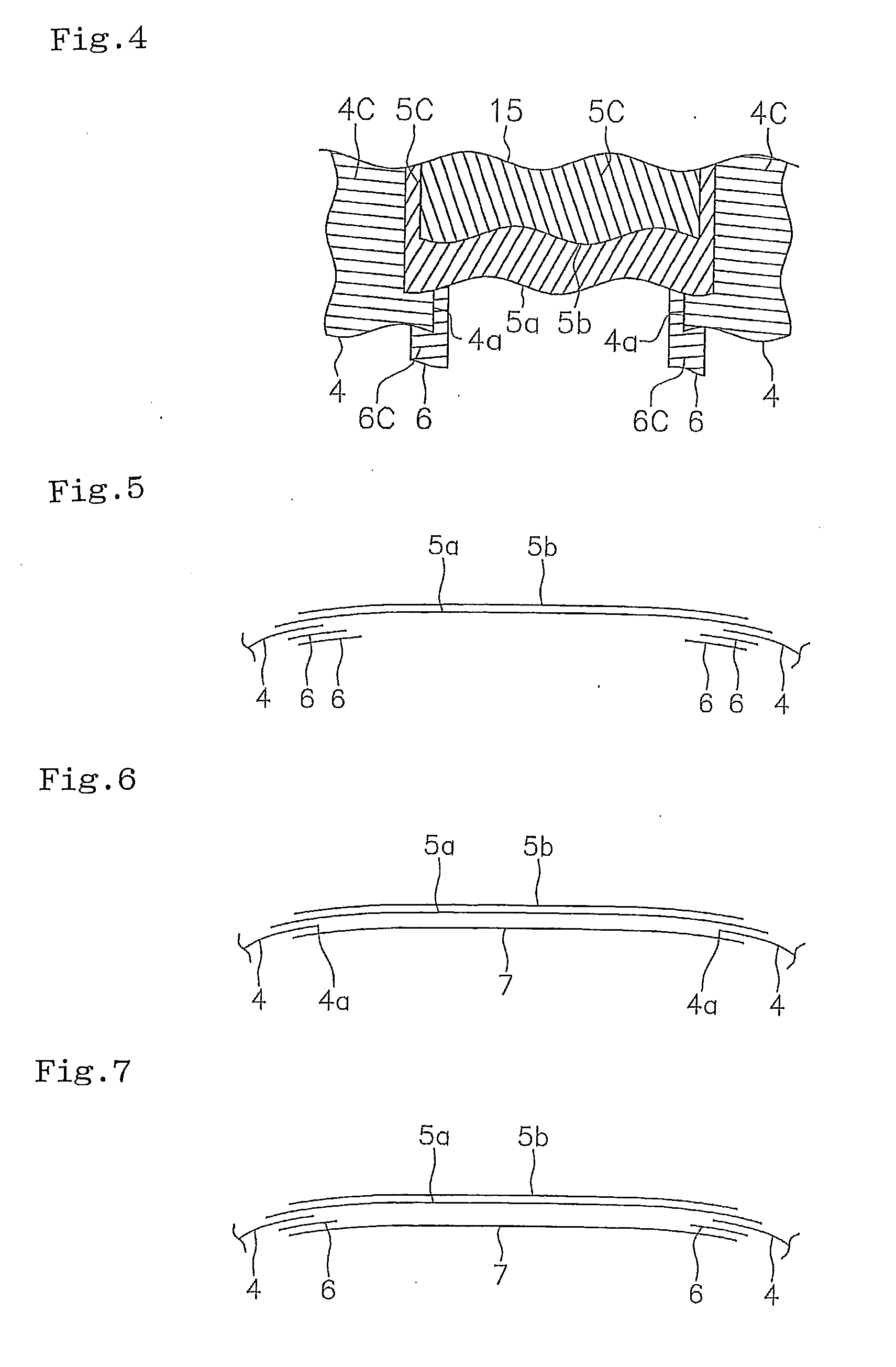

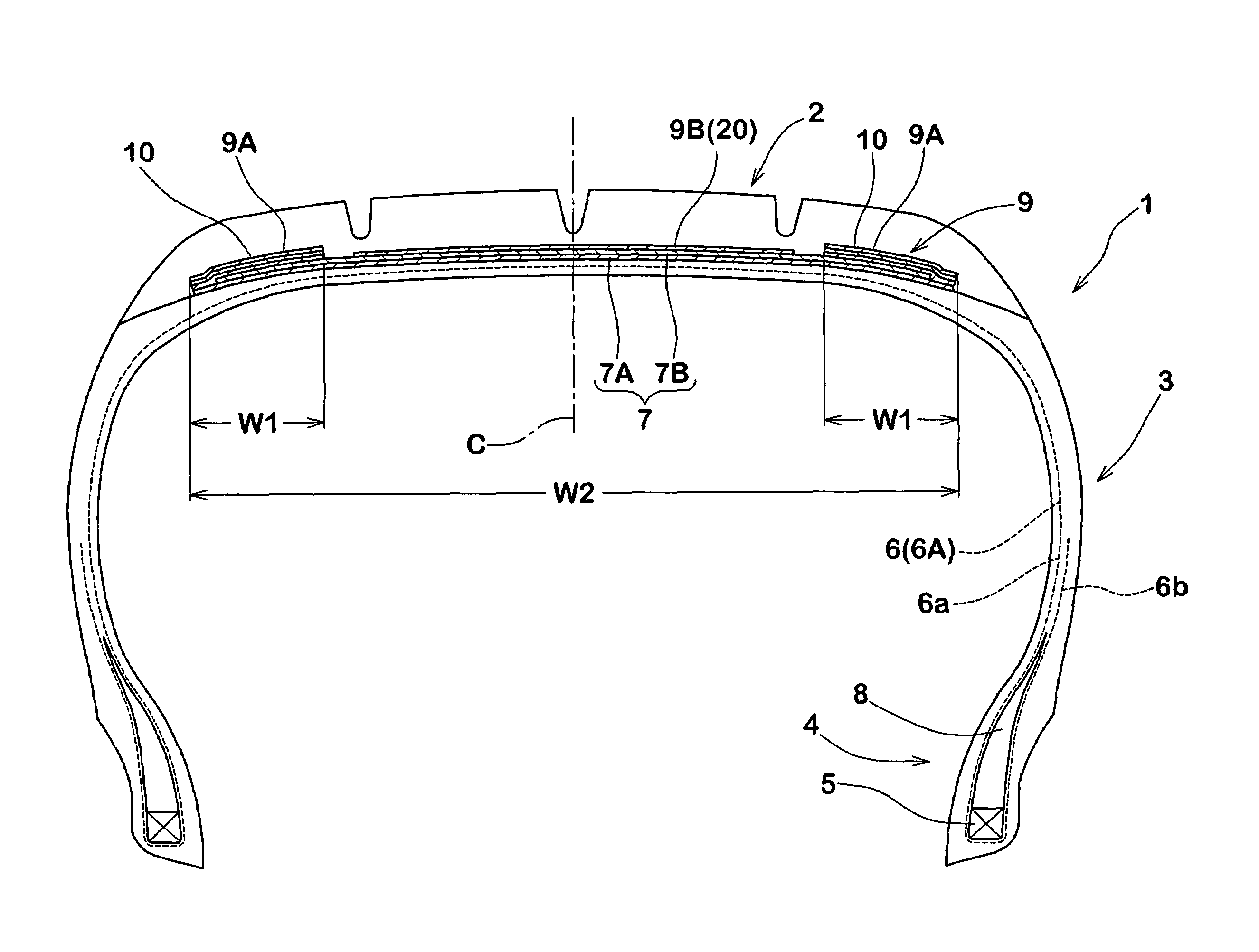

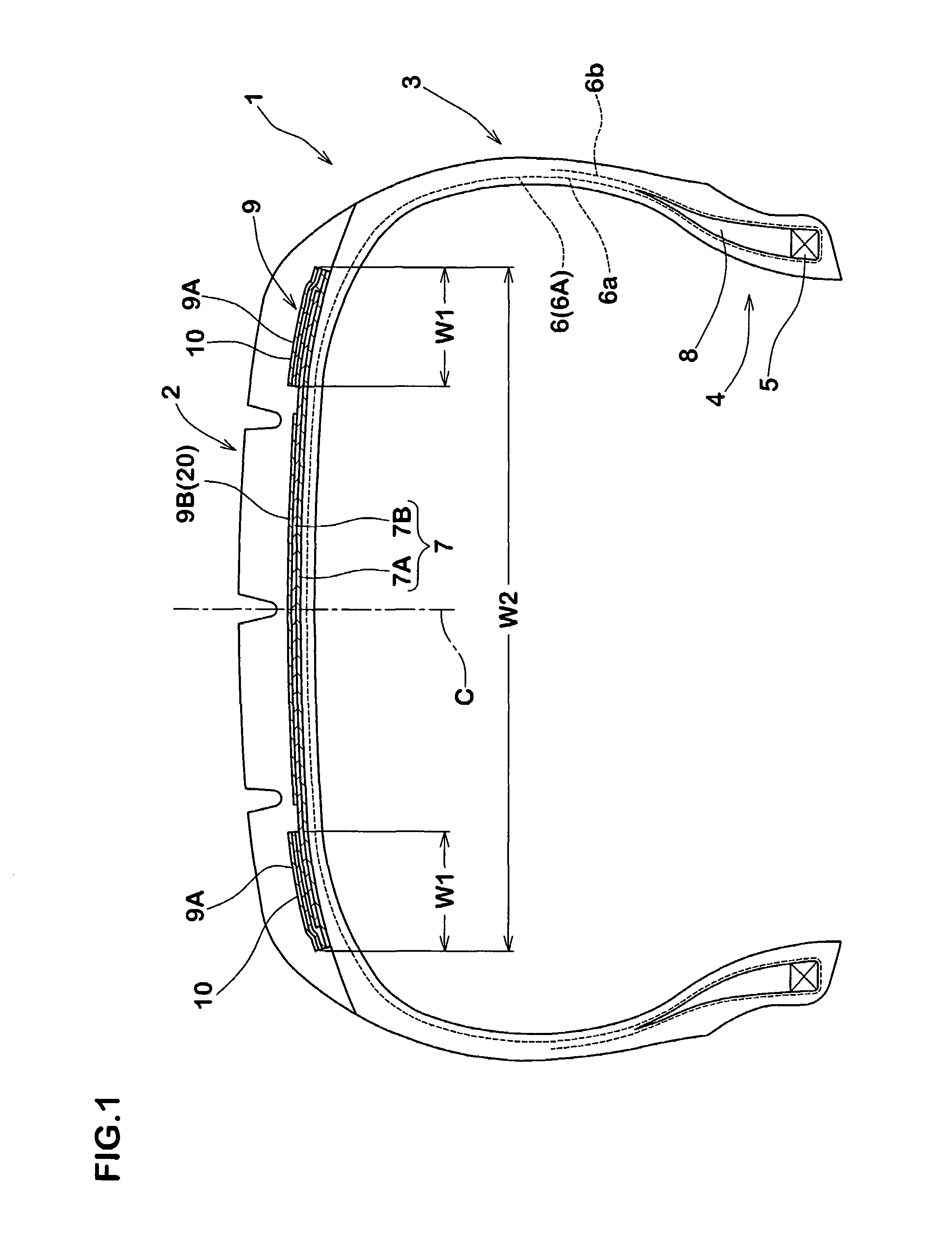

Pneumatic tire

InactiveUS20120048445A1Reduce vibrationReduce high-frequency road noisePneumatic tyre reinforcementsWheelsEngineeringMechanical engineering

A pneumatic tire has a belt ply buried in a tread portion and a carcass ply running into an inner peripheral side of an end portion of the belt ply from a pair of bead portions. The carcass ply was divided in a tire width direction at the tread portion. A division width of the carcass ply is equal to or more than 35% of a maximum width of the belt ply. An auxiliary ply formed by reinforcement cords extending at an angle within a range of ±20 degrees with respect to the tire width direction is arranged in such a manner as to overlap with the carcass ply in an inner peripheral side of the end portion of the belt ply and extend out to an inner side in the tire width direction than the division end portion of the carcass ply.

Owner:TOYO TIRE & RUBBER CO LTD

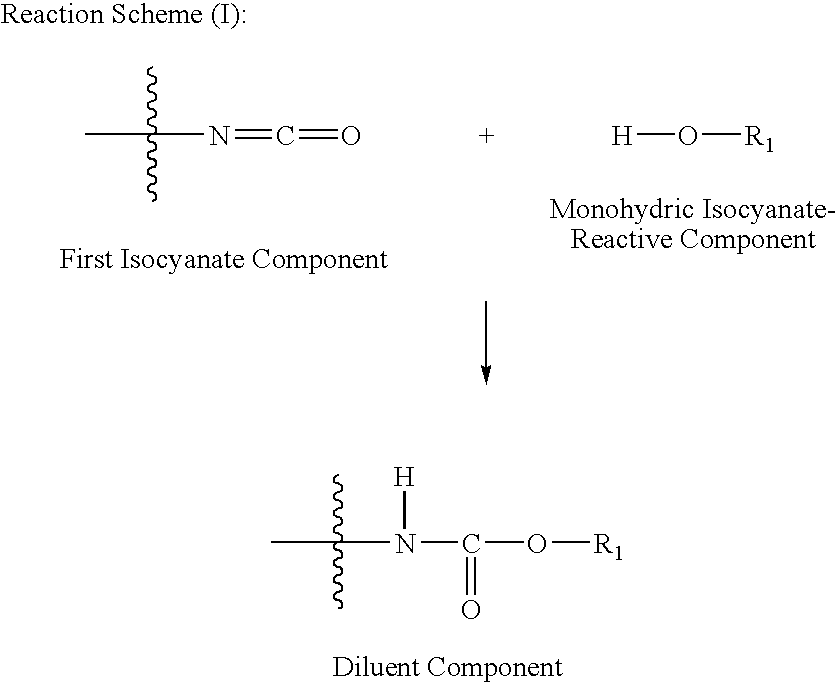

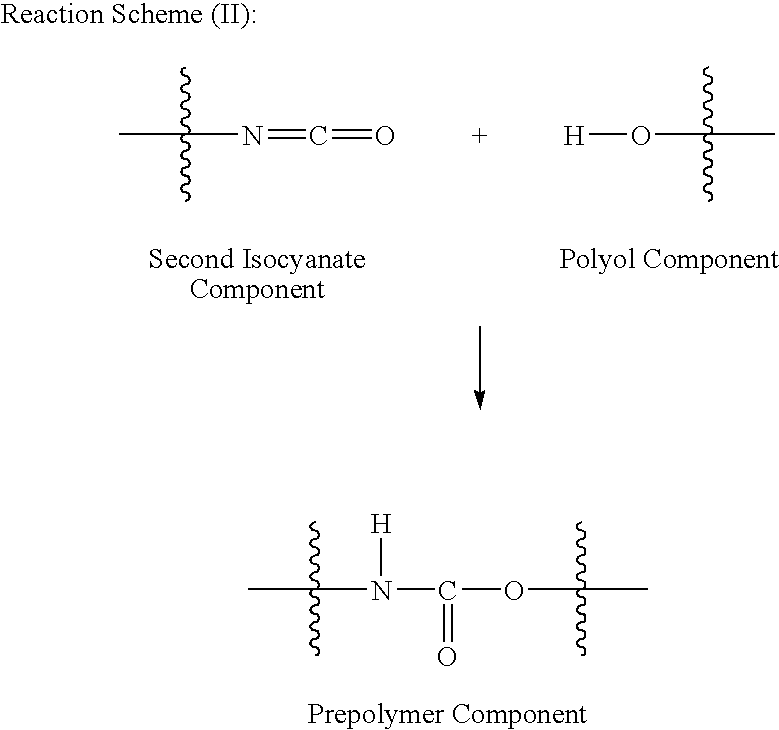

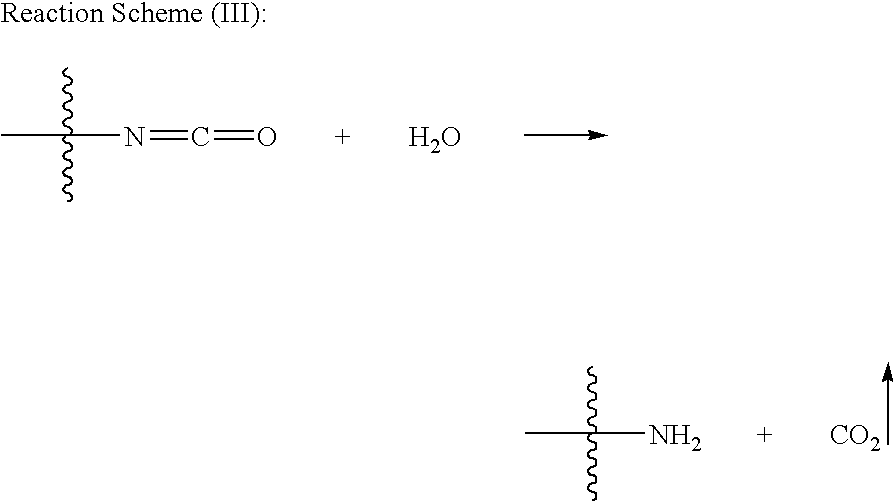

Prepolymer systems having reduced monomeric isocyanate contents

ActiveUS8455679B2Good storage stabilityLow monomeric isocyanate contentIsocyanic acid derivatives preparationCarbamic acid derivatives preparationDiluentLow density

A prepolymer system has a monomeric isocyanate content of no greater than about 10% by weight based on 100 parts by weight of the prepolymer system. The prepolymer system comprises a diluent component and a prepolymer component different than and separate from the diluent component. The diluent component has an excess of isocyanate (NCO) functional groups, and comprises the reaction product of a monohydric isocyanate-reactive component and an excess of a first isocyanate component. The first isocyanate component comprises monomeric isocyanates reactive with the monohydric isocyanate-reactive component. The prepolymer component also has an excess of NCO functional groups, and comprises the reaction product of a polyol component and an excess of a second isocyanate component. The prepolymer system can be used to prepare foams via reaction with water. The foams have low density and have excellent adhesion and sound dampening properties for use in cavities of automobile bodies.

Owner:BASF SE

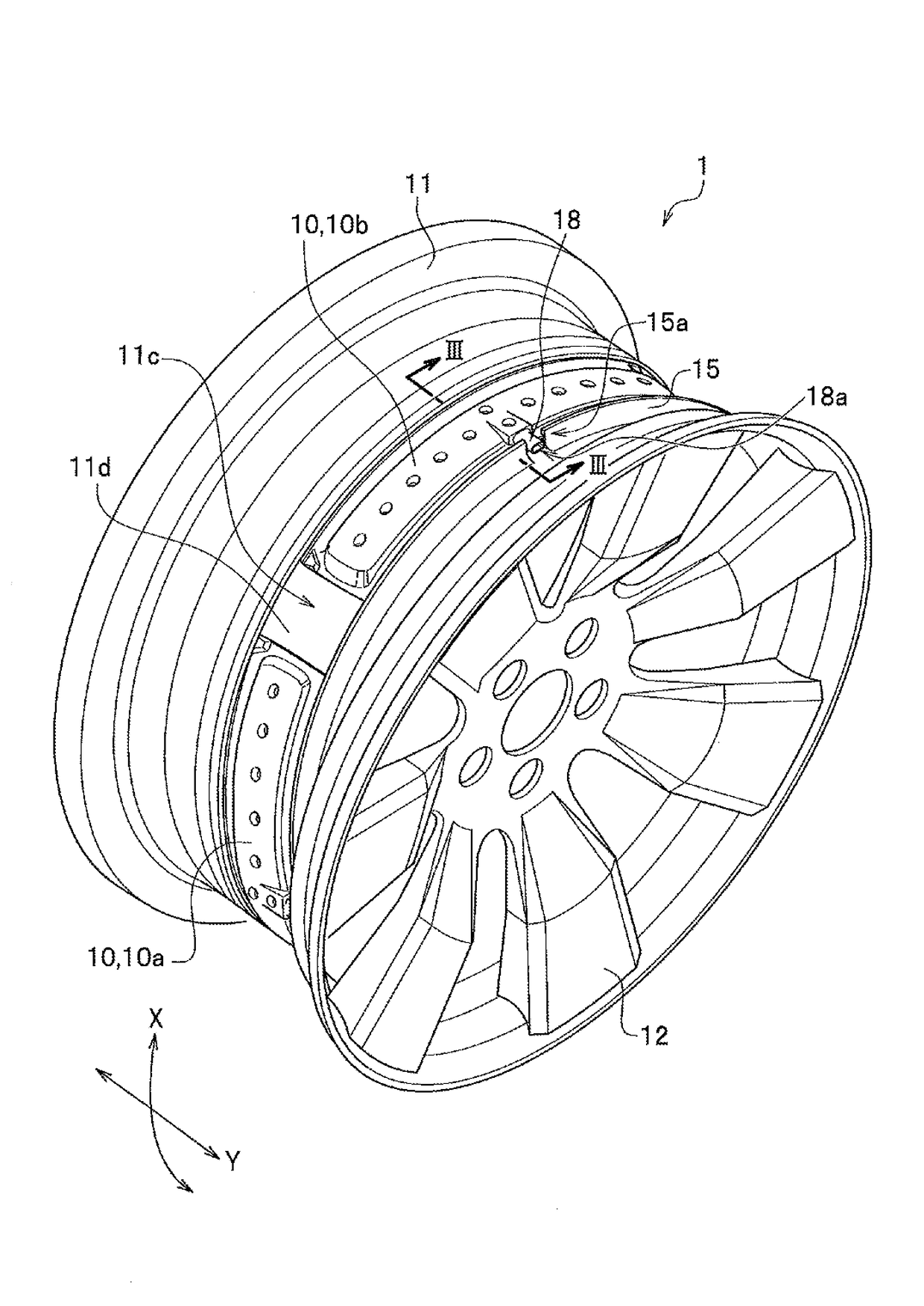

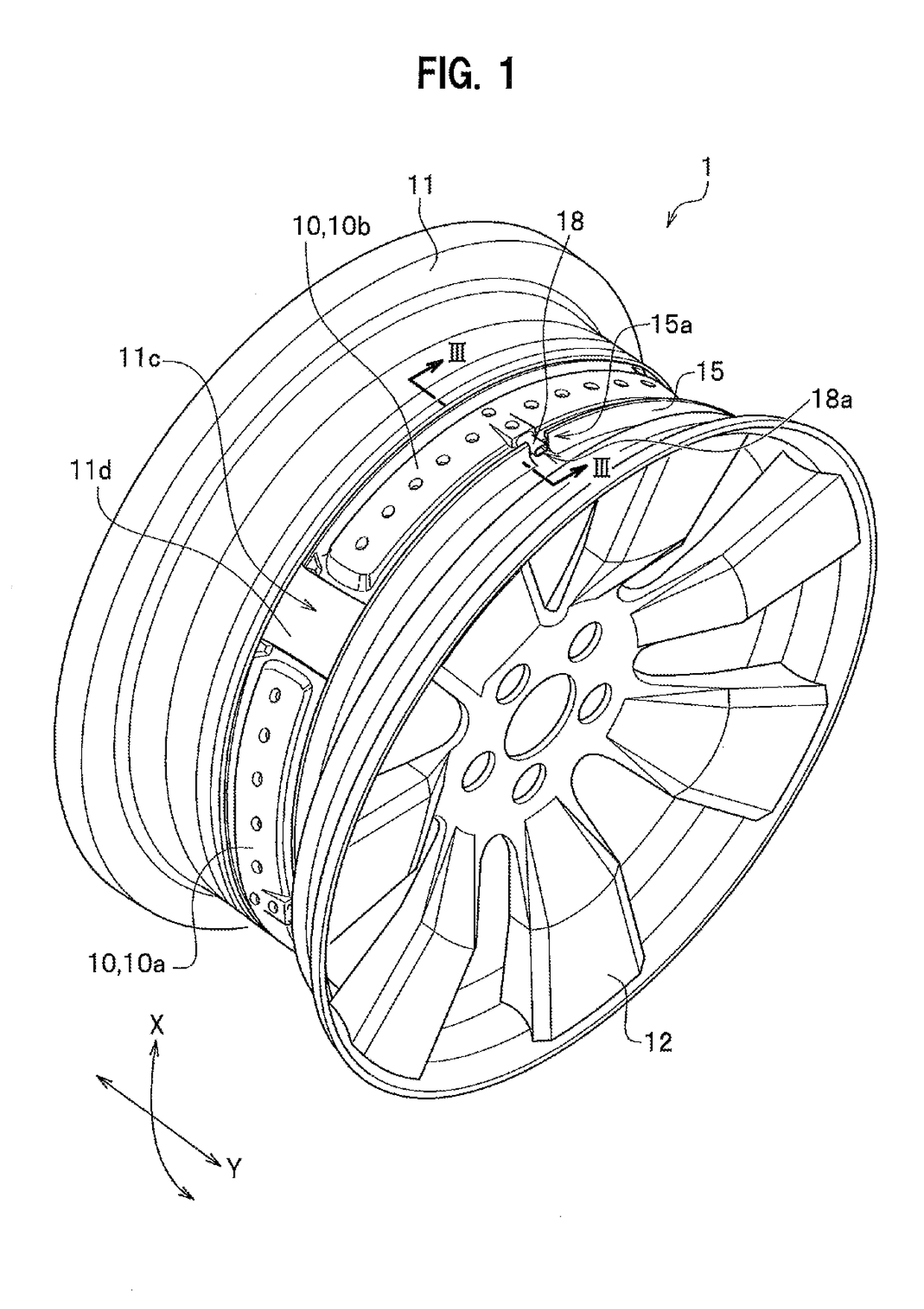

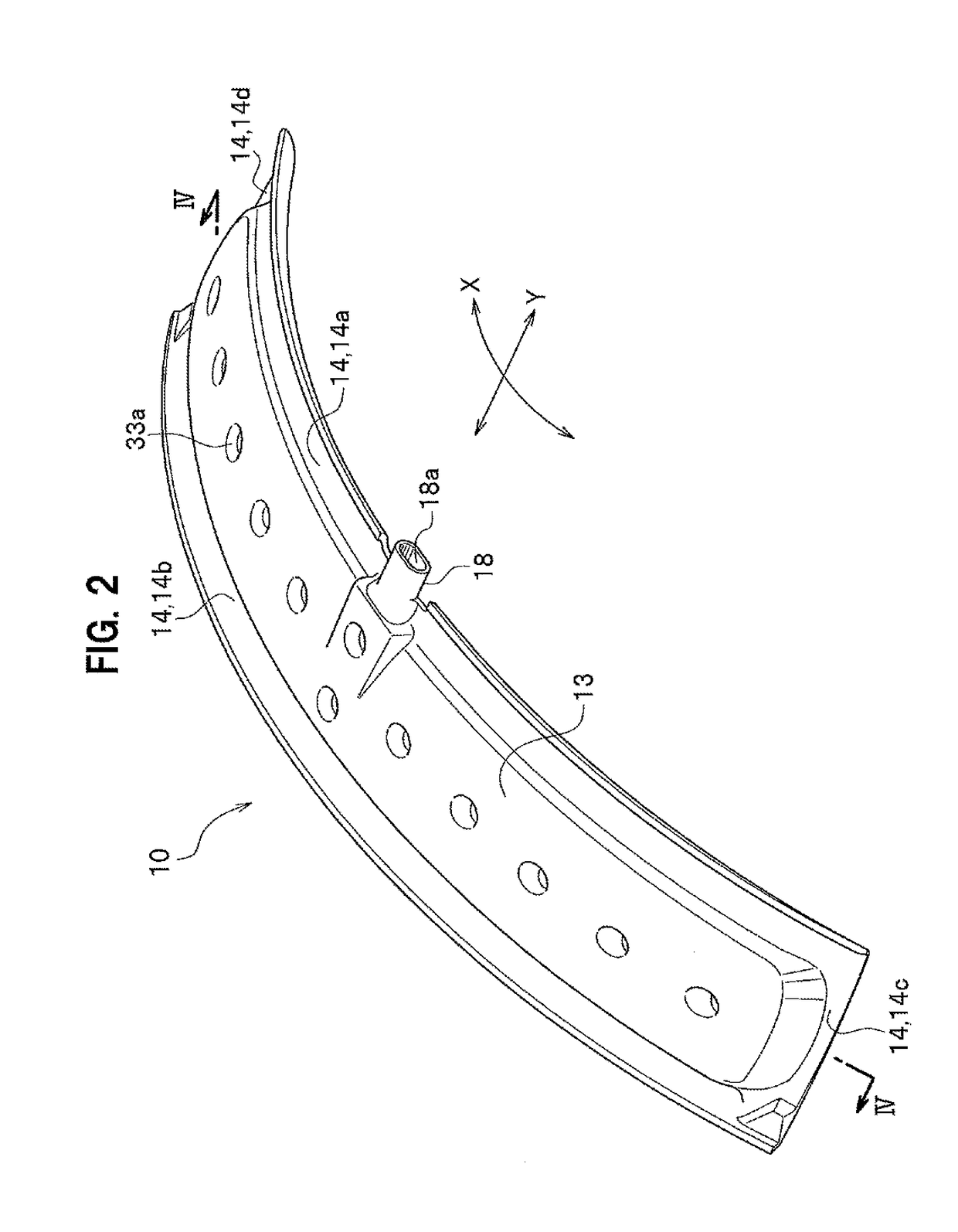

Vehicle wheel

ActiveUS9694626B2Improve the noise reduction effectReduce road noiseRimsSound producing devicesHelmholtz resonatorCentre of rotation

This vehicle wheel is provided with only two sub air chamber members each as a Helmholtz resonator having an sub air chamber which communicates with a tire air chamber via a communication hole, and characterized in that the respective communication holes of the sub air chamber members are provided apart from each other in a wheel circumferential direction so as to form approximately a right angle around a wheel rotation center.

Owner:HONDA MOTOR CO LTD

Pneumatic radial tire

ActiveUS7395845B2Improve noiseReduce road noisePneumatic tyre reinforcementsWheelsBand shapeMedicine

Owner:SUMITOMO RUBBER IND LTD

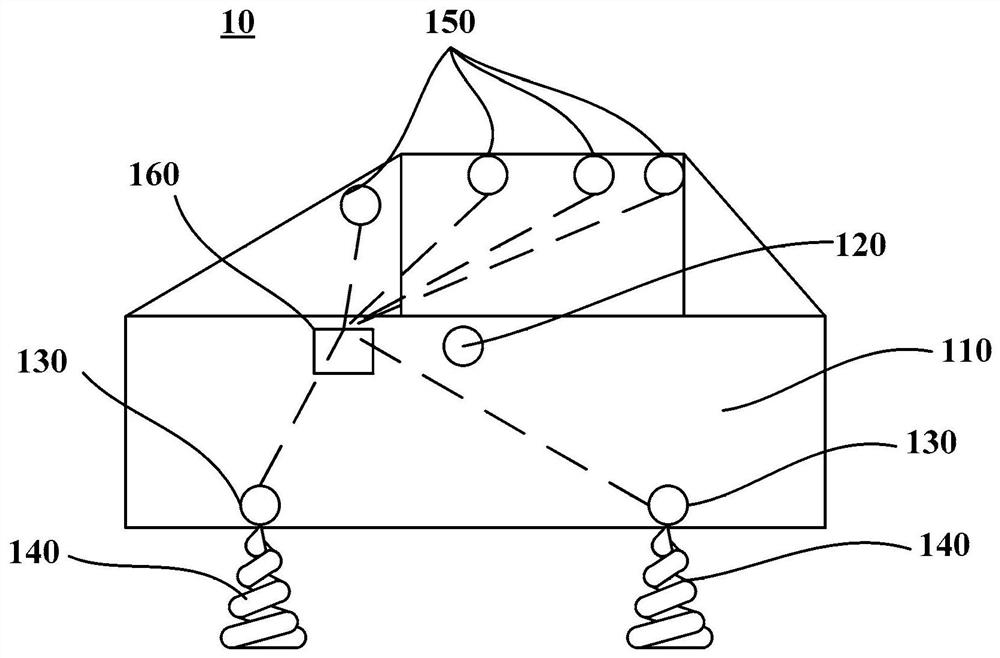

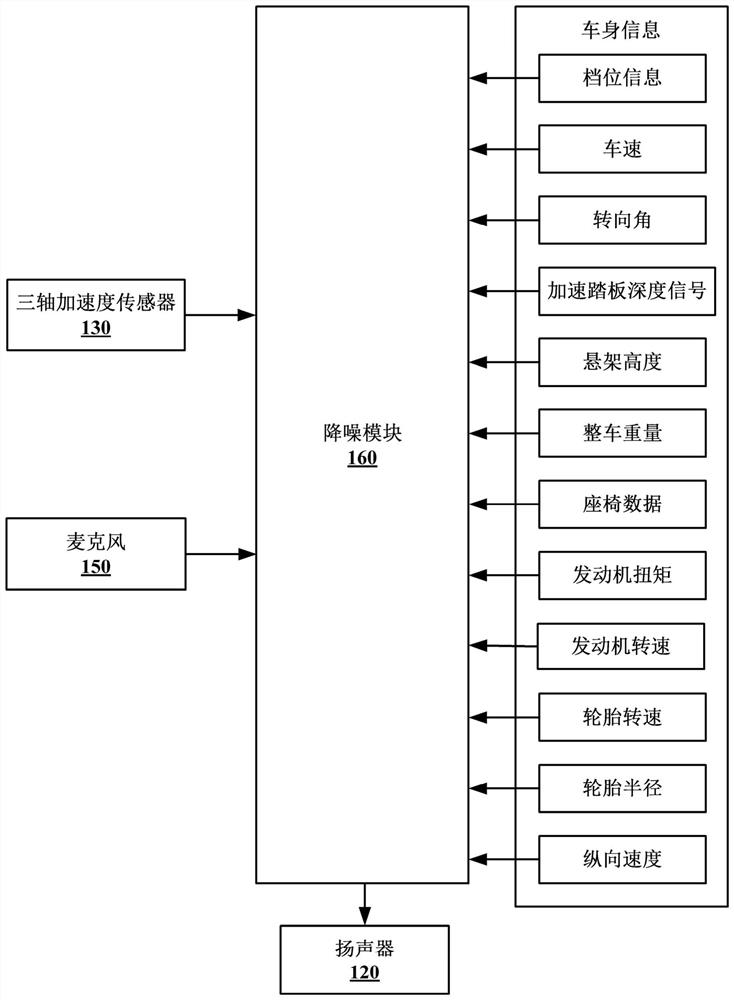

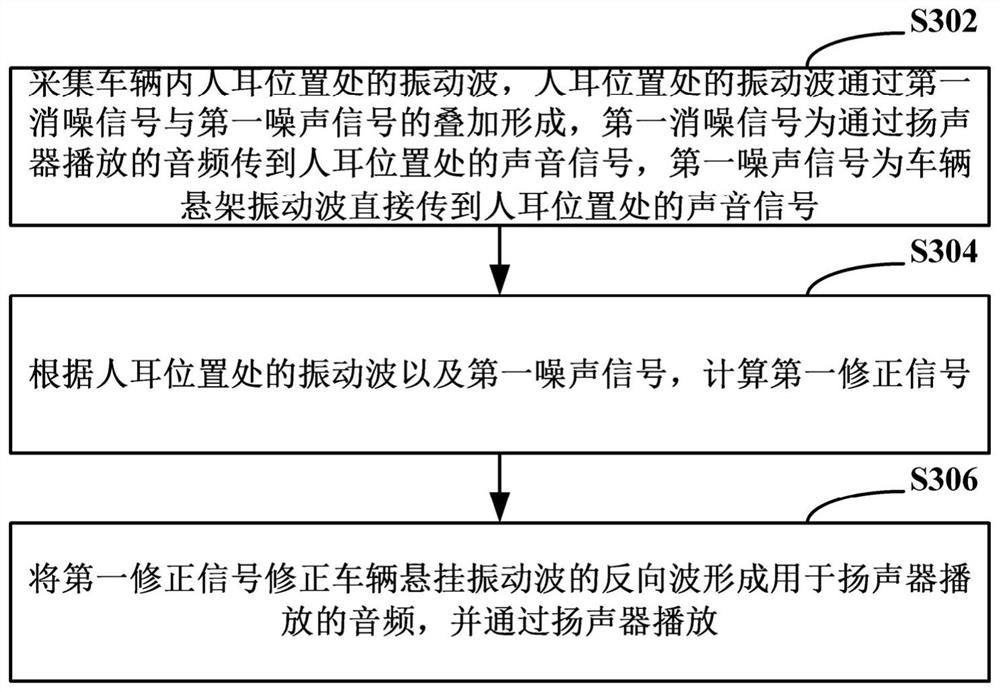

Vehicle active noise reduction system, active noise reduction method and computer storage medium

The invention provides a vehicle active noise reduction system, an active noise reduction method and a computer storage medium. The method comprises the steps: collecting vibration waves at human earpositions in a vehicle, wherein the vibration waves at the human ear positions re formed by superposing a first noise elimination signal and a first noise signal, the first noise elimination signal isa sound signal transmitted to the human ear positions through an audio played by a loudspeaker, and the first noise signal is a sound signal directly transmitted to the human ear positions by vehiclesuspension vibration waves; calculating a first correction signal according to the vibration waves at the human ear positions and the first noise signal; and correcting reverse waves of the vehicle suspension vibration waves by the first correction signal to form an audio for loudspeaker playing, and playing the audio through the loudspeaker. By using the method, the reverse waves of the vehiclesuspension vibration waves can be calculated and corrected to form the audio played by the loudspeaker, and the audio is played by the loudspeaker, so that the vehicle suspension vibration waves can be counteracted, the road noise is effectively reduced, and people in the vehicle feel comfortable.

Owner:ECARX (HUBEI) TECHCO LTD

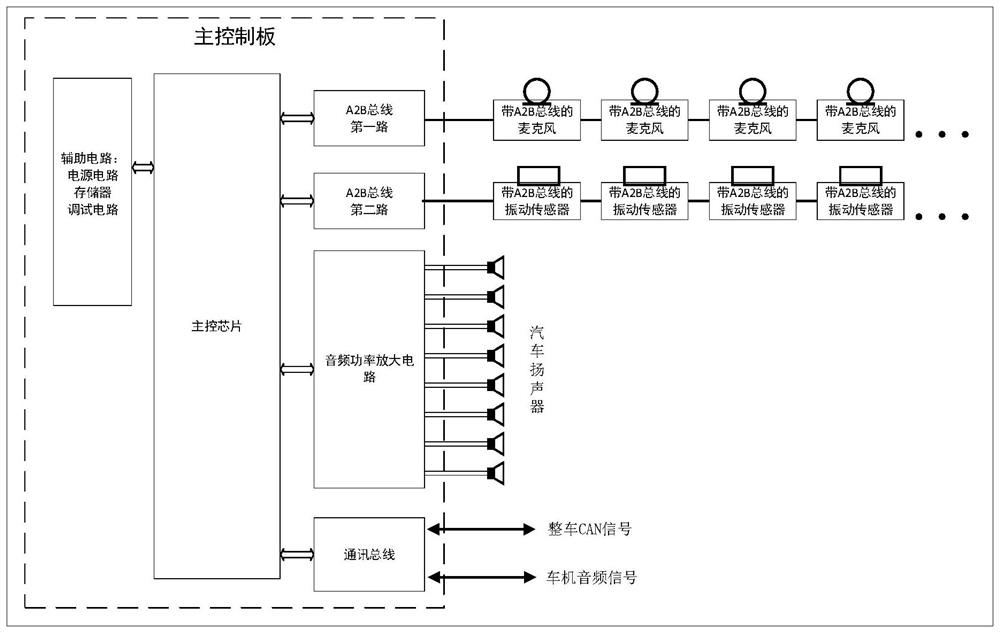

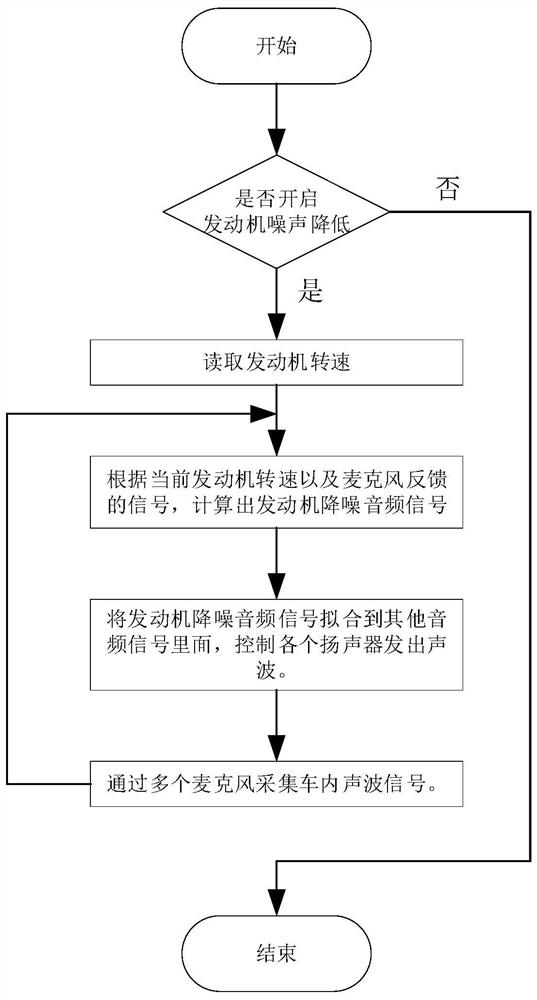

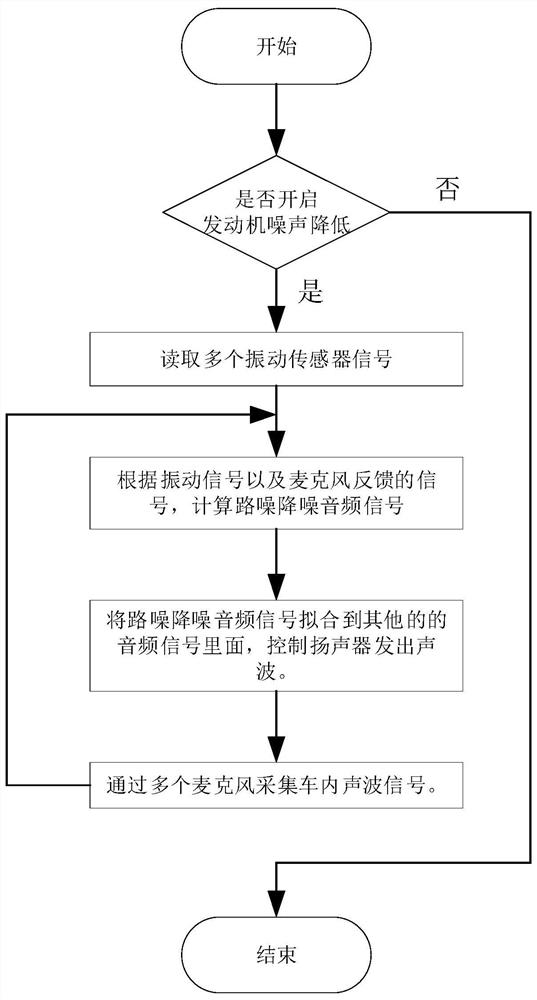

Automobile active noise reduction and audio power amplification integrated system

PendingCN113689842AShorten the development cycleReduce noiseSound producing devicesBus networksNoiseNoise reduction

The invention relates to an automobile active noise reduction and audio power amplification integrated system which comprises a main control chip, two A2B buses, an auxiliary circuit, a communication bus and an audio power amplification circuit, the main control chip is connected with the auxiliary circuit, the two A2B buses, the audio power amplification circuit and the communication bus, one A2B bus is connected with a microphone with the A2B bus, the other A2B bus is connected with the vibration sensor with the A2B bus, the communication bus is connected with a vehicle-mounted CAN signal and used for obtaining an engine rotating speed signal and a vehicle window opening signal, the microphone with the A2B bus collects a sound wave signal in a vehicle, the vibration sensor with the A2B bus obtains a vehicle vibration signal, and the main control chip performs engine noise reduction, road noise reduction and audio signal power amplification based on a vehicle-mounted CAN signal, an in-vehicle sound wave signal and an automobile vibration signal. Compared with the prior art, the system has the advantages of reduced overall cost, reduced weight and the like.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Tire with recessed portions formed on buttress portion

InactiveUS8783311B2Improve noiseReduce road noiseInflatable tyresTyre tread bands/patternsShoulder regionMechanical engineering

A pneumatic tire (1) comprises a tread (50), side walls (60), and buttress portions (70). In a cross-section of the pneumatic tire (1) in the tread width direction (TW), if the point at which a first curved line (R1) which follows the curvature of the surface of the tread (50) and a second curved line (R2) which follows the curvature of the surface of a buttress portion (70) intersect is defined as an imaginary point (IP) and also if the point at which a straight line (L) passing through the imaginary point (IP) and substantially perpendicular to the carcass (20) intersects the surface of the pneumatic tire (1) is defined as an intersection point (NP), the pneumatic tire (1) has a recessed shoulder region (US) including the intersection point (NP) and having a predetermined width. The recessed shoulder region (US) is provided with recesses (80) recessed from the surface of the pneumatic tire (1) and also with a surface portion (90) in which no recess (80) is formed. The recessed shoulder region (US) extends in the tire circumference direction (TC).

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com