Blast mitigation system for military vehicles

a technology for military vehicles and blast mitigation, applied in the direction of armoured vehicles, protective equipment, armour plates, etc., can solve the problems of significant occupant injury, death, and ineffective protection of armored vehicles, and achieve the effect of improving vehicular protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]As described above, one embodiment of the invention is a method of providing a degree of explosive blast shock protection to the occupants of a vehicle comprising adding one or more layers of rigid closed-cell spray polyurethane foam to the undercarriage of the vehicle. A preferred material used herein is Honeywell's TerraStrong® Rigid Foam.

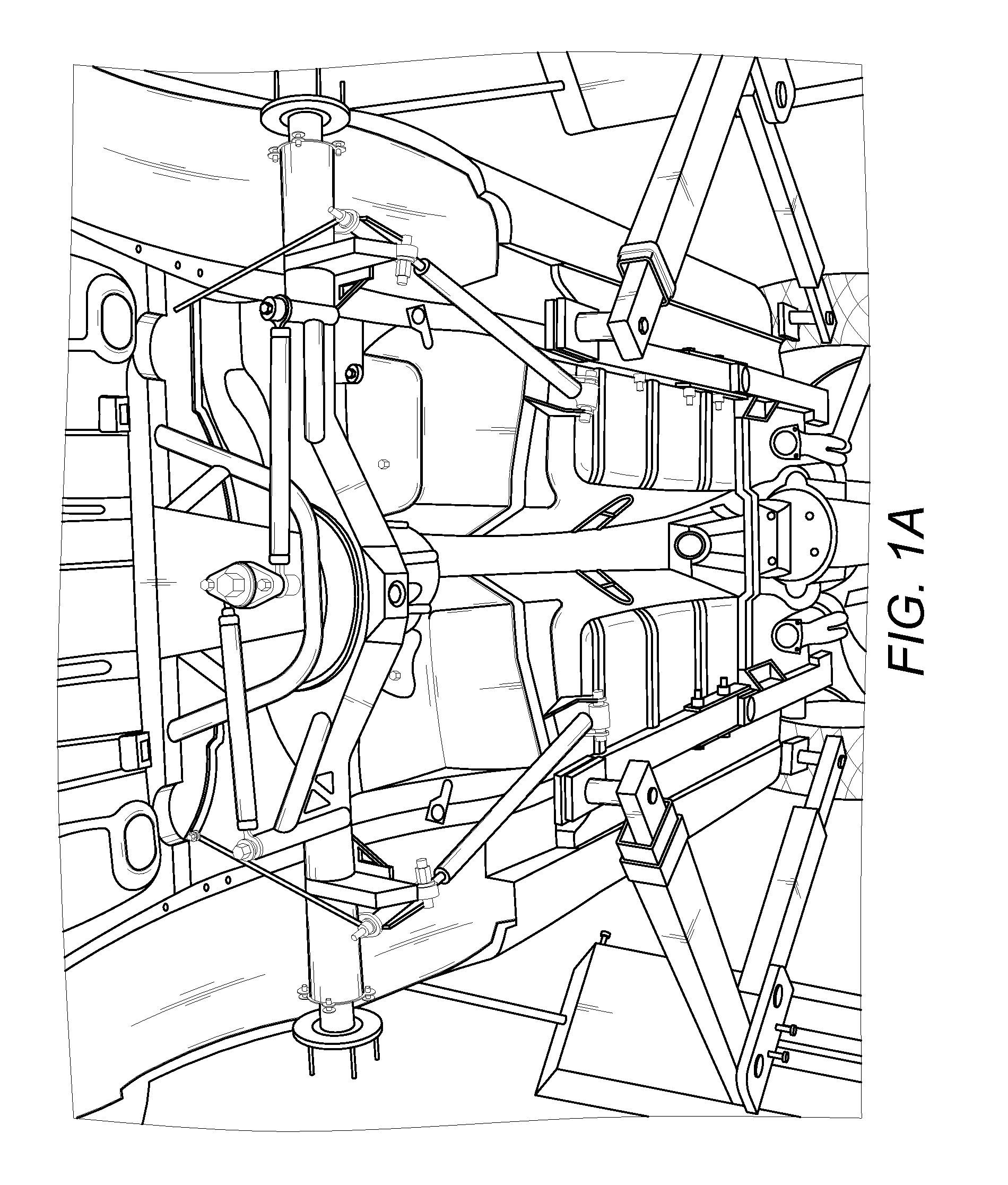

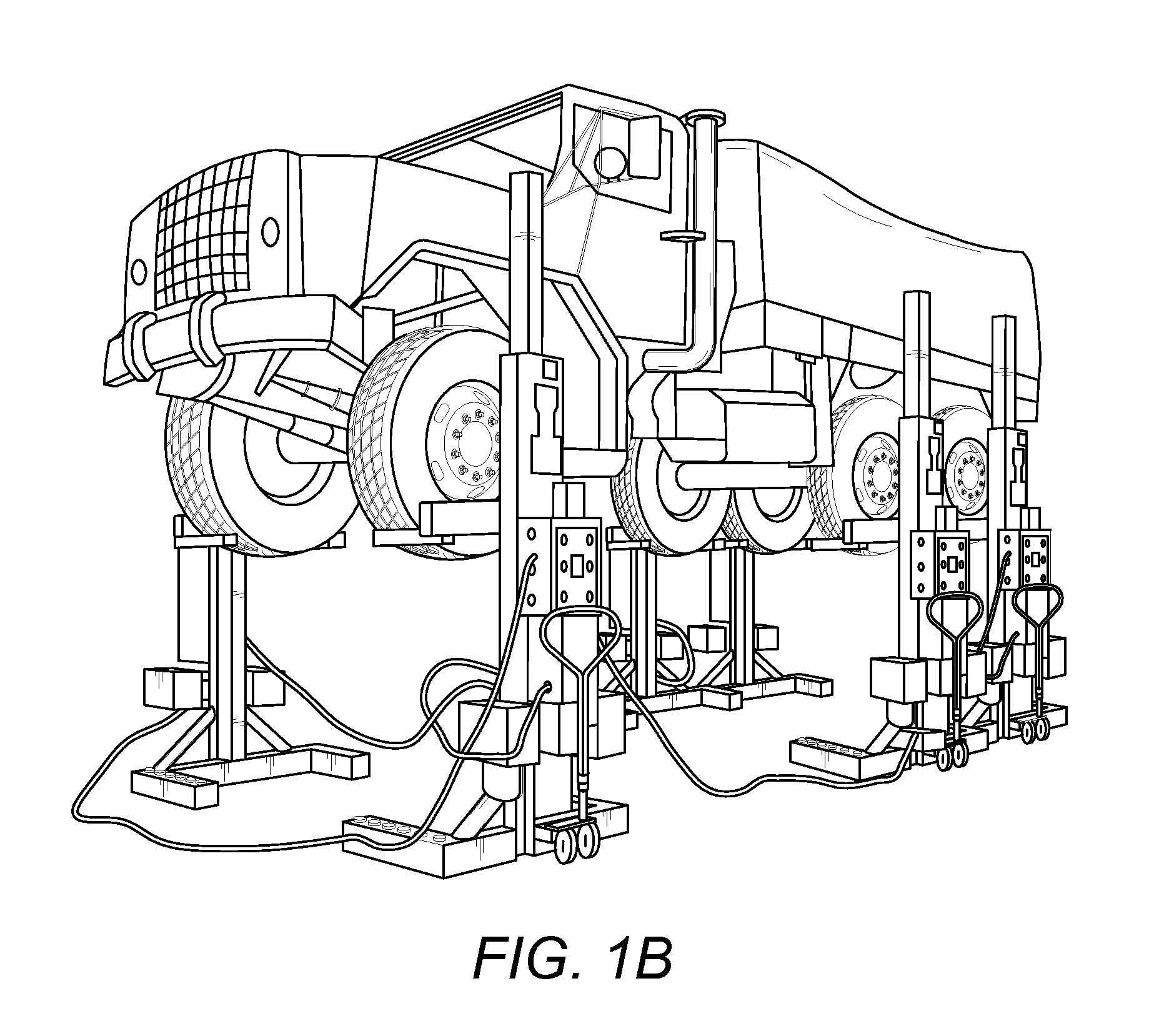

[0035]FIGS. 1A and 1B show a military vehicle (a truck) before treatment by this invention. FIG. 1A shows the underside or undercarriage of the vehicle. FIG. 1B is a plan view of the vehicle, shown on a lift which allows the treatment with one or more layers of rigid closed-cell spray polyurethane foam to the undercarriage of the vehicle.

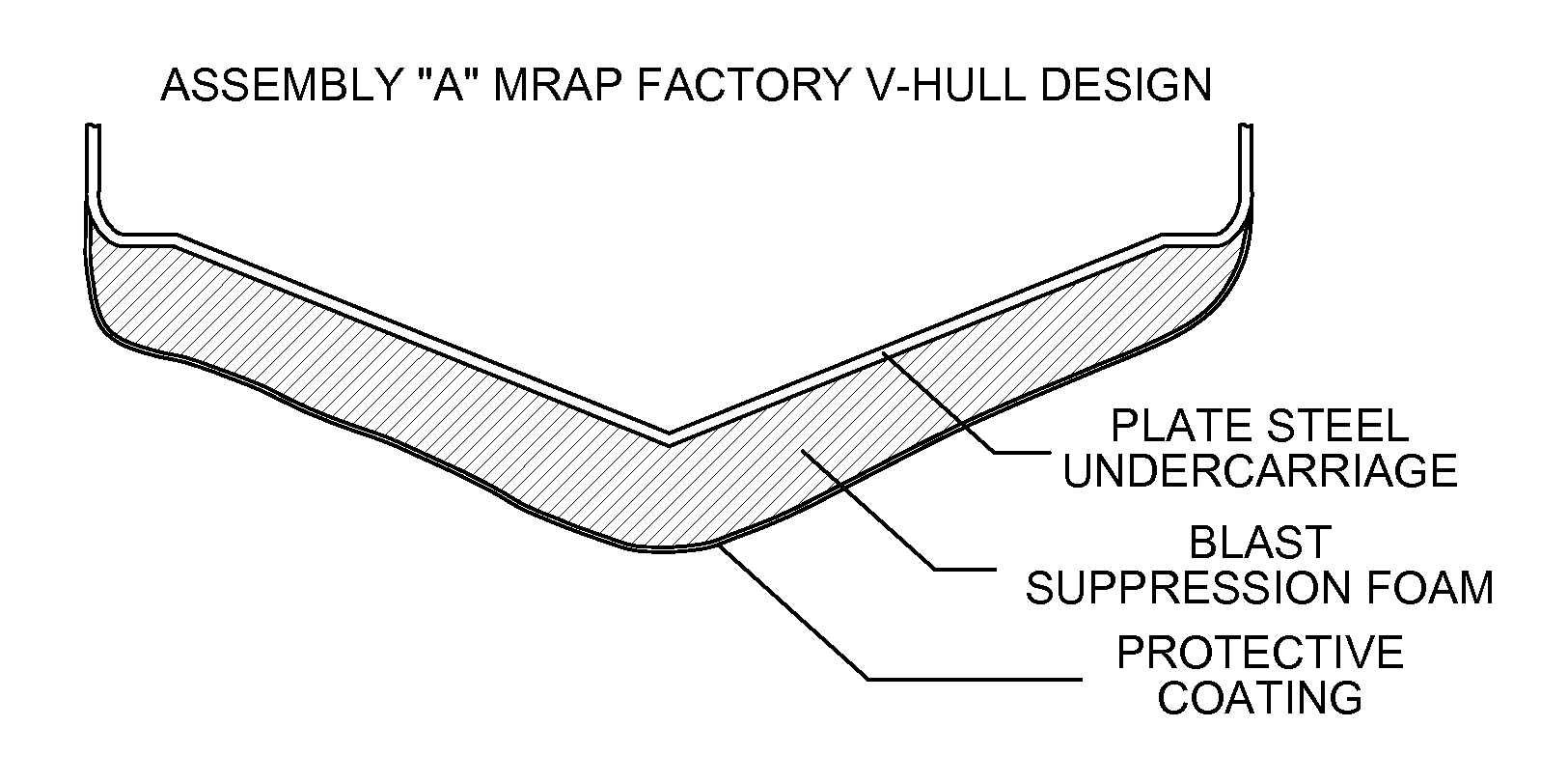

[0036]FIG. 2 illustrates Assembly “A” herein, an MRAP with a factory V-hull design modified with the blast suppression or mitigation materials of the present invention. As illustrated therein, the MRAP factory V-hull design has a “V”-shaped armor plate steel form added to the undercarriage of a vehicle. Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com