Patents

Literature

259results about How to "Reduce physical injury" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

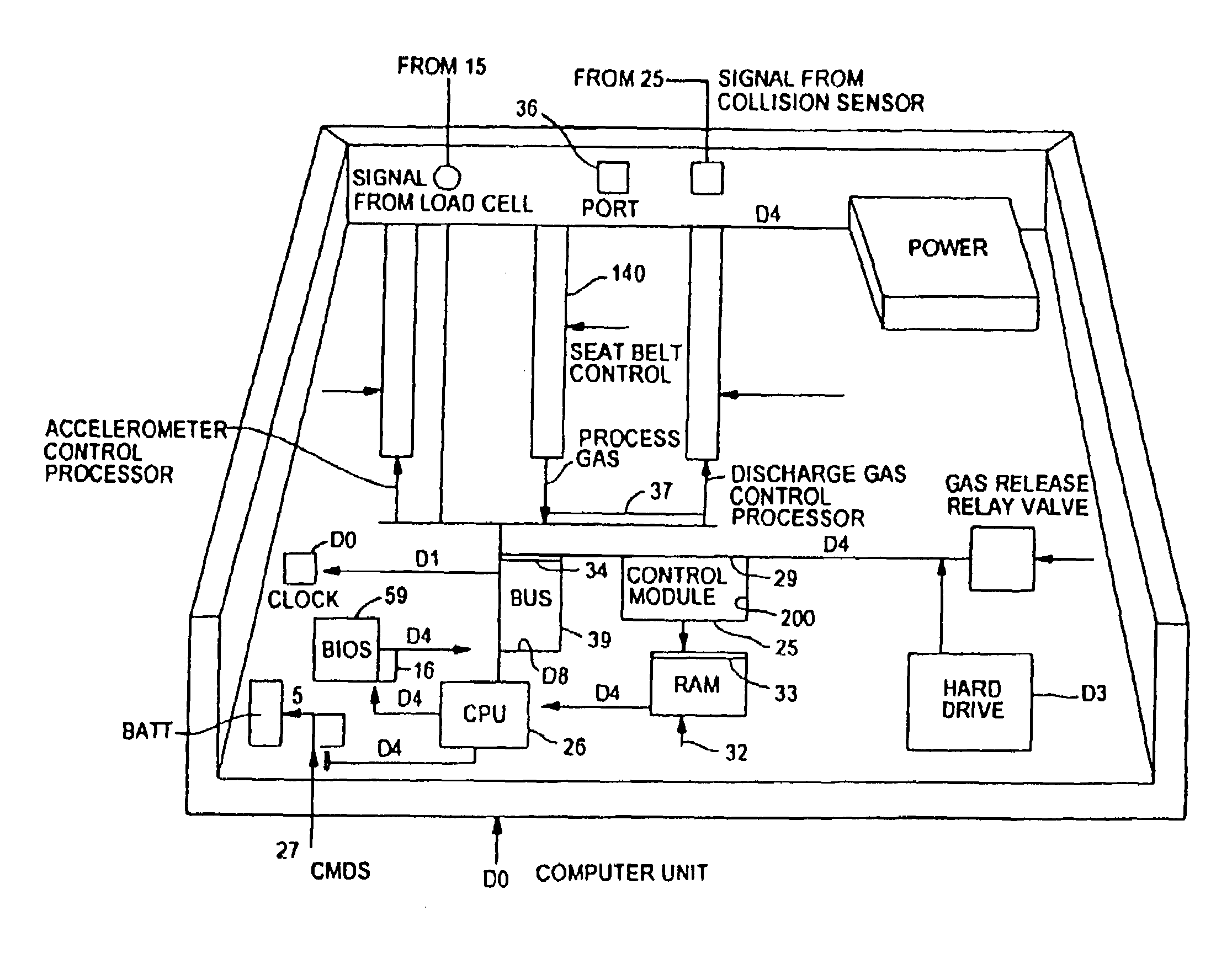

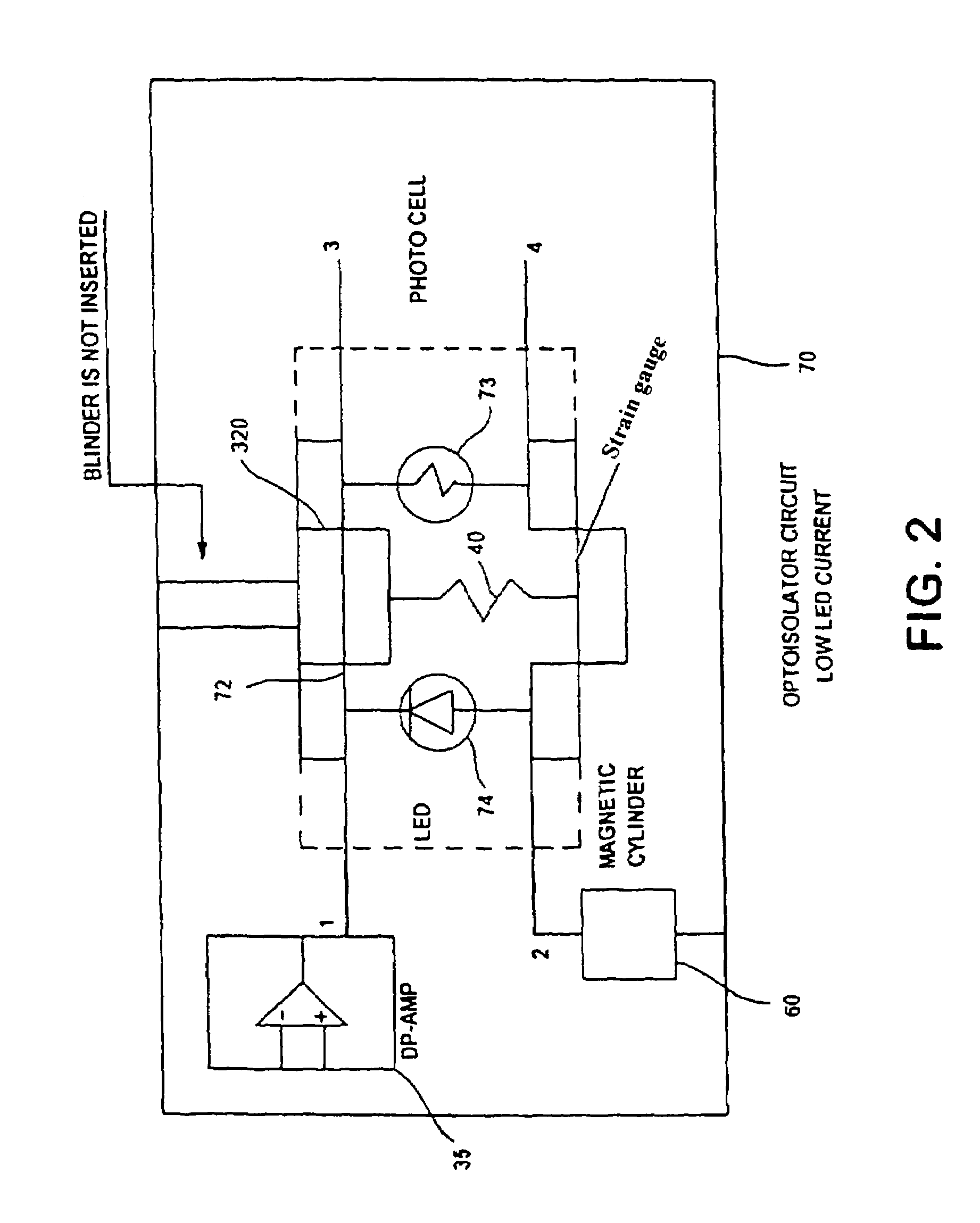

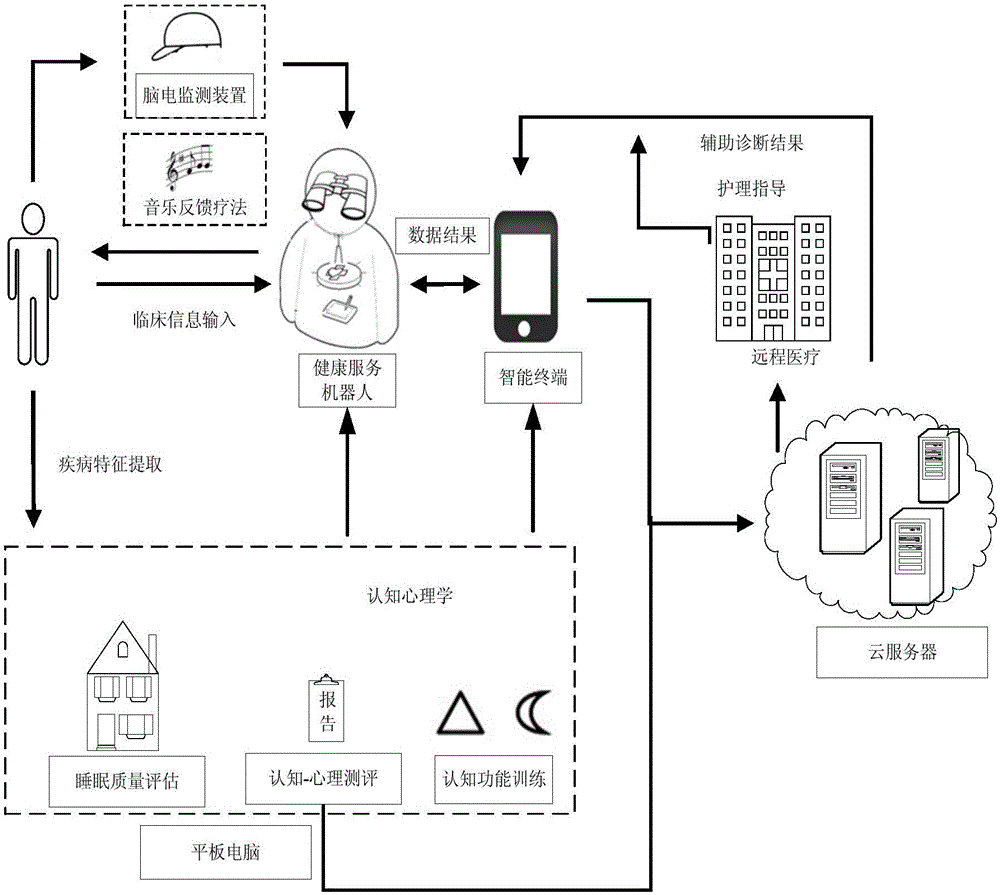

Smart seatbelt control system

InactiveUS7426429B2Effective timeEfficient deploymentBelt retractorsElectric devicesSeat beltBelt safety

Owner:TABE JOSEPH A

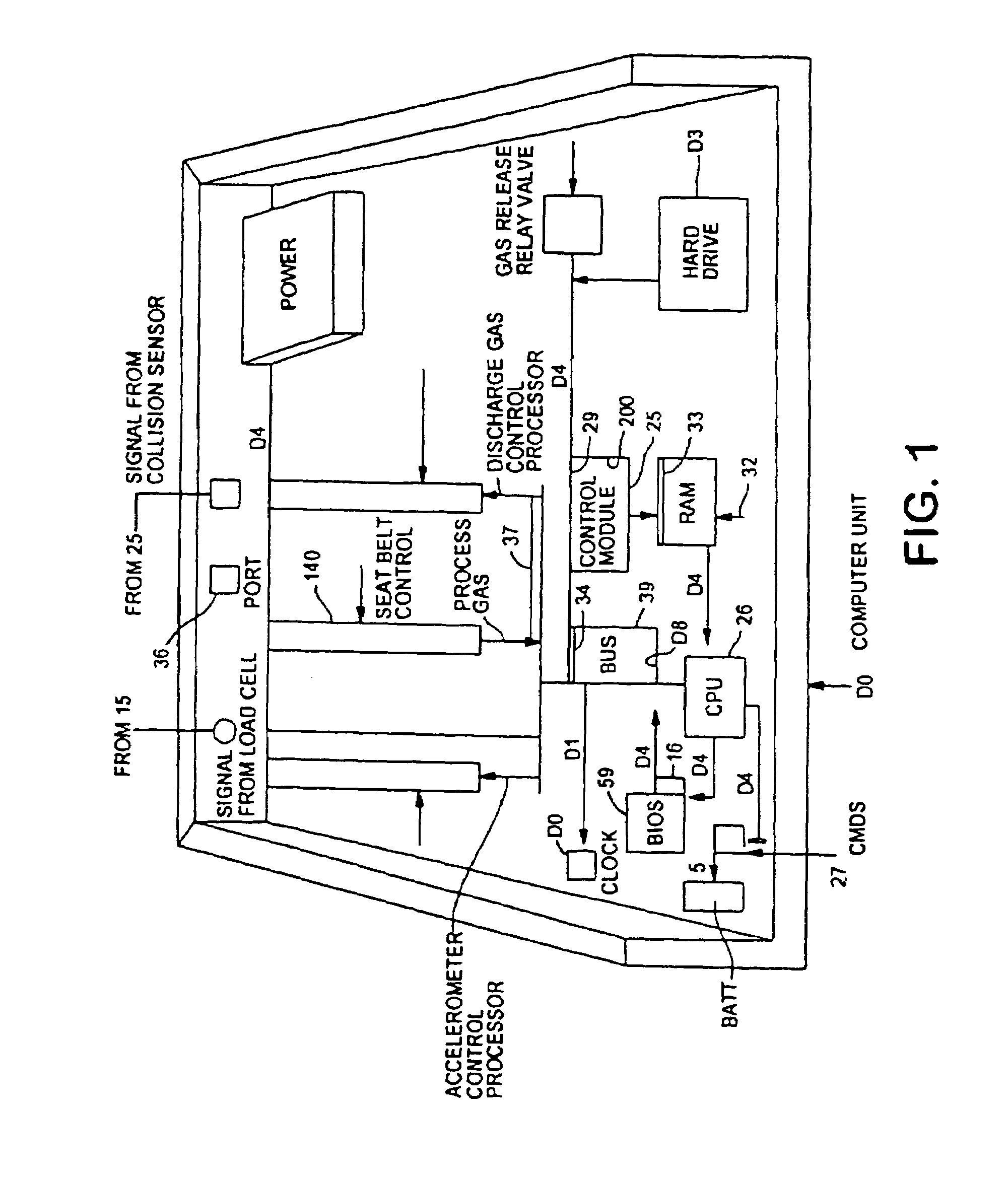

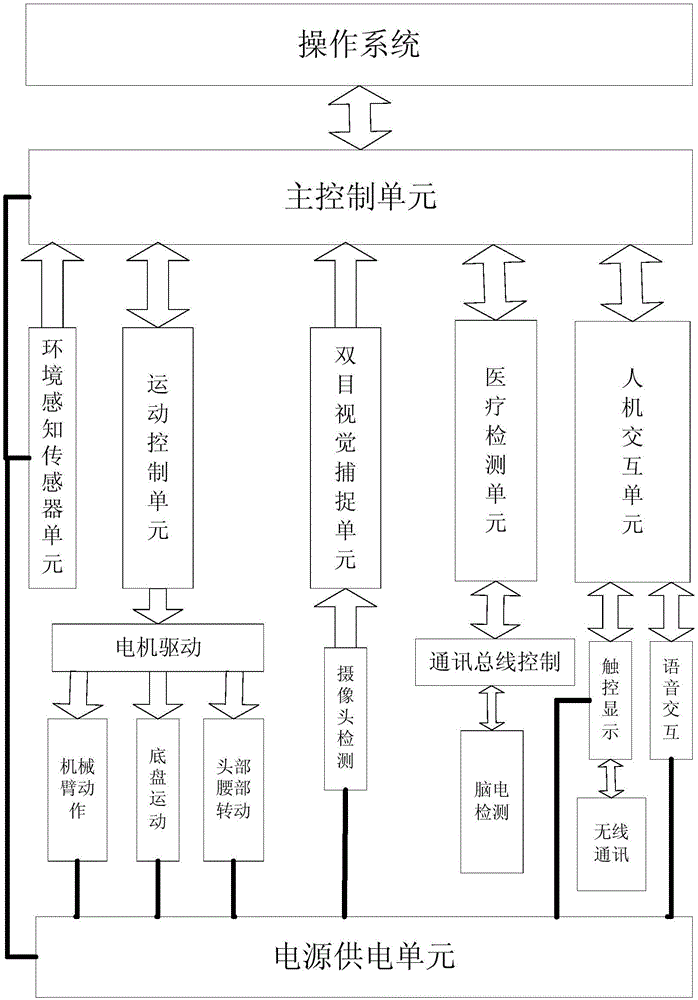

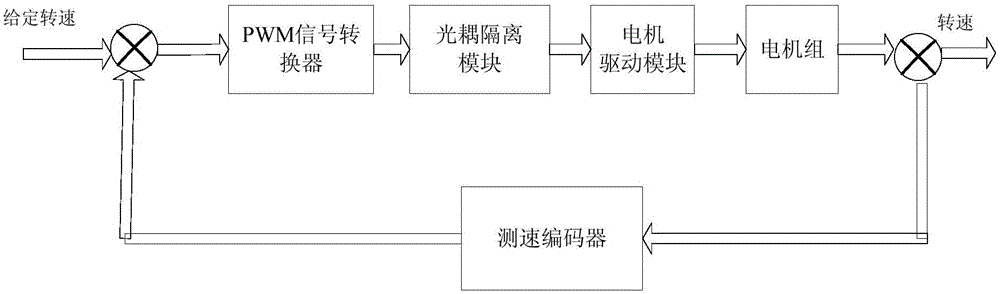

Senile dementia monitoring system based on healthy service robot

ActiveCN105078449AAvoid one-sidedness and inconsistency in diagnosisImprove accuracySensorsPsychotechnic devicesDiagnostic accuracyHealth services

The invention discloses a senile dementia monitoring system based on a healthy service robot. The senile dementia monitoring system based on the healthy service robot comprises the healthy service robot, an intelligent terminal and a cloud server. The healthy service robot comprises a robot body, a main control unit, a human-computer interaction unit and a medical detection unit; the human-computer interaction unit is connected with the main control unit and comprises a tablet computer, and the tablet computer is arranged in front of the chest of the robot body; the medical detection unit is connected with the main control unit and comprises a brain electrical detection device which is independent of the robot body, and the brain electrical detection device is connected with the intelligent terminal and the tablet computer through Bluetooth signals; the intelligent terminal and the tablet computer are connected with the cloud server through the mobile Internet, and data interaction between the intelligent terminal and the tablet computer is achieved through wireless signals. By means of the senile dementia monitoring system based on the healthy service robot, automatic auxiliary diagnosis and treatment of senile dementia can be achieved, the diagnostic accuracy is improved, prevention and early detection of the senile dementia are facilitated, the pathogenetic condition is mitigated from exacerbating, and the purpose of healing is achieved.

Owner:SOUTH CHINA UNIV OF TECH +1

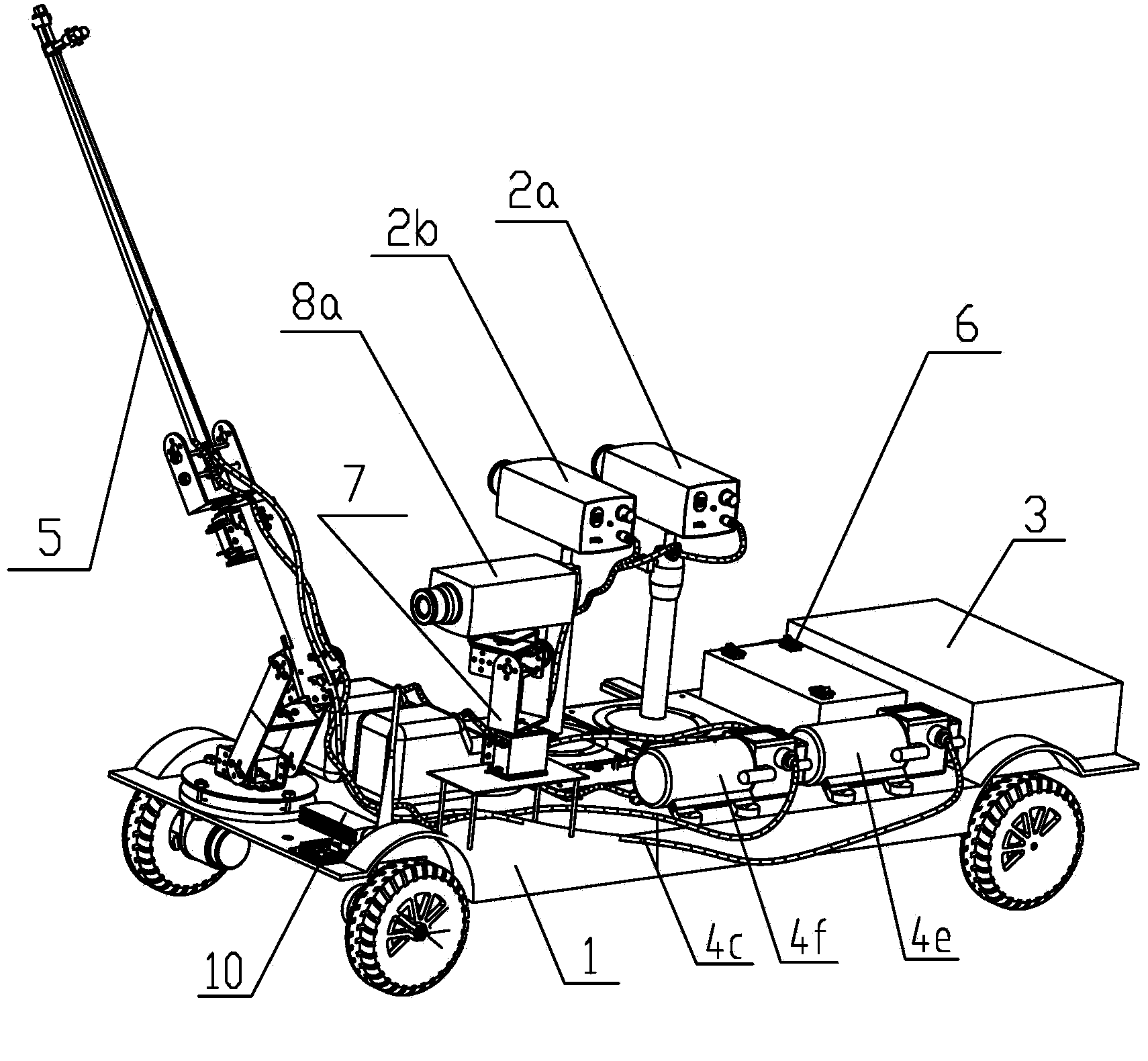

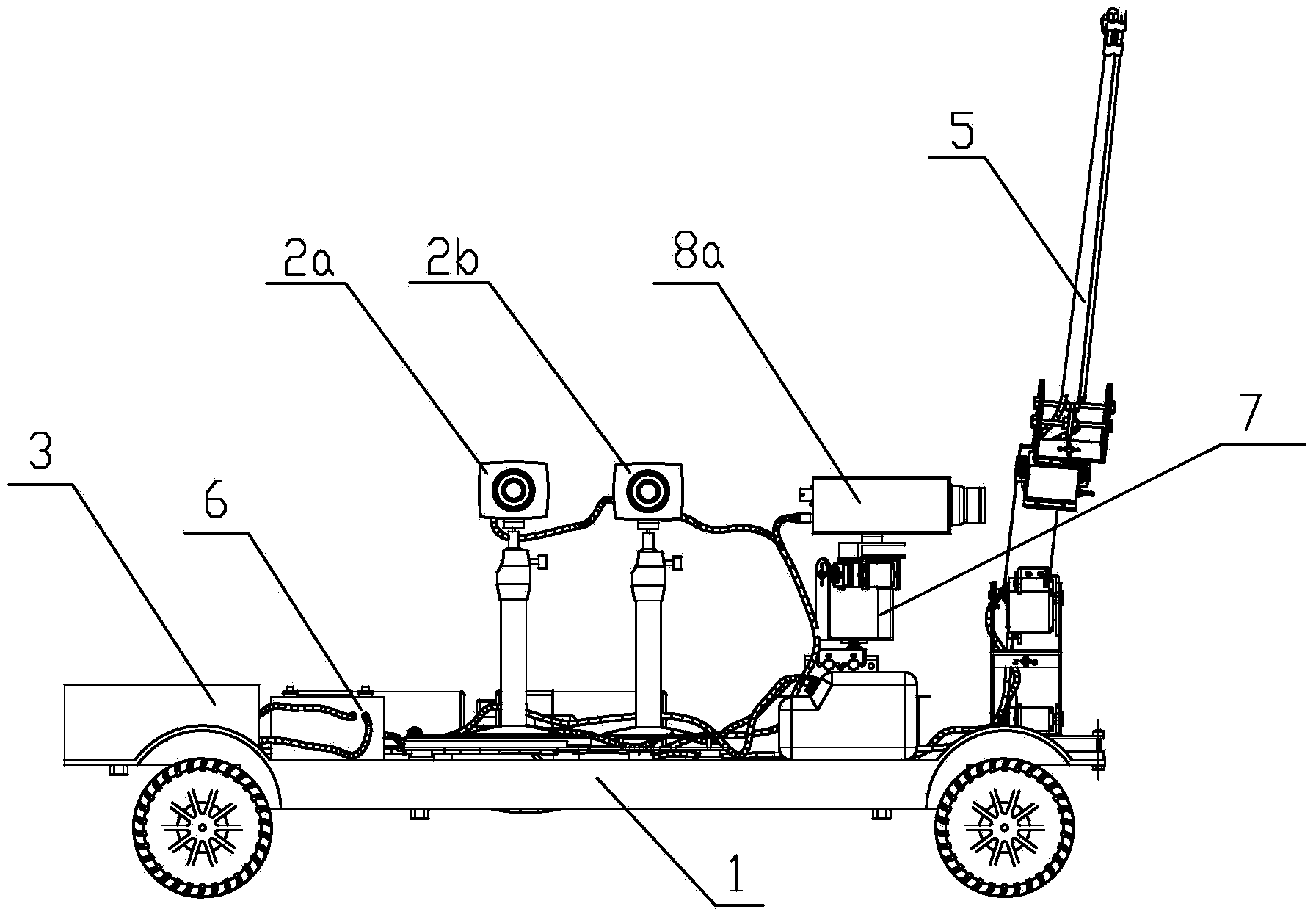

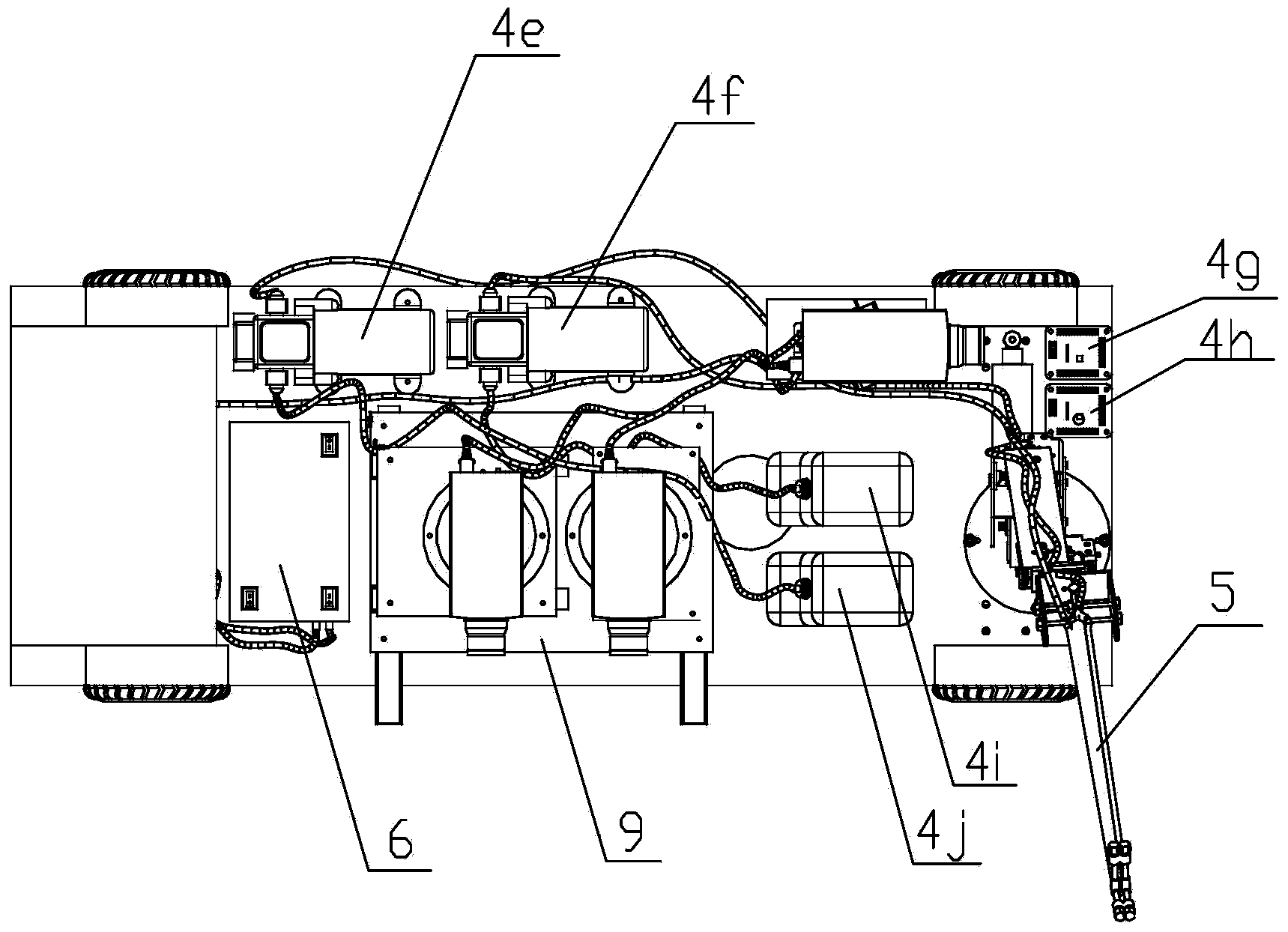

Intelligent spraying method based on image processing and spraying robot based on image processing

ActiveCN103918636AReduce labor intensityLow costManipulatorInsect catchers and killersPesticide residueDisinfectant

The invention provides an intelligent spraying method based on image processing and a spraying robot based on image processing. Through the method, the spraying robot can correctly distinguish specific crops and weeds and carry out targeted spraying according to the distribution condition of the crops and the weeds needing to be sprayed, that is, the spraying robot sprays weed killer on the weeds and sprays corresponding disinfectant and other pesticides on the crops, and consequently intelligent spraying without human interference is achieved. Meanwhile, a wireless video transmission mode is additionally adopted, and a worker can monitor and control the spraying robot by holding a monitor in hand. Thus, the intelligent spraying robot not only reduces the labor intensity of the workers and spraying cost but also reduces the use quantity of the pesticides and pesticide residues in the soil environment and has an immeasurable significance in improving spraying intellectualization and modernization of agriculture and accelerating agriculture precision in our country.

Owner:QINGDAO AGRI UNIV

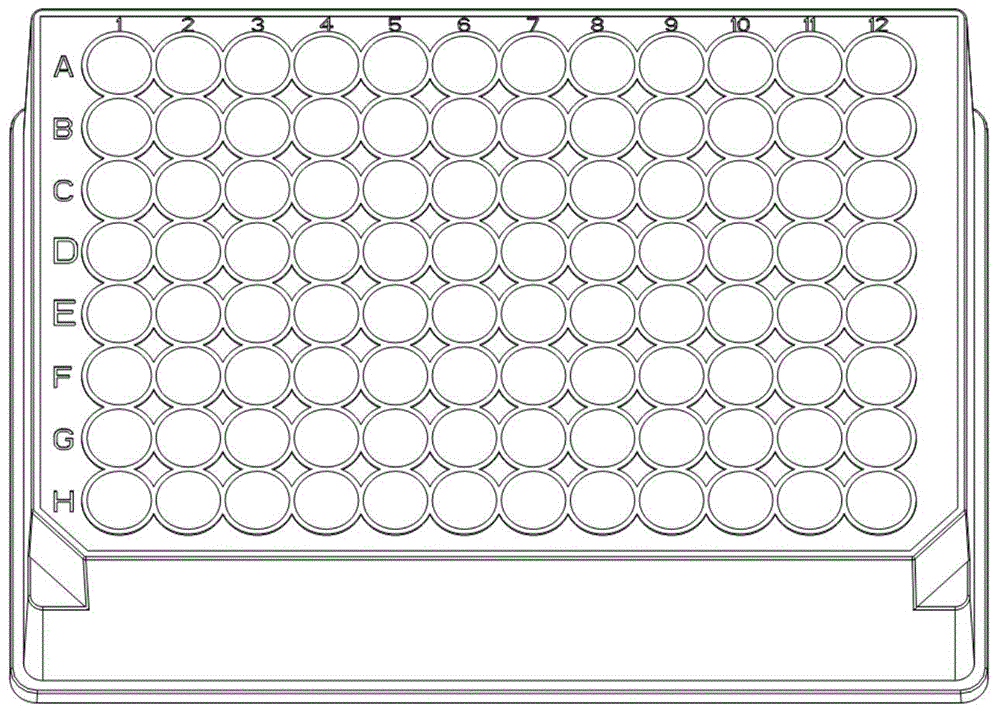

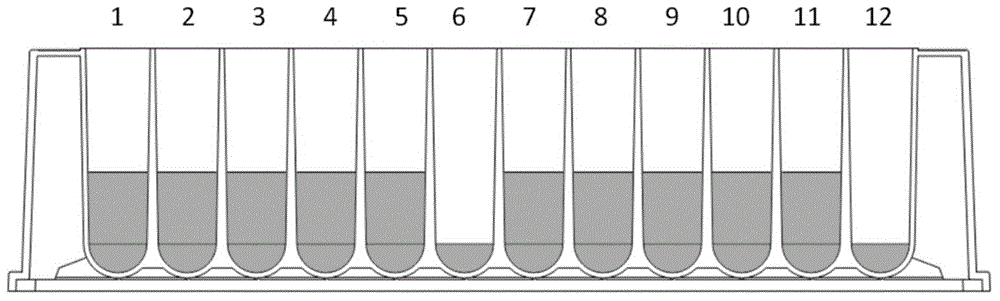

Kit for extracting nucleic acid from bacteria by using paramagnetic particle method and extracting method

InactiveCN104450684AStrong cracking abilityHigh purityDNA preparationHigh concentrationEthylenediamine

The invention discloses a kit for extracting nucleic acid from bacteria by using a paramagnetic particle method and an extracting method. The kit comprises a bacteria lysate, a magnetic bead binding solution, a magnetic bead scrubbing solution and a nucleic acid eluent. The bacteria lysate comprises sodium dodecyl sulfate, ethylenediaminetetraacetic acid, tri-hydroxymethyl aminomethane and sodium chloride; the magnetic bead binding solution comprises polyethylene glycol-8000 and sodium chloride; the magnetic bead scrubbing solution comprises ethanol; and the nucleic acid eluent comprises tri-hydroxymethyl aminomethane and ethylenediamine tetraacetic acid. The kit comprises the unique bacteria lysate which has a strong lysis function for the bacteria; and the kit can be used for manual extraction and instrument extraction by using a commercially available nucleic acid isolation machine, high-purity and high-concentration bacteria nucleic acid can be extracted.

Owner:NANJING ZHONGKE SHENGUANG TECH

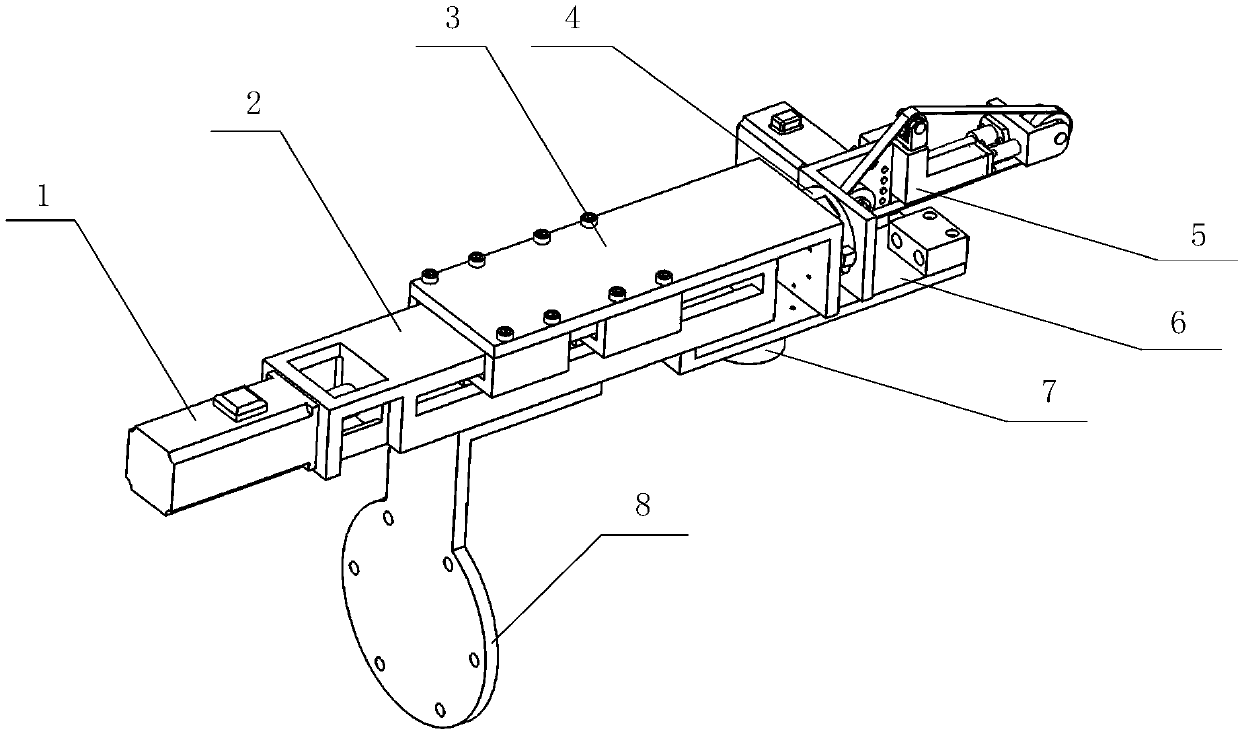

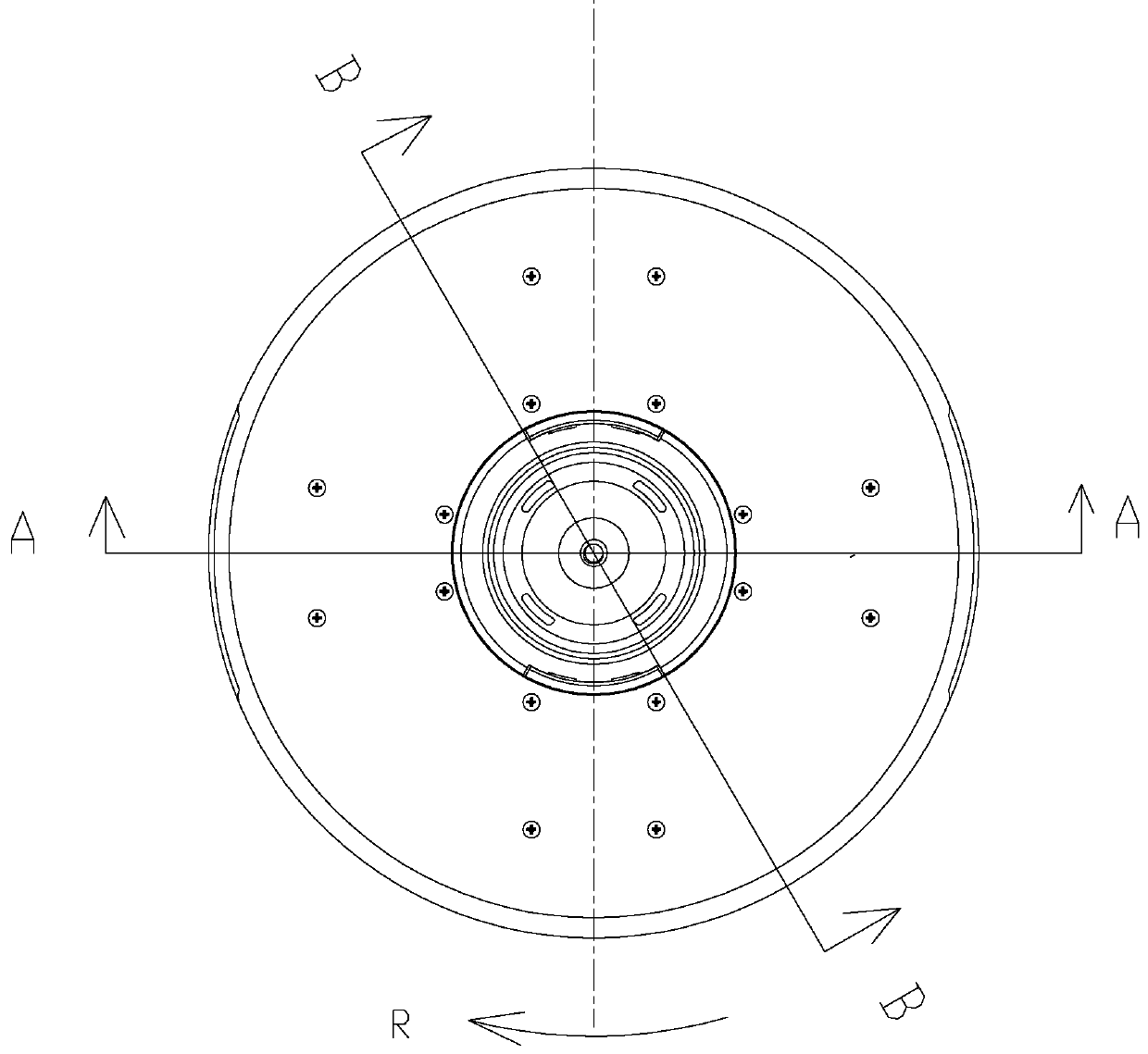

Integrated active-passive compliant one-dimensional variable force grinding and polishing device and control method

ActiveCN108044463ARealize variable force flexible contactAvoid shockBelt grinding machinesAutomatic grinding controlLinear motionManufacturing technology

The invention belongs to the technical field of intelligent processing and manufacturing, and particularly discloses an integrated active-passive compliant one-dimensional variable force grinding andpolishing device and a control method. The integrated active-passive compliant one-dimensional variable force grinding and polishing device comprises a linear module servo motion platform, a mountingflange, a limiting plate, a position and orientation sensor, a speed-adjustable compliant grinding and polishing mechanism and a controller, and the linear module servo motion platform is used for driving the grinding and polishing mechanism to perform linear motion; the mounting flange and the limiting plate are mounted on a base of the linear module servo motion platform, and the position and orientation sensor and the speed-adjustable compliant grinding and polishing mechanism are installed on the limiting plate; and the position and orientation sensor is used for measuring position and orientation of the one-dimensional variable force grinding and polishing device and sending the position and orientation to the controller, a force sensor is arranged between the compliant grinding and polishing mechanism and sliding blocks, the force sensor is used for collecting a contact force signal and send to the controller which can calculate speed control quantity, and the speed-adjustable compliant grinding and polishing mechanism is driven to move by rotation of a servo motor according to the speed control quantity. According to the integrated active-passive compliant one-dimensional variable force grinding and polishing device and the control method, the contact status of a abrasive belt and a workpiece can be adjusted in real time, and a stable and compliant grinding and polishingprocess is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

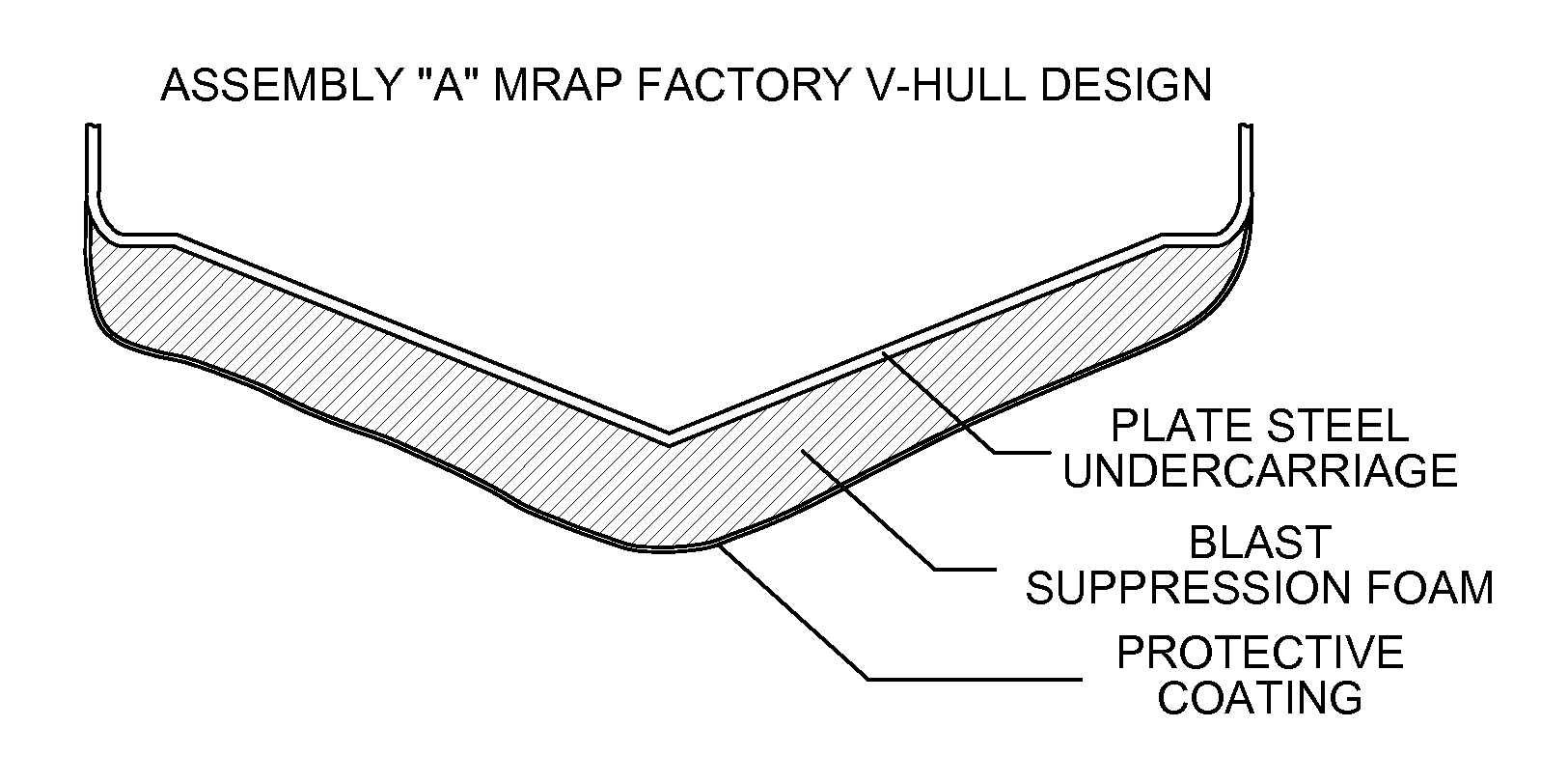

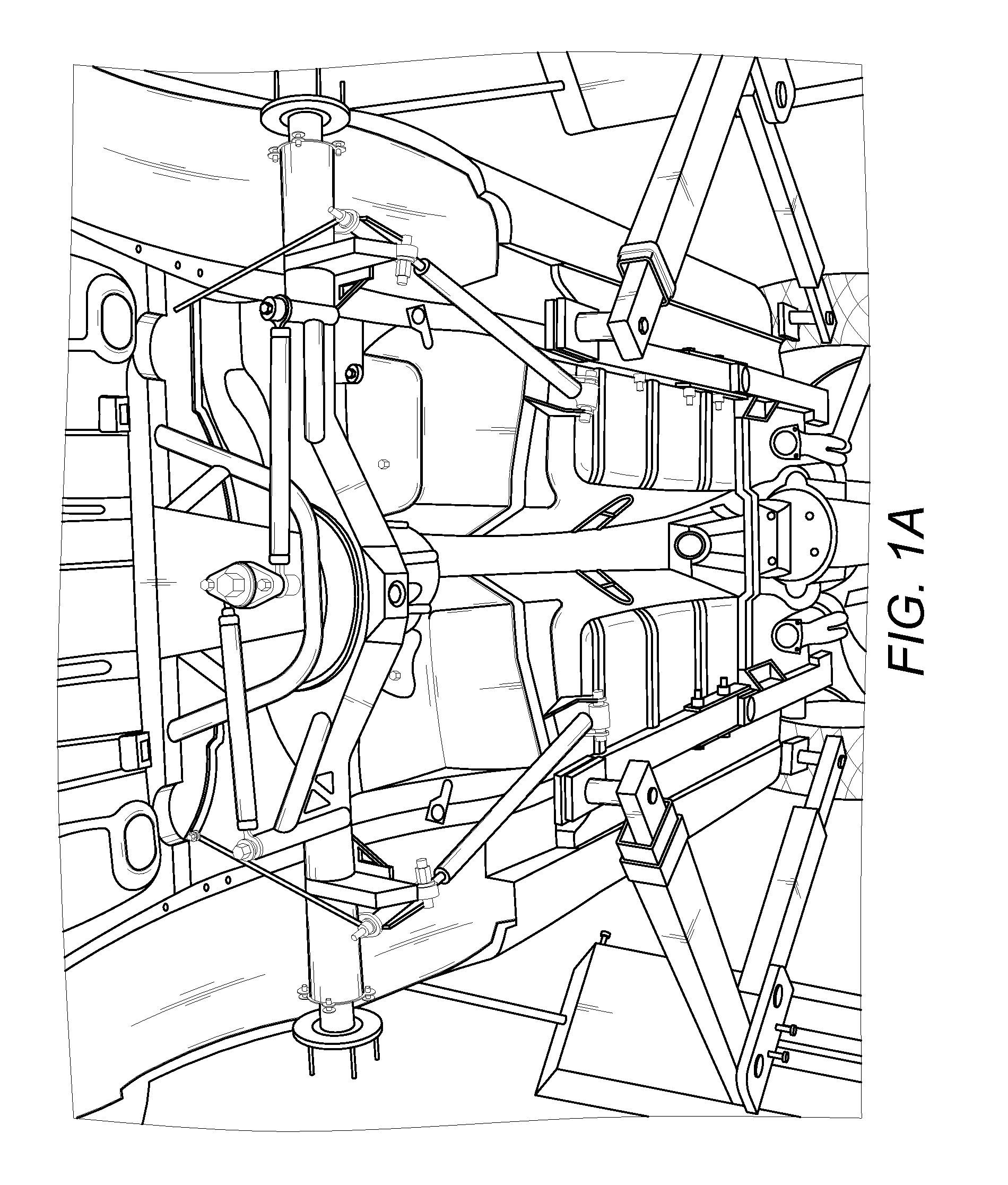

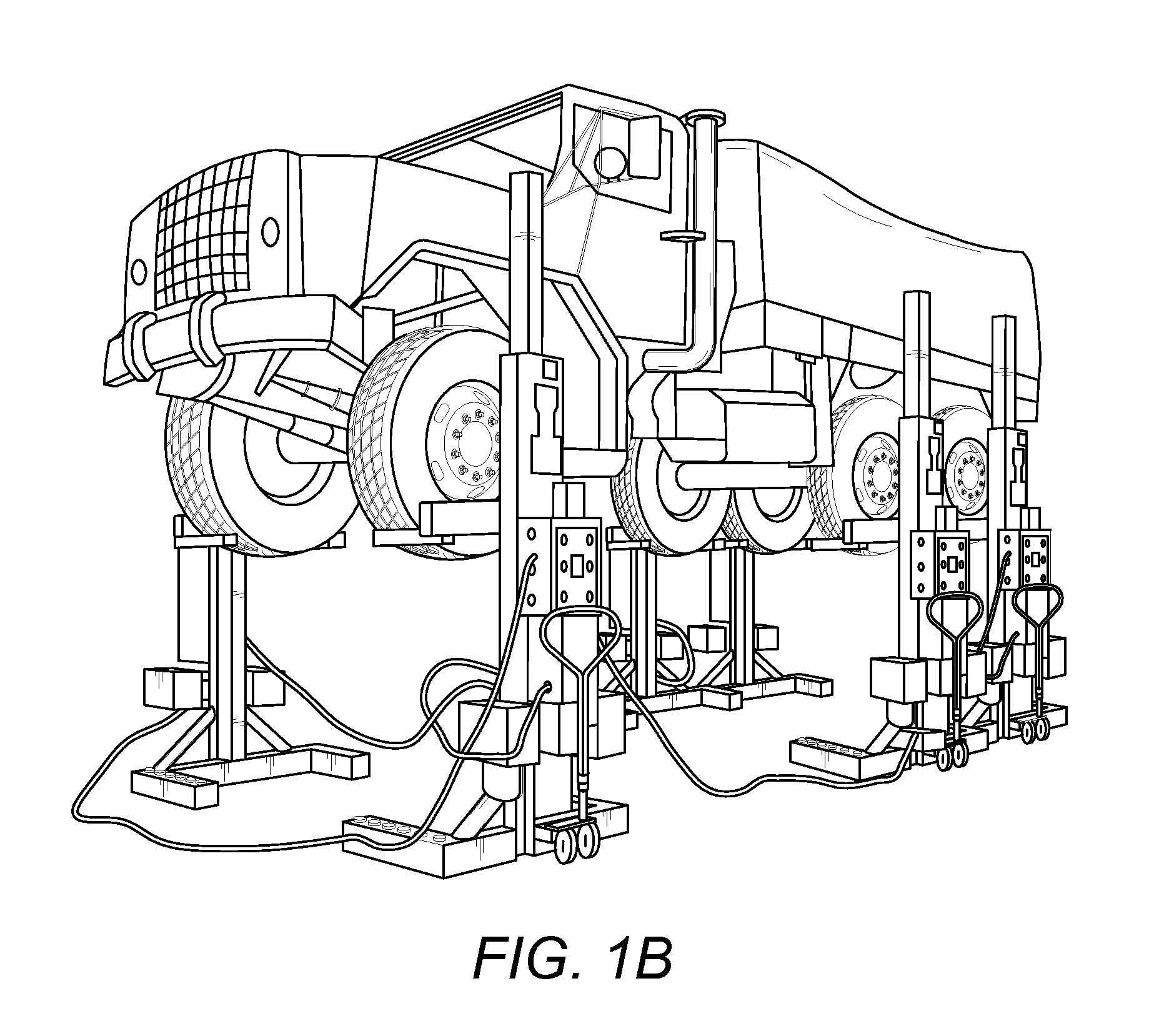

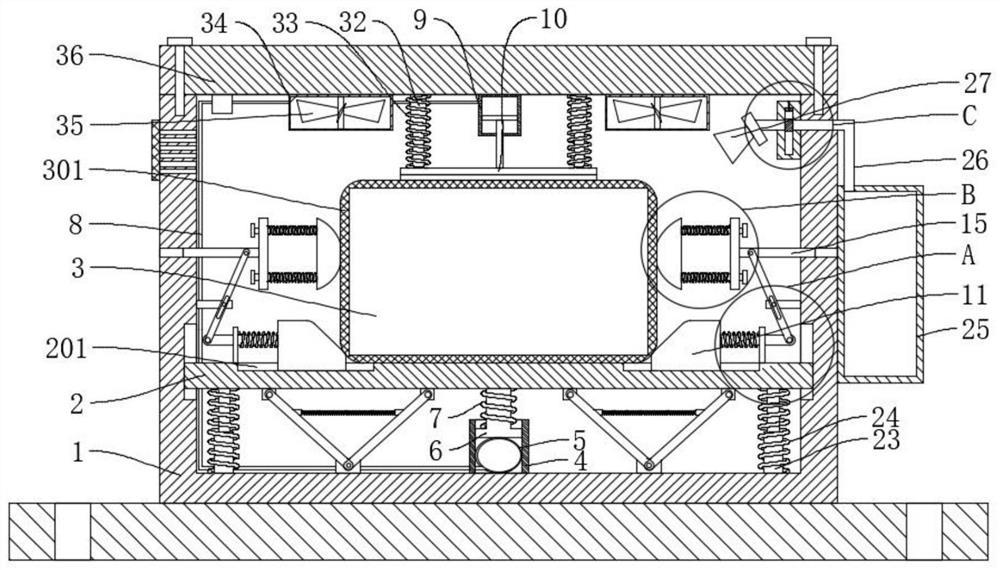

Blast mitigation system for military vehicles

InactiveUS20130036899A1Improved vehicular protectionImprove protectionArmoured vehiclesArmour platesShock waveAbsorbed energy

Disclosed is a system and method to both reduce a degree of explosive shock waves and to absorb a degree of explosive blast energy from the undercarriage of a vehicle which comprises the use of one or more layers of rigid closed-cell spray polyurethane foam, applied to the armored undercarriage of the vehicle. This invention combines two key aspects: 1) blast suppression or mitigation materials that absorb energy and 2) traditional military hardened armor solutions. The effectiveness of spray applied rigid foam has been proven to both dramatically reduce shock waves and absorb energy from explosive blasts (e.g., IEDs).

Owner:HONEYWELL INT INC

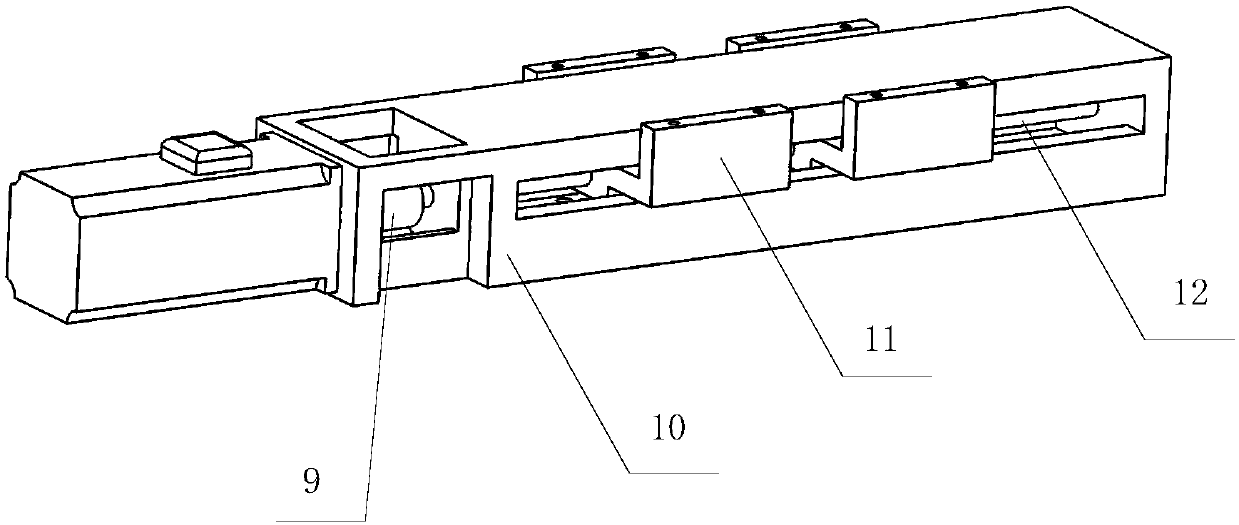

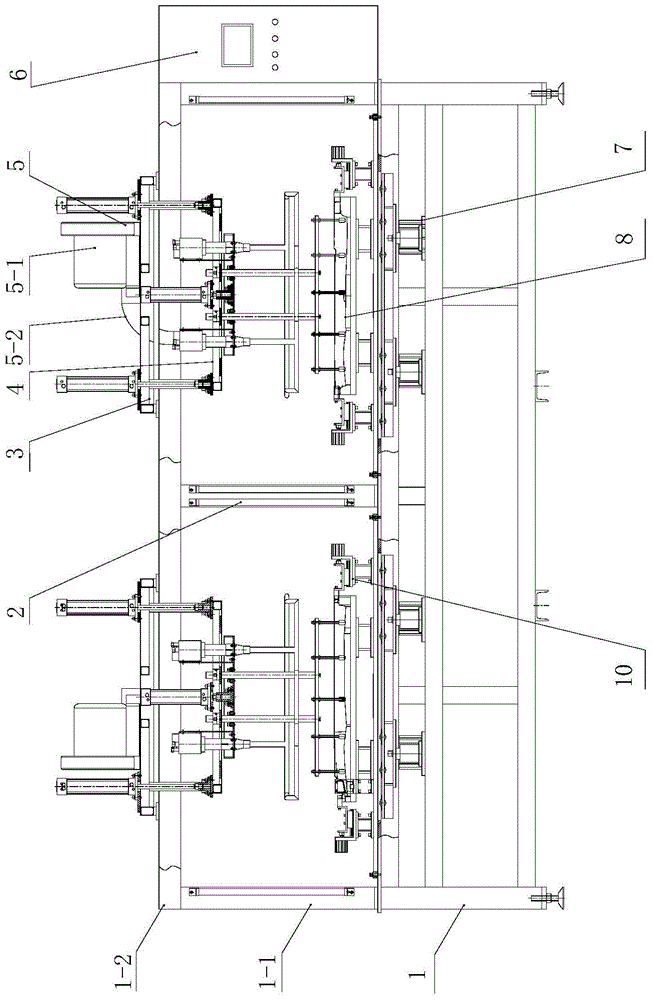

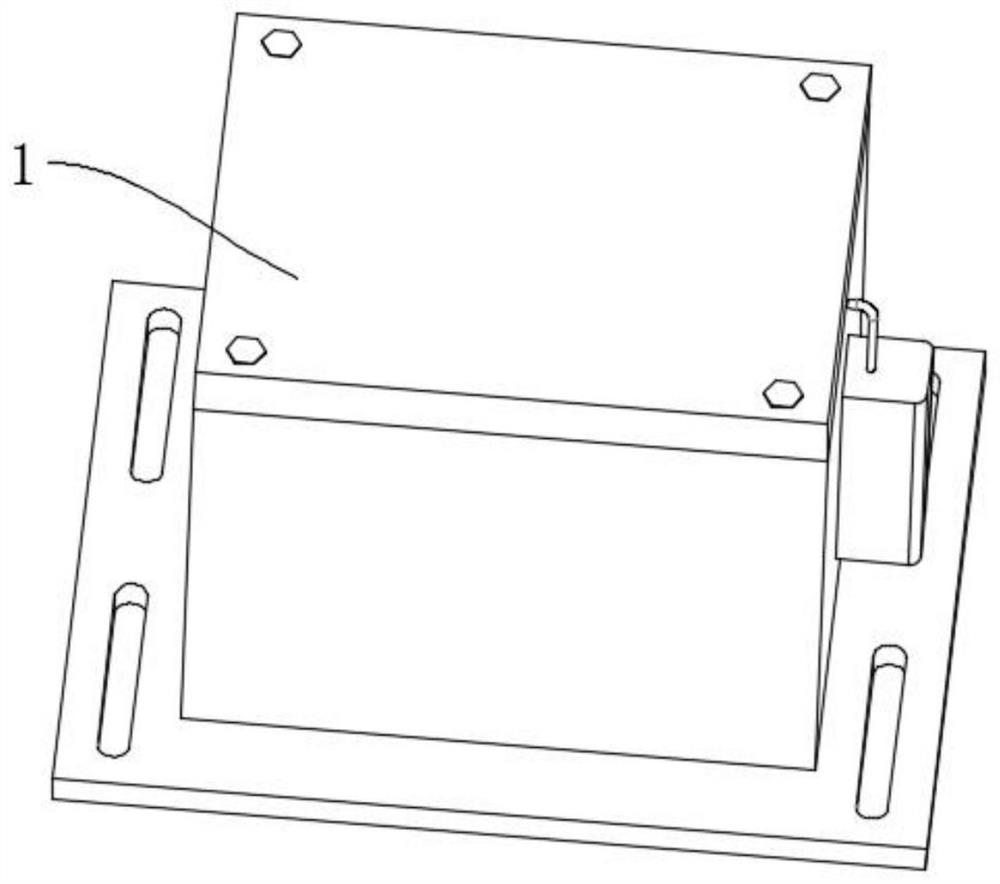

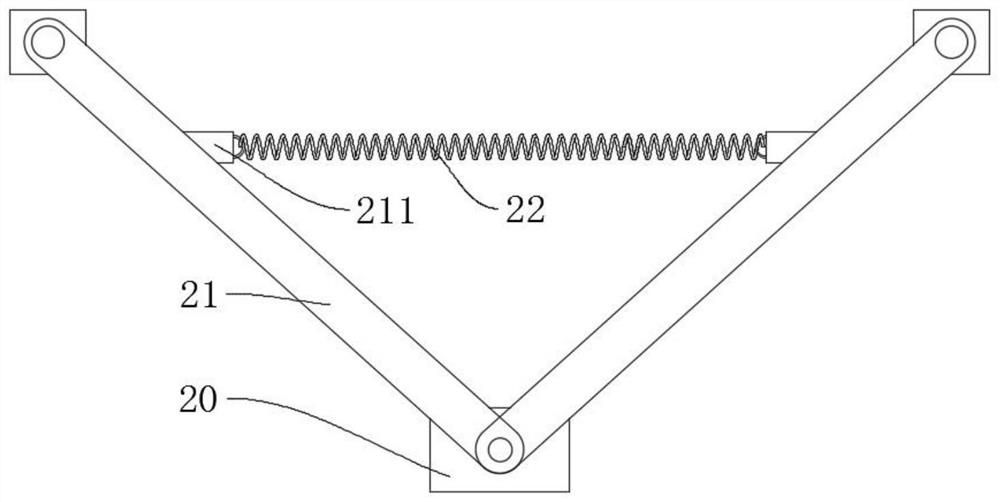

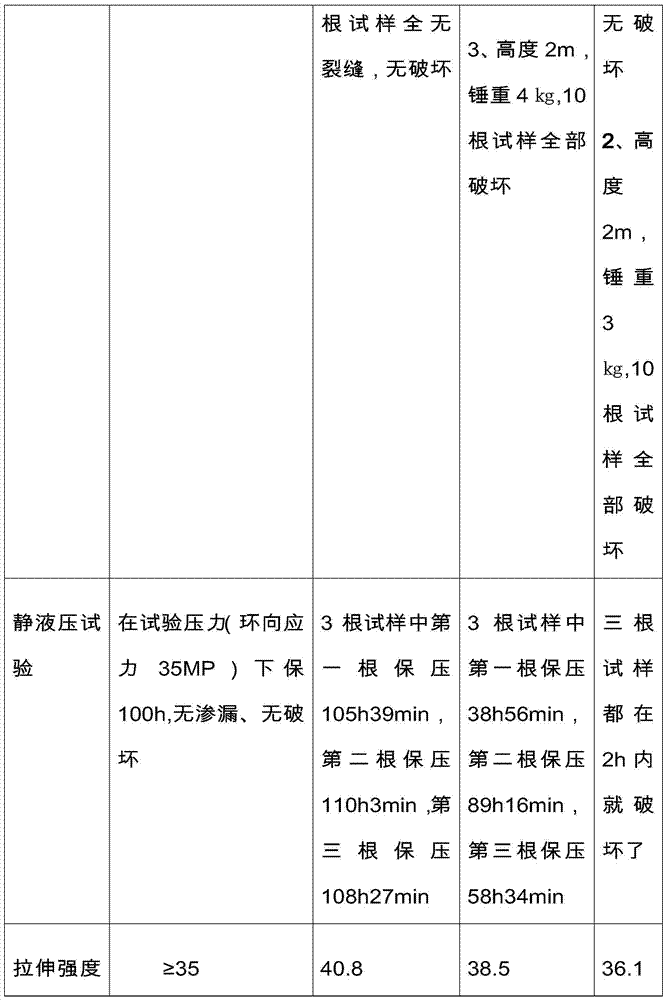

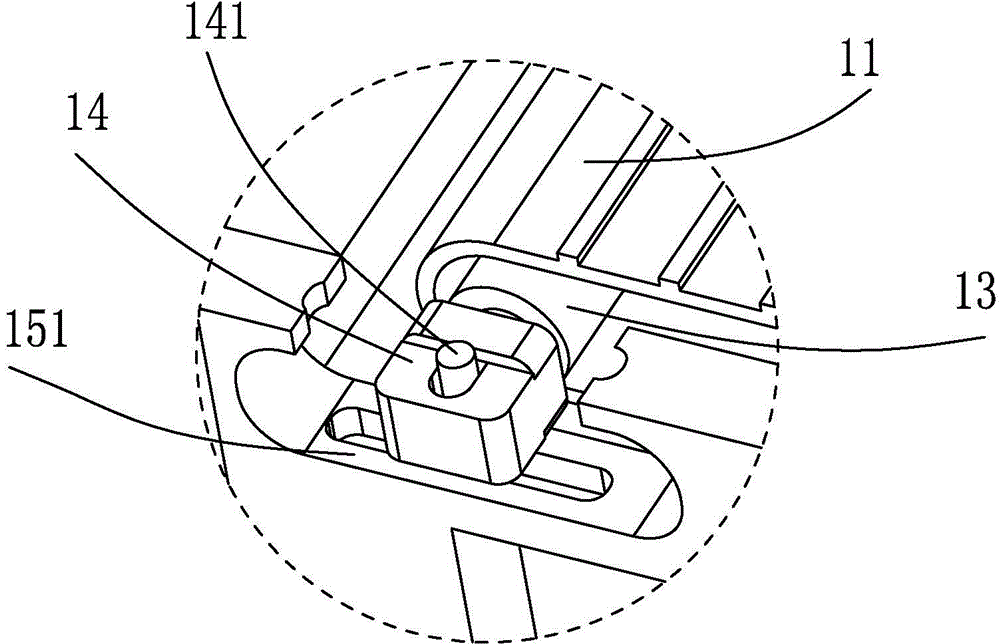

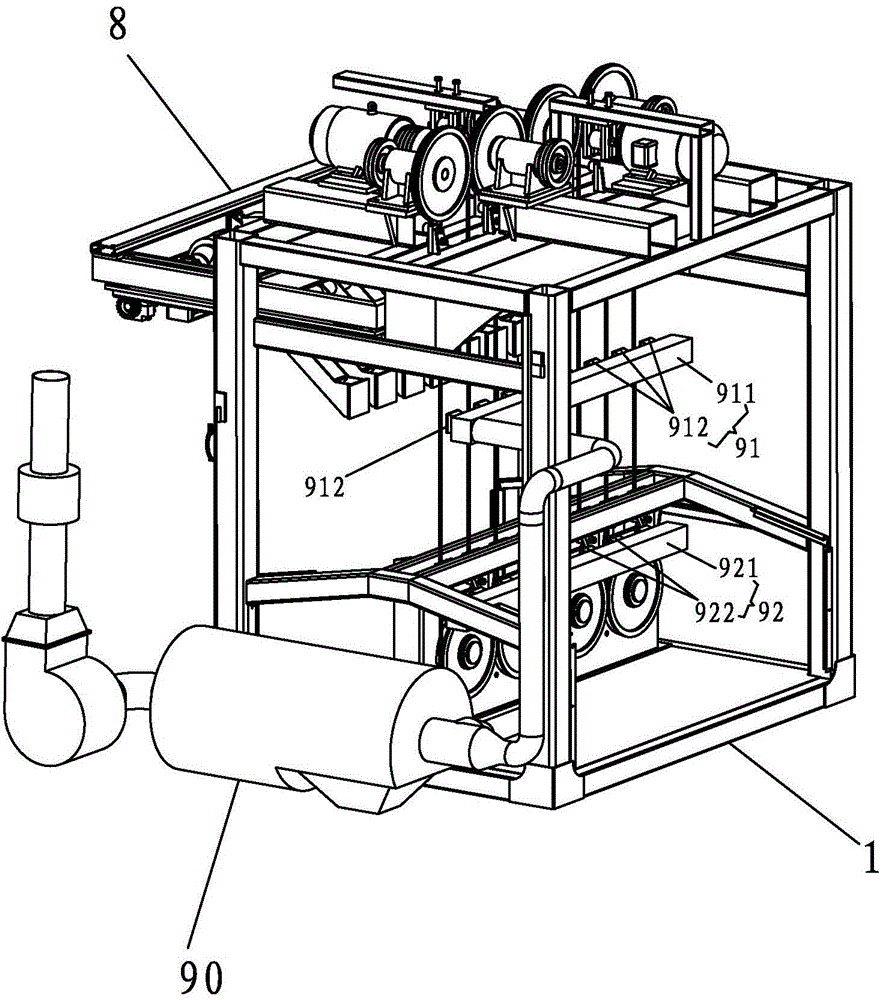

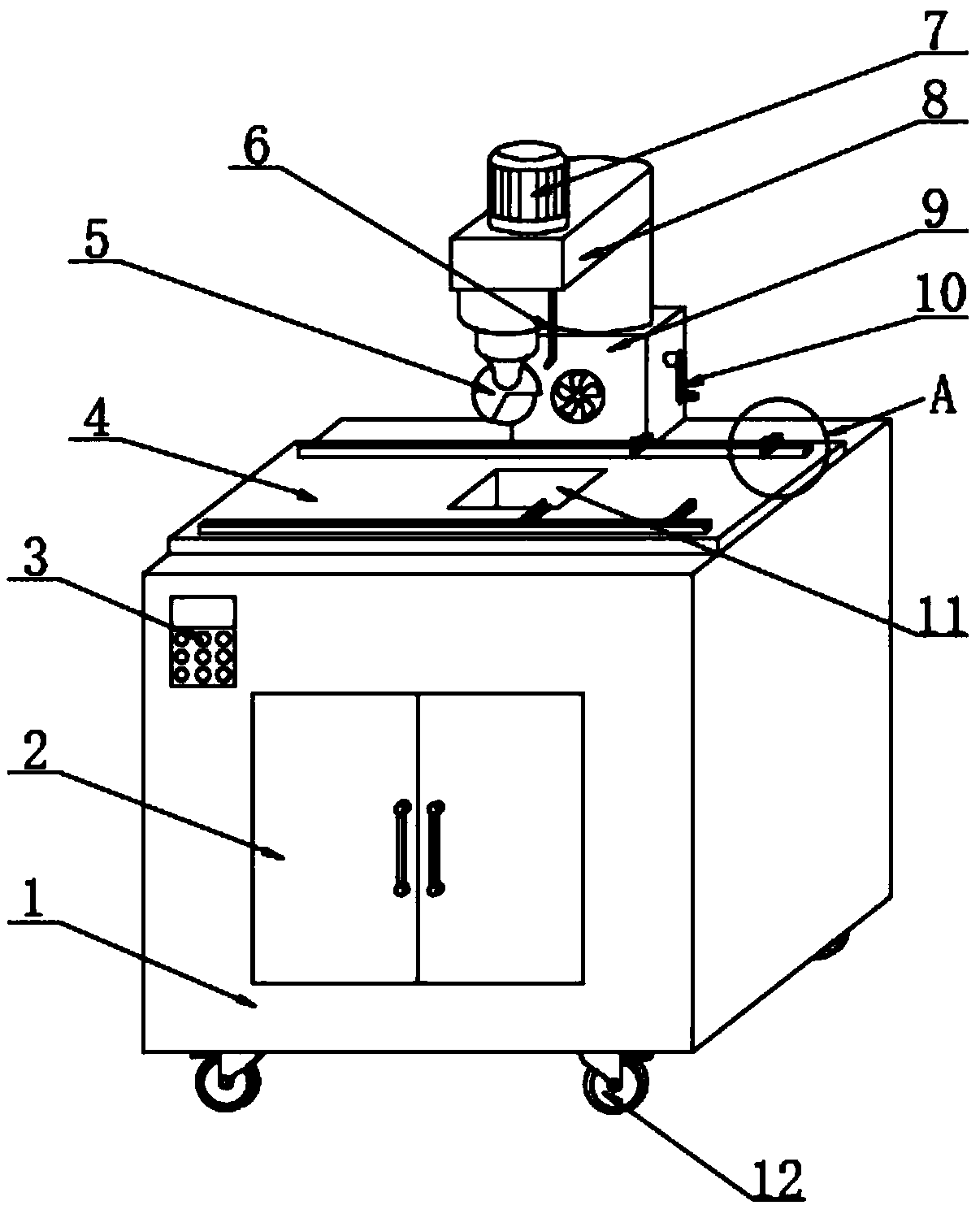

Taping machine for decorative plate and insertion plate on automobile door plate

InactiveCN103978677AReduce physical injuryAvoid defective and waste productsFrame basedCar manufacturing

The invention relates to a taping machine for a decorative plate and an insertion plate on an automobile door plate. The taping machine comprises a frame composed of a base, a beam and a bracket. The frame base is installed with a positioning tire membrane and taping assembly surrounding the positioning tire membrane; the bottom of the positioning tire membrane is provided with a die change system, and a positioning clamping device, a heating device and an air supply system are arranged on the beam of the frame above the positioning tire membrane; a security grating is arranged on both sides of the frame; and one side outside the frame is equipped with an electronic control system. The invention has the following advantages: the taping machine not only meets the demand of mass production of the automobile industry, and possesses the concept of energy saving and environmental protection, but also can greatly improve the quality of products to bring good economic benefits to the enterprises; and the taping machine has compact structure, reasonable layout, convenience for operation, and stable, safe and reliable operation, and is ideal irreplaceable equipment for door plate taping processing in the automobile manufacturing industry.

Owner:天津市精大稀机械设备制造公司

Battery fixing device with battery protection effect for new energy automobile

InactiveCN112350015AImprove cooling effectEasy to fixElectric propulsion mountingSecondary cellsNew energyBattery cell

The invention discloses a battery fixing device with a battery protection effect for a new energy automobile, and belongs to the field of new energy automobiles. The battery fixing device with the battery protection effect for the new energy automobile comprises a box body, a storage battery and a box cover, a supporting frame is connected to the box body in a sliding manner, and the storage battery is placed on the supporting frame; a sliding sleeve is fixedly connected in the box body, a first sliding rod is connected to the sliding sleeve in a sliding manner, and the end, away from the sliding sleeve, of the first sliding rod is fixedly connected with the supporting frame; an air bag is arranged in the sliding sleeve, and the two ends of the air bag abut against the box body and the first sliding rod correspondingly. By elastically fixing the storage battery, damage caused by excessive fixing of the storage battery is reduced, meanwhile, the fixing effect is not affected; meanwhile,the shock absorption protection and ignition protection of the storage battery when the automobile vibrates are improved, and the use safety of the storage battery is further improved.

Owner:刘思琪

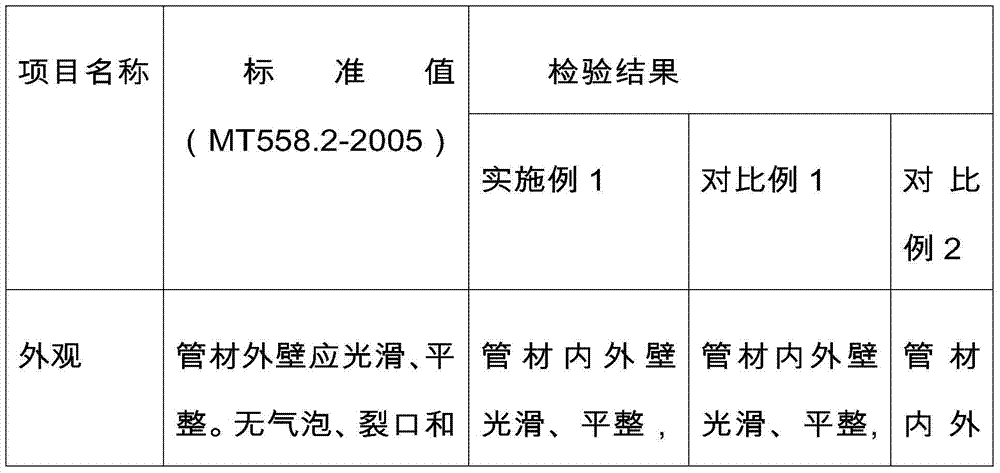

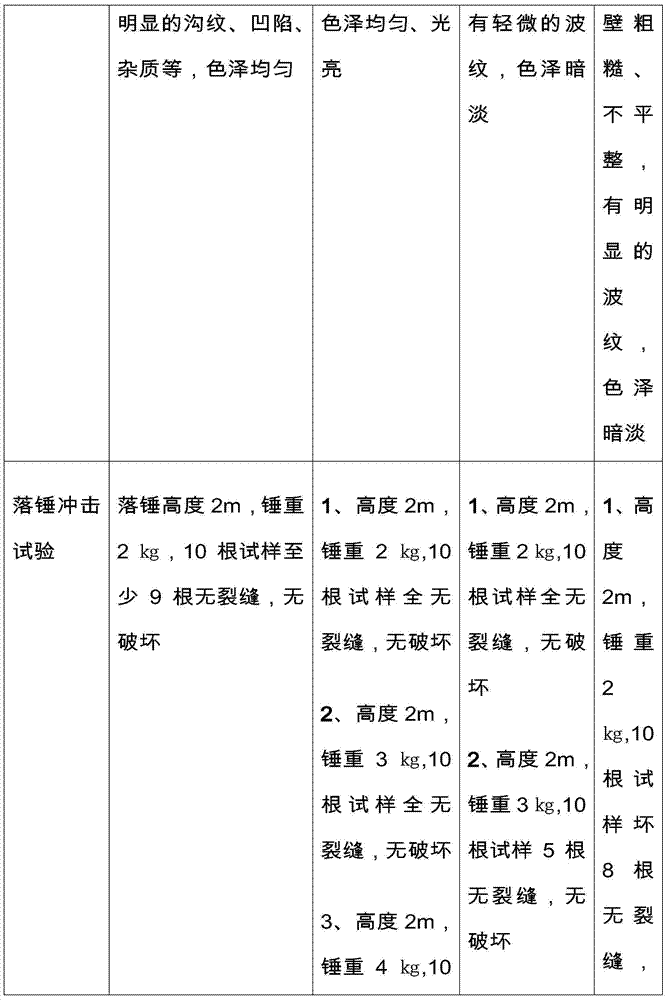

PVC extrusion grade particulate material and preparation method thereof, and preparation method of extrusion product

InactiveCN103524950AGood dispersionMeet the use requirementsPolymer scienceUltimate tensile strength

The invention provides a PVC extrusion particulate material and a preparation method thereof, and preparation method of an extrusion product. The invention relates to the field of PVC extrusion materials. The PVC extrusion particulate material is prepared from the raw materials of: PVC resin, a stabilizer, an impact-resistant modifier, a lubricant, a conducting agent, and a filler. The polymerization degree of the PVC resin is 1000-1100. According to the invention, with the method, the obtained PVC extrusion grade particulate material has the advantage of well dispersed raw materials. The extrusion product produced with the extrusion particulate material has good and stable comprehensive performances such as smooth and flat appearance, static resistance, good flame retardant property, good toughness, good strength, and the like. The material can satisfy higher and higher requirements of mining and other industries. Also, during the preparation process of the extrusion product, dust pollution can be greatly reduced, and damage to the bodies of workers can be reduced.

Owner:郭静利

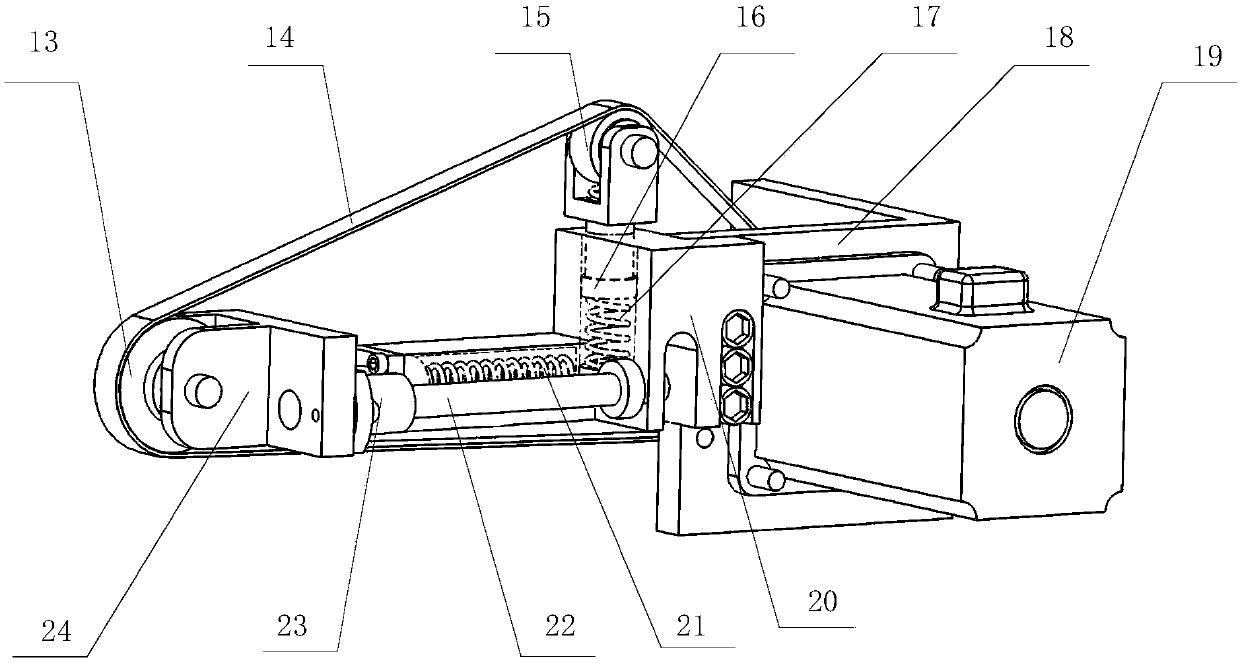

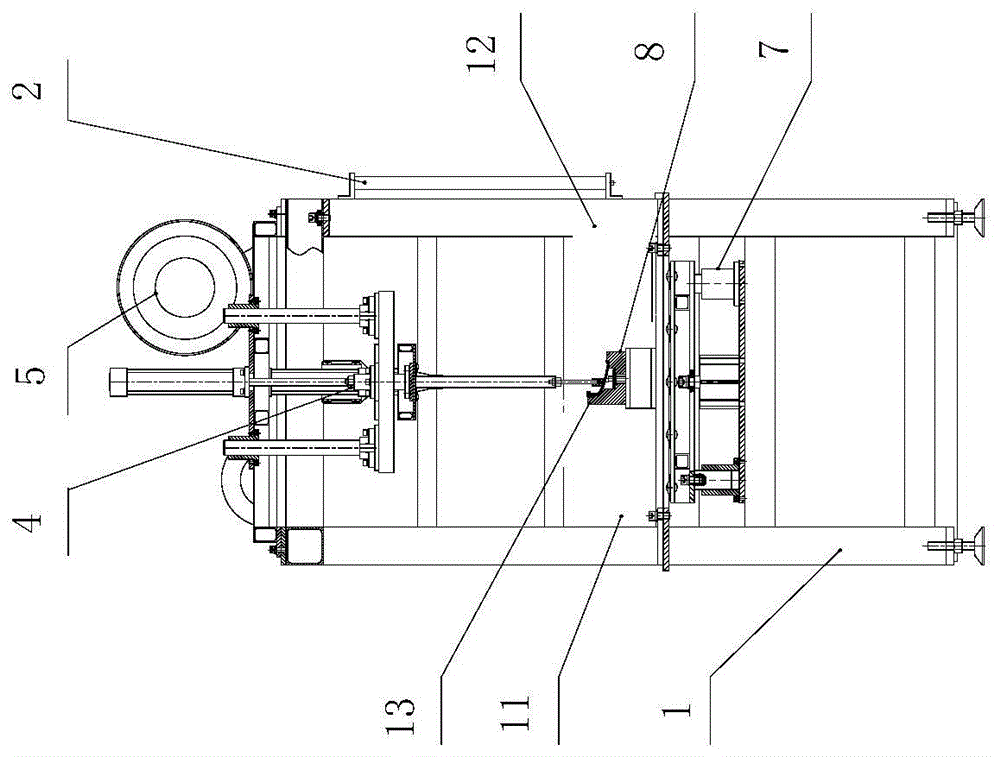

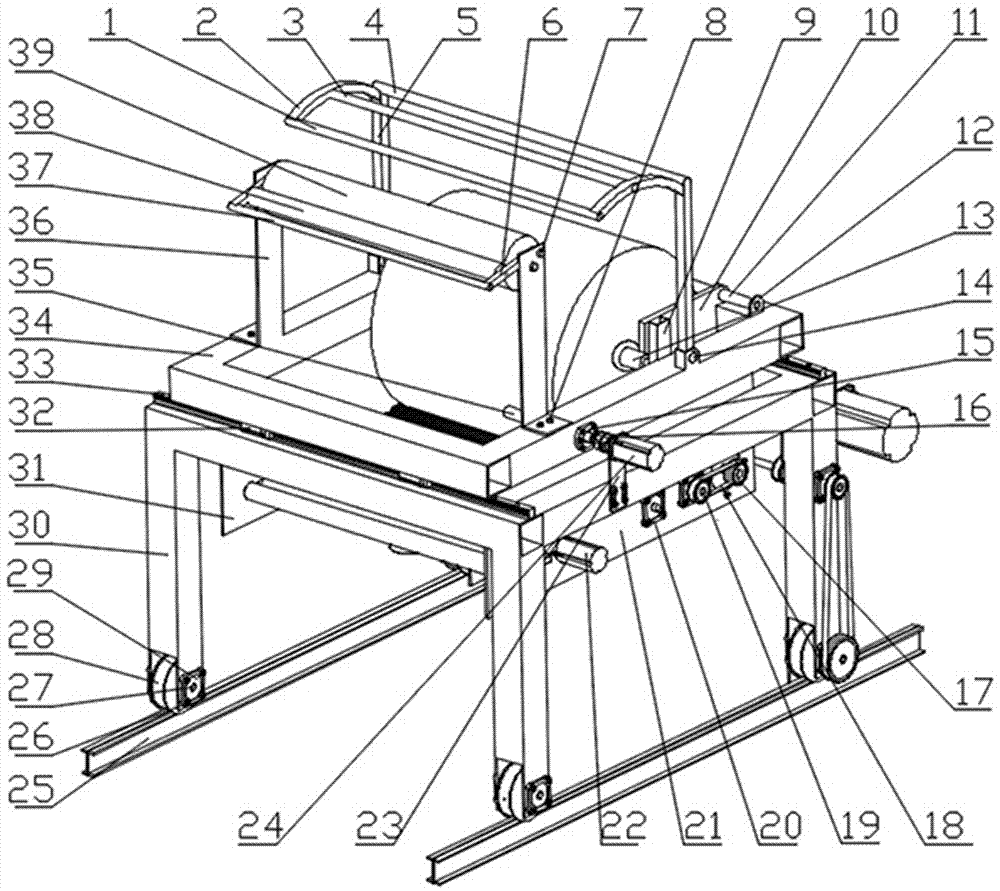

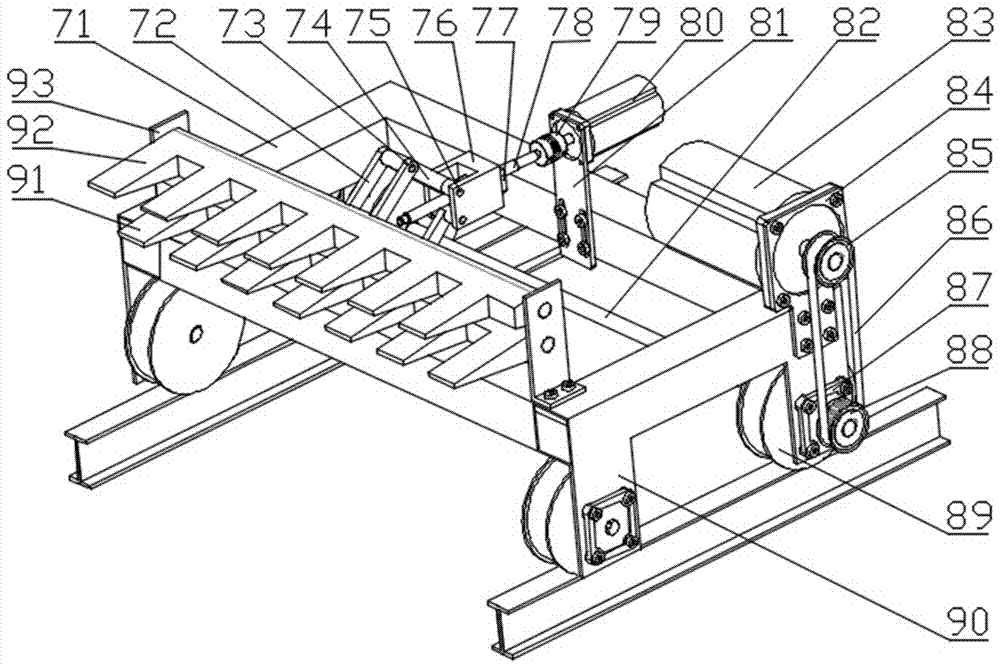

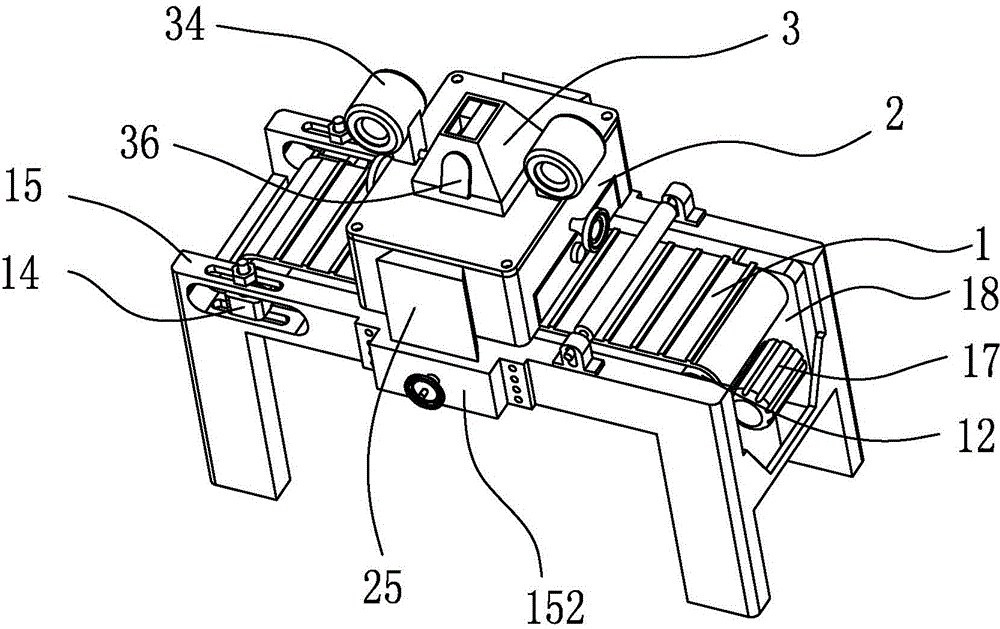

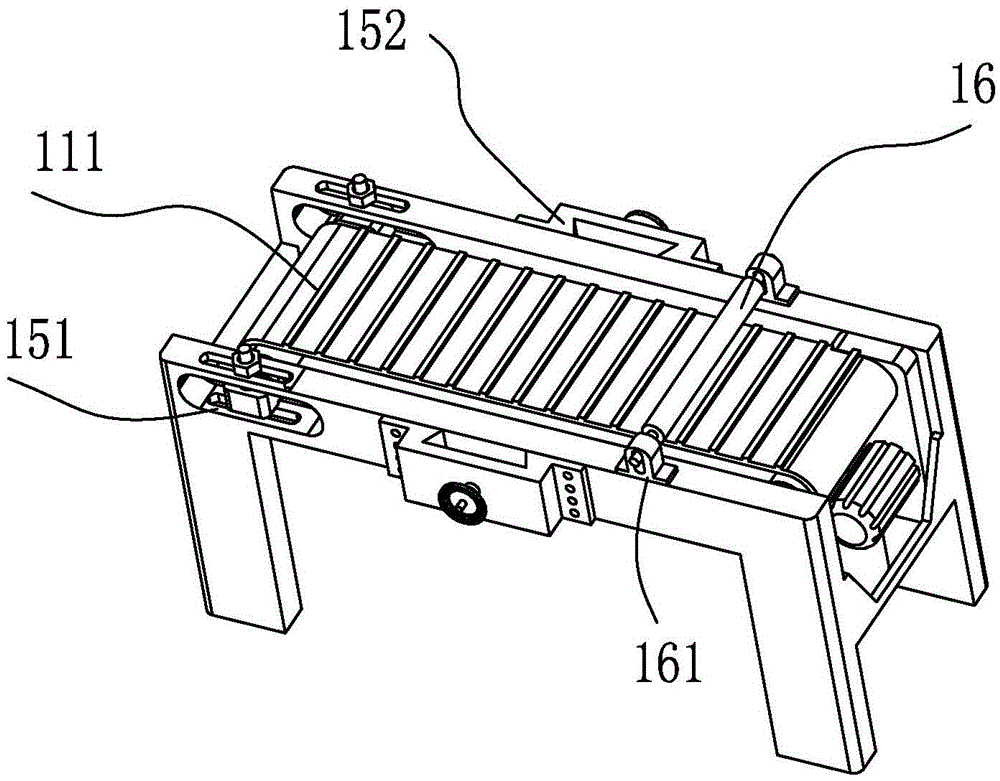

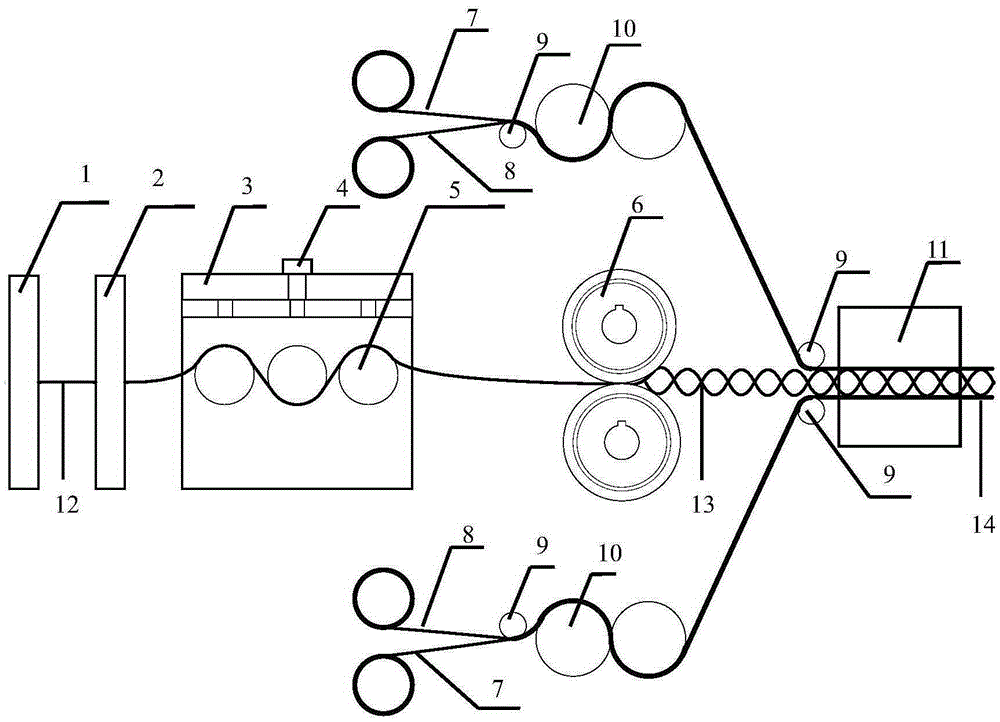

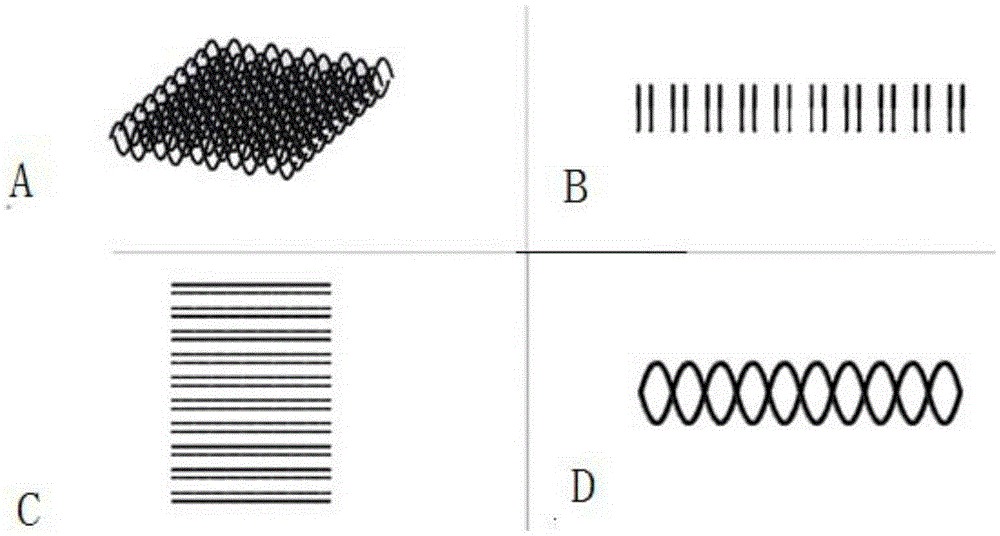

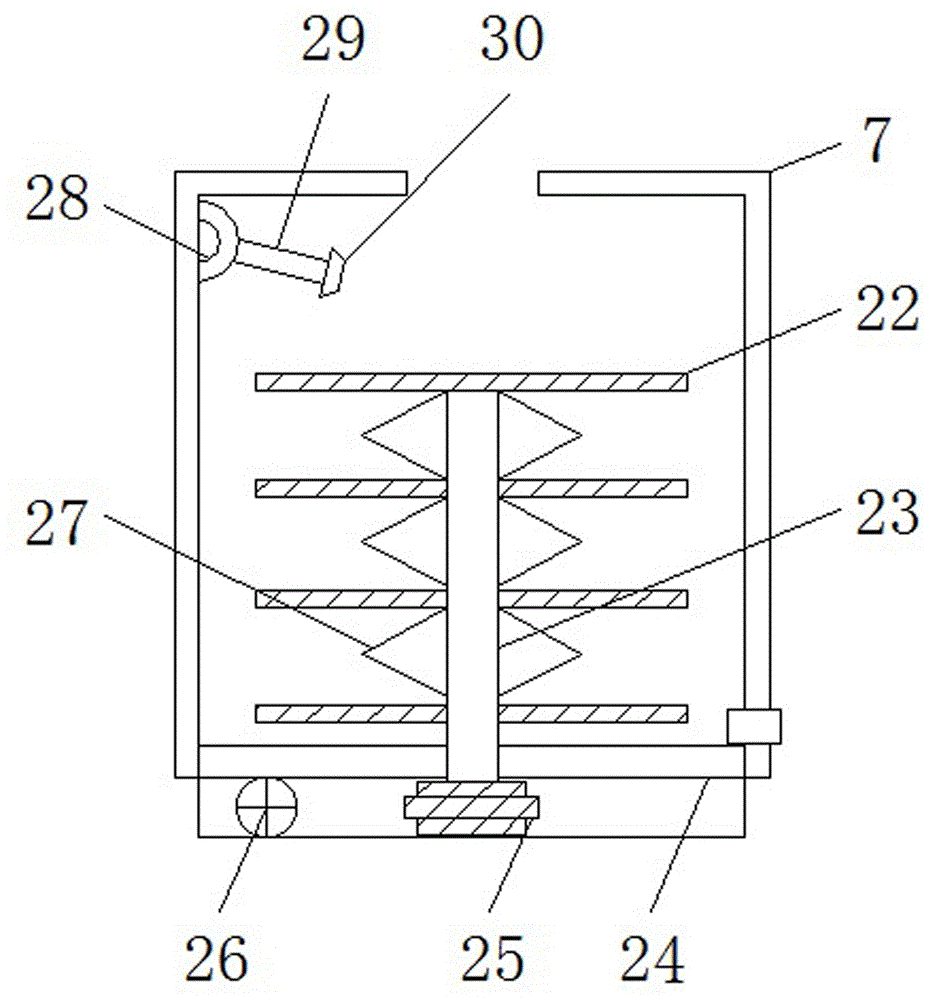

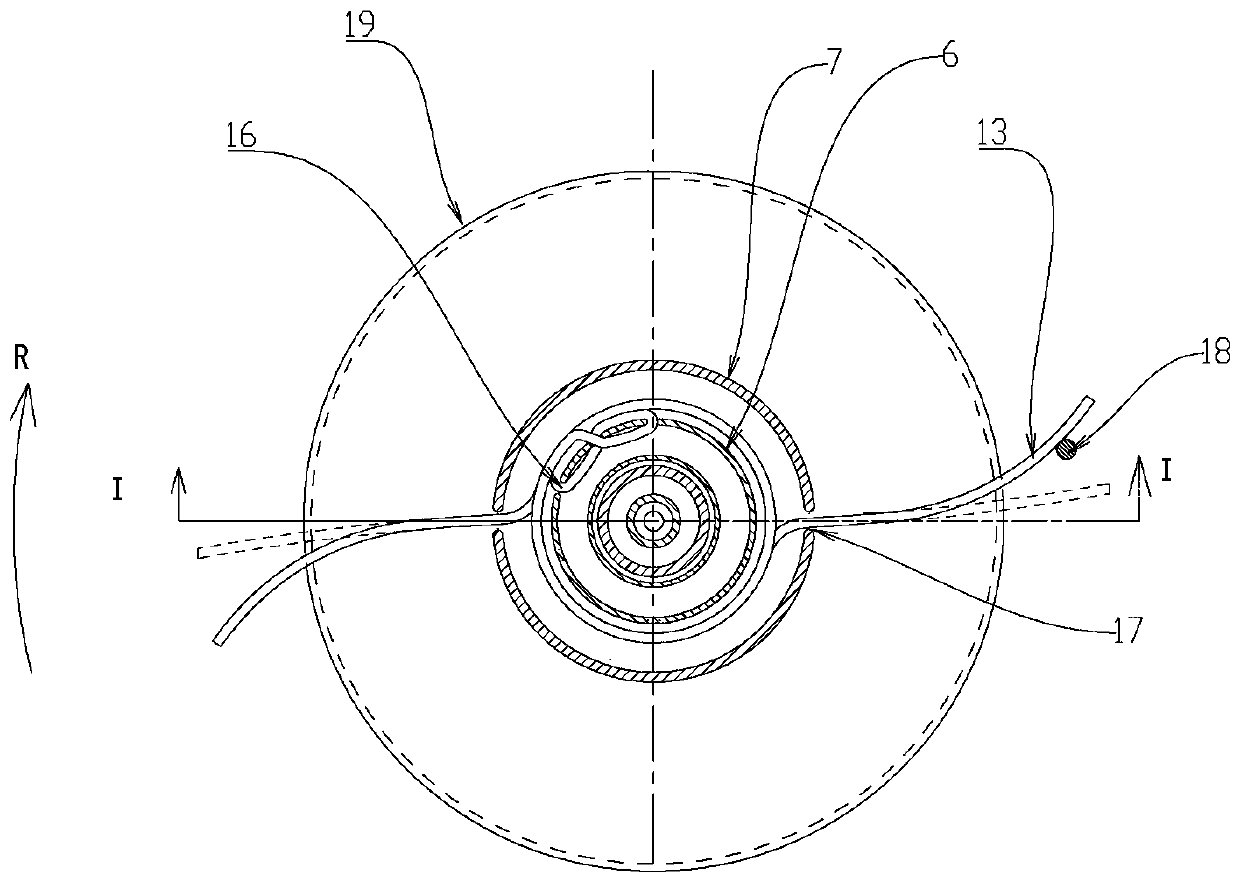

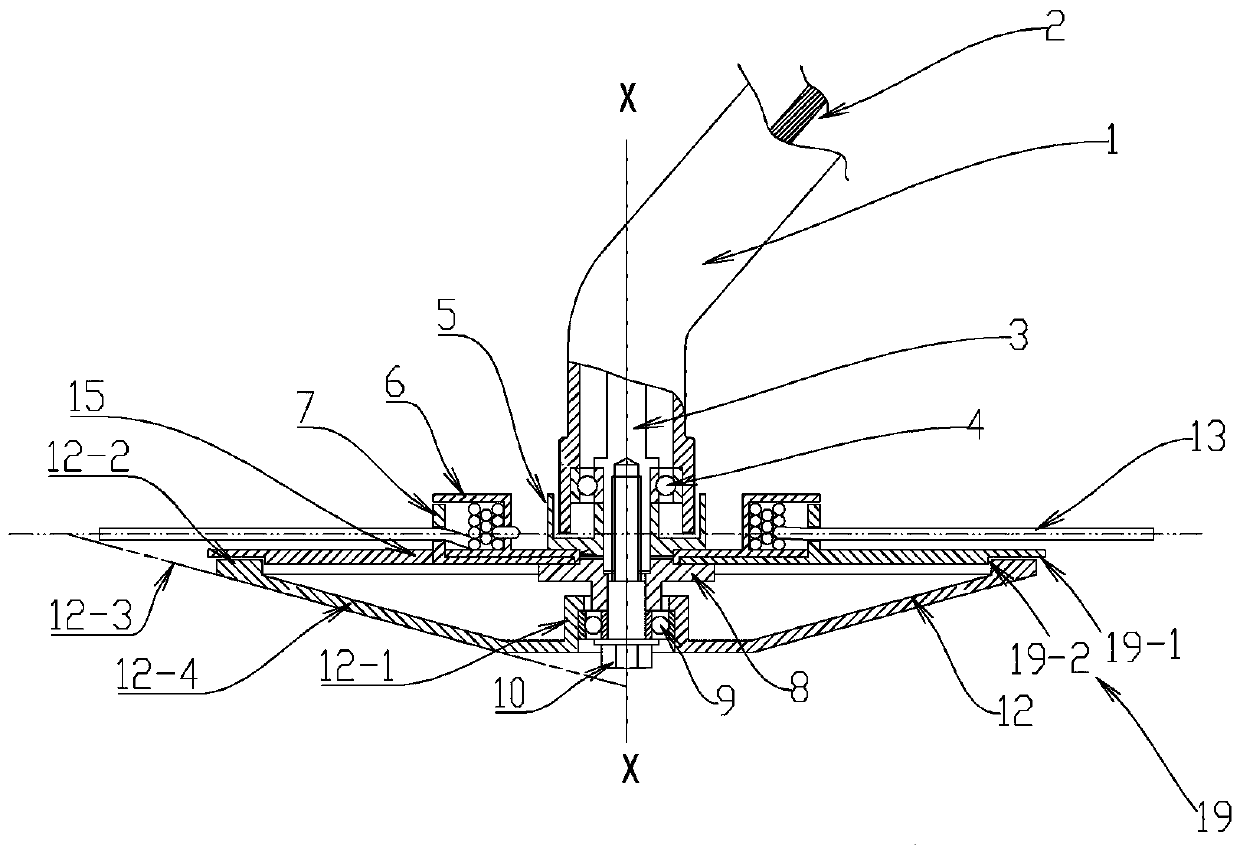

Automatic paving method and device of fiber cloth for wind power blade main beam molding

ActiveCN107472982AEnsure stable qualityReduce physical injuryUnfolding thin materialsArticle deliveryFiberCar driving

The invention provides automatic layer paving equipment of fiber cloth for a wind power blade main beam. The equipment comprises a main car and a cloth clamping positioning device. The main car comprises an upper frame, a lower frame, a cloth rack, a guide rubber roller mechanism, a cloth roll positioning mechanism, a cloth feeding mechanism, an upper frame left-right adjustment mechanism, a main car walking mechanism and a cloth cutting mechanism; the cloth clamping positioning device comprises a walking mechanism and a cloth clamping mechanism; the cloth clamping positioning device clamps cloth at one end; the main car drives a cloth roller to reach consistency with the advancement speed of the main car through a cloth feeding rubber roller I and a cloth feeding rubber roller II to guarantee constant tension of the fiber cloth in the paving process; the cloth paving length precision is guaranteed through transmission modes of servo motor driving and a synchronous belt; and the fiber cloth clamping stability is guaranteed through lead screw driven staggered-tooth clamping jaws in the cloth clamping positioning device. The equipment replaces manual fiber cloth paving work, is high in mechanical cloth paving efficiency, is simple in structure and liable to operate, and greatly reduces the cloth paving cost of wind power blades.

Owner:SHANDONG UNIV OF TECH

Degreasing agent used for workpieces, preparation method and workpiece surface spraying pretreatment method

ActiveCN108384645AGood degreasingImprove washing effectInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlcoholPretreatment method

The invention relates to a degreasing agent used for workpieces, a preparation method and a workpiece surface spraying pretreatment method. The degreasing agent includes 3-5% by mass of a component A,3-5% by mass of a component B and the balance of tap water or deionized water, wherein the component A includes deionized water, an inorganic base, a complexing agent and a compounded low-foam solubilizing surfactant, and a mass ratio of the deionized water to the inorganic base to the complexing agent to the compounded low-foam solubilizing surfactant is (65-70):(15-25):(1-2):(8-14); and the component B includes deionized water, a complexing dispersant, a corrosion inhibitor, a low-foam solubilizer, an end-capped / modified isomeric alcohol ether surfactant and a modified polyether, and a massratio of the deionized water to the complexing dispersant to the corrosion inhibitor to the low-foam solubilizer to the end-capped / modified isomeric alcohol ether surfactant to the modified polyetheris (50-70):(1-2):(0-5):(5-10):(8-15):(8-25). The degreasing agent provided by the invention can be used at room temperature during spraying, has an excellent degreasing effect, and does not generatea large amount of foam; and the method for preparing the degreasing agent and the workpiece surface spraying pretreatment method which uses the degreasing agent have simple operation, and are suitablefor mass production.

Owner:佛山科富科技有限公司

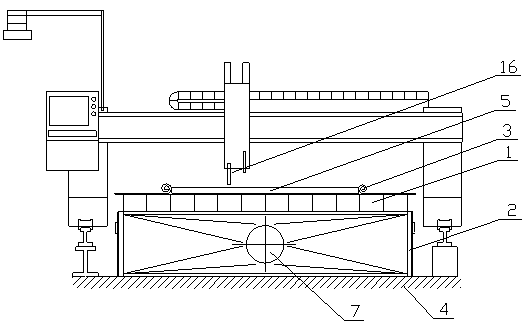

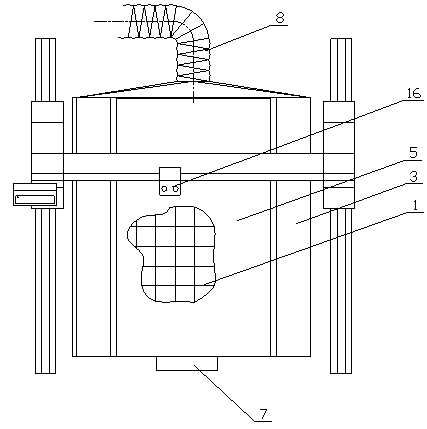

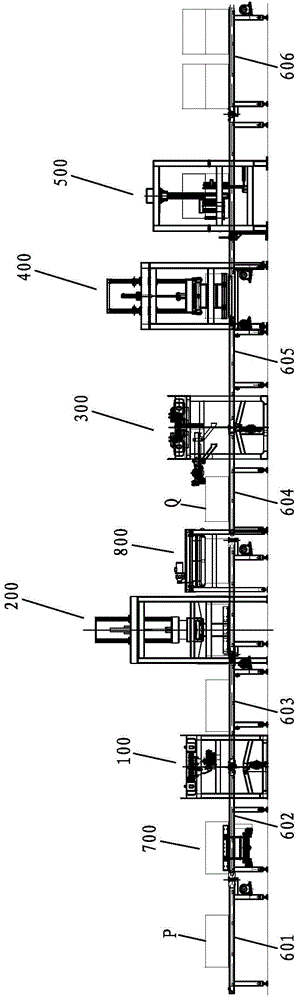

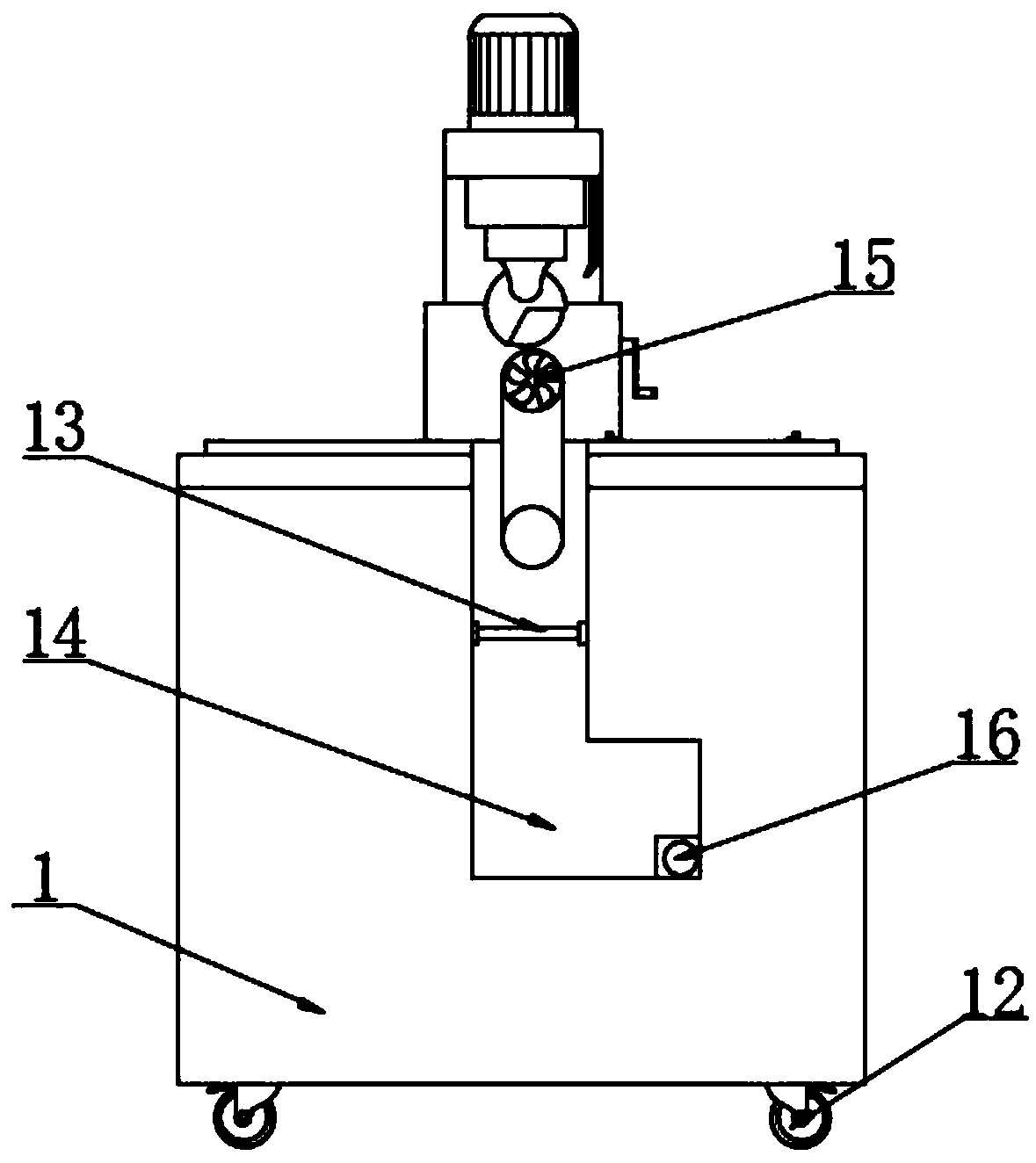

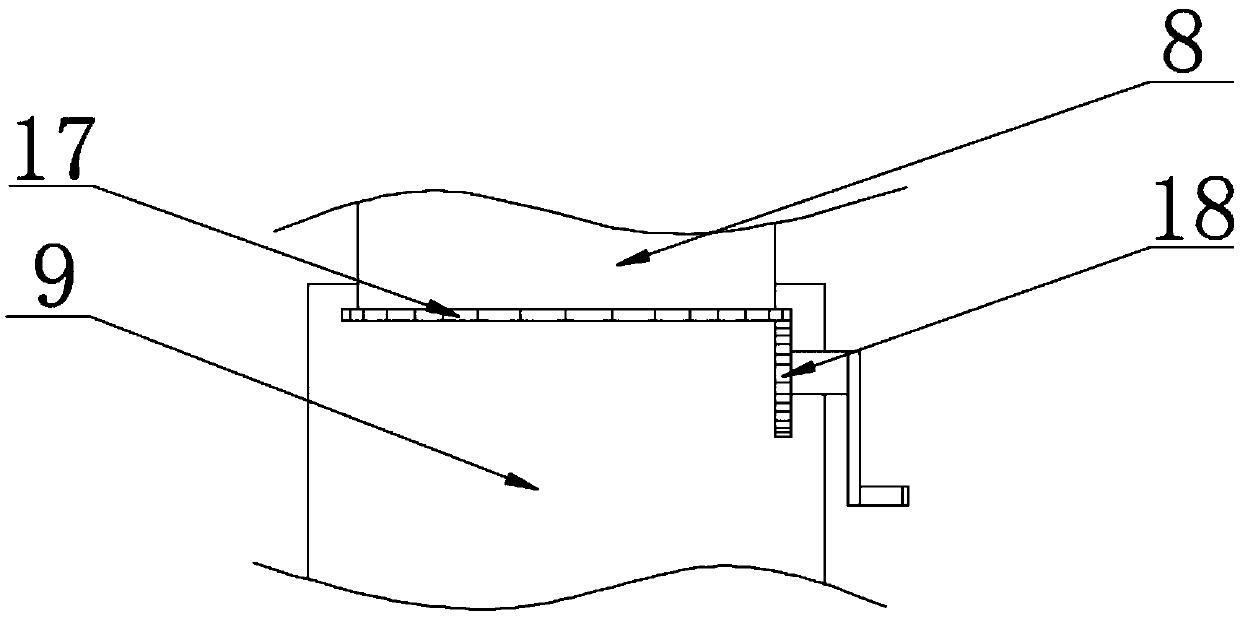

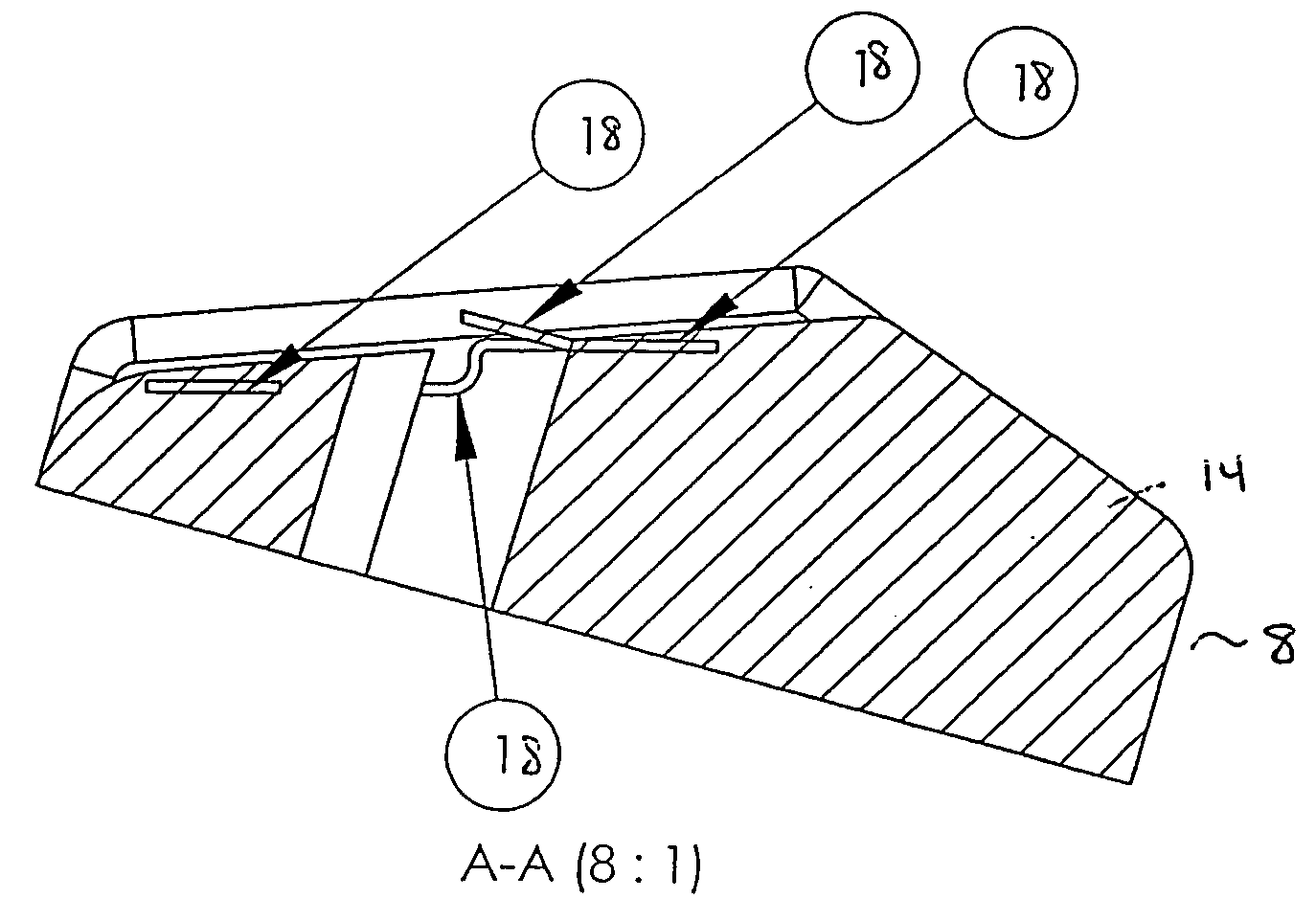

Dust collection purifying device of numerical control cutting machine

ActiveCN103056565AWon't leakReduce physical injuryWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlEngineering

The invention provides a dust collection purifying device of a numerical control cutting machine. The dust collection purifying device of the numerical control cutting machine is simple in structure, reliable, convenient to clean and safe to use and aims to overcome the influences on production workers, production equipment and workshop environments caused by dust generated by cutting. The dust collection purifying device of the numerical control cutting machine comprises a workbench for holding a workpiece, a baffle is arranged on the lower side face of the workbench, a shielding plate capable of extending from the edge to the center of the workbench is mounted at the edge of the top surface of the workbench, the baffle, the shielding plate, the ground, the workbench and the to-be-cut workpiece disposed on the workbench form a chamber, the workbench is provided with a grid hole portion communicated with the chamber, an air inlet is arranged at one end of the chamber, and the other end of the chamber is communicated with a fan through an air duct. Since the baffle and the shielding plate adjustable in shielding area are mounted at the workbench of the numerical control cutting machine, the dust generated by cutting is guaranteed not to escape into workshops and can be discharged only by the fan, and further the influences on the production workers, the production equipment and the workshop environments caused by the dust are reduced, and the dust collection purifying device is highly practical.

Owner:ANHUI ANFENG FAN

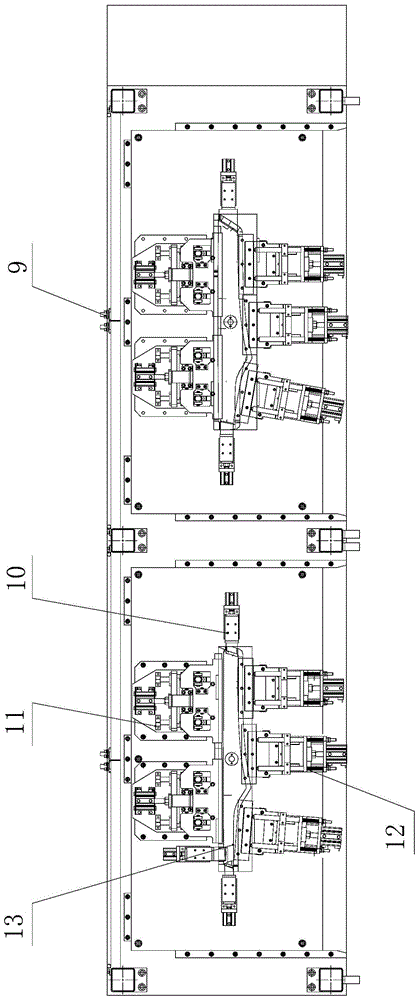

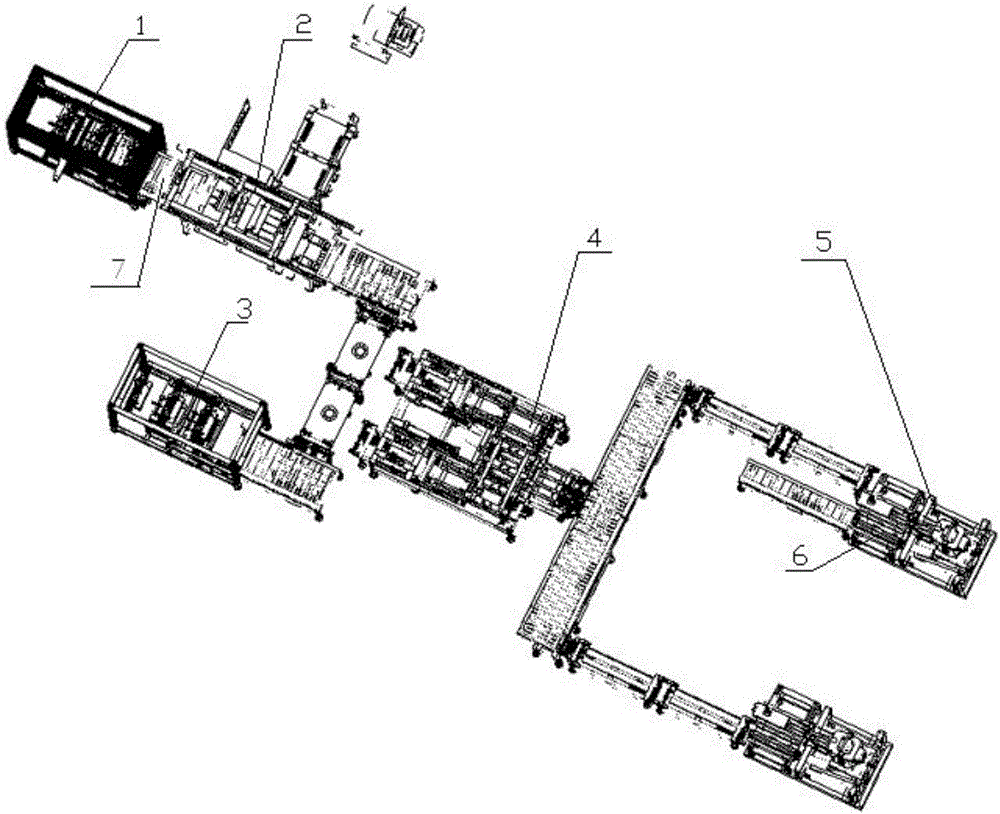

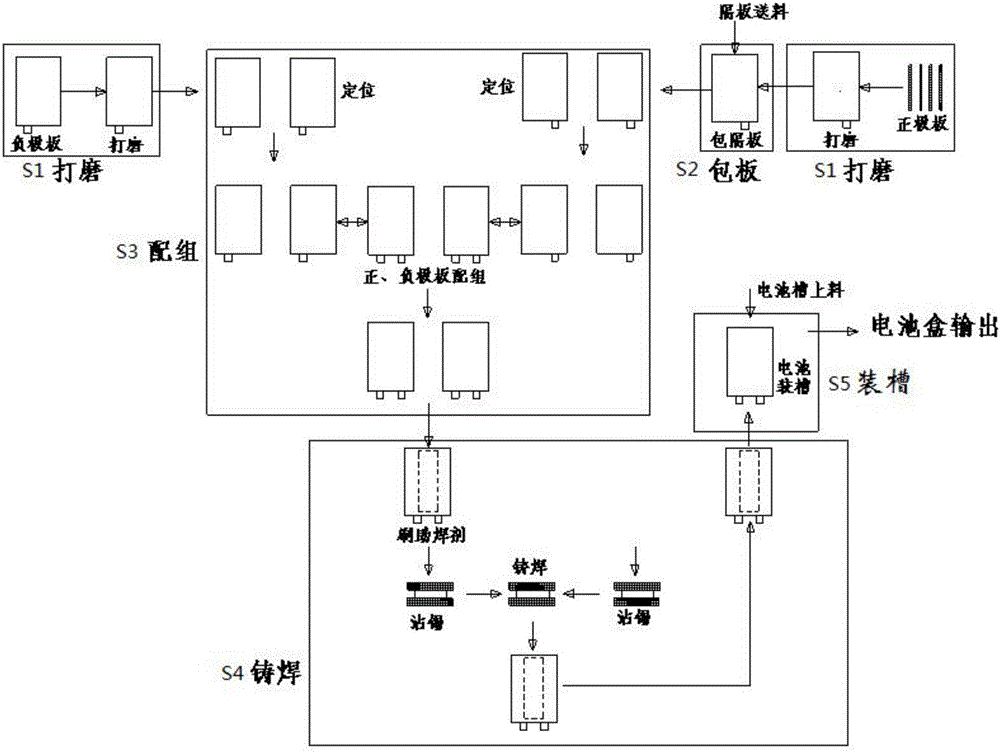

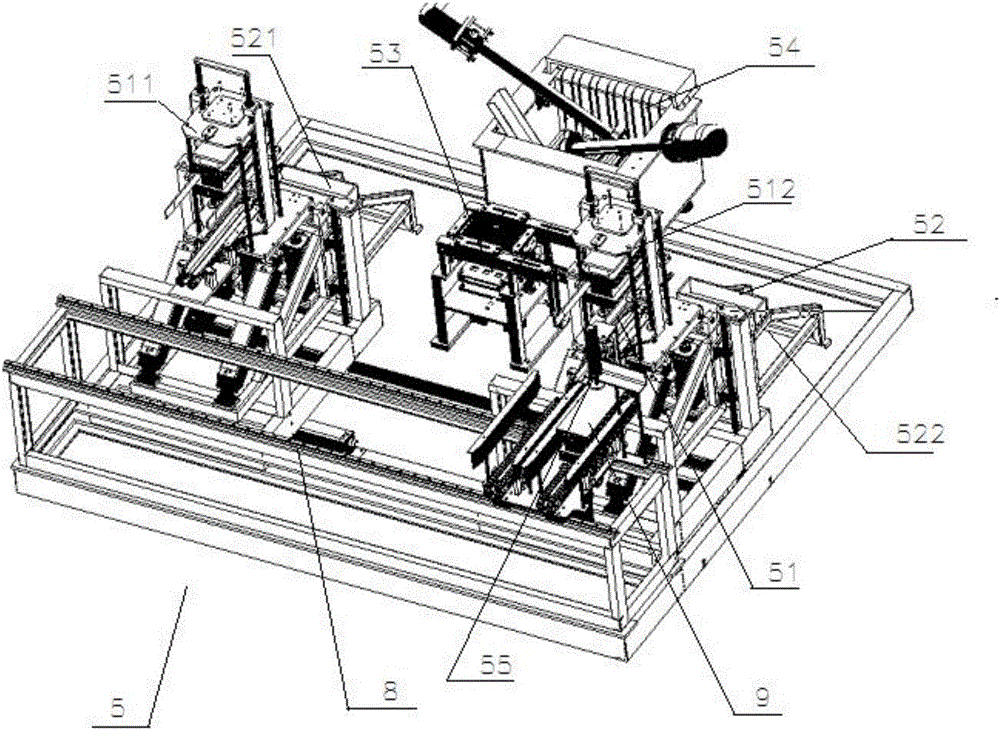

Automatic production equipment and technology of power storage battery

ActiveCN105977551AImprove casting and welding efficiencyImprove consistencyFinal product manufactureLead-acid accumulators constructionCasting moldEngineering

The invention provides an automatic production equipment and technology of a power storage battery. The cast welding efficiency is greatly improved and the product uniformity is improved through arranged conveyor chain and material carrier loader. Double cast welding platforms and double soldering baths are arranged and a same casting mold mechanism is shared; and the second cast welding platform carries out cast welding operation while the first cast welding platform carries out soldering operation, so that the cast welding efficiency is improved by two sets of cast welding platforms through alternating operation; cast welding defects of false welding, cold soldering and the like caused by lead layer oxidation are prevented through pre-treatment technologies of plate lug polishing, soldering flux brushing, soldering and the like; the cast welding quality is improved; and artificial field operation is not needed. A full-closed space is formed and is connected with a negative pressure ventilation system, so that the harm of lead fume to the body of an operator or the environmental pollution can be greatly reduced.

Owner:武汉海王新能源工程技术有限公司

Board brushing system capable of automatically removing dust

ActiveCN104588245AHigh precisionUniform thicknessLiquid surface applicatorsSpraying apparatusEngineeringMaterial storage

The invention discloses a board brushing system capable of automatically removing dust. The board brushing system comprises a brushing system, wherein the brushing system comprises a brushing roll wheel; the side edge of the brushing roll wheel is provided with a scraper device; the scraper device comprises a scraper blade and a scraper plate; the scraper plate is used for fixing the scraper blade; a material storage box is arranged below the scraper device; a dust removal device is arranged above the brushing system and comprises a conical cover body; the conical cover body internally comprises two air outlet pipes. The problems that a traditional brushing machine needs to be cleaned at regular intervals within a short period of time, and cannot remove dust are solved; the brushing accuracy on the board can be improved.

Owner:ZHEJIANG CHANGXING SENDA BAMBOO & WOOD PRODCO

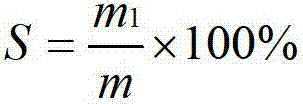

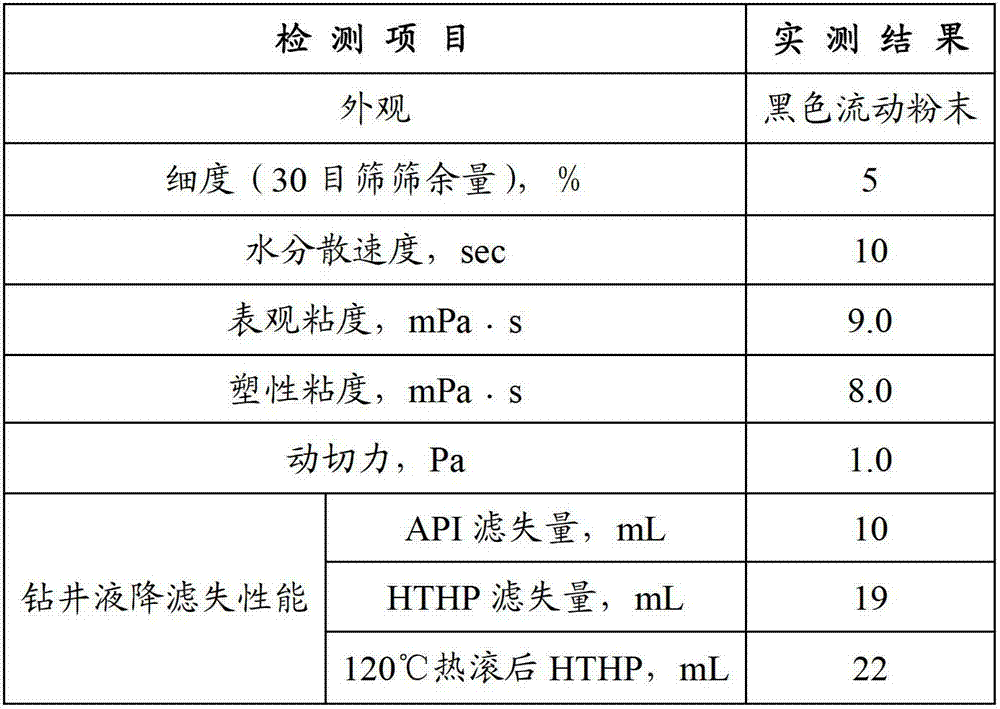

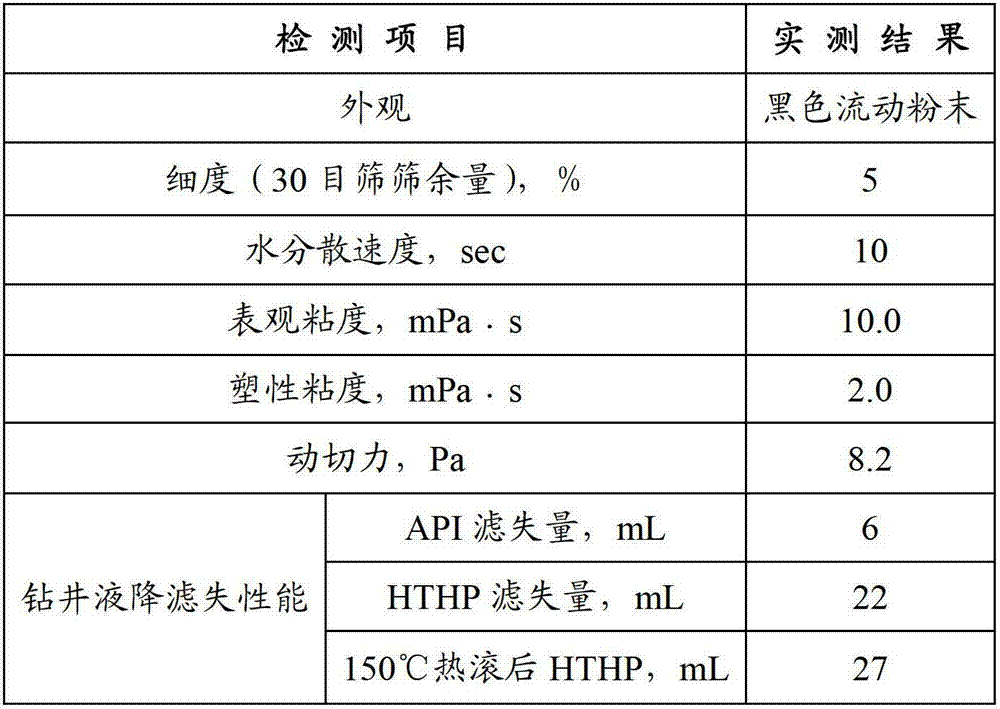

Plugging-type filtrate reducer for water-based drilling fluid and preparation method thereof

InactiveCN103045188AImprove fermentation performanceNothing producedDrilling compositionWater basedPolymer modified

The invention relates to a plugging-type filtrate reducer for water-based drilling fluid and a preparation method thereof. The filtrate reducer can be selected in accordance with different well section temperatures and strata characteristics, and comprises polymer modified oxidized asphalt (PMA), a modifying agent and an auxiliary filtrate reducer; and the filtrate reducer series samples can be prepared by a simple surface modification and dry-blending process. The sample disclosed by the invention is excellent in performance of reducing filtrate of the drilling liquid with the reducing rate of 80%, a dense and tough mud cake is formed, and the crack and fracture of the strata can be plugged in real time based on high-temperature softening and deforming characteristic of the asphalt; an appropriate product formula can be selected depending on the applied strata characteristics and well section temperatures; and the plugging-type filtrate reducer for the water-based drilling fluid is flexile to use, simple in production process, moderate in condition, high in production efficiency, low in cost, free from waste and dust, and low in harm on the body of an operator.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

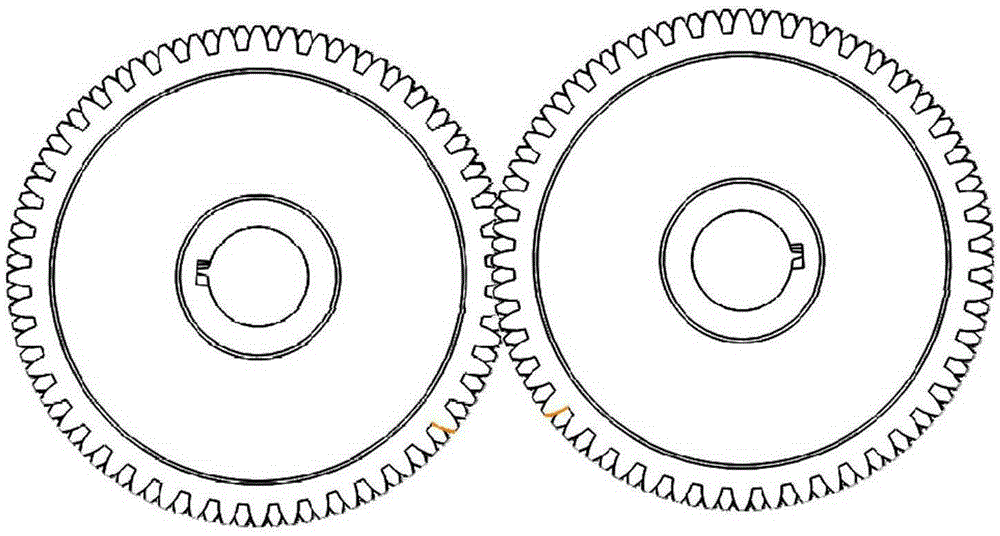

Preparation device and method for three-dimensional hollow composite material

ActiveCN105291448ASimple preparation processReduce labor intensityUltimate tensile strengthThermoplastic composites

The invention provides a preparation device and method for a three-dimensional hollow composite material. The preparation device is characterized by comprising a creel, a pre-dispersion device, a fusing and dipping device, a hot-pressing sizing device, hot-pressing rollers and a drying oven; dipping rollers are arranged in the fusing and dipping device, and an extruder is arranged on the fusing and dipping device; the hot-pressing sizing device comprises an upper gear set and a lower gear set, each gear set comprises a plurality of gears arranged in a staggered mode, and the corresponding gears in the upper gear set and the lower gear set are meshed. The three-dimensional hollow thermoplastic composite is prepared through the fusing and dipping hot-pressing process; compared with existing main three-dimensional hollow thermoset composites, the three-dimensional hollow composite material is simple in preparation process, low in labor intensity, high in automation degree, friendly to the environment, little in damage to worker bodies, high in production efficiency and capable of being industrially produced.

Owner:安徽安赛新材料有限公司

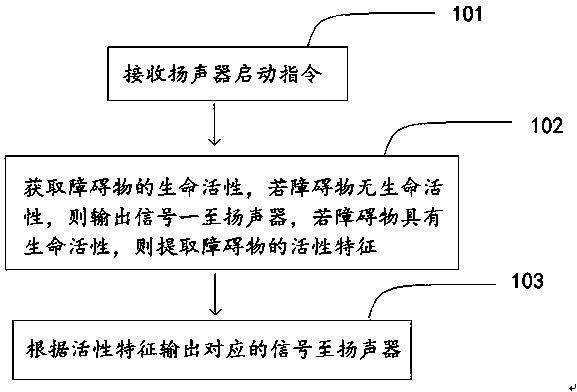

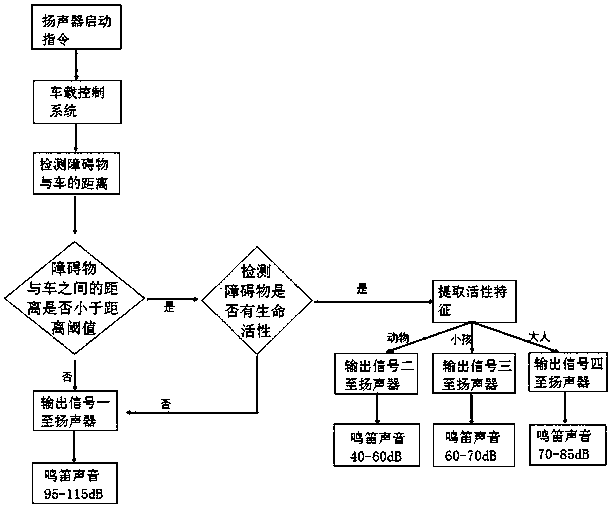

Vehicle intelligent whistling method

InactiveCN110329144AAvoid sudden shockReduce physical injuryAcoustic signal devicesScene recognitionEnvironmental noiseLife activity

The invention relates to a vehicle intelligent whistling method. The method comprises the following steps that a loudspeaker starting instruction is received; the life activity of an obstacle is acquired, if the obstacle has no life activity, a first signal is output to a loudspeaker, and if the obstacle has the life activity, the activity characteristic of the obstacle is extracted; and a corresponding signal is output to the loudspeaker according to the activity characteristic. Compared with the prior art, the intelligent whistling method can correspondingly adjust the volume of the loudspeaker in the whistling process according to the distance between the obstacle and a vehicle, whether the obstacle has the life activity or not and the activity characteristic of the obstacle, so that the problem of environmental noise pollution caused by the fact that unnecessary high-decibel whistling sounds are generated is solved, meanwhile, sudden scares caused by the whistling sounds to children and animals can be avoided, and the occurrence probability of accidents is reduced.

Owner:惠州德赛信息科技有限公司

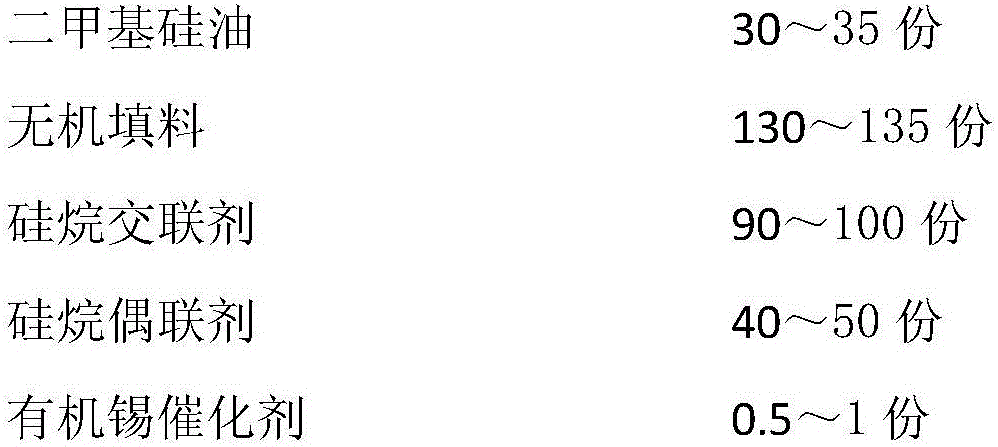

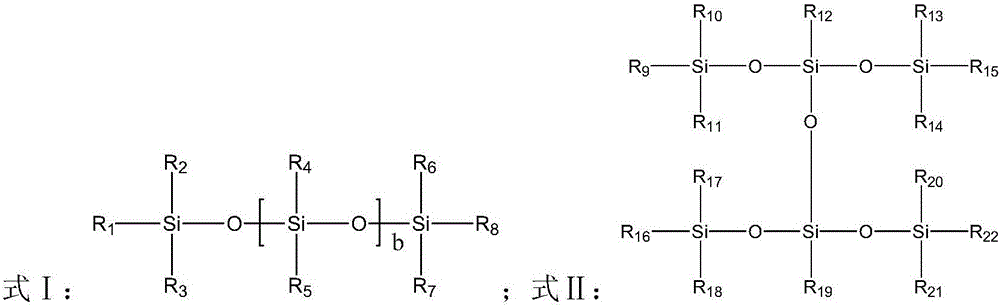

High-elasticity-recovery-rate silicone elastic sealant for hollow glass and preparation method of silicone elastic sealant

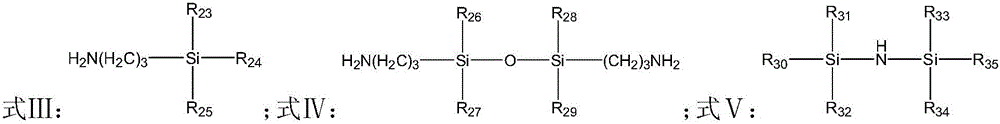

ActiveCN105950102AImprove strength and elasticityGood bonding performanceNon-macromolecular adhesive additivesOther chemical processesDibutyl tin dilaurateSilane coupling

The invention discloses a high-elasticity-recovery-rate silicone elastic sealant for hollow glass and a preparation method of the silicone elastic sealant. The silicone elastic sealant is mainly used for secondary sealing of the hollow glass. The silicone elastic sealant is characterized by containing a component A and a component B, wherein the mass ratio of A to B is (15-18):1. The preparation process comprises the following steps that alpha,omega-dyhydroxyl polydimethylsiloxane, inorganic filler and dimethicone are stirred to be uniform in a high-speed planetary stirring mechanism, and the component A is obtained; the component B is prepared from dimethicone, inorganic filler, an organosilicone cross-linking agent, a silane coupling agent, dibutyltin dilaurate and a titanium complex. In the using process, the component A and the component B are mixed to be uniform at room temperature according to the mass ratio. The silicone elastic sealant has good strength, elasticity and adhesion and excellent aging resistance, the elasticity recovery rate of the silicone elastic sealant is as high as 96%, and the service life of the hollow glass sealant can be greatly prolonged.

Owner:GUANGZHOU JOINTAS CHEM

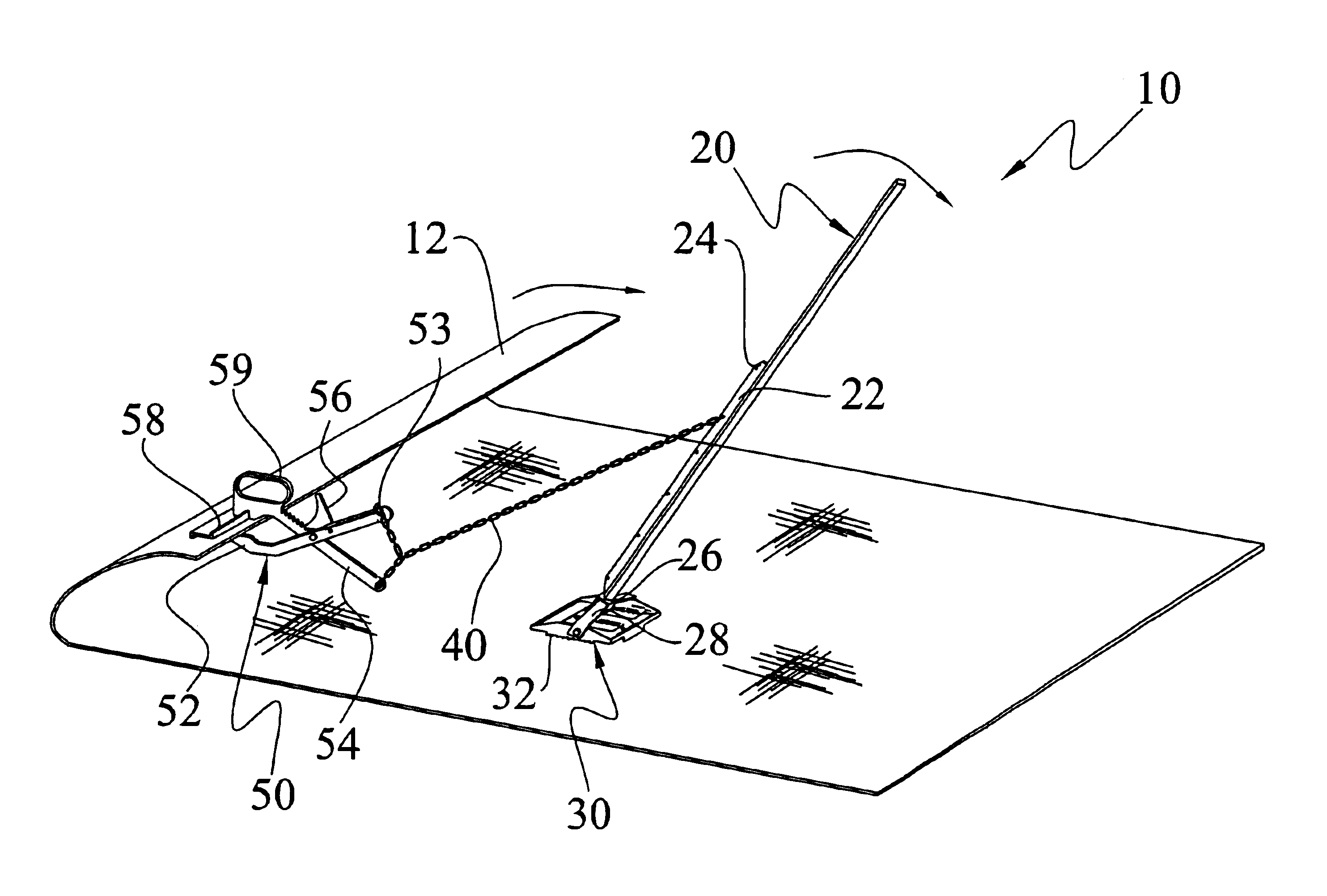

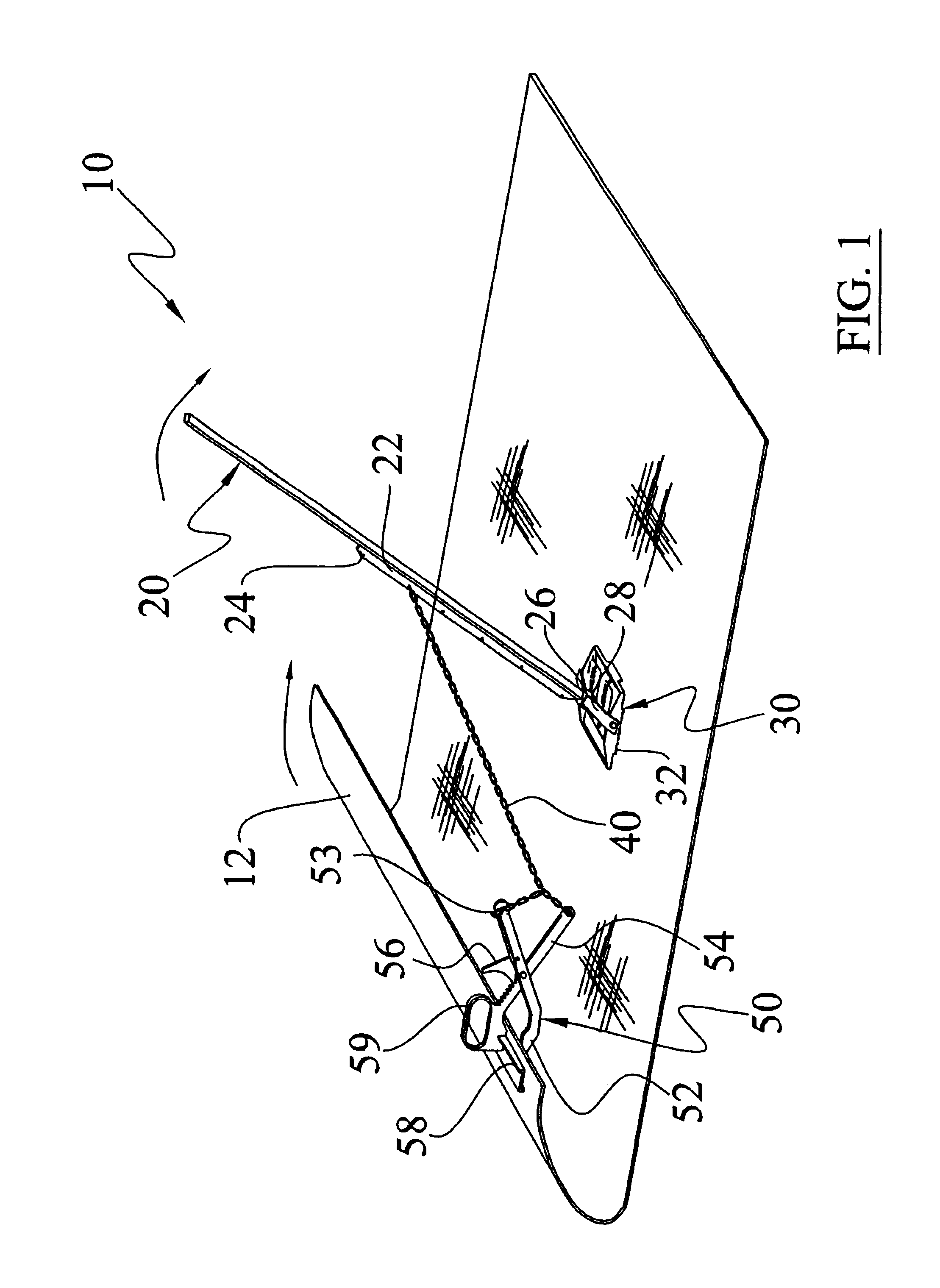

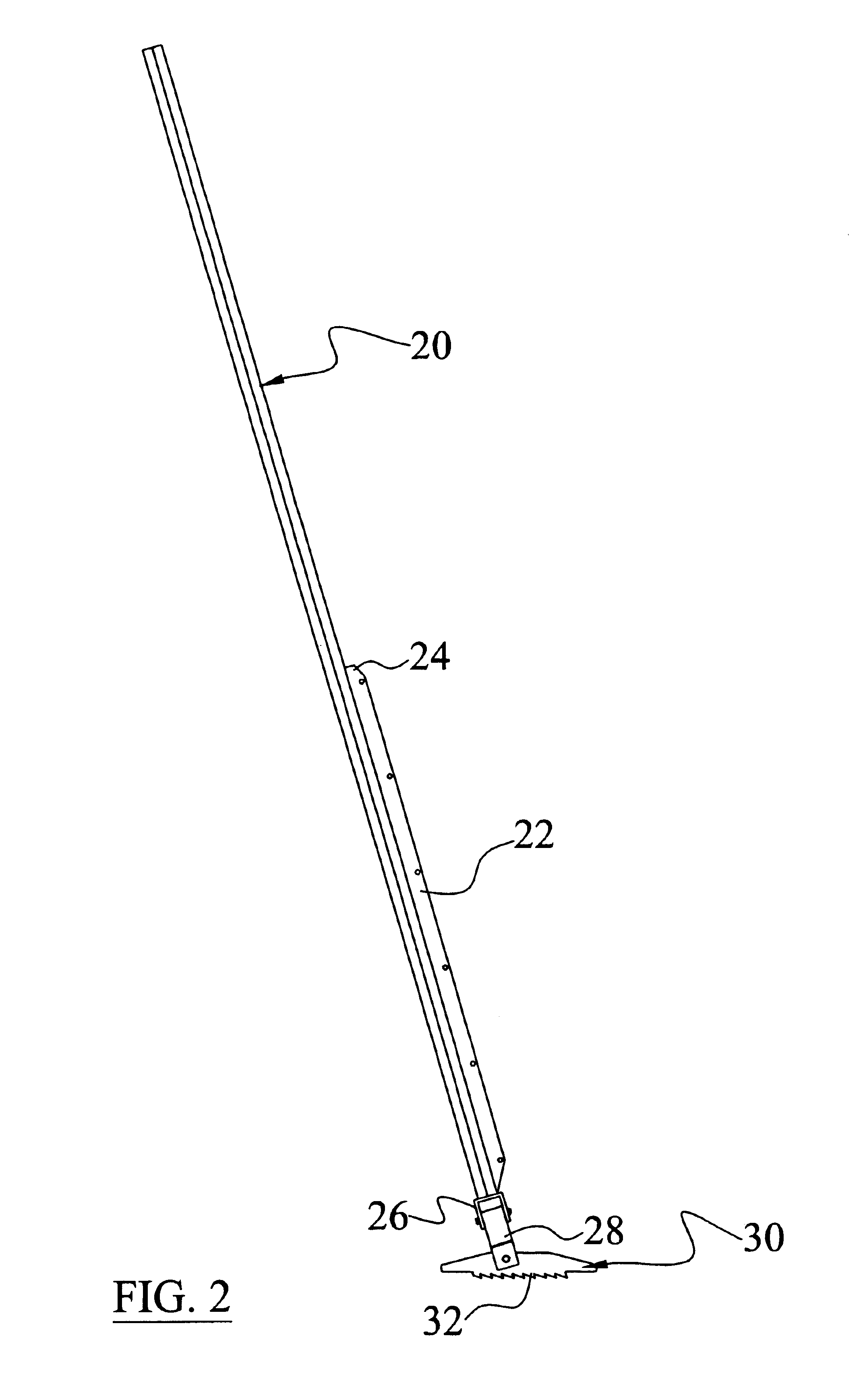

Carpet removal system

InactiveUS6840299B2Efficient removalReduce physical injuryLayered productsBuilding repairsEngineeringFootplate

A carpet removal system for efficiently removing carpet from a floor. The carpet removal system includes a leverage member, an engaging member for engaging the carpet to be removed, and a connecting member connected between the leverage member and the engaging member. The leverage member is an elongate structure which allows for the connecting member to be attached at various locations for providing various leverage forces. The leverage member includes a footplate having a plurality of engaging teeth for engaging the flooring.

Owner:ALLEN JOHN D +1

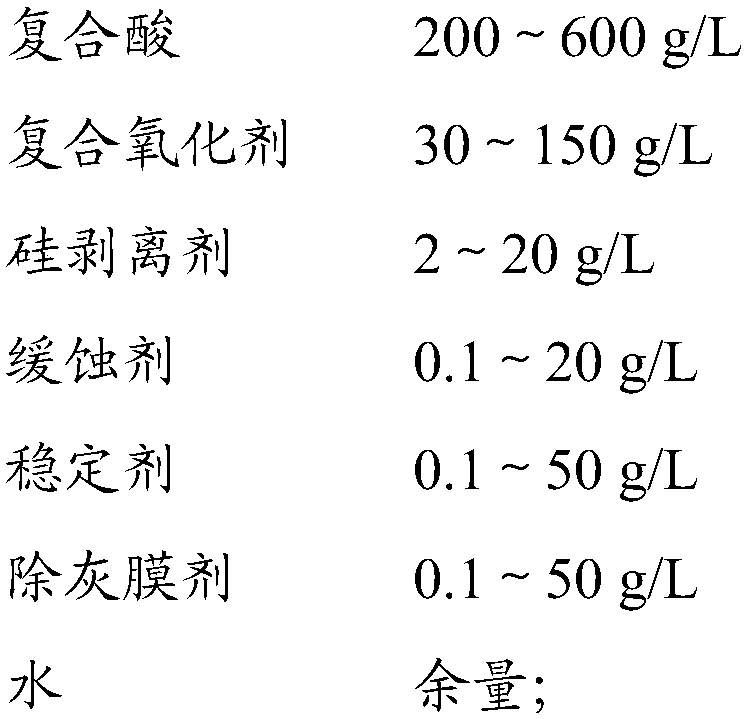

Aluminum and aluminum alloy film removing agent and application thereof

The invention relates to an aluminum and aluminum alloy film removing agent. The aluminum and aluminum alloy film removing agent comprises the following components: 200-600g / L of composite acid, 30-150g / L of a composite oxidant, 2-20g / L of a silicon remover, 0.1-20g / L of corrosion inhibitor, 0.1-50g / L of a stabilizer, 0.1-50g / L of an ash removal film agent and water, wherein the composite acid isselected from at least two of sulfuric acid, aminosulfonic acid, fluoboric acid and chloric acid; and the composite oxidant is selected from at least two of hydrogen peroxide, persulfate, perborate and percarbonate. On the premise of guaranteeing the film removal effect of the aluminum and the aluminum alloy, the aluminum and aluminum alloy film removing agent reduces treatment difficulty of industrial waste gas and industrial wastewater after aluminum and aluminum alloy electroplating.

Owner:GUANGZHOU SANFU NEW MATERIALS TECH

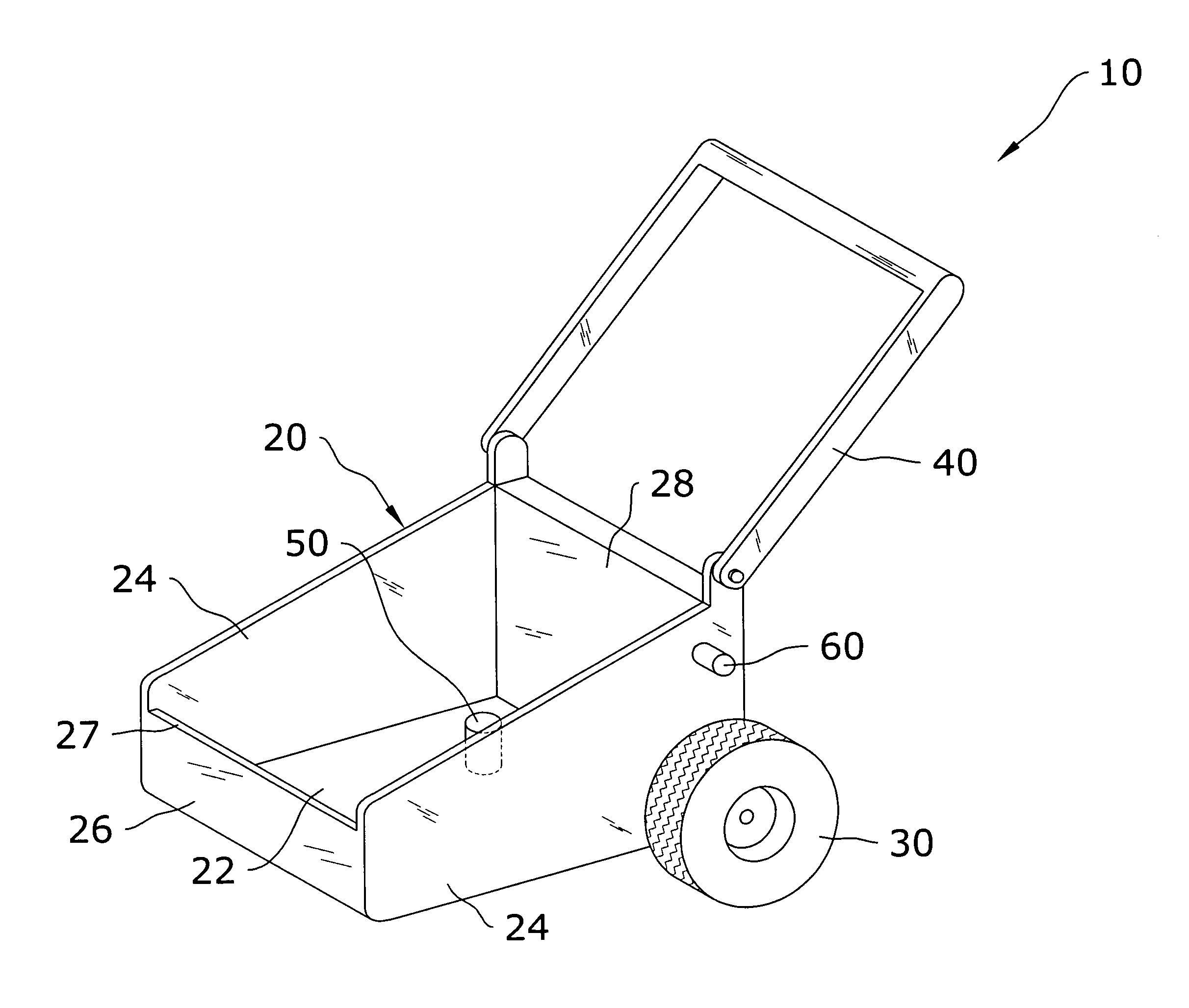

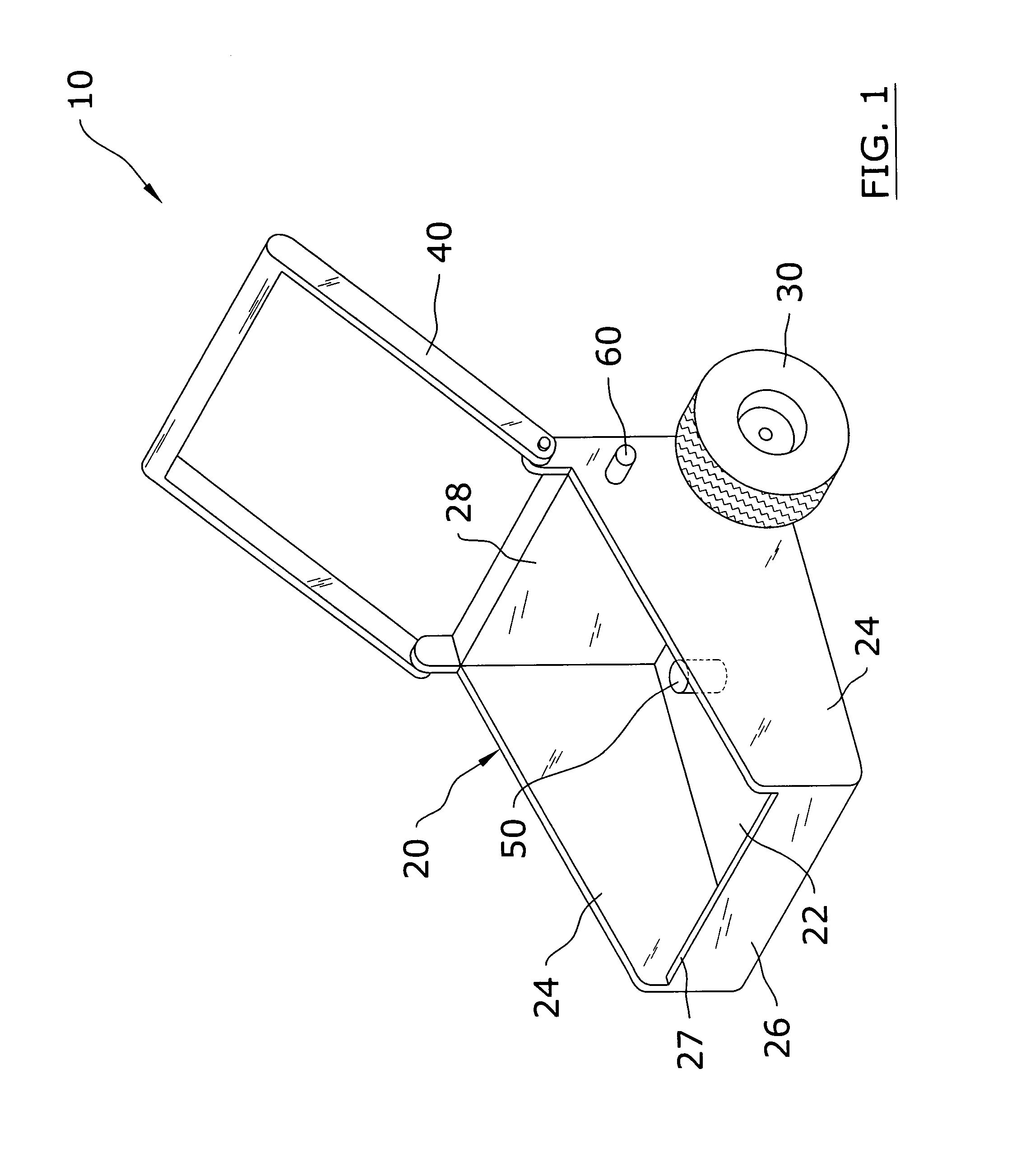

Toilet moving cart system

InactiveUS7231674B1Prevent water leakageEfficiently moving a toiletCarriage/perambulator with single axisBathroom accessoriesWater leakageEngineering

A toilet moving cart system for efficiently moving a toilet. The toilet moving cart system includes a base for receiving a conventional toilet, a stub member within the base, a plurality of wheels attached to the base, and a handle attached to the base. The stub member extends upwardly into the lower opening within the toilet when the toilet is positioned upon the base. A cap is removably attached to the base for sealing the fill valve within the toilet during transportation to prevent water leakage.

Owner:CERNIK DAVID A

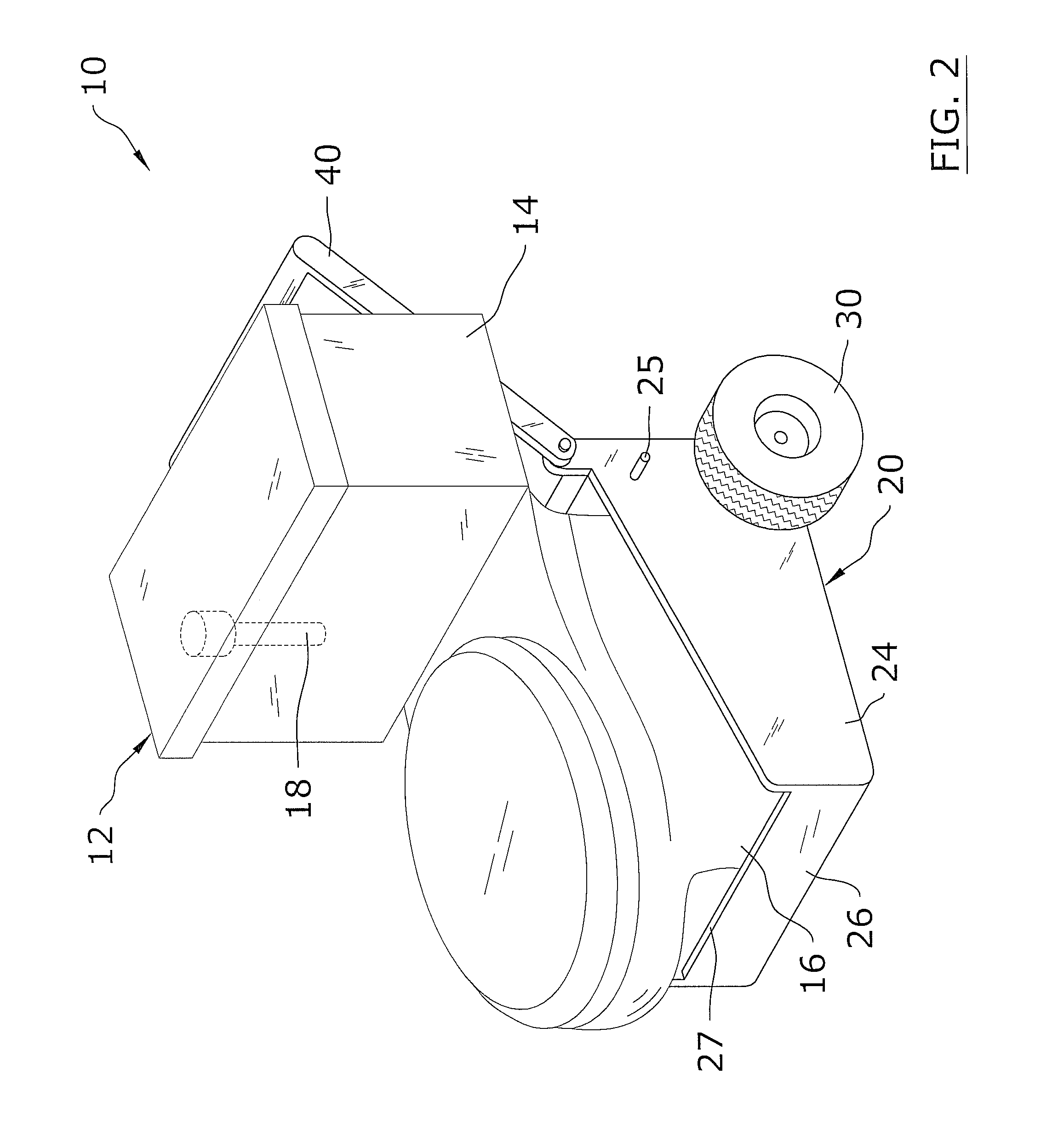

Automatic cutting production line for ceramsite blocks

InactiveCN104626370AIntegrity guaranteedAvoid breakingWorking accessoriesStone-like material working toolsLow noiseProduction line

The invention discloses an automatic cutting production line for ceramsite blocks. The automatic cutting production line mainly comprises a chain plate conveying line, a first cutting machine, a rotating stacking machine, a second cutting machine, a single-clamp stacking machine and a winding packing machine, wherein the first cutting machine, the rotating stacking machine, the second cutting machine, the single-clamp stacking machine and the winding packing machine are sequentially arranged along the chain plate conveying line. The first cutting machine and the second cutting machine comprise racks, upper saw belt wheel sets, lower saw belt wheel sets and a plurality of saw belts, wherein the upper saw belt wheel sets are horizontally and linearly arranged at the upper ends of the racks, the lower saw belt wheel sets are horizontally and linearly arranged at the lower ends of the racks, and the saw belts are arranged between corresponding upper saw belt wheels and lower saw belt wheels of the upper saw belt wheel sets and the lower saw belt wheel sets in a one-to-one closed surrounding mode. The upper saw belt wheel sets or the lower saw belt wheel sets are in transmission connection with first driving mechanisms driving the upper saw belt wheel sets or the lower saw belt wheel sets to rotate. By means of a unique cutting device, the cutting technology is greatly simplified, the advantages of the low noise and the good cutting performance are achieved, the labor intensity of workers is lowered, the working environment is optimized, and the production efficiency of the cutting line is greatly improved.

Owner:FUJIAN EXCELLENCE HONCHA BUILDING MATERIAL EQUIP

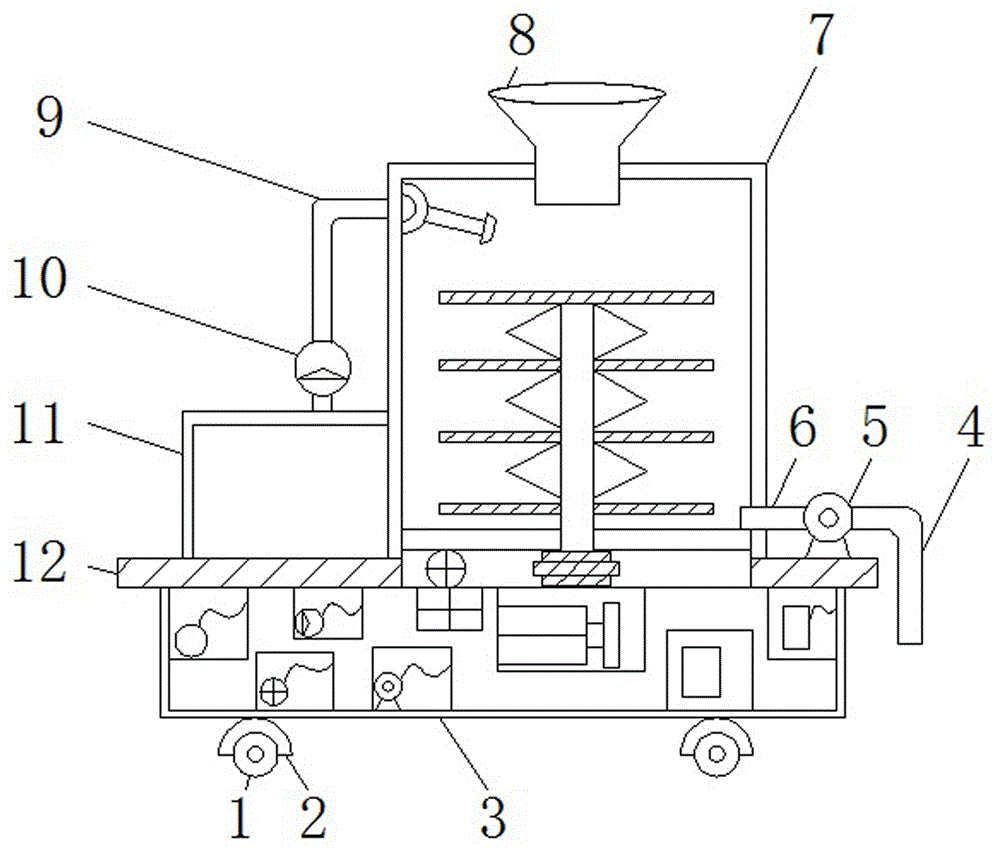

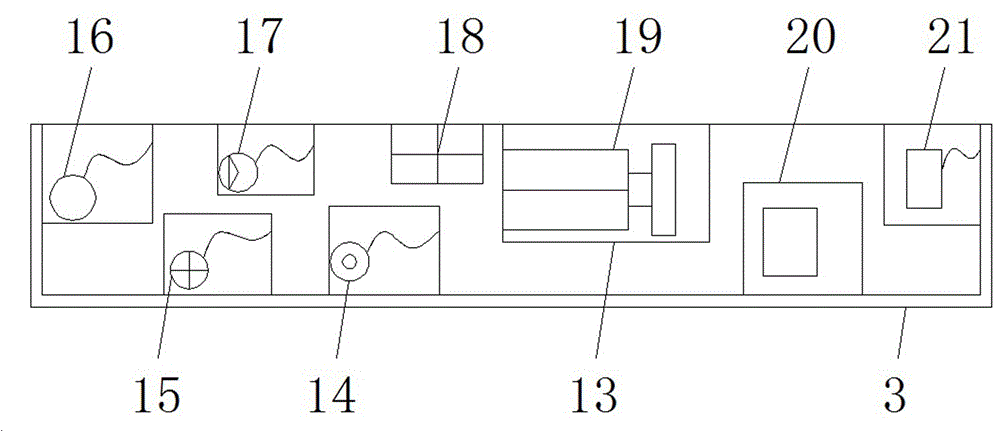

Kitchen food garbage processing crusher

InactiveCN106733019AReduce physical injuryImprove the living environmentDomestic plumbingGrain treatmentsCouplingLitter

The invention discloses a kitchen food garbage processing crusher comprising a device case, a crushing mechanism and a main support. A PLC electronic control unit is installed on the upper left portion inside the device case. A water delivery pump controller is installed on the right side of the PLC electronic control unit. A sensor control device is installed below the water delivery pump controller. A material suction machine controller is installed on the right side of the sensor control device. A silencer is installed on the upper right portion of the material suction machine controller. A feed hopper opening is formed in the upper portion of the crushing mechanism. A crushing platform is installed below the inner surface of the crushing mechanism. A pressure sensor is installed on the lower left portion of the crushing platform. A coupler is installed on the right side of the pressure sensor. A water storage tank is installed on the upper left portion of the main support. A water delivery pump is installed above the water storage tank. The water storage tank is connected with a water delivery pipe through the water delivery pump. By means of the kitchen food garbage processing crusher, convenience is provided for kitchen garbage processing.

Owner:SHENZHEN SHANGYU TECH CO LTD

Environmental protection plate rapid cutting equipment

ActiveCN108673594AScientific and reasonable structureEasy to useMetal working apparatusSuspended particlesEngineering

The invention discloses environmental protection plate rapid cutting equipment. The environmental protection plate rapid cutting equipment comprises a box body, a fixing base, a rotating seat, a crank, a fan and telescopic clamping plates. The fixing base is installed at the top of the box body, and the rotating seat is arranged at the top of the fixing base. The fan is installed on one side of the fixing base in an embedded mode, and the crank is arranged on the other side of the fixing base. The telescopic clamping plates are arranged above the box body. The environmental protection plate rapid cutting equipment is scientific and reasonable in structure and safe and convenient to use, the length of the telescopic clamping plates can be adjusted according to the width of a plate, and rapid clamping of the plate is facilitated. Water is sprayed through a spray pipe to cool a cutter to avoid damage to the cutter caused by excessive temperature, and at the same time, debris and floatingdust can be wetted; and combined with the operation of the fan, the remaining debris and floating dust can be collected to avoid the occurrence of suspended particles during cutting; and the crank isshook to drive second transmission teeth to rotate, the rotating seat can be rotated, so the cutter is turned out of a working table, and replacement and installation of the cutter are facilitated.

Owner:台州市高典机电有限公司

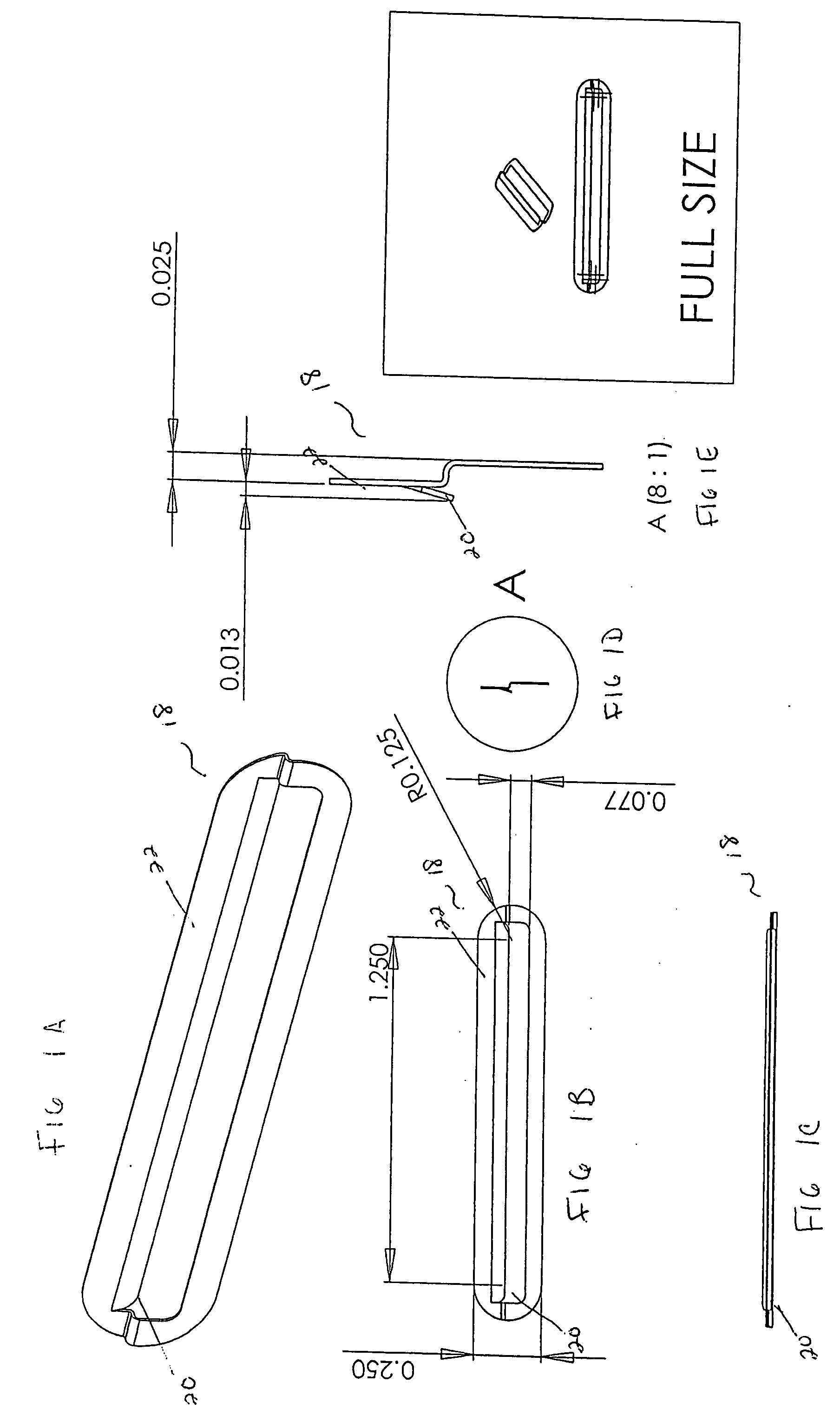

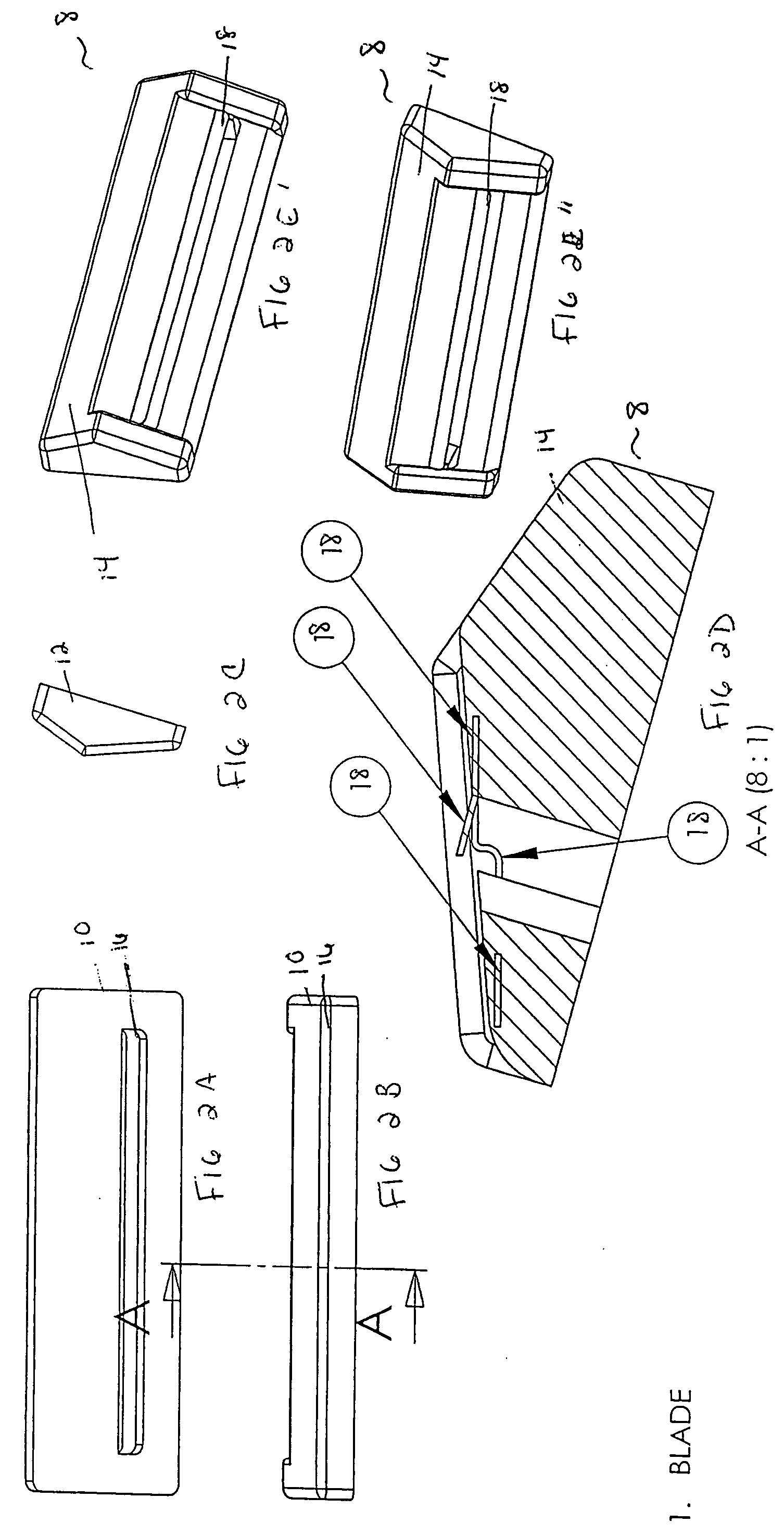

Method and apparatus for making a razor safe

The present invention provides persons in charge of the care of other individuals with a tool for shaving that is designed to be safer to individuals in institutionalized environments, due to a shallow razor blade with rounded corners that is encased in a durable material.

Owner:HANNAN MICHELLE A

Water soluble polyester slurry for sizing DTY polyester low elastic filaments and preparation method thereof

The invention discloses a water soluble polyester slurry for sizing DTY polyester low elastic filaments and a preparation method thereof, and belongs to the technical field of water soluble polyester slurry. The invention aims to solve the problems that the solid contents of acrylic acid slurry can only reach 30% or so, and the bonding force between the acrylic acid slurry and hydrophobic polyester fibers is weak. The water soluble polyester slurry is characterized by being composed of recycled polyester, glycol accounting for 5 to 10 wt% of polyester, m-phthalic acid-5-sulfonate or derivatives thereof accounting for 10 to 20 wt% of polyester, m-phthalic acid accounting for 3 to 15 wt% of polyester, other dibasic alcohols accounting for 5 to 10 wt% of polyester, a catalyst accounting for 0.03 to 0.15 wt% of polyester, and polyoxyethylene and / or polytetrahydrofuran accounting for 0 to 5 wt% of polyester. The slurry is prepared through steps of alcoholysis, copolymerization, cooling, and grinding. The slurry has a high glass-transition temperature, excellent chemical stability, anti-hydrolysis performance, and thermal stability, thus is convenient for transportation and storage, also has strong flexibility and a large breaking elongation rate, and is mainly used to size polyester low elastic filaments (DTY).

Owner:湖北山特莱新材料有限公司

Water-soluble polyester slurry for FDY filament sizing water-jet weaving and preparation method thereof

The invention discloses a water-soluble polyester slurry for FDY filament sizing water-jet weaving and a preparation method thereof, belongs to the technical field of water-soluble polyester slurry, and is used for mainly solving the problems that a conventional acrylic acid slurry has the product solid content of only about 30% and is high in transport costs, severe in environmental pollution, serious in moisture absorption and rebonding, low in adhesive power with hydrophobic polyester fibers and the like. The water-soluble polyester slurry is mainly characterized in that the water-soluble polyester slurry is prepared by alcoholysis, copolymerization, cooling and crushing of recycled polyester, ethylene glycol, m-phthalic acid-5-sulfonate or derivatives thereof, m-phthalic acid, other dihydric alcohols, a catalyst, an inorganic auxiliary agent and polyether with the weight-average molecular weight of 600-10000. The water-soluble polyester slurry has the characteristics of improving the product glass transition temperature, being excellent in chemical stability, hydrolysis resistance and thermal stability, being convenient to store and transport and having no addition and release of ammonia gas in the process of using, and is mainly used for preparation of the water-soluble polyester slurry for FDY filament sizing water-jet weaving.

Owner:湖北山特莱新材料有限公司

Rotary cutter for lawn mower and portable lawn mower using same

The invention discloses a rotary cutter for a lawn mower and a portable lawn mower using the same, which belong to the field of garden tools and are used for cleaning weeds during the greening processof gardens. The rotary cutter at least comprises a cutting tool installing shaft which is provided with a cutting tool rotating about the central axis of the installing shaft; a guiding member material which rotates with respective to the cutting tool installing shaft through a central part A is installed under the cutting tool; the central part A is connected with an edge A of the guiding membermaterial through a rotating surface A; the rotating surface A is formed by a ridge A rotating about the central axis of the cutting tool installing shaft and the ridge A is positioned outside a member rotating about the cutting tool installing shaft outside the cutting tool. In view of the above technical solution, the present invention can provide a rotary cutter for a lawn mower that is safe, efficient, and easy to adjust and maintain, and a portable mower using the same.

Owner:YITIANJI POWER MACHINERY RES DEV LINYI

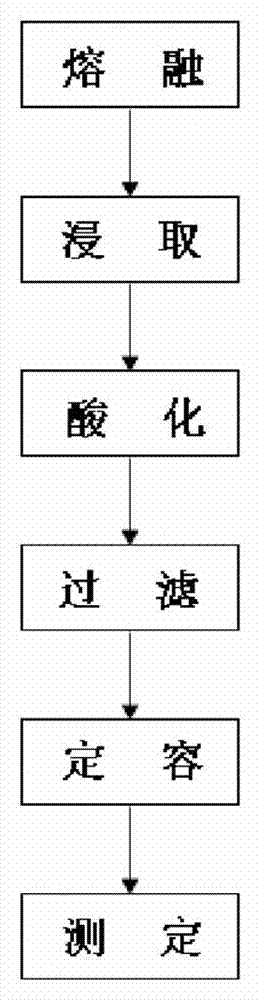

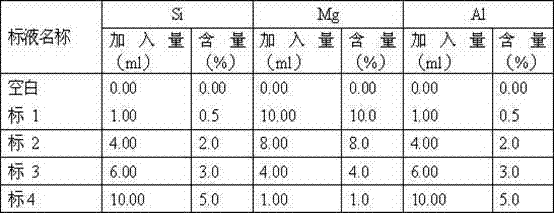

Method for measuring contents of silicon, magnesium and aluminum in coal combustion-supporting agent

ActiveCN103698317AEasy to operateShort detection cyclePreparing sample for investigationAnalysis by thermal excitationMagnesiumAluminium

The invention discloses a method for measuring contents of silicon, magnesium and aluminum in a coal combustion-supporting agent. The method comprises a pretreatment step and a measurement step and specifically comprises the following steps: adding a basic flux into a sample to be measured, placing the sample to be detected into a crucible to be uniformly mixed, heating and fusing, cooling, leaching the crucible by using 40-60 DEG C hot water, and cleaning the crucible to obtain a mixed solution a; acidifying, heating and dissolving, cooling and filtering to obtain a filtrate b; transferring the filtrate b to a volumetric flask, and setting the constant volume to obtain a sample solution; measuring the sample solution by using an emission spectroscopy; and obtaining the corresponding contents of the silicon, the magnesium and the aluminum in standard work curves of the silicon, the magnesium and the aluminum according to spectral line intensity. The method disclosed by the invention is convenient to operate and can be used for greatly shortening the detection period and reducing the labor intensity of detecting personnel; a measured result is favorable in stability, repeatability and accuracy; and the requirement for measuring the contents of the silicon, the magnesium and the aluminum in a coal catalytic combustion-supporting agent for daily injection of a blast furnace can be met.

Owner:WUKUN STEEL

Fur tanning method capable of removing residual formaldehyde in fur product

ActiveCN101613771AReduce physical injuryReduce environmental pollutionTanning treatmentRecycling and recovery technologiesSodium sulfiteSulfite salt

The invention discloses a fur tanning method capable of removing residual formaldehyde in fur products. The fur tanning method is as follows: after the process in the current commonly used fur tanning method of the industry, the processes comprising pickling, oxidizing washing and removal of residual formaldehyde in peltry in the removing and tanning processes are added; the reaction among sodium hydrosulfite used as reducing agent and hydrogen peroxide with oxidization and formaldehyde and the pro-nuclear reaction between sodium sulfite and formaldehyde are utilized to change the molecular structure of formaldehyde, thereby denaturing and removing free formaldehyde. The content of free formaldehyde in prepared fur products is less than 20ppm, thereby not only meeting the national standards, but also reducing hazards to operators and environmental pollution.

Owner:天津市雄冠科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com