Preparation device and method for three-dimensional hollow composite material

A composite material and three-dimensional hollow technology, which is applied in the field of preparation devices for three-dimensional hollow composite materials, can solve the problems of non-recyclable thermosetting resin, polluting the environment, workers' bodies, unfavorable industrial production, etc., and achieve light weight, low labor intensity, and heat insulation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

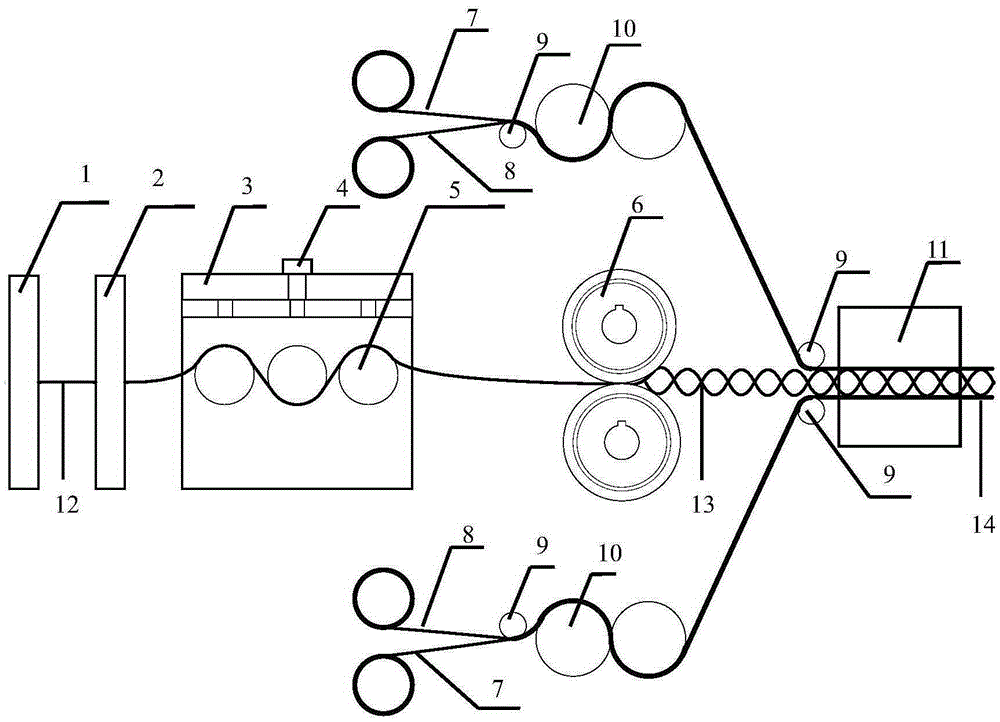

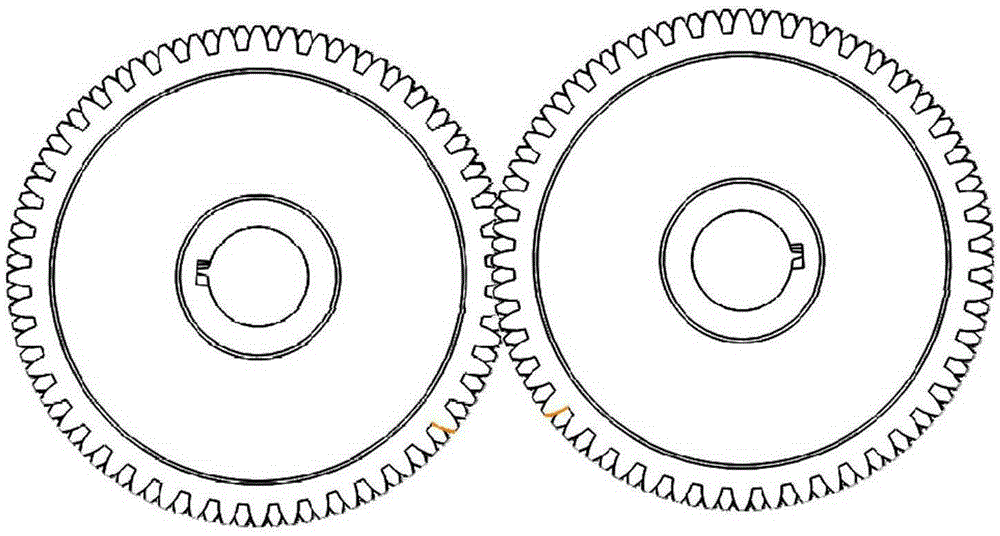

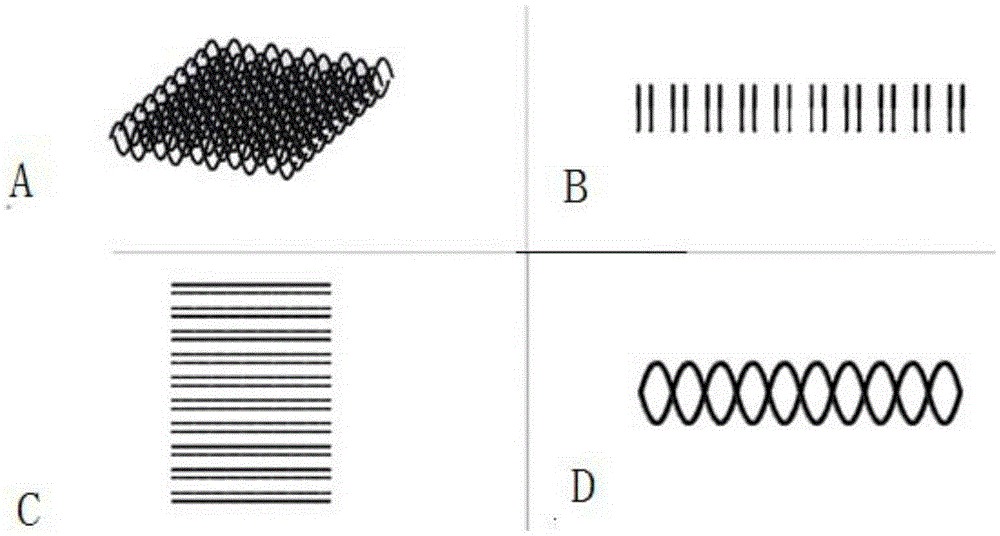

[0030] Such as figure 1 As shown, the preparation device of the three-dimensional hollow composite material of the present invention includes a creel 1, a pre-dispersion device 2, a melt impregnation device 3, a hot-press setting device 6, a transfer device 9, a hot-press roller 10, an oven 11 and a transfer device, The impregnation roller 5 is arranged in the melting and impregnation device 3, and the extruder 4 is arranged on the melting and impregnation device 3; arranged gears such as figure 2 As shown, the staggered arrangement refers to the staggered arrangement of the addendum 15 and the dedendum 16 of adjacent gears, such as image 3 As shown, the gears in the upper and lower gear sets are in one-to-one correspondence, and the corresponding gears in the upper and lower gear sets mesh with each other. The specific parameters of the gear are: module = 1, number of teeth = 32, pitch circle diameter = 32mm, addendum circle diameter = 34mm, dedendum circle diameter = 29....

Embodiment 2

[0035] A method for preparing a three-dimensional hollow composite material, using the preparation device for a three-dimensional hollow composite material in Example 1, the fiber bundles used are carbon fiber bundles, and the fabric is carbon fiber plain weave cloth, the specific steps are: a row of fiber bundles 12 Lead into the pre-dispersion device 2 from the creel 1, heat and dry the fibers while dispersing the fibers, make the fiber bundles fluffy, so as to better impregnate the resin, and guide the fiber bundles into the melt impregnation device 3, the melt impregnation The device 3 is provided with molten polyether ether ketone resin supplied by the extruder 4, and impregnates the fiber bundle under the action of the impregnating roller 5, and after the fiber bundle is impregnated with the polyether ether ketone resin, it is introduced into the heat-press setting device 6 , the temperature of the hot press setting device 6 is set between the heat distortion temperature ...

Embodiment 3

[0039] A preparation device for a three-dimensional hollow composite material, similar to Example 1, with the difference that: in order to increase the impact resistance of the composite material, the number of teeth of the interlaced gears remains unchanged, the gear modulus is reduced to 0.5, and the tooth width is reduced to 2mm. The obtained hollow fiber layer 13 is denser than that of Example 1 and has better impact resistance.

[0040] A method for preparing a three-dimensional hollow composite material, using the above-mentioned preparation device for a three-dimensional hollow composite material, the fiber bundles used are glass fiber bundles, and the fabric is carbon fiber plain weave cloth, the specific steps are: a row of fiber bundles 12 from The creel 1 is introduced into the pre-dispersion device 2, and the fibers are heated and dried while dispersing the fibers to make the fiber bundles fluffy, so as to better impregnate the resin, and the fiber bundles are intro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com