Dust collection purifying device of numerical control cutting machine

A purification device and cutting machine technology, applied in auxiliary devices, welding/cutting auxiliary equipment, gas flame welding equipment, etc., can solve problems such as difficulty, equipment worker injury, interference, etc., achieve good practicability and reduce physical injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

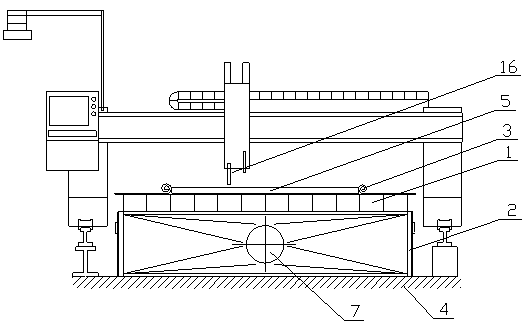

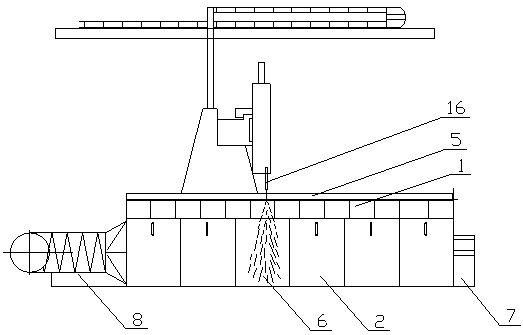

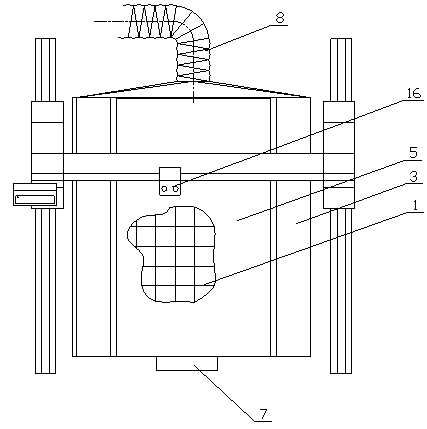

[0023] As shown in the figure, the dust collection and purification device of the CNC cutting machine in this embodiment includes a workbench 1 for placing workpieces. The lower side of the workbench 1 is provided with a baffle plate 2. The shutter 3 of rolling structure whose edge extends to the center of the worktable, the shutter 2, the shutter 3, the ground 4, the workbench 1 and the workpiece 5 placed on the worktable to be cut constitute a cavity; The table 1 is provided with a grid hole communicating with the cavity; one end of the cavity 6 is provided with an air inlet 7 , and the other end communicates with a fan 9 through an air duct 8 .

[0024] The air outlet of blower fan 9 is connected with a dust remover 10, and described dust remover 10 is provided with cylindrical pipeline, and the air outlet pipe of fan 9 is connected with dust remover 10 along the tangential direction of the pipeline of dust remover 10, and described dust remover 10 is provided with a water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com