Patents

Literature

831 results about "Composite phase change material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of metal organic framework based composite phase-change material

InactiveCN103756646AWide range of choicesPrevent leakage and other issuesProductsReagentsMetal-organic frameworkElectrical polarity

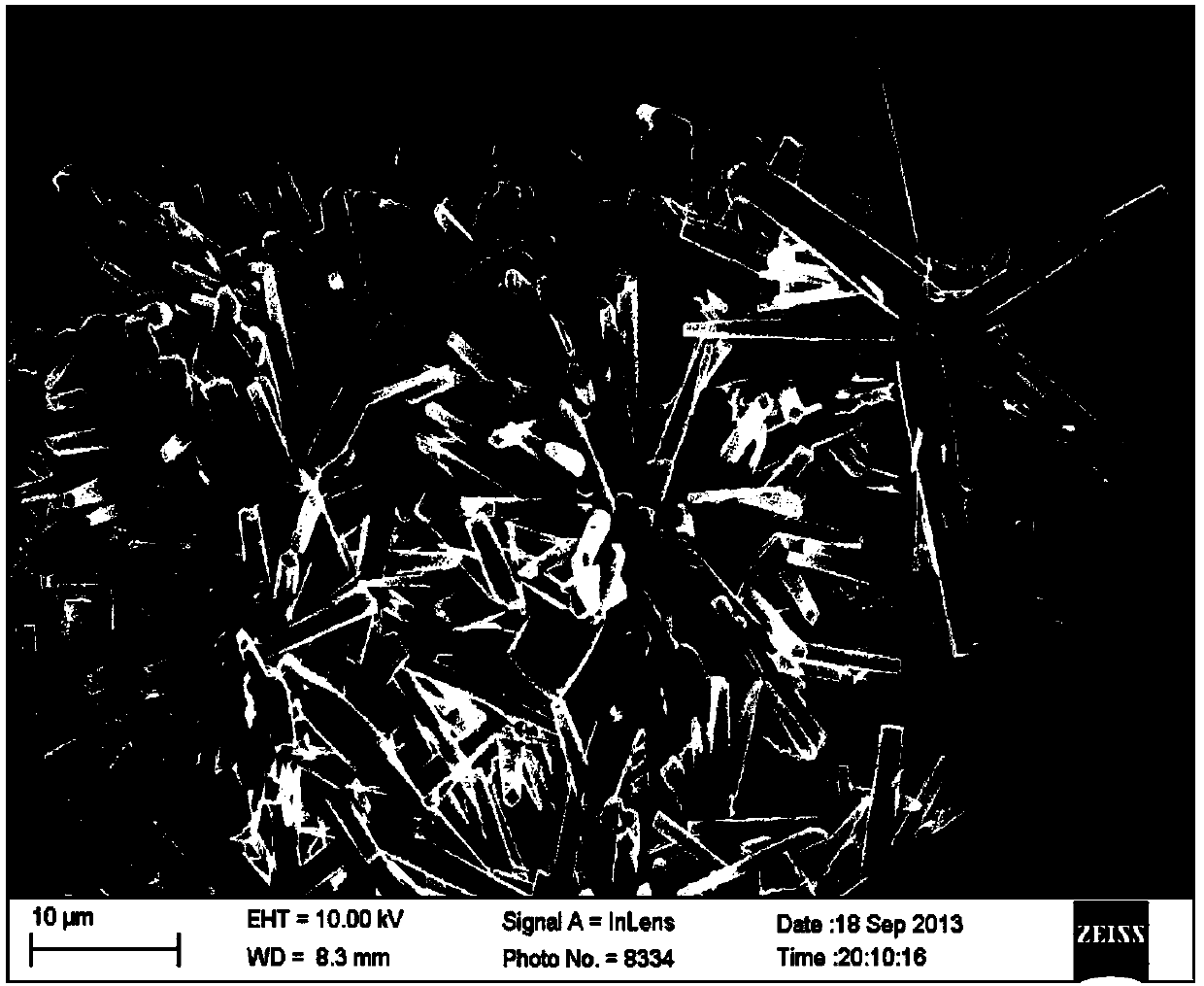

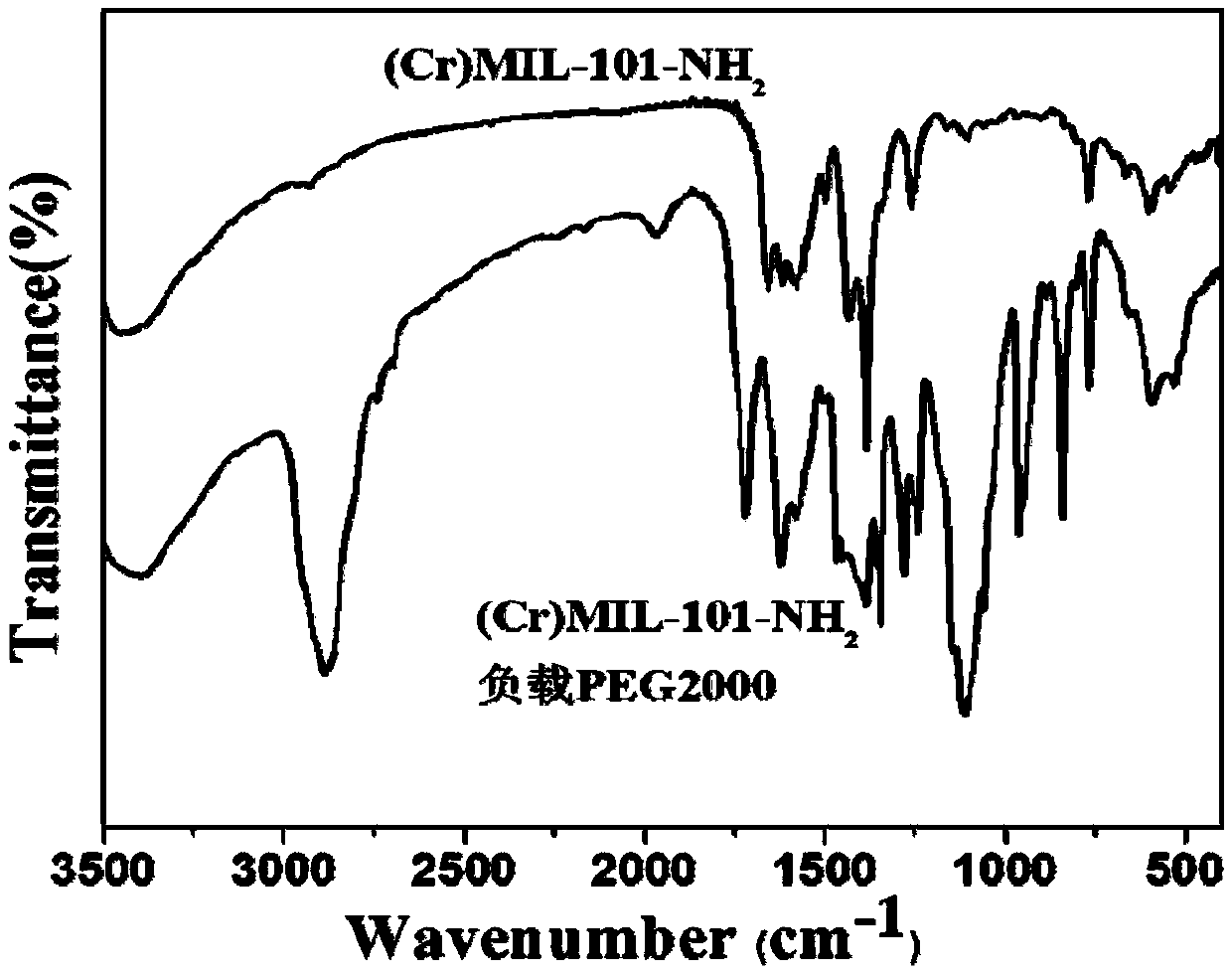

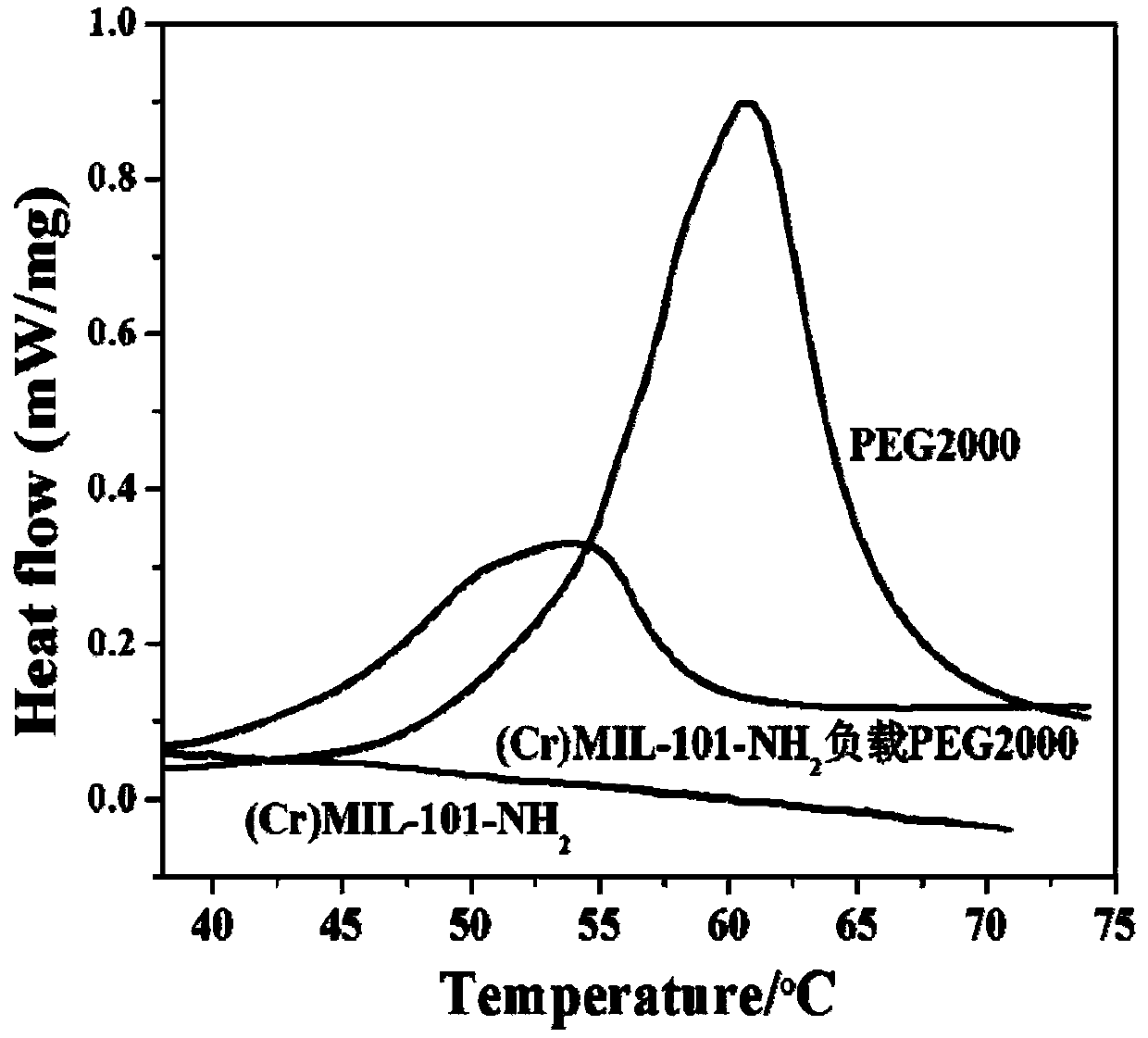

The invention relates to a preparation method of a metal organic framework based composite phase-change material. The method comprises the steps that a metal organic framework material substrate is prepared selectively; hole diameter size design and hole channel polarity regulation and control are performed on the substrate according to the size and the kind of a core material, so that a phase-change core material to be loaded is matched better; the soluble phase-change core material is prepared into a solution; a metal organic framework material is dispersed in the prepared phase-change material solution; a phase-change material is adsorbed by utilizing an extra-large specific surface area and a nano hole channel structure of the metal organic framework material; drying is performed; and then the metal organic framework composite phase-change material with a shaping effect is obtained. According to the method, a novel metal organic framework based composite phase-change material is developed; the prepared metal organic framework based composite phase-change material can effectively avoid leakage and the like, and has the advantages of adjustable nano hole structure and wide core material selection range; the method is simple in technology and mild in reaction condition, and is suitable for scale production; and a raw material is cheap and easy to obtain.

Owner:UNIV OF SCI & TECH BEIJING

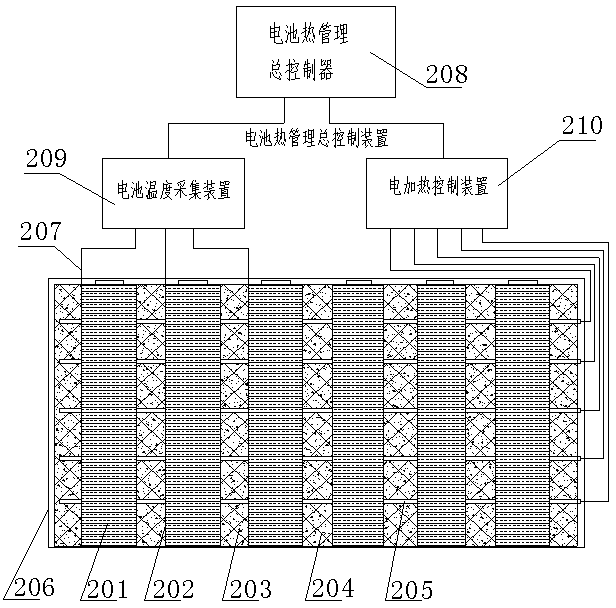

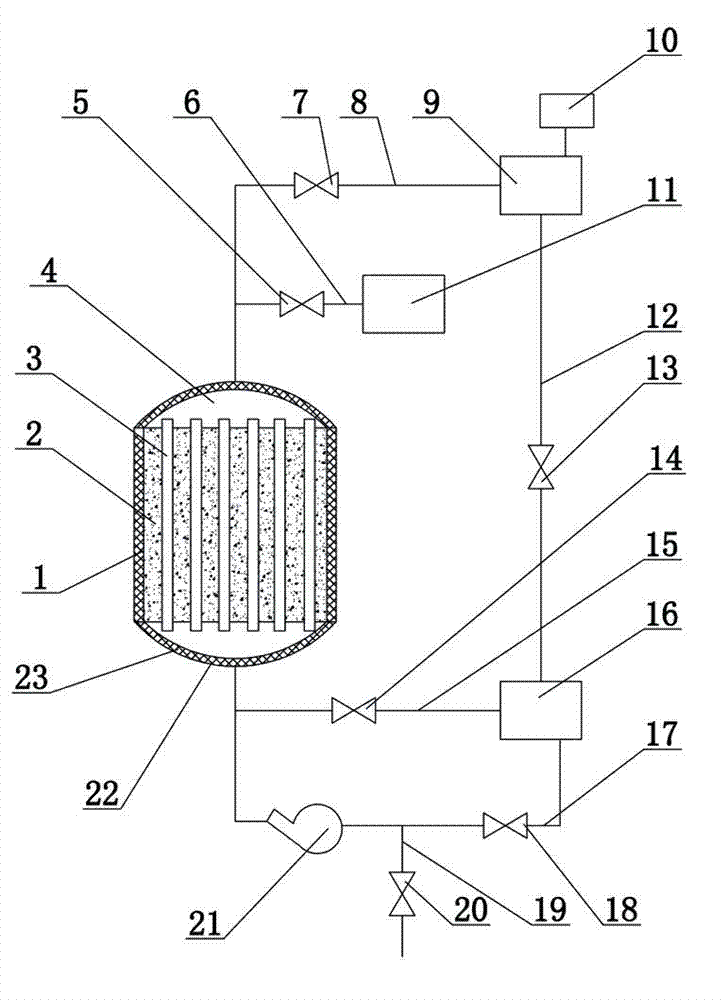

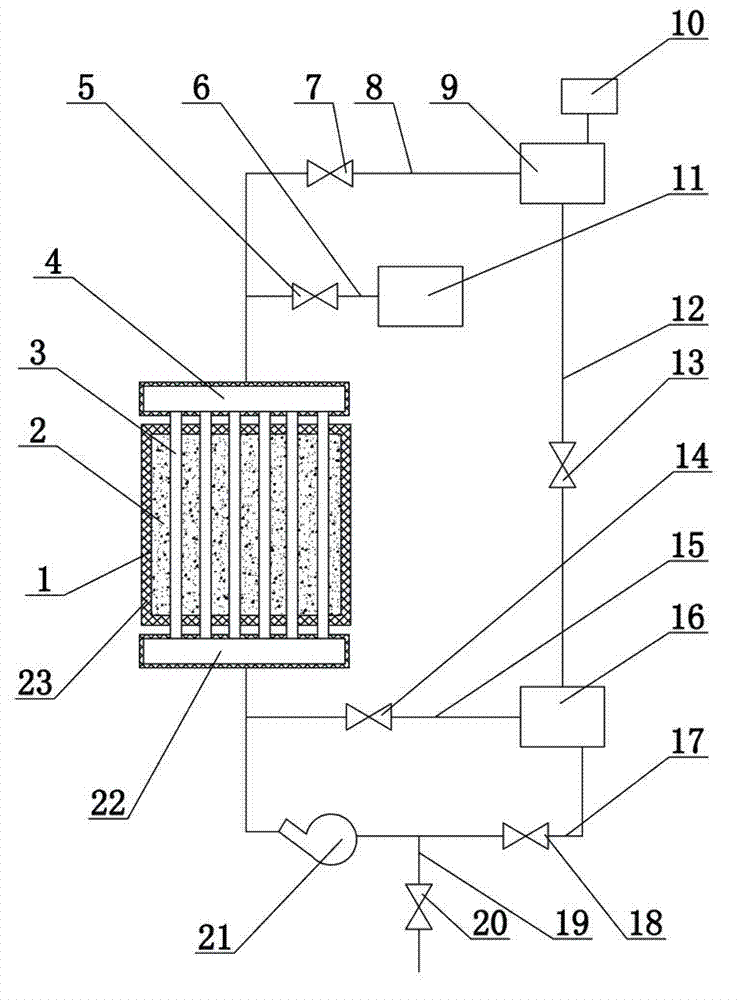

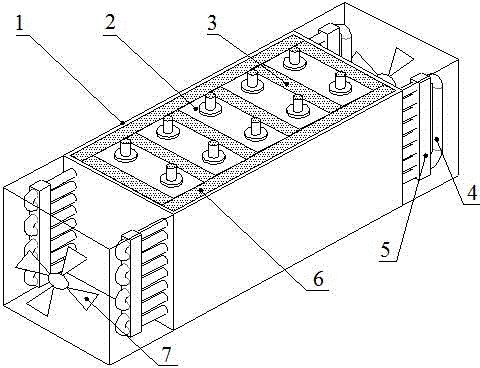

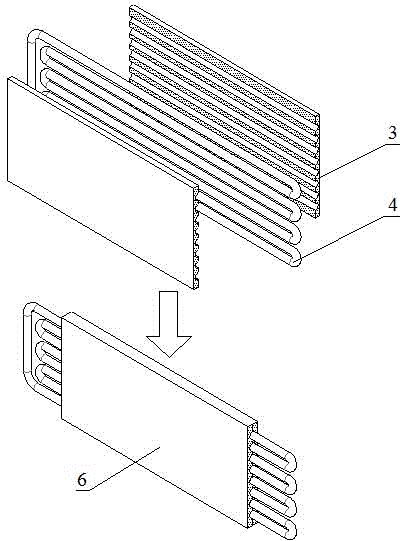

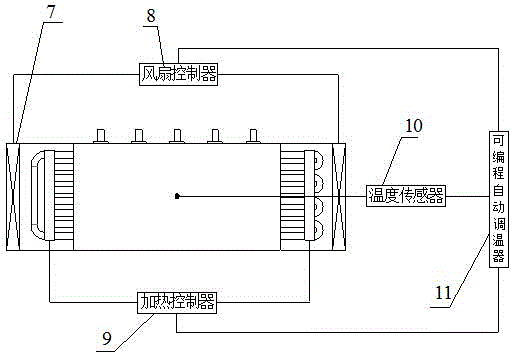

Battery heat management equipment with efficient balanced radiating function and electric heating function

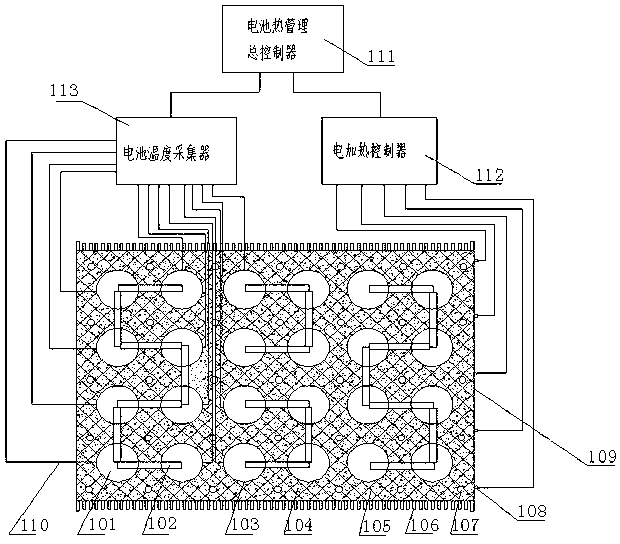

The invention discloses battery heat management equipment with an efficient balanced radiating function and an electric heating function. The battery heat management equipment comprises a radiating cooling device, an electric heating device and a temperature acquisition device, wherein a battery radiating device comprises a plurality of battery monomers, battery connecting pole pieces, insulating high heat conduction battery protection shells, a composite phase change material, a framework structure material for improving heat transfer and strength, heat pipes, a battery module box and heat pipe radiating fins; a battery electric heating device comprises the electric heating device and an electric heating controller; the electric heating device is embedded into the phase change material and connected with the electric heating controller; the temperature acquisition device comprises a thermocouple and a temperature acquirer; the thermocouple is arranged in a composite phase change material cooling module and transfers a sensed signal to the temperature acquirer; the temperature acquirer transfers the signal to a battery heat management equipment master controller; and the battery heat management equipment master controller is connected with the electric heating controller. According to the battery heat management equipment, a power battery is high in working performance, high in safety and long in cycle life.

Owner:GUANGDONG UNIV OF TECH

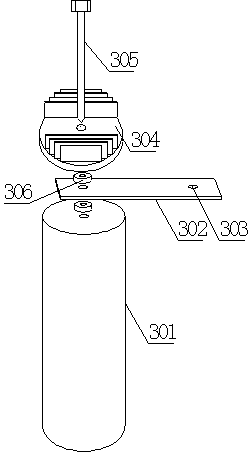

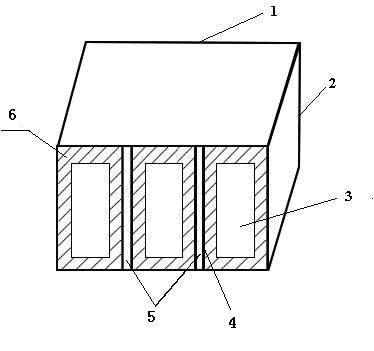

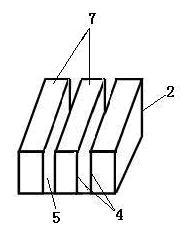

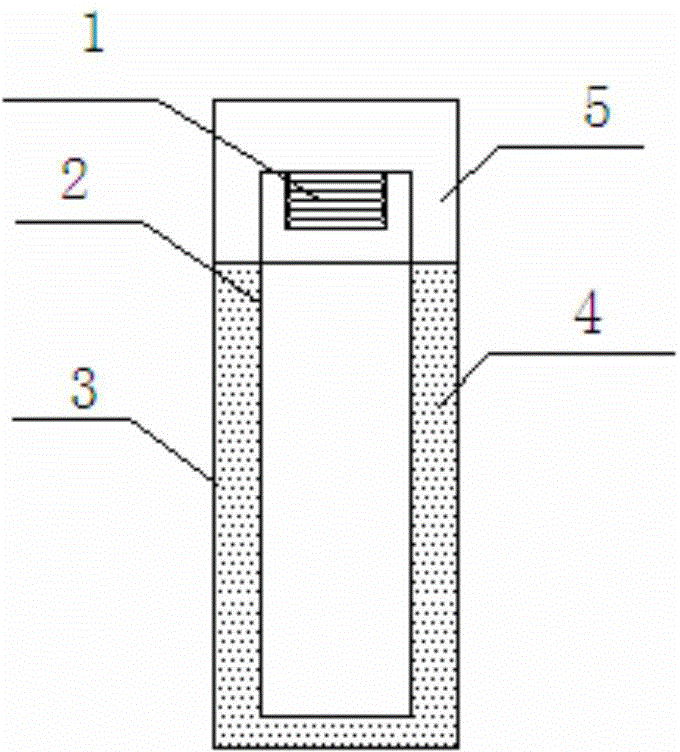

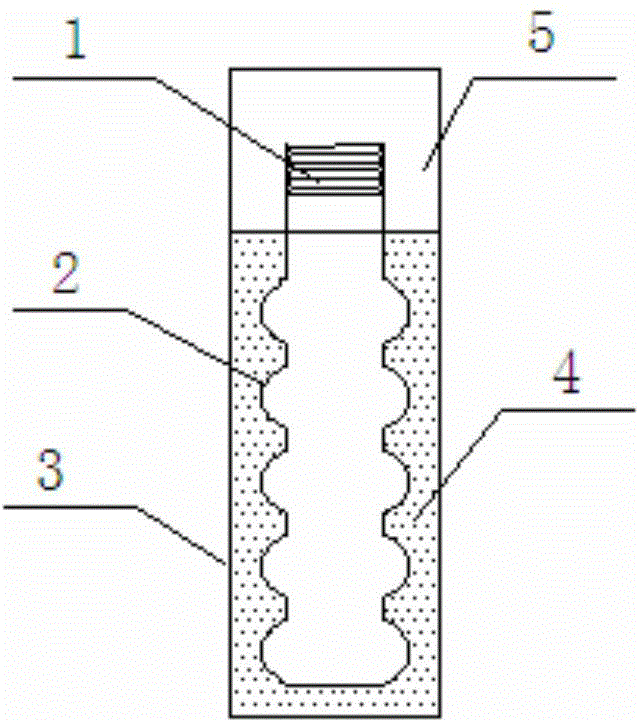

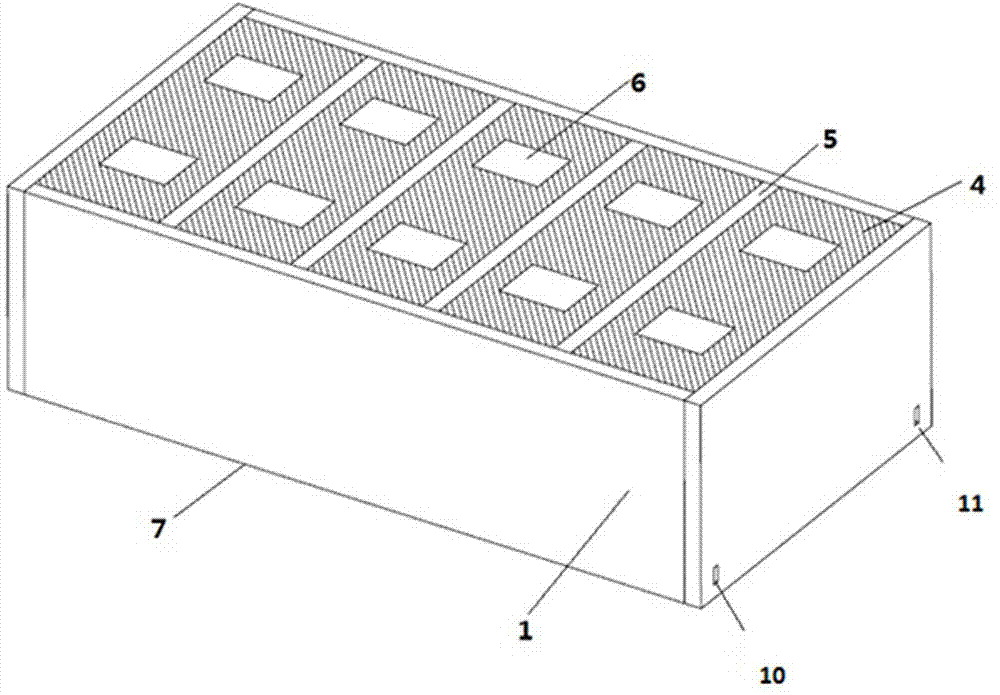

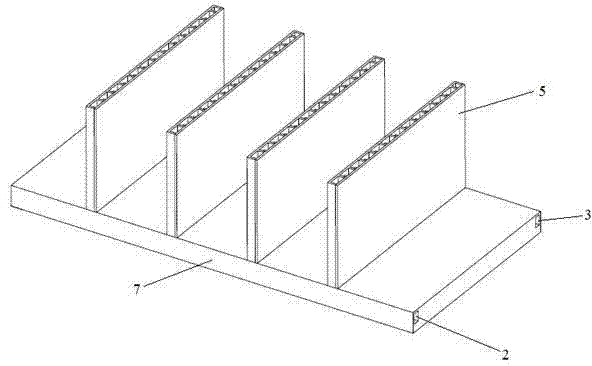

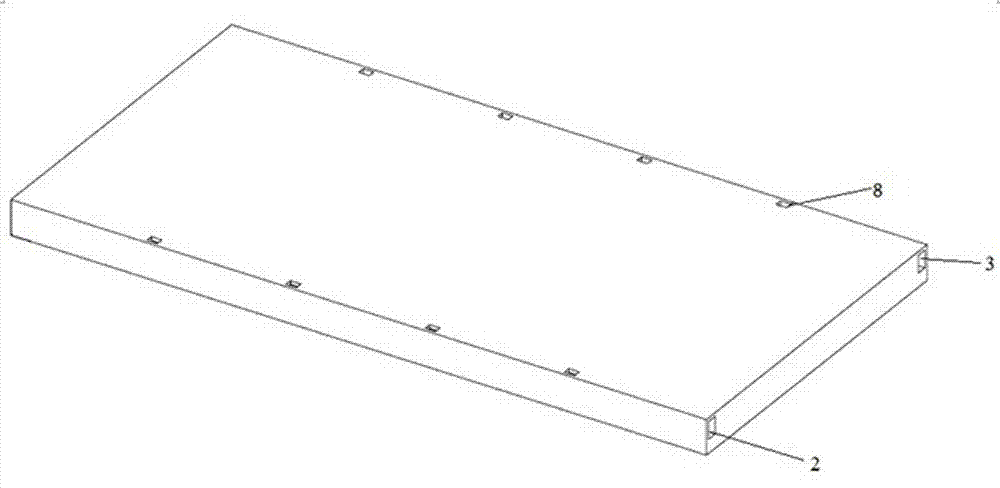

Composite phase change material for heat dissipation of lithium battery and device

InactiveCN102181270AImprove thermal conductivityIncrease heat storageSecondary cellsHeat-exchange elementsWork PerformancesPhase change

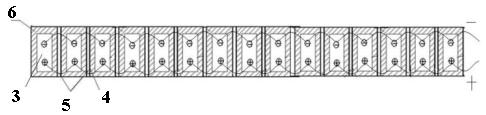

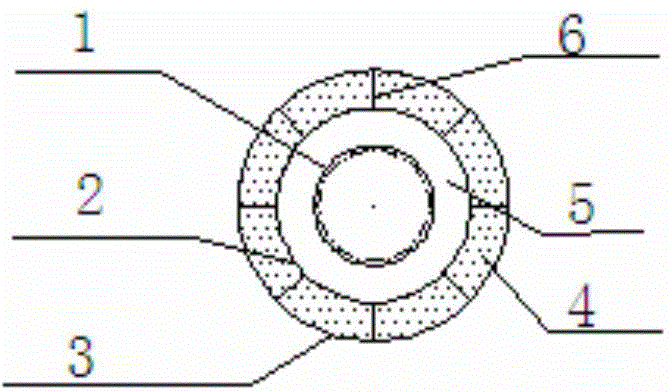

The invention discloses a composite phase change material for heat dissipation of a lithium battery and a device. The device comprises a top cap 1, a box body 2 and partition plates 4; and cavities of corresponding number are partitioned in the box body 2 according to the number of single batteries 3 to be radiated, an air runner 5 is formed between the adjacent partition plates, and the composite phase change material 4 with phase change temperature of between 40 and 70 DEG C is filled in the cavities. When the device starts working, the heat of the single batteries is transferred to the composite phase change material; and when the temperature is higher than the phase change temperature of the phase change material, the phase change material absorbs the heat, produces phase change and stores the heat so as to realize heat dissipation and cooling of the single batteries. The composite phase change material has high coefficient of heat conductivity, keeps the size in the phase change process, has high heat storage, heat release and heat dissipation rate, has no liquid liquidity or leakage, is easily encapsulated, is convenient to operate and maintain, and can improve the working performance and the reliability of the batteries when used for the heat dissipation of the high-power and quick charge / discharge power lithium batteries.

Owner:SOUTH CHINA UNIV OF TECH

Inorganic hydrated salt expanded graphite composite phase-changing heat storage material and preparation method thereof

The invention relates to an inorganic hydrated salt expanded graphite composite phase-changing heat storage material. In the preparation method thereof, 85-89 mass parts of inorganic hydrated salt sodium acetate trihydrate as a heat storage matrix, 5.5-6.5 mass parts of disodium hydrogenphosphate as a nucleating agent, 2.5-3.5 mass parts of carboxymethyl cellulose as a thickening agent, and 3-4.5 mass parts of expanded graphite is blended in an inorganic hydrated salt mixture as a material with a high thermal conductivity. Due to the use of the expanded graphite, the material not only maintains excellent properties of natural flake graphite such as good thermal conductivity, no toxicity and the like, but also has adsorbability which the natural flake graphite does not have. The invention solves the problems of sub-cooling degree, phase stratification and low thermal conductivity during the heat storage process. The composite phase-changing material has a low sub-cooling degree after the phase changing performance is improved, the solution thereof is uniform without sedimentation and stratification during the solid-liquid phase change, the performance is stable, the repeatability of good, and the phase-changing heat storage can be enhanced through improving the thermal conductivity of the material.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

Method for preparing multilevel porous carbon base composite phase change material

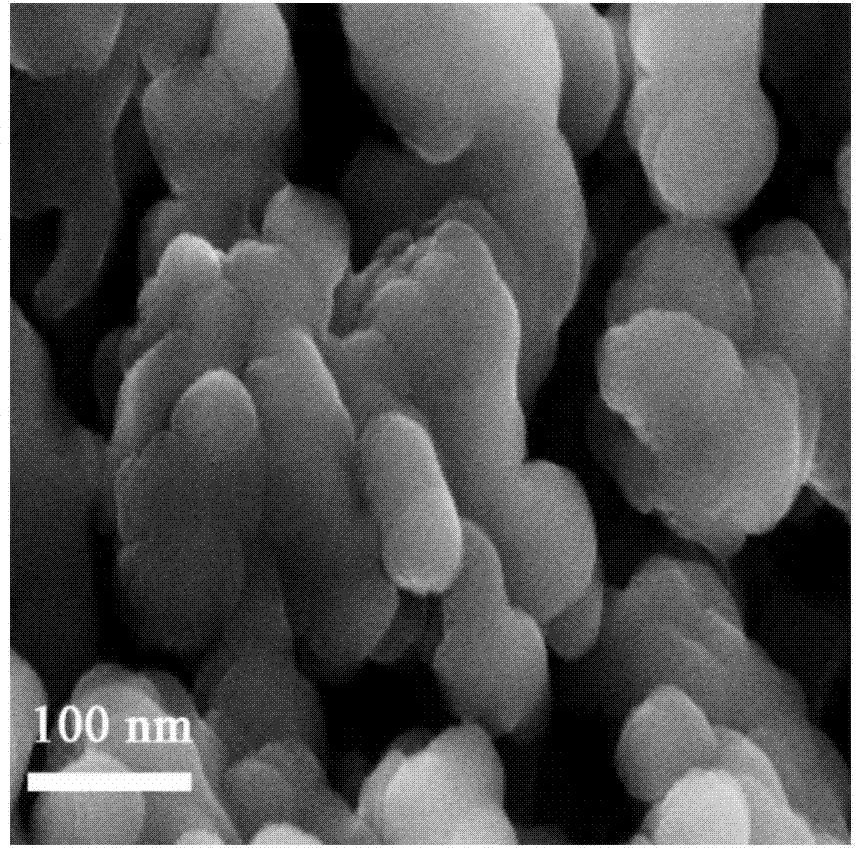

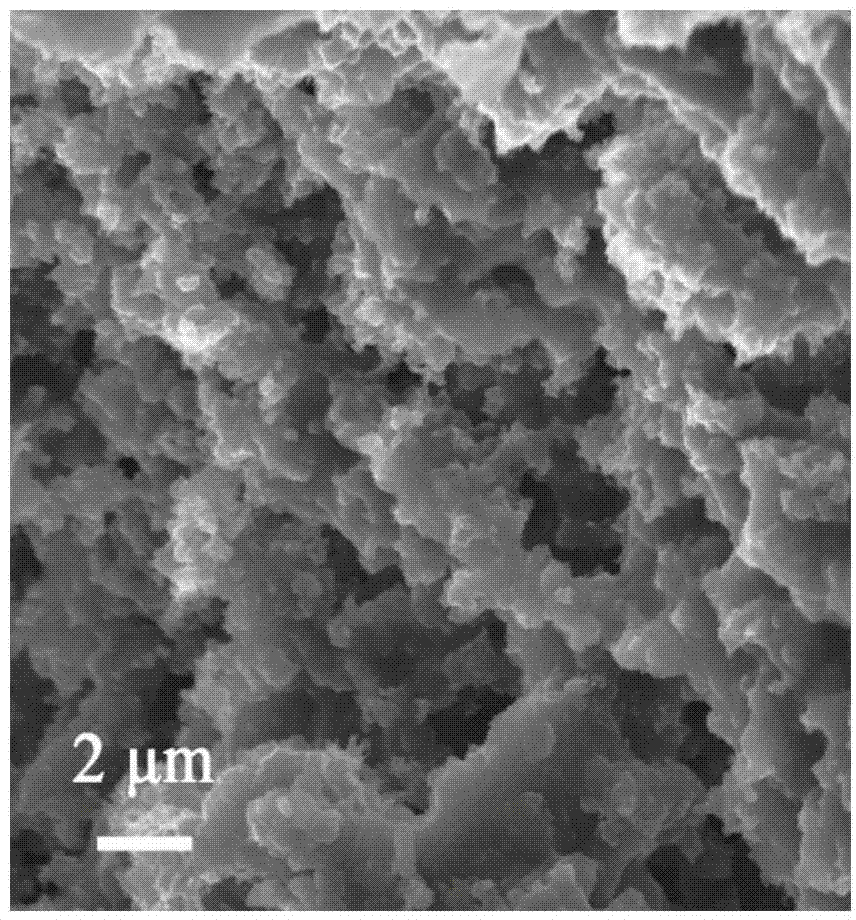

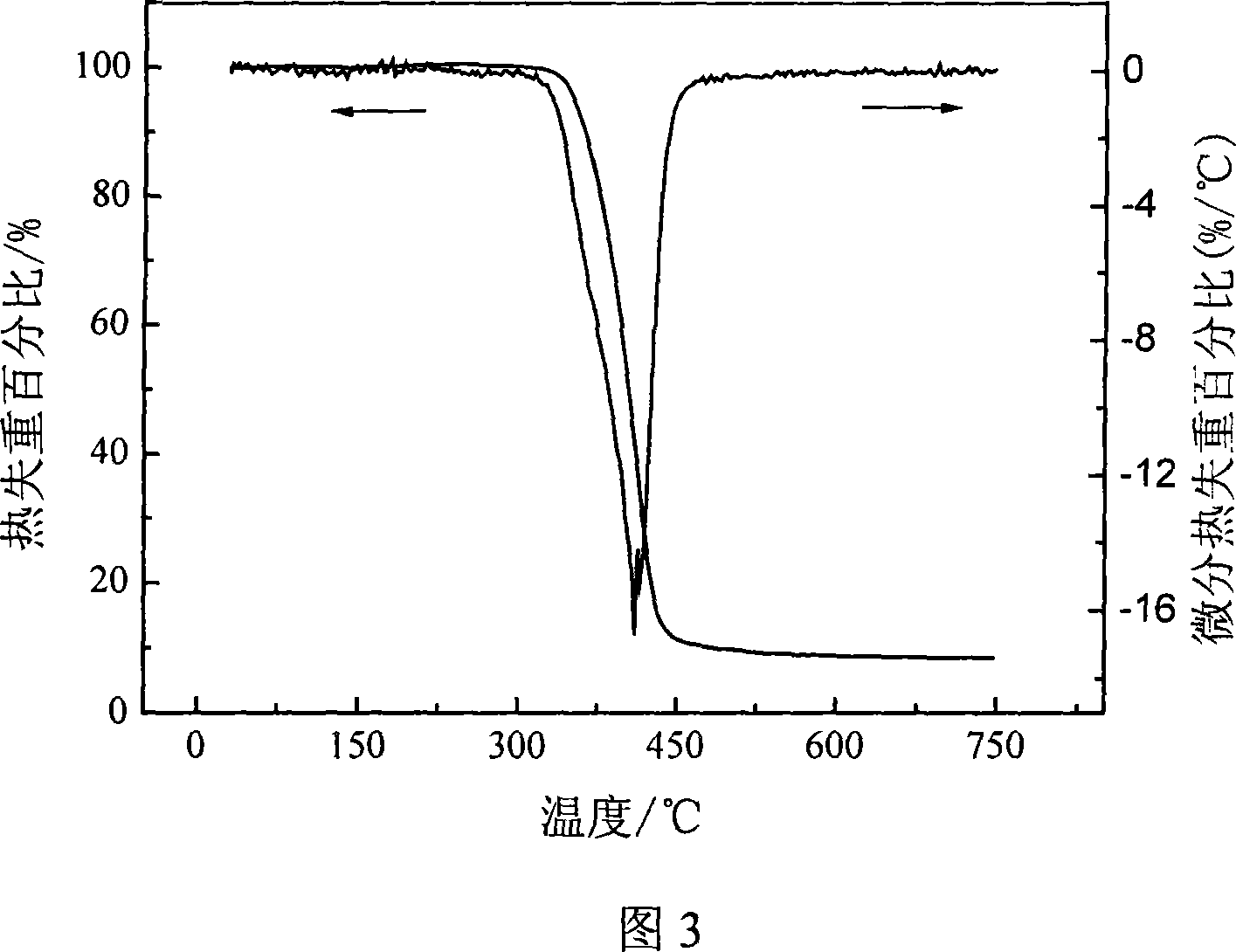

InactiveCN104710965AImprove heat storage capacityLarge temperature rangeProductsReagentsPorous carbonSynthesis methods

The invention provides a method for preparing a multilevel porous carbon base composite phase change material, and belongs to the field of composite phase change materials. The method comprises the following steps: at first, preparing an organic metal skeleton material by using such methods as a solution method, a solvothermal method or a stirring synthesis method; with the organic metal skeleton material as a template, high temperature carbonizing under the protection of an inert gas, and changing the carbonizing temperature and the post treatment manner to obtain a multilevel porous carbon material with a super-large specific surface area and a super-large pore volume; selecting proper solvents according to different kinds of phase change core materials, preparing the phase change core materials to a solution, dispersing the porous carbon material into the solution, removing the solvent by such manners as heating, and meanwhile the phase change core materials are adsorbed and limited in the porous carbon material. The composite phase change material prepared by the method provided by the invention has good thermal storage property, can effectively avoid the leakage problem of the phase change core material, and has the advantages of excellent heat transfer property, good cycling stability and wide application range, and the process is simple and is suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

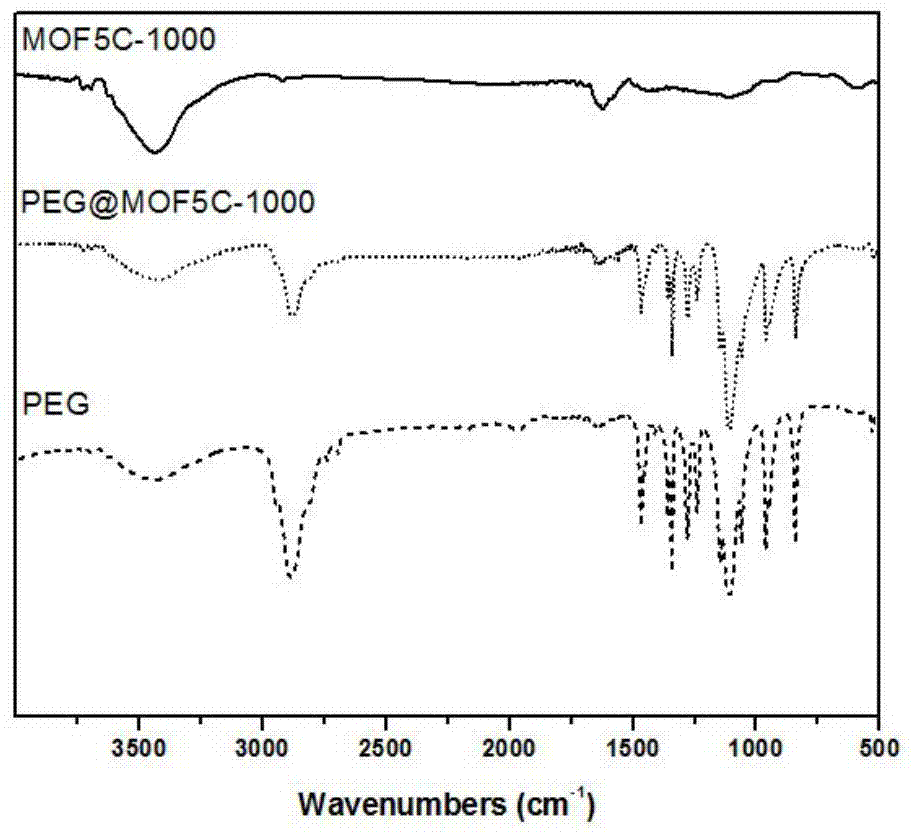

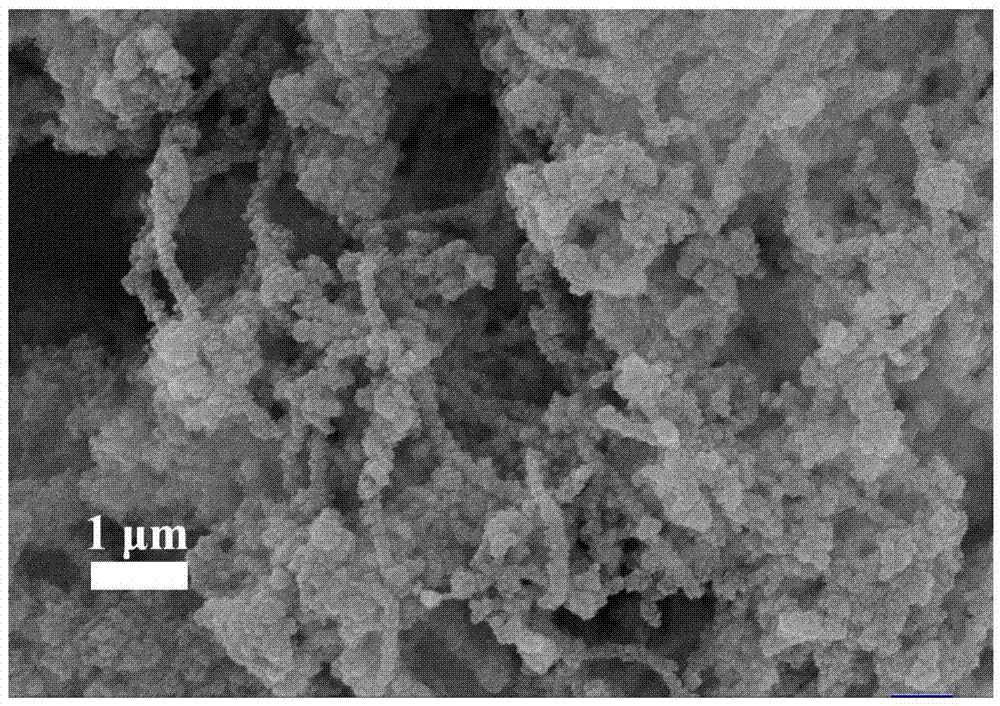

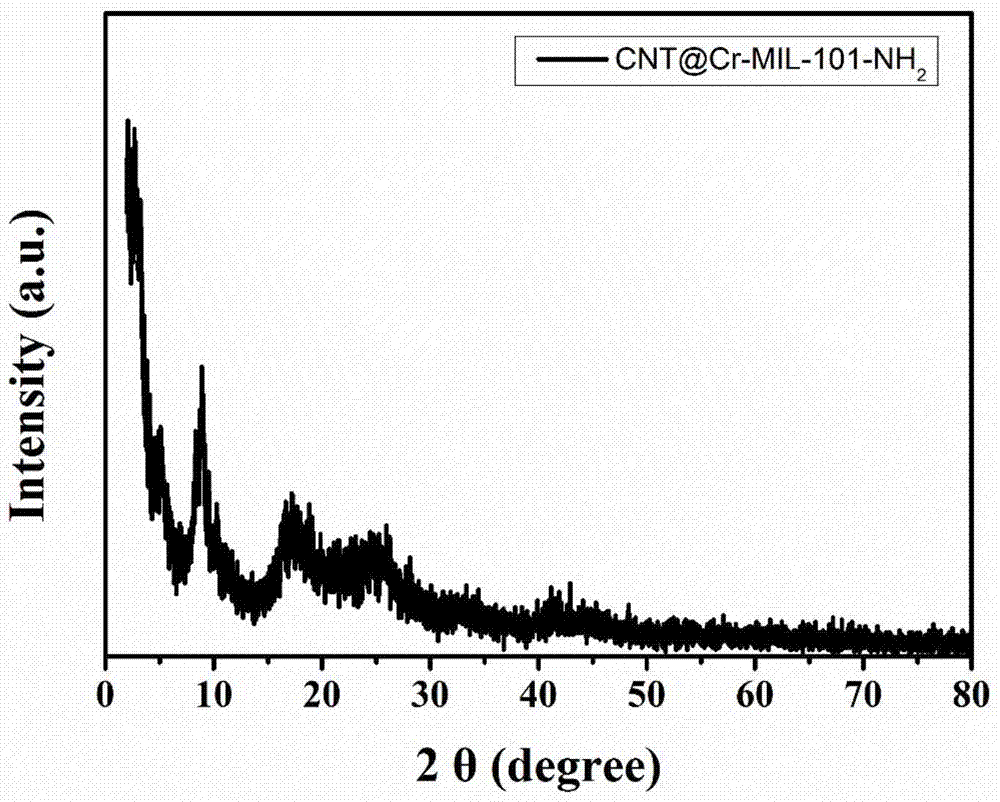

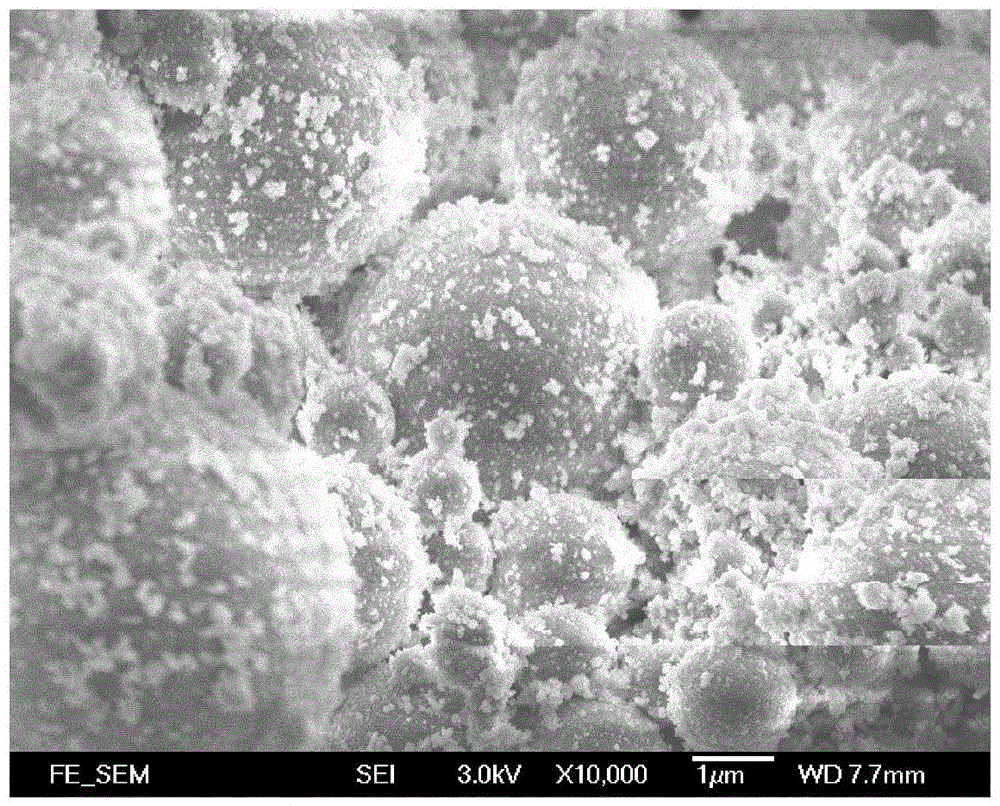

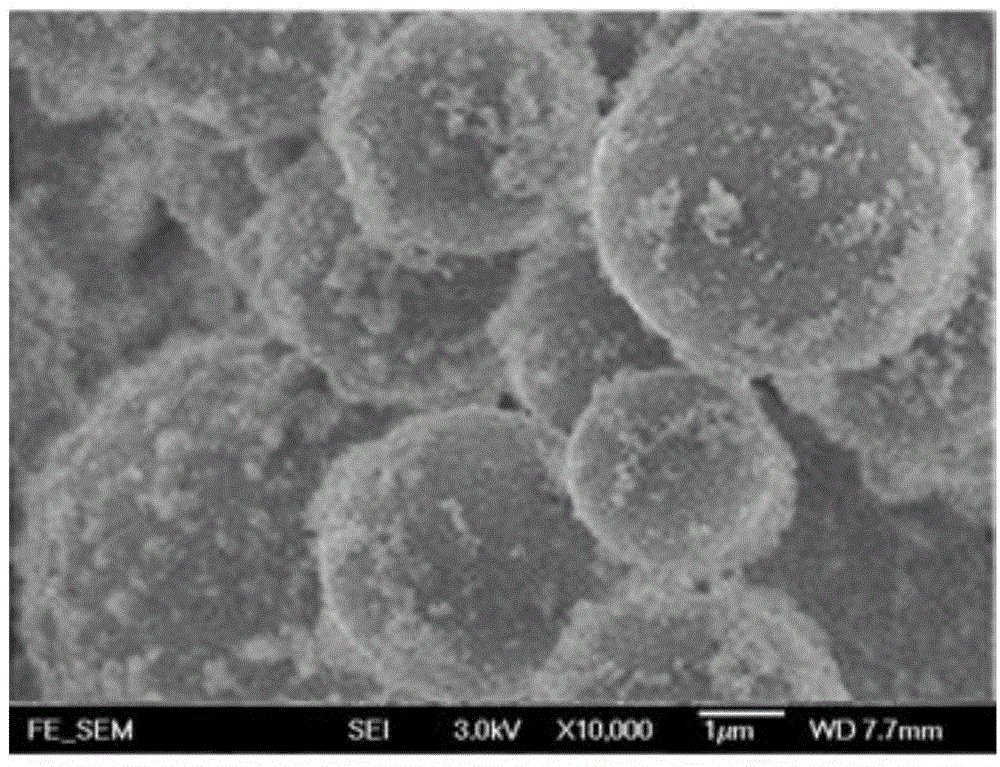

Preparation method for carbon-containing material metal organic framework-based composite phase change material

InactiveCN104745149AImprove heat transfer performanceImprove cycle stabilityHeat-exchange elementsModified carbonMetal-organic framework

The invention discloses a preparation method for a carbon-containing material metal organic framework-based composite phase change material and belongs to the field of nano composite materials and composite phase change materials. The preparation method comprises the following steps: carrying out in-situ growth of MOFs particles on a polyvinylpyrrolidone (PVP)-modified carbon material surface by adopting a hydrothermal method to prepare a carbon-containing material metal organic framework-based porous carrier material; then, dispersing a carbon material @MOFs porous carrier material into a prepared solution containing a phase change core material by adopting a solution dipping method; adsorbing a phase change core material by utilizing an oversized specific surface area of the metal organic framework material and a nao duct structure; and drying at a temperature higher than the phase change material to obtain the carbon-containing material metal organic framework-based composite phase change material. The material can be used for improving the heat transfer performances of the composite phase-change material, effectively preventing core material leakage, and has the advantages of wide core material selection range. The composite phase change material prepared by the method provided by the invention is excellent in heat transfer performance, good in circulating stability, simple in process and suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

Phase transition temperature adjusting system and phase transition temperature adjusting cup

ActiveCN104887011AHeat absorption and release performance are highly matchedGuaranteed to drink normallyDrinking vesselsCarbon nanotubeSodium Thiosulfate Pentahydrate

Owner:YUTIAN ENERGY CO LTD

Preparation of organic inorganic composite phase-change material

InactiveCN101348708ASolve the problem of extravasationSolve the key technology of combinationHeat-exchange elementsMaterials scienceOrganic inorganic

The invention relates to a method for preparing an organic and inorganic composite phase-transition material. The method comprises the following steps: firstly, inorganic porous minerals are added into a reaction kettle; and secondly, the reaction kettle is vacuumized and injected with an organic material and then pumped into the state of negative pressure, and the temperature and the stirring speed are required to be adequately controlled during the reaction process. The method takes the inorganic porous mineral materials as a carrier for vacsorb of organic phase-transition materials which accord with the phase-transition requirements; the composite phase-transition material product prepared has the characteristics of no leakage, inflaming retarding, high phase-transition potential, easily controllable phase-transition temperature and so on; and the preparation method has a simple technology and low cost, has no secondary pollution, and is suitable for flow production and industrial production.

Owner:贵州中益能新材料科技有限公司

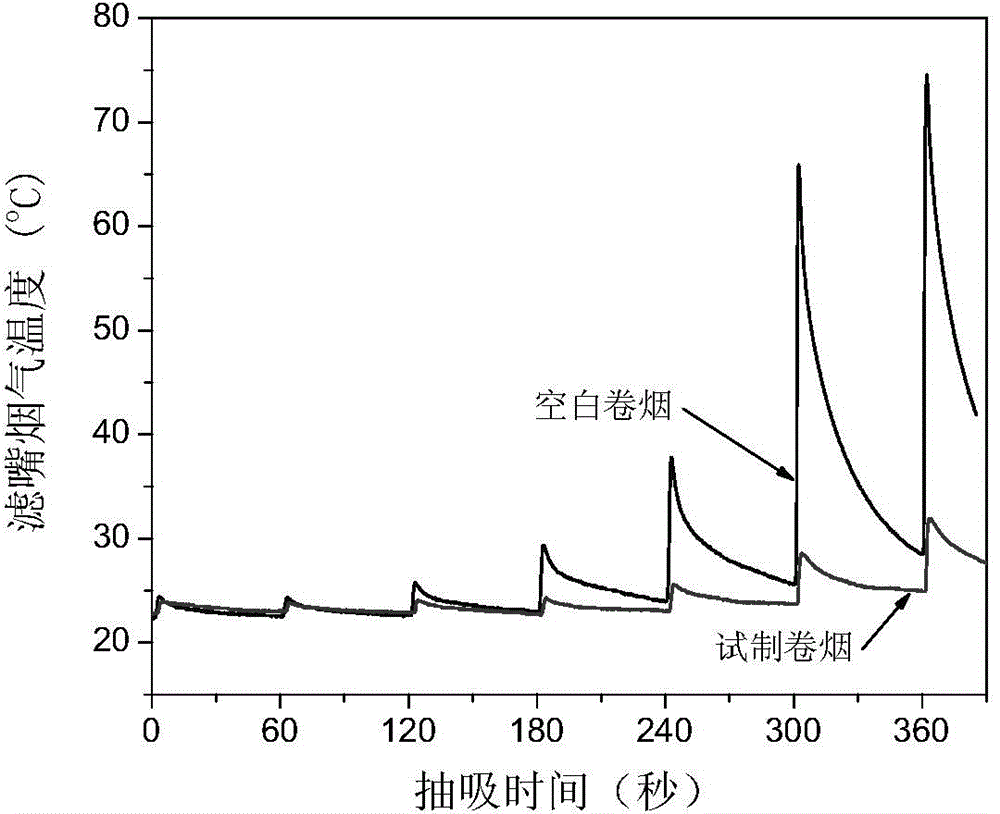

Organic/inorganic composite phase-changing material capable of controlling smoke temperature of cigarette filter as well as preparation method and application of organic/inorganic composite phase-changing material

ActiveCN104449586ALow costHigh latent heat of phase changeTobacco smoke filtersHeat-exchange elementsAlkaneCooling effect

The invention discloses an organic / inorganic composite phase-changing material capable of controlling the smoke temperature of a cigarette filter as well as a preparation method and an application of the organic / inorganic composite phase-changing material. The composite phase-changing material is formed by loading alkane of C19 to C21 onto expansive graphite or porous silicon oxide particles. The preparation method comprises the steps of heating the alkane of C19 to C21 for melting, adding expansive graphite and / or porous silica gel particles, adequately stirring the alkane and the expansive graphite and / or the porous silica gel particles to obtain a mixture, and cooling and crystallizing the mixture under the condition that the temperature is not more than 25 DEG C to obtain the organic / inorganic composite phase-changing material. In the preparation method, raw materials are easy to obtain, the method is simple to operate and low in cost; the prepared composite phase-changing material is high in phase-changing latent heat and high in heat transfer performance. When the prepared composite phase-changing material is added to a cigarette filter stick, the temperature of mainstream smoke of a cigarette can be effectively reduced; moreover, the prepared composite phase-changing material has characteristics of little addition amount and obvious cooling effect.

Owner:CHINA TOBACCO HUNAN INDAL CORP

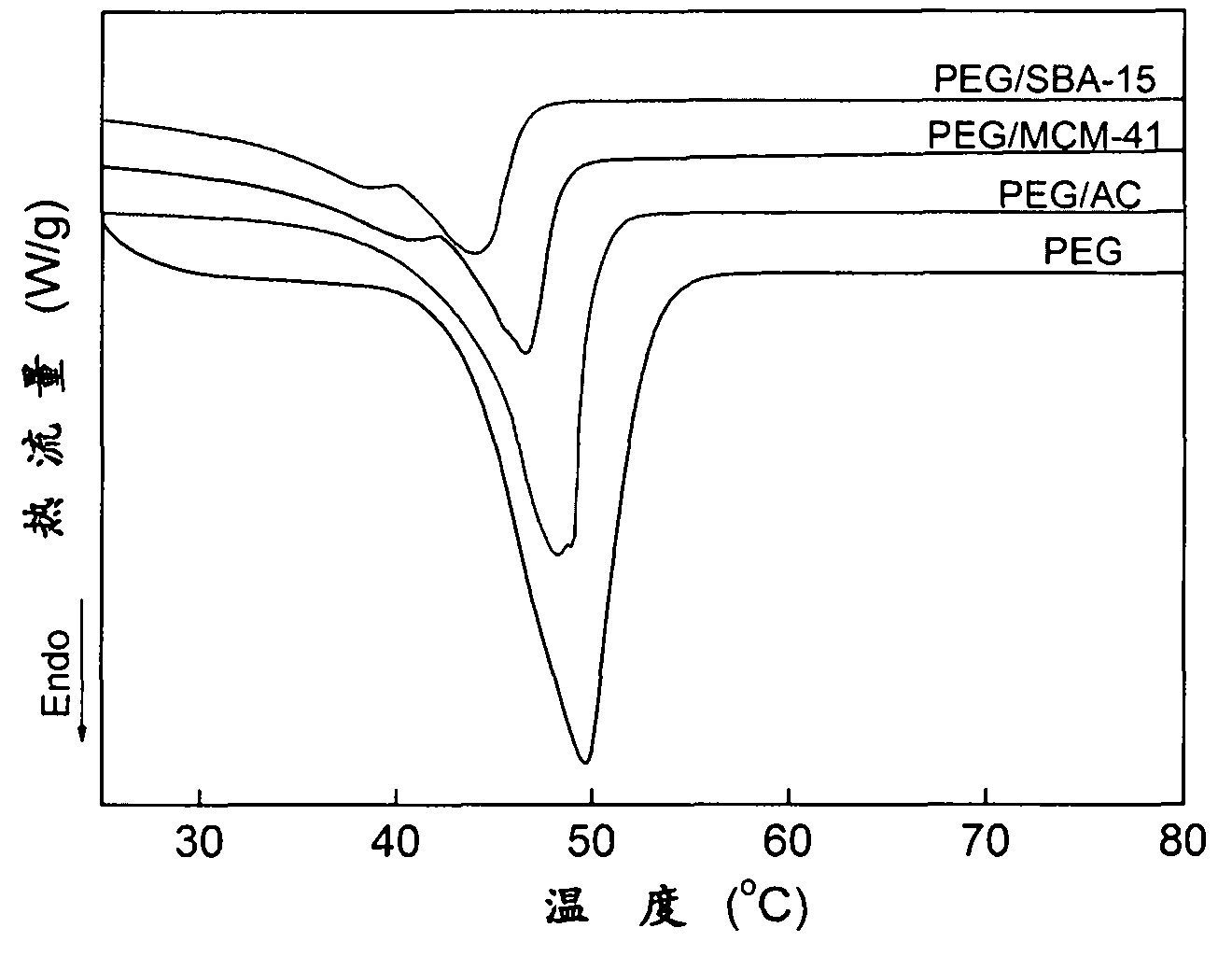

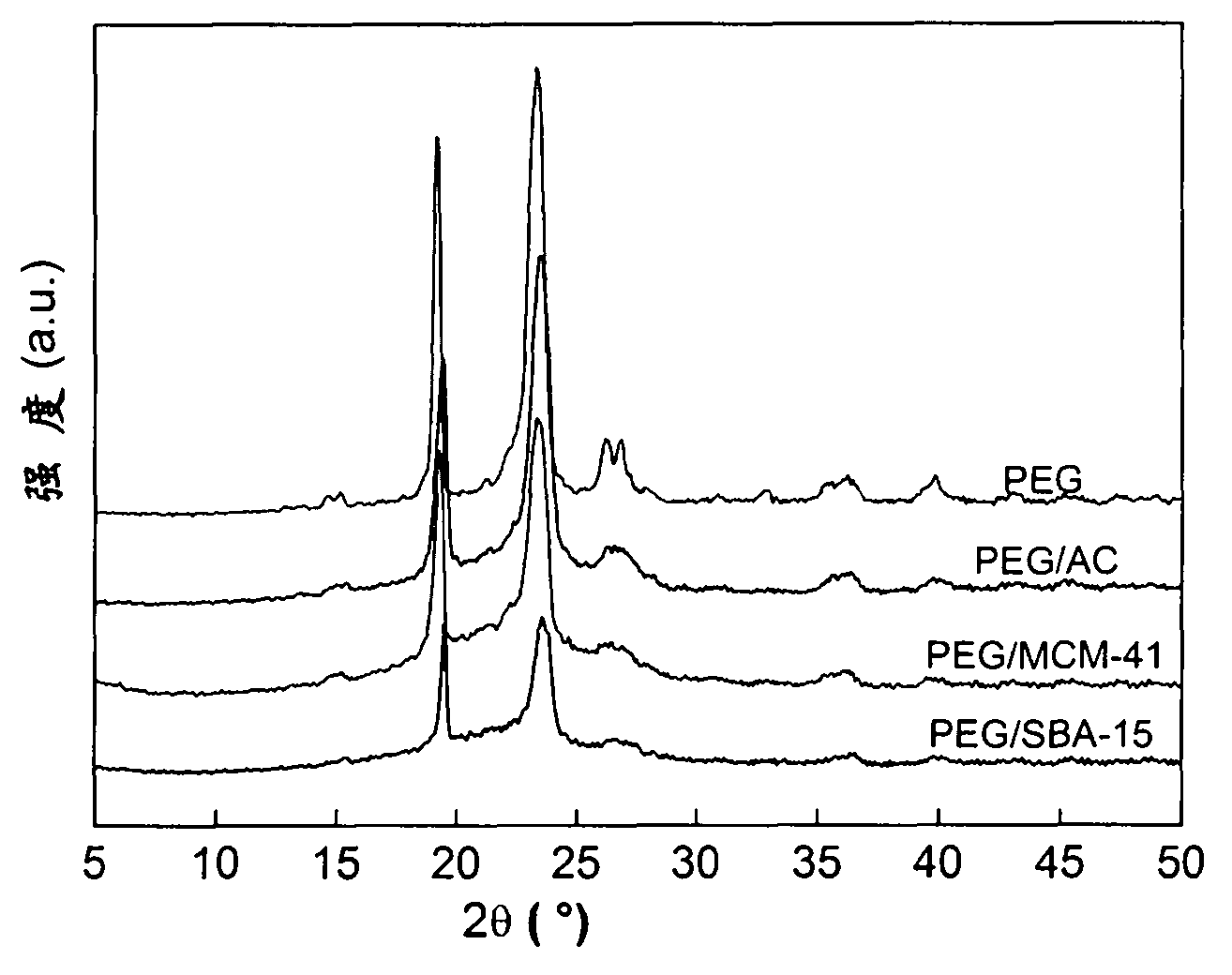

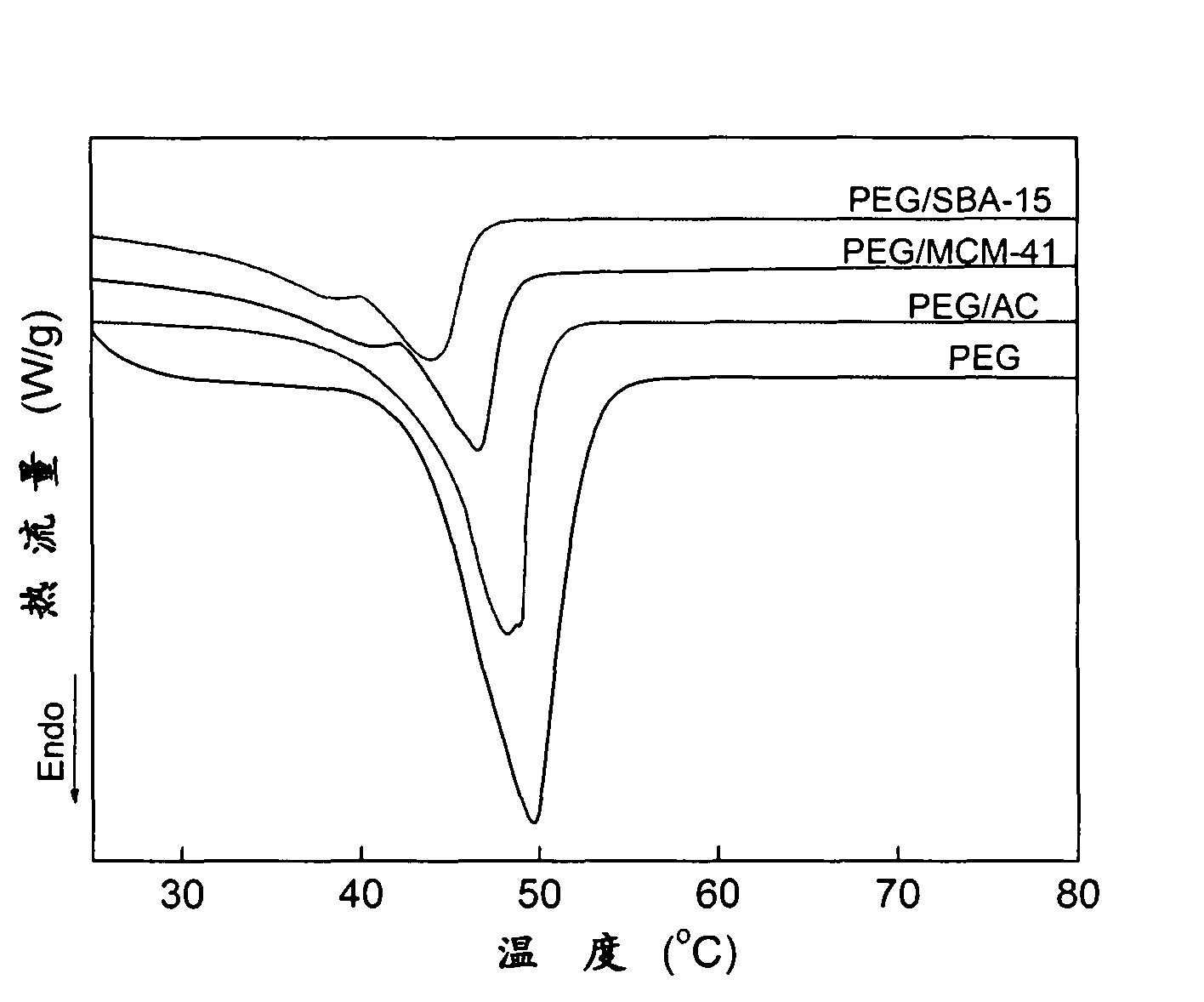

Mesoporous material-based composite phase change heat storage material and preparation method thereof

InactiveCN101812286AReduce contentSolving Phase Change Leakage ProblemsHeat-exchange elementsMesoporous materialHeat storage material

The invention discloses a mesoporous material-based composite phase change heat storage material and a preparation method thereof. The composite phase change heat storage material, which can still keep fixed shape even at the temperature higher than the melting point of phase change substance by 30 DEG C, is prepared by using mesoporous material as carrier matrix and organic substance as phase change substance according to methods of physical blending and impregnation. Compared with other technologies, reported in documents, for the preparation of shape-fixed composite phase change material, the preparation technology has the characteristics of great simplicity and saving time, and the prepared composite phase change heat storage material has high content of the phase change material, high latent heat of phase change and utilization rate of the latent heat, and obviously lowered phase change temperature.

Owner:PEKING UNIV

Nano-composite phase-changing material and preparation method

InactiveCN101429423AGood compatibilityWill not affect the mechanical propertiesHeat-exchange elementsPhase changeProcess complexity

The invention provides a nano composite phase change material and a method for preparing the same, and belongs to the field of material application. The nano composite phase change material comprises the following components in weight portion: 10 to 15 portions of phase change material, 5 to 60 portions of layer-shaped silicate powder, and 20 to 70 portions of deionized water; the phase change point of the phase change material is between 20 and 80 DEG C; the phase change material is heated up to be completely melted; the layer-shaped silicate powder is dispersed in water by a high shear mixed emulsion machine to prepare layer-shaped silicate gel state aqueous dispersion; and the melted phase change material is added to the layer-shaped silicate gel state aqueous dispersion and stirred at high speed by the high shear mixed emulsion machine to obtain the nano composite phase change material with oil-in-water structure. The nano composite phase change material can be directly added to building base materials such as concrete, gypsum, thereby greatly reducing process complexity and preparation cost; moreover, the composite phase change material also has the advantages of simple preparation, large heat storage, and better application prospect.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

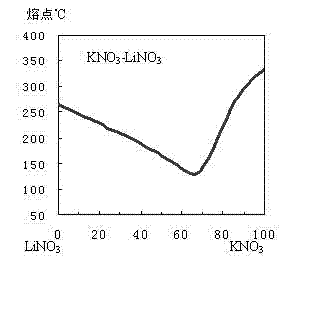

Phase change heat accumulation system for generating steam directly and preparation method of phase change heat accumulation agent

InactiveCN102777874AImprove efficiencyImprove heat transfer coefficientHeat storage plantsChemical industryPorous mediumToxic industrial waste

The invention relates to a phase change heat accumulation system for generating steam directly and a preparation method of a phase change heat accumulation agent. A phase change material is enhanced with graphite foam, and is absorbed in a porous medium of the graphite foam, so that a binary eutectic salt / graphite foam material is prepared and is used as a composite phase change material of a heat accumulation device, the composite phase change material is high in heat conduction coefficient, therefore under the same design condition, the phase change heat accumulation system provided by the invention is applied to systems of a focusing type solar thermal power generation system, an industrial waste heat recovery system and the like, and has the characteristics of high heat transfer efficiency, small volume, low cost and the like. In addition, the phase change heat accumulation system for generating steam directly can flexibly adopt a parallel connection or serial connection mode according to the temperature of high-temperature waste heat steam and the requirement of a steam user; and during serial connection, the binary eutectic salt / graphite foam composite phase change material can be combined in a cascaded manner according to a melting point, thus the efficiency of an energy accumulation system is increased, and the energy can be greatly accumulated.

Owner:ZHENGZHOU UNIV

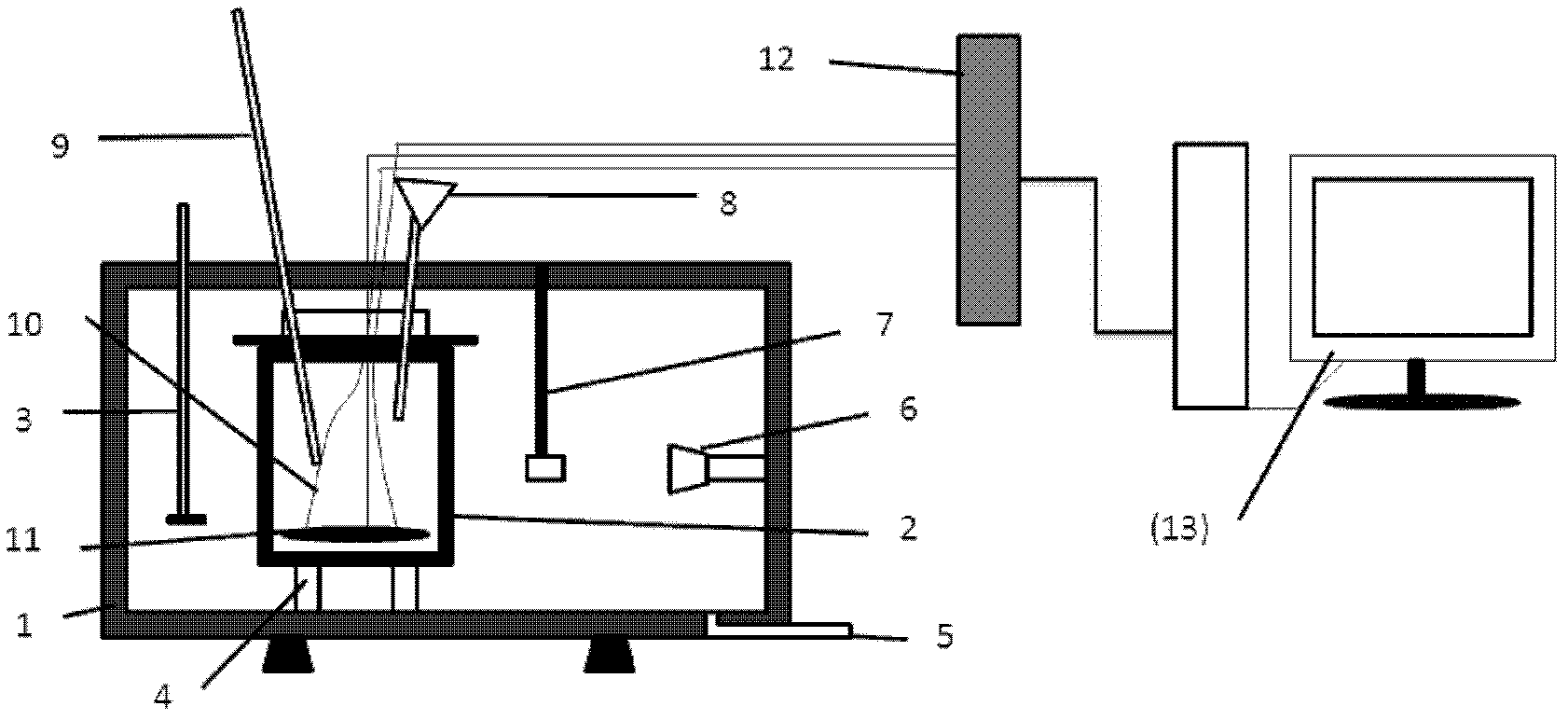

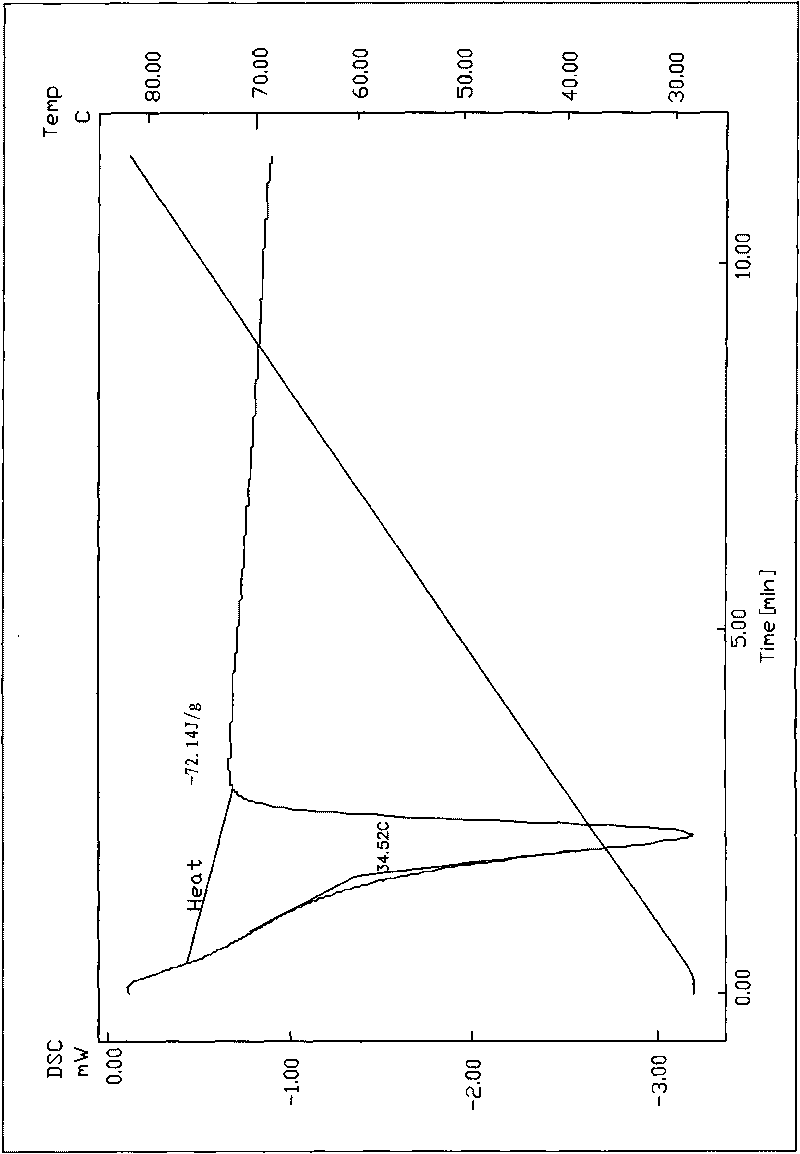

Device and method for measuring phase change latent heat of composite phase change energy storage material

ActiveCN102590263AIncrease reflectionReduce mistakesInvestigating phase/state changeWater bathsElectrical resistance and conductance

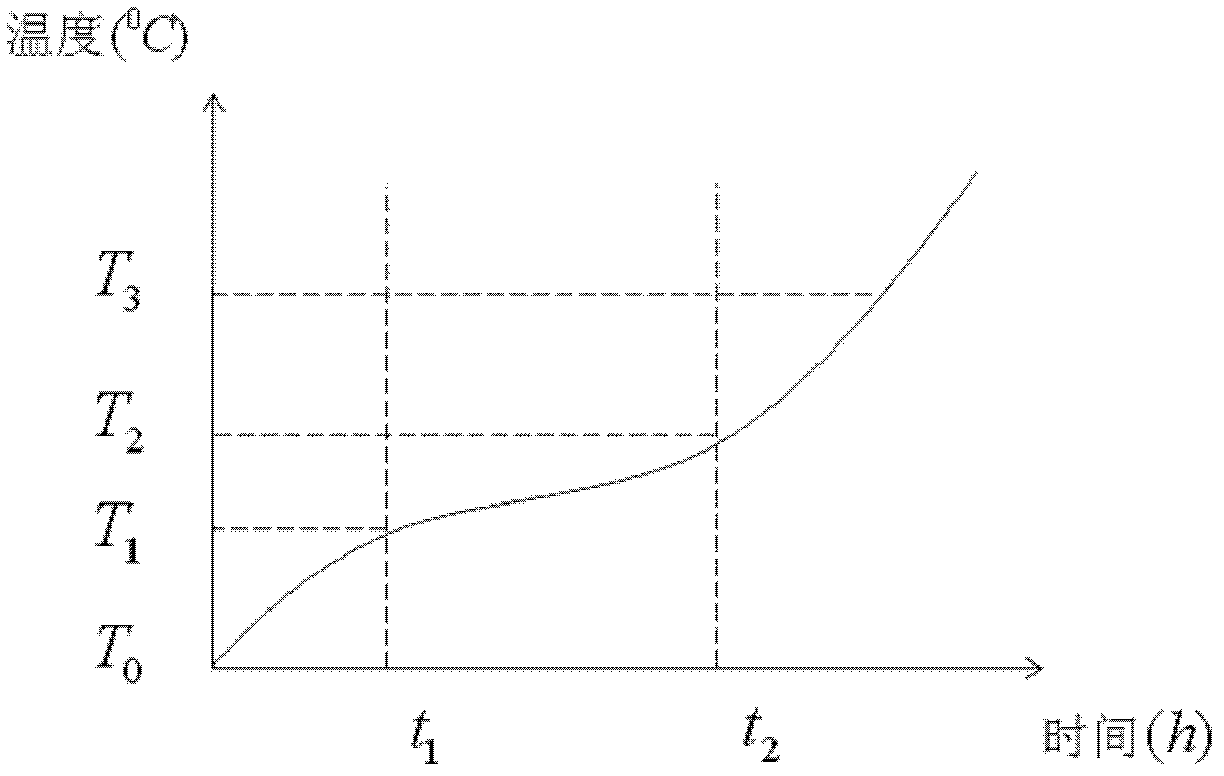

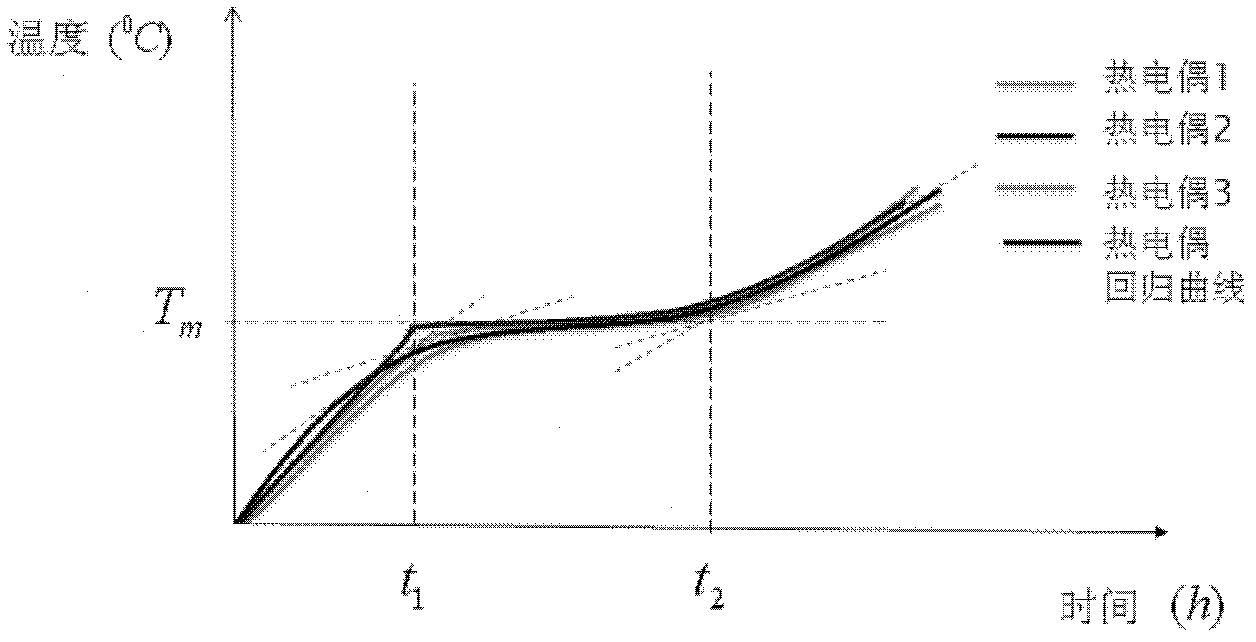

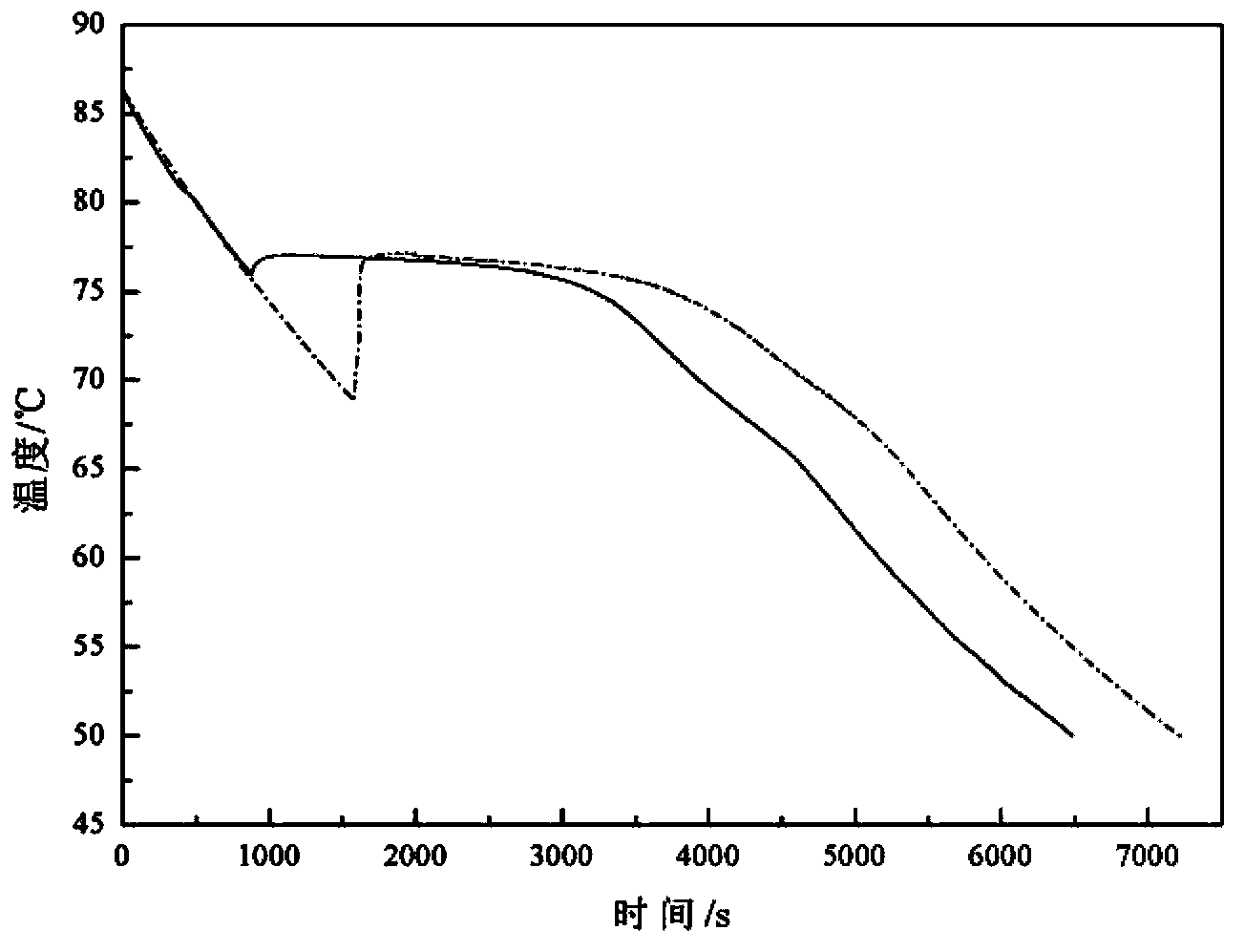

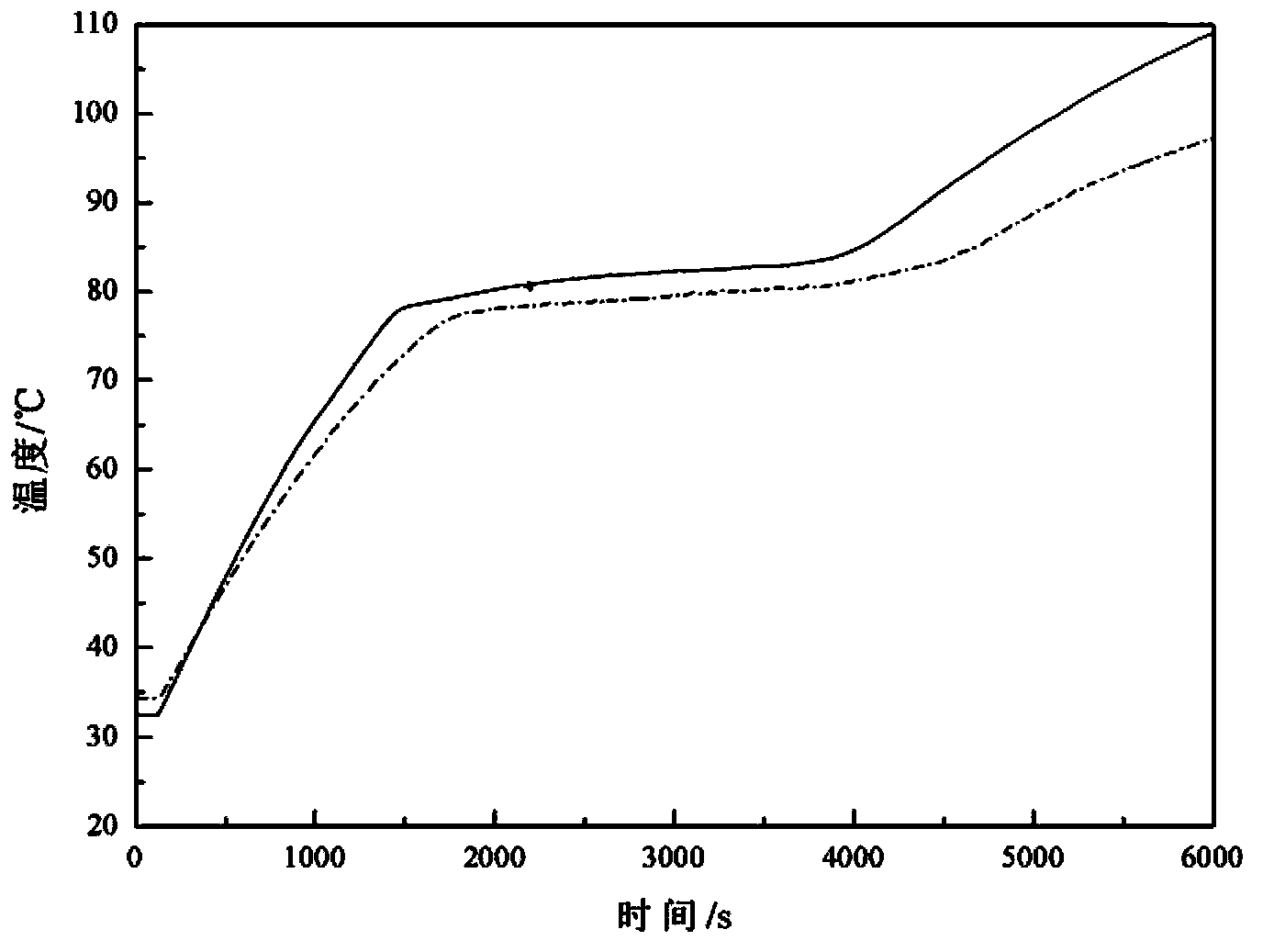

The invention discloses a device and a method for measuring phase change latent heat of a composite phase change energy storage material, and belongs to the technical field of test of building materials. Obvious shortcomings of small using amount of samples, large error, low representativeness and the like exist in the conventional method for measuring the thermal performance of a composite phase change material. The invention discloses a device for measuring the phase change latent heat of the composite phase change energy storage material and provides a corresponding measurement method. The invention is characterized in that a large quantity of phase change materials are heated by disk-type resistance wires under the condition that the heat of a constant-temperature water bath is preserved; and a curve of the temperature changed along with the time is measured by a plurality of groups of thermocouples and subjected to regression analysis, so that the thermal performance of the composite phase change material can be reflected really. The device and the method have great significance for popularization and application of the composite phase change material, particularly for building energy conservation.

Owner:CHINA BUILDING MATERIAL TEST & CERTIFICATION GRP XIAMEN HONGYE

Three-dimensional gel network carrier and form-stable phase change composite material

InactiveCN101709104AReduce lossesNo lossHeat-exchange elementsPhase change enthalpyPolyethylene glycol

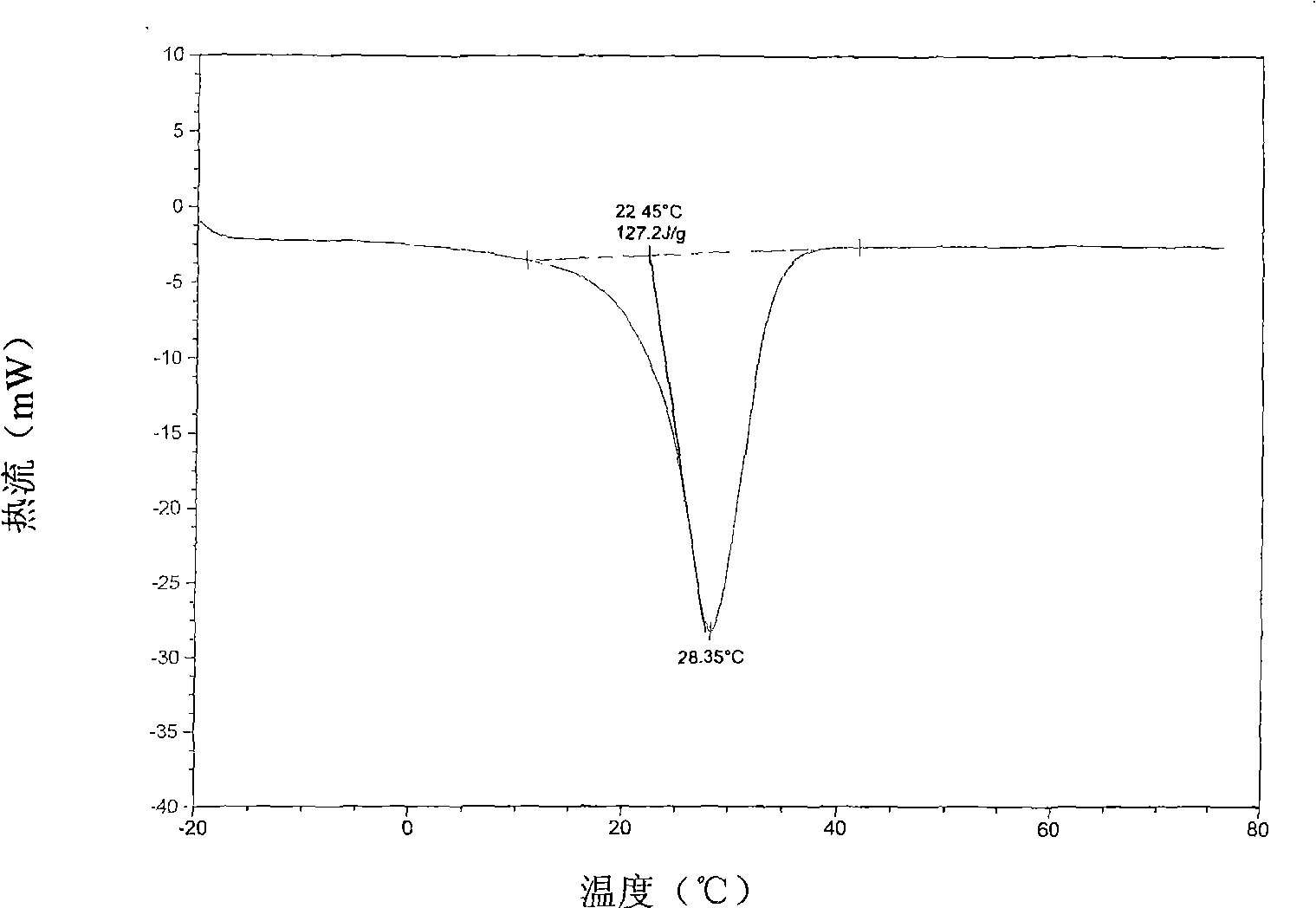

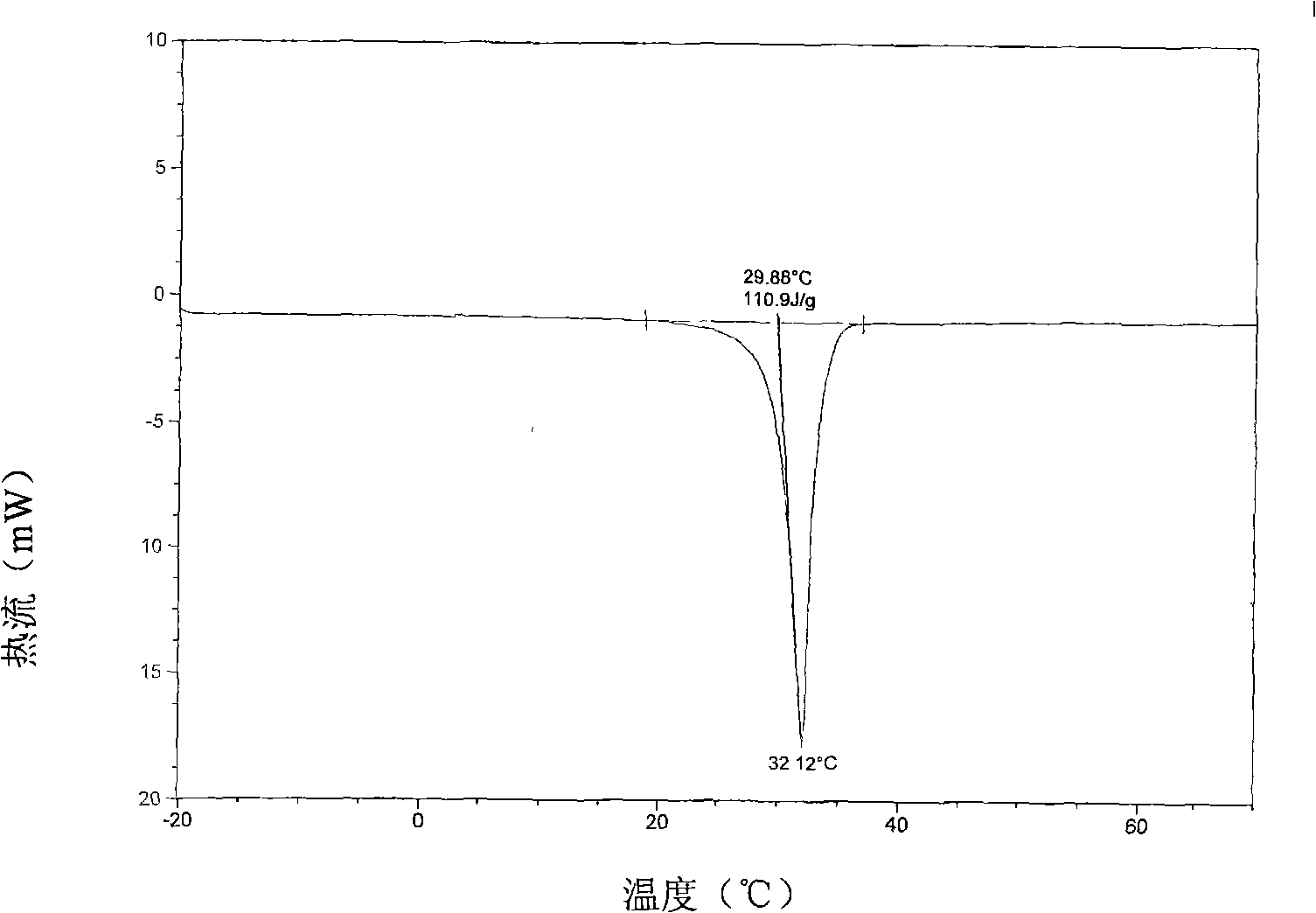

The invention relates to a three-dimensional gel network carrier and a form-stable phase change composite material which adopt fatty acid (hydrocarbon), polyethylene glycol and other organic phase change materials as work material and use poly-(N-hydroxymethyl)-acrylamide heat-shrinkable interpenetration network as form-stable carrier. The preparation method of the phase change composite material comprises the following steps: firstly adopting low temperature eutectic method to select multiple components composite phase change material with proper phase change temperature, high phase change enthalpy and low cost, designing and determining the preparation method of the interpenetration network carrier and the addition mode of the composite phase change material and the combination mode of the carrier, preparing the form-stable phase change composite material based on multiple actions of bonding, physical adsorption and network confinement, cooling and grinding to obtain the form-stable heat storage functional particles. The form-stable phase change composite material containing 50%-75% of material can be prepared by the method, the maximum phase change enthalpy can be up to 110J / g, and the form-stable phase change composite material prepared by the method can be directly applied in the textile field, building field, military field, etc.

Owner:DALIAN POLYTECHNIC UNIVERSITY

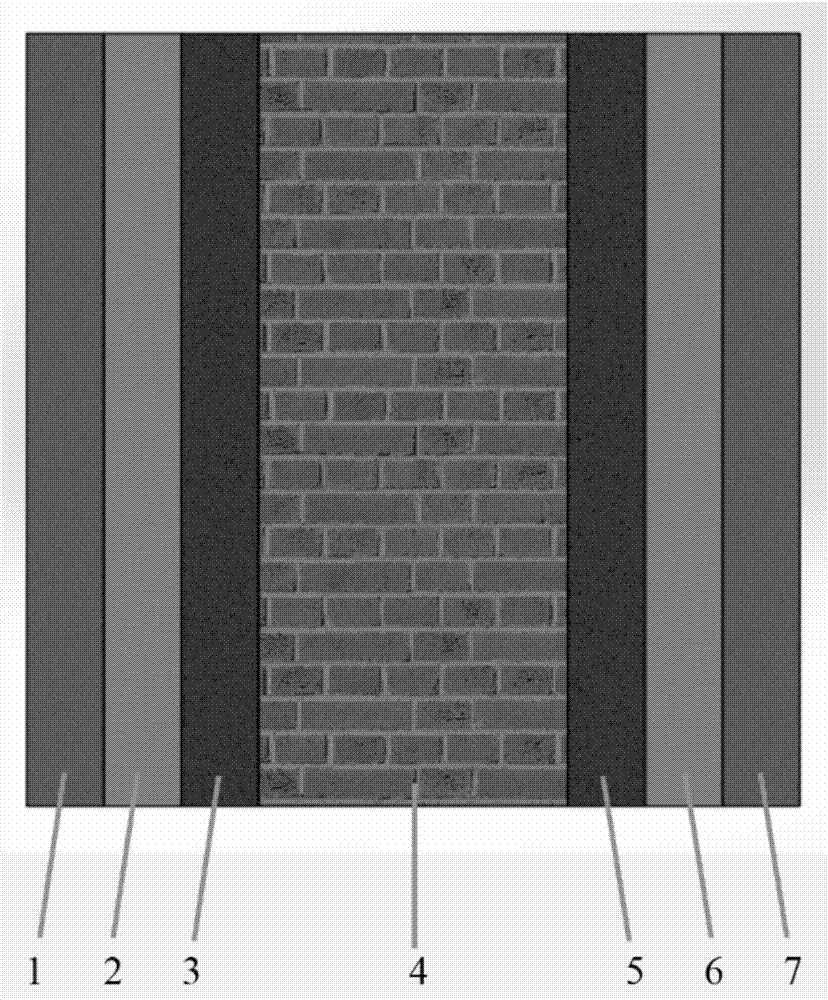

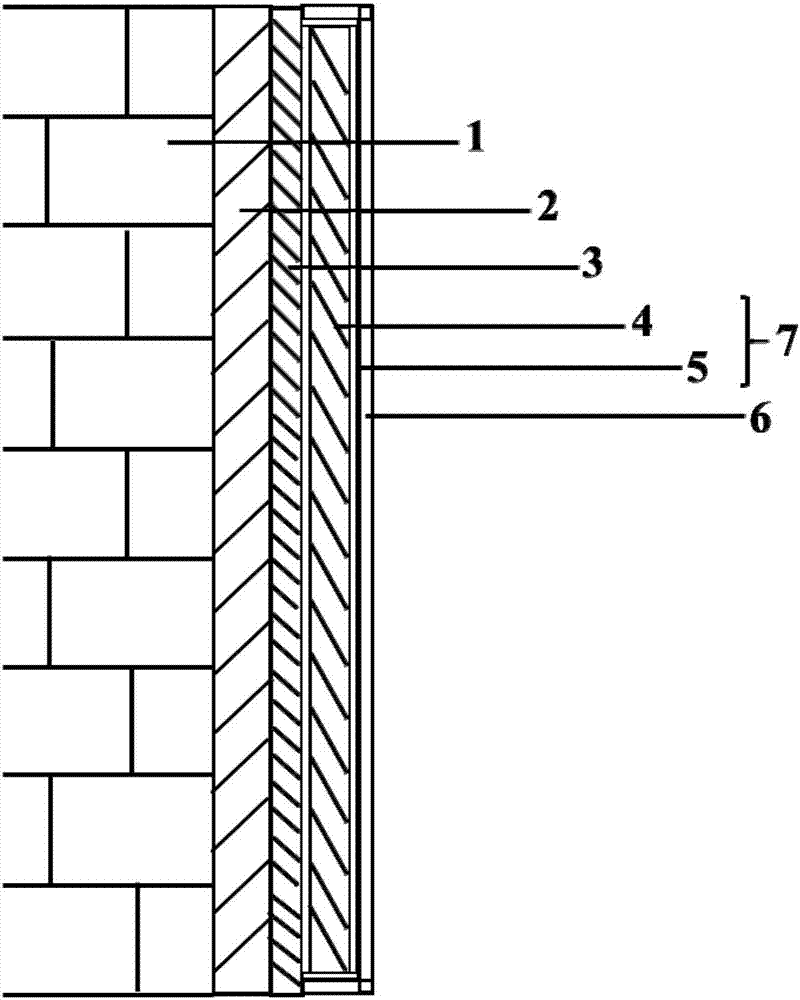

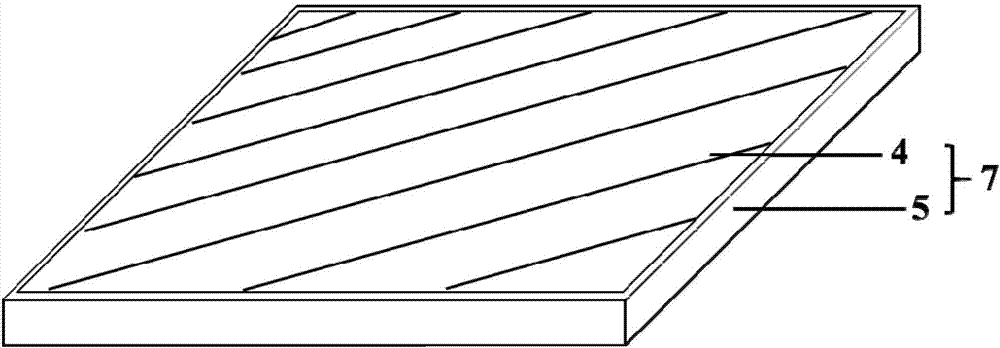

Energy-storing building wall structure containing double-layer phase-change material plate

Owner:SOUTH CHINA UNIV OF TECH

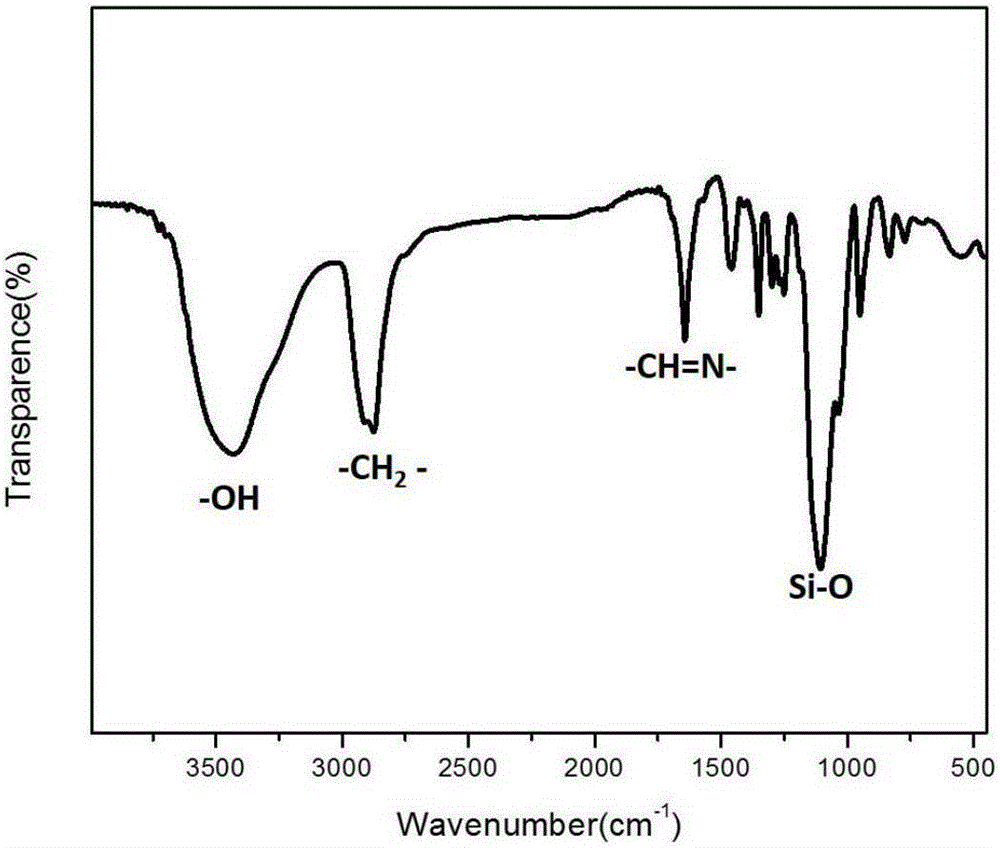

Preparation method of modified aerosil-based composite phase-change material

The invention discloses a preparation method of a modified aerosil-based composite phase-change material. The preparation method includes the steps that a modified aerosil carrier material is prepared first, prepared modified aerosil is placed into a prepared phase-change material solution after being subjected to vacuum drying, a phase-change core material is adsorbed based on the large specific area and the nanopore structure of the modified aerosil carrier material, and after drying, the modified aerosil-based composite phase-change material with a shaping effect is obtained. The preparation method has the advantages that the novel modified aerosil-based composite phase-change material is developed; the prepared modified aerosil-based composite phase-change material can effectively prevent leakage, corrosion and other problems, the loading capacity of the porous phase-change material can be improved, and the service life of the porous phase-change can be prolonged; the method just needs mild reaction conditions and is simple in process, short in period and suitable for industrial production.

Owner:南京逸柔蒂雯新材料科技有限公司

Power battery thermal management system with functions of efficient heat dissipation and efficient heating

InactiveCN106033827AEfficient dischargeAchieve temperature control effectSecondary cellsBatteriesAutomotive batteryElectrical battery

Owner:广东万锦科技股份有限公司

Phase-change energy-storage building insulation structure

InactiveCN107227807AResolve separabilitySolve the shortcomings of large supercoolingConstruction materialWallsInsulation layerPhase change

The invention discloses a phase-change energy-storage building insulation structure. A wall structure is successively provided with a wall substrate, an insulation layer, a directional structural plate, a fixed-form phase-change energy-storage insulation board and an exterior board in the direction from outdoor to indoor, and the fixed-form phase-change energy-storage insulation board comprises an inorganic composite phase change material and a packaging plate; the inorganic composite phase change material is composited from inorganic hydrated salt and a porous structure carrier, and the phase transition temperature of the phase change material is 10-40 DEG C; in inorganic composite phase change material, the weight percentage content of the inorganic hydrated salt is 40-95%, and the inorganic composite phase change material is coated with light-cured resin with fire resistance and corrosion resistance. The phase-change energy-storage building insulation structure has the good effects of heat preservation and thermal insulation, and can store cold quantity in outdoor air at summer night in the phase-change energy-storage insulation board; in the daytime, the stored cold quantity is released into indoor air so as to prolong the time of an indoor peak temperature, reduce the fluctuation of the indoor temperature, improve the environmental comfort and reduce the energy consumption of an air conditioner in summer.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of nano particle-doped phase change microcapsule

The invention discloses a preparation method of a nano particle-doped phase change microcapsule. The preparation method comprises following steps: a nano material is subjected to surface treatment, and then is added into a core material after surface treatment so as to obtain a composite nano core material emulsion; a prepared prepolymer capsule wall material is added into the nano core material emulsion so as to obtain a capsule suspension liquid loaded with the nano material; and the capsule suspension liquid is subjected to filtering, washing, drying, and grinding so as to obtain nano particle-doped phase change microcapsule powder. According to the preparation method, the functional nano material is subjected to pretreatment, and then is doped into a shell material or the core material of the microcapsule, so that synergistic effects with a phase change material in the microcapsule are achieved; and loading amount of the nano particle on different parts of the microcapsule is controlled by controlling surface energy of the nano material, and further more nano composite phase change material microcapsules with a plurality of functions (heat functions, optical functions, magnetic functions, and electric function) are prepared.

Owner:XI'AN POLYTECHNIC UNIVERSITY

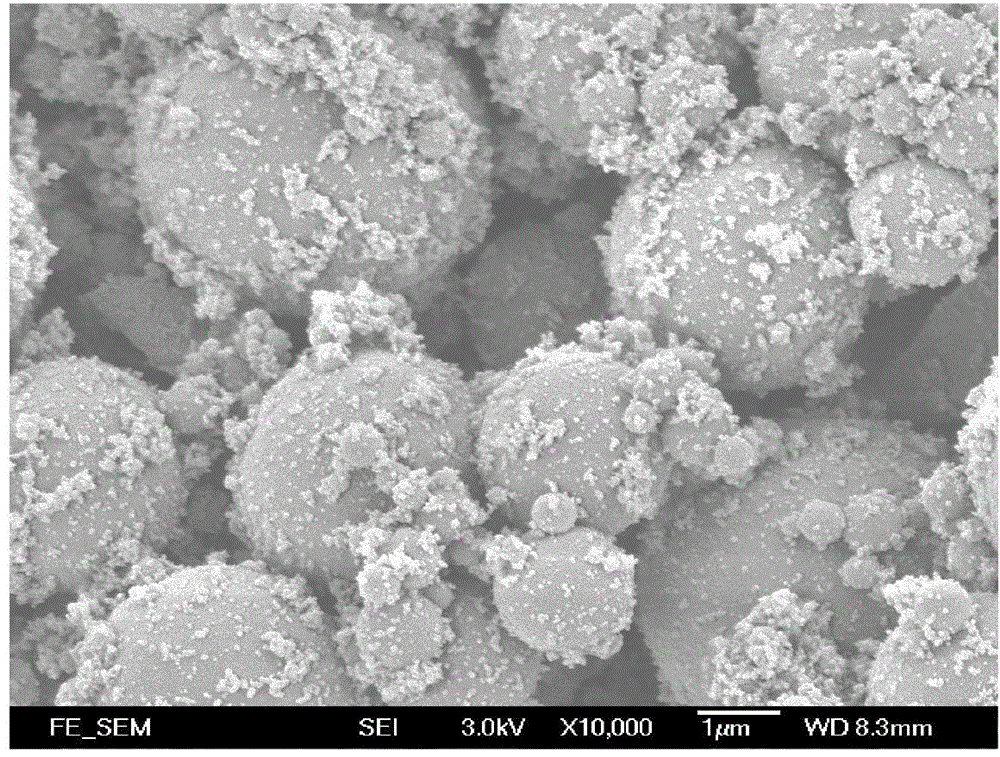

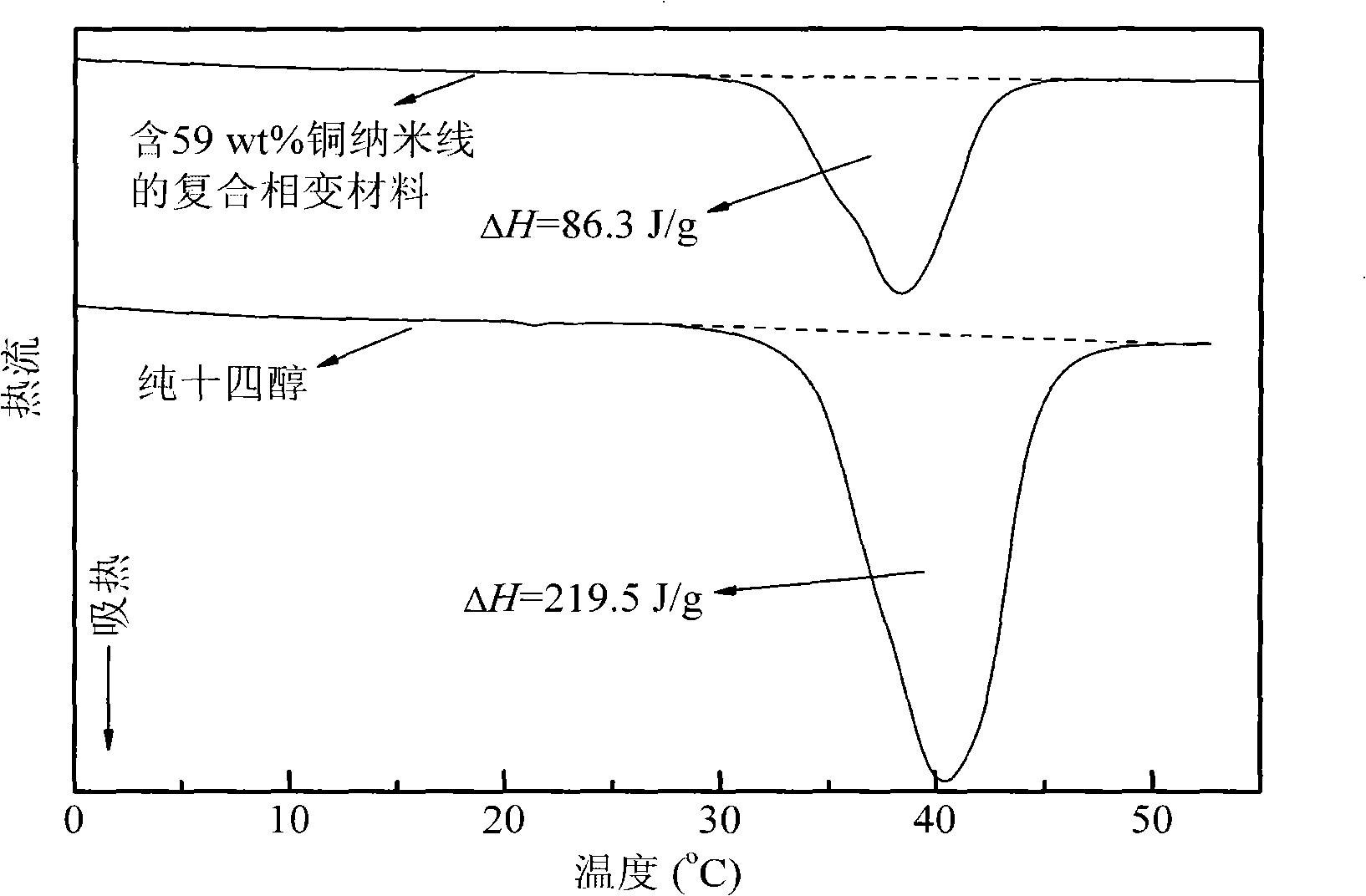

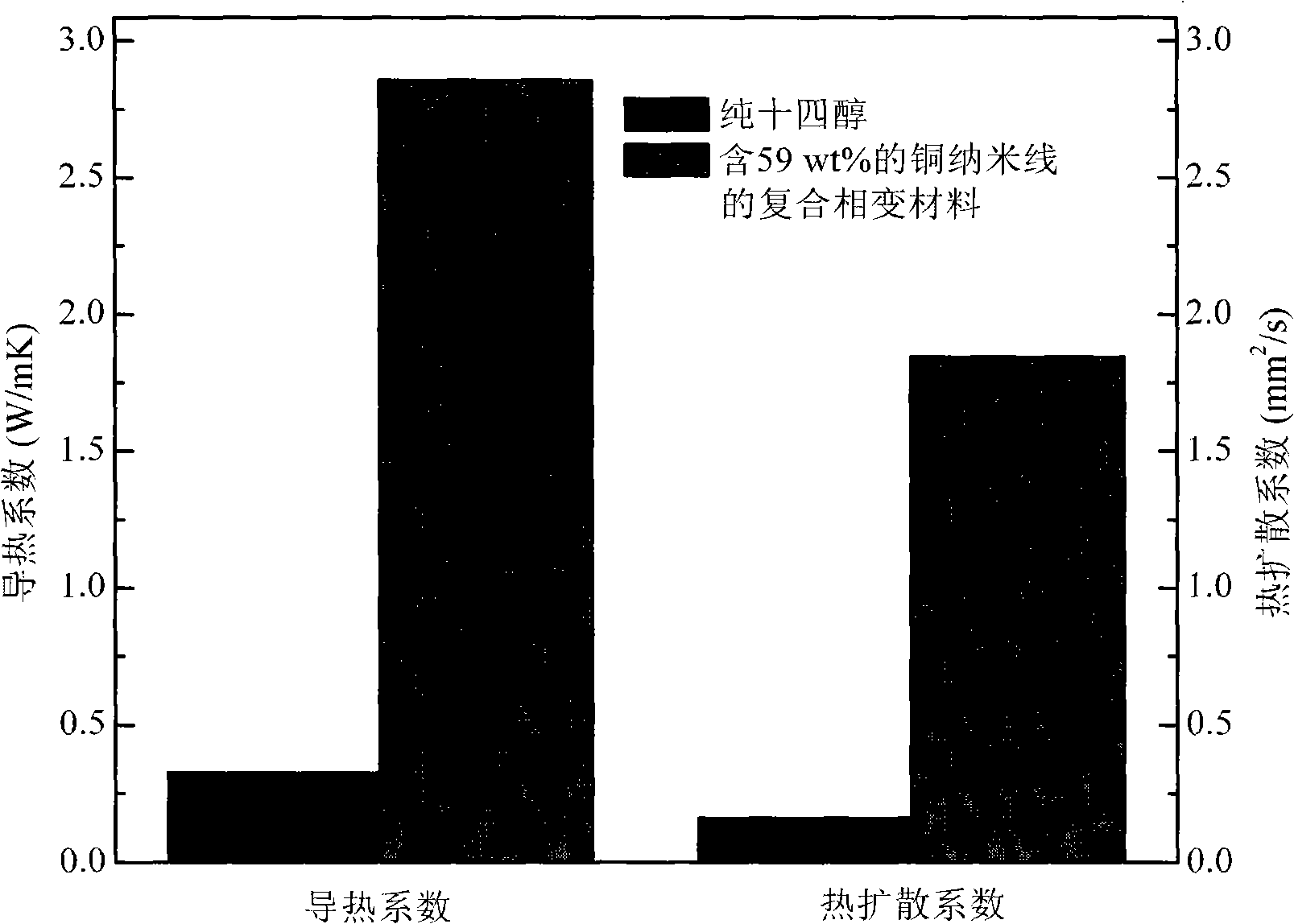

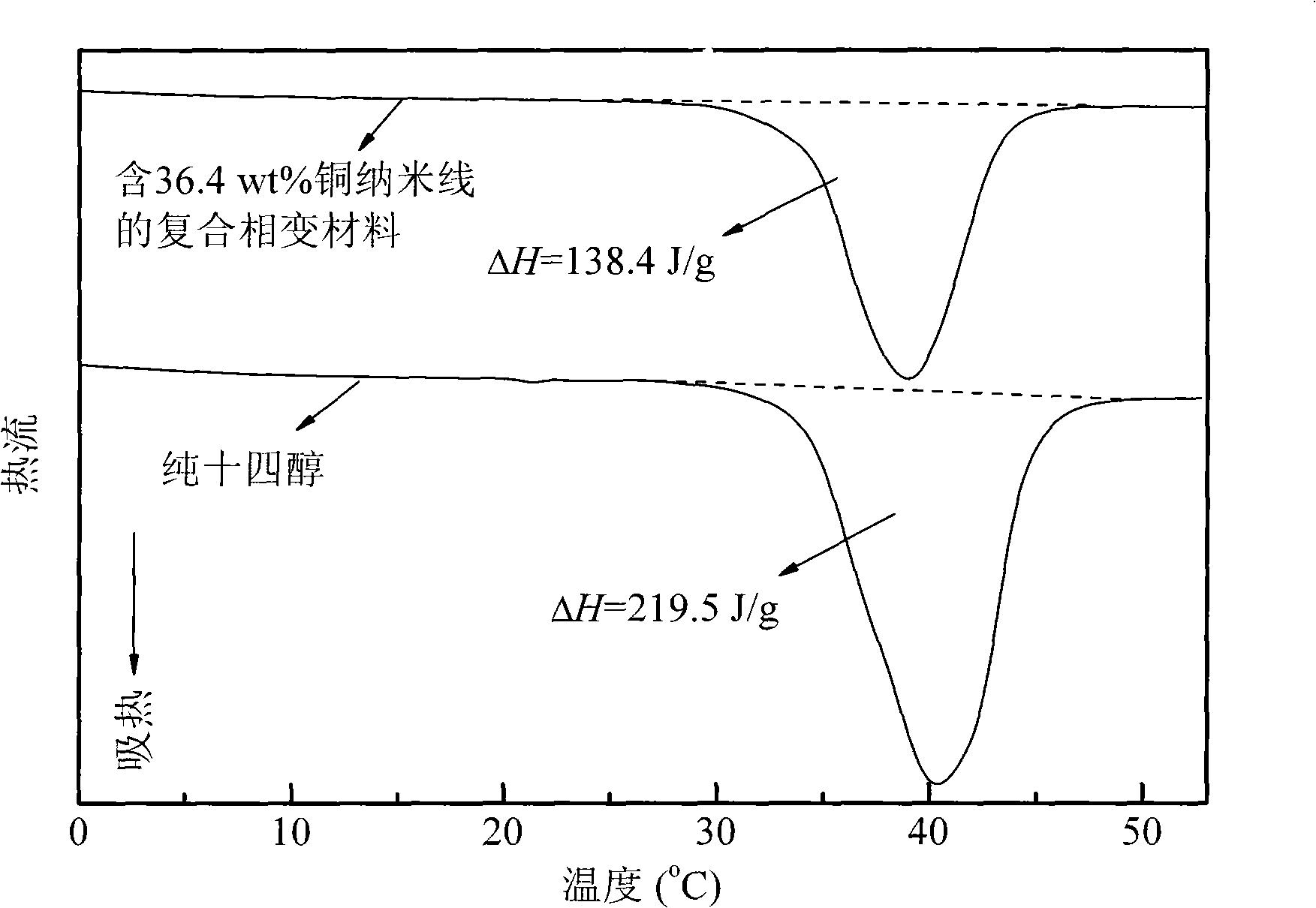

Method for preparing composite phase-changing material

The invention relates to a preparation method of the phase change material, in particular to a preparation method of the compound phase change material which has a higher latent heat of phase change and a high thermal conductivity under the solid and the liquid states. The preparation steps are as follows: firstly, metal nanowires are prepared; secondly, the metal nanowires are dispersed into an organic solvent; thirdly, an organic phase change material and the mixture are mixed; fourthly, the mixture is dispersed by ultrasonic under the condition of heating, and the organic solvent is removed. The phase change material prepared by the method has the advantages that the art is simple, the cost is low, and the thermal conductivity of the organic phase change material is enhanced greatly while the latent heat of phase change is maintained, thus the performance of the organic phase change material is improved effectively, and the application scope is greatly developed.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of phase transformation material for microcapsult packing and forming

InactiveCN1657587AHigh mechanical strengthImprove hydrophilicityHeat-exchange elementsMicroballoon preparationParaffin waxPhase change enthalpy

A phase-changing material in the form of micro capsule is prepared from the phase-changing material (paraffin wax) and basic supporting material (polystyrene and polyethene) through heating for fusing, mixing for coating, and microcapsule packing by in-situ polymerizing by melamine modified urea-aldehyde resin. It has adjustable phase-changing temp (0-70 deg.C) and high phase-changing enthalpy (138 KJ / kg).

Owner:北京巨龙博方科学技术研究院 +1

Water cooling and composite phase change material combined power battery heat dissipating device

ActiveCN104241729AImprove thermal conductivityIncrease heat storageSecondary cellsBatteriesPower batteryProcess engineering

The invention discloses a water cooling and composite phase change material combined power battery heat dissipating device which comprises a box body and a base plate arranged at the bottom of the box body, wherein a water inflow channel and a water outflow channel which are used for accommodating cooling water are respectively arranged inside the base plate and along two long edges, aperture passages communicated with the water inflow channel and the water outflow channel respectively are arranged on the upper surface of the base plate and along the two long edges, tabular micro-channel heat exchangers are arranged on the base plate at certain intervals in the length direction, micropore flow passages are arranged inside the tabular micro-channel heat exchangers, the two end ports of each micropore flow passage are respectively connected with an aperture passage I communicated with the water inflow channel and an aperture passage II communicated with the water outflow channel, and spaces formed by the tabular micro-channel heat exchangers, the base plate and the box body are filled with a composite phase change material. The water cooling and composite phase change material combined power battery heat dissipating device provided by the invention has the advantages of high heat accumulation and heat dissipation rates, convenience in operation and maintenance, low cost and the like, can be used for heat dissipation of high-power and quick charge-discharge power batteries, and can improve the working performance and the reliability of batteries.

Owner:SOUTH CHINA UNIV OF TECH

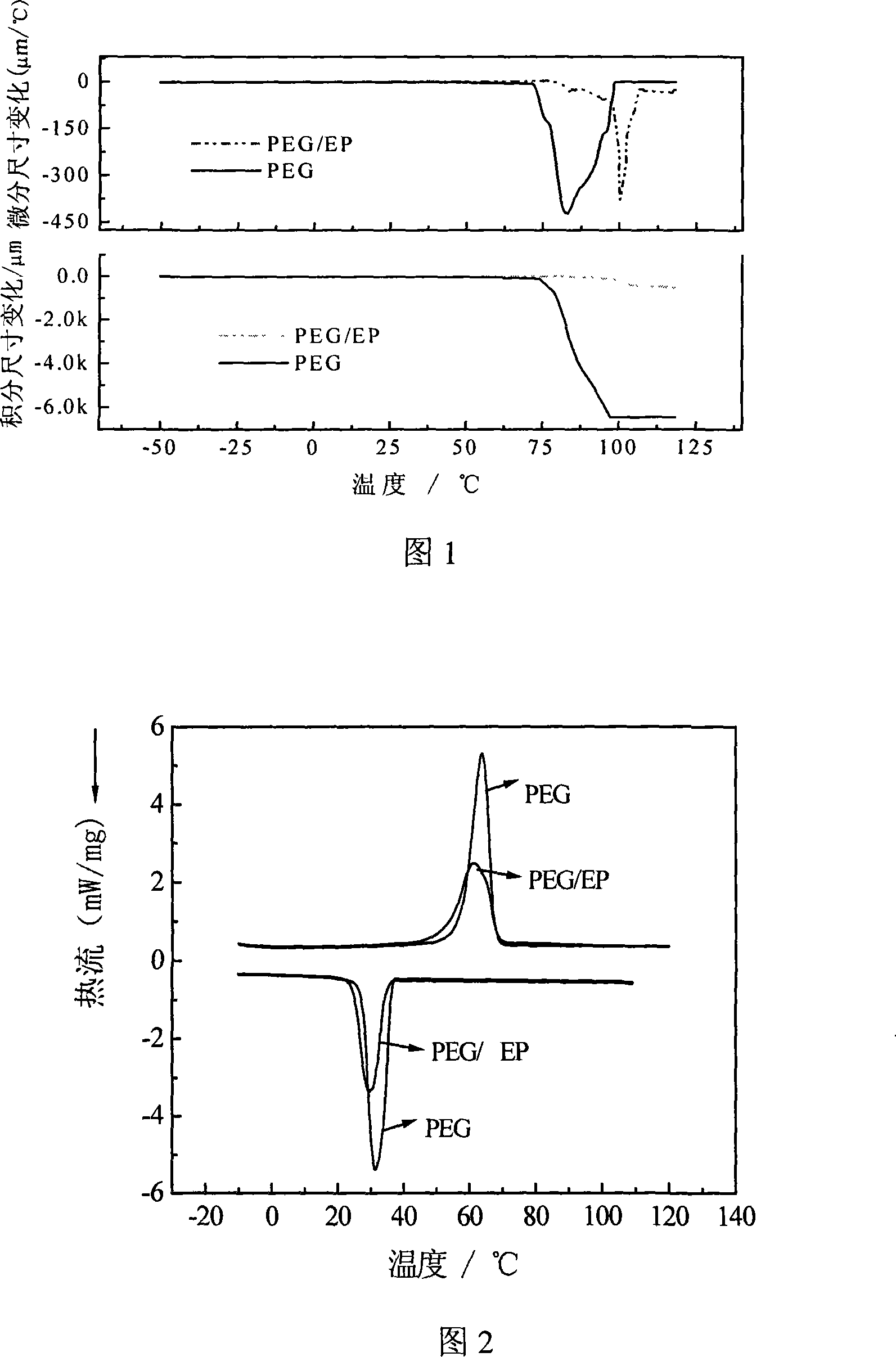

Method for preparing polyethylene glycol and epoxy resin formed composite phase-change materials

InactiveCN101230256ALarge latent heatGood energy storageHeat-exchange elementsFirming agentPolyethylene glycol

The invention discloses a preparation method of polyethylene glycol and epoxy resin shaping composite phase change material. The invention includes the following steps of (1) adding polyethylene glycol and epoxy resin into a reaction container, adding the mixture liquid of firming agent and accelerant after polyethylene glycol is completely dissolved and is dispersed evenly with the epoxy resin; (2) defoaming the mixture obtained from step (1) in vaccum, pouring the mixture into a die applied with parting agent, transferring the die into an oven for solidification and moulding for 24-48 hours, then cooling the die until demoulding. The materials proportions are that epoxy resin condensate is 10 to 50 percent, polyethyleneglycol is 50 to 90 percent; the contents of the firming agent and the accelerant respectively account for 8 to 40 percent and 1 to10 percent of the epoxy resin. The composite phase change material of the invention not only has large potential heat and excellent energy accumulating effect, but also has good figuration performance and high stability.

Owner:SOUTH CHINA UNIV OF TECH

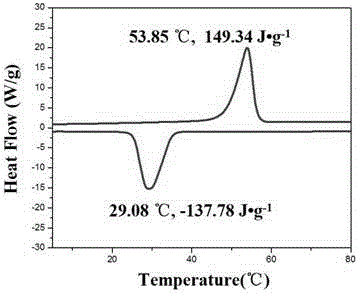

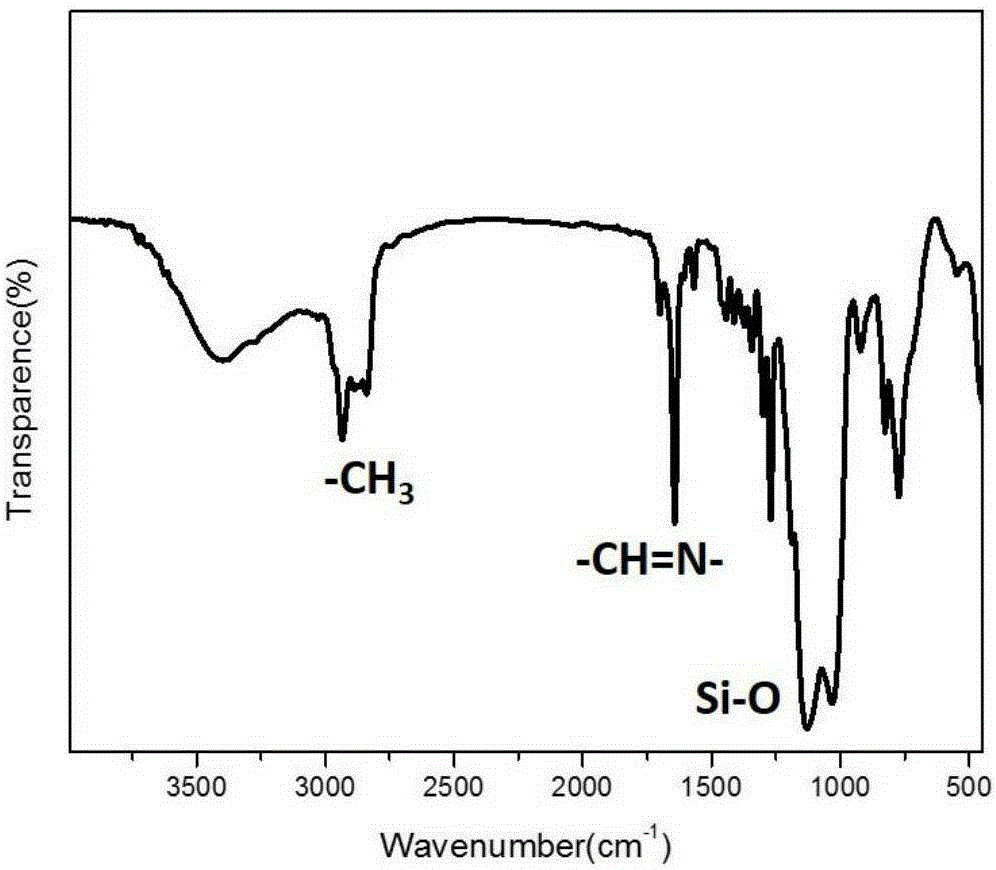

Composite phase-change material and preparation method thereof

The invention discloses a composite phase-changing material and making method, which comprises the following steps: 1) blending carbowax with molecular weight at 2000-10000 and anhydrous alcohol with weight rate at 0. 21-0. 34; heating to stir; forming the composite liquid; 2) dripping p-ethyl-siliconic acid with weight rate at 0. 61-0. 87 corresponding to carbowax at 0. 61-0. 87 into the composite solution in the step 1); stirring; adding water with molar weight at 2:1-6:1 corresponding to p-ethyl-siliconic acid; adjusting pH value of solution at 0. 5-2; stirring under normal temperature; 3) aging the sol in the step 2) for 24h under 40 deg. c; forming the gel; drying under high temperature to obtain the carbowax / silica composite phase-changing material. The invention stablizes the shape and good heat stability, which forms even composite phase-changing material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

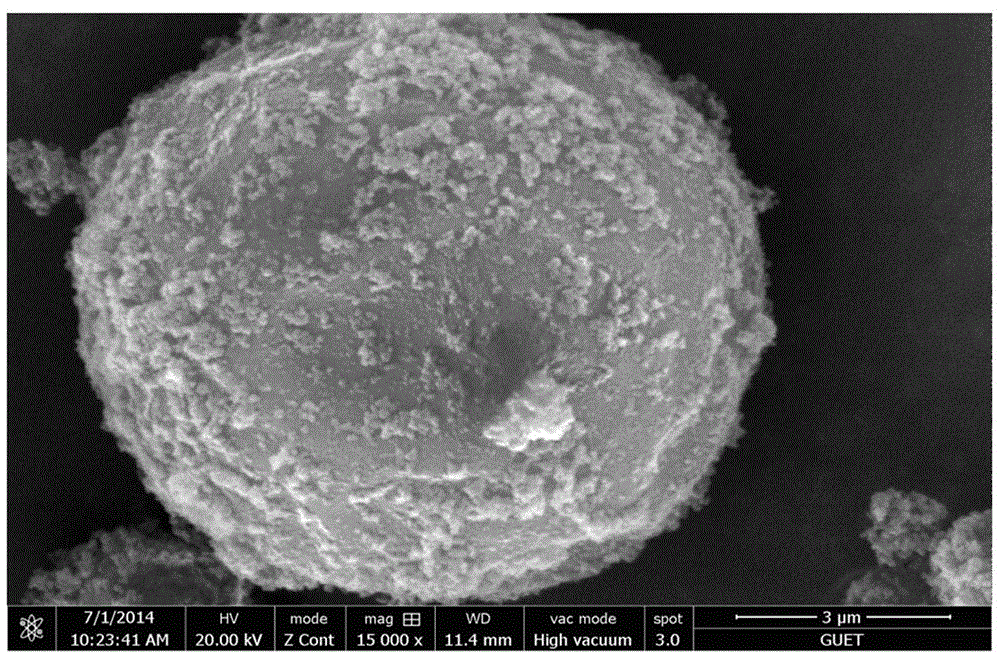

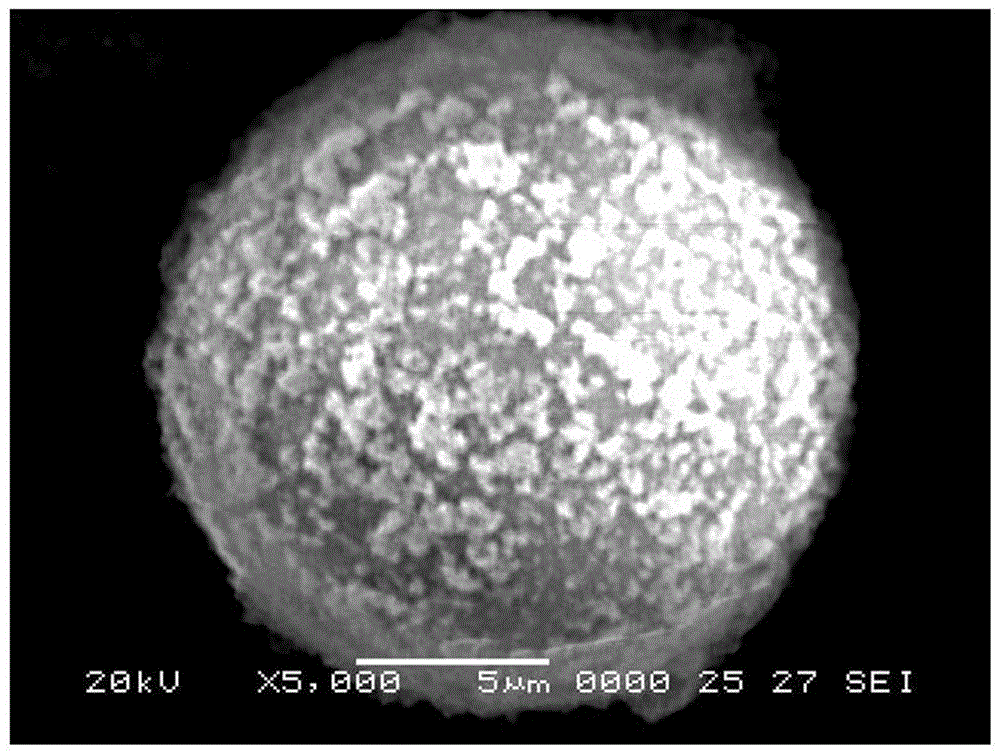

Nano thermal conductivity enhanced microcapsule composite phase change material and preparation method thereof

ActiveCN106085368AImprove efficiencyImprove thermal conductivityHeat-exchange elementsMicroballoon preparationPhase change enthalpyNanoparticle

The present invention discloses nano thermal conductivity enhanced microcapsule composite phase change material and a preparation method thereof, nano thermal conductivity enhancing material is high thermal conductivity nanoparticles such as boron nitride (BN), carbon nanotubes (CNTs) or graphene oxide (GO), and a microcapsule core material is organic phase change material. The phase change material, an emulsifier and a solvent are mixed and prepared according the preparation method of the invention to obtain thermal conductivity enhanced microcapsule composite phase change material based on nanoparticles such as BN, CNTs and GO, wherein all the added BN, CNTs and GO are modified to comprise hydroxyl groups. In addition, it is possible to add the nano thermal conductivity enhancing particles such as BN, CTNs or GR into the core material of the microcapsule core material according to actual needs. The composite phase change material prepared herein has high phase change enthalpy, good thermal cycle stability, excellent thermal conductivity and the like, has a simple preparation process, stable structure and high encapsulation rate and is widely applicable.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Energy-accumulating temp-controlled thermoplastic cross-link high-molecular composite material with solid-solid phase change and its preparing process

InactiveCN1482204AHigh energy storage densityImprove thermal stabilityHeat-exchange elementsCross-linkThermoplastic

The present invention features that the material has crosslinked crystalline polyolefin as base body and crystalline alkyl hydrocarbon dispersed inside the crosslinked net as the composite material for phase change energy accumulation. In the composite material, the phase change energy accumulating component accounting for 40-80 % has solid-solid phase conversion at phase change temperature of 20-80 deg.c and phase change enthalpy greater than 80 J / g. The composite phase change material has relatively high energy accumulating density and excellent heat stability, may be used as energy accumulating material for the accumulation of solar energy and industrial afterheat, constant temperature in building and energy saving in air conditioner and as temperature control material in electronic instrument, machinery, etc. widely.

Owner:云南玮昊能源发展有限公司

Preparation method of orderly porous matrix shaping composite phase change material

InactiveCN103923614AImprove thermal stabilityHigh porosityHeat-exchange elementsMesoporous silicaVolumetric Mass Density

The invention provides a preparation method of an orderly porous matrix shaping composite phase change material, and belongs to the field of a composite phase change material. The preparation method comprises the following steps: firstly preparing an orderly mesoporous silica carrier, and designing, adjusting and controlling the porous-channel structure, pore size and surface property of the carrier; secondly, using a phase change core material for preparing corresponding liquor, dispersing the prepared porous carrier in prepared phase change core material liquor, adsorbing the phase change core material by using the relatively strong capillary action, surface tension and the like of the porous carrier material so as to realize the high-efficiency filling of the core material in combination of the bonding effects of functional groups on the surface of the carrier on the core material, and drying so as to obtain the composite phase change material with relatively good heat storage capacity and relatively high stability. The composite phase change material has the advantages that the carrier is large in specific surface area, high in porosity and small in pore diameter, has orderly porous-channels and strong immobilization capacity on the phase change core material and is difficult to leak, the filling quantity of the core material is large, and the composite phase change material is high in energy storage density, good in heat stability, widely applied, difficult to burn, green and safe in use.

Owner:UNIV OF SCI & TECH BEIJING

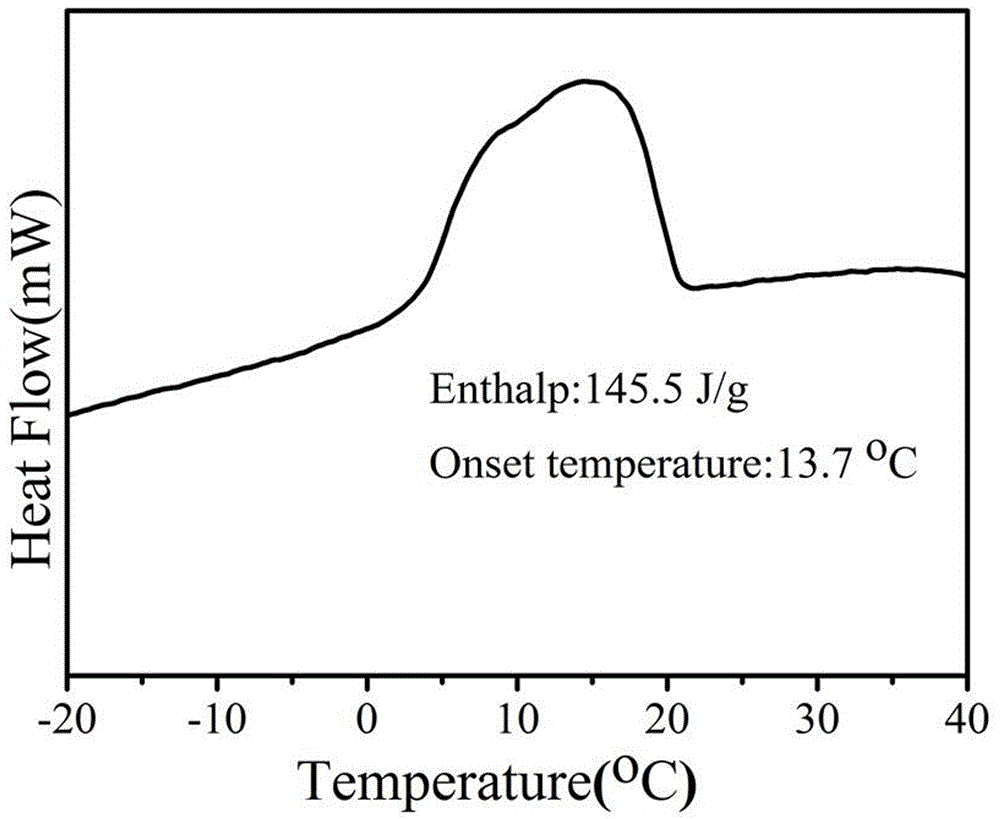

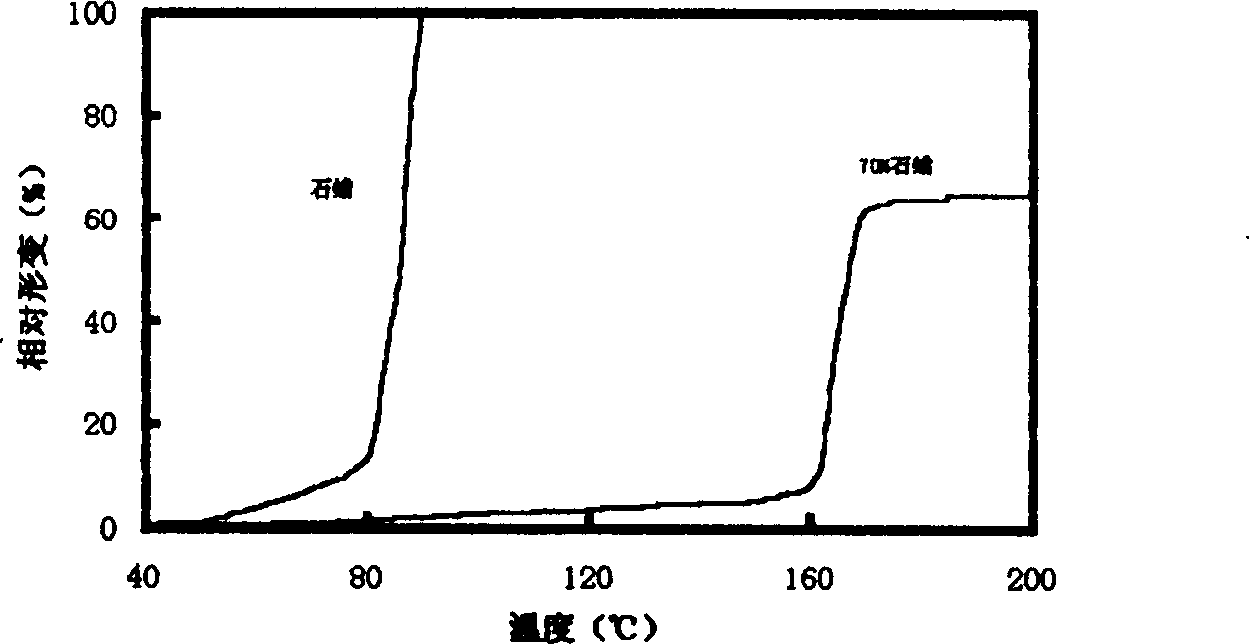

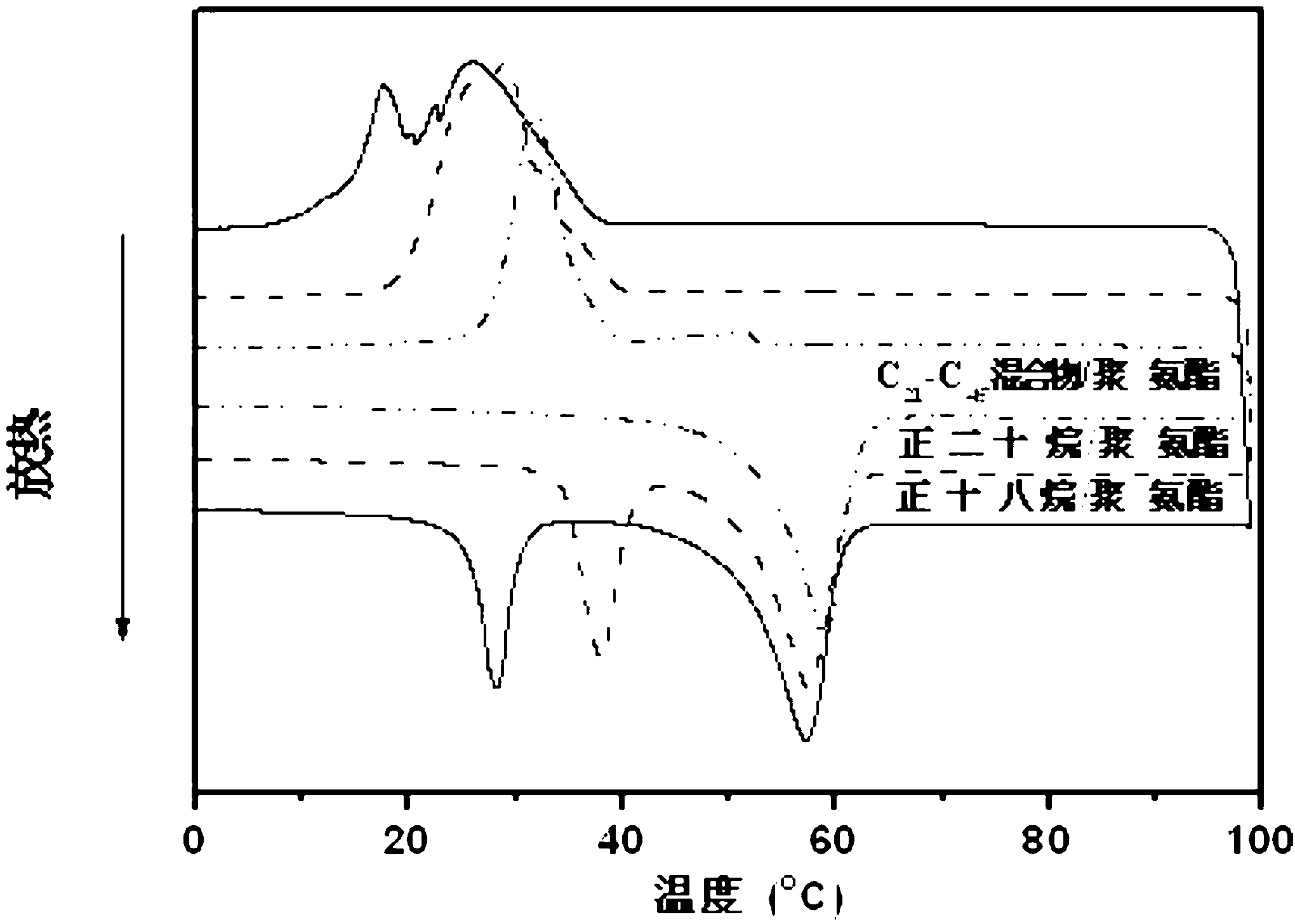

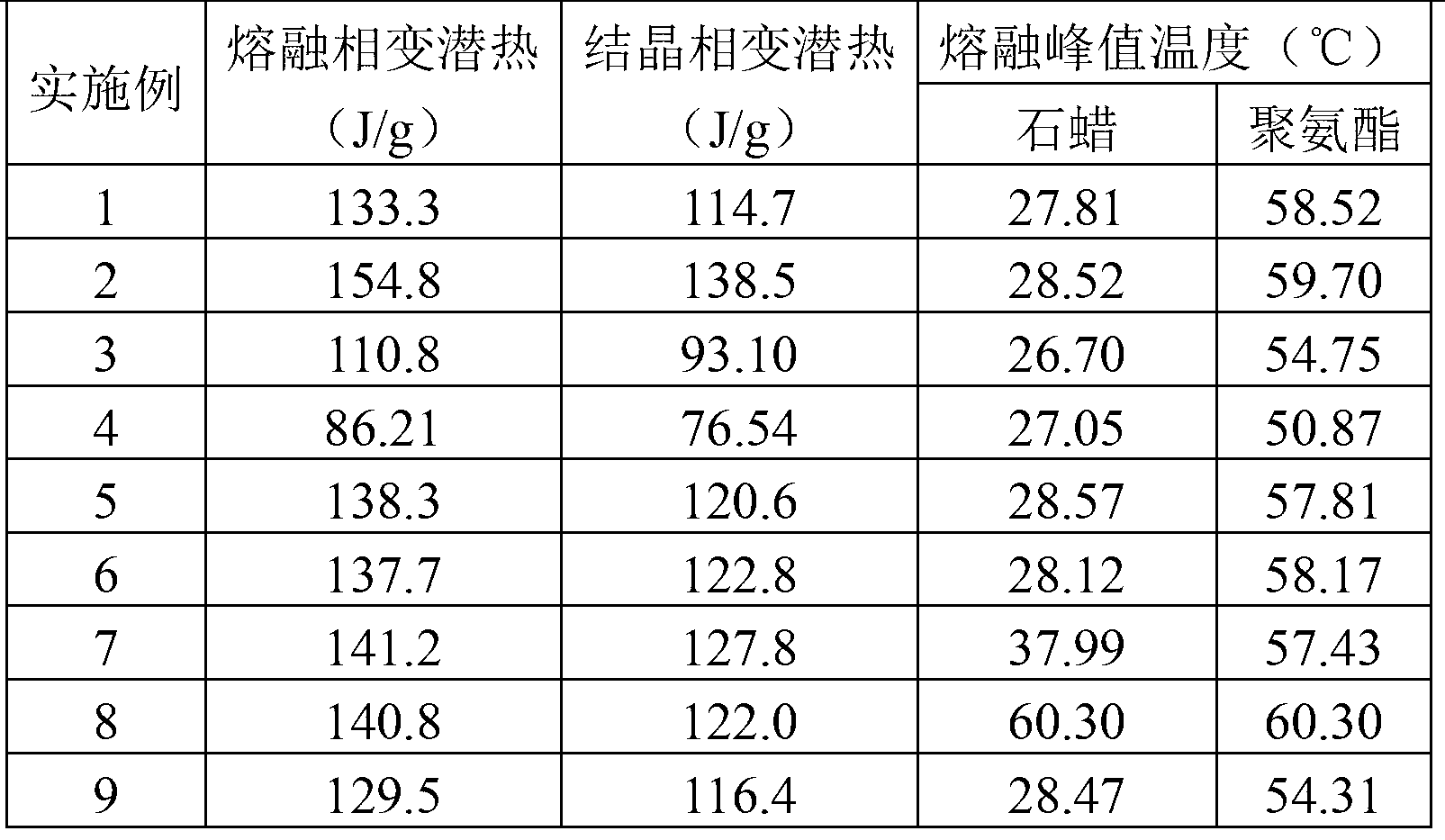

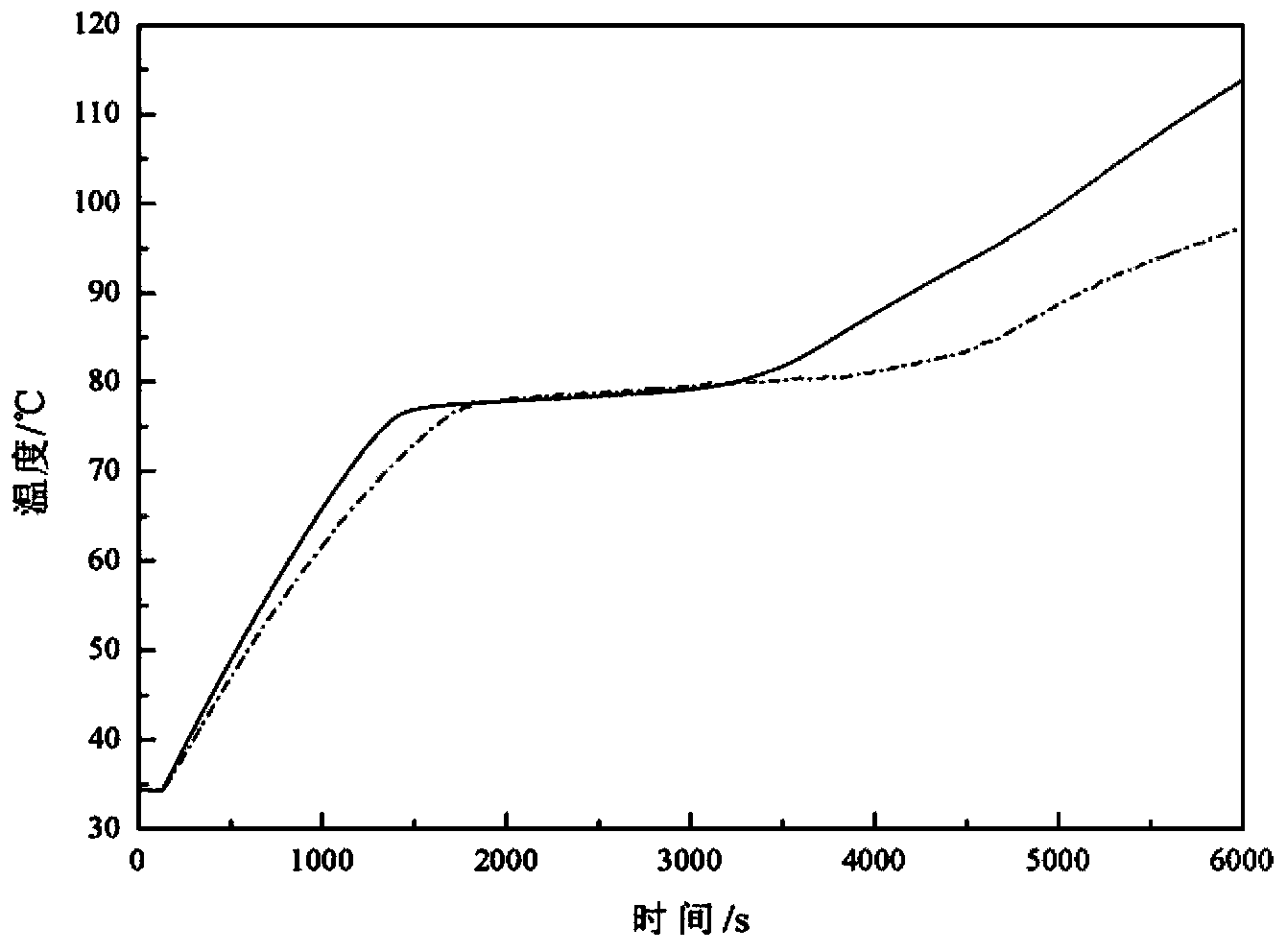

Preparation method of paraffin/polyurethane solid-solid composite double-phase change energy storage material

ActiveCN103224601AHigh latent heat of phase changeWide phase transition temperature rangeHeat-exchange elementsParaffin waxDouble phase

The invention discloses a preparation method of a paraffin / polyurethane solid-solid composite double-phase change energy storage material, comprising the following steps: selecting raw materials which comprises the following components: by weight, 40-90 parts of polyethylene glycol, 4-20 parts of isocyanate, 0-10 parts of a chain extender, 0-50 parts of paraffin, 0-5 parts of a surfactant and 0-1 part of a catalyst; melting glycol and carrying out vacuum-pumping processing, mixing the molten glycol with the surfactant and paraffin, adding isocyanate, the chain extender and the catalyst to react at a temperature of 60-90 DEG C to obtain a performed polymer, carrying out deaeration on the performed polymer, injecting the deaerated performed polymer into a mould, solidifying, cooling and demoulding. According to the composite double-phase change energy storage material provided by the invention, a paraffin hydrocarbon compound with large latent heat of phase change is used as a filling material, and a polyurethane material with a phase change function is used as a matrix. Latent heat of phase change of the prepared paraffin / polyurethane solid-solid composite double-phase change energy storage material reaches 154J / g, phase-change temperature ranges from 15 DEG C to 70 DEG C, and the material is a composite phase change material having a double-phase change character.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Foam metal composite phase-change material and preparation method thereof

InactiveCN103436240AImprove thermal performanceHigh heat storage densityHeat-exchange elementsHeat conductingImpurity

The invention relates to a foam metal composite phase-change material and a preparation method thereof, and belongs to the technical field of phase-change energy storage materials. A crystallized hydrated salt-foam metal composite phase-change energy storage material is prepared by adopting the adsorption characteristic of a porous foam metal skeleton structure, and a vacuum argon filling state is kept in a preparation process, so that impurities are prevented from entering, and the quality of a product is ensured. The phase-change material is relatively uniformly and sufficiently distributed in a substrate of the foam metal skeleton material, and the shaping characteristic of the composite material is maintained under the combined action of a capillary force and surface tension of foam metal, so that the phase-change material does not leak easily in a phase-change process, and the preparation method of the phase-change material is simple and convenient, high in recombination rate and good in operability. The composite phase-change material has the advantages of high phase-change latent heat in unit volume, high heat storage and release rates, good heat-conducting property, lower supercooling degree, and the like; and the lower heat conductivity and supercooling problems existing after the crystallized hydrated salt phase-change material is applied for a long time are solved effectively.

Owner:BEIHANG UNIV

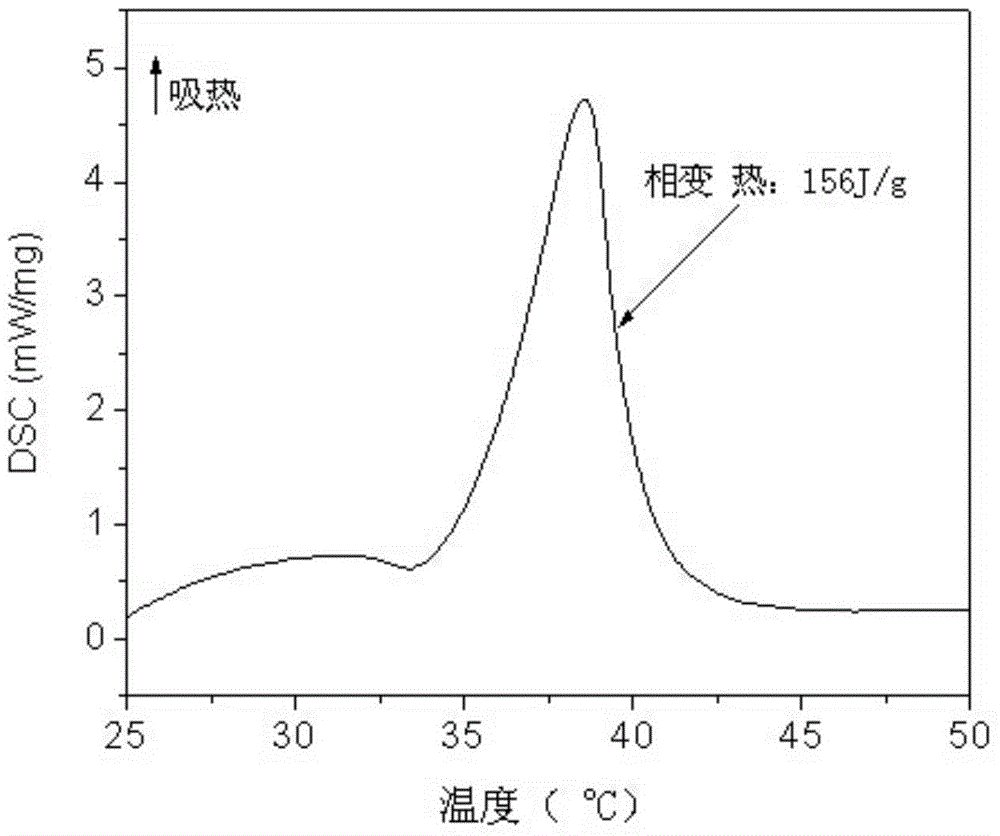

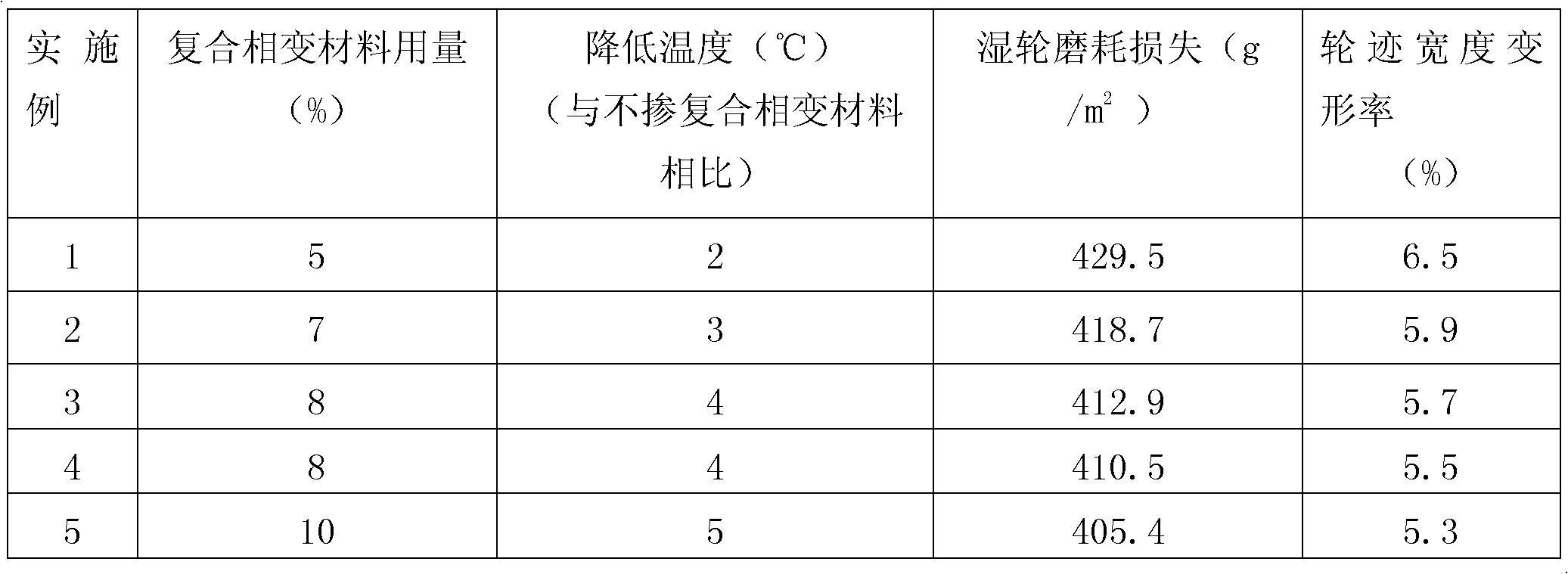

Self temperature adjustment cold mixing bituminous concrete and preparation method thereof

The invention belongs to the technical of bituminous pavement maintenance materials, and particularly relates top a cold mixing bituminous concrete and a preparation method thereof. The self temperature adjustment cold mixing bituminous concrete is characterized by being prepared from the following raw mateirals in percentage by weight: 70-80 percent for the aggregate, 1-3 percent for the filler, 5-10 percent for the composite phase change material, 8-10 percent for water and 6-8 percent for the modified emulsified asphalt. The composite phase change material is made of wax and expanded graphite composited together, the mass ratio of the expanded graphite and the wax is 1:8-9, the phase change temperature of the composite phase change material is 40-50 DEG C, and the phase change heat is 150-160kJ / kg. The process is simple, the cost is low and implementation is easy. The concrete has the function of reducing pavement temperature.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com