Foam metal composite phase-change material and preparation method thereof

A composite phase change material and foam metal technology, applied in the field of shape-setting composite phase change materials and their preparation, can solve the problems of high thermal conductivity, high time and energy consumption, and high heat storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of metal foam composite phase change material according to the present invention comprises:

[0018] - Evenly add the phase change material with a purity ≥ 98% after grinding into the heat storage container in the vacuum argon-filled box, and evacuate the argon-filled box through the vacuum system vacuum pump, and the vacuum degree is not lower than 1×10 -2 Torr;

[0019] - Then, fill the tank with high-purity (purity greater than or equal to 99.99%) argon gas, and close the main argon filling valve after the pressure of the argon gas is balanced with the atmosphere;

[0020] - (due to the low melting point of most crystalline hydrated salt phase change materials) Heating in a constant temperature water bath to achieve indirect and uniform heating of the phase change material, and at the same time put the processed and cleaned metal foam skeleton materials into the heat storage container for heating to make the metal foam Sufficient adsorption of...

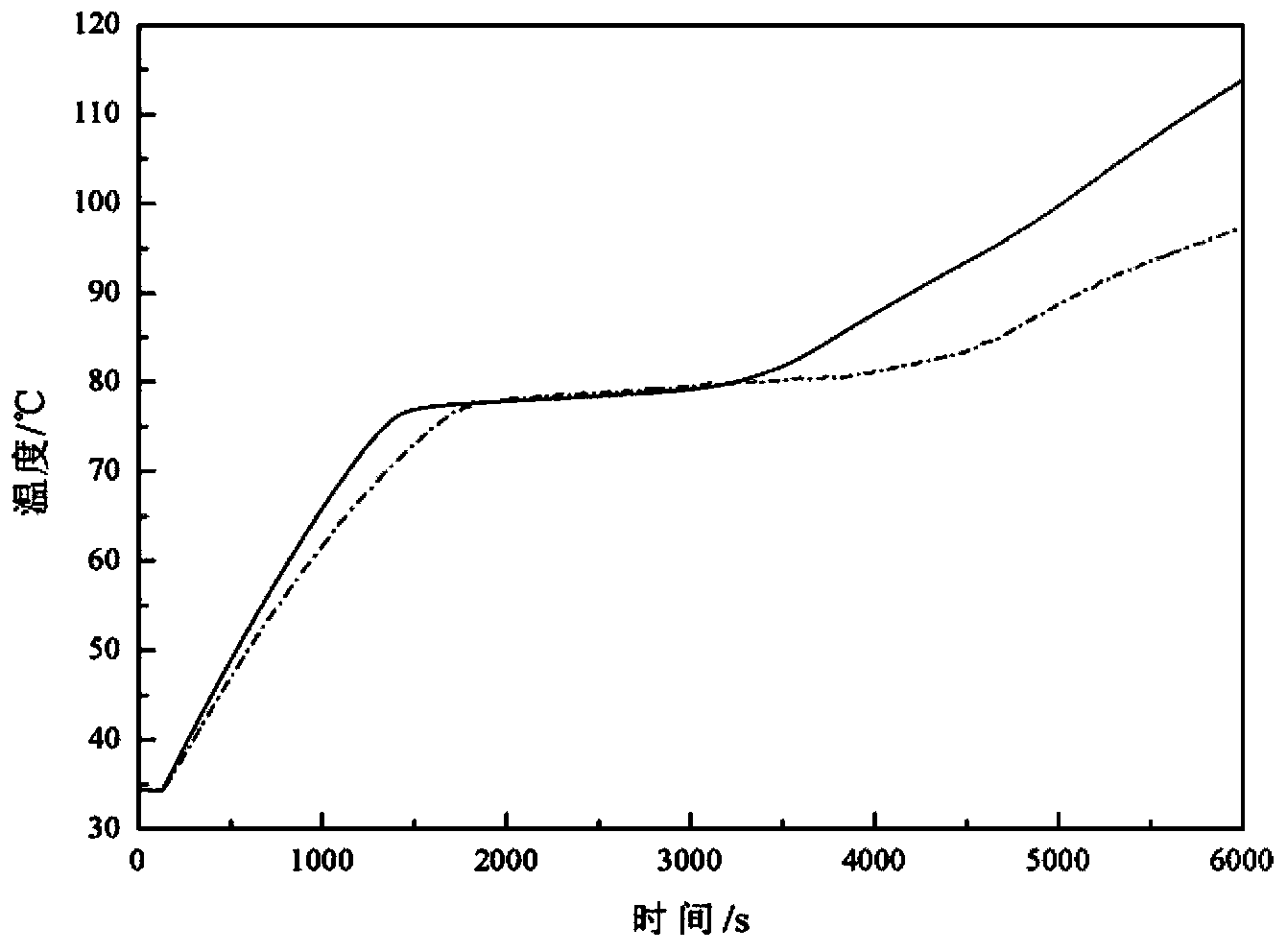

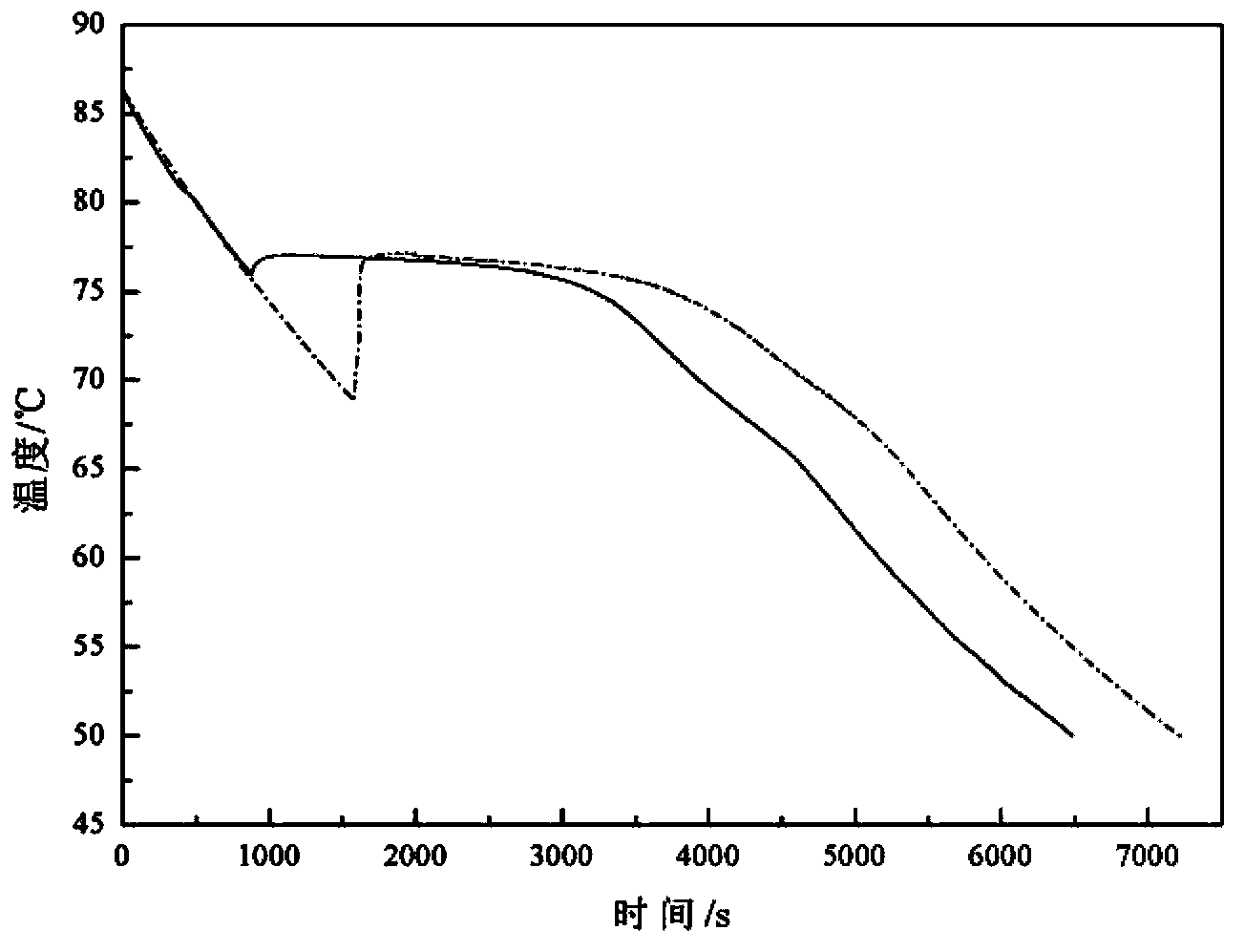

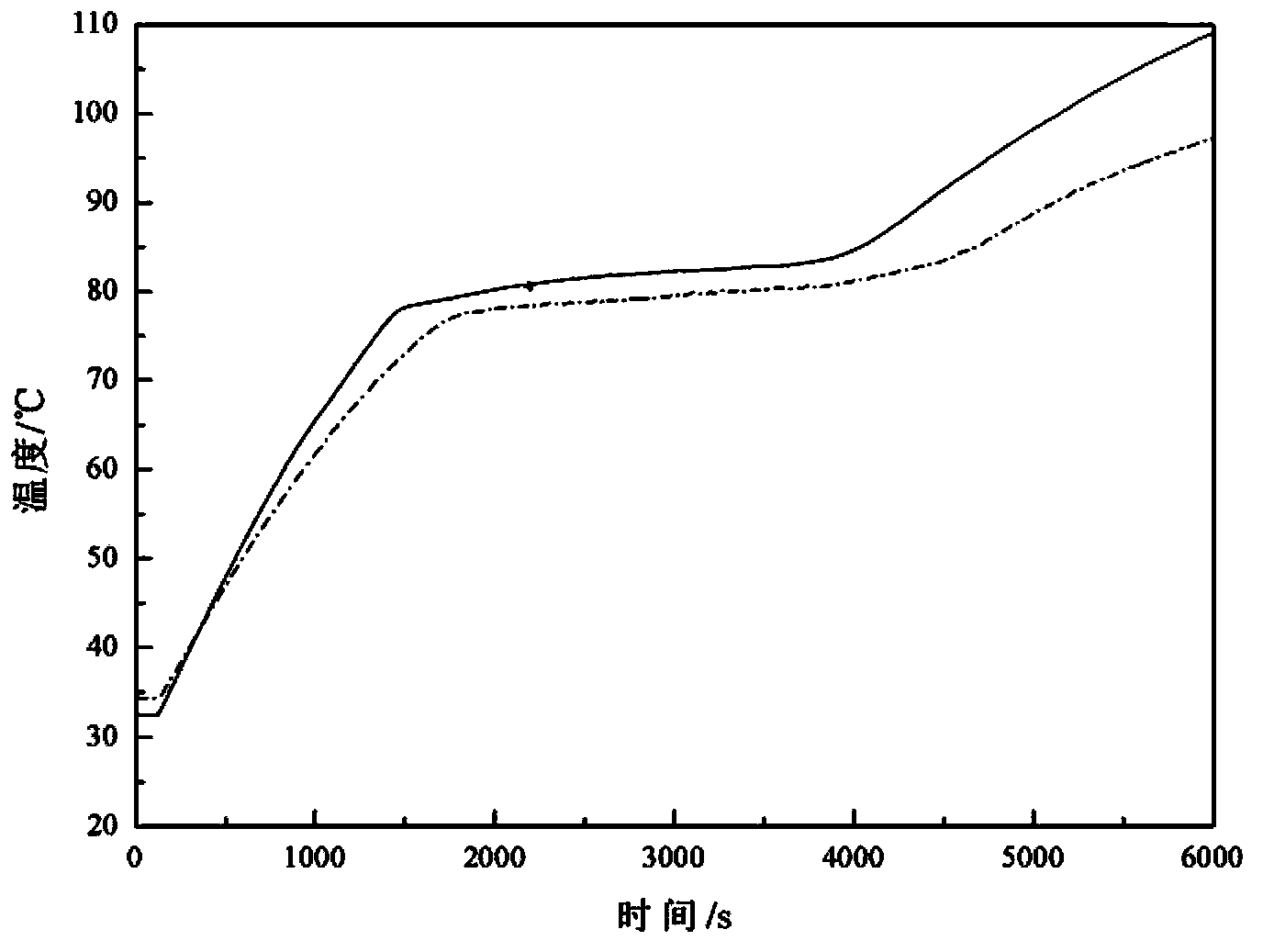

Embodiment 1

[0027] The porous metal foam skeleton material is made of foamed copper, the size of the foamed copper is 120mm (length) × 120mm (width) × 16mm (height), and the density of the foamed copper is 0.31g / cm 3 , foam copper hole density (pores per inch, PPI) is 25. The crystalline hydrated salt phase change material uses barium hydroxide octahydrate. The phase change temperature measured by differential scanning calorimeter (DSC) is 78°C, the latent heat of phase change is 276.8kJ / kg, and the temperature data acquisition module records an undercooling degree of 8.2 ℃.

[0028] A metal foam composite phase change material and its preparation method in this test are carried out according to the following steps: (1) weigh 500g of barium hydroxide octahydrate; (2) uniformly weigh the barium hydroxide octahydrate taken in step 1 Add it into the heat storage container, and put the processed and cleaned PPI25 copper foam into the heat storage container; (3) Put the heat storage container...

Embodiment 2

[0033] The porous metal foam skeleton material is made of foamed copper, the size of the foamed copper is 120mm (length) × 120mm (width) × 16mm (height), and the density of the foamed copper is 0.26g / cm 3 , the foam copper density (pores per inch, PPI) is 10. The crystalline hydrated salt phase change material uses barium hydroxide octahydrate. The phase change temperature measured by differential scanning calorimeter (DSC) is 78°C, the latent heat of phase change is 276.8kJ / kg, and the temperature data acquisition module records an undercooling degree of 8.2 ℃.

[0034] A metal foam composite phase change material and its preparation method in this test are carried out according to the following steps: (1) weigh 500g of barium hydroxide octahydrate; (2) uniformly weigh the barium hydroxide octahydrate taken in step 1 Add it into the heat storage container, and put the processed and cleaned PPI10 copper foam into the heat storage container; (3) Put the heat storage container ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com