Patents

Literature

323results about How to "Reduce subcooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

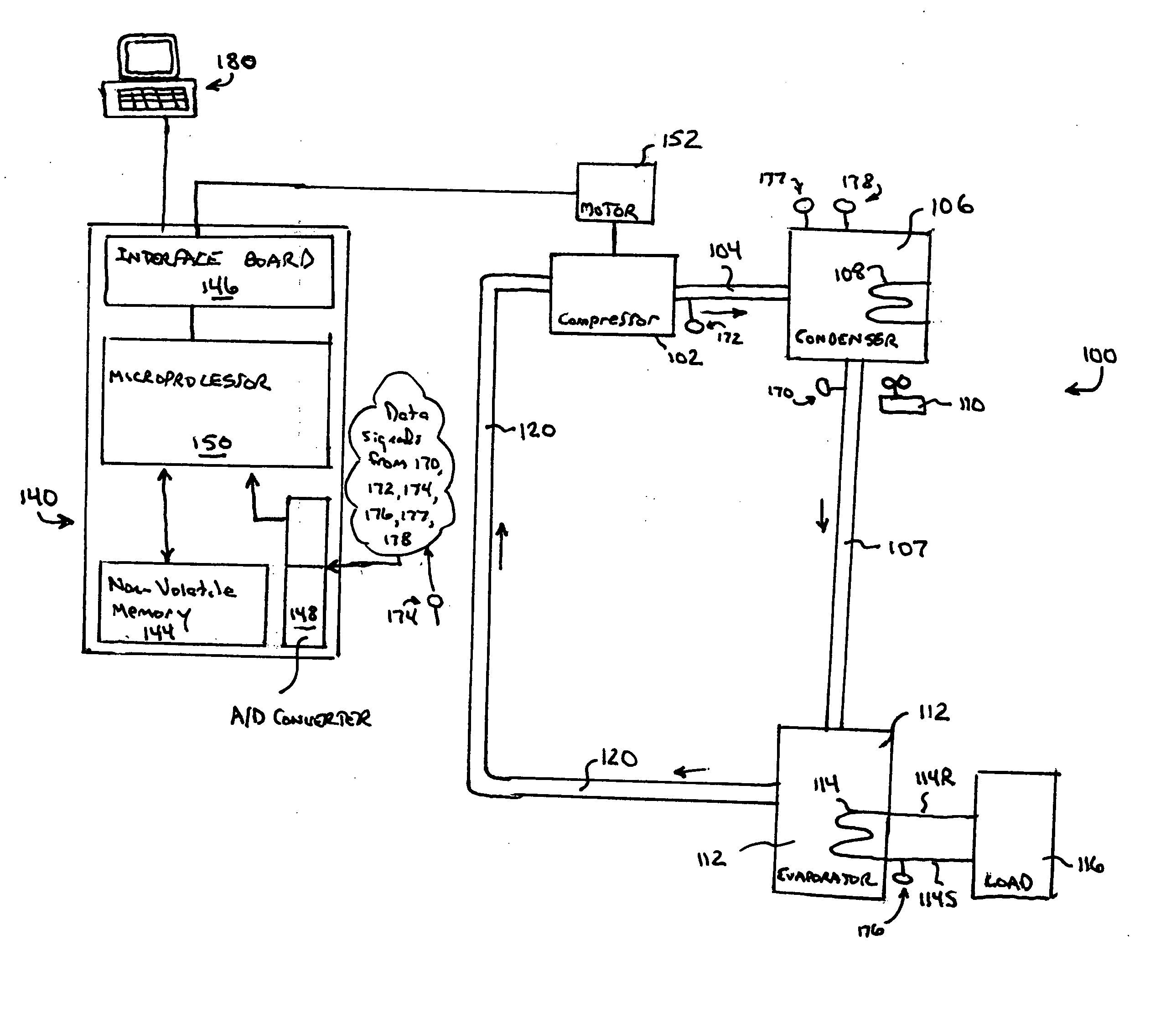

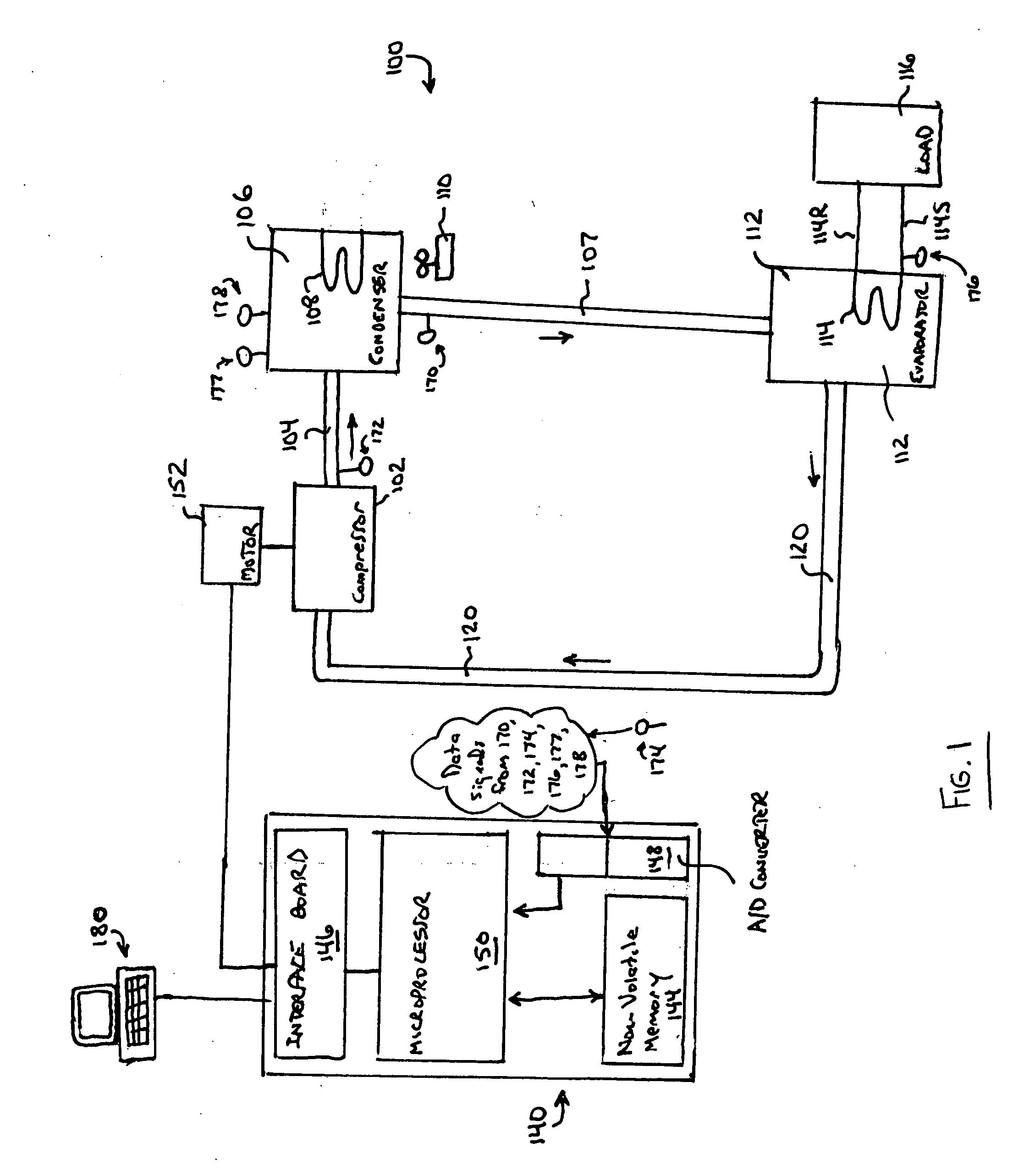

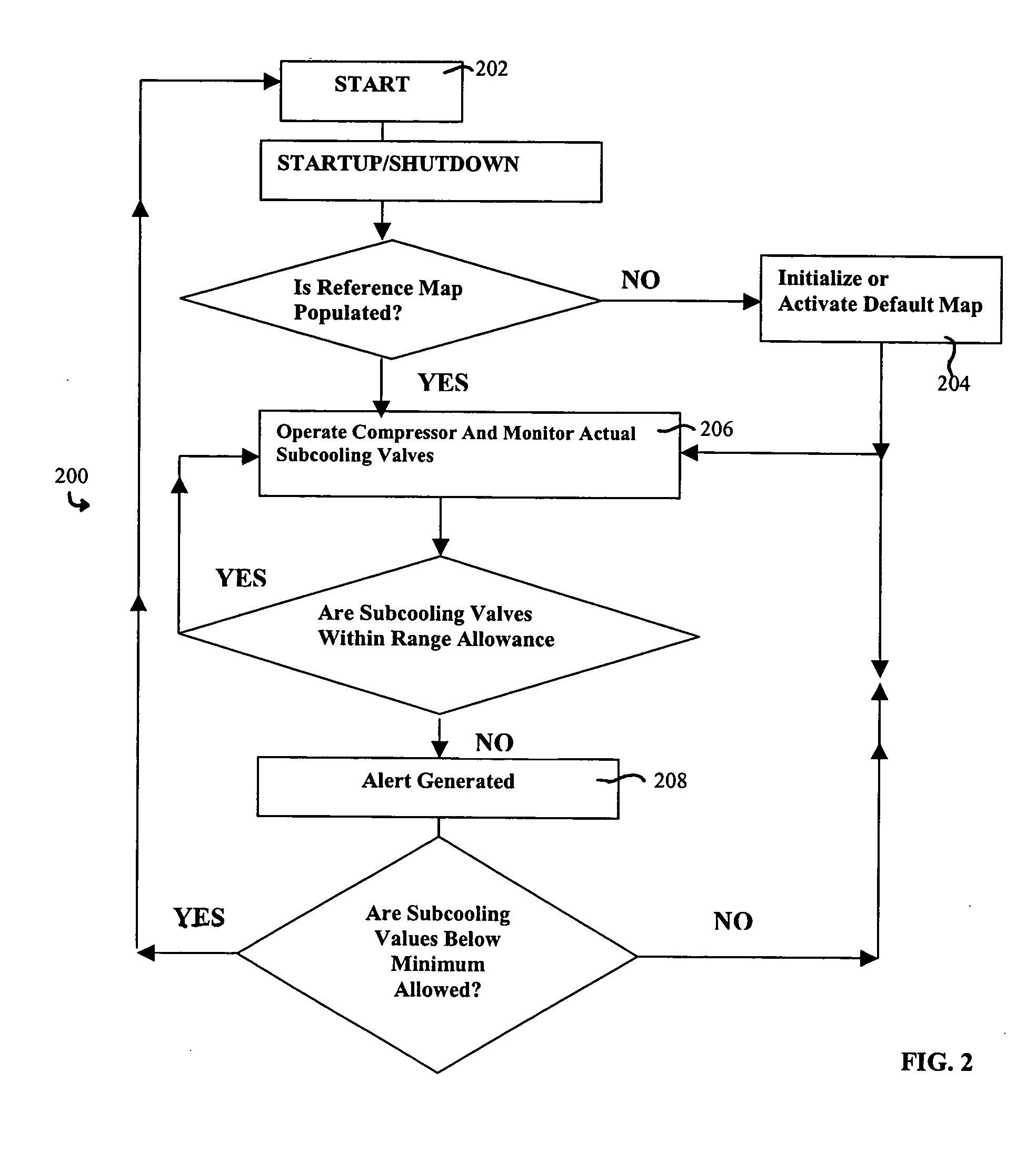

System and method for detecting decreased performance in a refrigeration system

InactiveUS20060042276A1Avoid downtimeEarly detectionElectric testing/monitoringThermometer applicationsEngineeringRefrigeration

Systems and methods are provided for detecting performance degradation in a refrigeration system. Specifically, the present invention provides systems and methods for detecting, at a very early stage, a low refrigerant charge and degradation in condenser performance of a refrigeration system.

Owner:YORK INT

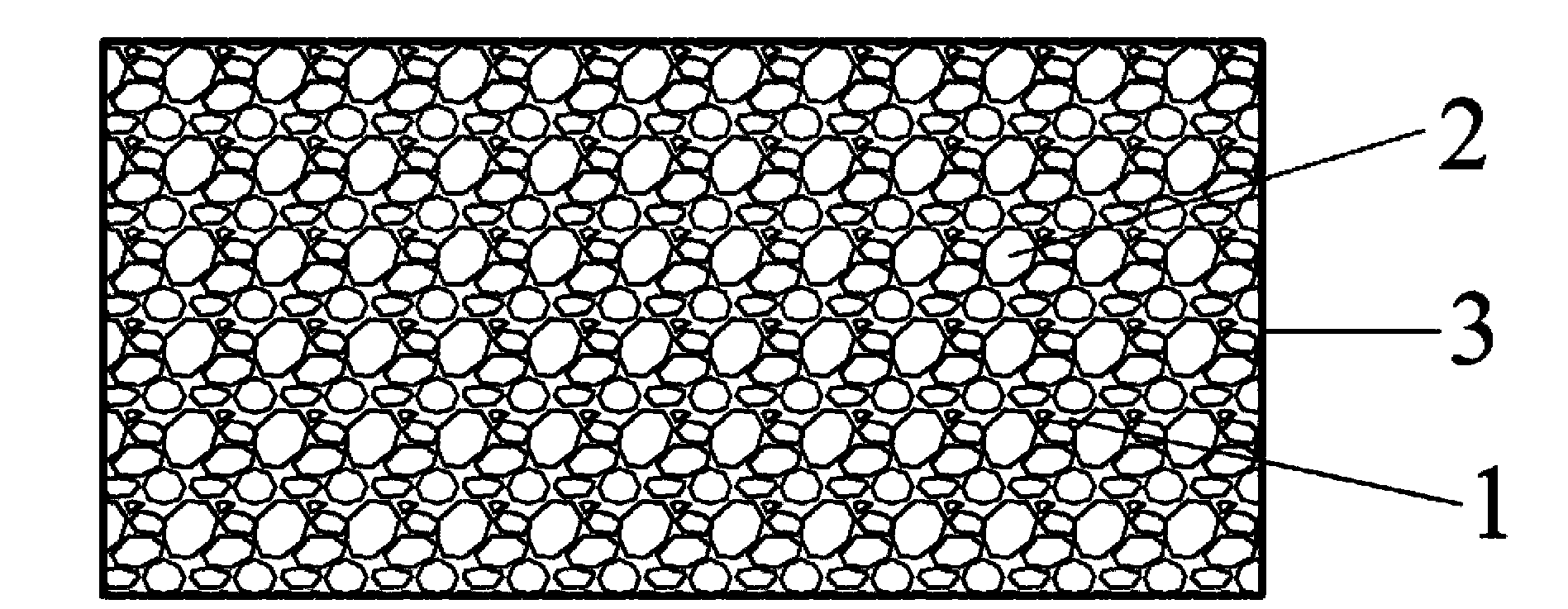

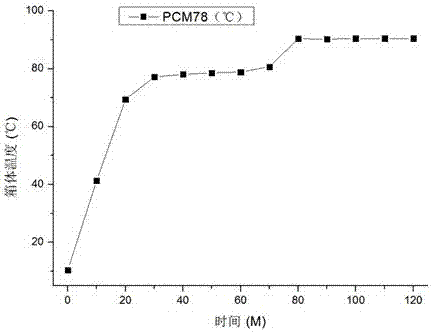

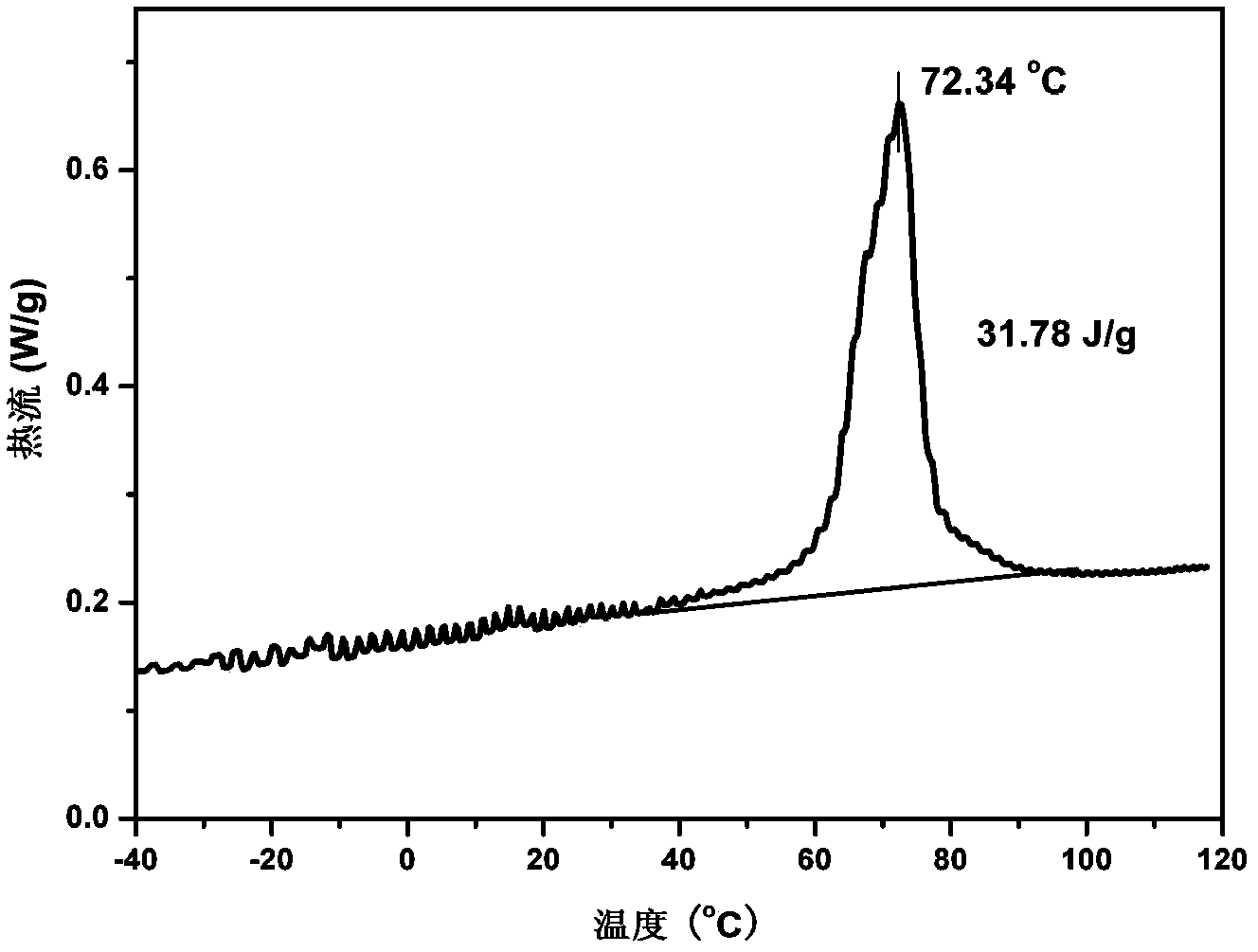

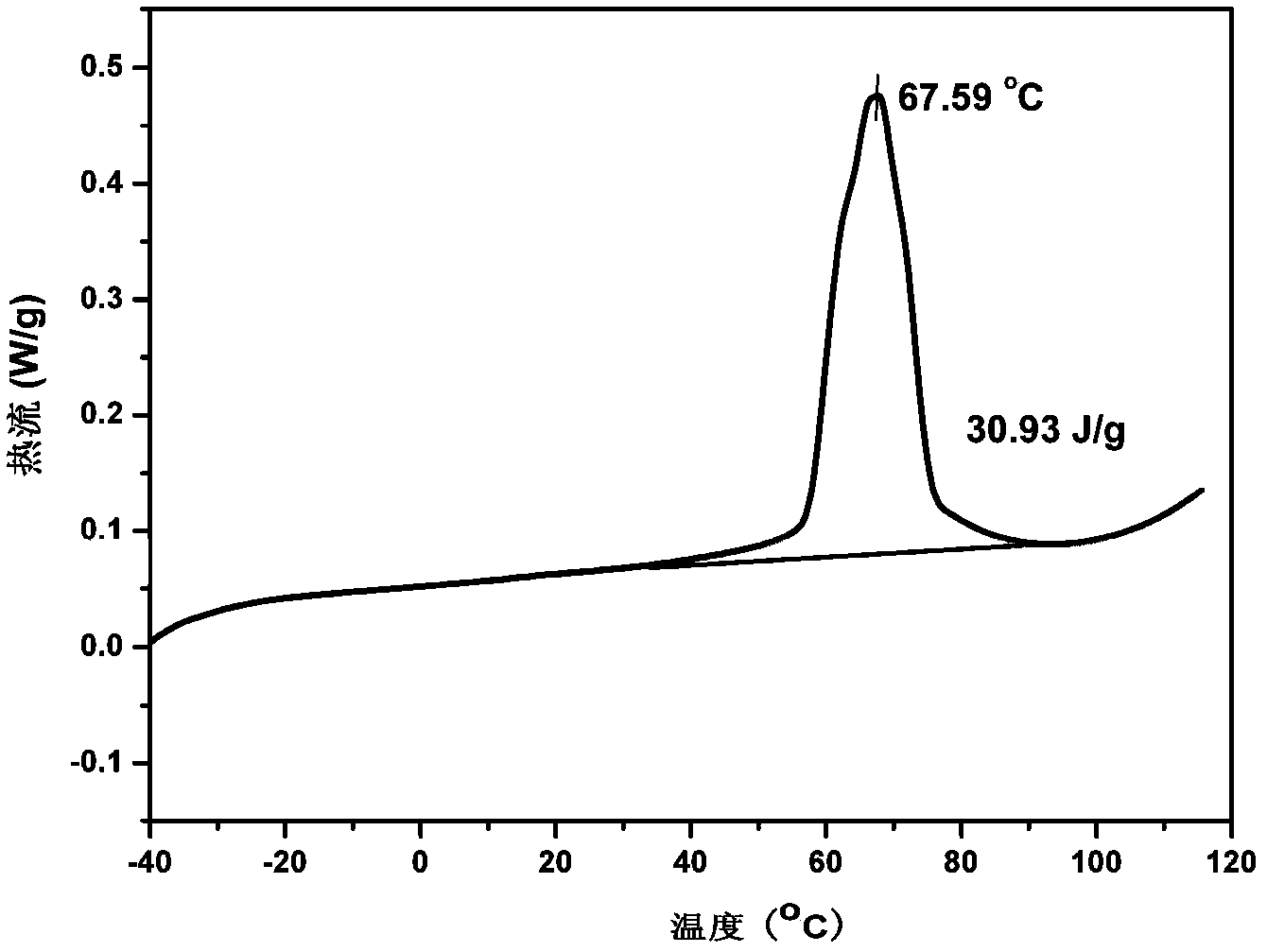

Composite phase-change thermal storage material

ActiveCN104140786AHigh freeze-thaw rateHigh thermal conductivityHeat-exchange elementsLiquid metalVolumetric Mass Density

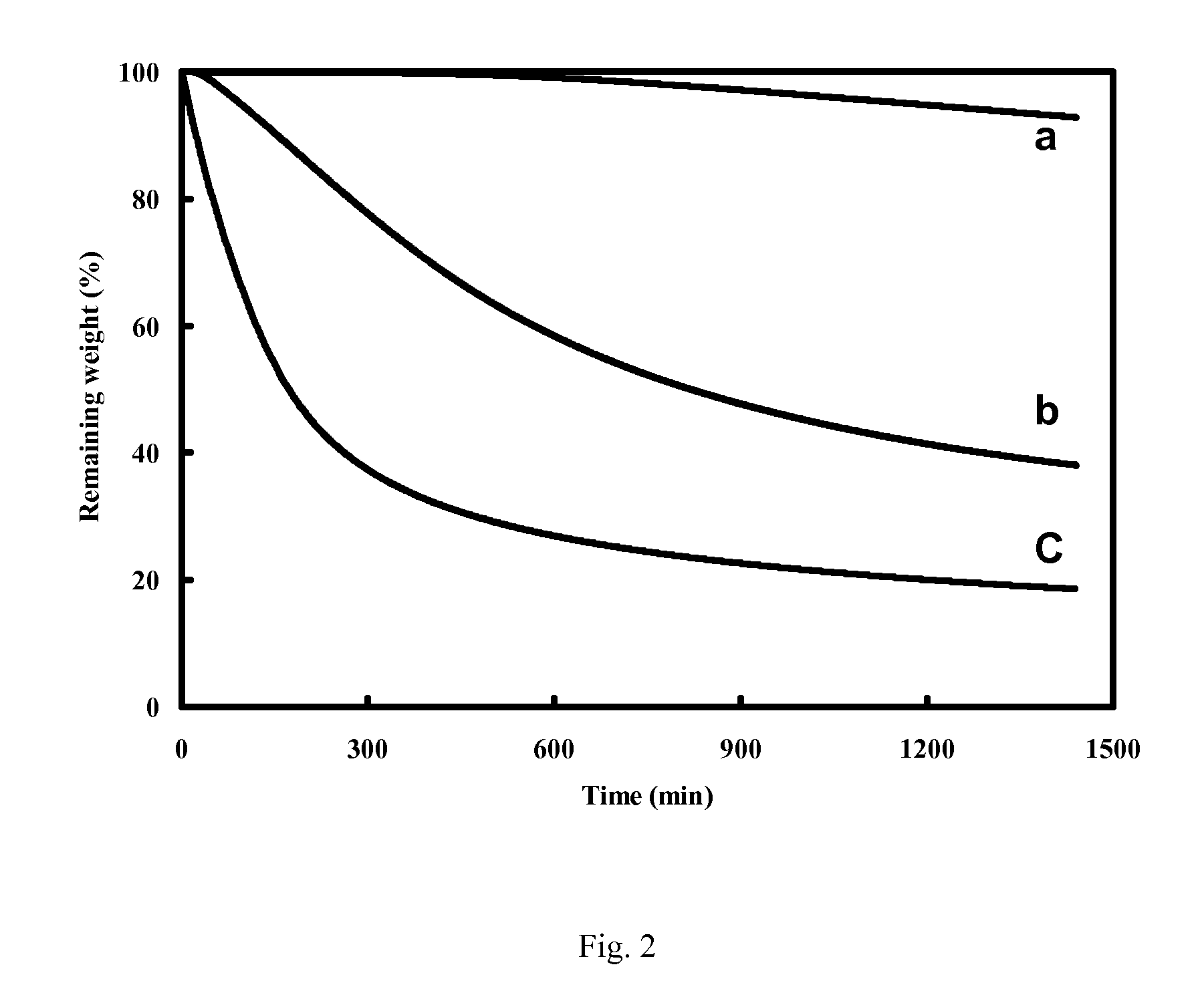

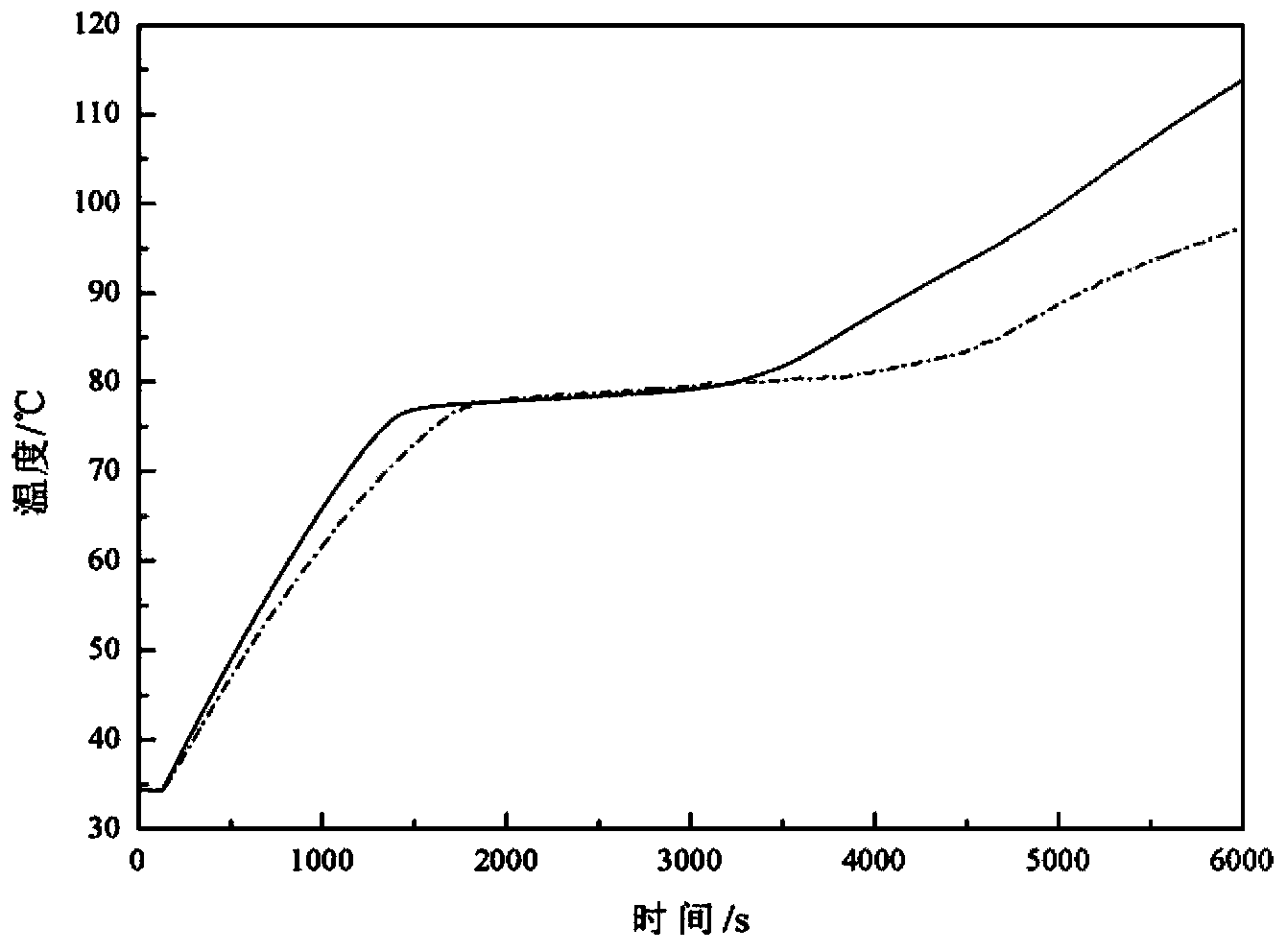

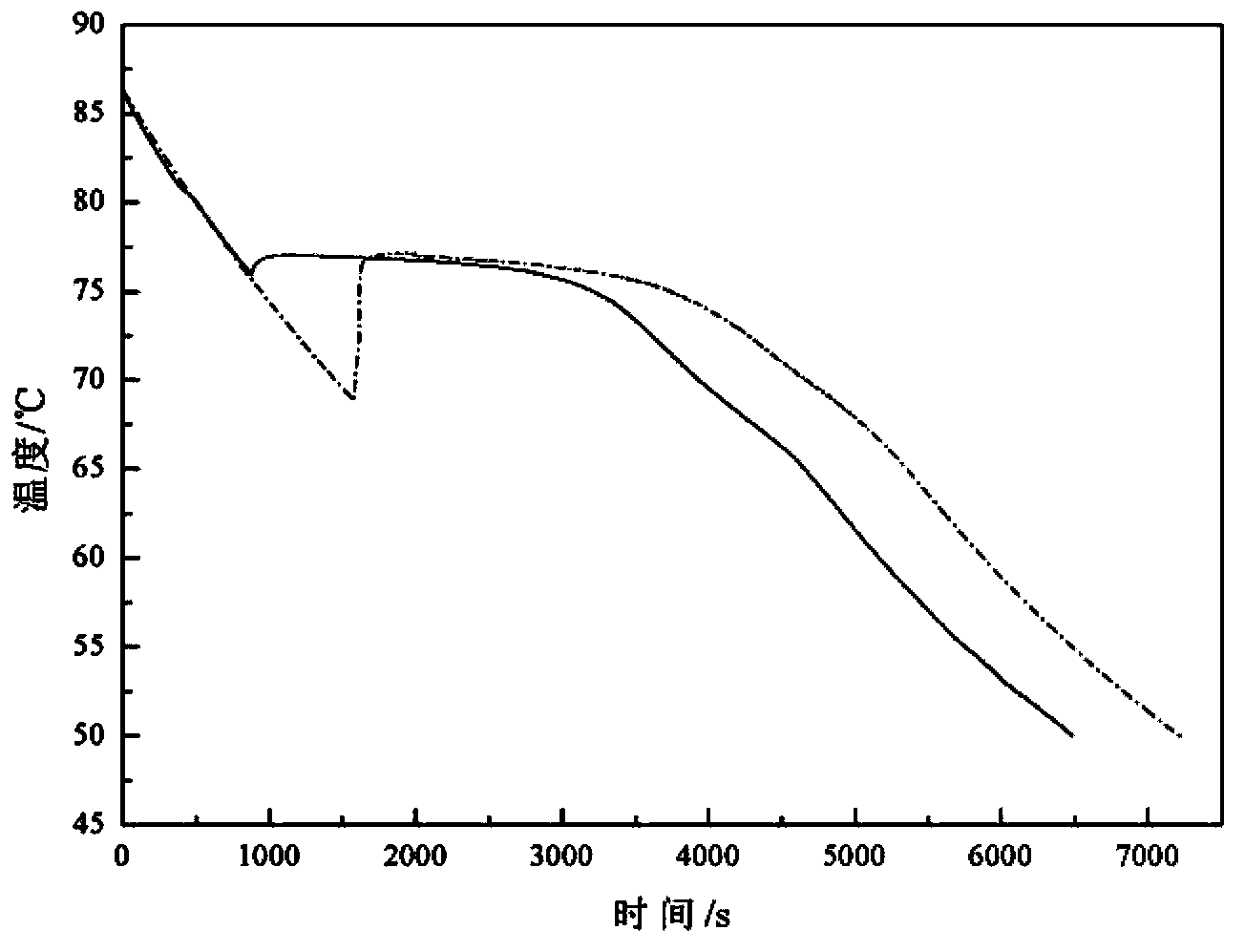

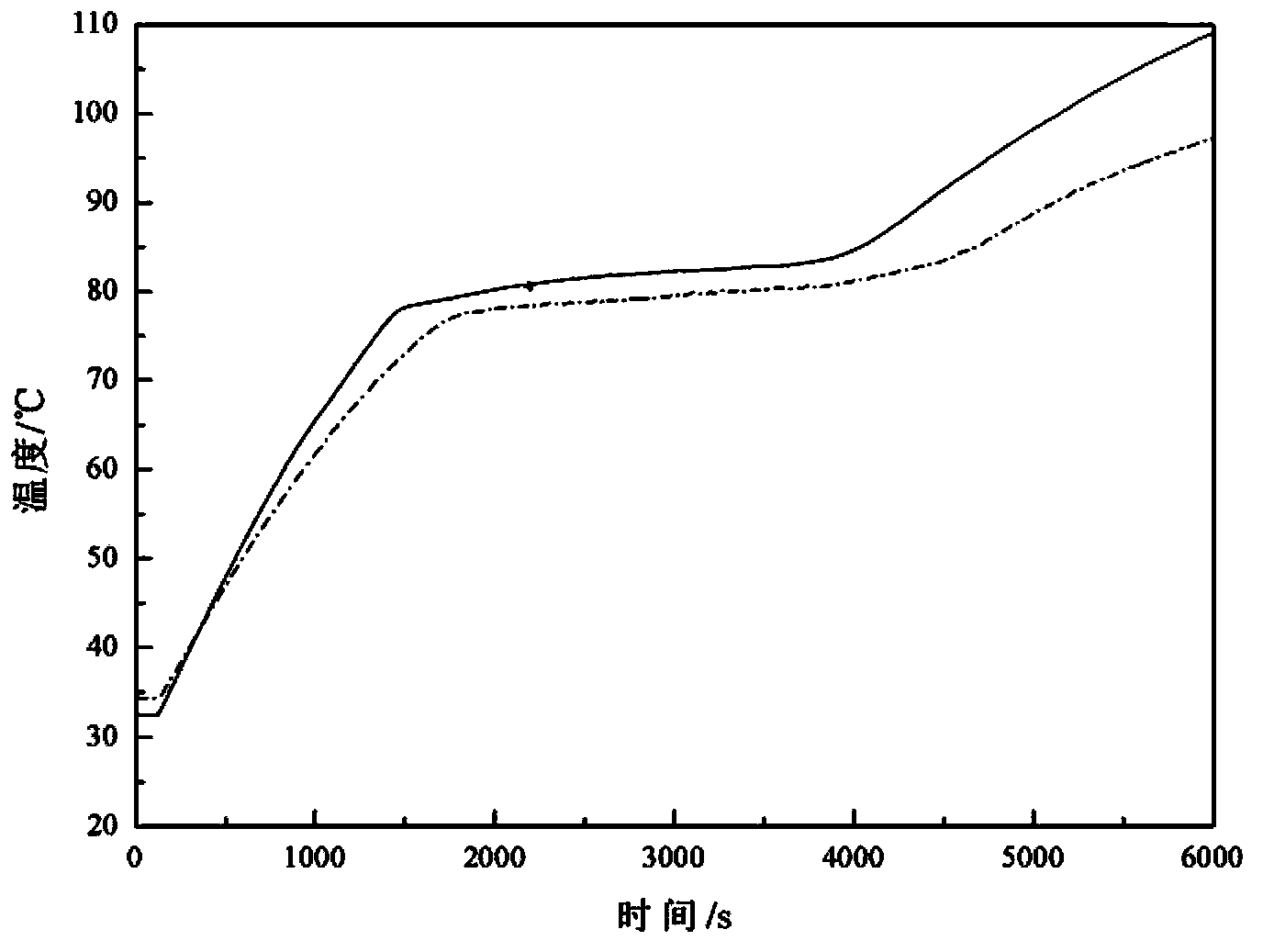

The invention provides a composite phase-change thermal storage material. A porous material with high thermal conductivity is used as a supporting framework, and low-melting-point metal or low-melting-point metal with nano-particles is distributed in pores of the porous material, wherein melting point or solidus temperature of the low-melting-point metal is less than or equal to 80 DEG C; and thermal conductivity of the porous material is within 40-400 W / (m.K). The material provided by the invention has high equivalent thermal conductivity and high storage energy density; there is a large contact area between the liquid metal and the porous material; and the material has a wide application temperature range, has good fixability, stable physico-chemical property and good reversibility; and the problem of decreasing heat storage efficiency after multiple times of heat adsorption and release cycles is avoided.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

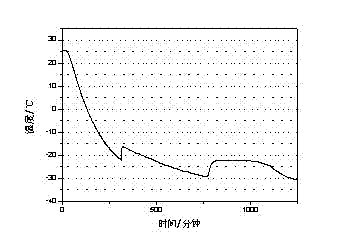

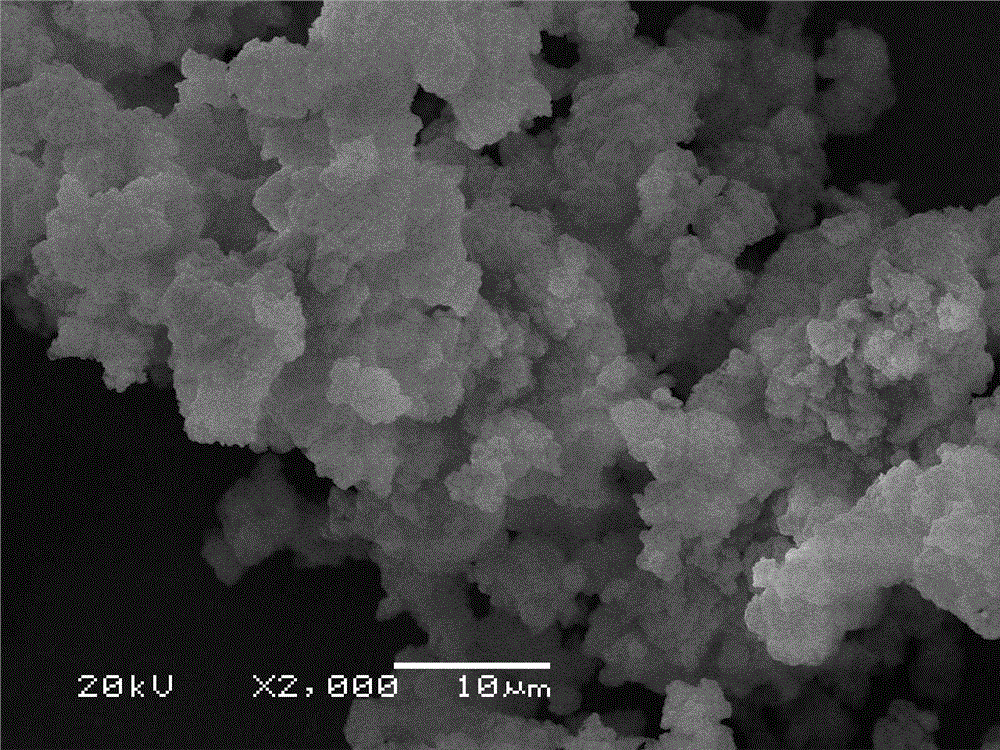

Nano solid-liquid phase change energy storage composite material

InactiveCN101982518AHigh energy storage densityGood heat transfer performanceHeat-exchange elementsIndustrial wasteCorrosion

The invention relates to a nano solid-liquid phase change energy storage composite material, belonging to a phase change energy storage technology. The composite material comprises the following components in parts by weight: 88 to 98 parts of hydrated salt, 1 to 7 parts of a nano material and 1 to 5 parts of thickener. With regard to the nano solid-liquid phase change energy storage composite material, the hydrated salt is taken as a main body for phase change energy storage, thus having higher energy storage density and good heat transfer performance; the nano material is taken as nucleating agent, thereby reducing and even eliminating the degree of supercooling of the hydrated salt and having stable property and corrosion resistance; and a proper amount of the thickener is added to increase the viscosity of liquid hydrated salt, thereby preventing the phase separation of the hydrated salt and simultaneously strengthening the suspension stability of the nano material. The nano solid-liquid phase change energy storage composite material of the invention can be widely applied to the fields of solar thermal utilization, industrial waste heat recovery, air conditioning energy storage and the like.

Owner:UNIV OF SCI & TECH OF CHINA

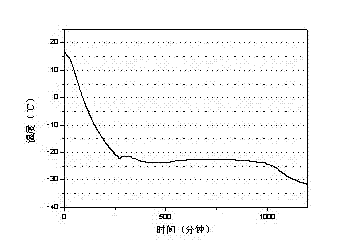

Inorganic salt phase-change cold accumulation material

ActiveCN103242806AHigh latent heat of phase changeImprove thermal conductivityHeat-exchange elementsHigh energyCold storage

The invention discloses an inorganic salt phase-change cold accumulation material which is prepared from the following raw materials in parts by weight: 100 parts of a 15-25% inorganic salt solution, 1-7 parts of a nucleation agent and 2-15 parts of a thickening agent. Inorganic salt is used as an inorganic phase-change material. The inorganic salt phase-change cold accumulation material has the advantages that the phase-change latent heat is high (can reach 200-400J / g); the heat conductivity coefficient is good (when being compared with an organic phase-change energy accumulation material); no toxin exists and a pH (Potential of Hydrogen) value is neutral; and the price is low. According to the inorganic salt phase-change cold storage material disclosed by the invention, compared with the prior art (the phase-change latent heat is in a range of 100-200J / g), the inorganic salt phase-change cold accumulation material has the advantages of high energy storage density, small condensate depression and good circulatory stability.

Owner:杭州鲁尔新材料科技有限公司

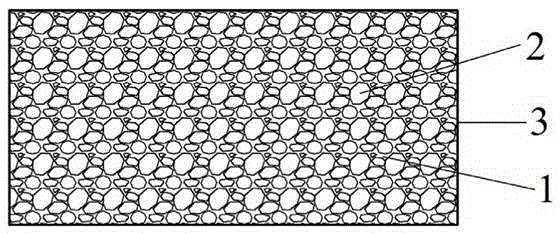

Packaging shape-stabilizing method of inorganic hydrated salt phase-change heat storage material

InactiveCN104371658AImprove thermal conductivitySimple structureHeat-exchange elementsMolten stateHydration reaction

The invention provides a packaging shape-stabilizing method of an inorganic hydrated salt phase-change heat storage material, which comprises the following steps: (1) adding a nucleator and deionized water into the inorganic hydrated salt phase-change material, and heating until the inorganic hydrated salt phase-change material achieves the molten state; (2) adding a porous propping material into the molten-state inorganic hydrated salt phase-change material, and stirring sufficiently and uniformly; (3) putting the molten-state mixture obtained in the step (2) in a vacuum environment to enhance the adsorptivity of the porous propping material for the inorganic hydrated salt phase-change material; and (4) moving the molten-state mixture out of the vacuum environment, and immediately putting the molten-state mixture into a low-temperature environment suitable for crystallization to perform recrystallization. The composite shape-stabilized phase-change material obtained by the method has the advantages of stable structure, high latent heat, no toxicity, simple preparation process, short time consumption and low cost.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Antioxidants for phase change ability and thermal stability enhancement

InactiveUS20090184283A1Improve thermal stabilityIncrease heatHeat-exchange elementsFiberSolid component

Phase change ability and thermal stability enhancement have been attained by use of antioxidants and solid component. The phase change component consists essentially of secondary antioxidant (preferably with a minor proportion of primary antioxidant). Both said secondary antioxidant and said primary antioxidant are not dissolved in a liquid solvent. Thus, phase change materials exhibiting high heat of fusion, high thermal stability of the liquid (phase after melting), good phase change cyclability and melting temperature below about 50° C. are provided. By the combined use of the phase change component and second solid that remains a solid above the melting temperature of said phase change component, a phase change composite is provided. Said composite, wherein said second solid is dispersed in said phase change component, is effective for use as a thermal interface material for enhancing thermal contacts at use temperatures above the melting temperature of said phase change component. By using secondary and primary antioxidants, both dissolved in polyol ester liquid, in combination with dispersed solid (dispersed in said liquid) that enhances the thermal stability of said liquid, polyol-ester-based pastes that exhibit high thermal stability at temperatures up to at least 220° C. are provided. The secondary antioxidant, whether it is dissolved in a liquid solvent or not, is preferably thioether, most preferably thiopropionate. The primary antioxidant is preferably half-hindered phenolic. In case that antioxidants are dissolved in polyol ester liquid, the primary antioxidant and secondary antioxidant in combination preferably amount to less than 5% by weight of the liquid part of the polyol-ester-based paste. Both said second solid in said phase change composite and said dispersed solid in said paste are selected from the group: boron nitride, zinc oxide, alumina, carbon black, carbon fiber, carbon nanotube, graphite, diamond, silver, gold, aluminum and nickel.

Owner:CHUNG DEBORAH DUEN LING +1

Foam metal composite phase-change material and preparation method thereof

InactiveCN103436240AImprove thermal performanceHigh heat storage densityHeat-exchange elementsHeat conductingImpurity

The invention relates to a foam metal composite phase-change material and a preparation method thereof, and belongs to the technical field of phase-change energy storage materials. A crystallized hydrated salt-foam metal composite phase-change energy storage material is prepared by adopting the adsorption characteristic of a porous foam metal skeleton structure, and a vacuum argon filling state is kept in a preparation process, so that impurities are prevented from entering, and the quality of a product is ensured. The phase-change material is relatively uniformly and sufficiently distributed in a substrate of the foam metal skeleton material, and the shaping characteristic of the composite material is maintained under the combined action of a capillary force and surface tension of foam metal, so that the phase-change material does not leak easily in a phase-change process, and the preparation method of the phase-change material is simple and convenient, high in recombination rate and good in operability. The composite phase-change material has the advantages of high phase-change latent heat in unit volume, high heat storage and release rates, good heat-conducting property, lower supercooling degree, and the like; and the lower heat conductivity and supercooling problems existing after the crystallized hydrated salt phase-change material is applied for a long time are solved effectively.

Owner:BEIHANG UNIV

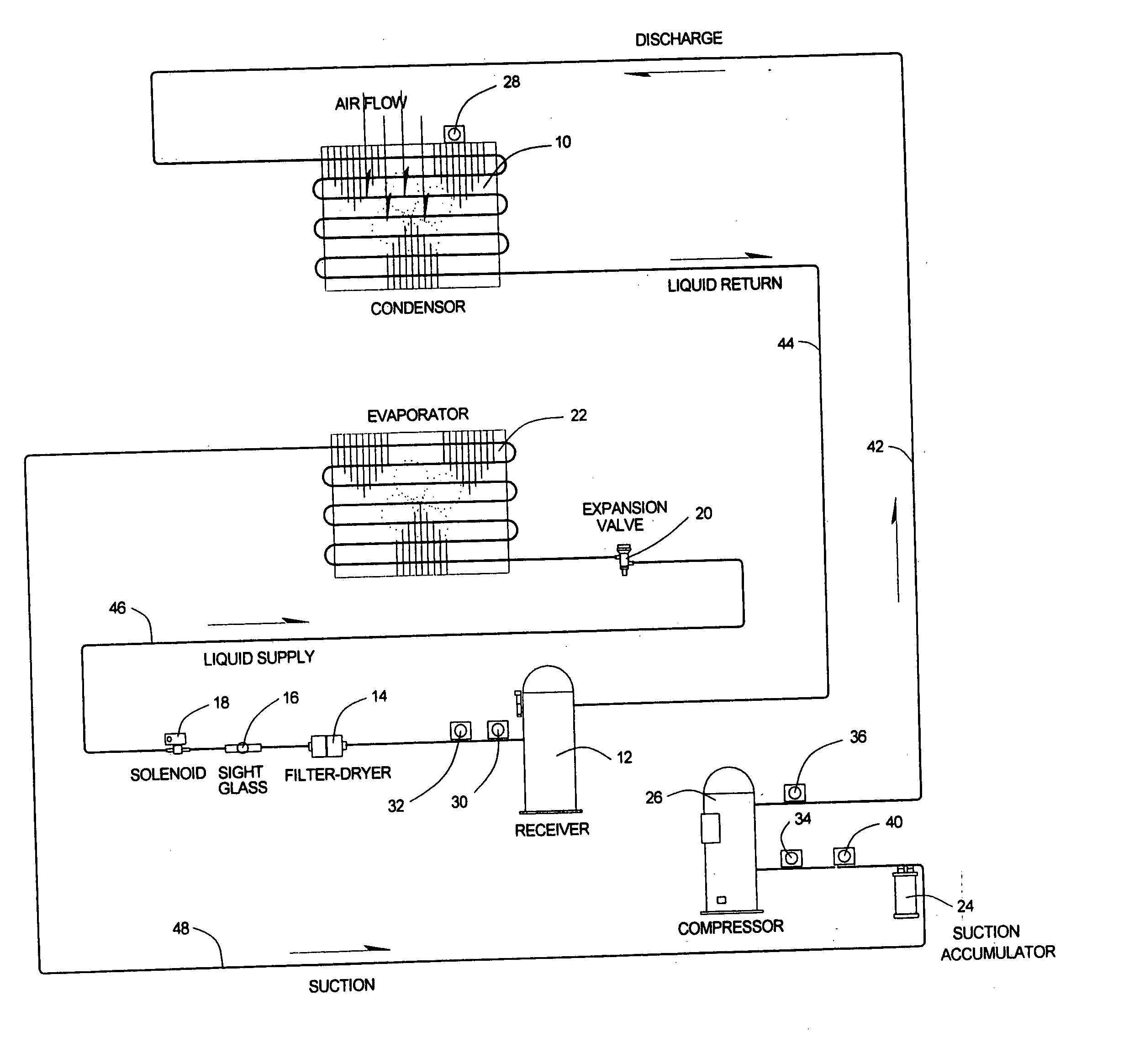

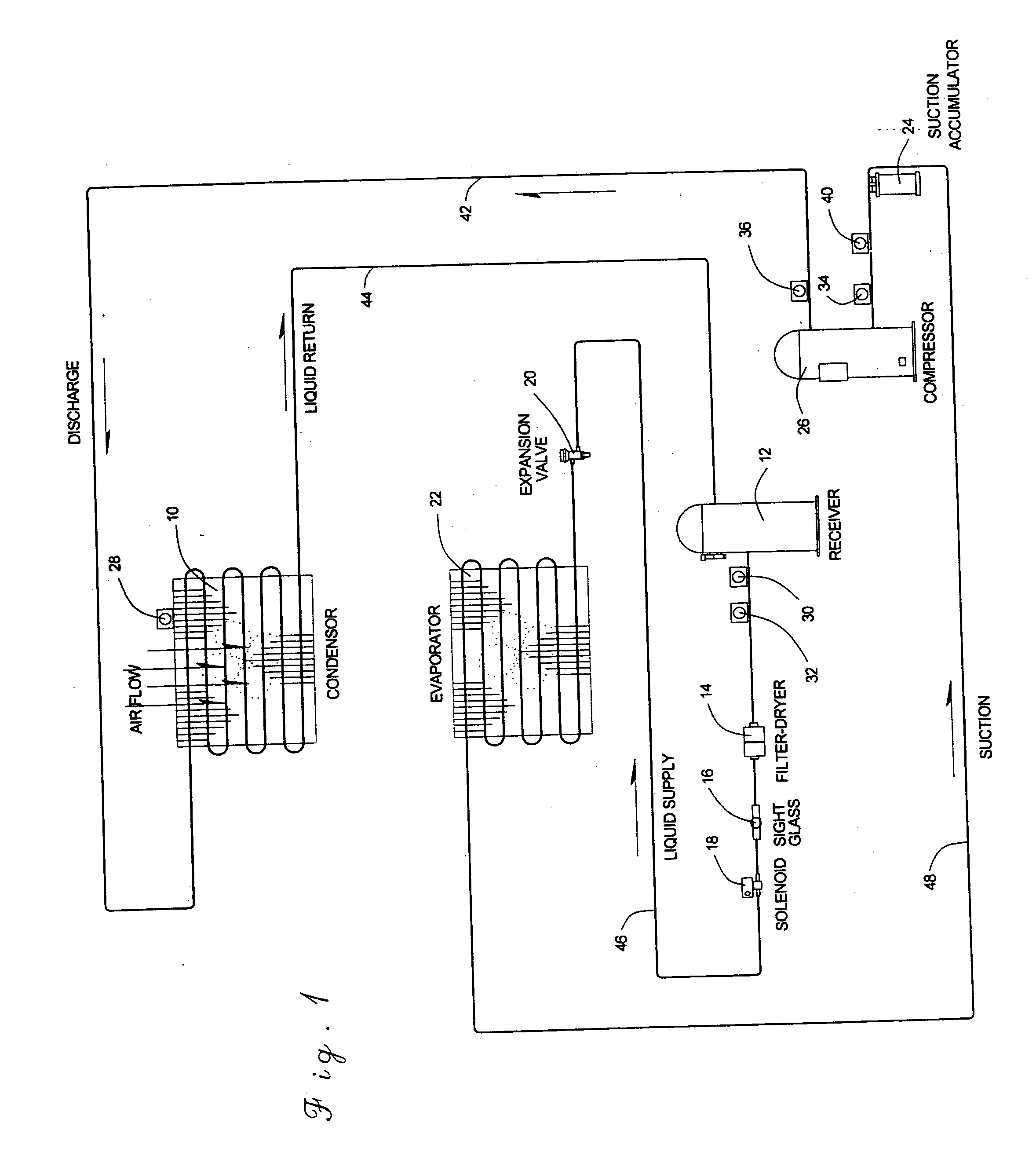

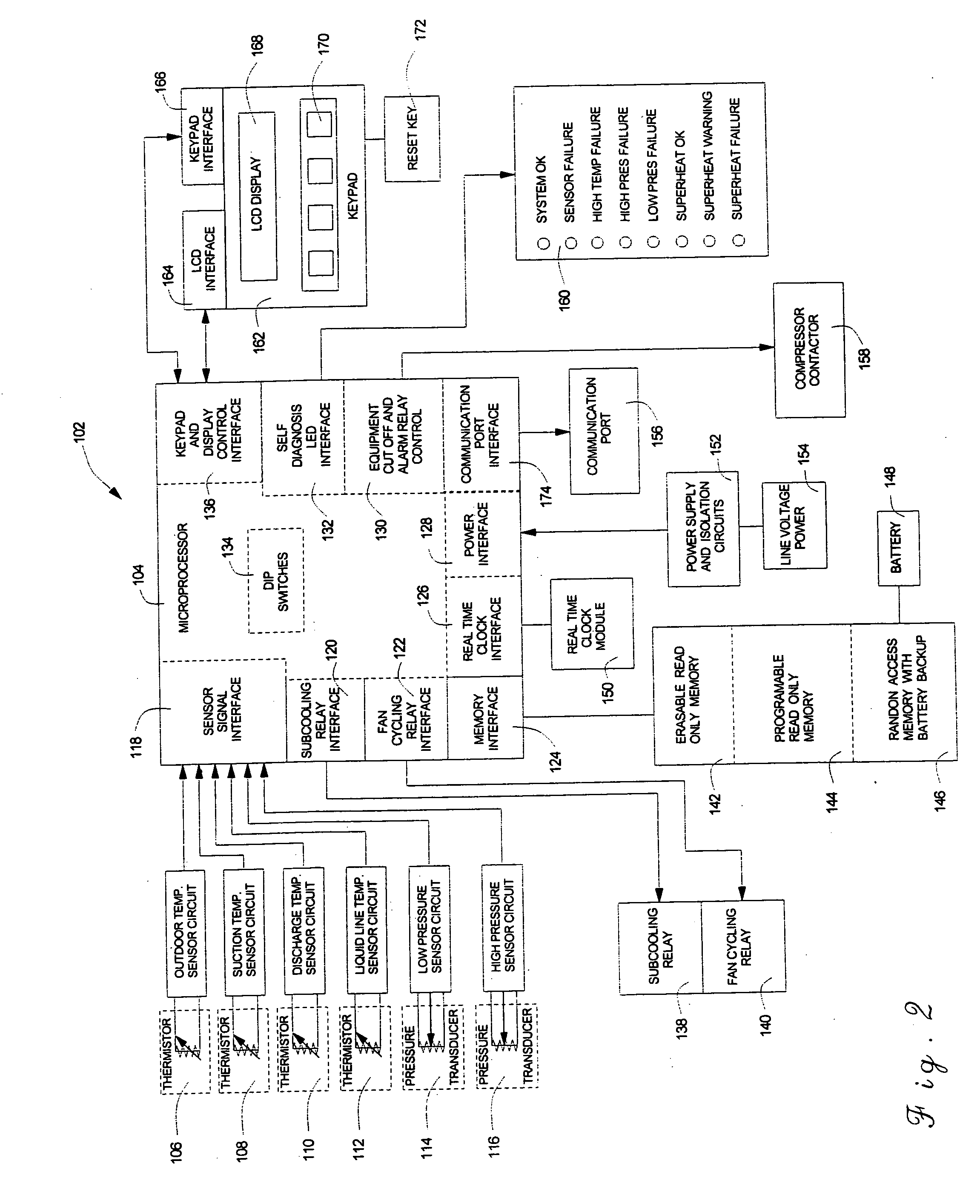

Refrigeration mechanical diagnostic protection and control device

InactiveUS20060075771A1Improve system efficiencyIncrease subcoolingCompression machines with non-reversible cycleEvaporators/condensersService personnelMonitoring system

In vapor compression refrigeration systems a mechanism and method are provided for protecting a compressor from failures related to lack of superheat, loss of lubricating oil and other system malfunctions. Also provided is a mean of monitoring system conditions and providing service personnel with a quick manner of diagnosing problems.

Owner:TRACEY GEORGE R JR +2

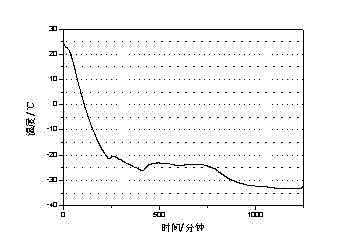

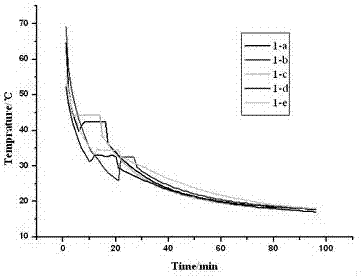

Inorganic combined phase-change material for heat storage

InactiveCN101418209AStable performanceReduce subcoolingHeat-exchange elementsPhase-change materialCarboxymethyl cellulose

The invention provides an inorganic mixed phase-change material for heat accumulation, which has stable performance, small supercooling degree and large phase-change heat. The inorganic mixed phase-change material for heat accumulation is formed through evenly mixing the following compositions in mass portion: 80 to 88 portions of sodium acetate trihydrate, 1 to 10 portion of carboxymethyl cellulose, 0.5 to 3.5 portions of disodium phosphatedodecahydrate, 0.1 to 2.5 portions of sodium carboxymethylcellulose, 5 to 10 portions of sodium chloride solution with mass concentration of between 20 and 30 percent and 0 to 10 ppm portions of nanometer copper powder. The inorganic mixed phase-change material is mainly applied to heat accumulation for an air conditioner and can be also used for other heat accumulation systems (solar energy, waste heat utilization and the like). The material solves two difficult problems of supercooling and precipitation, and has stable performance, small supercooling degree and phase-change heat. Simultaneously, after phase change, the prepared phase-change material at a liquid state has good fluidity and wide application occasions.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Nano refrigerant hydrate phase change cold-storage working substance and preparation thereof

InactiveCN101434833AEasy to passReduce running power consumptionHeat-exchange elementsSolubilityTurbidity

The invention provides a nano-refrigerant hydrate phase change cool-storage refrigerant and a preparation method thereof; surfactant is dissolved in water to prepare the water solution of the surfactant; subsequently, the refrigerant is dripped into the water solution of the surfactant and mixed till that the solution is changed from turbidity to brightness. According to the solubility of the surfactant in water and in the refrigerant, the surfactant can be dissolved in the water and can also be dissolved in the refrigerant. Under static state, the water phase and the refrigerant phase are uniformly mixed in microscopic scale to augment the two-phase diffusion interface, thus promoting the growth of the hydrate crystal. The system can lead the water phase and the refrigerant phase to be mixed uniformly without applying mixing, disturbing and external field; the refrigerant phase is dispersed in water in the form of micelle or (and) microemulsion; and alternatively, the water phase is dispersed in the refrigerant phase in the form of micelle or (and) microemulsion; the dripping size of the dispersing phase is 100nm or less. The hydrate phase change cool-storage refrigerant does not delaminate after being placed for a long time, is single-dispersion system with stable thermal-mechanics performance and has the appearance of transparent or semi-transparent solution.

Owner:XI AN JIAOTONG UNIV

Deposit welding rod containing rare earth and production method

InactiveCN101190481AReduce segregationReduce subcoolingWelding/cutting media/materialsSoldering mediaRare earthRoom temperature

The invention provides a surfacing electrode containing rare earths with a welding core but without a coating. The composition of the welding core is 3.2% to 6.5% of C, 0.4% to 2.5% of Si, 0.4% to 2.0% of Mn, 0.01% to 1.0% of Re, 10% to 35% of Cr, 0.0% to 2.0% of Mo, 0.0% to 2.8% of Ni, 0.0% to 2.5% of W, 0.0% to 1.5% of V, 0.0% to 1.0% of Ti, 0.0% to 1.5% of Nb, 0.0% to 0.5% of Cu, 0.0% to 0.6% of Al, not more than 0.08% of S, not more than 0.08% of P, not more than 0.08% of , not more than 0.08% of <N>, and 59.64% to 85.99% of Fe. The welding rod is suitable for the build-up welding of burning single-roll crusher hammer; the hardness HRC of the build-up welding layer at room temperature is not less than 50 and crack is allowable for build-up welding layer.

Owner:PANZHIHUA UNIV

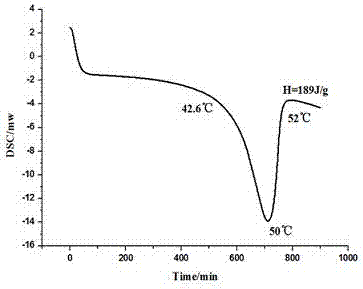

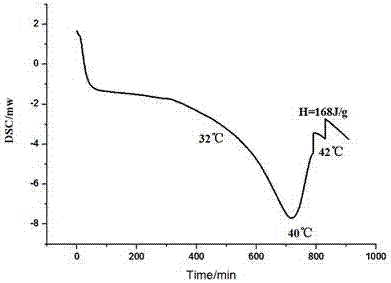

Phase transformation heat accumulating material

The invention discloses a phase change thermal storage material which is composed of substance according to mass ratio of 85-98 parts of trihydrate sodium acetate, 1-10 parts of carboxymethyl cellulose, 0.5-3.5 parts of hexahydrate magnesium chloride, 0.1-2.5 parts of sodium carboxymethyl cellulose, and 0-10ppm parts of nanophase powdered carbon. Raw materials of the phase change thermal storage material have rich supply and low cost. The phase change thermal storage is large (larger than 280MJ / m3), the thermal coefficient is large (larger than 0.8W / m,k),and the phase change temperature is 54-60 DEG C, thereby favoring recycle of condenser heat of air conditioners and other waste heat recovery field. The condenser depression is relatively small (3 DEG C-5 DEG C), which greatly favors releasing of required heat.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Inorganic phase-changing energy storage material

InactiveCN107011867AStrong cycle stabilityGood liquidityHeat-exchange elementsCyclic stabilityStorage material

The invention relates to the technical field of energy storage materials, in particular to an inorganic phase-changing energy storage material. The inorganic phase-changing energy storage material is prepared from the following components in percentage by mass: 86 to 98.5 percent of inorganic materials, 0.5 to 3 percent of nucleating agents, 1 to 10 percent of thickening agents, and 0 to 1 percent of water. The obtained phase-changing energy storage material is low in price, good in recycling stability, capable of effectively solving the phase separation problem of the materials, and constant in potential heat value after being recycled for thousand times.

Owner:北京华厚能源科技有限公司

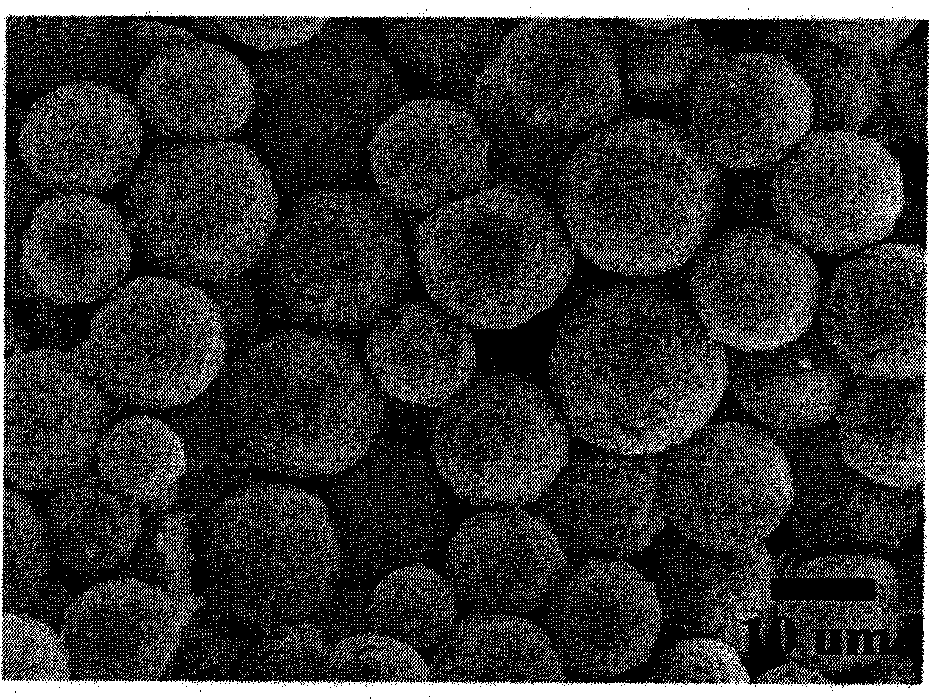

Phase change energy storage microcapsule of composite shell and its making method

InactiveCN1570014ASmooth and dense surfaceComplete appearanceHeat-exchange elementsMicroballoon preparationHexadecaneComposite construction

The invention discloses a phase change energy storage microcapsule of composite shell and its making method, wherein the core material of the microcapsule employs tetradecane, pentadecane or hexadecane, the shell layer has a composite construction, the inner layer is melamine resin, the outer layer is PEG200 modified melamine resin, or PEG200 modified melamine, or copolycondensation resin of methyl poultry manure amine, acetyl poultry manure amine or benzene substituted melamine.

Owner:TIANJIN UNIV

Microcapsule composite phase change material based on inorganic hydrous salt as well as preparation method and application thereof

InactiveCN103450856APrevent leakageHigh crystallinityHeat-exchange elementsPolymethyl methacrylatePolystyrene

The invention relates to a microcapsule composite phase change material based on an inorganic hydrous salt and a preparation method thereof. The material is a composite phase change material with a shell-core structure, wherein the microcapsule wall material is polystyrene, polymethyl methacrylate and the like; and the core material is an inorganic hydrous salt phase change material (for example Na2SO4.10H2O, CaCl2.6H2O, Na2HPO4.12H2O, Na2CO3.10H2O). The internal phase change material can be protected from being polluted and prevented from being leaked and run away by the polymer wall material. According to the invention, an emulsification dispersion polymerization technology is adopted for carrying out emulsification dispersion on a hydrophilic inorganic salt core material in an organic solvent to form a stable W / O (Water-In-Oil) emulsion, and a water-soluble initiator is added, so that a polymer monomer generates polymerization reaction on a micellar surface to obtain the microcapsule composite phase change material of a hydrous salt phase change material coated by the polymer wall.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Eutectic salt cold-storage material

InactiveCN101434830AApplicable temperature rangeReduce cooling efficiencyHeat-exchange elementsCool storageAir conditioning

The invention provides an eutectic-salt cool-storage material, comprising sodium sulfate decahydrate (Na2SO4 question mark 10H2O), ammonium chloride (NH4Cl), sodium borate decahydrate (Na2B4O7 question mark 10H2O), and silica gel (mSiO2 question mark nH2O); the eutectic-salt cool-storage material is characterized in that: according to the mass percentage, the eutectic-salt cool-storage material comprises 72.86 percent of Na2SO4 question mark 10H2O, 12.86 percent of NH4Cl, 2.86 percent of Na2B4O7 question mark 10H2O and 11.42 percent of mSiO2 question mark nH2O. The transformation temperature of the eutectic-salt cool-storage material is 8.47 DEG C, the undercooling degree thereof is 2.41 DEG C and the transformation latent heat thereof is 136.07-182.73Kj / kg. Owning to low transformation temperature and small undercooling degree, the material is the eutectic-salt cool-storage material applicable to cold accumulation air-conditioning systems.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

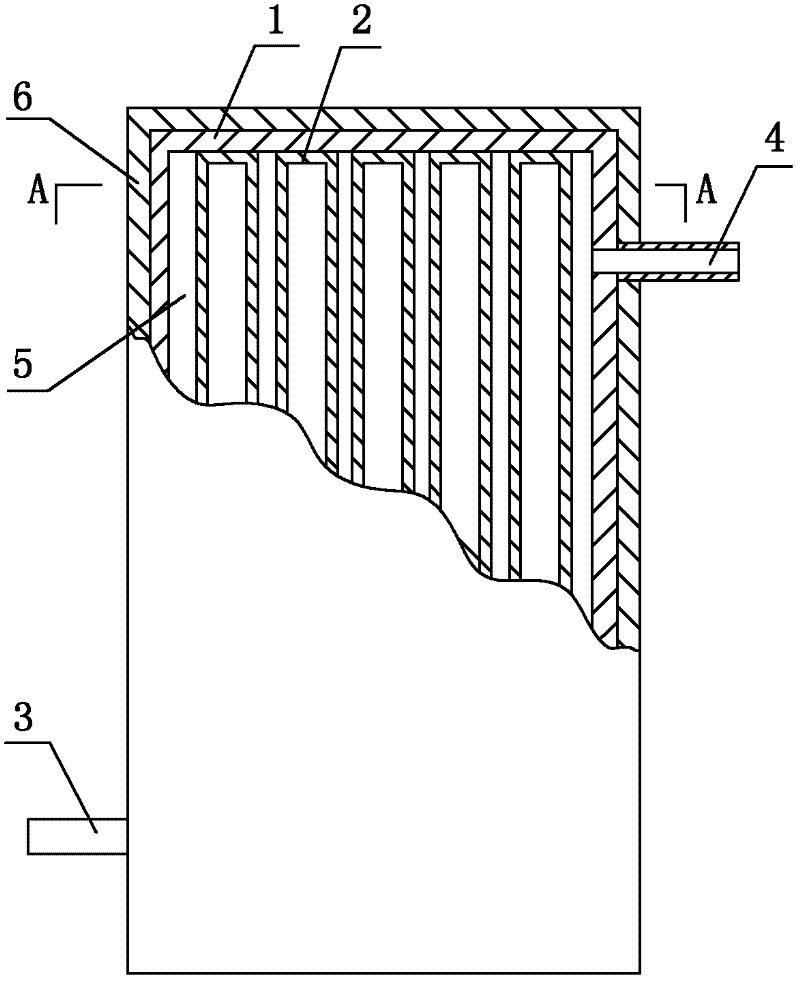

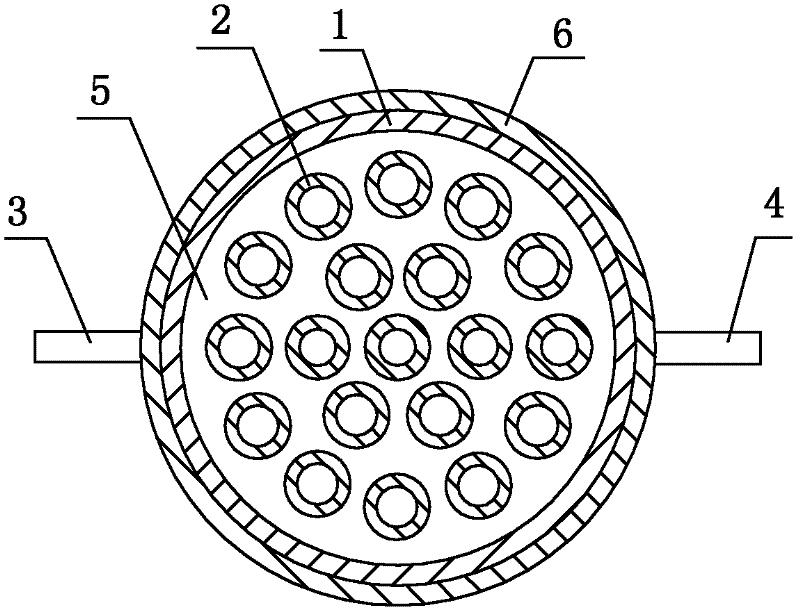

Fused salt phase change heat storage device applied to solar air conditioner

InactiveCN102252545AImprove heat transfer efficiencyGuarantee safety and reliabilityHeat storage plantsEnergy storageHeat conductingHeat storage material

The invention relates to a fused salt phase change heat storage device applied to a solar air conditioner. The fused salt phase change heat storage device applied to the solar air conditioner is characterized by comprising a heat storage chamber box, heat storage material accommodating pipelines, a heat storage material and heat conducting oil; a heat storage space is formed in the heat storage chamber box, the heat storage chamber box is provided with an oil inlet and an oil outlet, the oil inlet and the oil outlet are communicated with the heat storage space respectively, 2 to 200 heat storage material accommodating pipelines are arranged in the heat storage space of the heat storage chamber box, the heat storage material accommodating pipelines are fixed with the heat storage chamber box, and the heat storage material is filled in the heat storage material accommodating pipelines; and a heat transfer medium between the outer walls of the heat storage material accommodating pipelines and the inner wall of the heat storage chamber box is the heat conducting oil. The fused salt phase change heat storage device has the characteristics of simple structure, safety, reliability and high heat exchange efficiency.

Owner:WUHAN UNIV OF TECH

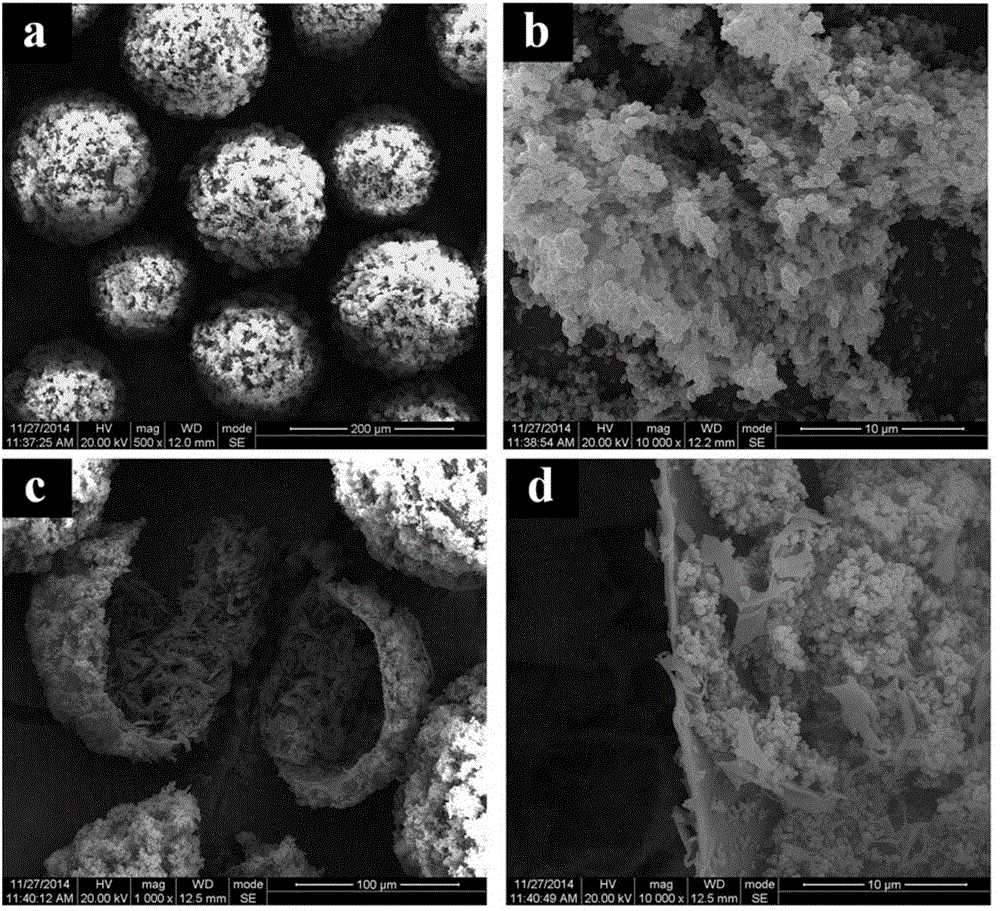

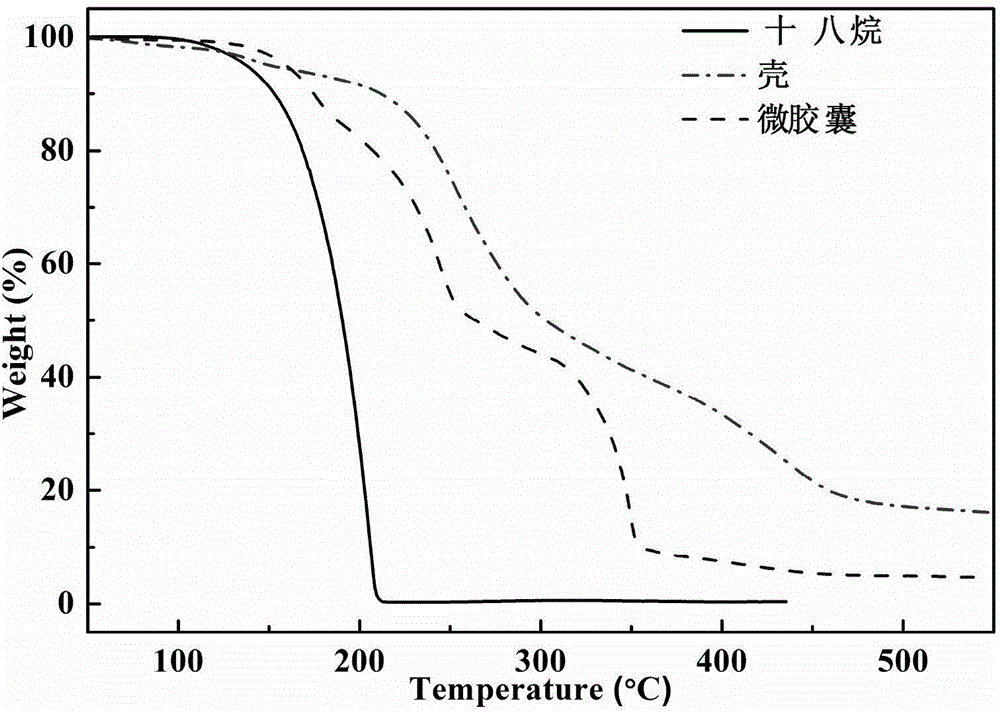

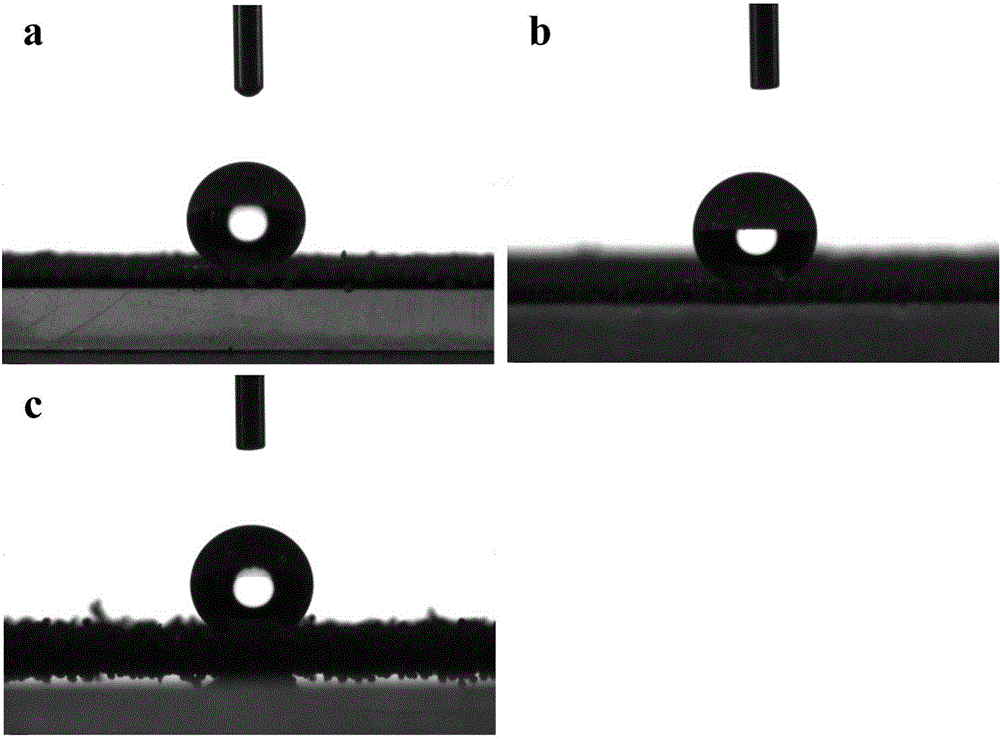

Super-hydrophobic microcapsule made from phase-change materials and preparation method of super-hydrophobic microcapsule

InactiveCN104927779AAdjustable sizeAdjustable microstructureHeat-exchange elementsMicroballoon preparationLevel structurePolymer science

The invention relates to a super-hydrophobic microcapsule made from phase-change materials and a preparation method of the super-hydrophobic microcapsule, and belongs to the technical field of the preparation of functional materials. The super-hydrophobic microcapsule made from phase-change materials comprises a capsule core and a capsule shell of which the external surface is provided with a micro nanometer multi-level structure, wherein according to the mass percentage, the content of the capsule core accounts for 60-90wt%, and the content of the capsule shell of which the external surface is provided with the micro nanometer multi-level structure accounts for 10-40wt%; the average diameter of the microcapsule is 10-1000 [mu] m, the average thickness of the capsule shell is 100-500 nm, and the average diameter of particles on the external surface of the capsule shell is 150-650 nm. The super-hydrophobic microcapsule made from the phase-change materials, obtained by the invention, has the advantages of controllable structure, high content of core materials, high super-hydrophobicity, good heat stability and the like; the preparation technology of the microcapsule is simple and environment-friendly, is convenient to operate and is wide in application range; raw materials are low in price and easy to obtain, so that the industrial mass production and application are easy to realize.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

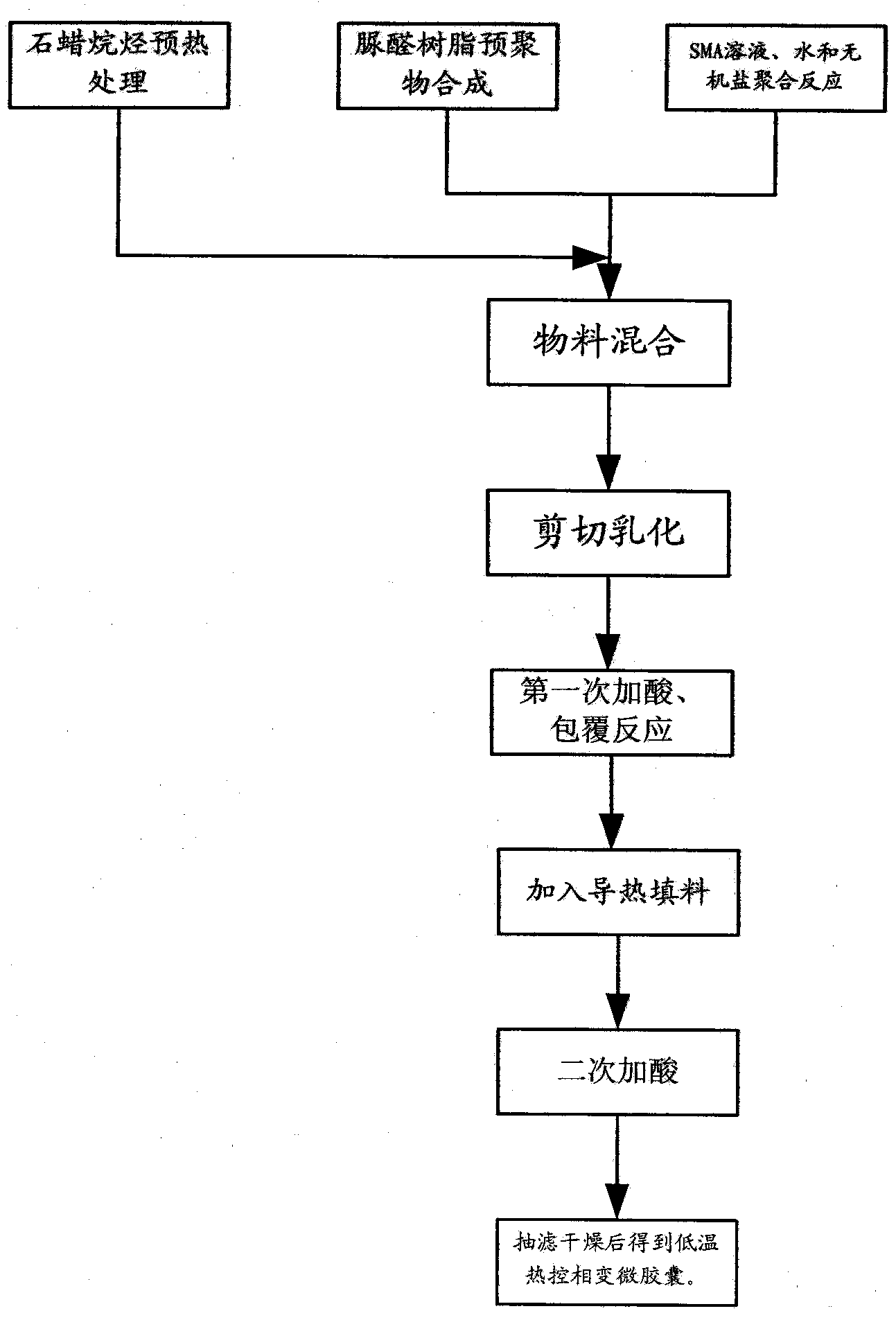

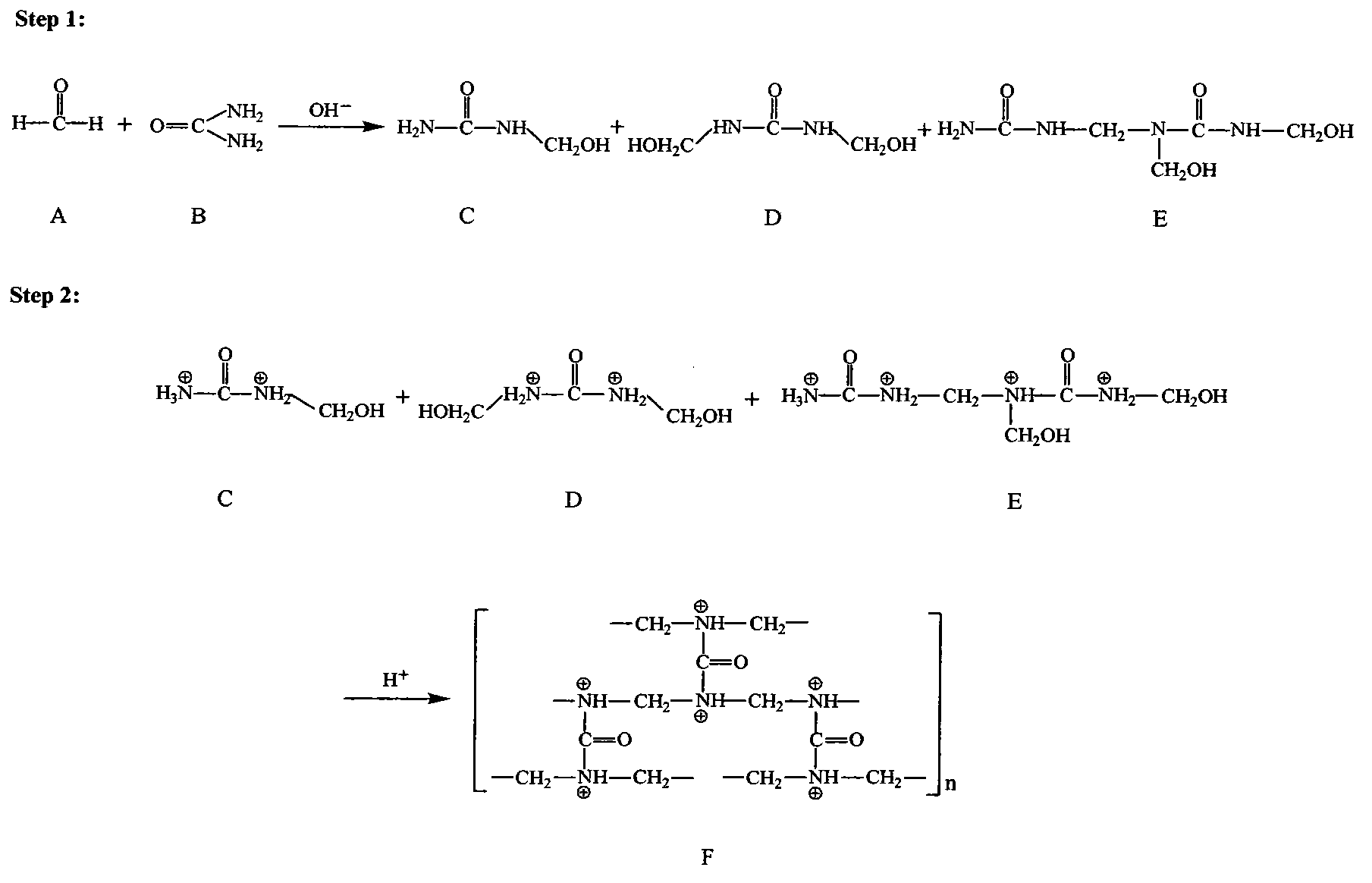

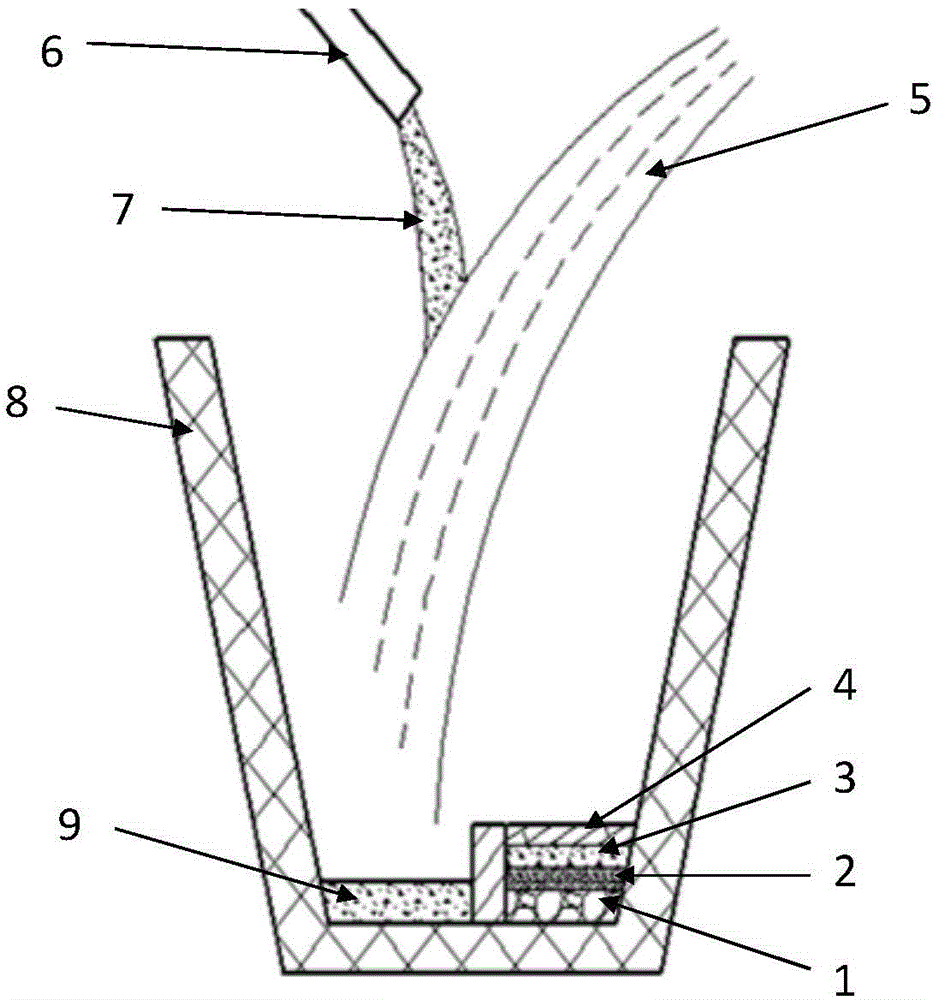

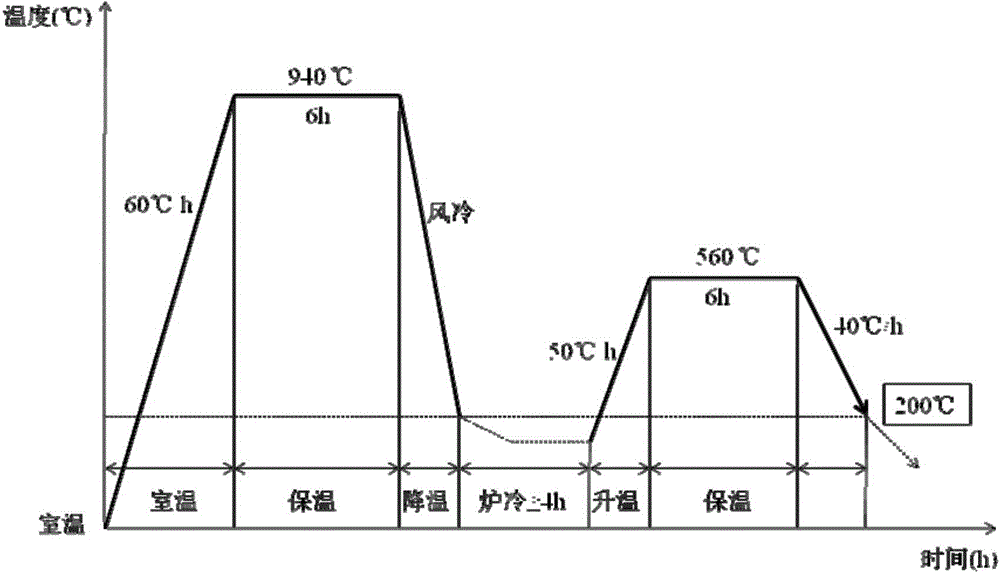

Low-temperature thermal control phase change microcapsule and preparation method thereof

ActiveCN104357019AImprove thermal conductivityEvenly dispersedHeat-exchange elementsMicroballoon preparationAlkanePermeation

The invention provides a low-temperature thermal control phase change microcapsule and a preparation method thereof. The low-temperature thermal control phase change microcapsule takes paraffin alkane as a core material and urea resin as a shell, and further comprises a heat conduction filler, the heat conduction filler is added in the process of coating the paraffin alkane by the urea resin, and the amount of the added heat conduction filler is 5%-30% that of the paraffin alkane. The low-temperature thermal control phase change microcapsule prepared by the invention is solid-solid phase change, the problems of fusion flowing and permeation migration are avoided, the range of phase change temperature is wide, the latent heat is large, the condensate depression is small, the phase change process is stable, the phase change is reversible, the material further has a higher heat conduction property, and as a relatively ideal thermal control phase change material, the low-temperature thermal control phase change microcapsule can be widely used in the fields of thermal protection, like aerospace, precise instruments, and electron devices.

Owner:海鹰空天材料研究院(苏州)有限责任公司

Nodular cast iron material and preparation method thereof

ActiveCN106191640APromote the increase of contentThe eutectoid transition temperature decreasesProcess efficiency improvementMagnesiumControllability

The invention discloses a nodular cast iron material and a preparation method thereof. The nodular cast iron material comprises the following components of, by weight, 3.300%-3.700% of carbon, 1.800%-2.400% of silicon, 0.100%-0.300% of manganese, 0.060%-0.120% of sulfur, 0.000%-0.050% of phosphorus, 1.200%-1.500% of copper, 0.120%-0.150% of tin, 0.020%-0.040% of antimony, 0.040%-0.060% of magnesium, 0.003%-0.010% of cerium, and the balance iron. The nodular cast iron material is 310 HB-340 HB in hardness, has good hardness uniformity and is suitable for production of heavy-section abrasion-resistant components. The production process of the nodular cast iron material is simple and convenient, the procedure is high in controllability, the production cost is low, and large-scale application and popularization are easy.

Owner:KOCEL EQUIP

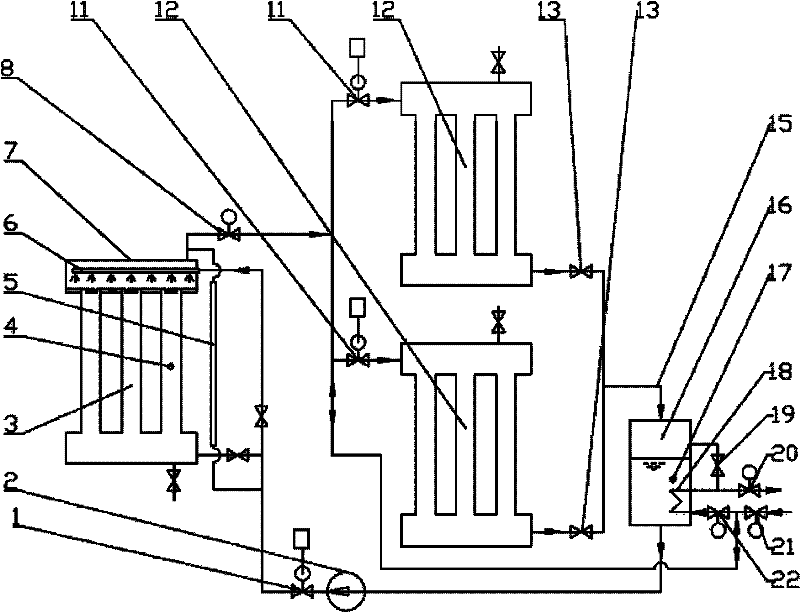

High-efficiency, sub-control and phase-change heat exchange system and method

InactiveCN102230753AWall temperature is not affectedReduce the chance of low temperature corrosionIndirect heat exchangersHeat exchange apparatusAirflowEngineering

The invention relates to a high-efficiency, sub-control and phase-change heat exchange system. The heat exchange system provided by the invention comprises a heat exchanger of heat source (3) and a heat exchanger of cold source (12) which are mutually communicated through a steam tube and a condensate line to from a sub-control and phase-change heat exchange circuit. The heat exchange circuit is provided with an air flow regulating valve and a liquid flow regulating valve which can control the circuit. A reservoir tank (16) is configured on the condensate line. The header of the steam tube on the top of the heat exchanger of heat source (3) is divided into two steam sub-tubes. A first steam sub-tube is connected with the heat exchanger of heat source (12) and an air flow regulating valve (11) is configured between the first steam sub-tube and the heat exchanger of cold source (12). A second steam tube communicates with the reservoir tank (16) via a condensate heater (18) configured inside the reservoir tank (16). A liquid distribution tube (6) is configured inside the collecting chamber (7) of the heat exchanger of heat source (3), and a plurality of sprayers are configured on the liquid distribution pipe which is used for the mixing heat exchange of steam and condensate. The efficiency of the system provided by the invention is much higher.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

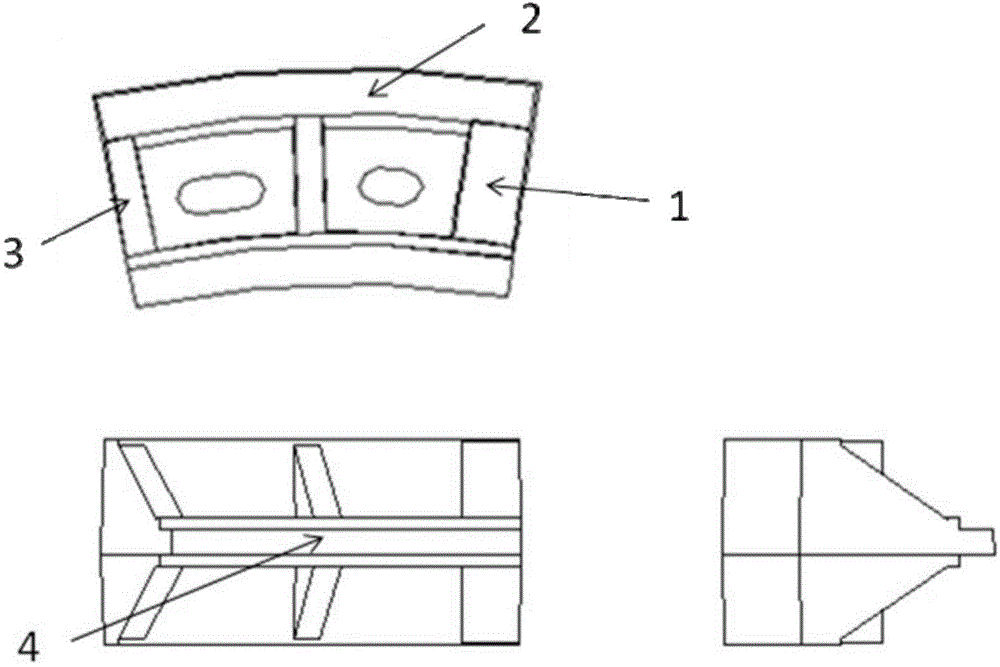

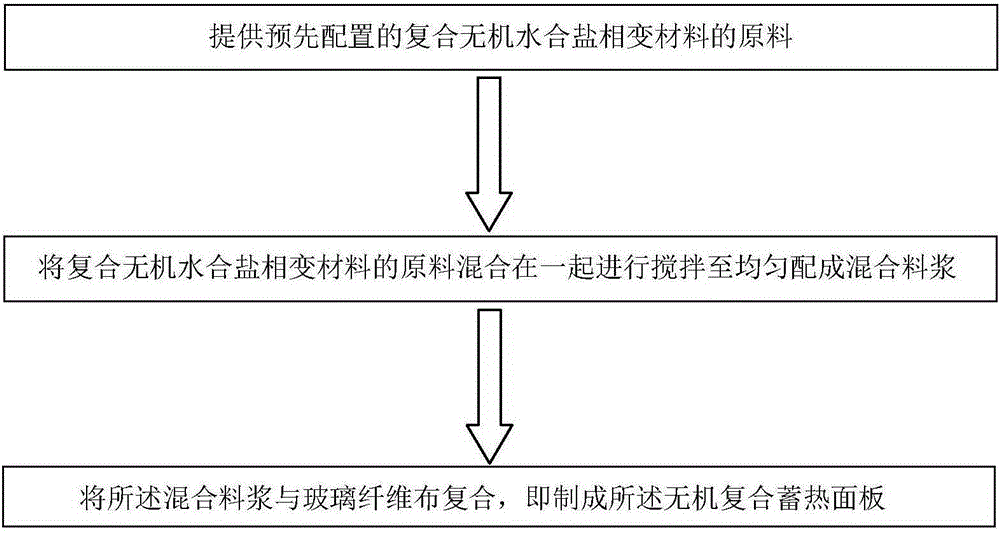

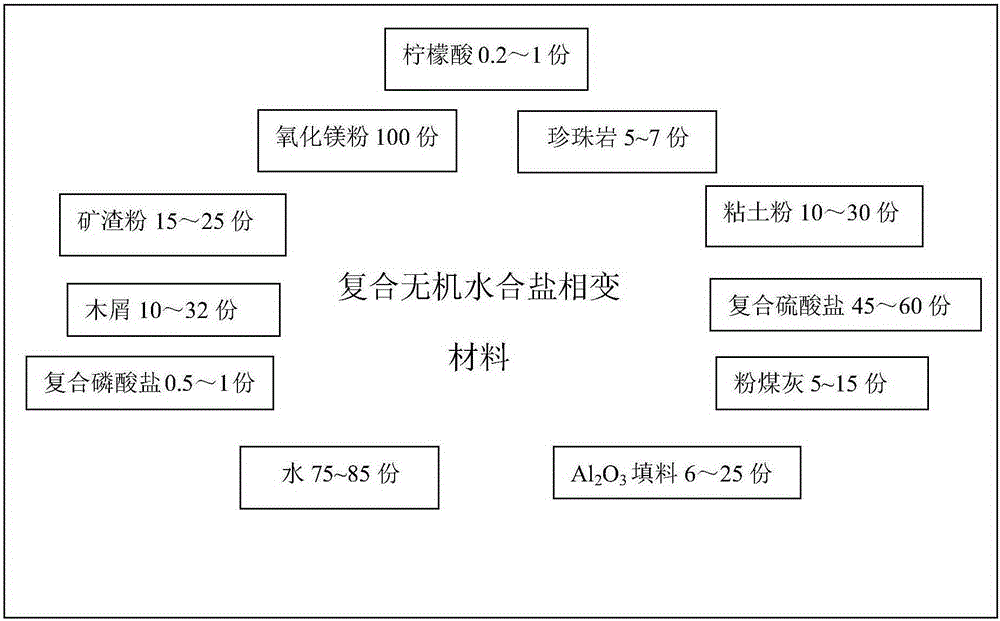

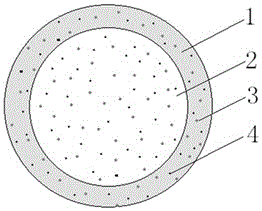

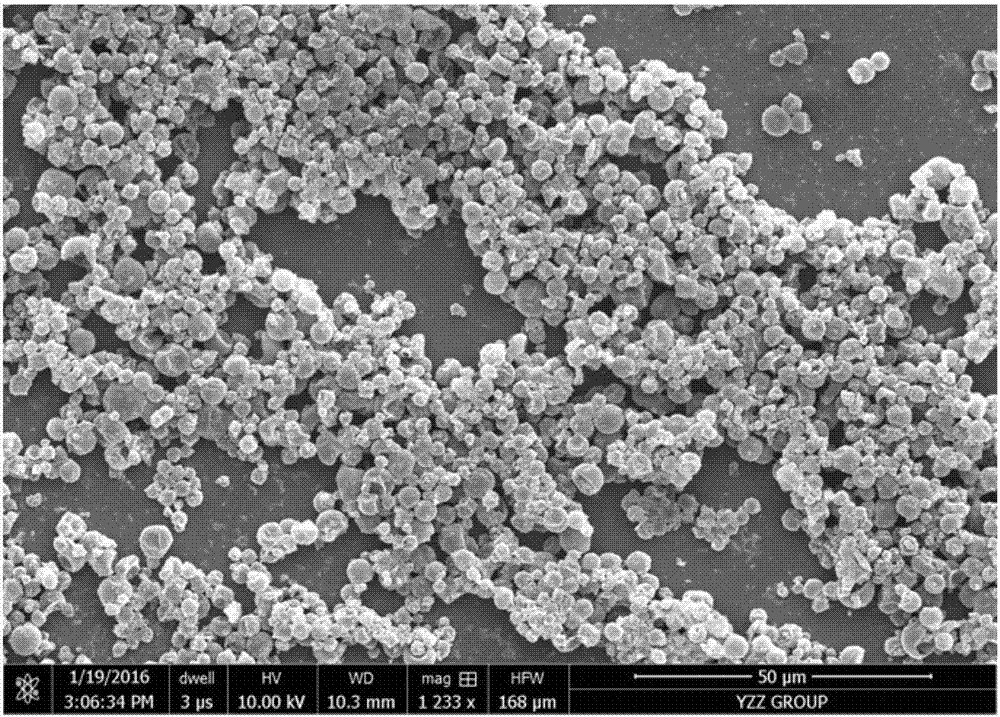

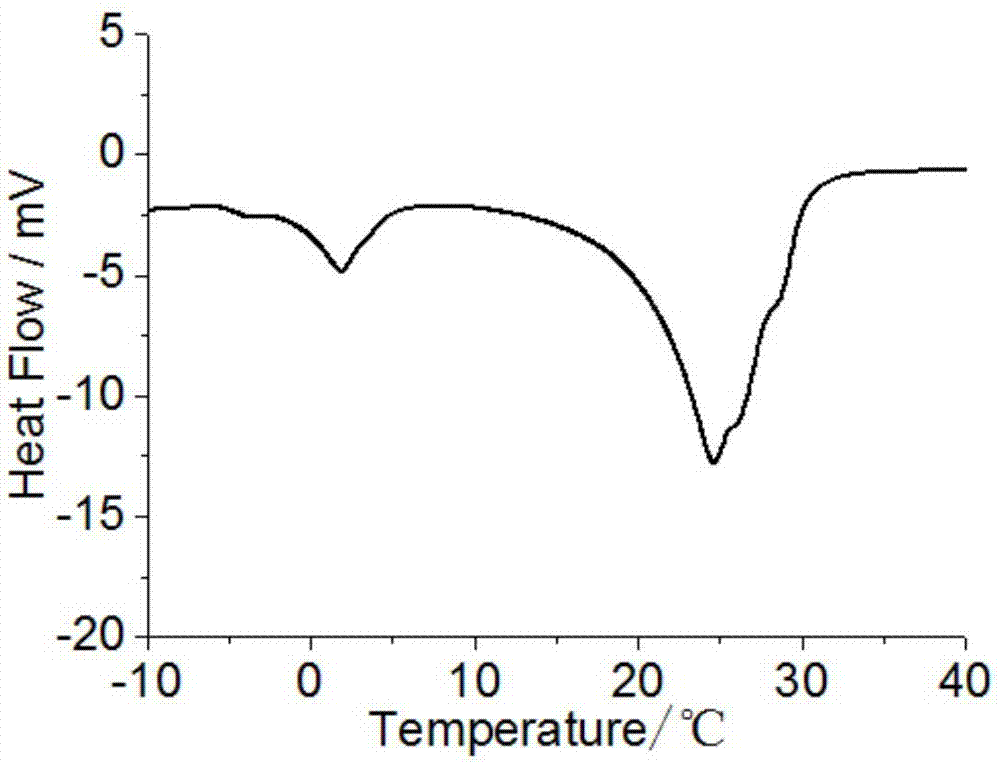

Composite inorganic hydrous salt phase-change material and preparation method of inorganic composite phase-change plate

The invention relates to the field of composite building and ornament materials, in particular to a composite inorganic hydrous salt phase-change material and a preparation method of an inorganic composite phase-change plate. The preparation method comprises the steps that the pre-configured composite inorganic hydrous salt phase-change material raw materials comprising 100 parts of magnesia powder, 10-30 parts of clay powder, 15-25 parts of slag powder, 6-25 parts of Al2O3 padding, 45-60 parts of composite sulfate, 10-32 parts of wood flour, 0.5-1 part of composite phosphate, 5-7 parts of perlite, 75-85 parts of water and 0.2-1 part of citric acid are provided; the raw materials are mixed and evenly stirred into mixed slurry; the mixed slurry is compounded with glass fiber cloth to form an inorganic composite heat accumulation panel. The inorganic composite phase-change plate has the advantages of being low in weight and high in strength, saving energy, preserving moisture, resisting water, being good in toughness, absorbing sound, being environmentally friendly and high in ornamental performance and the like, meanwhile, has the high energy storage density and low degree of supercooling, is free of layering and good in stability, has impermeability, and does not corrode metal.

Owner:上海唐盾材料科技有限公司

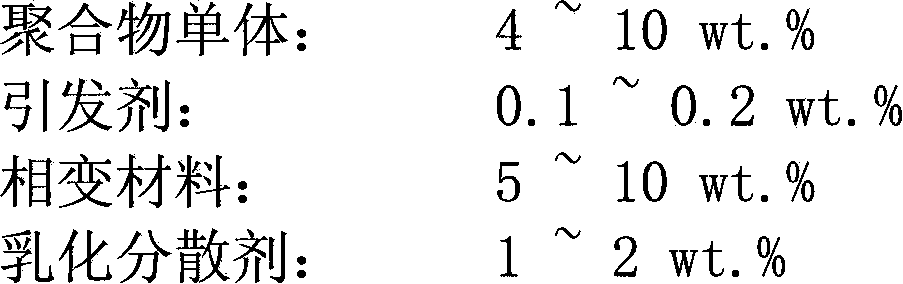

Microcapsule phase change material and preparation method thereof

InactiveCN106753261AAvoid stratificationImprove physical stabilityHeat-exchange elementsHigh densityNanoparticle

The invention provides a microcapsule phase change material. The microcapsule phase change material comprises a core material, wherein a wall material is arranged on the outer side of the core material; aluminum nanoparticles and graphite nanoparticles are contained in both the core material and the wall material. The invention further provides a preparation method of the microcapsule phase change material. The preparation method comprises the following steps: weighing the core material and the wall material; preparing a mixture of the aluminum nanoparticles and the graphite nanoparticles; determining the composite content of the nanoparticles; preparing a composite solution of the core material; preparing a composite solution of a first wall material; moulding a microcapsule; washing and drying the microcapsule. According to the microcapsule phase change material provided by the invention, three characteristics are improved at the same time by adding the composite aluminum and graphite nanoparticles into the core material and the wall material, namely the particle density of the microcapsule phase change material is adjusted, the thermal conductivity is increased, and the overcooling degree is reduced; the microcapsule phase change material which contains the composite aluminum and graphite nanoparticles and has high density, high thermal conductivity and low overcooling degree is obtained.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Preparation method of inorganic material-coated phase change microcapsule, product prepared thereby and application of product

ActiveCN107384328AIncrease coverageReduce breakage rateHeat-exchange elementsToxic materialSupercooling

The invention discloses a preparation method of an inorganic material-coated phase change microcapsule, a product prepared thereby and an application of the product. The inorganic material-coated phase change microcapsule is obtained in one step through sol-gel reaction on an emulsion interface. No toxic substance is generated in the preparation process of the inorganic material-coated phase change microcapsule and the preparation process is green and environmentally friendly; the phase change and energy storage microcapsule prepared through the preparation method is high in coating rate and low in breakage rate, the supercooling degree of the sol-liquid phase change material is effectively reduced, the obtained phase change material is free of a volatile gas and safe in use, and the application range is expanded; the preparation method is simple in process and low in cost, the used raw materials are cheap and available and industrialization is easy to implement; and the phase change and energy storage microcapsule can be widely applied to the fields, such as spinning, building energy conservation, thermal management of electronic components and waste heat recovery.

Owner:中科世宇(北京)科技有限公司

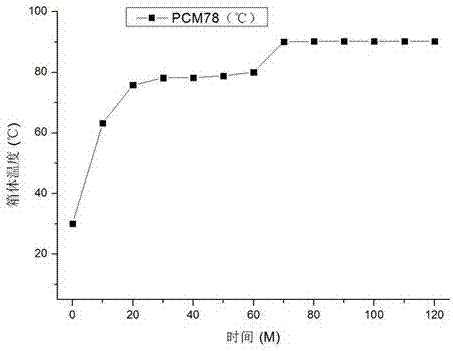

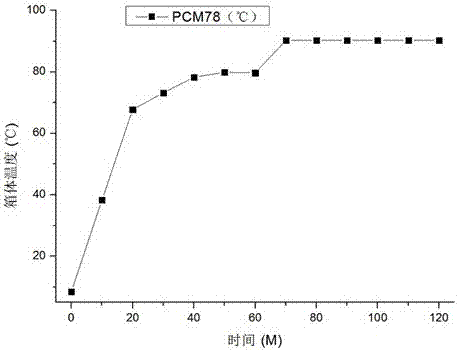

Composite phase-transition heat-storage material and preparation method thereof

InactiveCN106753252AHigh freeze-thaw rateHigh thermal conductivityHeat-exchange elementsStorage efficiencyThermal conductivity

The invention provides a composite phase-transition heat-storage material and a preparation method thereof. A porous material with high thermal conductivity is used as a supporting framework, and low-melting-point metal or low-melting-point metal with nano-particles is distributed in pores of the porous material, wherein melting point or solidus temperature of the low-melting-point metal is less than or equal to 80 DEG C; and thermal conductivity of the porous material is within 40-400 W / (m.K). The material provided by the invention has high equivalent thermal conductivity and high storage energy density; there is a large contact area between the liquid metal and the porous material; and the material has a wide application temperature range, has good fixability, stable physico-chemical property and good reversibility; and the problem of decreasing heat storage efficiency after multiple times of heat adsorption and release cycles is avoided.

Owner:CHANGDE LYRUN MATERIAL

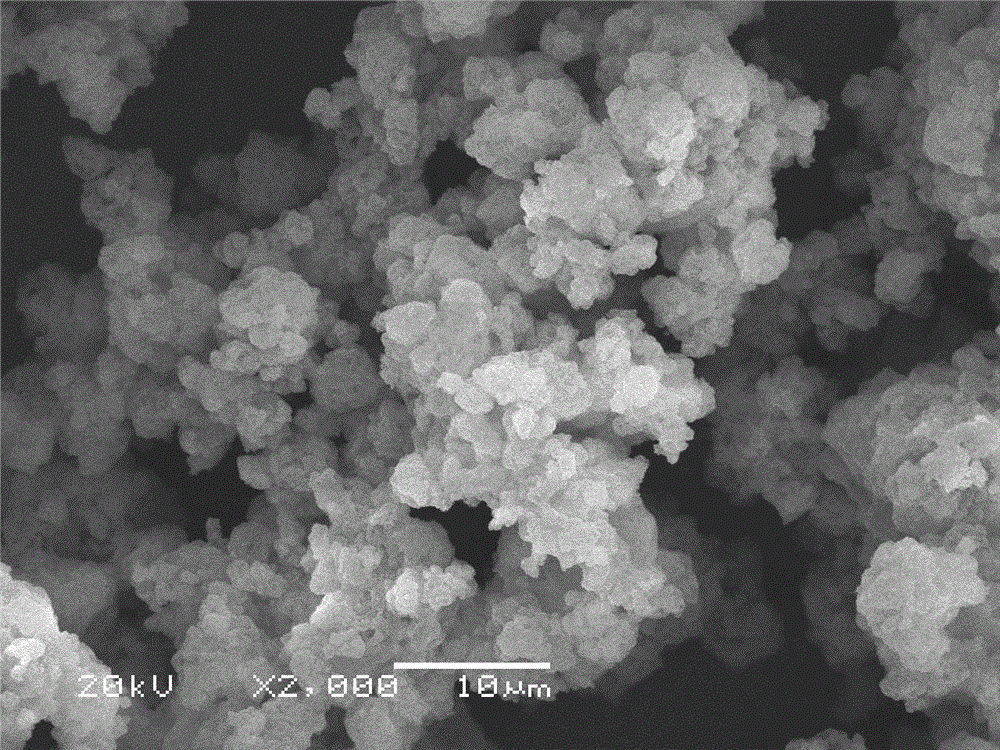

Graphene oxide nano inorganic phase-change material and preparation method thereof

ActiveCN106928906APromote nucleationReduce subcoolingHeat-exchange elementsInorganic saltsSide effect

The invention provides a preparation method of a graphene oxide nano inorganic phase-change material. The specific surface area of graphene oxide is utilized to promote crystal nucleation and lower the supercooling degree of an inorganic phase-change material, at the same time, graphene oxide contains a lot of hydroxy, which can bond with inorganic salt crystal water to produce a hydrogen bond, thus effectively avoiding or delaying agglomeration, and improving the system stability. The supercooling degree of an inorganic phase-change material is effectively lowered, and the supercooling degree of the phase-change material can be lowered to 1-3DEG C. According to the invention, the process is simple and easy for operation, the product has homogeneous and stable properties, and small toxic and side effects, etc., and belong to green and environment-friendly products.

Owner:JILIN JIANZHU UNIVERSITY

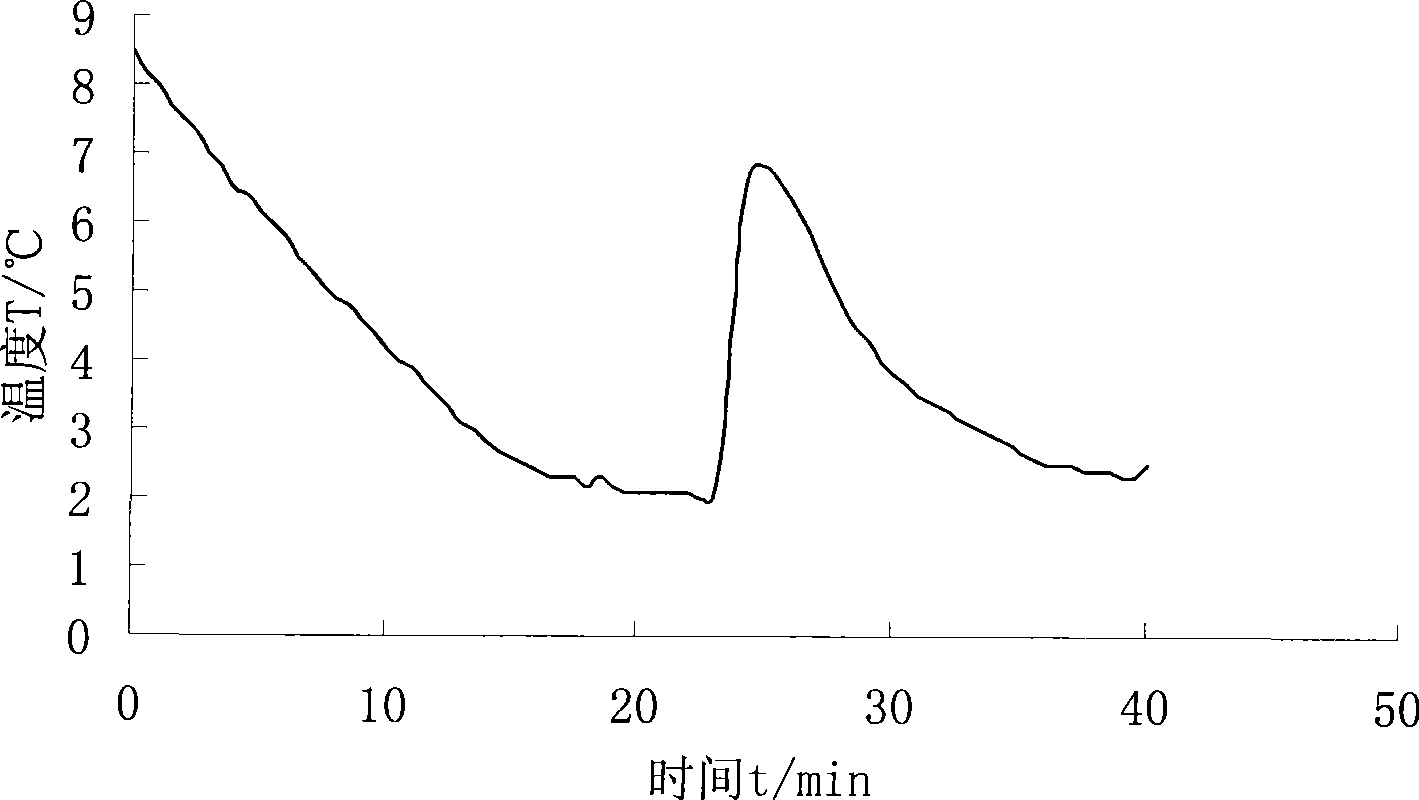

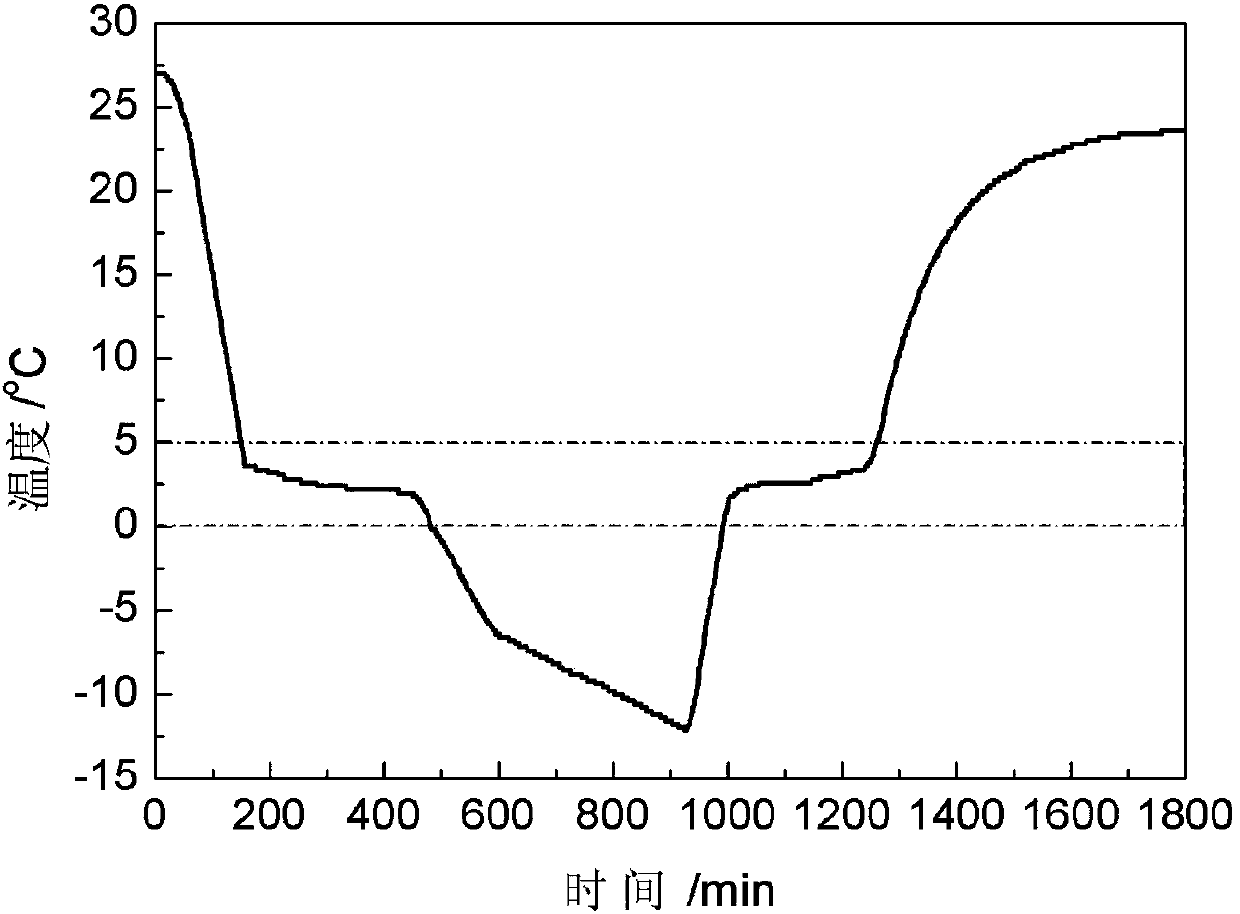

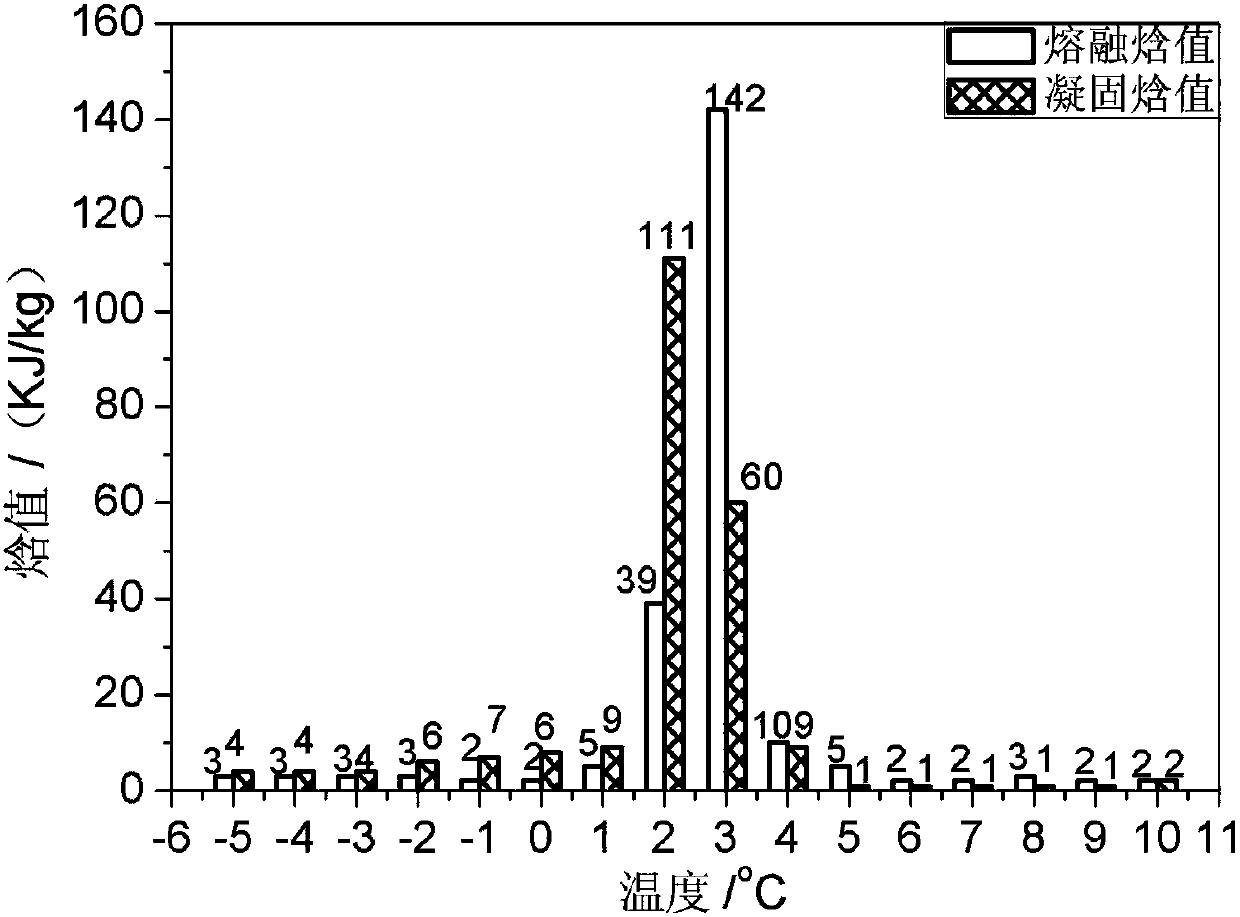

Low-temperature phase change material used in drug cold-chain transportation

ActiveCN107936928AImprove cycle stabilityHigh melting enthalpyHeat-exchange elementsCold chainN-dodecane

The invention discloses a low-temperature phase change material used in drug cold-chain transportation. The low-temperature phase change material is prepared by mixing the following components in percentage by weight: 88.5-91.8% of n-tetradecane, 4-5% of n-dodecane, 2-3% of n-tridecane, 2-3% of n-pentadecane, and 0.2-0.5% of iso-tetradecane. According to the material, the melting point is 2-3 DEGC, so that the drug temperature can be kept within the valid range of 0-5 DEG C during transportation; in addition, the melting enthalpy of the material is high; the degree of supercooling is low; andthe circulating stability is high.

Owner:杭州鲁尔新材料科技有限公司

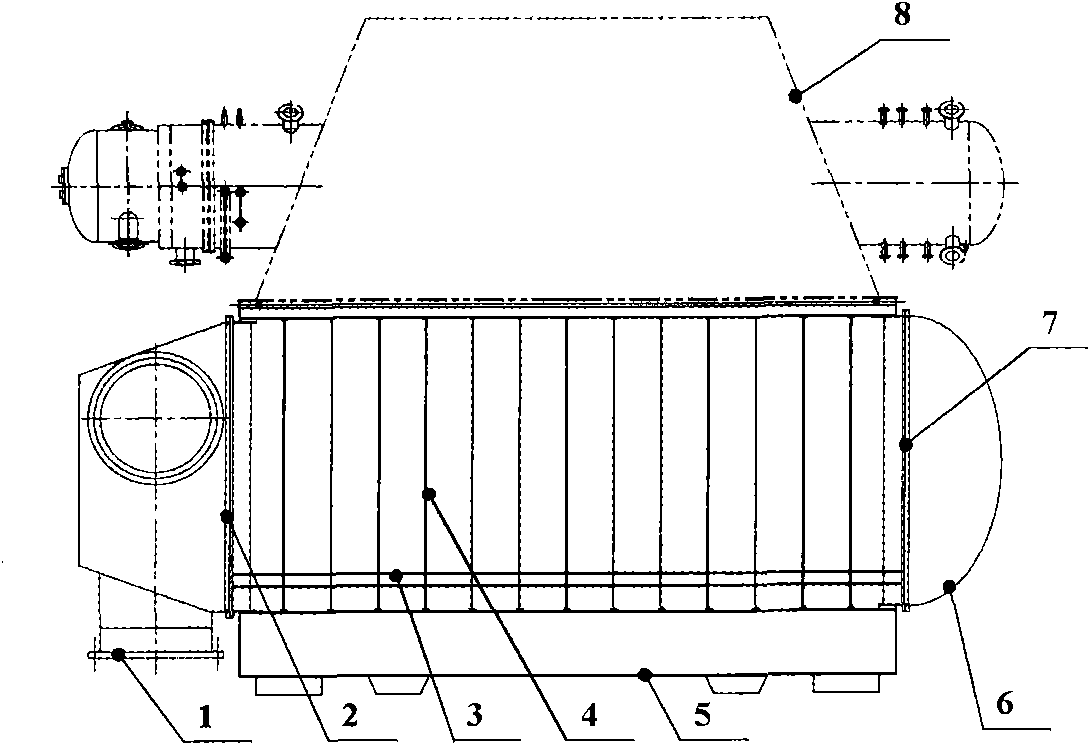

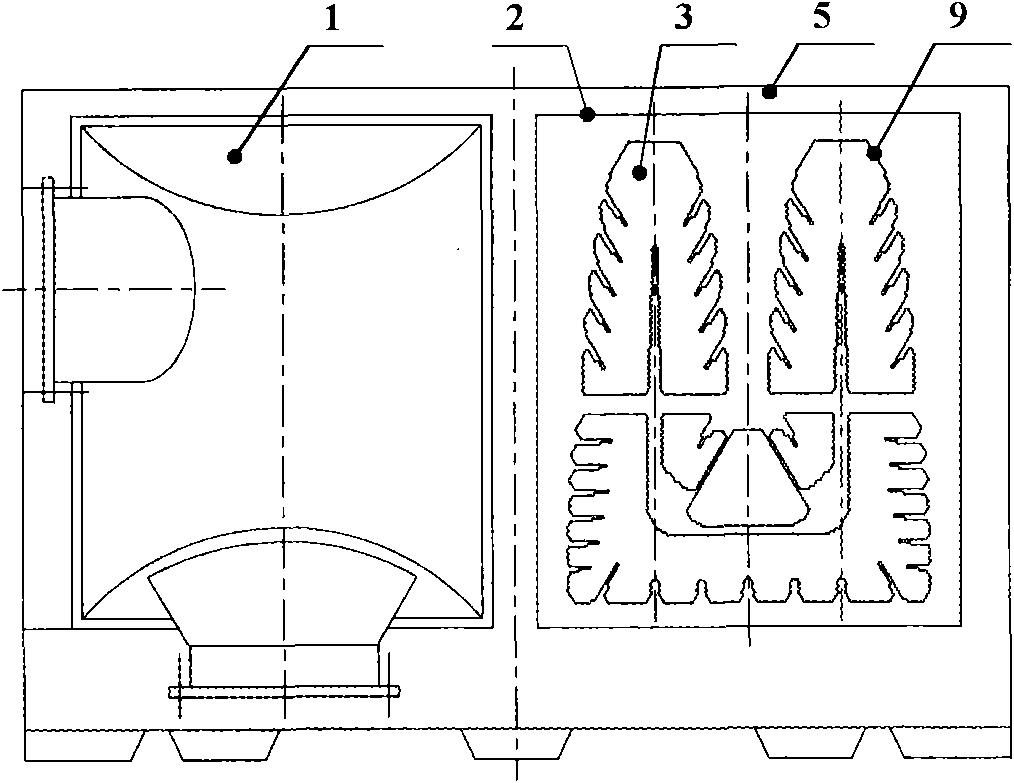

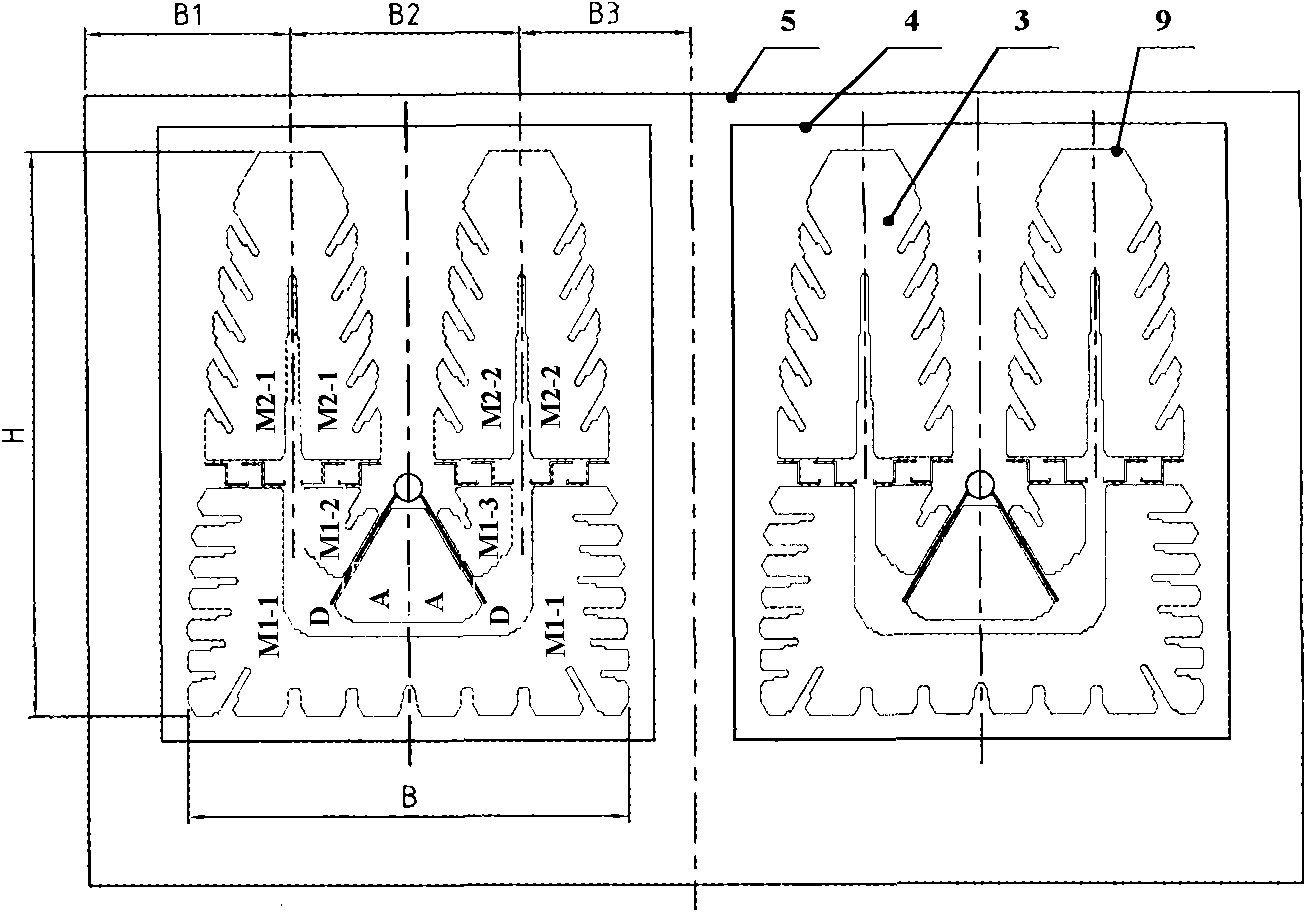

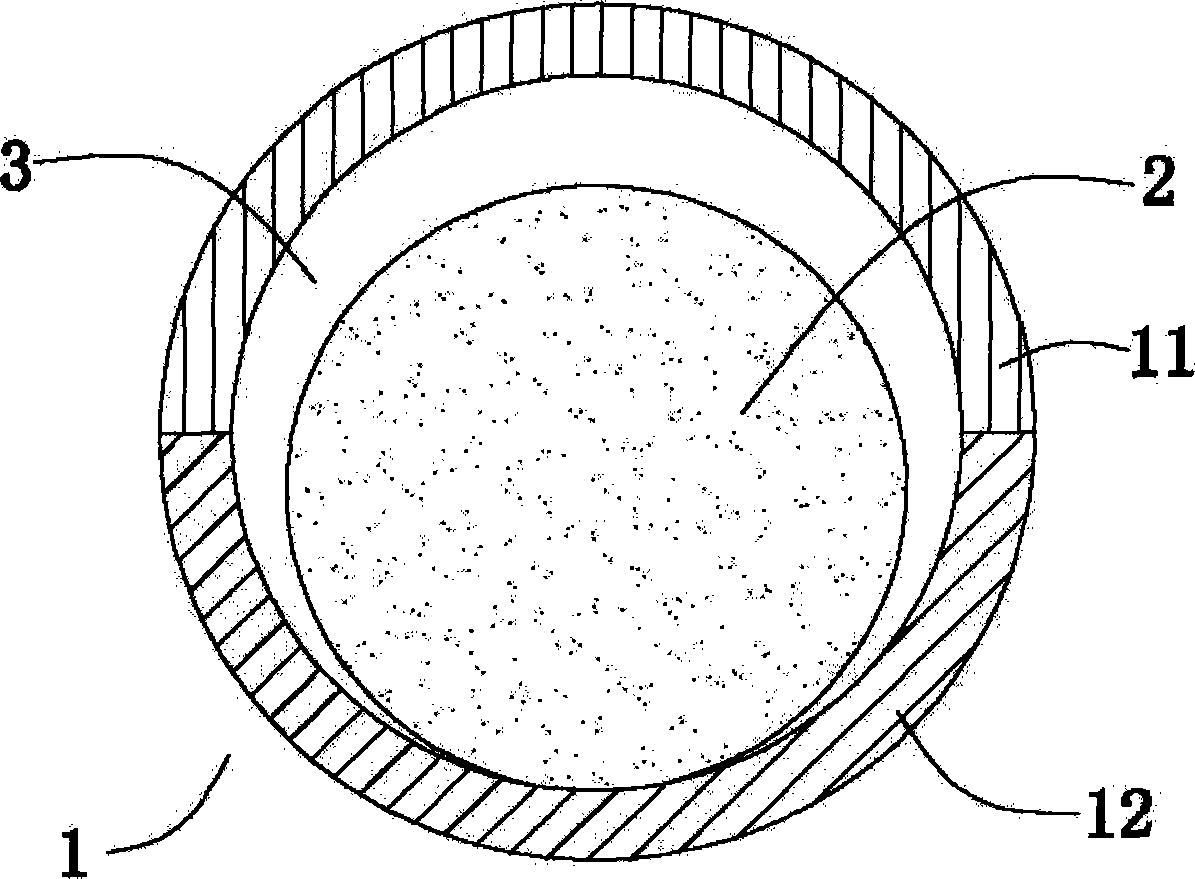

Simulated bicontinuous tree-shaped pipe bundle type steam condenser

ActiveCN101865612AReduce subcoolingImprove heat transfer performanceSteam/vapor condensersEngineeringTree shaped

The invention provides a simulated bicontinuous tree-shaped pipe bundle type steam condenser, which belongs to the technical field of heat exchangers. The simulated bicontinuous tree-shaped pipe bundle type steam condenser consists of a plurality of heat exchange pipes, a front end pipe plate, a middle pipe plate, a back end pipe plate, a case assembly, a steam baffle plate, a front water chamber, a back water chamber and the like. The invention is characterized in that the distribution of the heat exchange pipes of the steam condenser pipe bundle on the pipe plate is in simulated bicontinuous tree-shaped distribution, and the heat exchange pipes are formed by simulated bicontinuous tree loose tree branch pipe bundle region pipe bundles, simulated bicontinuous tree dense pipe bundle region pipe bundles, gradually reducing air cooling region pipe bundles and the like, wherein a simulated bicontinuous tree loose tree branch pipe bundle region consists of simulated tree branch-shaped pipe bundles with the upwards inclined upper part, simulated tree branch-shaped pipe bundles with the horizontal lower part, simulated tree branch-shaped pipe bundles with the downwards bottom and the like, the simulated bicontinuous tree-shaped span ratio is 0.3 to 0.4, the height to width ratio of the simulated bicontinuous tree-shaped pipe bundles is 1.1 to 2.0, the gap average permeability is 0.3 to 0.6, the peripheral average voidage is 0.2 to 0.4, the simulated tree branch relative width is 4 to 12, and the simulated tree branch relative gap is 2.5 to 5. The invention has the advantages of uniform and eddy-free pipe bundle steam flow flowing field, small steam resistance of the case side, uniform heat load distribution, small condensing water supercooling degree, high heat transfer coefficient and high operation vacuum degree. The heat exchange coefficient can be 10 to 20 percent higher than the HEI calculation value, and the machine set energy-saving effect is obvious.

Owner:TSINGHUA UNIV

Inorganic phase-change composite material and preparation method thereof

ActiveCN108467711AImprove corrosion resistanceReduced phase transition temperature rangeHeat-exchange elementsSodium acetateSodium stearate

The invention discloses an inorganic phase-change composite material and a preparation method of the material. The phase-change material comprises a main heat agent, a nucleator, a pH (potential of hydrogen) regulator, a corrosion inhibitor, a heat conduction agent and water, wherein the mass of the nucleator is 3-6% of that of the main heat agent; the mass of the pH regulator is 0-3% of that of the main heat agent; and the mass of the corrosion inhibitor is 0.5-2% of that of the main heat agent. Eutectic salt is prepared by a high-temperature hydrothermal reaction of sodium acetate, calcium chloride and sodium stearate in the pH regulator; a phase change temperature scope of the eutectic salt is reduced to 5-10 DEG C; a prepared product directly generates a self-organization framework toform the jelly-like eutectic salt, so that a thickening agent and a setting agent are not required to be added in a system; a degree of supercooling of the product is greatly reduced; and furthermore,since the ternary eutectic salt has a special structure, the ternary eutectic salt has the advantages of low lamination and supercooling possibility of an organic phase-change material and a high potential heat value of an inorganic phase-change material.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

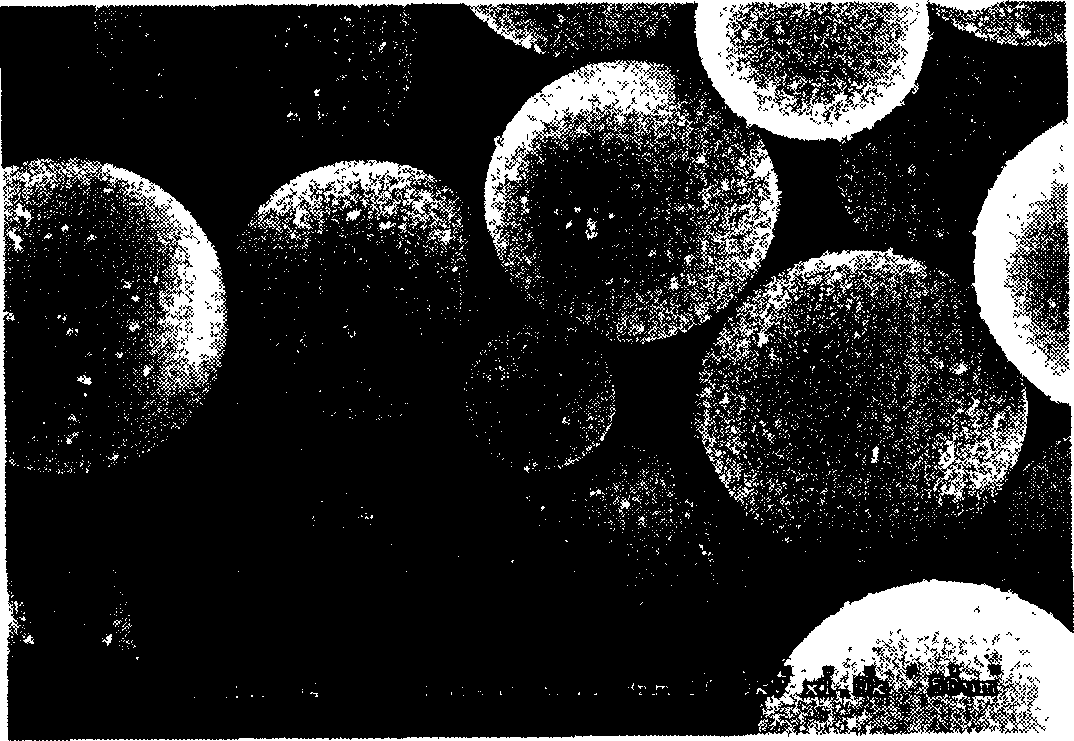

Phase-change material packaging process and phase change heat storage product

The invention discloses a phase-change material packaging process and a phase change heat storage product prepared by using the process. The phase change heat storage product comprises a spherical silica gel shell and a sphere prepared from a phase-change material, wherein the sphere is arranged in the spherical silica gel shell. The packaging process is simple, can realize packaging of phase-change materials with phase-change temperatures in a range of 100 to 200 DEG C and has the advantages of a good packaging effect, low cost and easy realization. The product provided by the invention is ingeniously designed, fully utilizes the characteristics of high temperature resistance, aging resistance, no toxicity, uneasy reaction with acid and alkaline substances and the like of silica gel and enables a packaged phase-change material to be used for a long time during heat storage; moreover, heat conduction powder is added, so good heat conductivity is obtained, the phase-change material is allowed to realize effective heat exchange with the outside, the utilization rate of energy is increased, and energy conservation and environmental protection are benefited. Since the product employs spherical structure design, the product can be more easily put into a variety of heat storage tanks or heat exchange apparatuses, which is beneficial for wide popularization and application of the product.

Owner:张曹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com