Simulated bicontinuous tree-shaped pipe bundle type steam condenser

A condenser and tube bundle type technology, which is applied in the field of bionic double-connected tree tube bundle type condensers, can solve the problems affecting the output and economy of the unit, low heat transfer coefficient, etc., and achieve obvious energy saving effect and steam flow field. Uniform, no eddy current, uniform heat load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

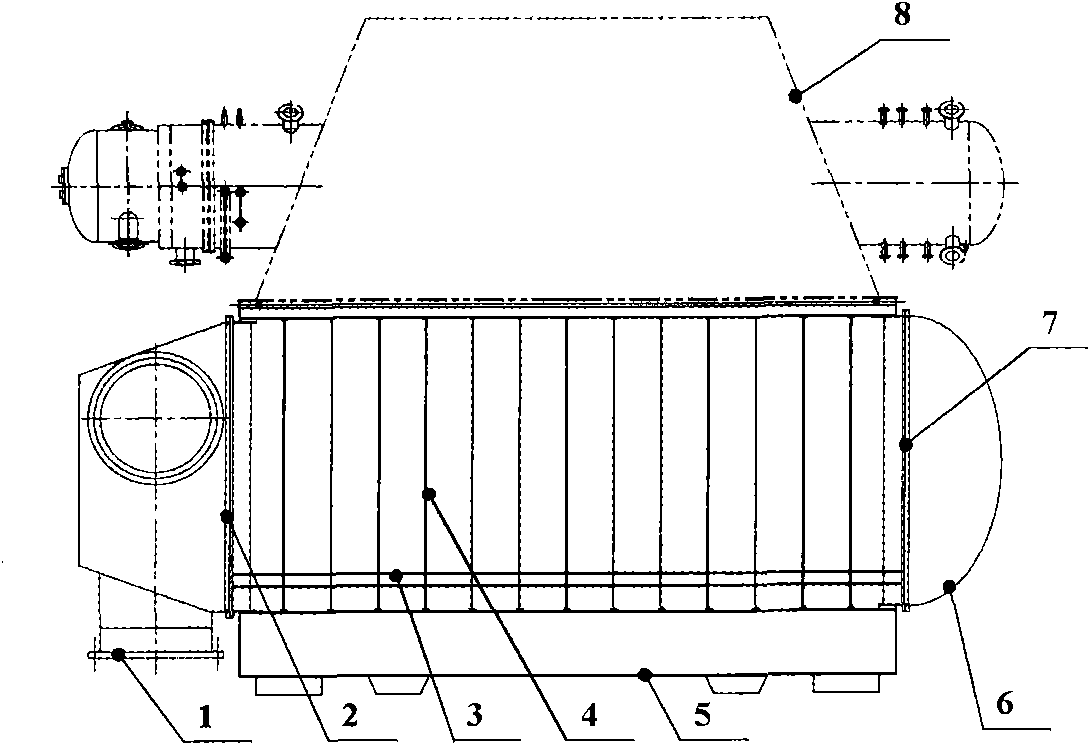

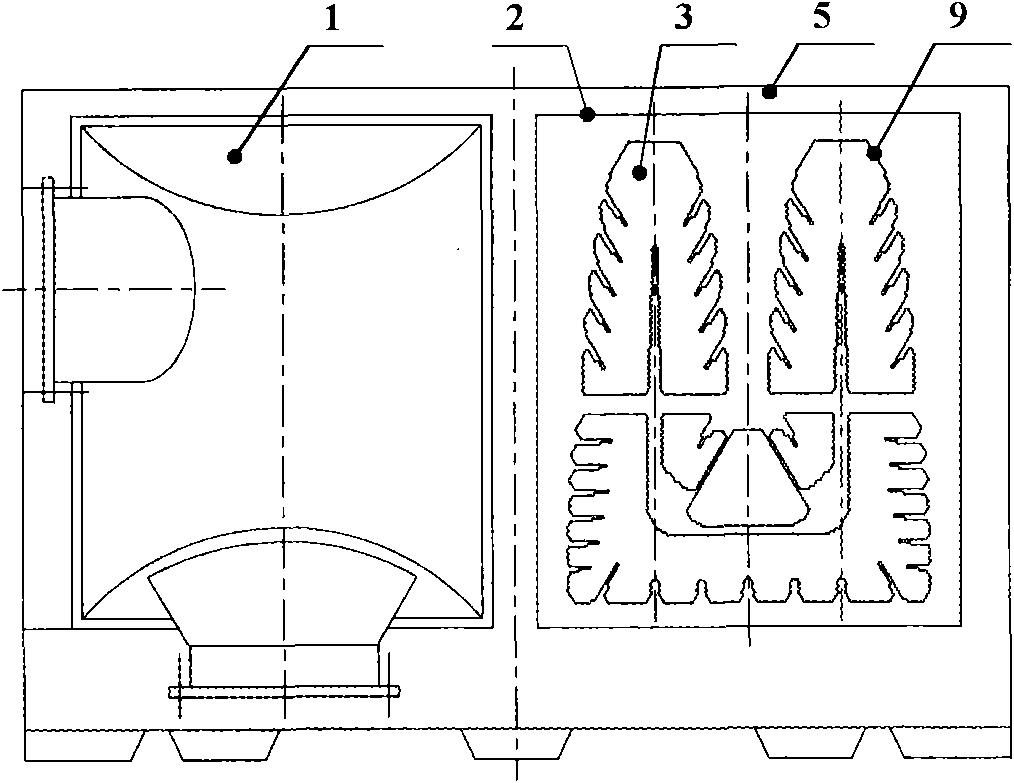

[0037] figure 1 It is a structural schematic diagram of a condenser according to an embodiment of the present invention. exist figure 1 Among them, 1 is the water chamber before the condenser (2 pieces in total), 2 is the front tube plate of the condenser (2 pieces in total), and 3 is a number of heat exchange tubes (there are 22992 heat exchange tubes in this embodiment, figure 1 Only 2 heat exchange tubes are schematically drawn in the figure), 4 is the intermediate tube plate (2x13 pieces in total), 5 is the condenser shell assembly, 6 is the water chamber after the condenser (2 pieces in total), and 7 is the condensing steam The tube plate at the rear end of the device (2 pieces in total), and 8 is the connecting part (neck) between the condenser and the steam turbine. The heat exchange tubes pass through the tube holes of the middle tube sheet and are connected to the tube sheets at both ends, and the connection between the heat exchange tubes and the tube sheets at bot...

Embodiment 2

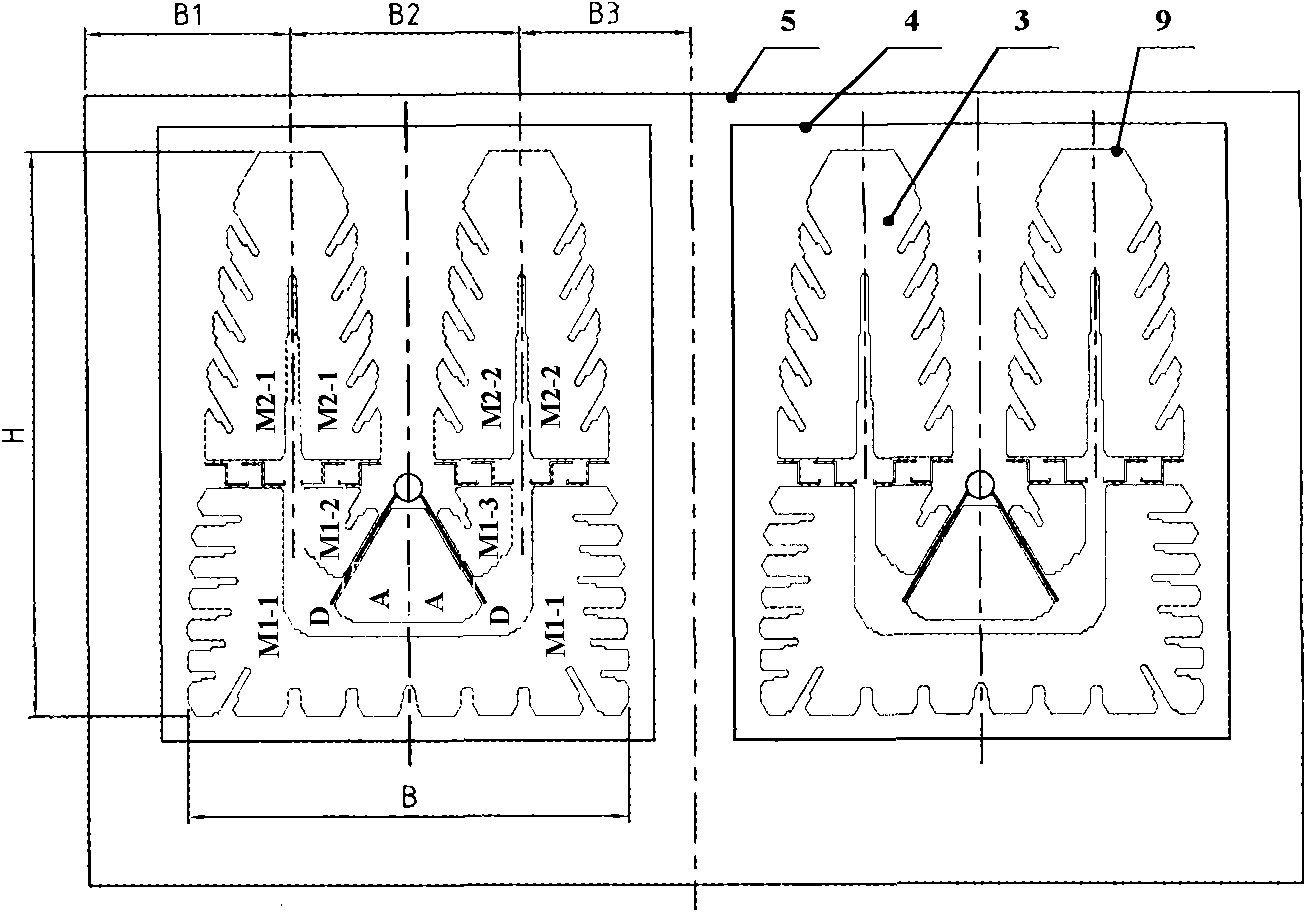

[0060] Figure 13 It is a schematic diagram of the bionic double-connected tree arrangement of the second embodiment of the present invention. Figure 14 It is a schematic diagram of the middle tube sheet of the bionic double-connected tree-shaped tube bundle in the second embodiment of the present invention. exist Figure 13 Among them, the tube bundle arrangement in this embodiment is two bionic double-connected tree-shaped arrangements arranged side by side symmetrically, each bionic double-connected tree-shaped tube bundle is composed of 11602 heat exchange tubes, and the tube bundle arrangement in this embodiment has a total of 23204 heat exchange tubes.

[0061] exist Figure 13 and Figure 14 Among them, B1 is the distance between the middle line of a bionic tree-shaped trunk and the inner wall of the nearest shell, and B2 is the distance between the middle lines of two bionic tree-shaped trunks in a bionic double-connected tree-shaped tube bundle (bionic double-conn...

Embodiment 3

[0064] Figure 15 It is a schematic diagram of the bionic double-connected tree arrangement of Embodiment 3 of the present invention. Figure 16 It is a schematic diagram of the middle tube sheet of the bionic double-connected tree-shaped tube bundle in the second embodiment of the present invention. exist Figure 15 Among them, the arrangement of the tube bundles in this embodiment is two bionic double-connected tree arrangements arranged symmetrically side by side.

[0065] The difference between Embodiment 3 and Embodiment 1 is that the bionic double-connected tree-shaped tube bundle in Embodiment 1 is a structure of bisected cooling water double tubes, while the bionic double-connected tree-shaped tube bundle in Embodiment 3 is a single cooling water tube program structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com