Low-temperature phase change material used in drug cold-chain transportation

A technology of low-temperature phase change and cold chain transportation, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem that cold chain medicines do not have phase change cold storage materials, etc., achieve low supercooling, high melting enthalpy, The effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

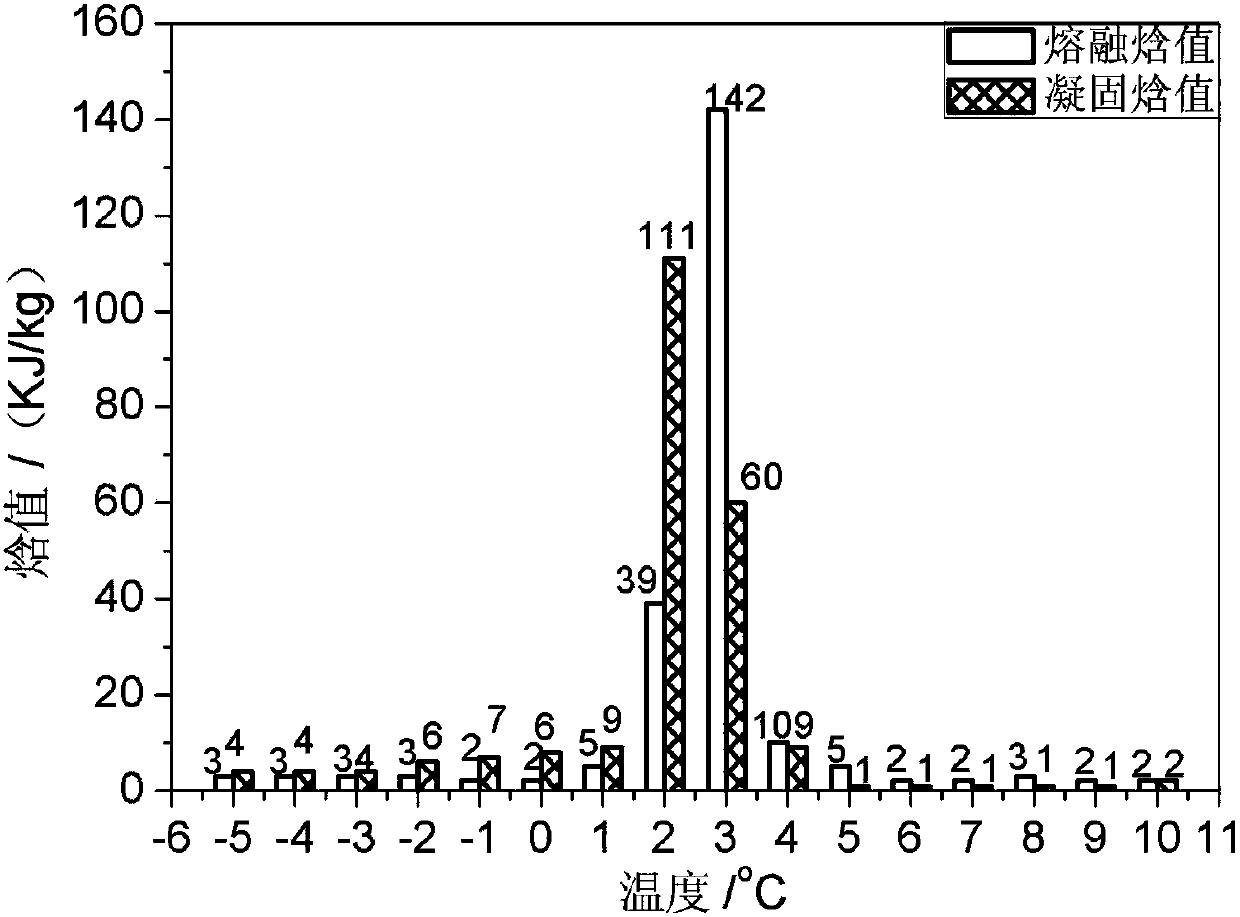

[0026] A low-temperature phase-change material for cold-chain transportation of medicines, which is made by mixing the following components by weight percentage: n-tetradecane 88.5%, n-dodecane 5%, n-tridecane 3%, n-pentadecane 3% alkane, 0.5% isotetradecane.

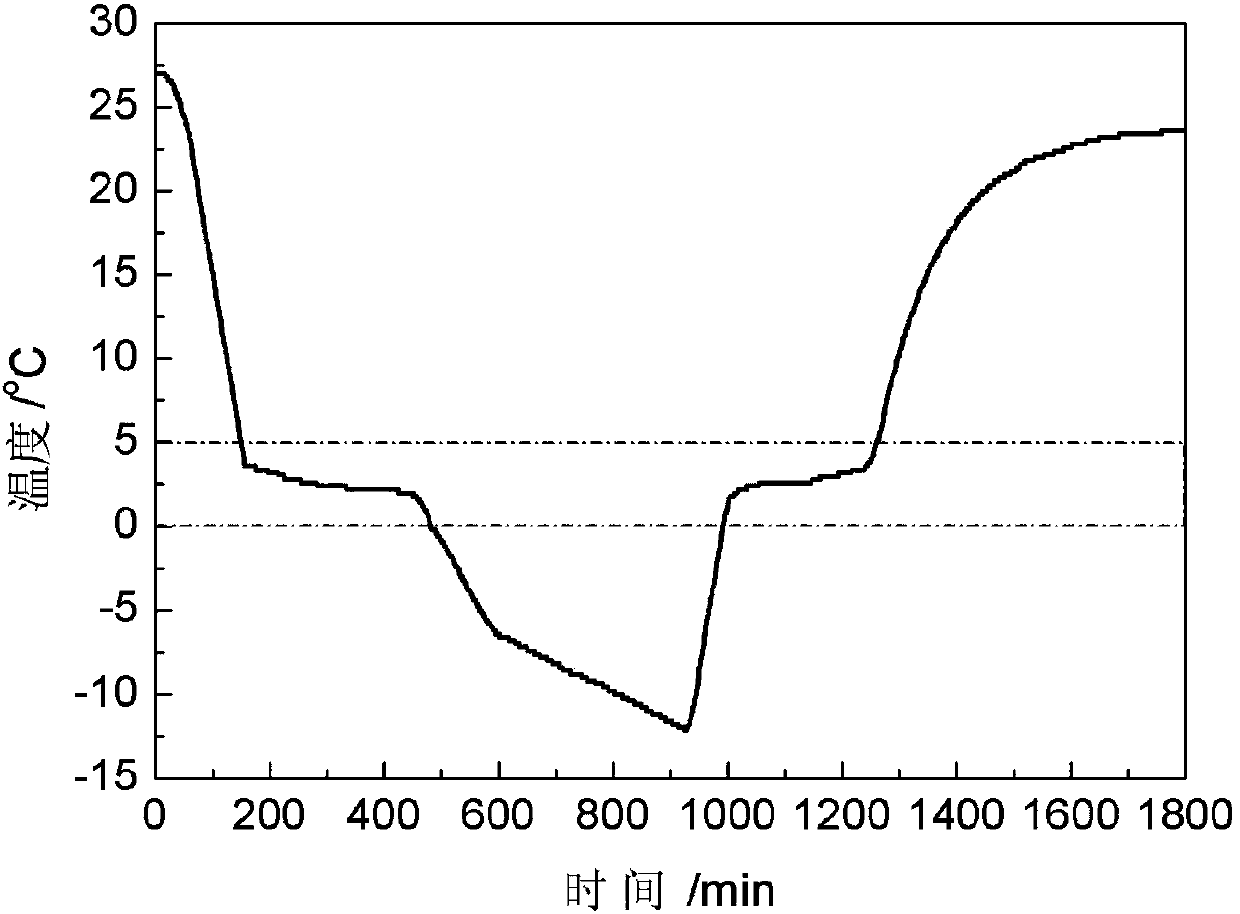

[0027] Preparation method: put n-tetradecane, n-dodecane, n-tridecane, n-pentadecane, and isotetradecane in different containers, preheat them to 35°C respectively, and put the five preheated materials Pour the mixture into a 500ml three-necked flask in turn, and stir the mixture for 1 hour in a constant temperature water bath at 35°C and a rotation speed of 200-300r / min to form a eutectic mixture. After the reaction is completed, the temperature is naturally lowered to room temperature, and a low-temperature phase change material with a melting point of 2-3°C and which can be used for cold-chain transportation of medicines can be obtained.

Embodiment 2

[0029] A low-temperature phase-change material for cold-chain transportation of medicines, which is made by mixing the following components by weight percentage: n-tetradecane 91.8%, n-dodecane 4%, n-tridecane 2%, n-pentadecane 2% alkane, 0.2% isotetradecane.

[0030] The preparation method is the same as in Example 1.

Embodiment 3

[0032] A low-temperature phase-change material for cold-chain transportation of medicines, which is made by mixing the following components by weight percentage: n-tetradecane 91%, n-dodecane 4%, n-tridecane 2.5%, n-pentadecane 2.2% alkane, 0.3% isotetradecane.

[0033] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com