Patents

Literature

777results about How to "Improve heat storage capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

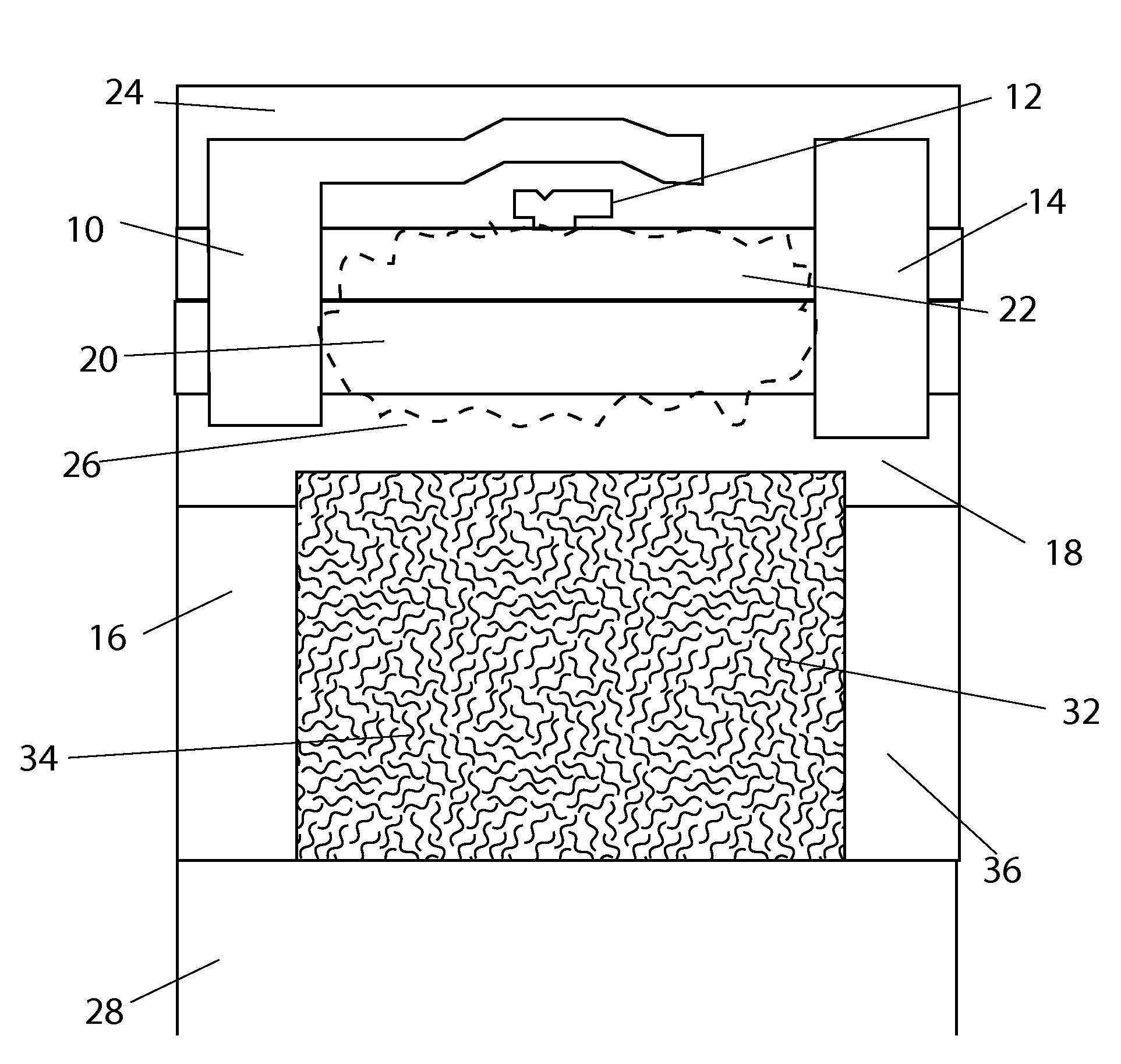

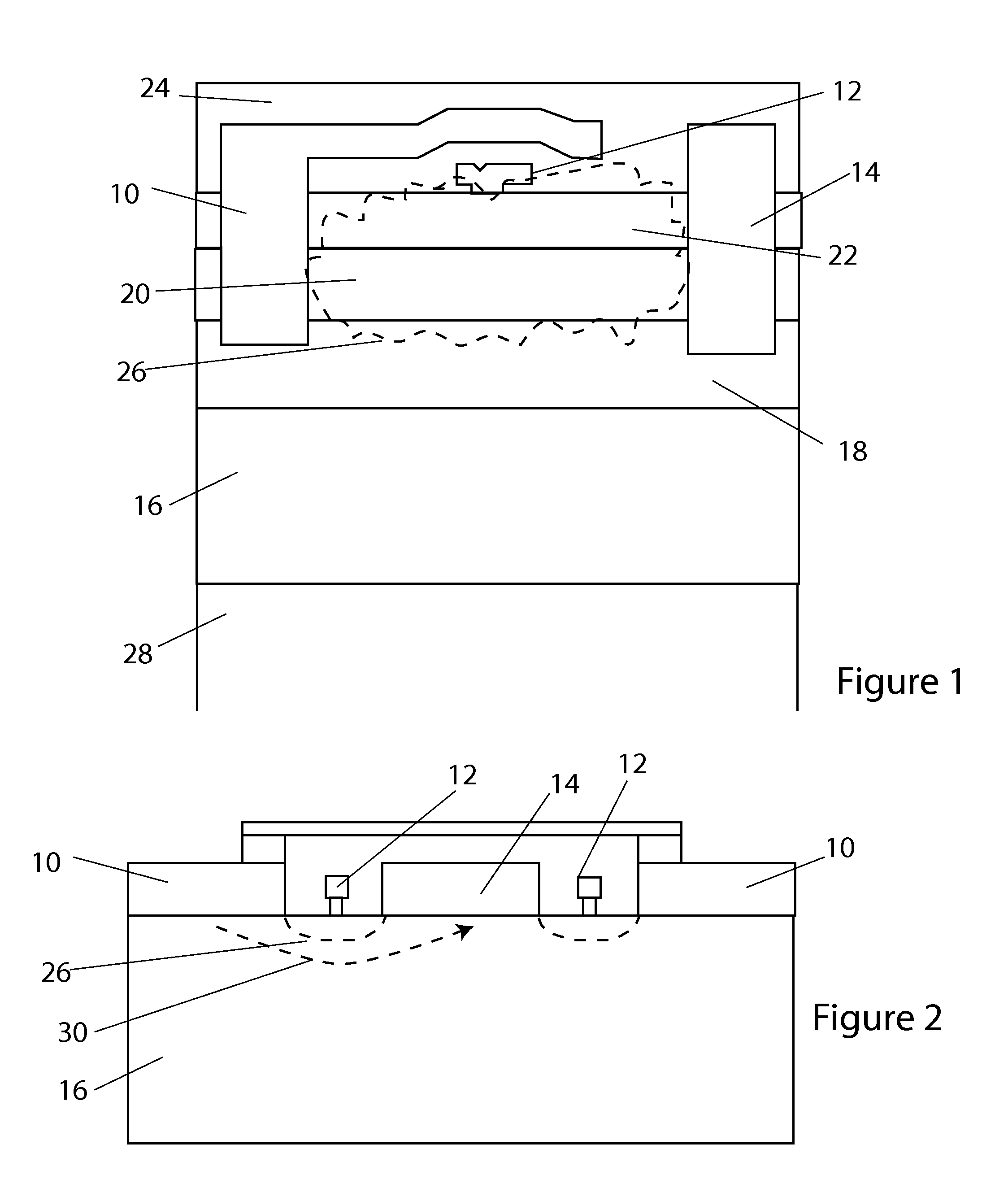

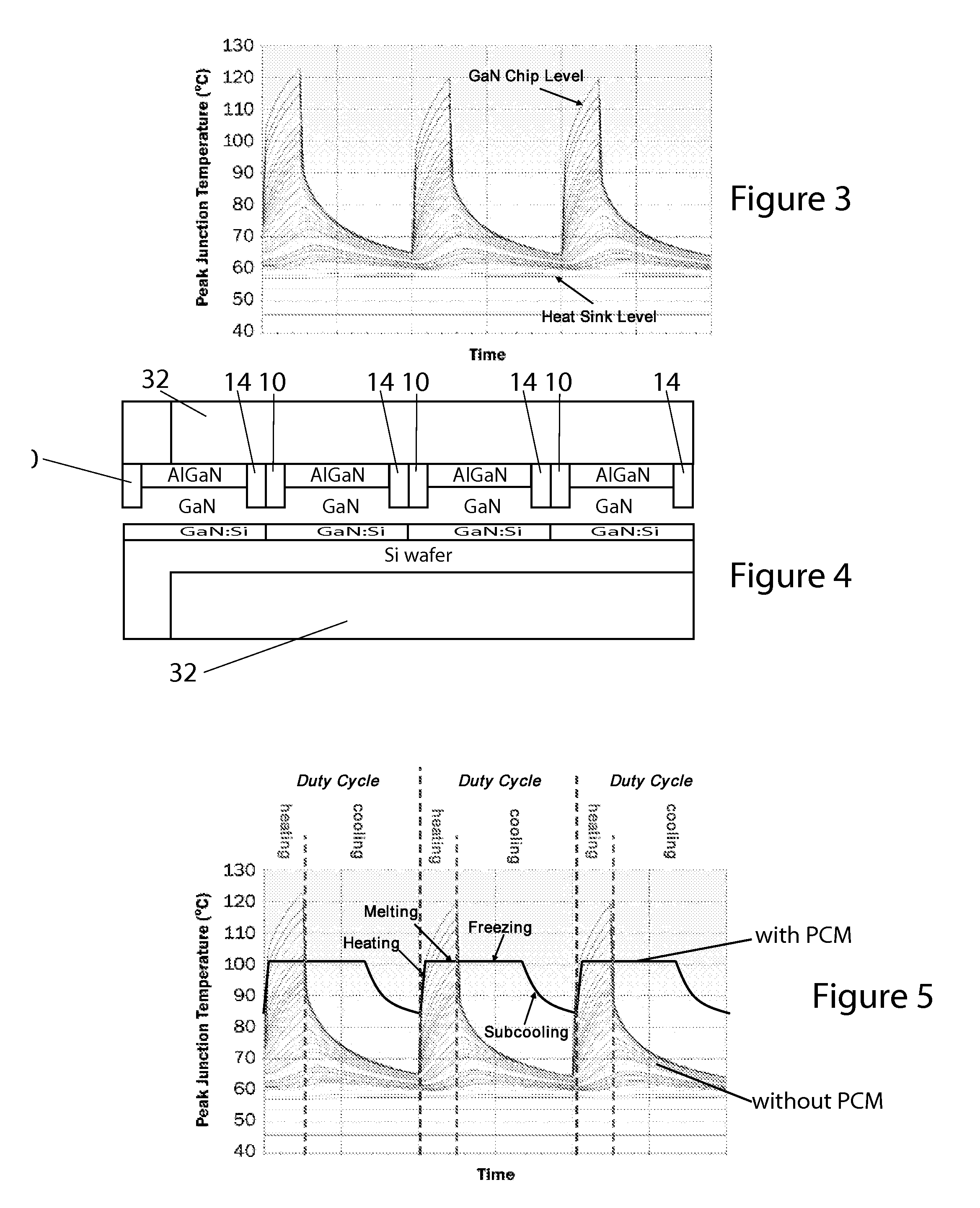

Semiconductor having integrally-formed enhanced thermal management

InactiveUS20130147050A1Increase heating capacityImproved thermal managementSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureElectron flow

A semiconductor structure and method of manufacturing that has integrally-formed enhanced thermal management. During operation of a semiconductor device, electron flow between the source and the drain creates localized heat generation. A containment gap is formed by selectively removing a portion of the back side of the semiconductor device substrate directly adjacent to a localized heat generation area. A thermal management material is filled in the containment gap. This thermal management material enhances the thermal management of the semiconductor device by thermally coupling the localized heat generation area to a heat sink. The thermal management material may be a Phase Change Material (PCM) having a heat of fusion effective for absorbing heat generated in the localized heat generation area by the operation of the semiconductor device for reducing a peak operating temperature of the semiconductor device.

Owner:ADVANCED COOLING TECH

Method for preparing multilevel porous carbon base composite phase change material

InactiveCN104710965AImprove heat storage capacityLarge temperature rangeProductsReagentsPorous carbonSynthesis methods

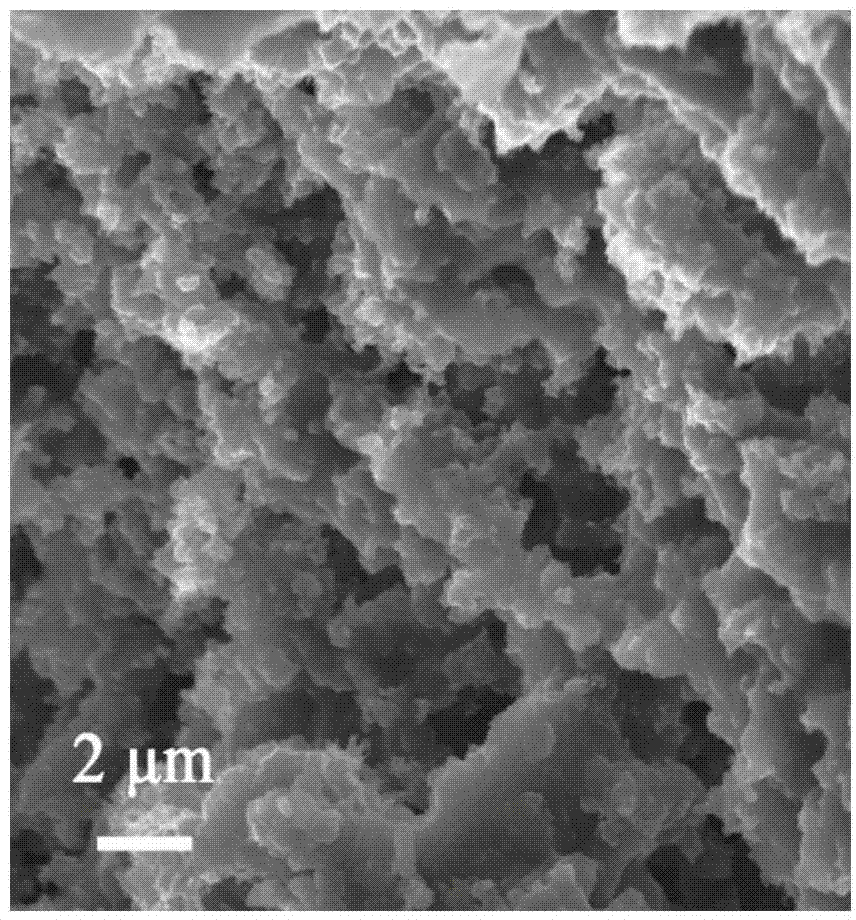

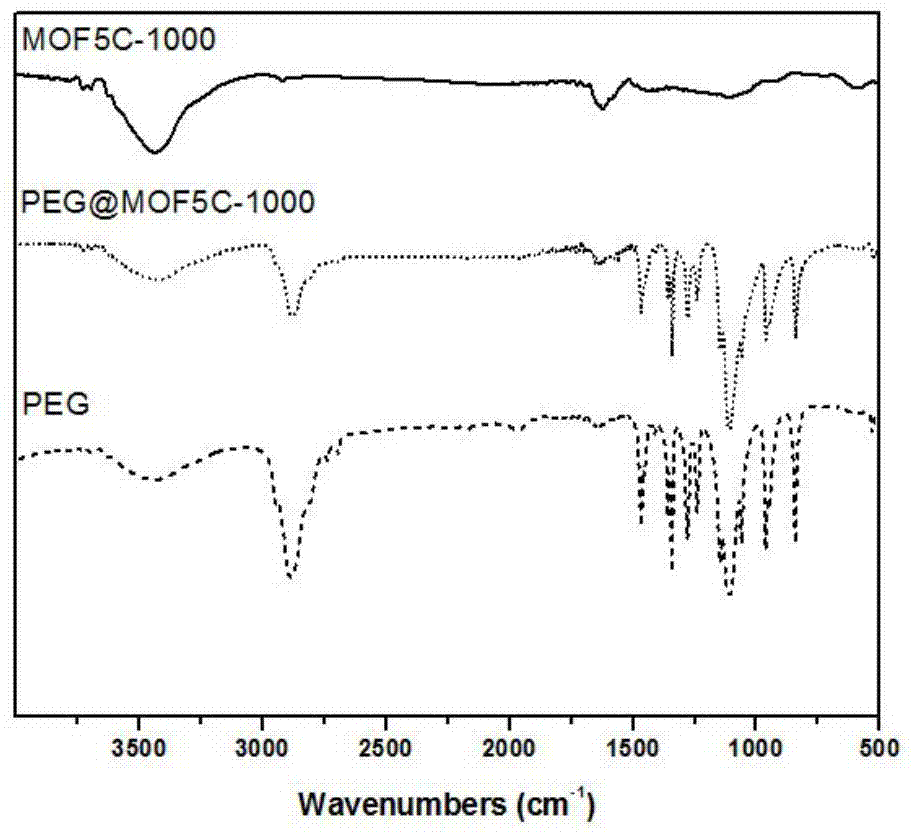

The invention provides a method for preparing a multilevel porous carbon base composite phase change material, and belongs to the field of composite phase change materials. The method comprises the following steps: at first, preparing an organic metal skeleton material by using such methods as a solution method, a solvothermal method or a stirring synthesis method; with the organic metal skeleton material as a template, high temperature carbonizing under the protection of an inert gas, and changing the carbonizing temperature and the post treatment manner to obtain a multilevel porous carbon material with a super-large specific surface area and a super-large pore volume; selecting proper solvents according to different kinds of phase change core materials, preparing the phase change core materials to a solution, dispersing the porous carbon material into the solution, removing the solvent by such manners as heating, and meanwhile the phase change core materials are adsorbed and limited in the porous carbon material. The composite phase change material prepared by the method provided by the invention has good thermal storage property, can effectively avoid the leakage problem of the phase change core material, and has the advantages of excellent heat transfer property, good cycling stability and wide application range, and the process is simple and is suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

Phase-change energy-storage temperature-regulation foam concrete and preparation method thereof

InactiveCN104649632AImprove heat storage capacityGood fire safetySolid waste managementCeramicwareFiberWater reducer

The invention discloses a phase-change energy-storage temperature-regulation foam concrete and a preparation method thereof, wherein the phase-change energy-storage temperature-regulation foam concrete comprises the following components in parts by weight: 70-100 parts of cement, 0-30 parts of fly ash, 10-50 parts of phase-change lightweight aggregate, 0-0.6 part of fiber, 0.2-0.4 part of water reducing agent, 0.1-0.3 part of cell regulator, 0.1-0.3 part of early strength agent, 0-1.5 parts of reinforcing agent, 0-3 parts of waterproof agent, 2-9 parts of chemical foaming agent and 25-40 parts of water. Therefore, the phase-change energy-storage temperature-regulation foam concrete has strong heat storage capacity and a temperature regulation function.

Owner:建筑材料工业技术监督研究中心

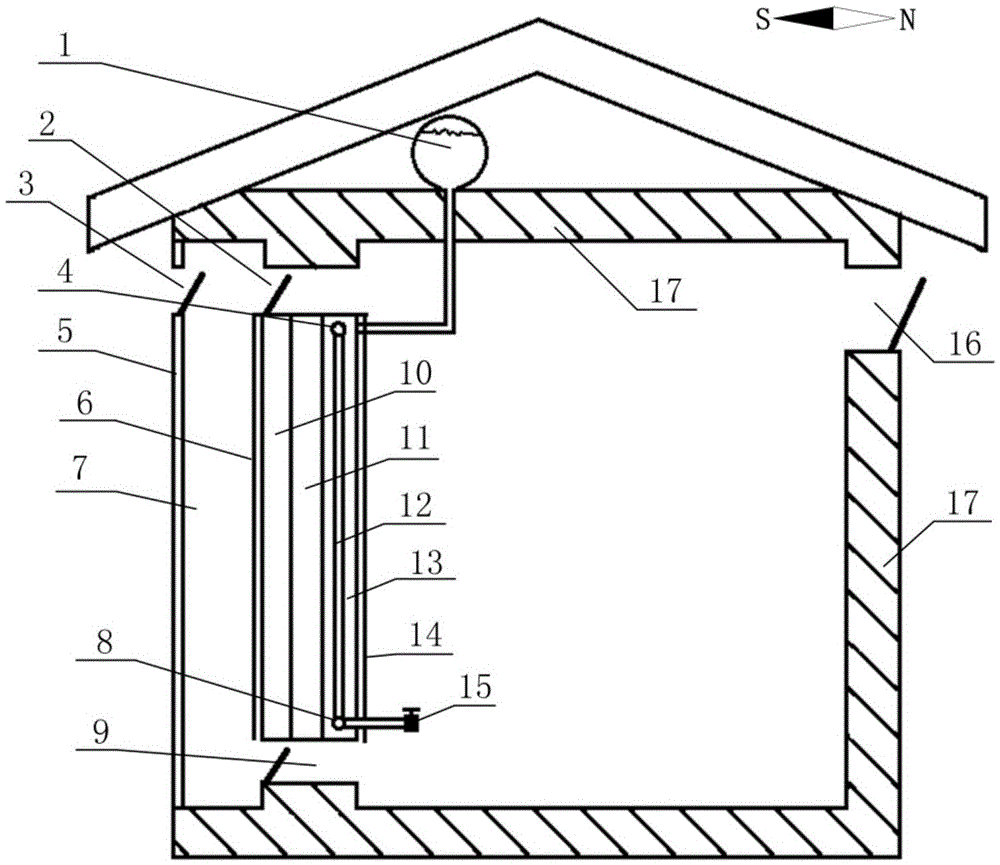

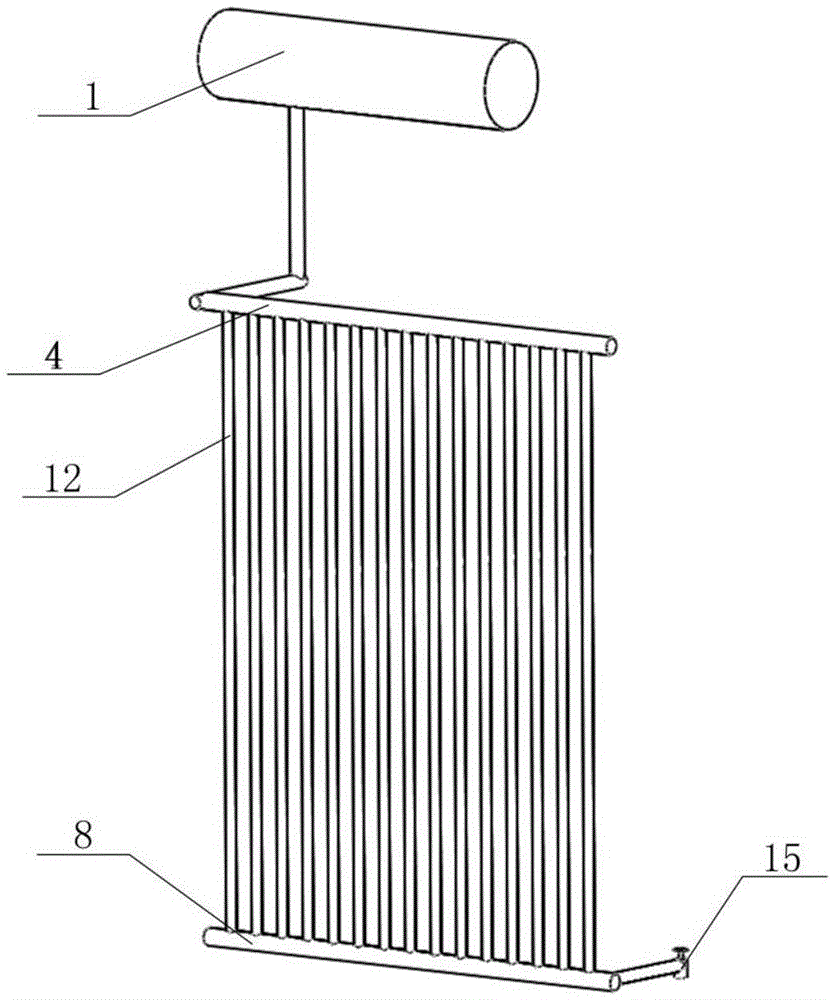

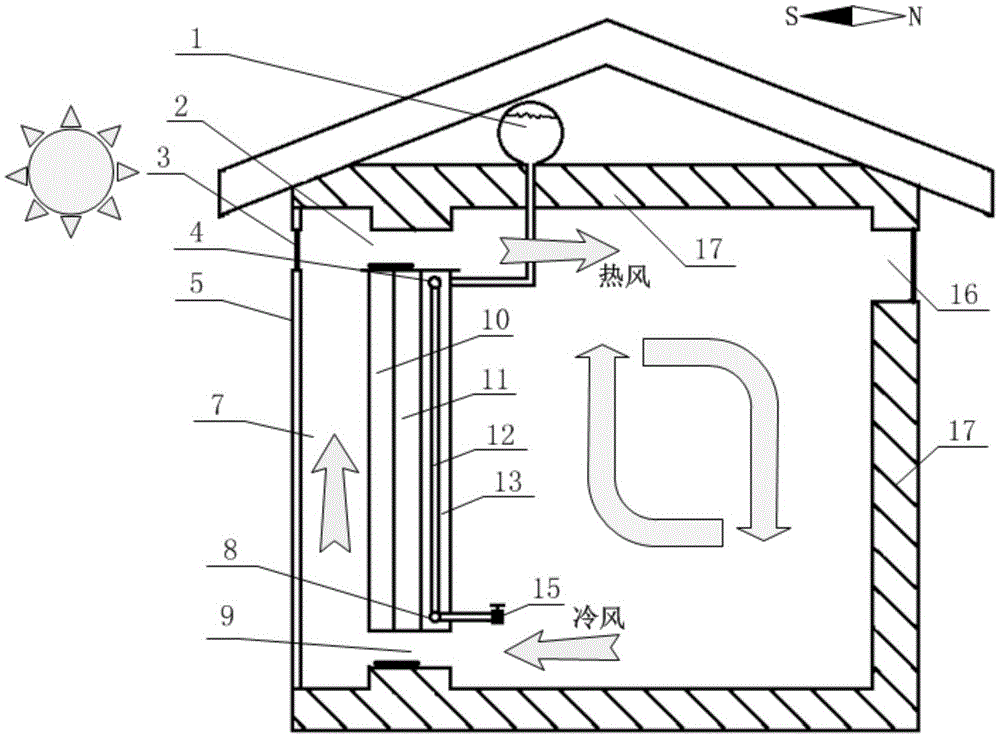

Solar phase change heat storage wall and ventilation system provided with same

ActiveCN105569213AAvoid instabilityIncrease heat storageSolar heating energyMechanical apparatusGlass coverEngineering

The invention provides a solar phase change heat storage wall and a ventilation system provided with the same. The solar phase change heat storage wall is formed by connecting a high-temperature phase change layer, a medium-temperature phase change layer and a low-temperature phase change layer sequentially, wherein the phase change temperatures of the high-temperature phase change layer, the medium-temperature phase change layer and the low-temperature phase change layer are set from high to low. A glass cover plate is arranged on the south side of the outer wall of the ventilation system; the rest part of the ventilation system is composed of an enclosure structure; an outdoor air inlet is formed in the upper part of the north side of the outer wall; and an outdoor air outlet is formed in the upper part of the south side. The solar phase change heat storage wall is positioned in the outer wall and close to the glass cover plate; the high-temperature phase change layer faces south; and an upper vent hole and a lower vent hole are formed in the upper part and lower part of the solar phase change heat storage wall respectively. A hot water system penetrates through the solar phase change heat storage wall to perform heat exchange. The solar phase change heat storage wall can overcome shortcomings of a conventional heat collection wall, has the advantages of good heat storage capability, diversified functions, simplicity for operation and no energy consumption, can achieve the effects of cooling by ventilation and domestic water heating in summer, and can be used for providing heat in winter, thereby having good application prospects.

Owner:陕西中为能源技术有限公司

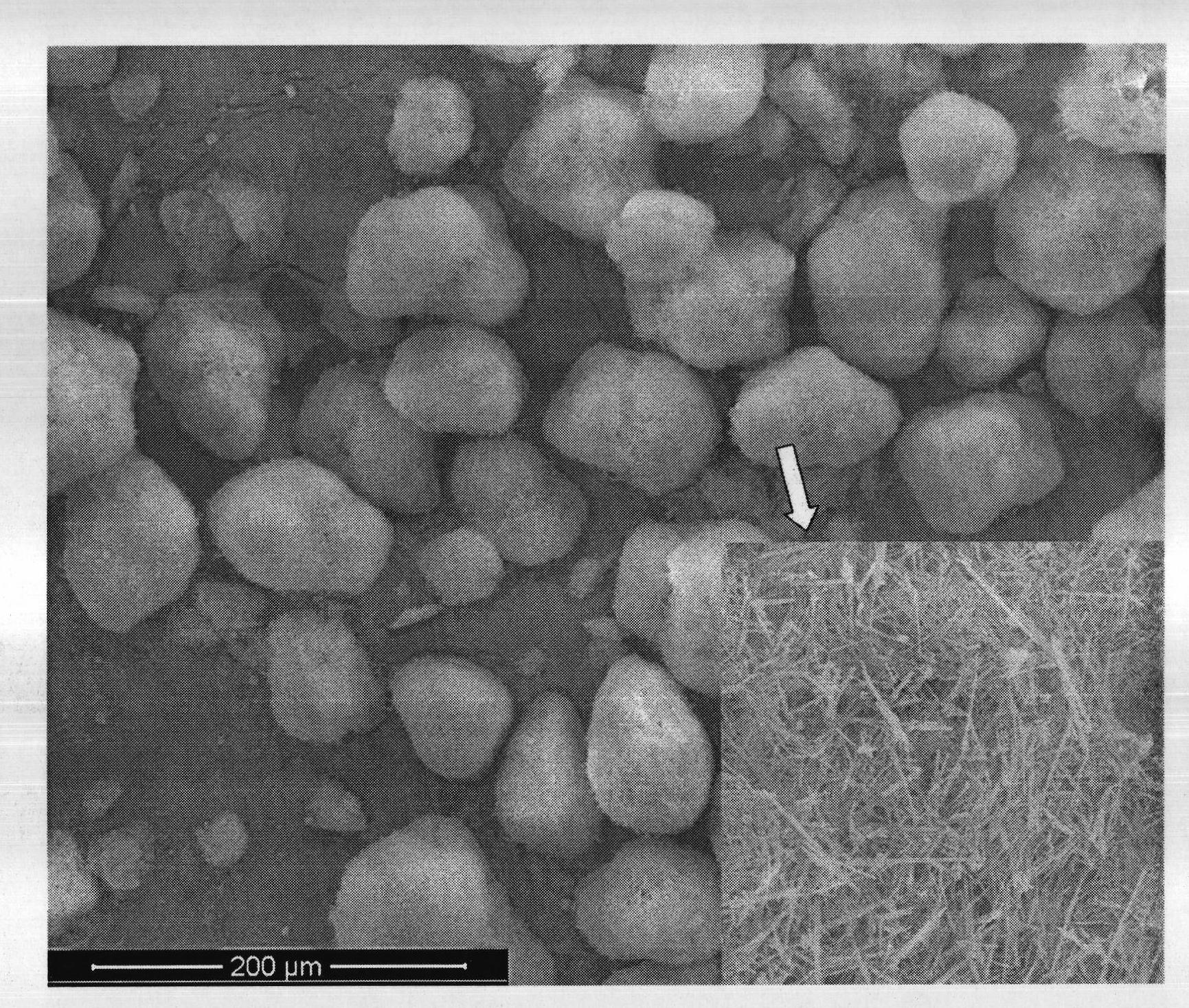

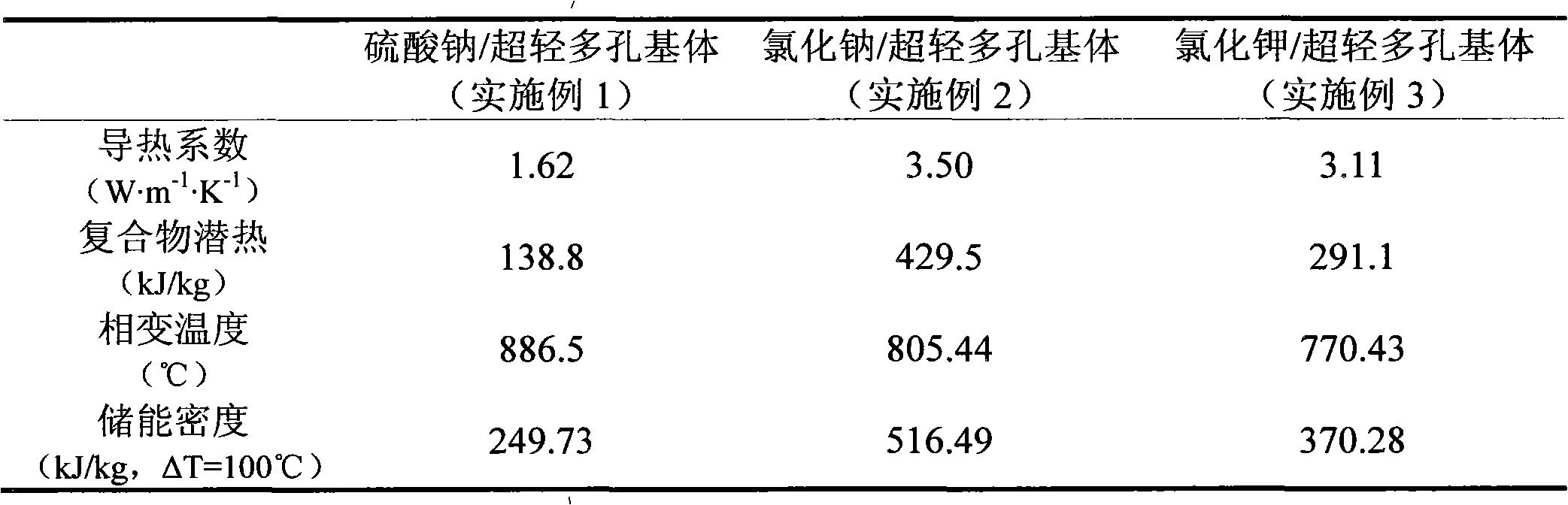

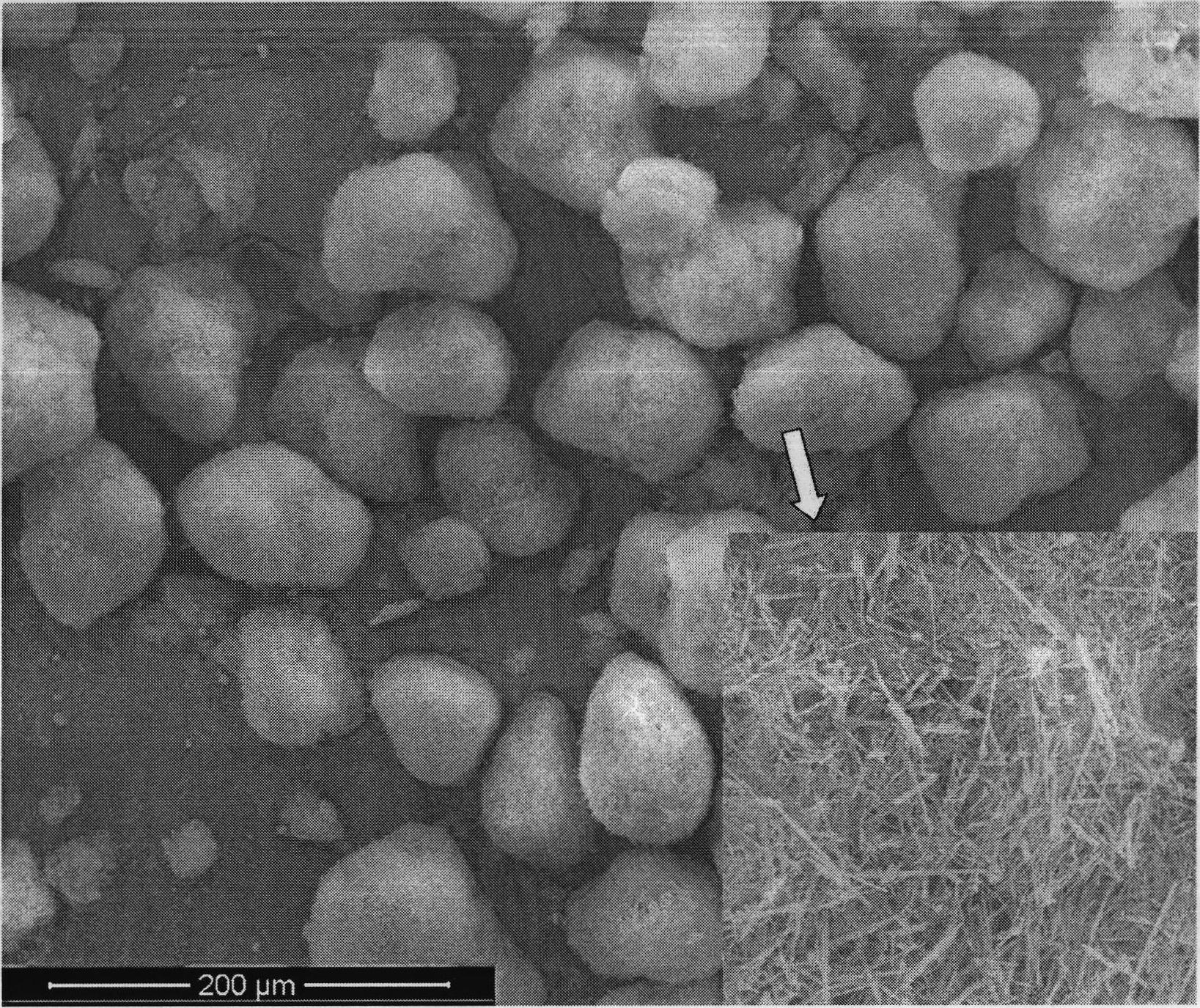

Porous material matrix and composite phase-change heat storage material and preparation methods thereof

InactiveCN102061403AIncrease contentImprove heat storage capacityHeat-exchange elementsCeramicwareWater basedHeat conducting

The invention provides a preparation method of a porous material matrix. The preparation method comprises the following steps: mixing a weighed calcium-containing raw material and a silicon-containing raw material at the mole ratio of Ca to Si of 1:(0.4-1), adding 20-40-times water based on the total weight of the raw materials, stirring and keeping the temperature of 180-320 DEG C for 4-12 hours, and obtaining porous material slurry; and adding 0%-5% of nano-metal powder after the slurry is cooled, drying and molding to obtain the porous material matrix. The preparation method of a composite phase-change heat storage material comprises the following steps: dipping the obtained porous material matrix into a fully fused inorganic salt phase-change material so that the phase-change material is completely infiltrated into a pore path of the porous material matrix; and blowing out for cooling, and then desalting the discharged sample to finally obtain the composite phase-change heat storage material. The obtained matrix material has the advantages of good infiltration property and excellent high-temperature chemical stability relative to inorganic salt; and the obtained composite phase-change heat storage material has the advantages of high heat storage density, good heat-conducting property and cheap raw material.

Owner:SOUTH CHINA UNIV OF TECH

Three-dimensional gel network carrier and form-stable phase change composite material

InactiveCN101709104AReduce lossesNo lossHeat-exchange elementsPhase change enthalpyPolyethylene glycol

The invention relates to a three-dimensional gel network carrier and a form-stable phase change composite material which adopt fatty acid (hydrocarbon), polyethylene glycol and other organic phase change materials as work material and use poly-(N-hydroxymethyl)-acrylamide heat-shrinkable interpenetration network as form-stable carrier. The preparation method of the phase change composite material comprises the following steps: firstly adopting low temperature eutectic method to select multiple components composite phase change material with proper phase change temperature, high phase change enthalpy and low cost, designing and determining the preparation method of the interpenetration network carrier and the addition mode of the composite phase change material and the combination mode of the carrier, preparing the form-stable phase change composite material based on multiple actions of bonding, physical adsorption and network confinement, cooling and grinding to obtain the form-stable heat storage functional particles. The form-stable phase change composite material containing 50%-75% of material can be prepared by the method, the maximum phase change enthalpy can be up to 110J / g, and the form-stable phase change composite material prepared by the method can be directly applied in the textile field, building field, military field, etc.

Owner:DALIAN POLYTECHNIC UNIVERSITY

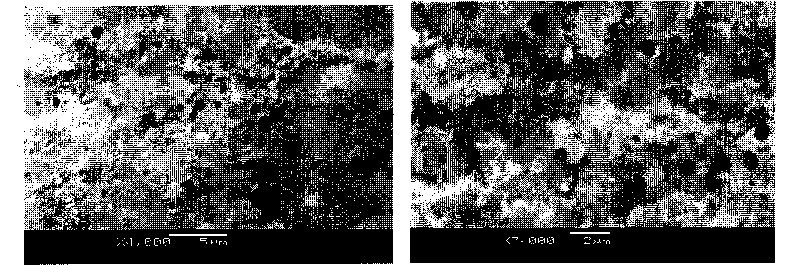

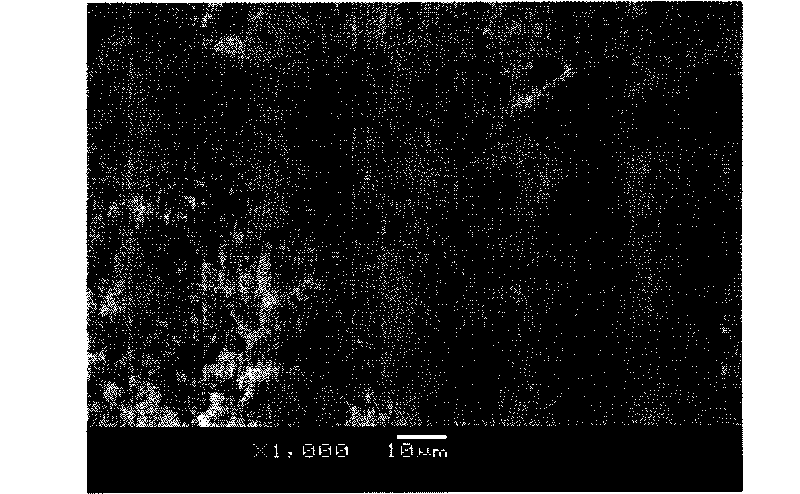

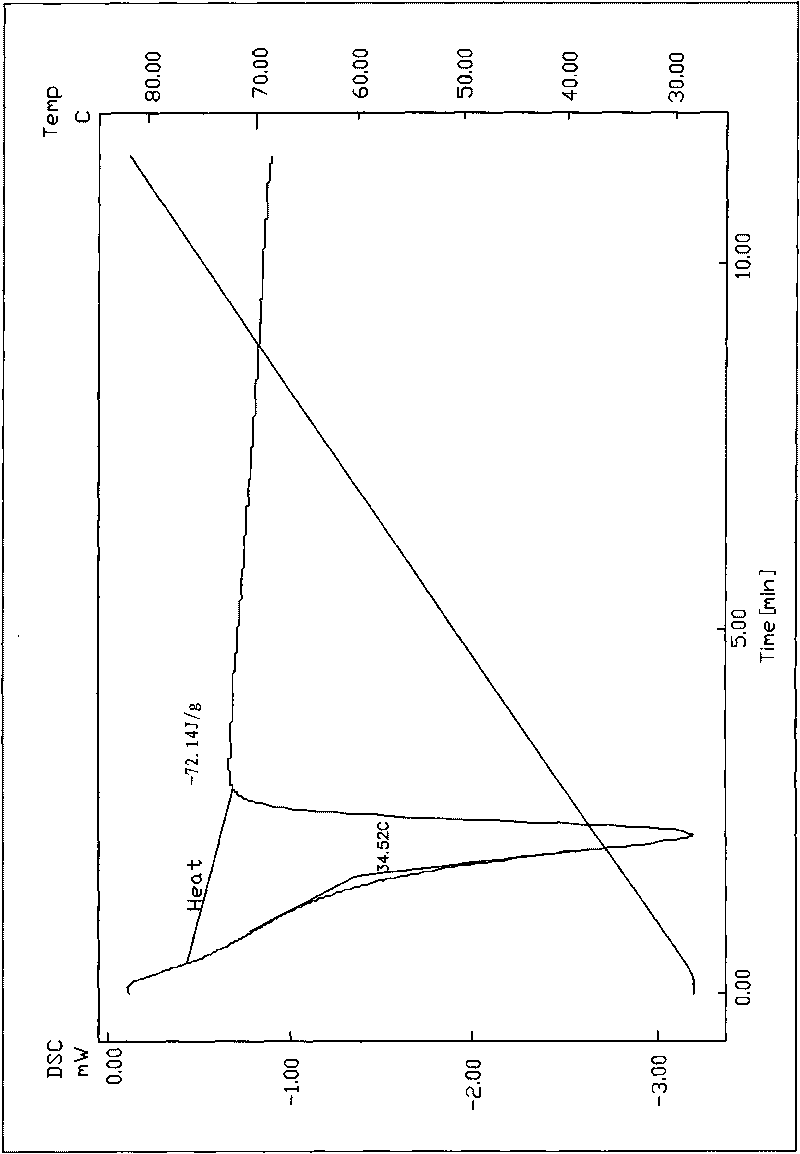

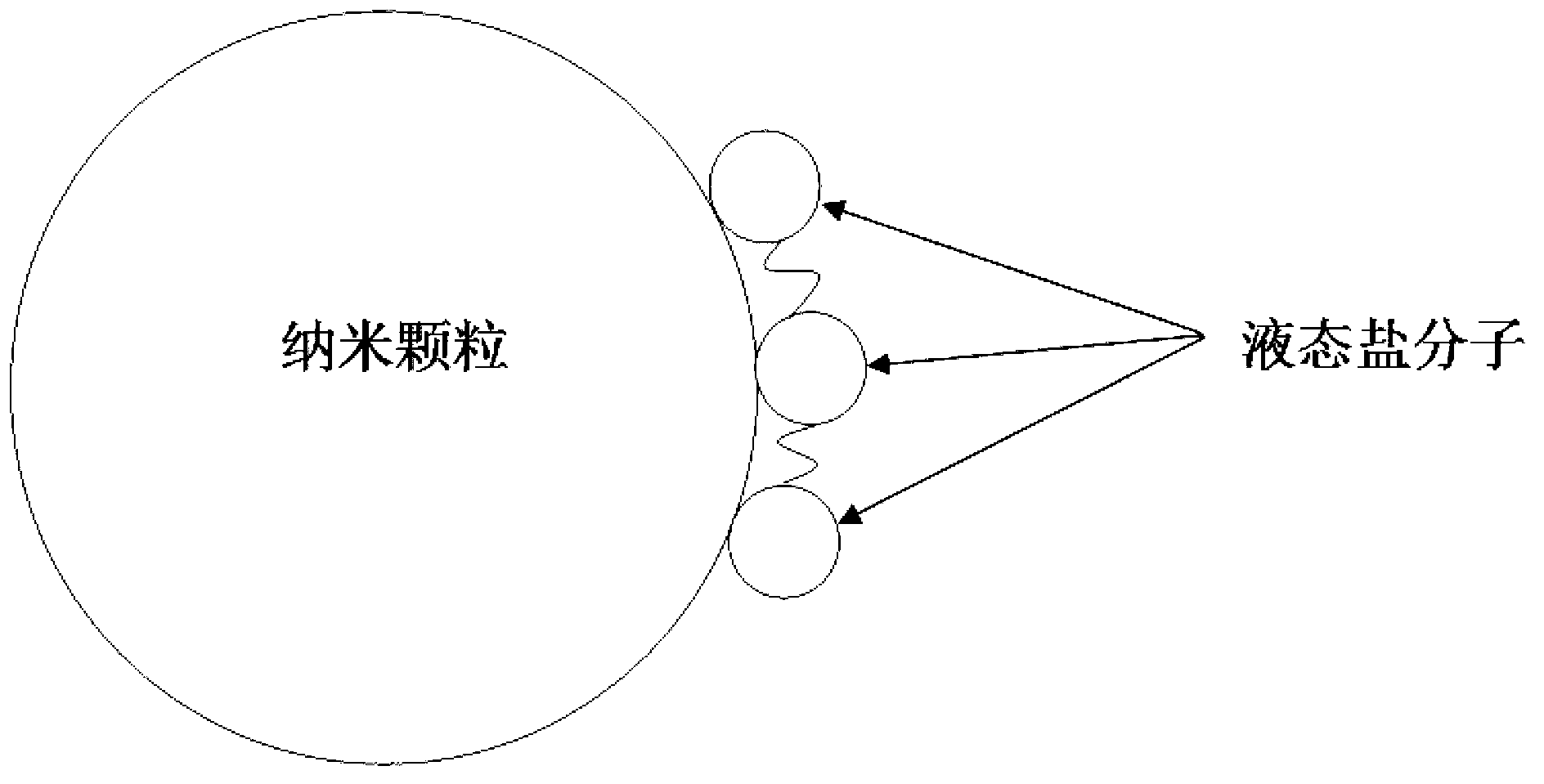

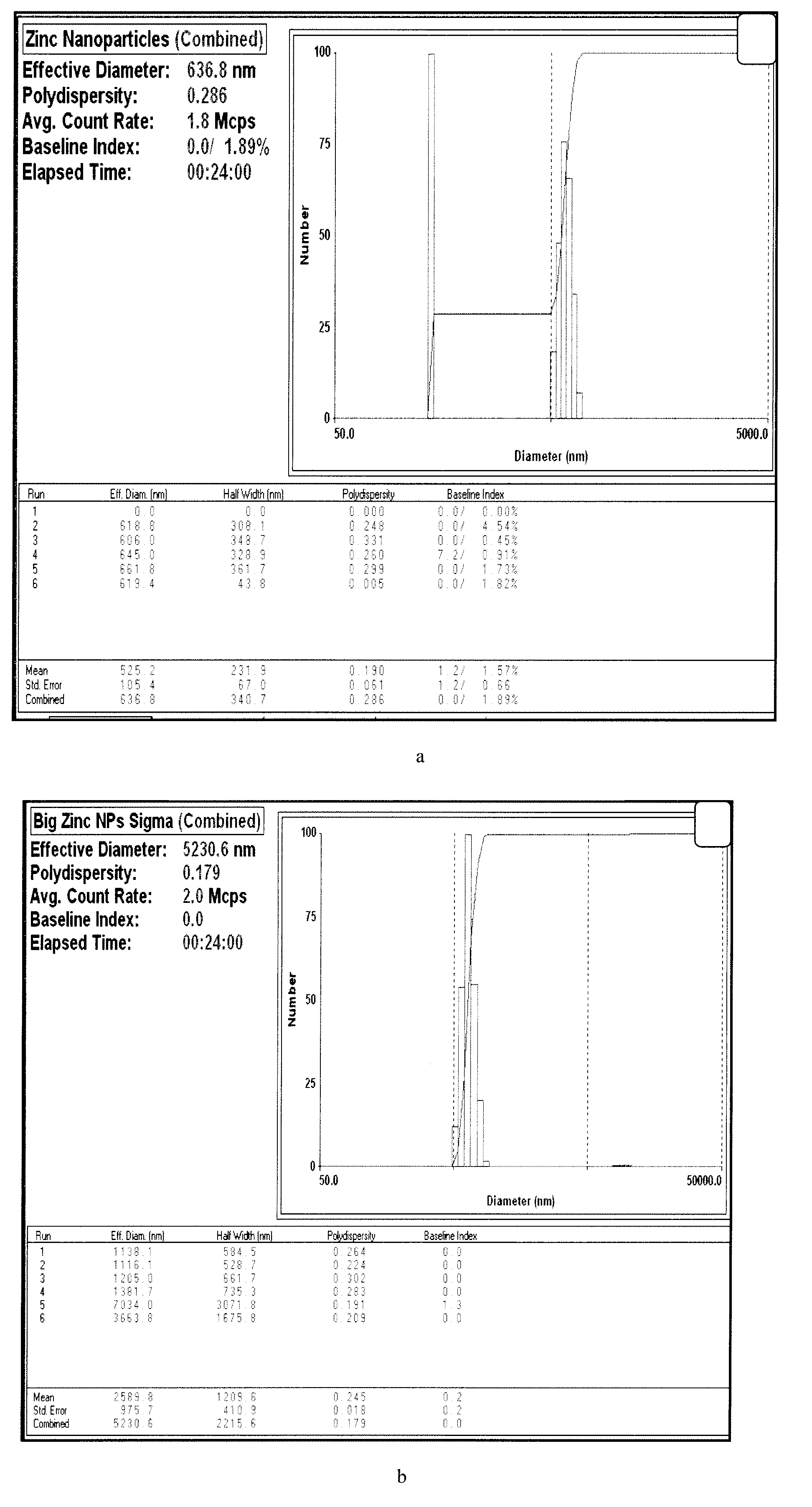

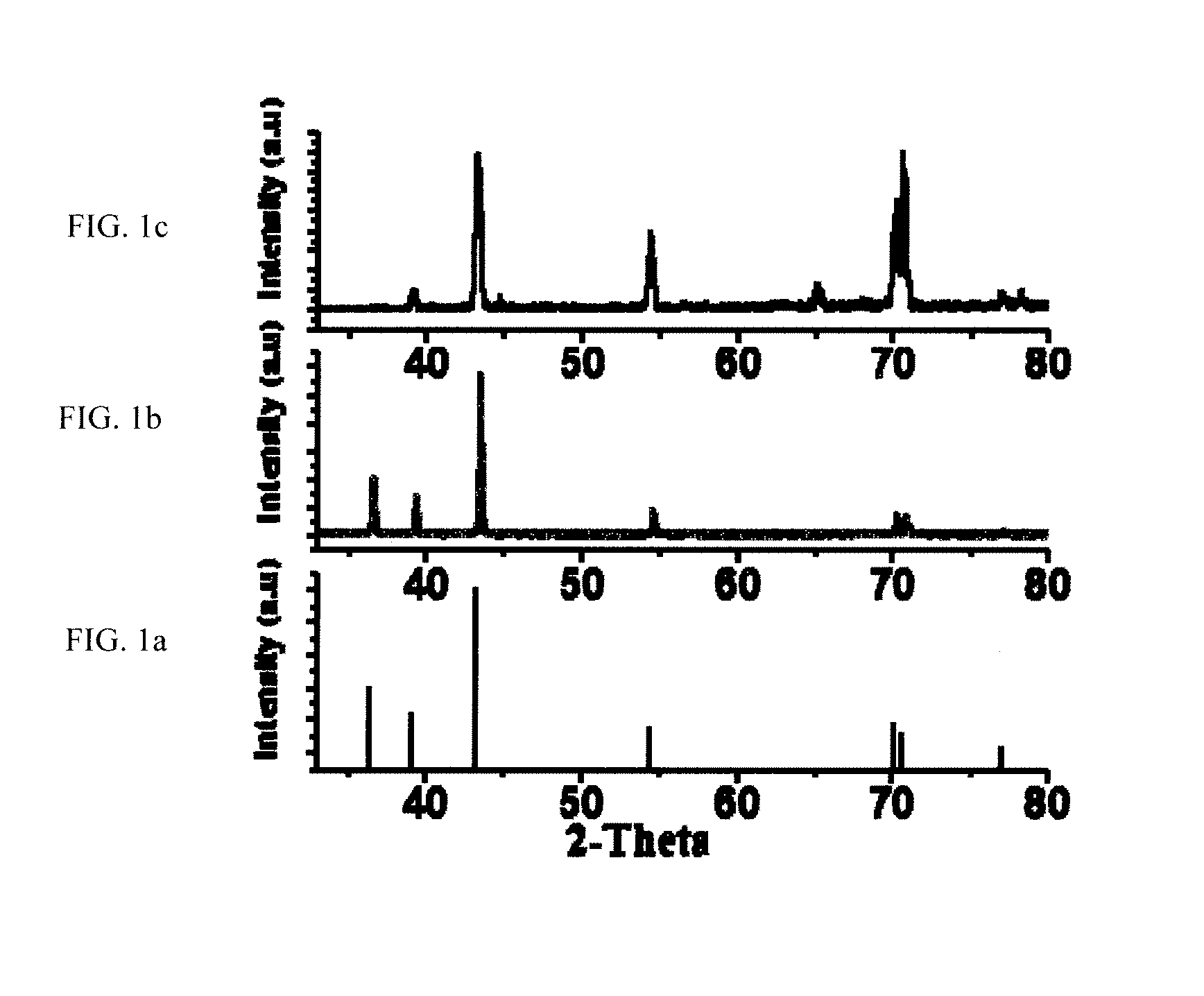

High-thermal-conductivity heat-storing nanometer-particle-mixed molten salt and preparation method thereof

InactiveCN103289653ASmall temperature fluctuationsImprove heat storage capacityHeat-exchange elementsHeat stabilitySolar power

The invention relates to the heat-storing field of solar thermal power generation, especially to a high-thermal-conductivity heat-storing nanometer-particle-mixed molten salt, and a preparation method thereof. The molten salt consists of a sold heat-storing molten salt, a dispersant and nanometer particles, wherein the dispersant and the nanometer particles disperse uniformly in the heat-storing molten salt and a eutectiform structure is formed, and the nanometer particles coat the surface of the heat-storing molten salt crystal particle. By adding the nanometer particles into the sold heat-storing molten salt, and by utilizing quantum size effect, surface effect, small size effect and the like possessed by the nanometer particles, the thermal physical property of the molten salt as a heat-storing medium has a substantial change. The preparation method is simple in technological process and low in cost, can help to substantially promote heat conductivity and specific heat capacity of the conventional heat-storing molten salt and substantially improve heat stability of the molten salt in a high temperature section, and can help to promote a heat storage capacity and system security of a concentrating solar power generation system and reduce costs of construction and operation of a power station.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

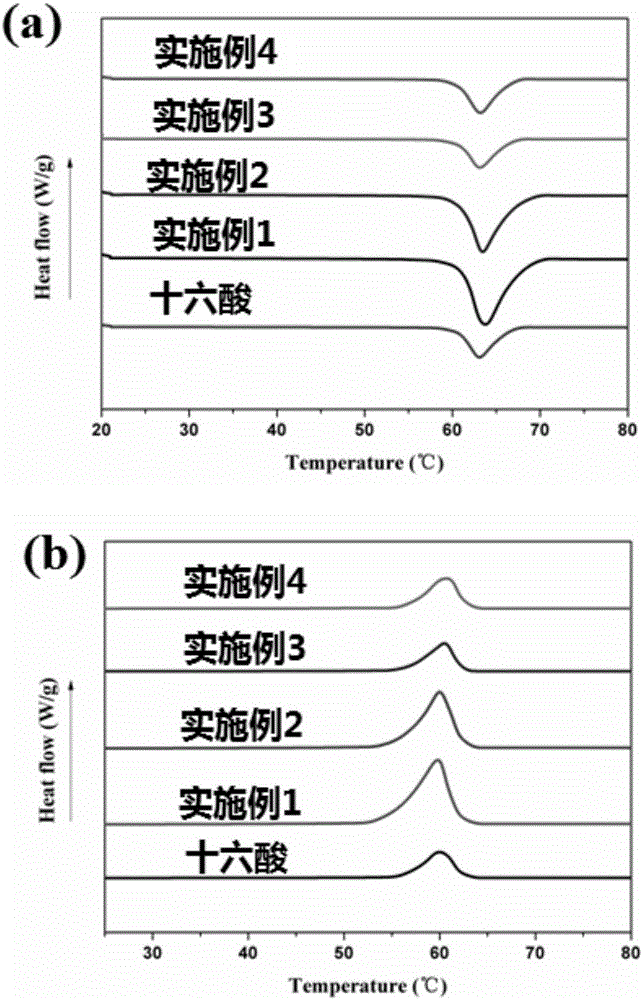

Microcapsule capable of improving heat storage properties and composition molded body thereof

InactiveCN107779173AImprove heat storage capacityImprove heat storage performanceHeat-exchange elementsMedical productPhase change

The invention discloses a microcapsule capable of improving heat storage properties and a composition molded body thereof. The microcapsule capable of improving heat storage properties is generally composed of shell materials and core materials. In aspect of improving heat storage properties of phase-change microcapsules, traditional methods do a large number of researches on core materials. The microcapsule capable of improving heat storage properties focuses on endowing or improving phase-change energy storage properties of the shell materials. Therefore, under the condition of identical coating rate or identical phase-change materials as the core materials, the microcapsule capable of improving heat storage properties can effectively improve the heat storage properties. The microcapsuleand the composition molded body thereof can be applied to textile products, clothes, shoes, medical products, masks, cosmetics, warehousing and transportation products, containers and wrapping materials, electronic devices, building materials, devices and other products.

Owner:YUTIAN ENERGY CO LTD

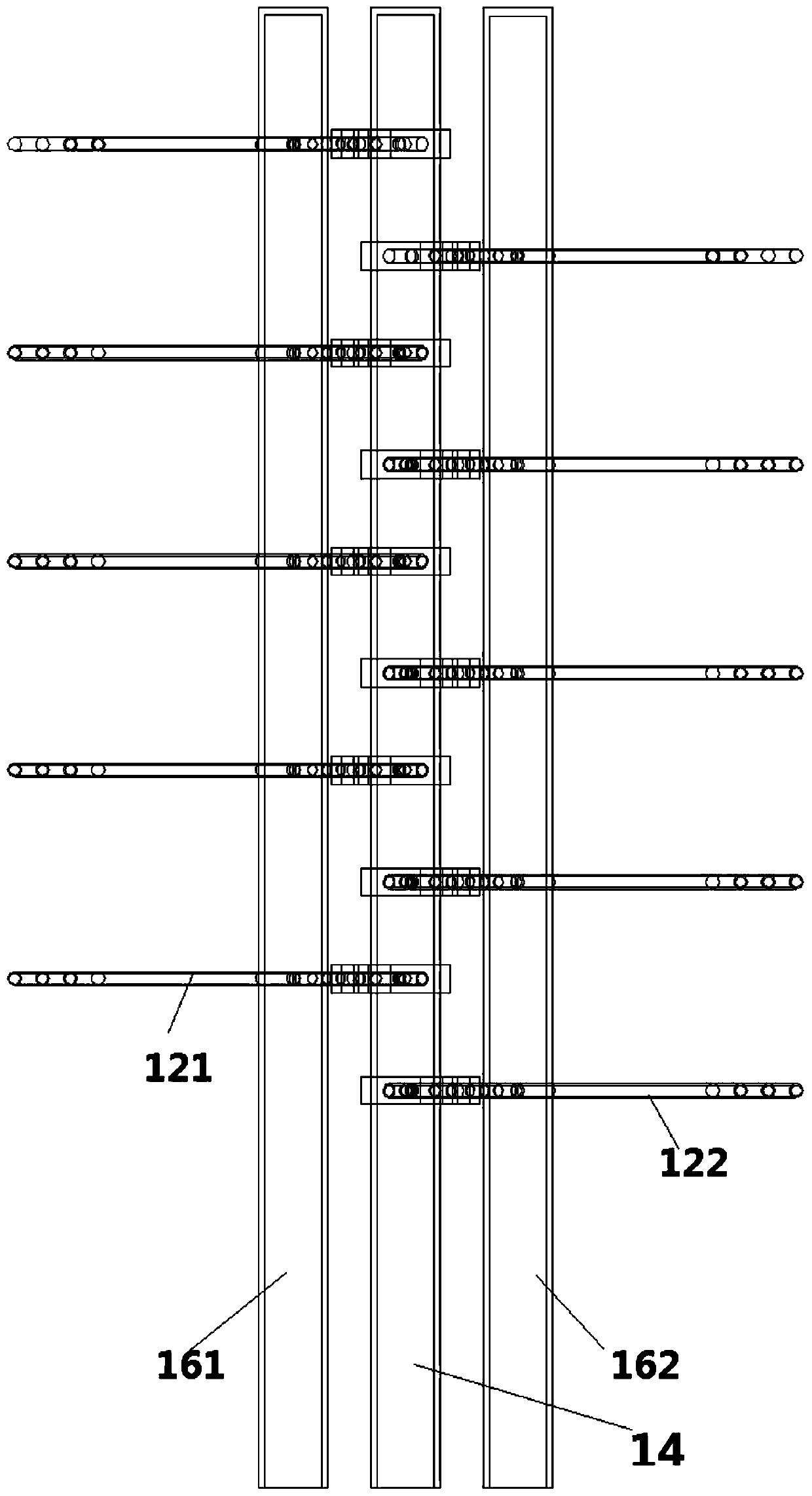

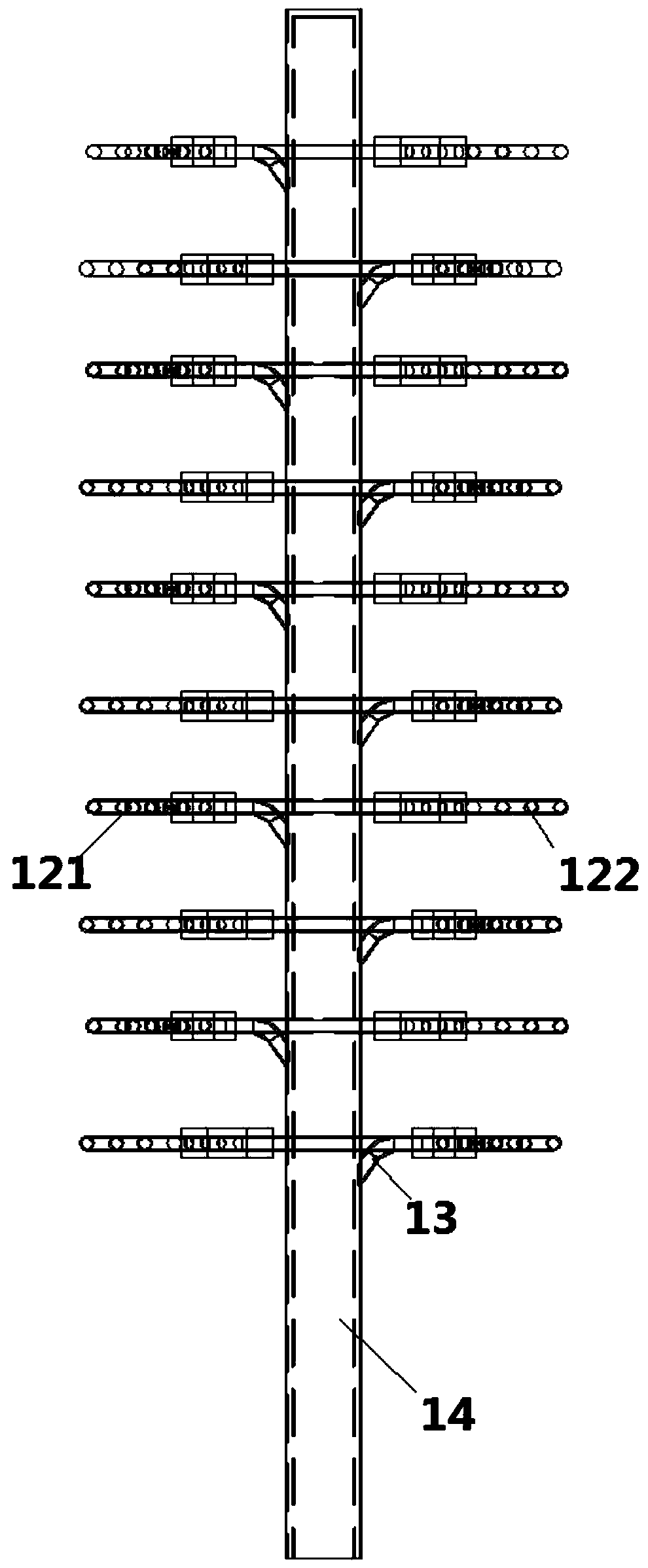

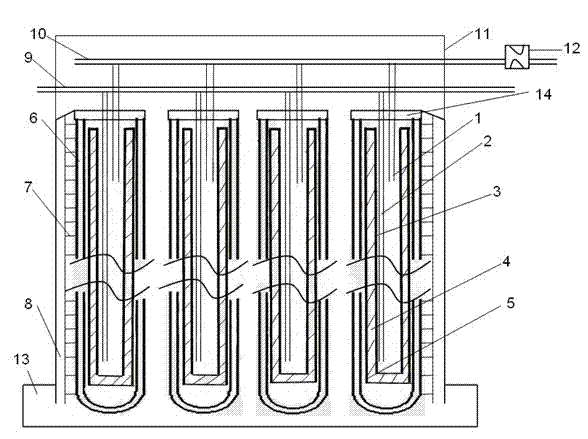

Three-riser pulsating tube bundle

ActiveCN110081739AIncreased vibration rangeImprove heat transfer performanceHeat storage plantsStationary tubular conduit assembliesEngineeringHeat transfer

The invention provides a three-riser pulsating tube bundle. The three-riser pulsating tube bundle comprises a middle riser, a left risers, a right riser and a plurality of coil tubes, wherein each coil tube comprises a plurality of arc-shaped heat exchange tubes, the ends of adjacent heat exchange tubes communicate, the plurality of heat exchange tubes form a series structure, the ends of the heatexchange tubes form free ends of the heat exchange tubes, the inlet of the middle riser is connected with a pulsating flow generating device for generating pulsating flow in the heat exchange tubes,the coil tubes comprise a left coil tube and a right coil tube, one side of the middle riser is connected with the inlet of the left coil tube, the other side is connected with the inlet of the rightcoil tube, the outlet of the left coil tube is connected with the left riser, and the outlet of the right coil tube is connected with the right riser. According to the pulsating tube bundle with the novel structure, more coil tubes are arranged in a limited space to increase the vibration range of the pulsating tube bundle, so that heat transfer and descaling are enhanced.

Owner:SHANDONG UNIV

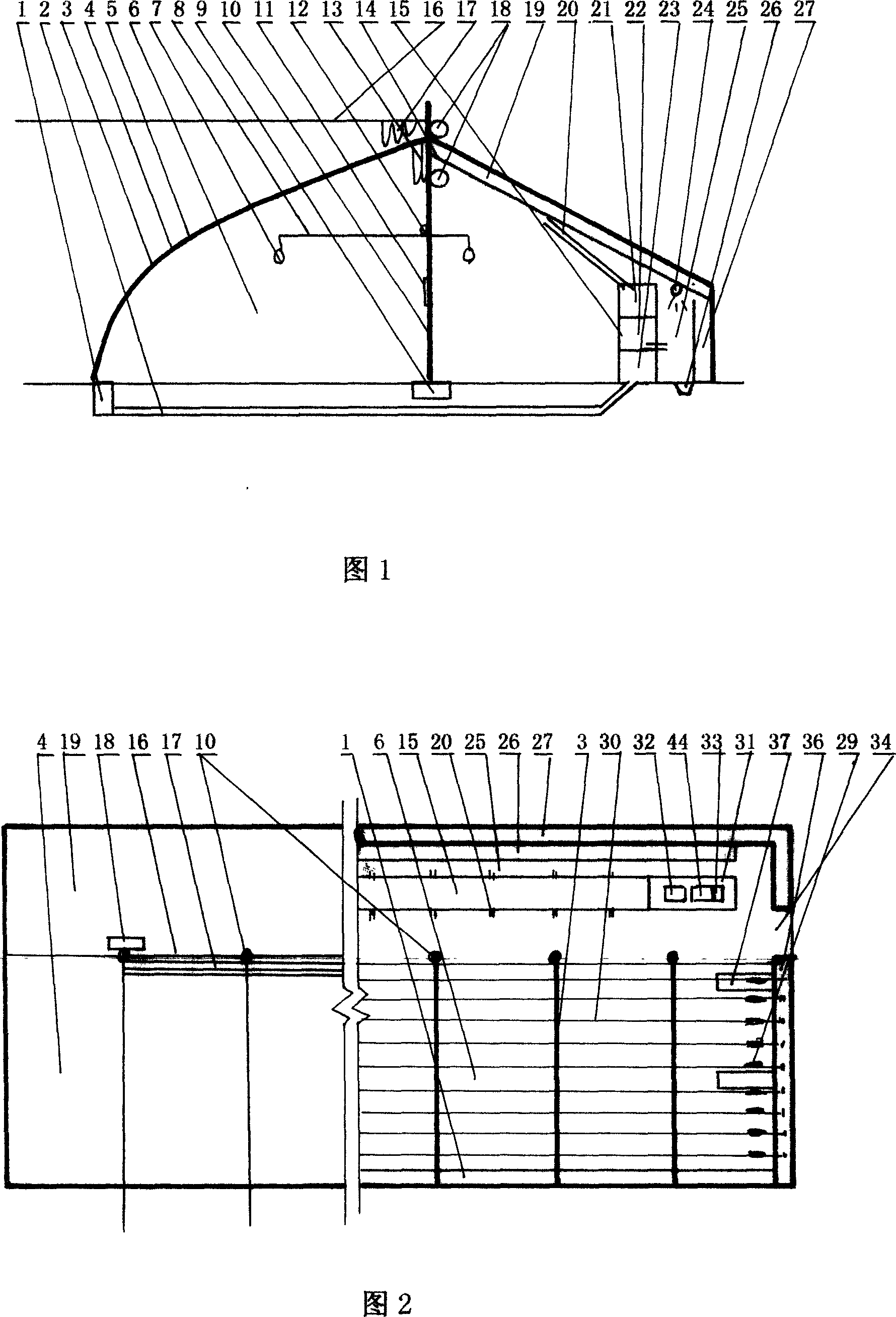

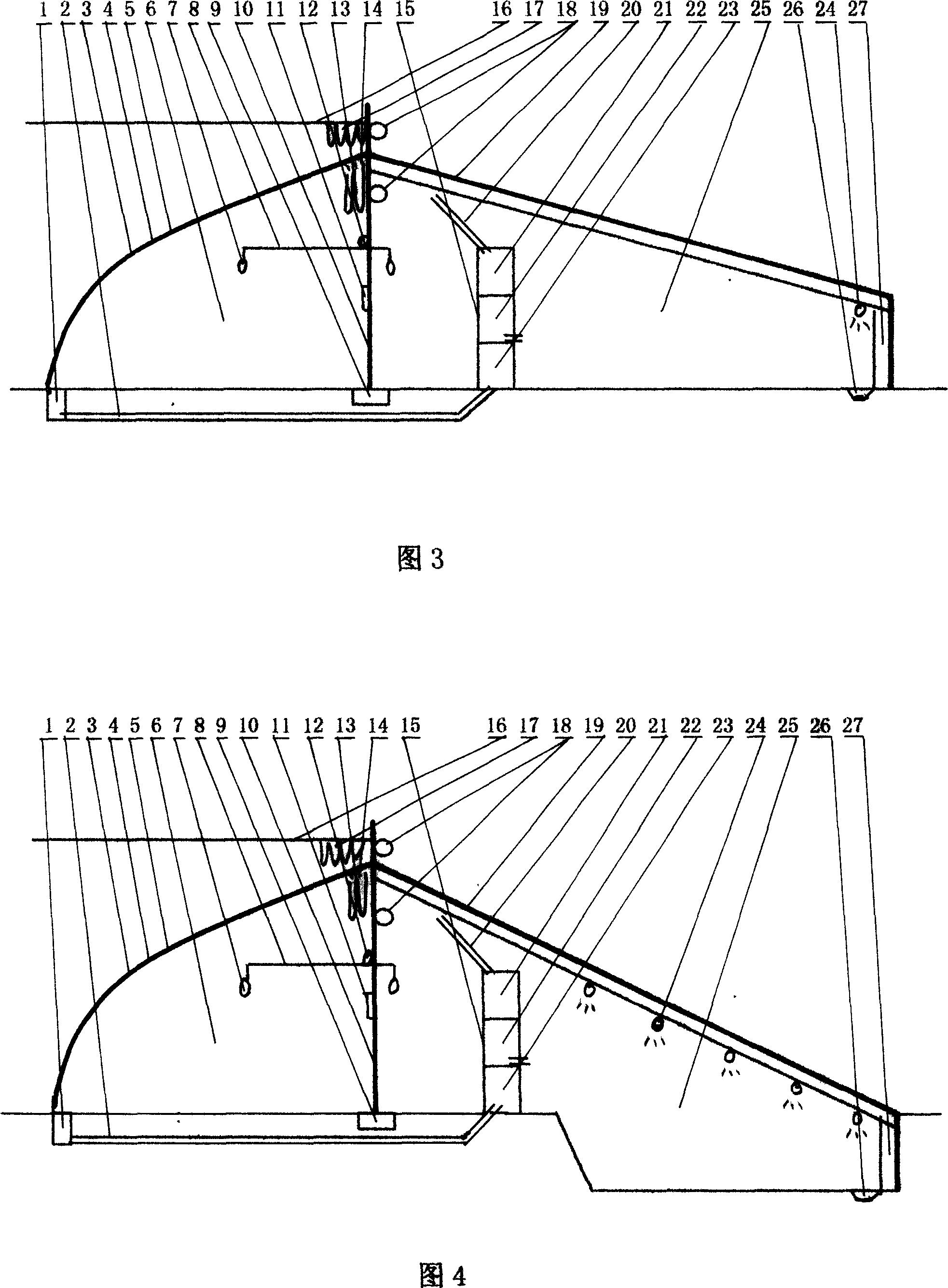

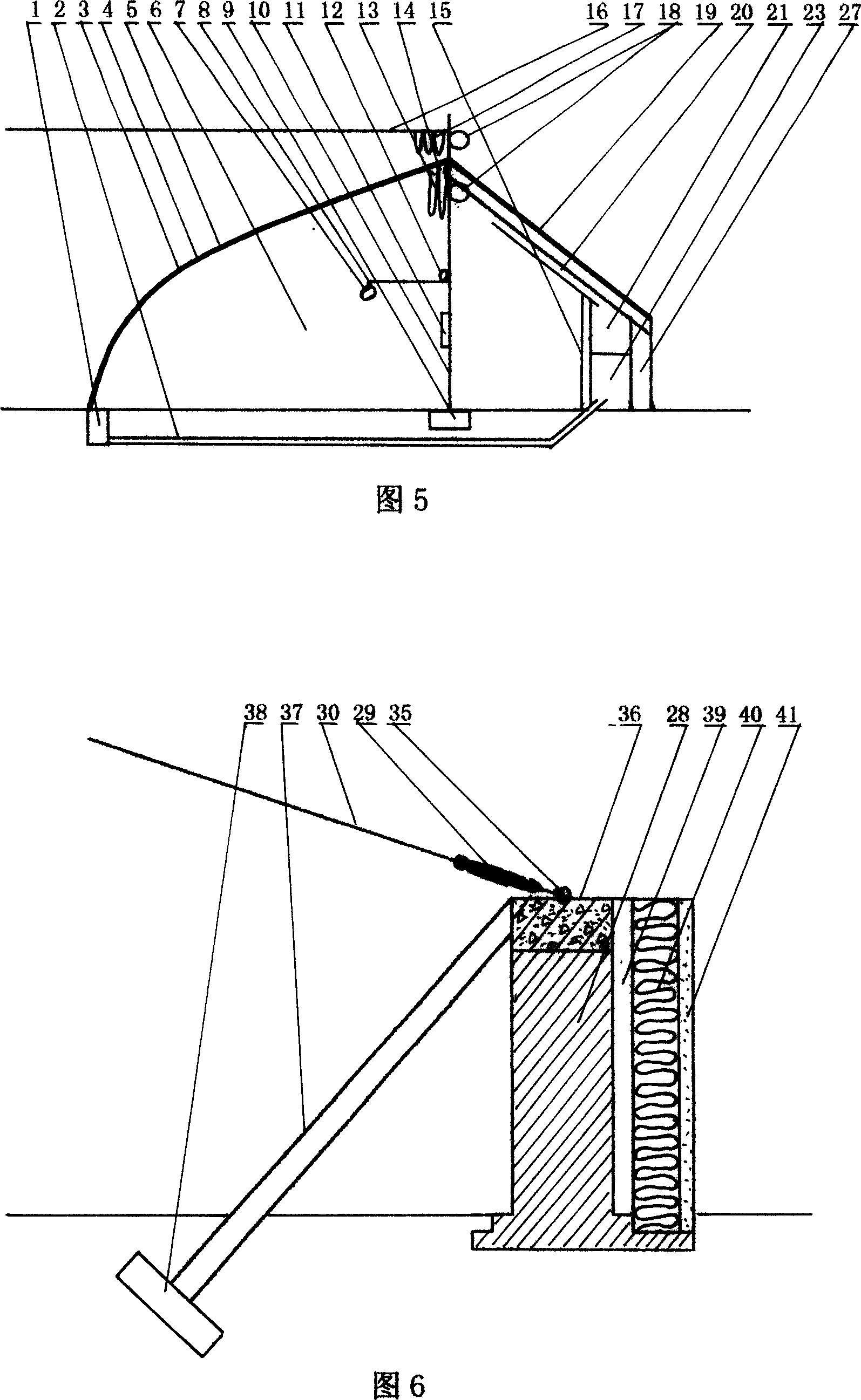

High performance heliogreenhouse

InactiveCN101019493APromote absorptionIncrease profitAgricultural buildingsClimate change adaptationWide areaBasement

The present invention discloses one kind of high performance heliogreenhouse with low building cost and running cost, and features the complete central air conditioner structure, effective utilization of solar energy and capacity of producing warm season vegetable, fruit and flower in wide area including up to 40 north latitude. The present invention may be also used in producing edible fungus and raising animal simultaneously to raise the soil utilization rate.

Owner:陆阳 +1

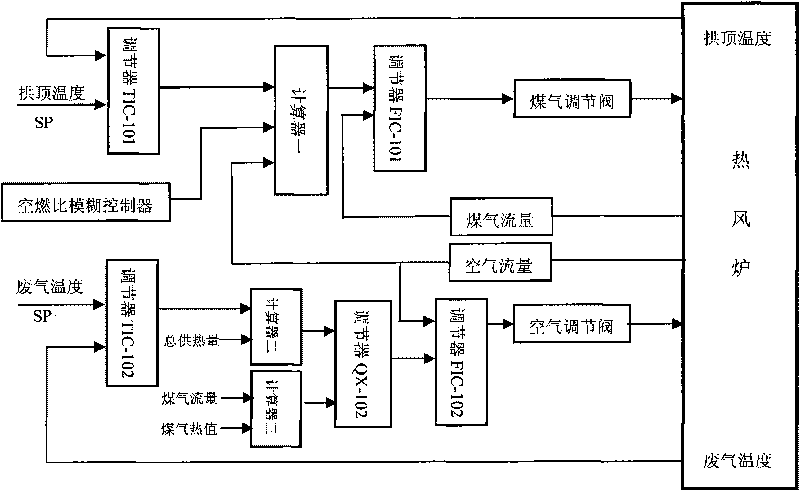

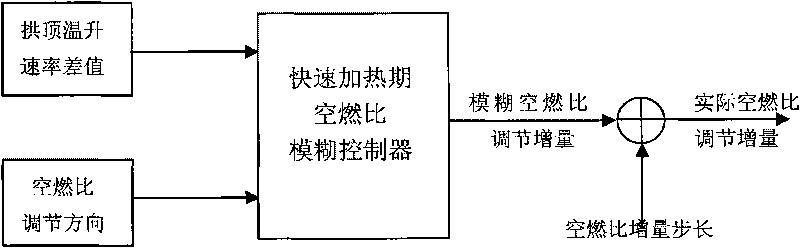

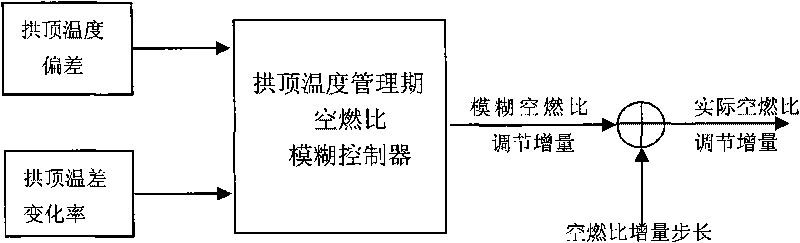

Intelligent control method for automatic optimization combustion of hot-blast stove

InactiveCN101736111AImproved combustion controlTake advantage ofFuel supply regulationBlast furnace detailsEngineeringAir conditioning

The invention provides an intelligent control method for automatic optimization combustion of a hot-blast stove. Based on computation of total heat supply amount, by setting the target values of the temperature of a combustion arch top and the temperature of exhaust gas, an air-fuel ratio fuzzy controller optimizes optimal air-fuel ratio coefficients in a combustion period in real time to regulate the flow of combustion-supporting air and mixed gas in real time; the control of the flow of the combustion-supporting air is completed by an exhaust gas temperature regulator, a heat supply amount regulator and a combustion-supporting air regulator; the control of the flow of the mixed gas is completed by an arch top temperature regulator and a mixed gas regulator; and the control of the air-fuel ratio is completed by the air-fuel ratio fuzzy controller. The invention can improve the combustion control level of the hot-blast stove and has the advantages of high combustion efficiency, full utilization of energy sources and strong heat storage capacity.

Owner:WISDRI ENG & RES INC LTD

Paraffin phase changed thermal mortar powder and preparing method thereof

A mortar powder containing paraffin wax for phase-change insulating is prepared from cement, light aggregate, fibres and paraffin wax through fusing paraffin wax or preparing the microcrystal powder of paraffin wax, and proportionally mixing it with others. Its advantages are low hydroscopicity and high water-proof performance and softening coefficient.

Owner:北京振利高新技术有限公司

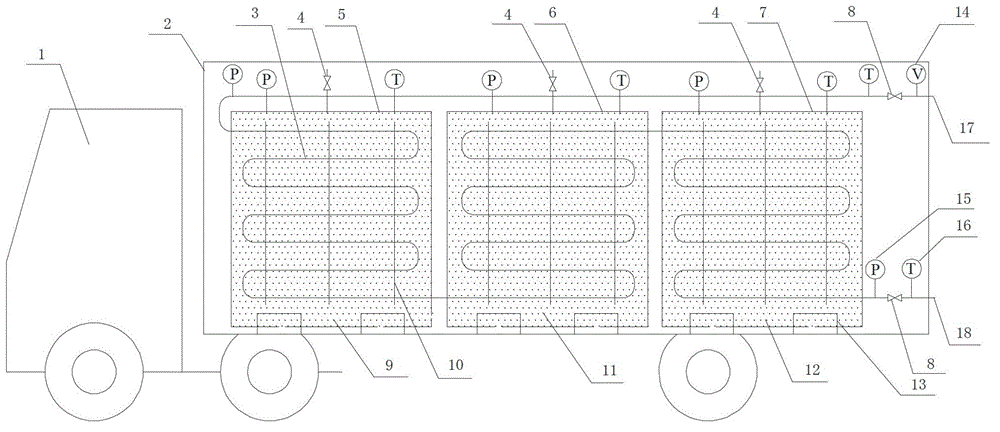

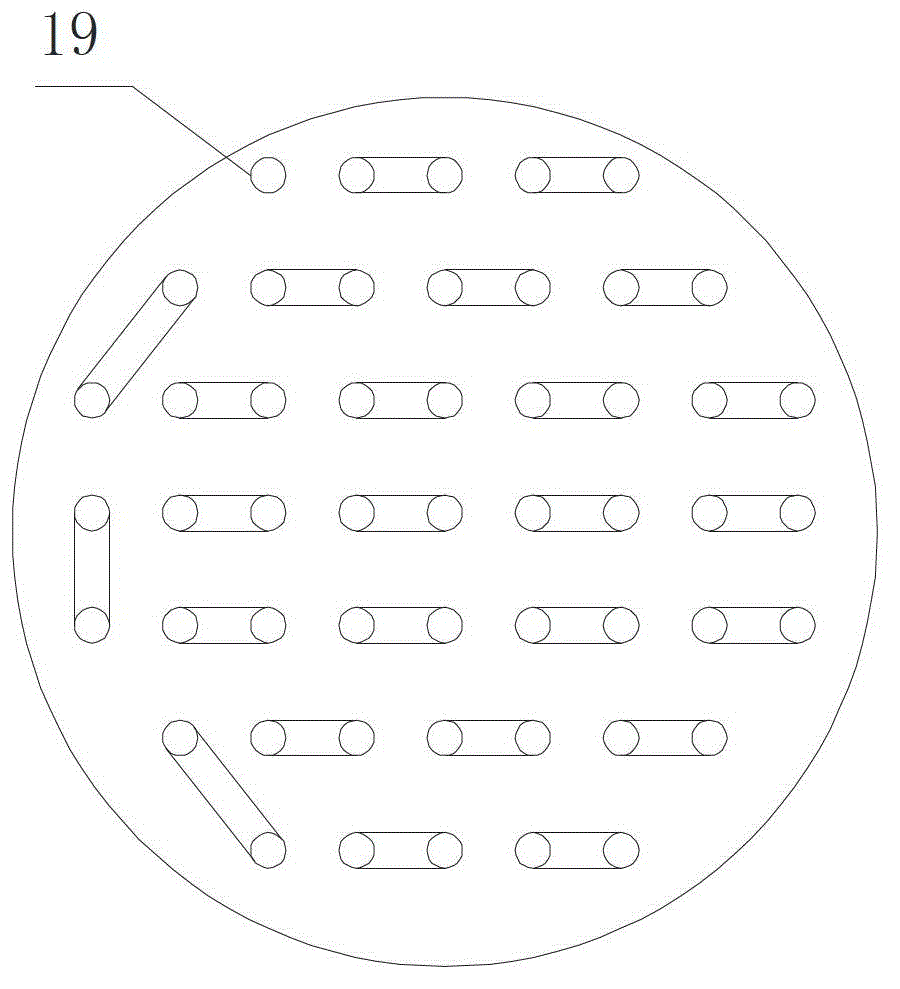

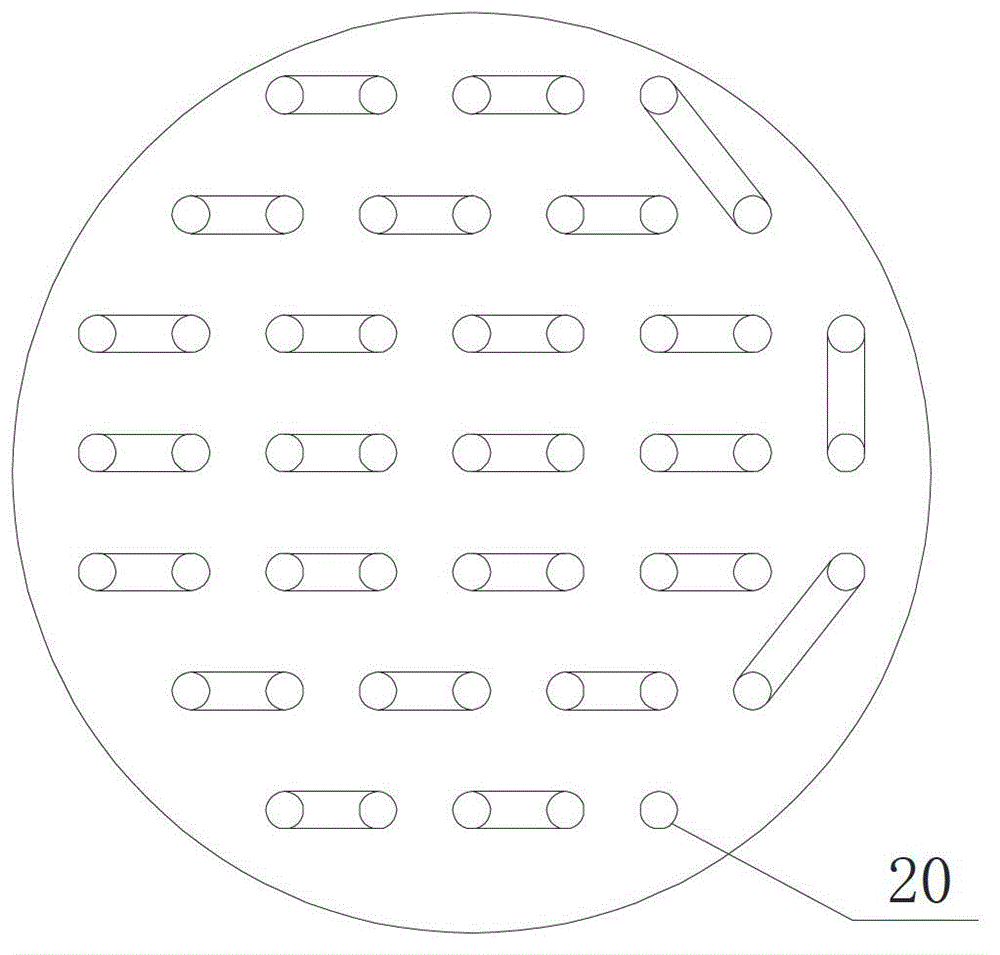

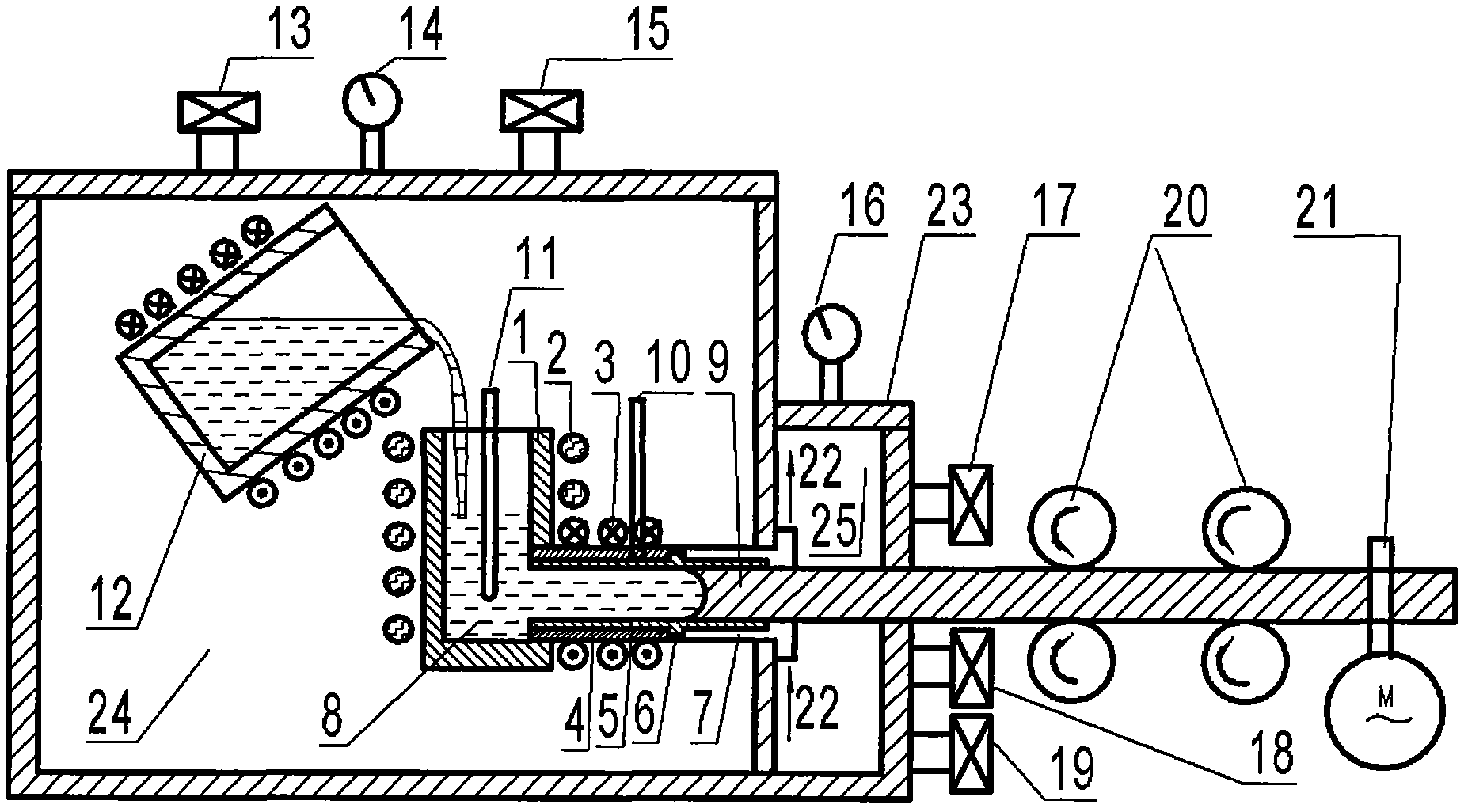

Composite phase-change energy storage movable heat supply vehicle

ActiveCN102910104AAchieve recyclingHigh energy storage densityHeat storage plantsItem transportation vehiclesThermal insulationRelease time

The invention discloses a composite phase-change energy storage movable heat supply vehicle, which is characterized by comprising a cargo truck body comprising a thermal insulation compartment, wherein high / medium / low-temperature phase-change heat accumulators are arranged in the thermal insulation compartment; each phase-change heat accumulator comprises an enclosure; corresponding phase-change materials and heat exchangers are respectively arranged in the enclosure; each phase-change heat accumulator is fixedly connected to the frame through a base; the heat exchangers of the high / medium / low-temperature phase-change heat accumulators are sequentially connected through a connecting pipeline; the heat exchanger of the high-temperature heat accumulator is provided with an outer joint; and the heat exchanger of the low-temperature heat accumulator is provided with an outer joint. The high / medium / low-temperature phase-change heat accumulators are sequentially connected in series, when the heat is filled, the waste heat or surplus waste heat of different temperature gradients can be recovered, and when the heat is released, steam or hot water at different temperatures can be generated. The heat storage capacity of the movable heat supply device can be greatly improved, and the heat filling and releasing time is shortened.

Owner:QINGDAO AOHUAN NEW ENERGY GRP CO LTD

Phase-change energy-storage dual-limit temperature adjustment mortar and preparation method thereof

The invention discloses phase-change energy-storage dual-limit temperature adjustment mortar and a preparation method thereof. The phase-change energy-storage dual-limit temperature adjustment mortar comprises the following raw materials in parts by weight: 25 parts of cement, 20-55 parts of medium sand, 10-30 parts of phase-change microcapsules, 10-40 parts of expanded perlite shape-stabilized phase-change particles, 0.25-1 part of fibers, 0.2-0.5 parts of cellulose ether, 1.5-3 parts of redispersible latex powder and 25-30 parts of water, wherein the phase-change temperature of the phase-change microcapsules is 18-20 DEG C and the phase-change temperature of the expanded perlite shape-stabilized phase-change particles is 26-28 DEG C. The phase-change energy-storage dual-limit temperature adjustment mortar prepared by the method has a dual-limit temperature adjustment function, not only can remarkably adjust a room temperature to be within upper and lower limit ranges of a comfortable temperature of a human body and improve thermal comfort of a human settlement environment but also improves energy-storage and temperature-adjustment capabilities of a phase-change mortar product and overcomes performance deficiencies existent during addition of a single phase-change medium through compound addition of two phase-change mediums, that is to say, the phase-change microcapsules and the expanded perlite shape-stabilized phase-change particles.

Owner:建筑材料工业技术监督研究中心

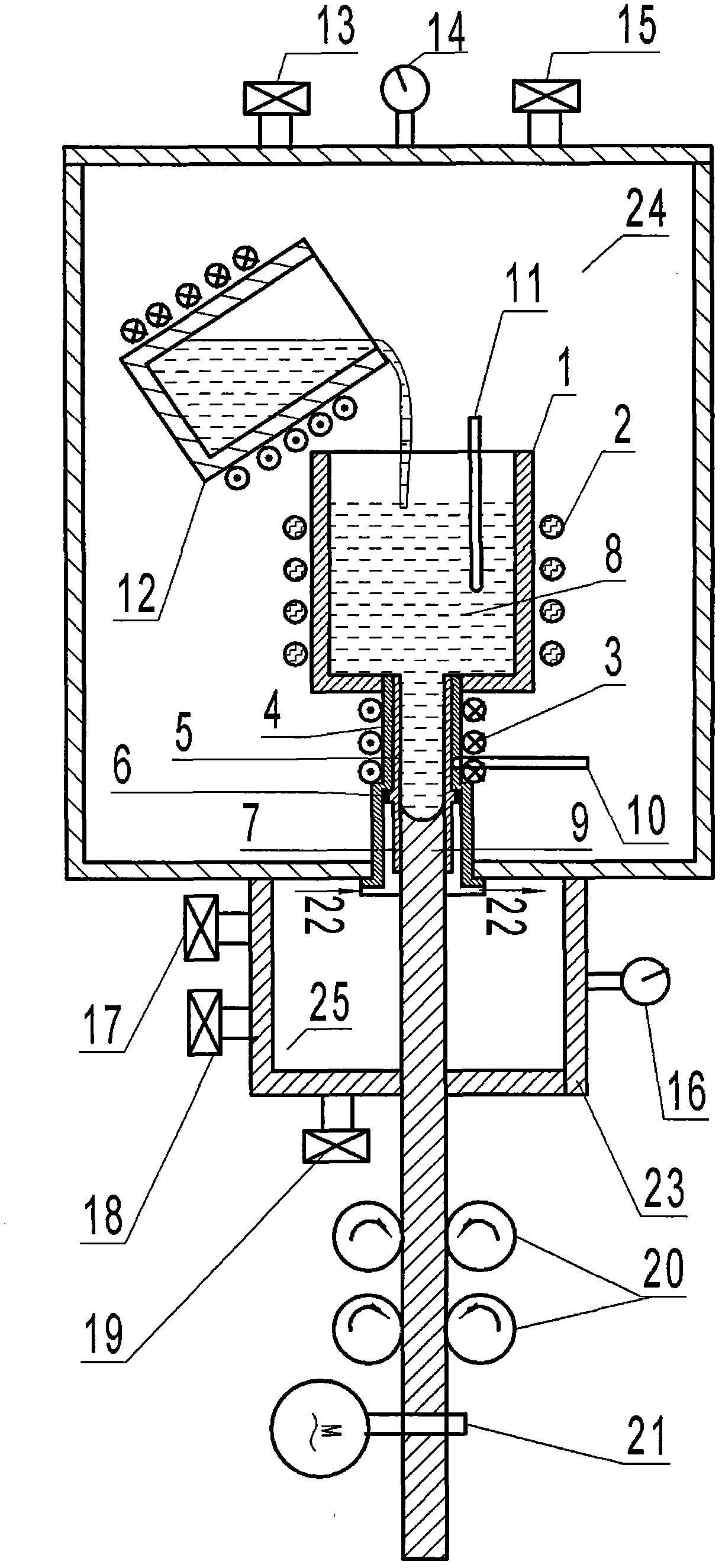

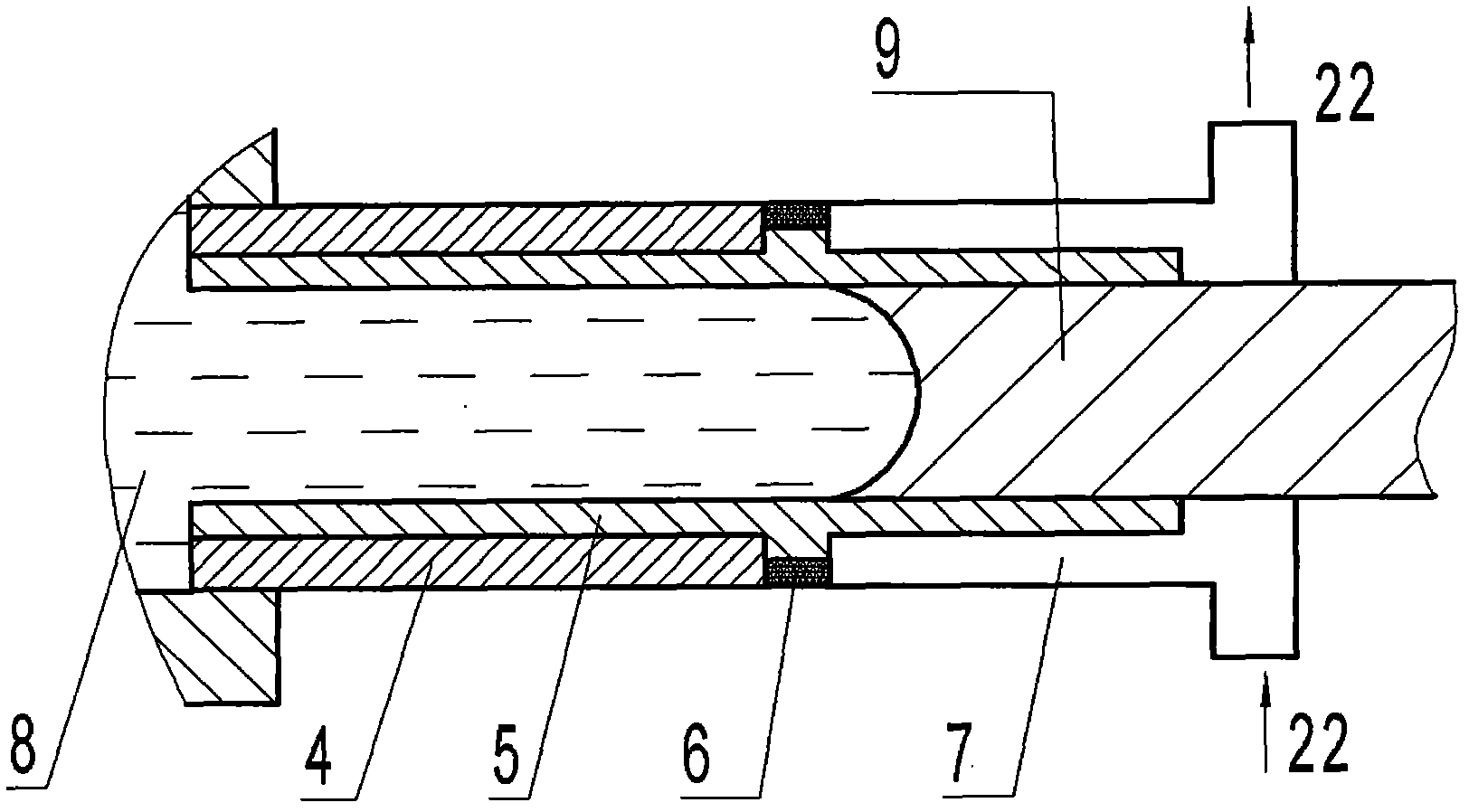

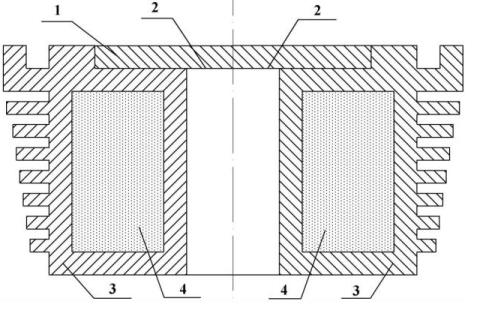

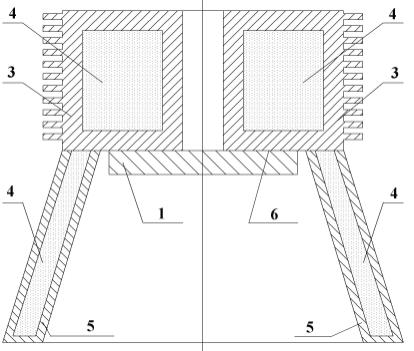

Device and method for continuously preparing bulk amorphous alloy ingots

The invention relates to a device and a method for continuously preparing bulk amorphous alloy ingots, which are characterized in that the preparation device comprises two vacuum chambers which are mutually independent. A main vacuum chamber is used for alloy melting and forming, and an auxiliary chamber is used for balancing pressure to facilitate throwing and secondary cooling. The primary cooling section of the preparation device and the method adopts a graphite pipe to be cast with a water cooling copper model embedding nest and is a main cooling part. The secondary cooling section adopts water cooling or natural cooling modes protected by inert gas and is an auxiliary cooling part. The device and the method have the advantages of having large cooling speed, meeting requirements of the bulk amorphous alloy ingots for formation, being simple in structure and capable of conveniently achieving metal continuous formation control and operation under vacuum inert gas atmosphere, and being strong in adaptability and capable of achieving continuous formation of ingots with various section shapes due to the fact that nesting cast with different inner cavity shapes and sizes, thereby being mainly suitable for continuous manufacture fields of the bulk amorphous alloy ingots.

Owner:王东

High-temperature wear-resisting coating for casting and preparation method thereof

ActiveCN104325067AHigh refractorinessLow thermal conductivityFoundry mouldsFoundry coresWear resistantSuspending Agents

The invention discloses a high-temperature wear-resisting coating for casting and a preparation method thereof. The coating comprises the following components: a fireproof material, a carrier, a bonding agent, a suspension agent and an auxiliary agent. The invention further designs the preparation method of the high-temperature wear-resisting coating for casting. The preparation method comprises the following steps: putting the suspension agent and the carrier into a dispersion machine and uniformly agitating; then adding the fireproof material and continually agitating; and slowly adding the bonding agent and the auxiliary agent in sequence under an agitating state; and agitating uniformly to obtain the high-temperature wear-resisting coating for casting. The high-temperature wear-resisting coating for casting is low in price, and is clean and is free from pollution; the preparation method is simple and the coating is high temperature resistant and wear resistant and is not easy to release; and a die for casting can be protected and the quality of a casting piece can be improved.

Owner:YANCHENG AOTONG TESCO FOUNDRY CO LTD

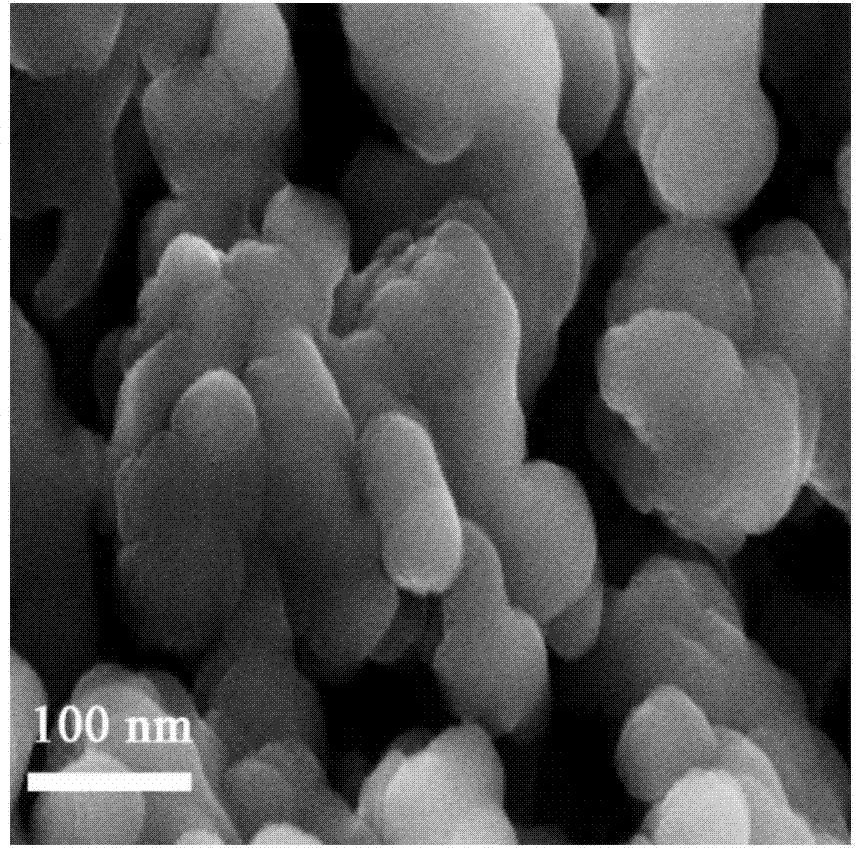

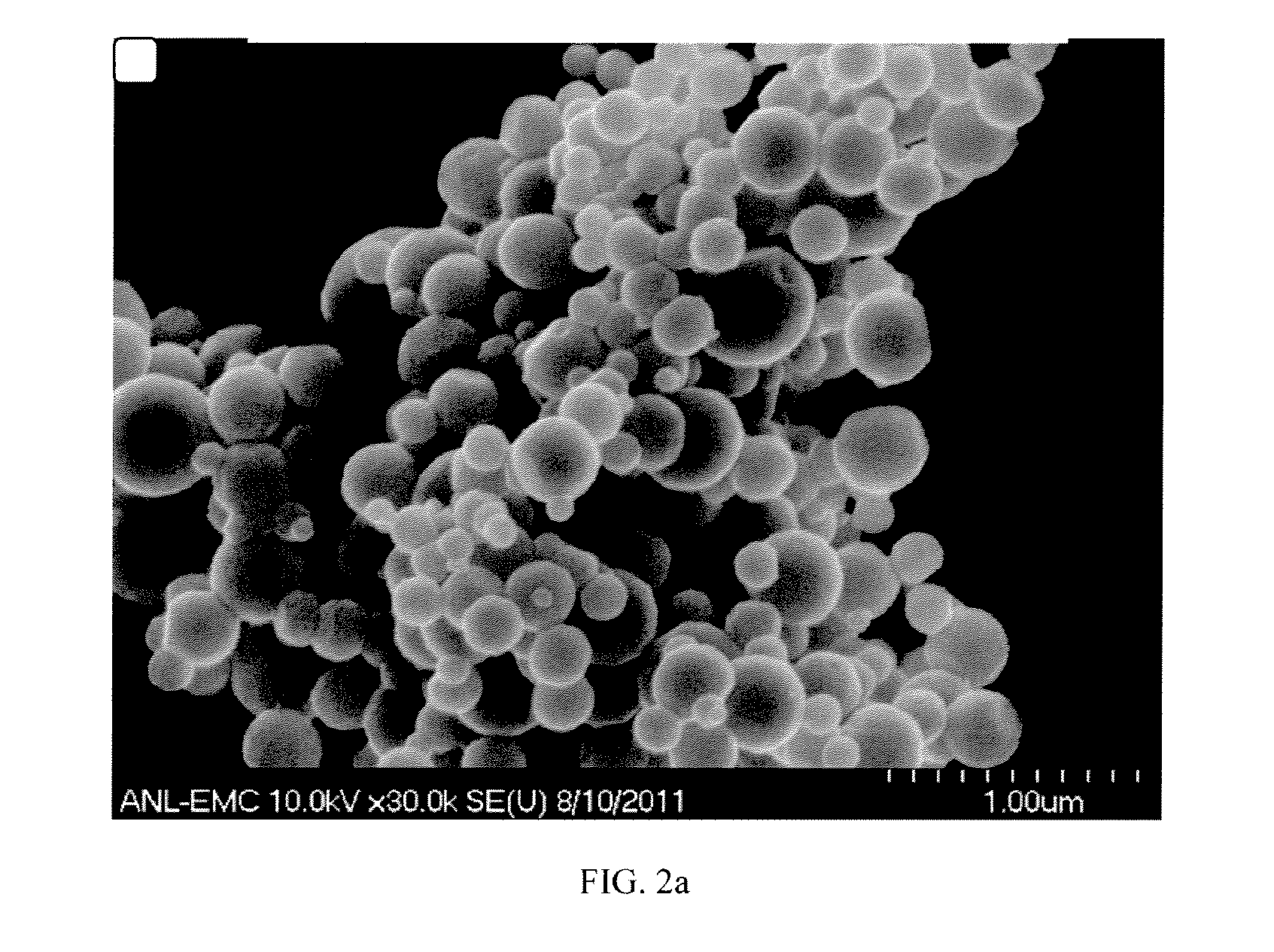

Nanoparticles for heat transfer and thermal energy storage

ActiveUS20140084205A1Increased TES storageEfficient processMaterial nanotechnologyHeat-exchange elementsThermal energy storageGraphite

An article of manufacture and method of preparation thereof. The article of manufacture and method of making the article includes an eutectic salt solution suspensions and a plurality of nanocrystalline phase change material particles having a coating disposed thereon and the particles capable of undergoing the phase change which provides increase in thermal energy storage. In addition, other articles of manufacture can include a nanofluid additive comprised of nanometer-sized particles consisting of copper decorated graphene particles that provide advanced thermal conductivity to heat transfer fluids

Owner:UCHICAGO ARGONNE LLC

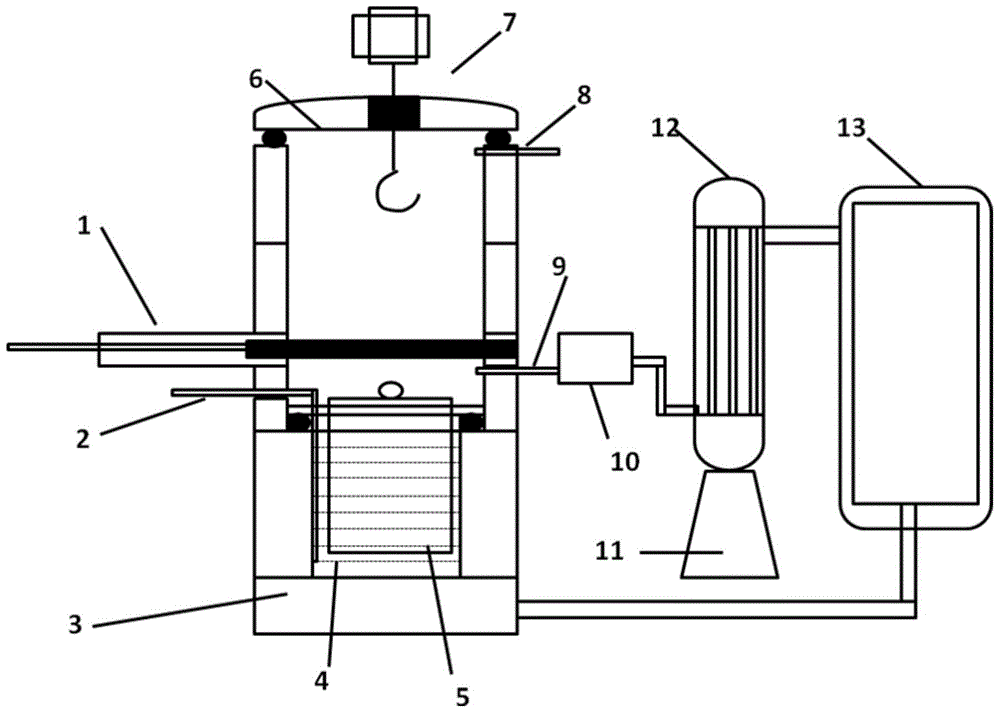

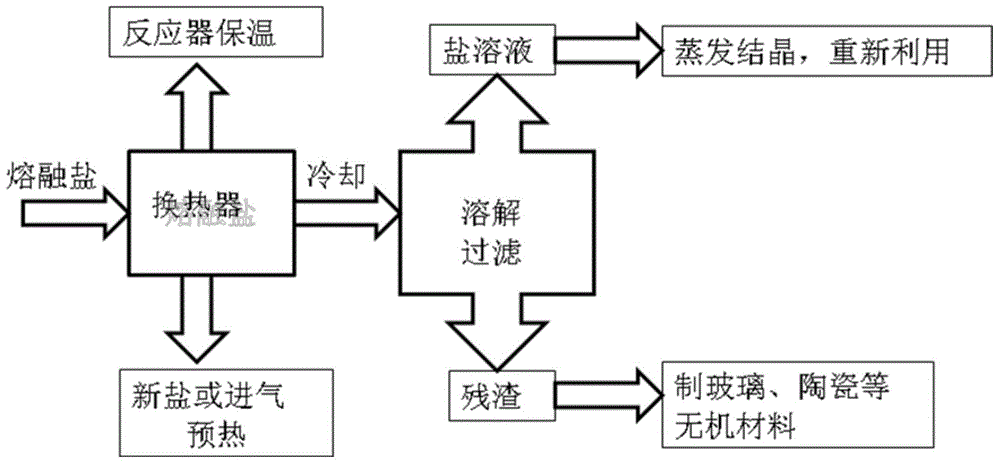

Apparatus for pyrolyzing solid wastes through molten salt, and method thereof

ActiveCN104399732AImprove heat storage capacityHigh thermal conductivitySolid waste disposalDecompositionPyrolysis

The invention belongs to the technical field of solid waste treatment and resource recovery, and relates to an apparatus for pyrolyzing solid wastes through molten salt, and a method thereof. The method uses the molten salt as a pyrolysis medium, the solid wastes are immersed in the molten salt and are effectively dissociated and decomposed under preset pyrolysis conditions, and various resource substances can be recovered. Pyrolysis products of organic components in the solid wastes are recycled as energy and resource substances. The method has the advantages of short process flow and simple operation. The apparatus allows the above raw material to be sent into or moved out of a molten salt reactor through a pyrolysis basket, and comprises a gas inlet, a gas outlet, and a feeding and discharging gate. The method uses the high heat accumulation capability and high heat conduction rate of the molten salt, effectively improves the decomposition rate of organic matters and the energy utilization rate, traps or converts acidic gases and harmful substances by using the characteristic of reaction of the molten salt with the acidic gases and the harmful substances, reduces secondary pollution to environment, and improves the cleanliness and resource of products.

Owner:DALIAN UNIV OF TECH

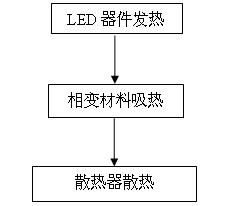

Heat dissipation method of LED (light-emitting diode) device and device

InactiveCN102155729AFast absorptionExtended service lifePoint-like light sourceLighting heating/cooling arrangementsJunction temperatureHeat sink

The invention discloses a heat dissipation method of an LED (light-emitting diode) device, which comprises the following steps of: conducting the heat of the LED device into a phase change material which emits heat with the external environment. The invention also discloses a heat sink of the LED device; the heat sink comprises a metal shell, a heat dissipation baseboard and a heat-conducting fin, wherein the metal shell is internally filled with the phase change material, and the heat dissipation baseboard is connected with the metal shell by the heat-conducting fin. The invention also discloses another heat sink of the LED device; the heat sink comprise the metal shell, the heat dissipation baseboard, a heat pipe and a metal outer cover, wherein the metal shell and the metal outer cover are internally filled with the phase change material, and the heat dissipation baseboard is connected with the metal shell by the heat pipe. The phase change materials of the invention is a composite phase change material of an organic matter and an inorganic metal, has faster heat response rate and heat storage capacity, can rapidly absorb the heat generated by the LED device, and controls the junction temperature of the LED device to be within 60 DEG C, thereby avoiding the luminous decay phenomenon caused by the overheating of the LED device and prolonging the service life of the LED device.

Owner:SOUTH CHINA UNIV OF TECH

Far infrared polyester and nylon composite superfine fiber and production method thereof

ActiveCN103290524AHigh tensile strengthLow thermal conductivityConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolyesterThermal insulation

The invention discloses a far infrared polyester and nylon composite superfine fiber and a production method thereof. The far infrared polyester and nylon composite superfine fiber is formed by externally coating a modified nylon 6 fiber layer by taking a superfine polyester fiber as a core thread, wherein a far infrared nano-powder material is arranged in the externally coated modified nylon 6 fiber layer; modified nylon 6 is modified by adding nylon 6 into a silica nano-powder material under active catalysis of a cerium oxide nano-powder material. According to the obtained far infrared polyester and nylon composite superfine fiber, the infrared emitting ability can be up to 90-92 percent within the normal temperature wavelength range of 2-16; according to the modified nylon 6, the tensile strength of the nylon 6 is improved, the heat conductivity coefficient is reduced, and the drawing performance of the nylon 6 is high, so that coating and the drawing between the nylon 6 and the superfine polyester fiber can be realized, and a piece of obtained textile fabric has good thermal insulation properties.

Owner:宁波三邦日用品有限公司

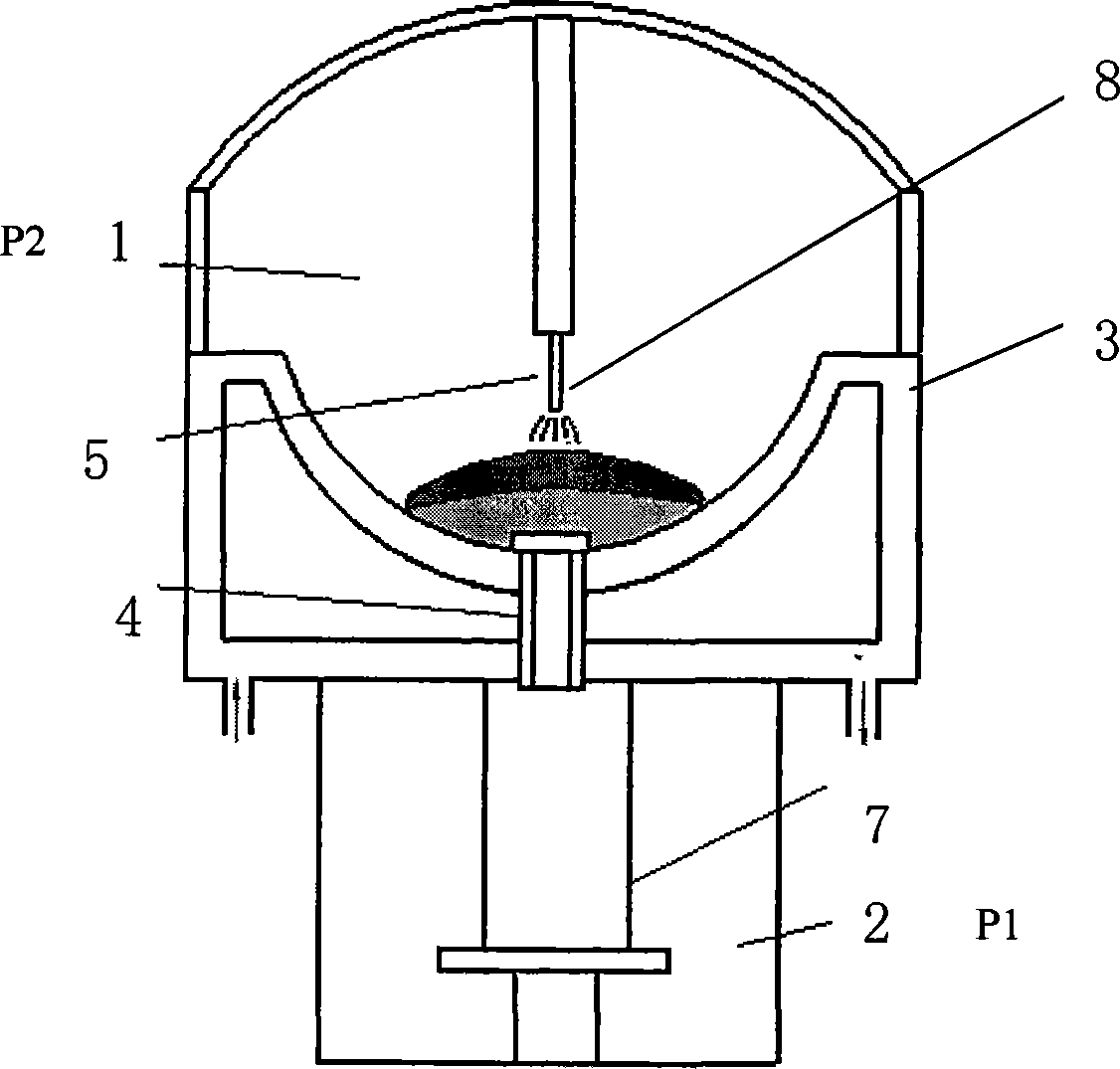

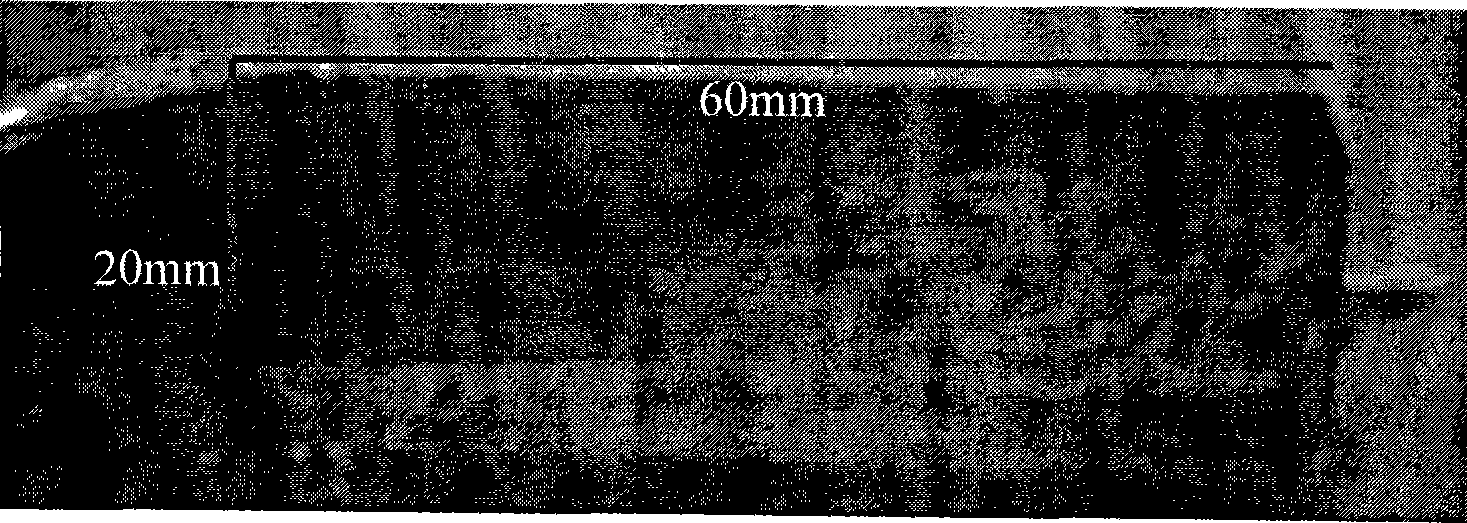

Accurate casting method for metal leakage type suction pouring titanium master alloy

InactiveCN101244454AImprove thermal conductivityImprove heat storage capacityPreparation proceduresMetal

The invention relates to a precision casting method for titanium master alloy by means of casting die bottom-drain vacuum suction casting, belonging to the technical field of precision casting methods for titanium master alloy. The precision casting method in the invention solves the problems in the prior processing technique for titanium master alloy, such as large workload, higher process costs, complex preparation processes, the liability of the alloy to the pollution of interstitial elements during the preparation procedure, poor compactness, and bad quality of the castings. The precision casting method comprises the following steps: making the casting die; conducting vacuum melting of the alloy in a non-consumable electrode arc furnace; turning over the melted titanium mater alloy into a suction casting crucible for remelting and keeping a certain degree of superheat; vacuumizing a vacuum chamber where the casting die is arranged, opening the suction casting button on the suction casting crucible, and enabling the liquid titanium master alloy to fill up the casting die under the actions of the self-gravity and pressure difference, thus obtaining the required casting member. The titanium master alloy casting member produced by the precision casting method in the invention has the advantages of full die filling, good surface quality, fine grains of the casting structure sized from 10 to 30 Mu m, correspondingly thinned dendritic crystal, less segregation, and compact structure.

Owner:HARBIN INST OF TECH

Heat accumulation and energy storage graphite material for solar thermal power generation and preparation method thereof

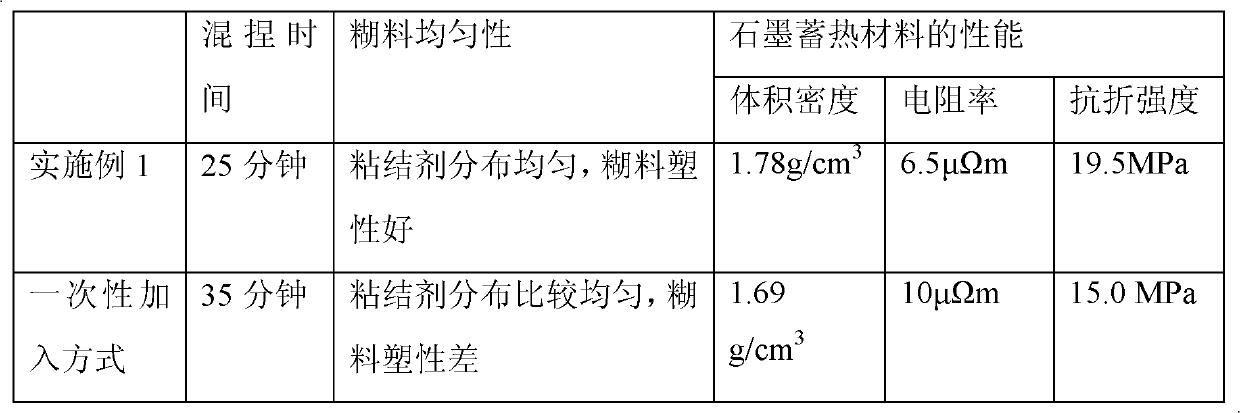

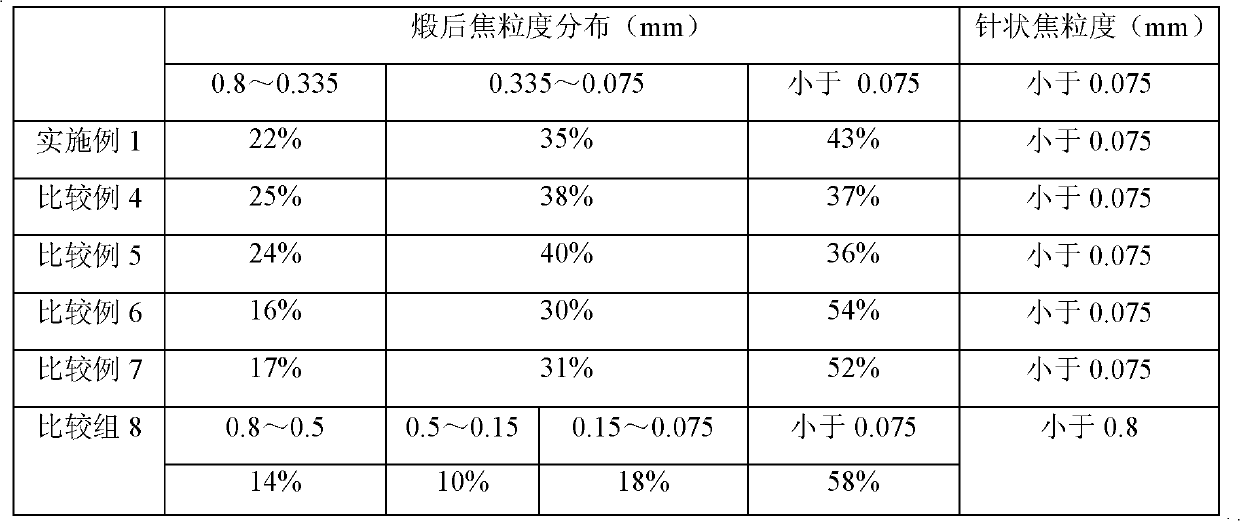

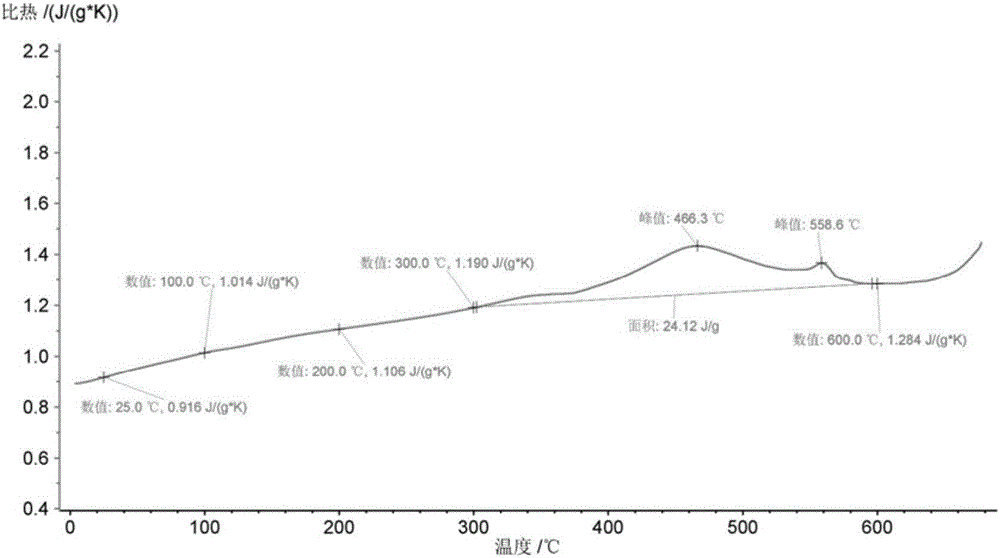

ActiveCN101948675AImprove thermal conductivityImprove heat storage capacityHeat-exchange elementsCooking & bakingThermal expansion

The invention relates to a heat accumulation and energy storage graphite material for solar thermal power generation and a preparation method thereof. The performance parameters of the graphite material meet the following requirements that: volume density is more than or equal to 1.75 g / cm<3>; electrical resistivity is less than or equal to 7.5 mu ohm m; ash content is less than or equal to 0.2 percent; rupture strength is more than or equal to 18.5 Mpa; elastic modulus is less than or equal to 8.8 Gpa; and thermal expansion coefficient is less than or equal to 2.0*10<-6> / DEG C<-1>. The graphite material of the invention has the advantages of high thermal capacity, high heat conductivity, long service life, low cost and the like. In the preparation method, the focusing solar thermal power generation and heat accumulating material is prepared from raw materials by the steps of sieving, burdening, kneading, airing, vibration molding, baking, soaking, secondary baking, graphitizing and machining.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Solid composite phase-change thermal storage material and preparation method thereof

InactiveCN106701034ANo pollution in the processHigh heat storage densityHeat-exchange elementsVolumetric Mass DensityHydroforming

The invention discloses a solid composite phase-change thermal storage material, belonging to the technical field of energy storage materials. The solid composite phase-change thermal storage material comprises water, sodium carbonate, potassium carbonate, magnesium oxide, kieselguhr, quartz sand and kaolin. The thermal storage material is non-toxic, harmless and free of pollution. The invention further discloses a preparation method of the solid composite phase-change thermal storage material. The preparation method comprises the following steps: stirring, rubbing sand, filtering, performing hydraulic molding, and performing sintering molding. By adopting the preparation method, the thermal storage density is improved, the thermal storage density of the material is 2 times better than that of a common material, the thermal storage material can endure high temperature, can be heated to be greater than 650 DEG C, and is not liable to efflorescence when being used for a long time.

Owner:BEIJING SONDEX ENERGY TECH

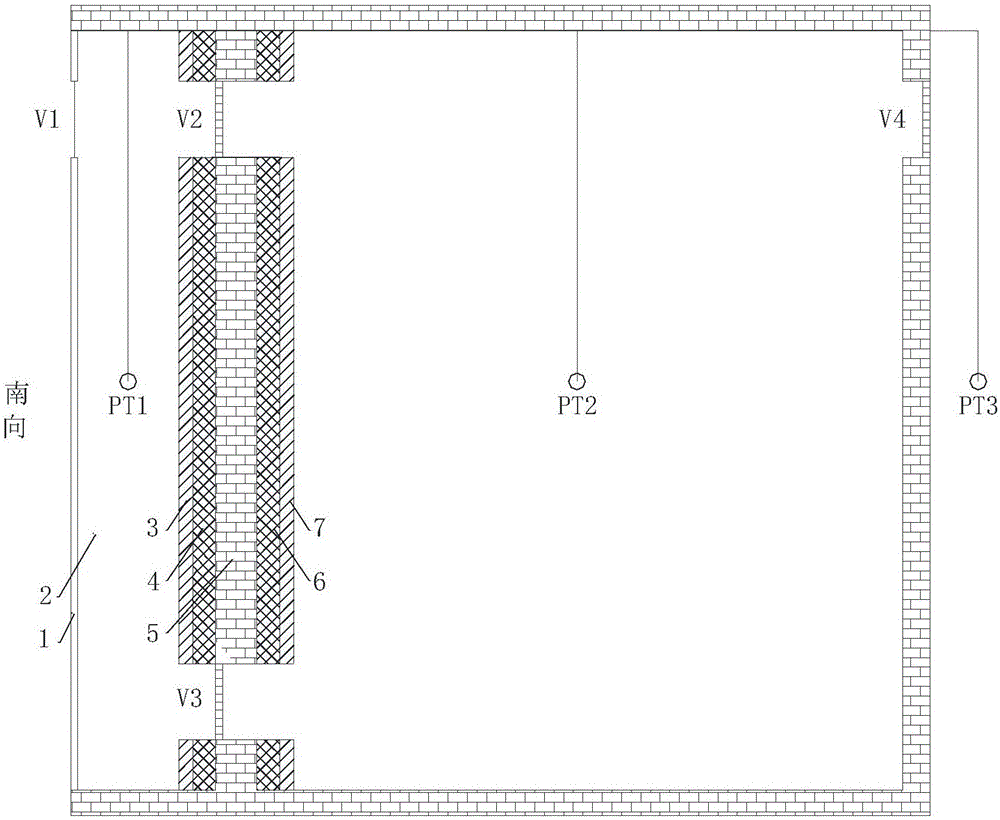

Composite phase change heat storage solar water heater without water tank

InactiveCN102338484AEasy to useNice appearanceSolar heating energySolar heat devicesSolar waterSteel tube

The invention discloses a composite phase change heat storage solar water heater without a water tank, comprising a vestlet, a bracket, a main cold water inlet tube, a main hot water outlet tube, a polyurethane insulation coating, a solar companion, a tailstock and a plurality of vacuum heat collecting units, wherein the bracket is fixedly connected with the tailstock, all the vacuum heat collecting units are arranged on the tailstock and fixed by the bracket, and the vestlet covers outside the bracket to protect the vacuum heat collecting units; the main cold water inlet tube is connected in parallel with a plurality of cold water branched tubes respectively extending to the bottom of every layer of stainless steel tube after penetrating through a sealing plug; and the main hot water outlet tube is connected in parallel with a plurality of hot water branched tubes respectively extending to the upper part of a stainless steel tube at an inner layer after penetrating through a sealing plug. The composite phase change heat storage solar water heater without the water tank has high heat storage capacity, therefore, advanced water storage is not needed; and the composite phase change heat storage solar water heater without the water tank is directly connected with a running water system, therefore, hot water can be used at any time, and the composite phase change heat storage solar water heater without the water tank has stable water temperature and is simple and convenient to operate.

Owner:陆飞飞

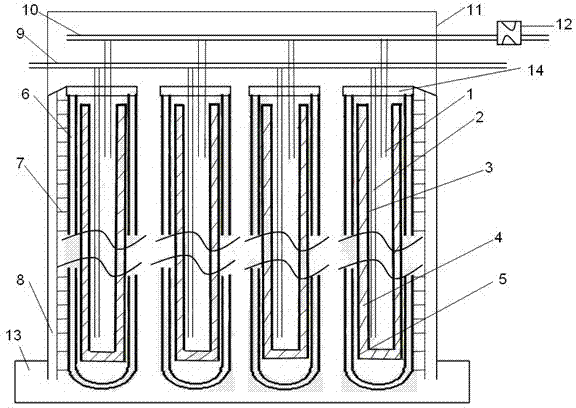

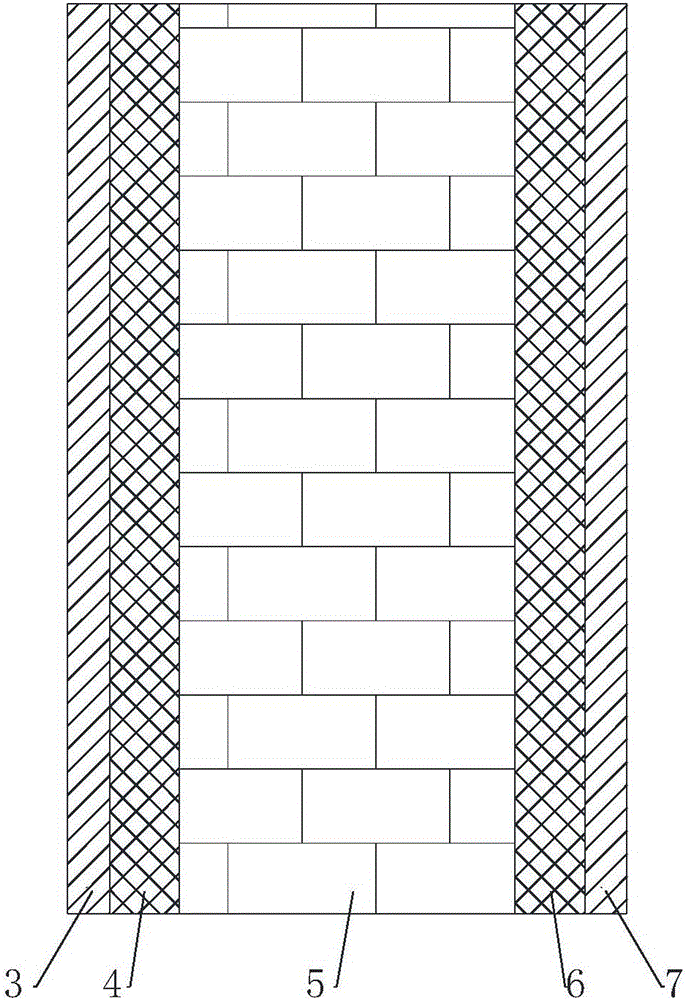

Self-regulating phase change Trombe wall

InactiveCN106836522AEnsure the role of latent heat storageGuaranteed package stabilityWallsTrombe wallParaffin oils

The invention discloses a self-regulating phase change Trombe wall. The self-regulating phase change Trombe wall is composed of a glass layer (1), an air layer (2), a first phase change wall layer (3), a first thermal insulating layer (4), a concrete wall layer (5), a second thermal insulating layer (6) and a second phase change wall layer (7) which are sequentially arranged from outside to inside, wherein the phase change temperature of the first phase change wall layer (3) is 27-29 DEG C; the phase change temperature of the second phase change wall layer (7) is 17-19 DEG C; both the first phase change wall layer (3) and the second phase change wall layer (7) are obtained by melting and blending the raw materials including high-density polyethylene, expanded graphite and paraffin. By improving the key heat storage wall structure, the setting manner of the heat storage wall structure, the setting mode of a ventilation port, the switching conditions of opening and closing states and the like, the self-regulating phase change Trombe wall can effectively solves the problem in the prior art that Trombe walls are insufficient in heat supply in winter days without sun or too hot in summer.

Owner:HUAZHONG UNIV OF SCI & TECH

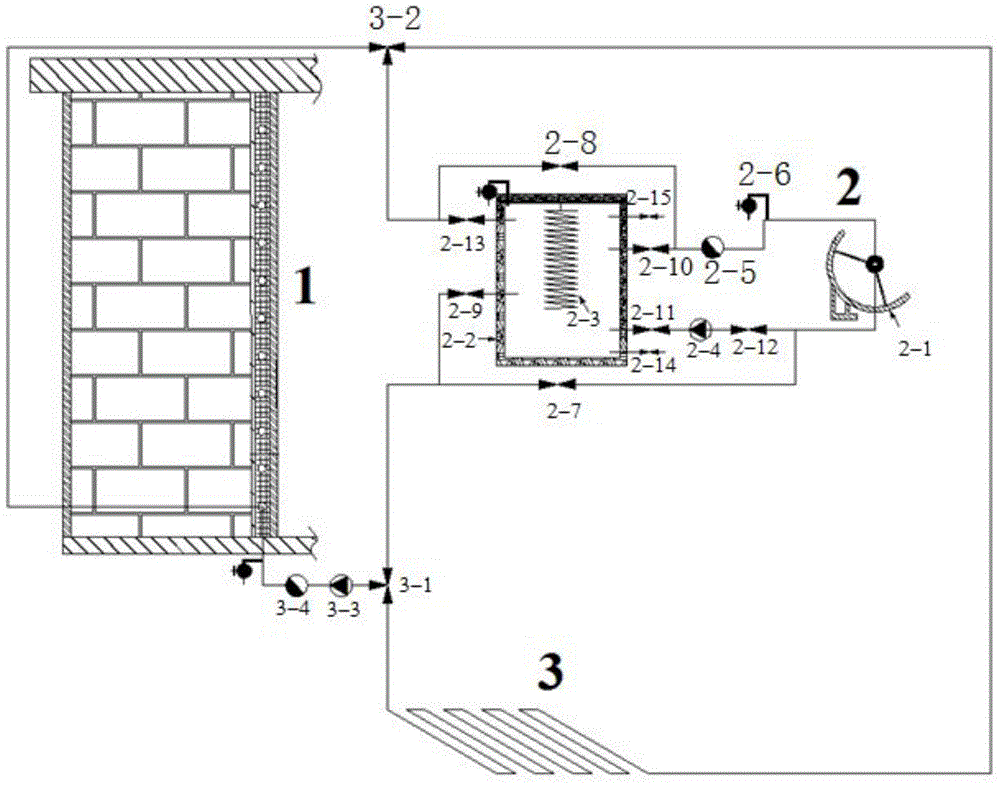

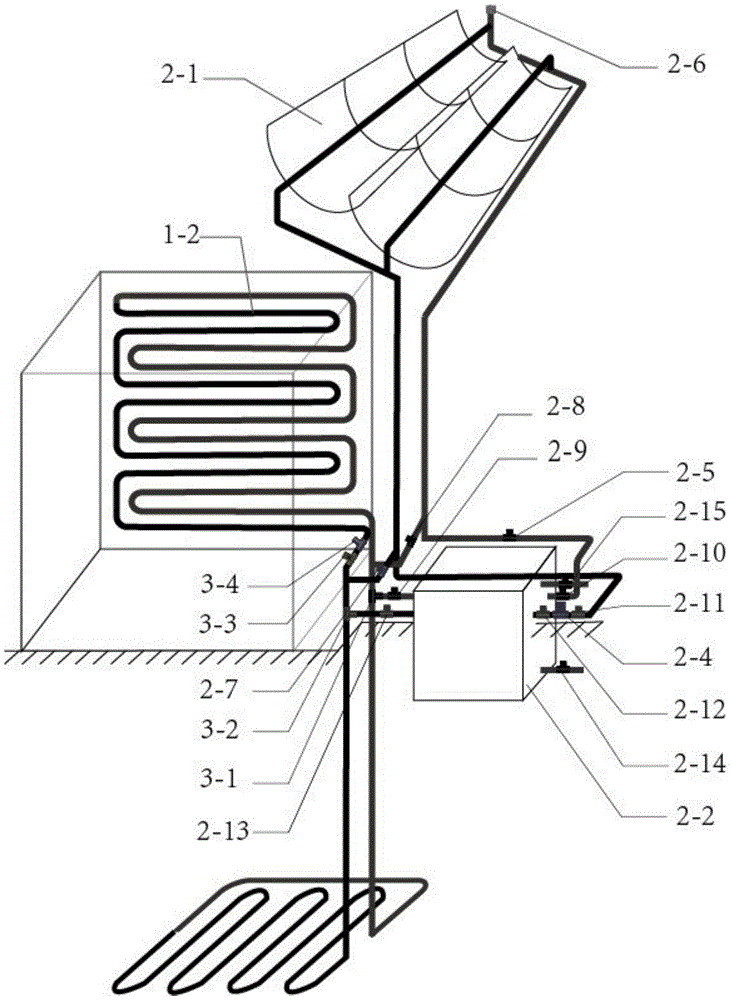

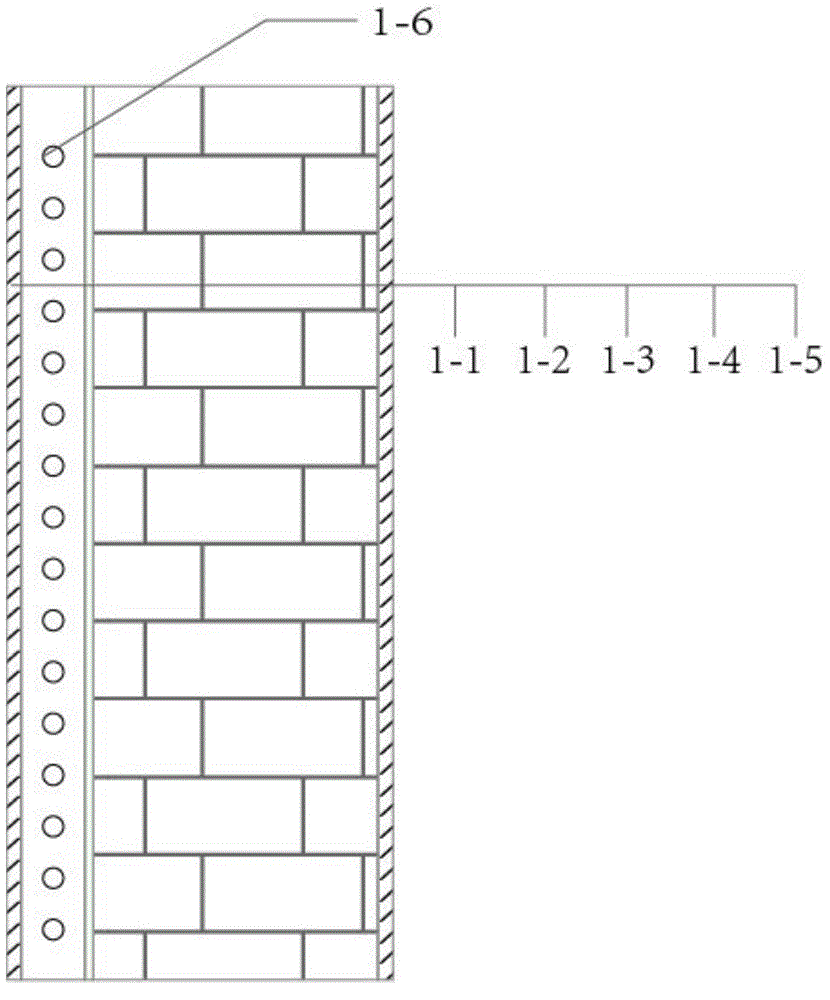

Renewable energy coupled energy storage and temperature regulation wall body system and using method thereof

ActiveCN104895218AImprove average energy utilizationImprove heat storage capacityRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringPhase change

The invention provides a renewable energy coupled energy storage and temperature regulation wall body system and a using method thereof. The renewable energy coupled energy storage and temperature regulation wall body system is characterized by comprising a temperature regulation wall body, a solar energy device and a shallow soil heat exchange tube; the solar energy device is arranged on a roof of a room; the shallow soil heat exchange tube is buried in the ground; the temperature regulation wall body is connected with the solar energy device and the shallow soil heat exchange tube; one end of the shallow soil heat exchange tube is connected with a water supply pipeline three-way reversing valve, a heat exchange tube water pump and a heat exchange tube flow meter; the other end of the shallow soil heat exchange tube is connected with a water return pipeline three-way reversing valve through a pipeline; the temperature regulation wall body comprises an inner wall plastering layer, a phase change energy storage plate, binding mortar, an inner wall body and an outer wall plastering layer in turn along the direction from interior to exterior; small pipe diameter of coiled pipes are uniformly embedded in the phase change energy storage plate along the direction of the height of the wall body; a water inlet end and a water outlet end of the small pipe diameter of coiled pipes re located at the bottom of the temperature regulation wall body. The using method is divided into three working condition modes of the winter working condition mode, the summer working condition mode and the transition season working condition mode.

Owner:HEBEI UNIV OF TECH

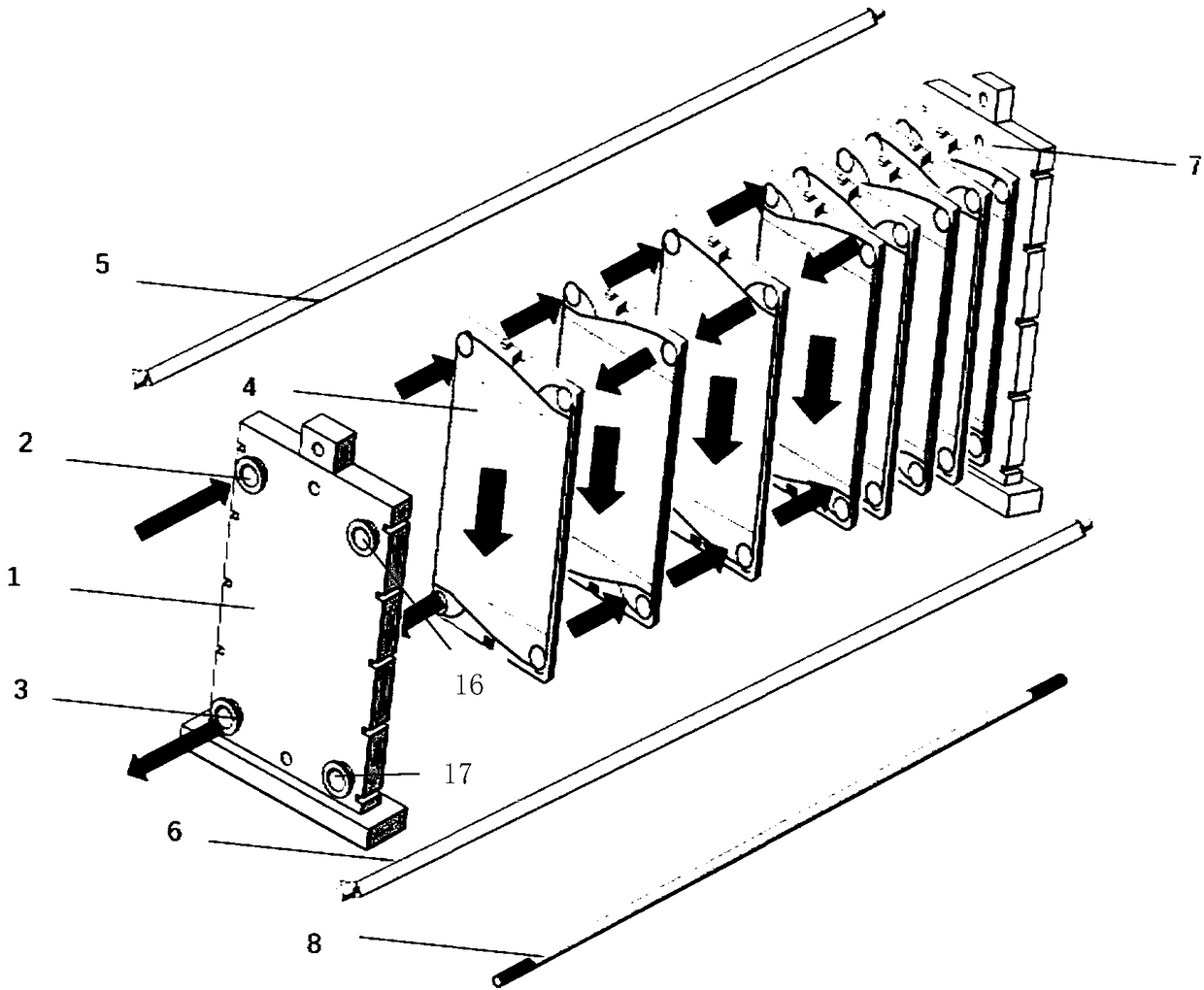

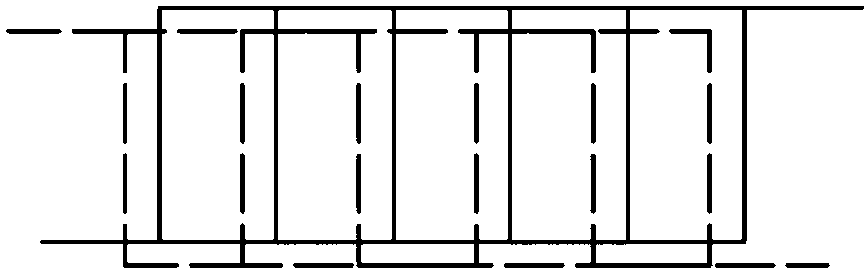

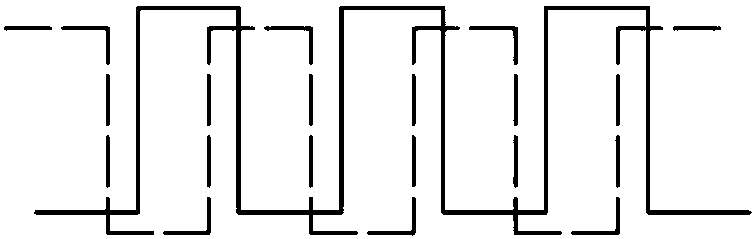

Temperature gradient energy storage heat exchanger

PendingCN108413796AImprove heat transfer efficiencyCompact structureHeat storage plantsSmall footprintEngineering

The invention discloses a temperature gradient energy storage heat exchanger. The temperature gradient energy storage heat exchanger comprises a front clamping plate, a rear clamping plate and at least two sets of plates overlapped between the front clamping plate and the rear clamping plate to form fluid channels in a sealed mode in sequence. The four corners of the front clamping plate, the fourcorners of the rear clamping plate and the four corners of the plates are provided with circular fluid through holes correspondingly. The spaces inside the at least sets of the plates are filled withthe same phase change materials. The phase change temperatures of the phase change materials in the different sets of the plates decrease progressively in the fluid flowing direction. The temperaturegradient energy storage heat exchanger gives full play to the advantages of a plate heat exchanger such as high heat transfer coefficient, small occupied space, light weight and convenient manufacturing and achieves the purpose of improving the energy utilization efficiency through combination with the phase change materials with the characteristics of large heat storage capacity, environmental protection and selection diversity. The operational suitability is improved through independent cold and hot fluid channels. The temperature gradient energy storage heat exchanger has the advantages ofbeing large in energy storage density, convenient to operate and high in adaptability and can be applied to the fields of solar thermal collectors, heat pump heat collectors and industrial waste heatrecovery.

Owner:SOUTH CHINA UNIV OF TECH

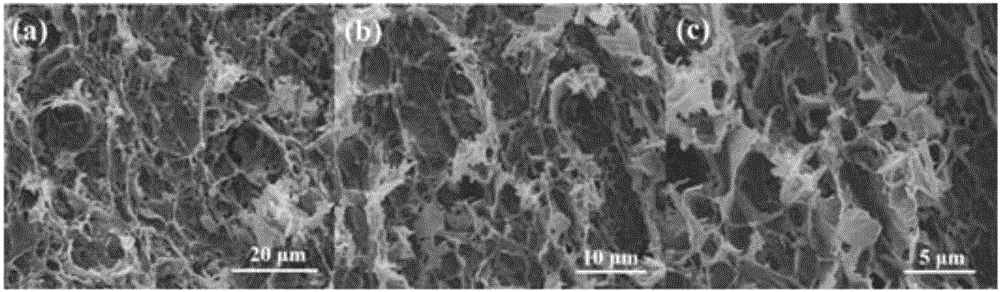

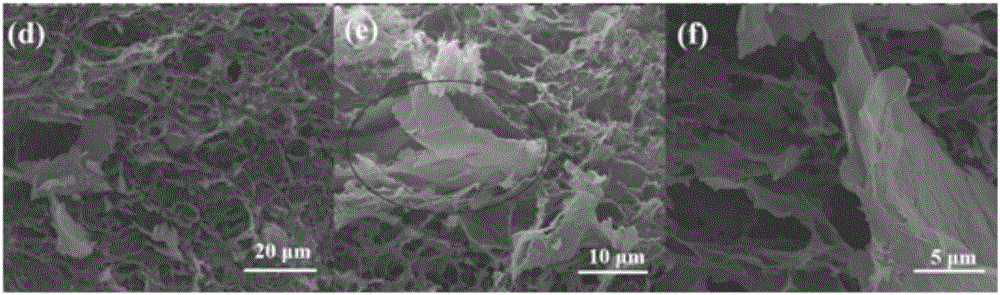

Preparation method of hybrid graphene gel/phase-change heat-conducting composite material

InactiveCN106634855AEvenly dispersedRegulatory performanceHeat-exchange elementsHeat conductingPhase change

The invention relates to a preparation method of a hybrid graphene gel / phase-change heat-conducting composite material. The preparation method comprises the following steps that 1, graphite oxide is taken and dispersed in water and is prepared into an oxidized graphene solution; 2, the oxidized graphene solution obtained in the step 1 is put in a reaction kettle, and hydrothermal reaction and drying are performed to obtain graphene gel; 3, then a solid-liquid organic phase-change material and the graphene gel prepared in the step 2 are put under vacuum condition, heating is performed to remove excessive solid-liquid organic phase-change material, and cooling is performed to obtain the graphene gel / phase-change heat-conducting composite material. Compared with the prior art, the prepared composite material has excellent thermal conductivity, electrical conductivity and thermal stability, the problems of low thermal conductivity, electrical insulation and the like of phase-change energy storage materials existing in the prior art are solved, and the preparation method is simple, low in cost, good in repeatability and the like.

Owner:TONGJI UNIV

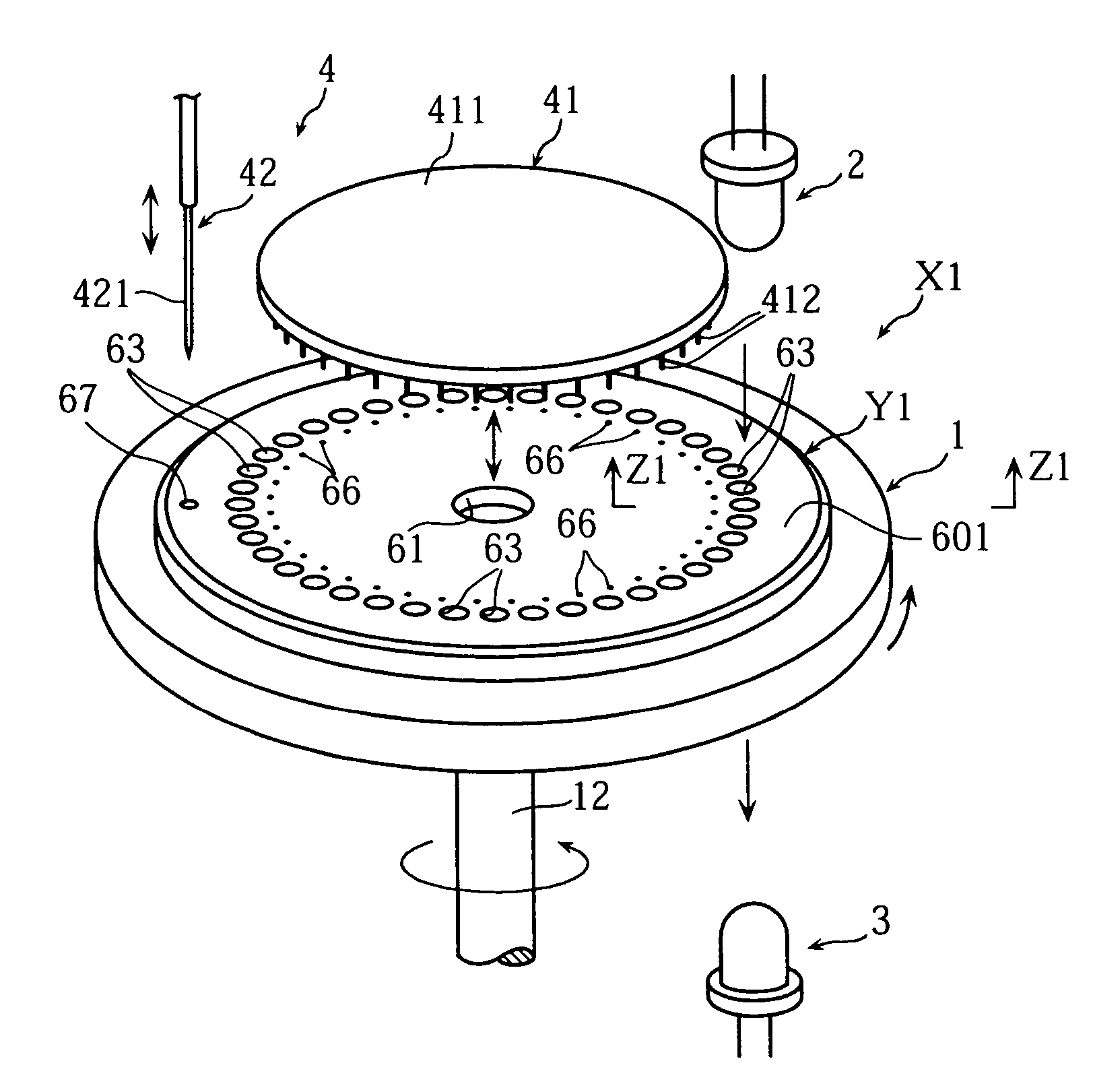

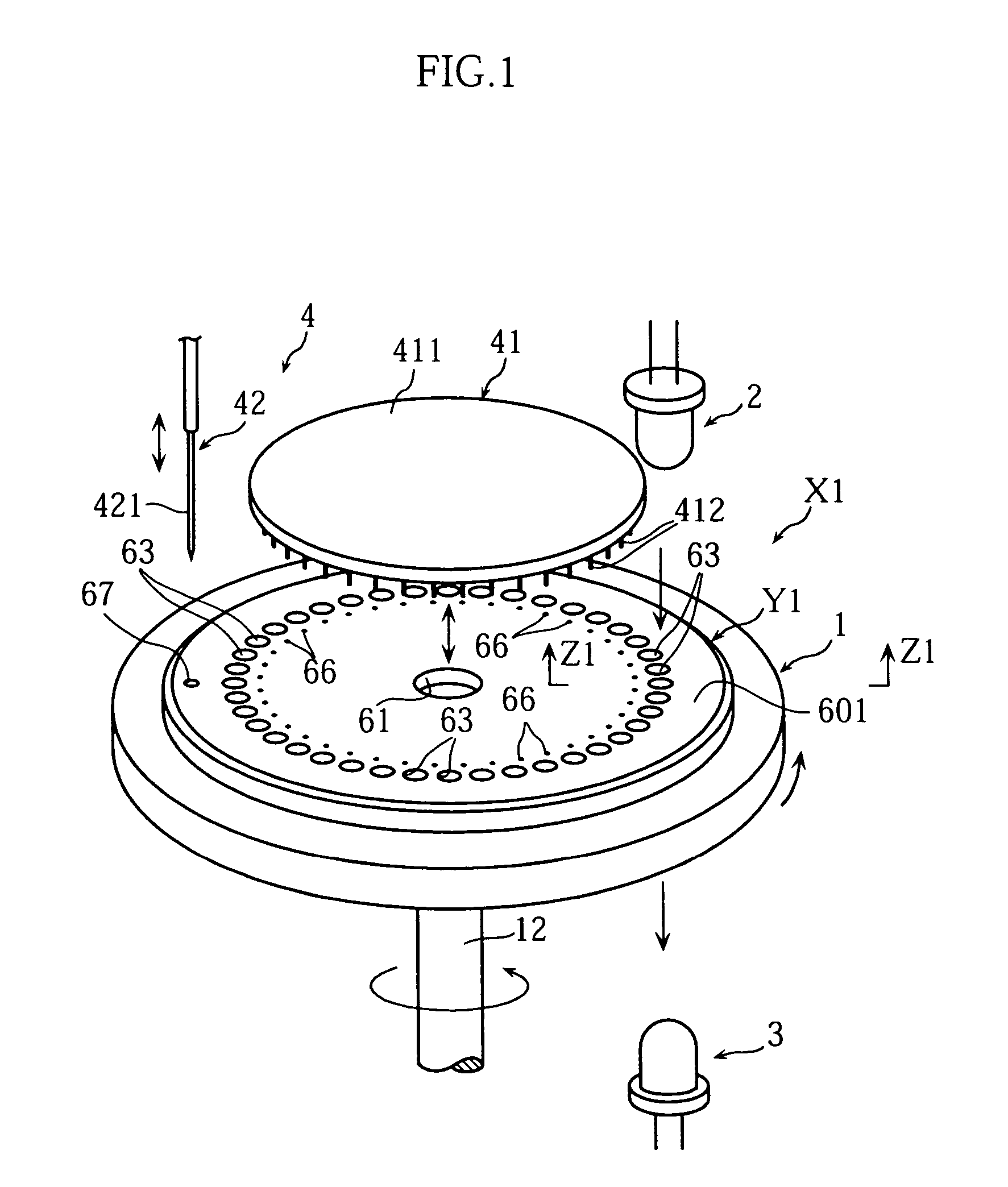

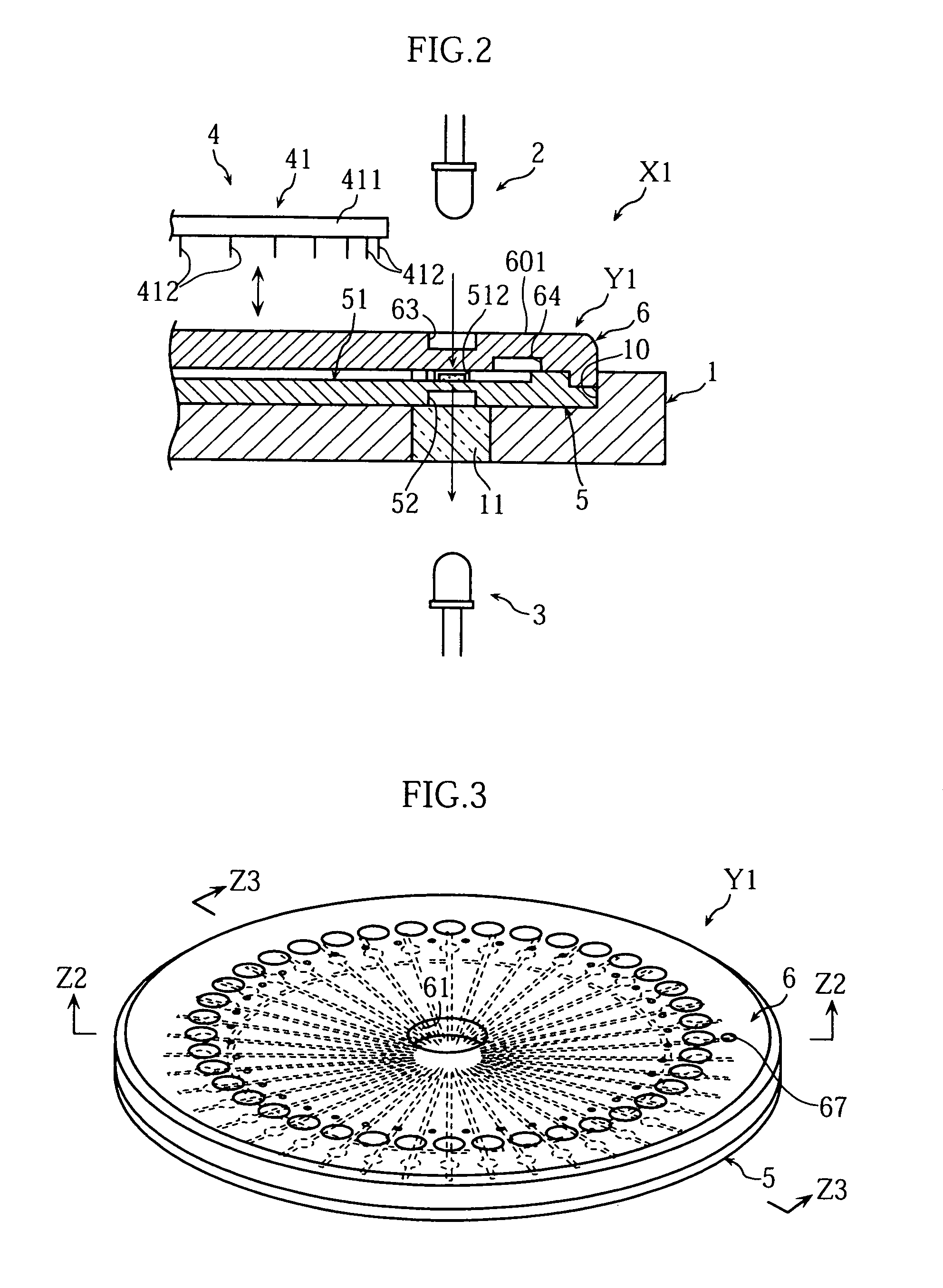

Analyzing article, analyzer and method of analyzing a sample using the analyzing article, and a method of forming an opening in the analyzing article

ActiveUS8128889B2Easy and cheap to formPromote absorptionBioreactor/fermenter combinationsBiological substance pretreatmentsProduct gasComputer science

The present invention relates to a technique for moving a mobile component such as a sample and a reagent, in an analyzing article. A method of analyzing a sample according to the present invention includes a first movement step of moving a mobile component from a fluid entrance port (61) to a first goal (511) in a passage (51), and a second movement step of moving the mobile component from the first goal (511) to a second goal (512) in the passage (51), in an analyzing article (Y1). The analyzing article (Y1) further includes a branch passage which branches from the first goal (511), and a first opening for releasing gas from within the branch passage. The first movement step is carried out by establishing communication between inside and outside of the branch passage via the first opening. The second movement step is carried out by providing a second opening downstream from the second goal (512) with respect to a flow direction of the mobile component, thereby establishing communication between inside and outside of the passage.

Owner:ARKRAY INC

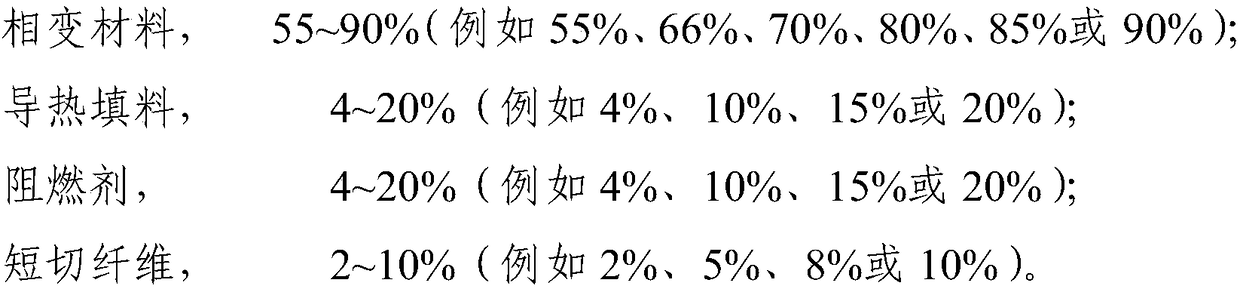

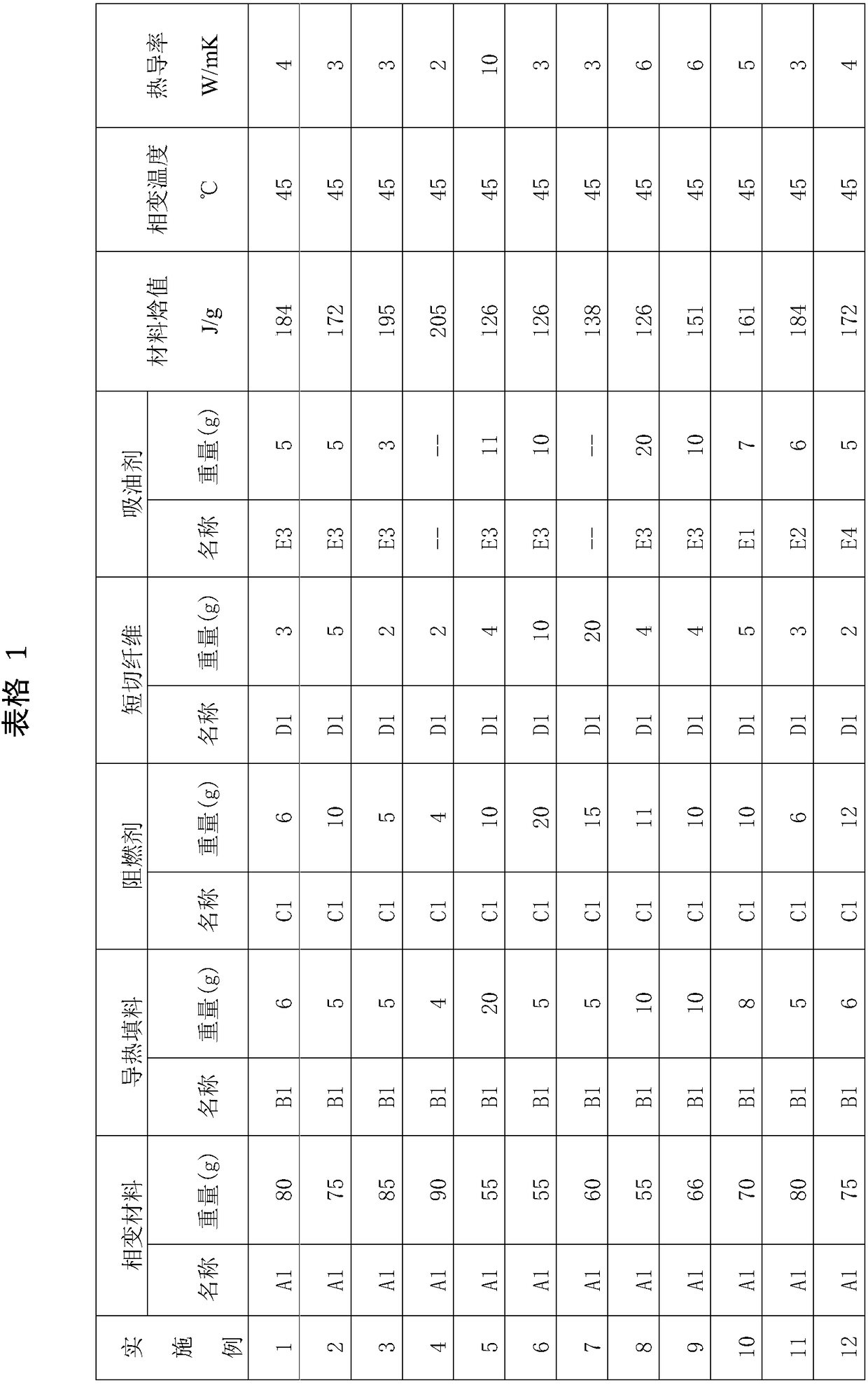

Phase-change-material-based thermal management material, preparation method and applications thereof

ActiveCN108199113AImprove thermal conductivityGood temperature control functionSecondary cellsHeat-exchange elementsFiberPhase-change material

The invention relates to a phase-change-material-based thermal management material, a preparation method and applications thereof, wherein the thermal management material comprises, by mass, 55-90% ofa phase change material, 4-20% of a thermal conduction filler, 4-20% of a flame retardant, and 2-10% of chopped fiber. According to the present invention, by adding an appropriate amount of the chopped fibers, the deformation of the phase change material due to volume expansion or contraction can be effectively prevented, such that the content of the phase change material in the thermal management material can be substantially increased so as to improve the heat storage capacity of the thermal management material and stably regulate and control the temperature.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com