High-thermal-conductivity heat-storing nanometer-particle-mixed molten salt and preparation method thereof

A nanoparticle, high thermal conductivity technology, applied in the field of mixed nanoparticle high thermal conductivity heat storage molten salt and its preparation, can solve the problems of poor stability in high temperature working area, single type of hot molten salt, unstable molten salt, etc. Improve thermal stability, increase power generation efficiency, and increase heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing mixed nano-particle high thermal conductivity heat storage molten salt, and its specific steps are as follows:

[0026] (1) Select commercially available from NaNO 3 And KNO 3 The configured heat storage molten salt is reserved, of which NaNO 3 The mass fraction is 60%, the rest is KNO 3 ;

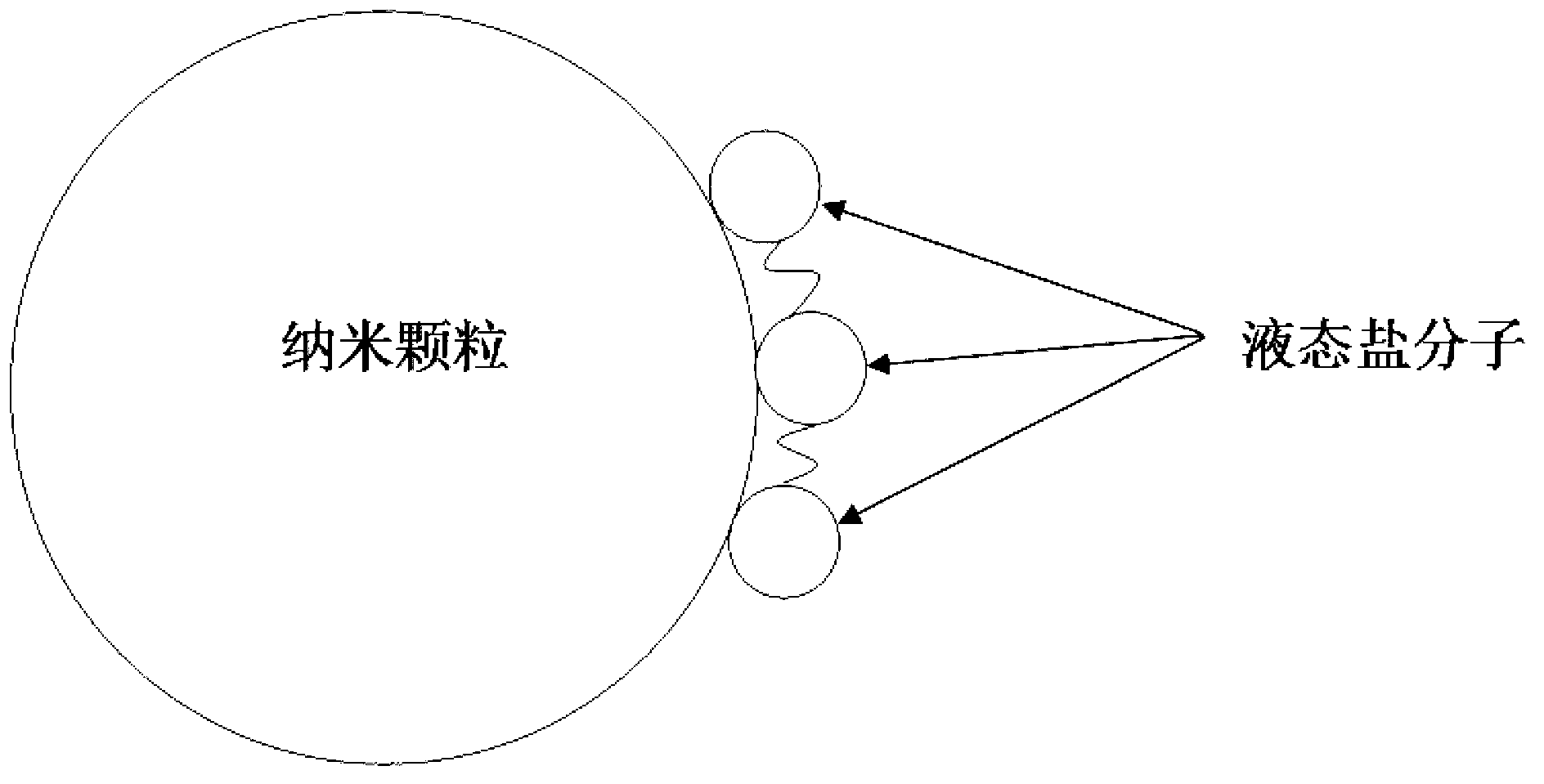

[0027] (2) Take multi-walled carbon nanotubes or metal nanoparticles, the mass of which is 0.1%~3% of the mass of the heat storage molten salt, and the particle size is 10 nm~50 nm, put it in distilled water, and oscillate fully with an ultrasonic oscillator , To make the nanoparticles evenly distributed in the solution without precipitation;

[0028] (3) Add gum arabic powder to the solution, the quality of which is 3 to 5 times that of the added multi-walled carbon nanotubes or metal nanoparticles, and fully oscillate with an ultrasonic oscillator to make it evenly dispersed;

[0029] (4) Add nitro heat storage molten salt to the evenly oscillating solution, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com