Intelligent control method for automatic optimization combustion of hot-blast stove

A technology of intelligent control and hot blast stove, which is applied in the direction of combustion method, combustion control, furnace, etc., can solve the problems that the air-fuel ratio cannot be changed, the application effect is not ideal, and the life of the oxygen measuring instrument is limited, so as to improve the combustion control level and energy consumption. Full utilization and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

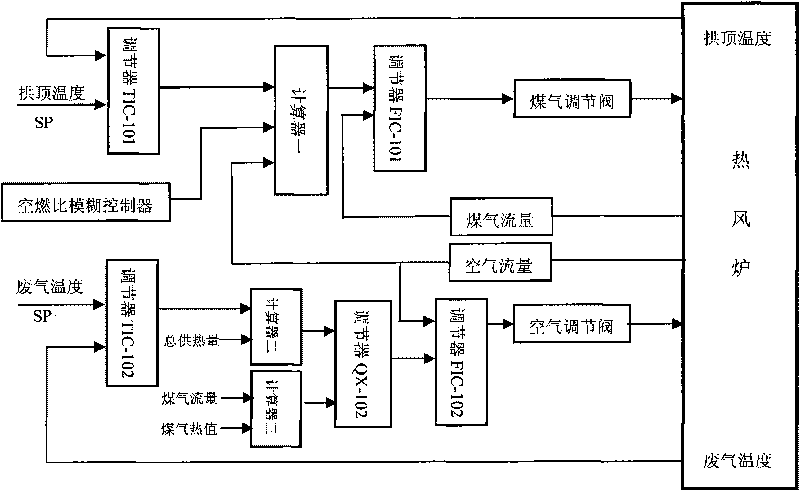

[0022] The ratio of combustion-supporting air to mixed gas (that is, the air-fuel ratio) is an important parameter in the combustion process of the hot blast stove. If the mixed gas is too much, the combustion will be insufficient, and the excess gas will be discharged into the atmosphere along with the combustion waste gas, which is not only a waste, but also a kind of pollution to the atmosphere; if the mixed gas is insufficient, the temperature of the top of the hot blast stove cannot be guaranteed to reach the set value. Value, that is, the heat stored in the hot blast stove is insufficient to meet the normal production of the blast furnace. Therefore, how to maximize the combustion rate of gas on the premise of ensuring the normal production of the blast furnace has great significance, which requires the best air-fuel ratio control. But under no circumstances can excessive gas be used. In other words, the air at the optimum air-fuel ratio is still in excess.

[0023] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com