Patents

Literature

90 results about "Excessive gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Is Kyle Gass from Tenacious D Segwaying across the country? The FCU team is stranded in the desert trying to get answers.

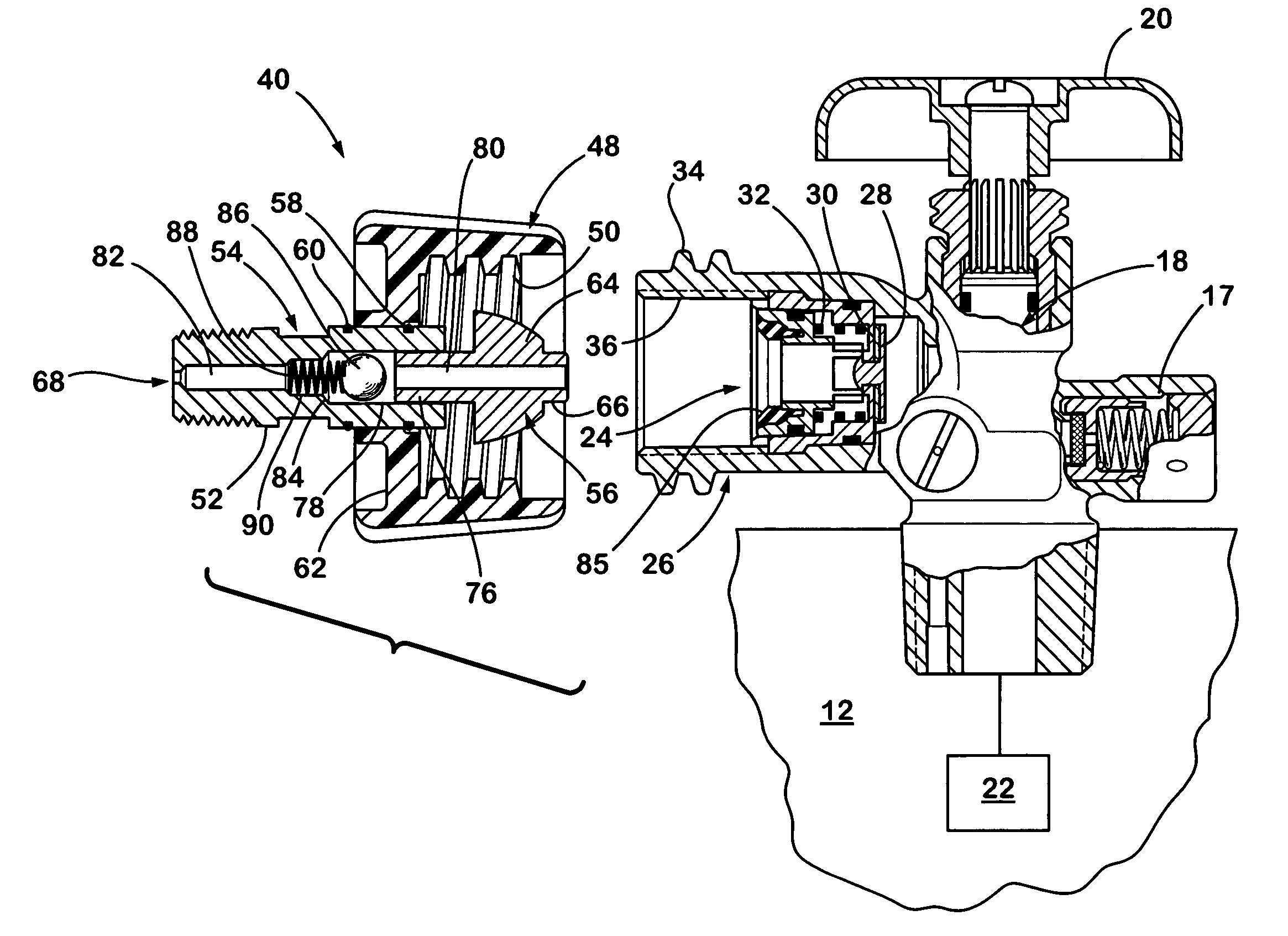

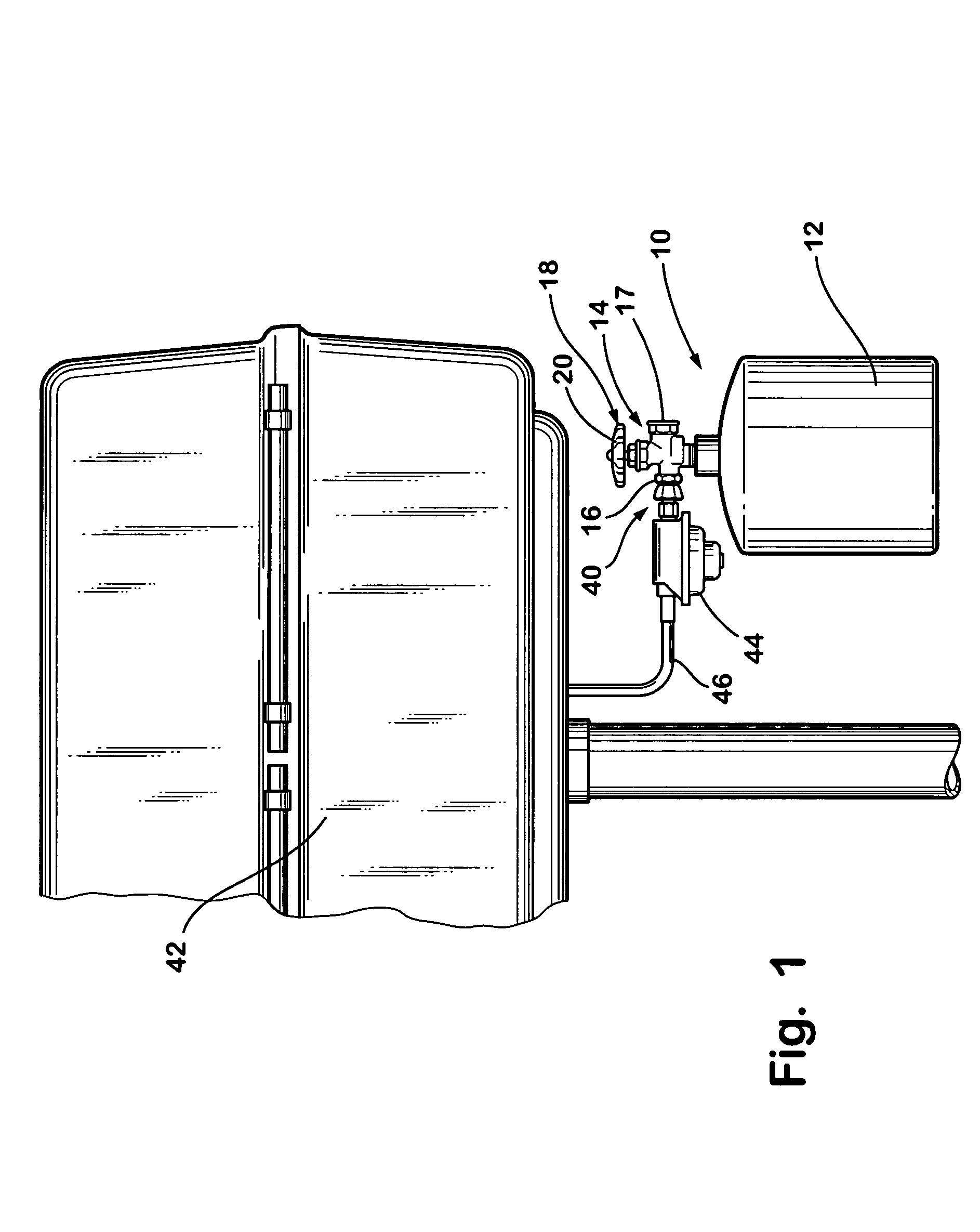

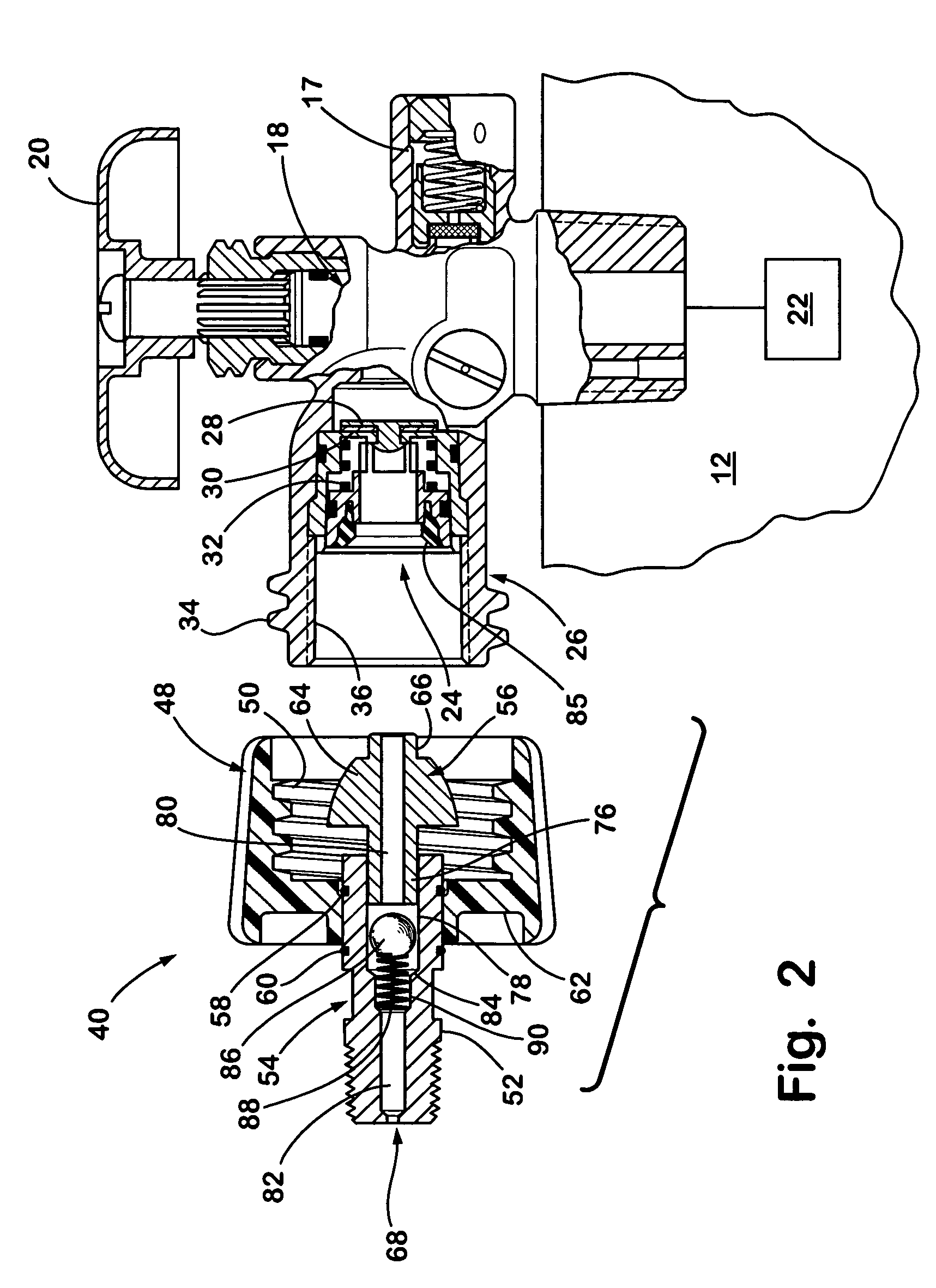

Appliance end fitting

An appliance end fitting for connecting a gas operated appliance to a pressurized gas cylinder includes a simplified interior valve that acts as both a thermal valve and an excess flow control valve. The end fitting has an elongated body formed in two telescoping sections, an inner section, and an outer section. An interior opening extends through both sections and includes an enlarged center portion. A floating valve member in the center portion is movable toward a valve seat at an outer end of the center section. A spring urges the valve member away from the valve seat but excessive gas flow moves the valve member toward the valve seat and restricts the valve. The two sections of the body are held in an extended axial position by a heat activated material, such as fusible solder, where the nipple opens the cylinder shutoff valve when the body is connected to the cylinder outlet. Excessive heat releases the heat activated material and causes the body sections to collapse to a retracted position, where the shutoff valve is permitted to close. At the same time, the stem of the inner section engages and closes the interior valve in the end fitting.

Owner:MARSHALL EXCELSIOR CO

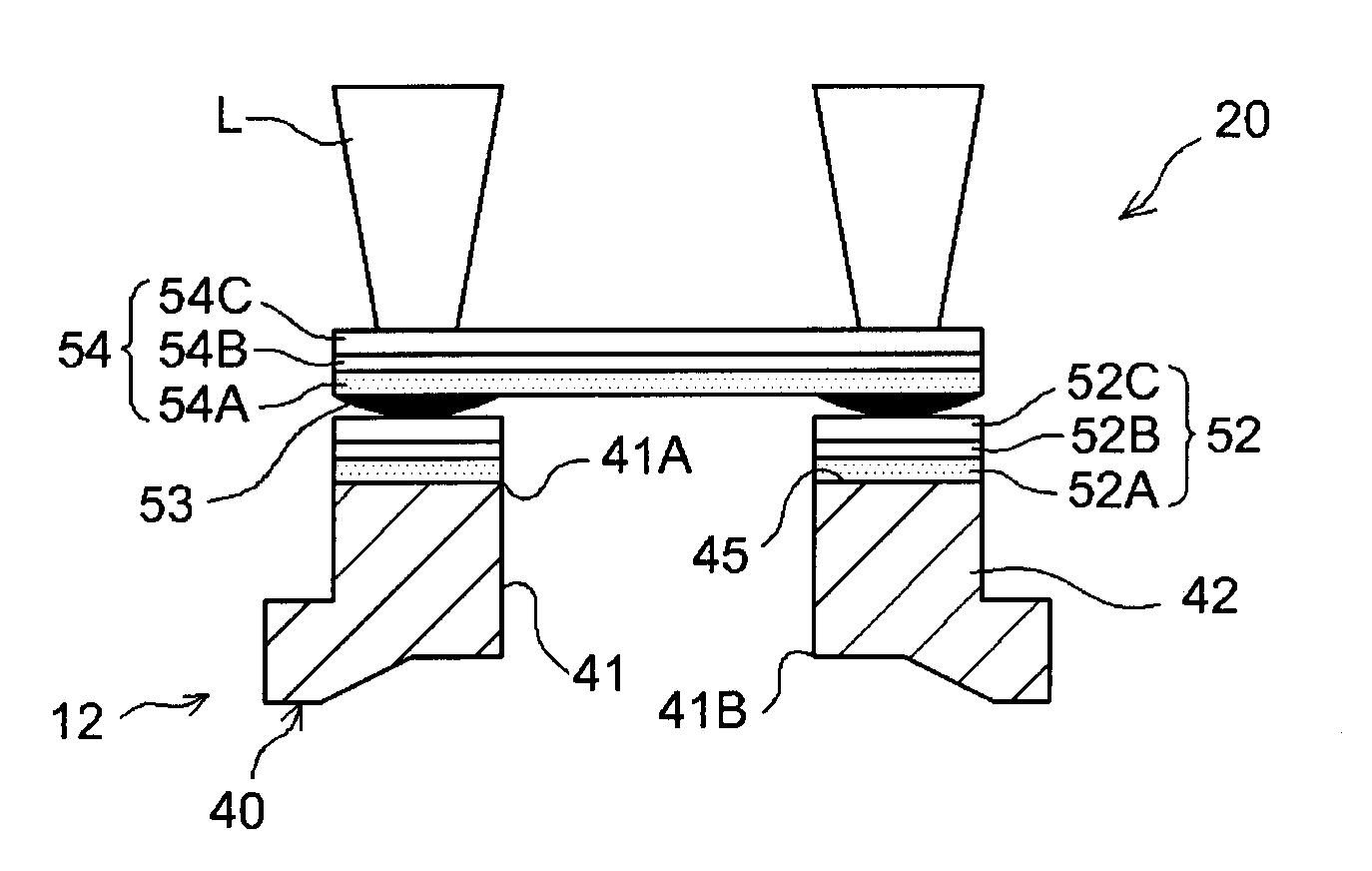

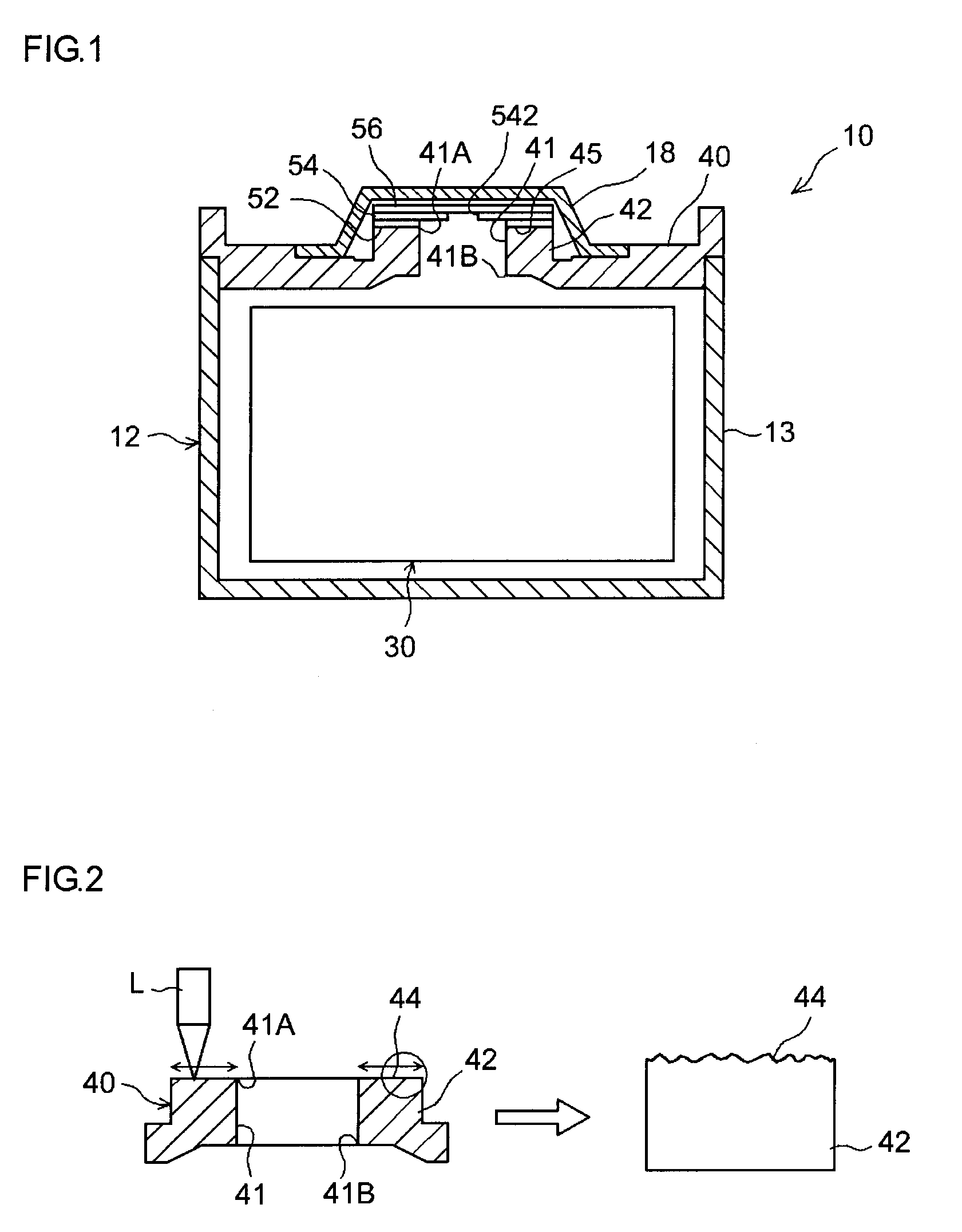

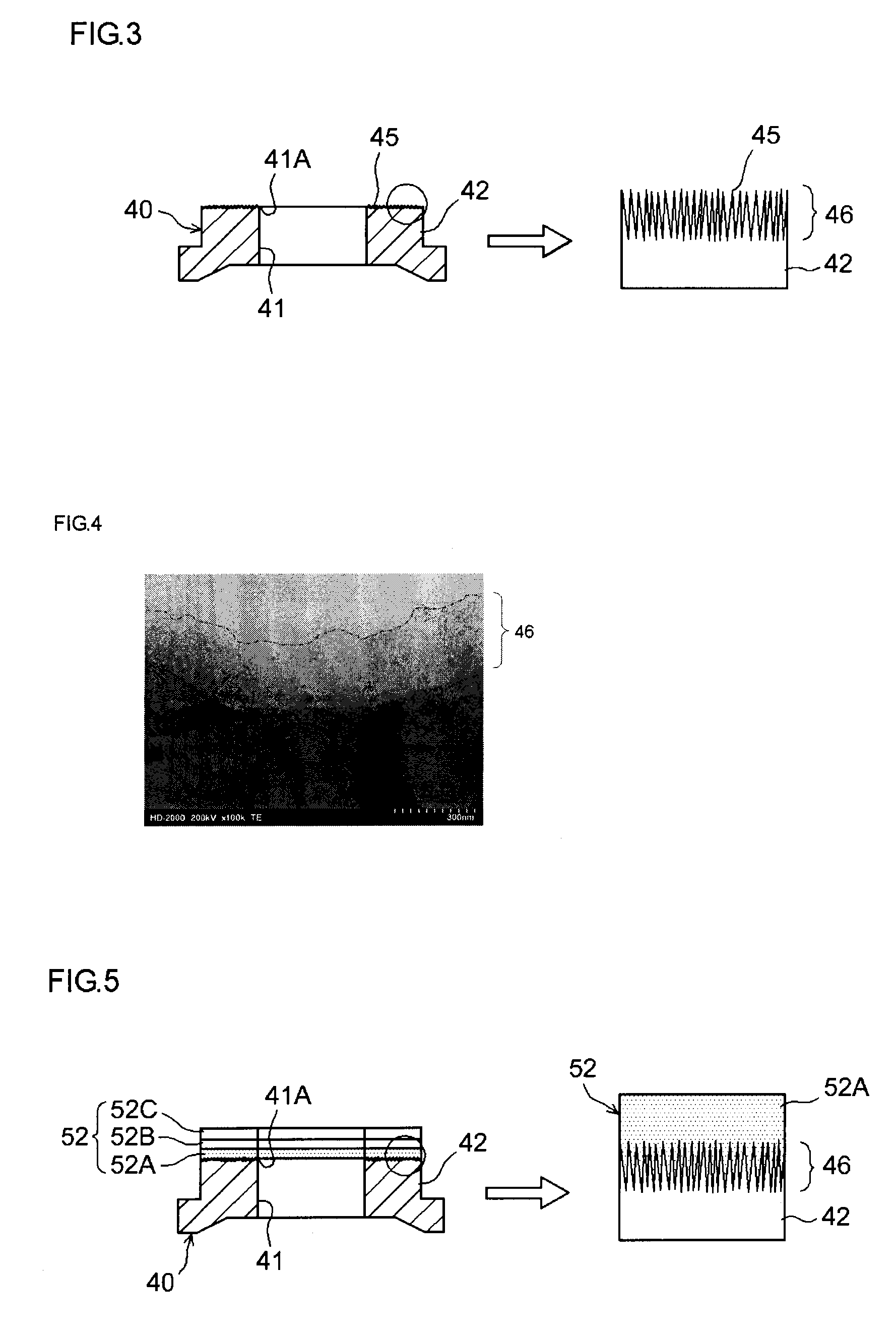

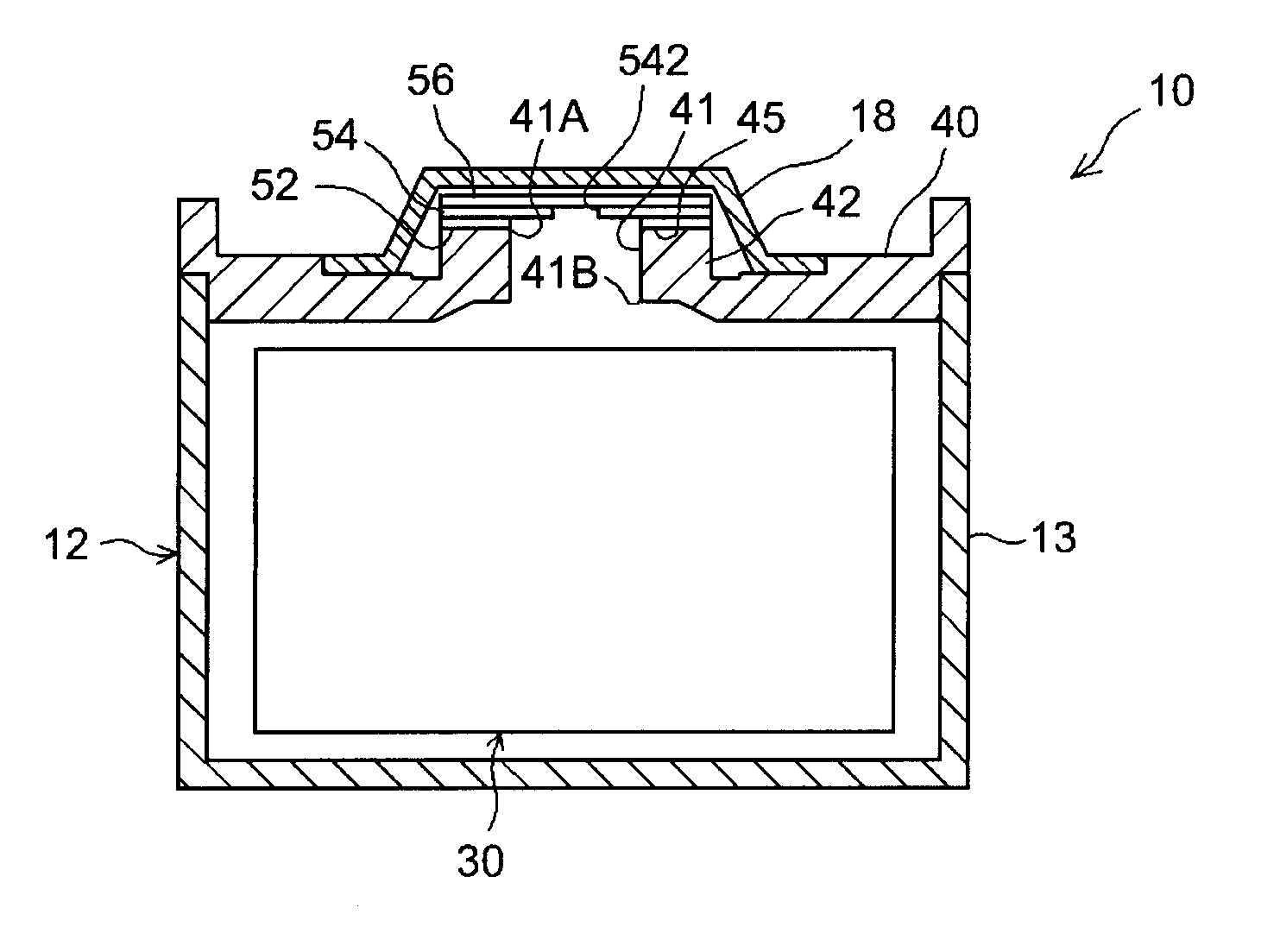

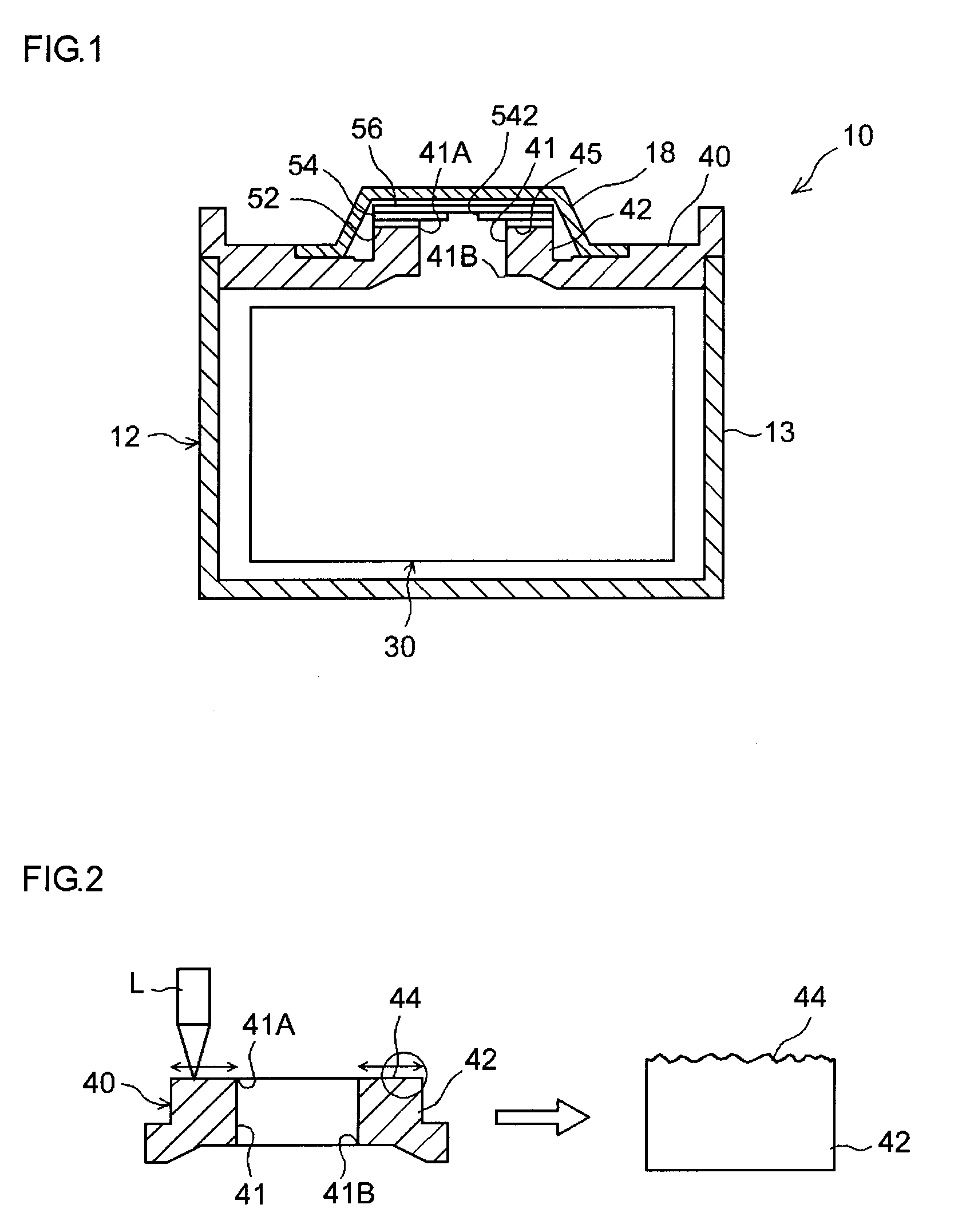

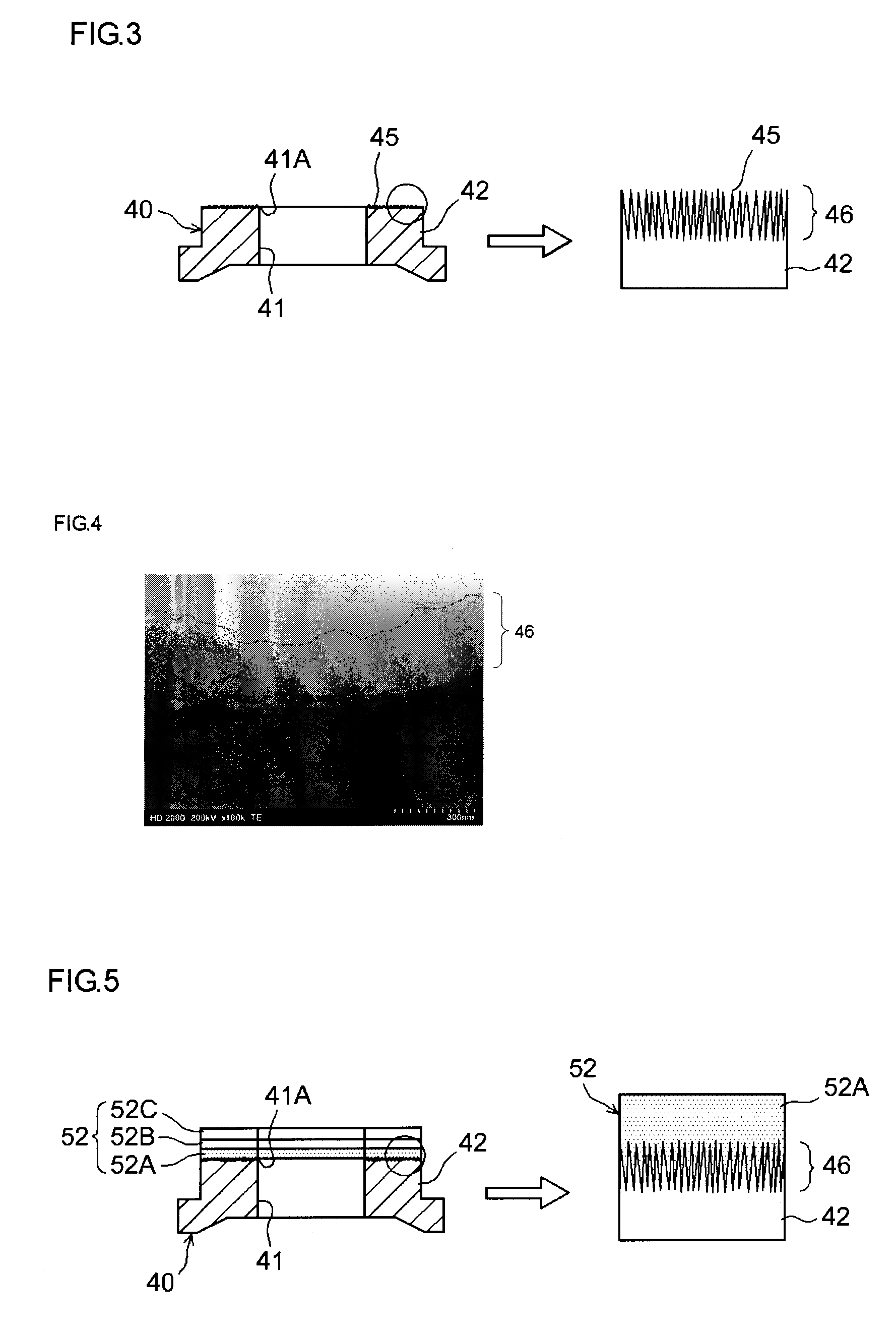

Sealed type cell manufacturing method

ActiveUS20110027645A1Improve solderabilityGood weldabilityLarge-sized flat cells/batteriesFinal product manufactureEngineeringAlloy

A cell assembly (20) is formed by arranging an electrode body and electrolyte in an external case (12) having a through hole (41). A laser is applied to an annular portion (formed by Al or Al-based alloy) surrounding an opening end (41A) of the through hole (41) toward outside the case so as to form a welded base (45). A sealing film (54) is welded to the surface of the welded base directly or via a base film (52) welded in advance, so as to temporarily seal the through hole (41). The cell assembly (20) in the temporarily sealed state is subjected to initial charge and then a hole is opened through the film (54) so as to form a gas discharge passage for communication between inside and outside of the case (12), thereby discharging an excessive gas from the case (12) outside.

Owner:TOYOTA JIDOSHA KK

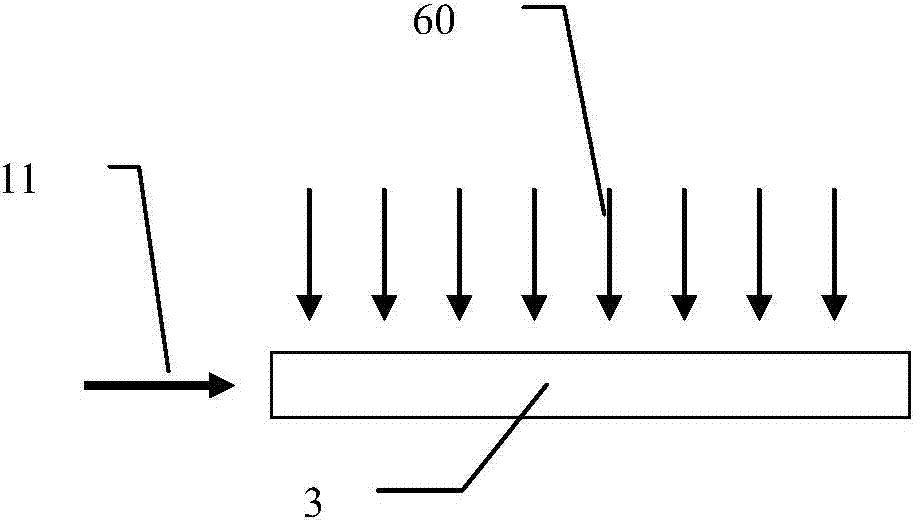

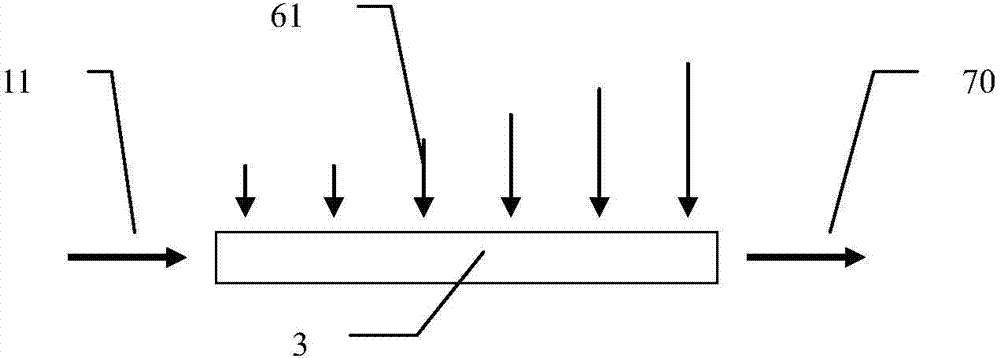

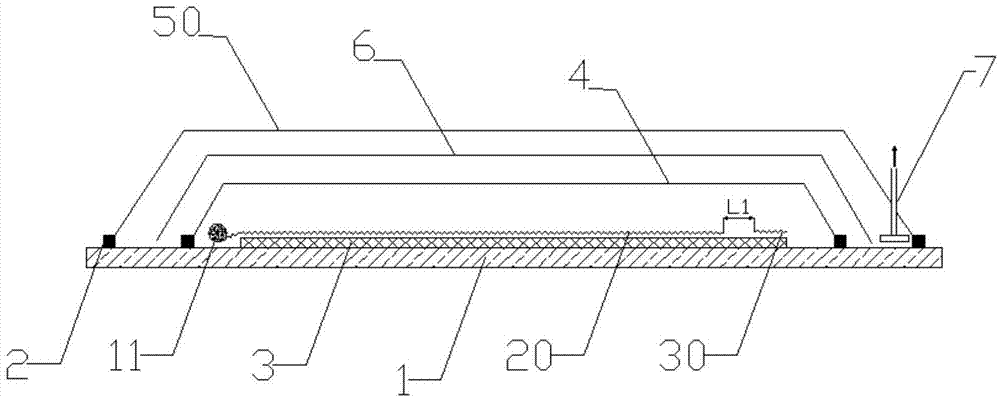

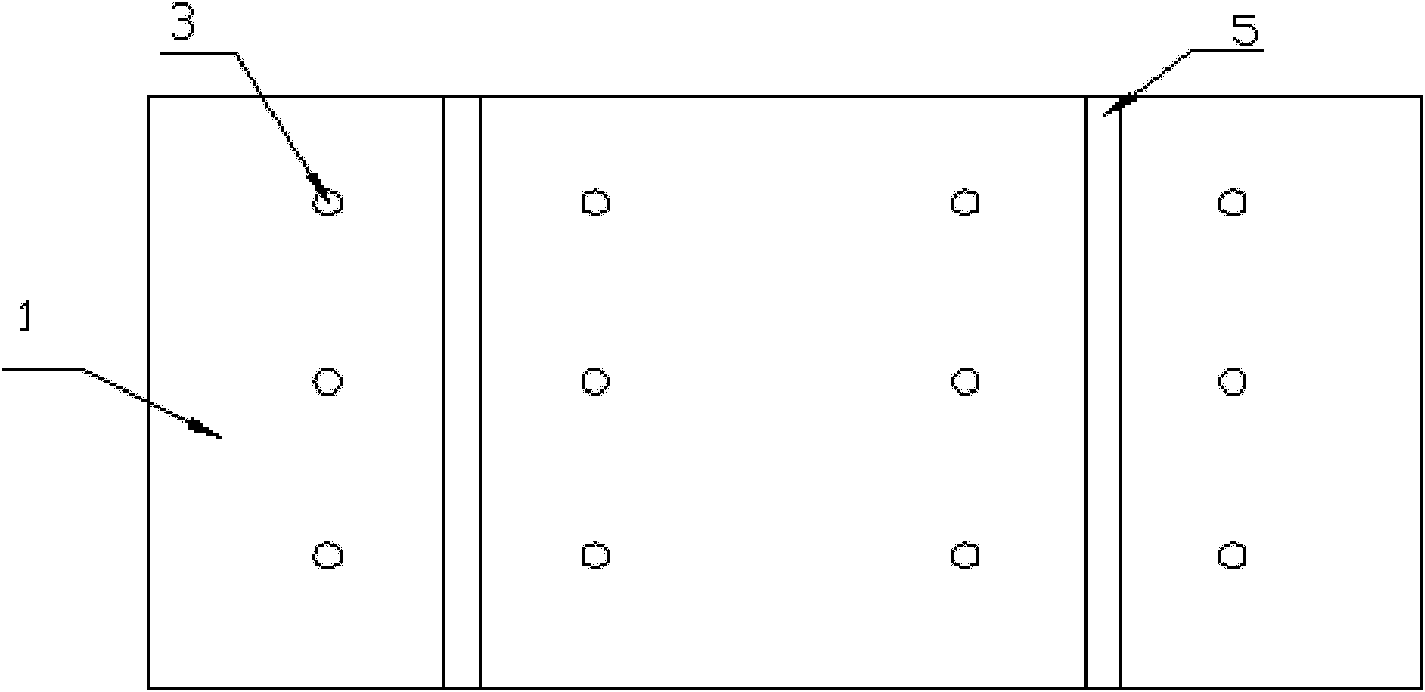

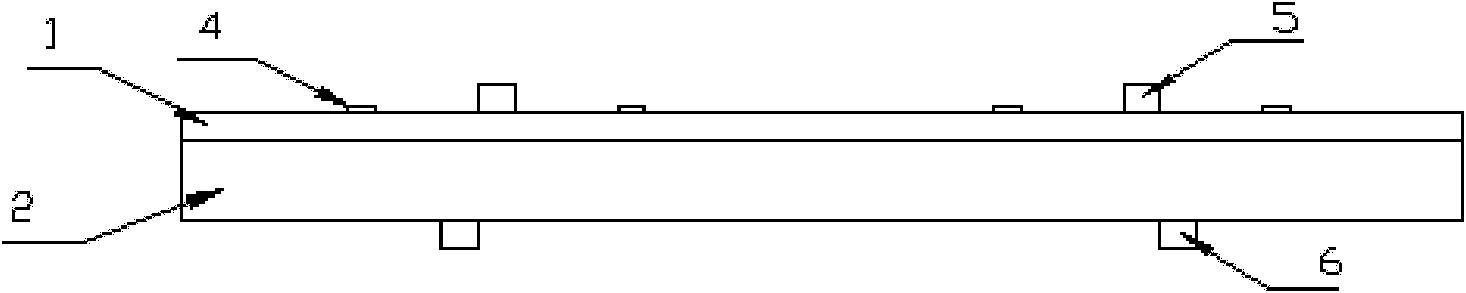

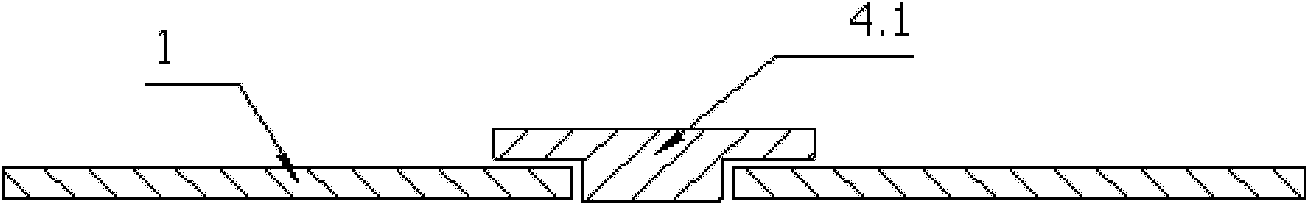

Method for molding resin matrix composite material by zero-adhesive-discharge vacuum assisted resin infusion (VARI)

The invention belongs to a resin matrix composite material liquid molding technology, and relates to a method for molding a resin matrix composite material by zero-adhesive-discharge vacuum assisted resin infusion (VARI). A glue inlet diversion net (20) and a resin drawing layer (30) are arranged on a fiber-reinforced premolded body (3); the outer surface of the fiber-reinforced premolded body (3) is covered with a micro-ventilation layer (4) and a glue blocking layer (5). According to the method, a resin glue discharge channel is omitted, so that zero adhesive discharge of the VARI molding technology is realized, and the using amount of resin is accurately controlled; the micro-ventilation layer (4) and the glue blocking layer (5) are additionally arranged, so that pressure is evenly transmitted into the fiber-reinforced premolded body (3); furthermore, the excessive gas in the resin and the fiber-reinforced premolded body (3) can be fully discharged, so that the porosity of parts can be reduced, the molding quality and the thickness uniformity of the parts can be improved, and the production cost is remarkably lowered.

Owner:AVIC COMPOSITES

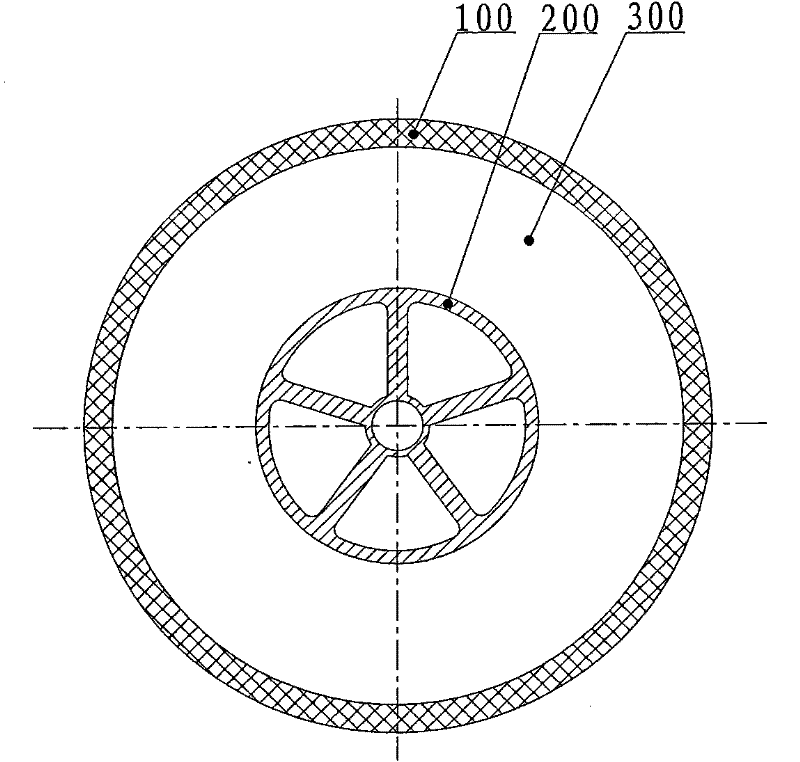

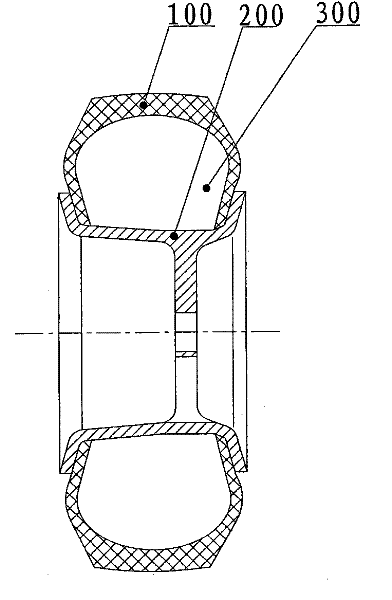

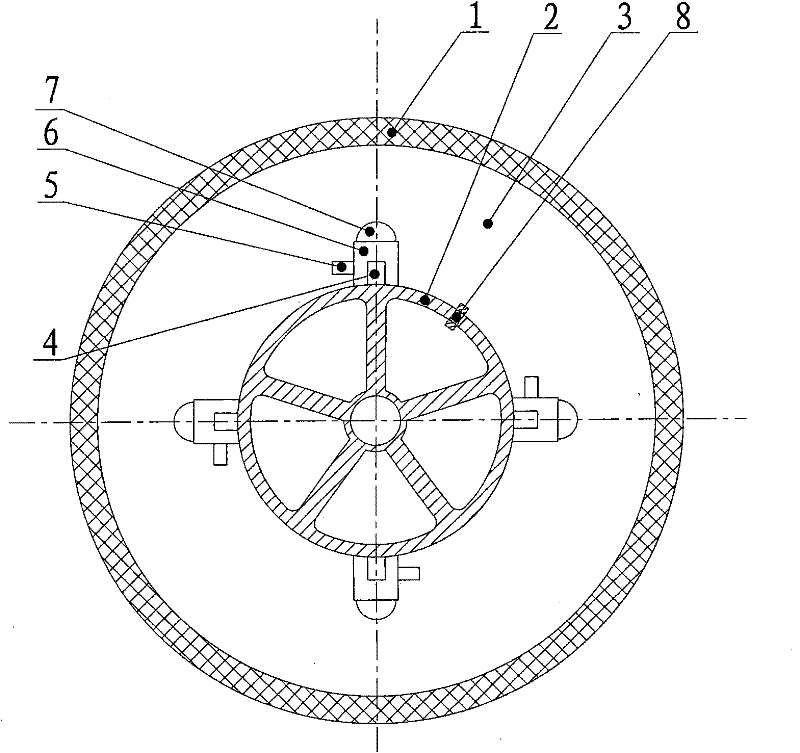

Anti-explosion wheel and vehicle provided with same

InactiveCN102529608APrevent tire blowoutsAvoid flat tire accidentsTyre measurementsTraffic accidentEngineering

The invention relates to an anti-explosion wheel which comprises a rim, a tire covered on the rim, and an inflating chamber arranged between the rim and the tire, and also comprises a pressure sensor, a gas generation and controller, wherein the pressure sensor is arranged to be used for monitoring an inside pressure value of the inflating chamber; the gas generation and controller is arranged on the rim and is connected to the pressure sensor to obtain the inside pressure value of the inflating chamber as well as is arranged to be as follows: when the inside pressure value is slowly reduced or is lower than a first preset pressure value, the gas generation and controller replenishes gas to the inflating chamber through a first channel communicated to the inflating chamber until reaching the first preset pressure value; and when the inside pressure value exceeds a second preset pressure value, the gas generation and controller opens a second channel capable of communicating the inflating chamber with outside air to exhaust excessive gas in the inflating chamber towards the outside until reaching the second preset pressure value, and the second preset pressure value is same as or different from the first preset pressure value. The anti-explosion wheel has the advantages of novel design and safety and reliability in use, and can avoid traffic accidents caused by abnormal tires, thus greatly improving driving safety performance.

Owner:SAIC MOTOR

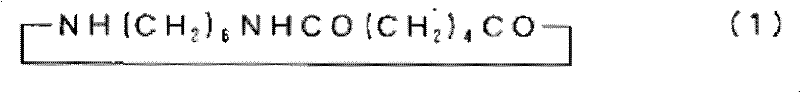

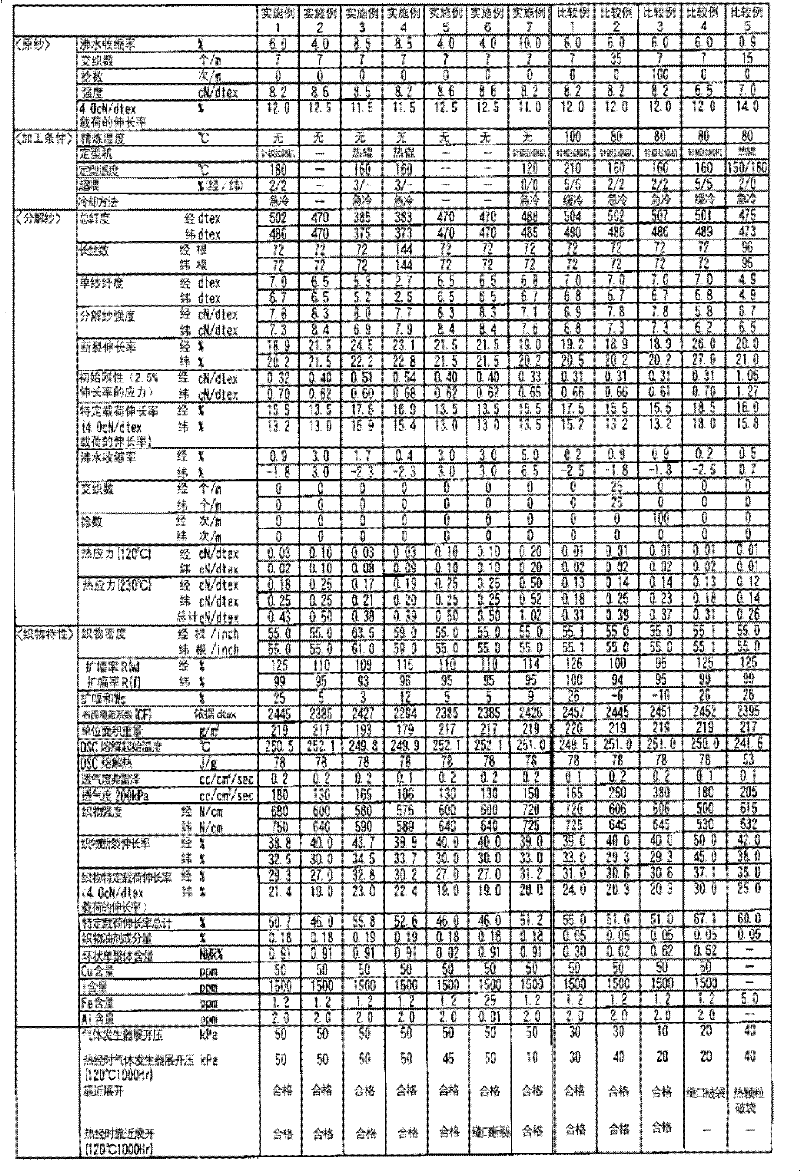

Fabric for airbag, and airbag

ActiveCN102471954AExcellent development gas utilizationInhibition of breathabilityFibre treatmentPedestrian/occupant safety arrangementHeat resistanceEngineering

Provided is an airbag module wherein, in deploying an airbag, which is formed of a polyamide fiber having excellent heat resistance, using an inflator gas, no loss of the gas arises and no excessive gas generation is required so that the inflator weight can be reduced. The airbag module comprises a fabric for an airbag formed of a polyamide fiber, characterized in that the air permeability of thefabric under a pressure of 200 kPa is 10-200 cc / cm2 / sec, and the total thermal stress of warp and weft yarns at 230oC is 0.33-1.20 cN / dtex, in the case of measuring the thermal stresses of the constituent yarns under the conditions wherein the initial load is 0.02 cN / dtex, the yarn length is 25 cm and the temperature rising speed is 80oC / min.

Owner:ASAHI KASEI KK

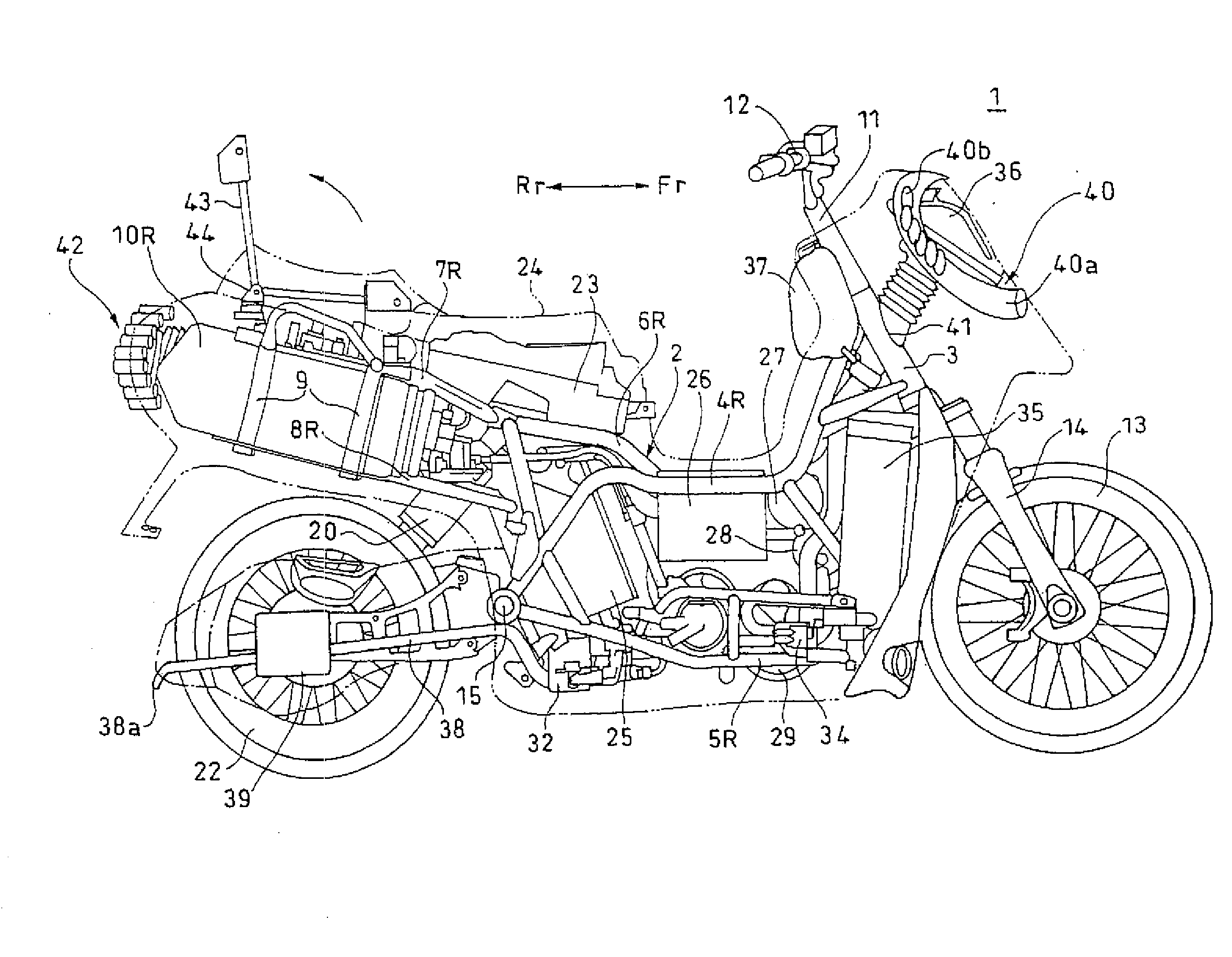

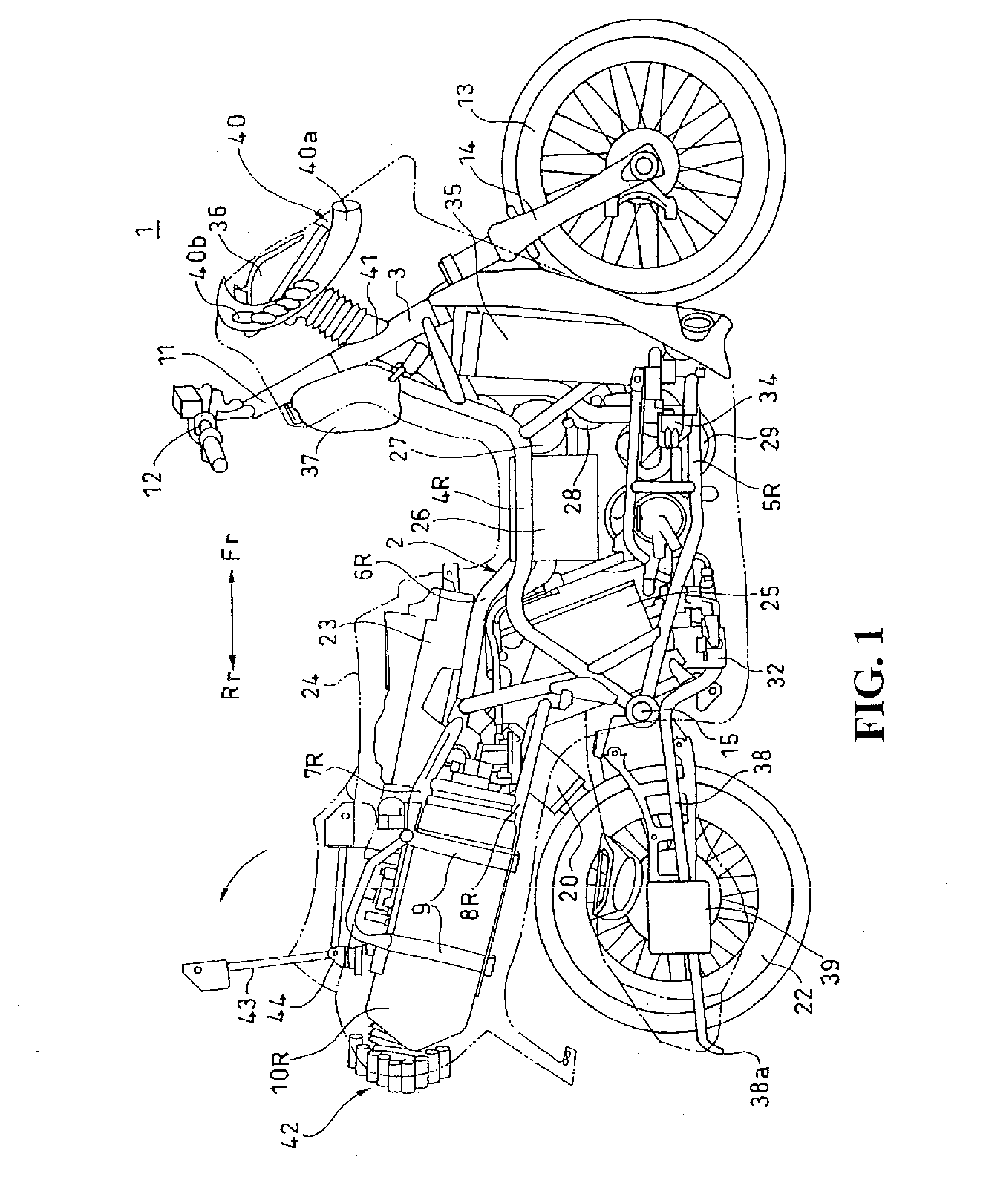

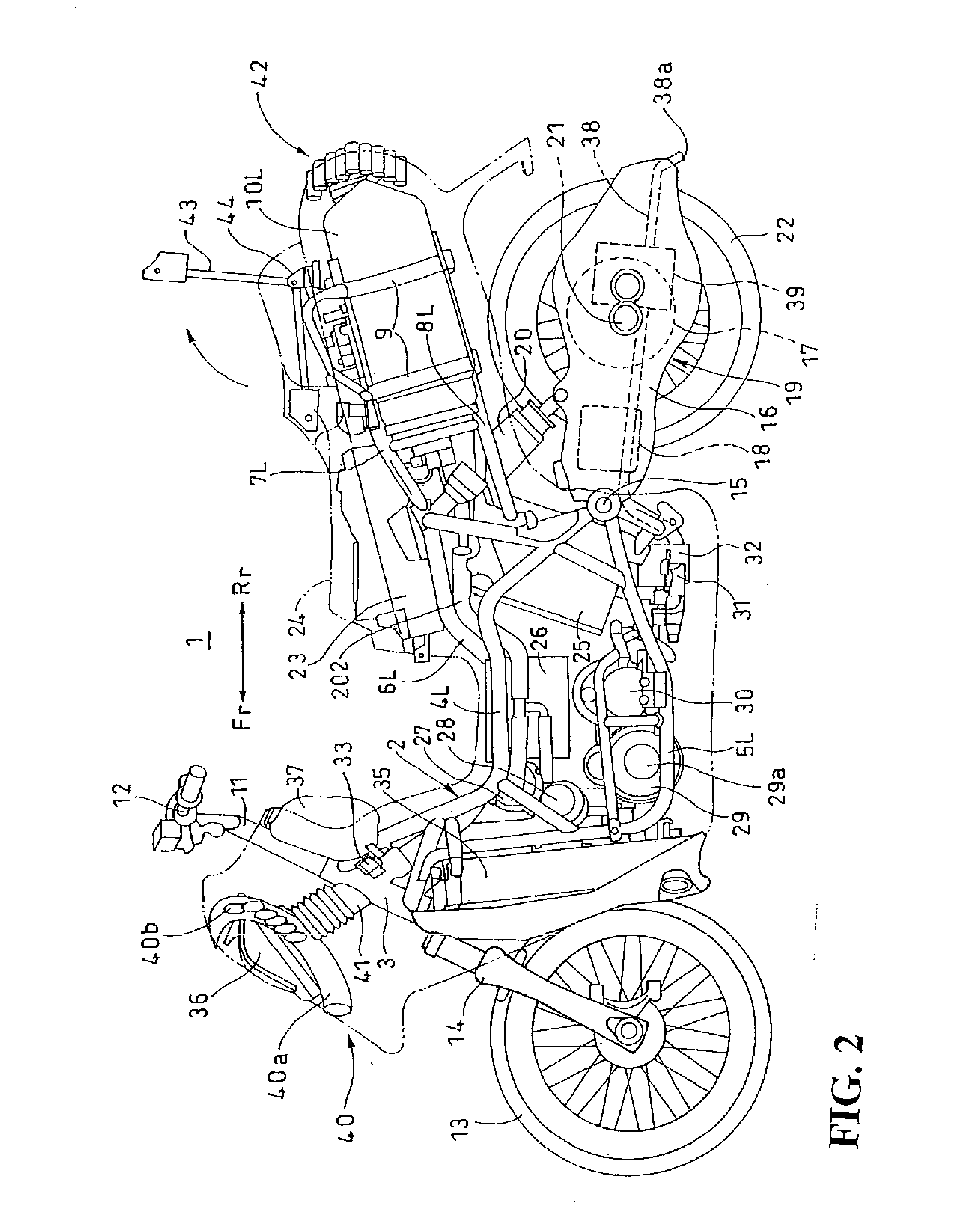

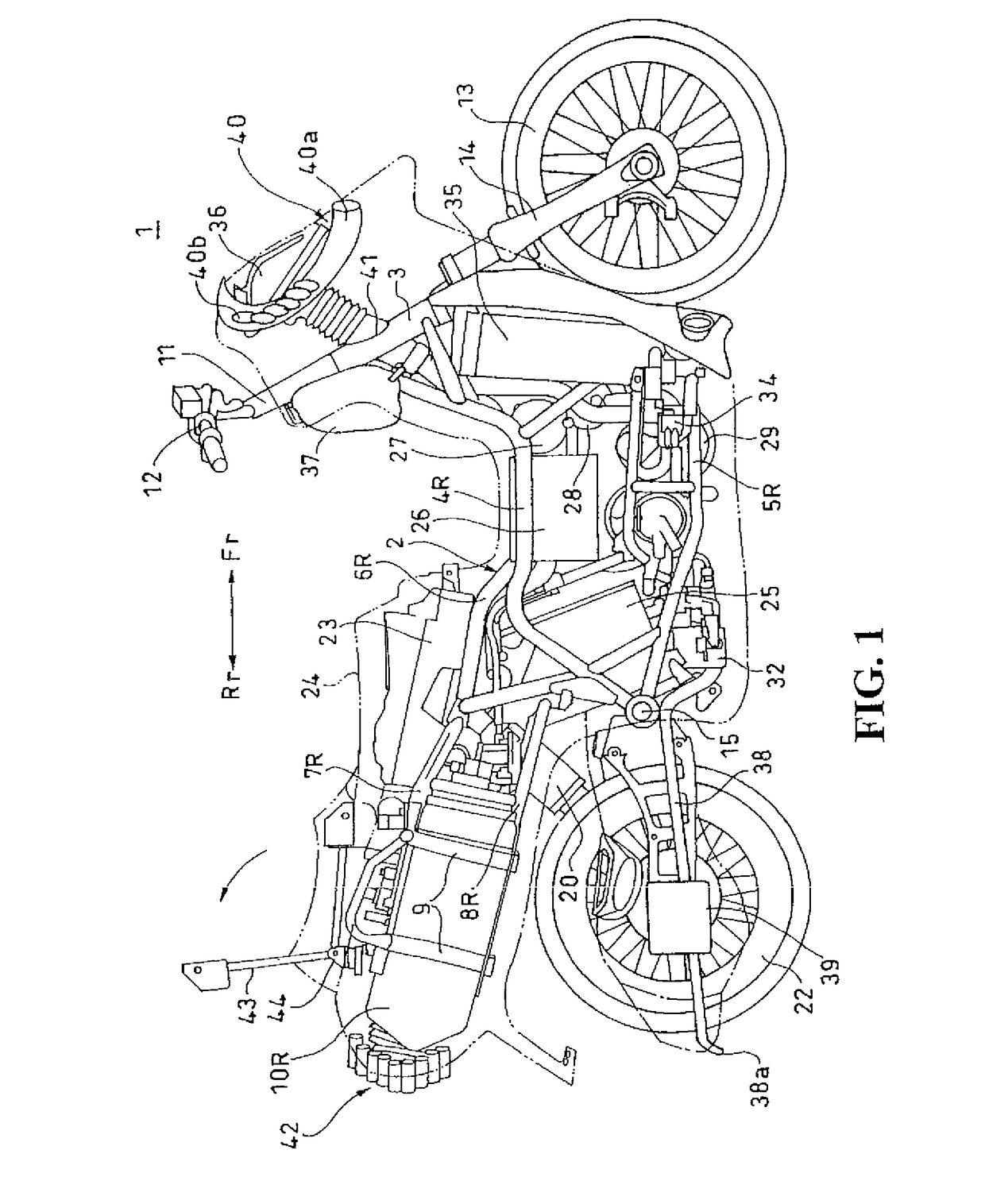

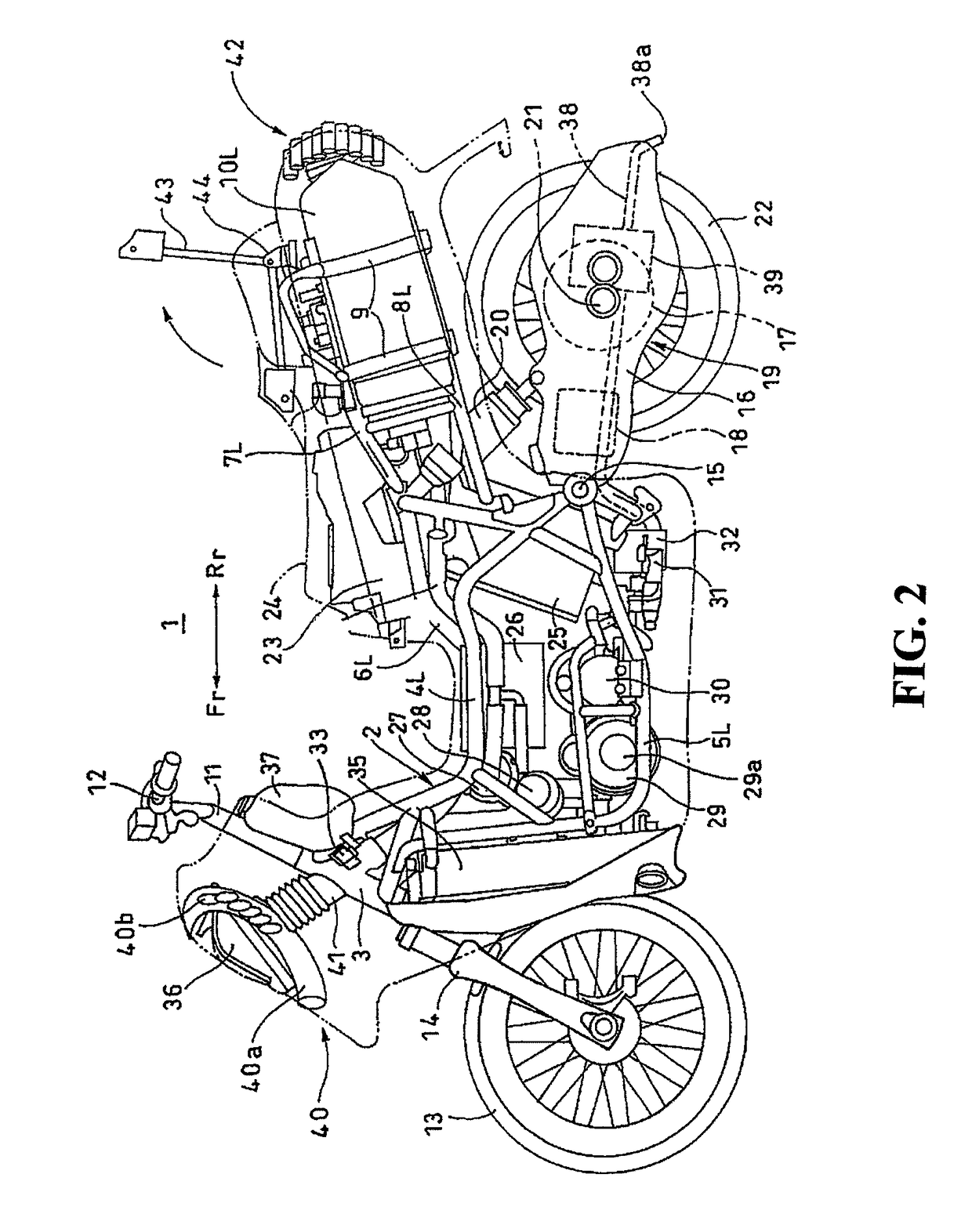

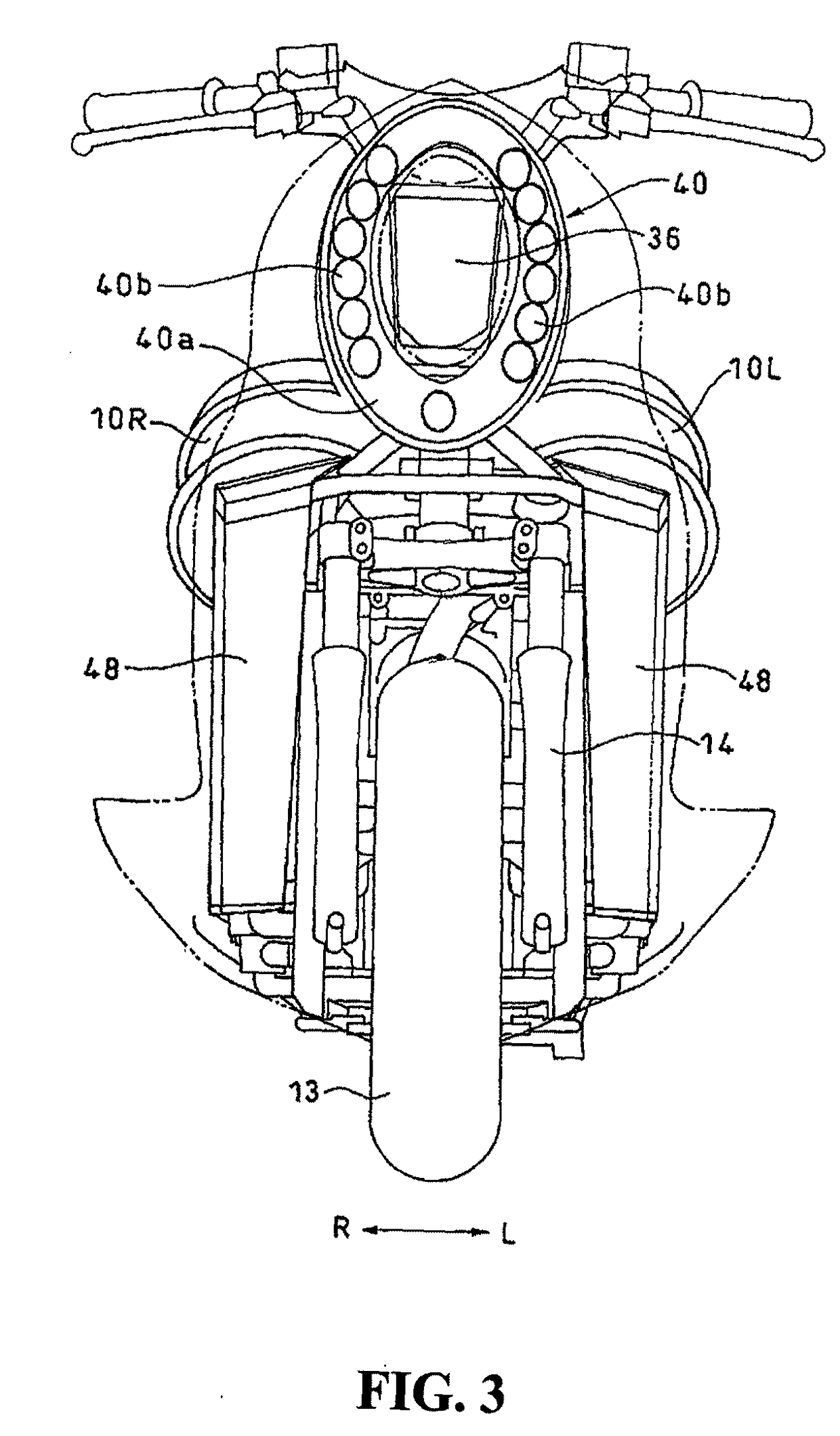

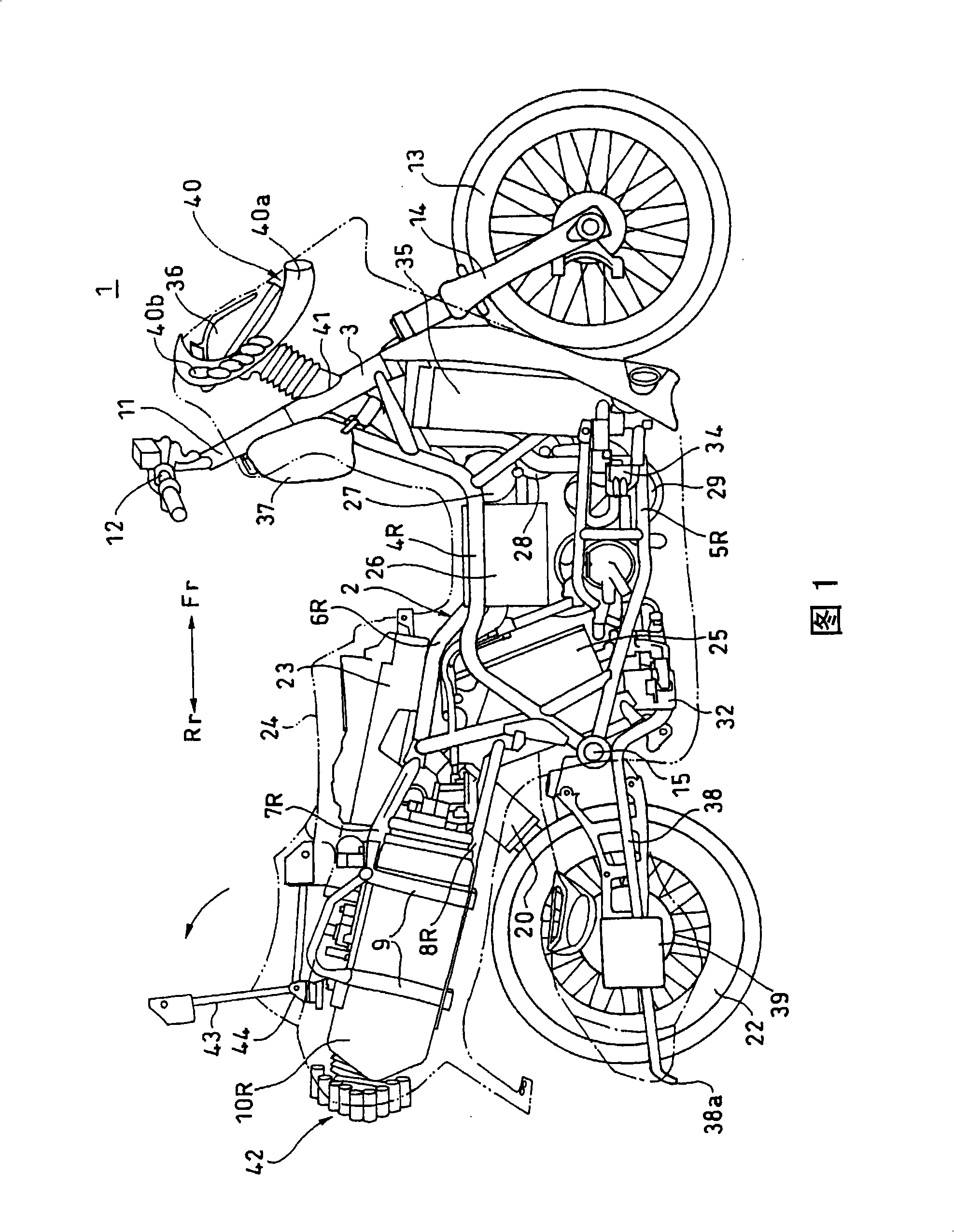

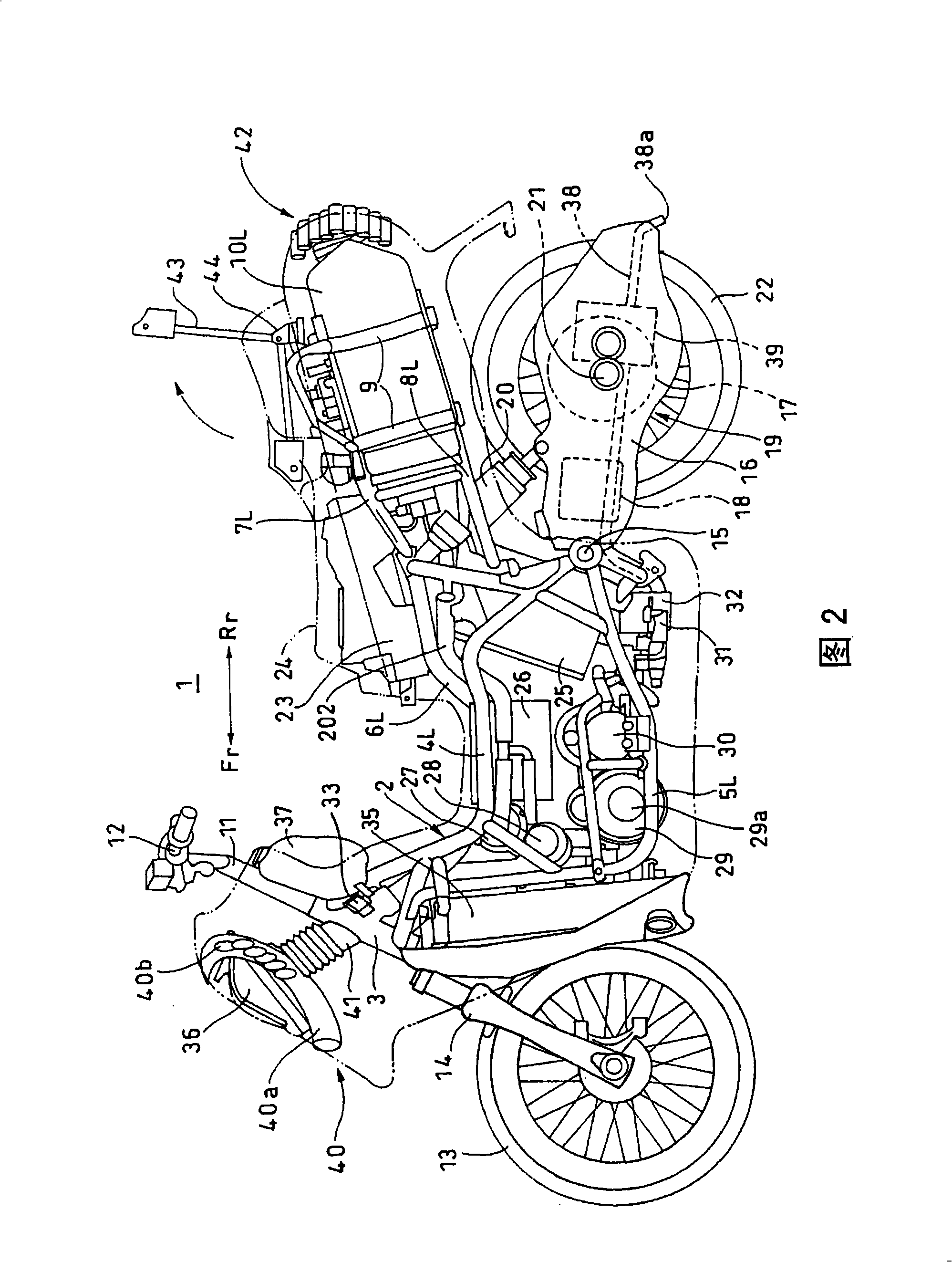

Fuel cell motorcycle

InactiveUS20080217087A1Increase widthReduce appearance problemsAuxillary drivesFinal product manufactureGas-discharge lampFuel cells

A layout for an exhaust pipe which also serves as a drainage pipe which prevents splashing of water generated in a fuel cell toward a passenger or splashing toward a tire. Humid excessive gas supplied from a fuel cell is diluted in a dilution box by off-gas discharged from the fuel cell and is used for humidifying air in the humidifier. An exhaust pipe is connected to the dilution box, and diluted hydrogen gas is discharged via the exhaust pipe. Vapor mixed in hydrogen gas is condensed in the exhaust pipe and turned into water, which is drained through the exhaust pipe that extends rearwardly of a vehicle body through the interior of a power unit. A discharge port of the exhaust pipe (which is also a drainage port for water generated in the fuel cell) is positioned at the widthwise center of the vehicle body.

Owner:HONDA MOTOR CO LTD

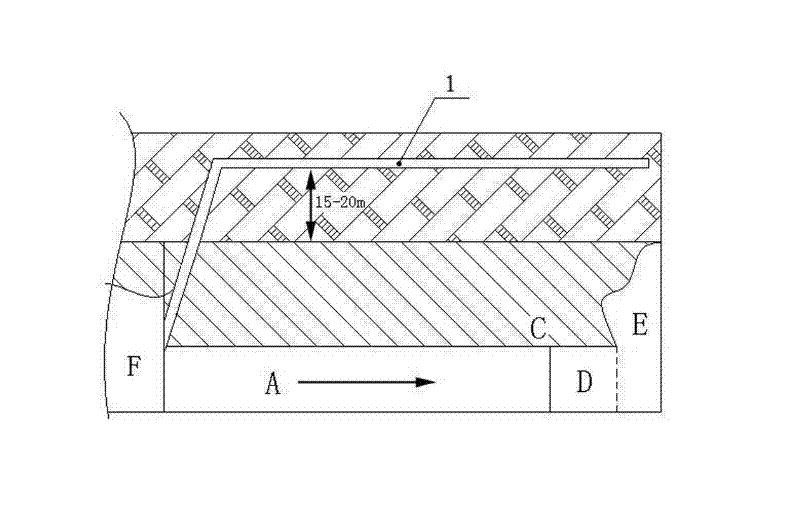

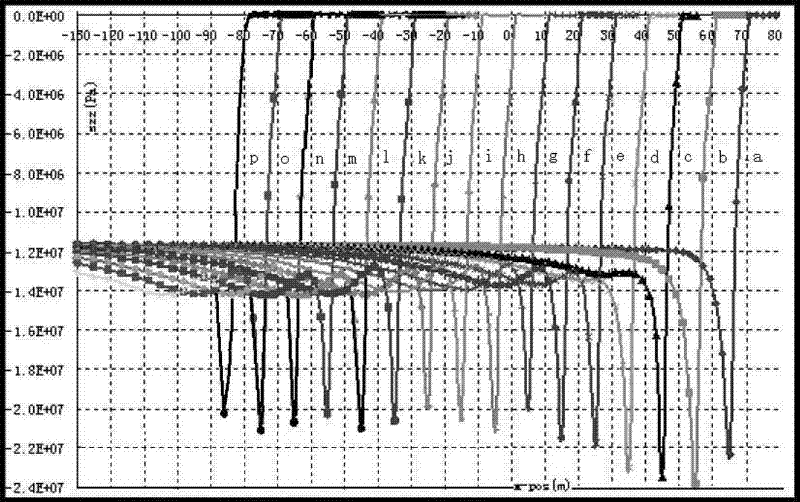

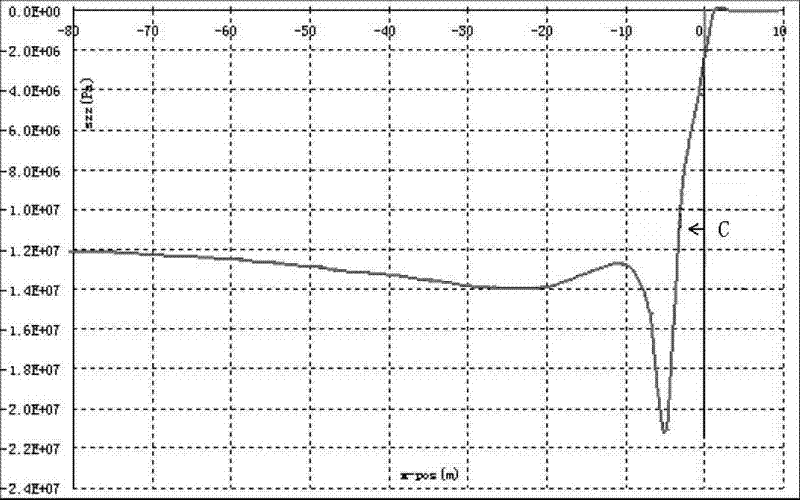

Comprehensive and integrative gas drainage method

The invention discloses a comprehensive and integrative gas drainage method which can be used for solving the problems that gas drainage is difficult to realize due to soft coal beds and low air permeability of the existing mines and the drainage effect of the current single gas drainage technology is unsatisfied. The method disclosed by the invention comprises the following steps: (1) high-position fracture borehole drainage of the top plate of a coal bed; (2) heterotropic high-position borehole drainage of a return airway; and (3) upper corner pipe-laying drainage of a gob. According to the invention, the stress field and fracture field caused by mining and a gas migration rule are fully utilized, so that drilled holes are high in drainage efficiency and flexible in arrangement, a drainage system is simple, the gas concentration at a drainage outlet can be up to 15-24%, and the gas drainage efficiency can reach 55-67.3%. The method disclosed by the invention is a new technology and method in fully mechanized caving face gas control methods, can be used for reducing the occurrence of excessive gas accidents and reducing the losses of life and property, has very important and far-reaching significance and is strongly worthy to be popularized and applied.

Owner:DATONG COAL MINE GRP

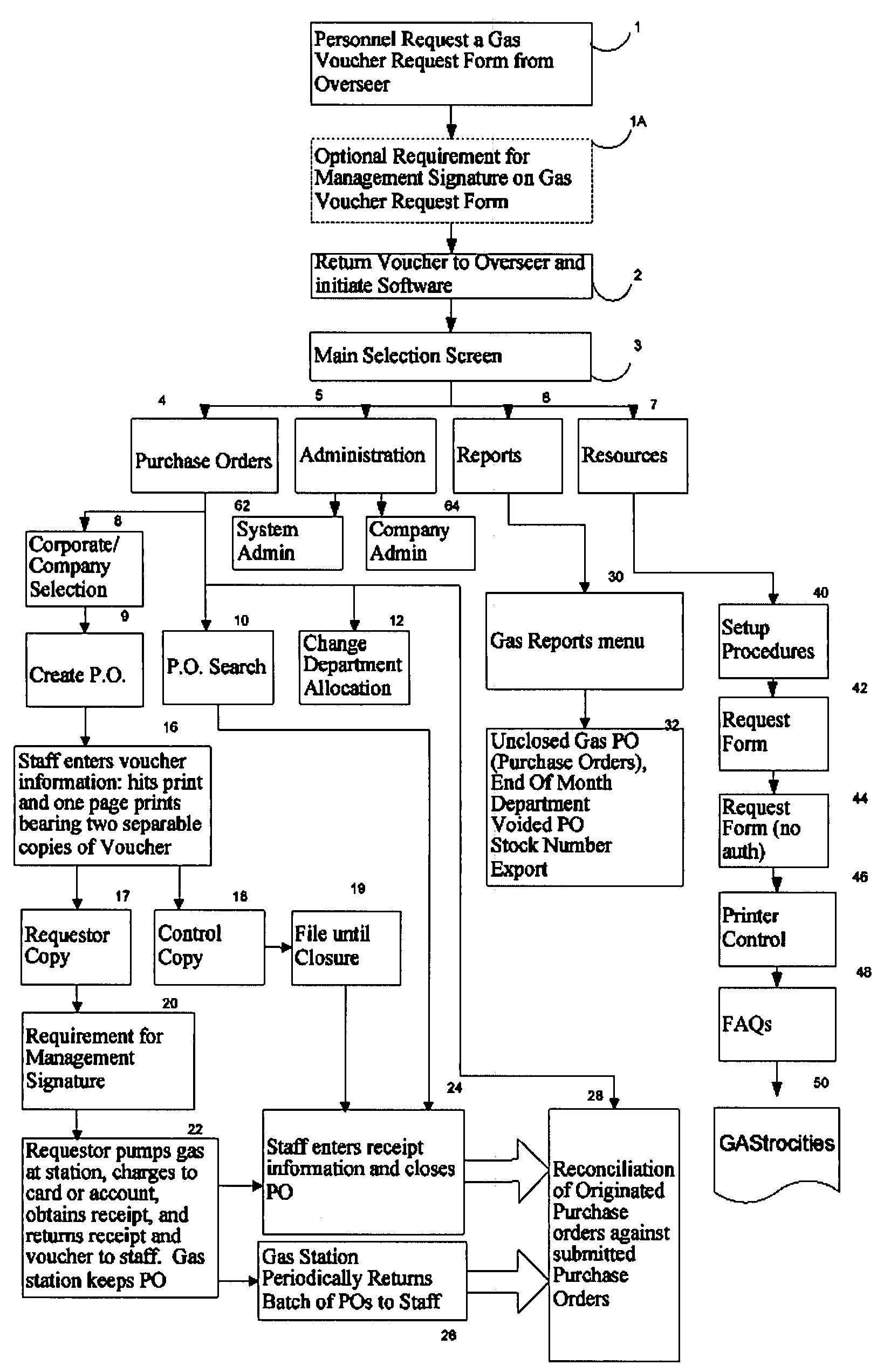

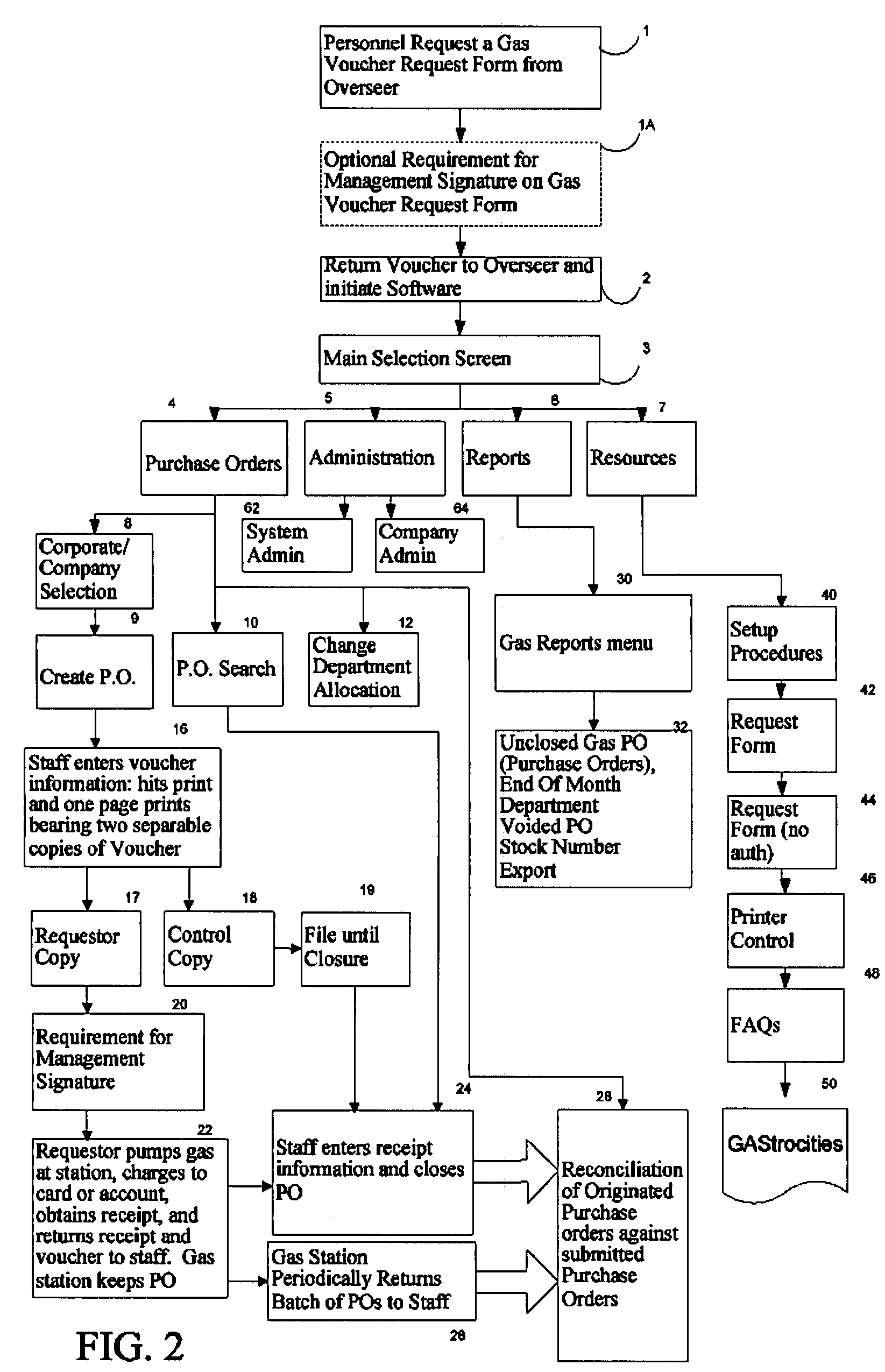

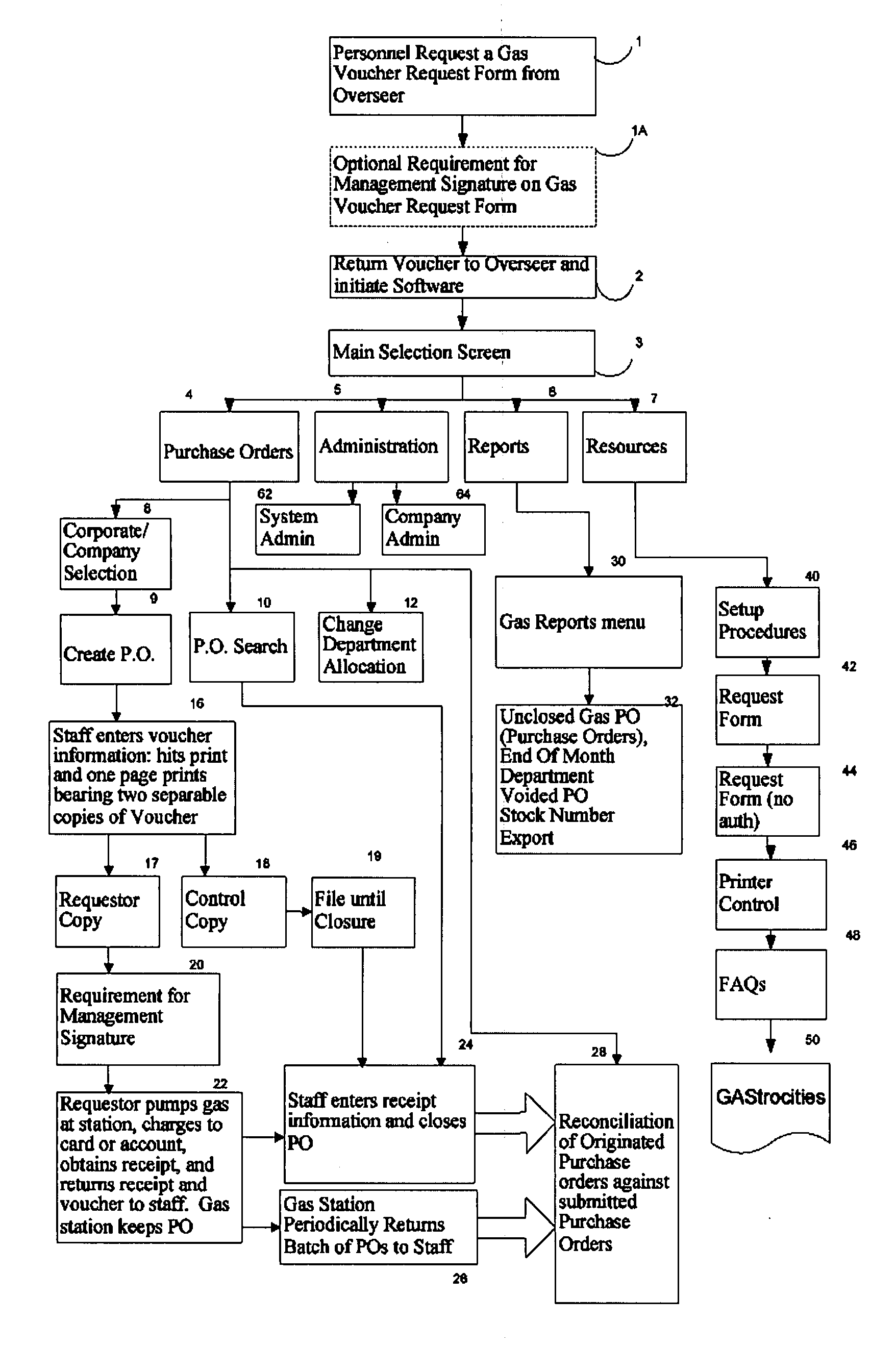

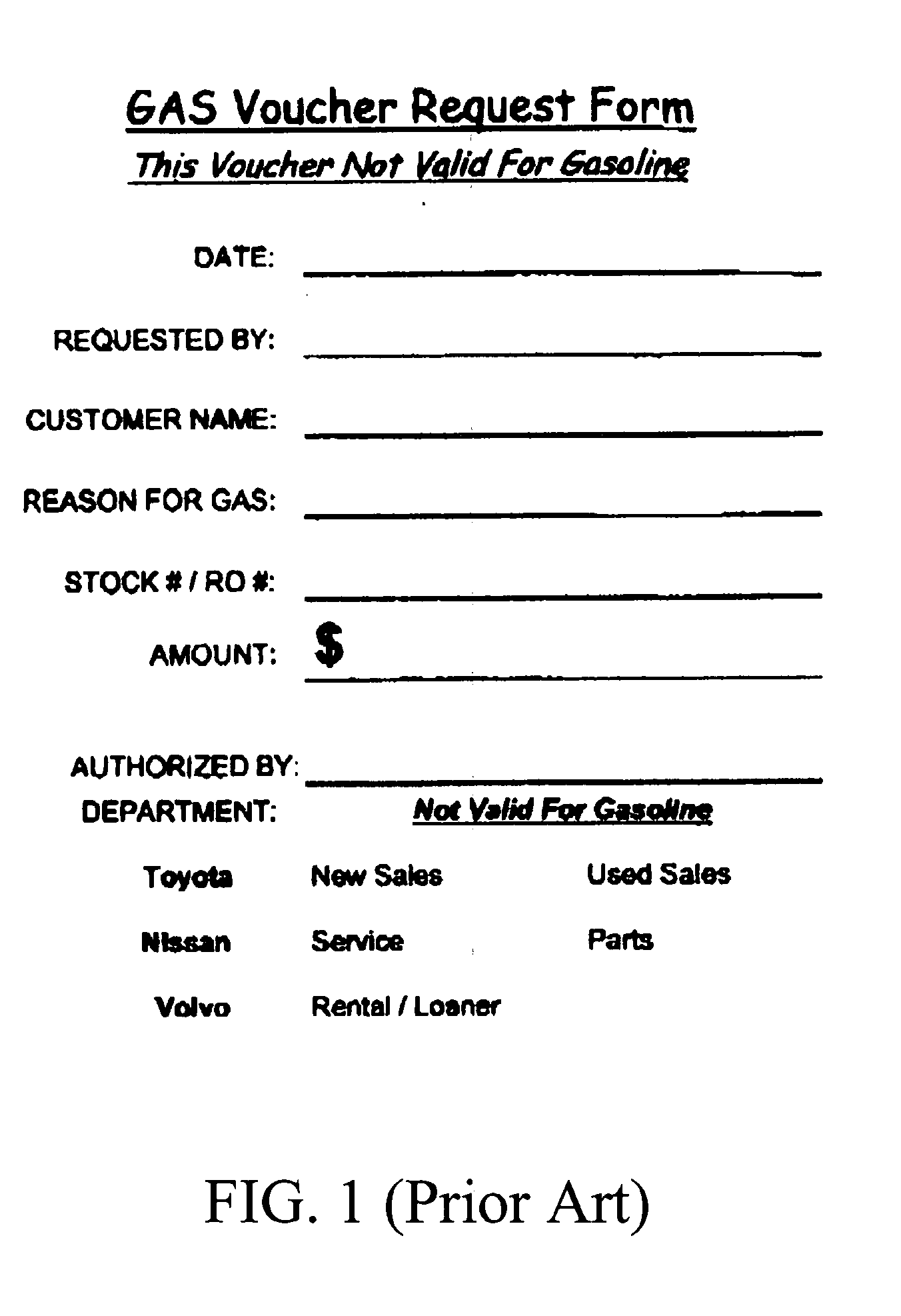

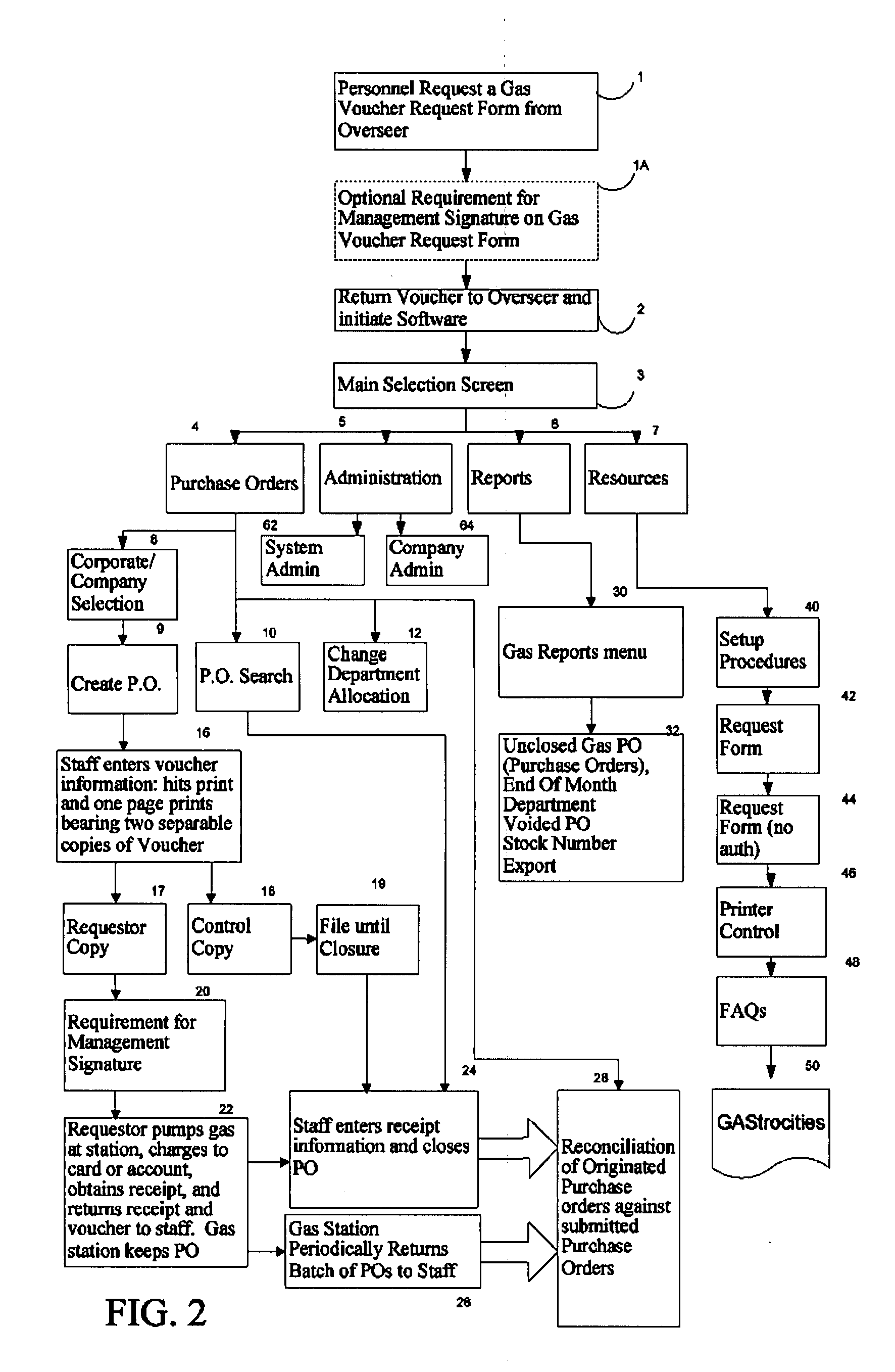

System for managing gas expenditures

The present invention is a system for providing businesses with comprehensive gas book management capabilities, inclusive of a process for authorizing and tracking gas book expenditures, as well as software for accounting, reconciling and reporting. An overseer runs the software and enters pertinent Request data into a database. The software prints two hard copies of the gas Purchase Order each bearing a unique auto-generated Purchase Order number. One copy is given to the requestor, and one is filed. When purchasing gas, the Requestor exchanges their Purchase Order with a receipt for gas. The requestor returns this receipt to the overseer, who enters pertinent Receipt data into the database. This allows the business to periodically reconcile the database against charge statements received from credit card issuers or gas stations, better manage gas usage, and identify fraud, excessive gas spending, and charge mistakes.

Owner:REYNOLDS AND REYNOLDS

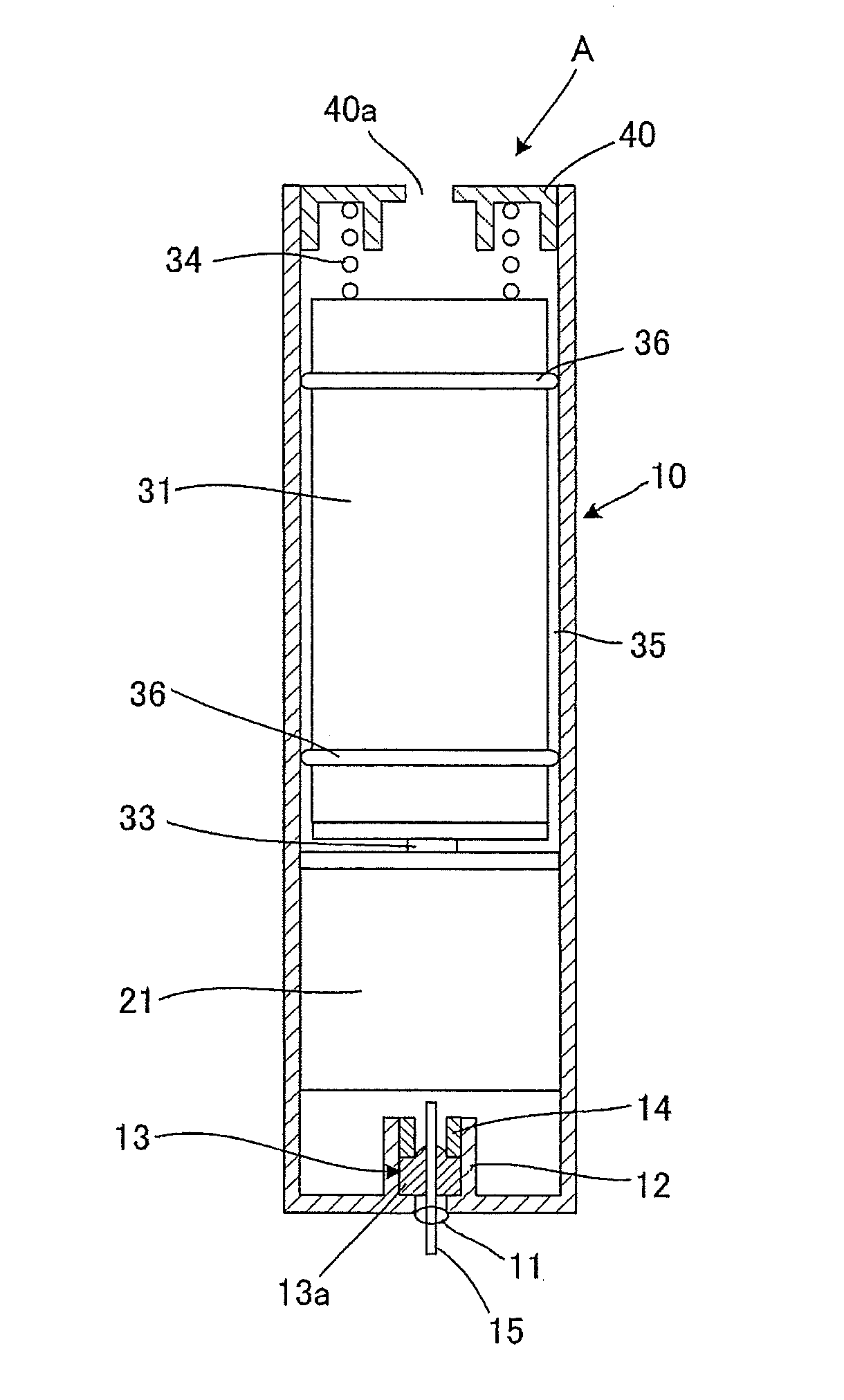

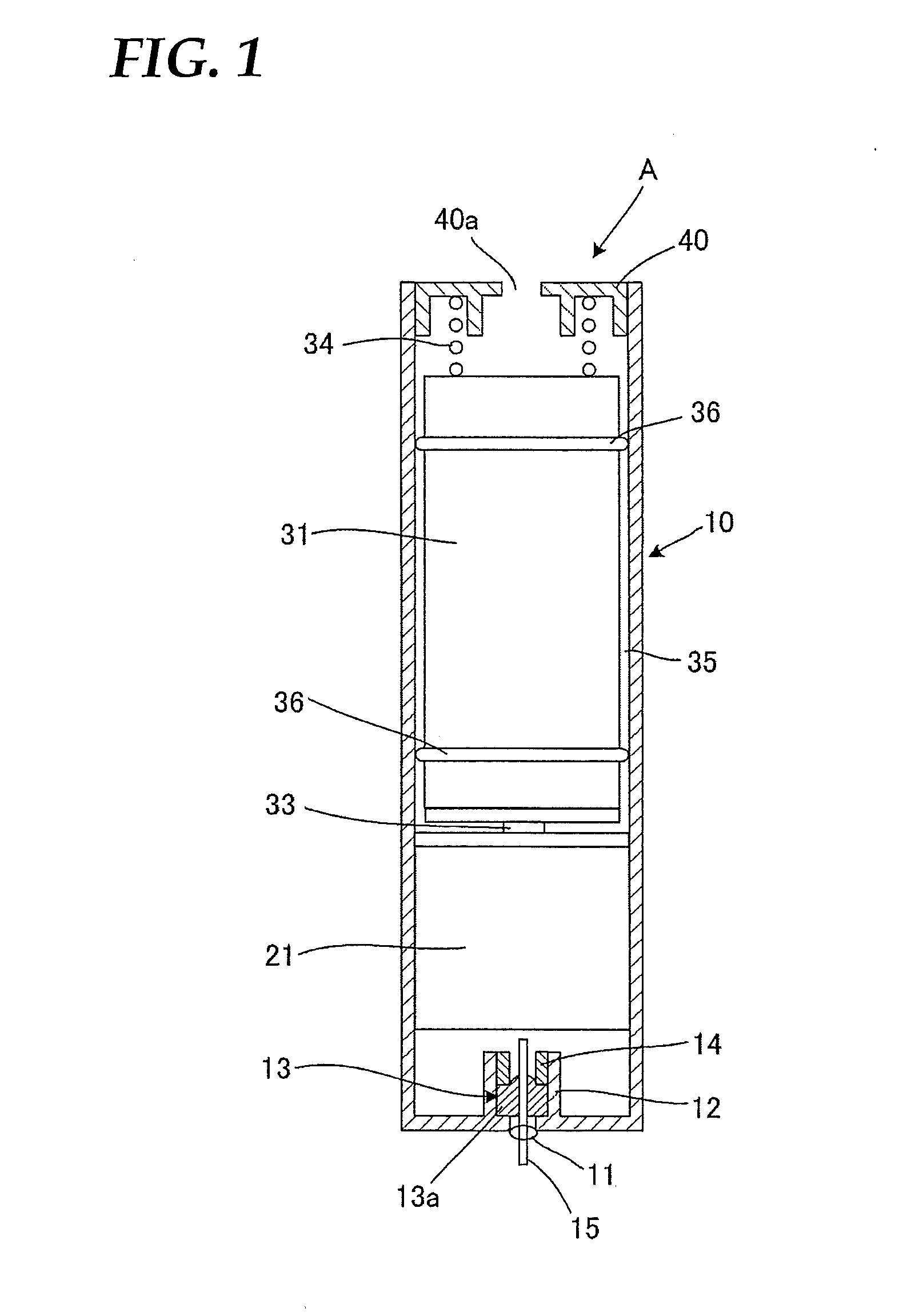

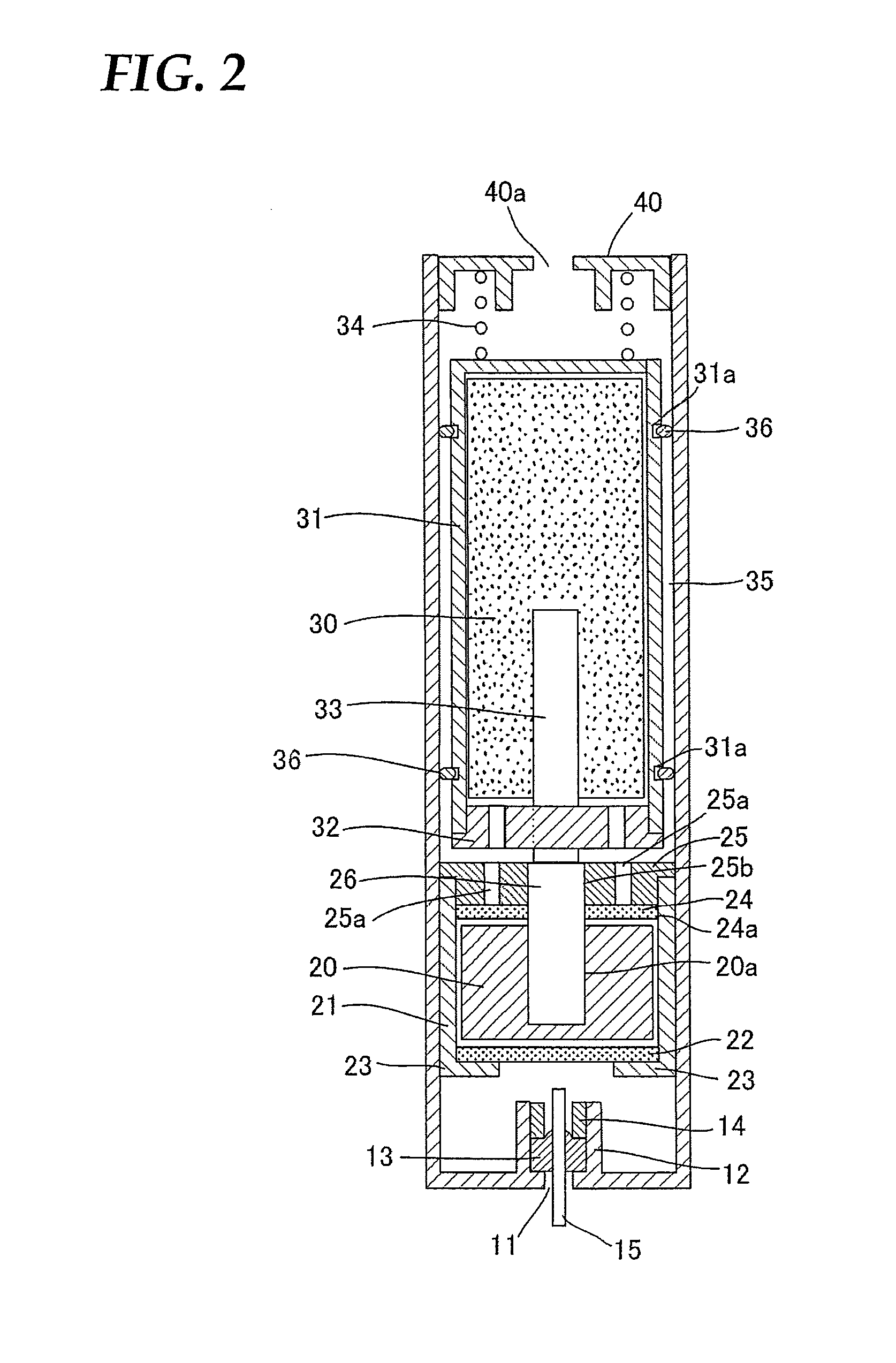

Gas generation apparatus

InactiveUS20100172805A1Avoid it happening againPhysical/chemical process catalystsReactant parameters controlFuel cellsHydrogen

In order to provide a gas generation apparatus such as a hydrogen gas generation apparatus for a fuel cell or an oxygen gas generation apparatus used in medical sites and at the time of disasters in which a solid gas generating agent such as metal is brought into contact with a reaction liquid to generate hydrogen gas or oxygen gas, a gas generation apparatus A having a solid gas generating agent and a reaction liquid in which the solid gas generating agent and the reaction liquid are stored respectively in separate storing vessels 21, 31 and in which the reaction liquid is supplied into the gas generating agent-storing vessel to generate gas by capillary-active connection of the respective storing vessels assumes a constitution in which capillary-active connection is shut off when a pressure of the gas is raised. In the above gas generation apparatus, generation of the gas can automatically be controlled by a simple mechanism when the gas is not consumed, and therefore generation of excessive gas can be controlled.

Owner:MITSUBISHI PENCIL CO LTD

System for managing gas expenditures

The present invention is a system for providing automobile dealerships and fleet businesses with comprehensive gas book management capabilities, inclusive of a process for authorizing and tracking gas book expenditures, as well as software for accounting, reconciling and reporting on them. An overseer (clerical staff) runs the present software and enters data into a database via an electronic gas Purchase Order form whenever a request for gas is made, the data including Date, Time, Requestor and other information pertinent to the Request. The software auto-generates a unique Purchase Order number for each Purchase Order, and prints two hard copies of the gas Purchase Order each bearing the unique number. One of the Purchase Orders is given to the requestor, and one is filed. The Requestor takes their Purchase Order, gets the gas, and exchanges their Purchase Order with a receipt for gas purchased therewith. The requestor returns this receipt to the overseer. The overseer enters pertinent Receipt data into the database, and this allows the dealership to periodically reconcile the database against charge statements received from credit card issuers or gas stations, better manage the usage of gas, as well as to spot fraud, excessive gas spending, and charge mistakes.

Owner:REYNOLDS AND REYNOLDS

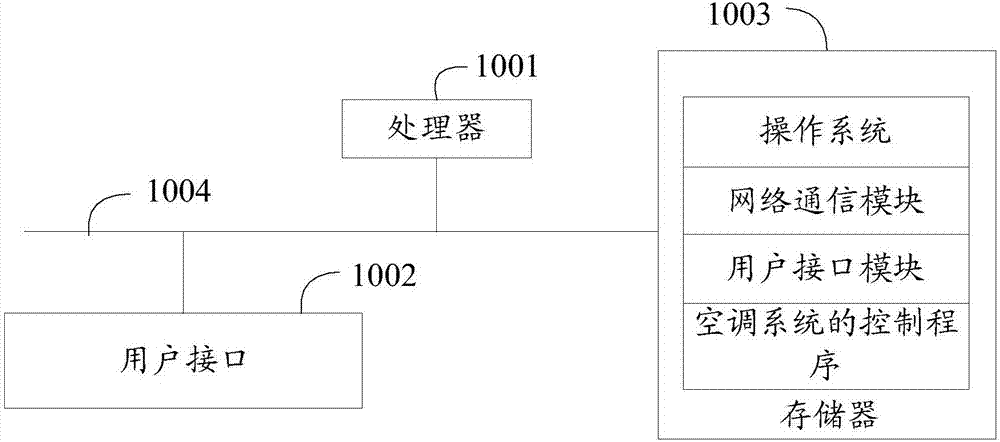

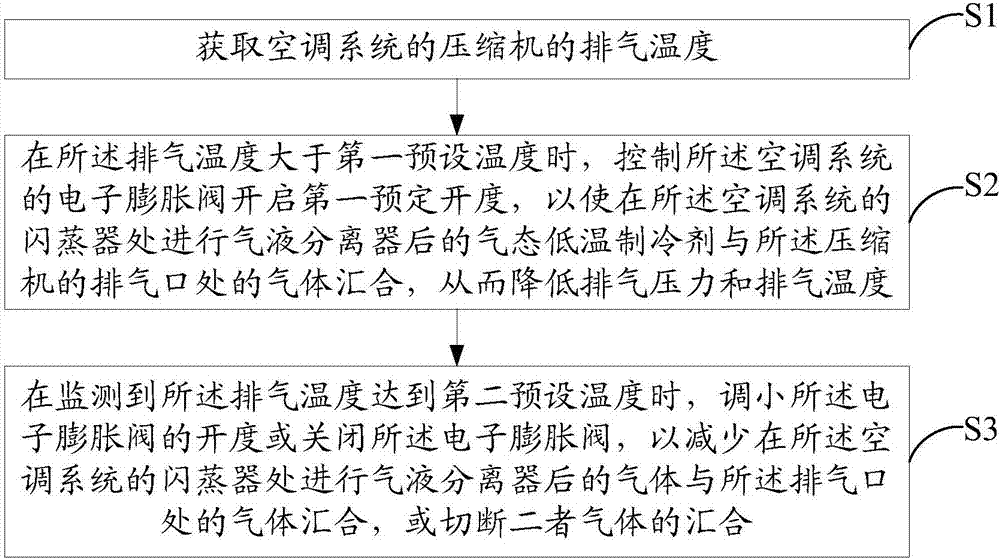

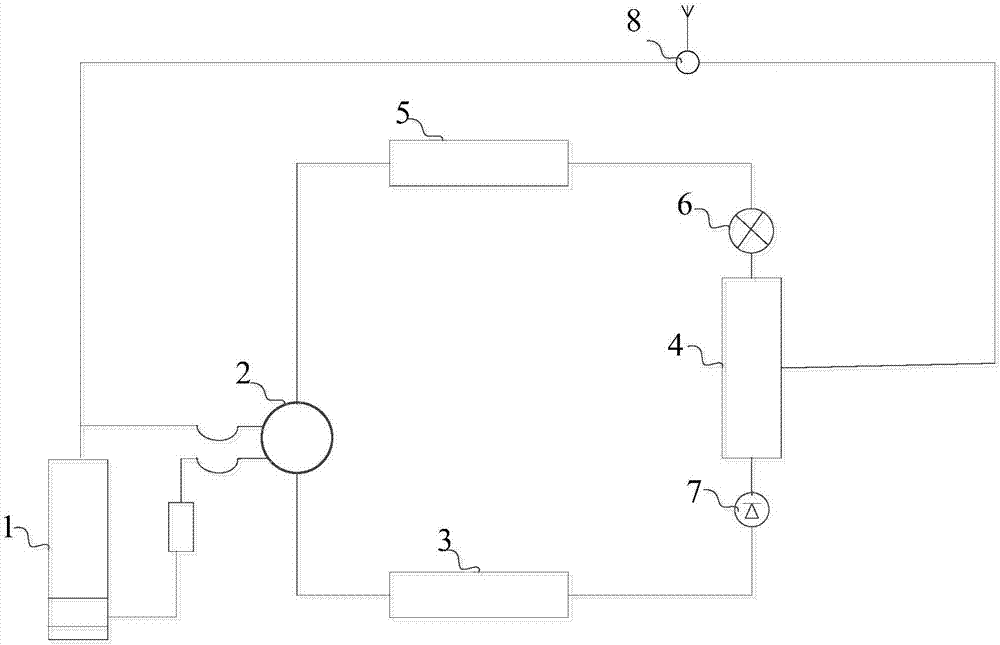

Air conditioning system, controlling method and computer readable storage medium

ActiveCN107255309AIncrease exhaust temperatureGuaranteed cooling effectSpace heating and ventilation safety systemsSpace heating and ventilation control systemsVapor–liquid separatorIntermittent control

The invention discloses a controlling method for an air conditioning system. The controlling method for the air conditioning system comprises the following steps that a gas discharging temperature of a compressor of the air conditioning system is acquired; when the gas discharging temperature is greater than a first preset temperature, an electronic expansion valve of the air conditioning system is controlled to open a first reserved opening degree, so that gaseous low temperature refrigerant after gas-liquid separation in a flash evaporator of the air conditioning system and the gas in a gas discharging outlet of the compressor are confluent, and gas discharging pressure and the gas discharging temperature are reduced accordingly; when the gas discharging temperature reaching a second preset temperature is monitored, an opening degree of the electronic expansion valve is turned down or the electronic expansion valve is closed, so that gas confluence between the gas after the gas-liquid separation in the flash evaporator of the air conditioning system and the gas in the gas discharging outlet is reduced, or the gas confluence between the gas after the gas-liquid separation in the flash evaporator of the air conditioning system and the gas in the gas discharging outlet is cut off. The invention further provides the air conditioning system and a computer readable storage medium. According to the air conditioning system, the controlling method and the computer readable storage medium, the excessive gas discharging temperature of the compressor of the air conditioning system is prevented through an intermittent control, so that stability of the air conditioning system is improved.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

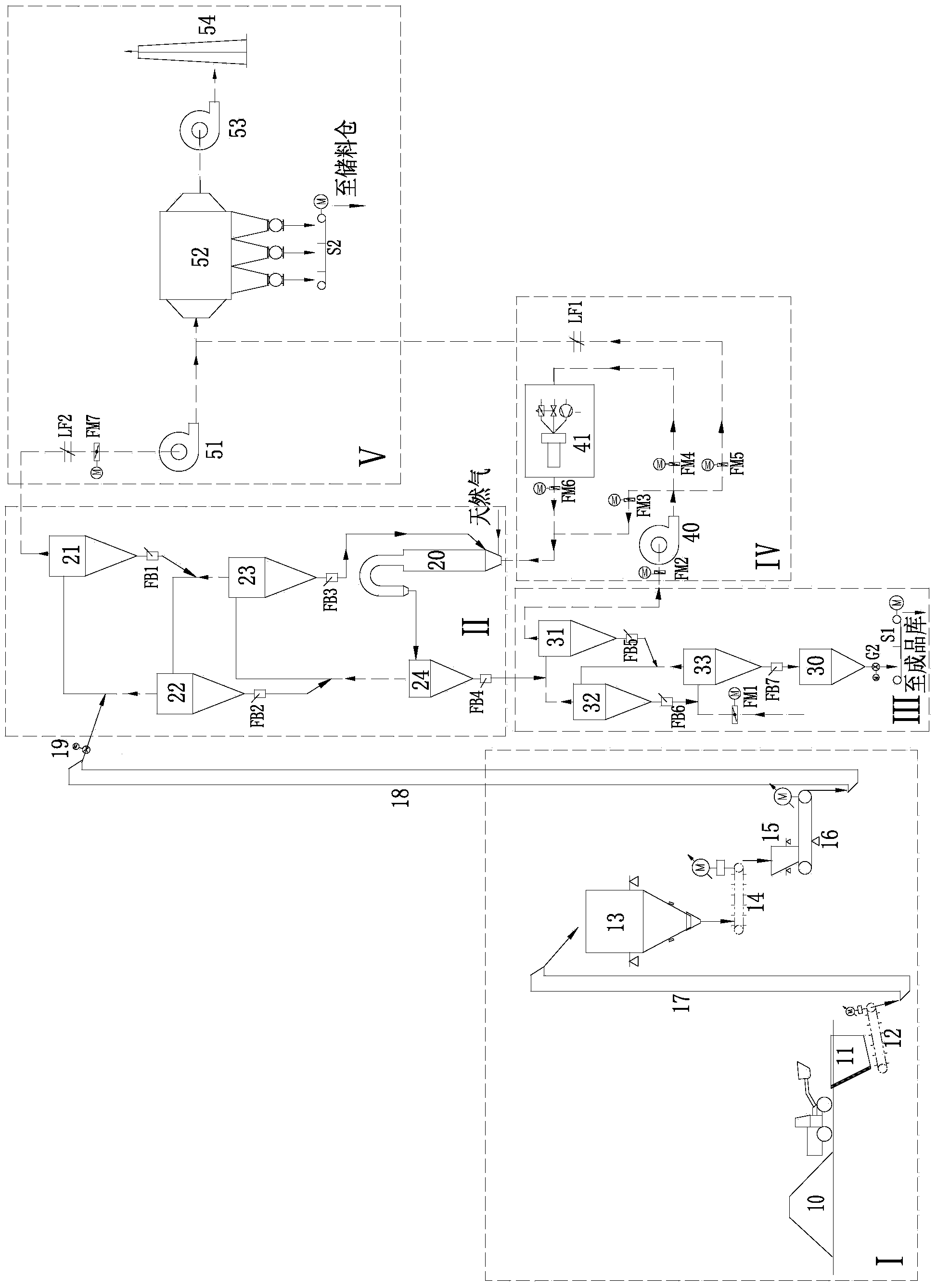

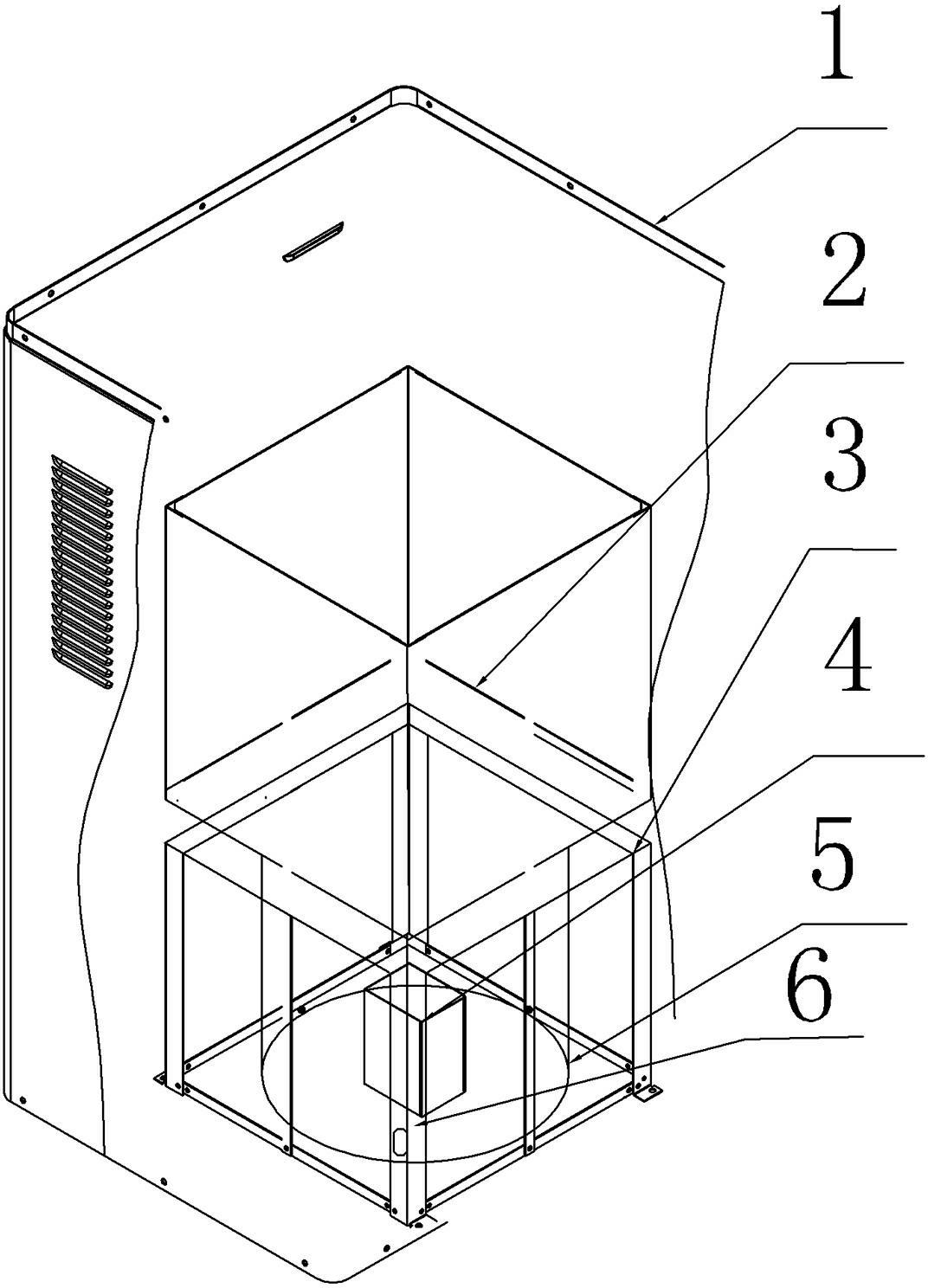

Production system of suspended-state calcined coal gangues

ActiveCN103864325AImprove thermal efficiencyHigh activitySolid waste managementCold airDecomposition

The invention discloses a production system of suspended-state calcined coal gangues. The production system comprises a material preparing and feeding sub system, a preheating and decomposition furnace-calcining sub system, a product cooling and heat-recycling sub system, a hot air preparing and supplying sub system and a system power and waste gas-purifying sub system, wherein the material preparing and feeding sub system is used for quantitatively and stably supplying coal gangue powder to a pre-heater; the preheating and decomposition furnace-calcining sub system is used for preheating materials to a set temperature under a suspended state, and decomposing and sintering the materials in a decomposition furnace; the product cooling and heat recycling sub system is used for sucking in cold air to cool the sintered materials under the suspended state to obtain low-temperature activated coal gangues; the hot air preparing and supplying sub system is used for ventilating hot air to the hot air furnace for burning pulverized coal or fluidized block coal, and providing hot air to the decomposition furnace of the preheating and decomposition furnace-calcining sub system, wherein the hot air is from the product cooling and heat-recycling sub system; and the system power and waste gas purifying sub system is used for providing gas flow power to the preheating and decomposition furnace-calcining sub system, purifying all waste gas of the preheating and decomposition furnace-calcining sub system and excessive gas emitted by the hot air preparing and supplying sub system. The production system disclosed by the invention can massively, efficiently, continuously and stably produce and process high-activity cinerite coal gangues.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

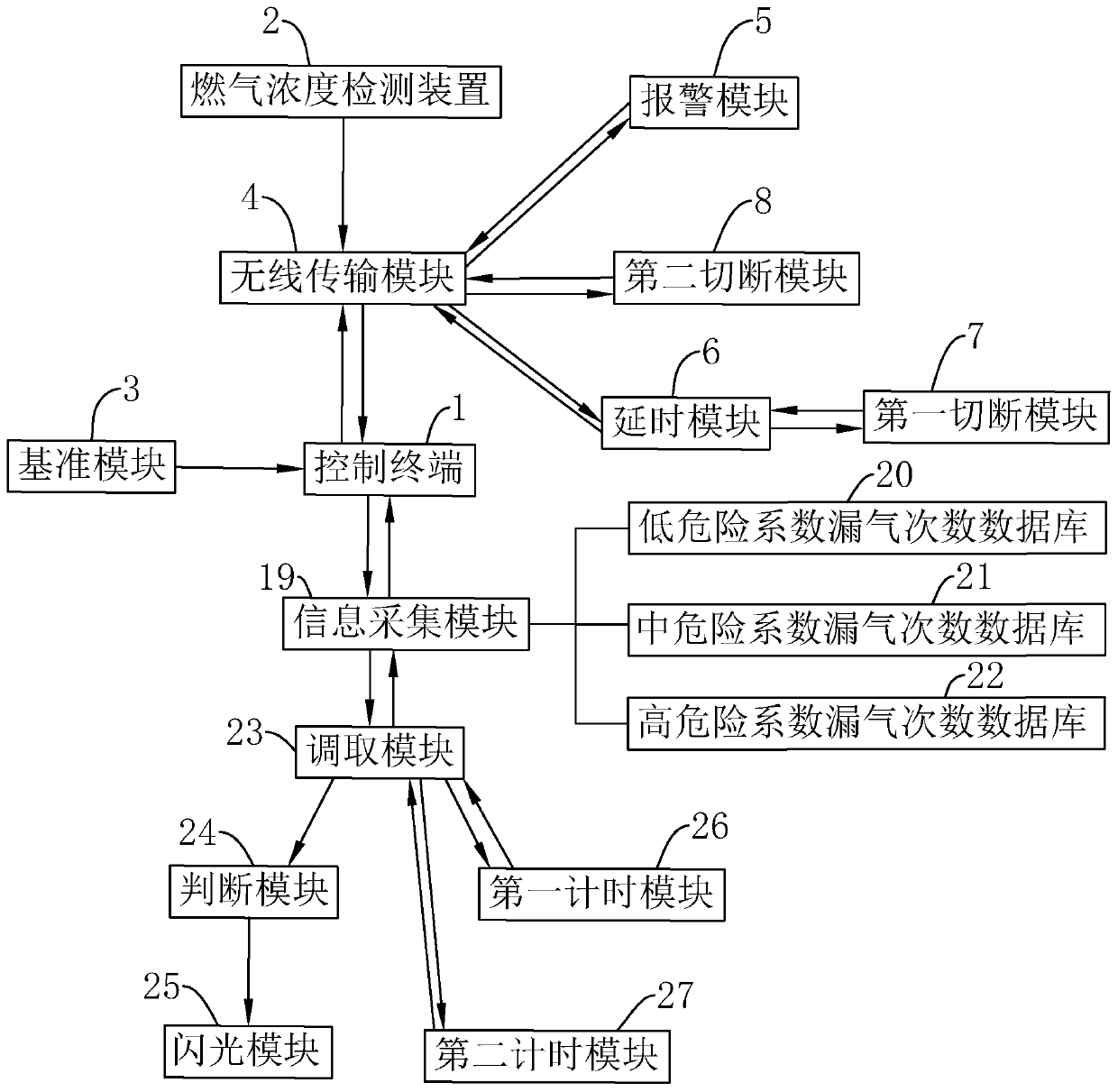

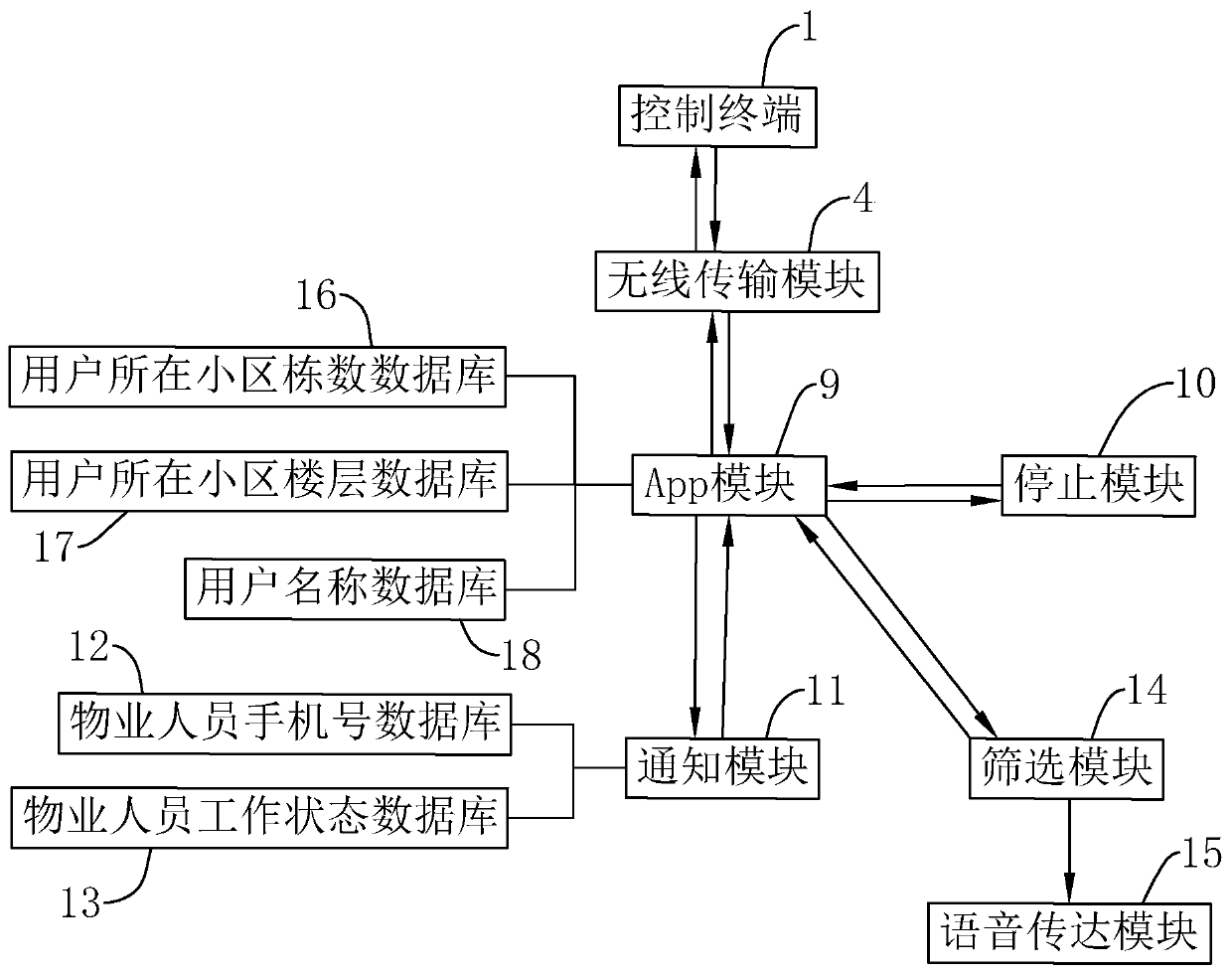

Gas pipeline detection system

InactiveCN110085002AImprove securityReduce the incidence of inhalation poisoningTransmission systemsPipeline systemsWireless transmissionInhalation

The invention relates to a gas pipeline detection system which comprises a control terminal, a gas concentration detection device, a reference module, a wireless transmission module and an alarm module, wherein the control terminal is used for processing data; the gas concentration detection device is used for detecting the indoor gas concentration and outputting gas concentration data; the reference module is coupled to the control terminal and used for providing a fuel gas concentration threshold value; the wireless transmission module is coupled with the control terminal and used for inputting the gas concentration data into the control terminal, comparing the gas concentration data with the gas concentration threshold and outputting the gas concentration data; the alarm module is coupled with the wireless transmission module to receive dangerous gas concentration data and give an alarm. According to the invention, the indoor gas concentration is detected in real time, so that people can be reminded to close a gas valve to stop gas delivery when the gas concentration exceeds a certain threshold value, the situation that people are poisoned by inhalation due to excessive gas leakage can be reduced, and the safety of the gas in the using process can be improved.

Owner:马继华

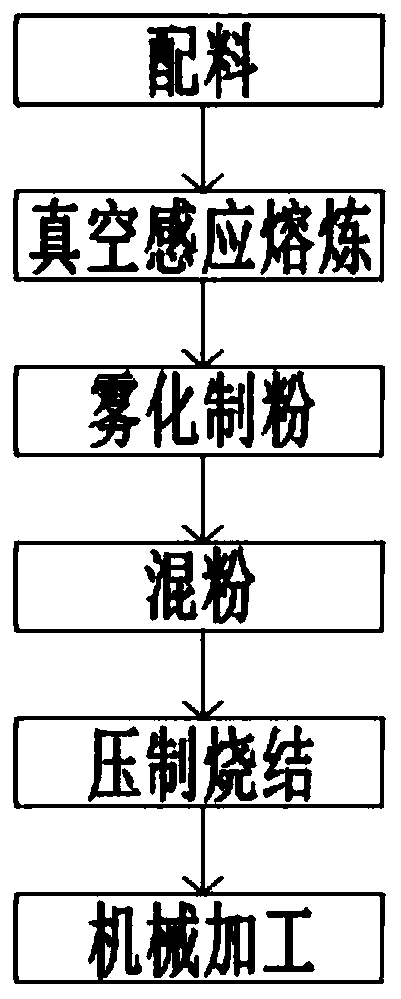

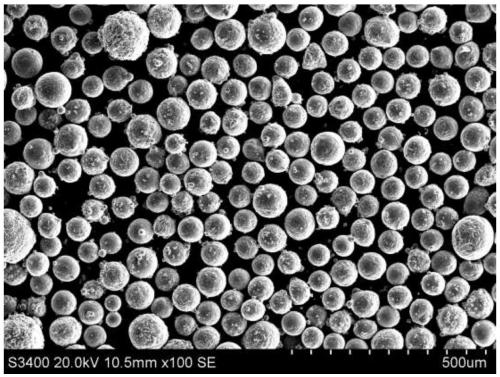

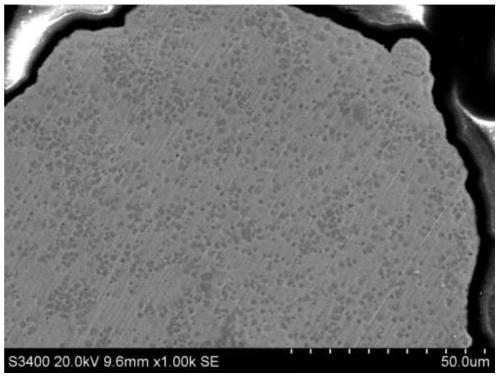

Preparation method for optimizing copper-chromium contact by adding ultrafine grain chromium phase

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

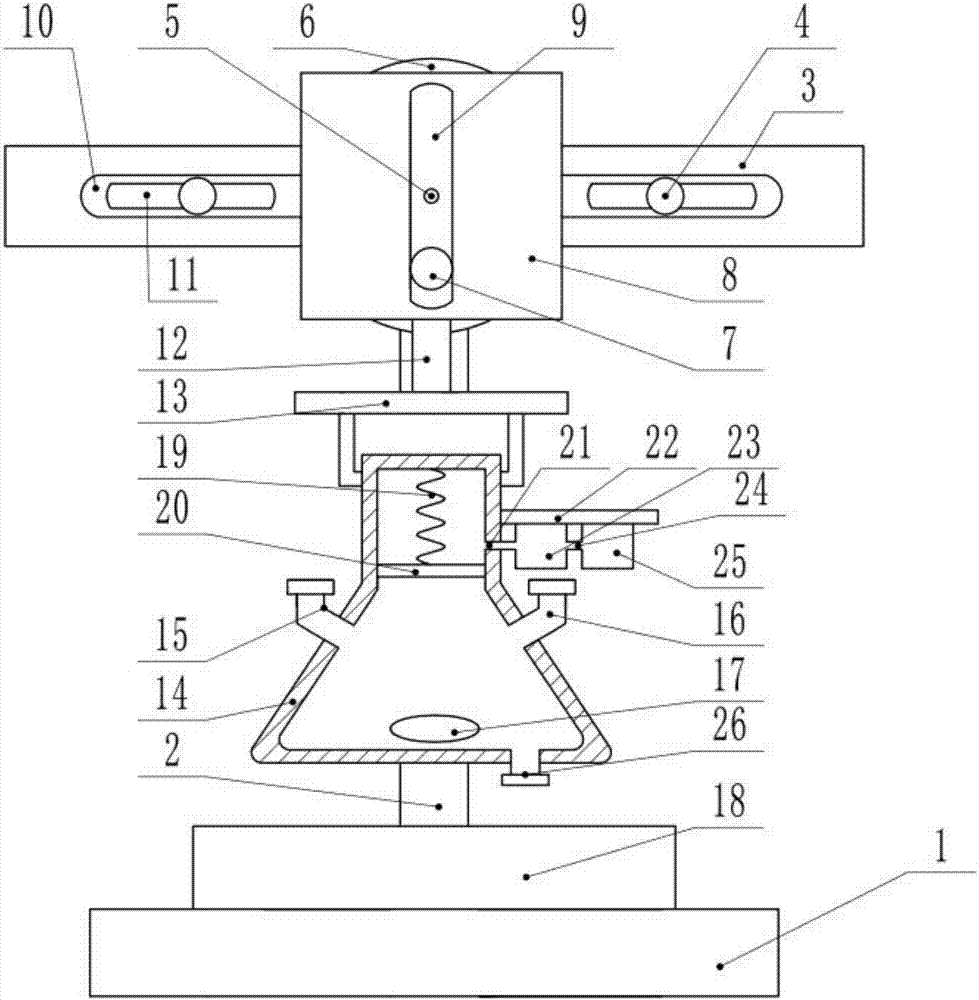

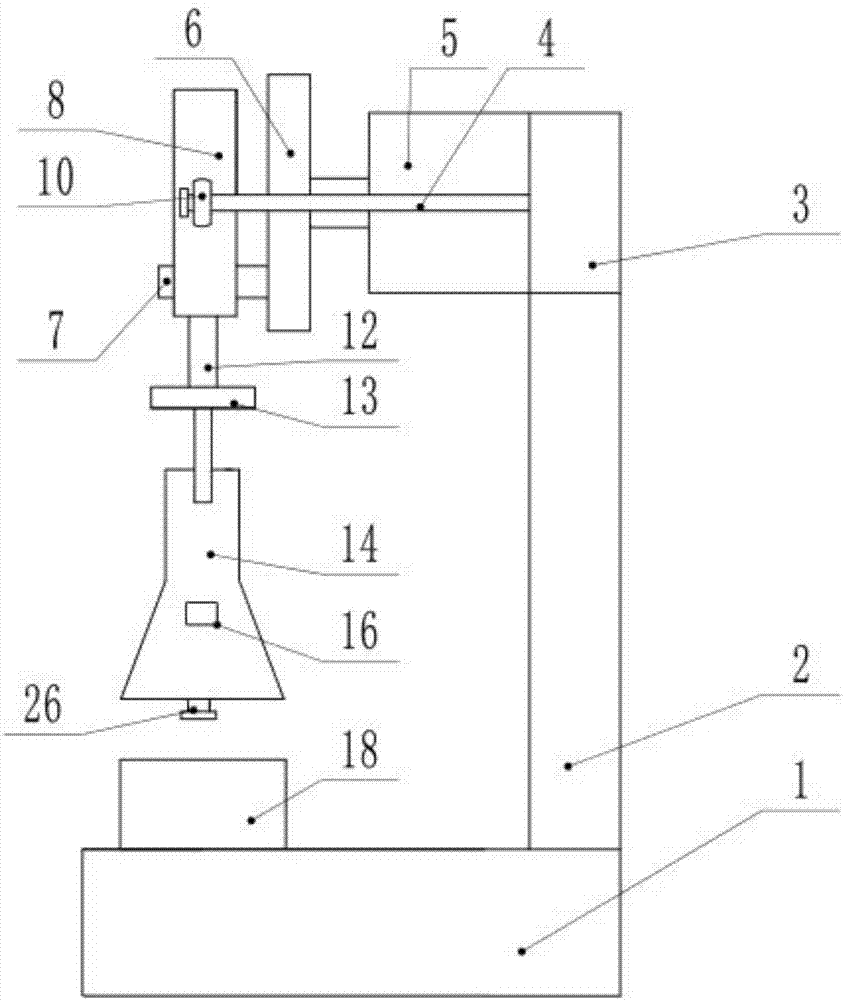

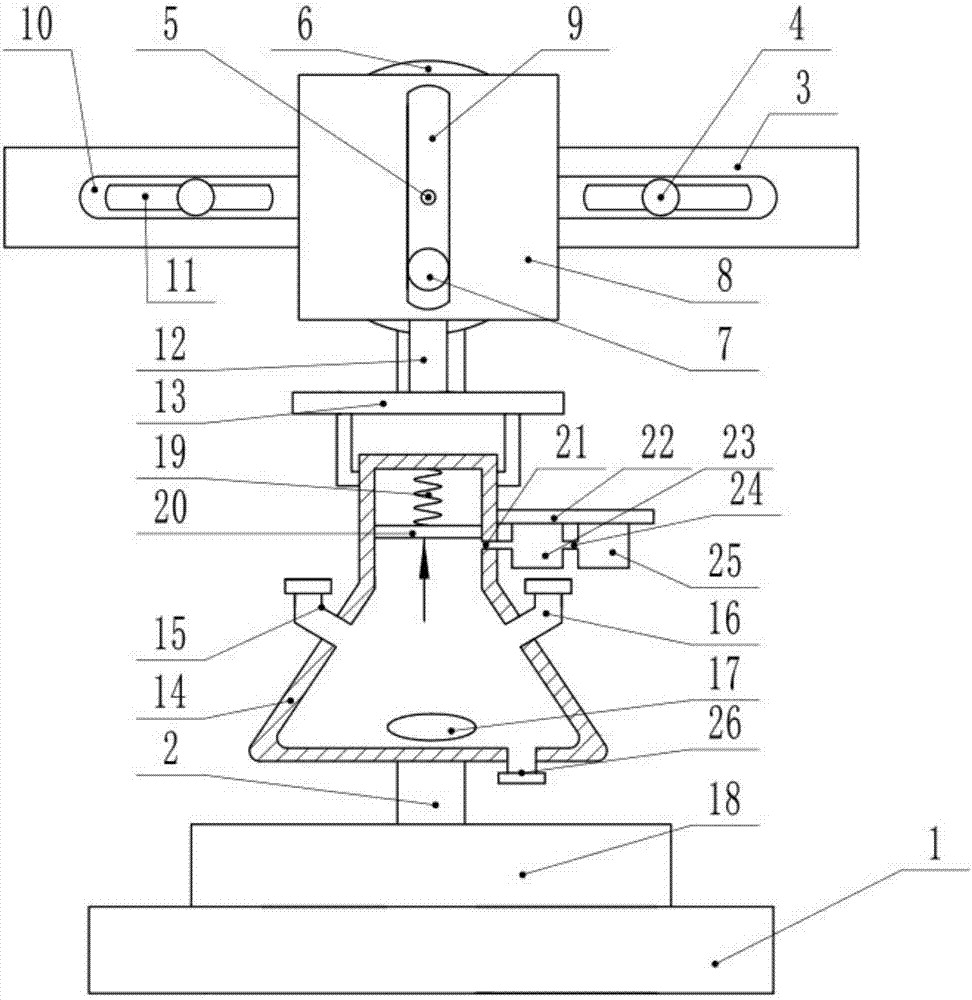

Mixing and shaking-up device for chemical reagents

InactiveCN107088396AAvoid poisoningImprove securityTransportation and packagingMixer accessoriesShake upCompound (substance)

The invention discloses a mixing and shaking-up device for chemical reagents. The device comprises a base, a main support, an auxiliary support, a driving motor, a wheel, a translation plate, a reagent bottle, a stirring bar, a magnetic stirrer and a gas filter, wherein the wheel is fixedly mounted on an output shaft of the driving motor, the translation plate is arranged in front of the wheel, the stirring bar is arranged in the reagent bottle, and the magnetic stirrer is fixedly mounted on the upper surface of the base; the gas filter is fixedly mounted on a support plate. The magnetic field is produced in the magnetic stirrer according to the principles that like charges repel but opposite charges attract in the magnetic field, the magnetic stirring bar in the reagent bottle rotates circumferentially to play a stirring role, and the reagents are mixed more uniformly and quickly; the gas filter sucks away poisonous gas in gas, an operator is prevented from being poisoned, meanwhile, explosion due to excessive gas in the reagent bottle can be effectively prevented, and the experiment safety is improved.

Owner:HANGZHOU XIAOCHENG IND DESIGN CO LTD

Drainage structure in fuel cell motorcycle

InactiveUS8118129B2Increase widthReduce appearance problemsAuxillary drivesFinal product manufactureGas-discharge lampDraining tube

A layout for an exhaust pipe which also serves as a drainage pipe which prevents splashing of water generated in a fuel cell toward a passenger or splashing toward a tire. Humid excessive gas supplied from a fuel cell is diluted in a dilution box by off-gas discharged from the fuel cell and is used for humidifying air in the humidifier. An exhaust pipe is connected to the dilution box, and diluted hydrogen gas is discharged via the exhaust pipe. Vapor mixed in hydrogen gas is condensed in the exhaust pipe and turned into water, which is drained through the exhaust pipe that extends rearwardly of a vehicle body through the interior of a power unit. A discharge port of the exhaust pipe (which is also a drainage port for water generated in the fuel cell) is positioned at the widthwise center of the vehicle body.

Owner:HONDA MOTOR CO LTD

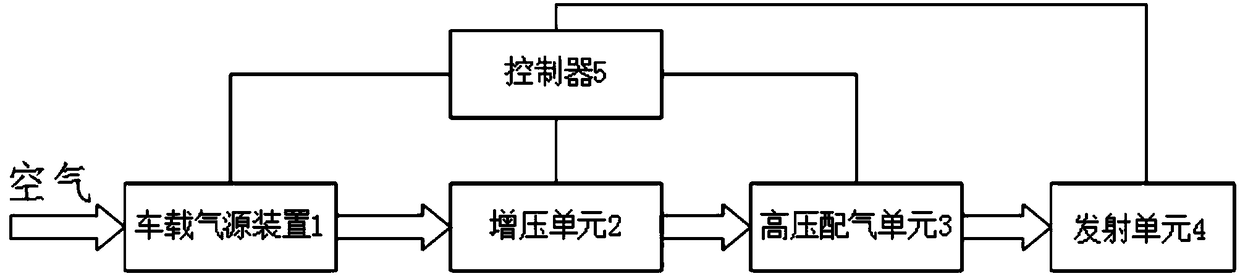

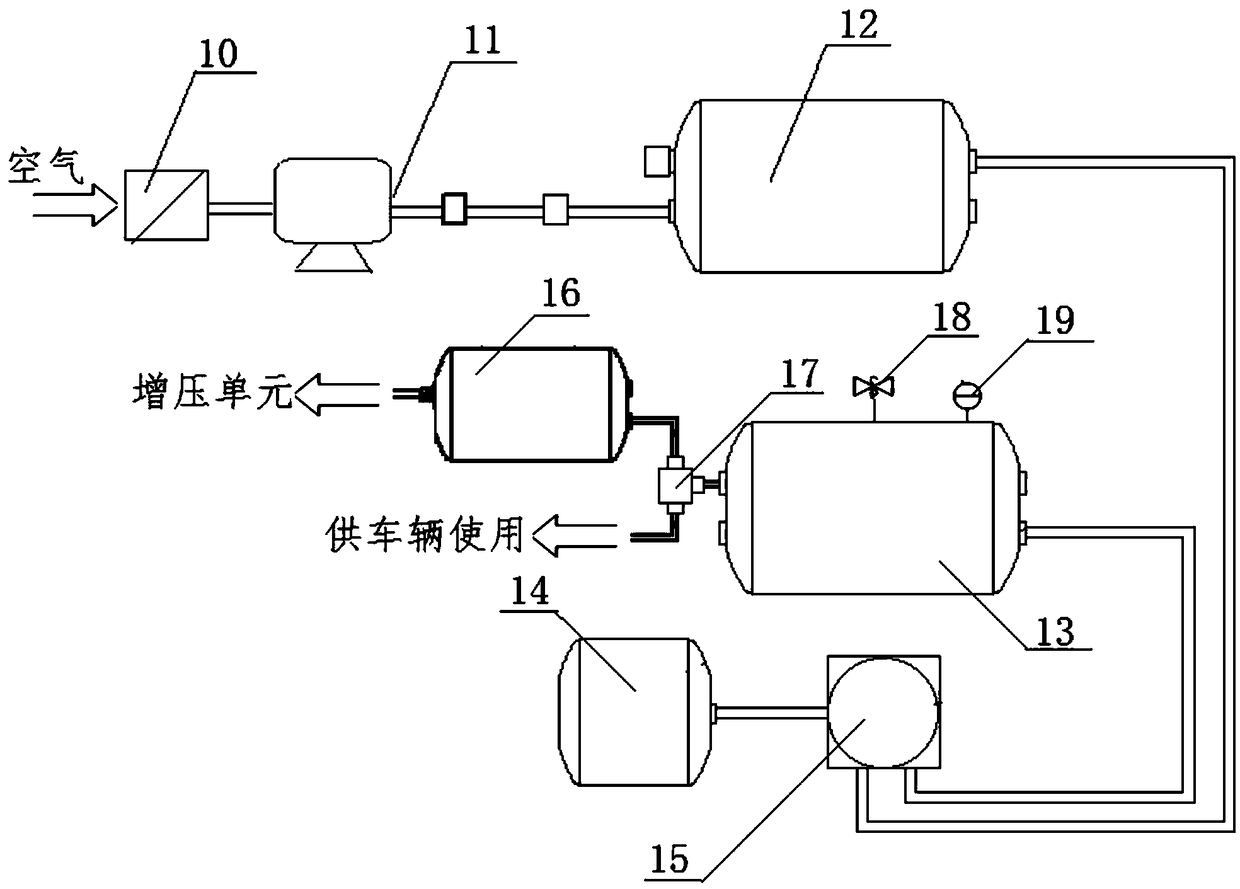

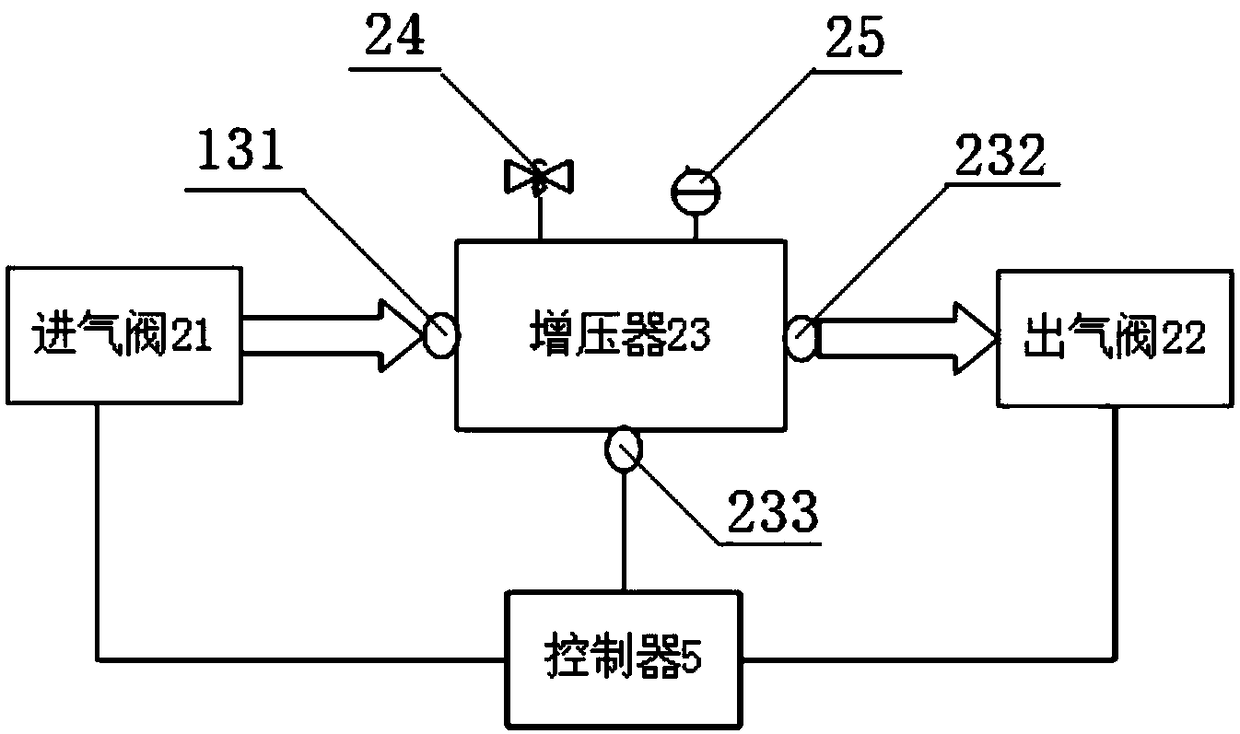

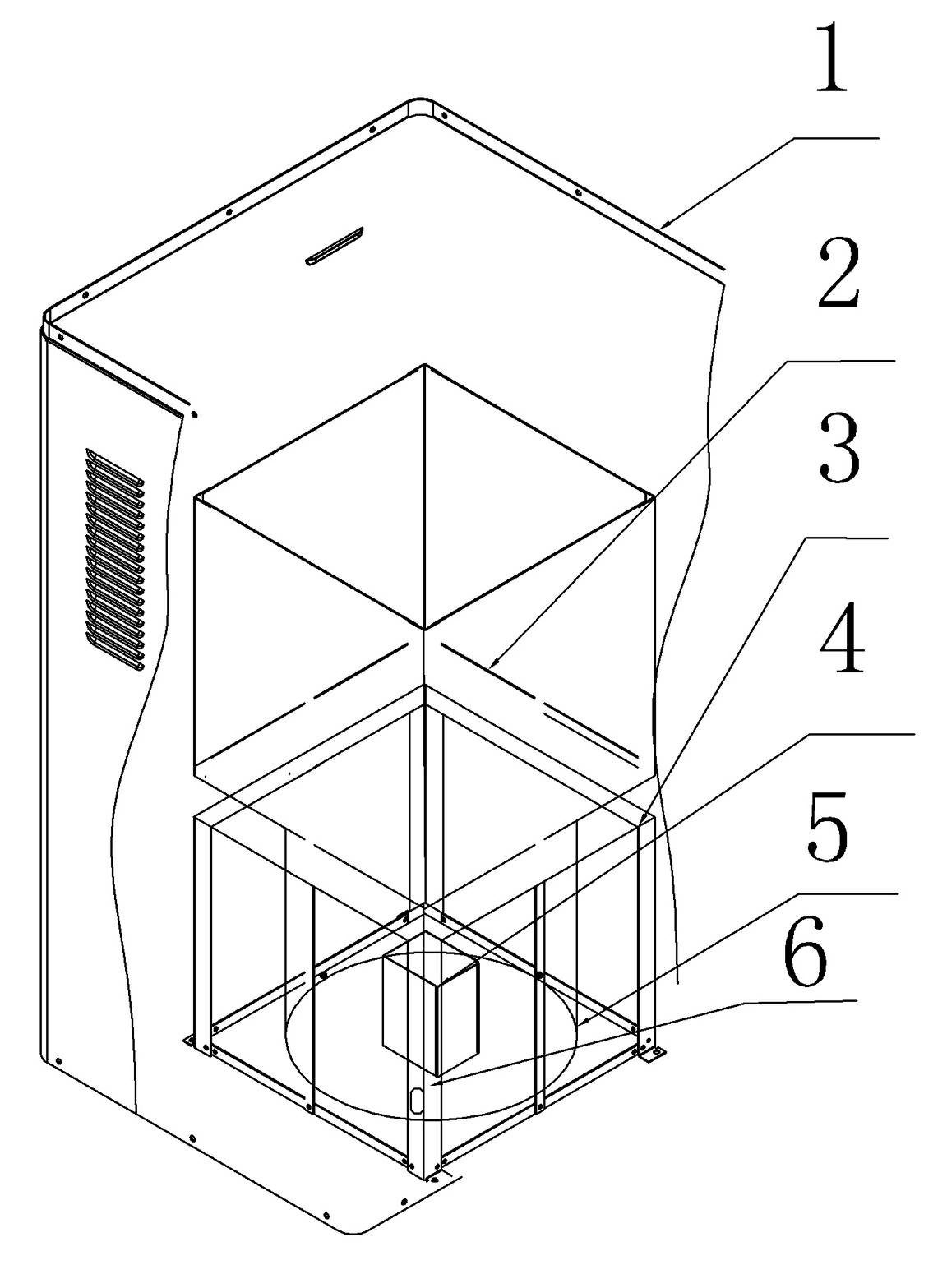

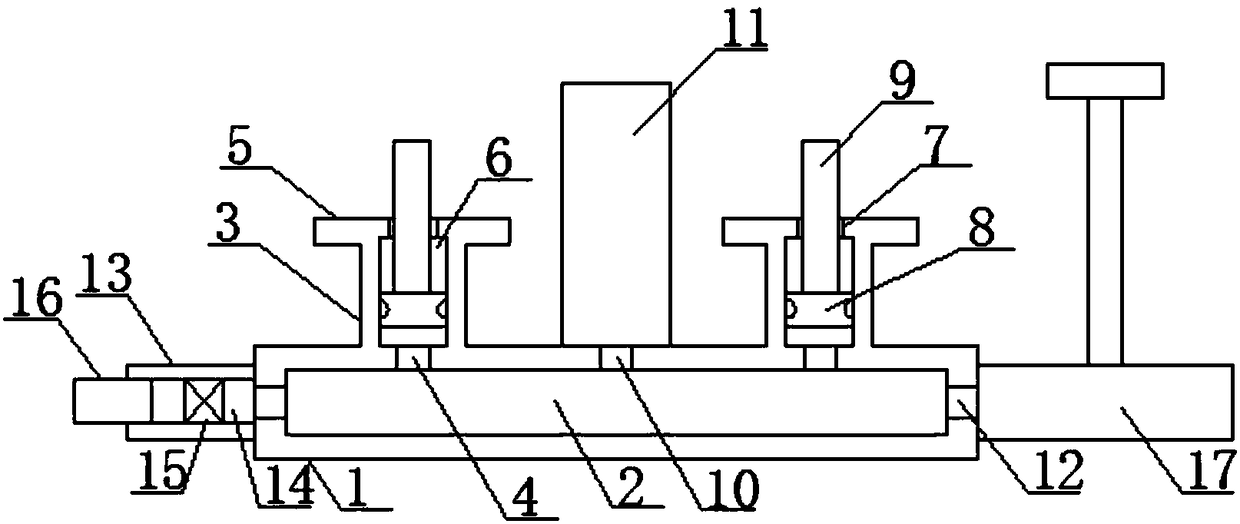

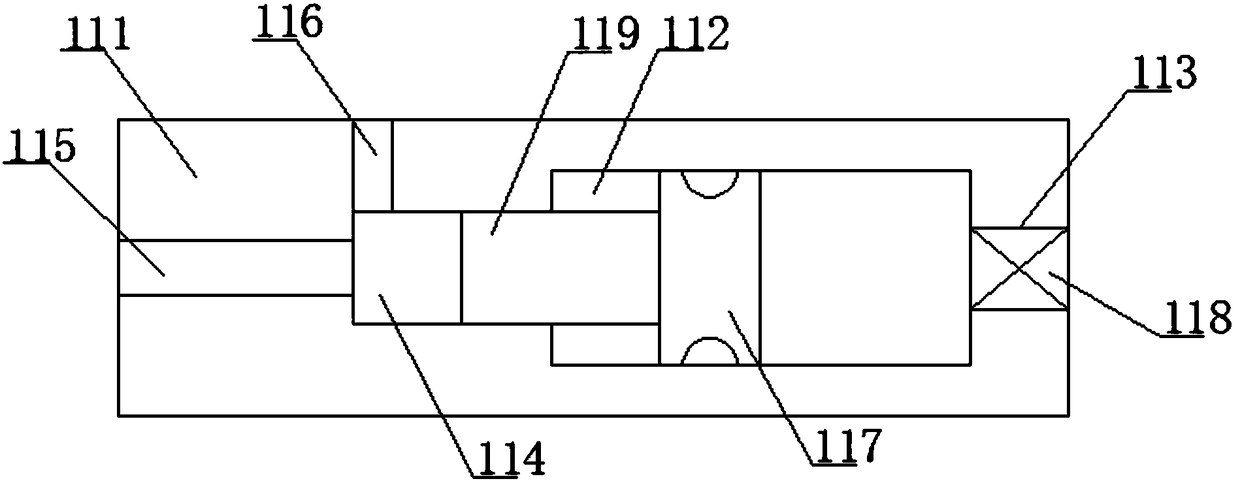

Pneumatic launching system for vehicle-mounted loitering unit

PendingCN108657460AOvercome the defect that the form gas supply is easily interruptedOvercome the defect that gas supply is easily interruptedLaunching/towing gearBuffer tankIn vehicle

The invention provides a pneumatic launching system for a vehicle-mounted loitering unit, and belongs to the technical field of vehicle-mounted weapon launching. The pneumatic launching system comprises a vehicle-mounted air source device, a pressurization unit, a high-pressure air distribution unit and a launching unit which communicate with each other in sequence through air flues. The launchingunit is provided with a launching tube, the launching tube is internally provided with a piston, the periphery of the piston is in contact with the inner wall of the launching tube and can slide along the inner wall of the launching tube, and the piston and the bottom of the launching tube form a sealing cavity. A launching cover is arranged at an outlet of the launching tube, and the loitering unit is located between the piston and the launching cover. According to the pneumatic launching system for the vehicle-mounted loitering unit, an own vehicle-mounted air source device of a vehicle isused, air is used as the raw material to realize continuous air supply to overcome the defect that air supply by an external air tank mode is prone to being interrupted, the cost is saved, and the working efficiency is high; a safety valve and a pressure gauge are arranged additionally to prevent excessive gas pressure during the working process, and the safety and working reliability of gas compression are enhanced; and by arranging buffer mechanisms such as a buffer tank, the work stability and security are guaranteed.

Owner:北京中资燕京汽车有限公司

Novel explosion-proof pressure relief device and aerosol fire extinguisher using same

InactiveCN102247678AAvoid explosive situationsGuaranteed service lifeFire rescuePressure riseFire extinguisher

The invention provides a novel explosion-proof pressure relief device. The novel explosion-proof pressure relief device is characterized in that organic plates with poor compression resistance or inorganic plates or heat-resistant films are adopted to define a closed space; when gas can not flow through the space smoothly, the pressure in the space is increased; and when the pressure exceeds a pressure limit of a heat insulation member, the heat insulation member cracks automatically to release the pressure, and thus explosion is prevented. In a fire extinguisher equipped with the explosion-proof pressure relief device, gas generated by a gas generator enters a dust-removing and cooling device via the explosion-proof pressure relief device rather than entering the dust-removing and cooling device directly. Accordingly, in case of pressure rise due to blockage of the dust-removing and cooling device or accumulation of excessive gases generated by the gas generator, the heat insulation member cracks in advance so that the gas is released into a box body and then discharged through a gas outlet which is formed on the box body, and thus explosion of the fire extinguisher is prevented, the fire extinguisher is safer and more reliable and the service life of the fire extinguisher is ensured.

Owner:深圳市鸿嘉利消防科技有限公司

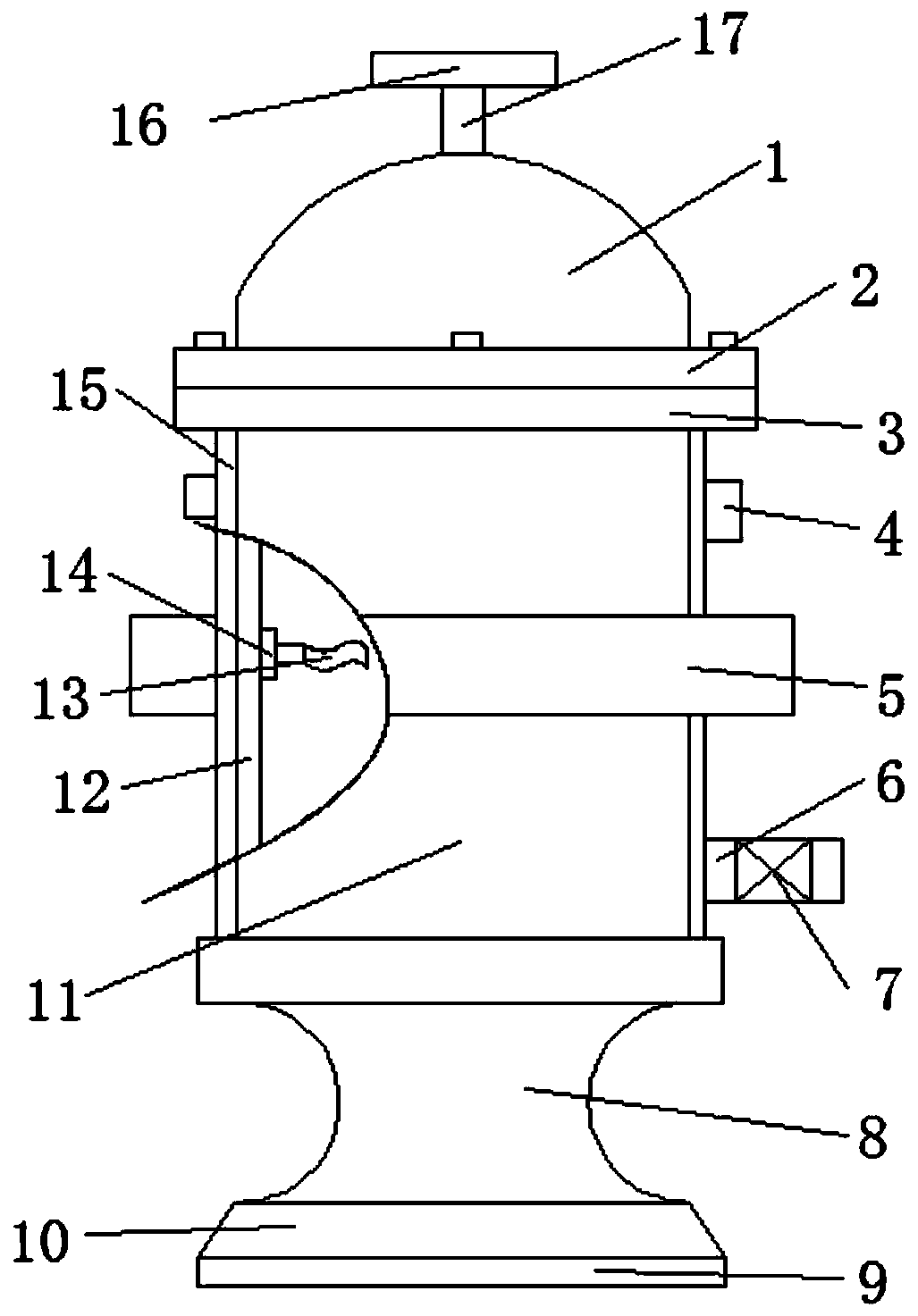

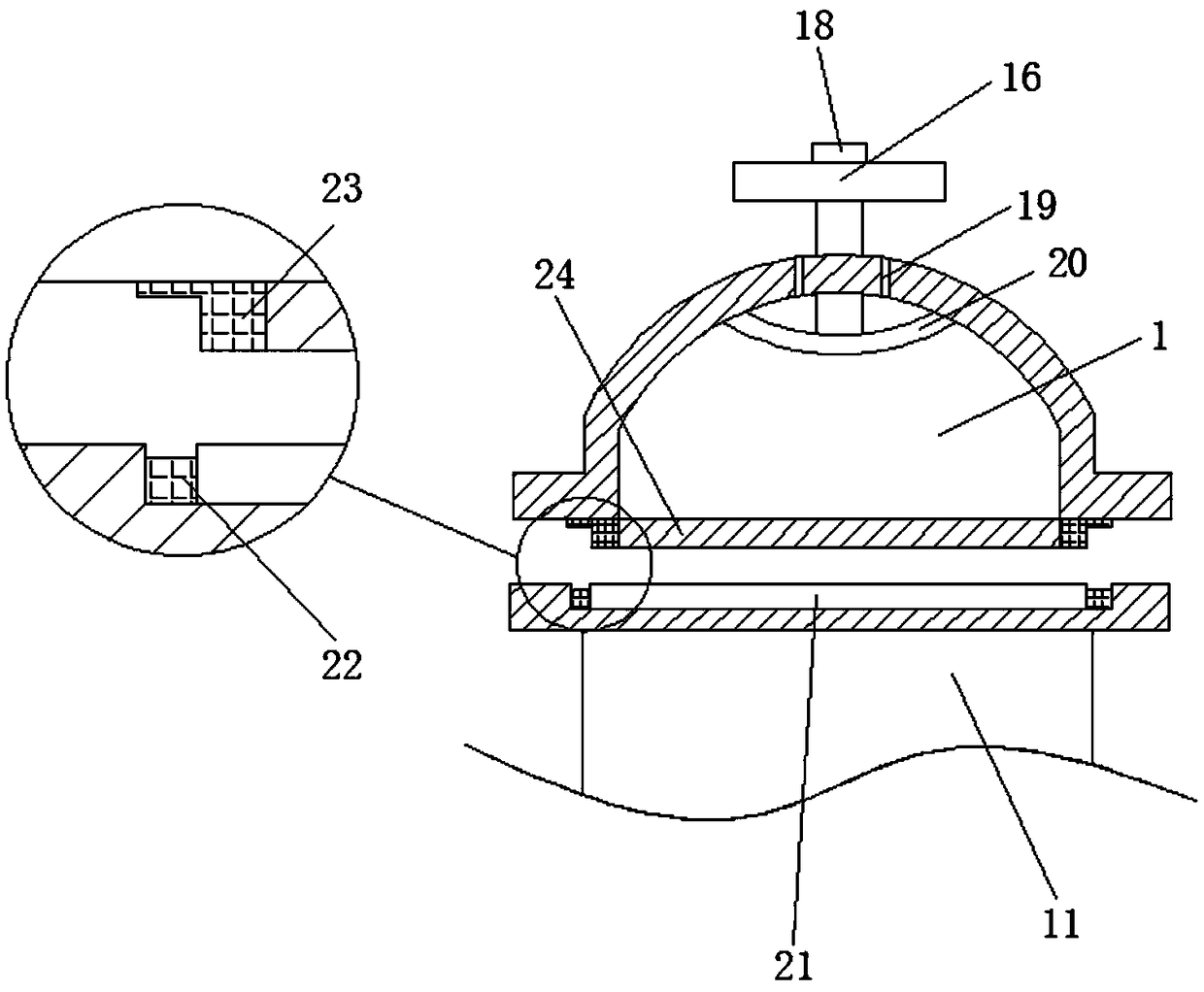

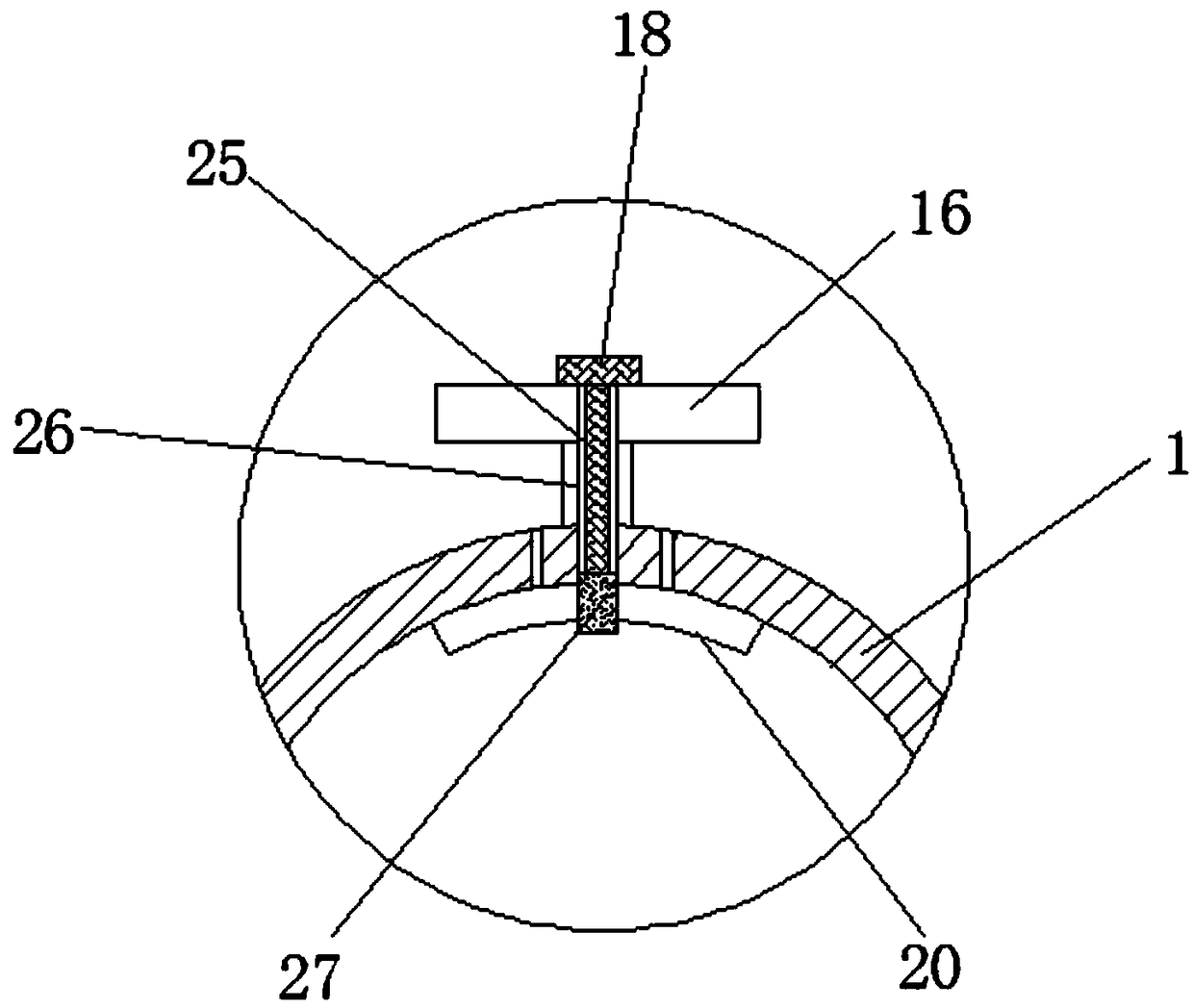

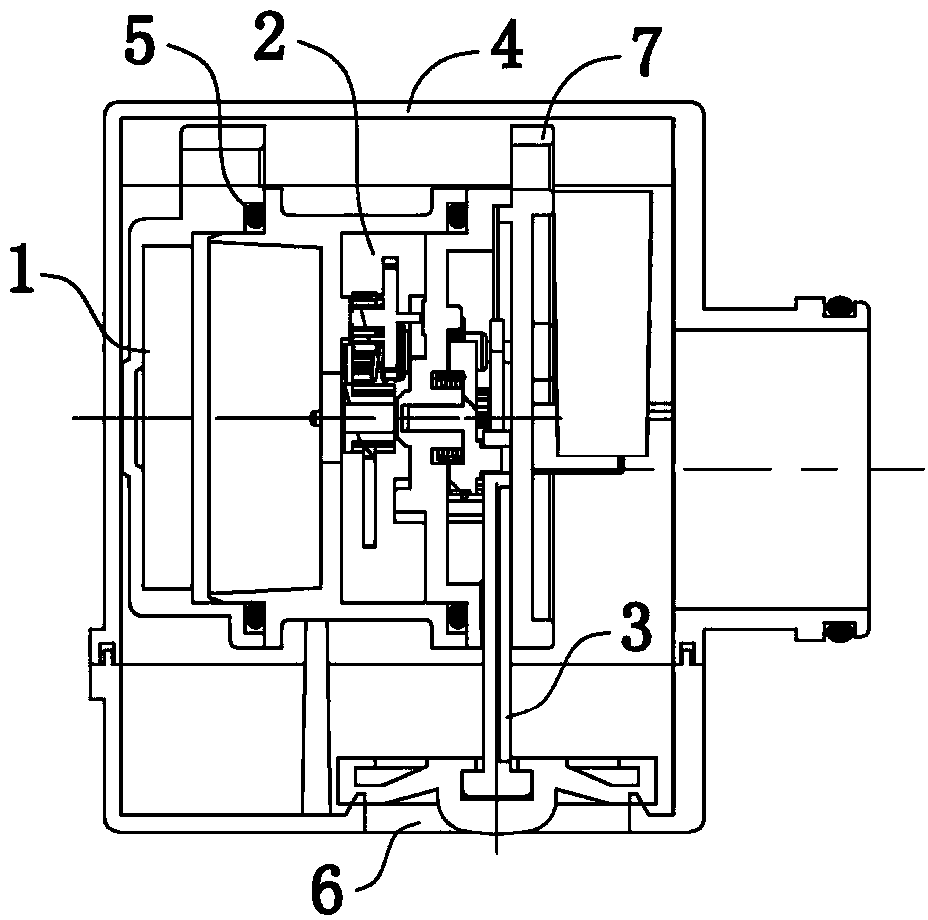

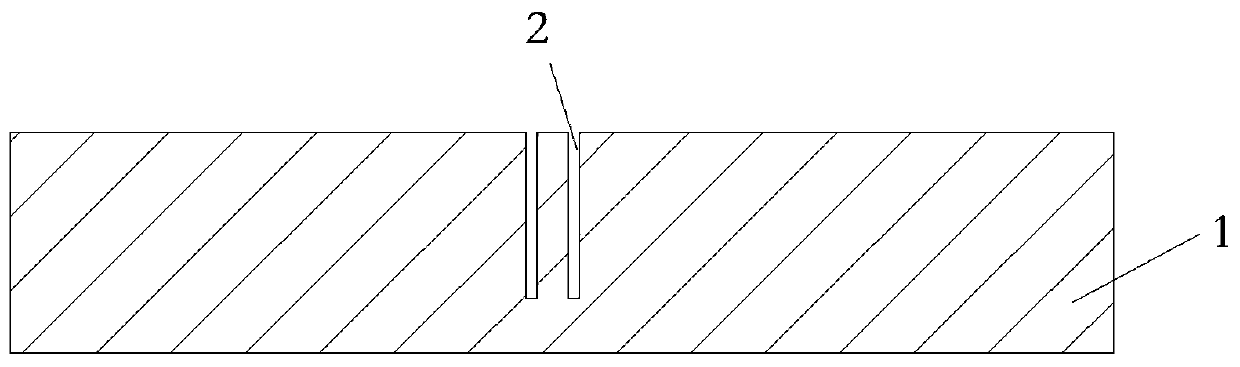

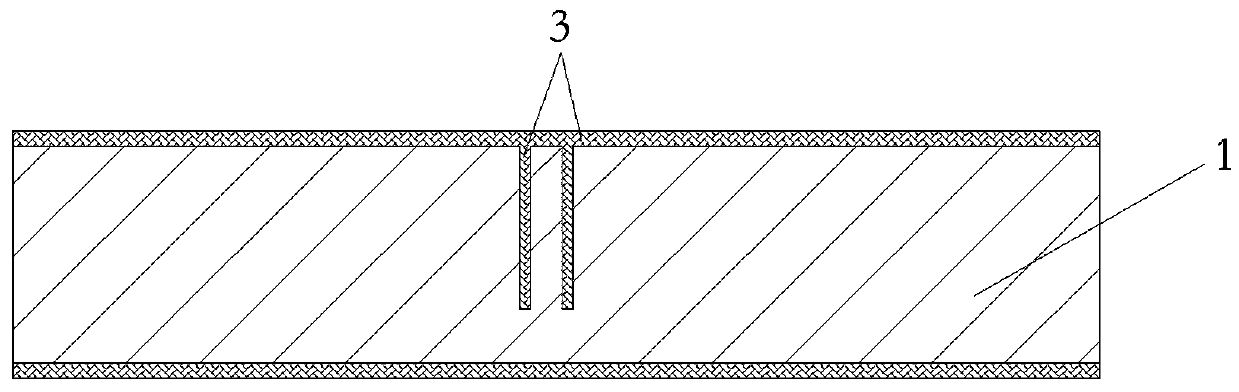

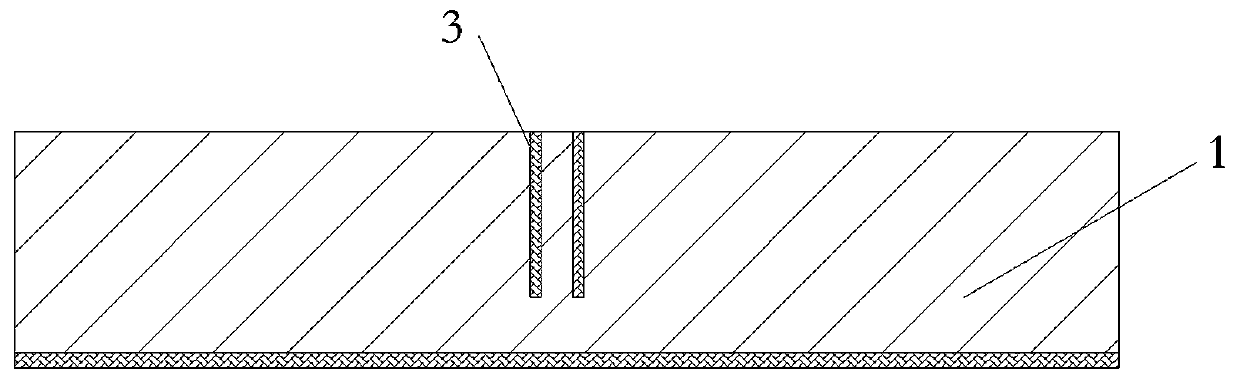

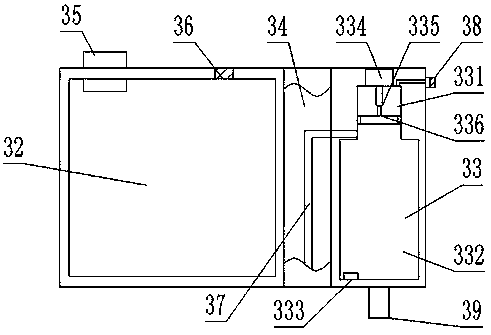

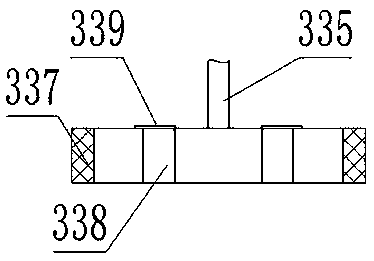

Nitrogen-filled type pressure vessel for sealed glass lining equipment

ActiveCN109335315AReduce shakingSimple structurePackaging under vacuum/special atmosphereContainers to prevent mechanical damageSEMI-CIRCLENoble gas

The invention belongs to the technical field of pressure vessels, and particularly relates to a nitrogen-filled type pressure vessel for sealed glass lining equipment to solve the problem that the physical design is simple, the function is single, excessive gas in a vessel can not be exhausted, and sealing setting is without rear gas filling. The nitrogen-filled type pressure vessel comprises an upper cover, a vessel cylinder body and a damping base. The upper cover is a semi-circle cover body. A threaded hole is formed in the top of the upper cover. A threaded connecting rod with matched specification is connected into the threaded hole in a threaded mode. A rotating disc is welded to the outer wall of the top of the threaded connecting rod. An annular suction cup with matched specification is fixed to the end, located in the upper cover, of the threaded connecting rod by bolts. Slow flow is conducted to stored objects in the vessel, and shaking amplitude of the objects is reduced. The device is rich is structure and has various functions. Function Diversity of the device is improved, excessive gas in the vessel can be removed, and the exhausting function of the device is improved.

Owner:江苏工搪化工设备有限公司

Method for realizing low nitrogen combustion in vertical flue of coke oven combustion chamber

ActiveCN107057721AReduce concentrationSuppress generationCombustible gas coke oven heatingEnergy inputCombustion chamberLow nitrogen

The invention relates to a method for realizing low nitrogen combustion in a vertical flue of a coke oven combustion chamber. Preheated combustion supporting air enters the vertical flue from an combustion supporting air bottom outlet, then is mixed with exhaust gas, and then jets upward to be in contact combustion with lean gas / mixed gas erupted from a rich gas outlet or lean gas bottom outlet to form mild and deep hypoxic dilution combustion; along the height direction of the vertical flue, each section of combustion supporting air outlets and gas outlets are arranged in a staggered mode, so that there is always excessive combustion supporting air to react with low-concentration gas or excessive gas to react with oxygen-lean combustion supporting air in the combustion process to form a concentration deviation combustion process; the gas flow of each outlet is controlled by a flow adjusting device, and the last section of the combustion supporting air outlets is arranged higher than the last section of the gas outlets, so that there is a high temperature reduction area in the vertical flue, and in the high temperature reduction area, there is residual reduction gas capable of reducing generated NOx in high temperature exhaust gas. The method can effectively reduce the NOx concentration in the exhaust gas.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Catalyst calcining box

ActiveCN102039206AHeating evenlySlow down exothermic reactionCatalyst activation/preparationHoneycombProduct gas

The invention discloses a catalyst calcining box comprising a box body and a box cover, wherein pores are evenly distributed on the box cover, each pore is provided with a pore cap, and the pore cap is matched with the pore to close the pore; under the action of airflow, the pore cap can be opened to uniaxially discharge gas in the box; the pore cap has a T-shaped cross section; and the pore cap closes the pore by self weight. The closed calcining box not only can evenly heat catalyst but also can alleviate and lower thermal shock; and the pore cap not only can prevent the undesired external gas atmosphere from entering the calcining box, but also can automatically discharge excessive gas in the box so as to control exothermal reaction. On the premise of ensuring sufficient catalyst activity, the calcination percent of pass can be greatly improved, and the calcination percent of pass is above 99% in producing honeycomb SCR (Selective Catalytic Reduction) smoke denitration catalyst.

Owner:CHENGDU DONGFANG KWH ENVIRONMENTAL PROTECTION CATALYSTS

Sealed type cell manufacturing method

ActiveUS9099754B2Simple structureImprove stress resistanceLarge-sized flat cells/batteriesFinal product manufactureAlloyCell assembly

A cell assembly (20) is formed by arranging an electrode body and electrolyte in an external case (12) having a through hole (41). A laser is applied to an annular portion (formed by Al or Al-based alloy) surrounding an opening end (41A) of the through hole (41) toward outside the case so as to form a welded base (45). A sealing film (54) is welded to the surface of the welded base directly or via a base film (52) welded in advance, so as to temporarily seal the through hole (41). The cell assembly (20) in the temporarily sealed state is subjected to initial charge and then a hole is opened through the film (54) so as to form a gas discharge passage for communication between inside and outside of the case (12), thereby discharging an excessive gas from the case (12) outside.

Owner:TOYOTA JIDOSHA KK

Gas-type road limit device

Owner:张礼国

Water seal type floor drain

InactiveCN106223452ARelieve pressureMove up and down steadilySewerage structuresWater dischargeEngineering

The invention relates to a water seal type floor drain, which comprises a filtering cover, a water seal, a water drainage opening and a semispherical floating body, wherein the semispherical floating body is arranged on the water drainage opening; a guide pipe is arranged in the center position of the floating body; a guide rod passes through the guide pipe and is in clearance fit with the guide pipe; the upper end of the guide rod is fixed on the filtering cover or the water seal; the floating body can vertically move along the guide rod through the guide pipe; the lower end of the guide pipe is in a horn opening shape; the lower end of the guide rod is provided with a cone body matched with the shape of the horn opening formed in the lower end of the guide pipe; the cone surface of the cone body is matched with the horn opening formed in the lower end of the guide pipe in a sealed way. The floor drain has the advantages that excessive gas accumulated between the floating body and the water seal can be released into a drain pipe through a gap formed between the guide pipe and the guide rod; the upwards floating pressure of the floating body can be effectively reduced; the free upward floating of the floating body can be ensured under the continuous mass water drainage condition of the floor drain; the water discharge is smooth; in addition, the stable vertical movement of the floating body can be realized; the deviation from the water drainage opening cannot occur.

Owner:李天放

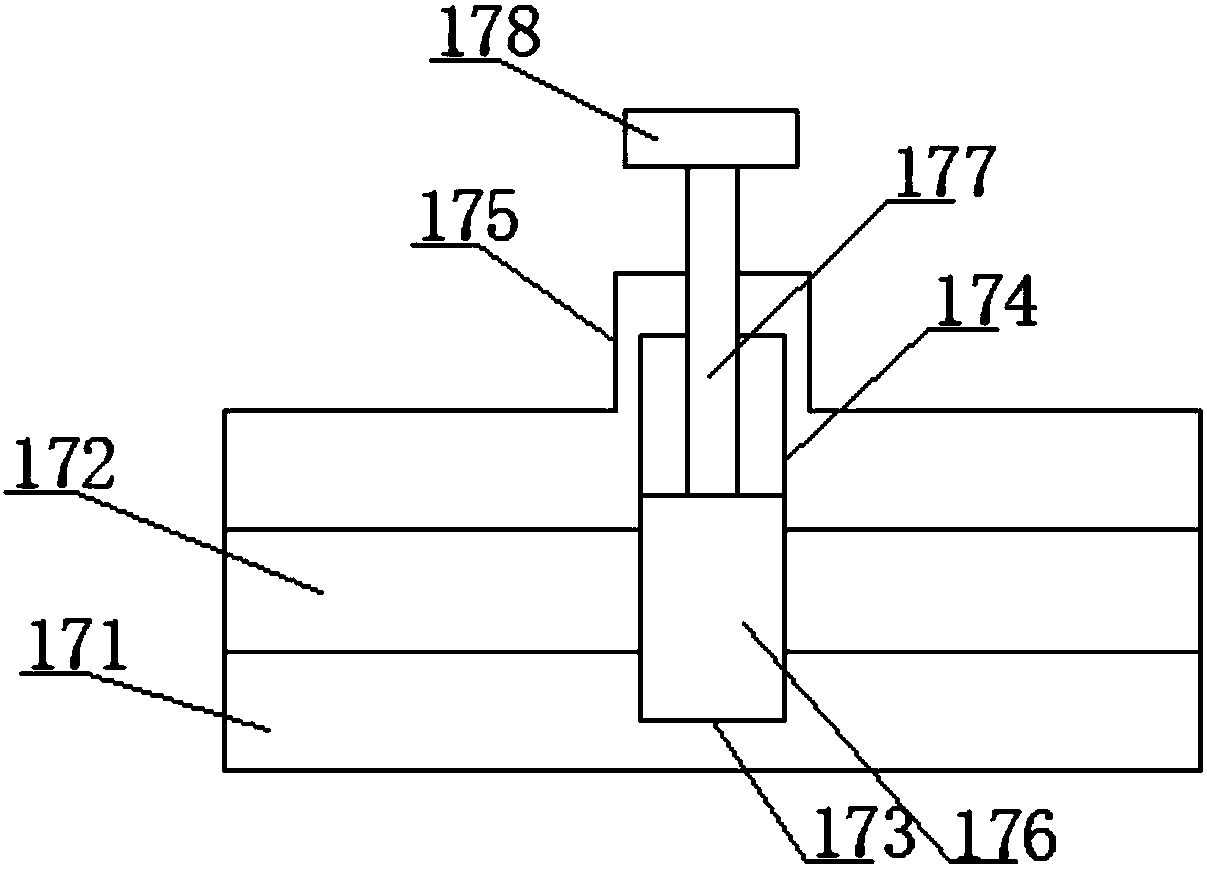

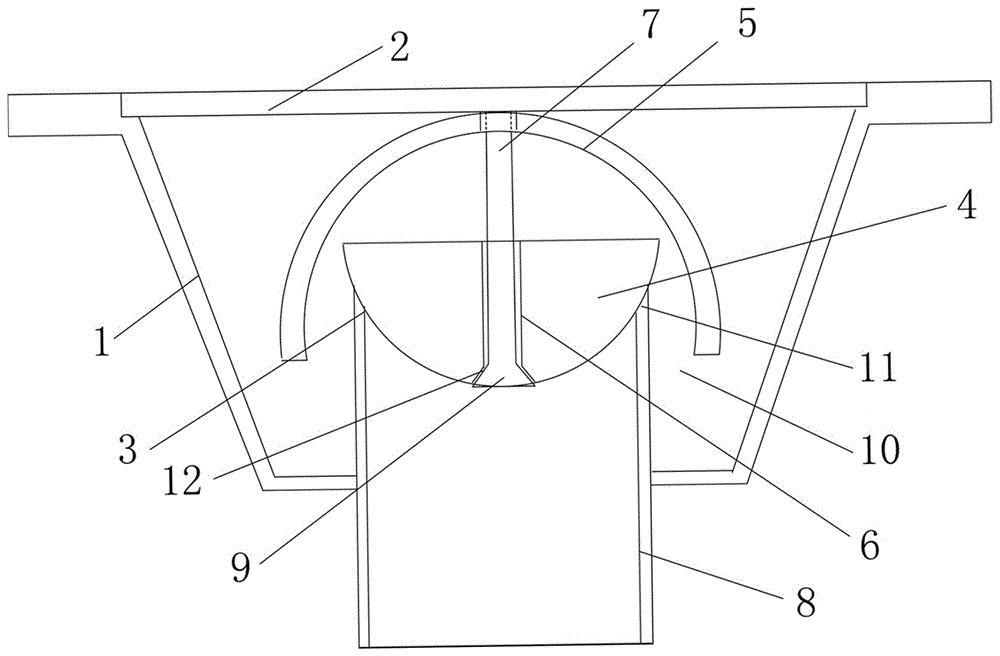

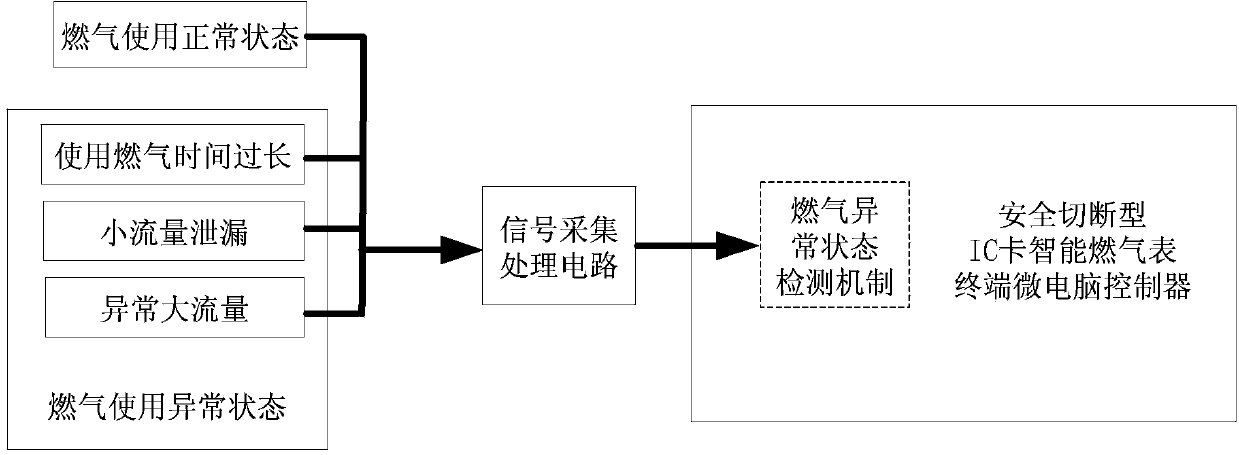

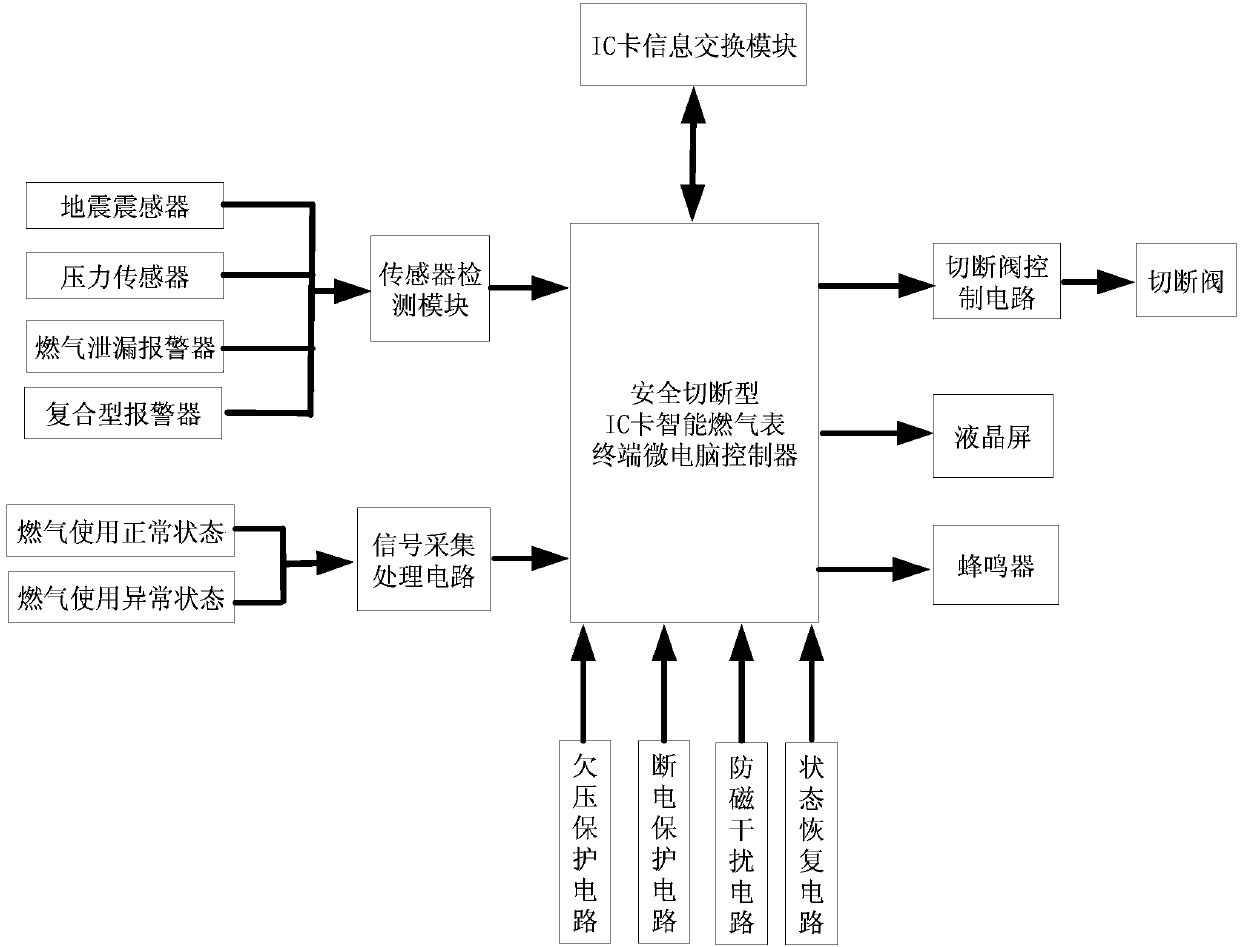

Safe-cutoff IC card intelligent gas meter

InactiveCN103745535ASimple structureSuitable for industrial productionOperating means/releasing devices for valvesApparatus for hiring articlesMicrocomputerGas meter

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

MEMS wafer-level vacuum packaging method

InactiveCN110562910AIncrease vacuumSolve problemsDecorative surface effectsSolid-state devicesLead bondingBonding process

The invention discloses an MEMS wafer-level vacuum packaging method, which comprises the following steps: S1, manufacturing a substrate layer: manufacturing an annular groove filled with an insulatingmedium on a double-polished silicon wafer to form a silicon vertical lead, and etching a deep cavity to serve as an activity space of an MEMS movable structure; S2, manufacturing a structural layer;S3, manufacturing a cap layer: manufacturing a vacuum chamber and a vacuum buffer chamber on the front surface of the double-polished silicon wafer, then manufacturing a Ti / Au gold-silicon bonding ring, and finally preparing a getter layer in the vacuum chamber and the vacuum buffer chamber; and S4, vacuum packaging: performing a gold-silicon bonding process on the prepared cap and the structure layer to complete MEMS wafer-level vacuum packaging, and finally preparing gold welding spots for lead bonding; the vacuum degree of the MEMS device is improved through the vacuum chamber and the vacuum buffer chamber, and excessive gas is absorbed by the getter, so that the vacuum degree can be kept for a long time.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

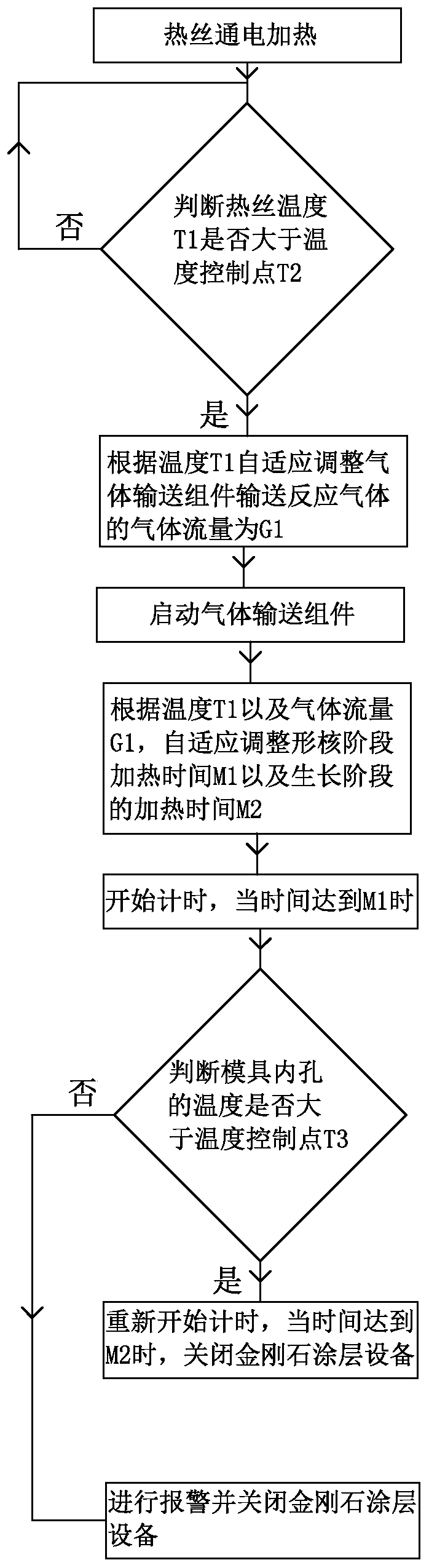

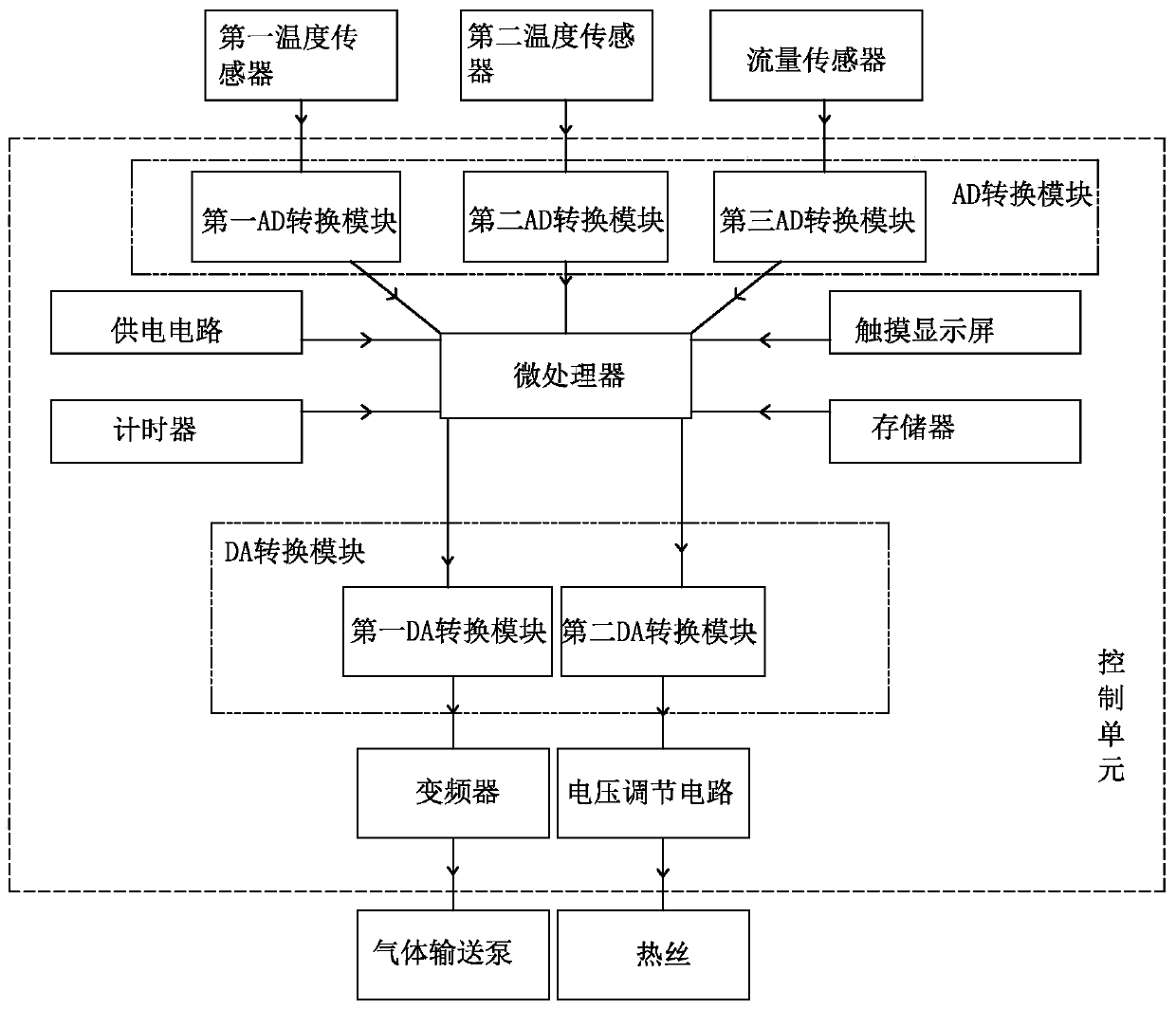

Automatic control method of hot wire CVD nano diamond coating

ActiveCN110387533AEffectImprove growth efficiencyChemical vapor deposition coatingTemperature controlHeating time

The invention discloses an automatic control method of a hot wire CVD nano diamond coating. A diamond coating device firstly detects whether a hot wire temperature T1 is larger than a temperature control point T2 or not in real time, when the hot wire temperature T1 is larger than the temperature control point T2, the flow G1 of the reaction gas is determined according to the hot wire temperatureT1 at the moment, meanwhile, the gas flow of an output opening of a gas conveying assembly is set according to the gas flow G1, and the heating time M1 of the nucleation stage of a die inner hole andthe heating time M2 of the growth stage are determined according to the current hot wire temperature T1 and the gas flow G1. By means of the automatic control method, the gas flow of the reaction gas,the heating time of the nucleation stage of the nano diamond coating and the heating time of the growth stage can be automatically adjusted according to the hot wire temperature, the growth efficiency of the nano diamond coating of the die inner hole can be effectively improved, meanwhile, the nano diamond coating of the die inner hole can be more uniform, and the phenomenon that due to the excessive gas, waste is caused or due to the too little gas, the effect of the nano diamond coating is affected can be avoided.

Owner:珠海中纳金刚石有限公司

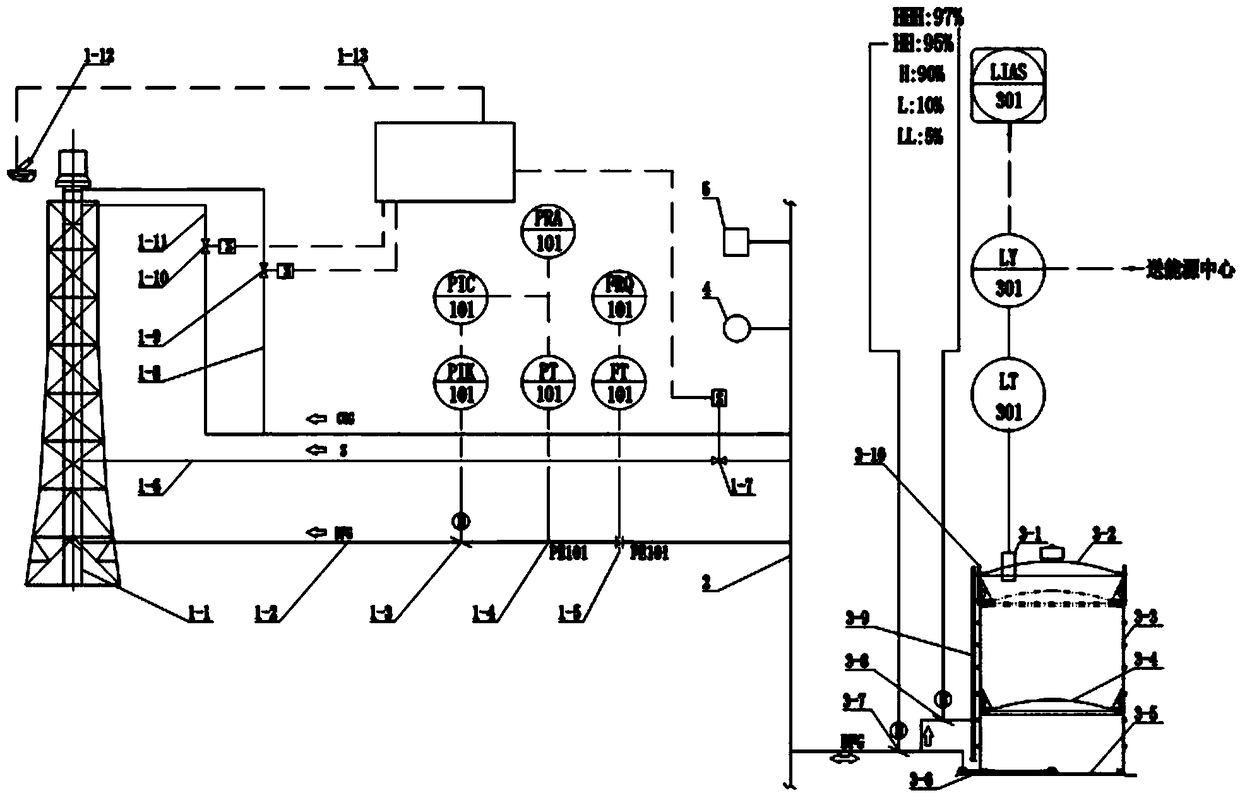

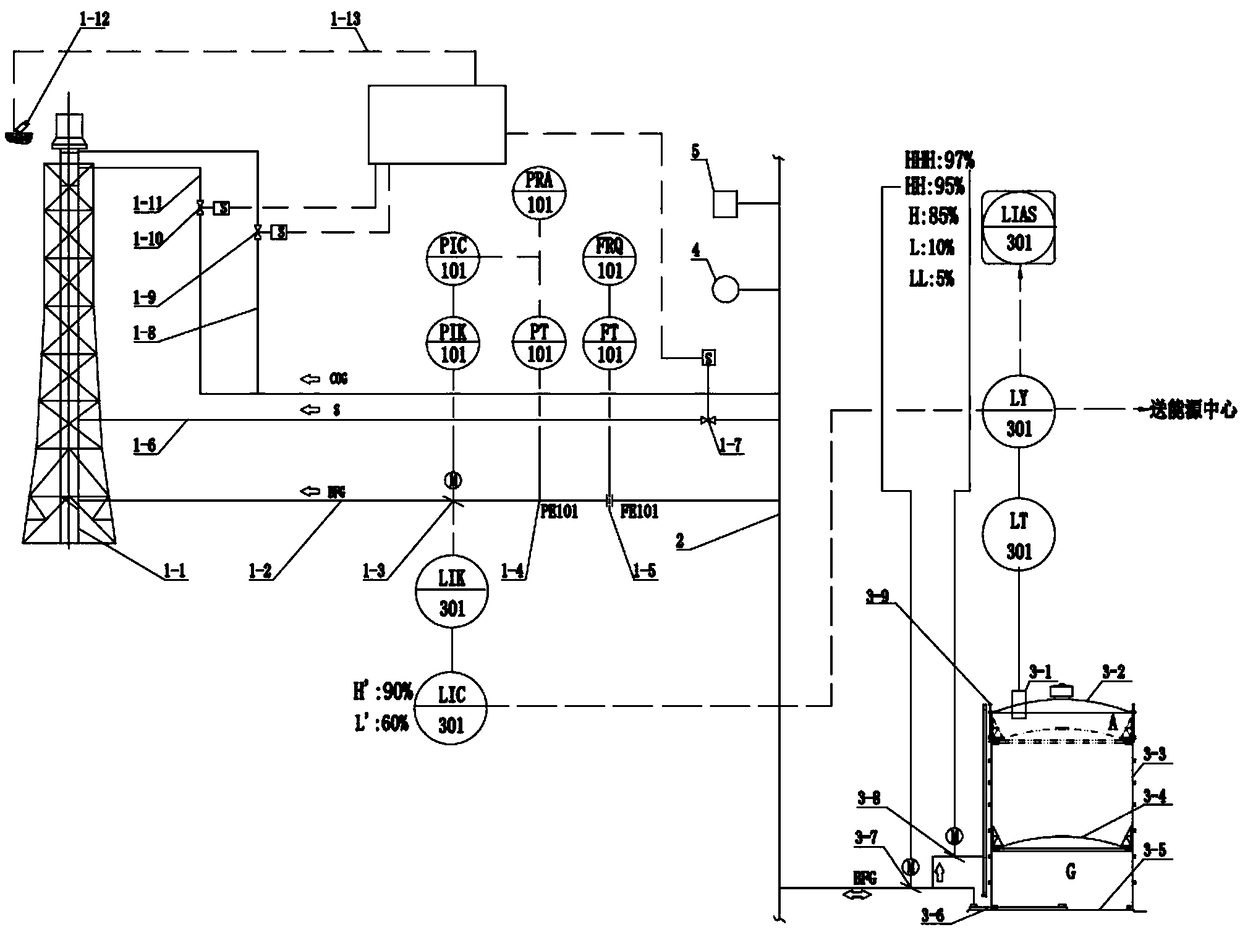

Automatic excessive gas diffusing system

The invention relates to an automatic excessive gas diffusing system and belongs to the field of gas distribution and storage projects. The automatic excessive gas diffusing system comprises a vertical burning and diffusing pipe, a diffusing system main gas pipe, a gas regulating valve, a pressure detecting device, a flowmeter, a steam pipeline, a magnetic steam valve, coke oven gas pipeline usedduring burning, a magnetic coke oven gas valve used during burning, a magnetic coke oven gas valve for ignition, a coke oven gas pipeline for ignition, a gasometer system and a diffusing ignition control module. A gasometer capacity signal of a gasometer is introduced into the automatic excessive gas diffusing system. The signal is sent when a gasometer piston rises to a certain height, the automatic excessive gas diffusing system is opened for gas diffusion and burning. The signal is sent after the piston descends to a certain height, the automatic excessive gas diffusing system is closed, excessive gas in a pipe network system and a gasometer in a whole plant is burned and diffused through the automatic excessive gas diffusing system so as to protect the environment and safety of personsnearby the gasometer to the most degree.

Owner:CISDI ENG CO LTD

Fuel cell motorcycle

InactiveCN101259863ALittle effect of inclinationImprove aestheticsFinal product manufactureMotorised scootersHydrogenFuel cells

Owner:HONDA MOTOR CO LTD

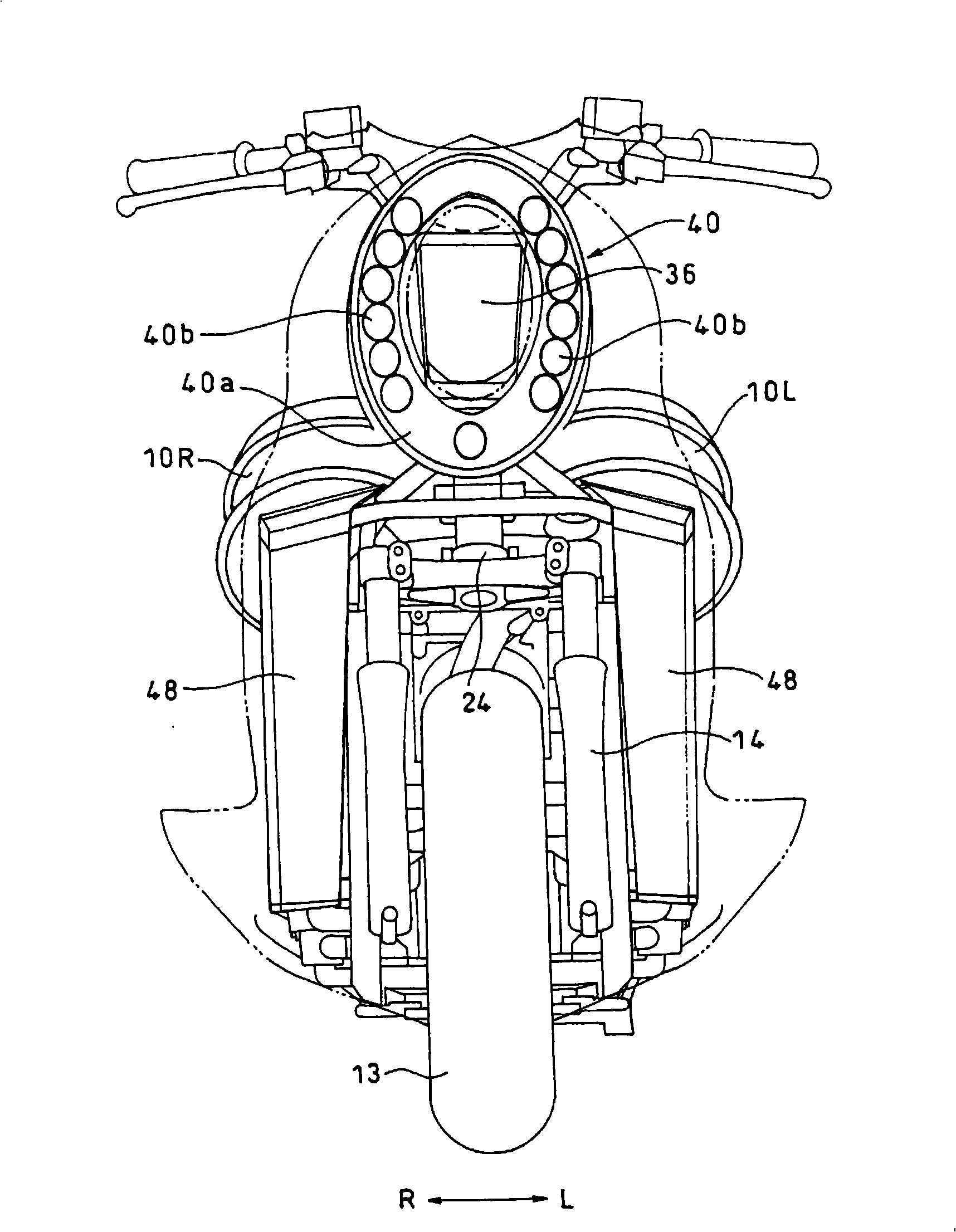

Plant protection unmanned aerial vehicle capable of quantitatively spraying

InactiveCN109398714AIngenious structureAvoid transmissionAircraft componentsLaunching weaponsPressure senseEngineering

The invention discloses a plant protection unmanned aerial vehicle capable of quantitatively spraying. The plant protection unmanned aerial vehicle capable of quantitatively spraying comprises a frameand a power frame fixed above the frame; a pesticide box is arranged between the frame and the power frame; a spraying pipe is arranged under the frame; multiple spraying heads are arranged at the bottom of the spraying pipe; the spraying pipe communicates with the pesticide box; a storage cavity, a transferring pipe cavity and a quantifying cavity are formed in the pesticide box in sequence; a pesticide supplementing port and a first pressure stabilizing port are formed in the top of the storage cavity; a transferring pipe for connecting the storage cavity with the quantifying cavity is arranged in the transferring pipe cavity; and the connecting part of the transferring pipe and the storage cavity is positioned at the bottom of the storage cavity. According to the plant protection unmanned aerial vehicle capable of quantitatively spraying, the internal structure of the pesticide box is skillful; by using a mechanical structure in the quantifying cavity, a pesticide liquid is quantitatively transferred; and by using a pressure sensing structure, the quantity of the transferred pesticide liquid is determined; as the quantitative transferring mode is different from a traditional pumping timing mode, a situation that the quantifying of the whole device is not accurate due to timed pumping after vibrating and mixing excessive gas in the pesticide liquid can be avoided, and therefore, accurate quantification value is guaranteed.

Owner:ZAOZHUANG CHENSHI MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com