Fabric for airbag, and airbag

A technology of fabrics and airbags, which is applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of poor impact absorption performance and slow deployment speed, etc., and achieve excellent crack resistance, thermal physical property change suppression, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

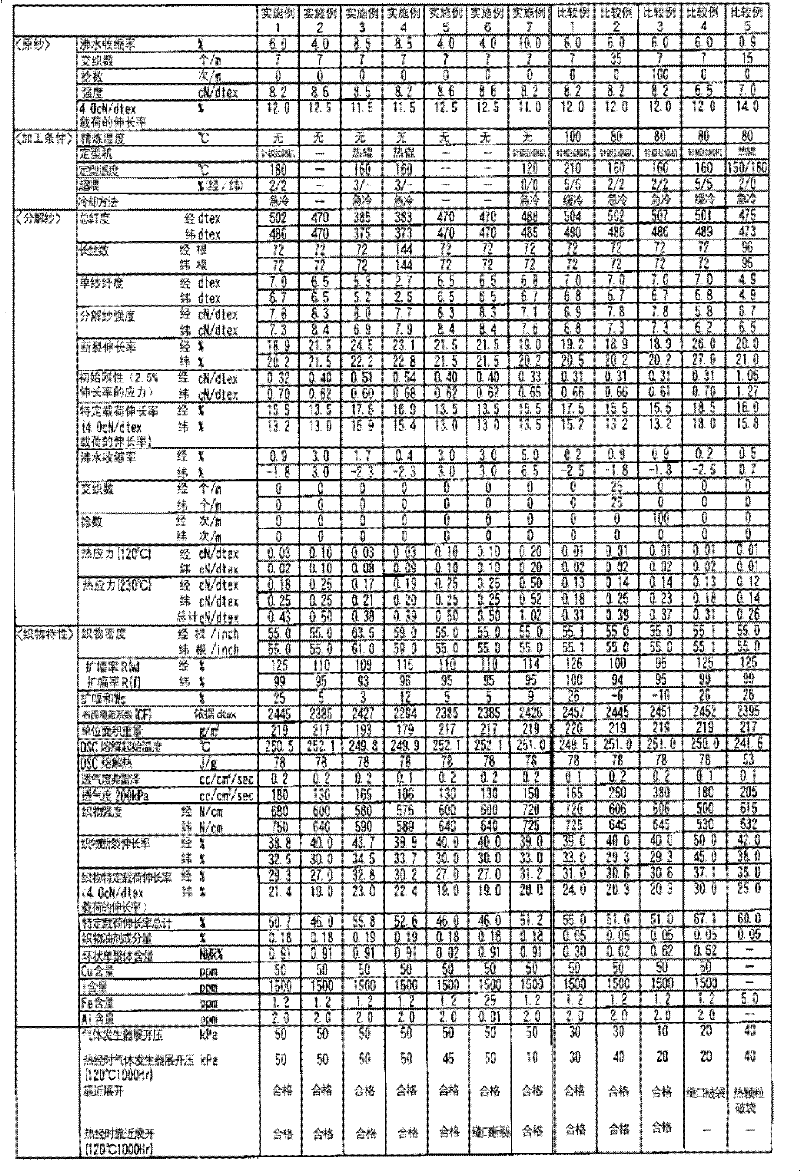

Embodiment 1

[0135] The polymerization catalyst sodium hypophosphite is added to the aqueous solution containing the neutralized salt of hexamethylenediamine and adipic acid, and after polycondensation by a continuous polymerization device, the aqueous solution of heat stabilizer copper iodide / potassium iodide is added to form a resin sheet through post-stage polymerization. Then use solid phase polymerization to obtain a polyamide 6.6 resin with a relative viscosity ηr3.1. The iron element content of the polyamide 6.6 resin was 0.12 ppm. When the polyamide 6.6 resin is melt-spun with a melt extruder, a cyclic monomer and aluminum montanate are added. A metal non-woven fabric filter (average pore size: 15 μm) made of Hastelloy alloy C22 was used as the filter of the melt spinning machine. Furthermore, a spinning finish component was applied to the extruded filaments, followed by thermal drawing to obtain polyamide 6·6 fibers. The spinning finish is composed of 60 parts by weight of diole...

Embodiment 2

[0141] A polyamide 6.6 fiber having a boiling water shrinkage rate of 4.0% was used for the yarn for weaving, and it was carried out in the same manner as in Example 1, except that it was not refined and set after weaving. The results are shown in Table 2. There is no loss of development gas, the gas generator development pressure is sufficient, and the gas generator development pressure is equally sufficient during the heat cycle. No hot particles break the bag.

Embodiment 3

[0143]The polyamide 6.6 fiber with a fineness of 350dtex, a number of filaments of 72, a single yarn fineness of 4.9dtex, and a boiling water shrinkage rate of 8.5% is used for weaving yarns. The heating roll of ℃ was carried out in the same manner as in Example 1, except that the cloth was overfeeded by 3% and quenched. The results are shown in Table 2. There is no loss of development gas, the gas generator development pressure is sufficient, and the gas generator development pressure is equally sufficient during the heat cycle. No hot particles break the bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com