Comprehensive and integrative gas drainage method

A gas drainage and gas technology, which is applied in the field of comprehensive and integrated gas drainage, can solve the problems of high coal falling intensity, difficulty in gas drainage, and gas exceeding the limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

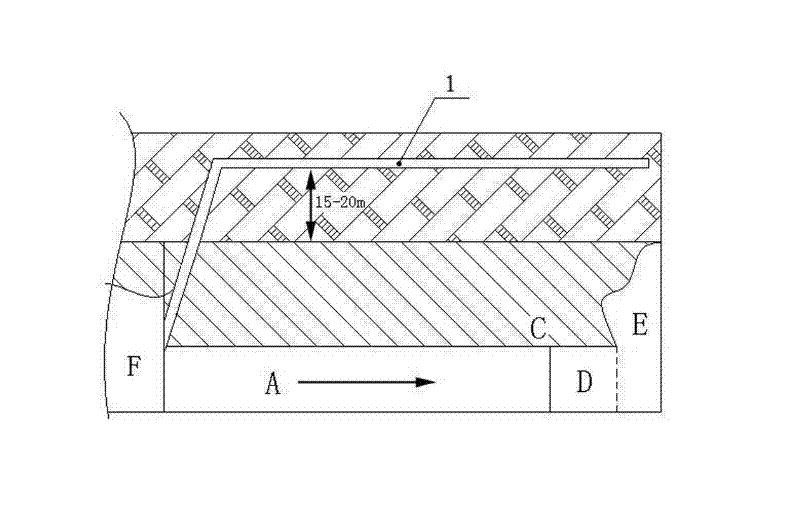

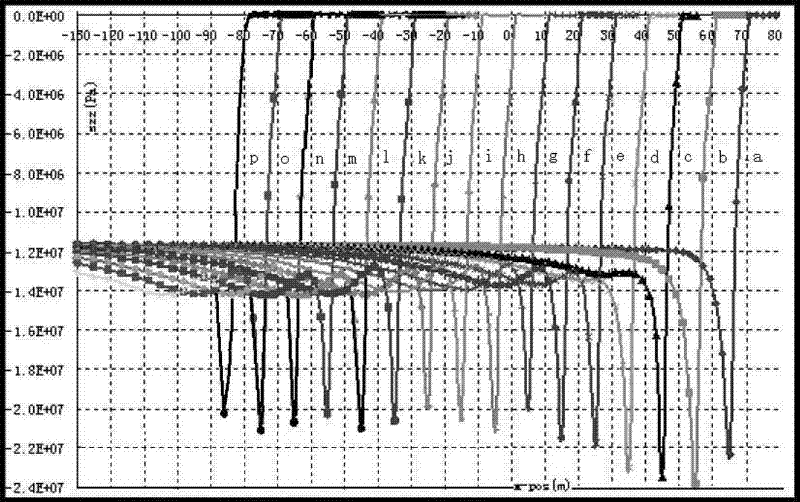

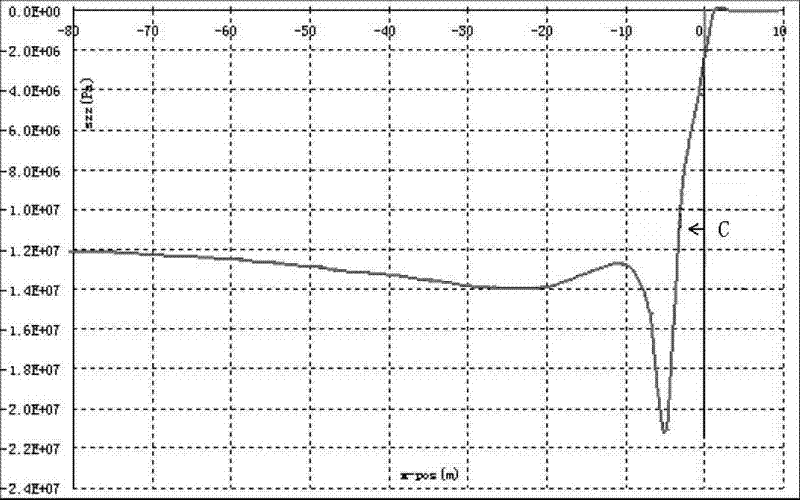

[0043] The method is further described in conjunction with the following figures:

[0044] A comprehensive and integrated gas drainage method, comprising the following steps: a) Drainage from a high-level fissure borehole 1 on the roof of a coal seam; b) Drainage from an oblique high-level drillhole 2 in a return airway; c) Upper corner of a goaf Corner buried pipe 3 extraction; Wherein, described coal seam roof high level fissure drilling hole 1 extraction specifically is: see figure 1 and figure 2 , Drill some obliquely upward drilling holes in the range of 7-15 meters near the return air lane in Xiabang, and change the oblique drilling to horizontal drilling when drilling to the range of 15-20 meters from the roof of the coal seam. hole, and then drilled into the rock formation fissure zone directly above the goaf, to drain the gas in the rock formation fissure zone above the goaf due to mining; put specifically: see Figure 5, there are several obliquely upward high-le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Elevation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com