Gas dust catcher

A trap and gas technology, applied in the direction of gas discharge, dust prevention, safety devices, etc., can solve the problems of threatening mine safety production, affecting the physical and mental health of employees, and excessive dust, so as to achieve convenient installation and removal, increase perforation rate, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

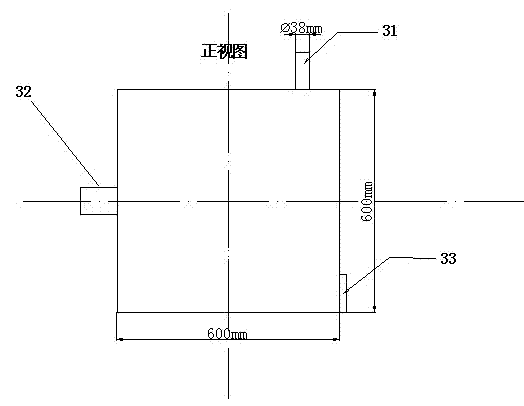

[0013] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

[0014] see Figure 4 , The gas dust trap consists of three parts, the first part is the sleeve 1, the second part is the gas dust capture box 2, and the third part is the gas and water slag diversion box 3, and each part is connected by a thread or a rubber hose.

[0015] A kind of concrete structure and size of the present invention are specifically exemplified below:

[0016] 1. Sleeve 1, see figure 1 :

[0017] The sleeve 1 is connected with the gas dust capture box 2, and this part is mainly used for lengthening when the nozzle of the confluence is not long enough to penetrate into the borehole. The overall length of the sleeve: 600mm (or 1000mm), the inner diameter: 78mm, the outer diameter: 86mm, and the end connected with the gas dust capture box 2 has an external thread.

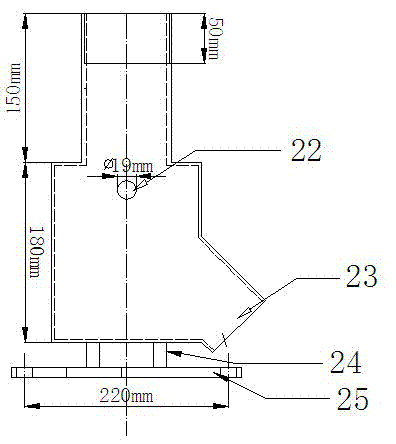

[0018] 2. Gas dust capture box 2, see figure 2 :

[0019] The gas dust ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com