Flight simulating system and driving unit

A flight simulation and drive unit technology, applied in the mechanical field, can solve the problems of insufficient functionality, poor reliability and lifespan, etc., and achieve the effect of simple structure, high reliability and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

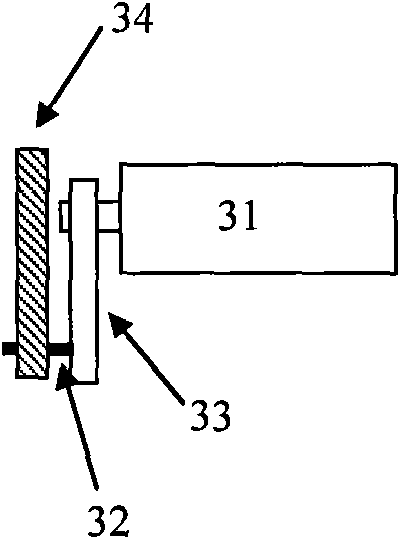

[0039] The preferred embodiment of the present invention proposes a flight simulation system, its structure is as image 3 , Figure 4 , Figure 5 It includes a motor 31, a load (not shown in the figure), and a connection mechanism. Connecting mechanism comprises active rod 33 and connecting rod 34, and active rod 33 one end is fixedly connected to the power output shaft of motor 31, and rotates with power output shaft; The other end of active rod 33 connects an end of connecting rod 34 by shaft 32; Connecting rod 34 The other end is fixedly connected to the load.

[0040] In a preferred embodiment of the present invention, the motor pushes the seat or the cockpit to move up and down through a crank linkage mechanism. When the motor is not working, such as image 3 As shown, the active rod 33 is at the lower limit position under the action of load gravity. Such as Figure 6 As shown, the active rod 33 can rotate 360 degrees with the power output shaft, so that the shak...

Embodiment 2

[0051] The preferred embodiment of the present invention proposes the driving unit of the flight simulation system, its structure is as follows image 3 , Figure 4 , Figure 5 Including motor 31, connecting mechanism. The connecting mechanism includes an active rod 33 and a connecting rod 34. One end of the active rod 33 is fixedly connected to the power output shaft of the motor 31 and rotates with the power output shaft;

[0052] When the driving device is used with a load, the other end of the connecting rod 34 is fixedly connected to the load (not shown in the figure).

[0053] In a preferred embodiment of the present invention, the motor pushes the seat or the cockpit to move up and down through a crank linkage mechanism. When the motor is not working, such as image 3 As shown, the active rod 33 is at the lower limit position under the action of load gravity. Such as Figure 6 As shown, the active rod 33 can rotate 360 degrees with the power output shaft, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com