Full-automatic small type block machinery having environment-protecting and energy-saving functions

A block forming machine, environmental protection and energy-saving technology, applied in ceramic forming machines, ceramic forming workshops, supply devices, etc., can solve the problems of unsatisfactory work performance and high production costs, and achieve reduced failure rates, improved accuracy, and pressure Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

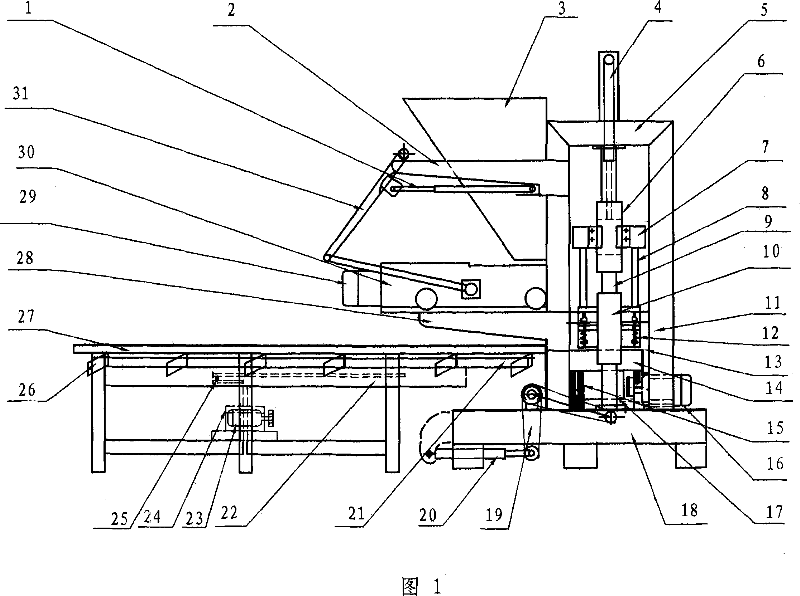

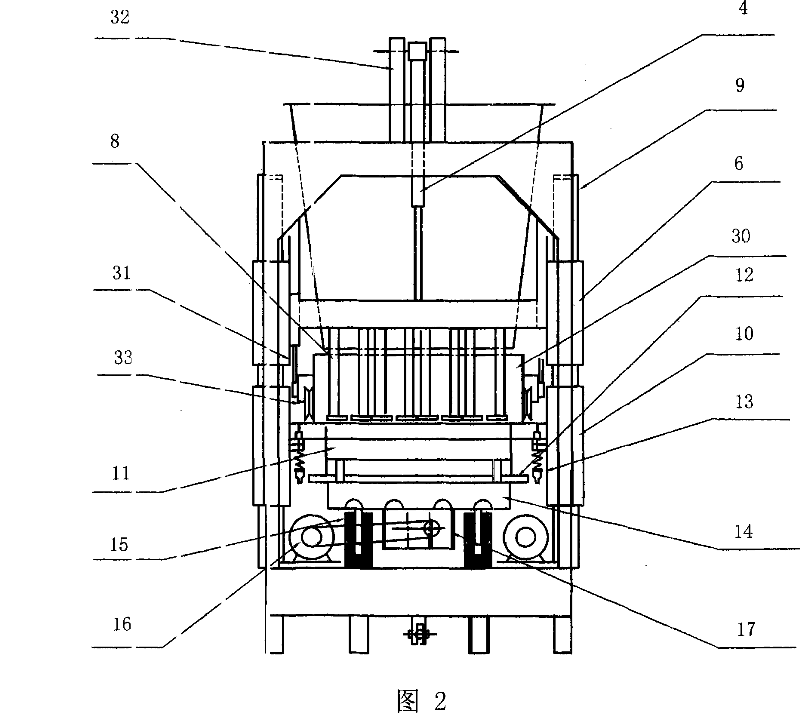

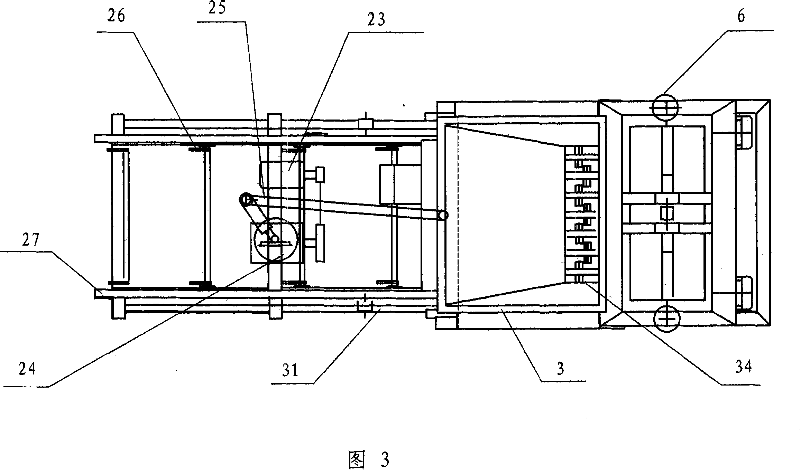

[0023] In Fig. 1, Fig. 2, Fig. 3, frame (5) and support (18) are all welded by channel steel, and the two form a rectangular frame by welding, and each main part of the present invention is installed therein, The dynamic and static force of each component is transmitted to the equipment foundation through the base (18). A material storage module system, a material distribution module system, a block forming module system, a hydraulic demoulding module system and a feeding plate module system are installed in the rectangular frame. The material storage module system is set at the uppermost part of the rectangular frame, the material distribution module system is set at the lower part of the material storage module system, and the two are connected through the discharge pipe of the material storage box; the block forming module system is set at the lower part of the material distribution The discharge pipe of the distribution box is connected with the distribution module system;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com