Mixing and shaking-up device for chemical reagents

A technology of chemical reagents and reagents, which is applied in the field of chemistry, can solve the problems of insufficient stirring of chemical reagents, affect the safety of experimenters, produce toxic gases, etc., and achieve the effects of preventing explosions, improving mixing and shaking, and fast mixing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of this patent is described in further detail below in conjunction with specific embodiments

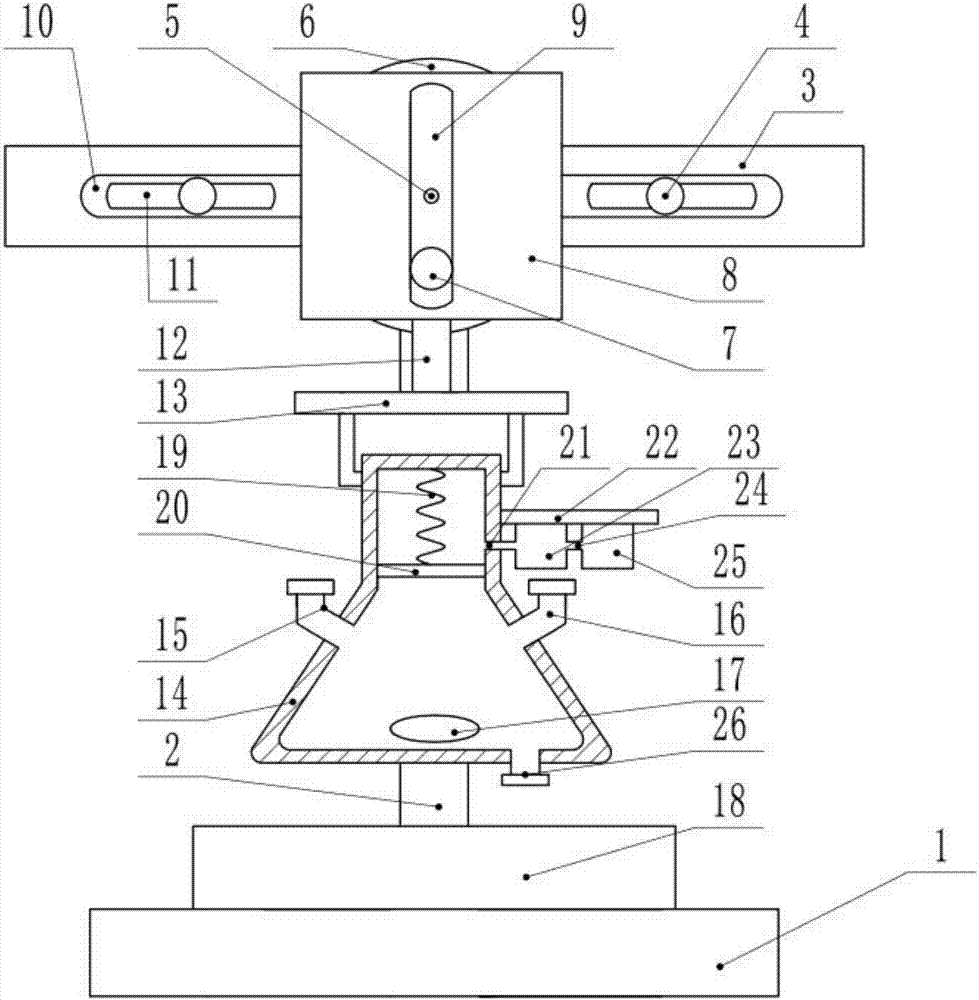

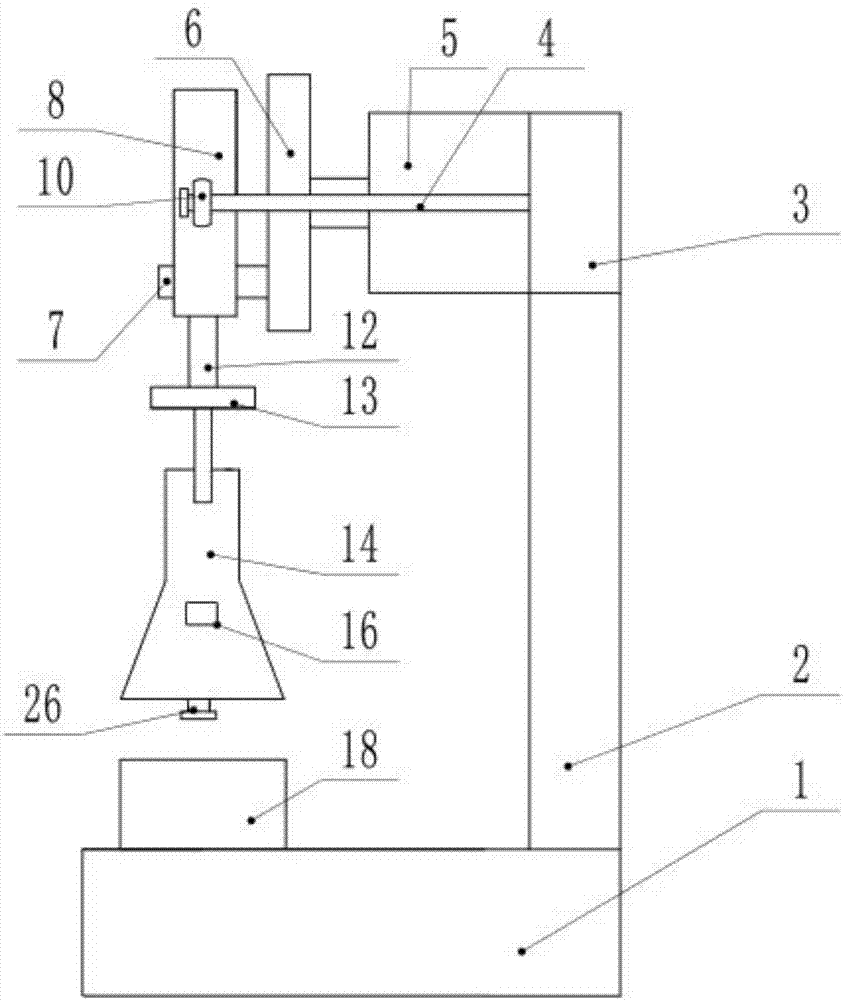

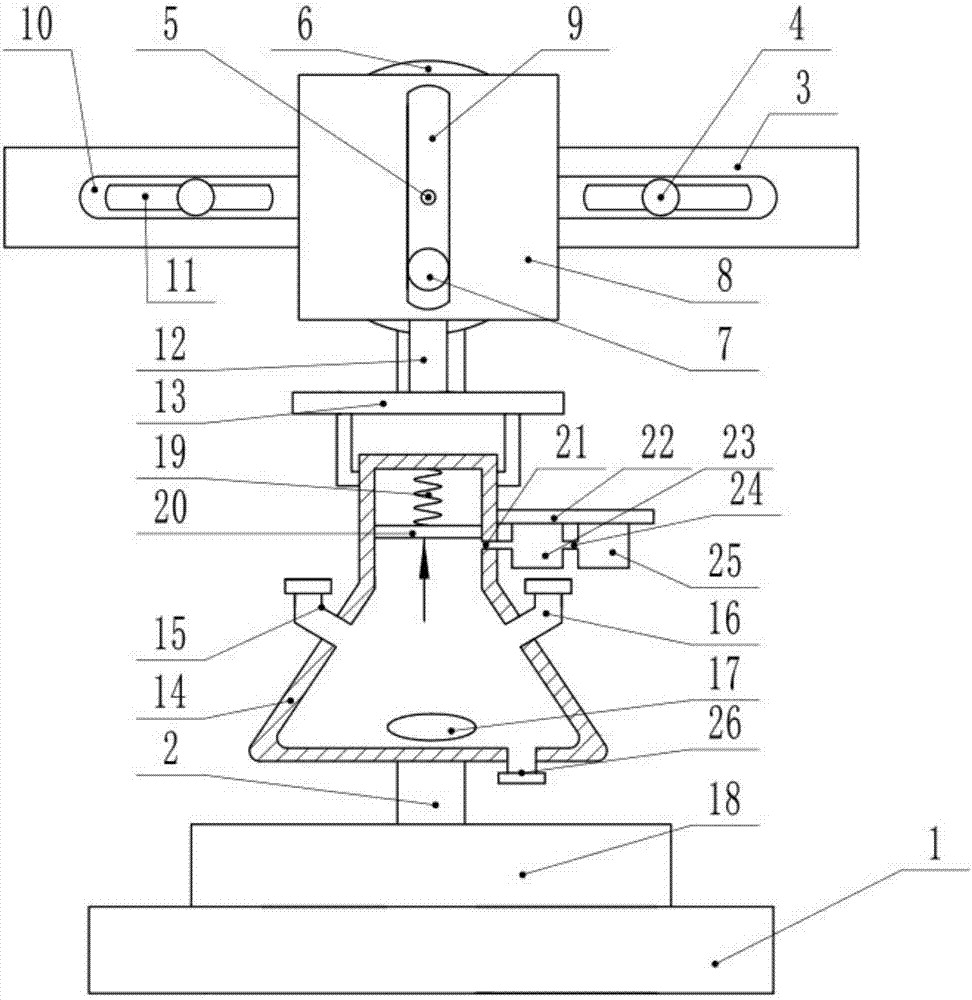

[0024] see Figure 1-4 , a chemical reagent mixing and shaking device, including a base 1, a main support 2, an auxiliary support 3, a drive motor 5, a round wheel 6, a translation plate 8, a reagent bottle 14, a stirring bar 17, a magnetic stirrer 18 and a gas filter device 25. The main support 2 is welded at the center of the base 1, the main support 2 is vertically upward, and the auxiliary support 3 is fixedly welded on the left and right sides of the upper end of the main support 2. The auxiliary support 3 is kept perpendicular to the main support 2 and is located on the left and right sides The auxiliary bracket 3 on the side is fixedly installed with a limit column 4, and the direction of the limit column 4 is forward and the limit column 4 is perpendicular to the auxiliary bracket 3; Forward, a round wheel 6 is fixedly installed on the output shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com