Patents

Literature

1902 results about "Oil additive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil additives are chemical compounds that improve the lubricant performance of base oil (or oil "base stock"). The manufacturer of many different oils can utilize the same base stock for each formulation and can choose different additives for each specific application. Additives comprise up to 5% by weight of some oils.

Production of synthetic lubricant and lubricant base stock without dewaxing

InactiveUS6103099AThermal non-catalytic crackingRefining to change hydrocarbon structural skeletonAutomatic transmissionBoiling point

A lubricating base stock useful for forming lubricants such as a multigrade automotive oils, automatic transmission oils, greases and the like is prepared by hydroisomerizing a waxy hydrocarbon feed fraction having an initial boiling point in the 650-750 DEG F. range and an end point of at least 1050 DEG F., synthesized by a slurry Fischer-Tropsch hydrocarbon synthesis process. The hydroisomerization forms a hydroisomerate containing the desired base stock which is recovered, without dewaxing the hydroisomerate. The hydroisomerization is conducted at conditions effective to convert at least 67 wt. % of the 650-750 DEG F.+ waxy feed hydrocarbons to lower boiling hydrocarbons. When combined with a standard lubricant additive package, these base stocks have been formed into multigrade automotive crankcase oils, transmission oils and hydraulic oils meeting the specifications for these oils.

Owner:EXXON RES & ENG CO

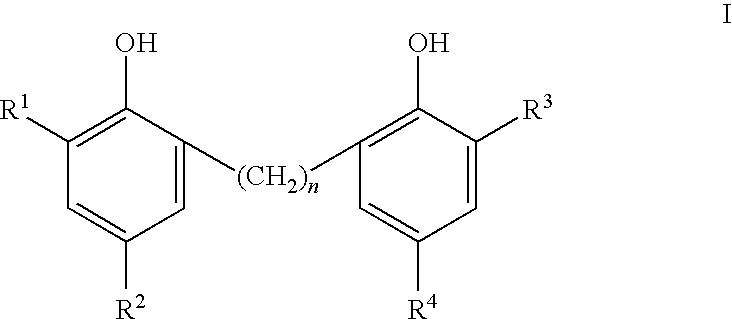

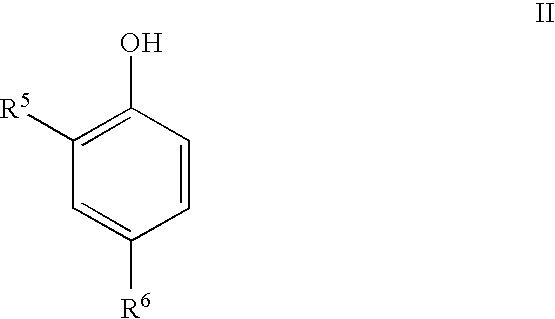

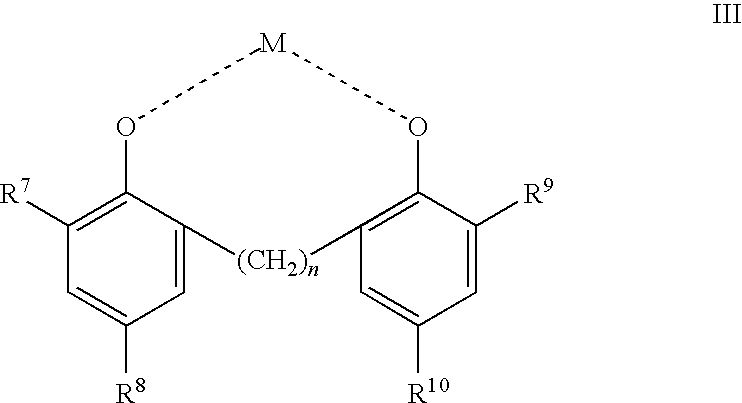

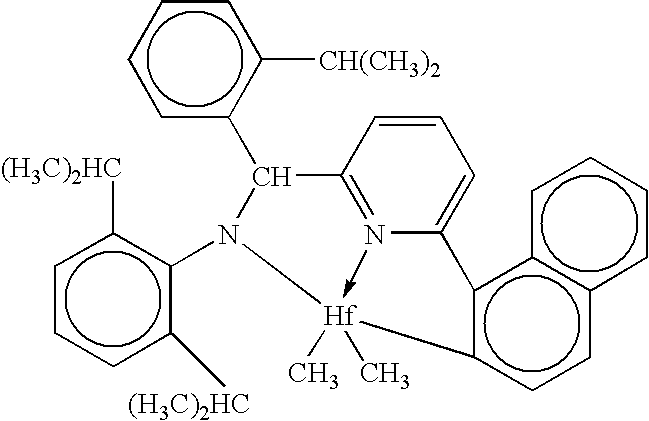

Phenolic dimers, the process of preparing same and the use thereof

Owner:AFTON CHEMICAL

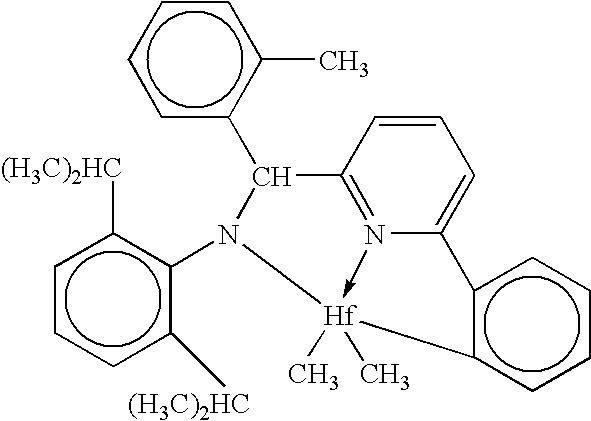

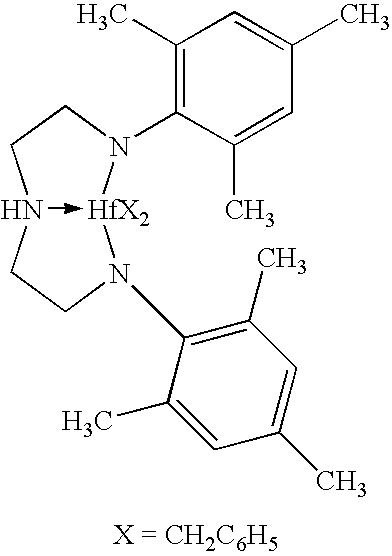

Low molecular weight ethylene/alpha-olefin interpolymer as base lubricant oils

A lubricant composition comprises an ethylene / α-olefin interpolymer having a number average molecular weight of less than 10,000 g / mol as a base oil and at least one oil additive. The ethylene / α-olefin interpolymer has at least one molecular fraction which elutes between 40° C. and 130° C. when fractionated using TREF, characterized in that the fraction has a molar comonomer content of at least 5 percent higher than that of a comparable random ethylene interpolymer fraction eluting between the same temperatures, wherein said comparable random ethylene interpolymer has the same comonomer(s) and has a melt index, density, and molar comonomer content (based on the whole polymer) within 10 percent of that of the ethylene / α-olefin interpolymer.

Owner:DOW GLOBAL TECH LLC

Fuel additives for treating internal deposits of fuel injectors

InactiveUS20130074794A1Reduce the amount requiredAvoid cloggingNon-fuel substance addition to fuelInternal combustion piston enginesHydrogenDicarboxylic acid

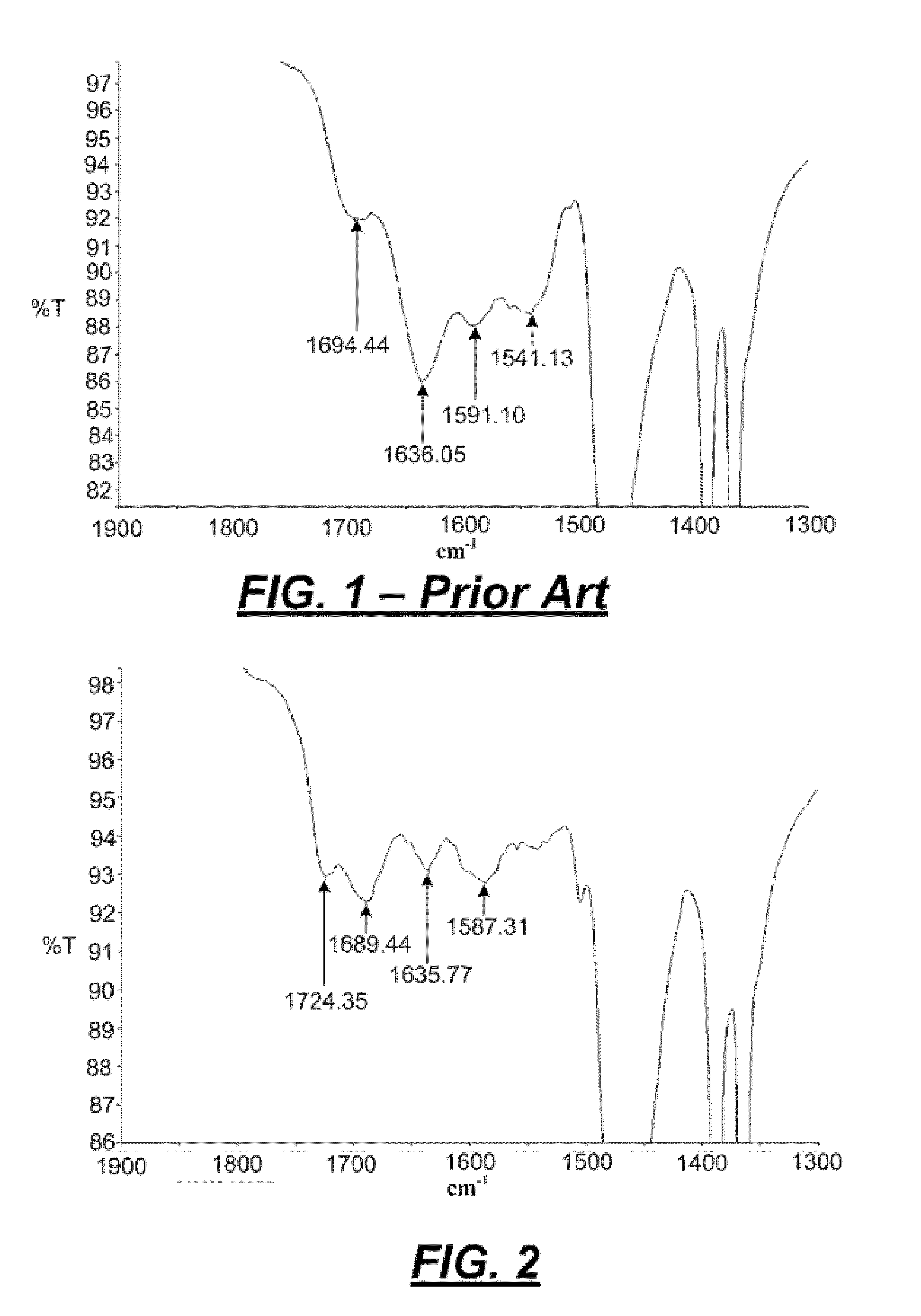

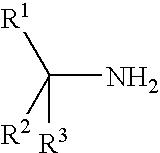

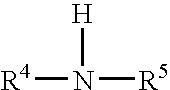

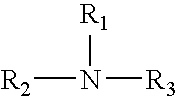

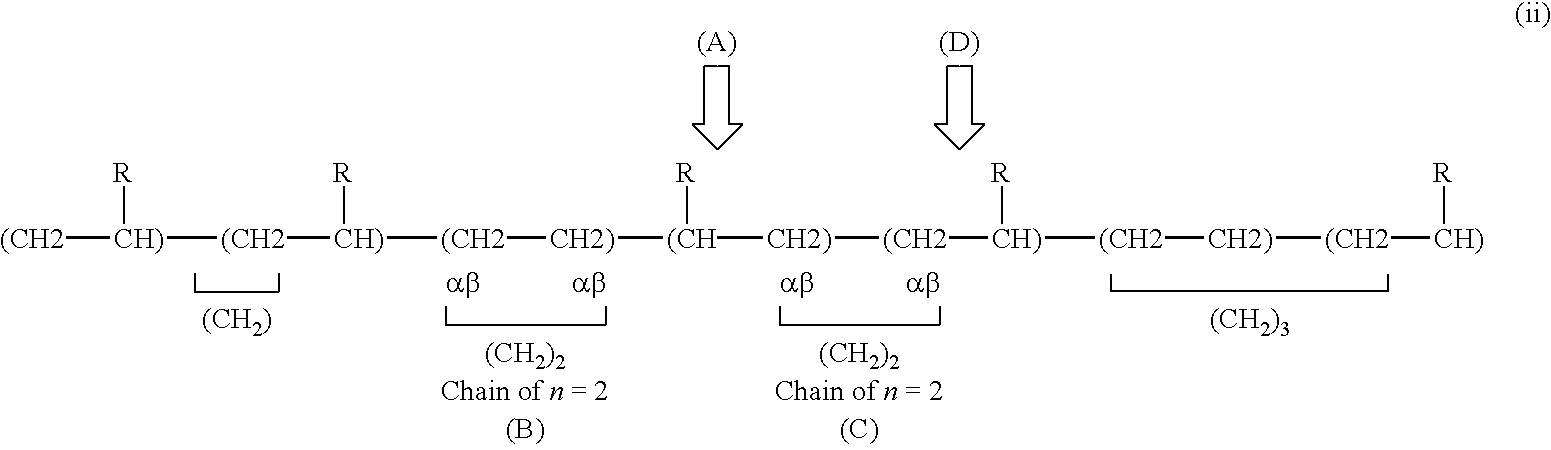

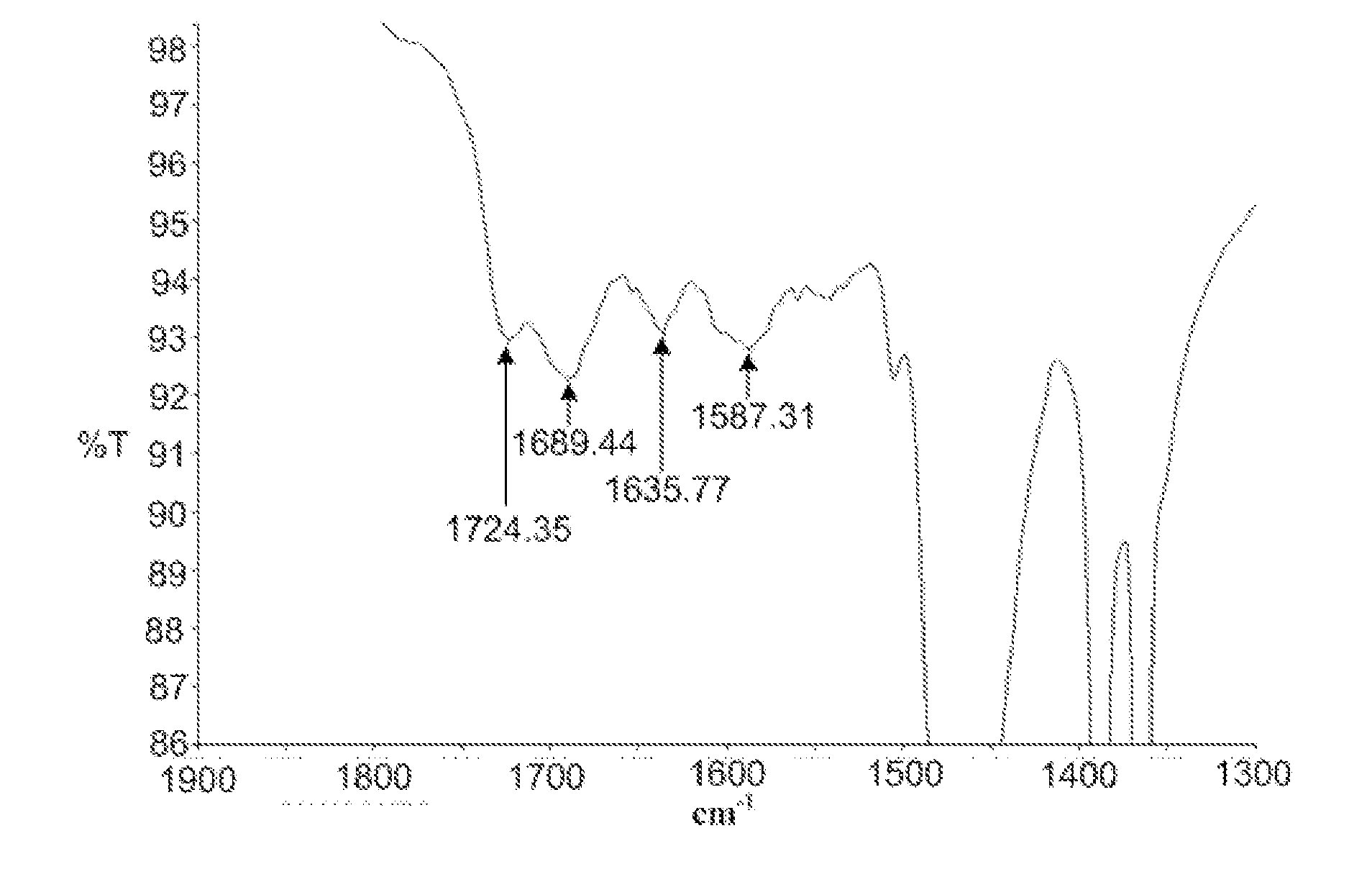

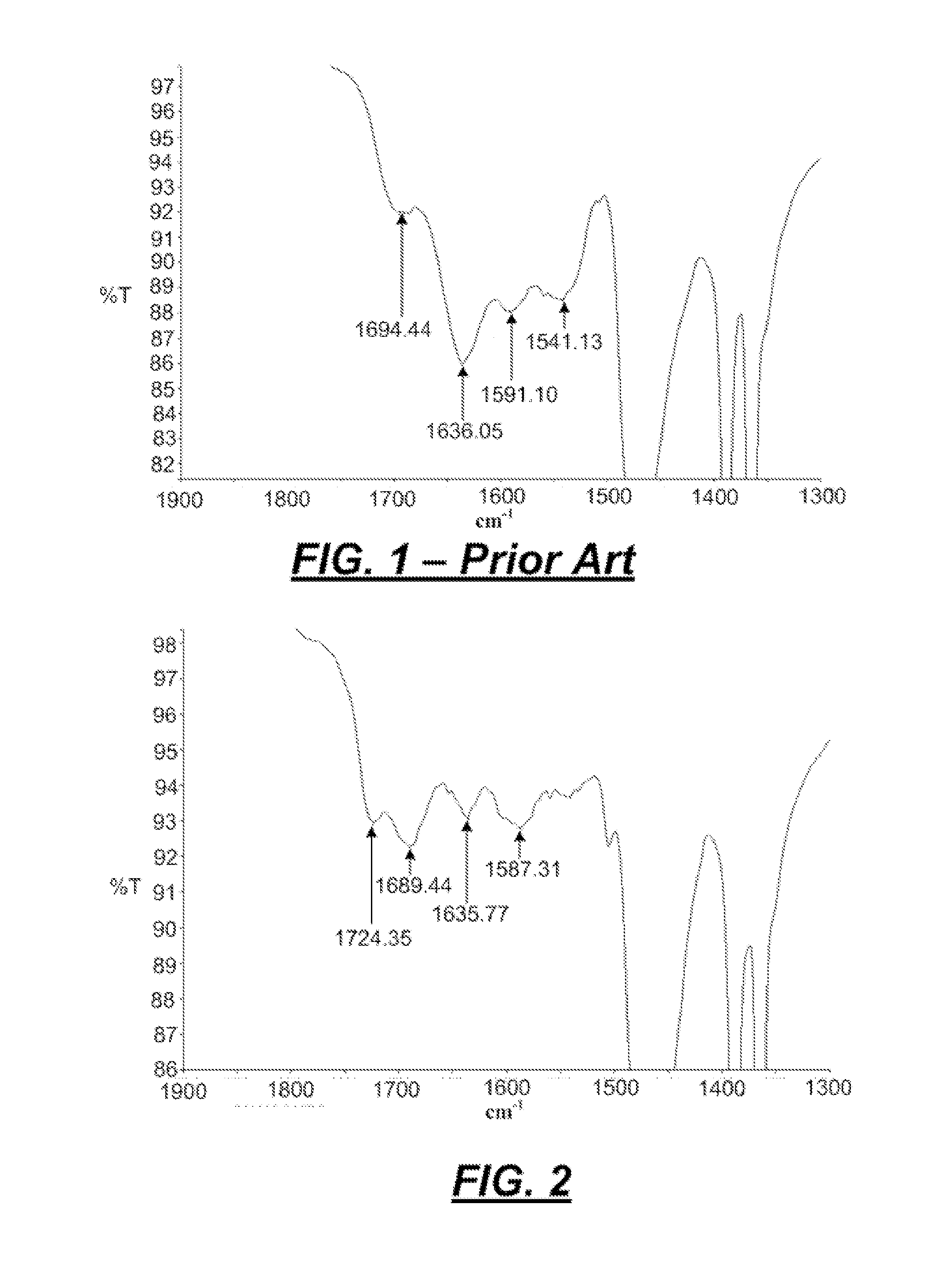

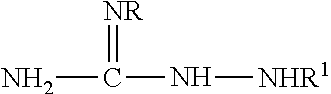

A method cleaning up internal components of a fuel injector for a diesel engine. The method includes operating a fuel injected diesel engine on a fuel composition that includes a major amount of diesel fuel and from about 5 to about 500 ppm by weight of a reaction product derived from (a) a hydrocarbyl substituted dicarboxylic acid, anhydride, or ester and (b) an amine compound or salt thereof of the formulawherein R is selected from the group consisting of hydrogen and a hydrocarbyl group containing from about 1 to about 15 carbon atoms, and R1 is selected from the group consisting of hydrogen and a hydrocarbyl group containing from about 1 to about 20 carbon atoms. The reaction product is characterized by a particular FTIR spectrum.

Owner:AFTON CHEMICAL

Hydraulic oil with excellent air release and low foaming tendency

ActiveUS20060131210A1Low air releaseImprove foam stabilityPositive displacement pump componentsTreatment with hydrotreatment processesCavitationHydraulic pump

This invention provides a hydraulic oil comprising: 1) a lubricant base oil having an average molecular weight greater than 475, a viscosity index greater than 140, and a weight percent olefins less than 10; and 2) an antiwear hydraulic oil additive package. The hydraulic oil of this invention has an air release by ASTM D 3427-03 of less than 0.8 minutes at 50 degrees C., and a sequence II foam tendency by ASTM D 892-03 of less than 50 ml. We describe a process for making the hydraulic oil of this invention, and a method of operating a hydraulic pump without pump cavitation using the hydraulic oil of this invention.

Owner:CHEVROU USA INC

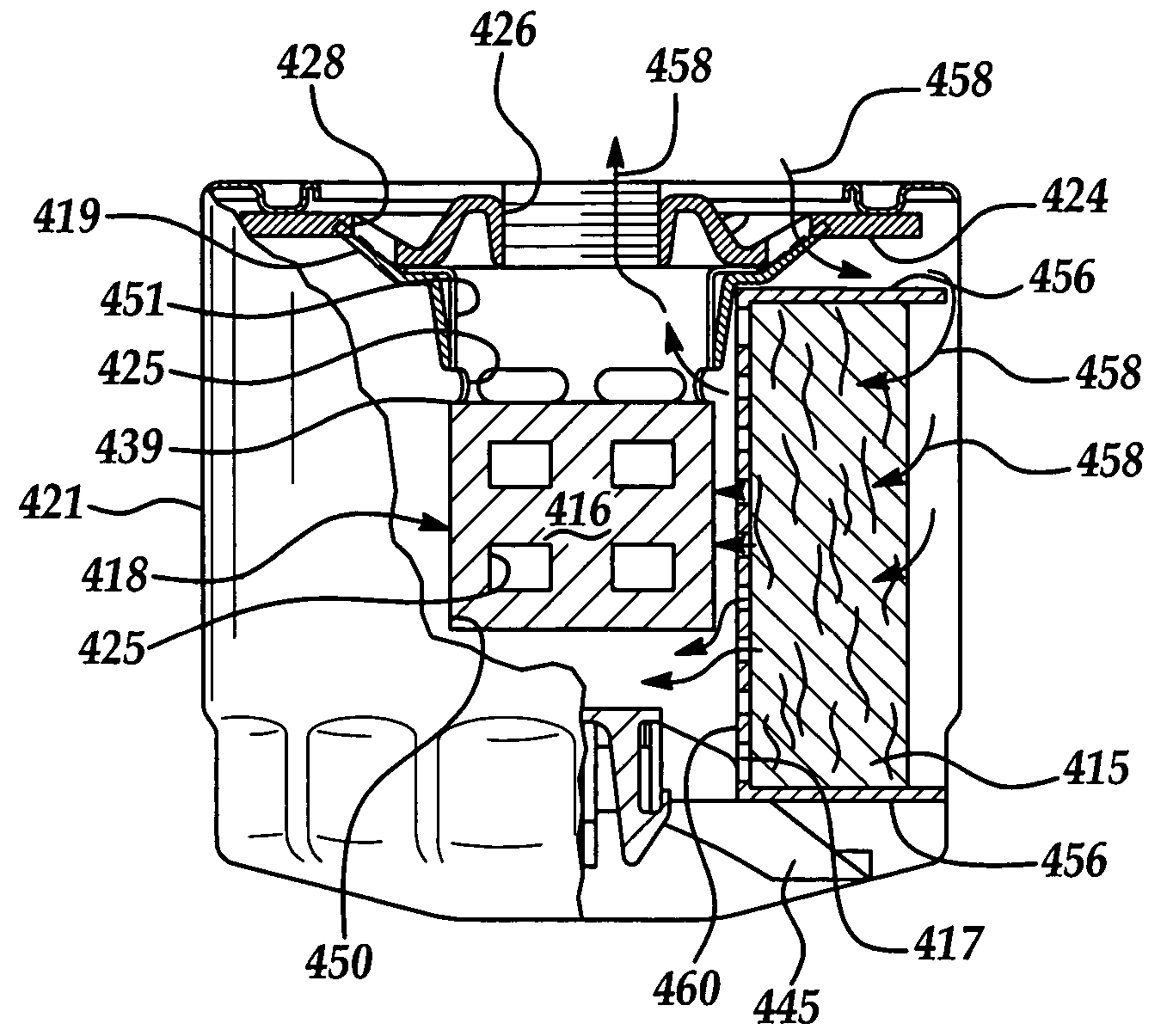

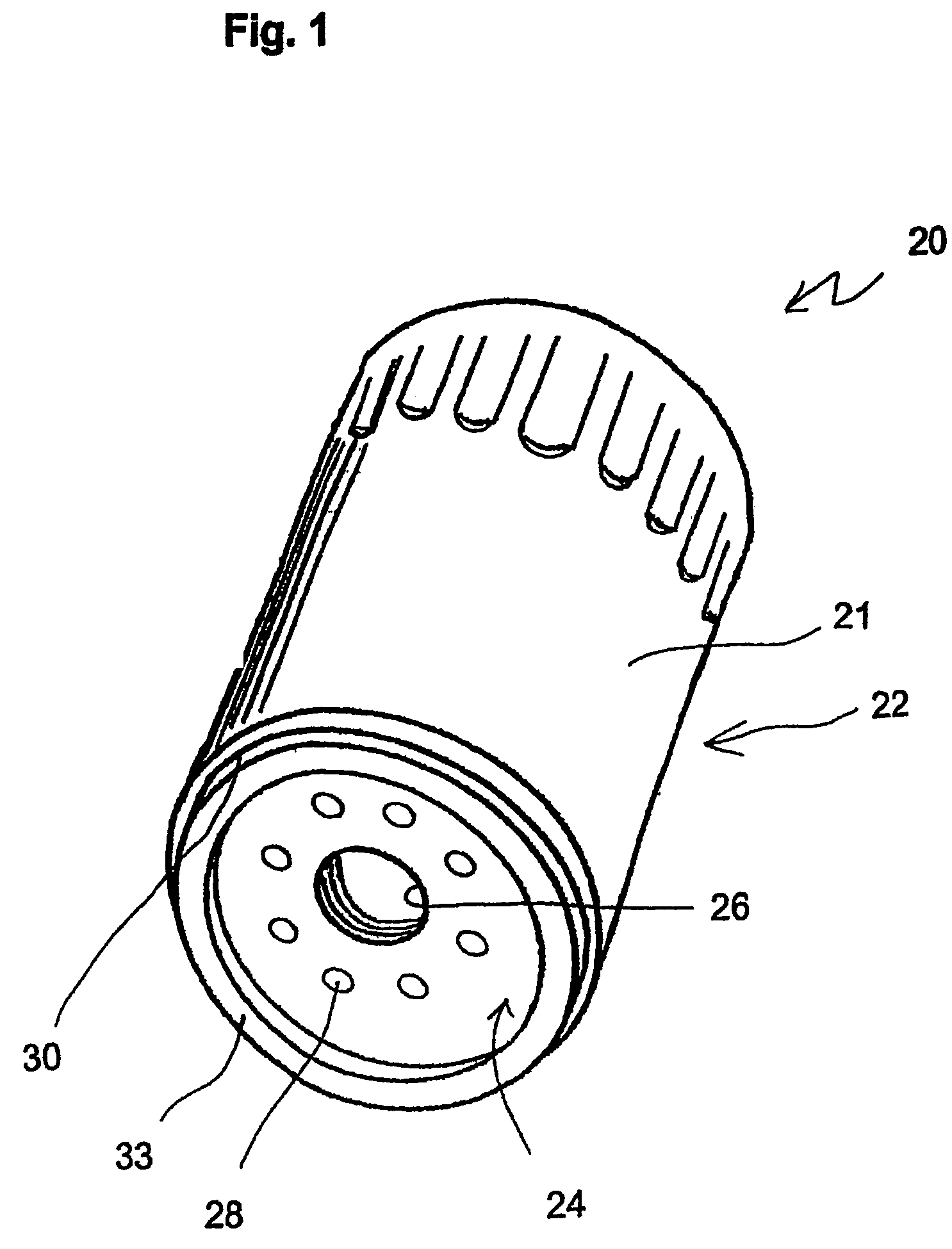

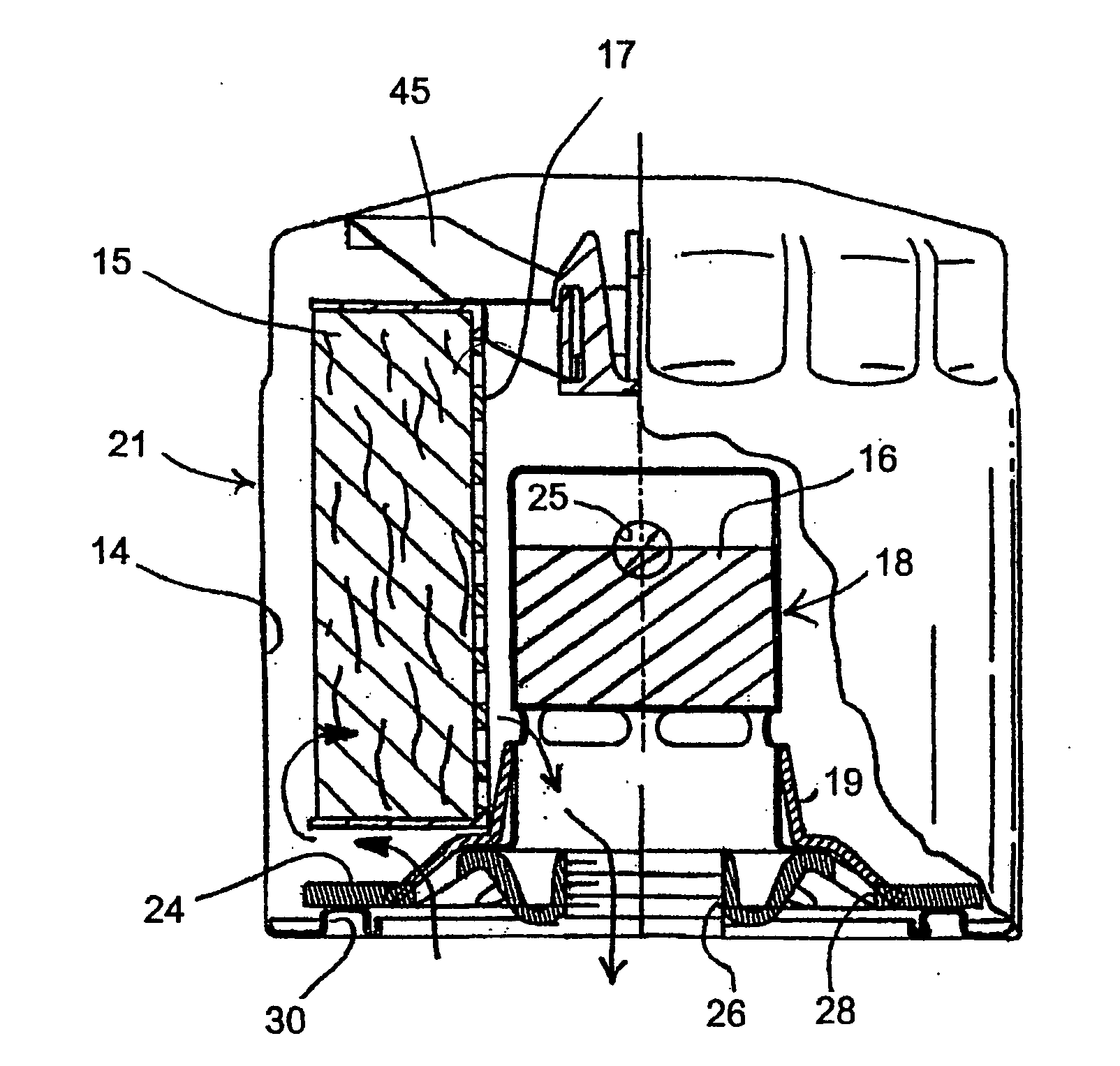

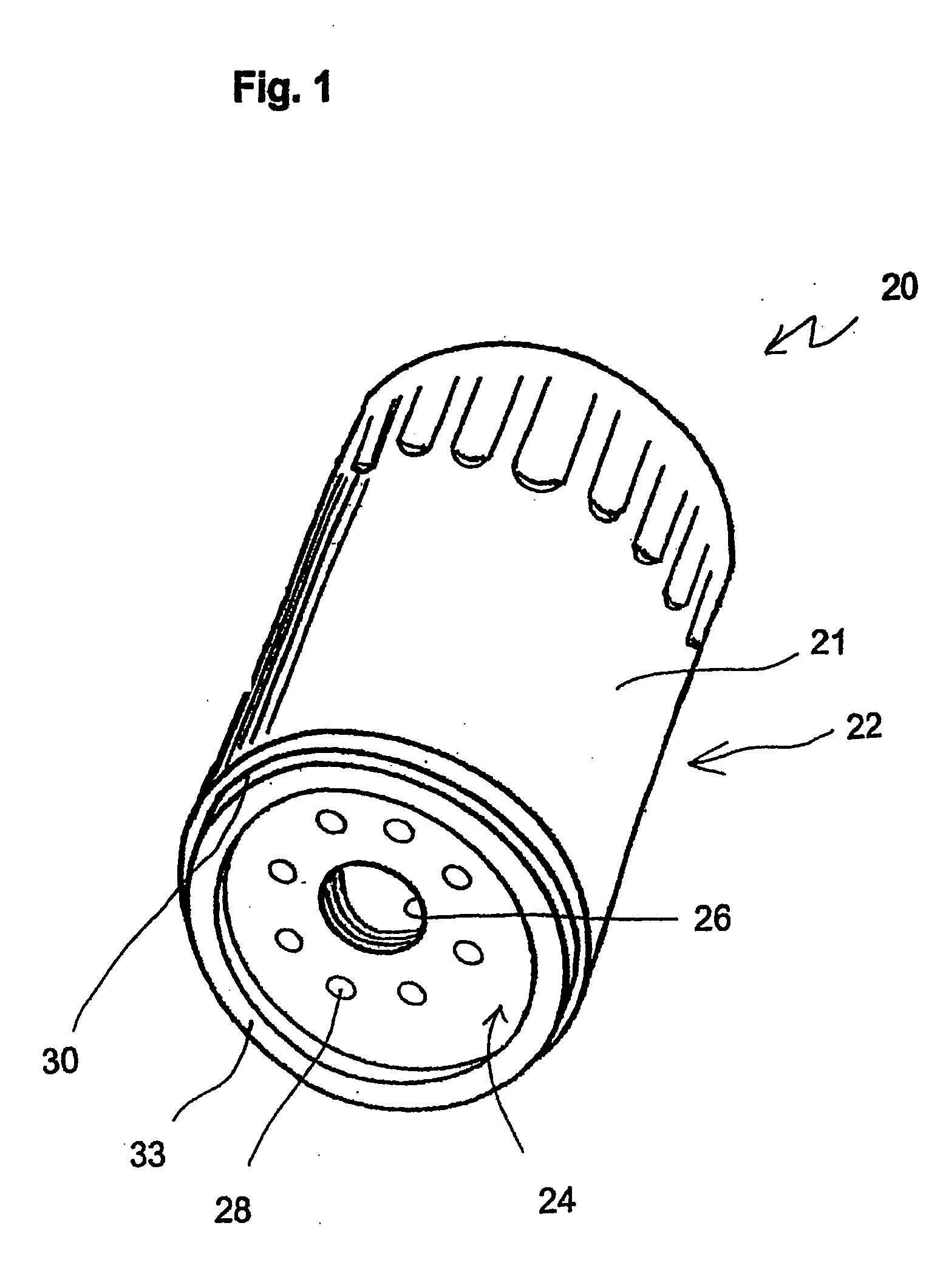

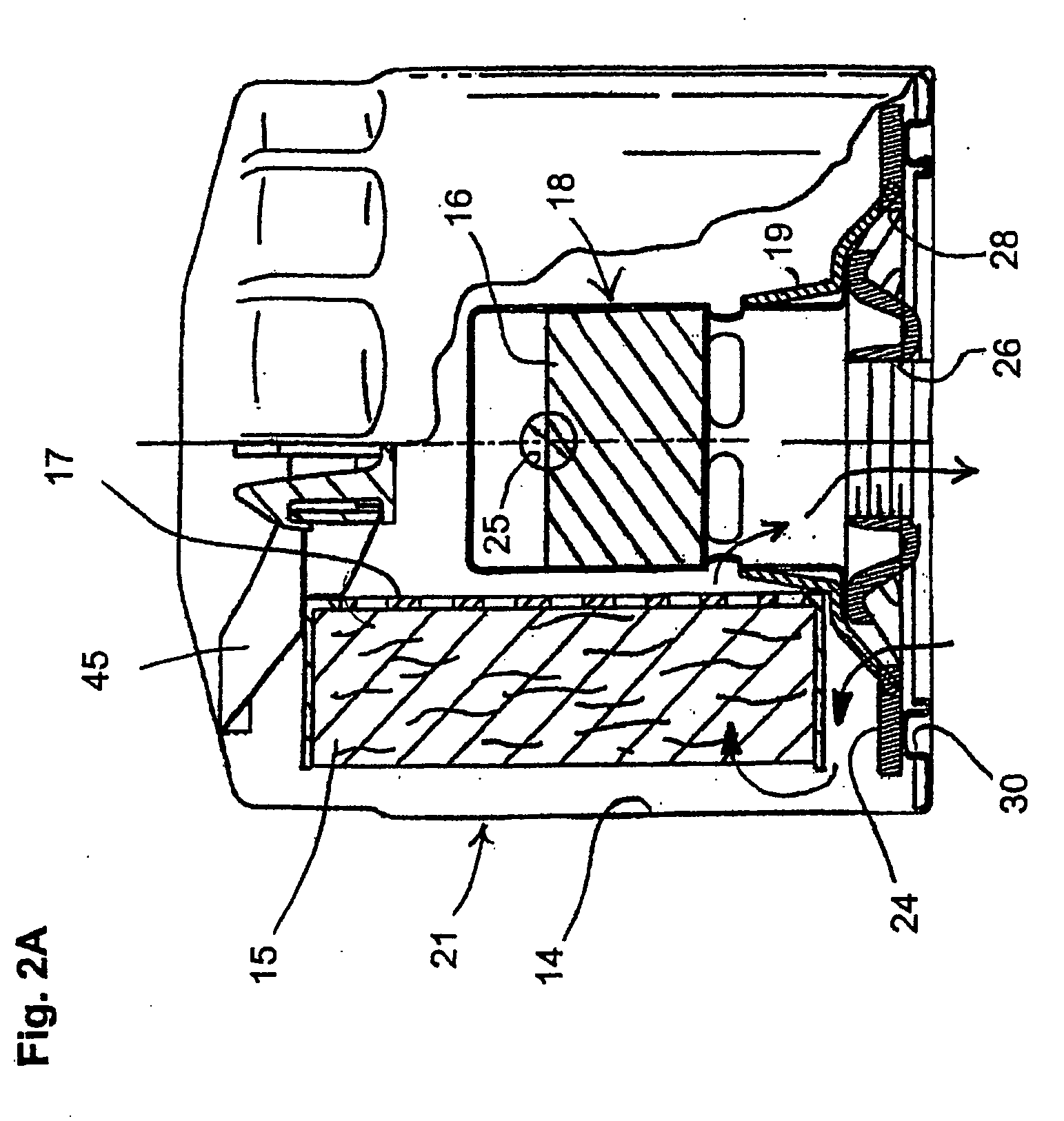

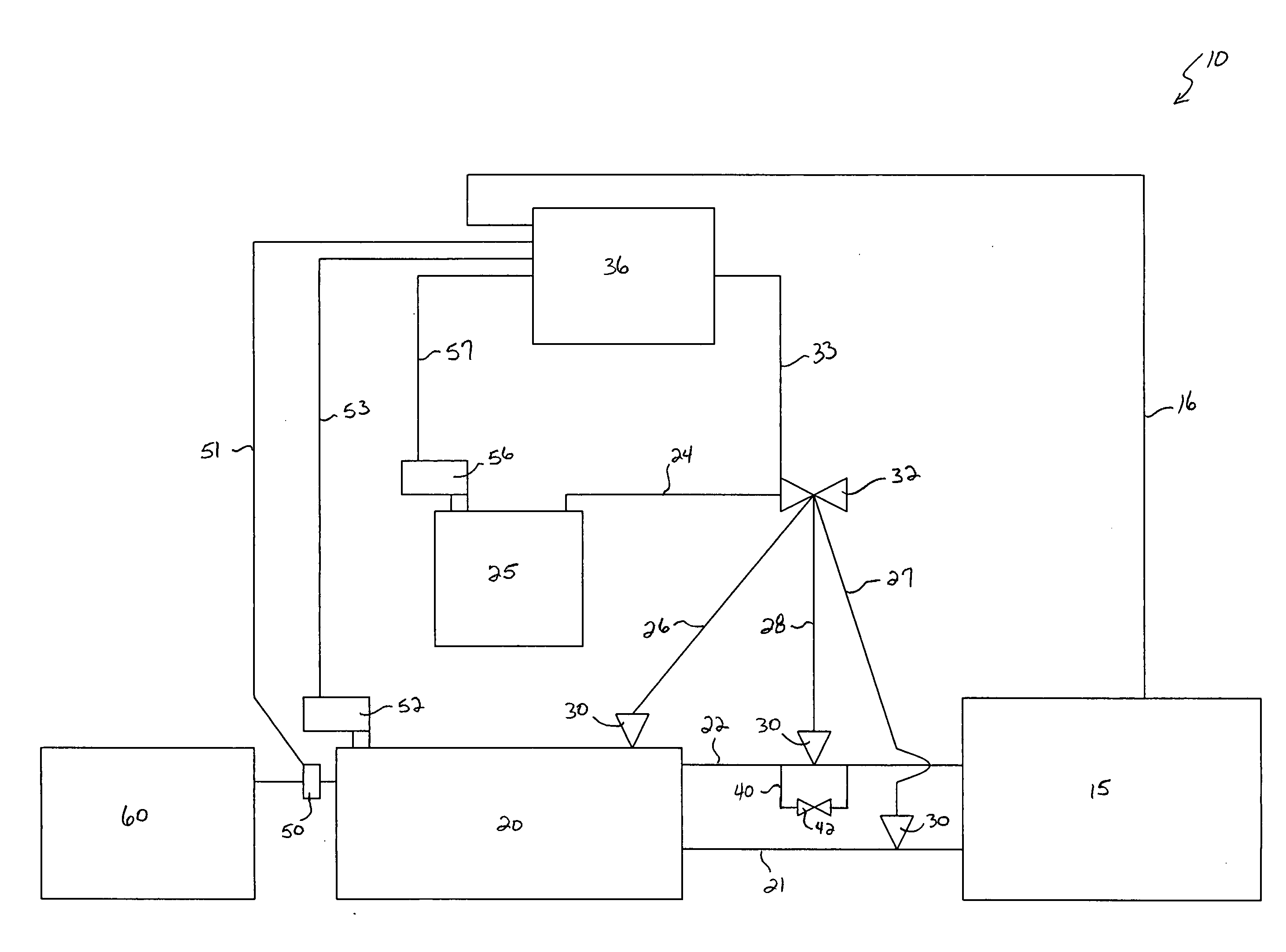

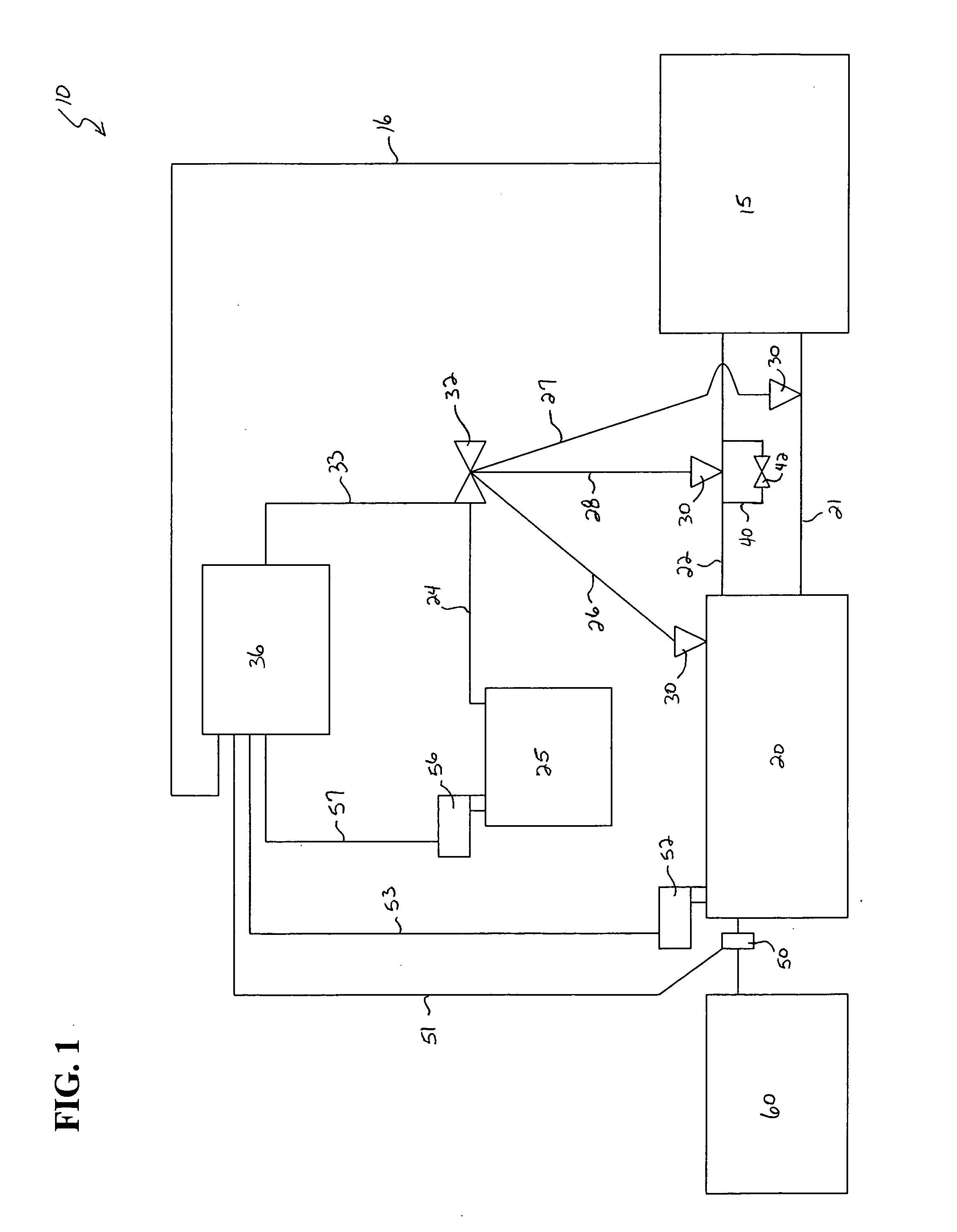

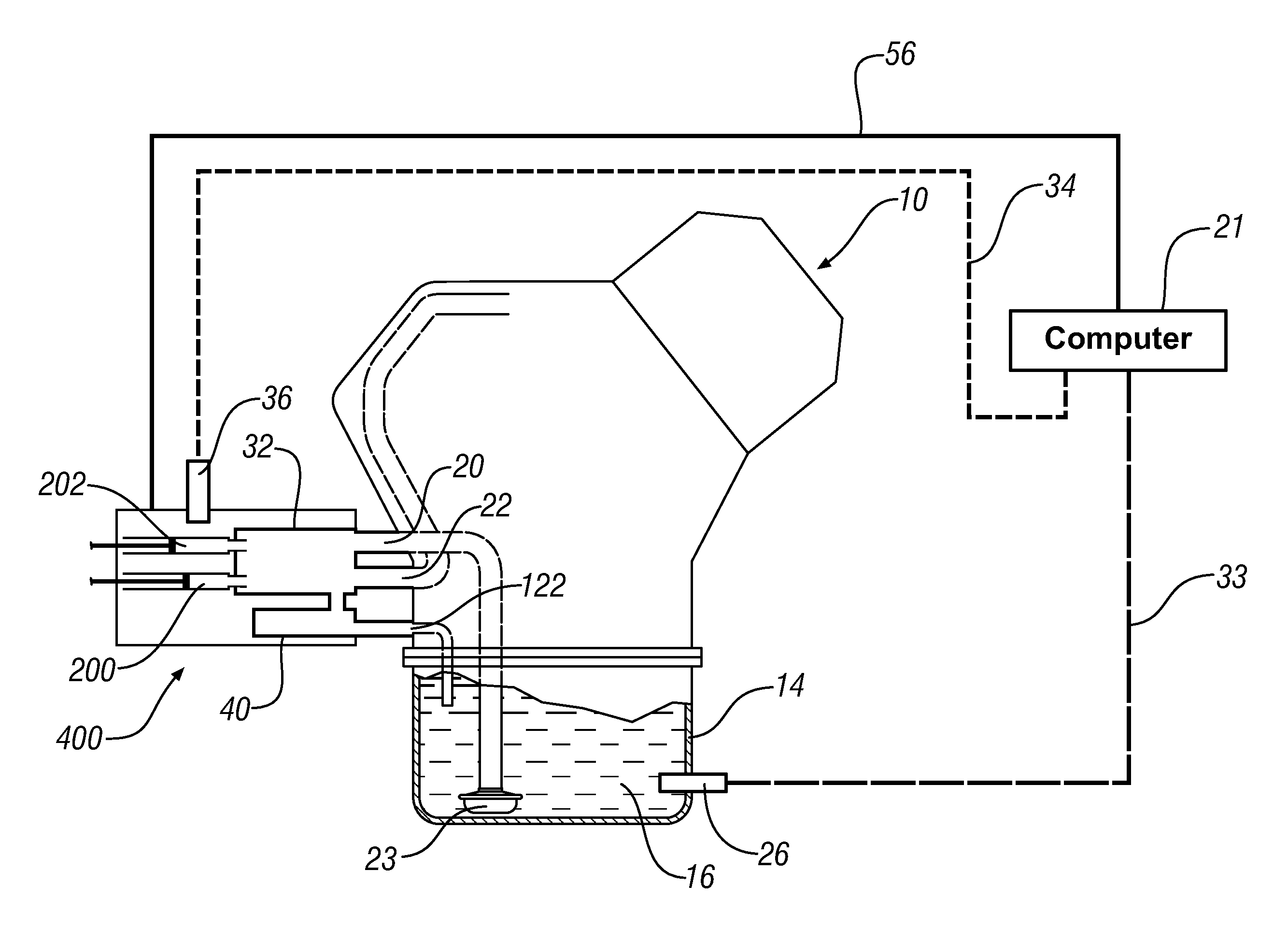

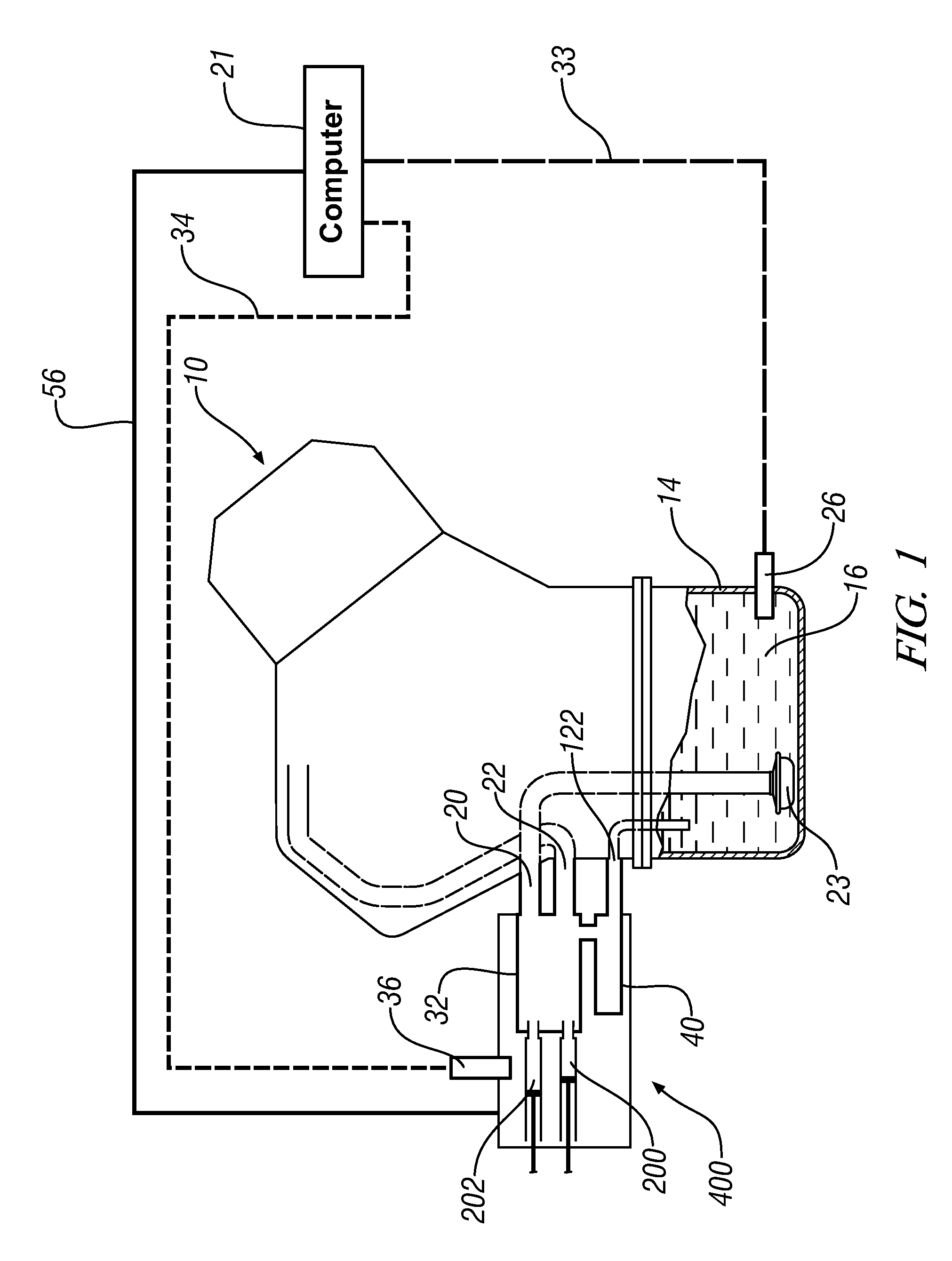

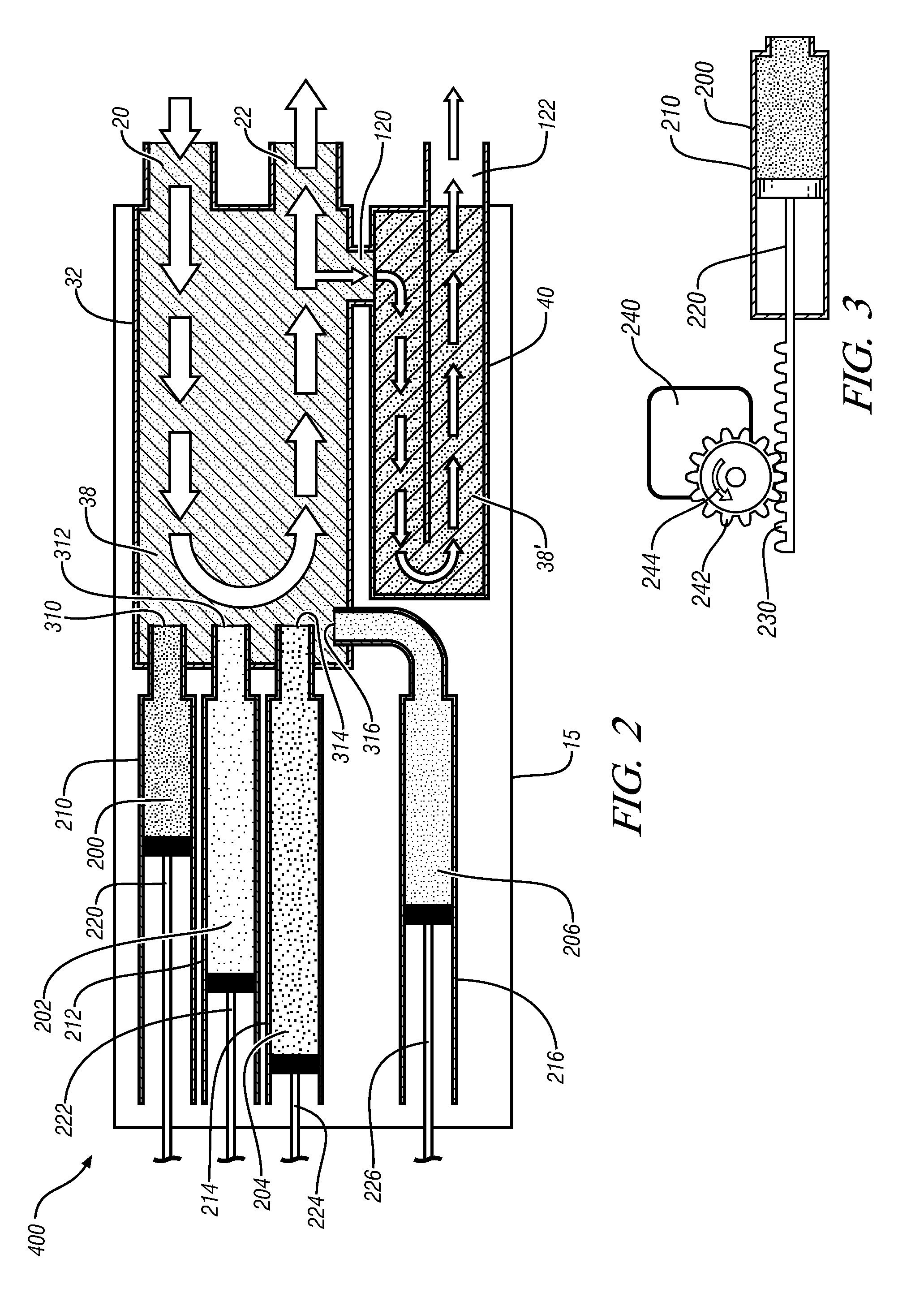

Additive dispersing filter and method of making

An oil-conditioning filter, for use with an internal combustion engine, includes a filter element and an additive cartridge, for gradually dispensing an oil additive over time. The additive cartridge has a beneficial oil-conditioning agent contained therein. Placement of the cartridge allows for fluid filtration through the filter element before fluid communication with the additive of the additive cartridge. An additive dispersing member is also described.

Owner:BMO HARRIS BANK N A AS SUCCESSOR COLLATERAL AGENT +1

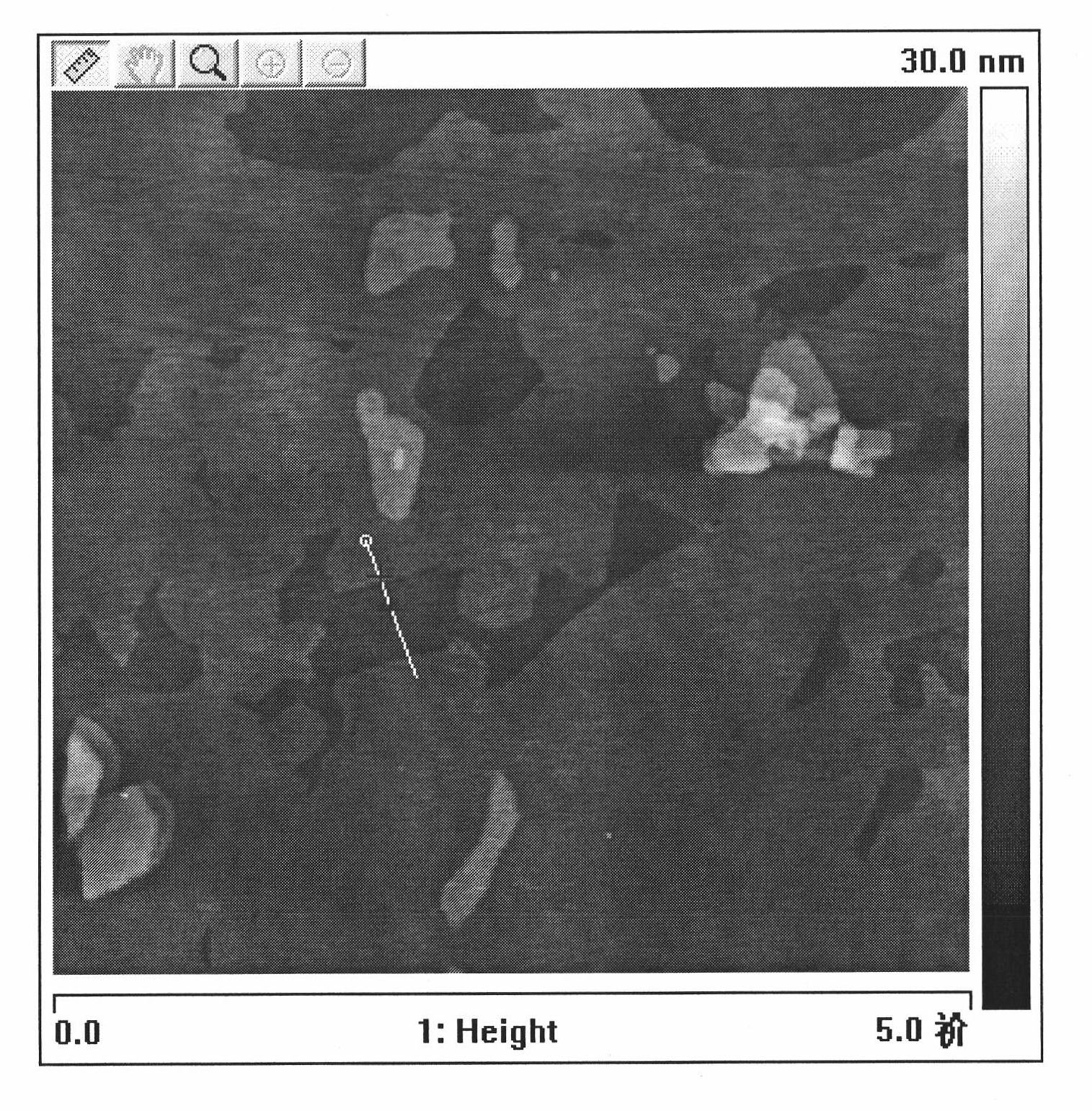

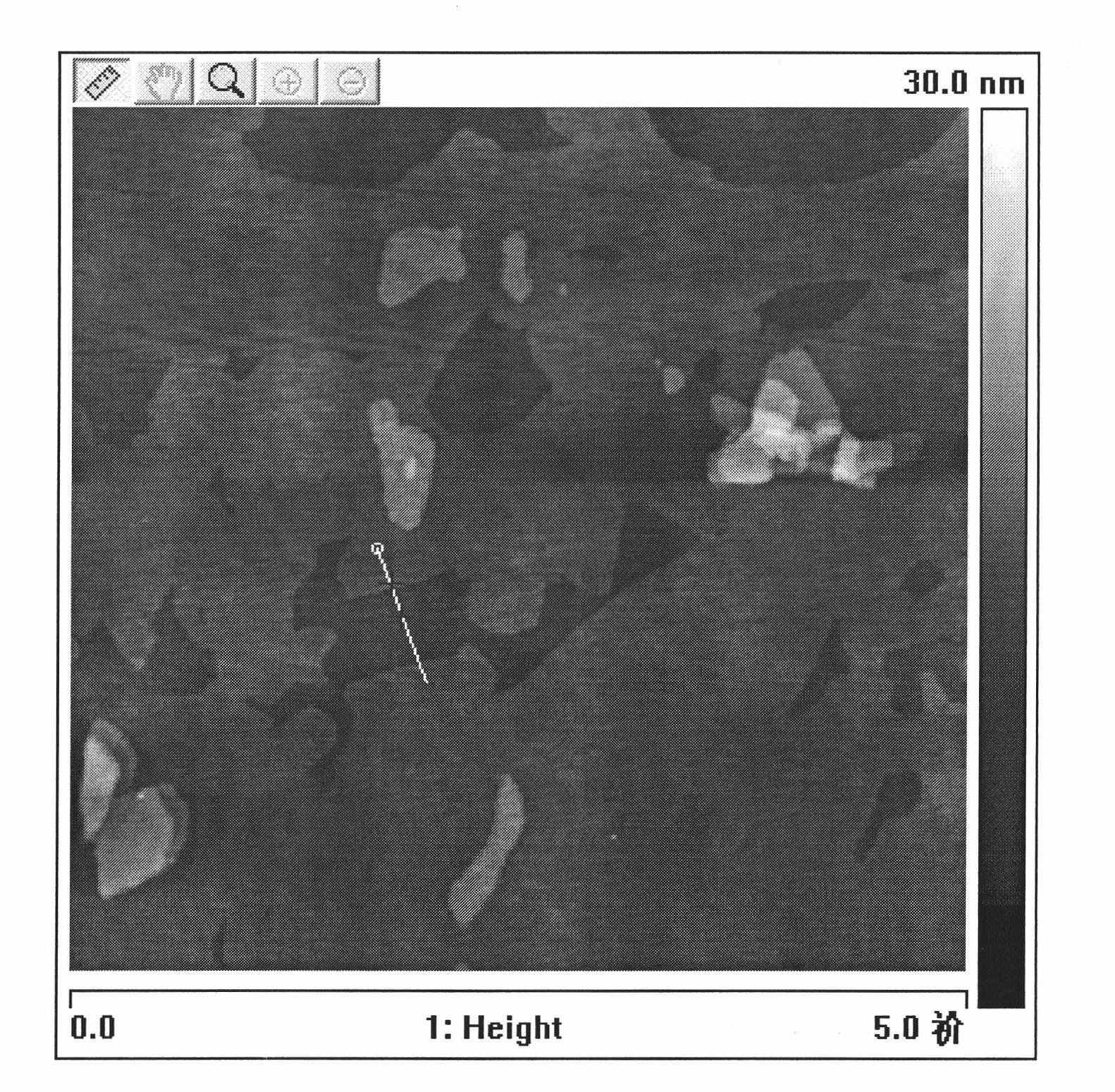

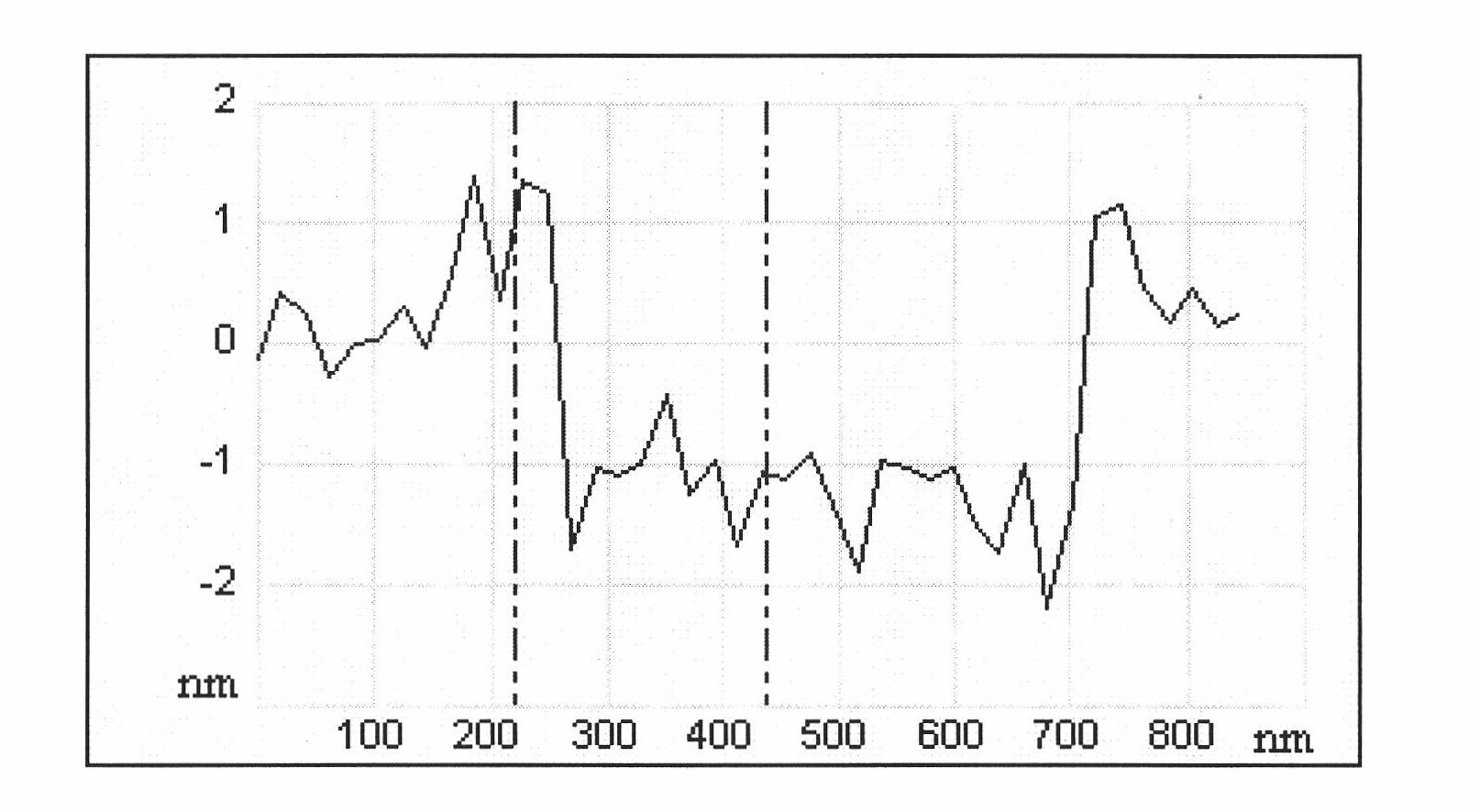

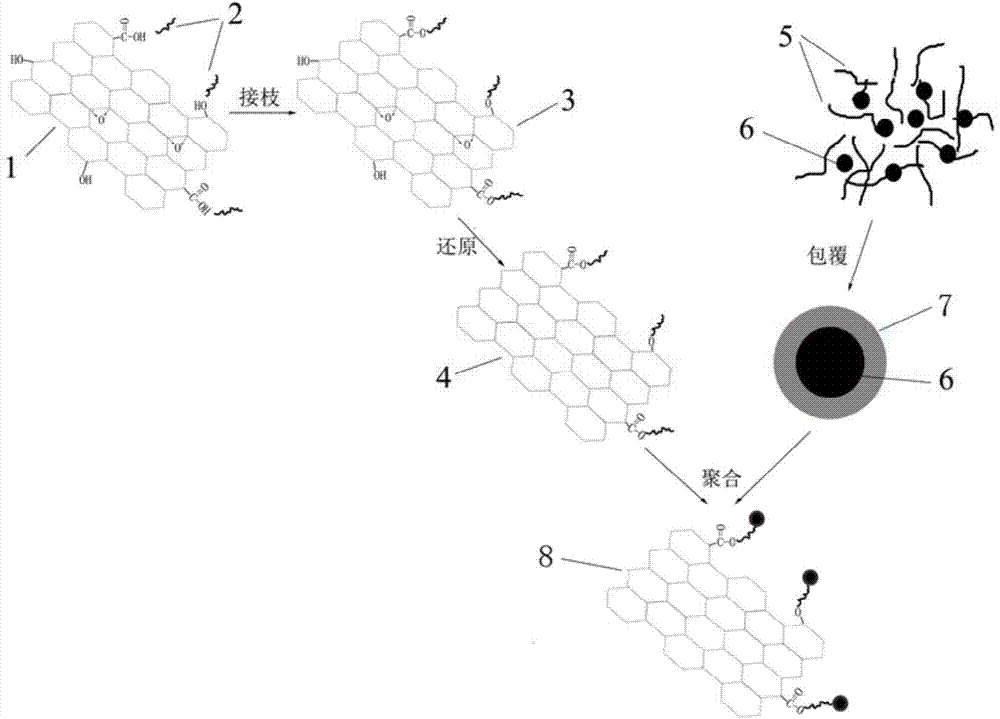

Lubricating oil additive based on single-layer or more-layer graphene

The invention relates to a lubricating oil additive based on single-layer or more-layer graphene, belonging to new high-tech materials and application field thereof and being mainly used for improving the property of lubricating oil. The lubricating oil additive is characterized in that single-layer or more-layer graphene and a dispersing agent are added into base oil, the content of the single-layer or more-layer graphene in the base oil is 0.0001-10 percent by mass, and the content of the dispersing agent in the lubricating oil is 0.001-2 percent by mass. The graphene has high specific surface area and thickness of 0.34-10 nanometers, is shaped as a sheet, is combined with the dispersing agent after being subjected to surface modification, and has excellent stability and dispersity in the base oil without easily precipitating like other additives. Under same filling amount, compared with the sheet graphite and the traditional graphite, more graphene can be absorbed on the secondary surface of the friction, the lubricating and anti-wear property of the base oil is improved, and the bearing capacity is enhanced.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Additive dispersing filter and method of making

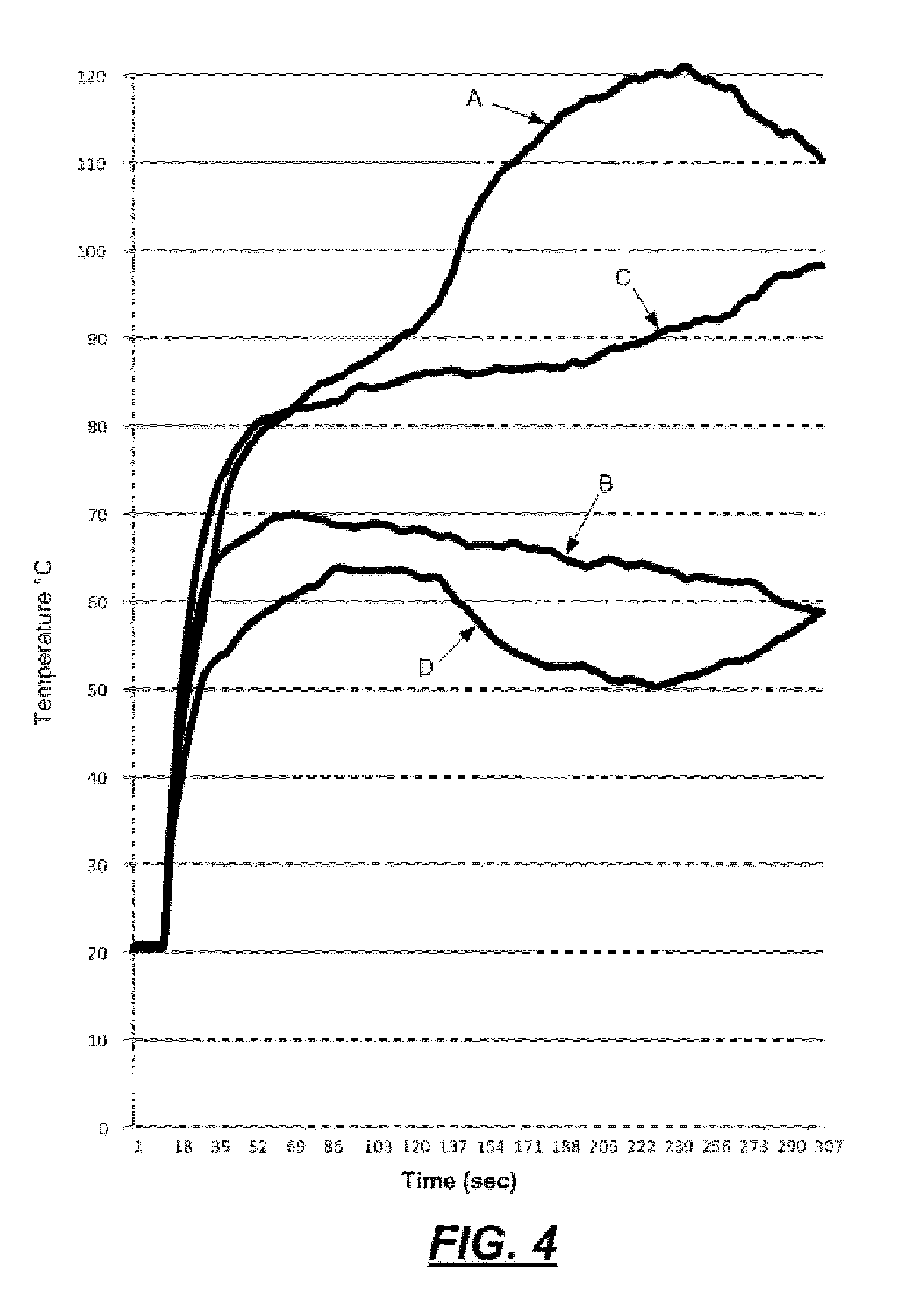

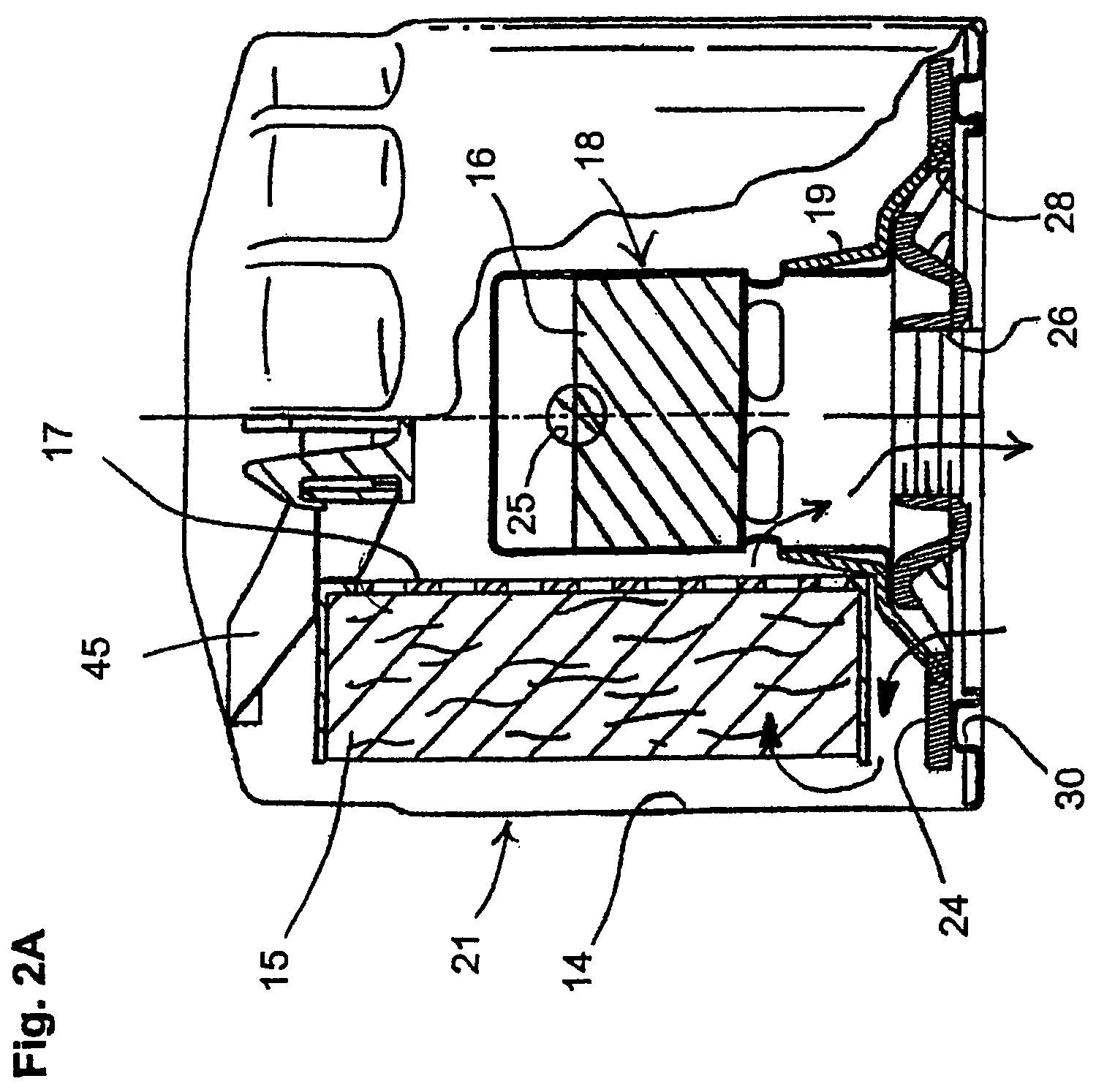

InactiveUS20050040092A1Extend life of engine oilExtended time intervalMachines/enginesSolid materialOil additiveEngineering

An oil-conditioning filter, for use with an internal combustion engine, includes a filter element and an additive cartridge, for gradually dispensing an oil additive over time. The additive cartridge has a beneficial oil-conditioning agent contained therein. Placement of the cartridge allows for fluid filtration through the filter element before fluid communication with the additive of the additive cartridge. An additive dispersing member is also described.

Owner:BMO HARRIS BANK N A AS SUCCESSOR COLLATERAL AGENT +1

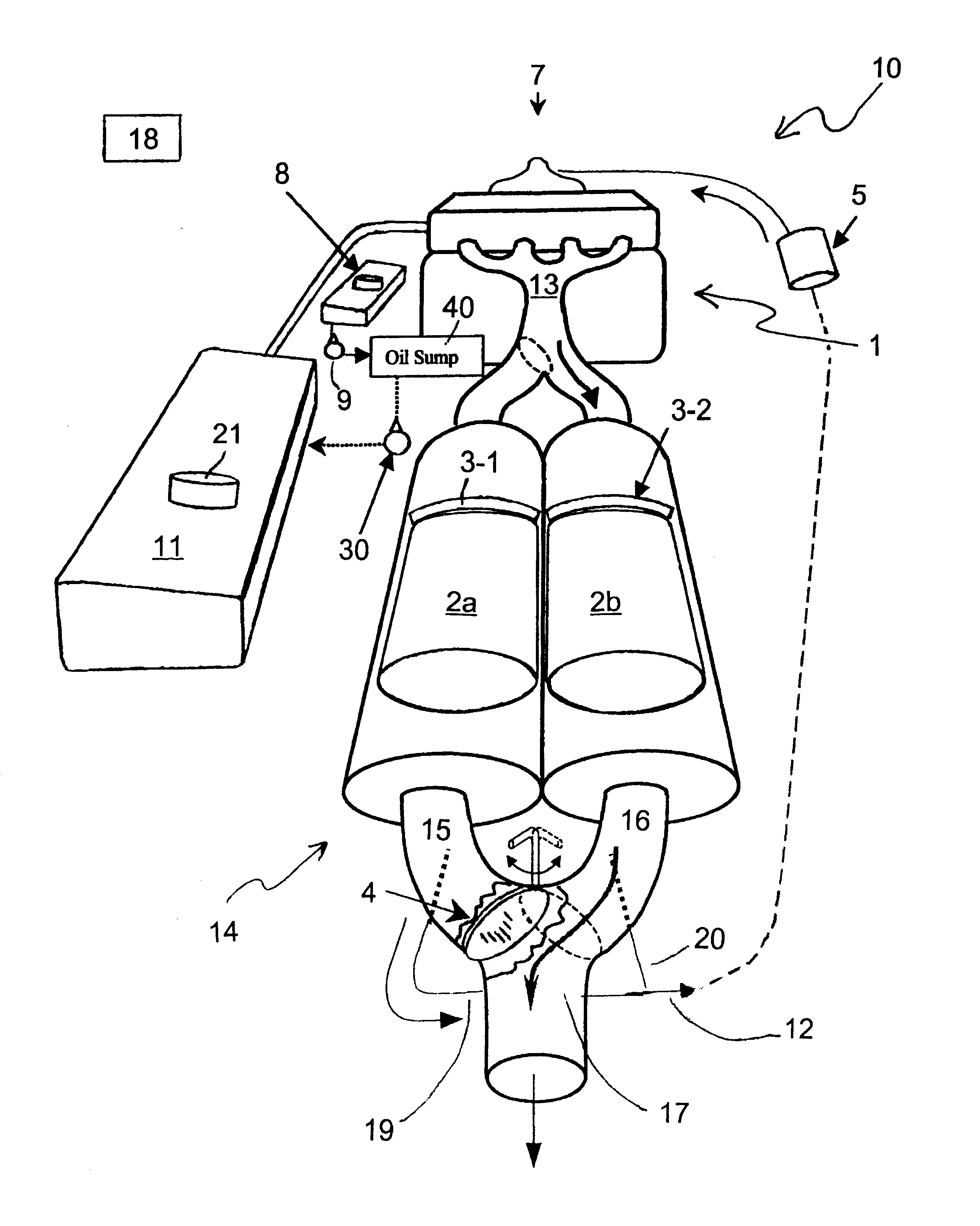

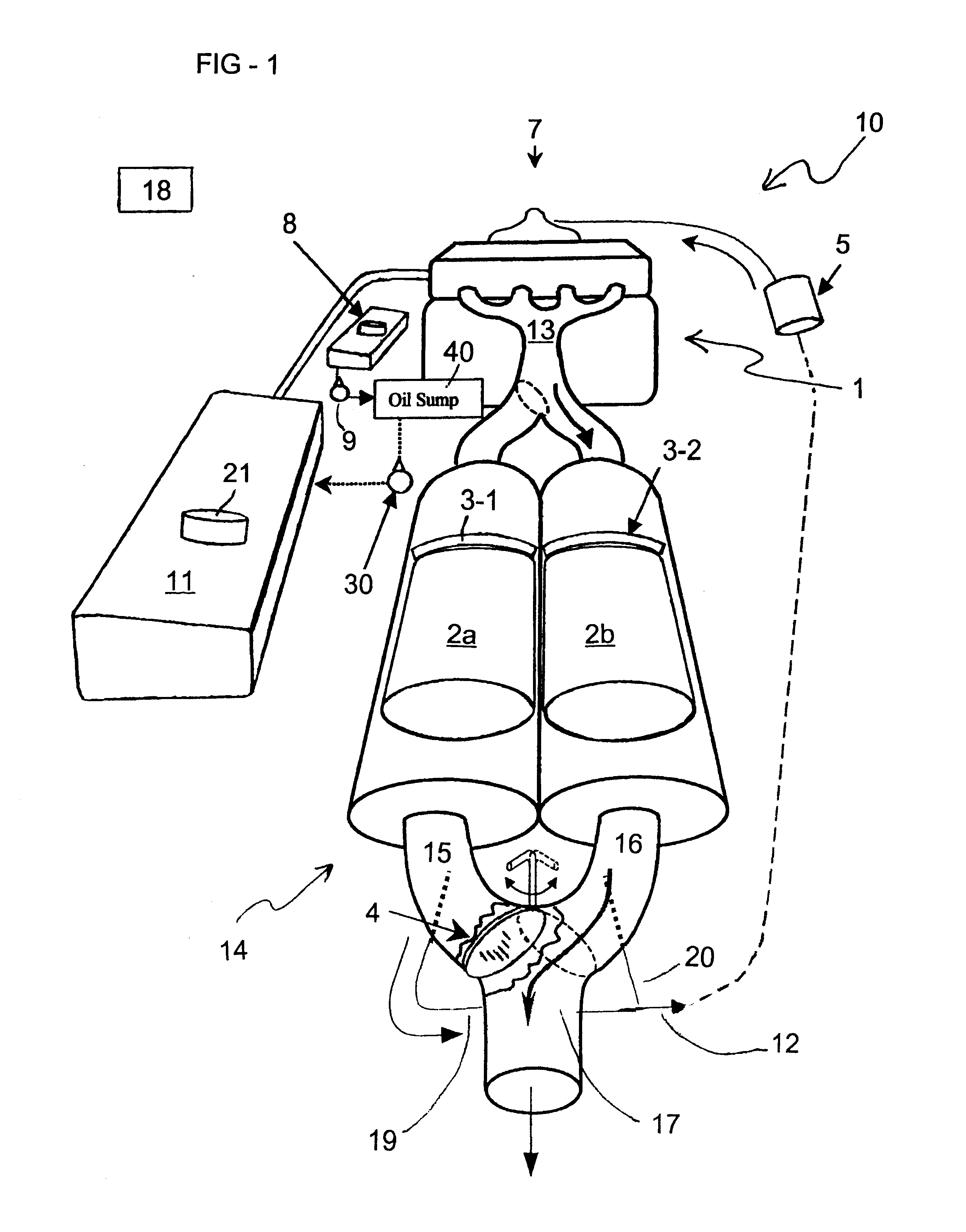

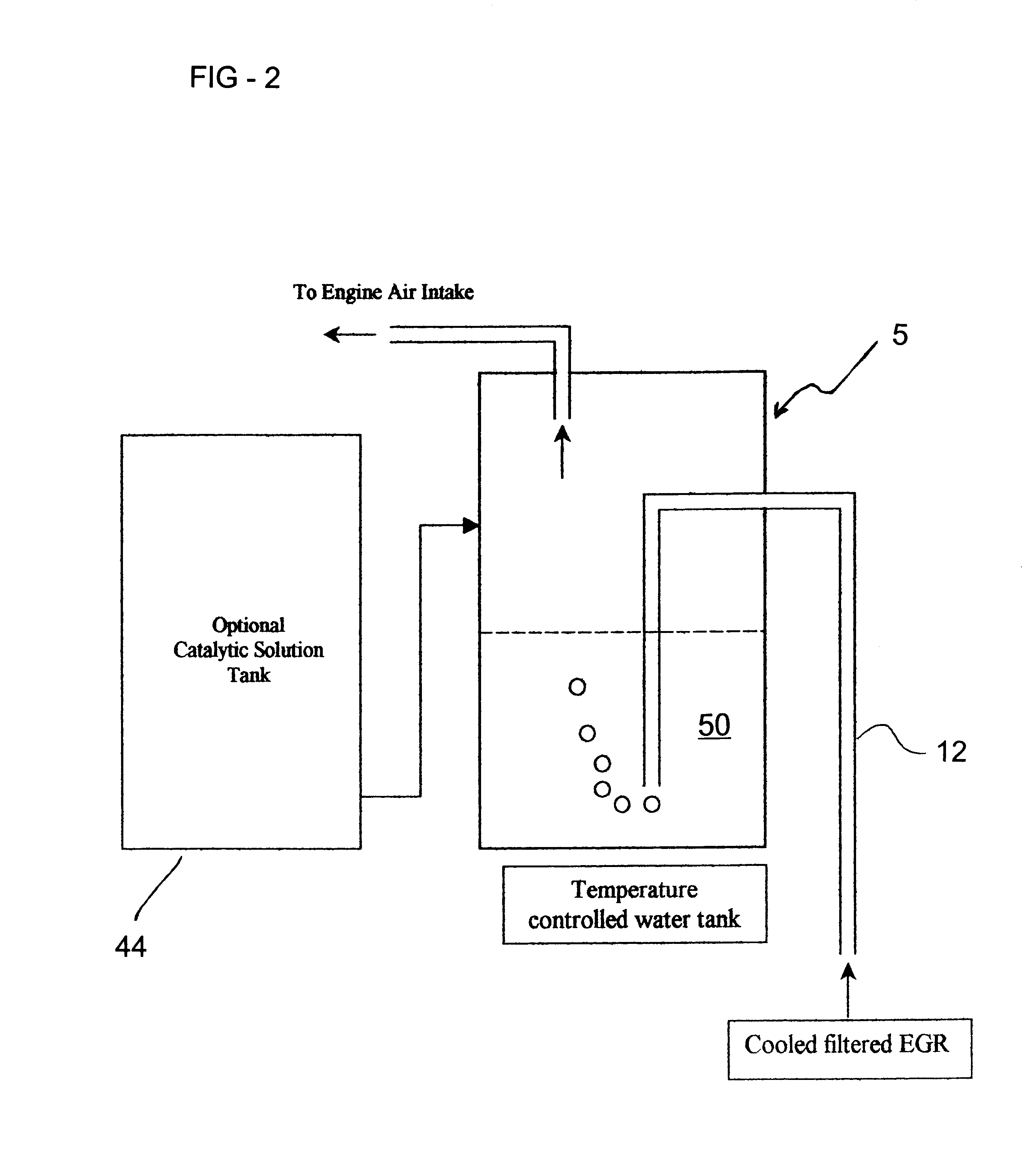

System for and methods of operating diesel engines to reduce harmful exhaust emissions and to improve engine lubrication

InactiveUS6892531B2Promote regenerationAnti-wear propertyInternal combustion piston enginesNon-fuel substance addition to fuelExhaust gas emissionsFuel tank

A Diesel engine anti-wear lubricant oil additive composition that includes organo-metallic compounds of Cu, Ce, etc., is used to catalytically burn-off diesel particulate matter (PM) collected by diesel particulate filter (DPF). A fuel borne catalyst (FBC) of Cu,Ce,Fe etc., required for regenerating the DPF is made by blending a predetermined quantity of used engine oil, removed from the engine crankcase oil system, with fuel in the fuel tank of a diesel engine equipped with DPF and EGR systems. A method of fumigating water and catalytic compounds of Cu, Fe, Ce, etc., into the air-intake system of a diesel engine in the EGR gases from the DPF or air, to reduce both PM and NOx emissions from a diesel engine, with improved engine lubrication performance, is also disclosed.

Owner:RIM JULIUS J

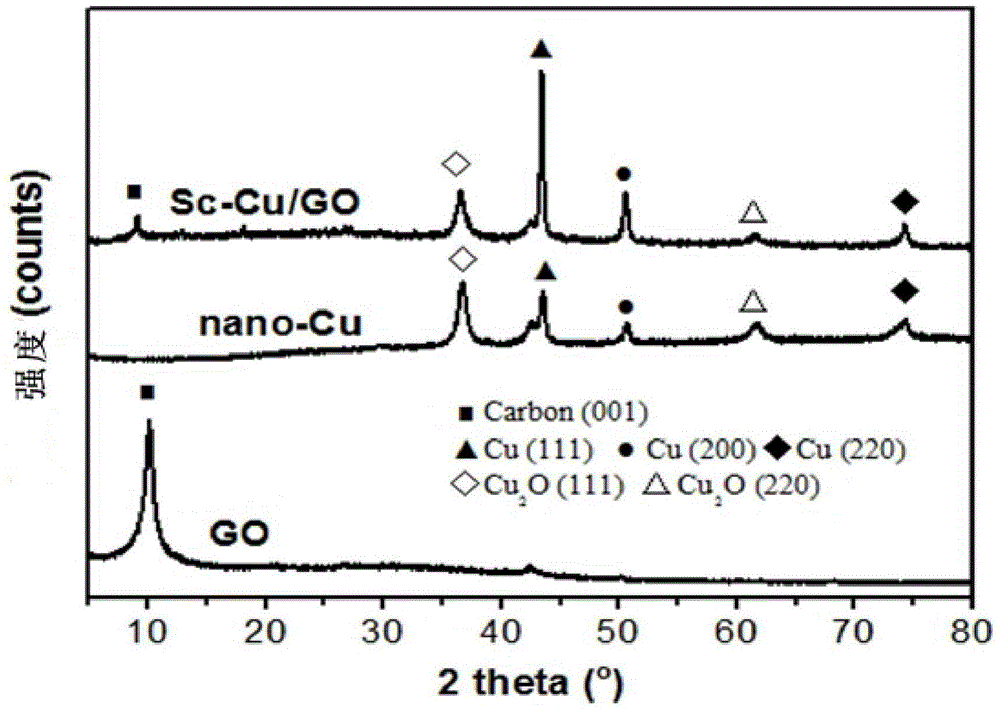

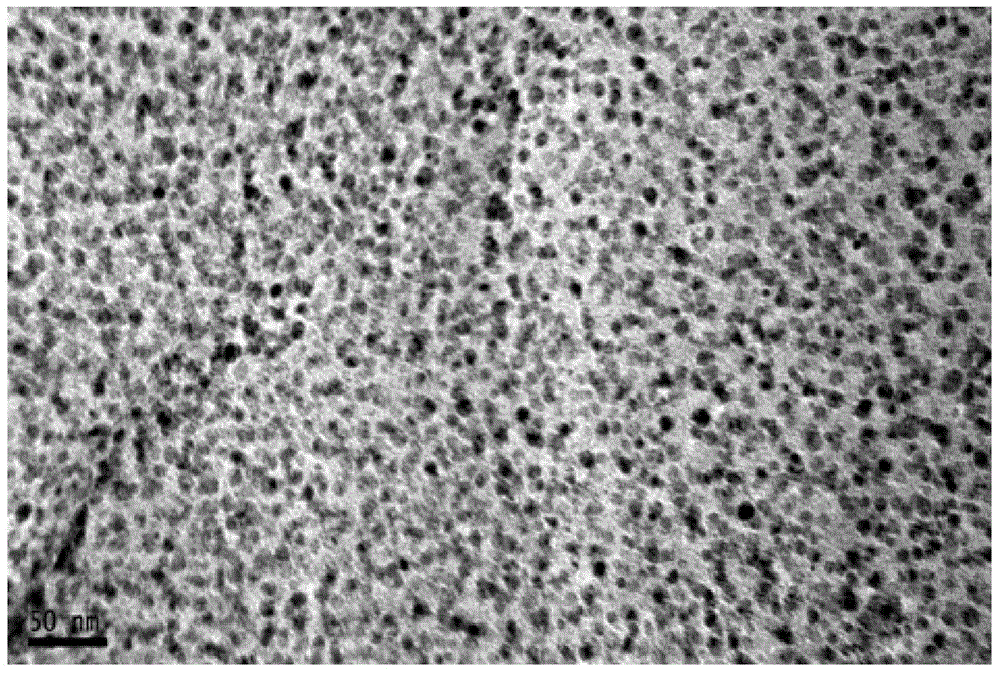

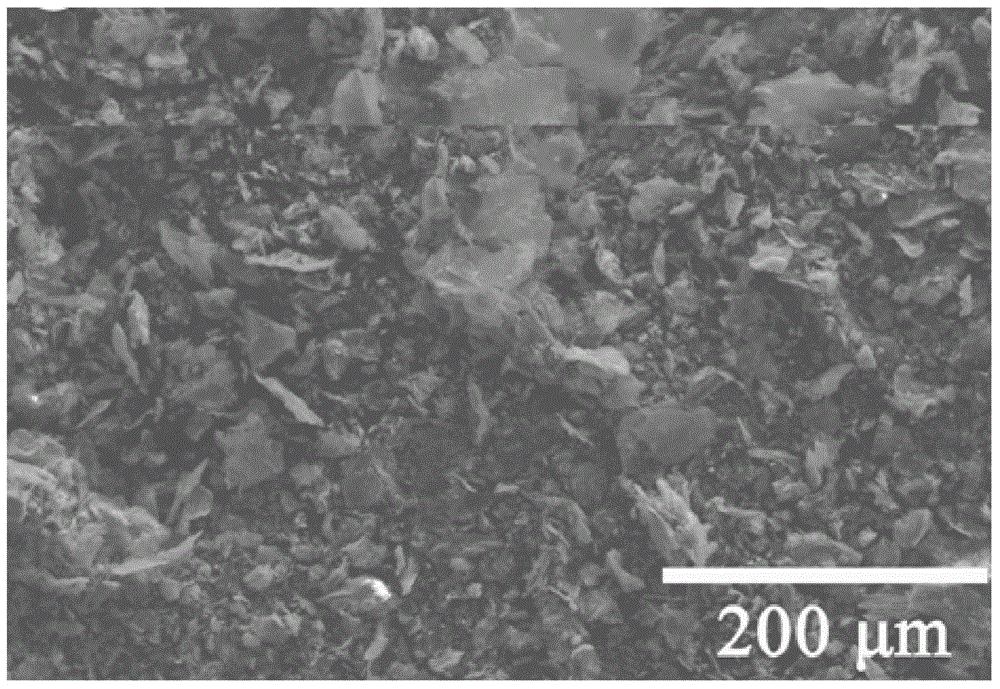

Nanometer copper/graphene composite material and preparation method and application thereof

InactiveCN104479804AThe preparation method is simple and quickShort processing timeAdditivesOil additiveSurface-active agents

The invention belongs to the technical field of new material preparation and lubricating oil additives, and discloses a nanometer copper / graphene composite material and a preparation method and application thereof. The preparation method comprises the following steps of: firstly dissolving a copper precursor compound, a surface active agent and a complexing agent into reducing alcohol, then adding graphene oxide, and carrying out ultrasonic dispersion to obtain a mixed solution; then adding a reducing agent to the mixed solution, transferring into a reaction kettle, introducing CO2 gas, and controlling gas pressure and temperature so that CO2 achieves a supercritical state; stirring the mixed solution inside the reaction kettle for reacting, cooling, decompressing, washing by centrifuging, and carrying out vacuum drying to obtain the nanometer copper / graphene composite material. The preparation method disclosed by the invention is simple, saved in time and fast. The prepared nanometer copper / graphene composite material has the characteristics of single phase, controllability in loading capacity, small nanometer copper particle size, uniformity in nanometer copper distribution on the surface of a graphene nanometer layer, and the like, has a synergetic lubricating effect, and can be used for outstandingly improving the antifriction and abrasion-resistant property of basic lubricating oil.

Owner:SOUTH CHINA UNIV OF TECH

Lubricant additive formulation

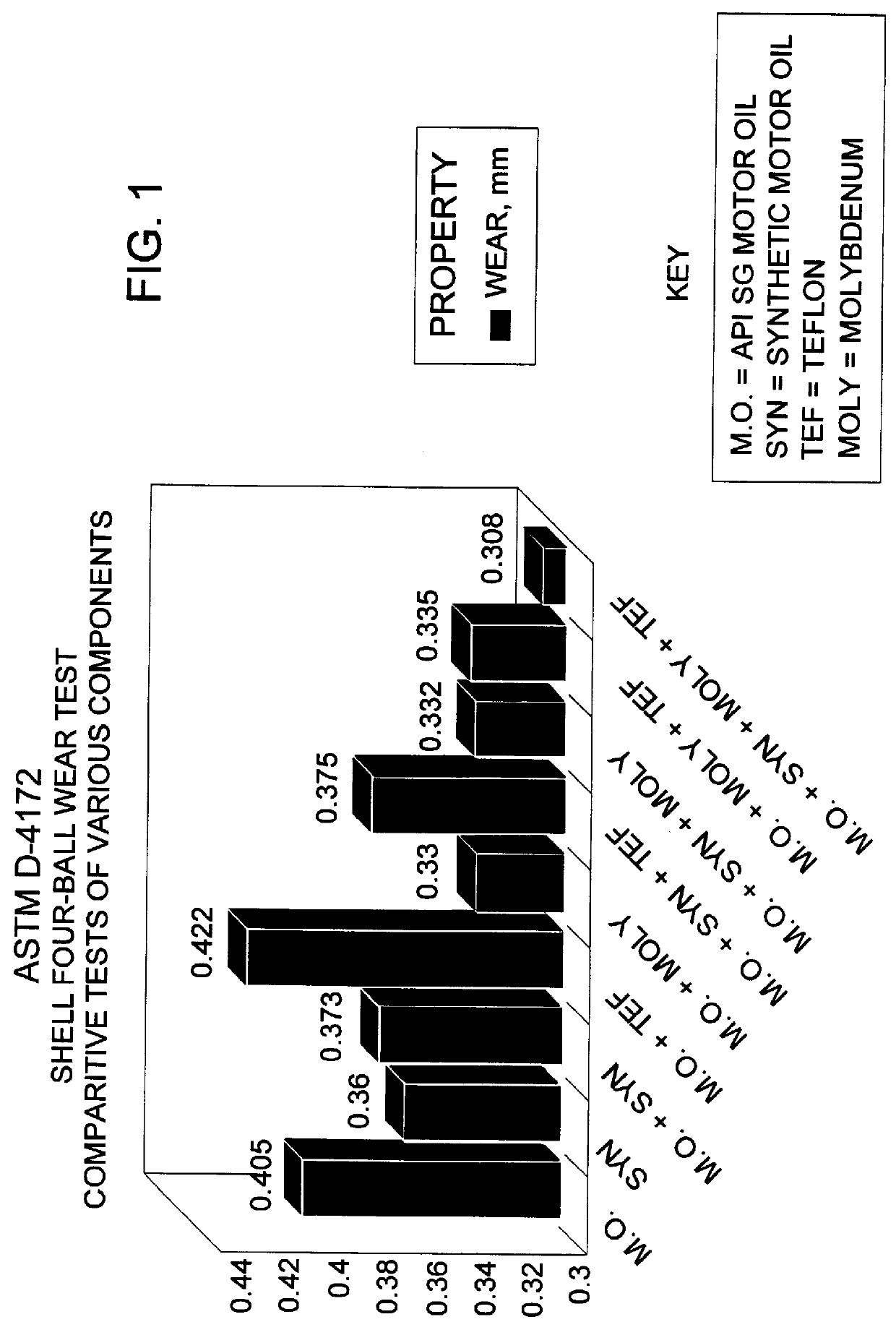

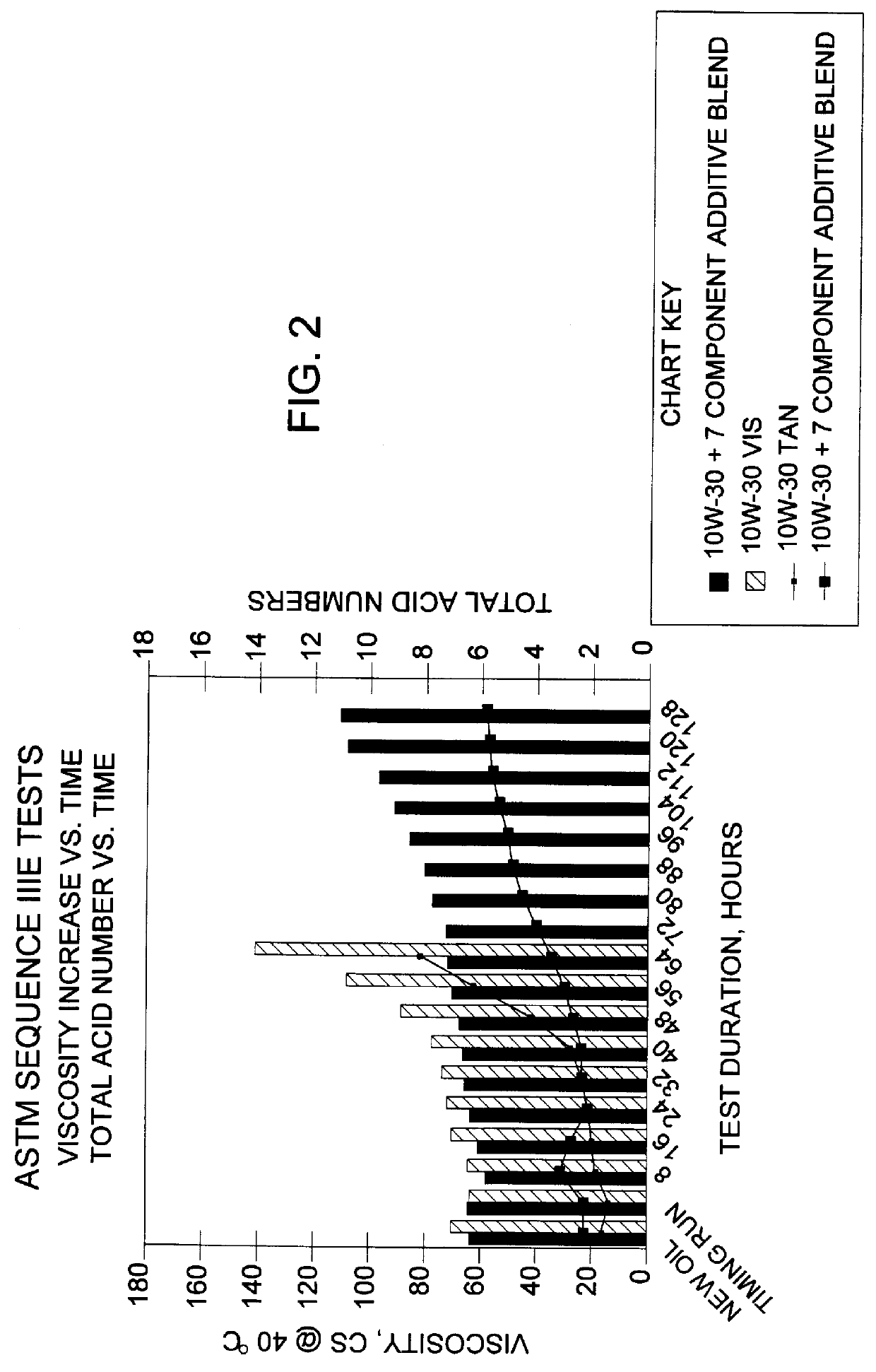

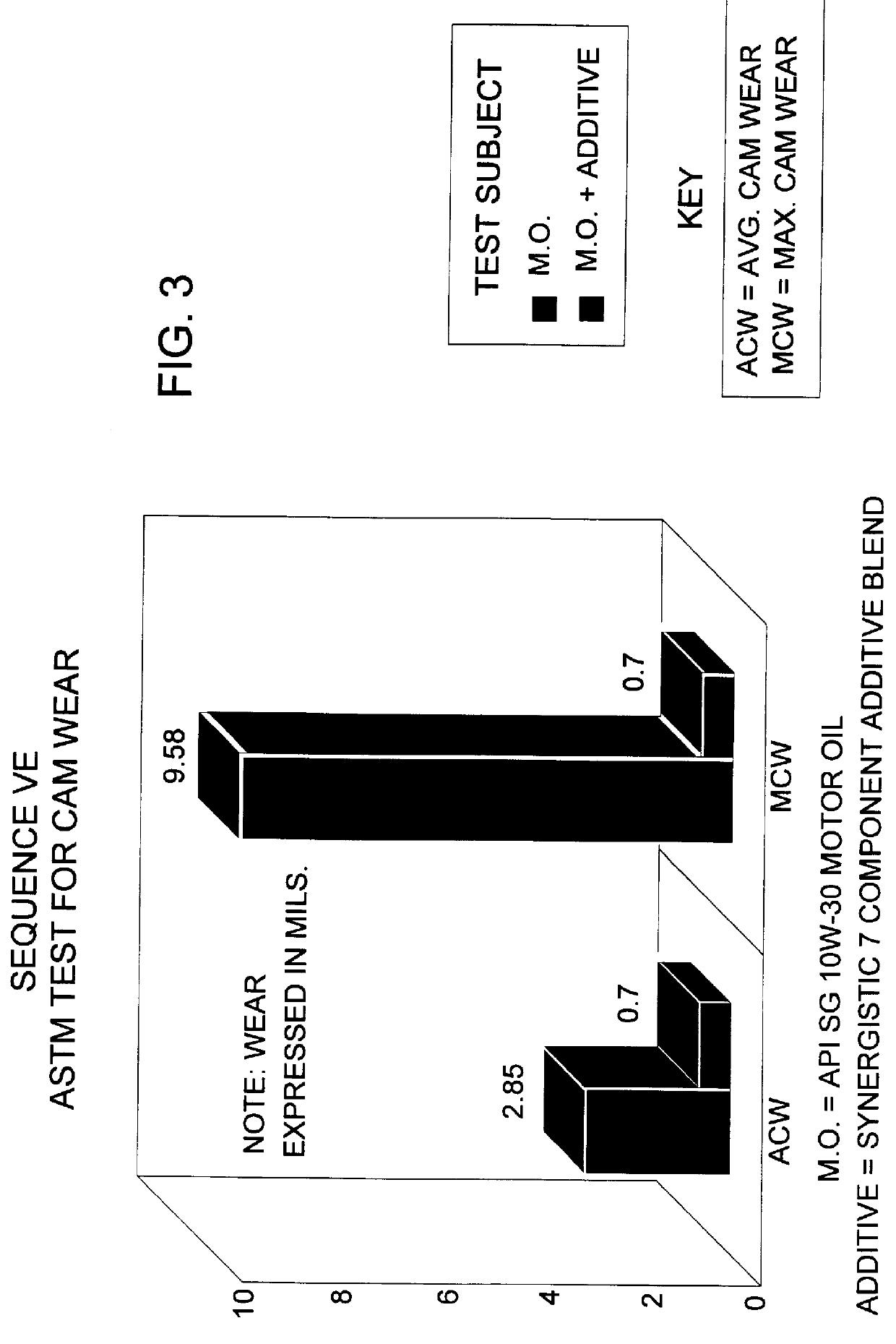

PCT No. PCT / US95 / 14186 Sec. 371 Date Aug. 27, 1997 Sec. 102(e) Date Aug. 27, 1997 PCT Filed Nov. 3, 1995 PCT Pub. No. WO96 / 15211 PCT Pub. Date May 23, 1996A lubricant additive formulation for addition to conventional motor oil to improve the lubricating properties of the engine oil and enhance the performance of the engine. The engine treatment oil additive comprises a synergistic blend of an oil soluble molybdenum additive, polyalphaolefin, ester such as a polyolester or diester, polytetrafluoroethylene, dispersant inhibitor containing zinc dithiophosphate, mineral oil base stock, viscosity index improvers, and borate ester used in combination with a conventional crankcase lubricant at about a 20 to about a 25% volume / percent. The improved performance of the engine additive in comparison with a conventional crankcase lubricants is attributable to the effect of optimizing the design parameters for each of the individual chemical constituents and combining the chemical constituents according to the present invention to obtain surprisingly good results including improved wear, oxidation resistance, viscosity stability, engine cleanliness, fuel economy, cold starting, and inhibition of acid formation.

Owner:VALVOLINE LICENSING & INTPROP LLC

Low molecular weight ethylene/α-olefin interpolymer as base lubricant oils

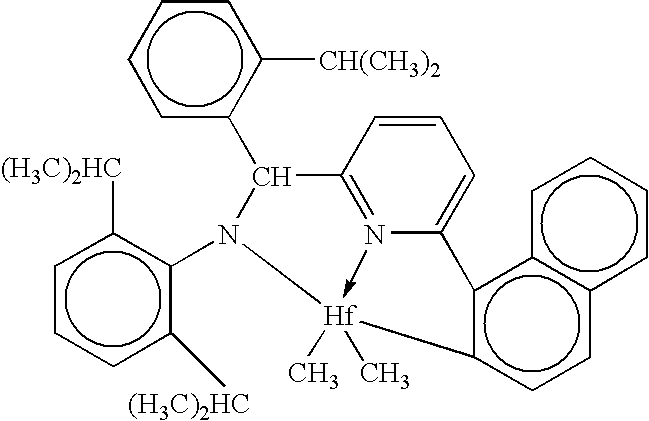

A lubricant composition comprises an ethylene / α-olefin interpolymer having a number average molecular weight of less than 10,000 g / mol as a base oil and at least one oil additive. The ethylene / α-olefin interpolymer has at least one molecular fraction which elutes between 40° C. and 130° C. when fractionated using TREF, characterized in that the fraction has a molar comonomer content of at least 5 percent higher than that of a comparable random ethylene interpolymer fraction eluting between the same temperatures, wherein said comparable random ethylene interpolymer has the same comonomer(s) and has a melt index, density, and molar comonomer content (based on the whole polymer) within 10 percent of that of the ethylene / α-olefin interpolymer.

Owner:DOW GLOBAL TECH LLC

Process for producing zinc dialkyldithiophosphates exhibiting improved seal compatibility properties

In general terms, the present invention includes a process for producing a new zinc dialkyldithiophosphate (ZDDP) offering improved seal compatibility characteristics in engine and transmission oil packages. The present invention additionally includes zinc dialkyldithiophosphate produced in accordance with the disclosed methodologies, and oil additives, lubricants, and engines and transmission comprising the zinc dialkyldithiophosphate of the present invention.

Owner:AFTON CHEMICAL

Method for preparing graphene lubricating oil additive

The invention relates to a method for preparing a graphene lubricating oil additive and belongs to the technical field of lubricating oil. An oxidized graphene solution is subjected to centrifugal separation at low speed, supernatant is obtained, and the supernatant is dried at low temperature to obtain oxidized graphene powder; the oxidized graphene powder is heated in vacuum to be constantly dry, oxidized graphene powder is obtained and mixed with a dispersing agent and basic oil, after uniform mixing, the mixture is placed in a high-temperature high-pressure reaction kettle to be processed, oleophylic graphene is obtained, and the graphene lubricating oil additive is obtained by mixing the oleophylic graphene, the dispersing agent and the basic oil or mixing the oleophylic graphene with finished lubricating oil. The technology is simple and convenient, cost is reduced, all components have excellent dispersity and stability, and the problem about long-time stability of nano additives is solved. When lubricating oil where the additive is added is applied to mechanical operation, the abrasion resistance and bearing capacity of mechanical devices can be improved, and meanwhile the surfaces of the mechanical devices can be protected and highly repaired.

Owner:TANGSHAN XIRUN SCI TECH DEV CO LTD

Graphene-fullerene-like molybdenum disulfide compounded lubricating oil additive and preparation method thereof

The invention discloses a graphene-fullerene-like molybdenum disulfide compounded lubricating oil additive and a preparation method thereof. The method is implemented by taking oxidized graphene and fullerene-like molybdenum disulfide nanoparticles as raw materials through carrying out surface grafting on oxidized graphene nanoparticles by using lipophilic 3-(methyl acryloyl oxy) propyl-trimethoxysilane (KH-570), and carrying out reduction by using hydrazine hydrate, so that grafted graphene nanoparticles are formed; wrapping the fullerene-like molybdenum disulfide nanoparticles with polystyrene (PS), so that PS / IF-MoS2 nano composite microspheres are formed; and finally, inducing KH-570 and PS to have a polymerization reaction, so that graphene-fullerene-like molybdenum disulfide compounded nanoparticles are formed. The compounded nanoparticles prepared according to the invention are used as a lubricating oil additive, and can be steadily dispersed in lubricating oil for a long time, and various organic dispersants are not required to be added.

Owner:NANJING UNIV OF SCI & TECH

On-board fuel additive injection systems

InactiveUS20070101969A1Improve performanceQuality improvementNon-fuel substance addition to fuelCombustion enginesCombustionOn board

Disclosed is a fuel additive system for internal combustion engines in which the fuel additive system is disposed on-board a vessel such as marine vessel or locomotive. The fuel additive system includes a fuel additive reservoir containing a fuel additive in fluid communication with an internal combustion engine. An electronically controlled injector, such as an eductor, is in fluid communication with the internal combustion engine and a fuel level meter or sensor, fuel efficiency meter or sensor, or other meter or sensor which, upon sensing certain pre-set conditions, e.g., increase of fuel level in a fuel storage tank or decrease in fuel efficiency, the injector injects an appropriate amount of fuel additive from the fuel additive reservoir and into the fuel stream that ultimately enters the internal combustion engine.

Owner:ENVIROFUELS LLC

Fuel oil additive and preparation method thereof

InactiveCN101671584ASimple preparation processEasy to operateLiquid carbonaceous fuelsAlcoholAntioxidant

The invention relates to a fuel oil additive which comprises the components based on parts by weight: 50-65 parts of surface active agent, 15-20 parts of alcohol auxiliary surface active agent, 2-5 parts of antioxidant, 2-5 parts of corrosion inhibitor and 15-30 parts of deionized water. The invention also relates to a preparation method of the fuel oil additive. The fuel oil additive has simple preparation technique, convenient operation and lower cost, and can generate the comprehensive effects such as saving fuel oil, increasing power, cleaning up sediment, reducing emission and the like; furthermore, the gasoline compound added with the fuel oil additive has good stability and strong applicability, is applicable to both gasoline stations and individual users, and can save the gasolineby 8%-15% in the comprehensive effect.

Owner:重庆泰壹环保新能源开发股份有限公司

Lubricating oil additive and lubricating oil composition containing same

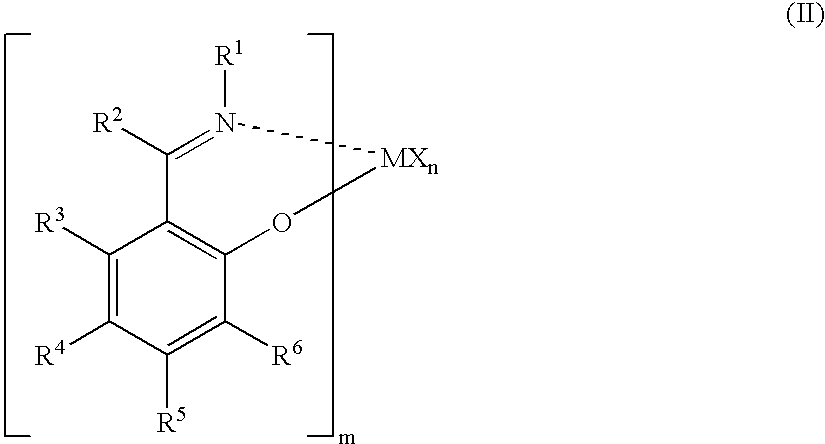

ActiveUS20110190185A1Disruptive effectImprove suppression propertiesOrganic chemistryOrganic compound preparationOligomerBoiling point

An overbased salt of an oligomerized alkylhydroxyaromatic compound for use in a lubricating oil composition is disclosed, wherein the alkyl group of the alkylhydroxyaromatic compound is derived from an olefin mixture comprising propylene oligomers having an initial boiling point of at least about 195° C. and a final boiling point of greater than 325° C. and up to about 400° C. as measured by ASTM D86. Also disclosed is a propylene oligomer having an initial boiling point of at least about 195° C. and a final boiling point of greater than 325° C. and up to about 400° C. as measured by ASTM D8, wherein the propylene oligomer contains a distribution of carbon atoms that comprise at least about 50 weight percent of C14 to C20 carbon atoms.

Owner:CHEVRON ORONITE SA

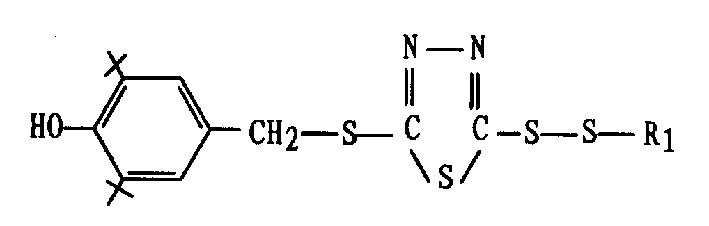

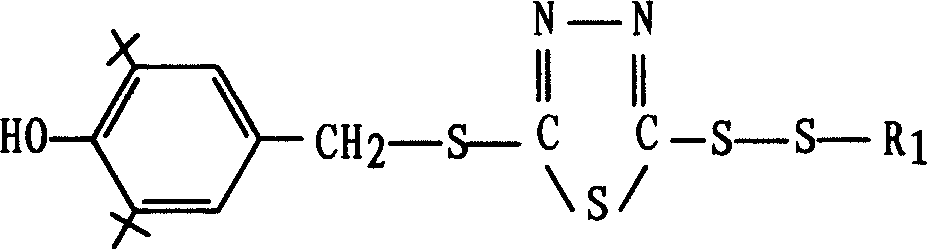

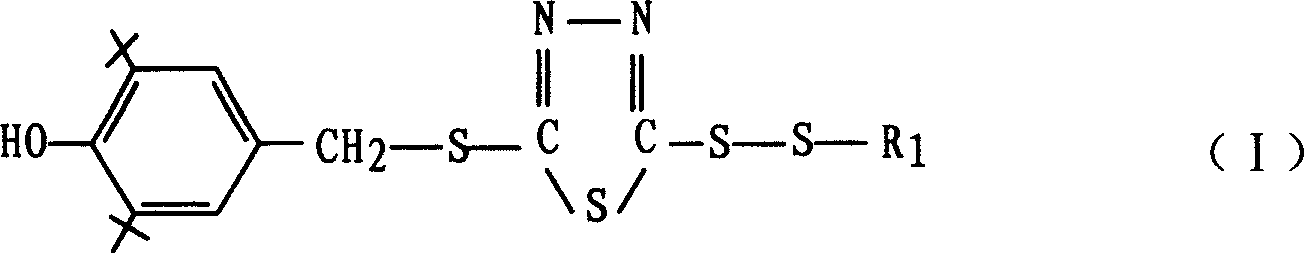

Preparation method of antioxidation antifriction lubricating oil additive

An antioxidizing and antiwear additive for lubricating oil is prepared from cryptophenol and 2-mercapto-5-alkylthio 1,3,4 thiadiazole through condensation reaction at 40-150 deg.C under existance of formaldehyde and acid catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Amine Tungstates and Lubricant Compositions

ActiveUS20070042917A1Improved deposit controlPromote oxidationAdditivesMolybdenum sulfidesTungstateAntioxidant

This invention relates to lubricating oil additives, and to lubricating oil compositions, their method of preparation, and use. More specifically, this invention relates to several novel lubricating oil additives and compositions which contain a tungsten compound and an antioxidant, namely aminic antioxidants such as a secondary diarylamine or an alkylated phenothiazine. The use of the tungsten compound with the secondary diarylamine and / or the alkylated phenothiazine provides improved oxidation and deposit control to lubricating oil compositions. The lubricating oil compositions of this invention are particularly useful as crankcase and transmission lubricants, gear oils and other high performance lubricant applications.

Owner:KING INDUSTRIES INC

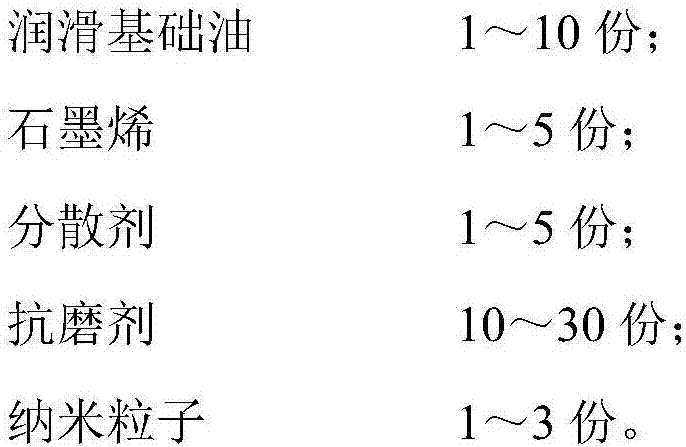

Graphene compounded lubricating oil additive and preparation method thereof

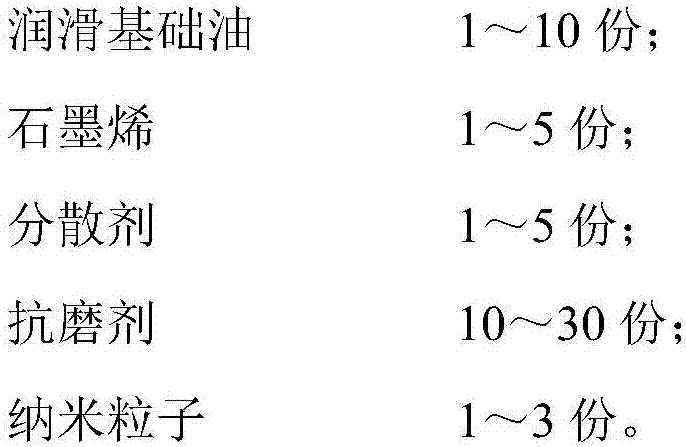

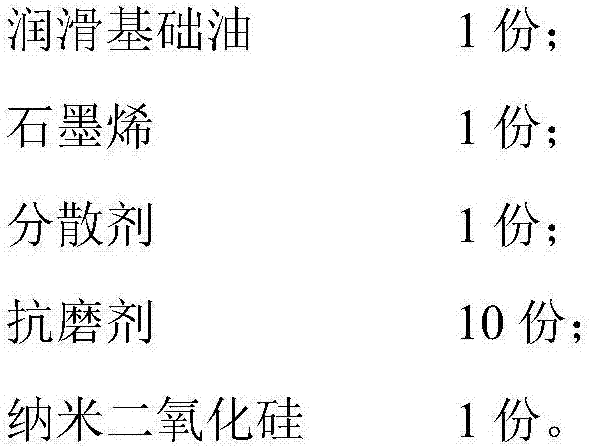

The invention relates to the technical field of lubricating oil additives and particularly relates to a graphene compounded lubricating oil additive and a preparation method of the graphene compounded lubricating oil additive. The invention particularly discloses the graphene compounded lubricating oil additive. The graphene compounded lubricating oil additive at least comprises the following components by weight: 1-10 parts of lubricating base oil, 1-5 parts of graphene, 1-5 parts of a dispersing agent, 10-30 parts of an antiwear agent, and 1-3 parts of nanoparticle. The preparation method of the graphene compounded lubricating oil additive at least comprises the following steps: (1) adding the lubricating base oil and the graphene into a high-speed mixer at the same time, raising the temperature to lower be than 100-130 DEG C, homogenizing and stirring for 1-5 hours; (2) adding corresponding weight parts of the dispersing agent, the antiwear agent and the nanoparticle into a mixture obtained in the step (1), raising the temperature to 90-150 DEG C, mixing for 5-30 minutes at the speed of 1500 r / min, and obtaining the graphene compounded lubricating oil additive.

Owner:GUANGXI LIUGONG MASCH CO LTD

Fuel oil additive and fuel oil products containing the fuel oil additive

InactiveUS20040065002A1Improve performanceBoost octaneLiquid carbonaceous fuelsFuel additivesAlkaline earth metalKerosene

The present invention provides a fuel oil additive capable of effectively improving the quality of fuel oils, which comprises an oil-soluble metal salt of organic acid having the general formula MR, where R is an organic acid radical and the corresponding organic acid is a C1-C40 saturated or unsaturated fatty acid, naphthenic acid, aromatic acid or alkylphenol, M is a metal cation and the corresponding metal is an alkali metal, alkali-earth metal, rare-earth metal, transition metal, or the like. The present invention also provides fuel oil products added to the fuel oil additive, including gasoline, diesel oil, kerosene, heavy oil, resid, or the like. The present invention especially provides a gasoline antiknock agent and a gasoline having excellent antiknock property, and this kind of gasoline antiknock agent is characteristic of effectiveness, economy, safety, no environmental pollution, no toxicity to human body, no adverse effect on parts of automobile engine, use convenience, and the like.

Owner:HU SHIBIN

Methanol gasoline and its preparation method

InactiveCN102260548AEasy to prepareExcellent performanceLiquid carbonaceous fuelsFuel additivesTruckSolvent

The invention discloses a methanol gasoline and a preparation method thereof, relating to the field of new energy. The methanol gasoline comprises 15-30wt% of methanol, 67-83wt% of gasoline and 2-3wt% of additive. The preparation method comprises the following steps: pouring solubilizer, energy increasing and consumption reducing agent, anti-oxidant, metal corrosion inhibitor, rubber swelling inhibitor into a reaction vessel according to a required proportion with stirring, mixing uniformly to obtain an additive; mixing the additive with methanol according to a required proportion to obtain modified methanol; and mixing the modified methanol with gasoline according to a required proportion to obtain the methanol gasoline. The methanol gasoline disclosed in the invention has the advantagesof simple preparation and good performance, can be used mixed with a national standard gasoline in any proportion with similar energy consumption with the national standard gasoline and emission indexes that conforms to requirements of environmental protection, and can be widely used for various petrol-engined motor vehicles, such as car, carriage, fork truck, power-assisted vehicle, farm vehicle, motorcycle, load wagon and forklift.

Owner:永州锦溁新能源开发有限公司

Ethylene/alpha-olefin copolymer, method for producing the same, and use thereof

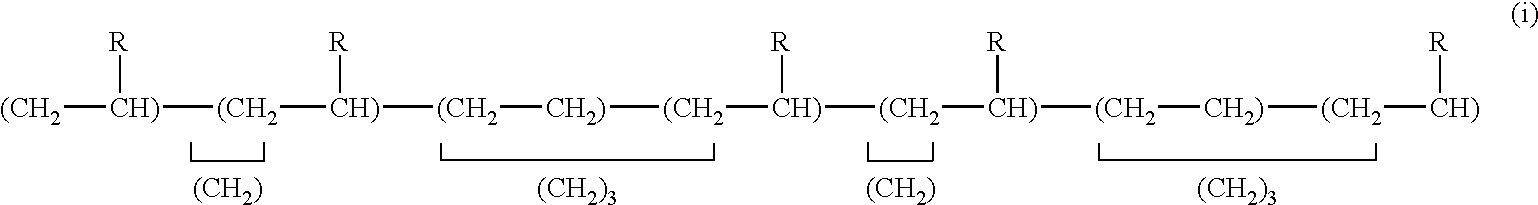

InactiveUS6459005B1Good shear stabilityHigh activityHydrocarbons from unsaturated hydrocarbon additionSolid fuelsOil additiveAlpha-olefin

The present invention intends to provide an ethylene / alpha-olefin copolymer of specific structure, exhibiting excellent performance as a lubricant oil additive, capable of having various functional groups in high ratio, and serviceable as raw material for various solubilizing agents. The ethylene / alpha-olefin copolymer of the present invention is composed of ethylene and an alpha-olefin having 3 to 10 carbon atoms, and characterized by specific characteristics.

Owner:MITSUI CHEM INC

Fuel additive for improved performance of low sulfur diesel fuels

InactiveUS20130074874A1Maximize driveabilityMaximize fuel economyHollow article cleaningLiquid carbonaceous fuelsHydrogenCarboxylic acid

A diesel fuel, diesel fuel additive concentrate and method for improving the performance of fuel injectors for a diesel engine are provided. The diesel fuel includes a major amount of middle distillate fuel having a sulfur content of 15 ppm by weight or less; and a reaction product of (a) a hydrocarbyl substituted dicarboxylic acid or anhydride, and (b) an amine compound or salt thereof of the formulawherein R is selected from hydrogen and a hydrocarbyl group containing from about 1 to about 15 carbon atoms, and R1 is selected from hydrogen and a hydrocarbyl group containing from about 1 to about 20 carbon atoms, wherein the reaction product contains less than one equivalent of an amino triazole group per molecule of reaction product, and wherein the reaction product is present in an amount sufficient to improve the performance of diesel direct and / or indirect fuel injectors.

Owner:AFTON CHEMICAL

Oil make-up and replenishment oil filter and method of use

An oil filter and oil-additive dispensing device comprising an oil filter and oil additive replenishment system further comprising: a full-flow oil filter; a by-pass oil filter; an oil additive dispensing system; and an on-vehicle controller to dispense additive as required, track additive consumption and signal the need for a replacement system is described. Also a method of using such oil filter and oil-additive dispensing device to extend the useful life of lubricating oil in a vehicle engine is described.

Owner:GM GLOBAL TECH OPERATIONS LLC

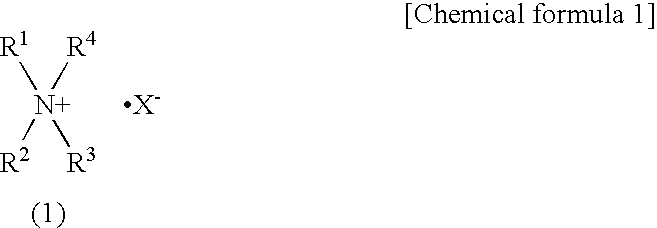

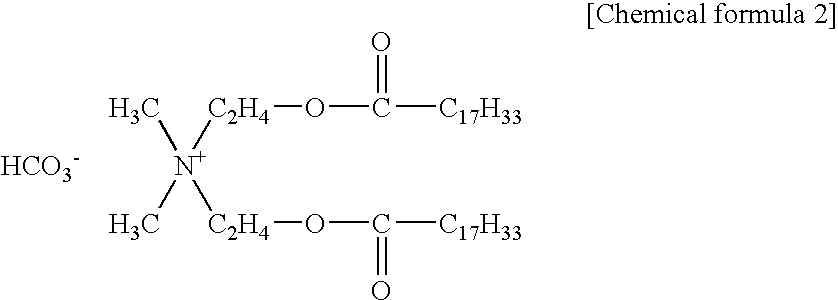

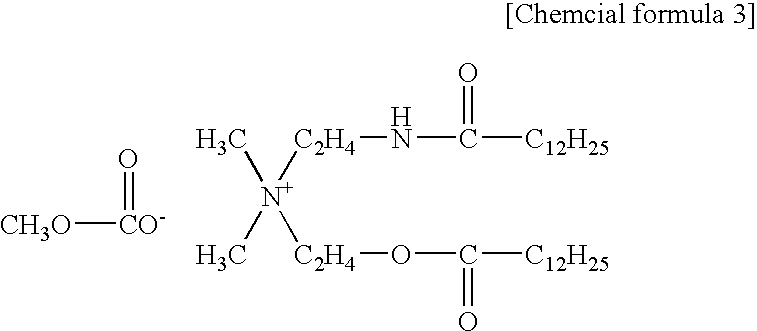

Lubricating oil additive and lubricating oil composition containing the same

InactiveUS20070155636A1Easy to cleanSmall amountLiquid carbonaceous fuelsAdditivesOil additiveChloride

The present invention provides a lubricating oil additive with excellent cleaning performance which does not include metal components such as calcium or magnesium, and a lubricating oil composition containing the same. The lubricating oil additive according to the present invention is characterized by containing a quaternary ammonium salt having a base number of at least 10 mgKOH / g. Examples of such a quaternary ammonium salt include quaternary ammonium salts obtained by subjecting counter anions in cationic surfactants such as tetraalkylammonium chloride and tetraalkylammonium sulfate to salt-exchange.

Owner:ADEKA CORP

Micro emulsion cutting fluid composition and preparation method thereof

InactiveCN102002424AGood rust protectionImprove the lubrication effectLubricant compositionEmulsionOil additive

The invention relates to a micro emulsion cutting fluid composition and a preparation method thereof. The composition comprises the following raw materials in percentage by weight: 22-32 mineral oil, 2-10 anionic surfactant, 1-5 nonionic surfactant, 1-3 emulsion stabilizer, 5-10 oiliness additive, 5-10 extreme pressure additive, 5-15 rust-inhibiting additive, 0.5-3 anticorrosion fungicide, 0.1-0.3 antifoam additive and the balance of water. The preparation method of the micro emulsion cutting fluid composition is simple and convenient, the provided cutting fluid S50 composition is an ecological stable product and has good lubricity and cooling performance, and the machining accuracy of workpieces can be improved. The cutting fluid S50 composition has strong antimicrobial capability, long service life and good PH value stability and provides good rust-inhibiting performance for the workpieces.

Owner:上海德润宝特种润滑剂有限公司

Lubricating oil

ActiveCN104031722AMagneticLiquidAdditivesPigment treatment with organosilicon compoundsIron powderOil additive

The invention discloses a lubricating oil which comprises the following components in percentage by weight: 10-25% of detergent dispersant, 5-15% of antioxidation and anticorrosion agent, 5-15% of extreme-pressure antiwear additive, 10-15% of tackifier, 1-3% of ferrite-base magnetic fluid and the balance of base oil. The lubricating oil additives can greatly improve the antiwear and anti-friction properties of the lubricating oil, enhance the heat stability and convert the iron powder and mud oil generated in the crankshaft and connecting rod tile working process into nano balls, thereby reducing the friction of the machine, lowering the oil temperature and prolonging the service life of the lubricating oil and machine.

Owner:丘寿勇 +2

Medium speed diesel engine oil

A lubricating oil having a CCS viscosity at −15° C. less than 7000 cP, good shear stability, and a TBN between 8 and 20 comprising: a) a lubricating base oil made from a waxy feed, b) an engine oil additive package formulated to protect silver bearings, and c) less than 2.0 wt % viscosity index improver. Also a process to make a lubricating oil having a CCS viscosity at −15° C. less than 7000 cP, good shear stability, and a TBN between 8 and 20. Additionally, a lubricating oil having low CCS viscosity comprising specified amounts of lubricating base oil made from a waxy feed, engine oil additive package formulated to protect silver bearings, up to 55 wt % bright stock with a VI greater than 120, and no viscosity index improver or conventional pour point depressant additives. Also, a method for operating a railroad engine using the lubricating oil of this invention.

Owner:CHEVROU USA INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com