Graphene compounded lubricating oil additive and preparation method thereof

A lubricating oil additive and graphene composite technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of lack of repair function, poor use effect, and short duration of action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

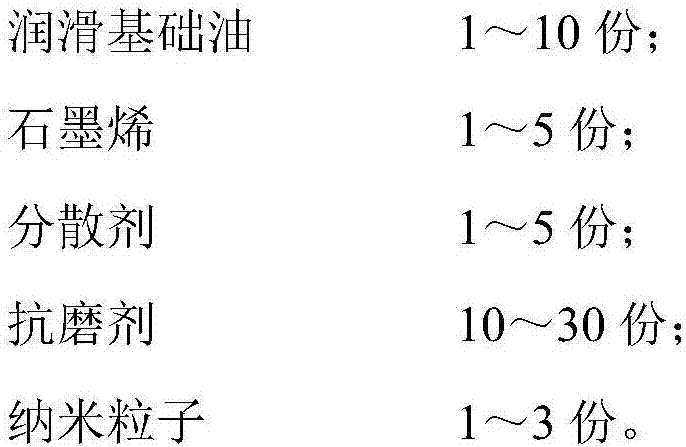

Image

Examples

preparation example Construction

[0039] The preparation methods of graphene include mechanical exfoliation method, epitaxial growth method, chemical vapor deposition method, chemical synthesis method, graphene oxide reduction method and longitudinal cutting carbon tube method. In this application, the graphene oxide is commercially available and purchased from Suzhou Hengqiu Graphene Co., Ltd.

[0040] As a preferred technical solution of the present invention, the graphene is layered graphene oxide.

[0041] The term "graphene oxide" means that graphene treated with a strong oxidant contains three elements, C, H, and O. Graphene oxide is stacked layer by layer through interlayer hydrogen bonds and other forces.

[0042] The three commonly used methods for preparing graphene oxide, namely Brodie method, Staudenmaier method and Hummers method, all use strong acid to strengthen the combination of oxidizing agents to treat graphite. A strong protonic acid enters the graphite interlayer to form a graphite inter...

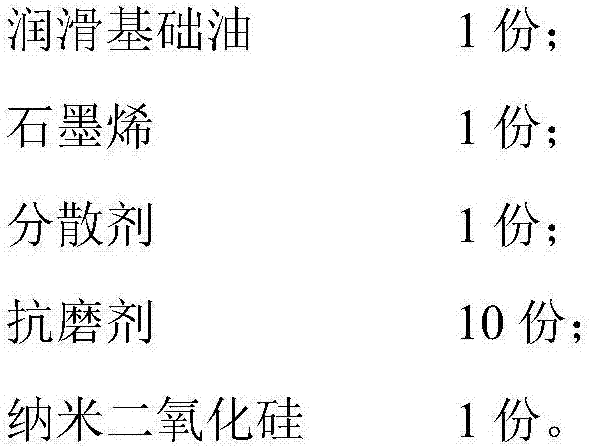

Embodiment 1

[0063] Embodiment 1 of the present application provides a graphene composite lubricating oil additive, in parts by weight, at least includes the following components,

[0064]

[0065] Described lubricating base oil is mineral oil, and described mineral oil is 120# white oil;

[0066] Described graphene is single-layer graphene, purchased from Suzhou Hengqiu Graphene Co., Ltd.;

[0067] Described dispersant is polyisobutylene succinimide;

[0068] Described antiwear agent is molybdenum disulfide;

[0069] Described nano silicon dioxide is purchased from Guangzhou Shenna Trading Co., Ltd., and the product model is SQ-1;

[0070] The preparation method of described graphene composite lubricating oil additive at least comprises the following steps:

[0071] (1) Add lubricating base oil and graphene to the high-speed mixer at the same time, heat up to 100°C, and stir for 1 hour;

[0072] (2) Add the dispersant, anti-wear agent, nano silicon dioxide of corresponding weight...

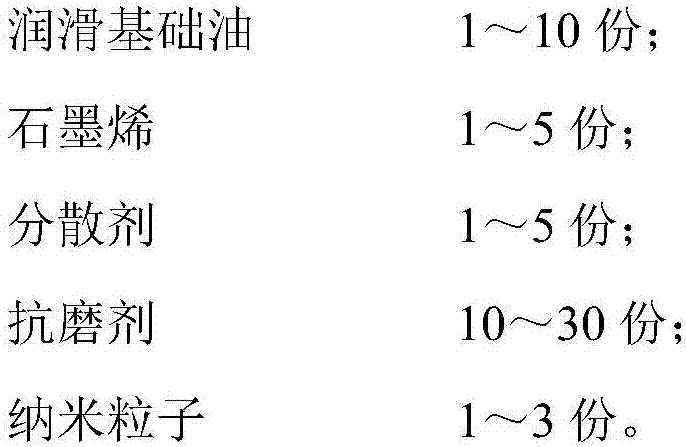

Embodiment 2

[0078] Embodiment 2 of the present application provides a kind of graphene composite lubricating oil additive, by weight, at least includes the following components,

[0079]

[0080] Described lubricating base oil is mineral oil, and described mineral oil is 120# white oil;

[0081] Described graphene is single-layer graphene, purchased from Suzhou Hengqiu Graphene Co., Ltd.;

[0082] Described dispersant is polyisobutylene succinimide;

[0083] Described antiwear agent is molybdenum disulfide;

[0084] Described nano silicon dioxide is purchased from Guangzhou Shenna Trading Co., Ltd., and the product model is SQ-1;

[0085] The preparation method of described graphene composite lubricating oil additive at least comprises the following steps:

[0086] (1) Add lubricating base oil and graphene to the high-speed mixer at the same time, heat up to 100°C, and stir for 1 hour;

[0087] (2) Add the dispersant, anti-wear agent, nano silicon dioxide of corresponding weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com