Patents

Literature

338 results about "Polyisobutylene succinimide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricant composition for gasoline engine

ActiveCN102690711AMeet performance requirementsImprove antioxidant capacityAdditivesAlkaline earth metalAntioxidant

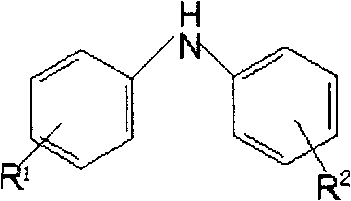

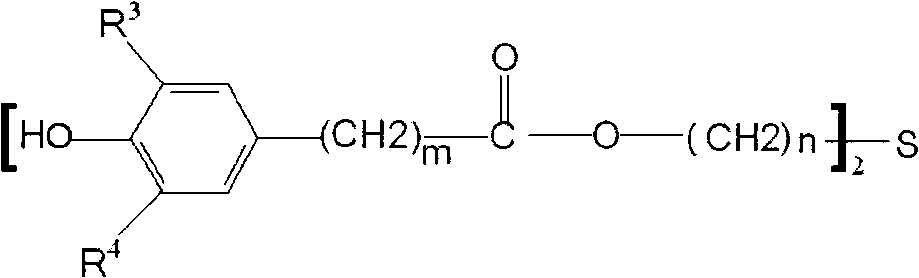

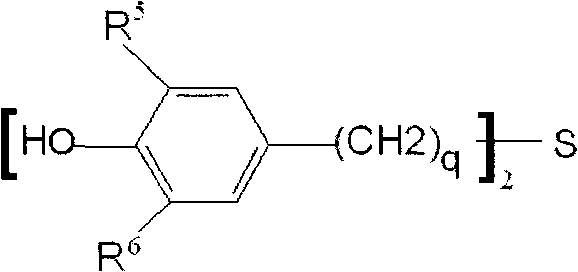

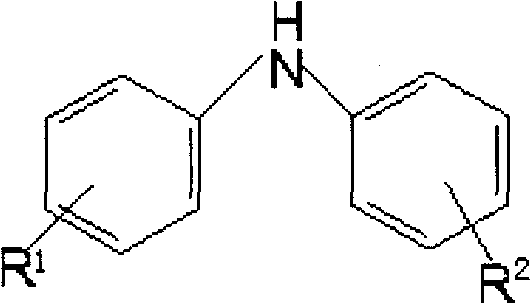

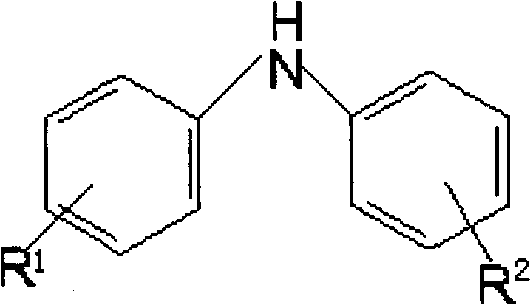

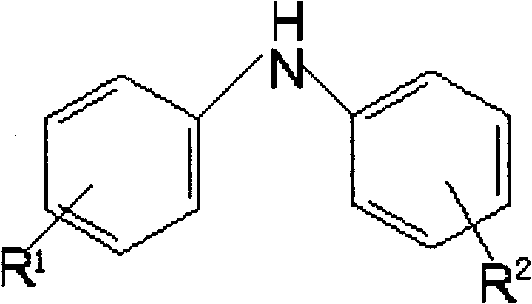

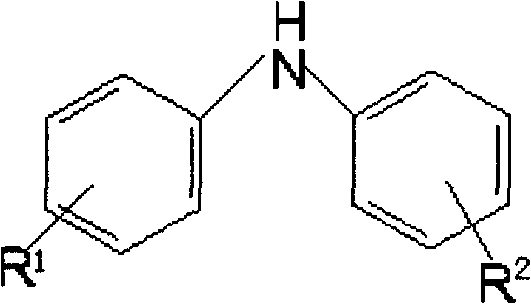

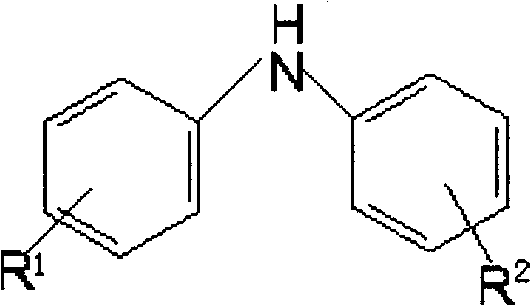

The invention relates to a lubricant composition for a gasoline engine. The lubricant composition contains: by mass, less than or equal to 0.08% of phosphorus and less than or equal to 0.9% of sulfate ash. The lubricant composition comprises A) a composite antioxidant comprising at least ingredients of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant and / or a boronized polyisobutylene succinimide dispersant, C) one or more alkaline earth metal salicylate cleaning agents, D) at least one zinc dialkyl dithiophosphate, E) one or more oil-soluble organic molybdenum friction modifiers, F) one or more ashless friction modifiers, and G) a main amount of lubricating base oil. The lubricant composition for a gasoline engine has synergistic effect of the additives, can satisfy antioxidation requirements of a high-grade gasoline engine lubricant, and has excellent piston cleanliness, wear resistance and a viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricant composition for diesel engine

ActiveCN102690707AImprove antioxidant capacityImprove high temperature wear resistanceAdditivesAntioxidantDiesel engine

The invention relates to a lubricant composition for a diesel engine. The lubricant composition for a diesel engine contains less than or equal to 0.09% by mass of phosphorus, less than or equal to 0.4% by mass of sulfur and less than or equal to 1.0% by mass of sulfate ash. The lubricant composition for a diesel engine comprises A) a composite antioxidant comprising at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant and / or a boronized polyisobutylene succinimide dispersant, C) a mixture of magnesium sulfate and sulfurized calcium alkyl phenate, D) at least one zinc dialkyldithiophosphate, E) one or more ashless friction modifiers, and F) a main amount of lubricating base oil. The lubricant composition for a diesel engine has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a diesel engine, and has excellent piston cleanliness, wear resistance and a viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cleaning agent for diesel oil system

InactiveCN1412290AEffective decontaminationEffective cleaningOrganic detergent compounding agentsSurface-active detergent compositionsIsobutanolVegetable oil

The cleaning agent for fuel oil system includes: 5-20% of macromolecular cleaning dispersing agent which can be one of polyisobutyramide, polyether amine, polyalkylphenol, alkylpolyuerthane and polyisobutylene succimide, 10-30% of breakout oil which can be one of alkylpolypropylene glycol ether, alkalpolybutaglycol ether, engine oil, base oil, liquid paraffin and vegetable oil, 5-20% of water-removing agent which can be one or two kinds of main group phenol polyethenoxy ether, octadecyl polyethenoxy ether, Peregral, dodecyl alcohol amide, Tween-80 and Span-80, 15-35% of polar solvent which can be one or several kinds of isopropanol, isobutanol, ethylene glycol monomethyl ether and ethylene glycol monobutyl ether and 30-65% of diluting agent.

Owner:中国船舶重工集团公司七一八研究所

Diesel detergent additive

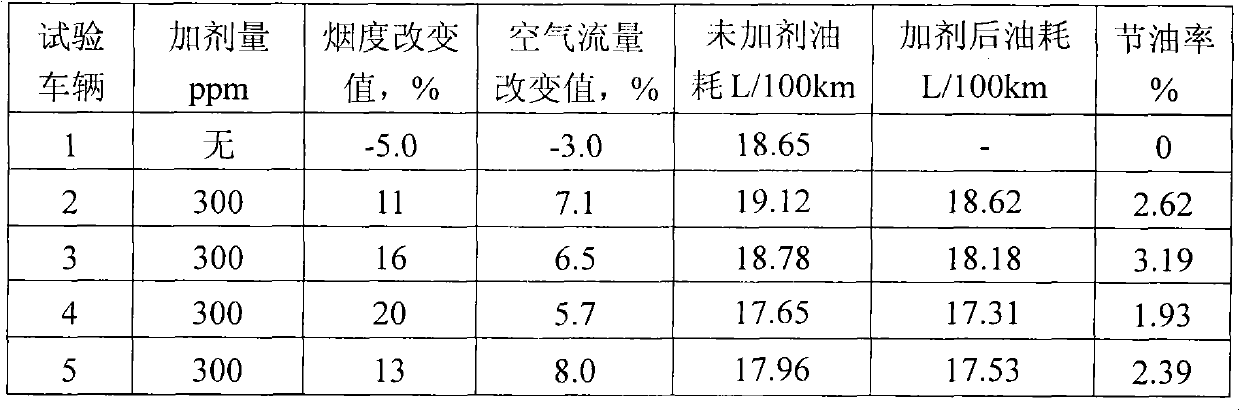

ActiveCN101921638AImprove the lubrication effectEasy to cleanLiquid carbonaceous fuelsFuel additivesPolyolefinOrganic solvent

The invention discloses a diesel detergent additive, which comprises the following components by weight percent: 15-60% of polyisobutylene succinimide, 5-20% of polyolefin amine, 5-20% of alkyl imidazole, 5-15% of glyceryl monooleate and 20-70% of organic solvent. The diesel detergent additive of the invention has good effects on cleaning oil ways of a diesel vehicle and eliminating carbon deposition of an oil nozzle, simultaneously can improve lubricating property of the diesel, improve exhaust emission and save the diesel.

Owner:北京奥力助兴石化科技有限公司

Special lubricating oil for fuel gas engine of public transport automobile

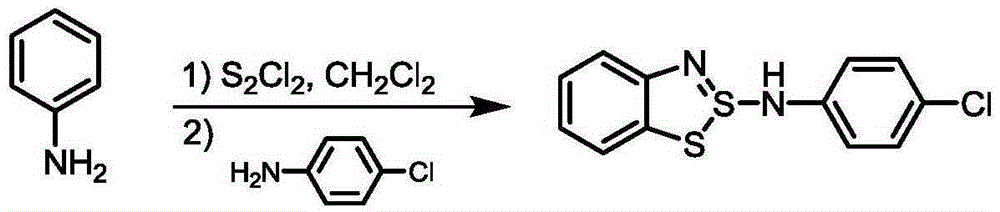

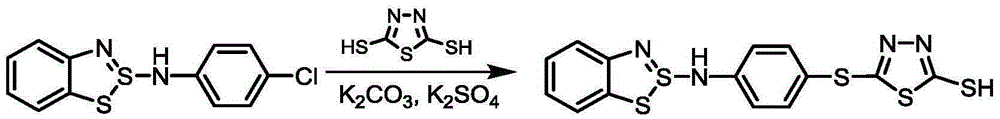

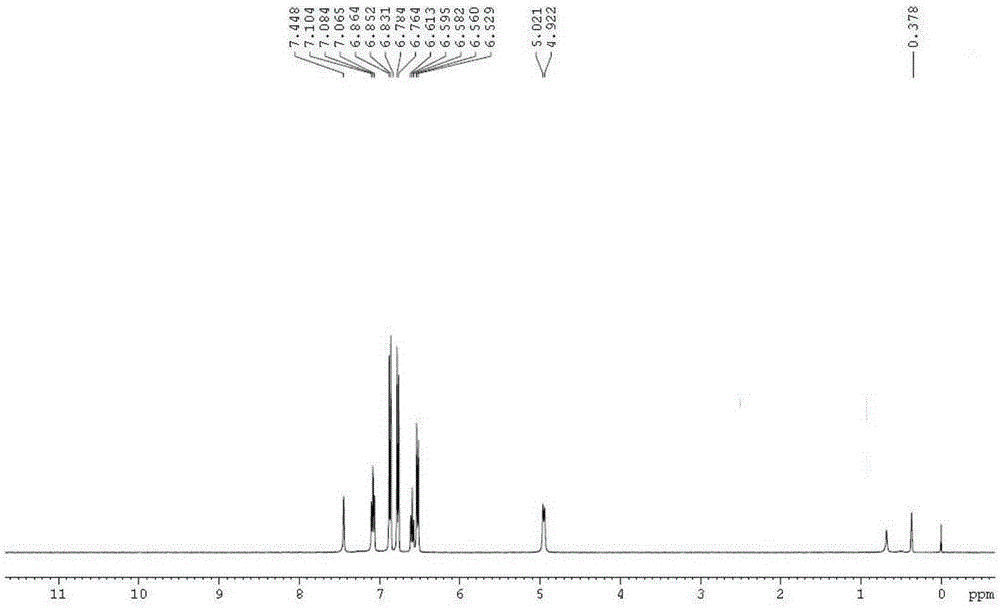

ActiveCN104342266AAntioxidant time is longImprove protectionLubricant compositionThiadiazolesPolyisobutylene succinimide

The invention discloses special lubricating oil for a fuel gas engine of a public transport automobile. The special lubricating oil is prepared from blended base oil, binary ethylene-propylene rubber, polymethacrylate, alkylphenol calcium sulfide, high-base-number calcium alkylbenzenesulfonate, polyisobutylene succinimide, boronated polyisobutylene succinimide, alkylated phenyl-alpha-naphthylamine, p,p'-dioctyl diphenylamine, a hindered phenol type antioxidant, dialkyl molybdenum dithiocarbamate, copper nanoparticle anti-wear additives, methyl silicone oil and thiadiazole polysulfide. According to the lubricating oil composition oil product, the sulfate ash content is lower than 0.5%, the content of phosphorus is lower than 0.03%, and the base number is 3-8mgKOH / g. According to the special lubricating oil for the fuel gas engine of the public transport automobile, aiming at the special requirements of the public transport automobile on engine oil, different additive varieties and charging sequences are adopted, so that physical and chemical indicators and use performance of the special lubricating oil are better than natural gas engine lubricating oil of the same grade, and the special lubricating oil has excellent cleaning and dispersion properties, lubricating property, abrasion resistance and oxidation resistance.

Owner:陕西通用润滑科技有限公司

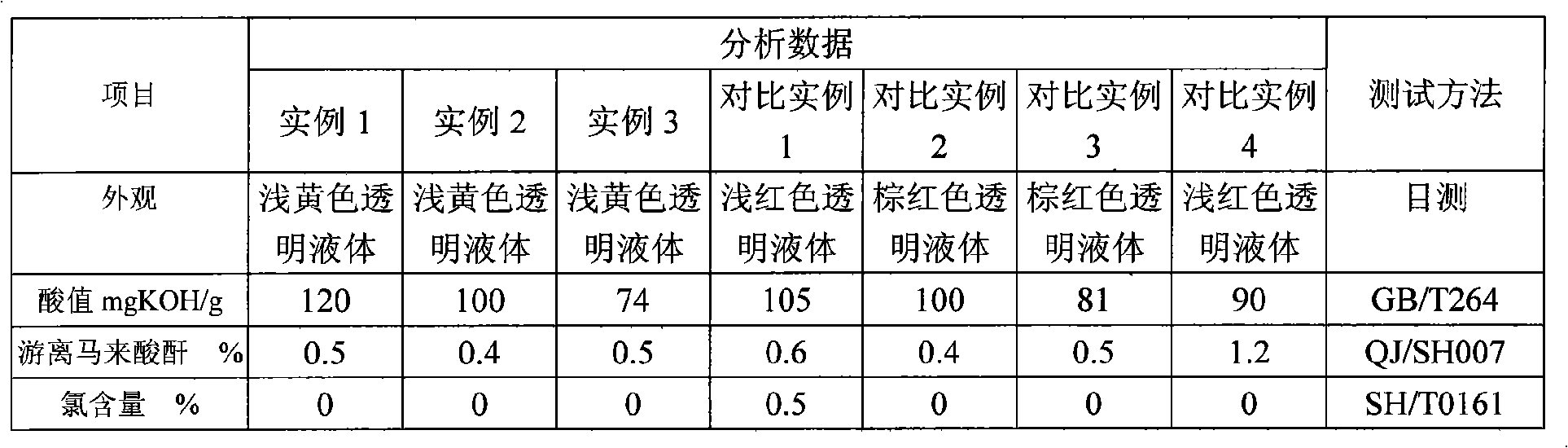

Process for producing polyisobutene succinimide ashless dispersant by free radical method

InactiveCN101284887AHigh reactivityNo pollution in the processLiquid carbonaceous fuelsAdditivesReaction temperatureSolvent

The invention provides a method for producing a polyisobutylene succinimide ashless disperser by adopting the freeradical method. The method comprises the following steps that: the polyisobutene is put into a reactor which is heated to a temperature of between 100 and 150 DEG C; the maleic anhydride is put into the reactor and is mixed evenly with the polyisobutene; a freeadical evocating agent is added drop by drop at a constant temperature; the mixture is heated to perform the alkylation reaction; the sampling analysis is performed at any time in the reaction process, after the reaction is finished, the mixture is filtered to obtain the polyisobutylene succinic anhydride; base oil is added into the polyisobutylene succinic anhydride; the mixture is heated and the polyene polyamine is added drop by drop to perform the amidation reaction; the subpressure dehydration is performed, the reaction is finished when no water is dehydrated; the reacting substance is filtered to obtain the polyisobutylene succinimide ashless disperser. In the alkylation reaction process, the method does not need a solvent, adopts the one step of freeradical alkylation technique and has the advantages of short production cycle, low reaction temperature, light chroma, low production energy consumption and environmental protection; the product performance is comparable with the like products at home and abroad.

Owner:锦州康泰润滑油添加剂有限公司

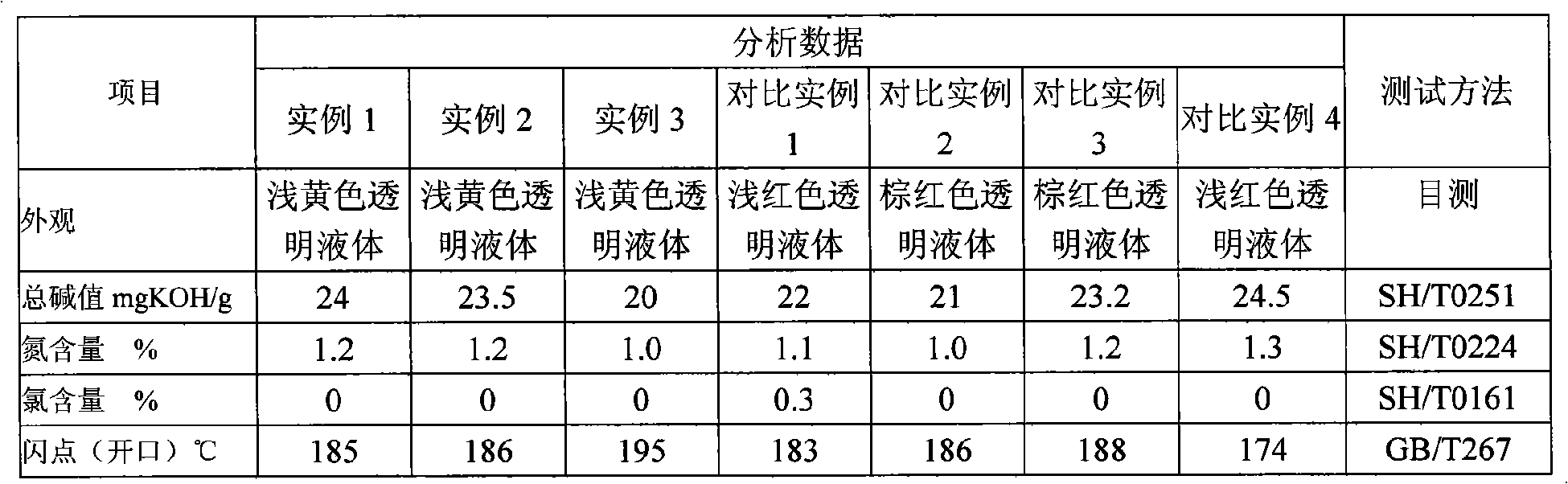

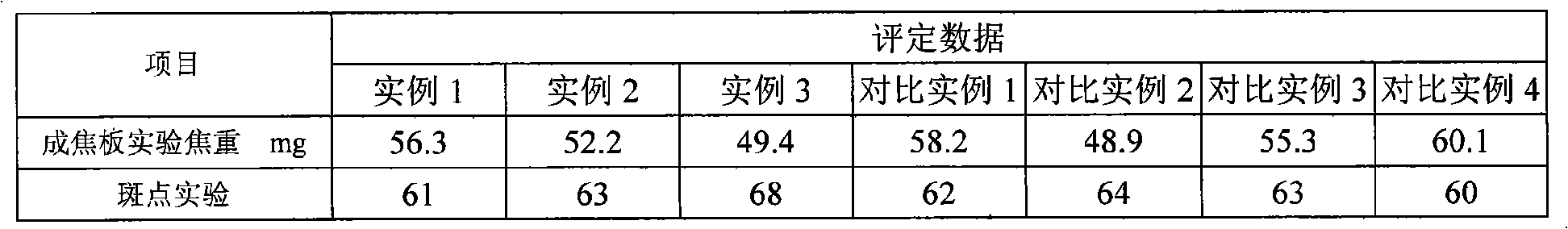

Directional power-assisted oil composition and its application

ActiveCN102337172AMaintain viscosity temperatureImprove anti-corrosion performanceAdditivesChemical compositionBoron

The invention relates to a directional power-assisted oil composition and its application and mainly solves the problems of poor compatibility between a directional power-assisted oil and a rubber sealing member and the fault of a power steering system due to deformation or failure of the rubber sealing member with the application of a power-assisted oil composition in the power-assisted steering system in the prior art. The directional power-assisted oil composition comprises the following components of: by weight, a) 0.1-5 parts of boron polyisobutylene succinimide; b) 95-99.9 parts of base oil. By the adoption of the technical scheme, the problems are greatly solved. In addition, the technical scheme can be used in the industrial production of the directional power-assisted oil composition provided by the invention.

Owner:CHINA PETROLEUM & CHEM CORP

Aerated concrete block added with bamboo carbon powder

The invention relates to an aerated concrete block added with bamboo carbon powder. The aerated concrete block added with the bamboo carbon powder is prepared by the following raw materials by weight: 5-7 parts of the bamboo carbon powder, ash 10-15 parts of fly ash, 16-22 parts of cement, 8-10 parts of gypsum, 2-4 parts of rice husk carbon, 0.2-0.4 part of acrylic fibers, 0.4-0.6 part of organosilicone emulsion, 3-5 parts of a sugar-calcium water reducing agent, 3-5 parts of aluminum magnesium metasilicate, 0.001-0.003 part of polyisobutylene succinimide, 0.002-0.004 part of tripolyglycerol diisopstearate, 0.002-0.003 part of isomeric alcohol polyoxyethylene ether, 0.002-0.004 part of coconut oil fatty acid diethanolamide, 1-2 parts of polyester fibers, 8-12 parts of modified attapulgite, 0.001-0.003 part of sugar calcium, 0.002-0.003 part of calcium formate, 0.02-0.06 part of aluminum powder and 0.01-0.03 part of oxidized paraffin soap.

Owner:安徽中龙建材科技有限公司

Polyisobutylene succinimide quaternary ammonium salt emulsifier and preparation method thereof

The invention provides a polyisobutylene succinimide quaternary ammonium salt emulsifier and a preparation method thereof. The preparation method comprises the following steps: performing amination reaction on polyisobutylene succinic anhydride and an amination reagent to obtain polyisobutylene succinimide; and then, performing quaternization reaction on the polyisobutylene succinimide and a quaternization reagent to obtain the polyisobutylene succinimide quaternary ammonium salt emulsifier. The emulsifier has fine stability quality and is used for the preparation of an emulsion explosive in the emulsion explosive industry.

Owner:GUIZHOU JUNENG CHEM

Lubricant composition for methanol engine

ActiveCN102690706AImprove antioxidant capacityImprove wear resistanceAdditivesAntioxidantPolyisobutylene succinimide

The invention relates to a lubricant composition for a methanol engine. The lubricant composition comprises A) a composite antioxidant comprising at least ingredients of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant and / or a polyisobutylene succinate dispersant, C) a mixture of magnesium sulfonate and sodium sulfonate, D) at least one zinc dialkyl dithiophosphate, E) one or more oil-soluble organic molybdenum friction modifiers, and F) a main amount of lubricating base oil. The lubricant composition for a methanol engine utilizes optimized combination of the multiple ashless antioxidants, is compounded with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a methanol engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

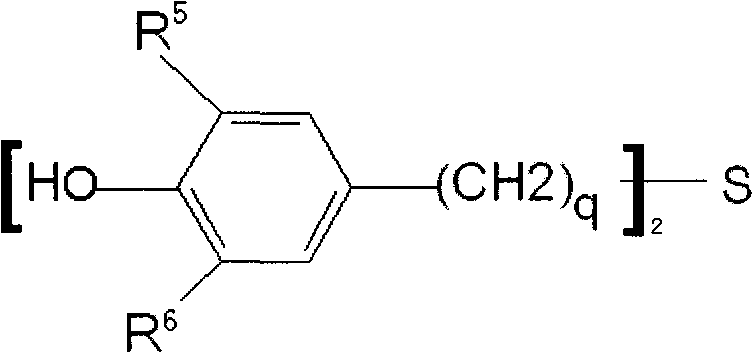

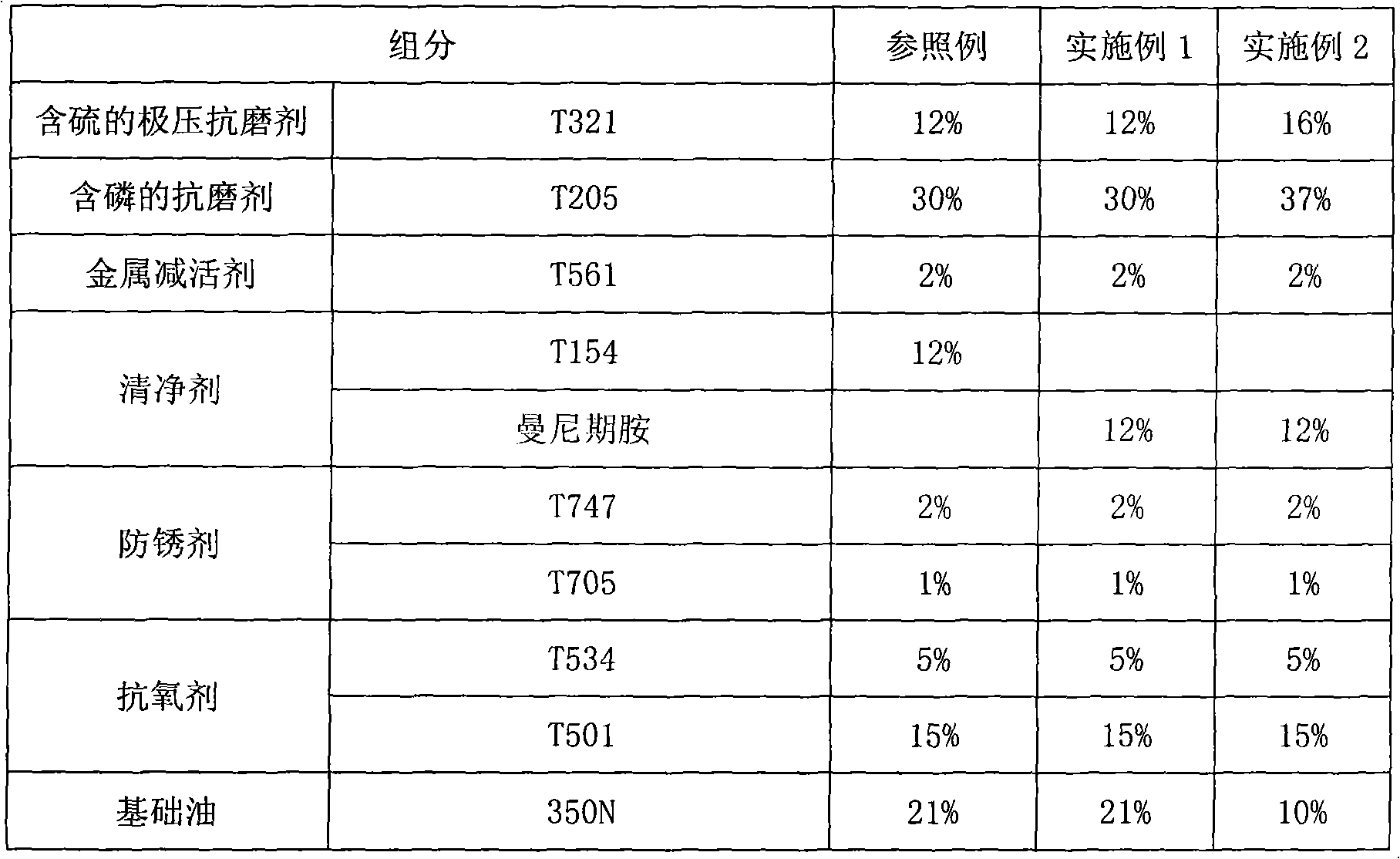

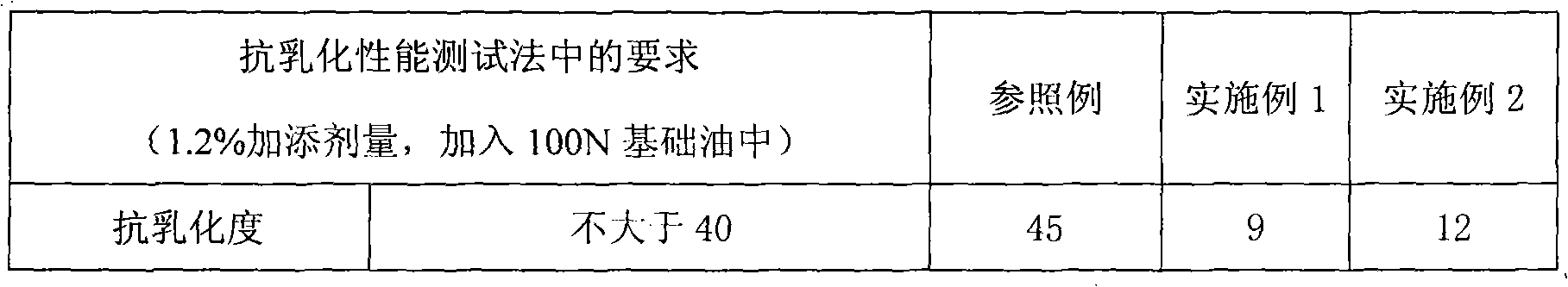

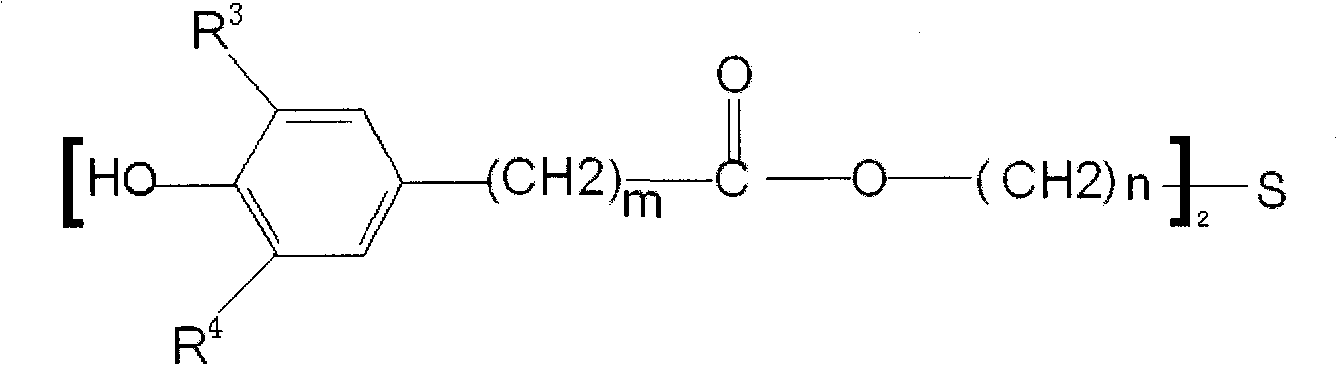

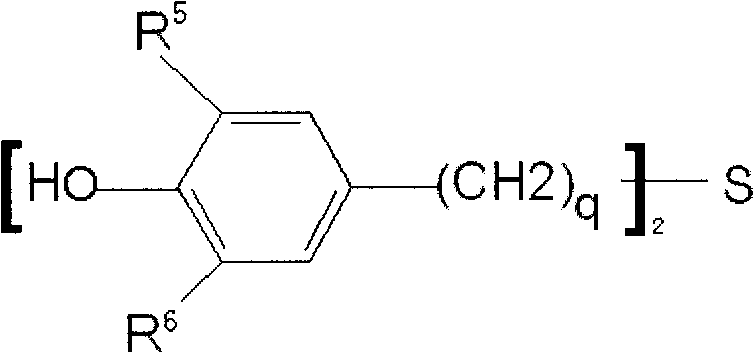

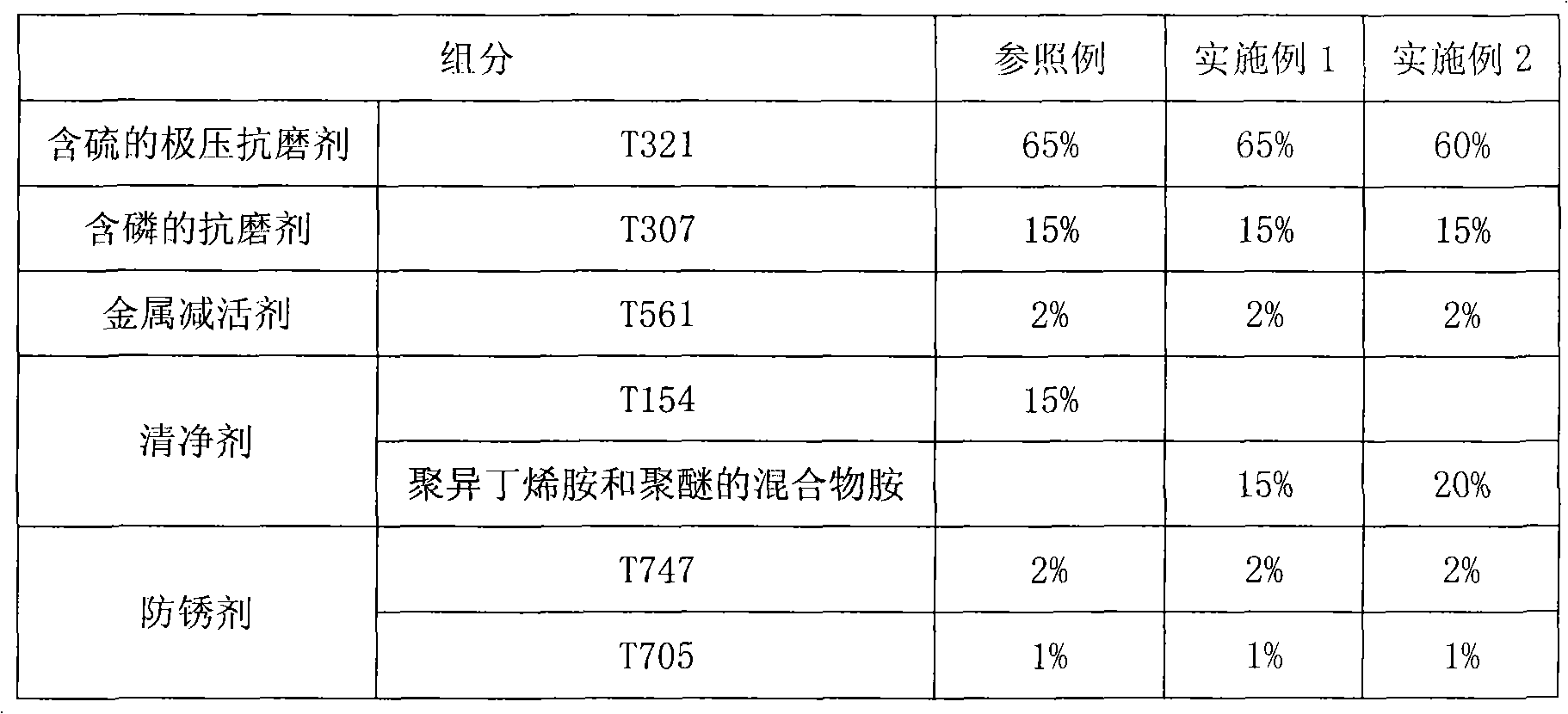

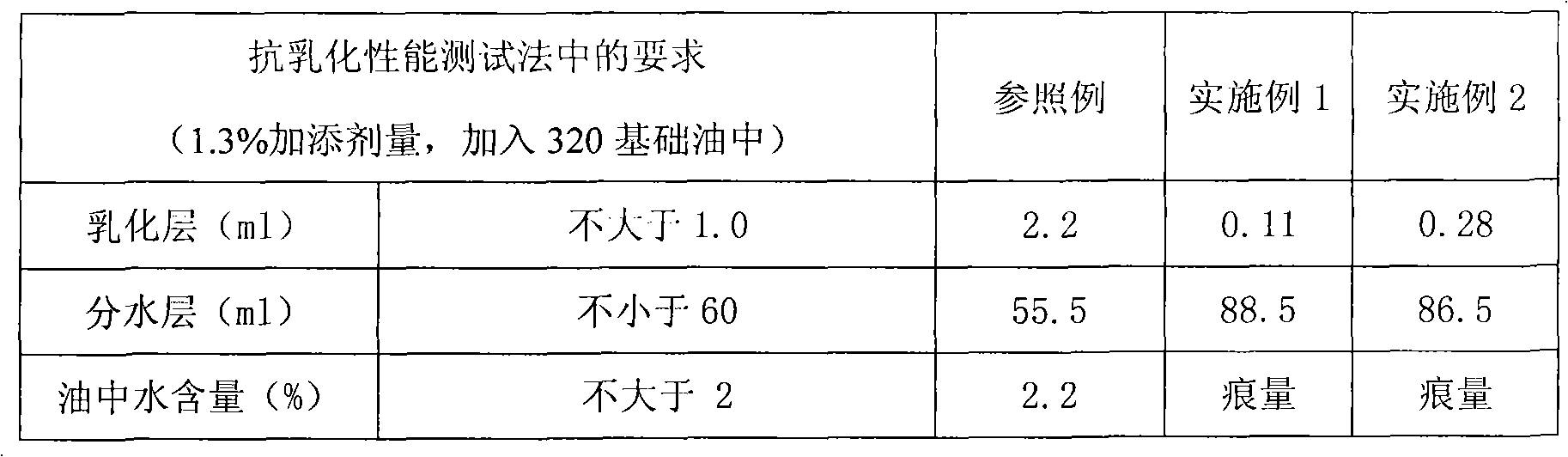

Wear-resistant hydraulic-oil additive composition with excellent anti-emulsifying property

The invention relates to a wear-resistant hydraulic-oil additive composition with excellent anti-emulsifying property for a lubricating oil additive composition of a hydraulic transmission system, belonging to the technical field of a lubricating oil additive. The wear-resistant hydraulic-oil additive composition comprises an extreme-pressure anti-wear agent containing sulfur, an anti-wear agent containing phosphorus, a metal deactivator, a detergent, an anti-rusting agent and an antioxidant. The raw material contains the following components in percentage by weight: 5-20 % of extreme-pressure anti-wear agent containing sulfur, 20-55% of anti-wear agent containing sulfur, 1-10% of metal deactivator, 5-20% of detergent, 2-5% of anti-rusting agent, 12-25% of antioxidant, and the balance of base oil, and the sum of the percentage of all the components is 100%. The additive composition adopts the existing mannich amine detergent usually used in the gasoline detergent to replace polyisobutylene succinimide, alkaline calcium sulfonate and a magnesium detergent used in the traditional lubricating oil additive, and obviously improves the anti-emulsifying property of industrial wear-resistant hydraulic oil.

Owner:北京泽华凯泰科技发展有限公司

Engine cleaning lubricant and preparation method thereof

The invention discloses an engine cleaning lubricant and a preparation method thereof. The engine cleaning lubricant is prepared through combining high-base-number sulfurized alkylphenol calcium, polyacrylate, polyisobutylene, polyisobutylene succinimide, organic molybdenum and cleaning oil, is used for cleaning an engine, can decompose quickly and is used for removing various colloids, stubborn scales, carbon deposits and attachments, such as metal powder and the like generated through metal friction from the interior of the engine, so that good lubricating property is guaranteed, the frictional resistance is reduced, the power of an automobile is increased, the elasticity of various sealing gaskets and cushions inside the engine is recovered, and the sealing performance is enhanced; and a layer of protective film is formed inside the engine, so that the rust preventing and wear resisting functions of the engine are improved, the oil consumption and engine wear are reduced, and the service lives of engine oil and the engine are prolonged.

Owner:ANHUI CHEWEISHI AUTOMOBILE ACCESSORIES

Lubricant composition for four-stroke motorcycle engine

ActiveCN102690715AImprove cleanlinessMeet lubrication requirementsAdditivesAntioxidantPolyisobutylene succinimide

The invention relates to a lubricant composition for a four-stroke motorcycle engine. The lubricant composition comprises A) a composite antioxidant comprising at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide dispersant and / or a polyisobutylene succinate dispersant, C) a mixture of calcium sulfonate and sulfurized calcium alkyl phenate, D) at least one zinc dialkyl dithiophosphate, E) one or more ashless friction modifiers, and F) a main amount of lubricating base oil. The lubricant composition adopts optimized combination of the multiple ashless antioxidants, is blended with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a four-stroke motorcycle engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal-based composite domestic fuel

InactiveCN103031163AEasy to ignitePromote atomizationLiquid carbonaceous fuelsFuel additivesPhosphoric acidEngineering

The invention relates to a clean fuel, in particular to a coal-based composite domestic fuel so as to solve the problem that existing domestic fuel oil has a lot of disadvantages. The composite domestic fuel is composed of light coal tar, methanol, a dispersing agent, a corrosion inhibitor, and a combustion-supporting agent. The light coal tar is the distillate distillated from coal tar during fractional distillation under a temperature below 280DEG C, and has a density of 0.91-0.99g / ml. The dispersing agent is any of polyisobutylene succinimide, phosphoric acid amide, alicyclic amine, and succinimide or a mixture of several of them in any proportion. The corrosion inhibitor is any of oleic acid glycol ester, N, N-bis(salicylidene)-propanediamine, benzotriazole, 2, 6-di-tert-butyl-p-cresol or a mixture of several of them in any proportion. The combustion-supporting agent is any of calcium naphthenate, magnesium naphthenate, iron naphthenate, and ferrocene or a mixture of several of them in any proportion. Being easy to ignite, the composite domestic fuel provided in the invention has good atomizing performance, more sufficient combustion, as well as higher thermal efficiency, the smoke blackness and other emission indexes all meet the requirements, and the economic effects are more significant.

Owner:山西佳新能源化工实业有限公司

Scale inhibitor for oil refining equipment and preparation method of scale inhibitor

InactiveCN106701194AWide variety of sourcesInhibition of coking and foulingTreatment apparatus corrosion/fouling inhibitionDiimidePolyisobutylene succinimide

The invention discloses a scale inhibitor for oil refining equipment. The scale inhibitor is prepared from the following raw materials: purified water, polyisobutylene succinimide, N,N'-disalicylidene-promethylene diamine, calcium alkyl salicylate, heavy aromatics, hexadecyl dimethyl amine, 2,2,6,6-tetramethylpiperidinooxyl, toluene, sodium persulfate, hydrogen peroxide and potassium superphosphate. The scale inhibitor is used for inhibiting coking and scale deposition of various devices and equipment in petroleum refining and petrochemical processes, particularly for coking and scale deposition of hydrogenation process equipment; coking and scale deposition of heat exchangers and steam generators for catalytic cracking, delayed coking and crude oil distillation processes are inhibited; and a high scale inhibition rate is achieved with the filling amount of 80 to 100 [mu]m / g in a crude oil heat exchanger, a reactor and a heating furnace, and each component synergistically acts to achieve the carbon steel corrosion rate of 0.001 to 0.003 [mu]m*a<-1> and the calcium carbonate scale inhibition rate of 85 to 95 percent.

Owner:JIANGSU JINGWEI TECH INNOVATION CONSULTING CO LTD

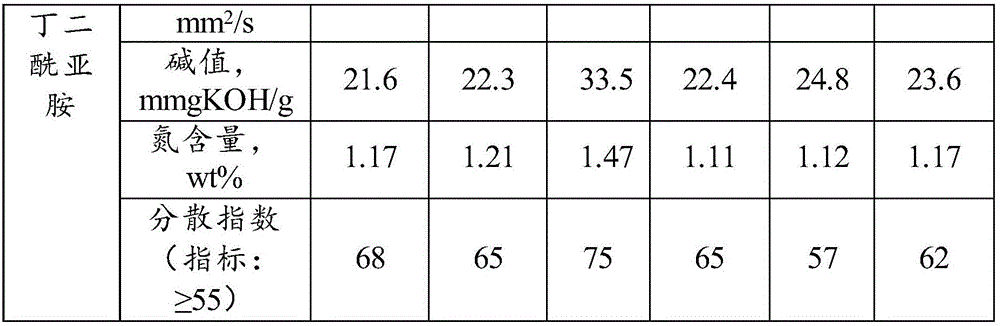

Preparation method for polyisobutylene succinimide

A provided preparation method for polyisobutylene succinimide comprises A) respectively dropwise adding a mixture of a radical initiator and base oil and maleic anhydride into polyisobutene for reaction, so as to obtain a mixture of polyisobutylene succinic anhydride and base oil; and B) mixing the mixture of polyisobutylene succinic anhydride and base oil, which is obtained in the step A), with polyethylene polyamine and second base oil, performing amination, so as to obtain polyisobutylene succinimide. The method reduces generation of byproducts such as autopolymer of maleic anhydride, polymer of polyisobutene and maleic anhydride and the like, reduces viscosity of the polyisobutylene succinic anhydride intermediate, and improves the effective utilization rate of maleic anhydride and saponification value of the polyisobutylene succinic anhydride intermediate. The dispersity of the prepared polyisobutylene succinimide is further improved.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

Environment-friendly electric wire and cable material

InactiveCN103910931AIncrease elasticityGood physical and mechanical propertiesInsulatorsElastomerEngineering

The invention provides an environment-friendly electric wire and cable material. The environment-friendly electric wire and cable material comprises following ingredients, by weight, 100 parts of PP, 30 to 35 parts of PET, 8 to 10 parts of ACR resin, 8 to 12 parts of polypropylene fiber, 30 to 35 parts of a mixture of ethylene-propylene-diene monomer and ethylene / butene elastomer, 31 to 33 parts of a plasticizer, 1.5 to 2.5 parts of a stabilizing agent, 8 to 12 parts of a lubricant, 10 parts of talc, 7.5 parts of a fire retardant, 1.5 to 2.5 parts of polyisobutylene succinimide, and 0.8 part of titanium dioxide. Main materials PP and PET, and auxiliary reagents of the environment-friendly electric wire and cable material are all environment-friendly materials, so that environmental protection performance of the environment-friendly electric wire and cable material is excellent.

Owner:KUNSHAN XINZHICHENG ELECTRONICS TECH

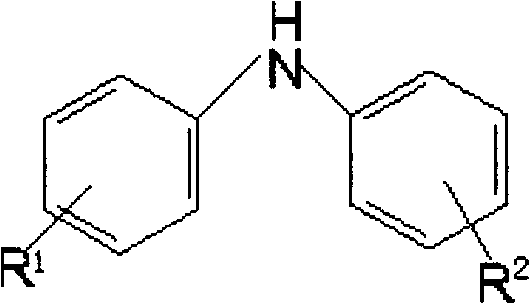

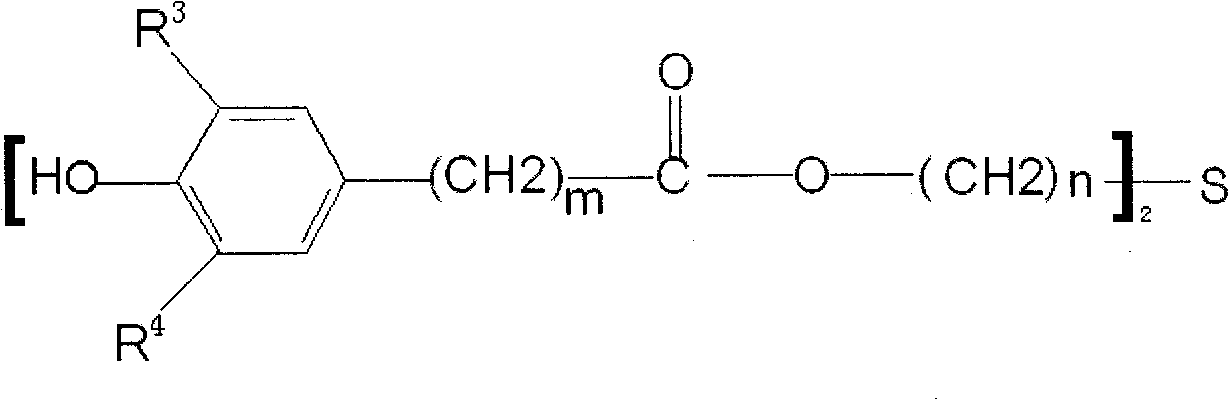

Diesel engine lubricating oil composition, preparation method, and application thereof

ActiveCN106753701AExcellent antioxidantImprove wear resistanceOrganic chemistryAdditivesSulfonateChemical composition

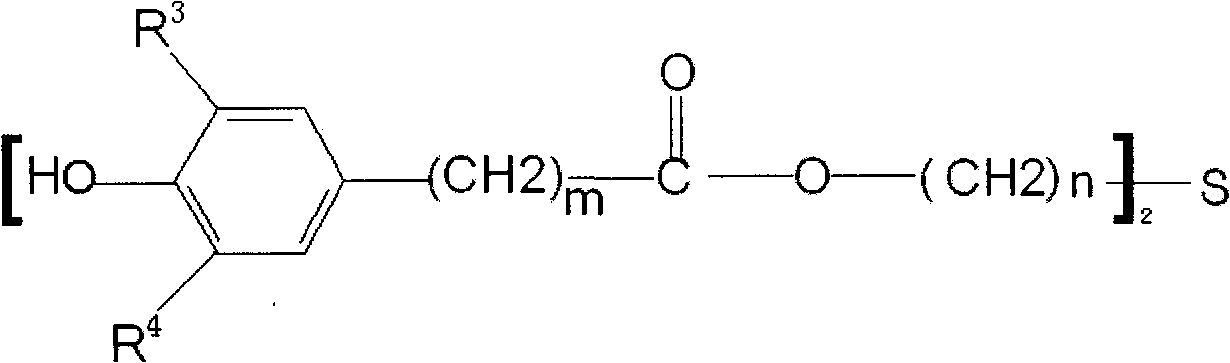

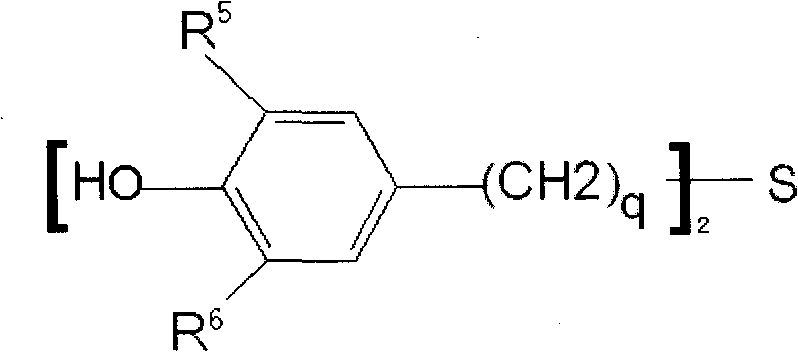

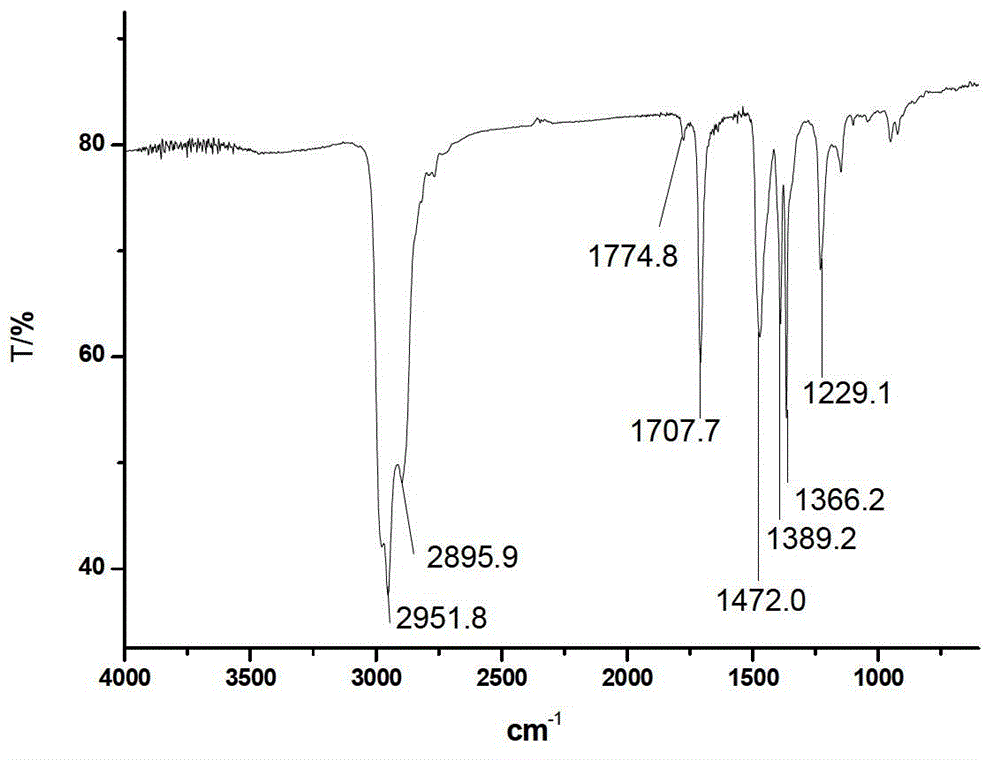

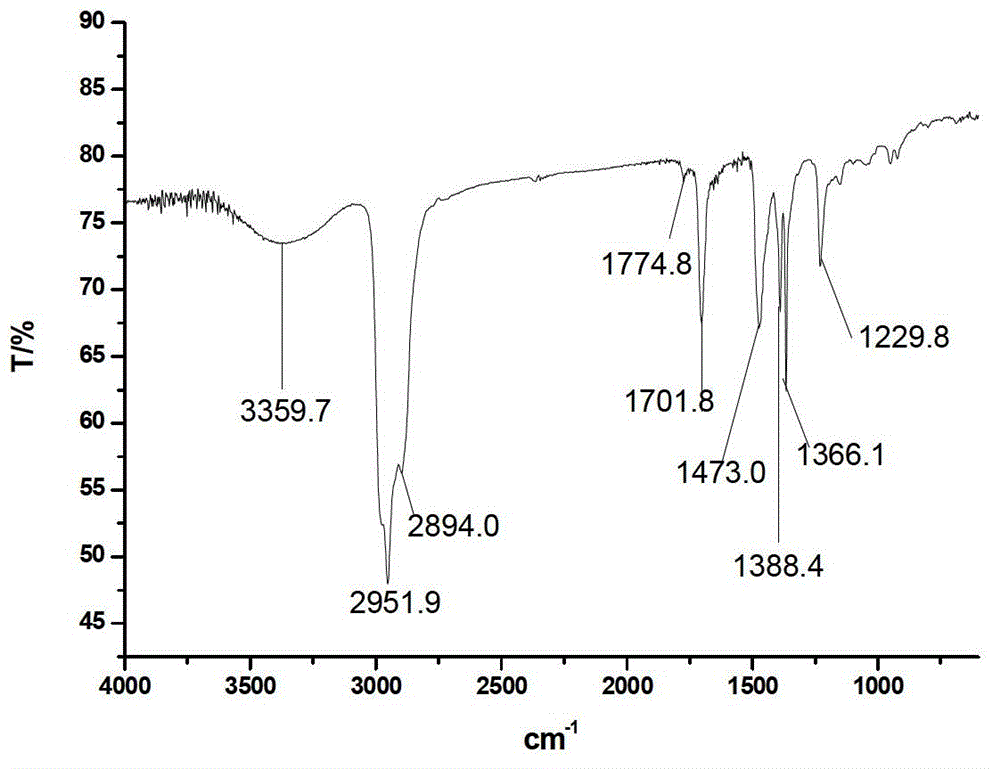

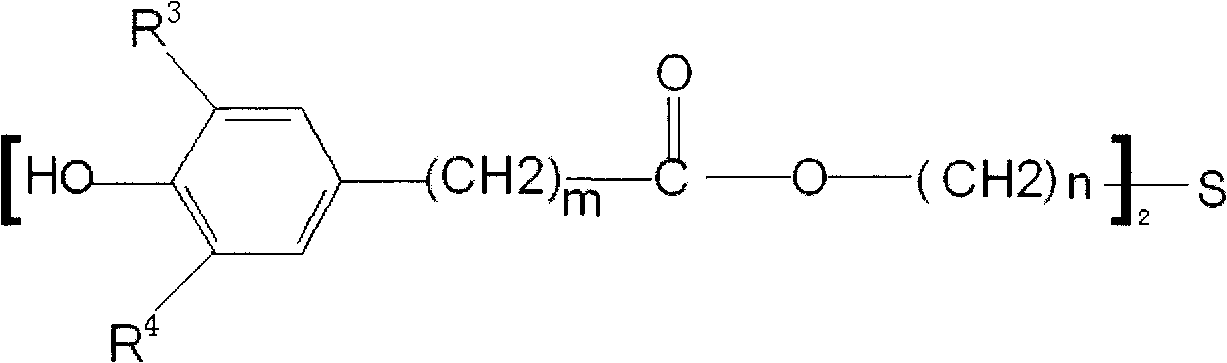

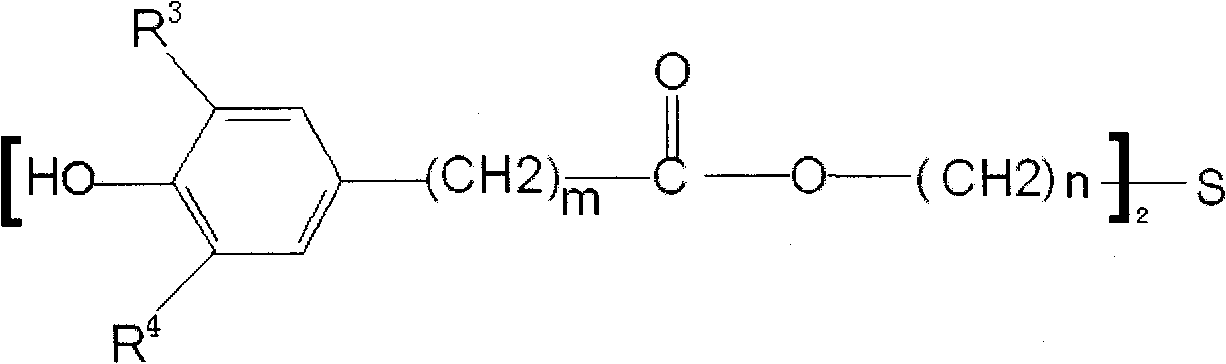

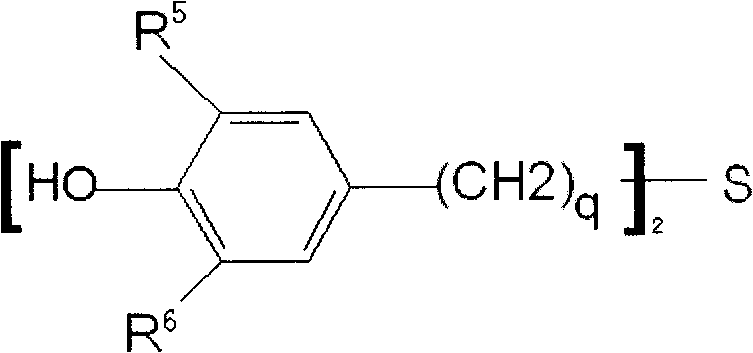

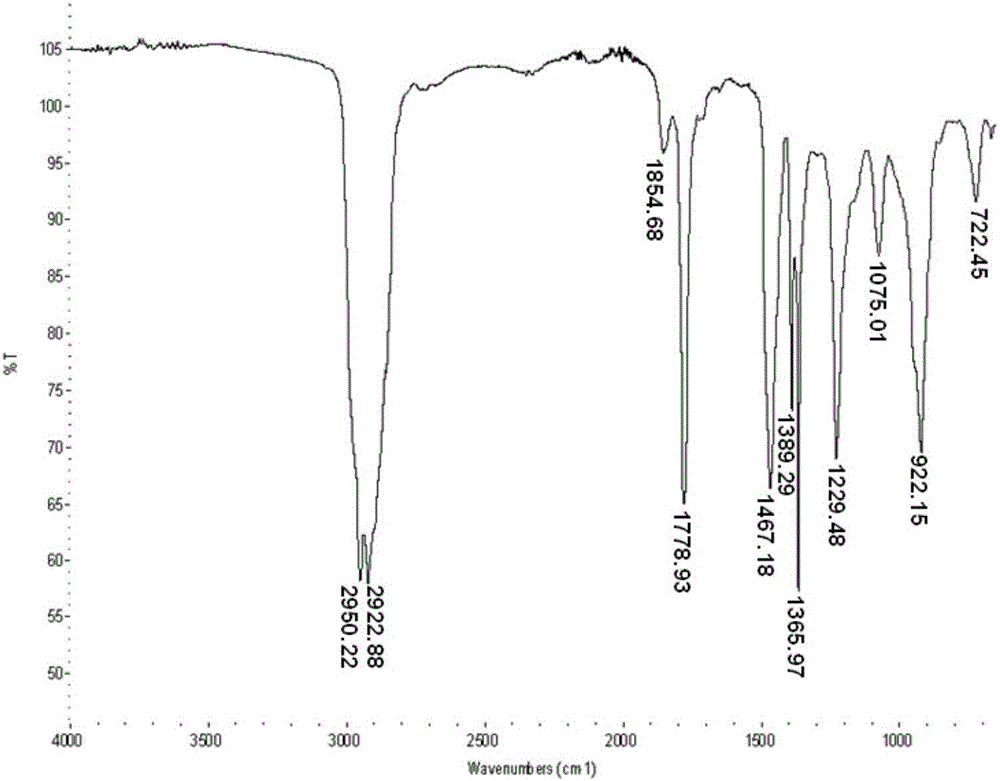

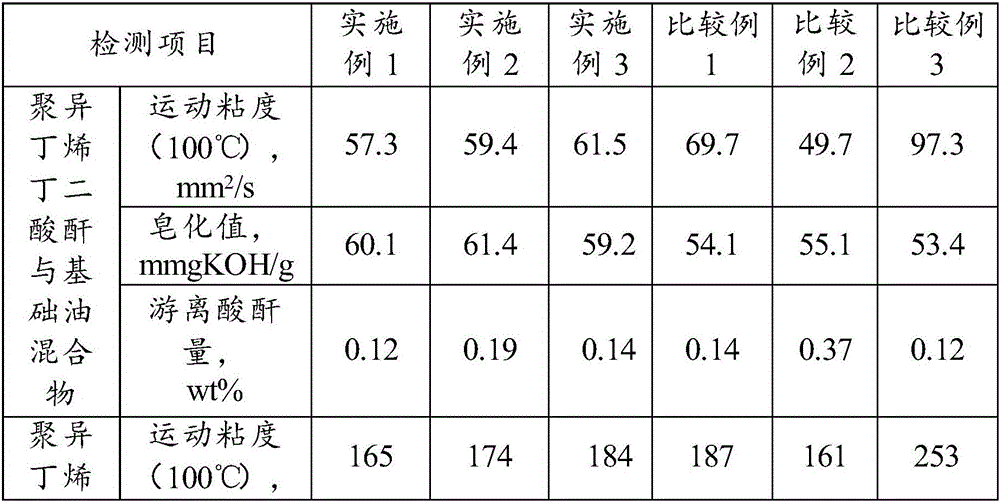

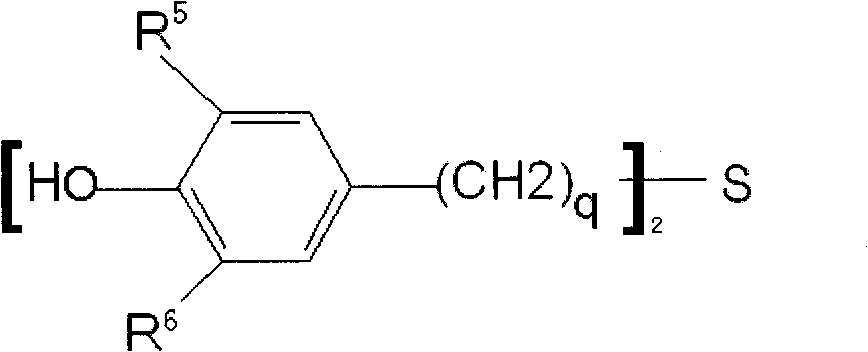

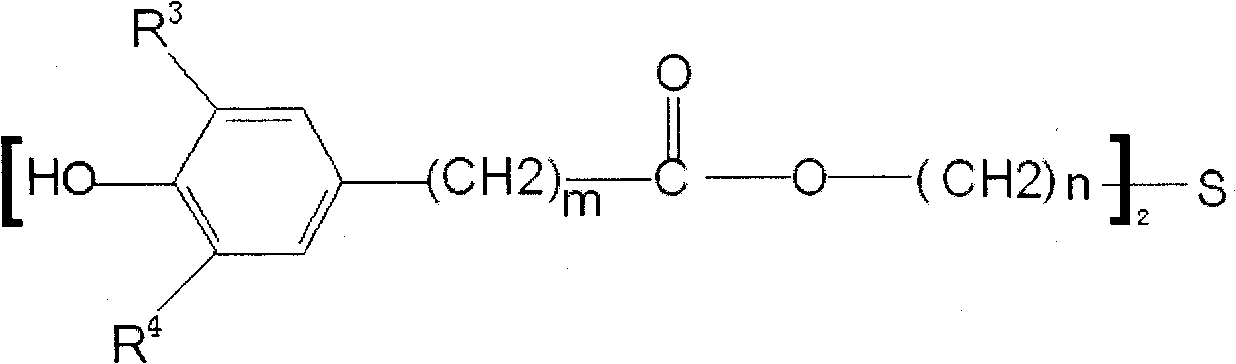

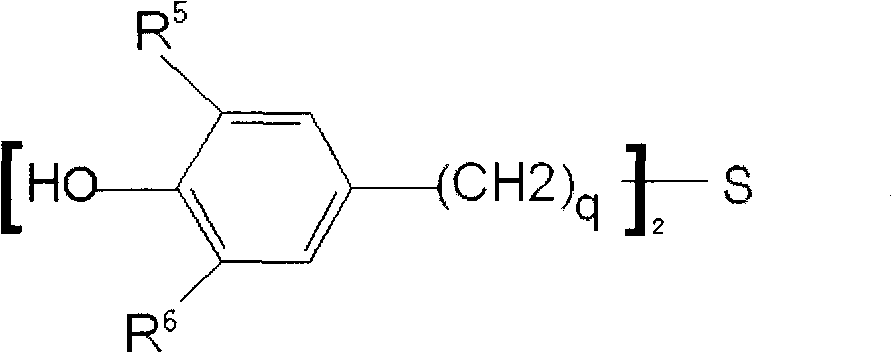

The invention provides a diesel engine lubricating oil composition, a preparation method, and an application thereof. The diesel engine lubricating oil composition includes: A) a multi-functional additive, which is represented as the formula (I); B) a boron-containing anti-oxygen-type polyisobutylene succinimide ash-free dispersant; C) at least one high-molecular-weight polyisobutylene succinimide ash-free dispersant; D) a sulfonate and / or a sulfurized alkylphenol salt; E) at least one dialkyl zinc dithiophosphate; F) an amine-type antioxidant and / or a phenolic ester antioxidant; and G) the balanced being lubricating basic oil. The lubricating oil composition is not higher than 0.09% in content of phosphorus and is not higher than 1% in sulfate ash content, has excellent anti-oxidizing, anti-wear and high-temperature cleaning performances, and can satisfy the demand of high-performance diesel engine lubricating oil at CH-4 and CI-4 grades.

Owner:CHINA PETROLEUM & CHEM CORP +1

Activated carbon adsorbent for adsorbing gasoline vapor

InactiveCN104923180AHigh carbon contentImprove adsorption capacityOther chemical processesSorbentSludge

The invention discloses an activated carbon adsorbent for adsorbing gasoline vapor. The activated carbon adsorbent is characterized by being prepared from the following raw materials in parts by weight: 100-150 parts of sludge, 13-17 parts of maize straw, 15-24 parts of peanut shell, 10-15 parts of manganese ore flour, 30-50 parts of zinc chloride, 13-16 parts of magnesium silicate, 5-8 parts of silicon dioxide, 3-5 parts of polyvinyl alcohol, 3-5 parts of polyacrylamide, 6-8 parts of basalt fiber, 2-4 parts of polyisobutylene succinimide, 8-11 parts of magnesium oxide and proper amount of distilled water. By adding the basalt fiber, the polyisobutylene succinimide and the magnesium oxide, the strength and the adsorption capacity of the sludge activated carbon can be enhanced, and the adsorbent has good purification and cleaning effects on gasoline; and the adsorbent prepared by the invention is high in gasoline adsorption capacity, good in desorption, high in strength, capable of effectively relieving the harm to environment and human bodies and is worthy of popularizing.

Owner:BENGBU PIONEER FILTER

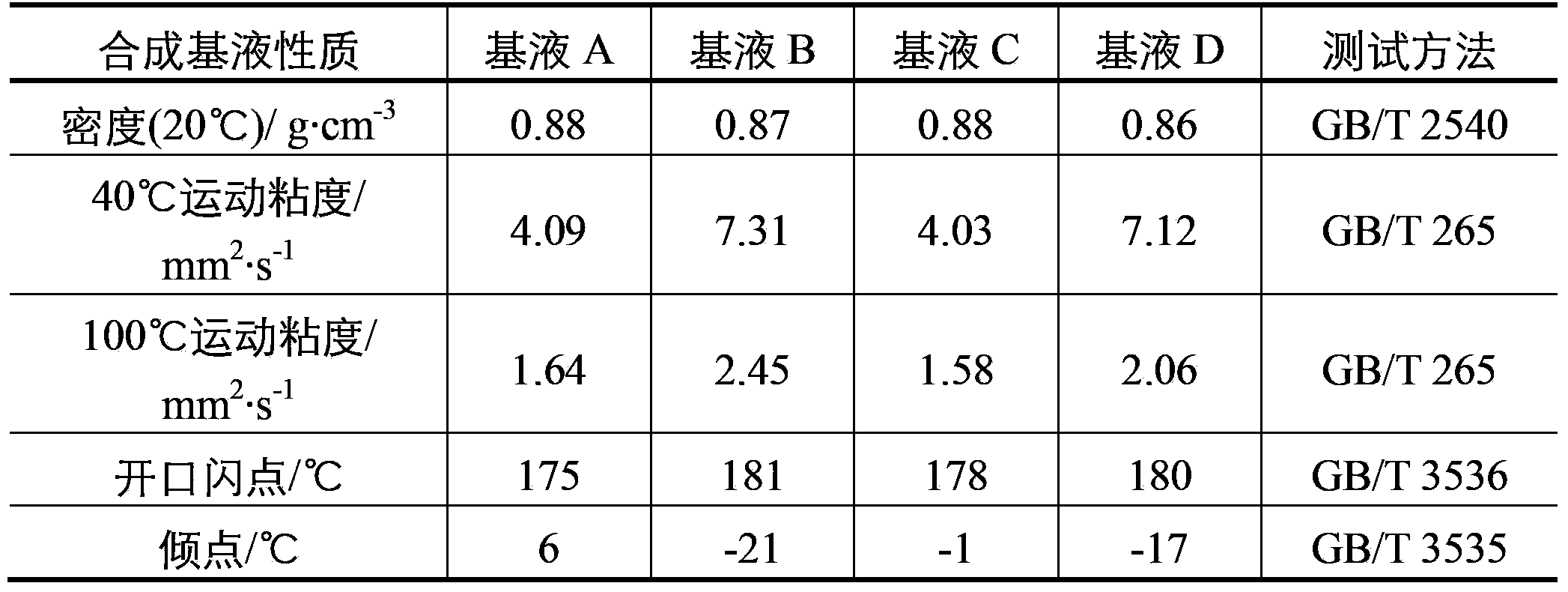

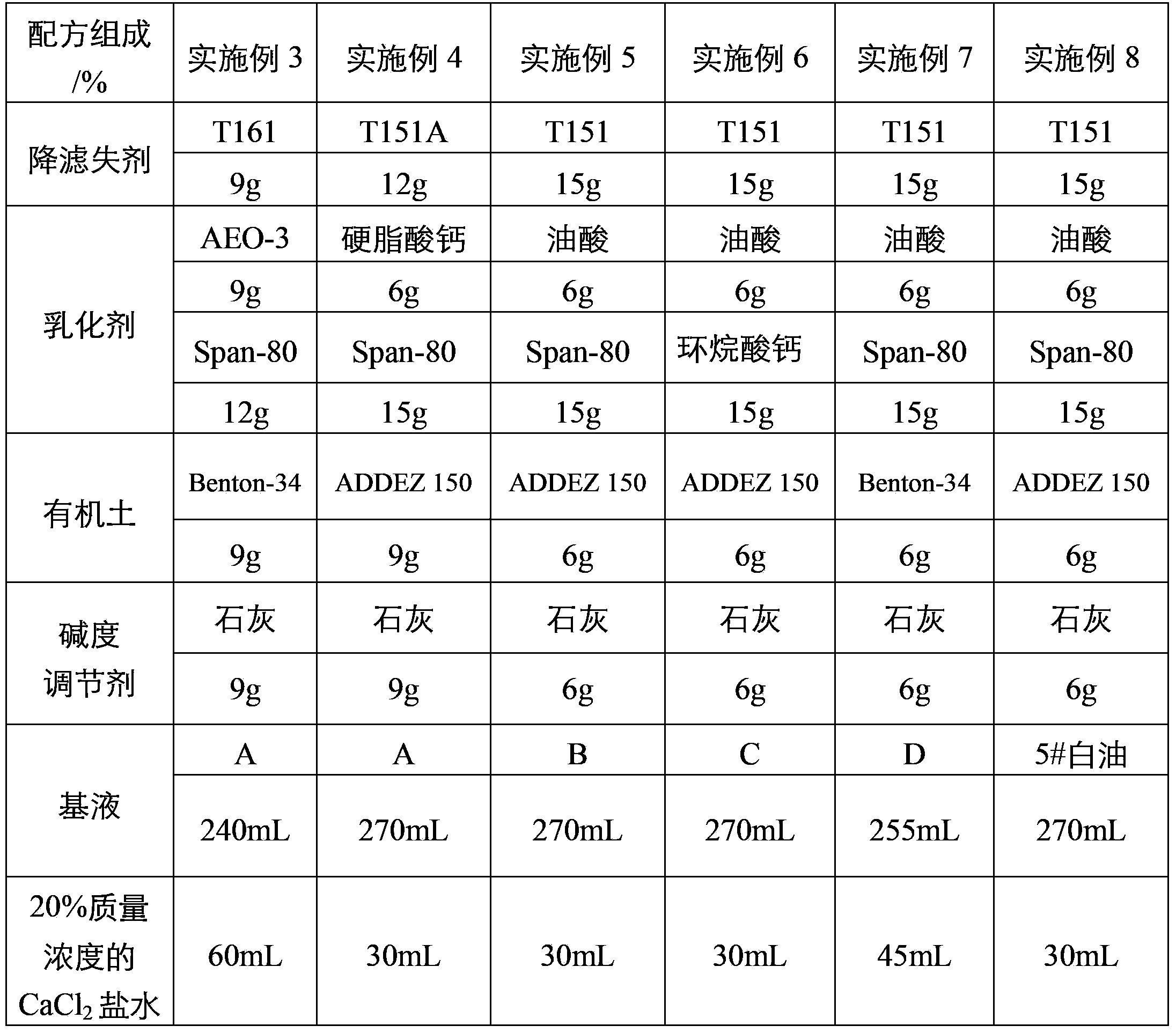

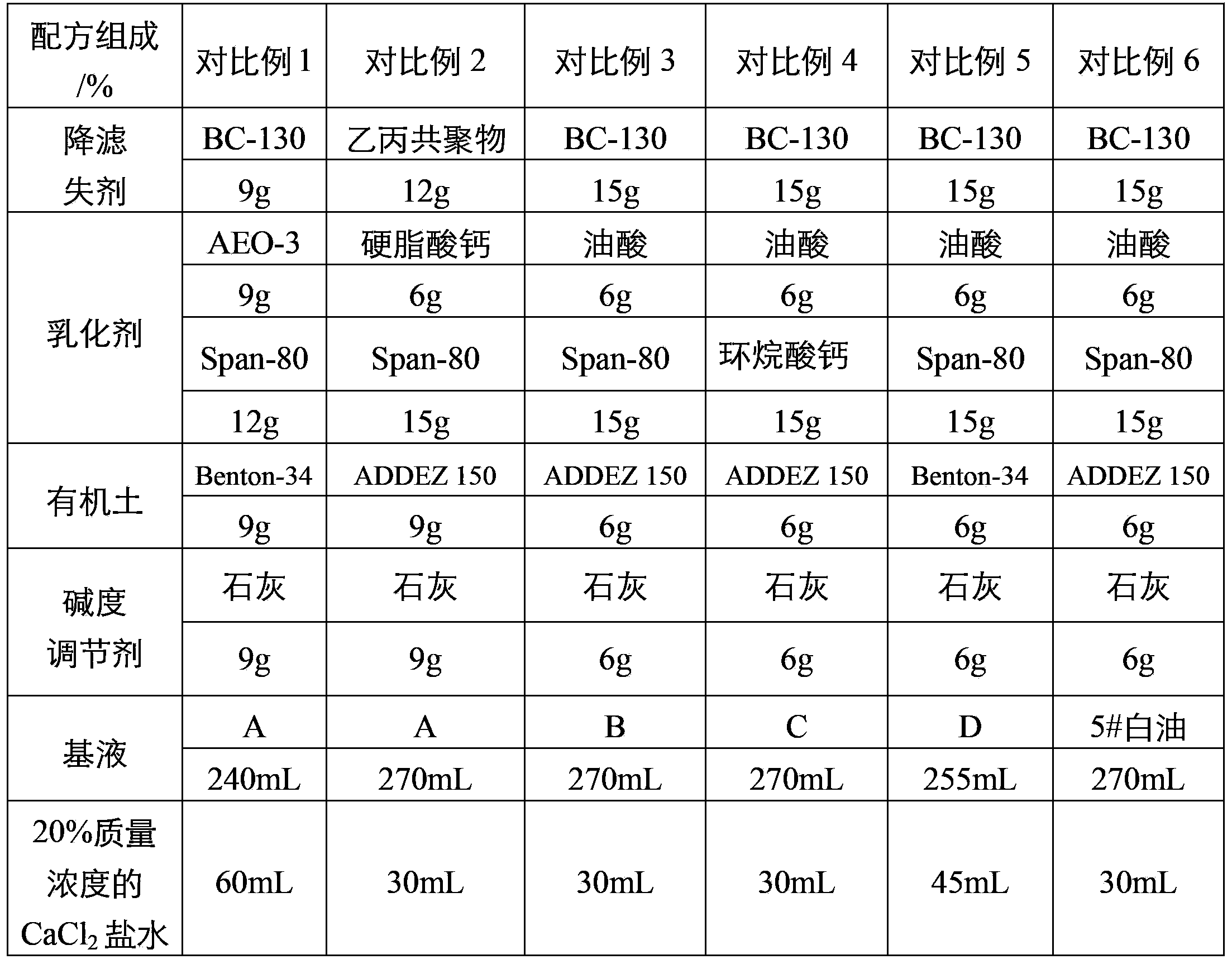

A drilling fluid and a method of improving fluid loss reduction performance of the drilling fluid

ActiveCN104232034AGood filter loss reduction effectExcellent adjustment of rheological propertiesDrilling compositionSaline waterAlkalinity

A drilling fluid and a method of improving fluid loss reduction performance of the drilling fluid are provided. The drilling fluid comprises polyisobutylene succinimide, an emulsifier, organic soil, an alkalinity conditioning agent, inorganic saline water and a main amount of a base liquid. The drilling fluid and the method are characterized by excellent fluid loss reduction performance, rheological adjustment performance, good lubrication performance, high hydrolytic stability, good water-loss wall-building performance, no aromatic hydrocarbons, low biotoxicity, good degradability, low pour point, high flash point, wide application ranges and good safety performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

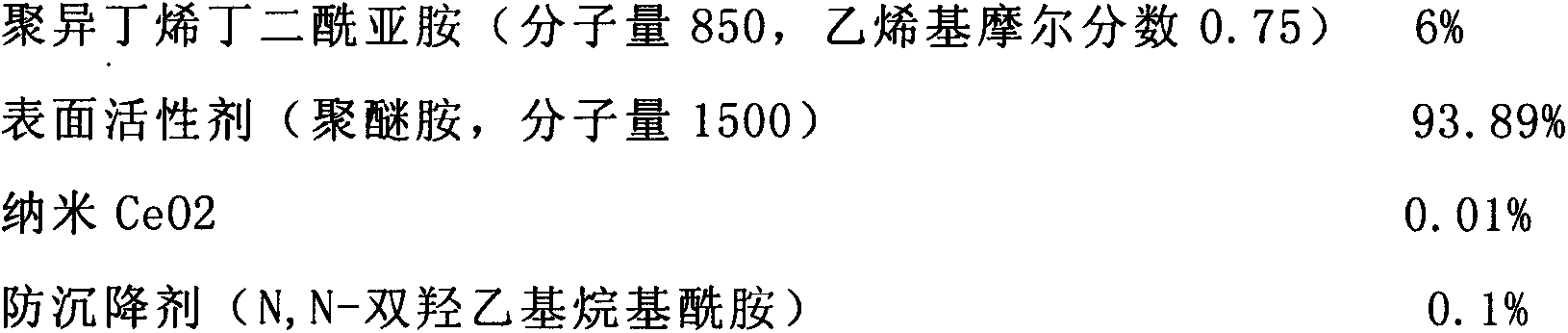

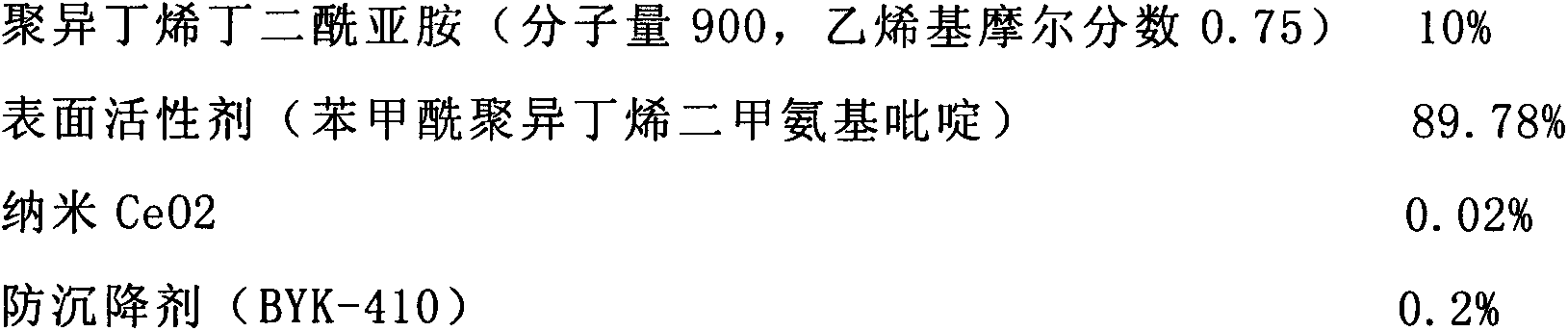

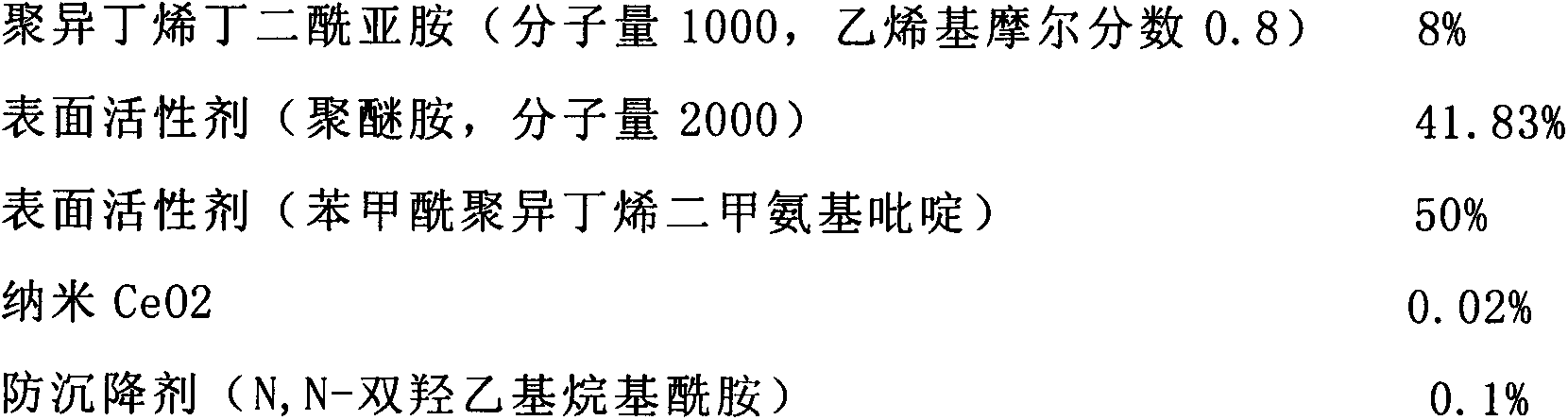

Cleaning agent capable of cleaning carbon deposition of engine

The invention discloses a cleaning agent capable of cleaning carbon deposition of an engine. The cleaning agent comprises the following components by mass percentage: 5-10% of polyisobutylene succinimide, 89-94% of surface-active agent, 0.01-0.02% of nano CeO2 and 0.05-0.2% of anti-sinking agent. The cleaning agent can effectively clean the deposition of an oil way and an air damper; the idling shaking of the engine is eliminated; noises are reduced; the power is improved; and the working stability of the engine is improved.

Owner:吕林利 +1

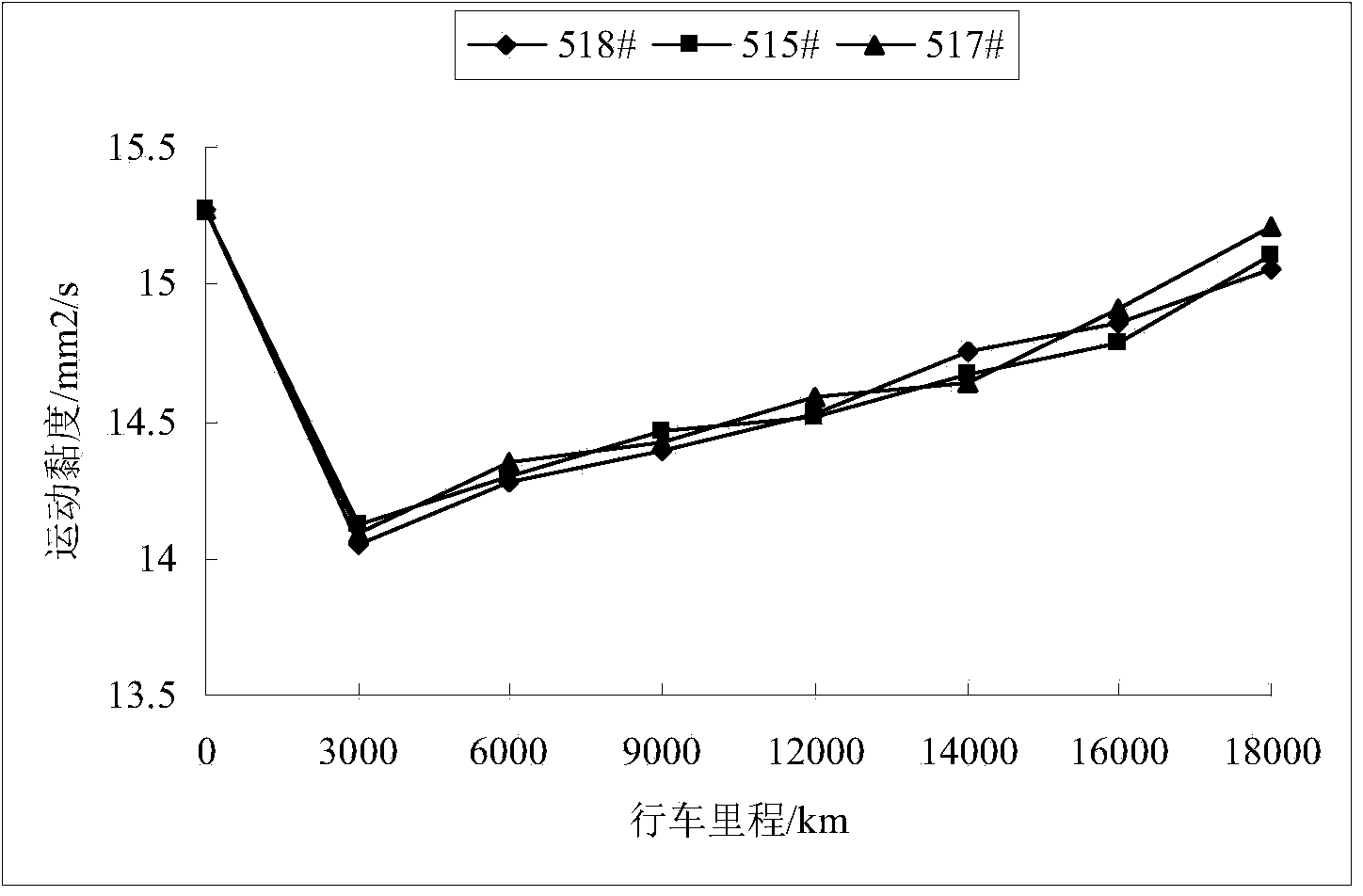

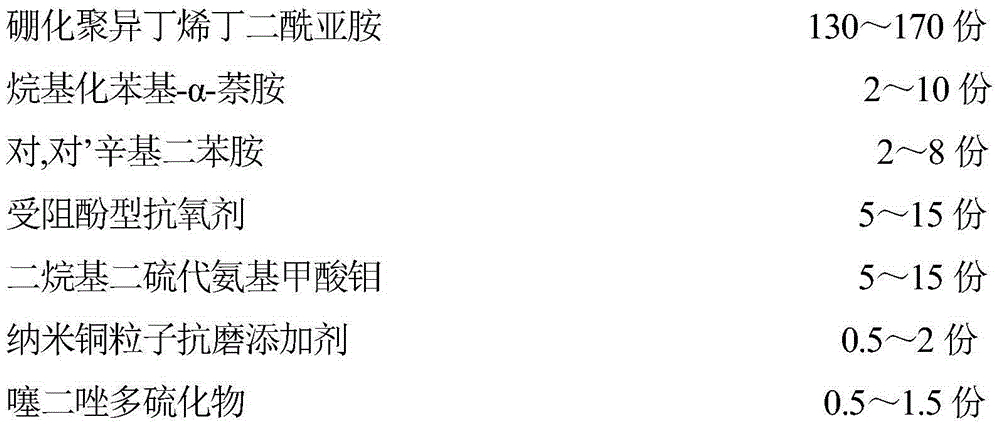

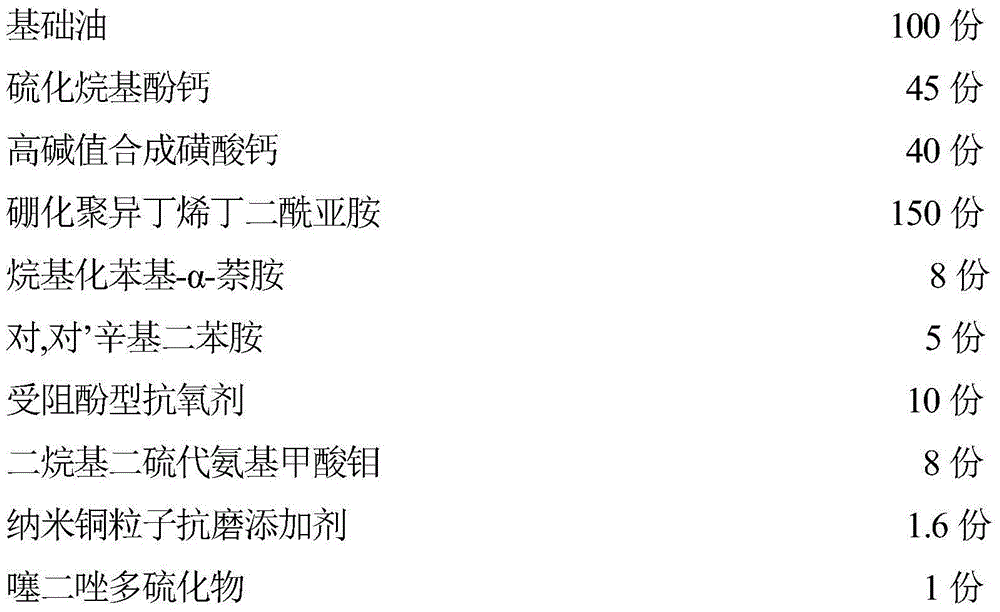

Lubricating oil compound additive for compressed natural gas engine

The invention discloses a lubricating oil compound additive for a compressed natural gas engine. The lubricating oil compound additive consists of the following components in parts by weight: 100 parts of base oil, 30-70 parts of sulfurized calcium alkyl phenate, 20-50 parts of high alkali value synthesized calcium sulfonate, 130-170 parts of borated polyisobutylene succinimide, 2-10 parts of alkylated phenyl-alpha-naphthylamine, 2-8 parts of p,p'-octyl diphenylamine, 5-15 parts of a hindered phenol-type antioxidant, 5-15 parts of molybdenum dialkyldithiocarbamate, 0.5-2 parts of a nano-copper particle antiwear additive, and 0.5-1.5 parts of thiadiazole polysulfide. The lubricating oil compound additive can be used for blending compressed natural gas engine oil of various quality grades, and can be particularly used for blending a special lubricating oil for a heavy-load compressed natural gas engine of a bus, the product blended by use of the lubricating oil compound additive is excellent in product performance, and has longer oil exchange period as well as relatively excellent lustration dispersivity, lubricating performance, abrasion resistance and oxidation resistance, and the additive dose is 6.0%-7.2%, and is lower than the average addition level of the industry.

Owner:陕西通用润滑科技有限公司

Lubricant composition for crosshead ship engine crankcase system

ActiveCN102690712AImprove cleanlinessMeet lubrication requirementsAdditivesAntioxidantOxidation resistant

The invention relates to a lubricant composition for a crosshead ship engine crankcase system. The lubricant composition comprises A) a composite antioxidant comprising at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) polyisobutylene succinimide, C) a mixture of magnesium sulfonate and calcium sulfonate, D) at least one zinc dialkyl dithiophosphate, E) one or more dialkyl dithiocarbamates, F) one or more metal deactivators, and G) a main amount of lubricating base oil. The lubricant composition adopts optimized combination of the multiple ashless antioxidants, is blended with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a crosshead ship engine crankcase system, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Compounding agent for preparing engine lubricating oil

A compounding agent for preparing engine lubricating oil is disclosed, and is characterized by being composed of base oil, a disperser, a detergent, an antiwear agent, an antioxidant, a viscosity index improver, a pour point depressant, an anti-foaming agent, a demulsifier, a metal magnesium powder and a metal chromium powder. The disperser is polyisobutene succinimide; the detergent is a phosphate; the antiwear agent is alkyl containing phosphatide and salt; the antioxidant is ainc dialkyl dithiocarbamate; the viscosity index improver is an ethylene-propylene polymer; the pour point depressant is a vinyl-ethylene polymer; the anti-foaming agent is an alkyl acrylate copolymer; and the demulsifier is poly-alkoxyl polyol. The compounding agent for preparing engine lubricating oil comprises the following components in percentage by weight: 12-13% of the disperser, 12-13% of the detergent, 4-5% of the antiwear agent, 14-15% of the antioxidant, 4-5% of the viscosity index improver, 7-8% of the pour point depressant, 6-8% of the anti-foaming agent, 9-10% of the demulsifier, 1-2% of the metal magnesium powder, 1-2% of the metal chromium powder, and the balance of base oil. A method for manufacturing the compound additive for engine lubricating oil disclosed by the invention is simple, economic and practical; and the manufactured product is low in price, high in quality, and capable of prolonging the service cycle of the lubricating oil, enhancing the antiwear and extreme-pressure-resisting effects of the lubricating oil, improving the various effects of oxidization resistance, corrosion resistance and forming resistance of the lubricating oil, keeping the clean effect of the lubricating oil for a long time, and comprehensively enhancing the integrated effect of the engine lubricating oil.

Owner:TIANJIN GONGBO SCI TECH DEV

Additive composite of lubricating oil for industrial gears

InactiveCN101864336AStrong demulsification abilityImprove transparencyAdditivesSulfonateOil additive

The invention relates to an additive composite of lubricating oil for industrial gears, in particular to an additive composite of lubricating oil for a gear transmission system, belonging to the technical field of additive for lubricating oil. The additive composite comprises the following components by mass percentage: 48% to 80% of sulfur-containing extreme-pressure anti-wear agent, 10% to 35% of phosphorus-containing anti-wear agent, 1% to 10% of metal deactivator, 5% to 20% of detergent and 2% to 5% of anti-rust agent, wherein the sum of the mass percentages of the components is equal to 100%. By substituting the amine mixture of poly-isobutene amine and polyether as detergent commonly used in the existing gasoline detergent for the detergent based on polyisobutylene succinimide, basic calcium sulfonate and basic magnesium sulfonate, which is used in the conventional additive for lubricating oil, the additive composite of the invention can obviously improve the anti-emulsification capacity of the lubricating oil for the industrial gears.

Owner:BEIJING ZEHUA CHEM ENG

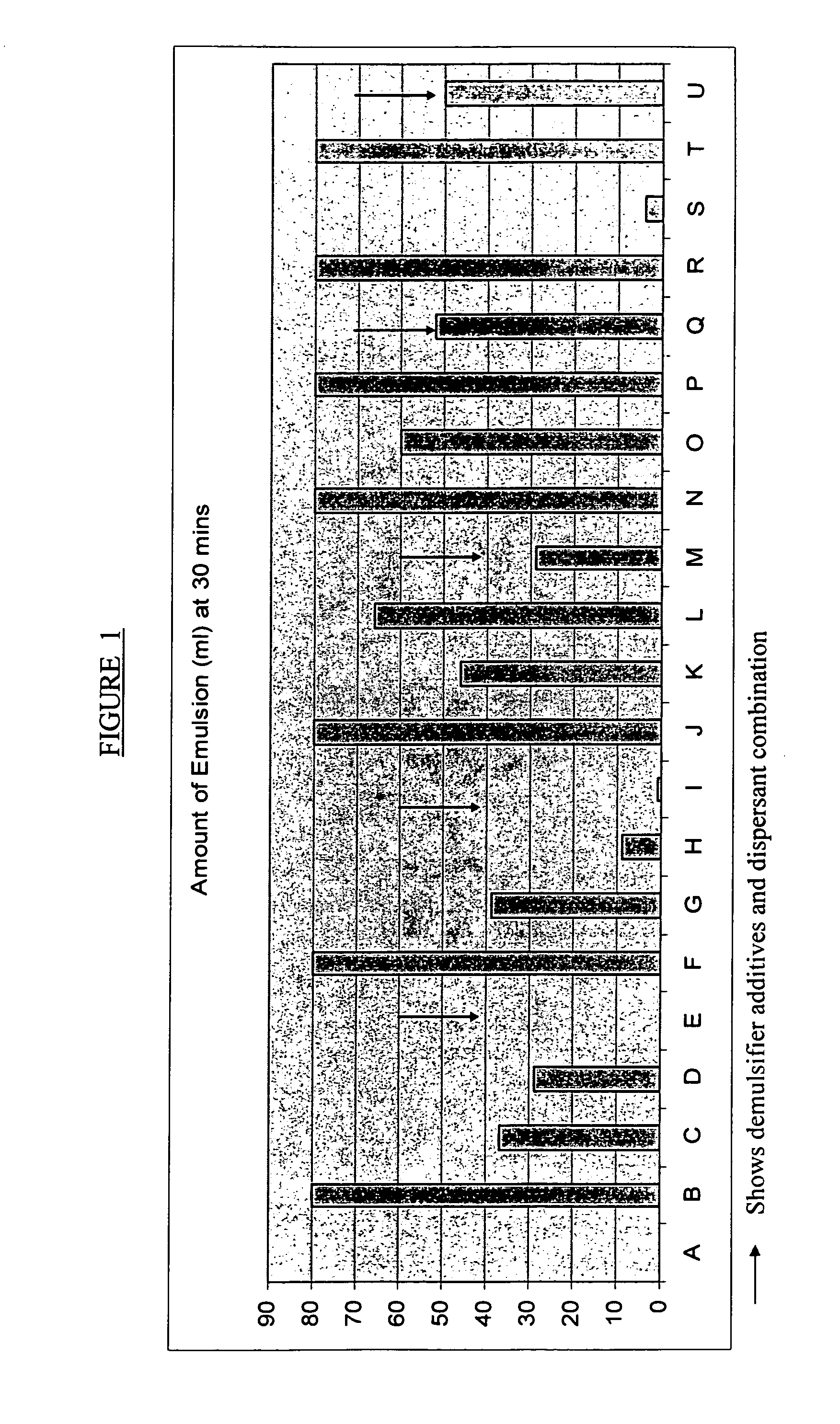

Synergistic combination of demulsifiers for enhancing demulsification properties in industrial lubricants

ActiveUS20080039537A1Good demulsification effectMinimize lacquer formationOther chemical processesAdditivesDemulsifierPolyolefin

A synergistic demulsifier composition for the improvement of demulsification properties and method of making said composition is disclosed along with a lubricant composition containing same. The demulsifier composition consists of effective amounts of one or more demulsifier additives and one or more dispersants. The demulsifier additives consist of a first copolymer of propylene oxide and ethylene oxide and a second copolymer of propylene oxide and ethylene oxide. The dispersant can be an untreated polyalkene succinimide type dispersant, preferably an untreated polyisobutylene succinimide type dispersant.

Owner:EXXON RES & ENG CO

Novel high-efficiency energy-saving emission-reduction fuel additive

InactiveCN102108312AImprove dispersion stabilityGood chemical stabilityLiquid carbonaceous fuelsFuel additivesCombustion chamberRare earth

The invention relates to a novel high-efficiency energy-saving emission-reduction fuel additive which is mainly prepared from 10-15% of oil-soluble nano rare earth, 5-20% iron salt of fatty acid, 10-30% of magnesium naphthenate, 5-10% of cobalt naphthenate, 5-8% of polyisobutylene succinimide and the balance of alkylbenzene. The novel high-efficiency energy-saving emission-reduction fuel additive is prepared by the following steps: sequentially adding rare earth, iron salt of fatty acid, magnesium naphthenate and cobalt naphthenate into a xylene solvent at room temperature, evenly mixing, adding polyisobutylene succinimide, and evenly mixing. When 1 / 1000-1 / 3000 of the compound additive is added into the fuel, the emission of carbon smoke of the engine and the oil burning boiler can be lowered by more than 38%, and the fuel can be saved by 5-20%. When being used for a long time, the additive can reduce deposit carbon in the combustion chamber of the diesel engine and prolong the service life of the engine; and the additive can also lower coking and corrosion of the furnace chamber of the oil burning boiler, and prolong the decoking cycle of the furnace chamber and the service life of the boiler.

Owner:北京君安润海科贸有限责任公司

Lubricant composition for railway high-speed diesel engine

ActiveCN102690714AImprove antioxidant capacityGood high temperature cleanAdditivesAntioxidantOxidation resistant

The invention relates to a lubricant composition for a railway high-speed diesel engine. The lubricant composition comprises A) a composite antioxidant comprising at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant and / or a polyisobutylene succinate dispersant, C) a mixture of calcium sulfonate and calcium naphthenate, D) at least one extreme pressure anti-wear agent, E) one or more ashless friction modifiers, and F) a main amount of lubricating base oil. The lubricant composition has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a railway high-speed diesel engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricant composition for ship outboard engine

ActiveCN102690713AImprove cleanlinessMeet lubrication requirementsAdditivesAntioxidantOxidation resistant

The invention relates to a lubricant composition for a ship outboard engine. The lubricant composition comprises A) a composite antioxidant composing at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant, C) a mixture of calcium salicylate and sulfurized calcium alkyl phenate, D) at least one zinc dialkyldithiophosphate, E) at least one extreme pressure anti-wear reagent, F) one or more metal deactivators, and G) a main amount of lubricating base oil. The lubricant composition utilizes optimized combination of the multiple ashless antioxidants, is compounded with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a ship outboard engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

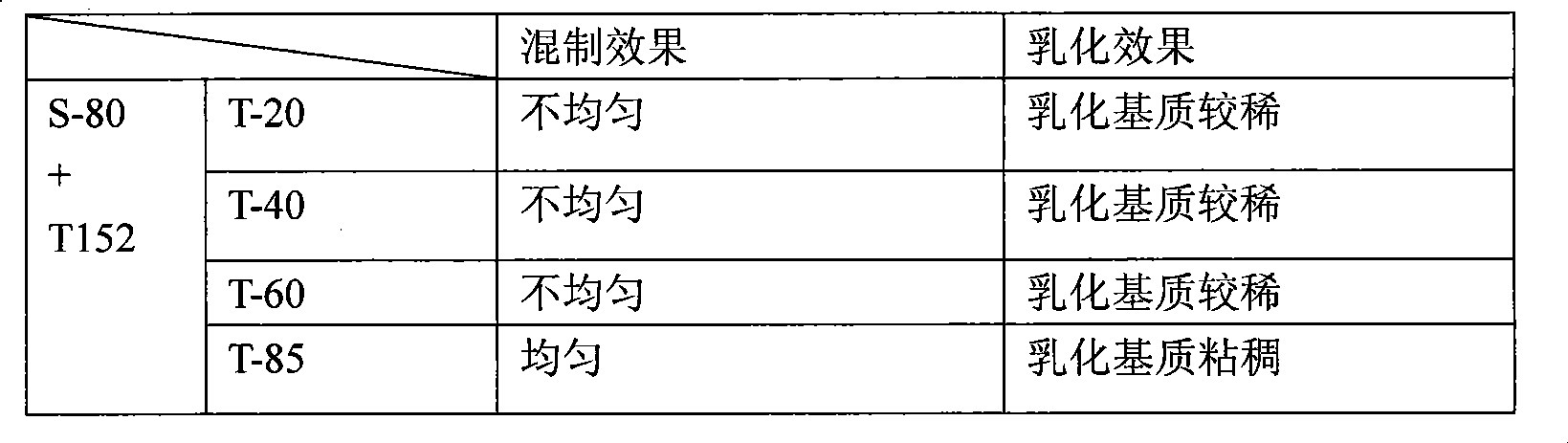

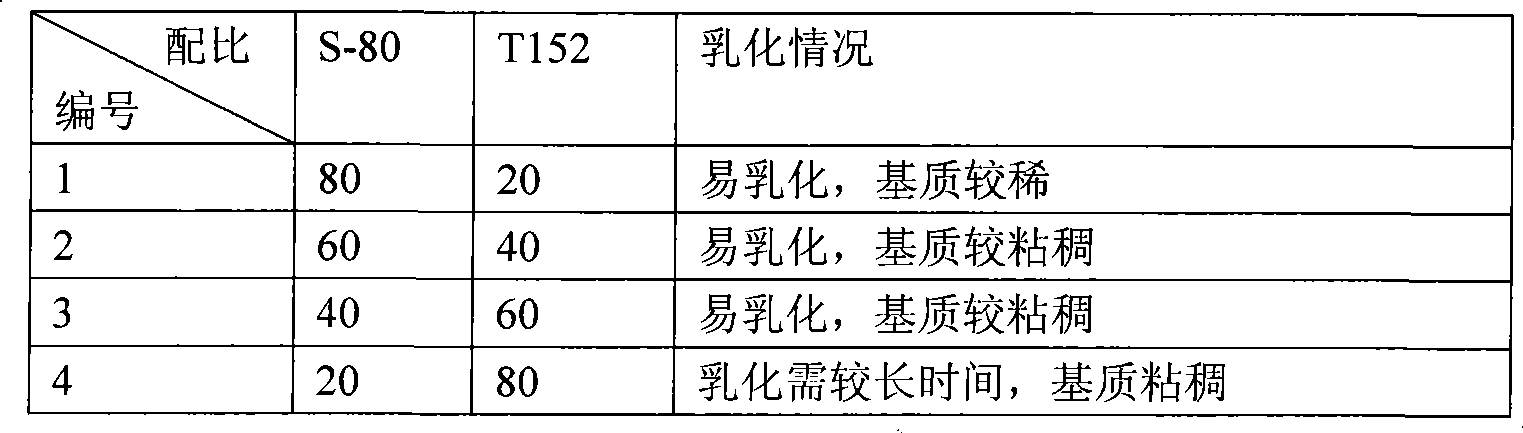

Environment protective emulsive explosive composite emulsifying agent

InactiveCN101462914AClosely arrangedCompact structureNon-explosive/non-thermic compositionsEtherEmulsion explosive

The invention relates to an emulsifier, in particular to an environment-friendly emulsion explosive compound emulsifying agent, aiming at solving the problems of being single in the type of the emulsifying agent used in the production of emulsion explosive and not being capable of meeting the market demand in the prior art. The emulsifying agent consists of the raw materials with the following parts by weight: 30-40 parts of bis-polyisobutylene-succinimide (T152), 50-65 parts of sorbitan monooleate (S-80), and 3-6 parts of sorbitan polyethenoxy ether glycerintrioleate (T-85). When in emulsification, stronger frame structure can be formed, so as to lead the molecular arrangement to be more compact, and increase the intensity of an interfacial film and the coating effect on water phase, thus not only realizing easy emulsification, but also ensuring the storage stability of the explosive. The explosion performance of the emulsion explosive can be effectively improved.

Owner:SHANXI JIANYE IND & TRADE

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com