Diesel detergent additive

A technology of detergent and diesel oil, which is used in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problem of lubricity of low-sulfur diesel, which can not be solved, affects the stability and oxidation stability of diesel, and has insufficient particle emission and inhibition ability. and other problems, to achieve good cleaning effect, simple and flexible use, and the effect of saving diesel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The distribution ratio of each component of embodiment 1 diesel oil detergent is as follows:

[0020] 1) 20 parts (weight, the same below) polyisobutylene succinimide (polyisobutylene number average molecular weight 1000, Suzhou Special Oil Factory product);

[0021] 2) 5 parts of isobutylene trimerized C12 primary amine;

[0022] 3) 5 parts of 2-methylimidazole;

[0023] 4) 5 parts of glyceryl oleate;

[0024] 5) 65 parts of high flash point aviation kerosene.

Embodiment 2

[0038] 1) 15 parts of polyisobutylene succinimide (polyisobutylene number average molecular weight 1300, product of Suzhou Special Oil Factory);

[0039] 2) 5 parts of isobutylene trimerized C12 primary amine;

[0040] 3) 5 parts of 2-phenylimidazole;

[0041] 4) 5 parts of glyceryl oleate;

[0042] 5) 70 parts of heavy aromatic solvent (flow process 170-210°C).

Embodiment 3

[0044] 1) 25 parts of polyisobutylene succinimide (polyisobutylene number average molecular weight 1300, product of Suzhou Special Oil Factory);

[0045] 2) 20 parts of propylene tetrapolymer C12 primary amine;

[0046] 3) 10 parts of 2-methylimidazole;

[0047] 4) 15 parts of glyceryl oleate;

[0048] 5) 30 parts of heavy aromatic hydrocarbon solvent (flow process 170-210°C).

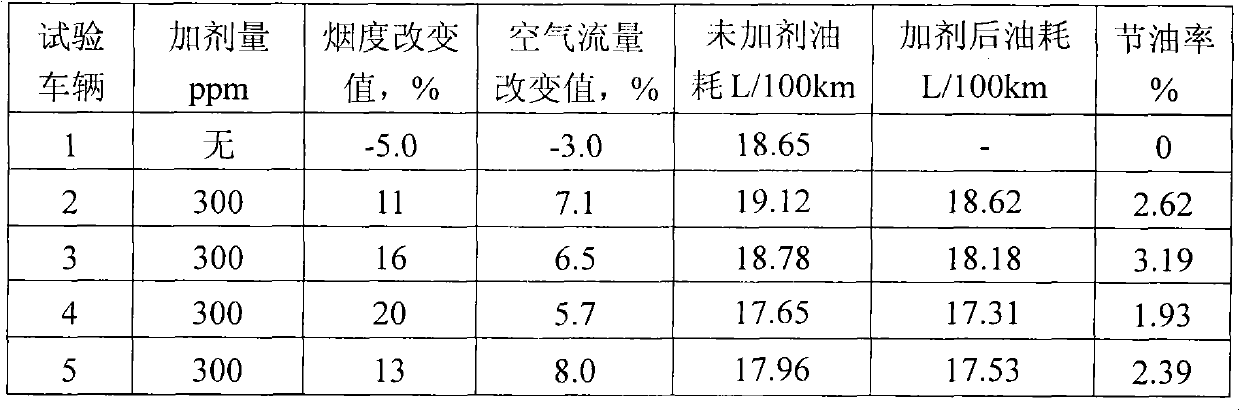

[0049] In order to illustrate the cleaning action of the diesel oil detergent provided by the present invention, the special diesel oil detergent prepared in Example 1 is added in No. 0 commercially available diesel oil, and it is loaded into 4 diesel vehicles and carried out the driving test of 3 weeks. The diesel vehicles without additives were tested (1, 2, 3 are large trucks; 4, 5 are large passenger cars). Measure the smoke of the vehicle before and after the test according to the GB / T3846 method, measure the nozzle air flow according to the ISO4010 method, and observe the fuel consumption. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com