Lubricating oil compound additive for compressed natural gas engine

A compound additive and compressed natural gas technology, applied in the field of lubricating oil, to achieve stable performance, improve dispersion, and reduce the rate of change of kinematic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

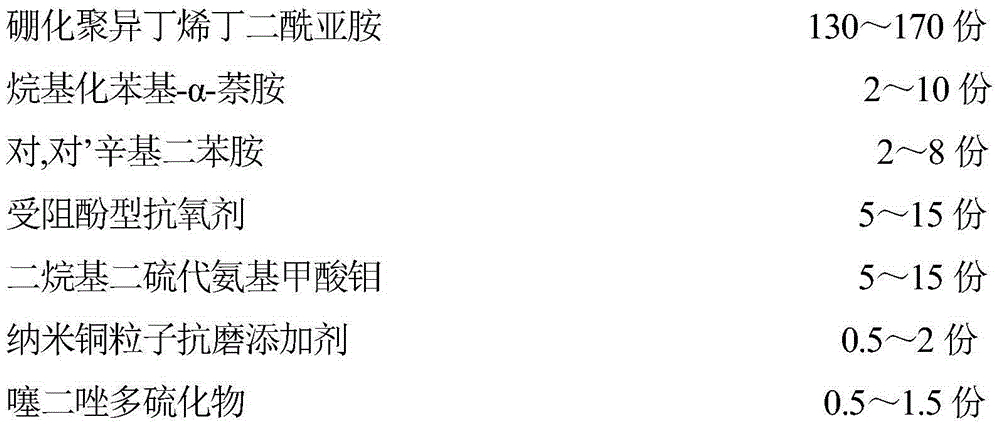

[0022] Taking the base oil 250N 100g used to prepare the compound additive for compressed natural gas engine lubricating oil as an example, its raw material composition and preparation method are as follows:

[0023]

[0024] The preparation method of the above-mentioned composite additive for compressed natural gas engine lubricating oil is: uniformly mixing sulfurized alkyl phenate calcium and high alkali value synthetic calcium sulfonate to obtain mixture A; boronated polyisobutylene succinimide, alkylated phenyl -α-naphthylamine, p-, p-'octyl diphenylamine, mixed uniformly to obtain mixture B; hindered phenolic antioxidant, molybdenum dialkyldithiocarbamate, and nano-copper particle anti-wear additives were uniformly mixed to obtain Mixture C: Pour the base oil into the blending kettle, heat to 55-60°C, then add thiadiazole polysulfide, mix well, then add mixtures A, B, and C in turn, and stir for 1 hour.

Embodiment 2

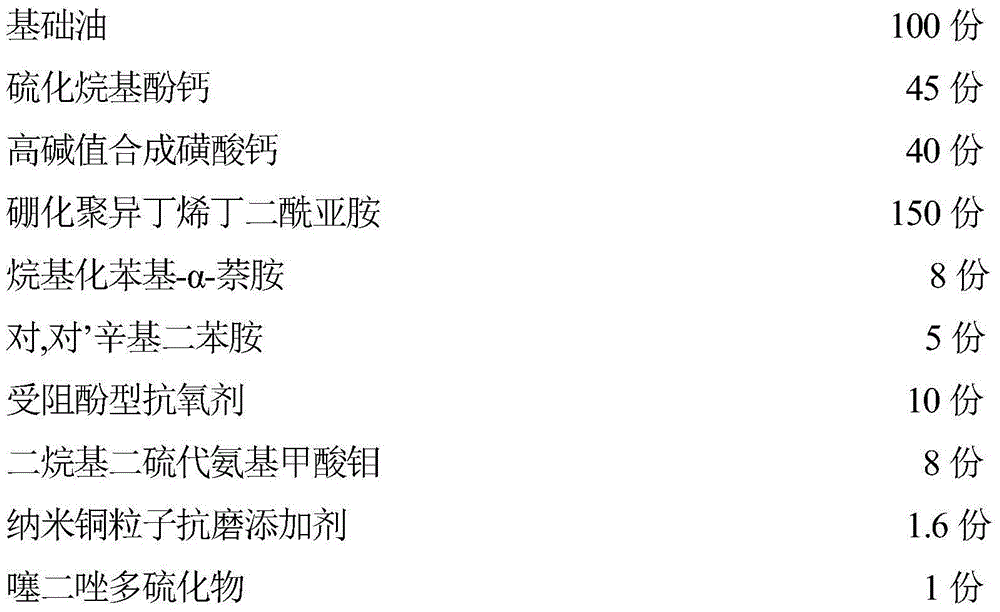

[0026]Taking the base oil 250N 100g used to prepare the compound additive for compressed natural gas engine lubricating oil as an example, its raw material composition and preparation method are as follows:

[0027]

[0028] Its preparation method is identical with embodiment 1.

Embodiment 3

[0030] Taking the base oil 250N 100g used to prepare the compound additive for compressed natural gas engine lubricating oil as an example, its raw material composition and preparation method are as follows:

[0031]

[0032] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com