Patents

Literature

596 results about "Antiwear additive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

AW additives, or antiwear additives, are additives for lubricants to prevent metal-to-metal contact between parts of gears. EP additives are used in applications such as gearboxes, while AW additives are used with lighter loads such as bushings.

Premium synthetic lubricants

InactiveUS6475960B1Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAntioxidantBoiling point

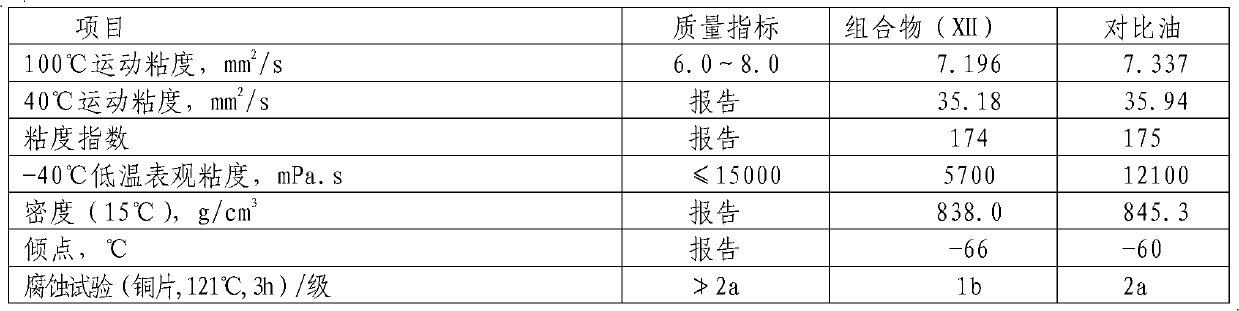

Premium synthetic lubricants comprise a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one, and typically a plurality of lubricant additives such as a detergent, dispersant, antioxidant, antiwear additive, pout point depresant, VI improver and the like. The base stock is derived from a waxy, paraffinic, Fischer-Tropsch synthesized hydrocarbon feed fraction having an initial boiling point in the range of about 650-750° F. and continuously boiling up to at least 1050° F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The waxy feed has a T90-T10 temperature difference of at least 350° F. and is preferably hydroisomerized without any pretreatment, other than optional fractionation. The lubricant may also contain hydrocarbonaceous and synthetic base stock material. Lubricants, such as fully formulated multigrade automotive crankcase and transmission oils formed by adding a suitable additive package to the isoparaffinic base stock have exhibited performance superior to similar fully formulated oils based on both PAO and conventional, petroleum derived base stocks.

Owner:EXXON RES & ENG CO

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

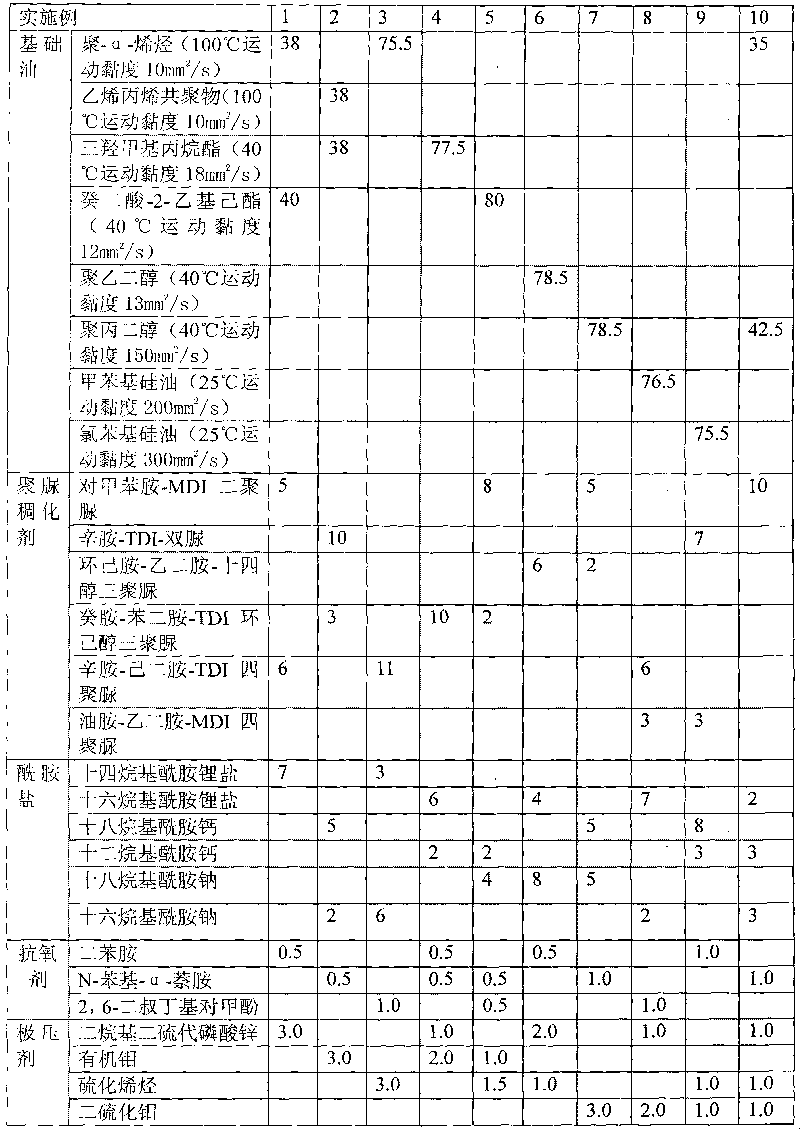

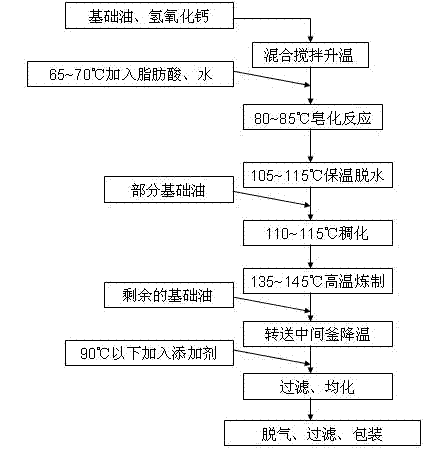

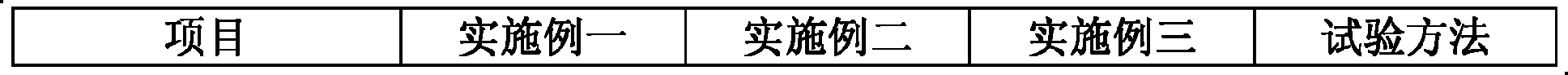

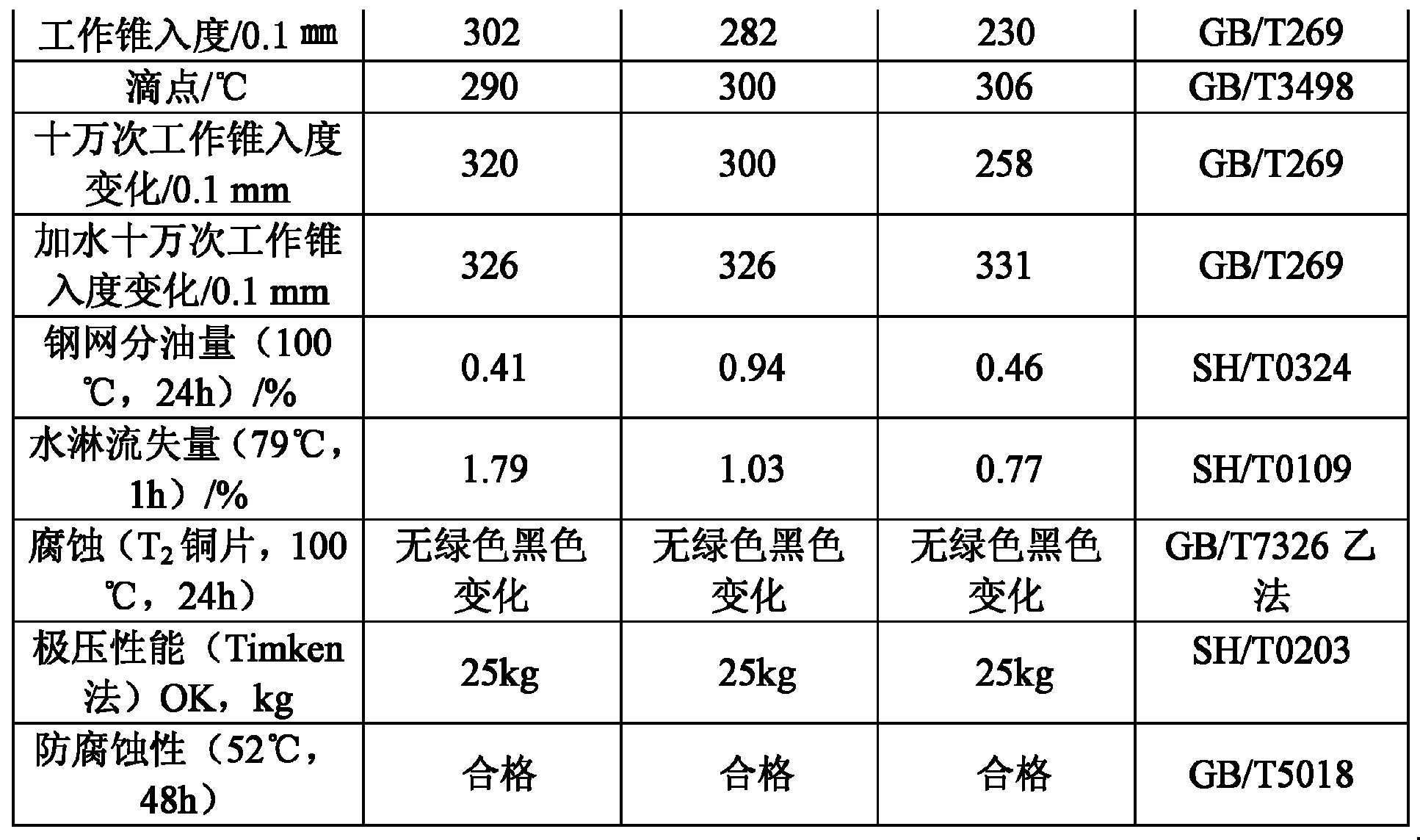

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

Composite lithium-base grease and method for making same

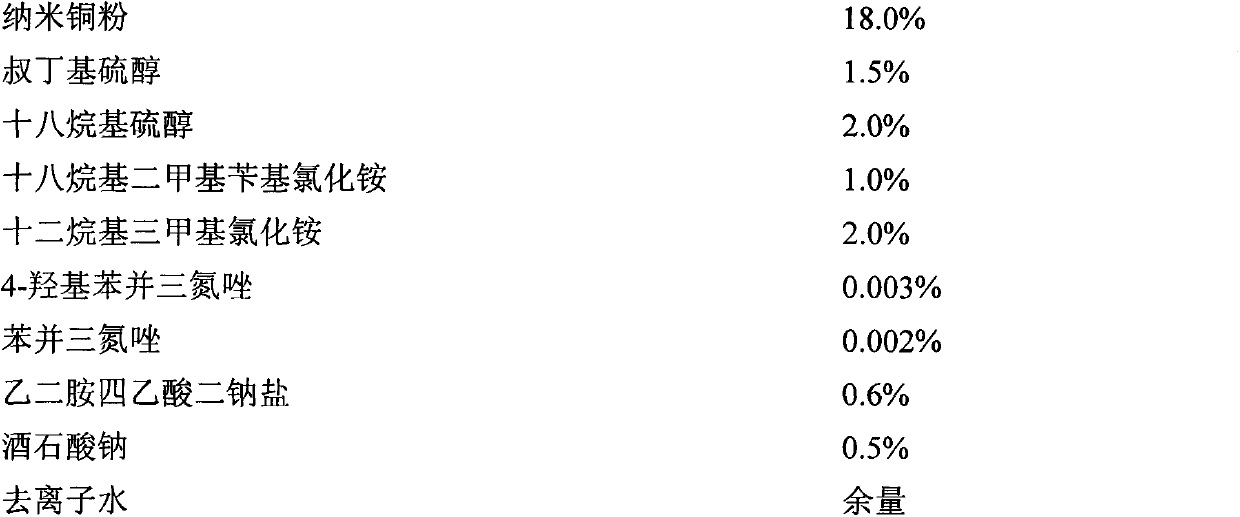

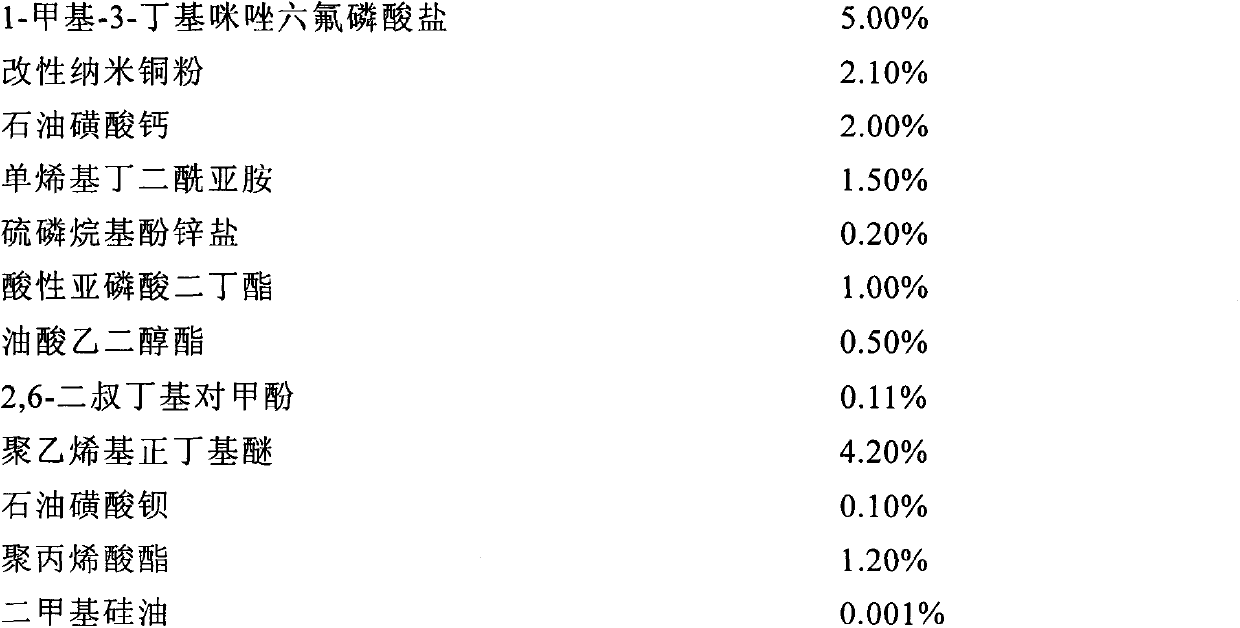

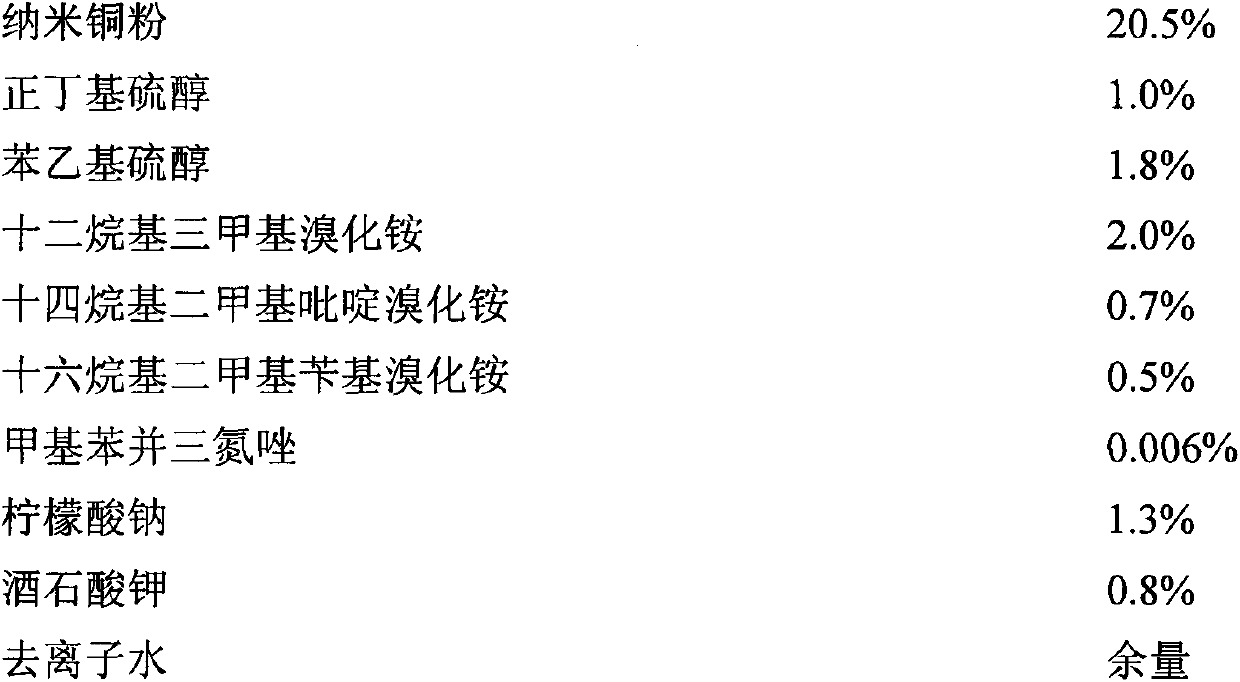

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Anhydrous albany grease and preparation method thereof

ActiveCN102757847AMeet the requirements of wide temperature rangeExcellent water shear stabilityLubricant compositionChemical industryCalcium hydroxide

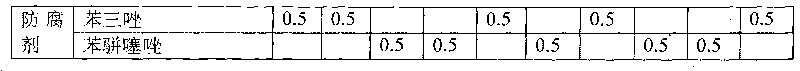

The invention belongs to the technical field of the chemical industry, and relates to grease and a preparation method thereof, in particular to anhydrous albany grease and the preparation method thereof. The anhydrous albany grease and the preparation method comprises the following components by weight: 82-90% of base oil, 1-4% of calcium hydroxide, 6-15% of fatty acid, 0.3-1% of antioxygen, 0.5-1.5% of rust inhibitor, and 0.5-3% of extreme pressure antiwear additive. The anhydrous albany grease and the preparation method have the benefits as follows: the grease is simple in preparation process and easy to control; and the prepared product has better water erosion resistance, favorable metal adhesivity and extreme pressure abrasion resistance, and can provide outstanding lubrication and abrasion resistance protection for wheel bearings and chassis.

Owner:JIANGSU LOPALTECH

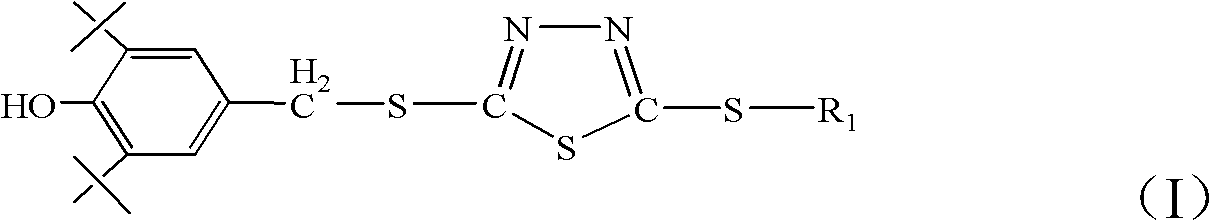

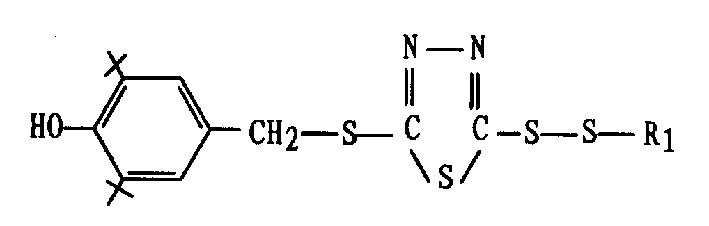

Screen phenol-containing thiadiazole type antioxygen antiwear additive and preparation method thereof

InactiveCN103320199AAntioxidant is goodExcellent extreme pressureOrganic chemistryAdditivesAlkaneThio-

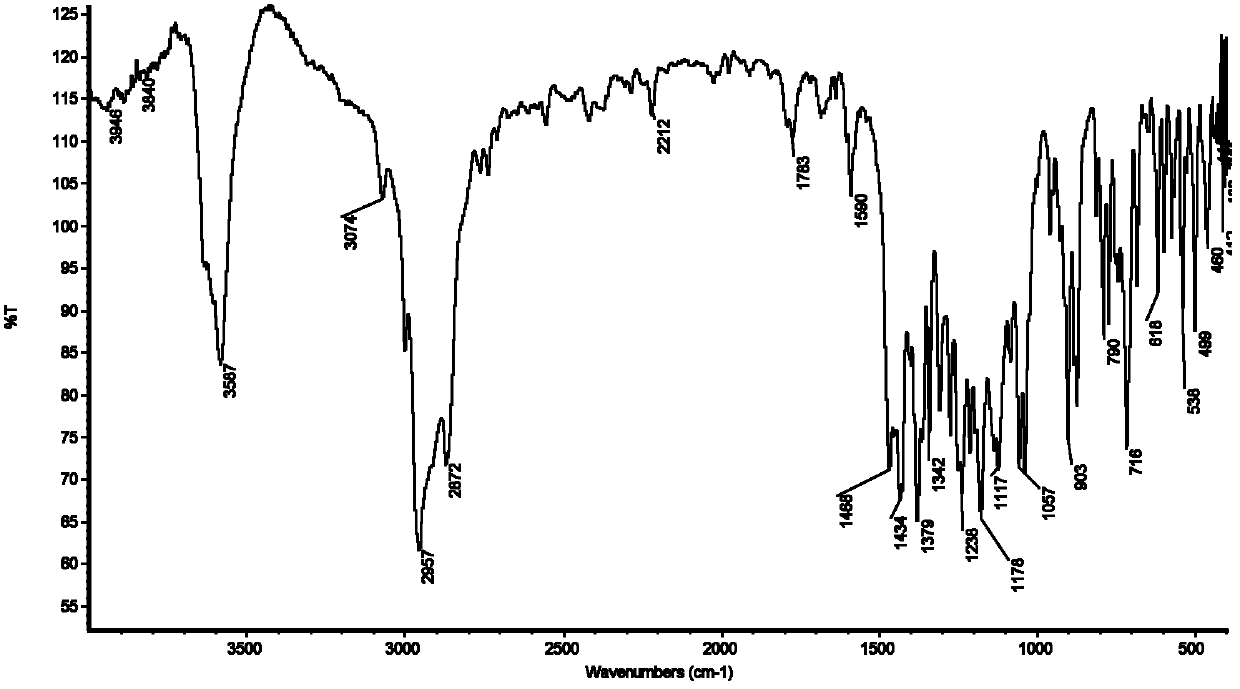

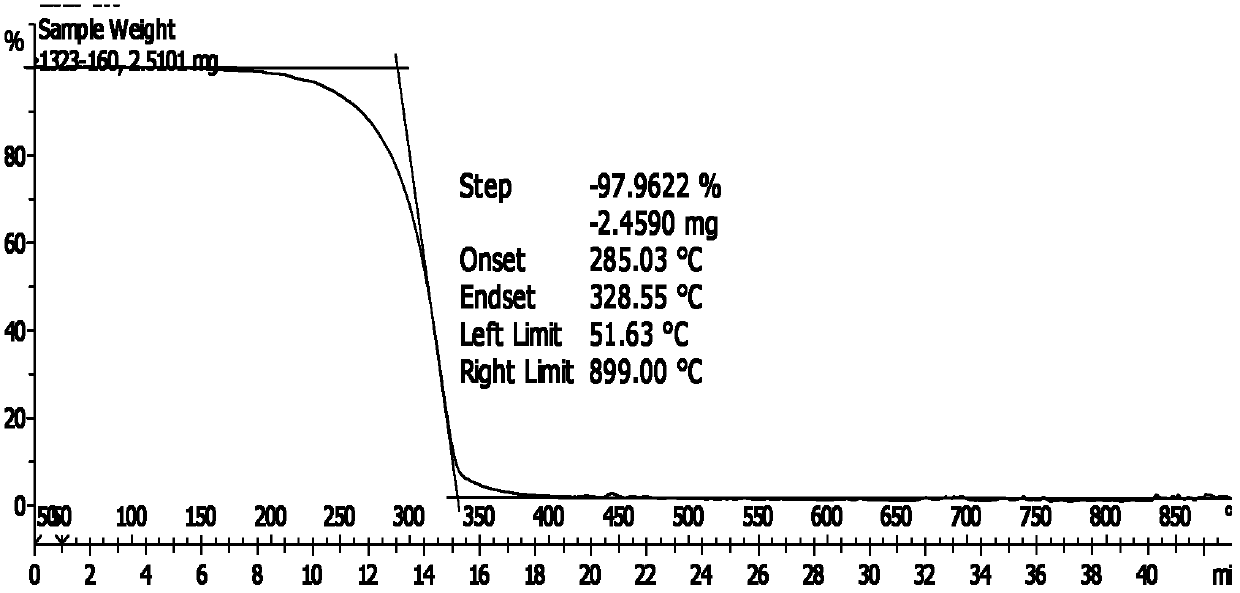

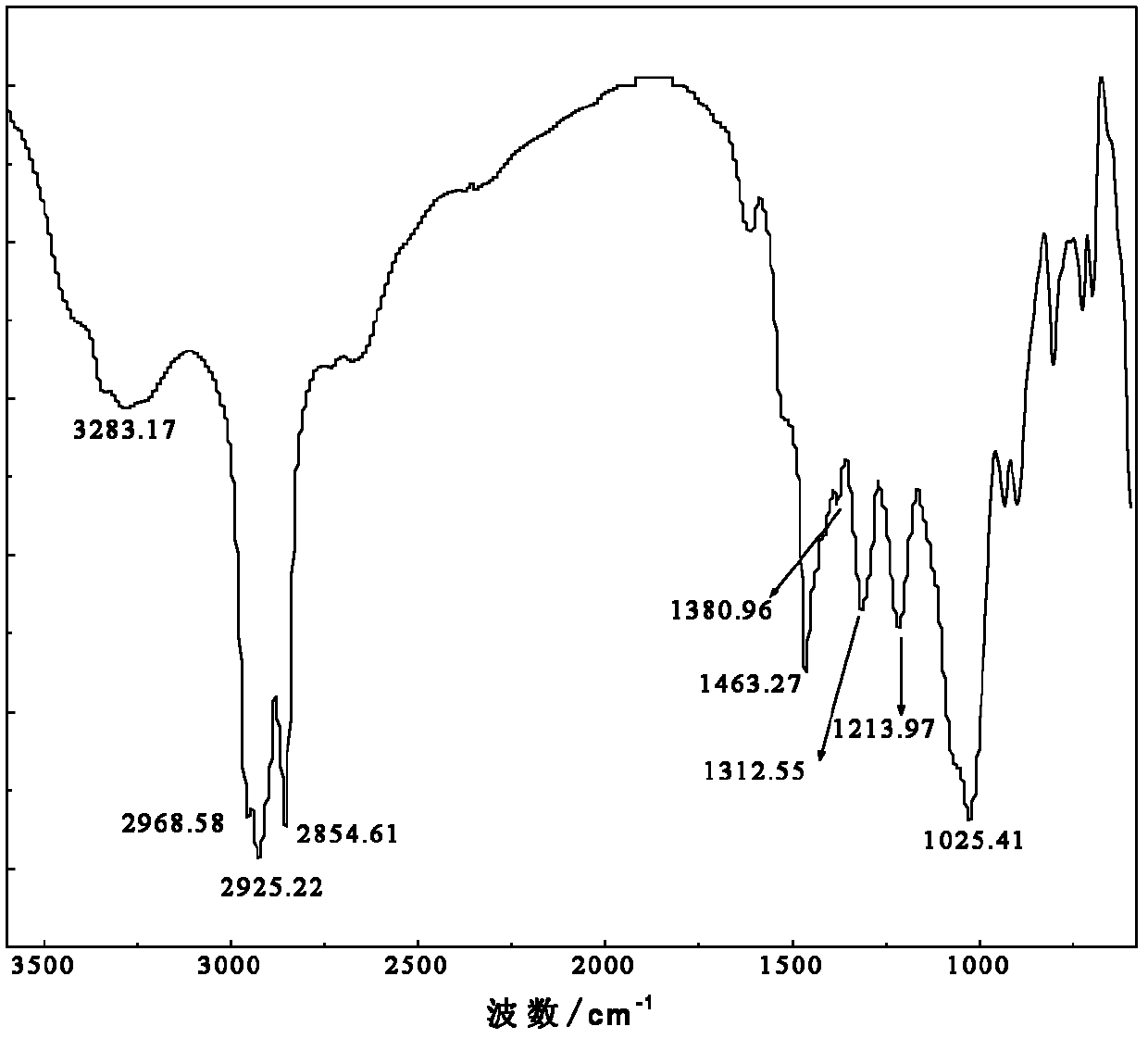

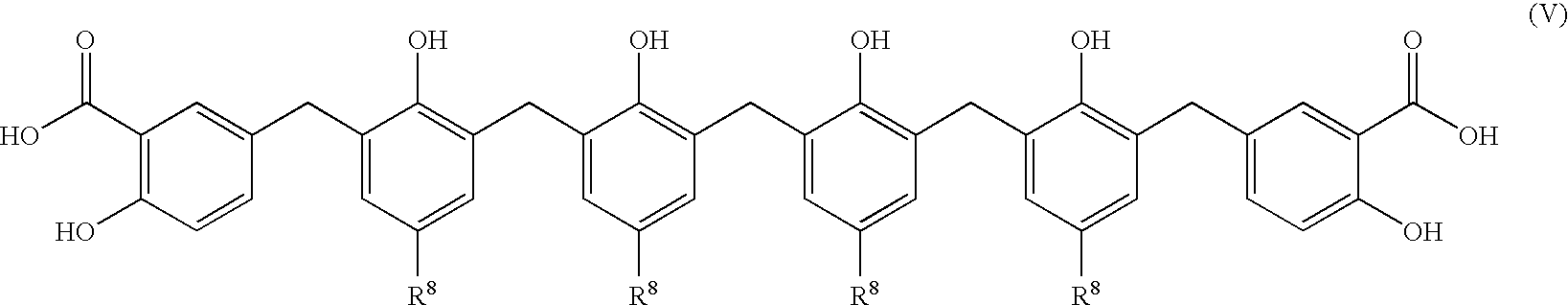

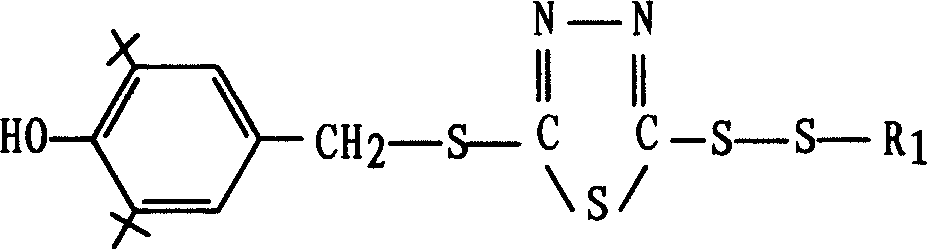

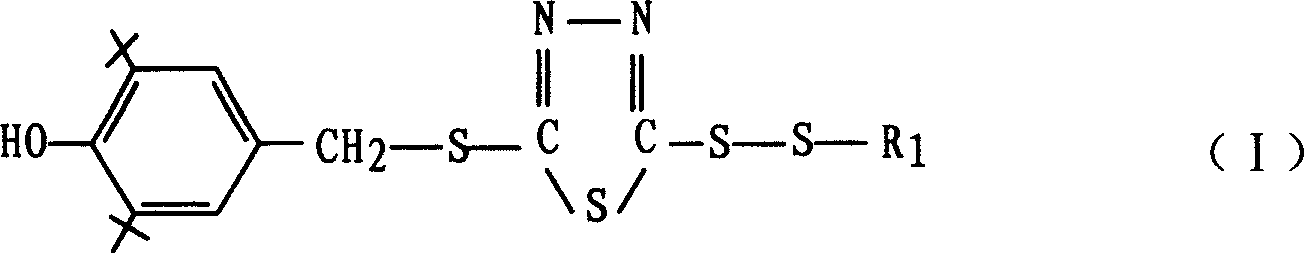

The invention discloses a screen phenol-containing thiadiazole type antioxygen antiwear additive and a preparation method thereof, wherein the chemical name of the additive is 2-(3,5-di-tert-butyl-4-hydroxy-benzyl)thio-5-alkylthio 1,3,4-thiadiazole. According to the preparation method, 2,5-dimercapto-1,3,4-thiadiazole is adopted as a raw material, the 2,5-dimercapto-1,3,4-thiadiazole and a halogenated alkane are subjected to a nucleophilic substitution reaction under a catalyst effect to generate monoalkyl thiadiazole, and the monoalkyl thiadiazole, formaldehyde and 2,6-di-tert-butylphenol are subjected to a condensation polymerization reaction under a catalyst effect to obtain 2-(3,5-di-tert-butyl-4-hydroxy-benzyl)thio-5-alkylthio 1,3,4-thiadiazole type lubricating oil multifunction additive, wherein the additive is characterized in that good oxidation resistance, extreme pressure property, wear resistance and corrosion resistance are provided for the lubricant with the additive, and the additive can be combined with other additives to provide good synergy effects, can be adopted to partly or completely replace ZDDP, and is applicable for internal combustion engine oils and industrial lubricating oils.

Owner:PETROCHINA CO LTD

Extreme pressure antiwear additive and preparation method and application thereof

InactiveCN102504913AModerate chemical activityGood oil solubilityGroup 5/15 element organic compoundsAdditivesSolubilityOil sludge

The invention provides an extreme pressure antiwear additive and a preparation method and application thereof; the extreme pressure antiwear additive has a general formula structure as shown in the specification, wherein R1, R2 and R3 in the formula is respectively alkyl groups, aryl groups or aralkyl of a C4-C20 linear chain or branched chain. The extreme pressure antiwear additive provided by the invention is formed by reacting phosphorus oxychloride, C1-C20 alcohols, organic amine and benzotriazole. The extreme pressure antiwear additive provided by the invention can be applied to lubrication oil and lubricating grease with 0.1-2.0wt% of recommended dosage. The extreme pressure antiwear additive provided by the invention has moderate chemical activity, good oil solubility, very good compatibility with other addition agents, no peculiar smell and good thermal oxidation stability, and can effectively reduce the abrasion of devices and oil sedimentation as well as generation of oil sludge. After applied to gear oil, the extreme pressure antiwear additive has excellent antiwear performance and thermal oxidation stability; and simultaneously the extreme pressure antiwear additive can be applied to a lubricating grease and automatic transmission liquid and hydraulic oil of automobiles.

Owner:天津市金岛润滑科技股份有限公司

Lubricated part having partial hard coating allowing reduced amounts of antiwear additive

InactiveUS20070197407A1Reduce wearReduces clogged filtersVacuum evaporation coatingSputtering coatingBorideSulfide

A lubricated part composition containing (a) a part with at least a partial hard surface coating of average thickness less than about 25 micrometres, said coating containing at least one moiety selected from the group consisting of silicides, nitrides, carbides, borides, oxides, sulphides and mixtures thereof; (b) a detergent selected from at least one of the group consisting of a phenate salt, a sulphonate salt, a salixarate salt and mixtures thereof; and (c) an oil of lubricating viscosity. The invention further relates to the use of the composition to decrease engine wear, decrease sludge formation, filter plugging, decrease sulphur emissions and decrease phosphorus emissions.

Owner:THE LUBRIZOL CORP

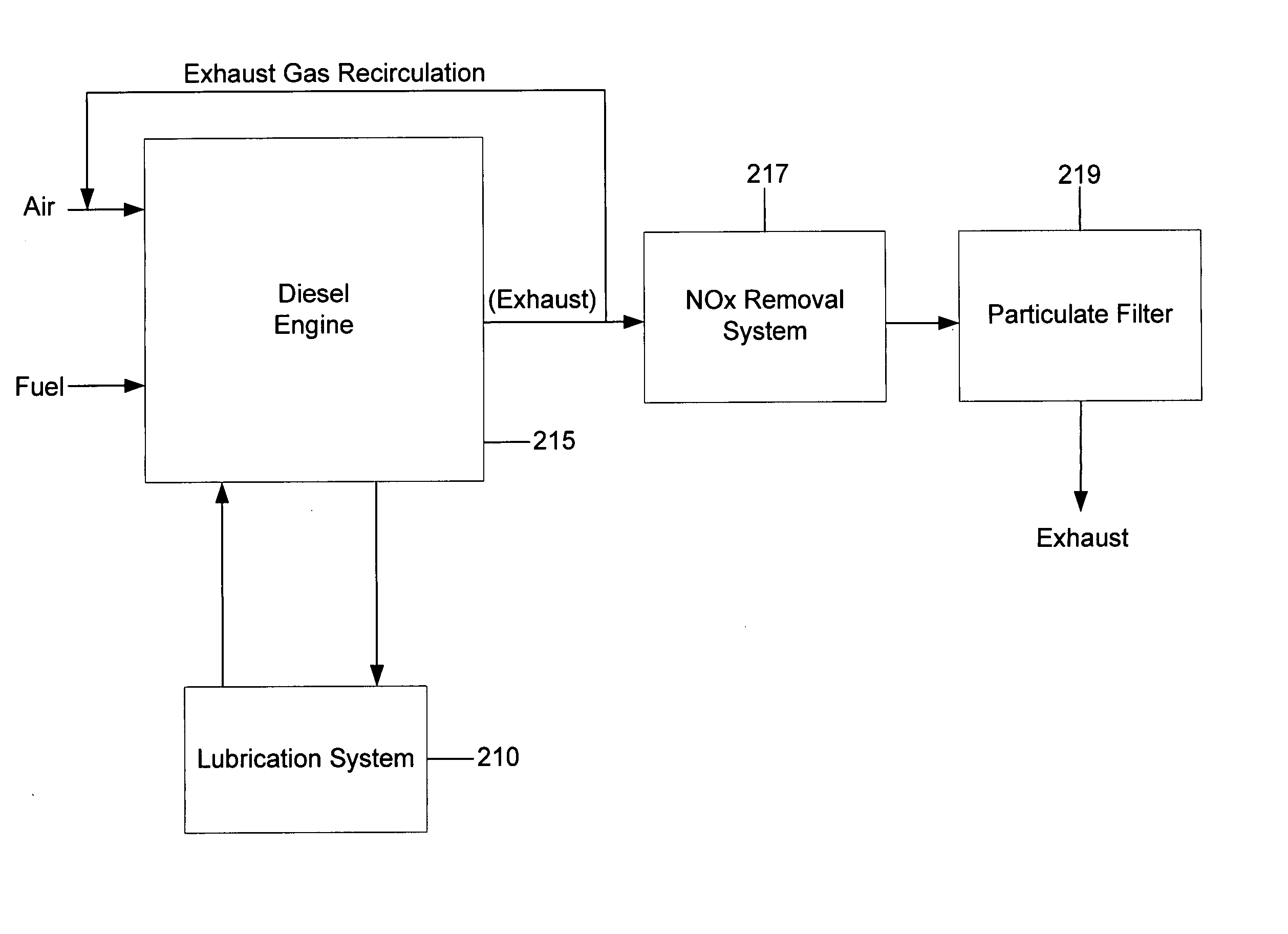

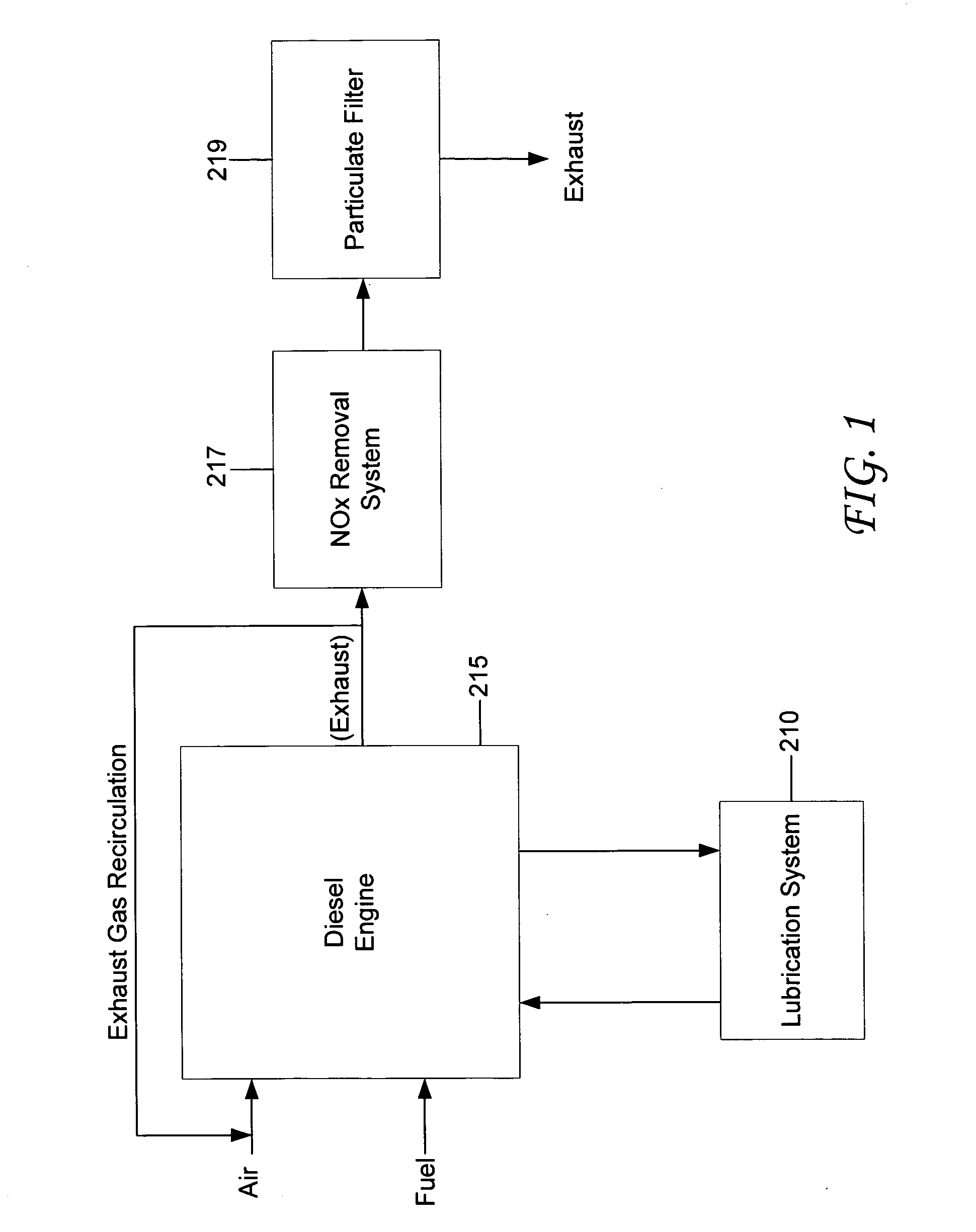

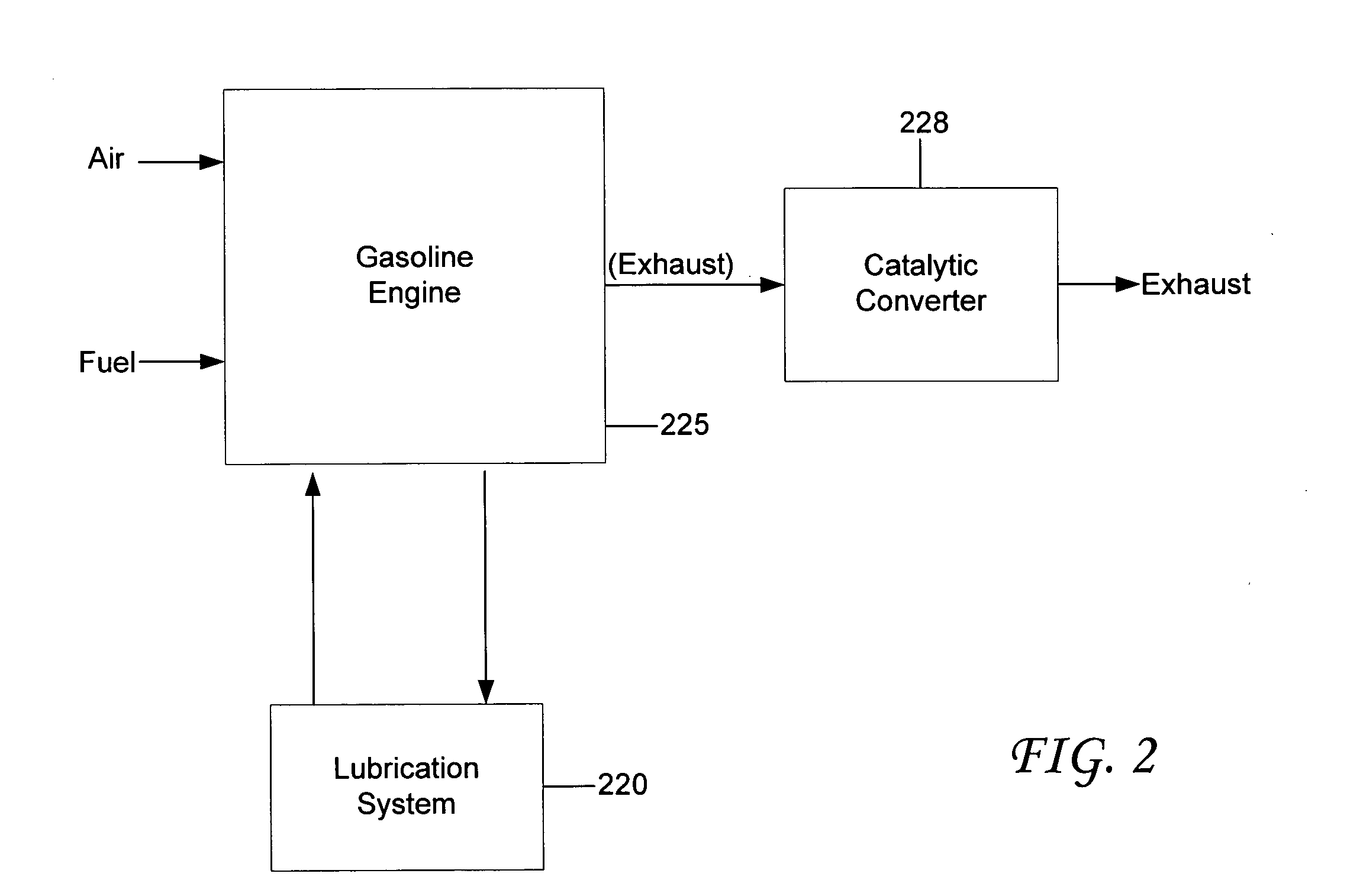

Materials and processes for reducing combustion by-products in a lubrication system for an internal combustion engine

InactiveUS20060260874A1Minimizes engine depositEfficient emissionsMachines/enginesLubricant mounting/connectionSolubilityExternal combustion engine

A lubrication system having an oil filter modified to replace or supplement the performance of lubricant additives that may be used within an internal combustion engine to increase the performance of a lubricant. The formulation of the lubricant is changed in accordance with the chemicals placed in the oil filter. For example, when the oil filter contains a strong base, the lubricant concentration of detergent will decrease, in some cases to zero, while the dispersant concentration in the lubricant will increase. The dispersant is the ideal weak base to neutralize combustion acid at the piston ring zone, carry the resultant weak base-combustion acid complex to the strong base in the oil filter, undergo ion exchange with the strong base, immobilize the acid in the oil filter and recycle back to the piston ring zone for reuse as an acid neutralization agent. The reduction or elimination of detergent from the lubricant will reduce the fouling of the emission filter and of deposit formation on engine parts such as the piston. The oil filter may also contain an additive which is slowly released into the lubricant. For example, a ZnDDP anti-wear additive may be slowly released from the oil filter to the lubricant. Because the ZnDDP has low molecular weight alkyl groups it has limited solubility in the lubricant. The rate of release is limited by the equilibrium concentration of the additive in the lubricant. As a result, a relatively constant concentration of the additive may be maintained in the lubricant. The resultant closed system allows the oil drain intervals to be significantly extended.

Owner:LUTEK

Light cured dry film lubricant

InactiveCN102433201AHigh speedImprove extreme pressure and anti-wear performanceLubricant compositionPolymer scienceOligomer

The invention discloses a light cured dry film lubricant. The film forming substance of the light cured dry film lubricant consists, by weight percent, of 10 to 50% of solid lubricant, 0.2 to 5% of dispersant, 4 to 10% of antiwear additive, 2 to 6% of antioxidant, 0.5 to 2.5% of magnetic additive and 35-80% of coating film bonding matrix, wherein the bonding matrix consists of oligomer, reactive diluent, photo-initiator and auxiliary. The dry film lubricant disclosed by the invention can be cured under ultraviolet light at normal temperature, and is fast in being cured, environment-friendly, excellent in antiwear property and small in frictional surface scratch. The light cured dry film lubricant is applicable for the lubricating antiwear coating on oil-free lubrication components, and especially applicable for the lubricating antiwear coating on the surface of non-temperature-resistant base materials.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Long life lubricating oil composition with very low phosphorus content

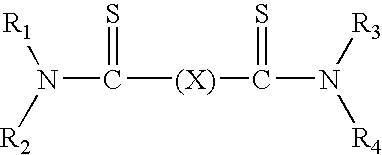

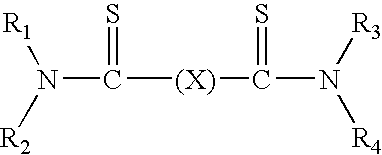

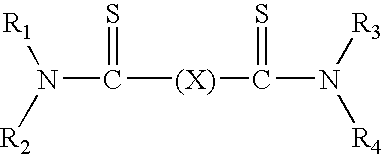

A lubricating oil with very low phosphorus content, and having long life as evidenced by a reduction in viscosity increase, oxidation and nitration, comprises a major amount of a base oil of lubricating viscosity and a minor amount of a mixture of neutral and overbased metallic detergents, at least a zinc dialkyldithiocarbamate antiwear additive and at least a dihydrocarbylthiocarbamoyl.

Owner:EXXON RES & ENG CO

Preparation method of antioxidation antifriction lubricating oil additive

An antioxidizing and antiwear additive for lubricating oil is prepared from cryptophenol and 2-mercapto-5-alkylthio 1,3,4 thiadiazole through condensation reaction at 40-150 deg.C under existance of formaldehyde and acid catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

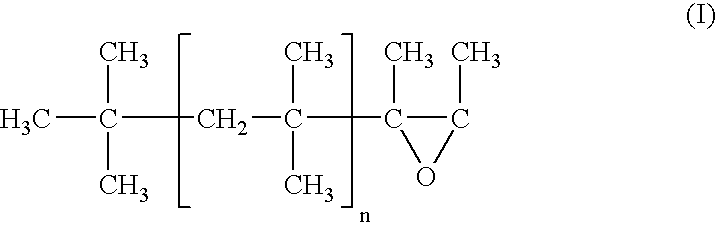

Borated-epoxidized polybutenes as low-ash anti-wear additives for lubricants

An engine lubricant that is substantially free of zinc and phosphorous contains an antiwear additive comprising borated 1,2 epoxy mixed polybutenes having an average carbon number in the range of C20 to about C120.

Owner:EXXON RES & ENG CO

Lubricant composition for double-clutch gearbox

ActiveCN102766507AImprove wear resistanceImprove friction characteristicsLubricant compositionDispersityPolyolefin

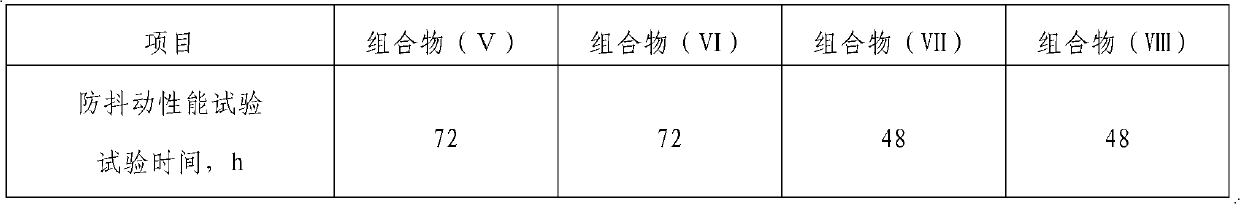

The invention provides a lubricant composition for a double-clutch gearbox. The lubricant composition comprises: (A) at least a hydrofinishing III mineral oil with high viscosity index, or polyolefin cogasin, or ester cogasin, or any combination of the above components; (B) at least a viscosity index improver; (C) at least a pour-point depressant; (D) at least a phosphorus-containing antiwear additive; (E) at least a friction modifier; (F) at least a high-temperature anti-oxidant; (G) at least an ashless dispersant; (H) at least a metal detersive; and (I) at least a metal passivator. The above lubricant composition has excellent abrasion resistance, frictional characteristic, synchronization performance, antiwear endurance, high-temperature lubrication stability, antirust and anti-corrosive property, high and low temperature performance, shearing stability, cleaning dispersity, high-temperature anti-foaming property and micropoint corrosion resistance, passes through Vickers pump experiments, FAGFE-8 bearing wear experiments, SAE No.2 frictional characteristic experiments, TE92M anti-shake experiments, SSP-180 synchronous bench durability experiments, CEC L-45 taper roller shearing experiments, CEC L-84 thermooxidizing soundness experiments and FAV-54 mircopoint corrosion experiments, and simultaneously meets lubrication requirements of clutches, a synchronizer, gears and bearings in the double-clutch gearbox.

Owner:PETROCHINA CO LTD

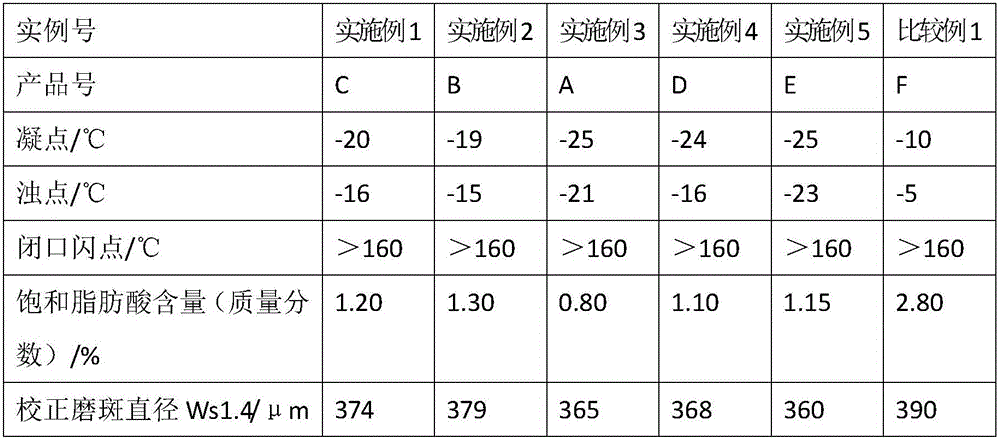

Preparation method of low-cloud-point fatty acid type diesel antiwear additive

ActiveCN106350217ALow cloud pointLowering the freezing pointLiquid carbonaceous fuelsFatty-oils/fats separationPetrochemicalSolvent

The invention belongs to the field of petrochemical industry, and relates to a preparation method of a low-cloud-point fatty acid type diesel antiwear additive. The method comprises the following steps: adding polyalpha-olefin into industrial unsaturated fatty acid, uniformly stirring, refrigerating to separate out crystals, filtering, and separating to remove the crystals so as to obtain a low-cloud-point fatty acid filtrate in which crystals are not separated out at a low temperature, wherein the polyalpha-olefin accounts for 0.1-1.0% of the industrial unsaturated fatty acid in percentage by mass; and adding a right amount of solvent oil and pour point depressant into the filtrate to obtain the low-cloud-point fatty acid type diesel antiwear additive. According to the method provided by the invention, the saturated fatty acid crystals can be easily separated out from the fatty acid solution, so that the saturated fatty acid content in the fatty acid is greatly reduced, and the diesel antiwear additive in which saturated fatty acid crystals can not be easily separated out at a low temperature is prepared from the fatty acid used as a raw material; and the cloud point reaches -15 DEG C or below.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Inorganic high-temperature-resistant dry-film lubricant

InactiveCN102226125AGood weather resistanceGood chemical resistanceLubricant compositionAntioxidantMetallic substrate

The invention discloses an inorganic high-temperature-resistant dry-film lubricant which is prepared from the following components in percentage by weight: 10-50% of solid lubricant, 4-10% of antiwear additive, 0.2-5% of dispersant, 2-6% of antioxidant, 0.5-2.5% of magnetic additive and 35-80% of binding matrix. The dry-film lubricant disclosed by the invention has the advantages of favorable antiwear property, small scratch on the wear surface, and wide range of application temperature, and is especially applicable to lubricating and antiwear application on the surface of a metal substrate part under high-temperature conditions.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Lubricating oil

ActiveCN104031722AMagneticLiquidAdditivesPigment treatment with organosilicon compoundsIron powderOil additive

The invention discloses a lubricating oil which comprises the following components in percentage by weight: 10-25% of detergent dispersant, 5-15% of antioxidation and anticorrosion agent, 5-15% of extreme-pressure antiwear additive, 10-15% of tackifier, 1-3% of ferrite-base magnetic fluid and the balance of base oil. The lubricating oil additives can greatly improve the antiwear and anti-friction properties of the lubricating oil, enhance the heat stability and convert the iron powder and mud oil generated in the crankshaft and connecting rod tile working process into nano balls, thereby reducing the friction of the machine, lowering the oil temperature and prolonging the service life of the lubricating oil and machine.

Owner:丘寿勇 +2

Ester flame-proof hydraulic-oil containing nano abrasion-resistant additive and production method thereof

ActiveCN101113383AExtended service lifeReduce use costAdditivesBase-materialsOrganic chemistryRaw material

The invention relates to ester type flame retardant hydraulic oil containing nano antiwear additive. The mixture ratio by weight of the raw materials is that: 90-95 percent of synthetic ester compound base oil, 1.0-5.0 percent of synthetic multifunctional additive and 1.0-5.0 percent of nano antiwear additive. The production method is that: first, the synthetic ester compound base oil is heated up to 100-120 DEG C, antioxidant is added and stirred for 1-2 hours at 100-120 DEG C until the solid is completely dissolved, then antirust agent and demulsifying agent are added, finally the finished products are filtered to be used; second, the synthetic ester compound base oil is heated up to 60-80 DEG C, and the synthetic multifunctional additive, the nano antiwear additive and antifoamer are added and stirred for 1-3 hours at a constant temperature of 60-80 DEG C, then heating is stopped, and sample is selected for analysis and packaged into finished products after the analysis. The beneficial effects of the invention are that: high temperature using performance and long time lubricant performance of the products are greatly promoted, the service life of hydraulic systems and oil change period can be greatly prolonged.

Owner:杭州新港润滑科技有限公司

Complex lithium base grease and preparation method thereof

The invention relates to complex lithium base grease and a preparation method thereof. The preparation method comprises the following processes of: adding 1 / 4 of base oil and dibasic organic acid into a reaction kettle, heating and melting, and adding monobasic organic acid for reaction; adding 1 / 4 of base oil, cooling the base oil, and adding lithium hydroxide oil solution for saponification andwarming; adding 1 / 4 of base oil, moving materials in the reaction kettle to an intermediate kettle, adding the rest 1 / 4 of base oil into the intermediate kettle, and circulating and cooling; adding an antioxidant, a corrosion inhibitor and an extreme pressure antiwear additive; and uniformly stirring, homogenizing and degassing to obtain the complex lithium base grease. The complex lithium base grease has a simple process, the time for producing the complex lithium base grease with a normal-pressure kettle is short, energy resources are saved, production cost is reduced, the utilization rate of equipment is improved, and the saponification reaction is quick and full.

Owner:无锡中石油润滑脂有限责任公司

Conducting polymer high-temperature lubricating grease and its preparing method

This invention involves a kind of conductive high polymer high temperature lubricant and preparing method. Made up by the following raw materials according to the ratio by weight: Basic oil is 50%- 90%, soap base thicken pharmaceutical 5% - 30%, conductive high polymer 0.1% - 10%, antirust additive 0.1% - 10%, resist oxygen additive 0.1% - 10%, resist and rub additive 0.1% - 10%.Is it mix attitude electric conduction gather aniline lose the pharmaceutical slowly as subject, conduct and gather aniline, basic oil to adopt. Thick to take pharmaceutical , rust inhibitor , resist oxygen pharmaceutical , is it rub pharmaceutical ,etc. additive mix altogether to resist, do not add any solute , through the craft of heating , mixing , grinding etc., the scattering of making the electric conduction gather the aniline and reach the nanometer grade in the basic oil. Its advantage lies in that it is acid and alkaline resisting, suitable for using under very abominable environmental condition such as being acid or alkaline, and especially suitable for the marine environment for antiseptic.

Owner:JILIN ZHENGJI TECH DEV

Volatile stamping cutting oil composite for machining for machining of moderate-thickness aluminum plate and preparation method thereof

InactiveCN102199476AImprove the lubrication effectImprove rust resistanceLubricant compositionIrritationPhosphate

The invention relates to volatile stamping cutting oil composite for machining of a moderate-thickness aluminum plate and a preparation method thereof. The stamping cutting oil composite comprises the following raw materials in percentage by weight: 90-95 percent of solvent oil, 1-4 percent of antiwear additive, 1-4 percent of oiliness additive, 0.5-2 percent of antirust additive and 0.2-1 percent of antioxidant; the solvent oil has low sulphur content, low aromatic hydrocarbon content, no toxicity and smell and has the kinematic viscosity of 1.5-3.5mm<2> / s at 20 DEG C; the antiwear additive is selected from phosphates; the oiliness additive contains more than one of fatty alcohol and fatty acid methyl ester; the antirust additive is sodium alkylsulfonate; and the antioxidant is an antioxidant BHT (butylated hydroxytoluene). The preparation method of the volatile stamping cutting oil composite for the machining of the moderate-thickness aluminum plate, provided by the invention, is simple and convenient; and the composite provided by the invention does not contain a chlorine extreme pressure agent, is a biological environment-friendly product and has the advantages of excellent extreme pressure lubrication performance and favorable demoulding performance, volatilization completeness, no trace leaving, no clean, extremely low smell, no irritation to skin, time and labor saving and capability of greatly prolonging the service life of a mould.

Owner:上海德润宝特种润滑剂有限公司

Lubricating compositions containing synthetic ester base oil, molybdenum compounds and thiadiazole-based compounds

ActiveUS20060035791A1Good for wear protectionImprove anti-wear performanceOrganic chemistryAdditivesCompound aEther

A lubrication composition providing excellent anti-wear protection for corrosion-resistant materials which comprises a major amount of a synthetic ester base oil, and a minor amount of a molybdenum compound and an anti-wear additive selected from the group consisting of 1,3,4-thiadiazole derivative as an anti-wear additive, the reaction products of 2,5-dimercapto-1,3,4-thiadiazole dimers and poly(ether)glycols, and 2,5-dimercapto-1,3,4-thiadiazole monomer and mixtures thereof. Also described is a method for imparting anti-wear properties to a corrosion resistant material, comprising using the lubricating composition of the invention.

Owner:VANDERBILT CHEM LLC

Antiwear lubricating paint for engine piston ring

The antiwear lubricating paint for engine piston ring is one kind of dry film lubricant. The paint consists of compoiste adhesive, antiseptic additive, antiwear additive, surfactant and dispersing medium. It is painted to the surface of piston and high temperature cured to form firm, compact and dense solid film with excellent antiwear resistance, high impact resistance and good sealing performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

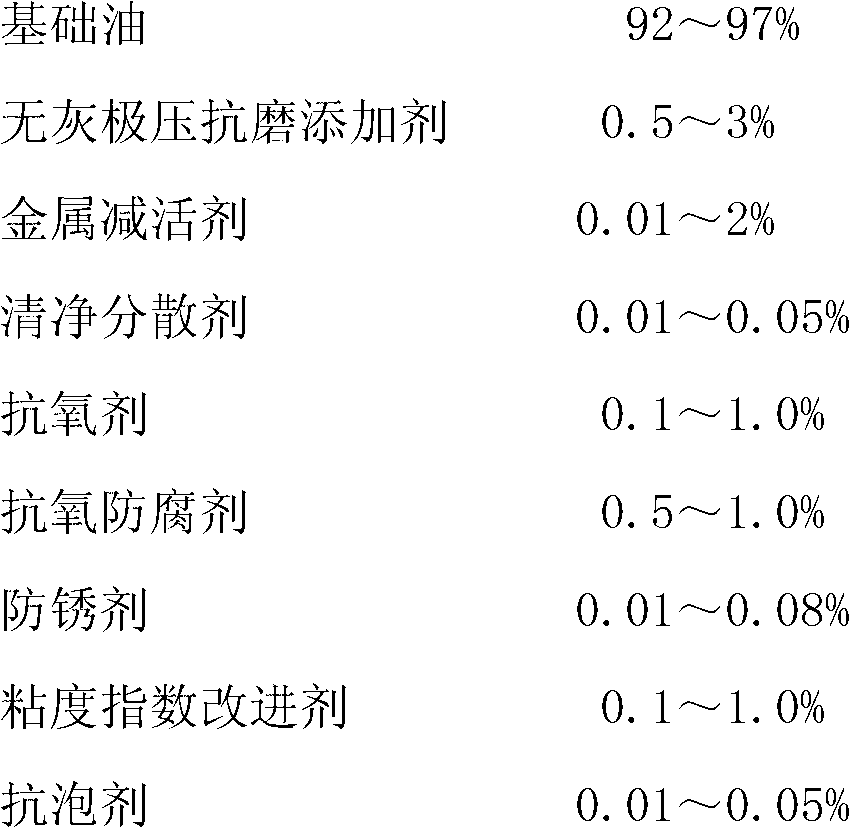

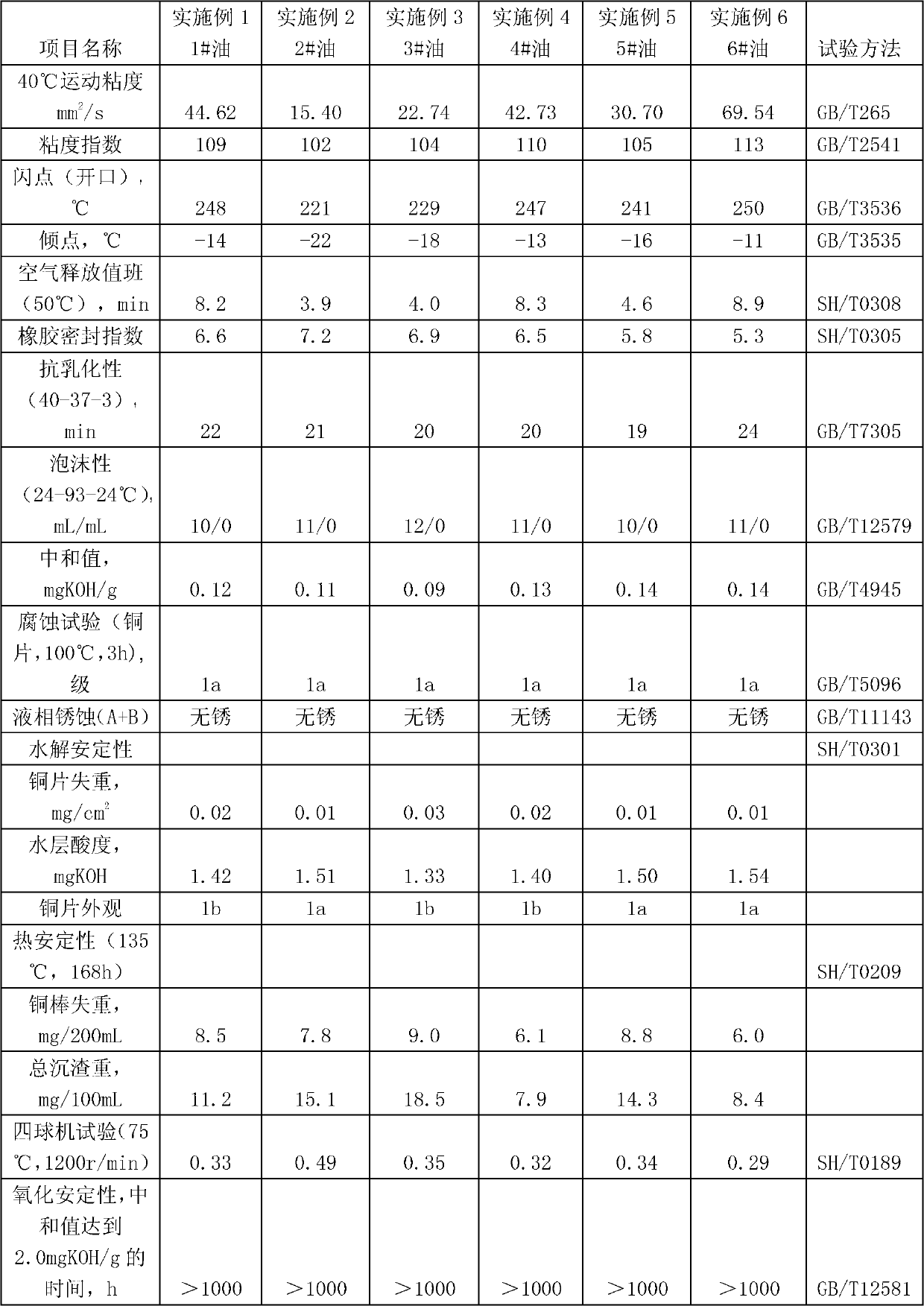

Ash-free anti-wear hydraulic oil

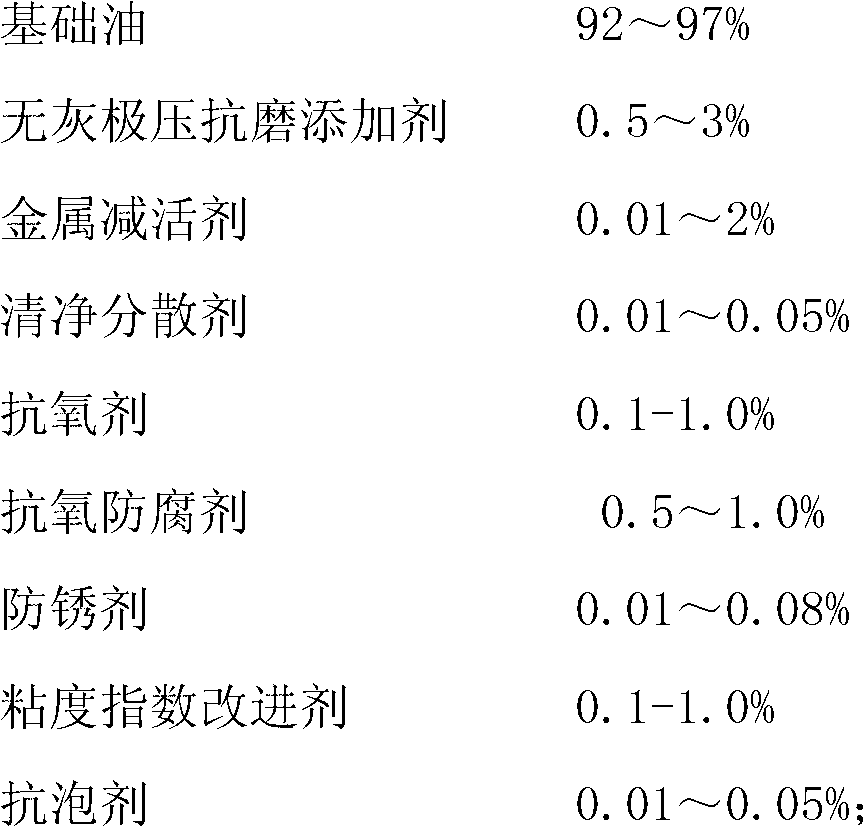

The invention discloses ash-free anti-wear hydraulic oil. The ash-free anti-wear hydraulic oil consists of the following components in percentage by weight: 92 to 97 percent of base oil, 0.5 to 3 percent of ash-free extreme-pressure anti-wear additive, 0.01 to 2 percent of metal deactivator, 0.01 to 0.05 percent of purification dispersant, 0.1 to 1.0 percent of antioxidant, 0.5 to 1.0 percent of antioxidant preservative, 0.01 to 0.08 percent of antirusting agent, 0.1 to 1.0 percent of viscosity index improver and 0.01 to 0.05 percent of anti-foaming agent, wherein the base oil is steam turbine oil with relatively high oxidation stability and emulsification resistance; the ash-free extreme-pressure anti-wear additive is at least one of S-P-N, S-P and P type ash-free extreme-pressure anti-wear additives; and the purification dispersant is DT-6 sulfurized calcium alkyl phenolate. The ash-free anti-wear hydraulic oil has high wear resistance, oxidation resistance, hydrolytic stability and rust resistance, can meet the requirement of high abrasion resistance of vane pumps, and can also meet the requirement of low corrosivity of plunger pumps.

Owner:上海福岛新材料科技有限公司

Compressor oil composition

ActiveCN101397521AHigh viscosity indexImprove the lubrication effectAdditivesBase-materialsPhenolic antioxidantViscosity index

The invention provides a compressor oil compound which comprises the following materials on the basis that the weight of base oil is 100 percent: (1) a main amount of hydrogenization mineral oil base oil; (2) 1 to 15 weight percent of ashless dispersant; (3) 0.01 to 1 weight percent of the combination of half-hindered phenolic antioxidant or amine antioxidant and half-hindered phenolic antioxidant; (4) 0.05 to 2 weight percent of antiwear additive; (5) 0.01 to 0.5 weight percent of friction modifier; (6) 0.01 to 0.2 weight percent of metal passivator; and (7) 0 to 1000ppm of antifoamer. The compressor oil has the advantages of high viscosity index, excellent lubricating property and good oxidative stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Green microemulsion metal cutting fluid and its preparation method

ActiveCN102719306AEffective protectionImprove machining accuracyLubricant compositionOil phaseAnti oxidant

The invention discloses a green microemulsion metal cutting fluid and is characterized in that its formula comprises mixed base oil, synthetic ester, an oiliness agent, an extreme pressure antiwear additive, a clean dispersant agent, an antirust anticorrosion additive, an anti-oxidant, an oil mist inhibitor, a bactericide, an antifoaming agent, an anionic surfactant, a nonionic surfactant and a cosurfactant. A preparation method of the green microemulsion metal cutting fluid comprises the following steps of: firstly preparing an oil phase, heating the base oil to 50-60 DEG C, successively adding the oiliness agent, synthetic ester, the extreme pressure antiwear additive, the clean dispersant agent and the antirust anticorrosion additive, uniformly stirring and mixing to prepare an oil phase system; then preparing a water phase, successively adding the bactericide and the antifoaming agent into water, uniformly stirring and mixing to prepare a water phase system; finally emulsifying the systems, and slowly adding the water phase into the oil phase system to form the green microemulsion metal cutting fluid. The green microemulsion metal cutting fluid provided by the invention has advantages of excellent extreme pressure wear resistance, resistance to hard water, long using period and the like.

Owner:上海福岛新材料科技有限公司

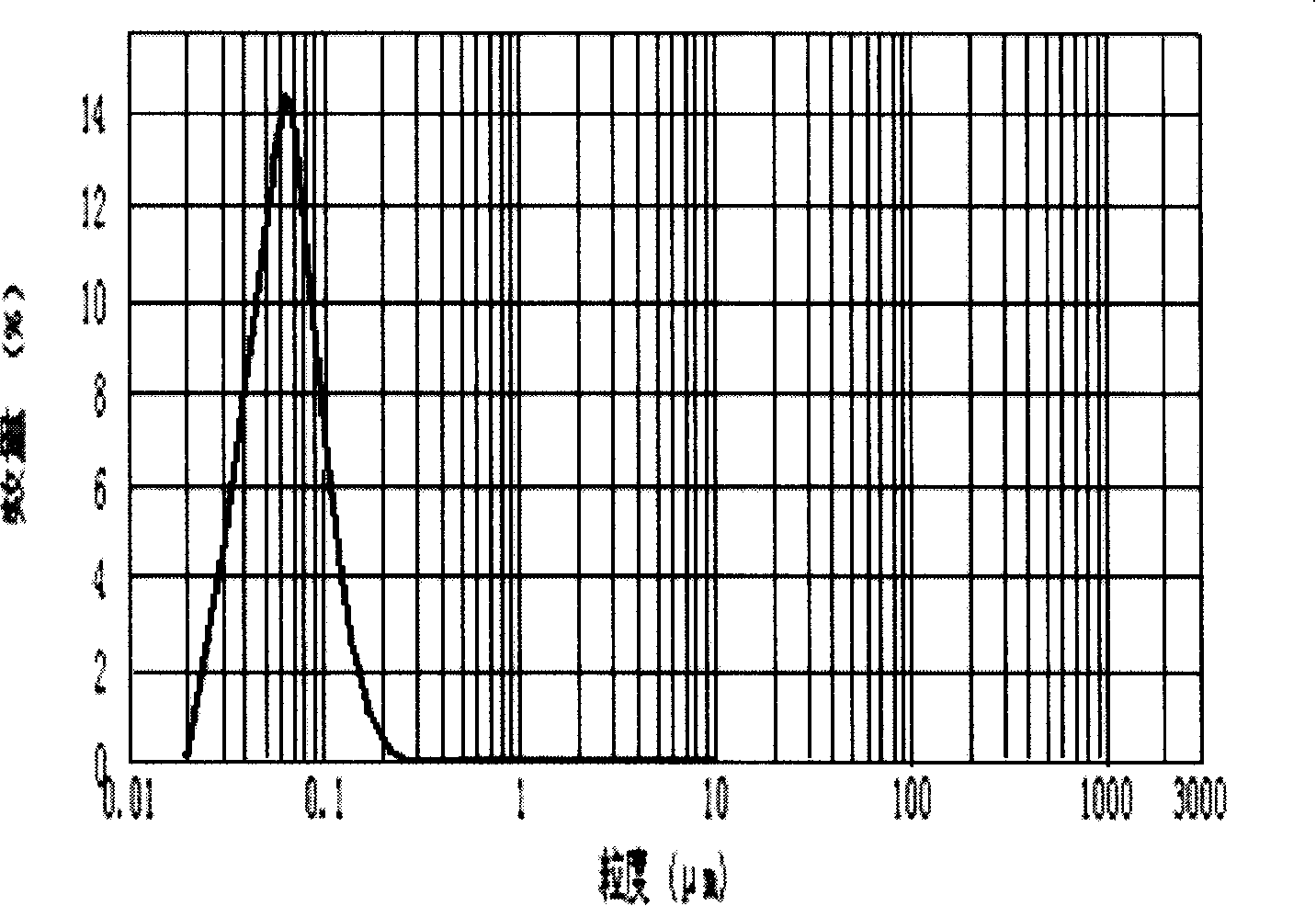

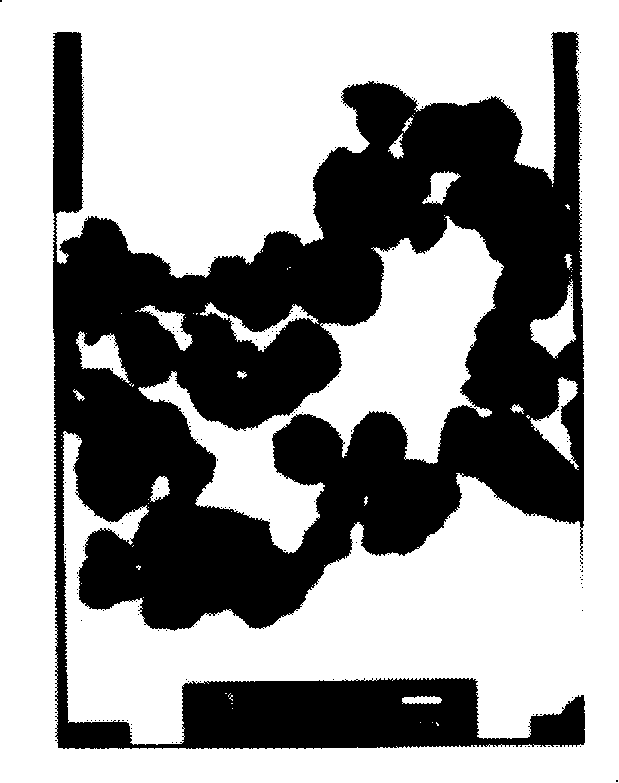

Nano core-shell type copper-nickel bimetal powder body and preparing method and application thereof

ActiveCN101209493AOvercome the disadvantage of easy oxidationMeet the requirement of transparent appearanceCoatingsThioureaConductive materials

The invention relates to a bimetal powder of copper and nickel and a preparation method thereof. The invention solves the defect of easy oxidation of the simple substance nanometer copper powder and improves the use effect of the ordinary copper nickel composite powder. Referring to the prior art, the invention firstly prepares a nanometer copper powder, the copper powder is stirred and dispersed homogeneously in the water, and suspension liquid of the copper powder is prepared; the suspension liquid of the copper powder is blended with the nickel sulfate solution comprising macromolecule protective agent and special copper coordination agent thiourea so as to cause a replacement reaction between nickel ion and the copper; surfaces of the ultrafine copper particles are partly or all coated with the nickel, thus forming the core-shell copper-nickel bimetal nanometer powder. The bimetal powder can be taken as lubricant, lubricating grease extreme pressure-antiwear additives, additives in powder metallurgy, or as porous materials, antibacterial materials, antifouling coatings, conductive materials, magnetic materials, self-lubricating materials, antifriction materials, diamond tools, and raw materials or additives of electrical carbon products.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

Lubricating oil additive and preparation method

ActiveCN1301319CGood dispersionImprove extreme pressure performanceAdditivesOil additiveSio2 nanoparticle

An extreme-pressure antiwear additive for lubricating oil is prepared from basic oil, SiO2 nanoparticles, disperser and synergist.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating agent for superfine copper wire drawing

The invention discloses a lubricating agent for superfine copper wire drawing. The lubricating agent comprises the following components in parts by mass: 5-25 parts of lubrication base oil, 10-30 parts of an emulsifying agent, 1-5 parts of a surface active agent, 1-10 parts of an antirust agent, 1-5 parts of an extreme pressure antiwear additive, 1-5 parts of a thickening agent, 5-25 parts of an alkali retention agent, 1-5 parts of a bactericide, 0.1 part of a defoaming agent and 30-50 parts of water. The lubricating agent for superfine copper wire drawing has good oxidation resisting, cooling, cleaning, lubricating, rust preventing, hard water resisting and copper soap dispersing properties, and is particularly suitable for superfine copper wire drawing.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Sedan hand gearshift case gear lubricating oil composition

ActiveCN101298578AMeet lubricationMeet lubrication requirementsAdditivesBase-materialsGear wheelBench test

The invention provides a gear lubricant composite for manual transmissions of the light cars, comprising (A) at least one type of refining mineral oil with high viscosity index, or polyolefin synthesis oil, or ester lubricants, or a free composite of the above components, (B) at least one type of viscosity index improver, (C) at least one type of pour point depressant, (D) at least one type of extreme pressure additive with sulfurs, (E) at least one type of anti-wear additive with phosphorus, (F) at least one type of wear, oxygen, and corrosion-preventing multifunctional additive with phosphorus, (G) at least one type of anti-rusting additive, and (H) at least one type of friction modifier. The lubricant composite has excellent performance of high and low temperature, which can meet the requirements of gear oil with a viscosity grade of 75W / 90. Moreover, passing the full-size gear bench tests as CRCL-42, L-37, L-33, L-60, and L-60-1 as well as cycle bench tests for the manual transmissions of the light cars, the gear lubricant composite can meet lubrication requirements of the manual transmissions of the light top-grade cars.

Owner:PETROCHINA CO LTD

Lubricating oil composition and preparation method thereof

ActiveCN103773565AGood dispersionImprove dispersion stabilityAdditivesPigment treatment with non-polymer organic compoundsChemical compositionOil additive

The invention discloses a lubricating oil composition and a preparation method thereof. According to the method, base oil, detergent, dispersant, preservative, extreme-pressure antiwear additive, oily agent, antioxidant, viscosity index improver, rust inhibitor, pour-point depressant, antifoaming agent and novel lubricating oil additive are compounded to obtain the lubricating oil composition. The method has the advantages of simple and feasible production technique, low equipment investment, low energy consumption and no environmental pollution, and is beneficial to popularization and application. The lubricating oil composition can be widely used in the fields of mechanical industry, automobile industry, precision instruments, power industry, metallurgical industry, die making and application industry, iron and steel industry, machine tool industry and the like, and has wide application prospects.

Owner:GUANGZHOU LEARNBER SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com